Page 1

19-3105; Rev 2; 8/96

EVALUATION KIT MANUAL

FOLLOWS DATA SHEET

Switch-Mode Regulator with

+5V to ±12V or ±15V Dual Output

_______________General Description

The MAX742 DC-DC converter is a controller for dual-output power supplies in the 3W to 60W range. Relying on

simple two-terminal inductors rather than transformers, the

MAX742 regulates both outputs independently to within

±4% over all conditions of line voltage, temperature, and

load current.

The MAX742 has high efficiency (up to 92%) over a wide

range of output loading. Two independent PWM currentmode feedback loops provide tight regulation and operation free from subharmonic noise. The MAX742 can

operate at 100kHz or 200kHz, so it can be used with small

and lightweight external components. Also ripple and

noise are easy to filter. The MAX742 provides a regulated

output for inputs ranging from 4.2V to 10V (and higher with

additional components).

External power MOSFETs driven directly from the MAX742

are protected by cycle-by-cycle overcurrent sensing. The

MAX742 also features undervoltage lockout, thermal shutdown, and programmable soft-start.

If 3W of load power or less is needed, refer to the MAX743

data sheet for a device with internal power MOSFETs.

________________________Applications

DC-DC Converter Module Replacement

Distributed Power Systems

Computer Peripherals

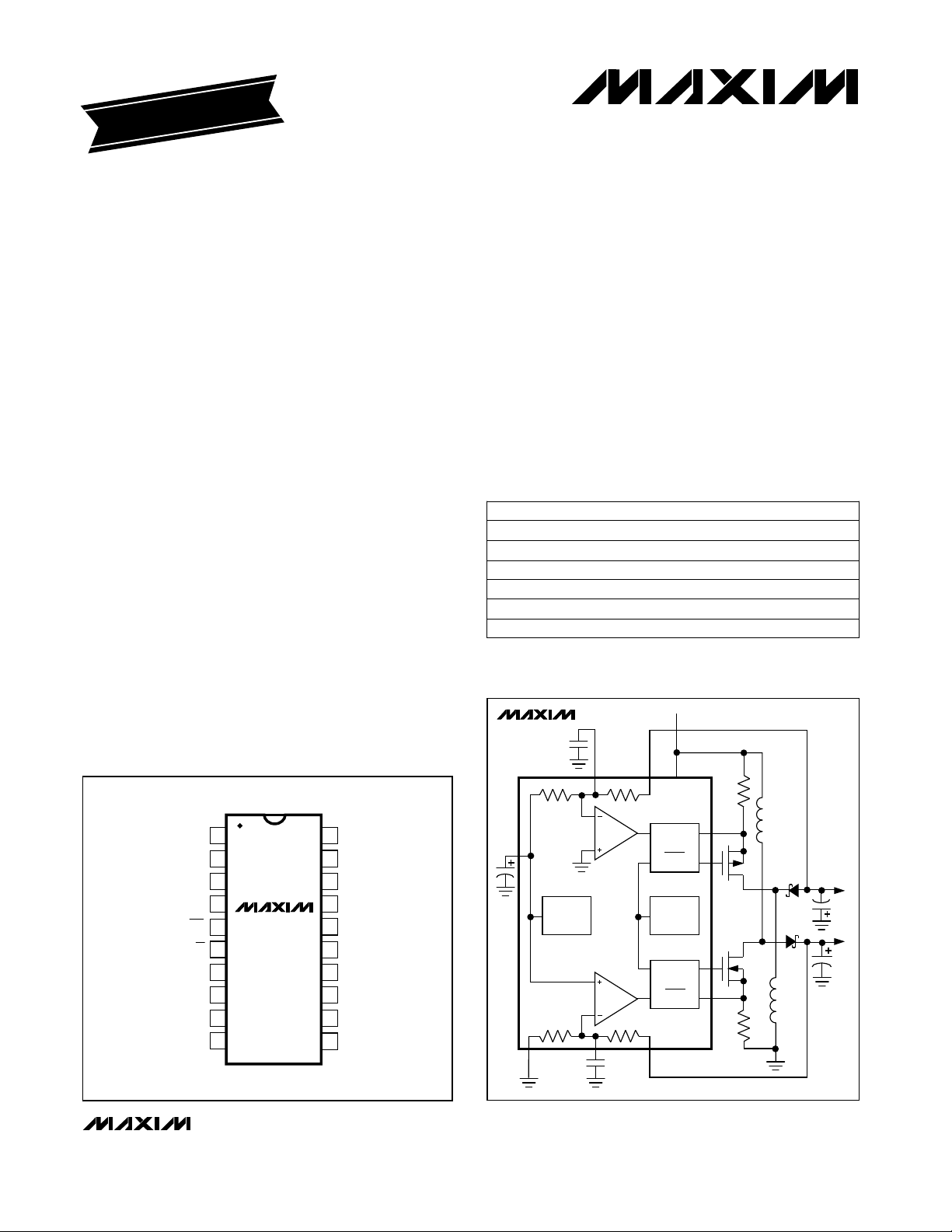

__________________Pin Configuration

____________________________Features

♦ Specs Guaranteed for In-Circuit Performance

♦ Load Currents to ±2A

♦ 4.2V to 10V Input-Voltage Range

♦ Switches From ±15V to ±12V Under Logic Control

♦ ±4% Output Tolerance Max Over Temp, Line,

and Load

♦ 90% Typ Efficiency

♦ Low-Noise, Current-Mode Feedback

♦ Cycle-by-Cycle Current Limiting

♦ Undervoltage Lockout and Soft-Start

♦ 100kHz or 200kHz Operation

______________Ordering Information

PART

MAX742CPP

MAX742CWP

MAX742C/D 0°C to +70°C

MAX742EPP -40°C to +85°C 20 Plastic DIP

MAX742EWP

MAX742MJP -55°C to +125°C

* Contact factory for dice specifications

TEMP. RANGE PIN-PACKAGE

0°C to +70°C

0°C to +70°C

-40°C to +85°C 20 Wide SO

20 Plastic DIP

20 Wide SO

Dice*

20 CERDIP

__________Simplified Block Diagram

+5V

MAX742

CC-

INPUT

MAX742

TOP VIEW

R

FB+

1

CC+

2

AGND

3

AV

4

100/200

12/15

VREF

SS

CC-

FB-

________________________________________________________________

MAX742

5

6

7

8

9

10

DIP/SO

CSH+

20

CSL+

19

GND

18

EXT+

17

PUMP

16

PDRV

15

EXT-

14

V+

13

CSH-

12

CSL-

11

+2.0V

VREF

CC+

-SENSE

PWM

S

-DRIVE

OSC

+DRIVE

S

PWM

+SENSE

R

Maxim Integrated Products

P

N

-VO

+VO

1

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800

Page 2

Switch-Mode Regulator with

+5V to ±12V or ±15V Dual Output

ABSOLUTE MAXIMUM RATINGS

V+, AV+ to AGND, GND.........................................-0.3V to +12V

PDRV to V+.............................................................+0.3V to -14V

FB+, FB- to GND..................................................................±25V

Input Voltage to GND

(CC+, CC-, CSH+, CSL+, CSH-, CSL-,

SS, 100/200

Output Voltage to GND

MAX742

(EXT+, PUMP) ..........................................-0.3V to (V+ + 0.3V)

