Page 1

_______________General Description

The MAX887 high-efficiency, step-down DC-DC converter provides an adjustable output from 1.25V to

10.5V. It accepts inputs from 3.5V to 11V and delivers

600mA. Operation to 100% duty cycle minimizes

dropout voltage (300mV typ at 500mA). Synchronous

rectification reduces output rectifier losses, resulting in

efficiency as high as 95%.

Fixed-frequency pulse-width modulation (PWM)

reduces noise in sensitive communications applications. Using a high-frequency internal oscillator allows

tiny surface-mount components to reduce PC board

area, and eliminates audio-frequency interference. A

SYNC input allows synchronization to an external clock

to avoid interference with sensitive RF and dataacquisition circuits.

The MAX887 features current-mode operation for superior load/line-transient response. Cycle-by-cycle current

limiting protects the internal MOSFET and rectifier. A

low-current (2.5µA typ) shutdown mode conserves battery life.

________________________Applications

Portable Instruments

Cellular Phones and Radios

Personal Communicators

Distributed Power Systems

Computer Peripherals

____________________________Features

♦ 95% Efficiency

♦ 600mA Output Current

♦ Cycle-by-Cycle Current Limiting

♦ Low-Dropout, 100% Duty-Cycle Operation,

300mV at 500mA

♦ Internal 0.6Ω (typ) MOSFET

♦ Internal Synchronous Rectifier

♦ High-Frequency Current-Mode PWM

♦ External SYNC or Internal 300kHz Oscillator

♦ Guaranteed 260kHz to 340kHz Internal Oscillator

Frequency Limits

♦ 2.5µA Shutdown Mode

MAX887

100% Duty Cycle, Low-Noise,

Step-Down, PWM DC-DC Converter

________________________________________________________________

Maxim Integrated Products

1

1

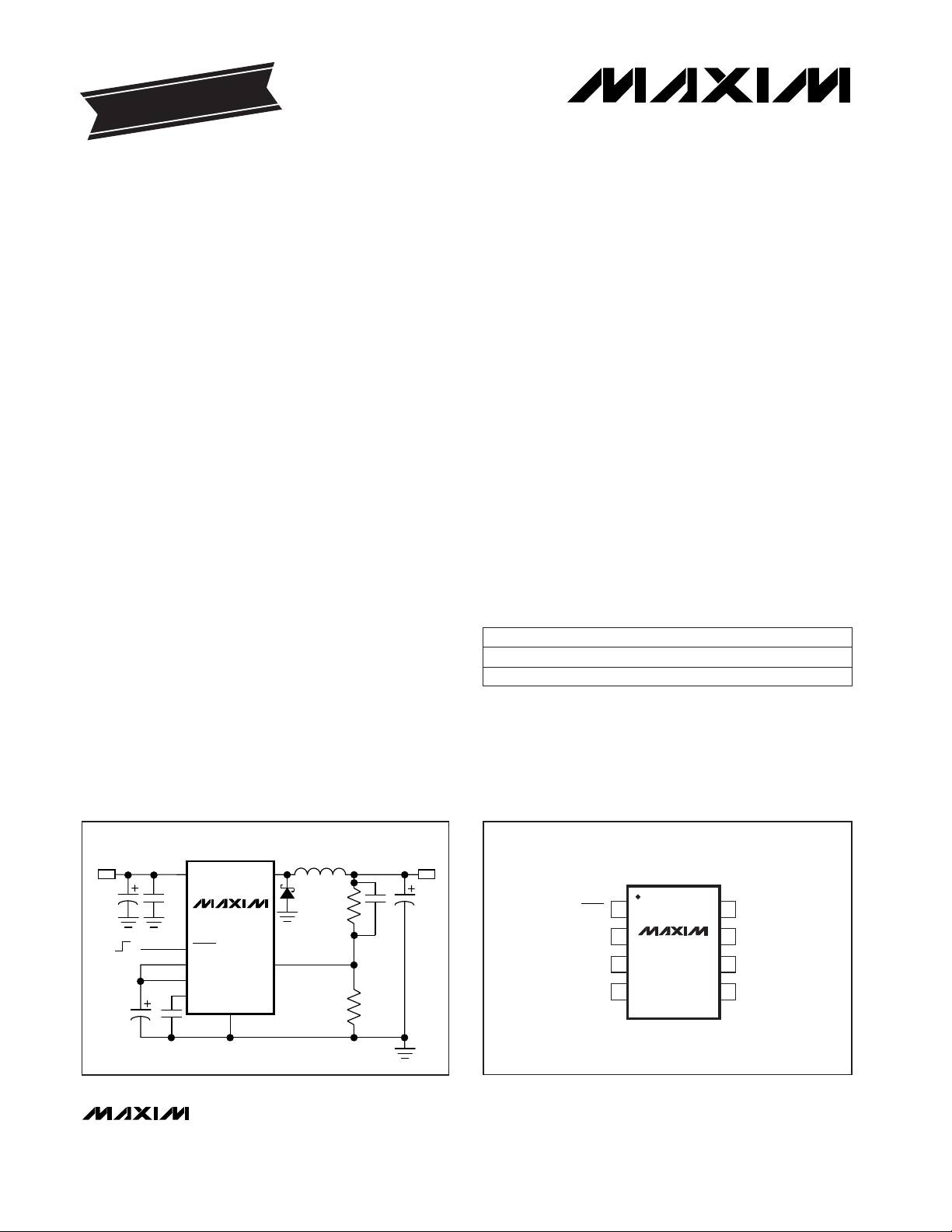

2

8

7

V+

LX

SYNC

GND

SHDN

FB

REF

VL

MAX887

SO

TOP VIEW

3

4

6

5

__________________Pin Configuration

MAX887

REF

R1

165kΩ

R2

100kΩ

0.047µF

2.2µF

47µF

47µF

C1

100pF

0.33µF

33µH

V+ LX

FB

GND

SYNC

VL

SHDN

V

OUT

= 3.3V

V

OUT

= 1.25V (R1/R2 + 1)

V

IN

= 3.5V to 11V

ON

OFF

__________Typical Operating Circuit

19-1142 Rev 0; 9/96

PART

MAX887HC/D

MAX887HESA -40°C to +85°C

0°C to +70°C

TEMP. RANGE PIN-PACKAGE

Dice*

8 SO

EVALUATION KIT MANUAL

AVAILABLE

______________Ordering Information

*

Contact factory for availability. Dice are tested at TA= +25°C.

