Page 1

General Description

The MAX8805Y/MAX8805Z high-frequency step-down

converters are optimized for dynamically powering the

power amplifier (PA) in WCDMA or NCDMA handsets.

The devices integrate a high-efficiency PWM step-down

converter for medium- and low-power transmission, and

a 60mΩ typical bypass FET to power the PA directly

from the battery during high-power transmission. Dual

200mA low-noise, high-PSRR low-dropout regulators

(LDOs) for PA biasing are also integrated.

Two switching frequency options are available—2MHz

(MAX8805Y) and 4MHz (MAX8805Z)—allowing optimization for smallest solution size or highest efficiency. Fast

switching allows the use of small ceramic 2.2µF input and

output capacitors while maintaining low ripple voltage.

The feedback network is integrated, further reducing

external component count and total solution size.

The MAX8805Y/MAX8805Z use an analog input driven

by an external DAC to control the output voltage linearly

for continuous PA power adjustment. At high duty

cycle, the MAX8805Y/MAX8805Z automatically switch

to the bypass mode, connecting the input to the output

through a low-impedance (60mΩ typ) MOSFET. The

user can also enable the bypass mode directly through

a logic-control input.

The LDOs in the MAX8805Y/MAX8805Z are designed

for low-noise operation (35µV

RMS

typ). Each LDO is indi-

vidually enabled through its own logic control interface.

The MAX8805Y/MAX8805Z are available in a 16-bump,

2mm x 2mm WLP package (0.7mm max height).

Applications

WCDMA/NCDMA Cellular Handsets

Wireless PDAs

Smartphones

Features

♦ PA Step-Down Converter

7.5µs (typ) Settling Time for 0.8V to 3.4V Output

Voltage Change

Dynamic Output Voltage Setting from 0.4V to

V

BATT

60mΩ pFET and 100% Duty Cycle for Low

Dropout

2MHz or 4MHz Switching Frequency

Low Output-Voltage Ripple

600mA Output Drive Capability

2% Maximum Accuracy

Tiny External Components

♦ Dual Low-Noise LDOs

Low 35µV

RMS

(typ) Output Noise

High 70dB (typ) PSRR

Guaranteed 200mA Output Drive Capability

Individual ON/OFF Control

♦ Low 0.1µA Shutdown Current

♦ 2.7V to 5.5V Supply Voltage Range

♦ Thermal Shutdown

♦ Tiny 2mm x 2mm x 0.7mm WLP Package

(4 x 4 Grid)

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

________________________________________________________________

Maxim Integrated Products

1

Ordering Information

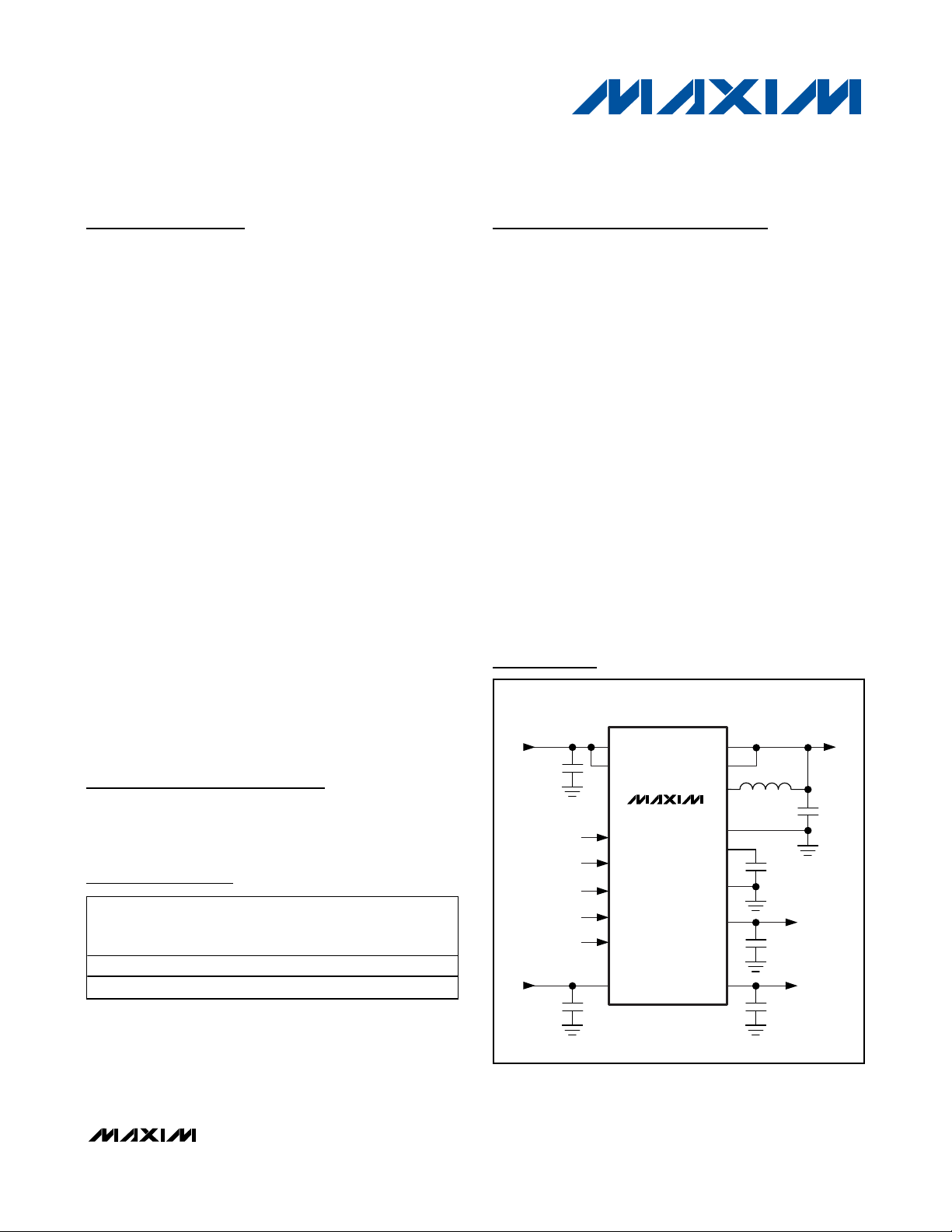

IN1A

LX

PAA

1μH

BATT

2.7V TO 5.5V

AGND

PA_EN

REFIN

EN1

EN2

IN2

BATT

2.7V TO 5.5V

PA ON/OFF

ANALOG CONTROL

V

PA

0.4V TO V

BATT

REFBP

IN1B

LDO1 ON/OFF

LDO2 ON/OFF

PAB

LDO2

LDO1

V

LDO2

UP

TO 200mA

PGND

HP

FORCED BYPASS

2.2μF

2.2μF

MAX8805Z

V

LDO1

UP

TO 200mA

Typical Operating Circuit

19-0777; Rev 0; 4/07

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

+

Denotes a lead-free package.

T

= Tape and reel package.

*

xy is the output voltage code (see Table 1 in the Output

Voltages section).

Note: All devices are specified over the -40°C to +85°C operating temperature range.

Pin Configuration appears at end of data sheet.

PART

PIN-

PKG

SWI T C H I N G

F R EQ U EN C Y

( M H z)

MAX8805YEWExy+T*

2

MAX8805ZEWExy+T*

4

PACKAGE

16 WLP-16 W162B2+ 1

16 WLP-16 W162B2+ 1

CODE

Page 2

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

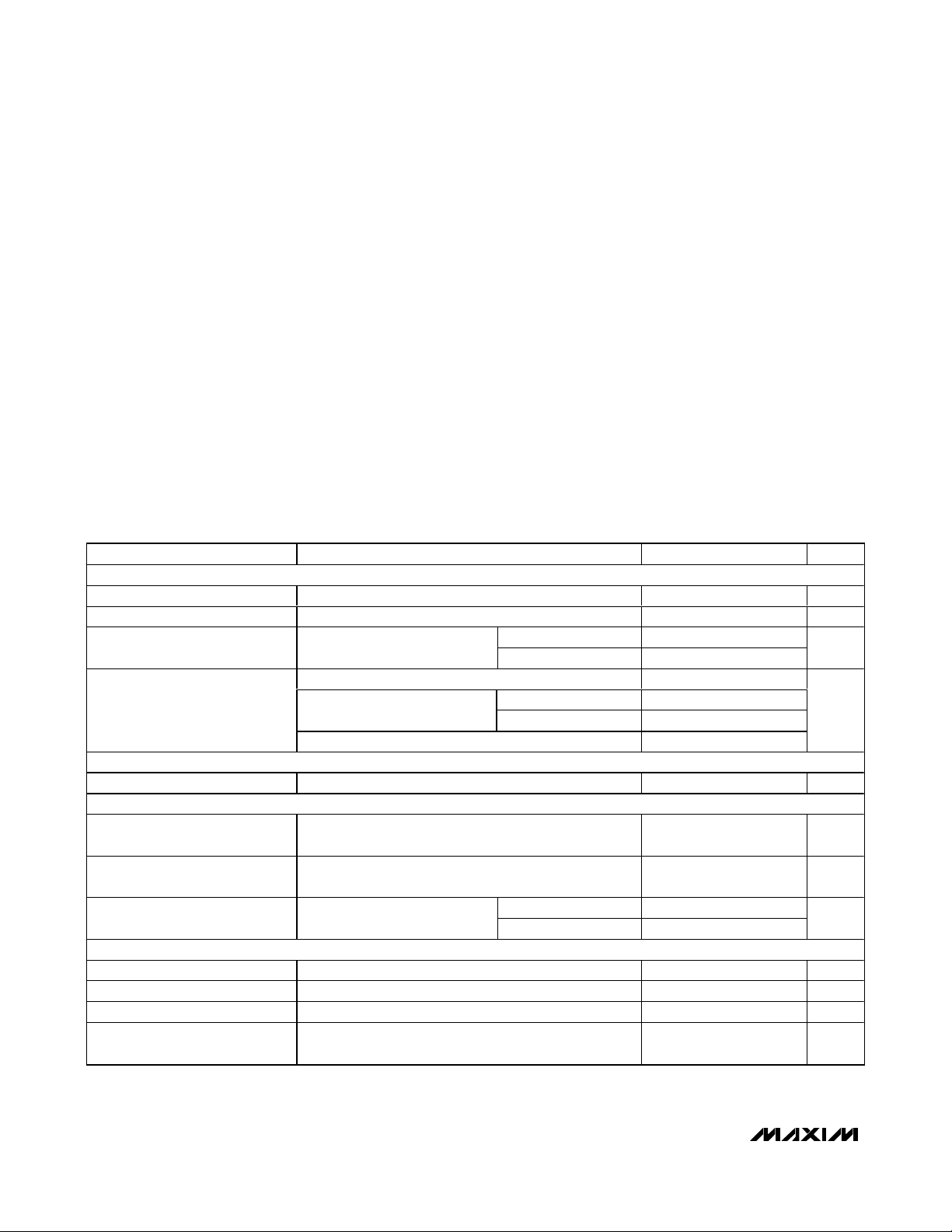

ELECTRICAL CHARACTERISTICS

(V

IN1A

= V

IN1B

= V

IN2

= V

PA_EN

= V

EN1

= V

EN2

= 3.6V, V

HP

= 0V, V

REFIN

= 0.9V, TA= -40°C to +85°C. Typical values are at TA =

+25°C, unless otherwise noted.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN1A, IN1B, IN2, REFIN, EN2, REFBP to AGND ...-0.3V to +6.0V

