VIPER TOOL

OPERATOR’S

SAFETY & OPERATING

INSTRUCTION MANUAL

DANGER

THIS TOOL FOR USE BY LICENSED OPERATORS ONLY.

READ AND OBEY ALL SAFETY AND OPERATING

INSTRUCTIONS BEFORE OPERATING TOOL.

SEMI-AUTOMATIC, LOW VELOCITY

PISTON TYPE FASTENING TOOL

Just as no one can merely read a book about driving an automobile and then hope

to drive one safely, no one should attempt to use any Ramset tool without adequate,

competent personal instruction. And just as one must be licensed to drive an automobile,

one must also be licensed to use a powder actuated tool. No automobile instruction

book or instructor can forewarn a learner against all possibilities and emergencies, nor

can Ramset instructors and printed material detail all possible conditions surrounding

the use of Ramset tools and products.

Responsibility for the safe and proper use of this tool rests with the tool user

and the employer.

SAFETY INTRODUCTION

DANGER

SAFETY INTRODUCTION

DANGER

2

Operator’s and bystanders

must wear eye and hearing

protection.

Never close tool with hand over fastener loading end of the tool.

A serious hand injury from penetration by the piston or a

discharged fastener could result.

Read manual before

operating tool.

DANGER

THIS TOOL IS TO BE USED ONLY BY PROPERLY TRAINED

AND LICENSED OPERATORS.

YOU MUST SUCCESSFULLY COMPLETE THE

RAMSET TRAINING PROGRAM FOR THE

TOOL AND OBTAIN A CERTIFIED OPERATOR’S LICENSE

BEFORE HANDLING, LOADING OR OPERATING THIS TOOL.

ATTEMPTING TO HANDLE OR OPERATE THIS TOOL

WITHOUT PROPER TRAINING AND LICENSING CAN RESULT IN

SERIOUS INJURY TO THE OPERATOR OR BYSTANDERS.

DANGER

Preparation

Acceptable Base Materials

Powder actuated fastening is suitable for

use in the following base materials only:

• PouredConcrete

• StructuralSteel

• MasonryJoints(seepage8)

Never attempt to fasten into any other

type of material.

Fastening into other

materials can cause blindness or other

serious injury.

Unacceptable Base Materials

Never attempt to fasten into very hard or

brittle materials such as cast iron, tile,

glass, or rock of any type. These materials

can shatter, causing the fastener and/or base

material fragments to fly free and cause

serious injury to the tool operator and others.

Never fasten into soft base materials, such as

drywall or lumber products.

These materials

may allow the fastener to travel completely

through and out the other side, endangering

those in the path of the fastener.

Never fasten into any base material that

does not pass the Center Punch test.

Failure to assure the suitability of the base

material can result in serious injury to the

eyes or other body parts.

Center Punch Test

ALWAYS WEAR SAFETY GOGGLES

WHEN PERFORMING THIS TEST.

1. Always check the material being

fastened into for hardness before

attempting any fastening operation.

2. Using a fastener as a center punch,

strike the fastener against the work

surface using an average hammer

blow and check the results.

Center Punch Test Results

1. If the fastener point is flattened,

the material is too hard for a

powder actuated fastening.

2. If the fastener penetrates the

material easily, the material is

too soft.

3. If the material cracks or shatters,

the material is too brittle.

4. If the fastener makes a small

indentation into the material, the

material is suitable for fastening.

DANGER

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

DANGER 3

NEVER FASTEN INTO VERY HARD OR

BRITTLE MATERIALS

NEVER FASTEN INTO SOFT MATERIALS

SUCH AS DRYWALL

Preparación

Materiales base aceptables

La fijación por medio de herramientas

activadas con pólvora es solamente

adecuada para usarse en los siguientes

materiales base:

•Concretovertido

•Aceroestructural

•

Nunca intente realizar las fijaciones en

otro tipo de material.

materiales puede ocasionar ceguera u

otras lesiones graves.

Materiales base inaceptables

Nunca intente realizar las fijaciones en

materialesmuydurosofrágilestales

comohierrofundido,cerámica,vidrio,o

piedra de cualquier tipo.

se pueden hacer pedazos, haciendo que

los fragmentos del material base o del

elemento de fijación salten y ocasionen

lesiones graves al operador de la

herramienta y a terceros.

Nunca fije los elementos sobre materiales

base blandos, tales como paredes de yeso

o productos de madera. Estos materiales

pueden permitir que el elemento de fijación

los atraviese completamente y salga por

el otro lado, poniendo en peligro a aquellos

que se encuentren en el paso del elemento

de fijación disparado.

Nunca realice las fijaciones en un material

base que no pase la prueba de Punzón

de Marcar.

del material base puede ocasionar lesiones

graves a los ojos y a otras partes del cuerpo.

