Page 1

General Description

The MAX9489 clock generator provides multiple clock

outputs, ideal for network routers. The MAX9489 provides 15 buffered clock outputs, each independently

programmable to any of 10 individual frequencies:

133MHz, 125MHz, 100MHz, 83MHz, 80MHz, 66MHz,

62.5MHz, 50MHz, 33MHz, or 25MHz. All of the outputs

are single-ended LVCMOS. The MAX9489 is controlled

through its I2C™ interface.

At power-up, the frequency of output CLK1 is set by the

tri-level input SEL to 100MHz, 125MHz, or 133MHz,

while all other outputs are logic low. All outputs are then

programmable to any available frequency through the

I2C interface. Additionally, all output frequencies are

adjustable up or down, by a margin of 5% or 10%,

through the I

2

C interface.

The MAX9489 requires a 25MHz reference that can be

either a crystal or an external clock signal. The

MAX9489 requires a +3.0V to +3.6V power supply and

is available in a 32-pin thin QFN package with an

exposed pad for heat removal.

Applications

Network Routers

Telecom/Networking Equipment

Storage Area Networks/Network Attached

Storage

Features

♦ 15 LVCMOS Outputs with 10 Independently

Programmable Frequencies: 133MHz, 125MHz,

100MHz, 83MHz, 80MHz, 66MHz, 62.5MHz, 50MHz,

33MHz, and 25MHz

♦ 25MHz Crystal or Clock Input Reference

♦ Programmable Through I

2

C Interface

♦ Programmable Output Frequency Margin of ±5%

or ±10%

♦ Pin-Selectable Power-Up Frequency for CLK1

Output: 100MHz, 125MHz, or 133MHz

♦ Low Output Period Jitter: < 48ps

RMS

♦ Output-to-Output Skew < 200ps

♦ Available in 32-Lead, 5mm x 5mm x 0.8mm,

Thin QFN Package

♦ Operates from +3.0V to +3.6V Power Supply

♦ Power Dissipation 450mW (typ)

