Page 1

19-5258; Rev 0; 4/10

1-Wire and SPI Authentication Microcontroller

General Description

The MAXQ1004 is a low-power microcontroller that

integrates a 10-bit ADC, 1-WireM slave interface, SPIK,

AES encryption, random-number generator (RNG), and

temperature sensor with a 16-bit MAXQM pipelined CPU.

Performance bandwidth is sufficient to handle master

or slave challenge-response authentication in portable

devices.

The device incorporates 16KB of flash memory and 640B

of RAM. Factory programming of a customer secret key

is available upon request. The microcontroller runs within

a wide 1.7V to 3.6V operating range.

For the ultimate in low-power performance, an ultra-lowpower stop mode (300nA typ) is available. In this mode,

only a minimum amount of circuitry is powered to support detection of the start of a 1-Wire transaction. When

1-Wire activity is detected, the microcontroller is turned

on and the command is executed in an atomic fashion.

This allows for stateless operation between commands,

providing the highest reliability and lowest power consumption.

Applications

Portable Electronics

Battery Chargers

Battery Packs

Ordering Information

PART

MAXQ1004-B01+

+Denotes a lead(Pb)-free/RoHS-compliant package.

*EP = Exposed pad.

TEMP

RANGE

-40°C to

+85°C

AES

ENCRYPTION

Yes

PIN-

PACKAGE

16 TQFN-

EP*

Features

S High-Performance, Low-Power, 16-Bit MAXQ20

RISC Core

S 6MHz Operation from an Internal Oscillator,

Approaching 1MIPS per MHz

S 1.7V to 3.6V Wide Operating Voltage

S Three Independent Data Pointers Accelerate Data

Movement with Automatic Increment/Decrement

S Up to Eight General-Purpose I/O Pins

S 16-Level Hardware Stack

S Optimized for C-Compiler (High-Speed/Density Code)

S Memory

16KB Flash Memory, In-Application Programmable

640B of Data RAM

4KB of ROM

JTAG/TAP Bootloader Mode for In-System

Programming

S Peripheral Features

10-Bit Delta-Sigma ADC, Internal Reference

1-Wire Slave Interface

On-Chip Power-On Reset (POR)/Power-Fail Reset

Overvoltage Detection

Programmable Watchdog Timer

Built-In Temperature Sensor, ±6NC

S Secure Programming Interface

Flash Programming Through Secure ROM Loader

Secret Key Destruction on Mass Erase

Permanent Loader Lockout Option

Code and Secret Scrambling

S Unique 64-Bit Serial Number

S Low-Power Consumption

300nA (typ) in Stop Mode

3.75mA (typ) at 6MHz, 0.8mA (typ) at 1MHz

Low-Power Divide-by Modes (2, 4, 8, 256)

1-Wire/Interrupt Activity Detector

MAXQ1004

1-Wire and MAXQ are registered trademarks of Maxim

Integrated Products, Inc.

SPI is a trademark of Motorola, Inc.

Note: Some revisions of this device may incorporate deviations from published specifications known as errata. Multiple revisions of any device

may be simultaneously available through various sales channels. For information about device errata, go to: www.maxim-ic.com/errata.

_______________________________________________________________ Maxim Integrated Products 1

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Page 2

1-Wire and SPI Authentication Microcontroller

TABLE OF CONTENTS

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Recommended DC Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

10-Bit ADC Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SPI Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SPI Master Communications Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SPI Slave Communications Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MAXQ1004

Pin Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Detailed Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

MAXQ Core Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Memory Organization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Utility ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Loading Flash Memory with the Bootstrap Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

In-Application Flash Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Code Scrambling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ADC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Nanopower Ring Wake-Up Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Serial Number/Device ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hardware AES Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Watchdog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

16-Bit Timer/Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Serial Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Serial Peripheral Interface (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-Wire Bus System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Slave Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

In-Circuit Debug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Applications Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Grounds and Bypassing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Design Guidelines for ESD Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Additional Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Development and Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Typical Application Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Package Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2

Page 3

1-Wire and SPI Authentication Microcontroller

LIST OF FIGURES

Figure 1. ADC Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 2. In-Circuit Debugger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 3. I/O Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 4. Typical Application Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

LIST OF TABLES

Table 1. Watchdog Interrupt Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MAXQ1004

3

Page 4

1-Wire and SPI Authentication Microcontroller

ABSOLUTE MAXIMUM RATINGS

Voltage Range on All Pins (including VDD),

except DQ to GND ............................................-0.5V to +3.6V

Voltage Range on DQ Relative to GND ...............-0.5V to +6.0V

Continuous Output Current

Any Single I/O Pin ...........................................................35mA

All I/O Pins Combined .....................................................35mA

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

MAXQ1004

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

RECOMMENDED DC OPERATING CONDITIONS

(VDD = 1.7V to 3.6V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at TA = +25NC and VDD = 3.3V, unless otherwise noted.) (Note 1)

