Page 1

MANUFACTURED

EXCLUSIVELY FOR

McDONALD'S

BY

Automated Equipment LLC

5140 Moundview Drive

Red Wing, Mn 55066

Phone: 1 (651) 385-2273

Fax: 1 (651) 385-2166

http://www.autoequipllc.com

MODEL AFD-200

Arch Fry Dispenser

EQUIPMENT MANUAL

p/n 202089

ARCH FRY DISPENSER AFD-200

PUSH TO:

BASKET

RAM CENTER, INC.

1-800-248-ARCH

LOADS

POWER

ON

OFF

START/RESET

ERROR MESSAGE S

LOW BLINK-HOPPER EMPTY

AST BLINK- SYSTEM ERROR

RED WING, MN 55066

CAUTION

BASKETS

ARE HOT

WARNING

PINCH HAZARD

KEEP HANDS AWAY

FROM ACCUMULATOR

DOORS

For Service Call

1 (800) 248-2724

After hours, your call will be handled by a

pager service. A Technical Support

Representative will return your call.

TABLE OF CONTENTS

AFD 200 - WARRANTY................................................................................................................2

INTRODUCTION...........................................................................................................................3

SPECIFICATIONS ........................................................................................................................3

INSTALLATION INSTRUCTIONS ................................................................................................4

PARTS IDENTIFICATION AND FUNCTION.................................................................................5

SET-UP AND CLOSE PROCEDURES.........................................................................................9

SYSTEM FUNCTIONS AND OPERATION...................................................................................10

BASKET LOAD ADJUSTMENTS.................................................................................................10

TROUBLESHOOTING..................................................................................................................11

ORDERING PARTS/SERVICE .....................................................................................................14

NON-SCHEDULED MAINTENANCE............................................................................................15

PREVENTATIVE MAINTENANCE................................................................................................18

DIAGRAMS...................................................................................................................................20

Copyright © 2005 Automated Equipment LLC All Rights Reserved

Page 2

AFD 200 - WARRANTY

SERVICE PROVIDED

Automated Equipment LLC (hereinafter "AELLC"),

warrants the purchased product to be free from

manufacturing defects in material and workmanship

under normal use and conditions for the period and

component specified below:

Components covered Term

Pneumatic Components 1 year

Electronic Circuit Board Assemblies 1 year

Electrical and Mechanical Moving Parts 1 year

Structural frame work or enclosures 1 year

Lift Saddle Assembly 90 days

Guide Assemblies 90 days

Quick Coupler 90 days

Fry Baskets 90 days

The Warranty period commences on the date of

shipment for the Arch Fry Dispenser (hereinafter

"Product").

EXCEPT AS OTHERWISE PROVIDED HEREIN

AELLC MAKES NO OTHER WARRANTIES,

EXPRESS OR IMPLIED AND SPECIFICALLY

DISCLAIMS ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

AELLC will provide 1 (1) year of Warranty Service and

toll free phone technical support to Purchaser. If the

Product fails to perform during the warranty period and

such failure is covered by this warranty, AELLC shall

repair or replace, at its option, the Product to restore it

to normal operating condition. AELLC shall make all

reasonable efforts to perform such repairs during

normal working hours Monday through Friday,

however, AELLC is not responsible for delays or

failures in performance of such services caused by

Acts of God, failure of transportation, accidents, labor

strikes, shutdowns or work stoppages or other causes

beyond AELLC's control.

Warranty service performed herein is provided through

AELLC's technical support department or other

authorized service agent. Purchaser's unauthorized

use of any service personnel or other unauthorized

repair will immediately invalidate this warranty.

Replacement parts will be new or rebuilt parts or

components. Purchaser is responsible for costs to

return damaged warranted components to AELLC for

credit. AELLC parts and components not returned to

AELLC after thirty (30) days of Purchaser's receipt of

replacement parts or components from AELLC will be

invoiced for the full spare part or component purchase

price.

AELLC shall not be liable for any direct, indirect,

consequential damages (including damages for loss of

business profits, business interruption, loss of

business information and the like) arising out of the

use of or inability to use the Product.

THIS WARRANTY IS VOID IF THE PRODUCT IS

NOT FUNCTIONING CORRECTLY DUE TO ABUSE

OR NEGLECT BY THE PURCHASER, ITS EMPLOYEES, AGENTS, OR OTHER REPRESENTATIVES

EITHER BY BREAKING, BENDING, MISUSE,

ABUSE, DROPPING, ALTERATION, IMPROPER

MAINTENANCE OR ANY OTHER FORM OF

NEGLECT OR IMPROPER USAGE, THIS

WARRANTY DOES NOT COVER DAMAGE TO THE

PRODUCT CAUSED BY NATURAL CAUSES SUCH

AS LIGHTNING, ELECTRICAL CURRENT

FLUCTUATIONS, FLOOD, FIRE, TORNADOES, OR

OTHER ACTS OF GOD. AELLC WILL INVOICE

PURCHASER FOR REPAIRS MADE NECESSARY

BY THE HEREIN LISTED CAUSES.

This warranty is non-transferable and applies only to

the original Purchaser. This warranty is valid only in

the United States of America.

Purchaser will assure that the Product will receive

normal preventive maintenance and adjustments

necessary to keep the Product in good operating

condition pursuant to guidelines provided by AELLC.

THIS WARRANTY WILL NOT COVER DAMAGE TO

THE PRODUCT WHICH OCCURS DUE TO

PURCHASER'S FAILURE TO PROPERLY MAINTAIN

AND MAKE ORDINARY ADJUSTMENTS REQUIRED

FOR PROPER OPERATION OF THE PRODUCT.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

2

Page 3

INTRODUCTION

SPECIFICATIONS

The Arch Fry Dispenser is a compact automated

system that replaces manual basketing of Fries and

the equipment that goes with it. The Arch Fry

Dispenser automatically weighs 1 pound (0.45 kg), or

1.5 pound (0.68 kg), loads of frozen French Fries and

dispenses them into the Fry Baskets.

The Arch Fry Dispenser's Hopper 42 lbs. (19 kg) of

frozen fries prior to Basket Loading. A rotating

Dispenser Drum inside the Hopper transfers the frozen

fries onto the Accumulator Doors where an electronic

Load Cell accurately weighs the French Fries.

Empty Fry Baskets are placed on the Upper Guide.

The Fry Baskets slide under the Accumulator Doors

where French Fries are dispensed into them. The

Basket Lift then lowers the filled Fry Baskets onto the

Lower Guide where the Fry Baskets wait to be picked

up by a crew person.

The Arch Fry Dispenser is usually positioned to the

right of an existing fry station and requires 36 linear

inches (92 cm) of floor space. 10 modified Fry

Baskets are provided with this equipment.

NOTE: This piece of equipment is made in America

and has American sizes of hardware. All hardware

metric conversions are approximate and can vary in

size.

HAZARD COMMUNICATION STANDARD (HCS) The

procedures in this manual include the use of chemical

products. These chemical products will be highlighted

with boldface letters followed by the abbreviation

(HCS) in the text portion of the procedure. See the

HCS Manual for the appropriate material safety data

sheets (MSDS).

The Arch Fry Dispenser consists of the following

components:

• Arch Fry Dispenser 200

• 10 Fry Baskets (Modified)

• 100 feet (30 meters) of Air Line

• 8 foot (2.5 meter) electrical cord for standard outlet

Optional Equipment:

• Oilless Air Compressor

• End Panel

• Replacement/Extra Fry Baskets

Electrical Requirements:

120 VAC, 15 Amp

Compressed Air Requirements:

2.0 CFM @ minimum of 80 PSI (5.4 bar)

Space Requirements:

Clear floor space near fry vat at least 36 inches

(92 cm) wide and 24 inches (60 cm) deep.

Basket Handles will extend to 29 inches (74 cm)

Arch Fry Dispenser:

Bulk storage of 42 lbs. (19 kg) of frozen French

Fries

Electrically and pneumatically (air) driven.

