Page 1

General Description

The MAX8759 integrated cold-cathode fluorescent lamp

(CCFL) inverter controller is designed to drive CCFLs

using a full-bridge resonant inverter. The resonant operation ensures reliable striking and provides near-sinusoidal

waveforms over the entire input range. The controller

operates over a wide input-voltage range of 4.5V to 28V

with high power to light efficiency. The device also

includes safety features that effectively protect against

single-point fault conditions such as lamp-out, secondary

overvoltage, and secondary short-circuit faults.

The MAX8759 provides accurate lamp-current regulation (±2.5%) for superior CCFL inverter performance.

The lamp current is adjustable with an external resistor;

10:1 dimming range can be achieved by turning the

CCFL on and off using a digital pulse-width modulation

(DPWM) method, while maintaining the lamp-current

constant. The MAX8759 provides three mechanisms for

controlling brightness: 2-wire SMBus™-compatible

interface, external ambient-light sensor (ALS), or system PWM control. The MAX8759 supports Intel display

power-saving technology (DPST) to maximize battery

life. The device includes two lamp-current feedback

input pins that support dual-lamp applications with a

minimum number of external components.

The MAX8759 controls a full-bridge inverter for maximum efficiency and directly drives four external n-channel power MOSFETs. An internal 5.35V linear regulator

powers the MOSFET drivers and most of the internal

circuitry. The MAX8759 is available in a space-saving,

28-pin, thin QFN package and operates over a -40°C to

+85°C temperature range.

Applications

Notebooks

LCD Monitors

Automotive Infotainment

Features

♦ Accurate Dimming Control Using SMBus, PWM

Interface, or Ambient Light Sensor

♦ 10:1 Dimming Range with 256-Step Resolution

♦ Resonant-Mode Operation

Longer Lamp Life with Near Sinusoidal LampCurrent Waveform

Guaranteed Striking Capability

High-Power-to-Light Efficiency

♦ Wide Input-Voltage Range (4.5V to 28V)

♦ Input Feed-Forward for Excellent Line Rejection

♦ ±2.5% Lamp-Current Regulation

♦ Adjustable 1.5% Accurate DPWM Frequency

♦ Dual Lamp-Current Feedback Inputs

♦ Comprehensive Fault Protection

Secondary Voltage Limiting

Primary Current Limit with Lossless Sensing

Lamp-Out Protection with Adjustable Timeout

Secondary Short-Circuit Protection

♦ Small 28-Pin, 5mm x 5mm, Thin QFN Package

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

MAX8759

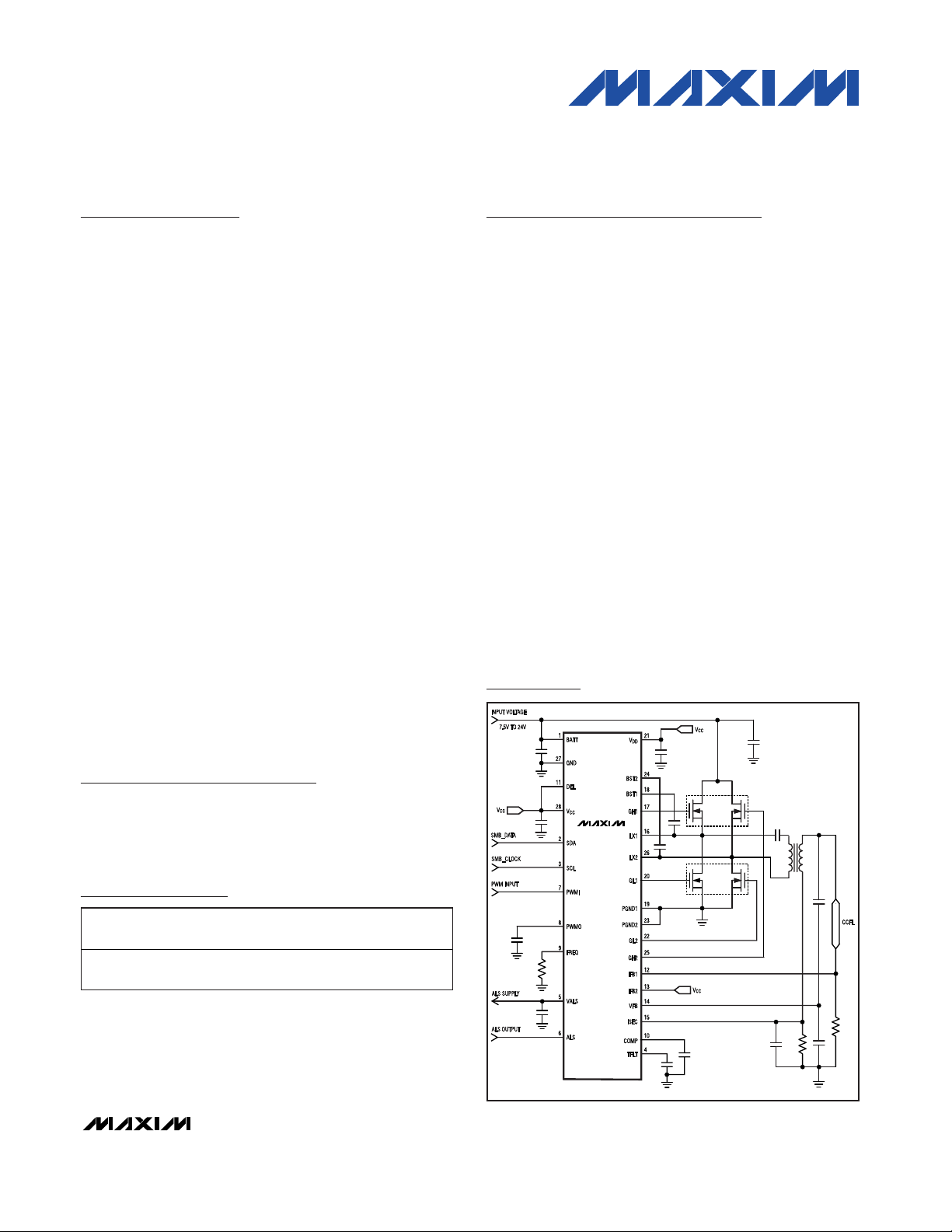

Minimal Operating Circuit

19-3874; Rev 0; 10/05

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

PART

TEMP RANGE

PINPACKAGE

PKG

CODE

MAX8759ETI+

5mm × 5mm

T2855-6

+ Denotes lead-free package.

*EP = Exposed pad.

Pin Configuration appears at end of data sheet.

SMBus is a trademark of Intel Corp.

-40°C to +85°C

28 Thin QFN-EP*

Page 2

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

2 _______________________________________________________________________________________

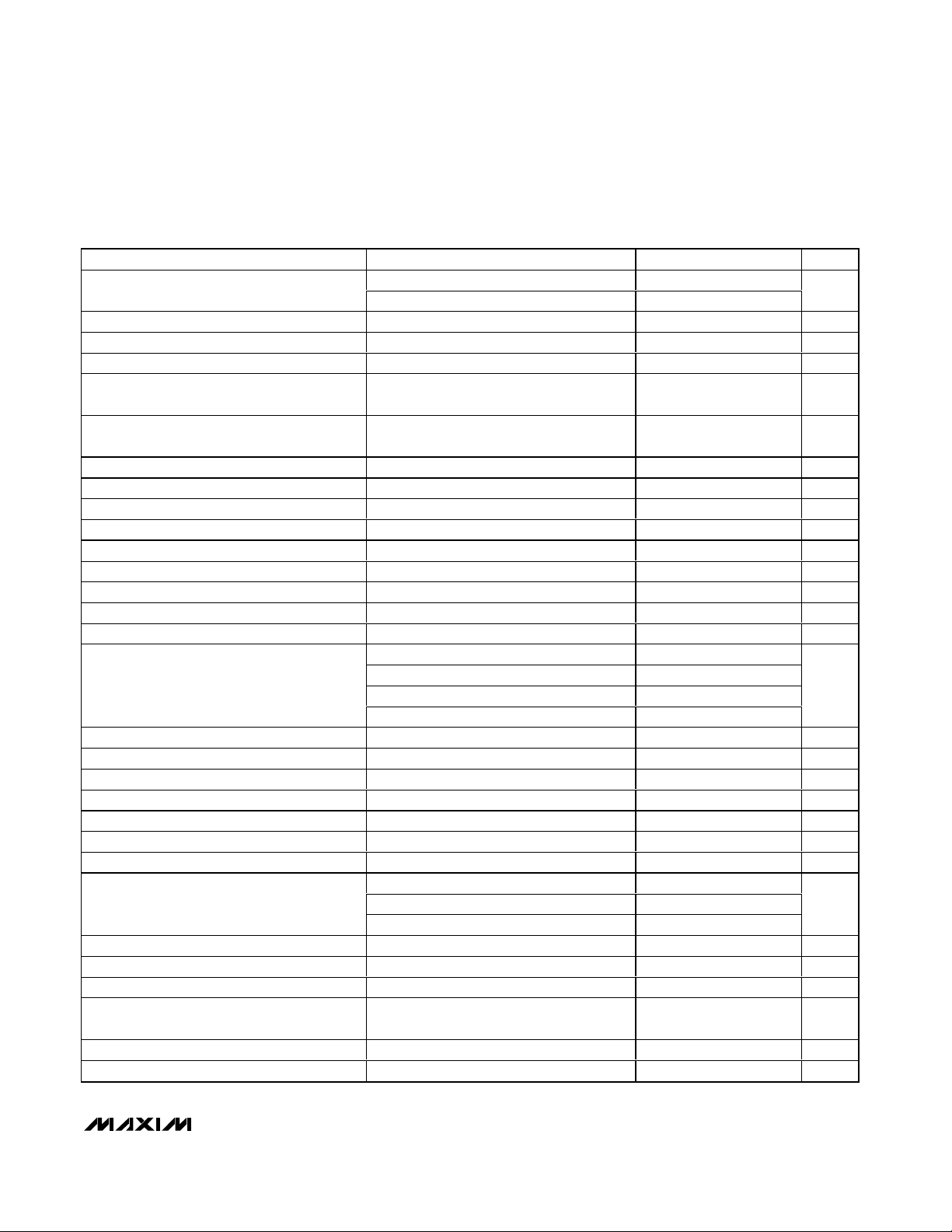

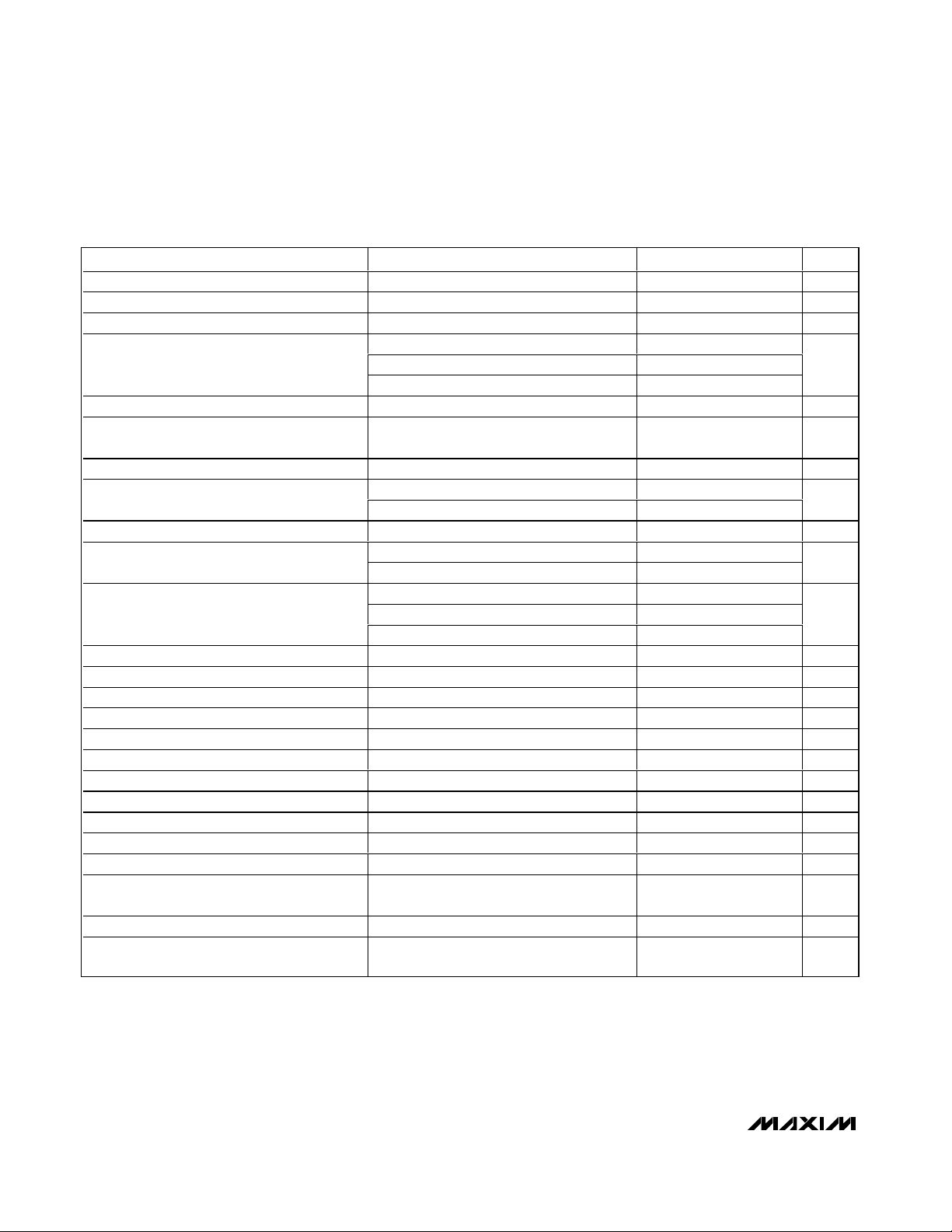

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, V

BATT

= 12V, VCC= V

DD,TA

= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

BATT to GND..........................................................-0.3V to +30V

