Original instructions

3/19

OPERATOR'S MANUAL

OMRSSRENG.319

SCRAP SHEAR

RAMMER RSS05R, RSS08R, RSS11R, RSS15R,

RSS23R, RSS34R, RSS45R, RSS58R, RSS80R

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1. Foreword . . . . . . . . . . . . . . . . . . . . . . . . 4

This manual . . . . . . . . . . . . . . . . . . . . . . 4

Important safety information . . . . . . . . . 5

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . 6

Spare part orders. . . . . . . . . . . . . . . . . . . 6

2. Machine numbers . . . . . . . . . . . . . . . . . . 7

Model and serial number . . . . . . . . . . . . 7

3. Product introduction. . . . . . . . . . . . . . . . 9

Overview. . . . . . . . . . . . . . . . . . . . . . . . . 9

Removal from package . . . . . . . . . . . . . . 9

Lifting instructions . . . . . . . . . . . . . . . . . 9

Main parts . . . . . . . . . . . . . . . . . . . . . . 12

Environmental protection and recycling

policy . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . 14

General safety . . . . . . . . . . . . . . . . . . . . 14

Safety instructions . . . . . . . . . . . . . . . . . 14

5. Operation . . . . . . . . . . . . . . . . . . . . . . . 26

Operating instructions. . . . . . . . . . . . . . 26

Daily operation . . . . . . . . . . . . . . . . . . . 28

Mounting and dismounting the product 34

Movement. . . . . . . . . . . . . . . . . . . . . . . 38

Special conditions of use . . . . . . . . . . . . 39

Storage . . . . . . . . . . . . . . . . . . . . . . . . . 39

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . 41

1. Greasing . . . . . . . . . . . . . . . . . . . . . . . . 42

Recommended greases. . . . . . . . . . . . . . 42

Greasing points . . . . . . . . . . . . . . . . . . . 42

2. Carrier hydraulic oil . . . . . . . . . . . . . . . 44

Requirements for hydraulic oil . . . . . . . 44

Oil cooler . . . . . . . . . . . . . . . . . . . . . . . 46

Oil filter . . . . . . . . . . . . . . . . . . . . . . . . 47

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . 49

1. Routine maintenance . . . . . . . . . . . . . . 50

Overview. . . . . . . . . . . . . . . . . . . . . . . . 50

Inspection and maintenance by the

operator . . . . . . . . . . . . . . . . . . . . . . . . 50

Inspection and maintenance by the

dealer . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Maintenance intervals in special

applications. . . . . . . . . . . . . . . . . . . . . . 52

Other maintenance procedures . . . . . . . 52

2. Turning and changing cutting blades . . 53

Wear limits, adjustments and torques for

cutting blades . . . . . . . . . . . . . . . . . . . . 53

Turning and changing cutting blades. . . 54

3. Hardfacing the jaw . . . . . . . . . . . . . . . . 57

Welding tools . . . . . . . . . . . . . . . . . . . . 57

Hardfacing crusher jaw . . . . . . . . . . . . . 57

4. Adjusting regulator clearance recovery . 59

Torques for screws . . . . . . . . . . . . . . . . 59

Adjusting a clearance . . . . . . . . . . . . . . 59

5. Adjusting regulator lateral guides. . . . . 61

Torques for screws . . . . . . . . . . . . . . . . 61

Adjusting the regulator lateral guides . . 61

6. Replacing lateral guide bushing . . . . . . 63

Torques for screws . . . . . . . . . . . . . . . . 63

Replacing lateral guide bushing . . . . . . 63

7. Changing oil in the rotation unit . . . . . 66

Description . . . . . . . . . . . . . . . . . . . . . . 66

Changing oil in the rotation unit . . . . . 66

8. Troubleshooting. . . . . . . . . . . . . . . . . . 68

Product does not crush . . . . . . . . . . . . . 68

Product does not cut. . . . . . . . . . . . . . . 68

Jaw does not move . . . . . . . . . . . . . . . . 68

Excessive moving . . . . . . . . . . . . . . . . . 69

Oil leakage . . . . . . . . . . . . . . . . . . . . . . 69

Product does not rotate . . . . . . . . . . . . 69

Further assistance . . . . . . . . . . . . . . . . . 69

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . 71

1. Product specifications. . . . . . . . . . . . . . 72

Technical specifications RSS05R . . . . . 72

Main dimensions RSS05R . . . . . . . . . . 73

Technical specifications RSS08R . . . . . 74

Main dimensions RSS08R . . . . . . . . . . 75

Technical specifications RSS11R . . . . . 76

Main dimensions RSS11R . . . . . . . . . . 77

Technical specifications RSS15R . . . . . 78

Main dimensions RSS15R . . . . . . . . . . 79

Technical specifications RSS23R . . . . . 80

Main dimensions RSS23R . . . . . . . . . . 81

Technical specifications RSS34R . . . . . 82

Main dimensions RSS34R . . . . . . . . . . 83

Technical specifications RSS45R . . . . . 84

Main dimensions RSS45R . . . . . . . . . . 85

Technical specifications RSS58R . . . . . 86

Main dimensions RSS58R . . . . . . . . . . 87

Technical specifications RSS80R . . . . . 88

Main dimensions RSS80R . . . . . . . . . . 89

2. EC Declaration of Conformity . . . . . . . 90

RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

OPERATION

Operation - Page 3COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Foreword RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

1. FOREWORD

1.1 THIS MANUAL

This manual is arranged to give you a good understanding of the product and its safe

operation. It also contains maintenance information and technical specifications.

Read this manual from front to back before installing, operating or maintaining the

product for the first time.

In this manual, the units of measurement are metric. For example, weights are given

in kilograms (kg). In some cases, an other unit follows in parenthesis (). For

example 28 litres (7.4 US gal).

The specifications and designs presented in this manual are subject to change

without prior notice.

SYMBOLS USED IN THIS MANUAL

This symbol identifies important safety messages within this manual. Carefully read

the message that follows. Failure to understand and obey this safety warning could

result in injury to you or others, and could also cause damage to product. See

illustration 1.

This symbol identifies prohibited action or hazardous location. Failure to

understand and obey this safety warning could result in injury to you or others, and

could also cause damage to product. See illustration 2.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 4 - Operation

RSS45R, RSS58R, RSS80R

R010265

This symbol identifies correct and recommended action. See illustration 3.

This symbol identifies environmental and recycling matter. See illustration 4.

ForewordRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

1.2 IMPORTANT SAFETY INFORMATION

Basic safety precautions are outlined in the "Safety" section of this manual and in

the instructions where hazards exist. These warnings are identified by a warning

symbol.

To use the product correctly, you must also be a competent operator of the carrier.

Do not use or install it if you cannot use the carrier. The product is a powerful tool.

Used without proper care, it can cause damage.

Do not rush when you are learning to use the product. Take your time and most

importantly, take it safely. Do not guess. If there is anything you do not understand,

ask your local dealer.

Improper operation, lubrication or maintenance of this product can be dangerous

and could result in injury.

Do not operate this product until you read and understand the instructions in this

manual.

Do not perform any lubrication and maintenance on this product until you read and

understand the instructions in this manual.

Operation - Page 5COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Foreword RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

1.3 WARRANTY

The customer is provided with a separate warranty sheet, where the export warranty

terms are explained. Check always that this warranty sheet is provided with the

product. If not, contact your local dealer immediately.

WARRANTY REGISTRATION CARD

A warranty registration card is filled out after the installation inspection by the

dealer and a copy of it is sent to the manufacturer. This card is very important

because no warranty claims are handled without it. Make sure that you get a copy

of it after the installation inspection and that it is correctly filled out.

INSTALLATION INSPECTION

An installation inspection must be carried out after the product has been installed on

the carrier. During the installation inspection, certain specifications (operating

pressure, oil flow, etc.) are checked so that they are within given limits. See

“Product specifications” on page 72.

1.4 SPARE PART ORDERS

When you need spare parts or some information concerning maintenance to your

product, please contact your local dealer. Quick deliveries are ensured by exact

orders.

Required information:

■ Name of customer, contact person

■ Order number (when available)

■ Delivery address

■ Mode of delivery (air mail, etc.)

■ Required delivery date

■ Invoicing address

■ Model and serial number of product

■ Name, number and required amount of spare parts

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 6 - Operation

RSS45R, RSS58R, RSS80R

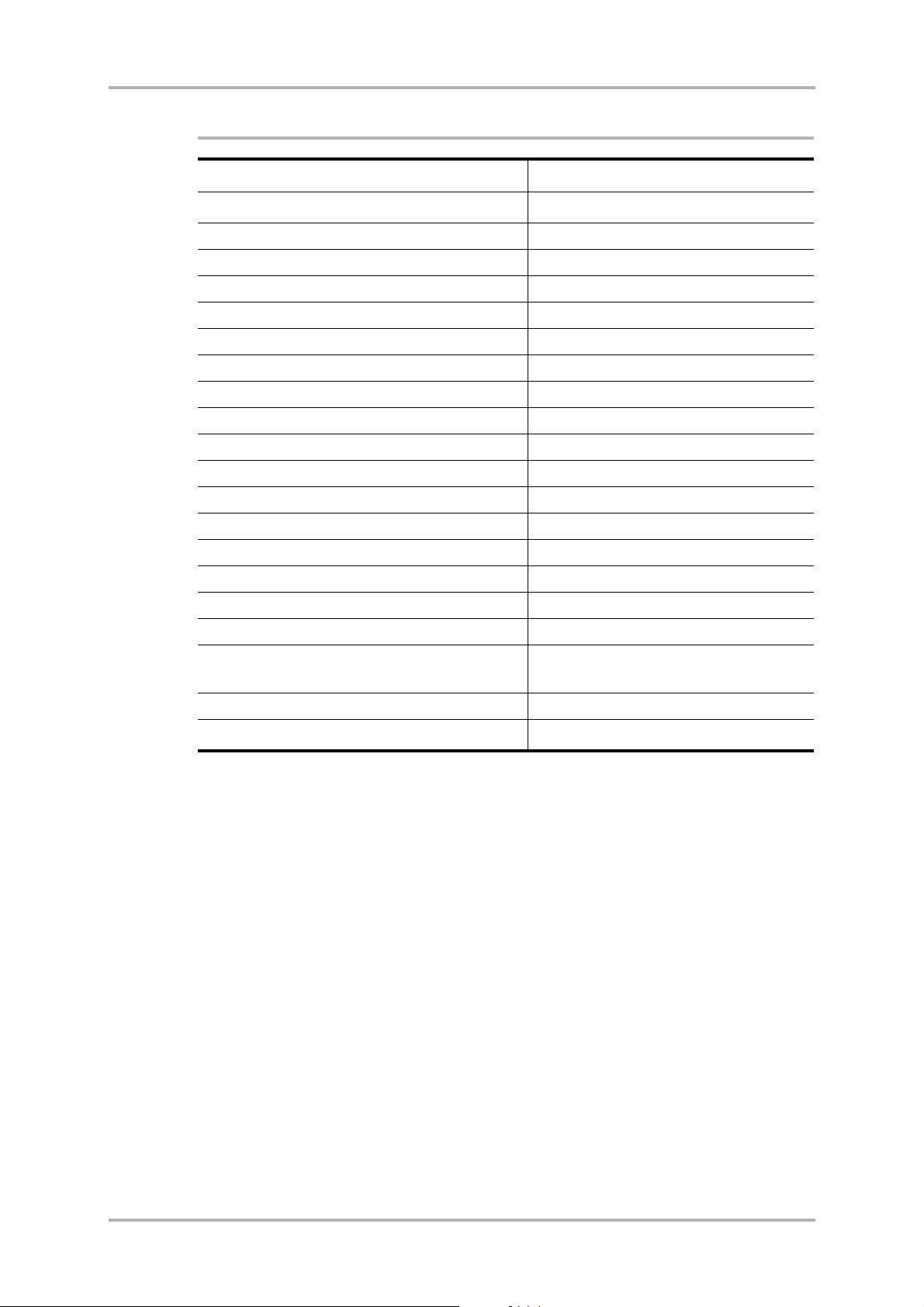

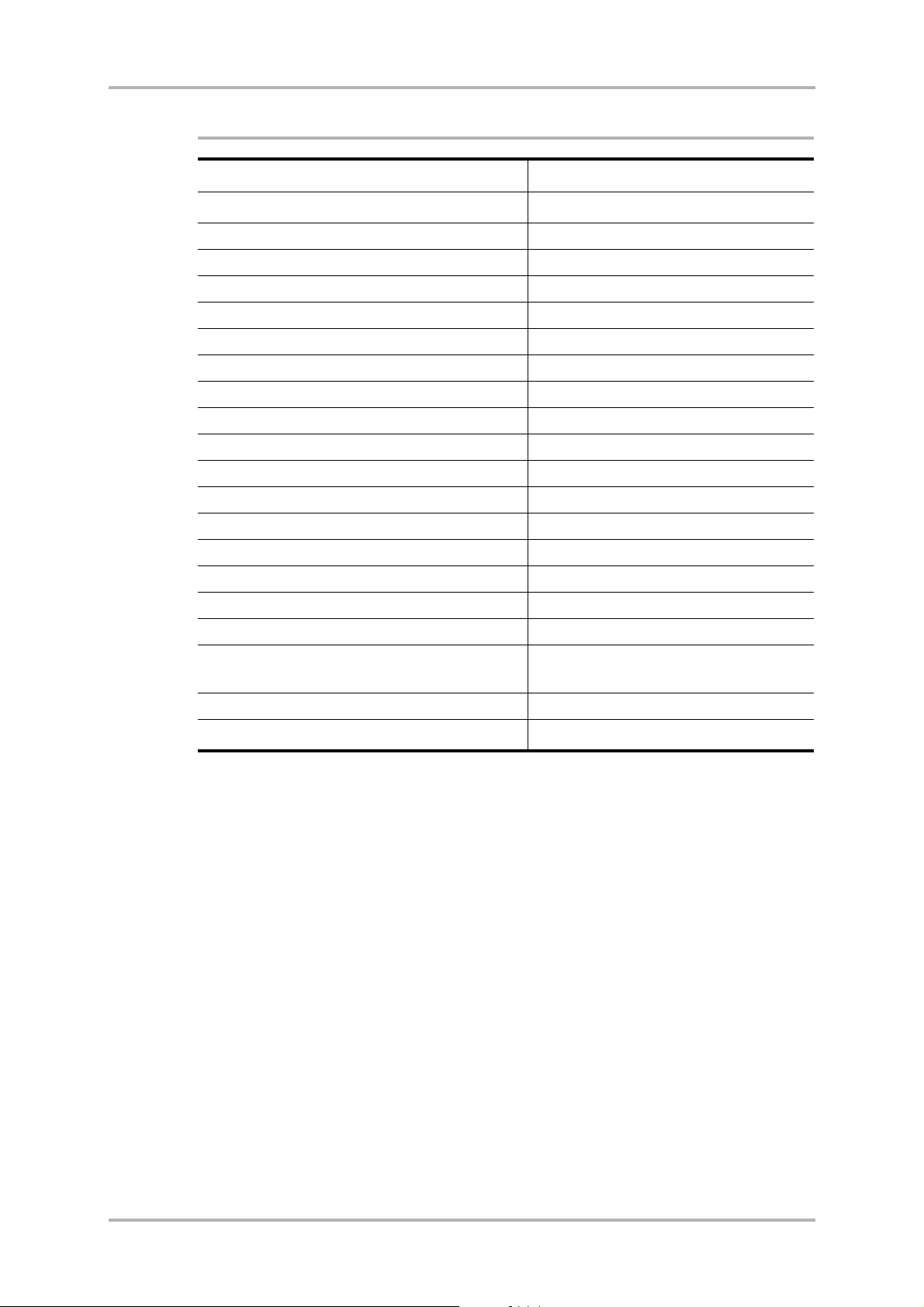

Sandvik Mining and Construction Oy, Taivalkatu 8, 15170 LAHTI, FINLAND

Demolition tool

Manufactured by: MANTOVANIBENNE srl

n° 6, Via Righi - 41037 MIRANDOLA (Mo) ITALY

Serial number

Model

Manufactured

Weight (kg)

Min working

weight (kg)

Max cylinder pressure (bar)

Max rotation pressure (bar)

Max cylinder oil flow (l/min)

Max rotation oil flow (l/min)

2

3

4

5

6

7

8

9

10

1

11

S/N

MB010161

2. MACHINE NUMBERS

2.1 MODEL AND SERIAL NUMBER

The product serial number is stamped on the product body. The model and serial

number are also located on the product identification plate.

