Page 1

Features

• Compatible with MCS-51

• 2K Bytes of Reprogrammable Flash Memory

– Endurance: 1,000 Write/Erase Cycles

• 2.7V to 6V Operating Range

• Fully Static Operation: 0 Hz to 24 MHz

• Two-level Program Memory Lock

• 128 x 8-bit Internal RAM

• 15 Programmable I/O Lines

• Two 16-bit Timer/Counters

• Six Interrupt Sources

• Programmable Serial UART Channel

• Direct LED Drive Outputs

• On-chip Analog Comparator

• Low-power Idle and Power-down Modes

™

Products

8-bit

Microcontroller

with 2K Bytes

Description

The AT89C2051 is a low-voltage, high-performance CMOS 8-bit microcomputer with

2K bytes of Flash programmable and erasable read only memory (PEROM). The

device is manufactured using Atmel’s high-density nonvolatile memory technology

and is compatible with the industry-standard MCS-51 instruction set. By combining a

versatile 8-bit CPU with Flash on a monolithic chip, the Atmel AT89C2051 is a powerful microcomputer which provides a highly-flexible and cost-effective solution to many

embedded control applications.

The AT89C2051 provides the following standard features: 2K bytes of Flash, 128

bytes of RAM, 15 I/O lines, two 16-bit timer/counters, a five vector two-level interrupt

architecture, a full duplex serial port, a precision analog comparator, on-chip oscillator

and clock circuitry. In addition, the AT89C2051 is designed with static logic for operation down to zero frequency and supports two software selectable power saving

modes. The Idle Mode stops the CPU while allowing the RAM, timer/counters, serial

port and interrupt system to continue functioning. The power-down mode saves the

RAM contents but freezes the oscillator disabling all other chip functions until the next

hardware reset.

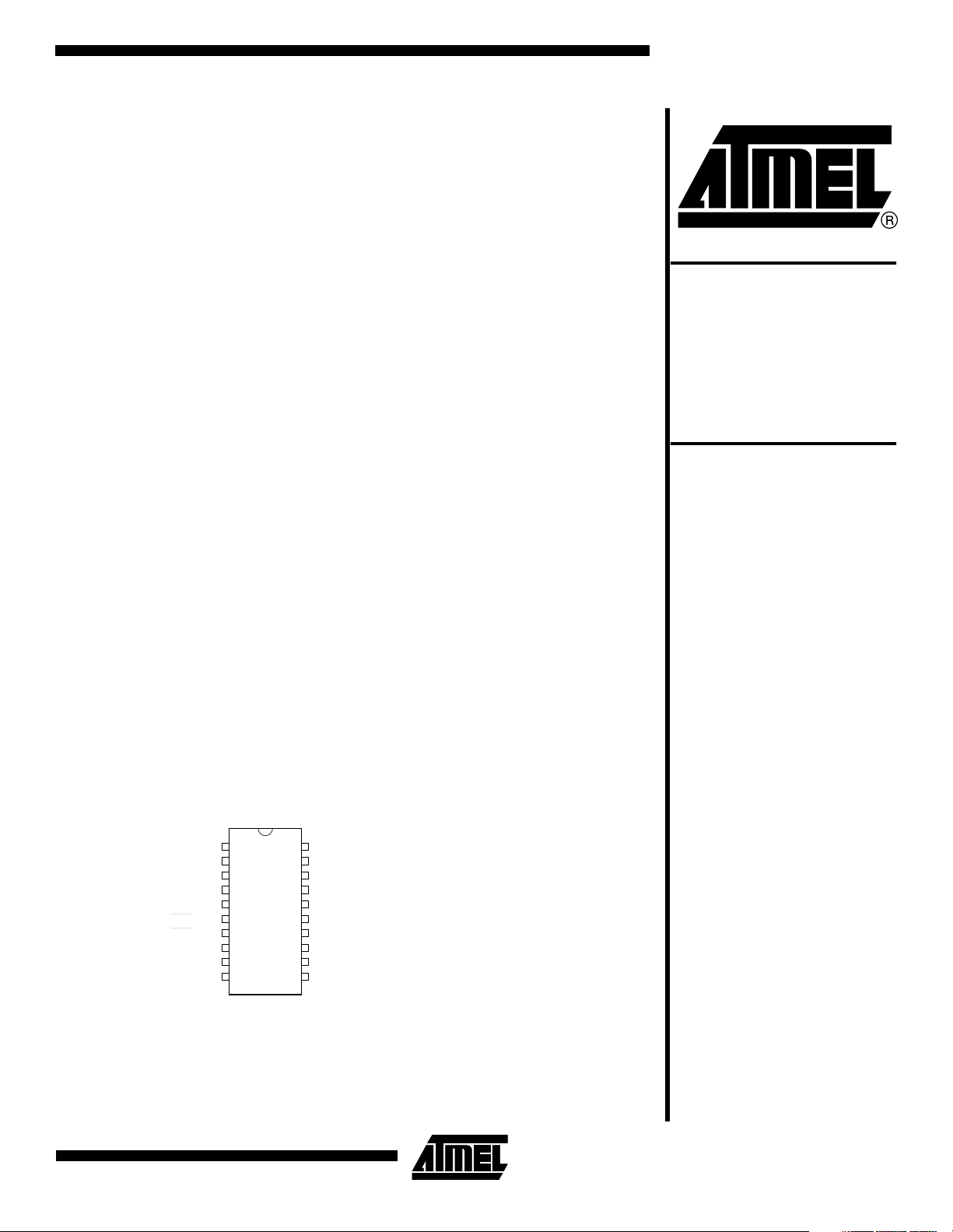

Pin Configuration

PDIP/SOIC

RST/VPP

(RXD) P3.0

(TXD) P3.1

XTAL2

XTAL1

(INT0) P3.2

(INT1) P3.3

(TO) P3.4

(T1) P3.5

GND

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

VCC

P1.7

P1.6

P1.5

P1.4

P1.3

P1.2

P1.1 (AIN1)

