Page 1

19-5320; Rev 2; 8/10

16-Bit Microcontroller with Infrared Module

General Description

The MAXQ613 is a low-power, 16-bit MAXQ® microcontroller designed for low-power applications including universal remote controls, consumer electronics, and white

goods. The device combines a powerful 16-bit RISC

microcontroller and integrated peripherals including a

universal synchronous/asynchronous receiver-transmitter (USART) and an SPI™ master/slave communications

port, along with an IR module with carrier frequency

generation and flexible port I/O capable of multiplexed

keypad control.

The device includes 48KB of flash program memory and

1.5KB of data SRAM. Intellectual property (IP) protection is provided by a secure MMU that supports multiple

application privilege levels and protects code against

copying and reverse engineering. Privilege levels enable

vendors to provide libraries and applications to execute

on the device, while limiting access to only data and

code allowed by their privilege level.

For the ultimate in low-power battery-operated performance, the device includes an ultra-low-power stop

mode (0.2µA typ). In this mode, the minimum amount of

circuitry is powered. Wake-up sources include external

interrupts, the power-fail interrupt, and a timer interrupt.

The microcontroller runs from a wide 1.70V to 3.6V operating voltage.

Applications

Remote Controls

Battery-Powered

Portable Equipment

Consumer Electronics

Home Appliances

White Goods

MAXQ613

Features

S High-Performance, Low-Power, 16-Bit RISC Core

S DC to 12MHz Operation Across Entire Operating Range

S 1.70V to 3.6V Operating Voltage

S 33 Total Instructions for Simplified Programming

S Three Independent Data Pointers Accelerate Data

Movement with Automatic Increment/Decrement

S Dedicated Pointer for Direct Read from Code Space

S 16-Bit Instruction Word, 16-Bit Data Bus

S 16 x 16-Bit General-Purpose Working Registers

S Secure MMU for Application Partitioning and IP

Protection

S Memory Features

48KB Program Flash Memory

512-Byte Sectors

20,000 Erase/Write Cycles per Sector

Masked ROM Available

1.5KB Data SRAM

S Additional Peripherals

Power-Fail Warning

Power-On Reset (POR)/Brownout Reset

Automatic IR Carrier Frequency Generation and

Modulation

Two 16-Bit Programmable Timers/Counters with

Prescaler and Capture/Compare

One SPI and One USART Port

Programmable Watchdog Timer

8kHz Nanopower Ring Oscillator Wake-Up Timer

Up to 24 General-Purpose I/Os

S Low Power Consumption

0.2µA (typ), 2.0µA (max) in Stop Mode,

TA = +25NC, Power-Fail Monitor Disabled

3.25mA (typ) at 12MHz in Active Mode

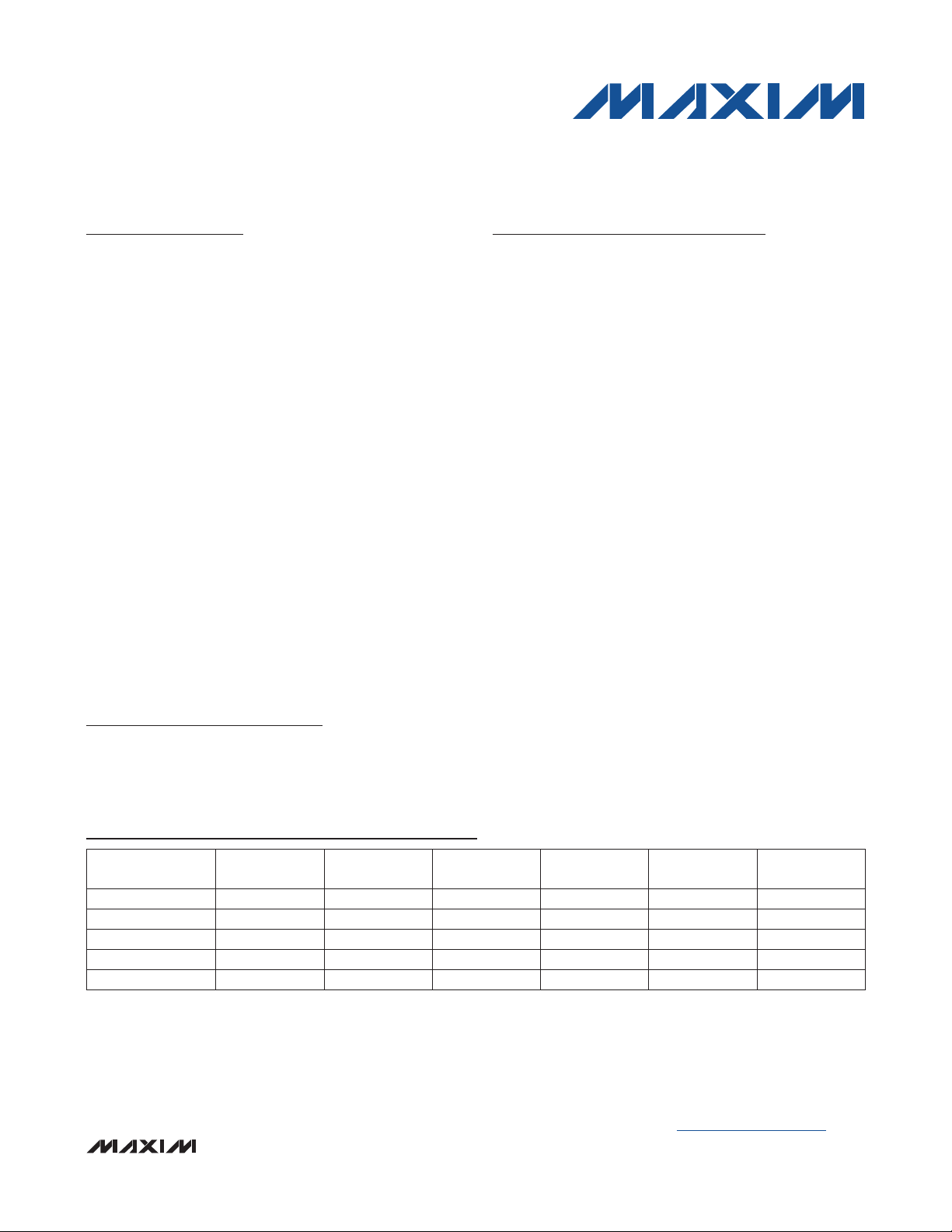

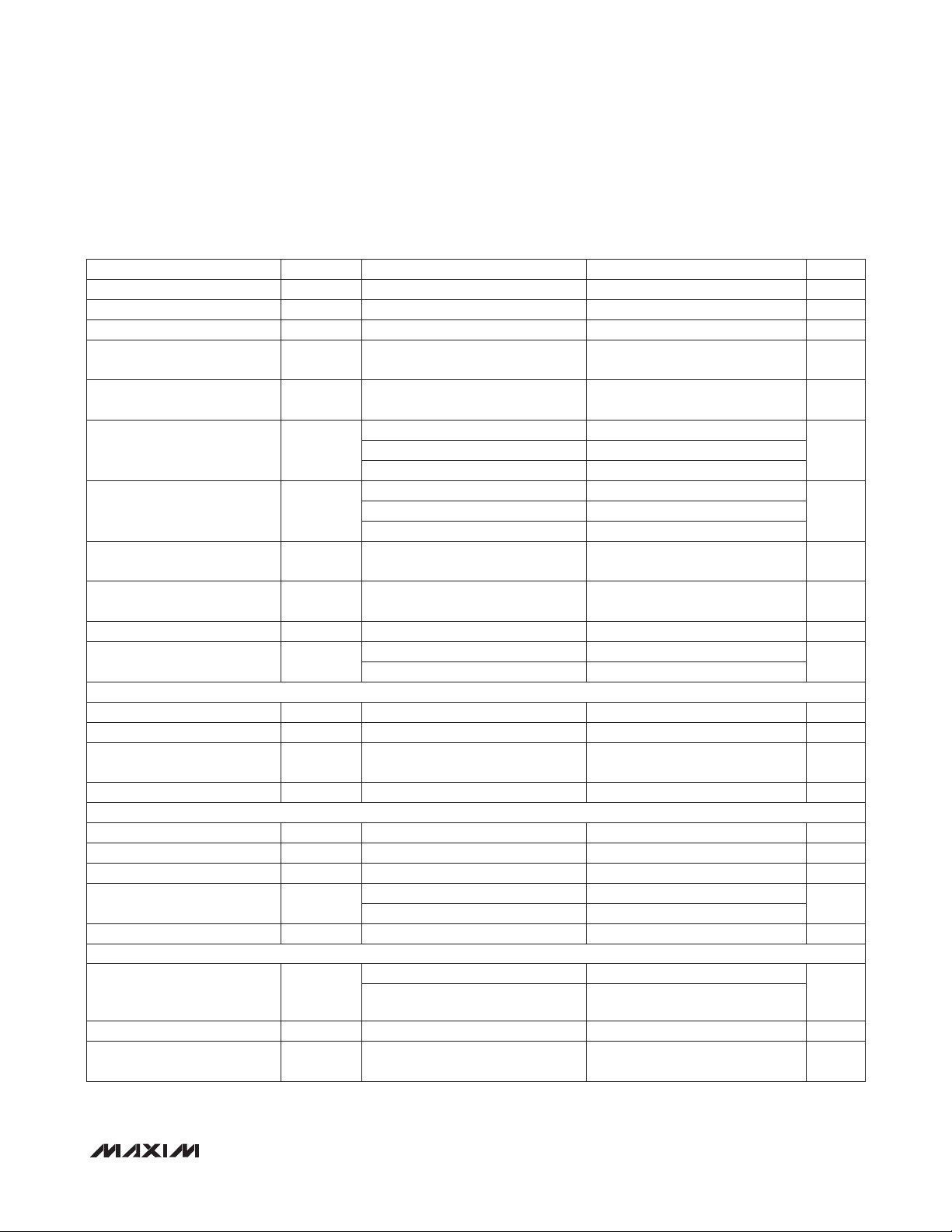

Ordering Information/Selector Guide

PART TEMP RANGE

MAXQ613A-0000+

MAXQ613E-0000+

MAXQ613J-0000+

MAXQ613K-0000+

MAXQ613X-0000+

+Denotes a lead(Pb)-free/RoHS-compliant package.

*EP = Exposed pad.

MAXQ is a registered trademark of Maxim Integrated Products, Inc.

SPI is a trademark of Motorola, Inc.

Note: Some revisions of this device may incorporate deviations from published specifications known as errata. Multiple revisions of any device

may be simultaneously available through various sales channels. For information about device errata, go to: www.maxim-ic.com/errata.

