Page 1

General Description

The MAX8667/MAX8668 dual step-down converters

with dual low-dropout (LDO) linear regulators are

intended to power low-voltage microprocessors or

DSPs in portable devices. They feature high efficiency

with small external component size. The step-down

converters are adjustable from 0.6V to 3.3V (MAX8668)

or factory preset (MAX8667) with guaranteed output

current of 600mA for OUT1 and 1200mA for OUT2. The

1.5MHz hysteretic-PWM control scheme allows for tiny

external components and reduces no-load operating

current to 100µA with all outputs enabled. Dual low-quiescent-current, low-noise LDOs operate down to 1.7V

supply voltage. The MAX8667/MAX8668 have individual enables for each output, maximizing flexibility.

The MAX8667/MAX8668 are available in the spacesaving, 3mm x 3mm, 16-pin thin QFN package.

Applications

Cell Phones/Smartphones

PDA and Palmtop Computers

Portable MP3 and DVD Players

Digital Cameras, Camcorders

PCMCIA Cards

Handheld Instruments

Features

♦ Tiny, Thin QFN 3mm x 3mm Package

♦ Individual Enables

♦ Step-Down Converters

600mA Guaranteed Output Current on OUT1

1200mA Guaranteed Output Current on OUT2

Tiny Size 2.2µH Chip Inductor (0805)

Output Voltage from 0.6V to 3.3V (MAX8668)

Ultra-Fast Line and Load Transients

Low 25µA Supply Current Each

♦ LDOs

300mA Guaranteed

Low 1.7V Minimum Supply Voltage

Low Output Noise

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

________________________________________________________________

Maxim Integrated Products

1

Pin Configuration

IN34

LX2

LX1

OUT2

OUT1

2.6V TO 5.5V

OUT3

OUT4

REF

GND

IN12

300mA

300mA

EN1

EN2

EN3

EN4

600mA

1.2A

PGND1 PGND2

10μF 4.7μF

4.7μF

4.7μF

0.01μF

2.2μH

2.2μH

2.2μF

2.2μF

MAX8667

Typical Operating Circuit

19-0784; Rev 0; 4/07

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Ordering Information continued at the end of data sheet.

Selector Guide appears at the end of data sheet.

Ordering Information

Note: All MAX8667/MAX8668 parts are in a 16-pin, thin QFN,

3mm x 3mm package and operate in the -40°C to +85°C

extended temperature range.

+

Denotes a lead-free package.

PART PKG CODE TOP MARK

T1633-4 AEQ

T1633-4 AFI

T1633-4 AFM

T1633-4 AFN

MAX8667ETEAA+

MAX8667ETEAB+

MAX8667ETEAC+

MAX8667ETECQ+

TOP VIEW

13

PGND1

EN1

EN2

14

15

16

OUT1 (FB1)

( ) ARE FOR THE MAX8668

LX2

IN34

PGND2

8

7

6

5

4

OUT4

LX1

12 10 9

11

MAX8667

MAX8668

13

2

EN3

OUT3 IN12

THIN QFN

(3mm x 3mm)

OUT2 (FB2)

REF

GND

EN4

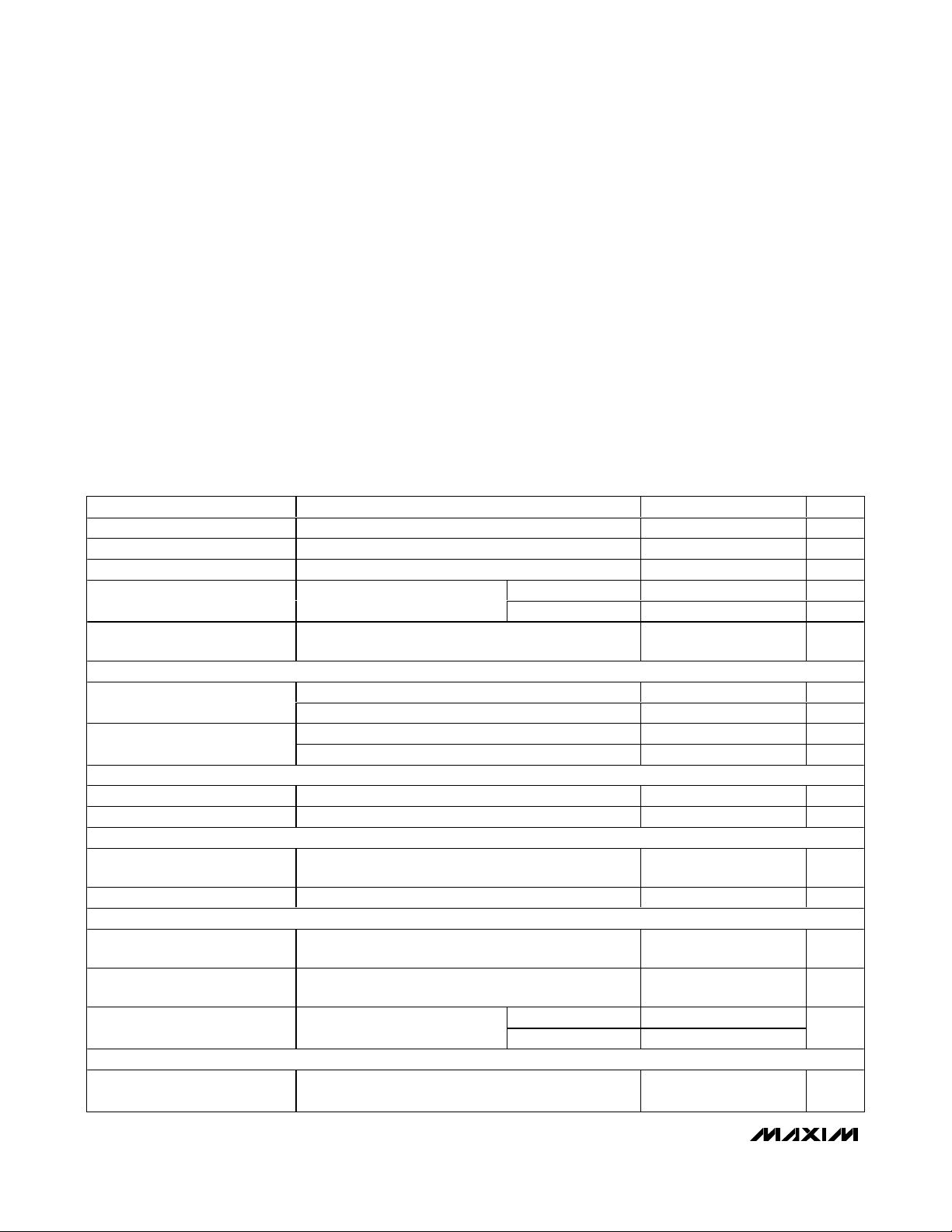

Page 2

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(V

IN34

= V

IN12

= 3.6V, TA = -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN12, IN34, FB1, FB2, EN1, EN2, EN3, EN4, OUT1,

OUT2, REF to GND............................................-0.3V to +6.0V

OUT3,

OUT4 to GND.....-0.3V to the lesser of + 6V or (V

IN34

+ 0.3V)

PGND1, PGND2 to GND .......................................-0.3V to +0.3V

LX1, LX2 Current ..........................................................1.5A RMS

LX1, LX2 to GND (Note 1) .......................-0.3V to (V

IN12

+ 0.3V)

Continuous Power Dissipation (TA= +70°C)

16-Pin, 3mm x 3mm Thin QFN

(derate 20.8mW/°C above +70°C).............................1667mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature..................................................... +150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

Note 1: LX_ has internal clamp diodes to GND and IN12. Applications that forward bias these diodes should take care not to exceed

the IC’s package-dissipation limits.

