Page 1

Pro2-Series 3D Printer

Quick Start Guide

* Please review this entire guide before operating the printer.

Pro2 Pro2 Plus

Page 2

The contents of this Quick Start Guide may be updated over time. For the latest

version, scan the QR code or visit the link below.

www.raise3d.com/pages/download#down-quickguide

Page 3

A. List of Parts

Pro2

Filament

Run-out Sensor

Filament Feeder

Fans

Hot Ends

Touch Screen

Pro2-Series 3D Printer

/ Quick Start Guide

Camera

Filament

Guide Tube

HEPA Filter

Z Ball Screws

Pro2 Plus

Print Bed

Z-Stage

Filament

Run-out Sensor

Filament Feeder

Fans

Hot Ends

Touch Screen

Print Bed

Z-Stage

Wheels

USB Storage Slots

Power Inlet

Ethernet Interface

Power Switch

Camera

Filament

Guide Tube

HEPA Filter

Z Ball Screws

USB Storage Slots

Power Inlet

Ethernet Interface

Power Switch

01 02

Page 4

Pro2-Series 3D Printer

/ Quick Start Guide

B. Hardware Installation

1

Remove!

Locate the four shipping zip ties, and

remove them.

It's recommend to unclip these as opposed

to cutting. They can be reused if you need

to transport your machine in the future.

3

2

Remove!

(×24)

Peel the yellow sticker and remove the 24

security spacers.

These clips are designed to hold the

extruder assembly in place during shipping

and should be saved for future transport.

Do not operate printer with clips installed.

4

Remove!

(×2) Hex Wrench

Select the largest of the included hex head

wrench (3mm), and remove all four hex

head security bolts from Z-axis clamps (2

bolts each).

These are located on the left and right

sides on the printer on the ball screw

thread.

(3 mm)

Plug the machine into a wall outlet using

the power adapter for your designated

country. (5 included)

Flip the switch to power the unit on.

Page 5

Pro2-Series 3D Printer

B. Hardware Installation (continued)

/ Quick Start Guide

5

6

Once the unit has been powered, the

printer will go through a start-up sequence.

Your Raise3D printer will take approximately 60 seconds to boot up. When the touch

screen displays the "Home" screen, the

printer is ready.

Open the "Utilities" tab, and press the Z

Homing button.

OK the request, and the print bed will

begin to “home” or move to the origin

position.

This will also allow you to access your

accessory packages.

7

Open the front door, and remove the

starter box and filament box from the base

of the printer.

Open these packages, and compare with

the following contents list.

03 04 05 06

Page 6

Pro2-Series 3D Printer

/ Quick Start Guide

B. Hardware Installation (continued)

List of Contents

3mm

2.5mm

2mm

1.5mm

Power Cable

(×5)

USB Storage

Nozzle

Cleaning Kit

Hex Wrenches

Heat Resistant Gloves

15A

10A

Tweezers

Fuse

Filament

(×2)

Filament Holder

(×2)

Thumb Screws

(Spare)

Build Plate

(with Build Surface

inside Protective Cover)

Spatula

Other Accessories

(Spare)

04 05 06

Page 7

Pro2-Series 3D Printer

B. Hardware Installation (continued)

/ Quick Start Guide

8

Lower the Z platform by 50mm.

To do this, set the interval at "10mm" by

selecting it in the "Move Steps" bar. This

will move the bed 10mm per arrow click.

Click this downward arrow 5 times to move

Z platform downward to 50mm.

10

Protective Foam

Cover

Build Plate

Remove!

9

Loose the two thumb screws on the Z

platform by rotating the two thumbscrews

counter-clockwise.

11

Remove the aluminum build plate from the

foam packaging.

Using the included spatula, remove the

leveling calibration model from your build

plate.

05 06

Page 8

Pro2-Series 3D Printer

/ Quick Start Guide

B. Hardware Installation (continued)

12

13

Slide the build plate onto the Z platform

with the logos facing upwards, and the

handle edge facing the front of the

machine.

Re-install the thumb screws, rotating

clockwise, to lock the build plate into

position.