0NC to +70NC

0NC to +70NC

0NC to +70NC

0NC to +70NC

0NC to +70NC

_______________________________________________________________ Maxim Integrated Products 1

OPERATING

VOLTAGE (V)

1.7 to 3.6 48 Flash 1.5 20 32 TQFN-EP*

1.7 to 3.6 48 Flash 1.5 20 32 LQFP

1.7 to 3.6 48 Flash 1.5 24 44 TQFN-EP*

1.7 to 3.6 48 Flash 1.5 24 44 TQFP

1.7 to 3.6 48 Flash 1.5 24 Bare die

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

PROGRAM

MEMORY (KB)

DATA

MEMORY (KB)

GPIO PIN-PACKAGE

Page 2

16-Bit Microcontroller with Infrared Module

TABLE OF CONTENTS

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Recommended Operating Conditions

SPI Electrical Characteristics

Pin Configurations

Pin Description

MAXQ613

Block Diagram

Detailed Description

Microprocessor

Memory

Watchdog Timer

IR Carrier Generation and Modulation Timer

16-Bit Timers/Counters

USART

Serial Peripheral Interface (SPI)

General-Purpose I/O

On-Chip Oscillator

ROM Loader

Loading Flash Memory

In-Application Flash Programming

In-Circuit Debug and JTAG Interface

Operating Modes

Applications Information

Additional Documentation

Development and Technical Support

Package Information

Revision History

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Memory Protection

Stack Memory

Utility ROM

Carrier Generation Module

IR Transmission

IR Transmit—Independent External Carrier and Modulator Outputs

IR Receive

Carrier Burst-Count Mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Power-Fail Detection

Grounds and Bypassing

Deviations from the MAXQ610 User’s Guide for the MAXQ613

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2 ______________________________________________________________________________________

Page 3

16-Bit Microcontroller with Infrared Module

LIST OF FIGURES

Figure 1. IR Transmit Frequency Shifting Example (IRCFME = 0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 2. IR Transmit Carrier Generation and Carrier Modulator Control

Figure 3. IR Transmission Waveform (IRCFME = 0)

Figure 4. External IRTXM (Modulator) Output

Figure 5. IR Capture

Figure 6. Receive Burst-Count Example

Figure 7. SPI Master Communication Timing

Figure 8. SPI Slave Communication Timing

Figure 9. On-Chip Oscillator

Figure 10. In-Circuit Debugger

Figure 11. Power-Fail Detection During Normal Operation

Figure 12. Stop Mode Power-Fail Detection States with Power-Fail Monitor Enabled

Figure 13. Stop Mode Power-Fail Detection with Power-Fail Monitor Disabled

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

LIST OF TABLES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

MAXQ613

Table 1. Memory Areas and Associated Maximum Privilege Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 2. Watchdog Interrupt Timeout (Sysclk = 12MHz, CD[1:0] = 00)

Table 3. USART Mode Details

Table 4. Power-Fail Detection States During Normal Operation

Table 5. Stop Mode Power-Fail Detection States with Power-Fail Monitor Enabled

Table 6. Stop Mode Power-Fail Detection States with Power-Fail Monitor Disabled

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . 26

_______________________________________________________________________________________ 3

Page 4

16-Bit Microcontroller with Infrared Module

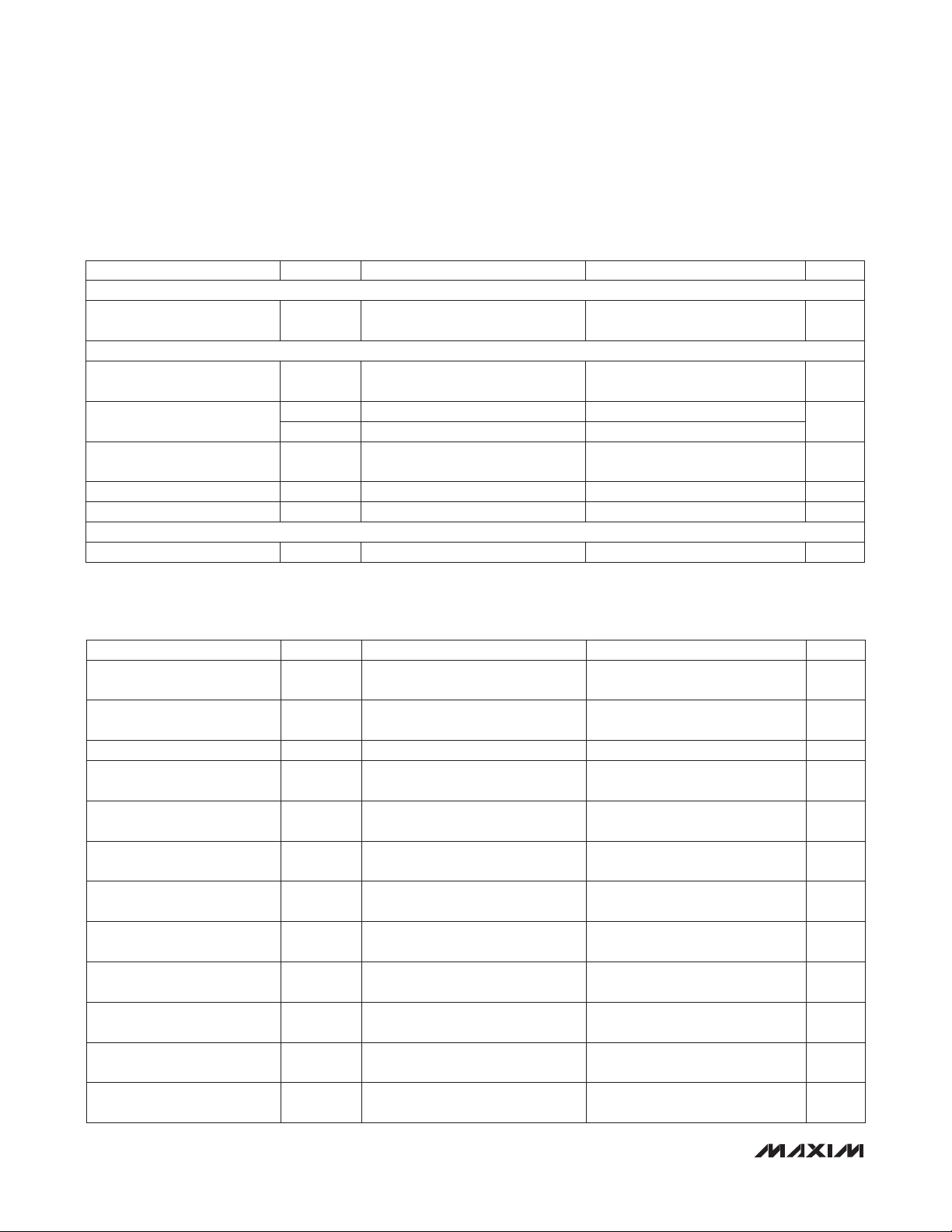

ABSOLUTE MAXIMUM RATINGS

Voltage Range on VDD with Respect to GND .....-0.3V to +3.6V

Voltage Range on Any Lead with

Respect to GND Except V

Continuous Power Dissipation (T

............... -0.3V to (VDD + 0.5V)

DD

= +70NC)

A

32-Pin TQFN (single-layer board)

(derate 21.3mW/NC above +70NC)..........................1702.1mW

32-Pin TQFN (multilayer board)

(derate 34.5mW/NC above +70NC)..........................2758.6mW

MAXQ613

32-Pin LQFP (multilayer board)

(derate 20.7mW/NC above +70NC)..........................1652.9mW

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

RECOMMENDED OPERATING CONDITIONS

(VDD = V

Supply Voltage V

1.8V Internal Regulator V

Power-Fail Warning Voltage for

Supply

Power-Fail Reset Voltage V

POR Voltage V

RAM Data-Retention Voltage V

Active Current I

Stop-Mode Current

Current Consumption During

Power-Fail

Power Consumption During

POR

Stop-Mode Resume Time t

Power-Fail Monitor Startup

Time

Power-Fail Warning Detection

Time

Input Low Voltage for IRTX,

IRRX, RESET, and All Port Pins

Input High Voltage for IRTX,

IRRX, RESET, and All Port Pins

to 3.6V, TA = 0NC to +70NC, unless otherwise noted.) (Note 1)

RST

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DD

REG18

V

PFW

RST

POR

DRV

DD_1

I

S1

I

S2

I

PFR

I

POR

ON

t

PFM_ON

t

PFW

V

V

Monitors V

Monitors V

Monitors V

DD

DD

DD

(Note 4) 1.0 V

Sysclk = 12MHz (Note 5) 3.25 4 mA

Power-Fail Off

Power-Fail On

(Note 6)

(Note 7) 100 nA

(Note 4) 150

(Note 8) 10

IL

IH

44-Pin TQFN (single-layer board)

(derate 27mW/NC above +70NC).............................2162.2mW

44-Pin TQFN (multilayer board)

(derate 37mW/NC above +70NC)................................2963mW

44-Pin TQFP (multilayer board)

(derate 19mW/NC above +70NC)................................1504mW

Operating Temperature Range

Storage Temperature Range

Lead Temperature (excluding dice; soldering, 10s)

Soldering Temperature (reflow)

V

RST

............................. 0NC to +70NC

............................ -65NC to +150NC

......+300NC

......................................+260NC

3.6 V

1.62 1.8 1.98 V

(Note 2) 1.75 1.8 1.85 V

(Note 3) 1.64 1.67 1.70 V

1 1.42 V

= +25NC

T

A

T

= 0°C to +70NC

A

= +25NC

T

A

= 0°C to +70NC

T

A

0.2 2.0

0.2 8

22 29.5

27.6 42

[(3 x I

S2

((PCI - 3) x (I

I

))]/PCI

NANO

) +

S1

+

375 + (8192 x

t

HFXIN)

V

GND

0.7 x V

DD

0.3 x V

V

DD

DD

FA

FA

Fs

Fs

Fs

V

V

4 ______________________________________________________________________________________

Page 5

16-Bit Microcontroller with Infrared Module

RECOMMENDED OPERATING CONDITIONS (continued)

(VDD = V

Input Hysteresis (Schmitt) V

Input Low Voltage for HFXIN V

Input High Voltage for HFXIN V

IRRX Input Filter Pulse-Width

Reject

IRRX Input Filter Pulse-Width

Accept

Output Low Voltage for IRTX V

Output Low Voltage for RESET

and All Port Pins (Note 9)

Output High Voltage for IRTX

and All Port Pins

Input/Output Pin Capacitance

for All Port Pins

Input Leakage Current I

Input Pullup Resistor for

RESET, IRTX, IRRX, P0, P1, P2

EXTERNAL CRYSTAL/RESONATOR

Crystal/Resonator f

Crystal/Resonator Period t

Crystal/Resonator Warmup

Time

Oscillator Feedback Resistor R

EXTERNAL CLOCK INPUT

External Clock Frequency f

External Clock Period t

External Clock Duty Cycle t

System Clock Frequency f

System Clock Period t

NANOPOWER RING

Nanopower Ring Frequency f

Nanopower Ring Duty Cycle t

Nanopower Ring Current I

to 3.6V, TA = 0NC to +70NC, unless otherwise noted.) (Note 1)