EXT- to PDRV................................................-0.3V to (V+ + 0.3V)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

, 12/15)..................................-0.3V to (V+ + 0.3V)

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 2, +4.5V < V+ < +5.5V.)

Continuous Power Dissipation (any package)

up to +70°C.....................................................................500mW

derate above +70°C by ..........................................100mW/°C

Operating Temperature Ranges

MAX742C_ _ .......................................................0°C to +70°C

MAX742E_ _ ....................................................-40°C to +85°C

MAX742MJP ..................................................-55°C to +125°C

Storage Temperature Range.............................-65°C to +150°C

Lead Temperature (soldering, 10sec).............................+300°C

Output Voltage, ±15V Mode

(Notes 1, 2)

Output Voltage, ±12V Mode

(Notes 1, 2)

0mA < IL< 100mA,

12/15 = 0V

0mA < IL< 125mA,

12/15 = V+

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 2, V+ = 5V, 100/200 = 12/15 = 0V; TA= T

V+ = 4.5V to 5.5V, PDRV from PUMP

I

Load Regulation (Note 2)

No-Load Supply Current

Oscillator Frequency

Positive Current-Limit Threshold

(CSH+ to CSL+)

Negative Current-Limit Threshold

(CSH- to CSL-)

f

OSC

= 0mA to 100mA

LOAD

No EXT- or PUMP load,

FB+ = FB- = open circuit

100/200 = 0V

100/200 = V+

EXT+ or EXTCSL+ = 0V, FB+ = open circuit

CSH- = V+, FB- = open circuit

CONDITIONS

to T

MIN

CONDITIONS

TA= +25°C

TA= T

TA= +25°C

TA= T

, unless otherwise noted.)

MAX

V+ = 5V

MIN

MIN

to T

to T

MAX

MAX

14.55 15.45

14.40 15.60

11.64 12.36

11.52 12.48

3

10V+ = 10V

170 200 230

75 100 125

/2PUMP Frequency

OSC

UNITSMIN TYP MAXSYMBOLPARAMETER

V

V

UNITSMIN TYP MAXSYMBOLPARAMETER

%/%0.01 0.05Line Regulation

mV30 100

mA

V3.8 4.2UVLOUndervoltage Lockout

V0.2Undervoltage Lockout Hysteresis

V2.0Reference Output Voltage

kHz

kHzf

%85 90Duty-Cycle Limit (Note 3)

mV150 225 300

mV150 225 300

2 _______________________________________________________________________________________

Page 3

Switch-Mode Regulator with

+5V to ±12V or ±15V Dual Output

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 2, V+ = 5V, 100/200 = 12/15 = 0V; TA= T

Output Voltage High

Output Voltage Low

Output Sink Current

Output Source Current

Output Rise/Fall Time

Note 1: Devices are 100% tested to these limits under 0mA to 100mA and to 125mA conditions using automatic test equipment.

The ability to drive loads up to 1A is guaranteed by the current-limit threshold, output swing, and the output current

source/sink tests. See Figures 2 and 3.

Note 2: Actual load capability of the circuit of Figure 2 is ±200mA in ±15V mode and ±250mA in ±12V mode. Load regulation is

tested at lower limits due to test equipment limitations.

Note 3: Guaranteed by design.

Note 4: Measured at Point A, circuit of Figure 2, with PDRV disconnected.

EXT+, EXT-, IL= 1mA, V+ = 4.5V, PDRV= -3V

OH

EXT+, EXT-, IL= -1mA, V+ = 4.5V, PDRV= -3V

OL

V+ = 4.5V, PDRV = -3V,

TA= +25°C

V+ = 4.5V, PDRV = -3V,

TA= +25°C

EXT+, C

LOAD

V+ = 4.5V, IL= -5mA, TA= +25°C

CC+, CC-

SS = 0V

V+ = 3.8V, SS = 2V

to T

MIN

MAX

CONDITIONS

= 2nF

LOAD

= 4nF, PDRV = -3V

, unless otherwise noted.)

