Page 1

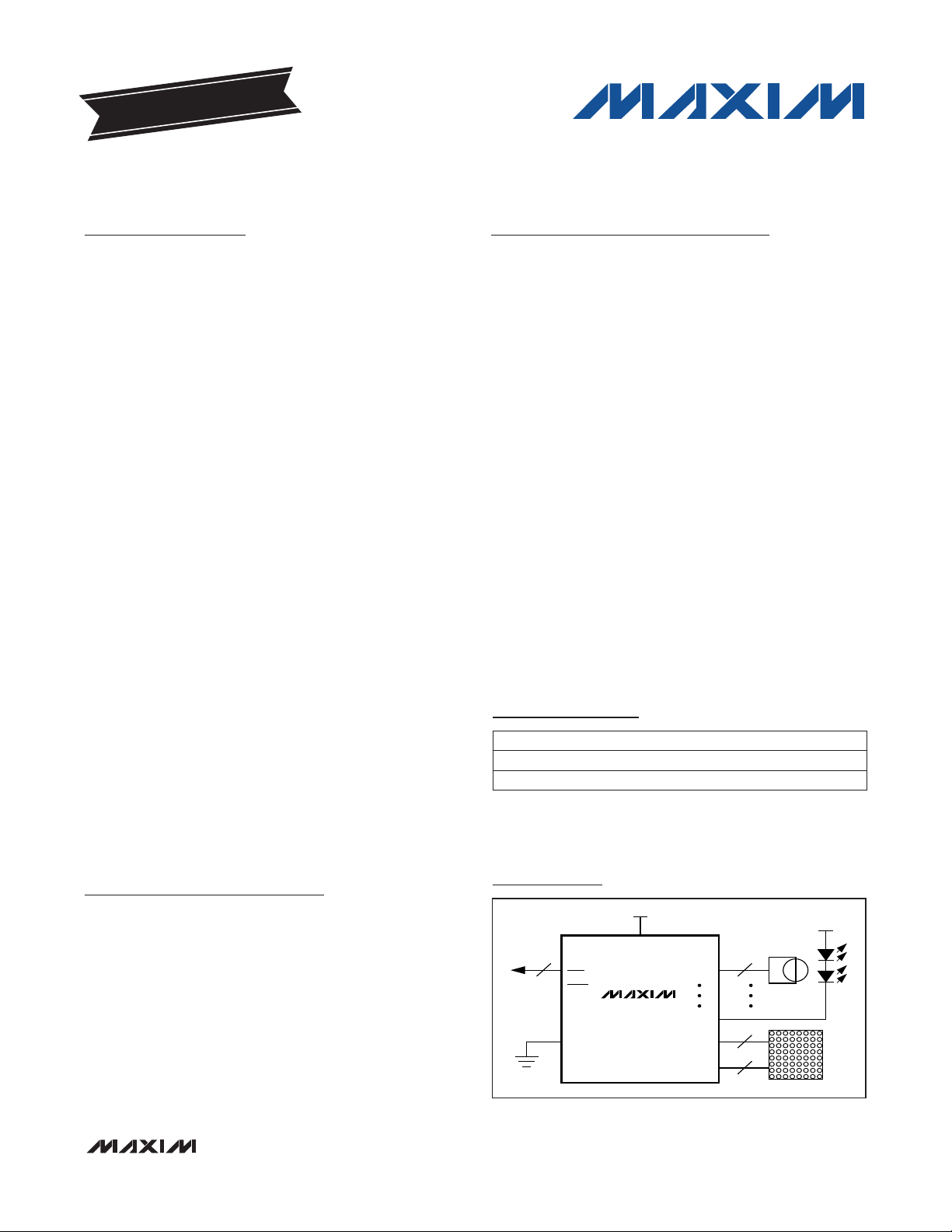

MAX7360

AD0

PORT7

PORT6

PORT0

COL_(8x)

ROW_(8x)

INTK

INTI

SDA

SCL

ROTARY

SWITCH

+14V

8 x 8

TO

FC

+1.8V

19-4566; Rev 0; 4/09

EVALUATION KIT

AVAILABLE

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

General Description

The MAX7360 I2C-interfaced peripheral provides microprocessors with management of up to 64 key switches,

with an additional eight LED drivers/GPIOs that feature

constant-current, PWM intensity control, and rotary

switch control options.

The key-switch drivers interface with metallic or resistive

switches with on-resistances up to 5kI. Key inputs

are monitored statically, not dynamically, to ensure

low-EMI operation. The MAX7360 features autosleep

and autowake modes to further minimize the power

consumption of the device. The autosleep feature puts

the device in a low-power state (1FA typ) after a sleep

timeout period. The autowake feature configures the

MAX7360 to return to normal operating mode from sleep

upon a keypress.

The key controller debounces and maintains a FIFO of

keypress and release events (including autorepeat, if

enabled). An interrupt (INTK) output can be configured

to alert keypresses, as they occur, or at maximum rate.

There are eight open-drain I/O ports, which can be used

to drive LEDs. The maximum constant-current level for

each open-drain port is 20mA. The intensity of the LED

on each open-drain port can be individually adjusted

through a 256-step PWM control. An input port pair

(PORT6, PORT7) can be configured to accept 2-bit gray

code inputs from a rotary switch. In addition, if not used

for key-switch control, up to six column pins can be used

as general-purpose open-drain outputs (GPOs) for LED

drive or logic control.

The MAX7360 is offered in a 40-pin (5mm x 5mm) thin

QFN package with an exposed pad, and a small 36-bump

wafer level package (WLP) for cell phones, pocket PCs,

and other portable consumer electronic applications. The

MAX7360 operates over the -40NC to +85NC extended

temperature range.

Applications

Cell Phones

PDAs

Handheld Games

Portable Consumer Electronics

Printers

Instrumentation

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

_______________________________________________________________ Maxim Integrated Products 1

Features

S Integrated ESD Protection

Q8kV IEC 61000-4-2 Contact Discharge

Q15kV IEC 61000-4-2 Air-Gap Discharge

S +14V Tolerant, Open-Drain I/O Ports Capable of

Constant-Current LED Drive

S Rotary Switch-Capable Input Pair (PORT6, PORT7)

S 256-Step PWM Individual LED Intensity Control

S Individual LED Blink Rates and Common LED

Fade In/Out Rates from 256ms to 4096ms

S FIFO Queues Up to 16 Debounced Key Events

S User-Configurable Key Debounce (9ms to 40ms)

S Keyscan Uses Static Matrix Monitoring for Low

EMI Operation

S +1.62V to +3.6V Operation

S Monitors Up to 64 Keys

S Key-Switch Interrupt (INTK) on Each Debounced

Event/FIFO Level, or End of Definable Time Period

S Port Interrupt (INTI) for Input Ports for Special-Key

Functions

S 400kbps, +5.5V Tolerant 2-Wire Serial Interface

with Selectable Bus Timeout

S Four I

2

C Address Choices

Ordering Information

PART TEMP RANGE PIN-PACKAGE

MAX7360ETL+ -40°C to +85°C 40 TQFN-EP*

MAX7360EWX+** -40°C to +85°C 36 WLP

+Denotes a lead(Pb)-free/RoHS-compliant package.

