Page 1

General Description

The MAX8545/MAX8546/MAX8548 are voltage-mode

pulse-width-modulated (PWM), step-down DC-DC controllers ideal for a variety of cost-sensitive applications.

They drive low-cost N-channel MOSFETs for both the

high-side switch and synchronous rectifier, and require

no external current-sense resistor. These devices can

supply output voltages as low as 0.8V.

The MAX8545/MAX8546/MAX8548 have a wide 2.7V to

28V input range, and do not need any additional bias

voltage. The output voltage can be precisely regulated

from 0.8V to 0.83 x VIN. These devices can provide efficiency up to 95%. Lossless short-circuit and current-limit

protection is provided by monitoring the R

DS(ON)

of the

low-side MOSFET. The MAX8545 and MAX8548 have a

current-limit threshold of 320mV, while the MAX8546 has

a current-limit threshold of 165mV. All devices feature

foldback-current capability to minimize power dissipation

under short-circuit condition. Pulling the COMP/EN pin

low with an open-collector or low-capacitance, opendrain device can shut down all devices.

The MAX8545/MAX8546 operate at 300kHz and the

MAX8548 operates at 100kHz. The MAX8545/

MAX8546/MAX8548 are compatible with low-cost aluminum electrolytic capacitors. Input undervoltage lockout prevents proper operation under power-sag

operations to prevent external MOSFETs from overheating. Internal soft-start is included to reduce inrush current. These devices are offered in space-saving 10-pin

µMAX packages.

Applications

Features

♦ 2.7V to 28V Input Range

♦ Foldback Short-Circuit Protection

♦ No Additional Bias Supply Needed

♦ 0.8V to 0.83 x V

IN

Output

♦ Up to 95% Efficiency

♦ Low-Cost External Components

♦ No Current-Sense Resistor

♦ All N-Channel MOSFET Design

♦ Adaptive Gate Drivers Eliminate Shoot-Through

♦ Lossless Overcurrent and Short-Circuit

Protection

♦ 300kHz Switching Frequency

(MAX8545/MAX8546)

♦ 100kHz Switching Frequency (MAX8548)

♦ Pin-Compatible with the MAX1967

♦ Thermal Shutdown

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

________________________________________________________________ Maxim Integrated Products 1

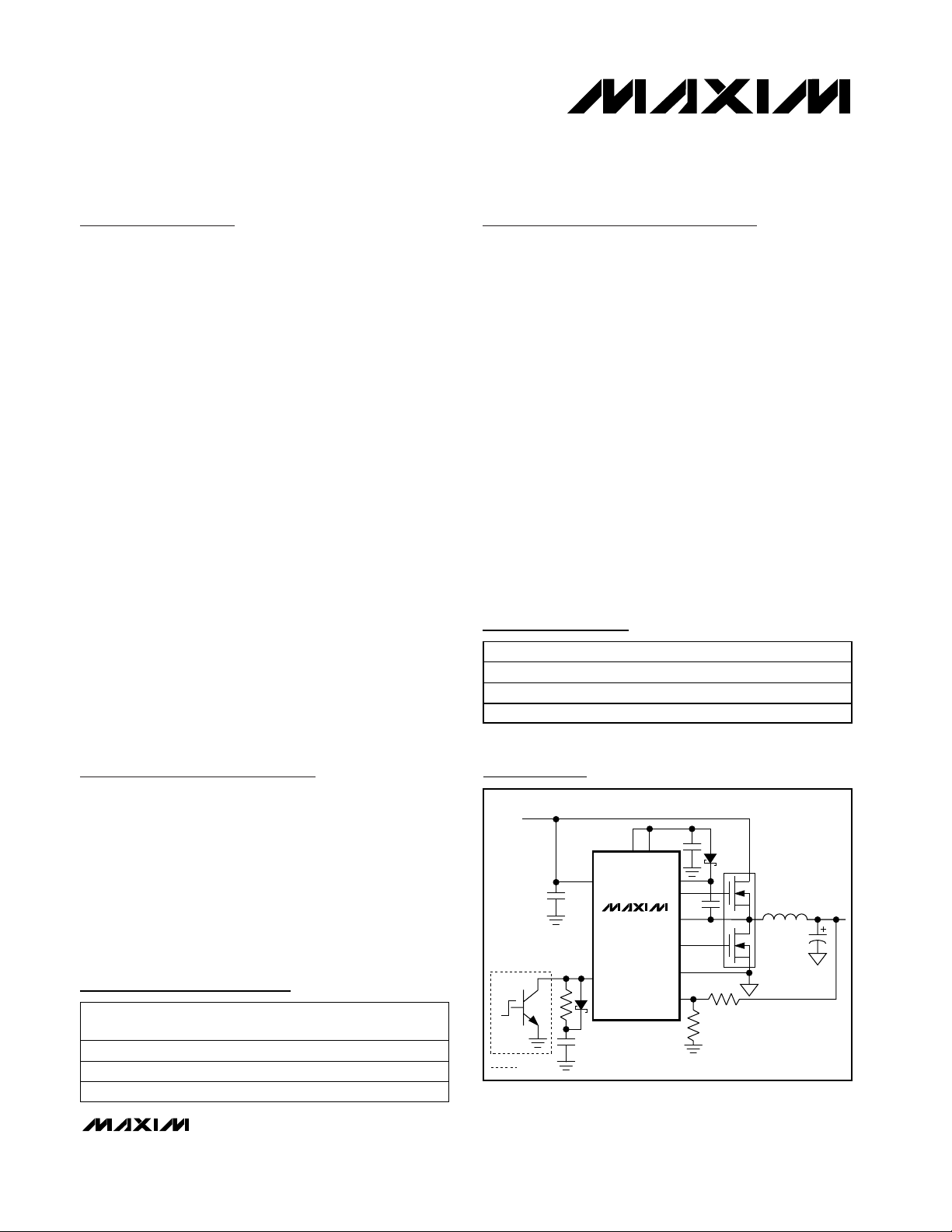

Typical Operating Circuit

Ordering Information

Pin Configuration appears at end of data sheet.

