Page 1

E2 3D Printer

Quick Start Guide

* Please review this entire guide before operating the printer.

Page 2

Raise3D E2_Quick Start Guide

CONTENTS

Safety ........................................................................................................................... 1

Electromagnetic Compatibility - EMC ........................................................................... 2

Technical Specifications ............................................................................................... 4

Printer Components and Parts ..................................................................................... 6

Raise3D Supplies and Accessories .............................................................................. 10

Precaution and Hardware Installation........................................................................ 11

Software Installation .................................................................................................. 13

WLAN Connection ...................................................................................................... 20

Maintenance .............................................................................................................. 21

Start Printing .............................................................................................................. 23

User Interface ............................................................................................................ 24

Experiencing Difficulties/Contact Information ........................................................... 25

www.raise3d.com

Page 3

Raise3D E2_Quick Start Guide

Safety

Warning: Indicates a potentially hazardous situation which, if not avoided, may result in injury or

damage.

Hot Nozzle: The hot nozzle sign indicates the presence of devices with high temperatures. Always

use extra care when working around heated components. Always wear the heat resistant gloves provided in the

Starter Box when working near the nozzle.

Nozzle temperatures in the printer can reach 300℃(572℉).

Hot Surface: The hot surface sign indicates the presence of devices with high temperatures.

Always use extra care when working around heated components. Always wear the heat resistant gloves provided

in the Starter Box when working near hot surfaces.

Moving Parts: The moving parts sign indicates that a hazard exists. If touched, it can cause serious

bodily injury. Always keeps hands clear of moving parts.

High Voltage: The high voltage sign indicates the presence of high voltages. Always stay away from

exposed circuitry. It is recommended that all conductors be removed.