It is important to make correct reference to the serial number of the product when

making repairs or ordering spare parts. Identification of the serial number is the only

proper means of maintaining and identifying parts for a specific product.

See the following figure for the location of the serial number on your product

model.

Machine numbersRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

1

S/N

2

Serial number

3

Sandvik Mining and Construction Oy, Taivalkatu 8, 15170 LAHTI, FINLAND

Model

4

5

Manufactured

6

Demolition tool

Max cylinder pressure (bar)

Weight (kg)

Min working

weight (kg)

Manufactured by: MANTOVANIBENNE srl

n° 6, Via Righi - 41037 MIRANDOLA (Mo) ITALY

Max rotation pressure (bar)

Max cylinder oil flow (l/min)

Max rotation oil flow (l/min)

7

8

9

10

11

MB010160

Operation - Page 7COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Machine numbers RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

CONTENT OF THE PRODUCT IDENTIFICATION PLATE

1 Demolition tool

2 Serial number

3 Model

4 Weight (kg)

5 Min working weight (kg)

6 Manufactured

7 Max cylinder pressure (bar)

8 Max rotation pressure (bar)

9 Max cylinder oil flow (l/min)

10 Max rotation oil flow (l/min)

11 Manufactured by

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 8 - Operation

RSS45R, RSS58R, RSS80R

3. PRODUCT INTRODUCTION

3.1 OVERVIEW

The product is a hydraulically operated scrap shear. It can be used on any carrier

which meets the necessary hydraulic and mechanical installation requirements.

3.2 REMOVAL FROM PACKAGE

Remove all the steel belts from the package. Open the package and remove all

plastics covering the product. Recycle all package materials (steel, plastic, wood)

properly.

Check that the product is in good condition and that there is no visible damage.

Check that all ordered parts and accessories have been enclosed with the product.

Some options may be provided by your local dealer, such as installation kits,

including hoses and mounting bracket.

Product introductionRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

3.3 LIFTING INSTRUCTIONS

Use a hoist when lifting components which weigh 23 kg (51 lb) or more, to avoid

back injury. Make sure all chains, hooks, slings, etc., are in good condition and are

in the correct capacity. Make sure hooks are positioned correctly. Do not side load

the lifting eye during a lifting operation.

PROVIDED LIFTING POINTS

The lifting points located on the product frame are to be used solely to lift or handle

the product itself. The lifting capacity calculation is based on the product's working

weight, including an average sized mounting bracket.

Warning! To avoid falling objects, do not use the product to lift other products.

The lifting points located on the product frame are to be used solely to lift or

handle the product itself.

The maximum allowed total weight is shown on the product's identification plate

and specification page. See “Product specifications” on page 72. If the weight

exceeds the maximum allowed total weight shown on the identification plate and

specification page, you will have to use other lifting points/methods than originally

provided on the product.

Operation - Page 9COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Product introduction RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

G010014

RSS45R, RSS58R, RSS80R

The other threaded holes on the product are intended for handling single parts only.

You must not lift the entire assembly by using these threaded holes. For handling

the parts, see product workshop documentation for suitable lifting methods and

lifting adapters.

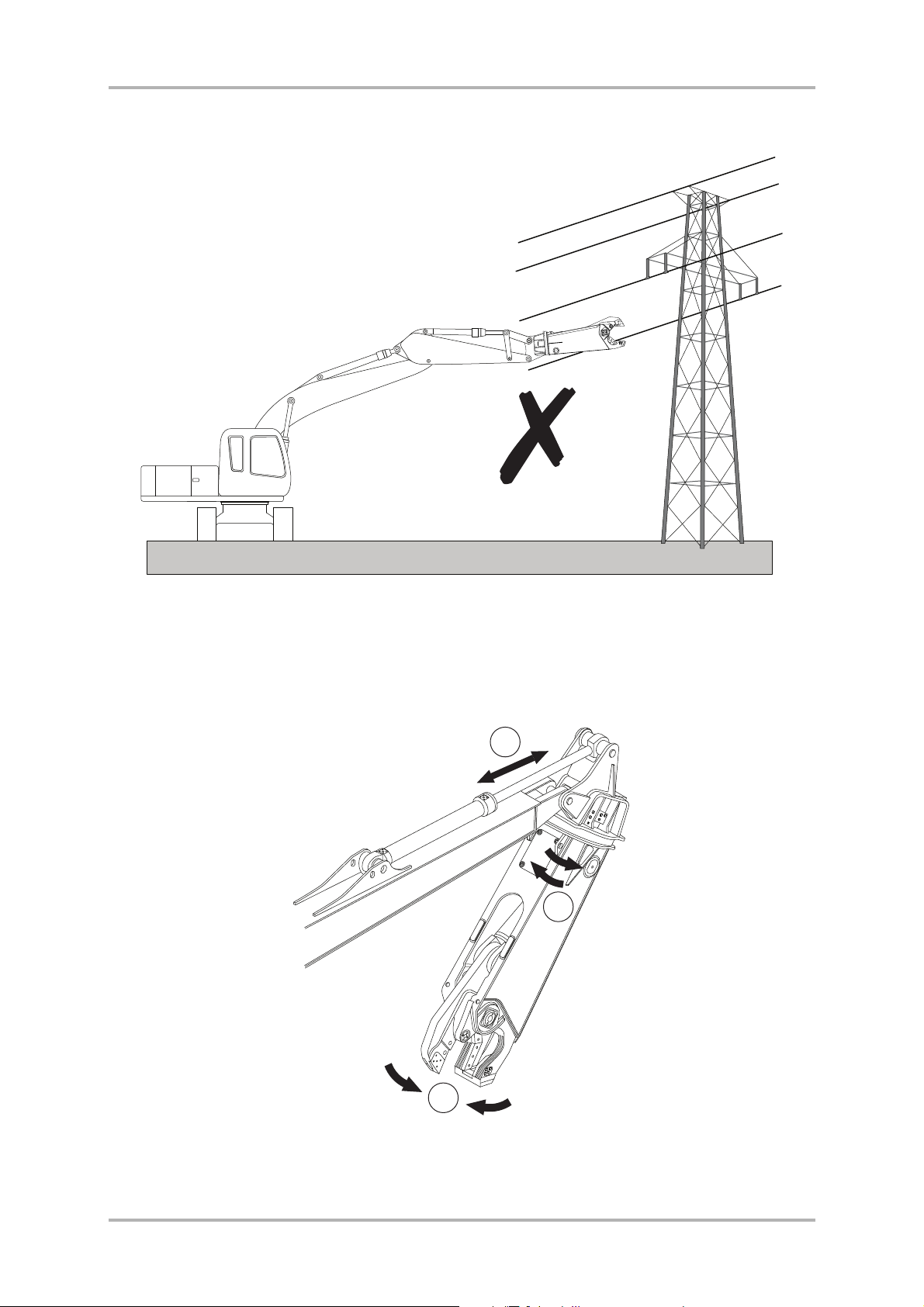

LIFTING EYE SCREWS

If lifting eye screws are used, lifting eye screws must be completely tightened. The

lifting eye can be loaded only if the screw is properly tightened to the frame.

Failure to properly tighten the screw before allowing load pressure on the

lifting eye may cause lifting eye to break and free fall of the product.

If you use mechanical tools for tightening, make sure not to overstrain the shank.

Before lifting, make sure that the rope and/or hook is stretched.

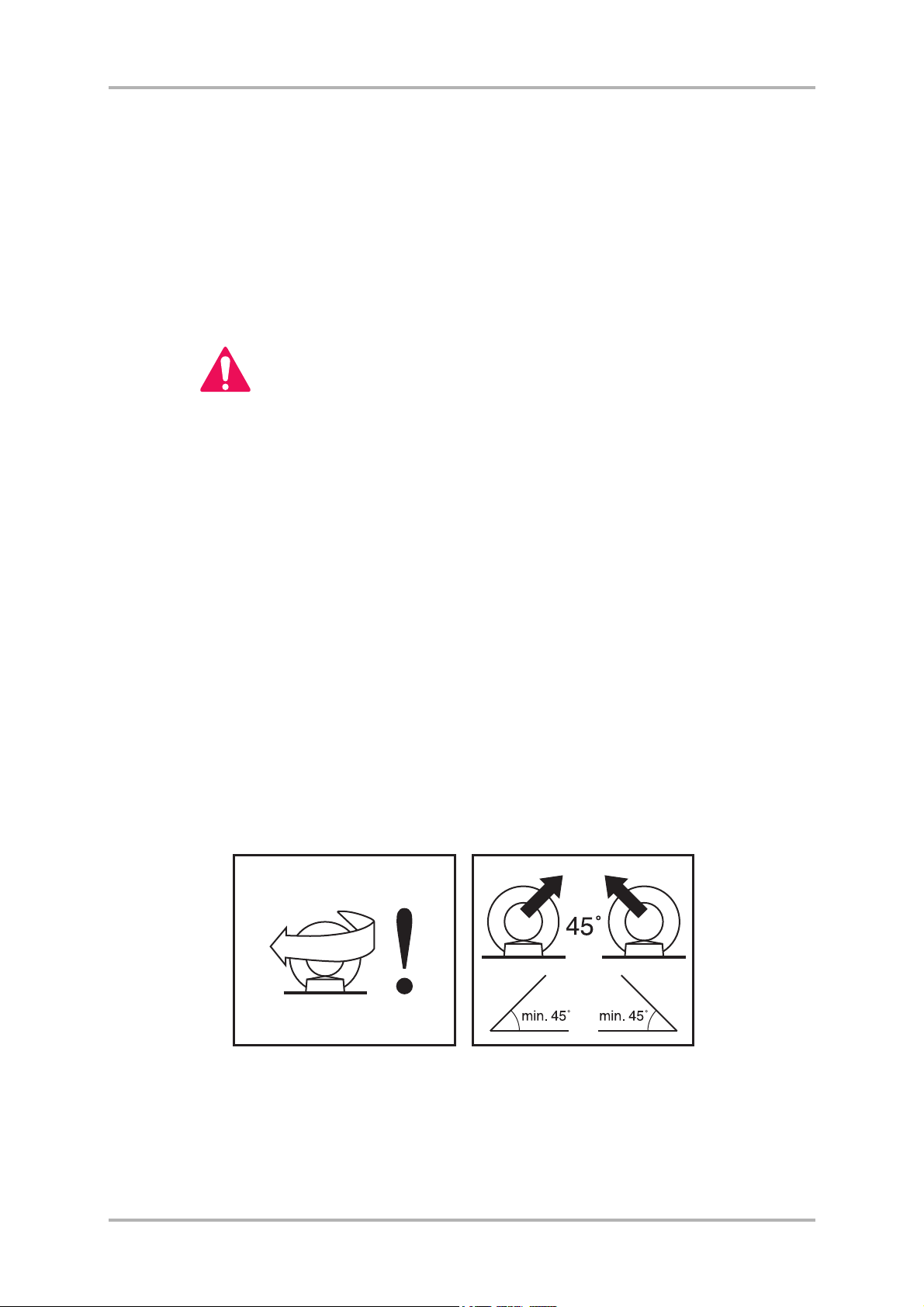

When two lifting points are used, the lifting capacity depends on the angle of the

lifting chains. The angle should not be less than 45°, as shown in the illustration.

When the lifting eye screws are tightened, both rings should be aligned.

The loading capacity calculation applies to temperatures between -10 °C (14 °F)

and 40 °C (104 °F).

Before reuse of lifting eye screws, make sure there are no surface flaws (for example

pits, voids, folds and seams, deformation of the ring, missing or broken threads,

rust, etc.).

The local, national safety standards for machines and lifting-tackles must always be

strictly observed.

Note: The lifting eye must always be removed from the product and replaced with

a screw before operation.

Lifting devices must safely carry the working weight of the product. See “Product

specifications” on page 72.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 10 - Operation

RSS45R, RSS58R, RSS80R

Place a chain or sling as shown in the illustration to lift the product.

Product introductionRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

MB010013

Note: The lifting eye screws must always be removed from the product and replaced

with a screw before operation.

SAFETY INSTRUCTIONS FOR LIFTING

Below are some common safety instructions concerning lifting operations. In

addition to this, the local, national standards for machines and lifting-tackles must

always be strictly observed. Please note that the list below is not all inclusive, you

must always ensure the procedure you choose is safe for you and others.

■ Do not lift the load over people. No one must be under the hoisted load.

■ Do not lift people and never ride the hoisted load.

■ Keep people clear from the lift area.

■ Avoid side pull of the load. Make sure you take up the slack slowly. Start and

stop carefully.

■ Lift the load a few centimeters and verify it before proceeding. Make sure the

load is well balanced. Check for any loose items.

■ Never leave the suspended load unattended. Maintain load control at all times.

■ Never lift the load over the rated capacity (see the product's operating weight

from the specification page).

■ Inspect all lifting product before use. Do not use twisted or damaged lifting

product. Protect lifting product from sharp corners.

■ Obey all local safety instructions.

Operation - Page 11COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Product introduction RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

MB010020

A

C

E

B

D

D

D

F

RSS45R, RSS58R, RSS80R

3.4 MAIN PARTS

The main parts of the scrap shear are shown below.

