Page 1

EVALUATION KIT

AVAILABLE

General Description

The MAX8645X/MAX8645Y charge pumps drive up to

eight white LEDs with regulated constant current for uniform intensity. The main group of LEDs (M1–M6) can be

driven up to 30mA per LED for backlighting. The flash

group of LEDs (F1 and F2) is independently controlled

and can be driven up to 200mA per LED (or 400mA total).

Two 200mA LDOs are on-board to provide power for

camera functions. The LDOs’ output voltages are pin programmable to meet different camera-module requirements. The MAX8645X and MAX8645Y differ only in LDO

output voltages. By utilizing adaptive 1x/1.5x/2x chargepump modes and very-low-dropout current regulators,

the MAX8645X/MAX8645Y achieve high efficiency over

the full 1-cell lithium-battery voltage range. The 1MHz

fixed-frequency switching allows for tiny external components, and the regulation scheme is optimized to ensure

low EMI and low input ripple.

The MAX8645X/MAX8645Y are available in a 28-pin TQFN,

4mm x 4mm (0.8mm max height) lead-free package.

Applications

Camera Phones and Smartphones

Backlighting and Flash

PDAs, Digital Cameras, and Camcorders

Features

♦ Power Up to Eight LEDs

Up to 30mA/LED Drive for Backlight

Up to 400mA Total Drive for Flash

♦ Two Internal Low-Noise 200mA LDOs

♦ 94% Max/85% Avg Efficiency (P

LED/PBATT

) over Li+

Battery Discharge

♦ 0.2% Typical LED Current Matching

♦ Adaptive 1x/1.5x/2x Mode Switchover

♦ Flexible Brightness Control

Single-Wire, Serial-Pulse Interface (32 Steps)

2-Bit Logic (Three Levels)

♦ Thermal T

A

Derating Function

♦ Low Input Ripple and EMI

♦ 2.7V to 5.5V Supply Voltage Range

♦ Soft-Start, Overvoltage, and Thermal-Shutdown

Protection

♦ 28-Pin TQFN, 4mm x 4mm Package

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pumps with

Two LDOs in 4mm x 4mm TQFN

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

19-3978; Rev 3; 12/06

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Pin Configuration appears at end of data sheet.

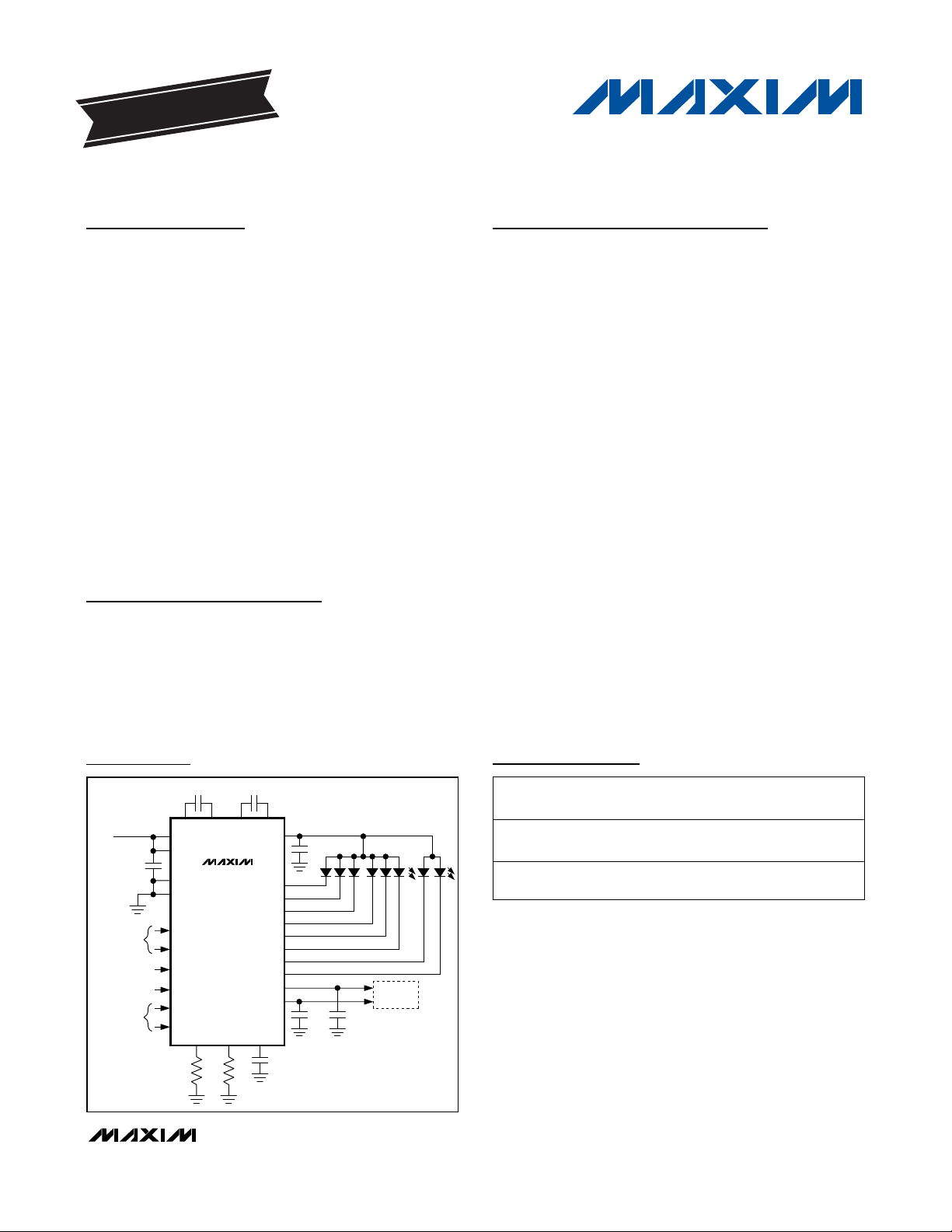

Typical Operating Circuit

EP = Exposed paddle.

+Denotes a lead-free package.