- 1 -

www.raise3d.com

Page 4

Raise3D E2_Quick Start Guide

AT

BE

BG

CZ

DK

EE

FR

DE

IS

IE

IT

EL

ES

CY

LV

LI

LT

LU

HU

MT

NL

NO

PL

PT

RO

SI

SK

TR

FI

SE

CH

UK

HR

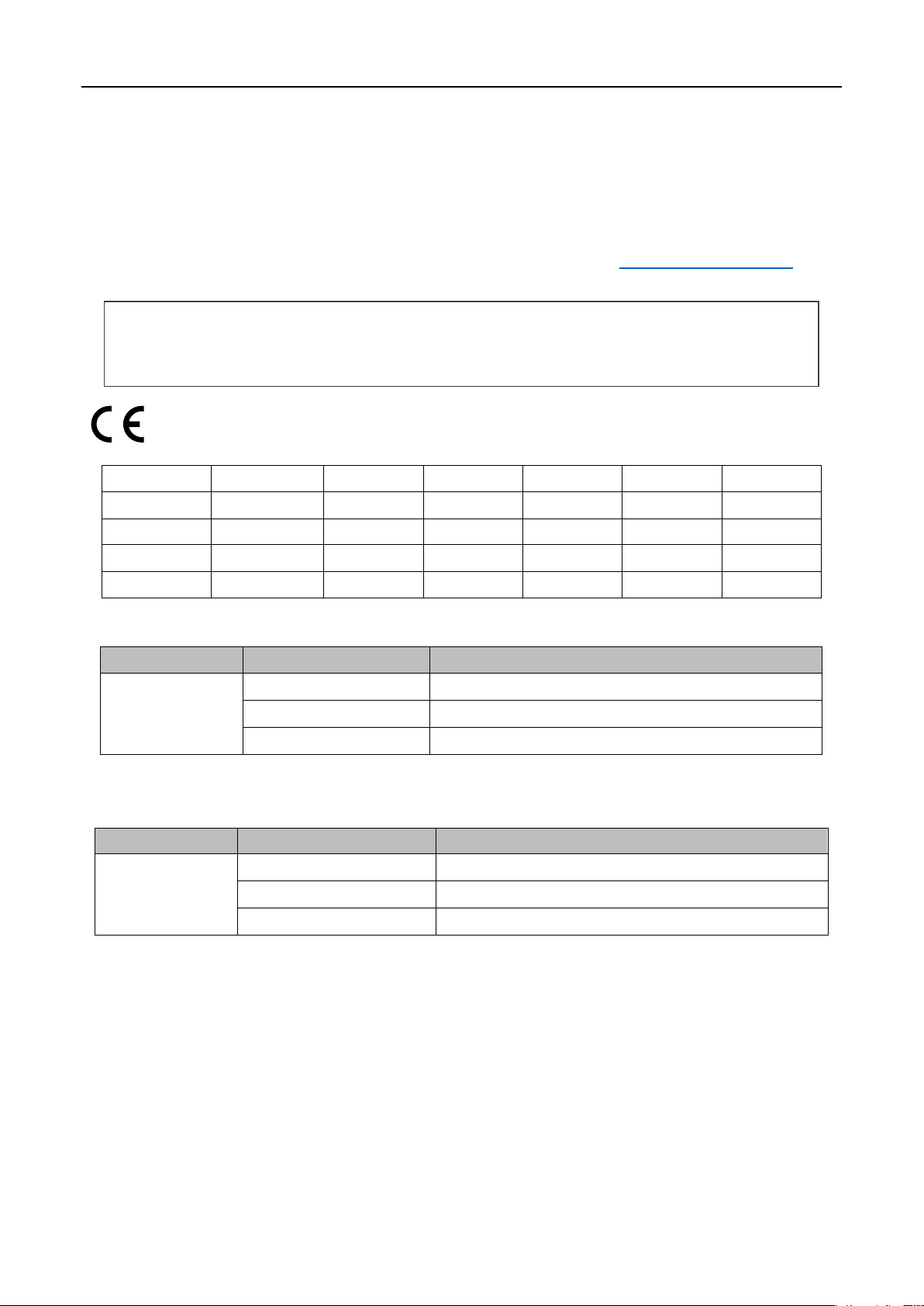

Function

Frequency

Maximum Output Power (EIRP)

Wi-Fi

2412-2472 MHz

18 dBm(b)/ 18 dBm (g)/ 13 dBm (HT)

5150-5250 MHz

19 dBm(a)/ 18.5 dBm(HT20)/ 17.5 dBm(HT40)

5725-5850 MHz

14 dBm(a)/ 14 dBm(HT20)/ 14 dBm(HT40)

Function

Frequency

Maximum Output Power (EIRP)

Wi-Fi

2412-2462 MHz

5150-5250 MHz

15.36 dBm(a)/ 14.79 dBm(HT20)/ 14.41 dBm(HT40)

5725-5850 MHz

15.48 dBm(a)/ 14.49 dBm(HT20)/ 14.06 dBm(HT40)

CE Mark Warning

This is a Class B product, in a domestic environment, may cause radio interference, in which case the user

may be required to take adequate measures.

Electromagnetic Compatibility - EMC

⚫ Simplified EU Declaration of Conformity

Raise3D declares that this device is in compliance with the essential requirements and other relevant provisions of

Directive 2014/53/EU. Full text of the EU declaration of conformity is available at https://www.raise3d.com.

CE Output power table:

FCC Output power table:

18.31dBm(b)/ 15.62dBm (g)/ 14.9 dBm (HT 20)

- 2 -

www.raise3d.com

Page 5

Raise3D E2_Quick Start Guide

⚫ FCC Statement

This device and its antenna must not be located or operated in conjunction with any other antenna and

transmitter.

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

NOTE: The manufacturer is not responsible for any radio or TV interference caused by unauthorized modifications

to this equipment. Such modifications could void the user’s authority to operate the equipment.

NOTE: This equipment has been tested and certified to comply with the limits of a Class B digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur to a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

RF exposure information: This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated at a minimum distance of 20cm between the