Equipped with swivel casters.

Handles up to 10 Fry Baskets.

Disassembles for cleaning.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

3

Page 4

INSTALLATION INSTRUCTIONS

L

e

S

s

G

s

U

e

S

e

O

l

H

d

FAS

S

A

1-800-ROBOTIC

R

R

E

S

P

OFF

O

00

S

O

CCUMU

G

Air Compressor Installation and Start-up

If you have purchased an Air Compressor from AELLC, you will

want to install it before you put the Arch Fry Dispenser into position.

1. Choose a suitable location for the Compressor. The

Compressor requires a standard 120 VAC outlet,. If you have an

existing Compressor you may wish to place this Compressor in the

same area.

NOTE: Do not place compressor above or near items that must

remain dry. The compressor requires weekly purging, and will spray

a small quantity of water when purged.

2. Connect the Air Line to the Compressor.

ASSEMBLING THE ARCH FRY DISPENSER

per at or Pane

top Gat

pper Guid

uide Hook

haf t Col lar

ower Guid

opper Li

AFD-2

RCH FRY DISPENSER

BASKET

USH TO:

TART/RESET

LOADS

RROR MESSAGES

POWER

LOW BLINK-HOPPER EMPTY

T BLINK-SYSTEM ERROR

N

AM CENTER, INC.

ED WING, MN 55066

CAUTI O

BASKET

ARE HOT

WARNIN

PINCH HAZARD

KEEP HANDS AWAY

FR

M A

LATOR

DOORS

Locki ng Pi ns

Hopper

Fr y D iverter

Dr um

Basket Sensor

Li ft Dovetail

Li ft Saddl e

Basket Sensor

1. Place the hooks of the Lower Guide between the Shaft

Collars and push the guide to the LEFT to lock it in place.

3. Run the Air Line from the Compressor to a location

approximately 3 feet (1 meter) above the floor on the wall behind the

Arch Fry Dispenser location. You may wish to use the gas line

chase (if provided) to run the Air Line.

4. Pull an extra 6 feet (2 meters) of Air Line to allow the Arch

Fry Dispenser to move around while connected.

CAUTION: Do NOT connect the Air Line to the Arch Fry Dispenser

at this time. The Arch Fry Dispenser has a self-purging water trap in

it. If the Air Line is connected to the Arch Fry Dispenser before the

Compressor is at full pressure, the purge valve may remain open,

which will prevent the Compressor from building pressure and may

damage the Compressor.

5. Turn the Compressor ON and allow the Compressor to

reach FULL pressure.

6. Verify that the air valve on the compressor (if there is one)

is in the OPEN position.

The AELLC supplied Air Compressor operation switch should

remain in the AUTOMATIC position.

2. Place the hooks of the Upper Guide between the Shaft

Collars and push the guide to the RIGHT to lock it in place.

3. Install the Lift Saddle on the Lift Dovetail. Make sure the

Lift Saddle is completely seated.

4. Find the square opening in one end of the Dispenser

Drum.

5. Place the Dispenser Drum in the Hopper, aligning the

square opening on the Dispenser Drum with the hole in the back of

the Hopper.

6. Grasp the Hopper so that the hole is toward the Arch Fry

Dispenser.

7. Align the indentations on the Hopper with the Hopper

Support Bars.

8. Push the Hopper forward onto the Hopper Supp ort Bars

until the Drum Motor shaft touches the Dispenser Drum.

9. Rotate the Dispenser Drum (CLOCKWISE or

COUNTERCLOCKWISE) while applying gentle pressure to the

Hopper until you can slide the Hopper fully onto the Hopper Support

Bars. Do not force the Hopper back, you may damage the

Dispenser Drum.

10. Lock the Hopper onto the Arch Fry Dispenser by pressing

the Locking Pins towards each other.

11. Place the Fry Diverter in the Hopper.

12. Place the Hopper Lid on the Hopper.

13. Verify the Compressor pressure is

at least 80 PSI (5.4

bar).

14. Verify that air valve on compressor is open.

15. Connect the Air Line to the back of the Arch Fry Dispenser

by pushing the Quick Coupler onto the Coupler Nipple until it is

secure.

NOTE: The Arch Fry Dispenser has a self-purging water trap in it. If

the Air Line is connected to the Arch Fry Dispenser before the

Compressor is at full pressure, the purge valve may remain open,

which will prevent the Compressor from building pressure.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

4

Page 5

16. Plug the Power Cord into a wall outlet.

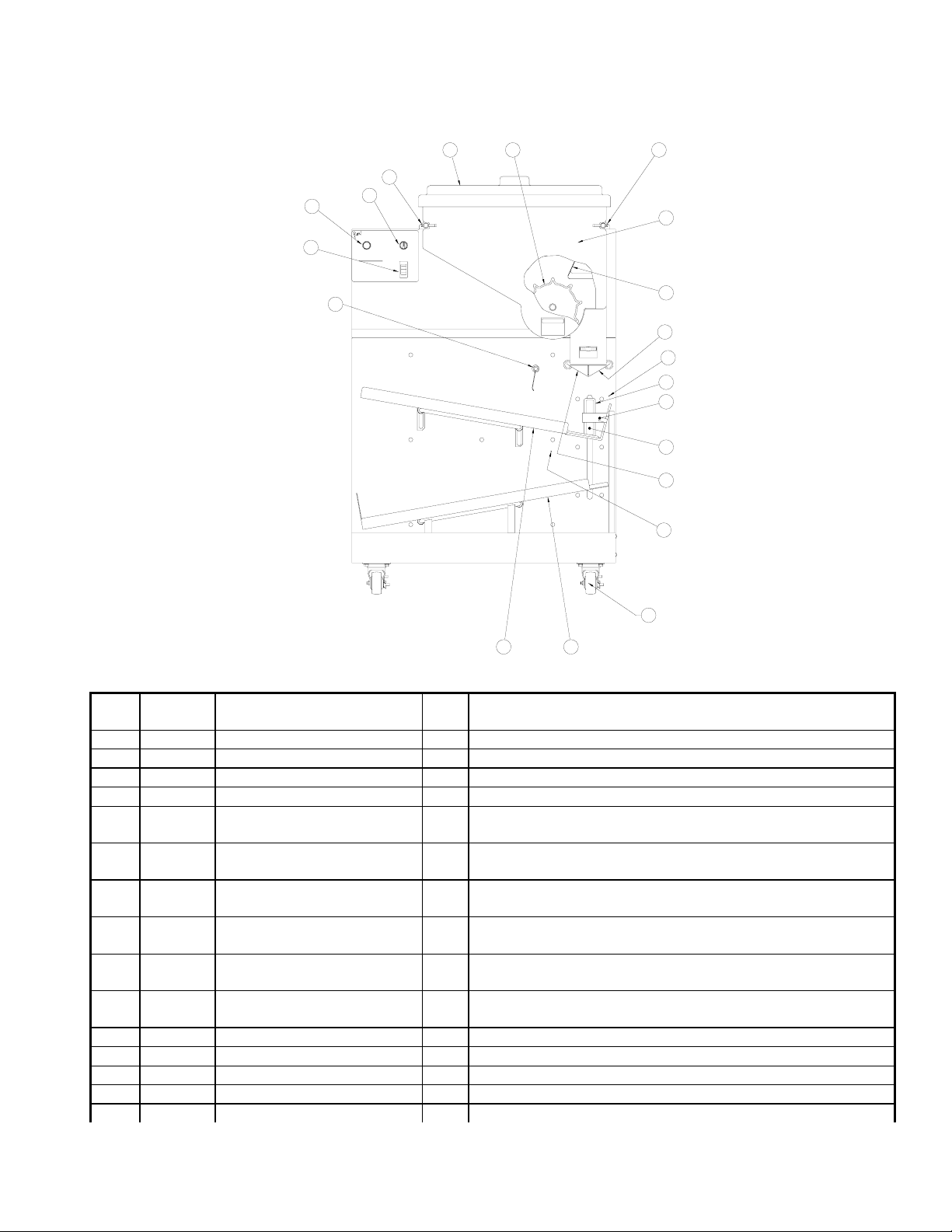

PARTS IDENTIFICATION AND FUNCTION

2 4

14

18

21

20

AFD-200

ARCH FRY DISPENSER

PUSH TO:

BASKET

LOADS

START/RESET

ERROR MESSAGES

POWER

SLOW BLINK-HOPPER EMPTY

FAST BLINK-SYSTEM ERROR

8

RAM CENTER, INC.