EXT+ = 4.5V

EXT- = 4.5V

EXT+ = 0V

EXT- = -3V

100 200

200 350

-200 -100

-350 -200

70

100EXT-, C

MAX742

UNITSMIN TYP MAXSYMBOLPARAMETER

V4.3V

V-2.8V

mA

mA

ns

V-3PUMP Output Voltage (Note 4)

kΩ10Compensation Pin Impedance

°C190Thermal-Shutdown Threshold

µA37Soft-Start Source Current

mA-2 -0.5Soft-Start Sink Current

_______________________________________________________________________________________ 3

Page 4

Switch-Mode Regulator with

+5V to ±12V or ±15V Dual Output

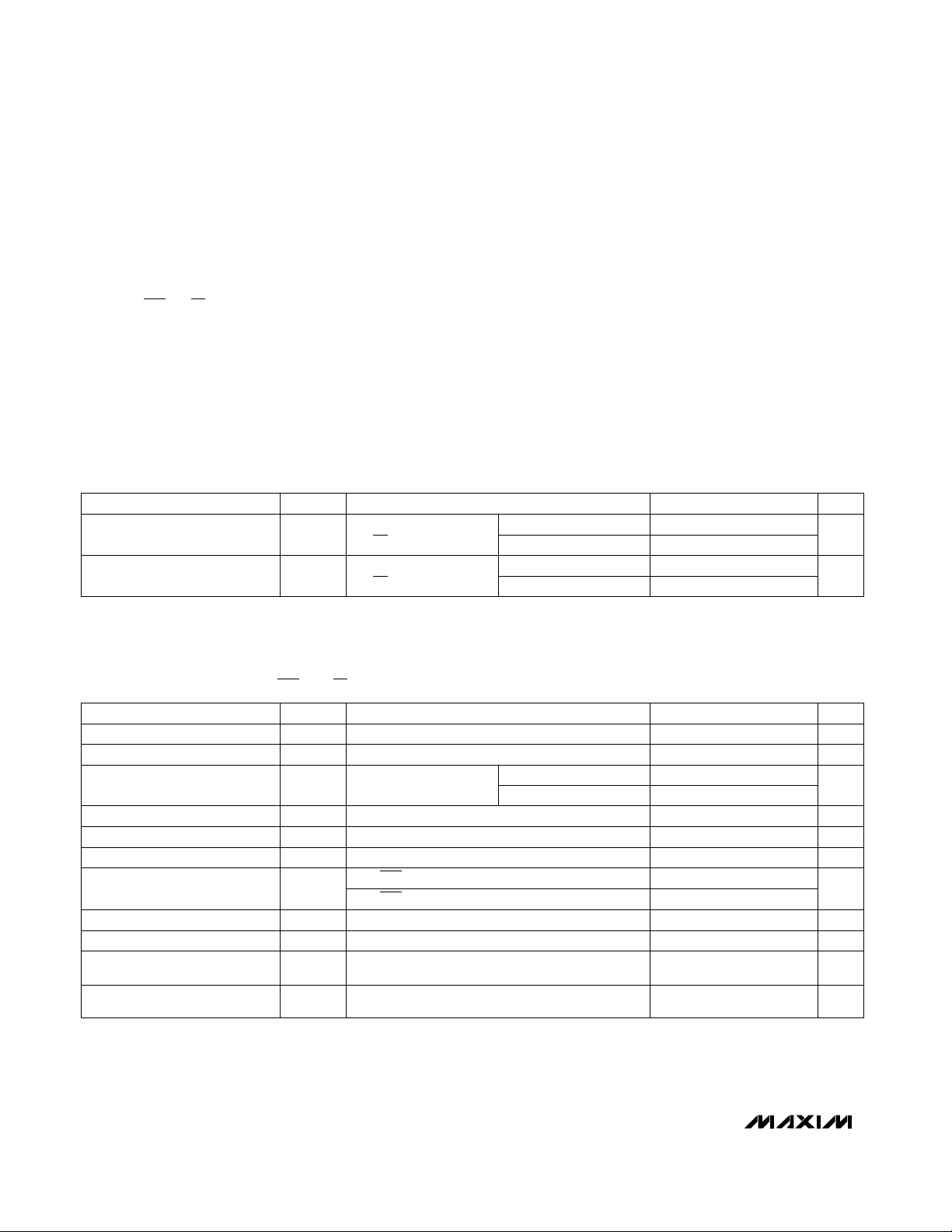

__________________________________________Typical Operating Characteristics

(Circuit of Figure 2, V+ = 5V, TA = +25°C, unless otherwise noted.)

UNDERVOLTAGE LOCKOUT HYSTERESIS

25

±15V MODE,

MAX742

QUIESCENT SUPPLY CURRENT (mA)

200kHz MODE

20

15

10

5

06

EFFICIENCY vs. LOAD CURRENT,

22W CIRCUIT, ±15V MODE

90

80

70

EFFICIENCY (%)

CIRCUIT OF FIGURE 3,

INDUCTORS = GOWANDA 121-AT2502

(MPP CORE),

60

Q2 = TWO IRF9Z30 IN PARALLEL

±15V MODE

50

0

LOCKOUT

ENABLED

23 51

SUPPLY VOLTAGE (V)

±400 ±600 ±1000±200

LOAD CURRENT (mA)

4

200kHz

±800

100kHz

CHARGE-PUMP LOAD REGULATION

-5.0

MAX742 -1

-4.5

-4.0

-3.5

-3.0

CHARGE-PUMP OUTPUT VOLTAGE (V)

-2.5

MEASURED AT POINT A

0

23 75 6 10 891

4

CHARGE-PUMP LOAD CURRENT (mA)