PAA, PAB, PA_EN, HP to AGND....-0.3V to (V

IN1A/VIN1B

+ 0.3V)

LDO1, LDO2, EN1 to AGND ......................-0.3V to (V

IN2

+ 0.3V)

IN2 to IN1B/IN1A ...................................................-0.3V to +0.3V

PGND to AGND .....................................................-0.3V to +0.3V

LX Current ......................................................................0.7A

RMS

IN1A/IN1B and PAA/PAB Current .....................................2A

RMS

PAA and PAB Short Circuit to GND or IN...................Continuous

Continuous Power Dissipation (T

A

= +70°C)

16-Bump WLP (derate 12.5mW/°C above +70°C).............1W

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Bump Temperature (soldering, reflow) ............................+235°C

Note: This device is constructed using a unique set of packaging techniques that impose a limit on the thermal profile the device

can be exposed to during board level solder attach and rework. This limit permits only the use of the solder profiles recommended in the industry-standard specification, JEDEC 020A, paragraph 7.6, Table 3 for IR/VPR and Convection reflow.

Preheating is required. Hand or wave soldering is not allowed.

Dual Mode is a trademark of Maxim Integrated Products, Inc.

INPUT SUPPLY

Input Voltage V

Input Undervoltage Threshold V

Shutdown Supply Current V

No-Load Supply Current

THERMAL PROTECTION

Thermal Shutdown TA rising, 20°C typical hysteresis +160 °C

LOGIC CONTROL

PA_EN, EN1, EN2, HP LogicInput High Voltage

PA_EN, EN1, EN2, HP LogicInput Low Voltage

Logic-Input Current

(PA_EN, EN1, EN2, HP)

REFIN

REFIN Common-Mode Range 0.1 2.2 V

REFIN to PA_ Gain (Falling Edge) V

REFIN Input Resistance 540 kΩ

REFIN

Dual Mode™ Threshold

PARAMETER CONDITIONS MIN TYP MAX UNITS

, V

, V

= V

= 0V, I

= V

IN1B

IN1B

EN2

, V

IN2

, V

rising, 180mV typical hysteresis 2.52 2.63 2.70 V

IN2

= V

EN2

= I

= 0V

LDO2

EN1

LDO1

= 0V, IPA = 0A,

IN1A

IN1A

PA_EN

V

PA_EN

V

EN1

switching

V

= V

EN1

2.7V ≤ V

2.7V ≤ V

= 0V or V

V

IL

REFIN

V

REFIN

= 0V, VHP = 3.6V 150

EN2

IN1A

IN1A

= V

= V

IH

= V

IN1B

IN1B

IN1A

= V

= V

= 5.5V

= 0.4V, 0.9V, 1.7V, 2.2V 1.96 2.00 2.04 V/V

rising, 50mV hysteresis

2.7 5.5 V

TA = +25°C 0.1 4

T

= +85°C 0.1

A

= 0A 150 250

MAX8805Y 3500

MAX8805Z 5000

≤ 5.5V 1.4 V

IN2

≤ 5.5V 0.4 V

IN2

TA = +25°C 0.01 1

T

= +85°C 0.1

A

0.45 x

0.465 x

V

IN2

V

IN2

0.48 x

V

IN2

µA

µA

µA

V

Page 3

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

_______________________________________________________________________________________ 3

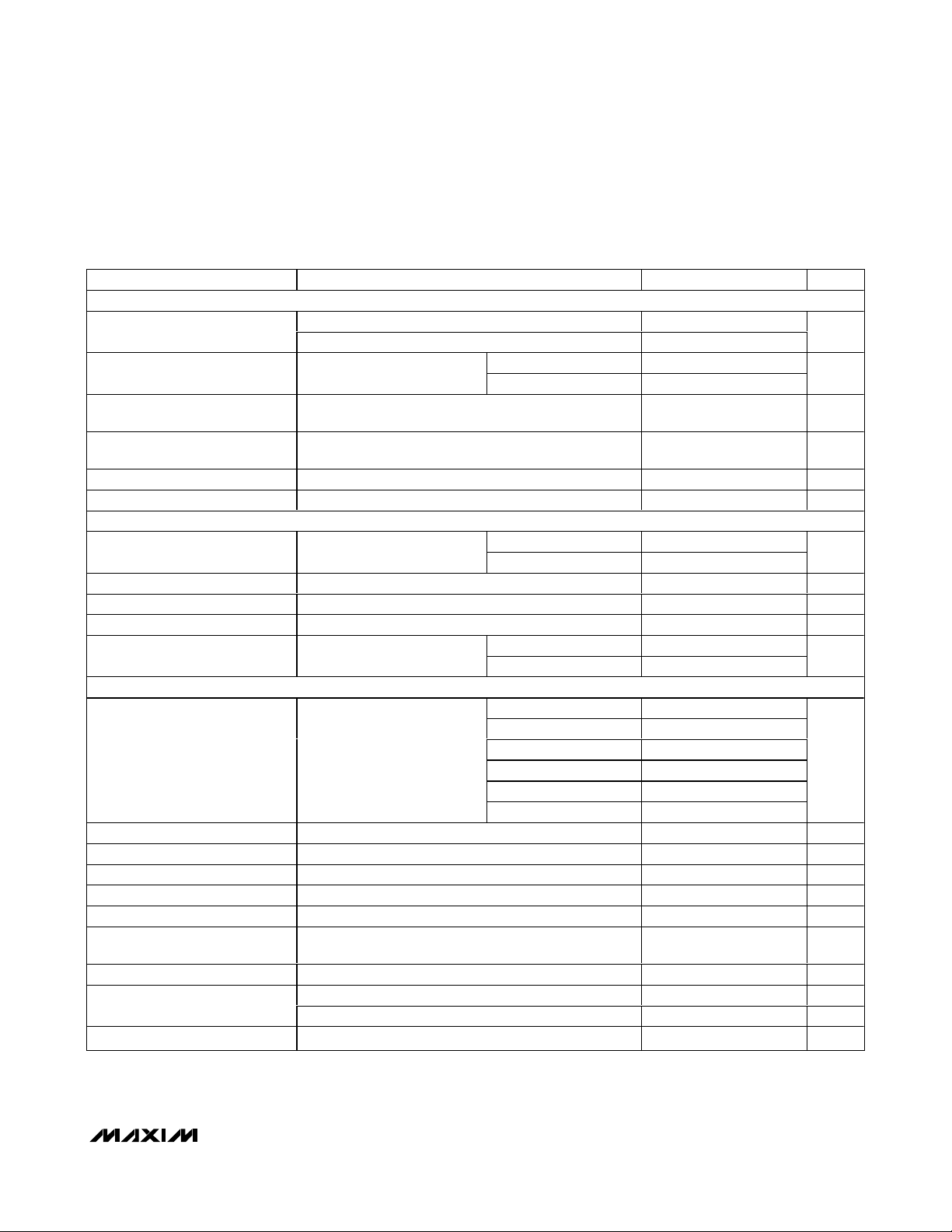

ELECTRICAL CHARACTERISTICS (continued)

(V

IN1A

= V

IN1B

= V

IN2

= V

PA_EN

= V

EN1

= V

EN2

= 3.6V, V

HP

= 0V, V

REFIN

= 0.9V, TA= -40°C to +85°C. Typical values are at TA =

+25°C, unless otherwise noted.) (Note 1)

LX

On-Resistance

LX Leakage Current

p-Channel MOSFET Peak

Current Limit

n-Channel MOSFET Valley

Current Limit

Minimum On- and Off-Times 0.1 µs

Power-Up Delay From PA_EN rising to LX rising 150 250 µs

BYPASS

On-Resistance

Bypass Current Limit VPA = 0 0.8 1.2 1.8 A

S tep - D ow n C ur r ent Li m i t i n Byp ass VLX = 0 0.7 0.9 1.1 A

Total Bypass Current Limit VLX = VPA = 0 1.5 2.1 2.9 A

Bypass Off-Leakage Current

LDO1

Output Voltage V

Output Current 200 mA

Current Limit V

Dropout Voltage I

Line Regulation V

Load Regulation I

Power-Supply Rejection

ΔV

LDO1

Output Noise 100Hz to 100kHz, C

Output Capacitor for Stable

Operation

Shutdown Output Impedance V

PARAMETER CONDITIONS MIN TYP MAX UNITS

p-channel MOSFET switch, ILX = -40mA 0.18 0.6

n-channel MOSFET rectifier, I

V

= V

IN1A

= 0V

V

LX

V

= 0V 0.7 0.9 1.1 A

LX

IN1B

= V

IN2

= 5.5V,

= 40mA 0.15 0.6

LX

TA = +25°C 0.1 5

T

= +85°C 1

A

0.5 0.7 0.9 A

p-channel MOSFET bypass,

= -90mA

I

OUT

V

V

IN1A

PAA

= V

= V

IN1B

PAB

= V

= 0V

IN2

= 5.5V,

TA = +25°C 0.060 0.1

T

= +85°C 0.1

A

TA = +25°C 0.01 10

T

= +85°C 1

A

MAX8805YEWEAA+T 1.746 1.8 1.854

MAX8805YEWEBC+T 2.425 2.5 2.575

LDO1

V

IN2

V

IN2

= 5.5V, I

= 3.4V, I

LDO1

LDO1

= 1mA;