19-2795; Rev 0; 7/03

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Selector Guide

Set-Top Boxes

Graphic Card and Video

Supplies

Desktops and Desknotes

PCI Express Power

Supplies

Telecom Power Supplies

Notebook Docking

Station Supplies

Cable Modems and

Routers

Networking Power

Supplies

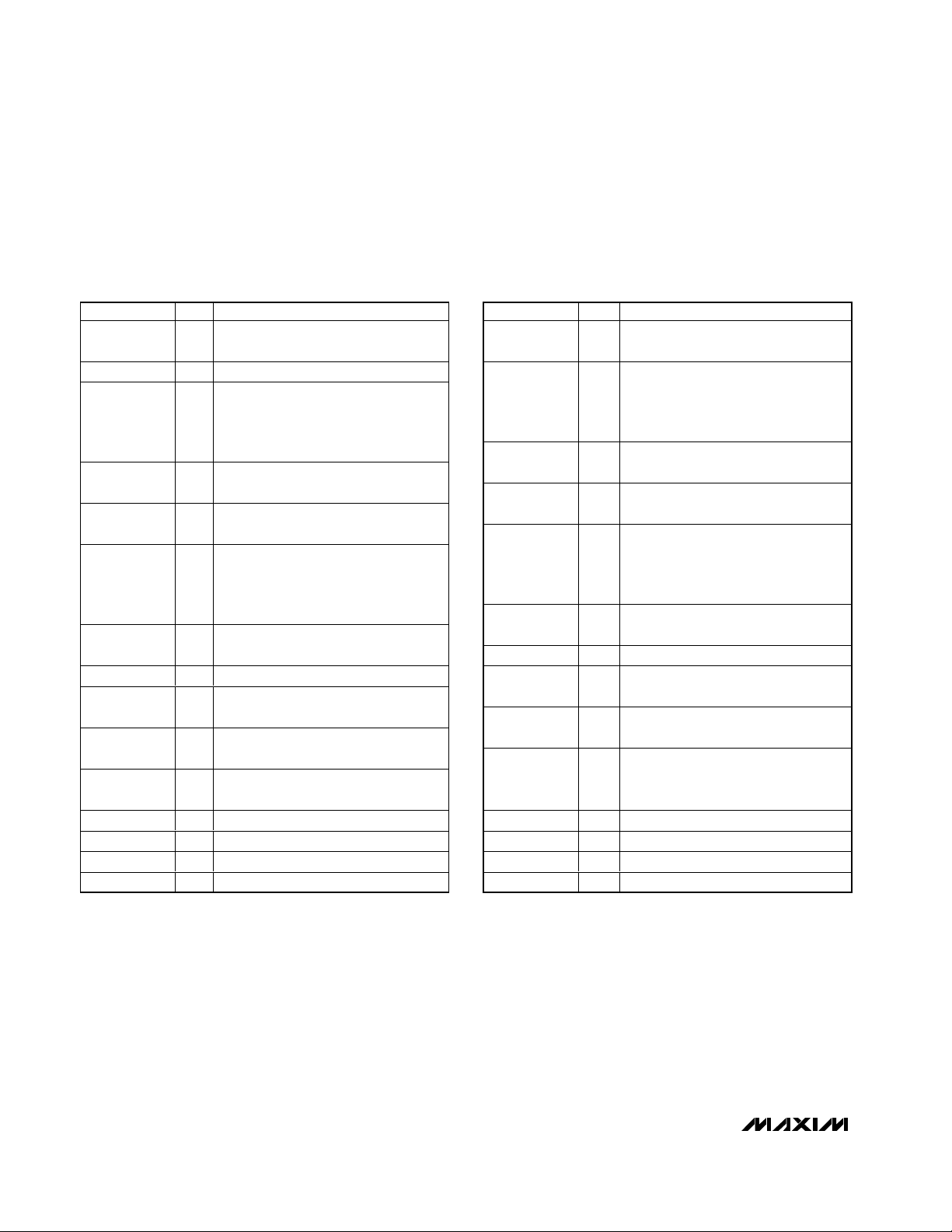

PART TEMP RANGE PIN-PACKAGE

MAX8545EUB -40°C to +85°C 10 µMAX

MAX8546EUB -40°C to +85°C 10 µMAX

MAX8548EUB -40°C to +85°C 10 µMAX

PART

MAX8545 300kHz -320mV

MAX8546 300kHz -165mV

MAX8548 100kHz -320mV

SWITCHING

FREQUENCY

CURRENT-LIMIT

THRESHOLD

2.7V TO 28V

OFF

ON

OPTIONAL

INPUT

VLV

CC

IN

COMP/

EN

MAX8545

MAX8546

MAX8548

BSTV

GND

DH

LX

DL

FB

OUTPUT

0.8V TO

0.9 x V

UP TO 6A

IN

Page 2

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VIN= VL= VCC= 5V, TA= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

(All voltages referenced to GND unless otherwise noted.)

V

IN

to GND ............................................................-0.3V to +30V

V

CC

to GND .............................-0.3V, lower of 6V or (VL + 0.3V)

FB to GND ................................................................-0.3V to +6V

BST to GND ............................................................-0.3V to +36V

VL, DL, COMP to GND ..............................-0.3V to (V

CC

+ 0.3V)

BST to LX..................................................................-0.3V to +6V

DH to LX....................................................-0.3V to (V

BST

+ 0.3V)

VL Short to GND ......................................................................5s

LX to GND ......................................................................0 to 30V

Input Current (any pin) .....................................................±50mA

Continuous Power Dissipation (T

A

= +70°C)

10-Pin µMAX (derate 5.6mW/°C above +70°C) ..........444mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

VIN Operating Range V

VIN Undervoltage Lockout

(UVLO) Trip Level

VIN Operating Supply Current VFB = 0.88V (no switching)

VL Output Voltage

Thermal Shutdown

OSCILLATOR

Frequency f

Minimum Duty Cycle DC

Maximum Duty Cycle DC

SOFT-START

Digital Ramp Period

Soft-Start Levels

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

VCC = VL, VIN separate from V

IN

VIN = VL = V

Rising and falling edge, hysteresis = 2% 2.35 2.50 2.66 V

OSC

MIN

MAX

5.5V < V

1mA < I

Rising temperature, typical

hysteresis = 10°C (Note 1)

MAX8545, MAX8546 250 300 360

MAX8548 80 100 120

DH output, MAX8545, MAX8546 5

MAX8548 10

DH output, MAX8545, MAX8546 83 86

MAX8548 90 95

MAX8545, MAX8546 6.6

MAX8548

MAX8545, MAX8546 V

MAX8548

< 28V, VCC = VL,

IN

LOAD

CC

CC

< 25mA

4.9 28.0

2.7 5.5

0.7

4.7 5 5.3 V

+160 °C

10.2

/ 64

OUT

V

/ 32

OUT

1.2 mA

V

kHz

%

%

ms

V

Page 3

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VIN= VL= VCC= 5V, TA= -40°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Note 1: Thermal shutdown disables the buck regulator when the die reaches this temperature. Soft-start is reset but the VL regulator

remains on.

ERROR AMPLIFIER

FB Regulation Voltage

FB to COMP/EN Gain

FB to COMP/EN

Transconductance

FB Input Bias Current V

COMP/EN Source Current V

Current-Limit Threshold Voltage

(Across Low-Side MOSFET)

Foldback Current-Limit Threshold

Voltage (Across Low-Side

MOSFET) When Output is Short

MOSFET DRIVERS

Break-Before-Make Time

DH On-Resistance in Low State 1.6 4 Ω

DH On-Resistance in High State 2.5 5.5 Ω

DL On-Resistance in Low State 1.1 2.5 Ω

DL On-Resistance in High State 2.5 5.5 Ω

BST Leakage Current V

LX Leakage Current V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

2.7V < VCC < 5.5V, 0°C to +85°C 0.787 0.800 0.815

2.7V < V

-5µA < I

FB

COMP/EN

LX to GND, MAX8545, MAX8548,

V

FB

LX to GND MAX8546, V

LX to GND, VFB = 0V,

MAX8545, MAX8548

MAX8546, LX to GND, V

Rising edge, DH going low to DL going high 96

Falling edge, DL going low to DH going high 28

BST

BST

< 5.5V, -40°C to +85°C 0.782 0.800 0.815

CC

4000 V / V

COMP/EN

= 0.88V 1 2 µA

= 0.8V

= 33V, V

= 33V, V

< +5µA 70 108 160 µS

= 0V 15 46 100 µA

-355 -320 -280

= 0.8V -185 -165 -140

FB

-105 -75 -45

= 0 -53 -38 -22

FB

= 28V, VFB = 0.88V 0 50 µA

LX

= 28V, VFB = 0.88V 33 100 µA

LX

V

mV

mV

ns

Page 4

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

4 _______________________________________________________________________________________

