Page 1

General Description

The MAXQ7670 is a highly integrated solution for measuring multiple analog signals and outputting the results

on a control area network (CAN) bus. The device operates from a single 5V supply and incorporates a highperformance, 16-bit reduced instruction set computing

(RISC) core, a SAR ADC, and a CAN 2.0B controller,

supporting transfer rates up to 1Mbps. The 10-bit SAR

ADC includes an amplifier with programmable gains of

1V/V or 16V/V, 8 input channels, and conversion rates up

to 250ksps. The eight single-ended ADC inputs can be

configured as four unipolar or bipolar, fully differential

inputs. For single-supply operation, the external 5V supply powers the digital I/Os and two separate integrated

linear regulators that supply the 2.5V digital core and the

3.3V analog circuitry. Each supply rail has a dedicated

power-supply supervisor that provides brownout detection and power-on reset (POR) functions. The 16-bit RISC

microcontroller (µC) includes 64KB (32K x 16) of nonvolatile program/data flash and 2KB (1K x 16) of data

RAM. Other features of the MAXQ7670 include a 4-wire

SPI™ interface, a JTAG interface for in-system programming and debugging, an integrated 15MHz RC oscillator, external crystal oscillator support, a timer/counter

with pulse-width modulation (PWM) capability, and seven

GPIO pins with interrupt and wake-up capability.

The system-on-a-chip (SoC) MAXQ7670 is a µC-based,

smart data acquisition system. As a member of the

MAXQ®family of 16-bit, RISC µCs, the MAXQ7670 is

ideal for low-cost, low-power, embedded-applications

such as automotive, industrial controls, and building

automation. The flexible, modular architecture used in

the MAXQ µCs allows development of targeted products for specific applications with minimal effort.

The MAXQ7670 is available in a 40-pin, 5mm x 5mm

TQFN package, and is specified to operate over the -40°C

to +125°C automotive temperature range.

Applications

Automotive Steering Angle and Torque Sensors

CAN-Based Automotive Sensor Applications

Industrial Control

Building Automation

Features

♦ High-Performance, Low-Power, 16-Bit RISC Core

0.166MHz to 16MHz Operation, Approaching

1MIPs/MHz

Low Power (< 1mA/MIPS, V

DVDD

= +2.5V)

16-Bit Instruction Word, 16-Bit Data Bus

33 Instructions, Most Require Only One Clock

Cycle

16-Level Hardware Stack

16 x 16-Bit, General-Purpose Working Registers

Three Independent Data Pointers with AutoIncrement/Decrement

Low-Power, Divide-by-256, Power-Management

Modes (PMM) and Stop Mode

♦ Program and Data Memory

64KB Internal Nonvolatile Program/Data Flash

2KB Internal Data RAM

♦ SAR ADC

8 Single-Ended/4 Differential Channels,

10-Bit Resolution with No Missing Codes

PGA Gain = 1V/V or 16V/V

250ksps (150.9ksps with PGA Gain = 16V/V)

♦ Timer/Digital I/O Peripherals

CAN 2.0B Controller (15 Message Centers)

Serial Peripheral Interface (SPI)

JTAG Interface (Extensive Debug and Emulation

Support)

Single 16-Bit/Dual 8-Bit Timer/PWM

Seven General-Purpose, Digital I/O Pins with

External Interrupt/Wake-Up Features

♦ Oscillator/Clock Module

Internal Oscillator Supports External Crystal

(8MHz or 16MHz)

Integrated 15MHz RC Oscillator

External Clock Source Operation

Programmable Watchdog Timer

♦ Power-Management Module

Power-On Reset

Power-Supply Supervisor/Brownout Detection

Integrated +2.5V and +3.3V Linear Regulators

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

________________________________________________________________

Maxim Integrated Products

1

19-4384; Rev 0; 11/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Typical Application Circuit and Pin Configuration appear at

end of data sheet.

SPI is a trademark of Motorola, Inc.

MAXQ is a registered trademark of Maxim Integrated Products, Inc.

Ordering Information

PART TEMP RANGE PIN-PACKAGE

MAXQ7670ATL+

40 TQFN-EP*

+

Denotes a lead-free/RoHS-compliant package.

*

EP = Exposed pad.

Note: Some revisions of this device may incorporate deviations from published specifications known as errata. Multiple revisions of

any device may be simultaneously available through various sales channels. For information about device errata, go to:

http://www.maxim-ic.com/errata

.

-40°C to +125°C

Page 2

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

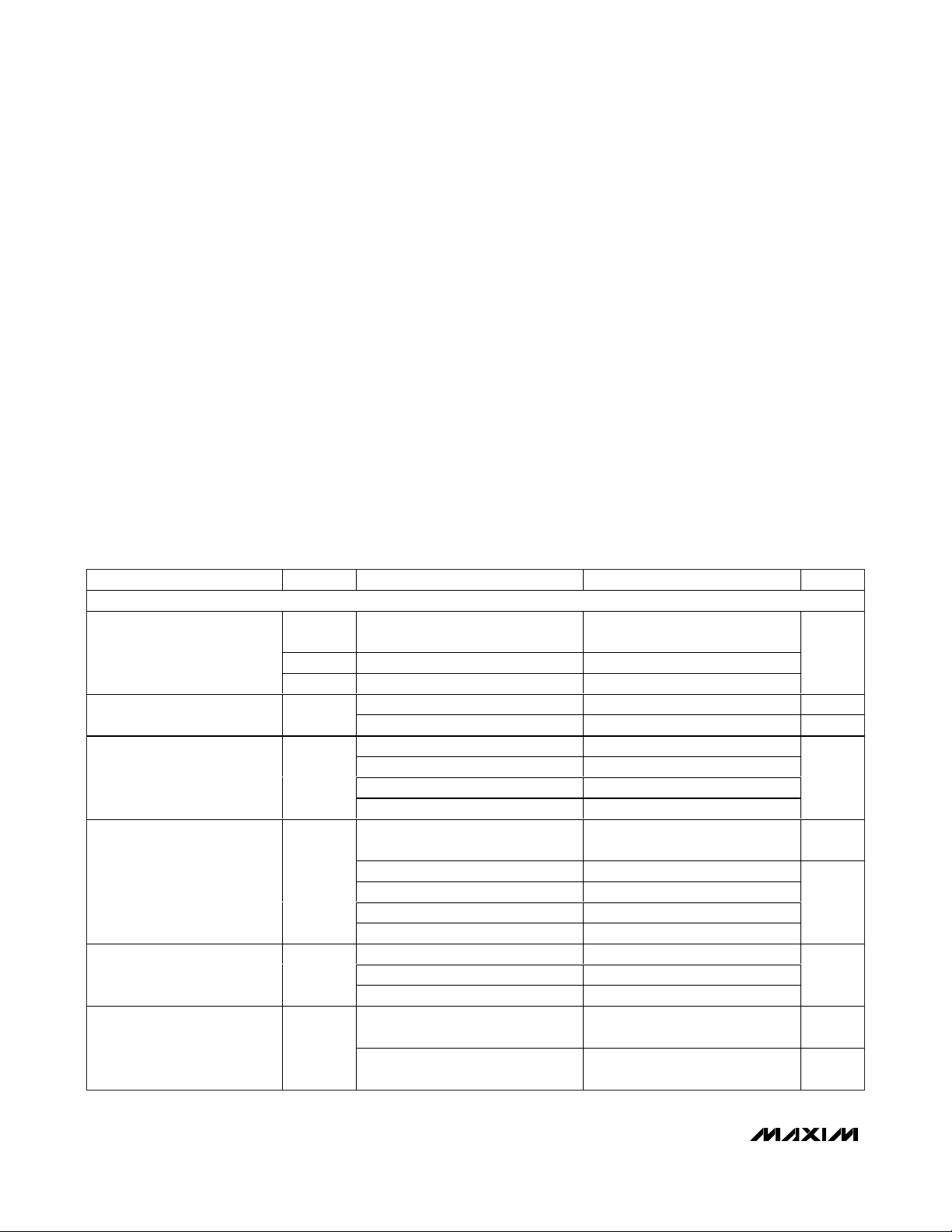

ELECTRICAL CHARACTERISTICS

(V

DVDDIO

= +5.0V, V

AVDD

= +3.3V, V

DVDD

= +2.5V, V

REFADC

= +3.3V, system clock = 16MHz. TA= T

MIN

to T

MAX

, unless otherwise

noted. Typical values are at T

A

= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

DVDD to DGND ........................................................-0.3V to +3V

DVDDIO to GNDIO ................................................-0.3V to +5.5V

AVDD to AGND ........................................................-0.3V to +4V

DGND to GNDIO. ..................................................-0.3V to +0.3V

GNDIO to AGND. ..................................................-0.3V to +0.3V

AGND to DGND.....................................................-0.3V to +0.3V

Analog Inputs to AGND..........................-0.3V to (V

AVDD

+ 0.3V)

RESET, Digital Inputs/Outputs to

GNDIO ............................................-0.3V to (V

DVDDIO

+ 0.3V)

XIN, XOUT to DGND ..............................-0.3V to (V

DVDD

+ 0.3V)

Continuous Power Dissipation (T

A

= +70°C)

40-Pin TQFN (derate 36mW/°C above +70°C) ..........2857mW

Continuous Current into Any Pin.......................................±50mA

Operating Temperature Range .........................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) ................................+300°C

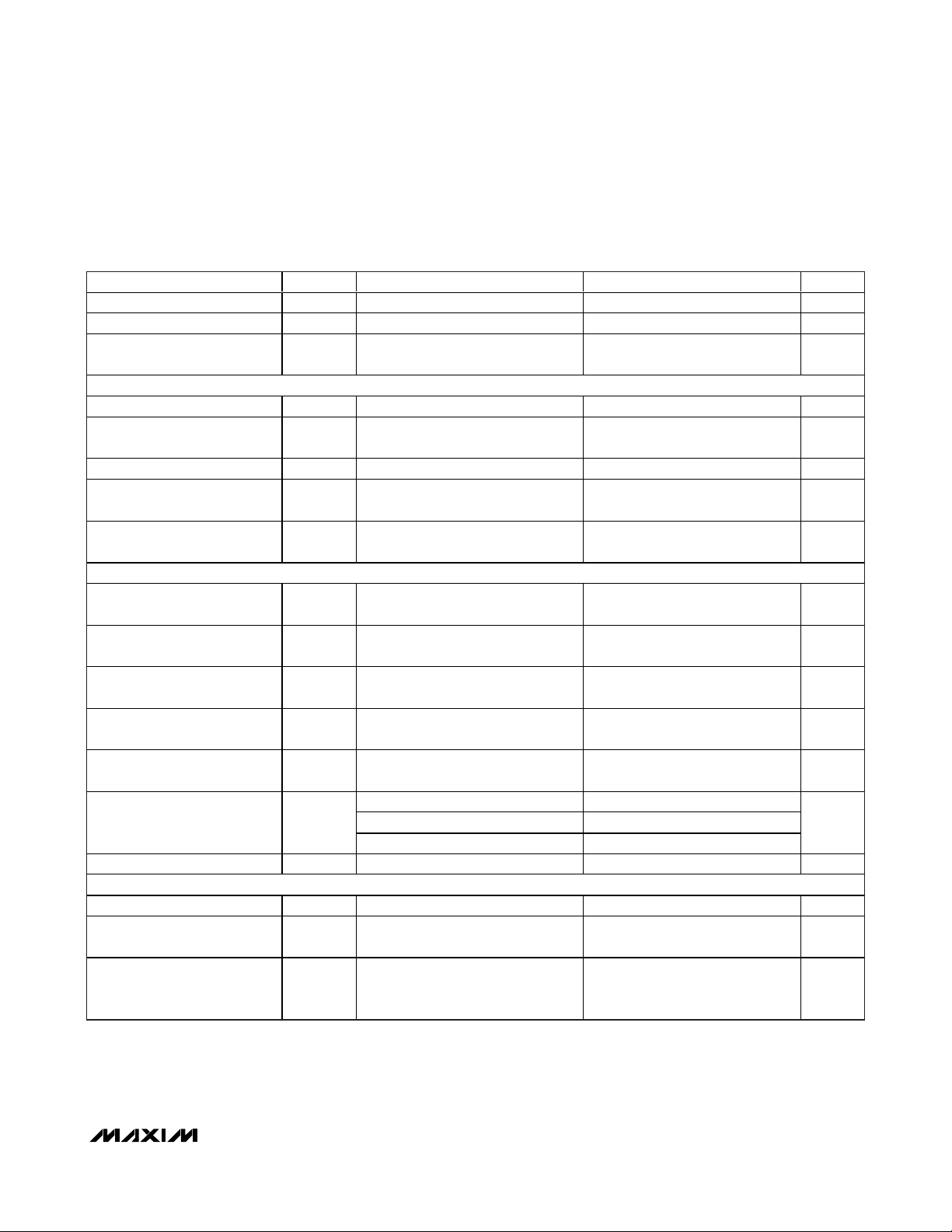

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

POWER REQUIREMENTS

Supply Voltage Ranges

AVDD Supply Current I

Analog Module Incremental

Subfunction Supply Current

DVDD Supply Current I

Digital Peripheral Incremental

Subfunction Supply Current

DVDDIO Supply Current I

DVDD

AVDD LRAPD = 1, AVDD ≤ DV

DVDDIO 4.5 5.0 5.25

AVDD

∆I

AVDD

DVDD

∆I

DVDD

DVDDIO

REGEN2 = DVDDIO, DV

≤ DV

DV

DD

Shutdown (Note 2) 3 10 µA

All analog functions enabled 6 7 mA

ADC, 50ksps, 4MHz ADCCLK 5200

ADC, 250ksps, 4MHz ADCCLK 5600

AVDD brownout interrupt monitor 3

PGA enabled 5500

CPU in stop mode, all peripherals

disabled

High speed/2MHz mode (Note 3) 2.0 2.5

High speed/16MHz mode (Note 4) 11.3

Low speed/625kHz mode (Note 5) 0.95

Program flash erase or write 14 23

DVDDIO brownout reset monitor 1

HF crystal oscillator 60

Internal fixed-frequency oscillator 50

All digital I/Os static at GNDIO or

DV

DDIO

CAN transmitting, timer output

switching (Note 6)

