Page 1

General Description

The MAX7469/MAX7470 triple-channel, anti-aliasing filters and buffers are ideal for high-definition (HD) and

standard-definition (SD) television (TV) applications.

Compatible with 1080i, 720p, 720i, 480p, and 480i

scanning system standards and computer format signals, the MAX7469/MAX7470 support component video

(Y P

bPr

, GsBR, and RGBHV), as well as composite

(CVBS) and S-video (Y/C).

The MAX7469/MAX7470 limit the input bandwidth for

anti-aliasing and out-of-band noise reduction prior to

digital conversion by an ADC or video decoder. The

MAX7469/MAX7470 frequency response can be continuously varied in 256 linear steps through an I2C* interface from below SD resolution to beyond HD resolution.

The output buffers of the MAX7469/MAX7470 drive a

2V

P-P

video signal into a standard 150Ω load. The inputs

are AC-coupled, and the outputs can be either DC- or

AC-coupled. The MAX7469 has a gain of 0dB, and the

MAX7470 has a gain of +6dB. Both devices are available

in a 20-pin TQFN package and are fully specified over

the 0°C to +85°C upper-commercial temperature range.

Applications

HDTV (LCD, PDP, DLP, CRT)

Set-Top Boxes

Personal Video Recorders

Home Theaters

Features

Continuously Variable Anti-Aliasing Filter

5MHz to 34MHz in 256 Steps

Supports All Standard Video and Computer Input

Formats

480i, 480p, 720i, 720p, 1080i

QVGA, VGA, SVGA, XGA, SXGA, UXGA

Y P

b Pr

, GsBR, RGBHV, Y/C, CVBS

Accepts Any Input Sync Format

Sync on Y, Sync on G, External Sync (Positive

or Negative)

Sync on All Channels

Buffered Outputs Drive Standard 150Ω Video

Load

0dB (MAX7469)

+6dB (MAX7470)

DC- or AC-Coupled Outputs

Single +5V Analog and +3.3V Digital Supplies

5mW Power-Down Mode

20-Pin TQFN Lead-Free Package

MAX7469/MAX7470

PART

BUFFER

PKG

CODE

M A X7 4 6 9 U TP + 20 TQFN-EP* 0

T2055-4

M A X7 4 7 0 U TP + **

20 TQFN-EP* +6

T2055-4

Ordering Information

19-0548; Rev 0; 5/06

HDTV Continuously Variable

Anti-Aliasing Filters

Typical Operating Circuit appears at end of data sheet.

*

Purchase of I2C components from Maxim Integrated Products,

Inc., or one of its sublicensed Associate Companies, conveys a

license under the Philips I

2

C Patent Rights to use these compo-

nents in an I

2

C system, provided that the system conforms to the

I

2

C Standard Specification defined by Philips.

________________________________________________________________

Maxim Integrated Products

1

For pricing delivery, and ordering information please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Note:

All devices are specified over the 0°C to +85°C operating

temperature range.

+

Indicates lead-free packaging.

*

EP = Exposed pad.

**

Future product—contact factory for availability.

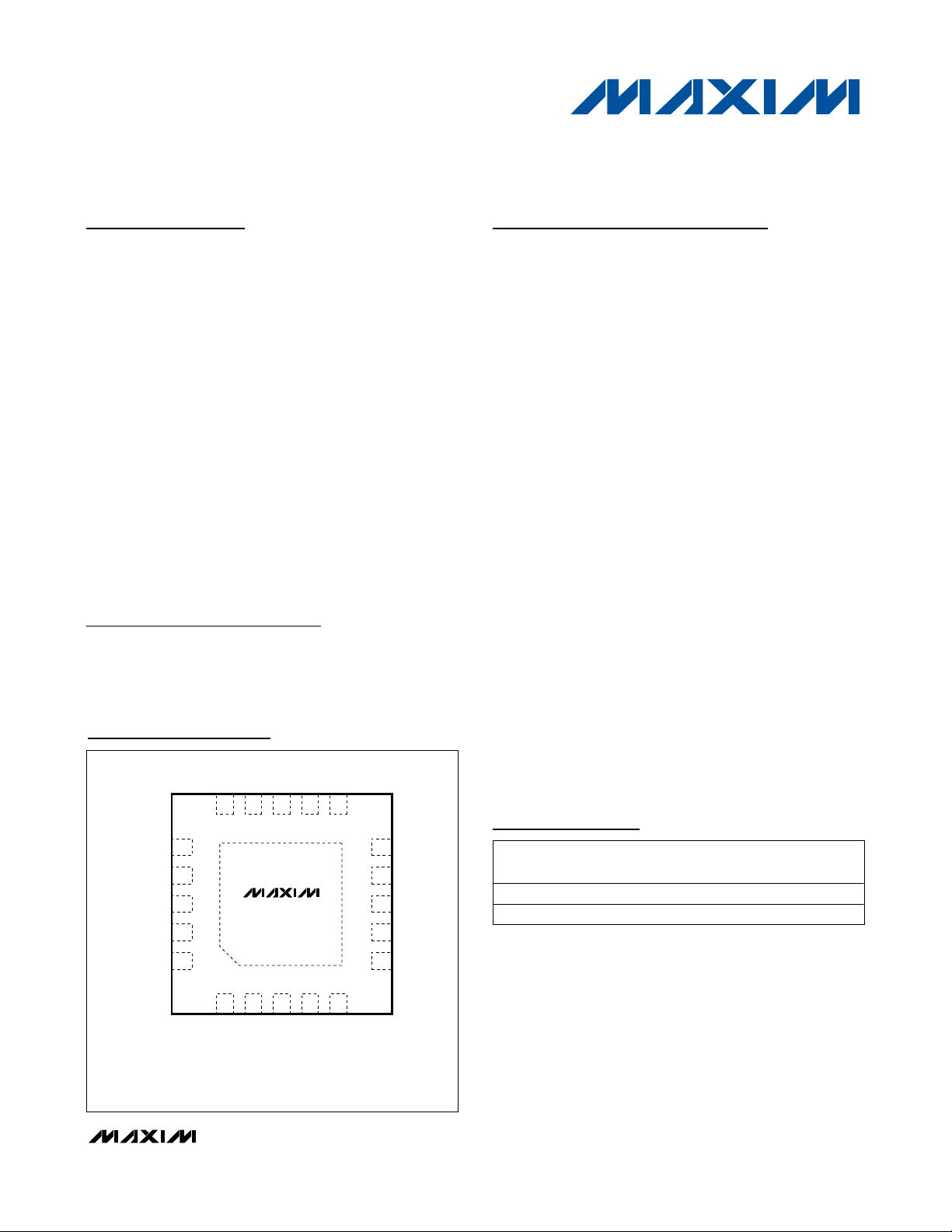

Pin Configuration

TOP VIEW

GND

GND

15 14 12 11

A1

13

DD

A0

AV

IN1

16

GND

17

18

IN2

GND

19

20

IN3

+

12

DGND

TQFN (5mm x 5mm)

*EXPOSED PAD.

SEE PIN DESCRIPTION FOR CONNECTION.

MAX7469

MAX7470

3

SCL

EXTSYNC

*EP

45

DD

SDA

DV

OUT1

10

AV

9

DD

8

OUT2

AV

7

DD

OUT3

6

PIN-PACKAGE

GAIN (dB)

Page 2

MAX7469/MAX7470

HDTV Continuously Variable

Anti-Aliasing Filters

2 ________________________________________________________________________________________

AVDDto GND............................................................-0.3V to +6V

DV

DD

to DGND.........................................................-0.3V to +4V

IN_, EXTSYNC to GND .................................................................

..................................-0.3V to the lower of (AV

DD

+ 3V) and +6V

OUT_ to GND ...............................................................................

..................................-0.3V to the lower of (AV

DD

+ 3V) and +6V

A_ to GND ....................................................................................