♦ Extended Temperature Range: -40°C to +85°C

MAX9489

Multiple-Output Network Clock Generator

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

19-3385; Rev 0; 8/04

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

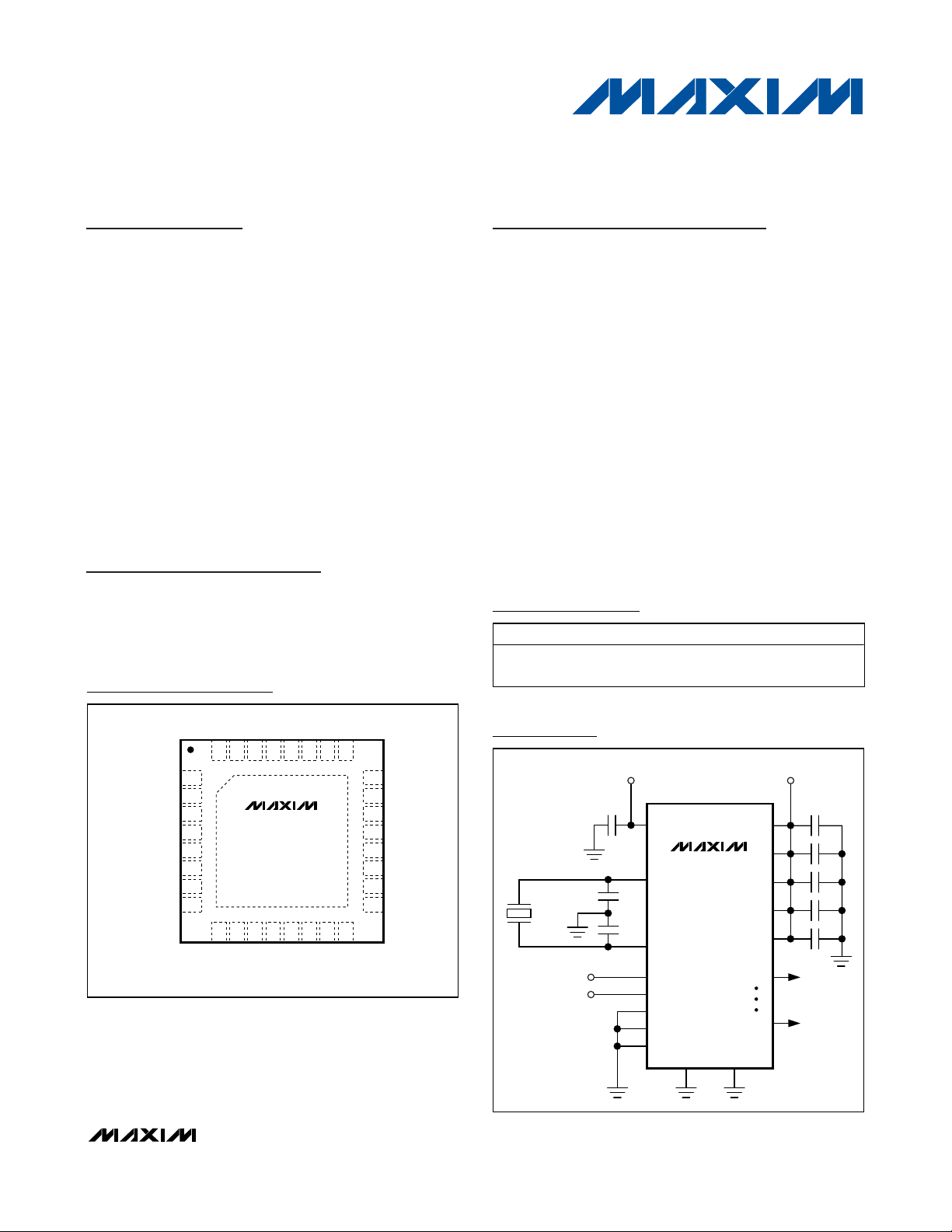

Pin Configuration

MAX9489

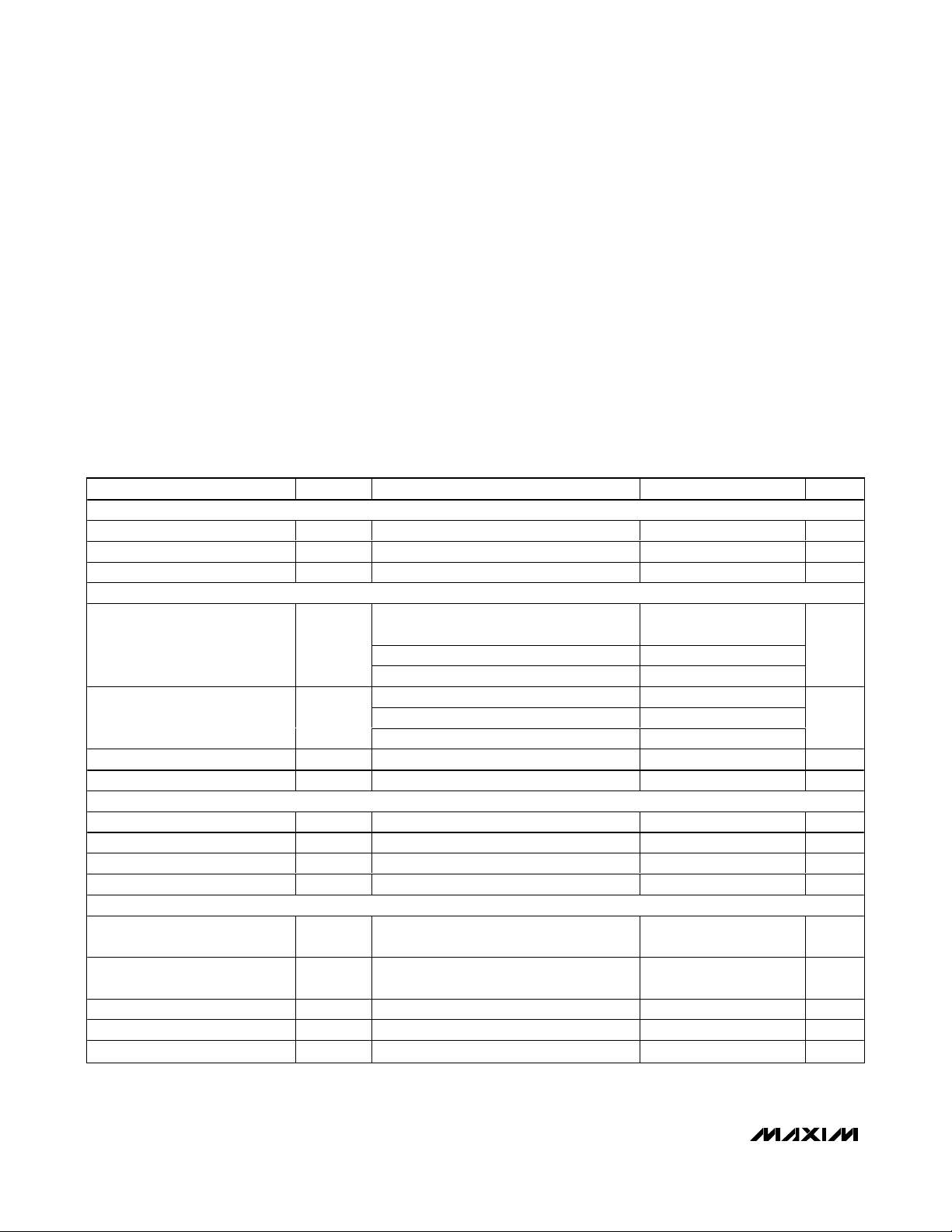

25MHz

10pF

10pF

X1

AV

DD

X2

SDA

0.1µF

SCL

SA0

SA1

SEL

AGND

GND

CLK15

CLK1

V

DD

V

DD

V

DD

V

DD

V

DD

+3.3V +3.3V

SERIAL

INTERFACE

CLOCK

OUTPUTS

0.1µF x 5

Typical Operating Circuit

I2C is a trademark of Philips Corp.

Purchase of I

2

C components of Maxim Integrated Products, Inc.,

or one of its sublicensed Associated Companies, conveys a

license under the Philips I

2

C Patent Rights to use these compo-

nents in an I

2

C system, provided that the system conforms to the

I

2

C Standard Specification as defined by Philips.

*EP = Exposed pad.

TOP VIEW

DD

V

32

SA131SA030GND29V

28

DD

CLK1527CLK1426CLK13

25

PART TEMP RANGE PIN-PACKAGE

MAX9489ETJ -40°C to +85°C

32 Thin QFN-EP*

5mm x 5mm x 0.8mm

24

GND 1

SCL

2

SDA

3

SEL

4

AV

5

DD

X1

6

X2

AGND

7

8

MAX9489

EXPOSED PAD (GND)

12

DD

V

CLK413CLK514CLK6

15

16

11

CLK19CLK210CLK3

THIN QFN-EP

V

DD

CLK12

23

CLK11

22

CLK10

21

V

20

DD

CLK9

19

CLK8

18

CLK7

17

DD

V

Page 2

MAX9489

Multiple-Output Network Clock Generator

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

DC ELECTRICAL CHARACTERISTICS

(VDD= AVDD= +3.0V to +3.6V, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VDD= AVDD= +3.3V, TA= +25°C.)

(Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDDto GND ..............................................…….….-0.3V to +4.0V

AGND to GND .............................................……...-0.3V to +0.3V

All Other Pins to GND.................................-0.3V to (V

DD

+ 0.3V)

Short-Circuit Duration for all CLK_ Outputs ...............Continuous

Continuous Power Dissipation (T

A

= +70°C)

32-Pin Thin QFN (derate 21.3mW/°C above +70°C) ....1702mW

Storage Temperature Range .............................-65°C to +150°C

Maximum Junction Temperature .....................................+150°C

Operating Temperature Range ...........................-40°C to +85°C

ESD Rating (Human Body Model) .......................................±2kV

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CLOCK INPUT (X1)

Input High Level V

Input Low Level V

Input Current I

CLOCK OUTPUTS (CLK_)

Output High Level V

Output Low Level V

Output Short-Circuit Current I

Output Capacitance C

TRI-LEVEL INPUTS (SEL, SA0, SA1)

Input High Level V

Input Low Level V

Input Open Level V

Input Current I

SERIAL INTERFACE (SCL, SDA) (Note 3)

Input High Level V

Input Low Level V

Input leakage Current IIH, I

Low-Level Output V

Input Capacitance Ci (Note 2) 10 pF

IL1

IL2

IH1

IL1

, I

IH1 VX

OH

OL

OS

O

IH2

IL2

IO2

, I

IH2

IH

IL

IL

OL

_ = 0 to V

IOH = -100µA

IOH = -4mA 2.4

IOH = -8mA 2.1

IOL = 100µA 0.2

IOL = 4mA 0.4

IOL = 8mA 0.75

CLK_ = VDD or GND 45 mA

(Note 2) 5 pF

V

= 0 or V

IL2

I

= 4mA 0 0.4 V

SINK

2.0 V

0.8 V

DD

-5 +5 µA

V

-

DD

0.2

2.5 V

0.8 V

1.35 1.90 V

IH2

= V

DD

-10 +10 µA

0.7 x

V

DD

0

V

0.3 x

V

-1 +1 µA

DD

DD

V

V

V

V

Page 3

MAX9489

Multiple-Output Network Clock Generator

_______________________________________________________________________________________ 3

DC ELECTRICAL CHARACTERISTICS (continued)

(VDD= AVDD= +3.0V to +3.6V, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VDD= AVDD= +3.3V, TA= +25°C.)

(Note 1)

AC ELECTRICAL CHARACTERISTICS

(VDD= AVDD= +3.0V to +3.6V, CL= 10pF, unless otherwise noted. Typical values are at VDD= AVDD= +3.3V, TA= +25°C, with all

CLK_ outputs at 133MHz.) (Note 2)

POWER SUPPLIES

Digital Power-Supply Voltage V

Analog Power-Supply Voltage AV

Total Supply Current C L = 10p f ( w i th al l C LK_ outp uts at 133M H z) 134 160 mA

Total Power-Down Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DD

PD

DD

All clock registers = 0x00 38 47 mA

3.0 3.6 V

3.0 3.6 V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

OUTPUTS (CLK_)

Crystal Frequency Tolerance ∆f

Output-to-Output Skew t

Rise Time t

Fall Time t

Duty Cycle 40 60 %

Output Period Jitter J

Power-Up Time t

PLL Lockup Time t

Margin Accuracy Select ±5% or ±10% margin -1 +1 %

A

SKO

R1

F1

P

PO

Lock

Any two CLK_ outputs 200 ps

20% VDD to 80% V

80% VDD to 20% V

RMS 53 ps

VDD > 2.8V to PLL lock 2 ms

PLL dividing ratio set to PLL lock 20 µs

DD

DD

-50 +50 ppm

1.8 2.5 ns

1.8 2.5 ns

Page 4

MAX9489

Multiple-Output Network Clock Generator

4 _______________________________________________________________________________________

Note 1: All DC parameters tested at TA= +25°C. Specifications over temperature are guaranteed by design.

Note 2: Guaranteed by design.

Note 3: No high output level is specified but only the output resistance to the bus. For I

2

C, the high-level voltage is provided by

pullup resistors on the bus.

Note 4: A master device must provide a hold time of at least 300ns for the SDA signal (referred to V

IL

of the SCL signal) to bridge

the undefined region of SCL’s falling edge.

Note 5: C

b

= total capacitance of one bus line in pF. tRand tFmeasured between 0.3(VDD) and 0.7(VDD).

Note 6: Input filters on the SDA and SCL inputs suppress noise spikes less than 50ns.

SERIAL INTERFACE TIMING

(VDD= AVDD= +3.3V, TA= -40°C to +85°C.) (Note 1, Figure 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Serial Clock f

Bus Free Time Between STOP

and START Conditions

Hold Time, Repeated START

Condition

Repeated START Condition

Setup Time

STOP Condition Setup Time t

Data Hold Time Master t

Data Hold Time Slave t

Data Setup Time t

SCL Clock Low Period t

SCL Clock High Period t

Rise Time of SDA and SCL,

Receiving

Fall Time of SDA and SCL,

Receiving

Fall Time of SDA, Transmitting t

Pulse Width of Spike Suppressed t

Capacitive Load for Each Bus

Line

SCL

t

BUF

t

HD,STA

t

SU,STA

SU,STO

HD,DAT

HD,DAT

SU,DAT

LOW

HIGH

t

R

t

F

F,TX

SP

C

b

1.3 µs

0.6 µs

0.6 µs

0.6 µs

(Note 4) 15 900 ns

(Note 4) 15 900 ns

100 ns

1.3 µs

0.7 µs

(Notes 2, 5)

(Notes 2, 5)

(Notes 2, 5)

(Notes 2, 6) 0 50 ns

(Note 2) 400 pF

20 +

0.1C

20 +

0.1C

20 +

0.1C

b

b

b

400 kHz

300 ns

300 ns

250 ns

Page 5

MAX9489

Multiple-Output Network Clock Generator

_______________________________________________________________________________________ 5

Typical Operating Characteristics

(VDD= 3.3V, TA= +25°C, unless otherwise noted.)

