Page 1

19-0146; Rev 2; 5/94

Evaluation Kit

Information Included

Controller for Notebook Computers

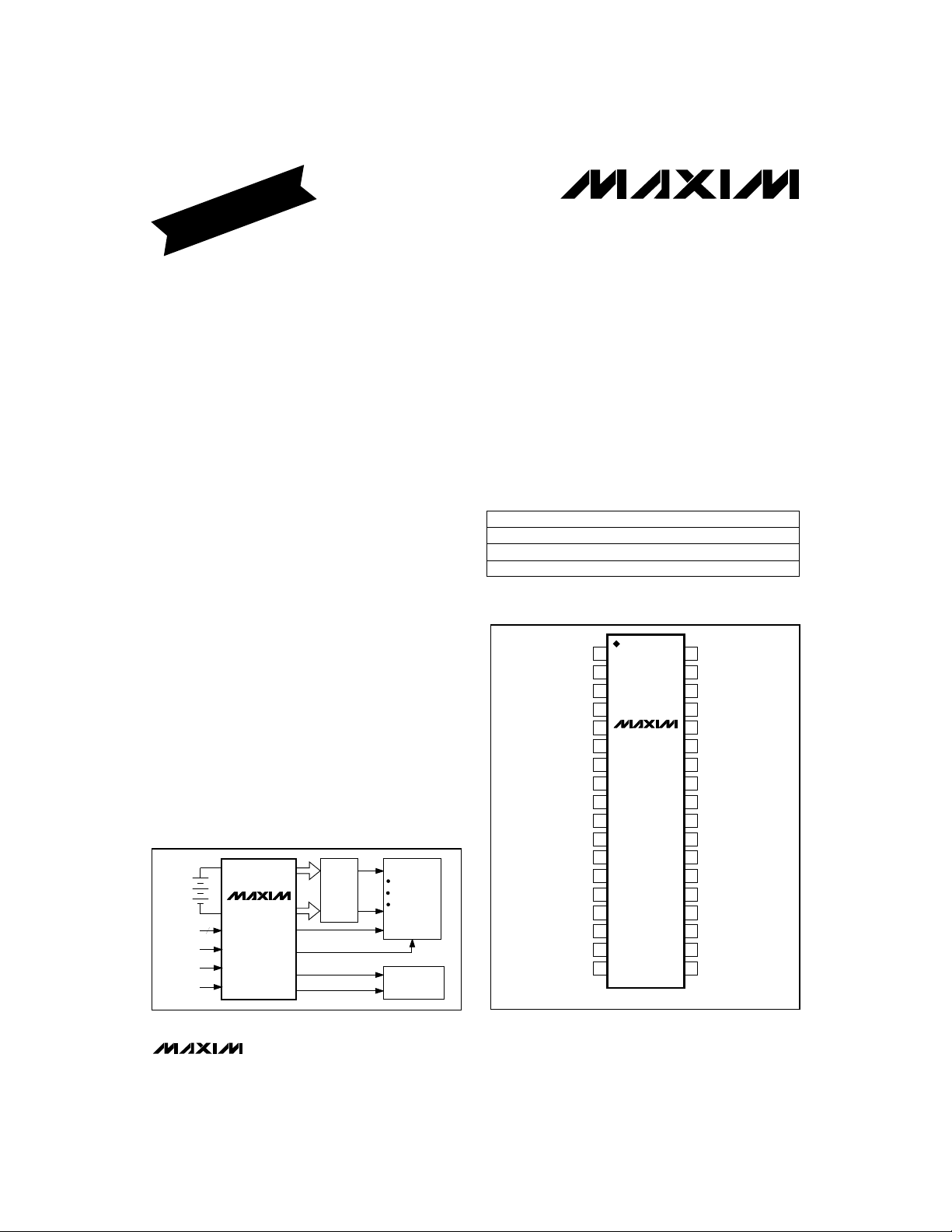

_______________General Description

The MAX782 is a system-engineered power-supply controller for notebook computers or similar battery-powered

equipment. It provides two high-performance step-down

(buck) pulse-width modulators (PWMs) for +3.3V and +5V,

and dual PCMCIA VPP outputs powered by an integral flyback winding controller. Other functions include dual, lowdropout, micropower linear regulators for CMOS/RTC backup, and three precision low-battery-detection comparators.

High efficiency (95% at 2A; greater than 80% at loads

from 5mA to 3A) is achieved through synchronous rectification and PWM operation at heavy loads, and IdleModeTMoperation at light loads. It uses physically

small components, thanks to high operating frequencies (300kHz/200kHz) and a new current-mode PWM

architecture that allows for output filter capacitors as

small as 30µF per ampere of load. Line- and load-transient response are terrific, with a high 60kHz unity-gain

crossover frequency allowing output transients to be

corrected within four or five clock cycles. Low system

cost is achieved through a high level of integration and

the use of low-cost, external N-channel MOSFETs. The

integral flyback winding controller provides a low-cost,

+15V high-side output that regulates even in the

absence of a load on the main output.

Triple-Output Power-Supply

___________________________Features

♦ Dual PWM Buck Controllers (+3.3V and +5V)

♦ Dual PCMCIA VPP Outputs (0V/5V/12V)

♦ Three Precision Comparators or Level Translators

♦ 95% Efficiency

♦ 420µA Quiescent Current;

70µA in Standby (linear regulators alive)

♦ 5.5V to 30V Input Range

♦ Small SSOP Package

♦ Fixed Output Voltages Available:

3.3 (standard)

3.45 (High-Speed Pentium™)

3.6 (PowerPC™)

______________Ordering Information

PART TEMP. RANGE PIN-PACKAGE

MAX782CBX 0°C to +70°C 36 SSOP

MAX782RCBX 0°C to +70°C 36 SSOP

MAX782SCBX 0°C to +70°C 36 SSOP

Ordering Information continued on last page.

__________________Pin Configuration

TOP VIEW

Other features include low-noise, fixed-frequency PWM

operation at moderate to heavy loads and a synchronizable oscillator for noise-sensitive applications such as

electromagnetic pen-based systems and communicating computers. The MAX782 is a monolithic BiCMOS IC

available in fine-pitch, SSOP surface-mount packages.

_______________________Applications

Notebook Computers

Portable Data Terminals

Communicating Computers

Pen-Entry Systems

______Typical Application Diagram

+3.3V

+5V

µP

MEMORY

PERIPHERALS

DUAL

PCMCIA

SLOTS

5.5V

TO

30V

VPP

CONTROL

ON3

ON5

SYNC

Idle-Mode is a trademark of Maxim Integrated Products. Pentium is a trademark of Intel

™

MAX782

4

POWER

SECTION

SUSPEND POWER

LOW-BATTERY WARNING

VPP (0V/5V/12V)

VPP (0V/5V/12V)

ON3

1

D1

2

D2

3

D3

4

VH

5

Q3

Q2

Q1

VPPA

VDD

VPPB

GND

REF

SYNC

DA1

DA0

DB1

DB0

MAX782

6

7

8

9

10

11

12

13

14

15

16

17

18

SSOP

.

PowerPC is a trademark of IBM.

MAX782

V

OUT

3.3V

3.45V

3.6V

36

SS3

CS3

35

FB3

34

DH3

33

LX3

32

31

BST3

30

DL3

29

V+

28

VL

27

FB5

26

PGND

25

DL5

24

BST5

23

LX5

22

DH5

21

CS5

20

SS5

19

ON5

________________________________________________________________

Maxim Integrated Products

Call toll free 1-800-998-8800 for free samples or literature.

1

Page 2

Triple-Output Power-Supply

Controller for Notebook Computers

ABSOLUTE MAXIMUM RATINGS

V+ to GND.................................................................-0.3V, +36V

PGND to GND........................................................................±2V

VL to GND ...................................................................-0.3V, +7V

BST3, BST5 to GND ..................................................-0.3V, +36V

LX3 to BST3.................................................................-7V, +0.3V

LX5 to BST5.................................................................-7V, +0.3V

Inputs/Outputs to GND

MAX782

(D1-D3, ON5, REF, SYNC, DA1, DA0, DB1, DB0, ON5,

SS5, CS5, FB5, CS3, FB3, SS3, ON3)..........-0.3V, (VL + 0.3V)

VDD to GND.................................................................-0.3V, 20V

VPPA, VPPB to GND.....................................-0.3V, (VDD + 0.3V)

VH to GND...................................................................-0.3V, 20V

Q1-Q3 to GND.................................................-0.3V, (VH + 0.3V)

DL3, DL5 to PGND...........................................-0.3V, (VL + 0.3V)

Stresses beyond those listed under “Absolute Maximum Ratings‘” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

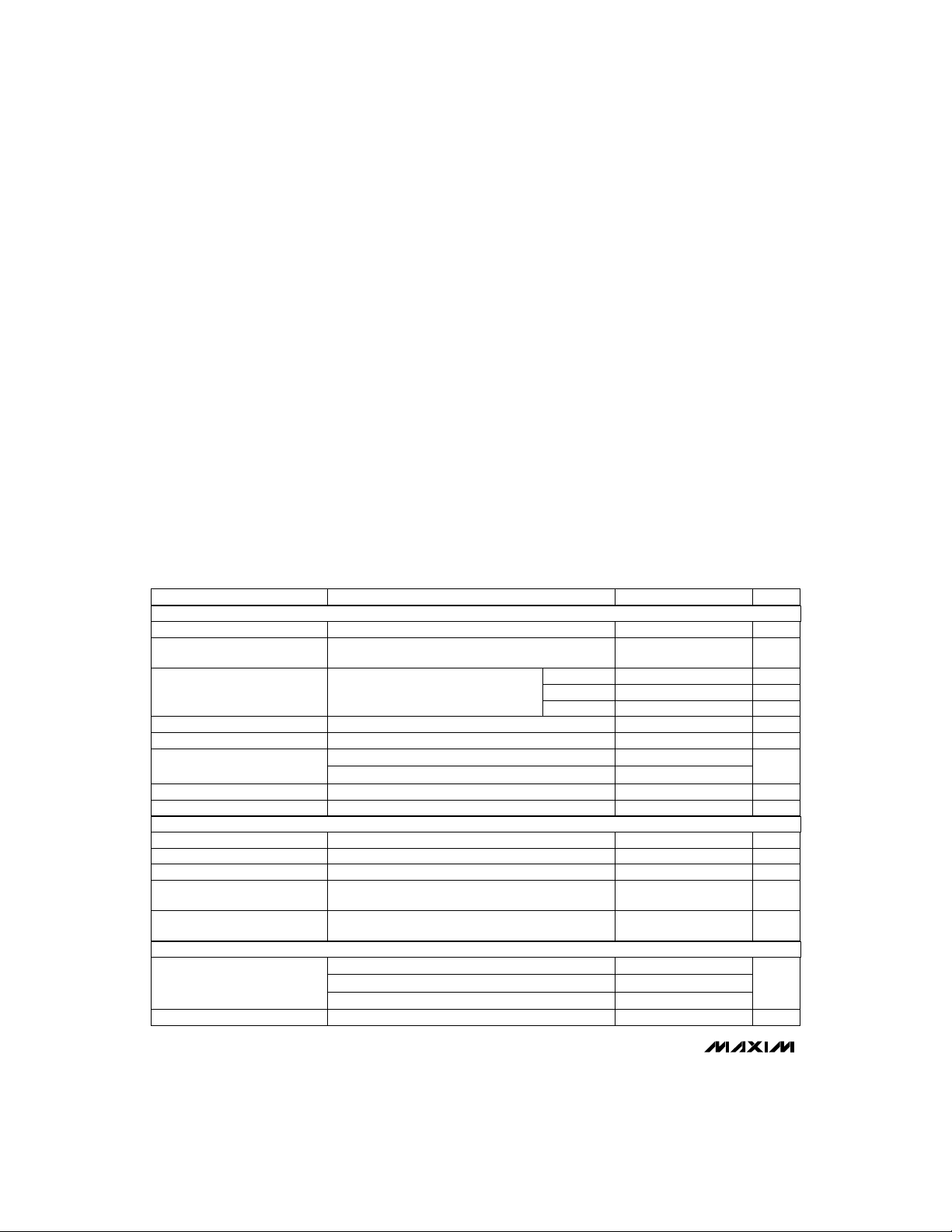

ELECTRICAL CHARACTERISTICS

(V+ = 15V, GND = PGND = 0V, IVL= I

unless otherwise noted.)