Prueba de Punzón de Marcar

USE SIEMPRE GAFAS DE SEGURIDAD

CUANDO REALICE ESTA PRUEBA.

1. Compruebe siempre la dureza del

2.

Loads & Load Selection Safety

1. Always make a test fastening after

being sure that the base material

is suitable for powder actuated

fastening. Failure to determine the

correct power level to be used may

result in the use of excessive power,

allowing the fastener to pass completely

through the work material, causing

serious or fatal injuries to others who

may be in the path of the fastener.

2. Color-blind operators must always

select loads by number to prevent

use of an incorrect load for the same

reasons as in #1 above.

Workplace Safety

1. Operators and bystanders must

always wear approved eye protection

and approved hearing protection.

Failure to do so may result in blindness

or serious eye injury from flying debris

and loss of hearing from constant or

repeated unprotected exposure to

fastening noise.

2. Always keep the work area clear of

bystanders and unnecessary materials

that could interfere with safe tool

operation. Operating the tool in a

congested or cluttered area may affect

your ability to operate the tool safely.

3. Never operate tool if flammable

or explosive materials are nearby.

Powder loads burn and create sparks

when fired and could ignite these

materials or fumes.

4. Always post warning signs within

50 ft. of the area where fastening

is to be done. Sign must state:

“WARNING - Powder Actuated

Tool In Use”. Failure to warn others

may result in serious injury to them.

Contact Ramset at 1-800-241-5640

to obtain this sign.

SAFETY INSTRUCTIONS

DANGER

SAFETY INSTRUCTIONS

DANGER

4

ALWAYS MAKE A TEST FASTENING

COLOR-BLIND OPERATORS MUST

ALWAYS SELECT LOADS BY NUMBER

KEEP WORK AREA CLEAR OF

BYSTANDERS AND CLUTTER

NEVER OPERATE THE TOOL AROUND

FLAMMABLE OR EXPLOSIVE MATERIALS

WARNING

POWDER

ACTUATED

TOOL IN USE

WITHIN 50 FEET

Safety is important – Take proper precautions.

