Page 1

MODEL GDF28

Fry Dispenser

EQUIPMENT MANUAL

English (Rev. F)

P/N 291635

Manufactured by

AFD-280E

Automated Equipment, LLC

5140 Moundview Drive

Red Wing, MN 55066 U.S.A.

PHONE: 1 (651) 385-2273

FAX: 1 (651) 385-2166

SERVICE FAX: 1 (651) 385-2172

FOR SERVICE in the U.S.A./CANADA, CALL:

1 (800) 248-2724

http:// www.autoequipllc.com

Business Hours: 8:00 AM – 5:00 PM CST

After hours, your call will be handled by a pager service;

a Technical Support Representative will return your call.

INTRODUCTION _____________________________________________________________________ 3

SPECIFICATIONS____________________________________________________________________ 3

FCC STATEMENT____________________________________________________________________ 3

WARRANTY ________________________________________________________________________ 4

REQUESTING SERVICE, ASSISTANCE, OR PARTS________________________________________ 5

SAFETY____________________________________________________________________________ 6

ASSEMBLING THE DISPENSER ________________________________________________________ 7

DAILY SET-UP ______________________________________________________________________ 8

DAILY CLOSING_____________________________________________________________________ 8

OPERATOR CONTROLS ______________________________________________________________ 9

SEQUENCE OF OPERATION __________________________________________________________ 11

CONTROLLER FUNCTIONS ___________________________________________________________ 13

ERROR CODES _____________________________________________________________________ 16

TROUBLESHOOTING ________________________________________________________________ 25

ADJUSTMENTS AND DIAGNOSTICS ____________________________________________________ 27

CONTROLLER BOARD LAYOUT _______________________________________________________ 29

GDF28 SCHEMATIC __________________________________________________________________ 31

PART IDENTIFICATION _______________________________________________________________ 33

BASKET LIFT ASSEMBLY_____________________________________________________________ 36

NEW BASKET LIFT ASSEMBLY ________________________________________________________ 37

STOPGATE DRIVE ASSEMBLY ________________________________________________________ 38

ACCUMULATOR ASSEMBLY __________________________________________________________ 39

DRUM MOTOR ASSEMBLY____________________________________________________________ 41

LIFT SADDLE ASSEMBLY_____________________________________________________________ 41

NON-CONTACT WEIGHING SYSTEM ASSEMBLY (NCWS) __________________________________ 42

TABLE OF CONTENTS

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

Page 2

GDF28 Dispenser

The information in this manual is subject to change without notice.

IN NO EVENT WILL AUTOMATED EQUIPMENT LLC BE LIABLE FOR TECHNICAL OR

EDITORIAL OMISSIONS MADE HEREIN; NOR FOR DIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES RESULTING FROM THE FURNISHING, PERFORMANCE, OR

USE OF THIS MATERIAL.

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may

not be copied, in whole or part, without the written consent of Automated Equipment LLC

Product names mentioned herein are for identification purposes only, and may be

trademarks and/or registered trademarks of their respective companies.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

2

Page 3

GDF28 Dispenser

INTRODUCTION

The Dispenser is a compact automated system

that replaces manual basketing of frozen french

fries. The Dispenser automatically weighs 12

ounce (350 gm), 16 ounce (450 gm) or 24 ounce

(700 gm) loads of frozen fries and dispenses them

into custom fry baskets.

The Dispenser's Hopper holds 42 lbs. (19 kg) of

frozen french fries prior to basket loading. A

rotating Dispenser Drum inside the Hopper

transfers the frozen fries onto the Accumulator

Doors where a weight sensor accurately weighs

the fries.

Empty baskets are manually placed on the Upper

Guide. The baskets slide under the Accumulator

Doors where fries are dispensed into them. The

Basket Lift then lowers the filled baskets onto the

Lower Guide where the baskets wait to be picked

up by a crew person.

INTENDED USE

The GDF28 Dispenser is intended to dispense

only frozen french fries. All food should be stored

and handled according to industry

recommendations. The GDF28 Dispenser is not

intended to be used for storage of food and

should be cleaned regularly as described in the

manual in order to avoid spoilage and

contamination.

HAZARD COMMUNICATION STANDARD (HCS)

The procedures in this manual may include

the use of chemical products. These chemical

products will be highlighted with boldface

letters followed by the abbreviation (HCS) in

the text portion of the procedure. See the HCS

Manual for the appropriate Material Safety

Data Sheets (MSDS).

NOTE: This equipment is manufactured in the

U.S., therefore all hardware measurements are in

English, and the metric conversions stated are

approximate.

ADAPTIVE WEIGHT TECHNOLOGY

This Dispenser utilizes adaptive weight

technology. This allows the optimal parameters

used in weighing to be learned for the product

being dispensed. It varies the Drum rotation

speed to keep the rate of weight gain constant. It

takes between 10-20 cycles for the Dispenser to

learn the product. The settings will not be

changed when the Dispenser is turned OFF, only

when the food properties change.

SPECIFICATIONS

Features:

Bulk storage of 42 lb. / 19kg frozen product

Manual or automatic Dispense modes

Electrically driven

Holds 7 Custom Fryer Baskets

Disassembles for cleaning

Electrical Requirements:

U.S./Canada (UL Listed):

110 Volts a.c., 60 Hertz, 1Ø, 0.7 A

International (CE Marked):

220-240 Volts a.c., 50 Hertz, 1Ø, 2.0A.

Internal Circuit Breaker: 5 Amps

Additional Equipment Information:

Noise Emissions: < 70 dB(A)

Maximum Altitude: 6000 ft. (1525 meters)

Maximum Humidity: 95% non-condensing

Ambient Temperature: 4° - 25°C (40° - 77°F)

Date of Manufacture:

The manufacturing date is encoded into the

serial number identification label on the side

panel of the Dispenser.

Example: S/N GDFR0403C000000 indicates a

manufacturing date of 03/04 or March 2004.

Space Requirements:

Clear floor space near fry vat at least 28 inches

(72 cm) wide and 24 inches (60 cm) deep.

Basket Handles will extend to 32 inches (81

cm). This equipment must be placed on a

horizontal surface with a tilt of less than 2

degrees. This equipment is only to be installed

in locations where use and maintenance is

restricted to trained personnel.

FCC STATEMENT

WARNING: This equipment generates, uses,

and can radiate radio frequency energy and, if

not installed and used in accordance with the

instruction manual, may cause interference to

radio communications.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

3

Page 4

GDF28 Dispenser

WARRANTY

The terms “we”, “us”, “our” or “factory” hereinafter refer to Automated Equipment LLC. We warrant the

purchased product to be free from manufacturing defects in material and workmanship under normal

use and conditions for the period and component specified below:

Components covered

Electronic Circuit Board Assemblies 1 year

Electrical and Mechanical Moving Parts 1 year

Structural frame work or enclosures 1 year

Crew removable components:

Drip Tray 90 days

Hopper, Hopper Lid, and Diverter 90 days

Drum 90 days

Hopper Extension 90 days

Lift Saddle Assembly 90 days

Guide Assemblies & Slides 90 days

Crumb Tray 90 days

Custom Baskets 90 days

Power Cord 90 days

The Warranty period commences on the date of shipment of the Dispenser (hereinafter

“Product”) from our manufacturing facility.

EXCEPT AS OTHERWISE PROVIDED HEREIN WE MAKE NO OTHER WARRANTIES, EXPRESSED

OR IMPLIED AND SPECIFICALLY DISCLAIM ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

Term

We shall not be liable for any direct, indirect, consequential damages (including damages for loss of

business profits, business interruption, loss of business information and the like) arising out of the use

of or inability to use the Product.

THIS WARRANTY IS VOID IF THE PRODUCT IS NOT FUNCTIONING CORRECTLY DUE TO ABUSE

OR NEGLECT BY THE PURCHASER, ITS EMPLOYEES, AGENTS, OR OTHER

REPRESENTATIVES EITHER BY BREAKING, BENDING, MISUSE, ABUSE, DROPPING,

ALTERATION, IMPROPER MAINTENANCE OR ANY OTHER FORM OF NEGLECT OR IMPROPER

USAGE. THIS WARRANTY DOES NOT COVER DAMAGE TO THE PRODUCT BY NATURAL

CAUSES SUCH AS LIGHTNING, ELECTRICAL CURRENT FLUCTUATIONS, FLOOD, FIRE,

TORNADOES, OR OTHER ACTS OF GOD. WE WILL INVOICE PURCHASER FOR REPAIRS MADE

NECESSARY BY THE HEREIN LISTED CAUSES.

This warranty is governed by the substantive laws of Minnesota, U.S.A., without giving effect to the

conflict of law provisions.

This warranty is non-transferable and applies only to the original purchaser.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

4

Page 5

GDF28 Dispenser

REQUESTING SERVICE, ASSISTANCE, OR PARTS

WARRANTY SERVICE

Warranty service must be initiated by calling our

Technical Support Hot Line at 1-800-248-2724

(U.S./Canada) or 651-385-2273 to establish all

warranty requests.

Our Technical Support personnel will determine

the cause of failure and provide the appropriate

resolution. If replacement parts are required, parts

will be provided by the factory or by an authorized

Service Support Center/Parts Distributor.

replacement parts other than those supplied by

the factory or by a factory Authorized Parts

Distributor will void the warranty.

All charges for parts and shipping are F.O.B.

factory, and are subject to change without notice.

Prices will be those in effect at the time of

shipment.

We reserve the right to make suitable

substitutions in materials, depending upon their

availability.

We will make all reasonable efforts to perform

such repairs during normal business hours, and

will not be responsible for any after-hours or

holiday charges.

NON-WARRANTY SERVICE

Service is normally conducted by customer

appointed personnel, or by contracting a local

service agent. Service fees are in accordance

with industry standards.

Replacement parts are available through local

Service Support Center/Parts Distributors or direct

from the factory by calling 1-800-248-2724

(U.S./Canada) or 651-385-2273 in the event a

local distributor is not available.

Our Technical Support Hot Line is available for

telephone assistance providing factory product

technical support, parts and parts information, and

service agent referral. Contact our Technical

Support Hot Line at 1-800-248-2724

(U.S./Canada) or 651-385-2273.

WARNING!

Only trained and/or qualified personnel should

perform service to this equipment.

Service functions described in this manual

could cause irreversible damage to the

equipment and/or injury to personnel if

performed improperly.

If the power cord is damaged, it must be

replaced by the manufacturer or its service

agent or a similarly qualified person in order

to avoid a hazard.

Record the following information for your records:

Date of Installation

Service Agency Telephone

Serial Number

When repairing this unit, use only replacement

parts supplied by the factory, or supplied by a

factory Authorized Parts Distributor. Use of

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

5

Page 6

GDF28 Dispenser

SAFETY

Here are some guidelines for operating and maintaining the GDF28 Dispenser:

• Disconnect the Dispenser Power Cord from the wall outlet before inspecting.

