Page 1

19-0197; Rev 1; 1/95

CCFL Backlight and

LCD Contrast Controllers

_______________General Description

The MAX753/MAX754 drive cold-cathode fluorescent

lamps (CCFLs) and provide the LCD backplane bias

(contrast) power for color or monochrome LCD panels.

These ICs are designed specifically for backlit notebook-computer applications.

Both the backplane bias and the CCFL supply can be

shut down independently. When both sections are shut

down, supply current drops to 25µA. The LCD contrast

and CCFL brightness can be adjusted by clocking separate digital inputs or using external potentiometers.

LCD contrast and backlight brightness settings are preserved in their respective counters while in shutdown.

On power-up, the LCD contrast counter and CCFL

brightness counter are set to one-half scale.

The ICs are powered from a regulated 5V supply. The

magnetics are connected directly to the battery, for

maximum power efficiency.

The CCFL driver uses a Royer-type resonant architecture. It can provide from 100mW to 6W of power to one

or two tubes. The MAX753 provides a negative LCD

bias voltage; the MAX754 provides a positive LCD bias

voltage.

________________________Applications

Notebook Computers

Palmtop Computers

Pen-Based Data Systems

Personal Digital Assistants

Portable Data-Collection Terminals

____________________________Features

♦ Drives Backplane and Backlight

♦ 4V to 30V Battery Voltage Range

♦ Low 500µA Supply Current

♦ Digital or Potentiometer Control of CCFL

Brightness and LCD Bias Voltage

♦ Negative LCD Contrast (MAX753)

♦ Positive LCD Contrast (MAX754)

♦ Independent Shutdown of Backlight and

Backplane Sections

♦ 25µA Shutdown Supply Current

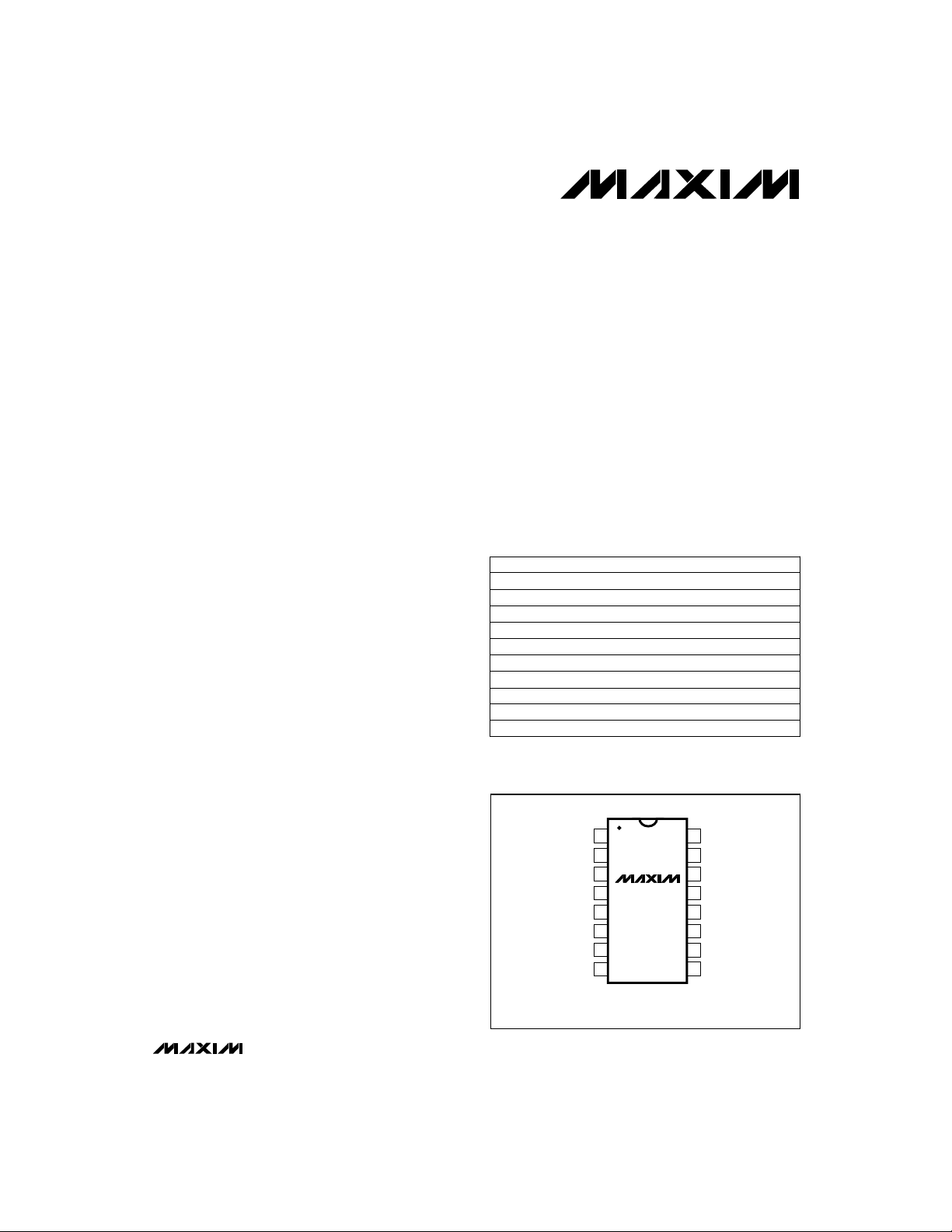

______________Ordering Information

PART TEMP. RANGE

MAX753CPE

MAX753CSE 0°C to +70°C

MAX753C/D 0°C to +70°C Dice*

MAX753EPE -40°C to +85°C

MAX753ESE -40°C to +85°C 16 Narrow SO

MAX754CPE

MAX754CSE 0°C to +70°C

MAX754C/D 0°C to +70°C Dice*

MAX754EPE -40°C to +85°C

MAX754ESE -40°C to +85°C 16 Narrow SO

* Contact factory for dice specifications.

0°C to +70°C

0°C to +70°C

PIN-PACKAGE

16 Plastic DIP

16 Narrow SO

16 Plastic DIP

16 Plastic DIP

16 Narrow SO

16 Plastic DIP

MAX753/MAX754

__________________Pin Configuration

TOP VIEW

V

DD

1

LADJ

2

LON

3

CON

CADJ

GND

REF

CFB

Block Diagram located at end of data sheet.

________________________________________________________________

MAX753

4

MAX754

5

6

7

8

DIP/SO

Maxim Integrated Products

Call toll free 1-800-998-8800 for free samples or literature.

LFB

16

BATT

15

LX

14

LDRV

13

PGND

12

CDRV

11

CS

10

CC

9

1

Page 2

CCFL Backlight and

LCD Contrast Controllers

ABSOLUTE MAXIMUM RATINGS

VDDto GND.................................................................-0.3V, +7V

PGND to GND.....................................................................±0.3V

BATT to GND.............................................................-0.3V, +36V

LX to GND............................................................................±50V

CS to GND.....................................................-0.6V, (V

Inputs/Outputs to GND (LADJ, CADJ, LON,

CON, REF, CFB, CC, CDRV, LDRV, LFB).....-0.3V, (V

Continuous Power Dissipation (T

Plastic DIP (derate 10.53mW/°C above +70°C) ...........842mW

Narrow SO (derate 8.70mW/°C above +70°C) .............696mW

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

= +70°C)

A

DD

DD

+ 0.3V)

+ 0.3V)