06

14

A B

Mount Points

C D

Open the side door of the printer, and

install the filament holders into the

mounting points. Open one of the included

spools of filament, and place it on the

holder.

NOTE: The direction of filament spool should be

placed to rotate in clockwise if at points B and D,

and should be oriented to rotate counterclockwise at mount points A and C.

Page 9

Pro2-Series 3D Printer

B. Hardware Installation (continued)

/ Quick Start Guide

15

16

Locate the open end of the filament, and

feed it through the guide tube.

Press the “Utilities” tab on the screen and

set the temperature of the left nozzle for

the filament that you're using.

Press the “Load” button and the printer will

begin to heat. When the target temperature is reached, press "Load". Complete

the feeding operation according to the

instructions on the screen.

NOTE: This document's instructions are based on

the properties of Raise3D PLA filament. This is

the standard filament included with your product

and it is advised to use the Raise3D PLA for

testing and initial setup.

07 08 09 10

Page 10

Pro2-Series 3D Printer

/ Quick Start Guide

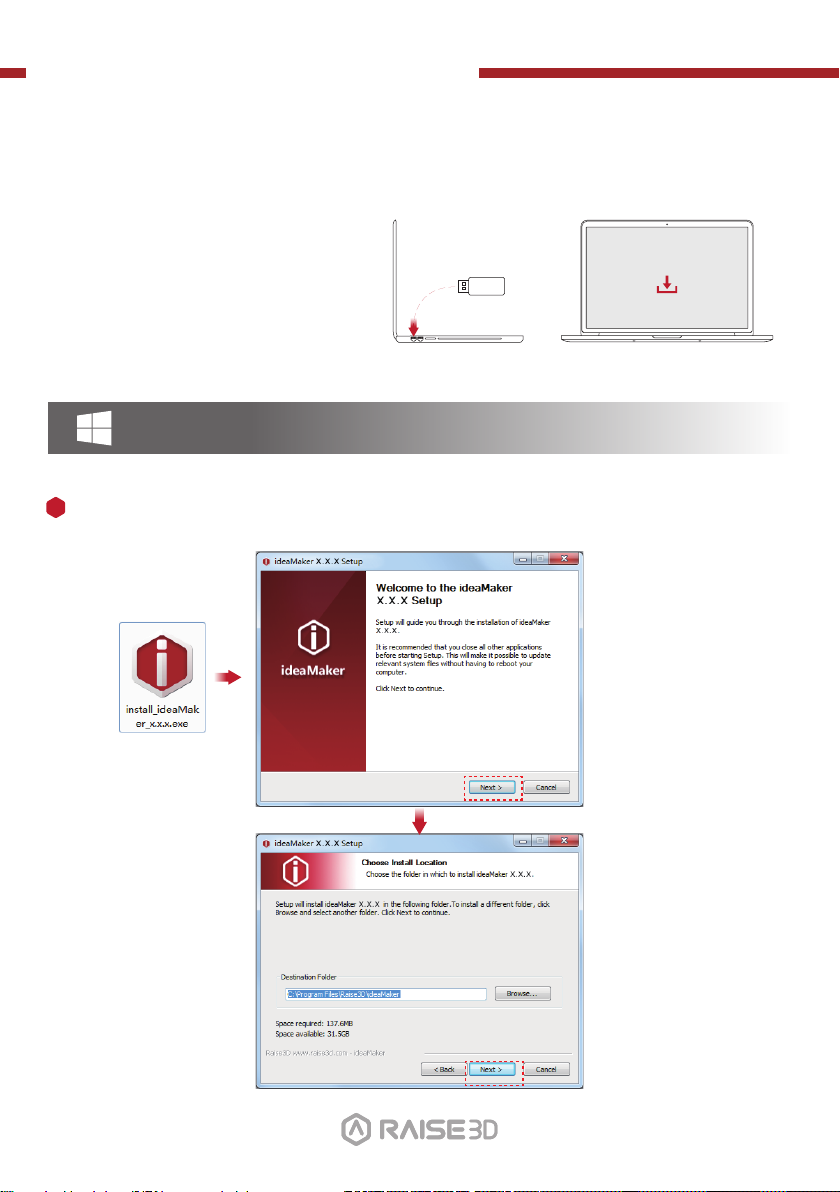

C. ideaMaker Installation

The ideaMaker slicing software is

available on the USB storage drive

included with your printer.