ALWAYS POST WARNING SIGNS

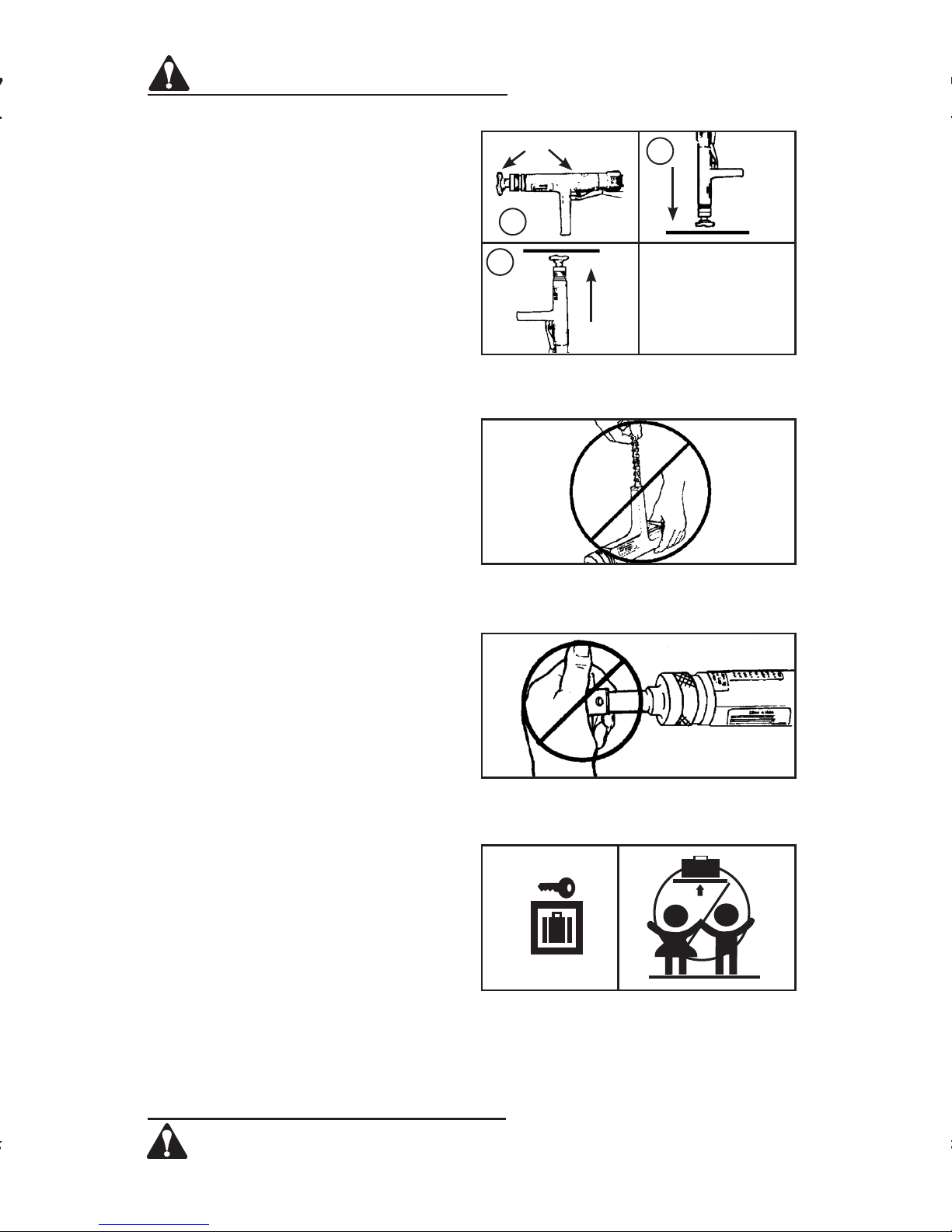

Tool Handling Safety

1. Always be sure tool is operating

properly before attempting to use

it. Follow the “Daily Function Test”

shown to the right and described

on page 9.

2. Always load tool using a strip load

selected directly from a box indicating

the power load type and number.

Never attempt to use loose strip

loads that could be mis-identified.

3.

Never carry loose loads in pockets

with pins or other hard objects.

4. Never load a tool unless you intend

to immediately make a fastening.

Loading a tool and leaving it unattended

in the work area can result in the tool

being accidentally discharged by others.

5. Never place your hand or any other

body part over the fastener loading

end of the tool. Serious hand injury

could result from being struck by either

a fastener or the tool piston should the

tool be accidentally fired.

6. Always store the tool unloaded and

keep the tool and the loads securely

locked in a tool box. Keep keys away

f

rom children and unlicensed persons.

7. Always keep the tool pointed away

from yourself and others.

8.Nevercarryaloadedtoolaround

the work area.

9. Never allow anyone not trained

to use the tool.

10. Never engage in horseplay with

the tool.

11. Using the tool in poorly ventilated

areas, cleaning tool or handling

loads may result in exposure to

lead or other substances known

to cause birth defects, and other

physical harm. Have adequate

ventilation at all times and wash

thoroughly after exposure.

DANGER

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

DANGER 5

NEVER LOAD THE TOOL UNLESS IT IS

TO BE USED IMMEDIATELY

NEVER PLACE HANDS OR BODY OVER

MUZZLE OPENING

KEEP TOOL LOCKED & OUT OF THE

REACH OF CHILDREN

A

B

C

Seguridad en el manejo de la

herramienta

1. Compruebe siempre que la herramienta

2.

3.

4. Nunca cargue una herramienta a menos

5. Nunca coloque la mano ni ninguna otra

6.

7. Mantenga siempre la herramienta

8. Nuncatransporteunaherramienta

9. Nunca permita que personas sin

10.

11. La utilización de la herramienta, limpiarla

Empty

CHECK

OPERATION

DAILY

ALWAYS DO A DAILY FUNCTION TEST

BEFORE LOADING TOOL

FAILURE TO FOLLOW

INSTRUCTIONS CAN

CAUSE INJURY TO THE

TOOL OPERATOR OR

TO BYSTANDERS.

Fastener Driving Safety

1. Only use the tool for fastening into

a suitable base material.

2. Never fire the tool without a fastener.

Firing a tool without a fastener will

cause the piston to strike the work

surface, and may cause serious injury

to you and others in the work area.

3. Always use the spall guard whenever

possible to minimize flying particles

or debris.

4. Always hold the tool perpendicular

to and firmly against the work

surface

when making a fastening.

Failure to do

so could allow a fastener

to ricochet.

5. Never attempt to drive a fastener

close to an edge or to another

fastener. See page 8 for guidelines.

ALWAYS FOLLOW THE

MISFIRE PROCEDURE.

If the tool does not fire after the normal

firing sequence, continue to hold the

depressed tool against the work surface

for at least 30 seconds. Then carefully lower

the tool, remove the strip load, and put it

in a can of water or other non-flammable

liquid. Never carelessly discard a strip with

live loads into a trash container.

If the tool becomes stuck or jammed with

a live powder load,

keep the tool pointed

in a safe direction, and immediately tag it,

“Danger- defective - do not use”.

Lock

the tool in a tool box and call your local

Ramset distributor for assistance.