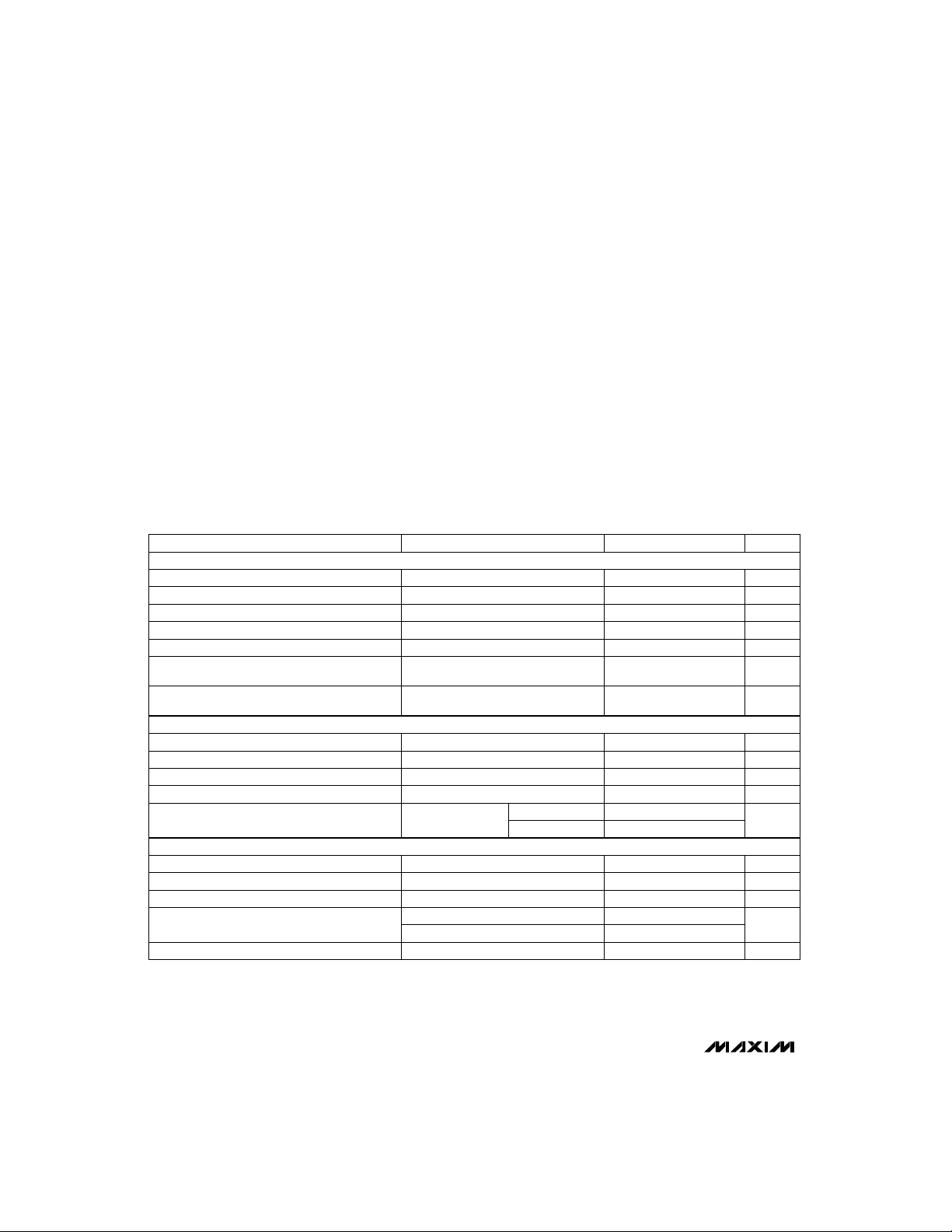

ELECTRICAL CHARACTERISTICS

MAX753/MAX754

(VDD= 5V, BATT = 15V, CON = LON = 5V, LX = GND = PGND = 0V, I

= T

to T

T

A

MIN

SUPPLY AND REFERENCE

DIGITAL INPUTS AND DRIVER OUTPUTS

Driver On-Resistance

CCFT CONTROLLER

VCO Frequency

, unless otherwise noted.)

MAX

No external load

4V < VDD< 6V

0µA < IL< 100µA

LON = CON = CS = LFB = CFB =

LADJ = CADJ = 5V

LON = CON = CS = LFB = CFB = LADJ

= CADJ = LX = BATT = 0V (Note 1)

LON, CON, CADJ, LADJ; VDD= 4.5V

LON, CON, CADJ, LADJ; VDD= 5.5V

LON, CON, CADJ, LADJ; VIN= 0V or 5V

LDRV = CDRV = 2V

LDRV, CDRV;

VDD= 4.5V

VCS= 0V

Minimum, CFB = 5V

Maximum, CFB = 0V

Guaranteed monotonic

Operating Temperature Ranges

MAX75_C_ _ ........................................................0°C to +70°C

MAX75_E_ _......................................................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range.............................-65°C to +160°C

Lead Temperature (soldering, 10sec).............................+300°C

= 0mA, all digital input levels are 0V or 5V,

REF

CONDITIONS

Output high

Output low

32 47

85 115

10

7

UNITSMIN TYP MAXPARAMETER

V430BATT Input Range

V4.5 5.5VDDSupply Range

V1.21 1.25 1.29REF Output Voltage

%/V0.1REF Line Regulation

mV515REF Load Regulation

mA0.5 2VDDQuiescent Current

µA25 40VDDShutdown Current

V0.8Input Low Voltage

V2.4Input High Voltage

µA±1Input Leakage Current

A0.5Driver Sink/Source Current

Ω

mV-10 20Zero-Crossing-Comparator Threshold Voltage (CS)

V1.2 1.3Overcurrent-Comparator Threshold Voltage (CS)

µA-5CS Input Bias Current

kHz

Bits5DAC Resolution

2 _______________________________________________________________________________________