BST1, BST2 to GND ...............................................-0.3V to +36V

BST1 to LX1, BST2 to LX2 ........................................-0.3V to +6V

FREQ, V

CC

, VDDto GND .........................................-0.3V to +6V

SDA, SCL to GND.....................................................-0.3V to +6V

ALS, COMP, PWMI, PWMO,

TFLT, DEL, VALS to GND.......................-0.3V to (V

CC

+ 0.3V)

GH1 to LX1 ..............................................-0.3V to (V

BST1

+ 0.3V)

GH2 to LX2 ..............................................-0.3V to (V

BST2

+ 0.3V)

GL1, GL2 to GND.......................................-0.3V to (V

DD

+ 0.3V)

IFB1, IFB2, ISEC, VFB to GND ....................................-3V to +6V

PGND1, PGND2 to GND .......................................-0.3V to +0.3V

Continuous Power Dissipation (TA= +70°C)

28-Pin Thin QFN 5mm x 5mm

(derate 21.3mW/°C above +70°C).............................1702mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER CONDITIONS

MIN

TYP

MAX

UNITS

VCC = VDD = V

BATT

4.5 5.5

BATT Input Voltage Range

V

CC

= VDD = open 5.5

V

V

BATT

= 28V 2.5 5

BATT Quiescent Current

V

BATT

= VCC = 5V 5

mA

BATT Quiescent Current, Shutdown MAX8759 is disabled 0.1 2 µA

VCC Output Voltage, Normal Operation

MAX8759 is enabled, 6V < V

BATT

< 28V,

0 < I

LOAD

< 10mA

5.2

5.5 V

VCC Output Voltage, Shutdown MAX8759 is disabled, no load 3.5 4.3 5.5 V

VCC rising (leaving lockout) 4.3

VCC Undervoltage Lockout Threshold

V

CC

falling (entering lockout) 3.7

V

VCC Undervoltage Lockout Hysteresis 230 mV

VCC POR Threshold Rising edge

V

VCC POR Hysteresis 50 mV

GH1, GH2, GL1, GL2 On-Resistance,

Low State

I

TEST

= 100mA, VCC = VDD = 5V 3 6 Ω

GH1, GH2, GL1, GL2 On-Resistance,

High State

I

TEST

= 100mA, VCC = VDD = 5V 10 18 Ω

BST1, BST2 Leakage Current V

BST

_ = 12V, V

LX

_ = 7V 4 10 µA

Resonant Frequency Range Guaranteed by design 30 80 kHz

Minimum On-Time 350 500 700 ns

Maximum Off-Time 40 60 80 µs

Current-Limit Threshold LX1 - PGND1, LX2 - PGND2 415 430 445 mV

Zero-Current-Crossing Threshold LX1 - PGND1, LX2 - PGND2 3 8 13 mV

Current-Limit Leading-Edge Blanking 350 ns

IFB1, IFB2 Input-Voltage Range -3 +3 V

IFB1 Regulation Point 765 785 805 mV

IFB2 Regulation Point 780 800 820 mV

MAX8759 is enabled

28.0

5.35

1.75

Page 3

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

_______________________________________________________________________________________ 3

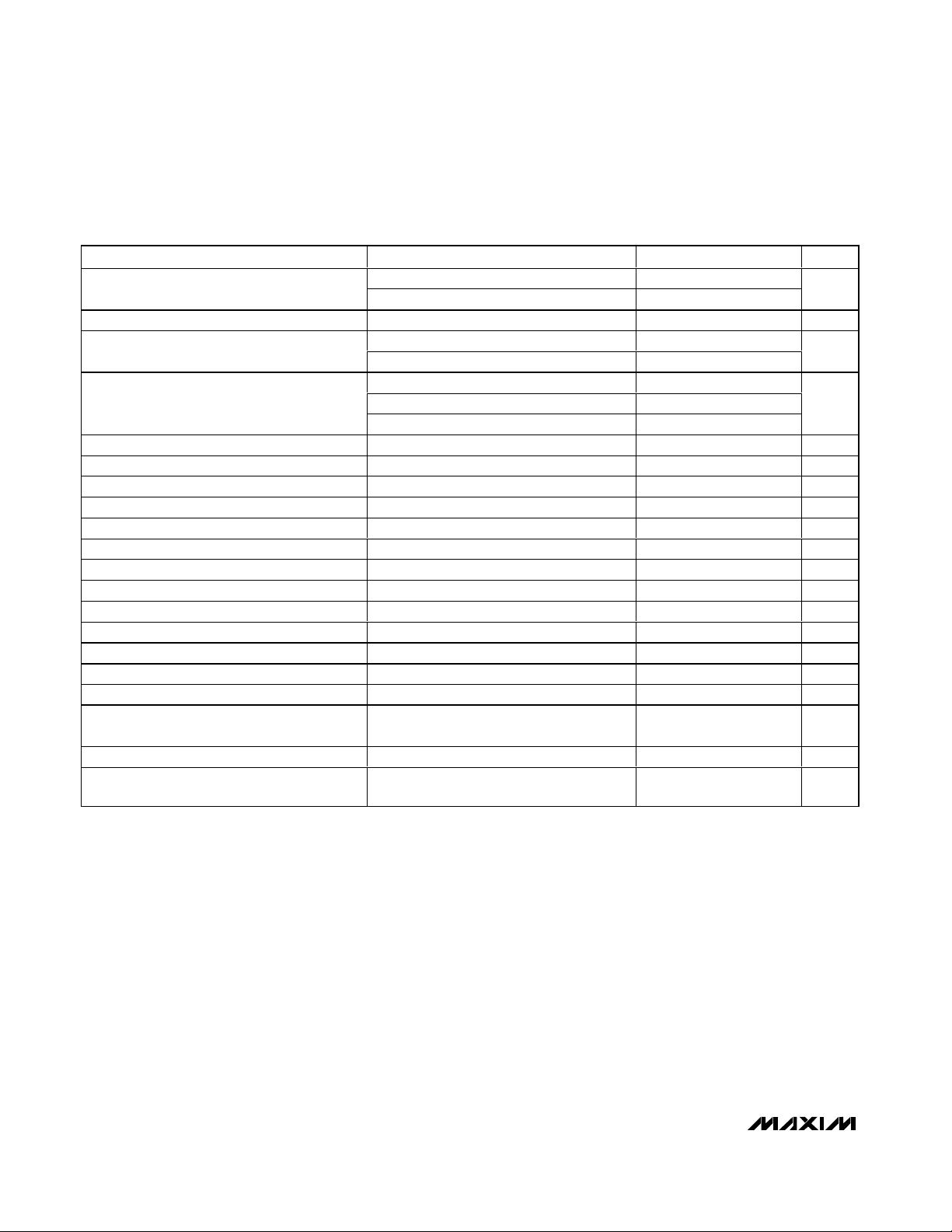

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

BATT

= 12V, VCC= V

DD,TA

= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

PARAMETER CONDITIONS

MIN

TYP

MAX

UNITS

0 < V

IFB1,2

< 3V -3 +3

IFB1, IFB2 Input Bias Current

-3V < V

IFB1,2

< 0

µA

IFB1, IFB2 Lamp-Out Threshold 575 600 625 mV

IFB1, IFB2 to COMP Transconductance 0.5V < V

COMP

< 4V 60 100 160 µS

COMP Output Impedance 61224MΩ

COMP Discharge Current During Overvoltage

or Overcurrent Fault

V

VFB

= 2.6V or V

ISEC

= 1.5V 500

µA

COMP Discharge Current During DPWM

Off-Time

V

COMP

= 1.5V 90 110 130 µA

DPWM Rising-to-Falling Ratio V

IFB1,2

= 0 2.5

ISEC Input Voltage Range -3 +3 V

ISEC Overcurrent Threshold

V

ISEC Input Bias Current V

ISEC

= 1.25V

µA

VFB Input Voltage Range -4 +4 V

VFB Input Impedance 150 300 450 MΩ

VFB Overvoltage Threshold 2.1 2.3 2.5 V

VFB Undervoltage Threshold 210 240 280 mV

VFB Undervoltage Delay R

FREQ

= 169kΩ 250 µs

R

FREQ

= 169kΩ, TA = +25°C to +85°C

213

R

FREQ

= 169kΩ

215

R

FREQ

= 340kΩ 106

DPWM Oscillator Frequency

R

FREQ

= 100kΩ 343

Hz

PWMO Output Impedance 20 40 60 kΩ

PWMI Input Low Voltage 0.7 V

PWMI Input High Voltage 2.1 V

PWMI Input Hysteresis 300 mV

PWMI Input Bias Current

µA

PWMI Input Frequency Range 5 50 kHz

PWMI Full-Range Accuracy 5 LSB

PWMI duty cycle = 100% 98 100

PWMI duty cycle = 50% 48 50 52PWMI Brightness Setting

PWMI duty cycle = 0% 9.7

%

ALS Full-Adjustment Range 0 1.8 V

ALS Full-Range Accuracy 5 LSB

ALS Input Bias Current

µA

VALS Output Voltage

MAX8759 is enabled, 6V < V

BATT

< 28V,

I

LOAD

= 1mA

V

VALS Leakage Current MAX8759 is disabled, VALS = GND -3 +3 µA

VALS On-Resistance MAX8759 is enabled 30 60 Ω

-230

1000 2000

1.18 1.21 1.26

-0.3 +0.3

207 210

205 210

-0.3 +0.3

-0.1 +0.1

5.10 5.30 5.50

10.0 10.3

Page 4

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

4 _______________________________________________________________________________________

