Page 1

RainDrop® Sense

Operator’s Manual

Page 2

Patent, Trademarks, & Copyrights

Patent

www.raindancetechnologies.com/patents

Trademarks

RainDance Technologies, ThunderStorm, RainDrop, ThunderBolts, RainDrop Analyst II, and

RainDrop Plus and logos thereof are trademarks of RainDance Technologies, Inc. All other

brands may be trademarks of their respective holders.

Copyrights

© 2018 RainDance Technologies, Inc. All rights reserved. RainDance Technologies, Inc. owns

the copyright to the RainDance software.

Reproduction Disclaimer

You may make a reasonable number of copies of this manual for internal use only and only for

use in connection with the RainDrop Sense Instrument. All such copies shall contain the copy

right info set forth on Page ii of this manual and this reproduction disclaimer. Except as explicitly

provided by this section, neither this manual nor any part of it may be reproduced, photocopied,

or electronically transmitted in any way without the advanced written permission of RainDance.

-

Contact

RainDance Technologies, Inc.

749 Middlesex Turnpike

Billerica, MA 01821

Fax: (978) 528-6090 (support)

Web: www.raindancetech.com/support

Email: customercare@raindancetech.com

For Research Use Only. Not for use in diagnostic procedures.

Page 3

RainDrop Sense Operator’s Manual

Table of Contents

Chapter 1: Foreword 1-1

About this Manual ............................................................................................. 1-2

Intended Use..................................................................................................... 1-2

Data Entry and Collection ................................................................................. 1-2

Design Change Disclaimer................................................................................ 1-3

Reproduction Disclaimer ................................................................................... 1-3

RainDance Support........................................................................................... 1-3

Microsoft Windows Familiarity........................................................................... 1-4

Notes, Warnings, and Cautions ........................................................................ 1-4

Notes ........................................................................................................... 1-4

Warnings...................................................................................................... 1-4

Cautions....................................................................................................... 1-5

Biohazard Safety Warnings ......................................................................... 1-5

Laser Safety Warnings ................................................................................ 1-6

Safety Information............................................................................................. 1-7

Electrical Safety Warnings........................................................................... 1-7

Mechanical Safety ....................................................................................... 1-8

Gas Pressure Safety.................................................................................... 1-8

Product Labels .................................................................................................. 1-8

Safety Interlock ................................................................................................. 1-8

Packing and Transport ...................................................................................... 1-8

Chapter 2: Introduction 2-1

System Overview .............................................................................................. 2-2

RainDrop System Major Components............................................................... 2-2

RainDrop Sense Major Components ................................................................ 2-3

RainDrop Sense Layout.................................................................................... 2-4

RainDrop Sense Barcode Reader ............................................................... 2-5

RainDrop Sense Chip .................................................................................. 2-6

Handling the Sense Chip............................................................................. 2-6

RainDrop Sense Chip Compression Plate................................................... 2-7

Specifications.................................................................................................... 2-8

Chapter 3: Installation and Setup 3-1

Space Requirements......................................................................................... 3-2

Gas Connectivity.......................................................................................... 3-2

Connecting RainDrop Sense and Instrument Controller ................................... 3-3

Connecting Cables to the RainDrop Sense Instrument ............................... 3-3

Connecting Cables to the Instrument Controller.......................................... 3-4

Gas Pressure Quality ........................................................................................ 3-6

Starting Up the RainDrop Sense Instrument..................................................... 3-6

Relocating RainDrop ......................................................................................... 3-7

LCN 50-04344 Rev. D iii

Page 4

RainDrop Sense Operator’s Manual

Chapter 4: Launching the Instrument Control Software (ICS) 4-1

Introduction ....................................................................................................... 4-2

The Microsoft Windows 7 Login ........................................................................ 4-2

Starting the ICS Application .............................................................................. 4-2

ICS Login Levels.......................................................................................... 4-3

Changing the ICS Password........................................................................ 4-5

The ICS Account Types............................................................................... 4-6

ICS Initialization ........................................................................................... 4-7

Status Indicators ............................................................................................. 4-10

Using Tabs in the ICS ..................................................................................... 4-10

Navigating Through the Tabs .................................................................... 4-12

Canceling a Process.................................................................................. 4-12

Completing a Process................................................................................ 4-13

Using Scan Buttons ................................................................................... 4-13

Alarms, Log, and Status Tabs......................................................................... 4-14

Chapter 5: Performing a Sense Run 5-1

Introduction ....................................................................................................... 5-2

Gathering Supplies............................................................................................ 5-2

Starting a Sense Run........................................................................................ 5-3

Completing the ICS Setup................................................................................. 5-9

Checking the Status Indicators .................................................................... 5-9

Completing the Run Data Tab......................................................................... 5-11

Completing the Run Info Tab..................................................................... 5-14

Completing the Run Tabs Using the Import Function................................ 5-15

Using Email Notification............................................................................. 5-15

Performing the Run......................................................................................... 5-17

Canceling a Run.............................................................................................. 5-18

Handling Data ................................................................................................. 5-19

Exporting Data........................................................................................... 5-20

Moving Data Files...................................................................................... 5-21

Chapter 6: Managing the System 6-1

Introduction ....................................................................................................... 6-2

Managing Users................................................................................................ 6-2

Adding a New User...................................................................................... 6-3

Editing a User .............................................................................................. 6-5

Deleting a User............................................................................................ 6-7

Resetting Password or Unlocking an Account............................................. 6-7

Viewing Past Runs ............................................................................................ 6-8

Viewing Runs............................................................................................... 6-8

LCN 50-04344 Rev. D iv

Page 5

RainDrop Sense Operator’s Manual

Chapter 7: Support, Customer Maintenance, and Troubleshooting 7-1

RainDance Support........................................................................................... 7-2

RainDance Planned Maintenance..................................................................... 7-2

Customer Maintenance ..................................................................................... 7-2

Restarting the IC Workstation...................................................................... 7-2

Cleaning the RainDrop Sense ..................................................................... 7-2

Refilling the Oil Reservoir.................................................................................. 7-3

Service and Diagnostic Requirements .............................................................. 7-6

Powering Off the System .................................................................................. 7-6

Powering On or Restarting the System............................................................. 7-6

Restoring the System After a Failure ................................................................ 7-6

Support Agreement Information ........................................................................ 7-6

Moving the System............................................................................................ 7-7

Storing the System............................................................................................ 7-7

Reinstalling/Updating ICS Application............................................................... 7-7

Error Messages................................................................................................. 7-7

Troubleshooting ................................................................................................ 7-8

Chapter 8: Waste Management 8-1

Introduction and Disclaimer............................................................................... 8-2

Classification of Waste...................................................................................... 8-2

Anticipated Typical Waste Stream Composition ............................................... 8-3

Recommended Waste Stream Disposal ........................................................... 8-4

Chapter 9: Customer Care Information 9-1

General Care Information.................................................................................. 9-2

Consumables .................................................................................................... 9-2

Chapter 10: Regulatory Information 10-1

Sense Instrument Declaration of Conformity .................................................. 10-2

Chapter 11: Symbol Glossary 11-1

Appendix A: RainDrop

®

Consumables and Equipment A-1

LCN 50-04344 Rev. D v

Page 6

Chapter 1:

CHAPTER 1

Chapter 1:

Foreword

This chapter covers the following topics:

About this Manual page 1-1

Intended Use page 1-2

Data Entry and Collection page 1-2

Design Change Disclaimer page 1-2

Reproduction Disclaimer page 1-3

RainDance Support page 1-3

Microsoft Windows Familiarity page 1-3

Notes, Warnings, and Cautions page 1-3

Notes page 1-4

1

Warnings page 1-4

Cautions page 1-5

Biohazard Safety Warnings page 1-5

Laser Safety Warnings page 1-6

Safety Information page 1-7

Electrical Safety Warnings page 1-7

Mechanical Safety page 1-8

Gas Pressure Safety page 1-8

Product Labels page 1-8

Safety Interlock page 1-8

Packing and Transport page 1-8

About this Manual

This manual is designed to serve the operators of the RainDance Technologies®, Inc.

(hereafter called “RainDance”) RainDrop

instructions, product illustrations, screen graphics, troubleshooting, error messages, and

other relevant information are contained in this manual. It is the operator's responsibility to

ensure that all safety instructions in this manual are strictly applied.

®

Sense instrument. All material operating

Where there is any conflict between the RainDance Software End User L

included in the software, and the terms and conditions of sale, the order of precedence shall

LCN 50-04344 Rev. D 1-1

icense Agreement

Page 7

be as follows: (1) the RainDance Software End User License Agreement and (2) the terms

and conditions.

Intended Use

For Research Use Only. Not for use in Diagnostic Procedures.

RainDance Technologies RainDrop Sense is the detection instrument that enables

identification and counting of target molecules in each picoliter droplet following PCR

amplification. Together the RainDance Source and RainDrop Sense instruments make up the

RainDrop Digital PCR System delivering quantitative results.

Data Entry and Collection

RainDance requires that you do not enter health information identifiable to a particular

person, or other information that is subject to regulatory or contractual protection, into any

RainDance instrument. Such information is not protected from disclosure to service or other

personnel and, as noted below, may be included in information provided to RainDance for

purposes of servicing or evaluating the performance of your instrument.

RainDrop Sense Operator’s Manual

Further, by requesting service of your RainDance instrument, you give RainDance consent to

access and use data stored in your RainDance instrument. RainDance uses the data to

troubleshoot and service the instrument in response to your service requests. RainDance

also may aggregate data collected from your instrument in response to service requests with

similar data from other customers and may use the aggregated data to improve instrument

performance.

Your instrument from RainDance is enabled with an automatic email functionality that allows

RainDance to receive performance data from the instrument from time to time without your

knowledge. You may choose to disable that functionality. Disabling that functionality prevents

the instrument from sending such data to RainDance. The data collected with this automatic

email functionality consists of the number of samples processed, the success rate of the

samples processed, data specific to the performance of your instrument, and data that is

entered by your operators. RainDance collects this data solely so that it may better

understand and improve instrument performance. By allowing the functionality to remain

enabled, you give RainDance permission to use the automatic email functionality.

Design Change Disclaimer

Due to design changes and product improvements, information in this manual is

subject to change without notice. RainDance reserves the right to change the product

design, including illustrations, screen shots, and diagrams, at any time without notice to

anyone, which may subsequently affect the contents of this manual.

LCN 50-04344 Rev. D 1-2

Page 8

RainDance assumes no responsibility for any errors that may appear in this manual.

RainDance will make every commercially reasonable effort to ensure that this manual

is up-to-date and corresponds with the shipped RainDrop Sense Instrument.

The depictions of the workstation screens in this manual are representative only.

Depending on the hardware and software versions of the system, minor differences

may appear between the actual displays and those shown in this manual.

Reproduction Disclaimer

You may make a reasonable number of copies of this manual for internal use only and only

for use in connection with the RainDrop Sense Instrument. Except as provided by the

previous sentence, neither this manual nor any part of it may be reproduced, photocopied, or

electronically transmitted in any way without the advanced written permission of RainDance.

RainDance Support

If you have any difficulty running the RainDance Source instrument, contact your RainDance

Support representative.

solutions. The information given is general. Some applications may require additional

procedures or equipment modification. Contact RainDance Support via email:

support@raindancetech.com, Monday through Friday, excluding holidays.

Chapter 7 of this manual includes a list of problems and possible

RainDrop Sense Operator’s Manual

Microsoft Windows Familiarity

The supplied Instrument Control Software (ICS) is designed for the Microsoft®

Windows® Embedded 7 operating system and uses the standard Windows interface.

This manual assumes that you are familiar with these standard techniques: clicking the

mouse, highlighting an item, right-clicking, dragging, using the keyboard, interacting

with dialog boxes, keyboard commands, selection techniques, and other Windows

basics.

If you require assistance with these aspects of the software user interface, refer to the

Microsoft Windows documentation.

Notes, Warnings, and Cautions

The symbols described in this section are used throughout this document to draw your

attention to specific situations involving safety and proper use of the equipment. Symbols

found on the instruments are listed in

Chapter 11: “Symbol Glossary.”

LCN 50-04344 Rev. D 1-3

Page 9

Notes

Warning: A Warning indicates a potentially hazardous situation that, if not avoided,

could result in serious personal injury or death to you or others. Warnings are set

within boxed rules and indented.