*EP = Exposed pad.

**Future product—contact factory for availability.

Simplfied Block Diagram

Pin Configurations appear at end of data sheet.

MAX7360

Page 2

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

ABSOLUTE MAXIMUM RATINGS

VCC to GND ............................................................. -0.3V to +4V

COL0–COL7, ROW0–ROW7 to GND ......................-0.3V to +4V

SDA, SCL, AD0, INTI, INTK to GND ........................ -0.3V to +6V

PORT0–PORT7 to GND ......................................... -0.3V to +16V

All Other Pins to GND ................................-0.3V to (VCC + 0.3V)

DC Current on PORT0–PORT7, COL2–COL7 ....................25mA

GND Current .......................................................................80mA

Continuous Power Dissipation (TA = +70NC)

MAX7360

40-Pin TQFN (derate 22.2mW/NC above +70NC).......1777mW

36-Bump WLP (derate 21.7mW/NC above +70NC) .... 1739mW

Junction-to-Case Thermal Resistance (BJC) (Note 1)

40-Pin TQFN .................................................................. 2NC/W

36-Bump WLP ...................................................................N/A

Junction-to-Ambient Thermal Resistance (BJA) (Note 1)

40-Pin TQFN ................................................................ 45NC/W

36-Bump WLP .............................................................46NC/W

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a single layer board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial.

Note 2: Refer to Pb-free solder-reflow requirements described in J-STD-020, Rev D.1, or any other paste supplier specification.

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these

or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended periods may

affect device reliability.

Operating Temperature Range .......................... -40NC to +85NC

Junction Temperature .....................................................+150NC

Storage Temperature Range ............................ -65NC to +150NC

ESD Protection

Human Body Model (RD = 1.5kI, CS = 100pF)

All Pins .............................................................................Q2kV

IEC61000-4-2 (RD = 330I, CS = 150pF)

Contact Discharge

ROW0–ROW7, COL0–COL7, PORT0–PORT7 to GND ....Q8kV

Air-Gap Discharge

ROW0–ROW7, COL0–COL7, PORT0–PORT7 to GND ..Q15kV

Lead Temperature (soldering, 10s)

40-Pin TQFN ................................................................+300NC

36-Bump WLP ........................................................... (Note 2)