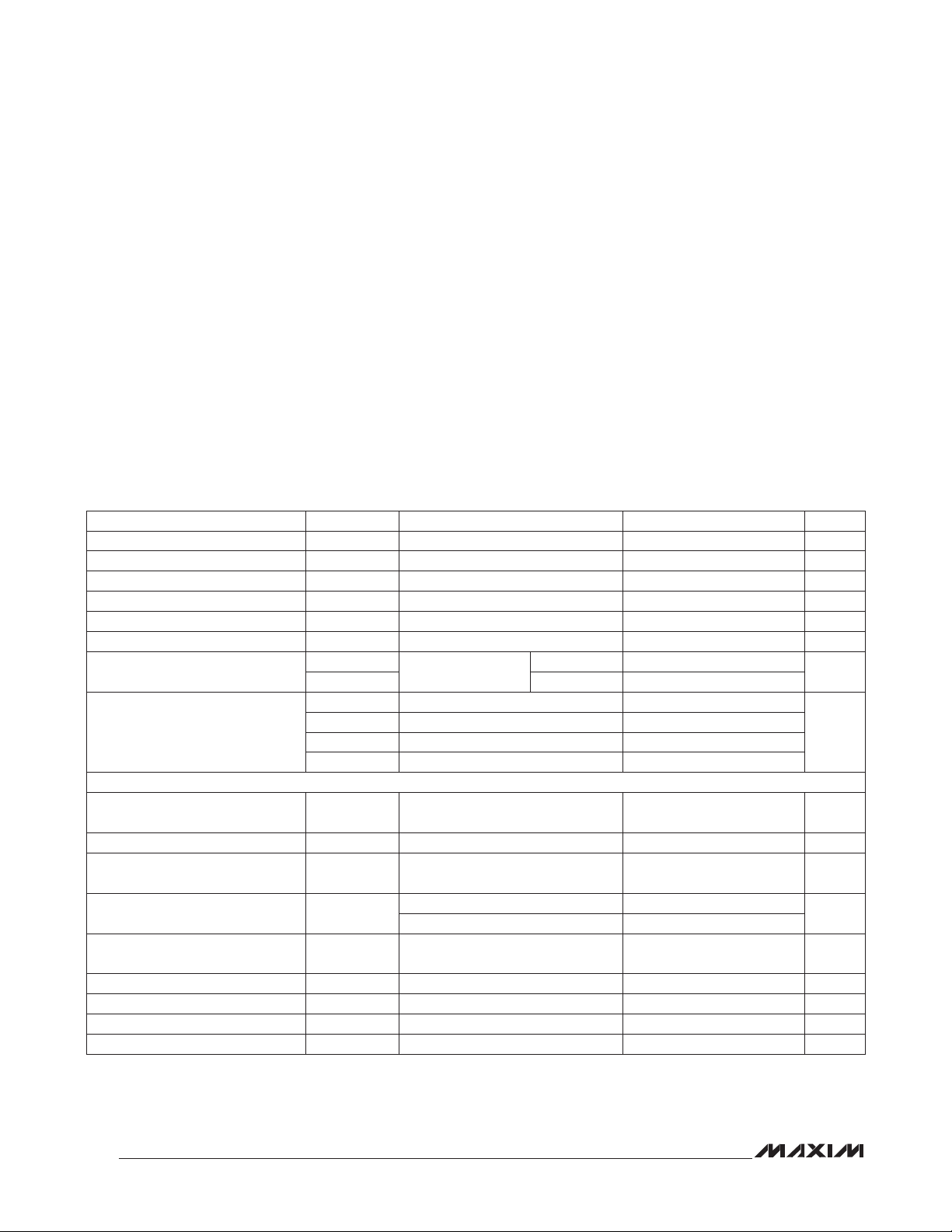

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage V

1.8V Internal Regulator V

Power-On Reset Voltage V

Power-Fail Reset Voltage V

Power-Fail Warning Voltage V

Digital Overvoltage Detect V

Supply Current (Note 5)

Stop-Mode Current (Note 5)

DIGITAL I/O

Input High Voltage (P0, RST)

Input Hysteresis V

Input Low Voltage (P0, RST)

Output Low Voltage (P0, RST)

(Note 7)

Output High Voltage (P0, RST)

Input Leakage Current I

Input/Output Pin Capacitance C

Input Low Current for All Pins I

RST Pullup Resistor

DD

REG18

POR

RST

PFW

HV

I

DD1

I

DD2

I

STOP1

I

STOP2

I

STOP3

I

STOP4

V

IH

IHYS

V

IL

V

OL

V

OH

L

IO

IL

R

RST

(Note 2) 1.64 1.695 V

(Notes 3, 4) 1.75 1.85 V

Monitors V

Device is executing

from flash

TA = +25NC, CPU not backed up

TA = +85NC, CPU not backed up

TA = +25NC, CPU backed up

TA = +85NC, CPU backed up

(Note 6) 0.3 V

VDD = 3.6V, IOL = 4mA (Note 6) 0.4

VDD = 1.85V, IOL = 4mA 0.4

IOH = -2mA

Internal pullup disabled -100 +100 nA

(Note 6) 15 pF

V

= 0.4V, pullup enabled -70

IN

Continuous Power Dissipation (TA = +70NC)

Single-Layer Board (derate 16.9mW/NC above +70NC) .. 1349.1mW

Multilayer Board (derate 25mW/NC above +70NC) ....2000mW

Operating Temperature Range .......................... -40NC to +85NC

Storage Temperature Range ............................ -65NC to +150NC

Lead Temperature (soldering, 10s) ................................+300NC

Soldering Temperature (reflow) ......................................+260NC

V

RST

3.3 3.6 V

1.62 1.8 1.98 V

1.0 1.42 V

REG18

f

= 6MHz 3.5

SYS

f

= 1MHz 0.8

SYS

2.4 2.8 V

5

7.5

6.5

9

0.7 x

V

DD

V

GND

VDD -

0.4

65

V

DD

0.3 x

V

DD

V

DD

Q20% kI

mA

FA

V

V

V

V

FA

4

Page 5

1-Wire and SPI Authentication Microcontroller

RECOMMENDED DC OPERATING CONDITIONS (continued)

(VDD = 1.7V to 3.6V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at TA = +25NC and VDD = 3.3V, unless otherwise noted.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

INTERNAL OSCILLATOR

Oscillator Frequency f

Oscillator Startup Time t

OSC

OSC_RDYVREG18

= 1.8V (Note 6) 350

Oscillator Duty Cycle (Note 6) 45 55 %

NANOPOWER RING OSCILLATOR

Nanopower Ring Frequency f

Nanopower Ring Current I

Wakeup Timer Interval t

NANO

NANO

WAKEUP

TA = +25NC

Typical at VDD = 3.0V, active

during wake-up (Note 6)

1/f

NANO

FLASH MEMORY

Flash Erase Time

Flash Programming Time per Word t

PROG

Mass erase 20 40

Page erase 20 40

Write/Erase Cycles 1000 Cycles

Data Retention

Analog Supply Voltage V

AVDD

TA = +25NC

5 6 7 MHz

3 11 22 kHz

120 400 nA

t

NANO

65,535

x t

NANO

20 40

100 Years

V

DD

Fs

s

ms

Fs

V

MAXQ1004

10-BIT ADC PERFORMANCE

(VDD = 1.7V to 3.6V, V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Resolution 10 Bits

ADC Clock Frequency f

ADC Clock Period t

AN0 Input Voltage Range V

Analog Input Capacitance C

Integral Nonlinearity INL (Note 6)

Differential Nonlinearity DNL No missing codes over temperature

Offset Error V

ADC Active Current Consumption I

ADC Setup Time t

ADC Output Latency t

ADC Settling Time t

ADC Throughput f

TEMPERATURE SENSOR

Temperature Sensor Setup Time t

Temperature Sensor Error

= 1.845V, TA = -40NC to +85NC, unless otherwise noted.)

