Page 1

General Description

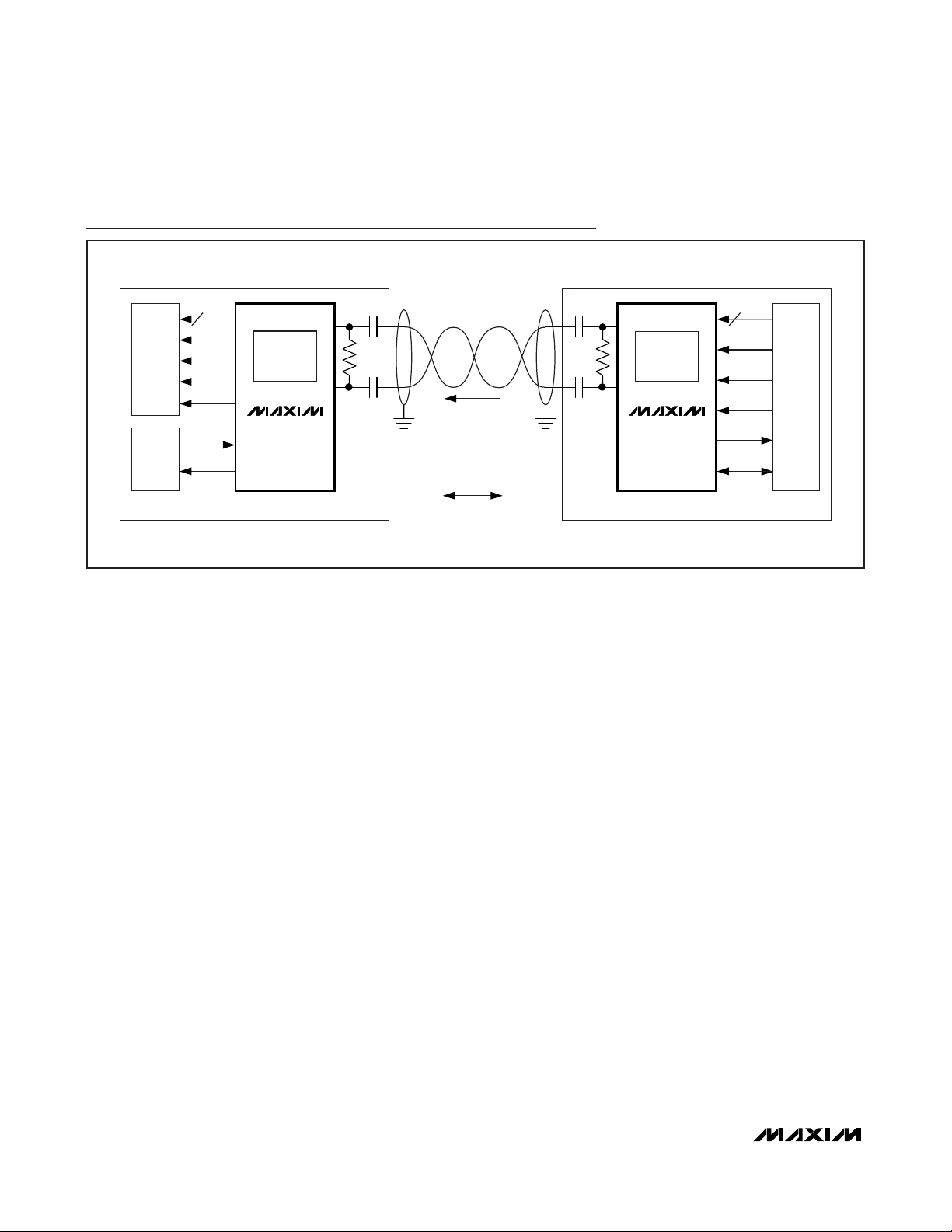

The MAX9257 serializer pairs with the MAX9258 deserializer to form a complete digital video serial link. The

MAX9257/MAX9258 feature programmable parallel data

width, parallel clock frequency range, spread spectrum,

and preemphasis. An integrated control channel transfers data bidirectionally at power-up during video blanking over the same differential pair used for video data.

This feature eliminates the need for external CAN or LIN

interface for diagnostics or programming. The clock is

recovered from input serial data at MAX9258, hence

eliminating the need for an external reference clock.

The MAX9257 serializes 10, 12, 14, 16, and 18 bits with

the addition of two encoding bits for AC-coupling. The

MAX9258 deserializer links with the MAX9257 to deserialize a maximum of 20 (data + encoding) bits per

pixel/parallel clock period for a maximum serial-data

rate of 840Mbps. The word length can be adjusted to

accommodate a higher pixel/parallel clock frequency.

The pixel clock can vary from 5MHz to 70MHz, depending on the serial-word length. Enabling parity adds two

parity bits to the serial word. The encoding bits reduce

ISI and allow AC-coupling.

The MAX9258 receives programming instructions from

the electronic control unit (ECU) during the control

channel and transmits to the MAX9257 over the serial

video link. The instructions can program or update the

MAX9257, MAX9258, or an external peripheral device,

such as a camera. The MAX9257 communicates with

the peripheral device with I2C or UART.

The MAX9257/MAX9258 operate from a +3.3V core

supply and feature separate supplies for interfacing to

+1.8V to +3.3V logic levels. These devices are available in 40-lead TQFN or 48-pin LQFP packages. These

devices are specified over the -40°C to +105°C temperature range.

Applications

Automotive Cameras

Industrial Cameras

Navigation Systems Display

In-Vehicle Entertainment Systems

Features

♦ 10/12/14/16/18-Bit Programmable Parallel Data

Width

♦ MAX9258 Does Not Require Reference Clock

♦ Parity Protection for Video and Control Channels

♦ Programmable Spread Spectrum

♦ Programmable Rising or Falling Edge for HSYNC,

VSYNC, and Clock

♦ Up to 10 Remotely Programmable GPIO on

MAX9257

♦ Automatic Resynchronization in Case of Loss of

Lock

♦ MAX9257 Parallel Clock Jitter Filter PLL with

Bypass

♦ DC-Balanced Coding Allows AC-Coupling

♦ 5 Levels of Preemphasis for Up to 20m STP Cable

Drive

♦ Integrity Test Using On-Chip Programmable

PRBS Generator and Checker

♦ LVDS I/O Meet ISO10605 ESD Protection (±10kV

Contact and ±30kV Air Discharge)

♦ LVDS I/O Meet IEC61000-4-2 ESD Protection

(±8kV Contact and ±20kV Air Discharge)

♦ LVDS I/O Meet ±200V Machine Model ESD

Protection

♦ -40°C to +105°C Operating Temperature Range

♦ Space-Saving, 40-Pin TQFN (5mm x 5mm) with

Exposed Pad or 48-Pin LQFP Packages

♦ +3.3V Core Supply

MAX9257/MAX9258

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

________________________________________________________________

Maxim Integrated Products

1

19-1044; Rev 0; 6/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

Ordering Information

+

Denotes a lead-free package.

*

EP = Exposed pad.

Typical Application Circuit and Pin Configurations appear

at end of data sheet.

PART TEMP RANGE

MAX9257GTL+ -40°C to +105°C 40 TQFN-EP* T4055+1

MAX9257GCM+ -40°C to +105°C 48 LQFP C48+3

MAX9258GCM+ -40°C to +105°C 48 LQFP C48+3

PINPACKAGE

PKG

CODE

Page 2

MAX9257/MAX9258

2 _______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VCC_ to GND .........................................................-0.5V to +4.0V

Any Ground to Any Ground...................................-0.5V to +0.5V

SDI+, SDI-, SDO+, SDO- to GND..........................-0.5V to +4.0V

SDO+, SDO- Short Circuit to GND or V

CCLVDS

.........Continuous

DIN[0:15], GPIO[0:9], PCLK_IN, HSYNC_IN, VSYNC_IN,

SCL/TX, SDA/RX, REM to GND............-0.5V to (V

CCIO

+ 0.5V)

DOUT[0:15], PCLK_OUT, HSYNC_OUT, VSYNC_OUT, RX,

LOCK, TX, PD, ERROR, to GND .......-0.5V to (V

CCOUT

+ 0.5V)

Continuous Power Dissipation (T

A

= +70°C)

40-Lead TQFN

Multilayer PCB (derate 35.7mW/°C above +70°C) .....2857mW

48-Lead LQFP

Multilayer PCB (derate 21.7mW/°C above +70°C) .....1739mW

Junction-to-Case Thermal Resistance (θ

JC

) (Note 1)

40-Lead TQFN .............................................................1.7°C/W

48-Lead LQFP...............................................................10°C/W

Junction-to-Ambient Thermal Resistance (θ

JA

) (Note 1)

40-Lead TQFN ..............................................................28°C/W

48-Lead LQFP...............................................................46°C/W

ESD Protection

Human Body Model (R

D

= 1.5kΩ, CS= 100pF)

All Pins to GND ..............................................................±3kV

IEC 61000-4-2 (R

D

= 330Ω, CS= 150pF)

Contact Discharge

(SDI+, SDI-, SDO+, SDO-) to GND................................±8kV

Air Discharge

(SDI+, SDI-, SDO+, SDO-) to GND..............................±20kV

ISO 10605 (R

D

= 2kΩ, CS= 330pF)

Contact Discharge

(SDI+, SDI-, SDO+, SDO-) to GND..............................±10kV

Air Discharge

(SDI+, SDI-, SDO+, SDO-) to GND..............................±30kV

Machine Model (R

D

= 0Ω, CS= 200pF)

All Pins to GND ............................................................±200V

Storage Temperature Range .............................-65°C to +150°C

Junction Temperature......................................................+150°C

Lead Temperature (soldering, 10s) .................................+300°C

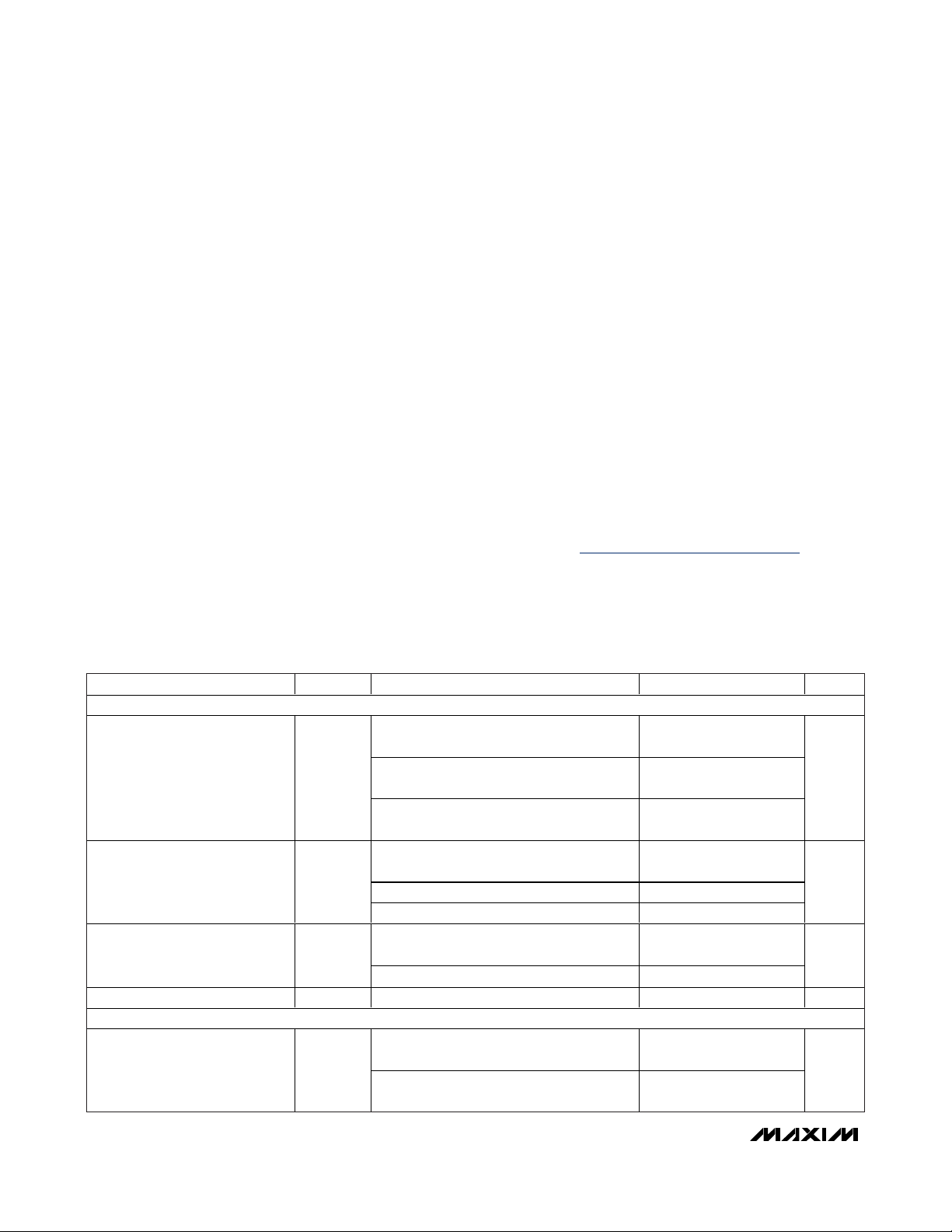

MAX9257 DC ELECTRICAL CHARACTERISTICS

(V

CC_

= +3.0V to +3.6V, RL= 50Ω ±1%, TA= -40°C to +105°C, unless otherwise noted. Typical values are at V

CC_

= +3.3V,

T

A

= +25°C.) (Notes 2, 3)

Note 1: Package thermal resistances were obtained using the method described in JDEC specification JESD51-7, using a 4-layer

board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial

.

SINGLE-ENDED INPUTS

High-Level Input Voltage V

Low-Level Input Voltage V

Input Current I

Input Clamp Voltage V

SINGLE-ENDED OUTPUTS

High-Level Output Voltage V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

0.65 x

V

CCIO

-20 +20

V

-

CCIO

0.1

V

-

CCIO

0.35

IN

CL

OH

V

= +1.71V to +3V

CCIO

V

= +3V to +3.6V 2

IH

IL

CCIO

REM input 2

V

= +1.71V to +3V 0

CCIO

V

= +3V to +3.6V 0 0.8

CCIO

REM input 0 0.8

VIN = 0 to V

V

CCIO

VIN = 0 to V

ICL = -18mA -1.5 V

IOH = -100µA

IOH = -2mA

CCIO

= +1.71V to +3.6V

REM input -20 +20

CC,

V

V

CCIO

0.3

CCIO

0.3

V

CC

0.3

0.3 x

V

CCIO

+

+

+

V

V

µA

V

Page 3

MAX9257/MAX9258

_______________________________________________________________________________________ 3

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

MAX9257 DC ELECTRICAL CHARACTERISTICS (continued)

(V

CC_

= +3.0V to +3.6V, RL= 50Ω ±1%, TA= -40°C to +105°C, unless otherwise noted. Typical values are at V

CC_

= +3.3V,

T

A

= +25°C.) (Notes 2, 3)

Low-Level Output Voltage V

Output Short-Circuit Current I

I2C/UART I/O

Input Leakage Current I

High-Level Input Voltage SDA/RX V

Low-Level Input Voltage SDA/RX V

Low-Level Output Voltage

SCL, SDA

LVDS OUTPUTS (SDO+, SDO-)

Differential Output Voltage V

Change in VOD Between

Complimentary Output States

Common-Mode Voltage V

Change in VOS Between

Complimentary Output States

Output Short-Circuit Current I

Magnitude of Differential Output

Short-Circuit Current

CONTROL CHANNEL TRANSCEIVER

Differential Output Voltage V

Input Hysteresis

(Figure 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

= 100µA 0.1

I

OL

= 2mA 0.3

I

OL

Shorted to GND -44 -10

Shorted to V

VI = V

R

PULLUP

Preemphasis off

(Figure 1)

V

SDO+

V

OD

Differential low-to-high threshold 25 90 135

Differential high-to-low threshold -25 -90 -135

CC_

CC

= 1.6k

Ω

or V

= 0 15 mA

= 0 or 3.6V -15 +15 mA

SDO-

10 44

-1 +1 µA

0.7 x

V

CC

250 350 460 mV

1.050 1.25 1.375 V

250 350 460 mV

ILKG

V

Δ

V

Δ

V

I

OSD

V

HYST+

V

HYST-

OL

OS

IH2

IL2

OL2

OD

OD

OS

OS

OS

OD

0.3 x

V

CC

0.4 V

20 mV

20 mV

V

mA

V

V

mV

Page 4

MAX9257/MAX9258

4 _______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

MAX9257 DC ELECTRICAL CHARACTERISTICS (continued)

(V

CC_

= +3.0V to +3.6V, RL= 50Ω ±1%, TA= -40°C to +105°C, unless otherwise noted. Typical values are at V

CC_

= +3.3V,

T

A

= +25°C.) (Notes 2, 3)