radiator and your body.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

- 3 -

www.raise3d.com

Page 6

Raise3D E2_Quick Start Guide

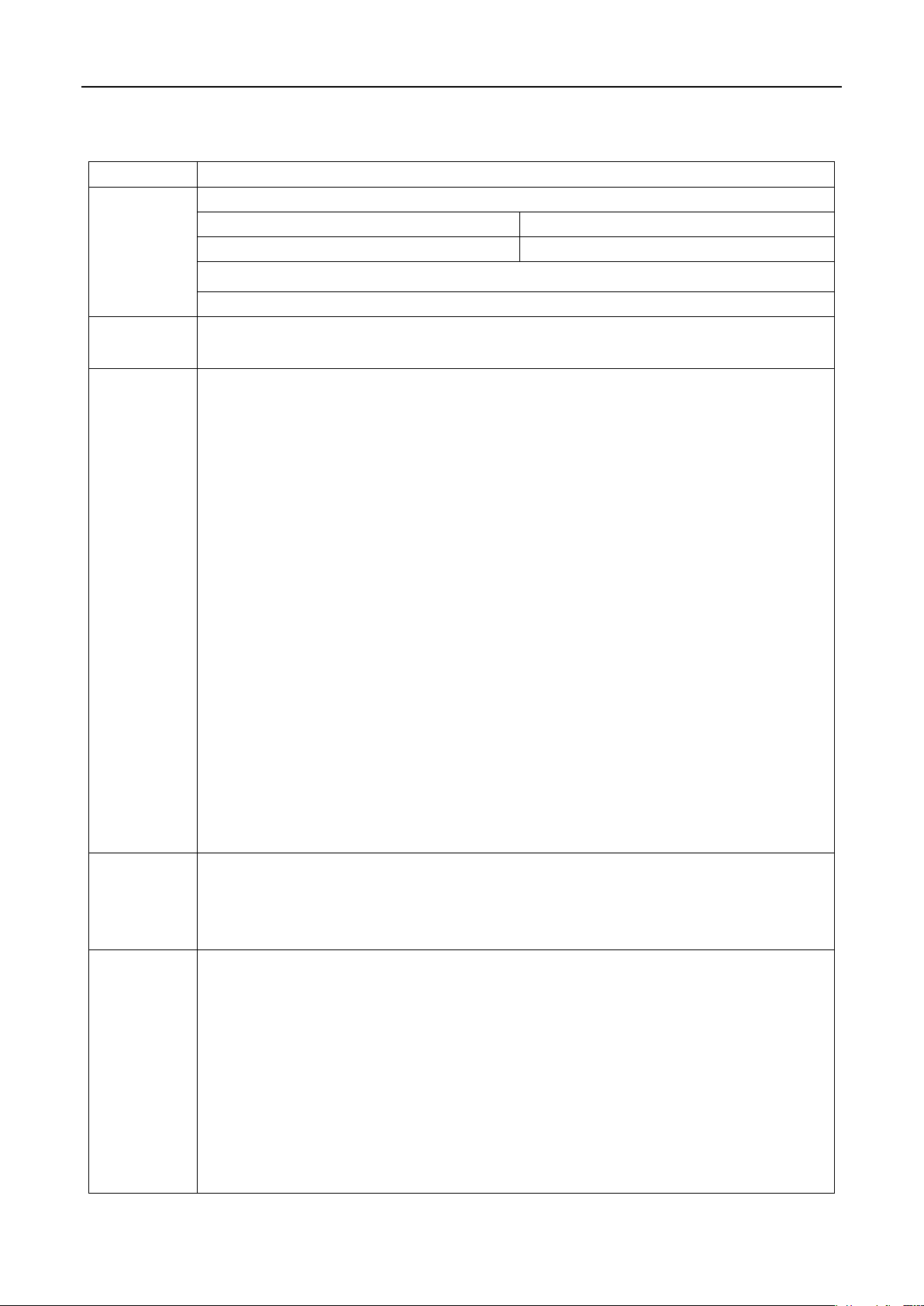

ITEM

E2

CONSTRUCTION

Build Volume (W×D×H)

Single Extruder Print

Dual Extruder Print

13.0×9.4×9.4 inch /330×240×240 mm

11.6×9.4×9.4 inch / 295×240×240 mm

Machine Size (W×D×H)

23.9×23.5×18.3 inch / 607×596×465 mm

ELECTRICAL

Power Supply Input

Power Supply Output

100-240 V AC, 50/60 Hz 230 V @2A

24 V DC,350 W

PRINTER

Print Technology

Print Head

Filament Diameter

XYZ Step Size

Print Head Travel Speed

Build Plate

Max Build Plate Temperature

Heated Bed Material

Build Plate Leveling

Supported Materials

Nozzle Diameter

Hotend

Max Nozzle Temperature

Connectivity

Noise Emission (Acoustic)

Operating Ambient Temperature

Storage Temperature

Technical Certifications

Filter

SOFTWARE

Slicing Software

Supported File Types

Supported OS

Machine Code Type

ideaMaker

STL/ OBJ/ 3MF

Windows/ macOS/ Linux

GCODE

PRINTER

CONTROLLER

User Interface

Network

Resume Print after Power Outage

Screen Resolution

Motion Controller

Logic Controller

Memory

Onboard Flash

OS

Ports

7-inch Touch Screen

Wi-Fi, Ethernet

Firmware recording, no need for battery installation

1024×600

Atmel ARM Cortex-M4 120MHz FPU

NXP ARM Cortex-A9 Quad 1 GHz

1 GB

8 GB

Embedded Linux

USB2.0×2, Ethernet×1

Technical Specifications

FFF

Independent Dual Extruders

1.75 mm

0.78125, 0.78125, 0.078125 micron

30 - 150 mm/s

Flexible Steel Plate with Buildtak

110 °C

Silicone

Mesh-leveling with Flatness Detection

PLA/ ABS/ HIPS/ PC/ TPU/ TPE/ NYLON/ PETG/ ASA/ PP/ PVA/ Glass

Fiber Infused/ Carbon Fiber Infused/ Metal Fill/ Wood Fill

0.4 mm (Default), 0.2/ 0.6/ 0.8/ 1.0 mm (Available)