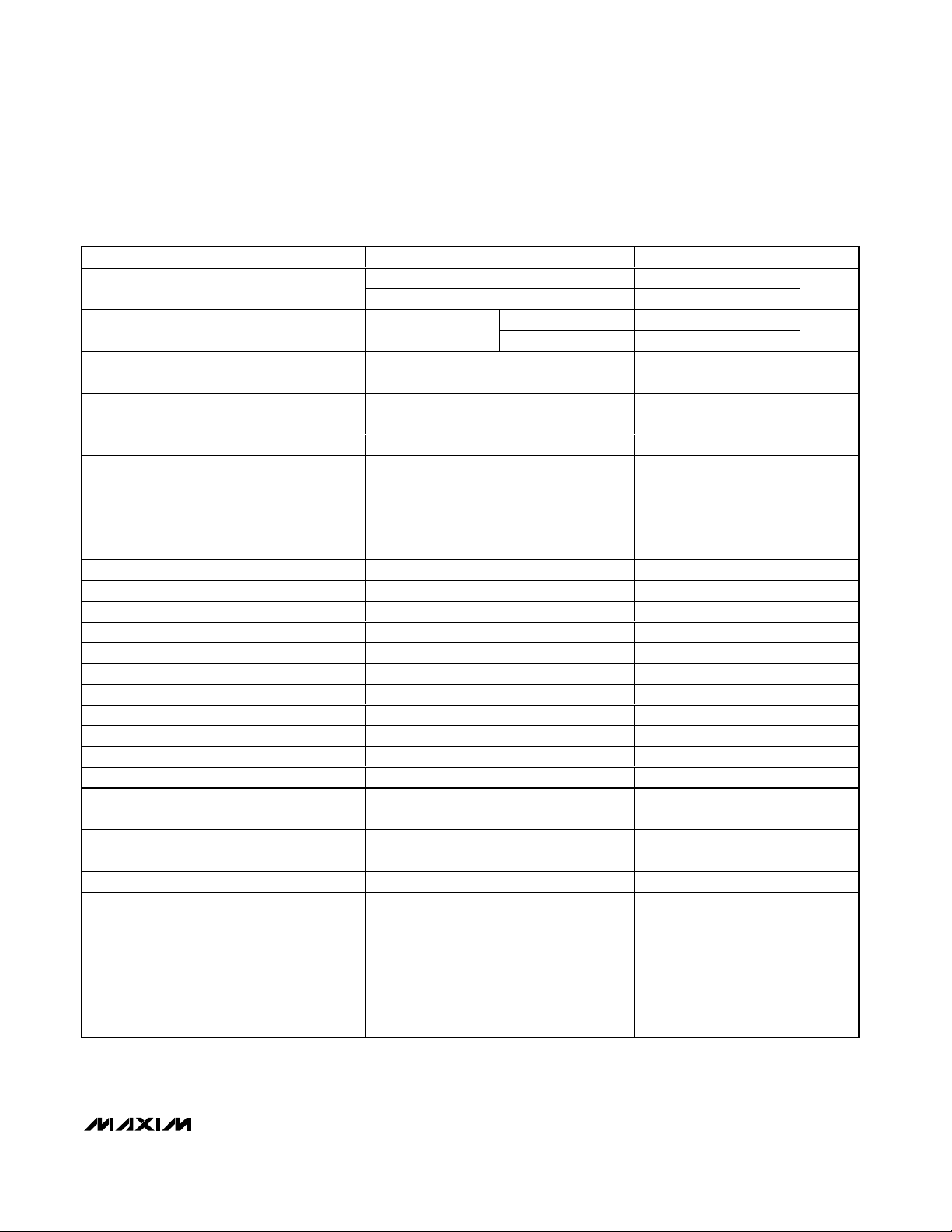

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

BATT

= 12V, VCC= V

DD,TA

= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

PARAMETER CONDITIONS

UNITS

V

BATT

= 9V, R

THR

= 100kΩ 0

Zero-Crossing Delay

V

BATT

= 12V, R

THR

= 100kΩ

µs

Maximum Zero-Crossing Delay V

BATT

= 16V, R

THR

= 100kΩ 3.2 3.8 4.4 µs

DEL rising 4.5

DEL Disable Threshold

DEL falling 3.8

V

0.9 1.0 1.1

TFLT Charge Current

115 135 155

µA

TFLT Trip Threshold Rising edge 3.7 4 4.3 V

SDA, SCL, Input Low Voltage 0.7 V

SDA, SCL, Input High Voltage 2.1 V

SDA, SCL, Input Hysteresis 100 mV

SDA, SCL, Input Bias Current -1 +1 µA

SDA Output Low Sink Current V

SDA

= 0.4V 4 mA

SMBus Frequency 10 100 kHz

SMBus Free Time t

BUF

4.7 1 µs

SCL Serial Clock High Period t

HIGH

4µs

SCL Serial Clock Low Period t

LOW

4.7 µs

START Condition Setup Time t

SU:STA

4.7 µs

START Condition Hold Time t

HD:STA

4µs

STOP Condition Setup Time from SCL t

SU:STO

4µs

SDA Valid to SCL Rising-Edge Setup Time,

Slave Clocking in Data

t

SU:DAT

250 ns

SCL Falling Edge to SDA Transition t

HD:DAT

0ns

SCL Falling Edge to SDA Valid, Reading Out

Data

t

DV

200 ns

MIN TYP MAX

1.50 1.80 2.10

0.15 0.30

V

< 1.25V and V

ISEC

V

< 1.25V and V

ISEC

V

> 1.25V and V

ISEC

< 540mV; V

IFB

> 660mV; V

IFB

> 660mV; V

IFB

= 2V

FLT

= 2V -1.5 -1.2 -0.8

FLT

= 2V

FLT

Page 5

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, V

BATT

= 12V, VCC= V

DD,TA

= -40°C to +85°C.) (Note 1)

PARAMETER CONDITIONS

MIN

TYP

MAX

UNITS

VCC = VDD = V

BATT

4.5 5.5

BATT Input Voltage Range

V

CC

= VDD = open 5.5

V

V

BATT

= 28V 5

BATT Quiescent Current

V

BATT

= VCC = 5V 5

mA

VCC Output Voltage, Normal Operation

MAX8759 is enabled, 6V < V

BATT

< 28V,

0 < I

LOAD

< 10mA

5.2 5.5 V

VCC Output Voltage, Shutdown MAX8759 is disabled, no load 3.5 5.5 V

VCC rising (leaving lockout) 4.3

VCC Undervoltage Lockout Threshold

V

CC

falling (entering lockout) 3.7

V

GH1, GH2, GL1, GL2 On-Resistance,

Low State

I

TEST

= 100mA, VCC = VDD = 5V 6 Ω

GH1, GH2, GL1, GL2 On-Resistance,

High State

I

TEST

= 100mA, VCC = VDD = 5V 18 Ω

Resonant Frequency Range Guaranteed by design 30 80 kHz

Minimum On-Time 350 700 ns

Maximum Off-Time 40 80 µs

Current-Limit Threshold LX1 - PGND1, LX2 - PGND2 410 450 mV

Zero-Current Crossing Threshold LX1 - PGND1, LX2 - PGND2 3 13 mV

IFB1, IFB2 Input Voltage Range -3 +3 V

IFB1 Regulation Point 760 810 mV

IFB2 Regulation Point 775 825 mV

IFB1, IFB2 Input Bias Current -3V < V

IFB1,2

< 0

µA

IFB1, IFB2 Lamp-Out Threshold 565 635 mV

IFB1, IFB2 to COMP Transconductance 0.5V < V

COMP

< 4V 60 160 µS

COMP Output Impedance 625MΩ

COMP Discharge Current During Overvoltage

or Overcurrent Fault

V

VFB

= 2.6V or V

ISEC

= 1.5V 500

µA

COMP Discharge Current During DPWM

Off-Time

V

COMP

= 1.5V 90 130 µA

ISEC Input Voltage Range -3 +3 V

ISEC Overcurrent Threshold

V

VFB Input Voltage Range -4 +4 V

VFB Input Impedance 150 450 MΩ

VFB Overvoltage Threshold 2.1 2.5 V

VFB Undervoltage Threshold 210 280 mV

DPWM Oscillator Frequency R

FREQ

= 169kΩ 203 217 Hz

PWMO Output Impedance 20 60 kΩ

MAX8759 is enabled

-230

1.18 1.26

28.0

2000

Page 6

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, V

BATT

= 12V, VCC= V

DD,TA

= -40°C to +85°C.) (Note 1)

PARAMETER CONDITIONS

UNITS

PWMI Input Low Voltage 0.7 V

PWMI Input High Voltage 2.1 V

PWMI Input Frequency Range 5 50 kHz

PWMI duty cycle = 100% 98

PWMI duty cycle = 50% 48 52PWMI Brightness Setting

PWMI duty cycle = 0% 9.7

%

ALS Full-Adjustment Range 0 1.8 V

VALS Output Voltage

MAX8759 is enabled, 6V < V

BATT

< 28V,

I

LOAD

= 1mA

V

VALS On-Resistance MAX8759 is enabled 60 Ω

V

BATT

= 9V, R

THR

= 100kΩ 0 0.3

Zero-Crossing Delay

V

BATT

= 12V, R

THR

= 100kΩ

µs

Maximum Zero-Crossing Delay V

BATT

= 16V, R

THR

= 100kΩ 3.2 4.4 µs

DEL rising 4.5

DEL Disable Threshold

DEL falling 3.9

V

0.8 1.2

TFLT Charge Current

115 155

µA

TFLT Trip Threshold Rising edge 3.7 4.3 V

SDA, SCL, Input Low Voltage 0.7 V

SDA, SCL, Input High Voltage 2.1 V

SDA Output Low-Sink Current V

SDA

= 0.4V 4 mA

SMBus Frequency 10 100 kHz

SMBus Free Time t

BUF

4.7 µs

SCL Serial Clock High Period t

HIGH

4µs

SCL Serial Clock Low Period t

LOW

4.7 µs

START Condition Setup Time t

SU:STA

4.7 µs

START Condition Hold Time t

HD:STA

4µs

STOP Condition Setup Time from SCL t

SU:STO

4µs

SDA Valid to SCL Rising-Edge Setup Time,

Slave Clocking in Data

t

SU:DAT

250 ns

SCL Falling Edge to SDA Transition t

HD:DAT

0ns

SCL Falling Edge to SDA Valid,

Reading Out Data

t

DV

200 ns

Note 1: Specifications to -40°C are guaranteed by design, not production tested.

MIN TYP MAX

5.10 5.50

V

< 1.25V and V

ISEC

V

< 1.25V and V

ISEC

V

> 1.25V and V

ISEC

< 540mV; V

IFB

> 660mV; V

IFB

> 660mV; V

IFB

= 2V

FLT

= 2V -1.5 -0.8

FLT

= 2V

FLT

1.50 2.10

10.3

Page 7

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

_______________________________________________________________________________________ 7

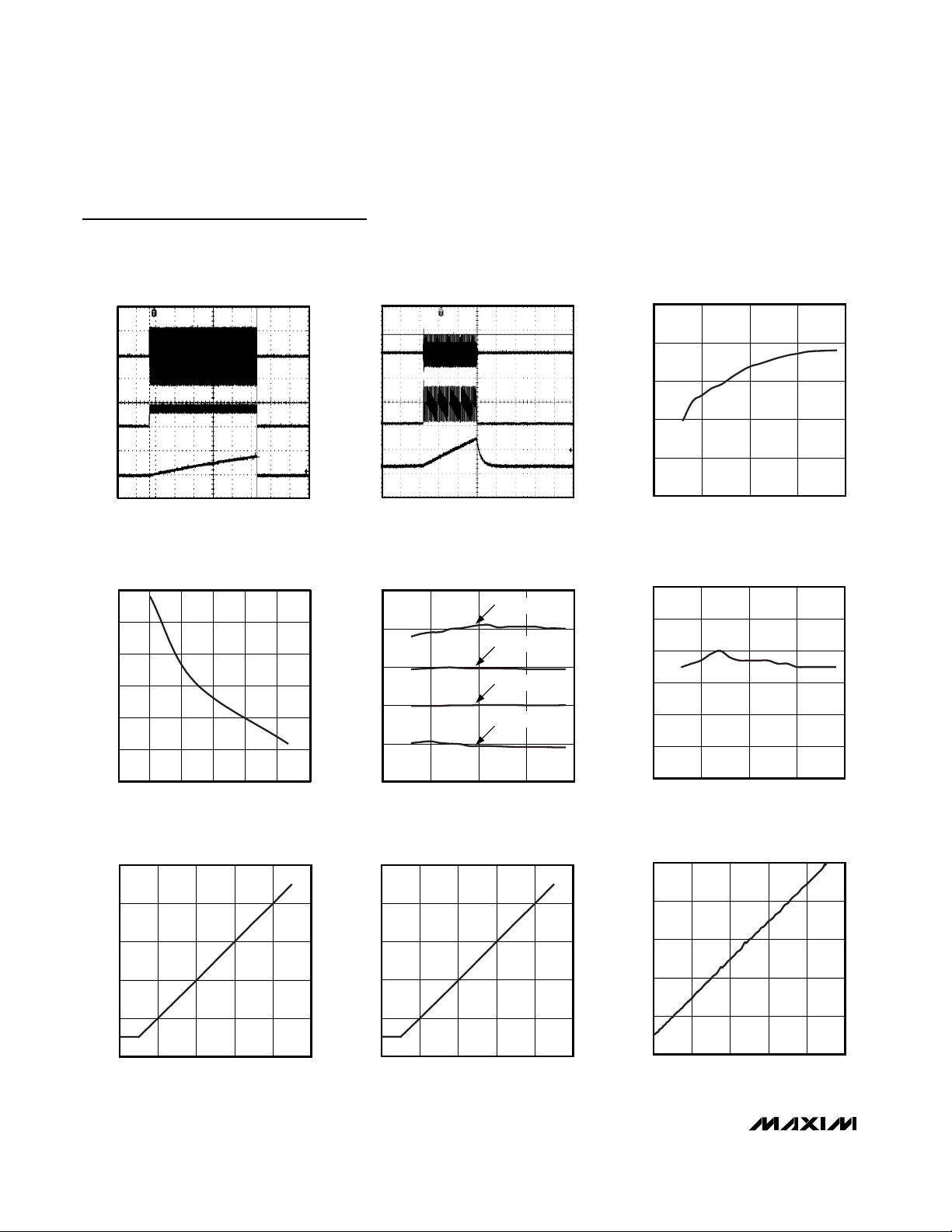

C

D

B

A

A: VFB, 2V/div

B: LX1, 10V/div

LOW-INPUT VOLTAGE OPERATION

(V

IN

= 8.0V)