A. Mounting bracket

B. Jaw

C. Thrust bearing

D. Cutting blades

E. Cylinder

F. Frame

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 12 - Operation

RSS45R, RSS58R, RSS80R

3.5 ENVIRONMENTAL PROTECTION AND RECYCLING POLICY

Rammer products support the recycling of materials to help customers achieve their

environmental objectives. During manufacturing all necessary precautions are

taken to make sure that no harm is done to the environment.

Every effort is made to foresee and minimize the risks that might be associated with

the operation and maintenance of Rammer products, and which could pose danger

to humans or the environment. We support customers in their efforts to consider the

environmental protection in their everyday work.

When working with a Rammer product please follow these guidelines:

■ Dispose of packaging materials properly. Wood and plastic can be burned or

recycled. Deliver the steel belts to metal recycling center.

■ Protect the environment from oil spills.

In case of hydraulic oil leaks, the product should be serviced immediately.

Follow the product's greasing instructions and avoid excessive greasing.

Product introductionRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

Be careful when handling, storing and transporting oils.

Dispose of empty oil or grease containers appropriately.

Consult local authorities for detailed instructions.

■ All metal parts of the product can be recycled by delivering them to an

authorized scrap metal collection facility.

■ Comply with local waste classification rules when disposing of used rubber or

plastic parts (wear plates, seals).

Consult with your local dealer for more information.

Operation - Page 13COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Safety RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

4. SAFETY

4.1 GENERAL SAFETY

All mechanical product can be hazardous if operated without due care or correct

maintenance. Most accidents involving machine operation and maintenance are

caused by failure to observe basic safety rules or precautions. An accident can often

be avoided by recognizing potentially hazardous situations before an accident

occurs.

Because it is impossible to anticipate every possible circumstance that might

involve a potential hazard, the warnings in this guide and on the product are not all

inclusive. If a procedure, tool, working method or operating technique not

specifically recommended by manufacturer is used, you must satisfy yourself that

it is safe for you and others. You should also ensure that the product will not be

damaged or made unsafe by the method of operation or maintenance procedures you

choose.

Safety is not just a matter of responding to the warnings. All the time you are

working with your product you must pay attention to what hazards there might be

and how to avoid them. Do not work with the product until you are sure that you can

control it. Do not start any job until you are sure that you and those around you will

be safe.

Warning! Read the following warning messages carefully. They tell you of

different hazards and how to avoid them. If proper precautions are not taken,

you or others could be seriously injured.

4.2 SAFETY INSTRUCTIONS

MANUALS

Study this manual before installing, operating or maintaining the product. If there is

anything you do not understand, ask your employer or your local dealer to explain

it. Keep this manual clean and in good condition.

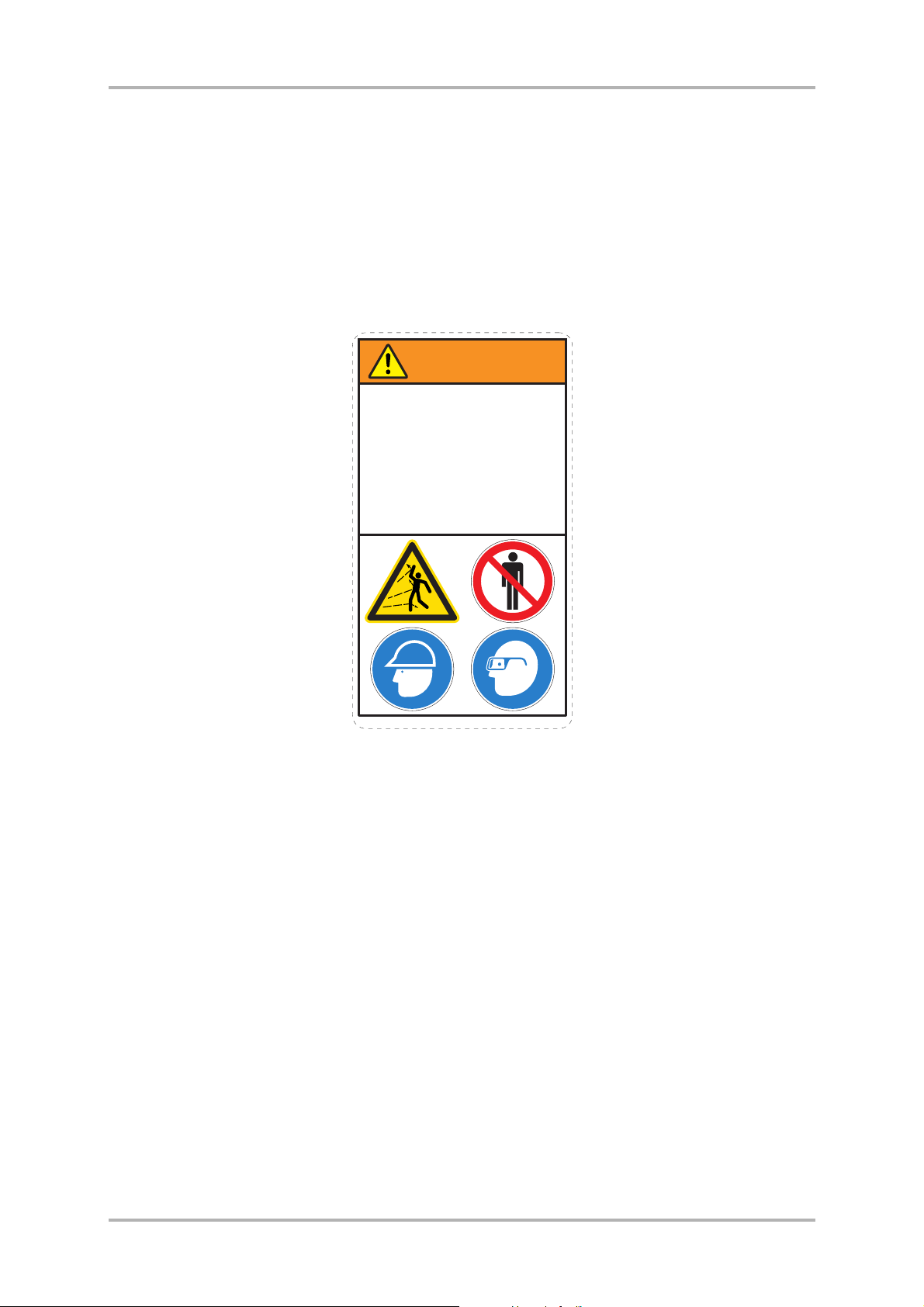

The related safety label on the product and the text on the label are shown below.

"IGNORING INSTRUCTIONS HAZARD

Faulty handling practice could cause death or serious injury.

Read and follow the instructions in the operator's manual."

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 14 - Operation

RSS45R, RSS58R, RSS80R

R010348

IGNORING

INSTRUCTIONS HAZARD

Faulty handling practice could

cause death or severe injury.

Read and follow the instructions

in the operator’s manual.

WARNING

169410_ENG-3

SafetyRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

CARE AND ALERTNESS

All the time you are working with the product, take care and stay alert. Always be

alert for hazards. The possibility of a serious or even fatal accident is increased

when you are intoxicated.

CLOTHING

You can be injured if you do not wear proper clothing. Loose clothing can get

caught in the machinery. Wear protective clothing to suit the job.

Examples are: a safety helmet, safety shoes, safety glasses, well-fitting overalls,

ear-protectors and industrial gloves. Keep cuffs fastened. Do not wear a necktie or

scarf. Keep long hair restrained.

PRACTICE

You and others can be killed or injured if you perform unfamiliar operations without

practicing them first. Practice away from the job site, in a clear area.

Keep other people away. Do not perform new operations until you are sure you can

do them safely.

REGULATIONS AND LAWS

Obey all laws, work site and local regulations which affect you and your product.

Operation - Page 15COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Safety RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

R010214

RSS45R, RSS58R, RSS80R

COMMUNICATIONS

Bad communications can cause accidents. Keep people around you informed of

what you will be doing. If you will be working with other people, make sure they

understand any hand signals you will be using.

Worksites can be noisy. Do not rely on spoken commands.

WORKSITE

Worksites can be hazardous. Inspect the site before working on it.

Check for potholes, weak ground, hidden rocks, etc. Check for utilities (electric

cables, gas and water pipes, etc.). Mark the positions of cables and pipes.

Poor visibility can cause accidents and damage. Make sure that visibility and

lighting in the working area are adequate.

Worksites can be noisy. Wear ear protection to prevent personal injury.

BANKS AND TRENCHES

Banked material and trenches can collapse. Do not work too close to banks and

trenches where there is a danger of collapse.

SAFETY BARRIERS

Unguarded product in public places can be dangerous. Place barriers around

machinery to keep people away.

AIRBORNE POLLUTANTS

The related safety label on the product and the text on the label are shown below.

"DUST HAZARD

Breathing dust will cause death or severe injury.

Always wear approved respirator."

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 16 - Operation

RSS45R, RSS58R, RSS80R

R010349

DUST HAZARD

Breathing dust will cause death

or severe injury.

Always wear approved

respirator.

DANGER

169410_ENG-1

Airborne pollutants are microscopic particles, which will damage your health when

inhaled. Aiborne pollutants on construction sites can be for example silica dust, oil

fumes or diesel exhaust particles, visible or invisible. Especially in demolition sites,

there may be other dangerous substances, such as asbestos, lead paints or other

chemical substances.

SafetyRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

The effect of airborne pollutants may be immediate if the substance is poisonous.

The main danger with airborne pollutants comes from long term exposure, where

particles are inhaled but not removed from the lungs. The disease is called silicosis,

asbestosis or other, and will result in death or serious injury.

To protect yourself from airborne pollutants, always keep excavator doors and

windows closed during operation. Excavators with pressurized cabins should be

utilized in product operation. Proper maintenance of fresh air filters of the excavator

is essential. Where pressurized cabins are not available, proper respirators must be

utilized.

Stop working when bystanders are in the area of airborne pollutants and make sure

they have proper respirators. Respirators are as important for bystanders as hard

hats.Respirators for both operator and bystanders must be approved by the

respirator manufacturer for the application in question. It is essential that the

respirators protect from the tiny dust particles which cause silicosis and which may

cause other serious lung diseases. Do not use the product until you are sure the

respirators are working properly. This means each respirator must be checked to

make sure that it is clean, that its filter has been changed, and to otherwise make sure

the respirator will protect in the way it is meant to.

Always make sure dust has been cleaned off your boots and clothes when you leave

your shift. The smallest particles of dust are the most harmful. They may be so fine

that you cannot see them. Remember, you MUST protect yourself and bystanders

from the danger of breathing or inhaling dust.

Always follow local laws and regulations for airborne pollutants in the working

environment.

Operation - Page 17COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Safety RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

R010350

FLYING OBJECTS HAZARD

Fragments fly up to 40 m (130 ft)

and could cause death or severe

injury.

Stop operation when a

person enters hazard zone.

Wear approved personal

protective equipment.

WARNING

169410_ENG-2

RSS45R, RSS58R, RSS80R

FLYING DEMOLITION DEBRIS

The safety label on the product is shown below:

"FLYING OBJECTS HAZARD

Fragments fly up to 40 m (130 ft) and could cause death or serious injury.

Stop operation when a person enters hazard zone.

Wear approved personal protective product."

Protect yourself and your surroundings from flying debris. Do not operate the

product or carrier with people around it.

The European standard EN 474-1 on safety of earth-moving machinery requires that

adequate operator's protection, such as bullet proof glass, mesh guard or an

equivalent protection is used.

Keep the cabin windows and doors closed during operation. Window bars are

recommended to protect the windows from flying debris.

CRUSHING HAZARD

The safety label on the product is shown below:

"CRUSHING HAZARD

Contact with moving parts or material could cause death or severe injury.

Keep yourself and bystanders out of hazard zone."

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 18 - Operation

RSS45R, RSS58R, RSS80R

G010031

SafetyRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

COLLAPSING CONCRETE FRAMES

Protect yourself and your surroundings from collapsing concrete frames. Do not

operate the product or carrier with people around it.

PRODUCT LIMITS

Operating the product beyond its design limits can cause damage. It can also be

dangerous. See “Product specifications” on page 72.

Do not try to upgrade the product's performance by unapproved modifications.

HYDRAULIC FLUID

Fine jets of hydraulic fluid at high pressure can penetrate the skin. Do not use your

fingers to check for hydraulic fluid leaks. Do not put your face close to suspected

leaks. Hold a piece of cardboard close to suspected leaks and then inspect the

cardboard for signs of hydraulic fluid. If hydraulic fluid penetrates your skin, seek

medical help immediately.

Hot hydraulic fluid can cause severe injuries.

HYDRAULIC HOSES AND FITTINGS

Ensure all hydraulic components will withstand maximum pressure and mechanical

stresses caused by operation of the product. Consult your local dealer for

instructions.

Operation - Page 19COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Safety RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

FIRE HAZARD

Most hydraulic fluids are flammable and might ignite when contacting hot surface.

Avoid spilling hydraulic fluid to hot surfaces.

Working with the product on certain materials can cause sparks and hot splinters to

get loose. These can ignite flammable materials around working area.

Ensure that adequate extinguisher is available.

HYDRAULIC PRESSURE

Hydraulic fluid at system pressure can injure you. Before disconnecting or

connecting hydraulic hoses, stop the carrier engine and operate the controls to

release pressure trapped in the hoses. During operation, keep people away from the

hydraulic hoses.

There might be pressurized oil trapped inside the product even if it is disconnected

from the carrier. Be aware of possible unexpected jaw movements while

maintaining product.

LIFTING EQUIPMENT

You can be injured if you use faulty lifting equipment. Make sure that lifting

equipment is in good condition. Make sure that the lifting tackle complies with all

local regulations and is suitable for the job. Make sure that the lifting equipment is

strong enough for the job and you know how to use it.

Do not use this product or any of its parts for lifting. Contact your carrier dealer to

find out how to lift with your carrier.

SPARE PARTS

Use only genuine spare parts. Use only genuine cutting blades with scrap shears.

The use of other spare part or cutting blade brands may damage the product.

PRODUCT CONDITION

Defective product can injure you or others. Do not operate product which is

defective or has missing parts.

Make sure the maintenance procedures in this manual are completed before using

the product.

REPAIRS AND MAINTENANCE

Do not try to do repairs or any other maintenance work you do not understand.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 20 - Operation

RSS45R, RSS58R, RSS80R

MODIFICATIONS AND WELDING

Non-approved modifications can cause injury and damage. Contact your local

dealer for advice before modifying the product. Before welding on the product

while it is installed on the carrier, consult your carrier dealer for precautions in

welding.

METAL SPLINTERS

You can be injured by flying splinters when driving metal pins in and out. Use softfaced hammer or drifts to remove and fit metal pins, such as pivot pins. Always wear

safety glasses.