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800

Page 2

100% Duty Cycle, Low-Noise,

Step-Down, PWM DC-DC Converter

ABSOLUTE MAXIMUM RATINGS

REF, FB, SYNC, VL to GND..................................... -0.3V to +6V

V+ to GND............................................................. -0.3V to +12V

SHDN, LX to GND ....................................... -0.3V to (V+ + 0.3V)

PGND to GND ......................................................-0.3V to +0.3V

Continuous Power Dissipation (T

SO (derate 9.09mW/°C above +70°C) .........................471mW

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

MAX887

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

= +70°C)

A

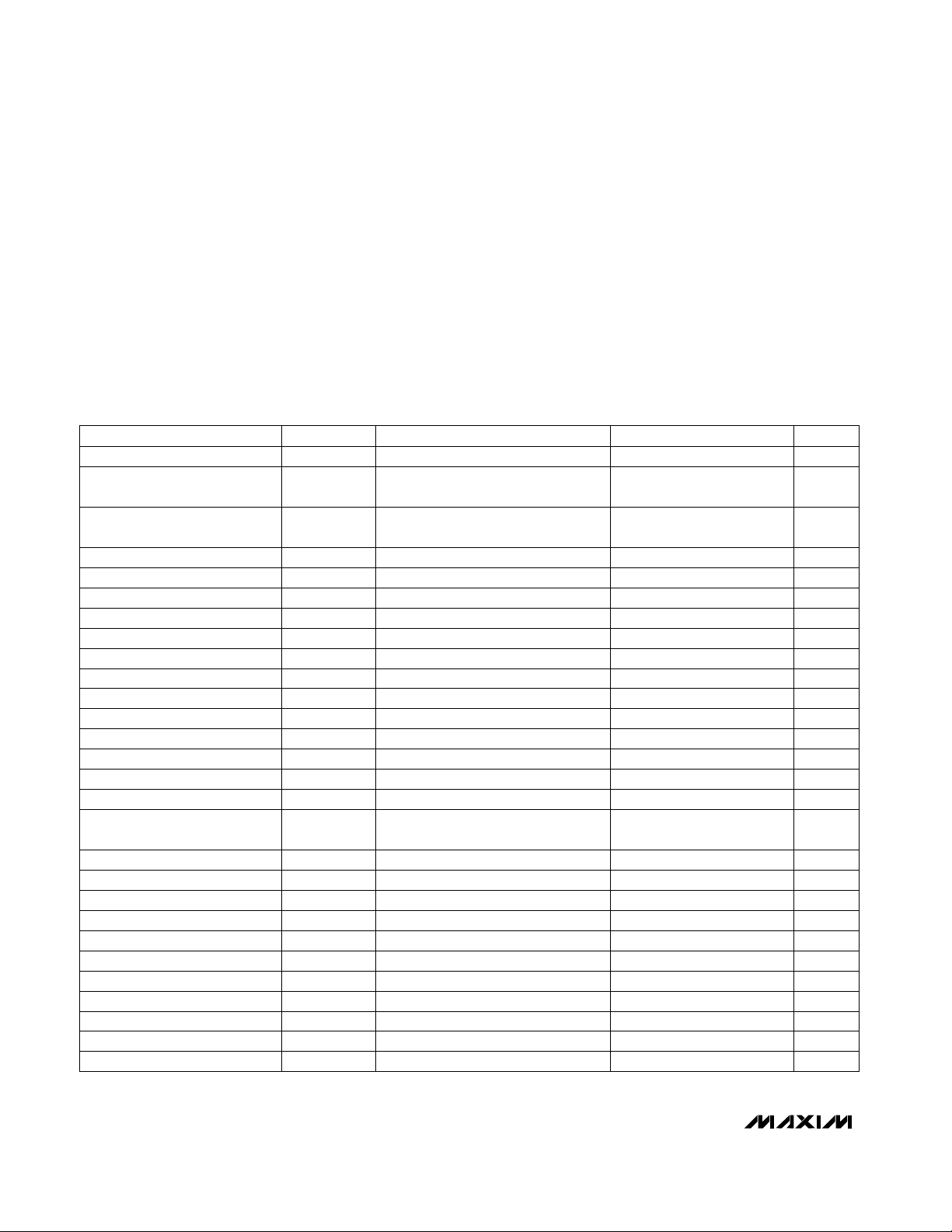

ELECTRICAL CHARACTERISTICS

(V+ = +7V, PGND = GND = 0V, SHDN = V+, (TA= 0°C to T

Quiescent Supply Current

(PWM Mode)

Quiescent Supply Current

(PFM Mode)

Shutdown Supply Current

Output Voltage Range

PWM FB Feedback Threshold

FB Input Current

SYNC Frequency

PWM Switching Frequency

High-Side Current Limit

LX On-Resistance

LX Leakage Current

LX Reverse Leakage Current,

Regulator Off

Undervoltage Lockout

Startup Voltage

SYNC Input High Voltage

SYNC Input Low Voltage

SYNC Input Current

SHDN Input High Voltage

SHDN Input Low Voltage

SHDN Input Current, Sinking

SHDN Input Capacitance

VL Output Voltage V

REF Output Voltage V

Note 1: Guaranteed by design and not production tested.

V+, PWM

V+, PFM

V+, SHDN

OUT, RANGE

FB

FB

SYNC

OSC

LIM+

ON, LX

LXLKG

LXLKGR

+, UVLO

+, START

IH, SYNC

IL, SYNC

IN, SYNC

IH, SHDN

V

IL, SHDN

I

IN-, SHDN

C

IN, SHDN

L

REF

I

I

SHDN = GND

Circuit of Figure 2

I

VIN= 4V to 11V, PWM mode

SYNC = 3.0V, PWM duty cycle = 50%

FB = 1.30V

SYNC = 3.0V, FB = 1.18V

SYNC = 3.0V

ILX= ±100mA

V+ = 12V, LX = GND to 12V

V+ = floating, LX = 5V, SHDN = GND

V+ falling

V+ rising

SYNC = GND or 3V

SHDN = GND or V+

(Note 1) 10 pF

IVL= 0mA to 1mA 3.3 V

0µA to 30µA 1.25 V

MAX

= 0mA, SYNC = 3.0V

OUT

= 0mA, SYNC = GND

OUT

= 0mA to 500mA

OUT

Operating Temperature Ranges

MAX887HC/D.......................................................0°C to +70°C

MAX887HESA...................................................-40°C to +85°C

Storage Temperature Range ........................... -65°C to +165°C

Lead Temperature (soldering, 10sec)............................ +300°C

), unless otherwise noted.)

