Page 1

19-0547; Rev 0; 5/06

High-Precision Clock Generators

with Integrated VCXO

General Description

The MAX9450/MAX9451/MAX9452 clock generators

provide high-precision clocks for timing in SONET/SDH

systems or Gigabit Ethernet systems. The MAX9450/

MAX9451/MAX9452 can also provide clocks for the highspeed and high-resolution ADCs and DACs in 3G base

stations. Additionally, the devices can also be used as a

jitter attenuator for generating high-precision CLK signals.

The MAX9450/MAX9451/MAX9452 feature an integrated

VCXO. This configuration eliminates the use of an external VCXO and provides a cost-effective solution for generating high-precision clocks. The MAX9450/MAX9451/

MAX9452 feature two differential inputs and clock outputs. The inputs accept LVPECL, LVDS, differential signals, and LVCMOS. The input reference clocks range

from 8kHz to 500MHz.

The MAX9450/MAX9451/MAX9452 offer LVPECL, HSTL,

and LVDS outputs, respectively. The output range is up

to 160MHz, depending on the selection of crystal. The

input and output frequency selection is implemented

through the I2C* or SPI™ interface. The MAX9450/

MAX9451/MAX9452 feature clock output jitter less than

0.8ps RMS (in a 12kHz to 20MHz band) and phasenoise attenuation greater than -130dBc/Hz at 100kHz.

The phase-locked loop (PLL) filter can be set externally,

and the filter bandwidth can vary from 1Hz to 20kHz.

The MAX9450/MAX9451/MAX9452 feature an input

clock monitor with a hitless switch. When a failure is

detected at the selected reference clock, the device

can switch to the other reference clock. The reaction to

the recovery of the failed reference clock can be

revertive or nonrevertive. If both reference clocks fail,

the PLL retains its nominal frequency within a range of

±20ppm at +25°C.

The MAX9450/MAX9451/MAX9452 operate from a 2.4V to

3.6V supply and are available in 32-pin TQFP packages

with exposed pads.

Applications

SONET/SDH Systems

10 Gigabit Network Routers and Switches

3G Cellular Phone Base Stations

General Jitter Attenuation

*Purchase of I2C components from Maxim Integrated Products,

Inc., or one of its sublicensed Associated Companies, conveys

a license under the Philips I

ponents in an I

2

C Standard Specification as defined by Philips.

the I

SPI is a trademark of Motorola, Inc.

2

C system, provided that the system conforms to

2

C Patent Rights to use these com-

Features

♦ Integrated VCXO Provides a Cost-Effective

Solution for High-Precision Clocks

♦ 8kHz to 500MHz Input Frequency Range

♦ 15MHz to 160MHz Output Frequency Range

♦ I2C or SPI Programming for the Input and Output

Frequency Selection

♦ PLL Lock Range > ±60ppm

♦ Two Differential Outputs with Three Types of

Signaling: LVPECL, LVDS, or HSTL

♦ Input Clock Monitor with Hitless Switch

♦ Internal Holdover Function within ±20ppm of the

Nominal Frequency

♦ Low Output CLK Jitter: < 0.8ps RMS in the 12kHz

to 20MHz Band

♦ Low Phase Noise > -130dBc at 100kHz

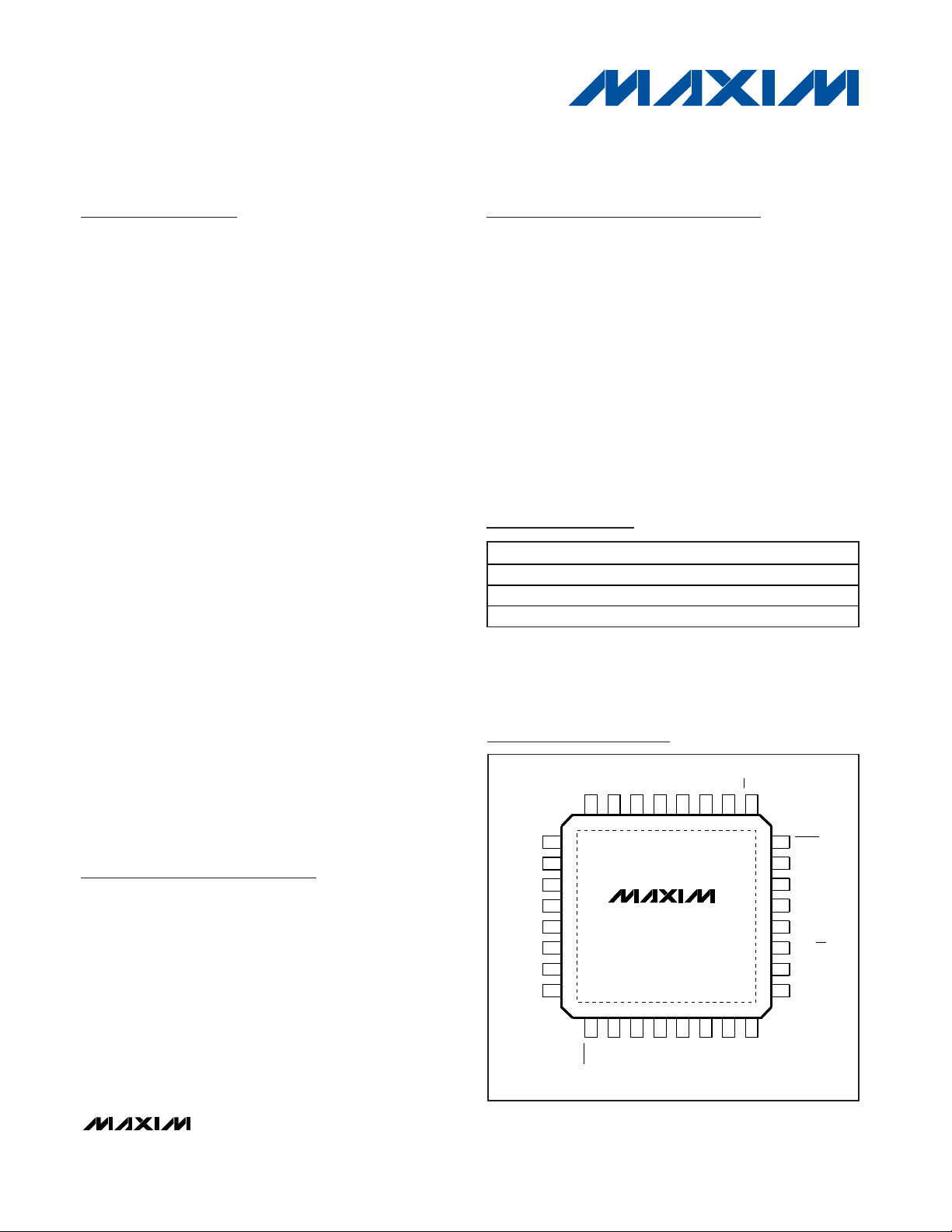

Ordering Information

PART PIN-PACKAGE OUTPUT PKG CODE

MAX9450EHJ+ 32 TQFP-EP** LVPECL H32E-6

MAX9451EHJ+† 32 TQFP-EP** HSTL H32E-6

MAX9452EHJ+† 32 TQFP-EP** LVDS H32E-6

Note: All devices are specified over the -40°C to +85°C

temperature range.

+Denotes lead-free package.

**EP = Exposed pad.

†Future product—contact factory for availability.

Pin Configuration

TOP VIEW

DD

X1

X2

V

DDA

LP1

LP2

GNDA

25V

26

27

28

29

30

31

32RJ

DDQ

CLK1+

CLK1-

MAX9450

MAX9451

MAX9452

EXPOSED PAD

SEL0

SEL1

GND

212223

(GND)

IN0+

TQFP

V

24 20

+

2

1

LOCK

(5mm x 5mm)

5

CLK0+

IN0-

19

6

CLK0-

DD

V

DDQ

V

OE

18

17

16

CMON

AD1

15

AD0

14

SDA

13

SCL

12

GND/CS

11

MR

10

INT

9

7

834

IN1-

IN1+

MAX9450/MAX9451/MAX9452

________________________________________________________________ Maxim Integrated Products 1

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Page 2

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

2 _______________________________________________________________________________________

