Page 1

Rako Curtain, Blind and Screen Modules – Installation, Programming and Operating Instructions.

The Rako RACUB curtain, blind and screen

modules allow control of most blind and

curtain motors from Rako transmitters.

Rako RACUB modules are designed to be

installed either separately or within a

lighting project and are controlled from

Rako scene-sender panels transmitting

Rako encoded radio signals.

The RACUB module provides 2 isolated

changeover relays which can be wired in a

number of ways to suit the motor type

being used. The relays can be configured

to be either closed or open in each of the 4

scenes but the default settings are given

below.

Scene Relay A Relay B

When wired correctly the default settings

will give Scene 2 = Open, Scene 3 = Stop

and Scene 4 = Close, this allows operation

from the Rako 3 and 6 button panels

specifically designed for blind and curtain

use (RPS03 and RPS06).

During normal operation the Raise and

Lower buttons have no effect on the

RACUB module; however, they can be

configured using the RASOFT software to

work as faders or as momentary controls,

particularly useful for Venetian blinds

which may need fine adjustment. See the

RASOFT documentation for more

information.

For blind and curtain motor control both

relays should be used. This allows ‘neutral

state’ where no power is applied to either

coils of the motor, an in-built ‘delay on

changeover’ feature also avoids hard

reversing of a motor which can damage the

relays.

General

1 Closed Closed

2 Open Closed

3 Open Open

4 Closed Open

Off Open Open

Default Settings

Fig 1.

Note

Installation

Before commencing installation of a Rako

RACUB module first read this instruction

manual carefully.

Rako Controls Ltd accepts no responsibility

for any damage or injury caused by

incorrect installation of a Rako product.

Installation should only be carried out by a

Never attempt to connect a Rako module

or remove the terminal covers without first

isolating the circuit at the fuse/MCB

board.

The circuit supplying a Rako RACUB

module should always be protected by

either a 5A fuse or 6A MCB. Under no

circumstances should any protection

devices with higher ratings be used.

Rako RACUB modules should be mounted

in areas that are adequately ventilated, dry

and outside of any enclosed metal casings.

Wherever possible the modules should be

securely fixed using the mounting holes

provided. The mounting holes are blanked

off when supplied but are designed so that

a woodscrew will easily cut through

without the need for drilling.

Whilst Rako modules are designed to be

completely maintenance free the units

should be mounted in a position where

access can be gained should there be a

fault or re-addressing of the unit be

necessary (see ‘Set-up and Addressing’).

The relays are designed to be used for

either low or mains voltages but not a

combination of both. The maximum

permissible current is 2A per relay. If in

doubt contact the Rako customer help-line

on 01634 226666.

competent electrician.

Permissible loadings.

