Page 1

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim's website at www.maxim-ic.com.

General Description

The MAX8625A PWM step-up/down regulator is intended to power digital logic, hard disk drives, motors, and

other loads in portable, battery-powered devices such

as PDAs, cell phones, digital still cameras (DSCs), and

MP3 players. The MAX8625A provides either a fixed

3.3V or adjustable output voltage (1.25V to 4V) at up to

0.8A from a 2.5V to 5.5V input. The MAX8625A utilizes

a 2A peak current limit.

Maxim’s proprietary H-bridge topology* provides a

seamless transition through all operating modes without

the glitches commonly seen with other devices. Four

internal MOSFETs (two switches and two synchronous

rectifiers) with internal compensation minimize external

components. A SKIP input selects a low-noise, fixedfrequency PWM mode, or a high-efficiency skip mode

where the converter automatically switches to PFM

mode under light loads for best light-load efficiency.

The internal oscillator operates at 1MHz to allow for a

small external inductor and capacitors.

The MAX8625A features current-limit circuitry that shuts

down the IC in the event of an output overload. In addition, soft-start circuitry reduces inrush current during

startup. The IC also features True Shutdown

TM

, which

disconnects the output from the input when the IC is

disabled. The MAX8625A is available in a 3mm x 3mm,

14-pin TDFN package.

Applications

PDAs and Smartphones

DSCs and Camcorders

MP3 Players and Cellular Phones

Battery-Powered Hard Disk Drive (HDD)

Features

♦ Four Internal MOSFET True H-Bridge Buck/Boost

♦ Glitch-Free, Buck-Boost Transitions

♦ Minimal Output Ripple Variation on Transitions

♦ Up to 92% Efficiency

♦ 37µA (typ) Quiescent Current in Skip Mode

♦ 2.5V to 5.5V Input Range

♦ Fixed 3.3V or Adjustable Output

♦ 1µA (max) Logic-Controlled Shutdown

♦ True Shutdown

♦ Output Overload Protection

♦ Internal Compensation

♦ Internal Soft-Start

♦ 1MHz Switching Frequency

♦ Thermal-Overload Protection

♦ Small 3mm x 3mm, 14-Pin TDFN Package

MAX8625A

High-Efficiency, Seamless Transition,

Step-Up/Down DC-DC Converter

________________________________________________________________

Maxim Integrated Products

1

Ordering Information

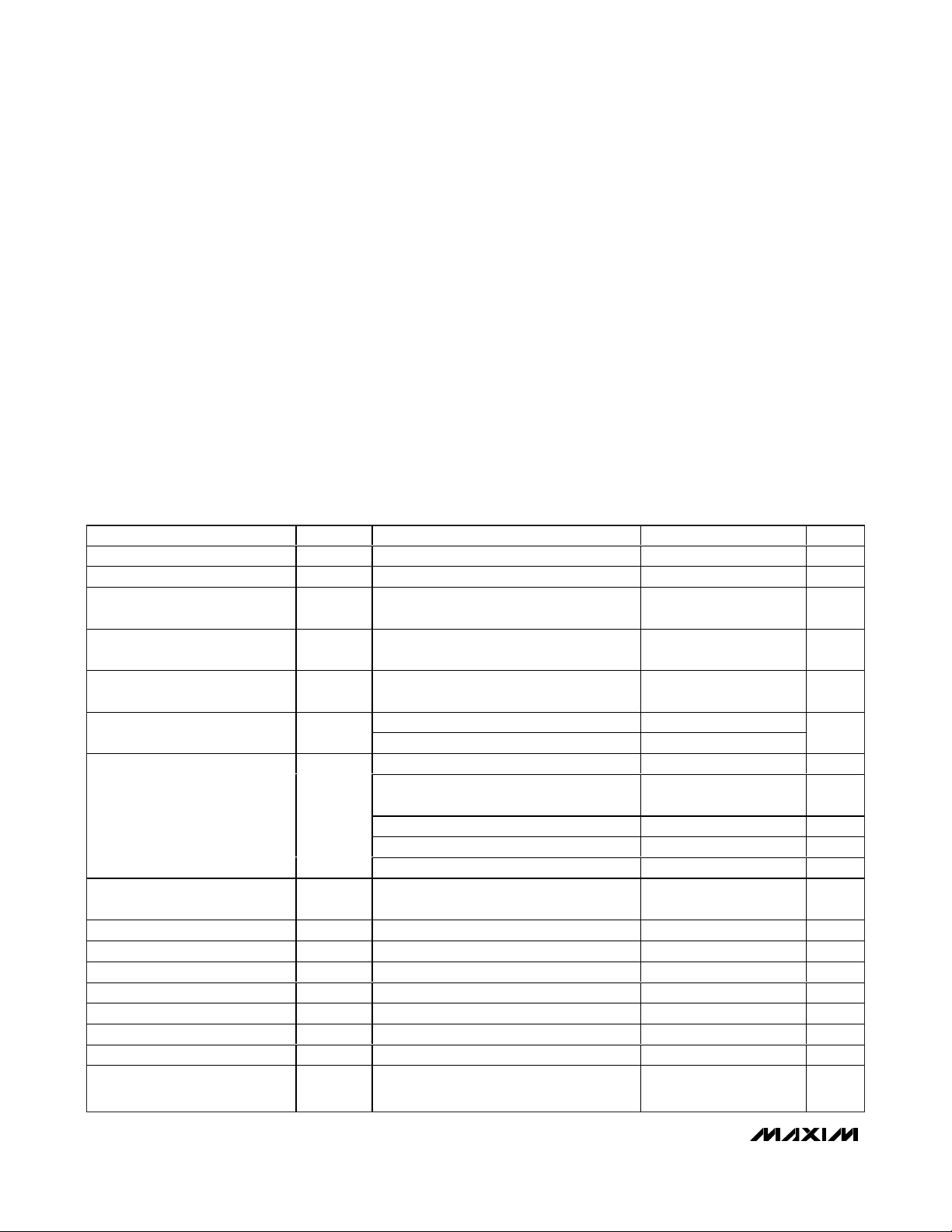

Typical Operating Circuit

19-1006; Rev 1; 5/08

*

US Patent #7,289,119.

True Shutdown is a trademark of Maxim Integrated Products, Inc.

