RAM Microlab 350/450 Instruction Manual

FOR YOUR SAFETY, KEEP THE FOLLOWING

Do not use with damaged our faulty power cord,

plug, and outlet, contact to the manufacturer. If

may cause the danger of re, electric shock.

When unplug the power cord, hold the plug and

do not touch with wet hand. Do to use with

loosing power plug causing the danger of electric

shock and re.

Do not bend the power cord excessively and do

not press with heay things. If may cause electric

shock and re.

Do not place near heat equipment and candles or

cigarette causing re.

Close supervision needs if this product is used by

or near by the very young, the elderly or invalid.

Do not leave children unattended in any room

where this products has been installed.

Use the grounding conductor. Breakage or

electric leak may cause the danger of electric

shock.

For grounding, inquiry to electrician or to main

oce.

In case of using extension cord, do not use many

electricity equipments in one time. It causes re

and electric shock.

Do not place or set up the product in the humid

and rainy or snowy location.

It brings the danger of electric shock and re.

Do not drop or damage the handpiece. In case of

malfunction, dropping, drowning, do not use and

contact to the manufacturer, (If may cause

vibration of the bur, overheating, or damage of

the bearings.)

Use the products in proper use as per the instruction and do not use not recommended by the

manufacturer.

If may cause injury or property loss if not

following the instructions.

Saeshin is not responsible for the accident causing

by not following the instructions.

Type of protection against electric shock:

Class I equipment

Degree of protection against electric shock:

Type B applied parts

Classication according to the degree of

protection against ingress of water as detailed

in the current edition of

IEC 60529:

Equipment: IPX0, ordinary equipment

Foot witch: IPXI

This equipment is not suitable for use in the

presence of ammable anesthetics or oxygen

Made of operation: continuous operation

“This equipment has been tested and found to

comply with the limits for medical devices in

IEC 60601-1-2:1994. These limits are designed

to provide reasonable protection against

harmful interference in a typical medical

installation. This equipment generates, uses

and can radiate radio frequency energy and, if

not installed and used in accordance with the

instructions,may cause harmful interference to

others devices in the vicinity. However, there is

no guarantee that interference will not occur

in a particular installation. If this equipment

does cause harmful interference to other

devices, which can be determined by turning

the equipment o and on the user is

encouraged to try to correct the interference

by one or more of the following measures:

Reorient or relocate the receiving device.

Increase the separation between the

equipment.

Connect the equipment into an outlet on a

circuit dierent from that to which the other

device(s) are connected.

Consult the manufacturer or eld services

technician for help.”

Ram Products, Inc.

182 Ridge Road, Suite D

Dayton, N.J. 08810

Monday thru Friday 8:30 - 6:30 EST

Phone: 1-877-RAM-PROD / 1-732-651-5500

Fax: 1-732-651-6688

or e-mail us at ram@ramhp.com

182 Ridge Road, Suite D Dayton, N.J. 08810

www.ramprodinc.com | Phone: 1-877-RAM-PROD / 1-732-651-5500

Read all instructions before using

This product is mainly designed for dental laboratory use.

This product can be used for clinical use at dental clinic.

Thank you for your purchase.

In order to have trouble-free performance

Please read all instructions before operating.

Please keep this manual for future reference.

Saeshin is not responsible for the accident causing by not

following the instructions.

Design and specication of the product can be subject to be

changed for improving the quality.

Informing the product, model faulty status, and the customer’

(tel# or email etc), the kind consulting and quick service will

provided.

[caution!]