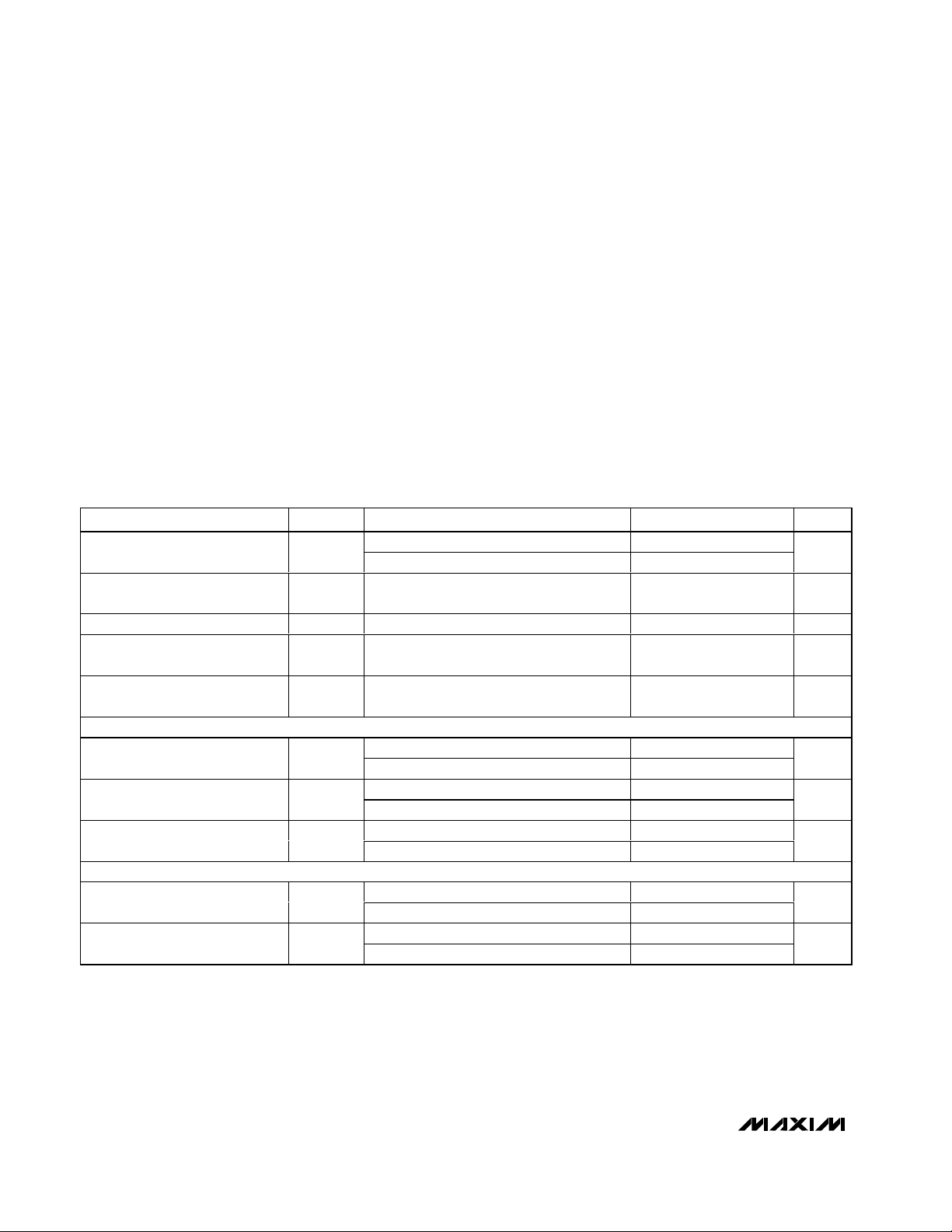

Typical Operating Characteristics

(VIN= VL= VCC= 5V, typical values are at TA = +25°C, unless otherwise noted.)

EFFICIENCY vs. LOAD CURRENT

MAX8545/46/48 toc01

LOAD CURRENT (A)

(CIRCUIT OF FIGURE 1; TABLE 1a)

EFFICIENCY (%)

10.1

10

20

30

40

50

60

70

80

90

100

0

0.01 10

VIN = 3.3V

V

OUT

= 1.2V

EFFICIENCY vs. LOAD CURRENT

MAX8545/46/48 toc02

LOAD CURRENT (A)

(CIRCUIT OF FIGURE 1; TABLE 1a)

EFFICIENCY (%)

10.1

10

20

30

40

50

60

70

80

90

100

0

0.01 10

VIN = 5V

V

OUT

= 1.8V

V

OUT

= 3.3V

EFFICIENCY vs. LOAD CURRENT

MAX8545/46/48 toc03

LOAD CURRENT (A)

(CIRCUIT OF FIGURE 2; TABLE 2a)

EFFICIENCY (%)

10.1

10

20

30

40

50

60

70

80

90

100

0

0.01 10

V

OUT

= 1.8V

V

OUT

= 3.3V

VIN = 12V

EFFICIENCY vs. LOAD CURRENT

MAX8545/46/48 toc04

LOAD CURRENT (A)

(CIRCUIT OF FIGURE 2; TABLE 2a)

EFFICIENCY (%)

10.1

10

20

30

40

50

60

70

80

90

100

0

0.01 10

VIN = 17V

V

OUT

= 3.3V

V

OUT

= 1.8V

EFFICIENCY vs. LOAD CURRENT

MAX8545/46/48 toc05

LOAD CURRENT (A)

EFFICIENCY (%)

10.1

10

20

30

40

50

60

70

80

90

100

0

0.01 10

V

OUT

= 1.8V

V

OUT

= 1.2V

VIN = 3.3V

(CIRCUIT OF FIGURE 1; TABLE 1b)

EFFICIENCY vs. LOAD CURRENT

MAX8545/46/48 toc06

LOAD CURRENT (A)

EFFICIENCY (%)

10.1

10

20

30

40

50

60

70

80

90

100

0

0.01 10

V

OUT

= 3.3V

V

OUT

= 2.5V

V

OUT

= 1.8V

V

OUT

= 1.2V

VIN = 5V

(CIRCUIT OF FIGURE 1; TABLE 1b)

EFFICIENCY vs. LOAD CURRENT

MAX8545/46/48 toc07

LOAD CURRENT (A)

EFFICIENCY (%)

10.1

10

20

30

40

50

60

70

80

90

100

0

0.01 10

V

OUT

= 3.3V

V

OUT

= 2.5V

V

OUT

= 1.8V

V

OUT

= 1.2V

VIN = 12V

(CIRCUIT OF FIGURE 2; TABLE 2b)

EFFICIENCY vs. LOAD CURRENT

MAX8545/46/48 toc08

LOAD CURRENT (A)

EFFICIENCY (%)

10.1

10

20

30

40

50

60

70

80

90

100

0

0.01 10

V

OUT

= 3.3V

V

OUT

= 2.5V

V

OUT

= 1.8V

V

OUT

= 1.2V

VIN = 17V

(CIRCUIT OF FIGURE 2; TABLE 2b)

CHANGE IN OUTPUT VOLTAGE

vs. LOAD CURRENT

MAX8545/46/48 toc09

LOAD CURRENT (A)

OUTPUT VOLTAGE (V)

5432

2.485

2.490

2.495

2.500

2.505

2.510

2.515

2.520

2.480

16

V

OUT

= 2.5V

V

IN

= 12V

Page 5

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

_______________________________________________________________________________________ 5

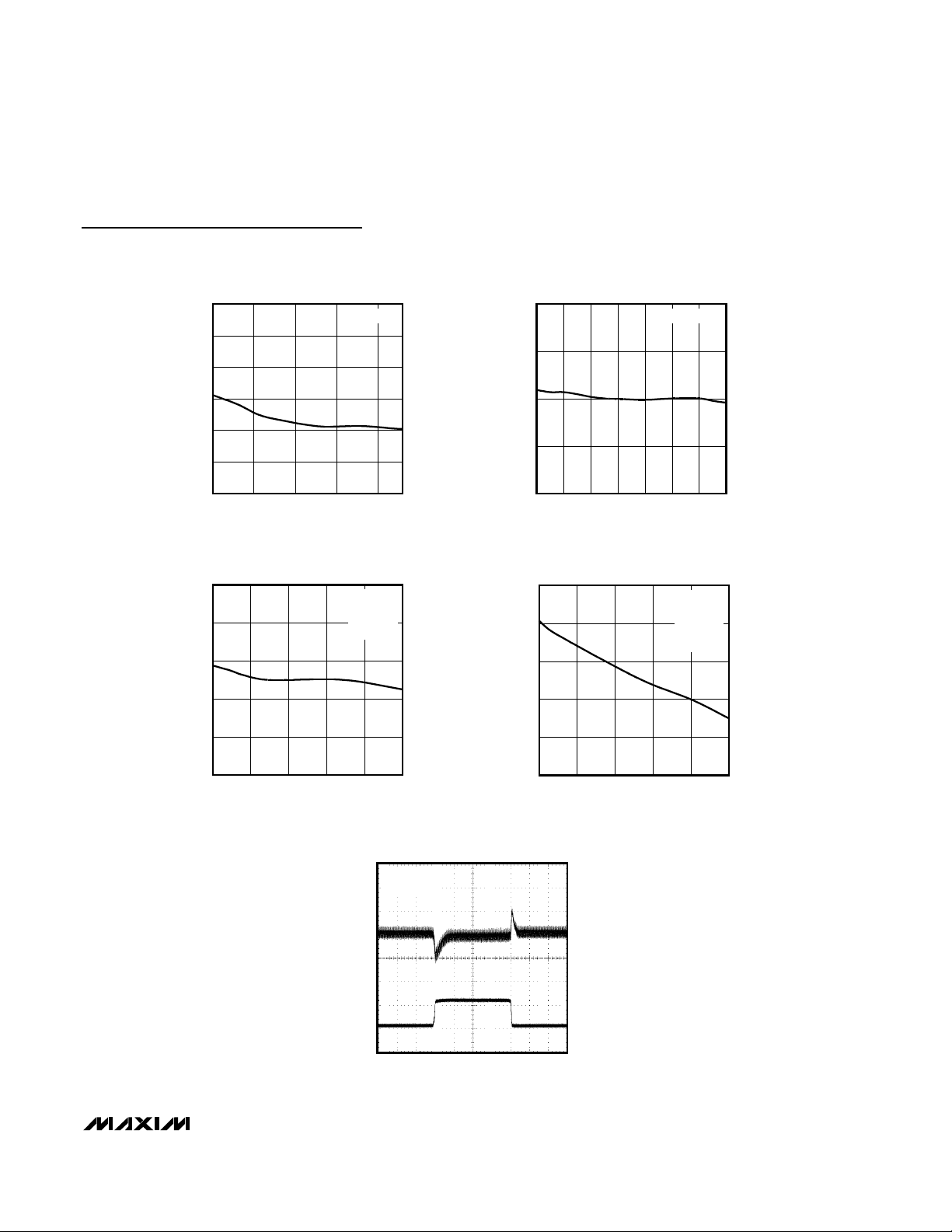

Typical Operating Characteristics (continued)

(VIN= VL= VCC= 5V, typical values are at TA = +25°C, unless otherwise noted.)