CONDITIONS

0.8 V

±1 µA

UNITSMIN TYP MAXSYMBOLPARAMETER

%/mA0.005Load Regulation

%/V0.2Line Regulation

kHz25 440f

kHz260 300 340f

V3.5 11.0V+Supply Range

mA2.7 4.0I

mA0.2 0.5I

µA2.5 5I

V1.25 10.50V

V1.225 1.250 1.275V

µA±0.10I

ns500SYNC, PWSYNC Pulse Width High or Low

%100PWM, DUTYPWM Maximum Duty Cycle

A0.75 1.0 1.40I

Ω0.6R

µA-10 1.0 10I

µA1.0 20I

V3.0 3.3V

V3.1 3.5V

V2.5V

V0.5V

µA±1I

V2.4V

2 _______________________________________________________________________________________

Page 3

100% Duty Cycle, Low-Noise,

Step-Down, PWM DC-DC Converter

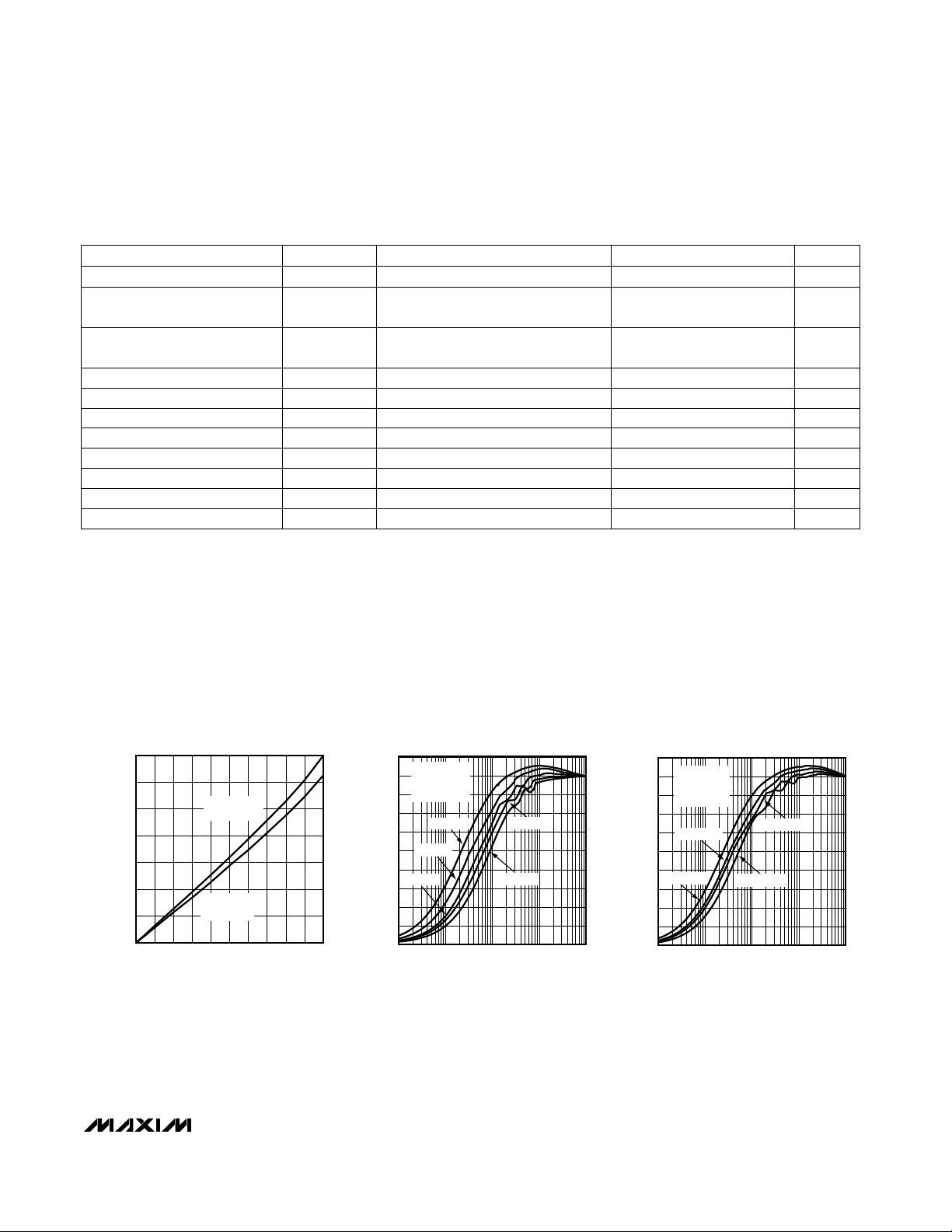

ELECTRICAL CHARACTERISTICS

(V+ = +7V, PGND = GND = 0V, SHDN = V+, (TA= -40°C to +85°C), unless otherwise noted.) (Note 2)

CONDITIONS

Quiescent Supply Current

(PWM Mode)

Quiescent Supply Current

(PFM Mode)

Shutdown Supply Current

Output Voltage Range

PWM FB Feedback Threshold

FB Input Current

PWM Switching Frequency

High-Side Current Limit

Undervoltage Lockout

Startup Voltage

V+, PWM

V+, PFM

V+, SHDN

OUT, RANGE

FB

FB

OSC

LIM+

+, UVLO

+, START

Note 2: Specifications from 0°C to -40°C are guaranteed by design and not production tested.