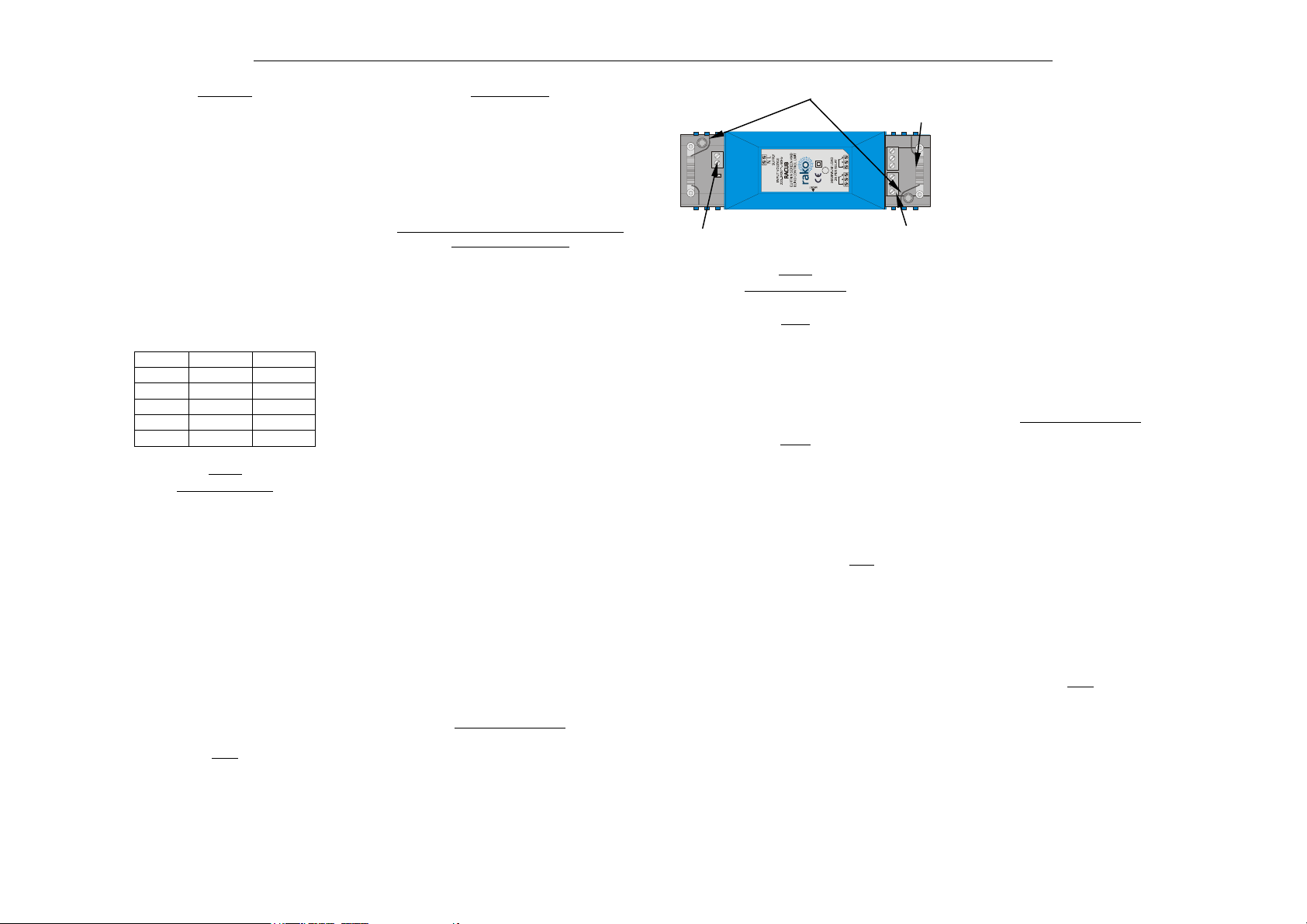

Mounting Holes

Clamping bar

M

AB

Supply

Termination Area

Fig 2.

Output

Note

For the appropriate connection details for

control of motors for curtains, blinds and

screens always consult the motor

manufacturer’s instructions.

To ensure that the cable clamping operates

satisfactorily the cabling both supplying

the module and to the load should be a

minimum of 0.5mm

insulation and the wires should be stripped

to ensure that the cable bar within the

terminal cover clamps firmly on both

of insulation.

To install a Rako RACUB module isolate

the supply then remove the Terminal

Covers, giving access to the supply

terminals. The necessary connections are

indicated on the label on the dimmer

housing. The notation is as follows:

L – Live wire from the supply (normally

coloured Brown)

N – Neutral (normally coloured Blue)

The label indicates the relay connections in

their de-energised state.

Note:

2

with double safety

sets

Once the supply and relay cables are

connected ensure that the terminal covers

are replaced and securely fastened,

clamping the cable correctly as detailed

above, before powering the unit.

Rako modules are not designed for loop

in/loop out connections. Should it be

necessary to loop the supply on to further

fittings then a junction box should be

connected in circuit to facilitate this.

With the supply and load connected and

prior to switching on the supply ensure

that the terminal covers are fitted and that

they are securely clamping the cables.

Set-up and Addressing

To avoid interference between rooms or

neighbouring installations a Rako system

should be set to an address other than the

factory default of House 1 Room 4. The

preferred addressing method is to select a

logical House address number for the

project and separate Room addresses for

each room within the house. It may also

be desirable to give each RACUB an

individual channel address within the room

(see Fig.4) if separate control of each blind

or curtain motor is required (usually from

programmable remotes via infra-red or

centralised control systems via RS232).