1.84

1.83

1.82

1.81

1.80

OUTPUT VOLTAGE (V)

1.79

1.78

CHANGE IN OUTPUT VOLTAGE

vs. INPUT VOLTAGE

2.5

INPUT VOLTAGE (V)

FREQUENCY vs. INPUT VOLTAGE

310

306

302

I

= 6V

LOAD

4.54.03.53.0

V

= 2.5V

OUT

NO LOAD

MAX8545/

MAX8546

MAX8545/46/48 toc10

MAX8545/46/48 toc12

2.52

2.51

2.50

OUTPUT VOLTAGE (V)

2.49

2.48

10

310

306

302

CHANGE IN OUTPUT VOLTAGE

vs. INPUT VOLTAGE

I

= 6V

LOAD

18 20 22 24161412

INPUT VOLTAGE (V)

FREQUENCY vs. TEMPERATURE

VIN = 12V

= 2.5V

V

OUT

NO LOAD

MAX8545/

MAX8546

MAX8545/46/48 toc11

MAX8545/46/48 toc13

298

FREQUENCY (kHz)

294

290

2.70 28.00

INPUT VOLTAGE (V)

22.9417.8812.827.76

LOAD TRANSIENT RESPONSE

VIN = 17V

= 2.5V

V

OUT

0

40µs/div

298

FREQUENCY (kHz)

294

290

-40.00 85.00

TEMPERATURE (°C)

MAX8545 toc14

V

OUT

AC COUPLED

100mV/div

I

OUT

5A/div

60.0035.0010.00-15.00

Page 6

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

6 _______________________________________________________________________________________

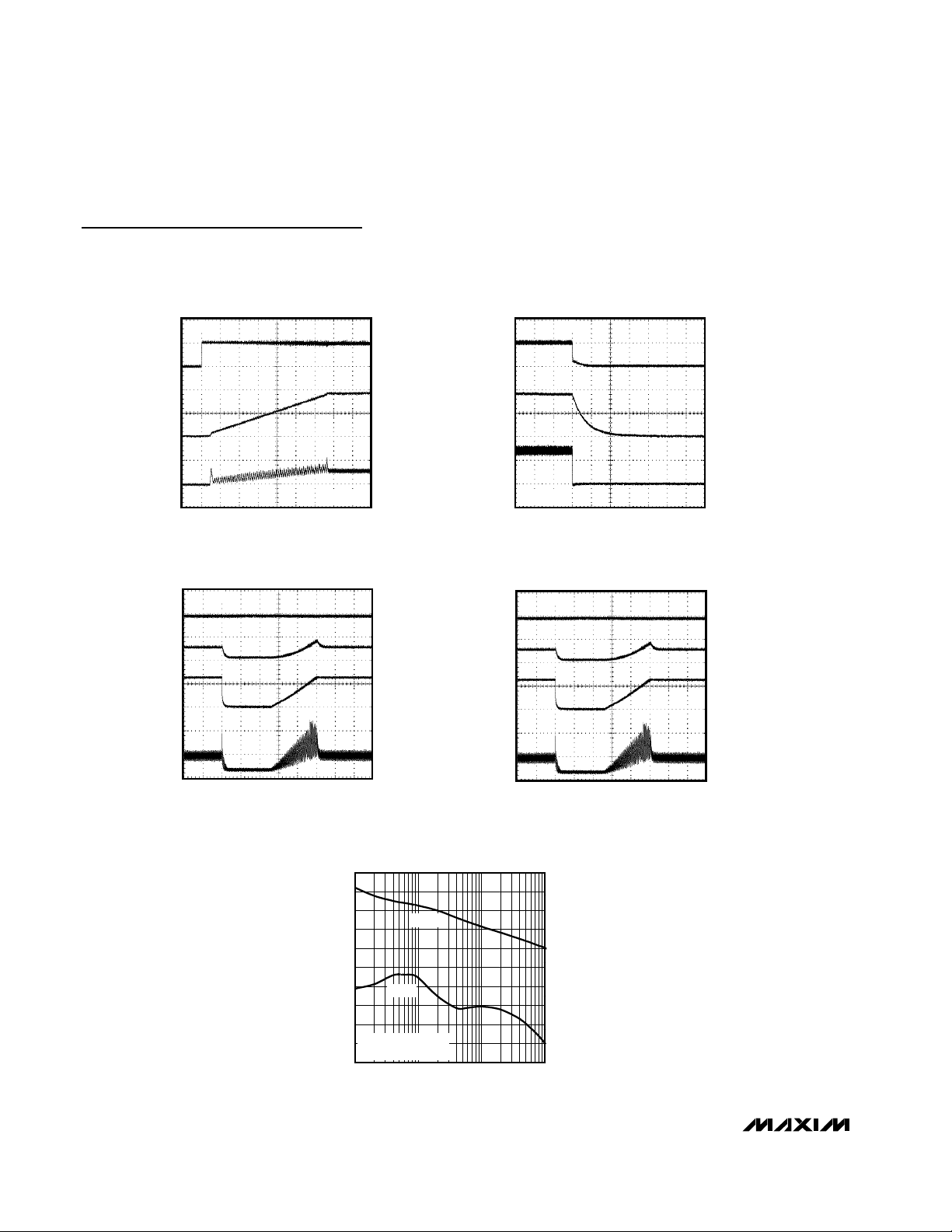

Typical Operating Characteristics (continued)

(VIN= VL= VCC= 5V, typical values are at TA = +25°C, unless otherwise noted.)

V

OUT

1V/div

V

IN

5V/div

INDUCTOR

CURRENT

5A/div

1ms/div

START-UP WAVEFORM

MAX8545 toc15

I

LOAD

= 3A

V

OUT

1V/div

V

IN

5V/div

INDUCTOR

CURRENT

2A/div

2ms/div

SHUTDOWN WAVEFORM

MAX8545 toc16

I

LOAD

= 3A

V

OUT

2V/div

V

IN

5V/div

I

IN

10A/div

I

OUT

5A/div

SHORT-CIRCUIT WAVEFORM

MAX8545 toc18

V

OUT

2V/div

V

IN

20V/div

I

IN

2A/div

INDUCTOR

CURRENT

5A/div

1ms/div

0

0

0

0

SHORT-CIRCUIT WAVEFORM

MAX8545 toc17

GAIN AND PHASE vs. FREQUENCY

MAX8545/46/48 toc19

FREQUENCY (kHz)

GAIN (dB)

PHASE (DEGREES)

101

-120

-100

-80

-60

-40

-20

0

20

40

60

-140

0.1 100

180

150

120

90

60

30

VIN = 17V, V

OUT

= 2.5V

I

LOAD

= 6A

GAIN

PHASE

Page 7

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

_______________________________________________________________________________________ 7

Pin Description

Functional Diagram

PIN NAME FUNCTION

1 COMP/EN

Compensation Input. Pull COMP/EN low with an open-collector or open-drain device to turn

off the output.

2 FB Feedback Input. Connect a resistive-divider network to set V

3V

4V

CC

IN

5VL

Internal Chip Supply. Connect VCC to VL through a 10Ω resistor. Bypass VCC to GND with at

least a 0.1µF ceramic capacitor.