P1.0 (AIN0)

P3.7

Flash

AT89C2051

Rev. 0368E–02/00

1

Page 2

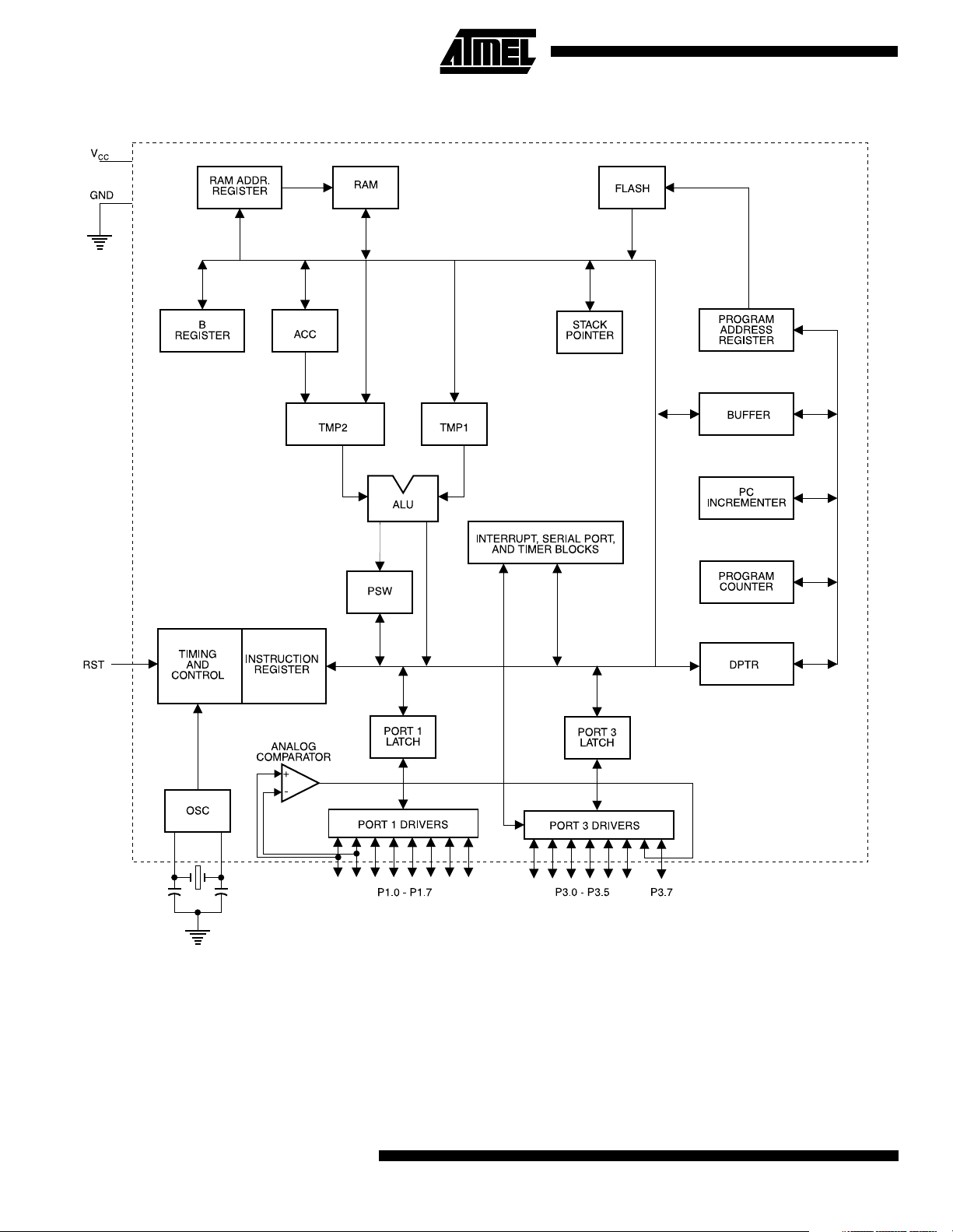

Block Diagram

2

AT89C2051

Page 3

AT89C2051

Pin Description

VCC

Supply voltage.

GND

Ground.

Port 1

Port 1 is an 8-bit bi-irectional I/O port. Port pins P1.2 to

P1.7 provide internal pullups. P1.0 and P1.1 require external pullups. P1.0 and P1.1 also serve as the positive input

(AIN0) and the negative input (AIN1), respectively, of the

on-chip precision analog comparator. The Port 1 output

buffers can sink 20 mA and can drive LED displays directly.

When 1s are written to Port 1 pins, they can be used as

inputs. When pins P1.2 to P1.7 are used as inputs and are

externally pulled low, they will source current (I

of the internal pullups.

Port 1 also receives code data during Flash programming

and verification.

Port 3

Port 3 pins P3.0 to P3.5, P3.7 are seven bi-irectional I/O

pins with internal pullups. P3.6 is hard-wired as an input to

the output of the on-chip comparator and is not accessible

as a general purpose I/O pin. The Port 3 output buffers can

sink 20 mA. When 1s are written to Port 3 pins they are

pulled high by the internal pullups and can be used as

inputs. As inputs, Port 3 pins that are externally being

pulled low will source current (I

) because of the pullups.