• Inspect the Dispenser on a regular basis to identify problems before they occur.

• Keep the Dispenser clean.

• Keep hands away from the Accumulator Doors and Dispenser Drum while the Dispenser is operating:

• Fryer Baskets may be hot. Pick them up by the handles only.

• Do NOT roll the Dispenser to the back sink for cleaning, this will cause unnecessary wear on the

Dispenser.

• If the supply cord is damaged it must be replaced by the manufacturer or its service agent or a similarly

qualified person in order to avoid a hazard.

• DO NOT SPRAY DOWN THE DISPENSER WITH WATER. It is not sealed against jetting water and

contamination may get into sensitive components. This will void the warranty

WARNING!

Only trained and/or qualified personnel should perform

service to this equipment.

Service functions described in this manual could cause

irreversible damage to the equipment and/or injury to personnel

if performed improperly.

INTERNATIONAL SAFETY LABELING

International Safety Labeling is represented with the symbols illustrated below. The labels are affixed to the

Hopper to clearly indicate areas that could be harmful to the operator of the Dispenser.

These safety issues are:

1. BASKETS MAY BE HOT: Baskets should always be picked up by the provided handle.

2. NO HANDS BELOW: Hands should not be placed near or below the Accumulator Doors while the

Dispenser is energized.

BASKETS MAY BE

HOT

NO HANDS BELOW

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

6

Page 7

GDF28 Dispenser

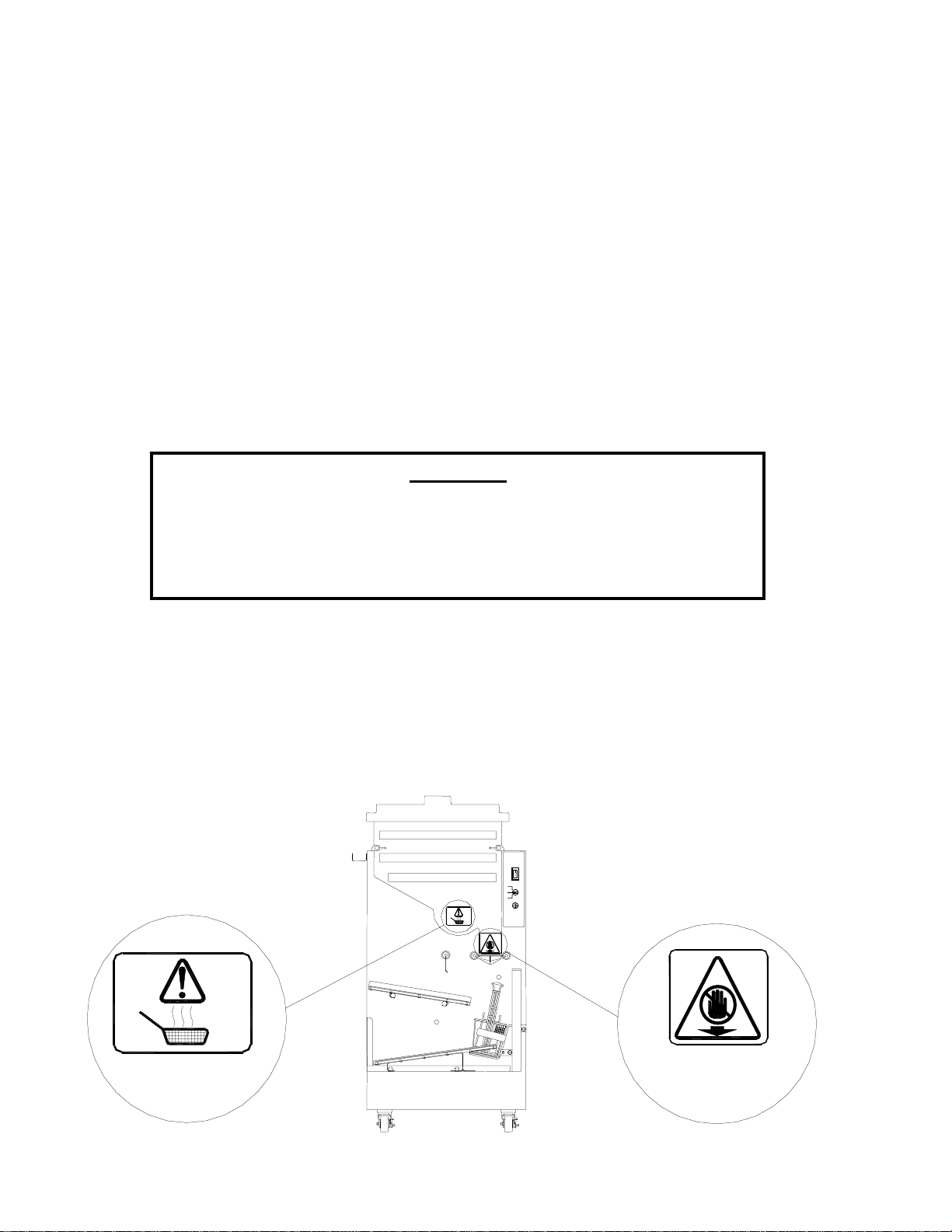

ASSEMBLING THE DISPENSER

INSTALL DRIP TRAY (Fig. 1)

• Position the Drip Tray with the Basket Stop away from

the Lift Saddle as shown.

• Slide the end of the Drip Tray under the Lift Saddle.

• Line up the holes in the Drip Tray with the Locator

Pins and set the Drip Tray down over the Locator

Pins.

INSTALL LOWER GUIDE (Fig. 2)

• Position the Lower Guide with the high end toward the

Lift Saddle. The low end should be toward the Basket

Stop as shown.

• Line up the holes in the Lower Guide with the Locator

Pins and set the Lower Guide down over the Locator

Pins.

INSTALL UPPER GUIDE (Fig. 3)

• Locate the Hooked Tab and the Straight Tab on the

bottom of the Upper Guide.

• Position the Upper Guide with the Hooked Tab away

from the Lift (as shown). Tilt the Upper Guide back

so that the end near the Lift is two to three inches (510cm) higher than the end with the hooked tab.

• Place the Hooked Tab of the Upper Guide around the

LEFT Guide Support . Align the slot in the Hooked

Tab with the screw in the middle of the Guide

Support, then slide the Upper Guide to the RIGHT,

hooking it on the LEFT Guide Support.

• Align the slot in the straight tab of the Upper Guide

with the screw on the RIGHT Guide Support. Press

the upper guide down, snapping it into place.

INSTALL THE HOPPER AND DRUM (Fig. 4 & 5)

• Find the square opening in one end of the Dispenser

Drum.

• Place the Dispenser Drum in the Hopper, aligning the

square opening on the Dispenser Drum with the hole

in the back of the Hopper.

• Grasp the Hopper so that the hole is toward the

Dispenser.

• Align the indentations on the Hopper with the Hopper

Support Bars.

• Push the Hopper forward onto the Hopper Support

Bars until the Drum Motor shaft touches the

Dispenser Drum.

CAUTION: Do NOT force the Hopper back; this could

damage the Hopper or Drum.

• Rotate the Dispenser Drum (CLOCKWISE or

COUNTER-CLOCKWISE) while applying gentle

pressure to the Hopper until you can easily slide the

Hopper fully onto the Hopper Support Bars.

• Lock the Hopper onto the Dispenser by pressing the

Locking Pins on the ends of the Hopper Support Bars

towards each other.

PLACE THE DIVERTER IN THE HOPPER (Fig. 6)

Be sure that it is hooked over the RIGHT edge of the

Hopper.

PLACE THE HOPPER LID ON THE HOPPER (Not

pictured)

Hook the lid's tab over the back rim of the Hopper,

then set the Lid down.

LOWER

BASKET

DRIP

LIFT SADDLE

LOCATOR PINS

FIGURE 1

FIGURE 2

LIFT SADDLE

LOCATOR PINS

DISPENSER DRUM

UPPER

GUIDE

HOOKED

TAB

STRAIGHT

TAB

SUPPORT

DRUM

MOTOR

SHAFT

BARS

LIFT SADDLE

FIGURE 3

FIGURE 4

DIVERTER

HOPPER

FIGURE 5

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

7

FIGURE 6

Page 8

GDF28 Dispenser

DAILY SET-UP

1. Verify that the Power Switch is in the OFF position.

2. Plug the Power Cord into a wall outlet.

3. Load the Hopper with frozen french fries. DO NOT

SHAKE OR DROP the fries into the Hopper (refer to

"LOADING THE HOPPER", page 8).

4. Turn the Load Select Switch to the desired load weight.

5. Fill the Upper Guide with empty Custom Baskets.

6. Turn the Power Switch to the ON position (illuminated).

Electric motors will orient themselves to starting positions

and the dispenser will initiate the filling process.

7. Use filled Baskets from the Lower Guide for Fry

production.

8. Return empty Baskets to the Upper Guide for refilling after

the cooking cycle is complete.

LOADING THE HOPPER

To achieve optimum fry yield and the most consistent basket

loads, it is important to use the following technique for loading

frozen fries into the hopper. Depending on your fry supplier, you

will receive your french fries packaged in boxes of six pounds

each, or bags of six pounds each. These bags or boxes will be

packed six to a case. The hopper will accept one full case plus

one bag or box of french fries (42 lbs. or 19 kg).

For each bag or box of french fries:

1. Remove the bag or box of french fries from the case. Be

careful not to crush the fries.

2. Open the top of the bag or box completely.

NOTE: If your supplier uses bags, be careful that the top is

fully open. If it is partially open, the bag may retain fries.

3. Hold the opened end of the box or bag closed with your

hand and lay it in the hopper with the opening toward the

side opposite of the diverter.

4. Release the opened end of the bag or box.

5. Empty the bag or box into the hopper by pulling it evenly

toward the Diverter. When adding multiple bags of fries,

alternate the placement of the bag or box in the hopper

opposite of the previous bag or box. The second bag of

fries should be emptied into the Hopper with the opening

toward the Diverter, and pulling it evenly toward the

Hopper Wall opposite the Diverter.

NOTE: This criss-cross loading method assures an even

distribution of fry lengths in the Hopper and the Baskets.

NOTE: Do NOT shake or drop fries from the bag or box

into the Hopper.

NOTE: If the loading is done correctly, you should be able

to leave a uniform layer of fries in the hopper by simply

pulling the bag or box across the hopper and then out of

the hopper.

6. Repeat steps 1 through 5 until the hopper is full.

NOTE: Do NOT fill the hopper past the top.

7. Close the lid on the hopper by engaging the hook at the

back of the hopper, and setting the lid down

DAILY CLOSING

1. Turn the Power Switch to the OFF position.

2. Remove all Baskets from the upper and Lower Guides.

Discard and record the uncooked fries.

NOTE: During the last few hours of the day, you may

want to keep only two or three bags of french fries in the

hopper and run the dispenser in SINGLE mode, to

minimize waste.

