Page 1

RDY5

19-0045; Rev 1; 5/94

Evaluation Kit

Information Included

Triple-Output Power-Supply Controller

for Notebook Computers

_______________General Description

The MAX783 is a system-engineered power-supply controller

for notebook computers or similar battery-powered equipment.

It provides two high-performance step-down (buck) pulsewidth modulators (PWMs) for +3.3V/+5V and dual PCMCIA

VPP outputs powered by an integral flyback winding controller.

Other functions include dual, low-dropout, micropower linear

regulators for CMOS/RTC back up, and two precision lowbattery-detection comparators.

High efficiency (95% at 2A, greater than 80% at loads from

5mA to 3A) is achieved through synchronous rectification

and PWM operation at heavy loads, and Idle-Mode

TM

operation at light loads. The MAX783 uses physically small

components, thanks to high operating frequencies

(300kHz/200kHz) and a new current-mode PWM architecture that allows for output filter capacitors as small as 30µF

per ampere of load. Line- and load-transient responses

are terrific, with a high 60kHz unity-gain crossover frequency that allows output transients to be corrected within four

or five clock cycles. Low system cost is achieved through

a high level of integration and the use of low-cost external

N-channel MOSFETs. The integral flyback winding controller provides a low-cost, +15V high-side output that regulates even in the absence of a load on the main output.

Other features include low-noise, fixed-frequency PWM

operation at moderate to heavy loads and a synchronizable

oscillator for noise-sensitive applications such as electromagnetic pen-based systems and communicating computers. The MAX783 is similar to the MAX782, except the flyback winding is on the 3.3V inductor instead of the 5V

inductor, the VPP outputs can be optionally programmed to

3.3V, and the device may be completely shut down.

________________________Applications

Notebook Computers

Portable Data Terminals

Communicating Computers

Pen-Entry Systems

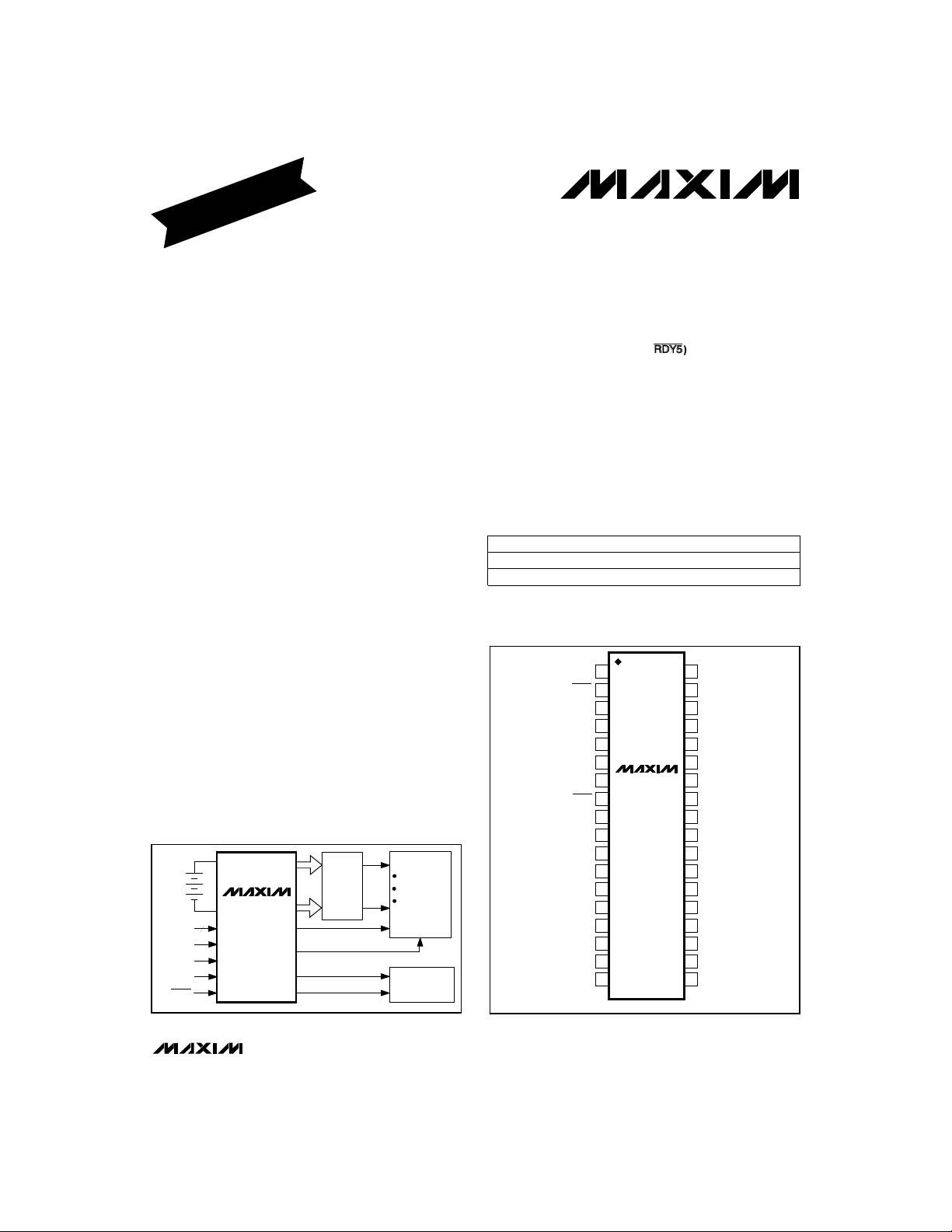

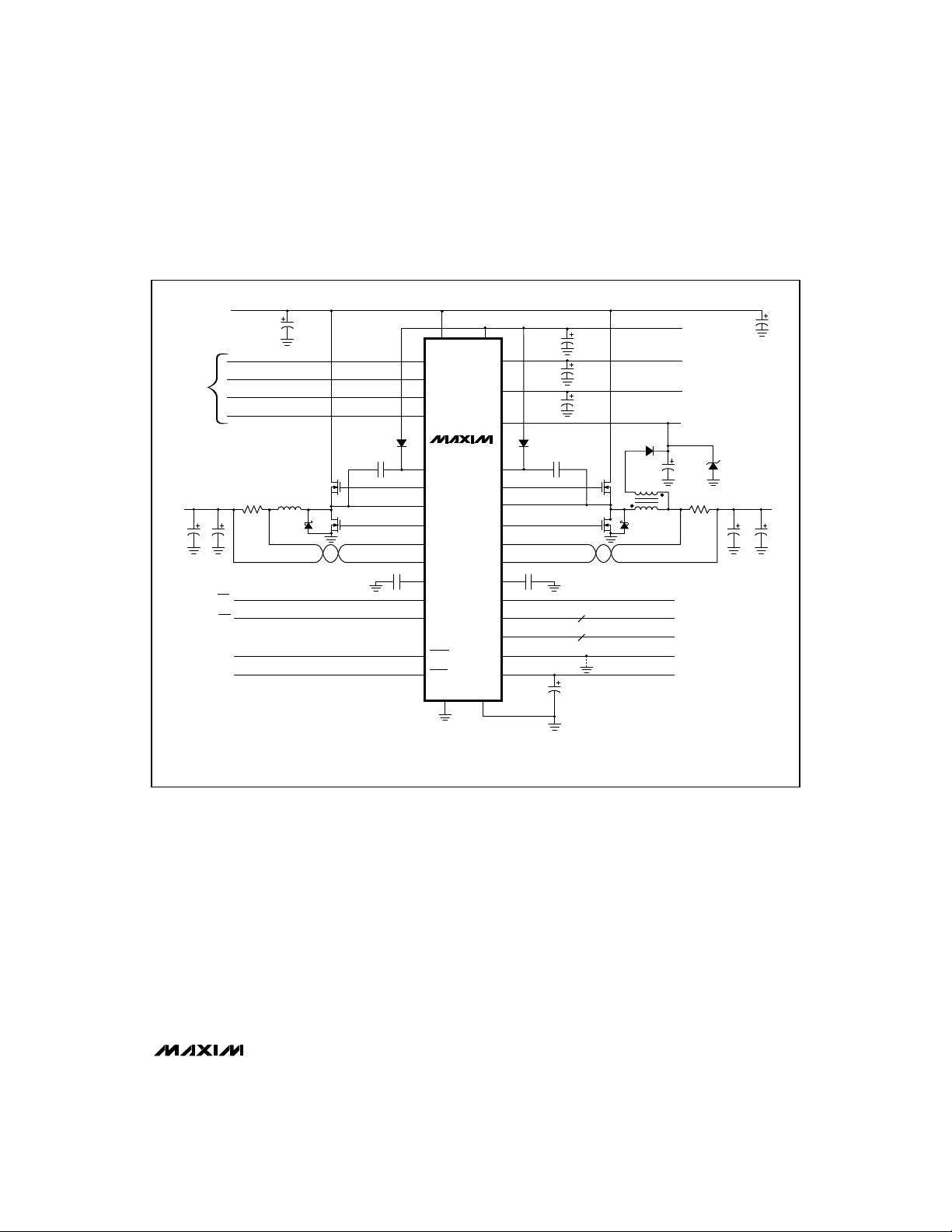

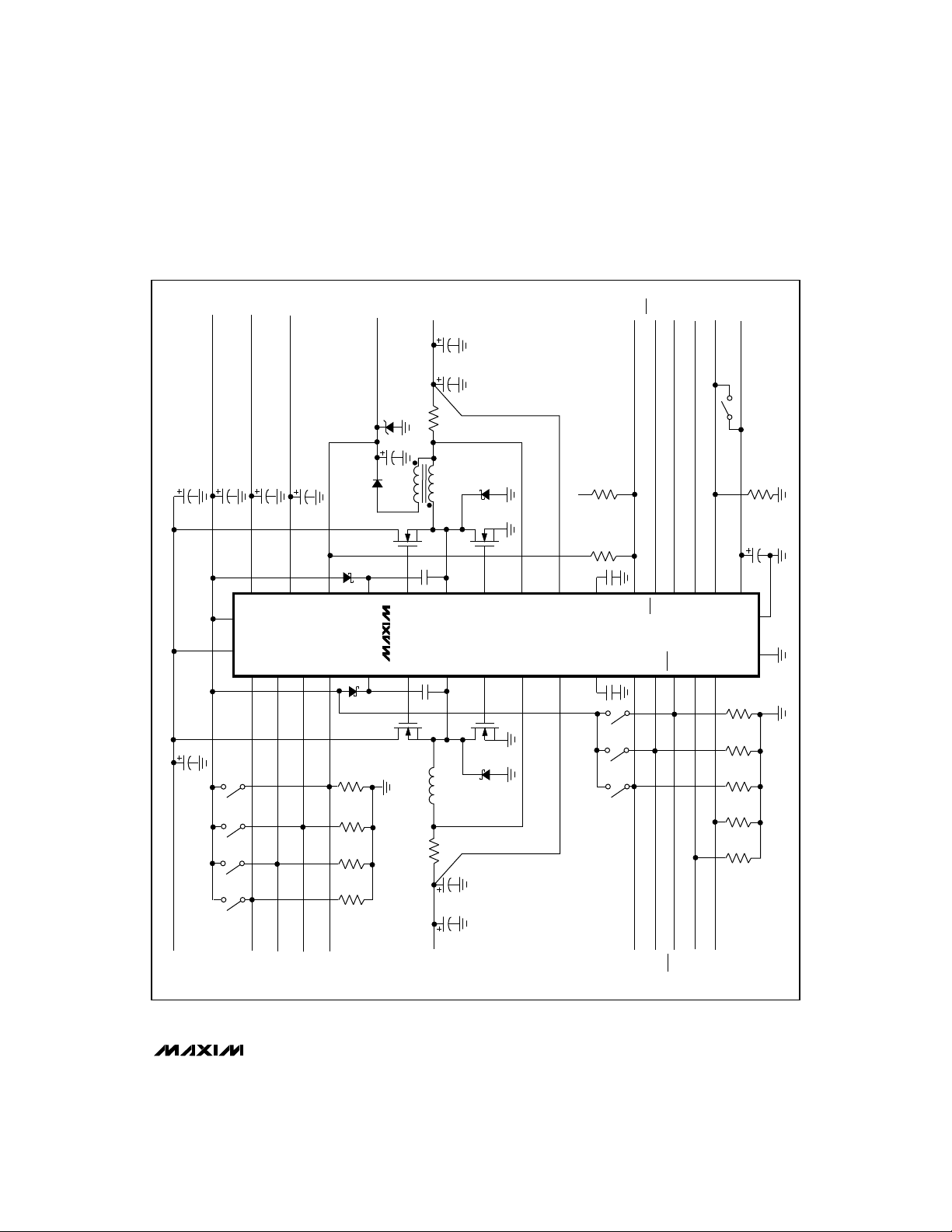

_______Typical Application Diagram

+3.3V

+5V

µP

MEMORY

PERIPHERALS

DUAL

PCMCIA

SLOTS

5.5V

TO

30V

VPP

CONTROL

ON3

ON5

SYNC

SHDN

™

Idle-Mode is a trademark of Maxim Integrated Products. Pentium is a trademark of Intel. PowerPC is a trademark of IBM.

MAX783

4

POWER

SECTION

SUSPEND POWER

LOW-BATTERY WARNING

VPP (0V/3.3V/5V/12V)

VPP (0V/3.3V/5V/12V)

________________________________________________________________

Call toll free 1-800-998-8800 for free samples or literature.

____________________________Features

♦ Dual PWM Buck Controllers (+3.3V and +5V)

♦ Dual PCMCIA VPP Outputs (0V/3.3V/5V/12V)

♦ Two Precision Comparators or Level Translators

♦ Power-Ready Status Output (

♦ 95% Efficiency

)

♦ Optimized for 6-Cell Applications

♦ 420µA Quiescent Current;

70µA in Standby (linear regulators alive)

25µA Shutdown Current

♦ 5.5V to 30V Input Range

♦ Small SSOP Package

♦ Fixed Output Voltages Available:

3.3V (standard)

3.45V (High-Speed Pentium™)

3.6V (PowerPC™)

______________Ordering Information

PIN-PACKAGETEMP. RANGEPART

36 SSOP0°C to +70°CMAX783CBX

36 SSOP0°C to +70°CMAX783RCBX

Ordering Information continued on last page.

__________________Pin Configuration

TOP VIEW

ON3

SHDN

RDY5

VPPA

VDD

VPPB

GND

REF

SYNC

DA1

DA0

DB1

DB0

1

2

D1

3

D2

4

VH

5

Q2

6

7

Q1

MAX783

8

9

10

11

12

13

14

15

16

17

18

36

SS3

CS3

35

FB3

34

DH3

33

LX3

32

31

BST3

30

DL3

29

V+

28

VL

27

FB5

26

PGND

25

DL5

24

BST5

23

LX5

22

DH5

21

CS5

20

SS5

19

ON5

SSOP

Maxim Integrated Products

V

OUT

3.3V

3.45V

MAX783

1

Page 2

Triple-Output Power-Supply Controller

for Notebook Computers

ABSOLUTE MAXIMUM RATINGS

V+ to GND.................................................................-0.3V, +36V

PGND to GND........................................................................±2V

VL to GND ...................................................................-0.3V, +7V

BST3, BST5 to GND ..................................................-0.3V, +36V

LX3 to BST3.................................................................-7V, +0.3V

LX5 to BST5.................................................................-7V, +0.3V

Inputs/Outputs to GND

MAX783

(D1, D2, S—H—D—N–, ON5, REF, SYNC, DA1, DA0, DB1, DB0, ON5,

SS5, CS5, FB5, R—D—Y—5–, CS3, FB3, SS3, ON3).-0.3V, (VL + 0.3V)

VDD to GND.................................................................-0.3V, 20V

VPPA, VPPB to GND.....................................-0.3V, (VDD + 0.3V)

VH to GND...................................................................-0.3V, 20V

Q1, Q2 to GND................................................-0.3V, (VH + 0.3V)

DL3, DL5 to PGND..........................................-0.3V , (VL + 0.3V)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

ELECTRICAL CHARACTERISTICS

(V+ = 15V, GND = PGND = 0V, IVL= I

T

= T

to T

A

MIN

3.3V AND 5V STEP-DOWN CONTROLLERS

Input Supply Range

FB5 Output Voltage

FB3 Output Voltage

Line Regulation

Current-Limit Voltage

15V FLYBACK CONTROLLER

VDD Regulation Setpoint

VDD Shunt Setpoint

VDD Shunt Current

Quiescent VDD Current

PCMCIA REGULATORS (Note 1)

VPPA/VPPB Output Voltage

, unless otherwise noted.)