EVALUATION KIT

AVAILABLE

Note: The device is specified over the -40°C to +85°C extended

temperature range.

+

Denotes a lead-free package.

**

EP = Exposed pad.

Pin Configuration

PART

MAX8625AETD+

PINPACKAGE

14 TDFN-EP**

(3mm x 3mm)

TOP MARK

ABQ

TOP VIEW

IN

GND

GNDLX2

MAX8625A

LX2

OUT

ON

OUTSKIP

REFFB

9

8

EP

6

7

INLX1

14

13 11 10

12

+

245

1

3

LX1

EP = EXPOSED PAD.

TDFN-EP

OFF

INPUT

2.7V TO 5.5V

PWM

SKIP

ON

LX1

IN

MAX8625A

SKIP

ON

LX2

OUT

GND

FB

REF

OUTPUT

3.3V

Page 2

MAX8625A

High-Efficiency, Seamless Transition,

Step-Up/Down DC-DC Converter

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

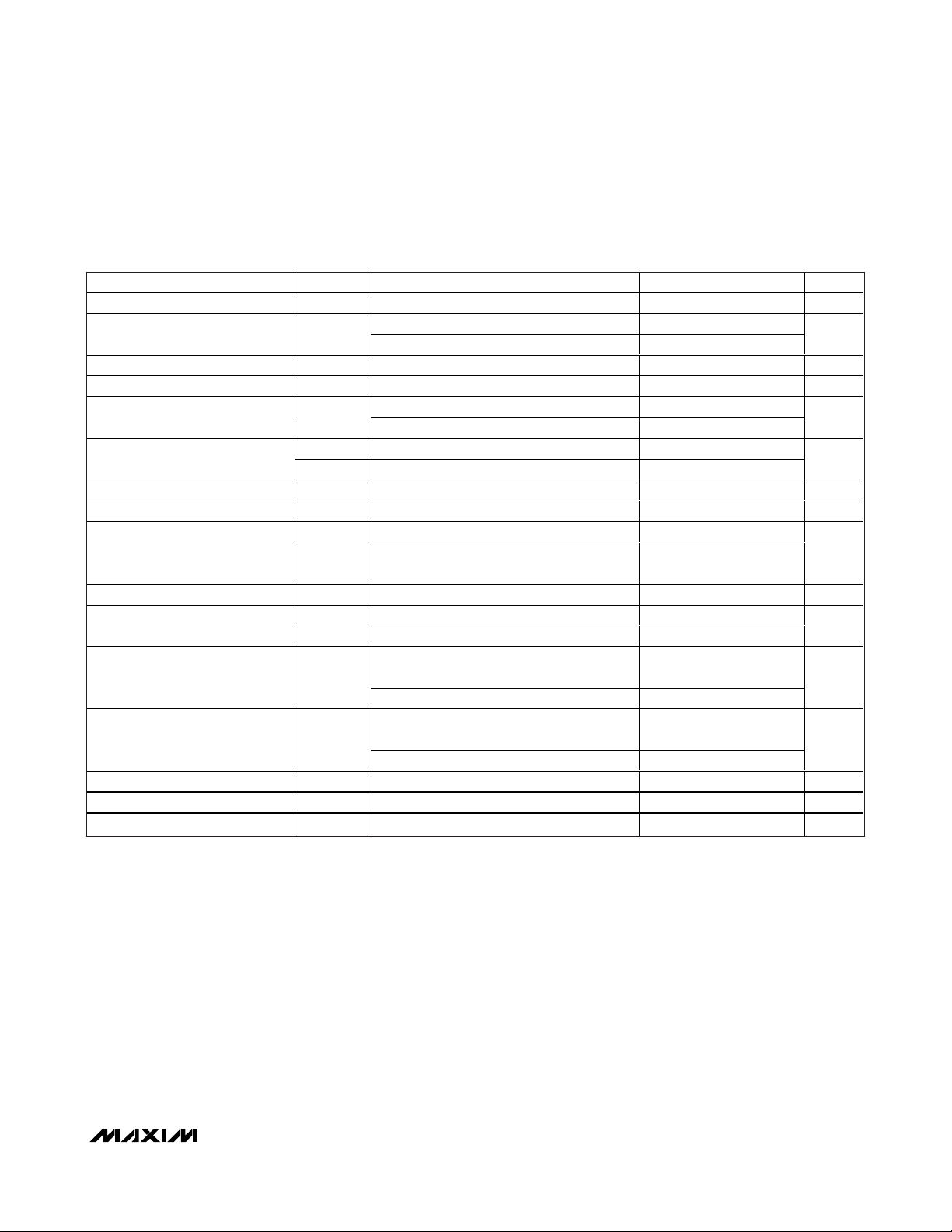

ELECTRICAL CHARACTERISTICS

(VIN= 3.6V, ON = SKIP = IN, FB = GND, V

OUT

= 3.3V, LX_ unconnected, C

REF

= C5 = 0.1µF to GND, Figure 4. TA= -40°C to +85°C.

Typical values are at T

A

= +25°C, unless otherwise noted.) (Note 2)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN, OUT, SKIP, ON to GND ......................................-0.3V to +6V

REF, FB, to GND...............................................-0.3V, (IN + 0.3V)

LX2, LX1 (Note 1).........................................................±1.5A

RMS

Continuous Power Dissipation (TA= +70°C)

Single-Layer Board (derate 18.5mW/°C

above T

A

= +70°C) ...................................................1482mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

Note 1: LX1 and LX2 have internal clamp diodes to IN, PGND and OUT, PGND, respectively. Applications that forward bias these

diodes should take care not to exceed the device's power-dissipation limits.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Range V

UVLO Threshold UVLO VIN rising, 60mV hysteresis 2.20 2.49 V

Quiescent Supply Current, FPWM

Mode, Switching

Quiescent Supply Current, Skip

Mode, Switching

Quiescent Supply Current, No

Switching, Skip Mode

Shutdown Supply Current I

Output Voltage Accuracy

(Fixed Output)

Output Voltage Range

(Adjustable Output)

