Page 1

Rev: V1.0

3D Printer Manual

RAISE3D PRO2 SERIES

www.raise3d.com

Shanghai Fusion Tech Co., Ltd.

4th Floor, B5 Building, No.1600 Guoquan N Rd, Shanghai, China 200438

Page 2

CONTENTS

WWW.RAISE3D.COM

AMERICA · ASIA · EUROPE

1

CONTENTS

Safty ............................................................................................................ 1

Electromagnetic Compatibility-EMC ............................................................ 5

Technical Specifications – Pro2 / Pro2 Plus ................................................. 7

Printer Components .................................................................................... 8

Spare Parts ................................................................................................ 10

Hardware Installation ................................................................................ 10

Operation .................................................................................................. 15

Wire Diagram ............................................................................................ 16

Page 3

SAFTY

Warning: Indicates a potentially hazardous situation which, if not avoided, may result in injury or

damage.

Hot Nozzle: The hot nozzle sign indicates the presence of devices with high temperatures. Always

use extra care when working around heated components. Always wear the heat resistant gloves provided in the

Starter Box.

Nozzle temperatures in the printer can exceed 300℃(572℉).

Hot Surface: The hot surface sign indicates the presence of devices with high temperatures. Always

use extra care when working around heated components. Always wear the heat resistant gloves provided in the

Starter Box.

Moving Parts: The moving parts sign indicates that a hazard exists where you touched, it can cause

serious bodily injury. Always keeps hands clear of Moving Parts.

High Voltage: The high voltage sign indicates the presence of high voltages. Always stay away from

any exposed electrical circuitry. It is recommended that all jewelry be removed.