MAX

PARAMETER

0mV < (CS5-FB5) < 70mV, 6V < V + < 30V

(includes load and line regulation)

0mV < (CS3-FB3) < 70mV, 6V < V + < 30V

(includes load and line regulation)

Either controller (0mV to 70mV)

Either controller (6V to 30V)

CS3-FB3 or CS5-FB5

CS3-FB3 (VDD < 13V, flyback mode)

Falling edge, hysteresis = 1%

Rising edge, hysteresis = 1%

VDD = 20V

VDD = 18V, ON3 = ON5 = 5V, VPPA/VPPB programmed to

12V with no external load

VDD = 18V, ON3 = ON5 = 5V, VPPA/VPPB programmed to

0V

Program to 12V, 13V < VDD < 19V, 0mA < IL< 60mA

Program to 5V, 13V < VDD < 19V, 0mA < IL< 60mA

Program to 3.3V, 13V < VDD < 19V, 0mA < IL< 60mA

Program to 0V, 13V < VDD < 19V, 0mA < IL< 0.3mA

= 0mA, S—H—D—N–= ON3 = ON5 = 5V, other digital input levels are 0V or +5V,

REF

CONDITIONS

DH3 to LX3..................................................-0.3V, (BST3 + 0.3V)

DH5 to LX5..................................................-0.3V, (BST5 + 0.3V)

REF, VL, VPP Short to GND........................................Momentary

REF Current.........................................................................20mA

VL Current...........................................................................50mA

VPPA, VPPB Current.........................................................100mA

Continuous Power Dissipation (TA= +70°C)

SSOP (derate 11.76mW/°C above +70°C) ...................762mW

Operating Temperature Ranges:

MAX783CBX/MAX783_CBX.................................0°C to +70°C

MAX783EBX/MAX783_EBX ..............................-40°C to +85°C

Storage Temperature Range.............................-65°C to +160°C

Lead Temperature (soldering, 10sec).............................+300°C

UNITS

MAX783

MAX783R

MAX783S

MIN TYP MAX

3.17 3.35 3.46

3.32 3.50 3.60

3.46 3.65 3.75

2.5Load Regulation

80 100 120

-50 -100 -160

2SS3/SS5 Fault Sink Current

13 14

18 20

140 300

11.60 12.10 12.50

4.85 5.05 5.20

3.17 3.30 3.43

-0.30 0.30

V5.5 30

V4.80 5.08 5.20

V

%

%/V0.03

mV

µA2.5 4.0 6.5SS3/SS5 Source Current

mA

V

V

mA23

µA

µA15 30Off VDD Current

V

2 _______________________________________________________________________________________

Page 3

Triple-Output Power-Supply Controller

for Notebook Computers

ELECTRICAL CHARACTERISTICS (continued)

(V+ = 15V, GND = PGND = 0V, IVL= I

T

= T

to T

A

MIN

INTERNAL REGULATOR AND REFERENCE

VL Output Voltage

VL Fault Lockout Voltage

VL/FB5 Switchover Voltage

(also R—D—Y—5–Trip Voltage)

REF Output Voltage 3.24 3.36µAV

REF Fault Lockout Voltage

REF Load Regulation 30 75 mV

Shutdown V+ Current

Standby V+ Current

Quiescent Power Consumption

(both controllers on)

Off V+ Current

COMPARATORS

D1, D2 Trip Voltage

D1, D2 Input Current

Q1, Q2 R—D—Y—5–Source Current

Q1, Q2 R—D—Y—5–Sink Current

Q1, Q2, R—D—Y—5–Output High Voltage

Q1, Q2, R—D—Y—5–Output Low Voltage

Quiescent VH Current

OSCILLATOR AND INPUTS/OUTPUTS

Oscillator Frequency

SYNC High Pulse Width 200 ns

SYNC Low Pulse Width 200 ns

SYNC Rise/Fall Time

Oscillator SYNC Range

Maximum Duty Cycle

Input Low Voltage 0.8

Input High Voltage

Input Current

, unless otherwise noted.)

MAX

PARAMETER

ON5 = ON3 = 0V, 5.5V < V+ < 30V, 0mA < IL< 25mA

Falling edge, hysteresis = 1%

Rising edge of FB5, hysteresis = 1%

No external load (Note 2)

Falling edge

0mA < IL< 5mA (Note 3)

–S—H—D—N–

DB1 = 0V, V+ = 30V

D1 = D2 = ON3 = ON5 = DA0 = DA1 = DB0 = DB1 = 0V,

V+ = 30V

D1 = D2 = D3 = DA0 = DA1 = DB0 = DB1 = 0V,

FB5 = CS5 = 5.25V, FB3 = CS3 = 3.5V

FB5 = CS5 = 5.25V, VL switched over to FB5

Falling edge, hysteresis = 1%

D1 = D2 = 0V to 5V

VH = 15V, V

VH = 15V, V

I

SOURCE

I

SINK

VH = 18V, D1 = D2 = 5V, no external load

SYNC = 3.3V

SYNC = 0V or 5V

SYNC = 3.3V

SYNC = 0V or 5V

S—H—D—N–, ON3, ON5, DA0, DA1, DB0, DB1, SYNC

S—H—D—N–, ON3, ON5, DA0, DA1, DB0, DB1

SYNC

S—H—D—N–, ON3, ON5, DA0, DA1, DB0, DB1, VIN= 0V or 5V

= 0mA, S—H—D—N–= ON3 = ON5 = 5V, other digital input levels are 0V or +5V,

REF

CONDITIONS

= D1 = D2 = ON3 = ON5 = DA0 = DA1 = DB0 =

= 2.5V

OUT

2.5V

OUT

= 5µA, VH = 3V

= 20µA, VH = 3V

MIN TYP MAX

4.5 5.5 V

3.6 4.2 V

4.2 4.7 V

2.4 3.2 V

25 40

70 110 µA

5.2 8.6

30 60

1.61 1.69

±100 nA

12 20 30 µA

200 500 1000%µA

VH - 0.5 V

0.4 V

410µA

270 300 330

170 200 230

200 nsNot tested

240 350

89 92

92 95

2.4

VL - 0.5

±1 µA

MAX783

UNITS

µA

mW

V

kHz

kHz

V

V

_______________________________________________________________________________________ 3

Page 4

Triple-Output Power-Supply Controller

for Notebook Computers

ELECTRICAL CHARACTERISTICS (continued)

(V+ = 15V, GND = PGND = 0V, IVL= I

T

= T

to T

A

MIN

, unless otherwise noted.)

MAX

PARAMETER

DL3/DL5 Sink/Source Current V

OUT

DH3/DH5 Sink/Source Current BST3-LX3 = BST5-LX5 = 4.5V, V

MAX783

DL3/DL5 On-Resistance High or low 7 Ω

DH3/DH5 On-Resistance High or low, BST3-LX3 = BST5-LX5 = 4.5V 7 Ω

Note 1: Output current is further limited by maximum allowable package power dissipation.

Note 2: Because the reference uses VL as its supply, the REF line regulation error is insignificant.

Note 3: The main switching outputs track the reference voltage. Loading the reference reduces the main outputs slightly according

to the closed-loop gain (AV

AVCLfor the +5V supply is 1.54.

) and the reference voltage load regulation error. AVCLfor the +3.3V supply is unity gain.

CL

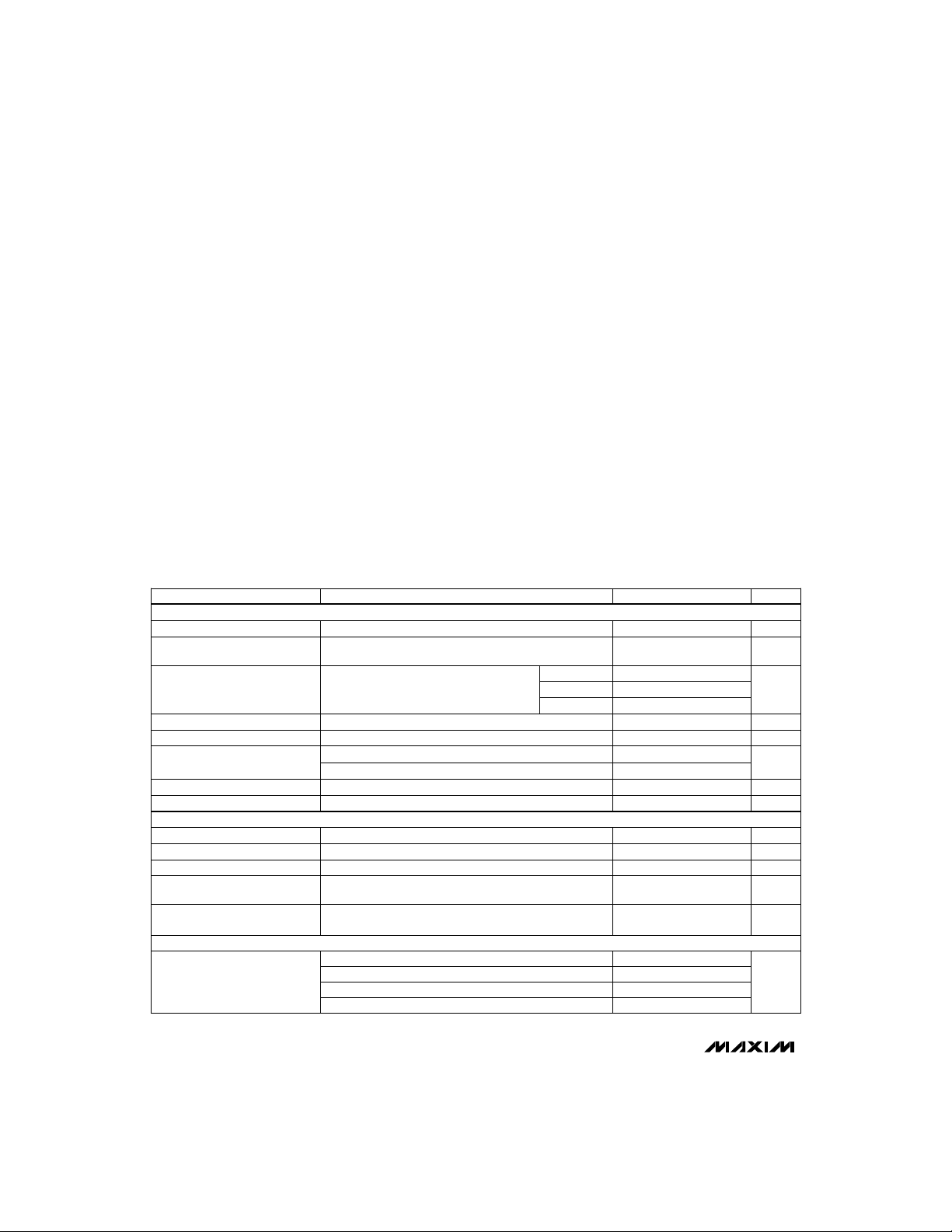

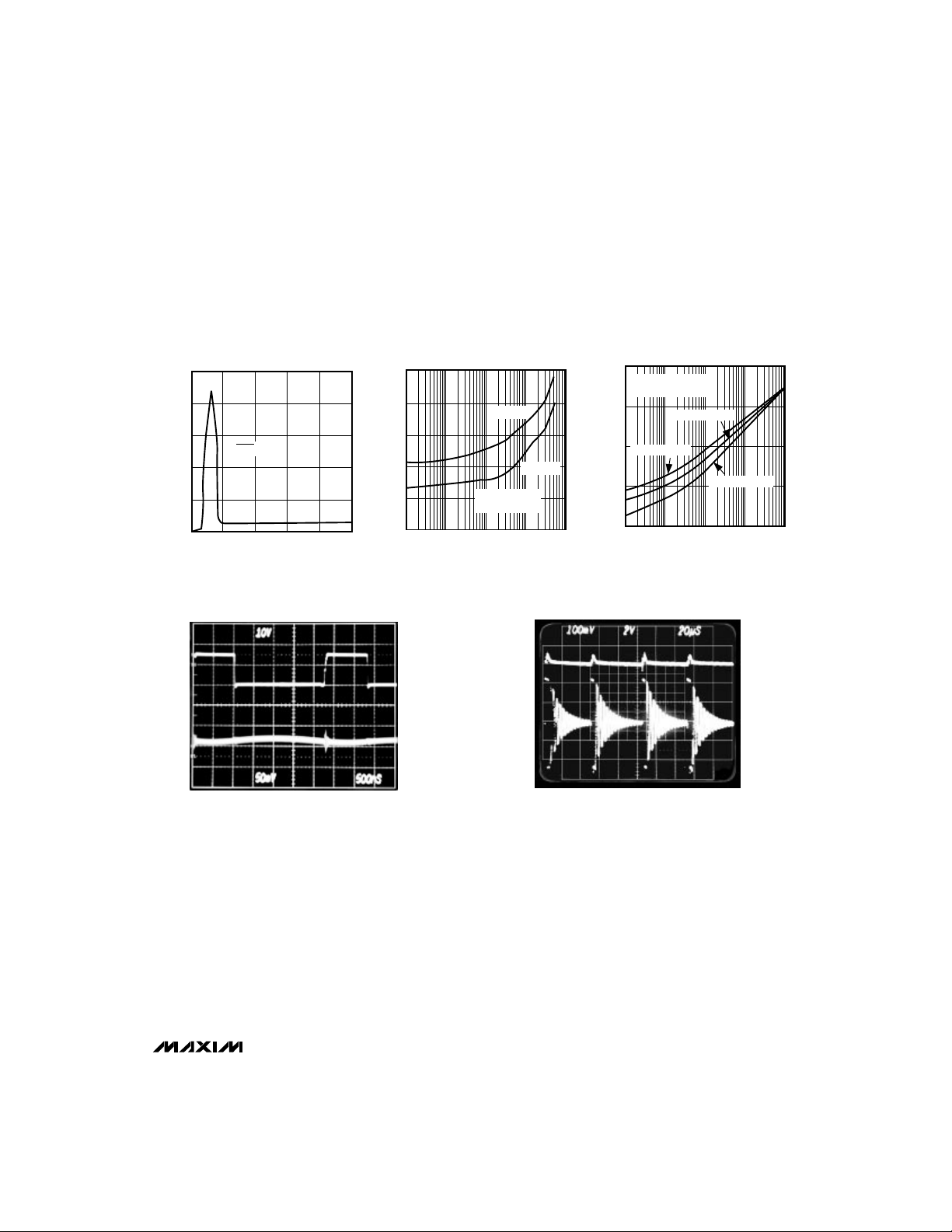

__________________________________________Typical Operating Characteristics

(Circuit of Figure 1, Transpower TTI5902 transformer, TA = +25°C, unless otherwise noted.)