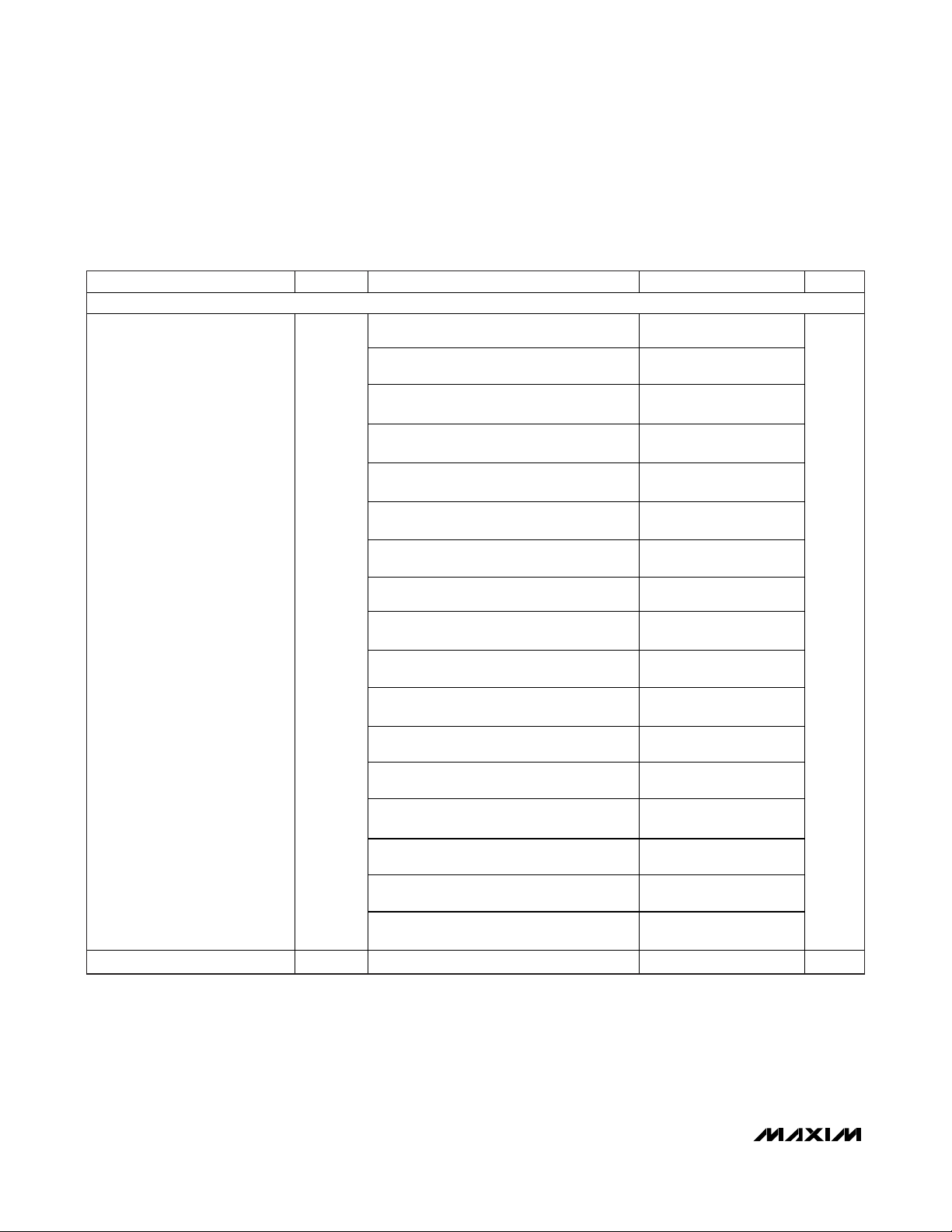

POWER SUPPLY

Worst-Case Supply Current

(Figure 3)

C

L

Sleep Mode Supply Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

= 8pF, 12 bits

I

CCW

CCS

±2% spread, preemphasis off,

PRATE = 60MHz, SRATE = 840Mbps

No spread, preemphasis off,

PRATE = 60MHz, SRATE = 840Mbps

N o sp r ead , p r eem p hasi s = 20%,

P RATE = 60M H z, S RATE = 840M b p s

N o sp r ead , p r eem p hasi s = 60%,

P RATE = 60M H z, S RATE = 840M b p s

N o sp r ead , p r eem p hasi s = 100%,

P RATE = 60M H z, S RATE = 840M b p s

±2% spread, preemphasis off,

PRATE = 28.57MHz, SRATE = 400Mbps

No spread, preemphasis off,

PRATE = 28.57MHz, SRATE = 400Mbps

No spread, preemphasis = 100%,

PRATE = 28.57MHz, SRATE = 400Mbps

±2% spread, preemphasis off,

PRATE = 14.29MHz, SRATE = 200Mbps

No spread, preemphasis off,

PRATE = 14.29MHz, SRATE = 200Mbps

No spread, preemphasis = 100%,

PRATE = 14.29MHz, SRATE = 200Mbps

±2% spread, preemphasis off,

PRATE = 7.14MHz, SRATE = 100Mbps

No spread, preemphasis off,

PRATE = 7.14MHz, SRATE = 100Mbps

N o sp r ead , p r eem p hasi s = 100%,

P RATE = 7.14M H z, S RATE = 100M b p s

±2% spread, preemphasis off,

PRATE = 5MHz, SRATE = 70Mbps

No spread, preemphasis off,

PRATE = 5MHz, SRATE = 70Mbps

No spread, preemphasis = 100%,

PRATE = 5MHz, SRATE = 70Mbps

Sleep mode 92 µA

104 126

99 121

99 120

108 127

110 129

78 96

77 94

86 105

55 68

54 67

59 73

44 55

43 54

46 57

34 43

34 42

36 45

mA

Page 5

MAX9257/MAX9258

_______________________________________________________________________________________ 5

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

MAX9257 AC ELECTRICAL CHARACTERISTICS

(V

CC_

= +3.0V to +3.6V, RL= 50Ω ±1%, TA= -40°C to +105°C, unless otherwise noted. Typical values are at V

CC_

= +3.3V,

T

A

= +25°C.) (Notes 5, 9)

PCLK_IN TIMING REQUIREMENTS

Clock Period t

Clock Frequency f

Clock Duty Cycle DC t

Clock Transition Time tR, t

SWITCHING CHARACTERISTICS

LVDS Output Rise Time t

LVDS Output Fall Time t

Control Transceiver Transition

Time

Input Setup Time t

Input Hold Time t

Parallel-to-Serial Delay

PLL Lock Time t

Random Jitter t

Deterministic Jitter t

SCL/TX, SDA/RX

Rise Time t

Fall Time t

Pulse Width of Spike Suppressed

in SDA

Data Setup Time t

Data Hold Time t

I2C TIMING (Note 8)

Maximum SCL Clock Frequency f

Minimum SCL Clock Frequency f

Start Condition Hold Time t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

T

CLK

F

R

F

t

R1A , tF1A

t

R2 , tF2

t

R1B , tF1B

S

H

t

PSD1

t

PSD2

LOCK

RJ

DJ

RS

FS

1/t

T

HIGH/tT

or t

LOW

/t

T

(Figure 7) 4 ns

20% to 80% (Figure 4) 315 370 ps

20% to 80% (Figure 4) 315 370 ps

20% to 80% (Figure 16)

(Figure 5) 0 ns

(Figure 5) 3 ns

Spread off (Figure 6)

±4% spread

Combined FPLL and SPLL; PCLK_IN stable

420MHz LVDS output, spread off,

FPLL = bypassed

18

2

- 1 PRBS, SRATE = 840Mbps, 18 bits,

no spread

0.3 x VCC to 0.7 x

, CL = 30pF

V

CC

0.7 x VCC to 0.3 x V

R

R

CC, CL

= 10k

PULLUP

= 1.6k

PULLUP

= 30pF 40 ns

14.28 200.00 ns

5 70 MHz

35 50 65 %

642 970 1390

810 1140 1420

290 386 490

Ω

Ω

95kbps to 400kbps 100

t

SPK

400kbps to 1000kbps 50

1000kbps to 4250kbps 10

DC to 10Mbps (bypass mode) 10

SETUP

HOLD

SCL

SCL

HD:STA

400kbps 100

4.25Mbps, CL = 10pF 60

400kbps 100

4.25Mbps, CL = 10pF 0

(Figure 30) 0.6 µs

ps

(4.55 x t

( 36.55 x t

T) +

11

T) +

11

32,768 x

t

T

12

ns

ns

ps

(RMS)

142 ps (p-p)

400

60

ns

ns

ns

ns

4.25 MHz

95 kHz

Page 6

MAX9257/MAX9258

6 _______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

MAX9257 AC ELECTRICAL CHARACTERISTICS (continued)

(V

CC_

= +3.0V to +3.6V, RL= 50Ω ±1%, TA= -40°C to +105°C, unless otherwise noted. Typical values are at V

CC_

= +3.3V,

T

A

= +25°C.) (Notes 5, 9)

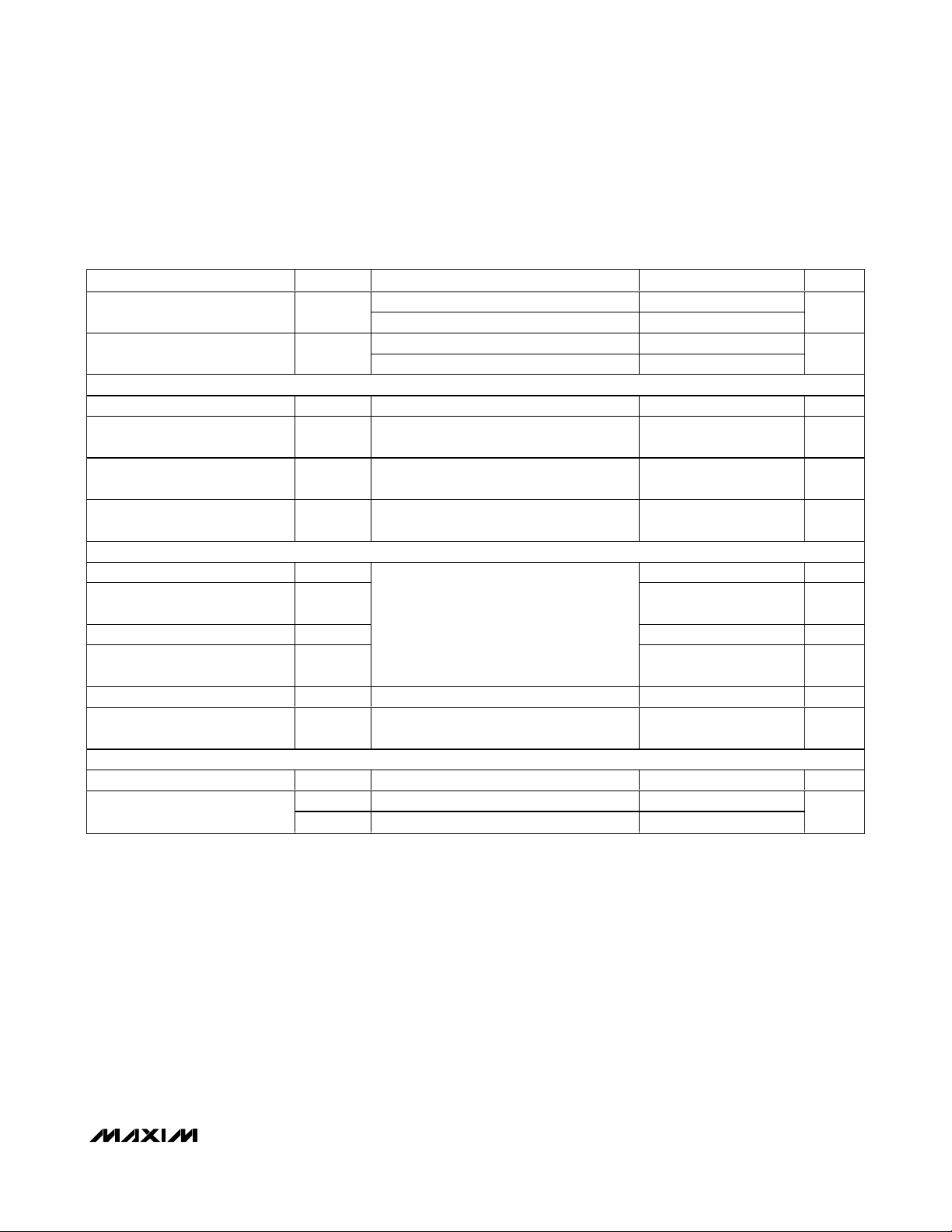

MAX9258 DC ELECTRICAL CHARACTERISTICS

(V

CC_

= +3.0V to +3.6V, RL= 50Ω ±1%, differential input voltage |VID| = 0.05V to 1.2V, input common-mode voltage VCM= |VID/2| to

V

CC

- |VID/2|, TA= -40°C to +105°C, unless otherwise noted. Typical values are at V

CC_

= +3.3V, |VID| = 0.2V, VCM= 1.2V,

T

A

= +25°C.) (Notes 2, 3)

Low Period of SCL Clock t

High Period of SCL Clock t

Repeated START Condition

Setup Time

Data Hold Time t

Data Setup Time t

Setup Time for STOP Condition t

Bus Free Time t

SINGLE-ENDED INPUTS

High-Level Input Voltage V

Low-Level Input Voltage V

Input Current I

Input Clamp Voltage V

SINGLE-ENDED OUTPUTS

High-Level Output Voltage V

Low-Level Output Voltage V

High-Impedance Output Current I

Output Short-Circuit Current I

OPEN-DRAIN OUTPUTS

Output Low Voltage V

Output Low Voltage V

Leakage Current I

LVDS INPUTS (SDI+, SDI-)

Differential Input High Threshold V

Differential Input Low Threshold V

Input Current I

Power-Off Input Current I

CONTROL CHANNEL TRANSCEIVER

Differential Output Voltage V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

LOW

HIGH

t

SU:STA

HD:DAT

SU:DAT

SU:STO

BUF

(Figure 30) 1.1 µs

(Figure 30) 0.6 µs

(Figure 30) 0.5 µs

(Figure 30) 0 0.9 µs

(Figure 30) 100 ns

(Figure 30) 0.5 µs

(Figure 30) 1.1 µs

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

IH

IL

IN

CL

VIN = 0 to V

ICL = -18mA -1.5 V

IOH = -100µA

OH

IOH = -2mA

OL

OZ

OS

OL

OL

LEAK

TH

IN+, IIN-

INO+, IINO-VCC_

OD

IOL = 100µA 0.1

IOL = 2mA 0.3

PD = low, VO = 0 to V

VO = 0V (Note 4) -16 -65

PCLK_OUT, VO = 0V -22 -80

V

CCOUT

V

CCOUT

VO = 0 or V

TL

CC

CCOUT

TXIN -60 +60

PD -20 +20

= +3V, IOL = 6.4mA 0.55 V

= +1.71V, IOL = 1.95mA 0.3 V

CC

= 0 or open -70 +70 µA

2.0 V

00.8V

V

CCOUT

-

0.1

V

CCOUT

-

0.35

-1 +1 µA

-50 mV

-60 +60 µA

250 460 mV

CC

V

µA

V

V

mA

1µA

50 mV

Page 7

MAX9257/MAX9258

_______________________________________________________________________________________ 7

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

MAX9258 DC ELECTRICAL CHARACTERISTICS (continued)

(V

CC_

= +3.0V to +3.6V, RL= 50Ω ±1%, differential input voltage |VID| = 0.05V to 1.2V, input common-mode voltage VCM= |VID/2| to

V

CC

- |VID/2|, TA= -40°C to +105°C, unless otherwise noted. Typical values are at V

CC_

= +3.3V, |VID| = 0.2V, VCM= 1.2V,

T

A

= +25°C.) (Notes 2, 3)

MAX9258 AC ELECTRICAL CHARACTERISTICS

V

CC_

= +3.0V to +3.6V, RL= 50Ω ±1%, CL= 8pF, differential input voltage |VID| = 0.1V to 1.2V, input common-mode voltage

V

CM

= |VID/2| to VCC- |VID/2|, TA= -40°C to +105°C, unless otherwise noted. Typical values are at V

CC_

= +3.3V, |VID| = 0.2V, VCM=

1.2V, T

A

= +25°C. (Notes 5, 6, and 7)

Input Hysteresis

(Figure 2)

POWER SUPPLY

Worst-Case Supply Current

C

L

(Figure 8)

Power-Down Supply Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

= 8pF, 12 bits

V

HYST+

V

HYST-

I

CCW

CCZ

Differential low-to-high threshold 25 90 135

Differential high-to-low threshold -25 -90 -135

±4% spread, PRATE = 60MHz,

SRATE = 840Mbps

Spread off, PRATE = 60MHz,

SRATE = 840Mbps

±4% spread, PRATE = 28.57MHz,

SRATE = 400Mbps

Spread off, PRATE = 28.57MHz,

SRATE = 400Mbps

±4% spread, PRATE = 14.29MHz,

SRATE = 200Mbps

Spread off, PRATE = 14.29MHz,

SRATE = 200Mbps

±4% spread, PRATE = 5MHz,

SRATE = 70Mbps

Spread off, PRATE = 5MHz,

SRATE = 70Mbps

PD = low 10 50 µA

85 128

71 115

67 102

57 84

55 82

46 67

42 57

34 49

mV

mA

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SWITCHING CHARACTERISTICS

Output Transition Time t

Output Transition Time,

PCLK_OUT

Output Transition Time t

Output Transition Time,

PCLK_OUT

t

Control Channel Transition Time

Control Channel Transition Time t

PCLK_OUT High Time t

PCLK_OUT Low Time t

R1A, tF1A,

t

R1B, tF1B

R, tF

t

R, tF

R, tF

t

R, tF

R2, tF2

HIGH

LOW

(Figure 9) 0.7 2.2 ns

(Figure 9) 0.5 1.5 ns

V

V

(Figure 16) 0.5 1.2 ns

(Figure 16) 0.6 1.3 ns

(Figure 10)

(Figure 10)