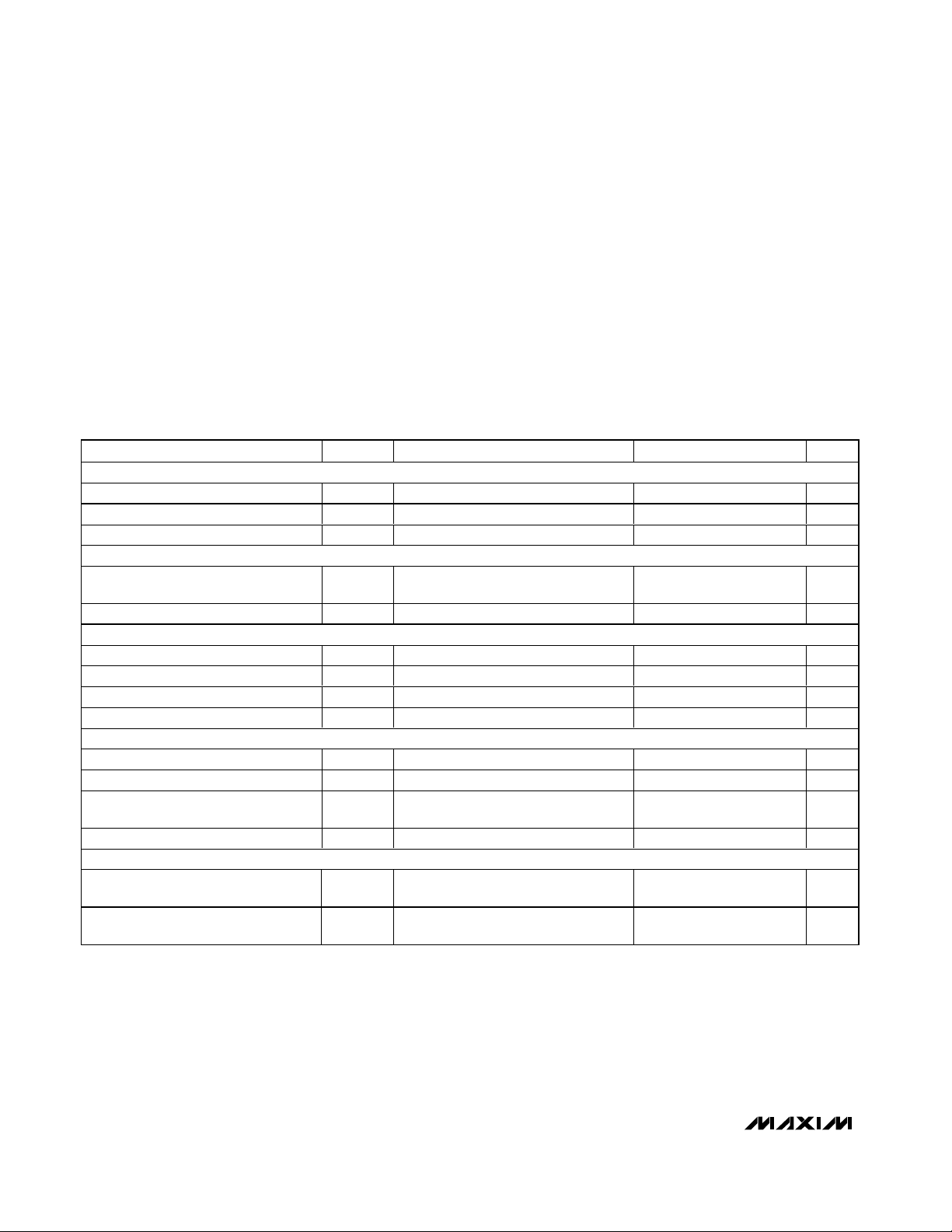

ABSOLUTE MAXIMUM RATINGS

DC ELECTRICAL CHARACTERISTICS

(V

DDA

= VDD= V

DDQ

= 2.4V to 3.6V, and V

DDQ

= 1.4V to 1.6V for MAX9451, TA= -40°C to +85°C. Typical values at V

DDA

= VDD=

V

DDQ

= 3.3V, and V

DDQ

= 1.5V for MAX9451, TA= +25°C, unless otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDDto GND...........................................................-0.3V to +4.0V

V

DDA

to GNDA ......................................................-0.3V to +4.0V

All Other Pins to GND ...................................-0.3V to V

DD

+ 0.3V

Short-Circuit Duration (all pins) ..................................Continuous

Continuous Power Dissipation (T

A

= +85°C)

32-Pin TQFP (derate 27.8mW/°C above +70°C)........2222mW

Storage Temperature Range .............................-65°C to +165°C

Maximum Junction Temperature .....................................+150°C

Operating Temperature Range ...........................-40°C to +85°C

Lead Temperature (soldering, 10s) .................................+300°C

ESD Protection

Human Body Model (R

D

= 1.5kΩ, CS= 100pF) ..............±2kV

PARAMETER

CONDITIONS

UNITS

LVCMOS INPUT (SEL_, CMON, OE, MR)

Input High Level V

IH1

2.0

V

Input Low Level V

IL1

0 0.8 V

Input Current I

IN1

VIN = 0V to V

DD

-50 +50 µA

LVCMOS OUTPUT (INT, LOCK)

Output High Level V

OH1IOH1

= -4mA

V

Output Low Level V

OL1IOL1

= 4mA 0.4 V

THREE-LEVEL INPUT (AD0, AD1)

Input High Level V

IH2

1.8 V

Input Low Level V

IL2

0.8 V

Input Open Level V

IO2

Measured at the opened inputs

V

Input Current

V

IL2

= 0V or V

IH2

= V

DD

-15 +15 µA

DIFFERENTIAL INPUTS (IN0, IN1)

Differential Input High Threshold V

IDH

V

ID

= V

IN+

- V

IN-

50 mV

Differential Input Low Threshold V

IDL

V

ID

= V

IN+

- V

IN-

-50 mV

Common-Mode Input-Voltage Range V

COM

V

ID

= V

IN+ - VIN-

2.4

V

Input Current

-1 +1 µA

MAX9450 OUTPUTS (CLK0, CLK1) (LVPECL)

Output High Voltage V

OH2

50Ω load connected to V

DDQ

- 2.0V

V

Output Low Voltage V

OL2

50Ω load connected to V

DDQ

- 2.0V

V

SYMBOL

MIN TYP MAX

V

DD

V

DD

- 0.4

I

IL2, IIH2

I

IN+, IIN-

1.05 1.35

|V

/ 2|

ID

V

D D Q

- |V

- 1.42

V

D D Q

- 2.15

ID

V

D D Q

- 1.00

V

D D Q

- 2.15

/ 2|

Page 3

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

_______________________________________________________________________________________ 3

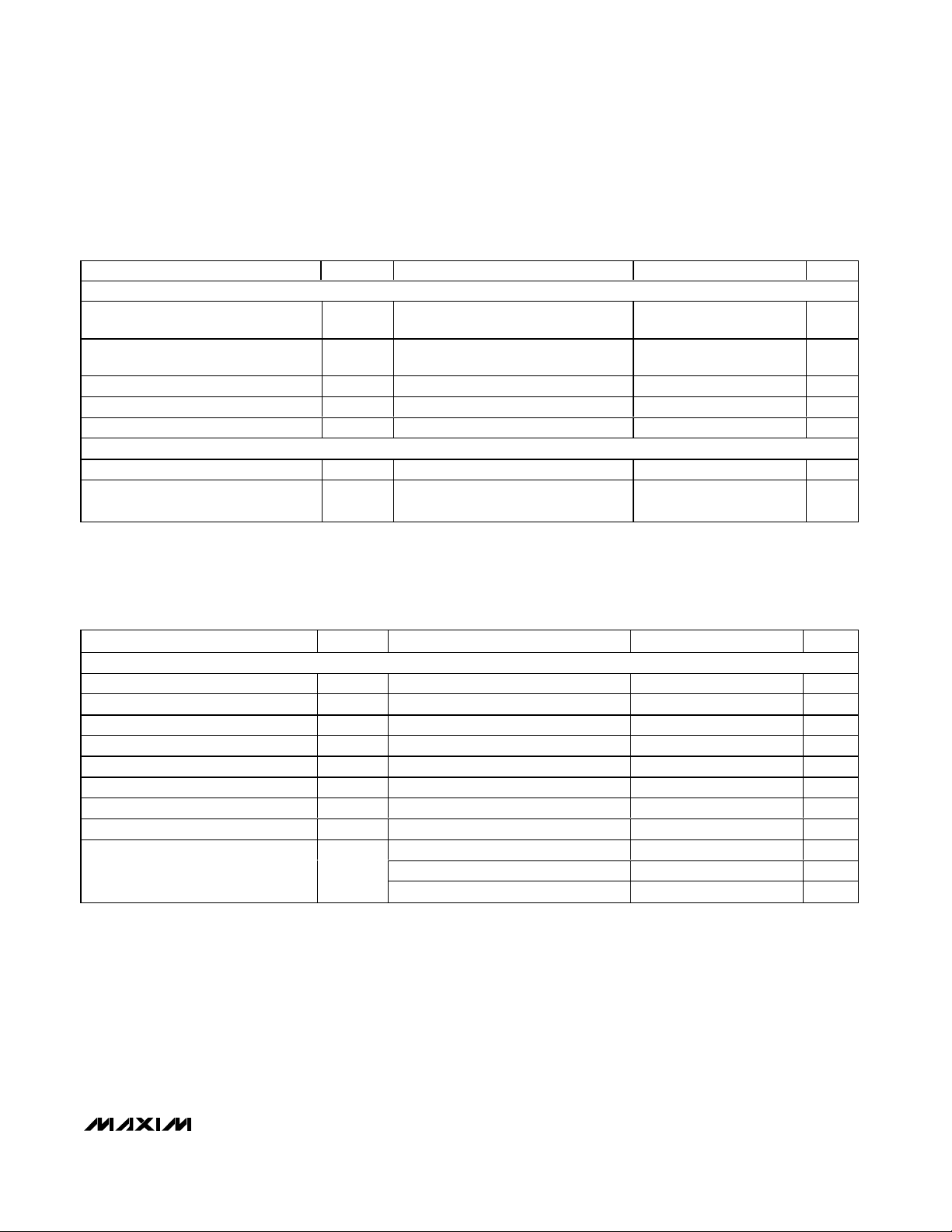

DC ELECTRICAL CHARACTERISTICS (continued)

(V

DDA

= VDD= V

DDQ

= 2.4V to 3.6V, and V

DDQ

= 1.4V to 1.6V for MAX9451, TA= -40°C to +85°C. Typical values at V

DDA

= VDD=

V

DDQ

= 3.3V, and V

DDQ

= 1.5V for MAX9451, TA= +25°C, unless otherwise noted.)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

SERIAL INTERFACE INPUT, OUTPUT (SCL, SDA, CS)

Input High Level V

IH

V

Input Low Level V

IL

V

Input Leakage Current I

IL

±1 µA

Output Low Level V

OL

3mA sink current 0.4 V

Input Capacitance C

I

10 pF

POWER CONSUMPTION

VDD and V

DDA

Supply Current I

CC1

Output clock frequency = 155MHz 55 85 mA

V

DDQ

Supply Current I

CC2

Output clock frequency = 155MHz

(MAX9450)