Additional downloads and versions

are available online at:

www.raise3d.com/

pages/download

WINDOWS

1

Open the installer and choose your preferred language. Select the installation location

for ideaMaker, and click "Next".

www.raise3d.com

Download ideaMaker

08 09 10

Page 11

Pro2-Series 3D Printer

/ Quick Start Guide

C. ideaMaker Installation (continued)

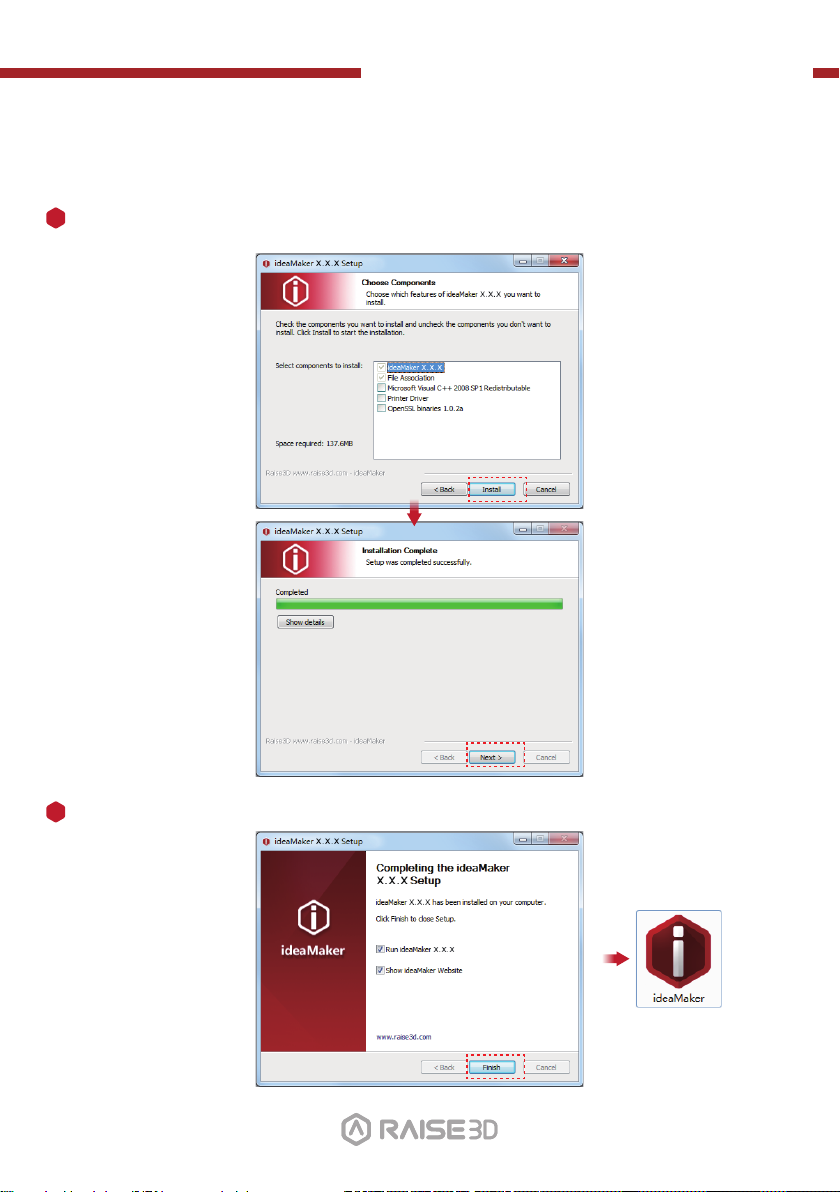

2

Follow the instructions provided by the console, and click "Install". After the installation

is finished, click "Next" to go to the next step.

3

Click "Finish" and ideaMaker is installed.