RST

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

IHYS

IL_HFXIN

IH_HFXIN

t

IRRX_R

t

IRRX_A

VDD = 3.3V, TA = +25NC

VDD = 3.6V, IOL = 25mA (Note 3) 1.0

OL_IRTX

= 2.35V, IOL = 10mA (Note 3) 1.0

DD

= 1.85V, IOL = 4.5mA 1.0

V

DD

VDD = 3.6V, IOL = 11mA (Note 3) 0.4 0.5

V

OL

V

OH

C

IO

L

R

PU

HFXIN

HFXIN

t

XTAL_RDY

OSCF

XCLK

XCLK

XCLK_DUTY

CK

CK

= 2.35V, IOL = 8mA (Note 3) 0.4 0.5

DD

= 1.85V, IOL = 4.5mA 0.4 0.5

V

DD

IOH = -2mA VDD - 0.5 V

(Note 4) 15 pF

Internal pullup disabled -100 +100 nA

VDD = 3.0V, VOL = 0.4V (Note 4) 16 28 39

V

= 2.0V, VOL = 0.4V 17 30 41

DD

From initial oscillation

(Note 4) 0.5 1.0 1.5

(Note 4) 45 55 %

HFXOUT = GND f

TA = +25NC

NANO

T

= +25NC, VDD = POR voltage

A

(Note 4)

NANO

NANO

(Note 4) 40 60 %

Typical at VDD = 1.64V,

T

= +25°C (Note 4)

A

300 mV

V

GND

0.7 x V

DD

0.3 x V

V

DD

DD

50 ns

300 ns

DD

1 12 MHz

1/f

HFXIN

8192 x

t

HFXIN

DC 12 MHz

1/f

XCLK

f

HFXIN

XCLK

1/f

CK

3.0 8.0 20.0

1.7 2.4

40 400 nA

MAXQ613

V

V

VV

VV

V

kW

ns

ms

MW

ns

MHz

ns

kHz

_______________________________________________________________________________________ 5

Page 6

16-Bit Microcontroller with Infrared Module

RECOMMENDED OPERATING CONDITIONS (continued)

(VDD = V

WAKE-UP TIMER

Wake-Up Timer Interval t

FLASH MEMORY

MAXQ613

System Clock During Flash

Programming/Erase

Flash Erase Time

Flash Programming Time per

Word

Write/Erase Cycles 20,000 Cycles

Data Retention

IR

Carrier Frequency f

SPI ELECTRICAL CHARACTERISTICS

(VDD = V

SPI Master Operating

Frequency

SPI Slave Operating

Frequency

SPI I/O Rise/Fall Time t

SCLK Output Pulse-Width

High/Low

MOSI Output Hold Time After

SCLK Sample Edge

MOSI Output Valid to Sample

Edge

MISO Input Valid to SCLK

Sample Edge Rise/Fall Setup

MISO Input to SCLK Sample

Edge Rise/Fall Hold

SCLK Inactive to MOSI

Inactive

SCLK Input Pulse-Width High/

Low

SSEL Active to First Shift

Edge

MOSI Input to SCLK Sample

Edge Rise/Fall Setup

to 3.6V, TA = 0NC to +70NC, unless otherwise noted.) (Note 1)

RST

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

WAKEUP

f

FPSYSCLK

t

ME

t

ERASE

t

PROG

IR

to 3.6V, TA = 0NC to +70NC, unless otherwise noted.) (Note 11)

RST

Mass erase 20 40

Page erase 20 40

(Note 10) 20 100

= +25NC

T

A

(Note 4) fCK/2 Hz

1/f

NANO

6 MHz

100 Years

65,535/

f

NANO

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

t

MCH

t

SCH

1/t

MCK

1/t

SCK

SPI_RF

, t

t

MOH

t

MOV

t

MIS

t

MIH

t

MLH

, t

t

SSE

t

SIS

CL = 15pF, pullup = 560W

MCL

SCL

8.3 23.6 ns

t

/2 -

MCK

t

SPI_RF

t

/2 -

MCK

t

SPI_RF

t

/2 -

MCK

t

SPI_RF

25 ns

0 ns

t

/2 -

MCK

t

SPI_RF

t

/2 ns

SCK

t

SPI_RF

t

SPI_RF

fCK/2 MHz

fCK/4 MHz

s

ms

Fs

ns

ns

ns

ns

ns

ns

6 ______________________________________________________________________________________

Page 7

16-Bit Microcontroller with Infrared Module

SPI ELECTRICAL CHARACTERISTICS (continued)

(VDD = V

MOSI Input from SCLK

Sample Edge Transition Hold

MISO Output Valid After SCLK

Shift Edge Transition

SSEL Inactive

SCLK Inactive to SSEL Rising

MISO Output Disabled After

SSEL Edge Rise

Note 1:

Note 2: V

Note 3: The power-fail reset and POR detectors are designed to operate in tandem to ensure that one or both of these signals

Note 4: Guaranteed by design and not production tested.

Note 5: Measured on the VDD pin and the device not in reset. All inputs are connected to GND or VDD. Outputs do not source/

Note 6: The power-check interval (PCI) can be set to always on, or to 1024, 2048, or 4096 nanopower ring clock cycles.

Note 7: Current consumption during POR when powering up while VDD is less than the POR release voltage.

Note 8: The minimum amount of time that VDD must be below V

Note 9: The maximum total current, I

Note 10: Programming time does not include overhead associated with utility ROM interface.

Note 11: AC electrical specifications are guaranteed by design and are not production tested.

to 3.6V, TA = 0NC to +70NC, unless otherwise noted.) (Note 11)

RST

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

t

SIH

t

SOV

t

SSH

t

SD

t

SLH

Specifications to 0NC are guaranteed by design and are not production tested. Typical = +25NC, VDD = +3.3V, unless

otherwise noted.

can be programmed to the following nominal voltage trip points: 1.8V, 1.9V, 2.55V, and 2.75V ±3%. The values

PFW

listed in the Recommended Operating Conditions table are for the default configuration of 1.8V nominal.

is active at all times when VDD < V

achieved.

sink any current. The device is executing code from flash memory.

User’s Guide for details.

OH(MAX)

maximum specified voltage drop. This does not include the IRTX output.

, ensuring the device maintains the reset state until minimum operating voltage is

RST

before a power-fail event is detected; refer to the MAXQ610

PFW

and I

OL(MAX)

, for all listed outputs combined should not exceed 32mA to satisfy the

t

SPI_RF

tCK +

t

SPI_RF

t

SPI_RF

2t

SPI_RF

2tCK +

2t

SPI_RF

ns

ns

ns

ns

ns

MAXQ613

_______________________________________________________________________________________ 7

Page 8

16-Bit Microcontroller with Infrared Module

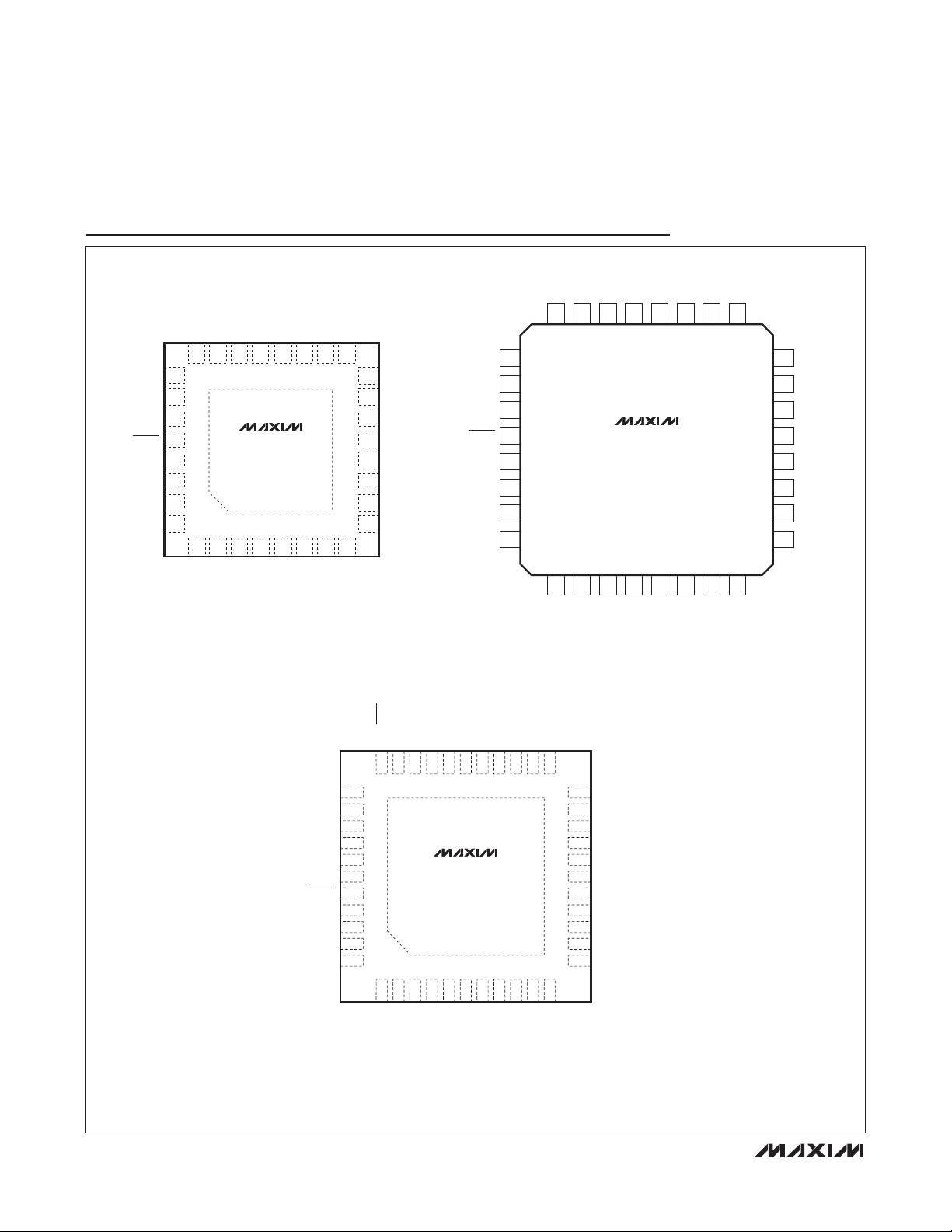

Pin Configurations

TOP VIEW

P2.4/TCK

MAXQ613

P2.5/TDI

P2.6/TMS

P2.7/TDO

RESET

V

GND

IRTX

IRRX

25

26

27

28

29

DD

30

31

+

32

1 2

P0.0/IRTXM/INT8

N.C.