Page 4

ELECTROMAGNETIC COMPATIBILITY

WWW.RAISE3D.COM

AMERICA · ASIA · EUROPE

3

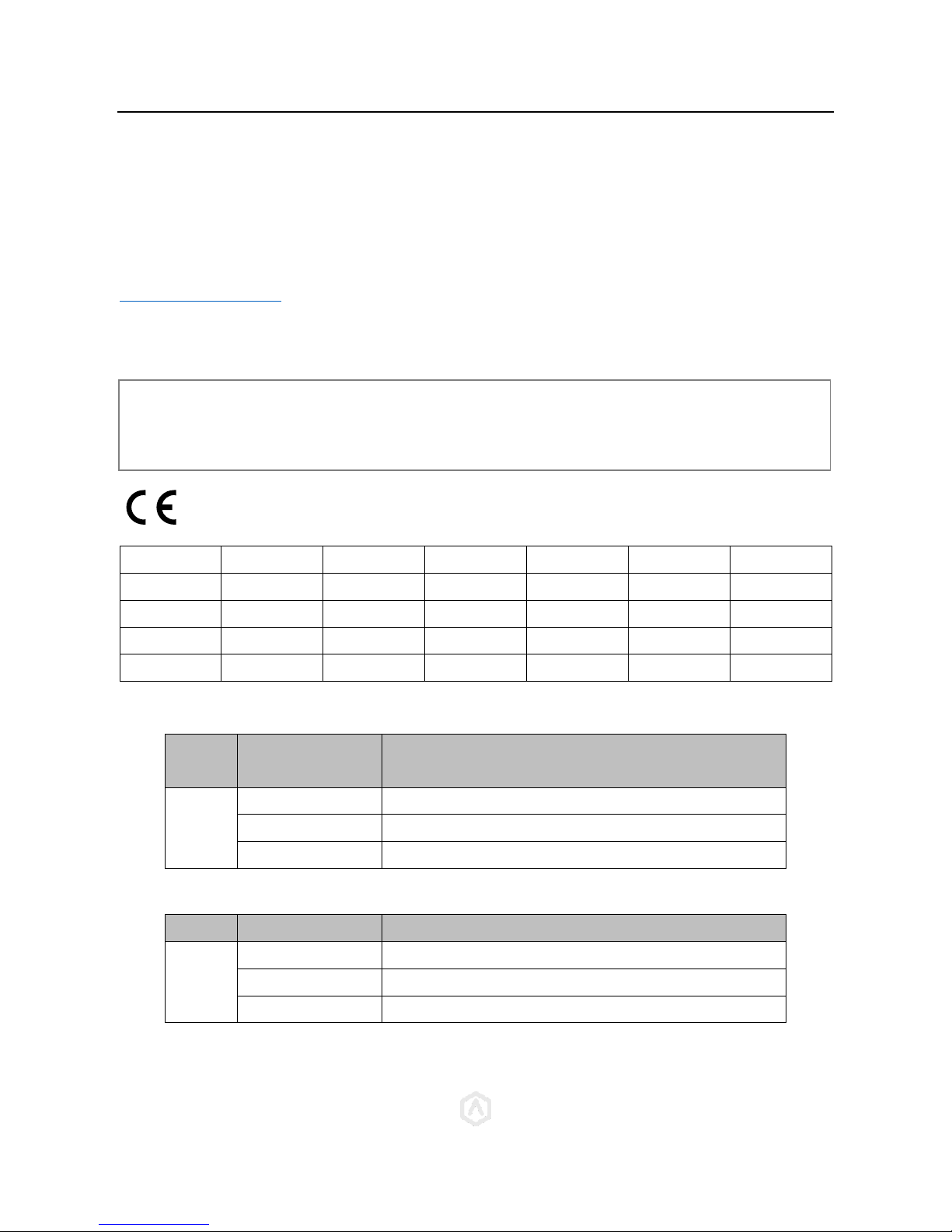

Electromagnetic Compatibility-EMC

Simplified EU Declaration of Conformity

Pro2/Pro2 Plus declares that this device is in compliance with the essential requirements and other relevant

provision of Directive 2014/53/EU.Full tex of EU declaration of conformity is available at

https://www.raise3d.com

The WIFI operation in the band 5150-5250MHz shall be restricted to indoor use for countries listed in the table

below:

AT

BE

BG

CZ

DK

EE

FR

DE

IS

IE

IT

EL

ES

CY

LV

LI

LT

LU

HU

MT

NL

NO

PL

PT

RO

SI

SK

TR

FI

SE

CH

UK

HR

Pro2/Pro2 Plus CE Output power table:

Function

Frequency

Maximum Output Power

(EIRP)

WiFi

2412-2472 MHz

18.25dBm(b)/ 16.30dBm (g)/ 15.21dBm (HT)

5150-5250 MHz

15.9 dBm(a)/ 14.71 dBm(HT20)/ 14.28 dBm(HT40)

5725-5850 MHz

15.9 dBm(a)/ 14.71 dBm(HT20)/ 14.28 dBm(HT40)

FCC Output power table

Function

Frequency

Maximum Output Power

WiFi

2412-2462 MHz

18.31dBm(b)/ 15.62dBm (g)/ 14.9dBm (HT 20)

5150-5250 MHz

15.36 dBm(a)/ 14.79 dBm(HT20)/ 14.41 dBm(HT40)

5725-5850 MHz

15.48 dBm(a)/ 14.49 dBm(HT20)/ 14.06 dBm(HT40)

CE Mark Warning

This is a Class B product, in a domestic environment, this product may cause radio interference, in which case

the user may be required to take adequate measures.

Page 5

ELECTROMAGNETIC COMPATIBILITY

WWW.RAISE3D.COM

AMERICA · ASIA · EUROPE

4

FCC Statement

This device and its antenna must not be located or operating in conjunction with any other antenna and

transmitter.

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

NOTE: The manufacturer is not responsible for any radio or TV interference caused by unauthorized modifications

to this equipment. Such modifications could void the user’s authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

RF exposure information: This equipment complies with FCC radiation exposure limits set forth for an

uncontrolled environment. This equipment should be installed and operated with minimum distance 20cm

between the radiator & your body.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

Page 6

TECHNICAL SPECIFICATIONS

Technical Specifications – Pro2 / Pro2 Plus

Item

Pro2

Pro2 Plus

Power Supply Input

100-240 VAC, 50/60 Hz 230V@3.3A

Power Supply Output

24VDC 600W

User Interface Controller

Freescale imx6, Quad core 1Ghz ARM processor

Ports

SD card*1, USB 2.0*2, Ethernet*1

Network

Ethernet

Ethernet 802.11b/g/n

WLAN

IEEE802.11b/g:2412MHz to 2472 MHz

IEEE802.11n HT20:2412MHz to 2472 MHz

IEEE802.11a:5150 - 5250MHz, 5725 -5850 MHz

IEEE802.11an HT20:5150 - 5250MHz, 5725 -5850 MHz

IEEE802.11an HT :5150 - 5250MHz, 5725 -5850 MHz

Print Technology

FDM

Build Volume (W×D×H)