= 0mA, S—H—D—N–= ON3 = ON5 = 5V, other digital input levels are 0V or +5V,

REF

CONDITIONS UNITS

MIN TYP MAX

= 2V 1 A

= 2V 1 A

OUT

100

90

80

70

EFFICIENCY (%)

60

50

1m

EFFICIENCY vs.

+5V OUTPUT CURRENT

V+ = 6V

V+ = 15V

N1-N4 = IRF7101

ON3 = LOW

F = 200kHz

10m 1

100m

+5V OUTPUT CURRENT (A)

QUIESCENT SUPPLY CURRENT vs.

SUPPLY VOLTAGE

14

13

ON3 = ON5 = HIGH

2

1

QUIESCENT SUPPLY CURRENT (mA)

0

0 6 12 18 24 30

SUPPLY VOLTAGE (V)

MAX183 5

10

100

90

80

70

EFFICIENCY (%)

60

50

1m

EFFICIENCY vs.

+3.3V OUTPUT CURRENT

V+ = 6V

V+ = 15V

N1-N4 = IRF7101

ON3 = ON5 = HIGH

F = 200kHz

10m 1

+3.3V OUTPUT CURRENT (A)

100m

MAXIMUM +15V VDD OUTPUT CURRENT vs.

500

MAX183 6

400

300

200

100

MAXIMUM +15V LOAD CURRENT (mA)

10

2.5

2.0

1.5

1.0

0.5

STANDBY SUPPLY CURRENT (mA)

0

0 6 12 18 24 30

0

STANDBY SUPPLY CURRENT vs.

SUPPLY VOLTAGE

ON3 = ON5 = 0V

SUPPLY VOLTAGE (V)

SUPPLY VOLTAGE

>

VDD

+13V

+3.3V REGULATING

+3.3V LOAD = 0A

05 20

+3.3V LOAD = 3A

10 15

SUPPLY VOLTAGE (V)

4 _______________________________________________________________________________________

Page 5

Triple-Output Power-Supply Controller

for Notebook Computers

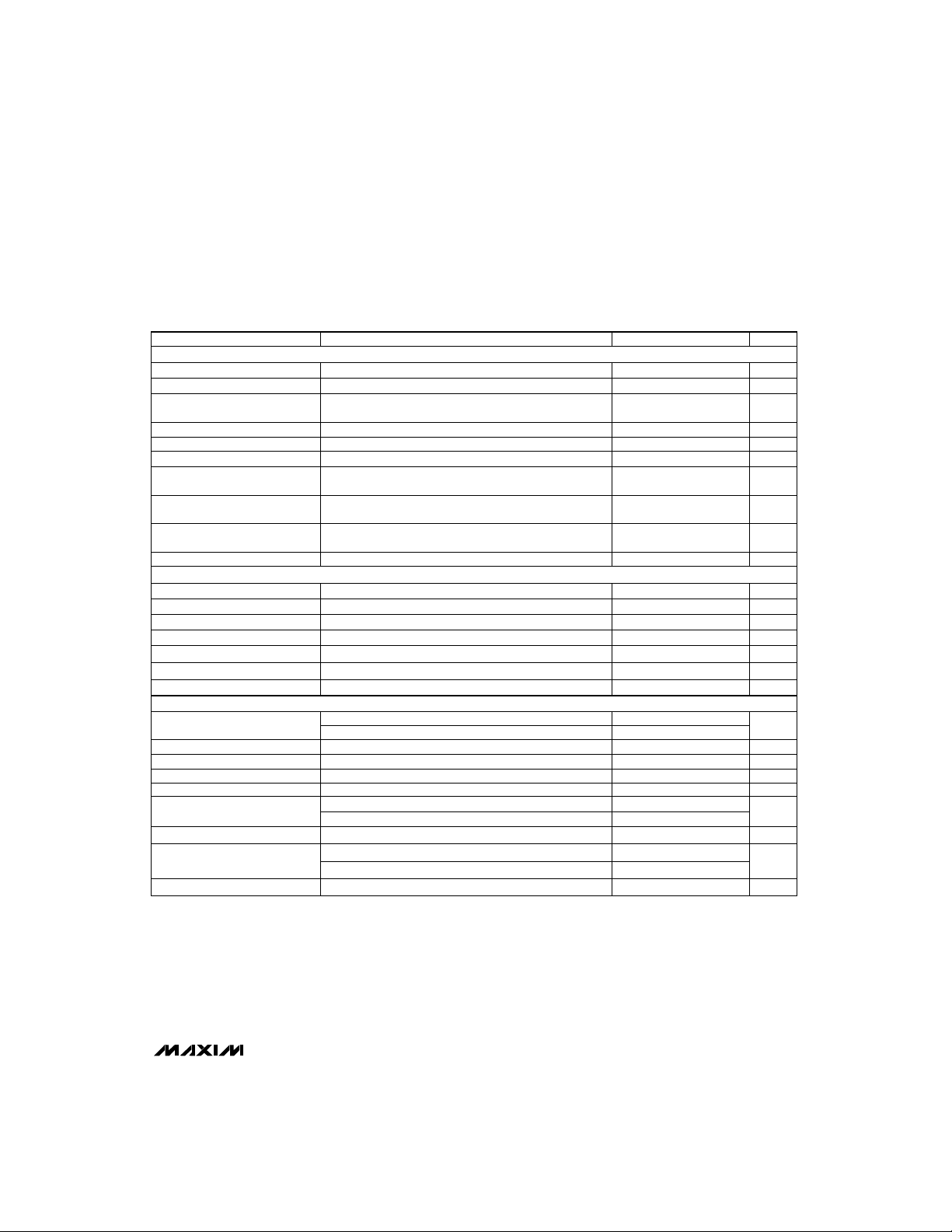

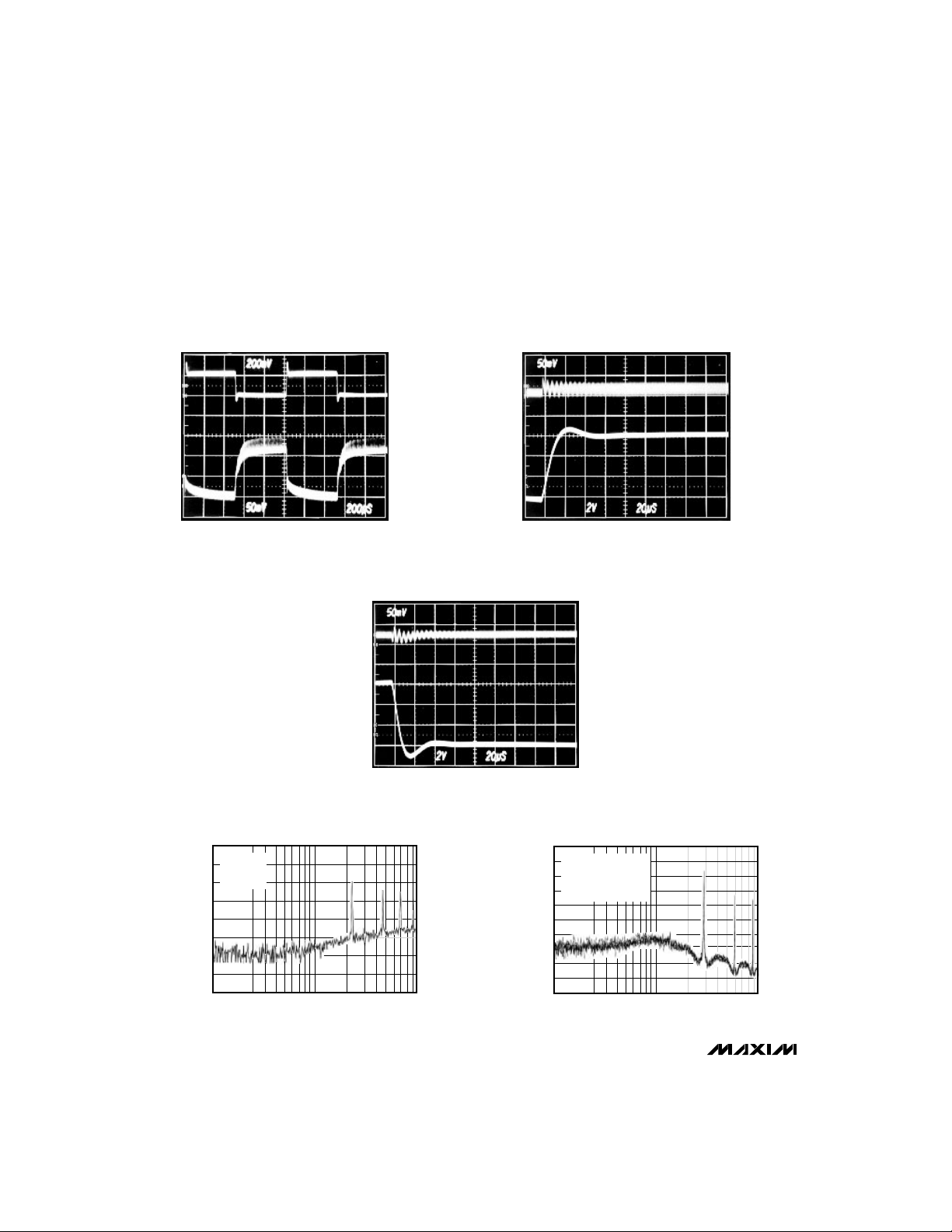

____________________________Typical Operating Characteristics (continued)

(Circuit of Figure 1, Transpower TTI5902 transformer, TA = +25°C, unless otherwise noted.)

SHUTDOWN SUPPLY CURRENT vs.

SUPPLY VOLTAGE

500

400

300

200

100

SHUTDOWN SUPPLY CURRENT (µA)

0

SHDN = 0V

0

612182430

SUPPLY VOLTAGE (V)

PULSE-WIDTH MODULATION MODE WAVEFORMS

MINIMUM VIN TO V

vs. +5V OUTPUT CURRENT

1.0

0.8

0.6

DIFFERENTIAL (V)

OUT

0.4

TO V

IN

0.2

MINIMUM V

0

1m 10m 100m 1 10

+5V OUTPUT CURRENT (A)

LX VOLTAGE

10V/div

+5V OUTPUT

VOLTAGE

50mV/div

DIFFERENTIAL

OUT

300kHz

+5V OUTPUT

STILL REGULATING

200kHz

SWITCHING FREQUENCY (kHz)

IDLE-MODE WAVEFORMS

SWITCHING FREQUENCY vs.

1000

100

10

1

0.1

100µ 10m 1

LOAD CURRENT

SYNC = REF (300kHz)

ON3 = ON5 = HIGH

+5V, VIN = 7.5V

+5V, VIN = 30V

1m 100m

LOAD CURRENT (A)