SAFETY INSTRUCTIONS

DANGER

SAFETY INSTRUCTIONS

DANGER

6

USE SPALL GUARD WHENEVER POSSIBLE

ALWAYS HOLD THE TOOL

PERPENDICULAR TO THE WORK SURFACE

NEVER DRIVE A FASTENER CLOSE TO

AN EDGE

HOLD THE TOOL FIRMLY AGAINST

THE WORK SURFACE FOR AT

LEAST 30 SECONDS

SPALL

GUARD

90°

Your Ramset Viper Tool uses only the Ramset fasteners and loads shown below or

listed for the tool in the Product Catalog.

FASTENERS AND FASTENER ASSEMBLIES

CEILING CLIP ASSEMBLIES - .300 HEAD DIA.

CAT. NO. SHANK DIA. LENGTH

SDC100 .145 1”

SDC125 .145 1-1/4”

SPC78* .150PowerPoint 7/8”

SPC114* .150/.180PowerPoint 1-1/4”

Note:*ForHardConcrete

FASTENERS / LOADS

FASTENERS / LOADS

7

Never use any other types of fasteners or strip loads in the Viper Tool. Use of other types

of fasteners or loads may cause unintentional load discharge, damage the tool, cause poor

fastening performance, or create a risk of serious injury to the operator or bystanders.

DANGER

LOADS

Ramset RS 27 strip loads are specially made for use in the Viper Tool.

The power level of the load is indicated by

the number marked on each box, the color

of the box, and the color on the tip of each load. As the number increases, the power

level also increases.

Always perform the center punch test

described on page 3 to test the base material.

Always make a test fastening using the lowest power level first. If more power is

required to set the fastener, use the next higher power level until the power level

necessary to drive the fastener is reached.

RS 27 10 SHOT STRIP LOAD

POWER CATALOG LOAD CASE

LEVEL NUMBER COLOR COLOR

2 2RS27 Brown Brass

3 3RS27 Green Brass

4 4RS27 Yellow Brass

5 5RS27 Red Brass

CARGAS

LastirasdecargasRS27estánespecialmentefabricadasparausarseconla

herramienta Viper.

Elniveldepotenciadelascargasestáindicadoporelnúmeromarcadoencadacaja,elcolor

de la caja y el color de la punta de cada carga. A medida que aumenta el número, también

aumenta el nivel de potencia de la carga.

Realice siempre la prueba de Punzón de Marcar

base.

Realice siempre una fijación de prueba usando

bajo.

potencia hasta

elemento.

Su herramienta Ramset Viper utiliza solamente elementos de fijación y cargas Ramset

comolosquesemuestranacontinuaciónoenelcatálogodeproductos.

ELEMENTOS DE FIJACÍON Y CONJUNTOS DE ELEMENTOS DE FIJACÍON

CAT. NO. DIA. VÁSTAGO LARGO

SDC100 .145 1 pulg.

SDC125 .145 1-1/4 pulg.

SPC78* .150PowerPoint 7/8pulg.

SPC114* .150/.180PowerPoint 1-1/4pulg.

Nota:*Paraconcretoduro

FASTENING APPLICATIONS

Your Ramset tool can be used for a wide

range of fastening needs in a variety of

base materials. Reading and follow these

important fastening guidelines will help you

get the best results from your tool, fasteners,

and powder loads, as well as help you

perform these fastening operations safely

and effectively.

Powder actuated fastenings are permanent

fastening so attempting to remove a fastener

from concrete or steel may result in serious

injury.

Fastening to Concrete

When fastening into concrete, always

maintain a minimum spacing of 3”

between fastenings

and 3” from any free

edge. Concrete thickness

should be at

least three times the intended penetration

depth into the concrete.

Driving fasteners too close to an edge or too

close to each other can cause the concrete

edge to fail or fasteners to fly free.

Fastening to Steel

Your Ramset tool can be used for fastening

on the flat surfaces of structural steel.

When fastening into steel, always maintain

a minimum spacing of 1-1/2” between

fastenings and 1/2” from any edge.

FASTENING APPLICATIONS

FASTENING APPLICATIONS

8

SPACING — FASTENING INTO CONCRETE

FASTENER LOCATIONS IN

LIGHTWEIGHT PAN DECK

SPACING IN STEEL

3”

3”

FASTENER LOCATION IN

PRECAST CONCRETE

PENETRATION INTO CONCRETE

3 x P

MIN.

P

1-1/2”

MIN.

1/2”

MIN.

MíN

1/2

pulg.

TOOL OPERATION

DAILY FUNCTION TEST

Always check the tool first to make sure

that it does not contain a load strip or

fastener. Test the tool overhead several

times by completely depressing it on a hard

surface. You should hear an audible click as

the firing pin releases. Let up on the

tool and

check to be sure that the barrel assembly

has opened to the starting position.

Next, place the tool, pointing downward, on

a hard surface and firmly, completely depress

the tool. You must not hear the firing pin

release! If the firing pin releases.

