Page 1

General Description

The MAXQ7667 smart system-on-a-chip (SoC) provides a

time-of-flight ultrasonic distance-measuring solution. The

device is optimized for applications involving large distance measurement with weak input signals or multiple

target identification. The MAXQ7667 features high signalto-noise ratio achieved by combining flexible electronics

with the intelligence necessary to optimize each function

as environmental and target conditions change.

An integrated burst signal generator and echo reception

components process ultrasonic signals between 25kHz

and 100kHz. Echo reception components include a programmable gain low-noise amplifier (LNA), a 16-bit

sigma-delta ADC to digitize the received echo signals,

and digital signal processing (DSP). DSP limits noise

with a bandpass filter, and creates an echo envelope

through demodulation and lowpass filtering. Input

referred noise is a low 0.7µV

RMS

. A programmable

phase-locked loop (PLL) frequency synthesizer supplies

the reference frequency for the burst generator and the

clock for the echo receiver’s digital filter. An embedded

16-bit MAXQ20 microcontroller (µC) controls all the preceding functions.

The µC optimizes the burst frequency and reception

frequency for each transmission at any temperature.

The MAXQ7667 achieves smart sensing by monitoring

the echo signals and then actively changing the transmitted and received parameters to obtain optimum

results. Digital filtering and burst synthesis do not

require CPU intervention. This leaves all the CPU power

available for echo optimization, communication, diagnostics, and additional signal processing.

The MAXQ7667 operates with three different power

supply voltages: +5V, +3.3V, and +2.5V. Two internal

linear regulators allow operation from a single +5V supply when three external power supplies are not available. Alternatively, the MAXQ7667 can control an

external pass transistor to allow operation from a single

supply voltage of +8V to +65V or more, depending on

the external component tolerance. The device is available in a 48-pin LQFP package and is specified to

operate from -40°C to +125°C.

Applications

Features

o Smart Analog Peripherals

Dedicated Ultrasonic Burst Generator

Echo Receiving Path (Includes LNA, Sigma-

Delta ADC)

5-Channel, 12-Bit SAR ADC with 250ksps

Sampling Rate

Internal Bandgap Voltage Reference for the

ADCs (Also Accepts External Voltage Reference)

o Timer/Digital I/O Peripherals

o High-Performance, Low-Power, 16-Bit RISC Core

o Program and Data Memory

o Crystal/Clock Module

o 16 x 16 Hardware Multiplier with 48-Bit

Accumulator, Single Clock Cycle

o Power-Management Module

o JTAG Interface

o Universal Asynchronous Receiver-Transmitter

(UART)

o Local Interconnect Network (LIN)

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

________________________________________________________________

Maxim Integrated Products

1

Ordering Information

19-4598; Rev 1; 7/09

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Note: Some revisions of this device may incorporate deviations from published specifications known as errata. Multiple revisions of any device

may be simultaneously available through various sales channels. For information about device errata, go to: ww.maxim-ic.com/errata

.

Pin Configuration appears at end of data sheet.

See the

Detailed Features

section for complete list of features.

Note: All devices are specified over the -40°C to +125°C operating temperature range.

/V denotes an automotive qualified part.

+

Denotes a lead(Pb)-free/RoHS-compliant package.

PART PIN-PACKAGE

RAM

(KB)

FLASH

(KB)

MAXQ7667AACM/V+

48 LQFP 4 32

Automotive Parking

Vehicle Security

Industrial Processing

Automation

Handheld Devices

Page 2

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

2 _______________________________________________________________________________________

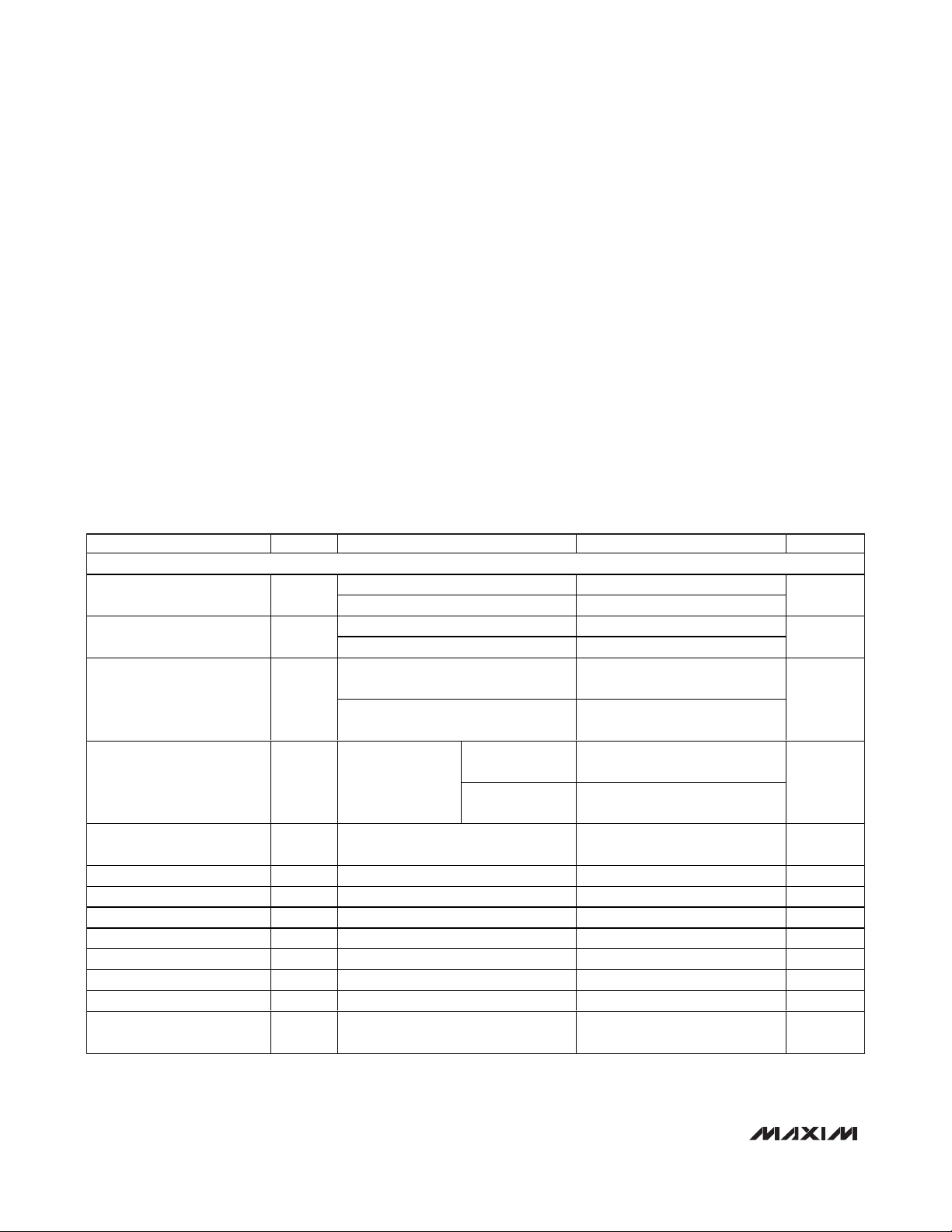

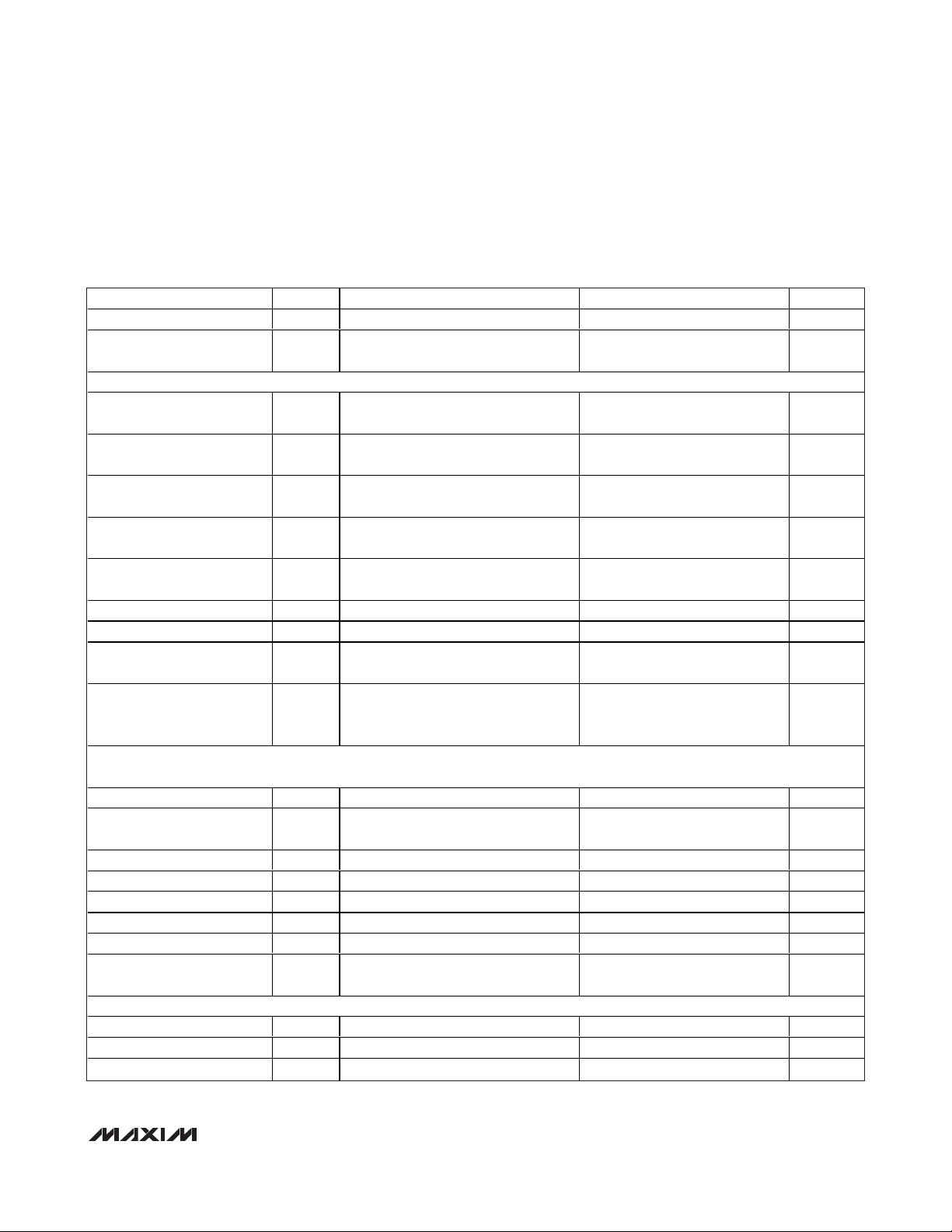

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(V

DVDDIO

= +5V, V

AVDD

= +3.3V; V

DVDD

= +2.5V, system clock (f

SYSCLK

) = 16MHz, burst frequency (f

BURST

) = bandpass frequency

(f

BPF

) = 50kHz, C

REFBG

= C

REF

= 1µF in parallel with 0.01µF, f

ADCCLK

= 2MHz (SAR data rate = 125ksps), TA= T

MIN

to T

MAX

, unless

otherwise specified. Typical values are at T

A

= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

DVDDIO, GATE5, REG3P3, REG2P5 to

DGND ................................................................-0.3V to +6.0V

AVDD to AGND .....................................................-0.3V to +4.0V

DVDD to DGND .....................................................-0.3V to +3.0V

DVDDIO to DVDD..................................................-0.3V to +6.0V

AVDD to DVDD......................................................-0.3V to +4.0V

AGND to DGND.....................................................-0.3V to +0.3V

Digital Inputs/Outputs to DGND..........-0.3V to (V

DVDDIO

+ 0.3V)

Analog Inputs/Outputs to AGND ............-0.3V to (V

AVDD

+ 0.3V)

XIN, XOUT to DGND ..............................-0.3V to (V

DVDD

+ 0.3V)

Maximum Current into Any Pin............................................50mA

Continuous Power Dissipation (T

A

= +70°C)

48-Pin LQFP (derate 21.7mW/°C above +70°C).....1739.1mW

Operating Temperature Range .........................-40°C to +125°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

ECHO INPUT (Low-Noise Amplifier and Sigma-Delta ADC)

Input-Referred Noise

(Note 1)

