THIS TOOL IS FOR USE ONLY BY LICENSED OPERATORS.

YOU MUST OBTAIN A LICENSE BEFORE USING IT. A

TOOL OPERATOR'S CARD WILL BE ISSUED TO YOU

AFTER SUCCESSFULLY COMPLETING THE ENCLOSED

EXAM AND RETURNING IT TO RECEIVE YOUR CARD

AND ACTIVATE YOUR WARRANTY. OPERATOR'S

LICENSE CAN ALSO BE OBTAINED AT: www.ramset.com

MODEL HD22

LOW VELOCITY POWDER ACTUATED TOOL

Operator's Instruction & Training Manual

• The Ramset HD22 is a light duty tool designed for applications such as small

room additions and basement remodels. Tool life will vary depending on work site

conditions and application.

• The model HD22 is a low velocity piston type fastening tool. It is designed for

use with Ramset .22 caliber CW powder loads and Ramset fasteners.

• Do not operate the Model HD22 before studying this manual carefully and

thoroughly understanding the material contained herein.

IMPORTANT: The tool warranty is only activated upon receipt by ITW Brands of the

completed Operator's Exam.

Part #00022

Rev. 8/07

RD v001MA

WARRANTY

ALL WARRANTIES OF THE PRODUCTS DESCRIBED HEREIN, EXPRESSED OR

IMPLIED, INCLUDING THE WARRANTY OF MERCHANTABILITY AND FITNESS

FOR PARTICULAR PURPOSES ARE SPECIFICALLY EXCLUDED, EXCEPT FOR THE

FOLLOWING: ITW BRANDS WILL REPAIR OR REPLACE AT ITS SOLE OPTION

ANY TOOL PART OR FASTENER WHICH WITHIN 90 DAYS AFTER SALE BY

ITW BRANDS IS FOUND BY ITW BRANDS TO BE DEFECTIVE IN MATERIAL OR

WORKMANSHIP, NORMAL WEAR AND TEAR EXCLUDED. THIS IS THE SOLE

WARRANTY OF ITW BRANDS AND THE SOLE REMEDY AVAILABLE TO THE BUYER.

NOTE: It is very important that the operator of this tool completely reads and understands the entire tool manual and completes the Operator's Exam on the last page.

The warranty will not be valid until the test is received, along with a copy of your

sales receipt, and reviewed by ITW Brands. Operator's license can also be obtained

at: www.ramset.com

TO AVOID SERIOUS INJURY OR DEATH

Operators and bystanders

must wear eye and hearing

protection.

Never close tool with hand over fastener loading end of the tool.

A serious hand injury from penetration by the piston or a

WARRANTY

Read manual before

operating tool.

discharged fastener could result.

SAFETY PRECAUTIONS

IMPORTANT: In order to activate your warranty, you must read this

manual thoroughly, complete the exam and return to the address on

the back page of this manual.

The following pages contain detailed warnings,

WARNING!

operator must be familiar and follow to avoid serious injury or death. After thoroughly reviewing this manual, complete the Operator's Exam and return to ITW Brands for

your Operator's Card and to activate your warranty.

BEFORE LOADING AND FIRING PROTECT YOURSELF AND OTHERS

1. Never place your hand or fingers over the

front muzzle of the tool - the fastener or

piston can seriously injure your hand in

the event of an accidental discharge.

2. Always use only Ramset fasteners and

loads at all times for consistent tool

functioning.

cautions, and rules of safe operation with which the

3. Operators and bystanders must wear

eye and hearing protection at all times.

Serious eye injury and hearing loss can

result if proper gear is not worn.

4. Keep work area clear and where required

always post warning signs when using

the tool. Sign should state, "Powder

Actuated Tool in Use" and can be obtained

by contacting Technical Services at

1-877-ITW-BRANDS (1-877-489-2726).

1 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Prepare for Loading

1. Prior to using the tool, make sure it

is unloaded and then do the functional

check: Check the functioning of the tool,

without a powder load or fastener, by

pushing down against the work surface,

making sure the groove on the barrel

aligns with the markings on the receiver.

Repeat this several times to insure tool is

operating properly.

2. Always check the material being fastened into, by performing the Center

Punch Test: Using a fastener as a center punch, strike the fastener against the

work surface using an average hammer blow and check the results. Wear eye

protection while performing this test.

1. If the fastener point

is blunted, material

is too hard.

(Typical base materials: poured concrete, structural steel and masonry.)

2. If material cracks or

shatters, material is

too brittle.