09 10

Page 12

Pro2-Series 3D Printer

/ Quick Start Guide

C. ideaMaker Installation (continued)

MAC OS X

Open the Disk Image for the ideaMaker installer. This is located in the USB storage drive

included with your printer, or download the latest version from

www.raise3d.com/pages/download#down-im.

Drag the ideaMaker icon(left) into the Application folder on the right side.

10

Page 13

Pro2-Series 3D Printer

/ Quick Start Guide

D. ideaMaker Initial Settings

1

When launching ideaMaker for the first time you, you will need to select your printer

model from the drop-down list, then press "Next".

2

Select the diameter of your filament. Press "Finish" to finalize the initial settings.

NOTE: ALL Pro2-Series printers use 1.75mm filaments.

11 12 13 14

Page 14

Pro2-Series 3D Printer

/ Quick Start Guide

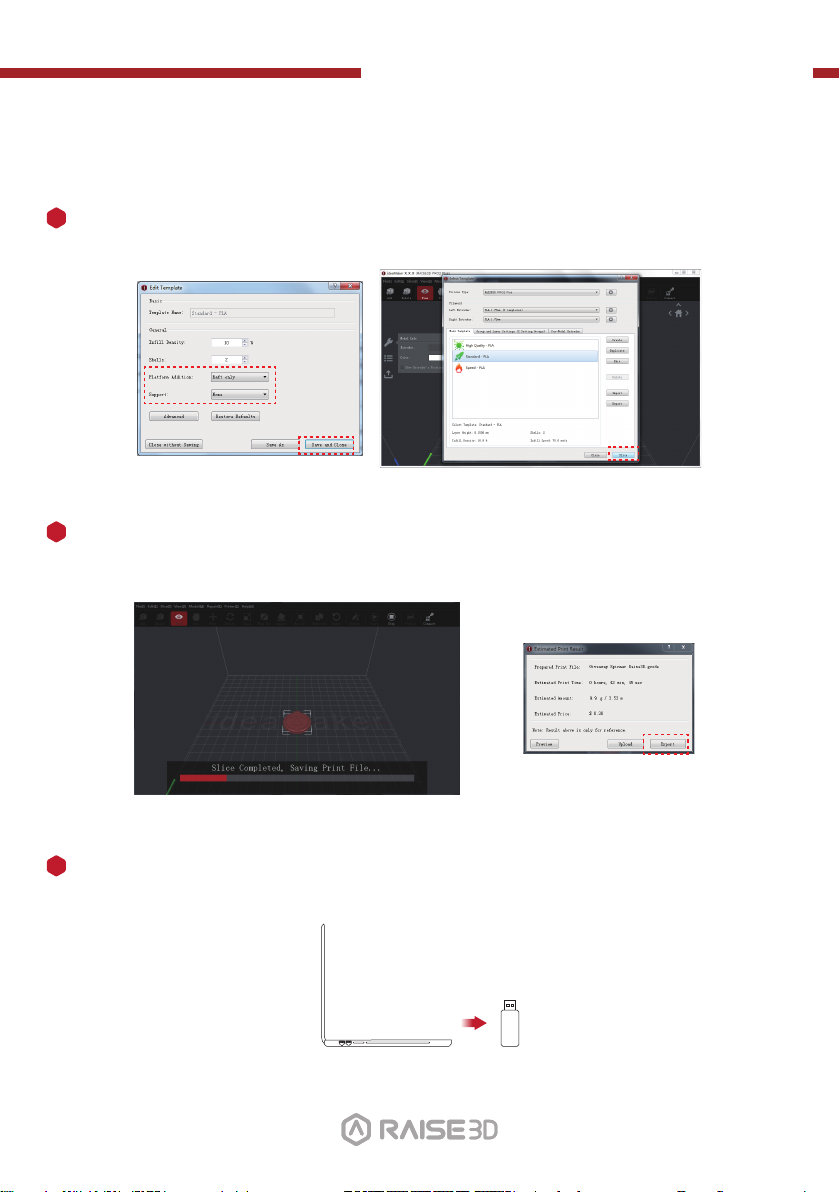

E. Using ideaMaker

1

Click the "+" button to import “Giveaway Spinner” included in the USB storage.