55 80 mA

AC ELECTRICAL CHARACTERISTICS

(V

DDA

= VDD= V

DDQ

= 2.4V to 3.6V, and V

DDQ

= 1.4V to 1.6V for MAX9451, TA= -40°C to +85°C. |VID| = 200mV, V

COM

= |VID/ 2| to

2.4 - |V

ID

/ 2|. Typical values at V

DDA

= VDD= V

DDQ

= 3.3V and V

DDQ

= 1.5V for MAX9451, TA= +25°C. CL= 10pF, clock output =

155.5MHz and clock input = 19.44MHz, unless otherwise noted.) (Note 1)

PARAMETER

CONDITIONS

UNITS

CLK OUTPUTS (CLK0, CLK1)

Reference Input Frequency f

IN

Measured at IN0 or IN1

500

MHz

Output Frequency f

OUT

Measured at CLK0 or CLK1 15 160

MHz

VCXO Pulling Range CL = 8pF (Note 2) ±50

ppm

Output-to-Output Skew t

SKO

Skew between CLK0 and CLK1 90 ps

Rise Time t

R

20% to 80% of output swing 0.4

ns

Fall Time t

F

80% to 20% of output swing 0.4

ns

Duty Cycle 44 56 %

Period Jitter (RMS) T

J

0.8 ps

1kHz offset -70

dBc/Hz

10kHz offset

dBc/Hz

Phase Noise

100kHz offset

dBc/Hz

SYMBOL

0.7

x V

DD

0.3

x V

MIN TYP MAX

DD

0.008

Measured at the band 12kHz to 20MHz

-110

-130

0.585

0.585

Page 4

Note 1: All timing AC electrical characteristics and timing specifications are guaranteed by design and not production tested.

Note 2: The VCXO tracks the input clock frequency by ±50ppm.

Note 3: A master device must provide a hold time of at least 300ns for the SDA signal to bridge the undefined regions of SCL’s

falling edge.

Note 4: C

B

= total capacitance of one bus line in pF. Tested with CB= 400pF.

Note 5: Input filters on SDA and SCL suppress noise spikes less than 50ns.

PARAMETER

CONDITIONS

UNITS

Serial-Clock Frequency f

SCL

2

MHz

CS Fall to CLK Rise Setup Time t

CSS

ns

DIN Setup Time t

DS

ns

DIN Hold Time t

DH

0ns

CLK High to CS High t

CSH

0ns

CS Pulse-High Time t

CSW

20 ns

SERIAL SPI INTERFACE TIMING CHARACTERISTICS

(VDD= 2.4V to 3.6V, TA= -40°C to +85°C. See Figure 7 for the timing parameters definition.)

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

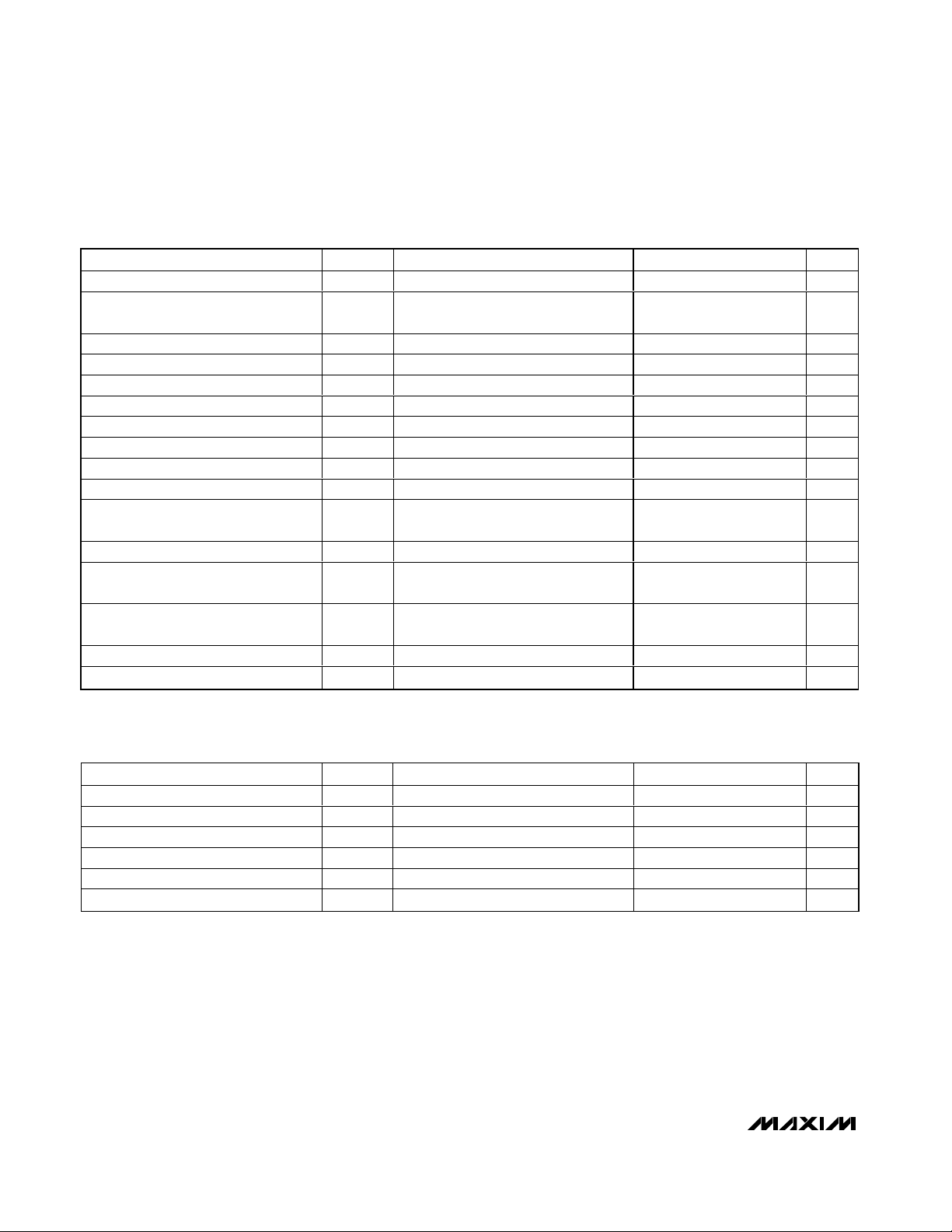

4 _______________________________________________________________________________________

PARAMETER

CONDITIONS

UNITS

Serial Clock f

SCL

400

kHz

Bus Free Time Between STOP and

START Conditions

t

BUF

1.3 µs

Rep eated H ol d Ti m e S TART C ond i ti on

0.6 µs

0.6 µs

STOP Condition Setup Time

0.6 µs

Data Hold Time

(Note 3) 100 ns

Data Setup Time

100 ns

SCL Clock-Low Period t

LOW

1.3 µs

SCL Clock-High Period t

HIGH

0.7 µs

t

R

300 ns

t

R

(Note 4)

20

ns

t

F

300 ns

Minimum Receive SCL/SDA Fall Time t

F

(Note 4)

20

ns

Fall Time of SDA, Transmitting t

F,TX

(Note 4)

20

250 ns

Pulse Width of Suppressed Spike t

SP

(Note 5) 0 50 ns

Capacitive Load for Each Bus Line C

B

(Note 4) 400 pF

SERIAL I2C-COMPATIBLE INTERFACE TIMING CHARACTERISTICS

(VDD= 2.4V to 3.6V, TA= -40°C to +85°C. See Figure 4 for the timing parameters definition.)