Maximum Output Current VIN = 3.6V 0.80 A

Soft-Start L = 3.3µH; C

Load Regulation I

Line Regulation VIN = 2.5V to 5.5V 0.03 %/V

OUT Bias Current I

REF Output Voltage V

REF Load Regulation I

FB Feedback Threshold V

IN

I

IN

I

IN

I

IN

IN

OUT

REF

FB

No load, V

SKIP = GND, no load 37 µA

SKIP = GND, FB = 1.3V 35 45 µA

ON = GND, TA = +25°C 0.1 1

TA = +85°C 0.2

PWM mode, VIN = 2.5V to 5.5V 3.30 V

I

OUT

T

A

SKIP mode, valley regulation value 3.28 V

Average skip voltage 3.285

Load step +0.5A -3 %

OUT

V

OUT

VIN = 2.5V to 5.5V 1.244 1.25 1.256 V

REF

I

OUT

to 5.5V

OUT

= 0 to 0.5A, VIN = 2.5V to 5.5V,

= -40°C to +85°C (Note 3)

= 0 to 500mA 0.1 %/mA

= 3.3V 3 µA

= 10µA 1 mV

= 0 to full load, PWM mode; VIN = 2.5V

2.5 5.5 V

= 3.2V 15 22 mA

-1 +1 %

1.25 4.00 V

= C3 + C4 = 44µF 250 mA/ms

OUT

1.244 1.25 1.258 V

µA

Page 3

MAX8625A

High-Efficiency, Seamless Transition,

Step-Up/Down DC-DC Converter

_______________________________________________________________________________________ 3

Note 2: Devices are production tested at TA= +25°C. Specifications over the operating temperature range are guaranteed by

design and characterization.

Note 3: Limits are guaranteed by design and not production tested.

Note 4: The idle-mode current threshold is the transition point between fixed-frequency PWM operation and idle-mode operation.

The specification is given in terms of output load current for an inductor value of 3.3µH. For the step-up mode, the idle-mode

transition varies with input to the output-voltage ratios.

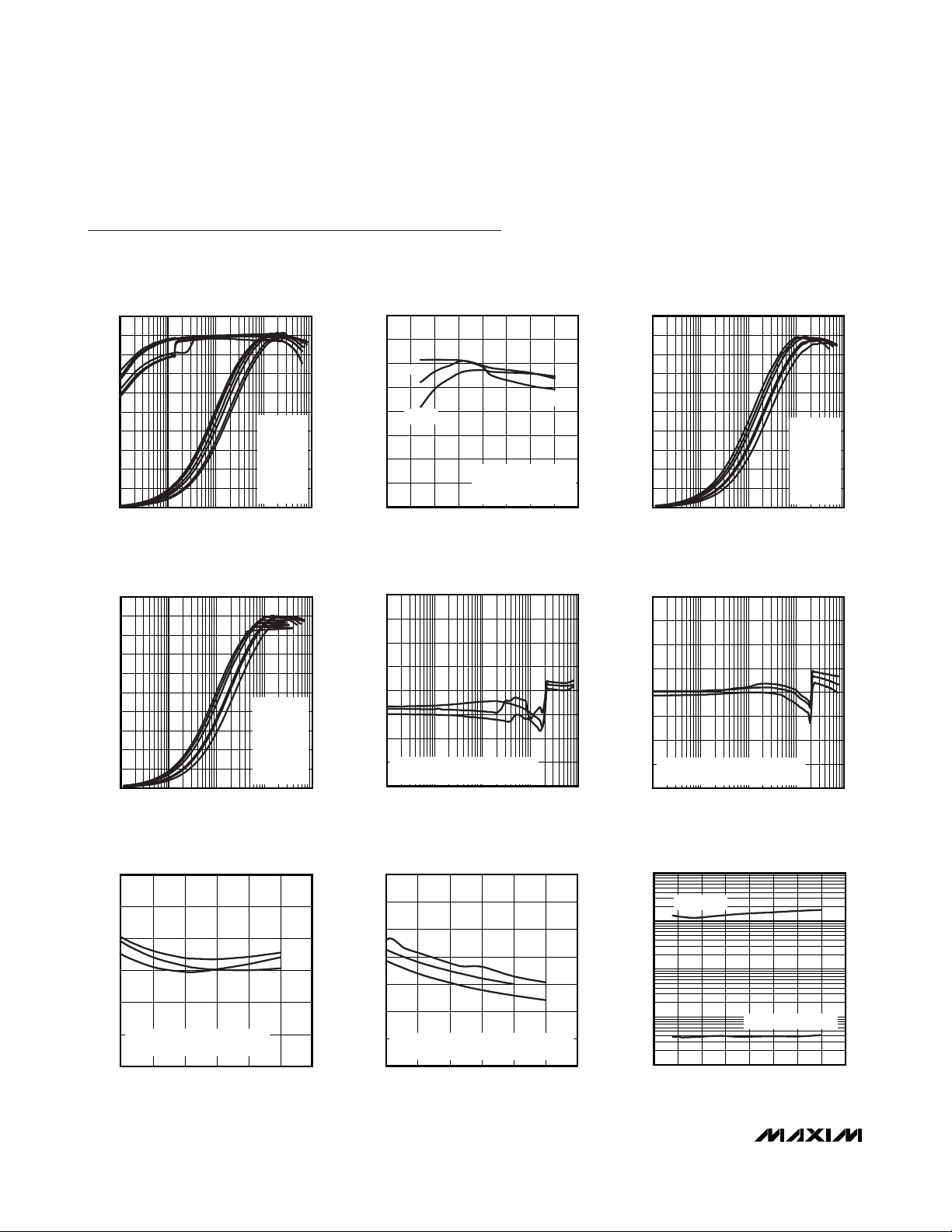

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 3.6V, ON = SKIP = IN, FB = GND, V

OUT

= 3.3V, LX_ unconnected, C

REF

= C5 = 0.1µF to GND, Figure 4. TA= -40°C to +85°C.