MAX8759 toc01

10µs/div

C: LX2, 10V/div

D:IFB, 2V/div

C

D

B

A

A: VFB, 2V/div

B: LX1, 20V/div

HIGH-INPUT VOLTAGE OPERATION

(V

IN

= 20.0V)

MAX8759 toc02

10µs/div

C: LX2, 20V/div

D: IFB, 2V/div

C

D

B

A

A: V

IN

, 10V/div

B: COMP, 2V/div

LINE TRANSIENT RESPONSE

(8V TO 20V)

MAX8759 toc03

100µs/div

C: IFB, 2V/div

D: LX1, 20V/div

C

D

B

A

A: V

IN

, 10V/div

B: COMP, 2V/div

LINE TRANSIENT RESPONSE

(20V TO 8V)

MAX8759 toc04

100µs/div

C: IFB, 2V/div

D: LX1, 20V/div

C

B

A

A: VFB, 2V/div

B: COMP, 1V/div

MINIMUM BRIGHTNESS STARTUP WAVEFORM

(SMBus MODE, BRIGHTNESS REGISTER = 0x00)

MAX8759 toc05

2ms/div

C: IFB, 2V/div

C

B

A

A: VFB, 2V/div

B: COMP, 1V/div

MINIMUM BRIGHTNESS DPWM OPERATION

(SMBus MODE, BRIGHTNESS REGISTER = 0x00)

MAX8759 toc06

2ms/div

C: IFB, 2V/div

C

B

A

A: VFB, 2V/div

B: COMP, 1V/div

50% BRIGHTNESS DPWM OPERATION

(SMBus MODE, BRIGHTNESS REGISTER = 0x80)

MAX8759 toc07

2ms/div

C: IFB, 2V/div

C

B

A

A: VFB, 2V/div

B: COMP, 1V/div

DPWM SOFT-START

MAX8759 toc08

40µs/div

C: IFB, 2V/div

C

B

A

A: VFB, 2V/div

B: COMP, 1V/div

DPWM SOFT-STOP

MAX8759 toc09

40µs/div

C: IFB, 2V/div

Typical Operating Characteristics

(Circuit of Figure 1, VIN= 12V, VCC= VDD, TA= +25°C, unless otherwise noted.)

Page 8

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= 12V, VCC= VDD, TA= +25°C, unless otherwise noted.)

C

B

A

A: VFB, 2V/div

B: COMP, 500mV/div

OPEN-LAMP VOLTAGE

LIMITING AND TIMEOUT

MAX8759 toc010

200ms/div

C: TFLT, 5V/div

C

B

A

A: ISEC, 2V/div

B: COMP, 1V/div

SECONDARY SHORT-CIRCUIT PROTECTION

AND TIMEOUT

MAX8759 toc011

2ms/div

C: TFLT, 1V/div

30

40

60

50

70

80

SWITCHING FREQUENCY

vs. INPUT VOLTAGE

MAX8759 toc12

VIN (V)

SWITCHING FREQUENCY (kHz)

51510 20 25

50

150

100

250

200

300

350

DPWM FREQUENCY

vs. R

FREQ

MAX8759 toc13

R

FREQ

(kΩ)

DPWM FREQUENCY (Hz)

50 150 200100 250 300 350

3

4

6

5

7

8

RMS LAMP CURRENT

vs. INPUT VOLTAGE

MAX8759 toc14

INPUT VOLTAGE (V)

RMS LAMP CURRENT (mA)

51510 20 25

I

LAMP

= 7mA

I

LAMP

= 6mA

I

LAMP

= 5mA

I

LAMP

= 4mA

5.6

5.8

5.7

6.0

5.9

6.1

6.2

51510 20 25

RMS LAMP CURRENT (I

LAMP

= 6mA)

vs. INPUT VOLTAGE

MAX8759 toc15

INPUT VOLTAGE (V)

RMS LAMP CURRENT (mA)

0

20

60

40

80

100

00.40.2 0.6 0.8 1.0

NORMALIZED BRIGHTNESS

vs. PWMI DUTY CYCLE

MAX8759 toc17

PWMI DUTY RATIO

NORMALIZED BRIGHTNESS (%)

0

20

60

40

80

100

0 0.80.4 1.2 1.6 2.0

NORMALIZED BRIGHTNESS

vs. ALS VOLTAGE

MAX8759 toc18

V

ALS

(V)

NORMALIZED BRIGHTNESS (%)

0

20

60

40

80

100

04020 60 80 100

NORMALIZED BRIGHTNESS

vs. SMBus BRIGHTNESS SETTING

MAX8759 toc16

BRIGHTNESS SETTING (%)

NORMALIZED BRIGHTNESS (%)

Page 9

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

_______________________________________________________________________________________ 9

0

20

60

40

80

100

00.40.2 0.6 0.8 1.0

NORMALIZED BRIGHTNESS

vs. SMBus BRIGHTNESS AND PWMI DUTY CYCLE

MAX8759 toc19

PWMI DUTY RATIO

NORMALIZED BRIGHTNESS (%)

SMB = 0xFF

SMB = 0x80

0

0.2

0.6

0.4

0.8

1.0

00.40.2 0.6 0.8 1.0

NORMALIZED BRIGHTNESS

vs. ALS VOLTAGE AND PWMI DUTY CYCLE

MAX8759 toc20

PWMI DUTY RATIO

V

ALS

= 1.8V

V

ALS

= 1.8V

V

ALS

= 0.8V

B

A

ALS TRANSIENT RESPONSE

(ALSDEL1 = ALSDEL0 = 0)

MAX8759 toc21

A: ALS, 1V/div B: COMP, 1V/div

1s/div

5.30

5.31

5.33

5.32

5.34

5.35

VCC LINE REGULATION

MAX8759 toc22

INPUT VOLTAGE (V)

V

CC

VOLTAGE (V)

81612 20 24

5.30

5.31

5.33

5.32

5.34

5.35

042681012

VCC LOAD REGULATION

MAX8759 toc23

LOAD CURRENT (mA)

V

CC

VOLTAGE (V)

VIN = 24V

VIN = 12V

5.27

5.28

5.30

5.29

5.31

5.32

-40 0-20 20 406080

VCC VOLTAGE

vs. TEMPERATURE

MAX8759 toc24

TEMPERATURE (°C)

V

CC

VOLTAGE (V)

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= 12V, VCC= VDD, TA= +25°C, unless otherwise noted.)

Page 10

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

10 ______________________________________________________________________________________

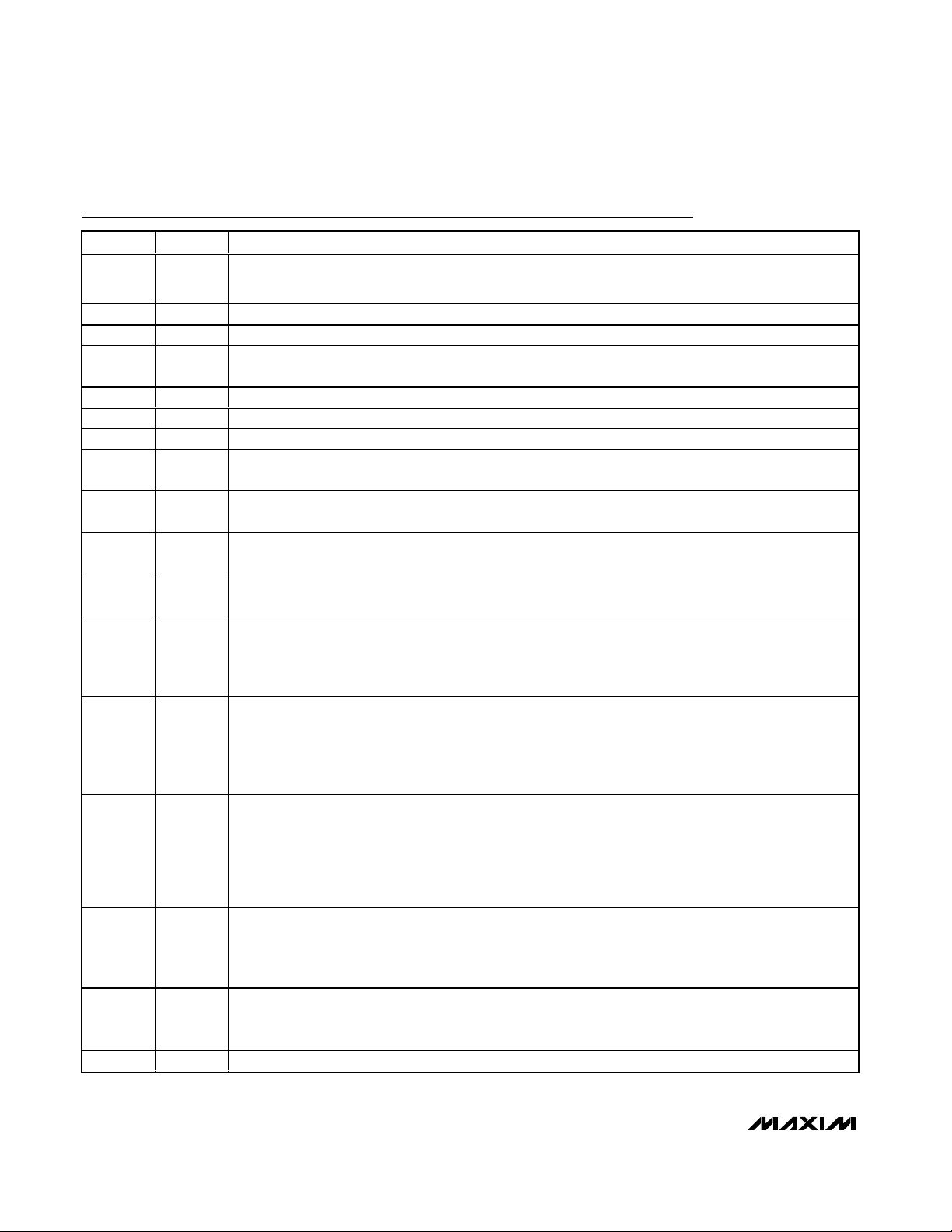

Pin Description

PIN NAME FUNCTION

1 BATT

Supply Input. BATT is the input to the internal 5.35V linear regulator that powers the device. Bypass BATT

to GND with a 0.1µF ceramic capacitor.

2 SDA SMBus Serial Data Input

3 SCL SMBus Serial Clock Input

4 TFLT

Fault-Timer Adjustment Pin. Connect a capacitor from TFLT to GND to set the time-out periods for open-

lamp and secondary overcurrent faults.

5 VALS Ambient-Light-Sensor Supply Pin. Bypass VALS to GND with a 0.1µF capacitor.

6 ALS Ambient-Light-Sensor Input

7 PWMI DPST Control Input

8

DPST Buffer Output. Connect a capacitor between PWMO and GND. The capacitor forms a lowpass filter

with an internal 40kΩ (typ) resistor for filtering the DPST signal.