≤ AVDD,

DD

DDIO

DDIO

2.25 2.5 2.75

3.0 3.3 3.6

25 200 µA

220µA

0.2 0.3 mA

V

µA

mA

µA

Page 3

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

_______________________________________________________________________________________ 3

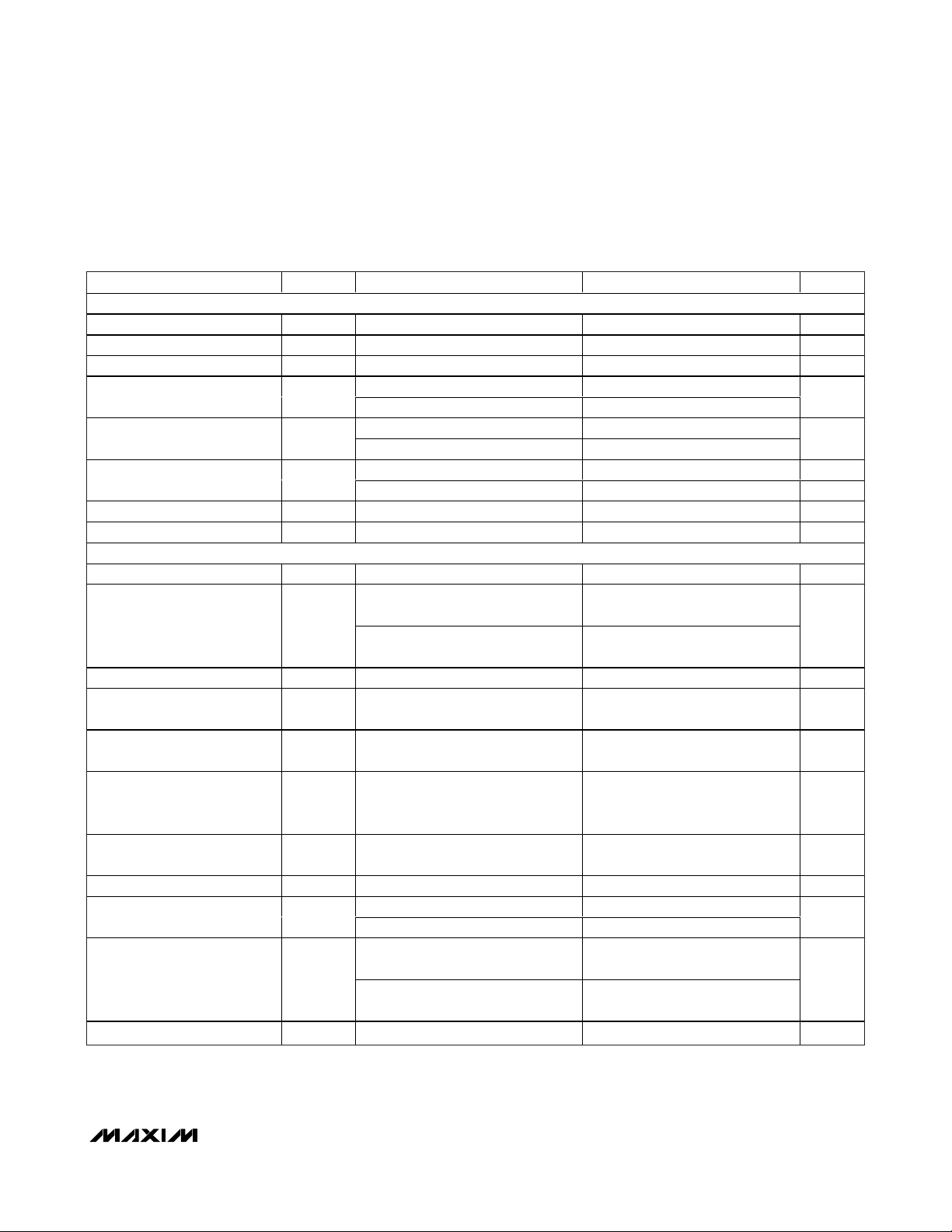

ELECTRICAL CHARACTERISTICS (continued)

(V

DVDDIO

= +5.0V, V

AVDD

= +3.3V, V

DVDD

= +2.5V, V

REFADC

= +3.3V, system clock = 16MHz. TA= T

MIN

to T

MAX

, unless otherwise

noted. Typical values are at T

A

= +25°C.) (Note 1)

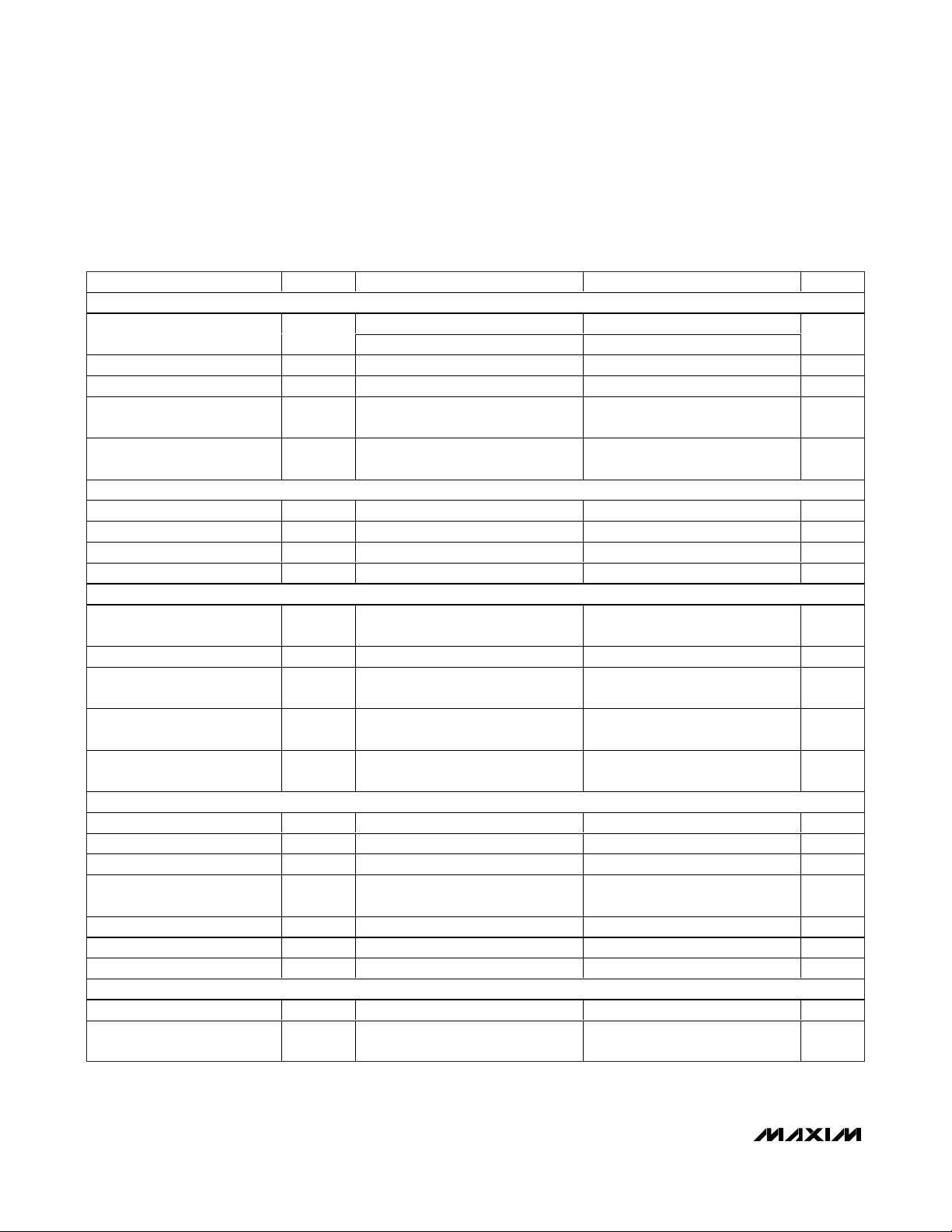

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

MEMORY SECTION

Flash Memory Size Program or data storage 64 KB

Flash Page Size 16-bit word size 256 Words

Flash Erase/Write Endurance Program or data (Note 7) 10,000 Cycles

Flash Data Retention (Note 7)

Flash Erase Time

Flash Programming Time

RAM Memory Size 2KB

Utility ROM Size 16-bit word size 4 KWords

ANALOG SENSE PATH (Includes PGA and ADC)

Resolution N

Integral Nonlinearity INL

Differential Nonlinearity DNL

Input-Referred Offset Error

Offset-Error Temperature

Coefficient

ADC

ADC

ADC

All flash, TA = +25°C 100

All flash, T

Flash page erase 20 50

Entire flash mass erase 200 500

Flash single word programming 20 40 µs

Entire flash programming 0.66 1.31 s

No missing codes 10 Bits

PGA gain = 16V/V, bipolar mode,

= ±100mV, 150.9ksps

V

IN

PGA gain = 1V/V, unipolar mode,

V

= +1.0V, 250ksps

IN

PGA gain = 1V/V or 16V/V ±0.4 ±1 LSB

Test at T

PGA gain = 1V/V or 16V/V

PGA gain = 16V/V, bipolar mode ±2 µV/°C

= +85°C 15

A

= +25°C,

A

±0.5 ±1

±0.4 ±1

±1 ±10 mV

Years

LSB

ms

10

10

Gain Error

Gain-Error Temperature

Coefficient

Conversion Clock Frequency f

Sample Rate f

Channel Select, Track-andHold Acquisition Time

Conversion Time t

PGA gain = 16V/V, bipolar mode,

excludes offset and reference error,

test at T

PGA gain = 16V/V, bipolar mode ±5 ppm/°C

ADCCLKfSYSCLK

SAMPLE

t

ACQ

CONV

PGA gain = 16V/V, f

PGA gain = 1V/V, f

PGA gain = 16V/V,

13.5 ADCCLK cycles at 4MHz

PGA gain = 1V/V,

three ADCCLK cycles at 4MHz

13 ADCCLK cycles at 4MHz 3.25 µs

-2 +2 %

= +25°C

A

= 8MHz or 16MHz 0.5 4.0 MHz

ADCCLK

ADCCLK

= 4MHz 150.9

= 4MHz 250

3.375

0.75

ksps

µs

Page 4

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

4 _______________________________________________________________________________________