Typical values are at T

A

= +25°C, unless otherwise noted.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

FB Dual-Mode Threshold V

FB Leakage Current I

ON, SKIP Input High Voltage V

ON, SKIP Input Low Voltage V

ON Input Leakage Current I

SKIP Input Leakage Current

Peak Current Limit I

Fault Latch-Off Delay 100 ms

MOSFET On-Resistance R

Rectifier-Off Current Threshold I

Idle-Mode Current Threshold

(Note 4)

LX1, LX2 Leakage Current I

Out Reverse Current I

Minimum T

OSC Frequency F

Thermal Shutdown 15°C hysteresis +165 °C

ON

T

FBDM

FB

IHL

I

SKIPH

I

SKIPL

LIMP

ON

LX1OFF

I

SKIP

LXLKG

LXLKGR

ONMIN

OSCPWM

VFB = 1.3V, TA = +25°C 0.001 0.1

VFB = 1.3V, TA = +85°C 0.01

2.5V < VIN < 5.5V 1.6 V

IH

2.5V < VIN < 5.5V 0.45 V

IL

2.5V < VIN < 5.5V, TA = +25°C 0.001 1

TA = +85°C 0.01

V

= 3.6V 3 12

SKIP

V

= 0V -2 -0.2

SKIP

LX1 PMOS 1700 2000 2300 mA

Each MOSFET, TA = +25°C 0.05 0.1

Each MOSFET, VIN = 2.5V to 5.5V,

T

= -40°C to +85°C

A

SKIP = GND 125 mA

SKIP = GND, load decreasing 100

Load increasing 300

VIN = V

V

= 0V to V

LX2

TA = +85°C 0.2

VIN = V

measure I (LX2), T

TA = +85°C 0.5

OUT

LX1

= V

= 5.5V, V

, TA = +25°C

OUT

= 0V, V

LX2

A

= 0V to VIN,

LX1

OUT

= +25°C

75 100 125 mV

0.2

0.01 1

= 5.5V,

850 1000 1150 kHz

0.01 1

25 %

µA

µA

µA

Ω

mA

µA

µA

Page 4

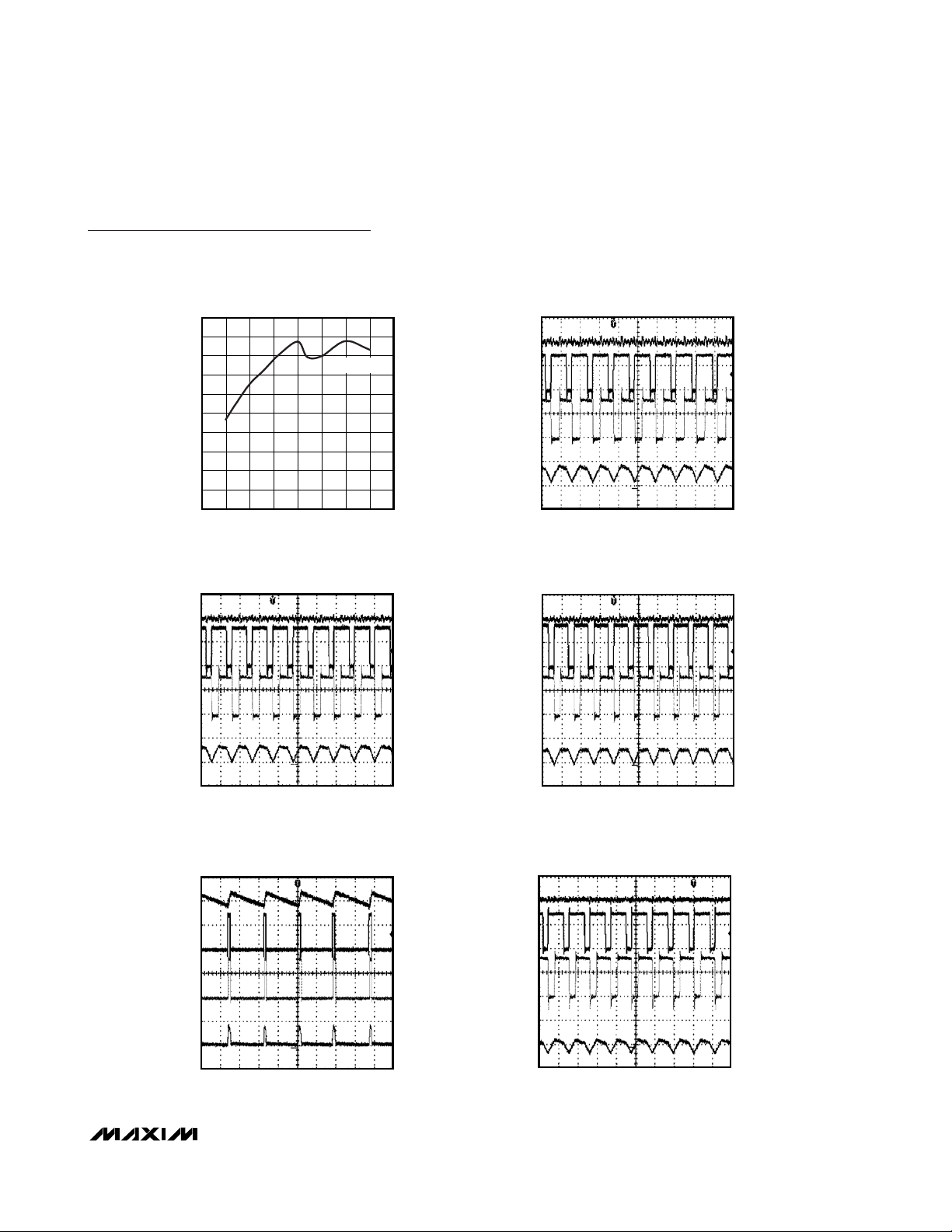

Typical Operating Characteristics

(VIN= 3.6V, SKIP = GND, TA= +25°C, Figure 4, unless otherwise noted.)