PINPACKAGE

28 TQFN-EP

4mm x 4mm

28 TQFN-EP

4mm x 4mm

INPUT

2.7V TO 5.5V

10μF

MAIN ON/OFF

AND DIMMING

FLASH ON/OFF

DUAL-LDO ON/OFF

DUAL-LDO

VOLTAGE

SELECTION

MAX8645X

MAX8645Y

1μF

C2P C2N

REFSETM SETF

OUT

LDO1

LDO2

M1

M2

M3

M4

M5

M6

F1

F2

0.01μF

OUTPUT

UP TO 580mA

10μF

MAIN

FLASH

CAMERA

MODULE

1μF1μF

1μF

C1P C1N

PIN

IN

GND

PGND

ENM1

ENM2

ENF

ENLDO

P1

P2

PART TEMP RANGE

MAX8645XETI+ -40°C to +85°C

MAX8645YETI+ -40°C to +85°C

PKG

CODE

T2844-1

T2844-1

Page 2

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pumps with Two

LDOs in 4mm x 4mm TQFN

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

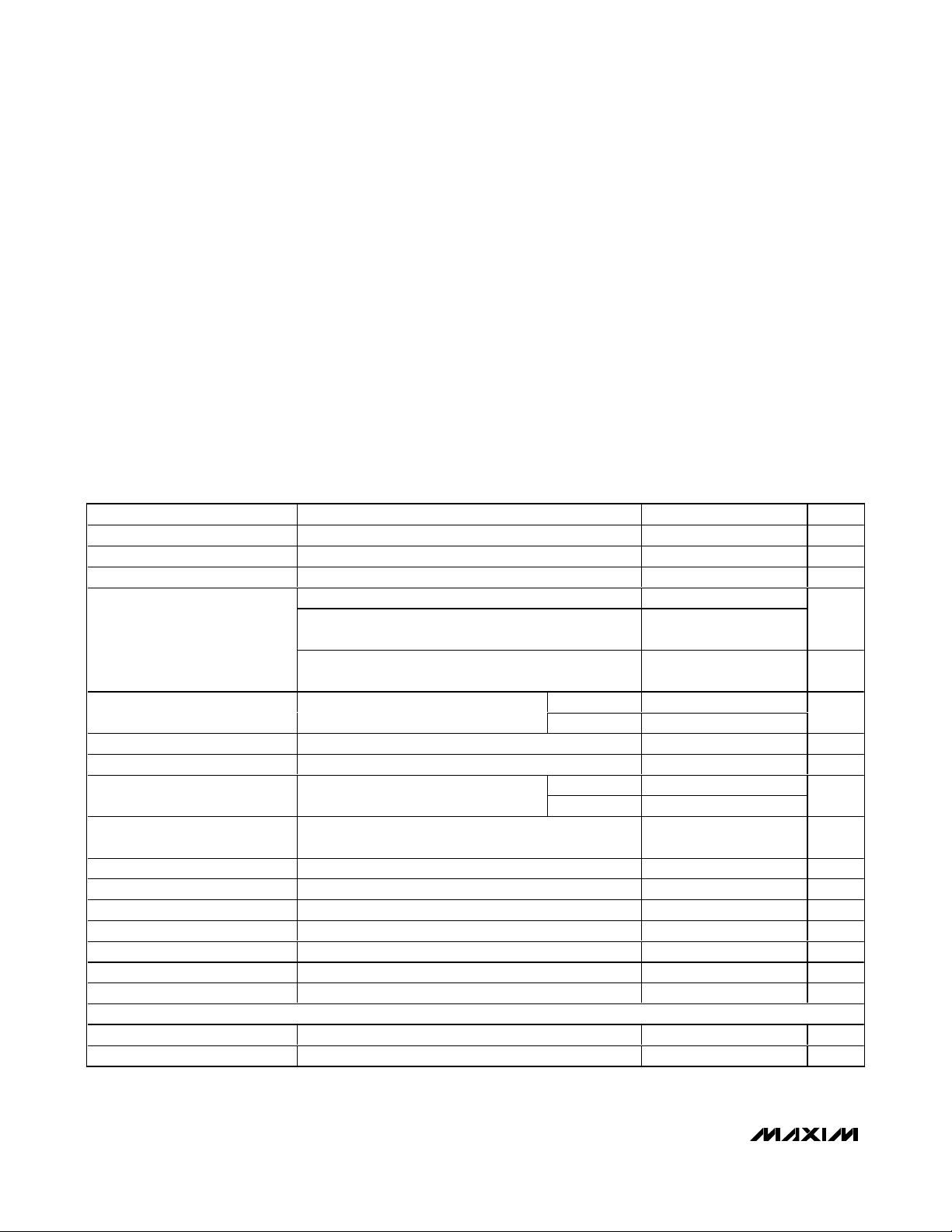

ELECTRICAL CHARACTERISTICS

(VIN= 3.6V, V

GND

= V

PGND

= 0V, ENM1 = ENM2 = ENF = IN, R

SETM

= R

SETF

= 6.8kΩ, P1 = P2 = unconnected, C

REF

= 0.01µF,

T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

PIN, IN, OUT, REFBP to GND................................-0.3V to +6.0V

SETF, SETM, ENLDO, ENM1, ENM2, ENF,

P1, P2, LDO1, LDO2 to GND....................-0.3V to (V

IN

+ 0.3V)

M1, M2, M3, M4, M5, M6, F1,

F2 to GND.............................................-0.3V to (V

OUT

+ 0.3V)

C1N, C2N to GND ......................................... -0.3V to (V

IN

+ 1V)

C1P, C2P

to GND........ -0.3V to the greater of (V

OUT

+ 1V) or (VIN+ 1V)

PGND to GND .......................................................-0.3V to +0.3V

OUT, LDO1, LDO2 Short Circuit to GND ...................Continuous

Continuous Power Dissipation (T

A

= +70°C)

28-Pin TQFN 4mm x 4mm

(derate 20.8mW/°C above +70°C).............................1666mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