RED WING, MN 55066

1-800-ROBOTIC

ON

OFF

CAUTION

BASKETS

ARE HOT

WARNING

PINCH HAZARD

KEEP HANDS AWAY

FROM ACCUMULATOR

DOORS

13

1

3

10

16

12

7

11

9

17

15

6

5

Arch Fry Dispenser (FRONT VIEW)

Item Part

Description Qty Function

Number

1 213267 Hopper 1 Holds frozen Fries until they are portioned into Fry Baskets.

2 213268 Hopper Lid 1 Covers the frozen Fries in the Hopper.

3 213277 Fry Diverter 1 Funnels uncooked Fries to the accumulator area.

4 213278 Dispenser Drum 1 Dispenses bulk uncooked Fries to the accumulator area.

5 216645

216024

6 216081

216055

7 215971

215961

Lower Guide

Lower Guide Ultem

Upper Guide

Upper Guide Ultem

Lift Saddle

Saddle Skids

1

Provides a smooth surface for filled Fry Basket staging.

2

Removable for cleaning.

1

Provides a smooth surface for empty Fry Basket movement

2

towards the Basket Lift. Removable for cleaning.

1

Carries Fry Baskets from the Upper Guide to the Lower

2

Guide.

8 213473 Pre-Stage Stop Gate 1 Holds Fry Bask ets on the Upper Guide when the Basket

Lift is not in the UP position.

9 213641 Accumulator Door (L) 1 Holds weighed Fries from the Hopper until a Fry Basket is

in position to receive them.

10 213642 Accumulator Door (R) 1 Holds weighed Fries from the Hopper until a Fry Basket is

in position to receive them.

11 213900 Lift Dovetail 1 Attachment for Lift Saddle.

12 215948 Carriage Guide-white nylon 1 Provides slip for Lift Dovetail on Arch Fry Dispenser face.

13 215951 Hopper Support Bar (Right) 1 Guides the Hopper on and off of the Arch Fry Dispenser.

14 216018 Hopper Support Bar (Left) 1 Guides the Hopper on and off of the Arch Fry Dispenser.

15 216596 Brake Caster - Front 2

Allows the Fry Dispenser to be locked into place. (Bolted style)

Copyright © 2005 Automated Equipment LLC All Rights Reserved

5

Page 6

215965 Brake Caster – Front 2

Allows the Fry Dispenser to be locked into place. (Threaded style)

16 213254 Fiber Optic Sensor #1 1 Detects when a Fry Basket is in position to receive a load

of Fries.

17 213254 Fiber Optic Sensor #2 1 Detects when the Lower Guide is full of Fry Baskets and

when a Fry Basket has left the Lift Saddle.

18 215606 Lighted Button (Green) 1 Start/ Reset Button.

19 216489 Bulb (not shown) 1 Replacement bulb for lighted Button.

20 215607 Three Position Switch 1 Selects the Fry Load Size

21 213400 Power Switch (Orange) 1 Turns the Dispenser ON and OFF

1

NOTICE

SET PRESSURE

2

SWITCH TO 50 PSI

3

4

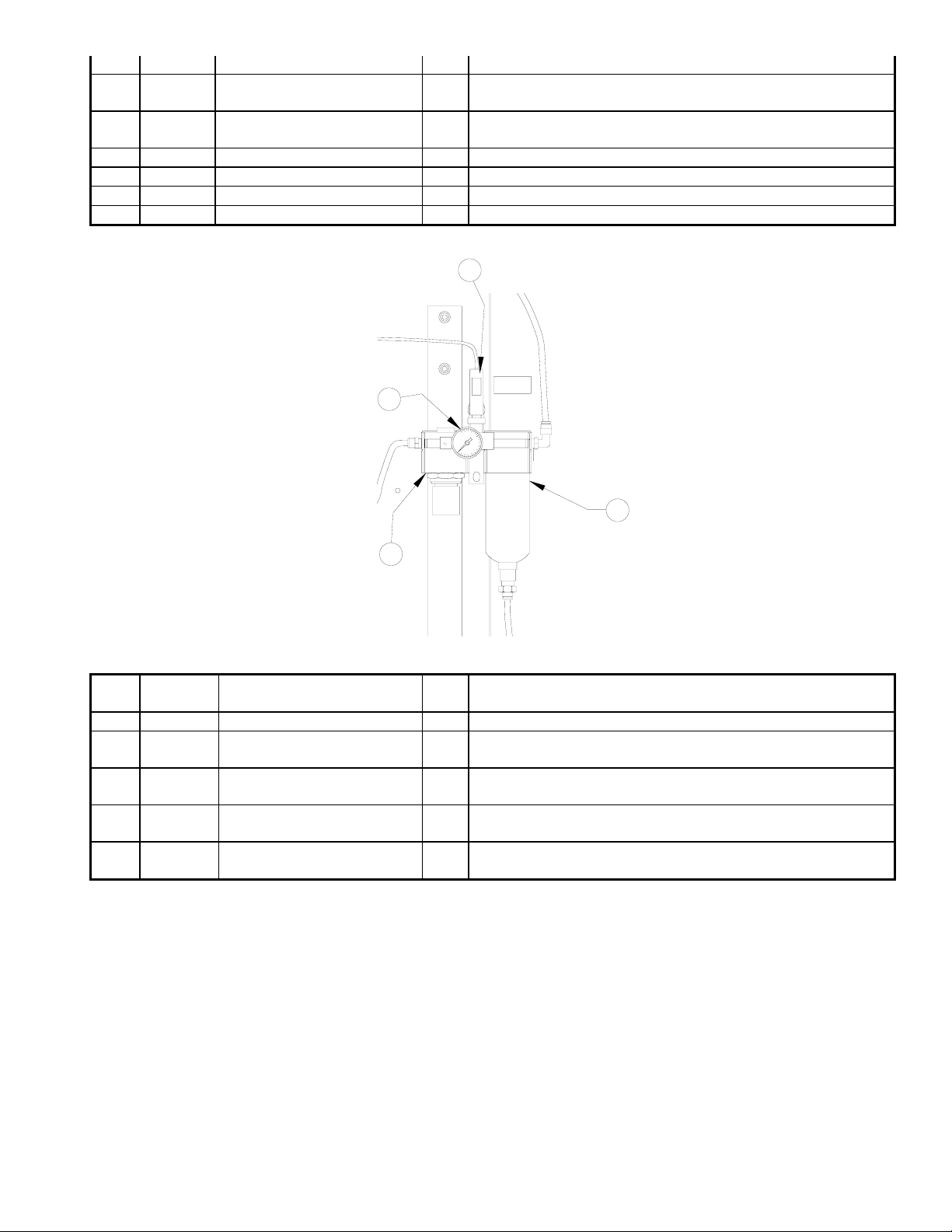

AIR FILTER/REGULATOR (Part Number 202250)

Item Part

Description Qty Function

Number

1 included Pressure Switch 1 Monitors the air pressure, and detects a loss of pressure.

2 202606 Pressure Gauge 1 Displays the current system pressure. Assists in adjusting

the regulator.

3 202245 Mist Separator with Auto

Drain – Watts (Black)

3 290095 Mist Separator with Auto

Drain – SMC (Gray)

1 Automatically drains water and debris from the Air Line that

may cause damage to the Arch Fry Dispenser.