MAX8625A

High-Efficiency, Seamless Transition,

Step-Up/Down DC-DC Converter

4 _______________________________________________________________________________________

EFFICIENCY vs. LOAD CURRENT

SKIP AND FPWM MODES

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0.1 1000

LOAD CURRENT (mA)

EFFICIENCY vs. LOAD CURRENT

FPWM MODE (FIGURE 3)

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0.1 1000

LOAD CURRENT (mA)

SKIP-MODE EFFICIENCY

100

95

MAX8625A toc01

V

= 3.3V

OUT

= 2.7V

V

IN

3.0V,

3.3V,

3.6V,

4.2V,

5.0V

100101

90

85

80

75

EFFICIENCY (%)

70

65

60

2.0 3.0 3.52.5 4.0 4.5 5.0 5.5 6.0

vs. INPUT VOLTAGE

300mA

500mA

INPUT VOLTAGE (V)

100mA

V

= 3.3V

OUT

LOAD CURRENT = 100mA,

300mA, 500mA

MAX8625A toc02

EFFICIENCY (%)

OUTPUT VOLTAGE (3.3V INTERNAL FB)

vs. LOAD CURRENT

2.0

1.5

MAX8625A toc04

1.0

0.5

V

= 3.45V

OUT

= 2.7V

V

IN

3.0V,

3.3V,

3.6V,

4.2V,

5.0V

100101

0

DEVIATION (%)

-0.5

-1.0

-1.5

V

= 3.3V

OUT

= +25°C, TA = -40°C, TA = +85°C,

T

A

-2.0

0.1 1000

LOAD CURRENT (mA)

100101

MAX8625A toc05

DEVIATION (%)

EFFICIENCY vs. LOAD CURRENT

FPWM MODE (FIGURE 3)

100

90

80

70

60

50

40

30

20

10

0

0.1 1000

LOAD CURRENT (mA)

V

OUT

V

100101

OUTPUT VOLTAGE (2.8V EXTERNAL FB)

vs. LOAD CURRENT (FIGURE 3)

2.0

1.5

1.0

0.5

0

-0.5

-1.0

V

-1.5

-2.0

= 2.8V

OUT

= +25°C, TA = -40°C, TA = +85°C

T

A

0.1 1000

LOAD CURRENT (mA)

100101

= 2.8V

= 2.7V

IN

3.0V,

3.3V,

3.6V,

4.2V,

5.0V

MAX8625A toc03

MAX8625A toc06

OUTPUT VOLTAGE vs. INPUT VOLTAGE

WITH INTERNAL FB RESISTORS

3.33

3.32

3.31

3.30

3.29

OUTPUT VOLTAGE (V)

3.28

LOAD: 500mA, V

= +25°C, TA = -40°C, TA = +85°C

T

A

3.27

3.0 4.0 4.53.5 5.0 5.5 6.0

= 3.3V

OUT

INPUT VOLTAGE (V)

MAX8625A toc07

OUTPUT VOLTAGE (V)

OUTPUT VOLTAGE vs. INPUT VOLTAGE

WITH EXTERNAL FB RESISTORS

2.82

2.81

2.80

2.79

2.78

2.77

2.76

LOAD: 500mA, V

= +25°C, TA = -40°C, TA = +85°C (FIGURE 3)

T

A

2.75

3.0 4.0 4.53.5 5.0 5.5 6.0

= 2.8V

OUT

INPUT VOLTAGE (V)

MAX8625A toc08

SUPPLY CURRENT vs. INPUT VOLTAGE

WITH NO LOAD

100

FPWM MODE

10

1

SUPPLY CURRENT (mA)

0.1

0.01

2.0 6.0

INPUT VOLTAGE (V)

NO LOAD V

OUT

MAX8625A toc09

= 3.3V

5.55.04.54.03.53.02.5

Page 5

Typical Operating Characteristics (continued)

(VIN= 3.6V, SKIP = GND, TA= +25°C, Figure 4, unless otherwise noted.)

MAX8625A

High-Efficiency, Seamless Transition,

Step-Up/Down DC-DC Converter

_______________________________________________________________________________________

5

MAXIMUM LOAD CURRENT

1000

900

800

700

600

500

400

300

MAXIMUM LOAD CURRENT (mA)

200

100

0

2.0 3.0 3.52.5 4.0 4.5 5.0 5.5 6.0

V

V

LX1

2V/div

vs. INPUT VOLTAGE

INPUT VOLTAGE (V)

SWITCHING WAVEFORMS

= 3.3V, LOAD = 500mA, V

IN

V

OUT

= 3.3V

= 3.3V

OUT

MAX8625A toc12

MAX8625A toc10

V

OUT

50mV/div

(AC-COUPLED)

SWITCHING WAVEFORMS

= 3V, LOAD = 500mA, V

V

IN

V

LX1

2V/div

V

LX2

2V/div

SWITCHING WAVEFORMS

= 3.6V, LOAD = 500mA, V

V

IN

V

LX1

2V/div

1

μs/div

OUT

MAX8625A toc11

OUT

MAX8625A toc13

= 3.3V

= 3.3V

V

OUT

50mV/div

(AC-COUPLED)

I

LX

500mA/div

V

OUT

50mV/div

(AC-COUPLED)

CH1 = V

CH2 = V

V

2V/div

2V/div

2V/div

LX2

I

LX

500mA/div

1

μs/div

SKIP MODE

= 3V, LOAD = 20mA,

V

IN

= 3.288V

V

OUT

LX1

LX2

10μs/div

MAX8625A toc14

V

OUT

20mV/div

(AC-COUPLED)

I

LX

500mA/div

V

2V/div

V

2V/div

V

2V/div

LX2

I

LX

500mA/div

1

μs/div

FPWM MODE

= 3V, LOAD = 20mA,

V

IN

= 3.308V

V

OUT

LX1

LX2

1μs/div

MAX8625A toc15

OUT

20mV/div

(AC-COUPLED)

I

LX

500mA/div

Page 6

MAX8625A

High-Efficiency, Seamless Transition,

Step-Up/Down DC-DC Converter

6 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VIN= 3.6V, SKIP = GND, TA= +25°C, Figure 4, unless otherwise noted.)