Rep eated S TART C ond i ti on S etup Ti m et

Maximum Receive SCL/SDA Rise Time

SYMBOL

t

HD,STA

SU,STA

t

SU,STO

t

HD,DAT

t

SU,DAT

MIN TYP MAX

Minimum Receive SCL/SDA Rise Time

Maximum Receive SCL/SDA Fall Time

SYMBOL

+ 0.1 x C

b

+ 0.1 x C

b

+ 0.1C

b

MIN TYP MAX

12.5

12.5

Page 5

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

_______________________________________________________________________________________ 5

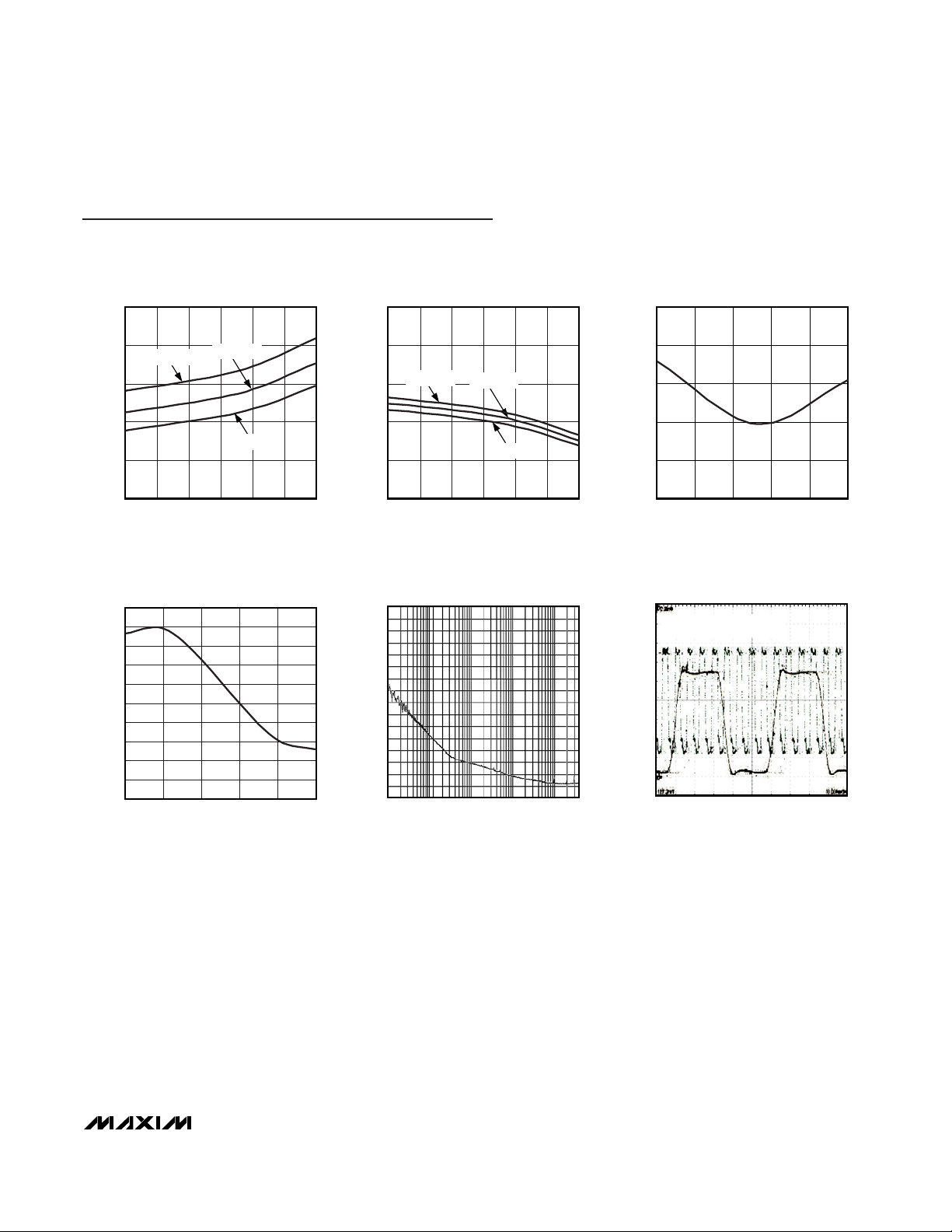

VDD AND V

DDA

SUPPLY CURRENT

vs. VOLTAGE

MAX9450 toc01

VOLTAGE (V)

I

DD

(mA)

3.43.33.23.1

48

56

64

72

80

40

3.0 3.63.5

TA = -40°C

TA = +25°C

TA = +85°C

V

DDQ

SUPPLY CURRENT

vs. VOLTAGE

MAX9450 toc02

VOLTAGE (V)

I

DD

(mA)

3.43.33.23.1

48

56

64

72

80

40

3.0 3.63.5

TA = -40°C

TA = +25°C

TA = +85°C

OUTPUT FREQUENCY CHANGE

vs. TEMPERATURE

MAX9450 toc04

TEMPERATURE (°C)

OUTPUT FREQUENCY CHANGE (ppm)

6035-15 10

-30

-20

-10

10

0

20

30

40

50

-50

-40

-40 85

PHASE NOISE

vs. FREQUENCY

MAX9450 toc05

PHASE NOISE (dB)

100k

FREQUENCY (Hz)

1M 10M10k1k

0

-20

-40

-60

-80

-100

-120

-140

-160

OUTPUT RMS JITTER

vs. TEMPERATURE

MAX9450 toc03

TEMPERATURE (°C)

RMS JITTER (ps)

603510-15

2

4

6

8

10

0

-40 85

OUTPUT CLOCK SYNCHRONIZED

TO INPUT REFERENCE

MAX9450 toc06

153.13mV/div

100mV/div

10ns/div

INPUT REFERENCE = 19.44MHz

OUTPUT CLOCK = 155.52 MHz

Typical Operating Characteristics

(VDD= V

DDA

= V

DDQ

= 3.3V. TA= +25°C, unless otherwise noted.)

Page 6

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

6 _______________________________________________________________________________________

Pin Description

NAME FUNCTION

1 LOCK Lock Indicator. LOCK goes low when the PLL locks. LOCK is high when the PLL is not locked.

INO_ and IN1_ Select Inputs. Drive SEL0 high to activate IN0; drive SEL1 high to activate IN1. Driving SEL0 and

SEL1 low disables the corresponding input. A 165kΩ pullup resistor pulls SEL0 and SEL1 up to V

DD

.

Differential Reference Input Pair. IN0+ and IN0- accept LVPECL, LVDS, and LVCMOS signals.

V

DD

Digital Power Supply. Connect a 2.4V to 3.6V power supply to VDD. Bypass VDD to GND with a 0.1µF capacitor.

Differential Reference Input Pair. IN1+ and IN1- accept LVPECL, LVDS, and LVCMOS signals.

9 INT Reference Input Condition Indicator. A high indicates a failed reference.

MR Master Reset. Drive MR high to reset all I2C registers to their default state and INT to 0.

Ground and Chip-Select Input. Connect to GND in I2C mode. This is the chip-select input in SPI mode.

SCL Clock Input. SCL is the clock input in I2C bus mode and SPI bus mode.

SDA Data Input. SDA is the data input in I2C bus mode and SPI bus mode.

I2C Address Selection. Drive AD0 and AD1 high to convert the serial interface from I2C to SPI. GND/CS

becomes CS. See Table 3 for the unique addresses list.

CMON Clock Monitor. Drive CMON low to enable the clock monitor. Drive CMON high to disable the clock monitor.

OE

Output Enable Input. Drive OE low to enable the clock outputs. Driving OE high disables the clock outputs, and

the outputs go high impedance. An internal 165kΩ pullup resistor pulls OE up to V

DD

.

V

DDQ

Clock-Output Power Supply. Connect a 2.4V to 3.6V power supply to V

DDQ

for the MAX9450 and MAX9452.

Connect a 1.5V power supply to V

DDQ

for the MAX9451. Connect a 0.1µF bypass capacitor from V

DDQ

to GND.

CLK0-,

Differential Clock Output 0. The MAX9450 features LVPECL outputs. The MAX9451 features HSTL outputs and

the MAX9452 features LVDS outputs.

GND Digital GND

CLK1-,

Differential Clock Output 1. The MAX9450 features LVPECL outputs. The MAX9451 features HSTL outputs, and

the MAX9452 features LVDS outputs.

X1, X2 Reference Crystal Input. Connect the reference crystal from X1 to X2.

V

DDA

Anal og P ow er S up p l y. C onnect a 2.4V to 3.6V p ow er sup p l y to V

D D A

. Byp ass V

D D A

to GN D A w i th a 0.1µF cap aci tor .

External Loop Filter. Connect an RC circuit between LP1 and LP2. See the External Loop Filter section.

GNDA Analog Ground

RJ

Charge-Pump Set Current. Connect an external resistor to GND to set the charge-pump current. See Table 11.

EP Exposed Pad. Connect to ground.

PIN

2, 3 S E L0, S E L1

4, 5 IN0+, IN0-

6, 25

7, 8 IN1+, IN1-

10

11 GND/CS

12

13

14, 15 AD0, AD1

16

17

18, 24

19, 20

CLK0+

21

22, 23

26, 27

29, 30 LP1, LP2

EP

CLK1+

28

31

32

Page 7

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

_______________________________________________________________________________________ 7

GNDA

V

DDA

V

DD

GND

VCXO

CRYSTAL

5MHz TO 160MHz

FUNDAMENTAL MODE

AND AT CUT

LOCK DET

1/M

LUT FOR P

LOOP FILTER

RJ

LP2

LP1

X1 X2

I2C PORT

SCL

SDA

LUT FOR N1, N2

LUT FOR M

AD0

AD1

IN0+

IN0-

IN1+

IN1-

SEL0

0

1

CLK

MONITOR

CMON

INT

1/N1

CLK1+

CLK1-

OE

CLK0+

CLK0-

1/N0

1/P

PFD/CP

SEL1

MR

SPI PORT

CONTROL

REGISTERS

GND/CS

MUX

LOCK

12kΩ TO 200k

Ω

DIV0

DIV1

MAX9450

MAX9451

MAX9452

Functional Diagram

Detailed Description

The MAX9450/MAX9451/MAX9452 clock generators

provide high-precision clocks for timing in SONET/SDH

systems or Gigabit Ethernet systems. The MAX9450/

MAX9451/MAX9452 can also provide clocks for the

high-speed and high-resolution ADCs and DACs in 3G

base stations. Additionally, the MAX9450/MAX9451/

MAX9452 can be used as a jitter attenuator for generating high-precision clock signals.

The MAX9450/MAX9451/MAX9452 feature two differential inputs and two differential clock outputs. The inputs

accept LVPECL, LVDS, and LVCMOS signals. The

input reference clock ranges from 8kHz to 500MHz and

the output clock ranges from 15MHz to 160MHz. The

internal clock monitor observes the condition of the

input reference clocks and provides a hitless switch

when an input failure is detected. The MAX9450/

MAX9451/MAX9452 also provide holdover in case no

input clock is supplied.

Control and Status Registers

The MAX9450/MAX9451/MAX9452 contain eight 8-bit

control registers named CR0 to CR7. The registers are

accessible through the I

2

C/SPI interface. CR0 is for the

frequency-dividing factor, P. CR1 and CR2 hold the

values of the divider, M. CR3 and CR4 are for dividers

Page 8

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

8 _______________________________________________________________________________________8 ____________________________________________________________________________________________________

N1 and N2, respectively. CR5 and CR6 are the control

function registers for output enabling, reference clock

selection, and activation of the clock monitor and the

holdover function. CR7 contains the status of clock

monitor, holdover, and PLL locking. The addresses of

the eight registers are shown in Table 4. Tables 5

through 10 show the register maps.