Minimum Detectable Signal

Operating Input Range

Programmable Gain

Programmable-Gain Adjust

Resolution

LNA Bandwidth 150 kHz

ADC Sampling Rate 80 x f

ADC Output Data Rate 10 x f

ADC Output Data Re solution 16 B its

Echo-Input Resistance RIN For each echo input 14 k

Echo-Input Capacitance 14 pF

Echo-Input DC Bias Voltage V

Maximum Overvoltage

Recovery Time

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

(Note 2) 10 %

Recover from 2V

VGA gain adjust = 1.55µV

VGA gain adjust = 0.1µV

VGA gain adjust = 1.55µV

VGA gain adjust = 0.1µV

VGA gain adjust = 1.55µV

unclipped

VGA gain adjust = 0.1µV

unclipped

From echo input to

bandpass filter in

reply to input

P-P

/LSB 5.6

P-P

/LSB 0.7

P-P

/LSB 80

P-P

/LSB 10

P-P

/LSB,

P-P

/LSB,

P-P

VGA gain adjust

P-P

P-P

/LSB

/LSB

= 1.55µV

VGA gain adjust

= 0.1µV

input 10 µs

100

6.7

1.55

0.1

AVDD

kHz

BPF

kHz

BPF

/2 V

µV

µV

RMS

µV

P-P

mV

P-P

/LSB

P-P

Page 3

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

_______________________________________________________________________________________ 3

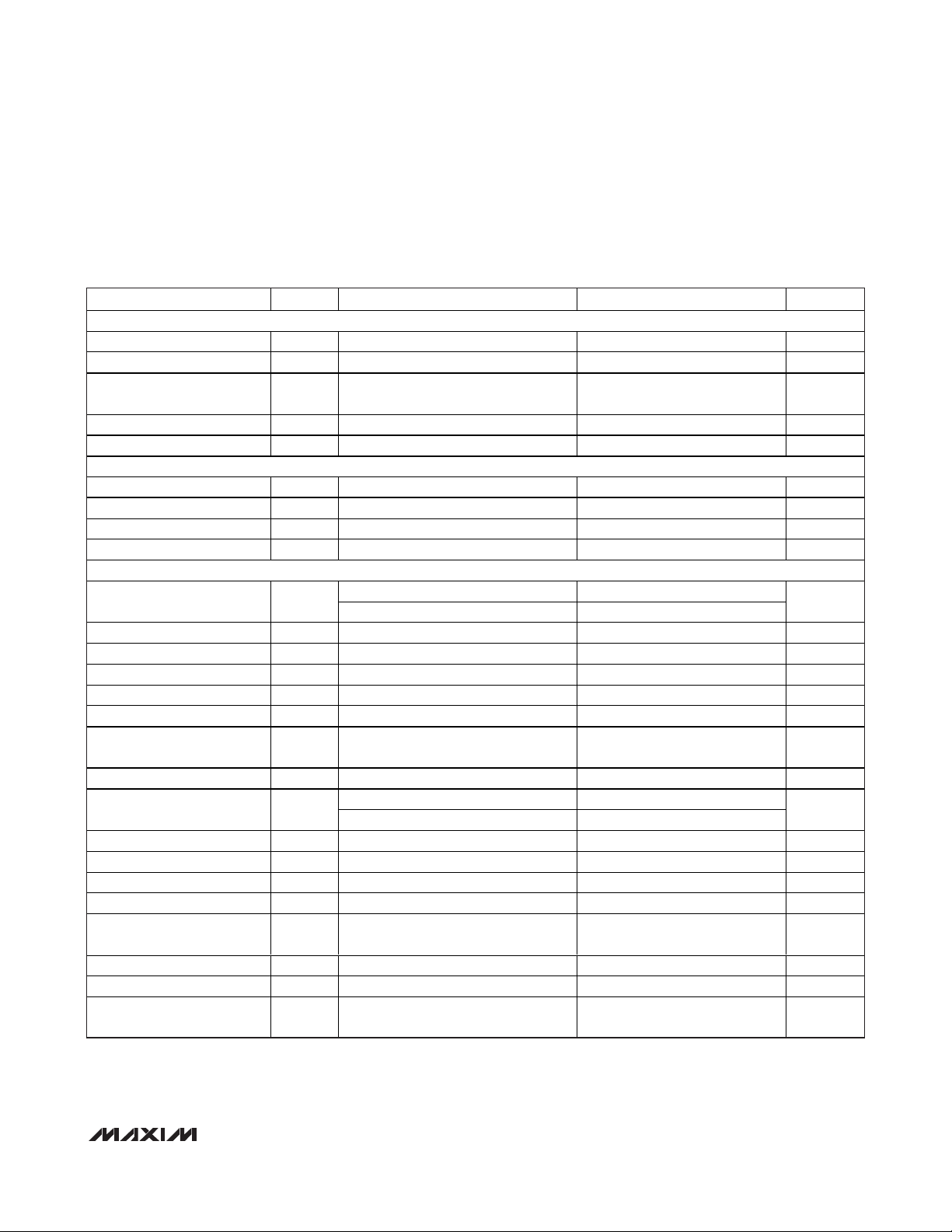

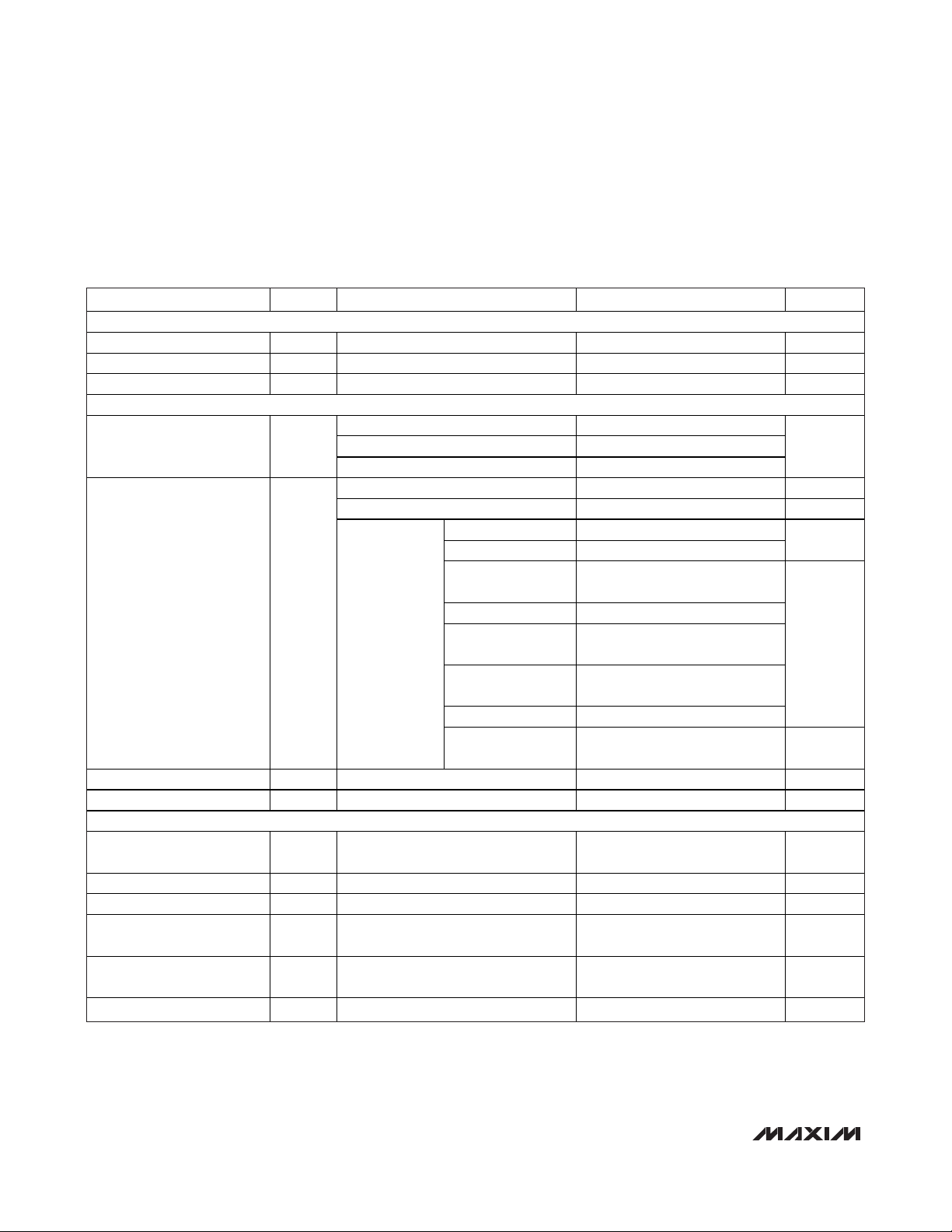

ELECTRICAL CHARACTERISTICS (continued)

(V

DVDDIO

= +5V, V

AVDD

= +3.3V; V

DVDD

= +2.5V, system clock (f

SYSCLK

) = 16MHz, burst frequency (f

BURST

) = bandpass frequency

(f

BPF

) = 50kHz, C

REFBG

= C

REF

= 1µF in parallel with 0.01µF, f

ADCCLK

= 2MHz (SAR data rate = 125ksps), TA= T

MIN

to T

MAX

, unless

otherwise specified. Typical values are at T

A

= +25°C.)

BANDPASS FILTER

Center Frequency f

Passband Width -3dB 0.14 x f

Minimum Stopband

Rejection

Output Data Rate 10 x f

Output Data Resolution 16 Bits

LOW PA S S FILTE R

Cor ner Frequency f

Rolloff 40 dB/Decade

Output Data Rate 5 x f

Output Data Resolution 16 Bits

SAR ADC

Resolution

Integral Nonlinearity Tested at 125ksps ±1 ±2 LSB

Differential Nonlinearity Te sted at 125ksps -2 +2 LSB

Offset Error ±1 ±3 mV

Offset-Error Drift ±5 µV/°C

Gain Error ±1 %

Gain-Error Temperature

Coefficient

Input-Referred Noise At ADC input s 400 µV

Differential Input Range

Abso lute Input Range 0 V

Input Leakage Current ±0.1 µA

Conversion Time 13 ADCCLK cycles at 2MHz 6.5 µs

Input Capacitance 14 pF

Track-and-Hold Acquisition

Time

Turn-On Time Eight ADCCLK cycles at 2MHz 4 µs

Conversion Clock

Conversion Rate

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

25 100 kHz

BPF

-3dB 0.1 x f

LPF

±0.4 ppmFS/°C

Three ADCCLK c ycles at 2MH z 1.5 µs

0.5 4 MHz

f

ADCCLK

One decade awa y from center

frequency

Measurement 12

No missing codes 11

Unipolar 0 V

Bipolar -V

f

tested)

= 4MH z (not production

ADCCLK

-60 dB

/2 +V

REF

250 ksp s

kHz

BPF

ksps

BPF

kHz

BPF

ksps

BPF

REF

/2

REF

V

AVDD

Bits

RMS

V

Page 4

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

4 _______________________________________________________________________________________

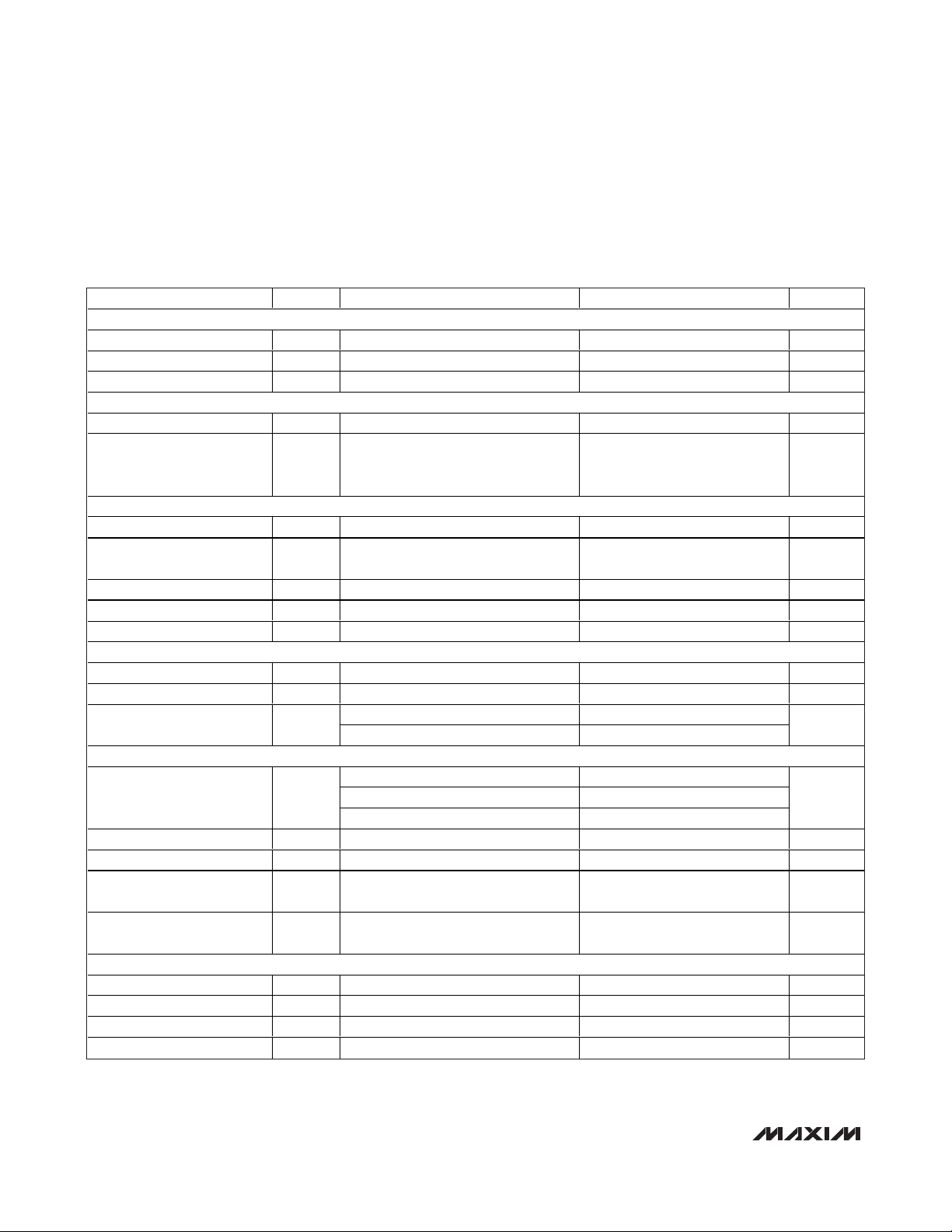

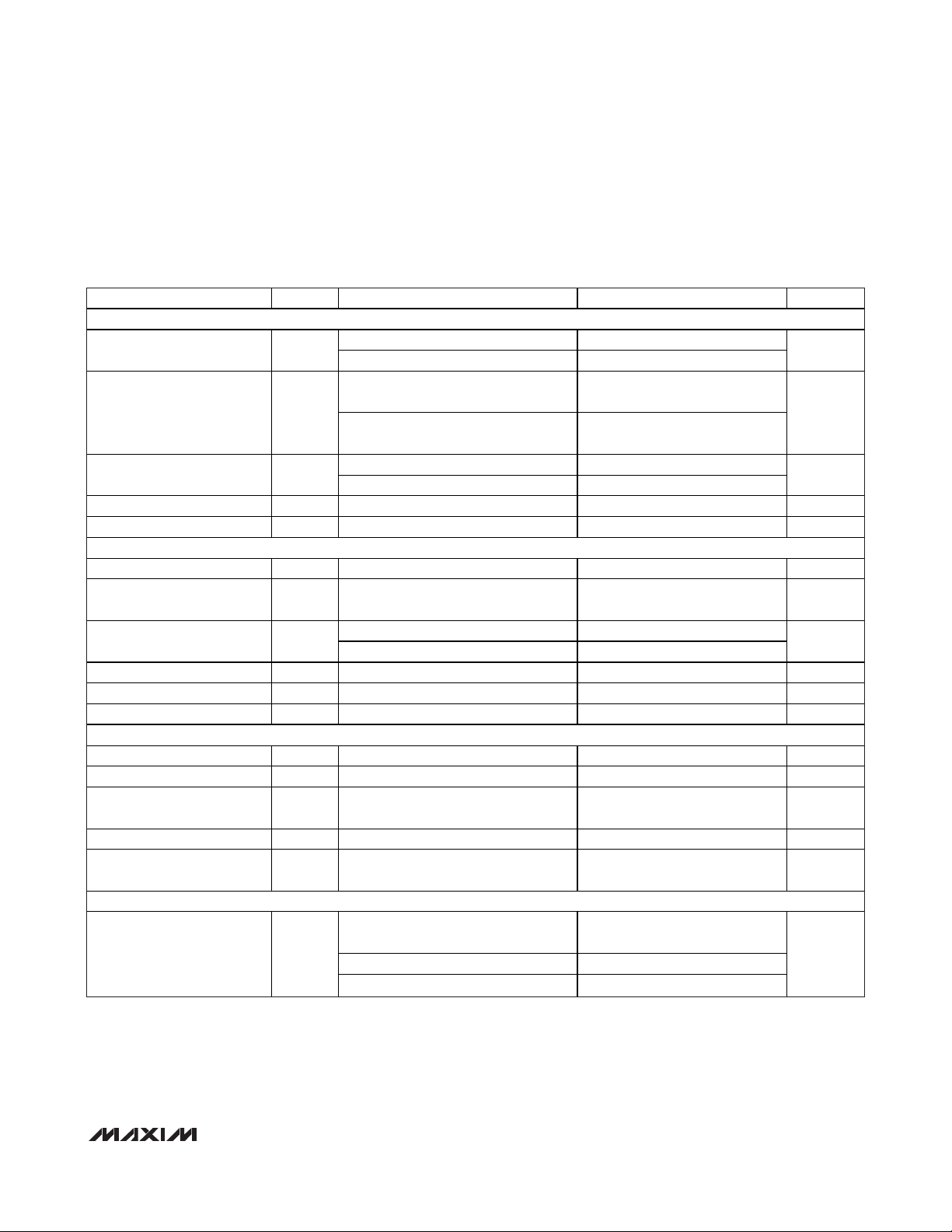

ELECTRICAL CHARACTERISTICS (continued)