IL

Port 3 also serves the functions of various special features

of the AT89C2051 as listed below:

) because

IL

Each machine cycle takes 12 oscillator or clock cycles.

XTAL1

Input to the inverting oscillator amplifier and input to the

internal clock operating circuit.

XTAL2

Output from the inverting oscillator amplifier.

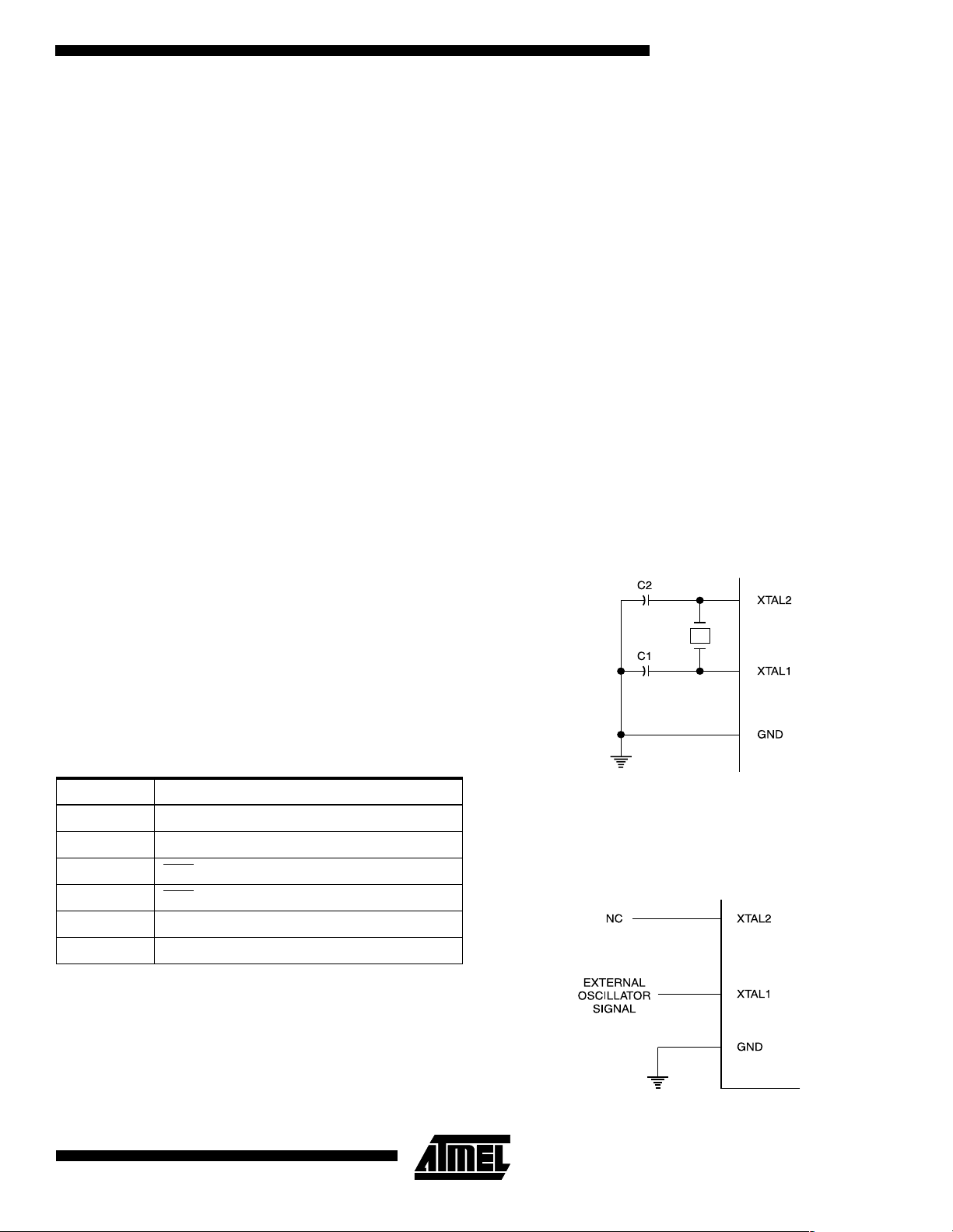

Oscillator Characteristics

XTAL1 and XTAL2 are the input and output, respectively,

of an inverting amplifier which can be configured for use as

an on-chip oscillator, as shown in Figure 1. Either a quartz

crystal or ceramic resonator may be used. To drive the

device from an external clock source, XTAL2 should be left

unconnected while XTAL1 is driven as shown in Figure 2.

There are no requirements on the duty cycle of the external

clock signal, since the input to the internal clocking circuitry

is through a divide-by-two flip-flop, but minimum and maximum voltage high and low time specifications must be

observed.

Figure 1. Oscillator Connections

Port Pin Alternate Functions

P3.0 RXD (serial input port)

P3.1 TXD (serial output port)

P3.2 INT0

P3.3 INT1

P3.4 T0 (timer 0 external input)

P3.5 T1 (timer 1 external input)

(external interrupt 0)

(external interrupt 1)

Port 3 also receives some control signals for Flash programming and verification.

RST

Reset input. All I/O pins are reset to 1s as soon as RST

goes high. Holding the RST pin high for two machine

cycles while the oscillator is running resets the device.