= 1.71V (Figure 9) 1.0 2.8 ns

CCOUT

= 1.71V (Figure 9) 0.7 2.2 ns

CCOUT

0.4 x

t

T

0.4 x

t

T

0.6 x

0.6 x

t

t

T

T

ns

ns

Page 8

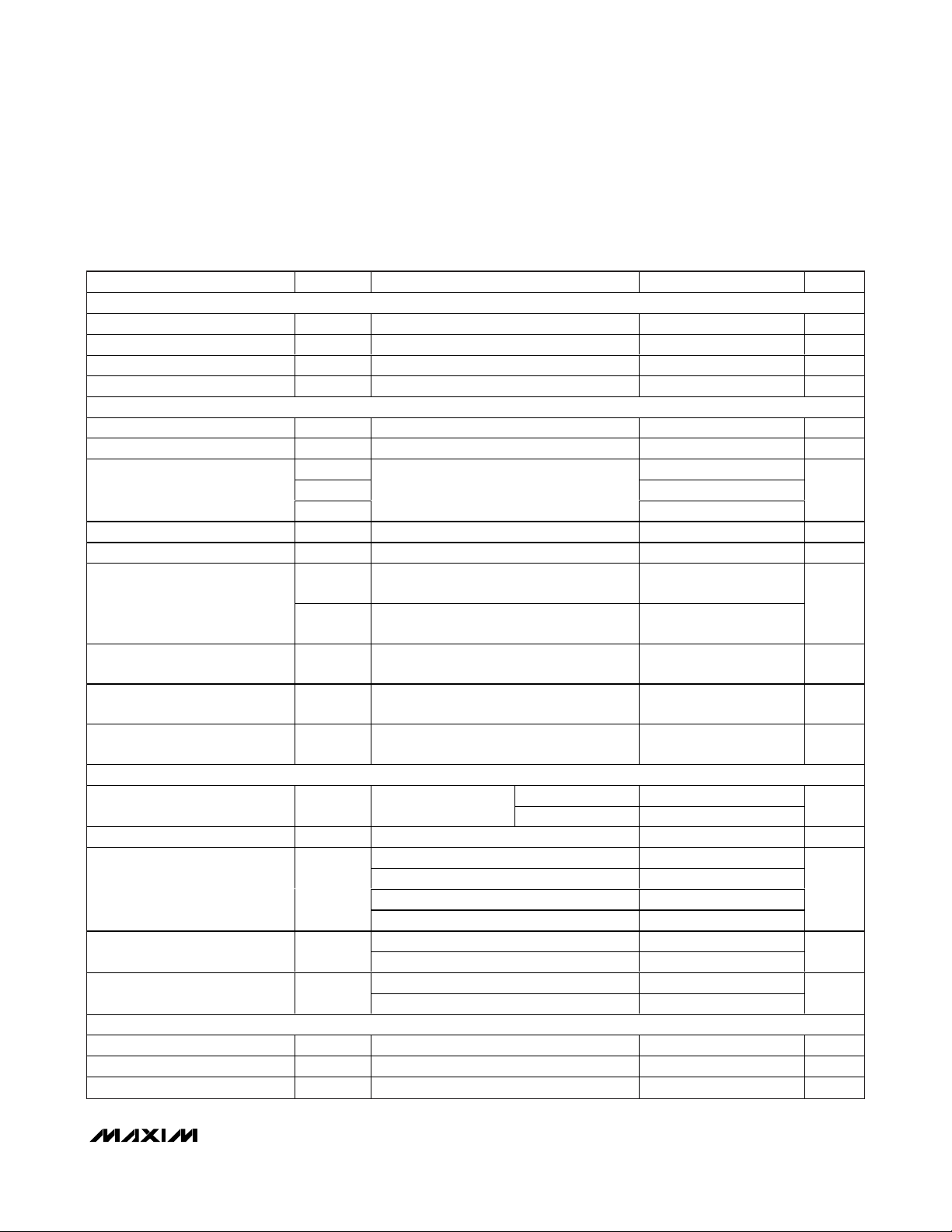

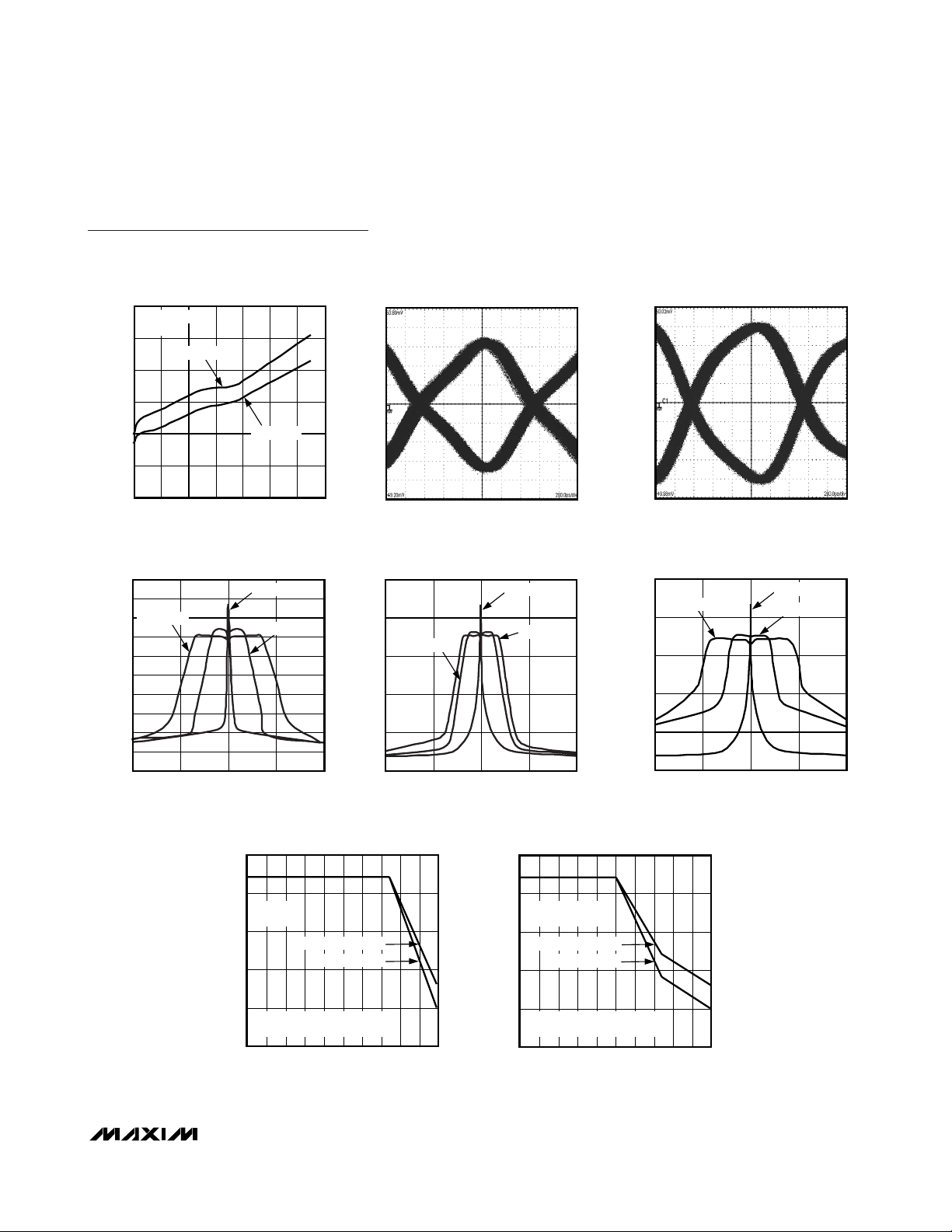

MAX9257 SUPPLY CURRENT

vs. FREQUENCY

MAX9257/58 toc01

PCLK FREQUENCY (MHz)

SUPPLY CURRENT (mA)

20 4025 3515 3010

20

40

60

80

100

120

0

545

PRBS PATTERN

18-BIT

100% PREEMPHASIS

NO PREEMPHASIS

MAX9257 SUPPLY CURRENT

vs. FREQUENCY

MAX9257/58 toc02

PCLK FREQUENCY (MHz)

SUPPLY CURRENT (mA)

5515 45

60

40

20

80

100

120

140

0

57535 6525

PRBS PATTERN

10-BIT

100% PREEMPHASIS

NO PREEMPHASIS

MAX9258 SUPPLY CURRENT

vs. FREQUENCY

MAX9257/58 toc03

PCLK FREQUENCY (MHz)

SUPPLY CURRENT (mA)

4010 3515

40

20

60

80

100

120

0

5452520 30

PRBS PATTERN

18-BIT

4% SPREAD

NO SPREAD

Typical Operating Characteristics

(V

CC_

= +3.3V, RL= 50Ω, CL= 8pF, TA= +25°C, unless otherwise noted.)

MAX9257/MAX9258

8 _______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

MAX9258 AC ELECTRICAL CHARACTERISTICS (continued)

V

CC_

= +3.0V to +3.6V, RL= 50Ω ±1%, CL= 8pF, differential input voltage |VID| = 0.1V to 1.2V, input common-mode voltage

V

CM

= |VID/2| to VCC- |VID/2|, TA= -40°C to +105°C, unless otherwise noted. Typical values are at V

CC_

= +3.3V, |VID| = 0.2V, VCM=

1.2V, T

A

= +25°C. (Notes 5, 6, and 7)

Note 2: Current into a pin is defined as positive. Current out of a pin is defined as negative. All voltages are referenced to ground

except V

TH

and VTL.

Note 3: Maximum and minimum limits over temperature are guaranteed by design and characterization. Devices are production

tested at T

A

= +105°C.

Note 4: One output at a time.

Note 5: AC parameters are guaranteed by design and characterization, and are not production tested.

Note 6: C

L

includes probe and test jig capacitance.

Note 7: t

T

is the period of the PCLK_OUT.

Note 8: For high-speed mode timing, see the

Detailed Description

section.

Note 9: I

2

C timing parameters are specified for fast-mode I2C. Max data rate = 400kbps.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Data Valid Before PCLK_ OUT t

Data Valid After PCLK_OUT t

Serial-to-Parallel Delay

Power-Up Delay t

Power-Down to High Impedance t

DVB

DVA

t

SPD1

t

SPD2

PUD

PDD

(Figure 11)

(Figure 11)

Spread off (Figure 14) 8t

±4% spread 40t

(Figure 12) 100 ns

(Figure 13) 100 ns

Each half of the UI, 12 bit,

Jitter Tolerance t

JT

SRATE = 840Mbps, PRBS

No spread 0.25 0.30 UI

pattern (Figure 15)

0.35 x

t

T

0.35 x

t

T

ns

ns

T

ns

T

Page 9

MAX9257/MAX9258

_______________________________________________________________________________________ 9

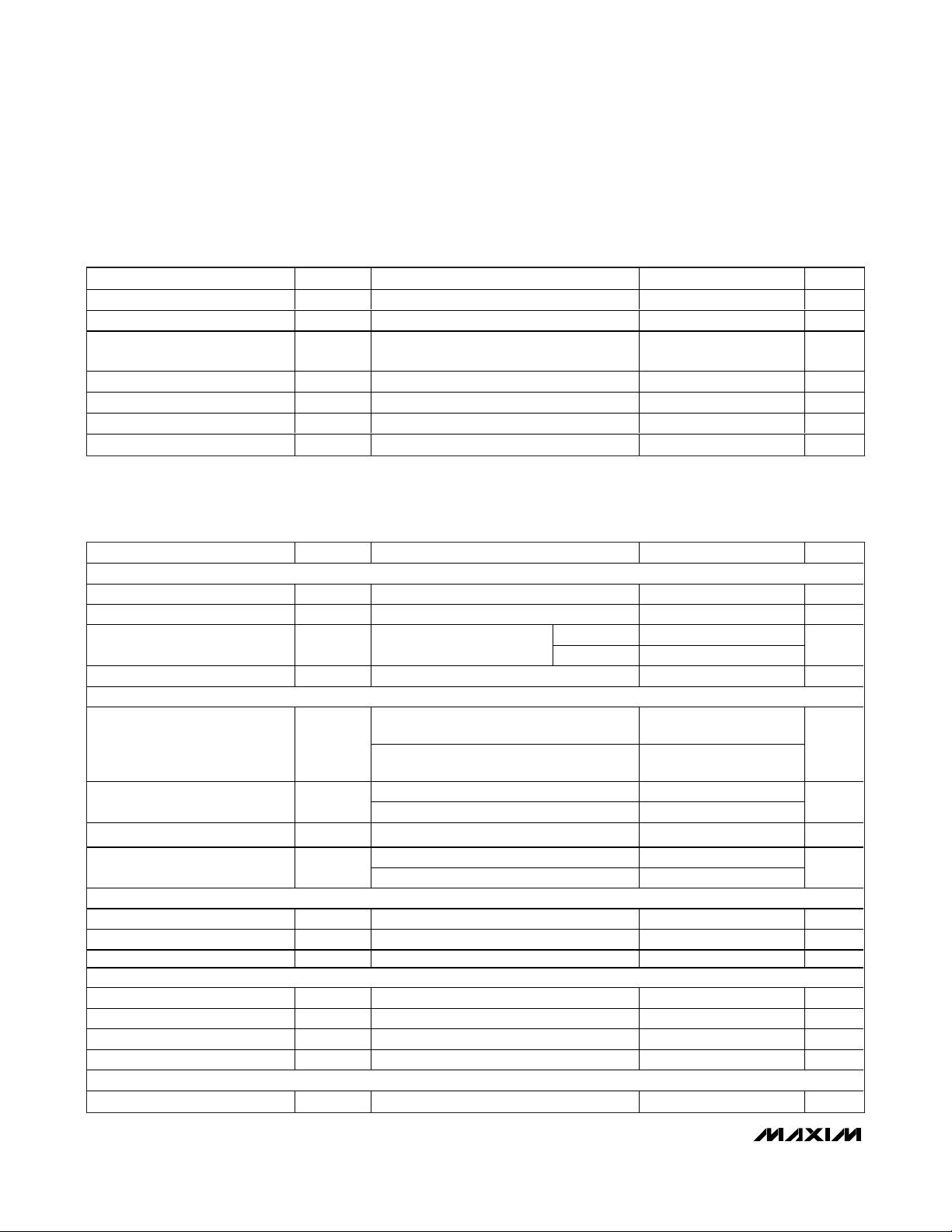

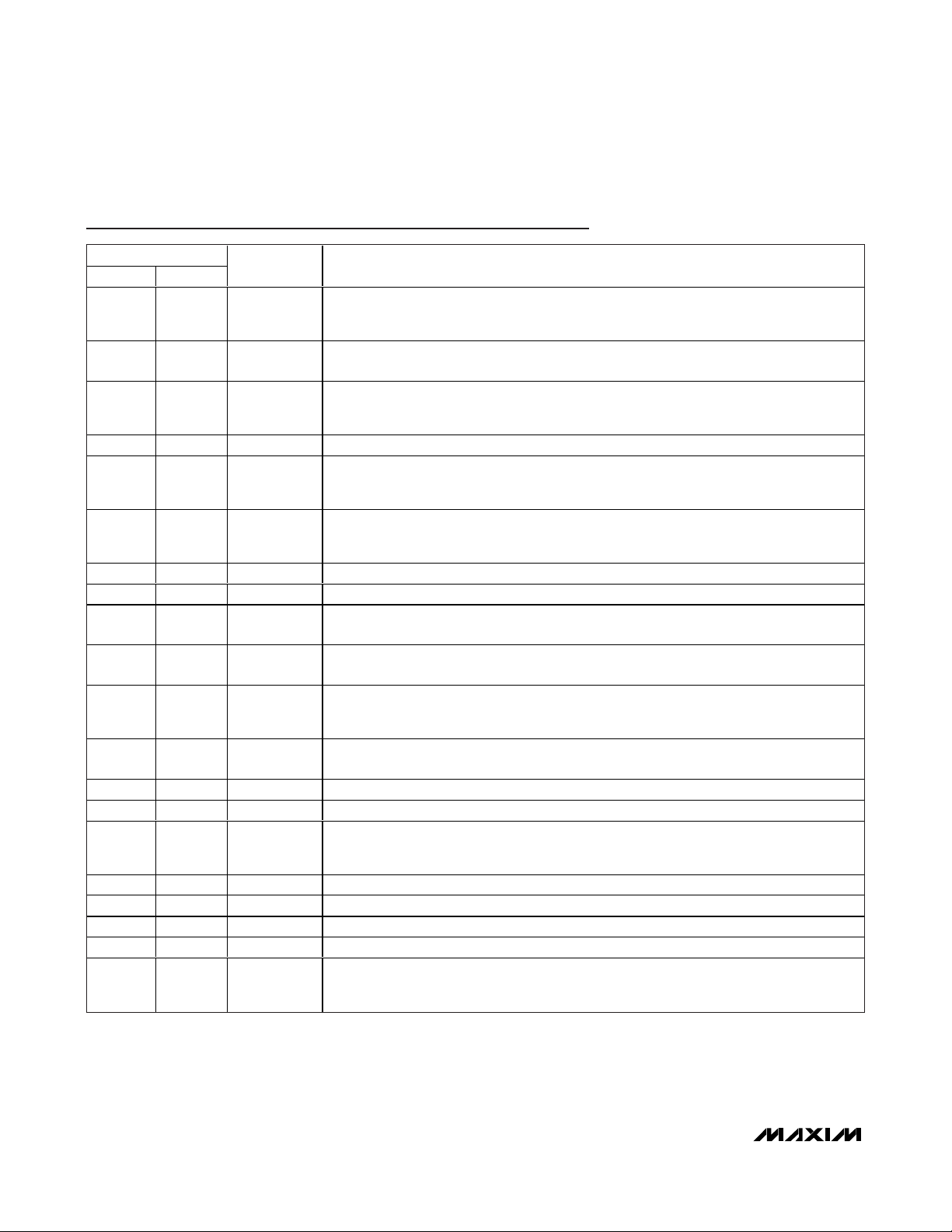

Typical Operating Characteristics (continued)

(V

CC_

= +3.3V, RL= 50Ω, CL= 8pF, TA= +25°C, unless otherwise noted.)

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

MAX9258 SUPPLY CURRENT

vs. FREQUENCY

120

PRBS PATTERN

10-BIT

100

80

60

40

SUPPLY CURRENT (mA)

20

0

4% SPREAD

5452520 30

PCLK FREQUENCY (MHz)

MAX9257 OUTPUT POWER

SPECTRUM vs. PCLK FREQUENCY

20

10kHz BW

10

4% SPREAD

0

-10

-20

-30

-40

-50

-60

OUTPUT POWER SPECTRUM (dBm)

-70

-80

18 2220

PCLK FREQUENCY (MHz)

900

NO SPREAD

4010 3515

NO SPREAD

2% SPREAD

2119

BIT ERROR RATE (< 10-9) vs.