REF

ACLK

ACLK

AN0

AIN

OS

ADC

ADC_SETUP

ADC

ACLK = 6MHz, internal reference

on, ADEN = 1 (Note 6)

Settling time due to channel, refer-

ADC_SETTLE

ence or scale change (not production tested)

ADC

TSN_SETUP

D

TSN

V

GND

f

SYSCLK

1/f

ACLK

V

AVDD

1 pF

Q2

Q1

Q2

100 150

25

1025 t

10

f

ADC/tADC

25

Q6 NC

MHz

ACLK

ksps

Fs

V

LSB

LSB

LSB

FA

Fs

Fs

Fs

5

Page 6

1-Wire and SPI Authentication Microcontroller

10-BIT ADC PERFORMANCE (continued)

(VDD = 1.7V to 3.6V, V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

10-BIT ADC REFERENCE VOLTAGE

Internal Reference Voltage V

Note 1: Specifications to -40NC are guaranteed by design and are not production tested.

Note 2: The power-fail reset and POR detectors operate in tandem so one or both of these signals are active at all times when

VDD < V

Note 3: The power-fail warning monitor and the power-fail reset monitor track each other with a typical delta between the two of 0.13V.

MAXQ1004

Note 4: Writes to flash memory must not be performed when the supply voltage drops below the power-fail warning levels, as

RST

there is uncertainty in the duration of continuous power supply. The user application should check the status of the powerfail warning flag before writing to flash to ensure valid write operations.

Note 5: Measured on the combined AVDD and VDD pins and the part not in reset. All inputs are connected to GND or VDD.

Outputs do not source/sink any current.

Note 6: Guaranteed by design and not production tested.

Note 7: The maximum total current, I

mum specified voltage drop.

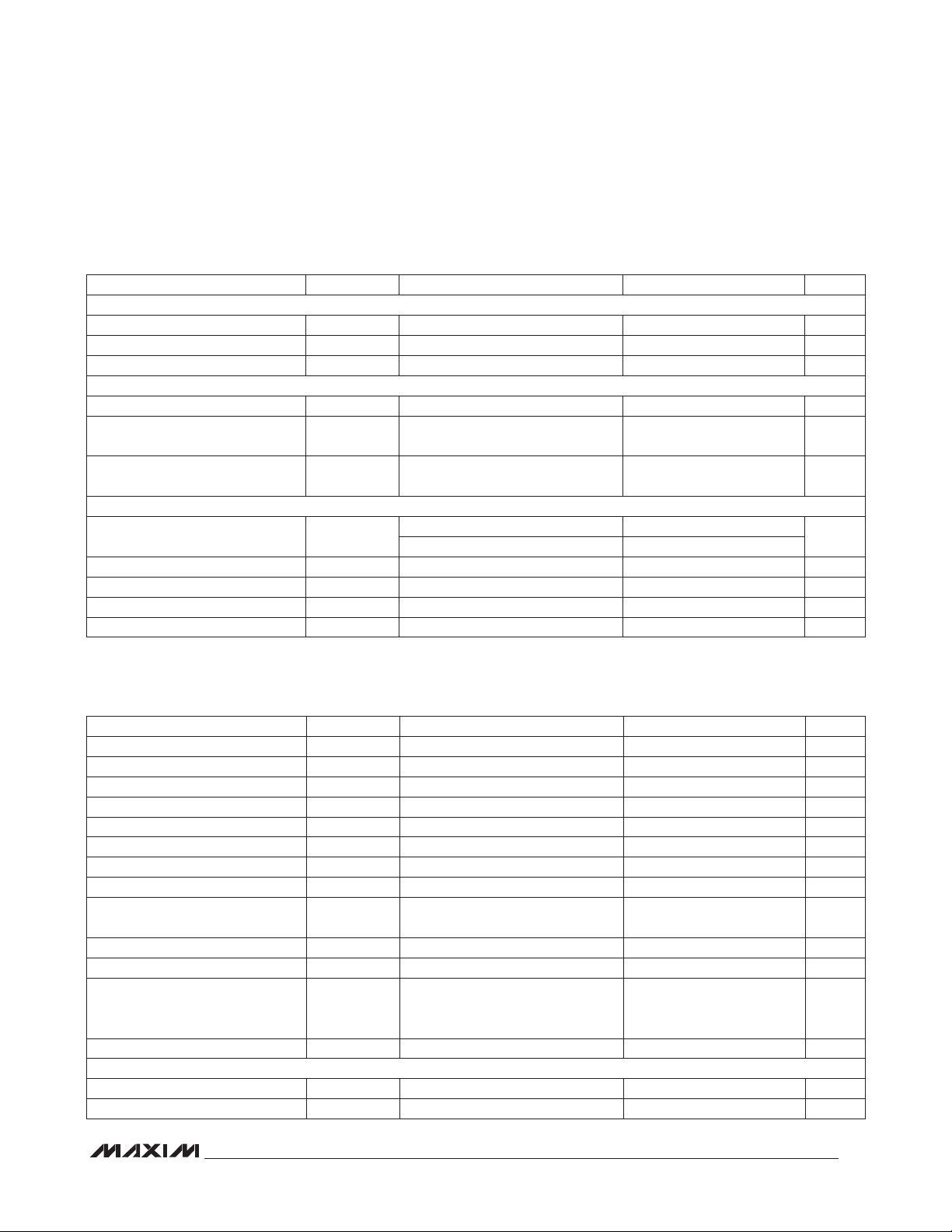

SPI ELECTRICAL CHARACTERISTICS

(VDD = 1.7V to 3.6V, TA = -40NC to +85NC, unless otherwise noted. AC electrical specifications are guaranteed by design and are

not production tested.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SPI Master Operating Frequency 1/t

SPI Slave Operating Frequency 1/t

SPI I/O Rise/Fall Time t

SCLK Output Pulse-Width High/Low t

MOSI Output Hold Time After SCLK

Sample Edge

MOSI Output Valid to Sample Edge t

MISO Input Valid to SCLK Sample

Edge Rise/Fall Setup

MISO Input to SCLK Sample Edge

Rise/Fall Hold

SCLK Inactive to MOSI Inactive t

SCLK Input Pulse-Width High/Low t

SSEL Active to First Shift Edge

MOSI Input to SCLK Sample Edge

Rise/Fall Setup

MOSI Input from SCLK Sample

Edge Transition Hold

MISO Output Valid After SCLK Shift

Edge Transition

SSEL Inactive

SCLK Inactive to SSEL Rising

MISO Output Disabled After SSEL

Edge Rise

= 1.845V, TA = -40NC to +85NC, unless otherwise noted.)

REF

IREF

1.845

, ensuring the device maintains the reset state until minimum operating voltage is achieved.