Output Buffers

Three different output formats (LVPECL, HSTL, and

LVDS) are available. Each output contains its own

frequency divider. All the output clocks align to their

coincident rising edges. After changing the dividing

ratio, the output clocks complete the current cycle and

stay logic-low until the rising edges of the newly divided

clock. When CR5[7] is high, the MAX9450/MAX9451/

MAX9452 set all the outputs to logic-low. Setting the

bits CR5[6] and CR5[5] properly enables and disables

the outputs individually, see Table 8. A disabled output

is always in high impedance. At the receiver end, the

two cables or PC board traces can be terminated as

shown in Figure 1.

The VCXO output is divided down before driving the output buffers. Program the dividing factor through the serial

interface. The MAX9450/MAX9451/MAX9452 feature two

output dividers DIV0 and DIV1 (see the Functional

Diagram). DIV0 drives OUT0 and either DIV0 or DIV1 can

drive OUT1. CR6[2] sets which divider output drives

OUT1. This function allows for programming OUT1 and

OUT0 to different frequencies.

Reference Clock Inputs

The MAX9450/MAX9451/MAX9452 feature two “anything” differential clock inputs. “Anything” means that

the inputs take any differential signals, such as CML,

LVDS, LVPECL, or HSTL. The inputs can also take a

single-ended input. For example, with LVCMOS reference inputs, connect the inputs to the positive pins

INn+ and connect the negative pins INn- to a reference

voltage of VDD- 1.32V. See Figure 2.

Setting CR5[4] and CR6[3] selects the input reference.

Failure detection and revert function apply only to IN0

and IN1. Also, SEL0 and SEL1 or CR5[3:2] can disable

the corresponding inputs. See Table 2.

Frequency Selection and Programming

The output frequency at CLKn, (n = 0, 1) is determined by

the reference clock and the dividing factors M, Ni (i = 0, 1),

and P, shown in the following equation:

ff

M

Ni P

CLKn REF

=×

×

LVCMOS CLK OUTPUT

V

REF

= VDD - 1.32V

ANYTHING INPUT

Figure 2. Connecting LVCMOS Output to LVPECL Input

Z = 50Ω

LVPECL

OUTPUT

127Ω

127Ω

3.3V

83Ω

83Ω

LVPECL

INPUT

(A) LVPECL DC COUPLING

Z = 50Ω

HSTL

OUTPUT

50Ω

50Ω

HSTL

INPUT

(C) HSTL DC COUPLING

(B) LVDS COUPLING

Z = 50Ω

LVDS

OUTPUT

100Ω

LVDS

INPUT

Figure 1. DC LVPECL, LVDS, and HSTL Termination

Page 9

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

_______________________________________________________________________________________ 9

10 GIGABIT ETHERNET SONET

INPUT CLK: 50MHz INPUT CLK: 19.44MHz

CRYSTAL

FREQUENCY

(MHz)

PMNi

OUTPUT

FREQUENCY

(MHz)

CRYSTAL

FREQUENCY

(MHz)

PM

OUTPUT

FREQUENCY

(MHz)

50 2 2 1 50 51.84 1 8 1 51.84

125 2 5 2 62.5 77.76 1 4 1 77.76

125 2 5 1 125 155.52 1 8 1 155.52

— — — — — 155.52 1 4 2 77.76

Table 1. Output Frequency Selection and Register Content Values

where f

CLKn

is the frequency at the CLKn output, f

REF

is the frequency of the reference clock, M (1 to 32,768)

is the dividing factor in the feedback loop, Ni (1, 2, 3, 4,

5, 6, 8, 16) are the dividing factors of the outputs, and P

(1 to 256) is the dividing factor to the input reference

clock. It is possible to set various frequencies at the

two differential CLK_ outputs with this configuration.

For example, in 10 Gigabit Ethernet or SONET applications, set the dividing factors to generate the required

frequencies, as shown in Table 1.

Input Clock Monitor

Failure Detection

The MAX9450/MAX9451/MAX9452 clock-failure-detection function monitors the two reference inputs simultaneously. If a reference input clock signal (IN_) does not

transition for two or more VCO cycles, the device reports

a failure by setting INT high and bit CR7[6] or CR7[5] to

1. See Table 9. After a reference clock failure, the monitor switches to the other valid input reference. At the

same time, the clock monitor loads CR7 with the status of

the reference clocks and which input is selected. The

mapping of CR7 is given in Table 9. If one of the inputs is

disabled according to the bits in CR5[3:2], then the monitor is disabled.

Revert Function

The response of the MAX9450/MAX9451/MAX9452 to a

detected input failure depends on the setting of the

revert function. If the failed input recovers from the

failure, INT and CR7[5:6] resets to 0 if revert is activated. If the recovered input is selected by CR5[4] as the

default input reference, the MAX9450/MAX9451/

MAX9452 reselect this input. If the revert function is not

activated, once an input failure is detected, the monitor

remains in the failure state with INT = 1 and CR7[5:6] =

1, until the MAX9450/MAX9451/MAX9452 are reset.

Activate the revert function using the bit CR5[1].

Failure-Detection Monitor Reset

Reset the fault by toggling CMON from low to high,

toggling MR or CR6[4] from low to high, or by toggling

the bit CR5[0] from low to high. In revert mode, when

the monitor is reset, INT and CR7[5:6] reset to 0 and

the default input is the one indicated by CR5[4].

Holdover Function

The holdover function locks the output frequency to its

nominal value within ±20ppm. Activate this function by

setting CR6[7] to 1. The MAX9450/MAX9451/MAX9452

enter holdover when the devices detect a failure from

both input references. Setting CR6[6] to 1 forces the

device into the holdover state, while resetting CR6[6]

exits holdover.

Use a reset-to-exit holdover. If the revert function is

activated once an input is recovered from the failure,

the device also exits holdover and switches to the

recovered input reference. If both inputs recover simultaneously, the device switches to the default input.

VCXO frequency during holdover is the value of the

frequency right before the failure of inputs.

When CR6[5] goes from 0 to 1, the value of the VCXO

frequency is acquired and stored. The VCXO can be

switched to this acquired frequency by setting CR6[1]

to 1. Such a transition can happen in both the normal

mode of operation and the holdover mode.

PLL Lock Detect

The MAX9450/MAX9451/MAX9452 also feature PLL

lock detection. The MAX9450/MAX9451/MAX9452

compare the frequency of the phase detector input with

the output frequency of the loop frequency divider.

When these two frequencies deviate more than 20ppm,

the LOCK output goes high. At power-up, LOCK is

high. LOCK goes low when the PLL locks. PLL lock

time will also depend on the loop filter bandwidth.

Ni

Page 10

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

10 ______________________________________________________________________________________

External Loop Filter

When the device switches from one input reference to

the other or reverts to an input reference from holdover,

the output phase changes smoothly during the transition

using an external PLL filter. The narrower the filter bandwidth is, the smoother the phase transition. However, if

bandwidth is too narrow, it can cause some degradation on output jitter performance.

Charge-Pump Current Setting

The MAX9450/MAX9451/MAX9452 allow external setting

of the charge-pump current in the PLL. Connect a resistor from RJ to GNDA to set the PLL charge-pump current:

charge-pump current (µA) = 2.48 x 1000 /

(R

SET

(kΩ) + 0.375)

where R

SET

is in kΩ and the value of the charge-pump

current is in µA. Use R

SET

to adjust the loop response

to meet individual application requirements. The

charge-pump current and the external filter components change the PLL bandwidth. Table 11 shows the

charge-pump current vs. the resistor’s value.

The loop response equation is defined as:

unity-gain bandwidth = (ICPx R

FILT

x 12kHz) / M

where ICPis the-charge pump current set by REXT,

R

FILT

is the external filter resistance, and M is the feed-

back divider.

Input Disable

The two inputs can be disabled separately by SEL0

and SEL1 or the two bits in CR5[3:2]. Table 2 shows the

state map.

Power-Up and Master Reset

Upon power-up, default frequency divider rates and the

states of the monitor, inputs, and outputs are set

according to Table 10. Setting MR high or CR6[4] to 1

also resets the device. When the device resets, INT

and CR7[5:6] go low and all the registers revert to their

default values.

I2C Interface

The control interface of the MAX9450/MAX9451/MAX9452

is an I2C or SPI depending on the states of AD0 and

AD1. Drive both AD0 and AD1 high to active SPI mode.

Otherwise, I2C is activated. The device operates as a

slave that sends and receives data through the clock

line, SCL, and data line, SDA, to achieve bidirectional

communication with the masters. A master (typically a

microcontroller) initiates all data transfers to and from

slaves, and generates the SCL clock that synchronizes

the data transfer. Figure 4 shows the timing of SCL and

SDA. The SDA line operates as both an input and an

open-drain output. SDA requires a pullup resistor, typically 4.7kΩ. The SCL line operates only as an input. A

pullup resistor, typically 4.7kΩ, is required on SCL if there

are multiple masters on the 2-wire bus, or if the master in

a single-master system has an open-drain SCL output.

I2C Device Address

Every I2C port has a 7-bit device address. This 7-bit

address is the slave (MAX9450/MAX9451/MAX9452)

ID for the master to write and read. In the MAX9450/

MAX9451/MAX9452, the first four bits (1101) of the

address are hard coded into the device at the factory.

See Table 3. The last three bits of the address are input

programmable by the three-level AD0 and AD1. This

configuration provides eight selectable addresses for

the MAX9450/MAX9451/MAX9452, allowing eight

devices to be connected to one master.