PARAMETER CONDITIONS MIN TYP MAX UNITS

+3.3V AND 5V STEP-DOWN CONTROLLERS

Input Supply Range 5.5 30 V

FB5 Output Voltage 4.80 5.08 5.20 V

FB3 Output Voltage

Load Regulation Either controller (CS_ - FB_ = 0mV to 70mV) 2 %

Line Regulation Either controller (V+ = 6V to 30V) 0.03 %/V

Current-Limit Voltage

SS3/SS5 Source Current 2.5 4.0 6.5 µA

SS3/SS5 Fault Sink Current 2 mA

15V FLYBACK CONTROLLER

VDD Regulation Setpoint Falling edge, hysteresis = 1% V

VDD Shunt Setpoint Rising edge, hysteresis = 1% V

VDD Shunt Current VDD = 20V 23 mA

Quiescent VDD Current 140 300 µA

VDD Off Current 15 30 µA

PCMCIA REGULATORS (Note 1)

VPPA/VPPB Output Voltage

VPPA/VPPB Off Input Current Program to Hi-Z, VDD = 19V, 0V < VPP < 12V 35 µA

= 0mA, ON3 = ON5 = 5V, other digital input levels are 0V or +5V, TA = T

REF

0mV < (CS5-FB5) < 70mV, 6V < V+ < 30V

(includes load and line regulation)

0mV < (CS3-FB3) < 70mV, 6V < V+ < 30V

(includes load and line regulation)

CS3-FB3 or CS5-FB5

CS5-FB5 (VDD < 13V, flyback mode) -50 -100 -160

VDD = 18V, ON3 = ON5 = 5V,

VPPA/B programmed to 12V with no external load

VDD = 18V, ON3 = ON5 = 5V,

VPPA/B programmed to Hi-Z or 0V

Program to 12V, 13V < VDD < 19V, 0mA < IL< 60mA 11.6 12.1 12.5

Program to 5V, 13V < VDD < 19V, 0mA < IL< 60mA 4.85 5.05 5.20

Program to 0V, 13V < VDD < 19V, -0.3mA < IL< 0.3mA -0.3 0.3

DH3 to LX3..................................................-0.3V, (BST3 + 0.3V)

DH5 to LX5..................................................-0.3V, (BST5 + 0.3V)

REF, VL, VPP Short to GND........................................Momentary

REF Current.........................................................................20mA

VL Current...........................................................................50mA

VPPA, VPPB Current.........................................................100mA

Continuous Power Dissipation (T

SSOP (derate 11.76mW/°C above +70°C) ...................941mW

Operating Temperature Ranges:

MAX782CBX/MAX782__CBX...............................0°C to +70°C

MAX782EBX/MAX782__EBX ............................-40°C to +85°C

Storage Temperature Range.............................-65°C to +160°C

Lead Temperature (soldering, 10sec).............................+300°C

MAX782

MAX782R

MAX782S

= +70°C)

A

3.17 3.35 3.46

3.32 3.50 3.60

3.46 3.65 3.75

80 100 120

13 14

18 20

MIN

to T

mV

V

V

V

V

MAX

,

2 _______________________________________________________________________________________

Page 3

Triple-Output Power-Supply

Controller for Notebook Computers

ELECTRICAL CHARACTERISTICS (continued)

(V+ = 15V, GND = PGND = 0V, IVL= I

unless otherwise noted.)

PARAMETER CONDITIONS MIN TYP MAX UNITS

INTERNAL REGULATOR AND REFERENCE

VL Output Voltage

VL Fault Lockout Voltage

VL/FB5 Switchover Voltage Rising edge of FB5, hysteresis = 1% 4.2 4.7 V

REF Output Voltage No external load (Note 2) 3.24 3.36 V

REF Fault Lockout Voltage Falling edge 2.4 3.2

REF Load Regulation 0mA < IL< 5mA 30 75 mV

V+ Standby Current 70 110 µA

Quiescent Power Consumption

(both PWM controllers on)

V+ Off Current

COMPARATORS

D1-D3 Trip Voltage Falling edge, hysteresis = 1%

D1-D3 Input Current D1 = D2 = D3 = 0V to 5V

Q1-Q3 Source Current VH = 15V, Q1-Q3 forced to 2.5V 12 20 30 µA

Q1-Q3 Sink Current

Q1-Q3 Output High Voltage

Q1-Q3 Output Low Voltage

Quiescent VH Current VH = 18V, D1 = D2 = D3 = 5V, no external load

OSCILLATOR AND INPUTS/OUTPUTS

Oscillator Frequency

SYNC High Pulse Width 200 ns

SYNC Low Pulse Width 200 ns

SYNC Rise/Fall Time Not tested 200 ns

Oscillator SYNC Range 240 350 kHz

Maximum Duty Cycle

Input Low Voltage ON3, ON5, DA0, DA1, DB0, DB1, SYNC 0.8 V

Input High Voltage

Input Current

DL3/DL5 Sink/Source Current DL3, DL5 forced to 2V 1 A

DH3/DH5 Sink/Source Current BST3-LX3 = BST5-LX5 = 4.5V, DH3, DH5 forced to 2V 1 A

DL3/DL5 On Resistance High or low 7 Ω

DH3/DH5 On Resistance High or low, BST3-LX3 = BST5-LX5 = 4.5V 7 Ω

Note 1: Output current is further limited by maximum allowable package power dissipation.

Note 2: Since the reference uses VL as its supply, V+ line regulation error is insignificant.

= 0mA, ON3 = ON5 = 5V, other digital input levels are 0V or +5V, TA = T

REF

ON5 = ON3 = 0V, 5.5V < V+ < 30V, 0mA < IL< 25mA

Falling edge, hysteresis = 1% 3.6 4.2 V

D1 = D2 = D3 = ON3 = ON5 = DA0 = DA1 = DB0 =

DB1 = 0V, V+ = 30V

D1 = D2 = D3 = DA0 = DA1 = DB0 = DB1 = 0V,

FB5 = CS5 = 5.25V, FB3 = CS3 = 3.5V

FB5 = CS5 = 5.25V, VL switched over to FB5 30 60 µA

VH = 15V, Q1-Q3 forced to 2.5V 200 500 1000 µA

I

= 5µA, VH = 3V

SOURCE

I

= 20µA, VH = 3V

SINK

SYNC = 3.3V 270 300 330

SYNC = 0V or 5V 170 200 230

SYNC = 3.3V 89 92

SYNC = 0V or 5V 92 95

ON3, ON5, DA0, DA1, DB0, DB1 2.4

SYNC VL-0.5

ON3, ON5, DA0, DA1, DB0, DB1, VIN= 0V or 5V

4.5 5.5

6.0 8.6

1.61 1.69 V

VH-0.5 V

610µA

MIN

±100

0.4 V

±1 µA

to T

V

V

mW

nA

kHz

%

V

MAX782

,

MAX

_______________________________________________________________________________________ 3

Page 4

Triple-Output Power-Supply

Controller for Notebook Computers

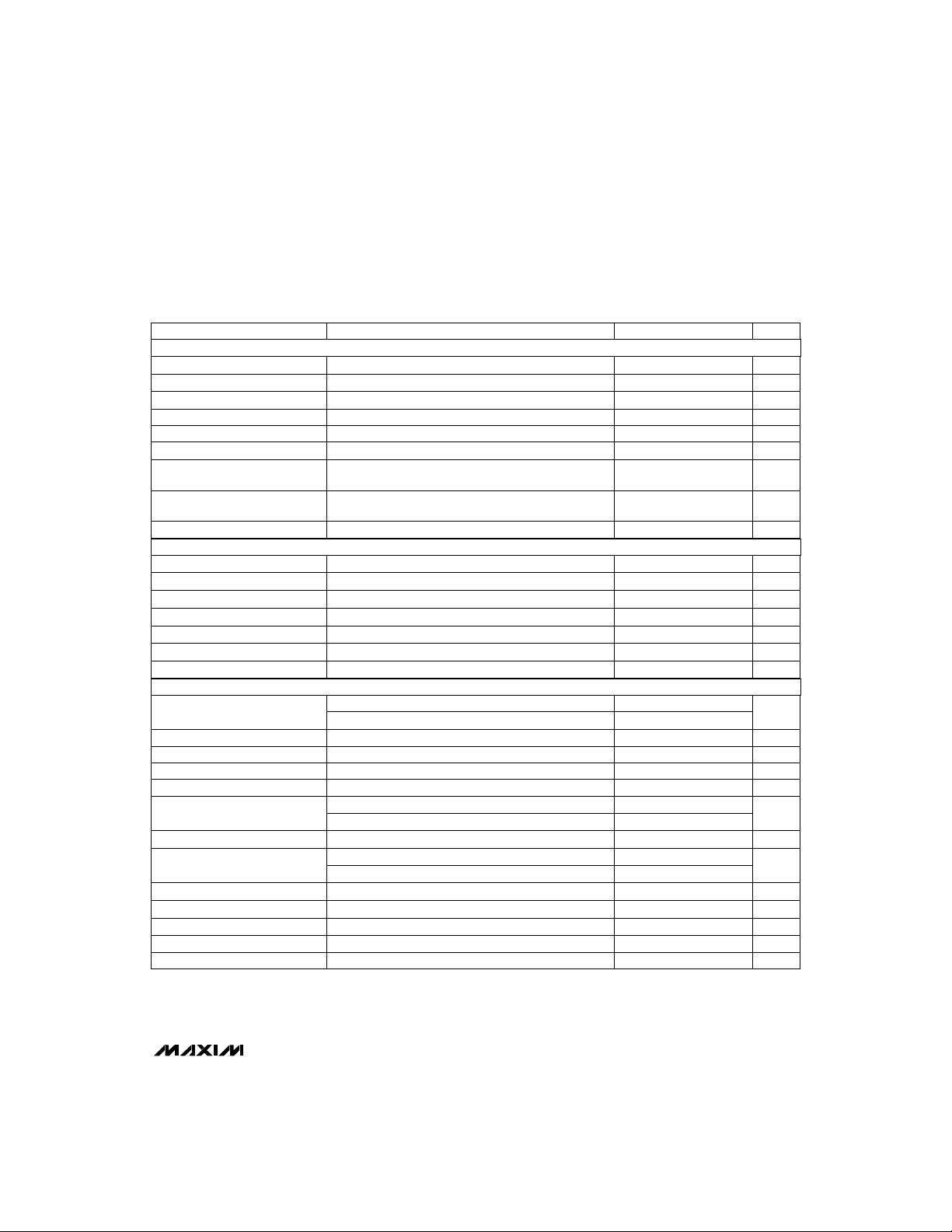

__________________________________________Typical Operating Characteristics

(Circuit of Figure 1, Transpower transformer type TTI5870, TA= +25°C, unless otherwise noted.)

+5V OUTPUT CURRENT, 200kHz

100

MAX782

90

EFFICIENCY (%)

80

70

0.001 0.1 10

0.01 1

+5V OUTPUT CURRENT (A)

+3.3V OUTPUT CURRENT, 200kHz

100

+5V ON, +5V LOAD = 0mA

IDD = 0mA,

COMPONENTS OF TABLE 5

90

EFFICIENCY (%)

80

70

0.001 0.1 10

0.01 1

+3.3V OUTPUT CURRENT (A)

+5V OUTPUT CURRENT vs.

MINIMUM INPUT VOLTAGE, 300kHz

9

8

EFFICIENCY vs.

VIN = 10V

VIN = 15V

COMPONENTS,

OF TABLE 5. SYNC = 0V,

+3.3V OFF, I

EFFICIENCY vs.

VIN = 6V

VIN = 15V

VIN = 6V

DD

VIN = 10V

IDD = 300mA

= 0mA

EFFICIENCY vs.