3. Remove the Hopper Lid by lifting it UP and BACK to

unhook the tab.

4. Hang the hopper lid on the front of the hopper, by

hooking the tab on the lip of the hopper.

5. Discard and record any fries remaining in the Hopper at

closing.

6. Check that the Accumulator Doors are empty of fries.

7. Disconnect the Power Cord from the electrical outlet

8. Remove the Diverter by grasping it and pulling it UP.

9. Slide the Locking Pins outward to release the Hopper.

10. Remove the Hopper (and the Dispenser Drum inside) by

pulling the Hopper OUT and AWAY from the Hopper

Support Bars.

11. Remove the Upper Guide assembly by lifting the RIGHT

end and sliding it to the LEFT.

12. Remove the Lower Guide by lifting it straight UP.

13. Remove the Drip Tray by lifting it from the Basket Stop

end and sliding it from under the saddle.

14. Take the hardware removed from the Dispenser to the

back sink. Wash it in a hot solution of McD APSC (HCS),

rinse with clear water, sanitize and allow to air dry.

15. Roll the dispenser out from the wall, so that you can

clean behind it and underneath it.

NOTE: Do NOT roll the dispenser to the back sink for

cleaning, this will cause unnecessary wear on the

dispenser and possible premature failure.

16. Wipe down the dispenser with a hot solution of McD

APSC (HCS) and water. Repeat wipe-down with clear

water, sanitize and allow to air dry.

NOTE: DO NOT SPRAY DOWN THE DISPENSER. It is

not sealed against jetting water and contamination may

get into sensitive components. SPRAYING MAY VOID

THE WARRANTY!

17. Reassemble the dispenser.

18. Roll the dispenser back into place.

WARNING

PINCH HAZARD

Personnel should take care not to place hands or fingers near the Drum inside the Hopper, while this machine is

in operation. Hands or fingers could be pinched between the Drum and the Hopper as the Drum turns.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

8

Page 9

GDF28 Dispenser

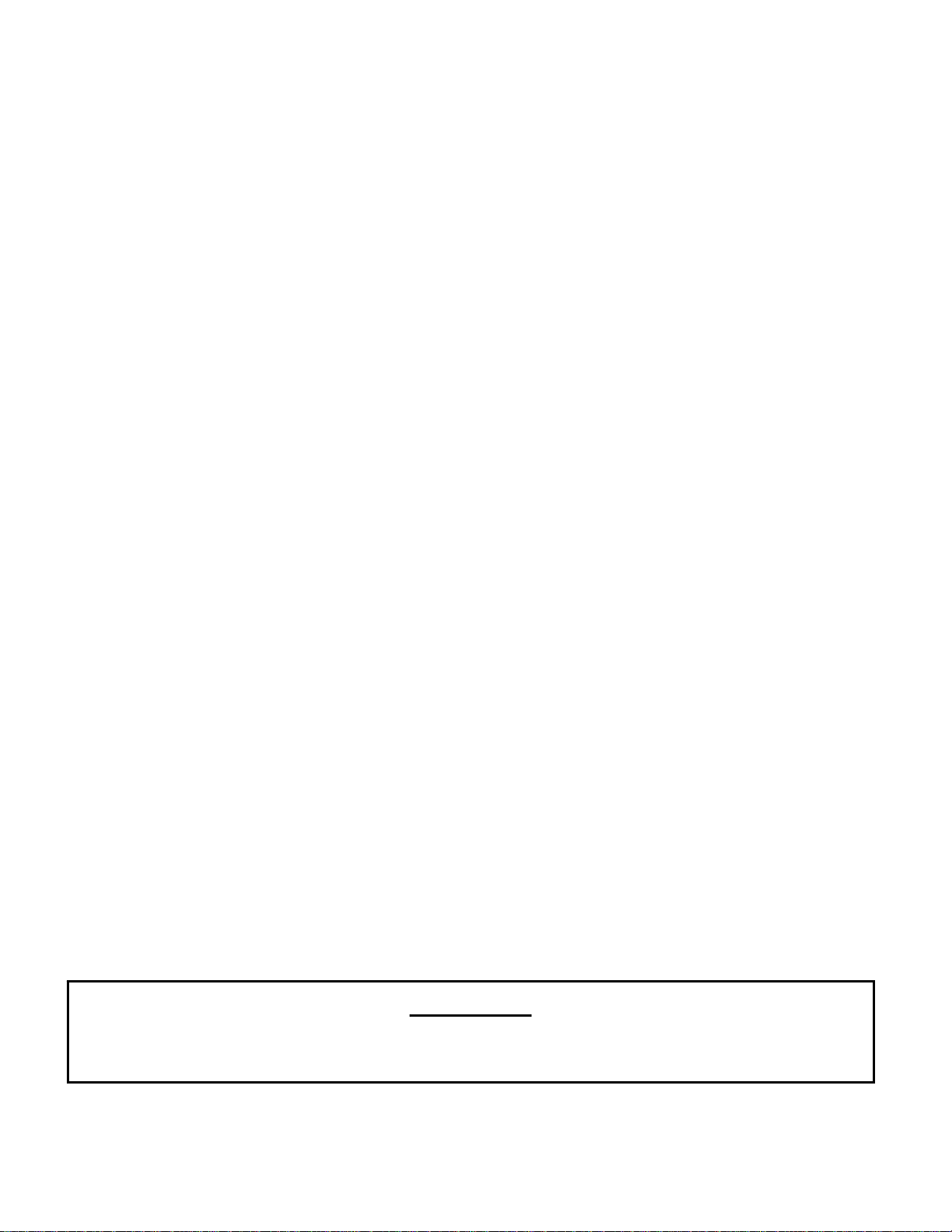

OPERATOR CONTROLS

The following switches and buttons are located on the

Operator Panel:

GDF28

Power Switch

1

2

3

Position #3: For Automatic dispensing of 1.5 lb./700

gm Basket Loads.

1

Load Select Switch

2

3

Start/Reset Button

Warning/Error

Light Symbols

Power Switch (Orange)

The Power Switch supplies electrical power to the

Dispenser. It illuminates when the Dispenser has

power. The Power Switch also functions as a circuit

breaker for the machine.

LOAD SELECT SWITCH

The Load Select Switch has 3 positions that allow the

operator to select Basket Load weights and control

operation.

1

2

3

Position #1: Single basket loading. Press the

Start/Reset Button to dispense a single basket of Fries.

Pre-set to .75 lb./350 gm/Single mode.

NOTE: International units are factory set to automatic

mode. US and Canadian units are factory set to single

mode. This can be reconfigured by performing function

#6 (see page Error! Bookmark not defined. & 13).

Start/Reset Button (Green)

Press to start the loading of a single Basket if the Load

Select Switch is set for Position #1 (0.75 lb./350gm).

Press to reset a System Error or an empty Hopper

warning.

The symbols below the button provide an explanation

of warning and error conditions.

A slow blink (about 1 per second) of the Start/Reset

Button indicates either an empty Hopper or bridged

appetizers.

A fast blink (about 5 per second) of the Start/Reset

Button indicates a system error.

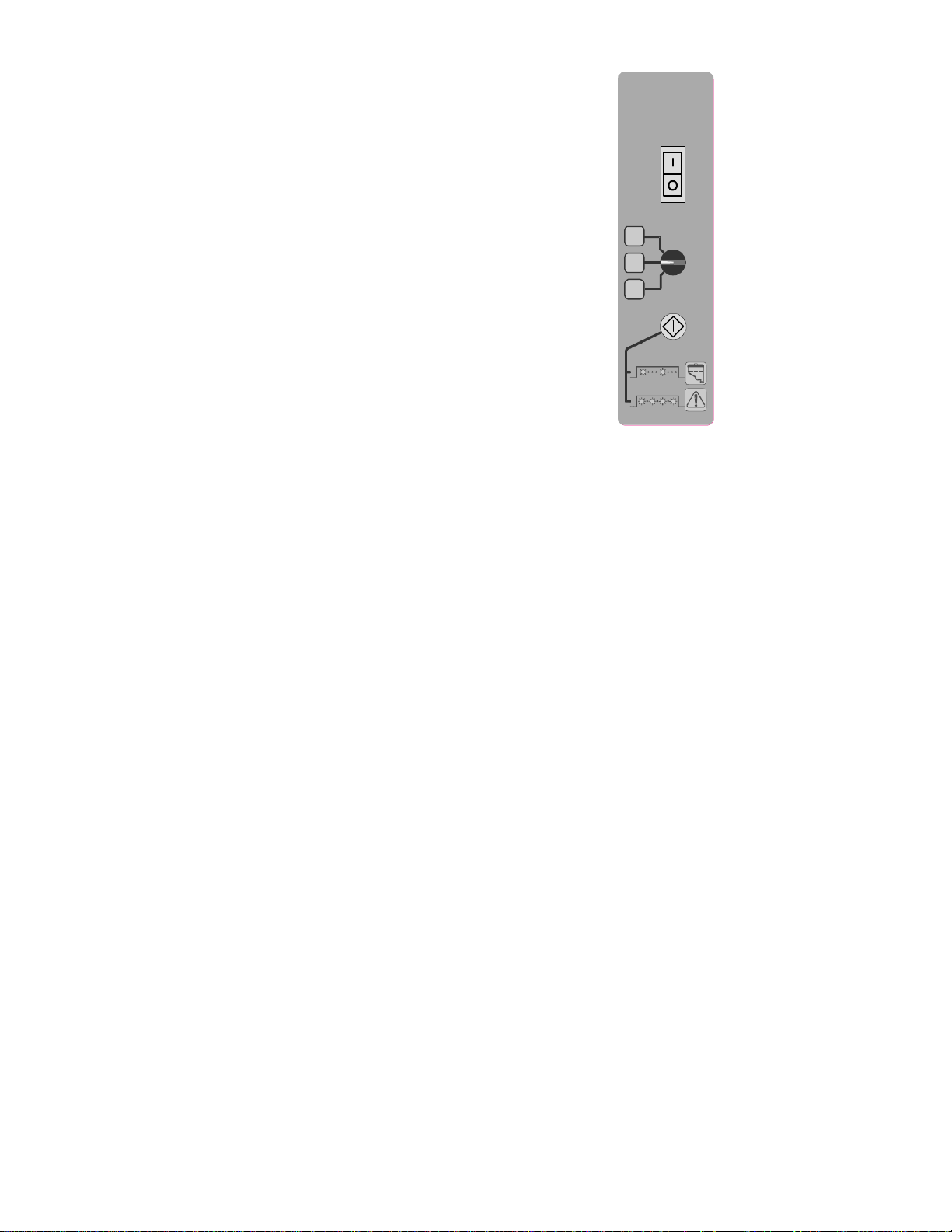

CALIBRATE WEIGHT SENSOR

For optimum performance, the weighing system should

be calibrated once per year. US Dispensers will need

two 1lb weights (eight ¼ lb hamburger patties will

work). International Dispensers should use two 450gm

weights. To calibrate, follow these steps:

GDF28

1

2

3

1

2

3

Position #2: Automatic dispensing of 1.0 lb./450 gm

Basket Loads.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

1. Turn the Dispenser OFF ( O ). Wait 15 seconds

2. Remove the Hopper and Drum to gain access to

the top of the Accumulator doors.