..................................-0.3V to the lower of (AV

DD

+ 3V) and +6V

SCL, SDA to DGND ..................................................-0.3V to +6V

Continuous Power Dissipation (TA= +70°C)

20-Pin TQFN (derate 33.3mW/°C above +70°C) ...2666.7mW

Maximum Current into IN_, A_, GND,

SCL, SDA, and EXTSYNC............................................±50mA

Operating Temperature Range...............................0°C to +85°C

Storage Temperature Range .............................-65°C to +150°C

Junction Temperature......................................................+150°C

Lead Temperature (soldering, 10s) .................................+300°C

ABSOLUTE MAXIMUM RATINGS

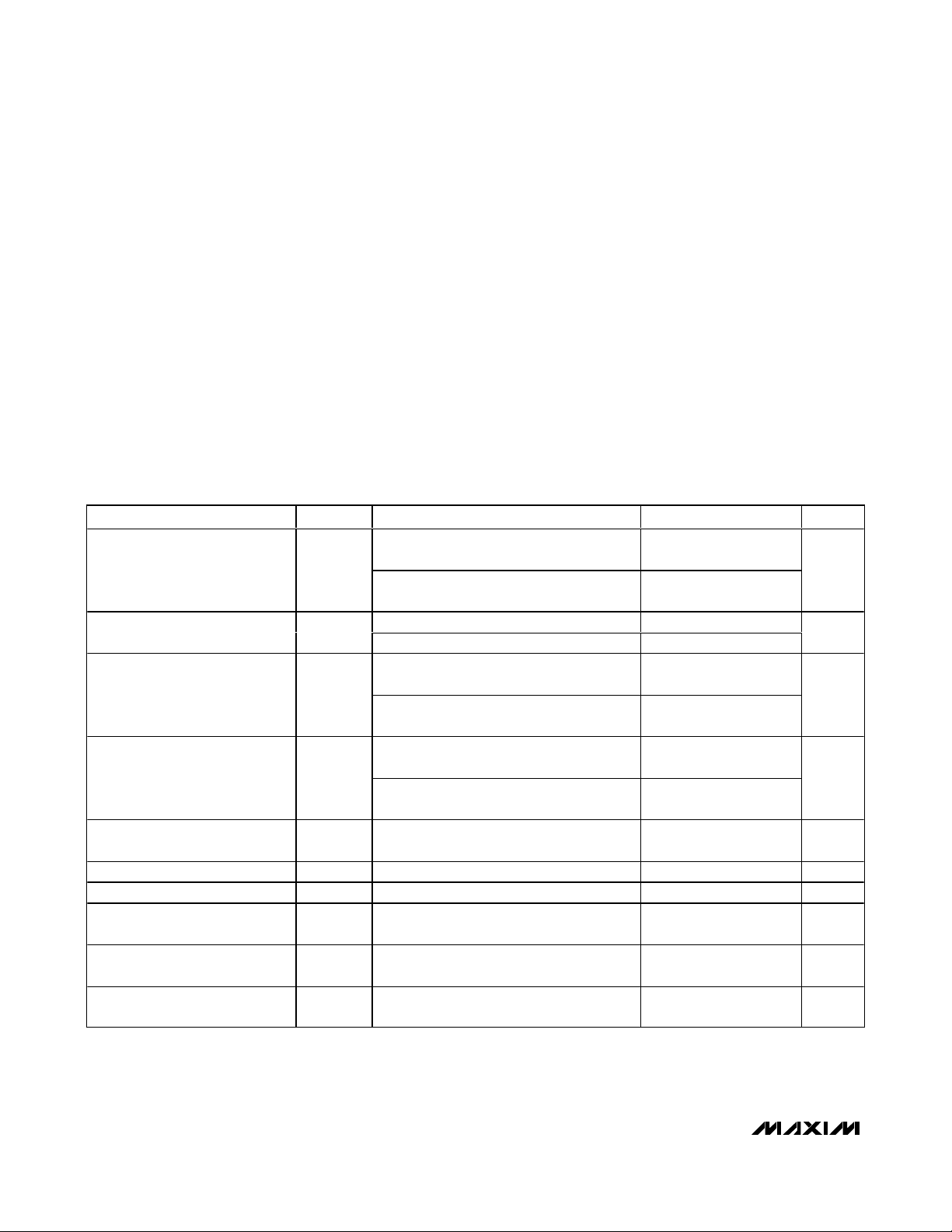

ELECTRICAL CHARACTERISTICS

(AVDD= +5V ±5%, DVDD= 2.7V to 3.6V, R

LOAD

= 150Ω to GND, CIN= 0.1µF, TA= 0°C to +85°C, unless otherwise noted. Typical

values are at AV

DD

= 5V, DVDD= 3.3V, TA= +25°C.)

)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Filter Passband Response A

Filter Stopband Attenuation A

Group Delay Deviation Δt

Group Delay Matching t

Bypass Frequency Response

SD Differential Gain dG Five-step modulated staircase (Note 2) 0.25 %

SD Differential Phase dφ Five-step modulated staircase (Note 2) 0.25 Degrees

Signal-to-Noise Ratio SNR

SD Line-Time Distortion H

SD Field-Time Distortion V

G(MATCH

HD: f = 100kHz to 30MHz, relative to

100kHz (Note 1)

PB

SD: f = 100kHz to 5.75MHz, relative to

100kHz (Note 2)

HD: f = 74MHz (Note 1) 45 57

SB

SD: f = 27MHz (Note 2) 52 63

HD: 100kHz to 30MHz, relative to 100kHz

(Note 1)

G

SD: 100kHz to 5.75MHz, relative to 100kHz

(Note 2)

HD: channel to channel, 100kHz to 2MHz,

(Note 1)

SD: channel to channel, 100kHz to 500kHz,

(Note 2)

-3dB, bypass mode, independent of filter

setting

Output signal (2V

to 30MHz), f = 30MHz

DIST

DIST

Deviations in a line with an 18µs, 100 IRE

bar; 1 line = 63.5µs (Note 2)

Deviations in 130 lines with 18µs, 100 IRE

bars (Note 2)