P1.7/INT7

P1.6/INT6

P0.3/INT11

P0.4/INT12

HFXOUT

EP

P0.5/TBA0/TBA1/INT13

GND

21

2324 22 20 19 18

MAXQ613

4 5 6 7

3

P0.1/RX/INT9

P0.2/TX/INT10

TQFN

(5mm × 5mm)

TOP VIEW

P1.5/INT5

HFXIN

17

16

15

14

13

12

11

10

9

8

P0.7/TBB1/INT15

P0.6/TBB0/INT14

TOP VIEW

P2.5/TDI

25 16 P1.4/INT4

P1.4/INT4

V

DD

REGOUT

GND

P1.3/INT3

P1.2/INT2

P1.1/INT1

P1.0/INT0

P2.6/TMS

P2.7/TDO

26 15 V

27

28

RESET

29

V

DD

GND

30

31 10IRTX P1.1/INT1

32 9IRRX P1.0/INT0

+

N.C.

N.C.

P2.1/MISO

GND

P2.0/MOSI

P1.7/INT7

P1.6/INT6

P2.2/SCLK

P2.3/SSEL

3332313029282726252423

HFXOUT

N.C.

P2.4/TCK

2324 22 20 19 18

1 2

P0.1/RX/INT9

P0.0/IRTXM/INT8

P1.7/INT7

GND

21

MAXQ613

4 5 6 7

3

P0.3/INT11

P0.2/TX/INT10

LQFP

(7mm × 7mm)

HFXIN

P1.6/INT6

HFXOUT

P0.4/INT12

P0.5/TBA0/TBA1/INT13

P1.5/INT5

HFXIN

17

8

P0.7/TBB1/INT15

P0.6/TBB0/INT14

14

13

12

11

DD

REGOUT

GND

P1.3/INT3

P1.2/INT2

P2.4/TCK

P2.5/TDI

N.C.

N.C.

P2.6/TMS

P2.7/TDO

RESET

V

GND

IRTX

IRRX

34

35

36

37

38

39

40

41

DD

42

43

+

44

123456789

P0.0/IRTXM/INT8

N.C.

P0.1/RX/INT9

MAXQ613

N.C.

P0.2/TX/INT10

TQFN

P0.3/INT11

P0.4/INT12

P0.5/TBA0/TBA1/INT13

P0.6/TBB0/INT14

EP

10

11

P1.0/INT0

P0.7/TBB1/INT15

22

21

20

19

18

17

16

15

14

13

12

P1.5/INT5

P1.4/INT4

GND

V

DD

REGOUT

GND

N.C.

N.C.

P1.3/INT3

P1.2/INT2

P1.1/INT1

(7mm × 7mm)

8 ______________________________________________________________________________________

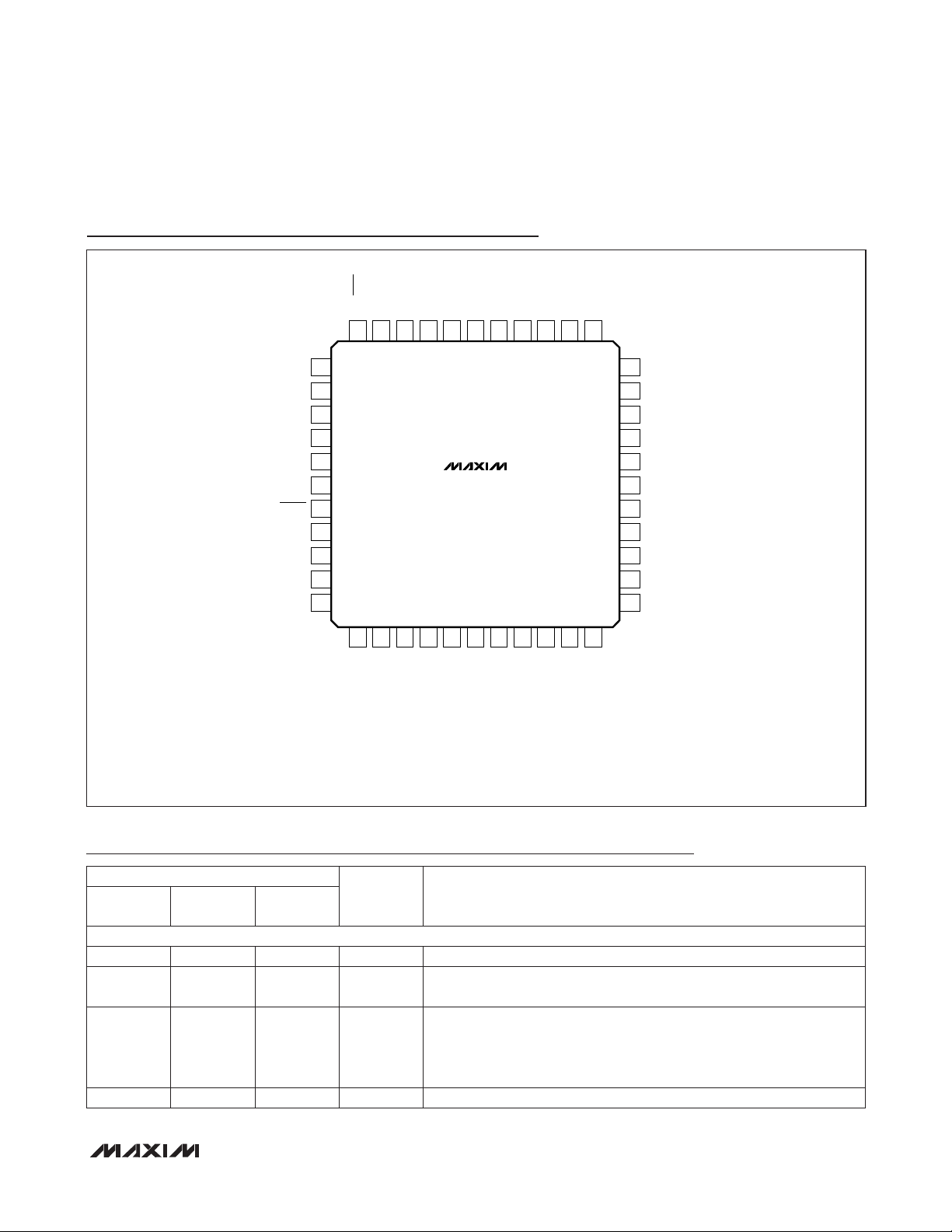

Page 9

16-Bit Microcontroller with Infrared Module

Pin Configurations (continued)

MAXQ613

TOP VIEW

P2.4/TCK

P2.5/TDI

P2.6/TMS

P2.7/TDO

N.C.

N.C.

RESET

V

GND

IRTX

IRRX

P2.3/SSEL

P2.2/SCLK

33

32

34

35

36

37

38

39

40

41

DD

42

43

44

+

1

2

N.C.

P0.0/IRTXM/INT8

N.C.

30

31

3

4

P0.1/RX/INT9

N.C.

N.C.

GND

P2.1/MISO

28

29

MAXQ613

5

P0.3/INT116P0.4/INT12

P0.2/TX/INT10

TQFP

(10mm × 10mm)

NOTE: CONTACT FACTORY FOR BARE DIE PAD CONFIGURATION.

P1.7/INT7

P2.0/MOSI

26

27

7

8

P0.5/TBA0/TBA1/INT13

HFXOUT24HFXIN

P1.6/INT6

23

25

9

11

10

P0.6/TBB0/INT14

P0.7/TBB1/INT15

P1.0/INT0

22 P1.5/INT5

21 P1.4/INT4

20 GND

19 V

DD

18 REGOUT

17 GND

16 N.C.

15 N.C.

14 P1.3/INT3

13 P1.2/INT2

12 P1.1/INT1

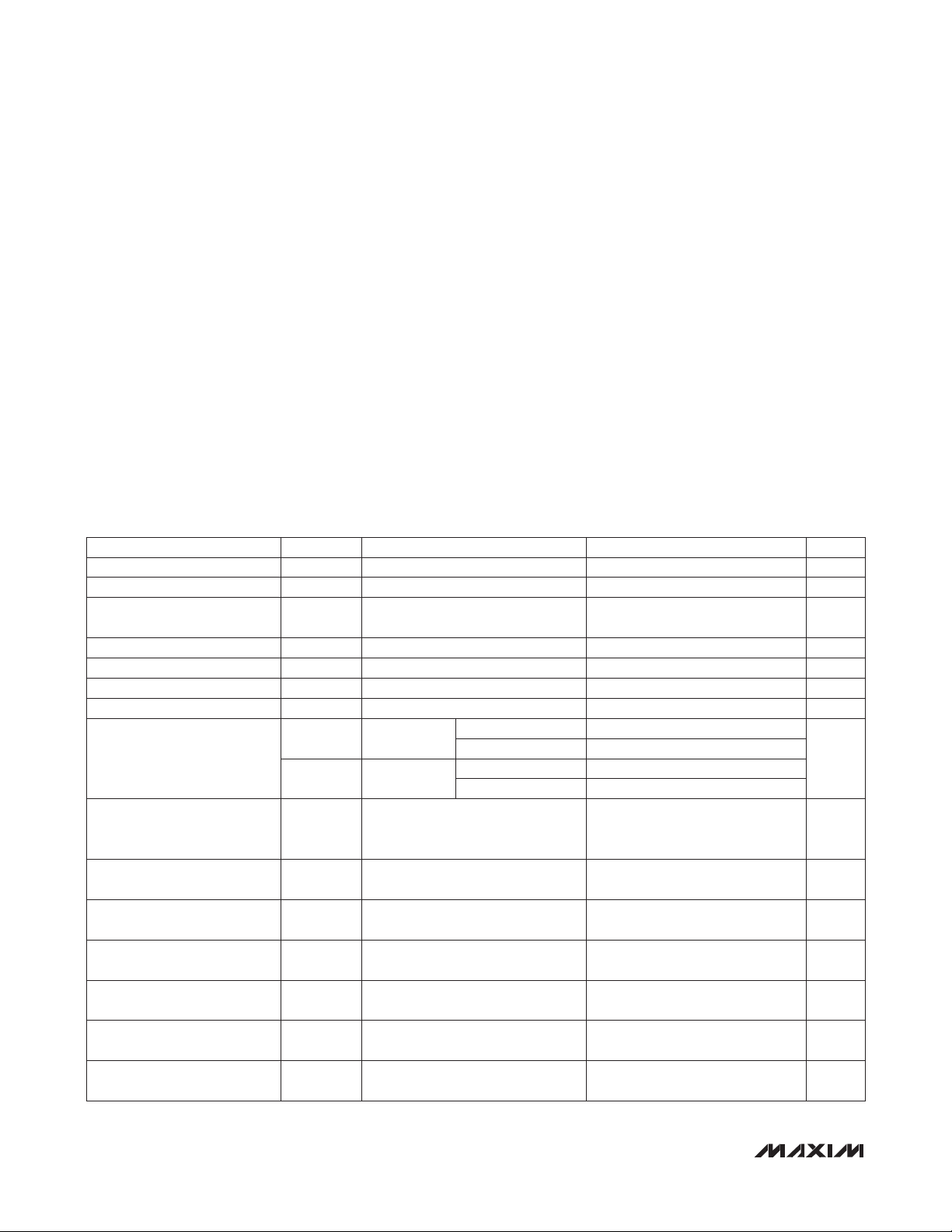

Pin Description

PIN

BARE DIE

32 TQFNEP/LQFP

44 TQFN-

EP/TQFP

15, 36 15, 29 19, 41 V

13, 16, 25,

37

13, 22, 30

17, 20, 28,

42

14 14 18 REGOUT

— — — EP Exposed Pad (TQFN Only). Connect EP directly to the ground plane.