2

Click the "Start" or “ ” button to begin slicing the model.

3

Confirm your printer type and material are correct, then select the standard slicing

template.

Click “Edit” to select the type of Platform Addition and the type of Support.

12 13 14

Page 15

Pro2-Series 3D Printer

/ Quick Start Guide

E. Using ideaMaker (continued)

4

Select your type of Platform Addition and Support in the "Edit" window. Click "Save

and Close" to return to the previous menu. Click "Slice" to generate your file.

5

Save the sliced files (.gcode and .data) by exporting to the USB storage drive.

NOTE: File names that do not conform to the Western Latin character set may not

display properly.

6

Confirm that the files are saved and eject the USB storage.

13 14

Page 16

Pro2-Series 3D Printer

/ Quick Start Guide

F. Start First Print

1

2

3

0.2mm

The Pro2/Pro2 Plus units are preleveled in the

factory, but we recommend verifying that the

leveling has not changed during shipping.

First, home the X/Y Axis by selecting the

"home" button, then Z axis "home" button.

If the homing procedures complete without

issues, reposition the print head.

Select "10mm" for "Move Steps" and move X to

50mm, Y to 10mm.

Please use the feeler gauge to check the

distance between nozzle and printing platform.

The optimal distance between is 0.2mm.

The best condition of this is that you can feel a

little friction when you slide the feeler gauge

into the gap.

Feeler Gage

The distance between the nozzle and the

printing platform can be adjusted by turning the

thumb screw on the left-front corner of the

Z-plate, the higher the screw stands out, the

further the distance between the nozzle to the

printing platform gets.