(V

DVDDIO

= +5V, V

AVDD

= +3.3V; V

DVDD

= +2.5V, system clock (f

SYSCLK

) = 16MHz, burst frequency (f

BURST

) = bandpass frequency

(f

BPF

) = 50kHz, C

REFBG

= C

REF

= 1µF in parallel with 0.01µF, f

ADCCLK

= 2MHz (SAR data rate = 125ksps), TA= T

MIN

to T

MAX

, unless

otherwise specified. Typical values are at T

A

= +25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

REFERENCE BUFFER

Offset 5mV

Minimum Load 2.5 kΩ

Output Bypass Capacitor 0.47 µF

EXTERNAL VOLTAGE REFERENCE (Reference Buffer Disabled)

Reference Input Range Applied at REF 1.0 V

Reference Input Impedance

INTERNAL VOLTAGE REFERENCE (REFBG)

Initial Accuracy 2.45 2.5 2.55 V

Maximum Temperature

Coefficient

Output Impedance 1.1 kΩ

Power-Supply Rejection Ratio V

Output Noise 0.5 mV

PROGRAMMABLE BURST-FREQUENCY OSCILLATOR

Burst-Frequency Range 0.025 1.335 MHz

Burst-Frequency Resolution 0.1 %

Burst-Frequency Locking

Time

CRYSTAL OSCILLATOR

Frequency Range

Temperature Stability Excluding crystal 25 ppm/°C

Startup Time 16MHz crystal 10 ms

XIN Input Low Voltage When driven with external clock source

XIN Input High Voltage When driven with external clock source

INTERNAL RC OSCILLATOR

Frequency 13.5 MHz

Initial Accuracy 10.5 %

Temperature Drift TA = T

Supply Rejection V

Measured at REF with the SAR and

sigma-delta ADCs running at

maximum frequency

= 3.0V to 3.6V 60 dB

AVDD

Change from 40kHz to 60kHz 5

Change from 50kHz to 50.5kHz 2

Tested crystal frequency 16

Minimum crystal frequency 4

External clock input 4 16

to T

MIN

MAX

= 2.25V to 2.75V -1.5 %

DVDD

0.7 x

V

DVDD

50 kΩ

100 ppm/°C

700 ppm

AVDD

0.3 x

V

DVDD

V

RMS

ms

MHz

V

V

Page 5

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

_______________________________________________________________________________________ 5

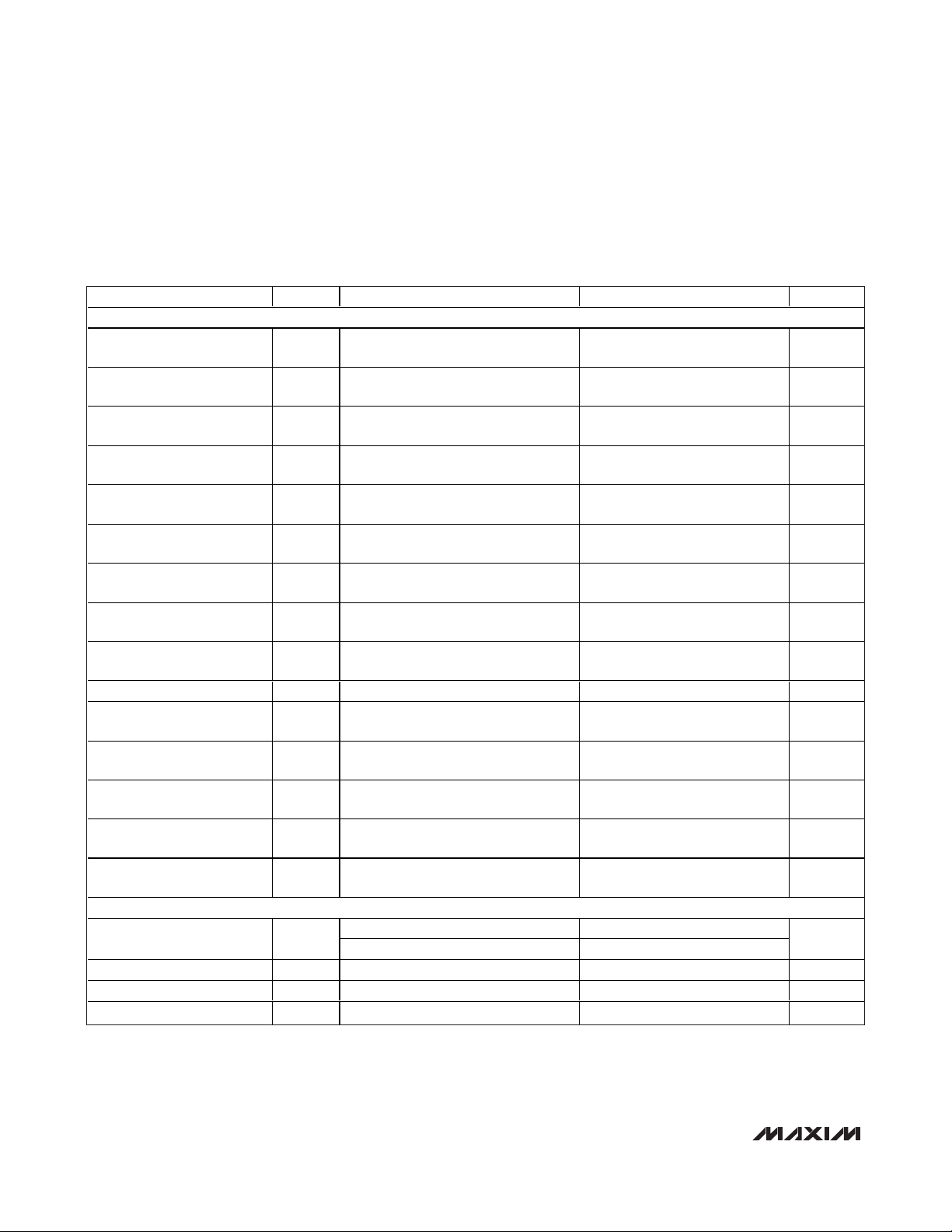

ELECTRICAL CHARACTERISTICS (continued)

(V

DVDDIO

= +5V, V

AVDD

= +3.3V; V

DVDD

= +2.5V, system clock (f

SYSCLK

) = 16MHz, burst frequency (f

BURST

) = bandpass frequency

(f

BPF

) = 50kHz, C

REFBG

= C

REF

= 1µF in parallel with 0.01µF, f

ADCCLK

= 2MHz (SAR data rate = 125ksps), TA= T

MIN

to T

MAX

, unless

otherwise specified. Typical values are at T

A

= +25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Adjustable Frequency Range Using the RCTRM register -40 +40 %

Frequency Adjustment

Resolution

SUPPLY VOLTAGE SUPERVISORS

DVDD Reset Threshold

DVDD Interrupt Threshold

Minimum Reset and Interrupt

Threshold Difference

AVDD Interrupt Threshold

DVDDIO Interrupt Threshold

Supervisor Operating Range At DVDD 1.5 2.75 V

Supervisor Hysteresis 1%

RESET Release Delay

Power-Up Time

Asserts RESET if V

this threshold

Generates an interrupt if V

below this threshold

Generates an interrupt if V

below this threshold

Generates an interrupt if V

below this threshold

After V

threshold

Time from RESET is released to the

execution of the first instruction (serial

bootloader off)

rises above the reset

DVDD

falls below

DVDD

falls

DVDD

falls

AVDD

falls

DVDDIO

0.2 %

2.10 2.25 V

2.25 2.38 V

150 mV

2.95 3.15 V

4.5 4.75 V

35 µs

1µs

+5V LINEAR REGULATOR (DVDDIO, GATE5, Requires External Pass Transistor, see the Typical Application

Circuit/Functional Diagram)

Regulator Output Voltage At DVDDIO 4.75 5.25 V

V

GATE5 Output High Voltage I

GATE5 Output Low Voltage I

GATE5 Output Resistance I

Gain Bandwidth DVDDIO to GATE5 1.58 kHz

Gain DVDDIO to GATE5 1700 V/V

GATE5 Slew Rate 4.3 V/ms

Maximum Load Capacitance

+3.3V LINEAR REGULATOR (REG3P3)

REG3P3 Output Voltage 3.15 3.45 V

Load Current 50 mA

Output Short-Circuit Current REG3P3 shorted to AGND 150 mA

Maximum capacitance on DVDDIO

when using an external pass transistor

= 0µA (no load)

SOURCE

= 500µA 2 V

SINK

= 0µA to 50µA 330 Ω

SINK

DVDDIO

- 0.1

1µF

V

Page 6

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V

DVDDIO

= +5V, V

AVDD

= +3.3V; V

DVDD

= +2.5V, system clock (f

SYSCLK

) = 16MHz, burst frequency (f

BURST

) = bandpass frequency

(f

BPF

) = 50kHz, C

REFBG

= C

REF

= 1µF in parallel with 0.01µF, f

ADCCLK

= 2MHz (SAR data rate = 125ksps), TA= T

MIN

to T

MAX

, unless

otherwise specified. Typical values are at T

A

= +25°C.)

SPI is a trademark of Motorola, Inc.

+2.5V LINEAR REGULATOR (REG2P5)

REG2P5 Output Voltage 2.38 2.62 V

Load Current 50 mA

Output Short-Circuit Current REG2P5 shorted to DGND 100 mA

POWER REQUIREMENTS

Supply Voltage Range

AVDD Supply Current

DVDD Supply Current 11 mA

DVDDIO Supply Current 2.5 mA

DIGITAL INPUTS (GPIO, UART, JTAG, SPI™)

Input High Voltage

Input Low Voltage 0.8 V

Input Hysteresis V

Input Leakage Current

Pullup/Pulldown Resistance

Input Capacitance 15 pF

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DVDD 2.25 2.5 2.75

AVDD 3.00 3.3 3.6

DVDDIO 4.5 5.0 5.5

All analog functions enabled 12 18 mA

All analog functions disabled 3 10 µA

Incremental

AVDD supply

current

= 5.0V 500 mV

DVDDIO

Digital input voltage = DGND or

DVDDIO, pullup disabled

Pulled up to DVDDIO internal ly, pulled

down to DGND internally

LNA 2.4

Sigma-delta ADC 12

SAR ADC, 250ksps,

f

PLL 300

Supply vo ltage

supervisors

Internal voltage

reference

Reference buffer 300

Bias (any AVDD

module enabled)

ADCCLK

= 4MHz

600

3

220

1.5 mA

V

DVDDIO

- 1

±0.01 ±1 µA

150 k

V

mA

V

µA

Page 7

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

_______________________________________________________________________________________ 7

ELECTRICAL CHARACTERISTICS (continued)

(V

DVDDIO

= +5V, V

AVDD

= +3.3V; V

DVDD

= +2.5V, system clock (f

SYSCLK

) = 16MHz, burst frequency (f

BURST

) = bandpass frequency

(f

BPF

) = 50kHz, C

REFBG

= C

REF

= 1µF in parallel with 0.01µF, f

ADCCLK

= 2MHz (SAR data rate = 125ksps), TA= T

MIN

to T

MAX

, unless

otherwise specified. Typical values are at T

A

= +25°C.)

DIGITAL OUTPUTS (GPIO, UART, JTAG, SPI)

Output Low Voltage

Output High Voltage

Maximum Output

Impedance

Three-State Leakage ±0.01 ±1 µA

Three-State Capacitance 15 pF

BURST OUTPUT

Output Low Voltage I

Output High Voltage I

Maximum Output

Impedance

Three-State Leakage ±0.01 ±1 µA

Three-State Capacitance 15 pF

Short-Circuit Current Burst drive set to high 50 mA

RESET

Internal Pullup Resistance Pulled up to DVDDIO 120 k

Output Low Voltage I

Output High Voltage No external load

Input Low Voltage When driven by external source 0.8 V

Input High Voltage When driven by external source

UART/LIN INTERFACE (UTX, URX)

UART Baud Rates

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

I

= 0.5mA, drive strength = low 0.4

SINK

= 1.0mA, drive strength = high 0.4

I

SINK

I

drive strength = low

I

SOURCE

drive strength = high

Drive strength = low 880

Drive strength = high 450

Drive strength = low 90

Drive strength = high 45

Asynchronous mode

(system clock/32)

Synchronous mode (system clock/8) 2000

LIN 2.0 compatibility (Note 3) 1 20

= 0.5mA,

SOURCE

= 1.0mA,

= 8mA 0.4 V

SINK

= 8mA

SOURCE

= 0.5mA 0.4 V

SINK

V

V

V

V

V

-

DVDDIO

0.5

-

DVDDIO

0.5

-

DVDDIO

0.5

-

DVDDIO

0.5

-

DVDDIO

1

500

V

V

V

V

V

kbps

Page 8

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

8 _______________________________________________________________________________________

Note 1: Noise measured at bandpass filter output with ECHO+ and ECHO- shorted divided by the gain with f

BPF

= 50kHz.

Note 2: Gain adjust resolution typically ranges between 6.25% and 12.5%.

Note 3: LIN 2.0 specifies a maximim data rate of 20kbps. Higher data rates could be possible with compatible devices and suitable

line conditions.