STOP, DO

NOT TRY TO USE THE TOOL UNTIL THE

PROPER REPAIRS HAVE BEEN MADE.

Contact your Ramset Distributor for repairs.

OPERATING THE VIPER TOOL

1. Insert a fastener assembly into the

muzzle bushing end of the tool until

it is fully seated. If a clip assembly is

being used, be sure it is positioned in

the cutout section of the spall guard.

2. Insert a load strip into the bottom of the

handle and push it in until your finger is

in firm contact with the handle recess.

Never try to insert a load strip into the

tool from the top of the receiver.

3. Carefully raise the tool to the ceiling

and depress the barrel assembly

where the fastening is to be made.

Hold the tool perpendicular and forcibly push upwards on the pole handle

to compress the firing pin spring and

release the sear to fire the tool. If the

tool does not fire, continue to hold it

in place for at least 30 seconds and

then follow the misfire procedure on

page 6. Always point the tool in a safe

direction and use care when raising it

to the ceiling to avoid bumping objects

that could cause the tool to fire.

TOOL OPERATING INSTRUCTIONS

TOOL OPERATING INSTRUCTIONS

9

INSERT FASTENER INTO THE MUZZLE END

OF THE TOOL

INSERT LOAD STRIP INTO THE OPENING IN

THE BOTTOM OF THE HANDLE

RAISE TOOL TO THE CEILING AND DEPRESS

THE BARREL ASSEMBLY. THEN PUSH UP

FORCIBLY AGAINST THE WORK SURFACE

TO FIRE THE TOOL

PERFORM FUNCTION TEST WITH EMPTY,

UNLOADED TOOL

A

B

C

Empty

CHECK

OPERATION

DAILY

FUNCIONAMIENTO DE

LA HERRAMIENTA

Prueba diaria de funcionamiento. Siempre

compruebe primero la herramienta para

cerciorarse de que no contenga una tira

de cargas o elementos de fijación. Pruebe

la herramienta varias veces elevándola y

presionándola sobre una superficie dura.

Debe oírse un clic en el momento en que

se desengancha el percutor. Retire la

herramienta y compruebe que la boquilla

se ha abierto a la posición de comienzo.

A continuación, coloque la herramienta,

apuntando hacia abajo, sobre una superficie

dura y oprímala con firmeza para hacer que

se retraiga completamente.

el desenganche del percutor! Se el percutor se

desengancha, DETÉNGASE, NO INTENTE

UTILIZAR LA HERRAMIENTA HASTA

QUE

APROPIADA.

distribuidor Ramset para estas reparaciones.

OPERACIÓN DE LA

HERRAMIENTA VIPER

1. Inserte un conjunto de elementos de fijación

2. Inserte una tira de cargas en la parte

3. Levante cuidadosamente la herramienta

DE LA HERRAMIENTA 9

90°

4. Lower the tool, keeping it pointed in

a safe direction, and insert the next

fastener or fastener assembly. Note:

While the Viper tool is being closed and

fired, the advance lever cam has caused

the load advance lever to be indexed

downward to pick up the next load.

When the tool is lowered and opens

up, the next unfired load is indexed

upward to the firing position. At the

same time, as the tool is lowered, the

piston is automatically reset for the

next fastening.

NEVER PLACE YOUR HAND OR

FINGERS OVER THE MUZZLE

BUSING WHILE AN UNFIRED LOAD

IS IN POSITION TO BE FIRED.

5. After all 10 loads in the strip have been

fired, pull the used load strip from the

top of the tool. NEVER try to pull a load

strip from the bottom of the tool.

6. If you are working in an area where

dirt or debris can fall onto the tool

while making fastenings, check the

tool frequently to be sure the muzzle

bushing and loads strip track are clear.

NOTE: Use of partially used load strips.

The design of the Viper tool is such that

the next load to be fired is automatically

indexed into the firing position during

the tool closing, firing and tool opening

sequence of operation. If it is necessary

to use a partially used load strip, the

end of the strip containing the live loads

should be placed into the bottom of the

tool handle just as if it were a new strip.

By counting the number of unfired loads

in the strip before inserting it and keeping

count as the fastenings are being made,

one can easily determine when all of the

loads have been used.

SHOULD YOU DECIDE NOT TO MAKE A

FASTENING AFTER THE TOOL HAS BEEN

LOADED, ALWAYS REMOVE THE POWDER

LOAD FIRST, THEN THE FASTENER. THIS

WILL PREVENT ACCIDENTAL DISCHARGING

OF THE FASTENER OR PISTON INTO THE

OPERATORS HAND.