Note: C1, C2 = 30 pF ± 10 pF for Crystals

= 40 pF ± 10 pF for Ceramic Resonators

Figure 2. External Clock Drive Configuration

3

Page 4

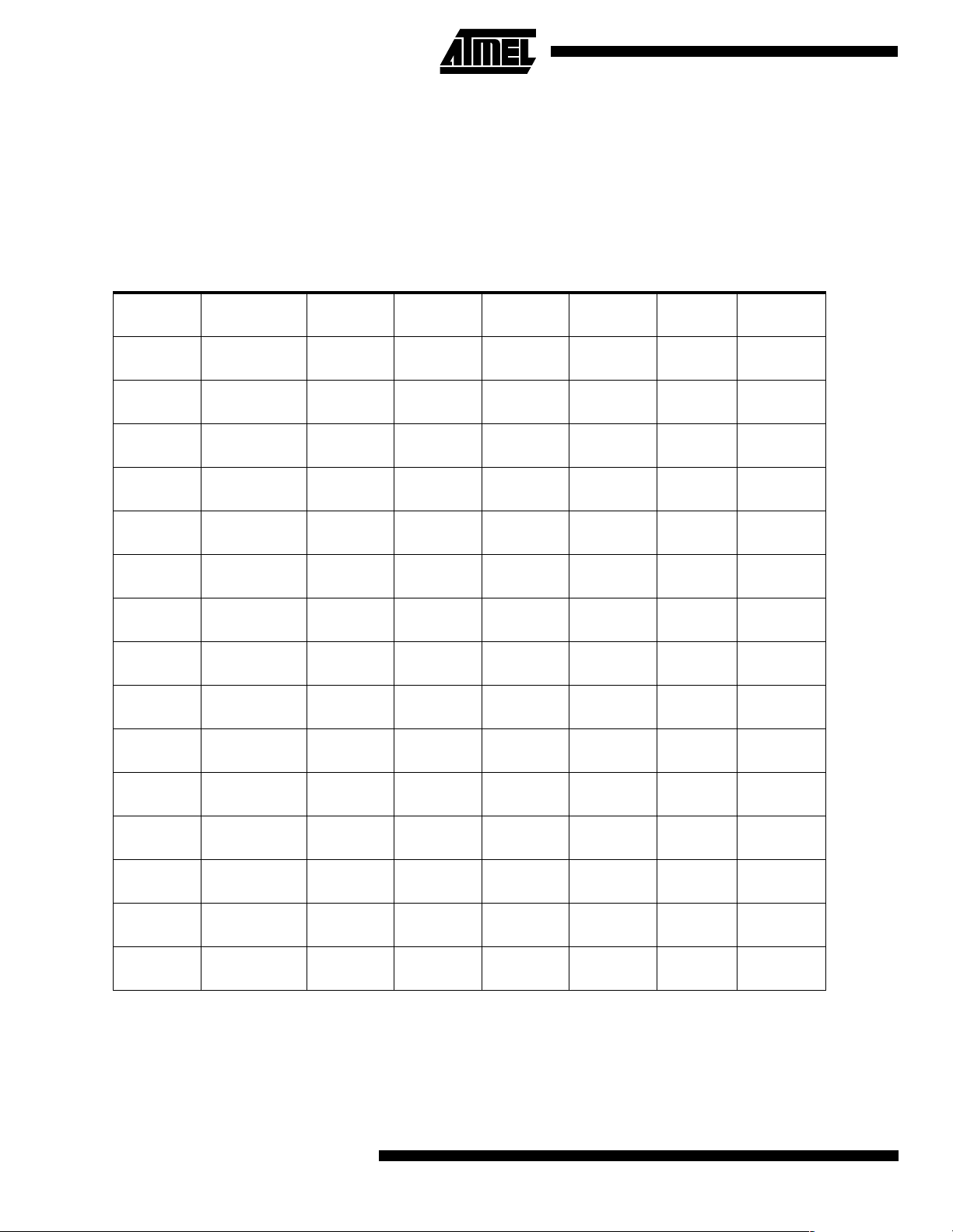

Special Function Registers

A map of the on-chip memory area called the Special Function Register (SFR) space is shown in the table below.

Note that not all of the addresses are occupied, and unoccupied addresses may not be implemented on the chip.

Read accesses to these addresses will in general return

random data, and write accesses will have an indeterminate effect.

User software should not write 1s to these unlisted locations, since they may be used in future products to invoke

new features. In that case, the reset or inactive values of

the new bits will always be 0.

Table 1. AT89C2051 SFR Map and Reset Values

0F8H 0FFH

0F0H B

00000000

0E8H 0EFH

0E0H ACC

00000000

0D8H 0DFH

0D0H PSW

00000000

0C8H 0CFH

0F7H

0E7H

0D7H

0C0H 0C7H

0B8H IP

XXX00000

0B0H P3

11111111

0A8H IE

0XX00000

0A0H 0A7H

98H SCON

00000000

90H P1

11111111

88H TCON

00000000

80H SP

SBUF

XXXXXXXX

TMOD

00000000

00000111

TL0

00000000

DPL

00000000

TL1

00000000

DPH

00000000

TH0

00000000

TH1

00000000

PCON

0XXX0000

0BFH

0B7H

0AFH

9FH

97H

8FH

87H

4

AT89C2051

Page 5

AT89C2051

Restrictions on Certain Instructions

The AT89C2051 and is an economical and cost-effective

member of Atmel’s growing family of microcontrollers. It

contains 2K bytes of flash program memory. It is fully compatible with the MCS-51 architecture, and can be

programmed using the MCS-51 instruction set. However,

there are a few considerations one must keep in mind

when utilizing certain instructions to program this device.

All the instructions related to jumping or branching should

be restricted such that the destination address falls within

the physical program memory space of the device, which is

2K for the AT89C2051. This should be the responsibility of

the software programmer. For example, LJMP 7E0H

would be a valid instruction for the AT89C2051 (with 2K of

memory), whereas LJMP 900H would not.