+5V OUTPUT CURRENT, 300kHz

100

IDD = 0mA

+3.3V OFF

VIN = 15V

90

EFFICIENCY (%)

80

70

0.001 0.01 1

+5V OUTPUT CURRENT (A)

EFFICIENCY vs.

+3.3V OUTPUT CURRENT, 300kHz

100

I

= 0mA

DD

+5V ON

+5V LOAD = 0mA

90

EFFICIENCY (%)

80

70

0.001 0.01 1

+3.3V OUTPUT CURRENT (A)

+5V OUTPUT CURRENT vs.

MINIMUM INPUT VOLTAGE, 200kHz

9

COMPONENTS OF TABLE 4,

SYNC = 0V

8

VIN = 6V

VIN = 30V

0.1 10

VIN = 6V

VIN = 15V

VIN = 30V

0.1 10

IDD = 300mA

IDD OUTPUT CURRENT vs. INPUT VOLTAGE

COILTRONIX CTX03-12062 TRANSFORMER

10

+3V LOAD = 0mA R

1

0.1

LOAD CURRENT (A)

DD

I

0.01

510 20 30

10000

1000

100

INPUT CURRENT (µA)

10

0 5 15 25

1000

100

+5V LOAD = 0A-1A

15 25

INPUT VOLTAGE (V)

QUIESCENT INPUT CURRENT vs.

INPUT VOLTAGE

+3.3V LOAD = +5V LOAD = 0mA

+5V, +3V ON

10 20 30

INPUT VOLTAGE (V)

SWITCHING FREQUENCY vs.

LOAD CURRENT

CIRCUIT OF FIGURE 1,

SYNC = REF (300kHz)

ON3 = ON5 = 5V

+5V, VIN = 7.5V

= 0.020Ω

SENSE

+5V LOAD = 3A

+5V, +3V OFF

7

6

MINIMUM INPUT VOLTAGE (V)

5

0.01 0.1 10

+5V OUTPUT CURRENT (A)

IDD = 140mA

IDD = 60mA

IDD = 0mA

1

7

6

MINIMUM INPUT VOLTAGE (V)

5

0.01 0.1 10

+5V LOAD CURRENT (A)

IDD = 140mA

I

= 60mA

DD

IDD = 0mA

1

10

+5V, VIN = 30V

1

SWITCHING FREQUENCY (kHz)

0.1

100µA 10mA 1A

1mA 100mA

LOAD CURRENT

4 _______________________________________________________________________________________

+3.3V, VIN = 7.5V

Page 5

Triple-Output Power-Supply

Controller for Notebook Computers

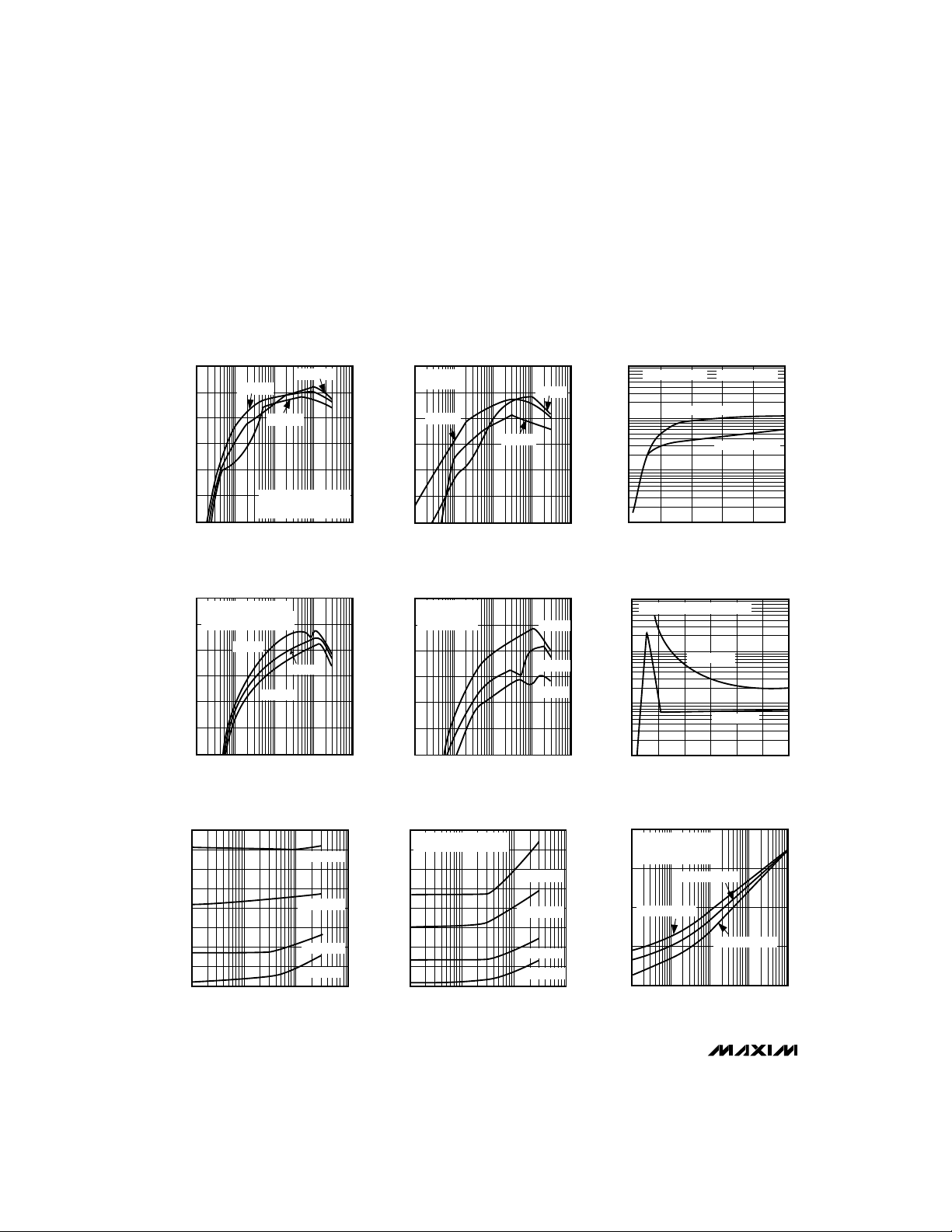

_____________________________Typical Operating Characteristics (continued)

(Circuit of Figure 1, Transpower transformer type TTI5870, TA= +25°C, unless otherwise noted.)

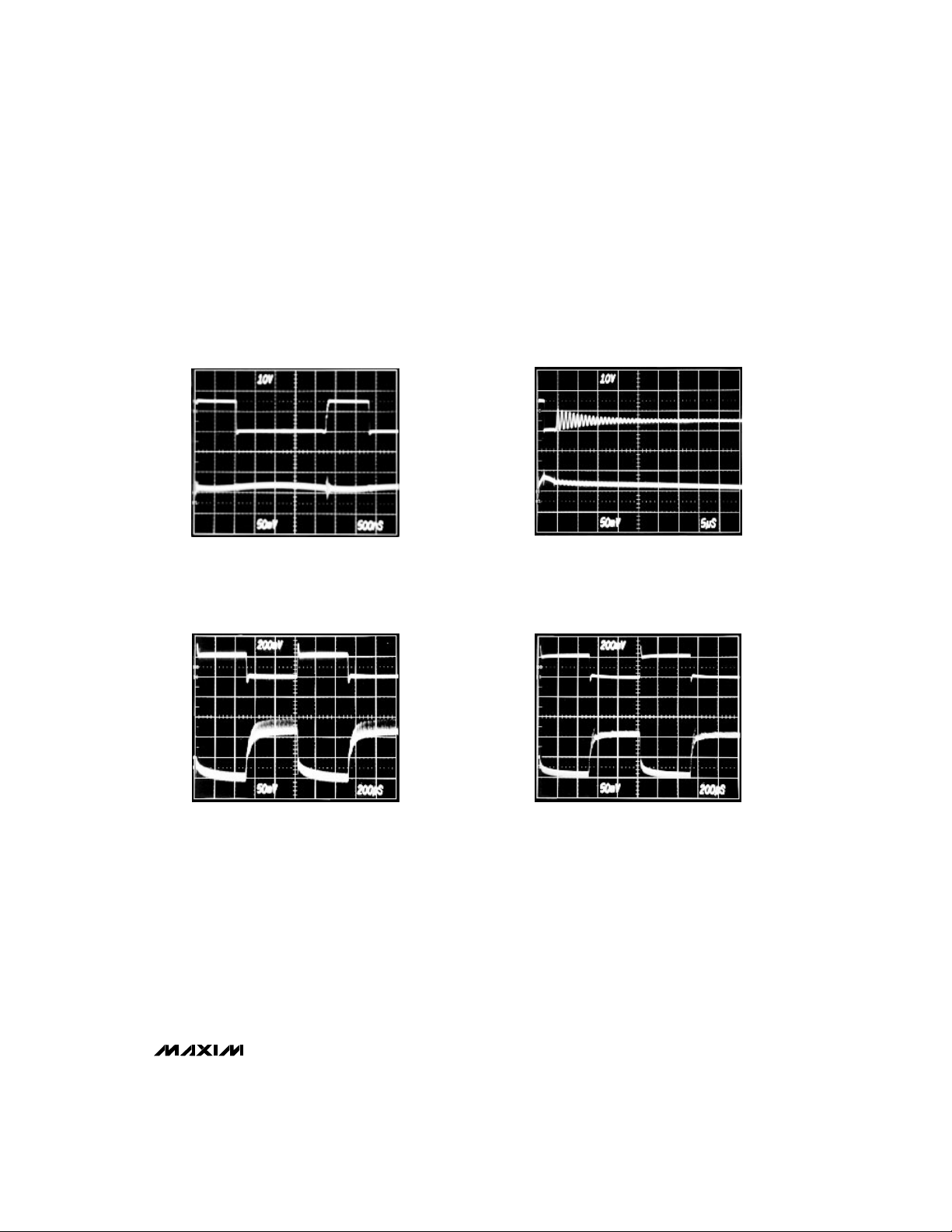

PULSE-WIDTH MODULATION MODE WAVEFORMS

HORIZONTAL = 500ns/div

+5V OUTPUT CURRENT = 1A

INPUT VOLTAGE = 16V

+5V LOAD-TRANSIENT RESPONSE

LX VOLTAGE

10V/div

+5V OUTPUT

VOLTAGE

50mV/div

3A

LOAD CURRENT

0A

HORIZONTAL = 5µs/div

+5V OUTPUT CURRENT = 42mA

INPUT VOLTAGE = 16V

IDLE-MODE WAVEFORMS

+3.3V LOAD-TRANSIENT RESPONSE

LX VOLTAGE

10V/div

+5V OUTPUT

VOLTAGE

50mV/div

3A

LOAD CURRENT

0A

MAX782

HORIZONTAL = 200µs/div

= 15V

V

IN

_______________________________________________________________________________________ 5

+5V OUTPUT

50mV/div

HORIZONTAL = 200µs/div

V

= 15V

IN

+3.3V OUTPUT

50mV/div

Page 6

Triple-Output Power-Supply

Controller for Notebook Computers

_____________________________Typical Operating Characteristics (continued)

(Circuit of Figure 1, Transpower transformer type TTI5870, VDD ≥ 13V, TA= +25°C, unless otherwise noted.)