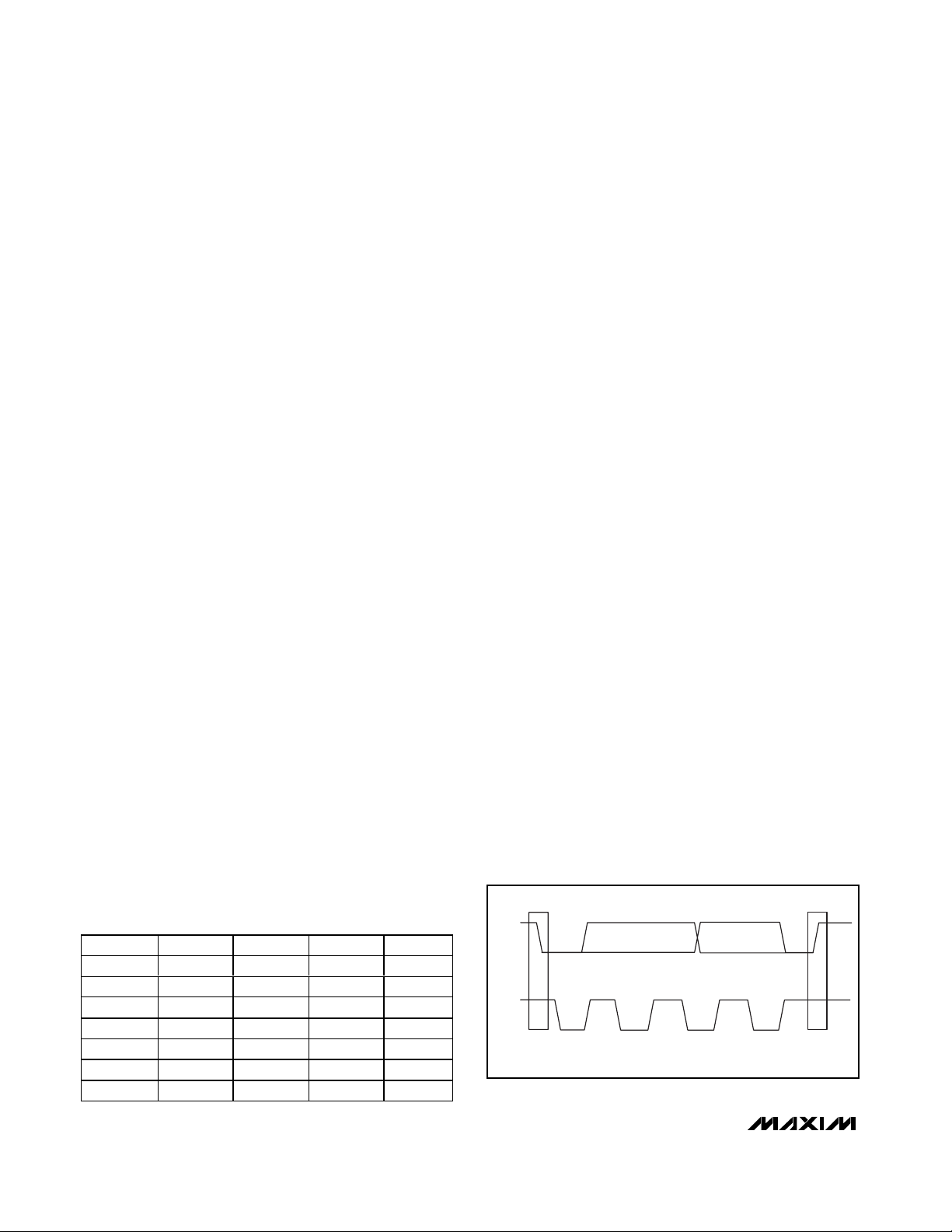

Start and Stop Conditions

Both SCL and SDA remain high when the interface is

not busy. The active master signals the beginning of a

transmission with a START (S) condition by transitioning

SDA from high to low while SCL is high. When the master

has finished communicating with the slave, it issues a

STOP (P) condition by transitioning SDA from low to

high while SCL is high. The bus is then free for another

transmission (Figure 3). The interval between a START

and a STOP is called a session.

SEL1 SEL0

CR5[3:2]

IN1 IN0

0000

Disabled

0100

Enabled

1000

Disabled

1100

Enabled

XX01

Enabled

XX10

Disabled

XX11

Enabled

Table 2. Input Activation by SEL0, SEL1,

or CR5[3:2]

SDA

SCL

S

START

CONDITION

P

STOP

CONDITION

Figure 3. Start and Stop Conditions

Disabled

Disabled

Enabled

Enabled

Disabled

Enabled

Enabled

Page 11

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

______________________________________________________________________________________ 11

Data Transfer and Acknowledge

Following the START condition, each SCL clock pulse

transfers one bit. Between a START and a STOP, multiple

bytes can be transferred on the 2-wire bus. The first

seven bits (B0–B6) are for the device address. The eighth

bit (B7) indicates the writing (low) or reading (high) operation (W/R). The ninth bit (B8) is the ACK for the address

and operation type. A low ACK bit indicates a successful

transfer; otherwise, a high ACK bit indicates an unsuccessful transfer. The next eight bits (register address),

B9–B16, form the address byte for the control register

to be written (Figure 4). The next bit, bit 17, is the ACK

for the register address byte. The following byte (Data1)

is the content to be written into the addressed register

of the slave. After this, the address counter of I2C is

increased by 1 (Rgst Addr + 1) and the next byte

(Data2) writes into a new register. To read the contents

in the MAX9450/MAX9451/MAX9452’s control registers,

the master sends the register address to be read to the

slave by a writing operation. Then it sends the byte of

device address + R to the slave. The slave (MAX9450/

MAX9451/MAX9452) responds with the content bytes

from the registers, starting from the pointed register to

the last register, CR8, consecutively back to the master

(Figure 5).

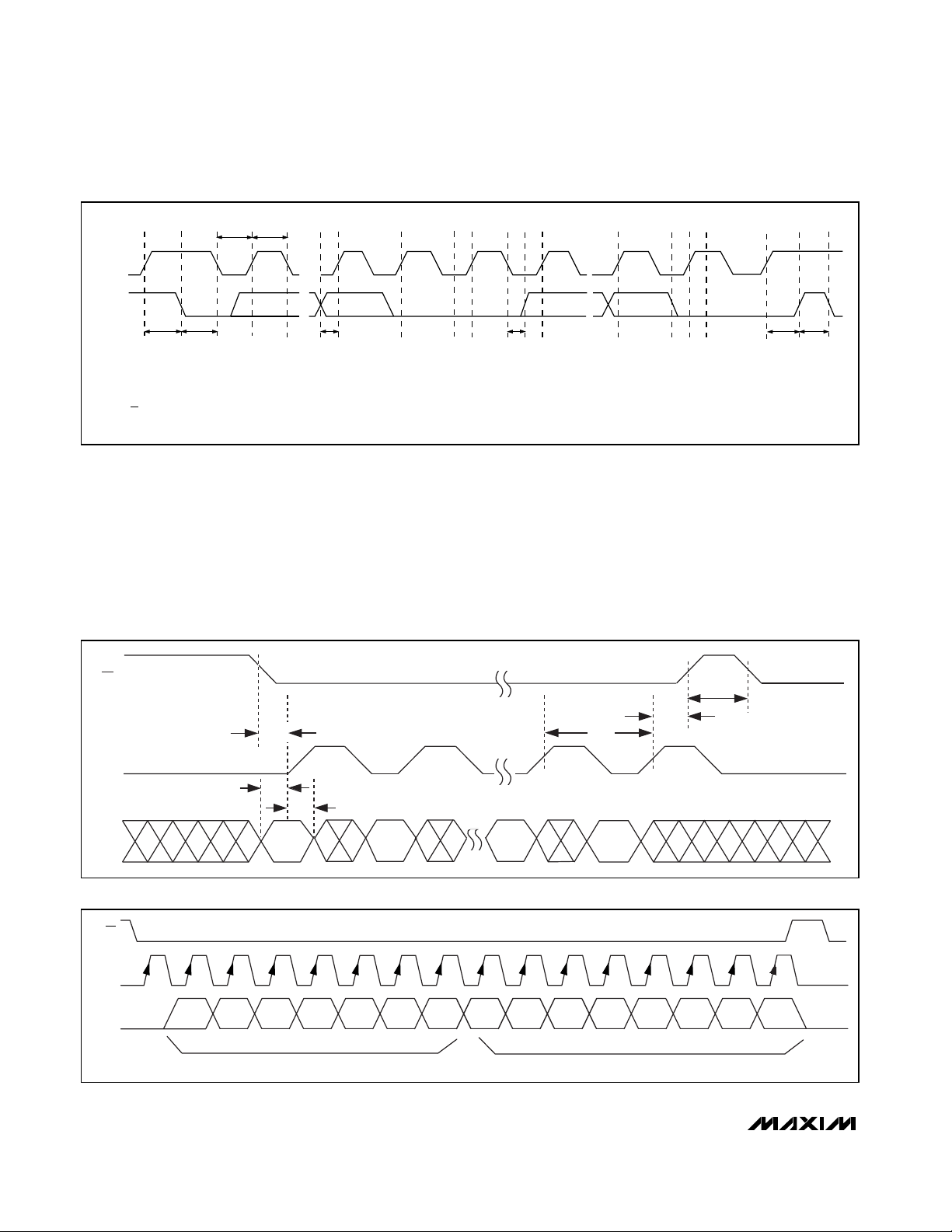

SMBCLK

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

AB CDEFG

HIJ

SMBDATA

t

SU:STAtHD:STA

t

LOW

t

HIGH

t

SU:DAT

t

SU:STOtBUF

LMK

E = SLAVE PULLS SMBDATA LINE LOW

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO SLAVE

H = LSB OF DATA CLOCKED INTO SLAVE

I = MASTER PULLS DATA LINE LOW

J = ACKNOWLEDGE CLOCKED INTO SLAVE

K = ACKNOWLEDGE CLOCK PULSE

L = STOP CONDITION

M = NEW START CONDITION

Figure 5. SMBus Write Timing Diagram

Write Byte Format

Read Byte Format

Send Byte Format

Receive Byte Format

Slave address: equivalent to chip-select line of

a 3-wire interface

Command byte: selects to

which register you are writing

Slave address: equivalent

to chip-select line

Command byte: selects

from which register you

are reading

Slave address: repeated

due to change in dataflow direction

Data byte: reads from

the register set by the

command byte

Command byte: sends command with no data, usually

used for one-shot command

Data byte: reads data from the register

commanded by the last read byte or

write byte transmission; also used for

SMBus alert response return address

S = Start condition Shaded = Slave transmission

P = Stop condition /// = Not acknowledged

Figure 4. I2C Interface Data Structure

S ADDRESS RD ACK DATA /// P

— 7 bits — — 8 bits — —

WRS ACK COMMAND ACK P

— — — 8 bits — —

ADDRESS

7 bits

P

1

ACK

—

DATA

8 bits

ACK

—

COMMAND

8 bits

ACK

—

S ADDRESS WR ACK COMMAND ACK S ADDRESS

7 bits——8 bits——7 bits—

RD—ACK—DATA

8 bits

///

—

P

—

Data byte: data goes into the register

set by the command byte (to set

thresholds, configuration masks, and

sampling rate)