ELECTRICAL CHARACTERISTICS (continued)

(V

DVDDIO

= +5V, V

AVDD

= +3.3V; V

DVDD

= +2.5V, system clock (f

SYSCLK

) = 16MHz, burst frequency (f

BURST

) = bandpass frequency

(f

BPF

) = 50kHz, C

REFBG

= C

REF

= 1µF in parallel with 0.01µF, f

ADCCLK

= 2MHz (SAR data rate = 125ksps), TA= T

MIN

to T

MAX

, unless

otherwise specified. Typical values are at T

A

= +25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SPI INTERFACE TIMING (Figures 11 and 12)

SPI Master Operating

Frequency

SPI Slave Operating

Frequency

SCLK Output Pulse-Width

High/Low

MOSI Output Hold Time

After SCLK Sample Edge

MOSI Output Valid to Sample

Edge

MISO Input Valid to SCLK

Sample Edge

MISO Input Hold Time After

SCLK Sample Edge

SCLK Inactive to MOSI

Inactive

SCLK Input Pulse-Width

High/Low

SS Active to First Shift Edge t

MOSI Input Setup Time to

SCLK Sample Edge

MOSI Input Hold Time After

SCLK Sample Edge

MISO Output Valid After

SCLK Shift Edge Transition

SS Inactive Duration t

SCLK Inactive to SS Rising

Edge

1/t

1/t

t

MCH

t

t

t

t

t

t

MCL

MOH

MOV

t

MIS

t

MIH

MLH

SCH

t

SCL

SSE

t

t

SIH

SOV

SSH

t

MCK

SCK

SIS

SD

,

,

0.5 x f

0.25 x f

SYSCLK

SYSCLK

8 MHz

4 MHz

t

/2

MCK

- 25

t

/2

MCK

- 25

t

/2

MCK

- 25

25 ns

0ns

0ns

t

/2 ns

SCK

4t

SYSCLK

25 ns

25 ns

50 ns

t

+

SYSCLK

25

t

+

SYSCLK

25

FLASH PROGRAMMING

Flash Erase Time

Mass erase 200

Page erase (512 bytes per page) 20

Flash Programming Time 20µs per word 657 ms

Write/Erase Cycles 10,000 Cycles

Data Retention Average temperature = +85°C 15 Years

ns

ns

ns

ns

ns

ns

ms

Page 9

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

_______________________________________________________________________________________ 9

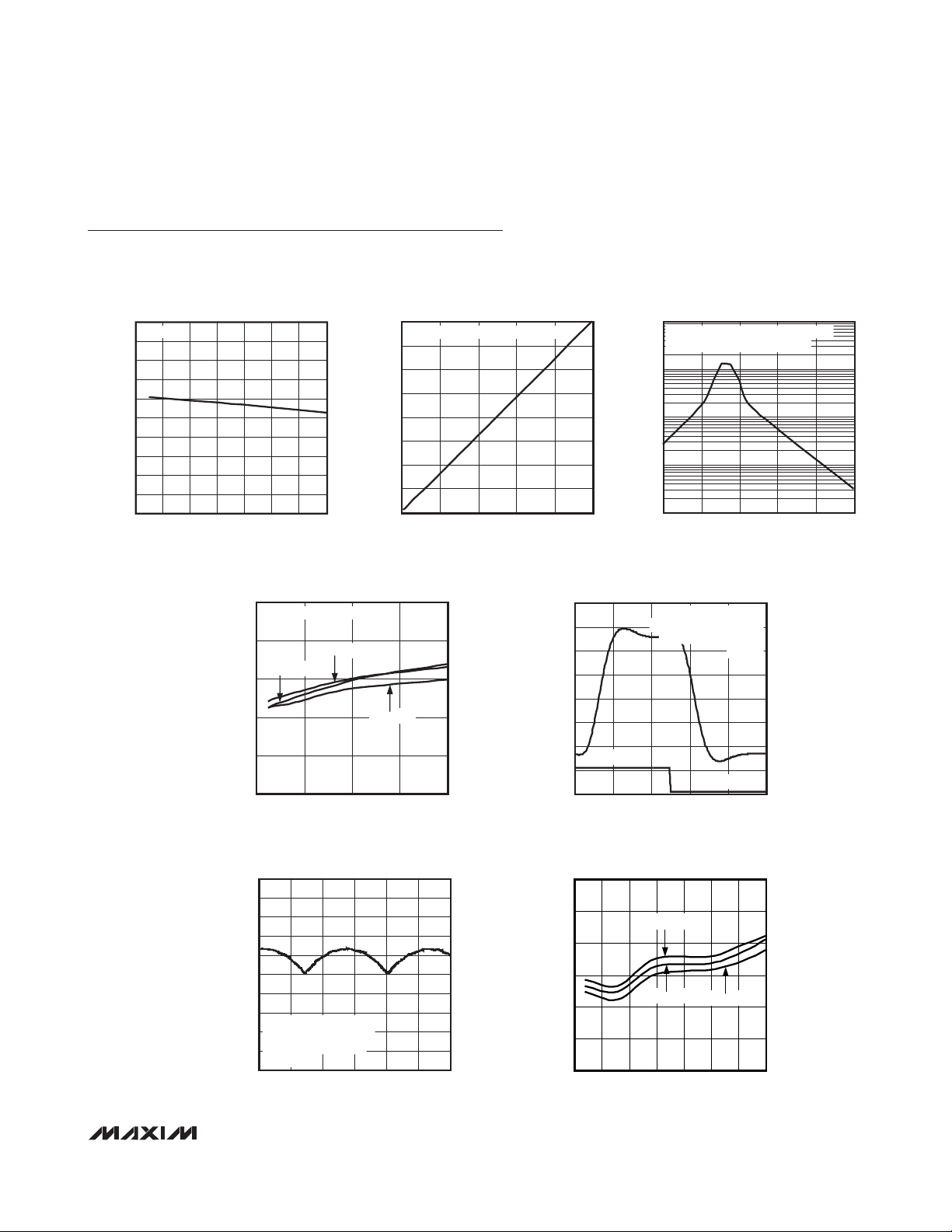

Typical Operating Characteristics

(V

DVDDIO

= +5V, V

AVDD

= +3.3V, V

DVDD

= +2.5V, f

SYSCLK

= 16MHz, burst frequency = bandpass frequency = 50kHz, TA= +25°C,

unless otherwise noted.)

BURST OUTPUT FREQUENCY

vs. TEMPERATURE

50.05

USING PLL

50.04

50.03

50.02

50.01

50.00

49.99

49.98

49.97

BURST OUTPUT FREQUENCY (kHz)

49.96

49.95

-50 125

TEMPERATURE (°C)

5025 100750-25

BANDPASS FILTER OUTPUT NOISE FLOOR

vs. BANDPASS FILTER CENTER FREQUENCY

15

RECEIVE PATH GAIN AT MAXIMUM

)

RMS

12

TA = +105°C

9

6

3

BANDPASS FILTER OUTPUT (LSB

0

20 100

LOWPASS FILTER OUTPUT RIPPLE vs. TIME

15,000

14,500

14,000

13,500

13,000

12,500

12,000

LPF OUTPUT (LSB)

11,500

MINIMUM ECHO GAIN

11,000

20mV

50kHz ECHO FREQUENCY

10,500

250ksps

10,000

012

65,536

57,344

MAXQ7667 toc01

49,152

40,960

32,768

24,576

LPF OUTPUT (LSB)

16,384

TA = +25°C

FREQUENCY (kHz)

ECHO AMPLITUDE

P-P

246 108

TIME (ms)

LOWPASS FILTER OUTPUT

vs. ECHO INPUT AMPLITUDE

PROGRAMMABLE ECHO GAIN = MINIMUM

8192

0

0 0.10

TA = -40°C

806040

0.040.02 0.080.06

ECHO INPUT AMPLITUDE (V

MAXQ7667 toc04

MAXQ7667 toc06

P-P

16,000

14,000

12,000

10,000

ADC COUNT (LSB)

OFFSET ERROR (mV)

LOWPASS FILTER OUTPUT

vs. ECHO INPUT FREQUENCY

100,000

PROGRAMMABLE ECHO GAIN = MINIMUM

ECHO INPUT AMPLITUDE = 20mV

MAXQ7667 toc02

10,000

1000

LPF OUTPUT (LSB)

100

10

25 100

)

ECHO INPUT FREQUENCY (kHz)

RECEIVE PATH RESPONSE TIME

(ECHO INPUT TO LOWPASS FILTER OUTPUT)

MINIMUM ECHO GAIN

ECHO AMPLITUDE

20mV

P-P

50kHz ECHO FREQUENCY

8000

6000

4000

2000

INPUT ON

0

0 1000

400200 800600

TIME (µs)

250ksps

INPUT OFF

SAR ADC OFFSET ERROR

vs. TEMPERATURE

2.0

1.5

1.0

0.5

0

-0.5

-1.0

-50 125

V

= 3.6V

AVDD

V

= 3.3V

AVDD

07525-25 10050

TEMPERATURE (°C)

V

AVDD

= 3V

P-P

MAXQ7667 toc03

5540 8570

MAXQ7667 toc05

MAXQ7667 toc07

Page 10

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

10 ______________________________________________________________________________________

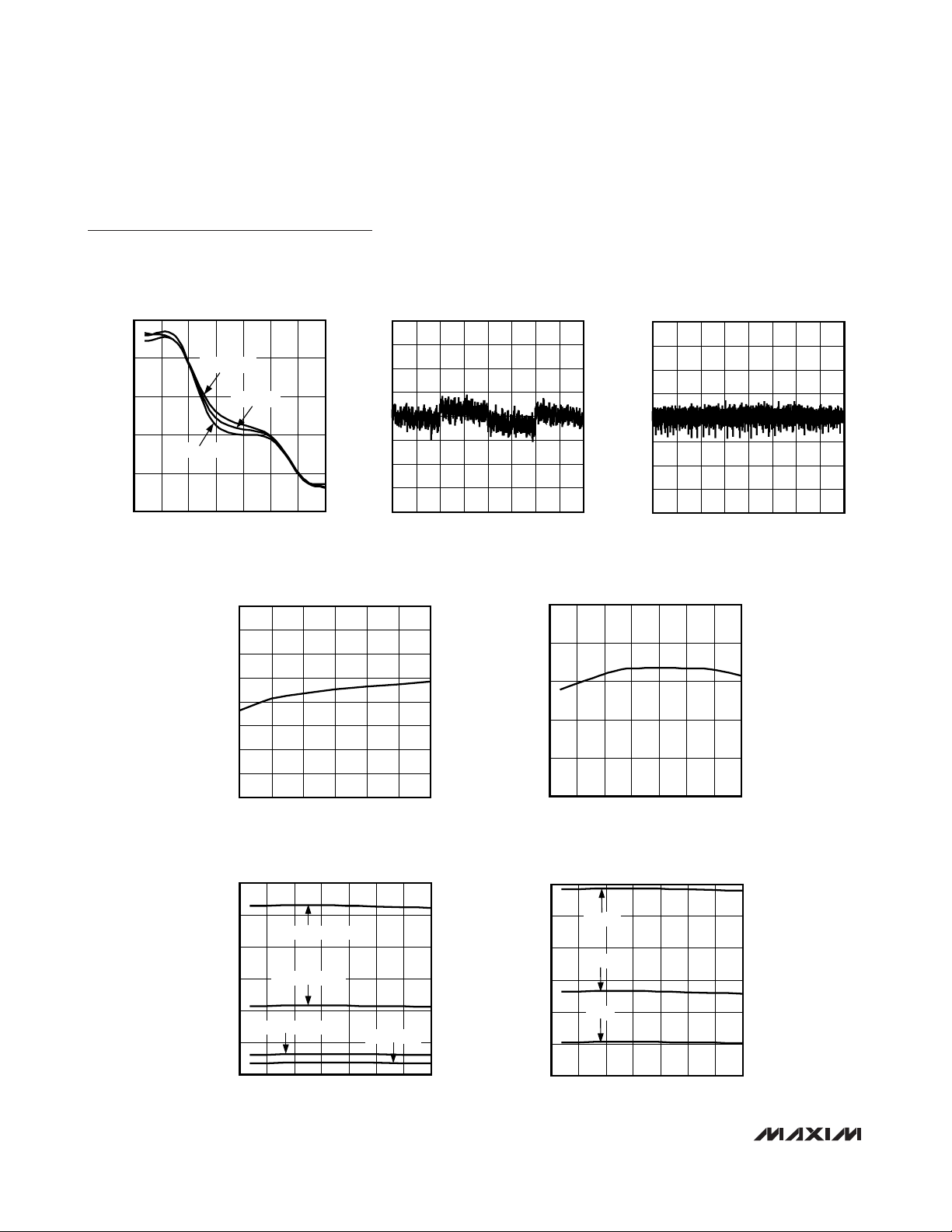

Typical Operating Characteristics (continued)

(V

DVDDIO

= +5V, V

AVDD

= +3.3V, V

DVDD

= +2.5V, f

SYSCLK

= 16MHz, burst frequency = bandpass frequency = 50kHz, TA= +25°C,

unless otherwise noted.)

GAIN ERROR (mV)

SAR ADC GAIN ERROR

vs. TEMPERATURE

3.0

2.5

2.0

1.5

1.0

0.5

-50 125

V

AVDD

V

= 3.6V

AVDD

07525-25 10050

TEMPERATURE (°C)

= 3.3V

V

AVDD

= 3V

MAXQ7667 toc08

INL (LSB)

-0.5

-1.0

-1.5

-2.0

SAR ADC INL vs. CODE

2.0

1.5

1.0

0.5

0

0409625601536512 3584

CODE

2.0

1.5

MAXQ7667 toc09

1.0

0.5

0

DNL (LSB)

-0.5

-1.0

-1.5

307220481024

-2.0

0 409625601536512 3584

SAR ADC DNL vs. CODE

MAXQ7667 toc10

307220481024

CODE

REFERENCE OUTPUT VOLTAGE

vs. SUPPLY VOLTAGE

2.520

2.519

2.518

2.517

2.516

2.515

REF OUTPUT VOLTAGE (V)

2.514

2.513

2.512

3.0 3.63.1 3.4

AVDD SUPPLY VOLTAGE (V)

SUPPLY BROWNOUT THRESHOLDS

vs. TEMPERATURE

5.0

4.5

4.0

3.5

3.0

SUPPLY THRESHOLD (V)

2.5

DVDDIO INTERRUPT

AVDD INTERRUPT

DVDD INTERRUPT

3.53.33.2

DVDD RESET

MAXQ7667 toc11

MAXQ7667 toc13

REFERENCE OUTPUT VOLTAGE

vs. TEMPERATURE

2.55

2.53

2.51

2.49

REF OUTPUT VOLTAGE (V)

2.47

2.45

-50 12550-25

025 10075

TEMPERATURE (°C)

REGULATOR OUTPUT VOLTAGE

vs. TEMPERATURE

5.0

4.5

4.0

3.5

3.0

REGULATOR OUTPUT VOLTAGE (V)

2.5

DVDDIO

AVDD

DVDD

MAXQ7667 toc12

MAXQ7667 toc14

2.0

-50 12550

TEMPERATURE (°C)

25 1000-25 75

2.0

25 1000-25 75-50 12550

TEMPERATURE (°C)