= 100mA

MAX8805YEWECC+T 2.619 2.7 2.781

MAX8805YEWEDD+T 2.716 2.8 2.884

MAX8805YEWEEE+T 2.765 2.85 2.936

/ ΔV

IN2

MAX8805YEWEGG+T 2.910 3.0

= 0V 250 550 750 mA

LDO1

= 100mA, TA = +25°C (V

LDO1

stepped from 3.5V to 5.5V, I

IN2

stepped from 50µA to 200mA 25 mV

LDO1

10Hz to 10kHz, C

0 < I

0 < I

EN1

< 10mA 100 nF

LDO1

< 200mA 1 µF

LDO1

= 0V 1 kΩ

LDO1

LDO1

= 1µF, I

= 1µF, I

≥ 2.5V) 70 200 mV

LDO1

= 100mA 2.4 mV

LDO1

= 30mA 70 dB

LDO1

= 30mA 35 µV

LDO1

3.090

Ω

µA

Ω

µA

V

RMS

Page 4

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

4 _______________________________________________________________________________________

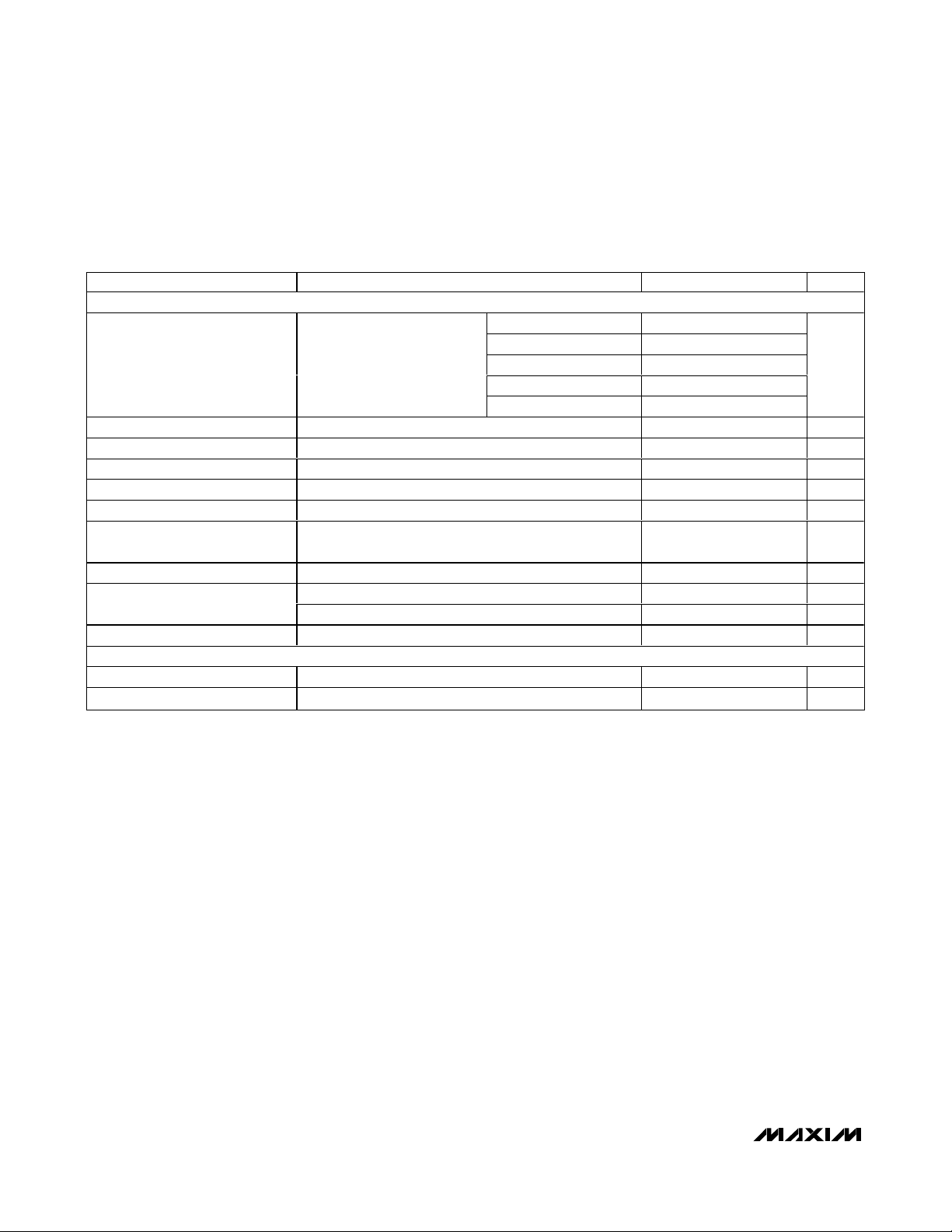

ELECTRICAL CHARACTERISTICS (continued)

(V

IN1A

= V

IN1B

= V

IN2

= V

PA_EN

= V

EN1

= V

EN2

= 3.6V, V

HP

= 0V, V

REFIN

= 0.9V, TA= -40°C to +85°C. Typical values are at TA =

+25°C, unless otherwise noted.) (Note 1)

Note 1: All devices are 100% production tested at TA= +25°C. Limits over the operating temperature range are guaranteed by design.

LDO2

Output Voltage V

Output Current 200 mA

Current Limit V

Dropout Voltage I

Line Regulation V

Load Regulation I

Power-Supply Rejection

ΔV

LDO2

Output Noise 100Hz to 100kHz, C

Output Capacitor for Stable

Operation

Shutdown Output Impedance V

REFBP

REFBP Output Voltage 0 ≤ I

REFBP Supply Rejection V

PARAMETER CONDITIONS MIN TYP MAX UNITS

/ ΔV

IN2

LDO2

V

= 5.5V, I

IN2

V

= 3.4V, I

IN2

= 0V 250 550 750 mA

LDO2

= 100mA, TA = +25°C 70 200 mV

LDO2

stepped from 3.5V to 5.5V, I

IN2

stepped from 50µA to 200mA 25 mV

LDO2

10Hz to 10kHz, C

0µA < I

0µA < I

= 0V 1 kΩ

EN2

REFBP

stepped from 2.55V to 5.5V 0.2 5 mV

IN2

LDO2

LDO2

< 10mA 100 nF

LDO2

< 200mA 1 µF

LDO2

≤ 1µA 1.237 1.250 1.263 V

= 1mA;

= 100mA

= 1µF, I

LDO2

LDO2

= 1µF, I

MAX8805YEWEAA+T 1.746 1.8 1.854

MAX8805YEWEAC+T 2.619 2.7 2.781

MAX8805YEWEAD+T 2.716 2.8 2.884

MAX8805YEWEBE+T 2.765 2.85 2.936

MAX8805YEWEGG+T 2.910 3.0

= 100mA 2.4 mV

LDO2

= 30mA 70 dB

LDO2

= 30mA 35 µV

LDO2

V

3.090

RMS

Page 5

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

_______________________________________________________________________________________

5

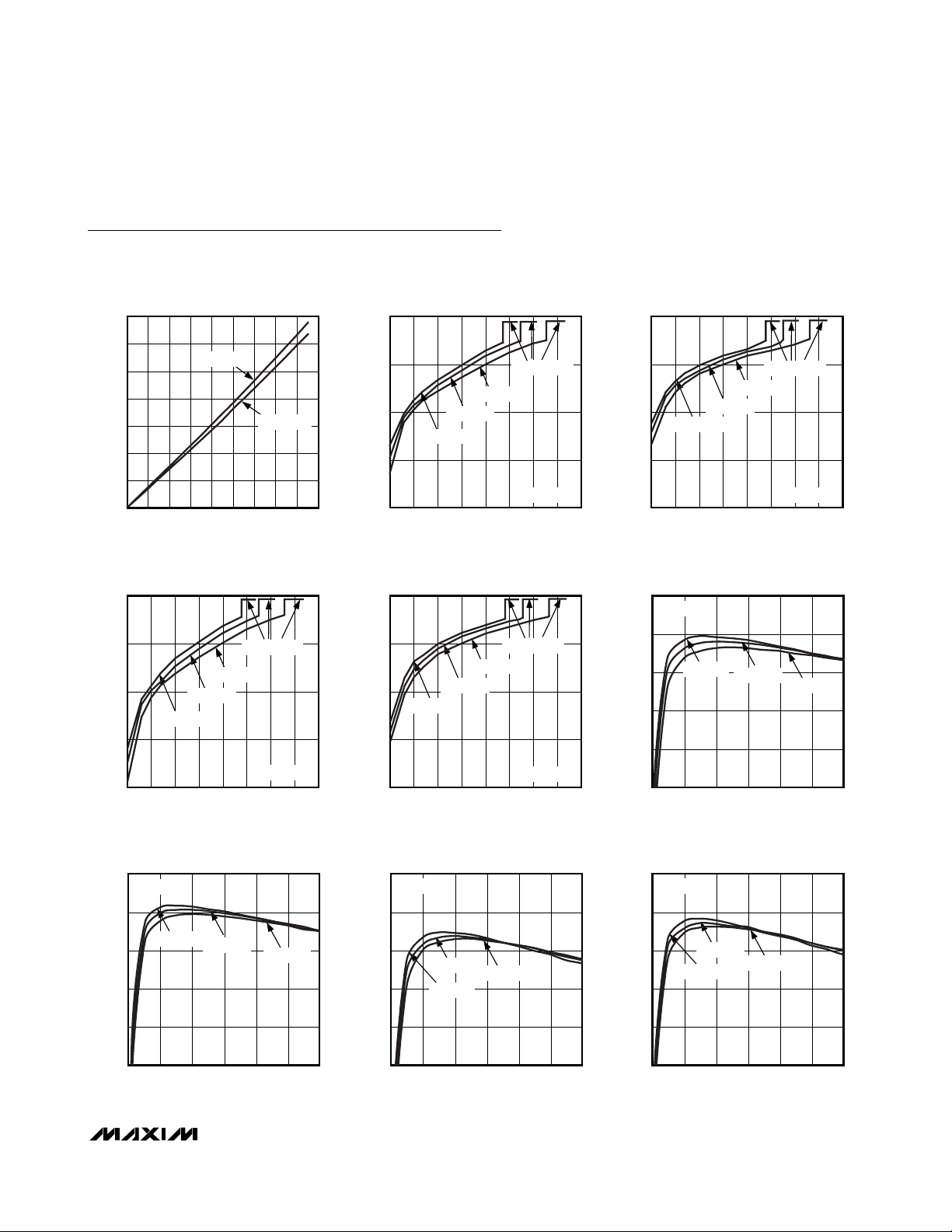

Typical Operating Characteristics

(V

IN1A

= V

IN1B

= V

IN2

= 3.6V, VPA= 1.2V, V

LDO1

= 2.85V, V

LDO2

= 2.85V, RPA= 7.5Ω, circuit of Figure 5, TA= +25°C, unless other-

wise noted.)