Page 3

CCFL Backlight and

LCD Contrast Controllers

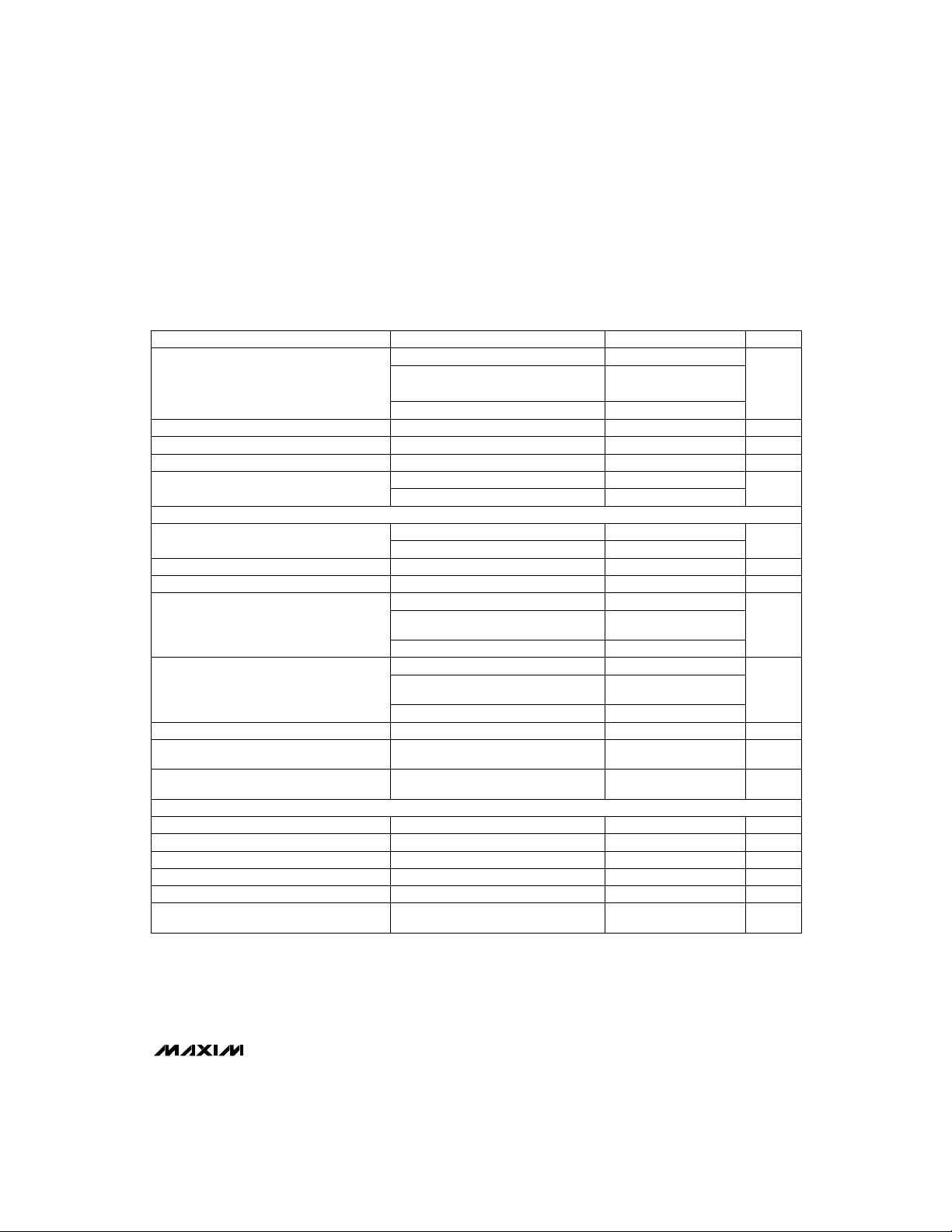

ELECTRICAL CHARACTERISTICS (continued)

(VDD= 5V, BATT = 15V, CON = LON = 5V, LX = GND = PGND = 0V, I

= T

to T

T

A

MIN

Feedback Voltage (CFB)

Feedback-Amplifier Output Current

LCD CONTROLLER

Switch On-Time

MAX753 Feedback Voltage (REF-LFB)

MAX754 Feedback Voltage (LFB)

TIMING (Note 2)

CADJ Low to CON Low or

LADJ Low to LON Low (t

Note 1: Maximum shutdown current occurs at BATT = LX = 0V.

Note 2: Timing specifications are guaranteed by design and not production tested.

, unless otherwise noted.)

MAX

)

SD

CONDITIONS

At full scale (DAC code = 31)

At preset DAC, CON = 0V, CADJ = 5V

(code = 15)

At zero scale (code = 0)

Source current, CFB = 0V, CC = 2.5V

Sink current, CFB = 5V, CC = 2.5V

BATT = 4V

BATT = 16V

BATT = 4V, LX = 0V

Guaranteed monotonic

At full scale (DAC code = 63)

At preset DAC, LON = 0V, LADJ = 5V

(code = 31)

At zero scale (code = 0)

At full scale (DAC code = 63)

At preset DAC, LON = 0V, LADJ = 5V

(code = 31)

At zero scale (code = 0)

LON = CON = CS = LFB = CFB = LADJ =

CADJ = LX = 0V

LON = CON = CS = LFB = CFB = LADJ =

CADJ = 0V, LX = BATT = 15V

REF

= 0mA, all digital input levels are 0V or 5V,

UNITSMIN TYP MAXPARAMETER

1210 1250 1290

745 782 820

320 343 365

50

200

25

0.5 1.5

1200 1240 1280

893 928 963

595 625 655

1210 1250 1290

905 938 971

610 635 660

mV

nA±100Feedback-Amplifier Input Bias Current

MHz1Feedback-Amplifier Unity-Gain Bandwidth

V/µs0.4Feedback-Amplifier Slew Rate

µA

µs

µs35 70Switching Period

Bits6DAC Resolution

mV

mV

nA±150LFB Input Leakage Current

µA12 20BATT Input Current

µA12 20LX Input Current

ns110Reset Pulse Width (tR)

ns0Reset Setup Time (tRS)

ns0Reset Hold Time (tRH)

ns100CADJ, LADJ High Width (tSH)

ns100CADJ, LADJ Low Width (tSL)

ns50

MAX753/MAX754

_______________________________________________________________________________________ 3

Page 4

CCFL Backlight and

LCD Contrast Controllers

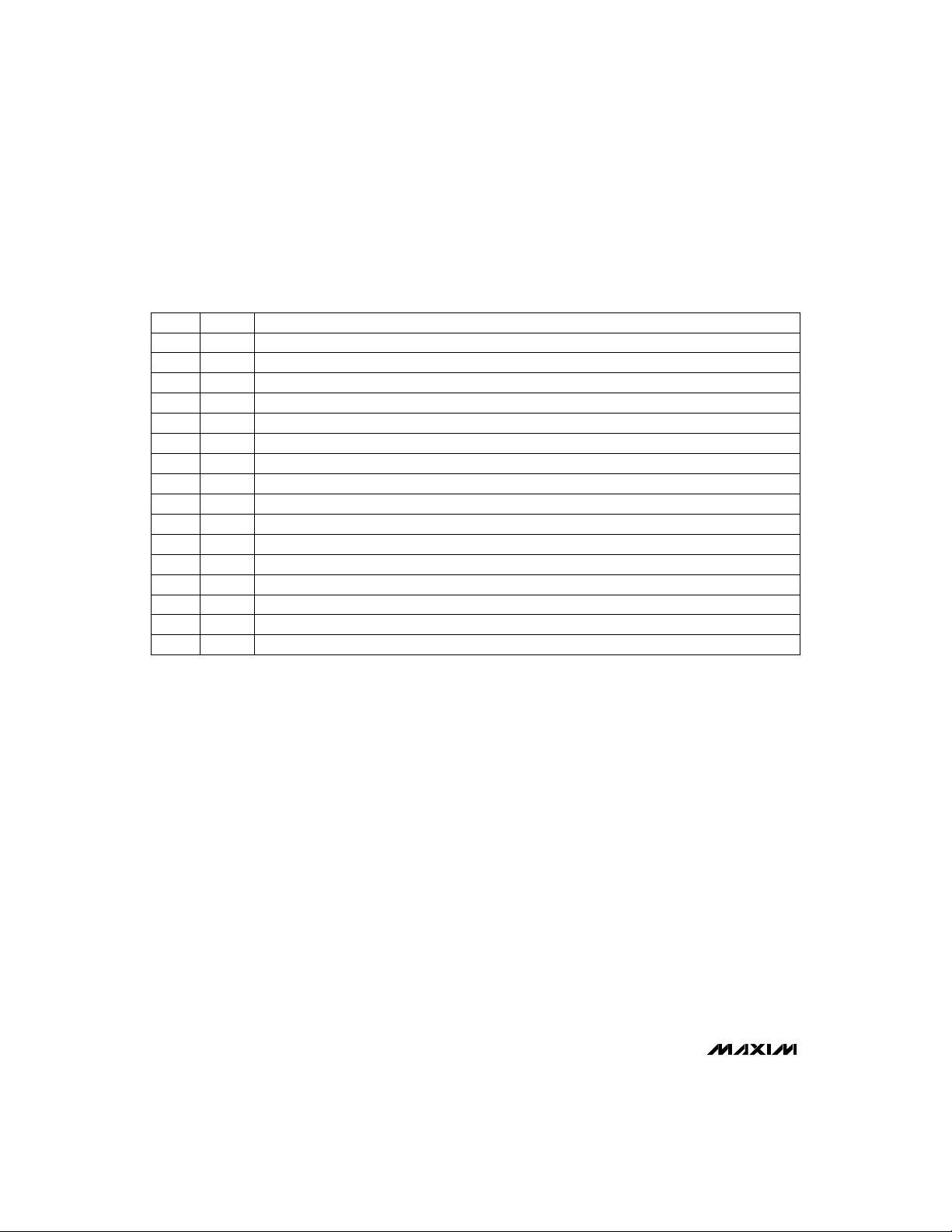

______________________________________________________________Pin Description

PIN

1

MAX753/MAX754

DD

CS10

5V Power-Supply InputV

Digital Input for LCD Backplane Bias Adjustment. See Table 1.LADJ2

Digital Input to Control LCD Bias Section. See Table 1.LON3

Digital Input to Control CCFT Section. See Table 1.CON4

Digital Input for CCFT Brightness Adjustment. See Table 1.CADJ5

Analog GroundGND6

Reference Voltage Output, 1.25VREF7

Inverting Input for the CCFT Error AmplifierCFB8

Output of the CCFT Error AmplifierCC9

Connect to V

Leave unconnectedCDRV11

Power Ground Connection for LDRVPGND12

Gate-Driver Output. Drives LCD backplane N-channel MOSFET.LDRV13

LCD Backplane Inductor Voltage-Sense Pin. Used to sense inductor voltage for on time determination.LX14