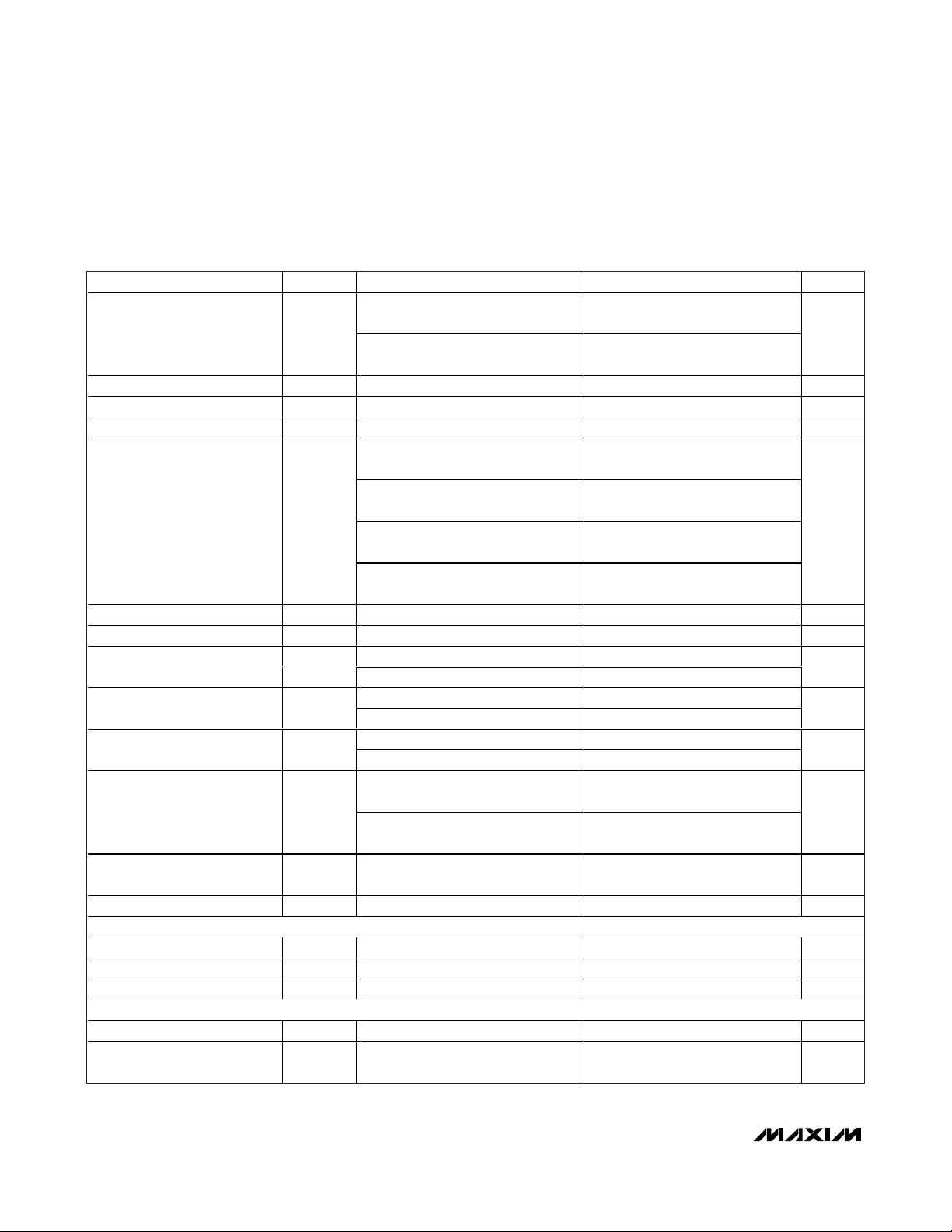

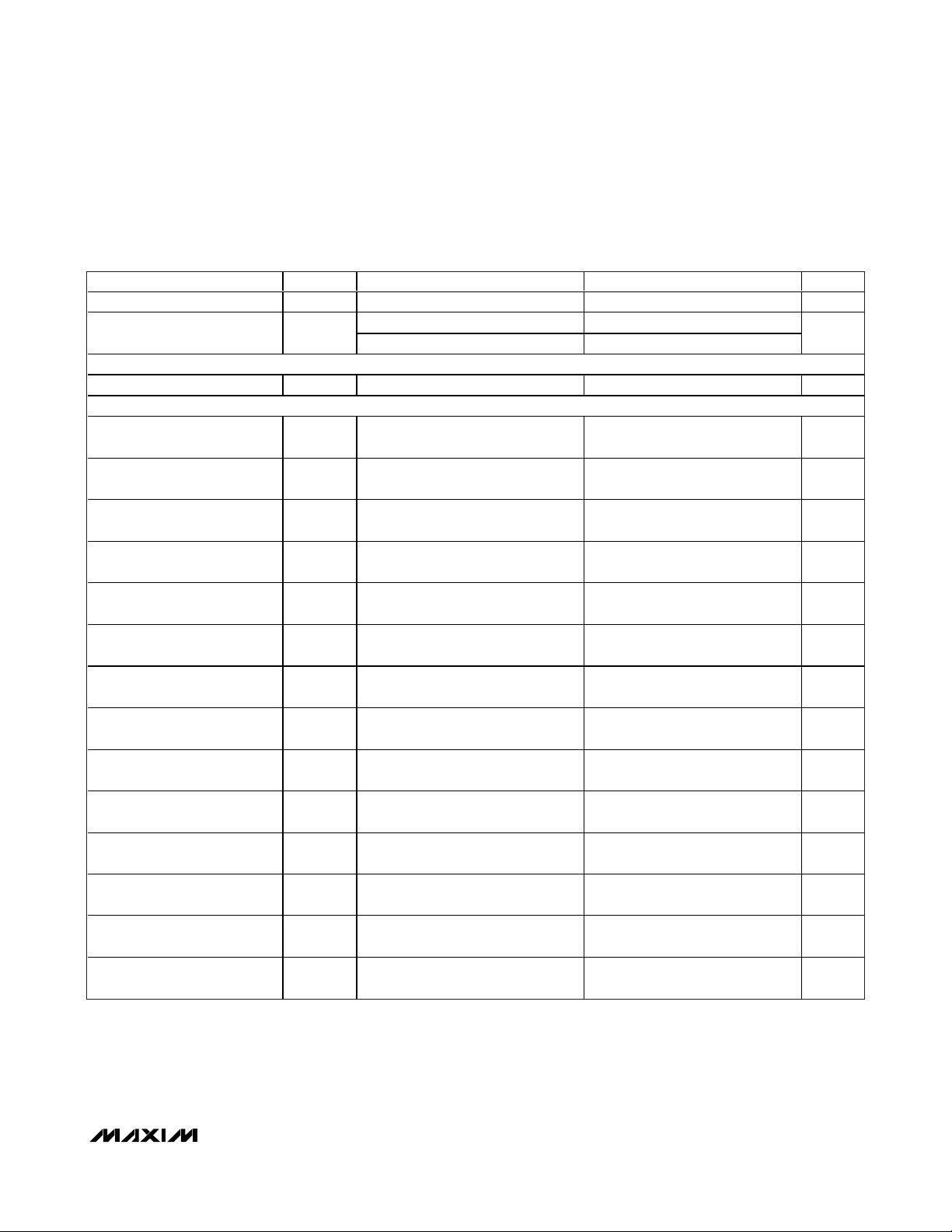

ELECTRICAL CHARACTERISTICS (continued)

(V

DVDDIO

= +5.0V, V

AVDD

= +3.3V, V

DVDD

= +2.5V, V

REFADC

= +3.3V, system clock = 16MHz. TA= T

MIN

to T

MAX

, unless otherwise

noted. Typical values are at T

A

= +25°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Channel Select Plus

Conversion Time

Turn-On Time t

Aperture Delay 60 ns

Aperture Jitter 100 ps

Differential Input Voltage

Range

Absolute Input Voltage Range At AIN0–AIN7 0 V

Input Leakage Current At AIN0–AIN7 ±0.1 µA

Input-Referred Noise

Small-Signal Bandwidth (-3dB)

Large-Signal Bandwidth (-3dB)

Input Capacitance (Note 8)

Input Common-Mode Rejection

Ratio

Power-Supply Rejection Ratio PSRR AV

EXTERNAL REFERENCE INPUTS

REFADC Input Voltage Range 1.0 3.3 V

REFADC Leakage Current ADC disabled 1 µA

Input Capacitance (Note 9) 20 pF

+3.3V (AVDD) LINEAR REGULATOR

AVDD Output Voltage LRAPD = 0 3.15 3.3 3.45 V

No-Load Quiescent Current

t

ACQ

t

CONV

RECOV

CMRR

+

PGA gain = 16V/V,

26.5 ADCCLK cycles at 4MHz

PGA gain = 1V/V,

16 ADCCLK cycles at 4MHz

At AIN0–AIN7, unipolar mode,

PGA gain = 1V/V

At AIN0–AIN7, unipolar mode,

PGA gain = 16V/V

At AIN0–AIN7, bipolar mode,

PGA gain = 1V/V

At AIN0–AIN7, bipolar mode,

PGA gain = 16V/V

At AIN0–AIN7, PGA gain = 16V/V 50

At AIN0–AIN7, PGA gain = 1V/V 400

VIN = 12mV

= 200mV

V

IN

VIN = 150mV

= 2.5V

V

IN

Single-ended, any AIN0–AIN7,

PGA gain = 16V/V

Single-ended, any AIN0–AIN7,

PGA gain = 1V/V

AIN0–AIN7,

V

= differential input range

CM

= 3.0V to 3.6V 90 dB

DD

LRAPD = 0, all internal analog

peripherals disabled

0V

0 0.125

-V

REFADC

/2

-V

REFADC

/32

, PGA gain = 16V/V 33

P-P

, PGA gain = 1V/V 23

P-P

, PGA gain =16V/V 33

P-P

, PGA gain = 1V/V 19

P-P

6.625

4

10 µs

16

13

75 dB

10 µA

REFADC

+V

REFADC

+V

REFADC

/32

AVDD

AVDD

µs

P-P

V

/2

V

µV

RMS

MHz

MHz

pF

V

Page 5

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

_______________________________________________________________________________________ 5

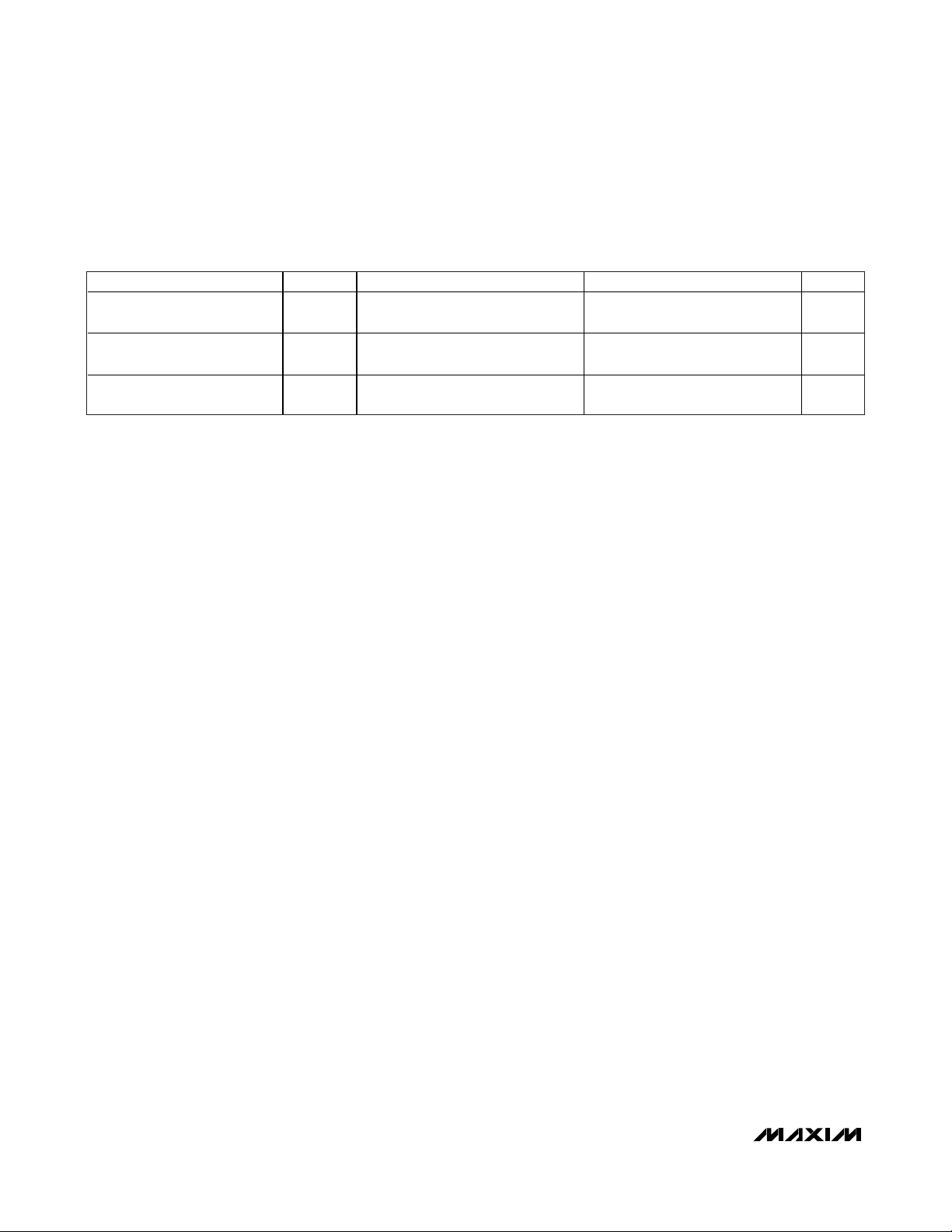

ELECTRICAL CHARACTERISTICS (continued)

(V

DVDDIO

= +5.0V, V

AVDD

= +3.3V, V

DVDD

= +2.5V, V

REFADC

= +3.3V, system clock = 16MHz. TA= T

MIN

to T

MAX

, unless otherwise

noted. Typical values are at T

A

= +25°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Output Current Capability LRAPD = 0 50 mA

Output Short-Circuit Current LRAPD = 0, AVDD shorted to AGND 100 mA

Maximum AVDD Bypass

Capacitor to AGND

+2.5V (DVDD) LINEAR REGULATOR

DVDD Output Voltage REGEN2 = GNDIO 2.38 2.5 2.62 V

No-Load Quiescent Current

Output Current Capability REGEN2 = GNDIO 50 mA

Output Short-Circuit Current

Maximum DVDD Bypass

Capacitor to DGND

SUPPLY-VOLTAGE SUPERVISORS AND BROWNOUT DETECTION

DVDD Reset Threshold

DVDD Interrupt Threshold

Minimum DVDD Interrupt and

Reset Threshold Difference

AVDD Interrupt Threshold

DVDDIO Interrupt Threshold

Operational Range

Supervisor Hysteresis ±0.7 %

CAN INTERFACE

CAN Baud Rate f

CANCLK Mean Frequency

Error

LRAPD = 0 0.47 µF

REGEN2 = GNDIO, all internal digital

peripherals disabled

REGEN2 = GNDIO, DV

DGND

REGEN2 = GNDIO 0.47 µF

Asserts RESET if V

threshold

Generates an interrupt if V

below this threshold

Generates an interrupt if V

below this threshold

Generates an interrupt if V

falls below this threshold

DV

DD

AV

DD

DV

DDIO

CANCLK

8MHz or 16MHz, 50ppm external

crystal

shorted to

DD

is below this

DVDD

falls

DVDD

falls

AVDD

DVDDIO

= 8MHz 1 Mbps

2.1 2.25 V

2.25 2.38 V

3.0 3.15 V

4.5 4.75 V

1 2.75

1 3.6

1 5.25

15 µA

100 mA

0.14 V

60 ppm

V

CANCLK Total Frequency Error

8MHz or 16MHz, 50ppm external

crystal; measured over a 12ms

interval; mean plus peak cycle jitter

< 0.5 %

Page 6

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V

DVDDIO

= +5.0V, V

AVDD

= +3.3V, V

DVDD

= +2.5V, V

REFADC

= +3.3V, system clock = 16MHz. TA= T

MIN

to T

MAX

, unless otherwise

noted. Typical values are at T

A

= +25°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

HIGH-FREQUENCY CRYSTAL OSCILLATOR

Clock Frequency

Stability Excluding crystal drift 25 ppm

Startup Time f

XIN Input Low Voltage Driven with external clock source

XIN Input High Voltage Driven with external clock source

INTERNAL FIXED-FREQUENCY OSCILLATOR

Frequency f

Tolerance TA = +25°C ±0.4 %

Temperature Drift TA = T

Power-Supply Rejection TA = +25°C, DV

RESET (RESET)

RESET Internal Pullup

Resistance

RESET Output Low Voltage RESET asserted, no external load 0.4 V

RESET Output High Voltage RESET deasserted, no external load

RESET Input Low Voltage Driven with external clock source

RESET Input High Voltage Driven with external clock source

DIGITAL INPUTS (P0._, CANRXD, MISO, MOSI, SS, SCLK, TCK, TDI, TMS)

Input Low Voltage 0.8 V

Input High Voltage 2.1 V

Input Hysteresis 500 mV

Input Leakage Current

Input Pullup Resistance 55 kΩ

Input Pulldown Resistance 55 kΩ

Input Capacitance 15 pF

DIGITAL OUTPUTS (P0._, CANTXD, MOSI, SCLK, SS, TDO)