IN34 Supply Range V

IN12 Supply Range MAX8668, V

IN12 Suppy Range MAX8667, V

Shutdown Supply Current,

I

IN12

No Load Supply Current,

I

IN12

UNDERVOLTAGE LOCKOUT

IN12 UVLO

IN34 UVLO

THERMAL SHUTDOWN

Threshold TA rising +160 °C

Hysteresis 15 °C

REFERENCE

Reference Bypass Output

Voltage

REF Supply Rejection 2.6V ≤ (V

LOGIC AND CONTROL INPUTS

EN_ Input Low Level

EN_ Input High Level

EN_ Input Leakage Current V

STEP-DOWN CONVERTERS

Minimum Adjustable Output

Voltage

PARAMETER CONDITIONS MIN TYP MAX UNITS

≥ V

IN12

IN34

≥ V

IN12

IN34

≥ V

IN12

IN34

V

+ I

+ I

IN34

IN34

= V

IN12

MAX8667ETEJS+, all regulators enabled 100 150 µA

V

rising 2.4 2.5 2.6 V

IN12

V

hysteresis 0.1 V

IN12

V

rising 1.5 1.6 1.7 V

IN34

V

hysteresis 0.1 V

IN34

1.7V ≤ V

2.6V ≤ V

1.7V ≤ V

2.6V ≤ V

= V

IN12

MAX8668 0.6 V

IN34

IN12

IN34

IN12

IN34

IN12

IN34

= 4.2V V

= V

≤ 5.5V

≤ 5.5V

≤ 5.5V

≤ 5.5V

= 5.5V

) ≤ 5.5V 0.15 mV/V

IN34

1.7 5.5 V

2.6 5.5 V

2.8 5.5 V

EN_

= 0V

TA = +25°C 1 µA

T

= +85°C 0.05 µA

A

0.591 0.600 0.609 V

1.44 V

TA = +25°C -1 +1

T

= +85°C 0.001

A

0.4 V

µA

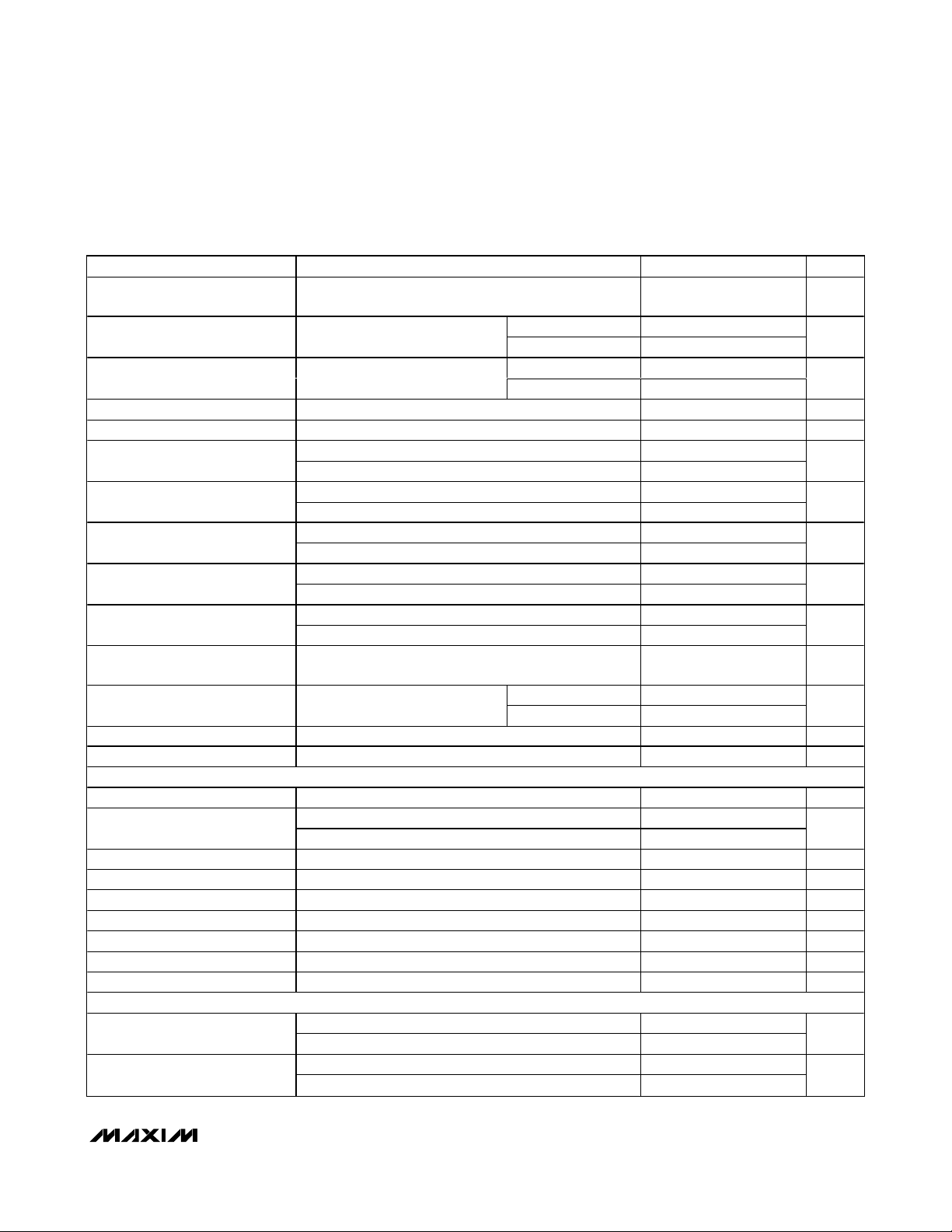

Page 3

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

_______________________________________________________________________________________ 3

Note 1: All devices are 100% production tested at TA= +25°C. Limits over the operating temperature range are guaranteed by design.

ELECTRICAL CHARACTERISTICS (continued)

(V

IN34

= V

IN12

= 3.6V, TA = -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

Maximum Adjustable Output

Voltage

FB1, FB2 Regulation Voltage

OUT1, OUT2 Regulation Voltage

FB1, FB2 Line Regulation MAX8668, V

OUT1, OUT2 Line Regulation MAX8667, V

FB1, FB2 Bias Current

OUT1 Current Limit

OUT2 Current Limit

OUT1 On-Resistance

OUT2 On-Resistance

Rectifier-Off Current Threshold

(I

LXOFF

LX Leakage Current LX_ = 5.5V

Minimum On-Time 100 ns

Minimum Off-Time 50 ns

LDO REGULATORS

Supply Current Each LDO 20 µA

Output-Voltage Accuracy

Line Regulation V

Dropout Voltage V

Current Limit V

Soft-Start Ramp Time To 90% of final value 0.1 ms

Output Noise 100Hz to 100kHz, 30mA load, V

Power-Supply Rejection Ratio f < 1kHz, 30mA load 57 dB

Shutdown Output Resistance 1kΩ

TIMING (See Figure 2)

Power-On Time (t

Enable Time (tEN)

PARAMETER CONDITIONS MIN TYP MAX UNITS

MAX8668 3.3 V

MAX8668, no load,

V

falling

FB_

MAX8667ETEJS+, no load, V

falling

= 2.6V to 5.5V 0.01 %/V

IN12

= 2.8V to 5.5V 0.05 %/V

IN12

MAX8668, shutdown mode 0.1

MAX8668, V

pMOSFET switch (I

nMOSFET rectifier (valley current) 500 750 1000

pMOSFET switch (I

nMOSFET rectifier (valley current) 1200 1500 1800

pMOSFET switch, I

nMOSFET rectifier, I

pMOSFET switch, I

nMOSFET rectifier, I

)

1mA load, TA = +25°C -1.5 +1.5

1mA to 300mA load -3.0 +3.0

= 3.6V to 5.5V, 1mA load 0.003 %/V

IN34

= 1.8V, 300mA load 130 250 mV

IN34

, V

OUT3

PWRON

)