I

= 0mA, SYNC = 3.0V

OUT

I

= 0mA, SYNC = GND

OUT

SHDN = GND

Circuit of Figure 2

SYNC = 3.0V, PWM duty cycle = 50%

FB = 1.30V

SYNC = 3.0V

V+ falling

V+ rising

MAX887

UNITSMIN TYP MAXSYMBOLPARAMETER

V3.5 11.0V+Supply Range

mA2.7 4.0I

mA0.2 0.6I

µA2.5 5I

V1.25 10.50V

V1.222 1.250 1.278V

µA±0.10I

kHz250 300 350f

A0.75 1.00 1.50I

V3.0 3.3V

V3.1 3.5V

__________________________________________Typical Operating Characteristics

(Circuit of Figure 2, TA = +25°C, unless otherwise noted.)

DROPOUT VOLTAGE

vs. LOAD CURRENT

0.7

0.6

0.5

0.4

0.3

DROPOUT VOLTAGE (V)

0.2

0.1

0

0 200 400 600 800 1000

3.3V SETTING

= 3.135V

V

OUT

5V SETTING

= 4.75V

V

OUT

LOAD CURRENT (mA)

MAX887-01

EFFICIENCY vs. OUTPUT CURRENT

100

PWM MODE

90

(SYNC = VL)

= 3.3V

V

80

70

60

50

40

EFFICIENCY (%)

30

20

10

OUT

V

V

= 11V

IN

IN

= 9V

VIN = 4V

= 5V

V

IN

V

= 7V

IN

0

0.0001 0.001 0.01 0.1 0.6

OUTPUT CURRENT (A)

MAX887-02

EFFICIENCY (%)

EFFICIENCY vs. OUTPUT CURRENT

100

PWM MODE

90

(SYNC = VL)

80

70

60

50

40

30

20

10

0

0.0001 0.001 0.01 0.1 0.6

V

OUT

VIN = 7V

VIN = 5.5V

= 5V

VIN = 9V

= 11V

V

IN

OUTPUT CURRENT (A)

MAX887-03

_______________________________________________________________________________________ 3

Page 4

100% Duty Cycle, Low-Noise,

Step-Down, PWM DC-DC Converter

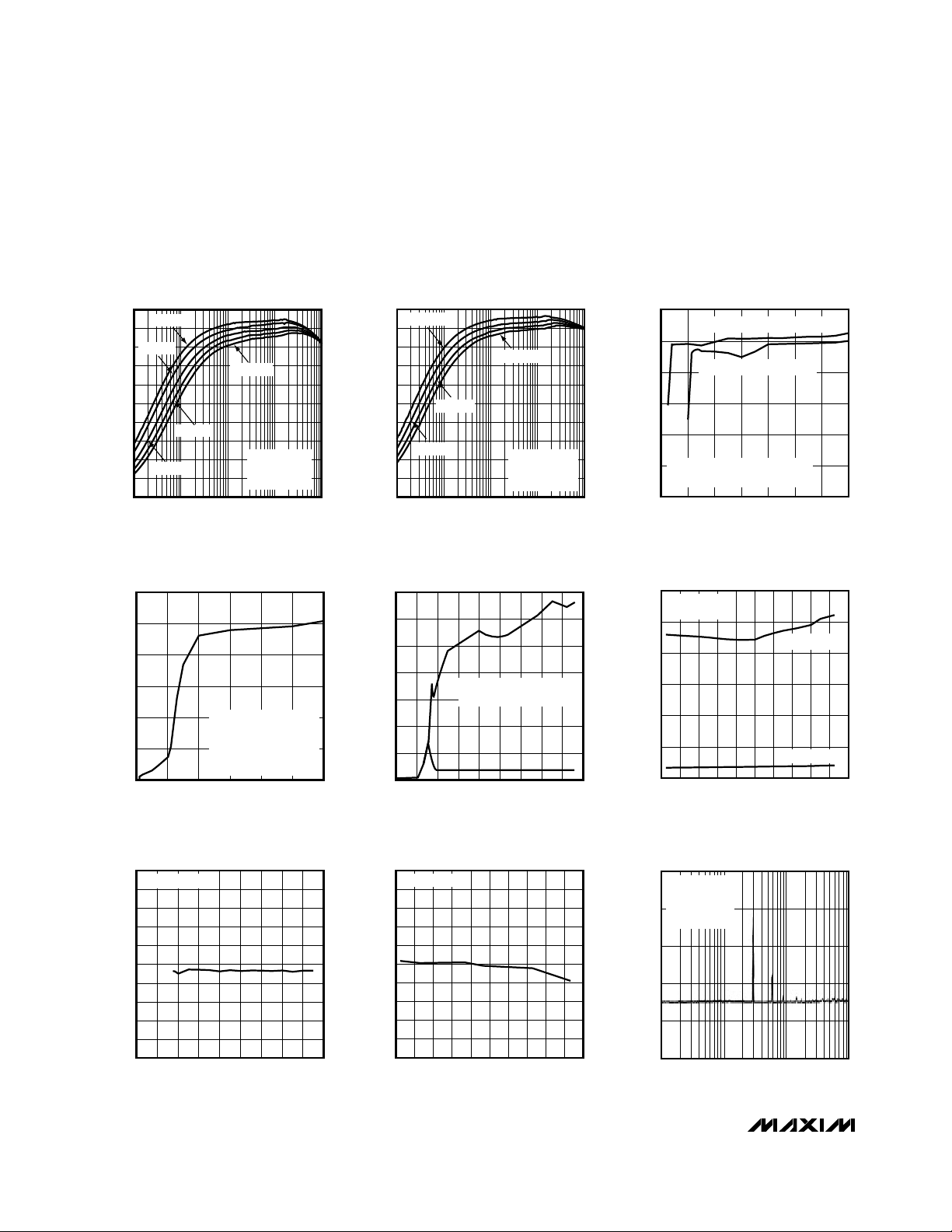

____________________________Typical Operating Characteristics (continued)

(Circuit of Figure 2, TA = +25°C, unless otherwise noted.)