Output Low Voltage I

Output High Voltage I

IFFCLKTA

Using external crystal 8 or 16 16

External input (Note 10) 0.166 16.67

SYSCLK

= T

MIN

MIN

Pulled up to DVDDIO 55 kΩ

V

= GNDIO or V

IN

pullup disabled

= 0.5mA 0.4 V

SINK

SOURCE

cycles 65,535 Cycles

0.7 x

V

DVDD

to T

MAX

to T

MAX

= 0.5mA

= 2.25V to 2.75V ±1.5 %

DD

,

DVDDIO

13.8 15 16.35 MHz

0.9 x

V

DVDDIO

0.7 x

V

DVDDIO

-10 ±0.01 +10 µA

V

DVDDIO

- 0.5

5%

0.3 x

V

DVDD

0.3 x

V

DVDD

MHz

V

V

V

V

V

V

Page 7

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

_______________________________________________________________________________________ 7

ELECTRICAL CHARACTERISTICS (continued)

(V

DVDDIO

= +5.0V, V

AVDD

= +3.3V, V

DVDD

= +2.5V, V

REFADC

= +3.3V, system clock = 16MHz. TA= T

MIN

to T

MAX

, unless otherwise

noted. Typical values are at T

A

= +25°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Output Capacitance I/O pins three-state 15 pF

Maximum Output Impedance

PD0._ = 0 880

PD0._ = 1 450

SYSTEM CLOCK

System Clock Frequency f

SYSCLK

From any clock source 0 16.67 MHz

SPI INTERFACE TIMING

SPI Master Operating

Frequency

SPI Slave Mode Operating

Frequency

SCLK Output Pulse-Width

High/Low

SCLK Input Pulse-Width

High/Low

t

SCH

MOSI Output Hold Time

After SCLK Sample Edge

MOSI Output Setup Time to

SCLK Sample Edge

MISO Input Setup Time to

SCLK Sample Edge

MISO Input Hold Time After

SCLK Sample Edge

SCLK Inactive to MOSI

Inactive

MOSI Input Setup Time to

SCLK Sample Edge

MOSI Input Hold Time After

SCLK Sample Edge

MISO Output Valid After

SCLK Shift Edge Transition

MISO Output Disabled After

SS Edge Rise

SS Falling Edge to MISO Active t

f

MCLK

f

SCLK

t

MCH

t

MCL

t

MOH

t

MOS

t

MIS

t

MIH

t

MLH

t

SIS

t

SIH

t

SOV

t

SLH

SOE

0.5 x f

SYSCLK

,

t

SYSCLK

8 MHz

f

/8 MHz

SYSCLK

- 25

, t

SCL

t

SYSCLK

t

SYSCLK

- 25

t

SYSCLK

- 25

30 ns

0ns

t

SYSCLK

- 25

30 ns

t

SYSCLK

+ 25

3 t

SYSCLK

+ 25

2 t

SYSCLK

+ 50

2 t

SYSCLK

+ 2.5

Ω

ns

ns

ns

ns

ns

ns

ns

ns

ns

Page 8

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

8 _______________________________________________________________________________________

Note 1: All devices are 100% production tested at TA= +25°C and +125°C. Temperature limits to TA= -40°C are guaranteed by

design.

Note 2: All analog functions disabled and all digital inputs connected to supply or ground.

Note 3: High-speed/8 mode without CAN; V

DVDD

= +2.5V, CPU and 16-bit timer running at 2MHz from an external, 16MHz crystal

oscillator; all other peripherals disabled; all digital I/Os static at V

DVDDIO

or GNDIO; TA= T

MIN

to T

MAX

.

Note 4: High-speed/1 mode with CAN; V

DVDD

= +2.5V, CPU and 16-bit timer running at 16MHz from an external, 16MHz crystal

oscillator; CAN enabled and communicating at 500kbps; all other peripherals disabled, all digital I/Os (except CANTXD

and CANRXD) static at V

DVDDIO

or GNDIO, TA= T

MIN

to T

MAX

.

Note 5: Low speed, PMM1 mode without CAN; V

DVDD

= +2.5V, CPU and one timer running from an external, 16MHz crystal oscilla-

tor in PMM1 mode; all other peripherals disabled; all digital I/Os static at V

DVDDIO

or GNDIO, TA= T

MIN

to T

MAX

.

Note 6: CAN transmitting at 500kbps; 16-bit timer output switching at 500kHz; all active I/Os are loaded with a 20pF capacitor; all

remaining digital I/Os are static at V

DVDDIO

or GNDIO, TA= T

MIN

to T

MAX

.

Note 7: Guaranteed by design and characterization.

Note 8: This is not a static capacitance. It is the capacitance presented to the analog input when the T/H amplifier is in sample mode.

Note 9: The switched capacitor on the REFADC input can disturb the reference voltage. To reduce this disturbance, place a 0.1µF

capacitor from REFADC to AGND as close as possible to REFADC.

Note 10: The digital design is fully static. However, the lower clock limit is set by a clock detect circuit. The MAXQ7670 switches to

the internal RC clock if the external input goes below 166kHz. This clock detect circuit also acts to detect a crystal failure

when a crystal is used.

ELECTRICAL CHARACTERISTICS (continued)

(V

DVDDIO

= +5.0V, V

AVDD

= +3.3V, V

DVDD

= +2.5V, V

REFADC

= +3.3V, system clock = 16MHz. TA= T

MIN

to T

MAX

, unless otherwise

noted. Typical values are at T

A

= +25°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SS Falling Edge to First SCLK

Sample Edge

SCLK Inactive to SS Rising

Edge

Minimum CS Pulse Width t

t

SSE

t

SD

SCW

2 t

SYSCLK

+ 5

t

SYSCLK

+ 10

t

SYSCLK

+ 10

ns

ns

ns

Page 9

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

_______________________________________________________________________________________ 9

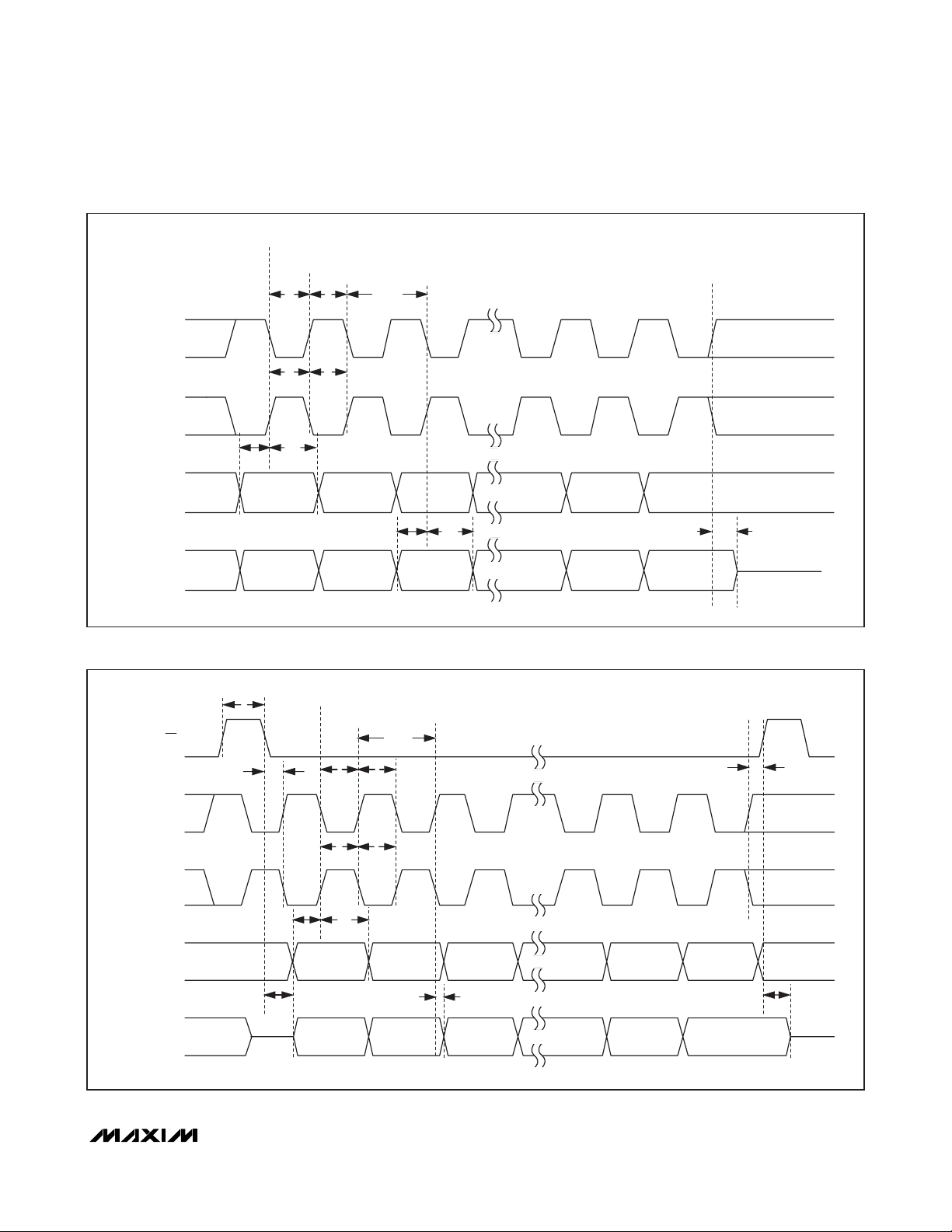

(CKPOL/CKPHA =

Figure 1. SPI Timing Diagram in Master Mode

Figure 2. SPI Timing Diagram in Slave Mode

SCLK

0/1 OR 1/0 MODE)

SCLK

(CKPOL/CKPHA =

0/0 OR 1/1 MODE)

MISO

MOSI

SAMPLE EDGE

SHIFT EDGE

t

t

t

MCH

MCL

t

t

MCL

MCH

t

MIH

t

MIS

MCLK

t

MOS

t

MOH

t

MLH

HIGH IMPEDANCE

t

SCW

SS

SCLK

(CKPOL/CKPHA =

0/1 OR 1/0 MODE)

SCLK

(CKPOL/CKPHA =

0/0 OR 1/1 MODE)

MOSI

MISO

t

SOE

HIGH

IMPEDANCE

SAMPLE EDGE

SHIFT EDGE

t

t

SCL

SSE

t

SCHtSCL

t

t

SIS

t

SCLK

t

t

SCH

SIH

t

SOV

SD

t

SLH

HIGH

IMPEDANCE

Page 10

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

10 ______________________________________________________________________________________

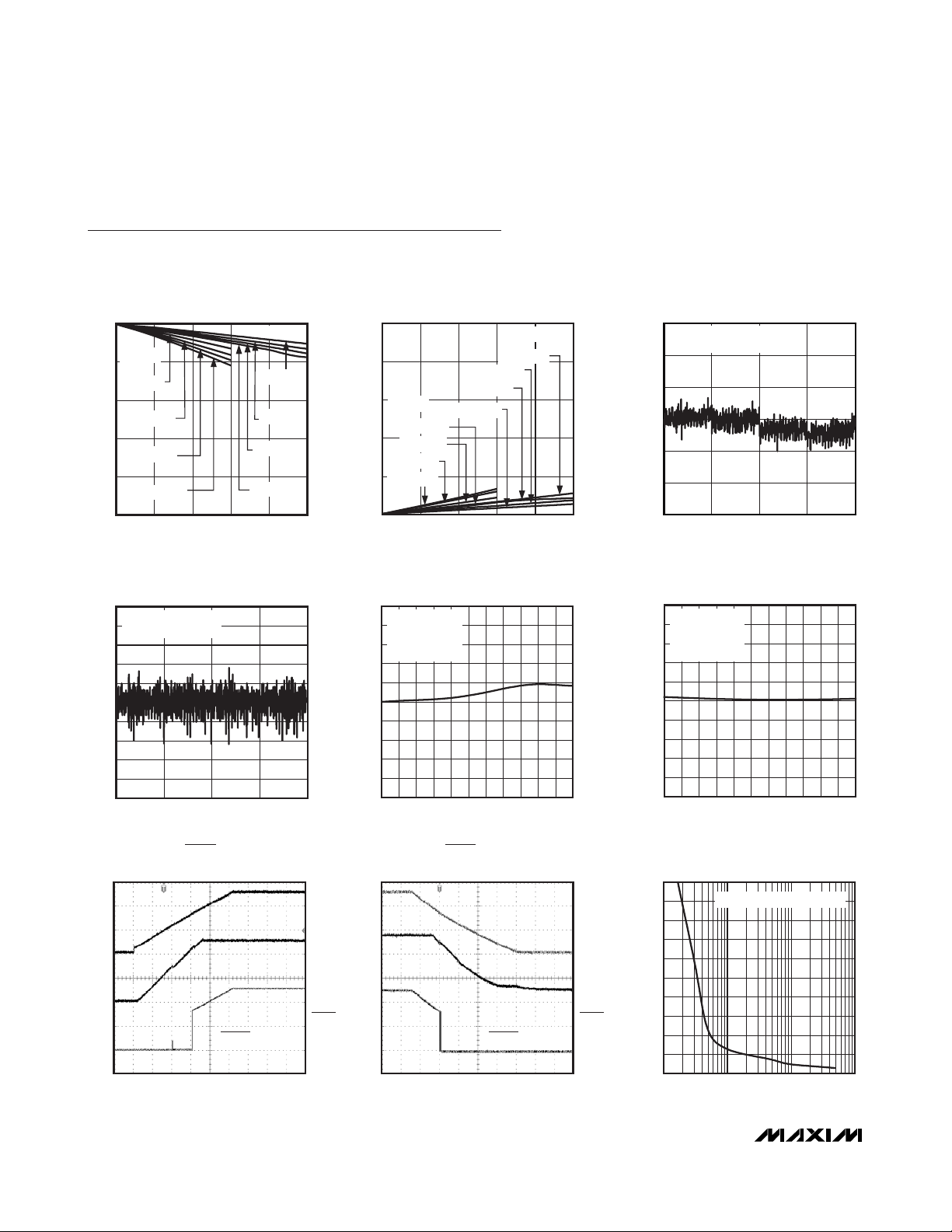

Typical Operating Characteristics

(V

DVDDIO

= 5.0V, V

AVDD

= 3.3V, V

DVDD

= 2.5V, f

SYSCLK

= 16MHz, ADC resolution = 10 bits, V

REFDAC

= 3.3V, TA = +25°C, unless

otherwise noted.)