-3 -0.6 +1

±0.1 ±1.0

20

15

5

1.5

100 MHz

) to RMS noise (100kHz

P-P

69 dB

0.3 %

0.3 %

dB

dB

ns

ns

Page 3

MAX7469/MAX7470

HDTV Continuously Variable

Anti-Aliasing Filters

_______________________________________________________________________________________

3

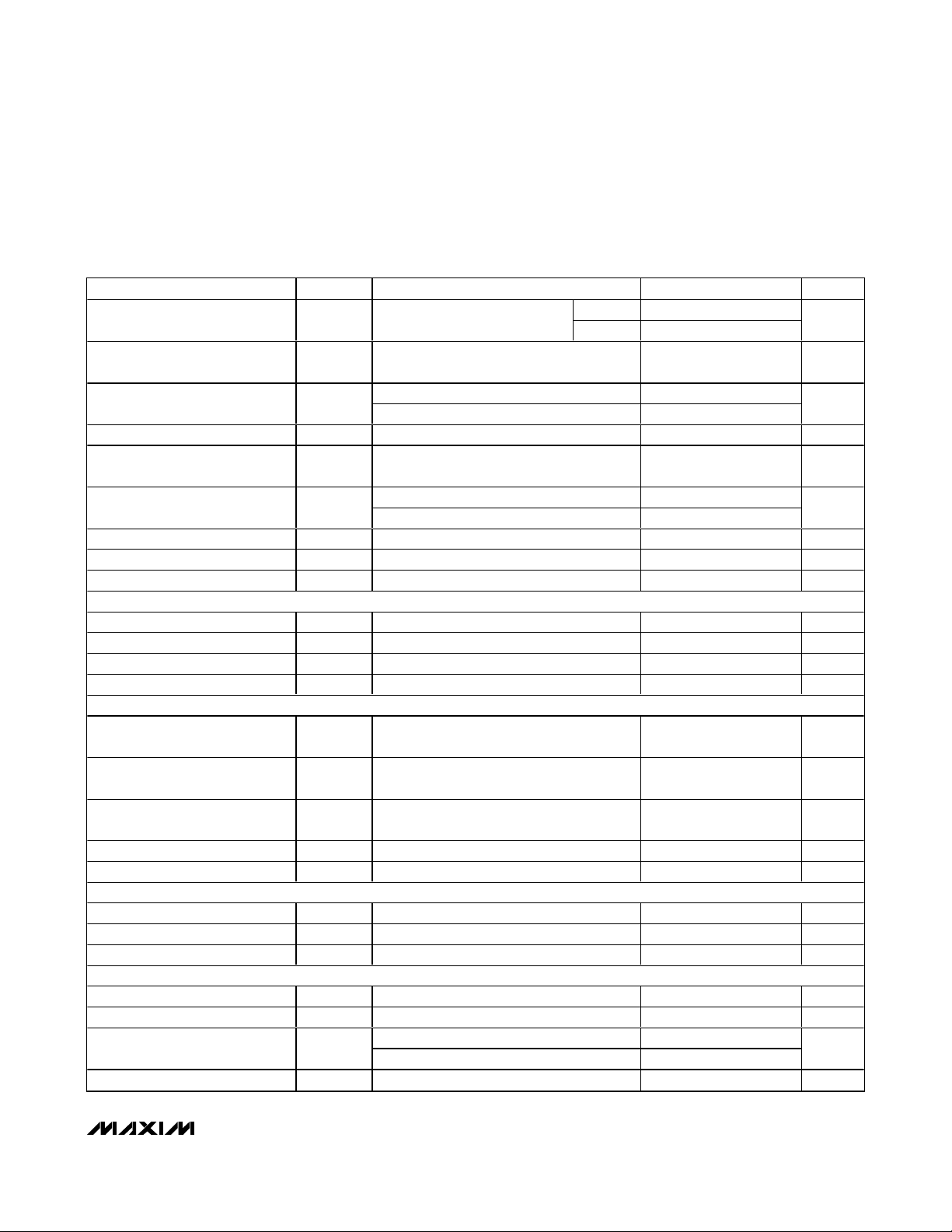

ELECTRICAL CHARACTERISTICS (continued)

(AVDD= +5V ±5%, DVDD= 2.7V to 3.6V, R

LOAD

= 150Ω to GND, CIN= 0.1µF, TA= 0°C to +85°C, unless otherwise noted. Typical

values are at AV

DD

= 5V, DVDD= 3.3V, TA= +25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Clamp Settling Time

Minimum Functional Input Sync

Amplitude

Low-Frequency Gain (Note 1)

Low-Frequency Gain Matching 100kHz 0.05 dB

Maximum Output Voltage

Amplitude

Maximum Input Voltage

Amplitude

Channel-to-Channel Isolation 62 dB

Output Clamping Level Variation (Notes 1, 4) ±100 mV

Power-Supply Rejection Ratio PSRR DC 50 dB

DIGITAL INPUTS (EXTSYNC, A1, A0)

Input Logic-High Voltage V

Input Logic-Low Voltage V

Input Leakage Current I

Input Capacitance C

DIGITAL INPUTS (SDA, SCL)

Input Logic-High Voltage V

Input Logic-Low Voltage V

Input Hysteresis V

Input Leakage Current I

Input Capacitance C

DIGITAL OUTPUT (SDA)

Output Logic-Low Voltage V

Tri-State Leakage Current I

Tri-State Output Capacitance C

POWER REQUIREMENTS

Analog Supply Voltage Range AV

Digital Supply Voltage Range DV

Analog Supply Current I

Digital Supply Current I

HYST

AVDD

DVDDfSCL

Positive 350

Negative 650

125 mV

2.0 V

±1 ±10 µA

6pF

0.7 x

DV

DD

0.05 x

DV

DD

±0.1 ±10 µA

6pF

±0.1 ±10 µA

6pF

4.75 5 5.25 V

2.7 3.3 3.6 V

IH

IL

IN

IN

IH

IL

IN

IN

OL

L

OUT

DD

DD

To 1% with 100 IRE step

(Note 4)

MAX7469 -0.5 0 +0.5

MAX7470 5.5 6 6.5

DC to 30MHz 2.4 V

MAX7469 2.4

MAX7470 1.2

VIN = 0 to DV

VIN = 0 to DV

I

= 3mA 0.4 V

SINK

VIN = 0 to DV

Normal operation, no load 180 200

Power-down mode, no load 1 1.5

= 400kHz 25 µA

DD

DD

DD

0.8 V

0.3 x

DV

DD

V

mA

H

dB

P-P

P-P

V

V

V

Page 4

MAX7469/MAX7470

HDTV Continuously Variable

Anti-Aliasing Filters

4 ________________________________________________________________________________________

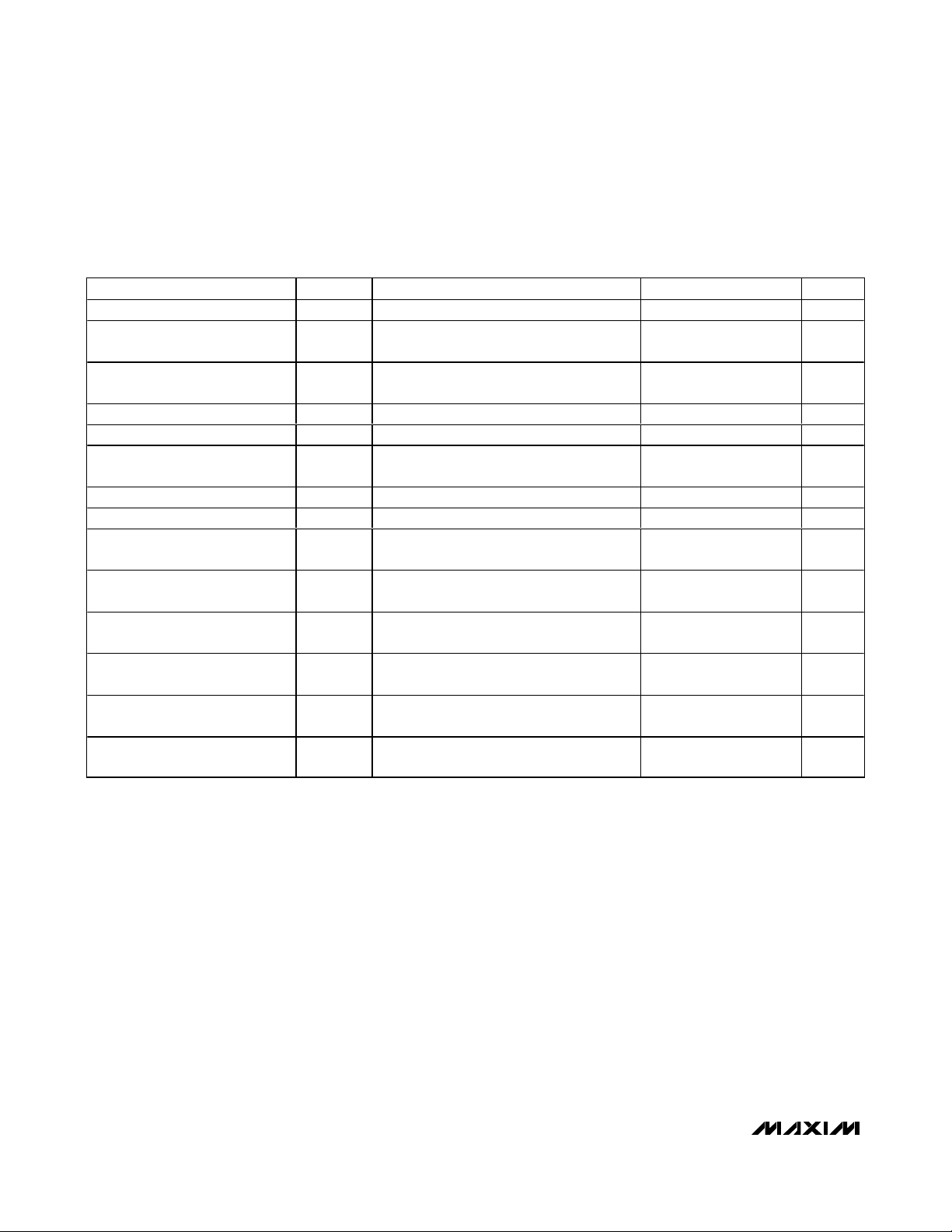

TIMING CHARACTERISTICS

(AVDD= +5V ±5%, DVDD= 2.7V to 3.6V, R

LOAD

= 150Ω to GND, CIN= 0.1µF, TA= 0°C to +85°C, unless otherwise noted. Typical

values are at AV

DD

= 5V, DVDD= 3.3V, TA= +25°C.)

Note 1: The filter passband edge is set to code 255.

Note 2: The filter passband edge is set to code 40.

Note 3: 1H is the total line period, depending on the video standard. For NTSC, this is 63.5µs; for HDTV, the line period is 29.64µs.

Note 4: The clamp level is at the sync tip for signals with sync pulses, and at the blanking level otherwise.