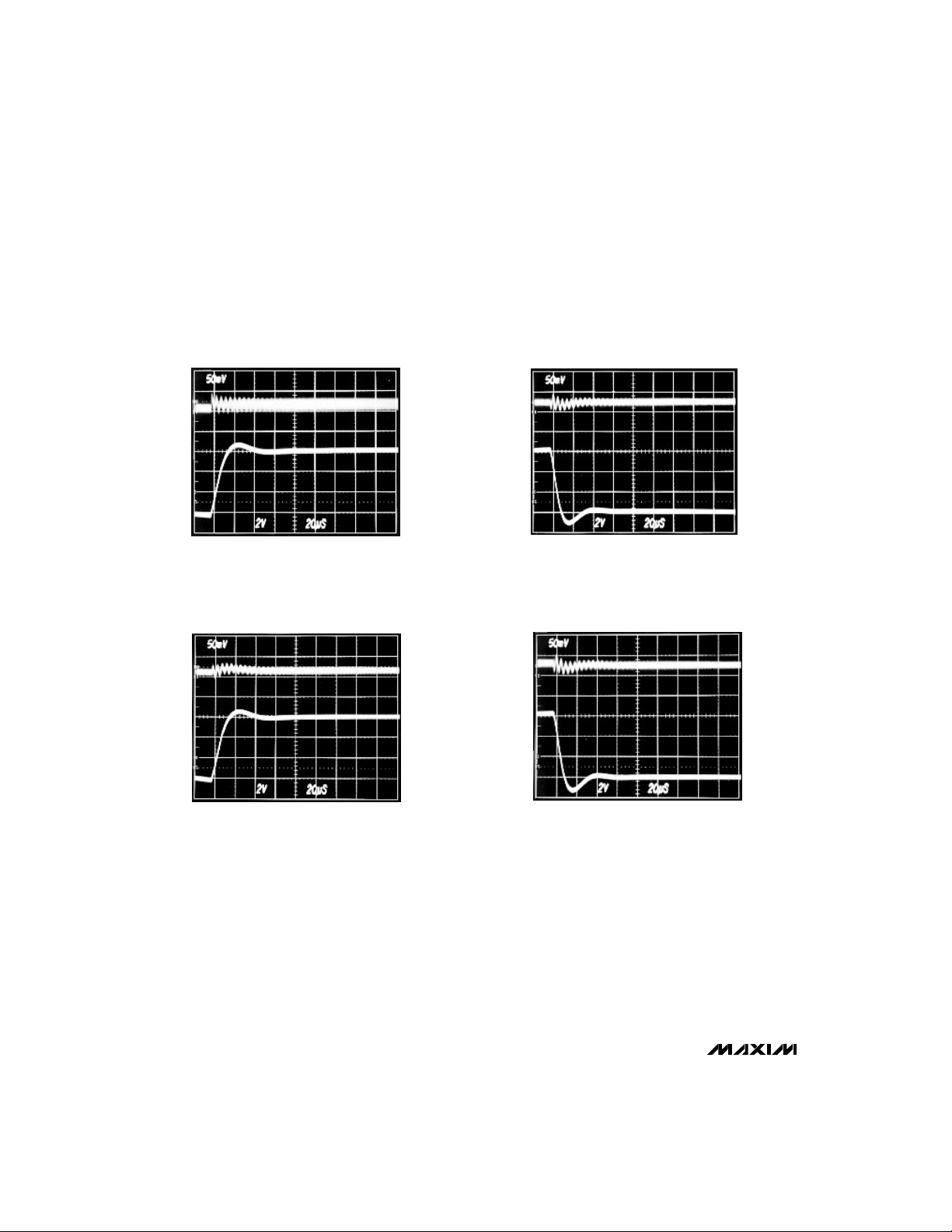

+5V LINE-TRANSIENT RESPONSE, RISING

MAX782

HORIZONTAL = 20µs/div

I

= 2A

LOAD

+3.3V LINE-TRANSIENT RESPONSE, RISING

+5V OUTPUT

50mV/div

VIN, 10V TO 16V

2V/div

+3.3V OUTPUT

50mV/div

, 10V TO 16V

V

IN

2V/div

+5V LINE-TRANSIENT RESPONSE, FALLING

HORIZONTAL = 20µs/div

I

= 2A

LOAD

+3.3V LINE-TRANSIENT RESPONSE, FALLING

+5V OUTPUT

50mV/div

VIN, 16V TO 10V

2V/div

+3.3V OUTPUT

50mV/div

, 16V TO 10V

V

IN

2V/div

HORIZONTAL = 20µs/div

I

= 2A

LOAD

HORIZONTAL = 20µs/div

I

= 2A

LOAD

6 _______________________________________________________________________________________

Page 7

Triple-Output Power-Supply

Controller for Notebook Computers

______________________________________________________________Pin Description

PIN

10

NAME FUNCTION

1

2

3

4

5

6

7

8

9

ON3 Logic input to turn on +3.3V. Logic high turns on the regulator. Connect to VL for automatic start-up.

D1

D2

D3

VH

Q3

Q2

Q1

VPPA 0V, 5V, 12V, Hi-Z PCMCIA VPP output. Sources up to 60mA. Controlled by DA0 and DA1.

VDD

VPPB 0V, 5V, 12V, Hi-Z PCMCIA VPP output. Sources up to 60mA. Controlled by DB0 and DB1.11

#1 level-translator/comparator noninverting input. Inverting comparator input is internally connected to

1.650V. Controls Q1. Connect to GND if unused.

#2 level-translator/comparator noninverting input. Inverting comparator input is internally connected to

1.650V. Controls Q2. Connect to GND if unused.

#3 level-translator/comparator noninverting input. Inverting comparator input is internally connected to

1.650V. Controls Q3. Connect to GND if unused.

External supply input for level-translator/comparator. For N-channel FET drive, connect to VDD or external

+13V to +18V supply. For low-battery comparators, connect to +3.3V or +5V (or to VL/REF).

#3 level-translator/comparator output. Sources 20µA from VH when D3 is high. Sinks 500µA to GND

when D3 is low, even with VH = 0V.

#2 level-translator/comparator output. Sources 20µA from VH when D2 is high. Sinks 500µA to GND

when D2 is low, even with VH = 0V.

#1 level-translator/comparator output. Sources 20µA from VH when D1 is high. Sinks 500µA to GND

when D1 is low, even with VH = 0V.

15V flyback input (feedback). A weak shunt regulator conducts 3mA to GND when VDD exceeds 19V.

Also the supply input to the VPP regulators.

MAX782

GND Low-current analog ground12

REF13

SYNC14

DA1, DA0,

DB1, DB0

SS520

21

23 LX5 +5V-supply inductor connection

CS5

DH5 +5V-supply external MOSFET high-side switch-drive output22

3.3V reference output. Sources up to 5mA for external loads. Bypass to GND with 1µF/mA load or

0.22µF minimum.

Oscillator frequency control and synchronization input: Connect to VL or to GND for f = 200kHz; connect

to REF for f = 300kHz. For external synchronization in the 240kHz to 350kHz range, a high-to-low transition causes the start of a new cycle.

Intel 82365 compatible PCMCIA VPP control inputs (see Table 1)15-18

Logic input to turn on +5V. Logic high turns on the regulator. Connect to VL for automatic startup.19 ON5

+5V-supply soft-start control input. Ramp time to full current limit is 1ms/nF of capacitance to GND.

+5V-supply current-sense input. +100mV = current limit in buck mode, -100mV = current limit in flyback

mode (where the ±100mV are referenced to FB5).

_______________________________________________________________________________________ 7

Page 8

Triple-Output Power-Supply

Controller for Notebook Computers

_________________________________________________Pin Description (continued)

PIN NAME FUNCTION

24

25

MAX782

26

27

28

29

30

31

32

33

34

BST5 +5V-supply boost capacitor connection (0.1µF to LX5)

DL5 +5V-supply external MOSFET synchronous-rectifier drive output

PGND Power ground

FB5 +5V-supply feedback input and low-side current-sense terminal

Internal 5V-supply output. Bypass with 4.7µF. This pin is linearly regulated from V+ or switched to the

VL

+5V output to improve efficiency. VL is always on and can source up to 5mA for external loads.

V+ Main (battery) input: 5.5V to 30V

DL3 +3.3V-supply external MOSFET synchronous-rectifier drive output

BST3 +3.3V-supply boost capacitor connection (0.1µF to LX3)

LX3 +3.3V-supply inductor connection

DH3

FB3

CS3 +3.3V-supply current-sense input. Maximum is +100mV referenced to FB3.35

SS3 +3.3V-supply soft-start control input. Ramp time to full current limit is 1ms/nF of capacitance to GND.36

+3.3V-supply external MOSFET high-side switch-drive output

+3.3V-supply feedback and low-side current-sense terminal

Table 1. Truth Table for VPP Control Pins

D_0 D_1 VPP_

0

0

1

1

0

1

0

1

0V

5V

12V

Hi-Z

_______________Detailed Description

The MAX782 converts a 5.5V to 30V input to five outputs

(Figure 1). It produces two high-power, switch-mode,

pulse-width modulated (PWM) supplies, one at +5V and

the other at +3.3V. These two supplies operate at either

200kHz or 300kHz, allowing extremely small external

components to be used. Output current capability

depends on external components, and can exceed 5A

on each supply. A 15V high-side (VDD) supply is also

provided, delivering an output current that can exceed

300mA, depending on the external components chosen.

Two linear regulators supplied by the 15V VDD line create programmable VPP supplies for PCMCIA slots.

These supplies (VPPA, VPPB) can be programmed to be

grounded or high impedance, or to deliver 5V or 12V at

up to 60mA.

An internal 5V, 25mA supply (VL) and a 3.3V, 5mA reference voltage (REF) are also generated, as shown in

Figure 2. Fault-protection circuitry shuts off the PWM

and high-side supply when the internal supplies lose

regulation.

Three precision comparators are included. Their output stages permit them to be used as level translators

for driving high-side external power MOSFETs: For

example, to facilitate switching VCC lines to PCMCIA

slots.

8 _______________________________________________________________________________________

Page 9

Triple-Output Power-Supply

Controller for Notebook Computers

MAX782

BATTERY INPUT

5.5V TO 30V

(NOTE 1)

VPP

CONTROL

INPUTS

R1

+3.3V at 3A

C14

150µF

N1-N4 = Si9410DY

NOTE 1: BATTERY VOLTAGE RANGE 6.5V to 30V

WITH COMPONENTS SHOWN

SEE

NOTE 2: SEE FIGURE 5.

25mΩ

C7

150µF

+3.3V ON/OFF

+5V ON/OFF

OSC SYNC

LOW-VOLTAGE (6-CELL) OPERATION

L1

10µH

1N5819

C1

33µF

N1

D3

(NOTE 2)

0.1µF

N3

0.01µF

D1A

1N4148

C5

C9

SECTION.

29 28

V+ VL

16

15

DA1

18

DB0

17

DB1

MAX782

31

BST3

33

DH3

32

LX3

30

DL3

35

CS3

34

FB3

36

SS3

1

ON3

19

ON5

14

SYNC

GND REF PGND

12 13 26

D1-D3

Q1-Q3

C3

1µF

VPPADA0

VPPB

VDD

BST5

DH5

LX5

DL5

CS5

FB5

SS5

C13

+5V at 3A

C6

330µF

33µF

C2

D1B

1N4148

4.7µF

C11

1µF

C4

0.1µF

C8

0.01µF

3

3

C10

1µF

N4

(NOTE 2)

9

11

10

24

22

23

25

21

27

20

5

VH

2, 3, 4

8, 7, 6

+5V at 5mA

0V, 5V, 12V

0V, 5V, 12V

+15V AT 300mA, SEE

HIGH-SIDE SUPPLY (VDD)

D2

EC11FS1

1:2.2

N2

L2 10µH

D4

1N5819

COMPARATOR SUPPLY INPUT

COMPARATOR INPUTS

COMPARATOR OUTPUTS

SECTION.

C12

2.2µF

3.3V AT 5mA

R2

20mΩ

Figure 1. MAX782 Application Circuit

+3.3V Supply

The +3.3V supply is produced by a current-mode PWM

step-down regulator using two small N-channel MOSFETs,

a catch diode, an inductor, and a filter capacitor.

Efficiency is greatly enhanced by the use of the second

MOSFET (connected from LX3 to PGND), which acts as

a synchronous rectifier. A 100nF capacitor connected

to BST3 provides the drive voltage for the high-side

(upper) N-channel MOSFET.

A current limit set by an external sense resistor prevents

excessive inductor current during start-up or under

short-circuit conditions. A soft-start capacitor can be

chosen to tailor the rate at which the output ramps up.

This supply can be turned on by connecting ON3 to

logic high, or can be turned off by connecting ON3 to

GND. All logic levels are TTL and CMOS compatible.