Page 11

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

______________________________________________________________________________________

11

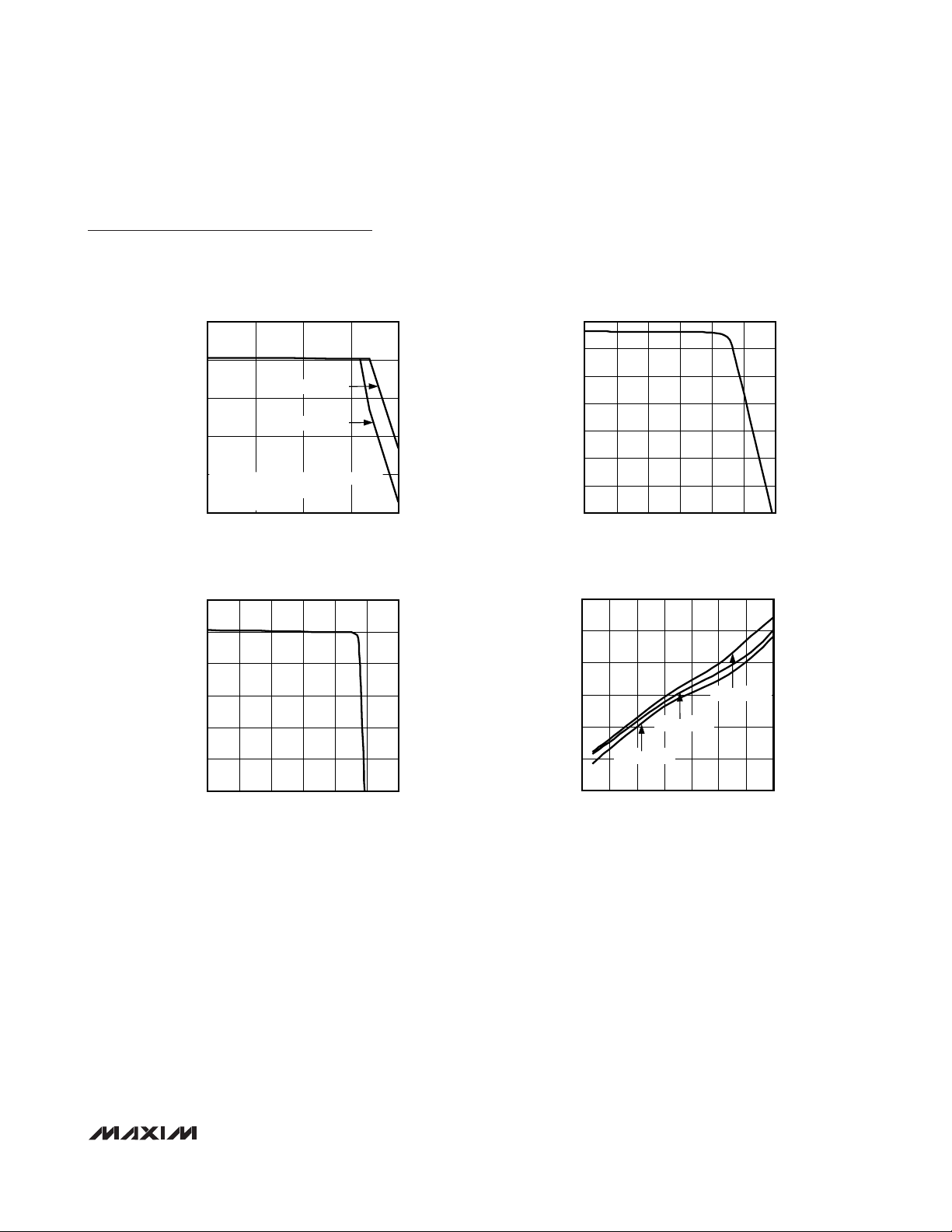

Typical Operating Characteristics (continued)

(V

DVDDIO

= +5V, V

AVDD

= +3.3V, V

DVDD

= +2.5V, f

SYSCLK

= 16MHz, burst frequency = bandpass frequency = 50kHz, TA= +25°C,

unless otherwise noted.)

DVDDIO REGULATOR OUTPUT VOLTAGE

5.5

5.0

4.5

4.0

3.5

EXTERNAL VOLTAGE SOURCE CONNECTED

TO THE DRAIN OF EXTERNAL PASS

DVDDIO REGULATOR OUTPUT VOLTAGE (V)

TRANSISTOR BSP129

3.0

0 200150

REG2P5 REGULATOR OUTPUT VOLTAGE

3.0

2.5

2.0

vs. LOAD CURRENT

DRAIN = 14V

DRAIN = 8V

10050

DVDDIO LOAD CURRENT (mA)

vs. LOAD CURRENT

REG3P3 REGULATOR OUTPUT VOLTAGE

vs. LOAD CURRENT

3.5

MAXQ7667 toc15

3.0

2.5

2.0

1.5

1.0

0.5

REG3P3 REGULATOR OUTPUT VOLTAGE (V)

0

0 12010020 80

REG3P3 LOAD CURRENT (mA)

6040

RC OSCILLATOR FREQUENCY

vs. TEMPERATURE

15.0

MAXQ7667 toc17

14.5

14.0

MAXQ7667 toc16

MAXQ7667 toc18

1.5

1.0

0.5

REG2P5 REGULATOR OUTPUT VOLTAGE (V)

0

012010020 80

REG2P5 LOAD CURRENT (mA)

6040

13.5

V

= 2.50V

V

= 2.75V

DVDD

07525-25 10050

TEMPERATURE (°C)

DVDD

13.0

RC OSCILLATOR FREQUENCY (MHz)

12.5

12.0

-50 125

V

DVDD

= 2.25V

Page 12

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

12 ______________________________________________________________________________________

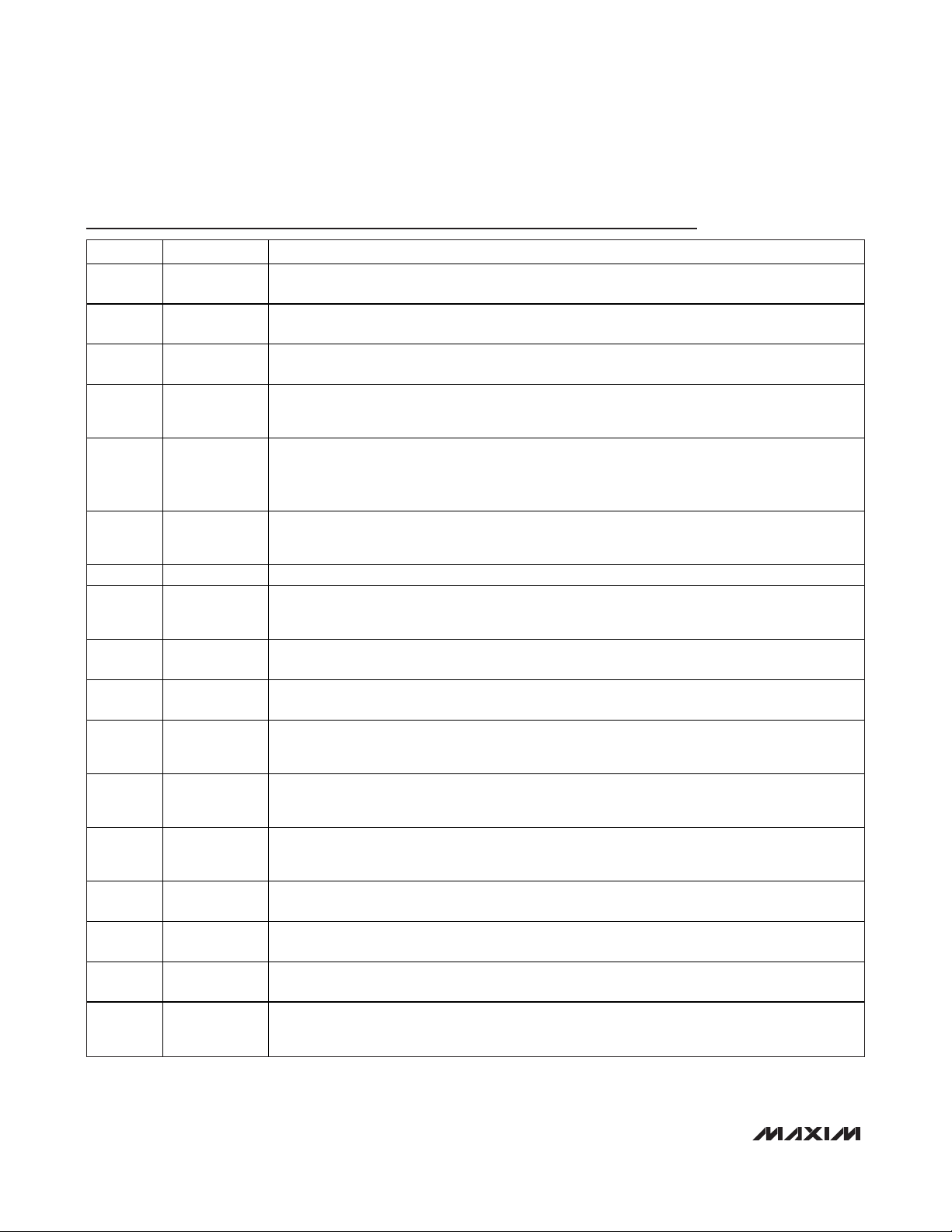

Pin Description

PIN NAME FUNCTION

1 P1.3/TCK

2 P1.4/MOSI

3 P1.5/MISO

4 P1.6/SCLK

5 P1.7/SYNC/SS

6, 19, 42 DVDD

7, 18, 43 DGND Digital Ground. Connect all DGND nodes together. Connect to AGND at a si ngle point.

8, 17, 44 DVDDIO

9 P0.0/URX

10 P0.1/UTX

11 P0.2/TXEN

12

13 P0.4/T0B

14 P0.5/T1

15 P0.6/T2

16 P0.7/T2B

20 XIN

P0.3/T0/

ADCCTL

Port 1 Data 3/JTAG Serial Clock Input. P1.3 i s a general-purpose digital I/O. TCK is the JTAG

serial test clock input. Refer to the MAXQ7667 User’s Guide Sections 5 and 11.

Port 1 Data 4/SPI Serial Data Output. P1.4 is a general-purpose digital I/O. MOSI is the master

output, sla ve input for the SPI interface. Refer to the MAXQ7667 User’s Guide Sections 5 and 9.

Port 1 Data 5/SPI Serial Data Input. P1.5 is a general-purpose digital I/O. MISO is the ma ster input,

slave output for the SPI interface. Refer to the MAXQ7667 User’s Guide Sections 5 and 9.

Port 1 Data 6/SPI Serial Clock Output. P1.6 is a general-purpose digital I/O. SCLK is the serial

clock for the SPI interface. SCLK is an input when operating as a s lave and an output when

operating as a master. Refer to the MAXQ7667 User’s Guide Sections 5 and 9.

Port 1 Data 7/Schedule Timer Sync Input/SPI Slave Select. P1.7 is a general-purpose digital I/O.

A rising edge on the SYNC input resets the schedule timer. In SPI slave mode, SS is the SPI

slave-select input. In SPI master mode, use SS or a GPIO to manually select an external slave.

Refer to the MAXQ7667 User’s Guide Sections 5, 7, and 9.

Digital Supply Voltage. Connect DVDD directly to a +2.5V external source or to REG2P5 output for

single supply operation. B ypass DVDD to DGND with a 0.1µF capacitor as clo se a s possible to

the device. Connect all DVDD nodes together.

Digital I/O Supply Voltage. DVDDIO powers al l digital I/Os except for XIN and XOUT. Bypass

DVDDIO to DGND with a 0.1µF capacitor as close as possible to the device. Connect all DVDDIO

nodes together.

Port 0 Data 0/UART Rece ive Data Input. P0.0 is a general-purpose digital I/O. URX is a UART or

LIN data receive input. Refer to the MAXQ7667 User ’s Guide Sections 5 and 8.

Port 0 Data 1/UART Transm it Data Output. P0.1 i s a general-purpose digital I/O. UTX is a UART or

LIN data transmit output. Refer to the MAXQ7667 User’s Guide Sections 5 and 8.

Port 0 Data 2/UART Transm it Output. P0.2 is a general-purpose digital I/O. TXEN asserts low when

the UART is transmitting. Use TXEN to enable an e xternal LIN/UART transcei ver. Refer to the

MAXQ7667 U ser’ s Guide Sections 5 and 8.

Port 0 Data 3/Timer 0 I/O/ADC Control Input. P0.3 is a general-purpose digital I/O. T0 is the

primary Type 2 timer/counter 0 output or input. ADCCTL is a sampling/conversion trigger input for

the SAR ADC. Refer to the MAXQ7667 User ’s Guide Sections 5, 6, and 14.

Port 0 Data 4/Timer 0B I/O/Comparator Output. P0.4 is a general-purpose d igital I/O. T0B is the

secondary Type 2 timer/counter 0 output or input. Refer to the MAXQ7667 User’s Guide Sections

5 and 6.

Port 0 Data 5/Timer 1 I/O. P0.5 is a general-purpose digital I/O. T1 is the primary Type 2

timer/counter 1 output or input. Refer to the MAXQ7667 User’s Guide Sections 5 and 6.

Port 0 Data 6/Timer 2 I/O. P0.6 is a general-purpose digital I/O. T2 is the primary Type 2

timer/counter 2 output or input. Refer to the MAXQ7667 User’s Guide Sections 5 and 6.

Port 0 Data 7/Timer 2B I/O. P0.7 is a general-purpose digital I/O. T2B is the secondary Type 2

timer/counter 2 output or input. Refer to the MAXQ7667 User’s Guide Sections 5 and 6.

Crystal Oscillator Input. Connect an external crystal or resonator between XIN and XOUT. When

using an external clock source drive XIN with 2.5V level clock while leaving XOUT unconnected.

Connect XIN to DGND when an external clock source i s not used.

Page 13

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

______________________________________________________________________________________ 13

Pin Description (continued)

PIN NAME FUNCTION

Crystal Oscillator Output. Connect an external crystal or resonator between XIN and XOUT. Leave

21 XOUT

22 REG2P5 +2.5V Voltage Regulator Output

23 REG3P3 +3.3V Voltage Regulator Output

24 GATE5

25 RESET

26 FILT

27, 32 AVDD

28, 31, 33 AGND Analog Ground. Connect all AGND nodes together. Connect to DGND at a single point.

29 ECHON Negati ve Echo Input. AC-couple ECHON to an u ltrasonic transducer.

30 ECHOP Positive Echo Input. AC-couple ECHOP to an ultrasonic transducer.

34 REF

35 REFBG +2.5V Reference Output/Reference Buffer Input. Bypas s to AGND with a 0.47µF capacitor.

36 AIN0 SAR ADC Input 0. AIN0 pairs with AIN1 in differential mode.

37 AIN1 SAR ADC Input 1. AIN1 pairs with AIN0 in differential mode.

38 AIN2 SAR ADC Input 2. AIN2 pairs with AIN3 in differential mode.

49 AIN3 SAR ADC Input 3. AIN3 pairs with AIN2 in differential mode.

40 AIN4 SAR ADC Input 4

41 N.C. No Connection. Internally connected. Leave unconnected.

45 BURST

46 P1.0/TDO

47 P1.1/TMS

48 P1.2/TDI

XOUT unconnected when driving XIN with a 2.5V level clock or when an external clock source is

not used.