Power Supply for LDO Regulator for VIN > 5.5V, and Chip Supply for VIN < 5.5V. Bypass VIN with

at least a 1µF ceramic capacitor to GND.

Output of Internal 5V LDO. Connect VL to V

for VIN < 5.5V. Bypass VL with at least a 1µF ceramic

IN

capacitor to GND.

. FB threshold is 0.8V.

OUT

6 DL Low-Side External MOSFET Gate-Driver Output. DL swings from VL to GND.

7 GND Ground and Negative Current-Sense Input

8 LX Inductor Switching Node. LX is used for both current limit and the return supply of the DH driver.

9 DH High-Side External MOSFET Gate-Driver Output. DH swings from BST to LX.

10 BST Positive Supply of DH Driver. Connect a 0.1µF ceramic capacitor between BST and LX.

V

VL

COMP/EN

FB

V

IN

CC

5V LINEAR

REGULATOR

RAMP

GENERATOR

INTERNAL

CHIP SUPPLY

800mV

SOFT-START

REF

100kHz/

300kHz*

CLOCK

GENERATOR

*SEE SELECTOR GUIDE

1V

ERROR

AMPLIFIER

PWM COMP

TEMPERATURE

SHUTDOWN

CONTROL

LOGIC

MAX8545

MAX8546

MAX8548

CURRENT-LIMIT

COMPARATOR

BST

DH

LX

DL

GND

FOLD-

FB

BACK

Page 8

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

8 _______________________________________________________________________________________

Detailed Description

The MAX8545/MAX8546/MAX8548 are BiCMOS switchmode power-supply controllers designed to implement

simple, buck-topology regulators in cost-sensitive

applications. The main power-switching circuit consists

of two N-channel MOSFETs, an inductor, and input/output filter capacitors. An all N-channel synchronous-rectified design provides high efficiency at reduced cost.

These devices have an internal 5V linear regulator that

steps down the input voltage to supply the IC and the

gate drivers. The low-side-switch gate driver is directly

powered from the 5V regulator (VL), while the highside-switch gate driver is indirectly powered from VL

plus an external diode-capacitor boost circuit.

Current-Limit and

Short-Circuit Protection

The MAX8545/MAX8546/MAX8548 employ a valley current-sensing algorithm that uses the R

DS(ON)

of the lowside N-channel MOSFET to sense the current. This

eliminates the need for an external sense resistor usually

placed in series with the output. The voltage measured

across the low-side MOSFET’s R

DS(ON)

is compared to

a fixed -320mV reference for the MAX8545/MAX8548

and a fixed -165mV reference for the MAX8546. The current limit is given by the equations below:

Aside from current limiting, these devices feature foldback short-circuit protection. This feature is designed

to reduce the current limit by 80% as the output voltage

drops to 0V.

MOSFET Gate Drivers

The DH and DL drivers are optimized for driving Nchannel MOSFETs with low gate charge. An adaptive

dead-time circuit monitors the DL output and prevents

the high-side MOSFET from turning on until the low-side

MOSFET is fully off. There must be a low-resistance,

low-inductance connection from the DL driver to the

MOSFET gate for the adaptive dead-time circuit to work

properly. Otherwise, the sense circuitry in the MAX8545/

MAX8546/MAX8548 may detect the MOSFET gate as off

while there is actually charge left on the gate. Use very

short, wide traces measuring no less than 50 to 100 mils

wide if the MOSFET is 1 inch away from the MAX8545/

MAX8546/MAX8548. The same type of adaptive deadtime circuit monitors the DH off edge. The same recommendations apply for the gate connection of the

high-side MOSFET.

The internal pulldown transistor that drives DL low is

robust, with a 1.1Ω (typ) on-resistance. This helps prevent DL from being pulled up due to capacitive coupling from the drain to the gate of the low-side

synchronous-rectifier MOSFET during the fast rise time

of the LX node.

Soft-Start

The MAX8545/MAX8546/MAX8548 feature an internally

set soft-start function that limits inrush current. It accomplishes this by ramping the internal reference input to the

controller’s transconductance error amplifier from 0 to

the 0.8V reference voltage. The ramp time is 1024 oscillator cycles for the MAX8548 and 2048 oscillator cycles

for the MAX8545/MAX8546. At the nominal 100kHz and

300kHz switching rate, the soft-start ramp is approximately 10.2ms and 6.8ms, respectively.

High-Side Gate-Drive Supply (BST)

A flying-capacitor boost circuit generates gate-drive voltage for the high-side N-channel MOSFET. The flying

capacitor is connected between the BST and LX nodes.

On startup, the synchronous rectifier (low-side MOSFET)

forces LX to ground and charges the boost capacitor to

VL. On the second half-cycle, the MAX8545/MAX8546/

MAX8548 turn on the high-side MOSFET by closing an

internal switch between BST and DH. This provides the

necessary gate-to-source voltage to drive the high-side

MOSFET gate above its source at the input voltage.

Internal 5V Linear Regulator

All MAX8545/MAX8546/MAX8548 functions are internally

powered from an on-chip, low-dropout 5V regulator (VL).

These devices have a maximum input voltage (VIN) of

28V. Connect VCCto VLthrough a 10Ω resistor and

bypass VCCto GND with a 0.1µF ceramic capacitor. The

VIN-to-VL dropout voltage is typically 140mV, so when V

IN

is less than 5.5V, VL is typically VIN- 140mV.

The internal linear regulator can source a minimum of

25mA and a maximum of approximately 40mA to supply

power to the IC low-side and high-side MOSFET drivers.

Duty-Cycle Limitations for

Low V

OUT/VIN

Ratios

The MAX8545/MAX8546/MAX8548’s output voltage is

adjustable down to 0.8V. However, the minimum duty

cycle can limit the ability to supply low-voltage outputs

I

LIMIT

=

320

R

DS ON

mV

(/)

MAX MAX

()

8545 8548

mV

=

165

R

DS ON

8546

()

MAX

()

I

LIMIT

Page 9

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

_______________________________________________________________________________________ 9

from high-voltage inputs. With high input voltages, the

required duty factor is approximately:

where R

DS(ON)

x I

LOAD

is the voltage drop across the

synchronous rectifier. Therefore, the maximum input

voltage (V

IN(DFMAX)

) that can supply a given output

voltage is:

If the circuit cannot attain the required duty cycle dictated by the input and output voltages, the output voltage still remains in regulation. However, there may be

intermittent or continuous half-frequency operation as

the controller attempts to lower the average duty cycle

by deleting pulses. This can increase output voltage

ripple and inductor current ripple, which increases

noise and reduces efficiency. Furthermore, circuit stability is not guaranteed.

Applications Information

Design Procedures

1) Input Voltage Range. The maximum value

(V

IN(MAX)

) must accommodate the worst-case high

input voltage. The minimum value (V

IN(MIN)

) must

account for the lowest input voltage after drops due

to connectors, fuses, and switches are considered.

In general, lower input voltages provide the best

efficiency.

2) Maximum Load Current. There are two current

values to consider. Peak load current (I

LOAD(MAX)

)

determines the instantaneous component stresses

and filtering requirements and is key in determining

output capacitor requirements. I

LOAD(MAX)

also

determines the required inductor saturation rating.

Continuous load current (I

LOAD

) determines the

thermal stresses, input capacitor, and MOSFETs,

as well as the RMS ratings of other heat-contributing components such as the inductor.

3) Inductor Value. This choice provides tradeoffs

between size, transient response, and efficiency.

Higher inductance value results in lower inductor

ripple current, lower peak current, lower switching

losses, and, therefore, higher efficiency at the cost

of slower transient response and larger size. Lower

inductance values result in large ripple currents,

smaller size, and poor efficiency, while also providing faster transient response.

Setting the Output Voltage

An output voltage between 0.8V and (0.83 x VIN) can

be configured by connecting FB to a resistive divider

between the output and GND (see Figures 1 and 2).

Select resistor R4 in the 1kΩ to 10kΩ range. R3 is then

given by:

where VFB= +0.8V.

Inductor Selection

Determine an appropriate inductor value with the following equation:

where LIR is the ratio of inductor ripple current to average continuous maximum load current. Choosing LIR

between 20% to 40% results in a good compromise

between efficiency and economy. Choose a low-coreloss inductor with the lowest possible DC resistance.