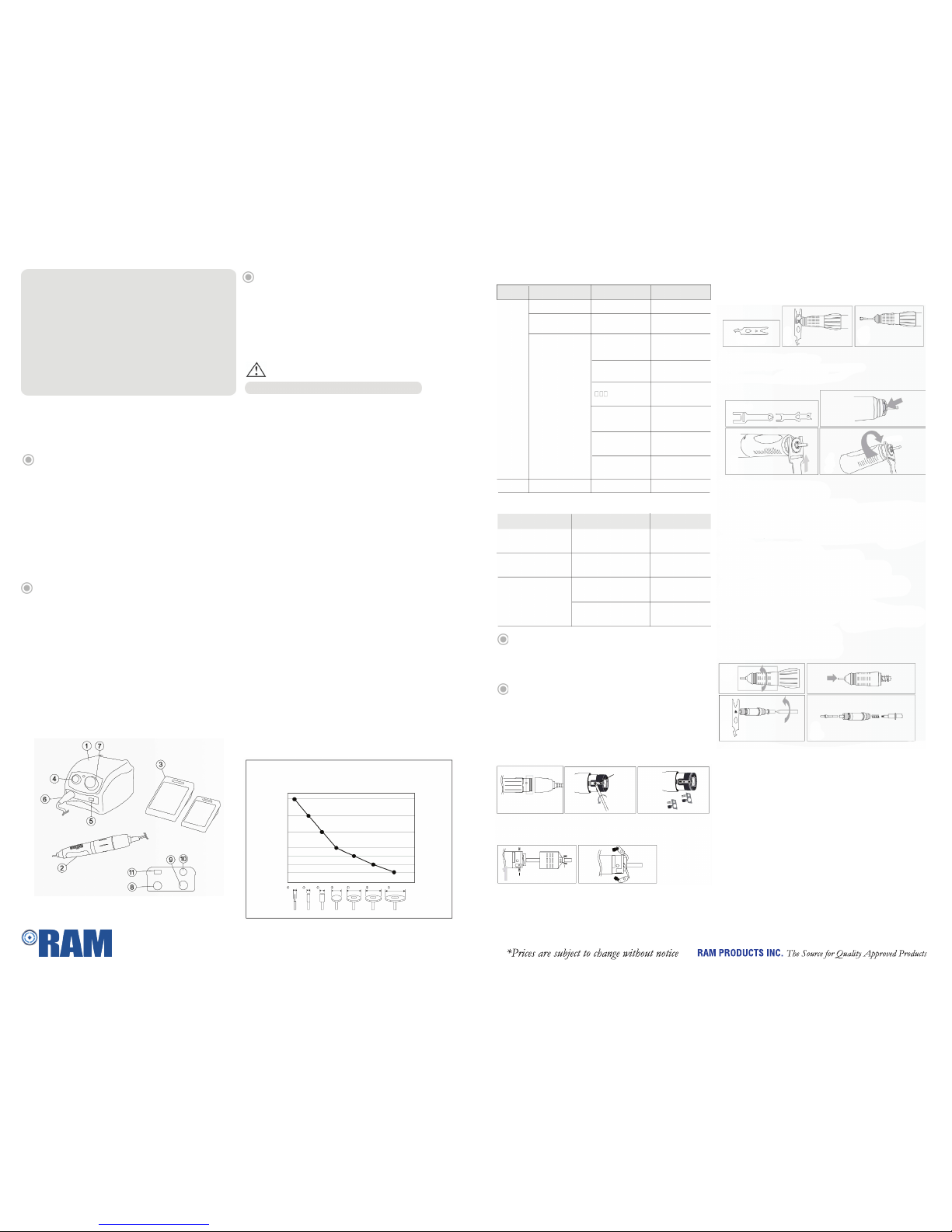

[CONTROL BOX ] CHANGE COLLET CHUCK

[STRONG102WL]-Easy chuck open type

[HANDPIECE]

REPLACEMENT OF FUSE

CAUTION

In case of easy chuck change type or front-chuck-open type (Forte, 103L,

107 and 102 WL HP), please use it after checking the bur is completely lock.

This is because the chuck coul could be loose after chuck or bur change.

5. Hold handpiece with one hand and with the other hand, tirn on the

power of control box.

6. Check handpiece running normally controlling speed dial in control box.

7. Turn o the power and connect the foot pedal to control box. Check

speed operating of the pedal.

8. Turn o the power and switch to reverse direction. Turn on the power

and check the operating.

Handpiece - 1year

Control box & Foot Pedal - 1 year

Warranty does not include misuse or normal wear of bearing,

carbon brush collet chuck, spindle and armature.