TOOL OPERATING INSTRUCTIONS

TOOL OPERATING INSTRUCTIONS

10

INSERT THE NEXT FASTENER OR

FASTENER ASSEMBLY INTO THE

MUZZLE BUSHING

REMOVE THE LOAD STRIP FROM THE TOP

OF THE TOOL

CHECK THE MUZZLE BUSHING AND

LOAD STRIP TRACK FOR DEBRIS

REFER TO PARTS SCHEMATIC FOR PROPER ASSEMBLY OF PARTS

– Overdriving of fasteners – Excessive power – Change to the next lower power

level load color and number.

– Soft base material – Check base material (see page 3)

– Tool fails to fire – Failure to depress – See “Tool does not completely

completely depress”

– Excessive dirt buildup on – After following misfire procedure,

breech face not allowing check firing pin indentation on

proper penetration of load. Clean breech face.

firing pin

– Firing pin and/or firing pin – Replace damaged parts

assembly damaged

– Tool does not completely – Misassembled or – Check all parts in the receiver for

depress damaged parts damage or improper assembly.

– Reduction or loss of power – Piston not being returned – Disassemble and clean barrel,

to the full rear position piston and nosepiece

– Worn or damaged piston – Replace damaged piston

– Failure to index strip – Strip not inserted in tool – Check load strip. Properly

correctly or is damaged dispose of damaged strip.

(See page 6)

– Damaged indexing – Contact your Ramset

mechanism Distributor for assistance

– Tool fails the – Contact your Ramset

Daily Function Test Distributor for assistance

TROUBLESHOOTING

TROUBLESHOOTING

11

CONSULTE EL DIAGRAMA DE PIEZAS PARA ARMAR CORRECTAMENTE LAS MISMAS

- Penetración excesiva - Potencia excesiva - Cambie la tira de cargas al número y

de elementos color de nivel de potencia anterior.

de fajación

- Material base blando - Verifique el material base

(vea la página 3).

- La herramienta - No se contrae completamente - Vea el párrafo “La herramienta

no dispara no se contrae completamante”.

- La acumulación excesiva - Después de haber completado

de suciedad en la cara de el procedimiento de falla de disparo,

la recámara no permite compruebe la marca del percutor

la penetración correcta sobre la carga. Revise la cara de

del percutor. la recámara

- EI percutor o la recámara - Reemplace las piezas dañadas

están dañados

- La herramienta - Piezas mal armadas o dañadas - Revise todas las piezas del

no se contrae receptor para buscar daños o

completamente armado incorrecto

- Reducción o pérdida - EI pistón no se retrae - Desarme y limpie el cañón el pistón

de potencia hasta su posición trasera total y la boquilla

- Pistón desgastado o dañado - Reemplace el pistón dañado

- Falla en la colocación - La tira no se insertó - Revise la tira de cargas. Deseche

tira de cargas correctamente en la correctamente la tira dañada (vea la

herramienta no esá dañada página 6).

- El mecanismo de avance - Comuníquese con su distribuidor

está dañado Ramset para obtener ayuda

La herramienta no pasa - Comuníquese con su distribuidor

la prueba diaria de Ramset para obtener ayuda

funcionamiento

PARTS SCHEMATIC

PARTS SCHEMATIC

12

PARTS LIST / MAINTENANCE

PARTS LIST / MAINTENANCE

13

Always make sure the tool is not loaded before performing any service or repair and

always wear safety goggles when cleaning or servicing the tool.

DAILY CLEANING

All front end parts shown in the disassembly section are to be cleaned daily with a good

detergent oil and wire brush. Remove all dirt and carbon buildup and wipe parts dry with

a clean rag. Check all parts for wear or damage before reassembly and replace or repair

any worn or damaged parts.

PERIODIC COMPLETE CLEANING / GENERAL MAINTENANCE

Heavy or constant exposure to dirt and debris may require that the tool be cleaned more

extensively. Complete disassembly and cleaning of all parts may be necessary to restore

the tool to normal operation. General maintenance should be performed every six months

or more often if the tool is subjected to heavy use. General maintenance/complete cleaning should be done by a qualified repair person.

IMPROPERLY MAINTAINED TOOLS CAN CAUSE SERIOUS INJURIES

TO TOOL OPERATOR AND BYSTANDERS

CLEAN TOOL DAILY

ALWAYS FUNCTION TEST THE TOOL AFTER PERFORMING ANY

SERVICE. SEE PAGE 9 FOR DETAILS ON THE FUNCTION TEST.