0

40

20

80

60

120

100

140

0 0.4 0.60.2 0.8 1.0 1.2 1.4 1.6 1.8

BYPASS MODE DROPOUT VOLTAGE

vs. PA LOAD CURRENT

MAX8805Y/Z toc01

PA LOAD CURRENT (A)

BYPASS MODE DROPOUT VOLTAGE (mV)

V

IN1

= 3.2V

V

IN1

= 3.6V

60

70

80

90

100

0.5 1.5 2.5 3.51.0 2.0 3.0 4.0 4.5

PA STEP-DOWN CONVERTER EFFICIENCY

vs. OUTPUT VOLTAGE (MAX8805Z)

MAX8805Y/Z toc02

OUTPUT VOLTAGE (V)

EFFICIENCY (%)

BYPASS MODE

V

IN1

= 4.2V

V

IN1

= 3.6V

V

IN1

= 3.2V

RPA = 7.5Ω

60

70

80

90

100

0.5 1.5 2.5 3.51.0 2.0 3.0 4.0 4.5

PA STEP-DOWN CONVERTER EFFICIENCY

vs. OUTPUT VOLTAGE (MAX8805Y)

MAX8805Y/Z toc03

OUTPUT VOLTAGE (V)

EFFICIENCY (%)

BYPASS MODE

V

IN1

= 4.2V

V

IN1

= 3.6V

V

IN1

= 3.2V

RPA = 7.5Ω

60

70

80

90

100

0.5 1.5 2.5 3.51.0 2.0 3.0 4.0 4.5

PA STEP-DOWN CONVERTER EFFICIENCY

vs. OUTPUT VOLTAGE (MAX8805Z)

MAX8805Y/Z toc04

OUTPUT VOLTAGE (V)

EFFICIENCY (%)

BYPASS MODE

V

IN1

= 4.2V

V

IN1

= 3.6V

V

IN1

= 3.2V

RPA = 10Ω

60

70

80

90

100

0.5 1.5 2.5 3.51.0 2.0 3.0 4.0 4.5

PA STEP-DOWN CONVERTER EFFICIENCY

vs. OUTPUT VOLTAGE (MAX8805Y)

MAX8805Y/Z toc05

OUTPUT VOLTAGE (V)

EFFICIENCY (%)

BYPASS MODE

V

IN1

= 4.2V

V

IN1

= 3.6V

V

IN1

= 3.2V

RPA = 10Ω

50

60

80

70

90

100

0200100 300 400 500 600

PA STEP-DOWN CONVERTER EFFICIENCY

vs. LOAD CURRENT (MAX8805Z)

MAX8805Y/Z toc06

LOAD CURRENT (mA)

EFFICIENCY (%)

V

IN1

= 4.2V

V

IN1

= 3.6V

V

IN1

= 3.2V

VPA = 1.8V

50

60

80

70

90

100

0 200100 300 500400 600

PA STEP-DOWN CONVERTER EFFICIENCY

vs. LOAD CURRENT (MAX8805Y)

MAX8805Y/Z toc07

LOAD CURRENT (mA)

EFFICIENCY (%)

V

IN1

= 4.2V

V

IN1

= 3.6V

V

IN1

= 3.2V

VPA = 1.8V

50

60

80

70

90

100

0200100 300 500400 600

PA STEP-DOWN CONVERTER EFFICIENCY

vs. LOAD CURRENT (MAX8805Z)

MAX8805Y/Z toc08

LOAD CURRENT (mA)

EFFICIENCY (%)

V

IN1

= 4.2V

V

IN1

= 3.6V

V

IN1

= 3.2V

VPA = 1.2V

50

60

80

70

90

100

0200100 300 500400 600

PA STEP-DOWN CONVERTER EFFICIENCY

vs. LOAD CURRENT (MAX8805Y)

MAX8805Y/Z toc09

LOAD CURRENT (mA)

EFFICIENCY (%)

V

IN1

= 4.2V

V

IN1

= 3.6V

V

IN1

= 3.2V

VPA = 1.2V

Page 6

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

6 _______________________________________________________________________________________

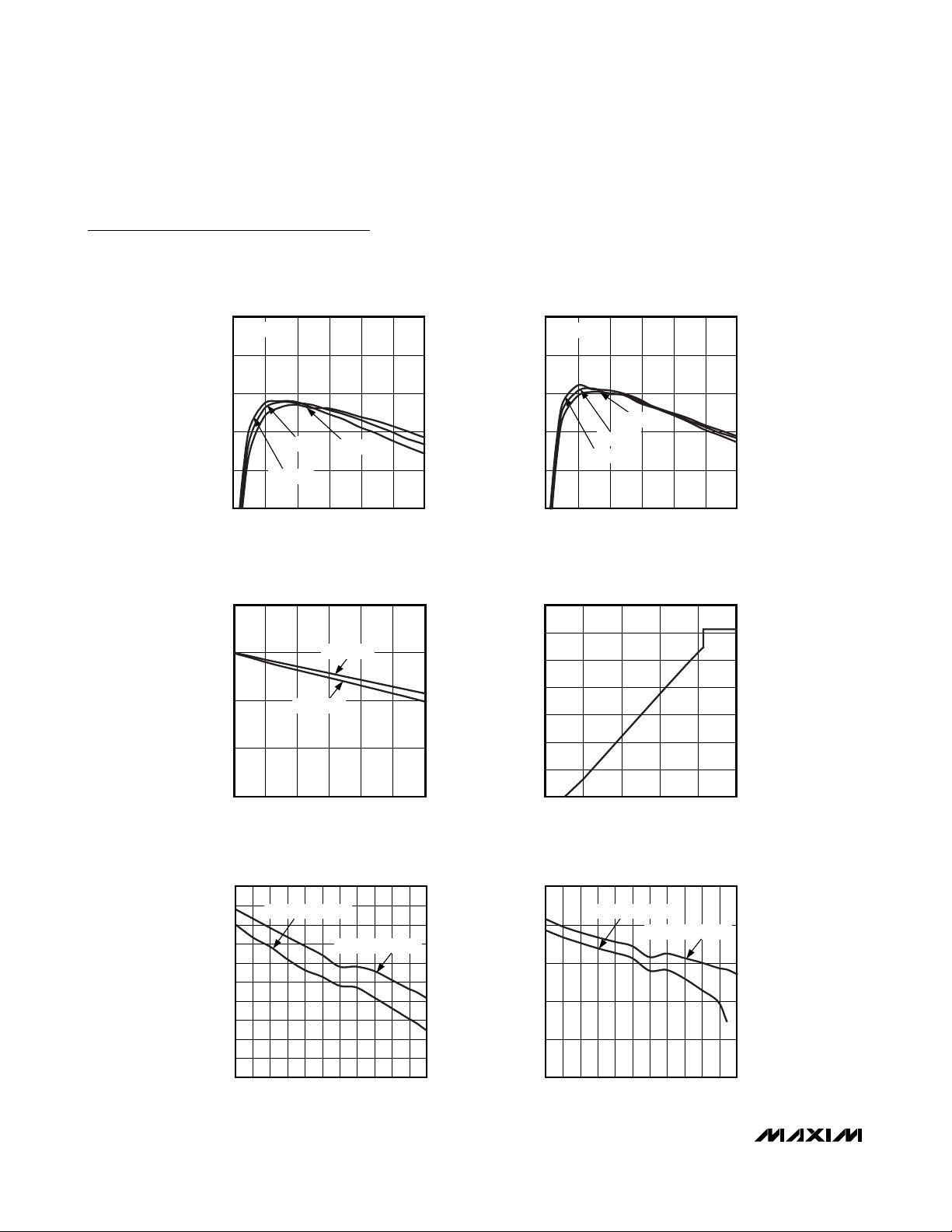

Typical Operating Characteristics (continued)

(V

IN1A

= V

IN1B

= V

IN2

= 3.6V, VPA= 1.2V, V

LDO1

= 2.85V, V

LDO2

= 2.85V, RPA= 7.5Ω, circuit of Figure 5, TA= +25°C, unless other-

wise noted.)