3. Place Selector Switch in Position 1.

4. While holding the Start / Reset Button in, Power the

Dispenser ON ( I ).

9

Page 10

GDF28 Dispenser

5. Continue holding the Start / Reset Button in until

the Green Light flashes rapidly, and then release.

6. Place an empty Basket on the Upper Guide. Any

product remaining on the Accumulator doors will be

dispensed into the Basket before calibration continues.

After dispensing, the Green light will stop flashing.

7. Place the Selector Switch in Position 2. The Green

Light will begin to flash again.

8. Place 1.0 lb. (450gm) On the Accumulator Doors.

9. When the Dispenser has reached a stable value,

the Green Light will stop flashing.

10. Place the Selector Switch in Position 3. The green

Light will begin to flash.

11. Place an additional 1.0 lb. (450gm) On the

Accumulator Doors, for a total of 2 lbs (900gm).

12. When the Dispenser has reached a stable value,

the Green Light will stop flashing.

13. Turn the power OFF ( O ).

14. Remove the weight from the Accumulator Doors.

15. Replace the Hopper and Drum

16. Place the Selector Switch in the desired Basket

size position.

17. Power the Dispenser ON ( I ).

18. The Green Light will illuminate indicating the

Dispenser is ready for Normal Operation.

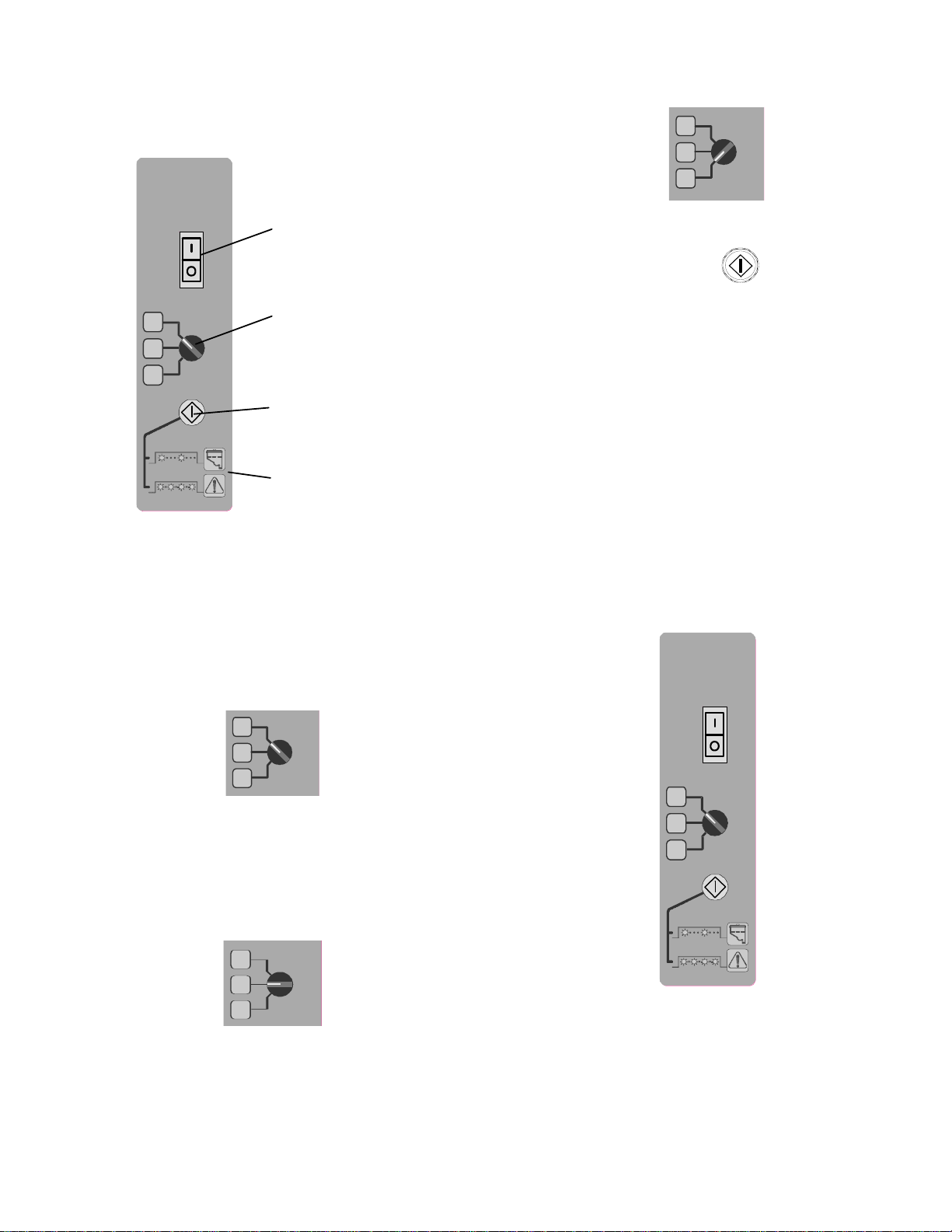

FRONT PANEL OPERATIONS

CUSTOMIZATION (Bypass Mode)

Bypass Mode will allow the dispenser to remain

functional in the event the weighing system or the

basket sensors fail.

NOTE: The BYPASS mode has two methods of

operation and the Dispenser will automatically select

the appropriate method.

Method 1:

GDF28

1

2

3

To Engage the BYPASS Mode of operation:

• Turn the Dispenser off. Wait 15 seconds.

• Select Position #2.

• Hold in the Start/Reset Button

• While holding in the Start/Reset Button, turn the

Dispenser power ON ( I ). Double flashing of the

Start/Reset button indicates BYPASS

This modification to the Dispenser operation is temporary:

When the Dispenser power is turned OFF ( O ), the

Dispenser resets to normal operations when the power is

turned ON ( I ) again.

NOTE: Allow 15 seconds before turning the Dispenser

Power Switch ON ( I ) after being turned OFF ( O ).

NOTE: The Bypass mode will significantly slow down the

operations of the Dispenser. The Start/Reset button has

to be used in either mode of Bypass operation.

The Dispenser detects a functioning Weight

Sensor.

The Dispenser will appear to operate normally, filling

the accumulator with the correct weight of appetizers.

The Start/Reset button must be pushed to dispense the

appetizers into a basket. This method allows the

Dispenser to operate with faulty basket sensors.

Method 2:

The Dispenser detects a failed Weight Sensor.

Holding in the Start/Reset Button, the Drum will turn to

dispense appetizers onto the Accumulator Doors.

Releasing the Start/Reset Button stops the Drum

motor, opens the Accumulator doors, closes the

Stopgate, and then lowers the filled Basket.

After lowering the Basket, the Lift Saddle will come

back up and the Stopgate will open to allow the next

Basket to move into the Lift Saddle for filling.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

10

Page 11

GDF28 Dispenser

SEQUENCE OF OPERATION

Initial Power Up

The chart below is an example of the Dispenser’s sequence of operations under the following conditions:

• The Hopper is fully loaded with french fries and properly installed on the Dispenser.

• There are 2 empty Baskets on the Upper Guide.

• There are no empty Baskets on the Lower Guide.

• The Dispenser Load Switch is in the 1.0 lb./450 gm position.

NOTE: The time for one basketing cycle is approximately 4 - 6 seconds.

Event Response

Power Switch Turned ON

Dispensing Begins.

Stopgate opens. When the weight is attained the Stopgate opens to allow a Basket to slide into the Lift

Accumulator doors open

and empty.

Stopgate Closes The Stopgate closes to allow clearance of the filled Basket in the Lift Saddle.

Lift Saddle lowers Basket. The Lift Saddle lowers the filled Basket to the Lower Guide.

Accumulator Doors close.

Lift Saddle raises up.

Stopgate opens. Stopgate opens to allow the next empty Basket to slide into the Lift Saddle.

Restart of Dispensing.

Stopgate moves to the home position.

The Lift moves to the home position, pauses, then raises to the up position.

The Drum turns and fries are dispensed from the Hopper to the Accumulator Doors.

The Accumulator Doors weigh the fries and signal to stop the Drum Motor when the

1.0 lb. (450 gm) weight is attained.

Saddle.

A sensor in the chassis of the Dispenser detects the Basket. If a Basket is not present,

the Dispenser will wait until it detects the Basket.

When the Basket is present, the Accumulator Doors open to dispense the fries into the

Basket.

As the Basket slides down the Lower Guide, another sensor detects the Basket

arriving on the Lower Guide..

The Accumulator Doors close and the Lift Saddle raises to the up position.

Cycle starts over again. Dispensing Begins

After filling the second Basket, the Dispenser will stop because there will not be a

Basket detected in the Lift Saddle.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

11

Page 12

GDF28 Dispenser

FUNCTION LIST

The following is a complete list of the available functions.

Number

Function Name Description

1 restart function Same as Start/Reset Button on front panel.

2 display last error Displays the last error number recorded.

3 weigh disable Turns the weighing cycle on and off.

4 tare function Not used.

5 calibrate Accepts 16oz (450gm) and 32 oz. (900 gm) reference weights; sets the 12 oz.

(350 gm) and, 16 oz. (450 gm), and 24 oz. (700 gm) targets.

6 adjust_Pos1 Programs selector switch position 1: (Default: 12 0z./350 gm, Manual, Single

Load).

Sub-Function 1 - Increases weight setting.

Sub-Function 2 - Decreases weight setting.

Sub-Function 3 - Sets “SL” (single load) or “AU” (automatic dispense)

Sub-Function 4 - Sets “1” (single) or “2” (double) Load

Sub-Function 5 - Closes F6 Sub-Functions.

7 adjust_Pos2 Programs selector switch position 2 (Default:16 0z./450 gm, Automatic, Single

Load). Sub-Functions same as Function 6.

8 adjust_Pos3 Programs selector switch position 3 (Default:24 0z./700 gm, Automatic, Single

Load). Sub-Functions same as Function 6.

9 not used

10 watchdog test Generates a signal to the program so that the watchdog timer fires. Invokes

error #8 (not displayed).

11 weight sensor readout Displays the current reading from the weight sensor (live display).

12 actuate lift Moves the lift up and down. Displays the Lift position counts (position of the lift).

13 actuate doors Opens and closes the accumulator doors.

14 actuate stopgate Opens and closes the stopgate.

15 actuate drum Turns the drum motor on and off. Displays speed (16 … 0), varies with each

press of the Enter button.