MAINTENANCE

VIPER TOOL PARTS LIST

KEY PART NO. DESCRIPTION

1 MVP100A MUZZLE BUSHING ASSEMBLY

2 MVP140 PISTON

3 MVP150 BARREL

4 MVP21A SPRINGS (barrel, firing pin & firing pin assembly)

5 MVP110A BUFFER (PKG of 3)

6 MVP101 HOUSING

7 2VP18 FIRING PIN ASSEMBLY

8 MVP500AP ADVANCE LEVER AND PIN

9 MVP600A ADVANCE LEVER CAM AND SCREW

10 MVP028 POLE CONNECTOR

11 2VP11 LOCKOUT BALL (PKG. OF 3)

12 2VP29 HANDLE CONNECTOR

13 MVP130 RETAINING COLLAR

14 MVP30 SPALL GUARD

15 2VP33 WAVE WASHER

16 MVP001A LINER BALLS AND SPRINGS (not shown)

17 316540 PAWLS (PKG of 2)

Verifique siempre que la herramienta no esté cargada antes de realizar cualquier operación de servicio

o reparación y utilice siempre gafas de seguridad cuando esté limpiándola o dándole servicio.

LIMPIEZA DIARIA

Todas las piezas del extremo anterior mostradas en la sección de desarmado se deben limpiar

diariamente con un buen aceite detergente y un cepillo de alambre. Elimine la acumulación

de suciedad y carbón y seque las piezas con un paño limpio. Revise el desgaste o el daño de

todas las piezas antes de volver a armar la herramienta y reemplace o repare cualquiera que se

encuentre desgastada o dañada.

LIMPIEZA COMPLETA PERIÓDICA / MANTENIMIENTO GENERAL

El uso continuo o la exposición constante a suciedad o los desechos puede requerir que la

herramienta se limpie más exhaustivamente. Puede ser necesario desarmarla completamente y

limpiar todas las piezas para restaurar la herramienta a su condición normal. El mantenimiento

general se debe realizar cada seis meses o más frecuentemente si la herramienta se usa

intensamente. El mantenimiento general y la limpieza completa los deberá hacer personal de

reparación calificado.

MANTENIMIENTO

LISTA DE PIEZAS DE LA HERRAMIENTA RAMSET VIPER

CLAVE No. DE PIEZA DESCRIPCIÓN

1 MVP100A CONJUNTO DEL MANGUITO EN LA BOCA

2 MVP140 PISTÓN

3 MVP150 CAÑÓN

4 MVP21A RESORTES (DEL CAÑÓN, DEL PERCUTOR Y DEL

CONJUNTO DEL PERCUTOR)

5 MVP110A SEPARADOR (PAQ. DE 3)

6 MVP101 BASTIDOR

7 2VP18 CONJUNTO DEL PERCUTOR

8 MVP500AP PALANCA DE AVANCE Y PASADOR

9 MVP600A PALANCA DE AVANCE Y TORNILLO DE LA LEVA

10 MVP028 CONECTOR DE LA CULATA

11 2VP11 ESFERA DE BLOQUEO (PAQ. DE 3)

12 2VP29 CONECTOR DEL MANGO

13 MVP130 COLLARÍN DE RETENCIÓN

14 MVP30 GUARDA DE PROTECCIÓN CONTRA ASTILLAS

15 2VP33 ARANDELA ONDULADA

16 MVP001A ESFERAS Y RESORTES DEL TUBO DE ÁNIMA (NO ILUSTRADO)

17 316540 RETENES (PAQ. DE 2)

DISASSEMBLY

14

DISASSEMBLY

TOOL DISASSEMBLY

1. Unscrew and remove the barrel

retention collar. Handle the tool

carefully after the collar is

unscrewed to prevent the two

barrel pawls from falling out.

2. Remove the two pawls from the slots

on either side of the tool housing.

3. Slide the barrel assembly and the barrel

spring out of the tool body. Note the

position of the slots on the sides of the

barrel since the tip ends of the pawls are

inserted into the barrel slots through the

tool housing in re-assembly.

4. Unscrew the muzzle bushing assembly

from the barrel. If this is difficult to do

by hand, grasp the barrel and use a

wrench on the flats of the muzzle

bushing assembly to loosen it for

complete removal.

5. Remove the piston from the barrel.

UNSCREW THE BARREL RETAINING

COLLAR

REMOVE BOTH PAWLS

SLIDE THE BARREL ASSEMBLY AND

BARREL SPRING OUT OF THE TOOL

BODY

UNSCREW THE MUZZLE BUSHING

FROM THE BARREL

PULL PISTON OUT OF THE BARREL

DISASSEMBLY

15

DISASSEMBLY

6. Remove the buffer from the muzzle

bushing.

Inspect all parts for wear or damage

and clean or replace as required. Use

cleaning solvent and cleaning brushes

to remove dirt and powder residues.

Wipe all parts dry before reassembly.

Wear safety goggles when cleaning

tool parts.

7. Check the piston tip for damage and

grind flat. The tip of the piston must be

90° to the shank. Grinding should only

be done by qualified personnel. The

minimum overall length of the piston

must not be less than 4” long. When

less than 4” long, the piston must be

replaced.