EFFICIENCY vs. LOAD CURRENT,

6W CIRCUIT, ±15V MODE

MAX742 -4

90

80

70

EFFICIENCY (%)

60

INDUCTORS = GOWANDA 050-AT1003

(MPP CORE)

50

0

±100 ±150 ±250±50

LOAD CURRENT (mA)

V+ = 4.5V

V+ = 5V

200kHz

±200

100kHz

6

MAX742 -2

5

4

3

2

PDRV CURRENT (mA)

1

MAX742 -5

90

80

70

EFFICIENCY (%)

60

50

PDRV CURRENT vs. C

PDRV FORCED TO -4V

PUMP DISCONNECTED

200kHz

100kHz

0

CAPACITANCE AT EXT- (nF)

231

EFFICIENCY vs. LOAD CURRENT,

6W CIRCUIT, ±12V MODE

200kHz

INDUCTORS = GOWANDA 050-AT1003

(MPP CORE)

0

±150 ±225±75

LOAD CURRENT (mA)

EXT-

MAX742 -3

4

MAX742 -6

100kHz

±300

PEAK INDUCTOR CURRENT vs.

LOAD CURRENT

1200

1100

1000

900

800

700

600

500

400

300

PEAK INDUCTOR CURRENT (mA)

200

100

0

MEASURED AT LX-,

±15V MODE

100 15050

LOAD CURRENT (mA)

100kHz

MAX742 -7

200

200kHz

150

100

CURRENT-LIMIT THRESHOLD (mV)

200

CURRENT-LIMIT THRESHOLD vs.

SOFT-START VOLTAGE

50

0

12

SOFT-START VOLTAGE (V)

4 _______________________________________________________________________________________

MAX742 -8

3

Page 5

Switch-Mode Regulator with

+5V to ±12V or ±15V Dual Output

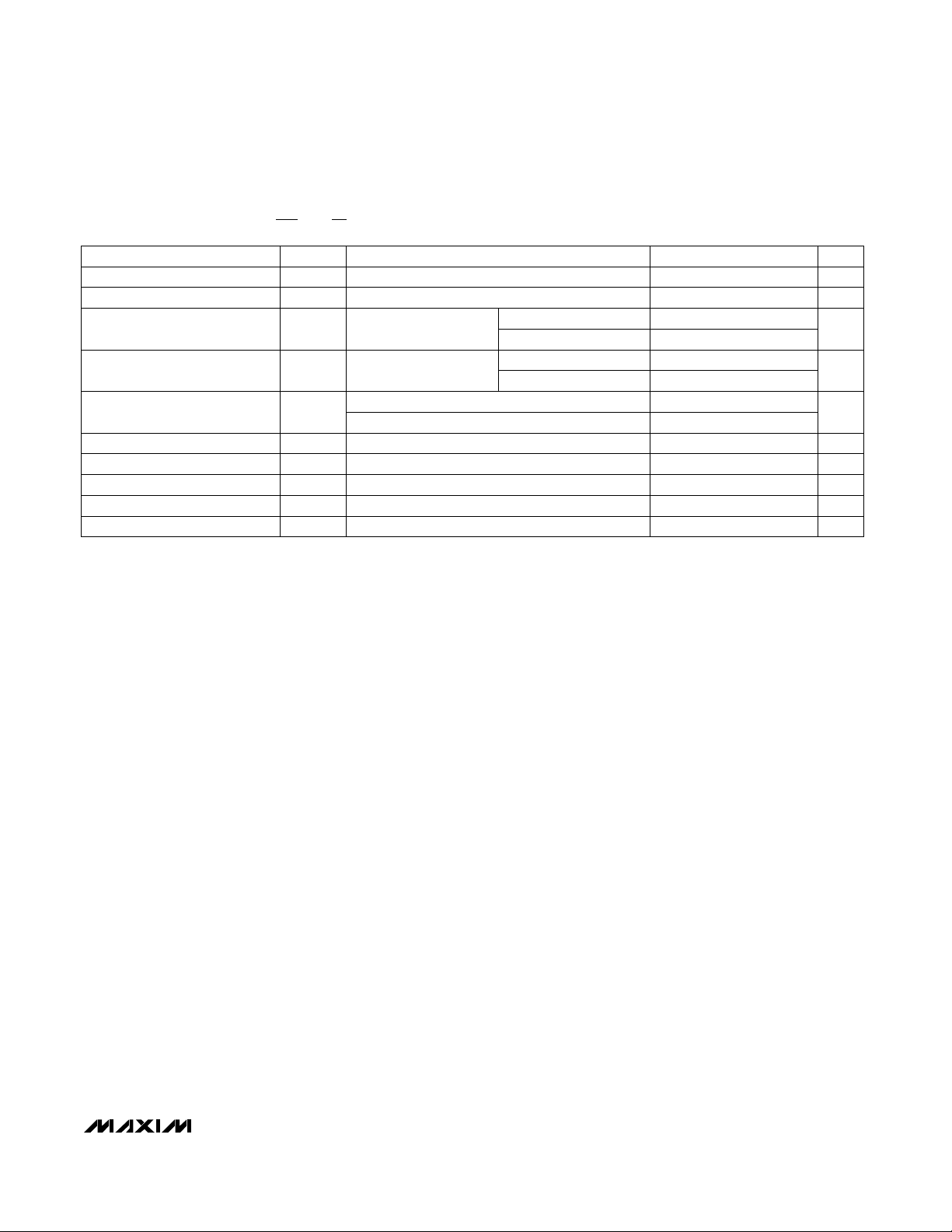

_____________________________Typical Operating Characteristics (continued)

(Circuit of Figure 2, I

A = GATE DRIVE, 5V/div

B = SWITCH VOLTAGE, 10V/div

C = SWITCH CURRENT, 0.2A/div

= 100mA, unless otherwise noted.)