RainDrop Sense Operator’s Manual

Notes are set apart from the body of the document with either the word Note or Important.

They are meant to draw your attention to reminders and information that is important to

successful operation of the RainDrop Sense Instrument.

Warnings

Note: A

Important: An

communicate greater weight to the issue at hand.

Warnings are represented by a red triangle with an exclamation point inside of it. Warnings

are reserved for situations that indicate the possibility of personal injury if the instructions are

not followed.

Note indicates a useful piece of information.

Important note is similar to a regular Note, except that it is meant to

LCN 50-04344 Rev. D 1-4

Page 10

Cautions

Caution: Do not operate the System in a manner other than specified in this

manual. Doing so could damage the instrument or produce erroneous results.

Caution: RainDance service representatives are trained in the safe operation of the

RainDrop Sense Instrument, including accessing those areas reserved for trained

service representatives.

Warning: Follow your laboratory's procedures and regulations when handling

biohazardous materials.

Warning: RainDance suggests that users be professional and conscientious and

take the appropriate safety measures when preparing, handling, and disposing of

any biohazardous samples or waste.

Warning: When working with biohazardous samples, or waste, always follow

standard universal safety procedures (lab coats, safety glasses, gloves, mask,

etc.).

Cautions are represented by a blue triangle with an exclamation point inside of it. They

indicate that you must follow a particular procedure in order to correctly operate the RainDrop

Sense Instrument and to avoid any possible damage to the equipment or loss of

consumables.

Biohazard Safety Warnings

A biohazard warning indicates that the user must use precautions, for example, gloves, when

handling biological samples, to prevent any infections or hazards that can be caused by

them.

RainDrop Sense Operator’s Manual

In addition, users should take precautions in accordance with local, state, and national

requirements.

LCN 50-04344 Rev. D 1-5

Page 11

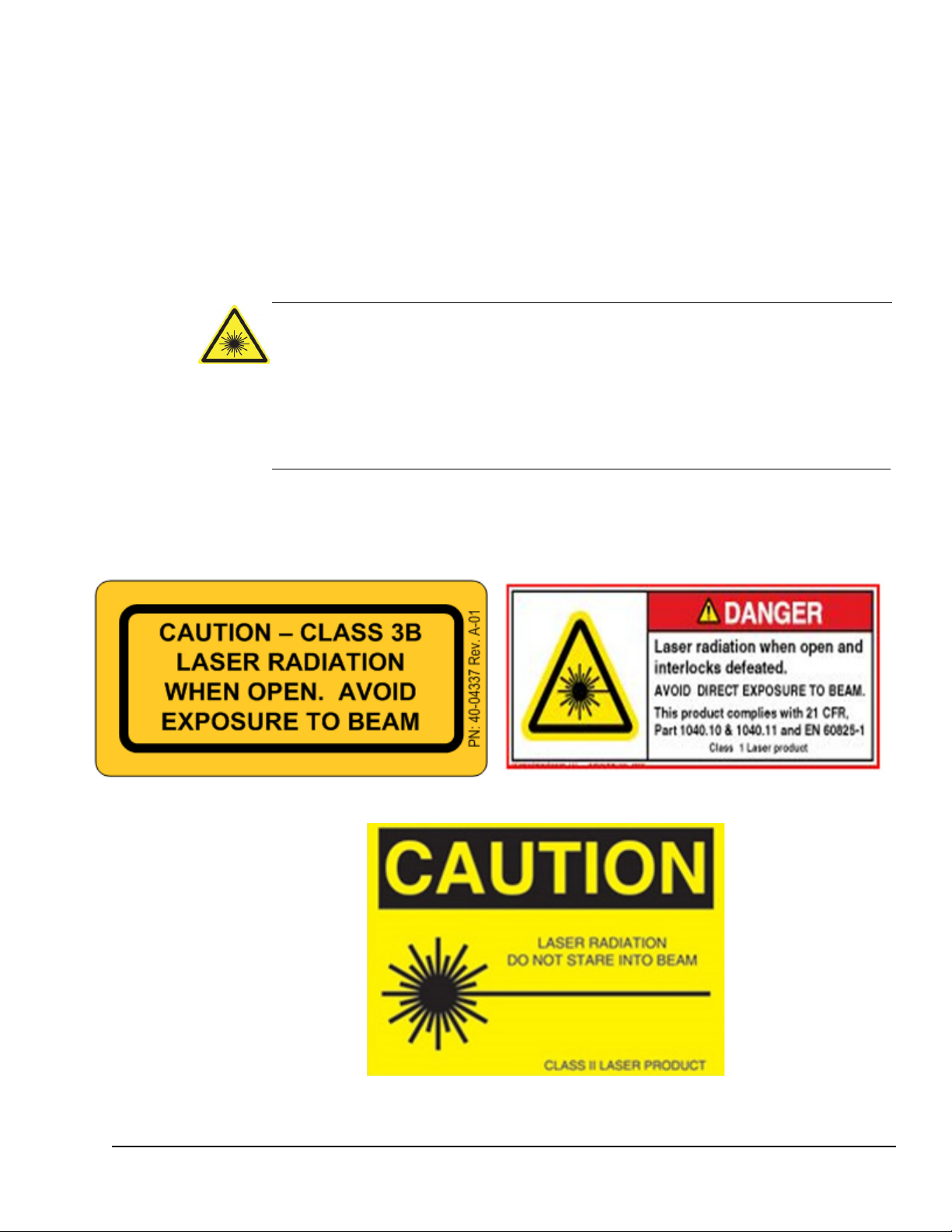

Laser Safety Warnings

Warning: A Class 3B laser is hazardous if the eye is exposed directly, but diffuse

reflections such as those from paper or other matte surfaces are not harmful. The

AEL for continuous lasers in the wavelength range from 315 nm to far infrared is

0.5 W. For pulsed lasers between 400 and 700 nm, the AEL is 30 mW. Other

limits apply to other wavelengths and to ultrashort lasers. Protective eye wear is

typically required where direct viewing of a class 3B laser beam may occur. Class3B lasers must be equipped with a key switch and a safety interlock.

The RainDrop Sense, classified as a Class 2 System, contains a Class 3B laser and Class 2

barcode laser. Avoid direct exposure to the Class 3B laser radiation when the unit is open

and interlocks are defeated. Only a qualified service person should remove the cover or

attempt to service this device, due to possible eye injury.

RainDrop Sense Operator’s Manual

A laser warning indicates that the user must use precautions whe

to avoid injury from the lasers.

In addition, users should take precautions in accordance with local, state, and national

requirements.

n operating the instrument

LCN 50-04344 Rev. D 1-6

Figure 1-1: Laser Safety Warnings

Page 12

Safety Information

Warning: This equipment is operated with hazardous voltages that can shock,

burn, or cause death. To reduce the possibility of electrical shock, do not remove

any fixed panels. Ensure that all service to the system is performed only by qualified

RainDance service personnel.

Warning: Remove the wall plug before servicing the equipment. Never pull cords

to remove the power cord from the outlet. Grasp the power cord plug and pull it

from the outlet to disconnect it.

Warning: Do not operate the equipment with a damaged power cord.

Warning: Ensure that there is easy and adequate clearance to the power cord so

that it can be disconnected in the event of a problem.

Warning: Position the power cord so that it cannot be tripped over, walked on,

rolled over, crimped, bent, pinched, or accidentally pulled from the wall outlet.

Warning: Connect the equipment only to a grounded outlet.

Warning: This instrument is not disconnected from the AC power source (mains)

as long as it is still connected to the wall outlet, even if the instrument is turned off.

The primary means of disconnecting the instrument is to remove the plug from the

wall outlet. Do not locate the instrument such that access to this plug is difficult.

Electrical Safety Warnings

RainDrop Sense Operator’s Manual

LCN 50-04344 Rev. D 1-7

Page 13

Mechanical Safety

Warning: The RainDrop Sense instrument weighs approximately 65 lbs (29 kg). To

avoid injury and damage to the instruments, do not move it without assistance from

RainDance Technologies.

Warning: The potential for serious injury to hands or fingers exists as a result of

rotating or clamping motion. Watch your hands and fingers when opening and

closing the cover. Keep your hands away from moving parts.

To move the instrument to another location, contact RainDance Support.

Gas Pressure Safety

Do not exceed a maximum input pressure of 120 psi at the instrument.

RainDrop Sense Operator’s Manual

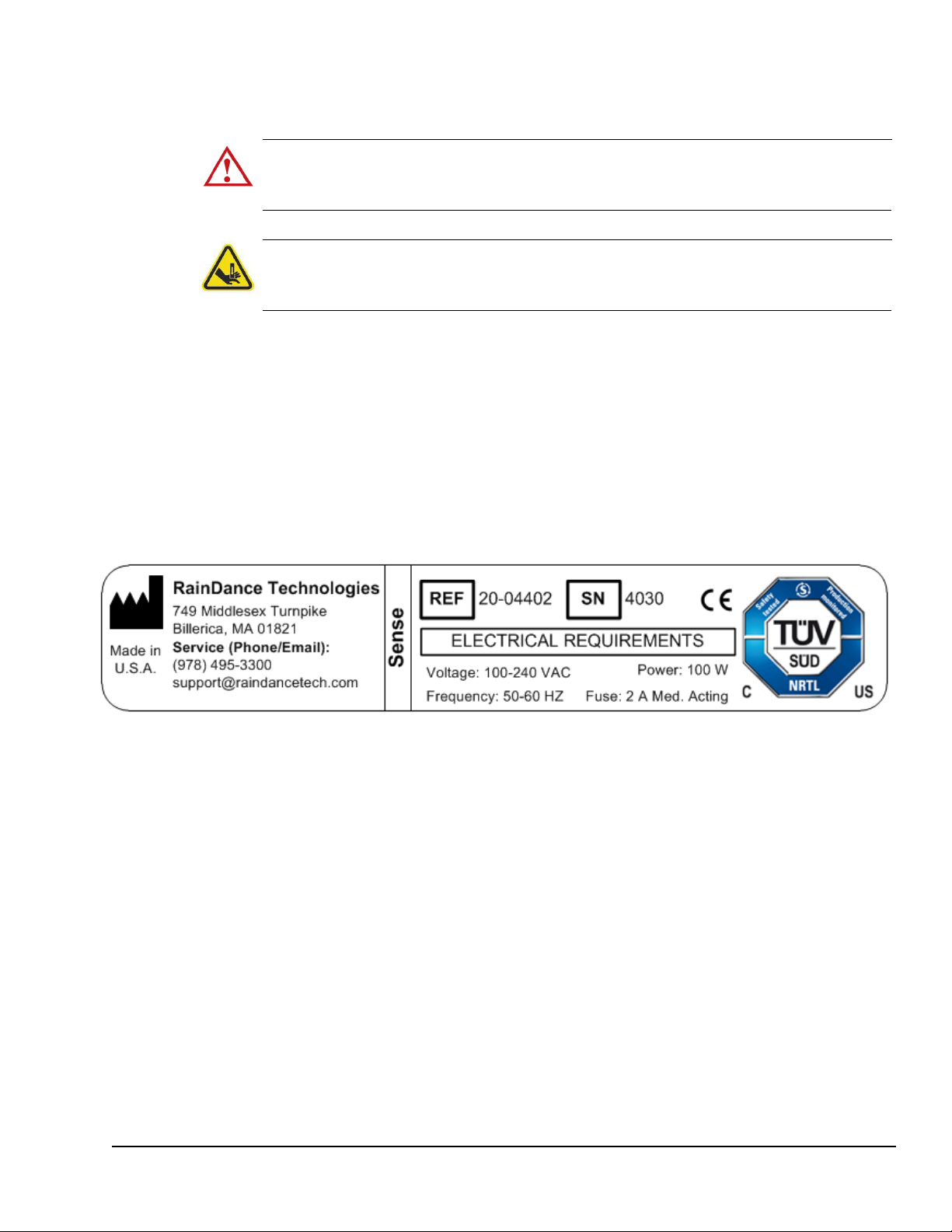

Product Labels

Figure 1-2 shows the RainDrop Sense product label.

Figure 1-2: RainDrop Sense Product Label

Safety Interlock

The RainDrop Sense is equipped with an automatic safety interlock, which prevents it from

operating unless its door is properly closed.