Battery Connection. Used to sense battery voltage for on time determination.BATT15

Voltage Feedback for the LCD Backplane SectionLFB16

DD

_______________Theory of Operation

The MAX753/MAX754’s CCFL inverter is designed to

drive one or two cold-cathode fluorescent lamps

(CCFLs) with power levels from 100mW to 6W. These

lamps commonly provide backlighting for LCD panels

in portable computers.

Drive Requirements for CCFL Tubes

CCFL backlights require a high-voltage, adjustable AC

power source. The MAX753/MAX754 generate this AC

waveform with a self-oscillating, current-fed, parallel

resonant circuit, also known as a Royer-type oscillator.

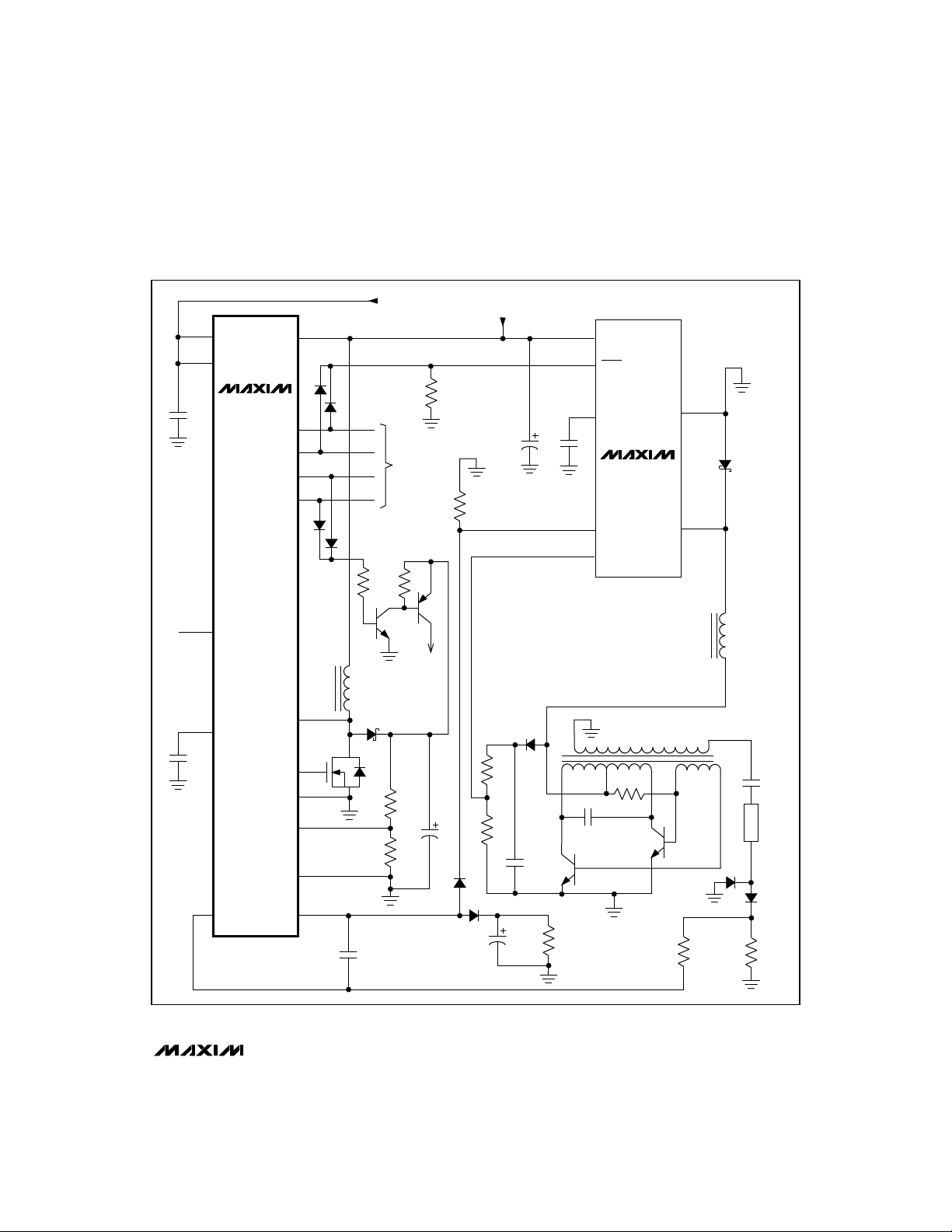

Figure 1 shows one such circuit. The Royer oscillator is

comprised of T1, C9, the load at the secondary, Q4,

and Q5. The circuit self-oscillates at a frequency determined by the effective primary inductance and capacitance. Q4 and Q5 are self-driven by the extra winding.

The current source feeding the Royer oscillator is comprised of L1, D5, and the MAX758A. When current from

the current source increases, so does the lamp current.

The lamp current is half-wave rectified by D7A and

CCFL Inverter

FUNCTIONNAME

D7B, and forms a voltage across resistor R8. The

MAX753’s error amplifier compares the average of this

voltage to the output of its internal DAC. Adjusting the

DAC output from zero scale to full scale (digital control)

causes the error amplifier to vary the tube current from

a minimum to a maximum. The DAC’s transfer function

is shown in Figure 2.

On power-up or after a reset, the counter sets the DAC

output to mid scale. Each rising edge of CADJ (with

CON high) decrements the DAC output. When decremented beyond full scale, the counter rolls over and

sets the DAC to the maximum value. In this way, a single pulse applied to CADJ decreases the DAC setpoint by one step, and 31 pulses increase the set-point

by one step.

The error amplifier’s output voltage controls the peak

current output of the MAX758A. The peak switch current is therefore controlled by the output of the error

amplifier. The lower the error amplifier’s output, the

lower the peak current. Since the current through the

current source is related to the current through the

tube, the lower the error amplifier’s output, the lower the

tube current.