_______________________________________________________________________________________ 9

The +5V output is produced by a current-mode PWM

+5V Supply

step-down regulator similar to the +3.3V supply. This

supply uses a transformer primary as its inductor, the

secondary of which is used for the high-side (VDD)

supply. It also has current limiting and soft-start. It can

be turned off by connecting ON5 to GND, or turned on

by connecting ON5 to logic high.

The +5V supply’s dropout voltage, as configured in

Figure 1, is typically 400mV at 2A. As VINapproaches

5V, the +5V output gracefully falls with VINuntil the VL

regulator output hits its undervoltage lockout threshold.

At this point, the +5V supply turns off.

The default frequency for both PWM controllers is

300kHz (with SYNC connected to REF), but 200kHz

may be used by connecting SYNC to GND or VL.

Page 10

Triple-Output Power-Supply

Controller for Notebook Computers

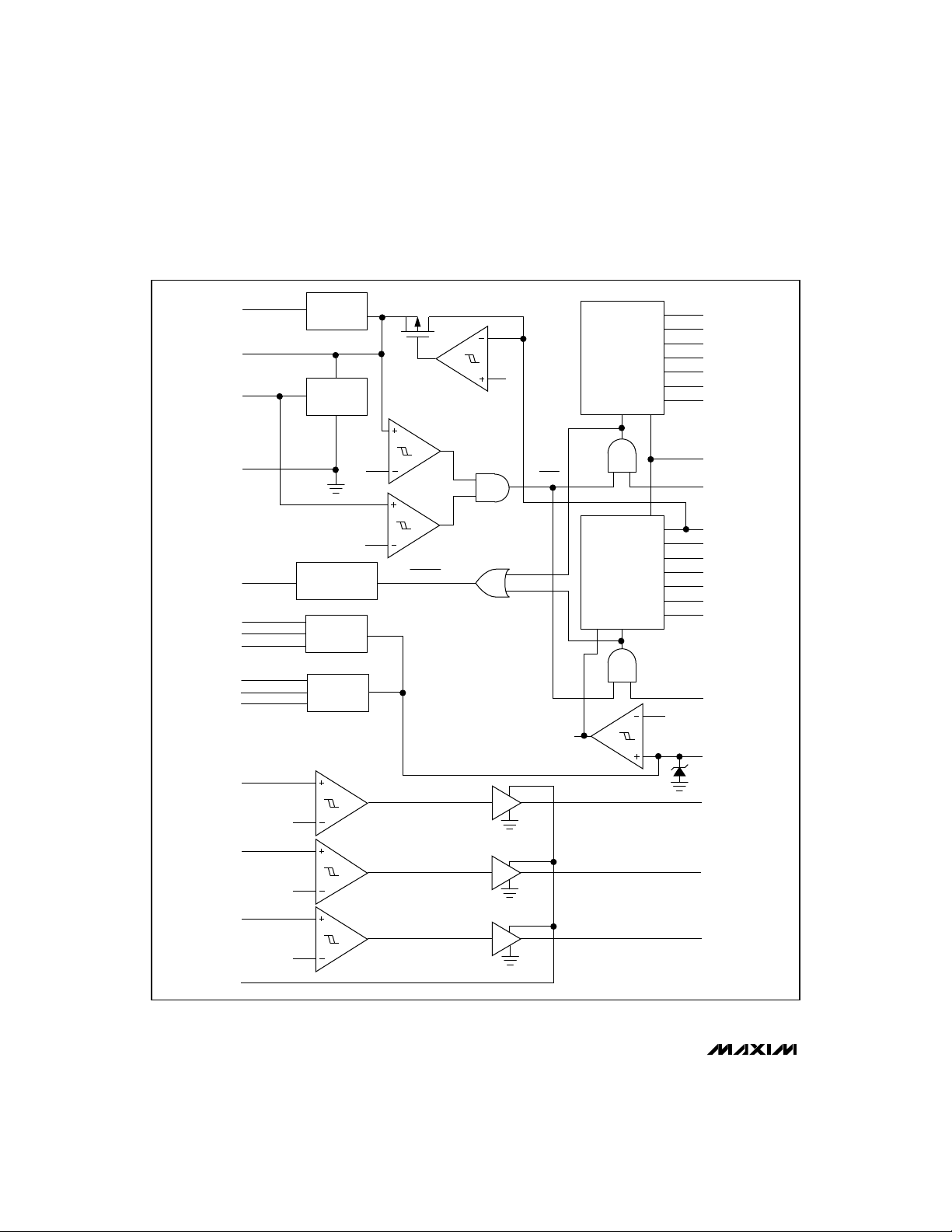

V+

VL

MAX782

REF

GND

SYNC

VPPA

DA0

DA1

VPPB

DB0

DB1

D3

5V

3.3V

1.65V

+5V LDO

LINEAR

REGULATOR

+3.3V

REFERENCE

300kHz/200kHz

OSCILLATOR

LINEAR

REGULATOR

LINEAR

REGULATOR

2.8V

P

3.3V

PWM

CONTROLLER

(SEE FIG. 3)

ON

5V

PWM

CONTROLLER

(SEE FIG. 3)

ON

4.5V

4V

STANDBY

ON

13V TO 19V

FAULT

VDD REG

13V

FB3

CS3

BST3

DH3

LX3

DL3

SS3

PGND

ON3

FB5

CS5

BST5

DH5

LX5

DL5

SS5

ON5

VDD

19V

Q3

D2

1.65V

D1

1.65V

VH

Figure 2. MAX782 Block Diagram

10 ______________________________________________________________________________________

Q2

Q1

Page 11

Triple-Output Power-Supply

Controller for Notebook Computers

CS_

1X

MAX782

REF, 3.3V

(OR INTERNAL

5V REFERENCE)

SS_

ON_

–100mV

60kHz

LPF

MAIN PWM

COMPARATOR

R

Q

S

SLOPE COMP

MINIMUM

CURRENT

N

(IDLE-MODE)

3.3V

VL

30R

1R

SYNCHRONOUS

RECTIFIER CONTROL

0mV-100mV

R

S

CURRENT

LIMIT

Q

25mV

4µA

N

OSC

LEVEL

SHIFT

SHOOT-

THROUGH

CONTROL

LEVEL

SHIFT

FB_

BST_

DH_

LX_

VL

DL_

PGND

N

VDD REG

(SEE FIG. 2)

SINGLE-SHOT

Figure 3. PWM Controller Block Diagram

______________________________________________________________________________________ 11

1µs

Page 12

Triple-Output Power-Supply

Controller for Notebook Computers

+3.3V and +5V PWM Buck Controllers

The two current-mode PWM controllers are identical

except for different preset output voltages and the

addition of a flyback winding control loop to the +5V

side (see Figure 3, +3.3V/+5V PWM Controller Block

Diagram). Each PWM is independent except for being

synchronized to a master oscillator and sharing a common reference (REF) and logic supply (VL). Each PWM

MAX782

can be turned on and off separately via ON3 and ON5.

The PWMs are a direct-summing type, lacking a traditional integrator-type error amplifier and the phase shift

associated with it. They therefore do not require any

external feedback compensation components if the filter capacitor ESR guidelines given in the

Procedure

The main gain block is an open-loop comparator that

sums four input signals: an output voltage error signal,

current-sense signal, slope-compensation ramp, and

precision voltage reference. This direct-summing

method approaches the ideal of cycle-by-cycle control

of the output voltage. Under heavy loads, the controller

operates in full PWM mode. Every pulse from the oscillator sets the output latch and turns on the high-side

switch for a period determined by the duty cycle

(approximately V

off, the synchronous rectifier latch is set and, 60ns later,

the low-side switch turns on (and stays on until the

beginning of the next clock cycle, in continuous mode,

or until the inductor current crosses through zero, in

discontinuous mode). Under fault conditions where the

inductor current exceeds the 100mV current-limit

threshold, the high-side latch is reset and the high-side

switch is turned off.

At light loads, the inductor current fails to exceed the

25mV threshold set by the minimum current comparator. When this occurs, the PWM goes into idle-mode,

skipping most of the oscillator pulses in order to reduce

the switching frequency and cut back switching losses.

The oscillator is effectively gated off at light loads

because the minimum current comparator immediately

resets the high-side latch at the beginning of each

cycle, unless the FB_ signal falls below the reference

voltage level.

A flyback winding controller regulates the +15V VDD

supply in the absence of a load on the main +5V output. If VDD falls below the preset +13V VDD regulation

threshold, a 1µs one-shot is triggered that extends the

on-time of the low-side switch beyond the point where

the inductor current crosses zero (in discontinuous

mode). This causes inductor (primary) current to

reverse, pulling current out of the output filter capacitor

and causing the flyback transformer to operate in the

are followed.

OUT/VIN

). As the high-side switch turns

Design

forward mode. The low impedance presented by the

transformer secondary in forward mode allows the

+15V filter capacitor to be quickly charged again,

bringing VDD into regulation.

Connecting capacitors to SS3 and SS5 allows gradual

build-up of the +3.3V and +5V supplies after ON3 and

ON5 are driven high. When ON3 or ON5 is low, the

appropriate SS capacitors are discharged to GND.

When ON3 or ON5 is driven high, a 4µA constant current source charges these capacitors up to 4V. The

resulting ramp voltage on the SS_ pins linearly increases the current-limit comparator setpoint so as to

increase the duty cycle to the external power MOSFETs

up to the maximum output. With no SS capacitors, the

circuit will reach maximum current limit within 10µs.

Soft-start greatly reduces initial in-rush current peaks

and allows start-up time to be programmed externally.

Synchronous rectification allows for high efficiency by

reducing the losses associated with the Schottky rectifiers. Also, the synchronous rectifier MOSFETS are

necessary for correct operation of the MAX782's boost

gate-drive and VDD supplies.

When the external power MOSFET N1 (or N2) turns off,

energy stored in the inductor causes its terminal voltage to reverse instantly. Current flows in the loop

formed by the inductor, Schottky diode, and load, an

action that charges up the filter capacitor. The Schottky

diode has a forward voltage of about 0.5V which,

although small, represents a significant power loss,

degrading efficiency. A synchronous rectifier, N3 (or

N4), parallels the diode and is turned on by DL3 (or

DL5) shortly after the diode conducts. Since the on

resistance (r

low, the losses are reduced.

The synchronous rectifier MOSFET is turned off when

the inductor current falls to zero.

Cross conduction (or “shoot-through”) is said to occur

if the high-side switch turns on at the same time as the

synchronous rectifier. The MAX782’s internal breakbefore-make timing ensures that shoot-through does not

occur. The Schottky rectifier conducts during the time

that neither MOSFET is on, which improves efficiency

by preventing the synchronous-rectifier MOSFET’s

lossy body diode from conducting.

The synchronous rectifier works under all operating conditions, including discontinuous-conduction and idle-mode.

The +5V synchronous rectifier also controls the 15V VDD

voltage (see the

) of the synchronous rectifier is very

DS(ON)

High-Side Supply (VDD)

Soft-Start/SS_ Inputs

Synchronous Rectifiers

section).

12 ______________________________________________________________________________________

Page 13

Triple-Output Power-Supply

Controller for Notebook Computers

Gate-drive voltage for the high-side N-channel switch is

Boost Gate-Driver Supply

generated with a flying-capacitor boost circuit as shown

in Figure 4. The capacitor is alternately charged from

the VL supply via the diode and placed in parallel with

the high-side MOSFET’s gate-source terminals. On startup, the synchronous rectifier (low-side) MOSFET forces

LX_ to 0V and charges the BST_ capacitor to 5V. On the

second half-cycle, the PWM turns on the high-side

MOSFET by connecting the capacitor to the MOSFET

gate by closing an internal switch between BST_ and

DH_. This provides the necessary enhancement voltage

to turn on the high-side switch, an action that “boosts”

the 5V gate-drive signal above the battery voltage.

Ringing seen at the high-side MOSFET gates (DH3 and

DH5) in discontinuous-conduction mode (light loads) is

a natural operating condition caused by the residual

energy in the tank circuit formed by the inductor and

stray capacitance at the LX_ nodes. The gate driver

negative rail is referred to LX_, so any ringing there is

directly coupled to the gate-drive supply.