OUT1, OUT2 25

OUT3, OUT4 45

OUT1, OUT2 15

OUT3, OUT4 35

= 0.5V 0.01

FB1

) 700 900 1100

LIMP1

) 1333 1667 2000

LIMP2

= -400mA 0.3 0.6

LX1

= 400mA 0.3 0.6

LX1

= -400mA 0.12 0.27

LX2

= 400mA 0.12 0.27

LX2

90% of nominal value 375 420 465 mA

OUT4

TA = +25°C 0.588 0.600 0.612

T

= -40°C to +85°C 0.582 0.600 0.618

A

TA = +25°C 1.274 1.300 1.326

OUT_

T

= -40°C to +85°C 1.261 1.300 1.339

A

TA = +25°C -1 +1

T

= +85°C 0.1

A

OUT3

and V

= 2.8V 75 µV

OUT4

60 120 mA

V

V

µA

mA

mA

Ω

Ω

µA

%

RMS

µs

µs

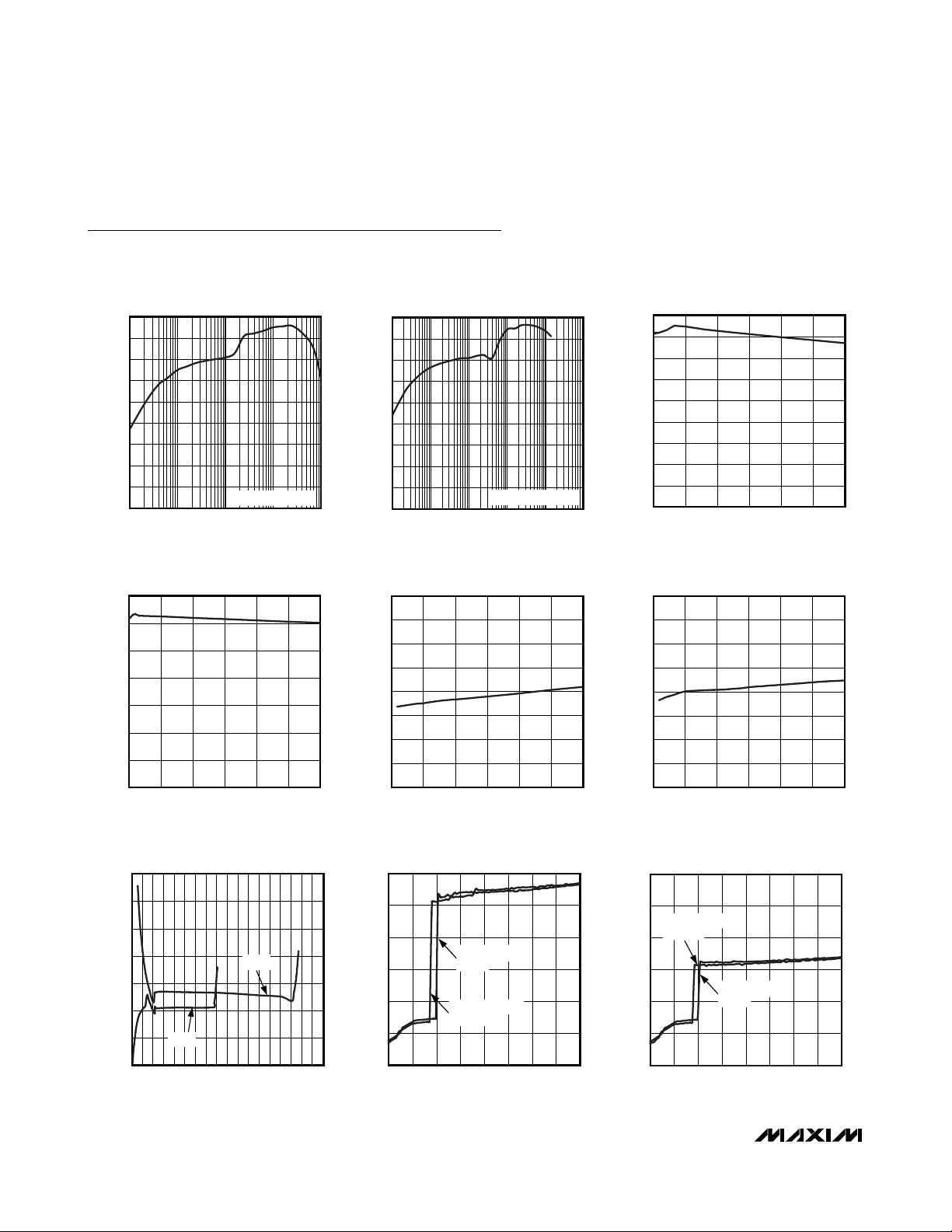

Page 4

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

4 _______________________________________________________________________________________

Typical Operating Characteristics

(V

IN12

= V

IN34

= 3.6V, circuit of Figure 4, V

OUT1

= 1.2V, V

OUT2

= 1.8V, V

OUT3

= 2.8V, V

OUT4

= 2.8V, TA = +25°C, unless otherwise noted.)

OUT1 EFFICIENCY vs. LOAD CURRENT

(V

OUT1

= 1.2V)

MAX8667/88 toc01

LOAD CURRENT (mA)

EFFICIENCY (%)

101

10

20

30

40

50

60

70

80

90

0

0.1 1000100

ONLY OUT1 ENABLED

OUT2 EFFICIENCY vs. LOAD CURRENT

(V

OUT2

= 1.8V)

MAX8667/88 toc02

LOAD CURRENT (mA)

EFFICIENCY (%)

1000100101

10

20

30

40

50

60

70

80

90

0

0.1 10000

ONLY OUT2 ENABLED

0.80

0.90

0.85

1.05

1.00

0.95

1.20

1.15

1.10

1.25

0 200100 300 400 500 600

OUT1 LOAD REGULATION

MAX8667/88 toc03

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

1.20

1.40

1.30

1.60

1.50

1.80

1.70

1.90

0 400 600200 800 1000 1200

OUT2 LOAD REGULATION

MAX8667/88 toc04

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

1.00

1.05

1.10

1.15

1.20

1.25

1.30

1.35

1.40

2.5 3.53.0 4.0 4.5 5.0 5.5

OUT1 OUTPUT VOLTAGE

vs. INPUT VOLTAGE (600mA LOAD)

MAX8667/88 toc05

INPUT VOLTAGE (V)

OUTPUT VOLTAGE (V)

1.60

1.65

1.70

1.75

1.80

1.85

1.90

1.95

2.00

2.5 3.53.0 4.0 4.5 5.0 5.5

OUT2 OUTPUT VOLTAGE

vs. INPUT VOLTAGE (1200mA LOAD)

MAX8667/88 toc06

INPUT VOLTAGE (V)

OUTPUT VOLTAGE (V)

0

1000

500

2000

1500

3000

2500

3500

0 600 900300 1200 1500 1800

SWITCHING FREQUENCY

vs. LOAD CURRENT

MAX8667/88 toc07

LOAD CURRENT (mA)

SWITCHING FREQUENCY (kHz)

OUT2

OUT1

0

20

40

60

80

100

120

1.5 2.52.0 3.0 3.5 4.0 4.5 5.0 5.5

NO-LOAD SUPPLY CURRENT vs. SUPPLY

VOLTAGE ALL REGULATOR ENABLED

MAX8667/88 toc08

SUPPLY VOLTAGE (V)

SUPPLY CURRENT (μA)

SUPPLY VOLTAGE

RISING

SUPPLY VOLTAGE

FALLING

0

20

40

60

80

100

120

1.5 2.52.0 3.0 3.5 4.0 4.5 5.0 5.5

NO-LOAD SUPPLY CURRENT

vs. SUPPLY VOLTAGE OUT1 AND OUT2 ONLY

MAX8667/88 toc09

SUPPLY VOLTAGE (V)

SUPPLY CURRENT (μA)