If the RACUB module is being installed in a

physical room with other Rako lighting

modules it may well be advisable to

Address the Lighting and RACUB modules

as separate ‘RAKO room numbers’ to allow

separate control of the blinds and lighting.

If this is the case then it is recommended

to use sequential room numbers as this

allows easier programming of a

programmable Infra Red remote at a later

stage.

Note

Page 2

Setting the address switches.

Each Rako transmitter has two, 8 way

banks of switches for setting its address.

The two sets of switches allow the user to

choose from 256 house addresses and 256

room addresses. To set the address, unclip

the rear cover whereupon the banks of

switches will be now become visible. To

set an address, use a small terminal

screwdriver or similar device and carefully

move some of the switches into the ‘ON’

position. Addressing uses binary encoding

and the value of the switches is shown in

Fig. 4.

Note: Any control panels set with the same

address will act as two or multi way

controls.

128

64

32

16

8

4

BINARY VALUE

2

1

ON

House address

= 128+16=144

Addressing Switches

HOUSE

Fig 3.

128

64

32

16

8

4

BINARY VALUE

2

1

ON

Room address

= 32+4=36.

ROOM

Notes on addressing.

A RACUB will not receive an address of

House 0 (All switches set to off)

A RACUB will respond to, but not receive

an address of Room 0 (All switches set to

off). This Room 0 address is used for

‘Master House’ control

A RACUB cannot be set to channel 0.

To program a lighting scene see Wall panel

or Hand held manual.

Channel 1 Channel 2

Blinds

House 144

Room 7

Lighting

House 144

Room 6

Channel 2

House 144

Channel 1

Room 5

Fig 4.

Addressing Example

144

To Set an Address.

RACUB modules can be addressed either

by a standard Rako RCP07 panel or an

RPS03/06 panel. Using an RCP07

individual channel addresses can be

assigned to each module. To set an

address from an RCP07 panel follow the

steps shown in ‘Initial Addressing of a

Rako Receiver Module’. To set an address

from and RPS03/06 control panel follow

the steps given in ‘Addressing from an

RPS03’.

Programming RACUB units from an RCP07

The relays in a RACUB unit can be

programmed using an RCP07 wallplate or

from RASOFT software. To program the

relay settings follow the wallplate

instructions for programming a scene.

Program the RACUB as though the level

was being set in a dimming module, the

way that the relays respond is given below.