Single Extrusion Print:

12×12×11.8 inch

305×305×300 mm

Dual Extrusion Print:

11×12×11.8 inch

280×305×300 mm

Single Extrusion Print:

12×12×23.8 inch

305×305×605 mm

Dual Extrusion Print:

11×12×23.5 inch

208×305×605 mm

Machine Size (W×D×H)

24.4×23.2×29.9 inch

620×590×760 mm

24.4×23.2×43.5 inch

620×590×1105 mm

Filament Diameter

0.2/ 0.4/ 0.6/ 0.8mm

Print Head Travel Speed

30 - 150 mm/s

Max Build Plate Temperature

110 ºC

Supported Materials

PLA / ABS / HIPS / PC / TPU / TPE / NYLON / PETG / ASA / PP / Glass

Fiber Enforced Carbon Fiber Enforced / Metal Particles Filled / Wood

Filled

Nozzle Diameter

0.2/ 0.4/ 0.6/ 0.8mm

Max Nozzle Temperature

300 ºC

Operating Temperature

5-35 ºC

Storage Temperature

-25°C to +55°C

Page 7

COMPONENTS AND PARTS

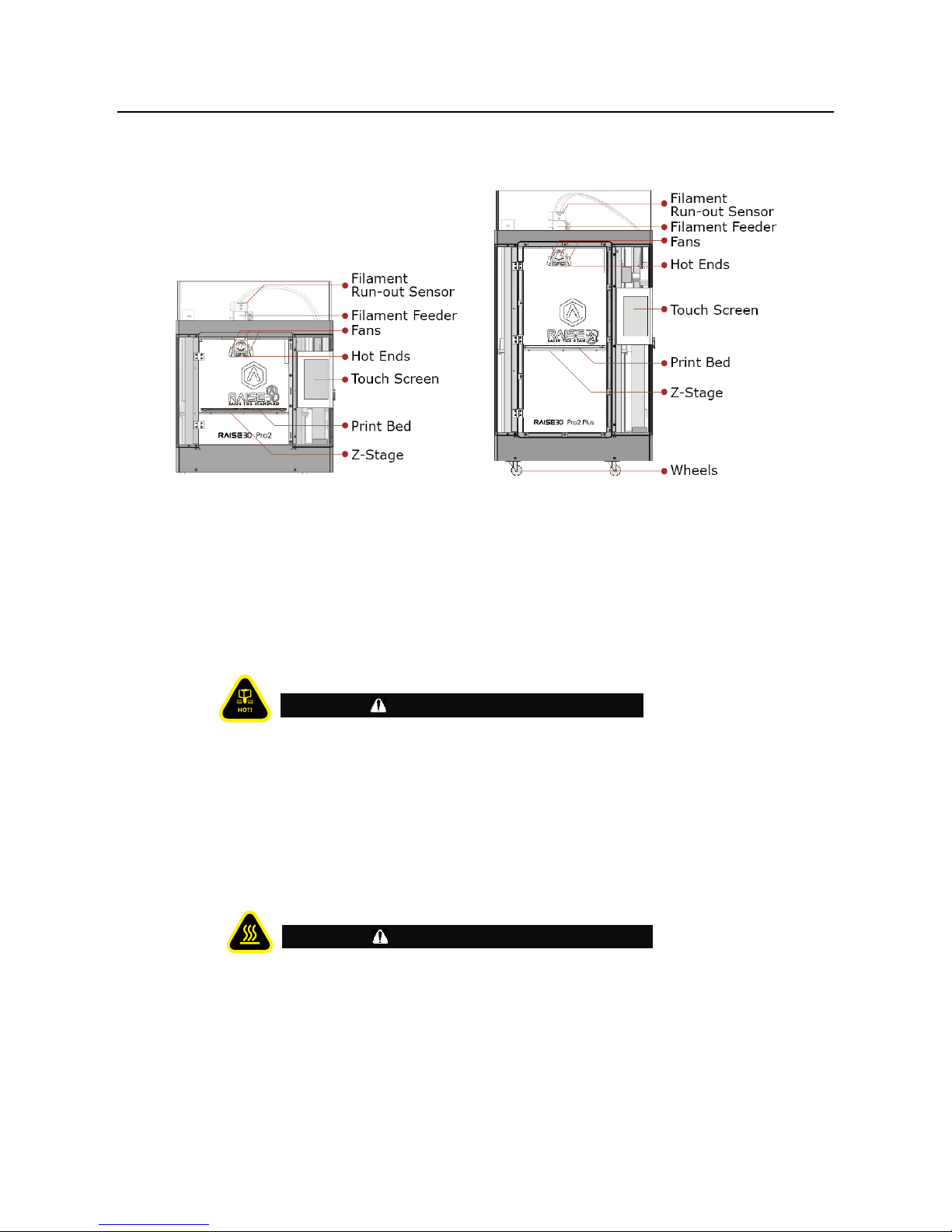

Printer Components and Parts

1. Front Parts

A Filament Run-out Sensor

That can detect whether filament has been run out.