V3P (V3 hotend with PTFE version)

300 °C

Wi-Fi, LAN, USB port, Live camera

<50 dB(A) when building

15 - 30 °C, 10 - 90% RH non-condensing

-25 to 55 °C, 10 - 90% RH non-condensing

CB, CE, FCC, RoHS, RCM

HEPA filter with activated charcoal

- 4 -

www.raise3d.com

Page 7

Raise3D E2_Quick Start Guide

The firmware is based on RepRapFirmware (https://github.com/dc42/RepRapFirmware)

The electronics inspired by Duet3D.

DUET 2 WIFI and DUET 2 ETHERNET LICENSE

The Duet WIFI/ DUET 2 WIFI and DUET ETHERNET are licensed under the terms of the CERL OHL 1.2 (see below or

http://www.ohwr.org/attachments/2388/cern_ohl_v_1_2.txt for full text) will the following additional conditions:

a. Attribution:

Any reproductions or modifications of the hardware must contain the following attribution on the silkscreen and

packaging:

"Based on the DuetWifi by Think3dPrint3d and Esher3d, see www.duet3d.com for the original DuetWifi

information. This reproduction/modification is not endorsed or supported in any way by Think3dPrint3d or

Escher3d".

b. Logos:

No reproduction or modification of the Duet 2 Wifi or Ethernet hardware may contain the Think3dPrint3d,

Escher3d or Duet3d logos.

Should you need any further information, please do not hesitate to email us at inquiry@raise3d.com.