16 actuate light Turns the restart light on and off.

17 restore defaults Clears the error log, sets default weighing parameters, defaults lift counts to 102.

18 clear errors Clears the error log.

19 error counts Displays the error log.

20 parameters Always displays default values.

21 not used

22 not used

23 not used

24 bypass mode Enables the dispenser to run in “Bypass”, single mode. Ignores select system

errors.

25 set units Sets weighing units to ounces “US”, or grams “In” International.

26 exercise mode Enables exercise mode, all motor functions cycle.

27 rev Displays revision level of installed EPROM

28 segment test The segments will illuminate in a moving display mode.

29 lift up counts Displays Lift Up position counts. Default range is from 77 (bottom) to 179 (top).

30 adjust lift down Decreases the Lift Up position, 1 count = 1/12” (2.1 mm). Number of counts is

displayed.

31 adjust lift up Increases the Lift Up position, 1 count = 1/12” (2.1 mm). 105 counts maximum.

Number of counts is displayed.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

12

Page 13

CONTROLLER FUNCTIONS

GDF28 Dispenser

In the back of the Dispenser, in the upper right corner

of the controller circuit board is the service interface.

This is used to adjust the basket load sizes and to test

and adjust the operation of the Dispenser.

Select Button

The following sections discuss the modes of this

display:

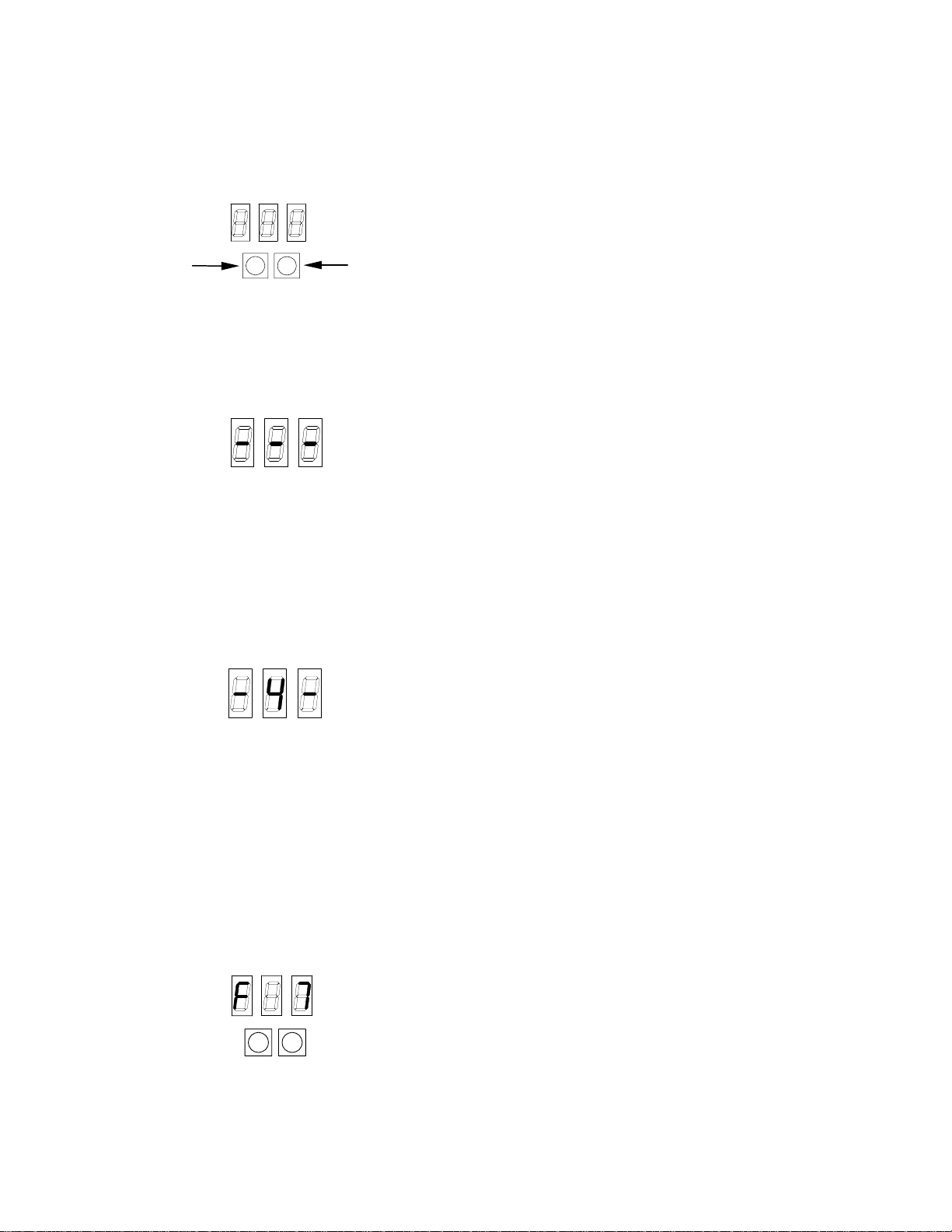

Normal Operation

During Normal Operation, the display will show a series

of horizontal bars, as shown below.

Error Conditions

When an error occurs, the Start/Reset Button will flash

rapidly (5 times per second) and the Lift Saddle will go

down. Normally, an error condition can be cleared by

pressing the Start/Reset Button. If an error persists or

occurs too often, you may need to know what error is

occurring. For this purpose, when an error occurs, the

center line of the display is replaced with an error code.

The example below is displaying error code 4.

A complete list of the error codes is given in the

troubleshooting section (See page 25).

The controller has several functions that may be used

to adjust and test the functions of the Dispenser.

These are accessed using the following procedure.

1. Press the Select Button the number of times as the

function number desired. Each time you press the

Select Button the display will show the function code

for the function that is ready. The example below

shows Function 7: (Adjust Basket Weight, Switch

Position #2, DOWN.)

Enter Butt on

2. When the display shows the desired function number,

press the Enter Button to activate the function.

What happens next depends on the function selected.

Pressing the Select Button will close the function;

pressing the Enter Button will advance the function to the

next step. The following is a detailed account of each

function.

Function 1 – Restart

Returns immediately to the normal display. This function

serves the same purpose as the Start/Reset button on

the front panel.

Function 2 - Display Last Error

Displays the last error number recorded. This allows the

Dispenser to be restarted after an error, and then find

out what the error was while the Dispenser is in service.

Function 3 - Disable Weighing

Turns the weighing process on and off. This is used for

testing of the mechanical systems. It allows you to work

on the dispenser without weighing fries. This is a

temporary setting and will automatically reset on power

up.

Function 4 – Not Used (NCWS)

Function 5 – Calibrate (NCWS)

Displays the word “CAL” on the display. Verify the doors

are empty and press the ENTER button: the display will

respond “C1.0.” Place 1.0 lb./ 16 ounces / 450 gm. on

the door, wait 10 seconds and press the ENTER button:

the display will respond “C2.0.” Place 2.0 lbs. / 32

ounces / 900 gm. on the door, wait 10 seconds and

press the ENTER button: the display will return to the

normal “- - -.“ Remove the weights. The unit is now

calibrated. When finished, turn machine off, wait 15

seconds, turn machine back on.

Function 6 - Load Select Button #1

(Default: US 12 0z, Manual, Single Load

International 0.350kg, Automatic, Single Load)

Press ENTER to enter the first Sub-Function:

Sub-Function 1 - Increases weight setting (1oz/.025kg).

Display reads the current weight setting (default is US

12 / IN .35).

Successive activation of the ENTER button increases

the value (13, 14, 15, etc. / .37, .40, .42, etc.).

Pressing the SELECT button again, closes this SubFunction and advances to the next F6 Sub-Function:

SELECT

NOTE: If you leave the display in this mode, it will

return to Normal Operation after a few seconds. This is

a safety feature, to prevent functions from being

selected by accident.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

ENTER

Sub-Function 2 - Decreases weight setting

(1oz/.025kg).

Display reads the current weight setting, preceded by a

minus sign (default is -12 / -.35).

Successive activation of the ENTER button decreases

the value (-11, -10, -09, etc. / -.32, -.30, -.27, etc.).

Pressing the SELECT button again closes this SubFunction and advances to the next F6 Sub-Function:

Sub-Function 3 - Sets “SL” (single load) or “AU”

(automatic dispense). The default is “SL”.

13

Page 14

GDF28 Dispenser

Successive activation of the ENTER button toggles the

display between “SL” and AU”.

Pressing the SELECT button again closes this SubFunction and advances to the next F6 Sub-Function.

Note: Two dispense cycles are needed before the

change from Automatic to Manual takes effect.

Sub-Function 4 - Sets “1” (single) or “2” (double) load.

Display reads “1” or “2”.

Successive activation of the ENTER button toggles the

value between “1” (single) and “2” (double) load.

Pressing the SELECT button again, closes this SubFunction and advances to the next F6 Sub-Function:

Sub-Function 5 - Closes F6 Sub-Functions.

Display reads “END” (end of available Sub-Functions).

Pressing the ENTER button closes the F6 functions.

OR

Pressing the SELECT button, will result in a return to

Sub-Function 1.

Function 7 -Program Switch Position 2

(Default: US 16 0z, Automatic, Single Load

International 0.450kg, Automatic, Single Load)

Programs switch position 2. Functions are the same as

for Switch Position 1 (Function 6).

Function 8 - Adjust Switch Position 3

(Default: US 24 0z, Automatic, Single Load

International 0.700kg, Automatic, Single Load)

Programs switch position 3. Functions are the same as

for Switch Position 1 (Function 6).

Function 9 -NOT USED

Function 10 - Watchdog Test

Causes an Error 8.

Function 11 – Weight Sensor Readout (NCWS)

Displays the current weight sensor reading and is used

to test the weight sensor. This is a live display,

changing constantly with the weight sensor input. Use

function 11 to check the operation of the weight sensor.

Applying 1 lb./450gm of weight to the accumulator

doors will cause a deflection of approximately 100

counts to the readout. Press the Select button to close

the function. NCWS tare should be 30 (+/-9).

Function 12 - Actuate Lift Saddle

The display shows the live lift position. Each time the

Enter Button is pressed, the controller will change the

state and direction of motion for the circuitry that drives

the Lift Saddle. If the Lift Saddle is down, it will go up. If

it is up, it will go down. Press the Select button to close

the function.

Function 13 - Actuate Doors

Display remains “F13”. Each time the Enter Button is

pressed, the controller will activate the Accumulator

Doors for one cycle. They will open or close. Press the

Select button to close the function.

Function 14 - Actuate Stopgate

Display remains “F14”. Each time the Enter Button is

pressed, the controller will change the state and

direction of motion for the circuitry that drives the

Stopgate. If the Stopgate is open, it will close. If the

Stopgate is closed, it will open. Press the Select button

to close the function.