WR

—

ADDRESS

7 bits

S

—

Page 12

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

12 ______________________________________________________________________________________

SMBCLK

AB CDEFG HIJ

K

SMBDATA

t

SU:STA

t

HD:STA

t

LOWtHIGH

t

SU:DAT

t

HD:DAT

t

SU:STO

t

BUF

A = START CONDITION

B = MSB OF ADDRESS CLOCKED INTO SLAVE

C = LSB OF ADDRESS CLOCKED INTO SLAVE

D = R/W BIT CLOCKED INTO SLAVE

E = SLAVE PULLS SMBDATA LINE LOW

L

M

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER

G = MSB OF DATA CLOCKED INTO MASTER

H = LSB OF DATA CLOCKED INTO MASTER

I = MASTER PULLS DATA LINE LOW

J = ACKNOWLEDGE CLOCKED INTO SLAVE

K = ACKNOWLEDGE CLOCK PULSE

L = STOP CONDITION

M = NEW START CONDITION

Figure 6. SMBus Read Timing Diagram

t

CSS

t

CSH

f

SCL

t

CSW

CS

SCLK

DIN

t

DS

t

DS

D0D1D14D15

Figure 7. SPI Write Operation Timing Diagram

SLK

SDA

D15

D14

D13 D12

D11 D10

D9

D8

D7 D6

D5 D4

D3

D2 D1

D0

REGISTER ADDRESS

REGISTER DATA

CS

Figure 8. SPI Register Address and Data Configuration Function Setting Tables

SPI Interface

The SPI interface is activated when AD0 = AD1 = high.

The SPI port is a write-only interface, and it uses the

three inputs: CS, SCL, and SDA. Bit D15 is always 0,

indicating the write-only mode, as shown in Figure 5.

D14–D8 are the register address bits and D7–D0 are

the data bits. In Table 4, the register address mapping

is still valid, except the first address bit on the left is not

used. D14 is the LSB of the address, and D7 is the LSB

of the data. D15–D0 are sent with LSB (D15) first. The

maximum SCL frequency is 2MHz.

To perform a write, set D15 = 0, drive CS low, toggle

SCL to latch SDA data on the rising edge, then drive

CS high after 16 SCL cycles for two SCL cycles to signal the boundary of a 16-bit word (Figure 5). SCL must

be low when CS falls at the start of a transmission.

Switching of SCL and SDA is ignored unless CS is low.

Page 13

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

______________________________________________________________________________________ 13

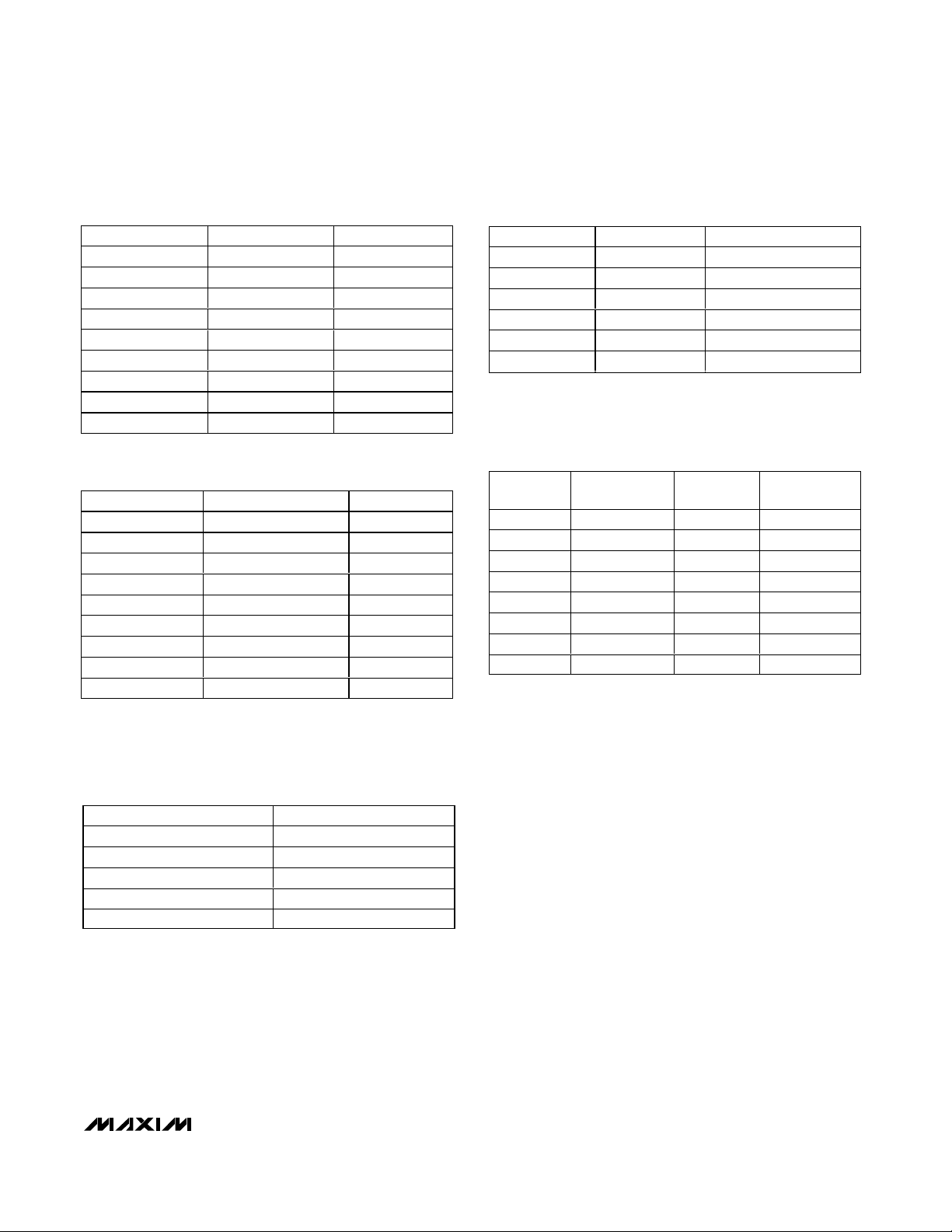

AD0 AD1 ADDRESS

Low Low 1101000

Low Open 1101001

Low High 1101010

Open Low 1101011

Open Open 1101100

Open High 1101101

High Low 1101110

High Open 1101111

High High Covert to SPI

Table 3. I2C Address Setting by AD0 and AD1

REGISTER NAME

REGISTER ADDRESS

FUNCTION

CR0 00000000 P divider

CR1 00000001

M divider byte 1

CR2 00000010

M divider byte 2

CR3 00000011 N1 divider

CR4 00000100 N2 divider

CR5 00000101 Control

CR6 00000110 Control

CR7 00000111 Status

CR8 00001000 Reserved

Table 4. I2C and SPI Register Address*

CR0 DIVIDING RATE FOR P

0000-0000 1

0000-0001 2

——

1111-1110 255

1111-1111 256

Table 5. Dividing Rate Setting for P Divider

CR1 CR2[7:1]*

DIVIDING VALUE OF M

0000-0000 0000-000 1

0000-0000 0000-001 2

—— —

1111-1111 0011-110 8191

1111-1111 0011-111 8192

1111-1111 1111-111 32,768

Table 6. Dividing Rate Setting for M Divider

*When the SPI port is activated, the first address bit on the left

is omitted and the remaining seven bits are used. The LSB is

the first bit on the right.

*The last 5 LSBs of CR3[4:0] and CR4[4:0] are reserved.

*CR2[0], the last LSB, is reserved.