CABLE LENGTH

SERIAL LINK SWITCHING PATTERN WITHOUT

PREEMPHASIS (BIT RATE = 840MHz, 2m STP CABLE)

MAX9257/58 toc04

MAX9257 OUTPUT POWER

SPECTRUM vs. PCLK FREQUENCY

20

10kHz BW

0

MAX9257/58 toc07

1.5% SPREAD

-20

-40

-60

OUTPUT POWER SPECTRUM (dBm)

-80

38 4642

NO SPREAD

PCLK FREQUENCY (MHz)

900

PREEMPHASIS (BIT RATE = 840MHz, 2m STP CABLE)

MAX9257/58 toc05

2% SPREAD

4440

MAX9257/58 toc08

OUTPUT POWER SPECTRUM (dBm)

BIT ERROR RATE (< 10-9) vs.

CABLE LENGTH

SERIAL LINK SWITCHING PATTERN WITH

(PREEMPHASIS = 100%)

MAX9258 OUTPUT POWER

SPECTRUM vs. PCLK FREQUENCY

20

10kHz BW

4% SPREAD

0

-20

-40

-60

-80

38 4642

PCLK FREQUENCY (MHz)

NO SPREAD

2% SPREAD

4440

MAX9257/58 toc06

MAX9257/58 toc09

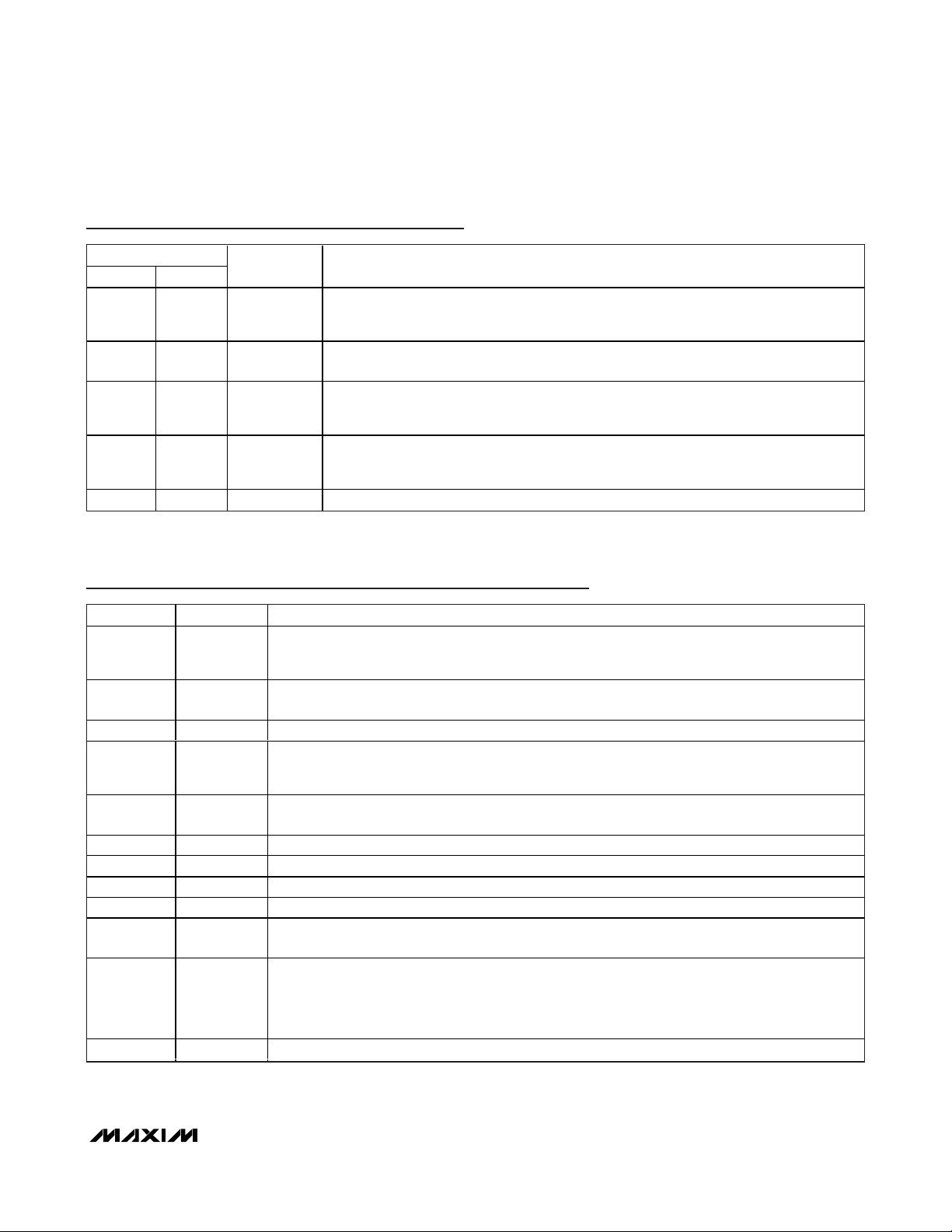

800

NO SPREAD

STP CABLE

700

600

SERIAL-DATA RATE (Mbps)

500

BER CAN BE AS LOW AS 10

CABLE LENGTHS LESS THAN 10m.

400

0862 4 10 12 14 16 18 20

100% PREEMPHASIS

NO PREEMPHASIS

-12

CABLE LENGTH (m)

MAX9257/58 toc10

FOR

800

2% SPREAD ON

MAX9257, STP CABLE

700

100% PREEMPHASIS

600

SERIAL-DATA RATE (Mbps)

500

400

NO PREEMPHASIS

BER CAN BE AS LOW AS 10

CABLE LENGTHS LESS THAN 10m.

0862 4 10 12 14 16 18 20

CABLE LENGTH (m)

-12

FOR

MAX9257/58 toc11

Page 10

MAX9257/MAX9258

10 ______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

MAX9257 Pin Description

PIN

TQFN LQFP

1, 18 2, 21 V

2, 11,

19, 34

3–8 4–9

9 10 GND

10 11 V

12 15 DIN15/GPIO7

13 16 HSYNC_IN Horizontal SYNC Input. HSYNC_IN is internally pulled down to ground.

14 17 VSYNC_IN Vertical SYNC Input. VSYNC_IN is internally pulled down to ground.

15 18 PCLK_IN

16 19 SCL/TX

17 20 SDA/RX

20, 33 23, 40 V

21 26 GPIO8 General Purpose Input/Output

22 27 GPIO9 General Purpose Input/Output

23 28 V

24 29 GND

25 30 GND

26 31 SDO- Serial LVDS Inverting Output

27 32 SDO+ Serial LVDS Noninverting Output

28 33 V

3, 14,

22, 41

NAME FUNCTION

Single-Ended Input/Output Buffer Supply Voltage. Bypass V

CCIO

GND Digital Supply Ground

DIN[9:14]/

GPIO[1:6]

FPLL

CCFPLL

CC

CCSPLL

SPLL

LVDS

CCLVDS

0.001µF capacitors in parallel as close as possible to the device with the smallest value

capacitor closest to V

Data Input/General Purpose Input/Output. When a serial-data word is less than 18 bits

word length, DIN_ not programmed as data inputs becomes GPIO (Table 22). DIN[9:14]

are internally pulled down to ground.

Filter PLL Ground

Filter PLL Supply Voltage. Bypass V

in parallel as close as possible to the device with the smallest value capacitor closest to

V

Data Input/General Purpose Input/Output. When a serial-data word is less than 18 bits

word length, DIN_ not programmed as data input becomes GPIO (Table 22). DIN15 is

internally pulled down to ground.

Parallel Clock Input. PCLK_IN latches data and sync inputs and provides the PLL reference

clock. PCLK_IN is internally pulled down to ground.

O p en- D r ai n C ontr ol C hannel Outp ut. S C L/TX b ecom es S C L outp ut w hen U ART- to- I

acti ve. S C L/TX b ecom es TX outp ut w hen U ART- to- I

Open-Drain Control Channel Input/Output. SDA/RX becomes bidirectional SDA when

UART-to-I2C is active. SDA/RX becomes RX input when UART-to-I2C is bypassed. SDA

output requires a pullup to V

Digital Supply Voltage. Bypass VCC to ground with 0.1µF and 0.001µF capacitors in p ar al l el

as cl ose as p ossi b l e to the d evi ce w i th the sm al l est val ue cap aci tor cl osest to V

Spread PLL Supply Voltage. Bypass V

capacitors in parallel as close as possible to the device with the smallest value capacitor

closest to V

SPLL Ground

LVDS Ground

LVDS Supply Voltage. Bypass V

parallel as close as possible to the device with the smallest value capacitor closest to

V

CCFPLL

CCLVDS

.

CCSPLL

.

.

CCIO

.

to GND

CCFPLL

.

CC

to GND

CCSPLL

to GND

CCLVDS

to GND with 0.1µF and

CCIO

with 0.1µF and 0.001µF capacitors

FPLL

2

C i s b yp assed . E xter nal l y p ul l up to V

with 0.1µF and 0.001µF

SPLL

with 0.1µF and 0.001µF capacitors in

LVDS

C C

2

C i s

.

C C

.

Page 11

MAX9257/MAX9258

______________________________________________________________________________________ 11

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

MAX9257 Pin Description (continued)

MAX9258 Pin Description

PIN

TQFN LQFP

29 34 REM

30, 31, 32,

35–39

40 47 DIN8/GPIO0

—

— — EP Exposed Pad for Thin QFN Package Only. Connect EP to ground.

35, 38,

39, 42–46

1, 12, 13

24, 25,

36, 37, 48

NAME FUNCTION

Remote Power-Up/Power-Down Select Input. Connect REM to ground for power-up to

follow VCC. Connect REM high to VCC through 10kΩ resistor for remote power-up. REM is

internally pulled down to GND.

DIN[0:7] Data Inputs. DIN[0:7] are internally pulled down to ground.

Data Input/General Purpose Input/Output. When a serial-data word is less than 18 bits

word length, DIN_ not programmed as data input becomes GPIO (Table 22). DIN8 is

internally pulled down to ground.

N.C. No Connection. Not internally connected.

PIN NAME FUNCTION

1, 12, 13, 24,

25, 36,

37

2V

3, 14 GND Digital Supply Ground

4 PD

5V

6 SDI- Serial LVDS Inverting Input

7 SDI+ Serial LVDS Noninverting Input

8 GND

9 GND

10 V

11 ERROR

15 RX LVCMOS/LVTTL Control Channel UART Output

N.C. No Connection. Not internally connected.

CC

CCLVDS

LVDS

PLL

CCPLL

Digital Supply Voltage. Bypass VCC to GND with 0.1µF and 0.001µF capacitors in parallel as close

as possible to the device with the smallest value capacitor closest V

LVCMOS/LVTTL Power-Down Input. Drive PD high to power up the device and enable all outputs.

Drive PD low to put all outputs in high impedance and reduce supply current. PD is internally pulled

down to ground.

LVDS Supply Voltage. Bypass V

as close as possible to the device with the smallest value capacitor closest to V

LVDS Supply Ground

PLL Supply Ground

PLL Supply Voltage. Bypass V

close to the device as possible with the smallest value capacitor closest to V

Active-Low, Open-Drain Error Output. ERROR asserts low to indicate a data transfer error was

detected (parity, PRBS, or UART control channel error). ERROR is high to indicate no error detected.

ERROR resets when the error registers are read for parity, control channel errors, and when PRBS

enable bit is reset for PRBS errors. Pull up to V

CCLVDS

CCPLL

to GND

to GND

PLL

with 0.1µF and 0.001µF capacitors in parallel

LVDS

with 0.1µF and 0.001µF capacitors in parallel as

with a 1kΩ resistor.

CCOUT

CC

.

.

CCLVDS

.

CCPLL

Page 12

MAX9257/MAX9258

12 ______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

MAX9258 Pin Description (continued)

PIN NAME FUNCTION

16 TX LVCMOS/LVTTL Control Channel UART Input. TX is internally pulled up to V

Open-Drain Lock Output. LOCK asserts high to indicate PLLs are locked with correct serial-word

17 LOCK

18 PCLK_OUT LVCMOS/LVTTL Recovered Clock Output

19 VSYNC_OUT LVCMOS/LVTTL Vertical SYNC Output

20 HSYNC_OUT LVCMOS/LVTTL Horizontal SYNC Output

21, 28–35,

40–46

22, 39 V

23, 38, 48 GND

26 V

27 GND

47 CCEN

DOUT[15:0] LVCMOS/LVTTL Data Outputs

CCOUT

OUT

CCSPLL

SPLL

boundary alignment. LOCK asserts low to indicate PLLs are not locked or incorrect serial-word

boundary alignment was detected. Pull up to V

Output Supply Voltage. V

0.1µF and 0.001µF capacitors in parallel as close as possible to the device with the smallest value

capacitor closest to V

Output Supply Ground

Spread-Spectrum PLL Supply Voltage. Bypass V

capacitors in parallel as close as possible to the device with the smallest value capacitor closest to

V

SPLL Ground

LVCMOS/LVTTL Control Channel Enabled Output. CCEN asserts high to indicate that control

channel is enabled.

CCSPLL

.

CCOUT

CCOUT

with a 1kΩ resistor.

CCOUT

is the supply for all output buffers. Bypass V

.

to GND

CCSPLL

SPLL

CCOUT

CCOUT

with 0.1µF and 0.001µF

.

to GND

OUT

with

Page 13

MAX9257/MAX9258

______________________________________________________________________________________ 13

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

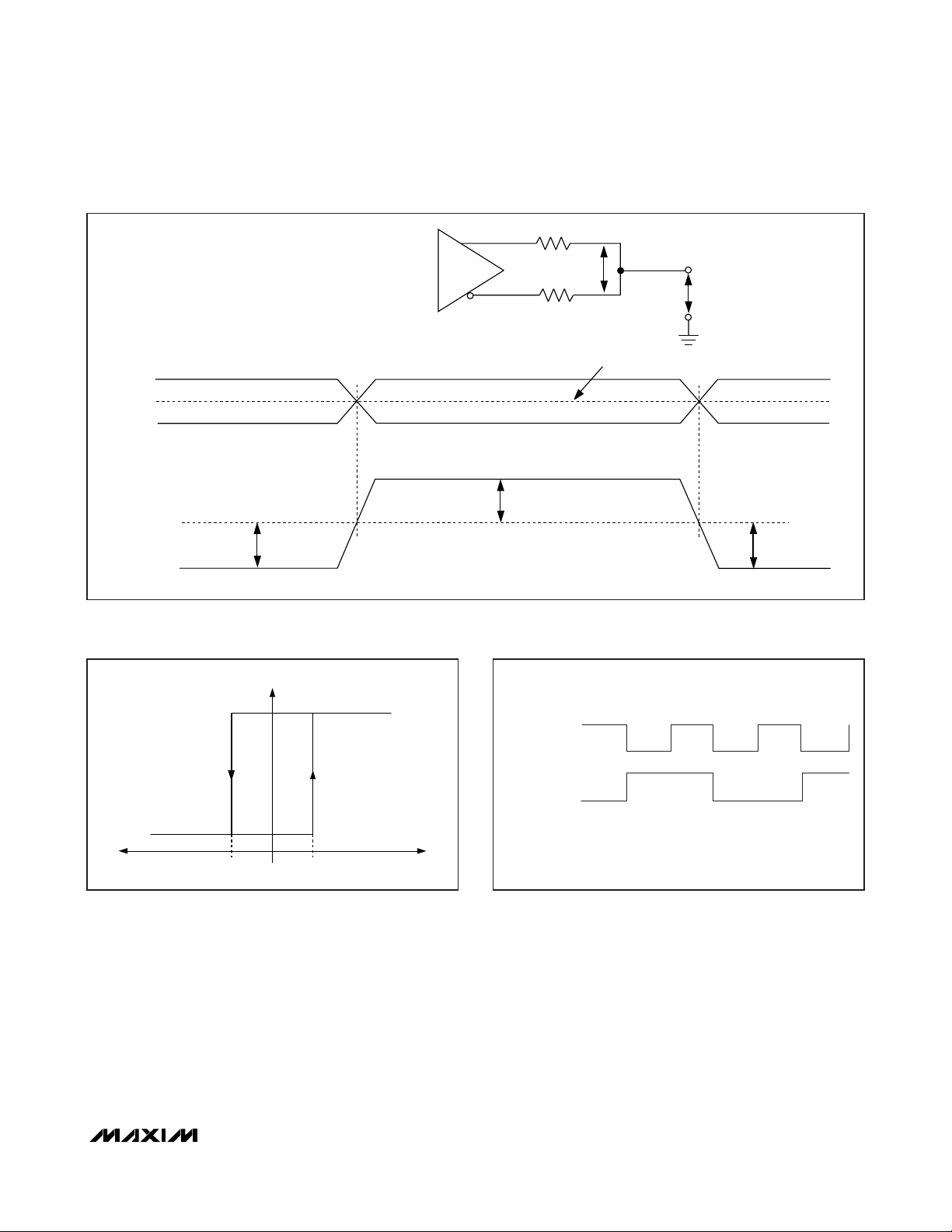

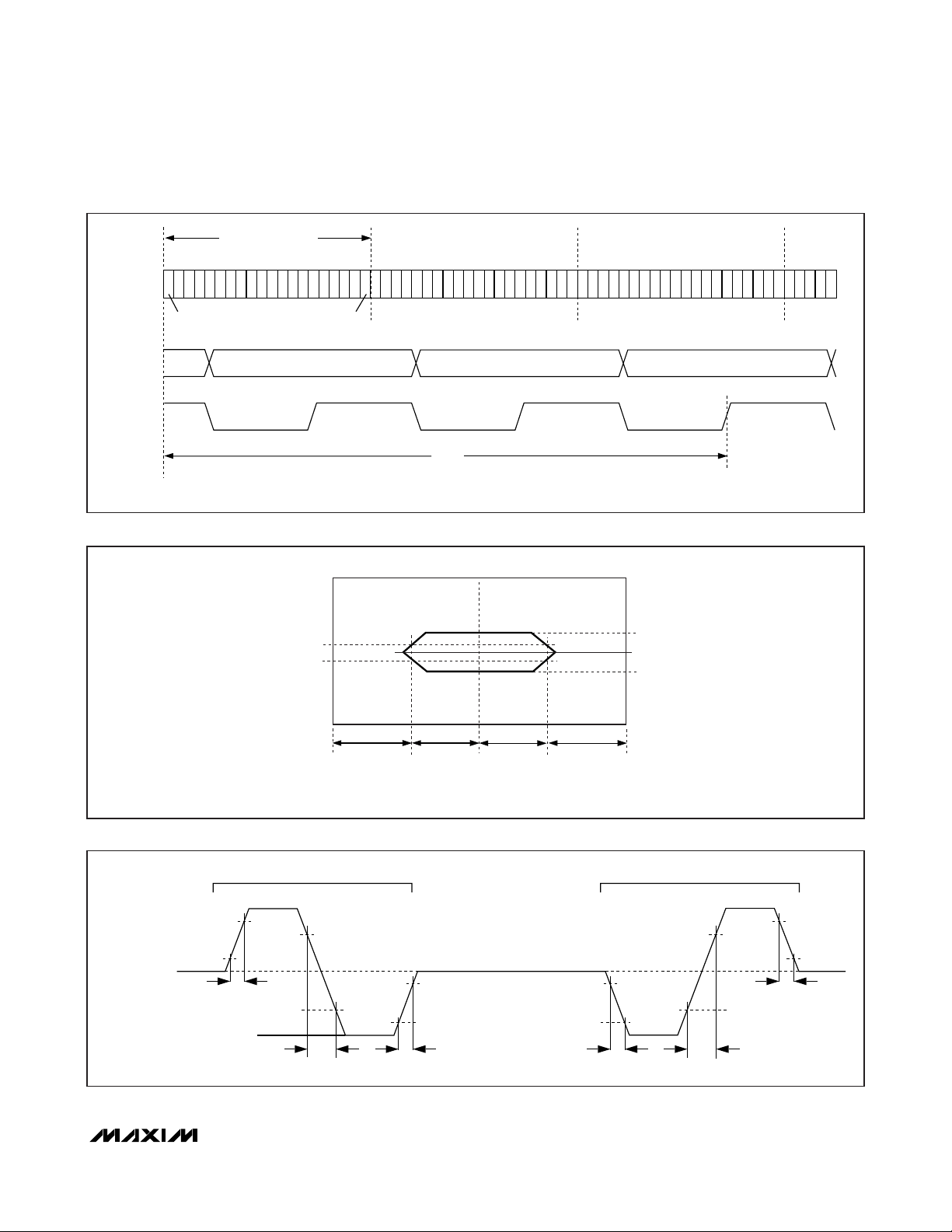

Figure 1. MAX9257 LVDS DC Output Parameters

Figure 2. Input Hysteresis

Figure 3. MAX9257 Worst-Case Pattern Input

SDO-

SDO+

(SDO+) - (SDO-)