SUPPLY VOLTAGE

RISING

SUPPLY VOLTAGE

FALLING

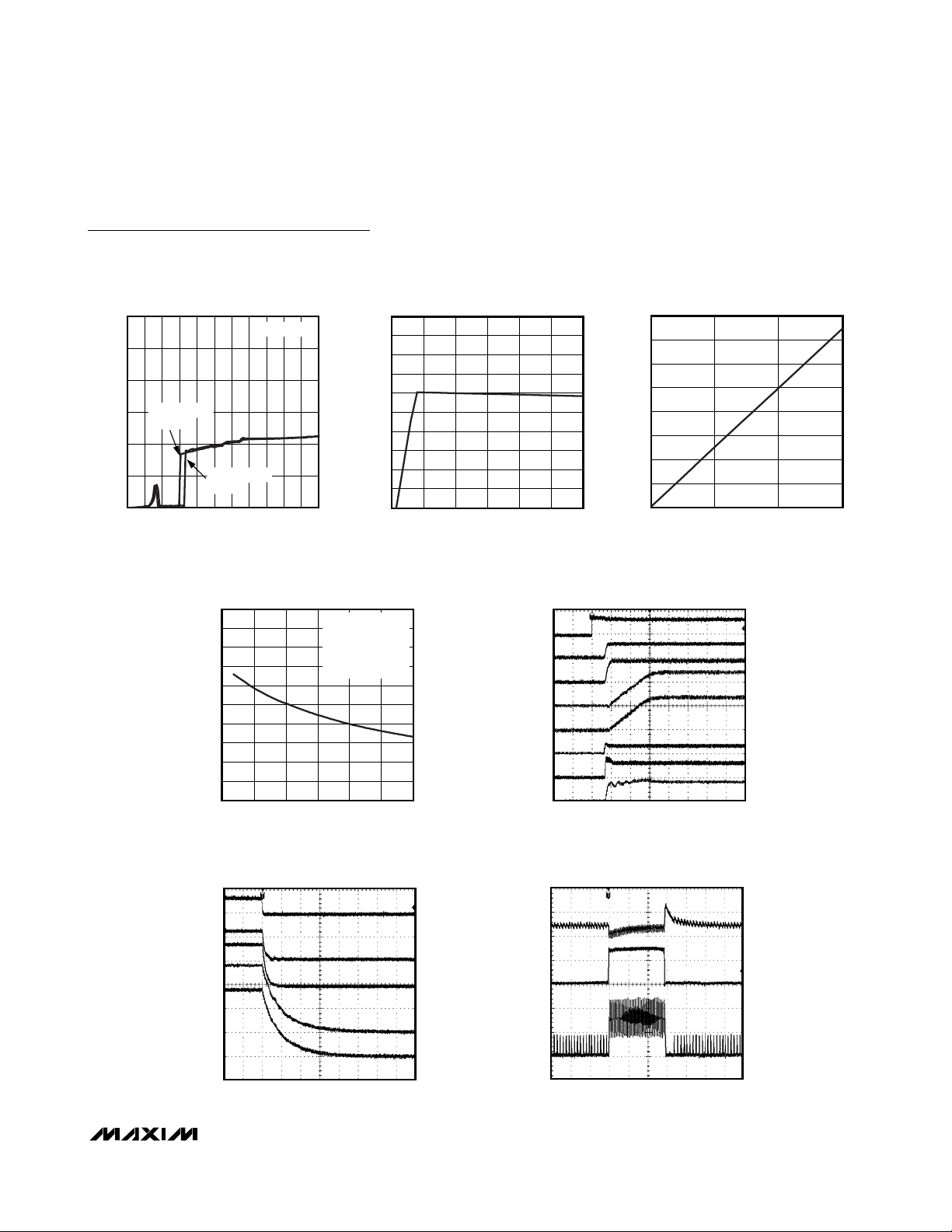

Page 5

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

_______________________________________________________________________________________

5

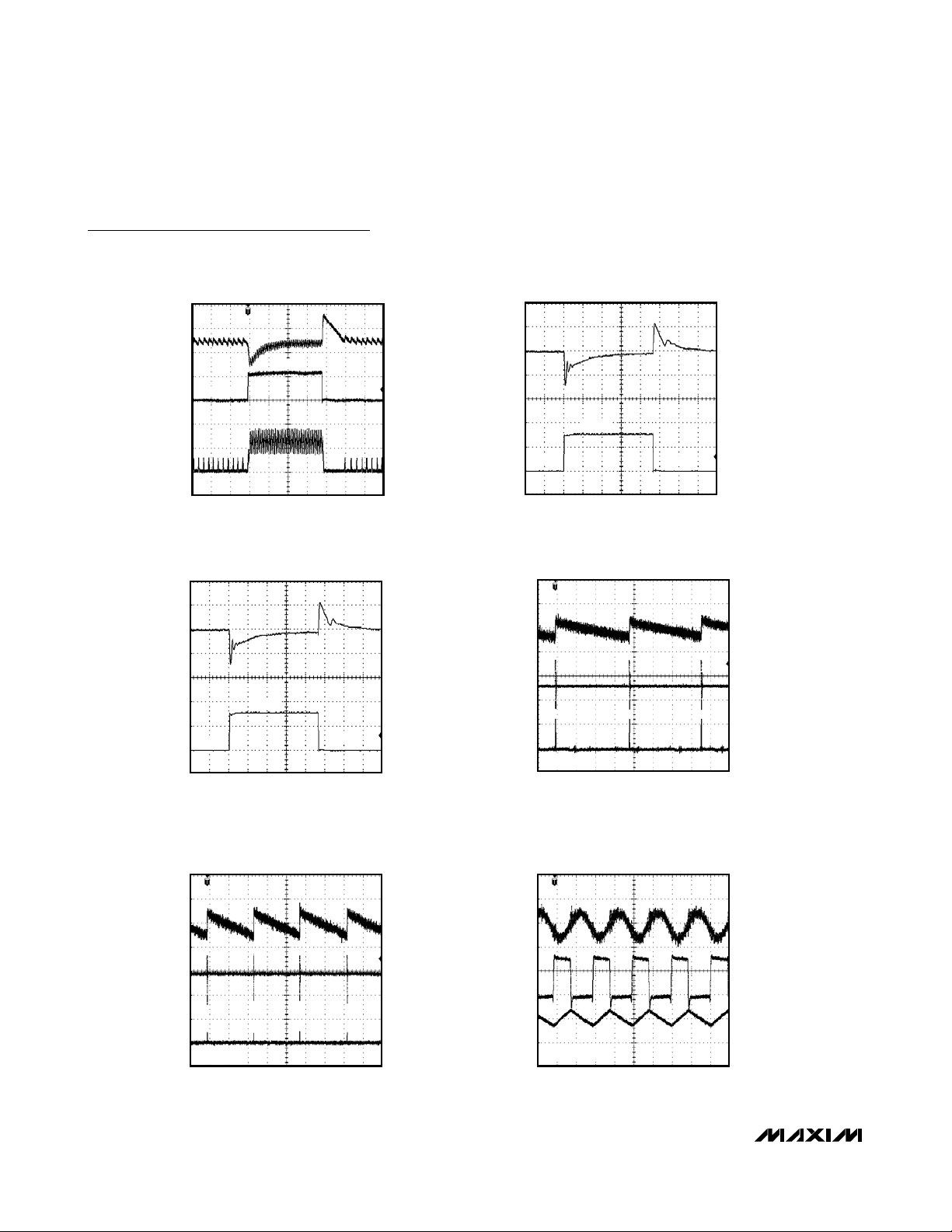

Typical Operating Characteristics (continued)

(V

IN12

= V

IN34

= 3.6V, circuit of Figure 4, V

OUT1

= 1.2V, V

OUT2

= 1.8V, V

OUT3

= 2.8V, V

OUT4

= 2.8V, TA = +25°C, unless otherwise noted.)

10μs/div

OUT1 LOAD TRANSIENT

V

OUT1

I

OUT1

100mV/div

(AC-COUPLED)

200mA/div

200mA/div

MAX8667/88 toc16

I

L1

300mA

10mA

10mA

NO-LOAD SUPPLY CURRENT vs. SUPPLY

VOLTAGE OUT3 AND OUT4 ONLY

120

100

80

(μA)

IN34

I

V

VOLTAGE

IN34

60

FALLING

40

V

VOLTAGE

20

0

012345

IN34

RISING

SUPPLY VOLTAGE (V)

SUPPLY CURRENT vs. SUPPLY VOLTAGE

1000

900

800

700

600

500

400

300

SUPPLY CURRENT (mA)

200

100

0

2.5 3.53.0 4.0 4.5 5.0 5.5

V

= 5.5V

IN12

SUPPLY VOLTAGE (V)

3.00

2.95

2.90

MAX8667/88 toc10

2.85

2.80

2.75

2.70

OUTPUT VOLTAGE (V)

2.65

2.60

2.55

2.50

IN12 = IN34

2.4Ω LOAD ON OUT1

3.6Ω LOAD ON OUT2

NO LOAD ON OUT3

NO LOAD ON OUT4

OUT3 OUTPUT VOLTAGE

vs. INPUT VOLTAGE (300mA LOAD)

2.5 3.53.0 4.0 4.5 5.0 5.5

INPUT VOLTAGE (V)

EN1/EN2/

I

IN12

EN3/EN4

V

OUT1

V

OUT2

V

OUT3

V

OUT4

+ I

IN34

I

L1

I

L2

MAX8667/88 toc13

OUT3 DROPOUT VOLTAGE

vs. LOAD CURRENT

80

70

MAX8667/88 toc11

60

50

40

30

DROPOUT VOLTAGE (mV)

20

10

0

0 100 200 300

LOAD CURRENT (mA)

ENABLE WAVEFORMS

40

μs/div

MAX8667/88 toc14

5V/div

2V/div

2V/div

2V/div

2V/div

2A/div

2A/div

2A/div

MAX8667/88 toc12

SHUTDOWN WAVEFORMS

EN1/EN2/

EN3/EN4

V

OUT1

V

OUT2

V

OUT3

V

OUT4

40μs/div

MAX8667/88 toc15

5V/div

1V/div

1V/div

1V/div

1V/div

Page 6

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

6 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(V

IN12

= V

IN34

= 3.6V, circuit of Figure 4, V

OUT1

= 1.2V, V

OUT2

= 1.8V, V

OUT3

= 2.8V, V

OUT4

= 2.8V, TA = +25°C, unless otherwise noted.)