Ferrite-core-type inductors are often the best choice for

performance; however, the MAX8548’s low switching

frequency also allows the use of powdered iron core

inductors in ultra-low-cost applications where efficiency

is not critical. With any core material, the core must be

large enough not to saturate at the peak inductor current (I

PEAK

).

Setting the Current Limit

The MAX8545/MAX8546/MAX8548 provide valley current limit by sensing the voltage across the external

low-side MOSFET. The minimum current-limit threshold

voltage is -280mV for the MAX8545/MAX8548 and

-140mV for the MAX8546. The MOSFET on-resistance

required to allow a given peak inductor current is:

where I

VALLEY

= I

LOAD(MAX)

x (1 - LIR / 2), and

R

DS(ON)MAX

is the maximum on-resistance of the lowside MOSFET at the maximum operating junction

temperature.

)

V

IN DFMAX

VR I

+×()

OUT DS ON LOAD

1

≤+×

DC

()

V

IN

VR I

()

MIN

()

OUT DS ON LOAD() ()

RR

V

34

OUT

V

FB

1=−

LV

=×

OUT

V f LIR I

IN OSC LOAD MAX

R

DS ON MAX

R

DS ON MAX

II

=+

PEAK LOAD MAX LOAD MAX

.

028

()

()

≤

I

VALLEY

.

014

I

VALLEY

VV

−

()

IN OUT

×××

LIR

() ()

2

×

()

I

V

( /

for the MAX MAX

V

( )≤

for the MAX

8545 8548

8546

Page 10

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

10 ______________________________________________________________________________________

Figure 1. Typical Application Circuit (2.7V to 5V) Input (see Tables 1a, 1b)

Figure 2. Typical Application Circuit (10V to 24V) Input (see Tables 2a, 2b)

+2.7V TO

+5.5V INPUT

C3 C2C4

R1

C9

IN

CC

MAX8545*

MAX8546

MAX8548*

COMP/

EN

D2 R2

C10 C11

*FOLLOW THE DATA SHEET DESIGN PROCEDURE TO SELECT THE

EXTERNAL COMPONENTS FOR THE MAX8545/MAX8548.

C1

VLV

BSTV

DH

LX

DL

GND

FB

D1

Q1

C5

R3

R4

L1

C6

C7 C8

OUT

1.8V/3A OR 6A

+10V TO

D2 R2

*FOLLOW THE DATA SHEET DESIGN PROCEDURE TO SELECT THE

EXTERNAL COMPONENTS FOR THE MAX8545/MAX8548.

+24V INPUT

C12

C10 C11

R1

C9

CC

V

IN

MAX8545*

MAX8546

MAX8548*

COMP/

EN

C1

VLV

BST

DH

LX

DL

GND

FB

D1

C5

R4

C3 C2C4

Q1

L1

C6

C7 C8

R3

OUT

2.5V/3A OR 6A

Page 11

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

______________________________________________________________________________________ 11

A limitation of sensing current across a MOSFET’s onresistance is that the current-limit threshold is not accurate since MOSFET R

DS(ON)

specifications are not

precise. This type of current limit provides a coarse level

of fault protection. It is especially suited when the input

source is already current-limited or otherwise protected.

Power MOSFET Selection

The MAX8545/MAX8546/MAX8548 drive two external,

logic-level, N-channel MOSFETs as the circuit switching elements. The key selection parameters are:

1) On-resistance (R

DS(ON)

): the lower, the better.

2) Maximum drain-to-source voltage (V

DSS

) should be

at least 10% higher than the input supply rail at the

high-side MOSFET’s drain.

3) Gate charges (Qg, Qgd, Qgs): the lower, the better.

Choose the MOSFETs with rated R

DS(ON)

at VGS= 4.5V

for an input voltage greater than 5V, and at VGS= 2.5V

for an input voltage less than 5.5V. For a good compromise between efficiency and cost, choose the high-side

MOSFET (N1) that has conduction losses equal to the

switching losses at nominal input voltage and maximum

output current. For N2, make sure it does not spuriously

turn on due to a dV/dt caused by N1 turning on as this

would result in shoot-through current degrading the

efficiency. MOSFETs with a lower Qgd/ Qgsratio have

higher immunity to dV/dt.

MOSFET Power Dissipation

For proper thermal-management design, the power dissipation must be calculated at the desired maximum

operating junction temperature, maximum output current, and worst-case input voltage (for the low-side

MOSFET (N2) the worst case is at V

IN(MAX)

, for the highside MOSFET (N1) the worst case can be either at

V

IN(MIN)

or V

IN(MAX)

). N1 and N2 have different loss

components due to the circuit operation. N2 operates as

a zero-voltage switch; therefore, the major losses are:

the channel conduction loss (P

N2CC

), the body-diode

conduction loss (P

N2DC

), and the gate-drive loss

(P

N2DR

).

Use R

DS(ON)

at T

J(MAX)

.

where V

F

is the body-diode forward voltage drop, tdtis

the dead time between N1 and N2 switching transitions

(which is 30ns), and fSis the switching frequency.

Because of zero-voltage switch operation, the N2 gatedrive losses are due to charging and discharging the

input capacitor, C

ISS

. These losses are distributed

between the average DL gate driver’s pullup and pulldown resistors and the internal gate resistance. The

RDLis typically 1.8Ω, and the internal gate resistance

(R

GATE

) of the MOSFET is typically 2Ω. The drive

power dissipated in N2 is given by:

N1 operates as a duty-cycle control switch and has the

following major losses: the channel conduction loss

(P

N1CC

), the voltage and current overlapping switching

loss (P

N1SW

), and the drive loss (P

N1DR

). N1 does not

have a body-diode conduction loss because the diode

never conducts current.

Use R

DS(ON)

at T

J(MAX)

.

where I

GATE

is the average DH high driver output-cur-

rent capability determined by:

where RDHis the high-side MOSFET driver’s average

on-resistance (2.05Ω typ) and R

GATE

is the internal

gate resistance of the MOSFET (2Ω typ).

where VGS~ VL.

In addition to the losses above, allow about 20% more

for additional losses due to MOSFET output capacitance and N2 body-diode reverse recovery charge dissipated in N1. Refer to the MOSFET data sheet for

thermal resistance specifications to calculate the PC

board area needed. This information is essential to

maintain the desired maximum operating junction temperature with the above calculated power dissipation.

To reduce EMI caused by switching noise, add a 0.1µF

ceramic capacitor from the high-side MOSFET drain to

the low-side MOSFET source or add resistors in series

P

NCC

1=−

PIVtf

N DC LOAD F dt S2

V

OUT

××

V

IN

2=× × × ×

2

IR

LOAD

DS ON2

()

PCVf

=×

N DR ISS GS S

2

2

()

××

R

GATE

RR

+

GATE DL

P

NCC

PVI f

=

=× ××

N SW IN LOAD S

1

V

OUT

V

IN

×

()

2

IR

LOAD DS ON1

×

QQ

GS GD

I

GATE

()

+

I

GATE ON

()

1

=×

2

VL

+

RR

DH GATE

PQVf

=×××

NDR GS GS S

1

R

GATE

+

RR

DH GATE

Page 12

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

12 ______________________________________________________________________________________

with DH and DL to slow down the switching transitions.

However, adding series resistors increases the power

dissipation of the MOSFET, so ensure temperature ratings of the MOSFET are not exceeded.

Input-Capacitor Selection

The input capacitors (C2 and C3 in Figure 1) reduce

noise injection and current peaks drawn from the input

supply. The input capacitor must meet the ripple-current requirement (I

RMS

) imposed by the switching cur-

rents. The RMS input ripple current is given by:

For optimal circuit reliability, choose a capacitor that

has less than 10°C temperature rise at the RMS current.

I

RMS

is maximum when the input voltage equals 2 x

V

OUT

, where I

RMS

= 1/2 I

LOAD

.

Output Capacitor Selection

The key parameters for the output capacitor are the

actual capacitance value, the equivalent series resistance (ESR), the equivalent series inductance (ESL),

and the voltage-rating requirements. All these parameters affect the overall stability, output ripple voltage,

and transient response.

The output ripple has three components: variations in the

charge stored in the output capacitor, the voltage drop

across the ESR, and the voltage drop across the ESL.