+3.3V, VIN = 7.5V

+5V OUTPUT

50mV/div

2V/div

MAX783

I

V

LOAD

IN

= 1A

= 16V

500ns/div

I

LOAD

V

IN

= 10V

= 100mA

200µs/div

_______________________________________________________________________________________

5

Page 6

Triple-Output Power-Supply Controller

for Notebook Computers

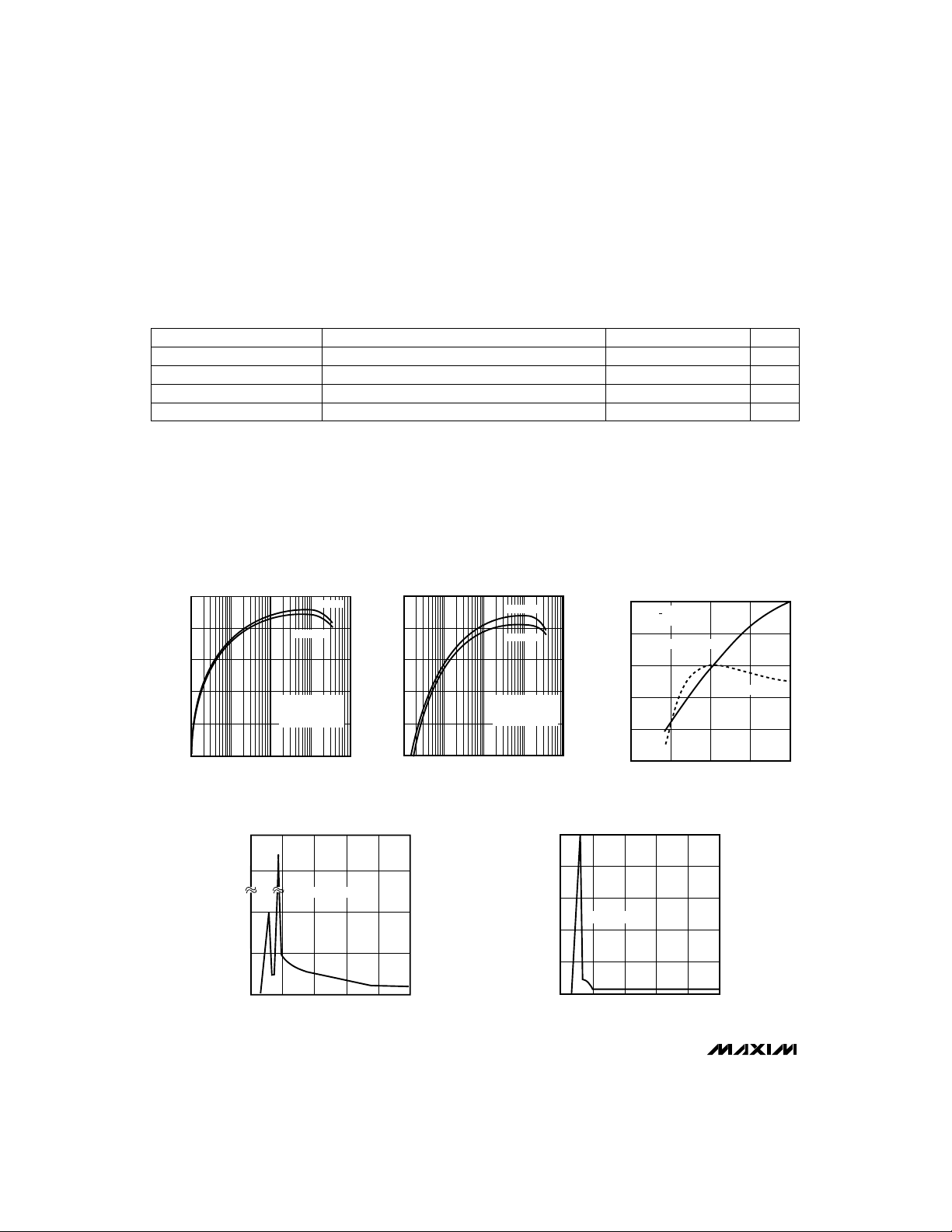

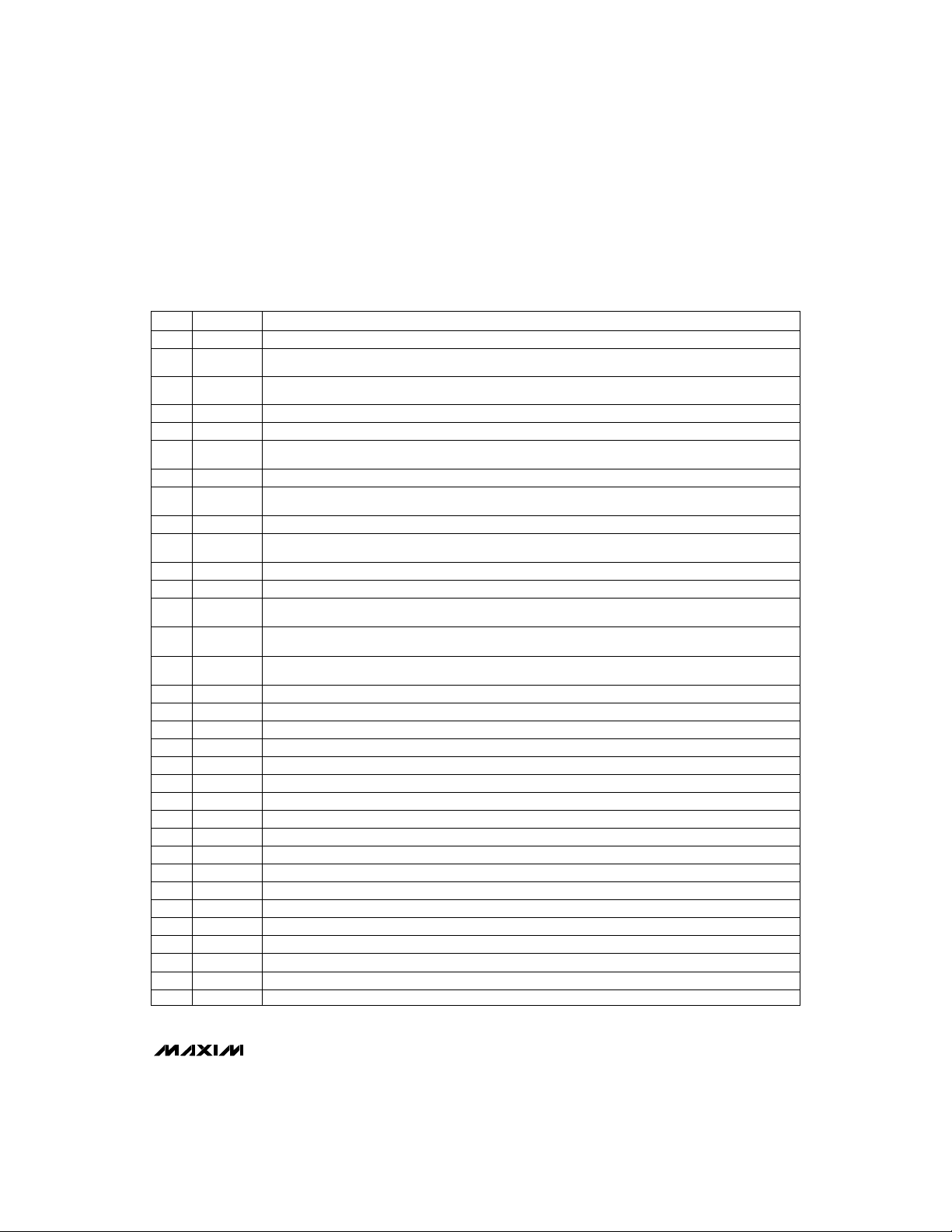

____________________________Typical Operating Characteristics (continued)

(Circuit of Figure 1, Transpower TTI5902 transformer, TA = +25°C, unless otherwise noted.)

+5V LOAD-TRANSIENT RESPONSE

MAX783

V

= 15V

IN

)

30

VIN = 10V

RMS

20

V

OUT

I

10

OUT

0

-10

-20

-30

OUTPUT VOLTAGE NOISE (dBmV

1

200µs/div

OUTPUT NOISE SPECTRUM

= 5V

= 50mA

10 100

FREQUENCY (kHz)

3A

LOAD CURRENT

0A

+5V OUTPUT

50mV/div

I

LOAD

+5V LINE-TRANSIENT RESPONSE, FALLING

I

LOAD

= 2A

20µs/div

)

RMS

OUTPUT VOLTAGE NOISE (dBmV

+5V LINE-TRANSIENT RESPONSE, RISING

20µs/div

= 2A

+5V OUTPUT

50mV/div

VIN, 16V TO 10V

2V/div

100k 1M

FREQUENCY (Hz)

30

VIN = 8V TO 12V

20

(PLOTS SUPERIMPOSED)

10

= 5V

V

OUT

0

= 1A

I

OUT

-10

-20

-30

-40

-50

-60

10k

OUTPUT NOISE SPECTRUM

+5V OUTPUT

50mV/div

VIN, 10V TO 16V

2V/div

6 _______________________________________________________________________________________

Page 7

Triple-Output Power-Supply Controller

for Notebook Computers

______________________________________________________________Pin Description

PIN

15-18

NAME FUNCTION

1 ON3 ON/O—F—F–control input to disable the +3.3V PWM. Tie directly to VL for automatic start-up.

Shutdown control input, low-true logic. Tie to VL for automatic start-up. The 5V VL supply stays active in

2 S—H—D—N

3 D1

4 D2 #2 level-translator/comparator noninverting input (see D1).

5 VH External positive supply voltage input for the level translators/comparators and R—D—Y—5–output.

6 Q2

7 Q1 #1 level translator/comparator output (see Q2).

8 R—D—Y—5

9 VPPA 0V, 3.3V, 5V, 12V switchable PCMCIA VPP output. Sources 60mA. Controlled by DA0 and DA1.

10 VDD

11 VPPB 0V, 3.3V, 5V, 12V switchable PCMCIA VPP output. Sources 60mA. Controlled by DB0 and DB1.

12 GND Low-current analog ground. Feedback reference point for all outputs.

13 REF

14 SYNC

19 ON5 ON/O—F—F–control input to disable the +5V PWM supply. Tie to VL for automatic start-up.

20 SS5 Soft-start control input for +5V. Ramp time to full current limit is 1ms/nF of capacitance to GND.

21 CS5 Current-sense input for +5V. Current limit level is +100mV referred to FB5.

22 DH5 Gate-drive output for the +5V high-side MOSFET.

23 LX5 Inductor connection for the +5V supply.

24 BST5 Boost capacitor connection for the +5V supply (0.1µF).

25 DL5 Gate-drive output for the +5V low-side MOSFET.

26 PGND Power ground

27 FB5 Feedback and current-sense input for the +5V PWM.

28 VL 5V logic supply voltage for internal circuitry. VL is always on and can source 5mA for external loads.

29 V+ Supply voltage input from battery, 5.5V to 30V

30 DL3 Gate-drive output for the +3.3V low-side MOSFET.

31 BST3 Boost capacitor connection for the +3.3V supply (0.1µF).

32 LX3 Inductor connection for the +3.3V supply.

33 DH3 Gate-drive output for the +3.3V high-side MOSFET.

34 FB3 Feedback and current-sense input for the +3.3V PWM.

35 CS3 Current-sense input for +3.3V, current limit level is +100mV referred to FB3.

36 SS3 Soft-start input for +3.3V. Ramp time to full current limit is 1ms/nF of capacitance to GND.

–

–

DA1, DA0,

DB1, DB0

shutdown. Don't force S—H—D—N–higher than VL + 0.5V.

#1 level-translator/comparator noninverting input, threshold = +1.650V. Controls Q1. Tie to GND if

unused.

#2 level-translator/comparator output. Sources 20µA from VH when D2 is high. Sinks 500µA to GND when

D2 is low, even with VH = 0V.

Power-good indication for the main +5V supply. Low indicates greater than 4.5V at the +5V output.

Swings 0V to VH.

+15V flyback input (feedback). A weak shunt regulator conducts 3mA to GND when VDD exceeds 19V.

VDD serves as the supply input for the VPP linear regulators.

3.3V reference output sources up to 5mA for external loads. Bypass to GND with 1µF/mA of load or

0.22µF minimum

Oscillator control/synchronization input. Connect to VL or GND for 200kHz; connect to REF for 300kHz.

For external clock synchronization in the 240kHz to 350kHz range, a high-to-low transition starts a new cycle.

PCMCIA digital control inputs with industry-standard coding (see Table 1).

MAX783

_______________________________________________________________________________________ 7

Page 8

Triple-Output Power-Supply Controller

for Notebook Computers

Table 1. Truth Table for VPP Control Pins

D_0 D_1 VPP

0 0 0V

0 1 5V

1 0 12V

MAX783

1 1 3.3V

_______________Detailed Description

The MAX783 converts a 5.5V to 30V input to six outputs

(Figure 1). It produces two high-power, PWM switchmode supplies, one at +5V and the other at +3.3V. The

two supplies operate at either 300kHz or 200kHz, allowing for small external components. Output current capability depends on external components, and can exceed

6A on each supply. Two 12V VPP outputs, an internal 5V,

25mA supply (VL) and a 3.3V, 5mA reference voltage

are also generated via linear regulators (Figure 2). Faultprotection circuitry shuts off the PWM and high-side supply when the internal supplies lose regulation.

Two precision voltage comparators are also included.

Their output stages permit them to be used as level

translators for driving external N-channel MOSFETs in

load-switching applications, or for more conventional

logic signals.

The MAX783 is capable of accepting input voltages

from 5.5V to 30V, but is optimized for the lower end of

this range because the +15V flyback winding controller

is appended to the +3.3V buck supply. This architecture

allows for lower input voltages than are possible with the

MAX782 sister chip, which puts the winding on the +5V

side, while maintaining high +15V load capability.

However, the MAX783’s transformer has a higher turns

ratio (4:1 vs. 2:1), which leads to higher interwinding

capacitance as well as higher switching noise amplitudes at the transformer secondary when the input voltage is high. Therefore, the MAX783 standard application circuit is optimized with external components for

low-voltage (6-8 cell) designs with maximum input voltages of 20V and less. The MAX783 itself can easily

accept 30V inputs, but expect to see more noise and

higher voltage swings at the transformer secondary

under these conditions. The inductor and filter capacitor

values may also require some adjustment for inputs

greater than 20V; see the

The +5V supply is generated by a current-mode PWM

step-down regulator using two N-channel MOSFETs, a

rectifier, plus an LC output filter (Figure 1). The gatedrive signal to the high-side MOSFET, which must

exceed the battery voltage, is provided by a boost cir-

Design Procedure

section.

+5V Switch-Mode Supply

cuit that uses a 100nF capacitor connected to BST5.

The +5V supply’s dropout voltage, as configured in

Figure 1, is typically 400mV at 2A. As V+ approaches

5V, the +5V output falls with V+ until the VL regulator

output hits its undervoltage lockout threshold at 4V. At

this point, the +5V supply turns off.

A synchronous rectifier at LX5 keeps efficiency high by

effectively clamping the voltage across the rectifier

diode. Maximum current limit is set by an external lowvalue sense resistor, which prevents excessive inductor

current during start-up or under short-circuit conditions.

Programmable soft-start is set by an optional external

capacitor; this reduces in-rush surge currents upon

start-up and provides adjustable power-up times for

power-supply sequencing purposes.

+3.3V Switch-Mode Supply

The +3.3V output is produced by a current-mode PWM

step-down regulator similar to the +5V supply. The +3.3V

supply uses a transformer primary winding as its inductor; the secondary is used for the 15V VDD supply.

The default switching frequency for both PWM controllers

is 200kHz (with SYNC connected to GND or VL), but

300kHz may be used by connecting SYNC to REF.

+3.3V and +5V PWM Buck Controllers

The two current-mode PWM buck controllers are nearly

identical except for different preset output voltages and

the addition of a flyback winding control loop to the

3.3V side. Each PWM is independent, except both are

synchronized to a master oscillator and share a common reference (REF) and logic supply (VL). Each PWM

can be turned on and off separately via ON3 and ON5.

The PWMs are a direct-summing type, lacking a traditional integrator-type error amplifier and the phase shift

associated with it. They therefore do not require external feedback compensation components if you follow

the filter capacitor ESR guidelines in the

Procedure

The main gain block is an open-loop comparator that

sums four input signals: output voltage error signal,

current-sense signal, slope-compensation ramp, and

precision reference voltage. This direct-summing

method approaches the ideal of cycle-by-cycle control

of the output voltage. Under heavy loads, the controller

operates in full PWM mode. Every pulse from the oscillator sets the output latch and turns on the high-side

switch for a period determined by the duty factor

(approximately V

off, the synchronous rectifier latch is set; 60ns later, the

low-side switch turns on. The low-side switch stays on

until the beginning of the next clock cycle (in continuous mode) or until the inductor current crosses through

.

). As the high-side switch turns

OUT/VIN

Design

8 _______________________________________________________________________________________

Page 9

Triple-Output Power-Supply Controller

for Notebook Computers

MAX783

BATTERY INPUT

5.5V TO 30V

(NOTE 1)

VPP

CONTROL

INPUTS

+5V

at

3A

C3

330µF

+3.3V ON/OFF

+5V ON/OFF

SHUTDOWN

5V POWERGOOD

C1–C6 = SPRAGUE 595D or AVX TPS SERIES

N1–N4 = Si9410DY or IRF7101 (BOTH SECTIONS)

D1A, D1B = LOW-POWER SCHOTTKY (CMPSH3 OR EQUIVALENT)

FOR V

NOTE 1: BATTERY VOLTAGE RANGE 6V to 20V WITH COMPONENTS SHOWN.

NOTE 2: KEEP KELVIN-CONNECTED CURRENT-SENSE TRACES SHORT AND CLOSE TOGETHER. SEE FIG.5.

NOTE 3: ZENER DIODE CLAMP REQUIRED FOR VIN

R1

25mΩ

C4

330µF

+ < 6V. FOR V+ > 6V, 1N4148 OR EQUIVALENT IS ACCEPTABLE.

L1

10µH

1N5819

C1

33µF

D1A

C10

0.1µF

N1

D2

(NOTE 2)

N2

C13

0.01µF

> 12V. ZENER CAN BE REPLACED WITH 20kΩ PULL-DOWN OR OTHER 1mA MINIMUM LOAD.

16

15

18

17

24

22

23

25

21

27

20

1

19

2

8

29 28

V+ VL

DA1

DB0

DB1

MAX783

BST5

DH5

LX5

DL5

CS5

FB5

SS5

ON3

ON5

SHDN

RDY5

VPPADA0

VPPB

VDD

BST3

DH3

LX3

DL3

CS3

FB3

SS3

D1-D2

Q1-Q2

SYNC

REF

GNDPGND

1226

9

11

10

31

33

32

30

35

34

36

5

VH

3, 4

7, 6

14

13

D1B

C11

0.1µF

C14

0.01µF

C15

1µF

C7

4.7µF

C8

1µF

C9

1µF

2

2

N4

(NOTE 2)

N3

D3

EC11FS1

1:4

L2 10µH

D5

1N5819

+5V at 5mA

0V, 3.3V, 5V, 12V

0V, 3.3V, 5V, 12V

+15V AT 200mA, SEE

HIGH-SIDE SUPPLY (VDD)

SECTION.

C12

2.2µF

R2

20mΩ

COMPARATOR SUPPLY INPUT

COMPARATOR INPUTS

COMPARATOR OUTPUTS

OSCILLATOR SYNC

3.3V AT 5mA

C2

33µF

D6

18V

100mW (NOTE 3)

+3.3V

C5

C6

150µF

150µF

3A

at

Figure 1. Standard Application Circuit

zero (in discontinuous mode). Under fault conditions

when the inductor current exceeds the 100mV currentlimit threshold, the high-side latch resets and the highside switch turns off.

At light loads, the inductor current fails to exceed the

25mV threshold set by the minimum current comparator. When this occurs, the PWM goes into idle mode,

skipping most of the oscillator pulses in order to reduce

the switching frequency and cut back switching losses.

The oscillator is effectively gated off at light loads

because the minimum current comparator immediately

resets the high-side latch at the beginning of each

cycle, unless the FB_ signal falls below the reference

voltage level.

_______________________________________________________________________________________ 9

A flyback winding controller regulates the +15V VDD

supply in the absence of a load on the main 3.3V output. If VDD falls below the preset +13V VDD regulation

threshold, a 1µs one-shot is triggered that extends the

low-side switch’s on-time beyond the point where the

inductor current crosses zero (in discontinuous mode).