+5V DVDDIO Voltage Regulator Control Output. GATE5 controls an external npn or nMOS

transistor that pas ses power to DVDDIO.

Reset Input/Output. RESET is open drain with an internal pullup resistor to DVDDIO. Internal

circuitry pulls RESET low when V

enabled and the watchdog timeout period e xpires. Force RESET low externally for manual reset.

PLL VCO Control Input. Connect external filter components on FILT for the in ternal PLL circu it. See

the Typical Application Circuit/Functional Diagram.

Analog Supply Voltage. Connect all AVDD inputs directly to a +3.3V source or to REG3P3 for selfpowered operation. Bypass each AVDD to AGND with a 0.1µF capacitor as close as possible to

the device.

ADC Reference Input/Reference Buffer Output. When using the internal reference, the buffered

bandgap reference voltage (V

external reference, apply an e xternal vo ltage source ranging between 1V and V

Disable the reference buffer when apply ing an external reference at REF. B ypass REF to AGND

with a 0.47µF capacitor.

Burst Output. Burst is the ultrasonic transducer excitation pulse output. BURST remains in threestate mode on power-up.

Port 1 Data 0/ JTAG Output. P1.0 is a general-purpose digital I/O. TDO is the JT AG ser ial data

output. Refer to the MAXQ7667 User’s Guide Sections 5 and 11.

Port 1 Data 1/ JTAG Test Mode-Select Input. P1.1 is a general-purpose digital I/O. TMS is the JTAG

mode-select input. Refer to the MAXQ7667 User’s Guide Section s 5 and 11.

Port 1 Data 2/ JTAG Input. P1.2 i s a general-purpose digital I/O. TDI is the JTAG serial data input.

Refer to the MAXQ7667 User’s Guide Sections 5 and 11.

REF

fal ls b elow its brownout reset va lue or watchdog reset is

DVDDIO

) is provided for both SAR and sigma-delta ADCs. When using an

at REF.

AVDD

Page 14

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

14 ______________________________________________________________________________________

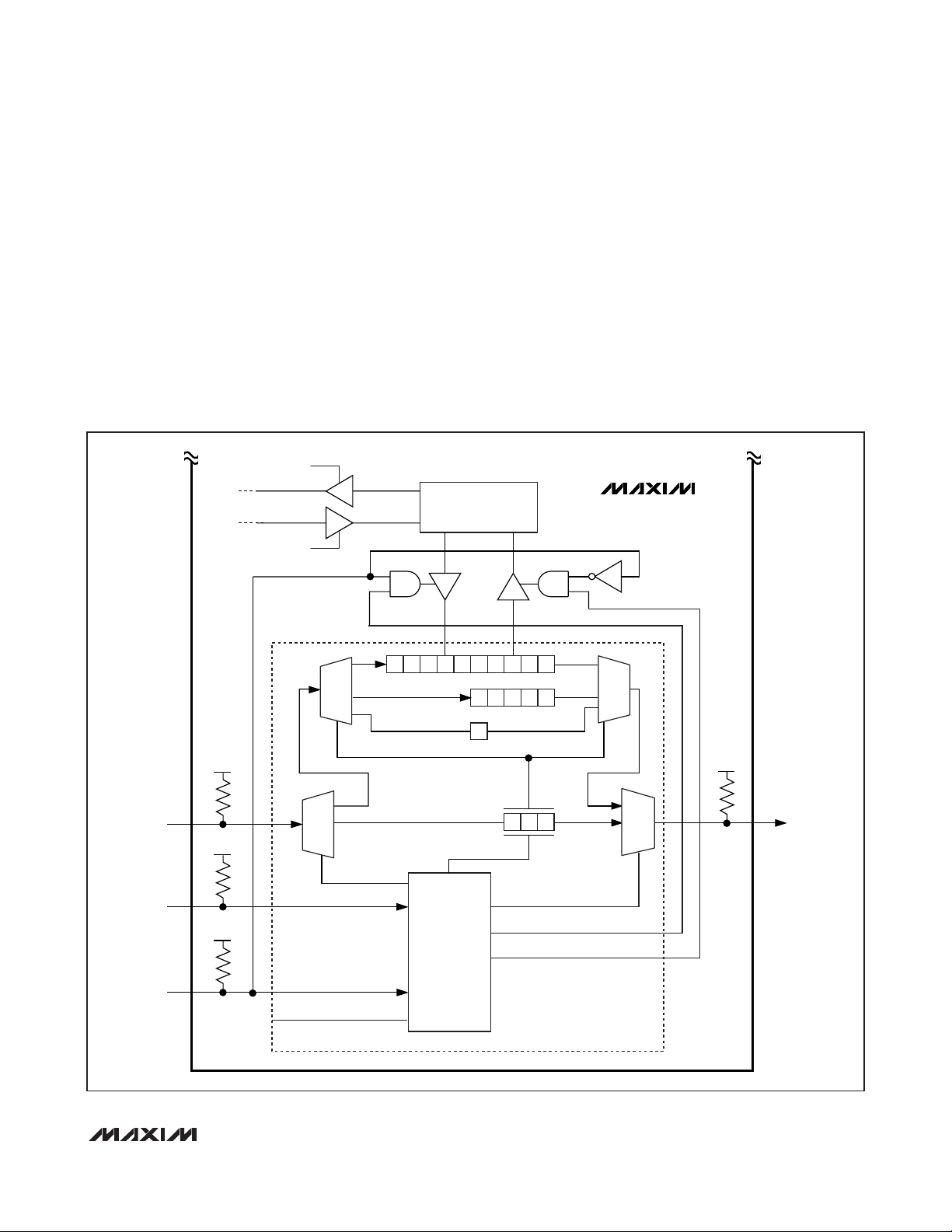

Typical Application Circuit/Functional Diagram

TRANSDUCER

0.01µF

470pF

0.01µF

470pF

BSP129

0.1µF

0.1µF

+8V TO

+20V

GND

LIN

V+

CONNECTOR

LIN

TRANSCEIVER

LIN

0.1µF

Rx

Tx

BURST

ECHON

ECHOP

DVDDIO

GATE5

REG3P3

AVDD

REG2P5

DVDD

DGND

GPIO/JTAG

P0.0/URX

P0.1/UTX

GPIO/SPI

0V

INTERFACE

MODULE

BURST ENABLE

2mV

P-P

AGND

POR/

BROWNOUT

LNA

BURST OUTPUT

DUTY CYCLE

AND PULSE

COUNTER

16 x 16

HW MULT

PLUS ACCUM

WATCHDOG

RESET

RAM

SIGMA-

DELTA

ADC

ROM

FLASH

13.5MHz

RC

OSCILLATOR

0.47µF

VOLTAGE

REFERENCE

DIGITAL

BANDPASS

FILTER

MAXQ20 RISC

OSCILLATOR

XIN XOUT

20pF

µC

MAXQ7667

CRYSTAL

16MHz

0.47µF

RECTIFIER

SCHEDULE

TIMER

20pF

FULLWAVE

REFREFBG

12-BIT

SAR ADC

DIGITAL

LOWPASS

FILTER

FIFO

PROGRAMMABLE

PLL

CLOCK PRESCALER

DIVIDE BY 1 TO 128

TIMER 2

PO.6/T2

PO.7/T2B

INTERRUPT

THRESHOLD

ADJUST

TIMER 1 TIMER 0

PO.3/T0/ADCCTL

PO.5/T1

PO.4/T0B

AIN0

AIN1

AIN2

AIN3

AIN4

FILT

330pF

AVDD

THERMISTOR

BATTERY+

24kΩ

33nF

Page 15

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

______________________________________________________________________________________ 15

Detailed Features

o Smart Analog Peripherals

Dedicated Ultrasonic Burst Generator

Echo Receiving Path

Low-Noise Amplifier

Time Variable Gain Amplifier

16-Bit Sigma-Delta ADC

Digital Bandpass Filter

Full-Wave Rectifier and Digital Lowpass Filter

8-Deep, 16-Bit Wide FIFO Simplifies Real-Time

Processing

Magnitude Comparator

5-Channel, 12-Bit SAR ADC with 250ksps

Sampling Rate

Internal Bandgap Voltage Reference for the ADCs

(Also Accepts External Voltage Reference)

o Timer/Digital I/O Peripherals

SPI Interface

Three 16-Bit (or Six 8-Bit) Programmable Type 2

Timers/Counters

16-Bit Schedule Timer

Programmable Watchdog Timer

16 General-Purpose Digital I/Os with

Multipurpose Capability

o High-Performance, Low-Power, 16-Bit RISC Core

1MHz–16MHz Operation, Approaching 1MIPS per

1MHz

Low Power (< 2.5mA/MIPS, DVDD = +2.5V)

16-Bit Instruction Word, 16-Bit Data Bus

33 Instructions (Most Require Only One Clock

Cycle)

16-Level Hardware Stack

Three Independent Data Pointers with Automatic

Increment/Decrement

o Program and Data Memory

Internal 32KB Program Flash

Internal 4KB Data RAM

Internal 8KB Utility ROM

o Crystal/Clock Module

1MHz–16MHz External Crystal Oscillator

13.5MHz Internal RC Oscillator

External Clock Source Operation

o 16 x 16 Hardware Multiplier with 48-Bit

Accumulator, Single Clock Cycle Operation

o Power-Management Module

Power-On Reset (POR)

Power-Supply Supervisor/Brownout Detection for

All Supplies

On-Chip +5V, +3.3V, and +2.5V Regulators for

Single Supply Operation

o JTAG Interface

Extensive Debug and Emulation Support

In-System Test Capability

Flash-Memory-Program Download

o UART

Synchronous and Asynchronous Transfers

Independent Baud-Rate Generator

2-Wire Interface

Transmit and Receive FIFOs

o LIN

Supports LIN 1.3, LIN 2.0, and SAE J2602

Automatic Baud-Rate Detection and LIN Frame

Synchronization

Up to 64 Bytes Frame Length

Automatic Calculation of Standard (LIN 1.3) and

Enhanced (LIN 2.0) Checksums

o 7mm x 7mm, 48-Pin LQFP Package

o -40°C to +125°C Operating Temperature Range

Page 16

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

16 ______________________________________________________________________________________

Detailed Description

The ultrasonic distance-measurement peripherals in the

MAXQ7667 include a burst signal generator for

acoustic transmission and mixed signal circuits for

amplifying and digitizing echo signals ranging between

25kHz and 100kHz. The burst signal is a square wave

with adjustable duty cycle and pulse count. The burst is

derived either directly from the system clock or from a

programmable PLL locked to the system clock. The

MAXQ7667 effectively digitizes the echo signals

received at the ECHOP and ECHON inputs using an

LNA, sigma-delta ADC with variable analog gain amplifier, noise-limiting digital bandpass filter, digital fullwave rectifier, and a digital lowpass filter (see the

Typical Application Circuit/Functional Diagram

). The

device detects echo signals at the burst frequency with

amplitudes ranging from 10µV

P-P

to 100mV

P-P

. Echoes

greater than 100mV

P-P

and less than 2V

P-P

are internally clipped but do not saturate the receiver. To optimize

echo reception, the clock used for processing the echo

locks to the burst frequency. The MAXQ7667’s burst

generator can generate higher frequencies, but the

maximum usable frequency for the echo receive path is

100kHz . For applications requiring transducer frequencies above 100kHz, implement an external echo

receive path. The SAR ADC can then digitize the filtered echo envelope.

An integrated 16-bit RISC µC (MAXQ20) provides timing control, signal processing, and data I/O. The 16-bit

Harvard architecture RISC core executes most instructions in a single clock cycle from instruction fetch to

cycle completion. The MAXQ20 provides optimal performance for noise-sensitive analog applications.

The MAXQ7667 includes a 13.5MHz RC oscillator,

external crystal oscillator, watchdog timer, schedule

timer, three general-purpose Type 2 timers/counters,

two 8-bit GPIO ports, SPI interface, JTAG interface, LIN

capable UART interface, 12-bit SAR ADC with five multiplexed input channels, supply-voltage monitors, and a

voltage reference for communication, diagnostics, and

miscellaneous support.

Burst Controller

The MAXQ7667 provides a square-wave burst signal at

the BURST output. Use the burst control to transmit an

ultrasonic signal. Typical applications use the burst signal to switch an external transistor that drives a highvoltage transformer, which excites the transducer (see

the

Typical Application Circuit/Functional Diagram

).

Use software to configure the duty cycle, frequency,

number of pulses, and drive current of the burst. See

Section 17 of the

MAXQ7667 User’s Guide

.

Derive the burst signal either directly from the system

clock or from a programmable oscillator phase locked

to the system clock (Figure 1). Using the system clock

limits the burst frequency to one of 16 choices. Integer

division of the system clock generates these 16 frequencies. The PLL allows a fractional division of the

system clock. Any frequency within the PLL range is

selectable to a resolution of 0.13% or better.

When using the internal PLL, connect external filter

components (C1, R1, and C2) to FILT as shown in

Figure 1. These components filter the analog voltage

that controls the VCO in the PLL. The filter component

values shown in the figure are suitable for the entire

PLL frequency range.

MAXQ7667

C2

330pF

SYSTEM

CLOCK

(f

SYSCLK

)

ECHO

RECEIVE

CLOCK

PLL

C1

33nF

FILT

R1

24kΩ

PWM

2mV

P-P

DIAGNOSTIC

BURST

1

0

BTRN.10:BCKS

BPH[9:0]

PLLF[10:9]:PLLC[1:0]

BTRN[15:12]:BDIV[3:0]

BTRN[7:0]:BCNT[7:0]

BPH.15:BSTT

BTRN.9:BTRI

BPH.14:BDSBTRN.11:BPOL

BTRN.8:BGT

BURST

PLLF[8:0]

BURST CLOCK

GENERATOR

RECEIVE CLOCK

PRESCALE

Figure 1. Burst Transmission Stage

Page 17

MAXQ7667

Echo Receive Path

Low-Noise Amplifier (LNA)

The LNA provides a 40V/V fixed gain to the input signal.

The differential inputs of the LNA are ECHOP and

ECHON. For proper biasing of the LNA, AC-couple the

transducer or any external circuitry to ECHOP and

ECHON. For a single-ended input signal, AC-couple the

signal to ECHOP with a 0.01µF capacitor and connect

ECHON to AGND through a 0.01µF capacitor placed as

close as possible to the signal source. The outputs of the

LNA connect to the inputs of a 16-bit sigma-delta ADC

and can connect internally to the AIN0 and AIN1 inputs

of the SAR ADC for external monitoring (Figure 2).