SUPPLY CURRENT

vs. TEMPERATURE

MAX9489 toc01

TEMPERATURE (°C)

SUPPLY CURRENT (mA)

603510-15

110

120

130

140

150

160

100

-40 85

RISE AND FALL TIMES

vs. TEMPERATURE

MAX9489 toc02

TEMPERATURE (°C)

TRANSITION TIME (ns)

603510-15

1.2

1.4

1.7

1.9

2.3

2.1

1.0

-40 85

t

FALL

t

RISE

JITTER vs. TEMPERATURE

MAX9489 toc03

TEMPERATURE (°C)

RMS PERIOD JITTER (ps)

603510-15

10

20

30

40

50

60

70

0

-40 85

133MHz

25MHz

JITTER vs. FREQUENCY

MAX9489 toc04

FREQUENCY (MHz)

RMS PERIOD JITTER (ps)

11597796143

15

30

45

60

75

0

25 133

TYPICAL CLOCK WAVEFORMS

MAX9489 toc05

10ns/div

A

B

A: 100MHz, 100mV/div

B: 25MHz, 100mV/div

Page 6

MAX9489

Multiple-Output Network Clock Generator

6 _______________________________________________________________________________________

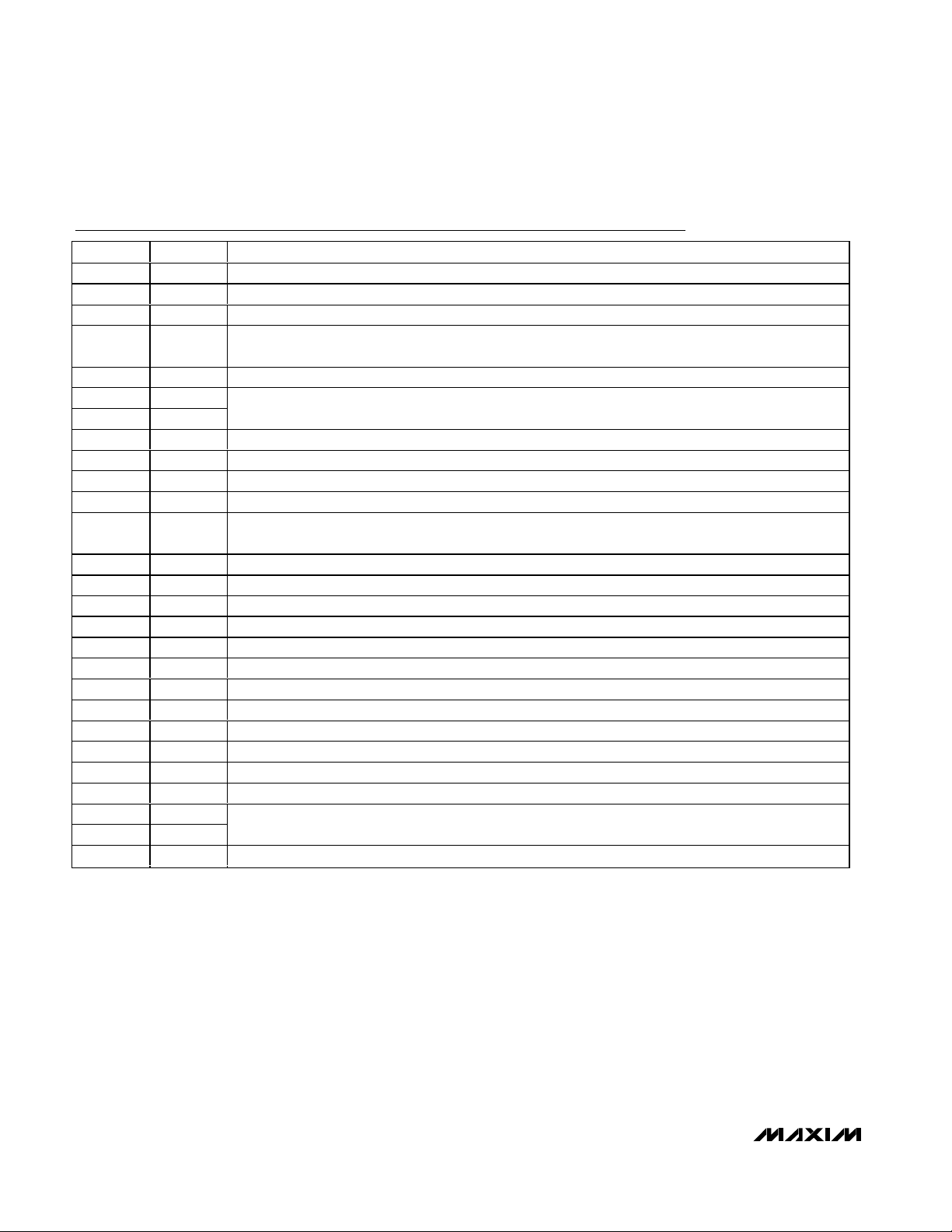

Pin Description

PIN NAME FUNCTION

1, 29 GND Digital Ground

2 SCL Serial Clock Input. Serial interface clock.

3 SDA Serial Data I/O. Data I/O of serial interface.

4 SEL

5AVDDPower-Supply Input for Analog Circuits

6X1

7X2

8 AGND Analog GND

9 CLK1 Clock 1 Output

10 CLK2 Clock 2 Output

11 CLK3 Clock 3 Output

12, 16, 20,

24, 28, 32

13 CLK4 Clock 4 Output

14 CLK5 Clock 5 Output

15 CLK6 Clock 6 Output

17 CLK7 Clock 7 Output

18 CLK8 Clock 8 Output

19 CLK9 Clock 9 Output

21 CLK10 Clock 10 Output

22 CLK11 Clock 11 Output

23 CLK12 Clock 12 Output

25 CLK13 Clock 13 Output

26 CLK14 Clock 14 Output

27 CLK15 Clock 15 Output

30 SA0

31 SA1

EP — Exposed pad. Connect to GND.

V

DD

Frequency Select for CLK1. Selects the frequency for CLK1 at power-up. SEL is a tri-level input. Force

SEL high for CLK1 = 100MHz. Leave SEL open for CLK1 = 125MHz. Force SEL low for CLK1 = 133MHz.

Crystal Connection or Clock Input. If using a 25MHz crystal, connect it to X1 and X2. If using a reference

clock, connect the clock signal to X1, and leave X2 floating. See the Typical Operating Circuit.

Power-Supply Input for Digital Circuits

Address-Select Inputs for Serial Interface. SA0 and SA1 select the serial interface address, as shown in

Table 1. SA0 and SA1 are tri-level inputs, making nine possible address combinations.

Page 7

MAX9489

Multiple-Output Network Clock Generator

_______________________________________________________________________________________ 7

Detailed Description

The MAX9489 clock generator produces 15 clock signals, CLK1 through CLK15. Each output is programmable through control registers to any of 10 individual

frequencies: 133MHz, 125MHz, 100MHz, 83MHz,

80MHz, 66MHz, 62.5MHz, 50MHz, 33MHz, or 25MHz.

Additionally, the frequency of all outputs can be

changed ±5% or ±10% through the frequency-margin

control register. At power-up, the frequency of CLK1 is

pin programmable to 100MHz, 125MHz, or 133MHz,

and all other CLK outputs are logic low. The required

25MHz input reference frequency can be either a crystal or an external clock signal. Figure 1 shows the

MAX9489 functional block diagram.

The MAX9489 is programmed through its I2C serial

interface. The I

2

C address is selected with two, tri-level

inputs, allowing up to nine MAX9489 devices to share

the same I2C bus. Power-supply and logic interface