4 _______________________________________________________________________________________

Page 5

CCFL Backlight and

LCD Contrast Controllers

MAX753/MAX754

+5V, ±5%

10

CS

1

V

DD

BATT

15

UNREGULATED INPUT VOLTAGE

1, 15, 16

V+

2

SHDN

D1B

CON

CADJ

LON

LADJ

LDRV

PGND

LFB

GND

D1A

4

5

3

2

D2B

D2A

L2

14

LX

13

12

16

6

9

CC

C1

MAX754CSE

11

CDRV

7

REF

C4

8

CFB

R16

3

C3C2

+5V CMOS

LOGIC

CONTROL

SIGNALS

R17

R2

R1

Q2

Q1

POSITIVE

CONTRAST

VOLTAGE

D3

Q3

R3

C6

R4

D6A

D6B

C5

D4

R5

R6

C8

Q4

C7

REF

MAX758ACWE

7

SS

8

CC

812

3,45

R10

C9

R7

GND

LX

T1

2

Q5

10, 11

D5

12, 13, 14

L1

61

CCFL

D7B

R18

C10

D7A

R8

Figure 1. CCFL and Positive LCD Power Supply

_______________________________________________________________________________________ 5

Page 6

CCFL Backlight and

LCD Contrast Controllers

1250

1221

1191

811

782

753

402

DAC OUTPUT VOLTAGE (mV)

372

343

MAX753/MAX754

01

2

3

ZERO SCALE

Figure 2. CCFT DAC Transfer Function

14 15 16 29 30 31

DAC CODE

MID SCALE FULL SCALE

MAX754

FULL-SCALE = 1.250V

HALF-SCALE = 0.782V

ZERO-SCALE = 0.343V

CON CADJ

LOGIC AND

5-BIT COUNTER

5-BIT VOLTAGE

OUTPUT DAC

In Figure 1, the MAX758A, L1, and D5 form a voltagecontrolled switch-mode current source. The current out

of L1 is proportional to the voltage applied to the SS

pin. The MAX758A contains a current-mode pulsewidth-modulating buck regulator that switches at

170kHz. The voltage on the SS pin sets the switch current limit and thus sets the current out of L1.

CCFL Current-Regulation Loop

Figure 3 shows a block diagram of the regulation loop,

which maintains a fixed CCFL average lamp current

despite changes in input voltage and lamp impedance.

This loop regulates the average value of the half-wave

rectified lamp current. The root mean square lamp current is related to, but not equal to, the average lamp

current. Assuming a sinusoidal lamp current, select R8

as follows:

where V

R

82=

= 1.25V and I

REF

V

π

REF

I

LAMP RMS

,

LAMP,RMS

is the desired full-

scale root mean square lamp current.

MAX758A

SS

SWITCH-MODE

VOLTAGE CONTROLLED

CURRENT SOURCE

I

BUCK

CENTER-TAP

ROYER

OSCILLATOR

TRANSISTOR

EMITTERS

C10

CCFL

R8

CFB

ERROR

AMPLIFIER

CC

C5

R18

Figure 3. CCFL Tube Current-Regulation Loop

6 _______________________________________________________________________________________

Page 7

CCFL Backlight and

LCD Contrast Controllers

MAX753/MAX754

V

(t)

V

TAP, PK

TAP

C10

V

(t)

SEC

(t)

V

LAMP

LAMP

LAMP,RMS

,

TAP

(t) =

.

T

pulse-frequency-modulation (PFM) switching regulator.

The MAX753 adds a simple diode-capacitor voltage

inverter to the switching regulator.

Constant-Current PFM Control Scheme

The LCD bias generators in these devices use a constant-peak-current PFM control scheme. Figure 6, which

shows the MAX754’s boost switching regulator, illustrates this control method. When Q3 closes (Q3 “on”) a

voltage equal to BATT is applied to the inductor, causing current to flow from the battery, through the inductor

and switch, and to ground. This current ramps up linearly, storing energy in the inductor’s magnetic field. When

Q3 opens, the inductor voltage reverses, and current

flows from the battery, through the inductor and diode,

and into the output capacitor. The devices regulate the

output voltage by varying how frequently the switch is

opened and closed.

The MAX753/MAX754 not only regulate the output voltage, but also maintain a constant peak inductor current, regardless of the battery voltage. The ICs vary the

switch on-time to produce the constant peak current,

and vary its off-time to ensure that the inductor current

reaches zero at the end of each cycle.

The internal circuitry senses both the output voltage

and the voltage at the LX node, and turns on the MOSFET only if: 1) The output voltage is out of regulation,

and 2) the voltage at LX is less than the battery voltage.

The first condition keeps the output in regulation, and

the second ensures that the inductor current always

resets to zero (i.e., the part always operates in discontinuous-conduction mode).

I

(t)

LAMP

Figure 4. Simple Model of the CCFL Figure 5. Voltage at the Center Tap of T1

The minimum operating input voltage is determined by

the transformer turns ratio (n), the lamp operating voltage (V

), and the ballast capactor (C10). Using a

LAMP

simple model of the CCFL (see Figure 4) we can calculate what the T1 center-tap voltage will be at maximum

lamp current. The voltage on the CCFL is in phase with

the current through it. Let us define I

√2I

LAMP,RMS

cos(ωt) and V

LAMP

(t) = √2V

cos(ωt); then the peak voltage at the center tap will be

as follows:

I

2

−

CV

10

I

LAMP RMS,,

nC

10ωφ()

,

LAMP RMS

,

LAMP RMS

sin

where,

V

TAP PK

φω=

tan

−

1

=−

n is the secondary-to-primary turns ratio of T1, and ω is

the frequency of Royer oscillation in radians per second. The voltage on the center tap of T1 is a full-wave

rectified sine wave (see Figure 5). The average voltage

at V

must equal the average voltage at the LX node

TAP

of the MAX758A, since there cannot be any DC voltage

on inductor L1; thus the minimum operating voltage

must be greater than the average voltage at V

LCD Bias Generators

The MAX753/MAX754’s LCD bias generators provide

adjustable output voltages for powering LCD displays.

The MAX753’s LCD converter generates a negative

output, while the MAX754’s generates a positive output.

The MAX753/MAX754 employ a constant-peak-current

t

_______________________________________________________________________________________ 7

Page 8

CCFL Backlight and

LCD Contrast Controllers

+5V INPUT

C1

0.22µF

2

3

LADJ

LON

CONTROL

MAX753/MAX754

MAX754

PGND

12

Figure 6. MAX754 Positive LCD-Bias Generator

V

DD

ON/OFF

PRESET

6-BIT COUNTER

CLK

6-BIT DAC

GND

6

1

ON-TIME

15

BATT

LOGIC

PULSE-SKIP

COMPARATOR

V

DAC

FULL-SCALE OUTPUT = 1.250V

HALF-SCALE OUTPUT = 0.938V

ZERO-SCALE OUTPUT = 0.635V

OFF-TIME

LOGIC

BATTERY

INPUT

L2

33µH

14

LX

LDRV

LFB

13

16

C2

10µF

D3

1N5819

Q3

R3

R4

POSITIVE

LCD-BIAS

OUTPUT

C6

10µF

35V

Table 1. CCFL Circuit Component Descriptions

ITEM DESCRIPTION

Integrating Capacitor. 1 / (C5 x R18) sets the dominant pole for the feedback loop, which regulates the lamp

C5

R18

R8

D7A, D7B

CCFL

8 _______________________________________________________________________________________

current. Set the dominant pole at least two decades below the Royer frequency to eliminate the AC component of the voltage on R8. For example, if your Royer is oscillating at 50kHz = 314159rad/s, you should set

1 / (C5 x R18) ≤ 3142rad/s.

Integrating Resistor. The output source-current capability of the CC pin (50µA) limits how small R18 can be.

Do not make R18 smaller than 70kΩ, otherwise CC will not be able to servo CFB to the DAC voltage (i.e., the

integrator will not be able to integrate) and the loop will not be able to regulate.

R8 converts the half-wave rectified lamp current into a voltage. The average voltage on R8 is not equal to the

root mean square voltage on R8. The accuracy of R8 is important since it, along with the MAX754 reference,

sets the full-scale lamp current. Use a ±1%-accurate resistor.

D7A and D7B half-wave rectify the CCFL lamp current. Half-wave rectification of the lamp current and then

averaging is a simple way to perform AC-to-DC conversion. D7A and D7B’s forward voltage drop and speed

are unimportant; they do not need to pass currents larger than about 10mA, and their reverse breakdown

voltage can be as low as 10V.

The circuit of Figure 1, with the components shown in the bill of materials (Table 4), will drive a 500V

ating cold-cathode fluorescent lamp at 6W of power with a +12V input voltage. The lower the input voltage,

the less power the circuit can deliver.