V

RIPPLE

= V

RIPPLE(ESR)

+ V

RIPPLE(C)

+ V

RIPPLE(ESL)

The output voltage ripple as a consequence of the ESR

and output capacitance is:

where I

P-P

is the peak-to-peak inductor current (see the

Inductor Selection section).

While these equations are suitable for initial capacitor

selection to meet the ripple requirement, final values

may also depend on the relationship between the LC

double-pole frequency and the capacitor ESR-zero frequency. Generally, the ESR zero is higher than the LC

double pole; however, it is preferable to keep the ESR

zero close to the LC double pole when possible to

negate the sharp phase shift of the typically high-Q

double LC pole (see the Compensation Design section). Aluminum electrolytic or POS capacitors are recommended. Higher output current requires multiple

capacitors to meet the output ripple voltage.

The MAX8545/MAX8546/MAX8548s’ response to a load

transient depends on the selected output capacitor. After

a load transient, the output instantly changes by (ESR x

∆I

LOAD

) + (ESL x dI/dt). Before the controller can

respond, the output deviates further depending on the

inductor and output capacitor values. After a short period

of time (see the Typical Operating Characteristics), the

controller responds by regulating the output voltage back

to its nominal state. The controller response time

depends on the closed-loop bandwidth. Higher bandwidth results in faster response time, preventing the output voltage from further deviation. Do not exceed the

capacitor’s voltage or ripple-current ratings.

Boost Diode and Capacitor Selection

A low-current Schottky diode, such as the CMPSH-3

from Central Semiconductor, works well for most applications. Do not use large power diodes since higher

junction capacitance can charge up BST to LX voltage

that could exceed the device rating of 6V. The boost

capacitor should be in the range of 0.1µF to 0.47µF,

depending on the specific input and output voltages

and the external components and PC board layout. The

boost capacitance needs to be as large as possible to

prevent it from charging to excessive voltage, but small

enough to adequately charge during the minimum lowside MOSFET conduction time, which happens at the

maximum operating duty cycle (this occurs at the minimum input voltage). In addition, ensure the boost

capacitor does not discharge to below the minimum

gate-to-source voltage required to keep the high-side

MOSFET fully enhanced for lowest on-resistance. This

minimum gate-to-source voltage V

GS(MIN)

is deter-

mined by:

where Qg is the total gate charge of the high-side

MOSFET and C

BOOST

is the boost capacitor value.

Compensation Design

The MAX8545/MAX8546/MAX8548 use a voltage-mode

control scheme that regulates the output voltage. This is

done by comparing the error amplifier’s output (COMP) to

a fixed internal ramp. The inductor and output capacitor

create a double pole at the resonant frequency, which

VVV

×−

()

II

=×

RMS LOAD

OUT IN OUT

V

IN

V I ESR

RIPPLE ESR P P

V

RIPPLE C

V

RIPPLE ESL

=

I

PP

−

=×

()

()

()

VV

IN OUTSWOUT

−

I

=

−

fLVV

PP

××

8

Cf

OUT SW

×

V ESL

IN

=

+

L ESL

×

−

IN

Q

VV

GS MIN L

=−

()

C

BOOST

G

Page 13

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

______________________________________________________________________________________ 13

has a gain drop of 40dB per decade, and a phase shift

of 180°. The error amplifier must compensate for this

gain drop and phase shift to achieve a stable highbandwidth, closed-loop system.

The basic regulator loop consists of a power modulator

(Figure 3), an output feedback divider, and an error

amplifier. The power modulator has DC gain set by

VIN/V

RAMP

, with a double pole set by the inductor and

output capacitor, and a single zero set by the output

capacitor (C

OUT

) and its equivalent series resistance

(ESR). Below are equations that define the power modulator:

The DC gain of the power modulator is:

where V

RAMP

= 1V.

The pole frequency due to the inductor and output

capacitor is:

The zero frequency due to the output capacitor’s ESR is:

The output capacitor is usually comprised of several

same capacitors connected in parallel. With n capacitors in parallel, the output capacitance is:

C

OUT

= n X C

EACH

The total ESR is:

The ESR zero (f

ZESR

) for a parallel combination of

capacitors is the same as for an individual capacitor.

The feedback divider has a gain of GFB= VFB/V

OUT

,

where VFBis 0.8V.

The transconductance error amplifier has DC gain

G

EA(dc)

of 72dB. A dominant pole (f

DPEA

) is set by the

compensation capacitor (CC), the amplifier output

resistance (RO) equals 37MΩ, and the compensation

resistor (RC):

The compensation resistor and the compensation

capacitor set a zero:

The total closed-loop gain must equal unity at the

crossover frequency. The crossover frequency should

be higher than f

ZESR

, so that the -1 slope is used to

cross over at unity gain. Also, the crossover frequency

should be less than or equal to 1/5 the switching frequency (fSW) of the controller.

The loop-gain equation at the crossover frequency is:

VFB/V

OUT

x G

EA(fC)

x G

MOD(fC)

= 1

where G

EA(fc)

= g

mEA

× RC, and G

MOD(fc)

= G

MOD(DC)

× (f

PMOD

)2 / (f

ZESR

× fC).

The compensation resistor, RC, is calculated from:

RC= V

OUT

/ g

mEA

x VFBx G

MOD(fC)

where g

mEA

= 108µS.

Due to the underdamped (Q > 1) nature of the output

LC double pole, the error-amplifier compensation zero

should be approximately 0.2 f

PMOD

to provide good

phase boost. CCis calculated from:

A small capacitor, CF, can also be added from COMP to

GND to provide high-frequency decoupling. CFadds

another high-frequency pole, f

PHF

, to the error-amplifier

response. This pole should be greater than 100 times the

error-amplifier zero frequency to have negligible impact

on the phase margin. This pole should also be less than

1/2 the switching frequency for effective decoupling.

100 f

ZEA

< f

PHF

< 0.5 f

sw

Select a value for f

PHF

in the range given above, then

solve for CFusing the following equation:

PC Board Layout Guidelines

Careful PC board layout is critical to achieve low switching losses and stable operation. If possible, mount all the

power components on the top side of the board with their

G

MOD DC

()

=

V

IN

V

RAMP

f

PMOD

f

ZESR

=

=

LC

2π

××

2π

1

OUT

1

ESR C

OUT

ESR

=

ESR

EACH

n

f

DPEA

=

2π

1

CRR

×× +

()

COC

f

ZEA

=

CR

××

2π

1

CC

ff

ZESR C

<≤

f

SW

5

C

=

C

2π

5

Rf

××

CPMOD

C

F

=

××

2π

1

Rf

C PHF

Page 14

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

14 ______________________________________________________________________________________

ground terminals flush against one another. Follow these

guidelines for good PC board layout:

1) Keep the high-current paths short, especially at the

ground terminals. This practice is essential for stable, jitter-free operation.

2) Connect the power and analog grounds close to

the IC pin 7.

3) Keep the power traces and load connections short.

This practice is essential for high efficiency. Using

thick copper PC boards (2oz vs. 1oz) can enhance

full-load efficiency by 1% or more. Correctly routing

PC board traces is a difficult task that must be

approached in terms of fractions of centimeters,

where a few milohms of excess trace resistance

cause a measurable efficiency penalty.

4) LX and GND connections to the low-side MOSFET

for current sensing must be made using Kelvin

sense connections to guarantee the current-limit

accuracy. With SO-8 MOSFETs, this is best done

by routing power to the MOSFETs from outside

using the top copper layer, while connecting LX

and GND inside (underneath) the SO-8 package.

5) When tradeoffs in trace lengths must be made, it’s

preferable to allow the inductor charging current

path to be longer than the discharge path. For

example, it’s better to allow some extra distance

between the inductor and the low-side MOSFET or

between the inductor and the output filter capacitor.

6) Ensure that the connection between the inductor

and C3 is short and direct.

7) Route switching nodes (BST, LX, DH, and DL) away

from sensitive analog areas (COMP and FB).

Ensure the C1 ceramic bypass capacitor is immediately

adjacent to the pins and as close to the device as possible. Furthermore, the VINand GND pins of MAX8545/

MAX8546/MAX8548 must terminate at the two ends of

C1 before connecting to the power switches and C2.