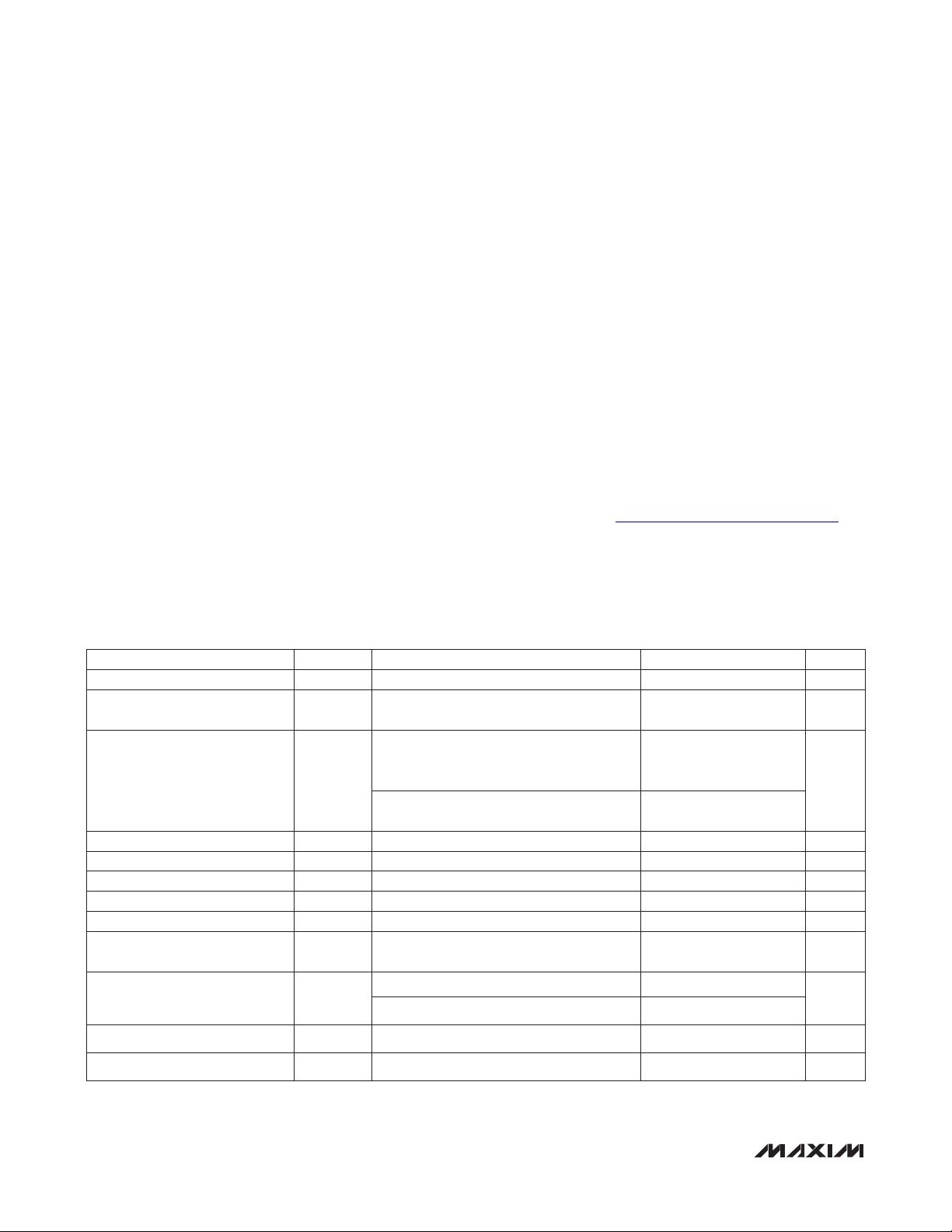

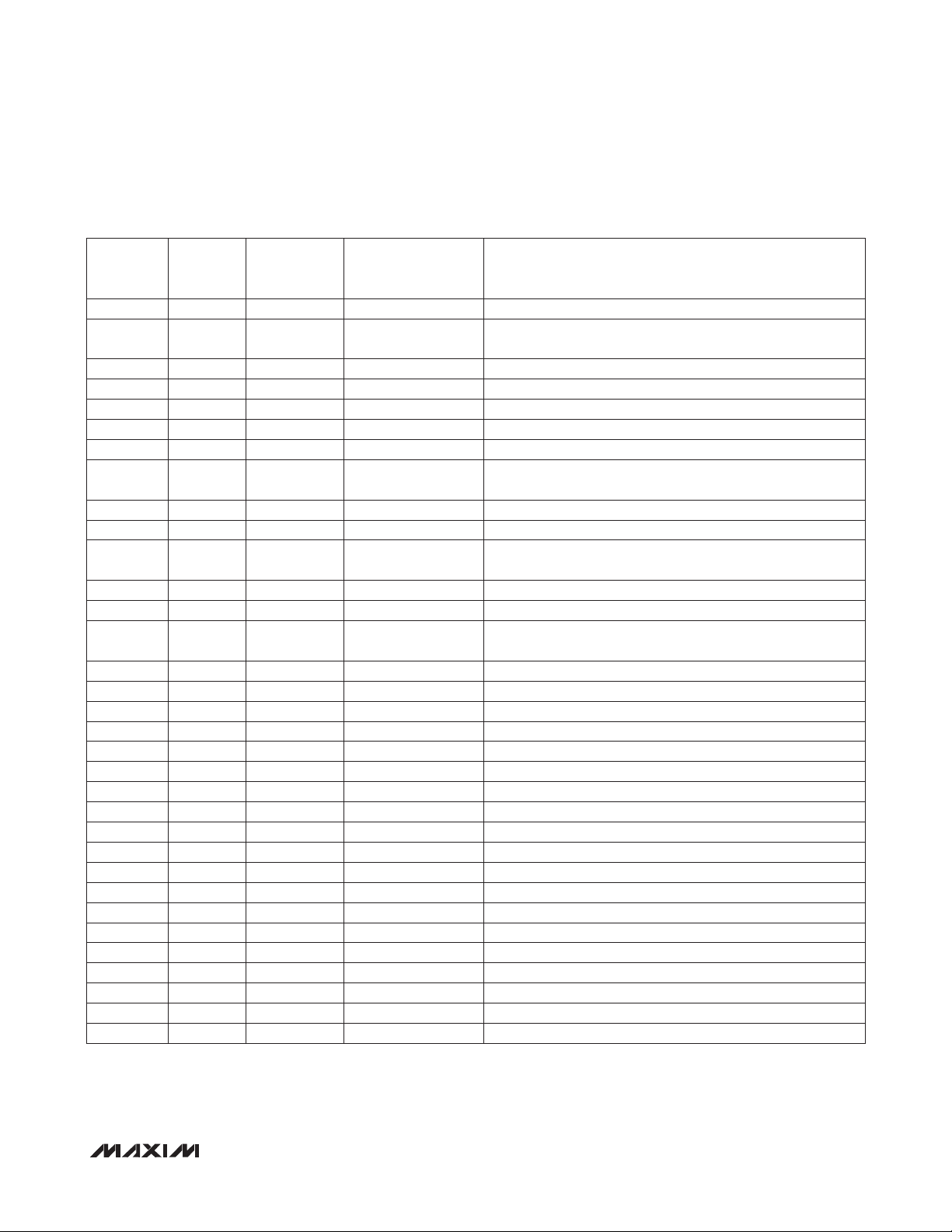

ELECTRICAL CHARACTERISTICS

(VCC = +1.62V to +3.6V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at VCC = +3.3V, TA = +25NC.) (Notes 3, 4)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Operating Supply Voltage V

External Supply Voltage

PORT0–PORT7

Operating Supply Current I

Sleep-Mode Supply Current I

Key-Switch Source Current I

Key-Switch Source Voltage V

Key-Switch Resistance R

Startup Time from Shutdown t

Output Low Voltage

COL2–COL7

Oscillator Frequency (PWM

Clock)

Oscillator Frequency Variation Df

Key-Scan Frequency f

V

CC

PORT_

CC

SL

KEY

KEY

KEY

START

V

OL

f

OSC

OSC

KEY

All key switches open, oscillator running,

COL2–COL7 configured as key switches,

V

_ = V

PORT

N keys pressed

(Note 5) 5 kI

I

SINK

TA = +25NC, VCC = +2.61V 125 128 131

TA = T

TA = +25NC -6 +8.5 %

Derived from oscillator clock 64 kHz

CC

= 10mA 0.5 V

- T

, V

MIN

MAX

P 3.6V 102 164

CC

1.62 3.3 3.6 V

14 V

34 50

FA

34 +

20 x N

1.3 3 FA

20 35 FA

0.43 0.5 V

2 2.4 ms

kHz

2 ______________________________________________________________________________________