LOAD

SWITCHING WAVEFORMS,

INVERTING SECTION

2µs/div

OUTPUT-VOLTAGE NOISE,

FILTERED AND UNFILTERED

SWITCHING WAVEFORMS,

STEP-UP SECTION

A

B

C

2µs/div

A = GATE DRIVE, 5V/div

B = SWITCH VOLTAGE, 10V/div

C = SWITCH CURRENT, 0.2A/div

LOAD-TRANSIENT RESPONSE

A

B

C

MAX742

A = NOISE WITH i FILTER, 1mV/div

B = NOISE WITHOUT FILTER, 20mV/div

MEASURED AT -V

V+ = 5V

BW = 5MHz

2µs/div

OUT

_______________________________________________________________________________________ 5

A

A

B

200µs/div

A = +VO, 20mV/div

B = -VO, 50mV/div

B

Page 6

Switch-Mode Regulator with

+5V to ±12V or ±15V Dual Output

______________________________________________________________Pin Description

PIN

MAX742

Step-Up Feedback InputFB+1

Step-Up Compensation CapacitorCC+2

Analog GroundAGND3

Analog Supply Voltage Input (+5V)AV+4

Selects oscillator frequency. Ground for 200kHz, or tie to V+ for 100kHz.100/2005

Selects V

Reference Voltage Output (+2.00V). Force to GND or V+ to disable chip.VREF7

Soft-Start Timing Capacitor (sources 5µA)SS8

Inverting Compensation CapacitorCC-9

Inverting Section Feedback InputFB-10

Current-Sense Low (inverting section)CSL-11

Current-Sense High (inverting section)CSH-12

Supply Voltage Input (+5V)V+13

Push-Pull Output—drives external P-channel MOSFET.EXT-14

Voltage Input—negative supply for P-channel MOSFET driver.PDRV15

Charge-Pump Driver—clock output at 1/2 oscillator frequency.PUMP16

OUT

FUNCTIONNAME

. Ground for ±15V, or tie to V+ for ±12V.12/156

Push-Pull Output—drives external logic-level N-channel MOSFET.EXT+17

High-Current GroundGND18

Current-Sense Low (step-up section)CSL+19

Current-Sense High (step-up section)CSH+20

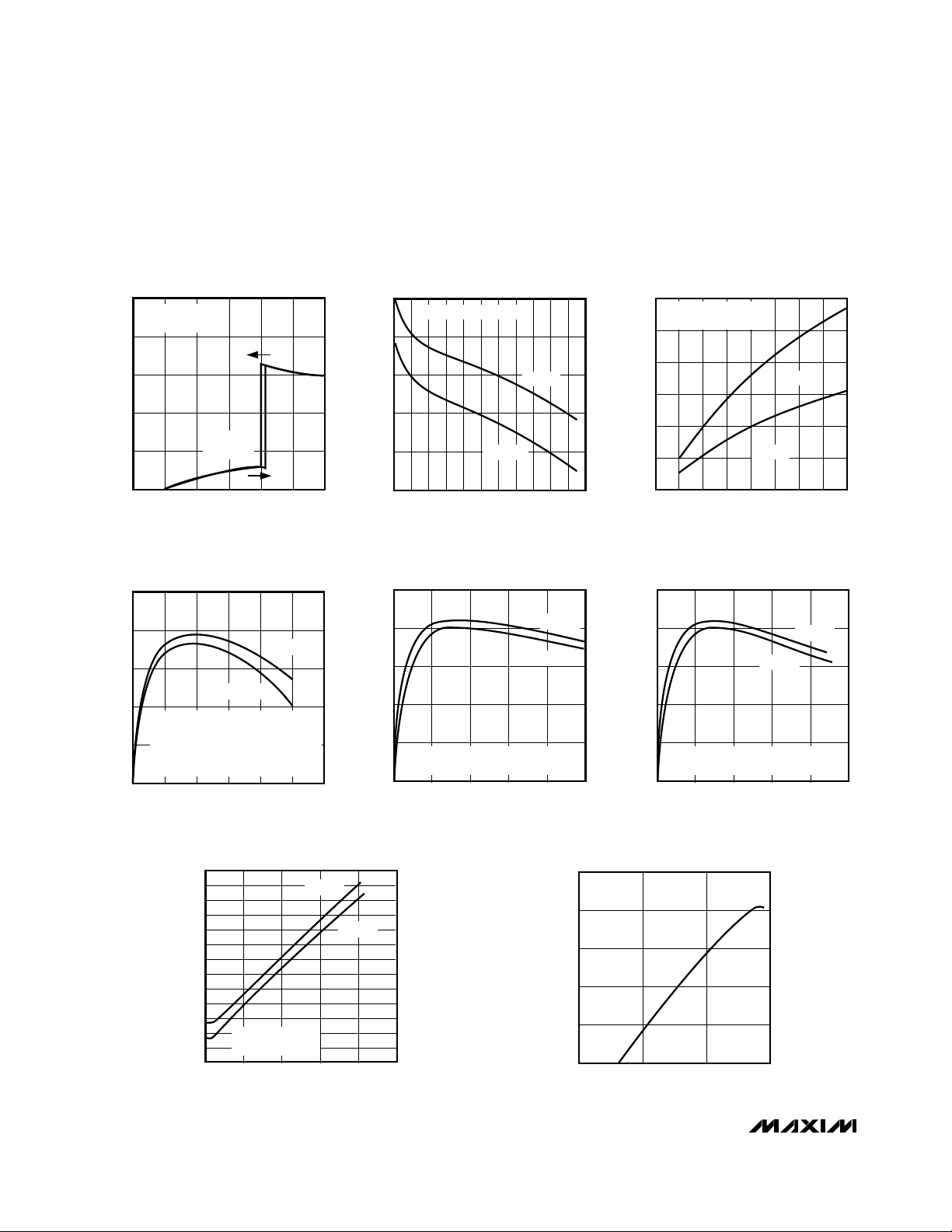

________________Operating Principle

Each current-mode controller consists of a summing

amplifier that adds three signals: the current waveform

from the power switch FET, an output-voltage error signal, and a ramp signal for AC compensation generated