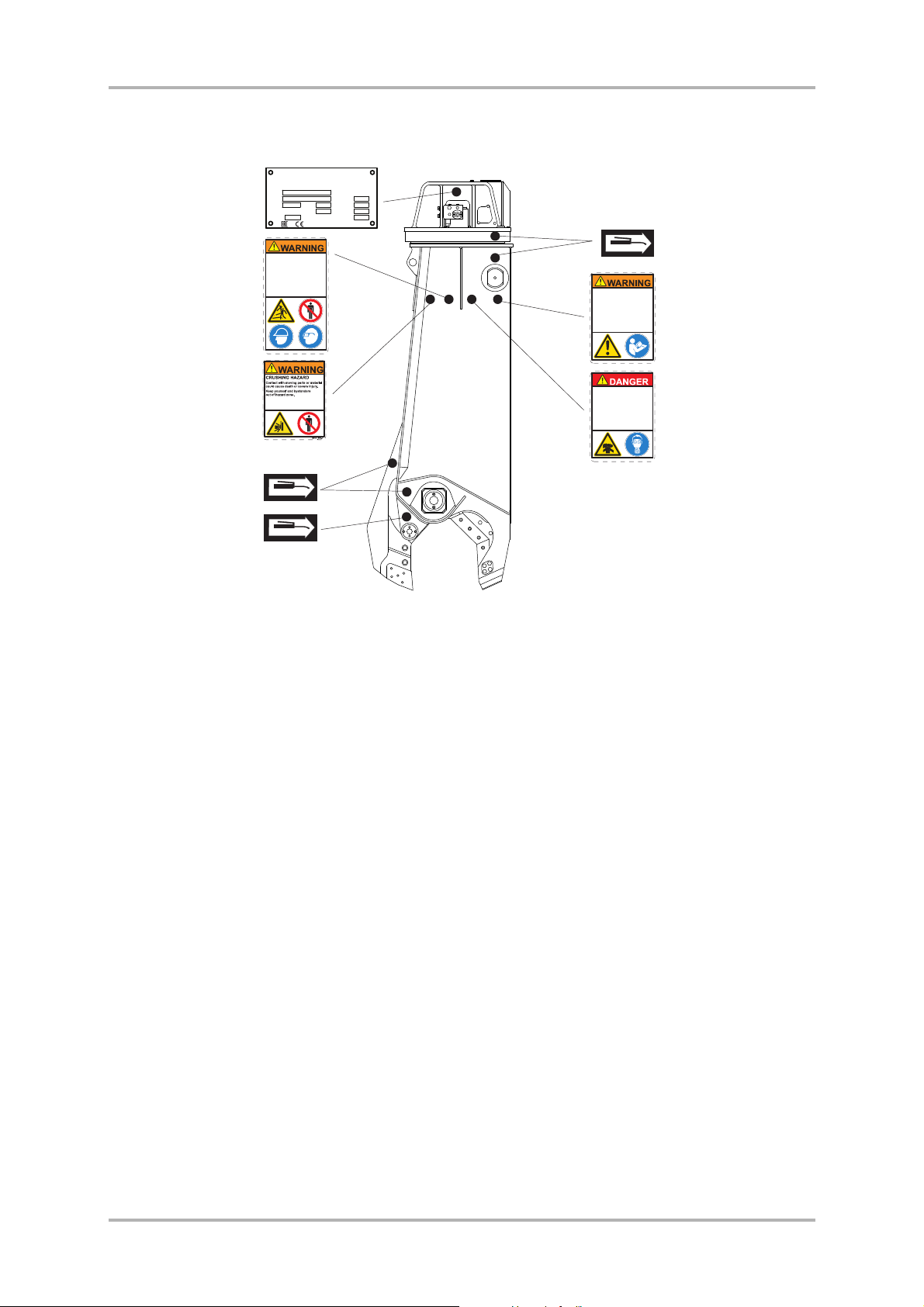

LABELS ON THE PRODUCT

Safety labels communicate the following four things:

■ The severity level of the risk (that is signal word "DANGER" or

"WARNING").

SafetyRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

■ The nature of the hazard (such as high pressure, dust, etc.).

■ The consequence of interaction with the hazard.

■ How to avoid the hazard.

You must ALWAYS follow the instructions in the safety messages, the messages

in the product safety labels and the instructions set forth in the manuals to avoid

death or severe injury!

Keep the safety labels clean and visible at all times. Check the condition of safety

labels daily. Safety labels and instructions which have disappeared, been damaged,

painted over, come loose, or do not meet the legibility requirements for safe viewing

distance must be replaced before operating the product.

If a safety label is attached to a part that is replaced, install a new safety label on the

replacement part. If this manual is available in your language, then the safety labels

should be available in the same language.

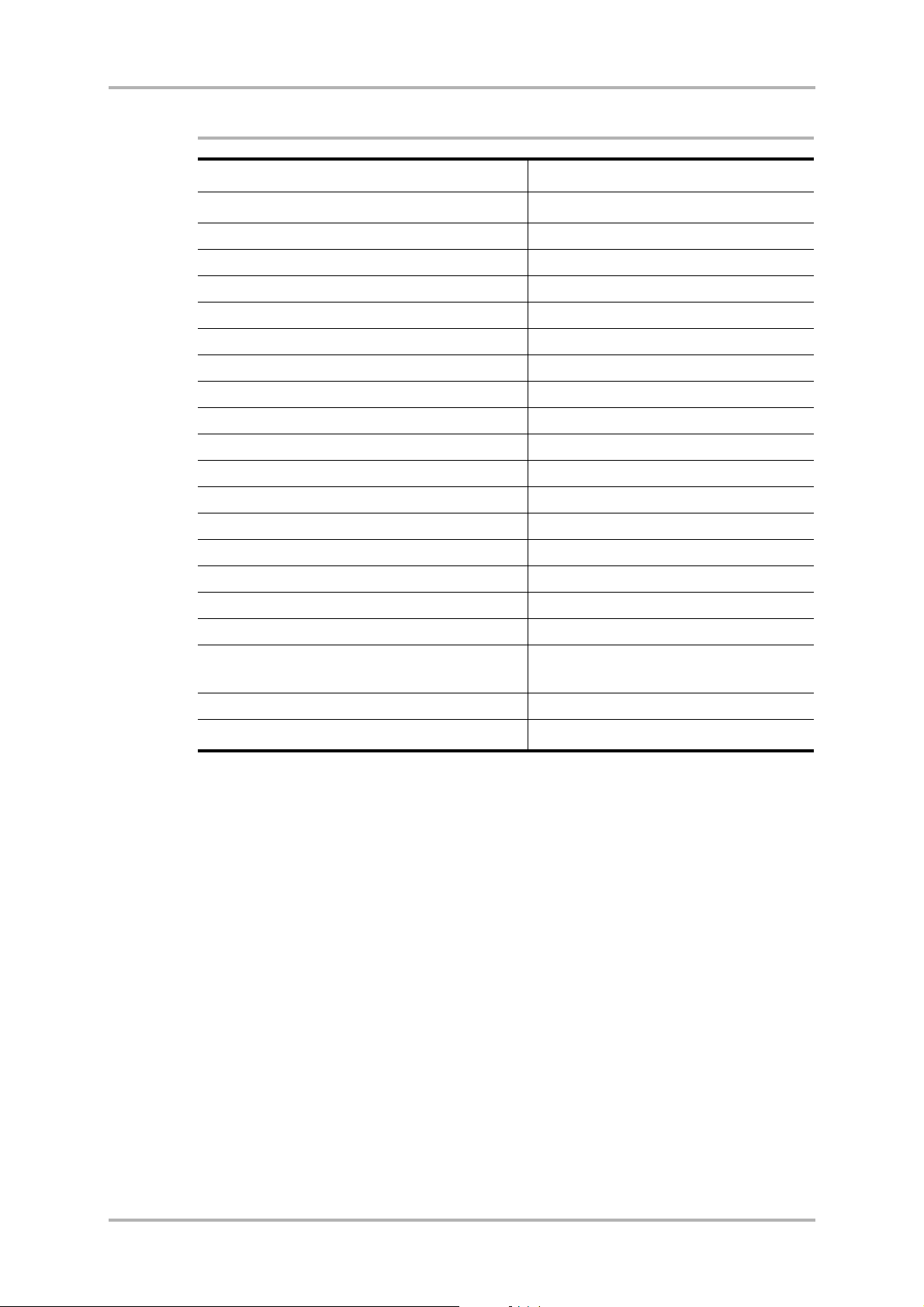

There are several specific safety labels on this product. Please become familiarized

with all safety labels. The location of the safety labels is shown in the illustration

below.

When you clean the safety labels, use a cloth, water and soap. Do not use solvent,

gasoline or other harsh chemicals to clean the safety labels.

Solvents, gasoline or harsh chemicals could loosen the adhesive that secures the

safety labels. Loose adhesive will allow the safety label to fall.

Operation - Page 21COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Safety RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

DUST HAZARD

Breathing dust will cause death

or severe injury.

Always wear approved

respirator.

169410_ENG-1

FLYING OBJECTS HAZARD

Fragments fly up to 40 m (130 ft)

and could cause death or severe

injury.

Stop operation when a

person enters hazard zone.

Wear approved personal

protective equipment.

169410_ENG-2

IGNORING

INSTRUCTIONS HAZARD

Faulty handling practice could

cause death or severe injury.

Read and follow the instructions

in the operator's manual.

169410_ENG-3

MB010110

Sandvik Mining and Construction Oy, Taivalkatu 8, 15170 LAHTI, FINLAND

Demolition tool

Manufactured by: MANTOVANIBENNE srl

n° 6, Via Righi - 41037 MIRANDOLA (Mo) ITALY

Serial number

Model

Manufactured

Weight (kg)

Min working

weight (kg)

Max cylinder pressure (bar)

Max rotation pressure (bar)

Max cylinder oil flow (l/min)

Max rotation oil flow (l/min)

RSS45R, RSS58R, RSS80R

RSS08R

Demolition tool

Sandvik Mining and Construction Oy, Taivalkatu 8, 15170 LAHTI, FINLAND

Serial number

Model

Manufactured

Max cylinder pressure (bar)

Max rotation pressure (bar)

Weight (kg)

Min working

Max cylinder oil flow (l/min)

weight (kg)

Max rotation oil flow (l/min)

Manufactured by: MANTOVANIBENNE srl

n° 6, Via Righi - 41037 MIRANDOLA (Mo) ITALY

DUST HAZARD

Breathing dust will cause death

or severe injury.

Always wear approved

respirator.

RSS15R

169410_ENG-1

IGNORING

INSTRUCTIONS HAZARD

Faulty handling practice could

cause death or severe injury.

Read and follow the instructions

in the operator's manual.

169410_ENG-3

FLYING OBJECTS HAZARD

Fragments fly up to 40 m (130 ft)

and could cause death or severe

injury.

Stop operation when a

person enters hazard zone.

Wear approved personal

protective equipment.

169410_ENG-2

MB010108

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 22 - Operation

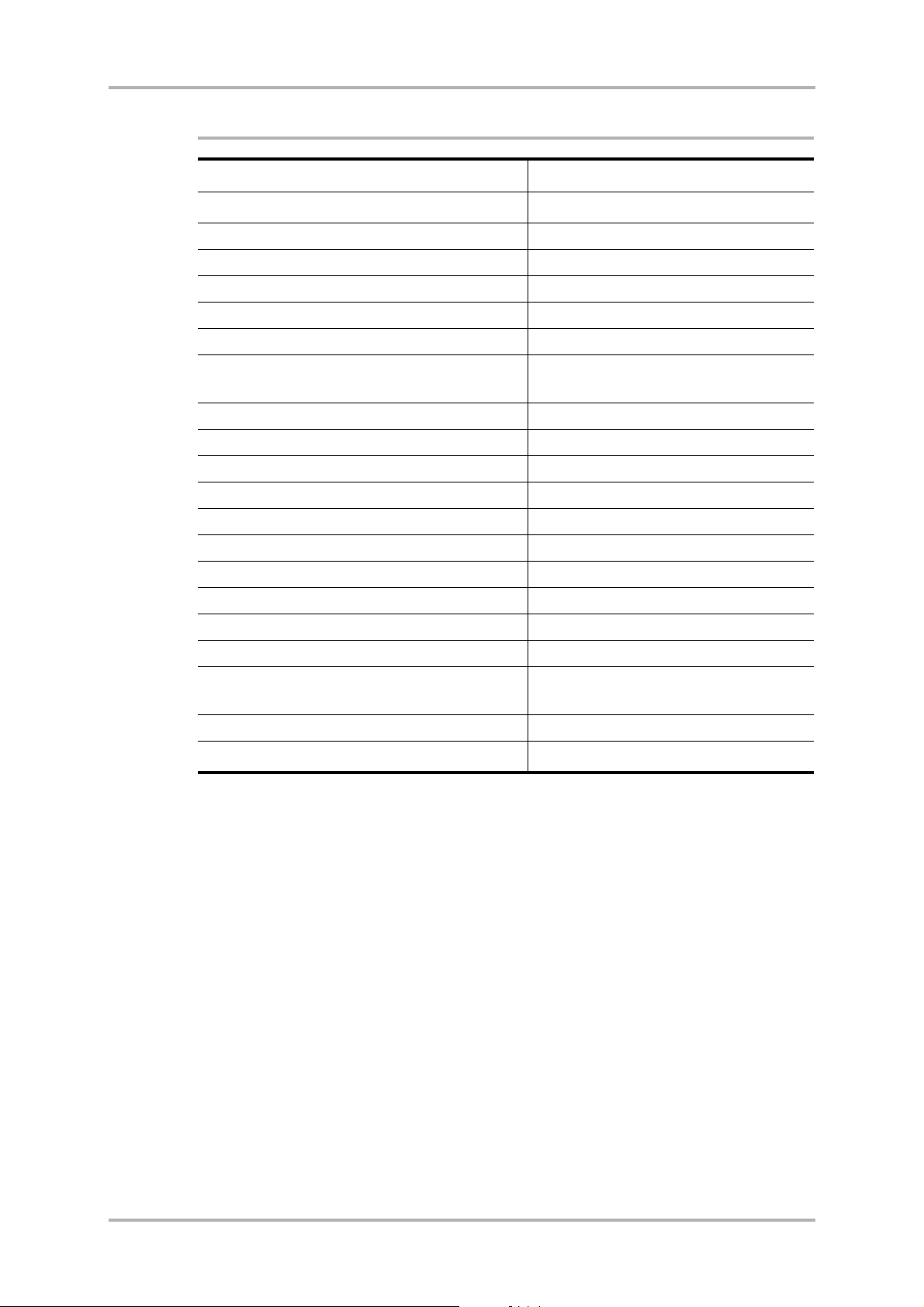

RSS45R, RSS58R, RSS80R

IGNORING

INSTRUCTIONS HAZARD

Faulty handling practice could

cause death or severe injury.

Read and follow the instructions

in the operator's manual.

169410_ENG-3

DUST HAZARD

Breathing dust will cause death

or severe injury.