3. If the fastener pen-

3. If the base material is suitable for powder

actuated fasteners, make a test fastening

into a suitable base material with a number 1 (gray) load. If the number 1 load

does not fully set the fastener, try the next

higher power load until the proper level

is found. Failure to properly test fire to

determine correct power level may result

in overpowering the fastener, causing

it to pass completely through the work

material, injuring someone on the other

side. Overpowering the fastener may also

damage the tool.

SAFETY PRECAUTIONS

etrates the material

easily, material is

too soft.

4. If the fastener makes

small indentation into

material, material is

suitable for fastening.

Power Levels Available for HD22:

Power Level No. Color

1. Gray Weakest

2. Brown

3. Green

4. Yellow Strongest

NOTE: Ramset loads are designed for

use with Ramset tools. Do not attempt

to use other power loads. Doing so may

lead to unintentional load discharge as

well as damage to the tool. This tool is

NOT designed to use red (5) or purple

(6) power level loads. Using red (5) or

purple (6) loads can result in serious

injury to the operator or bystanders.

2

SAFETY PRECAUTIONS

Operating the Tool

1. Always point the tool away from people

and in a safe direction.

2. Never use tool when explosives or flam-

mable materials are nearby.

3. Never fire the tool without a fastener.

The piston will protrude from the muzzle

of the tool, enter the work surface and

possibly cause injury to the operator or a

bystander. Firing without a fastener may

also damage the tool.

4. Always hold the tool perpendicular to the

work surface to avoid serious injury or

death from ricocheting fasteners. Use a

spall guard* whenever possible.

5. Never set a fastener too close to another

fastening or a free edge. This can cause

the fastener to ricochet. Always follow

the minimum spacing and edge distance

requirements.

6. Never fire into very hard or brittle mate-

rials such as cast iron, tile, glass or

rock. These materials can shatter, causing

sharp fragments and/or the fastener to fly

freely.

* To order optional spall guard,

call 1-877-ITW-BRANDS (1-877-489-2726)

3 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

7. Never fasten into structural steel base

material thinner than 3/16". Never fasten

into concrete base material thinner than 3

times shank penetration. Always maintain

minimum penetration requirements.

8. Fastening into block and masonry is not

recommended. When it is necessary to fasten into masonry walls, it is recommended

that fasteners be driven into the horizontal

joints only. Published holding values for

these materials is not available due to the

inconsistency of the materials.

9. Never fasten through or into a hole. Always

maintain at least 1/2" distance from any

pre-drilled or pre-punched hole.

10.

Should you decide not to make a fastening

after the tool has been loaded, always

remove the powder load first, then the

fastener. Never attempt to pry an unfired load

out of the tool. Call The Technical Department

at 1-877-ITW-BRANDS (1-877-489-2726) for

assistance.

STEEL

CONCRETE

Handling Tool and Powder Loads

1. Never leave a loaded tool unattended.

Someone may pick it up, not know it is

loaded and accidentally discharge the tool

causing serious injury or death. Never load

the tool until you are prepared to complete

the fastening. Always store loads and tool,

unloaded, under lock and key.

SAFETY PRECAUTIONS

4

SAFETY PRECAUTIONS

2. Never carry fasteners or other hard

objects in the same pocket or container

with powder loads. The loads could be set

off, causing serious injury or death.

3. A person that is color blind must be extra

careful when loading the tool. One must

only take a load from a box that is identified by powder load number. Never use

loose loads that can be misidentified.

4.

Powder loads must never be used in firearms. They are more powerful than the

charges normally used in small firearms.

This could result in serious injury or death.

Fasteners

1. A powder actuated fastener, after it has

been installed, is considered a permanent

fastening. Do not attempt to pull a fastener

out of concrete or steel. Attempting to do

so may result in serious injury.

Operating Problems

1.

If the tool fails to fire, hold the tool firmly against

the material for 30 seconds. Remove the tool

from the work surface, open the barrel to reset

the piston. Re-chamber the load and repeat

firing sequence. If the tool fails to fire again,

hold for 30 seconds, unload the tool, and then

discard the load into a bucket of water. Never

attempt to pry an unfired load out of the tool.

Call The Technical Department at

1-877-ITW-BRANDS (1-877-489-2726) for

assistance.

5 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

2. Never unload or disassemble a jammed,

stuck or broken tool which contains a

live powder load. This may cause the

tool to fire unintentionally. Always point

a jammed tool away from yourself

and other people. Immediately store

a jammed or broken tool in a locked

container after tagging it "Defective Do Not Use". Call 1-877-ITW-BRANDS

(1-877-489-2726) for technical assistance.