1. Branching instructions:

LCALL, LJMP, ACALL, AJMP, SJMP, JMP @A+DPTR

These unconditional branching instructions will execute

correctly as long as the programmer keeps in mind that the

destination branching address must fall within the physical

boundaries of the program memory size (locations 00H to

7FFH for the 89C2051). Violating the physical space limits

may cause unknown program behavior.

CJNE [...], DJNZ [...], JB, JNB, JC, JNC, JBC, JZ, JNZ With

these conditional branching instructions the same rule

above applies. Again, violating the memory boundaries

may cause erratic execution.

For applications involving interrupts the normal interrupt

service routine address locations of the 80C51 family architecture have been preserved.

2. MOVX-related instructions, Data Memory:

The AT89C2051 contains 128 bytes of internal data memory. Thus, in the AT89C2051 the stack depth is limited to

128 bytes, the amount of available RAM. External DATA

memory access is not supported in this device, nor is external PROGRAM memory execution. Therefore, no MOVX

[...] instructions should be included in the program.

A typical 80C51 assembler will still assemble instructions,

even if they are written in violation of the restrictions mentioned above. It is the responsibility of the controller user to

know the physical features and limitations of the device

being used and adjust the instructions used

correspondingly.

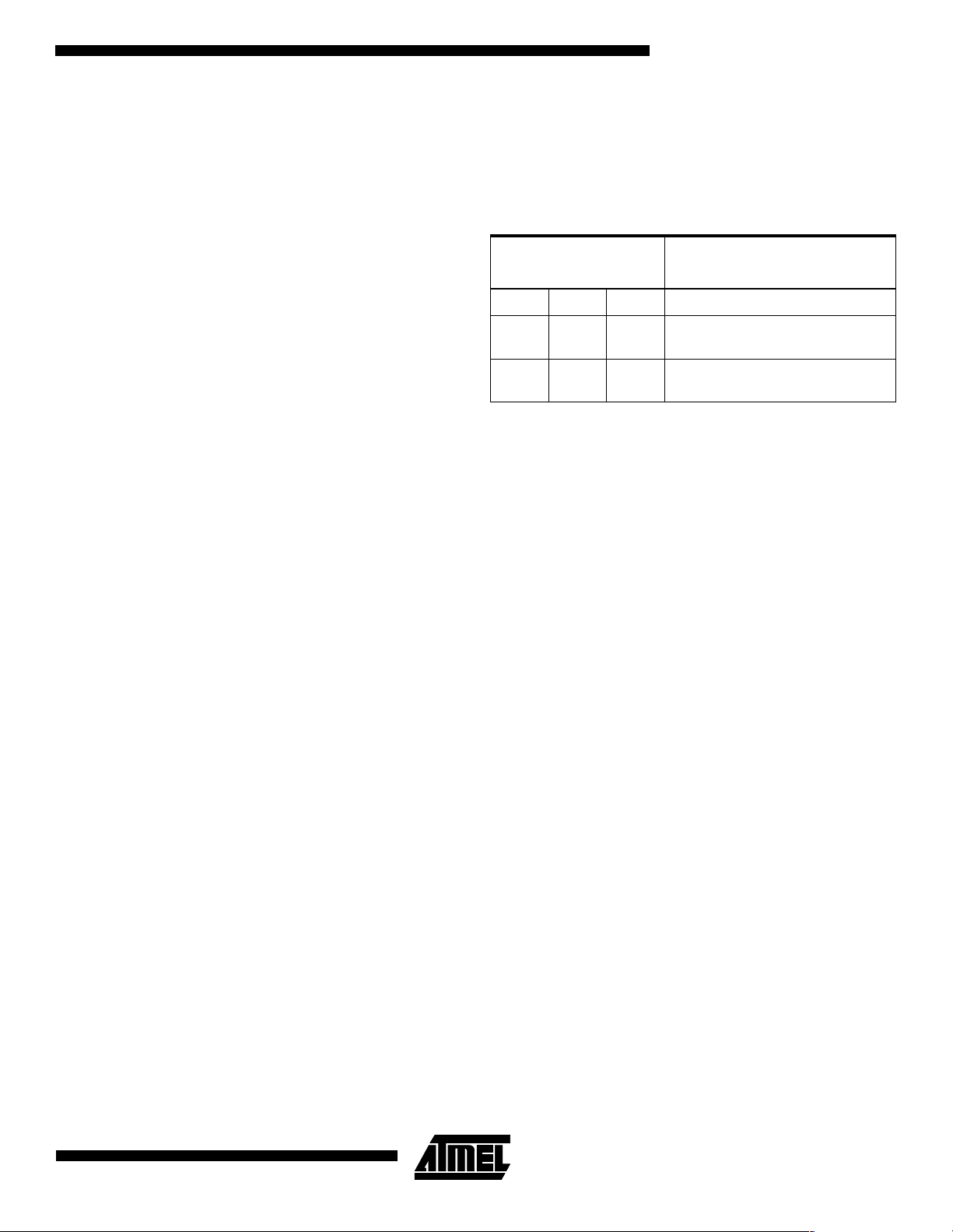

Program Memory Lock Bits

On the chip are two lock bits which can be left unprogrammed (U) or can be programmed (P) to obtain the

additional features listed in the table below:

Lock Bit Protection Modes

Program Lock Bits

LB1 LB2 Protection Type

1 U U No program lock features.

2 P U Further programming of the Flash

is disabled.

3 P P Same as mode 2, also verify is

disabled.

Note: 1. The Lock Bits can only be erased with the Chip Erase

operation.

(1)

Idle Mode

In idle mode, the CPU puts itself to sleep while all the onchip peripherals remain active. The mode is invoked by

software. The content of the on-chip RAM and all the special functions registers remain unchanged during this

mode. The idle mode can be terminated by any enabled

interrupt or by a hardware reset.