1 Automatically drains water and debris from the Air Line that

may cause damage to the Arch Fry Dispenser.

4 included Pressure Regulator 1 Regulates 80 PSI (5.4 bar) pressure from the 90-120 PSI

(6 - 8 bar) Compressor.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

6

Page 7

18

1

2

14

12

17

16

15

13

11

3

4

5

1.5

6

NOTICE

SET PRESSURE

SWITCH TO 50 PSI

7

8

9

10

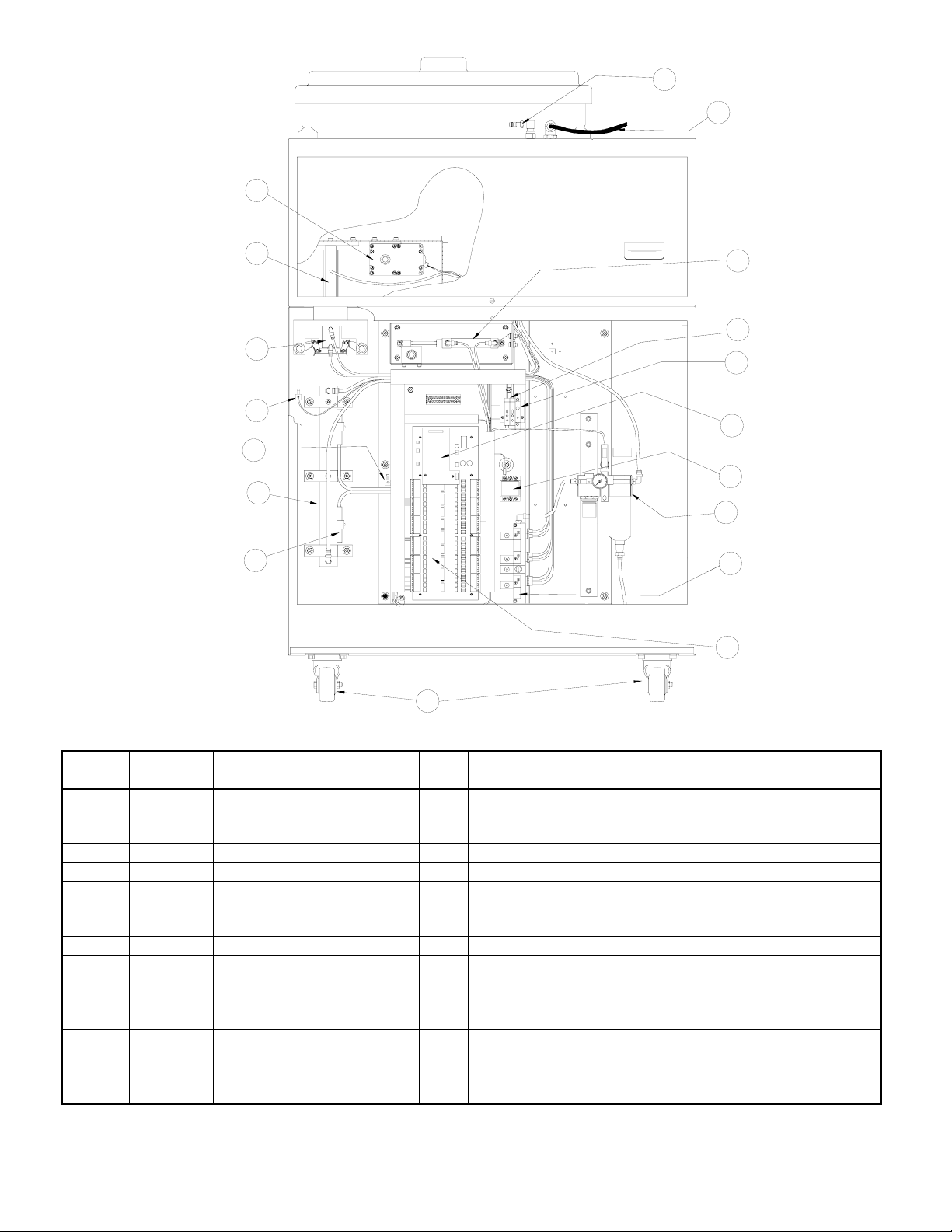

Arch Fry Dispenser (REAR VIEW)

Item Part

Description Qty Function

Number

1 213609

213610

213478

Quick Coupler Nipple

Quick Disconnect

Quick Disconnect Fitting

1

1

1

Connection point for the air line from the compressor.

Disconnects airline from the dispenser.

Adapts airline to quick disconnect.

2 202172 Power Cord 1 Supplies the Arch Fry Dispenser with power from the wall

3 216089 Stop Gate Cylinder 1 Air-operated cylinder that activates the stop gate.

4 213365 Fiber Optic Amplifiers #1-

#2

2 Generates a red light for sensors #1-#2, and controls the

sensitivity of the sensors, and inputs Fry Basket present

to control card.

5 216485 1.5 AMP Circuit Breaker 1 Protects the fry Drum Motor from electrical overload.

6 213367 Load Cell Board 1 Translates information from the Load Cell into data that

the Arch Fry Dispenser I/O Board computer can

understand.

7 213924 Solid State Relay 1 Provides high current drive to the drum motor.

8 202250 Filter/Regulator Assembly 1 Controls and monitors the pressure of the air supplied to

the Arch Fry Dispenser.

9 203985 4-Stack Air Valve Manifold 1 Air valves that control cylinders in the Arch Fry

Dispenser.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

7

Page 8

10 203984 Dispenser I/O Board 1 Computer that controls the I/O (input and output) of the

Arch Fry Dispenser.

11 216595 Caster 2

215960 Caster 2

Allows Fry Dispenser to be moved for cleaning. (Bolted style)

Allows Fry Dispenser to be moved for cleaning. (Threaded style)

12 213107 Lift Cylinder Switches 2 Indicates the position of the Basket Lift mechanism.

13 290688 Lift Cylinder 1 Air-operated cylinder that moves the Lift Saddle in both

UP and DOWN directions.

14 213254 Fiber Optic Sensor #1 1 Optic Sensor Head that detects baskets in the lift.

15 213254 Fiber Optic Sensor #2 1 Optic Sensor Head that detects baskets leaving the lift.

16 290686 Accumulator Door Cylinder 1 Air-operated cylinder that opens and closes the

Accumulator Doors.

17 203983 Load Cell 1 Electronic device that converts weight to an electrical

signal.

18 292546 Drum Motor 1 Turns the Dispenser Drum that moves the bulk uncooked

Fries into the accumulator area.

Air Line

Item Part

Description Qty Function

Number

1 213610 Quick Coupler 1 Mate for Quick Coupler Nipple on Arch Fry Dispenser.

2 213478 3/8" OD tube x 1/4" NPT 1 Connects the air supply line to the Quick Coupler body.

3 216482 Tubing, Nylon Reinforced,

3/8 In. O.D (100ft)

1 Supplies the Arch Fry Dispenser with air from a

compressor.

Miscellaneous Parts (Not Shown)

Part

Description Qty Function

Number

202002 E-Prom, Loader, 3.25R 1 Software for Dispenser I/O Board.

216044 24V Power Supply 1 Provides control voltage for dispenser operation.

219007 Lighted Button Lens Cap

1 Replacement lens cap for lighted button.

(Idec Switch Only)

213914 Screws, Lift Dovetail 4 Attaches Lift Dovetail to Lift Cylinder.

216055 Upper Guide Slide 2 Slide Mechanism for Baskets.

216024 Lower Guide Slide 2 Slide Mechanism for Baske t s.

290000 Screws, Slide 26 Attaches slide to guides.

216258 Fry Basket 10 Receives dispensed fries for cooking.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

8

Page 9

SET-UP AND CLOSE PROCEDURES

Daily Set-Up

1. Verify the Compressor pressure is

PSI (5.4 bar).