(V)

OH

V

1.0

0.8

0.6

0.4

0.2

-0.2

ADC DNL (LSB)

-0.4

-0.6

-0.8

-1.0

GPO._ OUTPUT HIGH VOLTAGE

vs. SOURCE CURRENT

5

PS0._ = 0

4

TA = -40°C

3

TA = +25°C

2

TA = +85°C

1

TA = +105°C

0

0 0.5 1.0 1.5 2.0 2.5

IOH (mA)

PS0._ = 1

TA = -40°C

TA = +25°C

TA = +85°C

TA = +105°C

ADC DNL vs. CODE

(REFADC = +3.3V, 150.9ksps,

PGA GAIN = 16V/V)

BIPOLAR MODE

= -100mV to +100mV

V

IN

0

-512 -256 0 256 512

DIGITAL OUTPUT CODE

DVDD, RESET POWER-UP

CHARACTERISTICS

10ms/div

MAXQ7670 toc07

REGEN2 = GNDIO

MAXQ7670 toc01

MAXQ7670 toc04

DVDDIO

2V/div

DVDD

1V/div

RESET

2V/div

GPO._ OUTPUT LOW VOLTAGE

vs. SINK CURRENT

5

4

3

PS0._ = 0

(V)

OL

V

TA = -40°C

2

TA = +25°C

TA = +85°C

1

TA = +105°C

0

0 0.5 1.0 1.5 2.0 2.5

TA = +105°C

TA = +85°C

TA = +25°C

TA = -40°C

IOL (mA)

ADC OFFSET ERROR vs. TEMPERATURE

2.0

BIPOLAR MODE

1.8

PGA GAIN = 16V/V

= 0

V

IN-DIFF

1.6

1.4

1.2

1.0

0.8

OFFSET ERROR (mV)

0.6

0.4

0.2

0

= +1.65V

V

IN-CM

-40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE (°C)

DVDD, RESET POWER-DOWN

CHARACTERISTICS

REGEN2 = GNDIO

20ms/div

PS0._ = 1

MAXQ7670 toc08

MAXQ7670 toc02

MAXQ7670 toc05

DVDDIO

2V/div

DVDD

1V/div

RESET

2V/div

ADC INL vs. CODE

(REF ADC = +3.3V, 150.9ksps, PGA GAIN = 16V/V)

1.5

BIPOLAR MODE

= -100mV TO +100mV

V

IN

1.0

0.5

0

ADC INL (LSB)

-0.5

-1.0

-1.5

-512 -256 0 256 512

DIGITAL OUTPUT CODE

ADC GAIN ERROR vs. TEMPERATURE

1.0

BIPOLAR MODE

0.8

PGA GAIN = 16V/V

= 200mV

V

IN-DIFF

0.6

0.4

0.2

0

-0.2

GAIN ERROR (%)

-0.4

-0.6

-0.8

-1.0

= +1.65V

V

IN-CM

-40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE (°C)

MAXIMUM DVDD TRANSIENT DURATION

vs. BOI THRESHOLD OVERDRIVE

200

180

160

140

120

100

80

60

40

MAXIMUM TRANSIENT DURATION (µs)

20

0

1 10 100 1000

BOI ASSERTED ABOVE THIS LINE

DVDD BOI THRESHOLD OVERDRIVE (mV)

MAXQ7670 toc03

MAXQ7670 toc06

MAXQ7670 toc09

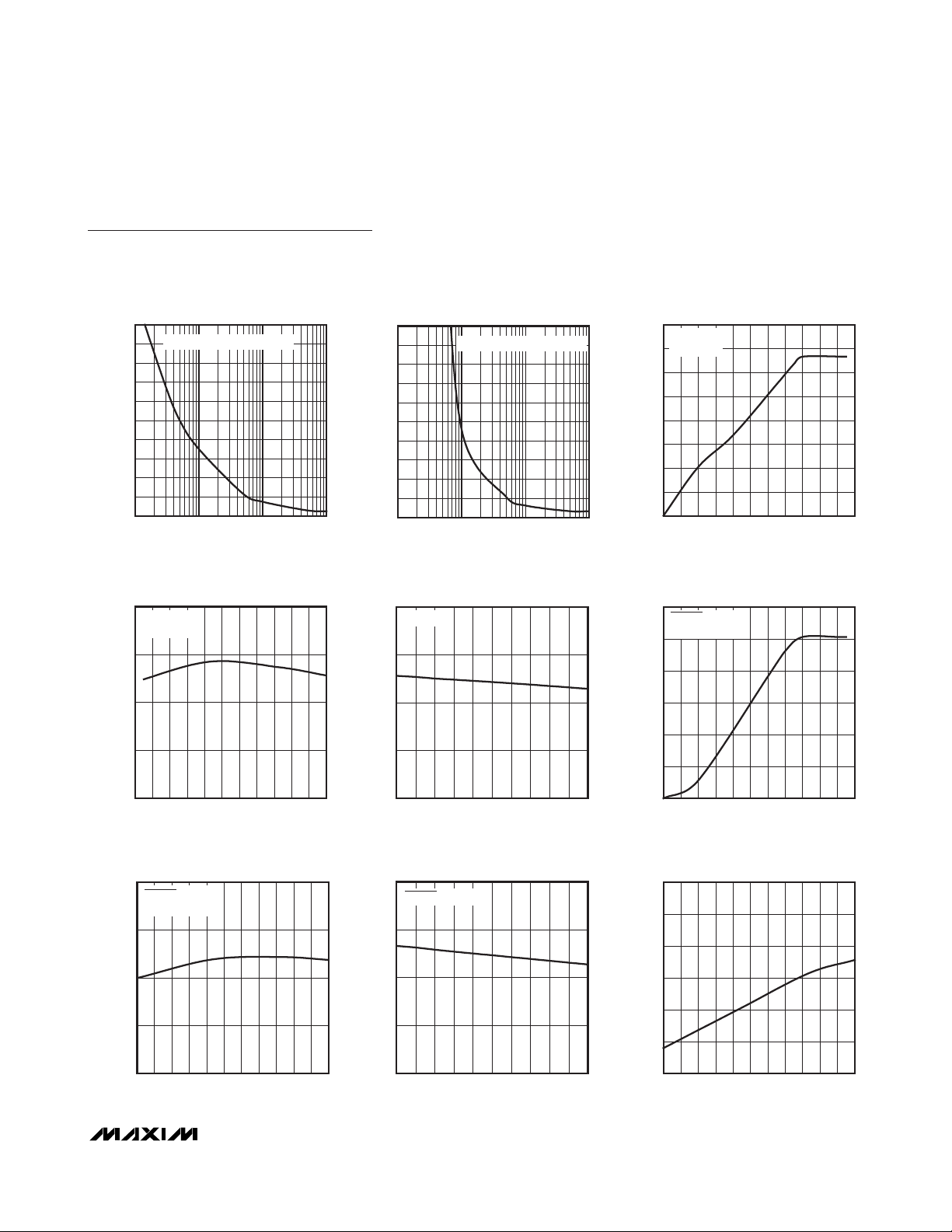

Page 11

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

______________________________________________________________________________________

11

E

Typical Operating Characteristics (continued)

(V

DVDDIO

= 5.0V, V

AVDD

= 3.3V, V

DVDD

= 2.5V, f

SYSCLK

= 16MHz, ADC resolution = 10 bits, V

REFDAC

= 3.3V, TA = +25°C, unless

otherwise noted.)

MAXIMUM DVDDIO TRANSIENT DURATION

vs. BOI THRESHOLD OVERDRIVE

200

180

160

140

120

100

80

60

40

MAXIMUM TRANSIENT DURATION (µs)

20

BOI ASSERTED ABOVE THIS LINE

0

1 10 100 1000

DVDDIO BOI THRESHOLD OVERDRIVE (mV)

AVDD LINEAR REGULATOR OUTPUT VOLTAGE

vs. TEMPERATURE

3.40

LRAPD = 0

= 10mA

I

OUT

3.35

MAXQ7670 toc10

MAXQ7670 toc13

MAXIMUM AVDD TRANSIENT DURATION

vs. BOI THRESHOLD OVERDRIVE

200

180

160

140

120

100

80

60

40

MAXIMUM TRANSIENT DURATION (µs)

20

0

1 10 100 1000

BOI ASSERTED ABOVE THIS LINE

AVDD BOI THRESHOLD OVERDRIVE (mV)

AVDD LINEAR REGULATOR OUTPUT VOLTAGE

vs. LOAD CURRENT

3.40

LRAPD = 0

3.35

MAXQ7670 toc11

AVDD (V)

MAXQ7670 toc14

AVDD LINEAR REGULATOR OUTPUT VOLTAGE

vs. DVDDIO SUPPLY VOLTAGE

4.0

LRAPD = 0

= 10mA

I

3.5

OUT

3.0

2.5

2.0

1.5

1.0

0.5

0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

DVDDIO (V)

DVDD LINEAR REGULATOR OUTPUT VOLTAGE

vs. DVDDIO SUPPLY VOLTAGE

3.0

REGEN2 = DVDDIO

= 10mA

I

OUT

2.5

2.0

MAXQ7670 toc12

MAXQ7670 toc15

3.30

AVDD (V)

3.25

3.20

-40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE (°C)

DVDD LINEAR REGULATOR OUTPUT VOLTAG

vs. TEMPERATURE

2.60

REGEN2 = DVDDIO

= 10mA

I

OUT

2.55

2.50

DVDD (V)

2.45

2.40

-40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE (°C)

MAXQ7670 toc16

3.30

AVDD (V)

3.25

3.20

0 5 10 15 20 25 30 35 40 45 50

LOAD CURRENT (mA)

DVDD LINEAR REGULATOR OUTPUT VOLTAGE

vs. LOAD CURRENT

2.60

REGEN2 = DVDDIO

2.55

2.50

DVDD (V)

2.45

2.40

0 5 10 15 20 25 30 35 40 45 50

LOAD CURRENT (mA)

MAXQ7670 toc17

1.5

DVDD (V)

1.0

0.5

0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

DVDDIO (V)

RC OSCILLATOR OUTPUT FREQUENCY

vs. TEMPERATURE

17.0

16.5

16.0

15.5

15.0

FREQUENCY (MHz)

14.5

14.0

-40 -25 -10 5 20 35 50 65 80 95 110 125

TEMPERATURE (°C)

MAXQ7670 toc18

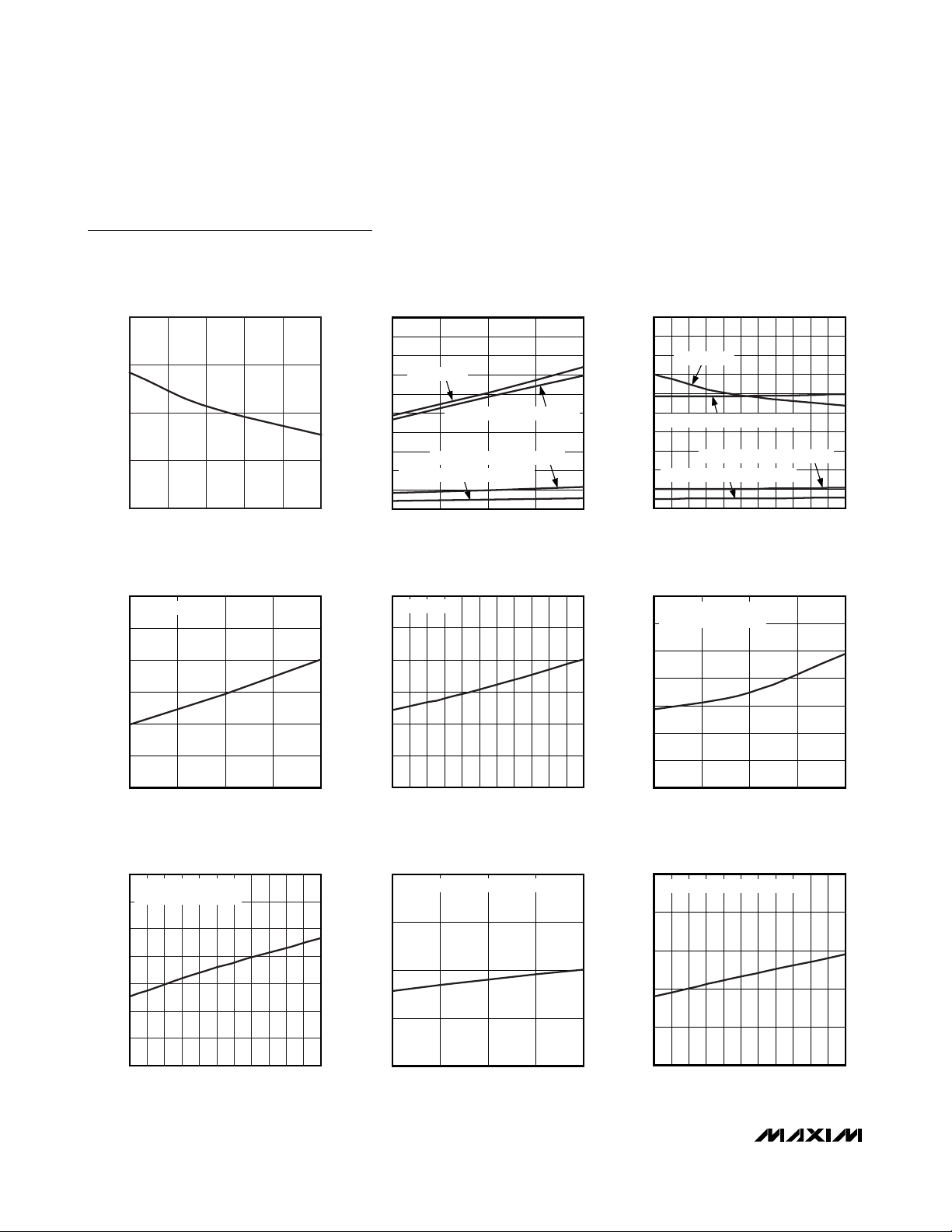

Page 12

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

12 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(V

DVDDIO

= 5.0V, V

AVDD

= 3.3V, V

DVDD

= 2.5V, f

SYSCLK

= 16MHz, ADC resolution = 10 bits, V

REFDAC

= 3.3V, TA = +25°C, unless

otherwise noted.)