Packing and Transport

RainDance provides initial shipping and installation. If you are considering moving the

RainDrop Sense instrument within your laboratory, refer to Chapter 3 for the space

requirements. Do not move the instrument without assistance from

LCN 50-04344 Rev. D 1-8

RainDance Technologies.

Page 14

Chapter 1:

CHAPTER 2

Chapter 2:

Introduction

This chapter covers the following topics:

RainDrop® System Overview page 2-2

RainDrop System Major Components page 2-2

RainDrop Sense Major Components page 2-3

RainDrop Sense Layout page 2-4

RainDrop Carrier and Drive Oils page 2-4

RainDrop Sense Barcode Reader page 2-5

RainDrop Sense Chip page 2-6

2

Handling the Sense Chip page 2-6

RainDrop Sense Chip Compression Plate page 2-7

Specifications page 2-8

LCN 50-04344 Rev. D 2-1

Page 15

RainDrop Sense Operator’s Manual

RainDrop® System Overview

The RainDance RainDrop® System comprises two instruments: the RainDance Source and

the RainDrop Sense.

RainDrop System Major Components

RainDance Source Instrument

RainDrop Sense Instrument

Two Instrument Control (IC) Workstations (computers), one for each instrument

Two Instrument Control (IC) Monitors, one for each instrument

Instrument Control Cables and Peripherals

IC Workstation Power Cables

IC Monitor Power Cables

IC Keyboards

IC Mouses

IC USB Cables

Instrument Control Software (ICS)

RainDrop Analyst II™ Software

Figure 2-1: RainDrop System Major Components

LCN 50-04344 Rev. D 2-2

Page 16

RainDrop Sense Operator’s Manual

Instrument control workstation monitor RainDrop Sense instrument

RainDrop Sense Major Components

Figure 2-2 shows the major components of RainDrop Sense instrument.

Figure 2-2: RainDrop Sense Major Components

LCN 50-04344 Rev. D 2-3

Page 17

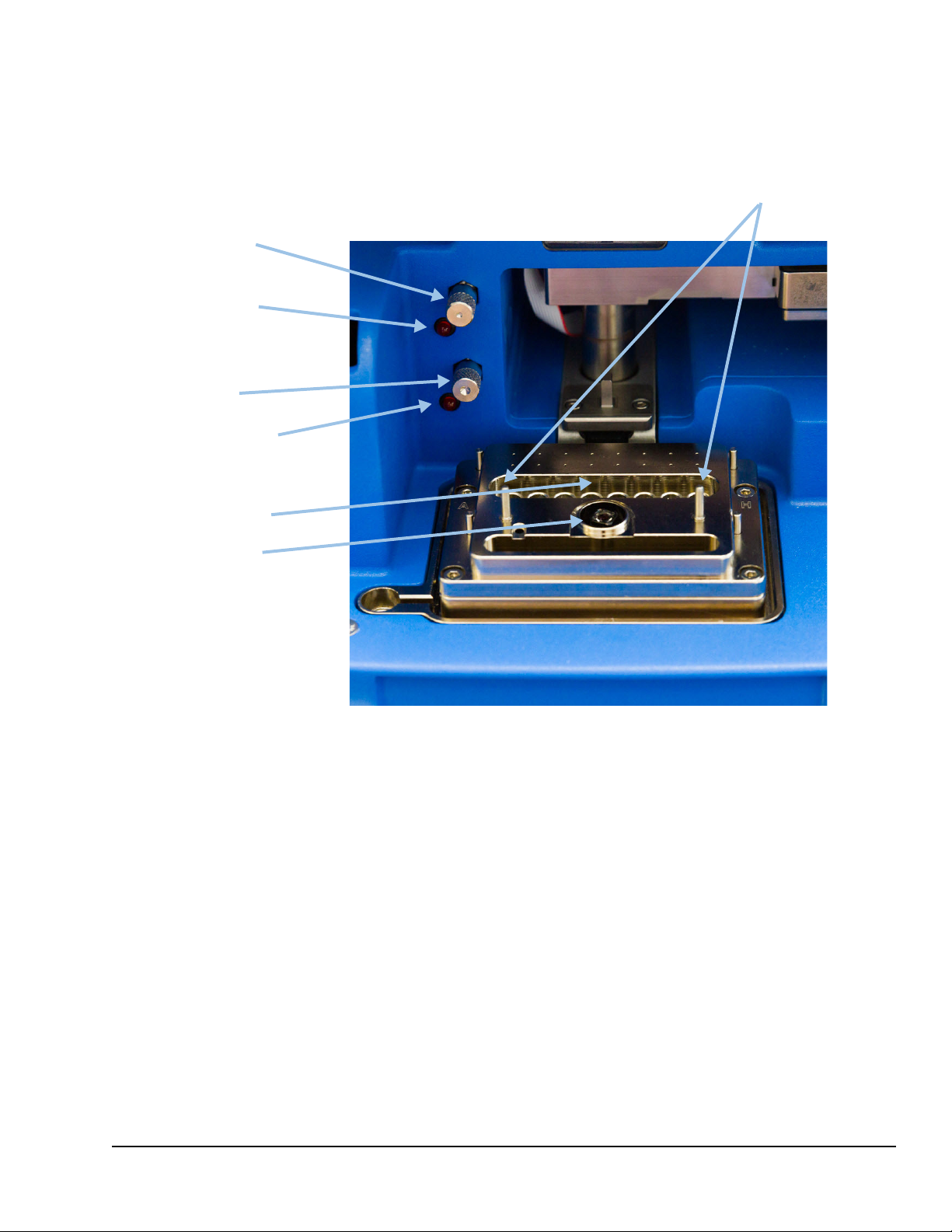

RainDrop Sense Layout

Chip alignment pins

Tube strip nest

Objective lens

Carrier oil

reservoir fill port

Carrier oil low

indicator light

Drive oil reservoir

fill port

Drive oil low

indicator light

Figure 2-3 shows the RainDrop Sense layout and oil reservoir fill ports.

RainDrop Sense Operator’s Manual

Figure 2-3: RainDrop Sense Layout

RainDrop Carrier and Drive Oils

Aqueous samples are encapsulated within each droplet on the Source instrument,

surrounded by an immiscible carrier oil. The droplets are stabilized with surfactants allowing

for robust manipulation both on and off the chip. Precise control of carrier and drive oil flow

rates on the Sense instrument allows for control of droplet spacing. Use only RainDancesupplied oils to avoid damage to the RainDrop System. The carrier oil and drive oil ports can

be filled with the oil provided in the Carrier Oil Syringe.

LCN 50-04344 Rev. D 2-4

Page 18

RainDrop Sense Barcode Reader

The barcode reader is used to scan barcodes that identify the various components used in

the RainDrop Sense (see Figure 2-4). The following lists the components to be scanned:

RainDrop Sense Chip(s)

RainDrop Carrier Oil

Tube Strips (May have a user-generated barcode. Scanning tube strips is optional.)

Items bearing a user-generated barcode for sample tracking (within the limits of

supported barcode formats)

RainDrop Sense Operator’s Manual

Figure 2-4: RainDrop Sense Barcode Reader

Scanning Barcodes

Scan items as follows:

1. Click Sc

2. Hold

the barcode, it automatically fills in the barcode information. The ICS accepts a

barcode in the 2D Data Matrix format, which allows up to 96 characters of text. You

may hear a subtle beep tone from the instrument when the barcode is accepted. If the

scanner does not read the barcode, the ICS software displays a message and allows

you to enter the barcode manually.

LCN 50-04344 Rev. D 2-5

an in the ICS software. The red scanner light pulses for 10 seconds.

the barcode on the item in front of the barcode reader. When the scanner reads

Page 19

RainDrop Sense Chip

Microfluidic chip

Droplet detection

region of interest (ROI)

Fluid lanes

Chip alignment hole

Chip alignment holeWaste collection area

Oil input gaskets

The RainDrop Sense Chip is placed into the instrument on top of the PCR tube strip. As part

of the Sense process, the chip punctures the tube strip caps and transfers the emulsified

sample through its lanes where the Sense instrument identifies and counts the droplets.

RainDrop Sense Operator’s Manual

Handling the Sense Chip

Figure 2-5: RainDrop Sense Chip

Handle the Sense Chip as follows:

Grasp the chip by its sides.

Do not touch the clear microfluidic chip and its droplet detection region of interest.

Save the bag the chip comes in for later disposal of the chip.

LCN 50-04344 Rev. D 2-6

Page 20

RainDrop Sense Chip Compression Plate

The RainDrop Sense Compression Plate is needed for smooth operation of the RainDrop

Sense Instrument. Position the plate over the Sense chip prior to start of the run. When the

plate is properly positioned, its RainDance logo should be facing you, the plate should be flat,

and it should not be movable left to right or front to back.

RainDrop Sense Operator’s Manual

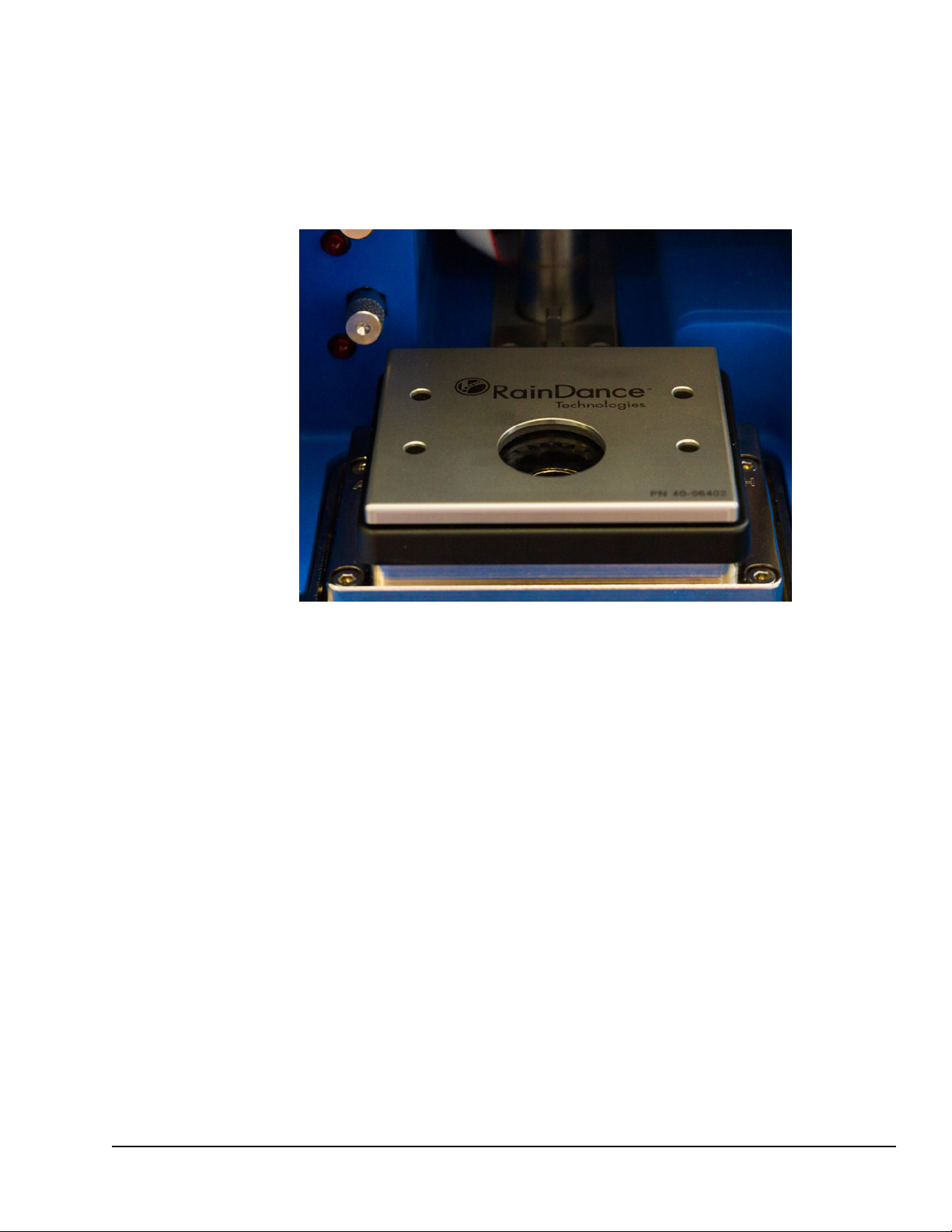

Figure 2-6: RainDrop Sense Chip Compression Plate

LCN 50-04344 Rev. D 2-7

Page 21

Specifications

Table 2-1 shows the specifications for the RainDrop Sense instrument. Table 2-2 shows the

specifications for the Instrument Control (IC) Workstation.