signals are +3.0V to +3.6V. The operating state of the

MAX9489 is set by writing to the control registers, and

read by reading the control registers.

Reference Frequency Input

A reference frequency is required for the MAX9489.

The reference can be a 25MHz crystal or an external

clock signal. If using a 25MHz crystal, connect it across

X1 and X2, and connect 10pF capacitors from X1 and

X2 to GND (see the Typical Operating Circuit). If using

an external clock, connect the signal to X1 and leave

X2 floating.

Serial Interface

The MAX9489 is programmed through its I2C serial

interface. This interface has a clock, SCL, and a bidirectional data line, SDA. In an I2C system, a master,

typically a microcontroller, initiates all data transfers to

and from slave devices, and generates the clock to

synchronize the data transfers.

The MAX9489 operates as a slave device. The timing of

the SDA and SCL signals is detailed in Figure 2, the

Serial Interface Timing diagram. SDA operates as both

an input and an open-drain output. A pullup resistor,

typically 4.7kΩ, is required on SDA. SCL operates only

as an input. A pullup resistor, typically 4.7kΩ, is

required on SCL if there are multiple masters on the 2wire bus, or if the master in a single-master system has

an open-drain SCL output.

Bit Transfer

One data bit is transferred during each SCL clock

cycle. SDA must remain stable during the high period

of SCL, because changes in SDA while SCL is high are

START and STOP control signals. Both SDA and SCL

idle high.

START and STOP Conditions

A master signals the beginning of a transmission with a

START condition by transitioning SDA from high to low

while SCL is high (Figure 2). When communication is

complete, a master issues a STOP condition by transitioning SDA from low to high while SCL is high. The bus

is then free for another transmission.

Acknowledge Bits

After each 8 bits transferred, the receiving device generates an acknowledge signal by pulling SDA low for

the entire duration of the 9th clock pulse. If the receiving device does not pull SDA low, a not-acknowledge is

indicated (Figure 3).

Device Address

The MAX9489 has a 7-bit device address, pin configured by the two tri-level address inputs SA1 and SA0.

To select the device address, connect SA1 and SA0 to

V

DD

, GND, or leave open, as indicated in Table 1. The

MAX9489 has nine possible addresses, allowing up to

nine MAX9489 devices to share the same interface bus.

Figure 1. MAX9489 Functional Diagram

SEL

SCL

SDA

SA0

SA1

X1

25MHz

X2

OSC

AV

DD

I2C

400MHz

PLL1

400MHz

PLL2

3, 4, 5, 6, 12

2, 3, 4, 5, 10

MAX9489

DIVIDE BY

DIVIDE BY

V

DD

MUX

MUX

MUX

MUX

CLK1

CLK2

CLK14

CLK15

AGND GND

Page 8

MAX9489

Multiple-Output Network Clock Generator

8 _______________________________________________________________________________________

Writing to the MAX9489

Writing to the MAX9489 begins with a START condition

(Figures 3 and 4). Following the START condition, each

pulse on SCL transfers 1 bit of data. The first 7 bits

comprise the device address (see the Device Address

section). The 8th bit is low to indicate a write operation.