OUT2 LOAD TRANSIENT

MAX8667/88 toc17

OUT3 LOAD TRANSIENT

MAX8667/88 toc18

V

OUT2

600mA

I

OUT2

I

L2

10μs/div

10mA10mA

V

OUT4

I

OUT4

OUT4 LOAD TRANSIENT

300mA

0mA

10μs/div

MAX8667/88 toc19

0mA

200mV/div

(AC-COUPLED)

500mA/div

500mA/div

50mV/div

(AC-COUPLED)

200mA/div

V

I

OUT3

OUT3

V

300mA

0mA

OUT1 LIGHT-LOAD SWITCHING

WAVEFORMS

OUT1

V

LX1

I

L1

500μA LOAD

10μs/div

10μs/div

0mA

MAX8667/88 toc20

50mV/div

(AC-COUPLED)

200mA/div

20mV/div

2V/div

100mA/div

V

OUT2 LIGHT-LOAD SWITCHING

WAVEFORMS

OUT2

V

LX2

I

L2

500μA LOAD

40μs/div

MAX8667/88 toc21

20mV/div

2V/div

500mA/div

V

OUT1 HEAVY-LOAD SWITCHING

WAVEFORMS

OUT1

V

LX1

I

L1

500μA LOAD

MAX8667/88 toc22

400ns/div

20mV/div

2V/div

500mA/div

Page 7

MAX8667/MAX8668

Typical Operating Characteristics (continued)

(V

IN12

= V

IN34

= 3.6V, circuit of Figure 4, V

OUT1

= 1.2V, V

OUT2

= 1.8V, V

OUT3

= 2.8V, V

OUT4

= 2.8V, TA = +25°C, unless otherwise noted.)

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

_______________________________________________________________________________________

7

V

OUT2

V

LX2

I

L2

OUT2 HEAVY-LOAD SWITCHING

WAVEFORMS

500mA LOAD

400ns/div

OUT3 NOISE

MAX8667/88 toc23

MAX8667/88 toc25

20mV/div

2V/div

500mA/div

100μV/div

PSRR (dB)

POWER-SUPPLY REJECTION RATIO

vs. FREQUENCY

70

60

50

40

30

20

10

0

0.01 10.1 10 100 1000

FREQUENCY (kHz)

OUT4 NOISE

V

I

LOAD

C

OUT3

OUT3

= 2.80V

= 100Ω

= 4.7μF

MAX8667/88 toc26

MAX8667/88 toc24

100μV/div

V

1ms/div

I

OUT3

LOAD

= 2.80V

= 100Ω

1ms/div

V

I

LOAD

OUT4

= 3.30V

= 100Ω

Page 8

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

8 _______________________________________________________________________________________

Pin Description

PIN

MAX8667 MAX8668

1 EN3 EN3

2 OUT3 OUT3

3 IN34 IN34

4 OUT4 OUT4

5 EN4 EN4

6 GND GND Ground

7 REF REF Reference Output. Bypass REF with a 0.01µF ceramic capacitor to GND.

8 OUT2 — Feedback Input for Regulator 2. Connect OUT2 directly to the output of step-down regulator 2.

9 PGND2 PGND2 Power Ground for Step-Down Regulator 2

10 LX2 LX2 Inductor Connection for Regulator 2

11 IN12 IN12

12 LX1 LX1 Inductor Connection for Regulator 1

13 PGND1 PGND1 Power Ground for Step-Down Regulator 1

14 OUT1 — Feed b ack Inp ut for Reg ul ator 1. C onnect OU T1 d i r ectl y to the outp ut of step - d ow n r eg ul ator 1.

15 EN1 EN1

16 EN2 EN2

— EP EP Exposed Paddle. Connect to GND, PGND1, PGND2, and circuit ground.

NAME

— FB2

— FB1

Enable Input for Regulator 3. Drive EN3 high or connect to IN34 to turn on regulator 3. Drive low

to turn off regulator 3 and reduce input quiescent current.

Output of Regulator 3. Bypass OUT3 with a 4.7µF ceramic capacitor to GND. OUT3 is

discharged to GND through an internal 1kΩ in shutdown.

Input Voltage for LDO Regulators 3 and 4. Supply voltage range is from 1.7V to 5.5V. This

supply voltage must not exceed V

to ground.

Output of Regulator 4. Bypass OUT4 with a 4.7µF ceramic capacitor to GND. OUT4 is

discharged to GND through an internal 1kΩ in shutdown.

Enable Input for Regulator 4. Drive EN4 high or connect to IN34 to turn on regulator 4. Drive low

to turn off regulator 4 and reduce input quiescent current.

Feedback Input for Regulator 2. Connect FB2 to the center of a resistor feedback divider

between the output of regulator 2 and ground to set the output voltage. See the Setting the

Output Voltages and Voltage Positioning section.

Input Voltage for Step-Down Regulators 1 and 2. Supply voltage range is from 2.6V to 5.5V. This

supply voltage must not be less than V

IN12 to ground.

Feedback Input for Regulator 1. Connect FB1 to the center of a resistor feedback divider

between the output of regulator 1 and ground to set the output voltage. See the Setting the

Output Voltages and Voltage Positioning section.

E nab l e Inp ut for Reg ul ator 1. D r i ve E N 1 hi g h or connect to IN 12 to tur n on step - d ow n r eg ul ator 1.

D r i ve l ow to tur n off the r eg ul ator and r ed uce i np ut q ui escent cur r ent.

E nab l e Inp ut for Reg ul ator 2. D r i ve E N 2 hi g h or connect to IN 12 to tur n on step - d ow n r eg ul ator 2.

D r i ve l ow to tur n off the r eg ul ator and r ed uce i np ut q ui escent cur r ent.

FUNCTION

. Connect a 4.7µF or larger ceramic capacitor from IN34

IN12

. Connect a 10µF or larger ceramic capacitor from

IN34

Page 9

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

_______________________________________________________________________________________ 9

Figure 1. Functional Diagram

REF

GND

IN34

1.7V TO 5.5V

UVLO

EN

REF AND BIAS

IN

EN

IN

REF

EN

STEP-DOWN

OUT1

GND

STEP-DOWN

OUT2

GND

IN12

2.8V TO 5.5V

(2.6V TO 5.5V)

LX1

FB

FB

OUT1

(FB1)

PGND1

LX2

OUT2

(FB2)

PGND2

EN1

EN2

EN3

EN4

PWRON LOGIC

AND ENABLES

() ARE FOR THE MAX8668

LDO

IN

EN

OUT3

GND

OUT

OUT3

LDO

OUT4

GND

OUT

OUT4

IN

EN

Page 10

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

10 ______________________________________________________________________________________

Detailed Description

The MAX8667/MAX8668 dual step-down converters

with dual low-dropout (LDO) linear regulators are

intended to power low-voltage microprocessors or

DSPs in portable devices. They feature high efficiency

with small external component size. The step-down outputs are adjustable from 0.6V to 3.3V (MAX8668) or

factory preset (MAX8667) with guaranteed output current of 600mA for OUT1 and 1200mA for OUT2. The

1.5MHz hysteretic-PWM control scheme allows for tiny

external components and reduces no-load operating

current to 100µA (typ) with all regulators enabled. Dual,

low-quiescent-current, low-noise LDOs operate down to

1.7V supply voltage. The MAX8667/MAX8668 have

individual enable inputs for each output to facilitate any

supply sequencing.