P1.0 and P1.1 should be set to “0” if no external pullups are

used, or set to “1” if external pullups are used.

It should be noted that when idle is terminated by a hardware reset, the device normally resumes program

execution, from where it left off, up to two machine cycles

before the internal reset algorithm takes control. On-chip

hardware inhibits access to internal RAM in this event, but

access to the port pins is not inhibited. To eliminate the

possibility of an unexpected write to a port pin when Idle is

terminated by reset, the instruction following the one that

invokes Idle should not be one that writes to a port pin or to

external memory.

Power-down Mode

In the power down mode the oscillator is stopped, and the

instruction that invokes power down is the last instruction

executed. The on-chip RAM and Special Function Registers retain their values until the power down mode is

terminated. The only exit from power down is a hardware

reset. Reset redefines the SFRs but does not change the

on-chip RAM. The reset should not be activated before V

is restored to its normal operating level and must be held

active long enough to allow the oscillator to restart and

stabilize.

P1.0 and P1.1 should be set to “0” if no external pullups are

used, or set to “1” if external pullups are used.

CC

5

Page 6

Programming The Flash

The AT89C2051 is shipped with the 2K bytes of on-chip

PEROM code memory array in the erased state (i.e., contents = FFH) and ready to be programmed. The code

memory array is programmed one byte at a time. Once the

array is programmed, to re-program any non-blank byte,

the entire memory array needs to be erased electrically.

Internal Address Counter: The AT89C2051 contains an

internal PEROM address counter which is always reset to

000H on the rising edge of RST and is advanced by applying a positive going pulse to pin XTAL1.

Programming Algorithm: To program the AT89C2051,

the following sequence is recommended.

1. Power-up sequence:

Apply power between V

Set RST and XTAL1 to GND

2. Set pin RST to “H”

Set pin P3.2 to “H”

3. Apply the appropriate combination of “H” or “L” logic

levels to pins P3.3, P3.4, P3.5, P3.7 to select one of the

programming operations shown in the PEROM Programming Modes table.

To Program and Verify the Array:

4. Apply data for Code byte at location 000H to P1.0 to

P1.7.

5. Raise RST to 12V to enable programming.

6. Pulse P3.2 once to program a byte in the PEROM array

or the lock bits. The byte-write cycle is self-timed and

typically takes 1.2 ms.

7. To verify the programmed data, lower RST from 12V to

logic “H” level and set pins P3.3 to P3.7 to the appropiate

levels. Output data can be read at the port P1 pins.

8. To program a byte at the next address location, pulse

XTAL1 pin once to advance the internal address

counter. Apply new data to the port P1 pins.

9. Repeat steps 5 through 8, changing data and advancing

the address counter for the entire 2K bytes array or until

the end of the object file is reached.

10.Power-off sequence:

set XTAL1 to “L”

set RST to “L”

Turn V

Data

Polling: The AT89C2051 features Data Polling to

indicate the end of a write cycle. During a write cycle, an

attempted read of the last byte written will result in the complement of the written data on P1.7. Once the write cycle

has been completed, true data is valid on all outputs, and

power off

CC

and GND pins

CC

the next cycle may begin. Data

after a write cycle has been initiated.

Ready/Busy

be monitored by the RDY/BSY

pulled low after P3.2 goes High during programming to indicate BUSY. P3.1 is pulled High again when programming is

done to indicate READY.

Program Verify: If lock bits LB1 and LB2 have not been

programmed code data can be read back via the data lines

for verification:

1. Reset the internal address counter to 000H by bringing

RST from “L” to “H”.

2. Apply the appropriate control signals for Read Code data

and read the output data at the port P1 pins.

3. Pulse pin XTAL1 once to advance the internal address

counter.

4. Read the next code data byte at the port P1 pins.

5. Repeat steps 3 and 4 until the entire array is read.

The lock bits cannot be verified directly. Verification of the

lock bits is achieved by observing that their features are

enabled.

Chip Erase: The entire PEROM array (2K bytes) and the

two Lock Bits are erased electrically by using the proper

combination of control signals and by holding P3.2 low for

10 ms. The code array is written with all “1”s in the Chip

Erase operation and must be executed before any nonblank memory byte can be re-programmed.

Reading the Signature Bytes: The signature bytes are

read by the same procedure as a normal verification of

locations 000H, 001H, and 002H, except that P3.5 and

P3.7 must be pulled to a logic low. The values returned are

as follows.

(000H) = 1EH indicates manufactured by Atmel

(001H) = 21H indicates 89C2051

: The Progress of byte programming can also

Polling may begin any time

output signal. Pin P3.1 is

Programming Interface

Every code byte in the Flash array can be written and the

entire array can be erased by using the appropriate combination of control signals. The write operation cycle is selftimed and once initiated, will automatically time itself to

completion.

All major programming vendors offer worldwide support for

the Atmel microcontroller series. Please contact your local

programming vendor for the appropriate software revision.

6

AT89C2051

Page 7

AT89C2051

PP

Flash Programming Modes

Mode RST/VPP P3.2/PROG P3.3 P3.4 P3.5 P3.7

Write Code Data

(1)(3)

12V L H H H

Read Code Data

Write Lock Bit - 1 12V H H H H

Chip Erase 12V H L L L

Read Signature Byte H H L L L L

Notes: 1. The internal PEROM address counter is reset to 000H on the rising edge of RST and is advanced by a positive pulse at

2. Chip Erase requires a 10 ms PROG

3. P3.1 is pulled Low during programming to indicate RDY/BSY

(1)

XTAL 1 pin.