Level

Relay A Relay B

76-100% Closed Closed

51-75% Open Closed

26-50% Closed Open

0-25% Open Open

Press and hold both

buttons for 5 seconds

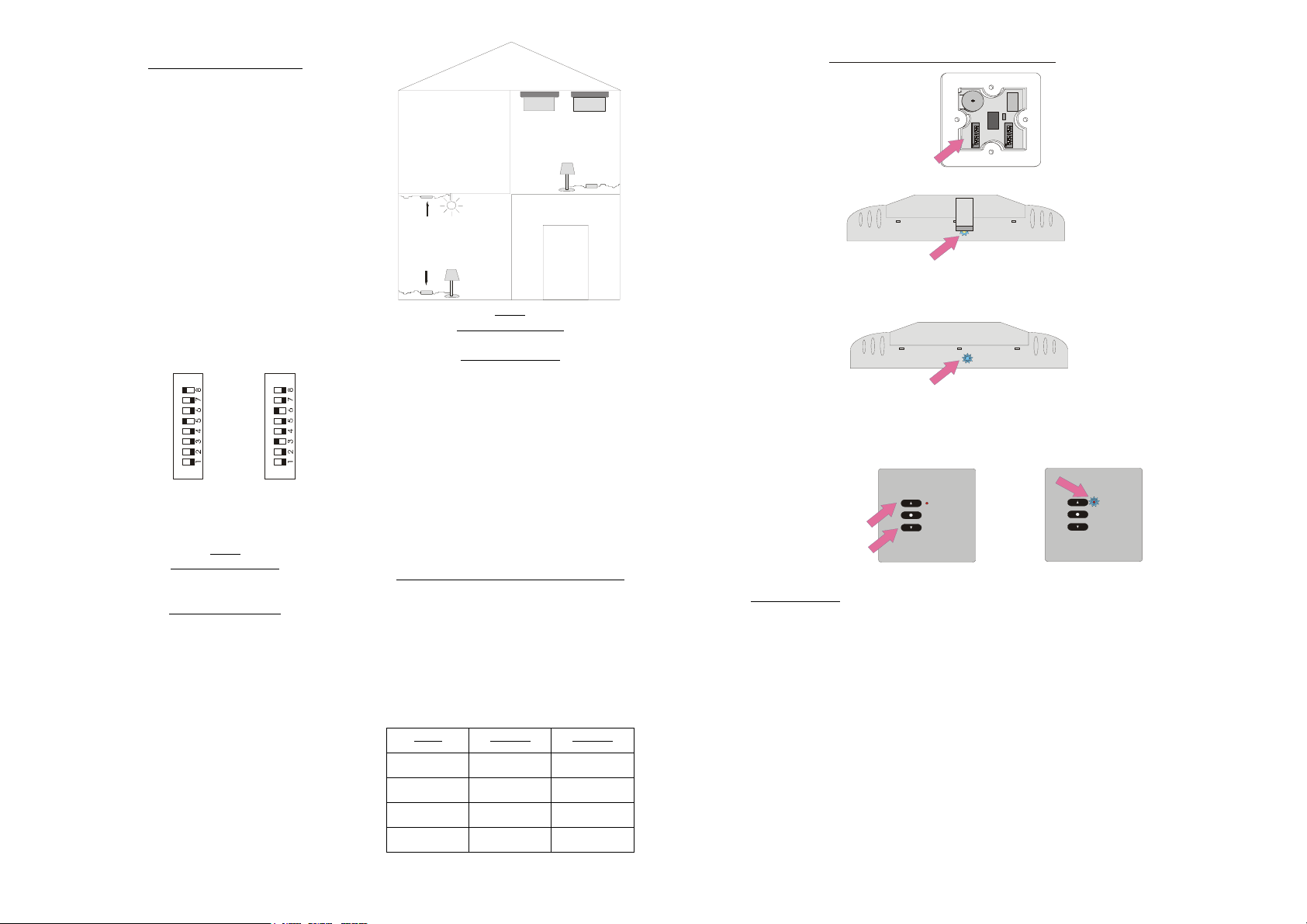

Addressing From An RPS03 Panel

Step 1

Set address

switches on

controller

Step 2

Hold magnet against casing until LED illuminates

Step 3

Remove magnet when LED starts to flash

Module is now in set-up mode

Step 4

Special Features.

The Rako RACUB module has some in-built

features and some special features that can

be set using RASOFT software, these

include.

Timeout

After 5 minutes the relays in the RACUB

module will both open. This feature allows

blinds or curtains time to travel to their full

extent but not be left with permanent

power on. If a blind/curtain motor is miswired or wired using only one relay then

this feature can cause the motor to reverse

after the time-out period. The timeout can

Magnet

LED flashes to

confirm address

command is sent

Momentary Action

This feature enables the RACUB unit to

respond to the raise/lower commands from

an RCP07 wall panel and with the motor

only operating all the time that a button is

depressed. If the latch after box is

checked then after the set period of time

the button can be released and the motor

will still operate. This feature is primarily

used for operation of Venetian blinds

where the tilt angle needs to be set by

small adjustments but latching after a short

time is desirable to fully open or close the

blinds.

be disabled using RASOFT but correct

wiring is the preferred option.

Page 3

NO

Is th e

fl ash ing )

controller

mode (re d L ED

still in programming

NO

YE S

YE S

Is there

addressed

TIP

Press the

scene button first

the room to be

another receiver in

Step 6

Press O ff bu tton

to exit controller

from programming

mode

Initial Addressing of a Rako Receiver Module

Note:

and

Step 2

Note:

Put controller into

programming mode

by pressing and holding

a scen e bu tton both

raise and lowe r b utt ons

together. After 5 seconds

the red LED on the panel

st ar ts to fl a sh . The p ane l

is now in programming

mode. Release the buttons

each

alw ays

this gives a consistent starting point.

It is not possible to give a receiver an address of Channe l 0 but

A Rako panel will enter programming mode at Channel 0.

Note:

detailed in table 1.