RMS

oper-

Page 9

CCFL Backlight and

LCD Contrast Controllers

Table 1. CCFL Circuit Component Descriptions (continued)

ITEM DESCRIPTION

The ballast capacitor linearizes the CCFL impedance and guarantees no DC current through the lamp. 15pF

C10

T1

C9

R10

R5, R6

D6B, C7, R7

D6A, R17

L1 Inductor for the Switching-Current Source. Use a 47µH to 150µH inductor with a 1A to 1.5A saturation current.

D5 Schottky Catch Diode. Use a 1A to 1.5A Schottky diode with low forward-voltage power.

C2 Supply Bypass Capacitor. Use low-ESR capacitor.

will work with just about any lamp. Depending on the lamp, you can try higher values, but this may cause the

regulation loop to become unstable. Larger values of C10 allow the circuit to operate with lower input voltages. Don’t forget that C10 must be a high-voltage capacitor and cannot be polarized. A lamp with a

1500V

T1 must have high primary inductance (greater than 30µH), otherwise an inflated value of C9 will be required

in order to keep the Royer frequency below 60kHz (the maximum allowed by most lamps). A higher T1 secondary-to-primary turns ratio allows lower-voltage operation, but increases the size of the transformer.

You must select a value for C9 high enough to keep the lamp current reasonably sinusoidal and yet low

enough that T1’s core does not saturate. For the Sumida EPS207 with a 171:1 turns ratio, choose a 0.22µF

value for C9. The characteristic impedance of the resonant tank equals , where L

netizing inductance of T1. The characteristic impedance is defined as the ratio of the voltage across the parallel LC circuit divided by the current flowing between the inductor and capacitor. This circulating current is

not delivered to the load. If C9 has too large a value, it will cause excessive circulating currents, which will in

turn saturate the core of T1. It’s easy to tell when you have excess circulating current in the resonant tank,

because when you touch T1 you burn your finger. However, reducing the value of C9 decreases tank Q,

which increases the harmonic content of the lamp-current waveform. If the lamp-current waveform does not

look sinusoidal, then the circuit may not regulate to the right root mean square current.

R10 sets the base current for Q4 and Q5. If you choose too large a value for R10, Q4 and Q5 will overheat.

Too small a value will waste base current and slightly degrade efficiency. The optimal value will depend on

how much power you are trying to deliver to the lamp. 510Ω is a good “always works but may not be the most

efficient” value for use with the FMMT619 transistors from ZETEX.

This resistive divider senses the voltage at the center tap of T1. When the CC pin on the MAX758A rises

above 1.25V, the internal switch turns off, interrupting power to the Royer oscillator and limiting the open-lamp

transformer center-tap voltage.

D6B, C7, and R7 form a soft-start clamp, which limits the rate-of-rise of the peak current in the MAX758A.

Make sure R7 is at least 100kΩ so it does not excessively load the CC pin.

D6A and R17 are also part of the soft-start clamp. The voltage on the SS pin controls the peak current in the

MAX758A’s switch. Make sure R17 is at least 100kΩ so it does not excessively load the CC pin.

maximum strike voltage will require C10 to withstand 1500 x √2= 2121V.

RMS

L

MAG

9

C

MAG

MAX753/MAX754

is the mag-

_______________________________________________________________________________________ 9

Page 10

CCFL Backlight and

LCD Contrast Controllers

Table 2. CCFL Circuit Design Example (Note 1)

PARAMETER SYMBOL MIN TYP MAX UNITS

CCFL Specifications

Strike Voltage (VS) V

Discharging Tube Current (IL) I

Discharging Tube Voltage (VL) V

LCD Contrast Voltage Specifications

Bias Voltage V

Output Current I

Royer Specifications

T1 Turns Ratio (Sec/Pri) (Note 2) n 171

T1 Resonating Inductance (Note 2) L

C9 Value (Note 3) C

MAX753/MAX754

C10 Value C

Royer Frequency w 317820.86 rad/s

MAX754 Specifications

Reference Voltage V

Second Volts Constant sV 0.000008 2.4E-05 sV

CCFL Circuit Calculations

R8 Current-Sensing Resistor R8 555.36037 Ω

Secondary Voltage Phase vs. Tube Voltage phi -1.1776341 Radian

T1 Center-Tap Peak Voltage V

Secondary Limit Voltage V

T1 Center-Tap Limit Peak Voltage 11.164844 V

R5/R6 R

LCD Circuit Calculations

V

Full-Load Switching Period T

IN(min)

L2 Inductance L2 1.96E-05 2.4E-05 H

L2 Peak Currrent 1.22704 A

R4/R3 R

Application Circuit Operating Range

Input Voltage V

Note 1: To perform your own calculations for the parameters given in Table 2 (Design Example), use the equations given in Table

Note 2: T1 = Sumida’s EPS207

Note 3: C9 = Wima’s SMD 7.3 __/63

3 (Design Equations).

S,RMS

LAMP,RMS

LAMP,RMS

LCD

LCD

MAG

RES

BAL

REF

TAP,PK

LIM

OTP,RATIO

FL

LCD,RATIO

IN

1100 1500 V

0.001376 0.005 A

435 V

16.3 32.6 V

0.0245 A

0.000045 H

2.2E-07 F

1.5E-11 F

1.25 V

9.3903817 V

1350 V

0.1341944 Ω/Ω

1.639E-06 s

0.0398724 Ω/Ω

5.978103 18 V

RMS

RMS

RMS

PEAK

RMS

PEAK

10 ______________________________________________________________________________________

Page 11

CCFL Backlight and

LCD Contrast Controllers

Table 3. Spreadsheet Design Equations

PARAMETER SYMBOL MIN TYP MAX

CCFL Specifications

Strike Voltage (VS) V

Discharging Tube Current (IL) I

Discharging Tube Voltage (VL) V

S,RMS

LAMP,RMS

LAMP,RMS

LCD Contrast Voltage Specifications

Bias Voltage V

Output Current I

LCD

LCD

Royer Specifications

T1 Turns Ratio (Sec/Pri) n 171

T1 Resonating Inductance L

C9 Value C

C10 Value C

MAG

RES

BAL

Royer Frequency w = SQRT [1 / (L

MAX754 Specifications

Reference Voltage V

REF

Second Volts Constant sV 0.000008 2.4E-05

CCFL Circuit Calculations

R8 Current-Sensing Resistor R8

Secondary Voltage Phase vs. Tube

Voltage

T1 Center-Tap Peak Voltage

Secondary Limit Voltage V

phi

V

TAP,PK

LIM

T1 Center-Tap Limit Peak Voltage = SQRT(2) * V

R5/R6 R

OTP,RATIO

LCD Circuit Calculations

V

Full-Load Switching Period T

IN(min)

FL

L2 Inductance L2 = L2(max) * 0.8

L2 Peak Currrent = sV(max) / L2(min)

R4/R3 R

LCD,RATIO

Application Circuit Operating Range

Input Voltage V

IN

1100 1500

= 0.28 *

I

LAMP,RMS(max)

435

= V

/ 2 32.6

LCD(max)

0.0245

0.000045

2.2E-07

1.5E-11

* C

RES

)]

MAG

1.25

= (2 / PI()) * V

TAP,PK

= PI() * V

(2 * I

= ATAN (-I

(C

BAL

= -SQRT(2) * I

(C

BAL

= V

= V

REF

= sV(min) / V

(V

= V

REF

* SQRT(2) /

REF

LAMP,RMS(max)

LAMP,RMS(max)

* w * + V

LAMP,RMS

LAMP,RMS(max)

* w * SIN(phi)) / n

S,RMS(max)

/ (D25 - 0.6 - V

IN(min)