EFFICIENCY vs. OUTPUT CURRENT

100

MAX887

EFFICIENCY (%)

VIN = 4V

90

80

VIN = 5V

70

60

50

40

30

20

10

0

0.0001 0.001 0.01 0.1 0.6

VIN = 9V

VIN = 7V

OUTPUT CURRENT (A)

MAXIMUM OUTPUT CURRENT

vs. SYNC FREQUENCY

1200

1000

800

600

400

200

MAXIMUM OUTPUT CURRENT (mA)

0

0 100 200 300 400 500 600

VIN = 11V

IDLE MODE

(SYNC = GND)

V

OUT

C2, C3 = 47µF

L1 = 33µH

= 5V

V

IN

= 3.3V

V

OUT

= -5% at I

V

OUT

SYNC FREQUENCY (kHz)

= 3.3V

OUT(MAX)

100

90

MAX887-04

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0.0001 0.001 0.01 0.1 0.6

3.5

MAX887-07

3.0

2.5

2.0

1.5

1.0

QUIESCENT CURRENT (mA)

0.5

0

EFFICIENCY vs. OUTPUT CURRENT

VIN = 5.5V

VIN = 11V

VIN = 9V

VIN = 7V

OUTPUT CURRENT (A)

IDLE MODE

(SYNC = GND)

= 5V

V

OUT

QUIESCENT SUPPLY CURRENT

vs. SUPPLY VOLTAGE

A

A

A: V

= 3.3V, PWM MODE

OUT

= 3.3V, PFM MODE

B: V

OUT

C

B

024681012141618

SUPPLY VOLTAGE (V)

MAXIMUM OUTPUT CURRENT

1200

MAX887-05

1000

800

600

400

200

MAXIMUM OUTPUT CURRENT (mA)

MAX887-08

QUIESCENT CURRENT (mA)

GUARANTEED OUTPUT CURRENT

OF FIGURE 2 IS 600mA

0

357911131517

3.0

VIN = 5.3V

= 3.3V

V

OUT

2.5

2.0

1.5

1.0

0.5

0

-60 -40 -20 0 20 40 60 80 100 120 140

vs. SUPPLY VOLTAGE

3.3V SETTING, V

5V SETTING, V

SUPPLY VOLTAGE (V)

OUT

OUT

= 3.135V

= 4.75V

QUIESCENT CURRENT

vs.TEMPERATURE

PWM MODE

PFM MODE

TEMPERATURE (°C)

MAX887-06

MAX887-09

SWITCHING FREQUENCY

vs. SUPPLY VOLTAGE

350

V

= 3.3V

340

330

320

310

300

290

280

270

SWITCHING FREQUENCY (kHz)

260

250

OUT

024681012141618

SUPPLY VOLTAGE (V)

350

340

MAX887-10

330

320

310

300

290

FREQUENCY (kHz)

280

270

260

250

SWITCHING FREQUENCY

vs. TEMPERATURE

V

= 3.3V

OUT

-60 -40 -20 0 20 40 60 80 100 120 140

TEMPERATURE (°C)

MAX887-11

OUTPUT NOISE (mV)

OUTPUT RIPPLE AND HARMONICS

4

VIN = 5V

= 3.3V

V

OUT

= 500mA

I

3

OUT

PWM MODE

2

1

0

-1

10k 10M

100k 1M

FREQUENCY (Hz)

4 _______________________________________________________________________________________

MAX887 TOC-20

Page 5

100% Duty Cycle, Low-Noise,

Step-Down, PWM DC-DC Converter

____________________________Typical Operating Characteristics (continued)

(Circuit of Figure 2, TA = +25°C, unless otherwise noted.)

LIGHT-LOAD, PWM-MODE

SWITCHING WAVEFORMS

A

B

C

VIN = 5V, V

OUT

A: LX, 5V/div

B: V

, 20mV/div, AC COUPLED

OUT

C: INDUCTOR CURRENT, 500mA/div

MAX887-13

1µs/div

= 3.3V, LOAD = 0mA

0mA

HEAVY-LOAD, PWM-MODE

SWITCHING WAVEFORMS

A

B

C

VIN = 5V, V

OUT

A: LX, 5V/div

B: V

, 20mV/div, AC COUPLED

OUT

C: INDUCTOR CURRENT, 500mA/div

MAX887-12

1µs/div

= 3.3V, LOAD = 500mA

MAX887

LIGHT-LOAD, PFM-MODE

SWITCHING WAVEFORMS

A

B

C

VIN = 5V, V

A: LX, 5V/div

B: V

, 20mV/div, AC COUPLED

OUT

C: INDUCTOR CURRENT, 200mA/div

1µs/div

= 3.3V, LOAD = 0mA

OUT

MAX887-14

MEDIUM-LOAD, PFM-MODE

SWITCHING WAVEFORMS

A

B

C

VIN = 5V, V

OUT

A: LX, 5V/div

B: V

, 20mV/div, AC COUPLED

OUT

C: INDUCTOR CURRENT, 200mA/div

MAX887-15

10µs/div

= 3.3V, LOAD = 70mA

_______________________________________________________________________________________

5

Page 6

100% Duty Cycle, Low-Noise,

Step-Down, PWM DC-DC Converter

_____________________________Typical Operating Characteristics (continued)

(Circuit of Figure 2, TA = +25°C, unless otherwise noted.)

MAX887

A

B

C

LOAD-TRANSIENT RESPONSE

40µs/div

V

= 5V, V

IN

LOAD = 0mA TO 500mA, PWM MODE

A: LX, 5V/div

B: V

C: LOAD CURRENT, 500mA/div

= 3.3V,

OUT

, 50mV/div, AC COUPLED

OUT

RECOVERY FROM 100% DUTY CYCLE

(DROP OUT)

MAX887-16

LINE-TRANSIENT RESPONSE

A

B

200µs/div

= 5V TO 11V, V

V

IN

LOAD = 500mA, PWM MODE

A: V

, 5V/div

IN

B: V

, 20mV/div, AC COUPLED

OUT

OUT

= 3.3V,

SHUTDOWN AND STARTUP RESPONSE

MAX887-17

A

B

C

D

V

= 5V, V

IN

OUT

LOAD = 100mA, PWM MODE

A: SHDN, 5V/div

B: V

, 2V/div, AC COUPLED

OUT

C: LX, 5V/div

D: INDUCTOR CURRENT, 500mA/div

500µs/div

= 3.3V,

A

B

C

= 3.3V TO 11V, V

V

IN

LOAD = 500mA, PWM MODE

A: V

IN

B: V

OUT

C: LX, 10V/div

200µs/div

= 3.3V,

OUT

, 5V/div

, 50mV/div, AC COUPLED

MAX887-18

6 _______________________________________________________________________________________

MAX887-19

Page 7

100% Duty Cycle, Low-Noise,

Step-Down, PWM DC-DC Converter

______________________________________________________________Pin Description

PIN

1

2 FB Feedback Input. Connect FB to a resistor voltage divider between the output and GND.

3 REF Reference Bypass Output. Connect a 0.047µF capacitor to GND very close to the MAX887, within 0.2 in. (5mm).

4 VL

5 GND Ground

6 SYNC

7 LX Inductor Connection to the drain of an internal P-channel MOSFET

8 V+

SHDN

VL

REF

NAME FUNCTION

SHDN Shutdown, Active-Low, Logic-Level Input. Connect SHDN to V+ for normal operation.