Step-Down DC-DC Regulators

(OUT1, OUT2)

Step-Down Regulator Architecture

The MAX8667/MAX8668 step-down regulators are optimized for high-efficiency voltage conversion over a

wide load range, while maintaining excellent transient

response, minimizing external component size, and

minimizing output voltage ripple. The DC-DC converters (OUT1, OUT2) also feature an optimized on-resistance internal MOSFET switch and synchronous

rectifier to maximize efficiency. The MAX8667/

MAX8668 utilize a proprietary hysteretic-PWM control

scheme that switches with nearly fixed frequency at up

to 1.5MHz allowing for ultra-small external components.

The step-down converter output current is guaranteed

up to 600mA for OUT1 and 1200mA for OUT2.

When the step-down converter output voltage falls below

the regulation threshold, the error comparator begins a

switching cycle by turning the high-side p-channel

MOSFET switch on. This switch remains on until the minimum on-time (t

ON

) expires and the output voltage is in

regulation or the current-limit threshold (I

LIMP_

) is

exceeded. Once off, the high-side switch remains off

until the minimum off-time (t

OFF

) expires and the output

voltage again falls below the regulation threshold.

During this off period, the low-side synchronous rectifier turns on and remains on until either the high-side

switch turns on or the inductor current reduces to the

rectifier-off current threshold (I

LXOFF

= 60mA typ). The

internal synchronous rectifier eliminates the need for an

external Schottky diode.

Input Supply and Undervoltage Lockout

The input voltage range of step-down regulators OUT1

and OUT2 is 2.6V to 5.5V. This supply voltage must be

greater than or equal to the LDO supply voltage (V

IN34

).

A UVLO circuit prevents step-down regulators OUT1

and OUT2 from switching when the supply voltage is

too low to guarantee proper operation. When V

IN12

falls

below 2.4V (typ), OUT1 and OUT2 are shut down.

OUT1 and OUT2 turn on and begin soft-start when

V

IN12

rises above 2.5V (typ).

Soft-Start

When initially powered up, or enabled with EN_, the

step-down regulators soft-start by gradually ramping

up the output voltage. This reduces inrush current during startup. See the startup waveforms in the

Typical

Operating Characteristics

section.

Current Limit

The MAX8667/MAX8668 limit the peak inductor current

of the p-channel MOSFET (I

LIMP_

). A valley current limit

is used to protect the step-down regulators during

severe overload and output short-circuit conditions.

When the peak current limit is reached, the internal

p-channel MOSFET turns off and remains off until the

output drops below regulation, the inductor current falls

below the valley current-limit threshold, and the minimum off-time has expired.

Voltage Positioning

The OUT1 and OUT2 output voltages and voltage positioning of the MAX8668 are set by a resistor network

connected to FB_. With this configuration, a portion of

the feedback signal is sensed on the switched side of

the inductor, and the output voltage droops slightly as

the load current is increased due to the DC resistance

of the inductor. This output voltage droop is known as

voltage positioning. Voltage positioning allows the load

regulation to be set to match the voltage droop during

a load transient, reducing the peak-to-peak output voltage deviation during a load transient, and reducing the

output capacitance requirements.

Dropout

As the input voltage approaches the output voltage, the

duty cycle of the p-channel MOSFET reaches 100%. In

this state, the p-channel MOSFET is turned on constantly (not switching), and the dropout voltage is the

voltage drop due to the output current across the onresistance of the internal p-channel MOSFET (R

PCH

)

and the inductor’s DC resistance (R

L

):

LDO Linear Regulators (OUT3, OUT4)

The MAX8667/MAX8668 contain two low-dropout linear

regulators (LDOs), OUT3 and OUT4. The LDO output

voltages are factory preset, and each LDO supplies

VI R R

=+

DO LOAD PCH L

()

Page 11

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

______________________________________________________________________________________ 11

loads up to 300mA. The LDOs include an internal reference, error amplifier, p-channel pass transistor, and

internal voltage-dividers. Each error amplifier compares

the reference voltage to the output voltage (divided by

the internal voltage-divider) and amplifies the difference. If the divided feedback voltage is lower than the

reference voltage, the pass-transistor gate is pulled

lower, allowing more current to pass to the outputs and

increasing the output voltage. If the divided feedback

voltage is too high, the pass-transistor gate is pulled

up, allowing less current to pass to the output.

Input Supply and Undervoltage Lockout

The input voltage range of LDO regulators OUT3 and

OUT4 is 1.7V to 5.5V. This supply voltage must be less

than or equal to the voltage applied to IN12 (V

IN34

≤

V

IN12

).

An undervoltage lockout circuit turns off the LDO regulators when the input supply voltage is too low to guarantee

proper operation. When V

IN34

falls below 1.5V (typ),

OUT3 and OUT4 are shut down. OUT3 and OUT4 turn

on and begin soft-start when V

IN34

rises above 1.6V (typ).

Soft-Start

When initially powered up, or enabled with EN_, the

LDOs soft-start by gradually ramping up the output

voltage. This reduces inrush current during startup. The

soft-start ramp time is typically 100µs from the start of

the soft-start ramp to the output reaching its nominal

regulation voltage.

Current Limit

The OUT3 and OUT4 output current is limited to 375mA

(min). If the output current exceeds the current limit, the

corresponding LDO output voltage drops.

Dropout

The maximum dropout voltage for the linear regulators

is 250mV at 300mA load. To avoid dropout, make sure

the IN34 supply voltage is at least 250mV higher than

the highest LDO output voltage.

Thermal-Overload Protection

Thermal-overload protection limits the total power dissipation in the MAX8667/MAX8668. Thermal-protection

circuits monitor the die temperature. If the die temperature exceeds +160°C, the IC is shut down, allowing the

IC to cool. Once the IC has cooled by 15°C, the IC is

enabled again. This results in a pulsed output during

continuous thermal-overload conditions. The thermaloverload protection protects the MAX8667/MAX8668 in

the event of fault conditions. For continuous operation,

do not exceed the absolute maximum junction temperature of +150°C. See the

Thermal Considerations

sec-

tion for more information.

Figure 2. Timing Diagram

IN12

ENx

OUTx

ENy

OUTy

t

IS THE PERIOD REQUIRED TO ENABLE FROM SHUTDOWN

PWRON

t

PWRON

tEN IS THE ENABLE TIME FOR SUBSEQUENT ENABLE

SIGNALS FOLLOWING THE FIRST ENABLE

t

EN

ENx, ENy ARE ANY COMBINATION OF EN1–EN4.

Page 12

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

12 ______________________________________________________________________________________

Figure 3. MAX8667 Typical Application Circuit

Figure 4. MAX8668 Typical Application Circuit

C3

INPUT

2.8V TO 5.5V

10μF

0.01μF

C2

C1

EN1

EN2

REF

GND

IN12

IN34

1.7V TO 5.5V

EN3

EN4

OUT3

OUT4

4.7μF

4.7μF

300mA

300mA

C8

C9

4.7μF

MAX8667

OUT2

1.2A

2.2μF

L2

2.2μH

C7

LX2

OUT2

PGND2 PGND1

LX1

OUT1

L1

2.2μH

OUT1

600mA

C6

2.2μF

INPUT

2.6V TO 5.5V

OUT2

0.6V TO 3.3V, 1.2A

C7

2.2μF

10μF

0.01μF

C5

C2

C1

C10*

L2

2.2μH

R5*

IN34

IN12

EN1

EN2

REF

GND

MAX8668

LX2

R3

FB2

R4

PGND1 PGND2

*C10, R5, AND R6 ARE OPTIONAL

EN3

EN4

OUT3

OUT4

LX1

FB1

4.7μF

R1

R2

C8

L1

2.2μH

R6*

C4

OUT3, 300mA

OUT4, 300mA

C9

4.7μF

OUT1

0.6V TO 3.3V, 600mA

C6

2.2μF

Page 13

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

______________________________________________________________________________________ 13

Applications Information

Setting the Output Voltages

and Voltage Positioning

The LDO output voltages of the MAX8667/MAX8668,

and the step-down outputs of the MAX8667 are factory

preset. See the

Selector Guide

to find the part number

corresponding to the desired output voltages.