_______________________________________________________________________________________ 9

NAME FUNCTION

POWER PINS

DD

Supply Voltage

GND Ground. Connect directly to the ground plane.

1.8V Regulator Output. This pin must be connected to ground through

a 1.0FF (ESR: 2W–10W) external ceramic-chip capacitor. The capacitor

must be placed as close to this pin as possible. No devices other than

the capacitor should be connected to this pin.

Page 10

16-Bit Microcontroller with Infrared Module

Pin Description (continued)

PIN

BARE DIE

32 TQFNEP/LQFP

MAXQ613

35 28 40 RESET

20 18 23 HFXIN

21 19 24 HFXOUT

38 31 43 IRTX

44 TQFN-

EP/TQFP

NAME FUNCTION

RESET PIN

Digital, Active-Low, Reset Input/Output. The device remains in reset

as long as this pin is low and begins executing from the utility ROM at

address 8000h when this pin returns to a high state. The pin includes

pullup current source; if this pin is driven by an external device, it should

be driven by an open-drain source capable of sinking in excess of 4mA.

This pin can be left unconnected if there is no need to place the device in

a reset state using an external signal. This pin is driven low as an output

when an internal reset condition occurs.

CLOCK PINS

High-Frequency Crystal Input. Connect an external crystal or resonator between HFXIN and HFXOUT for use as the high-frequency system

clock. Alternatively, HFXIN is the input for an external, high-frequency

clock source when HFXOUT is unconnected.

IR FUNCTION PINS

IR Transmit Output. IR transmission pin capable of sinking 25mA. This

pin defaults to a high-impedance input with the weak pullup disabled

during all forms of reset. Software must configure this pin after release

from reset to remove the high-impedance input condition.

IR Receive Input. This pin defaults to a high-impedance input with the

39 32 44 IRRX

GENERAL-PURPOSE I/O AND SPECIAL FUNCTION PINS

1 1 1

2 2 3

3 3 5

4 4 6 P0.3/INT11 P0.3 INT11

5 5 7 P0.4/INT12 P0.4 INT12

6 6 8

P0.0/IRTXM/

INT8

P0.1/RX/

INT9

P0.2/TX/

INT10

P0.5/TBA0/

TBA1/INT13

weak pullup disabled during all forms of reset. Software must configure

this pin after release from reset to remove the high-impedance input

condition.

Port 0 General-Purpose, Digital I/O Pins. These port pins function as

general-purpose I/O pins with their input and output states controlled by

the PD0, PO0, and PI0 registers. All port pins default to high-impedance

mode after a reset. Software must configure these pins after release

from reset to remove the high-impedance condition. All alternate functions must be enabled from software before they can be used.

GPIO PORT PIN SPECIAL FUNCTION

P0.0 IR Modulator Output/INT8

P0.1 USART Receive/INT9

P0.2 USART Transmit/INT10

P0.5

Type B Timer 0 Pin A or Type B

Timer 1 Pin A/INT13

10 _____________________________________________________________________________________

Page 11

16-Bit Microcontroller with Infrared Module

Pin Description (continued)

PIN

BARE DIE

7 7 9

8 8 10

9 9 11 P1.0/INT0 P1.0 INT0

10 10 12 P1.1/INT1 P1.1 INT1

11 11 13 P1.2/INT2 P1.2 INT2

12 12 14 P1.3/INT3 P1.3 INT3

17 16 21 P1.4/INT4 P1.4 INT4

18 17 22 P1.5/INT5 P1.5 INT5

22 20 25 P1.6/INT6 P1.6 INT6

23 21 26 P1.7/INT7

24 — 27 P2.0/MOSI P2.0 SPI: Master Out-Slave In

26 — 29 P2.1/MISO P2.1 SPI: Master In-Slave Out

28 — 32 P2.2/SCLK P2.2 SPI: Slave Clock

30 — 33 P2.3/SSEL P2.3 SPI: Active-Low Slave Select

31 24 34 P2.4/TCK P2.4 JTAG: Test Clock

32 25 35 P2.5/TDI P2.5 JTAG: Test Data In

33 26 38 P2.6/TMS P2.6 JTAG: Test Mode Select

34

— 23

32 TQFN-

EP/LQFP

27 39 P2.7/TDO

44 TQFN-

EP/TQFP

2, 4, 15, 16,

30, 31, 36,

37

NAME FUNCTION

P0.6/TBB0/

INT14

P0.7/TBB1/

INT15

Port 1 General-Purpose, Digital I/O Pins with Interrupt Capability. These

port pins function as general-purpose I/O pins with their input and output states controlled by the PD1, PO1, and PI1 registers. All port pins

default to high-impedance mode after a reset. Software must configure

these pins after release from reset to remove the high-impedance condition. All external interrupts must be enabled from software before they

can be used.

Port 2 General-Purpose, Digital I/O Pins. These port pins function as

general-purpose I/O pins with their input and output states controlled by

the PD2, PO2, and PI2 registers. All port pins default to high-impedance

mode after a reset. Software must configure these pins after release

from reset to remove the high-impedance condition. All special functions must be enabled from software before they can be used.

NO CONNECTION PINS

N.C. No Connection. Not internally connected.

P0.6 Type B Timer 0 Pin B/INT14

P0.7 Type B Timer 1 Pin B/INT15

GPIO PORT PIN EXTERNAL INTERRUPT

P1.7 INT7

GPIO PORT PIN SPECIAL FUNCTION

P2.7 JTAG: Test Data Out

MAXQ613

______________________________________________________________________________________ 11

Page 12

16-Bit Microcontroller with Infrared Module

Block Diagram

MAXQ613

REGULATOR

MAXQ613

VOLTAGE

MONITOR

GPIO

2x

16-BIT TIMER

16-BIT MAXQ

CLOCK

WATCHDOG

8kHz NANO

RING

RISC CPU

48KB FLASH

MEMORY

1.5KB

UTILITY ROM

5.5KB

DATA SRAM

IR DRIVER

IR TIMER

SPI

USART

Detailed Description

The MAXQ613 provides integrated, low-cost solutions

that simplify the design of IR communications equipment

such as universal remote controls. Standard features

include the highly optimized, single-cycle, MAXQ, 16-bit

RISC core; 48KB of program flash memory; 1.5KB data

RAM; soft stack; 16 general-purpose registers; and

three data pointers. The MAXQ core has the industry’s

best MIPS/mA rating, allowing developers to achieve

the same performance as competing microcontrollers

at substantially lower clock rates. Lower active-mode

current combined with the even lower MAXQ613 stopmode current (0.2FA typ) results in increased battery life.

Application-specific peripherals include flexible timers

for generating IR carrier frequencies and modulation. A

high-current IR drive pin capable of sinking up to 25mA

current and output pins capable of sinking up to 5mA

are ideal for IR applications. It also includes generalpurpose I/O pins ideal for keypad matrix input, and a

power-fail-detection circuit to notify the application when

the supply voltage is nearing the microcontroller’s minimum operating voltage.

At the heart of the device is the MAXQ 16-bit, RISC core.

Operating from DC to 12MHz, almost all instructions execute in a single clock cycle (83.3ns at 12MHz), enabling

nearly 12MIPS true-code operation. When active device

operation is not required, an ultra-low-power stop mode

can be invoked from software, resulting in quiescent

current consumption of less than 0.2FA (typ) and 2.0FA

(max). The combination of high-performance instructions

and ultra-low stop-mode current increases battery life

over competing microcontrollers. An integrated POR circuit with brownout support resets the device to a known

condition following a power-up cycle or brownout condition. Additionally, a power-fail warning flag is set, and a

power-fail interrupt can be generated when the system

voltage falls below the power-fail warning voltage, V

PFW

The power-fail warning feature allows the application to

notify the user that the system supply is low and appropriate action should be taken.

Microprocessor

The device is based on Maxim’s low-power, 16-bit MAXQ

family of RISC cores. The core supports the Harvard

memory architecture with separate 16-bit program and

data address buses. A fixed 16-bit instruction word is

standard, but data can be arranged in 8 or 16 bits. The

MAXQ core in the device is implemented as a pipelined processor with performance approaching 1MIPS

per MHz. The 16-bit data path is implemented around

register modules, and each register module contributes

specific functions to the core. The accumulator module

consists of sixteen 16-bit registers and is tightly coupled

with the arithmetic logic unit (ALU). A configurable soft

stack supports program flow.

Execution of instructions is triggered by data transfer

between functional register modules or between a functional register module and memory. Because data movement involves only source and destination modules,

circuit switching activities are limited to active modules

only. For power-conscious applications, this approach

localizes power dissipation and minimizes switching

noise. The modular architecture also provides a maximum of flexibility and reusability that are important for a

microprocessor used in embedded applications.

The MAXQ instruction set is highly orthogonal. All arithmetical and logical operations can use any register

in conjunction with the accumulator. Data movement

is supported from any register to any other register.

Memory is accessed through specific data-pointer registers with autoincrement/decrement support.

.

12 _____________________________________________________________________________________

Page 13

16-Bit Microcontroller with Infrared Module

Memory

The microcontroller incorporates several memory types:

• 48KB program flash memory

• 1.5KB SRAM data memory

• 5.5KB utility ROM

• Soft stack

Memory Protection

The optional memory-protection feature separates code

memory into three areas: system, user loader, and user

application. Code in the system area can be kept confidential. Code in the user areas can be prevented from

reading and writing system code. The user loader can

also be protected from user application code.

Memory protection is implemented using privilege levels

for code. Each area has an associated privilege level.

RAM/ROM are assigned privilege levels as well. Refer to

the MAXQ610 User’s Guide for a more thorough explanation of the topic. See Table 1.