RAMSET FASTENER SELECTION GUIDE

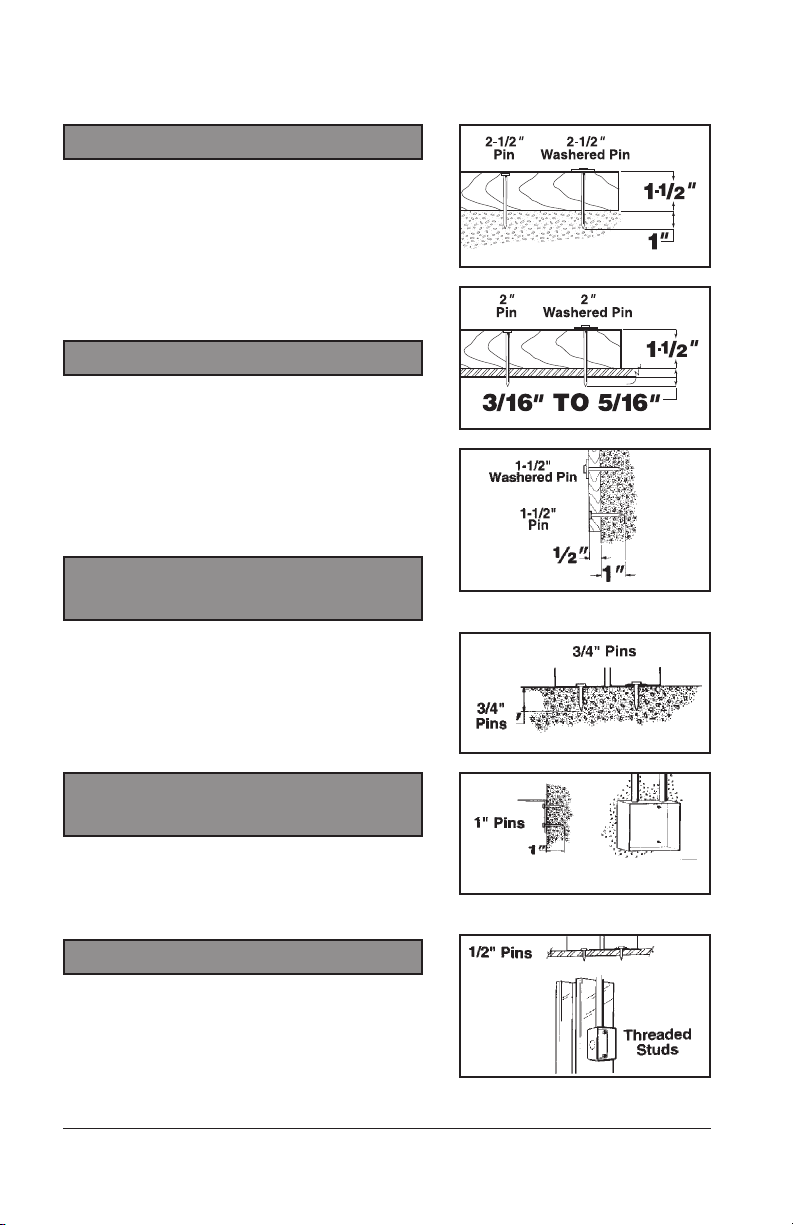

.300 Head Plastic Fluted Drive Pins

Shank Shank

Length Diameter

1/2" .145

5/8" .145

3/4" .145

1" .145

1-1/4" .145

1-1/2" .145

1-3/4" .145

2" .145

2-3/8" .145

2-1/2" .145

.300 Head Plastic Fluted Drive Pin

with 7/8" Washer

Shank Shank

Length Diameter

1" .145

1-1/4" .145

1-1/2" .145

2" .145

2-1/2" .145

SAFETY PRECAUTIONS

6

TOOL OPERATION

Be sure to read and understand all safety precautions

CAUTION!

operate the tool. Check to be sure the tool is unloaded and no foreign objects or

fasteners are in the barrel. Perform daily function test before operating.

OPERATION

Check the functioning of the tool, without a powder load or fastener in the tool, by

pushing down against the work surface, checking to be sure the groove portion of

the barrel aligns with the arrows on the tool body. Function unloaded tool several

times and insure that the breech parts and firing mechanism operate freely before

fastening with the tool.