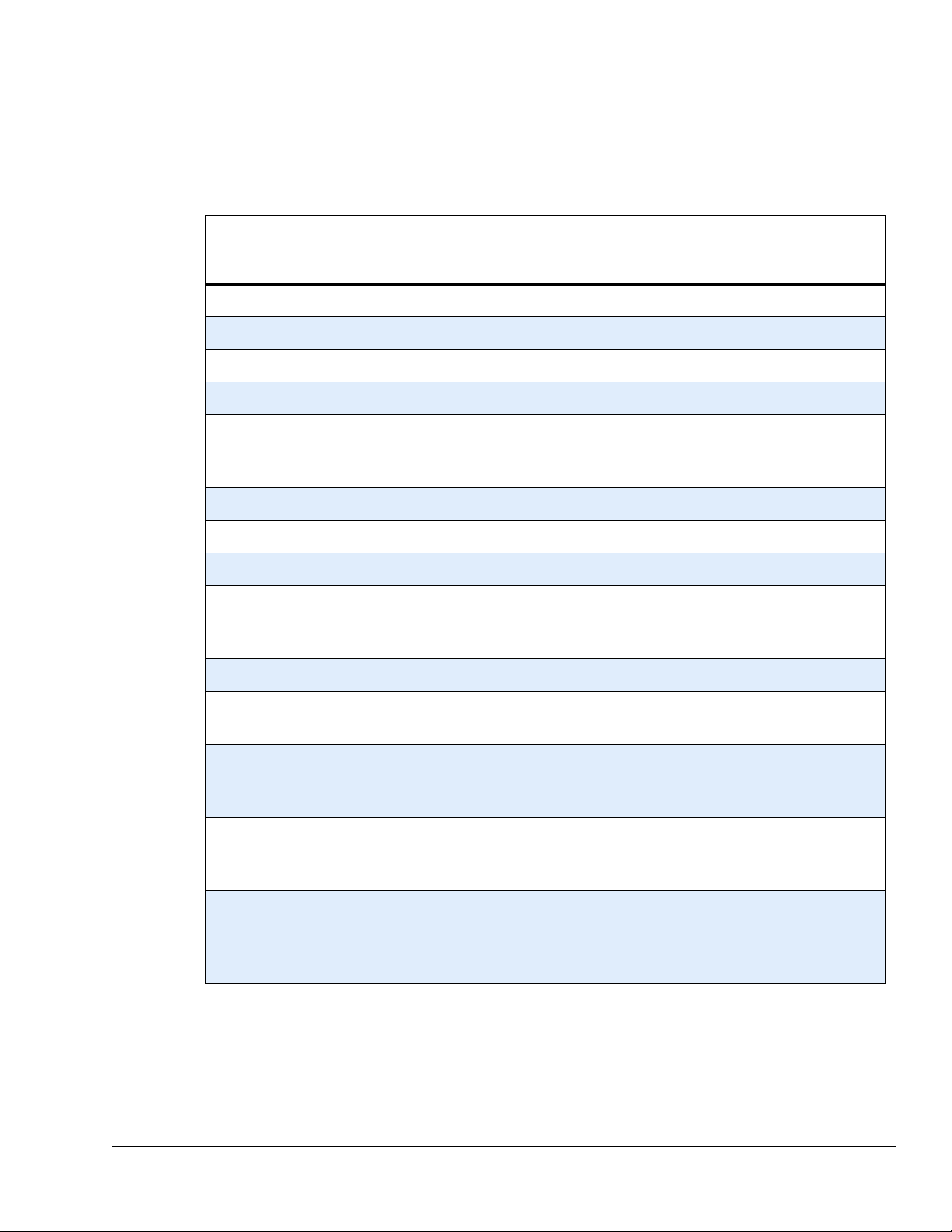

Table 2-1: RainDrop Sense Hardware Specifications

Requirement or

Spec

ification Description

RainDrop Sense Operator’s Manual

Width

Depth 17 inches (43.2 cm)

Height

Weight ~65 lbs (~29 kg)

Power Source (Electrical) Voltage: 100 to 240 VAC, 35 W max

Clearance 2 inches (5 cm) in rear

Fuses 2 fuses, 2 Amperes Medium Acting

Cable Connections USB: 1 USB 3.0 and 1 USB 2.0

Required compressed gas

input pressure range at the

instrument

Capacity 8 lanes per chip

Maximum Sample

Throughput per 8 hour shift

11 inches (27.9 cm)

15 inches (38.1 cm)

1 standard grounded outlet, within 6 ft (2 m) of the

instrument

90-120 PSI (0.62 MPa – 0.82 MPa)

24 samples per shift in Standard Mode

56 samples per shift in Fast Mode

Detection Time ~8 lanes in 4 hours for Standard Mode (for 25 µL

sample)

~8 lanes in < 2 hours for Fast Mode (for 25 µL sample)

Droplet Identification Precise control of relative pressure and oil flow rate

creates ideal spacing of the thermal cycled emulsion to

allow for proper droplet identification and analysis.

Droplet Processing Droplets are processed on a chip that has no moving

parts or valves. Samples have minimal contact with

either walls or air. In addition, one-time-only chip use

prevents sample cross-contamination.

LCN 50-04344 Rev. D 2-8

Page 22

RainDrop Sense Operator’s Manual

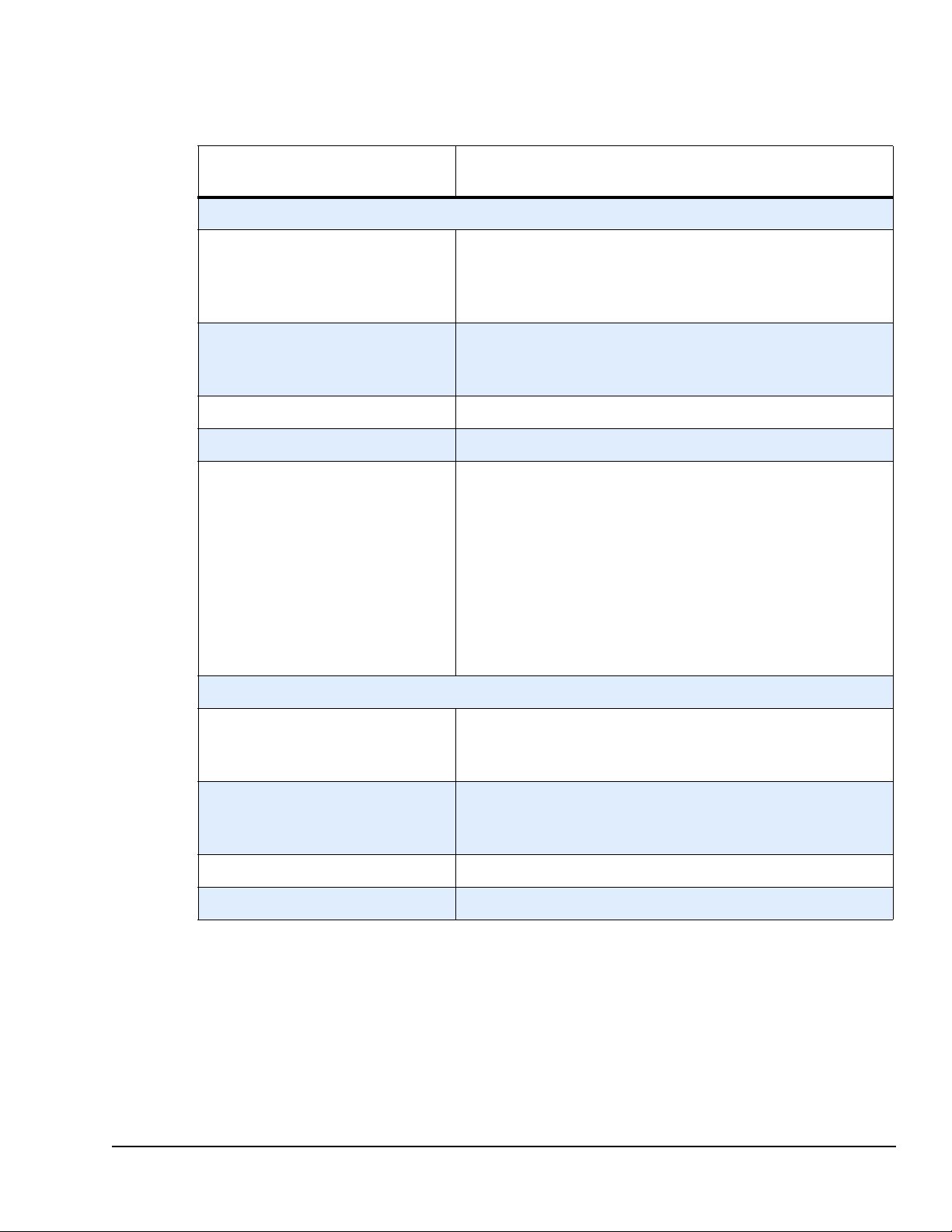

Table 2-2: Instrument Control (IC) Workstation Specifications

Requirement or Specification

Instrument Control (IC) Workstation

Power Voltage: 100-240 VAC

Dimensions Width: 1.36 inches (3.45 cm)

Weight

Clearance 2 inches (5 cm) in rear

Network Connection

Description

Intel Computer: 19 V, 65 W

Standard grounded outlet within 6 ft (2 m) of the

instrument

Depth: 4.41 inches (11.20 cm)

Height: 4.59 inches (11.66 cm)

1.4 lb (520 g)

TCP/IP connectivity (i.e., Internet) using a standard

Ethernet connector. Instruments must be placed near

an active Ethernet port so the computers can be

networked. The Instrument Control Software has the

ability to email notifications to customers if it is

networked. In addition, RainDance has software that

allows us, with customer permission, to access the

computers to look at log files to assist in

troubleshooting and to assess instrument performance.

Without Internet access, support is compromised.

Instrument Control (IC) Monitor

Power Voltage: 100 to 240 VAC

View Sonic Monitor: 22 W max, 20 W typical

grounded outlet within 6 ft (2 m) of the instrument

Dimensions Width: 16.4 inches (41.62 cm)

Depth: 7.8 inches (19.91 cm)

Height: 15.8 inches (40.22 cm)

Weight

Clearance 0.5 inches (1.2 cm) in all directions

6.6 lb (3.0 kg)

LCN 50-04344 Rev. D 2-9

Page 23

Table 2-3: Operating Environmental Requirements

RainDrop Sense Operator’s Manual

Requirement or Specification

Laboratory Ambient

Temperature Range

Ambient Temperature

F

luctuation

Relative Humidity 5-85% RH, non-condensing

Atmospheric Pressure

Safety Compliance IEC 61010-1:2010, the international safety standard for

Data Backup RainDance suggests using a standard backup

Description

15-30°C

<0.3°C per minute

101-81 kPa (1010-810 mbar) or sea level to 1800 m

laboratory equipment, including USA (UL), Canadian

(CSA), and European (CENELEC/EN) differences

dure for any computer system.

proce

LCN 50-04344 Rev. D 2-10

Page 24

Chapter 1:

CHAPTER 3

Chapter 3:

Installation and Setup

This chapter covers the following topics:

Space Requirements page 3-2

Connecting RainDrop Sense and Instrument Controller page 3-3

Connecting Cables to the RainDrop Sense Instrument page 3-3

Connecting Cables to the Instrument Controller page 3-4

Gas Pressure Quality page 3-7

Starting Up the RainDrop Sense Instrument page 3-8

Relocating RainDrop page 3-9

3

Important: Only train

RainDrop

®

Sense instrument from its packaging and install it.

ed and certified RainDance Service Representatives may remove the

LCN 50-04344 Rev. D 3-1

Page 25

Space Requirements

Caution: The RainDrop Sense instrument is sensitive to vibration and should be

placed on a bench top that is free from vibration.

The RainDrop® Sense instrument is designed to be placed on a standard laboratory bench.