- 5 -

www.raise3d.com

Page 8

Raise3D E2_Quick Start Guide

F. Power Saving Button

G. Filament Box

H. Flexible Plate

A. Air Filter Box

B. Extruder

C. Hotend

D. Platform Tray

E. Touch Screen

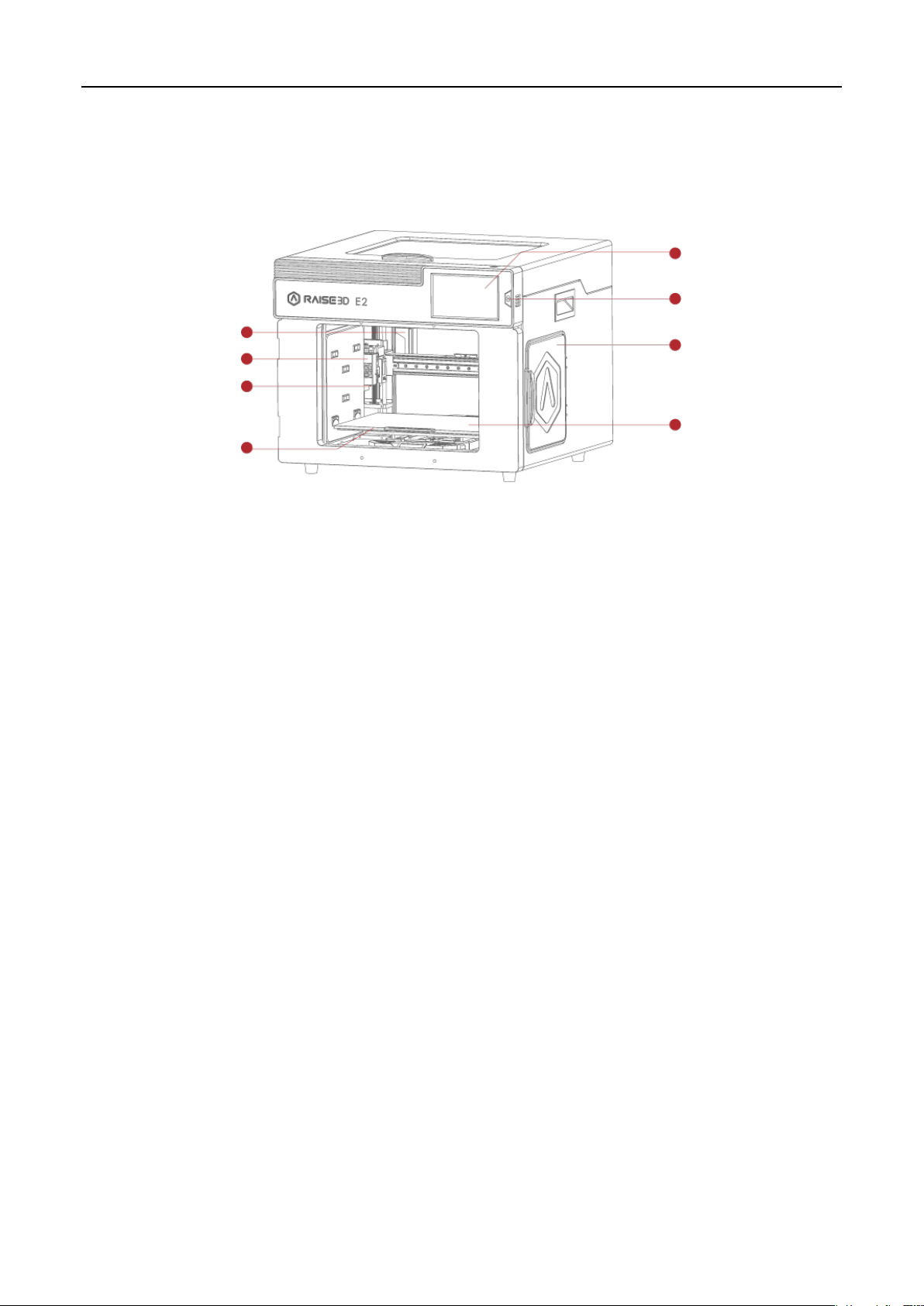

Printer Components and Parts

1. Front Parts

A. Air Filter Box

Contains the air filter, which can filter out part of the harmful gas produced in the printing process.

B. Extruder

Feeds the filament into the hotend.

C. Hotend

The hotend consists of a nozzle, heater block, thermocoupler, heater rod, throat tube, and heat sink.

D. Platform Tray

The Platform Tray is highly magnetized to ensure that the build plate stays in place.

E. Touch Screen

On-board computing system to display printer status, error messages, and receive commands.

F. Power Saving Button

Quick press to put the screen and LED in sleep/wake mode; Long press for 10 seconds to restart.

G. Filament Box

Holds the filament that will be printed.

H. Flexible Plate

You can easily remove your models after they've finished printing by bending the plate.