Modes of Operation

PWM Mode

Under heavy loads – over approximately 25% of full load

– the +3.3V and +5V supplies operate as continuous-current PWM supplies (see

Characteristics

). The duty cycle (%ON) is approximately:

%ON = V

Typical Operating

OUT/VIN

Current flows continuously in the inductor: First, it

ramps up when the power MOSFET conducts; then, it

ramps down during the flyback portion of each cycle

as energy is put into the inductor and then discharged into the load. Note that the current flowing

into the inductor when it is being charged is also

flowing into the load, so the load is continuously

receiving current from the inductor. This minimizes

output ripple and maximizes inductor use, allowing

very small physical and electrical sizes. Output ripple is primarily a function of the filter capacitor (C7 or

C6) effective series resistance (ESR) and is typically

under 50mV (see the

Design Procedure

section).

Output ripple is worst at light load and maximum

input voltage.

Idle Mode

Under light loads (<25% of full load), efficiency is further enhanced by turning the drive voltage on and off

for only a single clock period, skipping most of the

clock pulses entirely. Asynchronous switching, seen as

“ghosting” on an oscilloscope, is thus a normal operating

BATTERY

INPUT

VL

VL

LEVEL

TRANSLATOR

PWM

Figure 4. Boost Supply for Gate Drivers

BST_

DH_

LX_

VL

DL_

condition whenever the load current is less than

approximately 25% of full load.

At certain input voltage and load conditions, a transition

region exists where the controller can pass back and

forth from idle-mode to PWM mode. In this situation,

short bursts of pulses occur that make the current

waveform look erratic, but do not materially affect the

output ripple. Efficiency remains high.

Current Limiting

The voltage between CS3 (CS5) and FB3 (FB5) is continuously monitored. An external, low-value shunt resistor is

connected between these pins, in series with the inductor, allowing the inductor current to be continuously measured throughout the switching cycle. Whenever this

voltage exceeds 100mV, the drive voltage to the external

high-side MOSFET is cut off. This protects the MOSFET,

the load, and the battery in case of short circuits or temporary load surges. The current-limiting resistor R1 (R2)

is typically 25mΩ (20mΩ) for 3A load current.

Oscillator Frequency; SYNC Input

The SYNC input controls the oscillator frequency.

Connecting SYNC to GND or to VL selects 200kHz operation; connecting to REF selects 300kHz operation. SYNC

can also be driven with an external 240kHz to 350kHz

CMOS/TTL source to synchronize the internal oscillator.

Normally, 300kHz is used to minimize the inductor and

filter capacitor sizes, but 200kHz may be necessary for

low input voltages (see

Low-Voltage (6-cell) Operation

MAX782

).

______________________________________________________________________________________ 13

Page 14

Triple-Output Power-Supply

Controller for Notebook Computers

The 15V VDD supply is obtained from the rectified and

filtered secondary of transformer L2. VDD is enabled

whenever the +5V supply is on (ON5 = high). The primary and secondary of L2 are connected so that, during the flyback portion of each cycle (when MOSFET

N2 is off and N4 is on), energy stored in the core is

transferred into the +5V load through the primary and

MAX782

into VDD through the secondary, as determined by the

turns ratio. The secondary voltage is added to the +5V

to make VDD. See the

Characteristics

Unlike other coupled-inductor flyback converters, the

VDD voltage is regulated regardless of the loading on

the +5V output. (Most coupled-inductor converters can

only support the auxiliary output when the main output

is loaded.) When the +5V supply is lightly loaded, the

circuit achieves good control of VDD by pulsing the

MOSFET normally used as the synchronous rectifier.

This draws energy from the +5V supply’s output capacitor and uses the transformer in a forward-converter

mode (i.e., the +15V output takes energy out of the

secondary when current is flowing in the primary).

Note that these forward-converter pulses are interspersed with normal synchronous-rectifier pulses, and

they only occur at light loads on the +5V rail.

The transformer secondary’s rectified and filtered output is only roughly regulated, and may be between 13V

and 19V. It is brought back into VDD, which is also the

feedback input, and used as the source for the PCMCIA

VPP regulators (see

for the VDD supply’s load capability.

Generating Additional VPP Outputs

Using External Linear Regulators

as the VH power supply for the comparators or any

external MOSFET drivers.

When the input voltage is above 20V, or when the +5V

supply is heavily loaded and VDD is lightly loaded, L2’s

interwinding capacitance and leakage inductance can

produce voltages above that calculated from the turns

ratio. A 3mA shunt regulator limits VDD to 19V.

Clock-frequency noise on the VDD rail of up to 3Vp-p is

a facet of normal operation, and can be reduced by

adding more output capacitance.

Typical Operating

). It can also be used

PCMCIA-Compatible

Programmable VPP Supplies

Two independent regulators are provided to furnish

PCMCIA VPP supplies. The VPPA and VPPB outputs

can be programmed to deliver 0V, 5V, 12V, or to be high

impedance. The 0V output mode has a 250Ω pull-down

to discharge external filter capacitors and ensure that

flash EPROMs cannot be accidentally programmed.

These linear regulators operate from the high-side sup-

High-Side Supply (VDD)

Table 2. VPP Program Codes

DA0 DA1 VPPA

0

0

1

1

DB0 DB1 VPPB

0

0

1

1

ply (VDD), and each can furnish up to 60mA. Bypass

VPPA and VPPB to GND with at least 1µF, with the

bypass capacitors less than 20mm from the VPP pins.

The outputs are programmed with DA0, DA1, DB0 and

DB1, as shown in Table 2.

These codes are Intel 82365 (PCMCIA digital controller)

compatible. For other interfaces, one of the inputs can

be permanently wired high or low and the other toggled

to turn the supply on and off. The truth table shows that

either a “0” or “1” can be used to turn each supply on.

The high-impedance state is to accomodate external

programming voltages. The two VPP outputs can be

safely connected in parallel for increased load capability

if the control inputs are also tied together (i.e., DA0 to

DB0, DA1 to DB1). If VPAA and VPPB are connected in

parallel, some devices may exhibit several milliamps of

increased quiescent supply current when enabled, due

to slightly mismatched output voltage set points.

Three noninverting comparators can be used as precision voltage comparators or high-side drivers. The

supply for these comparators (VH) is brought out and

may be connected to any voltage between +3V and

+19V. The noninverting inputs (D1-D3) are high impedance, and the inverting input is internally connected to

a 1.650V reference. Each output (Q1-Q3) sources

20µA from VH when its input is above 1.650V, and

sinks 500µA to GND when its input is below 1.650V.

The Q1-Q3 outputs can be fixed together in wired-OR

configuration since the pull-up current is only 20µA.

Connecting VH to a logic supply (5V or 3V) allows the

comparators to be used as low-battery detectors. For driving N-channel power MOSFETs to turn external loads on

and off, VH should be 6V to 12V higher than the load voltage. This enables the MOSFETs to be fully turned on and

results in low r

DS(ON)

0

1

0

1

0

1

0

1

. VDD is a convenient source for VH.

0V

5V

12V

Hi-Z

0V

5V

12V

Hi-Z

Comparators

14 ______________________________________________________________________________________

Page 15

Triple-Output Power-Supply

Controller for Notebook Computers

The comparators are always active when V+ is above

+4V, even when VH is 0V. Thus, Q1-Q3 will sink current

to GND even when VH is 0V, but they will only source

current from VH when VH is above approximately 1.5V.

If Q1, Q2, or Q3 is externally pulled above VH, an internal diode conducts, pulling VH a diode drop below the

output and powering anything connected to VH. This

voltage will also power the other comparator outputs.

Internal VL and REF Supplies

An internal linear regulator produces the 5V used by the

internal control circuits. This regulator’s output is available on pin VL and can source 5mA for external loads.

Bypass VL to GND with 4.7µF. To save power, when

the +5V switch-mode supply is above 4.5V, the internal

linear regulator is turned off and the high-efficiency +5V

switch-mode supply output is connected to VL.

The internal 3.3V bandgap reference (REF) is powered

by the internal 5V VL supply, and is always on. It can

furnish up to 5mA. Bypass REF to GND with 0.22µF,

plus 1µF/mA of load current.

Both the VL and REF outputs remain active, even when

the switching regulators are turned off, to supply memory keep-alive power.

These linear-regulator ouputs can be directly connected

to the corresponding step-down regulator outputs (i.e.,

REF to +3.3V, VL to +5V) to keep the main supplies alive

in standby mode. However, to ensure start-up, standby

load currents must not exceed 5mA on each supply.

Fault Protection

The +3.3V and +5V PWM supplies, the high-side supply, and the comparators are disabled when either of

two faults is present: VL < +4.0V or REF < +2.8V (85%

of its nominal value).

__________________Design Procedure

Figure 1’s schematic and Table 2’s component list

show values suitable for a 3A, +5V supply and a 3A,

+3.3V supply. This circuit operates with input voltages

from 6.5V to 30V, and maintains high efficiency with

output currents between 5mA and 3A (see the

Operating Characteristics

). This circuit’s components

may be changed if the design guidelines described in

this section are used – but before beginning the design,

the following information should be firmly established:

V

, the maximum input (battery) voltage. This

IN(MAX)

value should include the worst-case conditions under

which the power supply is expected to function, such

Typical

as no-load (standby) operation when a battery charger

is connected but no battery is installed. V

not exceed 30V.

V

, the minimum input (battery) voltage. This

IN(MIN)

value should be taken at the full-load operating current under the lowest battery conditions. If V

is below about 6.5V, the power available from the

IN(MAX)

can-

IN(MIN)

VDD supply will be reduced. In addition, the filter

capacitance required to maintain good AC load regulation increases, and the current limit for the +5V

supply has to be increased for the same load level.

+3.3V Inductor (L1)

Three inductor parameters are required: the inductance

value (L), the peak inductor current (I

coil resistance (RL). The inductance is:

V

where: V

x (V

OUT

L = ————————————-

V

IN(MAX)

= output voltage, 3.3V;

OUT

V

f = switching frequency, normally 300kHz;

I

LIR = ratio of inductor peak-to-peak AC

= maximum input voltage (V);

IN(MAX)

= maximum +3.3V DC load current (A);

OUT

IN(MAX)

x f x I

OUT

- V

OUT

x LIR

)

LPEAK

), and the

current to average DC load current, typically 0.3.

A higher value of LIR allows smaller inductance, but

results in higher losses and higher ripple.

The highest peak inductor current (I

DC load current (I

inductor current (I

current is typically chosen as 30% of the maximum DC

) plus half the peak-to-peak AC

OUT

). The peak-to-peak AC inductor

LPP

LPEAK

) equals the

load current, so the peak inductor current is 1.15 times

I

.

OUT

The peak inductor current at full load is given by:

I

LPEAK

x (V

= I

OUT

OUT

+ —————————————.

2 x f x L x V

IN(MAX)

- V

IN(MAX)

OUT

)

V

The coil resistance should be as low as possible,

preferably in the low milliohms. The coil is effectively in

series with the load at all times, so the wire losses alone

are approximately:

Power loss = I

OUT

2

x R

L

In general, select a standard inductor that meets the L,

I

, and RLrequirements (see Tables 3 and 4). If a

LPEAK

standard inductor is unavailable, choose a core with an

LI2parameter greater than L x I

largest wire that will fit the core.

LPEAK

2

, and use the

MAX782

______________________________________________________________________________________ 15

Page 16

Triple-Output Power-Supply

Controller for Notebook Computers

Table 3 lists two commercially available transformers

+5V Transformer (T1)

and parts for a custom transformer. The following

instructions show how to determine the transformer

parameters required for a custom design:

LP, the primary inductance value

I

, the peak primary current

LPEAK

LI2, the core’s energy rating

MAX782

RPand RS, the primary and secondary resistances

N, the primary-to-secondary turns ratio.