B Filament Feeder

That’s part includes feeder motor and gear mechanical.

C Hot Ends

The hotend is made up of Nozzle,heater block, thermocouple, heater cartridge and heat sink. Nozzle

temperatures in the printer can exceed 300℃(572℉).

D Touch screen

That is human machine interface. All operation commands are from this. Some alarm information

can be displayed on the screen.

E Print bed

Print bed includes buildtak sheet and heat bed.

temperatures in the printer can exceed 110℃.

E Z-stage

That platform supports the print bed.

2. Rear Parts

WARNING

WARNING

Page 8

COMPONENENTS AND PARTS

WWW.RAISE3D.COM

AMERICA · ASIA · EUROPE

7

A Camera

That can monitor the printing process in remote place.

B Filament guide tube

This tube is perfect for minimizing bending and friction against the filament material.

C HEPA filter

That is designed to improve air quality on exhaust and deduce smell from filaments.

D Z ball screws

The parts can drive Z stage’s movement.

E USB storage slots

F Power inlet and Power switch

That is the power supply unit.

A 250V 10A fuse is located to protect the input power.

3. Bottom Parts.

Page 9

COMPONENENTS AND PARTS

WWW.RAISE3D.COM

AMERICA · ASIA · EUROPE

8

4. Electrical Parts

Page 10

SPARE PARTS

Spare Parts

Page 11

PRECAUTION AND INSTALLATION

Read the entire installation section before starting installation.

Connect equipment to a grounded facility power source. Do not defeat or bypass the ground lead.

• Know the location of equipment branch circuit interrupters or circuit breakers and how to turn them

on and off in case of emergency.

• Know the location of fire extinguishers and how to use them. Use only ABC type extinguishers on

electrical fires.

• Know local procedures for first aid and emergency assistance at the customer facility.

• Use adequate lighting at the equipment.

• Maintain the recommended range of temperature and humidity in equipment area.

• Do not use this product in an environment containing volatile or flammable compounds.

ENVIRONMENTAL REQUIREMENTS

• The 380mc and 450mc are for indoor use only.

• Air quality conditions with excessive solid particulates (conductive or

non-conductive) may result in system damage.

• Air quality conditions in which airborne oils are allowed to accumulate on or within the printer

can damage the plastic components.

• Operating temperature shall be in the range of 5°C to 35°C, with relative

humidity range of 30% to 70% non-condensing.

• Storage temperature shall be in the range of -40°C to 55°C, with relative

humidity range of 10% to 85% non-condensing.

• Altitude shall not exceed 6561.68 feet (2000 m).

• Noise emission (acoustic):

• <50dBA when building

Note: The 380mc and 450mc printers are capable of generating vibrations depending mainly on part build

geometry and material characteristics. This consideration will need to be taken into account if locating the printer

near vibration sensitive equipment.

Input Supply Connection

Installation and mains outlet socket shall be made and protected according to appropriate rules. Check the input

voltage, phase, and frequency supplied to this machine before turning it on. Verify the connection of grounding

wires from the machine to the input source. The allowable input voltages are 1x(90-240)V 50Hz/60Hz. For more

information about input supply refer to the technical specification section of this manual and to the rating plate of

AWARNING

Page 12

PRECAUTION AND INSTALLATION

WWW.RAISE3D.COM

AMERICA · ASIA · EUROPE

11

the machine. Make sure the amount of power available from the input connection is adequate for normal

operation of the machine.

After connecting the input cord to the machine, make the power switch on, the Pro2 / Pro2 Plus printer will start

to work.

Hardware Installation

Recommend to unclip the Zipties as you are able to

reuse the ties later.

Please remove the 24 clips holding the extruder

assembly in place before powering on your printer. If

you fail to remove these clips your printer will be

damaged. Please save these clips and re-install them

when you transport your printer.