Page 3

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

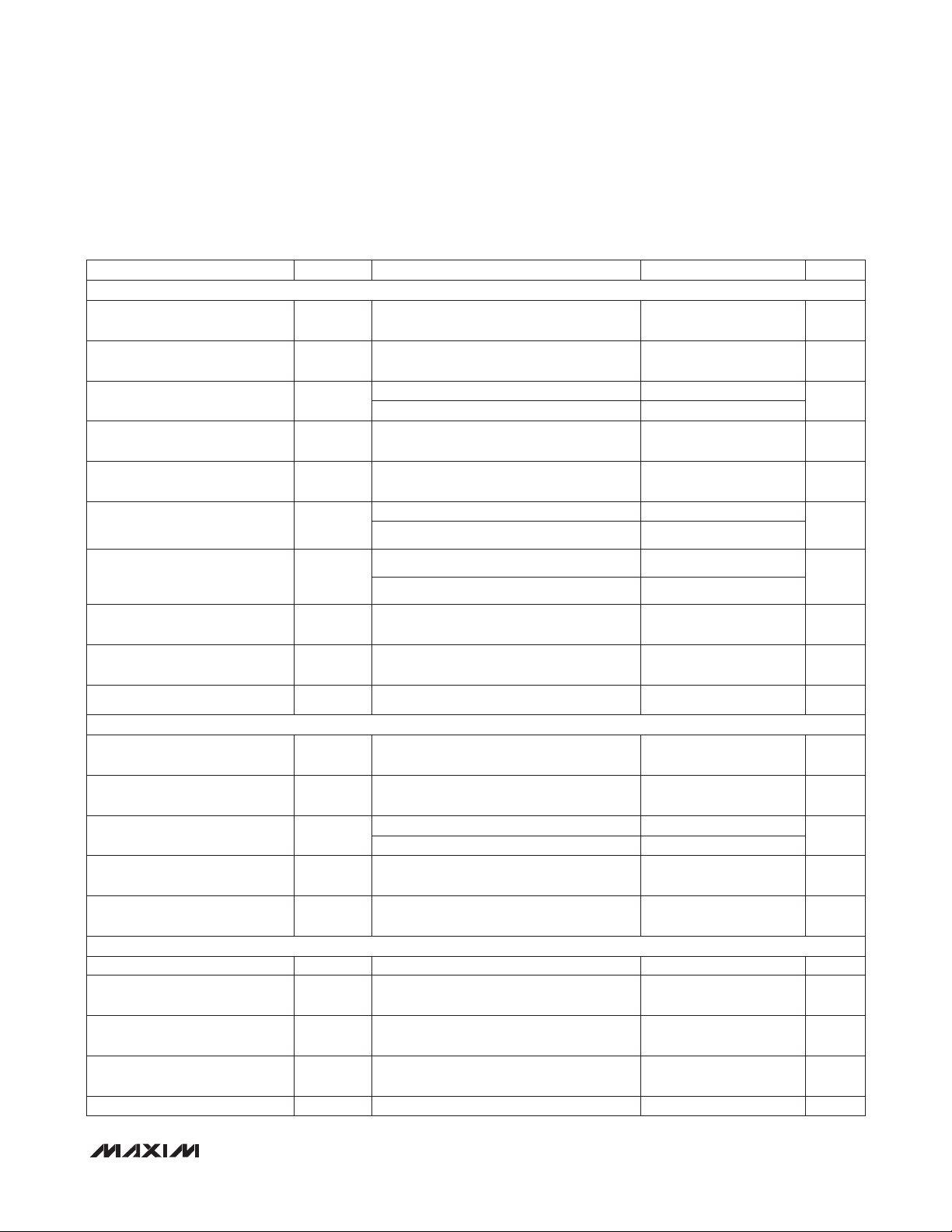

ELECTRICAL CHARACTERISTICS (continued)

(VCC = +1.62V to +3.6V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at VCC = +3.3V, TA = +25NC.) (Notes 3, 4)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

GPIO SPECIFICATIONS

Input High Voltage

PORT0–PORT7

Input Low Voltage

PORT0–PORT7

Input Leakage Current

PORT0–PORT7

Output Low Voltage

PORT0–PORT7

Input Capacitance

PORT0–PORT7

10mA Port Sinking Current

PORT0–PORT7

V

IH

V

IL

VIN P V

I

IN

V

OL

CC

VCC < V

I

VCC = +1.62V to +3.6V, TA = +25NC 8.55 11.52

VCC = +3.3V, VOL = +1V 8.67 9.76 10.51

IN

< 20mA 0.6 V

SINK

0.7 x

V

CC

0.3 x

V

CC

-0.25 +0.25

-1 +5

20 pF

V

V

FA

mA

MAX7360

20mA Port Sinking Current

PORT0–PORT7

Port Sink Current Variation

Output Logic-Low Voltage

INTI, INTK

PWM Frequency f

SERIAL-INTERFACE SPECIFICATIONS

Input High Voltage

SDA, SCL, AD0

Input Low Voltage

SDA, SCL, AD0

Input Leakage Current

SDA, SCL, AD0

Output Low Voltage

SDA

Input Capacitance

SDA, SCL, AD0

I2C TIMING SPECIFICATIONS

SCL Serial-Clock Frequency f

Bus Free Time Between a STOP

and START Condition

Hold Time (Repeated) START

Condition

Repeated START Condition

Setup Time

STOP Condition Setup Time t

PWM

V

C

t

t

HD, STA

t

SU, STA

SU, STO

V

IH

V

IL

I

IN

OL

IN

SCL

BUF

VCC = +1.62V to +3.6V, TA = +25NC 19.40 21.33

VCC = +3.3V, VOL = +1V 19.55 20 20.69

VCC = +3.3V, VOL = +1V, TA = +25NC,

20mA output mode

I

= 10mA 0.6 V

SINK

Derived from oscillator clock 500 Hz

0.7 x

V

VIN P V

CC

VIN > V

CC

I

= 6mA 0.6 V

SINK

Bus timeout disabled 0 400 kHz

-0.25 +0.25

-0.5 +0.5

1.3 Fs

0.6 Fs

0.6 Fs

0.6 Fs

+Q1.5 +Q2.4 %

CC

10 pF

0.3 x

V

CC

mA

V

V

FA

_______________________________________________________________________________________ 3

Page 4

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

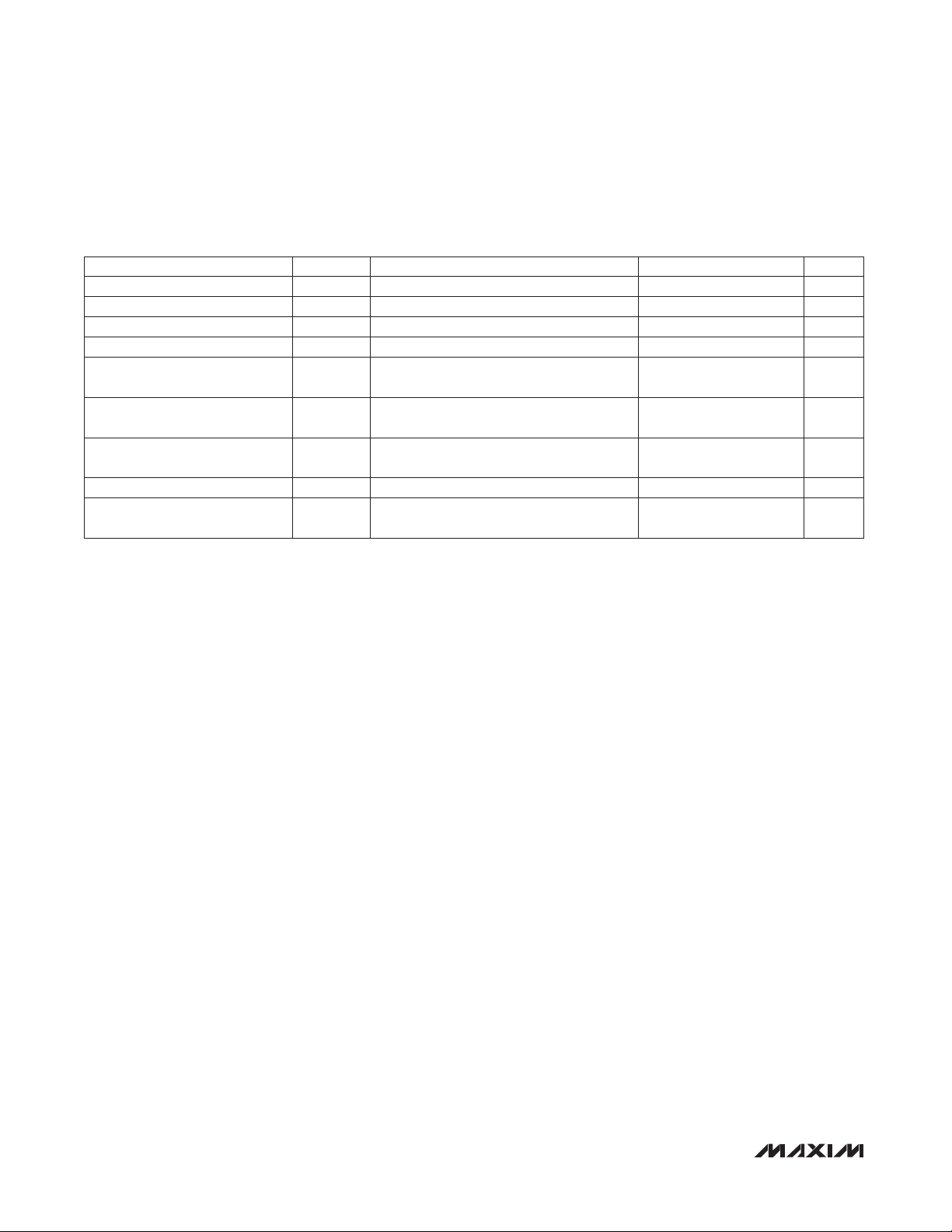

ELECTRICAL CHARACTERISTICS (continued)

(VCC = +1.62V to +3.6V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at VCC = +3.3V, TA = +25NC.) (Notes 3, 4)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Data Hold Time t

Data Setup Time t

SCL Clock Low Period t

SCL Clock High Period t

MAX7360

Rise Time of Both SDA and SCL

Signals, Receiving

Fall Time of Both SDA and SCL

Signals, Receiving

Fall Time of SDA Signal,

Transmitting

Pulse Width of Spike Suppressed t

Capacitive Load for Each Bus

Line

Note 3: All parameters are tested at TA = +25NC. Specifications over temperature are guaranteed by design.