This causes inductor (primary) current to reverse,

pulling current out of the output filter capacitor and

causing the flyback transformer to operate in the forward mode. The low impedance presented by the

transformer secondary in forward mode allows the

+15V filter capacitor to be quickly charged up again,

bringing VDD into regulation.

Page 10

Triple-Output Power-Supply Controller

for Notebook Computers

RDY5

V+

GND

SHDN

SYNC

VPPA

DA0

DA1

VPPB

DB0

DB1

VL

REF

D1

MAX783

5V

3.3V

1.65V

+5V LDO

LINEAR

REGULATOR

+3.3V

REFERENCE

300kHz/200kHz

OSCILLATOR

LINEAR

REGULATOR

LINEAR

REGULATOR

MAX783

P

5V

PWM

CONTROLLER

(SEE FIG. 3)

ON

3.3V

PWM

CONTROLLER

(SEE FIG. 3)

ON

4.5V

ON

2.8V

4V

ON

STANDBY

13V TO 19V

FAULT

VDD REG

FB5

CS5

BST5

DH5

LX5

DL5

SS5

PGND

ON5

FB3

CS3

BST3

DH3

LX3

DL3

SS3

ON3

13V

VDD

19V

Q1

D2

1.65V

Figure 2. Block Diagram

10 ______________________________________________________________________________________

Q2

VH

Page 11

Triple-Output Power-Supply Controller

for Notebook Computers

CS_

1X

MAX783

REF, 3.3V

(OR INTERNAL

5V REFERENCE)

SS_

ON_

-100mV

N

25mV

4µA

SLOPE COMP

3.3V

N

60kHz

LPF

MAIN PWM

COMPARATOR

MINIMUM

CURRENT

(IDLE-MODE)

30R

1R

RECTIFIER CONTROL

VL

0mV–100mV

SYNCHRONOUS

FB_

R

Q

S

OSC

CURRENT

LIMIT

R

Q

S

LEVEL

SHIFT

SHOOT-

THROUGH

CONTROL

LEVEL

SHIFT

BST_

DH_

LX_

VL

DL_

PGND

N

VDD REG

(SEE FIG. 2)

SINGLE-SHOT

Figure 3. PWM Controller Block Diagram

______________________________________________________________________________________ 11

MAX783

1µs

Page 12

Triple-Output Power-Supply Controller

for Notebook Computers

Connecting capacitors to SS3 and SS5 allows gradual

Soft-Start/SS_ Inputs

build-up of the +3.3V and +5V supplies after ON3 and

ON5 are driven high. When ON3 or ON5 is low, the

appropriate SS capacitors are discharged to GND.

When ON3 or ON5 is driven high, a 4µA constant current source charges these capacitors up to 4V. The

resulting ramp voltage on the SS_ pins linearly increas-

MAX783

es the current-limit comparator setpoint so as to

increase the duty cycle to the external power MOSFETs

up to the maximum output. With no SS capacitors, the

circuit will reach maximum current limit within 10µs.

Soft-start greatly reduces initial in-rush current peaks

and allows start-up time to be programmed externally.

Synchronous Rectifiers

Synchronous rectification allows for high efficiency by

reducing the losses associated with the Schottky rectifiers. Also, the synchronous rectifier MOSFETS are

necessary for correct operation of the MAX783's boost

gate-drive and VDD supplies.

When the external high-side power MOSFET turns off,

energy stored in the inductor causes its terminal voltage to reverse instantly. Current flows in the loop

formed by the inductor, Schottky diode, and load—an

action that charges up the filter capacitor. The Schottky

diode has a forward voltage of about 0.5V which,

although small, represents a significant power loss and

degrades efficiency. A synchronous rectifier MOSFET

parallels the diode and is turned on by DL3 (or DL5)

shortly after the diode conducts. Since the on resistance (r

the losses are reduced.

) of the synchronous rectifier is very low,

DS(ON)

The synchronous rectifier MOSFET is turned off when

the inductor current falls to zero.

Cross conduction (or “shoot-through”) occurs if the highside switch turns on at the same time as the synchronous

rectifier. Internal break-before-make timing ensures that

shoot-through does not occur. The Schottky rectifier conducts during the time that neither MOSFET is on, which

improves efficiency by preventing the synchronous-rectifier MOSFET’s lossy body diode from conducting.

The synchronous rectifier works under all operating conditions, including discontinuous-conduction and idle-mode.

The +3.3V synchronous rectifier also controls the 15V VDD

voltage (see the

High-Side Supply (VDD)

section).

Boost Gate-Driver Supply

Gate-drive voltage for the high-side N-channel switch is

generated with a flying-capacitor boost circuit as shown

in Figure 4. The capacitor is alternately charged from

the VL supply via the diode and placed in parallel with

BATTERY

INPUT

VL

VL

LEVEL

TRANSLATOR

PWM

Figure 4. Boost Supply for Gate Drivers

BST_

DH_

LX_

VL

DL_

the high-side MOSFET’s gate-source terminals. On startup, the synchronous rectifier (low-side) MOSFET forces

LX_ to 0V and charges the BST_ capacitor to 5V. On the

second half-cycle, the PWM turns on the high-side

MOSFET by connecting the capacitor to the MOSFET

gate by closing an internal switch between BST_ and

DH_. This provides the necessary enhancement voltage

to turn on the high-side switch, an action that “boosts”

the 5V gate-drive signal above the battery voltage.

Ringing seen at the high-side MOSFET gates (DH3 and

DH5) in discontinuous-conduction mode (light loads) is

a natural operating condition caused by the residual

energy in the tank circuit formed by the inductor and

stray capacitance at the LX_ nodes. The gate driver

negative rail is referred to LX_, so any ringing there is

directly coupled to the gate-drive supply.

Modes of Operation

PWM Mode

Under heavy loads—over approximately 25% of full

load—the +3.3V and +5V supplies operate as continuous-current PWM supplies (see

Characteristics

). The duty cycle (%ON) is approximately:

%ON = V

Typical Operating

OUT/VIN

Current flows continuously in the inductor: First, it ramps

up when the power MOSFET conducts; then, it ramps

down during the flyback portion of each cycle as energy

is put into the inductor and then discharged into the load.

Note that the current flowing into the inductor when it is

being charged is also flowing into the load, so the load is

12 ______________________________________________________________________________________

Page 13

Triple-Output Power-Supply Controller

for Notebook Computers

continuously receiving current from the inductor. This

minimizes output ripple and maximizes inductor use,

allowing very small physical and electrical sizes. Output

ripple is primarily a function of the filter capacitor effective series resistance (ESR) and is typically under 50mV

(see the

worst at light load and maximum input voltage.

Under light loads (<25% of full load), efficiency is further enhanced by turning the drive voltage on and off

for only a single clock period, skipping most of the

clock pulses entirely. Asynchronous switching, seen as

“ghosting” on an oscilloscope, is thus a normal operating

condition whenever the load current is less than

approximately 25% of full load.

At certain input voltage and load conditions, a transition

region exists where the controller can pass back and

forth from idle-mode to PWM mode. In this situation,

short bursts of pulses occur that make the current

waveform look erratic, but do not materially affect the

output ripple. Efficiency remains high.

The voltage between CS3 (CS5) and FB3 (FB5) is continuously monitored. An external, low-value shunt resistor

is connected between these pins, in series with the

inductor, allowing the inductor current to be continuously

measured throughout the switching cycle. Whenever

this voltage exceeds 100mV, the drive voltage to the

external high-side MOSFET is cut off. This protects the

MOSFET, the load, and the battery in case of short circuits or temporary load surges. The current-limiting

resistor R1 (R2) is typically 25mΩ (20mΩ) for a 3A load

current.

The SYNC input controls the oscillator frequency.

Connecting SYNC to GND or to VL selects 200kHz operation; connecting to REF selects 300kHz operation. SYNC

can also be driven with an external 240kHz to 350kHz

CMOS/TTL source to synchronize the internal oscillator.

300kHz operation is used to minimize the inductor and

filter capacitor sizes, but 200kHz may be necessary for

low input voltages (see

Design Procedure

Oscillator Frequency; SYNC Input

Low-Voltage Operation

section). Output ripple is

Idle Mode

Current Limiting

).

High-Side Supply (VDD)

The 15V VDD supply is obtained from the rectified and

filtered secondary of transformer L2. VDD is enabled

whenever the +3.3V supply is on (ON3 = high). The

primary and secondary of L2 are connected so that,

during the flyback (discharge) portion of each cycle,

energy stored in the core is transferred into the +3.3V

load through the primary and into VDD through the sec-

ondary, as determined by the turns ratio. The secondary voltage is added to the +3.3V to make VDD.

See the

supply’s load capability.

Unlike other coupled-inductor flyback converters, the

VDD voltage is regulated regardless of the loading on

the +3.3V output. (Most coupled-inductor converters

can only support the auxiliary output when the main

output is loaded.) When the +3.3V supply is lightly

loaded, the circuit achieves good control of VDD by

pulsing the MOSFET normally used as the synchronous

rectifier. This draws energy from the +3.3V supply’s

output capacitor and uses the transformer in a forwardconverter mode (i.e., the +15V output takes energy out

of the secondary when current is flowing in the primary). These forward-converter pulses are interspersed

with normal synchronous-rectifier pulses, and they only

occur at light loads on the +3.3V rail.

The transformer secondary’s rectified and filtered output is only roughly regulated, and may be between 13V

and 19V. It is brought back into VDD, which is also the

feedback input, and used as the source for the PCMCIA

VPP regulators. It can also be used as the VH power

supply for the comparators or any external MOSFET

drivers.

When the input voltage is above 12V, or when the

+3.3V supply is heavily loaded and VDD is lightly

loaded, L2’s interwinding capacitance and leakage

inductance can produce voltages above that calculated from the turns ratio. A 2.5mA shunt regulator limits

VDD to 19V. If the battery voltage can rise above 12V,

VDD must either be externally clamped with an 18V

zener diode, or there must be a 1mA minimum load on

VDD (or VPPA/VPPB).

Clock-frequency noise on the VDD rail of up to 3V

a facet of normal operation, and can be reduced by

adding more output capacitance.

Typical Operating Characteristics

for the VDD

P-P

PCMCIA-Compatible,

Programmable VPP Supplies

Two independent linear regulators furnish PCMCIA VPP

supplies. The VPPA and VPPB outputs can be programmed to deliver 0V, 3.3V, 5V, or 12V. The 0V output mode has a 250Ω pull-down to discharge external

filter capacitors and ensure that flash EPROMs cannot

be accidentally programmed. These linear regulators

draw their power from the high-side supply (VDD), and

each can furnish up to 60mA. Bypass VPPA and VPPB

to GND with at least 1µF, with the bypass capacitors

less than 20mm from the VPP pins.

The outputs are programmed with DA0, DA1, DB0 and

DB1, as shown in Table 2.

MAX783

is

______________________________________________________________________________________ 13

Page 14

Triple-Output Power-Supply Controller

for Notebook Computers

Table 2. VPP Program Codes

DA0 DA1 VPPA

0

0

1

1

MAX783

DB0 DB1 VPPB

0

0

1

1

0

1

0

1

0

1

0

1

These codes are compatible with many popular PCMCIA

digital controllers such as the Intel 82365SL. For other

interfaces, one of the inputs can be permanently wired

high or low and the other toggled to turn the supply on

and off. The truth table shows that either a “0” or “1” can

be used to turn each supply on. The two VPP outputs can

be safely connected in parallel for increased load capability if the control inputs are also tied together (i.e., DA0 to

DB0, DA1 to DB1). If VPAA and VPPB are connected in

parallel, some devices may exhibit several milliamps of

increased quiescent supply current when enabled, due to

slightly mismatched output voltage set points.

Two noninverting comparators can be used as precision voltage comparators or high-side drivers. The

supply for these comparators (VH) is brought out and

may be connected to any voltage between +3V and

+19V. The noninverting inputs (D1-D2) are high impedance, and the inverting input is internally connected to

a 1.650V reference. Each output (Q1-Q2) sources

20µA from VH when its input is above 1.650V, and

sinks 500µA to GND when its input is below 1.650V.

The Q1-Q2 outputs can be fixed together in wired-OR

configuration since the pull-up current is only 20µA.

Connecting VH to a logic supply (5V or 3V) allows the

comparators to be used as low-battery detectors. For driving N-channel power MOSFETs to turn external loads on

and off, VH should be 6V to 12V higher than the load voltage. This enables the MOSFETs to be fully turned on and

results in low r

. VDD is a convenient source for VH.

DS(ON)

Internal VREF and VL Supplies

An internal linear regulator produces the 5V used by the

internal control circuits. This regulator’s output is available on pin VL and can source 5mA for external loads.

Bypass VL to GND with 4.7µF. To save power, when the

+5V switch-mode supply is above 4.5V, the VL linear

regulator is turned off and the high-efficiency +5V

switch-mode supply output is internally connected to VL.

0V

5V

12V

3.3V

0V

5V

12V

3.3V

Comparators

The 3.3V precision reference (REF) is powered from the

internal 5V VL supply. It can furnish up to 5mA for external loads. Bypass REF to GND with 0.22µF, plus 1µF/mA

of load current. The main switch-mode outputs track the

reference voltage. Loading the reference reduces the

main output voltages slightly, according to the reference

voltage load regulation error.

Both the VL and REF supplies can remain active—even

when the switch-mode regulators are turned off—to supply

memory keep-alive power (see

Shutdown Mode

section).

These linear regulator outputs can be directly connected

to the corresponding switch-mode regulator outputs (i.e.,

REF to +3.3V, VL to +5V) to hold up the main supplies in

standby mode. However, to ensure start-up, standby

load currents must not exceed 5mA on each supply.

Shutdown Mode

Shutdown (S—H—D—N–= low) forces both PWMs off and disables the REF output and the auxiliary comparators

including R—D—Y—5–. Supply current in shutdown mode is

typically 25µA. The VL supply remains active and can

source 25mA for external loads. VL load capability is

higher in shutdown and standby modes than when the

PWMs are operating (25mA vs. 5mA).

Standby mode is achieved by holding ON3 and ON5

low while S—H—D—N–is high. This disables both PWMs, but

keeps VL, REF, and the precision comparators alive.

Supply current in standby mode is typically 70µA.

Other ways to shut down the MAX783 are suggested in

the applications section of the MAX782 data sheet.

__________________Design Procedure

Figure 1’s predesigned application circuit contains the

correct component values for 3A output currents and a

6V to 20V input range. Use the design procedure that

follows to optimize this basic schematic for different

voltage or current requirements.

Before beginning a design, firmly establish the following:

V

, the maximum input (battery) voltage. This

IN(MAX)

value should include the worst-case conditions under

which the power supply is expected to function, such

as no-load (standby) operation when a battery charger

is connected but no battery is installed. V

not exceed 30V.

V

, the minimum input (battery) voltage. This

IN(MIN)

value should be taken at the full-load operating current under the lowest battery conditions. If V

is below about 6V, the filter capacitance required to

maintain good AC load regulation increases, and the

current limit for the +5V supply has to be increased

for the same load level.

IN(MAX)

can-

IN(MIN)

14 ______________________________________________________________________________________

Page 15

Triple-Output Power-Supply Controller

for Notebook Computers

Three inductor parameters are required: the inductance

+5V Inductor (L1)

value (L), the peak inductor current (I

coil resistance (RL). The inductance is:

(V

where: V

) (V

OUT

L = ———————————

(V

IN(MAX)

= output voltage, 5V

OUT

V

f = switching frequency, normally 300kHz

I

LIR = ratio of inductor peak-to-peak AC

= maximum input voltage (V)

IN(MAX)

= maximum +5V DC load current (A)

OUT

IN(MAX)

) (f) (I

OUT

- V

) (LIR)

OUT

LPEAK

)

), and the

current to average DC load current, typically 0.3.