In case of the fault or malfunction from the misuse of the user

-Using with wrong Input Votalge (AC Voltage)

-Dropping down during setting or moving

-In case of user’s misuse or improper use

-Using consumable parts or accessorues not recommended by

manufacturer

-Malfunction after repairing at the places not recommended by

manufacturer

Other cases

- Faulty by Act of God (Fire, sea wind or water, ood etc).

-Replacing by the normal wear of the consumable parts

(ball bearings, collet chuck, carbon brush, spindle, or

armature etc.)

SERVICE FOR CHARGE

1 After checking o-switch in control box, plug in.

2. Connect handpiece to output of control box.

3. Set the speed dial of control box to “0”

1-CONTROL BOX

2-HANDPIECE

3-SPEED FOOT PEDAL

ON/OFF FOOT PEDAL

4-POWER SWITCH

5-FORWARD-REVERSE SWITCH

6-MOTOR CONNECTOR

7-SPEED CONTROL DIAL

8-FOOT PEDAL CONNECTOR

9-POWER CONNECTOR

10-FUSE HOLDER

11-HAND FOOT SWITCH

[PART NAME]

SETTING AND OPERATION

Ram Products, Inc. 182 Ridge Road, Suite D Dayton, N.J. 08810

Phone: 1-877-RAM-PROD / 1-732-651-5500 Fax: 1-732-651-6688

or e-mail us at ram@ramhp.com Monday thru Friday 8:30 – 6:30 EST

Please turn o the switch when you do not use the unit

1. Do not work in a dangerous place. Do not use the control box in a

humid place.

2. Transport and storage conditions:

3. Our handpiece & foot pedal should be only used for our control unit.

4. Bur

5. Check for any troubles, including vibration of bur, at low speed, and then

start high speed.

6. Operate the speed control dial in control box softly

7. Use a fuse of 220V/230V/2A for control box.

8. Turn o the power in order to change the bur.

9. Be careful not to drop the handpieces as it may be damages or broken.

In that case it is dropped, check if the bur is bent or if any excessive heat

is generated while carefully operating it.

10. If any problem occurs in handpiece use after repairing.

11. Do not turn on the power of control box while the collet chuck of

handpiece open (Short circuit of the motor may be caused).

12. Make sure that the switch is o before putting the power plug in the

socket, in order to avoid an unexpected injury due to sudden start.

13. A circuit breaker is provided to protect the motor. It is actuated when

there is an overload which the motor cannot stand. Work within a range

of load whis it is not actuated.

14. Do not open the chuck while operating.

15. Keep the handpiece with setting a bur to the collet church after

operation.

16. Do not put the handpiece down before it stops completely.

17. Be sure to pull out the power cord before moving the control box.

18. Use the specied voltage.

19. Use accessories suitable for this product.

20. For recommended speed in various applications, follow the

manufacturer’s instructions.

21. Wear proper protective clothes and equipment, including a dust mask

and safety googles. Use a proper suction unit and ventilator.

22. Keep the work place clean. Debris may cause an accident.

Temperature: 1~40C

Humidity 30~75% RH

Atmospheric Pressure

:700 hPa to 1060 hPa

*Dimensions of the bur: 2.35mm (ISO7785-2 TYPE2)

*Minimum tting length of bur: 10mm

*When locked in the chuck the maximum projection length of should be

less than 3mm Use a bur the conform to the ISO standards.

Avoid using a rusty or bent bur that may cause excessive wear of

bearings.

Keep safe speed, and precautions recommended by bur manufacturer.

[The allowable RPM according to the bur diameter]

Please keep the RPM according to below diagram against the accident.

<The allowable RPM could be dierent from the bur material and type.

RPM

50,000

45,000

40,000

35,000

30,000

25,000

20,000

15,000

10,000

5,000

0

2under 2-4 4-8 8-18 18-28 28-40 40 over

problem

The power is out.

The power lamp is

out, when the power

switch turn on

The handpiece does

not run, when the

hand/foot switch is

on and power lamp

is on.

The motor

does not

run

The motor

uns

Speed control is out

The control box

may have a problem.