2. Connect the Air Line to the back of the Arch

Fry Dispenser by pushing the Quick Coupler onto the

Coupler Nipple until it is secure.

NOTE: The Arch Fry Dispenser has a self-purging

water trap in it. If the Air Line is connected to the Arch

Fry Dispenser before the Compressor is at full

pressure, the purge valve may remain open, which will

prevent the Compressor from building pressure.

3. Verify that the Power Switch is in the OFF

position.

4. Plug the Power Cord into a wall outlet.

5. Load the Hopper with frozen French Fries.

DO NOT SHAKE OR DROP the Fries into the Hopper.

6. Turn the Load Select Switch to the desired

load weight.

7. Fill the Upper Guide with empty Fry Baskets.

at least 80

5. Check that the Accumulator Doors are empty

of Fries.

6. Disconnect the Air Line from the back of the

Arch Fry Dispenser by grasping the collar on the Quick

Coupler and pulling back until it releases from the

Coupler Nipple.

NOTE: Disconnecting the Air Line from the Arch Fry

Dispenser every day is an important part of

Preventative Maintenance. Releasing the air pressure

allows the self-purging water trap to drain, thus

preventing the water from getting into the system.

7. Disconnect the Power Cord from the electrical

outlet.

8. Remove the Fry Diverter by grasping it and

pulling it UP.

9. Slide the Locking Pins outward to release the

Hopper.

10. Remove the Hopper (and the Dispenser Drum

inside) by pulling the Hopper OUT and AWAY from the

Hopper Support Bars.

11. Remove the Upper Guide assembly by sliding

it to the LEFT then lifting it straight UP.

8. Turn the Power Switch to the ON position

(illuminated).

9. Press the Start/Reset Button. Automatic

basket loading will begin at the load weight selected.

10. Use filled Fry Baskets from the Lower Guide

for French Fry production.

11. Return each empty Fry Basket to the Upper

Guide for refilling after the cooking cycle is complete.

Daily Closing

1. Turn the Power Switch to the OFF position.

2. Remove all Fry Baskets from the upper and

Lower Guides. Discard and record the uncooked

Fries.

3. Remove the Hopper Lid by lifting it straight UP

and OFF of the Hopper.

4. Discard and record any Fries remaining in the

Hopper at closing.

12. Remove the Lift Saddle by grasping the back

support bar with both hands and lifting straight UP.

13. Remove the Lower Guide assembly by sliding

it to the RIGHT then lifting straight UP.

14. Take the hardware removed from the Arch Fry

Dispenser to the back sink. Wash it in a hot solution of

McD APC (HCS), and sanitize. Wipe dry.

NOTE: Do NOT roll the dispenser to the back sink for

cleaning, this will cause unnecessary wear on the

dispenser.

15. Wipe down the Arch Fry Dispenser with a hot

solution of McD APC (HCS) and water. Repeat wipedown with clear water to rinse away cleanser residue.

NOTE: Do NOT spray down the dispenser. It is not

sealed, and contamination may get into sensitive

components.

16. Dry all parts and reassemble the Arch Fry

Dispenser.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

9

Page 10

SYSTEM FUNCTIONS AND OPERATION BASKET LOAD ADJUSTMENTS

E

B

The following switches and buttons are located on the

Operator Panel:

ARCH FRY DI SPENSER

PUSH

ST ART /RES

ERROR MESSAGES

SLOW BLINK-HOPPER EMPTY

FAST BLI NK-REFER TO

EQUIPMENT MANUAL

FOR SERV I CE CALL

1-800- 248-2724

OFF/SI NGL

1-LB

1.5- L

AFD- 200

BA SKET

LOADS

POWER

ON

OFF

POWER SWITCH (Orange)

Supplies electrical power to the Arch Fry Dispenser. It

illuminates when the Arch Fry Dispenser has power.

LOAD SELECT SWITCH

Slight increases or decreases in Basket Load weights

are possible by re-positioning the yellow Basket Load

Offset ADJUSTMENT switches (located behind the

OPERATOR PANEL). Adjusting these switches

allows the crew to increase or decrease the load

weight 2, 4, or 6 ounces beyond either the 1 pound

(0.45 kg) or 1.5 pound (0.68 kg) setting. Once the

switches are re-positioned, the Arch Fry Dispenser will

continually basket the new weight until they are

changed.

NOTE: Adjusting the load weight above 1.5 pounds

(0.68 kg) is NOT recommended for proper cooking.

SWITCH NUMBER TS1 TS2 TS3

Normal Setting OFF OFF INCR

Increase 2 oz. (57 gm) ON OFF INCR

Increase 4 oz. (113 gm) OFF ON INCR

Increase 6 oz. (170 gm) ON ON INCR

Decrease 2 oz. (57 gm) ON OFF DEC

R

Decrease 4 oz. (113 gm) OFF ON DEC

R

Decrease 6 oz. (170 gm) ON ON DEC

R

It has 3 positions that allow the operator to select

Basket Load weights and control operation.

OFF/SINGLE: Stops automatic Fry Basket

loading. Press the Start/Reset Button to dispense

only 1 Fry Basket of Fries pre-set to 1.5 pounds.

1 LB: Position for continual dispensing of 1 pound

(0.45 kg) Basket Loads.

1.5 LB: Position for continual dispensing of 1.5

pound (0.68 kg) Basket Loads.

START/RESET BUTTON (Green)

Press to start the loading of a single Fry Basket when

the Load Select Switch is set for OFF/SINGLE.

Press to start automatic loading of Fry Baskets when

the Load Select Switch is set for 1 or 1.5 lb. (0.45 or

0.68 kg) loads.

Press to reset a System Error.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

10

Page 11

TROUBLESHOOTING

The status of the Arch Fry Dispenser is displayed in the Start/Reset Button light. When the Hopper is filled and

operating normally, the Start/Reset Button remains steadily illuminated. System Errors appear as a flashing green

light on the Operator Panel. System Errors are a result of incorrectly assembling the Arch Fry Dispenser, or an

interruption in the normal operation.

In the following charts, the PROBLEM columns contain a list of problems that may occur, the PROBABLE CAUSE

column describes why the problem may have appeared; and the CORRECTIVE ACTION column describes the action

that must be taken to eliminate the problem. If after performing the procedure listed under CORRECTIVE ACTION

you have not corrected the problem, call AELLC Service for assista nce.

NOTE: Press the Start/Reset Button after correcting the problem.

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Restart Button is

flashing slowly.

Fries have formed a “bridge” over

Hopper Drum is not locked onto

Restart Button Compressor is not running Check that compressor has power and is turned on.

begins flashing

immediately when

Dispenser is

turned on.

Air Pressure is below 60 PSI (4.0

Pressure switch is faulty. Contact AELLC Service

There is an air leak. Check the main Air Line, Compressor, and Arch Fry

Basket Loads are

consistently light

or heavy. The Hopper is touching the

The Load Cell is improperly

The Load Cell has malfunctioned. Contact AELLC Service.

Basket Loads

suddenly change.

The Hopper is empty. Refill the Hopper with Fries. Remove any empty Fry

The Fry Diverter is not properly

The Hopper is touching the

Dispenser Drum is

not rotating

Hopper is empty (Restart Button

Hopper is empty Fill the Hopper with Fries.

Remove the Hopper Lid and re-distribute the Fries inside.

the drum.

Remove the Hopper Lid and Fry Diverter. Turn the

the shaft.

Dispenser Drum, while applying pressure and slide it fully

onto the shaft. Re-install the Fry Diverter and Hopper Lid.

Air Line is not connected to the

Connect the Air Line to the Dispenser.

Dispenser.

Compressor has not been

allowed to charge before Air Line

was connected

Disconnect the Air Line from the Dispenser. Wait until the

compressor reaches full pressure (compressor will turn

itself off). Reconnect Air Line.