(-) VOS(+)

V

OS

V

(-)

OD

/2

R

SDO+

SDO-

ΔV

OS

ΔVOD = |VOD(+) - VOD(-)|

L

/2

R

L

((SDO+) + (SDO-))/2

= |VOS(+) - VOS(-)|

VOD(+)

V

OD

V

OS

GND

V

(-)

OS

= 0V

V

OD

(-)

V

OD

-V

ID

V

HYST-

V

OUT

VID = 0V

V

HYST+

PCLK_IN

DIN

NOTE: PCLK_IN PROGRAMMED FOR RISING LATCH EDGE.

+V

ID

Page 14

MAX9257/MAX9258

14 ______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

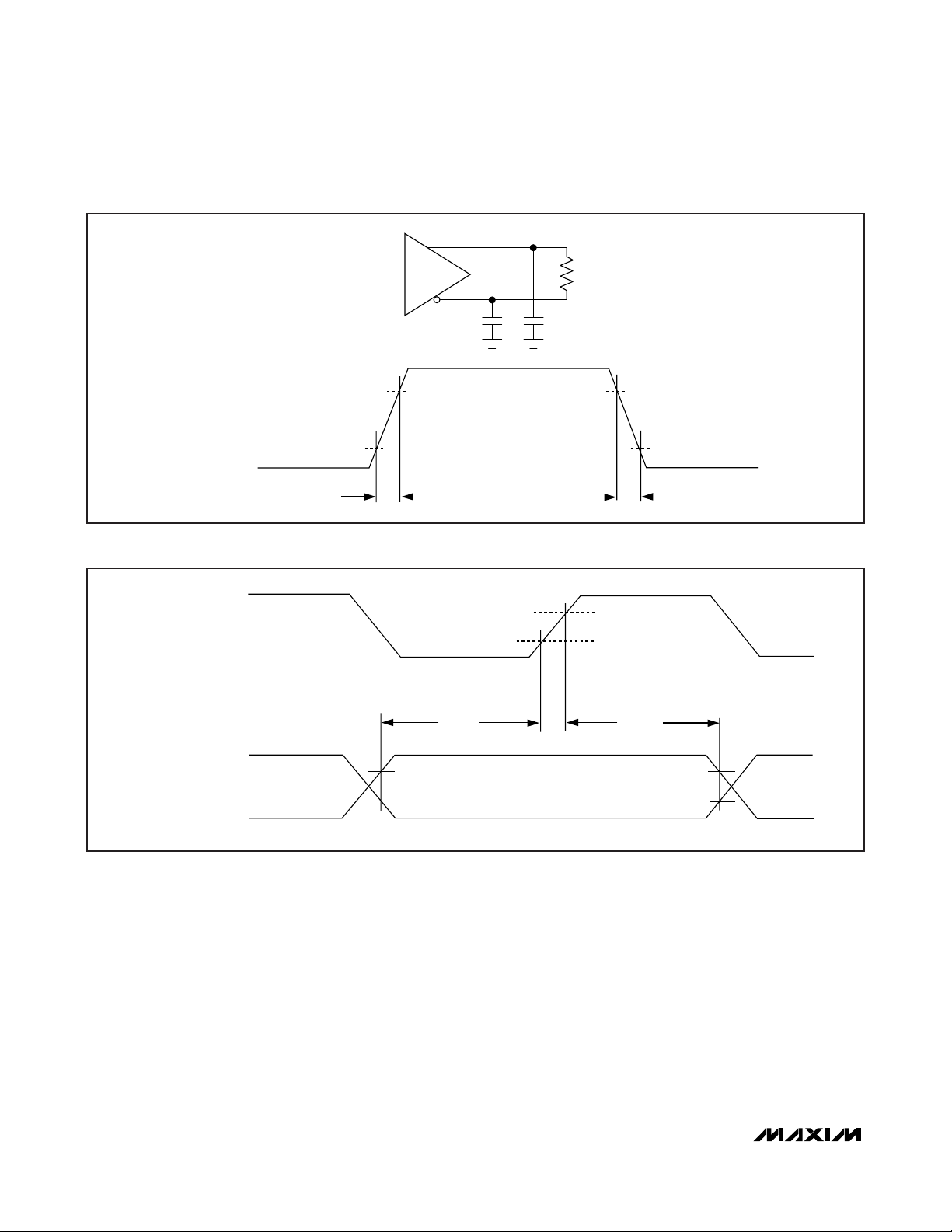

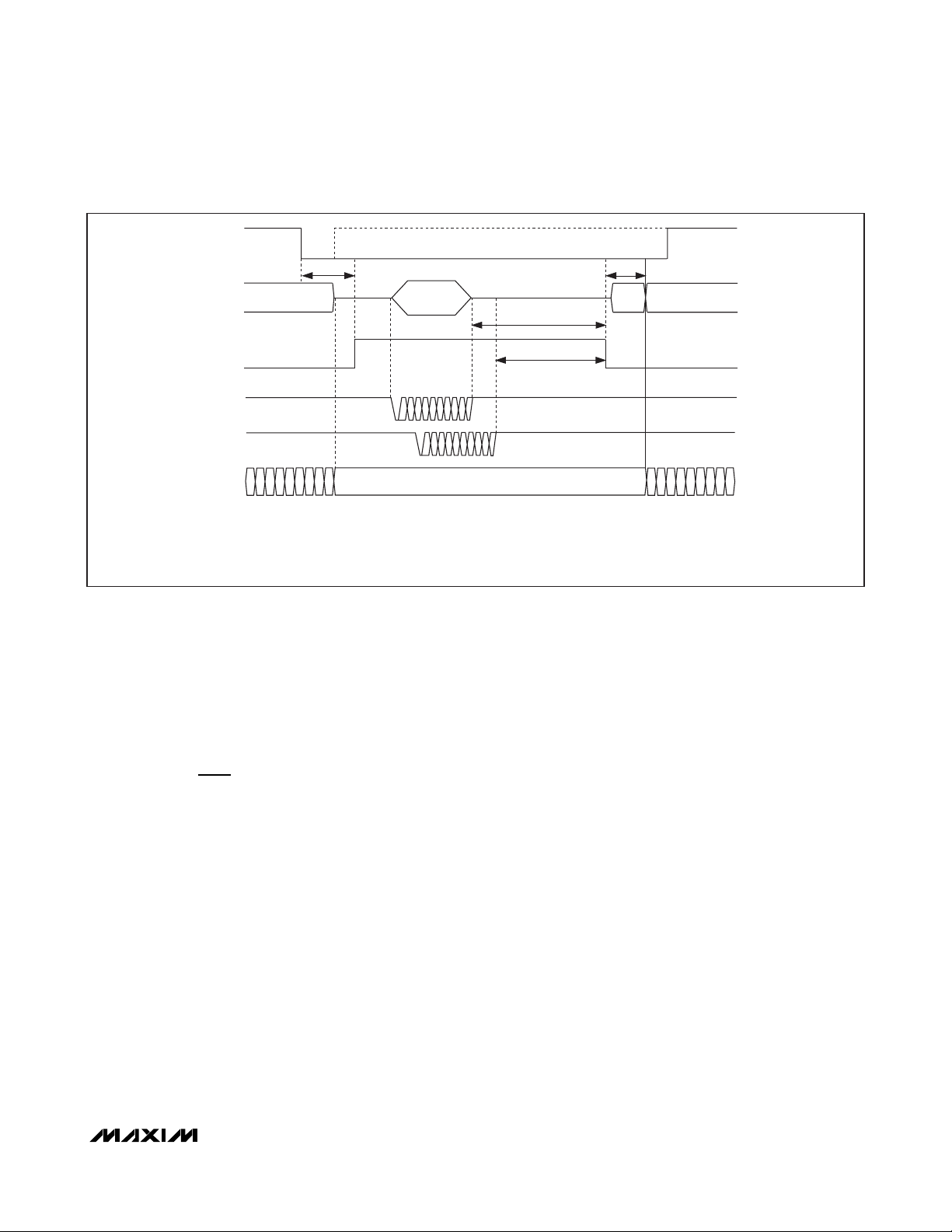

Figure 4. MAX9257 LVDS Control Channel Output Load and Output Rise/Fall Times

Figure 5. MAX9257 Input Setup and Hold Times

SDO+

R

L

SDO-

C

L

80%

(SDO+) - (SDO-)

t

RISE

PCLK_IN

V

ILMAX

t

SET

V

DIN, VSYNC_IN, HSYNC_IN

V

IHMIN

ILMAX

C

L

80%

20%20%

t

FALL

V

IHMIN

t

HOLD

V

IHMIN

V

ILMAX

NOTE: PCLK_IN PROGRAMMED FOR RISING LATCHING EDGE.

Page 15

MAX9257/MAX9258

______________________________________________________________________________________ 15

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

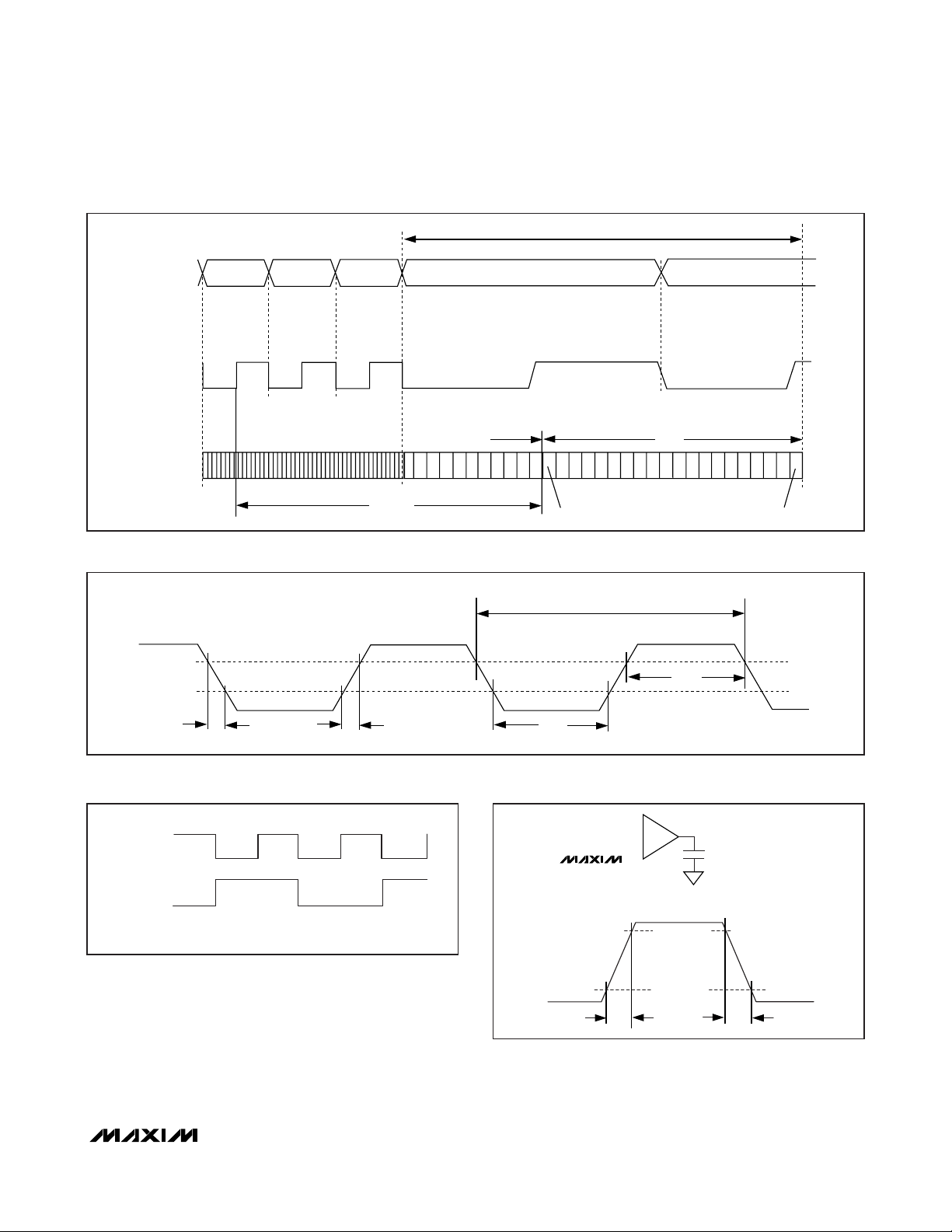

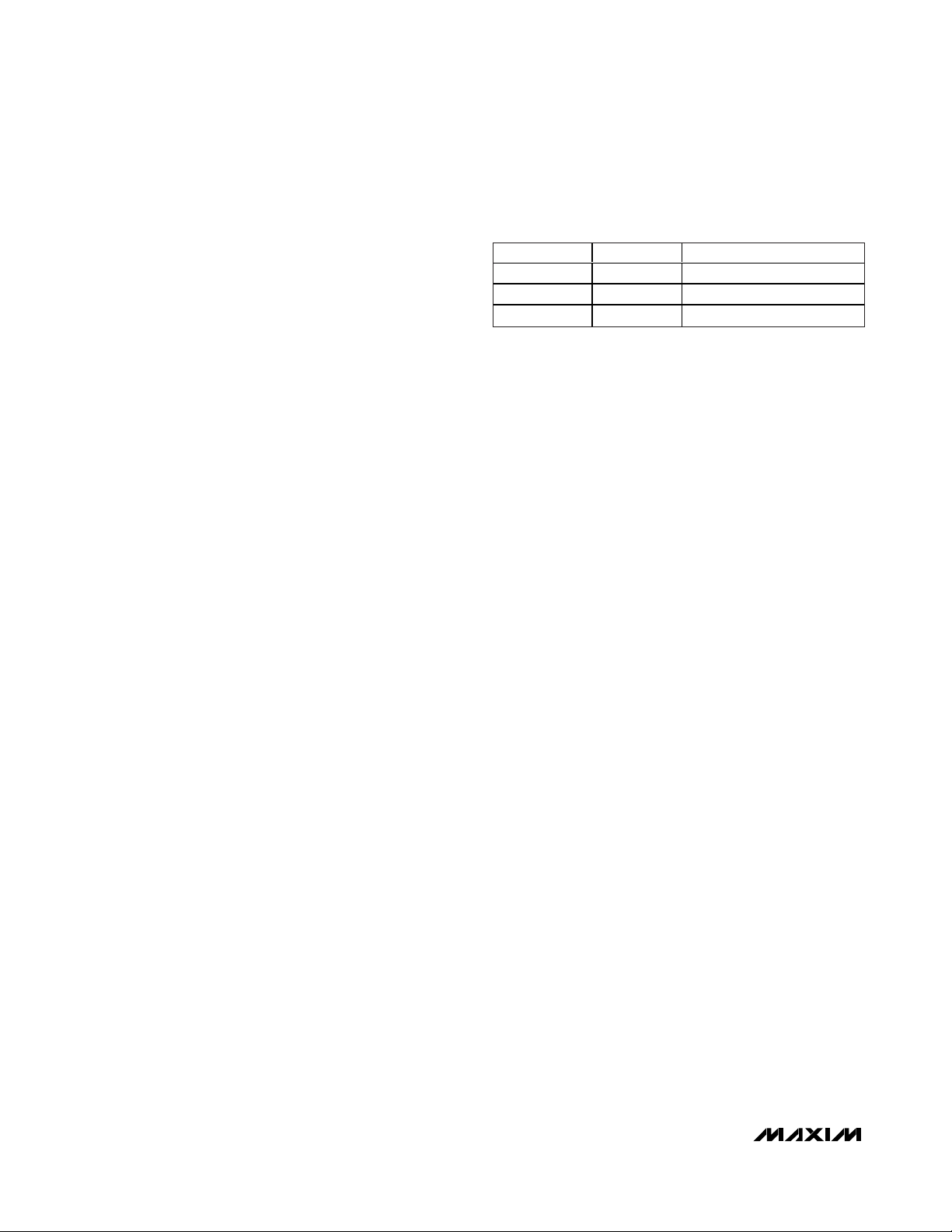

Figure 6. MAX9257 Parallel-to-Serial Delay

Figure 7. MAX9257 Parallel Input Clock Requirements

Figure 8. MAX9258 Worst-Case Pattern Output

Figure 9. MAX9258 Output Rise and Fall Times

DIN, HSYNC_IN,

VSYNC_IN

PCLK_IN

SDO

N

N+1

PCLK_IN

N+2

t

PSD1

N-1

EXPANDED TIME SCALE

N+3

N

FIRST BIT LAST BIT

t

T

t

HIGH

N+4

V

V

IHMIN

ILMAX

t

F

t

R

PCLK_OUT

DOUT

NOTE: PCLK_OUT PROGRAMMED FOR RISING LATCH EDGE.