HHLLHH

Bit - 2 12V H H L L

(2)

pulse.

.

Figure 3. Programming the Flash Memory Figure 4. Verifying the Flash Memory

7

Page 8

Flash Programming and Verification Characteristics

TA = 0°C to 70°C, VCC = 5.0 ± 10%

Symbol Parameter Min Max Units

V

PP

I

PP

t

DVGL

t

GHDX

t

EHSH

t

SHGL

t

GHSL

t

GLGH

t

ELQV

t

EHQZ

t

GHBL

t

WC

t

BHIH

t

IHIL

Programming Enable Voltage 11.5 12.5 V

Programming Enable Current 250 µA

Data Setup to PROG Low 1.0 µs

Data Hold after PROG 1.0 µs

P3.4 (ENABLE) High to V

PP

VPP Setup to PROG Low 10 µs

VPP Hold after PROG 10 µs

PROG Width 1 110 µs

ENABLE Low to Data Valid 1.0 µs

Data Float after ENABLE 01.0 µs

PROG High to BUSY Low 50 ns

Byte Write Cycle Time 2.0 ms

RDY/BSY\ to Increment Clock Delay 1.0 µs

Increment Clock High 200 ns

Note: 1. Only used in 12-volt programming mode.

Flash Programming and Verification Waveforms

1.0 µs

8

AT89C2051

Page 9

AT89C2051

Absolute Maximum Ratings*

Operating Temperature ................................. -55°C to +125°C

Storage Temperature..................................... -65°C to +150°C

Voltage on Any Pin

with Respect to Ground.....................................-1.0V to +7.0V

Maximum Operating Voltage ............................................ 6.6V

DC Output Current...................................................... 25.0 mA

DC Characteristics

TA = -40°C to 85°C, VCC = 2.0V to 6.0V (unless otherwise noted)

Symbol Parameter Condition Min Max Units

*NOTICE: Stresses beyond those listed under “Absolute

Maximum Ratings” may cause permanent damage to the device. This is a stress rating only and

functional operation of the device at these or any

other conditions beyond those indicated in the

operational sections of this specification is not

implied. Exposure to absolute maximum rating

conditions for extended periods may affect device

reliability.

V

IL

V

IH

V

IH1

V

OL

V

OH

I

IL

Input Low-voltage -0.5 0.2 V

Input High-voltage (Except XTAL1, RST) 0.2 V

Input High-voltage (XTAL1, RST) 0.7 V

Output Low-voltage

(Ports 1, 3)

Output High-voltage

(Ports 1, 3)

Logical 0 Input Current

(1)

IOL = 20 mA, VCC = 5V

I

= 10 mA, VCC = 2.7V

OL

IOH = -80 µA, VCC = 5V ± 10% 2.4 V

IOH = -30 µA 0.75 V

I

= -12 µA 0.9 V

OH

VIN = 0.45V -50 µA

+ 0.9 V

CC

CC

CC

CC

CC

V

CC

- 0.1 V

CC

+ 0.5 V

+ 0.5 V

0.5 V

(Ports 1, 3)

I

TL

Logical 1 to 0 Transition Current

VIN = 2V, VCC = 5V ± 10% -750 µA

(Ports 1, 3)

I

LI

Input Leakage Current

0 < VIN < V

CC

±10 µA

(Port P1.0, P1.1)

V

OS

V

CM

Comparator Input Offset Voltage VCC = 5V 20 mV

Comparator Input Common

0VCCV

Mode Voltage

RRST Reset Pull-down Resistor 50 300 KΩ

C

IO

I

CC

Pin Capacitance Test Freq. = 1 MHz, TA = 25°C10pF

Power Supply Current Active Mode, 12 MHz, VCC = 6V/3V 15/5.5 mA

Power-down Mode

Idle Mode, 12 MHz, V

P1.0 & P1.1 = 0V or V

(2)

VCC = 6V P1.0 & P1.1 = 0V or V

VCC = 3V P1.0 & P1.1 = 0V or V

= 6V/3V

CC

CC

CC

CC

5/1 mA

100 µA

20 µA

Notes: 1. Under steady state (non-transient) conditions, IOL must be externally limited as follows:

Maximum I

Maximum total I

exceeds the test condition, VOL may exceed the related specification. Pins are not guaranteed to sink current greater

If I

OL

per port pin: 20 mA

OL

for all output pins: 80 mA

OL

than the listed test conditions.

2. Minimum VCC for Power-down is 2V.

V

V

9

Page 10

External Clock Drive Waveforms

External Clock Drive

Symbol Parameter

VCC = 2.7V to 6.0V VCC = 4.0V to 6.0V

UnitsMin Max Min Max

1/t

t

CLCL

t

CHCX

t

CLCX

t

CLCH

t

CHCL

CLCL

Oscillator Frequency 0 12 0 24 MHz

Clock Period 83.3 41.6 ns

High Time 30 15 ns

Low Time 30 15 ns

Rise Time 20 20 ns

Fall Time 20 20 ns

10

AT89C2051

Page 11

()

Serial Port Timing: Shift Register Mode Test Conditions

VCC = 5.0V ± 20%; Load Capacitance = 80 pF

12 MHz Osc Variable Oscillator

AT89C2051

Symbol Parameter

t

XLXL

t

QVXH

t

XHQX

t

XHDX

t

XHDV

Serial Port Clock Cycle Time 1.0 12t

Output Data Setup to Clock Rising Edge 700 10t

Output Data Hold after Clock Rising Edge 50 2t

Input Data Hold after Clock Rising Edge 0 0 ns

Clock Rising Edge to Input Data Valid 700 10t

Shift Register Mode Timing Waveforms

CLCL

-133 ns

CLCL

-117 ns

CLCL

-133 ns

CLCL

UnitsMin Max Min Max

µs

AC Testing Input/Output Waveforms

(1)

Note: 1. AC Inputs during testing are driven at VCC - 0.5V for a

logic 1 and 0.45V for a logic 0. Timing measurements

are made at V

min. for a logic 1 and VIL max. for a

IH

logic 0.