- V

LCD(max)

/ (V

LCD(max)

)

* 0.9

/ n

LIM

REF

+ sV(min) /

)

IN(min)

- V

REF

)

0.005

/

)

/

= sV(min) ^ 2 / (2 * TFL*

V

LCD(max)

* I

)

18

LCD(min)

MAX753/MAX754

)

______________________________________________________________________________________ 11

Page 12

CCFL Backlight and

LCD Contrast Controllers

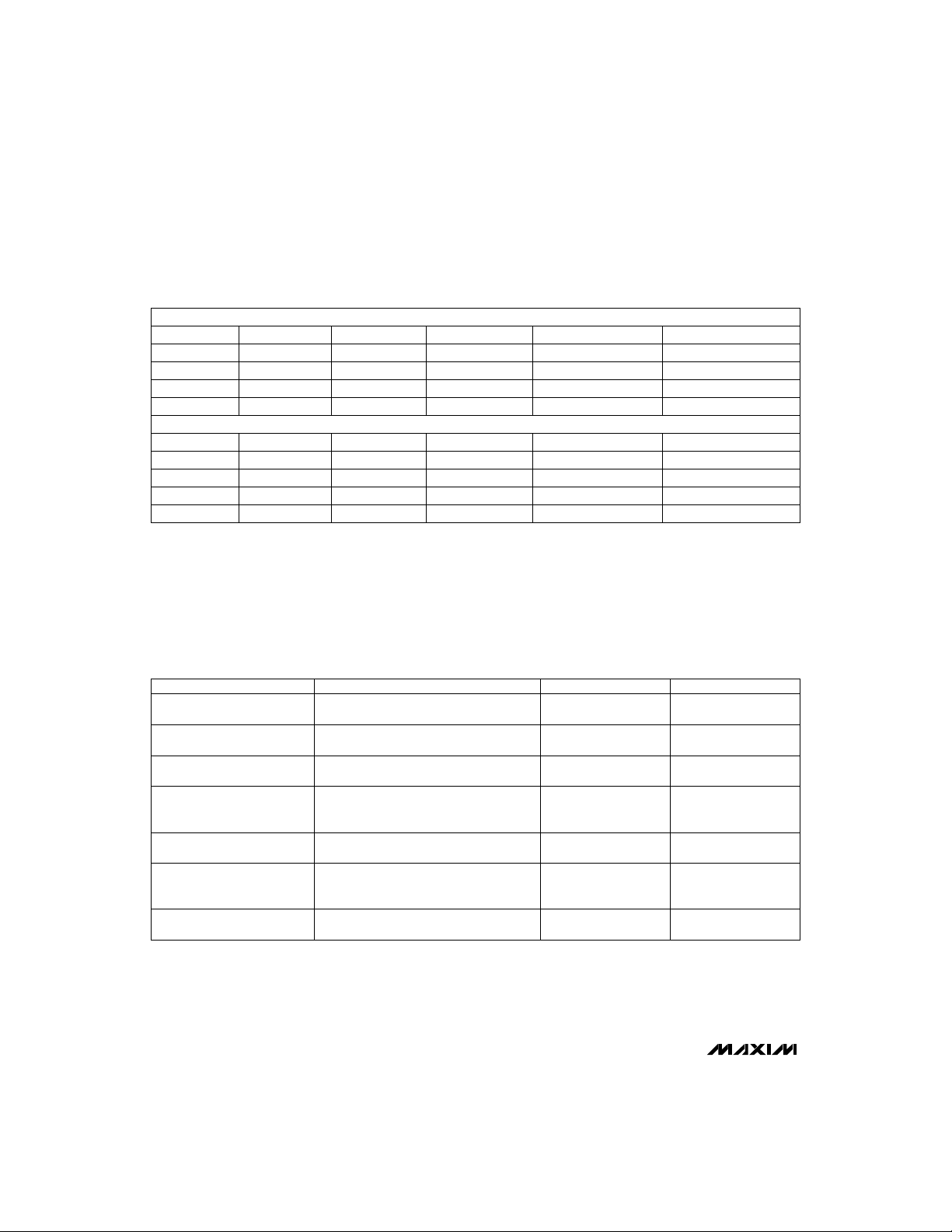

Table 4. Bill of Materials

RESISTOR VALUE (Ω) TOLERANCE (%)

R1 100,000 ±10

R2 100,000 ±10

R3 1,000,000 ±1

R4 40,200 ±1

R5 100,000 ±1

R6 13,300 ±1

R7 100,000 ±10

R8 549 ±1

R10 680 ±5

R16 100,000 ±10

R17 100,000 ±10

R18 100,000 ±5

MAX753/MAX754

CAPACITOR

C1 0.1 6

C2 22 20 Low ESR

C3 0.1 20

C4 0.1 6

C5 0.01 6 Non-polarized

C6 10 50

C7 1 6

C8 1 30

C9 22 63

C10 1.5E-5 3000 High voltage

VALUE (µF)

WORKING

VOLTAGE (V)

CHARACTERISTICS

OTHER

COMPONENTS

Q1 CMPTA06 SOT-23 80 MPSA06 Central Semi.

Q2 CMPT2907A SOT-23 60 2N2907 Central Semi.

Q3 SOT-23 60 3055EL Motorola

Q4

Q5 FMMT619 SOT-23 50 Zetex

D1A CMPD4150 SOT-23 75 1N4150 Central Semi.

D1B CMPD4150 SOT-23 75 1N4150 Central Semi.

D2A CMPD4150 SOT-23 75 1N4150 Central Semi.

D2B CMPD4150 SOT-23 75 1N4150 Central Semi.

D3 EC10QS05 D-64 50 1N5819 Nihon

D4 CMPD4150 SOT-23 75 1N4150 Central Semi.

D5 EC10QS02L D-64 20 1N5817 Nihon

D6A CMPD4150 SOT-23 75 1N4150 Central Semi.

D6B CMPD4150 SOT-23 75 1N4150 Central Semi.

D7A CMPD4150 SOT-23 75 1N4150 Central Semi.

D7B CMPD4150 SOT-23 75 1N4150 Central Semi.

Note: For T1, Use Sumida EPS207. Request No. USC-145, Special No. 6358-JP5-010.

12 ______________________________________________________________________________________

SURFACE-

MOUNT PART

NUMBER

MMFT3055ELT1

FMMT619

PACKAGE

SOT-23 50 Zetex

BREAKDOWN

VOLTAGE (V)

GENERIC

PART NO.

MANUFACTURER

Page 13

CCFL Backlight and

LCD Contrast Controllers

The voltage-regulation loop is comprised of resistors R3

Positive LCD Bias: MAX754

and R4, the pulse-skip comparator, the internal DAC,

the on-time and off-time logic, and the external power

components. The comparator compares a fraction of

the output voltage to the voltage generated by an onchip 6-bit DAC. The part regulates by keeping the voltage at LFB equal to the DAC’s output voltage. Thus,

you can set the output to different voltages by varying

the DAC’s output.

Varying the DAC output voltage (digital control) adjusts

the external voltage from 50% to 100% of full scale. On

power-up or after a reset, the counter sets the DAC output to mid scale. Each rising edge of LADJ (with LON

high) decrements the DAC output. When decremented

beyond zero scale, the counter rolls over and sets the

DAC to the maximum value. In this way, a single pulse

applied to LADJ decreases the DAC set point by one

step, and 63 pulses increase the set point by one step.

The MAX754’s DAC transfer function is shown in Figure 7.

The following equation relates the switching regulator’s

regulated output voltage to the DAC’s voltage:

VV1

OUT DAC

=+

R3

R4

Table 5 is the logic table for the LADJ and LON inputs,

which control the internal DAC and counter. As long as the

timing specifications for LADJ and LON are observed, any

sequence of operations can be implemented.