9 FREQ

Chopping-Frequency Adjustment Pin. Connect a resistor from FREQ to GND to set the DPWM frequency:

f

DPWM

= 210Hz × 169kΩ / R

FREQ

.

10 COMP

Transconductance Error Amplifier Output. A compensation capacitor connected between COMP and GND

sets the rise and fall time of the lamp-current envelope in DPWM operation.

11 DEL

Adaptive Zero-Crossing-Delay Adjustment Pin. Connect a resistor between DEL and GND to adjust the

range of the zero-crossing delay. Connecting DEL to V

CC

disables the zero-crossing delay function.

12 IFB1

Lamp-Current-Feedback Input. The IFB1 sense signal is internally full-wave rectified. IFB1 is compared

with IFB2 and the larger is used for lamp-current regulation. The average value of the rectified signal is

regulated to 785mV (typ) by controlling the on-time of high-side switch. An open-lamp fault is generated if

the peak voltage of IFB1 is below 600mV for a fault delay period set by TFLT.

13 IFB2

Lamp-Current-Feedback Input. The IFB2 sense signal is internally full-wave rectified. IFB1 is compared

with IFB2 and the larger is used for lamp-current regulation. The average value of the rectified signal is

regulated to 800mV (typ) by controlling the on-time of high-side switch. An open-lamp fault is generated if

the peak voltage of IFB2 is below 600mV for a fault-delay period set by TFLT. IFB2 input can be disabled

by connecting IFB2 to V

CC

.

14 VFB

Transformer Secondary Voltage-Feedback Input. A capacitive voltage-divider between the high-voltage

terminal of the CCFL tube and GND sets the maximum average lamp voltage during striking and lamp-out

fault. When the peak voltage on VFB exceeds the internal overvoltage threshold, the controller turns on an

internal current sink, discharging the COMP capacitor to limit the switch on-time. The VFB pin is also used

to detect a secondary undervoltage condition. If the peak voltage on VFB is below 230mV continuously for

250µs during the DPWM ON period, the MAX8759 shuts down.

15 ISEC

Transformer Secondary Current-Feedback Input. A current-sense resistor connected between the low-

voltage end of the transformer secondary and the ground sets the maximum secondary current during

short-circuit fault. When the peak voltage on ISEC exceeds the internal overcurrent threshold, the

controller turns on an internal current sink discharging the COMP capacitor.

16 LX1

GH1 Gate-Driver Return. LX1 is the input to the current-limit and zero-crossing comparators. The device

senses the voltage across the low-side MOSFET NL1 to detect primary current zero crossing and primary

overcurrent.

17 GH1 High-Side MOSFET NH1 Gate Driver Output

PWMO

Page 11

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

______________________________________________________________________________________ 11

PIN NAME FUNCTION

18 BST1 GH1 Gate-Driver Supply Input. Connect a 0.1µF capacitor from LX1 to BST1.

19

Power Ground. PGND1 is the return for the GL1 gate driver.

20 GL1 Low-Side MOSFET NL1 Gate Driver Output

21 V

DD

Low-Side Gate-Driver Supply Input. Connect V

DD

to the output of the internal linear regulator (VCC).

22 GL2 Low-Side MOSFET NL2 Gate-Driver Output

23

Power Ground. PGND2 is the return for the GL2 gate driver.

24 BST2 GH2 Gate-Driver Supply Input. Connect a 0.1µF capacitor from LX2 to BST2.

25 GH2 High-Side MOSFET NH2 Gate-Driver Output

26 LX2

GH2 Gate-Driver Return. LX2 is the input to the current-limit and zero-crossing comparators. The device

senses the voltage across the low-side MOSFET NL2 to detect primary current zero crossing and primary

overcurrent.

27 GND

Analog Ground. The ground return for V

CC

, REF, and other analog circuitry. Connect GND to PGND under

the IC at the IC’s backside exposed metal pad.

28 V

CC

5.35V/10mA Internal Linear-Regulator Output. VCC is the supply voltage for the device. Bypass VCC with a

0.47µF ceramic capacitor to GND.

—EPExposed Backside Pad. Connect PAD to GND.

Pin Description (continued)

PGND1

PGND2

Page 12

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

12 ______________________________________________________________________________________

N2A

19

24

21

21

C7

0.1µF

C8

0.47µF

C1

10µF

25V

C10

0.1µF

C11

0.1µF

C13

6.8nF

C6

68nF

C5

10nF

C4

10pF

3kV

C2

2.2µF

C3

2.2µF

T1

1:110

R1

150Ω

1%

CCFL

R2

3.9kΩ

C14

0.22µF

FDC6561AN

FDC6561AN

C9

0.47µF

C12

1µF

C15

0.1µF

R3

169kΩ

1%

V

CC

27

11

28

2

3

7

8

9

5

6

BATT

GND

DEL

V

CC

SDA

SCL

PWMI

PWMO

FREQ

VALS

ALS

18

17

16

26

20

23

22

25

12

13

V

CC

14

15

10

4

PGND1

BST2

V

DD

BST1

GH1

LX1

LX2

GL1

PGND2

GL2

GH2

IFB1

IFB2

VFB

ISEC

COMP

TFLT

N2B

N1A N1B

PWM INPUT

INPUT VOLTAGE

SMB_DATA

SMB_CLOCK

F1

2A

ALS SUPPLY

ALS OUTPUT

7.5V TO 24V

MAX8759

Figure 1. Typical MAX8759 Single-Lamp Operating Circuit

Page 13

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

______________________________________________________________________________________ 13

Typical Operating Circuit

The MAX8759 typical operating circuit (Figure 1) is a

single-lamp CCFL backlight inverter for notebook computer TFT LCD panels. The input voltage range of the

circuit is from 7.5V to 24V. The maximum RMS lamp

current is set to 6mA and the maximum RMS striking

voltage is set to 1800V. Table 1 lists some important

components and Table 2 lists the component suppliers’

contact information.

Detailed Description

The MAX8759 controls a full-bridge resonant inverter to

convert an unregulated DC input into a high-frequency

AC output for powering CCFLs. The resonant operation

maximizes striking capability and provides near-sinu-

soidal waveforms over the entire input range to improve

CCFL lifetime. The lamp brightness is adjusted by turning the lamp on and off with a DPWM signal. The

DPWM frequency can be accurately adjusted with a

resistor. The brightness of the lamp is proportional to

the duty cycle of the DPWM signal, which is controlled

either with a 2-wire SMBus-compatible interface, with

an external ALS, or with an external PWM signal. The

device also includes safety features that effectively protect against single-point fault conditions such as lampout and secondary short-circuit faults. An internal 5.35V

linear regulator powers the MOSFET drivers and most

of the internal circuitry. Figure 2 is the functional diagram of the MAX8759 and Figure 3 is the detailed diagram of the SMBus and ALS input block.

Resonant Operation

The MAX8759 drives four n-channel power MOSFETs

that make up the zero-voltage-switching (ZVS) fullbridge inverter as shown in Figure 4. Assume that NH1

and NL2 are on at the beginning of a switching cycle

as shown in Figure 4(a). The primary current flows

through MOSFET NH1, DC blocking capacitor C2, the

primary side of transformer T1, and MOSFET NL2.

During this interval, the primary current ramps up until

the controller turns off NH1. When NH1 is turned off, the

primary current forward biases the body diode of NL1,

which clamps the LX1 voltage just below ground as

shown in Figure 4(b). When the controller turns on NL1,

its drain-to-source voltage is near zero because its forward-biased body diode clamps the drain. Since NL2

is still on, the primary current flows through NL1, C2,

the primary side of T1, and NL2. Once the primary current drops to the minimum current threshold

(6mV/R

DS(ON)

), the controller turns off NL2. The

remaining energy in T1 charges up the LX2 node until

the body diode of NH2 is forward biased. When NH2

turns on, it does so with near-zero drain-to-source voltage. The primary current reverses polarity as shown in

Figure 4(c), beginning a new cycle with the current

flowing in the opposite direction, with NH2 and NL1 on.

The primary current ramps up until the controller turns

off NH2. When NH2 is turned off, the primary current

forward biases the body diode of NL2, which clamps

the LX2 voltage just below ground as shown in Figure

4(d). After the LX2 node goes low, the controller losslessly turns on NL2. Once the primary current drops to

the minimum current threshold, the controller turns off

NL1. The remaining energy charges up the LX1 node

until the body diode of NH1 is forward biased. Finally,

NH1 losslessly turns on, beginning a new cycle as

shown in Figure 4(a). Note that switching transitions on

all four power MOSFETs occur under ZVS conditions,

which reduces transient power losses and EMI.

DESIGNATION

DESCRIPTION

C1

10µF ±20%, 25V X5R ceramic capacitor

(1210)

Murata GRM32DR61E106M

TDK C3225X5R1E106M

C2, C3

2.2µF ±10%, 25V X5R ceramic capacitors

(0805)

Murata GRM21BR61E225K

TDK C2012X5R1E225K

C4

10pF ±10%, 3kV HV ceramic capacitor

(1808)

Kemet C1808C100KHGAC

TDK C4520C0G3F100F

NH1/2, NL1/2

Dual n-channel MOSFETs, 30V, 0.095Ω,

6-pin SOT23

Fairchild FDC6561AN

T1

CCFL transformer, 1:110 turns ratio

TMP UI9.8L type

Table 1. List of Important Components

SUPPLIER WEBSITE

Fairchild

Semiconductor

www.fairchildsemi.com

Kemet www.kemet.com

Murata www.murata.com

TDK www.components.tdk.com

TMP www.tmp.com

Table 2. Component Suppliers

Page 14

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

14 ______________________________________________________________________________________

Figure 2. MAX8759 Functional Diagram

BATT

GND

V

CC

VALS

ISEC

IFB1

IFB2

COMP

VFB

FREQ

SCL

SDA

ALS

PWMI

PWMO

2.3V

40kΩ

FW

FW

DWPM

OSC

SMBus

ALS

ADC

PWM

ADC

OV

COMP

LINEAR

REGULATOR

RDY

OC

COMP

1.21V

MAX

V

REF

OC

ERROR

AMP

1000µA 100µA

8-BIT

COUNTER

BRIGHTNESS

CONTROL

OC

BIAS

Z

X

600mV

DPWM

COMP

4.3V

MIN

EN

S

Q

R

OPEN-LAMP

DPWM

LATCH

S

Q

R

UVLO

COMPARATOR

COMP

RDY

BATT

MAX8759

V

CC

135µA

1µA

PWM

COMP

ILIM

COMP

230mV

VFB

FAULT

LATCH

S

Q

R

GATE-DRIVER

CONTROL

STATE

MACHINE

MUX

SHUTDOWN

DH

DH

DL

DL

4V

UV

COMP

MIN

TON

Q

R

TON FF

S

Q

400mV

ZERO-CROSS

ZX

DETECTIONS

DELAY BLOCK

AND

LX_

TFLT

BST1

GH1

LX1

BST2

GH2

LX2

VDD

GL1

PGND2

GL2

PGND1

DEL

Page 15

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

______________________________________________________________________________________ 15

Figure 3. MAX8759 SMBus and Ambient-Light-Sensor Input Block

ALS

STATUS

REGISTER

ALS

LOW-LIMIT

REGISTER

ALS

HIGH-LIMIT

REGISTER

ALS

CLAMP

BRIGHT

CONTROL

REGISTER

DEVICE

CONTROL

REGISTER

MUX

DIGITAL

MULTIPLIER

BUFFER

DIGITAL

POT

SMBus

INTERFACE

DPWM

SETTING

PWMI

SDA

SCL

0X04 0X00 0X010X060X05

MUX

"1"

PWMO

ALS

SMBus AND AMBIENT-LIGHT-SENSOR INPUT BLOCK

INVERTER

ON/OFF

MUX

PWM_SEL

ALS_CTL

PWM_MD

BUFFER

FAULT/

STATUS

REGISTER

0X02

OFFSET

A

D

A

D

A simplified CCFL inverter circuit is shown in Figure 5

(a). The full-bridge power stage is simplified and represented as a square-wave AC source. The resonant tank

circuit can be further simplified to Figure 5(b) by

removing the transformer. CSis the primary series

capacitor, CS’ is the series capacitance reflected to the

secondary, CPis the secondary parallel capacitor, N is

the transformer turns ratio, L is the transformer secondary leakage inductance, and RLis an idealized

resistance that models the CCFL in normal operation.