- 6 -

www.raise3d.com

Page 9

Raise3D E2_Quick Start Guide

F. Filament Exit

G. Filament Run-out Sensor

I. Air Filter Fan

H. Switching Power Supply

J. Ethernet Port

A. Electric Control

System

B. Camera

C. LED Light Bar

D. Filament Holders

E. Input Power

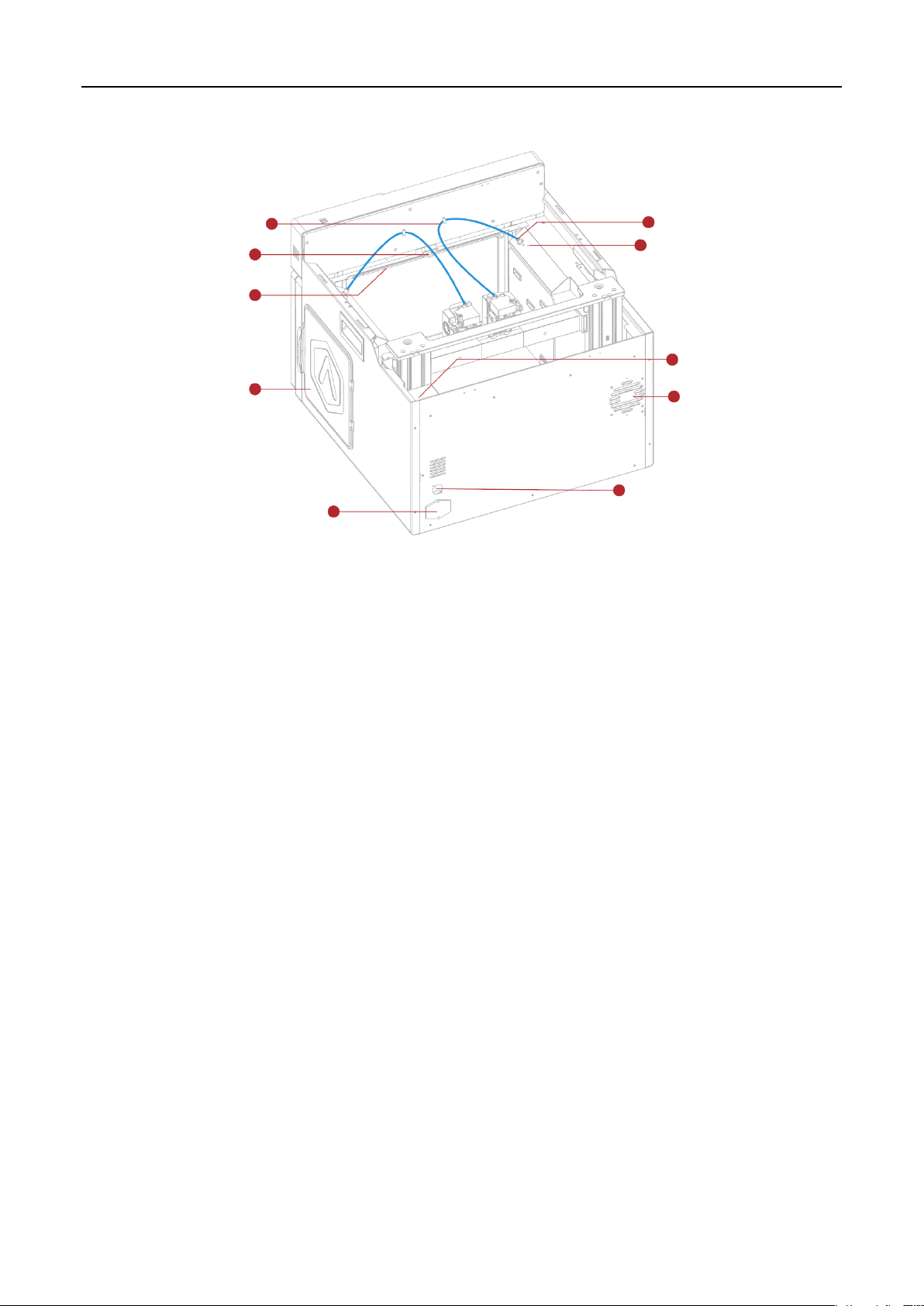

2. Back Parts

A. Electric Control System

Includes screen components and the motion control panel. Do not open without permission.

B. Camera

Used to observe the operation of the printer.

C. LED Light Bar

Provides interior lighting of the chassis.

D. Filament Holder

Holds the filament spool, maximum weight 3 kg.

E. Input Power

AC input and switching.

F. Filament Exit

The filament leads from here to the extruder.

G. Filament Run-out Sensor

Detects when the material has run out.

- 7 -

www.raise3d.com

Page 10

Raise3D E2_Quick Start Guide

H. Switching Power Supply

Switches from alternating current to direct current. Please be careful, it’s dangerous! Do not remove the

power box without permission.

I. Air Filter Fan

Pulls air out of the machine through the air filter.

J. Ethernet Port

RJ45 port to connect the printer to a network.

- 8 -

www.raise3d.com

Page 11

Raise3D E2_Quick Start Guide

D. X-axis Left Motor

A. Z-axis Endstop

Limit Switch

B. Left Extruder

B. Right Extruder

C. X-axis Guide Rail

D. X-axis Right Motor

E. Z-axis Right Motor

E. Z-axis Left Motor

C. X-axis Guide Rail

3. Other Parts

A. Z-axis Endstop Limit Switch

Limits the maximum position in the Z direction and provides a Z-axis zero reference.

B. Extruder (Left/Right)

Feeds the filament into the hotend.

C. X-axis Guide Rail

Guides the extruder’s movement along the X-axis.

D. X-axis Motor (Left/Right)

Respectively controls the corresponding extruder for horizontal movement.

E. Z-axis Motor (Left/Right)

Controls both ends of the X-axis beam for synchronous lifting movements.

- 9 -

www.raise3d.com

Page 12

Raise3D E2_Quick Start Guide

Power Cable

(×5)

Hex Wrenches

Filament

(×2)

Tweezers

Heat Resistant Gloves

Spatula

Filament

Guide Tube

(×2)

Nozzle

Cleaning Kit

(×1)

Filament Holder

(×4)

USB Storage

Fuse

0.3 mm Feeler Gauge

(×1)

Filament Box Block

(×4)

quick connector

(×2)

Plastic rivet

(×4)

Raise3D Supplies and Accessories

- 10 -

www.raise3d.com

Page 13

Raise3D E2_Quick Start Guide

WARNING

Precaution and Hardware Installation

⚫ Read the entire installation section before starting installation

Connect equipment to a grounded facility power source. Do not defeat or bypass the ground lead.