Stack Memory

The device provides a soft stack that can be used to

store program return addresses (for subroutine calls

and interrupt handling) and other general-purpose data.

This soft stack is located in the 1.5KB SRAM data

memory, which means that the SRAM data memory must

be shared between the soft stack and general-purpose

application data storage. However, the location and

size of the soft stack is determined by the user, providing maximum flexibility when allocating resources for a

particular application. The stack is used automatically

by the processor when the CALL, RET, and RETI instructions are executed and when an interrupt is serviced. An

application can also store and retrieve values explicitly

using the stack by means of the PUSH, POP, and POPI

instructions.

The SP pointer indicates the current top of the stack,

MAXQ613

which initializes by default to the top of the SRAM data

memory. As values are pushed onto the stack, the SP

pointer decrements, which means that the stack grows

downward towards the bottom (lowest address) of the

data memory. Popping values off the stack causes the

SP pointer value to increase. Refer to the MAXQ610

User’s Guide for more details.

Utility ROM

The utility ROM is a 5.5KB block of internal ROM memory

located in program space beginning at address 8000h.

This ROM includes the following routines:

• In-system programming (bootstrap loader) using

JTAG interface

• In-circuit debugging routines using JTAG interface

• Production test routines (internal memory tests,

memory loader, etc.), which are used for internal

testing only, and are generally of no use to the endapplication developer

• User-callable routines for in-application flash programming, buffer copying, and fast table lookup (more

information on these routines can be found in the

MAXQ610 User’s Guide)

Following any reset, execution begins in the utility ROM

at address 8000h. At this point, unless loader mode or

test mode has been invoked (which requires special programming through the JTAG interface), the utility ROM in

the device always automatically jumps to location 0000h,

which is the beginning of user application code in program flash memory.

Some applications require protection against unauthorized viewing of program code memory. For these applications, access to in-system programming, in-application programming, or in-circuit debugging functions is

prohibited until a password has been supplied. Three

Table 1. Memory Areas and Associated Maximum Privilege Levels

AREA PAGE ADDRESS MAXIMUM PRIVILEGE LEVEL

System 0 to ULDR-1 High

User Loader ULDR to UAPP-1 Medium

User Application UAPP to top Low

Utility ROM N/A High

Other (RAM) N/A Low

______________________________________________________________________________________ 13

Page 14

16-Bit Microcontroller with Infrared Module

Table 2. Watchdog Interrupt Timeout (Sysclk = 12MHz, CD[1:0] = 00)

WD[1:0] WATCHDOG CLOCK WATCHDOG INTERRUPT TIMEOUT

00 Sysclk/2

01 Sysclk/2

10 Sysclk/2

11 Sysclk/2

15

18

21

24

MAXQ613

different password locks are provided, each of which

can be used to protect a different area of memory (system memory, user loader, and user application). Each

password lock is controlled by a 16-word area of flash

memory; if the password is set to all FFFFh values or all

0000h values, the password is disabled. Otherwise, the

password is active and must be matched by the user of

the bootloader or debugger before access is granted to

the corresponding area of flash program memory. Refer

to the MAXQ610 User’s Guide for more details.

Watchdog Timer

The internal watchdog timer greatly increases system

reliability. The timer resets the device if software execution is disturbed. The watchdog timer is a free-running

counter designed to be periodically reset by the application software. If software is operating correctly, the counter is periodically reset and never reaches its maximum

count. However, if software operation is interrupted,

the timer does not reset, triggering a system reset and

optionally a watchdog timer interrupt. This protects the

system against electrical noise or electrostatic discharge

(ESD) upsets that could cause uncontrolled processor

operation. The internal watchdog timer is an upgrade to

older designs with external watchdog devices, reducing

system cost and simultaneously increasing reliability.

The watchdog timer functions as the source of both the

watchdog timer timeout and the watchdog timer reset.

The timeout period can be programmed in a range of

15

to 224 system clock cycles. An interrupt is gener-

2

ated when the timeout period expires if the interrupt

is enabled. All watchdog timer resets follow the programmed interrupt timeouts by 512 system clock cycles.

If the watchdog timer is not restarted for another full

interval in this time period, a system reset occurs when

the reset timeout expires. See Table 2.

WATCHDOG RESET AFTER

WATCHDOG INTERRUPT (µs)

2.7ms 42.7

21.9ms 42.7

174.7ms 42.7

1.4s 42.7

IR Carrier Generation

and Modulation Timer

The dedicated IR timer/counter module simplifies lowspeed infrared (IR) communication. The IR timer implements two pins (IRTX and IRRX) for supporting IR

transmit and receive, respectively. The IRTX pin has no

corresponding port pin designation, so the standard

PD, PO, and PI port control status bits are not present.

However, the IRTX pin output can be manipulated high

or low using the PWCN.IRTXOUT and PWCN.IRTXOE

bits when the IR timer is not enabled (i.e., IREN = 0).

The IR timer is composed of a carrier generator and a

carrier modulator. The carrier generation module uses

the 16-bit IR carrier register (IRCA) to define the high

and low time of the carrier through the IR carrier high

byte (IRCAH) and IR carrier low byte (IRCAL). The carrier

modulator uses the IR data bit (IRDATA) and IR modulator time register (IRMT) to determine whether the carrier

or the idle condition is present on IRTX.

The IR timer is enabled when the IR enable bit (IREN) is

set to 1. The IR Value register (IRV) defines the beginning value for the carrier modulator. During transmission,

the IRV register is initially loaded with the IRMT value

and begins down counting towards 0000h, whereas

in receive mode it counts upward from the initial IRV

register value. During the receive operation, the IRV

register can be configured to reload with 0000h when

capture occurs on detection of selected edges or can be

allowed to continue free-running throughout the receive

operation. An overflow occurs when the IR timer value

rolls over from 0FFFFh to 0000h. The IR overflow flag

(IROV) is set to 1 and an interrupt is generated if enabled

(IRIE = 1).

14 _____________________________________________________________________________________

Page 15

16-Bit Microcontroller with Infrared Module

Carrier Generation Module

The IRCAH byte defines the carrier high time in terms of

the number of IR input clocks, whereas the IRCAL byte

defines the carrier low time.

• IR Input Clock (f

IRCLK

• Carrier Frequency (f

) = f

CARRIER

SYS

IRDIV[1:0]

/2

) = f

IRCLK

/(IRCAH +

IRCAL + 2)

• Carrier High Time = IRCAH + 1

• Carrier Low Time = IRCAL + 1

• Carrier Duty Cycle = (IRCAH + 1)/(IRCAH + IRCAL + 2)

During transmission, the IRCA register is latched for

each IRV down-count interval, and is sampled along with

the IRTXPOL and IRDATA bits at the beginning of each

new IRV down-count interval so that duty-cycle variation

and frequency shifting is possible from one interval to the

next, which is illustrated in Figure 1.

IRCA

IRMT IRMT = 5

IRCA = 0202h IRCA = 0002h

IRMT = 3

Figure 2 illustrates the basic carrier generation and its

MAXQ613

path to the IRTX output pin. The IR transmit polarity bit

(IRTXPOL) defines the starting/idle state and the carrier

polarity of the IRTX pin when the IR timer is enabled.

IR Transmission

During IR transmission (IRMODE = 1), the carrier generator creates the appropriate carrier waveform, while

the carrier modulator performs the modulation. The carrier modulation can be performed as a function of carrier

cycles or IRCLK cycles dependent on the setting of the

IRCFME bit. When IRCFME = 0, the IRV down counter is

clocked by the carrier frequency and thus the modulation is a function of carrier cycles. When IRCFME = 1, the

IRV down counter is clocked by IRCLK, allowing carrier

modulation timing with IRCLK resolution.

The IRTXPOL bit defines the starting/idle state as well as

the carrier polarity for the IRTX pin. If IRTXPOL = 1, the

3 12 0 5 4 3 2 1 0

CARRIER OUTPUT

(IRV)

IRDATA

0

IR INTERRUPT

IRTX

IRTXPOL = 1

IRTX

IRTXPOL = 0

Figure 1. IR Transmit Frequency Shifting Example (IRCFME = 0)

IRCA, IRMT, IRDATA SAMPLED AT END OF IRV

DOWN-COUNT INTERVAL

01

______________________________________________________________________________________ 15

Page 16

16-Bit Microcontroller with Infrared Module

IRTX pin is set to a logic-high when the IR timer module is

enabled. If IRTXPOL = 0, the IRTX pin is set to a logic-low

when the IR timer is enabled.

A separate register bit, IR data (IRDATA), is used to

determine whether the carrier generator output is output

to the IRTX pin for the next IRMT carrier cycles. When

IRDATA = 1, the carrier waveform (or inversion of this

waveform if IRTXPOL = 1) is output on the IRTX pin dur-

MAXQ613

ing the next IRMT cycles. When IRDATA = 0, the idle

CARRIER GENERATION

IRCAL + 1IRCAH + 1

condition, as defined by IRTXPOL, is output on the IRTX

pin during the next IRMT cycles.

The IR timer acts as a down counter in transmit mode. An

IR transmission starts when the IREN bit is set to 1 when

IRMODE = 1; when the IRMODE bit is set to 1 when IREN

= 1; or when IREN and IRMODE are both set to 1 in the

same instruction. The IRMT and IRCA registers, along

with the IRDATA and IRTXPOL bits, are sampled at the

beginning of the transmit process and every time the IR

IRDATA

IRMT

IRTXPOL

CARRIERIRCLK

IRCFME

0

1

SAMPLE

IRDATA ON

IRV = 0000h

CARRIER MODULATION

0

IRTX PIN

1

IR INTERRUPT

Figure 2. IR Transmit Carrier Generation and Carrier Modulator Control

IRMT = 3

CARRIER OUTPUT

(IRV)

IRDATA

IR INTERRUPT

IRTX

IRTXPOL = 1

IRTX

IRTXPOL = 0

23 1 0 23 1 0

0

01

Figure 3. IR Transmission Waveform (IRCFME = 0)

16 _____________________________________________________________________________________

Page 17

16-Bit Microcontroller with Infrared Module

timer value reloads its value. When the IRV reaches 0000h

value, on the next carrier clock, it does the following:

1) Reloads IRV with IRMT.

2) Samples IRCA, IRDATA, and IRTXPOL.

3) Generates IRTX accordingly.

4) Sets IRIF to 1.

5) Generates an interrupt to the CPU if enabled (IRIE = 1).

To terminate the current transmission, the user can

switch to receive mode (IRMODE = 0) or clear IREN to 0.

Carrier Modulation Time = IRMT + 1 carrier cycles

IR Transmit—Independent External Carrier

and Modulator Outputs

The normal transmit mode modulates the carrier based

upon the IRDATA bit. However, the user has the option

to input the modulator (envelope) on an external pin if

desired. If the IRENV[1:0] bits are configured to 01b or

10b, the modulator/envelope is output to the IRTXM pin.