Note 4: All digital inputs at VCC or GND.

Note 5: Guaranteed by design.

Note 6: A master device must provide a hold time of at least 300ns for the SDA signal (referred to VIL of the SCL signal) to bridge

the undefined region of SCL’s falling edge.

Note 7: Cb = total capacitance of one bus line in pF. tR and tF measured between +0.8V and +2.1V.

Note 8: I

Note 9: Input filters on the SDA, SCL, and AD0 inputs suppress noise spikes less than 50ns.

P 6mA. Cb = total capacitance of one bus line in pF. tR and tF measured between +0.8V and +2.1V.

SINK

HD, DAT

SU, DAT

LOW

HIGH

t

R

t

F

t

F, TX

SP

C

(Note 6) 0.9 Fs

100 ns

1.3 Fs

0.7 Fs

(Notes 5, 7)

(Notes 5, 7)

(Notes 5, 8)

(Notes 5, 9) 50 ns

(Note 5) 400 pF

b

20 +

0.1C

20 +

0.1C

20 +

0.1C

b

b

b

300 ns

300 ns

250 ns

4 ______________________________________________________________________________________

Page 5

I2C-Interfaced Key-Switch Controller and LED

SINK CURRENT (mA)

SINK CURRENT (mA)

CONSTANT-CURRENT GPIO OUTPUT

CONSTANT-CURRENT GPIO OUTPUT

CONSTANT-CURRENT GPIO OUTPUT

Driver/GPIOs with Integrated ESD Protection

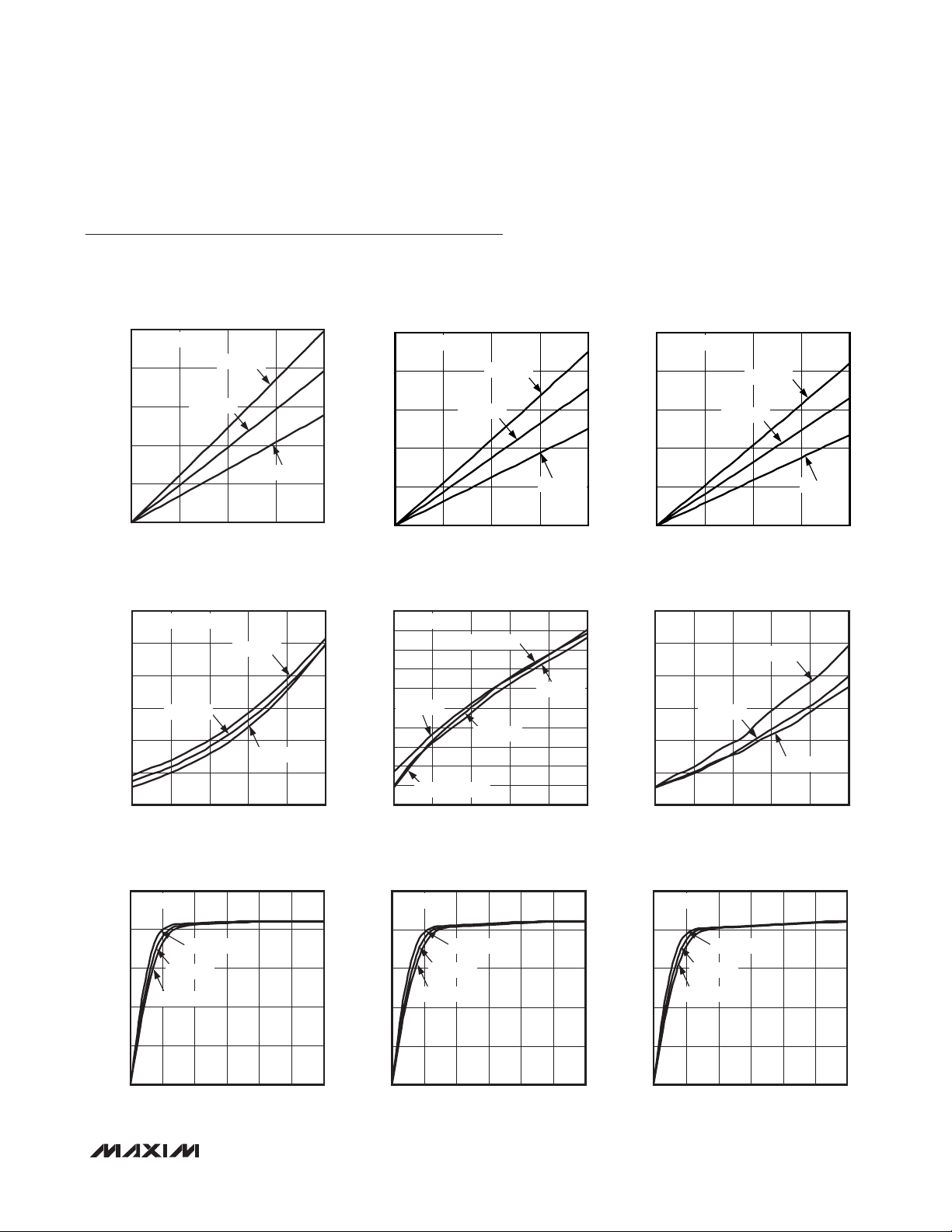

Typical Operating Characteristics

(VCC = +2.5V, TA = +25NC, unless otherwise noted.)