Note 5: A master device must provide a hold time of at least 300ns for the SDA signal (referred to V

IL

of the SCL signal) to bridge

the undefined region of SCL’s falling edge.

Note 6: C

b

= total capacitance of one bus line in pF. tRand tFmeasured between 0.3VDDand 0.7VDD.

Note 7: Input filters on the SDA and SCL inputs suppress noise spikes less than 50ns.

Serial-Clock Frequency f

Bus Free Time Between STOP (P)

and START (S) Condition

Hold Time (Repeated) START (Sr)

Condition

SCL Pulse-Width Low t

SCL Pulse-Width High t

Setup Time for a Repeated

START (Sr) Condition

Data Hold Time t

Data Setup Time t

Rise Time of Both SDA and SCL

Signals, Receiving

Fall Time of Both SDA and SCL

Signals, Receiving

Fall Time of SDA Signal,

Transmitting

Setup Time for STOP (P)

Condition

Capacitive Load for Each Bus

Line

Pulse Width of Spikes that Are

Suppressed by the Input Filter

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SCL

t

BUF

t

HD;STA

LOW

HIGH

t

SU;STA

HD;DAT

SU;DAT

t

SU;STO

C

t

After this period, the first clock pulse is

generated

(Note 5) 0.0 0.9 µs

t

r

t

f

t

SP

(Note 6)

f

b

(Note 7) 0 50 ns

0 400 kHz

1.3 µs

0.6 µs

1.3 µs

0.6 µs

0.6 µs

100 ns

0 300 ns

0 300 ns

20 +

0.1C

b

0.6 µs

250 ns

400 pF

Page 5

MAX7469/MAX7470

HDTV Continuously Variable

Anti-Aliasing Filters

_______________________________________________________________________________________

5

SDA

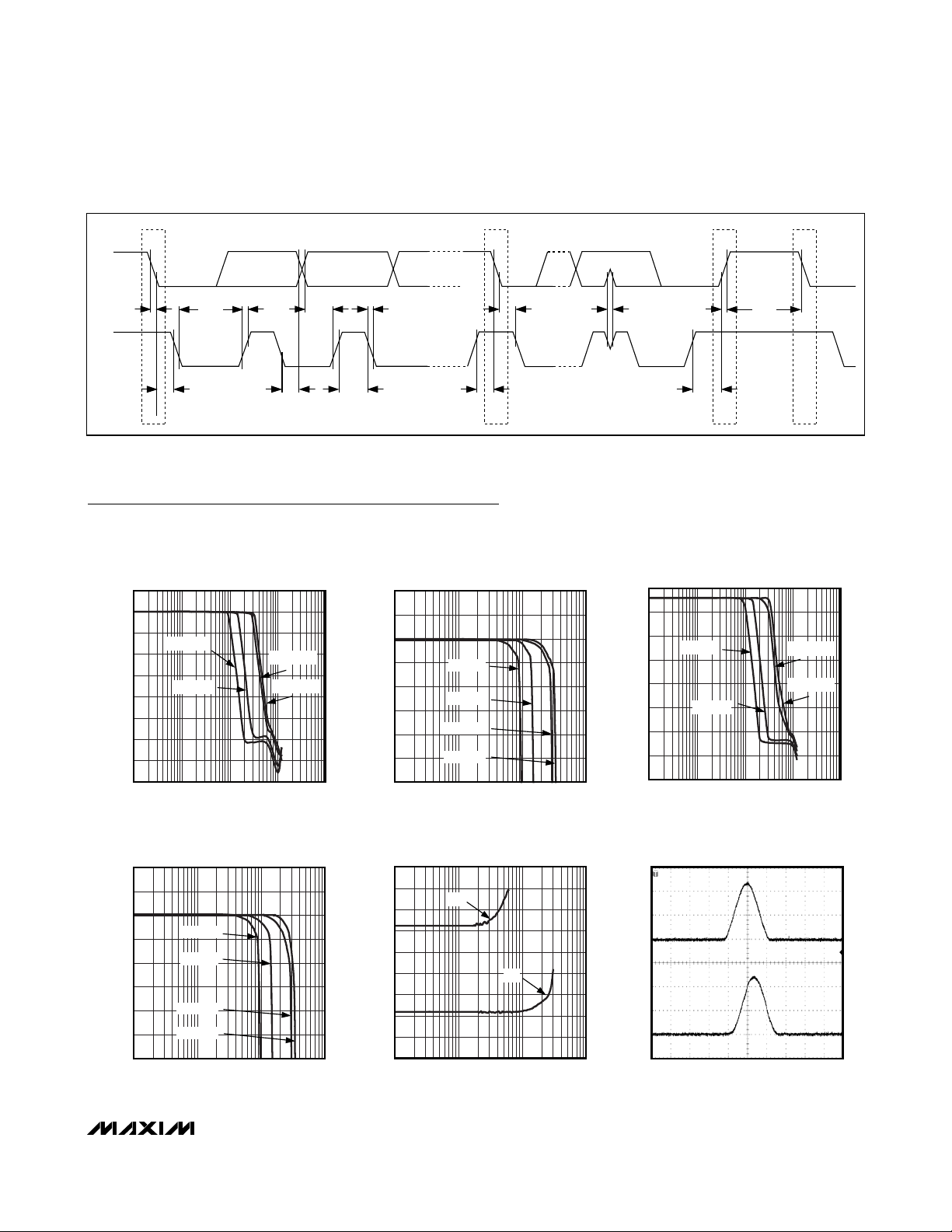

Figure 1. 2-Wire, Serial-Interface Timing Diagram

(AVDD= +5V, DV

DD

= 3.3V, R

LOAD

= 150Ω to GND, C

LOAD

= 0 to 20pF to GND, CIN= 0.1µF, TA= +25°C, unless otherwise noted.)