RC OSCILLATOR OUTPUT FREQUENCY

vs. DVDD

16.0

15.5

15.0

FREQUENCY (MHz)

14.5

14.0

2.25 2.35 2.45 2.55 2.65 2.75

DVDD (V)

20

18

16

MAXQ7670 toc19

14

12

10

8

6

DVDD SUPPLY CURRENT (mA)

4

2

0

DVDD SUPPLY CURRENT

vs. DVDD SUPPLY VOLTAGE

FLASH ERASE

EC CHARACTERISTICS

NOTE 4 IN

EC CHARACTERISTICS

NOTE 3 IN

EC CHARACTERISTICS

NOTE 5 IN

2.250 2.750

DVDD SUPPLY VOLTAGE (V)

2.6252.5002.375

MAXQ7670 toc020

DVDD SUPPLY CURRENT

vs. TEMPERATURE

20

18

16

FLASH ERASE

14

12

10

8

6

DVDD SUPPLY CURRENT (mA)

4

2

0

-40 125

NOTE 4 IN

NOTE 5 IN

EC CHARACTERISTICS

EC CHARACTERISTICS

NOTE 3 IN

EC CHARACTERISTICS

TEMPERATURE (°C)

MAXQ7670 toc21

1109565 80-10 5 20 35 50-25

DVDD SUPPLY CURRENT

vs. DVDD SUPPLY VOLTAGE

26.5

STOP MODE

26.0

25.5

25.0

24.5

DVDD SUPPLY CURRENT (µA)

24.0

23.5

2.250 2.750

DVDD SUPPLY VOLTAGE (V)

2.6252.5002.375

AVDD SUPPLY CURRENT

vs. TEMPERATURE

140

SHUTDOWN (NOTE 2)

EC CHARACTERISTICS

IN

120

100

80

60

40

AVDD SUPPLY CURRENT (nA)

20

28

STOP MODE

27

MAXQ7670 toc22

26

25

24

DVDD SUPPLY CURRENT (µA)

23

22

-40 125

6.0

ALL ANALOG FUNCTIONS ENABLED

MAXQ7670 toc25

5.9

5.8

5.7

AVDD SUPPLY CURRENT (mA)

DVDD SUPPLY CURRENT

vs. TEMPERATURE

TEMPERATURE (°C)

AVDD SUPPLY CURRENT

vs. AVDD SUPPLY VOLTAGE

AVDD SUPPLY CURRENT

vs. AVDD SUPPLY VOLTAGE

140

SHUTDOWN (NOTE 2)

EC CHARACTERISTICS

IN

120

MAXQ7670 toc23

100

80

60

40

AVDD SUPPLY CURRENT (nA)

20

1109580655035205-10-25

0

3.00 3.60

AVDD SUPPLY VOLTAGE (V)

3.453.303.15

MAXQ7670 toc24

AVDD SUPPLY CURRENT

vs. TEMPERATURE

6.2

ALL ANALOG FUNCTIONS ENABLED

6.0

MAXQ7670 toc26

5.8

5.6

AVDD SUPPLY CURRENT (mA)

5.4

MAXQ7670 toc27

0

-40 125

TEMPERATURE (°C)

1109565 80-10 5 20 35 50-25

5.6

3.00 3.60

AVDD SUPPLY VOLTAGE (V)

3.453.303.15

5.2

-40 125

TEMPERATURE (°C)

1109580655035205-10-25

Page 13

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

______________________________________________________________________________________

13

Typical Operating Characteristics (continued)

(V

DVDDIO

= 5.0V, V

AVDD

= 3.3V, V

DVDD

= 2.5V, f

SYSCLK

= 16MHz, ADC resolution = 10 bits, V

REFDAC

= 3.3V, TA = +25°C, unless

otherwise noted.)

DVDDIO INCREMENTAL SUPPLY CURRENT

vs. DVDDIO SUPPLY VOLTAGE

MAXQ7670 toc33

DVDDIO SUPPLY VOLTAGE (V)

DVDDIO SUPPLY CURRENT (µA)

5.1255.0004.875

1

2

3

4

5

0

4.750 5.250

BOI ENABLED

DVDDIO INCREMENTAL SUPPLY CURRENT

vs. TEMPERATURE

MAXQ7670 toc34

TEMPERATURE (°C)

DVDDIO SUPPLY CURRENT (µA)

5-10-25 503520 110958065

1

2

3

4

5

0

-40 125

BOI ENABLED

ADC SAMPLING ERROR

vs. INPUT SOURCE IMPEDANCE

SOURCE IMPEDANCE (Ω)

SAMPLING ERROR (LSB)

MAXQ7670 toc35

-5

-4

-3

-2

-1

0

1

1 10 100 1000 10,000 100,000

PGA GAIN = 16V/V

f

S

= 150.9ksps

AVDD SUPPLY CURRENT

vs. ADC SAMPLING RATE

5.7

PGA GAIN = 16V/V

5.6

5.5

AVDD SUPPLY CURRENT (mA)

5.4

1 1000

10 100

ADC SAMPLING RATE (ksps)

DVDDIO STATIC SUPPLY CURRENT

vs. DVDDIO SUPPLY VOLTAGE

160

140

120

MAXQ7670 toc28

MAXQ7670 toc31

DVDDIO DYNAMIC SUPPLY CURRENT

vs. DVDDIO SUPPLY VOLTAGE

260

240

220

200

180

160

140

DVDDIO SUPPLY CURRENT (µA)

120

100

2.250 2.750

EC CHARACTERISTICS

NOTE 6 IN

DVDDIO SUPPLY VOLTAGE (V)

2.6252.5002.375

DVDDIO STATIC SUPPLY CURRENT

vs. TEMPERATURE

160

140

120

MAXQ7670 toc29

DVDDIO SUPPLY CURRENT (µA)

MAXQ7670 toc32

250

240

230

220

210

200

DVDDIO DYNAMIC SUPPLY CURRENT

vs. TEMPERATURE

EC CHARACTERISTICS

NOTE 6 IN

-40 125

TEMPERATURE (°C)

1109580655035205-10-25

MAXQ7670 toc30

100

80

DVDDIO SUPPLY CURRENT (µA)

60

40

4.750 5.250

DVDDIO SUPPLY VOLTAGE (V)

100

80

DVDDIO SUPPLY CURRENT (µA)

60

40

5.1255.004.875

-40 125

TEMPERATURE (°C)

1109580655035205-10-25

SNR

0

-20

-40

-60

-80

MAGNITUDE (dB)

-100

-120

-140

0 5 10 15 20 25 30 35

FREQUENCY (kHz)

fIN = 10kHz

= 62.5ksps

f

S

MAXQ7670 toc36

Page 14

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

14 ______________________________________________________________________________________

Pin Description

PIN NAME FUNCTION

1 AIN7

2 AIN6

3 AIN5

4 AIN4

5 REFADC ADC External Reference Input. Connect an external reference between 1V and V

6 AGND Analog Ground

7 AIN3

8 AIN2

9 AIN1

10 AIN0

11 I.C. Internally Connected. Connect to GNDIO for proper operation.

12 P0.0 Port 0 Bit 0. P0.0 is a general-purpose digital I/O with interrupt/wake-up capability.

13 P0.1 Port 0 Bit 1. P0.1 is a general-purpose digital I/O with interrupt/wake-up capability.

14 P0.2 Port 0 Bit 2. P0.2 is a general-purpose digital I/O with interrupt/wake-up capability.

15, 22, 38 GNDIO Digital I/O Ground and Regulator Ground

16 CANRXD CAN Bus Receiver Input. CAN receiver input.

17 CANTXD CAN Bus Transmitter Output. CAN transmitter output.

18 SS

Analog Input Channel 7. AIN7 is multiplexed to the PGA or ADC as single-ended analog input 7 or as a

differential input with AIN6. As a differential input, the polarity of AIN7 is negative.

Analog Input Channel 6. AIN6 is multiplexed to the PGA or ADC as a single-ended analog input 6 or as a

differential input with AIN7. As a differential input, the polarity of AIN6 is positive.

Analog Input Channel 5. AIN5 is multiplexed to the PGA or ADC as single-ended analog input 5 or as a

differential input with AIN4. As a differential input, the polarity of AIN5 is negative.

Analog Input Channel 4. AIN4 is multiplexed to the PGA or ADC as single-ended analog input 4 or as a

differential input with AIN5. As a differential input, the polarity of AIN4 is positive.

Analog Input Channel 3. AIN3 is multiplexed to the PGA or ADC as single-ended analog input 3 or as a

differential input with AIN2. As a differential input, the polarity of AIN3 is negative.

Analog Input Channel 2. AIN2 is multiplexed to the PGA or ADC as single-ended analog input 2 or as a

differential input with AIN3. As a differential input, the polarity of AIN2 is positive.

Analog Input Channel 1. AIN1 is multiplexed to the PGA or ADC as single-ended analog input 1 or as a

differential input with AIN0. As a differential input, the polarity of AIN1 is negative.

Analog Input Channel 0. AIN0 is multiplexed to the PGA or ADC as single-ended analog input 0 or as a

differential input with AIN1. As a differential input, the polarity of AIN0 is positive.

Active-Low, SPI Port Slave Select Input. In SPI slave mode, this is the slave select input. In SPI master

mode, this is an input and connection is optional (connect if mode fault enable is required, refer to the

MAXQ7670 User’s Guide for a description of the SPICN register). In master mode, use an available GPIO

as a slave selector and pull SS high to DVDDIO through a pullup resistor.

.

AVDD

Port 0 Bit 6/Timer 0 I/O. P0.6 is a general-purpose digital I/O with interrupt/wake-up input capability. T0 is a

19 P0.6/T0

20 P0.7/T0B

21, 39 DVDDIO

primary timer/PWM input or output. The alternative function, T0, is selected using the T2CNA0 register.

When this function is selected, it overrides the GPIO functionality.

Port 0 Bit 7/Timer 0 Output. P0.7 is a general-purpose digital I/O with interrupt/wake-up input capability.

T0B is a secondary timer/PWM output. The alternative function, T0B, is selected using the T2CNB0 register.

When this function is selected, it overrides the GPIO functionality.

Digital I/O Supply Voltage and Regulator Supply Input. DVDDIO supplies all digital I/O except for XIN and

XOUT, and supplies power to the two internal linear regulators, AVDD and DVDD. Bypass DVDDIO to

GNDIO with a 0.1µF capacitor as close as possible to the device.

Page 15

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

______________________________________________________________________________________ 15

Pin Description (continued)

PIN NAME FUNCTION

23 SCLK

24 MOSI

25 MISO

26 REGEN2

27 TDO JTAG Serial Test Data Output. TDO is the JTAG serial test, data output.

28 TMS JTAG Test Mode Select. TMS is the JTAG test mode, select input.

29 TDI JTAG Serial Test Data Input. TDI is the JTAG serial test, data input.

30 TCK JTAG Serial Test Clock Input. TCK is the JTAG serial test, clock input.

31

32 P0.5 Port 0 Bit 5. P0.5 is a general-purpose digital I/O with interrupt/wake-up capability.

33 RESET

34 DGND Digital Ground

35 XOUT

P0.4/

ADCCNV

SPI Serial Clock. SCLK is the SPI interface serial clock I/O. In SPI master mode, SCLK is an output. While in

SPI slave mode, SCLK is an input.

SPI Serial Data I/O. MOSI is the SPI interface serial data output in master mode or serial data input in slave

mode.

SPI Serial Data I/O. MISO is the SPI interface serial data input in master mode or serial data output in slave

mode.

Active-Low +2.5V Linear Regulator Enable Input. Connect REGEN2 to GNDIO to enable the +2.5V linear

regulator. Connect to DVDDIO to disable the +2.5V linear regulator.

Port 0 Bit 4/ADC Start Conversion Control. P0.4 is a general-purpose digital I/O with interrupt/wake-up

capability. ADCCNV is a firmware-configurable, rising or falling edge, start/convert signal used to trigger

ADC conversions. The alternative function, ADCCNV, is selected using the register bits ACNT[2:0]. When

using ADCCNV as a trigger for ADC conversion, set P0.4/ADCCNV as an input using the PD0 register. This

action prevents any unintentional interference in the SARADC operation.

Reset Input/Output. Active-low input/output with internal 55kΩ pullup to DVDDIO. Drive low to reset the

MAXQ7670. The MAXQ20 µC core holds RESET low during POR and during DVDD brownout conditions.

High-Frequency Crystal Output. Connect an external crystal to XIN and XOUT for normal operation, or leave

unconnected if XIN is driven with an external clock source. Leave unconnected if an external clock source

is not used.

36 XIN

37 DVDD

40 AVDD

— EP Exposed Pad. Connect EP to the ground plane.

H i g h- Fr eq uency C r ystal Inp ut. C onnect an exter nal cr ystal or r esonator to X IN and X OU T for nor m al op er ati on,

or d r i ve X IN w i th an exter nal cl ock sour ce. Leave unconnected i f an exter nal cl ock sour ce i s not used .

D i g i tal S up p l y V ol tag e. D V D D sup p l i es i nter nal d i g i tal cor e and fl ash m em or y. D V D D i s d i r ectl y connected to

the outp ut of the i nter nal + 2.5V l i near r eg ul ator . D i sab l e the i nter nal r eg ul ator ( thr oug h REG EN 2) to connect an

exter nal sup p l y. Byp ass D V D D to D GN D w i th a 0.1µF cap aci tor as cl ose as p ossi b

Analog Supply Voltage. AVDD supplies PGA and ADC. AVDD is directly connected to the output of the

internal +3.3V linear regulator. Disable the internal regulator (via software) to connect an external supply.

Bypass AVDD to AGND with a 0.1µF capacitor as close as possible to the device.

l e to the d evi ce.

Page 16

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

16 ______________________________________________________________________________________

Block Diagram

DVDDIO

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

AGND

REGEN2

RESET

DVDD

TCK

TMS

TDO

XOUT

GNDIO

DGND

AIN7

DVDDIO

DVDDIO

+2.5V

LINEAR

REGAULATOR

GNDIO

DGND

DVDDIO

TDI

XIN

GNDIO

DGND

DVDD

HF

XTAL

OSC.