The IRDATA bit is output directly to the IRTXM pin (if

IRTXPOL = 0) on each IRV down-count interval boundary just as if it were being used to internally modulate

the carrier frequency. If IRTXPOL = 1, the inverse of

the IRDATA bit is output to the IRTXM pin on the IRV

interval down-count boundaries. See Figure 4. When

the envelope mode is enabled, it is possible to output

either the modulated (IRENV[1:0] = 01b) or unmodulated

(INENV[1:0] = 10b) carrier to the IRTX pin.

IR Receive

MAXQ613

When configured in receive mode (IRMODE = 0), the

IR hardware supports the IRRX capture function. The

IRRXSEL[1:0] bits define which edge(s) of the IRRX pin

should trigger the IR timer capture function.

The IR module starts operating in the receive mode when

IRMODE = 0 and IREN = 1. Once started, the IR timer

(IRV) starts up counting from 0000h when a qualified

capture event as defined by IRRXSEL happens. The IRV

register is, by default, counting carrier cycles as defined

by the IRCA register. However, the IR carrier frequency

detect (IRCFME) bit can be set to 1 to allow clocking of

the IRV register directly with the IRCLK for finer resolution. When IRCFME = 0, the IRCA defined carrier is

counted by IRV. When IRCFME = 1, the IRCLK clocks

the IRV register.

On the next qualified event, the IR module does the

following:

1) Captures the IRRX pin state and transfers its value

to IRDATA. If a falling edge occurs, IRDATA = 0. If a

rising edge occurs, IRDATA = 1.

2) Transfers its current IRV value to the IRMT.

3) Resets IRV content to 0000h (if IRXRL = 1).

4) Continues counting again until the next qualified event.

If the IR timer value rolls over from 0FFFFh to 0000h

before a qualified event happens, the IR timer overflow

(IROV) flag is set to 1 and an interrupt is generated, if

IRTXM

IRTXPOL = 1

IRTXM

IRTXPOL = 0

IRDATA

0 1 0 1 01 01

IR INTERRUPT

IRV INTERVAL

Figure 4. External IRTXM (Modulator) Output

IRMT IRMT IRMTIRMT

______________________________________________________________________________________ 17

Page 18

16-Bit Microcontroller with Infrared Module

CARRIER GENERATION

IRCLK

IRCAL + 1IRCAH + 1

MAXQ613

IRRX PIN

Figure 5. IR Capture

enabled. The IR module continues to operate in receive

mode until it is stopped by switching into transmit mode

(IRMODE = 1) or clearing IREN = 0.

Carrier Burst-Count Mode

A special mode reduces the CPU processing burden

when performing IR learning functions. Typically, when

operating in an IR learning capacity, some number of

carrier cycles are examined for frequency determination. Once the frequency has been determined, the IR

receive function can be reduced to counting the number

of carrier pulses in the burst and the duration of the

combined mark-space time within the burst. To simplify

this process, the receive burst-count mode (as enabled

by the RXBCNT bit) can be used. When RXBCNT = 0,

the standard IR receive capture functionality is in place.

When RXBCNT = 1, the IRV capture operation is disabled and the interrupt flag associated with the capture

no longer denotes a capture. In the carrier burst-count

mode, the IRMT register only counts qualified edges.

The IRIF interrupt flag (normally used to signal a capture

when RXBCNT = 0) now becomes set if two IRCA cycles

elapse without getting a qualified edge. The IRIF interrupt flag thus denotes absence of the carrier and the

beginning of a space in the receive signal. When the

RXBCNT bit is changed from 0 to 1, the IRMT register

is set to 0001h. The IRCFME bit is still used to define

whether the IRV register is counting system IRCLK

clocks or IRCA-defined carrier cycles. The IRXRL bit

defines whether the IRV register is reloaded with 0000h

on detection of a qualified edge (per the IRXSEL[1:0]

bits). Figure 6 and the descriptive sequence embedded

EDGE DETECT

0

1

IRCFME

CARRIER MODULATION

IR TIMER OVERFLOW

INTERRUPT TO CPU

0000h IRV

IR INTERRUPT

COPY IRV TO IRMT

ON EDGE DETECT

IRXRL

RESET IRV TO 0000h

IRDATA

in the figure illustrate the expected usage of the receive

burst-count mode.

16-Bit Timers/Counters

The microcontroller provides two timers/counters that

support the following functions:

• 16-bit timer/counter

• 16-bit up/down autoreload

• Counter function of external pulse

• 16-bit timer with capture

• 16-bit timer with compare

• Input/output enhancements for pulse-width modulation

• Set/reset/toggle output state on comparator match

• Prescaler with 2n divider (for n = 0, 2, 4, 6, 8, 10)

USART

The device provides a USART peripheral with the following features:

• 2-wire interface

• Full-duplex operation for asynchronous data transfers

• Half-duplex operation for synchronous data transfers

• Programmable interrupt when transmit or receive data

operation completes

• Independent programmable baud-rate generator

• Optional 9th bit parity support

• Start/stop bit support

18 _____________________________________________________________________________________

Page 19

16-Bit Microcontroller with Infrared Module

CARRIER FREQUENCY

IRRX

IRV

IRMT

CALCULATION

1

2 3 4 6 7

IRMT = PULSE COUNTING IRMT = PULSE COUNTING

5

IRV = CARRIER CYCLE COUNTING

8

9

MAXQ613

1 4

CAPTURE INTERRUPT (IRIF = 1).

TO

≥ IRMT.

IRV

IRV = 0 (IF IRXRL = 1).

SOFTWARE SETS IRCA = CARRIER FREQUENCY.

SOFTWARE SETS RXBCNT = 1 (WHICH CLEARS IRMT = 0001 IN HARDWARE).

5

SOFTWARE CLEARS IRCFME = 0 SO THAT IRV COUNTS CARRIER CYCLES. IRV IS RESET TO 0 ON QUALIFIED EDGE DETECTION IF IRXRL = 1.

SOFTWARE ADDS TO IRMT THE NUMBER OF PULSES USED FOR CARRIER MEASUREMENT.

IRCA x 2x COUNTER FOR SPACE CAN BEGIN IMMEDIATELY (QUALIFIED EDGE RESETS).

QUALIFIED EDGE DETECTED: IRMT++

6

IRV RESET TO 0 IF IRXRL = 1.

IRCA x 2 PERIOD ELAPSES: IRIF = 1; CARRIER ABSENCE = SPACE.

7

BURST MARK = IRMT PULSES.

SOFTWARE CLEARS RXBCNT = 0 SO THAT WE CAPTURE ON THE NEXT QUALIFIED EDGE.

8

QUALIFIED EDGE DETECTED: IRIF = 1, CAPTURE IRV IRMT AS THE BURST SPACE (PLUS UP TO ONE CARRIER CYCLE).

9

SOFTWARE SET RXBCNT = 1 AS IN (5).

CONTINUE (5) TO (8) UNTIL LEARNING SPACE EXCEEDS SOME DURATION. IRV ROLLOVERS CAN BE USED.

Figure 6. Receive Burst-Count Example

Table 3. USART Mode Details

MODE TYPE START BITS DATA BITS STOP BITS

Mode 0 Synchronous N/A 8 N/A

Mode 1 Asynchronous 1 8 1

Mode 2 Asynchronous 1 8 + 1 1

Mode 3 Asynchronous 1 8 + 1 1

Serial Peripheral Interface (SPI)

The integrated SPI provides an independent serial

communication channel that communicates synchronously with peripheral devices in a multiple master or

multiple slave system. The interface allows access to

a 4-wire, full-duplex serial bus, and can be operated in

either master mode or slave mode. Collision detection

______________________________________________________________________________________ 19

is provided when two or more masters attempt a data

transfer at the same time.

The maximum SPI master transfer rate is Sysclk/2. When

operating as an SPI slave, the device can support up to

Sysclk/4 SPI transfer rate. Data is transferred as an 8-bit

or 16-bit value, MSB first. In addition, the SPI module

supports configuration of an active SSEL state (active

low or active high) through the slave active select.

Page 20

16-Bit Microcontroller with Infrared Module

SHIFT SAMPLE SHIFT SAMPLE

SSEL

t

SCLK

CKPOL/CKPHA

0/1 OR 1/0

MAXQ613

SCLK

CKPOL/CKPHA

0/0 OR 1/1

MOSI

MCK

t

MCH

t

MOH

MSB MSB-1

t

MCL

t

MOV

t

RF

LSB

t

MLH

t

MIS

MISO

MSB MSB-1

Figure 7. SPI Master Communication Timing

SHIFT SAMPLE SHIFT SAMPLE

SSEL

SCLK

CKPOL/CKPHA

0/1 OR 1/0

SCLK

CKPOL/CKPHA

0/0 OR 1/1

MOSI

t

SSE

t

SIS

MSB MSB-1

t

SCK

t

SCH

t

MIH

LSB

t

SSH

t

SD

t

SCL

t

SIH

LSB

MISO

t

SOV

MSB MSB-1

t

RF

LSB

t

SLH

Figure 8. SPI Slave Communication Timing

20 _____________________________________________________________________________________

Page 21

16-Bit Microcontroller with Infrared Module

General-Purpose I/O

The microcontroller provides port pins for general-purpose I/O that have the following features:

• CMOS output drivers

• Schmitt trigger inputs

• Optional weak pullup to VDD when operating in input

mode

While the microcontroller is in a reset state, all port pins

become high impedance with both weak pullups and

input buffers disabled, unless otherwise noted.

From a software perspective, each port appears as a

group of peripheral registers with unique addresses.

Special function pins can also be used as general-purpose I/O pins when the special functions are disabled.

For a detailed description of the special functions available for each pin, refer to the MAXQ610 User’s Guide.

On-Chip Oscillator

An external quartz crystal or a ceramic resonator can be

connected between HFXIN and HFXOUT, as illustrated

in Figure 9.

Noise at HFXIN and HFXOUT can adversely affect onchip clock timing. It is good design practice to place the

crystal and capacitors near the oscillator circuitry and

connect HFXIN and HFXOUT to ground with a direct

short trace. The typical values of external capacitors vary

with the type of crystal to be used and should be initially

selected based on load capacitance as suggested by

the manufacturer.

V

DD

HFXIN

HFXOUT

C1

C2

Figure 9. On-Chip Oscillator

R

F

R

= 1MI Q50%

F

C1 = C2 = 12pF

CLOCK CIRCUIT

STOP

MAXQ613

ROM Loader

The ROM loader denies access to the system, user loader, or user-application memories unless an area-specific

password is provided. The ROM loader is not available

in ROM-only versions.