1. Point the tool in a safe direction and slide

the barrel forward with your other hand.

This action resets the piston for the next

fastening. Loss of power may be the result

of an improperly reset piston.

2. Place a fastener, point out, into the front

end of the barrel until the plastic fluted tip

fits inside. Always load the fastener before

inserting the power load to prevent accidental discharge. Do not use excessive

force when inserting the fastener. Stop if

excessive force is required and call 1-877

ITW-BRANDS for technical assistance.

and complete the Operator's Exam before attempting to

3. Insert the powder load after making sure

the chamber is clear. The powder load will

not fully set until the tool is compressed

against the work surface. Always start

with the lowest level and increase until the

proper level is found. Note: Overpowering

a fastener into steel or concrete is

dangerous.

Note: Before making the fastening, the base material should be center punch tested

for suitability of powder actuated fastenings (see pg. 2).

7 TOOL OPERATION

TOOL OPERATION

4. Close tool by pulling the barrel back to

the semi-closed position. Never attempt

to close the tool by exerting force on the

front of the barrel. Never place your fingers

or hands over the muzzle end of the barrel. The proper position of the hands and

fingers are shown in the illustration.

5. With the tool in the semi-closed position,

place it against the material to be fastened.

Hold the tool firmly at 90º with one hand and

completely depress, check to be sure the

groove on the barrel aligns with the marking

on the receiver.

6. Using a one pound hammer, strike the

firing pin button with a sharp, firm blow.

If the tool fails to fire, follow the misfire

procedure on page 5.

Note: It is important to strike the firing pin button

firmly and squarely. A light blow or one off-center

may not activate the load, however it will jar the

piston out of position which will cause a reduction in

power. (See Troubleshooting, page 10.)

Semi-close

position

7. To prepare for the next fastening, point the

tool in a safe direction, and slide the barrel

firmly forward. This action ejects the fired

load out of the tool and properly resets the

piston. The tool is now ready for the next

fastening.

THOROUGH CLEANING

To maintain your tool in good working condition, it is recommended that the tool be

cleaned after heavy use or constant exposure to dirt and debris. Call 1-877-ITW-BRANDS

(1-877-489-2726) for service information.

TOOL OPERATION

8

TROUBLESHOOTING

Tool operator must carefully follow all operating instructions and

precautions to successfully operate the tool. Following is a list of

potential situations an operator may encounter and the probable causes:

• If a tool problem occurs and technical assistance is required, please

call 1-877-ITW-BRANDS (1-877-489-2726)

WARNING: Do not operate a tool that is not functioning properly.

TOOL FAILS TO FIRE

There are three causes for most all misfires.

• Firing pin button struck

too lightly

• Firing pin button

struck off center

• Tool not completely

compressed

INCONSISTENT FASTENER SETTING

The major reason for inconsistent fastening is the improper position of

the piston. There are two reasons for an improperly positioned piston:

1. Failure to completely reset the piston.

2. A missed hit of the rear button.

In both cases the barrel must be fully

extended to reset the piston.

Note: It is a good practice to fully extend the

barrel and re-chamber the load after the tool is

improperly struck causing a misfire, and after

the misfire procedure has been followed.

9 TROUBLESHOOTING

TROUBLESHOOTING

PISTON OVERDRIVE

Piston overdrive is a problem that occurs after

the tool is fired. The piston may extend into the

work surface as much as 1/2".

can occur because of several reasons:

• Powder load too strong

• Soft base material

• Void in the masonry

material that you're

fastening into.

• Incorrect fastener selection.

Piston overdrive

Caution: Constant overdrive will damage the tool beyond repair. For technical

assistance or service information call 1-877-ITW-BRANDS (1-877-489-2726).

Note: When overdrive occurs, the piston may jam

into the front barrel. In this case be sure the tool

is unloaded, turn the tool upside down and place

on the work surface. Strike the exposed piston

with a hammer until it moves downward into the

barrel. Reset the piston. Wear safety goggles when

performing this task.

TO AVOID PISTON OVERDRIVE

• Decrease power level.

Always make test fastenings

with lightest load and increase

until proper level is found.

• Make sure base material is

checked according to the

Center Punch Test.

• When fastening into masonry,

always make fastenings into

horizontal joints.

• Check page 12, "How to Select

a Power Actuated Fastener."

Note:

Fastening to Concrete

When fastening into concrete always maintain a minimum 3" spacing between

fastenings and 3" from any free edge. Penetration into concrete should always be 1"

(see page 12, "How to Select a Powder Actuated Fastener"). The concrete thickness

should be at least 3 times the penetration depth.