MAX7360

GPO OUTPUT LOW VOLTAGE

vs. SINK CURRENT (COL2–COL7)

250

VCC = 2.4V

200

150

100

OUTPUT VOLTAGE (mV)

50

0

0 20

TA = +85NC

TA = +25NC

SINK CURRENT (mA)

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

45

AUTOSLEEP = OFF

40

35

30

25

SUPPLY CURRENT (A)

20

15

TA = +25NC

2.0

1.6 3.6

SUPPLY VOLTAGE (V)

TA = +85NC

TA = -40NC

2.4

2.8

TA = -40NC

15105

3.2

GPO OUTPUT LOW VOLTAGE

vs. SINK CURRENT (COL2–COL7)

250

VCC = 3.0V

MAX7360 toc01

200

150

100

OUTPUT VOLTAGE (mV)

50

0

0 20

KEY-SWITCH SOURCE CURRENT

18.4

V

= O

COL0

18.3

MAX7360 toc04

18.2

18.1

18.0

TA = +85NC

17.9

17.8

17.7

17.6

KEY-SWITCH SOURCE CURRENT (A)

17.5

TA = -40NC, +25NC

17.4

1.6 3.63.2

TA = +85°C

TA = +25°C

vs. SUPPLY VOLTAGE

TA = -40NC, +85NC

TA = -40NC

2.42.0

2.8

SUPPLY VOLTAGE (V)

TA = -40°C

15105

TA = +25NC

GPO OUTPUT LOW VOLTAGE

vs. SINK CURRENT (COL2–COL7)

250

VCC = 3.6V

MAX7360 toc02

200

150

100

OUTPUT VOLTAGE (mV)

50

0

0 20

SHUTDOWN SUPPLY CURRENT

3.0

2.5

MAX7360 toc05

2.0

1.5

1.0

SHUTDOWN SUPPLY CURRENT (A)

0.5

0

1.6 3.63.2

TA = +85°C

TA = +25°C

vs. SUPPLY VOLTAGE

TA = -40NC

TA = +25NC

TA = +85NC

2.8

2.42.0

SUPPLY VOLTAGE (V)

MAX7360 toc03

TA = -40°C

15105

MAX7360 toc06

SINK CURRENT vs. OUTPUT VOLTAGE

25

VCC = 2.4V

20

TA = -40NC

15

10

SINK CURRENT (mA)

5

0

TA = +25NC

TA = +85NC

0 3.02.5

OUTPUT VOLTAGE (V)

_______________________________________________________________________________________ 5

SINK CURRENT vs. OUTPUT VOLTAGE

25

VCC = 3.0V

MAX7360 toc07

20

TA = -40NC

15

10

SINK CURRENT (mA)

5

0

1.5 2.01.00.5

TA = +25NC

TA = +85NC

0 3.02.5

1.5 2.01.00.5

OUTPUT VOLTAGE (V)

MAX7360 toc08

SINK CURRENT vs. OUTPUT VOLTAGE

25

VCC = 3.6V

20

TA = -40NC

15

10

SINK CURRENT (mA)

5

0

TA = +25NC

TA = +85NC

0 3.02.5

1.5 2.01.00.5

OUTPUT VOLTAGE (V)

MAX7360 toc09

Page 6

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

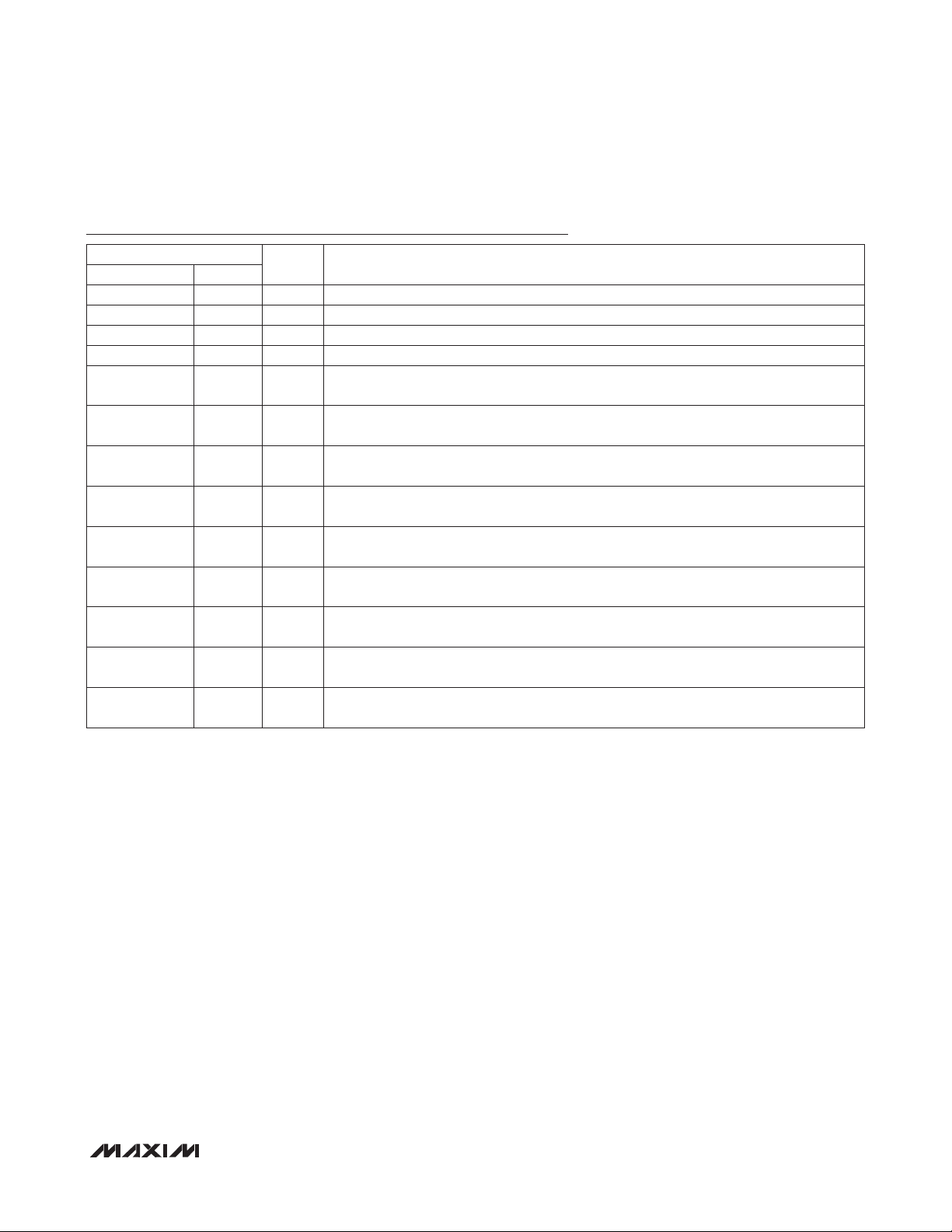

Pin Description

PIN

TQFN WLP

1 A6 ROW0 Row Input from Key Matrix. Leave ROW0 unconnected or connect to GND if unused.

2 B6 ROW1 Row Input from Key Matrix. Leave ROW1 unconnected or connect to GND if unused.

3 C4 ROW2 Row Input from Key Matrix. Leave ROW2 unconnected or connect to GND if unused.

MAX7360

4 C6 ROW3 Row Input from Key Matrix. Leave ROW3 unconnected or connect to GND if unused.

5, 15, 25, 35B4, C5, D2,

E4

6 D6 ROW4 Row Input from Key Matrix. Leave ROW4 unconnected or connect to GND if unused.

7 D5 ROW5 Row Input from Key Matrix. Leave ROW5 unconnected or connect to GND if unused.

8 E6 ROW6 Row Input from Key Matrix. Leave ROW6 unconnected or connect to GND if unused.

9 D4 ROW7 Row Input from Key Matrix. Leave ROW7 unconnected or connect to GND if unused.

10, 20, 27,

30, 40

11 F6 COL0 Column Output to Key Matrix. Leave COL0 unconnected if unused.

12 E5 COL1 Column Output to Key Matrix. Leave COL1 unconnected if unused.

13 F5 COL2

14 F4 COL3

16 F3 COL4

17 E3 COL5

18 F2 COL6

19 F1 COL7

21 E2 SDA I2C-Compatible, Serial-Data I/O

22 E1 SCL I2C-Compatible, Serial-Clock Input

23 D3 INTK

C2 N.C. No Connection. Not internally connected. Leave unconnected.