8. Reassemble the tool in the reverse

order of disassembly. When sliding the

barrel and spring into the housing, align

the slot in the barrel with the slot in the

tool housing and install both pawls and

the retaining collar

9. Always check before using the tool to

be sure that the advance lever cam is

tightened securely on the end of the

pole connection.

ALWAYS PERFORM THE DAILY

FUNCTION TEST DISCUSSED AND

SHOWN ON PAGE 9 BEFORE USING

THE TOOL AFTER CLEANING OR

SERVICING.

DESARMADO

15

6. Quite el separador de la boquilla en

Revise todas las piezas para ver si

Seque con un trapo todas las piezas

Use gafas de seguridad cuando esté

7. Revise la punta del pistón para vet si

8. Vuelva a armar la herramienta en orden

9. Verifique siempre antes de hacer uso

SIEMPRE REALICE LA PRUEBA

PULL THE BUFFER OUT OF

THE MUZZLE BUSHING

BE SURE THE ADVANCE CAM IS

TIGHTENED SECURELY AND IS

FLUSH WITH THE END OF THE

POLE CONNECTOR

GRIND PISTON TIP FLAT AND BEVEL

EDGEAT18°

5/16”

18°

90°

FLUSH AND TIGHT

VIPER WARRANTY AND LIMITATIONS

POWDER ACTUATED TOOL

MANUFACTURES' INSTITUTE INC.

TM

Concrete Fastening Systems

Glendale Heights, IL 60139

800-RAMSET6(1-800-726-7386)

www.ramset.com

Buy with Confidence...

Buy From Your Authorized Distributor

AN ILLINOIS TOOL WORKS COMPANY

© ILLINOIS TOOL WORKS 2009

PRINTED IN THE U.S.A. REVISED 04/09 Form No. MV1000- 04/09

THE MODEL VIPER TOOL COMPLIES WITH OSHA REQUIREMENTS

AND WITH ANSI A10.3 SPECIFICATIONS

FOR TOOL REPAIR SERVICE CONTACT YOUR LOCAL AUTHORIZED

RAMSET DISTRIBUTOR OR TO FIND YOUR NEAREST RAMSET TOOL

REPAIR CENTER VISIT OUR WEB SITE AT WWW.RAMSET.COM

ORCALL800-241-5640

Copyright 2009 Ramset

Ramset warrants that new Viper power fastening

tools, parts and accessories will be free from

defects in material and workmanship for the

period shown below.

THREE-YEAR WARRANTY

A three-year warranty will apply to all parts,

except those listed below as normal wearing

parts, or parts which are specifically covered

by an extended warranty.

The following parts are considered normal

wearing parts and are excluded from the

warranty:

• Piston • Buffer • Spring Clips

• Pawls • Piston Rings

The warranty period is based off of tool build

date, determined from the tool serial number.

Ramset may extend the warranty time frame

from the date of purchase with a qualifying

document proving date of purchase.

WARRANTY STATEMENT

Ramset’s sole liability hereunder will be to

replace any part or accessory which proves

to be defective within the specific time period.

Any replacement

part or accessory provided

in accordance

with this warranty will carry a

warranty for the balance of the period of

warranty applicable to the part it replaces.

This warranty does not apply to part

replacement required due to normal wear.

This warranty is void as to any tool which

has

been subjected to misuse, abuse,

accidental

or intentional damage, use with fasteners, and

loads

not meeting Ramset specification, size,

or quality, improperly maintained, repaired

with other than genuine Viper replacement

parts, damaged in transit or handling, or

which,

in Ramset’s opinion, has been altered

or repaired in a way that affects or detracts

from

the performance of the tool.

Ramset MAKES NO WARRANTY, EXPRESSED OR

IMPLIED, RELATING TO MERCHANTABILITY,

FITNESS, OR OTHERWISE, EXCEPT AS STATED

ABOVE and the liability AS STATED ABOVE

AND AS ASSUMED ABOVE is in lieu of all other

warranties arising out of, or in connection with,

the use and performance of the tool, except to

the extent otherwise provided by applicable law.

Ramset SHALL IN NO EVENT BE LIABLE FOR

ANY

DIRECT, INDIRECT, OR

CONSEQUENTIAL

DAMAGES, INCLUDING,

BUT NOT LIMITED

TO

DAMAGES WHICH

MAY ARISE FROM LOSS

OF ANTICIPATED

PROFITS OR

PRODUCTION,

SPOILAGE OF MATERIALS,

INCREASED COST

OF OPERATION OR OTHERWISE.

Ramset reserves the right to change specifications,

equipment, or designs at any time without notice

and without incurring obligation.

Loading...

Loading...