Adjust the compressor to maintain between 90 and 120

bar)

PSI (6 and 8 bar). If you need assistance, contact AELLC

Service

Dispenser for leaks. If you are unable to find it, or need

assistance repairing it, contact AELLC Service

Basket Load Offset switches were

not set properly.

Verify proper switch settings. Re-position the switches if

necessary.

Re-assemble the Hopper. No objects, other than Fries,

Accumulator Doors.

may touch the Accumulator Doors.

Refer to the Load Cell Calibration procedure in the noncalibrated.

Fries have formed a “bridge” over

scheduled maintenance section.

Remove the Hopper Lid and redistribute the Fries.

the drum.

Baskets from the Lower Guide and place them on the

Upper Guide.

Remove and re-install the Fry Diverter.

installed.

Re-assemble the Hopper. No objects, other than Fries,

Accumulator Doors.

may touch the Accumulator Doors.

The accumulator doors are full. The Dispenser Drum will rotate only when the accumulator

doors require more Fries.

Fill the Hopper with Fries. The Dispenser Drum will rotate

is flashing slowly).

when the next empty Fry Basket is cycled through the

Upper Guide.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

11

Page 12

NOTE: Press the Start/Reset Button after correcting the fault condition.

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Dispenser Drum is

not rotating (cont.)

The Dispenser has detected a

Hopper Drum is not locked onto

Fries have formed a “bridge” over

the drum (Restart Button is

flashing slowly).

SYSTEM FAULT (Restart Button

is flashing rapidly).

the shaft.

Remove the Hopper Lid and re-distribute the Fries inside.

The Dispenser Drum will rotate when the next empty Fry

Basket is cycled through the Upper Guide.

Continue troubleshooting. If the accumulator doors need

Fries, the Dispenser Drum will continue rotating when the

Restart Button is pressed.

Remove the Hopper Lid and Fry Diverter. Turn the

Dispenser Drum, while applying pressure and slide it fully

onto the shaft. Re-install the Fry Diverter and Hopper Lid.

The Hopper is touching the

Accumulator Doors.

The Fry Diverter fell inside the

Hopper preventing the Dispenser

Re-assemble the Hopper. No objects, other than Fries,

may touch the Accumulator Doors.

Remove the Fry Diverter from inside the Hopper and

install correctly.

Drum from turning.

The Drum Motor Circuit Breaker

(CB1) has tripped.

The Fry Basket sensors are dirty

or covered with shortening.

The Load Cell is improperly

calibrated.

Remove the LOWER BACK panel. Reset the Circuit

Breaker by pushing IN the black button labeled 1.5.

Turn off the Power Switch. Clean the sensors with a hot

wet towel.

Refer to the Load Cell Calibration procedure in the non-

scheduled maintenance section.

The Load Cell has malfunctioned. Contact AELLC Service.

Fry Basket is filled

more than once.

Shortening build-up on Sensors

blocked the sensor from detecting

a Fry Basket.

Turn off the Power Switch. Clean the sensor with a HOT

wet towel. Place an empty Fry Basket on the Lift Saddle.

Restart the Arch Fry Dispenser to see if sensor #2 detects

the Fry Basket and operation resumes.

A Fry Basket is positioned

Re-position the Fry Basket in the Lift Saddle.

incorrectly on the Lift Saddle.

Fry Baskets are

sticking or tipping

on Upper or Lower

Fries, crumbs, or shortening have

accumulated on the Guide or Lift

Saddle.

Turn the Power Switch off, and clean the Guide and Lift

Saddle with a hot towel.

Guide. A Fry Basket is bent or damaged. Replace the damaged Fry Basket.

The Lift Saddle is assembled

Re-assemble the Lift Saddle correctly.

incorrectly.

The guide is not assembled

correctly.

Re-assemble the guide. If the guide locating Collars are

loose, adjust the Collars so that the guide has equal

spacing to the nylon runners on the Lift Saddle.

The Lift Saddle or Guide is bent

Contact AELLC Service.

or damaged.

Hopper Compressor is not running Check that compressor has power and is turned on.

Accumulator

Doors do not shut

Compressor has not been

Air Line is not connected to the

Dispenser.

allowed to charge before Air Line

was connected

Connect the Air Line to the Dispenser.

Disconnect the Air Line from the Dispenser. Wait until the

compressor reaches full pressure (compressor will turn

itself off). Reconnect Air Line.

There is an air leak. Check the main Air Line, Compressor, and Arch Fry

Dispenser for leaks. If you are unable to find it, or need

assistance repairing it, contact AELLC Service

The Accumulator Door Cylinder

Tighten the bolts holding the cylinder cross bar in place.

actuator is loose.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

12

Page 13

NOTE: Press the Start/Reset Button after correcting the fault condition.

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Fry Basket stop Compressor is not running Check that compressor has power and is turned on.

gate does not hold

Fry Baskets in

place. Compressor has not been

Air Line is not connected to the

Dispenser.

allowed to charge before Air Line

was connected

Connect the Air Line to the Dispenser.

Disconnect the Air Line from the Dispenser. Wait until the

compressor reaches full pressure (compressor will turn

itself off). Reconnect Air Line.

There is an air leak. Check the main Air Line, Compressor, and Arch Fry

Dispenser for leaks. If you are unable to find it, or need

assistance repairing it, contact AELLC Service

One of the Fry

Basket sensors is

OFF. The Power

Switch lamp is ON.

Does not dispense

fries into a waiting

basket.

The Sensor or Amplifier has

failed.

The power supply is not

functioning properly.

Shortening build-up on sensor #1

blocked the sensor from detecting

a Fry Basket.

Turn off the Dispenser and contact AELLC Service.

Turn off the Dispenser and contact AELLC Service.

Turn off the Power Switch. Clean the sensor with a HOT

wet towel. Place an empty Fry Basket on the Lift Saddle.

Restart the Arch Fry Dispenser to see if sensor #1 detects

the Fry Basket and operation resumes.

A Fry Basket is positioned

Reposition the Fry Basket in the Lift Saddle.

incorrectly on the Lift Saddle.

No light is coming from Sensor. Contact AELLC Service.

SYSTEM ERROR

(Restart Button

flashes rapidly) as

lift reaches top or

bottom

The Basket Lift cylinder speed is

either too fast or too slow.

A tipped Fry Basket stopped the

Basket Lift.

Refer to the Maintenance Section of this manual for the

procedure to adjust the Basket Lift cylinder speed.

Remove the Fry Basket. Check it to be sure that it is not

bent or damaged. Clear the Lift Saddle of any Fries or

shortening. Press the restart button. If problem re-occurs,

remove and re-assemble the guides.

Some shortening on Sensor #1 or

#2 blocked the sensor from

Clean the sensors with a HOT wet towel. Press the restart

button.

detecting a Fry Basket.

Compressor is not running Check that compressor has power and is turned on.

Air Line is not connected to the

Connect the Air Line to the Dispenser.

Dispenser.

There is an air leak. Check the main Air Line, Compressor, and Arch Fry

Dispenser for leaks. If you are unable to find it, or need

assistance repairing it, contact AELLC Service

Lift Cylinder Switches not working Contact AELLC Service

Lift Cylinder Failure Contact AELLC Service

Copyright © 2005 Automated Equipment LLC All Rights Reserved

13

Page 14

ORDERING PARTS/SERVICE

Warranty service is initiated by calling AELLC's

TECHNICAL SUPPORT HOT LINE at 1-800-248-

2724. Technical Support personnel will determine the

cause of failure and recommend solutions. If parts are

required, the parts will be shipped directly to the

restaurant. A local service agent will be dispatched

once the problem has been identified and parts have

been shipped.

Record the following information for your records:

Date of Installation:

Service Agency Telephone:

When repairing this unit, use only replacement parts

supplied by AELLC. Use of replacement parts other

than those supplied by AELLC will void the warranty.

All shipping charges are F.O.B. AELLC, and are

subject to change without notice. Prices will be those

in effect at the time of shipment. AELLC reserves the

right to make suitable substitutions in materials,

depending upon their availability.