The Instrument Controller (IC) Workstation can be located on either the left or right side of the

instrument.

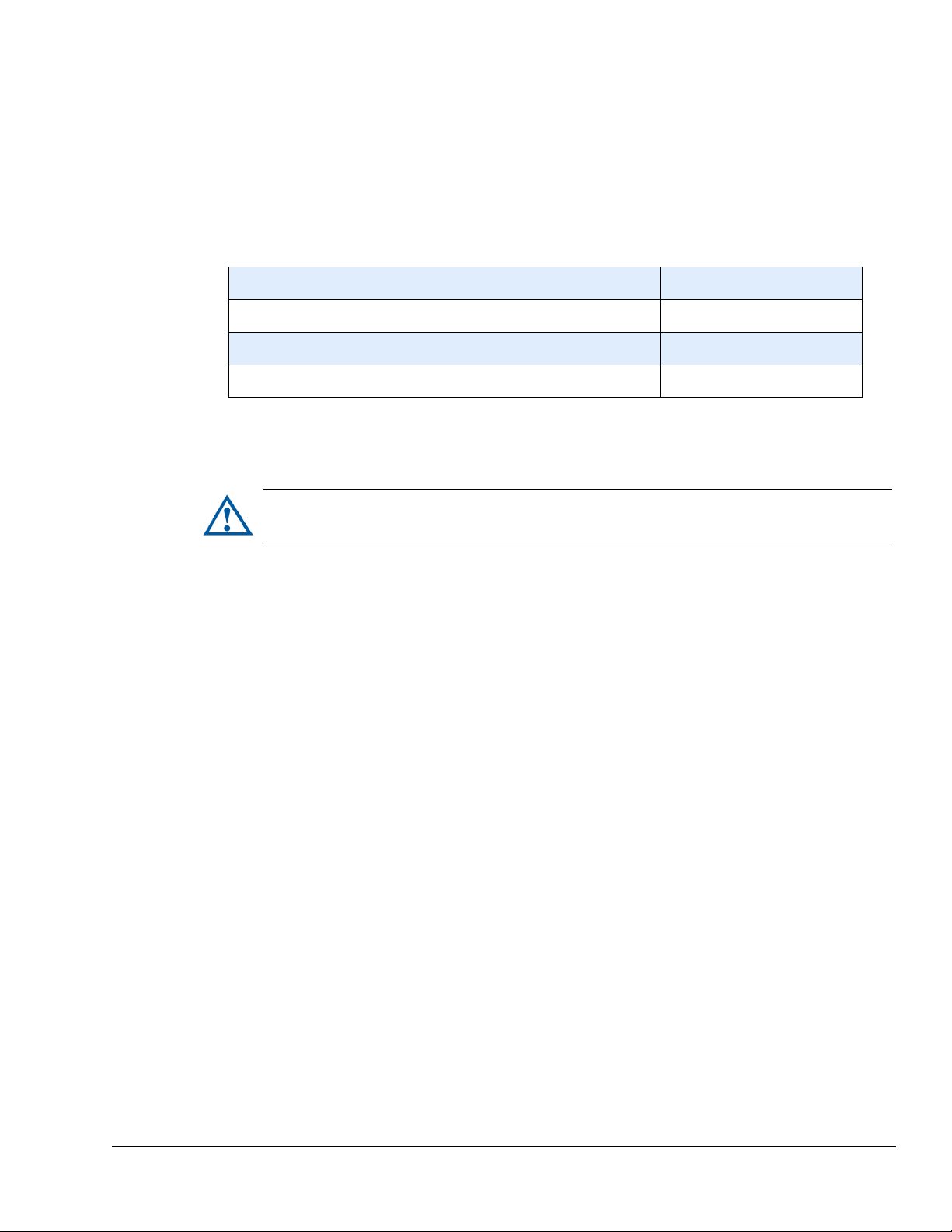

Table 3-1: RainDrop Sense Dimensions (Including the IC Workstation)

Minimum Height (door open) 28 inches (71.1 cm)

RainDrop Sense Operator’s Manual

Minimum Depth

Bench Loading Weight 73 lb (26.4 kg)

Minimum Width 29 inches (74 cm)

Note: Refer to

Gas Connectivity

Gas source should be located in proximity to the instrument because the gas supply

connection is located on the back of the instrument. Use 4mm OD polyurethane tubing with

an in-line shutoff valve. See Appendix A for information on suppliers.

19 inches (48.3 cm)

the Pre-Site Guide for any additional installation details.

LCN 50-04344 Rev. D 3-2

Page 26

RainDrop Sense Operator’s Manual

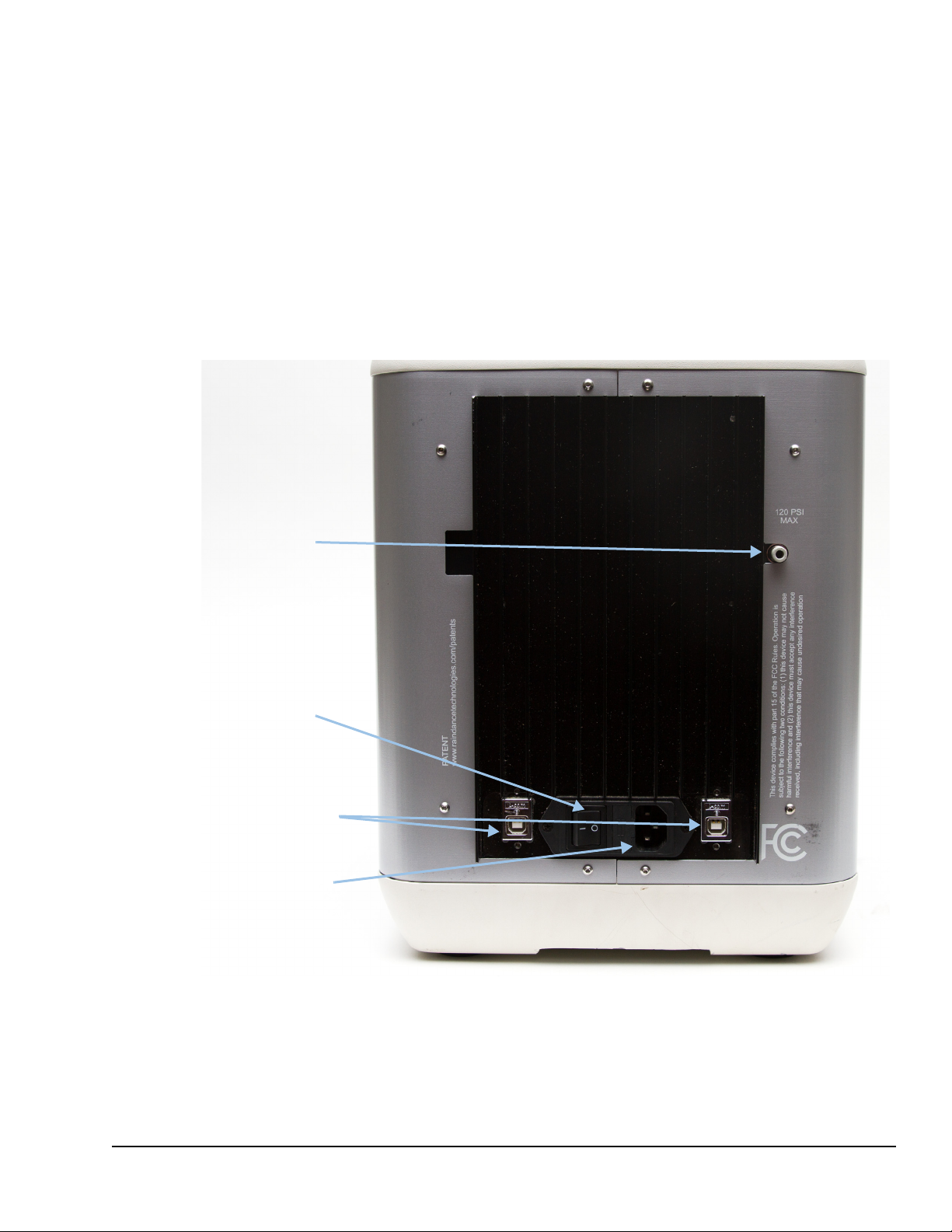

Power switch

AC power

cable

Gas pressure

USB connections

Connecting RainDrop Sense and Instrument Controller

Before powering on the RainDrop Sense instrument and its IC Workstation, make sure all

cables are properly connected as described in “Connecting Cables to the RainDrop Sense

Instrument” on page 3-3 and “Connecting Cables to the Instrument Controller” on page 3-4.

Connecting Cables to the RainDrop Sense Instrument

The RainDrop Sense instrument has three cable connections (AC Power Cable and two

USB) and a gas pressure connection as shown in Figure 3-1.

Figure 3-1: Cable Connections on RainDrop Sense

LCN 50-04344 Rev. D 3-3

Page 27

RainDrop Sense Operator’s Manual

To plug cables into the back of the Sense instrument:

1. Plug one end of the AC Power Cable into the Power Cable Connection and the other

end into a standard grounded wall outlet.

Important: The Detachable Main AC Power Cable for North America or other

countries with 120 VAC 50/60 Hz supply voltage provided for the RainDrop Sense

instrument is a 3-wire cord, 18 AWG, 10 A, 125 VAC. Never substitute a Detachable

Main AC Power Cable with a lower current or voltage rating.

2. Plug the two USB Cables into the USB Connections on the Sense instrument as

shown in

Figure 3-1.

Connecting Cables to the Instrument Controller

The RainDrop IC Workstation has USB connections used for:

The mouse

The keyboard

The RainDrop Sense instrument

Both the Source and Sense instruments connect to their IC Workstations via USB

connections.

Figure 3-2 illustrates the USB cable connections on the IC Workstation.

Note: It is important that all the USB cables on the instruments are connected to USB ports

on the workstations. Failure to connect the USB cable correctly can result in a loss of

communication with the RainDrop instrument. In addition, the USB connections on your

workstation may differ from those shown in

Figure 3-2.

LCN 50-04344 Rev. D 3-4

Page 28

RainDrop Sense Operator’s Manual

USB port that connects to

the left output from the

Sense

USB port that connects to

the right output from the

Sense

HDMI port that connects to

the monitor

The left USB/output connects to the USB port furthest from the gas inlet and the right USB/output

Figure 3-2: Cable Connections to the IC Workstation

connects to the other available USB port.

LCN 50-04344 Rev. D 3-5

Page 29

RainDrop Sense Operator’s Manual

USB receiver

LCN 50-04344 Rev. D 3-6

Figure 3-3: USB Receiver

1. With the IC Workstation turned off, plug the USB receiver for the keyboard and mouse

into the IC Workstation.

2. Plu

3. Plu

g the right USB output from the Sense instrument into the right USB in Figure 3-2.

g the left USB output from the Sense instrument into left USB in Figure 3-2.