Float Waveforms

(1)

Note: 1. For timing purposes, a port pin is no longer floating

when a 100 mV change from load voltage occurs. A

port pin begins to float when 100 mV change frothe

loaded V

OH/VOL

level occurs.

11

Page 12

AT89C2051

TYPICAL ICC - ACTIVE (85°C)

20

15

I

C

C

10

m

5

A

0

0 6 12 18 24

Vcc= 5.0V

Vcc= 6.0V

Vcc= 3.0V

FREQUENCY (MHz)

AT89C2051

TYPICAL ICC - IDLE (85°C)

3

I

2

C

C

1

m

A

0

036912

FREQUENCY (MHz)

Vcc= 5.0V

Vcc= 6.0V

Vcc= 3.0V

12

AT89C2051

TYPICAL ICC vs. VOLTAGE- POWER DOWN (85°C)

20

15

I

C

C

10

µ

5

A

0

3.0V 4.0V 5.0V 6.0V

Vcc VOLTAGE

Notes: 1. XTAL1 tied to GND for ICC (power-down)

2. P.1.0 and P1.1 = V

or GND

CC

3. Lock bits programmed

AT89C2051

Page 13

Ordering Information

AT89C2051

Speed

(MHz)

12 2.7V to 6.0V AT89C2051-12PC

24 4.0V to 6.0V AT89C2051-24PC

Power

Supply Ordering Code Package Operation Range

AT89C2051-12SC

AT89C2051-12PI

AT89C2051-12SI

AT89C2051-24SC

AT89C2051-24PI

AT89C2051-24SI

20P3

20S

20P3

20S

20P3

20S

20P3

20S

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Package Type

20P3 20-lead, 0.300” Wide, Plastic Dual In-line Package (PDIP)

20S 20-lead, 0.300” Wide, Plastic Gull Wing Small Outline (SOIC)

13

Page 14

Packaging Information

20P3, 20-lead, 0.300" Wide, Plastic Dual Inline

Package (PDIP)

Dimensions in Inches and (Millimeters)

JEDEC STANDARD MS-001 AD

1.060(26.9)

.210(5.33)

SEATING

PLANE

.980(24.9)

.900(22.86) REF

MAX

.150(3.81)

.115(2.92)

.110(2.79)

.090(2.29)

.014(.356)

.008(.203)

PIN

1

.070(1.78)

.045(1.13)

.325(8.26)

.300(7.62)

0

REF

15

.430(10.92) MAX

.090(2.29)

.005(.127)

.015(.381) MIN

.022(.559)

.014(.356)

.280(7.11)

.240(6.10)

MAX

MIN

20S, 20-lead, 0.300" Wide, Plastic Gull WIng Small

Outline (SOIC)

Dimensions in Inches and (Millimeters)

0.020 (0.508)

0.013 (0.330)

0.420 (10.7)

0.299 (7.60)

0.393 (9.98)

0.012 (0.305)

0.003 (0.076)

0.291 (7.39)

0.013 (0.330)

0.009 (0.229)

0.105 (2.67)

0.092 (2.34)

PIN 1

0

8

REF

0.035 (0.889)

0.015 (0.381)

.050 (1.27) BSC

0.513 (13.0)

0.497 (12.6)

14

AT89C2051

Page 15

Atmel Headquarters Atmel Operations

Corporate Headquarters

2325 Orchard Parkway

San Jose, CA 95131

TEL (408) 441-0311

FAX (408) 487-2600

Europe

Atmel U.K., Ltd.

Coliseum Business Centre

Riverside Way

Camberley, Surrey GU15 3YL

England

TEL (44) 1276-686-677

FAX (44) 1276-686-697

Asia

Atmel Asia, Ltd.

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimhatsui

East Kowloon

Hong Kong

TEL (852) 2721-9778

FAX (852) 2722-1369

Japan

Atmel Japan K.K.

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

TEL (81) 3-3523-3551

FAX (81) 3-3523-7581

Atmel Colorado Springs

1150 E. Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906

TEL (719) 576-3300

FAX (719) 540-1759

Atmel Rousset

Zone Industrielle

13106 Rousset Cedex

France

TEL (33) 4-4253-6000

FAX (33) 4-4253-6001

Fax-on-Demand

North America:

1-(800) 292-8635

International:

1-(408) 441-0732

e-mail

literature@atmel.com

Web Site

http://www.atmel.com

BBS

1-(408) 436-4309

© Atmel Corporation 2000.

Atmel Corporation makes no warranty for the use of its products, other than those expressly contained in the Company’s standard warranty which is detailed in Atmel’s Terms and Conditions located on the Company’s web site. The Company assumes no responsibility for

any errors which may appear in this document, reserves the right to change devices or specifications detailed herein at any time without

notice, and does not make any commitment to update the information contained herein. No licenses to patents or other intellectual property of Atmel are granted by the Company in connection with the sale of Atmel products, expressly or by implication. Atmel’s products are

not authorized for use as critical components in life support devices or systems.

Marks bearing ® and/or ™ are registered trademarks and trademarks of Atmel Corporation.

Terms and product names in this document may be trademarks of others.

Printed on recycled paper.

0368E–02/00/xM

Loading...

Loading...