50

60

80

70

90

100

0 200100 300 500400 600

PA STEP-DOWN CONVERTER EFFICIENCY

vs. LOAD CURRENT (MAX8805Z)

MAX8805Y/Z toc10

LOAD CURRENT (mA)

EFFICIENCY (%)

V

IN1

= 4.2V

V

IN1

= 3.6V

V

IN1

= 3.2V

VPA = 0.6V

50

60

80

70

90

100

0 200100 300 500400 600

PA STEP-DOWN CONVERTER EFFICIENCY

vs. LOAD CURRENT (MAX8805Y)

MAX8805Y/Z toc11

LOAD CURRENT (mA)

EFFICIENCY (%)

V

IN1

= 4.2V

V

IN1

= 3.6V

V

IN1

= 3.2V

VPA = 0.6V

1.25

1.20

1.15

1.10

1.05

0 300100 200 400 500 600

PA STEP-DOWN CONVERTER OUTPUT

VOLTAGE vs. LOAD CURRENT

MAX8805Y/Z toc12

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

MAX8805Y

MAX8805Z

0.5

1.5

1.0

2.5

2.0

3.5

3.0

4.0

00.80.4 1.2 1.6 2.0

PA STEP-DOWN CONVERTER OUTPUT

VOLTAGE vs. REFIN VOLTAGE

MAX8805Y/Z toc13

REFIN VOLTAGE (V)

OUTPUT VOLTAGE (V)

-100

-60

-80

0

-20

-40

20

40

80

60

100

0.4 0.6 0.70.5 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5

REFIN vs. REFIN TO OUT GAIN (MAX8805Z)

MAX8805Y/Z toc14

REFIN VOLTAGE (V)

OUTPUT VOLTAGE ERROR (mV)

V

IN1

= 3.2V, NO LOAD

V

IN1

= 4.2V, NO LOAD

-50

-30

-10

10

30

50

0.4 0.6 0.70.5 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5

REFIN vs. REFIN TO OUT GAIN (MAX8805Y)

MAX8805Y/Z toc15

REFIN VOLTAGE (V)

OUTPUT VOLTAGE ERROR (mV)

V

IN1

= 3.2V, NO LOAD

V

IN1

= 4.2V, NO LOAD

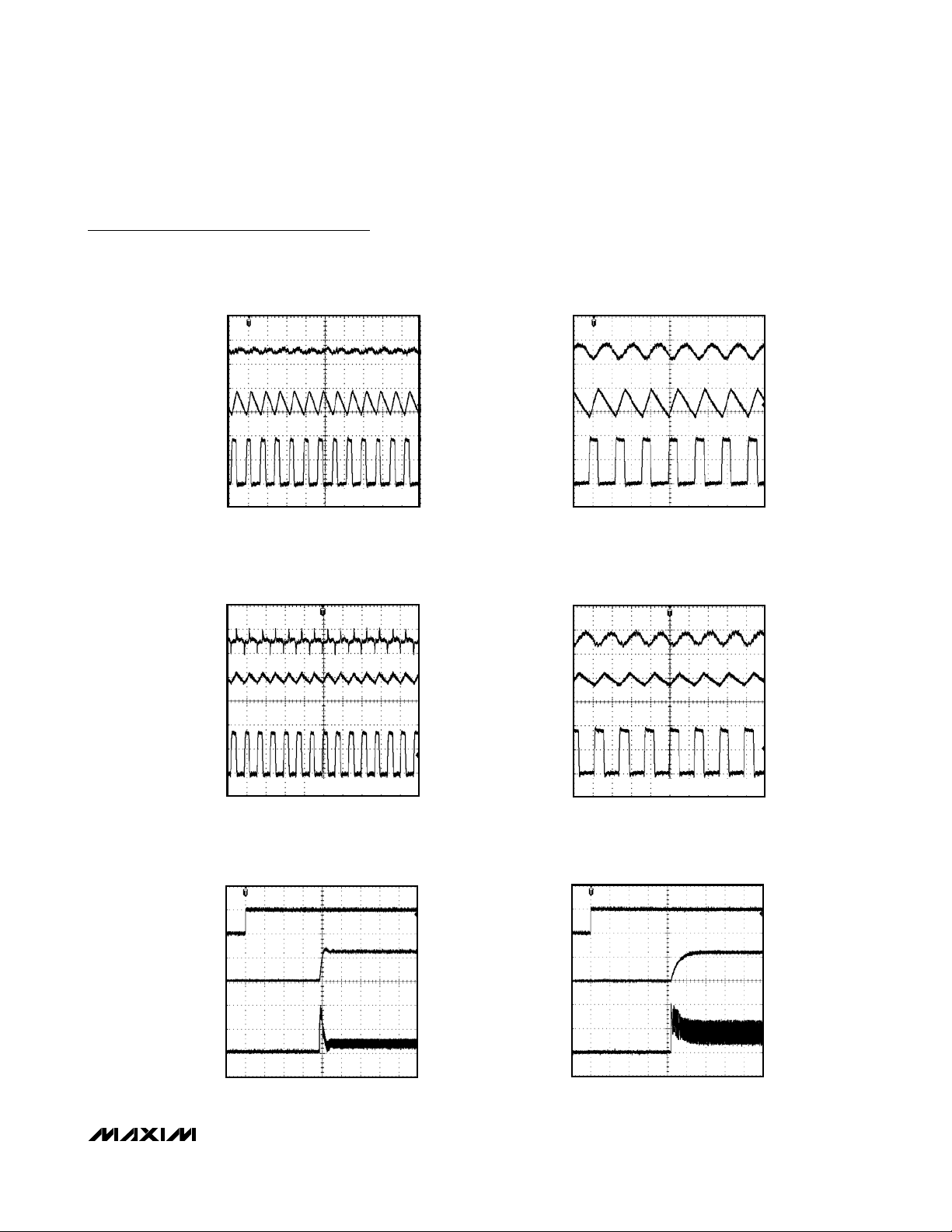

Page 7

400ns/div

PA STEP-DOWN CONVERTER LIGHT-LOAD

SWITCHING WAVEFORMS (MAX8805Z)

V

PA

AC-COUPLED

I

LX

200mA/div

20mV/div

2V/div

MAX8805Y/Z toc16

V

LX

VPA = 1.2V, IPA = 50mA

400ns/div

PA STEP-DOWN CONVERTER LIGHT-LOAD

SWITCHING WAVEFORMS (MAX8805Y)

V

PA

AC-COUPLED

I

LX

200mA/div

20mV/div

2V/div

MAX8805Y/Z toc17

V

LX

VPA = 1.2V, IPA = 50mA

400ns/div

PA STEP-DOWN HEAVY-LOAD

SWITCHING WAVEFORMS (MAX8805Z)

V

PA

AC-COUPLED

I

LX

500mA/div

20mV/div

2V/div

MAX8805Y/Z toc18

V

LX

VPA = 1.2V, IPA = 500mA

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

_______________________________________________________________________________________

7

Typical Operating Characteristics (continued)

(V

IN1A

= V

IN1B

= V

IN2

= 3.6V, VPA= 1.2V, V

LDO1

= 2.85V, V

LDO2

= 2.85V, RPA= 7.5Ω, circuit of Figure 5, TA= +25°C, unless other-

wise noted.)

_______________________________________________________________________________________

7

PA STEP-DOWN HEAVY-LOAD

V

AC-COUPLED

SWITCHING WAVEFORMS (MAX8805Y)

PA

MAX8805Y/Z toc19

20mV/div

V

PA_EN

V

PA

I

LX

PA STEP-DOWN SOFT-START

WAVEFORMS (MAX8805Z)

20μs/div

MAX8805Y/Z toc20

2V/div

1V/div

500mA/div

V

PA_EN

V

I

LX

V

LX

PA STEP-DOWN SOFT-START

WAVEFORMS (MAX8805Y)

PA

I

LX

500mA/div

2V/div

VPA = 1.2V, IPA = 500mA

400ns/div

MAX8805Y/Z toc21

2V/div

1V/div

200mA/div

20μs/div

Page 8

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(V

IN1A

= V

IN1B

= V

IN2

= 3.6V, VPA= 1.2V, V

LDO1

= 2.85V, V

LDO2

= 2.85V, RPA= 7.5Ω, circuit of Figure 5, TA= +25°C, unless other-

wise noted.)

10μs/div

PA STEP-DOWN CONVERTER OUTPUT

VOLTAGE TRANSIENT RESPONSE

V

REFIN

V

PA

500mV/div

500mV/div

500mA/div

MAX8805Y/Z toc26

I

LX

0.5V

1V

0.5V

20μs/div

PA STEP-DOWN CONVERTER FORCED

BYPASS-FET TRANSIENT RESPONSE

V

HP

V

PA

2V/div

2V/div

500mA/div

MAX8805Y/Z toc27

I

LX

0.5V

0V

0V

1.2V

1.2V

3.6V

10μs/div

PA STEP-DOWN CONVERTER LOAD

TRANSIENT RESPONSE (MAX8805Y)

I

PA

I

LX

500mA/div

500mA/div

100mV/div

MAX8805Y/Z toc25

V

PA

AC-COUPLED

0mA

500mA

0mA

10μs/div

PA STEP-DOWN CONVERTER LOAD

TRANSIENT RESPONSE (MAX8805Z)

I

PA

I

LX

500mA/div

500mA/div

100mV/div

MAX8805Y/Z toc24

V

PA

AC-COUPLED

0mA

500mA

0mA

10μs/div

PA STEP-DOWN CONVERTER LINE

TRANSIENT RESPONSE (MAX8805Z)

V

IN1

V

PA

AC-COUPLED

50mV/div

500mV/div

200mA/div

MAX8805Y/Z toc22

I

LX

4.0V

3.5V

4.0V

10μs/div

PA STEP-DOWN CONVERTER LINE

TRANSIENT RESPONSE (MAX8805Y)

V

IN1

V

PA

AC-COUPLED

50mV/div

500mV/div

200mA/div

MAX8805Y/Z toc23

I

LX

4.0V

3.5V

4.0V

Page 9

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

_______________________________________________________________________________________

9

Typical Operating Characteristics (continued)

(V

IN1A

= V

IN1B

= V

IN2

= 3.6V, VPA= 1.2V, V

LDO1

= 2.85V, V

LDO2

= 2.85V, RPA= 7.5Ω, circuit of Figure 5, TA= +25°C, unless other-

wise noted.)