NAME FUNCTION

GND Ground

Column Output to Key Matrix. Leave COL2 unconnected if unused. COL2 can be

configured as a GPO (see Table 9 in the Register Tables section).

Column Output to Key Matrix. Leave COL3 unconnected if unused. COL3 can be

configured as a GPO (see Table 9 in the Register Tables section).

Column Output to Key Matrix. Leave COL4 unconnected if unused. COL4 can be

configured as a GPO (see Table 9 in the Register Tables section).

Column Output to Key Matrix. Leave COL5 unconnected if unused. COL5 can be

configured as a GPO (see Table 9 in the Register Tables section).

Column Output to Key Matrix. Leave COL6 unconnected if unused. COL6 can be

configured as a GPO (see Table 9 in the Register Tables section).

Column Output to Key Matrix. Leave COL7 unconnected if unused. COL7 can be

configured as a GPO (see Table 9 in the Register Tables section).

Active-Low Key-Switch Interrupt Output. INTK is open drain and requires a pullup

resistor.

6 ______________________________________________________________________________________

Page 7

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

Pin Description (continued)

MAX7360

PIN

TQFN WLP

24 D1 INTI Active-Low GPI Interrupt Output. INTI is open drain and requires a pullup resistor.

26 C1 V

28 B1 AD0 Address Input. AD0 selects up to four device slave addresses (Table 3).

29 A1 I.C. Internally Connected. Connect to GND for normal operation.

31 B2 PORT0

32 A2 PORT1

33 B3 PORT2

34 A3 PORT3

36 A4 PORT4

37 C3 PORT5

38 A5 PORT6

39 B5 PORT7

— — EP

NAME FUNCTION

Positive Supply Voltage. Bypass VCC to GND with a 0.1FF or higher ceramic capacitor.

CC

GPIO Port. Open-drain I/O rated at +14V. PORT0 can be configured as a constantcurrent output.

GPIO Port. Open-drain I/O rated at +14V. PORT1 can be configured as a constantcurrent output.

GPIO Port. Open-drain I/O rated at +14V. PORT2 can be configured as a constantcurrent output.

GPIO Port. Open-drain I/O rated at +14V. PORT3 can be configured as a constantcurrent output.

GPIO Port. Open-drain I/O rated at +14V. PORT4 can be configured as a constantcurrent output.

GPIO Port. Open-drain I/O rated at +14V. PORT5 can be configured as a constantcurrent output.

GPIO Port. Open-drain I/O rated at +14V. PORT6 Can be configured as a constantcurrent output, or a rotary switch input.

GPIO Port. Open-drain I/O rated at +14V. PORT7 can be configured as a constantcurrent output, or a rotary switch input.

Exposed Pad (TQFN only). EP is internally connected to GND. Connect EP to a ground

plane to increase thermal performance.