by the oscillator. The output of the summing amplifier

resets a flip-flop, which in turn activates the power FET

driver stage (Figure 1).

Both external transistor switches are synchronized to

the oscillator and turn on simultaneously when the flipflop is set. The switches turn off individually when their

6 _______________________________________________________________________________________

source currents reach a trip threshold determined by

the output-voltage error signal. This creates a dutycycle modulated pulse train at the oscillator frequency,

where the on time is proportional to both the outputvoltage error signal and the peak inductor current. Low

peak currents or high output-voltage error signals result

in a high duty cycle (up to 90% maximum).

AC stability is enhanced by the internal ramp signal

applied to the error amplifier. This scheme eliminates

regenerative “staircasing” of the inductor current, which

is otherwise a problem when in continuous current

mode with greater than 50% duty cycle.

Page 7

Switch-Mode Regulator with

+5V to ±12V or ±15V Dual Output

MAX742

AGND

VREF

12/15

VREF

CC+FB+

12/15

SELECT

∑

PULSE

RAMP

OSC

SQUARE

∑

AV+100/200

MAX742

SOFT-START

AND THERMAL

SHUTDOWN

RQ

S

TO V+

S

RQ

CSH+

CSL+

V+

EXT+

GND

SS

PUMP

EXTPDRV

CSH-

CSL-

CC-FB-

Figure1. MAX742 Detailed Block Diagram

_______________Detailed Description

100kHz/200kHz Oscillator

The MAX742 oscillator frequency is generated without

external components and can be set at 100kHz or

200kHz by pin strapping. Operating the device at

100kHz results in lower supply current and improved

efficiency, particularly with light loads. However, component stresses increase and noise becomes more difficult to filter. For a given inductor value, the lower

operating frequency results in slightly higher peak currents in the inductor and switch transistor (see

Operating Characteristics

, Peak Inductor Current vs.

Load Current graph). When the lower frequency is used

in conjunction with an LC-type output filter (optional

components in Figure 2), larger component values are

required for equivalent filtering.

_______________________________________________________________________________________ 7

Typical

Charge-Pump Voltage Inverter

The charge-pump (PUMP) output is a rail-to-rail square

wave at half the oscillator frequency. The square wave

drives an external diode-capacitor circuit to generate a

negative DC voltage (Point A in Figure 2), which in turn

biases the inverting-output drive stage via PDRV. The

charge pump thus increases the gate-source voltage

applied to the external P-channel FET. The low onresistance resulting from increased gate drive ensures

high efficiency and guarantees start-up under heavy

loads. If a -5V to -8V supply is already available, it can

be tied directly to PDRV and all of the charge-pump

components removed. For input voltages greater than

8V, ground PDRV to prevent overvoltage. Observe

PDRV absolute maximum ratings.

Page 8

Switch-Mode Regulator with

+5V to ±12V or ±15V Dual Output

VIN

4.5V to 6V*

L1

R1

MAX742

100Ω

100µH

D1

Q1

150µF

L3

25µH

C8

150µF

C9

C14

2.2µF

+VO

C1

0.1µF

1

C2

3.3nF

J1

C3

10µF

C4

C5

3.3nF

FB+

CC+

AGND

AV+

100/200

12/15

VREF

SS

CC-

FB-

MAX742

CSH+

CSL+

GND

EXT+

PUMP

PDRV

EXT-

CSH-

CSL-

R2

0.16Ω

NOTES:

Q1 = Motorola MTP15N05L

Q2 = Motorola MTP12P05

L1, L2 = MAXL001

C6

1µF

V+

D3

1µF

D4

100µH

POINT

A

C10

150µF

R3

0.1Ω

Q2

D2

L2

C11

150µF

C7

C8–C12 = MAXC001

D1, D2 = 1N5817

D3, D4 = Fuji ERA82-004 or 1N5817

R2, R3 = RCD RSF 1A Metal Film ±3%

L3, L4 = Wilco MFB 250

C13

0.1µF

DISC CERAMIC

C12

150µF

OPTIONAL

L4

25µH

-VO

C15

2.2µF

OPTIONAL

* FOR HIGHER INPUT VOLTAGE, SEE

SUPPLY-VOLTAGE RANGE

SECTION.

Figure 2. Standard 6W Application Circuit

8 _______________________________________________________________________________________

Page 9

VIN

4.5V to 6V*

100Ω

Switch-Mode Regulator with

+5V to ±12V or ±15V Dual Output

MAX742

C13

330µF

R1

25µH

L1

D1

1N5820

C8

Q1

1000µF

+VO

C9

1000µF

C1

0.1µF

1

C2

6.8nF

J1

C3

10µF

C4

2.2µF

C5

6.8nF

FB+

CC+

AGND

AV+

100/200

12/15

VREF

SS

CC-

FB-

MAX742

CSH+

CSL+

GND

EXT+

PUMP

PDRV

EXT-

CSH-

CSL-

R2

0.02Ω

C6

1µF

V+

1N914

D3

1N914

C7

1µF

D4

25µH

C10

1000µF

R3

10V

0.02Ω

Q2

D2

L2

1N5820

NOTES:

Q1 = Motorola MTP25N06L

Q2 = International Rectifier IRF9Z30

L1, L2 = Gowanda 121AT2502VC

R2, R3 = KRL LB4-1 ±3%

C8–C13 = Nichicon PL Series (25V or 35V)

C14

0.1µF

DISC CERAMIC

C11

1000µF

C12

-VO

1000µF

* FOR HIGHER INPUT VOLTAGE, SEE

SUPPLY-VOLTAGE RANGE

SECTION.

