Page 1

RAK-LINK Instruction Manual

For programming information: Wired system Programming Guide

For further installation information: Wired RAK Application Sheet

What is the RAK-LINK?

The RAK-LINK is a required element of any wired system.

The RAK-LINK powers the wired network and also provides a link between the keypads and

RAK dimmers.

Up to 32 RAK circuits can be used per RAK-LINK. These 32 circuits can be designated in

any combination of RAK8s and RAK4s.

The RAK-LINK supports up to approximately 40 wired devices communication devices in a

typical installation of 1000m of data cable. “Wired communication devices” refers to WCMs

(keypads), WAPIR (motion sensor) etc.

For a more exact calculation of power requirements please refer to “RAK-LINK diagnostics”

application sheet.

Typical Wired Installation layout:

Installation of the RAK-LINK

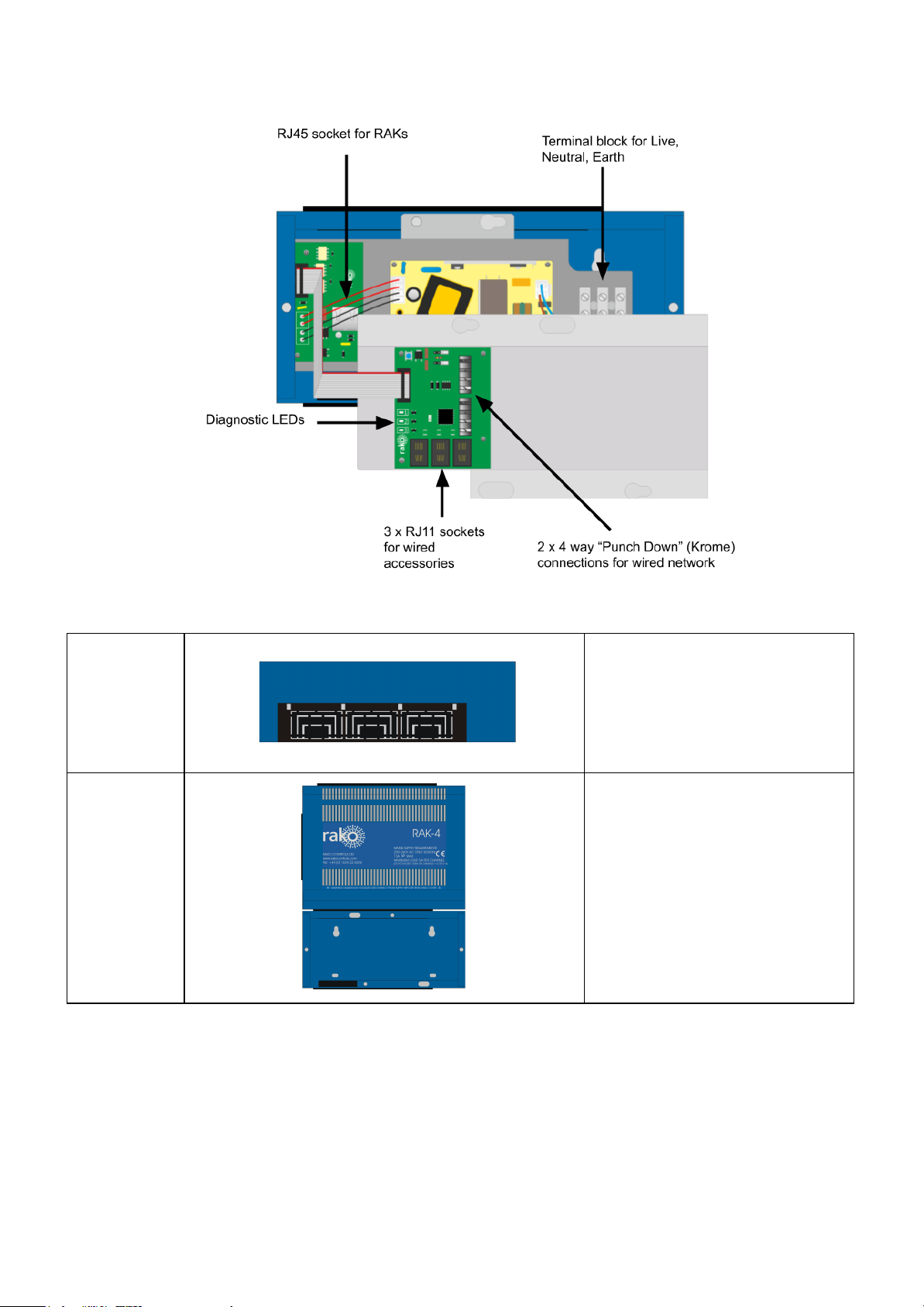

The connections to the RAK-LINK, as shown below are:

1) Mains AC connection to power supply

2) RJ45 patch lead to RAK stacks

3) Krone connector punchdowns and RJ11 sockets to wired network

4) Optional 3 x RJ11 sockets for wired accessories

RAK-LINK Manual Version 3.1.2

Page 2

Step 1

Remove lid.

Remove plastic knockouts to

allow cables to pass in and out of

RAK-LINK.

Step 2

Slot the RAK-LINK housing into

the RAK metal work

Screw RAK-LINK to wall and

prepare mains supply cable.

RAK-LINK Manual Version 3.1.2

Page 3

Step 3

Remove the top tray by

disconnecting the ribbon cable

and screws

Fix the lower tray into the wall

mounted metal housing using the

screws indicated in the diagram.

Step 4

Wire the mains supply into the

terminal block.

Insert the RJ45 cable that links

the RAK-LINK to a stack of

RAKs.

Prepare two remaining screws to

be slotted into top tray

Step 5

Reattach the ribbon cable

between the top and bottom

board

Slot the top tray into the bottom

tray and screw down

Step 6

Punchdown the CAT5 to wired

network to complete installation.

If required plug devices (for

example HUB or Bridges) into

the RJ11 ports

RAK-LINK Manual Version 3.1.2

Page 4

Terminating the RAK-LINK

The final step in the installation process is to terminate the RAK-LINK. The termination that

is required depends on the nature of the installation and the position of the RAK-LINK within

the system.

Termination Jumper settings:

No Term - Both Jumpers removed

Used when the RAK-LINK is not at the end of line. This is usually identifiable by two cables

being punched down to the RAK-LINK.

Term - Jumper fitted across 1+2 & 4+5

Used when the RAK-LINK is end of line in a daisy chain configuration (such as the

RAK-LINK shown in “Typical Wired Installation layout” on page one).

Star Term - Jumper fitted across 2+3 & 5+6

Used when the RAK-LINK is end of line in a STAR wire configuration.

Programming the RAK-LINK

The RAK-LINK is programmed using the Rasoft pro programming software. A WK-HUB or

WA/WTC-Bridge is required for any programming of a wired system.

For more information on how to programme a RAK-LINK please refer to “Wired System

Setup Guide”

RAK-LINK Manual Version 3.1.2

Page 5

Appendix: RAK-LINK diagnostics

Requires ISSUE B circuit board and firmware version 0.4.6

RAK-LINK Blue LED Status

Number

Colour

Indicates

Uses/example

1

Blue

Device activity

● Device in setup

● Network looping poll

2

Blue

Power/ CAN bus

activity

● Solid Power detected

● Flashing CAN Bus Transmitting or

receiving

3

Red

CAN Diagnostics

● CAN warning

● CAN error

Red LED Status

Troubleshooting (Potential causes)

Warning: RED LED Fast flash

Continuously checked

Cause: Incorrect voltages measured

on the RAK-LINK data lines. The

system may still function.

● One or more data line(s) have been

shorted to a power line.

● RAK-LINK put into setup mode with no

network attached.

● The network is very busy (LED 2 will also

be flashing fast).

Warning: RED LED Slow flash

Continuously checked

Cause: Power supply detected to be

below 12V

● Power Supply failing.

● Power is supplied from another source.

Error: RED LED solid

Checked on power-up and attempted transmission

Cause: CAN Transmission failure.

The RAK-LINK has repeatedly failed

to transmit a message.

● RAK-LINK put into polling mode with no

network attached or CAN bus shorted

together.

When the suspected fault has been resolved a power cycle is required to refresh the

diagnostic LED.

NB

Caution should be exercised while using this table for diagnostic purposes. The suggested possible

cause is the most likely of many possible outcomes but is not a guaranteed solution.

RAK-LINK Manual Version 3.1.2

Loading...

Loading...