OH(MAX)

SPI_RF

MCH

t

SCH

and I

MCK

SCK

, t

MOH

MOV

t

MIS

t

MIH

MLH

, t

t

SSE

t

SIS

t

SIH

t

SOV

t

SSH

t

SD

t

SLH

OL(MAX)

MCL

SCL

, for all outputs combined should not exceed 35mA to satisfy the maxi-

CL = 15pF, pullup = 560W

8.3 23.6 ns

t

/2 - t

MCK

t

MCK

t

MCK

/2 - t

/2 - t

SPI_RF

SPI_RF

SPI_RF

25 ns

0 ns

t

/2 - t

MCK

tCK + t

t

SPI_RF

t

SPI_RF

t

SPI_RF

t

SPI_RF

SPI_RF

SPI_RF

t

/2 ns

SCK

2tCK + 2t

Q5%

f

SYSCLK

f

SYSCLK

2t

SPI_RF

SPI_RF

/2 MHz

/4 MHz

V

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

6

Page 7

1-Wire and SPI Authentication Microcontroller

SPI Master Communications Timing

SHIFT SAMPLE SHIFT SAMPLE

SSEL

(SAS = 0)

t

MCK

1/0

0/1

SCLK

CKPOL/CKPHA

1/0

0/1

MAXQ1004

SCLK

CKPOL/CKPHA

MOSI

MISO

1/1

0/0

t

MCH

t

MOH

MSB MSB-1

t

MIS

MSB MSB-1

t

MCL

t

MOV

1/1

0/0

t

RF

LSB

t

MIH

LSB

t

MLH

SPI Slave Communications Timing

SHIFT SAMPLE SHIFT SAMPLE

t

SSEL

(SAS = 1)

SCLK

CKPOL/CKPHA

1/0

0/1

t

SSE

t

SCK

SSH

t

SD

1/0

0/1

SCLK

CKPOL/CKPHA

MOSI

MISO

1/1

0/0

t

SCH

t

SIS

MSB MSB-1

MSB MSB-1

t

SCL

t

SOV

1/1

0/0

t

SIH

LSB

t

RF

LSB

t

SLH

7

Page 8

1-Wire and SPI Authentication Microcontroller

Pin Configuration

TOP VIEW

MAXQ1004

AVDD

GND

REG18

V

AN0

AVREF

12 11 9

13

14

15

16

DD

+

1 2

RST

MAXQ1004

DQ

10

EP

4

3

P0.0/INT0/MOSI P0.7/INT7/TDO

P0.6/INT6/TMS

8

7

6

5

P0.1/INT1/MISO

P0.5/INT5/TDI/T0G

P0.4/INT4/TCK/T0

P0.3/INT3/SSEL

P0.2/INT2/SCLK

TQFN

(4mm × 4mm)

Pin Description

PIN NAME FUNCTION

POWER PINS

11 AN0 Analog Input 0. This pin is the analog input to the ADC.

12 AVREF Analog Voltage Reference. Do not connect anything external to this pin.

13 AVDD Analog Supply Voltage. Directly connect AVDD to DVDD.

14 GND Digital Ground

15 REG18

16 V

DD

— EP Exposed Pad. Connect the EP to the ground plane.

1

RST

Regulator Capacitor. This pin must be connected to ground through an external 1FF low ESR

(< 5I) capacitor.

Digital Supply Voltage. +3.3V nominal supply voltage.

RESET AND STATUS PINS

Active-Low Reset. This bidirectional pin recognizes external active-low reset inputs and

employs an internal pullup resistor to allow for a combination of wired-OR external reset

sources. This pin also acts as an output when the source of the reset is internal to the device

(e.g., watchdog timer, power-fail, etc.). In this case, the pin is low while the processor is in a

reset state, and it returns high as the processor exits this state.

8

Page 9

1-Wire and SPI Authentication Microcontroller

Pin Description (continued)

PIN NAME FUNCTION

GENERAL-PURPOSE I/O PINS

General-Purpose, Digital I/O, Type D Port/SPI Interface/JTAG Interface/External EdgeSelectable Interrupt. This port functions as 8-bit I/O and as an alternate interface to external

interrupts. Each interrupt can be individually enabled and the active edge can be selected.

The default reset condition of the pins is as a weak pullup input. To drive port 0 as output, the

port direction register must be programmed to enable output. P0.7–P0.4 default to their JTAG

P0.0–P0.7,

INT0–INT7,

3–10

MOSI, MISO,

SCLK, SSEL,

TCK, TDI,

TMS, TDO

2 DQ

function on any reset.

PIN PORT

EXTERNAL

INTERRUPT

SPECIAL FUNCTION

3 P0.0 INT0 MOSI: Master Out-Slave In (SPI)

4 P0.1 INT1 MISO: Master In-Slave Out (SPI)

5 P0.2 INT2 SCLK: Slave Clock (SPI)

6 P0.3 INT3

SSEL: Active-Low Slave Select (SPI)

7 P0.4 INT4 TCK: Test Clock (JTAG)/T0

8 P0.5 INT5 TDI: Test Data In (JTAG)/T0G

9 P0.6 INT6 TMS: Test Mode Select (JTAG)

10 P0.7 INT7 TDO: Test Data Out (JTAG)

1-Wire Slave Interface, I/O. This 5V tolerant, open-drain I/O pin serves as both transmit and

receive pin for the 1-Wire interface. The DQ pin requires an external pullup resistor, the value

of which is determined by the speed mode.

MAXQ1004

Block Diagram

16KB FLASH MEMORY

INTERNAL

REFERENCE

10-BIT ADC

TEMP

SENSOR

AES ENCRYPTION

ENGINE

RANDOM-NUMBER

GENERATOR

640B DATA SRAM

4KB UTILITY ROM

MAXQ RISC

WATCHDOG TIMER

INTERNAL

6MHz

OSCILLATOR

CPU

VOLTAGE

MONITOR

GND +1.7V TO +3.6V

MAXQ1004

TIMER 0

1-Wire

INTERFACE

JTAG

SPI

GPIO

(UP TO 8)

9

Page 10

1-Wire and SPI Authentication Microcontroller

Detailed Description

The MAXQ1004 is a low-power, high-performance, 16-bit

MAXQ microcontroller providing the high security and

reliability demanded in today’s portable electronics, battery chargers, and battery packs. An ISO/IEC 9797-1

standards-based authentication protocol is available as

standard application code.