Negative LCD Bias: MAX753

The LCD bias generator of the MAX753 (Figure 8) generates its negative output by combining the switching

regulator of the MAX754 with a simple diode-capacitor

voltage inverter. To best understand the circuit, look at

the part in a steady-state condition. Assume, for

instance, that the output is being regulated to -30V, and

that the battery voltage is +10V. When Q3 turns on, two

things occur: current ramps up in the inductor, just like

with the boost converter; and the charge on C15 (transferred from the inductor on the previous cycle) is transferred to C6, boosting the negative output. At the end of

the cycle, the voltage on C15 is 30V + Vd, where Vd is

the forward voltage drop of Schottky diode D3, and 30V

is the magnitude of the output.

When the MOSFET turns off, the inductor’s energy is

transferred to capacitor C15, charging the capacitor to

a positive voltage (V

) that is higher than |V

HIGH

OUT

|. In

this instance, diode D8 allows current to flow from the

right-hand side of the flying capacitor (C15) to ground.

When the MOSFET turns on, the left-hand side of

capacitor C15 is clamped to ground, forcing the right-

1250

1240

1230

947

938

928

655

DAC OUTPUT VOLTAGE (mV)

645

635

01

2

ZERO SCALE

Figure 7. MAX754 LCD DAC Transfer Function

hand side to -V

HIGH

30 31 32 61 62 63

DAC CODE

MID SCALE FULL SCALE

. This voltage is more negative than

the output, forcing D3 to conduct, and transferring

charge from the flying capacitor C15 to the output

capacitor C6. This charge transfer happens quickly,

resulting in a voltage spike at the output due to the

product of the output capacitor’s equivalent series

resistance (ESR) and the current that flows from C15 to

C6. To limit this drop, resistor R19 has been placed in

series with D3. R19 limits the rate of current flow. At the

end of this cycle, the flying capacitor has been discharged to 30V + Vd.

If BATT(MAX) (i.e., either the fully charged battery voltage, or the wall-cube voltage) is greater than

|V

(MIN)|, tie the cathode of D8 to BATT instead of

OUT

GND, as shown by the dashed lines in Figure 8.

Efficiency is lower with this method, so tie the cathode

of D8 to GND whenever possible.

The MAX753’s regulation loop is similar to that of the

MAX754. The MAX753, however, uses different power

components, and its feedback resistors are returned to

the reference (1.25V) rather than ground.

The MAX753’s PFM comparator compares a fraction of

the output voltage to the voltage generated by the onchip 6-bit DAC. The part regulates by keeping the voltage at LFB equal to the DAC’s output voltage. Thus,

you can set the LCD bias voltage to different voltages

by varying the DAC’s output.

MAX753/MAX754

______________________________________________________________________________________ 13

Page 14

CCFL Backlight and

LCD Contrast Controllers

Table 5. Logic-Signal Truth Table

CCF CONTROL

LON LADJ CON CADJ CCFT STATUS

X X 0 0 Off

X X 0 1 On

X X 1 0 On

X X 1

LCD BIAS CONTROL

LON LADJ CON CADJ LCD STATUS

0 0 X X Off

0 1 X X On

MAX753/MAX754

1 0 X X On

1

0→1

X X On

Hold = maintain last DAC value in counter

Reset = set DAC counter to half scale

Dec = decrement DAC counter one step

Off = section turned off, sleep state

On = section turned on

X = don’t care

Table 6. Component Suppliers

MANUFACTURER

Central Semiconductor

Coiltronics

Maxim

Nihon (NIEC)*

Sumida

Wima

Zetex (516) 543-7100 (516) 864-7630

* Contact John D. Deith, ask for “Maxim Discount” on orders less than 5k units.

145 Adams Ave.

Hauppauge, NY 11788

6000 Park of Commerce Blvd.

Boca Raton, FL 33287

120 San Gabriel Dr.

Sunnyvale, CA 94025

c/o Quantum Marketing

12900 Rolling Oaks Rd.

Twin Oaks, CA 93518

5999 New Wilke Rd., Suite 110

Rolling Meadows, IL 60008

2269 Saw Mill River Rd., Suite 400

P.O. Box 217

Elmsford, NY 10523

87 Modular Ave.

Commack, NY 11725

ADDRESS PHONE FAX

0→1

On

(516) 435-1110 (516) 435-1824

(407) 241-7876 (407) 241-9339

(408) 737-7600 (408) 737-7194

(805) 867-2555 (805) 867-2698

(708) 956-0666 (708) 956-0702

(914) 347-2474 (914) 347-7230

CCFT DAC

Hold

Reset

Hold

Dec

LCD DAC

Hold

Reset

Hold

Dec

14 ______________________________________________________________________________________

Page 15

+5V INPUT

C1

0.22µF

2

LADJ

CONTROL

MAX753

PGND

3

LON

12

V

DD

ON/OFF

PRESET

6-BIT COUNTER

CLK

6-BIT DAC

GND

6

1

15

ON-TIME

LOGIC

BATT

V

DAC

PULSE-SKIP

COMPARATOR

Figure 8. MAX753 Negative LCD-Bias Generator

1240

1230

1220

937

928

918

645

DAC OUTPUT VOLTAGE (mV)*

635

625

14

LX

OFF-TIME

LOGIC

CCFL Backlight and

LCD Contrast Controllers

BATTERY

INPUT

L2

33µH

C15

1µF

LDRV

13

Q3

LFB

16

7

REF

C4

0.22µF

The MAX753’s DAC transfer function is shown in Figure 9.

The following equation relates the switching regulator’s

regulated output voltage to the DAC’s voltage (REF - LFB):

V REF 1

OUT

The value REF - LFB (and not LFB) is specified in the

Electrical Characteristics

voltage occurs for the largest value of REF - LFB.

The MAX753’s combination boost converter and

charge-pump inverter was chosen over a conventional

buck-boost inverter because it allows the use of lowcost N-channel MOSFETs instead of more expensive Pchannel ones. Additionally, its efficiency is 5% to 10%

better than a standard buck-boost inverter.

ALTERNATE

D8 CONNECTION

(SEE TEXT)

C2

10µF

R19

2.2Ω

D8

1N5819

=−+

. The most negative output

D3

1N5819

R3

R4

NEGATIVE

LCD-BIAS

OUTPUT

C6

10µF

35V

V

DD

R3

REF LFB

−

()

R4

MAX753/MAX754

01

2

ZERO SCALE

* DAC OUTPUT VOLTAGE = REF - LFB

30 31 32 61 62 63

DAC CODE

MID SCALE FULL SCALE

Figure 9. MAX753 LCD DAC Transfer Function

______________________________________________________________________________________ 15

Page 16

CCFL Backlight and

LCD Contrast Controllers

_____________________Block Diagram

LADJ LON BATT LX

MAX753/MAX754

32

CONTROL

PRESETCLK

6-BIT

COUNTER

6-BIT

D/A CONVERTER

ON-TIME

LOGIC

MAX753/MAX754

5-BIT

D/A CONVERTER

5-BIT

COUNTER

PRESETCLK

LOGIC

CONTROL

CON CADJ

45

12 6

OFF-TIME

PULSE-SKIP

COMPARATOR

AMPLIFIER

PGND GND

1415

LOGIC

ERROR

LDRV

LFB

V

CDRV

CFB

REF

REF

___________________Chip Topography

V

13

16

1

DD

7

11

8

9

CC

10

CS

LADJ

LON

CON

CADJ

GND

REF

TRANSISTOR COUNT: 321;

SUBSTRATE CONNECTED TO VDD.

DD

LFB

CFB

0.076"

(1.930mm)

CC

BATT

CS

LX

LDRV

PGND

CDRV

0.112"

(2.845mm)

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

16

__________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

© 1995 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Loading...

Loading...