14

Closer Further

Page 17

Pro2-Series 3D Printer

F. Start First Print (continued)

/ Quick Start Guide

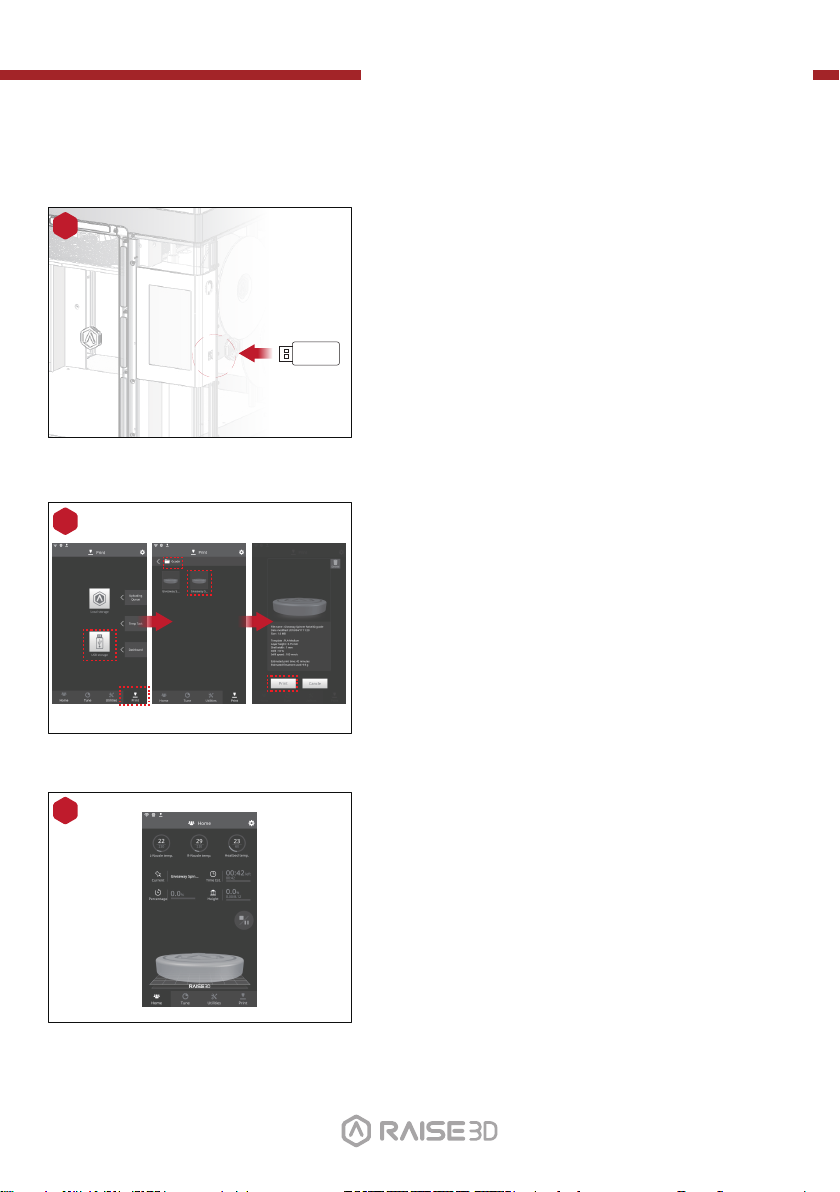

4

USB Storage

5

Insert the USB storage that contains your sliced

model (.gcode and .data files).

Insert this USB drive into the USB slot on the

side of touchscreen.

Select the “Print” tab, and choose “USB Storage”.

Select the file and check the printing parameters

and settings. Press “Print” to start printing the

test file.

6

During printing, you can check the status of your

print including printing time remaining and other

parameters from the touchscreen in the “Home”

interface.

NOTE: The touch screen will display an image of your

model on-screen during printing. This image will only be

shown when the file is sliced by ideaMaker and the

.data file is saved in USB storage or uploaded to screen.