A 1-Wire communication interface minimizes batterypack connections required to authenticate and monitor

MAXQ1004

battery health. The 1-Wire I/O pin (DQ) can wake the

device from low-power stop mode. In stop mode, power

is supplied only to the circuitry required to wake up the

slave microcontroller. During stop mode, 512 bytes of

data memory are preserved, with an option to preserve

the CPU state and the remaining 128 bytes of data

memory.

MAXQ Core Architecture

The microcontroller is based on a low-power implementation of the 16-bit MAXQ family of RISC cores. The core

supports the Harvard memory architecture with separate

16-bit program and data address buses. A fixed 16-bit

instruction word is standard, but data can be arranged in

8 or 16 bits. The core is implemented as a pipelined processor with performance approaching 1MIPS per MHz.

The 16-bit data path is implemented around register

modules, and each register module contributes specific

functions to the core. The accumulator module consists

of sixteen 16-bit registers and is tightly coupled with the

arithmetic logic unit (ALU).

Execution of instructions is triggered by data transfer

between functional register modules or between a functional register module and memory. Because data movement involves only source and destination modules,

circuit-switching activities are limited to active modules

only. For power-conscious applications, this approach

localizes power dissipation and minimizes switching

noise. The modular architecture also provides a maximum of flexibility and reusability that is important for a

microprocessor used in embedded applications.

The MAXQ instruction set is highly orthogonal. All arithmetical and logical operations can use any register

in conjunction with the accumulator. Data movement

is supported from any register to any other register.

Memory is accessed through specific data-pointer registers with automatic increment/decrement support.

Memory Organization

There are three distinct memory areas: registers, program memory, and data memory. All registers are

located on-chip. The device contains built-in program

and data memory, including:

• 16KB flash memory, in-application programmable

• 640B of data RAM

• 4KB of ROM

Program flash memory is arranged in 1024-byte pages

that can be individually erased and programmed through

the use of utility ROM functions.

Utility ROM

The utility ROM is a block of internal ROM that defaults to

a starting address of 8000h. The utility ROM consists of

subroutines that can be called from application software.

These include the following:

• In-system programming using a bootstrap loader

• Test routines (internal memory tests, memory loader,

etc.)

• User-callable routines for in-application flash programming and fast table lookup

Following any reset, execution begins in the utility ROM.

The ROM software determines whether the program

execution should immediately jump to location 0000h,

the start of application code, or to one of the special

routines mentioned. Routines within the utility ROM are

user-accessible and can be called as subroutines by the

application software. More information on the utility ROM

functions is contained in the MAXQ1004 User’s Guide.

Some applications require protection against unauthorized viewing of program code memory. For these

applications, access to in-system programming, inapplication programming, or in-circuit debugging functions is prohibited until a password has been supplied.

The password is defined as the 16 words of physical

program memory at addresses 0010h–001Fh.

A single password lock (PWL) bit is implemented in

the SC register. When the PWL is set to one (POR

default) and the contents of the memory at addresses

0010h–001Fh are any value other than FFh or 00h, the

password is required to access the utility ROM, including in-circuit debug and in-system programming routines

that allow reading or writing of internal memory. When

PWL is cleared to zero, these utilities are fully accessible

without the password. The password is automatically set

to all ones following a mass erase.

10

Page 11

1-Wire and SPI Authentication Microcontroller

Loading Flash Memory with

the Bootstrap Loader

An internal bootstrap loader allows the device to be

reloaded over a simple JTAG interface. As a result, software can be upgraded in-system, eliminating the need

for a costly hardware retrofit when updates are required.

Remote software uploads are possible that enable

physically inaccessible applications to be frequently

updated. If in-system programmability is not required,

a commercial gang programmer can be used for mass

programming.

In-Application Flash Programming

From user-application code, internal flash memory can

be programmed/erased by calling internal ROM utility

functions from either C or assembly language. Memory

protection is enforced by the ROM utility functions. The

function declarations below show examples of some of

the ROM utility functions provided for in-application flash

memory programming.

/* Write one 16-bit word to code address ‘dest’.

* Dest must be aligned to 16 bits.

* Returns 0 = failure, 1 = OK.

*/

int flash_write16(uint16_t dest, uint16_t data);

To erase, the following function would be used:

/* Erase the given Flash page

* addr: Flash offset (anywhere within page)

*/

int flash_erasepage(uint16_t addr);

Code Scrambling

Automated code scrambling protects user-code memory against attempts to determine the code contents.

The proprietary scrambling algorithm is transparent to

the user and still allows in-application programming.

Address shuffling prevents well-known startup code from

always being at the known location 0000h and interrupt

vector code at known locations. This obfuscates confidential software and makes the application secure from

hackers and copiers.

ADC

The 10-bit delta-sigma analog-to-digital converter (ADC)

allows the application to measure external voltages,

most commonly the voltage of the batteries driving VDD.

The analog input, AN0, can be optionally scaled by 50%

for direct supply voltage measurement. The ADC value

saturates (all data bits read 1) when the input voltage

exceeds the maximum allowable ADC reference voltage.

The internal temperature sensor is measured by the ADC

when selected.

Each conversion can choose its own reference from

AVDD or the internal reference. Data can be retrieved

in either left-justified or right-justified format, giving the

application direct control on data format.

A conversion takes 1025 ADCCLK cycles to complete. The ADCCLK is derived from the system clock

with divide ratio defined by the ADC clock-divider bits

(ADCCLK). Therefore, with 1025 ADCCLK to acquire

one data, the fastest ADC rate = Sysclk/1025 (ADCCLK

= 0h). See Figure 1.

Temperature Sensor

An integrated temperature sensor measures the internal

temperature of the device with an error of Q6NC. The temperature sensor is connected to channel 1 of the ADC.

To read the temperature sensor, select ADCH to 1.

Nanopower Ring Wake-Up Timer

A nanopower-ring oscillator can be used to drive a

wake-up timer that causes the device to exit stop mode

after a user-selectable time period. The wake-up timer is

software programmable in 16-bit steps of the nanopower

ring clock up to approximately 8 seconds.

Serial Number/Device ID

Each device has a factory-programmed, unique, 64-bit

device identification number (ID). This ID ensures device

traceability and serves as an input to the device’s

authentication protocol.

The first 8 bits of the device ID are a 1-Wire family code

that is the same for all MAXQ1004 devices. The next 48

bits are a factory-programmed unique serial number.

Even if multiple devices are used in a 1-Wire network, the

unique, 48-bit serialization field prevents any address

conflict, allowing communication with each device individually. The last 8 bits are a factory-programmed cyclic

redundancy check (CRC) of the first 56 bits. The 1-Wire

CRC is generated using a polynomial generator consisting of a shift register and XOR gates. The polynomial is

x8 + x5 + x4 + 1.