PA STEP-DOWN CONVERTER AUTOMATIC

BYPASS-FET TRANSIENT RESPONSE

1.8V

V

REFIN

0.6V

3.6V

V

PA

1.2V

I

LX

10μs/div

PA STEP-DOWN CONVERTER

SHUTDOWN RESPONSE (MAX8805Y)

2V

V

PA_EN

V

1.2V

PA

0V

MAX8805Y/Z toc28

MAX8805Y/Z toc30

0.6V

1.2V

1V/div

2V/div

500mA/div

2V/div

1V/div

PA STEP-DOWN CONVERTER AUTOMATIC

BYPASS-FET TRANSIENT RESPONSE

V

IS A 0.4V TO

REFIN

2V SINUSOIDAL

V

SIGNAL

REFIN

V

PA

I

LX

3.6V

200μs/div

MAX8805Y/Z toc29

1V/div

1V/div

500mA/div

PA STEP-DOWN CONVERTER

SHUTDOWN RESPONSE (MAX8805Z)

2V

V

PA_EN

1.2V

V

PA

0V

MAX8805Y/Z toc31

2V/div

2V/div

I

LX

10μs/div

LDO1, LDO2 SUPPLY CURRENT

vs. SUPPLY VOLTAGE

200

150

100

50

NO-LOAD SUPPLY CURRENT (μA)

0

2.0 3.5 4.02.5 3.0 4.5 5.0 5.5

SUPPLY VOLTAGE (V)

100mA/div

MAX8805Y/Z toc32

I

LX

10μs/div

LDO1, LDO2 DROPOUT VOLTAGE

vs. LOAD CURRENT

150

120

90

60

30

LDO1, LDO2 DROPOUT VOLTAGE (mV)

0

0 10050 150 200

LOAD CURRENT (mA)

100mA/div

MAX8805Y/Z toc33

Page 10

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

10 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(V

IN1A

= V

IN1B

= V

IN2

= 3.6V, VPA= 1.2V, V

LDO1

= 2.85V, V

LDO2

= 2.85V, RPA= 7.5Ω, circuit of Figure 5, TA= +25°C, unless other-

wise noted.)

80

70

60

50

PSRR (dB)

40

30

LDO PSRR vs. FREQUENCY

MAX8805Y/Z toc34

LDO OUTPUT NOISE SPECTRAL DENSITY

vs. FREQUENCY

1.0E+04

1.0E+03

1.0E+02

MAX8805Y/Z toc35

20

I

= 30mA

LDO

10

0.01 1000

FREQUENCY (kHz)

LDO1, LDO2 OUTPUT NOISE WAVEFORM

400μs/div

1001010.1

MAX8805Y/Z toc36

50mV/div

LDO1, LDO2 LOAD TRANSIENT

I

LDO1

RESPONSE NEAR DROPOUT

80mA

0mA

MAX8805Y/Z toc38

0mA

100mA/div

OUTPUT NOISE DENSITY NOISE (nV/√Hz)

1.0E+01

0.01 1000

FREQUENCY (kHz)

LDO LINE TRANSIENT RESPONSE

4.0V

V

V

IN2

LDO_

3.5V

20μs/div

LDO1, LDO2 TURN ON AND

SHUTDOWN RESPONSE

V

EN1,2

1001010.1

MAX8805Y/Z toc37

I

LDO_

MAX8805Y/Z toc39

4.0V

500mV/div

5mV/div

= 80mA

2V/div

V

V

LDO1

I

LDO2

LDO2

0mA

80mA

V

IN2

20μs/div

= V

LDO1,2

0mA

+ 200mV

50mV/div

100mA/div

50mV/div

V

LDO1

V

LDO2

1ms/div

2V/div

2V/div

Page 11

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

______________________________________________________________________________________ 11

Pin Description

PIN NAME FUNCTION

A1 REFBP

A2 AGND Low-Noise Analog Ground

A3 REFIN

A4 PGND Power Ground for PA Step-Down Converter

B1 LDO2

B2 PA_EN

B3 EN2

B4 LX Inductor Connection. Connect an inductor from LX to the output of the PA step-down converter.

C1 IN2

C2 HP

C3, C4

D1 LDO1

D2 EN1

D3, D4 PAB, PAA

IN1B,

IN1A

Reference Noise Bypass. Bypass REFBP to AGND with a 0.22µF ceramic capacitor to reduce noise on the

LDO outputs. REFBP is internally pulled down through a 1kΩ resistor during shutdown.

DAC-Controlled Input. The output of the PA step-down converter is regulated to 2 x V

reaches 0.465 x V

200mA LDO Regulator 2 Output. Bypass LDO2 with a 1µF ceramic capacitor as close as possible to LDO2

and AGND. LDO2 is internally pulled down through a 1kΩ resistor when this regulator is disabled.

PA Step-Down Converter Enable Input. Connect to IN_ or logic-high for normal operation. Connect to GND

or logic-low for shutdown mode.

LDO2 Enable Input. Connect to IN2 or logic-high for normal operation. Connect to AGND or logic-low for

shutdown mode.

Supply Voltage Input for LDO1, LDO2, and Internal Reference. Connect IN2 to a battery or supply voltage

from 2.7V to 5.5V. Bypass IN2 with a 2.2µF ceramic capacitor as close as possible to IN2 and AGND.

Connect IN2 to the same source as IN1A and IN1B.

High-Power Mode Set Input. Drive HP high to invoke forced bypass mode. Bypass mode connects the

input of the PA step-down converter directly to its output through the internal bypass MOSFET. Drive HP

low to disable the forced bypass mode.

Supply Voltage Input for PA Step-Down Converter. Connect IN1_ to a battery or supply voltage from 2.7V to

5.5V. Bypass the connection of IN1_ with a 2.2µF ceramic capacitor as close as possible to IN1_, and

PGND. IN1A

200mA LDO Regulator 1 Output. Bypass LDO1 with a 1µF ceramic capacitor as close as possible to LDO1

and AGND. LDO1 is internally pulled down through a 1kΩ resistor when this regulator is disabled.

LDO1 Enable Input. Connect to IN2 or logic-high for normal operation. Connect to AGND or logic-low for

shutdown mode.

PA Connection for Bypass Mode. Internally connected to IN1_ using the internal bypass MOSFET during

bypass mode. PA_ is connected to the internal feedback network. Bypass PA_ with a 2.2µF ceramic

capacitor as close as possible to PA_ and PGND.

and IN1B are internally connected together. Connect IN1_ to the same source as IN2.

, bypass mode is enabled.

IN2

REFIN

. When V

REFIN

Page 12

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

12 ______________________________________________________________________________________

Figure 1. Block Diagram

IN1A

IN1B

R5R4

BYPASS FET

PAA

HP

PWM ERROR

REFIN

R7

C2

R6

IN2

REFBP

AGND

EN1

EN2

PA_EN

1.25V

REFERENCE

BANDGAP

CONTROL

LOGIC

COMPARATOR

R2 R1

BANDGAP

BANDGAP

CURRENT-LIMIT CONTROL

PWM LOGIC

STEP-DOWN CURRENT LIMIT

ERROR AMP

C1

LDO1 CURRENT LIMIT

LDO2 CURRENT LIMIT

R3

R9

R8

R7

PAB

LX

PGND

LDO1

ERROR AMP

R12

LDO2

R11

R10

Page 13

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

______________________________________________________________________________________ 13

Detailed Description

The MAX8805Y/MAX8805Z are designed to dynamically power the PA in WCDMA and NCDMA handsets. The

devices contain a high-frequency, high-efficiency stepdown converter, and two LDOs. The step-down converter delivers over 600mA. The hysteretic PWM control

scheme provides extremely fast transient response,

while 2MHz and 4MHz switching-frequency options

allow the trade-off between efficiency and the smallest

external components. A 60mΩ bypass FET connects

the PA directly to the battery during high-power transmission.

Step-Down Converter Control Scheme

A hysteretic PWM control scheme ensures high efficiency, fast switching, fast transient response, low-output ripple, and physically tiny external components.

The control scheme is simple: when the output voltage

is below the regulation threshold, the error comparator

begins a switching cycle by turning on the high-side

switch. This high-side switch remains on until the minimum on-time expires and the output voltage is within

regulation, or the inductor current is above the currentlimit threshold. Once off, the high-side switch remains

off until the minimum off-time expires and the output

voltage falls again below the regulation threshold.

During the off period, the low-side synchronous rectifier

turns on and remains on until the high-side switch turns

on again. The internal synchronous rectifier eliminates

the need for an external Schottky diode.

Voltage-Positioning Load Regulation

The MAX8805Y/MAX8805Z step-down converters utilize

a unique feedback network. By taking DC feedback

from the LX node through R1 in Figure 1, the usual

phase lag due to the output capacitor is removed, making the loop exceedingly stable and allowing the use of

very small ceramic output capacitors. To improve the

load regulation, resistor R3 is included in the feedback.

This configuration yields load regulation equal to half of

the inductor’s series resistance multiplied by the load

current. This voltage-positioning load regulation greatly

reduces overshoot during load transients or when

changing the output voltage from one level to another.

However, when calculating the required REFIN voltage,

the load regulation should be considered. Because

inductor resistance is typically well specified and the

typical PA is a resistive load, the MAX8805Y/MAX8805Z

V

REFIN

to V

OUT

gain is slightly less than 2V/V.

Step-Down Converter Bypass Mode

During high-power transmission, the bypass mode connects IN1A and IN1B directly to PAA and PAB with the

internal 60mΩ (typ) bypass FET, while the step-down

converter is forced into 100% duty-cycle operation. The

low on-resistance in this mode provides low dropout,

long battery life, and high output current capability.

Forced and Automatic Bypass Mode

Invoke forced bypass mode by driving HP high or

invoke automatic bypass mode by applying a high voltage to REFIN. To prevent excessive output ripple as the

step-down converter approaches dropout, the

MAX8805Y/MAX8805Z enter bypass mode automatically

when V

REFIN

> 0.465 x V

IN2

(see Figure 2). Note that

IN2 is used instead of IN1 to prevent switching noise

from causing false enagement of automatic bypass

mode. For this reason, IN2 must be connected to the

same source as IN1.

Shutdown Mode

Connect PA_EN to GND or logic-low to place the

MAX8805Y/MAX8805Z PA step-down converter in shutdown mode. In shutdown, the control circuitry, internal

switching MOSFET, and synchronous rectifier turn off

and LX becomes high impedance. Connect PA_EN to

IN1_ or logic-high for normal operation.