The OUT1 and OUT2 output voltages of the MAX8668

are set by a resistor network connected to FB_ as

shown in Figure 5. With this configuration, a portion of

the feedback signal is sensed on the switched side of

the inductor (LX), and the output voltage droops slightly

as the load current is increased due to the DC resistance of the inductor (DCR). This allows the load regulation to be set to match the voltage droop during a

load transient (voltage positioning), reducing the peakto-peak output-voltage deviation during a load transient, and reducing the output capacitance

requirements.

For the simplest method of setting the output voltage,

R6 is not installed. Choose the value of R2 (a good

starting value is 100kΩ), and then calculate the value of

R1 as follows:

where VFBis the feedback regulation voltage (0.6V).

With the voltage set in this manner, the voltage positioning depends only on the DCR, and the maximum

output voltage droop is:

Setting the Output Voltages with

Reduced Voltage Positioning

To obtain less voltage positioning than described in the

previous section, use the following procedure for setting the output voltages. The OUT1 and OUT2 output

voltages and voltage positioning of the MAX8668 are

set by a resistor network connected to FB_ as shown in

Figure 5.

To set the output voltage (V

OUT

), first select a value for

R2 (a good starting value is 100kΩ). Then calculate the

value of REQ(the equivalent parallel resistance of R1

and R6) as follows:

where VFBis the feedback-regulation voltage (0.6V).

Calculate the factor m based on the desired load-regulation improvement:

where I

OUT(MAX)

is the maximum output current, DCR is

the inductor series resistance, and ΔV

OUT(DESIRED)

is the

maximum allowable droop in the output voltage at full

load. The calculated value for m must be between 1.1 and

2; m = 2 results in a 2x improvement in load regulation.

Now calculate the values of R1 and R6 as follows:

The value of R1 should always be lower than the value

of R6.

Power-Supply Sequencing

The MAX8667/MAX8668 have individual enable inputs

for each regulator to allow complete control over the

power sequencing. When all EN_ inputs are low, the IC

is in low-power shutdown mode, reducing the supply

current to less than 1µA. After one of the EN_ inputs

asserts high, the corresponding regulator begins softstart after a delay of tEN(see Figure 2). The first output

enabled from shutdown mode or initially powering up

the IC has a longer delay (t

PWRON

) as the IC exits the

low-power shutdown mode.

Inductor Selection

The MAX8667/MAX8668 step-down converters operate

with inductors between 2.2µH and 4.7µH. Low inductance values are physically smaller, but require faster

switching, resulting in some efficiency loss. The inductor’s DC current rating must be high enough to account

Figure 5. MAX8668 Feedback Network

RR

12 1=× −

ΔV DCR I

OUT MAX OUT MAX() ()

V

⎛

OUT

⎜

⎝

V

FB

⎞

⎟

⎠

=×

R1

R2

L1 DCR

C4

(OPTIONAL)

OUT

R6

ESR

C6

R

LOAD

LX_

FB_

I DCR

OUT MAX

m

=

V

Δ

OUT DESIRED

×

()

()

RR m

1

=×

EQ

RR

6

=×

EQ

m

m

1

−

R

V

⎛

OUT

=−

EQ

⎜

⎝

V

FB

⎞

×12

R

⎟

⎠

Page 14

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

14 ______________________________________________________________________________________

for peak ripple current and load transients. The stepdown converter’s unique architecture has minimal current overshoot during startup and load transients and in

most cases, an inductor capable of 1.3x the maximum

load current is acceptable.

For output voltages above 2V, when light-load efficiency

is important, the minimum recommended inductor is

2.2µH. For optimum voltage-positioning load transients,

choose an inductor with DC series resistance in the

50mΩ to 150mΩ range. For higher efficiency at heavy

loads (above 200mA) and minimal load regulation,

keep the inductor resistance as small as possible. For

light-load applications (up to 200mA), higher resistance

is acceptable with very little impact on performance.

Capacitor Selection

Input Capacitors

The input capacitor for the step-down converters (C2 in

Figures 3 and 4) reduces the current peaks drawn from

the battery or input power source and reduces switching noise in the IC. The impedance of C2 at the switching frequency should be very low. Surface-mount

ceramic capacitors are a good choice due to their

small size and low ESR. Make sure the capacitor maintains its capacitance over temperature and DC bias.

Ceramic capacitors with X5R or X7R temperature characteristics generally perform well. A 10µF ceramic

capacitor is recommended.

A 4.7µF ceramic capacitor is recommended for the

LDO input capacitor (C3 in Figure 3).

Step-Down Output Capacitors

The step-down output capacitors (C6 and C7 in Figures

3 and 4) are required to keep the output-voltage ripple

small and to ensure regulation loop stability. These

capacitors must have low impedance at the switching

frequency. Surface-mount ceramic capacitors are a

good choice due to their small size and low ESR. Make

sure the capacitor maintains its capacitance over temperature and DC bias. Ceramic capacitors with X5R or

X7R temperature characteristics generally perform well.

The output capacitance can be very low. For most

applications, a 2.2µF ceramic capacitor is sufficient.

For optimum load-transient performance and very low

output ripple, the output capacitor value in µF should

be equal to or greater than the inductor value in µH.

Feed-Forward Capacitor

The feed-forward capacitors on the MAX8668 (C4 and

C5 in Figure 4) set the feedback loop response, control

the switching frequency, and are critical in obtaining

the best efficiency possible. Small X7R and C0G

ceramic capacitors are recommended.

For OUT1, calculate the value of C4 as follows:

C4 = 1.2 x 10-5(s/V) x (V

OUT

/ R1)

For OUT2, calculate the value of C5 and C10 as follows:

Cff= 1.2 x 10-5(s/V) x (V

OUT

/ R3)

Cff= C5 + (C10 / 2)

(C10 / C5) + 1 = (V

OUT

/ VFB), where VFBis 0.6V.

Rearranging the formulas:

C10 = 2 x Cffx (V

OUT

- VFB)/(V

OUT

+ VFB)

C5 = Cff– (C10 / 2)

C10 is needed if V

OUT

> 1.5V or V

IN12

can be less than

V

OUT

/ 0.65.

Table 1. Recommended Inductors

MANUFACTURER INDUCTOR L (µH) RL (mΩ) CURRENT RATING (A) L x W x H (mm)

FDK MIPF2016 2.2 110 1.1 2.0 x 1.6 x 1.0

FDK MIPF2520D 2.2 80 1.3 2.5 x 2.0 x 1.0

Murata

Sumida CDRH2D09 2.2 120 0.44 3.2 x 3.2 x 1.0

TDK GLF251812T 2.2 200 0.6 2.5 x 1.8 x 1.35

TOKO D2812C 2.2 140 0.77 2.8 x 2.8 x 1.2

TOKO MDT2520-CR 2.2 80 0.7 2.5 x 2.0 x 1.0

Wurth

Taiyo Yuden CB2518T 2.2 90 0.51 2.5 x 1.8 x 2.0

LQH32CN2R2M5 2.2 97 0.79 3.2 x 2.5 x 1.55

LQM31P 2.2 220 0.9 3.2 x 1.6 x 0.95

TPC Series 2.2 55 1.8 4.0 x 4.0 x 1.1

TPC Series 4.7 124 1.35 4.0 x 4.0 x 1.1

Page 15

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

______________________________________________________________________________________ 15

LDO Output Capacitor and Stability

Connect a 4.7µF ceramic capacitor between OUT3 and

GND, and a second 4.7µF ceramic capacitor from

OUT4 to GND. For a constant loading above 10mA, the

output capacitors can be reduced to 2.2µF. The equivalent series resistance (ESR) of the LDO output capacitors affects stability and output noise. Use output

capacitors with an ESR of 0.1Ω or less to ensure stable

operation and optimum transient response. Surfacemount ceramic capacitors have very low ESR and are

commonly available. Connect these capacitors as

close as possible to the IC’s pins to minimize PCB trace

inductance.

Thermal Considerations

The maximum package power dissipation of the

MAX8667/MAX8668 is 1667mW. Make sure the power

dissipated by the MAX8667/MAX8668 does not exceed

this rating. The total IC power dissipation is the sum of

the power dissipation of the four regulators:

Estimate the OUT1 and OUT2 power dissipations as

follows:

where RLis the inductor’s DC resistance, and η is the

efficiency (see the

Typical Operating Characteristics

section).