1ms/div

LINE TRANSIENT

V

OUT

= 3.3V, LOAD = 5.5Ω,

V

IN

RAMP 3V TO 4V

MAX8625A toc19

CH1 = V

IN

500mV/div

3V OFFSET

CH2 = V

OUT

50mV/div

(AC-COUPLED)

BODE PLOT

GAIN AND PHASE vs. FREQUENCY

MAX8625A toc20

FREQUENCY (kHz)

GAIN (dB)

10010

-50

-40

-30

-20

-10

0

10

20

30

40

-60

1 1000

VIN = 3.6

V

OUT

= 3.3V

LOAD = 200mA

-180

-144

-108

-72

-36

0

36

72

108

144

180

PHASE (DEG)

GAIN

PHASE

0.90

0.94

0.92

0.98

0.96

1.04

1.02

1.00

1.06

-40 0-20 20 40 60 80 100

OSCILLATOR FREQUENCY

vs. TEMPERATURE

MAX8625A toc21

TEMPERATURE (°C)

OSCILLATOR FREQUENCY (MHz)

= 3.6V, LOAD = 5Ω, V

V

IN

SHDN

2V/div

I

BATT

500mA/div

STARTUP WAVEFORMS

OUT

2ms/div

LOAD TRANSIENT

= 3.3V

V

OUT

= 3.288V

MAX8625A toc16

MAX8625A toc18

V

OUT

20mV/div

I

LX

500mA/div

V

OUT

100mV/div

(DC OFFSET = 3.3V)

I

BATT

250mA/div

SHDN

2V/div

V

OUT

500mA/div

STARTUP WAVEFORMS (FIGURE 3)

= 3.6V, LOAD = 30Ω, V

V

IN

2ms/div

OUT

MAX8625A toc17

= 1.5V

I

LX

500mA/div

I

BATT

100mA/div

I

LX

500mA/div

400

μs/div

Page 7

MAX8625A

High-Efficiency, Seamless Transition,

Step-Up/Down DC-DC Converter

_______________________________________________________________________________________

7

Typical Operating Characteristics (continued)

(VIN= 3.6V, SKIP = GND, TA= +25°C, Figure 4, unless otherwise noted.)

2.28

2.34

2.32

2.30

2.36

2.38

2.40

2.42

2.44

2.46

2.48

-50 0-25 25 50 75 100

MINIMUM STARTUP VOLTAGE

vs. TEMPERATURE

MAX8625A toc22

TEMPERATURE (°C)

MINIMUM STARTUP VOLTAGE (V)

V

OUT

= 3.3V, NO LOAD

1.22

1.24

1.23

1.26

1.25

1.27

1.28

-40 20 40-20 0 60 80 100

REFERENCE vs. TEMPERATURE

NO LOAD

MAX8625A toc23

TEMPERATURE (°C)

REFERENCE (V)

V

OUT

= 3.3V

V

IN

= 3.0V,

3.6V,

4.2V,

5.0V

1.22

1.24

1.23

1.26

1.25

1.27

1.28

-40 20 40-20 0 60 80 100

REFERENCE vs. TEMPERATURE

WITH 300mA LOAD

MAX8625A toc24

TEMPERATURE (°C)

REFERENCE (V)

V

OUT

= 3.3V

V

IN

= 3.0V,

3.6V,

4.2V,

5.0V

100

μs/div

SHUTDOWN DUE TO OVERLOAD

V

IN

= 3.6V, V

OUT

= 3.288V

MAX8625A toc25

V

LX2

2V/div

V

LX2

2V/div

V

OUT

500mV/div

I

LX

500mA/div

2μs/div

BOOST-TO-BUCK TRANSITION

FPWM MODE V

IN

= 3.6V, V

OUT

= 3.288V

MAX8625A toc26

V

IN

1V/div

DC OFFSET = 3V

V

OUT

100mV/div

AC-COUPLED

I

LX

200mA/div

Page 8

MAX8625A

High-Efficiency, Seamless Transition,

Step-Up/Down DC-DC Converter

8 _______________________________________________________________________________________

Detailed Description

The MAX8625A step-up/down architecture employs a

true H-bridge topology that combines a boost converter

and a buck converter topology using a single inductor

and output capacitor (Figure 1). The MAX8625A utilizes

a pulse-width modulated (PWM), current-mode control

scheme and operates at a 1MHz fixed frequency to

minimize external component size. A proprietary

H-bridge design eliminates mode changes when transitioning from buck to boost operation. This control

scheme provides very low output ripple using a much

smaller inductor than a conventional H-bridge, while

avoiding glitches that are commonly seen during mode

transitions with competing devices.

The MAX8625A switches at an internally set frequency

of 1MHz, allowing for tiny external components. Internal

compensation further reduces the external component

count in cost- and space-sensitive applications. The

MAX8625A is optimized for use in HDDs, DSCs, and

other devices requiring low-quiescent current for optimal light-load efficiency and maximum battery life.

Control Scheme

The MAX8625A basic noninverting step-up/down converter operates with four internal switches. The control

logic determines which two internal MOSFETs operate

to maintain the regulated output voltage. Unlike a traditional H-bridge, the MAX8625A utilizes smaller peakinductor currents, thus improving efficiency and

lowering input/output ripple.

The MAX8625A uses three operating phases during

each switching cycle. In phase 1 (fast-charge), the

inductor current ramps up with a di/dt of VIN/L. In phase

2 (slow charge/discharge), the current either ramps up

or down depending on the difference between the input

voltage and the output voltage (VIN- V

OUT

)/L. In phase 3

(discharge), the inductor current discharges at a rate of

V

OUT

/L through MOSFETs P2 and N1 (see Figure 1). An

additional fourth phase (phase 4: hold) is entered when

the inductor current falls to zero during phase 3. This

fourth phase is only used during skip operation.

The state machine (Figure 2) decides which phase to

use and when to switch phases. The converter goes

through the first three phases in the same order at all

Pin Description

PIN NAME FUNCTION

1, 2 LX1

3, 4 LX2

5 ON Enable Input. Connect ON to the input or drive high to enable the IC. Drive ON low to disable the IC.

6 SKIP

7FB

Inductor Connection 1. Connect the inductor between LX1 and LX2. Both LX1 pins must be connected

together externally. LX1 is internally connected to GND during shutdown.

Inductor Connection 2. Connect the inductor between LX1 and LX2. Both LX2 pins must be connected

together externally. LX2 is internally connected to GND during shutdown.

Mode Select Input. Connect SKIP to GND to enable skip mode. This mode provides the best overall

efficiency curve.

Connect SKIP to IN to enable forced-PWM mode. This mode provides the lowest noise, but reduces lightload efficiency compared to skip mode.

Feedback Input. Connect to ground to set the fixed 3.3V output. Connect FB to the center tap of an

external resistor-divider from the output to GND to set the output voltage to a different value. VFB regulates

to 1.25V.

8 REF

9, 10 OUT

11, 12 GND Ground. Connect the exposed pad and GND directly under the IC.