An acknowledge bit is then generated by the

MAX9489, signaling that it recognizes its address. The

next 8 bits form the register address byte (Table 2) and

determine which control register will receive the following data byte. The MAX9489 then generates another

acknowledge bit. The data byte is then written into the

addressed register of the MAX9489. An acknowledge

bit by the MAX9489 followed by a required STOP condition by the master complete the communication. To

write to the device again, repeat the entire write procedure; I2C burst write mode is not supported by the

MAX9489.

Reading the MAX9489 Setup

Reading from the MAX9489 registers begins with a

START condition and a device address with the write

bit set low, then the register address that is to be read,

followed by a repeated START condition and a device

address with the write bit set high, and finally the data

are shifted out (Figure 4). Following a START condition,

the first 7 bits comprise the device address. The 8th bit

is low to indicate a write operation (to write in the

following register address). An acknowledge bit is

then generated by the MAX9489, signaling that it recognizes its address. The next 8 bits form the register

address, indicating the location of the data to be read,

followed by another acknowledge, again generated by

the MAX9489. The master then produces a repeated

START condition and readdresses the device, this time

with the R/W bit high to indicate a read operation

(Figure 4). The MAX9489 generates an acknowledge

bit, signaling that it recognizes its address. The data

byte is then clocked out of the MAX9489. A final notacknowledge bit, generated by the master (not

required), and a STOP condition, also generated by the

master, complete the communication. To read from the

device again, the entire read procedure is repeated;

I2C burst read mode is not supported by the MAX9489.

Device Control Registers

The MAX9489 has 17 control registers. The register

addresses and functions are shown in Table 2. The first

16 registers are used to set the 15 outputs, with register

0x00 controlling all outputs simultaneously and the rest

mapped to individual outputs. Register 0x10 accesses

the frequency-margin control. All other addresses are

reserved and are not to be used.

Figure 2. Serial Interface Timing

Table 1. Device I2C Address Selection

SDA

t

SU, STA

t

HD, STA

t

SU, STO

SCL

t

LOW

t

SU, DAT

t

HD, DAT

t

BUF

t

HD, STA

START CONDITION

t

HIGH

t

R

t

F

PIN

SA1 SA0

Open V

Open GND 110 0100

Open Open 110 1000

GND V

GND GND 110 1001

GND Open 110 1100

V

DD

V

DD

V

DD

DD

DD

V

DD

GND 111 0010

Open 111 0001

DEVICE

ADDRESS

110 0010

111 0000

111 0100

REPEATED START CONDITION

START CONDITIONSTOP CONDITION

Page 9

MAX9489

Multiple-Output Network Clock Generator

_______________________________________________________________________________________ 9

Setting the Clock Frequencies

Each CLK_ output has an associated control register.

The contents of the registers determine the frequency

of their associated outputs. Table 3 provides the frequency mapping for the registers.

Example: To program CLK3 to 80MHz, first address the

device with R/W low, then send register address byte

0x03 followed by data byte 0x05 (Figure 5).

Frequency Margin Control

Frequency margin is controlled through control register

0x10. Table 4 provides the mapping for the available

margins. A selected margin applies to all outputs.

Example: To increase all clock outputs by 5%, address

the device, then send register address byte 0x10 followed by data byte 0x01.

Power Supply

The MAX9489 uses a 3.0V to 3.6V power supply connected to VDD, and 3.0V to 3.6V connected to AVDD.

Bypass each VDDat the device with a 0.1µF capacitor.

Also bypass AVDDat the device with a 0.1µF capacitor.

Additionally, use a bulk bypass capacitor of 10µF

where power enters the circuit board.

Board Layout Considerations

As with all high-frequency devices, board layout is

critical to proper operation. Place the crystal as close

as possible to X1 and X2, and minimize parasitic

capacitance around the crystal leads. Ensure that the

exposed pad makes good contact with GND.

Chip Information

TRANSISTOR COUNT: 15,219

PROCESS: CMOS

Figure 3. I2C Address and Acknowledge

Figure 4. I2C Interface Data Structure

SDA

SCL

START

MASTER-WRITE DATA STRUCTURE

START DEVICE ADDRESS REGISTER ADDRESS DATA IN STOPR/W

S 1 1 A4 A3 A2 A1 0 ACK RA7 RA6 RA5 RA4 RA3 RA2 RA1 RA0 ACK D7 D6 D5 D4 D3 D2 D1 D0 ACK P

MASTER-READ DATA STRUCTURE

START DEVICE ADDRESS REGISTER ADDRESSR/W

S 1 1 A4 A3 A2 A1 0 ACK RA7 RA6 RA5 RA4 RA3 RA2 RA1 RA0 ACK

S = START CONDITION

A_ = DEVICE ADDRESS

ACK = ACKNOWLEDGE

ACK = NOT ACKNOWLEDGE

1

MSB

RA_ = REGISTER ADDRESS

D_ = DATA

P = STOP CONDITION

RS = REPEATED START

1 A4 A3 A2 A1 A0 ACK

NOT ACKNOWLEDGE

R/W

LSB

DEVICE ADDRESS DATA OUT STOPR/W

RS 1 1 A4 A3 A2 A1 A0 1 ACK D7 D6 D5 D4 D3 D2 D1 D0 P

DATA DIRECTION

= MASTER TO SLAVE

= SLAVE TO MASTER

ACKNOWLEDGE

ACK

Page 10

MAX9489

Multiple-Output Network Clock Generator

10 ______________________________________________________________________________________

Table 2. Register Address Mapping

Table 3. Output Frequency Control

Table 4. Output Frequency Margin Control

*Power-up default for CLK2 through CLK15.