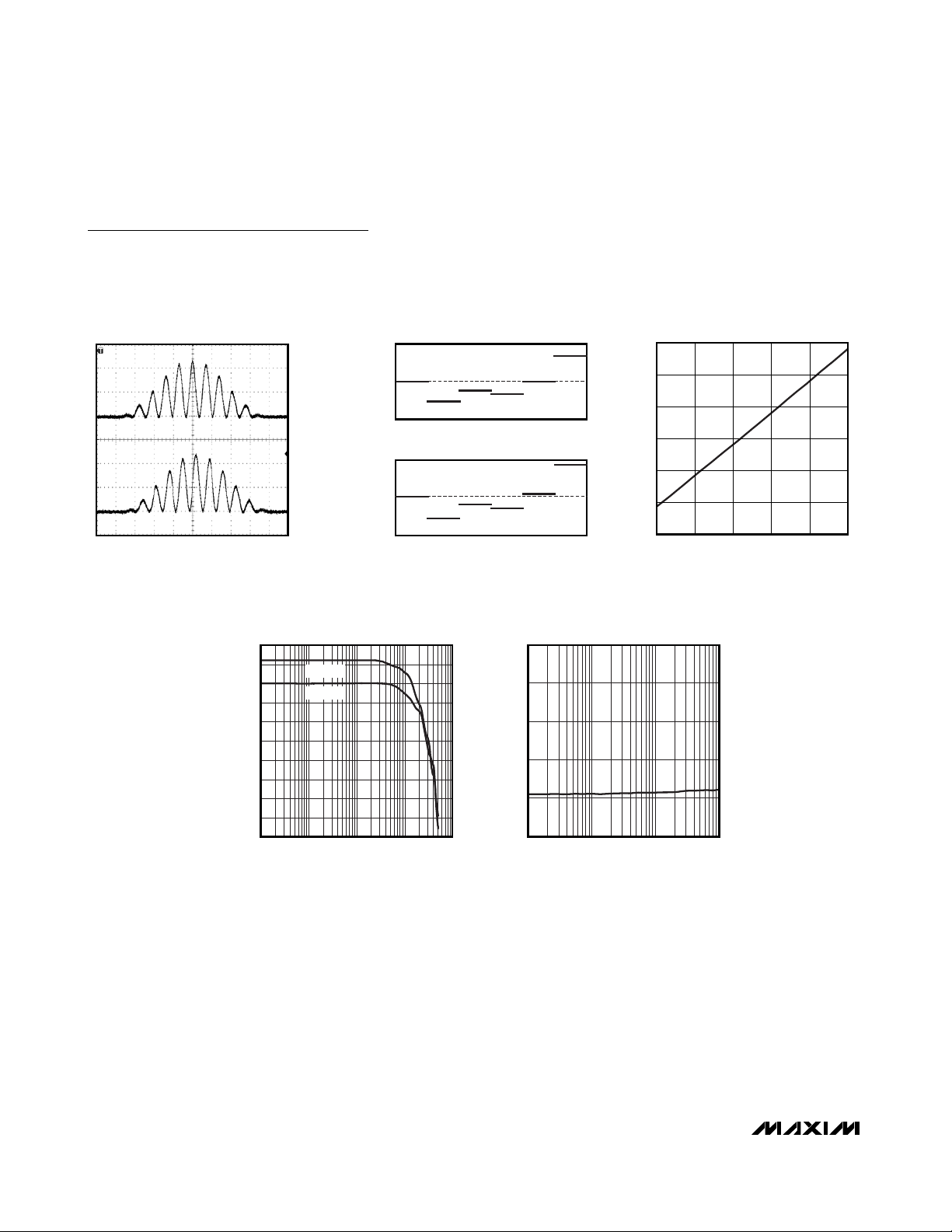

Typical Operating Characteristics

-80

-60

-70

-30

-40

-50

0

-10

-20

10

0.1 101 100 1000

FREQUENCY RESPONSE (MAX7469)

MAX7469 toc01

FREQUENCY (MHz)

RESPONSE (dB)

CODE 40

CODE 90

CODE 220

CODE 255

-1.5

-2.0

-2.5

-3.0

-1.0

0

-0.5

0.5

1.0

0.1 101100

PASSBAND FLATNESS (MAX7469)

MAX7469 toc02

FREQUENCY (MHz)

RESPONSE (dB)

CODE 40

CODE 255

CODE 220

CODE 90

-40

-50

-60

-70

-30

-10

-20

0

10

0.1 101 100 1000

FREQUENCY RESPONSE (MAX7470)

MAX7469 toc03

FREQUENCY (MHz)

RESPONSE (dB)

CODE 40

CODE 90

CODE 220

CODE 255

4.5

4.0

3.5

3.0

5.0

6.0

5.5

6.5

7.0

0.1 101 100

PASSBAND FLATNESS (MAX7470)

MAX7469 toc04

FREQUENCY (MHz)

RESPONSE (dB)

CODE 40

CODE 255

CODE 220

CODE 90

40

30

20

10

0

50

70

60

80

90

0.1 1 10 100

GROUP DELAY

MAX7469 toc05

FREQUENCY (MHz)

DELAY (ns)

SD

HD

200ns/div

2T RESPONSE (1 IRE = 7.14mV)

300mV/div

MAX7469 toc06

300mV/div

SCL

t

t

f

t

LOW

SU;DAT

t

r

t

f

t

HD;STA

t

SP

t

r

t

SP

t

HD;STA

S SP

t

HD;DAT

t

HIGH

t

SU;STA

Sr

t

SU;STO

Page 6

MAX7469/MAX7470

HDTV Continuously Variable

Anti-Aliasing Filters

6 ________________________________________________________________________________________

(AVDD= +5V, DV

DD

= 3.3V, R

LOAD

= 150Ω to GND, C

LOAD

= 0 to 20pF to GND, CIN= 0.1µF, TA= +25°C, unless otherwise noted.)

Typical Operating Characteristics (continued)

400ns/div

MODULATED 12.5T RESPONSE

(1 IRE = 7.14mV)

300mV/div

MAX7469 toc07

300mV/div

DIFFERENTIAL GAIN

MAX7469 toc08

DIFFERENTIAL PHASE (deg)

1324567

1324567

0.1

0.2

0

-0.1

-0.2

0.1

0.2

0

-0.1

-0.2

DIFFERENTIAL GAIN (%)

DIFFERENTIAL PHASE

-3dB FREQUENCY

vs. CONTROL CODE

MAX7469 toc09

CODE

MEASURED -3dB FREQUENCY (MHz)

20415310251

6

12

18

24

30

36

0

0255

-40

-10

-15

-20

-25

-30

-35

0

-5

5

10

0.1 101 100 1000

BYPASS-MODE FREQUENCY RESPONSE

MAX7469 toc10

FREQUENCY (MHz)

RESPONSE (dB)

MAX7470

MAX7469

0

4

12

8

16

20

0.1 101 100

BYPASS-MODE GROUP DELAY

MAX7469 toc11

FREQUENCY (MHz)

DELAY (ns)

Page 7

MAX7469/MAX7470

Detailed Description

The MAX7469/MAX7470 are complete video anti-aliasing solutions, ideal for fixed-pixel HDTV display technologies, such as plasma and LCD, which digitize the

input video signal and then scale the resolution to

match the native pixel format of the display. With a software-selectable corner frequency ranging from 5MHz

to 34MHz, the MAX7469/MAX7470 support both SD

and HD video signals, including 1080i, 720p, 720i,

480p, and 480i. Higher bandwidth computer resolution

signals are also supported.

Integrated lowpass filters limit the analog video input

bandwidth for anti-aliasing and out-of-band noise

reduction prior to sampling by an ADC or video

decoder. By allowing the corner frequency to be adjusted from below SD resolution to beyond HD resolutions

in 256 linear steps, the filter’s corner frequency can be

optimized dynamically for a specific input video signal

and the sampling frequency of the ADC or video

decoder. For applications requiring a passband greater

than the maximum frequency setting, a filter bypass

mode is also provided.

An I

2

C interface allows a microcontroller (µC) to configure the MAX7469/MAX7470s’ performance and functionality, including the clamp voltage, the filter corner

frequency, the sync source (internal/external), filter

bypassing, etc.

The

Typical Operating Circuit

shows the MAX7469/

MAX7470 block diagram and typical external connections.

Sync Detector and Clamp Settings

The MAX7469/MAX7470 use a video clamp circuit to

establish a DC offset for the incoming video signal after

the AC-coupling capacitor. This video clamp sets the DC

bias level of the circuit at the optimum operating point.

The MAX7469/MAX7470 support both internal and

external sync detection. Selection of internal vs. external

detection is achieved by programming the command

byte (see Table 3). After extracting the sync information

from channel 1 (or an external sync: SYNCA, SYNCB, or

SYNC), the MAX7469/MAX7470 clamp the video signal

during the sync tip portion of the video. Select one of

two possible clamp levels according to the input signal

format. Use the low level when the input signal contains

sync information, such as a Y (luma) or CVBS signal.

Pin Description

HDTV Continuously Variable

Anti-Aliasing Filters

_______________________________________________________________________________________

7

PIN NAME FUNCTION

1 DGND Digital Ground. See the Power-Supply Bypassing and Layout Considerations section.

2 EXTSYNC E xter nal S ync Inp ut. E X TS Y N C has an i nter nal 3M Ω r esi stor to g r ound . C onnect to g r ound i f not used .

3 SCL I2C-Compatible Serial-Clock Input

4 SDA I2C-Compatible Serial-Data Input/Output

5DV

6 OUT3 Video Output 3. OUT3 can be either DC- or AC-coupled.

7, 9, 11 AV

8 OUT2 Video Output 2. OUT2 can be either DC- or AC-coupled.

10 OUT1 Video Output 1. OUT1 can be either DC- or AC-coupled.

12 A0 I2C Device Address Bit 0

13 A1 I2C Device Address Bit 1

14, 15, 17, 19 GND

16 IN1 Video Input 1. AC-couple IN1 with a series 0.1µF capacitor.

18 IN2 Video Input 2. AC-couple IN2 with a series 0.1µF capacitor.

20 IN3 Video Input 3. AC-couple IN3 with a series 0.1µF capacitor.

—EP

Digital Power Supply. Bypass to DGND with a 0.1µF capacitor. See the Power-Supply Bypassing and

DD

Layout Considerations section.

Analog Power Supply. Bypass to GND with a 0.1µF capacitor. See the Power-Supply Bypassing and

DD

Layout Considerations section.

Ground. Connect all GND pins to the ground plane. See the Power-Supply Bypassing and Layout

Considerations section.

E xp osed P ad . Inter nal l y connected to GN D . D o not r oute any P C b oar d tr aces und er p ackag e. C onnect

E P to the g r ound p l ane. S ee the P ow er - S up p l y Byp assi ng and Layout C onsi d er ati ons secti on.