3.3V Internal Logic Regulator Output. Bypass VL to GND with a 2.2µF capacitor very close to the MAX887,

within 0.2 in. (5mm).

Oscillator Synchronization and PWM Control Input. SYNC is a logic-level input. Tie SYNC to VL for internal

300kHz PWM operation at all loads. The oscillator synchronizes to the negative edge of an external clock

between 10kHz and 400kHz. The MAX887 operates in PWM mode when SYNC is clocked. Tying SYNC to

GND allows a reduced supply-current mode at light loads.

Supply-Voltage Input. 3.5V min to 11V max. Bypass V+ to GND with a 0.33µF and large-value electrolytic

capacitor in parallel. These capacitors must be as close to the V+ and GND pins as possible. Place the

0.33µF capacitor within 0.2 in. (5mm) of the MAX887.

REF

GND

V+

VL

GND

25mV

100mV

PFM CURRENT COMPARATOR

LEVEL

SHIFTER

ILIM COMPARATOR

0.1X

SENSE FET

V+

1Ω

LX

MAX887

RAMP

GEN

SLOPE COMPENSATION

FROM CONTROL LOGIC

PWM

PWM ON

SIGNAL

PFM

COMPARATOR

SYNC

SYNC

CELL

FB

REF

Figure 1. Simplified Functional Block Diagram

_______________________________________________________________________________________ 7

REF

PWM

COMPARATOR

CONTROL &

DRIVER LOGIC

FB

50mV

REF

FB

OVERVOLTAGE

COMPARATOR

NEGLIM

COMPARATOR

0mV in PFM

ADJ. IN PWM

SENSE FET

0.1X

1Ω

GND

Page 8

100% Duty Cycle, Low-Noise,

Step-Down, PWM DC-DC Converter

_______________Detailed Description

The MAX887 is a step-down, pulse-width modulation

(PWM) DC-DC converter that provides an adjustable

output from 1.25V to 10.5V. It accepts inputs from 3.5V

to 11V and delivers up to 600mA. An internal MOSFET

and synchronous rectifier reduce PC board area while

maintaining high efficiency. Cycle-by-cycle current lim-

MAX887

iting protects the internal MOSFETs and reduces system stress during overload conditions. Operation with

up to 100% duty cycle for an output of 3V and higher

minimizes dropout voltage. Fixed-frequency PWM operation reduces interference in sensitive communications

and data-acquisition applications. A SYNC input allows

synchronization to an external clock. When enabled,

Idle Mode™ extends battery life under light loads by

placing the regulator in low quiescent current (200µA

typ) pulse-frequency modulation (PFM) operation.

Shutdown quiescent current is 2.5µA typ.

PWM Control Scheme

The MAX887 uses an oscillator-triggered minimum/

maximum on-time current-mode control scheme. The

minimum on-time is approximately 280ns unless in

dropout. The maximum on-time is approximately

4/f

, allowing operation to 100% duty cycle. Current-

OSC

mode feedback provides cycle-by-cycle current limiting for superior load and line response and protection

of the internal MOSFET and rectifier.

At each falling edge of the internal oscillator, the SYNC

cell sends a PWM ON signal to the control and drive

logic, turning on the internal P-channel MOSFET (main

switch) (Figures 1 and 2). This allows current to ramp

up through the inductor (Figure 2) to the load, and

stores energy in a magnetic field. The switch remains

on until either the current-limit (ILIM) comparator is

tripped, the maximum on-time is reached (not shown),

V

= 3.5V to 11V

IN

47µF

OFF

2.2µF

ON

0.33µF

0.047µF

V+ LX

MAX887

SHDN

SYNC

VL

REF

GND

V

= 1.25V (R1/R2 + 1)

OUT

33µH

R1

165kΩ

FB

R2

100kΩ

V

OUT

C1

100pF

= 3.3V

47µF

or the PWM comparator signals that the output is in

regulation. When the switch turns off, during the second half of each cycle, the inductor’s magnetic field

collapses, releasing the stored energy and forcing current through the output diode to the output filter capacitor and load. The output filter capacitor stores charge

when the inductor current is high and releases it when

the inductor current is low, smoothing the voltage

across the load.

During normal operation, the MAX887 regulates output

voltage by switching at a constant frequency and then

modulating the power transferred to the load per pulse

using the PWM comparator. A multi-input comparator

sums three weighted differential signals (the output

voltage with respect to the reference, the main switch

current sense, and the slope-compensation ramp) and

changes states when a threshold is reached. It modulates

output power by adjusting the inductor peak current

during the first half of each cycle, based on the output

error voltage. The MAX887’s loop gain is relatively low

to enable the use of a small, low-valued output filter

capacitor. The resulting load regulation is 2.5% typ at

500mA. Slope compensation is added to account for

the inductor current waveform’s down slope during the

second half of each cycle, and to eliminate the inductor

current staircasing characteristic of current-mode controllers at high duty cycles.

100% Duty-Cycle Operation

For the internal oscillator frequency, the f

mum on-time exceeds one cycle and permits operation

to 100% duty cycle. As the input voltage drops, the

duty cycle increases until the P-channel MOSFET is

held on continuously and 100% duty cycle is reached.

Dropout voltage in 100% duty cycle is the output current multiplied by the on-resistance of the internal

switch and inductor around 300mV (I

OUT

PWM mode, subharmonic oscillation can occur near

dropout, but subharmonic voltage ripple is small, since

the ripple current is low. When using synchronization to

an external oscillator, 100% duty cycle is available for

SYNC frequencies higher than f

OSC

/4.