Figure 6 shows the frequency response of the resonant

tank’s voltage gain under different load conditions. The

primary series capacitor is 1µF, the secondary parallel

capacitor is 15pF, the transformer turns ratio is 1:93,

and the secondary leakage inductance is 260mH.

Notice that there are two peaks, fS,and fP, in the frequency response. The first peak fSis the series resonant peak determined by the secondary leakage

inductance (L) and the series capacitor reflected to the

secondary (C’S):

f

1

2LC

S

S

=

′

π

Page 16

MAX8759

The second peak fPis the parallel resonant peak determined by the secondary leakage inductance (L), the

parallel capacitor (CP), and the series capacitor reflected to the secondary (C’S):

The inverter is designed to operate between these two

resonant peaks. When the lamp is off, the operating

point of the resonant tank is close to the parallel resonant peak due to the lamp’s infinite impedance. The circuit displays the characteristics of a parallel-loaded

resonant converter. While in parallel-loaded resonant

operation, the inverter behaves like a voltage source to

generate the necessary striking voltage. Theoretically,

the output voltage of the resonant converter increases

until the lamp is ionized or until it reaches the IC’s secondary voltage limit. Once the lamp is ionized, the

equivalent load resistance decreases rapidly and the

operating point moves toward the series resonant peak.

While in series resonant operation, the inverter behaves

like a current source.

Lamp-Current Regulation

The MAX8759 uses a lamp-current control loop to regulate the current delivered to the CCFL. The heart of the

control loop is a transconductance error amplifier. The

f

L

CC

CC

P

SP

SP

=

′

′

+

1

2π

Low-Cost, SMBus, CCFL Backlight Controller

16 ______________________________________________________________________________________

T1

C2

V

BATT

(a)

NH1

ON

NL1

OFF

NH2

OFF

NL2

ON

LX2LX1

T1

C2

V

BATT

(b)

NH1

OFF

NL1

ON

NH2

OFF

NL2

ON

LX2LX1

T1

C2

V

BATT

(c)

NH1

OFF

NL1

ON

NH2

ON

NL2

OFF

LX2LX1

T1

C2

V

BATT

(d)

NH1

OFF

NL1

ON

NH2

OFF

NL2

ON

LX2LX1

(BODY DIODE TURNS ON FIRST) (BODY DIODE TURNS ON FIRST)

Figure 4. Resonant Operation

Page 17

AC lamp current is sensed with a resistor connected in

series with the low-voltage terminal of the lamp. The

MAX8759 has two lamp-current feedback inputs (IFB1

and IFB2) to support dual-lamp application. The voltages across the sense resistors are fed to the IFB1 and

IFB2 inputs and are internally full-wave rectified. The

transconductance error amplifier selects the higher one

of the two feedback signals and compares the rectified

voltage with an internal threshold to generate an error

current. The error current charges and discharges a

capacitor connected between COMP and ground to

create an error voltage (V

COMP

). V

COMP

is then compared with an internal ramp signal to set the high-side

MOSFET switch on-time (tON).

Feed-Forward Control

The MAX8759 is designed to maintain tight control of

the lamp current under all transient conditions. The

feed-forward control instantaneously adjusts the ontime for changes in input voltage (V

BATT

). This feature

provides immunity to input-voltage variations and simplifies loop compensation over wide input-voltage

ranges. The feed-forward control also improves the line

regulation for short DPWM on-times and makes startup

transients less dependent on the input voltage.

Feed-forward control is implemented by increasing the

internal voltage ramp rate for higher V

BATT

. This has

the effect of varying tONas a function of the input voltage while maintaining approximately the same signal

levels at V

COMP

. Since the required voltage change

across the compensation capacitor is minimal, the controller’s response to input voltage changes is essentially

instantaneous.

Lamp Startup

A CCFL is a gas-discharge lamp that is normally driven in

the avalanche mode. To start ionization in a nonionized

lamp, the applied voltage (striking voltage) must be

increased to the level required for the start of avalanche.

At low temperatures, the striking voltage can be several

times the typical operating voltage.

Because of the MAX8759’s resonant topology, the striking

voltage is guaranteed. Before the lamp is ionized, the

lamp impedance is infinite. The transformer secondary

leakage inductance and the high-voltage parallel capacitor determine the unloaded resonant frequency. Since the

unloaded resonant circuit has a high Q, it can generate

very high voltage across the lamp.

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

______________________________________________________________________________________ 17

AC

SOURCE

CCFL

C

P

L

C

S

1:N

(a)

AC

SOURCE

R

L

C

P

L

C'

S

=

(b)

C

S

N

2

Figure 5. Equivalent Resonant Tank Circuit

FREQUENCY (kHz)

VOLTAGE GAIN (V/V)

80604020

1

2

3

4

0

0 100

RL INCREASING

Figure 6. Frequency Response of the Resonant Tank

Page 18

MAX8759

Dimming Control

The MAX8759 controls the brightness of the CCFL by

“chopping” the lamp current on and off using a low-frequency (between 100Hz and 350Hz) DPWM signal.

The frequency of the internal DPWM oscillator is

adjustable through a resistor connected between the

FREQ pin and GND. The CCFL brightness is proportional to the DPWM duty cycle, which can be adjusted

from 10.15% to 100%.

In DPWM operation, the COMP voltage controls the

dynamics of the lamp-current envelope. At the beginning of the DPWM ON cycle, the average value of the

lamp-current feedback signal is below the regulation

point, so the transconductance error amplifier sources

current into the COMP capacitor. The switch on-time

(tON) gradually increases as V

COMP

rises, which provides soft-start. At the end of the DPWM ON cycle, the

MAX8759 turns on a 110µA internal current source. The

current source linearly discharges the COMP capacitor,

gradually decreasing tON, and providing soft-stop.

The DPWM frequency can be set with an external resistor. Connect a resistor between FREQ and GND. The

DPWM frequency is given by the following equation:

The adjustable range of the DPWM frequency is

between 100Hz and 350Hz (R

FREQ

is between 100kΩ

and 350kΩ).

The MAX8759 has three ways for brightness control.

The brightness can be controlled by a 2-wire serial

interface (SMBus), by an external PWM signal, or by an

external ambient-light sensor signal. There are five

operating modes, which can be selected by setting bits

1 to 3 in device control register 0x01 (see the SMBus

Register Definitions section for details).

ALS Mode

The MAX8759 can work with several types of ambientlight sensors. The ideal ambient-light sensors should

have a linear response to ambient light and should

have a spectral response equivalent to that of the

human eye. Ambient-light sensors must provide filtering

of low-frequency harmonics found in the electrical

spectrum of the many light sources. The ALS’s output

should be a DC analog voltage that is linearly proportional to the ambient luminance.

In ALS mode, the MAX8759 sets the brightness based

on the analog voltage on the ALS pin. The ALS pin is

connected to the output of an external ambient-light

sensor. The usable input-voltage range of the ALS pin

is 0 to 1.8V. The MAX8759 compares the ALS input

voltage against user-programmable low and high limits.

When the ALS input voltage is below the low limit, the

brightness is clamped to the ALS low limit. When the

ALS input voltage is above the high limit, the brightness is

clamped to the ALS high limit. If the minimum ALS setting

is below 10%, the brightness is clamped to 10%. Figure 7

shows the brightness change as a function of the ALS

voltage.

The ALS input voltage is sampled every DPWM period

and is loaded in ALS status register 0x04. The analog

voltage on the ALS pin is converted into an 8-bit digital

code. The total number of brightness levels is 256. One

step change results in a 0.391% change in the DPWM

duty cycle.

PWM Mode

In PWM mode, the MAX8759 sets the brightness based

on the duty cycle of the PWMI signal. The absolute minimum brightness is 10%. If the PWMI duty cycle is less

than 10%, the brightness stays at 10%. The frequency

range of the PWMI signal is between 5kHz and 50kHz

when the PWMO capacitor is 1µF.

SMBus Mode

In SMBus mode, the MAX8759 sets the brightness

based on the brightness control register (0x00). The

brightness control register contains 8 bits and supports

256 brightness levels. A setting of 0xFF for register

0x00 sets the inverter to the maximum brightness. A

setting of 0x00 for register 0x00 sets the inverter to the

minimum brightness (10%).

ALS with DPST Mode

In ALS with DPST mode, the MAX8759 sets the brightness based on the analog voltage on the ALS pin and

duty cycle at the PWMI pin. The MAX8759 lowers the

ALS brightness setting by an additional amount that is

proportional to the duty cycle of the PWMI signal. For

example, if the ALS brightness setting is 80% and the

duty cycle of PWMI signal is 60%, the resulting brightness setting is 80% x 60% = 48%.

SMBus with DPST Mode

In SMBus with DPST mode, the MAX8759 sets the

brightness based on the brightness control register

(0x00). The MAX8759 lowers the SMBus brightness setting by an additional amount that is proportional to the

duty cycle of the PWMI signal. For example, if the

brightness control register is set to 0x80 (corresponding to 50% brightness setting) and the duty cycle of the

PWMI signal is 60%, the resulting brightness setting is

50% x 60% = 30%.

fHzkR

DPWM FREQ

=×210 169 Ω/

Low-Cost, SMBus, CCFL Backlight Controller

18 ______________________________________________________________________________________

Page 19

Fault Protections

Lamp-Out Protection

For safety, the MAX8759 monitors the lamp-current

feedback inputs (IFB1 and IFB2) to detect faulty or

open CCFL tubes. As described in the Lamp-Current

Regulation section, the voltage on IFB1 and IFB2 is

internally full-wave rectified. If the rectified IFB1 or IFB2

voltage is below 600mV, the MAX8759 charges the

TFLT capacitor with 1µA. The MAX8759 sets the fault

latch and the device is shut down when the voltage on

TFLT exceeds 4V. Unlike the normal shutdown mode,

the linear regulator output (V

CC

) remains at 5.35V.

Clearing bit 0 of the device control register (0x01) or

cycling the input power clears the fault latch.

During the fault-delay period, the current control loop

tries to maintain the lamp-current regulation by increasing the high-side MOSFET on-time. Because the lamp

impedance is very high when it is open, the transformer

secondary voltage rises as a result of the high Q-factor

of the resonant tank. Once the secondary voltage

exceeds the overvoltage threshold, the MAX8759 turns

on a 1000µA current source that discharges the COMP

capacitor. The on-time of the high-side MOSFET is

reduced, lowering the secondary voltage as the COMP

voltage decreases. Therefore, the peak voltage of the

transformer secondary winding never exceeds the limit

during the lamp-out delay period.

Primary Overcurrent Protection

The MAX8759 senses primary current in each switching cycle. When the regulator turns on the low-side

MOSFET, a comparator monitors the voltage drop from

LX_ to PGND_. If the voltage exceeds the current-limit

threshold (430mV, typ), the regulator immediately turns

off the high-side switch to prevent the transformer primary current from increasing further.

Secondary Voltage Limiting (VFB)

The MAX8759 reduces the voltage stress on the transformer’s secondary winding by limiting the secondary

voltage during startup and open-lamp faults. The AC

voltage across the transformer secondary winding is

sensed through a capacitive voltage-divider formed by

C4 and C5 in Figure 1. The voltage across C5 is fed to

the VFB input. An overvoltage comparator compares

the VFB peak voltage with a 2.3V (typ) internal threshold. Once the VFB peak voltage exceeds the overvoltage threshold, the MAX8759 turns on an internal

1000µA current source that discharges the COMP

capacitor. The high-side MOSFET’s on-time shortens as

the COMP voltage decreases, limiting the transformer

secondary’s peak voltage at the threshold determined

by the capacitive voltage-divider.

Secondary Undervoltage Protection (VFB)

The MAX8759 senses the VFB voltage for undervoltage

condition. During the DPWM ON period, if the VFB voltage is below the undervoltage threshold (230mV, typ)

continuously for an internal delay period (250µs typ, for

R

FREQ

= 169kΩ), the MAX8759 shuts down.