Ask to the seller

Change the carbon

brush or ask to the

seller

Check the carbon

brush

check if the cord

is broke down or

disconnected.

Check the pedal

connection.

Connect the pedal

properly

Check the connection

connector and HP cord

Connect the

handpiece

properly

Open the end cap of

handpiece and check the

burnt smell.

Check if the

OV (overload)

lamp is on

Check the connection

of power cord

The control box may

have a problem

Check the fuse.

Connect the power cord

properly.

Turn o the power and

then turn on.

Ask to the seller.

Ask the seller.

check cause solution

problem cause

The handpiece does not run

although the chuck is lock.

Check the connection of

bearing, carbon brush,

control box

Ask to the seller.

Ask to the seller.

The handpiece is getting

warm during use.

Check the bearing. Ask to the seller.

The noise and vibration

happen during use.

Check the bearing and chuck.

Check if the bur is bent

Ask to the seller.

Change the bur.

solution

CHANGE CARBON BRUSH

The fuse is in a small fuse box beside the power connector at the back of

the control box

Pull out the fuse box then replace it with a new one

(120V-T3.15A/250V,230V-T2A/250V)

Please make sure the power is o, before you change the carbon brush.

Please run the motor for 1 minute with non-load in order to put the carbon

brush in right place.

Please check periodically the carbon brush wear in order to prevent the

sever damage.

The motor can be damaged if the carbon brush worn out is not changed in

proper time.

[ 102, 102L, 102LS, 102WL, 102L, 107II, 120II, 108E, 108EI ]

[caution!]

Carbon part

1 2 3

Terminal

Carbon

1. Unscrew the carbon bolt. The terminal is separated at the same time.

2. Change carboon brush.

1. Unscrew the bolt 130-23 and unscrew 130-13 xed the carbon brush.

2. Remove the soldered carbon and change the new one.

[130]

130-13

130-23

1 2

1

1

1 2

2

2

WRENCH

WRENCH

open

1. Open the chuck and remove the bur.

2. Fix the wrench to chuck and turn into

1. Set and x the wrench turning the bur.

2. Turn to open direction. check open.

3. Turn the chuck to the counter-clockwise In case of not turning by

hand,use wrench.

4. Change the chuck.

5. Fix the bur and chuck turning to clockwise.

And then turn again to counter clockwise a bit and set the tension to

remove the bur.

[caution!]

Lock the handle properly.

If the handle is turned continuously with pressure,

the handle and motor part may be disassemble.

If not skilled engineer, do not disassemble. It may cause the breakage.

For the replacing the ball bearings, x the wrench on the nose tip and then

turn the handle to the “open” direction.

Turn the wrench and loosen the nose tip slightly.

Turn the handle again to the “close” direction.

Spin the wrench again until the nose tip is disassembled and then bearings

can be replaced.

However, if the process is not followed property, the nose tip may be damaged

or broken.

If not skilled engineer, do not disassemble.

1. Fix the wrench to the collet chuck in spindle ass’y and turn to the arrow

mark directon with screwdriver.

2. Change the chuck.

[caution!]

Clean and assembly the chuck very carefully..

If not skilled engineer, do not disassemble the handle and motor part.

It may cause the breakage.

If disassembled, delrin joint of handle and the shaft of the motor part has to be

t each other.

If it does’t, vibration, nose, heat and bearing damage may caused.

*If the chuck is not open, please turn it with the wrench.

SUGGESTION FOR MAINTENANCE

1. Keep the place around in the handpiece clean from dust and grindings.

2. Remove dust on handpiece wiping with isoprophyl alcohol and avoid wet inside.

Do not apply the oil to the goods or clean with water.

The grease inside of the bearing could melt away due to the oil.

3. Air cleaning is acceptable but air pressure may aect the handpiece or motor.

4. Insertion and removal of bur

Turn the handle in the open direction to open the chuck.

Then the chuck is opened and the bur is removed, turn the handle in the close

direction, and the chuck is closed and the bur is recurred. Turn the ring until a

click sound.

[STRONG 102, 102L, 102LS, 107II,120II]

spindle

ass’y

Loading...

Loading...