Page 8

MAX7469/MAX7470

HDTV Continuously Variable

Anti-Aliasing Filters

8 ________________________________________________________________________________________

Use the high level for bipolar signals, such as C (chroma) or Pb/Pr. See Table 1 for more details.

Component/Composite Selection

The MAX7469/MAX7470 accept component or composite inputs. When configured for composite video

inputs, the color-burst filter is enabled; if configured for

component video inputs, the color-burst filter is disabled. This filter is separate from the main filter and not

in the direct signal path so that it has no effect on the

overall frequency response. With normal video signals

and levels, the use of this color-burst filter has a negligible effect on the sync detection. It has a more significant effect under conditions of low-signal amplitude

coupled with higher relative amplitude color burst.

External Sync Detection (EXTSYNC)

When filtering a video signal without embedded sync

information, such as computer formats (RGBHV) with

separate sync signals, use the external sync mode (see

Table 3) and apply the horizontal sync source to the

EXTSYNC pin. The sync detector determines when the

clamp circuit is turned on.

The MAX7469/MAX7470 are able to detect positive or

negative polarity external syncs with TTL logic levels.

Use the I2C interface to program the polarity of the

external sync signal.

Filter

The internal video filter delivers an optimized response

with a steep transition band to achieve a wide passband along with excellent stopband rejection. In addition, the filter is optimized to provide an excellent time

domain response with low overshoot.

Setting the Filter Frequency

Use the I2C interface to vary the frequency response

(-3dB cutoff frequency) of the filter in the MAX7469/

MAX7470 from less than the SD passband to beyond the

HD passband in 256 linear steps. Write command byte

12h to access the frequency register, followed by an 8-bit

data word that corresponds to the desired frequency. See

the

Frequency Register

section for more details.

The frequency set by the MAX7469/MAX7470 is the

-3dB point. Set the frequency according to the desired

flat passband response.

Optimizing the Frequency Response

Select the frequency response according to the resolution

of the video-signal format. High-definition signals require

higher bandwidth, while standard-definition signals

require less bandwidth. The actual bandwidth contained

in the video signal is a function of the visual resolution of

the signal. This bandwidth is typically less than what is

indicated by the format resolution (1080i, 720p, etc.). For

more information, see Maxim Application Note 750:

Bandwidth Versus Video Resolution

, which is available on

www.maxim-ic.com.

The frequency response can be optimized to improve

the overall performance. It is important, at a minimum, to

meet the Nyquist criterion. Beyond this, the frequency

response can be further optimized. In oversampled systems, the sample rate is significantly more than the

desired passband response. The extra frequency span

between the passband and the sample rate contains

noise and other undesirable interferers that can be eliminated by setting the corner frequency of the filter to just

pass the desired bandwidth. This results in a higher signal-to-noise ratio of the overall system.

Filter Bypass

The MAX7469/MAX7470 offer selectable filter bypassing that allows the input video signals to bypass the

internal filters and reach the output buffers unfiltered.

Write the appropriate command byte to enable (0Eh) or

disable (0Fh) filter-bypass mode as shown Table 3.

Output Buffer

Each output buffer can drive a 2V

P-P

signal into a 150Ω

video load. The MAX7469/MAX7470 can drive a DC- or

AC-coupled load. Output AC-coupling capacitors can

be eliminated when driving a cable, thereby eliminating

the normal adverse effects caused by these large

capacitors, such as line, and field-time distortion, also

known as droop. The output DC level is controlled to

limit the DC voltage on the cable so that the blanking

level of the video signal is always less than 1V, meeting

digital TV specification. See the

Output Considerations

section for more information.

Gain Options

The MAX7469 features an overall gain of 0dB, while the

MAX7470 features an overall gain of +6dB. Use the

MAX7470 when driving a back-matched cable and the

Table 1. Clamp Levels

INPUT SIGNAL

FORMAT

Y Pb P

r

GSBR Low High High

CVBS Y C Low Low High

Y Pb Pr (sync on

all signals)

R G B H V High High High

CHANNEL 1 CHANNEL 2 CHANNEL 3

Low High High

Low Low Low

CLAMP LEVEL

Page 9

MAX7469/MAX7470

HDTV Continuously Variable

Anti-Aliasing Filters

_______________________________________________________________________________________

9

MAX7469 when driving an ADC or video decoder with an

input range the same as the input to the MAX7469. For

added flexibility, the MAX7469 accepts input signals with

twice the standard video-signal range, which can be

used for driving an ADC or video decoder with an input

signal range that accepts a larger signal swing. The

MAX7470 can also be used to drive an ADC or video

decoder when a gain of two is desired.

Output Clamp Level

The MAX7469/MAX7470 output can be DC- or ACcoupled. The nominal output clamp level in the

DC-coupled case depends on the clamp voltage setting and can be determined according to Table 2.

As shown in the

Sync Detector and Clamp Settings

section, the low clamp level is used for signals with

sync information and determines the voltage level of the

sync tip, while the high clamp level is used for signals

without sync information and sets the blanking level.

The absolute voltage level of the output signal is relative to the output clamp level. A video signal containing

sync information (i.e., CVBS or Y) is unipolar above the

clamp level and conversely, a video signal without sync

(i.e., PbPror C) is bipolar around the clamp level.

Power-Down Mode

The MAX7469/MAX7470 include a power-down mode

that reduces the supply current from 180mA (typ) to 1mA

(typ) by powering down the analog circuitry. The I2C

interface remains active, allowing the device to return to

full-power operation. The clamp settling time (see the

Electrical Characteristics

section) limits the wake-up time

of the MAX7469/MAX7470. After exiting the power-down

mode, the MAX7469/MAX7470 resume normal operation

using the settings stored prior to power-down. The

power-down and wake-up modes are controlled through

the command byte (see Table 3). A software reset sets

the control/status register to its default conditions, but

the frequency register is not affected.

Power-On Reset (POR)

The MAX7469/MAX7470 include a POR circuit that

resets the internal registers and I

2

C interface to their

default conditions (see Tables 4, 5, and 6).

Serial Interface

The MAX7469/MAX7470 feature an I2C-compatible, 2-wire

serial interface consisting of a bidirectional serial-data line

(SDA) and a serial-clock line (SCL). SDA and SCL facilitate

bidirectional communication between the MAX7469/

MAX7470 and the master at rates up to 400kHz.

The MAX7469/MAX7470 have a command interpreter

that is accessed by writing a valid command byte.

Once a command byte is written to the MAX7469/

MAX7470, the command interpreter updates the control/status register accordingly. See the

Control/Status

Register

section for more information. The command

interpreter also controls access to the frequency register through a command byte (see the

Command Byte

(

Write Cycle)

section).

The MAX7469/MAX7470 are transmit/receive slave-only

devices, relying upon a master to generate a clock signal. The master (typically a µC) initiates data transfer on

the bus and generates SCL.

A master device communicates to the MAX7469/

MAX7470 by transmitting the proper address (see the

Slave Address

section) followed by a command and/or

data words. Each transmit sequence is framed with a

START (S) or REPEATED START (Sr) condition and a

STOP (P) condition.

The SDA driver is an open-drain output, requiring a

pullup resistor (2.4kΩ or greater) to generate a logichigh voltage. Optional resistors (24Ω) in series with

SDA and SCL protect the device inputs from high-voltage spikes on the bus lines. Series resistors also minimize crosstalk and undershoot of the bus signals.

Bit Transfer

Each SCL rising edge transfers 1 data bit. Nine clock

cycles are required to transfer the data into or out of the

MAX7469/MAX7470. The data on SDA must remain stable

during the high period of the SCL clock pulse. Changes in

SDA while SCL is high are read as control signals (see the

START and STOP Conditions

section). When the serial

interface is inactive, SDA and SCL idle high.

Table 2. Output Clamp Level

CLAMP SETTING OUTPUT CLAMP LEVEL (V)

Low 1.0 (typ)

High 1.6 (typ)

Page 10

MAX7469/MAX7470

HDTV Continuously Variable

Anti-Aliasing Filters

10 _______________________________________________________________________________________

START and STOP Conditions

A master device initiates communication by issuing a

START condition, a high-to-low transition on SDA with SCL

high (Figure 2). The master terminates transmission by a

STOP condition (see the

Acknowledge Bit (ACK) and Not-

Acknowledge Bit (NACK)

section). A STOP condition is a

low-to-high transition on SDA while SCL is high (Figure 2).