IN Operating Voltage 2.7 5.5 V

Undervoltage-Lockout Threshold VIN rising or falling 2.25 2.45 2.60 V

Undervoltage-Lockout Hysteresis 130 mV

Supply Current

Shutdown Supply Current ENM1 = ENM2 = ENF = ENLDO = GND

EN_ High Voltage VIN = 2.7V to 5.5V 1.4 V

EN_ Low Voltage V

EN_ Input Current V

ENM_ or ENF Low Shutdown

Delay t

SHDN

ENM_ or ENF t

ENM_ or ENF t

Initial ENM_ or ENF t

P1, P2 Shutdown Input Current 1µA

P1, P2 Input Impedance 150 kΩ

Thermal-Shutdown Threshold Temperature rising +160 °C

Thermal-Shutdown Hysteresis 20 °C

CHARGE PUMP

Overvoltage-Protection Threshold V

Soft-Start Time 2ms

PARAMETER CONDITIONS MIN TYP MAX UNITS

LO

HI

1MHz switching, no load, 1.5x or 2x mode 4.0 5.5

1x mode 10% setting, ENF = GND, V

= I

I

LDO1

ENM1 = ENM2 = ENF = GND, V

I

LDO1

See Figure 1 1.5 2.0 2.5 ms

See Figure 1 0.5 250.0 µs

See Figure 1 0.5 µs

HI

Only required for first ENM_ or ENF pulse; see Figure 1 200 µs

LDO2

= I

LDO2

= 2.7V to 5.5V 0.4 V

IN

= 0V or 5.5V

EN_

rising 5 V

OUT

= 0A

= 0A

ENLDO

= VIN,

ENLDO

= VIN,

TA = +25°C 0.01 5

T

= +85°C 0.1

A

TA = +25°C 0.01 1

= +85°C 0.1

T

A

0.4

110 µA

mA

µA

µA

Page 3

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pumps with Two

LDOs in 4mm x 4mm TQFN

_______________________________________________________________________________________ 3

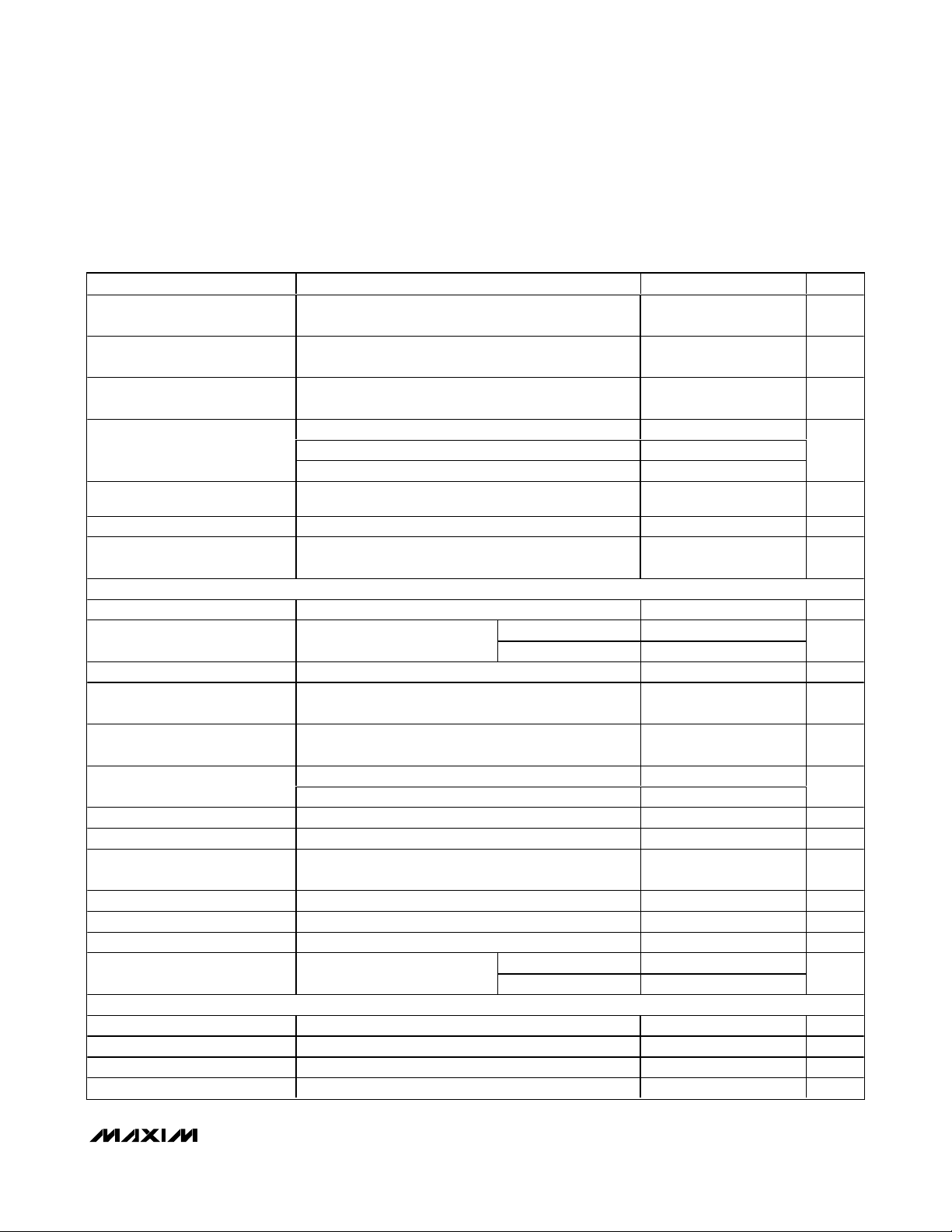

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 3.6V, V

GND

= V

PGND

= 0V, ENM1 = ENM2 = ENF = IN, R

SETM

= R

SETF

= 6.8kΩ, P1 = P2 = unconnected, C

REF

= 0.01µF,

T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

PARAMETER CONDITIONS MIN TYP MAX UNITS

1x to 1.5x or 1.5x to 2x Mode

Transition Threshold

Input Voltage-Mode Transition

Hysteresis

Charge-Pump Maximum OUT

Current

Charge-Pump Short-Circuit

Current

Switching Frequency 1 MHz

OUT Pulldown Resistance in

Shutdown

LED DRIVER

SET_ Bias Voltage TA = +25°C 0.6 V

SET_ Leakage in Shutdown ENM_ = ENF = GND

SET_ Current Range 10 145 µA

SETM-to-Main LED Current Ratio

/I

(I

M_

SETM

SETF-to-Flash LED Current Ratio

F_/ISETF

)

(I

M_, F_ Current Accuracy

Maximum Main LED Sink Current R

Maximum Flash LED Sink Current R

Current-Derating-Function Start

Temperature

Current-Derating-Function Slope TA = +40°C to +85°C -1.7 %/°C

Dropout Voltage (Note 2) 40 90 mV

1.5x and 2x Regulation Voltage 150 mV

M_, F_ Leakage in Shutdown ENM_ = ENF = GND

LDO_

Output Voltage Accuracy

Output Current Range 0 200 mA

Current Limit V

Soft-Start Current Limit 160 mA

)

V

≥ 3.15V, V

IN

1x mode (VIN - V

1.5x mode (1.5VIN - V

2x mode (2V

V

< 1.25V 500 mA

OUT

ENM_ = ENF = GND 5 kΩ

100% setting, M1–M6 230 A/A

100% setting, F1 and F2 1380 A/A

TA = +25°C -1.25 +1.25

T

= -40°C to current derating start temperature -4 +4

A

SETM

= 4.12kΩ, IF1 + I

SETF

I

= 150mA, relative to V

LDO_

LDO_

OUT

- V

IN

= 4.6kΩ, for each M_ 30 mA

= 0V 280 475 750 mA

= 3.9V 580 mA

) / I

OUT

OUT

) / I

OUT

OUT

) / I

OUT

OUT

TA = +25°C 0.01 1

T

A

F2

TA = +25°C 0.01 2

T

A

OUT(NOM)

90 100 110 mV

150 mV

0.3 1.0

1.1 4.0Open-Loop OUT Resistance

1.5 4.14

= +85°C 0.1

400 mA

+40 °C

= +85°C 0.1

(Note 3) -1.7 0 +1.7 %

Ω

µA

%

µA

Page 4

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pumps with

Two LDOs in 4mm x 4mm TQFN

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 3.6V, V

GND

= V

PGND

= 0V, ENM1 = ENM2 = ENF = IN, R

SETM

= R

SETF

= 6.8kΩ, P1 = P2 = unconnected, C

REF

= 0.01µF,

T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

Note 1: All devices are 100% production tested at TA= +25°C. Limits over the operating temperature range are guaranteed by

design.