• Know the location of equipment branch circuit interrupters or circuit breakers and how to turn them

on and off in case of emergency.

• Know the location of fire extinguishers and how to use them. Use only ABC type extinguishers on

electrical fires.

• Know local procedures for first aid and emergency assistance at the customer facility.

• Use adequate lighting for the equipment.

• Maintain the recommended range of temperature and humidity in the equipment area.

• Do not use this product in an environment containing volatile or flammable compounds.

⚫ Environmental requirements

• E2 is for indoor use only.

• Excessive solids (conductive or non-conductive) in the air may cause system damage.

• The accumulation of oil in the air can damage the plastic parts of the printer.

• The operating temperature should be in the range of 15°C to 30°C, with a relative humidity range of 10% to 90%

without condensation. The storage temperature shall be in the range of -25°C to 55°C, and the relative humidity

range shall be 10% to 90% non-condensation.

• The altitude shall not exceed 2,000 meters.

• Noise (Acoustics) : <50dB(A) during printing

NOTE: E2 printers may generate vibrations which depend mainly on the geometry of parts being printed and

material characteristics. This will need to be taken into account if locating the printer near vibration sensitive

equipment. Please note that during transportation in low temperatures, there is a chance the machine may frost

or freeze. The printer can resume use after being kept 4 - 6 hours in an area that is room temperature.

⚫ Input supply connection and grounding

During installation, the main outlet socket should be protected according to appropriate rules. Check the input

voltage, phase, and frequency supplied to this machine before turning it on. Verify the connection of grounding

wires from the machine to the input source. The allowable input voltages are 1x (90-240)V 50Hz/60Hz. For more

information about input supply refer to the technical specification section of this manual and to the rating plate of

the machine. Make sure the amount of power available from the input connection is adequate for normal

operation of the machine.

- 11 -

www.raise3d.com

Page 14

Raise3D E2_Quick Start Guide

Use hands to remove the Z-axis and X-axis locks.

Please carefully store the removed locks, so that

they can be installed again and used in

subsequent transportation.

The top foam contains five power cords of

different standards. Please use the power cord

that conforms to your current country (or region)

and connect it to the power socket. Turn on the

switch and start the device.

Turn on the power and the printer will enter the

boot process. Your Raise3D printer will take about

60 seconds to boot. When the touch screen

displays the "Welcome" window, the printer is

ready. Then you can finish the installation and

first print according to the Setup guide.

⚫ Hardware Installation and First Print

- 12 -

www.raise3d.com

Page 15

Raise3D E2_Quick Start Guide

Software Installation

⚫ ideaMaker Installation

The slicing software, ideaMaker, is available

on the USB storage device included with your

printer.

Additional downloads and versions are

available online at:

https://www.raise3d.com/download/

➢ Open the installer and choose your preferred language. Select your preferred installation location for

ideaMaker, and click "Next".

- 13 -

www.raise3d.com

Page 16

Raise3D E2_Quick Start Guide

➢ Follow the instructions provided by the guide, and click "Install". After the installation is finished, click "Next"

to go to the next step.

➢ Click "Finish" and ideaMaker is installed.

- 14 -

www.raise3d.com

Page 17

Raise3D E2_Quick Start Guide

Open the Disk Image for the ideaMaker installer. This is located in the USB storage device included with your

printer. Alternatively, you can download the latest version from https://www.raise3d.com/download/.

Next, drag the ideaMaker icon(left) into the Application folder on the right side.

- 1 5 -

www.raise3d.com

Page 18

Raise3D E2_Quick Start Guide

⚫ ideaMaker Initial Settings

➢ When launching ideaMaker for the first time, you will need to select your printer model. Select "printer

setting" and choose the type of the printer you are using, then press "Next".

➢ Select the diameter of your filament. Press "Finish" to finalize the initial settings.

NOTE: ALL E2 printers use 1.75 mm filaments.

- 16 -

www.raise3d.com

Page 19

Raise3D E2_Quick Start Guide

⚫ Using ideaMaker

➢ Click the "+" button to import "Giveaway Spinner" included in the USB storage device.

➢ Click the "Start" or " " button to begin slicing the model.