t

LOW

C

L

MAX9258

SINGLE-ENDED OUTPUT LOAD

0.9 x V

CCOUT

0.1 x V

CCOUT

t

R

t

F

Page 16

MAX9257/MAX9258

16 ______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

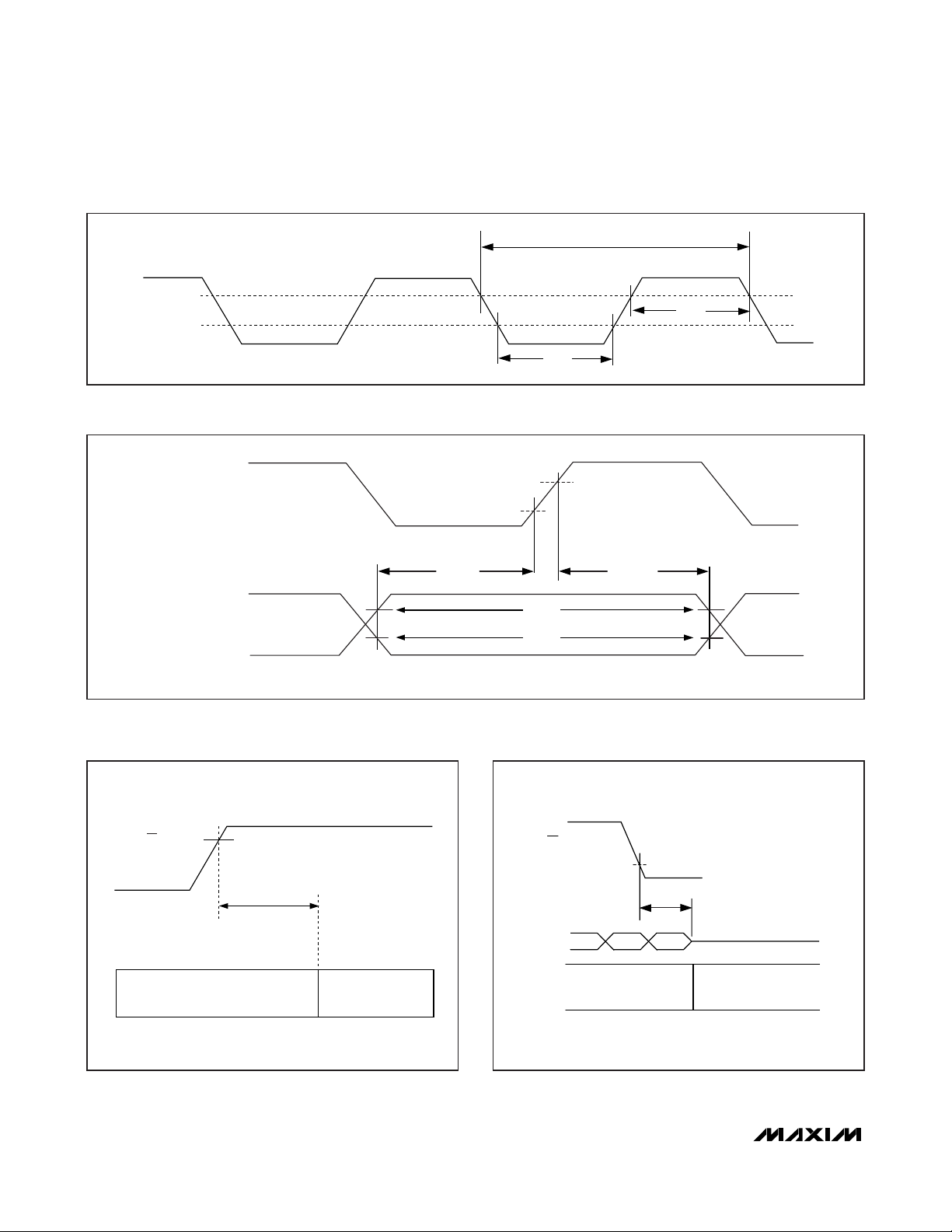

Figure 10. MAX9258 Clock Output High and Low Time

Figure 11. MAX9258 Output Data Valid Times

Figure 12. MAX9258 Power-Up Delay

Figure 13. MAX9258 Power-Down Delay

t

T

t

PCLK_OUT

t

LOW

HIGH

V

PCLK_OUT

V

OLMAX

OHMIN

V

OHMIN

V

OLMAX

DOUT, VSYNC_OUT,

HSYNC_OUT, LOCK

PD

POWERED DOWN

V

IHMIN

t

PUD

POWERED UP

(OUTPUTS ACTIVE)

t

DVB

V

OHMIN

V

OLMAX

NOTE: PCLK_OUT PROGRAMMED FOR RISING LATCHING EDGE.

PD

DOUT,

VSYNC,

HSYNC

V

ILMAX

t

DVA

t

PDD

HIGH IMPEDANCE

POWERED DOWNPOWERED UP

Page 17

MAX9257/MAX9258

______________________________________________________________________________________ 17

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

Figure 14. MAX9258 Serial-to-Parallel Delay

Figure 15. MAX9258 Jitter Tolerance

Figure 16. Control Channel Transition Time

SERIAL-WORD LENGTH

SERIAL WORD N

SDI

SERIAL WORD N+1 SERIAL WORD N+2

LAST BIT

PARALLEL WORD N-2

DOUT,

HSYNC_OUT,

VSYNC_OUT

PCLK_OUT

FIRST BIT

NOTE: PCLK_OUT PROGRAMMED FOR RISING LATCHING EDGE.

+25mV

-25mV

PARALLEL WORD N-1 PARALLEL WORD N

t

SPD1

INPUT TEMPLATE FOR LVDS SERIAL

- V

V

SDI+

SDI-

+100mV

0V

-100mV

t

JT

t

S

t

S

t

JT

1.0UI0.75UI0.50UI0.25UI0.0UI

NOTE: UI IS ONE SERIAL BIT. TIME INPUT IS MEASURED DIFFERENTIALLY (V

1 0

0.8V

(SDO+) - (SDO-)

0.2V

OD(+)

0.2 x | V

OD(+)

t

R1A

+ V

OD(+)

0.8 x | V

| 0.2 x | V

OD(-)

t

F2

OD(+)

+ V

| 0.8 x | V

OD(-)

0.2V

OD(-)

0.8V

OD(-)

t

R1B

0.2V

0.8V

OD(-)

OD(-)

SDI+

- V

).

SDI-

0.8V

OD(+)

OD(+)

0.2V

OD(+)

t

F1B

+ V

|

OD(-)

+ V

OD(-)

|

t

R2

OD(+)

t

F1A

Page 18

MAX9257/MAX9258

Detailed Description

The MAX9257 serializer pairs with the MAX9258 deserializer to form a complete digital video serial link. The

electronic control unit (ECU) programs the registers in

the MAX9257, MAX9258, and peripheral devices, such

as a camera, during the control channel phase that

occurs at startup or during the vertical blanking time.

All control channel communication is half-duplex. The

UART communication between the MAX9258 and the

MAX9257 is encoded to allow transmission through ACcoupling capacitors. The MAX9257 communicates to

the peripheral device through UART or I2C.

The MAX9257/MAX9258 DC-balanced serializer and

deserializer operate from a 5MHz-to-70MHz parallel

clock frequency, and are capable of serializing and

deserializing programmable 10, 12, 14, 16, and 18 bits

parallel data during the video phase. The MAX9257/

MAX9258 have two phases of operation: video and

control channel (Figures 19 and 20). During the video

phase, the MAX9257 accepts parallel video data and

transmits serial encoded data over the LVDS link. The

MAX9258 accepts the encoded serial LVDS data and

converts it back to parallel output data. The MAX9257

has dedicated inputs for HSYNC and VSYNC. The

selected VSYNC edge causes the MAX9257/MAX9258

to enter the control channel phase. Nonactive VSYNC

edge can be asserted after eight pixel clock cycles.

The video data are coded using two overhead bits

(EN0 and EN1) resulting in a serial-word length of N+2

bits. The MAX9257/MAX9258 feature programmable

18 ______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

Figure 17. Serial Link with I2C Camera Programming Interface (Base Mode)

Figure 18. Serial Link with UART Camera Programming Interface (Bypass Mode)

CAMERAECU

VIDEO DATA

MAX9258

MAX9257

VIDEO DATA

PIXEL CLOCK

HSYNC_OUT

VSYNC_OUT

PD

CCEN

ERROR

LOCK

RX

TX

DESERIALIZER

UARTUART

VIDEO DATA

PIXEL CLOCK

HSYNC_OUT

VSYNC_OUT

PD

CCEN

ERROR

LOCK

RX

TX

MAX9258

DESERIALIZER

UARTUART

PIXEL CLOCK

SERIALIZER

100Ω100Ω

UART-

2

C

TO-I

MAX9257

SERIALIZER

100Ω100Ω

UART

HSYNC_IN

VSYNC_IN

GPIO

SDA

SCL

VIDEO DATA

PIXEL CLOCK

HSYNC_IN

VSYNC_IN

GPIO

RX

TX

I2C

CAMERAECU

UART

Page 19

parity encoding that adds two parity bits to the serial

word. Bit 0 (EN0) is the LSB that is serialized first without parity enabled. The parity bits are serialized first

when parity is enabled.

The ECU programs the MAX9258, MAX9257, and

peripheral devices at startup and during the control

channel phase. In a digital video system, the control

channel phase occurs during the vertical blanking time

and synchronizes to the VSYNC signal. The programmable active edge of VSYNC initiates the control channel

phase. Nonactive edge of VSYNC can transition at any

time after 8 x t

T

if MAX9257 spread is not enabled and

0.5/f

SSM

when enabled. At the end of video phase, the

MAX9258 drives CCEN high to indicate to the ECU that

the control channel is open. Programmable timers and

ECU signal activity determine how long the control

channel stays open. The timers are reset by ECU signal

activity. ECU programming must not exceed the vertical

blanking time to avoid loss of video data.

After the control channel phase closes, the MAX9257

sends a 546 or 1090 word pattern as handshaking

(HSK) to synchronize the MAX9258’s internal clock

recovery circuit to the MAX9257’s transmitted data.

Following the handshaking, the control channel is

closed and the video phase begins. The serial LVDS

data is recovered and parallel data is valid on the programmed edge of the recovered pixel clock.

MAX9257/MAX9258

______________________________________________________________________________________ 19

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

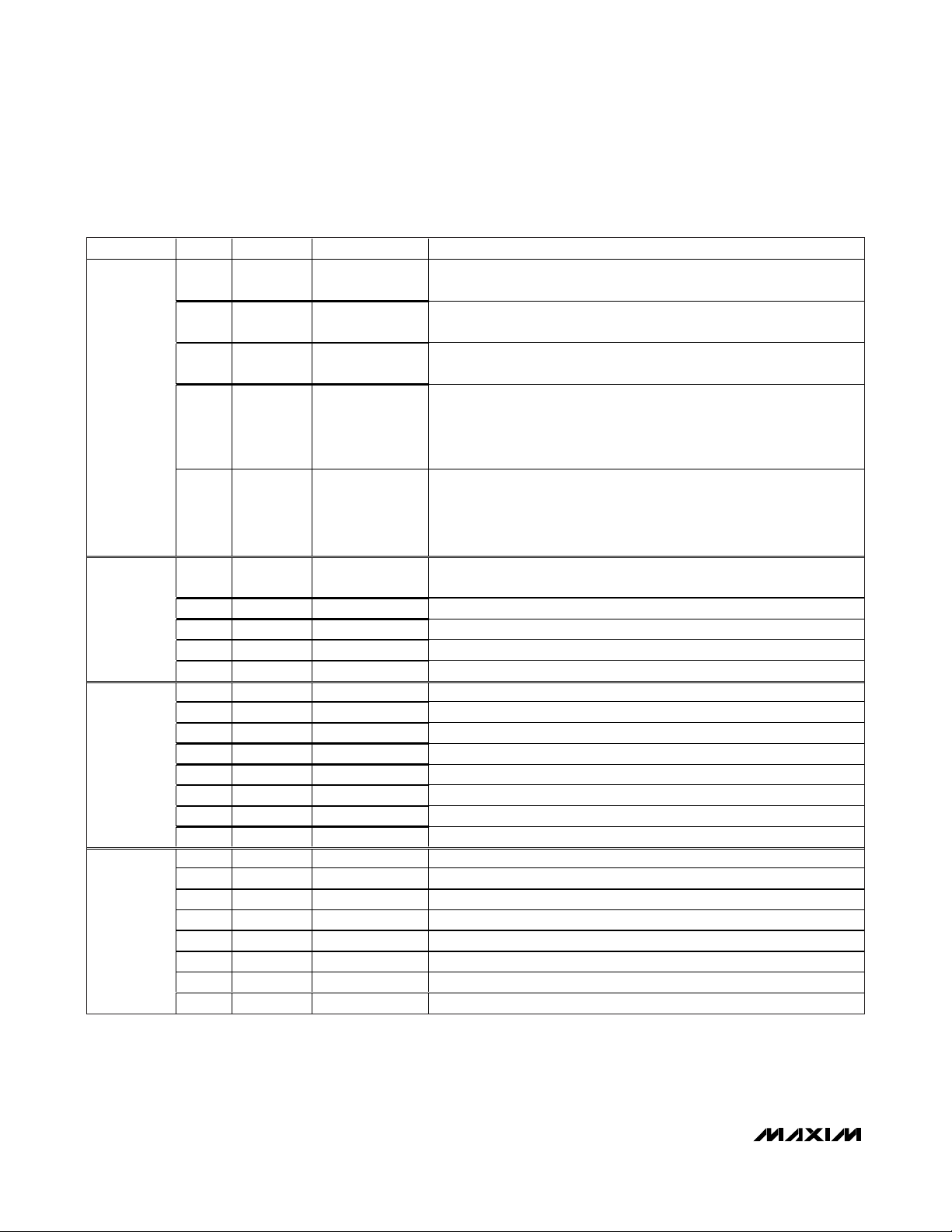

Figure 20. Video and Control Channel Phases (MAX9257 Spread is Enabled)

Figure 19. Video and Control Channel Phases (Spread Off)

8t

VSYNC_IN

SDI/O±

SDI/O±

T

VIDEO

CONTROL

HSK

VIDEO

CCEN

HSK = HANDSHAKING

0.5/f

SSM

VSYNC_IN

SDI/O±

SPREAD

PROFILE

SDI/O±

CCEN

VIDEO

(max)

CONTROL

HSK = HANDSHAKING

HSK

VIDEO

Page 20

MAX9257/MAX9258

20 ______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

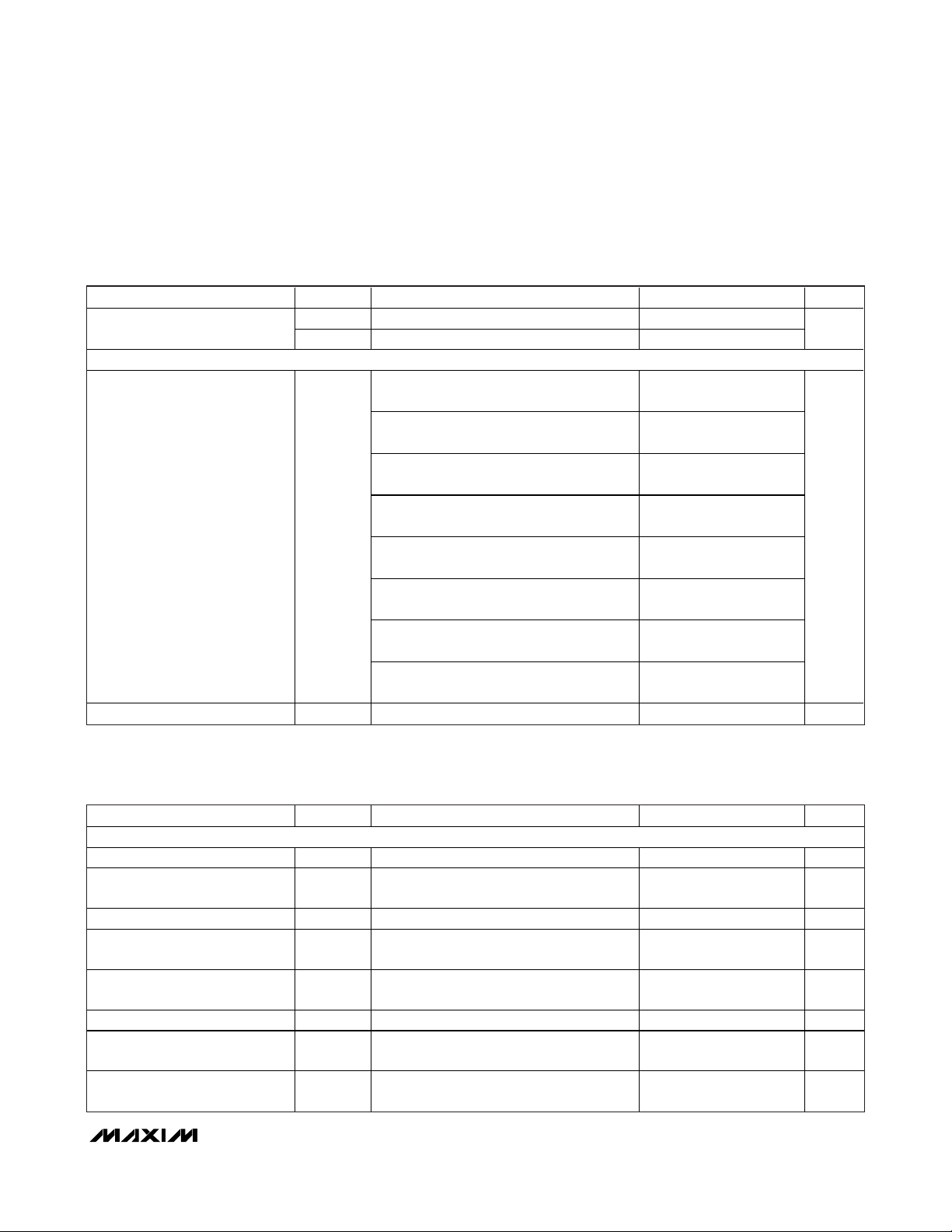

Table 1. MAX9257 Power-Up Default Register Map (see the

MAX9257 Register Table

)