The transformer primary is specified just as the +3.3V

inductor, using V

(VDD)

power

= +5.0V; but the secondary output

OUT

must be added in as if it were part of the

primary. VDD current (IDD) usually includes the VPPA

and VPPB output currents. The total +5V power, P

is the sum of these powers:

P

= P5 + P

where: P5 = V

TOTAL

PDD= VDD x IDD;

and: V

OUT

I

OUT

VDD = VDD output voltage, 15V;

OUT

= output voltage, 5V;

= maximum +5V load current (A);

x I

OUT

DD

;

IDD= maximum VDD load current (A);

so: P

and the equivalent +5V output current, I

TOTAL

I

TOTAL

= (5V x I

= P

TOTAL

= [(5V x I

) + (15V x IDD)

OUT

/ 5V

) + (15V x IDD)] / 5V.

OUT

TOTAL

, is:

The primary inductance, LP, is given by:

V

where: V

x (V

OUT

LP= ———————————————

V

= output voltage, 5V;

OUT

V

IN(MAX)

f = switching frequency, normally 300kHz;

I

= maximum equivalent load current (A);

TOTAL

LIR = ratio of primary peak-to-peak AC

x f x I

IN(MAX)

= maximum input voltage;

IN(MAX)

TOTAL

- V

OUT

x LIR

)

current to average DC load current, typically 0.3.

The highest peak primary current (I

total DC load current (I

AC primary current (I

current is typically chosen as 30% of the maximum DC

) plus half the peak-to-peak

TOTAL

). The peak-to-peak AC primary

LPP

LPEAK

) equals the

load current, so the peak primary current is 1.15 times

I

. A higher value of LIR allows smaller inductance,

TOTAL

but results in higher losses and higher ripple.

The peak current in the primary at full load is given by:

V

x (V

I

= I

LPEAK

Choose a core with an LI2parameter greater than LPx

I

LPEAK

TOTAL

2

.

OUT

+ —————————————.

2 x f x LPx V

IN(MAX

) - V

OUT

IN(MAX)

)

TOTAL

The winding resistances, RPand RS, should be as low

as possible, preferably in the low milliohms. Use the

largest gauge wire that will fit on the core. The coil is

effectively in series with the load at all times, so the

resistive losses in the primary winding alone are

approximately (I

The minimum turns ratio, N

to accommodate the tolerance of the +5V supply. A

TOTAL

)2x RP.

, is 5V:(15V-5V). Use 1:2.2

MIN

greater ratio will reduce efficiency of the VPP regulators.

Minimize the diode capacitance and the interwinding

capacitance, since they create losses through the

VDD shunt regulator. These are most significant when

the input voltage is high, the +5V load is heavy, and

there is no load on VDD.

,

Ensure the transformer secondary is connected with the

right polarity: A VDD supply will be generated with either

polarity, but proper operation is possible only with the correct polarity. Test for correct connection by measuring the

VDD voltage when VDD is unloaded and the input voltage

(VIN) is varied over its full range. Correct connection is

indicated if VDD is maintained between 13V and 20V.

Current-Sense Resistors (R1, R2)

The sense resistors must carry the peak current in the

inductor, which exceeds the full DC load current.

The internal current limiting starts when the voltage

across the sense resistors exceeds 100mV nominally,

80mV minimum. Use the minimum value to ensure

adequate output current capability: For the +3.3V

supply, R1 = 80mV / (1.15 x I

R2 = 80mV/(1.15 x I

TOTAL

); for the +5V supply,

OUT

), assuming that LIR = 0.3.

Since the sense resistance values (e.g. R1 = 25mΩ for

I

= 3A) are similar to a few centimeters of narrow

OUT

traces on a printed circuit board, trace resistance can

contribute significant errors. To prevent this, Kelvin

connect the CS_ and FB_ pins to the sense resistors;

i.e., use separate traces not carrying any of the inductor or load current, as shown in Figure 5.

Run these traces parallel at minimum spacing from one

another. The wiring layout for these traces is critical for

stable, low-ripple outputs (see the

Grounding

section).

Layout and

MOSFET Switches (N1-N4)

The four N-channel power MOSFETs are usually identical and must be “logic-level” FETs; that is, they must

be fully on (have low r

source drive voltage. The MOSFET r

ideally be about twice the value of the sense resistor.

MOSFETs with even lower r

capacitance, which increases switching time and

) with only 4V gate-

DS(ON)

have higher gate

DS(ON)

DS(ON)

transition losses.

should

16 ______________________________________________________________________________________

Page 17

Triple-Output Power-Supply

Controller for Notebook Computers

FAT, HIGH-CURRENT TRACES

MAIN CURRENT PATH

KELVIN SENSE TRACES

MAX782

Figure 5. Kelvin Connections for the Current-Sense Resistors

SENSE RESISTOR

MOSFETs with low gate-threshold voltage specifications (i.e., maximum V

preferred, especially for high-current (5A) applications.

= 2V rather than 3V) are

GS(TH)

Output Filter Capacitors (C6, C7, C14)

The output filter capacitors determine the loop stability

and output ripple voltage. To ensure stability, the minimum capacitance and maximum ESR values are:

V

CF> —————————————

V

OUT

REF

x RCSx 2 x π x GBWP

and,

V

x R

OUT

ESRCF< ——————

CS

V

REF

where: CF= output filter capacitance, C6 or C7 (F);

= reference voltage, 3.3V;

V

REF

= output voltage, 3.3V or 5V;

V

OUT

= sense resistor (Ω);

R

CS

GBWP = gain-bandwidth product, 60kHz;

= output filter capacitor ESR (Ω).

ESR

CF

Be sure to select output capacitors that satisfy both the

minimum capacitance and maximum ESR requirements. To achieve the low ESR required, it may be

appropriate to use a capacitance value 2 or 3 times

larger than the calculated minimum.

The output ripple in continuous-current mode is:

V

OUT(RPL)

= I

LPP(MAX)

x (ESRCF+1/(2 x π x f x CF)).

In idle-mode, the ripple has a capacitive and resistive

component:

4 x 10-4x L

V

(C) = ——————— x

OUT(RPL)

2

R

x C

CS

F

1 1

——— + ————— ) Volts

(

V

OUTVIN

V

OUT(RPL)

The total ripple, V

lows:

if V

OUT(RPL)

then V

OUT(RPL)

otherwise, V

OUT(RPL)

V

OUT(RPL)

- V

OUT

0.02 x ESR

(R) = ——————- Volts

, can be approximated as fol-

OUT(RPL)

(R) < 0.5 V

= V

OUT(RPL)

= 0.5 V

(R).

R

CS

OUT(RPL)

(C),

OUT(RPL)

CF

(C),

(C) +

Diode D2

The voltage rating of D2 should be at least 2 x VIN+

5V plus a safety margin. A rating of at least 75V is

necessary for the maximum 30V supply. A Schottky

diode is preferable for lower input voltages, and is

required for input voltages under 7V. Use a highspeed silicon diode (with a higher breakdown voltage

and lower capacitance) for high input voltages. D2’s

current rating should exceed twice the maximum current load on VDD.

Diodes D3 and D4

Use 1N5819s or similar Schottky diodes. D3 and D4

conduct only about 3% of the time, so the 1N5819’s

1A current rating is conservative. The voltage rating

of D3 and D4 must exceed the maximum input supply

voltage from the battery. These diodes must be

Schottky diodes to prevent the lossy MOSFET body

diodes from turning on, and they must be placed

physically close to their associated synchronous rectifier MOSFETs.

Soft-Start Capacitors (C8, C9)

A capacitor connected from GND to either SS pin causes that supply to ramp up slowly. The ramp time to full

current limit, tSS, is approximately 1ms for every nF of

capacitance on SS_, with a minimum value of 10µs.

Typical capacitor values are in the 10nF to 100nF

range; a 5V rating is sufficient.

MAX782

______________________________________________________________________________________ 17

Page 18

Triple-Output Power-Supply

Controller for Notebook Computers

Because this ramp is applied to the current-limit circuit,

the actual time for the output voltage to ramp up

depends on the load current and output capacitor

value. Using Figure 1’s circuit with a 2A load and no

SS capacitor, full output voltage is reached about

600µs after ON_ is driven high.

MAX782

Capacitors C4 and C5 store the boost voltage and pro-

Boost Capacitors (C4, C5)

vide the supply for the DH3 and DH5 drivers. Use 0.1µF

and place each within 10mm of the BST_ and LX_ pins.

Boost Diodes (D1A, D1B)

Use high-speed signal diodes; e.g., 1N4148 or equivalent.

Table 3. Surface-Mount Components

(See Figure 1 for schematic diagram and Table 4 for phone numbers.)

33µF, 35V tantalum capacitors

1N4148SMTN diodes (fast recovery)

Transformer (these two have different

sizes and pinouts)

Transformer (for 5.5V, 200kHz operation)

Custom Transformer:

L2

Core Set

Bobbin

Clamp

Primary

Secondary

Bypass Capacitors

Input Filter Capacitors (C1, C13)

Use at least 3µF/W of output power for the input filter

capacitors, C1 and C13. They should have less than

150mΩ ESR, and should be located no further than

10mm from N1 and N2 to prevent ringing. Connect

the negative terminals directly to PGND. Do not

exceed the surge current ratings of input bypass

capacitors.

VPP and VDD Bypass Capacitors (C10, C11, C12)

Use 2.2µF for VDD, and 1µF for VPPA and VPPB.

PART NO.MANUFACTURERSPECIFICATIONCOMPONENT

595D336X0035R2BSpragueC1, C13

Sprague

Sprague

Murata-Erie

Sprague

Sprague

NihonFast-recovery high voltage diodeD2

Coiltronics

Transpower Technologies

TDK

TDK

TDK

595D475X0016A2B4.7µF, 16V tantalum capacitorC2

595D475X0016A2B1µF, 20V tantalum capacitorC3

GRM42-6X7R104K50V0.1µF, 16V ceramic capacitorsC4, C5

595D337X0010R2BSprague330µF, 10V tantalum capacitorC6

595D157X0010D2BSprague150µF, 10V tantalum capacitorsC7, C14

GRM42-6X7R103K50VMurata-Erie0.01µF, 16V ceramic capacitorsC8, C9

595DD105X0035A2B1µF, 35V tantalum capacitorsC10, C11

595DD225X0025B2B2.2µF, 25V tantalum capacitorC12

BAW56PhilipsD1A, D1B

EC11FS1

EC10QS04Nihon1N5819 SMT diodesD3, D4

CDR125-100Sumida10µH, 2.65A inductorL1

Si9410DYSiliconixN-channel MOSFETs (SO-8)N1-N4

LR2010-01-R025-FIRC0.025Ω, 1% (SMT) resistorR1

LR2010-01-R020-FIRC0.020Ω, 1% (SMT) resistorR2

CTX03-12067-1

TTI5870

CTX03-12062-1Coiltronics

PC40EEM12.7/13.7-A160

BEM12.7/13.7-118G

FEM12.7/13.7-A

8 turns #24 AWG

18 turns #26 AWG

18 ______________________________________________________________________________________

Page 19

Triple-Output Power-Supply

Controller for Notebook Computers

Table 4. Surface-Mount Components

Company USA Phone

Central Semi

Coiltronics

IRC

Murata-Erie

Nihon

Siliconix

Sprague

Sumida

TDK

Transpower Tech.

Factory FAX

[country code]

[ 1] (516) 435-1824

[ 1] (407) 241-9339

[ 1] (213) 772-9028

[ 1] 404 736-3030

[81] 3-3494-7414

[ 1] (408) 727-5414

[ 1] (603) 224-1430

[81] 3-3607-5144

[81] 3-3278-5358

[ 1] 702 831-3521

(516) 435-1110

(407) 241-7876

(512) 992-7900

(404) 736-1300

(805) 867-2555

(408) 988-8000

(603) 224-1961

(708) 956-0666

(708) 803-6100

(702) 831-0140

__________Applications Information

Achieving outstanding efficiency over a wide range of

loads is a result of balanced design rather than bruteforce overkill, particularly with regard to selecting the

power MOSFETs. Generally, the best approach is to

design for two loading conditions, light load and heavy

load (corresponding to suspend and run modes in the

host computer), at some nominal battery voltage (such

as 1.2V/cell for NiCd or NiMH). Efficiency improves as

the input voltage is reduced, as long as the high-side

switch saturation voltage is low relative to the input voltage. If there is a choice, use the lowest-voltage battery

pack possible, but with at least six cells.