MAXQ1004

11

Page 12

1-Wire and SPI Authentication Microcontroller

ADCH

ADSCL

ADEN

ADCONV

ADCCLK

ADDATA

ADREF

1

10-BIT

DELTA-SIGMA

CONVERTER

/2

0

1

AN0

TEMP

SENSOR

MAXQ1004

INTERNAL REFERENCE

ADC

CONTROLLER

AVDD

Figure 1. ADC Block Diagram

0

Hardware AES Engine

The AES engine is a bidirectional block cipher supporting encryption and decryption for all three key lengths

recommended by the National Institute of Standards and

Technology (NIST). Secret keys can be generated by

an on-chip RNG and stored in a predetermined memory

location. The AES engine operates independently of the

processor, except for setting up an operation through

the AES Control register (AESC). The AESC register

provides AES engine operation status and option control.

The AES engine shares the cryptographic memory with

the 1-Wire communications peripheral. Application software must ensure that the two peripherals do not access

the cryptographic memory at the same time or data in

the memory may be corrupted. Application software can

interrogate activity bits to ensure that one peripheral

does not interrupt the other. To perform an encryption

or decryption, the keys and data are loaded into the

cryptographic memory and the operation is started with

the appropriate write to the AESC register. Completion

of the operation can be detected by user firmware either

by polling the AESC register or through the use of an

interrupt.

The AES engine displays excellent performance. Based

on key size, the following encryption throughputs are

achieved:

• 128-bit key size—55 cycles (9.2µs at 6MHz)

• 192-bit key size—70 cycles (12.0µs at 6MHz)

• 256-bit key size—75 cycles (12.5µs at 6MHz)

An optional jitter injection feature reduces the effectiveness of differential power analysis (DPA) attacks

against the device. Adding jitter causes random delays

in both the start and ending times of the calculation,

confounding attempts to determine the values in the AES

operation by measuring minute power fluctuations. When

active, the feature adds a variable random delay of 0

to 30 clock cycles to AES calculations. This is accomplished by randomly adding 0 to 15 clock cycles before

the AES operation is started, and adding 0 to 15 clock

cycles after the operation is complete.

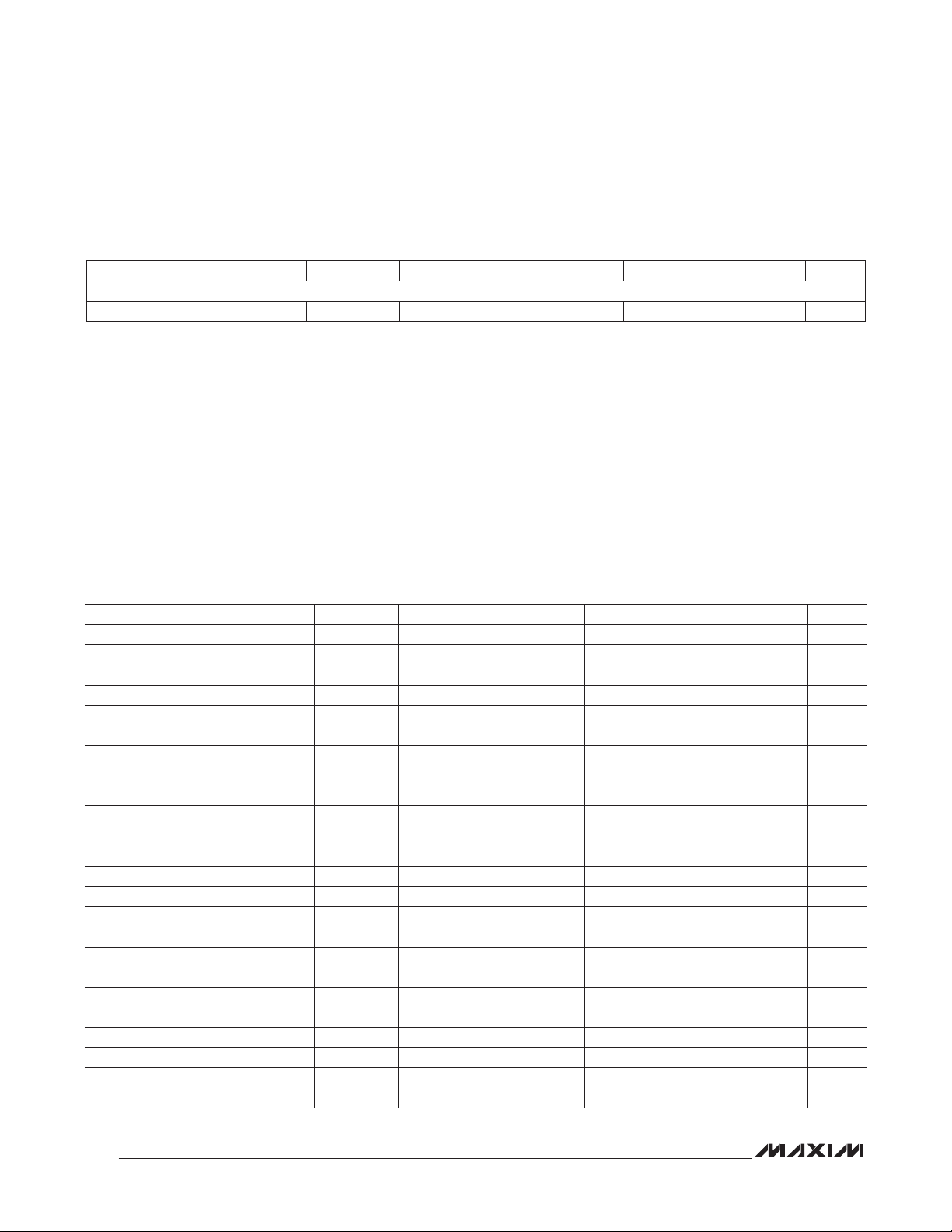

Watchdog Timer

The watchdog timer functions as the source of both the

timer timeout and the watchdog timer reset. The timeout

period can be programmed in a range of 212 to 229 system clock cycles. An interrupt is generated when the timeout period expires, if the interrupt is enabled. All watchdog

timer resets follow the programmed interrupt timeouts by

512 clock cycles. If the watchdog timer is not restarted

for another full interval in this time period, a system reset

occurs when the reset timeout expires. Table 1 shows

values that demonstrate the various interrupt timeouts

based on an internal clock frequency of 6MHz.