Use the 3mm hex wrench to remove the Z axis clamps

on both Z axis ball screws.

The 3mm hex wrench is packed inside the tool box

located inside the top foam.

Page 13

PRECAUTION AND INSTALLATION

WWW.RAISE3D.COM

AMERICA · ASIA · EUROPE

12

Plug the machine into a wall outlet and power on. The

power cable is packed inside the tool box located inside

the top foam.

The printer will go through a start-up sequence. When

the touch screen displays "Home", the printer is ready.

Go to "Utilities" and press Z homing button to home

the Z print bed to origin position.

Take the starter box and filament box out from the

base of the printer. And open for standby.

Page 14

PRECAUTION AND INSTALLATION

WWW.RAISE3D.COM

AMERICA · ASIA · EUROPE

13

Select "10mm" for "Move Steps" and move Z platform

downward to 50mm.

Loose the two thumb screws in front of the build plate

with anti-clockwise rotation.

Take build plate off from the protective cover.

Please remove the leveling testing model carefully

from the build plate.

Page 15

PRECAUTION AND INSTALLATION

WWW.RAISE3D.COM

AMERICA · ASIA · EUROPE

14

Slide the build plate onto the Z platform. Face the

surface with Raise3D logo up.

Re-install the thumb screws back with clockwise

rotation.

Install the filament holder in the mount point on the

side of the printer and place a spool of filament on the

holder.

NOTE: The direction of filament spool should be placed

to rotate in clockwire at mount points B and D and

counterclockwise at mount points A and C.

Feed the filament through the guide tube.

Page 16

PRECAUTION AND INSTALLATION

WWW.RAISE3D.COM

AMERICA · ASIA · EUROPE

15

Press the “Utilities” menu on the screen and set the

temperature of the left nozzle for the filament, then

press the “Load” button. Finish the feeding operation

step by step according to the instructions on the

screen.

NOTE: This document is set based on the Raise3D PLA

filament, which is delivered together with the printer.

Therefore we advise that you use this PLA for testing.

Page 17

OPERATION

Operation

Even though Pro2/Pro2 Plus is preleveled in the

factory, please press X/Y axis ‘home’ button first and

then Z axis 'home' button to check whether the leveling

is changed during shipping.

Select "10mm" for "Move Steps" and move X to 50mm,

Y to 10mm.

Please use the feeler gauge to check the distance

between nozzle and printing platform. The optimal

distance between is 0.2mm.

The best condition of this is that you can feel a little

friction when you slide the feeler gauge into the gap.

The distance between the nozzle and the printing

platform can be adjusted by turning the thumb screw

on the left-front corner of the Z-plate, the higher the

screw stands out, the further the distance between the

nozzle to the printing platform gets.

The USB storage included with the printer comes

loaded already with sliced models. It is a good place to

start for your first print.

Insert the USB storage into the USB slot on the side of

touchscreen.

Page 18

OPERATION

WWW.RAISE3D.COM

AMERICA · ASIA · EUROPE

1

Select “Print” menu, choose “USB Storage” in the file

storage path. Select the file to check the printing

parameters and settings, then press “Print” to start

printing test file.

During printing, you can check status, printing time

remaining and other parameters from the touchscreen

in the “Home” interface.

NOTE: The image on the touch screen will only be

shown when the file is sliced by ideaMaker.

The .data file is saved in USB storage or uploaded to

screen.

WLAN Connection:

You can choose a network to join by inputting the password. When the WIFI module is manufactured, 2.4G is set

at HT20, 5GHz is set at HT40. The wifi’s frequency is fixed before being manufactured. The customer is not

allowed to modified WIFI’s parameter. If there’s needed, please connect Raise 3D.

Page 19

OPERATION

WWW.RAISE3D.COM

AMERICA · ASIA · EUROPE

2

Or Add Other Network with inputting its name and password.

Figure 1.40: Inputting Network’s Name

Page 20

WIRE DIAGRAM

Wire Diagram

MOTION CONTROL BOARD

SCREEN BOARD

SCREEN

Extruder board

CAERA

-12V+ -12V+ -12V+

+24V-

+24V-

+24V-

+

-

PRO2 / Pro2 Plus WIRE DIAGRAM

Raise3d

WIFI

Antenna

Page 21

WWW.RAISE3D.COM

AMERICA · ASIA · EUROPE

1

NOTES

Loading...

Loading...