Loading Flash Memory

An internal bootstrap loader allows reloading over a

simple JTAG interface. As a result, software can be

upgraded in-system, eliminating the need for a costly

hardware retrofit when updates are required. Remote

software uploads are possible that enable physically

inaccessible applications to be frequently updated. The

interface hardware can be a JTAG connection to another

microcontroller, or a connection to a PC serial port using

a serial-to-JTAG converter such as the MAXQJTAG-001,

available from Maxim. If in-system programmability is not

required, a commercial gang programmer can be used

for mass programming. Activating the JTAG interface

and loading the test access port (TAP) with the system

programming instruction invokes the bootstrap loader.

Setting the SPE bit to one during reset through the JTAG

interface executes the bootstrap-loader mode program

that resides in the utility ROM. When programming is

complete, the bootstrap loader can clear the SPE bit and

reset the device, allowing the device to bypass the utility

ROM and begin execution of the application software.

In addition, the ROM loader also enforces the memoryprotection policies. Passwords that are 16 words are

required to access the ROM loader interface.

Loading memory is not possible for ROM-only versions

of the device.

In-Application Flash Programming

From user-application code, flash memory can be programmed using the ROM utility functions from either C

or assembly language. The function declarations below

show examples of some of the ROM utility functions

provided for in-application flash memory programming:

/* Write one 16-bit word to code address ‘dest’.

* Dest must be aligned to 16 bits.

* Returns 0 = failure, 1 = OK.

*/

int flash_write (uint16_t dest, uint16_t

data);

______________________________________________________________________________________ 21

Page 22

16-Bit Microcontroller with Infrared Module

• Debug mode:

Debugger takes over the control of the CPU

DEBUG

SERVICE

MAXQ613

MAXQ613

TMS

TCK

TDI

TDO

Figure 10. In-Circuit Debugger

TAP

CONTROLLER

ROUTINES

(UTILITY ROM)

CPU

DEBUG

ENGINE

CONTROL

BREAKPOINT

ADDRESS

DATA

To erase, the following function would be used:

/* Erase the given Flash page

* addr: Flash offset (anywhere within page)

*/

int flash_erasepage(uint16_t addr);

The in-application flash memory programming must call

ROM utility functions to erase and program any of the

flash memory. Memory protection is enforced by the

ROM utility functions. In-application is not available in

ROM-only versions of the device.

In-Circuit Debug and JTAG

Interface

Embedded debug hardware and software are developed and integrated to provide full in-circuit debugging

capability in a user-application environment. These hardware and software features include the following:

• Debug engine

• Set of registers providing the ability to set breakpoints

on register, code, or data using debug service routines stored in ROM

Collectively, these hardware and software features support two modes of in-circuit debug functionality:

• Background mode:

CPU is executing the normal user program

Allows the host to configure and set up the in-circuit

debugger

Read/write accesses to internal registers and memory

Single-step of the CPU for trace operation

The interface to the debug engine is the TAP controller. The interface allows for communication with a bus

master that can either be automatic test equipment or a

component that interfaces to a higher level test bus as

part of a complete system. The communication operates

across a 4-wire serial interface from a dedicated TAP

that is compatible with the JTAG IEEE Standard 1149.

The TAP provides an independent serial channel to communicate synchronously with the host system.

To prevent unauthorized access of the protected memory regions through the JTAG interface, the debug engine

prevents modification of the privilege registers and

disallows all access to system memory, unless memory

protection is disabled. In addition, all services (such as

register display or modification) are denied when code

is executing inside the system area. The debugger is not

available for ROM-only versions of the device.

Operating Modes

The lowest power mode of operation is stop mode. In this

mode, CPU state and memories are preserved, but the

CPU is not actively running. Wake-up sources include

external I/O interrupts, the power-fail warning interrupt,

wake-up timer, or a power-fail reset. Any time the microcontroller is in a state where code does not need to be

executed, the user software can put the device into stop

mode. The nanopower ring oscillator is an internal ultralow-power (400nA) 8kHz ring oscillator that can be used

to drive a wake-up timer that exits stop mode. The wakeup timer is programmable by software in steps of 125Fs

up to approximately 8s.

The power-fail monitor is always on during normal operation. However, it can be selectively disabled during stop

mode to minimize power consumption. This feature is

enabled using the power-fail monitor disable (PFD) bit

in the PWCN register. The reset default state for the PFD

bit is 1, which disables the power-fail monitor function

during stop mode. If power-fail monitoring is disabled

(PFD = 1) during stop mode, the circuitry responsible

for generating a power-fail warning or reset is shut down

and neither condition is detected. Thus, the V

condition does not invoke a reset state.

DD

< V

RST

22 _____________________________________________________________________________________

Page 23

16-Bit Microcontroller with Infrared Module

Power-Fail Detection

Figures 11, 12, and 13 show the power-fail detection and

response during normal and stop-mode operation. If a

reset is caused by a power-fail, the power-fail monitor

can be set to one of the following intervals:

• Always on—continuous monitoring

11

nanopower ring oscillator clocks (~256ms)

• 2

12

• 2

nanopower ring oscillator clocks (~512ms)

13

• 2

nanopower ring oscillator clocks (~1.024s)

In the case where the power-fail circuitry is periodically

turned on, the power-fail detection is turned on for two

V

DD

V

PFW

V

RST

V

POR

A

C

B

< t

t

PFW

D

t ≥ t

PFW

E

nanopower ring-oscillator cycles. If V

detection, V

ring-oscillator period. If V

is monitored for an additional nanopower

DD

remains above V

DD

DD

> V

RST

during

for

RST

the third nanopower ring period, the CPU exits the reset

state and resumes normal operation from utility ROM at

8000h after satisfying the crystal warmup period.

If a reset is generated by any other event, such as the

RESET pin being driven low externally or the watchdog

timer, the power-fail, internal regulator, and crystal

remain on during the CPU reset. In these cases, the CPU

exits the reset state in less than 20 crystal cycles after

the reset source is removed.

t ≥ t

PFW

F

t ≥ t

PFW

G

H

I

MAXQ613

INTERNAL RESET

(ACTIVE HIGH)

Figure 11. Power-Fail Detection During Normal Operation

______________________________________________________________________________________ 23

Page 24

16-Bit Microcontroller with Infrared Module

Table 4. Power-Fail Detection States During Normal Operation

STATE POWER-FAIL

A On Off Off — V

B On On On —

MAXQ613

C On On On —

D On On On —

E On On On —

F

G On On On —

On

(Periodically)

INTERNAL

REGULATOR

Off Off Yes

CRYSTAL

OSCILLATOR

SRAM

RETENTION

COMMENTS

< V

DD

V

POR

Crystal warmup time, t

CPU held in reset.

> V

V

DD

CPU normal operation.

Power drop too short.

Power-fail not detected.

V

RST

PFI is set when V

maintains this state for at least t

which time a power-fail interrupt is generated (if enabled).

CPU continues normal operation.

V

POR

Power-fail detected.

CPU goes into reset.

Power-fail monitor turns on periodically.

VDD > V

Crystal warmup time, t

CPU resumes normal operation from 8000h.

.

POR

< VDD < V

.

RST

< VDD < V

< VDD < V

.

RST

.

RST

.

PFW

< VDD < V

RST

.

RST

XTAL_RDY

XTAL_RDY

.

PFW

PFW

.

and

, at

< VDD < V

V

POR

H

I Off Off Off —

24 _____________________________________________________________________________________

On

(Periodically)

Off Off Yes

Power-fail detected.

CPU goes into reset.

Power-fail monitor turns on periodically.

V

< V

DD

Device held in reset. No operation allowed.

POR

.

RST

.

Page 25

16-Bit Microcontroller with Infrared Module

V

DD

A

V

PFW

V

RST

V

POR

STOP

INTERNAL RESET

(ACTIVE HIGH)

Figure 12. Stop Mode Power-Fail Detection States with Power-Fail Monitor Enabled

t < t

PFW

B C

t ≥ t

PFW

MAXQ613

t ≥ t

PFW

D

E

F

Table 5. Stop Mode Power-Fail Detection States with Power-Fail Monitor Enabled

STATE POWER-FAIL

INTERNAL

REGULATOR

A On Off Off Yes

B On Off Off Yes

C On On On Yes

D On Off Off Yes

E

On

(Periodically)

Off Off Yes

F Off Off Off —

CRYSTAL

OSCILLATOR

SRAM

RETENTION

COMMENTS

Application enters stop mode.

> V

V

DD

RST

.

CPU in stop mode.

Power drop too short.

Power-fail not detected.

V

RST

< VDD < V

PFW

.

Power-fail warning detected.

Turn on regulator and crystal.

Crystal warmup time, t

XTAL_RDY

.

Exit stop mode.

Application enters stop mode.

V

> V

RST

.

DD

CPU in stop mode.

V

POR

< VDD < V

RST

.

Power-fail detected.

CPU goes into reset.

Power-fail monitor turns on periodically.

V

DD

< V

POR

.

Device held in reset. No operation allowed.

______________________________________________________________________________________ 25

Page 26

16-Bit Microcontroller with Infrared Module

V

DD

A

V

PFW

V

RST

B

C

D

MAXQ613

V

POR

STOP

INTERNAL RESET

(ACTIVE HIGH)

E

F

INTERRUPT

Figure 13. Stop Mode Power-Fail Detection with Power-Fail Monitor Disabled

Table 6. Stop Mode Power-Fail Detection States with Power-Fail Monitor Disabled

STATE POWER-FAIL

INTERNAL

REGULATOR

A Off Off Off Yes

B Off Off Off Yes

C On On On Yes

CRYSTAL

OSCILLATOR

SRAM

RETENTION

COMMENTS

Application enters stop mode.

> V

V

DD

RST

.

CPU in stop mode.

V

DD

< V

PFW

.

Power-fail not detected because power-fail

monitor is disabled.

V

RST

< VDD < V

PFW

.

An interrupt occurs that causes the CPU to

exit stop mode.

Power-fail monitor is turned on, detects a

power-fail warning, and sets the power-fail

interrupt flag.

Turn on regulator and crystal.

Crystal warmup time, t

XTAL_RDY

.

On stop mode exit, CPU vectors to the

higher priority of power-fail and the interrupt that causes stop mode exit.

26 _____________________________________________________________________________________

Page 27

16-Bit Microcontroller with Infrared Module

Table 6. Stop Mode Power-Fail Detection States with Power-Fail Monitor Disabled

(continued)

MAXQ613

STATE POWER-FAIL

D Off Off Off Yes

E

F Off Off Off —

On

(Periodically)

INTERNAL

REGULATOR

Off Off Yes

CRYSTAL

OSCILLATOR

Applications Information

The low-power, high-performance RISC architecture of

this device makes it an excellent fit for many portable

or battery-powered applications. It is ideally suited for

applications such as universal remote controls that