Note 2: LED dropout voltage is defined as the M_ or F_ to GND voltage at which current into M_ or F_ drops 10% from the value at

M_ or F_ = 0.2V.

Note 3: (Greater of 2.7V or (V

LDO_

+ 0.5V)) ≤ VIN≤ 5.5V.

Note 4: LDO dropout voltage is defined as V

IN

- V

OUT

when V

OUT

is 100mV below the value of V

OUT

measured when VIN=

V

OUT(NOM)

+ 1V. Since the minimum input voltage is 2.7V, this specification is only meaningful when V

OUT(NOM)

> 2.5V.

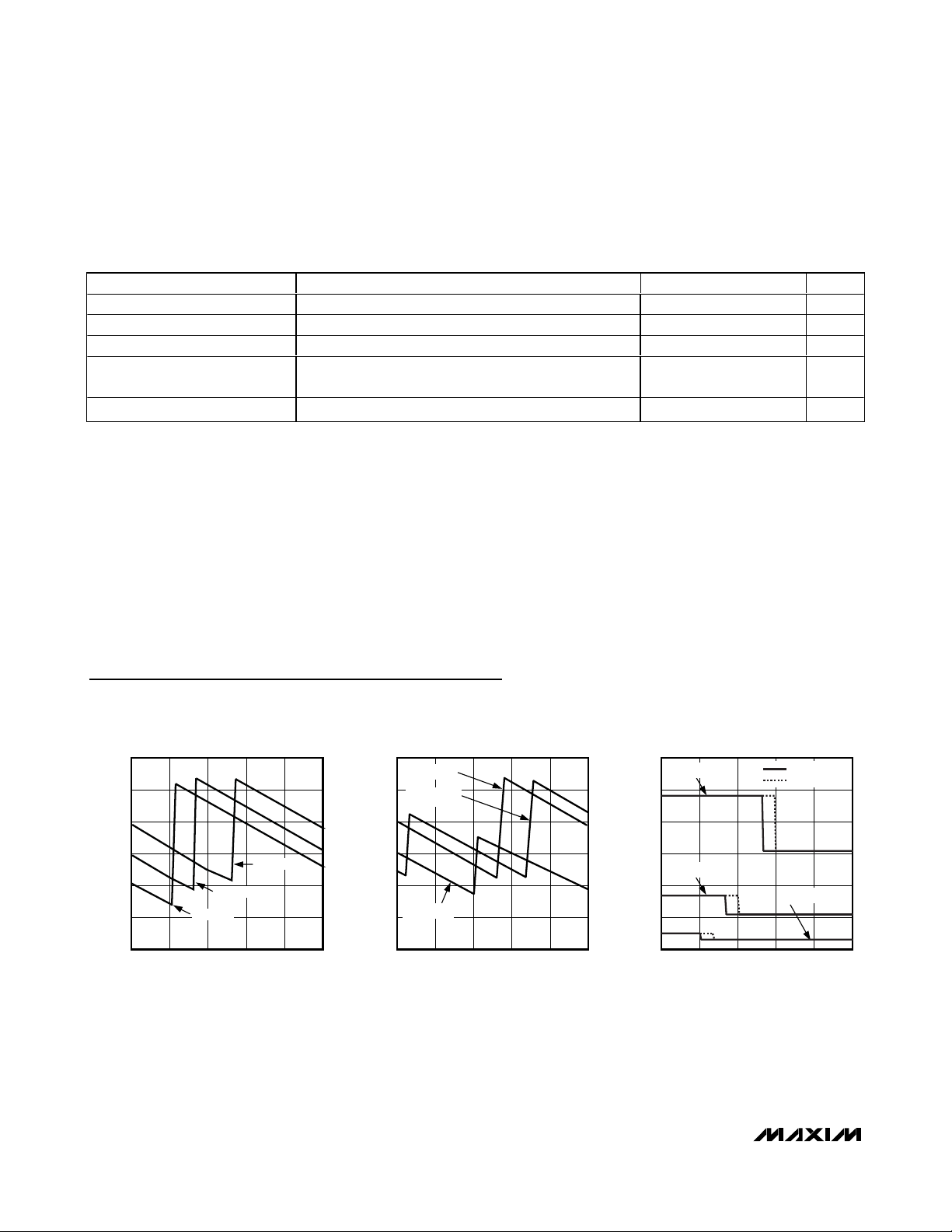

Typical Operating Characteristics

(VIN= V

EN_

= 3.6V, circuit of Figure 2, TA= +25°C, unless otherwise noted.)

EFFICIENCY vs. Li+ BATTERY

VOLTAGE DRIVING SIX MAIN LEDs

MAX8645Y toc01

Li+ BATTERY VOLTAGE (V)

EFFICIENCY P

LED

/P

BATT

(%)

3.93.63.33.0

50

60

70

80

90

100

40

2.7 4.2

15mA/LED

4.5mA/LED

1.5mA/LED

EFFICIENCY vs. Li+ BATTERY

VOLTAGE DRIVING FLASH LED MODULE

MAX8645Y toc02

Li+ BATTERY VOLTAGE (V)

EFFICIENCY P

LED

/P

BATT

(%)

3.93.63.33.0

50

60

70

80

90

100

40

2.7 4.2

80mA TOTAL

160mA TOTAL

400mA TOTAL

BATTERY CURRENT vs. SUPPLY VOLTAGE

DRIVING SIX MAIN LEDs

MAX8645Y toc03

SUPPLY VOLTAGE (V)

BATTERY CURRENT (mA)

3.93.63.33.0

30

60

90

120

150

180

0

2.7 4.2

I

LED

= 15mA

I

LED

= 4.5mA

I

LED

= 1.5mA

V

IN

FALLING

V

IN

RISING

Soft-Start Done Time 100 µs

Dropout Voltage I

Load Regulation VIN = 3.7V, 100µA < I

Power-Supply Rejection

ΔV

/ΔV

OUT

Output Noise Voltage (RMS) 10Hz to 100kHz, C

PARAMETER CONDITIONS MIN TYP MAX UNITS

= 200mA (Note 4) 120 320 mV

LDO_

< 200mA 1.3 %

LDO_

IN

10Hz to 10kHz, C

= 1µF, I

LDO_

LDO_

= 10µA -60 dB

LDO_

= 1µF, I

= 10mA 40 µV

LDO_

RMS

Page 5

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pumps with

Two LDOs in 4mm x 4mm TQFN

_______________________________________________________________________________________ 5

Typical Operating Characteristics (continued)

(VIN= V

EN_

= 3.6V, circuit of Figure 2, TA= +25°C, unless otherwise noted.)