15 16 17 18

Page 18

Pro2-Series 3D Printer

/ Quick Start Guide

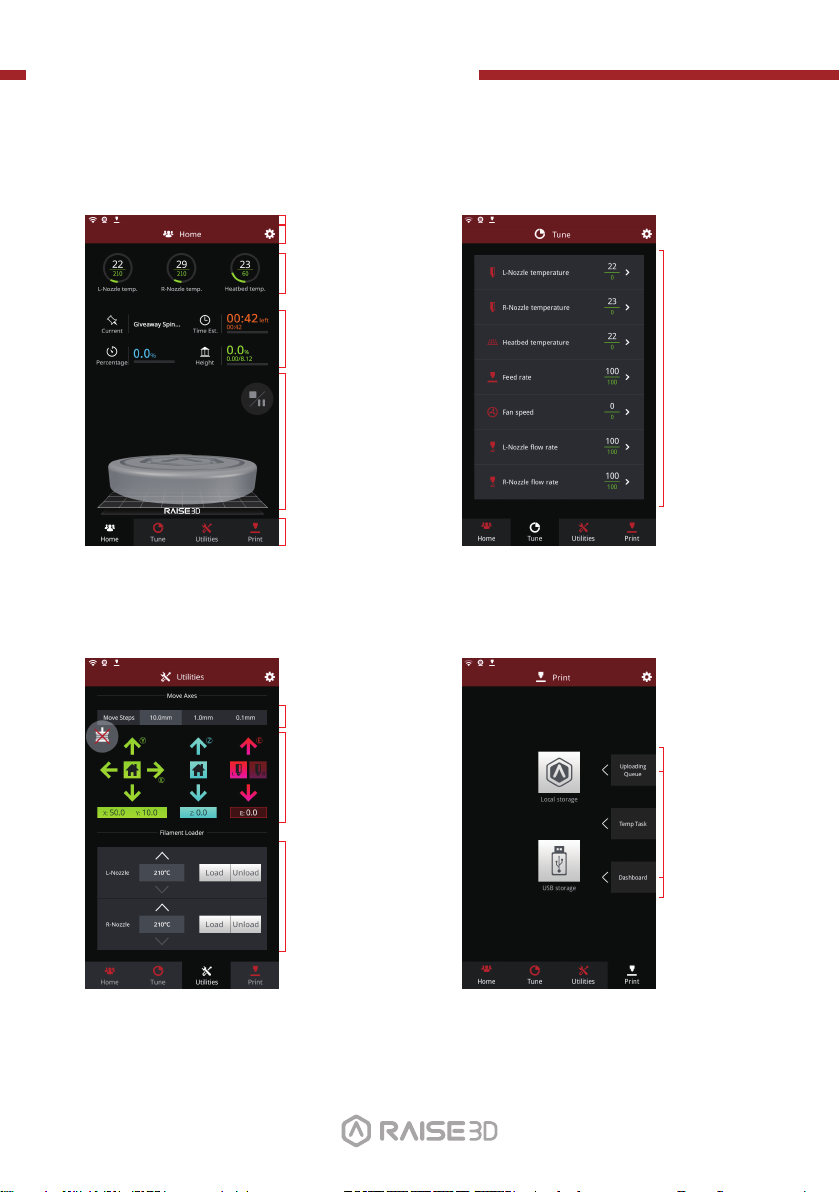

G. User Interface

Home Tune

· Status bar

· Menu title, Settings Button

· Extruder and Heat

Bed temperature

· Current model name,

total print time, current

printing status and height

· Visual display of current

model

· Pause/Resume button

· Stop button

· Taskbar

· Printing

parameters and

adjustment

· Moving step distance

setting

· Disable motor button

· X/Y/Z axes move/return

to original position

· Load and unload

function for the L&R

extruders.

· Choose where to

load the print job

from

· Check uploading

list, recovery task

list, printing

statistics

Utilities Print

16 17 18

Page 19

Pro2-Series 3D Printer

/ Quick Start Guide

H. Dual-Extruder Print - Slicing

1

Open ideaMaker, Click the "+" button to import your two models (.stl/.obj/.3mf file). You

can download a file or use the test model included in the USB storage drive.

Choose one of the models and set its designated Extruder as Left Extruder from the

2

left side 'Model Info' window.

17 18

Page 20

Pro2-Series 3D Printer

/ Quick Start Guide

H. Dual-Extruder Print - Slicing (continued)

Choose the other model and set Extruder as the Right Extruder using the 'Model Info'

3

window.

4

Click the "Start" or “i” button to begin the slicing of the model.

5

Confirm your printer type and materials for both extruders, then select the standard

slicing template.

Click “Edit” to select the type of Platform Addition and the type of Support.

18

Page 21

Pro2-Series 3D Printer

/ Quick Start Guide

H. Dual-Extruder Print - Slicing (continued)

6

Select your type of Platform and Support in the "Edit" window. Click "Save and Close"

to return to the previous menu. Click "Slice" to generate your file.

7

Save the sliced files (.gcode and .data) to your USB storage drive.

NOTE: File names that do not conform to the Western Latin character set may not

display properly.

8

Confirm that the files are saved and eject the USB storage.

19 20 21 22

Page 22

Pro2-Series 3D Printer

/ Quick Start Guide

H. Dual-Extruder Print - Hardware Installation

The following steps show how to feed the right nozzle. For the other hardware installations

steps please see with Part B. Hardware Installation in this guide.

1

A B

Mount Points

C D

2

Install the filament holder in the mount

point on the side of the printer and place a

spool of filament on the holder.

NOTE: The direction of filament spool should be

placed to rotate in clockwise at mount points B

and D and counterclockwise at mount points A

and C.

Feed the filament through the guide tube.

20 21 22

Page 23

Pro2-Series 3D Printer

/ Quick Start Guide

H. Dual-Extruder Print - Hardware Installation (continued)

3

Open the “Utilities” tab on the screen and

set the temperature of the right nozzle for

the filament you're using, then press the

“Load” button.

Finish the feeding operation step by step

according to the instructions on the

screen.

NOTE: This document is set based on the

Raise3D PLA filament, delivered with the printer.

We advise that using the Raise3D PLA for this

initial setup and testing.

21 22

Page 24

Pro2-Series 3D Printer

/ Quick Start Guide

H. Dual-Extruder Print - Start First Print

1

2

3

0.2mm

The Pro2/Pro2 Plus units are preleveled in the

factory, but we recommend verifying that the

leveling has not changed during shipping.

First, home the X/Y Axis by selecting the

"home" button, then Z axis "home" button.

If the homing procedures complete without

issues, reposition the print head.

Select "10mm" for "Move Steps" and move X to

50mm, Y to 10mm.