Figure 3. High-Power 22W Application Circuit

_______________________________________________________________________________________ 9

Page 10

Switch-Mode Regulator with

+5V to ±12V or ±15V Dual Output

Supply-Voltage Range

Although designed for operation from a +5V logic

supply, the MAX742 works well from 4.2V (the upper

limit of the undervoltage lockout threshold) to +10V

(absolute maximum rating plus a safety margin). The

upper limit can be further increased by limiting the

voltage at V+ with a zener shunt or series regulator.

To ensure AC stability, the inductor value should be

MAX742

scaled linearly with the nominal input voltage. For

example, if Figure 3’s application circuit is powered

from a nominal 9V source, the inductor value should be

increased to 40µH or 50µH. At high input voltages

(>8V), the charge pump can cause overvoltage at

PDRV. If the input can exceed 8V, ground PDRV and

remove the capacitors and diodes associated with the

charge pump.

In-Circuit Testing for

Guaranteed Performance

Figure 2’s circuit has been tested at all extremes of line,

load, and temperature. Refer to the

Characteristics

table for guaranteed in-circuit specifica-

Electrical

tions. Successful use of this circuit requires no component calculations.

Soft-Start

A capacitor connected between Soft-Start (SS) and

ground limits surge currents at power-up. As shown in

the

Typical Operating Characteristics

, the peak switch

current limit is a function of the voltage at SS. SS is

internally connected to a 5µA current source and is

diode-clamped to 2.6V (Figure 8). Soft-start timing is

therefore set by the SS capacitor value. As the SS voltage ramps up, peak inductor currents rise until they

reach normal operating levels. Typical values for the SS

capacitor, when it is required at all, are in the range of

1µF to 10µF.

Fault Conditions Enabling SS Reset

In addition to power-up, the soft-start function is enabled

by a variety of fault conditions. Any of the following conditions will cause an internal pull-down transistor to discharge the SS capacitor, triggering a soft-start cycle:

Undervoltage lockout

Thermal shutdown

VREF shorted to ground or supply

VREF losing regulation

EXTERNAL

SS

CAPACITOR

Figure 4. Soft-Start Equivalent Circuit

__________________Design Procedure

An exact inductor value isn’t critical. The inductor value

can be varied in order to make tradeoffs between

noise, efficiency, and component sizes. Higher inductor

values result in continuous-conduction operation, which

maximizes efficiency and minimizes noise. Physically

smallest inductors (where E = 1/2 LI2is minimum) are

realized when operating at the crossover point between

continuous and discontinuous modes. Lowering the

inductor value further still results in discontinuous current even at full load, which minimizes the output

capacitor size required for AC stability by eliminating

the right-half-plane zero found in boost and inverting

topologies. Ideal current-mode slope compensation

where m = 2 x V/L is achieved if L (Henries) = R

(Ω) x 0.001, but again the exact value isn’t critical and

the inductor value can be adjusted freely to improve

AC performance. The following equations are given for

continuous-conduction operation since the MAX742 is

mainly intended for low-noise analog power supplies.

See Appendix A in Maxim’s

DC-DC Converter Circuit Collection

and discontinuous-mode equations.

Boost (positive) output:

L = ———————————————

Inverting (negative) output:

L = —————————————

+5V

SS

8

N

(VIN- VSW)2(V

(V

+ VD)2(I

OUT

(V

IN

(V

+ VD)(I

OUT

5µA

MAX742

+2V

REFERENCE

TO CURRENT–

LIMIT COMPARATOR

FAULT

Inductor Value

Battery Management and

for crossover point

+ VD- VIN)

OUT

)(F)(LIR)

LOAD

2

- VSW)

)(F)(LIR)

LOAD

SENSE

10 ______________________________________________________________________________________

Page 11

Switch-Mode Regulator with

+5V to ±12V or ±15V Dual Output

where:

VSWis the voltage drop across the the switch transistor

and current-sense resistor in the on state (0.3V typ).

VDis the rectifier forward voltage drop (0.4V typ).

LIR is the ratio of peak-to-peak ripple current to DC

offset current in the inductor (0.5 typ).

Current-Sense Resistor Value

The current-sense resistor values are calculated according to the worst-case-low current-limit threshold voltage

from the

inductor current. The peak inductor current calculations

that follow are also useful for sizing the switches and

specifying the inductor current saturation ratings.