900

800

700

I

600

500

I

FLASH

400

300

BATTERY CURRENT (mA)

200

100

0

2.7 4.2

INPUT RIPPLE VOLTAGE vs. SUPPLY

VOLTAGE WITH FLASH AND MAIN LEDs

10

FOUR MAIN LEDs AT 15mA EACH

9

8

)

7

RMS

6

5

4

3

INPUT RIPPLE (mV

2

1

0

2.7 5.5

BATTERY CURRENT vs. SUPPLY

VOLTAGE DRIVING FLASH

= 400mA

FLASH

= 160mA

I

= 80mA

FLASH

3.93.63.33.0

SUPPLY VOLTAGE (V)

I

= 40mA

FLASH

I

= 160mA

FLASH

I

= 400mA

FLASH

SUPPLY VOLTAGE (V)

160

150

MAX8645Y toc04

140

130

120

110

100

GROUND-PIN SUPPLY CURRENT (μA)

90

80

16.0

15.8

15.6

MAX8645Y toc07

15.4

15.2

15.0

14.8

14.6

MAIN LED CURRENT (mA)

14.4

14.2

5.14.73.1 3.5 3.9 4.3

14.0

LDO GROUND-PIN SUPPLY

CURRENT vs. SUPPLY VOLTAGE

V

= V

ENM_

NO LOAD, BOTH LDOs

2.7 5.5

= 0V, V

ENF

ENLDO

SUPPLY VOLTAGE (V)

LED CURRENT MATCHING vs. SUPPLY

VOLTAGE WITH SIX MAIN LEDs

2.7 5.5

SUPPLY VOLTAGE (V)

= VIN

150mA, BOTH LDOs

5.14.73.9 4.33.53.1

5.14.73.9 4.33.53.1

1.8

1.5

MAX8645Y toc05

)

RMS

1.2

0.9

0.6

INPUT RIPPLE (mV

0.3

0

2.7 5.5

LED CURRENT MATCHING vs. SUPPLY

102.0

101.5

MAX8645Y toc08

101.0

100.5

100.0

99.5

99.0

FLASH LED CURRENT (mA)

98.5

98.0

2.7 5.5

INPUT RIPPLE VOLTAGE vs. SUPPLY

VOLTAGE WITH SIX MAIN LEDs

I

= 15mA

LED

I

= 4.5mA

LED

I

= 1.5mA

LED

5.14.74.33.93.53.1

SUPPLY VOLTAGE (V)

VOLTAGE WITH TWO FLASH LEDs

5.14.74.33.93.53.1

SUPPLY VOLTAGE (V)

MAX8645Y toc06

MAX8645Y toc09

LED CURRENT vs. AMBIENT

TEMPERATURE WITH SIX MAIN LEDs

105

90

75

60

45

30

TOTAL LED CURRENT (mA)

15

0

-40 85

TA (°C)

LED CURRENT vs. AMBIENT

TEMPERATURE WITH FLASH

450

400

MAX8645Y toc10

350

300

250

200

150

TOTAL LED CURRENT (mA)

100

50

0

603510-15

-40 85

TA (°C)

603510-15

MAX8645Y toc11

MAIN LED CURRENT (mA)

INDIVIDUAL MAIN LED CURRENT

vs. R

100

10

1

R

SETM

SETM

10

(kΩ)

MAX8645Y toc12

1001

Page 6

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pumps with Two

LDOs in 4mm x 4mm TQFN

6 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VIN= V

EN_

= 3.6V, circuit of Figure 2, TA= +25°C, unless otherwise noted.)

INDIVIDUAL FLASH LED CURRENT

vs. R

2000

200

20

FLASH LED CURRENT (mA)

2

1100

OPERATING WAVEFORMS (1.5x MODE)

V

OUT

V

IN

I

IN

6 MAIN LEDS AT 20mA EACH

SETF

10

R

(kΩ)

SETF

MAX8645Y toc15

MAX8645Y toc13

50mV/div

AC-COUPLED

20mV/div

AC-COUPLED

2mA/div

AC-COUPLED

OPERATING WAVEFORMS (1x MODE)

V

OUT

V

IN

I

IN

6 MAIN LEDS AT 20mA EACH

400ns/div

OPERATING WAVEFORMS (2x MODE)

V

OUT

V

IN

6 MAIN LEDS AT 20mA EACH,

FLASH AT 400mA TOTAL

I

IN

MAX8645Y toc14

MAX8645Y toc16

50mV/div

AC-COUPLED

20mV/div

AC-COUPLED

2mA/div

AC-COUPLED

50mV/div

AC-COUPLED

20mV/div

AC-COUPLED

2mA/div

AC-COUPLED

V

ENM_

I

OUT

V

OUT

400ns/div

STARTUP AND SHUTDOWN

MAIN LED RESPONSE

6 MAIN LEDS AT 20mA EACH

1ms/div

MAX8645Y toc17

5V/div

0V

100mA/div

0A

5V/div

0V

STARTUP AND SHUTDOWN

V

ENF

I

IN

I

OUT

V

OUT

400ns/div

FLASH LED RESPONSE

6 MAIN LEDS AT 20mA EACH,

400mA TOTAL FLASH

1ms/div

MAX8645Y toc18

5V/div

0V

500mA/div

0A

500mA/div

0A

5V/div

0V

Page 7

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pumps with Two

LDOs in 4mm x 4mm TQFN

_______________________________________________________________________________________ 7

Typical Operating Characteristics (continued)

(VIN= V

EN_

= 3.6V, circuit of Figure 2, TA= +25°C, unless otherwise noted.)

SINGLE-WIRE DIMMING RESPONSE

V

ENM1,

V

ENM2

I

OUT

V

OUT

10ms/div

LDO OUTPUT VOLTAGE

ACCURACY vs. OUTPUT CURRENT

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

OUTPUT VOLTAGE ACCURACY (%)

-0.8

-1.0

0200

OUTPUT CURRENT (mA)

MAX8645Y toc19

15010050

5V/div

0V

500mA/div

0A

2V/div

0V

MAX8645Y toc21

LDO DROPOUT VOLTAGE

vs. OUTPUT CURRENT

140

120

100

80

60

40

DROPOUT VOLTAGE (mV)

20

0

0200

OUTPUT CURRENT (mA)

LOAD-TRANSIENT RESPONSE

V

= 2.6V

LDO_

V

LDO_

I

LDO_

10μs/div

15010050

MAX8645Y toc22

MAX8645Y toc20

50mV/div

AC-COUPLED

100mA

1mA

LOAD-TRANSIENT RESPONSE

NEAR DROPOUT

VIN - V

= 77mV, V

OUT

V

LDO_

I

LDO_

LDO_

10μs/div

= 2.6V

MAX8645Y toc23

50mV/div

AC-COUPLED

100mA

1mA

Page 8

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pumps with Two

LDOs in 4mm x 4mm TQFN

8 _______________________________________________________________________________________

Pin Description

PIN NAME FUNCTION

1 PIN

2IN

3 GND G r ound . C onnect G N D to system g r ound and the i np ut b yp ass cap aci tor as cl ose as p ossi b l e to the IC .