The STOP condition frees the bus. If a repeated START

condition is generated instead of a STOP condition, the

bus remains active. When a STOP condition or incorrect

address is detected, the MAX7469/

MAX7470 then ignore all communication on the I

2

C bus

until the next START or REPEATED START condition,

minimizing digital noise and feedthrough.

Early STOP Conditions

The MAX7469/MAX7470 recognize a STOP condition at

any point during transmission except when a STOP

condition occurs in the same high pulse as a START

condition (Figure 3). This condition is not a legal I

2

C format; at least one clock pulse must separate any START

and STOP conditions. The MAX7469/MAX7470 discard

any data received during a data transfer aborted by an

early STOP condition.

Repeated START (Sr) Conditions

An Sr condition is used to indicate a change in direction of data flow (see the

Read Cycle

section). Sr can

also be used when the bus master is writing to several

I

2

C devices and does not want to relinquish control of

the bus. The MAX7469/MAX7470 serial interface supports continuous write operations with (or without) an Sr

condition separating them.

Figure 3. Early STOP Conditions

Figure 2. START/STOP Conditions

SCL

SDA

SS

r

P

LEGAL STOP CONDITION ILLEGAL STOP CONDITION

SCL

SDA

STARTSTOP

SCL

SDA

START

ILLEGAL STOP

Page 11

MAX7469/MAX7470

HDTV Continuously Variable

Anti-Aliasing Filters

______________________________________________________________________________________

11

Acknowledge Bit (ACK) and Not-Acknowledge Bit

(NACK)

Successful data transfers are acknowledged with an

acknowledge bit (ACK) or a not-acknowledge bit

(NACK). Both the master and the MAX7469/MAX7470

(slave) generate acknowledge bits. To generate an

acknowledge, the receiving device must pull SDA low

before the rising edge of the acknowledge-related clock

pulse (ninth pulse) and keep it low during the high period

of the clock pulse (Figure 4). To generate a NACK, the

receiver allows SDA to be pulled high before the rising

edge of the acknowledge-related clock pulse (ninth

pulse) and leaves it high during the high period of the

clock pulse. Monitoring the acknowledge bits allows for

detection of unsuccessful data transfers. An unsuccessful data transfer happens if a receiving device is busy or

if a system fault has occurred. In the event of an unsuccessful data transfer, the master should reattempt communication at a later time.

The MAX7469/MAX7470 generate an acknowledge bit

when receiving an address or data by pulling SDA low

during the ninth clock pulse. When transmitting data

during a read, the MAX7469/MAX7470 do not drive

SDA during the ninth clock pulse (i.e., the external

pullups define the bus as a logic-high) so that the

receiver of the data can pull SDA low to acknowledge

receipt of data.

Slave Address

A bus master initiates communication with a slave device

by issuing a START condition, followed by the 7-bit slave

address (Figure 5). When idle, the MAX7469/MAX7470

wait for a START condition, followed by their slave

address. The serial interface compares each address bit

by bit, allowing the interface to power down and disconnect from SCL immediately if an incorrect address is

detected. After recognizing a START condition followed

by the correct address, the MAX7469/MAX7470 are

ready to accept or send data. The least significant bit

(LSB) of the address byte (R/W) determines whether the

master is writing to or reading from the

MAX7469/MAX7470 (R/W = 0 selects a write condition,

R/W = 1 selects a read condition). After receiving the

proper address, the MAX7469/MAX7470 (slave) issue an

ACK by pulling SDA low for one clock cycle.

The MAX7469/MAX7470 slave address consists of 5

fixed bits, A6–A2 (set to 10010), followed by 2 pin-programmable bits, A1 and A0. The most significant

address bit (A6) is transmitted first, followed by the

remaining bits. Addresses A1 and A0 can also be driven

dynamically if required, but the values must be stable

when they are expected in the address sequence.

Figure 4. Acknowledge and Not-Acknowledge Bits

Figure 5. Slave-Address Byte Definition

S

SDA

SCL

.

SDA

SCL

1 0 1 0 A1 A00

MSB

1

NOT ACKNOWLEDGE

ACKNOWLEDGE

8

LSB

9

R/W

ACK

Page 12

MAX7469/MAX7470

HDTV Continuously Variable

Anti-Aliasing Filters

12 _______________________________________________________________________________________

Command Byte (Write Cycle)

A write cycle begins with the bus master issuing a

START condition followed by 7 address bits (Figure 5)

and 1 write bit (R/W = 0). After successfully receiving its

address, the MAX7469/MAX7470 (slave) issue an ACK.

The slave recognizes the next byte after a successfully

received address as the command byte (Table 3).

Use the command byte to configure the MAX7469/

MAX7470. While most of the commands listed in Table

3 modify the functionality of the MAX7469/MAX7470,

some commands prepare the device for further data

transfers (see the

Control/Status Register

and

Frequency Register

sections). If the write cycle is pre-

maturely aborted, the register is not updated, and the

Table 3. Command Byte Definition

COMMAND BYTE:

INDIVIDUAL BIT DEFINITIONS

C7 C6 C5 C4 C3 C2 C1 C0

00000000Enters power-down mode.

00000001

00000010Sets IN1 clamp voltage level to low.

00000011Sets IN1 clamp voltage level to high.

00000100Sets IN2 clamp voltage level to low.

00000101Sets IN2 clamp voltage level to high.

00000110Sets IN3 clamp voltage level to low.

00000111Sets IN3 clamp voltage level to high.

00001000Selects component input, color-burst filter disabled.

00001001Selects composite input, color-burst filter enabled.

00001010Selects internal sync.

00001011Selects external sync.

00001100Selects positive polarity external sync.

00001101Selects negative polarity external sync.

00001110Enables filters.

00001111Disables filters, enters bypass mode.

00010000

00010001

00010010Loads the frequency register with the data byte following the command byte.

00010011

Wake-up; resumes normal operation using the frequency/status previously stored

(unless power has been cycled).

Resets the control/status register to the default values as described in the Control/

Status Register section. This command does not affect the frequency register.

Requests a control/status register read. The interface expects an Sr condition to

follow with address and read/write set to read so data can be driven onto the bus.

Requests a frequency register read. The interface expects an Sr condition to follow

with address and read/write set to read so data can be driven onto the bus.

DESCRIPTION

Page 13

MAX7469/MAX7470

HDTV Continuously Variable

Anti-Aliasing Filters

______________________________________________________________________________________

13

write sequence must be repeated. Figures 6 and 7

show examples of write sequences.

Read Cycle

In read mode (R/W = 1), the MAX7469/MAX7470 write

the contents of the control/status or frequency registers

to the bus. When the command byte indicates a read

operation of either the control/status or the frequency

register, the serial interface expects an Sr condition to

follow the command byte. After sending an Sr, the master sends the MAX7469/MAX7470 slave address byte

followed by a R/W bit (set to 1 to indicate a read). The

slave device (MAX7469/MAX7470) generates an ACK

for the second address word and immediately after the

ACK clock pulse, the direction of data flow reverses.

The slave (MAX7469/MAX7470) then transmits 1 byte of

data containing the value of the register that was

Figure 6. Write Sequence to Update the Frequency Register

Figure 7. Write Sequence for a Command Byte

SCL

SDA

SDA

DIRECTION

START

SCL (CONT)

SDA (CONT)

SDA

DIRECTION

1001 0A1A0

F7 F6 F5 F4 F3 F2 F1 ACK

IN IN

R/W

000 1001 0

ACK ACK

C7 C6 C5 C4 C3 C2 C1 C0

F0

OUT

OUTINOUTIN TO MAX7469/MAX7470

COMMAND BYTE C7–C0 IS 0010010.

SCL

SDA

SDA

DIRECTION

START STOP

10010A1A0R/W

THE COMMAND BYTE IS FOR POWER-DOWN.

STOP

ACK ACK

00000 00 0

C7 C6 C5 C0

C4 C3 C2 C1

IN

OUTINOUTIN TO MAX7469/MAX7470

Page 14

MAX7469/MAX7470

HDTV Continuously Variable

Anti-Aliasing Filters

14 _______________________________________________________________________________________

Table 6. Frequency Register Setting for Different Video-Signal Formats

selected in the command byte. Figure 8 shows a basic

read sequence.