Always wear approved

respirator.

169410_ENG-1

FLYING OBJECTS HAZARD

Fragments fly up to 40 m (130 ft)

and could cause death or severe

injury.

Stop operation when a

person enters hazard zone.

Wear approved personal

protective equipment.

169410_ENG-2

MB010109

Sandvik Mining and Construction Oy, Taivalkatu 8, 15170 LAHTI, FINLAND

Demolition tool

Manufactured by: MANTOVANIBENNE srl

n° 6, Via Righi - 41037 MIRANDOLA (Mo) ITALY

Serial number

Model

Manufactured

Weight (kg)

Min working

weight (kg)

Max cylinder pressure (bar)

Max rotation pressure (bar)

Max cylinder oil flow (l/min)

Max rotation oil flow (l/min)

MB010133

IGNORING

INSTRUCTIONS HAZARD

Faulty handling practice could

cause death or severe injury.

Read and follow the instructions

in the operator's manual.

169410_ENG-3

DUST HAZARD

Breathing dust will cause death

or severe injury.

Always wear approved

respirator.

169410_ENG-1

FLYING OBJECTS HAZARD

Fragments fly up to 40 m (130 ft)

and could cause death or severe

injury.

Stop operation when a

person enters hazard zone.

Wear approved personal

protective equipment.

169410_ENG-2

Sandvik Mining and Construction Oy, Taivalkatu 8, 15170 LAHTI, FINLAND

Demolition tool

Manufactured by: MANTOVANIBENNE srl

n° 6, Via Righi - 41037 MIRANDOLA (Mo) ITALY

Serial number

Model

Manufactured

Weight (kg)

Min working

weight (kg)

Max cylinder pressure (bar)

Max rotation pressure (bar)

Max cylinder oil flow (l/min)

Max rotation oil flow (l/min)

RSS23R

SafetyRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS34R

Operation - Page 23COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Safety RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

MB010131

IGNORING

INSTRUCTIONS HAZARD

Faulty handling practice could

cause death or severe injury.

Read and follow the instructions

in the operator's manual.

169410_ENG-3

DUST HAZARD

Breathing dust will cause death

or severe injury.

Always wear approved

respirator.

169410_ENG-1

FLYING OBJECTS HAZARD

Fragments fly up to 40 m (130 ft)

and could cause death or severe

injury.

Stop operation when a

person enters hazard zone.

Wear approved personal

protective equipment.

169410_ENG-2

Sandvik Mining and Construction Oy, Taivalkatu 8, 15170 LAHTI, FINLAND

Demolition tool

Manufactured by: MANTOVANIBENNE srl

n° 6, Via Righi - 41037 MIRANDOLA (Mo) ITALY

Serial number

Model

Manufactured

Weight (kg)

Min working

weight (kg)

Max cylinder pressure (bar)

Max rotation pressure (bar)

Max cylinder oil flow (l/min)

Max rotation oil flow (l/min)

RSS45R, RSS58R, RSS80R

RSS45R

Demolition tool

Sandvik Mining and Construction Oy, Taivalkatu 8, 15170 LAHTI, FINLAND

Serial number

Model

Manufactured

Max cylinder pressure (bar)

Weight (kg)

Max rotation pressure (bar)

Min working

Max cylinder oil flow (l/min)

weight (kg)

Max rotation oil flow (l/min)

Manufactured by: MANTOVANIBENNE srl

n° 6, Via Righi - 41037 MIRANDOLA (Mo) ITALY

DUST HAZARD

Breathing dust will cause death

or severe injury.

Always wear approved

respirator.

169410_ENG-1

RSS58R

IGNORING

INSTRUCTIONS HAZARD

Faulty handling practice could

cause death or severe injury.

Read and follow the instructions

in the operator's manual.

169410_ENG-3

FLYING OBJECTS HAZARD

Fragments fly up to 40 m (130 ft)

and could cause death or severe

injury.

Stop operation when a

person enters hazard zone.

Wear approved personal

protective equipment.

169410_ENG-2

MB010130

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 24 - Operation

RSS45R, RSS58R, RSS80R

RSS05R, RSS11R, RSS80R

Sandvik Mining and Construction Oy, Taivalkatu 8, 15170 LAHTI, FINLAND

Serial number

Model

Weight (kg)

Min working

weight (kg)

Manufactured

Manufactured by: MANTOVANIBENNE srl

n° 6, Via Righi - 41037 MIRANDOLA (Mo) ITALY

FLYING OBJECTS HAZARD

Fragments fly up to 40 m (130 ft)

and could cause death or severe

injury.

Stop operation when a

person enters hazard zone.

Wear approved personal

protective equipment.

Demolition tool

Max cylinder pressure (bar)

Max rotation pressure (bar)

Max cylinder oil flow (l/min)

Max rotation oil flow (l/min)

IGNORING

INSTRUCTIONS HAZARD

Faulty handling practice could

cause death or severe injury.

Read and follow the instructions

in the operator's manual.

SafetyRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

169410_ENG-2

DUST HAZARD

Breathing dust will cause death

or severe injury.

Always wear approved

respirator.

MB010024

169410_ENG-3

169410_ENG-1

Operation - Page 25COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Operation RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

5. OPERATION

5.1 OPERATING INSTRUCTIONS

RECOMMENDED USE

The scrap shear is designed for use in cutting steel sections and scraps with

maximum efficiency to prepare them for the furnace or for transport. For more

information, contact your local dealer.

OPERATING CONDITIONS

Principles of installation

Almost all carriers meeting mechanical and hydraulic requirements can be used to

operate products. See “Product specifications” on page 72. The product is installed

on the carrier much in the same manner as installing a bucket or other attachment.

A flange-mounted products requires also a separate mounting bracket.

The products is connected to a carrier's hydraulic circuit with an installation kit. If

the carrier is already fitted with an installation kit, the installation requires only

suitable hoses and fittings. For product installation, secondary relief valves in the

bucket cylinder circuit and the carrier auxiliary circuit are needed. If the carrier does

not have a suitable kit to run attachments, one must be built. This may require a

more complex installation, including new piping and additional valves such as a

flow control valve or pressure relief valve.

Suitable kits can be ordered from the manufacturer or their local dealers, carrier

manufacturers and their dealers, or third party suppliers.

Note: In models equipped with a system to prevent rotation of the product,

remember to unlock the system before starting operation. See “Mounting and

dismounting the product” on page 34.

Hydraulic oil

In general, the hydraulic oil originally intended for the carrier can be used with this

product.

Operating temperature

The operating temperature is -20 °C (-4 °F) to 80 °C (176 °F). If you must work in

a temperature lower than -20 °C (-4 °F), the product must be preheated before any

operation can begin. Start the operation with low hydraulic flow.

Note: The temperature of the hydraulic oil must be monitored. Ensure that oil grade

and monitored oil temperature together guarantee correct oil viscosity.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 26 - Operation

RSS45R, RSS58R, RSS80R

PRINCIPLES OF OPERATION

The operation of the product is based on a static force produced by the hydraulic

cylinder of the product. To increase the product's working life, pay particular

attention to correct working methods.

Cutting is performed with cutting blades at the rear of the jaws. The cutting blades

can be reversed.

JAWS, TEETH AND CUTTING BLADES

Jaws

The jaws are operated by the hydraulic cylinder. One jaw is fixed and the other,

equipped with breaking teeth, is moving. Crushing is performed using the crushing

teeth of the jaws.

Cutting blades

The cutting blades are fastened with screws. You can turn them to use unused

cutting edges or replace them with new cutting blades. See “Turning and changing

cutting blades” on page 53.

OperationRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

Operation - Page 27COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Operation RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

MB010036

RSS45R, RSS58R, RSS80R

5.2 DAILY OPERATION

Warning! Protect yourself and your surroundings from flying debris and

collapsing concrete frames. Do not operate the product or carrier with people

around it.

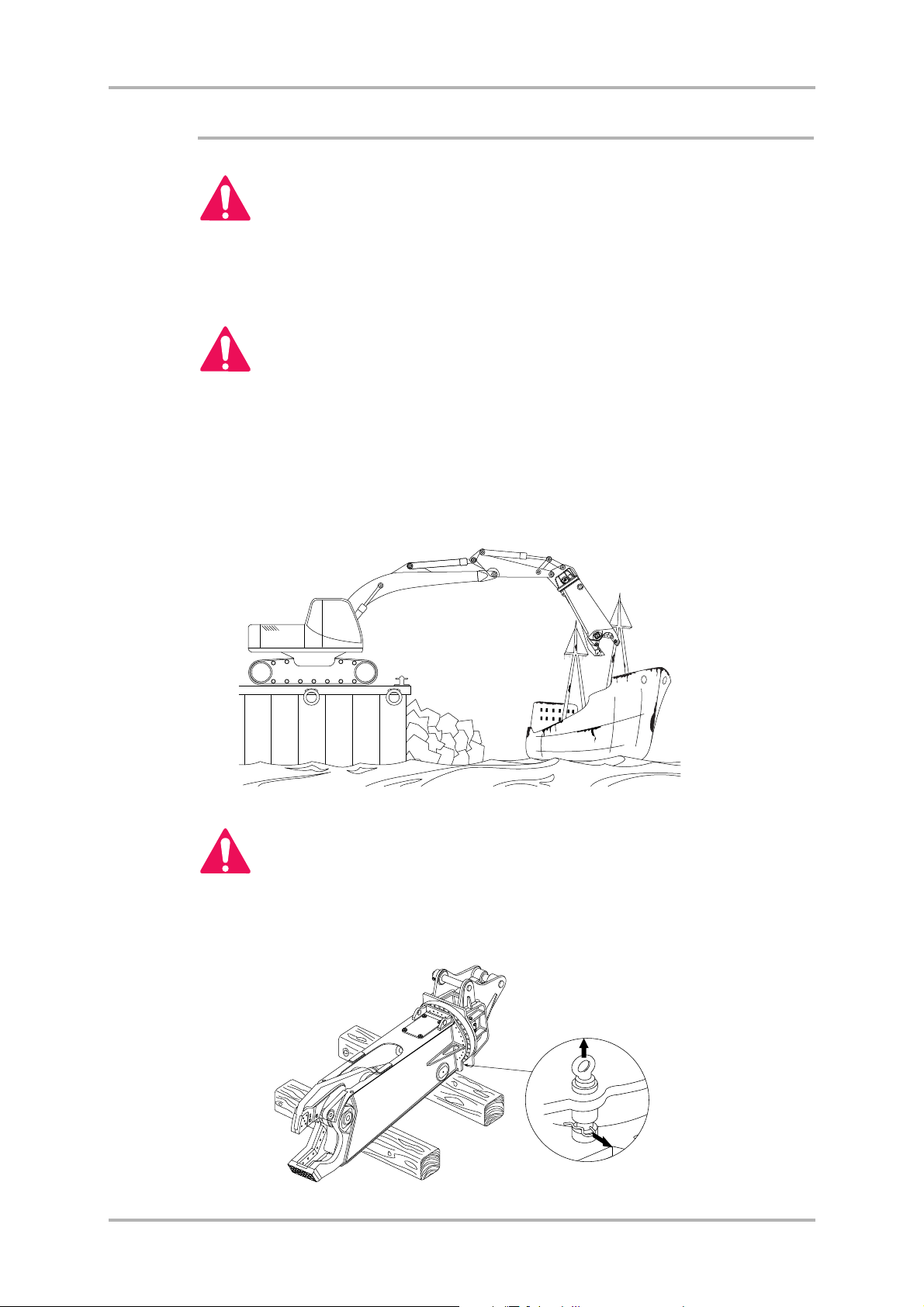

The product, as a standard assembly, must not be used under water. It must be

adapted for underwater applications. Contact your local dealer for more

information on underwater use.

After operating the product under water or in environments close to the sea,

carefully wash the product. Subsequently disassemble the hinges and carefully

clean the pins and bushings to remove all traces of oxidation. Lastly, grease the

disassembled parts.

MB010035

In models equipped with a rotation prevention system, remember to unlock the

system before starting operation.

Remove the cotter pin and take out the locking pin.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 28 - Operation

RSS45R, RSS58R, RSS80R

MB010071

MB010070

■ Prepare the carrier for normal excavation work. Move the carrier to the required

position. Set the drive to neutral.

■ Set the engine speed to the recommended engine RPM.

■ NOTICE! Carefully operate the carrier controls to place the product and boom

into the working position. Quick and careless boom movements can result in

damage to the product.

OperationRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

■ Use a safety screen to protect the operator from flying debris. Keep the cabin

windows and doors closed during operation.

MB010072

■ Do not move or cut material over people, the excavator cab, or other operating

machines.

Operation - Page 29COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Operation RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

MB010069

MB010073

RSS45R, RSS58R, RSS80R

■ To avoid a dangerous fall, ensure that the structure your carrier is on is strong

enough to support it.

■ Do not operate excavator hydraulic cylinders when the jaws are closed.

Bending the object up and down when the jaws are pressed on it may cause

excessive wearing of teeth and cutting blades.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 30 - Operation

RSS45R, RSS58R, RSS80R

MB010074

■ Do not use the product for lifting. Lifting eyes on the product are for storage and

maintenance purposes only.

OperationRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

■ When cutting horizontal steel frames, concentrate the shearing action at the

proper working angle. Cut through at one point on the frame. Cut partially

through at another point. Then, bend the framework down with the product and

make the final cut.

Operation - Page 31COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Operation RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

■ Place steel frames properly between the cutting blades, as shown in the

illustration. Note: If the cutting object does not fit into the product mouth, first

press it between the jaws to flatten it and then perform the final cutting with the

cutting blades.

■ Do not use the product to move the excavator.

MB010078

■ When operating the product, make sure that it does not make contact with the

carrier boom or hydraulic lines.