Secondary Current Limit (ISEC)

The secondary current limit provides fail-safe current

limiting in case of a short circuit or leakage from the

lamp high-voltage terminal to ground that prevents the

current control loop from functioning properly. ISEC

monitors the voltage across a sense network placed

between the transformer’s low-voltage secondary terminal and ground. The ISEC voltage is continuously compared to the ISEC regulation threshold (1.21V, typ). Any

time the ISEC voltage exceeds the threshold, the

MAX8759 turns on a 1000µA current source that discharges the COMP capacitor, reducing the on-time of

the high-side switches. At the same time, the MAX8759

charges the TFLT capacitor with a 135µA current. The

MAX8759 sets the fault latch and shuts down when the

voltage on TFLT exceeds 4V. Clearing bit 0 of the

device control register (0x01) or cycling the input

power clears the fault latch.

Linear Regulator Output (VCC)

The internal linear regulator steps down the DC input

voltage at BATT pin to 5.35V (typ). The linear regulator

supplies power to the internal control circuitry of the

MAX8759 and is also used to power the MOSFET drivers by connecting VCCto VDD. The VCCvoltage drops

to 4.5V in shutdown.

POR and UVLO

The MAX8759 includes power-on reset (POR) and

undervoltage lockout (UVLO) features. POR resets the

fault latch and sets all the SMBus registers to their POR

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

______________________________________________________________________________________ 19

0

0.2

0.6

0.4

0.8

1.0

0 0.80.4 1.2 1.6 2.0

V

ALS

(V)

NORMALIZED BRIGHTNESS

Figure 7. Normalized Brightness vs. ALS Voltage

Page 20

MAX8759

values. POR occurs when VCCrises above 1.75V (typ).

The UVLO occurs when VCCis below 4.2V (typ). The

MAX8759 disables both high-side and low-side switch

drivers below the UVLO threshold.

Low-Power Shutdown

The MAX8759 is placed into shutdown by clearing bit 0

of the device control register (0x01).When the

MAX8759 is shut down, all functions of the IC are

turned off except the 5.35V linear regulator. In shutdown, the linear regulator output voltage drops to 4.5V

and the supply current is 6µA (typ). While in shutdown,

the fault latch is reset. The device can be reenabled by

setting bit 0 of the device control register to 1.

Ambient-Light-Sensor Supply Pin (VALS)

The MAX8759 provides the supply voltage of the ALS

through the VALS pin. VALS is internally connected to

the 5.35V linear regulator output through a p-channel

MOSFET. The p-channel MOSFET is turned on when the

MAX8759 is enabled and turned off when the part is disabled. Bypass VALS to ground with a minimum 0.lµF

ceramic capacitor. Place the capacitor as close to the

ALS supply input as possible.

SMBus Interface (SDA, SCL)

The MAX8759 supports an SMBus-compatible 2-wire

digital interface. SDA is the bidirectional data line and

SCL is the clock line of the 2-wire interface corresponding respectively to SMBDATA and SMBCLK lines of the

SMBus. SDA and SCL have Schmidt-triggered inputs

that can accommodate slow edges; however, the rising

and falling edges should still be faster than 1µs and

300ns, respectively. The MAX8759 uses the write-byte

and read-byte protocols (Figure 8). The SMBus protocols are documented in System Management Bus

Specification V1.08 and are available at

http://www.sbs-forum.org/.

The MAX8759 is a slave-only device and responds to

the 7-bit address 0b0101100. The read and write commands can be distinguished by adding ONE more bit

(R/W bit) to the end of the 7-bit slave address, with one

indicating read and zero indicating write. The MAX8759

has seven registers: a brightness control register

(0x00), a device control register (0x01), a fault/status

register (0x02), an identification register (0x03), an ALS

status register (0x04), an ALS low-limit register (0x05),

Low-Cost, SMBus, CCFL Backlight Controller

20 ______________________________________________________________________________________

1b

ACK

1b7 BITS

ADDRESS ACK

1b

WR

8 BITS

DATA

1b

ACK

—

P

8 BITS

—

S COMMAND

WRITE-BYTE FORMAT

RECEIVE-BYTE FORMAT

SLAVE ADDRESS DATA BYTE: DATA GOES INTO THE

REGISTER SET BY THE COMMAND BYTE

1b

ACK

1b7 BITS

ADDRESS ACK

1b

WR

—

S

1b

ACK

8 BITS

DATA

7 BITS

ADDRESS1bRD

1b8 BITS

—

///

—

PS COMMAND

SLAVE ADDRESS

SLAVE ADDRESS

COMMAND BYTE: SENDS COMMAND WITH NO DATA; USUALLY

USED FOR ONE-SHOT COMMAND

COMMAND BYTE: SELECTS

WHICH REGISTER YOU ARE

READING FROM

SLAVE ADDRESS: REPEATED

DUE TO CHANGE IN DATAFLOW DIRECTION

DATA BYTE: READS FROM THE

REGISTER SET BY THE COMMAND

BYTE

1b

ACK

7 BITS

ADDRESS1bRD

8 BITS

DATA

1b

///

—

P

—

S

DATA BYTE: READS DATA FROM THE

REGISTER COMMANDED BY THE

LAST READ-BYTE OR WRITE-BYTE

TRANSMISSION; ALSO USED FOR

SMBus ALERT RESPONSE RETURN

ADDRESS

S = START CONDITION SHADED = SLAVE TRANSMISSION WR = WRITE = 0

P = STOP CONDITION ACK = ACKNOWLEDGED = 0 RD = READ = 1

/// = NOT ACKNOWLEDGED = 1

1b

ACK

7 BITS

ADDRESS1bWR

8 BITS

COMMAND1bACK—P

—

S

SEND-BYTE FORMAT

READ-BYTE FORMAT

Figure 8. SMBus Protocols

COMMAND BYTE: SELECTS

WHICH REGISTER YOU ARE

WRITING TO

Page 21

and an ALS high-limit register (0x06). The MAX8759

only acknowledges these seven registers.

Communication starts with the master signaling the

beginning of a transmission with a START condition,

which is a high-to-low transition on SDA while SCL is

high. When the master has finished communicating

with the slave, the master issues a STOP condition,

which is a low-to-high transition on SDA while SCL is

high. The bus is then free for another transmission.

Figures 9 and 10 show the timing diagrams for signals

on the 2-wire interface. The address byte, command

byte, and data byte are transmitted between the START

and STOP conditions. The SDA state is allowed to

change only while SCL is low, except for the START

and STOP conditions. Data is transmitted in 8-bit words

and is sampled on the rising edge of SCL. Nine clock

cycles are required to transfer each byte in or out of the

MAX8759 since either the master or the slave acknowledges the receipt of the correct byte during the ninth

clock. If the MAX8759 receives its correct slave

address followed by R/W = 0, it expects to receive 1 or

2 bytes of information (depending on the protocol). If

the device detects a START or STOP condition prior to

clocking in the bytes of data, it considers this an error

condition and disregards all the data. If the transmission is completed correctly, the registers are updated

immediately after a STOP (or RESTART) condition. If

the MAX8759 receives its correct slave address followed by R/W = 1, it expects to clock out the register

data selected by the previous command byte.

SMBus Register Definitions

All MAX8759 registers are byte wide and accessible

through the read/write byte protocols mentioned in the

previous section. Their bit assignments are provided in

the following sections with reserved bits containing a

default value of zero.

Table 3 summarizes the register assignments, as well

as each register’s POR state. During shutdown, the serial interface remains fully functional.

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

______________________________________________________________________________________ 21

SMBCLK

AB CDEFG HIJ

K

SMBDATA

t

SU:STA

t

HD:STA

t

LOWtHIGH

t

SU:DAT

t

HD:DAT

t

HD:DAT

t

SU:STO

t

BUF

A = START CONDITION.

B = MSB OF ADDRESS CLOCKED INTO SLAVE.

C = LSB OF ADDRESS CLOCKED INTO SLAVE.

D = R/W BIT CLOCKED INTO SLAVE.

E = SLAVE PULLS SMBDATA LINE LOW .

L

M

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER.

G = MSB OF DATA CLOCKED INTO SLAVE.

H = LSB OF DATA CLOCKED INTO SLAVE.

I = SLAVE PULLS SMBDATA LINE LOW.

J = ACKNOWLEDGE CLOCKED INTO MASTER.

K = ACKNOWLEDGE CLOCK PULSE.

L = STOP CONDITION, DATA EXECUTED BY SLAVE.

M = NEW START CONDITION .

Figure 9. SMBus Write Timing

Page 22

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

22 ______________________________________________________________________________________

Table 3. Commands Description

DATA-REGISTER BIT ASSIGNMENT

SMBus

PROTOCOL

BYTE

BIT 7

BIT 6 BIT 5

BIT 3 BIT 2 BIT 1

BIT 0

(LSB)

Read and

Write

0x00

BR7 BRT6 BRT5 BR4 BRT3 BRT2 BRT1 BRT0

Read and

Write

0x01

LAMP_CTL

Read Only

0x02

FAULT

Read Only

0x03

MFG2

MFG0 REV2 REV1 REV0

Read Only

0x04

ALS7 ALS6 ALS5

ALS3 ALS2 ALS1 ALS0

Read and

Write

0x05

ALSLL3

ALSLL0

Read and

Write

0x06

ALSHL0

Figure 10. SMBus Read Timing

AB CDEFG H

t

t

HIGH

LOW

SMBCLK

SMBDATA

t

SU:STAtHD:STA

A = START CONDITION.

B = MSB OF ADDRESS CLOCKED INTO SLAVE.

C = LSB OF ADDRESS CLOCKED INTO SLAVE.

D = R/W BIT CLOCKED INTO SLAVE.

COMMAND

POR

STATE

0xFF

t

SU:DAT

(MSB)

t

HD:DAT

E = SLAVE PULLS SMBDATA LINE LOW.

F = ACKNOWLEDGE BIT CLOCKED INTO MASTER.

G = MSB OF DATA CLOCKED INTO MASTER.

H = LSB OF DATA CLOCKED INTO MASTER.

BIT 4

I

t

SU:DAT

I = ACKNOWLEDGE CLOCK PULSE.

J = STOP CONDITION.

K = NEW START CONDITION.

t

SU:STO

J

K

t

BUF

0x00 Reserved Reserved ALSDEL1 ALSDEL0 ALS_CTL PWM_MD PWM_SEL

N/A Reserved Reserved Reserved Reserved LAMP_STAT OV_CURR Reserved

0x00 MFG4 MFG3

0x00

0x00 ALSLL7 ALSLL6 ALSLL5 ALSLL4

MFG1

ALS4

ALSLL2 ALSLL1

0xFF ALSHL7 ALSHL6 ALSHL5 ALSHL4 ALSHL3 ALSHL2 ALSHL1

Page 23

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

______________________________________________________________________________________ 23

BIT 7 BIT 6

Reserved Reserved ALSDEL1 ALSDEL0 ALS_CTL PWM_MD PWM_SEL

ALSDEL1: ALS delay select bit.

ALSDEL0: ALS delay select bit.

ALS_CTL: Ambient-light-sensor select bit (1 = use ALS, 0 = not use ALS).

PWM_MD: PWM mode select bit (1 = absolute brightness, 0 = percentage change).

PWM_SEL: Brightness control select bit (1 = control by PWM, 0 = control by SMBus).

LAMP_CTL: Inverter on/off bit (1 = on, 0 = off).

A value of 1 written to LAMP_CTL turns on the lamp as

quickly as possible. A value of zero written to LAMP_CTL

immediately turns off the lamp.

The PWM_SEL bit determines whether the SMBus or

PWM input should control brightness when the inverter is

not in ALS mode. This bit has no effect when ALS_CTL is

set to 1.

The PWM_MD bit selects the manner in which the PWM

input is to be interpreted. When this bit is zero, the PWM

input reflects a percentage change in the current brightness (i.e., DPST mode) and follows the following equation:

DPST brightness = BRT

CURRENT

× D

PWM

where BRT

CURRENT

is the current brightness setting from

either ALS or SMBus without influence from the PWM

input and D

PWM

is the duty cycle of the PWM signal.

When PWM_MD bit is 1, the PWM input has no effect on

the brightness setting unless the inverter is in PWM mode.

When ALS_CTL is 1, the inverter controls brightness

based primarily on the light reading from the ALS.

However, the ALS brightness setting can be modified if

the PWM_MD bit is set to zero. When the ALS_CTL bit

is zero, the inverter controls the brightness according

to the PWM input (PWM mode), the SMBus setting

(SMBus mode), or a combination of the two (SMBus

mode with DPST).