Losses due to parasitic resistances in the switches,

coil, and sense resistor dominate at high load-current

levels. Under heavy loads, the MAX782 operates in the

continuous-conduction mode, where there is a large

DC offset to the inductor current plus a small sawtooth

AC component (see the

DC current is exactly equal to the load current – a fact

that makes it easy to estimate resistive losses through

the assumption that total inductor current is equal to

this DC offset current.

Efficiency Considerations

Heavy-Load Efficiency

+3.3V Inductor

section). This

The major loss mechanisms under heavy loads are, in

usual order of importance:

2

● I

R losses

● gate-charge losses

● diode-conduction losses

● transition losses

● capacitor-ESR losses

● losses due to the operating supply current of the IC.

Inductor core losses are fairly low at heavy loads

because the inductor current’s AC component is small.

Therefore, they are not accounted for in this analysis.

Efficiency = P

PD

TOTAL

PD

= resistive loss = (I

(I2R)

where R

COIL

the drain-source on resistance of the MOSFET, and

OUT/PIN

PD

= PD

(I2R)

PD

CAP

is the DC resistance of the coil, r

TOTAL

+ PD

+ PD

x 100% = P

) x 100%

+ PD

GATE

IC

2

) x (R

LOAD

RCS)

DIODE

COIL

OUT

+ PD

/(P

+ r

OUT

TRAN

DS(ON)

DS(ON)

RCSis the current-sense resistor value. Note that the

r

employed for both the synchronous rectifier and high-

term assumes that identical MOSFETs are

DS(ON)

side switch, because they time-share the inductor current. If the MOSFETs are not identical, losses can be

estimated by averaging the two individual r

terms according to duty factor.

PD

= gate driver loss = qGx f x VL

GATE

DS(ON)

where VL is the MAX782’s logic supply voltage (nominally 5V) and qGis sum of the gate charge for lowside and high-side switches. Note that gate charge

losses are dissipated in the IC, not the MOSFETs,

and therefore contribute to package temperature rise.

For matched MOSFETs, qGis simply twice the gate

charge of a single MOSFET (a data sheet specification). If the +5V buck SMPS is turned off, replace VL

in this equation with VIN.

P

= diode conduction losses = I

DIODE

LOAD

x VDx tDx f

where tDis the diode’s conduction time (typically

110ns), VDis the forward voltage of the Schottky diode,

and f is the switching frequency.

2

V

x C

x I

PD

= transition loss = ———————————

TRAN

IN

RSS

I

DRIVE

LOAD

x f

MAX782

+

+

+

is

______________________________________________________________________________________ 19

Page 20

Triple-Output Power-Supply

Controller for Notebook Computers

where C

high-side MOSFET (a data sheet parameter), f is the

switching frequency, and I

available from the MAX782’s large high-side gate dri-

is the reverse transfer capacitance of the

RSS

is the peak current

DRIVE

ver outputs (DH5 or DH3, approximately 1A).

Additional switching losses are introduced by other

sources of stray capacitance at the switching node,

including the catch diode capacitance, coil interwind-

MAX782

ing capacitance, and low-side switch-drain capacitance. They are given as PDSW= V

but are usually negligible compared to C

The low-side switch introduces only tiny switching

2

x C

IN

STRAY

RSS

losses, since its drain-source voltage is already low

when it turns on.

PD

= capacitor ESR loss = I

CAP

RMS

2

x ESR

and,

I

= RMS AC input current

RMS

= I

√ V

x ————————

LOAD

OUT(VIN

V

IN

- V

OUT

)

where ESR is the equivalent series resistance of the

input bypass capacitor. Note that losses in the output

filter capacitors are small when the circuit is heavily

loaded, because the current into the capacitor is not

chopped. The output capacitor sees only the small AC

sawtooth ripple current. Ensure that the input bypass

capacitor has a ripple current rating that exceeds the

value of I

RMS

.

PDICis the IC’s quiescent power dissipation and is a data

sheet parameter (6mW typically for the entire IC at VIN=

15V). This power dissipation is almost completely independent of supply voltage whenever the +5V step-down

switch-mode power supply is on, since power to the chip

is bootstrapped from the +5V output. When calculating

the efficiency of each individual buck controller, use 3mW

for PDIC, since each controller consumes approximately

half of the total quiescent supply current.

Example: +5V buck SMPS at 300kHz, VIN= 15V, I

= 2A, RCS= R

Si9410DY with r

= 30nC.

PD

(DIODE) + 22mW (TRAN) + 22mW (CAP) + 3mW (IC)

= 400mW (I2R) + 90mW (GATE) + 36mW

TOTAL

= ESR = 25mΩ, both transistors are

COIL

DS(ON)

= 0.05Ω, C

= 160pF, and q

RSS

= 573mW

Efficiency = 10W/(10W + 573mW) x 100% = 94.6%

(actual measured value = 94%).

Light-Load Efficiency

Under light loads, the PWMs operate in the discontinuous-conduction mode, where the inductor current discharges to zero at some point during each switching

x f,

losses.

LOAD

cycle. New loss mechanisms, insignificant at heavy

loads, start to become important. The basic difference

is that, in discontinuous mode, the inductor current’s

AC component is large compared to the load current.

This increases core losses and losses in the output filter capacitors. Ferrite cores are recommended over

powdered toroid types for best light-load efficiency.

At light loads, the inductor delivers triangular current

pulses rather than the nearly constant current found in

continuous mode. These pulses ramp up to a point set

by the idle-mode current comparator, which is internally

fixed at approximately 25% of the full-scale current-limit

level. This 25% threshold provides an optimum balance between low-current efficiency and output voltage

noise (the efficiency curve would actually look better if

this threshold were set at about 45%, but the output

noise would then be too high).

Reducing I

specifying huge, low-r

atrocious efficiency, especially at mid-range and light-

2

R losses though the brute-force method of

MOSFETs can result in

DS(ON)

load conditions. Even at heavy loads, the gate charge

losses introduced by huge 50A MOSFETs usually more

than offset any gain obtained through lower r

Layout and Grounding

Good layout is necessary to achieve the designed output power, high efficiency, and low noise. Good layout

includes use of a ground plane, appropriate component placement, and correct routing of traces using

appropriate trace widths. The following points are in

order of importance:

1. A ground plane is essential for optimum performance.

In most applications, the power supply is located on a

multilayer motherboard, and full use of the four or

more copper layers is recommended. Use the top

and bottom layers for interconnections, and the inner

layers for an uninterrupted ground plane.

2. Keep the Kelvin-connected current-sense traces

short, close together, and away from switching

nodes. See Figure 5.

G

3. Place the LX node components N1, N3, D3, and L1

as close together as possible. This reduces resistive

and switching losses and keeps noise due to

ground inductance confined. Do the same with the

other LX node components N2, N4, D4, and L2.

4. The input filter capacitor C1 should be less than

10mm away from N1’s drain. The connecting copper trace carries large currents and must be at least

2mm wide, preferably 5mm.

Similarly, place C13 close to N2’s drain, and connect them with a wide trace.

DS(ON)

.

20 ______________________________________________________________________________________

Page 21

Triple-Output Power-Supply

Controller for Notebook Computers

5. Keep the gate connections to the MOSFETs short for

low inductance (less than 20mm long and more than

0.5mm wide) to ensure clean switching.

6. To achieve good shielding, it is best to keep all

high-voltage switching signals (MOSFET gate drives DH3 and DH5, BST3 and BST5, and the two LX

nodes) on one side of the board and all sensitive

nodes (CS3, CS5, FB3, FB5 and REF) on the other

side.

7. Connect the GND and PGND pins directly to the

ground plane, which should ideally be an inner layer

of a multilayer board.

8. Connect the bypass capacitor C2 very close (less

than 10mm) to the VL pin.

9. Minimize the capacitance at the transformer secondary. Place D5 and C12 very close to each other

and to the secondary, then route the output to the IC’s

VDD pin with a short trace. Bypass with 0.1µF close

to the VDD pin if this trace is longer than 50mm.

The layout for the evaluation board is shown in the

Evaluation Kit

section. It provides an effective, low-

noise, high-efficiency example.

Power-Ready and Power Sequencing

A “power-ready” signal can be generated from one of

the comparator outputs by connecting one of the supplies (e.g., the +5V output – see Figure 6) through a

high-resistance voltage divider to the comparator input.

The threshold for the +5V-output comparator is set by

R1 and R2 according to the formula: VTH= 1.65V x (R1

+ R2) / R2. For example, choosing R1 = 1MΩ and R2 =

604kΩ sets the nominal threshold to 4.38V.

If the power-ready signal is required to indicate when

both the +3.3V and the +5V supplies have come up,

use the MAX707 supervisory circuit shown in Figure 7.

The threshold for the +3.3V-line comparator is set by

R1 and R2 according to the formula: VTH= 1.25V x (R1

+ R2) / R2. For example, choosing R1 = 1.2MΩ and R2

= 1MΩ sets the nominal threshold to 2.75V. The threshold for the +5V supply is preset inside the MAX707,

and is typically 4.65V. The reset outputs remain asserted while either supply line is below its threshold, and

for at least 140ms after both lines are fully up.

If sequencing of the +3.3V and +5V supplies is critical,

several approaches are possible. For example, the

SS3 and SS5 capacitors can be sized to ensure that

the two supplies come up in the desired order. This

technique requires that the SS capacitors be selected

specifically for each individual situation, because the

loading on each supply affects its power-up speed.

+5V

SUPPLY

FB5

1M

R1

D_

604k

R2

Figure 6. Power-Ready Signal for the +5V Supply

+5V

SUPPLY

+3.3V

SUPPLY

R1

1.24M

R2

1M

Figure 7. Power-Ready Signal Covers Both +3.3V and +5V

Supplies with External Voltage Monitor IC (MAX707)

V

CC

4.65V

PFI

1.25V

GND

1.65V

MAX782

GND

RESET

MAX707

Q_

RESET

RESET

MR

PFO

+5V

POWER-READY

POWER READY

POWER READY

Another approach uses the “power-ready” comparator

output signal (see Figure 6) from one supply as a control input to the ON_ pin of the other supply.

MAX782

______________________________________________________________________________________ 21

Page 22

Triple-Output Power-Supply

Controller for Notebook Computers

+5V SUPPLY

VCC

GND

C4

100nF

P

HYST1

OUT2

N

POWER READY

R6

R3

C1

22nF

1M

1M

+3.3V SUPPLY

R4

1M

MAX782

SET1

C2

100

nF

R5

820k

R1

1M

SET2

R2

390k

ICL7665

1.3V

Figure 8. Power-Up Sequencing for the Intel 486SL

Figure 8 shows a more complex example of power

sequencing. On power-up, the Intel 486SL computer

requires the +5V supply to come up before the +3.3V

supply. A power-ready signal is required ≥50ms later.

This circuit’s ON3 output connects to the MAX782’s

ON3 pin, and can be wire-OR connected with an opendrain output to enable another circuit to turn the +3.3V

supply off.

PCMCIA Slot +3.3V/+5V VCC Switching

The MAX782 contains level shifters that simplify driving

external power MOSFETs to switch PCMCIA card VCC

to 3.3V and 5V. While a PCMCIA card is being inserted

into the socket, the VCC pins on the card edge should

be powered down to 0V so “hot insertion” does not

damage the PCMCIA card. The simplest way to do this

is to use a mechanical switch that has to be physically

opened before the PCMCIA card can be inserted. The

switch, which disconnects VCC, can be closed only

when the card has been fitted snugly into its socket.

Figure 9’s circuit illustrates this approach and correctly

shows the connections to both MOSFETs: N2 appears

to be inserted with drain and source the wrong way

around, but this is necessary to prevent its body diode

from pulling the +3.3V supply up to 5V when VCC is

connected to the +5V supply.

ON3

C3

100nF

g

+3.3V SUPPLY

s

N2

d

+5V SUPPLY

d

N1

s

SLOT

VCC

MECHANICAL

SWITCH

VDD VH

FB5

PCMCIA 2.0

DIGITAL