A higher value of LIR allows smaller inductance, but

results in higher losses and higher ripple.

The highest peak inductor current (I

DC load current (I

inductor current (I

current is typically chosen as 30% of the maximum DC

) plus half the peak-to-peak AC

OUT

). The peak-to-peak AC inductor

LPP

LPEAK

) equals the

load current, so the peak inductor current is 1.15 times

I

.

OUT

The peak inductor current at full load is given by:

I

LPEAK

) (V

= I

OUT

OUT

+ ———————————

(2) (f) (L) (V

IN(MAX)

IN(MAX)

- V

OUT

)

)

(V

The coil resistance should be as low as possible,

preferably in the low milliohms. The coil is effectively in

series with the load at all times, so the wire losses alone

are approximately:

Power loss = (I

OUT

2

)(RL)

In general, select a standard inductor that meets the L,

I

, and RLrequirements (see Tables 3 and 4). If a

LPEAK

standard inductor is unavailable, choose a core with an

LI2parameter greater than (L)(I

largest wire that will fit the core.

LPEAK

2

), and use the

+3.3V Transformer (L2)

Table 3 lists two commercially available transformers

and parts for a custom transformer. The following

instructions show how to determine the transformer

parameters required for a custom design:

LP, the primary inductance value

I

, the peak primary current

LPEAK

LI2, the core’s energy rating

RPand RS, the primary and secondary resistances

N, the primary-to-secondary turns ratio.

The transformer primary is specified just as the +5V

inductor, using V

(VDD)

power

= +3.3V; but the secondary output

OUT

must be added in as if it were part of the

primary. VDD current (I

and VPPB output currents. The total +3.3V power,

P

, is the sum of these powers:

TOTAL

P

= P3 + P

where: P3 = (V

and: V

TOTAL

OUT

PDD= (VDD) (IDD);

= output voltage, 3.3V;

OUT

I

= maximum +3.3V load current (A);

OUT

VDD = VDD output voltage, 15V;

) usually includes the VPPA

DD

DD

) (I

);

OUT

IDD= maximum VDD load current (A);

so: P

and the equivalent +3.3V output current, I

TOTAL

I

TOTAL

= (3.3V x I

= P

TOTAL

= [(3.3V x I

) + (15V x IDD)

OUT

/ 3.3V

) + (15V x IDD)] / 3.3V.

OUT

TOTAL

, is:

The primary inductance, LP, is given by:

(V

where: V

) (V

LP= —————————————

f = switching frequency, normally 300kHz

I

LIR = ratio of primary peak-to-peak AC

OUT

(V

IN(MAX)

= maximum input voltage

IN(MAX)

= maximum equivalent load current (A)

TOTAL

IN(MAX)

) (f) (I

- V

TOTAL

OUT

) (LIR)

)

current to average DC load current, typically 0.3.

The highest peak primary current (I

total DC load current (I

AC primary current (I

current is typically chosen as 30% of the maximum DC

) plus half the peak-to-peak

TOTAL

). The peak-to-peak AC primary

LPP

LPEAK

) equals the

load current, so the peak primary current is 1.15 times

I

. A higher value of LIR allows smaller inductance,

TOTAL

but results in higher losses and higher ripple.

The peak current in the primary at full load is given by:

(V

) (V

I

= I

LPEAK

Choose a core with an LI2parameter greater than

(LP) (I

LPEAK

2

).

TOTAL

OUT

+ —————————————.

(2) (f) (LP)(V

IN(MAX

) - V

OUT

IN(MAX)

)

)

The winding resistances, RPand RS, should be as low

as possible, preferably in the low milliohms. Use the

largest gauge wire that will fit on the core. The coil is

effectively in series with the load at all times, so the

resistive losses in the primary winding alone are

approximately (I

The minimum turns ratio, N

1:4 to accommodate the tolerance of the +3.3V supply. A

TOTAL

)2(RP).

, is 3.3V:(15V-3.3V). Use

MIN

greater ratio will reduce efficiency of the VPP regulators.

Minimize the diode capacitance and the interwinding

capacitance, since they create losses through the

VDD shunt regulator. These are most significant when

the input voltage is high, the +3.3V load is heavy, and

there is no load on VDD.

MAX783

______________________________________________________________________________________ 15

Page 16

Triple-Output Power-Supply Controller

for Notebook Computers

about twice the value of the sense resistor. MOSFETs

FAT, HIGH-CURRENT TRACES

MAIN CURRENT PATH

MAX783

KELVIN SENSE TRACES

MAX783

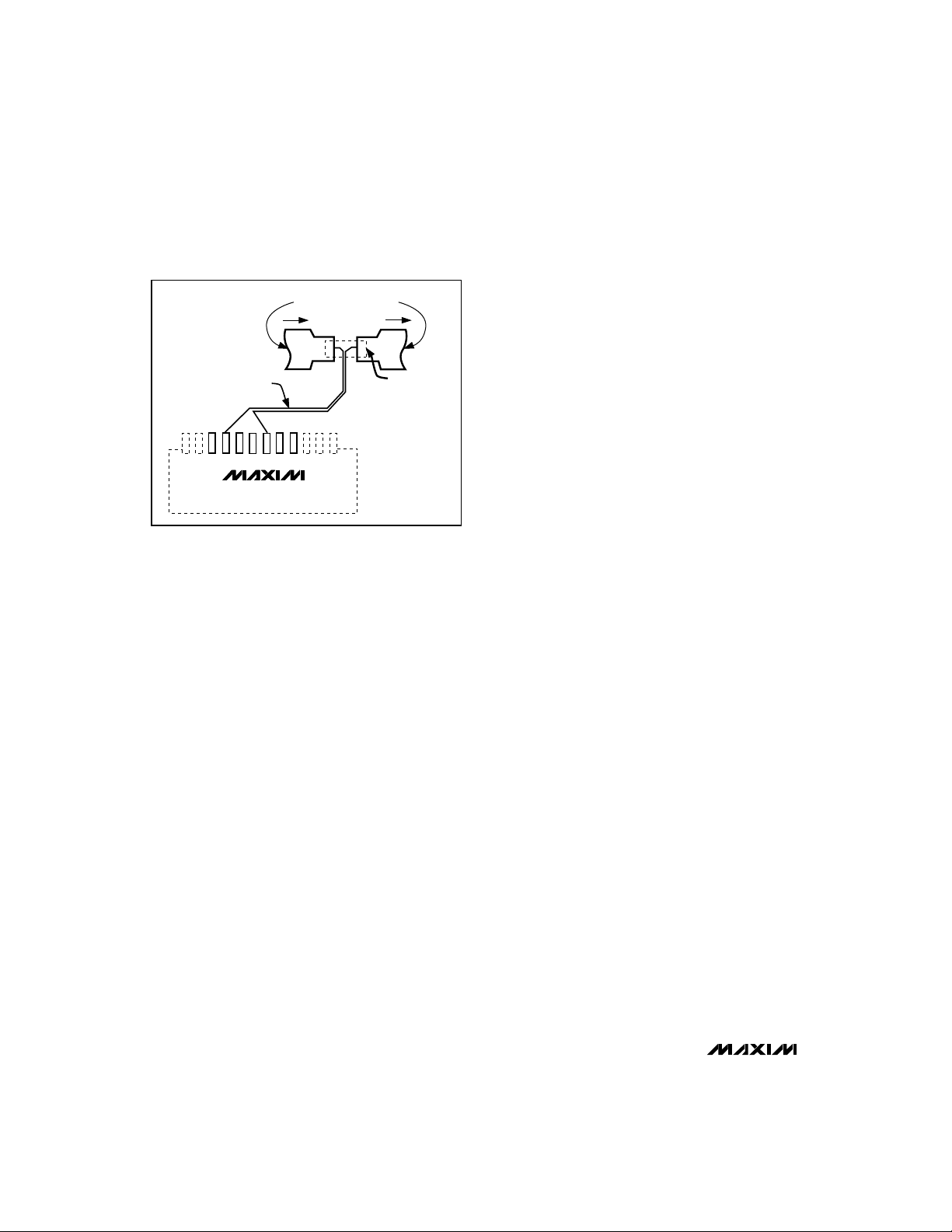

Figure 5. Kelvin Connections for the Current-Sense Resistors

SENSE RESISTOR

Ensure the transformer secondary is connected with the

right polarity: A VDD supply will be generated with either

polarity, but proper operation is possible only with the correct polarity. Test for correct connection by observing the

phase relationship between the LX3 switching node and

the transformer secondary under load. The two waveforms must be 180° out of phase.

Current-Sense Resistors (R1, R2)

The sense resistors must carry the peak current in the

inductor, which exceeds the full DC load current.

The internal current limiting starts when the voltage

across the sense resistors exceeds 100mV nominally,

80mV minimum. Use the minimum value to ensure

adequate output current capability: For the +5V supply, R1 = 80mV / (1.15 x I

R2 = 80mV/(1.15 x I

TOTAL

); for the +3.3V supply,

OUT

), assuming that LIR = 0.3.

Since the sense resistance values (e.g., R1 = 25mΩ for

I

= 3A) are similar to a few centimeters of narrow

OUT

traces on a printed circuit board, trace resistance can

contribute significant errors. To prevent this, Kelvin

connect the CS_ and FB_ pins to the sense resistors;

use separate traces not carrying any of the inductor or

load current, as shown in Figure 5. Run these traces

parallel at minimum spacing from one another. The

wiring layout for these traces is critical for stable, lowripple outputs (see the

Layout and Grounding

section).

MOSFET Switches (N1-N4)

The four N-channel power MOSFETs are usually identical and must be “logic-level” FETs; that is, they must be

fully on (have low r

drive voltage. The MOSFET r

) with only 4V gate-source

DS(ON)

should ideally be

DS(ON)

with even lower r

which increases switching time and transition losses.

DS(ON)

MOSFETs with low gate-threshold voltage specifications (i.e., maximum V

preferred, especially for high-current (5A) applications.

Output Filter Capacitors (C3–C6)

The output filter capacitors determine the loop stability

and output ripple voltage. To ensure stability, the minimum capacitance and maximum ESR values are:

CF> —————————————

(V

) (RCS) (2) (π) (GBWP)

OUT

and,

(V

ESRCF< ——————

OUT

where: CF= output filter capacitance, C6 or C7 (F)

= reference voltage, 3.3V

V

REF

= output voltage, 3.3V or 5V

V

OUT

= sense resistor (Ω)

R

CS

GBWP = gain-bandwidth product, 60kHz

= output filter capacitor ESR (Ω).

ESR

CF

Be sure to select output capacitors that satisfy both the

minimum capacitance and maximum ESR requirements. To achieve the low ESR required, it may be

appropriate to use a capacitance value 2 or 3 times

larger than the calculated minimum.

The output ripple in continuous-current mode is:

V

OUT(RPL)

= (I

) [(ESRCF+1/(2 x π x f x CF)].

LPP(MAX)

In idle-mode, the ripple has a capacitive and resistive

component:

V

(C) = ——————— x

OUT(RPL)

1 1

——— + ————— ) Volts

(

V

V

OUT(RPL)

The total ripple, V

lows:

if V

then V

otherwise, V

VIN- V

OUT

(R) = ——————- Volts

OUT(RPL)

OUT(RPL)

OUT(RPL)

OUT(RPL)

V

OUT(RPL)

have higher gate capacitance,

= 2V rather than 3V) are

GS(TH)

V

REF

) (RCS)

V

REF

(4 x 10-4) (L)

2

(R

) (CF)

CS

OUT

(0.02) (ESRCF)

R

CS

, can be approximated as fol-

(R) < 0.5 V

= V

OUT(RPL)

= 0.5 V

OUT(RPL)

(R).

OUT(RPL)

(C),

(C) +

(C),

16 _______________________________________________________________________________________

Page 17

Triple-Output Power-Supply Controller

for Notebook Computers

The voltage rating of D3 should be at least 4 x VIN+

Diode D3

5V plus a safety margin. A rating of at least 100V is

necessary for the maximum 20V supply. Use a highspeed silicon diode (with a higher breakdown voltage

and low capacitance) rather than a Schottky diode.

D3’s current rating should exceed twice the maximum

current load on VDD.

Diodes D2 and D5

Use 1N5819s or similar Schottky diodes. D2 and D5

conduct only about 3% of the time, so the 1N5819’s 1A

current rating is conservative. The voltage rating of D2

and D5 must exceed the maximum input supply voltage from the battery. These diodes must be Schottky

diodes to prevent the lossy MOSFET body diodes from

turning on, and they must be placed physically close to

their associated synchronous rectifier MOSFETs.

Soft-Start Capacitors (C13, C14)

A capacitor connected from GND to either SS pin causes that supply to ramp up slowly. The ramp time to full

current limit, tSS, is approximately 1ms for every nF of

capacitance on SS_, with a minimum value of 10µs.

Typical capacitor values are in the 10nF to 100nF range.

Because this ramp is applied to the current-limit circuit,

the actual time for the output voltage to ramp up

depends on the load current and output capacitor

value. Using Figure 1’s circuit with a 2A load and no

SS capacitor, full output voltage is reached in less than

1ms after ON_ is driven high.

Bypass Capacitors

Input Filter Capacitors (C1, C2)

Use at least 3µF/W of output power for the input filter

capacitors, C1 and C2. They should have less than

150mΩ ESR, and should be located no further than

10mm from N1 and N2 to prevent ringing. Connect the

negative terminals directly to PGND. Be careful not to

exceed the surge current ratings of the bypass capacitors. If the battery pack or AC adapter has very low

output impedance, tantalum capacitors may be damaged when initial connection is made. In this situation,

electrolytic capacitors such as Sanyo OS-CON may be

necessary. Also, take care that the RMS input current

of the MAX783 circuit does not exceed the bypass

capacitor ripple current rating. The RMS input current

(I

) can be calculated as shown below:

RMS

IRMS = RMS AC input current

= I

LOAD

————————

√V

OUT(VIN

———————–——

- V

)

OUT

V

IN

)(

Low-Voltage Operation

Low input voltages, such as the 6V end-of-life voltage

of a 6-cell NiCd battery, place extra demands on the

+5V buck regulator because of the very low input-output differential voltage. The standard application circuit works well with supply voltages down to 6V; at

input voltages less than 6V, the +5V filter capacitor

values must be increased. If the minimum battery

voltage is 6.5V or higher, the 660µF total 5V filter

capacitance can be reduced to 330µF.

The +5V supply’s load-transient response is

impaired due to reduced inductor-current slew rate,

which is in turn caused by reduced voltage applied

across the buck inductor during the high-side

switch-on time. So, the +5V output sags when hit

with an abrupt load current change, unless the +5V

filter capacitor value is increased. Only the capacitance is affected and ESR requirements don’t

change. Therefore, the added capacitance can be

supplied by an additional low-cost bulk capacitor in

parallel with the normal low-ESR switching-regulator

capacitor. The equation for voltage sag under a

step-load change follows:

2

(I

)(L)

V

= —————————————————

SAG

where DMAX is the maximum duty cycle. Higher duty

cycles are possible when the oscillator frequency is

reduced to 200kHz, due to fixed propagation delays

through the PWM comparator becoming a lesser part of

the whole period. The tested worst-case limit for DMAX

is 92% at 200kHz. Lower inductance values can reduce

the filter capacitance requirement, but only at the

expense of increased noise at high input voltages

(resulting from higher peak currents).