Connect EN1 or EN2 to GND or logic-low to place

LDO1 or LDO2, respectively, in shutdown mode. In

shutdown, the outputs of the LDOs are pulled to ground

through an internal 1kΩ resistor.

When the PA step-down and LDOs are all in shutdown,

the MAX8805Y/MAX8805Z enter a very low power

state, where the input current drops to 0.1µA (typ).

Figure 2. V

IN2

and V

PA_

with Automatic Entry/Exit into Bypass

Mode

2.5

2.0

1.5

1.0

REFIN VOLTAGE (V)

0.5

0

IN2 AND PA_

5.0

4.5

4.0

3.5

3.0

2.5

VOLTAGE (V)

2.0

1.5

1.0

0.5

0

IN2

PA_

REFIN

010152052530354540 50

TIME (ms)

Page 14

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

14 ______________________________________________________________________________________

Step-Down Converter Soft-Start

The MAX8805Y/MAX8805Z PA step-down converter has

internal soft-start circuitry that limits inrush current at

startup, reducing transients on the input source. Softstart is particularly useful for supplies with high output

impedance such as Li+ and alkaline cells. See the SoftStart Waveforms in the

Typical Operating Characteristics.

Analog REFIN Control

The MAX8805Y/MAX8805Z PA step-down converter uses

REFIN to set the output voltage. The output voltage is regulated at twice the voltage applied at REFIN minus the

load regulation. This allows the converter to operate in

applications where dynamic voltage control is required.

Thermal Shutdown

Thermal shutdown limits total power dissipation in the

MAX8805Y/MAX8805Z. If the junction temperature

exceeds +160°C, thermal-shutdown circuitry turns off

the IC, allowing it to cool. The IC turns on and begins

soft-start after the junction temperature cools by 20°C.

This results in a pulsed output during continuous thermal-overload conditions.

Applications Information

Output Voltages

The MAX8805Y/MAX8805Z PA step-down converters

set the PA_ output voltage to twice the voltage applied

to REFIN.

LDO1 and LDO2 output voltages are determined by the

part number suffix, as shown in Table 1.

LDO Dropout Voltage

The regulator’s minimum input/output differential (or

dropout voltage) determines the lowest usable supply

voltage. In battery-powered systems, this determines

the useful end-of-life battery voltage. Because the

MAX8805Y/MAX8805Z LDOs use a p-channel MOSFET

pass transistor, their dropout voltages are a function of

drain-to-source on-resistance (R

DS

(ON)) multiplied by the

load current (see the

Typical Operating Characteristics

).

Inductor Selection

The MAX8805Y operates with a switching frequency of

2MHz and utilizes a 2.2µH inductor. The MAX8805Z

operates with a switching frequency of 4MHz and utilizes a 1µH inductor. The higher switching frequency of

the MAX8805Z allows the use of physically smaller

inductors at the cost of slightly lower efficiency. The

lower switching frequency of the MAX8805Y results in

greater efficiency at the cost of a physically larger

inductor. See the

Typical Operating Characteristics

for

efficiency graphs for both the MAX8805Y and

MAX8805Z.

The inductor’s DC current rating only needs to match the

maximum load of the application because the

MAX8805Y/MAX8805Z feature zero current overshoot

during startup and load transients. For optimum transient

response and high efficiency, choose an inductor with

DC series resistance in the 50mΩ to 150mΩ range. See

Table 2 for suggested inductors and manufacturers.

Output Capacitor Selection

For the PA step-down converter, the output capacitor

(CPA) is required to keep the output voltage ripple small

and ensure regulation loop stability. CPAmust have low

impedance at the switching frequency. Ceramic capacitors with X5R or X7R dielectric are highly recommended

due to their small size, low ESR, and small temperature

coefficients. Due to the unique feedback network, the

output capacitance can be very low. A 2.2µF capacitor

is recommended for most applications. For optimum

load-transient performance and very low output ripple,

the output capacitor value can be increased.

For LDO1 and LDO2, the minimum output capacitance

required is dependent on the load currents. For loads

less than 10mA, it is sufficient to use a 0.1µF capacitor

for stable operation over the full temperature range.

With rated maximum load currents, a minimum of 1µF is

recommended. Reduce output noise and improve loadtransient response, stability, and power-supply rejection by using larger output capacitors.

Note that some ceramic dielectrics exhibit large capacitance and ESR variation with temperature. With dielectrics

such as Z5U and Y5V, it is necessary to use 2.2µF or larger to ensure stability at temperatures below -10°C. With

X7R or X5R dielectrics, 1µF is sufficient at all operating

temperatures. These regulators are optimized for ceramic

capacitors. Tantalum capacitors are not recommended.

Table 1. LDO1 and LDO2 Output Voltage

Selection

Note: Contact the factory for other output-voltage options.

PART

FREQUENCY

(MHz)

LDO1

(V)

LDO2

(V)

2 1.80 1.80

2 1.80 2.85

2 2.85 2.85

4 1.80 1.80

4 1.80 2.85

4 2.85 2.85

MAX8805YEWEAA+T

MAX8805YEWEAE+T

MAX8805YEWEEE+T

MAX8805ZEWEAA+T

MAX8805ZEWEAE+T

MAX8805ZEWEEE+T

Page 15

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

______________________________________________________________________________________ 15

Input Capacitor Selection

The input capacitor (C

IN1

) of the PA converter reduces

the current peaks drawn from the battery or input

power source and reduces switching noise in the

MAX8805Y/MAX8805Z. The impedance of C

IN1

at the

switching frequency should be kept very low. Ceramic

capacitors with X5R or X7R dielectric are highly recommended due to their small size, low ESR, and small

temperature coefficients. A 2.2µF capacitor is recommended for most applications. For optimum noise

immunity and low input ripple, the input capacitor value

can be increased.

For the LDOs, use an input capacitance equal to the

value of the sum of the output capacitance of LDO1 and

LDO2. Larger input capacitor values and lower ESR provide better noise rejection and line transient response.

Note that some ceramic dielectrics exhibit large capacitance and ESR variation with temperature. With

dielectrics such as Z5U and Y5V, it may be necessary to

use two times the sum of the output capacitor values of

LDO1 and LDO2 (or larger) to ensure stability at temperatures below -10°C. With X7R or X5R dielectrics, a

capacitance equal to the sum is sufficient at all operating

temperatures.

Table 2. Suggested Inductors

SERIES

INDUCTANCE

(µH)

ESR

(Ω)

CURRENT RATING

(mA)

DIMENSIONS

(mm)

Coilcraft LPO3310

1.0

1.5

2.2

0.07

0.10

0.13

1600

1400

1100

3.3 x 3.3 x 1.0 = 11mm

3

MIPF2520

1.0

1.5

2.2

0.05

0.07

0.08

1500

1500

1300

2.5 x 2.0 x 1.0 = 5mm

3

MIPS2520

1.3

2.0

0.09

0.11

1500

1200

2.5 x 2.0 x 1.0 = 5mm

3

FDK

MIPF2016

1.0

2.2

0.11 1100

2.0 x 1.6 x 1.0 = 3.2mm

3

Hitachi

1.5

2.2

0.115

0.080

—

2.5 x 2.0 x 1.0 = 5mm

3

Murata LQH32C_53

1.0

2.2

0.06

0.10

1000

790

3.2 x 2.5 x 1.7 = 14mm

3

Sumida CDRH2D09

1.2

1.5

2.2

0.08

0.09

0.12

590

520

440

3.0 x 3.0 x 1.0 = 9mm

3

CDRH2D11

1.5

2.2

3.3

0.05

0.08

0.10

680

580

450

3.2 x 3.2 x 1.2 = 12mm

3

Taiyo Yuden

CB2518T

2.2

4.7

0.09

0.13

510

340

2.5 x 1.8 x 2.0 = 9mm

3

D3010FB 1.0 0.20 1170

3.0 x 3.0 x 1.0 = 9mm

3

D2812C

1.2

2.2

0.09

0.15

860

640

3.0 x 3.0 x 1.2 = 11mm

3

D310F

1.5

2.2

0.13

0.17

1230

1080

3.6 x 3.6 x 1.0 = 13mm

3

TOKO

D312C

1.5

2.2

0.10

0.12

1290

1140

3.6 x 3.6 x 1.2 = 16mm

3

MANUFACTURER

KSLI-252010

Page 16

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

16 ______________________________________________________________________________________

Thermal Considerations

In most applications, the MAX8805Y/MAX8805Z do not

dissipate much heat due to their high efficiency.

However, in applications where the MAX8805Y/

MAX8805Z run at high ambient temperature with heavy

loads, the heat dissipated may exceed the maximum

junction temperature of the IC. If the junction temperature reaches approximately +160°C, all power switches

are turned off and LX and PA_ become high impedance, and LDO1 and LDO2 are pulled down to ground

through an internal 1kΩ pulldown resistor.

The MAX8805Y/MAX8805Z maximum power dissipation

depends on the thermal resistance of the IC package

and circuit board, the temperature difference between

the die junction and ambient air, and the rate of airflow.

The power dissipated in the device is:

P

DISS

= PPAx (1/ηPA- 1) + I

LDO1

x (V

IN2

- V

LDO1

) +

I

LDO2

x (V

IN2-VLDO2

)

where ηPAis the efficiency of the PA step-down converter and PPAis the output power of the PA step-down

converter.

The maximum allowed power dissipation is:

P

MAX

= (T

JMAX

- TA) / θ

JA

where (T

JMAX

- TA) is the temperature difference

between the MAX8805Y/MAX8805Z die junction and

the surrounding air; θJAis the thermal resistance of the

junction through the PCB, copper traces, and other

materials to the surrounding air.