/4 maxi-

OSC

= 500mA). In

Synchronous Rectification

Although an external Schottky diode is used as the primary output rectifier, an N-channel synchronous rectifier turns on to reduce power loss across the diode and

improve efficiency. During the second half of each

cycle, when the inductor current ramps below the

threshold set by the NEGLIM comparator or when the

end of the oscillator period is reached, the synchronous

rectifier turns off. This keeps excess current from flowing

Figure 2. Typical Operating Circuit

8 _______________________________________________________________________________________

Page 9

100% Duty Cycle, Low-Noise,

Step-Down, PWM DC-DC Converter

backward through the inductor, from the output filter

capacitor to GND, or through the switch and synchronous rectifier to GND.

During PWM operation, the NEGLIM threshold adjusts

to permit small amounts of reverse current to flow from

the output during light loads. This allows regulation with

a constant switching frequency and eliminates minimum load requirements. The NEGLIM comparator

threshold is 0mA if VFB < 1.25V, and decreases as VFB

exceeds 1.25V to prevent the output from rising. The

NEGLIM threshold in PFM mode is 0mA. (See

PWM and Idle Mode operation.

)

Forced

Forced PWM and Idle Mode Operation

Connect SYNC to VL for normal forced PWM operation.

Forced PWM operation is desirable in sensitive RF and

data-acquisition applications, to ensure that switchingnoise harmonics do not interfere with sensitive IF and

data-sampling frequencies. A minimum load is not

required during forced PWM operation, since the synchronous rectifier passes reverse inductor current as

needed to allow constant-frequency operation with no

load.

Connecting SYNC to GND enables Idle Mode operation. This proprietary control scheme places the

MAX887 in PFM mode at light loads to improve efficiency and reduce quiescent current to 200µA typ. With

Idle Mode enabled, the MAX887 initiates PFM operation

when the output current drops below 100mA. During

PFM operation, the MAX887 switches only as needed

to service the load, reducing the switching frequency

and associated losses in the internal switch and

synchronous rectifier, Schottky diode, and external

inductor.

During PFM mode, a switching cycle is initiated when

the PFM comparator senses that the output voltage has

dropped too low. The P-channel MOSFET switch turns

on and conducts current to the output filter capacitor

and load until the inductor current reaches the PFM

peak current limit (100mA). Then the switch turns off

and the magnetic field in the inductor collapses, forcing

current through the output diode to the output filter

capacitor and load. The output filter capacitor stores

charge when the inductor current is high and releases

charge when it is low, smoothing the voltage across the

load. Then the MAX887 waits until the PFM comparator

senses a low output voltage again. During PFM mode,

the synchronous rectifier is disabled and the external

Schottky diode is used as an output rectifier.

The PFM current comparator controls both entry into

PWM mode and the peak switching current during PFM

mode. Consequently, some jitter is normal during tran-

sition from PFM to PWM modes with loads around

100mA, and has no adverse impact on regulation.

Output ripple is higher during PFM operation, and the

output filter capacitor should be selected on this basis

when PFM mode is used. Output ripple and noise are

higher during PFM operation.

SYNC Input and Frequency Control

The MAX887H comes with an internal oscillator set for a

fixed switching frequency of 300kHz. Connect SYNC to

VL for normal forced-PWM operation. Do not leave

SYNC floating. Connecting SYNC to GND enables Idle

Mode operation to reduce supply current at light loads.

SYNC is a logic-level input useful for operating-mode

selection and frequency control. It is a negative edge

triggered input that allows synchronization to an external frequency between 25kHz and 440kHz. When

SYNC is clocked by an external signal, the converter

operates in PWM mode. If SYNC is low or high for more

than 100µs, the oscillator defaults to 300kHz. Operating

at a lower switching frequency reduces quiescent current, but reduces maximum load current as well

(Table 1). For example, at 330kHz, maximum output

current is 600mA, while at 30kHz, maximum output current is only 30mA. Note that 100% duty cycle will only

occur for f

SYNC

> f

OSC

/4.

VL Regulator

The MAX887 uses an internal 3.3V linear regulator for

logic power in the IC. This logic supply is brought out

using the VL pin for bypassing and compensation with

an external 2.2µF capacitor to GND. Connect this

capacitor close to the MAX887, within 0.2in (5mm).

Shutdown

Connecting SHDN to GND places the MAX887 in a lowcurrent shutdown mode (IQ= 2.5µA typ at V+ = 7V). In

shutdown, the reference, VL regulator, control circuitry,

internal switching MOSFET, and the synchronous rectifier turn off and the output falls to 0V. Connect SHDN to

V+ for normal operation.

Current-Sense Comparators

Several internal current-sense comparators are used

inside the MAX887. In PWM operation, the PWM comparator is used for current-mode control. Current-mode

control imparts cycle-by-cycle current limiting and provides improved load and line response, allowing tighter

specification of the inductor saturation current limit to

reduce inductor cost. A second 100mA current-sense

comparator is used across the P-channel switch to control entry into PFM mode. A third current-sense comparator monitors current through the internal N-channel

MOSFET to set the NEGLIM threshold and determine

MAX887

_______________________________________________________________________________________ 9

Page 10

100% Duty Cycle, Low-Noise,

Step-Down, PWM DC-DC Converter

when to turn off this synchronous rectifier. A fourth

comparator (ILIM) is used at the P-channel MOSFET

switch for overcurrent detection. This protects the system, external components, and internal MOSFETs

under overload conditions.

________________Design Information

MAX887

To select an output voltage between 1.25V and 10.5V,

connect FB to a resistor voltage divider between the

output and GND (Figure 2). Select feedback resistor R2

in the 5kΩ to 100kΩ range, since FB input leakage is

±100nA max. R1 is then given by:

R1 R2

where VFB= 1.25V. A small ceramic capacitor (C1)

around 100pF to 470pF should be added in parallel

with R1 to compensate for stray capacitance at the FB

pin, and output capacitor equivalent series resistance

(ESR).