Calculate the OUT3 and OUT4 power dissipations as

follows:

The maximum junction temperature of the MAX8667/

MAX8668 is +150°C. The junction-to-case thermal

resistance (θ

JC

) of the MAX8667/MAX8668 is 6.9°C/W.

When mounted on a single-layer PCB, the junction to

ambient thermal resistance (θ

JA

) is about 64°C/W.

Mounted on a multilayer PCB, θJAis about 48°C/W.

Calculate the junction temperature of the

MAX8667/MAX8668 as follows:

where TAis the maximum ambient temperature. Make

sure the calculated value of TJdoes not exceed the

+150°C maximum.

PCB Layout

High switching frequencies and relatively large peak

currents make PCB layout a very important aspect of

design. Good design minimizes excessive EMI on the

feedback paths and voltage gradients in the ground

plane, both of which can result in instability or regulation errors. Connect the input capacitors as close as

possible to the IN_ and PGND_ pins. Connect the

inductor and output capacitors as close as possible to

the IC and keep the traces short, direct, and wide.

The feedback network traces are sensitive to inductor

magnetic field interference. Route these traces away

from the inductors and noisy traces such as LX. Keep

the feedback components close to the FB_ pin.

Connect GND and PGND_ to the ground plane.

Connect the exposed paddle to the ground plane with

one or more vias to help conduct heat away from the

IC.

Refer to the MAX8668 evaluation kit for a PCB layout

example.

PPPPP

=+++

DDDDD

1234

=× ×

PI V

D OUT OUT 11 1

=× ×

PI V

D OUT OUT 22 2

PI V V

=× −

D OUT IN OUT 3334 3

()

1

1

−η

η

−η

η

TTP

=+× θ

JADJA

PI V V

=×−

D OUT IN OUT 4434 4

()

Page 16

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

16 ______________________________________________________________________________________

Chip Information

PROCESS: BiCMOS

Ordering Information (continued)

All MAX8667/MAX8668 parts are in a 16-pin, thin QFN, 3mm x

3mm package and operate in the -40°C to = +85°C extended

temperature range.

+

Denotes a lead-free package.

PART PKG CODE TOP MARK

T1633-4 AFJ

T1633-4 AFQ

T1633-4 AER

T1633-4 AFK

T1633-4 AFR

MAX8668ETET+ T1633-4 AFS

T1633-4 AFL

T1633-4 AFT

T1633-4 AFU

T1633-4 AFV

Selector Guide

PART

OUT1

(V)

OUT2

(V)

OUT3

(V)

OUT4

(V)

1.20 1.80 2.80 2.80

1.20 1.80 2.85 2.85

1.20 1.80 1.20 1.20

1.60 1.80 2.80 1.20

1.80 1.20 2.60 2.80

1.30 1.30 3.30 2.70

MAX8668ETEA+ ADJ ADJ 2.80 2.80

MAX8668ETEP+ ADJ ADJ 3.30 1.80

ADJ ADJ 2.80 1.20

MAX8668ETET+ ADJ ADJ 3.30 3.30

MAX8668ETEU+ ADJ ADJ 3.30 2.80

MAX8668ETEV+ ADJ ADJ 3.30 2.50

ADJ ADJ 3.30 3.00

MAX8668ETEX+ ADJ ADJ 2.80 1.80

MAX8667ETEHR+

MAX8667ETEJS+

MAX8668ETEA+

MAX8668ETEP+

MAX8668ETEQ+

MAX8668ETEU+

MAX8668ETEV+

MAX8668ETEW+

MAX8668ETEX+

MAX8667ETEAA+

MAX8667ETEAB+

MAX8667ETEAC+

MAX8667ETECQ+

MAX8667ETEHR+

MAX8667ETEJS+

MAX8668ETEQ+

MAX8668ETEW+

Page 17

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

______________________________________________________________________________________ 17

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

MARKING

D/2

D

E

E/2

AAAA

C

L

0.10 C 0.08 C

A

A2

A1

(NE - 1) X e

(ND - 1) X e

C

L

L

e

k

L

C

L

e

E2/2

E2

D2/2

D2

b

0.10 M C A B

C

L

L

e

12x16L QFN THIN.EPS

PACKAGE OUTLINE

8, 12, 16L THIN QFN, 3x3x0.8mm

21-0136

1

I

2

Page 18

MAX8667/MAX8668

1.5MHz Dual Step-Down DC-DC Converters

with Dual LDOs and Individual Enables

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

18

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2007 Maxim Integrated Products is a registered trademark of Maxim Integrated Products. Inc.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

8L 3x3

PKG

REF. MIN.

MIN.

NOM. M

3.00 3.10

0.65 BSC.

0.55 0.75

8

2

2

0.02

0.20 REF

-

AX.

0.05

-

0.70 0.75 0.80

A

b

0.25 0.30 0.35

2.90

D

2.90 3.00 3.10

E

e

0.35

L

ND

NE

A1

A2

k

0.25

0

12L 3x3

NOM. MAX. NOM.

0.70

0.75

0.50 BSC.

0

0.20 REF

0.25

3.00

3.00

0.55

0.02

0.80

0.30

3.10

3.10

0.65

12N

3

3

0.05

-

-

0.20

2.90

2.90

0.45

0.25

16L 3x3

MIN. MAX.

0.70

0.75

0.25

3.00

3.00

0.50 BSC.

0.40

040.02

0.20 REF

0.80

0.30

3.10

3.10

0.50

16

4

0.05

-

0.20

2.90

2.90

0.30

0.25

EXPOSED PAD VARIATIONS

PKG.

CODES

TQ833-1 1.250.25 0.70 0.35 x 45° WEE C1.250.700.25

T1233-1

3

T1233-

T1233-4

T1633-2 0.9 5

T1633F-3

T1633FH-3 0.65 0.80 0.95

T1633-4 0.9 5

-

T1633-5 0.9 5

D2

MIN.

0.95

0.95

0.95

0.65

MAX.

NOM.

1.25

1.10

1.25

1.10

1.251.10

1.25

1.10

0.95

0.80

1.10 1.25 0.95 1.10

1.25

1.10

E2

NOM.

MIN.

0.95

0.95 1.10 0.35 x 45°1.25 WEED-1

0.95

0.65

0.65 0.80

1.10

1.100.95

1.10

0.80

1.10

MAX.

1.25

1.25

0.95

0.95

1.25

1.25

ID

PIN

0.35 x 45°

0.35 x 45°

0.35 x 45°

0.225 x 45°

0.225 x 45°

0.35 x 45°

0.35 x 45°

JEDEC

WEED-1

WEED-11.25

WEED-2

WEED-2

WEED-2

WEED-2

WEED-20.95

NOTES:

1. DIMENSIONING & TOLERANCING CONFORM TO ASME Y14.5M-1994.

2. ALL DIMENSIONS ARE IN MILLIMETERS. ANGLES ARE IN DEGREES.

3. N IS THE TOTAL NUMBER OF TERMINALS.

4. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL CONFORM TO

JESD 95-1 SPP-012. DETAILS OF TERMINAL #1 IDENTIFIER ARE OPTIONAL, BUT MUST BE LOCATED

WITHIN THE ZONE INDICATED. THE TERMINAL #1 IDENTIFIER MAY BE EITHER A MOLD OR

MARKED FEATURE.

5. DIMENSION b APPLIES TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.20 mm AND 0.25 mm

FROM TERMINAL TIP.

6. ND AND NE REFER TO THE NUMBER OF TERMINALS ON EACH D AND E SIDE RESPECTIVELY.

7. DEPOPULATION IS POSSIBLE IN A SYMMETRICAL FASHION.

8. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS.

9. DRAWING CONFORMS TO JEDEC MO220 REVISION C.

10. MARKING IS FOR PACKAGE ORIENTATION REFERENCE ONLY.

11. NUMBER OF LEADS SHOWN ARE FOR REFERENCE ONLY.

12. WARPAGE NOT TO EXCEED

0.10mm.

PACKAGE OUTLINE

8, 12, 16L THIN QFN, 3x3x0.8mm

21-0136

I

2

2

Loading...

Loading...