Diagnostic Signals

An analog multiplexer located at the input of the LNA

selects one of three possible signals for processing by

the echo receive path; the normal echo signal AC-coupled to the ECHOP and ECHON inputs, 0V signal, or a

2mV

P-P

internally generated signal (Figure 2). The

2mV

P-P

square-wave signal, with frequency and duty

cycle matching the burst signal, allows the echo

receive chain to process a simulated echo.

MAXQ7667

0.47µF

AGND

REFGB

0.47µF

TO EXTERNAL VOLTAGE

REFERENCE

AGND

REF

VARIABLE

GAIN SIGMA-

DELTA ADC

FIFO

8 x 16

FIFO

CONTROL

BANDPASS

FILTER

CLOCK

CONTROL

ECHO

RECEIVE

CLOCK

RCVC[4:0]:RCVGN[4:0]

RCVC[7:6]:LNAISEL[1:0]

RCVC.8:LNAOSEL

BPFI[15:0]

APE.13:RSARE

2.5V

BANDGAP REF

APE.12:BGE

FULL-WAVE

RECTIFIER PLUS

LOWPASS FILTER

R*

R*

*R = ECHO INPUT RESISTANCE. SEE THE ELECTRICAL CHARACTERISTICS SECTION.

40R*

AIN0

TO SAR ADC

AIN1

0V

2mV

P-P

40R*

LNA

AVDD/2

ECHOP

ECHON

MUX

BPFO[15:0]

LPFD[15:0]

CMPC[14:0]:CMPH[14:0]

CMPT[15:0]

LPFC[15:12]:FFIL[3:0]

LPFC[2.0]:FFLS[2:0]

LPFC.7:FFOV

ASR.2:LPFFL

LPFC[11:8]:FFDP[3:0]

CMPC.15:CMPP

ASR.12:CMPLVL

AIE.3:CMPIE

LPFF[15:0]

ASR.3:CMPI

COMPARATOR

AIE.1:LPFIE

ASR.1:LPFRDY

LPFC.3:FFLD

TIMER 0

TIMER 1

TIMER 2

DATA READY

INTERRUPT

AIE.2:LFLIE

Figure 2. Echo Receive Path

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

______________________________________________________________________________________ 17

Page 18

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

18 ______________________________________________________________________________________

Sigma-Delta ADC

The MAXQ7667 features a 16-bit sigma-delta ADC with

an analog gain adjustable from 38dB to 60dB (including the fixed LNA gain) with a maximum gain step of

12.5% (typical). Gain changes settle within one ADC

conversion. Use software to create a virtual time variable gain amplifier. A digital bandpass and lowpass filters remove switching glitches and DC offset at the

output of the ADC.

In a typical application, the software sets the gain to a

low value when the burst is first sent and increases the

gain as the time from when the burst was sent increases. As a result, strong echoes from nearby objects are

processed without clipping while small signals from distant objects are processed with the maximum gain. The

ADC samples the amplified echo signal from the LNA at

80 times the burst output frequency. The ADC provides

conversion results at a data rate equal to 10 times the

burst output frequency. The ADC conversion results

also load to an 8-deep first-in-first-out (FIFO) at the

native data rate or a separate time base without loading

the CPU.

Digital Bandpass Filter

The digital bandpass filter has a center frequency that

tracks the burst output frequency. The bandpass width

is 14% of the center frequency. The bandpass filter provides the 16-bit output data at a data rate equal to 10

times the burst output frequency.

Full-Wave Rectifier

The full-wave rectifier detects the envelope of the digital

bandwidth filter output to generate a DC output proportional to the peak-to-peak amplitude of the input signal.

Full-wave rectification allows the digital lowpass filter to

respond faster without excessive ripple.

Digital Lowpass Filter

The lowpass filter removes the ripple from the full-wave

detector output. The output of the lowpass filter is available at a data rate equal to five times the burst output

frequency. The corner frequency is 1/5 the burst frequency with approximately 40dB per decade rolloff.

The 16-bit output data of the lowpass filter is stored in a

FIFO register with a depth of eight samples. The

MAXQ7667 allows data transfer from the lowpass filter

SARC[2:0]:SARS[2:0]

SARC[11:9]:SARMX[2:0]

REFERENCE TO

SIGMA-DELTA ADC

ADC DATA

READY INTERRUPT

ASR.0:SARRDY

APE.12:BGE

APE.14:RBUFE

AIE.0:SARIE

BANDGAP

REF

SARC.3:SARBY

SARC.6:SARDUL

SARC.4:SARASD

SARC.7:SARBIP

SARC.8:SARDIF

OSCC[3:2]:SARCD[1:0]

ADC

CLOCK

DIV

TIMER 0

TIMER 1

TIMER 2

APE.4:SARE ADCCLK

AVDD

V

REF

MUX

SARC[11:9]:SARMX[2:0]

12-BIT

ADC

AIN0

MUX

AIN1

AIN2

AIN3

DATA BUS[15:0]

AIN4

V

REF

AGND

AVDD

AGND

REFBG

ADCCTL

REF

SYSCLK

BUF

x1.0

Figure 3. SAR ADC Block Diagram

Page 19

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

______________________________________________________________________________________ 19

output to the FIFO automatically each time the lowpass

filter output updates, through the control of one of the

timer outputs, or through software. The device includes

a FIFO depth counter with programmable interrupt levels and generates an interrupt if a FIFO overflow condition occurs. The output of the digital lowpass filter

connects to a digital comparator that can generate an

interrupt for a specified echo signal level.

Digital Comparator and Threshold Adjust

The digital comparator output asserts when the echo

amplitude at the output of the digital lowpass filter crosses a given threshold. The comparator’s threshold level,

hysteresis, and interrupt polarity are programmable.

SAR ADC

The MAXQ7667 incorporates a 12-bit unbuffered SAR

ADC with sample-and-hold and conversion rate up to

250ksps. The ADC allows measurements of tempera-

ture, battery voltage, or other parameters using five single-ended or two fully differential analog inputs

(AIN0–AIN4). All of the analog inputs have a range of 0

to V

REF

in unipolar mode and ±V

REF

/2 in bipolar mode.

The SAR ADC supports three different conversion start

sources: timers, ADC control input (ADCCTL), and software write. The conversion start source triggers the

ADC acquisition and conversion. The system clock provides the ADC clock frequency programmable to 1/2,

1/4, 1/8, or 1/16 of the system clock. Use internal

bandgap reference, external reference, or AVDD for

voltage reference of the SAR ADC. Figure 3 shows a

simplified block diagram of the SAR ADC.

The output of the SAR ADC is straight binary in unipolar

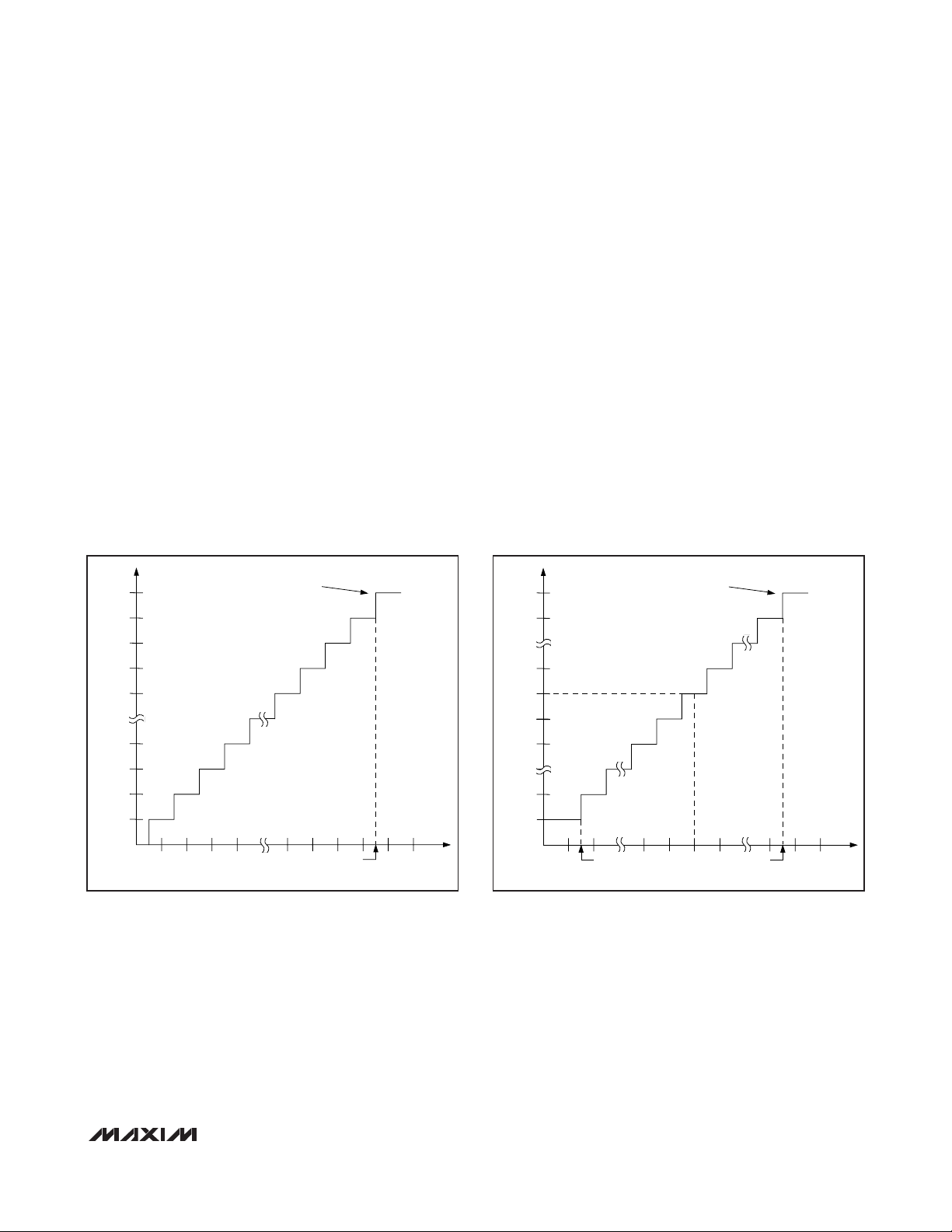

mode and two’s complement in bipolar mode. Figures 4

and 5 show the ADC transfer functions in unipolar

mode and bipolar mode.

000

001

002

003

004

FFC

FFB

FFD

FFE

FFF

0123

4

FS

FS - 1.5 LSB

FULL-SCALE

TRANSITION

FS = REF

ZS = 0

1 LSB = REF/4096

OUTPUT CODE (hex)

DIFFERENTIAL INPUT VOLTAGE (LSB)

Figure 4. Unipolar Transfer Function

800

801

FFE

001

000

FFF

7FE

7FF

-FS

0

+FS

OUTPUT CODE (hex)

DIFFERENTIAL INPUT VOLTAGE (LSB)

+FS - 1.5 LSB

FULL-SCALE

TRANSITION

+FS = REF/2

ZS = 0

-FS = -REF/2

1 LSB = REF/4096

-FS + 0.5 LSB

Figure 5. Bipolar Transfer Function

Page 20

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

20 ______________________________________________________________________________________

SAR ADC Analog Input Track-and-Hold (T/H)

Figures 6 and 7 show the equivalent input circuit of the

MAXQ7667 analog input architecture. During acquisition (track), a sampling capacitor charges to the positive input voltage at AIN0–AIN4 in single-ended mode

or AIN0 and AIN2 in differential mode while a second

sampling capacitor connects to AGND in single-ended

mode or AIN1 and AIN3 in differential mode. The ADC

conversion start source and the ADC dual mode selection bits control the T/H timing.

Voltage Reference

The MAXQ7667 supports three possible voltage reference sources for ADC conversion; 2.5V internal

buffered bandgap reference, external source, and

AVDD. The internal 2.5V bandgap reference has high

initial accuracy and temperature coefficient of typically

less than 100ppm/°C. When operating in internal reference mode, either the buffered output of the internal

reference or AVDD connects to the SAR ADC while the

buffered output of the internal reference connects to the

sigma-delta ADC. When operating in external reference

mode, an external source ranging between 1V and

V

AVDD

applied at either the REF or REFBG inputs pro-

vides the reference to the SAR ADC and sigma-delta

ADC. Bypass REFBG and REF to AGND with a 0.47µF

capacitor for optimum performance. See Section 14 of

the

MAXQ7667 User’s Guide

.

Schedule Timer

The MAXQ7667’s schedule timer provides general timekeeping and software synchronization to an external I/O.

The schedule timer features include the following:

• 16-bit autoreload up-counter for the timer

• Programmable 16-bit alarm register

• Alarm interrupts

• Schedule timer incremented by a programmable

system clock prescaler (1, 1/2, 1/4, 1/8, 1/16, 1/32,

1/64, 1/128)

• Schedule timer up-counter resettable through an

external I/O pin, which allows synchronization of a

schedule timer to an external event

• Wake-up alarm to pull the system clock from stopmode to normal operation

Figure 8 shows a simplified block diagram of the

schedule timer.

AGND

AIN+

AIN-

C

IN+

AVDD

C

IN-

R

IN+

R

IN-

Figure 6. Equivalent Input Circuit (Track/Acquisition Mode)

AGND

AIN+

AIN-

C

IN+

C

IN-

R

IN+

R

IN-

AVDD

Figure 7. Equivalent Input Circuit (Hold/Conversion Mode)

Page 21

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

______________________________________________________________________________________ 21

MAXQ is a registered trademark of Maxim Integrated Products, Inc.

Type 2 Timers/Counters

The MAXQ7667 includes three 16-bit timers/counters

with programmable I/O (Figure 9). Each timer is a Type

2 timer implemented in the MAXQ®family. The Type 2

timer is an autoreload 16-bit timer/counter offering the

following functions:

• 8-bit/16-bit timer/counter

• Up/down autoreload

• Counter function of external pulse

• Capture

• Compare

Clock Sources

The MAXQ7667 oscillator module supplies the system

clock for the µC core and all of the peripheral modules.

The high-frequency oscillator operates with a 1MHz to

16MHz crystal. Use the internal RC oscillator as the

system clock for applications that do not require precise timing. See Section 15 of the

MAXQ7667 User’s

Guide

.

The MAXQ7667 supports the following master clock

sources:

• Internal high-frequency oscillator drives an external 1MHz–16MHz crystal or ceramic resonator

• Internal, fast-starting, 13.5MHz RC oscillator

(default oscillator at startup and in the event the

external crystal fails)

• External 4MHz–16MHz clock input

Crystal Selection

The MAXQ7667 requires a crystal with the following

specifications:

Frequency: 1MHz–16MHz

C

LOAD

: 6pF (min)

Drive level: 5µW

Series resonance resistance: 30Ω (max)

Note: Quartz crystal vendors often specify series resonance resistance (R1). Series resonance resistance is

the resistance observed when the resonator is in the

series resonant condition. When a resonator is used in

the parallel resonant mode with an external load capacitance, as is the case with the MAXQ7667 oscillator circuit, the effective resistance at the loaded frequency of

oscillation is:

R1 x (1 + (CO/C

LOAD

))

2

For typical shunt capacitance (CO) and load capacitance (C

LOAD

) values, the effective resistance poten-

tially exceeds R1 by a factor of 2.