4 LDO1

5 LDO2

6 REFBP Reference Filter. Bypass REFBP with a 0.01µF ceramic capacitor to GND.

7 SETF

8 SETM

Supply Voltage Input. Bypass to PGND with a 10µF ceramic capacitor. The input voltage range is

2.7V to 5.5V. PIN is high impedance during shutdown.

Chip Supply Voltage Input. Bypass to GND with a 10µF ceramic capacitor as close as possible to the

IC. The input voltage range is 2.7V to 5.5V. IN is high impedance during shutdown.

LDO1 Output. Bypass with a 1µF ceramic capacitor to GND. LDO1 is pulled to ground through an

internal 400kΩ resistor during shutdown.

LDO2 Output. Bypass with a 1µF ceramic capacitor to GND. LDO2 is pulled to ground through an

internal 400kΩ resistor during shutdown.

Bias Current Set Input for F1, F2. The current flowing out of SETF sets the maximum (100%) bias

current into each LED. V

GND to set the flash current. R

Bi as C ur r ent S et Inp ut for M 1–M 4. The cur r ent fl ow i ng out of S E TM sets the m axi m um ( 100%) b i as

cur r ent i nto each LE D . V

to set the m ai n LE D cur r ent. R

is internally biased to 0.6V. Connect a resistor (R

SETF

S E T M

= 82.8 / I

SETF

i s i nter nal l y b i ased to 0.6V . C onnect a r esi stor ( R

= 138 / I

S E T M

LED(MAX)

L E D ( M AX )

. SETF is high impedance during shutdown.

. S E TM i s hi g h i m p ed ance d ur i ng shutd ow n.

) from SETF to

SETF

) fr om S E TM to GN D

S E T M

9, 10 F2, F1

11–16 M6–M1

17 P2

18 ENLDO

19 ENM2

20 ENM1

21 ENF

22 C1N

400m A C om b i ned - C ur r ent Fl ash LE D C athod e C onnecti on and C har g e- P um p Feed b ack. C ur r ent fl ow i ng

i nto F_ i s b ased on I

i np ut for ces OU T to op er ate at ap p r oxi m atel y 5V . C onnect F_ to OU T i f thi s LE D i s not p op ul ated .

30mA M ai n LE D Cathod e Connecti on and C har g e- P ump Feed b ack. C ur rent fl owi ng i nto M _ i s based on the

E N _ confi g ur ation and I

any M _ for ces OU T to oper ate at ap pr oxim atel y 5V . Connect M_ to OU T i f thi s L E D i s not p op ul ated .

Default Output-Voltage Select Input. P1 and P2 set the LDO1 and LDO2 voltages to one of nine

combinations (Table 2). P2 is high impedance in an off condition and shortly after an on condition.

LDO Output Enable. Drive to a logic-level high to turn on both LDOs. Drive to a logic-level low to turn

off both LDOs.

Enable and Dimming Control for M1–M6. Drive both ENM1 and ENM2 to a logic-level high to turn on

the main LEDs. Drive both ENM1 and ENM2 to a logic-level low to turn off the main LEDs. Alternate

dimming techniques are discussed in the Applications Information section.

Enable and Dimming Control for M1–M6. Drive both ENM1 and ENM2 to a logic-level high to turn on

the main LEDs. Drive both ENM1 and ENM2 to a logic-level low to turn off the main LEDs. Alternate

dimming techniques are discussed in the Applications Information section.

Enable and Dimming Control for F1, F2. Drive ENF to a logic-level high to turn on the flash LEDs.

Drive ENF to a logic-level low to turn off the flash LEDs. Dimming techniques are discussed in the

Applications Information section.

Transfer Capacitor 1 Negative Connection. Connect a 1µF ceramic capacitor between C1P and C1N.

C1N is internally shorted to IN during shutdown.

. The char g e p um p r eg ul ates the l ow est F_ vol tag e to 0.15V . Gr ound i ng any F_

S E T F

. The char ge p um p reg ulates the l owest M _ inp ut voltag e to 0.15V . Gr ound i ng

S E TM

Page 9

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pumps with Two

LDOs in 4mm x 4mm TQFN

_______________________________________________________________________________________ 9

Detailed Description

The MAX8645X/MAX8645Y charge pumps drive up to

six white LEDs in the main display for backlighting and

up to two white LEDs for flash, all with regulated constant current for uniform intensity. By utilizing adaptive

1x/1.5x/2x charge-pump modes and very-low-dropout

current regulators, they achieve high efficiency over the

1-cell lithium-battery input voltage range. 1MHz fixedfrequency switching allows for tiny external components and low input ripple. Two on-board 200mA

programmable-output-voltage LDOs are provided to

meet camera-module requirements.

1x to 1.5x Switchover

When VINis higher than V

OUT

, the MAX8645X/

MAX8645Y operate in 1x mode and V

OUT

is pulled up

to VIN. The internal current regulators regulate the LED

current. As VINdrops, VM_(or VF_) eventually falls

below the switchover threshold of 100mV and the

MAX8645X/MAX8645Y start switching in 1.5x mode.

When the input voltage rises above V

OUT

by approximately 50mV, the MAX8645X/MAX8645Y switch back to

1x mode.

1.5x to 2x Switchover

When VINis less than V

OUT

but greater than 2/3 V

OUT

,

the MAX8645X/MAX8645Y operate in 1.5x mode. The

internal current regulators regulate the LED current. As

VINdrops, VM_(or VF_) eventually falls below the

switchover threshold of 100mV, and the MAX8645X/

MAX8645Y start switching in 2x mode. When the input

voltage rises above 2/3 V

OUT

by approximately 50mV,

the MAX8645X/MAX8645Y switch back to 1.5x mode.

Soft-Start

The MAX8645X/MAX8645Y include soft-start circuitry to

limit inrush current at turn-on. Once the input voltage is

applied, the output capacitor is charged directly from

the input with a ramped current source (with no chargepump action) until the output voltage approaches the

input voltage. Once the output capacitor is charged,

the charge pump determines if 1x, 1.5x, or 2x mode is

required. In the case of 1x mode, the soft-start is terminated and normal operation begins. In the case of 1.5x

or 2x mode, soft-start operates until the lowest voltage

of M1–M6 and F1, F2 reaches regulation. If the output

is shorted to ground or is pulled to less than 1.25V, the

output current is limited by soft-start.