A 1.3A inductor with the value recommended in Table 1

is sufficient for most applications. However, the exact

inductor value is not critical, and values within 50% of

those in Table 1 are acceptable. For best efficiency, the

inductor’s DC resistance should be less than 0.25Ω.

The inductor saturation current rating must exceed the

1A I

Input and output filter capacitors should be chosen to

service inductor currents with acceptable voltage ripple. The input filter capacitor also reduces peak currents and noise at the voltage source. See Table 1 for

suggested values. The MAX887’s loop gain is relatively

low, to enable the use of small, low-valued output filter

capacitors. Higher values provide improved output rip-

Table 1. Inductor and Output Filter

vs. Sync Frequency

current limit. Table 2 lists component suppliers.

LIM

SYNC

RANGE (kHz)

300–400 33 33

200–300 47 47

150–200 68 68

100–150 100 100

75–100 150 150

Output Voltage Selection

V

=−

OUT

V

FB

1

Inductor Selection

Capacitor Selection

L1

(µH)

C

(µF)

OUT

ple and transient response. Lower oscillator frequencies require a larger-value output capacitor. When Idle

Mode is used, verify capacitor selection with light loads

during PFM operation, since output ripple is higher

under these conditions.

Low-ESR capacitors are recommended. Capacitor ESR

is a major contributor to output ripple (usually more

than 60%). Ordinary aluminum-electrolytic capacitors

have high ESR and should be avoided. Low-ESR aluminum-electrolytic capacitors are acceptable and relatively inexpensive. Low-ESR tantalum capacitors

are better and provide a compact solution for spaceconstrained surface-mount designs. Do not exceed

the ripple current ratings of tantalum capacitors.

Ceramic capacitors have the lowest ESR overall, and

OS-CON capacitors have the lowest ESR of the highvalue electrolytic types. It is generally not necessary to

use ceramic and OS-CON capacitors for the MAX887;

they need only be considered in very compact, highreliability, or wide-temperature applications, where the

expense is justified. When using very-low-ESR capacitors, such as ceramic or OS-CON, check for stability

while examining load-transient response, and increase

the compensation capacitor C1 if needed. Table 2 lists

suppliers for the various components used with the

MAX887.

Table 2. Component Suppliers

COMPANY PHONE FAX

AVX USA (803) 946-0690 (803) 626-3123

(800) 282-4975

Coilcraft USA (847) 639-6400 (847) 639-1469

Coiltronics USA (561) 241-7876 (561) 241-9339

Dale USA (605) 668-4131 (605) 665-1627

International USA (310) 322-3331 (310) 322-3332

Rectifier

Motorola USA (602) 303-5454 (602) 994-6430

Nichicon USA (847) 843-7500 (847) 843-2798

Japan 81-7-5231-8461 81-7-5256-4158

Nihon USA (805) 867-2555 (805) 867-2698

Japan 81-3-3494-7411 81-3-3494-7414

Sanyo USA (619) 661-6835 (619) 661-1055

Japan 81-7-2070-6306 81-7-2070-1174

Siliconix USA (408) 988-8000 (408) 970-3950

(800) 554-5565

Sprague USA (603) 224-1961 (603) 224-1430

Sumida USA (847) 956-0666 (847) 956-0702

Japan 81-3-3607-5111 81-3-3607-5144

United USA (714) 255-9500 (714) 255-9400

Chemi-Con

10 ______________________________________________________________________________________

Page 11

100% Duty Cycle, Low-Noise,

Step-Down, PWM DC-DC Converter

Bypass V+ to GND using a 0.33µF capacitor. Also

bypass VL to GND with a 2.2µF capacitor, and VREF to

GND using a 0.047µF capacitor. These capacitors

should be placed within 0.2in (5mm) of their respective

pins. A small ceramic capacitor (C1) of around 100pF

to 470pF should be added in parallel with R1 to compensate for stray capacitance at the FB pin and output

capacitor ESR.

Output Diode Selection

A 1A external diode (D1) is required as an output rectifier to pass inductor current during the second half of

each cycle. This diode operates in PFM mode and during transition periods while the synchronous rectifier is

off. Use a Schottky diode to prevent the slow internal

diode of the N-channel MOSFET from turning on.

PC Board Layout and Routing

High switching frequencies and large peak currents

make PC board layout a very important part of design.

Poor design can result in excessive EMI on the feedback paths and voltage gradients in the ground plane,

both of which can result in instability or regulation

errors. Power components, such as the MAX887,

inductor, input filter capacitor, and output filter capacitor should be placed as close together as possible,

and their traces kept short, direct, and wide. Connect

their ground pins at a common node in a star-ground

configuration. Keep the extra copper on the board and

integrate into ground as a pseudo-ground plane. The

external voltage-feedback network should be very

close to the FB pin, within 0.2in (5mm). Keep noisy

traces, such as from the LX pin, away from the voltagefeedback network, and separate using grounded copper. Place the small bypass capacitors (C1, C3, C5,

and C6) within 0.2in (5mm) of their respective pins. The

MAX887 evaluation kit manual illustrates an example

PC board layout, routing, and pseudo-ground plane.

___________________Chip Information

TRANSISTOR COUNT: 2006

SUBSTRATE CONNECTED TO GND

MAX887

______________________________________________________________________________________ 11

Page 12

100% Duty Cycle, Low-Noise,

Step-Down, PWM DC-DC Converter

________________________________________________________Package Information

MAX887

e

DIM

D

A

0.101mm

0.004in.

A1

B

C

L

0°-8°

Narrow SO

HE

SMALL-OUTLINE

PACKAGE

(0.150 in.)

A

A1

B

C

E

e

H

L

DIM

D

D

D

INCHES MILLIMETERS

MIN

0.053

0.004

0.014

0.007

0.150

0.228

0.016

PINS

8

14

16

MAX

0.069

0.010

0.019

0.010

0.157

0.244

0.050

INCHES MILLIMETERS

MIN

MAX

0.189

0.197

0.337

0.344

0.386

0.394

MIN

1.35

0.10

0.35

0.19

3.80

5.80

0.40

MIN

4.80

8.55

9.80

1.270.050

MAX

1.75

0.25

0.49

0.25

4.00

6.20

1.27

MAX

5.00

8.75

10.00

21-0041A

12 ______________________________________________________________________________________

Loading...

Loading...