- 17 -

www.raise3d.com

Page 20

Raise3D E2_Quick Start Guide

➢ Confirm your printer type and material are correct, then select the standard slicing template.

Click "Edit" to select the type of Platform Addition and the type of Support.

➢ Click "Save and Close" to return to the previous menu. Click "Slice" to generate your file.

- 18 -

www.raise3d.com

Page 21

Raise3D E2_Quick Start Guide

➢ Save the sliced files (.gcode and .data) by exporting them to the included USB storage device.

NOTE: File names that do not conform to the Western Latin character set may not display properly.

➢ Confirm that the files are saved and eject the USB storage device.

- 19 -

www.raise3d.com

Page 22

Raise3D E2_Quick Start Guide

You can connect to a network by selecting

the SSID and inputting the password. When

the Wi-Fi module is manufactured, 2.4G is

set at HT20, 5GHz is set at HT40.

Note: The Wi-Fi’s frequency is fixed before

being manufactured. The customer is not

allowed to modify the Wi-Fi’s parameters.

(If needed, please contact our tech support

team).

Alternatively, you can select "Add Other

Network" and input a name and password.

WLAN Connection

- 2 0 -

www.raise3d.com

Page 23

Raise3D E2_Quick Start Guide

The printers are pre-leveled at the factory, but

we recommend verifying that the leveling has not

changed during shipping.

How to level up the X-axis:

As shown in figure 1, click "Maintenance" to level

up the X-axis and it will touch the top beam until

horizontal.

Click the "Utilities" menu and home the Z-axis.

Press the upward arrow to lift the Z-axis about

0.3 mm-0.7 mm.

Check the distance between the nozzle and the

printing platform. After pushing the left extruder

to the center position on the platform, loosen the

nozzle screw.

Maintenance

- 2 1 -

www.raise3d.com

Page 24

Raise3D E2_Quick Start Guide

Take out the gauge from the Accessory Kit and

insert it between the nozzle and the platform.

Adjust the nozzle so that the distance between

the nozzle and the printing platform exactly

matches the thickness of the gauge (about 0.3

mm). Tighten the nozzle screw and remove the

gauge. The other nozzle is adjusted in the same

way.

Follow the steps shown in the figure on the touch

screen to run 9-point automatic leveling.

After the 9 grid interface automatically closes, the

leveling is finished.

- 2 2 -

www.raise3d.com

Page 25

Raise3D E2_Quick Start Guide

Insert the USB storage device into the USB slot on

the side of the touch screen.

Select the "Print" tab, and choose "USB Storage".

Select the file and check the printing parameters

and settings. Press "Print" to start printing the

test file.

During printing, you can check the status of your

printing, including printing time and other

parameters, from the touch screen in the "Home"

interface.

NOTE: The touch screen will display an image of

your model on-screen during printing. This image

will only be shown when the file is sliced by

ideaMaker before being uploaded to the printer.

Start Printing

- 2 3 -

www.raise3d.com

Page 26

Raise3D E2_Quick Start Guide

Home

Tune

Extruder and heatbed

temperature

Current model name

Total print time

Current print status

Print height

Status

Pause, Resume and Stop

button

Menu and Settings button

Taskbar

Visual display of the

current model

Print parameters

Move the axis

Loading/Unloading

Leveling

Visual display of X/Y/Z axes

Coordinate value and

Custom edit function

Choose the X/Y/Z axes

Move distance "Unit Settings"

X/Y/Z axes move and return

button

Disable motor button

Upload, Resume Print

Task, and Print Statistics

The storage location of the

printed file

Utilities

Print

User Interface

- 2 4 -

www.raise3d.com

Page 27

Raise3D E2_Quick Start Guide

- 25 -

Experiencing Difficulties/Contact Information

If you run into any issues during this guided setup, please contact our expert technicians by creating a ticket at

support.raise3d.com. Customers outside of the US, please contact your local Raise3D distributor or reseller.

For sales information please contact us at sales@raise3d.com.

Other inquiries: for any other inquiry please send an email to inquiry@raise3d.com.

www.raise3d.com

Page 28

US Office

43 Tesla, Irvine, CA 92618, USA

+1 888 963 9028

Netherlands Office

Stationsplein 45 Unit A4.004 3013AK Rotterdam, the Netherlands

China Office

4th Floor B5, 1688 North Guoquan Road, Yangpu District, Shanghai 200438

400 6367 888 (For the Mainland of China only)

Loading...

Loading...