Function 15 - Actuate Drum

The display shows the drum speed (16: fastest, 0:

slowest). Each time the Enter Button is pressed, the

controller will change the speed (16……0 -16) of the

Dispenser Drum. This function is used to test the Drum

Motor. Press the Select button to close the function.

Function 16 - Actuate Light

Display remains “F16”. Each time the Enter button is

pressed, the controller will change the state of the output

that drives the Start/Reset Light. If it is off it will turn it on.

If it is on it will turn it off. This function is used to test the

Start/Reset Light. Press the Select button to close the

function.

Function 17 - Restore Defaults

This function clears the error log, and restores the

weighing parameters and lift height values to factory

defaults. Calibration and lift height must be

reprogrammed.

NOTE: Function 17 will reset Int'l units to US units.

Function 25 can be performed to return to "Int'l" status.

Function 18 - Clear Errors

This function resets the counts in the error log to zero.

We recommend that this be done periodically to prevent

records of occasional errors from building up (even a

perfectly running dispenser will get occasional errors

from improper handling) and confusing a service tech at

a time when the error log could be useful.

Function 19 - Error Counts

Displays the word “Err”. Each time the Enter Button is

pressed, it moves to the next error count. When the last

count is passed, the display returns to normal mode.

The error counts are displayed in numerical order. Error

number 9 is not included (error number 9 indicates a

memory failure, and therefore renders any history

meaningless). For example, if you saw this sequence of

displays:

“Err”

“1. 0”

“2. 0”

“3. 1”

“4. 3”

“5. 2”

“6. 0”

“7. 21”

“8. 0”

This would indicate that, since the last time the errors

were cleared, there had been one error 3, 3 error 4’s, 2

error 5’s, and 21 error 7’s.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

14

Page 15

GDF28 Dispenser

Function 20 - Parameters

Displays the word “Con”. Each time the Enter button is

pressed, it moves to the next weighing parameter.

When all parameters have been displayed, the display

returns to the normal mode.

The weighing parameters are (in order of appearance):

1. Switch position #1 target - the number of digitizer

steps that represents .75lbs/12 oz./350gm. The

default value is 75 US / 70 INTL (NCWS).

2. Switch position #2 target - the number of digitizer

steps that represents 1.0lb/16 oz./450gm. The

default value is 100 US / 90 INTL (NCWS).

3. Switch position #3 target - the number of digitizer

steps that represents 1.5lb/24 oz./700gm.The

default value is 150 US / 140 INTL (NCWS).

If the loads have been adjusted, these may be slightly

different. The tare value after calibration should be

approximately 30 (+/- 9). For details, see the section

on operation/ calibration of the weight sensor. (NCWS)

Function 21 – Not Used

Function 22 – Not Used

Function 23 – Not Used

Function 24 - Bypass Mode Enable (volatile setting)

Entering this function the display will read either “nor,”

(normal) Bypass mode disabled, or “bYP”, Bypass

mode enabled. BYPASS mode allows the machine to

run in single mode when an optical sensor has failed.

The “BYPASS” mode has two methods of operation:

Method 1:

The Dispenser detects a functioning Weight

Sensor. When the Start/Reset Button is pressed, the

Dispenser utilizes the Weight Sensor to determine the

weight of the frozen appetizers. The Dispenser will

appear to cycle normally, ignoring other system errors.

NOTE: Bypass Mode is significantly slower than normal

operation.

NOTE: All settings function in single basket operation

while in Bypass Mode.

Method 2:

The Dispenser detects a failed Weight Sensor.

Holding in the Start/Reset Button, the Drum will turn to

dispense frozen appetizers onto the Accumulator

Doors. Releasing the Start/Reset Button stops the

Drum motor, opens the Accumulator Doors closes the

Stopgate, and lowers the filled Basket.

After lowering the Basket, the Lift Saddle will come

back up and the Stopgate will open to allow the next

Basket to move into the Lift Saddle for filling.

The Bypass Mode is further identified by double

flashing of the reset button.

NOTE: The Bypass mode will significantly slow down

the operations of the Dispenser. The Start/Reset button

has to be used in either mode of Bypass operation.

Entering this function permits selection of ounces or

grams as the weighing units. Pressing the enter button

will toggle the display between ounces “US” and grams

“In” (international) for the weight units. Pressing the

Select Button sets the displayed weight units for

dispenser operations. The weight sensor should be

calibrated after changing this setting.

Function 26 - Exercise Mode (volatile setting).

When the dispenser is in the exercise mode, all systems

will continuously cycle. The exercise mode is designed

to “break in” a replaced component. The exercise mode

is volatile and will reset when the dispenser power is

turned off.

Function 27 - Display EPROM Revision Level.

The readout will display the revision level of the installed

EPROM.

Function 28 - Segment Test

Verifies that all display segments are functional. The

segments will illuminate in a moving display mode.

Function 29 - Lift Position Counts

The readout will display the encoder counts for the lift

and will change as the lift travels up or down. Default is

77 at the bottom of travel and 179 at the top of travel.

Function 30 - Adjust Lift Down

The readout will display the current or default value for

the Lift height (102). Each time the Enter button is

pressed, this value will decrease by 1, or approximately

1/12” (2.1 mm). The Select button must be pushed after

lowering the lift height to complete the change. The new

height setting will take effect on the next lift cycle.

Function 31 - Adjust Lift Up

The readout will display the current or default value for

the Lift height (102). Each time the Enter button is

pressed, this value will increase by 1, or approximately

1/12” (2.1 mm). The Select button must be pushed after

raising the lift height to complete the change. The lift will

raise slightly each time the count is incremented.

NOTE: Do not adjust the lift height to compensate for

bent saddle/shoulder screws. Maximum recommended

lift height is 105. An adjustment of 106 and higher may

result in damage to the controller PCB.

Function 25 - Select Weight Units “US” or “In”

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

15

Page 16

GDF28 Dispenser

ERROR CODES

The status of the Dispenser is displayed on the Start/Reset Button light. When the Hopper is filled and operating

automatically, the Start/Reset Button remains steadily illuminated. When a System Error occurs, the Start/Reset

button flashes rapidly (about 5 per second). System Errors are a result of incorrectly assembling the Dispenser, or

an interruption in the normal operation. System Errors are also displayed inside the Dispenser on the controller

PCB. Each error has its own error code; these are summarized below.

Number Error Name Definition

Error #1 ACCUMULATOR TIME-

OUT

Error #2 LIFT MOTION

Error #3 STOPGATE MOTION

Error #4 LIFT SENSOR

Error #5 GUIDE SENSOR

Error #6 Not Used

Error #7 ENCODER

SEQUENCE

Error #8 ABNORMAL RESET

(WATCHDOG)

Error #9 NVRAM CHECKSUM

Accumulator Home Switch fails to turn off within 0.6 seconds of the motor

being turned on, or it fails to turn on within 5.0 seconds of the motor output

starting. Error will occur if the motor or home switch is disconnected,

obstructed, broken, or the associated input or output on the controller PCB

has failed.

Error will occur if the motor or encoder inputs are disconnected, or the

associated input or output on the controller PCB has failed. Error will occur if

there is a physical obstruction of Lift Saddle or damage to Lift Saddle

components. Error will occur if there is a Failure of lift drive motor w/ gear

box, lift tube, encoder, or encoder disk.

The stop gate allows 1.0 second to home itself. Error will occur if the motor

or home switch is disconnected, obstructed, broken, or the associated input

or output on the controller PCB has failed, or if the Hardstop screw is broken

off.

The controller PCB has sent the Lift Saddle down and the controller PCB is

still receiving the Lift sensor input. Sensor is operating out of sequence.

The controller PCB has not received a signal from the guide sensor after the

Lift is down. The Guide Sensor has failed to detect a Basket leaving the Lift

Saddle.

This is caused by both of the encoder sensors changing at the same time. If

the count rate of the encoder exceeds 100 counts per second (normal speed

is 51 counts) or something electrically interferes with the encoder sensors,

the error would occur. This error could also be caused by contamination.

An event other than a normal power up has caused the processor to restart.

This could be a watchdog reset, (indicating that the processor has hung or

Function 10 was entered), a processor reset (an EMI/RFI problem), or the

processor has detected corrupted memory. NOTE: Error code #8 is not

displayed.

The processor writes the permanent data (error logs, configuration, and

operating parameters) along with extra data that it uses to verify the data is

valid. Data may be invalid for several reasons:

a) The first time the controller PCB has been used.

b) Software upgrade. (When new software has a different memory

configuration).

c) Power down interrupted a Non Volatile RAM write cycle. The write

cycle usually happens when the reset button is pressed to reset an

error.

d) The NVRAM has failed

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

16

Page 17

GDF28 Dispenser

NOTE:

- All "L" numbers refer to numbered LEDs on the controller board. (see Page 29 & 30)

- All "F" numbers refer to controller functions. (see Page 13)

ERROR 1

Do

Accumulator

NO

doors open?

Does L11

come on?

NO

Go to F13 and

see if L11 will

come on when

enter is toggled. If

not, replace

controller and

correct version of

eprom.

YES

Does L7

come on

when the

doors open?

YES

Make sure

the cam

follower Hblock screw is

tight on the

left door shaft

(left from the

front)

NO

Check the

accumulator

home switch

wiring and

operation, L7

should blink

on when

switch is

acitvated.

YES

Does the

motor make

noise?

YES

Check the

white cam on

the motor

shaft, not

loose or

broken. Check

home switch.

NO

Check wires to

accumulator

motor (M2) and

to control board.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

17

Page 18

NO

Check wiring

connections at

motor and at output

#1, terminals 5 and

6 on controller

board. Also check

board for corrosion.

Remove lift

tube and press

reset, does

motor run?

NO

Remove lift motor wires

5,6 on input one, and

hot-wire to the 24v input

plug by touching the

wires on the screws.

Does the motor

spin both

directions?

(Reverse wiring)

NO

Replace the lift

drive motor

290147

ERROR 2

Does the lift move

at power up?

Should go down

first, unless

already there.

Check lift tube,

YES

should move

smoothly. If

not, replace or

clean/relube it.

Replace the

YES

controller board,

290626. Verify

proper software.

GDF28 Dispenser

YES

Does the lift

move both

directions, or

just one way?

Check for water

damage to

controller board

and plugs.

Replace

controller

290626, and

appropriate

version of

software.

ONE

BOTH

Check the

saddle for

binding. Check

lift height setting

(F30), not to

exceed 106.

Remove lift

tube, check for

binding. Check

lift motor for

water damage.

With lift tube out,

and while still in a

system error,

manually verify

encoder operation.

Using a flat blade

screwdriver, place

blade inside center

of motor next to the

center pin. Be

careful not to

damage encoder

disk/vane. Turn the

handle either

direction. L4/5

should go on/off

completely, but

never change at the

same time. Also

check encoder

disk/vane for

damage. Replace

both encoders or

disk/vane as

needed.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

18

Page 19

GDF28 Dispenser

ERROR 3

YES

L6 should be

ON when stop

gate is fully

open or closed,

OFF when gate

is anywhere in

between.