Parts Location and Ordering Information

Use the

Parts Identification and Function section in

this manual to help you identify the correct part

number and quantity of items to order.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

14

Page 15

NON-SCHEDULED MAINTENANCE

This section gives the procedures for several repairs

that do not require special tools.

REPLACEMENT OF WATER TRAP BOWL

3. Remove the lower back panel of the Arch Fry

Dispenser.

4. Ensure at least 80 PSI (5.4 bar) is being

supplied to the Filter/Regulator.

5. Pull DOWN on the black adjustment knob

located below the air pressure gauge.

Parts: Water trap bowl

1. Turn the main Power Switch for the Arch Fry

Dispenser to the OFF position.

2. Remove the Fry Baskets from the Arch Fry

Dispenser.

3. Disconnect the Air Line from the back of the

Arch Fry Dispenser by grasping the collar on the

Quick Coupler and pulling back until it releases from

the Coupler Nipple.

CAUTION: Failure to remove the system air

pressure could result in injury.

4. Remove the lower back panel of the Arch Fry

Dispenser.

5. Make sure the air pressure gauge reads 0 PSI

on the regulator inside the Arch Fry Dispenser.

6. Pull down on the thumb clip that locks the

water trap bowl and by turning it to the LEFT. The

plastic bowl will come off by pulling down on the guard.

7. Remove the old bowl. Insert the new water

trap bowl into the metal guard. Ensure that the O-ring

is located on TOP of the bowl.

6. Turn the knob COUNTERCLOCKWISE to

decrease air pressure and CLOCKWISE to increase

air pressure. Adjust the air pressure to 80 PSI

(indicated on the gauge) by turning the knob.

7. Push UP on the knob to lock it in place.

8. Replace the lower rear panel.

9. Plug the Power Cord into the wall outlet.

10. Move the Arch Fry Dispenser back into

position.

11. Turn the ARCH Fry Dispenser Power Switch

to the ON position.

RESETTING THE DRUM MOTOR CIRCUIT

BREAKER.

WARNING: ELECTRICAL SHOCK HAZARD!

Keep hands and tools away from all electrical

components.

1. Turn the Arch Fry Dispenser main Power

Switch to the OFF position.

2. Unplug the ARCH Fry System from the wall

outlet.

8. Replace the guard and bowl assembly on the

Filter/Regulator unit by pushing up and turning it to the

RIGHT.

CAUTION: Hand-tighten only!

9. Reconnect the main Air Line to the Quick

Coupler. Check for leaks. Replace the outside cover.

ADJUSTING FILTER/REGULATOR AIR

PRESSURE SETTING

1. Turn the Arch Fry Dispenser Power Switch to

the OFF position.

2. Disconnect the electrical power plug from the

wall outlet.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

3. Remove the LOWER BACK PANEL of the

Arch Fry Dispenser.

4. Locate the Circuit Breaker. If the Start/Reset

Button on the breaker has popped out (tripped,

showing white), reset the breaker by pushing the

BLACK button IN.

5. Re-install the LOWER BACK PANEL.

6. Verify that the Dispenser Drum and Fry

Diverter are installed properly.

7. Plug the Power Cord into the wall outlet.

8. Turn the main Power Switch to the ON

position.

15

Page 16

9. If the breakers trip again, turn the Power

Switch to the OFF position, unplug the Arch Fry

Dispenser from the wall outlet, and call AELLC for

service.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

16

Page 17

ADJUSTING AIR CYLINDERS

NOTE: The following procedures should be done

under the direction of AELLC Technical Support

personnel. Please call AELLC Service before

proceeding

All air cylinders have flow controls that adjust the

speed at which they operate. These factory-adjusted

cylinders provide accurate and consistent operation for

the loading and staging of Fry Baskets.

If Lift Cylinder speed adjustment is

needed, follow the procedures below.

1. Turn the Power Switch to the OFF position.

2. Remove the Arch Fry Dispenser lower back

panel.

3. Locate the solenoid valves SV 4 and SV 5 on

the manifold. When looking at the valve, you will

notice a small round "eye" in the end of the solenoid.

This is the solenoid "actuator".

4. Adjust SV 4 (E-STOP) flow control 2 1/2 to 3

full turns counter CLOCKWISE from closed.

5. Using a ball point pen press and hold SV 4

actuator. The Basket Lift will go up.

6. While holding the SV 4 actuator, press and

hold the SV 5 actuator. The Basket Lift will go down.

When SV 5 is released, the Basket Lift will go up.

7. Monitor the up and down speed of the Basket

Lift. It should be 2 seconds in each direction (Count

“one-thousand-one, one thousand-two”).

For the Stop Gate cylinders perform the

following steps:

1. Turn the Power Switch to the OFF position.

2. Remove the Arch Fry Dispenser LOWER

BACK PANEL.

3. Locate the solenoid valve SV 1 on the

manifold. When looking at the valve, you will notice a

small round "eye" in the end of the solenoid. This is

the solenoid "actuator".

4. Using a ball point pen press and hold SV 1

actuator. The stop gate will open. When SV 1 is

released, the stop gate will close.

5. Monitor the speed of the stop gate. It should

be 1 SECOND opening or closing.

6. If the stop gate speed is correct, skip to step

10.

7. If the stop gate speed needs adjustment,

loosen the lock nut on the flow control adjustment

screw located to the right of SV 1. The "A" flow control

is "closed" and the "B" flow control is "open".

8. Adjust the flow control screw for proper speed.

CLOCKWISE will decrease the speed,

COUNTERCLOCKWISE will increase the speed.

9. Tighten the lock nut, and return to step 5.

10. Turn the Power Switch ON, and cycle a Fry

Basket to verify proper operation.

8. If the Basket Lift speed is correct, skip to step

12.

9. If the Basket Lift speed needs adjustment,

loosen the lock nut on the flow control adjustment

screw located to the right of SV 5. The "A" flow control

is "up" and the "B" flow control is "down".

10. Adjust the flow control screw for proper speed.

Clockwise will decrease the speed, counterCLOCKWISE will increase the speed.

11. Tighten the lock nut, and return to step 7.

12. Turn the Power Switch ON, and cycle a Fry

Basket to verify proper operation.

13. Replace the LOWER BACK PANEL.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

11. Replace the LOWER BACK PANEL.

17

Page 18

For the Accumulator Doors cylinder

perform the following steps:

PREVENTATIVE MAINTENANCE

1. Turn the Power Switch to the OFF position.

2. Remove the Arch Fry Dispenser LOWER

BACK PANEL.

3. Locate the solenoid valve SV 3 on the

manifold. When looking at the valve, you will notice a

small round "eye" in the end of the solenoid. This is

the solenoid "actuator".

4. Using a ball point pen press and hold SV 3

actuator. The Accumulator Doors will open. When SV

3 is released, the Accumulator Doors will close.

5. Monitor the speed of the Accumulator Doors.

It should be QUICK OPENING and 1 SECOND

closing).

6. If the Accumulator Door speed is correct, skip

to step 10.

7. If the Accumulator Door speed needs

adjustment, loosen the lock nut on the flow control

adjustment screw located to the right of SV 3. The "A"

flow control is "up" and the "B" flow control is "down".

8. Adjust the flow control screw for proper speed.

CLOCKWISE will decrease the speed, COUNTERCLOCKWISE will increase the speed.

9. Tighten the lock nut, and return to step 5.

10. Turn the Power Switch ON, and cycle a Fry

Basket to verify proper operation.

11. Replace the LOWER BACK PANEL.

You are responsible for performing all indicated

maintenance tasks. Careful adherences to these

scheduled maintenance tasks will help ensure the

most consistent system operation.

Daily Maintenance

The following tasks must be performed daily to ensure

the proper operation of your Arch Fry Dispenser.

1. Disassemble and Clean all moving parts and

all parts that touch food or shortening.