Page 30

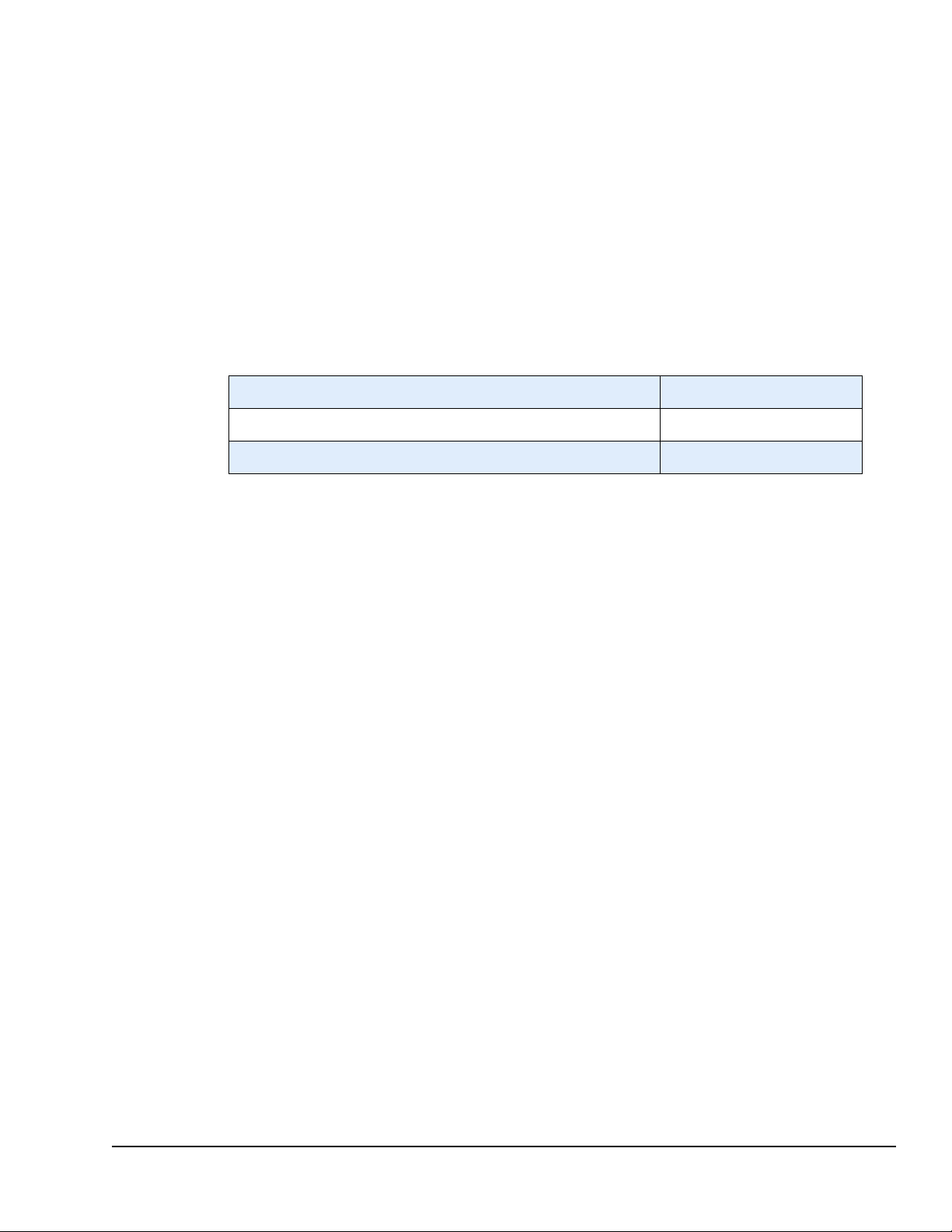

Gas Pressure Quality

You may use compressed argon or nitrogen. Ensure that the compressed gas system you

use meets the following standards.

RainDrop Sense Operator’s Manual

The input pressure must be regulated to a value, at the system, within the

120 psi.

In addition, the quality must meet the ISO/DIS8573 compressed gas qu

Class 2 for instrument quality gas, as follows:

Table 3-2:

Oil (ppm) 0.1

Water (dew point)

Dirt (µ) 1.0

GasPressure Quality

-40°F

ality standard,

range of 90-

LCN 50-04344 Rev. D 3-7

Page 31

RainDrop Sense Operator’s Manual

Starting Up the RainDrop Sense Instrument

Use the following startup sequence for the RainDrop Sense instrument:

1. With the

have been connected properly as described in “Connecting Cables to the RainDrop

Sense Instrument” on page 3-3 and “Connecting Cables to the Instrument Controller”

on page 3-4.

2. T

urn on the IC Workstation (on the top of the workstation).

3. Lo

g on to the Windows 7 operating system using the RDT account.

Note: Logg

User name = RDT

No password

4. T

urn on the RainDrop Sense instrument (located on the back of the instrument).

5. W

ait 1 minute for the RainDrop Sense instrument to perform internal initialization. As

the instrument initializes, the lights on the panel illuminate to indicate its status (see

Figure 3-4).

RainDrop Sense and IC Workstation turned off, ensure that all the cables

ing on using any other account results in ICS failures.

Figure 3-4: RainDance LED Lights

6. Launch the Instrument Control Software (ICS) application as described in Chapter 4.

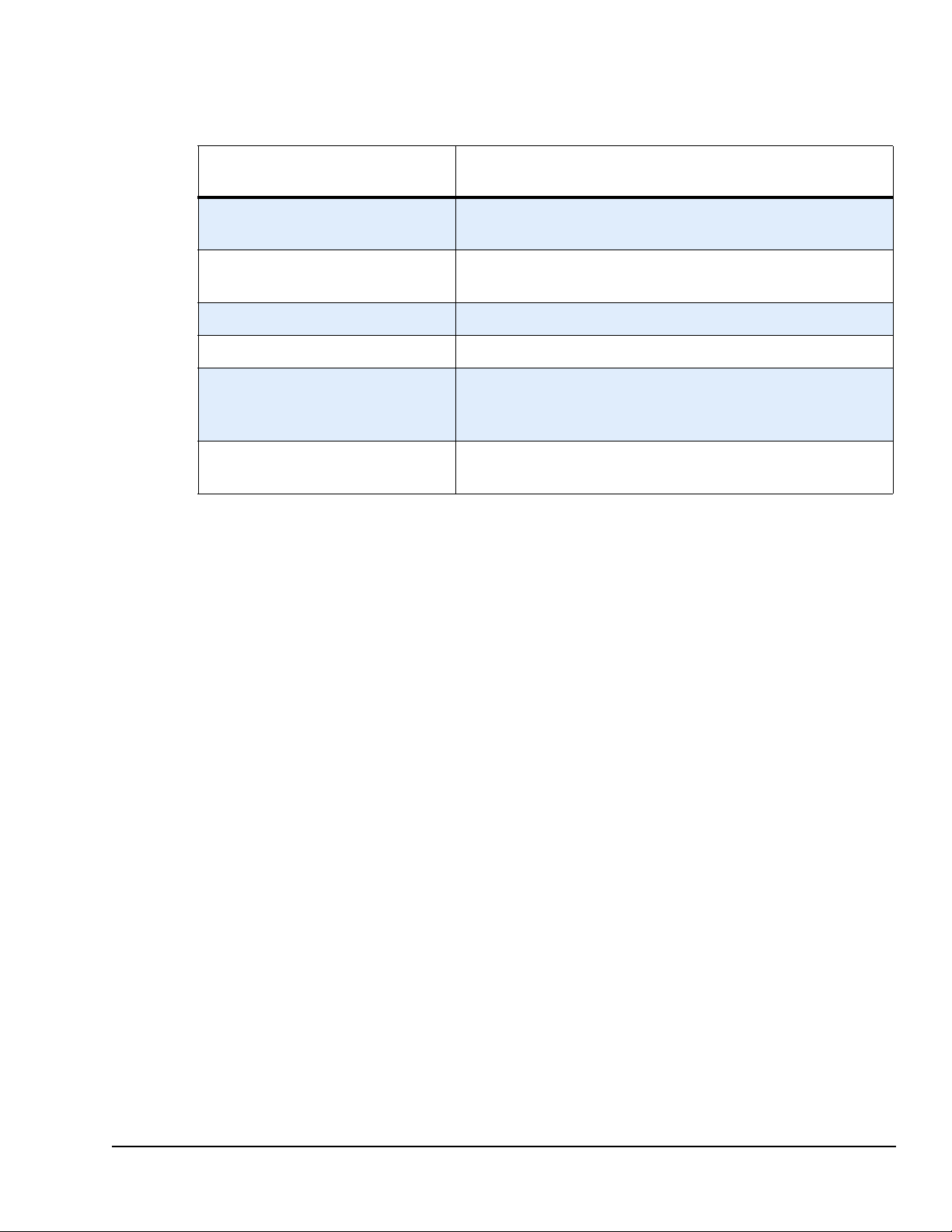

Table 3-3 lists the LED lights that indicate the status of the instrument.

Table 3-3: LED Lights Within the RainDance Logo

LED Name and Illumination Pattern Meaning

LCN 50-04344 Rev. D 3-8

Page 32

RainDrop Sense Operator’s Manual

Caution: The RainDrop Sense instrument weighs approximately 65 lbs (29 kg). To

avoid injuries and damage to the instrument, do not move it without assistance from

RainDance Technologies. If you want to move your instrument either within your

laboratory or to another location, contact RainDance Technologies.

Table 3-3: LED Lights Within the RainDance Logo

Main Power LED (Solid) Instrument is powered on.

All LEDs except Main Power are rotating

and off.

on

All LEDs are flashing simultaneously. Instrument has detected an error.

All LEDs are on.

All LEDs except Main Power are off. Instrument is disconnected from the ICS.

Relocating RainDrop

Instrument is operating normally.

Instrument is connected to the ICS.

LCN 50-04344 Rev. D 3-9

Page 33

Chapter 1:

CHAPTER 4

Chapter 4:

Launching the Instrument Control Software (ICS)

This chapter covers the following topics:

Introduction page 4-2

The Microsoft Windows 7 Login page 4-2

Starting the ICS Application page 4-2

ICS Login Levels page 4-3

Changing the ICS Password page 4-5

4

The ICS Account Types page 4-6

ICS Initialization page 4-7

Status Indicators page 4-10

Using Tabs in the ICS page 4-11

Navigating Through the Tabs page 4-12

Canceling a Process page 4-12

Completing a Process page 4-13

Using Scan Buttons page 4-13

Alarms, Log, and Status Tabs page 4-14

LCN 50-04344 Rev. D 4-1

Page 34

Introduction

The Instrument Control Software (ICS) application controls the operation of the RainDrop®

Sense.

The Microsoft Windows 7 Login

The Instrument Control Workstation is configured with a single Microsoft Windows 7

Operating System login. Do not edit this account or add additional accounts. Failure to

comply will result in ICS failures. The default login is an administrative account. The system

differentiates between upper and lower case characters.

RainDrop Sense Operator’s Manual

Note: Do not

use the RainDance Support Windows Logon. This will result in ICS failure.

Starting the ICS Application

The startup sequence works as follows:

1. Power on

Power on the IC Controller and log in to Windows.

Power on the RainDrop Sense. Wait one minute.

2. Click the ICS icon on

Note: You can also start the ICS application by selecting Windows 7 Start Program Menu,

and then selecting Start > All Programs > RainDance Technologies > Launch ICS.exe.

each component of the RainDrop Sense in the following sequence:

your desktop:

Note: The

designated application and software uses.

LCN 50-04344 Rev. D 4-2

IC Workstation must be dedicated to ICS Operation. Use it only for RainDance

Page 35

RainDrop Sense Operator’s Manual

The Login window opens (see Figure 4-1).

Figure 4-1: Login Window

3. Enter your Login information in the appropriate fields. Enter the Username followed by

the Password and then click Login. See ICS Login Levels for more information.

Note: Microsoft

application, both usernames and passwords are case sensitive.

ICS Login Levels

The ICS application supports two levels of access to the ICS program: User and

Administrator. The ICS application is configured with two default login IDs: one for User and

one for Administrator. RainDance recommends that you change the default password on

each of these accounts after initial use.

Table 4-1: ICS Default User and Administrator Login Information

Requirement or Specification Description

User Login Username User

User Login Password

Administrator Login User Name Admin

Administrator Login Password admin

Windows 7 usernames are not case sensitive, but passwords are. In the ICS

user

LCN 50-04344 Rev. D 4-3

Page 36

Caution: After three failed attempts to login with the wrong password, the ICS

application locks the account. You will not be able to login to your account. If this

happens, you must contact someone in your facility with an Administrator account

who can either unlock or reset your password. For details, see “Resetting Password

or Unlocking an Account” on page 6-7.

Figure 4-2 shows the message for a failed login.

RainDrop Sense Operator’s Manual

Figure 4-2: Invalid Username Message

LCN 50-04344 Rev. D 4-4

Page 37

Changing the ICS Password

This section describes how to change an ICS password. RainDance recommends that you

change the default User and Administrator passwords after initial use.

RainDrop Sense Operator’s Manual

1. Select Chan

(Figure 4-3).

2. Enter the old password in the Old Password field, the new password in the New

Password field, and the new password again in the Verify Password field. Click Save

when you are done to save the new password. Click Cancel to dismiss the dialog

without saving your changes.

ge Password from the Home menu. The Change Password dialog opens

Figure 4-3: Change Password Window

LCN 50-04344 Rev. D 4-5

Page 38

The ICS Account Types

Your account type defines the features you have access to (User and Administrator) within

the ICS application.