Figure 5. Example—Setting CLK3 to 80MHz

REGISTER ADDRESS BYTE REGISTER FUNCTION

0x00 Broadcast to all CLK registers

0x01 CLK1

0x02 CLK2

0x03 CLK3

0x04 CLK4

0x05 CLK5

0x06 CLK6

0x07 CLK7

0x08 CLK8

0x09 CLK9

0x0A CLK10

0x0B CLK11

0x0C CLK12

0x0D CLK13

0x0E CLK14

0x0F CLK15

0x10 Frequency margin control

0x11 – 0xFF Reserved, do not use

CLK_ REGISTER DATA

BYTE

0x00 Logic low*

0x01 133.3

0x02 125

0x03 100

0x04 83.3

0x05 80

0x06 66.6

0x07 62.5

0x08 50

0x09 33

0x0A 25

OUTPUT FREQUENCY

(MHz)

MARGIN REGISTER DATA

BYTE

0x00 0%

0x01 5%

0x02 10%

0x07 -5%

0x06 -10%

OUTPUT FREQUENCY

(MHz)

START DEVICE ADDRESS REGISTER ADDRESS DATA IN STOPR/W

S11A4A3A2A10ACK00000011ACK00000101ACKP

S = START CONDITION

A_ = DEVICE ADDRESS

ACK = ACKNOWLEDGE

P = STOP CONDITION

DATA DIRECTION

= MASTER TO SLAVE

= SLAVE TO MASTER

Page 11

MAX9489

Multiple-Output Network Clock Generator

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 11

© 2004 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

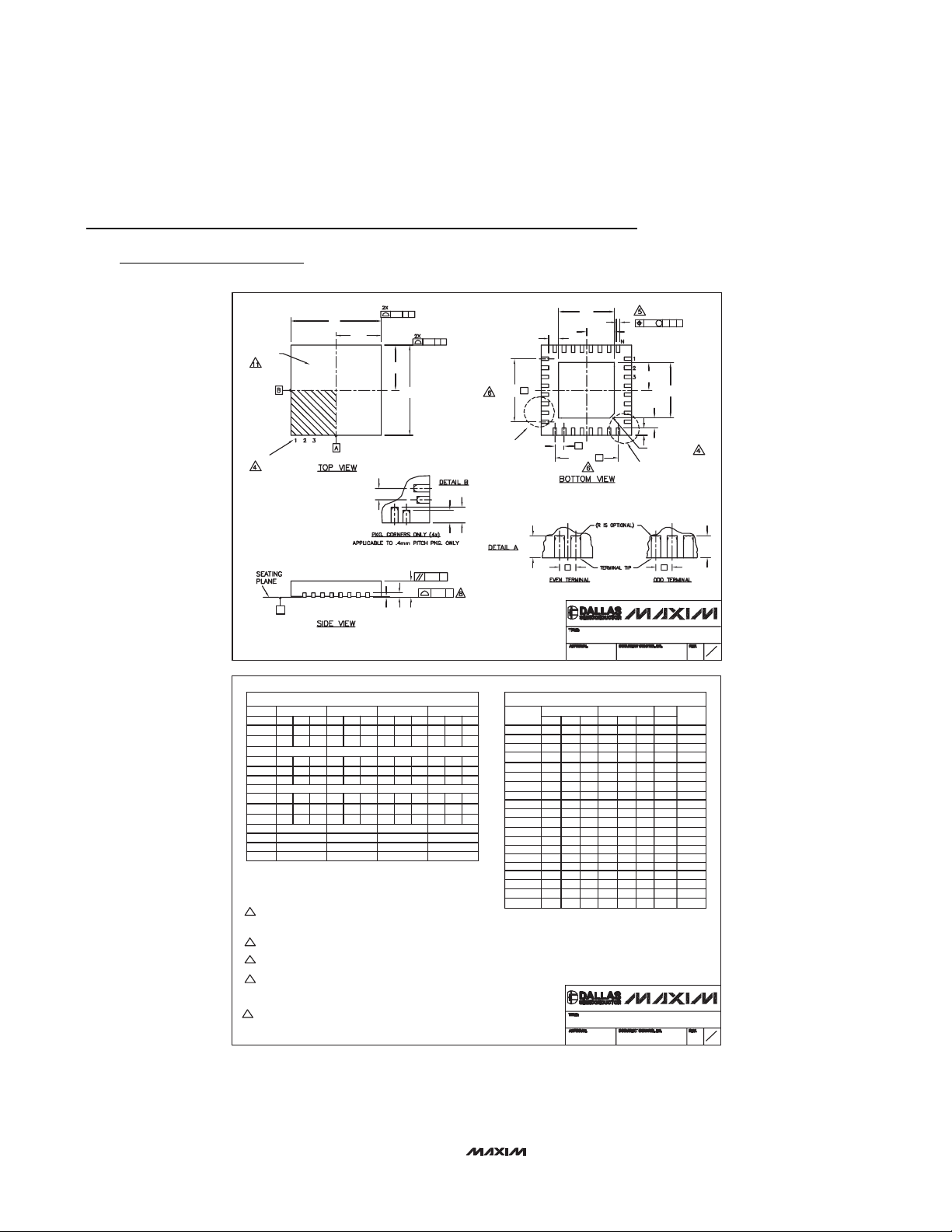

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

C

XXXXX

D

0.15 C A

D/2

e

0.15

C B

E/2

E

L1

0.10 C

A

0.08 C

A3

A1

(NE-1) X e

DETAIL A

L

D2

C

L

D2/2

k

e

(ND-1) X e

L

e e

PACKAGE OUTLINE,

16, 20, 28, 32L THIN QFN, 5x5x0.8mm

b

E2/2

L

DETAIL B

21-0140

0.10 M C A B

C

E2

L

k

PIN # 1 I.D.