Note: The master has to write a command byte,

requesting to read the control/status or frequency register, to the slave (MAX7469/MAX7470) before the master can read the contents of the selected register.

Control/Status Register

The MAX7469/MAX7470 store their status in an 8-bit

register that can be read back by the master. The individual bits of the control/status register are summarized

in Tables 4 and 5. The power-on default value of this

register is 03h.

Frequency Register

The frequency response (-3dB passband edge) of the

MAX7469/MAX7470 can be continuously varied in 256

linear steps by changing the codes in the frequency register (Table 6). See the

Command Byte (Write Cycle)

sec-

tion for a write sequence to update the frequency register.

Figure 8. Basic Read Sequence

Table 4. Control/Status Register

Table 5. Control/Status Register Bit

Description

SCL

SDA

SDA

DIRECTION

SCL (CONT)

SDA (CONT)

SDA

DIRECTION

10010A1A0

START

1 0 0 1 0 A1 A0 R/W

Sr

CONTROL/STATUS REGISTER

S7 S6 S5 S4 S3 S2 S1 S0

ACK ACK

R/W

0001001/0

C7 C6 C5 C4 C3 C2 C1 C0

D7 D6 D5 D4 D3 D2 D1 D0ACK ACK

OUTIN IN

BIT DESCRIPTION

S7

S6

S5

S4

S3

S2

S1

S0

0 = component input signal selected (default).

1 = composite input signal selected.

0 = internal sync enabled (default).

1 = external sync enabled.

0 = external sync: positive polarity (default).

1 = external sync: negative polarity.

0 = normal operation mode (default).

1 = power-down mode.

0 = filters enabled (default).

1 = bypass mode—no filtering.

0 = clamp voltage for IN1 set to low (default).

1 = clamp voltage for IN1 set to high.

0 = clamp voltage for IN2 set to low.

1 = clamp voltage for IN2 set to high (default).

0 = clamp voltage for IN3 set to low.

1 = clamp voltage for IN3 set to high (default).

1

OUTINOUTIN TO MAX7469/MAX7470

STOP

VIDEO-SIGNAL FORMAT F7 F6 F5 F4 F3 F2 F1 F0 CODE NO.

Standard Definition (Interlaced) 0 0 1 0 1 0 0 0 40 10

Standard Definition (Progressive) 0 1 0 1 1 0 1 0 90 15

High-Definition Low Bandwidth 1 1 0 1 1 1 0 0 220 30

High-Definition High Bandwidth 1 1 1 1 1 1 1 1 255 34 (default)

APPROXIMATE FREQUENCY

(-3dB) MHz

Page 15

MAX7469/MAX7470

HDTV Continuously Variable

Anti-Aliasing Filters

______________________________________________________________________________________

15

I2C Compatibility

The MAX7469/MAX7470 are compatible with existing

I

2

C systems supporting standard I2C 8-bit communications. The general call address is ignored, and CBUS

formats are not supported. The device’s address is

compatible with 7-bit I2C addressing protocol only; 10bit address formats are not supported.

Applications Information

Input Considerations

Use 0.1µF ceramic capacitors to AC-couple the inputs.

The inputs cannot be DC-coupled. The internal clamp

circuit stores a DC voltage across the input capacitors

to obtain the appropriate output DC voltage level.

Increasing the value of these capacitors to improve linetime distortion is not necessary due to the extremely low

input leakage current yielding a very low line-time distortion performance.

The MAX7469/MAX7470 provide a high input impedance to allow a nonzero source impedance to be used,

such as when the input is connected directly to a backmatched video cable, ensuring the external resistance

determines the termination impedance.

Output Considerations

The MAX7469/MAX7470 outputs can be DC- or ACcoupled. The MAX7470, with its +6dB gain, is typically

connected to a 75Ω series back-match resistor followed by the video cable. Because of the inherent

divide-by-two of this configuration, the blanking level of

the video signal is always less than 1V, which complies

with digital TV requirements.

The MAX7469, with its 0dB gain, is typically connected

to an ADC or video decoder. This can be a DC or AC

connection. If a DC connection is used, ensure that the

DC input requirements of the ADC or video decoder

are compatible.

If an AC connection is used, choose an AC-coupling

capacitor value that ensures that the lowest frequency

content in the video signal is passed and the line-time

distortion is kept within desired limits. The selection of

this value is a function of the input impedance and,

more importantly, the input leakage of the circuit being

driven. Use a video clamp to reestablish the DC level, if

not already included in the subsequent circuit.

The outputs of the MAX7469/MAX7470 are fully protected

against a short-circuit condition either to ground or the

positive supply of the device.

Power-Supply Bypassing and Layout

Considerations

The MAX7469/MAX7470 operate from a single +5V analog supply and a +3.3V digital supply. Bypass AV

DD

to

GND with a 0.1µF capacitor and an additional 1µF

capacitor in parallel for additional low-frequency decoupling. Determine the proper power-supply bypassing

necessary by taking into account the desired disturbance level tolerable on the output, the power-supply

rejection of the MAX7469/MAX7470, and the amplitude

and frequency of the disturbance signals present in the

vicinity of the MAX7469/MAX7470. Use an extensive

ground plane to ensure optimum performance. The three

AV

DD

pins (pins 7, 9, and 11) that supply the individual

channels can be connected together and bypassed as

one, provided the components are close to the pins.

Bypass DV

DD

to DGND with a 0.1µF capacitor. All

ground pins (GND) must be connected to a low impedance ground plane as close as possible to the device.

Place the input termination resistors as close as possible to the device. Alternatively, the terminations can be

placed further from the device if the PC board traces

are designed to be a controlled impedance of 75Ω.

Minimize parasitic capacitance as much as possible to

avoid performance degradation in the upper frequency

range possible with the MAX7469/MAX7470.

Refer to the MAX7469/MAX7470 evaluation kit for a

proven PC board layout.

Exposed Pad and Heat Dissipation

The MAX7469/MAX7470 TQFN package has an

exposed pad on its bottom. This pad is electrically connected, internal to the device, to GND. Do not route any

PC board traces under the package.

The MAX7469/MAX7470 typically dissipate 900mW of

power, therefore, pay careful attention to heat dispersion. The use of at least a two-layer board with a good

ground plane is recommended. To maximize heat dispersion, place copper directly under the MAX7469/

MAX7470 package so that it matches the outline of the

plastic encapsulated area. Do the same thing on the

bottom ground plane layer and then place as many

vias as possible connecting the top and bottom layers

to thermally connect it to the ground plane.

Maxim has evaluated a four-layer board using FR-4

material and 1oz copper with equal areas of metal on

the top and bottom side coincident with the plastic

encapsulated area of the 20-pin TQFN package. The

two middle layers are used as power and ground

Page 16

MAX7469/MAX7470

HDTV Continuously Variable

Anti-Aliasing Filters

16 _______________________________________________________________________________________

planes. The board has 21, 15-mil, plated-through via

holes between the top, bottom, and ground plane layers. Thermocouple measurements confirm device temperatures to be safely within maximum limits.

Chip Information

PROCESS: BiCMOS

Typical Operating Circuit

EXT SYNC

SYNC DETECTOR

Y/G

75Ω

/B

P

b

75Ω

0.1μF

0.1μF

IN1

IN2

CLAMP/

BIAS

CLAMP/

BIAS

PROGRAMMABLE PASSBAND

PROGRAMMABLE PASSBAND

5MHz TO 34MHz

LOWPASS FILTER

5MHz TO 34MHz

LOWPASS FILTER

AV

DD

MAX7469

MAX7470

0dB

(+6dB)

0dB

(+6dB)

DECODER

OUT1

A/D

0.1μF

OUT2

A/D

0.1μF

/R

P

r

75Ω

( ) FOR MAX7470

0.1μF

IN3

CLAMP/

BIAS

5MHz TO 34MHz

PROGRAMMABLE PASSBAND

LOWPASS FILTER

CLAMP LEVEL

EXT SYNC

ENABLE

GND

BYPASS

SCL SDA

0dB

(+6dB)

FREQUENCY

I2C

INTERFACE

DGND

SELECT

DV

A1 A0

DD

OUT3

0.1μF

A/D

Page 17

MAX7469/MAX7470

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________

17

© 2006 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products, Inc.

Heslington

HDTV Continuously Variable

Anti-Aliasing Filters

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

QFN THIN.EPS

Loading...

Loading...