(2)(CF) (V

STEP

IN(MIN)

x DMAX - V

OUT

)

MAX783

______________________________________________________________________________________ 17

Page 18

Triple-Output Power-Supply Controller

for Notebook Computers

Good layout is necessary to achieve the designed out-

Layout and Grounding

put power, high efficiency, and low noise. Good layout

includes use of a ground plane, appropriate component placement, and correct routing of traces using

appropriate trace widths. The following points are in

order of importance:

1. A ground plane is essential for optimum performance.

MAX783

In most applications, the power supply is located on a

multilayer motherboard, and full use of the four or

more copper layers is recommended. Use the top

and bottom layers for interconnections, and the inner

layers for an uninterrupted ground plane.

2. Keep the Kelvin-connected current-sense traces

short, close together, and away from switching

nodes. See Figure 5. Important: Place the currentsense resistors close to the IC (less than 10mm

away if possible).

3. Place the LX node components N1, N2, D2, and L1

as close together as possible. This reduces resistive

and switching losses and keeps noise due to

ground inductance confined. Do the same with the

other LX node components N3, N4, D5, and L2.

4. The input filter capacitor C1 should be less than

10mm away from N1’s drain. The connecting copper trace carries large currents and must be at least

2mm wide, preferably 5mm.

Similarly, place C2 close to N3’s drain, and connect

them with a wide trace.

5. Keep the gate connections to the MOSFETs short for

low inductance (less than 20mm long and more than

0.5mm wide) to ensure clean switching.

6. To achieve good shielding, it is best to keep all

high-voltage switching signals (MOSFET gate drives DH3 and DH5, BST3 and BST5, and the two LX

nodes) on one side of the board and all sensitive

nodes (CS3, CS5, FB3, FB5 and REF) on the other

side.

7. Connect the GND and PGND pins directly to the

ground plane, which should ideally be an inner layer

of a multilayer board.

8. Connect the bypass capacitor C7 very close (less

than 10mm) to the VL pin.

9. Minimize the capacitance at the transformer secondary. Place D3 and C12 very close to each other

and to the secondary, then route the output to the

IC’s VDD pin with a short trace. Bypass with 0.1µF

close to the VDD pin if this trace is longer than

50mm.

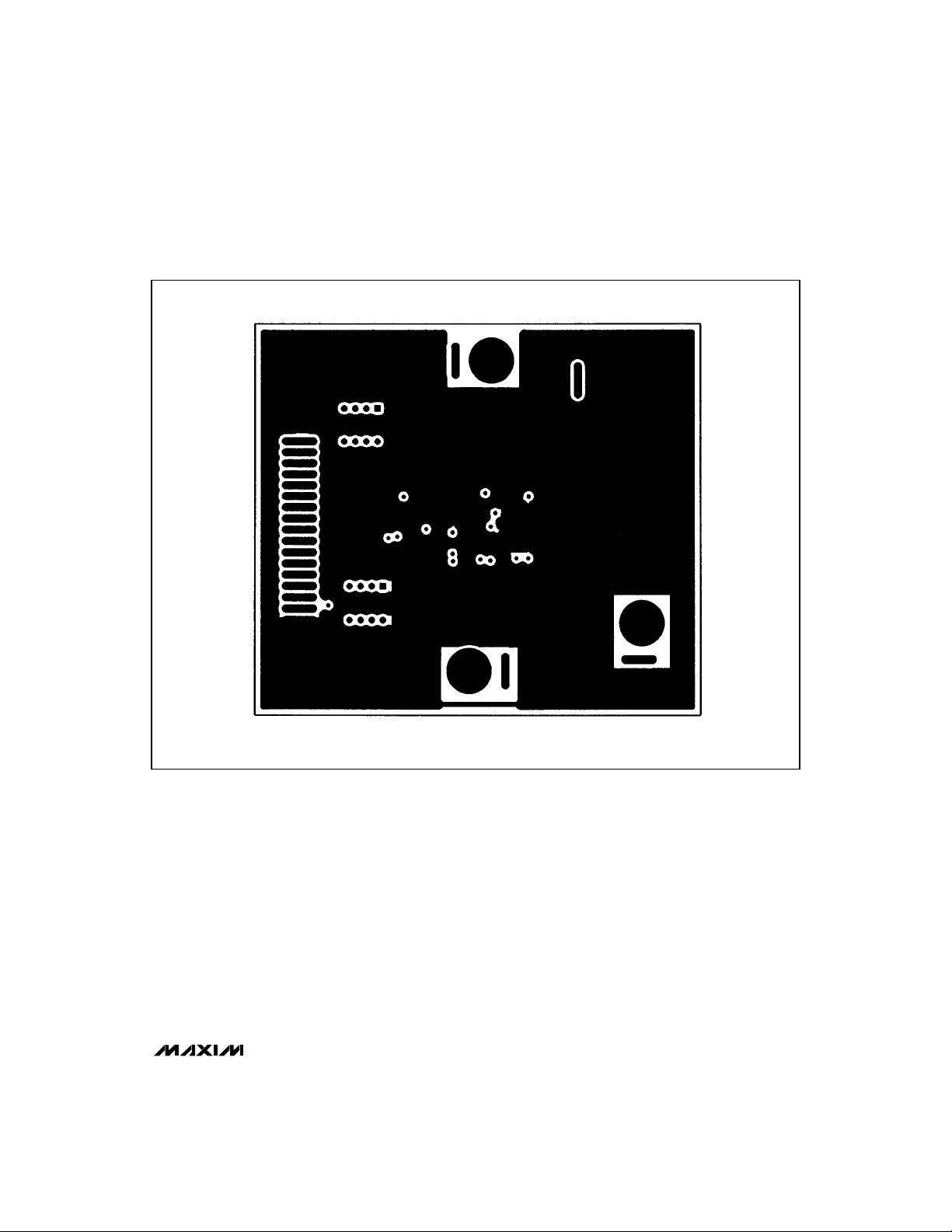

The layout for the evaluation board is shown in the

Evaluation Kit

noise, high-efficiency example.

section. It provides an effective, low-

18 ______________________________________________________________________________________

Page 19

Triple-Output Power-Supply Controller

for Notebook Computers

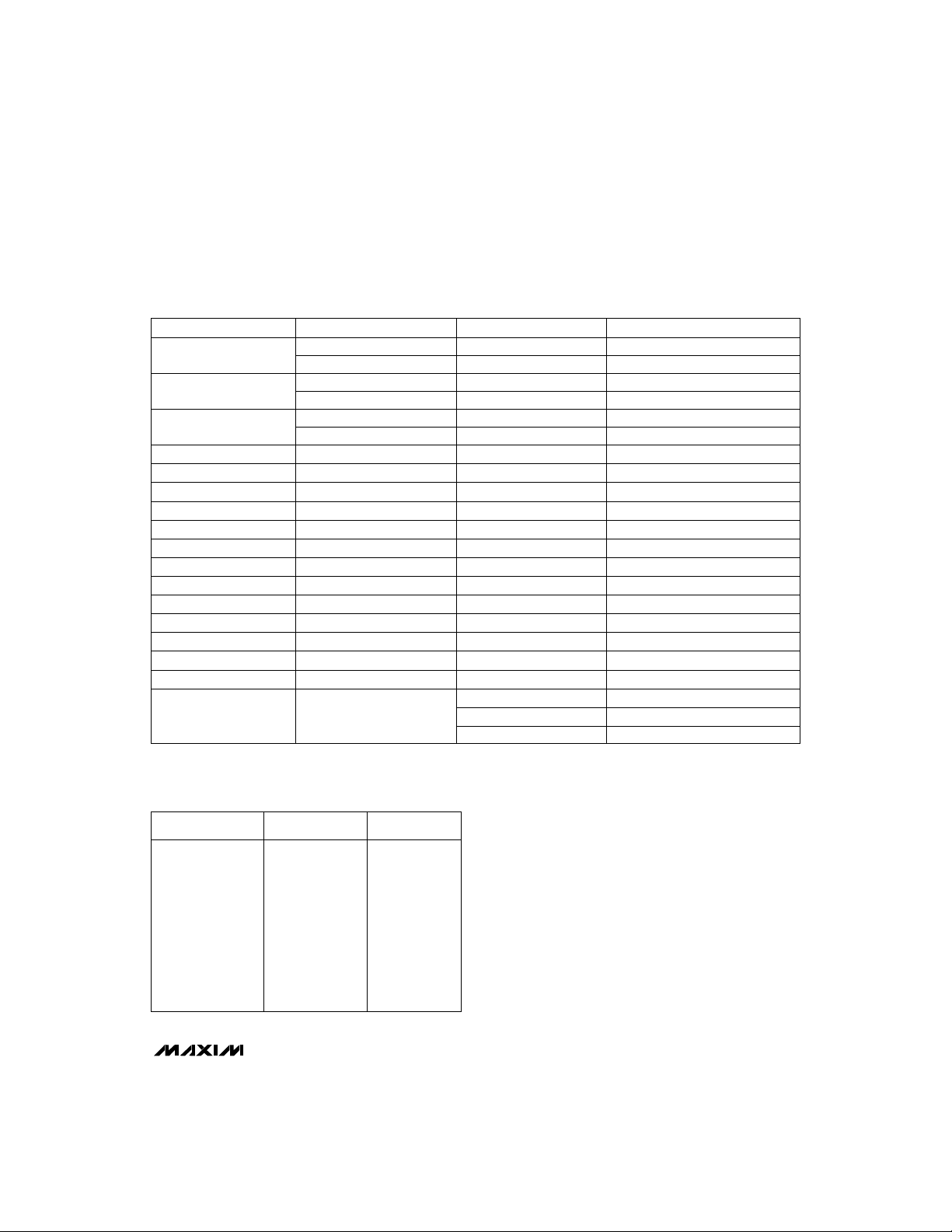

Table 3. Surface-Mount Components

(See Figure 1 for schematic and Table 4 for manufacturers' telephone numbers.)

COMPONENT TYPE MANUFACTURER PART NUMBER

C1, C2

C3, C4

C5, C6

C7 4.7µF 16V tantalum Sprague 595D475X0016A

C8, C9, C15 1µF, 20V tantalum Sprague 595D105X0020T

C10, C11 0.1µF, 16V tantalum Murata-Erie GRM42-6X7R104K50V

C12 2.2µF, 25V tantalum Sprague 595D225X0025B

C13, C14 0.01µF, ceramic Murata-Erie GRM42-6X7R103K50V

D1 Dual low-power Schottky Central Semiconductor CMPSH-3A

D3 Fast silicon rectifier Nihon EC11FS1

D2, D5 1N5819 Schottky Nihon EC10QS04

D6 18V, 100mW zener diode Central Semiconductor CMPZ5248

R1 0.025Ω SMT resistor IRC LR2010-01-R025-F

R2 0.02Ω SMT resistor IRC LR2010-01-R020-F

N1-N4 N-channel MOSFETs International Rectifier IRF7101 (Note 1)

L1 10µH, 2.5A inductor Sumida CDR125-100

L2 10µH, 1:4 transformer (Note 2)

Note 1: Four IRF7101s total; each device has both sections connected in parallel.

Note 2: These transformers have different sizes and pinouts. The MAX783 EV kit has the correct pad layout for the TTI5902 trans-

former, but all the transformers listed can be wired in easily.

33µF, 35V tantalum Sprague 595D336X0035R2B

33µF, 25V tantalum

330µF, 10V tantalum Sprague 595DD337X0010R2B

330µF, 6.3V tantalum AVX TPSE337M006R0100

150µF, 10V tantalum Sprague 595D157X0010D2B

220µF, 10V tantalum AVX TPSE227M010R0100

AVX TPSE336M025R0300

Transpower TTI5897 (for 3.3V at 1A)

Transpower TTI5902 (for 3.3V at 3A)

Coiltronics CTX03-12210 (for 3.3V at 2A)

Table 4. Surface-Mount Component Suppliers

Company USA Phone

Factory Fax

[country code]

MAX783

AVX

Central Semi

Coiltronics

International Rectifier

IRC

Murata-Erie

Nihon

Sprague

Sumida

Transpower Tech.

*Distributor

[ 1 ] 207-283-1941

[ 1 ] 516-435-1824

[ 1 ] 407-241-9339

[ 1 ] 310-322-3332

[ 1 ] 512-992-3377

[ 1 ] 404-736-3030

[81] 3-3494-7414

[ 1 ] 508-339-5063

[81] 3-3607-5428

[ 1 ] 702-831-3521

______________________________________________________________________________________ 19

(207) 282-5111

(800) 282-4975

(516) 435-1110

(407) 241-7876

(310) 322-3331

(512) 992-7900

(404) 736-1300

(805) 867-2555*

(508) 339-8900

(708) 956-0666

(702) 831-0140

Page 20

Triple-Output Power-Supply Controller

for Notebook Computers

______________________________________________

___________EV Kit Standard Features

♦ Battery Range: 5.5V to 20V*

♦ Load Capability: 5V at 3A*

MAX783

♦ 3.3V and 5V Keep-Alive Linear Regulator Outputs

♦ Dual PCMCIA VPP Outputs

♦ Oscillator Sync Input

For wider input voltage range or higher load current,

*

see the Design Procedure.

3.3V at 3A*

12V at 120mA or

15V at 200mA

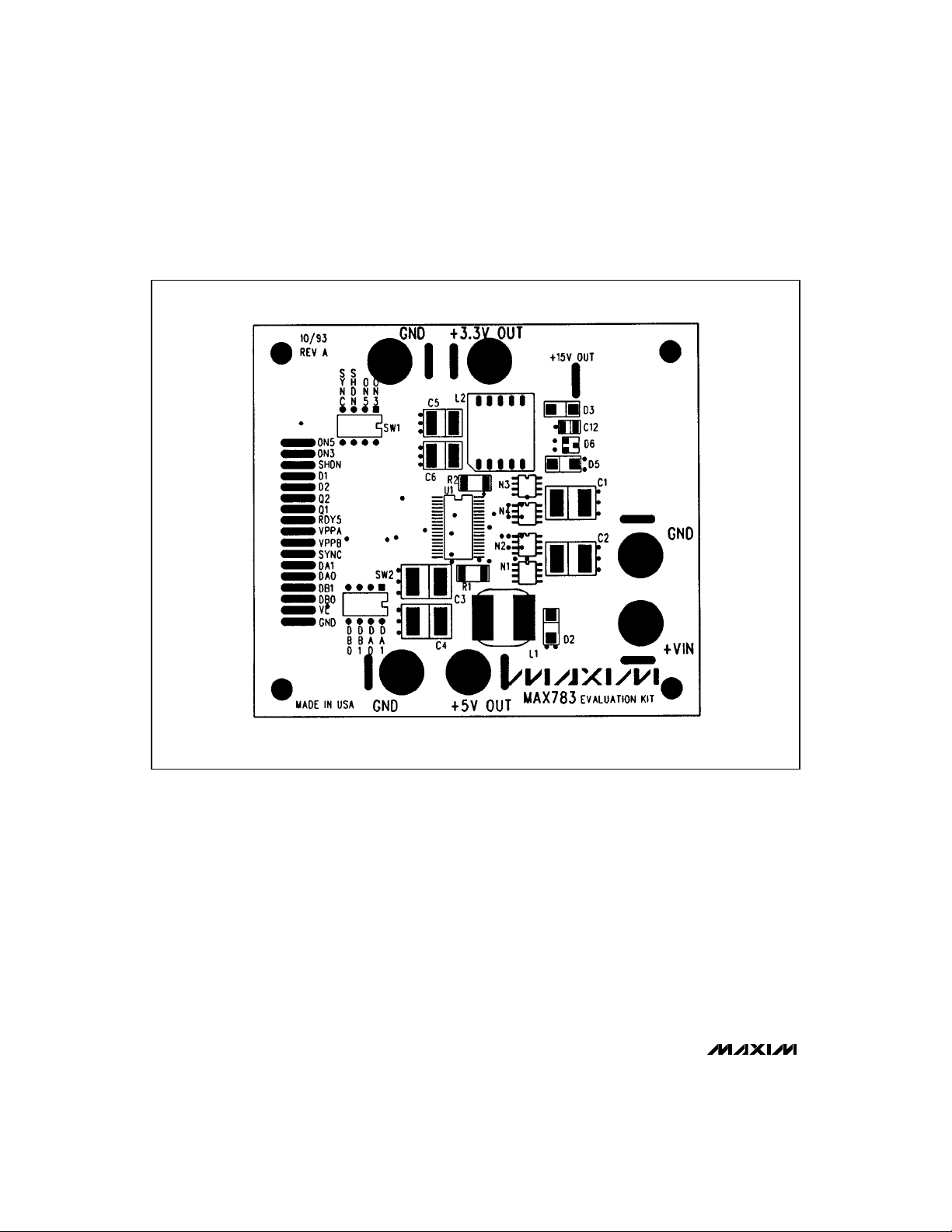

_________________EV Kit Description

The MAX783 evaluation kit (EV kit) is a preassembled

and tested demonstration board that embodies the

standard application circuit, with some extra pull-up

and pull-down resistors needed to set default logic signal levels. The board comes configured to accept battery voltages between 5.5V and 20V, but it can be

reconfigured for voltages between 5.5V and 30V. The

maximum voltage for safe operation (20V) is determined by the breakdown voltage rating of the external

MOSFETs and input filter capacitor (C1 and C2) voltage ratings; if these are replaced with high-voltage

devices, the board can tolerate 30V input without damage (36V absolute max).