12

Page 13

1-Wire and SPI Authentication Microcontroller

Table 1. Watchdog Interrupt Timeout

PMME CD[1:0]

0 00

0 01 2

0 10 2

0 11 2

1 xx 2

WD[1:0] = 00 WD[1:0] = 01 WD[1:0] = 10 WD[1:0] =11

212 (683Fs)

13

(1.36ms) 216 (11ms) 2

14

(2.73ms) 2

15

(5.46ms) 2

20

(175ms) 2

WATCHDOG INTERRUPT TIMEOUT (Sysclk = 6MHz)

15

2

(5.46ms) 2

17

(21.8ms) 2

18

(43.7ms) 2

23

(1.4s) 2

18

(43.7ms) 2

19

(87.4ms) 222 (700ms)

20

(175ms) 2

21

(350ms) 2

26

(11.2s) 2

21

(350ms)

23

24

29

(1.4s)

(2.8s)

(89.5s)

MAXQ1004

16-Bit Timer/Counter

The microcontroller has one instance of the 16-bit Timer

0 timer/counter peripheral, which supports the following

functions:

• 13-bit timer/counter

• 16-bit timer/counter

• 8-bit timer with autoreload

• 2 8-bit timer/counters

Serial Peripherals

Serial Peripheral Interface (SPI)

The integrated SPI is an independent serial communication channel that communicates synchronously with

peripheral devices in a multiple-master or multiple-slave

system. The interface allows access to a 4-wire, fullduplex serial bus and can be operated in either master

mode or slave mode. Collision detection is provided

when two or more masters attempt a data transfer at the

same time.

The maximum SPI master transfer rate is Sysclk/2. When

operating as an SPI slave, the device can support up to

Sysclk/4 SPI transfer rate. Data is transferred as an 8-bit

or 16-bit value, MSB first. In addition, the SPI module

supports configuration of an active SSEL state through

the slave active select.

1-Wire Bus System

The 1-Wire bus is a system that has a single bus master

and one or more slaves. This microcontroller is always

a slave device in any system. The bus master is typically another microcontroller. The discussion of this bus

system is broken down into three topics: hardware configuration, transaction sequence, and 1-Wire signaling

(signal types and timing). The 1-Wire protocol defines

bus transactions in terms of the bus state during specific

time slots, which are initiated on the falling edge of sync

pulses from the bus master. Refer to Application Note

937: Book of iButton® Standards for a more detailed

description the 1-Wire network and protocols.

The device permits the use of lower 1-Wire voltage levels

(as low as 1.7V) to support the device’s full operating

voltage, but can still be connected to a regular 1-Wire

bus of up to 6V.

Hardware Configuration

The 1-Wire bus has only a single data line (DQ); all

devices on the bus must be able to drive it at the appropriate time. This means that each device attached to the

1-Wire bus must have open-drain or high-impedance

outputs. The 1-Wire port is open drain.

Both the standard and overdrive communication speed

of 15.4kbps (max) and 111kbps (max), respectively,

are supported. The value of the pullup resistor primarily depends on the network size and load conditions.

Recommended pullup resistor values can be found in

Table 4-1 of Application Note 937: Book of iButton®

Standards.

The idle state for the 1-Wire bus is high. If, for any reason, a transaction needs to be suspended, the bus must

remain in the idle state if the transaction is to resume. If

this does not occur and the bus is left low for more than

120Fs (standard speed), one or more devices on the bus

can be reset.

iButton is a registered trademark of Maxim Integrated

Products, Inc.

13

Page 14

1-Wire and SPI Authentication Microcontroller

Slave Functionality

The 1-Wire slave provides three functions. The first is

that of a totally independent slave function, which can

be externally accessed at any time to verify its identity.

The 1-Wire front-end functions in an identical fashion to

that of the DS1990 serial ID to verify the serial ID number.

The bus master must provide one of the ROM function

commands:

• Read ROM

MAXQ1004

• Match ROM

• Search ROM

• Skip ROM

• Overdrive-Skip ROM

• Overdrive-Match ROM

• Resume

The second function is that of a 1-Wire that includes full

bidirectional data flow and data flow control. The 1-Wire

functions that become accessible after a ROM function

command is successfully executed initiate communications with the microcontroller through the use of specific

1-Wire commands:

• Read I/O Buffer

• Write I/O Buffer

• Read Command Buffer

• Write Command Buffer

• Read Command Buffer Extended

• Write Command Buffer Extended

• Status Register Read

• Status Register Write

The third function controls the operation of the 1-Wire

interface:

• 1-Wire Micro Reset

And the remaining are 1-Wire run commands:

• Start Program

• Continue Program

• Write Command Buffer Extended and Start Program

• Write Command Buffer Extended and Continue Program

Operating Modes

The low-power mode of operation is stop mode. In this

mode, CPU state and memories are preserved, but the

CPU is not actively running. Wake-up sources include

external I/O interrupts, the power-fail warning interrupt,

a valid 1-Wire command received, or a power-fail reset.

Any time the microcontroller is in a state where code

does not need to be executed, the user software can

enter stop mode.

An even lower stop mode is the data-retention mode,

in which the CPU is not active. When the data-retention

mode option is invoked (DRET = 1) and the regulator is disabled (REGEN = 0), only the first 512 bytes

of data memory is retained (data memory word offset

0000h–00FFh). CPU status and 1-Wire/AES memory are

powered down and contents are lost. A POR occurs

when exiting stop mode from data-retention mode. This

mode can be exited from any of the following enabled

interrupt sources:

• Enabled external interrupts

• External reset

• Enabled PFW interrupt

• Valid 1-Wire command received

• Wake-up timer

The wake-up timer causes the device to exit stop mode

after a user-selectable time period. The power-fail monitor is always on during normal operation. However, it can

be selectively disabled during stop mode using the power-fail monitor disable (PFD) bit in the PWCN register. By

default, the power-fail monitor function is enabled during

stop mode. If power-fail monitoring is disabled (PFD = 1)

during stop mode, the circuitry responsible for generating a power-fail warning or reset is shut down and neither

condition is detected. Thus, the VDD < V

does not invoke a reset state. However, in the event that

VDD falls below the POR level, a POR is generated. The

power-fail monitor is enabled prior to stop mode exit and

before code execution begins. If a power-fail warning

condition (VDD < V

interrupt flag is set on stop mode exit. If a power-fail condition is detected (VDD < V

The 1-Wire peripheral can operate in a special mode

that draws minimal power, yet can serve as a wakeup source to bring the device out of stop mode. If the

1-Wire peripheral is required to run in stop mode, it can

be enabled so a regular 1-Wire reset pulse briefly wakes

up the 1-Wire controller. The 1-Wire controller then determines if it was addressed. If so, the 1-Wire controller

wakes up the CPU from stop mode. If the microcontroller

is not being addressed, then stop mode continues and

the 1-Wire controller is powered down again, and the

device returns to its lowest power state. The device does

not respond to an overdrive reset pulse in stop mode.