Fastening to Steel

When fastening into steel always maintain a minimum 1-1/2" spacing between fastenings and 1/2" from any free edge. Fastener length should be long enough to penetrate

the steel completely (see page 12) Steel thickness is limited to 3/16" to 5/16".

TROUBLESHOOTING

10

Wood to Concrete

7/8" washer provides a greater bearing surface to the wood member, minimizing uplift.

Wood to Steel

Fastener should penetrate steel completely

for maximum holding power.

Furring Strip to Concrete

or Masonry Walls

When fastening into masonry, shoot into

horizontal joints only.

APPLICATIONS

Thin Gauge Metal to Concrete

or Masonry

Thin Gauge Metal to Steel

11 APPLICATIONS

HOW TO SELECT A POWDER

ACTUATED FASTENER

DETERMINE FASTENER TYPE

Drive pins are used to directly fasten an object (permanent installation). Threaded

studs are used where the object fastened may later be removed or where shimming

is required. The following shows how to determine shank and thread length:

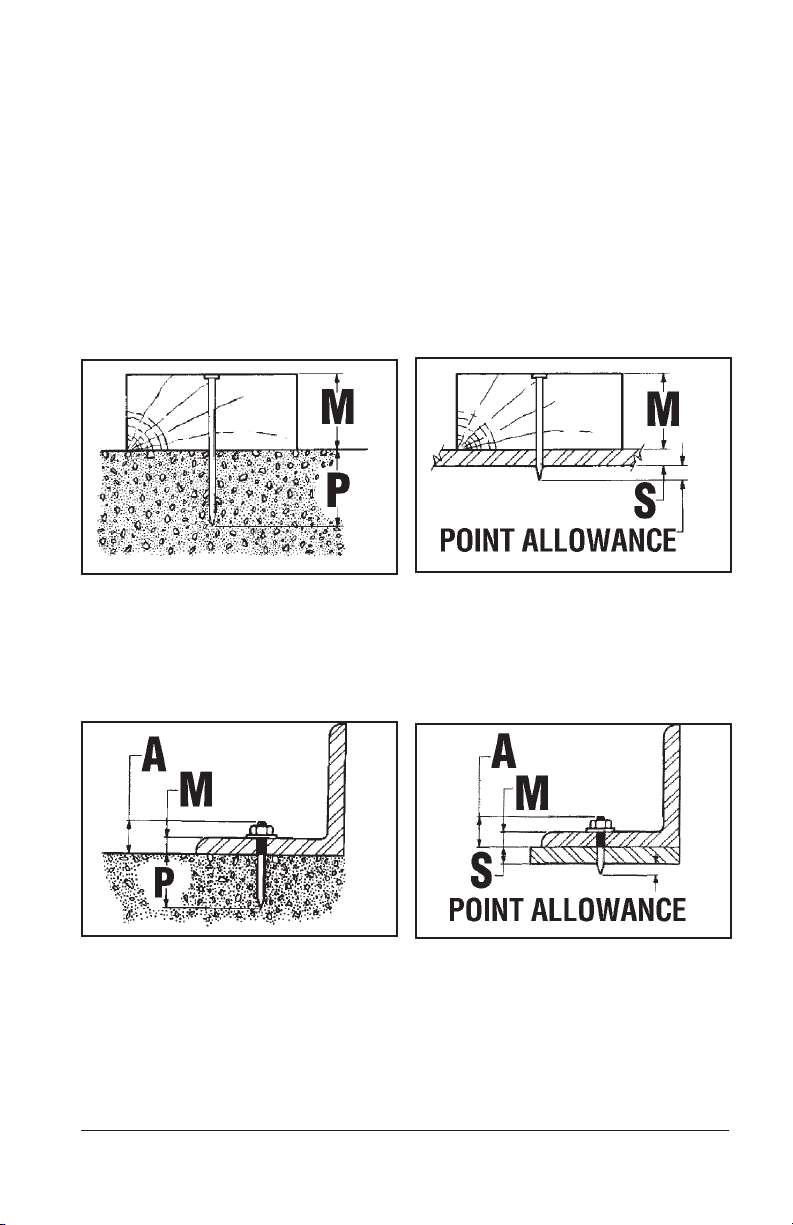

PERMANENT INSTALLATION

1A To Concrete 1B To Steel

of

Minimum Thickness Required

Shank Length = of Material + Penetration

(M) (P)

Minimum Thickness Thickness

Shank Length = of Material + of Steel + 1/4" min. pt.

