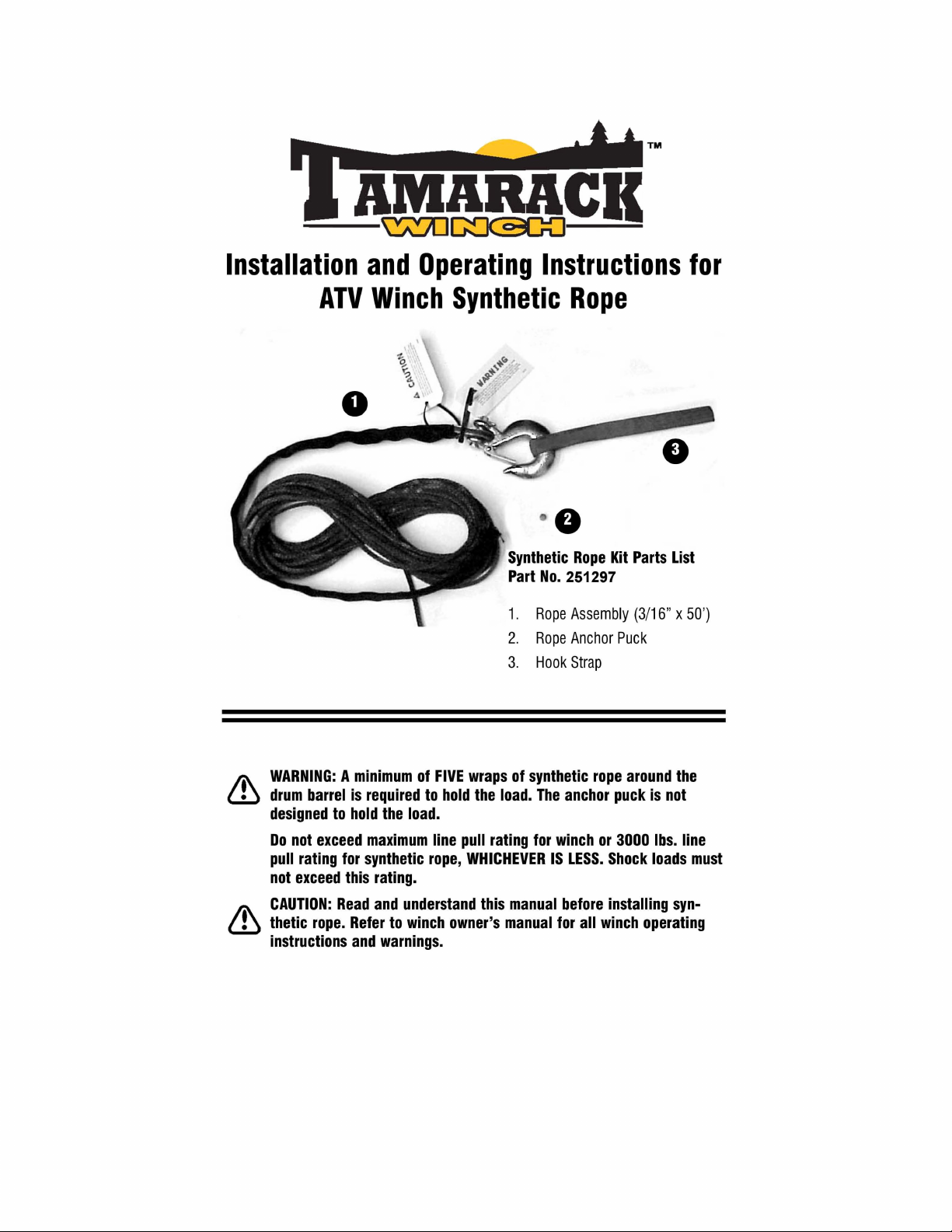

Page 1

Page 2

Tips for Safe Operation

Do not expose rope to chemicals or heat sources.

Avoid prolonged exposure of synthetic rope to ultraviolet rays from sunlight which can

degrade rope strength over time. Use a winch cover over winch and rope when not in use.

Any sharp bend in the rope under load decreases its strength substantially and may cause

premature damage or failure. Sheave diameters on rotating snatch blocks should be at least 8

times the rope diameter (1-1/2” for 3/16” rope).

Avoid pulling rope over rough surfaces or sharp edges. Slide the protective sleeve along the

length of the rope to place it at a location where the rope would encounter rough surfaces

such as rock or tree branches.

See Rope Inspection, opposite page for information on when to replace the synthetic rope.

Installation

Notes:

· Rope should be installed so that it feeds from the bottom of the drum.

· An Aluminum Hawse Fairlead, P/N , is recommended for use with the

Tamarack Synthetic Rope.

· Before installing synthetic rope, inspect winch drum and smooth any sharp

edges on drum barrel, flanges and other winch accessories that may contact the

rope.

1. Unwind the new rope by rolling it out along the

ground. Remove old cable and anchor puck. Retain

wire cable for any future use.

2. Feed the synthetic rope through the aluminum hawse

fairlead and under the drum.

3. Slide the taped end of the synthetic rope through the

narrow end of the pocket against drum flange and

wrap the rope around the new anchor puck. Pull the

rope and puck back into the wide end of the pocket

leaving approximately 1/8” beyond edge of pocket as

shown. Pull firmly on the rope to fully seat the rope and puck into the pocket.

4. Carefully run winch in the “reel-in” direction. Keeping tension on end of rope, spool all

the rope onto the drum, taking care to form neatly wrapped layers.

Anchor Puck

Maintenance

The most important par t of maintenance of the synthetic rope is to inspect it regularly. Any

time the winch is used, the synthetic rope should be inspected thoroughly as described on

the opposite page.

Likewise, inspect the protective sleeve and replace if it becomes torn, fused, or threadbare.

Keep the rope and protective sleeve free of moisture, grease, dirt or other debris. If necessary, clean with a damp cloth.

2

Page 3

Rope Inspection

When rope is first used, the outer filaments of the rope will quickly fuzz up. This is the result

of these filaments breaking and this roughened surface will actually protect the fibers underneath. The condition should stabilize, not progress. If the surface roughness increases,

excessive abrasion is taking place and strength is being lost.

Look closely at both the inner and outer fibers. When either is worn the rope is obviously

weakened. Open the strands and look for powdered fiber--this is a sign of internal wear.

Rope should be replaced when

· Rope bulk anywhere along the length is reduced by 25% or more by abrasion

· Two or more adjacent strands are cut.

· Flat areas or lumps are found that are not eliminated by flexing rope.

· Excessive fused or melted fibers are found. Any such areas will be stiff and the

rope will have a glazed appearance.

Examples:

Rope with original bulk

Rope displaying 25% strand volume reduction from abrasion--rope should be replaced.

Rope strand showing full volume

Rope strand reduced by 25% abrasion--rope should be

replaced.

Rope exhibits fiber-set from compression. A slight

sheen is visible. This is not a permanent characteristic

and can be eliminated by flexing the rope.

Rope displays two adjacent cut strands--rope should

be replaced.

3

Page 4

Warranty Information

New Synthetic Rope assemblies are warranted against defects

in workmanship and materials. No warranty applies after initial

use.

TAMARACK ATV ACCESSORIES, LA BOITE, INC

697 Lincoln Lake Ave SE, Lowell, MI USA, PHONE (800) 269-6701 http://www.tamarackatv.com

OM-913422-0509-A

Loading...

Loading...