REGISTER NAME

REG0 0x00 0xB5

REG1 0x01 0x1F

REG2 0x02 0xA0

REG3 0x03 0xA0

REGISTER

ADDRESS (hex)

REG4 0x04

REG5 0x05 0xFA MAX9257 address = 1111 1010

REG6 0x06 0xFF End frame = 1111 1111

REG7 0x07 0xF8 MAX9258 address = 1111 1000

REG8 0x08 0x00

REG9 0x09 0x00

REG10 0x0A 0x00

POWER-UP VALUE

(hex)

1) REM = 0, 0x28

2) REM = 1, 0x30

PRATE = 10, 20MHz to 40MHz

SRATE = 11, 400Mbps to 840Mbps

PAREN = 0, parity disabled

PWIDTH = 101, parallel data width = 18

SPREAD = 000, spread = off

Reserved = 11111

STODIV = 1010, STO clock is pixel clock divided by 1024

STOCNT = 0000, STO counter counts to 1

ETODIV = 1010, ETO clock is pixel clock divided by 1024

ETOCNT = 0000, ETO counter counts to 1

VEDGE = 0, VSYNC active edge is falling

Reserved = 0

CKEDGE = 1, pixel clock active edge is rising

PD: 1) If REM = 0, PD = 0

2) If REM = 1, PD = 1

SEREN: 1) If REM = 0, SEREN = 1

2) If REM = 1, SEREN = 0

BYPFPLL = 0, filter PLL is active

Reserved = 0

PRBSEN = 0, PRBS test disabled

INTMODE = 0, interface with peripheral is UART

INTEN = 0, interface with peripheral is disabled

FAST = 0, UART bit rate = DC to 4.25Mbps

CTO = 000, never come back

BITRATE = 00, base mode bit rate = 95kbps to 400kbps

PRBSLEN = 0000, PRBS word length = 2

GPIO9DIR = 0, GPIO9 = input

GPIO8DIR = 0, GPIO8 = input

GPIO9 = 0

GPIO8 = 0

GPIO7DIR = 0, GPIO7 = input

GPIO6DIR = 0, GPIO6 = input

GPIO5DIR = 0, GPIO5 = input

GPIO4DIR = 0, GPIO4 = input

GPIO3DIR = 0, GPIO3 = input

GPIO2DIR = 0, GPIO2 = input

GPIO1DIR = 0, GPIO1 = input

GPIO0DIR = 0, GPIO0 = input

POWER-UP DEFAULT SETTINGS

21

Page 21

MAX9257/MAX9258

______________________________________________________________________________________ 21

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

Table 1. MAX9257 Power-Up Default Register Map (continued)

Table 2. MAX9258 Power-Up Default Register Map (see the

MAX9258 Register Table

)

REGISTER NAME

REG11 0x0B 0x00

REG12 0x0C 0xE0

REG13 0x0D 0x00

REG14 0x0E 0x00

REGISTER

ADDRESS (hex)

REGISTER NAME

REG0 0x00 0xB5

REG1 0x01 0x00

REG2 0x02 0xA0

REG3 0x03 0xA0

REG4 0x04 0x20

REG5 0x05 0xF8 MAX9258 address = 1111 1000

REG6 0x06 0xFF End frame = 1111 1111

REG7 0x07 0x00

REGISTER

ADDRESS (hex)

POWER-UP VALUE

(hex)

POWER-UP VALUE

(hex)

POWER-UP DEFAULT SETTINGS

GPIO7 = 0

GPIO6 = 0

GPIO5 = 0

GPIO4 = 0

GPIO3 = 0

GPIO2 = 0

GPIO1 = 0

GPIO0 = 0

PREEMP = 111, preemphasis = 0%

Reserved = 00000

Reserved = 000000

I2CFILT = 00, I

1) 95kbps to 400kbps = 100ns

2) 400kbps to 1000kbps = 50ns

3) 1000kbps to 4250kbps = 10ns

Reserved = 0000 000

LOCKED = read only

2

C glitch filter settings:

POWER-UP DEFAULT SETTINGS

PRATE = 10, 20MHz to 40MHz

SRATE = 11, 400Mbps to 840Mbps

PAREN = 0, parity disabled

PWIDTH = 101, parallel data width = 18

SPREAD = 00, spread spectrum = off

AER = 0, error count is reset by reading error registers

Reserved = 0 0000

STODIV = 1010, STO clock is pixel clock divided by 1024

STOCNT = 0000, STO counter counts to 1

ETODIV = 1010, ETO clock is pixel clock divided by 1024

ETOCNT = 0000, ETO counter counts to 1

VEDGE = 0, VSYNC active edge is falling

HEDGE = 0, HSYNC active edge is falling

CKEDGE = 1, pixel clock active edge is rising

Reserved = 0000

PRBSEN = 0, PRBS test disabled

INTMODE = 0, interface with peripheral is UART

INTEN = 0, interface with peripheral is disabled

FAST = 0, UART bit rate = DC to 4.25Mbps

CTO = 000, never come back

BITRATE = 00, base mode bit rate = 95kbps to 400kbps

Page 22

MAX9257/MAX9258

Tables 1 and 2 show the default power-up values for

the MAX9257/MAX9258 registers. Tables 3 and 4 show

the input and output supply references.

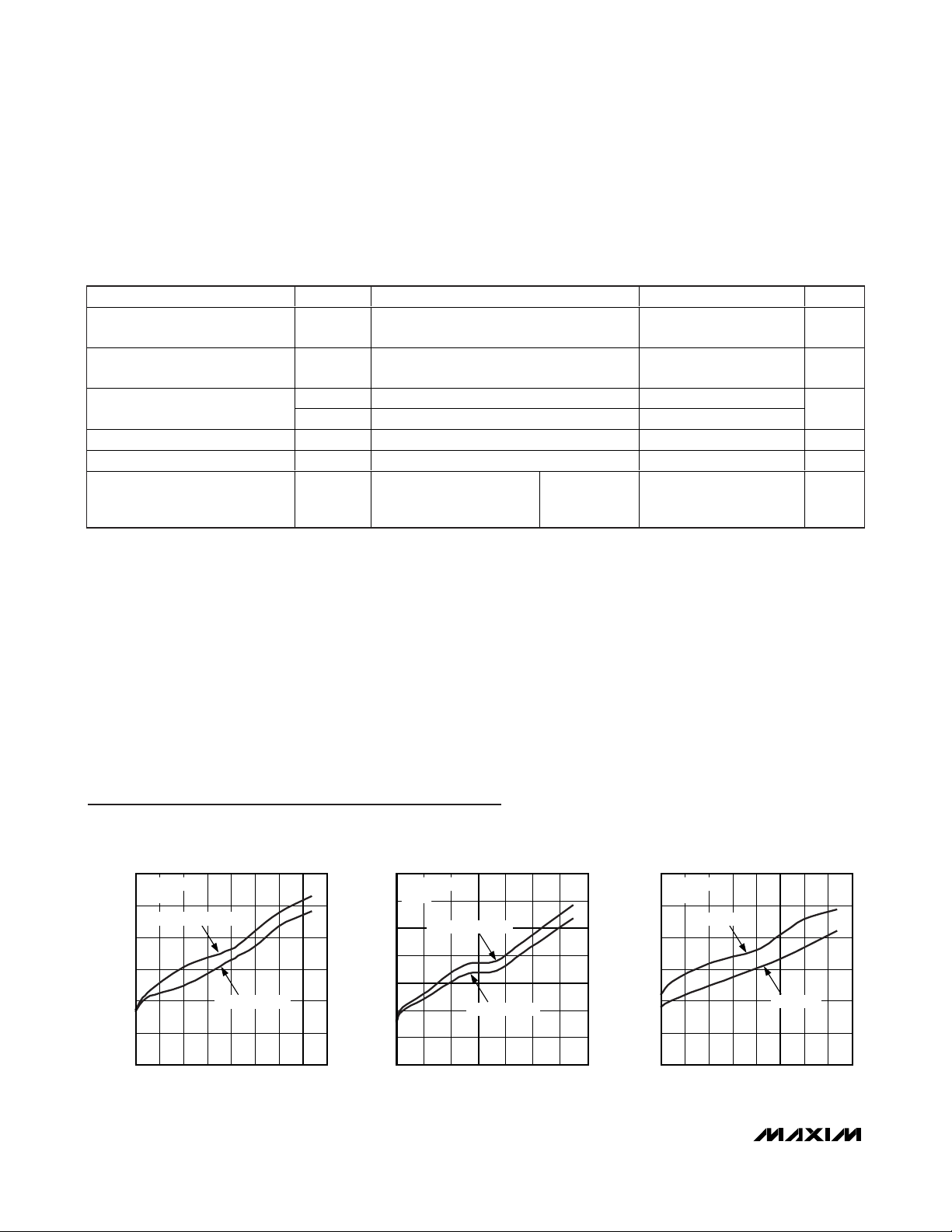

Parallel-Word Width

The parallel-word width is made up of the video data

bits, HYSNC, and VSYNC. The video data bits are programmable from 8 to 16 depending on the pixel clock,

serial-data rate, and parity. Table 16 shows the parallelword width.

Serial-Word Length

The serial-word length is made up of the parallel-word

width, encoding bits, and parity bits. Tables 5–9 show

the serial video format and serial-word lengths without

parity. Tables 10–13 show with parity bits included.

LVDS Serial Data

Serial LVDS data is transmitted least significant bit (LSB)

to most significant bit (MSB) as shown in Tables 5

through 13. The ECU at startup can program the parallel

word width, serial frequency range, parity, spread-spectrum, and pixel clock frequency range

(

see the

MAX9257

Register Table

and the

MAX9258 Register Table)

.

22 ______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

Table 2. MAX9258 Power-Up Default Register Map (continued)

Table 3. MAX9257 I/O Supply

Table 4. MAX9258 I/O Supply

REGISTER NAME

REG8 0x08 0x10

REG9 0x09 0x00

REG10 0x0A 0x00 Parity errors video (8 LSBs) = read only

REG11 0x0B 0x00 Parity errors video (8 MSBs) = read only

REG12 0x0C 0x00 PRBS bit errors = read only

REG13 0x0D 0x00

REGISTER

ADDRESS (hex)

POWER-UP VALUE

(hex)

POWER-UP DEFAULT SETTINGS

PATHRLO = 0001 0000

parity threshold = 16

PATHRHI = 0000 0000,

parity threshold = 16

Reserved = 000

Parity error, communication with MAX9258 = read only

Frame error, communication with MAX9258 = read only

Parity error, communication with MAX9257 = read only

Frame error, communication with MAX9257 = read only

2

C error, communication with peripheral = read only

I

INPUTS/OUTPUTS SUPPLY

PCLK_IN, HSYNC_IN, VSYNC_IN,

DIN[0:7], DIN[8:15]/GPIO[0:7],

GPIO8, GPIO9

SDO+, SDO- V

SCL/TX, SDA/RX, REM V

V

CCIO

CCLVDS

CC

INPUTS/OUTPUTS SUPPLY

All inputs and outputs V

SDI+, SDI- V

CCOUT

CCLVDS

Page 23

MAX9257/MAX9258

______________________________________________________________________________________ 23

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

Table 5. Serial Video Data Format for 20-Bit Serial-Word Length (Parallel-Word Width = 18)

Table 6. Serial Video Data Format for 18-Bit Serial-Word Length (Parallel-Word Width = 16)

Table 7. Serial Video Data Format for 16-Bit Serial-Word Length (Parallel-Word Width = 14)

Table 8. Serial Video Data Format for 14-Bit Serial-Word Length (Parallel-Word Width = 12)

Table 9. Serial Video Data Format for 12-Bit Serial-Word Length (Parallel-Word Width = 10)

Table 10. Format for 20-Bit Serial-Word Length with Parity (Parallel-Word Width = 16)

Table 11. Format for 18-Bit Serial-Word Length with Parity (Parallel-Word Width = 14)

Table 12. Format for 16-Bit Serial-Word Length with Parity (Parallel-Word Width = 12)

Table 13. Format for 14-Bit Serial-Word Length with Parity (Parallel-Word Width = 10)

BIT 1 2 3 4 567891011121314151617181920

NAME EN0 EN1 HSYNC VSYNC D0 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11 D12 D13 D14 D15

BIT 1 2 3 4 5 6 7 8 9 101112131415161718

NAME EN0 EN1 HSYNC VSYNC D0 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11 D12 D13

BIT 12 3 4 5678910111213141516

NAME EN0 EN1 HSYNC VSYNC D0 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11

BIT 1 2 3 4 5 6 7 8 9 10 11 12 13 14

NAME EN0 EN1 HSYNC VSYNC D0 D1 D2 D3 D4 D5 D6 D7 D8 D9

BIT 1234 5 6 7 8 9 101112

NAME EN0 EN1 HSYNC VSYNC D0 D1 D2 D3 D4 D5 D6 D7

BIT 1 2 3 4 5 6 7 8 9 10111213141516 17 18 19 20

NAME PR PRB EN0 EN1 HSYNC VSYNC D0 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11 D12 D13

BIT 1 2 3 4 5 6 7 8 9 10111213141516 17 18

NAME PR PRB EN0 EN1 HSYNC VSYNC D0 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11

BIT 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

NAME PR PRB EN0 EN1 HSYNC VSYNC D0 D1 D2 D3 D4 D5 D6 D7 D8 D9

BIT 1 2 3 4 5 6 7 8 9 10 11 12 13 14

NAME PR PRB EN0 EN1 HSYNC VSYNC D0 D1 D2 D3 D4 D5 D6 D7

Page 24

MAX9257/MAX9258

Pixel Clock Frequency Range

The MAX9257/MAX9258 each have registers that can

be configured at startup. Depending on the word

length, the MAX9257 multiplies PCLK_IN (pixel clock)

by 12, 14, 16, 18, or 20 using an internal PLL to generate the serial clock. Use Table 20 for proper selection

of available PCLK frequency and serial-data ranges.

Parallel data is serialized using the serial-clock and

serialized bits are transmitted at the MAX9257 LVDS

outputs. The MAX9257/MAX9258 support a wide range

for PCLK_IN (Table 14). If the pixel clock frequency

needs to change to a frequency outside the programmed range, the ECU must program both the

MAX9257 and the MAX9258 in the same control channel session.

Serial-Data Rate Range

The word length and pixel clock is limited by the maximum serial-data rate of 840Mbps. The following formula

shows the relation between word length, pixel clock,

and serial clock:

Serial-word length x pixel clock = serial-data rate

≤

840Mbps

For example, if PCLK_IN is 70MHz, the serial-word

length has to be 12 bits including DC balance bits if

parity is not enabled to keep the serial-data rate under

840Mbps. If the serial-word length is 20 bits, the maximum PCLK_IN frequency is 42MHz. The serial-data

rate can vary from 60Mbps to 840Mbps and can be

programmed at power-up (Table 15). Use Table 20 for

proper selection of available PCLK frequency and serial

data ranges. Operating in the incorrect range for either

the serial-data rate or PCLK_IN can result in excessive

current dissipation and failure of the MAX9258 to lock

to the MAX9257.

LVDS Common-Mode Bias

The output common-mode bias is 1.2V at the LVDS

inputs on the MAX9258 and LVDS outputs on the

MAX9257. No external resistors are required to provide

bias for AC-coupling the LVDS inputs and outputs.

LVDS Termination

Terminate the LVDS link at both ends with the characteristic impedance of the transmission line (typically

100Ω differential). The LVDS inputs and outputs are

high impedance to GND and differentially.

Spread-Spectrum Selection

The MAX9257/MAX9258 each have spread-spectrum

options. Both should not be turned on at the same time.

When the MAX9257 is programmed for spread spectrum,

the MAX9258 tracks and passes the spread to its clock

and data outputs. The MAX9257/MAX9258 are both

center spread (Figure 21). The control channel does

not use spread spectrum, but has slower transition

times.

MAX9258 Spread Spectrum

The MAX9258 features a programmable spread-spectrum clock and data outputs for reduced EMI. The single-ended data outputs are programmable for no

spread, ±2%, or ±4% (see the

Typical Operating

Characteristics

) around the recovered pixel clock frequency. The output spread is programmed in register

REG1[7:6]. Table 17 shows the spread options, and

Table 18 shows the various modulation rates.

MAX9257 Spread Spectrum

The MAX9257 features programmable spread spectrum

for the LVDS outputs. Table 19 shows various spread

options, and Table 20 shows the various modulation

rates. Only one device (the MAX9257 or the MAX9258)

should be programmed for spread spectrum at a time. If

the MAX9257 is programmed for spread, the MAX9258

24 ______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

Table 14. MAX9257 Pixel Clock Range

(PCLK_IN)

Table 15. Serial-Data Rate Range

Table 16. Parallel-Word Width

FREQUENCY (MHz) PRATE (REG0[7:6])

5–10 00

10–20 01

20–40 10

40–70 11

SERIAL-DATA RATE (Mbps) SRATE (REG0[5:4])

60–100 00

100–200 01

200–400 10

400–840 11

PARALLEL-WORD WIDTH PWIDTH (REG0[2:0])

10 000

12 001

14 010

16 011

18 1XX

Page 25

tracks and passes the spread to the data and clock outputs. The PRATE range of 00 and 01 (5MHz ≤ PCLK ≤

20MHz) supports all the spread options. The PRATE

range of 10 and 11 (20MHz ≤ PCLK ≤ 70MHz) requires

that the spread be 2% or less.