Load current capability of the standard board is 3A at

each main output (5V and 3.3V) and 60mA at each 12V

VPP output. Load current capability can also be configured by selecting appropriate external components

and sense resistor values, with practical load capability

up to 7A at each main output and 500mA on the 15V

flyback output (see the

uring both load and input voltage capability). All functions are controlled by two on-board dipswitches,

which can be overridden by external CMOS/TTL logic

signals if desired (provided the dipswitches are set to

off first).

See Table 3 for the EV kit components. These components correspond exactly to Figure 1's Standard

Application Circuit, with the addition of the following

chip resistors (which are required only to set default

logic and supply levels). The comparator outputs both

swing 0V to 5V unless R14 is removed and R12 is

installed, in which case their output swing is 0V to 15V.

R3-R11 1MΩ 5% resistors (logic pull-down, usually not

needed and not installed in normal applications)

Design Procedure

for reconfig-

Evaluation Kit Information

R12 Open-circuit (no resistor installed)

R13 100kΩ 5% chip resistor (SYNC pull-down,

R14 560Ω 5% resistor (pull-up for comparator sup-

Connect a stiff (30W or better) bench power supply to the

+VINand GND pads found on the edge of the board.

Turn up the input voltage to somewhere between 5V and

20V. Set switches SW2A, SW2B, and SW2C on (if they

are not already on), taking the device out of shutdown

and turning on the main switching regulators. Set switch

SW2D off so that the oscillator is set to 200kHz, which is

the appropriate frequency for the 6V-20V input range.

The main outputs are now regulating and ready for heavy

loads. For best output accuracy and noise characteristics, loads should be returned separately to the GND

pad corresponding to and adjacent to each output

(+3OUT and +5OUT). Normal full-load regulation

error is typically -2.5% while keeping the outputs within tolerance. If the measured error is higher, there may

be drops in the wiring or ground. Ensure the voltmeter

is sensing directly at the output and ground pads.

To observe normal PWM switching action, place a 1A

load on either output and observe the corresponding

switching node (device LX_ pin) while varying the input

voltage. Without a load, the switching waveforms are

intermittent and difficult to trigger on and it may appear

that the board isn’t working (except for the presence of

output voltage).

To exercise the VPP controls, first ensure the 3.3V

switch-mode supply is ON. The loosely regulated flyback voltage (13V to 19V) will be present at the edge

pad marked “+15OUT”. Turn on each VPP output by

setting the appropriate code on SW1, where ON = HIGH

(see Table 1).

The 5V linear regulator output is always present, even in

shutdown mode, and can be measured at the VL pad. If

the battery is connected and VL is not at 5V or close to it,

something is wrong (excess VL load, possibly). The precision 3.3V linear regulator (REF) is activated by taking the

device out of shutdown mode (by turning SW2C on).

Turning on the SW2D sets the oscillator to 300kHz, but

the external component values should be changed first

(see the

chronized to an external clock signal by driving the

SYNC pad with a 240kHz to 350kHz pulse train of 5V

amplitude while SW2D is off.

usually shorted out)

ply, usually shorted out or left open)

___________EV Kit Quick Reference

Design Procedure

). The oscillator can be syn-

20 ______________________________________________________________________________________

Page 21

Triple-Output Power-Supply Controller

for Notebook Computers

MAX783

VPPA

VL

VPPB

+15OUT

+3.3OUT

C6

C5

Q1

VH

RDY5

150µF

150µF

SYNC

Q2

REF

D6

18V

R2

20mΩ

D1B

C12

D3

31

BST3

L2

2.2µF

N3

C11

33

DH3

D5

10µH

N4

0.1µF

32

30

35

LX3

DL3

CS3

MAX783

BST5

DH5

LX5

DL5

24

D1A

R6

R5R4

R3

23

22

C10

0.1µF

N1

L1

10µH

R1

25mΩ

C4

330µF

C3

330µF

+5OUT

CS5

25

21

N2

D2

C2

33µF

C7

4.7µF

C8

1µF

C9

1µF

11

VPPB

10

VDD

DB0

DB1

18

17

DB0

DB1

9

28

VPPA

29

V+ VL

DA0

DA1

16

15

C1

33µF

BC D

A

SW1

IN

+V

DA1

DA0

34

FB3

FB5

27

R14

TO VL

R12

C14

0.01µF

36

SS3

SS5

20

C13

0.01µF

BC

A

560Ω

OPEN

5VH8

ON31ON519SHDN2D1

SW2

ON3

RDY5

ON5

7

6

Q1

3

SHDN

SW2D

R13

100k

C15

13

R11R10

R8

1µF

REF

1226

PGND GND

R9

R3 - R11 = 1MΩ

R7

14

Q2

SYNC

D2

4

D1

D2

Figure 6. MAX783 EV Kit Schematic

______________________________________________________________________________________ 21

Page 22

Triple-Output Power-Supply Controller

for Notebook Computers

MAX783

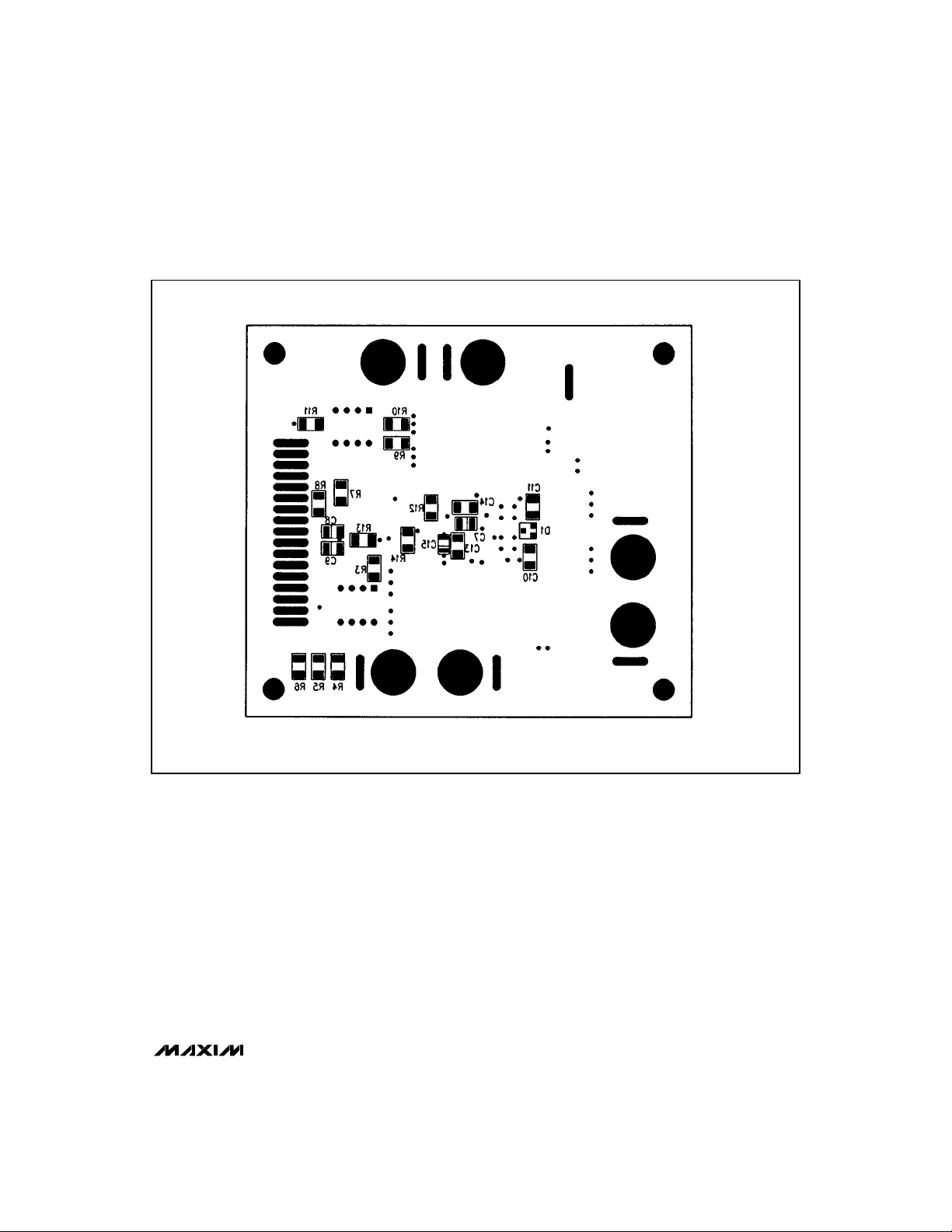

Figure 7. MAX783 EV Kit Top Component Layout and Silk Screen, Top View

22 ______________________________________________________________________________________

Page 23

Triple-Output Power-Supply Controller

for Notebook Computers

MAX783

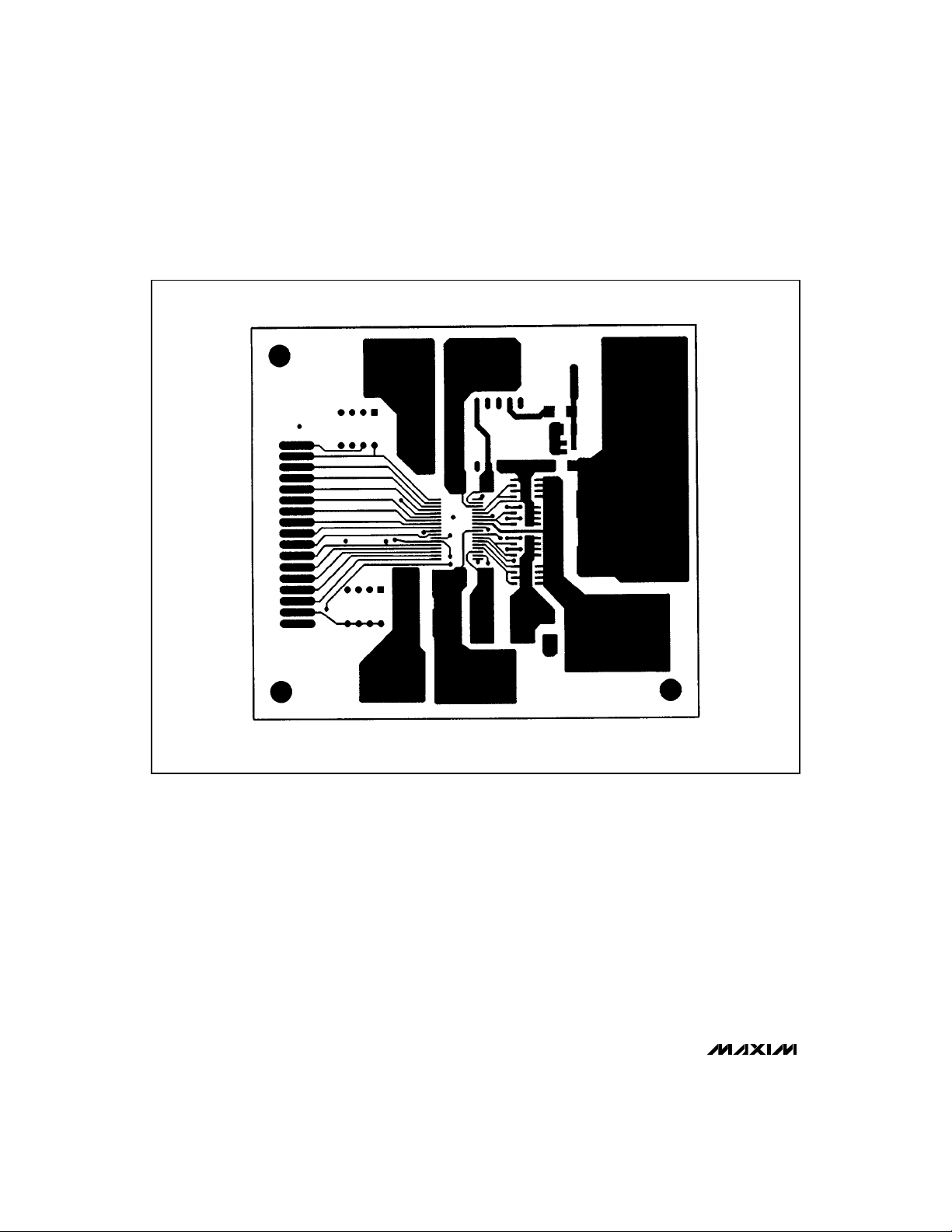

Figure 8. MAX783 EV Kit Ground Plane (Layers 2 and 3), Top View

______________________________________________________________________________________ 23

Page 24

Triple-Output Power-Supply Controller

for Notebook Computers

MAX783

Figure 9. MAX783 EV Kit Top Layer (Layer 1), Top View

24 ______________________________________________________________________________________

Page 25

Triple-Output Power-Supply Controller

for Notebook Computers

MAX783

Figure 10. MAX783 EV Kit, Bottom Component Layout and Silk Screen, Bottom View

______________________________________________________________________________________ 25

Page 26

Triple-Output Power-Supply Controller

for Notebook Computers

MAX783

Figure 11. MAX783 EV Kit, Bottom Layer (Layer 4), Top View

26 ______________________________________________________________________________________

Page 27

Triple-Output Power-Supply Controller

for Notebook Computers

MAX783

Figure 12. MAX783 EV Kit, Drill Schedule

______________________________________________________________________________________ 27

Page 28

Triple-Output Power-Supply Controller

for Notebook Computers

___________________Chip Topography _Ordering Information (continued)

FB3

SS3

SHDN

D2

DH3

CS3

ON3

D1

VH

Q2

Q1

MAX783

RDY5

VPPA

VPPB

SYNC

VDD

GND

REF

DA1

DA0

DB1

DB0

SS5 DH5

ON5

0.132"

(3.353mm)

CS5

LX3

BST3

DL3

V+

VL

FB5

PGND

DL5

BST5

LX5

0.181"

(4.597mm)

TRANSISTOR COUNT: 1569

SUBSTRATE CONNECTED TO GND

________________________________________________________Package Information