DGND

BUFFERS

GNDIO

INT

FIXED

FREQ

OSC.

IFE

I/O

AIN1

AIN3

AIN5

AIN7

AIN9

HFFINT

XHFRY

HFE

DVDD

POWER-ON

RESET

MONITOR

VDPE

JTAG INTERFACE

M

U

X

10:1

MUX

6:1

MUX

MAXQ7670

DVDDIO

PORT 0

I/O REGISTERS

HFCLK

IFFCLK

SYSCLK

PGAE

DVDD

DGND

GAIN = 1x, 16x

ADCMX[3:0]

IFFCLK

EWT

UTILITY ROM

64KB (32K x 16)

PROGRAM/DATA

FLASH

2KB (1K x 16)

DATA RAM

CAN CLOCK

PRESCALER

ADC CLOCK

PRESCALER

HF CLOCK

PRESCALER

TIMER CLOCK

PRESCALER

PGA

4K x 16

HFFINT

EIFO

WATCHDOG

TIMER

WTR

SPI

ADCREF

ADCE

WDI

CANCLK

ADCCLK

2:1

T0CLK

M

10-BIT ADC

U

X

ADCCNV

ADCRY

SOFTWARE-

INTERRUPT

CONTROLLER

DV

DD

16-BIT

MAXQ20 CORE

RISC CPU

DGND

ADCBY

SYSCLK

ADCCLK

CANSTI

CANERI

T0I

CANSTI

CANERI

T0CLK

PD0

PO0

PI0

EIF0

DVDDIO

T0I

SPI

VABI

VIOBI

CANCLK

LRAPD

+3.3V

LINEAR

REGAULATOR

GNDIO

AVDD BROWNOUT

MONITOR

DVDDIO BROWNOUT

MONITOR

16-BIT TIMER0

PORT 0

I/O REGISTERS

SERIAL PERIPHERAL

INTERFACE (SPI)

CAN 2.0B

INTERFACE

VABE

VIBE

I/O

BUFFERS

DVDDIO

I/O

BUFFERS

GNDIO

AVDD

AGND

DVDDIO

GNDIO

GNDIO

REFADC

AVDD

P0.7/T0B

P0.6/T0

P0.5

P0.4/ADCCNV

P0.2

P0.1

P0.0

SS

SCLK

MOSI

MISO

CANTXD

CANRXD

Page 17

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

______________________________________________________________________________________ 17

Detailed Description

The MAXQ7670 incorporates a 16-bit RISC arithmetic

logic unit (ALU) with a Harvard memory architecture

that addresses 64KB (32K x 16) of flash and 2048

bytes (1024 x 16) of RAM memory. This core combined

with digital and analog peripherals provide versatile

data-acquisition functions. The peripherals include up to

seven digital I/Os, a 4-wire SPI interface, a CAN 2.0B

bus, a JTAG interface, a timer, an integrated RC oscillator, two linear regulators, a watchdog timer, three

power-supply supervisors, a 10-bit 250ksps SAR ADC

with programmable-gain amplifier (PGA) and eight single-ended or four differential multiplexed inputs. The

power-efficient MAXQ20 µC core consumes less than

1mA/MIPS. Refer to the

MAXQ7670 User’s Guide

for

more detailed information on configuring and programming the MAXQ7670.

Analog Input Peripheral

The integrated 10-bit ADC employs an ultra-low-power

SAR-based conversion method and operates up to

250ksps with PGA = 1V/V (150.9ksps with PGA =

16V/V). The integrated 8-channel multiplexer (mux) and

PGA allow the ADC to measure eight single-ended (relative to AGND) or four fully differential analog inputs

with software-selectable input ranges through the PGA.

See Figures 3 and 4.

Figure 3. Simplified Analog Input Diagram (Eight Single-Ended Inputs)

MAXQ7670

P0.4/ADCCNV

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

AIN7

8:1

MUX

1V/V OR

16V/V

TIMER 0

ADCBY

ACTL

120

ADCDUL

ADCBIP

ADCRDY

DATA

BUS

PGA

PGG

CONVERSION

CONTROL

10-BIT ADC

250ksps

10

AGND

ADCMX

1 032

REFADC

ADCE

ADC

CLOCK

DIV

1 0

ADCCD

ADCASD

ADCCLK

SOURCE

Page 18

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

18 ______________________________________________________________________________________

Figure 4. Simplified Analog Input Diagram (Four Fully Differential Inputs)

P0.4/ADCCNV

AIN0

AIN2

AIN4

AIN6

AIN1

AIN3

AIN5

AIN7

REFADC

4:1

MUX

4:1

MUX

ADCMX

MAXQ7670

1 032

PGG

PGA

1V/V OR

16V/V

TIMER 0

CONVERSION

CONTROL

10-BIT ADC

250ksps

ADCE

ADC

CLOCK

DIV

1 0

ADCCD

ADCBY

ADCRDY

10

ACTL

120

ADCDUL

ADCBIP

DATA

BUS

ADCASD

ADCCLK

SOURCE

Page 19

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

______________________________________________________________________________________ 19

The MAXQ7670 ADC uses a fully differential SAR conversion technique and an integrated T/H (track and

hold) block to convert voltage signals into a 10-bit digital result. Both single-ended and differential configurations are implemented using an analog input channel

multiplexer that supports 8 single-ended or 4 differential channels.

In single-ended mode, the mux selects from either of

the ground-referenced analog inputs AIN0–AIN7. In differential input configuration, analog inputs are selected

from the following pairs: AIN0/AIN1, AIN2/AIN3,

AIN4/AIN5, and AIN6/AIN7. Table 1 shows the singleended and differential input configurations possible for

the ADC mux.

Analog Input Track and Hold

A SAR conversion in the MAXQ7670 has different T/H

cycles depending on whether a gain of 1 (bypass) or a

gain of 16 (PGA enabled) is selected.

Gain = 1V/V

In gain = 1V/V, the conversion has a two-stage T/H

cycle. In track mode, a positive input capacitor connects to the signal channel. A negative input capacitor

connects to the reference channel. After the T/H enters

hold mode, the difference between the signal and the

reference channel is converted to a 10-bit value. This

two-stage cycle takes 16 SARCLKs to complete.

Gain = 16V/V

In gain = 16V/V, the conversion has a three-stage T/H

cycle: amplification, ADC track, and ADC hold. First,

the PGA tracks the selected input and reference signals. The PGA amplifies the difference between the two

signals and holds the result for the next stage, ADC

track. The ADC tracks and converts the PGA result into

a 10-bit value. The SAR operation itself does not

change irrespective of the chosen gain. This threestage cycle takes 26.5 SARCLKs to complete. Figure 5

shows the conversion timing differences between gain

= 1V/V and gain = 16V/V.

Table 1. ADC Mux Input Configurations

SAR CHANNEL

SELECT

(REGISTER

ACNT[14:11])

0000 AIN0 AGND Single-ended measurement on AIN0

0001 AIN1 AGND Single-ended measurement on AIN1

0010 AIN2 AGND Single-ended measurement on AIN2

0011 AIN3 AGND Single-ended measurement on AIN3

0100 AIN4 AGND Single-ended measurement on AIN4

0101 AIN5 AGND Single-ended measurement on AIN5

0110 AIN6 AGND Single-ended measurement on AIN6

0111 AIN7 AGND Single-ended measurement on AIN7

1000 — — Reserved

1001 — — Reserved

1010 AIN0 AIN1 AIN0/AIN1

1011 AIN2 AIN3 AIN2/AIN3

1100 AIN4 AIN5 AIN4/AIN5

1101 AIN6 AIN7 AIN6/AIN7

1110 — — Reserved

1111 — — VCIM differential zero offset trim

SIGNAL CHANNEL

INTO ADC

REFERENCE

CHANNEL INTO

ADC

MEASUREMENT TYPE

Page 20

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

20 ______________________________________________________________________________________

Input Impedance

The input-capacitance charging rate determines the

time required for the T/H to acquire an input signal. The

required acquisition time lengthens with the increase of

the input signals source resistance. Any source below

5kΩ does not significantly affect the ADC’s performance. A high-impedance source can be accommodated by placing a 1µF capacitor between the input

channel and AGND. The combination of analog-input

source impedance and the capacitance at the analog

input creates an RC filter that limits the analog-input

bandwidth.

Controlling ADC Conversions

Use the following methods to control the ADC conversion timing:

1) Software register bit control

2) Continuous conversion

3) Internal timer (T0)

4) External input through ADCCNV

Refer to the

MAXQ7670 User’s Guide

for more detailed

information on the ADC and mux.

POR and Brownout

The MAXQ7670 operates from a single, external +5V

supply connected to the DVDDIO. DVDDIO is the supply rail for the digital I/O and the supply input for both

integrated linear regulators. The +3.3V linear regulator

powers AVDD, while the +2.5V linear regulator powers

DVDD. Alternatively, connect REGEN2 to DVDDIO and

apply external power supplies to AVDD and DVDD.

Power supplies DVDDIO, DVDD, and AVDD each

include a brownout monitor that alerts the µC through

an interrupt when the corresponding supply voltages

drop below a defined threshold. This condition is generally referred to as brownout interrupt (BOI). Enable

BOI by setting the VABE, VDBE, and VIBE bits in the

APE register. By continually checking for low supply

voltages, appropriate action can be taken for brownout

conditions.

Startup Using Internal Regulators

Once the +5V DVDDIO supply reaches approximately

1.25V, the +2.5V linear regulator turns on and DVDD

begins ramping. Between the DVDD levels of 1V and

the reset threshold, the DVDD monitor holds RESET

low. DVDD releases RESET after reaching the reset

threshold. The MAXQ7670 jumps to the reset vector

location (8000h in the utility ROM). During this time,

DVDD finishes ramping to its nominal voltage of +2.5V.

During this POR time, the software-enabled +3.3V linear regulator remains off. Turn on the +3.3V linear regulator after the MAXQ7670 has completed its bootup

routines and is running application code. To turn on the

+3.3V regulator, set the LRAPD bit in the APE register

to 0. The AVDD supply begins ramping to its nominal

voltage of +3.3V.

Brownout Detectors

The MAXQ7670 features brownout monitors for the +5V

DVDDIO, +3.3V AVDD, and +2.5V DVDD power supplies. When enabled, these monitors generate interrupts

when DVDDIO, AVDD, or DVDD fall below their respective brownout thresholds. Monitoring the supply rails

alerts the µC to brownout conditions so appropriate

action can be taken. Under normal conditions the DVDDIO

brownout monitor signals a falling +5V supply before

the DVDD or AVDD brownout monitors indicate that the

+2.5V or +3.3V are falling. The exceptions to this condition are:

• If either DVDD or AVDD are externally powered and

the source of power is removed

• If there is some type of device failure that pulls the reg-

ulator outputs low without affecting the +5V DVDDIO

supply

Figure 5. Conversion Timing Differences Between Gain = 1V/V and Gain = 16V/V

3 SCLK

SAR CYCLE

PGA = 1V/V

SAR CYCLE

PGA = 16V/V

SAR TRACK HOLD AND SAR CONVERT

7.5 SCLK 6 SCLK 13 SCLK

PGA TRACK PGA HOLD, SAR TRACK HOLD AND SAR CONVERT

13 SCLK

Page 21

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

______________________________________________________________________________________ 21

The DVDD reset supervisor resets the MAXQ7670 when

the +2.5V DVDD falls below the reset threshold. The

processor remains in reset until DVDD returns above

the reset threshold. The µC does not execute commands in reset mode. See Figure 6 for the µC response

to DVDD brownout and reset.

Refer to the

MAXQ7670 User’s Guide

for detailed programming information, and a more thorough description of POR and brownout behavior.

Internal 3.3V Linear Regulator

The integrated 3.3V 50mA linear regulator or an external 3.3V supply powers AVDD. The integrated 3.3V regulator is inactive upon power-up. Enable the integrated

regulator with software programming after power-up.

When using an external supply, connect a regulated

3.3V supply to AVDD after applying DVDDIO.

Internal 2.5V Linear Regulator

The integrated 2.5V 50mA linear regulator or an external 2.5V supply applied at DVDD powers DVDD.

Connect REGEN2 to GNDIO to enable the integrated

regulator. Connect REGEN2 to DVDDIO to use an

external supply. When using an external supply, connect a regulated 2.5V supply to DVDD after applying

DVDDIO.

DVDDIO Current Requirements

Both internal linear regulators are capable of supplying

up to 50mA each. When using the regulators to power

AVDD and DVDD and to provide power to external

devices, make sure DVDDIO’s power input can source

a current greater than the sum of the MAXQ7670 supply current and the load currents of the two regulators.

µ

Figure 6. DVDD Brownout and Reset Behavior

NOMINAL

DVDD (+2.5V)

+2.38V

+2.25V

BROWNOUT

INTERRUPT

(BOI)

DGND

DVLVL FLAG

(ASR[14])

DVBI FLAG

(ASR[4])

BROWNOUT

RESET

(BOR)

INTERNAL RESET

RESET OUTPUT

BOR STATE

FLAG ARBITRARILY

CLEARED BY

C

DVDD BROWNOUT

INTERRUPT

THRESHOLD RANGE

VDBE BIT SET BY µC

Page 22

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

22 ______________________________________________________________________________________

System Clock Generator

The MAXQ7670 oscillator module provides the master

clock generator that supplies the system clock for the

µC core and all of the peripheral modules. The high-frequency oscillator operates with an 8MHz or 16MHz

crystal. Alternatively, use the integrated RC oscillator in

applications that do not require precise timing. The

MAXQ7670 executes most instructions in a single

SYSCLK period. The oscillator module contains all of

the primary clock generation circuitry. Figure 7 shows a

block diagram of the system clock module.