Pixel Clock Jitter Filter

The MAX9257 has a PLL to filter high-frequency pixel

clock jitter on PCLK_IN. The FPLL can be bypassed by

writing 1 to REG4[2]. The FPLL improves the

MAX9258’s data recovery by filtering out the high-frequency components from the pixel clock that the

MAX9258 cannot track. The 3db bandwidth of the FPLL

is 100kHz (typ).

LVDS Output Preemphasis (SDO±)

The MAX9257 features programmable preemphasis

where extra current is added when the LVDS outputs

transition on the serial link. Preemphasis provides additional current to the normal drive current. For example,

20% preemphasis provides 20% greater current than

the normal drive current. Current is boosted only on the

transitions and returns to the normal drive current after

switching. Select the preemphasis level to optimize the

eye diagram. Preemphasis boosts the high-frequency

content of the LVDS outputs to enable driving greater

cable lengths. The amount of preemphasis is programmed in REG12[7:5] (Table 21).

VSYNC, HSYNC, and Pixel Clock Polarity

PCLK: The MAX9257 is programmable to latch data on

either rising or falling edge of PCLK. The polarity of

PCLKOUT at the MAX9258 can be independent of the

MAX9257 PCLK active edge. The polarity of PCLK can

be programmed using REG4[5] of the MAX9257 and

the MAX9258.

VSYNC: The MAX9257 and the MAX9258 enter control

channel on the falling edge of VSYNC. The default register settings are VSYNC active falling edge for both the

MAX9257 and the MAX9258. If the VSYNC active edge

is programmed for rising edge at the MAX9257, the

MAX9258 VSYNC active edge must also be programmed for rising edge to reproduce VSYNC rising

edge at the MAX9258 output. However, matching the

polarity of the VSYNC active edge between the

MAX9257 and the MAX9258 is not a requirement for

proper operation.

HSYNC: HSYNC active-edge polarity is programmable

for the MAX9258.

General Purpose I/Os (GPIOs)

The MAX9257 has up to 10 GPIOs available. GPIO8

and GPIO9 are always available while GPIO[0:7] are

available depending on the parallel-word width (Table

22). If GPIOs are not available, the corresponding GPIO

bits are not used.

MAX9257/MAX9258

______________________________________________________________________________________ 25

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

Figure 21. Simplified Modulation Profile for the MAX9257/MAX9258

Table 17. MAX9258 Spread

Table 18. MAX9258 Modulation Rate

Table 19. MAX9257 LVDS Output Spread

FREQUENCY

1/f

SSM

(MAX)

f

SPREAD

f

PCLK_IN

f

(MIN)

SPREAD

TIME

PRATE (REG1[7:6]) SPREAD (%)

00 Off

01 ±2

10 Off

11 ±4

PRATE

(REG1[7:6])

00 PCLK/312 16 to 32

01 PCLK/520 19.2 to 38.5

10 PCLK/1040 19.2 to 38.5

11 PCLK/1248 32 to 56

MODULATION RATE f

RANGE (kHz)

SSM

REG1[7:5] SPREAD (%)

000 Off

001 ±1.5

010 ±1.75

011 ±2

100 Off

101 ±3

110 ±3.5

111 ±4

Page 26

MAX9257/MAX9258

A GPIO can be programmed to drive an LVCMOS logic

level or to read a logic input. The register bit that sets

the output level when the GPIO is programmed as an

output stores the input level when the GPIO is programmed as an input.

Open-Drain Outputs (LOCK,

ERROR

)

LOCK and ERROR are open-drain outputs that require

a pullup resistor to an external supply. ERROR asserts

low when an error occurs and LOCK is high impedance

when the MAX9258 is locked to the MAX9257 and

remains high under the locked condition. When the

devices are in shutdown, the channel is not locked and

LOCK goes high impedance, is pulled high, and should

be ignored. ERROR is high impedance at shutdown

and remains high. In choosing pullup resistors, there is

a tradeoff between power dissipation and speed; 10kΩ

pullup should be sufficient.

26 ______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

Table 20. MAX9257 Modulation Rate

SERIAL-WORD

LENGTH

12

14

16

18

20

SRATE PRATE

11 11 40–70 PCLK/2728 14.7 to 25.7

11 10 33.3–40 PCLK/1736 19.2 to 23.0

10 10 20–33.3 PCLK/1612 12.4 to 20.7

10 01 16.6–20 PCLK/992 16.7 to 20.2

01 01 10–16.6 PCLK/1116 9.0 to 14.9

01 00 8.3–10 PCLK/744 11.2 to 13.4

00 00 5–8.3 PCLK/868 5.8 to 9.6

11 11 40–60 PCLK/2304 17.4 to 26.0

11 10 28.6–40 PCLK/1728 16.6 to 23.1

10 10 20–28.6 PCLK/1440 13.9 to 19.9

10 01 14.3–20 PCLK/1008 14.2 to 19.8

01 01 10–14.3 PCLK/1008 9.9 to 14.2

01 00 7.1–10 PCLK/720 9.9 to 13.9

00 00 5–7.1 PCLK/720 6.9 to 9.9

11 11 40–52.5 PCLK/1968 20.3 to 26.7

11 10 25–40 PCLK/1640 15.2 to 24.4

10 10 20–25 PCLK/1312 15.2 to 19.1

10 01 12.5–20 PCLK/984 12.7 to 20.3

01 01 10–12.5 PCLK/820 12.2 to 15.2

01 00 6.25–10 PCLK/656 9.5 to 15.2

00 00 5–6.25 PCLK/656 7.6 to 9.5

11 11 40–46.6 PCLK/1840 21.7 to 25.3

11 10 22.2–40 PCLK/1472 15.1 to 27.2

10 10 20–22.2 PCLK/1104 18.1 to 20.1

10 01 11.1–20 PCLK/920 12.1 to 21.7

01 01 10–11.1 PCLK/736 13.6 to 15.1

01 00 5.6–10 PCLK/736 7.6 to 13.6

00 00 5–5.6 PCLK/552 9.1 to 10.1

11 11 40–42 PCLK/1632 24.5 to 25.7

11 10 20–40 PCLK/1632 12.3 to 24.5

10 01 10–20 PCLK/1020 9.8 to 19.6

01 00 5–10 PCLK/816 6.1 to 12.3

PCLK RANGE

(MHz)

MODULATION RATE f

RANGE (kHz)

SSM

Page 27

The LOCK and ERROR outputs can be wired in an

AND configuration if you have multiple serializers and

deserializers, or a single serializer fanned out to multiple deserializers through a repeater. For such situations, wire the multiple LOCK outputs together and use

a single pullup resistor to pull up all the lines high.

LOCK is high if all the devices are locked. Do the same

thing for ERROR; ERROR is low if any MAX9258 reports

errors.

Base Mode and Bypass Mode (Basics)

In the control channel phase, there are two modes: base

and bypass. In base mode, ECU always communicates

using the MAX9257/MAX9258 UART protocol and communication with a peripheral device is performed in I2C

by the MAX9257. Packets not addressed to the

MAX9257 or the MAX9258 get converted to I2C and

passed to the peripheral device. Similarly, I2C packets

from the peripheral device get converted to UART packets in the reverse direction. ECU can disable communication to the peripheral device by writing a 0 to INTEN

(REG8[6] in the MAX9257 and REG7[6] in the MAX9258).

Base mode is the default mode. Bypass mode is entered

by writing a 0 to INTMODE and 1 to INTEN (Table 23).

Bypass mode is exited if there is no activity from ECU in

the control channel for the duration of CTO. When CTO

times out, INTEN reverts back to 0 and MAX9257/

MAX9258 revert back to base mode. To permanently

stay in bypass mode, ECU can lock the CTO timer or

program CTO to be longer than ETO and STO.

Timers

The MAX9257/MAX9258 feature three different timers.

The start timeout (STO) and end timeout (ETO) control

the duration of the control channel. The come-back

timeout (CTO) controls the duration of bypass mode.

STO Timer

The STO (start timeout) timer closes the control channel if

the ECU does not start using the control channel within

the STO timeout period. The STO timer is configured by

MAX9257/MAX9258

______________________________________________________________________________________ 27

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

Table 21. Preemphasis

Table 22. GPIOs vs. Parallel-Word Width

Table 23. Selection of Base Mode or

Bypass Mode

Table 24. STO Clock Divide Ratio

REG12[7:5] PREEMPHASIS (%)

000,101,110 20

001 40

010 60

011 80

100 100

111 0

PARALLEL-WORD

WIDTH (N)

18 GPIO[8:9]

16 GPIO[6:9]

14 GPIO[4:9]

12 GPIO[2:9]

10 GPIO[0:9]

GPIOs AVAILABLE

INTEN

MAX9257 REG8[6],

MAX9258 REG7[6]

0X

11

10

INTMODE

MAX9257 REG8[7],

MAX9258 REG7[7]

MODE

Base mode,

communication

with peripheral is

not enabled

Base mode,

communication

with peripheral is

enabled (I

Bypass mode,

communication

with MAX9257/

MAX9258 is not

enabled,

communication

with peripheral is

enabled (UART)

2

C)

REG2[7:4] STODIV

00XX 16

0100 16

0101 32

0110 64

0111 128

1000 256

1001 512

1010 1024

1011 2048

1100 4096

1101 8192

1110 16,384

1111 32,768

Page 28

MAX9257/MAX9258

register REG2 for both the MAX9257 and the MAX9258.

The four bits of REG2[7:4] select the divide ratio (STODIV)

for the STO clock as a function of the pixel clock (Table

24). The timeout period is determined by counter bits

REG2[3:0] that increment once every STO clock period.

Write to REG2[3:0] to determine the counter end time.

The STO counter counts to the programmed STOCNT +

1. The ECU must begin communicating before STO times

out, otherwise, the control channel closes (Figure 22). The

STO timeout period is given by:

For example:

If the pixel clock frequency is set to 16MHz, STODIV is

set to 1010 (STODIV = 1024), and STOCNT is set to

1001 (STOCNT = 9), the STO timer counts with

15.625kHz STO clock (16MHz/1024) internally until it

reaches 10 and timer expires. The t

STO

is equal to tTx

1024 x 10 = 640µs.

The default value for STODIV is 1024 while the default

value for STOCNT is 0. That means the STO timeout

period is equal 1024 pixel clock cycles. Activity from

the ECU on the control channel shuts off the STO timer

and starts the ETO timer.

ETO Timer

The ETO (end timeout) timer closes the control channel

if the ECU stops communicating for the ETO timeout

period. Configure register REG3[7:4] for both the

MAX9257 and the MAX9258 to select the divide ratio

(ETODIV) for the ETO clock as a function of the pixel

clock (Table 25). The timeout period is determined by

28 ______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

Table 25. ETO Clock Divide Ratio

Figure 22. Control Channel Closing Due to STO Timeout

VSYNC_IN

T1

SDI/O±

CCEN

TX

RX

DOUT_

T1 = TIME TO ENTER CONTROL CHANNEL

T2 = STO TIMEOUT PERIOD

T3 = CONTROL CHANNEL EXIT TIME DUE TO STO

HSK = HANDSHAKING BETWEEN THE MAX9257 AND THE MAX9258

VIDEO

⎛

⎞

t

STO

1

=

⎜

f

⎝

CLK

STODIV STOCNT

×× +

⎟

⎠

1()

T2

FROZEN

REG3[7:4] ETODIV

00XX 16

0100 16

0101 32

0110 64

0111 128

1000 256

1001 512

1010 1024

1011 2048

1100 4096

1101 8192

1110 16,384

1111 32,768

T3

HSK

VIDEO

Page 29

counter bits REG3[3:0] that increment once every ETO

clock period. Write to REG3[3:0] to determine the

counter end time. The ETO counter counts to the programmed ETOCNT + 1. Any ECU activity resets the

ETO timer. When the ECU stops transmitting data for

the ETO timeout period, the control channel closes

(Figure 23).

For example:

If the pixel clock frequency is set to 16MHz, ETODIV is

set to 1010 (ETODIV = 1024), and ETOCNT is set to

1001 (ETOCNT = 9), the ETO timer counts with the

15.625kHz ETO clock (16MHz/1024) internally until it

reaches 10 and timer expires. The t

ETO

is equal to tTx

1024 x 10 = 640µs.

The default value for ETODIV is 1024 while the default

value for ETOCNT is 0. That means the ETO timeout

period is equal to 1,024 pixel clock cycles.

Closing the Control Channel

After the MAX9257 detects the active VSYNC edge, it

sends three synchronization words. Once the MAX9258

sees the active VSYNC transition and detects three synchronization words, it enters the control channel phase

and CCEN goes high. There is a brief delay of T1

between the VSYNC transition and CCEN transitioning

high. The ECU is allowed to communicate when CCEN

is high.

If the ECU does not communicate while CCEN is high

(Figure 22), the link remains silent and STO starts

counting towards its preset timeout counter value. If

STO times out (T2), CCEN transitions low and the control channel closes.

If the ECU communicates while CCEN is high and

before STO expires (Figure 23), the STO timer is turned

off and ETO timer is enabled. The ETO counter (ETOCNT+1) is reset to 0 whenever activity from ECU (base

mode) or ECU and Camera (bypass mode) is detected.

As long as there is activity from ECU (base mode) or

ECU and Camera (bypass mode) on the link, the channel does not close and the ETO counter resets. After

the ECU (base mode) or ECU and Camera (bypass

mode) ceases link activity, ETO times out (T4), CCEN

transitions low, and the control channel closes.

Another way to close the control channel in base mode

is for the ECU to send an end frame (EF) to close the

control channel without waiting for ETO to time out.

Whenever EF is received by both the MAX9257/

MAX9258, control channel closes immediately and

CCEN goes low. A synchronization frame must precede

EF. End frame cannot be used in bypass mode. The

control channel must close by EF to report errors back

to the ECU.

MAX9257/MAX9258

______________________________________________________________________________________ 29

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel

Figure 23. Control Channel Closing Due to ETO Timeout

VSYNC_IN

T1

SDI/O±

CCEN

TX

RX

DOUT_

T1 = TIME TO ENTER CONTROL CHANNEL

T4 = ETO TIMEOUT PERIOD

T5 = CONTROL CHANNEL EXIT TIME DUE TO ETO

HSK = HANDSHAKING BETWEEN MAX9257 AND MAX9258

VIDEO

ECU

ACTIVITY

⎛

⎞

t

ETO

1

=

⎜

f

⎝

CLK

ETODIV ETOCNT

×× +

⎟

⎠

1()

T5

HSK

T4 (BASE MODE)

T4 (BYPASS MODE)

FROZEN

VIDEO

Page 30

MAX9257/MAX9258

After the control channel closes, there is a brief handshake period (T3 in Figure 22 and T5 in Figure 23)

between the MAX9257 and the MAX9258. The

MAX9258 sends a special lock frame to the MAX9257

to indicate if PLL is still locked. The MAX9258 sends the

lock frame if the number of decoding errors didn’t

exceed a threshold in the last LVDS video phase session. The MAX9258 features a proprietary VCO lock

that prevents frequency drift while in the control channel for extended periods of time. If MAX9257 receives

the lock frame, it understands that the MAX9258 is in a

locked state and sends a short training sequence. If the

lock frame is not received by the MAX9257, it assumes

that the MAX9258 is not locked and sends a long training sequence. After the short or long training sequence

is complete, the MAX9257 sends three special synchronization words before entering the video phase.

Training sequence is used to resynchronize the

MAX9257/MAX9258 before the video phase starts.

The MAX9257/MAX9258 control channel duration is

independent of VSYNC. The control channel does not

close when VSYNC deasserts, which allows the use of

a VSYNC interrupt signal on VSYNC_IN. The control

channel must be closed by STO, ETO, or EF. If the control channel does not close before video data becomes

available, video data can be lost.

STO/ETO Timer Programming

STO and ETO can be programmed given the values of

T2, T4, and maximum values of T1, T3, and T5 (Figures

22, 23):

tT= pixel clock period, t

UCLK

= UART period

When spread spectrum is not enabled in MAX9257:

max(T1) = 2.5µs + (3 x tT) + (4 x t

UCLK

)

When spread spectrum is enabled in MAX9257:

max(T1) = 2.5µs + (1400 x tT) + (4 x t

UCLK

)

T2 = t

STO

T4 = t

ETO

When pixel clock frequency range (PRATE) is 00 or 01:

When pixel clock frequency range (PRATE) is 10 or 11:

CTO Timer

The CTO (come-back timeout) timer temporarily or permanently blocks programming to the MAX9257/

MAX9258 registers. CTO keeps the MAX9257/ MAX9258

in bypass mode for the CTO timeout period (Table 26).

Bypass mode can only be exited when the CTO timer

expires. The CTO timer uses the UART bit times for its

counter. Note that STO and ETO timers use the pixel

clock while CTO uses the UART bit times. The UART

period t

UCLK

synchronizes with the UART bit times,

which synchronize every time the SYNC frame is sent.

When the CTO timer times out, INTEN bit in both

devices is set to 0 and the MAX9257/MAX9258 revert

back to base mode. If communication with the

MAX9257/MAX9258 is not needed after initial programming is complete, CTO may be set to 000 (never come

back). In this case, CTO never expires and the

MAX9257/MAX9258 stay in bypass mode until they are

powered down. This prevents accidental programming

of the MAX9257/MAX9258 while ECU communicates

with the peripheral using a different UART protocol from

the MAX9257/MAX9258 UART protocol.

The overall CTO timeout is calculated as follows:

t

CTO

= t

UCLK

x CTO

30 ______________________________________________________________________________________

Fully Programmable Serializer/Deserializer

with UART/I2C Control Channel