True Shutdown™ Mode

When ENM1, ENM2, and ENF are simultaneously held

low for 2ms or longer, the MAX8645X/MAX8645Y are

shut down and put in a low-current shutdown mode,

and the input is isolated from the output. OUT is internally pulled to GND with 5kΩ during shutdown.

Thermal Derating

The MAX8645X/MAX8645Y limit the maximum LED current depending on the die temperature. The maximum

LED current is set by the R

SETM

and R

SETF

resistors.

Once the temperature reaches +40°C, the LED current

decreases by 1.7%/°C. Due to the package’s exposed

paddle, the die temperature is always very close to the

PCB temperature.

The temperature derating function allows the LED current to be safely set higher at normal operating temperatures, thereby allowing either a brighter display or

fewer LEDs to be used for normal display brightness.

Pin Description (continued)

True Shutdown is a trademark of Maxim Integrated Products, Inc.

PIN NAME FUNCTION

23 C1P

24 PGND Power Ground. Connect PGND to system ground. PGND is used for charge-pump switching currents.

25 OUT

26 C2P

27 C2N

28 P1

— EP Exposed Paddle. Connect to GND and PGND.

Transfer Capacitor 1 Positive Connection. Connect a 1µF ceramic capacitor between C1P and C1N.

During shutdown, if OUT > IN, C1P is shorted to OUT. If OUT < IN, C1P is shorted to IN.

Charge-Pump Output. Bypass OUT to GND with a 10µF ceramic capacitor. Connect to the anodes of

all the LEDs. OUT is internally pulled to ground through a 5kΩ resistor during

Transfer Capacitor 2 Positive Connection. Connect a 1µF ceramic capacitor between C2P and C2N.

During shutdown, if OUT > IN, C2P is shorted to OUT. If OUT < IN, C2P is shorted to IN.

Transfer Capacitor 2 Negative Connection. Connect a 1µF ceramic capacitor between C2P and C2N.

C2N is internally shorted to IN during shutdown.

Default Output-Voltage Select Input. P1 and P2 set the LDO1 and LDO2 voltages to one of nine

combinations (Table 2). P1 is high impedance in an off condition and shortly after in an on condition.

shutdown.

Page 10

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pumps with Two

LDOs in 4mm x 4mm TQFN

10 ______________________________________________________________________________________

Thermal Shutdown

The MAX8645X/MAX8645Y include a thermal-limit circuit

that shuts down the IC at approximately +160°C. Turnon occurs after the IC cools by approximately 20°C.

Applications Information

Setting the Main Output Current

SETM controls M1–M6 regulation current. Current flowing into M1, M2, M3, M4, M5, and M6 is a multiple of

the current flowing out of SETM:

IM1= IM2= IM3= IM4= IM5= IM6= K x (0.6V / R

SETM

)

where K = 23, 69, or 230 (depending upon the state of

ENM1 and ENM2; see Table 1), and R

SETM

is the resistor connected between SETM and GND (see the

Typical Operating Circuit).

Setting the Flash Output Current

SETF controls the F1, F2 regulation current. Current

flowing into F1 and F2 is a multiple of the current flowing out of SETF:

IF1= IF2= N x (0.6V / R

SETF

)

where N = 1380.

Single-Wire Pulse Dimming

For more dimming flexibility or to reduce the number of

control traces, the MAX8645X/MAX8645Y support serial

pulse dimming. Connect ENM1 and ENM2 together to

enable single-wire pulse dimming of the main LEDs (or

ENF only for single-wire pulse dimming of the flash

LEDs). When ENM1 and ENM2 (or ENF) go high

simultaneously, the main (or flash) LEDs are enabled at

full brightness. Each subsequent low-going pulse

(500ns to 250µs pulse width) reduces the LED current

by 3.125% (1/32), so after one pulse, the LED current is

96.9% (or 31/32) x I

LED

. The 31st pulse reduces the

current to 0.03125 x I

LED

. The 32nd pulse sets the LED

current back to I

LED

. Figure 1 shows a timing diagram

for single-wire pulse dimming. Because soft-start is

longer than the initial tHI, apply dimming pulses quickly

upon startup (after initial tHI) to avoid LED current transitioning through full brightness.

Simple On/Off Control

If dimming control is not required, connect ENM1 to

ENM2 for simple on/off control. Drive both ENM1 and

ENM2 to a logic-level high to turn on the main LEDs.

Drive both ENM1 and ENM2 to a logic-level low to turn

off the main LEDs. ENF is the simple on/off control for

the flash LEDs. Drive ENF to a logic-level high to turn

on the flash LEDs. Drive ENF to a logic-level low to turn

off the flash LEDs. In this case, LED current is set by

the values of R

SETM

and R

SETF

.

Dimming Using PWM into ENM1

Use ENM2 for shutdown and drive ENM1 with a PWM

signal. LED brightness can be varied from 10% to full

brightness based upon the duty cycle of the PWM signal. Drive ENM2 high to keep the IC on, eliminating any

soft-start delay that would impede PWM control and

allowing a PWM frequency up to 5kHz (Figure 2).

Driving Fewer than Eight LEDs

When driving fewer than eight LEDs, two connection

schemes can be used. The first scheme is shown in

Figure 3 where LED drivers are connected together.

This method allows increased current through the LED

and effectively allows total LED current to be I

LED

multiplied by the number of connected drivers. The second

method of connection is shown in Figure 4 where standard white LEDs are used and fewer than eight are

connected. This scheme does not alter current through

each LED but ensures that the unused LED driver is

properly disabled.

Figure 1. ENM_ and ENF Timing Diagram

Table 1. ENM1/ENM2 States

INITIAL t

HI

≥ 200μs

ENM1 AND ENM2

OR

ENF

I

OR I

M_

SHUTDOWN

t

SOFT-START

32/32

F_

ENM1/ENM2 STATES BRIGHTNESS

ENM1 = low, ENM2 = low Shutdown 0

ENM1 = low, ENM2 = high 1/10 brightness 23 x I

ENM1 = high, ENM2 = low 3/10 brightness 69 x I

ENM1 = high, ENM2 = high Full brightness 230 x I

10243 5 27 28 29 30 31 32

31/32

30/32

500ns TO 250μs

29/32

28/32

27/32

t

LO

t

HI

≥ 500ns

5/32

4/32

3/32

2/32

M1–M6

CURRENT

SETM

SETM

SETM

t

SHDN

31/32

2ms (typ)