2. Disconnect the Air Line at the Quick Coupler,

and allow the Arch Fry Dispenser to drain for several

minutes.

For directions on these steps, see the section titled

"DAILY CLOSING".

Compressor Maintenance

The Compressor requires WEEKLY draining of the

tank to remove any moisture that has collected.

Follow the procedure below. Failure to perform

regular maintenance may cause damage and void any

warranty claims on the Arch Fry Dispenser.

1. Disconnect the Air Line from the back of the

Arch Fry Dispenser by grasping the collar on the

Quick Coupler and pulling back until it releases from

the Coupler Nipple.

2. Open the purge valve on the Compressor tank

and allow any collected moisture to escape.

3. Close the purge valve.

4. Allow the Compressor to run and build

pressure to MAXIMUM. The Compressor will turn

OFF.

5. Re-connect the main Air Line supply to the

Arch Fry Dispenser.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

18

Page 19

LOAD CELL CALIBRATION

21. Place a 2 pound (0.9 kg) weight on the

Accumulator Doors.

1. For optimum performance, the weighing system

should be calibrated twice per year. To do this,

follow these steps:

2. Pull the Arch Fry Dispenser away from the wall.

3. Remove the upper back panel of the Arch Fry

Dispenser.

4. Verify that all of the Basket Load Offset Switches

are in the OFF position.

5. Remove the lower back panel of the Arch Fry

Dispenser.

6. Turn the Power Switch to the ON position.

7. Trip the Circuit Breaker for the Drum Motor by

pressing the red button on the Circuit Breaker.

8. Cycle a Fry Basket through the Arch Fry

Dispenser to empty the Accumulator Doors.

9. Remove the Hopper from the Arch Fry Dispenser.

22. Adjust Potentiometer labeled RP2 GAIN until the

voltage is 4.8 volts DC.

23. Remove the 2 pound weight.

24. Reset the Circuit Breaker for the Drum Motor by

pressing the BLACK button on the Circuit Breaker.

25. Reinstall the Hopper on the Arch Fry Dispenser

and fill it with Fries.

26. Manually run Fry Baskets through the Arch Fry

Dispenser at the 1 lb. (0.45 kg) and 1.5 lb. (0.68

kg) settings. Check Basket Loads and adjust if

necessary.

27. Replace both Back Panels and roll the Arch Fry

Dispenser into its original position.

LOAD CELL BOARD

10. Verify that the Accumulator Doors are empty.

11. The Load Cell Board is a small "L" shaped board

piggybacked on the Dispenser I/O Board.

12. Turn the Power Switch to the OFF position.

13. Disconnect the Load Cell Connector and clean the

connector pins on the Load Cell Board with a

clean pencil eraser.

14. Reconnect the Load Cell Connector and turn the

Power Switch to the ON position.

15. Set a digital voltmeter to volts DC.

16. Connect the negative lead to the test point labeled

ANALOG on the Load Cell Board.

17. Connect the positive lead to the test point labeled

VREF2.

18. Adjust Potentiometer labeled RP3 A/D VREF to

2.4 volts DC.

RP3

19. Connect the positive lead to the test point labeled

V OUT.

20. Adjust Potentiometer labeled RP1 OFFSET until

the voltage is 0 volts DC.

Copyright © 2005 Automated Equipment LLC All Rights Reserved

19

Page 20

DIAGRAMS

ABA

A

SV1

MD3

(PRE-STAGE STOP GATE CLOSED- A DJUS T

B

(PRE-STAGE STOP GATE OPEN-ADJUST

(ACCUMULATOR DOORS CLOSED-ADJUST

A)(5/32

B)(5/32 G R EEN )

RED)

A)(5/32 PURPLE)

SV3

SV4

SV5

(

B

ACCUMULATOR DOORS OPEN-ADJUST

EXHAUST AIR FROM PRE-STAGE AND POST-STAGE

LIFTS WHEN POWER IS REMOVED

EMERGENCY STOP CONDITIONS

(PRE-STAGE LIFT UP-ADJUST A)(1/4 CLEAR)

(PRE-STAGE LIFT DOWN-ADJUST

OR

B)(1/4

ADJUSTMENT DIRECTIONS

ADJUST VALVE CLOCKWISE TO DECREASE FLOW

ADJUST VALV E COUNTER CLOCKWI S E TO INCREAS E FLOW

B)(5/32 ORANGE)

DURING

CLEAR)

Copyright © 2005 Automated Equipment LLC All Rights Reserved

20

Page 21

+24V

L

T

D

P

R

L

LIF

T

A

S

A

A

VSVSVSV

H

E

T

T

T

K

3

4

T

T

T

D

H41H

H10

H

L

.BLGR

1

.

PN

WH

PU

2

.

ROTA

a

R

1

a

a

1

a

1

a

1

a

a

1

INSERT

VIP1 P1

PCB5

LOAD CEL

BOARD

VO VRE ANA

MD3

DR

PRE-ST DOOOP E-RELE PRE-

RED

GRN

BLK

WHT

RED

SHD

J

1

LC1

LOAD CELL

25

LL

BLK

ST

EE I NSERT

S

BLK

BLK

BLK

BLK

1

O

BLK

BLK

BLK

BLK

BLK

LI G

STA

RED

RED

GRN

++++++++++++++++++++++++

222221111111111987654321

PCB

DISPENSER I /O BOARD

E

EPROM

N1

1

ESTOP

1

JSTSTST

1234 5678 9111 1111 1112 2222

++++ ++++ ++++ ++++ ++++ ++++

1

J

WHT

WHT

BRN

BRN

BLU

BLU

BLK

BLK

BLU

YEL

PNK

WHT

RED

BLK

PUR

GRY

ORN

NEUTRA

120 VAC

GROUND

18 g

24VDC

SUPPLY

CLASS 2

120

PU1

OWE

+O

+

-

-

8 g

8 g

NEUT

1324

8 g

RED

RED

RED

1

RED

RED

RED

WH WH

TB4

BLK

BLK

BLK

BLK

1

PE PE LS LS

BASKEPRE-BASKETPOST- PRE- LI FTPRE-LIF

RED

RED

BR

BLBL

BLBRBL

RE

MAIN AI R

BL

BLK

RED

2 (RE

BL

+/- 2

T1 (BLK

+/- 4

OR

BL

YE

BL

BL

BL

BL

DECRINCRE

BL

CYCLE1 LB

.5 LB

LB

+

CB1

18 ga18 ga

6 g

PI N

W

16 ga

BL

16 ga

G

16 g

16 g

T1

PL1

SW1

POWER

PI N

10A

PI N

RED

BLK

18 ga

35

RED

1 (RE

2+1

3 (WH

BLK

SSR1

M2

2 (WH

24V

DRU

1 (BL

MOT O

Copyright © 2005 Automated Equipment LLC All Rights Reserved

21

Page 22

M

PREFIX DESCRIPTION

AY

QD QUICK DISCONNECT

FR

PS PRESSURE SWITCH

SV SOLENOID VALVE

ES

E-STOP PRESSURE RELEASE

AIR CYLINDER

FILTER-REGULATOR

60 PSI

AY

R

O

AY

T

A

L

U

M

S

U

R

C

O

C

O

A

D

E

E

G

L

N

P

A

R

R

U

O

P

ES

E

E

G

T

A

A

T

G

S

-

P

E

O

R

T

P

S

N

E

D

E

E

R

R

G

AY

E

G

A

T

S

E

R

P

TOP

END

BOTTOM

END

T

F

I

L

R

R

A

A

E

E

L

L

C

C

0 PSI

QD

FR

PS1

EX

IN

B

A

SV1 SV3 SV4 SV5

Solenoids Illustrated in the De-energized Condition

Copyright © 2005 Automated Equipment LLC All Rights Reserved

22

EX

IN

B

A

IN

EX

EX

IN

B

A

UFFLER

Page 23

NOTES

Copyright © 2005 Automated Equipment LLC All Rights Reserved

23

Loading...

Loading...