YES

Does it

move BOTH

directions?

Does the

stop gate

move at all?

NO

Verify wiring to

motor and

control board.

Replace the

stop-gate motor.

Verify that L22

comes on as gate

closes, L23 as

gate opens. If not,

replace control

board 290626 and

appropriate

software.

YES

NO

Does

L22/23

come on?

NO

Go to F14, L22/23

should toggle

on/off as the

enter button is

pressed, if not,

replace control

board 290626

and appropriate

software.

Does L6

NO

operate

properly?

YES

Assure hard-stop

screw is present.

Rotate stop gate

manually clockwise,

should not be able to

rotate past the

7 o-clock position.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

Check encoder

and termination to

control board.

Replace encoder

290690.

19

Page 20

Error 4

Verify that the

L2 light on the

circuit board is

not damaged.

Is the lift

down?

Yes

NO

GDF28 Dispenser

Press the left button on the controll

board until the display reads F12,

then immediately press the right

button. Press the right button again

to make the lift go down.

Is the LED L2

lit on the

control board?

NO

Place your hand

on the front of the

machine so your

palm covers the

upper sensor.

Is L2 lit

up?

NO

Yes

Slowly pull hand

away from machine

until light goes off.

Should be about 5-6

inches from the

machine. Adjust

sensor as needed.

Yes

sensor window

using a warm

moist towel.

Check wiring for

optical sensor.

Black and blue wire

on bottom right

connector, and

brown wire on top

right connector.

Now will L2

come on

Clean the

Yes

when sensor

blocked?

Is L2

still on?

NO

Turn sensor

adjustment

counter clock

wise until L2

goes off.

Yes

Remove the bottom

right connector from

the control board. If

L2 does not go out,

replace the circuit

board 290626. If L2

does go off, replace

the sensor 290038.

NO

Replace Sensor

290038.

Yes

Did L2 go

off?

NO

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

20

Page 21

GDF28 Dispenser

5

Error

Verify that the L3 light

on the circuit board is

not damaged.

Remove all baskets

from the lower guide

Is the LED L3

lit on the

control board?

NO

Place your hand on the

front of the machine so

your palm covers the

lower sensor.

Yes

Is L3 lit

NO

up?

Yes

Slowly pull hand

away from machine

until light goes off.

Should be about 5-6

inches from the

machine. Adjust

sensor as needed.

Before doing this procedure, assure the

lower guide was installed correctly, and

the lower guide slides are not

damaged. Baskets should slide down

without sticking or tipping.

Replace lower guide slides as needed.

Clean the

Yes

sensor window

using a warm

moist towel.

Check wiring for

optical sensor.

Black and blue wire

on bottom right

connector, and

brown wire on top

right connector.

Yes

Is L3

still on?

NO

Now will L3

come on

when sensor

blocked?

Yes

Turn sensor

adjusment

screw ccw

until light

goes off.

Yes

Did L3

go off?

NO

Remove the bottom right

connector from the

control board. If L3 does

not go out, replace the

circuit board 290626. If

L3 does go off, replace

the sensor 290038.

NO

Replace Sensor 290038.

DONE

Adjust to 5-6 inch range.

ERROR 6

Error 6 is not used on

this model of machine.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

21

Page 22

ERROR 7

Press reset while

watching the lights on

the circuit board in the

back of the machine.

GDF28 Dispenser

When the lift is

moving, do L4

and L5 flash?

Yes

Do all the lights

dim at the

same time?

Yes

Press reset again, and

observe at what point

In the cycle the board

dims. Remove the

associated motor from

the circuit. Press reset.

No

No

Remove the lift saddle. Remove lift tube by

removing the socket head cap screw and

bracket on the lift motor, then twist and pull

on the tube. Remove the nut on the bottom

of the machine that holds the motor in, and

remove the motor. Remove the encoders

and encoder disk/vane assembly. Inspect

the encoder disk/vane and encoders for any

damage. Check for debris, etc inside

encoder block.

Clean and dry the

disk/vane and

Is there any

damage to

the disk or

encoders?

No

encoders. Check

encoders for damage

and proper operation.

Replace if damaged.

Reassemble and

retest.

Still get

No

error 7?

Yes

Replace controller

board 290626 and

appropriate EPROM.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

Troubleshoot

or replace the

motor that was

removed from

the circuit.

Yes

Replace encoder

disk/vane or encoder.

Reassemble and retest.

22

Page 23

GDF28 Dispenser

ERROR 8

Check power cord, on/off

switch, and power supply

connections. Replace/repair

as needed.

ERROR 9

Turn the

machine off for

15 seconds and

turn it back on.

This error means the program is being reset by

means other than the reset button.

Error 8 automatically resets by itself, so it will not

show up on the display. The only way to check for

error 8 is to access the error log by going to

function 19, and pressing the Enter button 9 times.

Some error 8's are to be expected, as it can be

caused by turning the machine on/off too quickly.

If problem persists, call Automated Equipment

LLC for technical support.

Error 9 is normal for the

first time a machine is

turned on after

replacing an EPROM.

Still get

error 9?

No

Done

Yes

Turn the machine off. Remove

the EPROM M1 from the board.

Check for bent or broken legs.

If all looks well, reinstall the

EPROM. Power up

No

Still get

error 9?

Yes

Replace the

board 290626

and EPROM

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

23

Page 24

DRUM MOTOR WON'T TURN

Is the green

YES

start/reset

button flashing?

GDF28 Dispenser

Check the error

Is the green

Fast

button flashing

fast or slow?

code and

proceed to the

appropriate error

resolution page.

NO

Is the

machine

cycling empty

NO

Are there

fries on the

accumulator

doors?

NO

YES

YES

Slow

Press the reset button

Calibrate weighing

system as per

instructions in manual.

Check L2, L3 lights. L2

should be on if basket is

present on the lift, L3 should

be off unless there are three

baskets on the lower guide.

Clean and check sensors.

NO

Is the

drum

turning?

YES

Check for

low fries.

Check for

bridging of

fries in the

hopper.

On the circuit board,

press the select

button until F15 is

displayed, then

press the enter

button twice. Display

should say 16.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

Is L10 on

the circuit

board lit up?

NO

Replace the control

board 290626 and

appropriate software

24

YES

Is the drum

motor

turning?

NO

Verify drum

motor wiring at

motor and at

circuit board, if

wiring is ok,

replace drum

motor 290692.

YES

Calibrate weighing

system as per

instructions in

manual.

Page 25

GDF28 Dispenser

TROUBLESHOOTING

In the following charts, the PROBLEM columns contain a list of problems that may occur, the PROBABLE CAUSE

column describes why the problem may have appeared; and the CORRECTIVE ACTION column describes the

action that must be taken to eliminate the problem. If, after performing the procedure listed under CORRECTIVE

ACTION, you have not corrected the problem, call our Service Department for assistance (see page 5).

NOTE: Press the Start/Reset Button after correcting the problem.

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Start/Reset

Button is

flashing slowly

(about once

per second)

and Lift

remains up.

Basket Loads

are consistently

light or heavy.

Dispenser

Drum is not

rotating.

Baskets are

sticking or

tipping on

Upper or Lower

Guide

Hopper is empty Fill the Hopper with french fries.

Frozen fries in the hopper

have formed a “bridge” over

the Drum.

Hopper Drum is not locked

onto the shaft.

Drum is damaged. Replace Drum.

Diverter not installed. Verify diverter is installed correctly.

The Hopper is touching the

Accumulator Doors.

Basket Load targets were not

set properly.

The Weight Sensor has

malfunctioned.

The Hopper Accumulator is

full.

Hopper is empty (Start/Reset

Button is flashing slowly).

Fries have formed a “bridge”

over the Drum (Start/Reset

Button is flashing slowly).

The Dispenser has detected a

SYSTEM FAULT (Start/Reset

Button is flashing rapidly).

Hopper Drum is not locked

onto the shaft.

The Hopper is touching the

Accumulator Doors.

The Diverter fell inside the

Hopper preventing the

Dispenser Drum from turning.

Basket Load targets were not

set properly.

The Weight Sensor has

malfunctioned.

Drum is damaged. Replace Drum.

Fries, crumbs, or shortening

have accumulated on the

Guide or Lift Saddle.

A Basket is bent or damaged. Replace the damaged Basket.

The Lift Saddle is assembled

incorrectly or damaged.

The guide is not assembled

correctly.

Incorrect Basket. Use the Custom Fry Baskets supplied with the Dispenser.

Lift height improperly adjusted.

The Guide is bent or the

Basket Slides are damaged.

Remove the Hopper Lid and re-distribute the fries inside. Press

the Start/Reset button. The Drum will begin rotating in a few

seconds.

Install the Hopper Assembly correctly.

Re-assemble the Hopper. No objects, other than french fries,

may touch the Accumulator Doors.

Verify proper target values. Adjust if necessary (refer to

Functions 6-9, 21 & 22, beginning on on page 13).

Verify Weight Sensor tare and calibration. (See page Error!

Bookmark not defined. for calibration procedures.)

The Dispenser Drum will rotate only when the Hopper

Accumulator requires more fries.

Fill the Hopper with fries and press the Start/Reset button. The

Drum will begin rotating in a few seconds.

Remove the Hopper Lid and re-distribute the fries inside. Press

the Start/Reset button. The Drum will begin rotating in a few

seconds.

Continue troubleshooting. If the Accumulator needs more fries,

the Dispenser Drum will continue rotating when the Start/Reset

Button is pressed.

Install the Hopper Assembly correctly.

Re-assemble the Hopper. No objects, other than fries, may

touch the Accumulator Doors.

Remove the Diverter from inside the Hopper and install

correctly.

Verify proper target values. Adjust if necessary (refer to

Functions 6-9, 21 & 22, beginning on on page 13).

Perform a Weight Sensor calibration procedure. (See page

Error! Bookmark not defined..)

Turn the Power Switch off, and clean the Guide and Lift Saddle

with a hot towel.

Re-assemble, repair or replace the Lift Saddle. Check that

shoulder screws are not loose, bent, or missing (See page 28).

Re-assemble the guide

Adjust the Lift height (Functions 30 and 31, see page Error!

Bookmark not defined.).

Repair or replace the components.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

25

Page 26

GDF28 Dispenser

NOTE: Press the Start/Reset Button after correcting the fault condition.

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Accumulator

Doors do not

close

Basket Stopgate does not

hold Baskets in

place

Does not

dispense fries

into a waiting

Basket.

SYSTEM

ERROR:

(Start/Reset

Button flashes

rapidly as Lift

reaches top or

bottom)

with no basket

present

Accumulator Motor failure Observe L11 on the Controller Board, when it is ON the

motor should turn. Check for broken or loose wiring to the

motor.