(M) (S) allowance

REMOVABLE INSTALLATION

2A To Concrete 2B To Steel

Thread Thickness Allowance*

Length = of Material + for

(A) (M) Nut &Washer

Shank Length = Required Penetration (P)

*Allowance for thickness of nut & washer = thread size (i.e. allow 1/4" for 1/4-20 thread, etc.)

Thread Thickness Allowance*

Length = of Material + for

(A) (M) Nut &Washer

Minimum Thickness of 1/4" min. pt.

Shank Length

=

Steel (S) + allowance

SAFETY PRECAUTIONS 12

OPERATOR'S EXAMINATION

After studying and understanding the material in this tool manual, answer the

following questions. Complete the information on the other side of this page. Enclose

a copy of your sales receipt and send to the address on the back of this manual to

activate your tool warranty and receive your tool license. Operator's license can also

be obtained at: www.ramset.com

1. Safety goggles and hearing protection must

always be worn by the operator and any necessary bystanders when using the tool.

■ True ■ False

2. The strongest power level should be tried first

when making the first fastening.

■ True ■ False

3. Never attempt to fire the tool until the muzzle end

is compressed against the work surface and you

are ready to make a fastening.

■ True ■ False

4. Sheet rock, drywall board, wood, fiberglass,

ceramic tile, brick and thin sheet metal are

examples of materials not to be fastened into.

■ True ■ False

5. A powder actuated tool can be safely used in an

explosive or flammable atmosphere.

■ True ■ False

6. Malfunctioning tools can be used and do not have

to be removed from service immediately?

■ True ■ False

7. When operating a powder actuated tool, your hand

should never be placed in front of the tool muzzle.

■ True ■ False

8. Poured concrete and structural steel are suitable

materials for fastening into.

■ True ■ False

9. To determine the suitability of a base material,

use a fastener as a center punch as follows:

A) If the fastener is blunted, do not fasten; the

material is too hard.

B) If the fastener penetrates easily, do not fasten;

the material is too soft.

C)

If the material cracks or shatters, do not fasten;

the material is too brittle. ■ True ■ False

10. In concrete, a fastener should be driven no

closer to a free edge than 3".

■ True ■ False

11. When fastening into concrete, the base

material should be greater than the shank

penetration by at least 3 times.

■ True ■ False

■ True ■ False

■ True ■ False

12. Do not drive fasteners into steel that is thinner

than 3/16".

■ True ■ False

13. Powder actuated tools, fasteners and loads,

must always be kept in a secure, locked area

when not in use to avoid access by unauthorized persons.

■ True ■ False

14. When considering the safety of a particular

application, the operator must think about all

of the following: a) the powder load power

level, b) the operator's safety, c) the safety of

bystanders and fellow workers, d) the base or

receiving material.

■ True ■ False

15. It is not necessary to read the Operator's

Manual prior to operating the Model HD22 low

velocity powder actuated tool.

■ True ■ False

16. The best way to check the receiving material

is to set several fasteners using the most

powerful load.

■ True ■ False

17. Piston overdrive is caused by overpowering

of the tool or by discharging the tool against

a soft surface.

■ True ■ False

18. One should never attempt to pry a stuck load

out of a tool.

■ True ■ False

19. Placing a hand over the muzzle end of a loaded

tool can result in serious injury from piston

overdrive or an escaping fastener if the tool is

discharged accidentally.

■ True ■ False

Signed ____________________________

Date ______________________________

13 OPERATOR'S EXAMINATION

LICENSE AND WARRANTY ACTIVATION

The Model HD22 Tool is warranted for 90 days from date of purchase.

I certify that I have read and understand the Model HD22 Tool Operator's Instruction

and Training Manual and have taken the Operator's Exam on the reverse side.

(Please Print Clearly)

The serial number on my tool is: ______________________________________

Please send my tool license to:

Name ___________________________________________________________

Address _________________________________________________________

City _______________________ State ________________ Zip _____________

Phone ___________________________________________________________

Email ___________________________________________________________

o Yes. I would like to receive product updates and information from Ramset.

RETURN TO:

In USA

ITW Brands

ATTN: License Coordinator

955 National Parkway, Suite 95500

Schaumburg, IL 60173

In CANADA

ITW Construction Products

ATTN: Retail Marketing

120 Travail Road, Markham

Ontario, L3S 3J1

Loading...

Loading...