MB010079

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 32 - Operation

RSS45R, RSS58R, RSS80R

MB010076

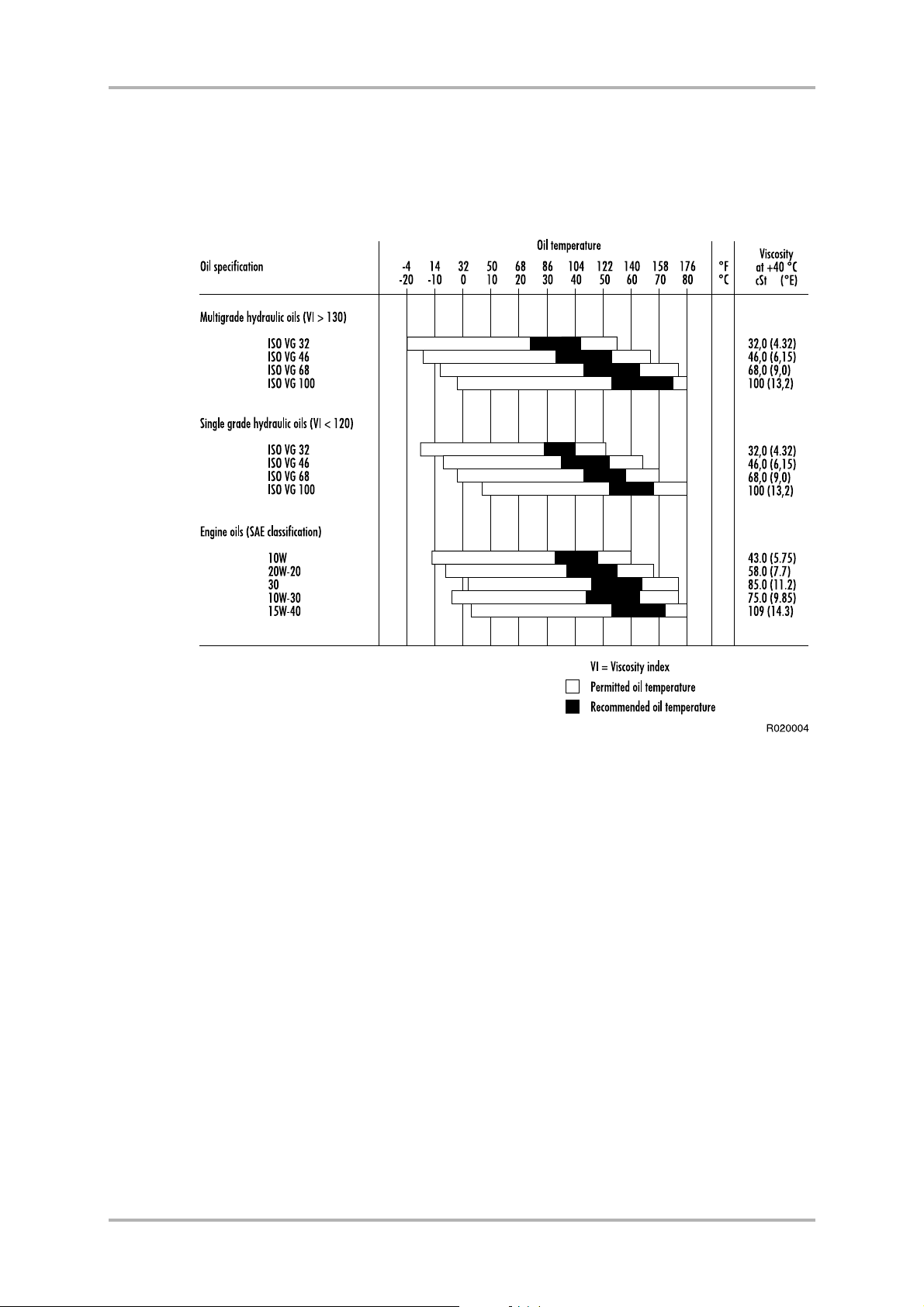

■ Stay more than 10 meters (33 feet) away from live, overhead electric cables

with any part of the machine.

OperationRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

■ When carrying out demolition work, position the product by means of hydraulic

rotation (2), in such a way as to ensure that always have the correct angle of

penetration (1). Use just the force of the cylinder for demolishing, without

trying to tear at the material with the excavator arm (3). If necessary, re-position

the product.

3

2

1

MB010080

Operation - Page 33COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Operation RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

MB010092

RSS45R, RSS58R, RSS80R

■ The bearings must be well greased during operation. Make regular inspections

during operation. If no grease is visible, the bearings require more frequent

greasing. If bearings are covered with excessive grease, they require less

frequent greasing.

5.3 MOUNTING AND DISMOUNTING THE PRODUCT

REMOVAL FROM CARRIER

Warning! The product must be secured from falling over when disconnecting

it from the carrier. Only use a skilled operator to position the carrier for the

removal!

Warning! Hydraulic pressure inside the product must always be released

before opening hose connections!

Warning! Hot hydraulic fluid can cause severe injuries!

Warning! The thrust bearing must be locked to prevent the product from

rotating during maintenance or transportation.

1. Position the product horizontally on the floor.

2. Stop the carrier engine. Operate the boom and product controls to release

pressure trapped inside hoses.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 34 - Operation

RSS45R, RSS58R, RSS80R

MB010082

3. Close the product shut-off valve. If quick couplers are used, disconnection

automatically closes product lines. If the line includes ball valves, make sure

that they are closed.

4. Disconnect the hoses. Protect the environment from oil spills. Plug the hoses.

5. Remove the mounting bracket pins and other parts.

OperationRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

MB010091

Operation - Page 35COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Operation RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

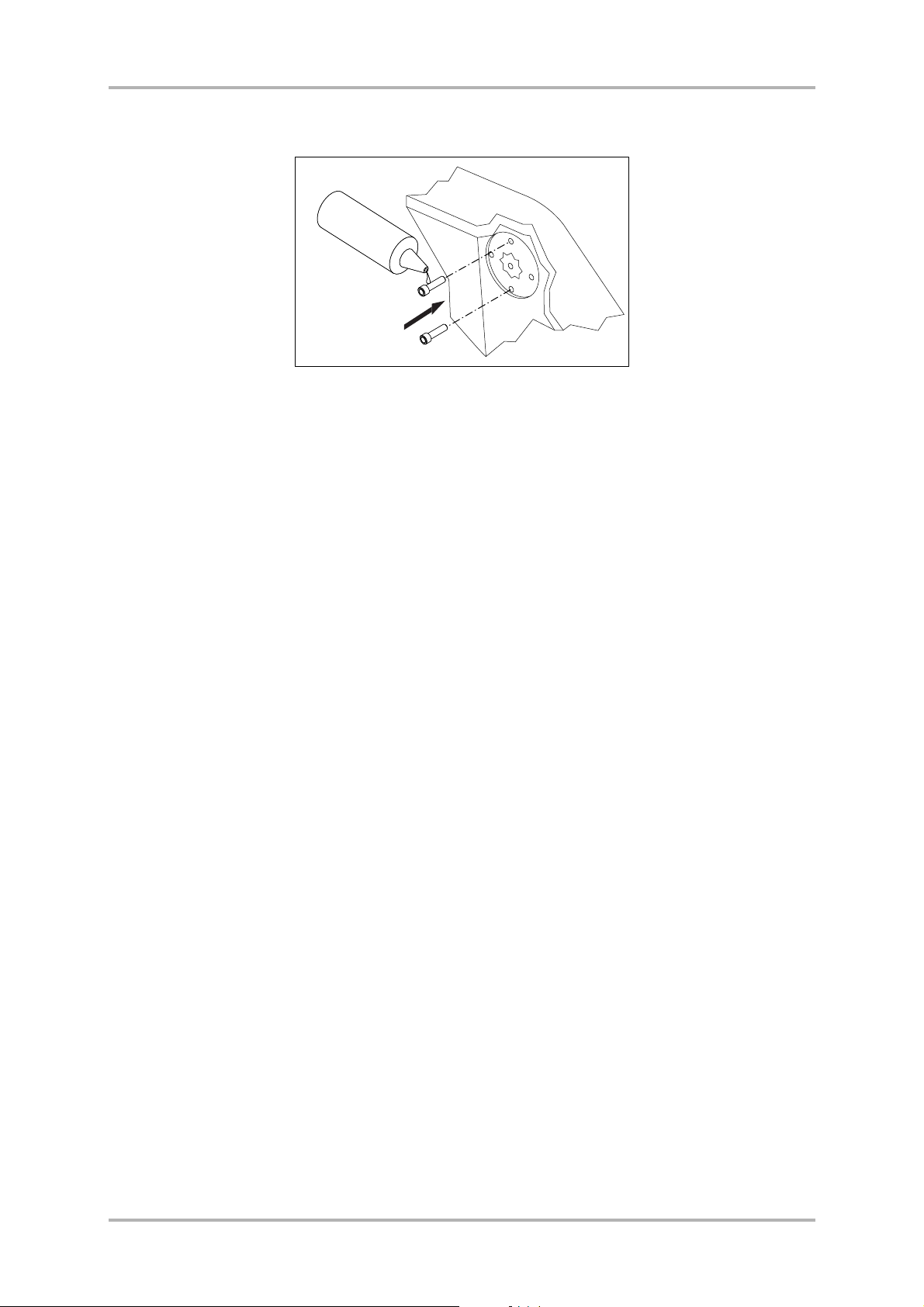

6. Install the locking pins and cotter pins.

MB010087

7. Move the carrier aside, if needed.

INSTALLATION ON THE CARRIER

Warning! The residual air in the hoses must always be removed before

operation!

1. Remove the cotter pins and take out the locking pins.

MB010086

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 36 - Operation

RSS45R, RSS58R, RSS80R

2. Install the product in the same manner as mounting a bucket. Install bucket pins.

OperationRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

MB010093

3. Connect the hoses. An installation inspection must be carried out after the

product has been mounted on the carrier. During installation inspection, certain

specifications (operating pressure, oil flow, etc.) are checked so that they are

within given limits. See “Product specifications” on page 72.

4. Open the ball valves.

5. Remove the air from the hoses by carefully operating the crusher cylinder.

Open and close the empty jaws several times.

Note:

■ If the lines going to the opening and closing connection have two different

pressure values, connect the line with the highest pressure (which should not

exceed the max. value) to the connection fitting jaw closing and the lower

pressure line to the connection fitting jaw opening, in order to have the

maximum clamping force.

■ Remove the cap from the fitting of the hydraulic hoses connecting the excavator

and the crusher.

■ Make sure that the hose fittings are perfectly clean and dust-free, and attach

them to the machine by tightening the screws or the fittings.

Operation - Page 37COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Operation RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

MB010096

RSS45R, RSS58R, RSS80R

Note:

■ The hydraulic rotation motor can operate with the drainage outlet plugged if,

during activation, the back-pressure on the drainage branch during operation is

not greater than 15 bar (218 psi).

■ At first installation, check the backpressure value on the return branch of the

rotation system, activating the hydraulic rotation in both directions.

■ If the measured back pressure is greater than 15 bar (218 psi), connect a

drainage line that connects the drainage attachment of the motor to the tank.

■ The drainage attachment of the motor, normally plugged, is located on the

bottom of the motor (see illustration).

1&4” GAS

MB010101

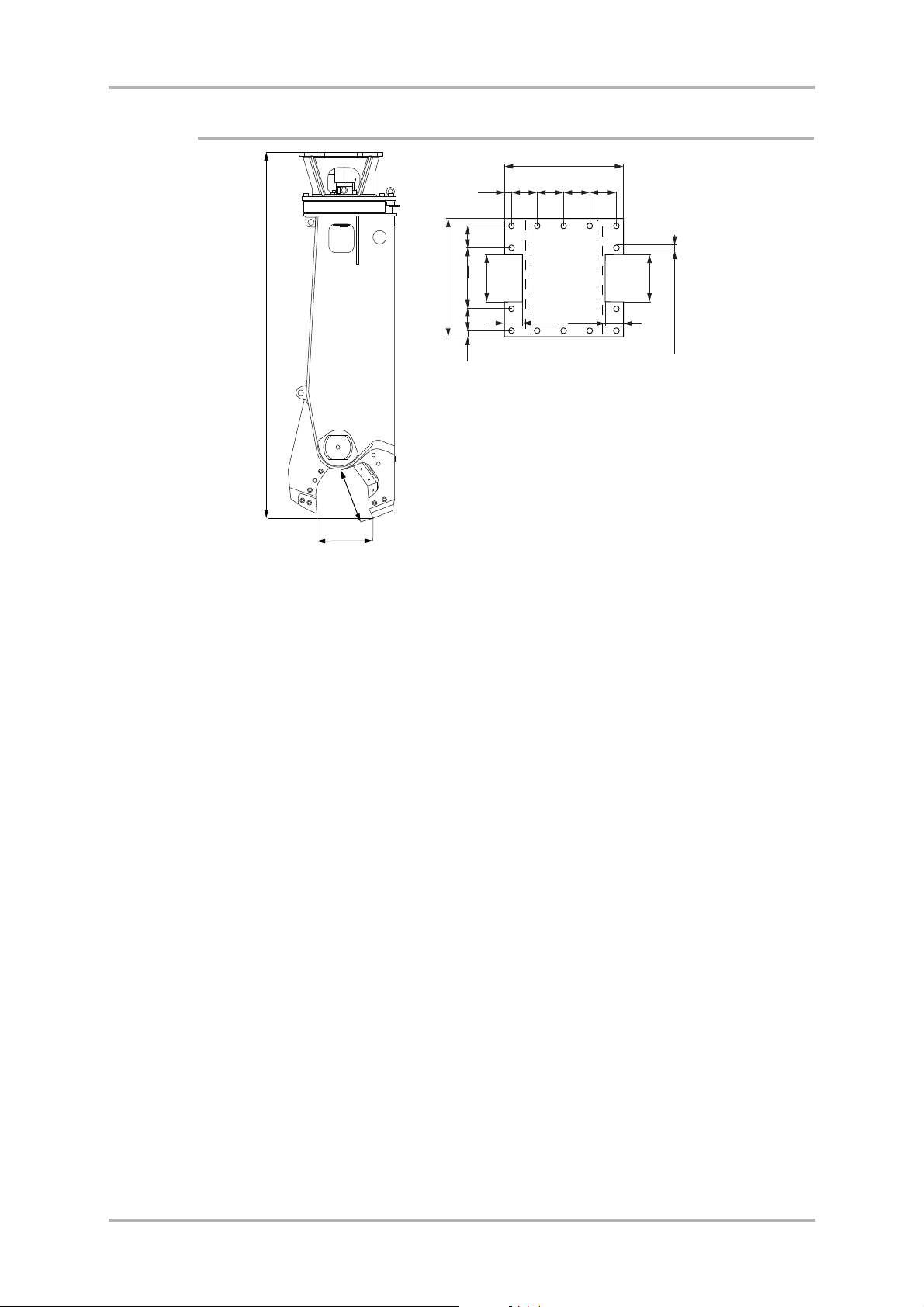

5.4 MOVEMENT

The transportation and parking positions are shown below. When moving the

carrier, ensure that the product is not too close to the carrier.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 38 - Operation

RSS45R, RSS58R, RSS80R

5.5 SPECIAL CONDITIONS OF USE

The product may require modifications, special operating techniques, increased

maintenance or special wear items if it is used in conditions that differ from normal

breaking or demolition work. Special conditions of use are:

■ Underwater operations

■ Operations in extremely low or high temperatures

■ Use of special hydraulic fluids

■ Operations with special carrier

■ Other special conditions

In case of special conditions of use, contact your local dealer for instructions.

OperationRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

The product as a standard assembly, must not be used under water. Contact

your local dealer for more information on underwater use.

5.6 STORAGE

LONG TERM STORAGE

Observe the following points when the product is stored. This way, the vital parts

of the product are protected from rust and the product is ready to be used whenever

necessary.

1. Make sure your storage area is dry.

2. To avoid damaging the cylinder rod, operate the cylinder to the shortest position

by leaving the jaws open.