Table 4-2: ICS Account Type

RainDrop Sense Operator’s Manual

Feature User

Change Passwords X X

Export Instrument Files X

View Runs X X

Maintenance Actions

Add New Users X

Edit Users

Reset Passwords X

Unlock Passwords

Start Runs X X

Stop Runs X X

The pull-down menu selections differ depending on your access righ

different for a User and an Administrator account.

Administrator

X

X

X

X

ts; they are slightly

LCN 50-04344 Rev. D 4-6

Page 39

ICS Initialization

When you login to the instrument, the Initialization screen appears (see Figure 4-4).

RainDrop Sense Operator’s Manual

Figure 4-4: Initialization Screen

From the Initialization screen, click Start Initialization to initialize the system. A progress bar

shows the progress of the initialization.

Figure 4-5: Initialization Progress Bar

LCN 50-04344 Rev. D 4-7

Page 40

RainDrop Sense Operator’s Manual

If initialization fails, the following message appears:

Figure 4-6: Initialization Failure Message

Click OK and contact RainDance Support. See “RainDance Support” on page 1-3.

This error is often the result of starting ICS right after you turn on

recommends the following steps:

1. Exit the

2. T

urn the instrument off.

3. T

urn the instrument back on.

4. W

ait 1 minute.

5. Start t

ICS.

he ICS.

If the message appears again, restart the ICS.

the instrument. RainDance

LCN 50-04344 Rev. D 4-8

Page 41

RainDrop Sense Operator’s Manual

If initialization is successful, the ICS home page is displayed (see Figure 4-7).

Note: All

menu items are inactive until the initialization is finished.

Figure 4-7: Home Page

From the home page, you can Setup a Run (see Chapter )

You can perform additional tasks by ma

View Runs (see Chapter 6)

Maintenance Actions (see Chapter 7)

Add New Users (Administrator only) (see Chapter 6)

Edit Users (Administrator only) (see Chapter 6)

king selections from the drop down menus:

LCN 50-04344 Rev. D 4-9

Page 42

Status Indicators

A common set of status indicators appears throughout the system indicating the status of an

item or process being performed. In general, the green check mark (

everything is working as expected and you can proceed. The orange exclamation point (!)

indicator is a warning that means that you can continue, but that some optional fields are

blank. The red X indicator means there is a problem that needs to be resolved before you can

continue.

RainDrop Sense Operator’s Manual

?

) indicator means that

Table 4-3 shows the status indicators a

Table 4-3: Status Icons

Icon

Meaning

Ready – If all icons are green check marks, the system is ready to start a

run.

Warning (Run Will Proceed) – If there is one or more orange

exclamation point icons on the tabs, the run can start. These represent

optional information.

Error (Run Will Not Proceed) – If there is one or more red X icons on the

tabs, there is an issue that may prevent the run from being performed.

nd describes their meanings.

LCN 50-04344 Rev. D 4-10

Page 43

Using Tabs in the ICS

There are two tabs in the ICS that appear after you click Setup a Run: Run Data and Run

Info. To perform a run, you will need to complete some of the fields on each tab.

RainDrop Sense Operator’s Manual

To ensure that all of the steps are completed correctly, RainDrop

the right side of the tabs to indicate the state of each of the required items. As you complete

each step in the process the status icon for that step is updated. This section provides

general information on what appears on the tabs and how to complete these processes.

Details on how to complete each of these pro

descriptions assume you are familiar with how to use the tabs described h

Figure 4-8 shows an example of the Sense interface.

process are shown on the left side of the screen:

Run Data

Run Info

cesses is provided in Chapter . Those

The tabs required to complete the

provides a System Status on

ere.

Figure 4-8: Sense Tabs

Only one tab is visible at a time. The selected (or active) tab has a white background and the

inactive tab has a transparent background (Run Data is the active tab in Figure 4-8).

LCN 50-04344 Rev. D 4-11

Page 44

RainDrop Sense Operator’s Manual

To prepare for a run on the Sense instrument, you must complete the following fields in the

Sense ICS:

Run Data Tab:

Run Name

Sense Chip barcode lot and serial number

At least one selected lane (indicated by a green check mark)

In addition, before you can proceed with the run on the Sense instrument, you

must have clicked the Insert PCR Tube button to indicate that you have inserted

the closed tube strip into the instrument.

Select Standard or Fast Mode detection.

Run Info Tab:

Carrier Oil field and Drive Oil field and only if the instrument is out of one of those

oils

As you complete each tab, the software updates the System Status fo

green check mark is displayed, the item is ready to go. If an orange exclamation point is

displayed, it means that optional fields are blank. If a red X is displayed, there are errors or

missing data required for the run (see Table 4-3).

For a description of the meaning of the Status Indicators used on

system, see “Status Indicators” on page 4-10.

Navigating Through the Tabs

You can switch back and forth between the two tabs at will. Click the tab name to move to a

tab.

Canceling a Process

The Run Data tab has a red Cancel button in the lower left corner (Figure 4-8). If you click

Cancel while a

run is active, the application asks you to confirm that you want to cancel.

r various items. If the

the tabs and throughout the

Figure 4-9: Cancel Confirmation

When you click Yes, the information you entered when you started the process is deleted, the

run is canceled and you are returned to the RainDrop main screen.

LCN 50-04344 Rev. D 4-12

Page 45

Completing a Process

When you have completed each step to prepare for a run, review the System Status

indicators. Ideally, all the status indicators will be green check marks, although you can still

continue with orange exclamation points since they indicate only that optional fields are

blank. The process cannot be started if there is even one red X (error indications) on any of

the tabs.

RainDrop Sense Operator’s Manual

When you are satisfied that the steps for the process are complete

bottom right side of the Run Data tab. This starts the process on the RainDrop Sense

instrument.

Using Scan Buttons

The ICS allows you to scan barcodes to enter information into various text fields. There are

two types of Scan buttons available in the system as shown in Table 4-4.

Table 4-4: Scan Buttons

Button Description Use

, click Start Run on the

Figure 4-10: Start Run Button

Manual Scan Button The instrument requires that you

manually enter a barcode.

Scan Button The system allows you to scan any

type of barcode.

Clicking either type of scan butt

to scan the barcode.

If you scan the wrong type of barcode, an error message appears. ICS will not a

invalid barcode.

LCN 50-04344 Rev. D 4-13

on activates the barcode reader on the system and allows you

ccept an

Page 46

Alarms, Log, and Status Tabs

The Alarms, Log, and Status tabs are displayed on the bottom of the screen (see Figure 4-

11). Each of these tabs is described below.

Figure 4-11: Example of Screen Showing Alarms, Log, and Status Tab at Bottom

The Alarms tab is displayed by default. Click Log or Status to display that tab.

Alarms Tab – This tab lists instrument errors that exist in the system. If an error

appears, the system is in a warning or error state. Different errors occur during the

setup of the instrument. If an error does not clear when you close the door and click

Start Run, check “Troubleshooting” on page 7-8. If the issue is still not resolved,

contact supp

Log Tab – This tab is used for service purposes. It is used to check on the system

automation.

Status Tab – This tab is used for service purposes. It is used to determine the status of

the instrument at different points during operation.

ort@raindancetech.com for assistance.

RainDrop Sense Operator’s Manual

LCN 50-04344 Rev. D 4-14

Page 47

Chapter 1:

CHAPTER 5

Chapter 5:

Performing a Sense Run

This chapter covers the following topics:

Introduction page 5-2

Gathering Supplies page 5-2

Starting a Sense Run page 5-3

Completing the ICS Setup page 5-10

Checking the Status Indicators page 5-10

Completing the Run Data Tab page 5-12

Completing the Run Info Tab page 5-15

5

Completing the Run Tabs Using the Import Function page 5-16

Using Email Notification page 5-16

Performing the Run page 5-18

Canceling a Run page 5-20

Handling Data page 5-21

Exporting Data page 5-22

Moving Data Files page 5-23

LCN 50-04344 Rev. D 5-1

Page 48

Introduction

Perform the operations described in this chapter on the RainDrop® Sense instrument. This

procedure requires a number of consumables (available from RainDance Technologies

other manufacturers).

Note: For the list of required consumables, see “RainDrop® Consumables and Equipment”

on page A-1.

This chapter describes how to start a run on the RainDrop Sense instrument. Some of the

steps involve preparing the physical components of the system and some of them take place

within the RainDrop ICS.

For detailed information the ICS software, see Chapter 4 and Chapter 6.

Note: Extraneous clusters have been noted in 50ul samples run in the FAST mode on the

Sense instrument. For the highest quality data we recommend limiting sample volumes to

25ul if the samples are to be run in the FAST mode on the Sense instrument.

RainDrop Sense Operator’s Manual

®

and

Gathering Supplies

To start a run on the RainDrop Sense instrument, have the following equipment and supplies

available:

Gloves, nitrile or latex

Sense Chip, P/N 30-06086

Sense Chip Compression Plate, P/N 30-06423

Drive Oil, shipped in syringes, P/N 30-07117

PCR tube strip containing emulsion generated on the RainDance Source instrument

and following thermal cycling.

For Standard Mode detection, standard PCR Tube Strip Caps (P/N 40-06087)

For Fast Mode detection, High Speed Caps (P/N 40-08286)

LCN 50-04344 Rev. D 5-2

Page 49

Starting a Sense Run

This procedure assumes you have prepared your sample and that you have assembled all

the necessary equipment and supplies. It also assumes that you have completed thermal

cycling the sample. It shows you how to start a run on the RainDrop Sense instrument.

unch the ICS software for the Sense instrument and log in.

1. La

RainDrop Sense Operator’s Manual

Figure 5-1: Login Screen

2. Click Start Initialization.

Figure 5-2: Initialization Screen

When you click Start Initialization, the system automatically prepares the instrument

for normal operation. It sets valves and pressures and turns the laser in the barcode

reader off. In addition, it homes the motion control subsystem. Initialization takes

approximately four minutes.

LCN 50-04344 Rev. D 5-3

Page 50

RainDrop Sense Operator’s Manual

Note: If initialization fails, the ICS returns to the Initialization screen after about

fifteen minutes. Contact RainDance Support for assistance. See “RainDance Support”

on page 1-3.

3. Click Se

tup a Run.

Figure 5-3: Instrument Status and Setup a Run Screen

LCN 50-04344 Rev. D 5-4

Page 51

4. Select the Run Info tab.

RainDrop Sense Operator’s Manual

Figure 5-4: Run Info Tab

5. On the Run Info tab, click Open Door. The door on the Sense instrument unlocks

allowing you to lift it to the upright, open position.

6. If ru

nning in Fast Mode, use High Speed Caps. Following thermal cycling, carefully

remove the domed caps (Axygen) and replace with High Speed Caps. Rock the caps

back and forth to seat properly, then press into place. Ensure the cap is secured and

the strip is tightly covered.

A properly covered PCR tube strip has:

A flat cap all the way across

Its tab oriented to the left (over number 1 on the tube strip)

An improperly covered PCR tube strip has:

A bump or buckle

A loosely fitting cap

Its tab to right (over number 8 on the tube strip)

LCN 50-04344 Rev. D 5-5

Page 52

A bump in the cap

7. Lift the door to the fully open position.

.

RainDrop Sense Operator’s Manual

Figure 5-5: Improperly Covered PCR Tube Strip

LCN 50-04344 Rev. D 5-6

Page 53

RainDrop Sense Operator’s Manual

Figure 5-6: Sense Door in Fully Open Position

LCN 50-04344 Rev. D 5-7

Page 54

RainDrop Sense Operator’s Manual

8. Insert a tube strip into the tube strip nest (see Figure 2-3). Orient the tabbed end to the

left.

Figure 5-7: Insert a Tube Strip

9. Remove a Sense Chip from its packaging; for more information on the chip, see see

“RainDrop Sense Chip” on page 2-6. Handle the Sense Chip as follows:

With gloved hands, grasp the chip by its sides.

Do not touch the clear microfluidic chip and its droplet detection region of

interest.

Save the bag the chip comes in for later disposal of the chip.

Do not touch the objective lens.

10. Scan the

chip by clicking Scan in the ICS software. The red scanner light pulses for

10 seconds. Hold the Sense Chip in front of the barcode reader. If the scanner reads

the barcode, it automatically fills in the barcode information. The ICS accepts a

barcode in the 2D Data Matrix format, which allows up to 96 characters of text. You

may hear a subtle beep tone from the Sense instrument.