0.35x45∞

CC

L

F

LL

1

2

QFN THIN.EPS

MARKING

PIN # 1

I.D.

-DRAWING NOT TO SCALE-

PKG.

SYMBOL

A

A1

A3

b

D

E

e

k

L

L1

N

ND

NE

JEDEC

NOTES:

1. DIMENSIONING & TOLERANCING CONFORM TO ASME Y14.5M-1994.

2. ALL DIMENSIONS ARE IN MILLIMETERS. ANGLES ARE IN DEGREES.

3. N IS THE TOTAL NUMBER OF TERMINALS.

4. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL

CONFORM TO JESD 95-1 SPP-012. DETAILS OF TERMINAL #1 IDENTIFIER ARE

OPTIONAL, BUT MUST BE LOCATED WITHIN THE ZONE INDICATED. THE TERMINAL #1

IDENTIFIER MAY BE EITHER A MOLD OR MARKED FEATURE.

5. DIMENSION b APPLIES TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.25 mm AND 0.30 mm

FROM TERMINAL TIP.

6. ND AND NE REFER TO THE NUMBER OF TERMINALS ON EACH D AND E SIDE RESPECTIVELY.

7. DEPOPULATION IS POSSIBLE IN A SYMMETRICAL FASHION.

8. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS.

9. DRAWING CONFORMS TO JEDEC MO220, EXCEPT EXPOSED PAD DIMENSION FOR T2855-1,

T2855-3 AND T2855-6.

10. WARPAGE SHALL NOT EXCEED 0.10 mm.

11. MARKING IS FOR PACKAGE ORIENTATION REFERENCE ONLY.

12. NUMBER OF LEADS SHOWN ARE FOR REFERENCE ONLY.

-DRAWING NOT TO SCALE-

COMMON DIMENSIONS

16L 5x5

MIN. MAX.NOM.

0.70 0.800.75

0.05

0.02

0.20 REF.

0.350.30

0.25

5.10

5.00

4.90

5.105.00

4.90

0.80 BSC.

0.250--

0.30 0.500.40

---

16

4

4

WHHB

0.70

0.25

4.90

4.90

0.25

0.45

MIN.

0

---

20L 5x5

NOM.

0.75

0.02

0.20 REF.

0.30

5.00

5.00

0.65 BSC.

0.55

20

5

5

WHHC

MAX.

0.80

0.05

0.35

5.10

5.10

0.65

NOM.

0.75

0.02

0.25

5.00

5.00

0.55

28

7

7

MAX.

0.80

0.05

0.30

5.10

5.10

--

0.65

32L 5x5

NOM.

MIN.

0.75

0.70

0.02

0

0.20 REF.

0.20 0.25 0.30

5.00

4.90

5.00

4.90

0.50 BSC.

0.25

0.40

0.30

---

32

8

8

WHHD-2

MAX.

0.80

0.05

5.10

5.10

0.50

--

28L 5x5

MIN.

0.70

0

0.20 REF.

0.20

4.90

4.90

0.50 BSC.

--

0.25

0.45

---

WHHD-1

EXPOSED PAD VARIATIONS

PKG.

CODES

T1655-1

T2855-1 3.25 3.353.15 3.25

T2855-2 2.60 2.602.80 2.70 2.80

T2855-3 3.15 3.25 3.35 3.15 3.25 3.35

T2855-4 2.60 2.70 2.80 2.60 2.70 2.80

T2855-5 2.60 2.70 2.80 2.60 2.70 2.80

T2855-6 3.15 3.25 3.35 3.15 3.25 3.35

T2855-7 2.60 2.70

T3255-2

D2

MAX.

NOM.MIN.

MIN.E2NOM. MAX.

3.203.00 3.10 3.00 3.10 3.20

3.203.00T1655-2 3.10 3.00 3.10 3.20 YES

3.20

3.00T2055-2 3.10

3.103.00 3.203.103.00 3.20T2055-4

3.353.15T2055-5 3.25 3.15 3.25 3.35

3.353.15

2.70

2.80

2.60 2.70 2.80

3.35

3.15T2855-8 3.25 3.15 3.25 3.35

3.35

3.15T2855N-1 3.25 3.15 3.25 3.35

3.20

3.00

3.00 3.10 3.20

3.10

3.203.00 3.10T3255-3 3.203.00 3.10

3.203.00 3.10T3255-4 3.203.00 3.10

3.203.10T3255N-1 3.00

SEE COMMON DIMENSIONS TABLE

**

PACKAGE OUTLINE,

16, 20, 28, 32L THIN QFN, 5x5x0.8mm

21-0140

DOWN

L

BONDS

±0.15

ALLOWED

NO

**

**

NO3.203.103.003.10T1655N-1 3.00 3.20

**

3.203.00 3.10

3.203.103.00

NO

**

YES3.103.00 3.203.103.00 3.20T2055-3

**

NO

**

Y

0.40

NO

**

NO

**

YES

**

YES

**

NO

**

NO

**

YES

**

Y

0.40

N

**

NO

**

YES

**

NO

**

NO

**

2

F

2

Loading...

Loading...