Operation - Page 39COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Operation RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

MB010099

RSS45R, RSS58R, RSS80R

3. Insert blocks under the product to keep it off the ground. If the product is stored

outside, cover it to prevent rusting.

4. Apply grease to all product parts. Protect the mounting bracket, pin holes,

cutting blades and pivot ends with an anticorrosive agent.

5. Seal connections with clean plugs to prevent oil leakage and dirt from getting

into the couplings.

6. Make sure the product cannot fall over.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 40 - Operation

RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

LUBRICATION

Lubrication - Page 41COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Greasing RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

1. GREASING

1.1 RECOMMENDED GREASES

Item Recommended greases Greasing interval

Pins and bushings every 8 hours

Thrust bearing every 40...80 hours

Additives: molybdenum disulfide

Minimum working temperature below

lowest ambient temperature

Penetration 0 ... 2 (NLGI)

No reaction with hydraulic oils

Water resistant

Good adhesion with steel

1.2 GREASING POINTS

Follow the product's greasing instructions and avoid excessive greasing.

Dispose of empty grease containers appropriately.

The greasing points of the product are marked with the following sticker.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 42 - Lubrication

RSS45R, RSS58R, RSS80R

MB020003

The greasing points of the product are shown below.

GreasingRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

Lubrication - Page 43COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Carrier hydraulic oil RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

2. CARRIER HYDRAULIC OIL

2.1 REQUIREMENTS FOR HYDRAULIC OIL

GENERAL REQUIREMENTS

In general, the hydraulic oil originally intended for the carrier can be used with this

product. However, since working with the product heats the oil more than with the

usual excavation work, the temperature of the oil must be monitored.

If the temperature of the hydraulic oil exceeds 80 °C (176 °F), an auxiliary oil cooler

is needed. The oil viscosity must be between 1000-20 cSt while the product is being

used.

When the product is used continuously, the temperature of the hydraulic oil

normalizes at a certain level depending on conditions and on the carrier. The

temperature in the tank must not exceed the maximum allowed.

The product must not be started if the ambient temperature is below freezing and

the oil is very thick. The machine must be moved to bring the oil temperature above

0 °C (32 °F) before working can start (viscosity 1000 cSt or 131 °E).

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 44 - Lubrication

RSS45R, RSS58R, RSS80R

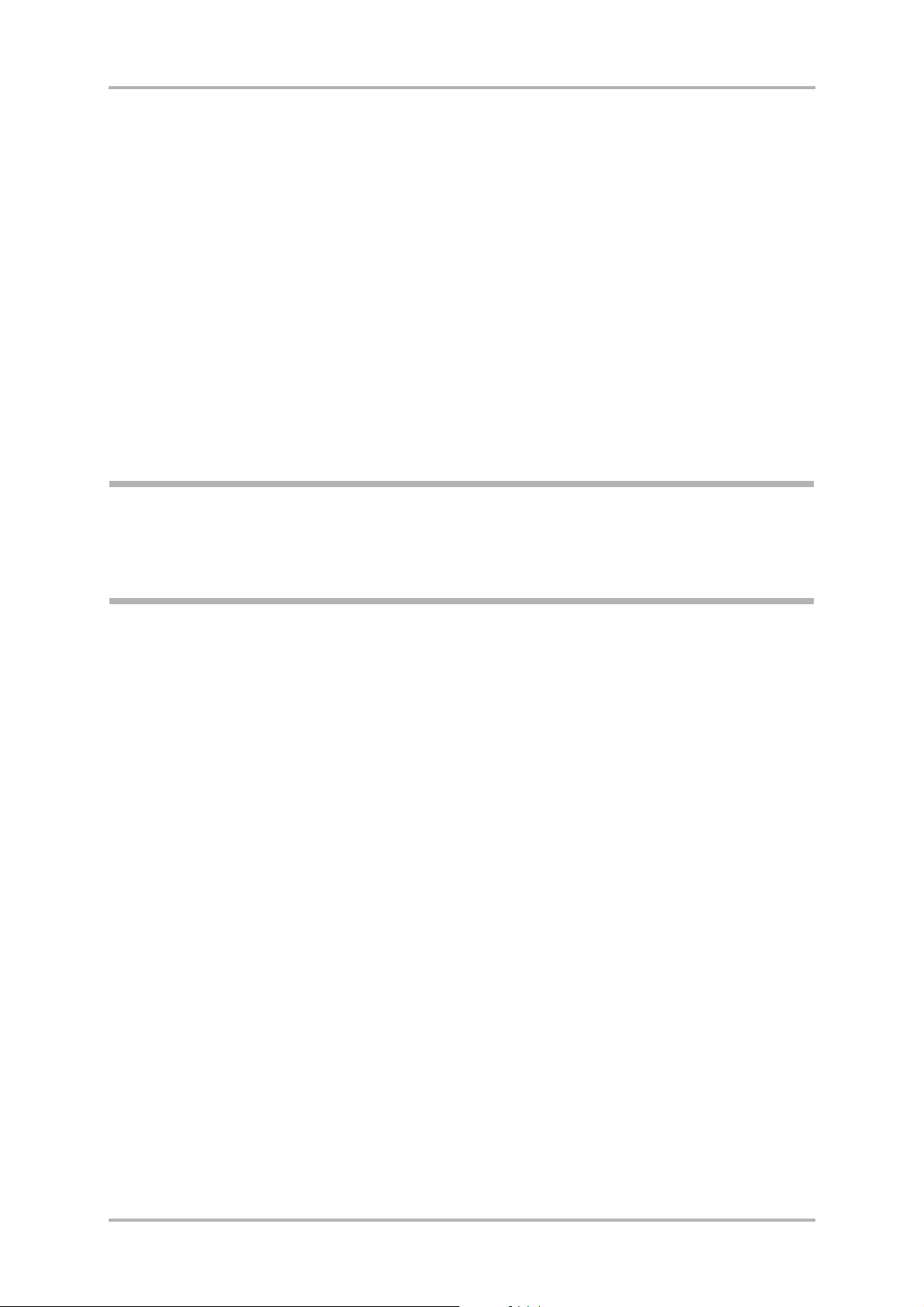

OIL SPECIFICATIONS

The table below shows hydraulic oils recommended for product use. The most

suitable oil is selected in such a way that the temperature of the hydraulic oil in

continuous use is in the ideal area on the chart and the hydraulic system is used to

best advantage.

Carrier hydraulic oilRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

Problems due to incorrect hydraulic oil viscosity in the product:

Oil too thick

■ Difficult start up

■ Stiff operation

■ Danger of cavitation

■ Sticky valves

■ Filter bypass opens, impurities in the oil are not removed

Oil too thin

■ Efficiency losses (internal leaks)

■ Damage to gaskets and seals, leaks

■ Accelerated wearing of parts, because of decreased lubrication efficiency

■ Danger of cavitation

Lubrication - Page 45COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Carrier hydraulic oil RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

Note: We strongly recommend the use of different hydraulic oils in the summer and

in the winter if there is an average temperature difference of more than 35 °C (95

°F). The correct hydraulic oil viscosity is thus ensured.

SPECIAL OILS

In some cases, special oils (for example biological oils and nonflammable oils) can

be used with the product Observe the following aspects when considering the use

of special oils:

■ The viscosity range in the special oil must be in the given range (1000-20 cSt).

■ The lubrication properties must be sufficient.

■ The corrosion resistance properties must be good enough.

Note: Although a special oil could be used in the carrier, always check its suitability

with the product Contact the oil manufacturer or your local dealer for more

information about special oils.

2.2 OIL COOLER

The carrier hydraulic system must be able to maintain a temperature within an

acceptable level during the product operation. This is because:

1. Seals, wipers, membranes and other parts manufactured from the corresponding

materials can normally stand temperatures up to 80 °C (176 °F).

2. The higher the temperature is, the less viscous the oil gets, thus losing its

capability to lubricate.

A standard carrier, with a proper product circuit, meets the requirements of the

necessary cooling capacity. If the oil temperature tends to be too high during

product operation, the following must be checked:

■ The product circuit pressure relief valve should not be opened unnecessarily.

■ The product circuit pressure drops must be reasonable; that is, less than 20 bar

(290 psi) in the hydraulic line.

■ There should be no internal leakages in product or carrier hydraulic pumps,

valves, cylinders, motors, etc.

If all of the above-mentioned items are in order, and the temperature of the hydraulic

oil still tends to be too high, extra cooling capacity is needed. Contact the carrier

manufacturer or your local dealer for details.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 46 - Lubrication

RSS45R, RSS58R, RSS80R

2.3 OIL FILTER

The purpose of the oil filter is to remove impurities from the hydraulic oil. Air and

water are also impurities in oil. Not all impurities can be seen with the naked eye.

Impurities enter the hydraulic system:

■ During hydraulic oil changes and refilling.

■ When components are repaired or serviced.

■ When the product is being installed on the carrier.

■ Because of component wear.

Normally the existing, main oil filters of the carrier are used as attachment circuit

return line filters. Contact the carrier manufacturer or your local dealer concerning

instructions for the filter change intervals.

In product work, the carrier oil filter must fulfill the following specifications:

■ The oil filter must allow maximum particle size of 25 microns (0.025 mm).

Carrier hydraulic oilRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

■ The oil filter material must be man-made fibre cloth or very fine gauge metallic

mesh to withstand pressure fluctuations.

■ The oil filter must have a nominal flow capacity of at least twice the product's

maximum flow.

In general, oil companies guarantee new oils to have a maximum particle size of 40

microns. Therefore, filter the oil when filling the tank.

The damage caused by hydraulic oil impurities in the carrier and attachment circuits

include:

Shortened working life of pumps and other components

■ Rapid wear of parts.

■ Cavitation.

■ Wear of cylinder and gaskets.

Reduced attachment efficiency

■ Accelerated wear of moving parts and seals.

■ Oil leakages.

Shortened working life and reduced lubricating capability of oil

■ Overheated oil.

■ Deteriorated oil quality.

■ Electrochemical changes in hydraulic oil.

Lubrication - Page 47COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Carrier hydraulic oil RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

Malfunction of valves

■ Binding spools.

■ Rapid wear of parts.

■ Blocking of small holes.

Note: Component damage is only a symptom. The trouble itself will not be cured

by removing the symptom. After any component damage due to impurities in the

oil, the entire hydraulic system must be cleaned. Dismantle, clean and reassemble

the product and change the hydraulic oil.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 48 - Lubrication

RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

MAINTENANCE

Maintenance - Page 49COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Routine maintenance RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

1. ROUTINE MAINTENANCE

1.1 OVERVIEW

This product is a precision-made hydraulic machine. Therefore, great care and

cleanliness should be taken when handling any of the hydraulic components. Dirt is

the worst enemy in hydraulic systems.

Handle the parts carefully and remember to cover any cleaned and dried parts with

a clean, lint-free cloth. Do not use anything other than purpose-designed materials

for cleaning hydraulic parts. Never use water, paint thinners or carbon tetrachloride.

Components, gaskets and seals in the hydraulic system should be oiled with clean

hydraulic oil before assembly.

Remember to grease the product parts regularly, according to the instructions in this

manual.

Prior to maintenance or inspection, operate all the control levers to their fully

extended stroke. This will release pressure within the hydraulic piping and prevent

unexpected movement of the jaw and loss of oil through the hydraulic lines.

Close the jaws during maintenance or inspection. If you must leave the jaws

open, remember to block the jaws to prevent them from closing.

1.2 INSPECTION AND MAINTENANCE BY THE OPERATOR

Note: The times given refer to the carrier hours with the product installed.

EVERY EIGHT HOURS

Grease shafts and pins.

DAILY MAINTENANCE

1. Check the hydraulic hoses and hose connections. Tighten if necessary.

2. Check the cutting blades and their clearance. Tighten bolts or replace the

cutting blades, if necessary. See “Turning and changing cutting blades” on page

53.

3. Check the jaws and teeth for wear. Hardface or replace, if necessary. See

“Hardfacing the jaw” on page 57.

4. Check the grease nipples.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 50 - Maintenance

RSS45R, RSS58R, RSS80R

5. Check the clearance of the regulator. See “Adjusting regulator clearance

recovery” on page 59. See “Adjusting regulator lateral guides” on page 61.

6. Check the clearance of the pins. See “Adjusting regulator lateral guides” on

page 61.

WEEKLY MAINTENANCE

1. Check the main body for wear.

2. Check the pins and bushings for wear.

3. Check the cylinder rod, seals and connection points for wear. Tighten if

necessary.

4. Observe hydraulic oil temperature for all lines and connections.

5. Check that the product works smoothly by operating the jaws.

6. Tighten connections, if necessary.

Routine maintenanceRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

EVERY 40...80 HOURS

Grease the thrust bearing. Adapt the greasing interval and amount of grease to

working conditions.

AFTER FIRST 150 HOURS

Change the oil in the rotation units after the first 150 working hours. See “Changing

oil in the rotation unit” on page 66.

EVERY 2000 HOURS OR ONCE A YEAR

After the first 150 hours oil change, change the oil in the rotation unit every 2000

operating hours, or at least once a year. See “Changing oil in the rotation unit” on

page 66.

1.3 INSPECTION AND MAINTENANCE BY THE DEALER

Note: The times given refer to carrier hours with the product installed.

INITIAL 50 HOUR INSPECTION

It is recommended that your local dealer perform the first inspection after 50 to 100

operating hours. Contact your local dealer for more information about the initial 50hour inspection.

Maintenance - Page 51COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Routine maintenance RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

EVERY 600 HOURS OR ONCE A YEAR

The 600-hour/yearly service is performed by your local dealer. It is recommended

every 600 operating hours or once a year, whichever comes first. Neglecting the

600-hour/yearly service can cause severe damage to the product.

Your local dealer will reseal the product and replace safety decals as needed.

Contact your local dealer for more information about 600-hour/yearly servicing.

During this service, you should also perform the following tasks:

■ Check all hydraulic connections.

■ Check that the hydraulic hoses do not rub against anything in any boom/stick

position.

1.4 MAINTENANCE INTERVALS IN SPECIAL APPLICATIONS

The service interval is considerably shorter with special applications such as

underwater use. In special applications, consult your local dealer for the correct

service intervals.

The product, as a standard assembly, must not be used under water. It must be

adapted for underwater applications. Contact your local dealer for more

information on underwater use.

1.5 OTHER MAINTENANCE PROCEDURES

WASHING THE PRODUCT

When working with product and removing it from the carrier, dirt (mud, rock

powder, etc.) can become attached to it. Wash the outside of the product with a

steam washer before sending it to the workshop. Otherwise dirt can cause

difficulties in disassembly and assembly.