Page 22

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

22 ______________________________________________________________________________________

Figure 9. Type 2 Timer/Counter in 16-Bit Mode

PROGRAMMABLE

DIVIDE BY

1, 2, 4, ..., 128

COMPARATOR

STIM = SALM

SALM

REGISTER

SALM[15:0]

STIM

16-BIT UP-

COUNTER

SCNT.11:STDIV2

SCNT.0:STIME

CLR

CLR

SCHEDULE TIMER

SYSTEM

CLOCK

MAXQ7667

SCNT.8:SSYNC_EN

SCNT.7:SALIE

SCNT.1:SALME

INT

AN INTERRUPT IS

GENERATED WHEN

SALIE = 1 AND

SALMF = 1

SCNT.6:SALMF

STIM[15:0]

P1.7/SYNC

Figure 8. Schedule-Timer Module Block Diagram

CAPTURE

INPUT CONDITIONING

SCALING

GATING

CLOCK

T2Cx REGISTER

16-BIT CAPTURE/COMPARE

T2Vx REGISTER

16-BIT UP-COUNTER

T2Rx REGISTER

16-BIT RELOAD

OVERFLOW

RELOAD

EQUAL

OUTPUT CONDITIONING

POLARITY SELECTION

Page 23

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

______________________________________________________________________________________ 23

Figure 10. JTAG Interface Block Diagram

JTAG Interface

The joint test action group (JTAG) IEEE 1149.1 standard

defines a unique method for in-circuit testing and programming. The MAXQ7667 conforms to this standard,

implementing an external test access port (TAP) and

internal TAP controller for communication with a JTAG

bus master, such as an automatic test equipment (ATE)

system. The MAXQ7667 JTAG interface does not allow

boundary scan. For detailed information on the TAP and

TAP controller, refer to IEEE Std 1149.1 “IEEE Standard

Test Access Port and Boundary-Scan Architecture” on

the IEEE website at www.standards.ieee.org.

The TAP controller communicates synchronously with

the host system (bus master) through four digital I/Os:

test mode select (TMS), test clock (TCK), test data

input (TDI), and test data output (TDO). The internal

TAP module consists of shift registers and a TAP controller (Figure 10). The shift registers serve as transmit

and receive data buffers for a debugger. Maintain the

maximum TCK clock frequency to below 1/8 the system

clock frequency for proper operation.

READ

TO DEBUG

ENGINE

WRITE

MUX

SHADOW REGISTER

765432 10S1S0

DEBUG REGISTER

SYSTEM PROGRAMMING REGISTER

MAXQ7667

43210

MUX

DVDDIO

P1.2/TDI

DVDDIO

P1.1/TMS

DVDDIO

P1.3/TCK

POWER-ON

RESET

MUX

BYPASS

INSTRUCTION REGISTER

TAP

CONTROLLER

2

10

UPDATE-DR

UPDATE-DR

MUX

DVDDIO

P1.0/TDO

Page 24

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

24 ______________________________________________________________________________________

The following four digital I/Os form the TAP interface:

• TDO—Serial output signal for test instruction and

data. Data transitions on the falling edge of TCK.

TDO idles high when inactive. TDO serially transfers internal data to the external host. Data transfers lease significant bit first.

• TDI—Serial input signal for test instruction and

data. Transition data on the rising edge of TCK.

TDO pulls high when unconnected. TDI serially

transfers data from the external host to the internal

TAP module shift registers. Data transfers least

significant bit first.

• TCK—Serial clock for the test logic. When TCK

stops at 0, storage elements in the test logic must

retain their data indefinitely. Force TCK high when

inactive.

• TMS—Test mode selection. The rising edge of TCK

samples the test signals at TMS. The TAP controller

decodes the test signals at TMS to control the test

operation. Force TMS high when inactive.

UART/LIN Interface

The MAXQ7667 includes a UART/LIN transceiver combination that supports communication speeds up

2MBd. The LIN standard for example limits communication speed to 20kBd or less. Connect a LIN transceiver

or other UART connections such as RS-232 and RS-485

directly to the MAXQ7667’s 2-wire interface: URX and

UTX. The MAXQ7667 operates as a LIN slave or LIN

master device. The UART provides the programmable

baud-rate generators to communicate effectively to or

from the LIN transceiver. The device holds up to 8

bytes of data in each of the transmit and receive FIFOs.

The following characteristics apply to the MAXQ7667

UART/LIN interface:

• Full-duplex operation for asynchronous data transfers up to 500kBd (system clock/32)

• Half-duplex operation for synchronous data transfers up to 2MBd (system clock/8)

• 8-deep receive and transmit FIFO with programmable interrupt for receive and transmit

• Independent baud-rate generator

• Programmable 9th data bit (commonly used for

parity or address/data selection)—UART mode

only

• Hardware support for LIN including break detection, autobaud, address identity filtering, checksum calculation, and block length checking

• Supports common RS-232 and LIN baud rates:

1000, 1200, 2400, 4800, 9600, 19,200, 20,000,

38,400, 57,600, and 115,200 with system clock =

16MHz.

SPI Interface

The MAXQ7667 supports 4-wire SPI interface communication with 8-bit or 16-bit data streams operating in

either master mode or slave mode. The SPI interface

allows synchronous half-duplex or full-duplex serial

data transfers to a wide variety of external serial

devices using MISO, MOSI, SS, and SCLK signals.

Collision detection is provided when two or more masters attempt a data transfer at the same time. See

Section 9 of the

MAXQ7667 User’s Guide

.

General-Purpose Digital I/O Ports

Two 8-bit digital I/O ports (P0._ and P1._), with dedicated one or more alternative functions, are available as

general-purpose I/Os (GPIOs) under the control of the

integrated MAXQ20. Set each I/O within each port individually as an input or output. The GPIOs incorporate a

Schmitt trigger receiver and a full CMOS output driver

(Figure 13). Each GPIO configures as an input with

pullup to DVDDIO at power-up. When programmed as

an input, each I/O is configurable for high-impedance,

weak pullup to DVDDIO or pulldown to DGND. When

programmed as an output, writing to the port output

register (PO) controls the output logic state. The outputs source or sink at least 1.6mA. Configure the drive

strength for each I/O within each port to high or low

using the pad drive strength register for optimum EMI

performance. All the I/O ports have interrupt capability

that wake up the device while in stop mode and have

protection circuitry to DVDDIO and DGND.

Supply-Voltage Regulators

The MAXQ7667 requires three different power-supply

voltages. DVDDIO, nominally +5V, allows interfacing to

standard 5V logic on all the digital I/Os including the

LIN/UART, JTAG, and SPI ports. DVDD, nominally

+2.5V, powers all the high-speed digital circuits. AVDD,

nominally 3.3V, powers the analog circuits.

External power supplies or internal voltage regulators

provide each of the supply voltages. The internal voltage regulators provide 3.3V and 2.5V supplies from the

5V DVDDIO input. Obtain the 5V supply from a higher

external voltage supply by using a few external components. The MAXQ7667 includes an internal error amplifier used to regulate the voltage on DVDDIO by driving

the gate or base of an external pass transistor. Refer to

the

MAXQ7667 User’s Guide

for more details on the

external components needed for 5V regulation.

Page 25

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

______________________________________________________________________________________ 25

Figure 11. SPI Timing Diagram in Master Mode

Figure 12. SPI Timing Diagram in Slave Mode

SHIFT SAMPLE SHIFT

SS

SCLK

CKPOL/CKPHA

0/1 OR 1/0

SCLK

CKPOL/CKPHA

0/0 OR 1/1

MOSI

MISO

MSB

t

MIS

MSB

SHIFT SAMPLE SHIFT SAMPLE

t

SS

SCLK

CKPOL/CKPHA

0/1 OR 1/0

SCLK

CKPOL/CKPHA

0/0 OR 1/1

SSE

t

SCK

t

SIS

t

MCK

SAMPLE

t

MCH

t

MOH

t

SCH

t

MCL

t

MLH

LSB

LSB

t

SSH

t

SD

MSB - 1

t

MOV

t

MIH

MSB - 1

t

SCL

t

SIH

MOSI

MISO

MSB LSBMSB - 1

MSB

t

SOV

MSB - 1

Page 26

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

26 ______________________________________________________________________________________

Connect bypass capacitors at each power-supply input

as close as possible to the device. Use a bypass

capacitor less than 0.47µF on DVDDIO. For most applications, 0.1µF bypass capacitors are adequate.

Supply Brownout Monitor

Power supplies DVDD, AVDD, and DVDDIO each

include a brownout monitor/supervisor that alerts the

µC when their corresponding supply voltages drop

below the interrupt threshold. Activate each brownout

monitor independently using the corresponding

brownout enable bits: VDBE, VIBE, and VABE.

Reset

In reset mode, no instruction execution occurs and all

inputs/outputs return to their default states. Code execution resumes at address 8000h (in the utility ROM)

once the reset condition is removed.

Four different sources reset the MAXQ7667: POR,

watchdog timer reset, external reset, and internal system reset.

During normal operation, force RESET low for at least

four system clock cycles for an external reset. Set the

ROD bit in the SC register, while the SPE bit in the ICDF

register is set, for an internal system reset. See Section

16 of the

MAXQ7667 User’s Guide

.

Power-On Reset (POR)

The MAXQ7667 includes a DVDD voltage supervisor to

control the µC POR. On power-up, internal circuitry

pulls RESET low and resets all the internal registers.

RESET is held low for the duration of the power-on

delay after V

DVDD

rises above the DVDD reset threshold. The internal RC oscillator starts up and software

execution begins at the reset vector location 8000h

immediately after the device exits POR while RESET is

I/O PAD

DVDDIO

P0._

100ΩK

100ΩK

DGND

DGND

EIE0._

EIES0._

DETECT

CIRCUIT

INTERRUPT

FLAG

PS0._

PR0._

PD0._

PO0._

SF DIRECTION

SF ENABLE

SF OUTPUT

PI0._ OR

SF INPUT

FLAG

MUX

MUX

MAXQ7667

Figure 13. Port 0 Digital I/O Basic Circuitry. Port 1 Circuitry is the Same as Port 2.

Page 27

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

______________________________________________________________________________________ 27

not externally forced low. An internal POR flag indicates

the source of a reset. Ramp up the DVDD supply at a

minimum rate of 60mV/ms to keep the device in POR

until DVDD fully settles.

Watchdog Timer

The primary function of the watchdog timer is to watch

for stalled or stuck software. The watchdog timer performs a controlled system restart when the µP fails to

write to the watchdog timer register before a selectable

timeout interval expires. The internal 13.5MHz RC oscillator drives the MAXQ7667’s watchdog timer.

Figure 14 shows the watchdog timer functions as the

source of both the watchdog interrupt and watchdog

reset. The watchdog interrupt timeout period is programmable to 212, 215, 218, or 221cycles of the RC

oscillator resulting in a nominal range of 273µs to

139.8ms. The watchdog reset timeout period is a fixed

512 RC clock cycles (34µs). When enabled, the watchdog generates an interrupt upon expiration; then, if not

reset within 512 RC clock cycles, the watchdog asserts

RESET low for eight RC clock cycles.

Hardware Multiplier/Accumulator

A hardware multiplier supports high-speed multiplications. The multiplier completes a 16-bit x 16-bit multiplication in a single clock cycle and contains a 48-bit

accumulator. The multiplier is a peripheral that performs seven different multiplication operations:

• Unsigned 16-bit multiplication

• Unsigned 16-bit multiplication and accumulation

• Unsigned 16-bit multiplication and subtraction

• Signed 16-bit multiplication

• Signed 16-bit multiplication and negation

• Signed 16-bit multiplication and accumulation

• Signed 16-bit multiplication and subtraction

MAXQ Core Architecture

The MAXQ20 µC is an accumulator-based Harvard

memory architecture. Fetch and execution operations

complete in one clock cycle without pipelining because

the instruction contains both the op code and data. The

µC streamlines 16 million instructions per second

(MIPS). Integrated 16-level hardware stack enables fast

subroutine calling and task switching. Manipulate data

quickly and efficiently with three internal data pointers.

Multiple data pointers allow more than one function to

access data memory without having to save and

restore data pointers each time. The data pointers automatically increment or decrement following an operation, eliminating the need for software intervention.

Instruction Set

The instruction set consists of a total of 33 fixed-length

16-bit instructions that operate on registers and memory locations. The highly orthogonal instruction set allows

arithmetic and logical operations to use any register

along with the accumulator. System registers control

functionality common to all MAXQ µCs, while peripheral

registers control peripherals and functions specific to

the MAXQ7667. All registers are subdivided into register modules.

The architecture is transport-triggered. Writes or reads

from certain register locations potentially have side

effects. These side effects form the basis for the higher

level op codes defined by the assembler, such as

ADDC, OR, JUMP, etc. The op codes are implemented

as MOVE instructions between system registers. The

assembler handles all the instruction encoding.

Memory Organization

In addition to the internal register space, the device

incorporates several memory areas:

• 16Kwords of flash memory for program storage

• 2Kword of SRAM for storage of temporary variables

• 4Kwords utility ROM

• 16-level, 16-bit-wide hardware stack for storage of

program return addresses and general-purpose use

Use the internal memory-management unit (MMU) to

map data memory space into a predefined program

memory segment for code execution from data memory.

Use the MMU to map program memory space as data

space for access to constant data stored in program

Figure 14. Watchdog Functional Diagram

RC CLOCK

(13.5MHz)

DIV 2

12

DIV 2

3

DIV 2

3

DIV 2

3

WD1

WD0

RWT

12

2

2152182

TIME

TIMEOUT

WDIF

RESET

21

EWDI

EWT

INTERRUPT

WTRF

RESET

Page 28

MAXQ7667

16-Bit, RISC, Microcontroller-Based,

Ultrasonic Distance-Measuring System

28 ______________________________________________________________________________________

memory. Access physical memory segments (other

than the stack and register memories) as either program memory or data memory, but not both at once.

By default, the memory is arranged in a Harvard architecture, with separate address spaces for program and

data memory. The configuration of program and data

space depends on the current execution location.

• When executing code from flash memory, access

the SRAM and utility ROM in data space.

• When executing code from SRAM, access the

flash memory and utility ROM in data space.

• When executing code from the utility ROM, access

the flash memory and SRAM in data space.

Utility ROM (see Section 18 of

the MAXQ7667 User’s Guide)

The utility ROM is a 4K x 16 block of internal ROM

memory that defaults to a starting address of 8000h.

The utility ROM consists of subroutines called from

application software. The subroutines include:

• In-system programming (bootloader) over the

JTAG or UART interface

• In-circuit debug routines

• Test routines (internal memory tests, memory

loader, etc.)