Figure 3. Compensation Scheme

V

IN

RAMP

GENERATOR

PWM

COMP/EN

R2

C10

MAX8545

MAX8546

MAX8548

ERROR

AMPLIFIER

0.8V

DH

LX

DL

FB

N

L

N

V

OUT

C

OUT

R3

R4

Page 15

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

______________________________________________________________________________________ 15

Table 1a. Component Selection for

Standard Applications for VIN= 2.7V to

5.5V, V

OUT

= 1.8V / 3A (Figure 1)

(MAX8546 Only)

Table 1b. Component Selection for

Standard Applications for V

IN

= 2.7V to

5.5V, V

OUT

= 1.8V / 6A (Figure 1)

(MAX8546 Only)

COMPONENT QTY DESCRIPTION

C1, C4 2

C2 0 Not installed

C3 1

C5, C8, C9 3

C6, C7 2

C10 1

C11 0 Not installed

D1, D2 2

L1 1

Q1 1

R1 1 10Ω ±5% resistor

R2 1 150kΩ ±5% resistor

R3 1 5.11kΩ ±1% resistor

R4 1 4.02kΩ ±1% resistor

1µF, 10V X7R ceramic capacitors

Taiyo Yuden LMK212BJ105MG

1200µF, 10V, 44mΩ, 1.25A aluminum

electrolytic capacitor

Sanyo 10MV1200AX

(10 x 16 case size)

0.1µF, 10V X7R ceramic capacitors

Kemet C0603C104M8RAC

1000µF, 6.3V, 69mΩ, 0.8A aluminum

electrolytic capacitors

Sanyo 6.3MV1000AX (8 x 20 case size)

1.5nF, 10V X7R ceramic capacitor

Kemet C0603C152M8RAC

30V, 100mA Schottky diodes

Central Semiconductor CMPSH-3

4.7µH, 5.7A, 18mΩ inductor

Sumida CDRH124-4R7

20V/30V, 35mΩ dual N-channel

8-pin SO

V i shay S i 4966D Y ( f o r 2.7 V t o 3.6 V

Fair chil d FD S 6912A ( f or 4 .5 V t o 5 .5 V

IN

)

IN

COMPONENT QTY DESCRIPTION

C1, C4 2

C2, C3 2

C5, C8, C9 3

C6, C7 2

C10 1

C11 0 Not installed

D1, D2 2

L1 1

Q1 1

R1 1 10Ω ±5% resistor

)

R2 1 110kΩ ±5% resistor

R3 1 5.11kΩ ±1% resistor

R4 1 4.02kΩ ±1% resistor

1µF, 10V X7R ceramic capacitors

Taiyo Yuden LMK212BJ105MG

1200µF, 10V, 44mΩ, 1.25A aluminum

electrolytic capacitors

Sanyo 10MV1200AX

(10 x 16 case size)

0.1µF, 10V X7R ceramic capacitors

Kemet C0603C104M8RAC

1500µF, 6.3V, 44m Ω, 1.25A al um i num

el ectr ol ytic cap acitor s

S anyo 6.3M V1500AX (10 x 20 case si ze)

1.5nF, 10V X7R ceramic capacitor

Kemet C0603C152M8RAC

30V, 100mA Schottky diodes

Central Semiconductor CMPSH-3

2.1µH, 8A, 11.6mΩ inductor

Sumida CEP122-2R1

20V, 18m Ω d ual N- channel 8- pi n SO

Fair chil d FD S 6898A ( f or 2 .7 V t o 3 .6 V

Fair chil d FD S 6890A ( f or 4 .5 V t o 5 .5 V

IN

IN

)

)

Page 16

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

16 ______________________________________________________________________________________

Table 2a. Component Selection for

Standard Applications for VIN= 10V to

24V, V

OUT

= 2.5V / 3A (Figure 2)

(MAX8546 Only)

Table 2b. Component Selection for

Standard Applications for V

IN

= 10V to

24V, V

OUT

= 2.5V / 6A (Figure 2)

(MAX8546 Only)

COMPONENT QTY DESCRIPTION

C1 1

C2 0 Not installed

C3 1

C4, C12 2

C5, C8, C9 3

C6, C7 2

C10 1

C11 0 Not installed

D1, D2 2

L1 1

Q1 1

R1 1 10Ω ±5% resistor

R2 1 82kΩ ±5% resistor

R3 1 8.66kΩ ±1% resistor

R4 1 4.02kΩ ±1% resistor

1µF, 10V X7R ceramic capacitor

Taiyo Yuden LMK212BJ105MG

470µF, 35V, 39mΩ, 1.45A aluminum

electrolytic capacitor

Sanyo 35MV470AX

(10 x 22 case size)

1µF, 35V X7R ceramic capacitors

Taiyo Yuden GMK316BJ105ML

0.1µF, 10V X7R ceramic capacitors

Kemet C0603C104M8RAC

1000µF, 6.3V, 69mΩ, 0.8A aluminum

electrolytic capacitors

Sanyo 6.3MV1000AX

(8 x 20 case size)

6.8nF, 10V X7R ceramic capacitor

Kemet C0603C6822M8RAC

30V, 100mA Schottky diodes

Central Semiconductor CMPSH-3

8.2µH, 5.8A, 9.5mΩ inductor

Sumida CEP125-8R2

30V, 35mΩ dual N-channel 8-pin SO

Fairchild FDS6912A

COMPONENT QTY DESCRIPTION

C2, C3 2

C4, C12 2

C5, C8, C9 3

C6, C7 2

D1, D2 2

C1 1

C10 1

C11 0 Not installed

L1 1

Q1 1

R1 1 10Ω ±5% resistor

R2 1 68kΩ ±5% resistor

R3 1 8.66kΩ ±1% resistor

R4 1 4.02kΩ ±1% resistor

1µF, 10V X7R ceramic capacitor

Taiyo Yuden LMK212BJ105MG

470µF, 35V, 39mΩ, 1.45A aluminum

electrolytic capacitors

Sanyo 35MV470AX

(10 x 22 case size)

1µF, 35V X7R ceramic capacitors

Taiyo Yuden GMK316BJ105ML

0.1µF, 10V X7R ceramic capacitors

Kemet C0603C104M8RAC

1500µF, 6.3V, 44mΩ, 1.25A aluminum

electrolytic capacitors

Sanyo 6.3MV1500AX

(10 x 20 case size)

6.8nF, 10V X7R ceramic capacitor

Kemet C0603C682M8RAC

30V, 100mA Schottky diodes

Central Semiconductor CMPSH-3

4µH, 8.3A, 6.6mΩ inductor

Sumida CEP125-4R0

30V, 18mΩ (LSFET)/35mΩ (HSFET)

dual N-channel 8-pin SO

Fairchild FDS6982

Page 17

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

______________________________________________________________________________________ 17

Pin Configuration

Chip Information

TRANSISTOR COUNT: 3351

PROCESS: BiCMOS

TOP VIEW

COMP/EN

V

1

2

MAX8545

MAX8546

3

CC

IN

MAX8548

4

56

µMAX

109BST

DHFB

8

LX

7

GNDV

DLVL

Page 18

MAX8545/MAX8546/MAX8548

Low-Cost, Wide Input Range, Step-Down

Controllers with Foldback Current Limit

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

18 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2003 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

0.6±0.1

e

10

ÿ 0.50±0.1

1

0.6±0.1

TOP VIEW

D2

A2

b

D1

FRONT VIEW

4X S

10

H

1

BOTTOM VIEW

GAGE PLANE

A

A1

α

E2

E1

SIDE VIEW

INCHES

MAX

MIN

DIM

A1

A2 0.030 0.037 0.75 0.95

D1

D2

E1

E2

H

L

L1

b

e

c

S

α

c

L

L1

PROPRIETARY INFORMATION

TITLE:

0.043

-A

0.006

0.002

0.116

0.120

0.114

0.118

0.116

0.120

0.114

0.118

0.187

0.199

0.0157

0.0275

0.037 REF

0.007

0.0106

0.0197 BSC

0.0035

0.0078

0.0196 REF

6∞

0∞ 0∞ 6∞

PACKAGE OUTLINE, 10L uMAX/uSOP

21-0061

MILLIMETERS

MAX

MIN

1.10

-

0.15

0.05

3.05

2.95

3.00

2.89

3.05

2.95

2.89

3.00

4.75

5.05

0.40

0.70

0.940 REF

0.177

0.270

0.500 BSC

0.090

0.200

0.498 REF

10LUMAX.EPS

REV.DOCUMENT CONTROL NO.APPROVAL

1

I

1

Loading...

Loading...