Electrical Characteristics

R

SENSE

+I

+I

PEAK

(boost) = ————————— +

PEAK

(VIN- VSW) (V

—————————————

(2)(F)(L)(V

(inverting) = ———————————— +

(VIN- VSW) (V

—————————————

(2)(F)(L) (V

150mV

= ————

I

PEAK

I

LOAD(VOUT

VIN- V

+ VD- VIN)

OUT

+ VD)

OUT

I

LOAD(VOUT

VIN- V

+ VD+ VIN)

OUT

+ VD)

OUT

table and the peak

+ VD)

SW

+ VD+ VIN)

SW

Filter Capacitor Value

The output filter capacitor values are generally determined by the effective series resistance (ESR) and voltage rating requirements rather than actual capacitance

requirements for loop stability. In other words, the

capacitor that meets the ESR requirement for noise purposes nearly always has much more output capacitance than is required for AC stability. Output voltage

noise is dominated by ESR and can be roughly calculated by an Ohm’s Law equation:

V

where V

Ensure the output capacitors selected meet the follow-

ing minimum capacitance requirements:

Minimum CF = 60µF per output or the following, whichev-

er is greater:

NOISE

CF = 0.015/R

CF = 0.01/R

(peak-to-peak) = I

NOISE

is typically 0.15V.

LOAD

LOAD

x R

PEAK

(in Farads, ±15V mode)

(in Farads, ±12V mode)

ESR

Compensation Capacitor (CC) Value

The compensation capacitors (CC+ and CC-) cancel

the zero introduced by the output filter capacitors’ ESR,

improving phase margin, and AC stability. The compensation poles set by CC+ and CC- should be set to

match the ESR zero frequencies of the output filter

capacitors according to the following:

R

x CF

CC (in Farads) = —————— (use 1000pF minimum)

ESR

10kΩ

Standard 6W Application

The 6W supply (Figure 2) generates ±200mA at ±15V,

or ±250mA at ±12V. Output capability is increased to

10W or more by heatsinking the power FETs, using

cores with higher current capability (such as Gowanda

#050AT1003), and using higher filter capacitance.

Ferrite and MPP inductor cores optimize efficiency and

size. Iron-power toroids designed for high frequencies

are economical, but larger.

Ripple is directly proportional to filter capacitor equivalent series resistance (ESR). In addition, about 250mV

transient noise occurs at the LX switch transitions. A

very short scope probe ground lead or a shielded

enclosure is need for making accurate measurements

of transient noise. Extra filtering, as shown in Figure 2,

reduces both noise components.

High-Power 22W Application

The 22W application circuit (Figure 3) generates ±15V

at ±750mA or ±12V at ±950mA. Noninductive wirewound resistors with Kelvin current-sensing connections replace the metal-film resistors of the previous

(6W) circuit. Gate drive for the P-channel FET is bootstrapped from the negative supply via diode D6. The

2.7V zener (D5) is required in 15V mode to prevent

overvoltage. The charge pump (D3, D4, and C6) may

not be necessary if the circuit is lightly loaded

(<100mA) on start-up. AIE part #415-0963 is a ferrite

pot-core inductor that can be used in place of a smaller, more expensive moly-permalloy toroid inductor (L1,

L2). Higher efficiencies can be achieved by adding

extra MOSFETs in parallel. Load levels above 10W

make it necessary to add heatsinks, especially to the Pchannel FET.

MAX742

______________________________________________________________________________________ 11

Page 12

Switch-Mode Regulator with

+5V to ±12V or ±15V Dual Output

Table 1. Trouble-Shooting Chart

SYMPTOM CORRECTION

Unstable Output.

Noise or jitter on

output ripple

waveform. Scope

may not trigger

MAX742

correctly.

Noisy Output.

Switching is

steady, but large

inductive spikes

are seen at the

outputs.

Self-Destruction.

Transistors or IC

die on power-up.

Poor Efficiency.

Supply current is

high. Output will

not drive heavy

loads.

No Output. +VO

= 5V or less. -VO

= 0V.

No Switching.

±VO are correct,

but no waveform is

seen at LX+ or LX-.

Loop stability problem.

A. CC+ or CC- disconnected.

B. EMI: Move inductor away from IC or use

shielded inductors. Keep noise sources

away from CC- and CC+.

C. Grounding: Tie AGND directly to the filter

capacitor ground lead. Ensure that current spikes from GND do not cause noise

at AGND or compensation capacitor or

reference bypass ground leads. Use wide

PC traces or a ground plane.

D. Bypass: Tie 10µF or larger between AGND

and VREF. Use 150µF to bypass the input

right at AV+. If there is high source resistance, 1000µF or more may be required.

E. Current limiting: Reduce load currents.

Ensure that inductors are not saturating.

F. Slope compensation: Inductor value not

matched to sense resistor.

A. Ground noise: Probe ground is picking up

switching EMI. Reduce probe ground lead

length (use probe tip shield) or put circuit

in shielded enclosure.

B. Poor HF response: Add ceramic or

tantalum capacitors in parallel with output

filter capacitors.

A. Input overvoltage: Never apply more

than +12V.

B. FB+ or FB- disconnected or shorted. This

causes runaway and output overvoltage.

C. CC+ or CC- shorted.

D. Output filter capacitor disconnected.

A. Inductor saturation: Peak currents

exceed coil ratings.

B. MOSFET on-resistance too high.

C. Switching losses: Diode is slow or has high

forward voltage. Inductor has high DC resis-

tance. Excess capacitance at LX nodes.

D. Inductor core losses: Hysteresis losses

cause self-heating in some core materials.

E. Loop instability: See Unstable Output

above.

A. Check connections. VREF should be +2V.

B. When input voltage is less than +4.2V,

undervoltage lockout is enabled.

Output is unloaded. Apply ±30mA or

greater load to observe waveform.

___________________Chip Topography

CSH+ CSL+

FB-

0.080"

(2.03mm)

GND

EXT+

PUMP

0.135"

(3.45mm)

PDRV

EXT-

V+

CSH-

CSL- CC-

AV+

100/200

12/15

VREF

AGND

SS

CC+ FB+

TRANSISTOR COUNT: 375

SUBSTRATE CONNECTED TO V+

12 ______________________________________________________________________________________

Loading...

Loading...