The MAXQ7670 contains the following features for generating its master clock signal timing source:

• Internal, fast-starting, 15MHz RC oscillator eliminates

external crystal

• Internal high-frequency oscillator that can drive an

external 8MHz or 16MHz crystal

• External high-frequency 0.166MHz to 16MHz clock input

• Power-up timer

• Power-saving management modes

• Fail-safe modes

Watchdog Timer

The primary function of the watchdog timer is to supervise software execution, watching for stalled or stuck

software. The watchdog timer performs a controlled

system restart when the µC fails to write to the watchdog timer register before a selectable timeout interval

expires. A watchdog timer typically has four objectives:

1) To detect if a system is operating normally

2) To detect an infinite loop in any of the tasks

3) To detect an arbitration deadlock involving two or

more tasks

4) To detect if some lower priority tasks are not getting

to run because of higher priority tasks

As illustrated in Figure 8, the internal RC oscillator

(CLK_RC) drives the watchdog timer through a series

of dividers. The programmable divider output determines the timeout interval. When enabled, the interrupt

flag WDIF sets. A system reset occurs after a time

delay (based on the divider ratio) unless an interrupt

service routine clears the watchdog interrupt.

The watchdog timer functions as the source of both the

watchdog interrupt and the watchdog reset. The interrupt timeout has a default divide ratio of 2

12

of the

CLK_RC, with the watchdog reset set to timeout 2

9

clock cycles later. With the nominal RC oscillator value

of 15MHz, an interrupt timeout occurs every 0.273ms,

followed by a watchdog reset 34µs later. The watchdog

timer resets to the default divide ratio following any

reset event. Use the WD0 and WD1 bits in the WDCN

register to increase the watchdog interrupt period.

Changing the WD[1:0] bits before a watchdog interrupt

timeout occurs (i.e. before the watchdog reset counter

begins) resets the watchdog timer count. The watchdog reset timeout occurs 512 RC oscillator cycles after

the watchdog interrupt timeout. For more information on

the MAXQ7670 watchdog timer, refer to the

MAXQ7670

User’s Guide.

Figure 7. High-Frequency and RC Oscillator Functional

Diagram

Figure 8. Watchdog Functional Diagram

HFE

XIN

XOUT

RCE

HF

XTAL

OSC

CD1

CLOCK

DIVIDE

CD0 PMME

EXTHF

XT

RC

OSC

MUX

CLK_RC

SYSCLK

WD1

WD0

RWT

DIV 2

12

12

2

CLK_RC

(15MHz)

DIV 2

2152182

TIME

TIMEOUT

WDIF

RESET

3

DIV 2

21

EWDI

EWT

3

DIV 2

3

INTERRUPT

WTRF

RESET

Page 23

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

______________________________________________________________________________________ 23

Timer and PWM

The MAXQ7670 includes a 16-bit timer channel. The

timer offers two ports, T0 and T0B, to facilitate PWM

outputs, and capture timing events. The autoreload 16bit timer/counter offers the following functions:

• 8-/16-bit timer/counter

• Up/down autoreload

• Counter function of external pulse

• Capture

• Compare

• PWM output

• Event timer

• System supervisor

Refer to the

MAXQ7670 User’s Guide

and Application

Note 3205:

Using Timers in the MAXQ Family of

Microcontrollers

for more information about the timer

module.

CAN Interface Bus

The MAXQ7670 incorporates a fully compliant CAN

2.0B controller.

Two groups of registers provide the µC interface to the

CAN controller. To simplify the software associated with

the operation of the CAN controllers, most of the global

CAN status and controls as well as the individual message center control/status registers are located in the

peripheral register map. The remaining registers associated with the data identification, identification masks,

format, and data are located in a dual port memory to

allow the CAN controller and the processor access to

the required functions. The CAN controller can directly

access the dual port memory. The processor accesses

the dual port memory through a dedicated interface

that consists of the CAN 0 data pointer (C0DP) and the

CAN 0 data buffer (C0DB) special function registers.

See Figure 9 for CAN controller details.

CAN Functional Description

The CAN module stores up to 15 messages. Each message consists of an acceptance identifier and 8 bytes

of data. The MAXQ7670 supports both the standard 11bit and extended 29-bit identification modes.

Configure each of the first 14 message centers either to

transmit or receive. Message center 15 is a receiveonly center, storing any message that centers 1–14 do

not accept.

A message center only accepts an incoming message

if the following conditions are satisfied:

• The incoming message’s arbitration value matches

the message center’s acceptance identifier

• The first 2 data bytes of the incoming message match

the bytes in the media arbitration registers (C0MA0

and C0MA1)

Use the global mask registers to mask out bits in the

incoming message that do not require a comparison.

A message center, configured to transmit, meets these

conditions: T/R = 1, TIH = 0, DTUP = 1, MSRDY = 1,

and MTRQ = 1. The message center transmits its contents when it receives an incoming request message

containing the same identifier (i.e., a remote frame).

Global control and status registers in the CAN unit

enable the µC to evaluate error messages, validate and

locate new data, establish the bus timing for the CAN

bus, establish the identification mask bits, and verify the

source of individual messages. In addition, each message center is individually equipped with the necessary

status and controls to establish directions, interrupt generation, identification mode (standard or extended), data

field size, data status, automatic remote frame request

and acknowledgment, and masked or nonmasked identification acceptance testing.

JTAG Interface Bus

The joint test action group (JTAG) IEEE®1149.1 standard defines a unique method for in-circuit testing and

programming. The MAXQ7670 conforms to this standard, implementing an external test access port (TAP)

and internal TAP controller for communication with a

JTAG bus master, such as an automatic test equipment

(ATE). For detailed information on the TAP and TAP controller, refer to IEEE Standard 1149.1 on the IEEE website

at www.standards.ieee.org. The JTAG on the MAXQ7670

does not support boundary scan test capability.

IEEE is a registered service mark of the Institute of Electrical and Electronics Engineers.

Page 24

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

24 ______________________________________________________________________________________

The TAP controller communicates synchronously with

the host system (bus master) through four digital I/Os:

test mode select (TMS), test clock (TCK), test data

input (TDI), and test data output (TDO). The internal

TAP module consists of several shift registers and a

TAP controller (see Figure 11). The shift registers serve

as transmit-and-receive data buffers for a debugger.

4-Wire SPI Bus

The MAXQ7670 includes a powerful hardware SPI module, providing serial communication with a wide variety

of external devices. The SPI port on the MAXQ7670 is a

fully independent module that is accessed through software. This full 4-wire, full-duplex serial bus module supports master and slave modes. The SPI clock

Figure 9. CAN 0 Controller Block Diagram

CAN 0 CONTROLLER BLOCK DIAGRAM

DUAL PORT MEMORY CAN PROCESSOR

MESSAGE CENTERS 1–15

MESSAGE CENTER 1

ARBITRATION 0–3

MESSAGE CENTER 2

ARBITRATION 0–3

MESSAGE CENTER 14

ARBITRATION 0–3

MESSAGE CENTER 15

ARBITRATION 0–3

FORMAT

FORMAT

FORMAT

FORMAT

DATA 0–7

DATA 0–7

DATA 0–7

DATA 0–7

8-BIT

Rx

CAN INTERRUPT

CAN 0 PERIPHERAL REGISTERS

CAN 0 TRANSMIT ERROR

CAN 0 RECEIVE ERROR

CRC

CHECK

8-BIT

Tx

SOURCES

COUNTER

COUNTER

BUS ACTIVITY WAKE-UP

BIT

DESTUFFRxSHIFT

CRC

GENERATE

PROTOCOL

BIT

STUFFTxSHIFT

CAN

FSM

CAN 0 CONTROL REGISTER

CAN 0 OPERATION CONTROL

BIT

TIMING

CANRXD

CANTXD

CONTROL/STATUS/MASK REGISTERS

MEDIA ID MASK 0–1 STD GLOBAL MASK 0–1

MEDIA ARBITRATION 0–1 EXT GLOBAL MASK 0–3

BUS TIMING 0–1 MSG15 MASK 0–3

CAN 0 MESSAGE 1–15

CONTROL REGISTERS

CAN 0 DATA POINTER

CAN 0 DATA BUFFER

MAXQ7670

CAN 0 STATUS REGISTER

CAN 0 INTERRUPT REGISTER

CAN 0 TRANSMIT MSG ACK

CAN 0 RECEIVE MSG ACK

Page 25

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

______________________________________________________________________________________ 25

frequency is limited to SYSCLK/2 in master mode and

SYSCLK/8 in slave mode. Figure 10 shows the functional diagram of the SPI port. Figures 1 and 2 illustrate the

timing parameters listed in the

Electrical Characteristics

table.

General-Purpose Digital I/Os

The MAXQ7670 provides seven general-purpose digital

I/Os (GPIOs). Some of the GPIOs include an additional

special function (SF), such as a timer input/output. For

example, the state of P0.6/T0 is programmable to

depend on timer channel 0 logic. When used as a port,

each I/O is configurable for high-impedance, weak

pullup to DVDDIO or pulldown to GNDIO. At power-up,

each GPIO is configured as an input with a pullup to

DVDDIO. In addition, each GPIO can be programmed

to cause an interrupt (on falling or rising edges). In stop

mode, use any interrupt to wake-up the device.

The port direction (PD) register determines the

input/output direction of each I/O. The port output (PO)

register contains the current state of the logic output

buffers. When an I/O is configured as an output, writing

to the PO register controls the output logic state.

Reading the PO register shows the current state of the

output buffers, independent of the data direction. The

port input (PI) register is a read-only register that

always reflects the logic state of the I/Os.

Figure 10. SPI Functional Diagram

MAXQ7670

MSB (15)

SHIFT REGISTER

SFR DATA BUS

LSB(0)

DVDDIO

MASTER

SLAVE

MASTER

SLAVE

MISO

MOSI

SPI INTERRUPT

SYSCLK

/2 MASTER (MAX)

/8 SLAVE (MAX)

READ BUFFER

SPI CONTROL UNIT

SHIFT CLK

SCLK OUT

SCLK IN

MASTER/SLAVE SELECT

SPI ENABLE

SPI CONTRL REG (SPICN)

SPI CONTRL REG (SPICF)

SPI CONTRL REG (SPICK)

07

MASTER

SLAVE

DVDDIO

SS

SCLK

Page 26

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

26 ______________________________________________________________________________________

The drive capability of the I/O, when configured for output, depends on the value in the PS0 (pad drive

strength) register and can be set for either 1mA or

2mA. When an I/O is configured as an input, writing to

the PO register enables/disables the pullup/pulldown

resistor. The value in the PRO (pad resistive pull direction) register sets the enabled resistor at the I/O as

either a pullup to DVDDIO or pulldown to GNDIO.

Refer to the

MAXQ7670 User’s Guide

for more detailed

information.

Port Characteristics

The MAXQ7670 includes a bidirectional 7-bit I/O port

(P0) whose features include:

• Schmitt trigger input circuitry with software-selectable

high-impedance or weak pullup to DVDDIO or pulldown to GNDIO

• Software-selectable push-pull CMOS output drivers

capable of sinking and sourcing 0.5mA

• Falling or rising edge interrupt capability

• P0.4, P0.6, and P0.7 I/Os contain an additional special

function, such as a logic input/output for a timer channel

• Selectable pad drive strength and resistive pull direction

Refer to the

MAXQ7670 User’s Guide

for more details.

Figure 11 illustrates the functional blocks of an I/O.

MAXQ20 Core Architecture

The MAXQ7670’s core is a member of the low-cost,

high-performance, CMOS, fully static, 16-bit MAXQ20

core µCs. The MAXQ7670 is structured on a highly

advanced, accumulator-based, 16-bit RISC architecture. Fetch and execution operations complete in one

cycle without pipelining because the instruction contains both the op code and data. The result is a streamlined 1 million instructions-per-second-per-megahertz

(MIPS/MHz) µC.

The highly efficient core is supported by a 16-level

hardware stack, enabling fast subroutine calling and

task switching. The internal data pointers manipulate

data quickly and efficiently. Multiple data pointers allow

more than one function to access data memory without

having to save and restore data pointers each time. The

data pointers can automatically increment or decrement following an operation, eliminating the need for

software intervention and increasing application speed.

Instruction Set

The instruction set is composed of fixed-length, 16-bit

instructions that operate on registers and memory locations. The highly orthogonal instruction set allows arithmetic and logical operations to use any register along

with the accumulator. Special-function registers (also

called peripheral registers) control the peripherals and

are subdivided into register modules. The modular family architecture allows new devices and modules to

reuse code developed for existing products. The architecture is transport-triggered. This means that writes or

reads from certain register locations can also cause

side effects to occur. These side effects form the basis

for the higher-level op codes defined by the assembler,

such as ADDC, OR, JUMP, etc.

Memory Organization

The MAXQ7670 incorporates the following memory

areas (see Figure 12):

• 8KB (4K x 16) utility ROM

• 64KB (32K x 16) of flash memory for program storage

• 2048 bytes (1024 x 16) of SRAM for storage of tempo-

rary variables

• 16-level stack memory for storage of program return

addresses and general-purpose use

A 16-bit-wide x 16 deep internal hardware stack provides storage for program return addresses and general-purpose use. The MAXQ7670 core implicitly uses the

stack when executing an interrupt service routine (ISR)

and also when running CALL, RET, and RETI instructions. The stack can also be explicitly used by the

Figure 11. Digital I/O Circuitry

MAXQ7670

V

DVDDIO

P

PI0._

PR0._

PD0._

PO0._

PS0._

PULLUP/

PULLDOWN

LOGIC

N

P0._

PO0._

PD0._

Page 27

MAXQ7670

Microcontroller with 10-Bit ADC,

PGA, 64KB Flash, and CAN Interface

______________________________________________________________________________________ 27

application code to store data when context switching

(e.g., during a call or an interrupt). Storing and retrieving data is executed through the PUSH, POP, and POPI

instructions.

The incorporation of flash memory allows device reprogramming, eliminating the expense of discarding onetime programmable devices during development and

field upgrades (see Figure 13 for the flash memory sector maps).

A 16-word key protects the flash memory from access

by unauthorized individuals. Without supplying the 16word key, the password lock (PWL) bit in the SC register remains set, and the utility ROM is inaccessible.

Supplying the 16-word key makes the utility ROM transparent. The password-unlock command is issued

through the TAP interface. The 16-word password is

compared to the password in the program space to

determine its validity.

Enabling a pseudo-Von Neumann memory map places

the utility ROM, code, and data memory into a single

contiguous memory map. Use this mapping scheme for