CAUTION! Plug the pressure and return line before washing the product or else dirt

could get into it and cause damage to the components.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 52 - Maintenance

Turning and changing cutting bladesRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

2. TURNING AND CHANGING CUTTING BLADES

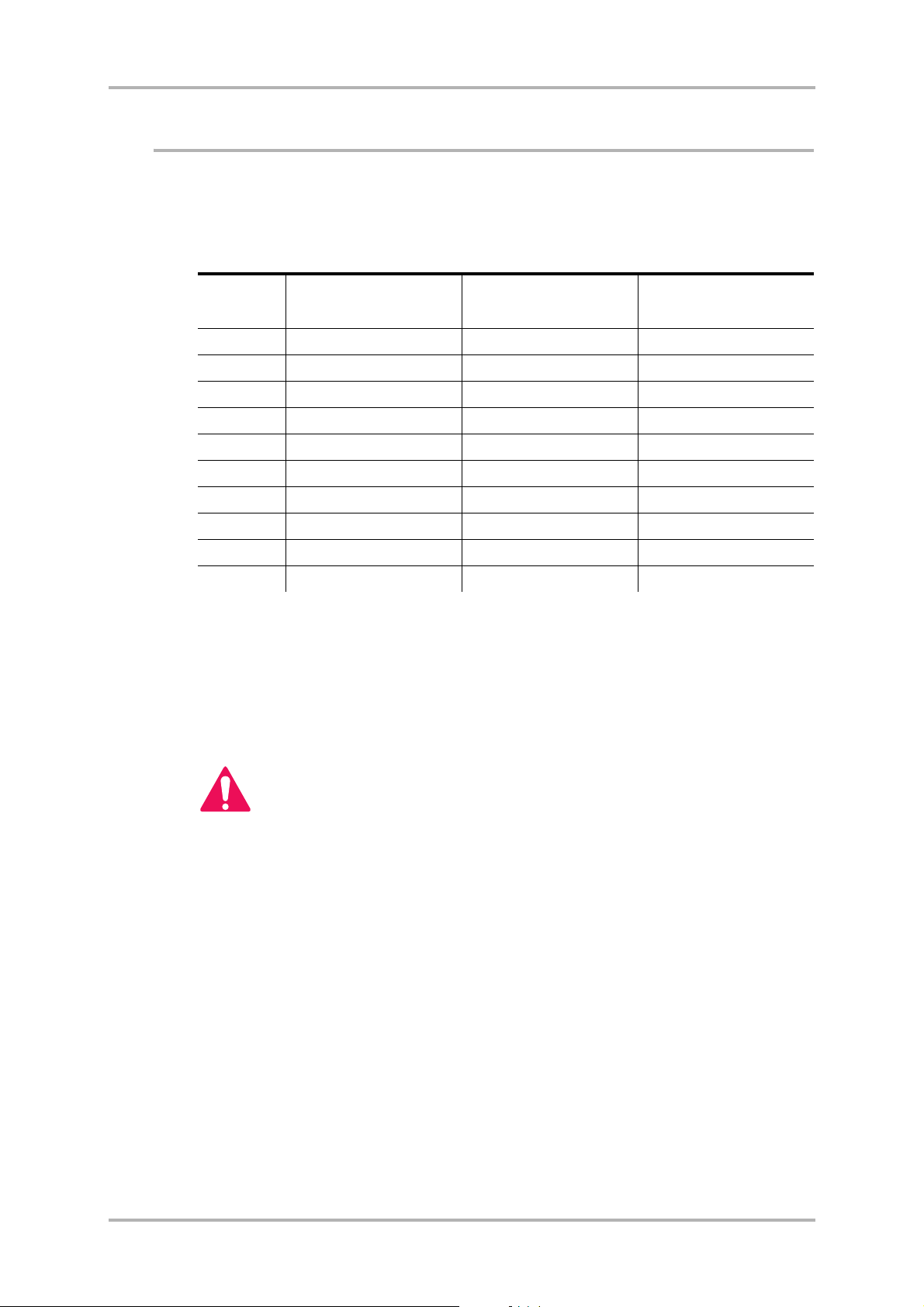

WEAR LIMITS, ADJUSTMENTS AND TORQUES FOR CUTTING BLADES

Item Adjustment

Cutting blade clearance (C) 0.2...0.5 mm (0.01...0.02 in)

Wear plates clearance 1.5 mm (0.06 in)

Screw

M8 25 Nm (18 lbf ft) 35 Nm (26 lbf ft) 42 Nm (31 lbf ft)

M10 50 Nm (37 lbf ft) 70 Nm (52 lbf ft) 85 Nm (63 lbf ft)

M12 85 Nm (63 lbf ft) 120 Nm (89 lbf ft) 145 Nm (107 lbf ft)

M14 135 Nm (100 lbf ft) 190 Nm (140 lbf ft) 230 Nm (170 lbf ft)

M16 210 Nm (155 lbf ft) 295 Nm (218 lbf ft) 355 Nm (262 lbf ft)

M18 290 Nm (214 lbf ft) 410 Nm (302 lbf ft) 490 Nm (361 lbf ft)

M20 410 Nm (302 lbf ft) 575 Nm (424 lbf ft) 690 Nm (509 lbf ft)

M24 710 Nm (524 lbf ft) 995 Nm (734 lbf ft) 1240 Nm (915 lbf ft)

M27 1050 Nm (774 lbf ft) 1450 Nm (1069 lbf ft) 1750 Nm (1291 lbf ft)

M30 1420 Nm (1047 lbf ft) 2000 Nm (1475 lbf ft) 2350 Nm (1733 lbf ft)

Tightening torque, grade

8.8

Tightening torque, grade

10.9

Tightening torque, grade

12.9

Maintenance - Page 53COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Turning and changing cutting blades RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

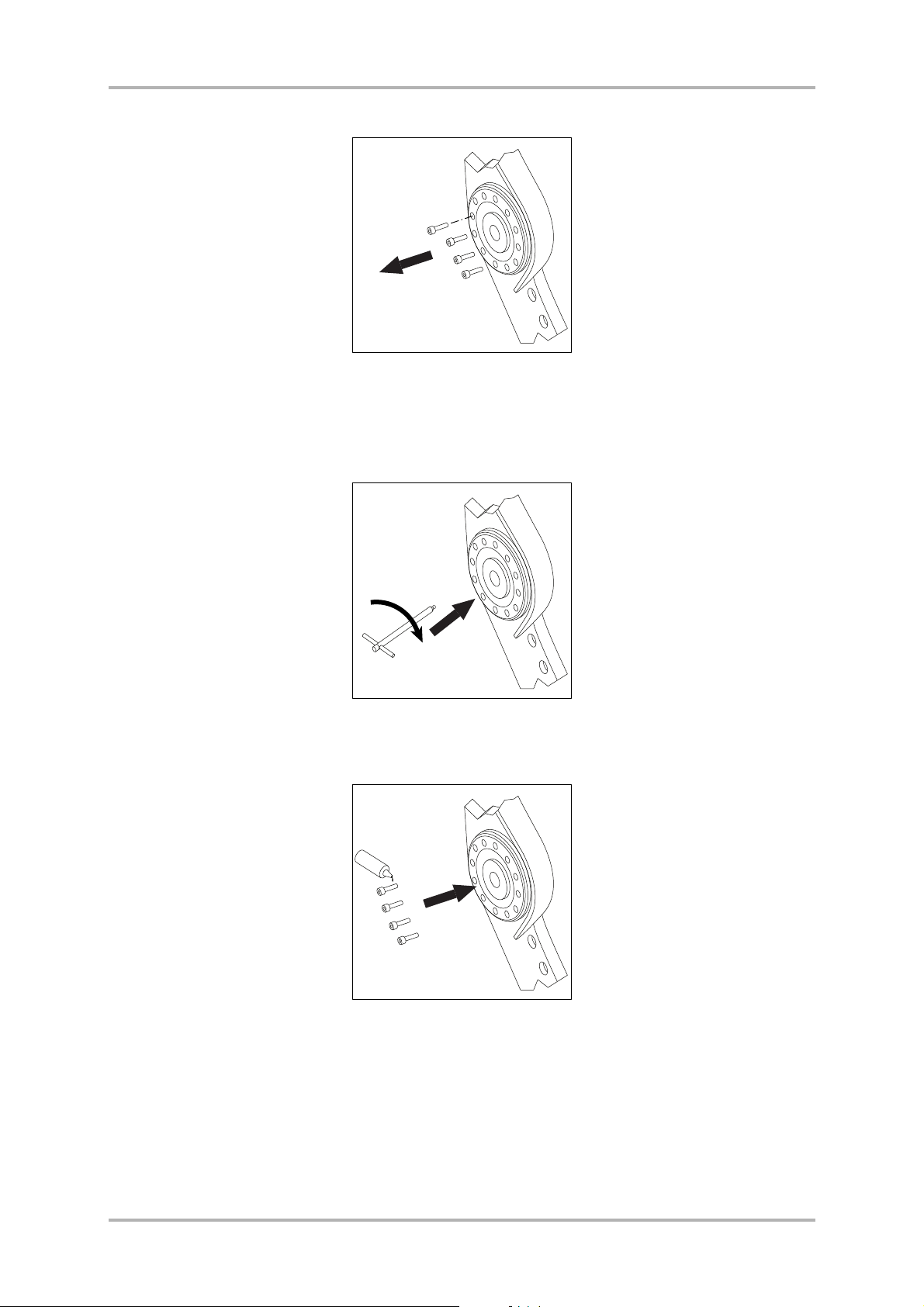

TURNING AND CHANGING CUTTING BLADES

Warning! Prior to maintenance or inspection, operate all the control levers to

their fully extended stroke. This will release pressure within the hydraulic

piping and prevent unexpected movement of the jaw and loss of oil through the

hydraulic lines.

Warning! Support the jaw to prevent it from closing unexpectedly during

maintenance.

Used cutting blades can be recycled. Contact your dealer for more information

about local regulations of recycling.

■ We recommend rotating the blades every 100-200 hours of work to ensure

uniform wear of the cutting edges.

■ Once you have rotated or replaced the blades, it is necessary to control the play

between the cutting edges of the lower jaw and those of the upper jaw. This

distance must be between 0.3 mm (0.01 in) and 0.5 mm (0.02 in) in order to

prevent the material, especially if it is thin, from getting caught between the

blades.

■ If the blades are not rotated regularly (every 100-200 hours), uneven wear can

develop, which makes it impossible to shim the cutting edges correctly.

■ The blades should be rotated, on average, every 100-200 hours of work,

depending on the material being cut.

■ Remove and rotate the blades where possible, using one of the 4 cutting edges

(some blades cannot be rotated, others can be rotated up to 4 times).

MB030020

1. Position the product on level ground.

2. Support the jaw.

3. Make sure the carrier's transmission is in neutral and the parking brake is

engaged.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 54 - Maintenance

RSS45R, RSS58R, RSS80R

MB030021

0,5 mm

4. Stop the carrier engine.

5. Clean the cutting blades and the base.

6. Lower the upper jaw until just before the front blade engage the corresponding

blade of the fixed lower jaw. Measure the distance with a gauge.

7. Continue lowering the moving shank until the entire front blade has engaged the

corresponding fixed blade. Measure the clearance between the blades with a

thickness gauge in the rearmost part of the blade.

8. Continue to lower the shank, repeating the procedure for the rear blades.

9. If the measured clearance exceeds the recommended value of 0.3 mm (0.01

in)...0.5 mm (0.02 in), insert an appropriate number of shims behind the blades

to restore the correct clearance between the blades.

NOTICE! It is recommended to keep the less worn blades in the upper jaw and

to shim only in the lower jaw. Do not exceed 3.5 mm (0.14 in) thickness;

instead, replace the worn blade.

■ To add thickness, open the shear completely, loosen the screws holding the

Turning and changing cutting bladesRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

blades, and insert the shims between the blade and its housing.

WARNING! Use external constraints to prevent the mobile body from closing

accidentally.

■ Tighten the screws to the specified torque.

■ Close the shear slowly and recheck that the clearance is correct.

10. After any rotate of the blades, always use a gauge to check that the relative

clearance between the primary and secondary blade of the moving body and the

respective blades of the fixed body does not exceed 0,5 mm (0.02 in).

Maintenance - Page 55COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Turning and changing cutting blades RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

MB030022

0,5 mm

RSS45R, RSS58R, RSS80R

11. With a gauge, check that the relative distance between the upper wear plate and

the lower one is 1.5 mm (0.06 in).

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 56 - Maintenance

RSS45R, RSS58R, RSS80R

3. HARDFACING THE JAW

WELDING TOOLS

Item Welding tool

Repair of parent MIG-wire, DIN 8559: SG 2

Hardfacing MIG-wire, DIN 8555: SG 6 - 60

HARDFACING CRUSHER JAW

Hardfacing the jawRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

Welding rod, DIN 1913: E 51 53 B 10

Welding rod, DIN 8555: E 6 - 55

Welding must occur in a workshop with proper welding tools. If you must weld

the product when it is on the carrier, consult your carrier dealer for

precautions during welding.

Warning! Support the jaw to prevent it from closing unexpectedly during

maintenance.

1. Position the product on level ground.

2. Support the jaw.

3. Carefully remove the worn part by carbon arc gouging or by gas cutting at the

base. Note: Connect an earth cable to the part to be repaired.

4. Repair the parent by filling it with a welding rod and finish the surface by

grinding.

5. Preheat hardfacing area to 150 °C... (302 °F)200 °C (392 °F).

Maintenance - Page 57COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OY

Hardfacing the jaw RSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

MB030018

RSS45R, RSS58R, RSS80R

6. Perform the hardfacing. The weld bead must be at least 10 mm (0.39 in) away

from the cutting edge. The hardfacing area of the product is shown in the

illustration below.

COPYRIGHT © 2019 SANDVIK MINING AND CONSTRUCTION OYPage 58 - Maintenance

Adjusting regulator clearance recoveryRSS05R, RSS08R, RSS11R, RSS15R, RSS23R, RSS34R,

RSS45R, RSS58R, RSS80R

4. ADJUSTING REGULATOR CLEARANCE RECOVERY

TORQUES FOR SCREWS

Screw

M8 25 Nm (18 lbf ft) 35 Nm (26 lbf ft) 42 Nm (31 lbf ft)

M10 50 Nm (37 lbf ft) 70 Nm (52 lbf ft) 85 Nm (63 lbf ft)

M12 85 Nm (63 lbf ft) 120 Nm (89 lbf ft) 145 Nm (107 lbf ft)

M14 135 Nm (100 lbf ft) 190 Nm (140 lbf ft) 230 Nm (170 lbf ft)

M16 210 Nm (155 lbf ft) 295 Nm (218 lbf ft) 355 Nm (262 lbf ft)

M18 290 Nm (214 lbf ft) 410 Nm (302 lbf ft) 490 Nm (361 lbf ft)

M20 410 Nm (302 lbf ft) 575 Nm (424 lbf ft) 690 Nm (509 lbf ft)

M24 710 Nm (524 lbf ft) 995 Nm (734 lbf ft) 1240 Nm (915 lbf ft)