32/32

1/32

SHUTDOWN

Page 11

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pumps with Two

LDOs in 4mm x 4mm TQFN

______________________________________________________________________________________ 11

Figure 3. Providing Increased LED Current per LED

Figure 2. Dimming Using PWM Signal into ENM1

INPUT

2.7V TO 5.5V

C1

10μF

OFF

PWM INPUT

ON/OFF

ON/OFF

VOLTAGE

SELECTION

ON

R

SETM

6.81kΩ

PIN

IN

GND

ENM2

ENM1

ENF

ENLDO

P1

P2

C3

1μF

C1P C1N

R

SETF

4.12kΩ

C2P C2N

MAX8645X

MAX8645Y

REFBPSETM SETF PGND

C8

0.01μF

C4

1μF

LDO1

LDO2

OUT

C6

1μF

C7

1μF

OUTPUT

UP TO 480mA

C5

10μF

M1

M2

M3

M4

M5

M6

F1

F2

MAIN FLASH

INPUT

2.7V TO 5.5V

10μF

ON/OFF AND

VOLTAGE

SELECTION

6.81kΩ

C1P C1N

PIN

IN

GND

ENM2

ENM1

ENF

ENLDO

P1

P2

4.12kΩ

1μF

C2P C2N

MAX8645X

MAX8645Y

REFBPSETM SETF PGND

0.01μF

1μF

LDO1

LDO2

OUT

M1

M2

M3

M4

M5

M6

1μF

1μF

OUTPUT

UP TO 480mA

MAIN FLASH

10μF

F1

F2

Page 12

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pumps with Two

LDOs in 4mm x 4mm TQFN

12 ______________________________________________________________________________________

Input Ripple

For LED drivers, input ripple is more important than output ripple. Input ripple is highly dependent on the

source supply’s impedance. Adding a lowpass filter to

the input further reduces input ripple. Alternately,

increasing CINto 22µF cuts input ripple in half with only

a small increase in footprint. The 1x mode always has

very low input ripple.

Typical operating waveforms shown in the Typical

Operating Characteristics show input ripple current in

1x, 1.5x, and 2x modes.

LDO Output Voltage Selection (P1 and P2)

As shown in Table 2, the LDO output voltages, LDO1

and LDO2 are pin programmable by the logic states of

P1 and P2. P1 and P2 are tri-level inputs: IN, open, and

GND. The input voltage, VIN, must be greater than the

selected LDO1 and LDO2 voltages. The logic states of

P1 and P2 can be programmed only during ENLDO

low. Once the LDO_ voltages are programmed, their

values do not change by changing P1 or P2 during

ENLDO high.

Component Selection

Use only ceramic capacitors with an X5R, X7R, or better

dielectric. See Table 3 for a list of recommended parts.

Connect a 1µF ceramic capacitor between LDO1 and

GND, and a second 1µF ceramic capacitor between

LDO2 and GND for 200mA applications. The LDO output capacitor’s (C

LDO

) equivalent series resistance

(ESR) affects stability and output noise. Use output

capacitors with an ESR of 0.1Ω or less to ensure stability

and optimum transient response. Connect C

LDO_

as

close as possible to the MAX8645X/MAX8645Y to minimize the impact of PCB trace inductance.

Figure 4. Schematic for When Fewer than 8 LEDs Are Acceptable

Table 2. P1 and P2, LDO Output Voltage

Selection

1μF

INPUT

2.7V TO 5.5V

10μF

ON/OFF AND

VOLTAGE

SELECTION

6.81kΩ

C1P C1N

PIN

IN

GND

ENM2

ENM1

ENF

ENLDO

P1

P2

4.12kΩ

C2P C2N

MAX8645X

MAX8645Y

REFBPSETM SETF PGND

1μF

0.01μF

LDO1

LDO2

OUT

M1

M2

M3

M4

M5

M6

1μF

1μF

OUTPUT

UP TO 240mA

MAIN FLASH

10μF

F1

F2

P1 P2

IN IN 3.3 1.8 2.8 2.6

IN OPEN 3.0 1.5 2.8 2.8

IN GND 2.8 1.5 2.9 1.5

OPEN IN 3.3 1.5 2.6 1.9

OPEN OPEN 2.6 1.8 2.6 2.6

OPEN GND 2.6 1.5 2.8 1.9

GND IN 3.0 1.8 2.9 1.8

GND OPEN 2.8 1.8 2.9 1.9

GND GND 2.5 1.8 2.9 2.9

MAX8645X MAX8645Y

LDO1 (V) LDO2 (V)

LDO1 (V) LDO2 (V)

Page 13

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pump with

Two LDOs in 4mm x 4mm TQFN

______________________________________________________________________________________ 13

MAX8645YETI

PCB Layout and Routing

The MAX8645X/MAX8645Y are high-frequency,

switched-capacitor voltage regulators. For best circuit

performance, use a solid ground plane and place CIN,

C

OUT

, C3, and C4 as close as possible to the IC. There

should be no vias on CIN. Connect GND and PGND to

the exposed paddle directly under the IC. Refer to the

MAX8645Y evaluation kit for an example.

Table 3. Recommended Components for Figure 2

Chip Information

PROCESS: BiCMOS

Pin Configuration

DESIGNATION VALUE MANUFACTURER PART DESCRIPTION

C1, C5 10µF TDK C2012X5R0J106M 10µF ±20%, 6.3V X5R ceramic capacitors (0805)

C3, C4, C6, C7 1µF TDK C1005X5R0J105M 1µF ±20%, 6.3V X5R ceramic capacitors (0402)

C8 0.01µF TDK C1005X7R1E103K 0.01µF ±10%, 25V X7R ceramic capacitor (0402)

D1–D4 — Nichia NSCW215T White LEDs

D5 (D5–D8) — Nichia NBCW011T White LEDs, 4 LEDs in one package

R

, R

SETM

SETF

As

required

Panasonic

Vishay

— 1% resistors

TOP VIEW

21 20 19 18 17 16 15

C1N

22

C1P

23

24

PGND

25

OUT

C2P

26

27

C2N

28

P1

ENF

ENM1

ENM2

MAX8645X

MAX8645Y

ENLDO

P2

M2

M1

14

M3

M4

13

12

M5

11

M6

10

F1

9

F2

8

SETM

1234567

IN

PIN

(4mm x 4mm, 0.4mm LEAD PITCH)

+ DENOTES A LEAD-FREE PACKAGE.

GND

LDO1

THIN QFN

LDO2

REFBP

SETF

Page 14

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pumps with

Two LDOs in 4mm x 4mm Thin QFN

14 ______________________________________________________________________________________

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

24L QFN THIN.EPS

PACKAGE OUTLINE,

12, 16, 20, 24, 28L THIN QFN, 4x4x0.8mm

21-0139

1

E

2

Page 15

MAX8645X/MAX8645Y

1x/1.5x/2x White LED Charge Pumps with Two

LDOs in 4mm x 4mm TQFN

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

15 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2006 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

PACKAGE OUTLINE,

12, 16, 20, 24, 28L THIN QFN, 4x4x0.8mm

21-0139

2

E

2

Loading...

Loading...