13, 14 IN

—EP

Reference Output. Bypass REF to GND with a 0.1µF ceramic capacitor. V

pulled to GND during shutdown.

Power Output. Bypass OUT to GND with two 22µF ceramic capacitors. Both OUT pins must be connected

together externally.

Power-Supply Input. Bypass IN to GND with two 22µF ceramic capacitors. Connect IN to a 2.5V to 5.5V

supply. Both IN pins must be connected together externally.

Exposed Pad. Connect to GND directly under the IC. Connect to a large ground plane for increased

thermal performance.

is 1.25V and is internally

REF

Page 9

MAX8625A

High-Efficiency, Seamless Transition,

Step-Up/Down DC-DC Converter

_______________________________________________________________________________________ 9

times. This reduces the ripple and removes any mode

transitions from boost-only or buck-only to hybrid modes

as seen in competing H-bridge converters.

The time spent in each phase is set by a PWM controller, using timers and/or peak-current regulation on a

cycle-by-cycle basis. The heart of the PWM control

block is a comparator that compares the output voltage-error feedback signal and the sum of the currentsense and slope compensation signals. The currentmode control logic regulates the inductor current as a

function of the output error voltage signal. The currentsense signal is monitored across the MOSFETs (P1, N1,

and N2). A fixed time delay of approximately 30ns

occurs between turning the P1 and N2 MOSFETs off,

and turning the N1 and P2 MOSFETs on. This dead

time prevents efficiency loss by preventing “shootthrough” current.

Step-Down Operation (V

IN

> V

OUT

)

During medium and heavy loads and V

IN

> V

OUT

,

MOSFETs P1 and N2 turn on to begin phase 1 at the

clock edge and ramp up the inductor current. The

duration of phase 1 is set by an internal timer. During

phase 2, N2 turns off, and P2 turns on to further ramp

up inductor current and also transfer charge to the output. This slow charge phase is terminated on a clock

edge and P1 is turned off. The converter now enters the

fast discharge phase (phase 3). In phase 3, N1 turns

on and the inductor current ramps down to the valley

current-regulation point set by the error signal. At the

end of phase 3, both P2 and N1 turn off and another

phase 1 is initiated and the cycle repeats.

With SKIP asserted low, during light loads when inductor current falls to zero in phase 3, the converter switches to phase 4 to reduce power consumption and avoid

Figure 1. Simplified Block Diagram

IN

P1 P2

LX1 LX2

OUT

ON

SKIP

REF

GND

UVLO

REFERENCE

MAX8625

P1

CURRENT SENSE

1.25V

125mV

Gm

N1

PWM/PFM

CONTROL

N2

OSCILLATOR

FB

Page 10

MAX8625A

High-Efficiency, Seamless Transition,

Step-Up/Down DC-DC Converter

10 ______________________________________________________________________________________

shuttling current in and out of the output capacitor. If

SKIP is asserted high for forced-PWM mode, phase 4 is

not entered and current shuttling is allowed (and is

necessary to maintain the PWM operation frequency

when no load is present).

Step-Up Operation (V

IN

< V

OUT

)

During medium and heavy loads when V

IN

< V

OUT,

MOSFETs P1 and N2 turn on at the clock edge to ramp

up the inductor current. Phase 1 terminates when the

inductor current reaches the peak target current set by

the PWM comparator and N2 turns off. This is followed

by a slow-discharge phase (phase 2) instead of a

charge phase (since VINis less than V

OUT

) when P2

turns on. The slow-discharge phase terminates on a

clock edge. The converter now enters the fast-discharge phase (phase 3). During phase 3, P1 turns off

and N1 turns on. At the end of the minimum time, both

P2 and N1 turn off and the cycle repeats.

If SKIP is asserted low, during light loads when inductor

current falls to zero in phase 3, the converter switches to

phase 4 (hold) to reduce power consumption and avoid

shuttling current in and out of the output. If SKIP is high

to assert forced-PWM mode, the converter never enters

phase 4 and allows negative inductor current.

Step-Up/Down Transition-Zone Operation

(V

IN

= V

OUT

)

When V

IN

= V

OUT

, the converter still goes through the

three phases for moderate to heavy loads. However,

the maximum time is now spent in phase 2 where

inductor current di/dt is almost zero, since it is proportional to (VIN- V

OUT

). This eliminates transition glitches

Figure 2. State Diagram

FAULT

TIMEOUT

(ASYNCHRONOUS

FROM ANYWHERE)

ERROR

ON = 1

P1, P2 = OFF

N1, N2 = ON

PHASE 2

SLOW CHARGE/

DISCHARGE

OSC = ON

P1, P2 = ON

N1, N2 = OFF

T2-3

PHASE 3

FAST DISCHARGE

OSC = ON

P2, N1 = ON

P1, N2 = OFF

ON = 1, P1, P2 = OFF, N1, N2 = ON,

POWER-UP

OSC = ON AND REF = ON IF UVLO OK

T1-2

T1-3

T3-1

T3-4

(SKIP)

OFF

ON = 0

P1, P2 = OFF

N1, N2 = ON

= 0μA

I

Q

TRUN

PHASE 1

FAST-CHARGE

OSC = ON

P1, N2 = ON

P2, N1 = OFF

T4-1

PHASE 4

HOLD

OSC = OFF

N1, N2 = ON

P1, P2 = OFF

ON = 0

(ASYNCHRONOUS

FROM

ANYWHERE)

TPUP

REFOK = 0 OR

UVLO = 0

(ASYNCHRONOUS

FROM ANYWHERE)

Page 11

MAX8625A

High-Efficiency, Seamless Transition,

Step-Up/Down DC-DC Converter

______________________________________________________________________________________ 11

or oscillation between the boost and buck modes as

seen in other step-up/down converters. See the switching waveforms for each of the three modes and transition waveforms in the

Typical Operating Characteristics

section.

Forced-PWM Mode

Drive SKIP high to operate the MAX8625A in forcedPWM mode. In this mode, the IC operates at a constant

1MHz switching frequency with no pulse skipping. This

scheme is desirable in noise-sensitive applications

because the output ripple is minimized and has a predictable noise spectrum. Forced PWM consumes higher

supply current at light loads due to constant switching.