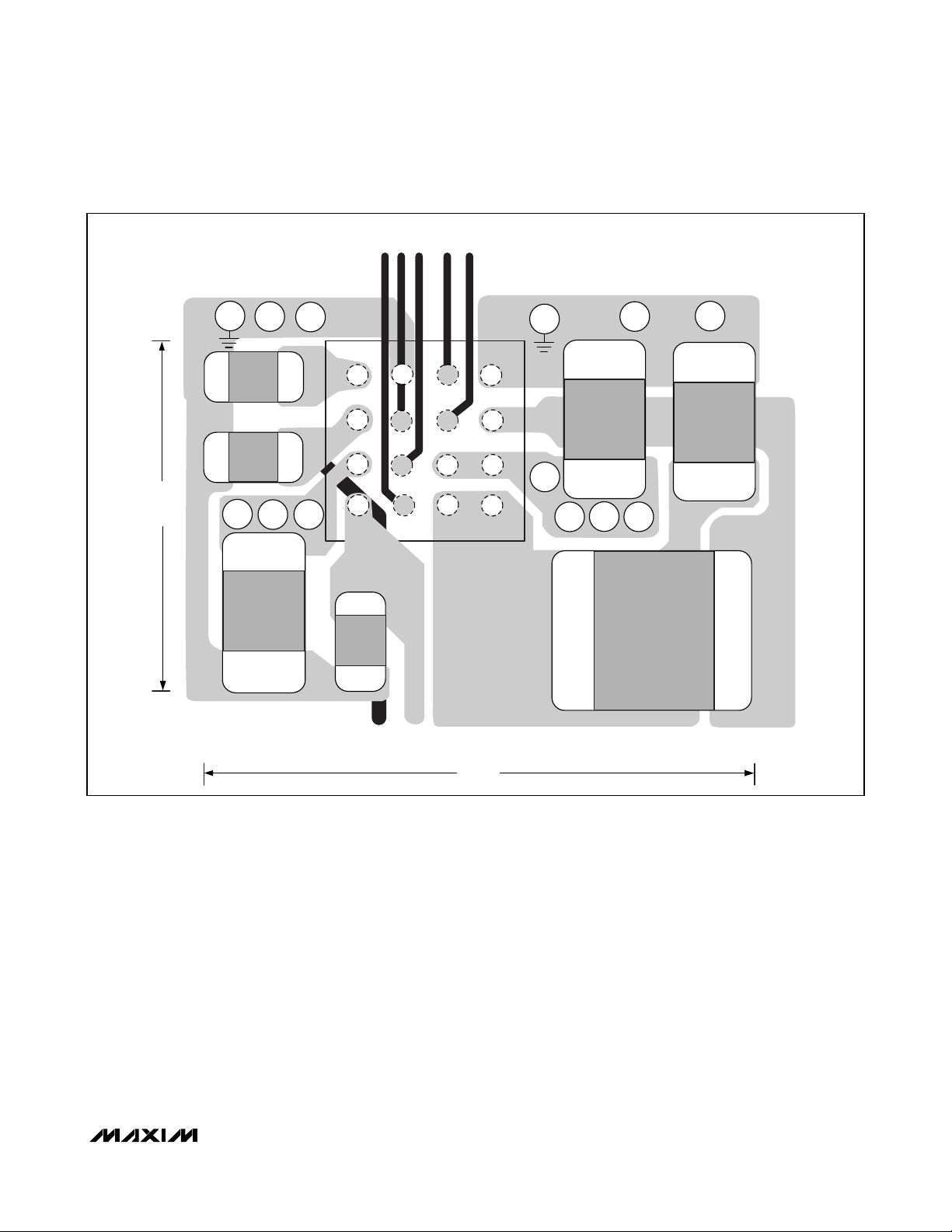

PCB Layout

High switching frequencies and relatively large peak

currents make the PCB layout a very important part of

design. Good design minimizes excessive EMI on the

feedback paths and voltage gradients in the ground

plane, resulting in a stable and well-regulated output.

Connect C

IN1

close to IN1A/IN1B and PGND. Connect

the inductor and output capacitor as close as possible

to the IC and keep their traces short, direct, and wide.

Keep noisy traces, such as the LX node, as short as

possible. Figure 3 illustrates an example PCB layout

and routing scheme.

Page 17

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

______________________________________________________________________________________ 17

Figure 3. Recommended PCB Layout

REFIN

PA_EN

EN1

HP

EN2

3.8mm

AGND

C

C

LDO2

BYP

PGND

C

IN1

C

IN2

VIN

C

LDO1

LDO1

LDO2

VPA

L

PA

C

PA

5.5mm

Page 18

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

18 ______________________________________________________________________________________

Figure 4. Typical Application Circuit Using LDOs for PA Enable/Bias

MAX8805Y/MAX8805Z

2MHz OR 4MHz

2.2μF

1μF

IN1A

IN1B

REFIN

PA_EN

HP

EN1

EN2

IN2

Li+ BATTERY

DAC

BASEBAND

PROCESSOR

GPIO

GPIO

GPIO

GPIO

BUCK

CONTROL

REF

LDO1

LX

PBA

PBB

PGND

REFBP

AGND

LDO1

1μH OR

2.2μH*

2.2μF

IN

PA1

EN/BIAS

0.22μF

0.1μF

LDO2

LDO2

*1μH FDK MIPS 2520D1R0

2.2μH FDK MIPF 2520D2R2

0.1μF

EN/BIAS

PA2

IN

Page 19

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

______________________________________________________________________________________ 19

Figure 5. Typical Application Circuit Using LDOs for RF Power

BASEBAND

PROCESSOR

Li+ BATTERY

DAC

GPIO

GPIO

GPIO

GPIO

2.2μF

2.2μF

IN1A

IN1B

REFIN

PA_EN

HP

EN1

EN2

IN2

MAX8805Y/MAX8805Z

2MHz OR 4MHz

BUCK

CONTROL

REF

LDO1

LX

PBA

PBB

PGND

REFBP

AGND

LDO1

1μH OR

2.2μH*

2.2μF

0.22μF

1μF

IN

IN

PA

RF RECEIVER

LDO2

*1μH FDK MIPS 2520D1R0

2.2μH FDK MIPF 2520D2R2

LDO2

1μF

IN

RF TRANSMITTER

Page 20

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

20 ______________________________________________________________________________________

Pin Configuration

Chip Information

PROCESS: BiCMOS

TOP VIEW

REFBP AGND

A1

LDO2

B1

IN2

C1

LDO1 PABEN1

D1

16-Bump, 2mm × 2mm WLP

A2 A3

PA_EN

B2

HP

C2

D2

(BUMP IN BOTTOM)

REFIN

EN2

B3

IN1B

C3

D3

PGND

A4

LX

B4

IN1A

C4

PAA

D4

Page 21

MAX8805Y/MAX8805Z

600mA PWM Step-Down Converters in

2mm x 2mm WLP for WCDMA PA Power

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________

21

© 2007 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

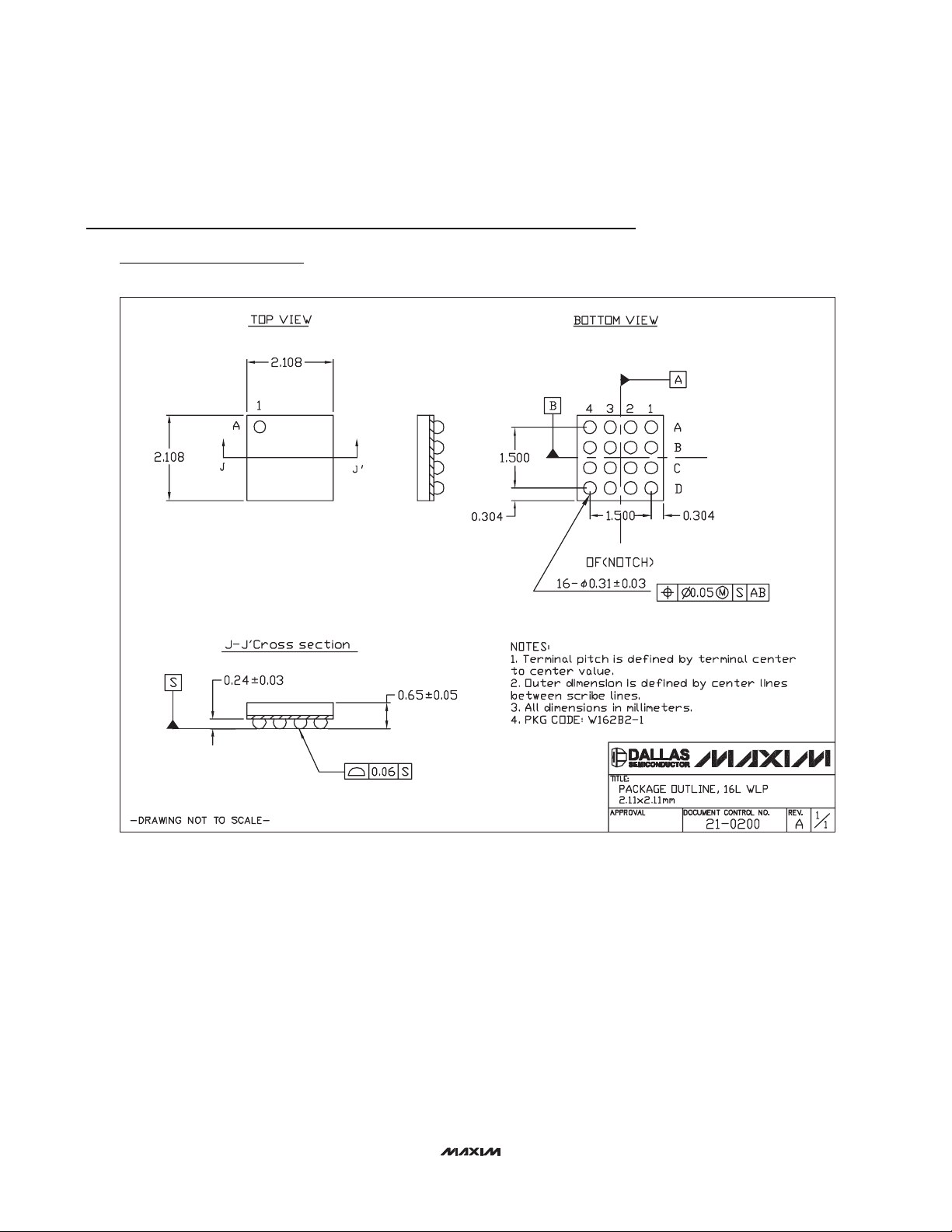

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

16L WLP.EPS

Loading...

Loading...