CR3*

DIVIDING

CR4*

DIVIDING

VALUE OF N1

1

1

2

2

3

3

4

4

5

5

6

6

8

8

16

16

Table 7. Dividing Rate Setting for N0 and

N1 Divider

VALUE OF N0

000XXXXX

001XXXXX

010XXXXX

011XXXXX

100XXXXX

101XXXXX

110XXXXX

111XXXXX

000XXXXX

001XXXXX

010XXXXX

011XXXXX

100XXXXX

101XXXXX

110XXXXX

111XXXXX

Page 14

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

14 ______________________________________________________________________________________

ACTION

DEFAULT

CR0 P = 1 00000000

CR1 M = 1 00000000

CR2 M = 1 00000000

CR3 N0 = 1 00000000

CR4 N1 = 1 00000000

1. Outputs enable

2. IN0 is the default input

3. Both inputs are enabled by

SEL0 and SEL1

4. Monitor is nonrevertive

5. Holdover is disabled

CR5: 01100000

CR6: 00000000

CR7 Status 00000000

CR8 Reserved 00000000

Table 10. Register Default Values at Power-Up

CR5, CR6

FUNCTION STATE

Output disable

0: Outputs are enabled

1: Outputs disabled to logic-low

CLK0 enabling

0: CLK0 is disabled to high impedance (overrides CR5[7] = 1 setting)

1: CLK0 is enabled

CLK1 enabling

0: CLK1 is disabled to high impedance (overrides CR5[7] = 1 setting)

1: CLK1 is enabled

Default input

setting

0: IN0 is the default input

1: IN1 is the default input

Input enabling

00: The selection is controlled by SEL0, SEL1 (see Table 2)

01: Enable IN0, disable IN1

10: Enable IN1, disable IN0

11: Enable both IN0 and IN1

Revert function

0: The function is not activated

1: The function is activated

C LK m oni tor i s r eset i n r ever t m od e: IN T = 0 and C R7[ 7] = 0, and the P LL sw i tches to the d efaul t i np ut

Holdover function

enabling

0: Holdover function is disabled

1: Holdover function is enabled

Forced holdover

0: Holdover is in normal mode

1: Holdover is forced to be activated

As the bit goes from 0 to 1, the current VCXO frequency is taken as the nominal value

Acquiring nominal

As this bit is toggling from 0 to 1, the current VCXO frequency is taking as the nominal holdover

value

Master reset The bit acts at the same as the input MR; CR6[4] = 1, the chip is reset

REF This bit is always set to zero

ODIV select

CR6[2] = 0: DIV0 output drives CLK2

CR6[2] = 1: DIV1 output drives CLK2

Acquire select

CR6[1] = 0 PLL controls the Xtal frequency

CR6[1] = 1 Xtal frequency is controlled by the acquired value (acquired at rising edge of CR6[5])

Reserved —

Table 8. Control Registers and Control Functions

CR7 FUNCTION STATE

Status of IN0

Status of IN1

0: Normal

1: Failure detected

Input clock

0: IN0 is currently used

1: IN1 is currently used

LOCK indicator

1: PLL not locked

0: PLL locked

Holdover status

1: Device is in holdover state

0: Device is in normal state

Reserved —

Table 9. Mapping for the Input Monitor Status

CR5[7]

CR5[6]

CR5[5]

CR5[4]

CR5[3:2]

CR5[1]

CR5[0] CLK monitor reset

CR6[7]

CR6[6]

CR6[5]

CR6[4]

CR6[3]

CR6[2]

CR6[1]

CR6[0]

CR7[6]

CR7[5]

CR7[4]

CR7[3]

CR7[2]

CR7[1:0]

VCXO frequency

selection indicator

REGISTER

CR5, CR6

Page 15

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

______________________________________________________________________________________ 15

Applications Information

Crystal Selection

The MAX9450/MAX9451/MAX9452 internal VCXO circuitry requires an external crystal. The frequency of the

crystal ranges from 15MHz to 160MHz, depending on

the application. It is important to use a quartz crystal

that prevents reduction of the frequency pulling range,

temperature stability, or excessive output phase jitter.

Choose an AT-cut crystal that oscillates at the required

frequency on its fundamental mode with a variation of

25ppm, including frequency accuracy and operating

temperature range. Select a crystal with a load capacitance of 8pF and a motional capacitance of at least 7fF

to achieve the specified pulling range.

LVDS Cables and Connectors

The interconnect for LVDS typically has a 100Ω differential impedance. Use cables and connectors that

have matched differential impedance to minimize

impedance discontinuities.

Twisted-pair and shielded twisted-pair cables offer

superior signal quality compared to ribbon cable and

tend to generate less EMI due to magnetic-field-canceling effects. Balanced cables pick up common-mode

noise, which is rejected by the LVDS receiver.

Power-Supply Bypassing

Bypass V

DDA

, VDD, and V

DDQ

to ground with high-frequency, surface-mount ceramic 0.1µF and 0.01µF

capacitors. Place the capacitors as close as possible

to the device with the 0.01µF capacitor closest to the

device pins.

Board Layout

Circuit-board trace layout is very important to maintain

the signal integrity of high-speed differential signals.

Maintaining integrity is accomplished in part by reducing signal reflections and skew and increasing common-mode noise immunity.

Signal reflections are caused by discontinuities in the

50Ω (100Ω for LVDS outputs) characteristic impedance

of the traces. Avoid discontinuities by maintaining the

distance between differential traces, not using sharp

corners or vias. Ensure the two traces are parallel and

close to each other to increase common-mode noise

immunity and reduce EMI. Matching the electrical length

of the differential traces further reduces signal skew.

Output Termination

Terminate the MAX9450 outputs with 50Ω to VCC- 2V

or use an equivalent thevenin termination. When a single-ended signal is taken from a differential output, terminate both outputs.

The MAX9452 outputs are specified for a 100Ω load,

but can drive 90Ω to 132Ω to accommodate various

types of interconnects. The termination resistor at the

driven receiver should match the differential characteristic impedance of the interconnect and be located

close to the receiver input. Use a ±1% surface-mount

termination resistor.

Chip Information

PROCESS: CMOS

RESISTOR (kΩ) CURRENT (µA)

12 200.5

20 121.88

50 49.41

100 24.86

150 16.61

200 12.48

Table 11. Resistor Value vs. Charge-Pump

Current

Page 16

MAX9450/MAX9451/MAX9452

High-Precision Clock Generators

with Integrated VCXO

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

16 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2006 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products, Inc.

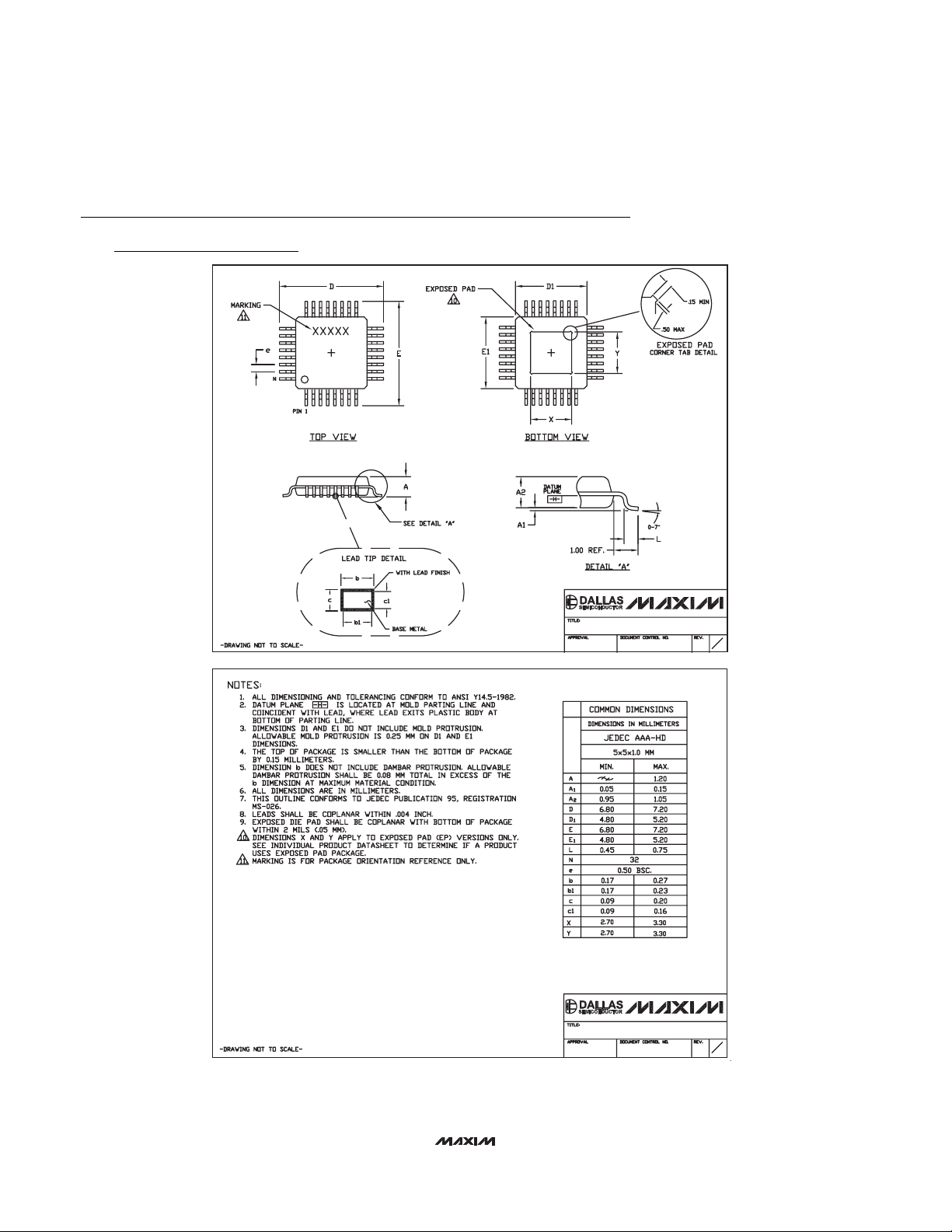

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

32L,TQFP.EPS

F

1

2

21-0079

PACKAGE OUTLINE,

32L TQFP, 5x5x1.0mm, EP OPTION

F

2

2

21-0079

PACKAGE OUTLINE,

32L TQFP, 5x5x1.0mm, EP OPTION

Loading...

Loading...