Skip Mode

Drive SKIP low to operate the MAX8625A in skip mode

to improve light-load efficiency. In skip mode, the IC

switches only as necessary to maintain the output at

light loads, but still operates with fixed-frequency PWM

at medium and heavy loads. This maximizes light-load

efficiency and reduces the input quiescent current to

37µA (typ).

Load Regulation and Transient Response

During a load transient, the output voltage instantly

changes due to the ESR of the output capacitors by an

amount equal to their ESR times the change in load

current (ΔV

OUT

= R

ESR

x ΔI

LOAD

). The output voltage

then deviates further based on the speed at which the

loop compensates for the load step. Increasing the output capacitance reduces the output-voltage droop. See

the

Capacitor Selection

section. The typical application

circuit limits the output transient droop to less than 3%.

See the

Typical Operating Characteristics

section.

Soft-Start

Soft-start prevents input inrush current during startup.

Internal soft-start circuitry ramps the peak inductor current with an internal DAC in 8ms. Once the output

reaches regulation, the current limit immediately jumps

to the maximum threshold. This allows full load capability as soon as regulation is reached, even if it occurs

before the 8ms soft-start time is complete.

Shutdown

Drive ON low to place the MAX8625A in shutdown

mode and reduce supply current to less than 1µA.

During shutdown, OUT is disconnected from IN, and

LX1 and LX2 are connected to GND. Drive ON high for

normal operation.

Fault and Thermal Shutdown

The MAX8625A contains current-limit and thermal shutdown circuitry to protect the IC from fault conditions.

When the inductor current exceeds the current limit (2A

for the MAX8625A), the converter immediately enters

phase 3 and an internal 100ms timer starts. The converter continues to commutate through the three phases, spending most of its time in phase 1 and phase 3. If

the overcurrent event continues and the output is out of

regulation for the duration of the 100ms timer, the IC

enters shutdown mode and the output latches off. ON

must then be toggled to clear the fault. If the overload

is removed before the 100ms timer expires, the timer is

cleared and the converter resumes normal operation.

The thermal-shutdown circuitry disables the IC switching if the die temperature exceeds +165°C. The IC

begins soft-start once the die temperature cools by

15°C.

Page 12

MAX8625A

High-Efficiency, Seamless Transition,

Step-Up/Down DC-DC Converter

12 ______________________________________________________________________________________

Applications Information

Selecting the Output Voltage

The MAX8625A output is nominally fixed at 3.3V.

Connect FB to GND to select the internally fixed-output

voltage. For an adjustable output voltage, connect FB

to the center tap of an external resistor-divider connected from the output to GND (R1 and R2 in Figure 3).

Select 100kΩ for R2 and calculate R1 using the following equation:

where VFB= 1.25V and V

OUT

is the desired output reg-

ulation voltage. V

OUT

must be between 1.25V and 4V.

Note that the minimum output voltage is limited by the

minimum duty cycle. V

OUT

cannot be below 1.25V.

Calculating Maximum Output Current

The maximum output current provided by the MAX8625A

circuit depends on the inductor value, switching frequency, efficiency, and input/output voltage.

See the

Typical Operating Characteristics

section for

the Maximum Load Current vs. Input Voltage graph.

Capacitor Selection

The input and output ripple currents are both discontinuous in this topology. Therefore, select at least two

22µF ceramic capacitors at the input. Select two 22µF

ceramic output capacitors. For best stability over a

wide temperature range, use X5R or better dielectric.

Inductor Selection

The recommended inductance range for the

MAX8625A is 3.3µH to 4.7µH. Larger values of L give a

smaller ripple, while smaller L values provide a better

transient response. This is because, for boost and stepup/down topologies, the crossover frequency is

inversely proportional to the value of L for a given load

and input voltage. The MAX8625A is internally compensated, and therefore, the choice of power components

for stable operation is bounded. A 3.3µH inductor with

2A rating is recommended for the 3.3V fixed output with

0.8A load.

PCB Layout and Routing

Good PCB layout is important to achieve optimal performance from the MAX8625A. Poor design can cause

excessive conducted and/or radiated noise.

Conductors carrying discontinuous currents and any

high-current path should be made as short and wide as

possible. Keep the feedback network (R1 and R2) very

close to the IC, preferably within 0.2 inches of the FB

and GND pins. Nodes with high dv/dt (switching

nodes) should be kept as small as possible and routed

away from FB. Connect the input and output capacitors

as close as possible to the IC. Refer to the MAX8625A

evaluation kit for a PCB layout example.

Figure 3. Typical Application Circuit (Adjustable Output)

Rk

1 100 1 =× −

⎛

V

Ω

OUT

⎜

V

⎝

FB

⎞

⎟

⎠

L

3.3μH

12

INPUT

2.7V TO 5.5V

C1, C2

22μF

MODE

SELECTION

INPUT

OFF

0.1μF

ON

C5

13

IN

14

IN

6

SKIP

5

ON

8

REF

34

LX1LX1 LX2

U1

MAX8625A

LX2

OUT

OUT

GND

GND

9

10

R1

140kΩ

7

FB

R2

100kΩ

11

12

OUTPUT

C3, C4

22μF

3V

Page 13

MAX8625A

High-Efficiency, Seamless Transition,

Step-Up/Down DC-DC Converter

______________________________________________________________________________________ 13

Chip Information

PROCESS: BiCMOS

Figure 4. Typical Application Circuit (Fixed 3.3V Output)

Package Information

For the latest package outline information and land patterns, go

to www.maxim-ic.com/packages

.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

14 TDFN-EP T1433-2

21-0137

12

INPUT

2.7V TO 5.5V

C1, C2

22μF

MODE

SELECTION

INPUT

OFF

ON

C5

0.1μF

13

IN

14

IN

6

SKIP

5

ON

8

REF

L

3.3μH

34

LX1LX1 LX2

U1

MAX8625A

LX2

OUT

OUT

GND

GND

9

10

7

FB

11

12

OUTPUT

3.3V

C3, C4

22μF

Page 14

MAX8625A

High-Efficiency, Seamless Transition,

Step-Up/Down DC-DC Converter

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

14

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2008 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products. Inc.

Revision History

REVISION

NUMBER

0 3/08 Initial release —

1 5/08 Added PCB Layout and Routing section 12

REVISION

DATE

DESCRIPTION

PAGES

CHANGED

Loading...

Loading...