Please use the feeler gauge to check the

distance between nozzle and printing platform.

The optimal distance between is 0.2mm.

The best condition of this is that you can feel a

little friction when you slide the feeler gauge

into the gap.

Feeler Gage

The distance between the nozzle and the

printing platform can be adjusted by turning the

thumb screw on the left-front corner of the

Z-plate, the higher the screw stands, the further

the distance between the nozzle will be from the

printing platform.

22

Home the Z axis after each adjustment.

Closer Further

Page 25

Pro2-Series 3D Printer

/ Quick Start Guide

H. Dual-Extruder Print - Start First Print (continued)

4

USB Storage

5

Insert the USB storage that contains your sliced

model (.gcode and .data files).

Insert this USB drive into the USB slot on the

side of touchscreen.

Open the “Print” tab, and choose “USB Storage”

to open the file storage path. Select your dual

extrusion file to check the printing parameters

and settings. Press “Print” to start printing test

file.

6

During printing, you can check the status of your

model including the remaining printing time and

other parameters from the “Home” interface on

the touchscreen.

NOTE: The touch screen will display an image of your

model on-screen during printing. This image will only be

shown when the file is sliced by ideaMaker and the

.data file is saved in USB storage or uploaded to screen.

23

Page 26

Technical Specifications

CONSTRUCTIONITEM

PRINTER

Single Print Dual Print Single Print Dual Print

12×12×11.8 inch

305×305×300 mm

24.4×23.2×29.9 inch

620×590×760 mm

Power Supply Input

Power Supply Output

Print Technology

Filament Diameter

Print Head Travel Speed

Max Build Plate Temperature

Build Plate Material

Build Plate Leveling

Supported Materials

Nozzle Diameter

Max Nozzle Temperature

Operating Sound

Operating Ambient Temperature

Pro2

11×12×11.8 inch

280×305×300 mm

Print Head

XYZ Step Size

Build Plate

Connectivity

Monitoring

Pro2 Plus

Build Volume (W×D×H)

12×12×23.8 inch

* *

305×305×605 mm

Machine Size (W×D×H)

24.4×23.2×43.5 inch

620×590×1105 mm

Universal 100-240 VAC, 50/60 Hz

600 Watts, 24 VDC

FFF

Dual-head with electronic lifting system

1.75mm

0.78125, 0.78125, 0.078125 micron

30 - 150 mm/s

Heated aluminum build plate with magnetic holding

110 ºC

Silicone

Pre-calibrated leveling

PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ NYLON/ PETG/ ASA/

PP/ Glass Fiber Filled/ Carbon Fiber Enforced/ Metal

Particles Filled / Wood Filled

0.2/ 0.4/ 0.6/ 0.8mm

300 ºC

Wi-Fi, LAN, USB port

Live camera

50 dB

15 - 30 °C, 10 - 90% RH non-condensing

11×12×23.8 inch

280×305×605 mm

24

SOFTWARE

PRINTER CONTROLLERELECTRICAL

Resume Print after Power Outage

Slicing Software

Supported File Types

Supported OS

Machine Code Type

User Interface

Screen Resolution

Motion Controller

Logic Controller

Onboard Flash

Network

Memory

OS

Ports

ideaMaker

STL, OBJ, 3MF

WINDOWS/ IOS/ LINUX

GCODE

7 inch Touch Screen

Ethernet 802.11b/g/n Wifi 2.4GHz/5GHz

Second Generation

1024*600

ATM Cortex M7.400MHZ FPU

32 bit freescale imx6, Quad core 1Ghz ARM processor

1GB

8GB

Embedded Linux

Usb2.0*2, Ethernet*1

: When you are prin ting with dual material.

Page 27

Experiencing Difficulties?

If you run into any issues during the guided setup, please contact our expert technicians by opening a ticket online at: http://help.raise3d.com.

Page 28

4th Floor, Building B5, 1600 North Guoquan Rd, Shanghai, China 200438

+86 21 65337855

43 Tesla, Irvine, CA 92618, USA

+1 888 963 9028

www.raise3d.com

Loading...

Loading...