) is then detected, the power-fail

PFW

), the CPU goes into reset.

RST

condition

RST

14

Page 15

1-Wire and SPI Authentication Microcontroller

In-Circuit Debug

Embedded debugging capability is available through

the JTAG-compatible test access port (TAP). Embedded

debug hardware and embedded ROM firmware provide

in-circuit debugging capability to the user application,

eliminating the need for an expensive in-circuit emulator.

See Figure 2. The in-circuit debug features include the

following:

• Hardware debug engine

• Set of debug service routines stored in the utility ROM

The embedded hardware debug engine is an independent hardware block in the microcontroller. The debug

engine can monitor internal activities and interact with

selected internal registers while the CPU is executing

user code. Collectively, the hardware and software features allow two basic modes of in-circuit debugging:

• Background mode allows the host to configure and set

up the in-circuit debugger while the CPU continues to

execute the application software at full speed. Debug

mode can be invoked from background mode.

• Debug mode allows the debug engine to take control

of the CPU, providing read/write access to internal

registers and memory and single-step trace operation.

DEBUG

SERVICE

MAXQ1004

TMS

TCK

TDI

TDO

Figure 2. In-Circuit Debugger

TAP

CONTROLLER

ROUTINES

(UTILITY ROM)

CPU

DEBUG

ENGINE

CONTROL

BREAKPOINT

ADDRESS

DATA

Applications Information

Grounds and Bypassing

Careful PCB layout significantly minimizes crosstalk

among the high-speed external address/data bus signals and with digital I/O that could cause improper

operation. The use of multilayer boards is essential to

allow the use of dedicated power planes. Bypass VDD

on each microcontroller with a 0.1FF capacitor located

as close as possible to the pin.

Design Guidelines for ESD Protection

CMOS design guidelines for any semiconductor require

that no pin be taken above VDD or below ground.

Violation of this guideline can result in a hard failure

(damage to the silicon inside the device) or a soft failure

(unintentional modification of memory contents). Voltage

spikes above or below the device’s absolute maximum

ratings can cause a temporary brownout of the internal

power rail, possibly corrupting memory.

Microcontrollers commonly experience negative voltage spikes through either their power pins or generalpurpose I/O pins. Negative voltage spikes on power pins

are especially problematic as they directly couple to the

internal power buses. Devices such as keypads can

conduct electrostatic discharges directly into the microcontroller and seriously damage the device. System

designers must protect components against these transients that can corrupt system memory.

In a practical application, it is difficult to remove all voltages above VDD or below ground. Undershoots of 0.3V

can be tolerated by the microcontroller, and 5V tolerant

pins can accept up to 5.5V. Figure 3 demonstrates a

diode protection scheme that can be used to protect the

I/O pins of a microcontroller. The scheme relies on the

use of a Schottky diode and current limiting resistor to

reduce the effect of current spikes on the device. When

the voltage approaching the device pin exceeds VDD

or GND by more than 0.1V to 0.2V, the Schottky diodes

become forward biased, conducting the excess voltage

away from the device pins. The current limiting resistors

also help dampen the effect of the voltage spike on the

microcontroller.

MAXQ1004

15

Page 16

1-Wire and SPI Authentication Microcontroller

MAXQ1004

EXTERNAL CONNECTION

EXPOSED TO ESD

LOW-LEAKAGE

SCHOTTKY DIODE

Figure 3. I/O Protection

Any Schottky diode used should have a leakage well

below the maximum drive current of the sourcing device.

Diodes with low reverse leakage currents are available

from many vendors.

Additional Documentation

Designers must have the following documents to fully

use all the features of this device. This data sheet

contains pin descriptions, feature overviews, and electrical specifications. Errata sheets contain deviations

from published specifications. The user’s guides offer

detailed information about device features and operation. The following documents can be downloaded from

www.maxim-ic.com/microcontrollers.

• This MAXQ1004 data sheet, which contains electrical/

timing specifications, pin descriptions, and package

information.

• The MAXQ1004 revision-specific errata sheet

(www.maxim-ic.com/errata).

• The MAXQ1004 User’s Guide, which contains detailed

information on core features and operation, including

programming.

1kΩ

V

DD

I/O

GND

USER APPLICATION

I/O

I/O

I/O

I/O

µC

I/O

I/O

I/O

I/O

I/O

INTERNAL

CIRCUIT

INTERNAL

CIRCUIT

NOT SUBJECT TO

NEGATIVE VOLTAGE OR ESD

Development and

Technical Support

Maxim and third-party suppliers provide a variety of

highly versatile, affordably priced development tools for

this microcontroller, including the following:

• Compilers

• In-circuit emulators

• Integrated Development Environments (IDEs)

• Serial-to-JTAG converters for programming and

debugging.

A partial list of development tool vendors can be found

at www.maxim-ic.com/MAXQ_tools.

For technical support, go to https://support.maxim-ic.

com/micro.

Typical Application Circuit

The 1-Wire interface can be used to authenticate a

3-contact battery pack and also measure the battery

voltage and temperature. See Figure 4 for a typical application circuit.

16

Page 17

1-Wire and SPI Authentication Microcontroller

FACTORY-ISSUE

PACK+

PROTECTOR

150Ω

1-Wire

ORIGINAL BATTERY PACK

DQ

MAXQ1004

V

DD

AVDD

REG18

1kΩ

AN0

GND

MAXQ1004

100nF

PACK-

1µF

Figure 4. Typical Application Circuit

Package Information

For the latest package outline information and land patterns, go to www.maxim-ic.com/packages. Note that a “+”, “#”, or “-” in the

package code indicates RoHS status only. Package drawings may show a different suffix character, but the drawing pertains to the

package regardless of RoHS status.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

16 TQFN-EP T1644+4

21-0139

17

Page 18

1-Wire and SPI Authentication Microcontroller

Revision History

REVISION

NUMBER

0 4/10 Initial release —

REVISION

DATE

MAXQ1004

DESCRIPTION

PAGES

CHANGED

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied.

Maxim reserves the right to change the circuitry and specifications without notice at any time.

18 Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

©

2010 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Loading...

Loading...