BRT7 BRT6 BRT5 BRT4 BRT3 BRT2 BRT1 BRT0

BRT[7..0]: 256 brightness levels.

Brightness Control Register [0x00]

(POR = 0xFF)

The brightness control register of the MAX8759 contains 8 bits and supports 256 brightness levels. A writebyte cycle to register 0x00 sets the brightness level if

the inverter is in SMBus mode. A write-byte cycle to

register 0x00 has no effect if the inverter is not in

SMBus mode. A read-byte cycle to register 0x00

returns the current brightness level regardless of the

operation mode. A setting of 0xFF for register 0x00 sets

the inverter to the maximum brightness. A setting of

0x00 for register 0x00 sets the inverter to the minimum

brightness.

Device Control Register [0x01] (POR = 0x00)

This register has a single bit that controls the inverter

ON/OFF state, 3 bits that control the operating mode of

the inverter, and 2 bits for setting ALS delay time. The

remaining bits are reserved for future use.

BIT 7 (R/W)BIT 6 (R/W)BIT 5 (R/W) BIT 4 (R/W) BIT 3 (R/W)BIT 2 (R/W) BIT 1 (R/W)BIT 0 (R/W)

BIT 5 (R/W)BIT 4 (R/W)BIT 3 (R/W)BIT 2 (R/W) BIT 1 (R/W) BIT 0 (R/W)

LAMP_CTL

Page 24

MAX8759

The relationships among these 3 control bits can be

thought of as specifying an operating mode for the inverter. The defined modes are shown in Table 4. Note that

depending on the settings of some bits, other bits have

no effect and are don’t-care bits—they are shown with a

value of X in Table 4. For example, when the ALS_CTL bit

is 1, the value of PWM_SEL has no effect on the operation

of the inverter, so its value is shown as X.

ALSDEL0 and ALSDEL1 set the delay time required

to change the brightness in ALS mode. This delay time is

necessary for smooth transitions during brightness

change. Table 5 shows the available delays.

Note that the behavior of register 0x00 (brightness control register) is affected by certain combinations of the

control bits as shown in Table 4.

When SMBus mode is selected, register 0x00 reflects the

last value written to it. However, when any non-SMBus

mode is selected, register 0x00 reflects the current brightness value based on the current mode of operation.

Fault/Status Register [0x02] (POR = 0x00)

This register has 3 status bits that allow monitoring the

inverter’s operating state. Bit 0 is a logical OR of openlamp fault and overcurrent fault. Bit 2 indicates secondary/UL overcurrent fault. Bit 3 always indicates the

current lamp on/off status. The value of this bit is one

whenever both lamp 1 and lamp 2 are on. The value of

this bit is zero whenever lamp 1 or lamp 2 is off. The

remaining bits are reserved for future use. All reserved

bits return a zero when read. All the bits in this register

are read only. A write-byte cycle to register 0x02 has

no effect. Write zero to bit 0 of register 0x01 to clear the

fault bit.

Low-Cost, SMBus, CCFL Backlight Controller

24 ______________________________________________________________________________________

ALS_CTL

PWM_MD

PWM_SEL

MODE

11XALS mode

10X

ALS mode with DPST

0X1PWM mode

010SMBus mode

000

SMBus mode with

DPST

Table 4. Operating Modes Selected by

Device Control Register Bits 3, 2, and 1

Table 5. Delay Time Selected by Device

Control Register Bits 5, 4

BIT 7 (R) BIT 6 (R) BIT 5 (R) BIT 4 (R) BIT 3 (R) BIT 2 (R) BIT 1 (R) BIT 0 (R)

Reserved Reserved Reserved Reserved LAMP_STAT OV_CURR Reserved FAULT

ALSDEL1 ALSDEL0

11 25 5

10 15 3

01 10 2

0020 (default) 4

DELAY TIME

(ms)

N

PERIODS

LAMP_STAT: Lamp status bit (1 = lamp 1 and lamp 2 are on, 0 = lamp 1 or lamp 2 is off).

OV_CURR: Secondary/UL overcurrent fault (1 = secondary/UL overcurrent fault, 0 = no secondary/UL overcurrent).

FAULT: Fault bit (1 = open-lamp or primary overcurrent fault, 0 = no fault).

Page 25

MAX8759

Low-Cost, SMBus, CCFL Backlight Controller

______________________________________________________________________________________ 25

BIT 7 (R) BIT 6 (R) BIT 5 (R) BIT 4 (R) BIT 3 (R) BIT 2 (R) BIT 1 (R) BIT 0 (R)

MFG4 MFG3 MFG2 MFG1 MFG0 REV2 REV1 REV0

MFG[4..0]: Manufacturer ID (the vendor ID for Maxim is 0).

REV[2..0]: Silicon rev (revs 0–7 allowed for silicon spins).

BIT 7 (R) BIT 6 (R) BIT 5 (R) BIT 4 (R) BIT 3 (R) BIT 2 (R) BIT 1 (R) BIT 0 (R)

ALS7 ALS6 ALS5 ALS4 ALS3 ALS2 ALS1 ALS0

ALS[7..0]: 256 steps of ambient-light sensor reading.

Identification Register [0x03] (POR = 0x00)

The identification register contains two bit fields to

denote the manufacturer and the silicon revision. The bit

field widths allow up to 32 vendors with up to eight silicon revisions each. This register is read only. A writebyte cycle to register 0x03 has no effect.

ALS Status Register [0x04] (POR = 0x00)

The ALS should return a value reflecting the brightness

setting based on the ALS input. The register has 8 bits

that define a full range of 256 brightness levels. The

register is read only and a write-byte cycle has no

effect. A read-byte cycle to register 0x04 returns the

current reading of ALS, regardless of the operating

mode set in register 0x01.

ALS Low-Limit Register [0x05] (POR = 0x00)

The value in this read-write register reflects the lowest

possible brightness value the inverter can set based on

inputs from the ALS. Users can change this value so that

they can control the effect of ALS. A write-byte cycle to

register 0x05 sets the lowest possible brightness value

that can be set based on ALS inputs. If the brightness

setting due to ALS is lower than the value written to this

register, the inverter immediately increases the brightness setting to the newly written value. A read-byte cycle

to register 0x05 returns the current minimum brightness

value that can be set based on ALS inputs.

ALSLL7 ALSLL6 ALSLL5 ALSLL4 ALSLL3 ALSLL2 ALSLL1 ALSLL0

ALSLL[7..0]: The lowest brightness setting that can be set based on ALS inputs.

BIT 7 (R/W)BIT 6 (R/W)BIT 5 (R/W)BIT 4 (R/W)BIT 3 (R/W) BIT 2 (R/W) BIT 1 (R/W) BIT 0 (R/W)

Page 26

MAX8759

Applications Information

MOSFETs

The MAX8759 requires four external n-channel power

MOSFETs: NL1, NL2, NH1, and NH2 to form a fullbridge inverter circuit. The controller senses the on-state

drain-to-source voltage of the two low-side MOSFETs

NL1 and NL2 to detect the transformer primary current,

so the R

DS(ON)

of NL1 and NL2 should be matched. For

instance, if dual MOSFETs are used to form the full

bridge, NL1 and NL2 should be in one package. Since

the MAX8759 uses the low-side MOSFET R

DS(ON)

for

primary overcurrent protection, the lower the MOSFET

R

DS(ON)

, the higher the current limit. Therefore,

the user should select a dual logic-level n-channel

MOSFET with low R

DS(ON)

to minimize conduction loss,

and keep the primary current limit at a reasonable level.

The regulator uses ZVS to softly turn on each of four

switches in the full bridge. ZVS occurs when the external power MOSFETs are turned on when their respective drain-to-source voltages are near 0V (see the

Resonant Operation section). ZVS effectively eliminates

the instantaneous turn-on loss of MOSFETs caused by

C

OSS

(drain-to-source capacitance) and parasitic

capacitance discharge, and improves efficiency and

reduces switching-related EMI.

Setting the Lamp Current

The MAX8759 senses the lamp current flowing through

sense resistors connected between the low-voltage ter-

minals of the lamps and ground. The voltages across

the sense resistors are fed to IFB1 and IFB2 and are

internally full-wave rectified. The MAX8759 controls the

desired lamp current by regulating the average of the

rectified IFB_ voltages. To set the RMS lamp current in

a single-lamp application, determine the value of the

sense resistor as follows:

where I

LAMP(RMS)

is the desired RMS lamp current and

785mV is the typical value of the IFB1 regulation point

specified in the Electrical Characteristics table. To set

the RMS lamp current to 6mA, the value of the sense

resistor should be 148Ω. The closest standard 1%

resistors are 147Ω and 150Ω. The precise shape of the

lamp-current waveform, which is dependent on lamp

parasitics, influences the actual RMS lamp current. Use

a true RMS current meter to make final adjustments.

Setting the Secondary Voltage Limit

The MAX8759 limits the transformer secondary voltage

during startup and lamp-out faults. The secondary voltage is sensed through the capacitive voltage-divider

formed by C4 and C5 (Figure 1). The VFB voltage is

proportional to the CCFL voltage. The selection of the

parallel resonant capacitor C1 is described in the

Transformer Design and Resonant Component

Selection section. C4 is usually between 10pF and

22pF. After the value of C4 is determined, select C5

R

mV

I

LAMP RMS

1

785

22

=

××π

()

Low-Cost, SMBus, CCFL Backlight Controller

26 ______________________________________________________________________________________

ALSHL7 ALSHL6 ALSHL5 ALSHL4 ALSHL3 ALSHL2 ALSHL1 ALSHL0

ALSHL[7..0]: The highest brightness setting that can be set based on ALS inputs.

ALS High-Limit Register [0x06] (POR = 0xFF)

The value in this read-write register reflects the highest

possible brightness value the inverter can set based on

inputs from the ALS. Users can change this value so

that they can control the effect of ALS. A write-byte

cycle to register 0x06 sets the highest possible brightness value that can be set based on ALS inputs. If the

brightness setting due to ALS is higher than the value

written to this register, the inverter immediately decreases the brightness setting to the newly written value. A

read-byte cycle to register 0x06 returns the current

maximum brightness value that can be set based on

ALS inputs. The default value of register 0x06 is 0xFF,

which corresponds to the maximum brightness.

BIT 7 (R/W)BIT 6 (R/W) BIT 5 (R/W)BIT 4 (R/W)BIT 3 (R/W) BIT 2 (R/W)BIT 1 (R/W) BIT 0 (R/W)

Page 27

using the following equation to set the desired maximum RMS secondary voltage V

LAMP(RMS)_MAX

:

where the 2.3V is the typical value of the VFB peak voltage when the lamp is open. To set the maximum RMS

secondary voltage to 1800V when C4 is 10pF, use

10nF for C5.

Setting the Secondary Current Limit

The MAX8759 limits the secondary current even if the

IFB_ sense resistors are shorted or transformer secondary current finds its way to ground without passing

through the sense resistors. ISEC monitors the peak voltage across the sense network (R2 and C6 in Figure 1)

connected between the low-voltage terminal of the transformer secondary winding and ground. Using an RCsense network instead of a single-sense resistor makes

the secondary current-limit frequency dependent. The UL

safety standard requires the AC peak current in a limitedcurrent circuit should not exceed 0.7mA for frequencies

below 1kHz. For frequencies above 1kHz, the limit of

0.7mA is multiplied by the value of the frequency in kilohertz but should not exceed 70mA peak when the frequency is equal to or above 100kHz. To meet the UL

current-limit specifications, determine the value of R2

using the current limit at 1kHz and determine the value of

C6 using the current limit at 100kHz:

where 1.23V is the typical value of the ISEC peak voltage when the transformer secondary is shorted. The

circuit of Figure 1 uses 3.9kΩ for R2 and 68nF for C6.

Transformer Design and Resonant

Component Selection

The transformer is the most important component of the

resonant tank circuit. The first step in designing the

transformer is to determine the transformer turns ratio.

The ratio must be high enough to support the CCFL

operating voltage at the minimum supply voltage. The

transformer turns ratio N can be calculated as follows:

where V

LAMP(RMS)

is the maximum RMS lamp voltage in

normal operation, and V

IN(MIN)

is the minimum DC input