If the scanner does not read the barcode, the ICS software displays a

message and

allows you to enter the barcode manually. To do so, click the Manual button and

enter the barcode numbers from the label of the chip. In manual format, the ICS

accepts 99 characters of text.

11. In

sert the chip into the Sense instrument. Orient the Sense Chip over the alignment

pins and ensure that the pins are coming through the alignment holes on the chip. Do

not insert it at an angle. The instrument is designed so that the Sense Chip punctures

the caps of the tube strip. Do not apply pressure to the chip after inserting it. It is

important that the instrument is able to make a seal and then puncture the tube caps.

The Sense instrument will not allow you to proceed until the chip is oriented properly.

LCN 50-04344 Rev. D 5-8

Page 55

RainDrop Sense Operator’s Manual

Figure 5-8: Inserting a Sense Chip

12. Locate the Chip Compression Plate; for more information on the plate, see see

“RainDrop Sense Chip Compression Plate” on page 2-7.

13. Place t

When the plate is properly positioned, its RainDance logo should be

he Chip Compression Plate over the Sense chip as shown in Figure 5-9.

facing you, the

plate should be flat, and it should not be movable left to right or front to back.

Figure 5-9: Placing the Chip Compression Plate

After you insert the Chip Compression Plate, you are done setting up the physical

components.

14. Clo

se the door on the Sense instrument.

LCN 50-04344 Rev. D 5-9

Page 56

Completing the ICS Setup

Before starting a run on the Sense instrument, you must complete a number of setup steps.

The steps ensure that the instrument is ready for operation and provide data about the run.

They include:

Check the status of various components.

Complete the Run Data.

Complete the Run Info.

Checking the Status Indicators

Status indicators tell you about the readiness of the instrument.

RainDrop Sense Operator’s Manual

Figure 5-10: System Statuses

Observe the status indicators in the software.

Table 5-1: System Status Indicators

Indicator

Pressure

Ready

Carrier Oil

Drive Oil Indicates the status of the drive oil reservoir. When there is sufficient oil to

Meaning

Indicates the status of the instrument gas pressure. When the pressure is

sufficient, the ready indicator is displayed.

Indicates the status of the carrier oil reservoir. When there is sufficient oil

to complete a run, the ready indicator is displayed. A valid carrier oil lot

number is required for the green check mark to be displayed.

complete a run, the ready indicator is displayed. A valid drive oil lot

number is required for the green check mark to be displayed.

LCN 50-04344 Rev. D 5-10

Page 57

Table 5-1: System Status Indicators

RainDrop Sense Operator’s Manual

Chip

Inserted

Indicates the presence of the Sense Chip. When the Sense Chip is

present and inserted properly, the ready indicator is displayed.

Note: You must scan the chip prior to use; otherwise, the instrument will

not detect it. If you have scanned the chip before inserting it and it is still

not detected, wiggle the chip and try again.

Door Closed Indicates the status of the instrument door. When the door is properly

closed, the ready indicator is displayed.

System

Ready

Indicates the overall status of the instrument. When all the requirements

of the instrument are present and ready for a run, the ready indicator is

displayed.

In addition to satisfying the Status Indicators, in order to start a run you must also have:

Scanned or input the barcode number from a Sense Chip

Clicked Insert Tube Strip to affirm that you have inserted the tube strip

LCN 50-04344 Rev. D 5-11

Page 58

Completing the Run Data Tab

The Run Data tab opens after you click Start Run on the startup screen and contains the

details about the contents of the run. You can enter this information manually or you can

import it from a file you saved on the Source instrument.

RainDrop Sense Operator’s Manual

Figure 5-11: Run Data Tab

Only the following fields on the Run Data tab are required for the run to proceed:

Run Name

Sense Chip barcode lot and serial number

At least one selected lane (indicated by a green check mark)

Your lab procedures determine how much of the optional information

specific situation.

In addition, before you can proceed with the run, you must have

button to indicate that you have inserted the closed tube strip into the instrument.

is necessary for your

clicked the Insert PCR Tube

LCN 50-04344 Rev. D 5-12

Page 59

Table 5-2: Run Data Fields

RainDrop Sense Operator’s Manual

Field Name

Run Name The name of the run. Run name is required and can contain up to 20

Lanes A - H

Lane

Description

Sense Chip Lot

& Serial

Number

Meaning

characters. This is required.

The identifiers for each tube (or lane) on the chip. These fields are not

required. The lane letter identifiers are hard-coded and cannot be

edited.

The text description that you enter. This is not required.

The identifiers for each Sense Chip.

completed when you scan the chip and is required.

This information is automatically

Run Filenames

When the ICS saves data at the end of a run, it uses the information you enter in the fields in

the above table to name the file. It creates one file per lane in a folder named for the Run ID,

as follows:

The filename for one lane of a run looks like this:

<Run ID>-<Lane Letter>-<Lane Description>.fcs

For example: 1302181535-A-ExampleDescription.fcs

The Run ID is the numeric run number from the upper right corner of

appears on both the Run Data tab and the Run Info tab. See “Handling Data” on page 5-21

for more information.

the ICS screen. It

Entering the Run Data

Enter the run data as follows:

1. T

ype the name of the run into the Run Name field.

2. All lan

3. If n

es are selected by default. Deselect any lanes you are not using. At least one

lane must be selected in order for the run to proceed.

ecessary, enter lane information in one of the following ways:

Type the name for the lane manually. When you enter the name manually, the field

limits entry to 99 characters.

LCN 50-04344 Rev. D 5-13

Page 60

RainDrop Sense Operator’s Manual

Scan the barcode from a printout. To do so, place the printout in front of the

barcode reader and click Scan next to the correct lane. When you enter the name

using the scanner, the field limits entry to 96 characters.

Import the lane information as described in see “Completing the Run Tabs Using

the Import Function” on page 5-16.

4. Select the number of droplets you want from the Droplet drop-down.

5. Click Insert PCR Tube to confirm that you have inserted the tube strip into the

instrument.

Note: The Sense Chip field should already display the information you scanned earlier in see

“Starting a Sense Run” on page 5-3.

LCN 50-04344 Rev. D 5-14

Page 61

Completing the Run Info Tab

The fields on the Run Info tab contain information about the run. The only fields on this tab

that are required are the Carrier Oil and Drive Oil fields and only if the instrument is out of one

of these types of oil.

RainDrop Sense Operator’s Manual

Figure 5-12: Run Info Tab

Your lab procedures determine how much of the information is necessary for your specific

situation. Enter the run information as follows:

Table 5-3: Run Info Fields

Field Name

Operator The name of the person performing the run.

PCR Tube ID

Run

Comments

LCN 50-04344 Rev. D 5-15

Meaning

The identifier of the sample to be run.

Any detailed descriptive information you want stored with the run

information.

Page 62

RainDrop Sense Operator’s Manual

Completing the Run Tabs Using the Import Function

To complete the run tabs using the import function:

1. Click Import at the top of the Run Data tab. The import works only with XML files

generated by the Source instrument. The page displays a list of runs.

2. Locate the file to import and click on it.

3. ICS imports only the following fields:

On the Run Data tab:

Run Name

Lane information

On the Run Info tab:

Operator

PCR Tube ID

Run Comments

4. Complete any other of the optional fields, as needed.

Using Email Notification

The RainDrop Sense instrument is located in a lab space which may be a distance from your

desk or usual work area. Email Notification allows you to receive messages when a run is

finished, so that you do not have to continually check the instrument. Select Send Run

Emails on the Run Info tab. If email addresses have been entered by an Administrator, they

appear in the Email Notification field. You can leave these addresses as is, edit them, or add

to them. Notifications are sent to those addresses.

Note: Email notification does not support text messaging.

Setting Up Email Notification (Administrator)

Setup Email Notification as needed. You do not have to edit these settings for each run. You

can establish email settings and then not change them unless you need to change who is

notified at the end of a run.

To enter email addresses:

1. Select Setup Email from the Actions menu. The Email dialog opens.

2. Enter email addresses in the Email Notification field, separated by semi-colons.

These email addresses will appear on the Run Info tab by default.

3. Select Send Run Emails, if you want this to be the default action.

LCN 50-04344 Rev. D 5-16

Page 63

RainDrop Sense Operator’s Manual

4. Click Save to save the new addresses. Click Close to dismiss the dialog.

Email Messages

Email messages contain the following information:

Table 5-4: Email Message Data

Field Name What is reported

RainDance ID

Run Name The name the user entered in the Run Name field prior to

Description

Start Time The date and time the run was started

End Time

Sample Info For each sample, it lists: Lane, Sample Description, Droplets,

Total Samples The number of samples attempted

Samples

Succe

Samples Failed The number of samples that generated an error, including any

Errors All errors encountered during the run

ssful

The serial number of the instrument

beginning the run. If the user does not enter a Run Name, this

lists a name provided by the RainDrop Sense instrument.

The comments entered by the user at run time, if any

The date and time the run ended

CV (coefficient of variance), Read Length, and Status

The number of samples that successfully ran without errors

samples not processed because the run was stopped because

of a prior/fatal error

LCN 50-04344 Rev. D 5-17

Page 64

Performing the Run

After you have entered the required run data, you are ready to begin the run.

RainDrop Sense Operator’s Manual

1. Click the Start Run bu

progress as shown in the following image.

tton. The screen displays information about the Sense run in

Figure 5-13: Sense Run Screen

The center of the screen displays information about which sample is being processed.

The right side of the screen displays information about the progress of the run.

2. Whe

3. Lift the

4. T

LCN 50-04344 Rev. D 5-18

n the sample is done, the door unlocks automatically.

door to its full open position.

o minimize the potential for contaminating the lab environment with the amplicon,

return the used chip to the bag it came in and discard it in a solid waste disposal

container.

Page 65

The ICS displays the Run Complete screen.

RainDrop Sense Operator’s Manual

Figure 5-14: Sense Run Complete Screen

5. Click View Run Report to review the run data.

6. Click Sa

ve and Close. ICS saves the data from the run in a file in FCS format, which

can be read by the RainDrop Analyst software.

Note:

As stated above, the instrument door unlocks after the run is complete. If you

accidentally close the door and still need access, click Open Door to open it.

LCN 50-04344 Rev. D 5-19

Page 66

Canceling a Run

If you want to stop a run after you have started filling out the Run Data tab, but before clicking

Start Run, click Cancel. This brings you back to the Instrument Status and Setup a Run

Screen (see

If you want to stop a run after clicking Start Run, click the Abort button. This brings you to the

Run Completion screen.

Figure 5-3) and blanks out any data you have entered for this run.

RainDrop Sense Operator’s Manual

LCN 50-04344 Rev. D 5-20

Page 67

Handling Data

The data from Sense runs is collected on the hard drive of the ICS Workstation. Files are

stored in folders on the D drive named for their runs within a RainDance folder as follows:

D:\RainDance\RunLogs\<RunID>

The <RunID> is displayed in the upper right corner of the ICS screen on both the Run Data

tab and the Run Info tab.

The Run ID is built on the date and time as follows: YYMMDDHHMM. In the above image, the

number 1302181529 represents 3:29 pm on February 18, 2013. The Sense ICS creates the

folder when you click Start Run.

Upon completing the run, the Sense ICS creates one FCS file per lane within the Run ID

folder. The filename for one lane of a run looks like this:

<RunID>-<Lane Letter>-<Lane Description>.fcs

For example: 1302181529-A-ExampleDescription.fcs

RainDrop Sense Operator’s Manual

The lane letter and lane description come from data you enter on the Run Data tab. See

“Completing the Run Data Tab” on page 5-12 for more information.

LCN 50-04344 Rev. D 5-21

Page 68

Exporting Data

The Export Data function allows you to search for previous runs and to save that run data to

either the same or a new location. This allows you to move your FCS files from one location

to another to make them available for use by other applications such as analysis software. To

export data:

1. La

RainDrop Sense Operator’s Manual

unch the ICS as you normally do. See “Starting the ICS Application” on page 4-2.

2. Click Export Data.

The Export Data screen opens.

Figure 5-15: Export Data Screen

3. Use the Start Date and End Date fields to specify a range for the data. Click Update

List to tell ICS to display only data that fall between the dates you enter.

4. Select o

runs or Ctrl+Click to select non-contiguous runs.