Accumulator Home Switch failure When the Accumulator cycles, L7 on the Controller Board

should blink. If not, check for loose or broken wires for the

Accumulator. Verify that the switch functions by manually

activating it.

The Accumulator Door linkage is

loose or binding, or the linkage

spring is disconnected or broken.

Stopgate Motor failure Observe L22 and L23 on the Controller Board (L13 on

Encoder failure When the Stopgate cycles, L6 on the Controller Board

Hard Stop broken If Stopgate can be rotated all the way around, the Hard

The Lift Saddle is assembled

incorrectly or damaged.

A Basket is positioned incorrectly

on the Lift Saddle.

Lift height improperly adjusted. Adjust the Lift height (Functions 30 and 31, see page

Lift Sensor is not working. Verify by observing L2 on Controller Board. (See pages 29

Lift Motion fault. An Error #2 may have occurred. Pressing the Start/Reset

A tipped Basket stopped the

Basket Lift.

Lift Sensor or Guide Sensor is not

functioning properly.

Lift Mechanism Failure Verify by manually cycling the Lift with Function #12.

A system Error has occurred. Check the controller board service interface for an error

Lift Position Encoder Error Verify encoder operations, (on the controller board,

Shortening on Sensor Power off, clean sensor with hot wet towel. Dispenses fries

Sensor too sensitive Adjust sensor. (See page 28.)

Examine the linkages for loose or broken components.

Lubricate Accumulator Door pivot points.

Controller 290322). When either is ON the motor should

turn. Check for broken or loose wiring to the motor.

should blink. If not, check for loose or broken wires for the

Stopgate.

Stop needs to be replaced.

Re-assemble, repair or replace the Lift Saddle.

Reposition the Basket in the Lift Saddle.

Error! Bookmark not defined.).

& 30.)

Button will clear this error. If problem persists, there may be

a problem with the Lift mechanism or electronics.

Remove the Basket. Check it to be sure that it is not bent

or damaged. Clear the Lift Saddle of any fries or

shortening. Press the Start/Reset button. If problem re-

occurs, remove and re-assemble the guides.

Clean the sensors with a HOT wet towel. Press the

Start/Reset button. Verify proper sensor operation.

(Refer to Function 12, page 14.)

code. (See page 16 for a description of all the error codes.)

observe L4 and L5 pulsing as the Lift moves) repair or

replace the encoder that does not function.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

26

Page 27

GDF28 Dispenser

ADJUSTMENTS AND DIAGNOSTICS

For optimum performance, the weighing system

should be calibrated twice per year. To do this, follow

these steps:

NON-CONTACT WEIGHING SYSTEM (NCWS)

CALIBRATION

1. Remove the BACK PANEL of the Dispenser.

2. Turn the Power Switch to the ON position.

3. Select Function 30. Record the lift height setting.

4. Select Function 17. Press the ENTER button.

5. Select Function 3 on the controller and press the

ENTER button to disable the weighing.

6. Run a Basket through the Dispenser to empty the

Accumulator Doors.

7. Remove the Hopper from the Dispenser.

8. Verify that the Accumulator Doors are empty.

9. For International units, select Function 25 and

press the ENTER button. Press ENTER again to

change from “US” to “In”. Press Select to exit the

function.

17. Reset the Lift height using either Function 30 (lower

lift) or 31 (raise lift) to input the setting recorded in step

3. The default is 102.

18. Cycle baskets through the Dispenser. Check basket

loads and adjust if necessary.

19. Replace the Back Panel.

SERVICE NOTE:

Calibration must be performed any

time a controller pcb, e-prom, or

NCWS component is replaced.

10. Select Function 5 (Calibrate) on the controller and

press the ENTER button. The word “CAL” will

appear on the display.

11. Wait 10 seconds, and press the ENTER button:

the display will respond "C1.0".

12. Place 1.0 lb. (450 gm) on the Accumulator Doors

(use a 1 lb. reference weight), wait 10 seconds,

and press the ENTER button: the display will

respond "C2.0".

13. Place 2.0 lbs. (900 gm) (an additional 1.0 lb. (450

gm)) on the Accumulator Doors. Wait 10 seconds

and press the ENTER button: the display will

respond "---".

14. Select Function 11 and press the ENTER button.

With 2 lb. (900 gm) on the Accumulator Doors the

readout should be approximately 230 (+/-9).

Remove 1 lb. (450 gm) from the Accumulator

doors. The readout should be approximately 130

(+/-9). Remove all weight from the Accumulator

doors. The readout should be 30 (+/-9).

15. Turn the Dispenser off, wait 15 seconds, turn the

Dispenser on. The new calibration will now be

active.

16. Reinstall the Hopper on the Dispenser.

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

27

Page 28

GDF28 Dispenser

LIFT DRIVE ASSEMBLY INFORMATION

The bottom of the Lift Cylinder stroke is home by

definition. This is found at power up and set to 77. This is

an arbitrary number, mathematically chosen for maximum

flexibility in the Lift control. The default stroke is 102

counts, and is adjustable. There are 12 counts per inch

and full stroke is 8.5 inches (12 * 8.5 = 102, 102 + 77 =

179). There is approximately 1/4 inch between top of

stroke and hard stop. The dispenser logic controls the

Lift to the specified location. If adjusted to the hard stop

(approximately 105), it will still function. Adjusting it past

the hard stop will result in an endless chain of Error #2’s,

and may result in permanent damage to controllers and

lift drive motor.

CHECK/ADJUST SENSOR RANGES

1. Remove all baskets on the dispenser.

2. Select Function 12 on the controller board (see

pages 12 & 14) and press ENTER to lower the Lift

Saddle. This will prevent the Accumulator Doors from

accidentally opening.

3. Verify that the indicator lights for the Basket Sensors

are OFF (Lights L2 and L3). See the CONTROLLER

BOARD illustrations on pages 29 and 30.

4. Place your hand directly in front of the Basket Sensor

Verify that indicator light L2 turns ON. Move your

hand away from the sensor until the light turns OFF.

5. Place the palm of your hand in front of the sensor.

The indicator light should stay on until your hand is 46 inches (10-15 cm) away from the sensor. If this

range is incorrect, adjust the GAIN control on the rear

of the sensor.

6. Repeat steps 3 through 6 for the Guide Sensor. The

guide sensor lights indicator light L3.

7. Select Function 18 and press ENTER to clear the

error log.

8. Turn the power switch OFF.

9. Replace the BACK PANEL.

10. Finish reassembling the dispenser.

СHECK SADDLE FOR DAMAGE

Inspect the four Shoulder Screws for being bent or loose.

Measure the Saddle at each Skid Plate position to determine

if the Saddle frame is damaged. Measure as shown by the

dashed line in the illustration below. Saddle frame should

measure 11 5/8" +/-1/16" (295.3mm +/- 2mm).

SKID PLATE

TO HERE

SHOULDER SCREWS

MEASURE FROM HERE

GAIN Control

+

Indicator Light

Copyright © 2005 Automated Equipment LLC. All Rights Reserved

28

Page 29

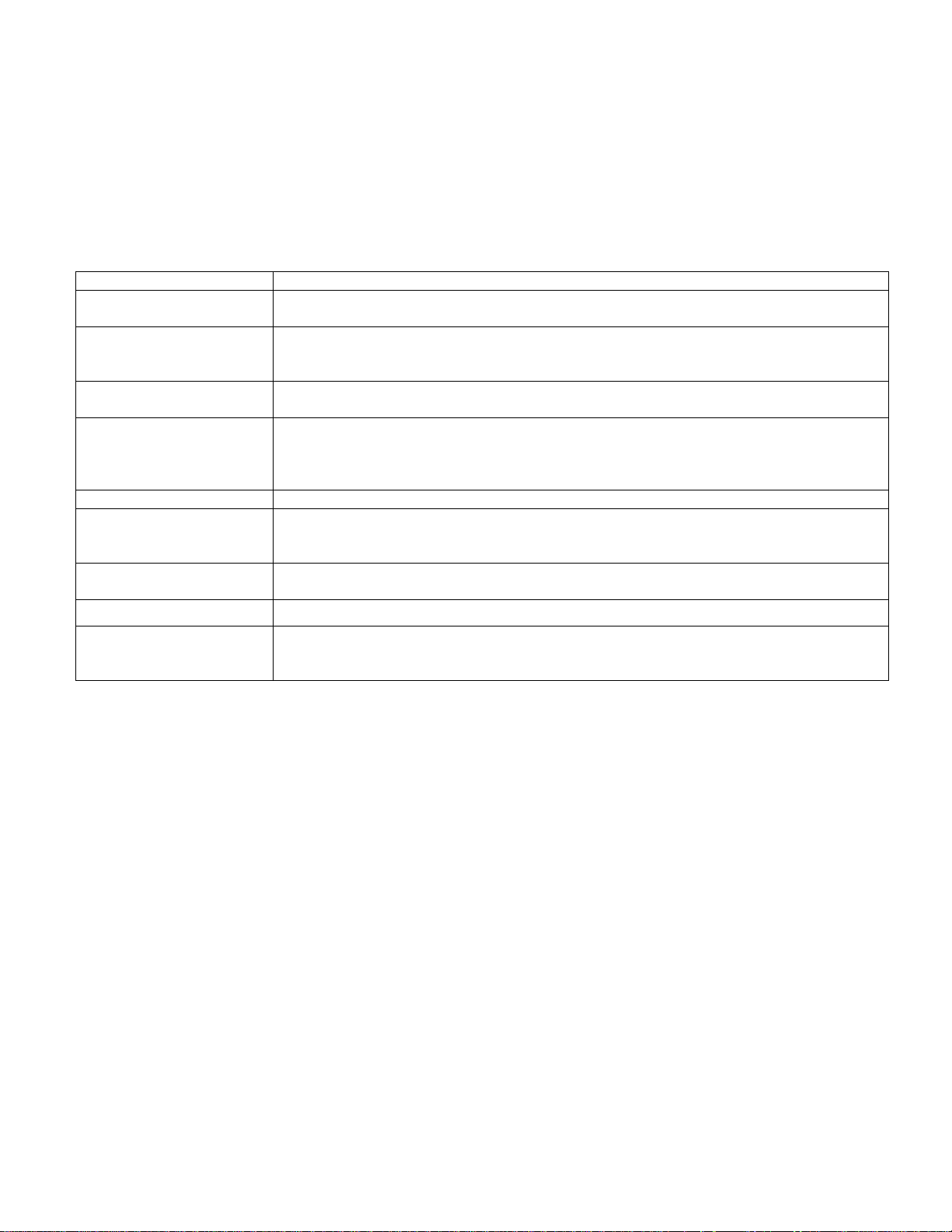

CONTROLLER BOARD LAYOUT

Plus Controller PCB (P/N 290626)

GDF28 Dispenser

ITEM DESCRIPTION ITEM DESCRIPTION ITEM DESCRIPTION

1

2

3