When in programming mode the buttons have functions as

Note

To add a new receiver to an existing installation step up through

the channels to an available channel number. It is possible to tell which

channels modules are addressed to by looking at the LED in the module.

When the channel address for a module is reached, instead of puls ing the

LED will momentarily go solid.

Step 5

Press button 3

to se nd the ident

of the cha nnel

se lec ted in st ep 3.

Re ceiver aut om atically

return s to no rm al m od e

(blue LED goes out)

while controller rem ains

in p ro g ramm ing mo de

(red LED keeps flashing)

TAB L E 1

Action

Step up one channel and ident

Step down one channel and ident

Ident

No ac tion

Exit programming

123

in programming or set-up mode. This feature avoids the possibility of either being le ft permanently in programming or s et-up mode. This may cause confusion if

In the following procedure both the controllers (wallpanels and hand held remotes ) and the receivers have an automatic time out after approximately 3 minutes when

eithe r the cont roller or receiver tim es ou t before the procedur e is complete. It is worth becoming familiar with the procedures before starting the addressing procedure.

If at any time it is necessary to start again the controllers can be returned to normal mode by pressing the ‘Off’ button and the re ce ive rs by res et t in g the e le ctr ical s upp ly.

Step 1

Set address

switches on

controller

Pick an Hous e address from 1-255

(keep same address for all pan els in house)

Select Room addresses from 1-255 for

room (Room 0 is master house control)

Button

4

Off

Step 3

Go to the receiver to be addressed

Hold the

magnet against casing at point indicated

Press button 1 once to step up one channel.

If this is the desired channel i.e. Channel 1(for the 1st receiver)

then go to Step 4. If not, press button 1 again to step up to

channel 2 (for the 2nd receiver), again to step to channel 3 etc,

until the desired channel number is reached (maximum = 15).

It is this channel number (along with the House and Room address)

that is sent to the re ceiver in Step 5. If at any point it is necessary to

step down a channel, press button 2 once.

Step 4

on the label until LED illuminates and keep the

If a receiver is already addressed to a

magnet held with the LED on until it starts to

flash. Then remove magnet. Module is now in

set-up mode.

controller (for example a receiver is addressed to

the controller but with the wrong channel number)

then th e LE D w ill be fla shing a s soon as the pan el

is put into programming mode. It will, however,

still be possible to re-address this receiver using

Note:

the magnet as normal.

Page 4

L,N

L,N

LN

240 v

Protected

6A Suppy

L,N

L

N

L

240 v

N

Protected

6A Suppy

Note s

L

N

LN

SUPP LY

INPUT VOLTAGE

220-240V 50Hz

CURTAIN SCREEN AND

BLIND CONTROL UNIT

M

MAXIMUM LOAD

2A PER RELAY

AB

(1)

L

(2)

L, (1), (2)

N

Link

Blue

4 Way

Junction

Black

(2)

(1)

L

Box

Brown

Note

Do not co nnect tw o

mot or s in para llel ( use

tw o RA CU B u nits )

Blue

Brown

Black

Somfy 240V

Blind Motor

(Blue, Brown, Black Cable

Connections)

Drawing T itle

Connection Diagram For RACUB to

240v Somfy Blind / Screen Motor

Drawi ng N o

RD 1005 Rev A

AG

Sca le

Date

NTS

18/3/05

Drawn

DA

Checked

Tel 0870 043 3905 Fax 0870 043 3906 www.rakocontrols.com

Note s

LN

SUP PLY

INPUT VOLTAGE

220-240V 50Hz

CURTAIN SCREEN AND

BLIND CONTROL UNIT

M

MAXIMUM LOAD

2A PER RELAY

AB

Links

L

N

Junction

Box

Somfy

240v to

12v or 24v

DC Supply

(De pend ant on

the m otor)

Somfy 24vDC

Blind Motor

Drawing T itle

Connection Diagram For RACUB to

L.V. D C Somfy M o tor

Drawi ng N o

RD 1007 Rev A

AG

Sca le

Date

NTS

18/3/05

Drawn

DA

Checked

Tel 0870 043 3905 Fax 0870 043 3906 www.rakocontrols.com

Loading...

Loading...