_______________________________________________________________________________________ 7

Page 8

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

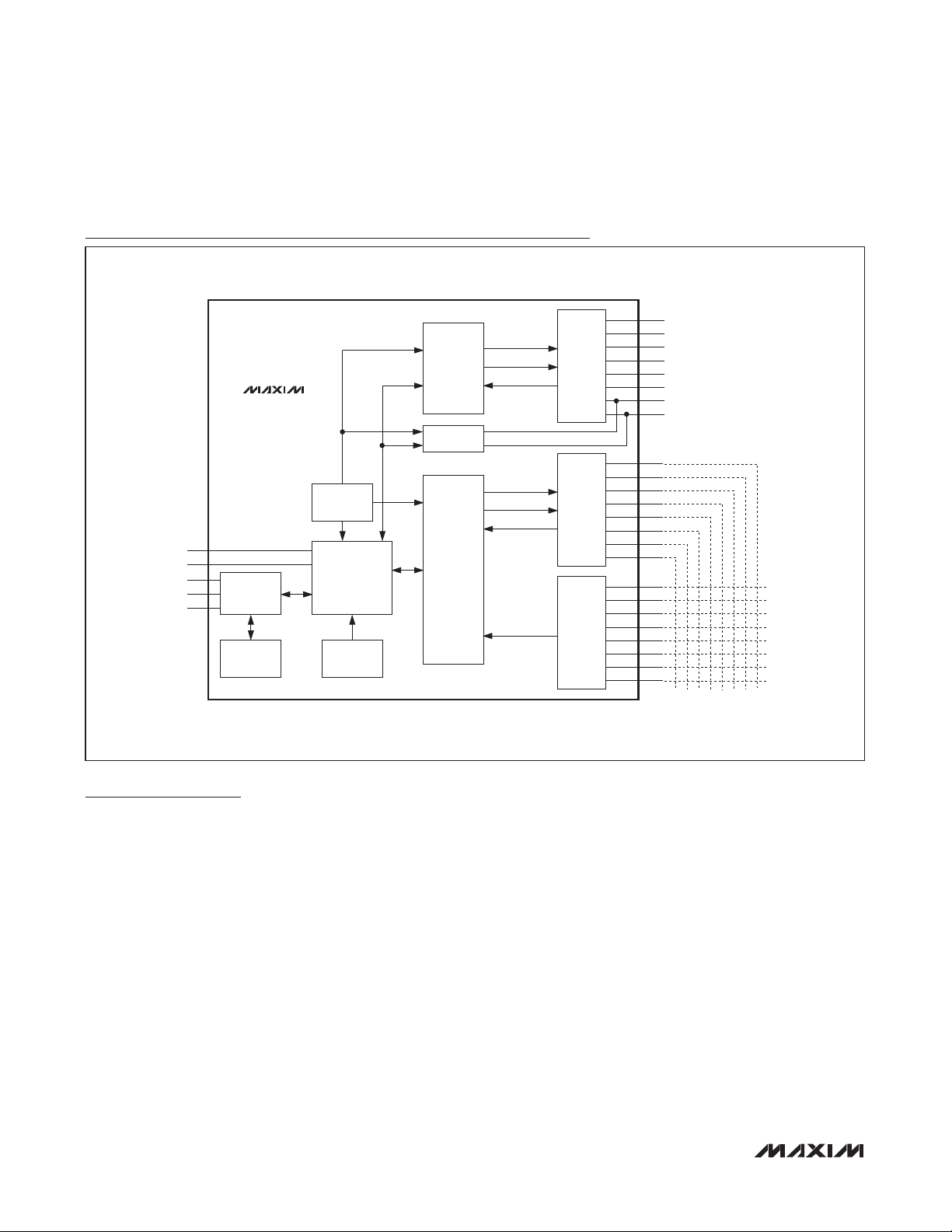

Functional Block Diagram

PORT0

PORT1

PORT2

PORT3

PORT4

PORT5

PORT6

PORT7

COL0

COL1

COL2*

COL3*

COL4*

COL5*

COL6*

COL7*

ROW0

ROW1

ROW2

ROW3

ROW4

ROW5

ROW6

ROW7

MAX7360

INTI

INTK

SDA

SCL

AD0

MAX7360

I2C

INTERFACE

BUS

TIMEOUT

128kHz

OSCILLATOR

CONTROL

REGISTERS

FIFO

POR

PWM

GPIO

LOGIC

ROTARY

KEY

SCAN

LED ENABLE

GPIO ENABLE

GPIO INPUT

COLUMN ENABLE

GPO ENABLE

CURRENT DETECT

ROW ENABLE

PORT GPIO

AND

CONSTANT-

CURRENT

LED DRIVE

CURRENT

SOURCE

COLUMN

DRIVES

OPENDRAIN

ROW

DRIVES

*GPO

Detailed Description

The MAX7360 is a microprocessor peripheral low-noise

key-switch controller that monitors up to 64 key switches

with optional autorepeat, and key events that are

presented in a 16-byte FIFO. The MAX7360 also features

eight open-drain GPIOs configured for digital I/O or

constant-current output for LED applications up to +14V.

The MAX7360 features an automatic sleep mode and

automatic wakeup that further reduce supply current

consumption. The MAX7360 can be configured to enter

sleep mode after a programmable time following a key

event. The FIFO content is maintained and can be read

in sleep mode. The MAX7360 does not enter autosleep

when a key is held down. The autowake feature takes

To prevent overloading the microprocessor with too

many interrupts, interrupt requests are issued on a

programmable number of FIFO entries, and/or after a

set period of time (Table 10). The key-switch status is

checked by reading the key-switch FIFO. A 1-byte read

access returns both the next key event in the FIFO (if

there is one) and the FIFO status. INTK functions as an

open-drain general-purpose output (GPO) capable of

driving an LED if key-switch interrupts are not required.

Up to six of the key-switch outputs function as opendrain GPOs capable of driving additional LEDs when

the application requires fewer keys to be scanned. For

each key-switch output used as a GPO, the number of

monitored key switches reduces by eight.

the MAX7360 out of sleep mode following a keypress

event. Enable/disable autosleep and autowake through

the configuration register (Table 8).

8 ______________________________________________________________________________________

On power-up, all control registers are set to power-up

values and the MAX7360 is in sleep mode (Table 1).

Initial Power-Up

Page 9

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

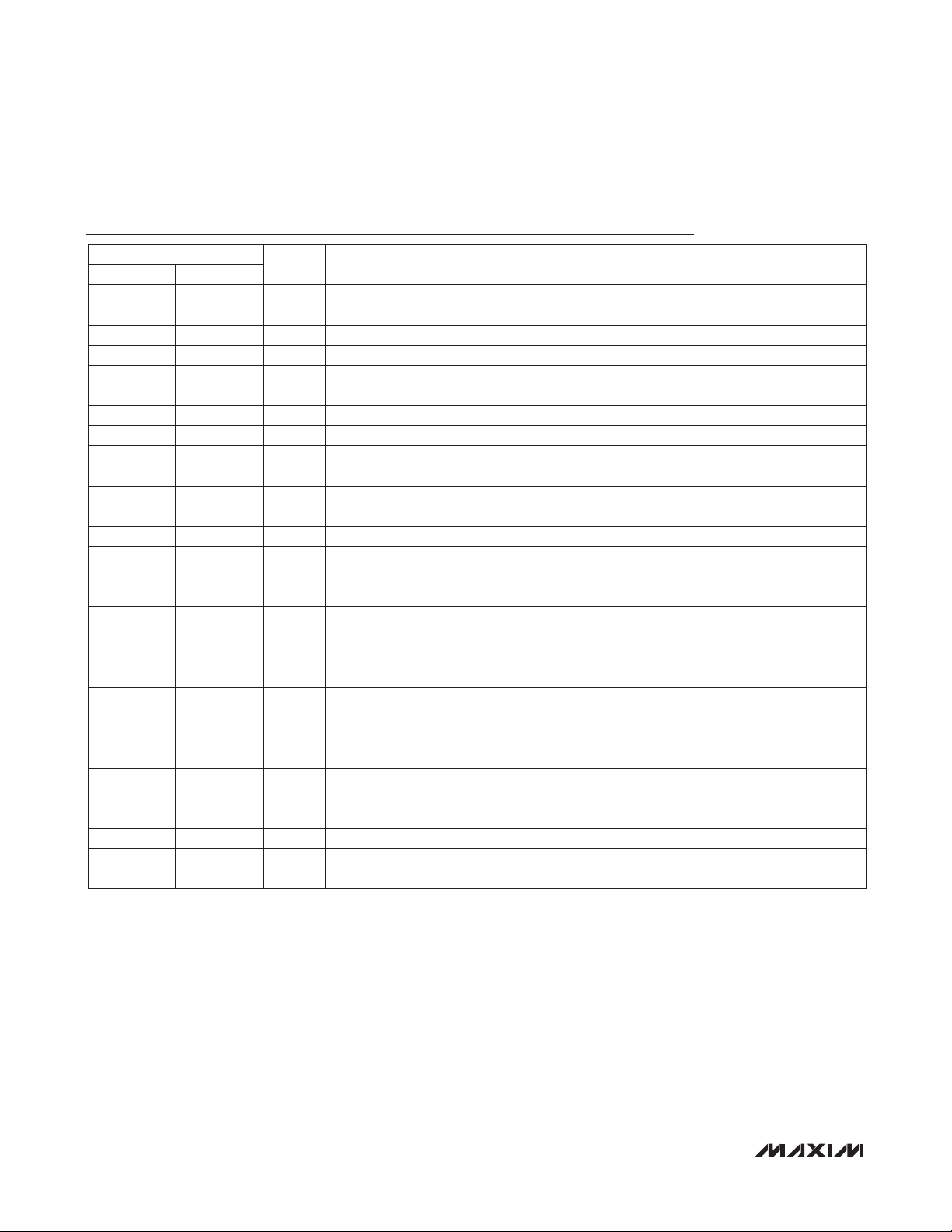

Table 1. Register Address Map and Power-Up Condition

MAX7360

ADDRESS

CODE

(hex)

0x00 Read only 0x3F Keys FIFO Read FIFO key-scan data out

0x01

0x02

0x03

0x04

0x05

0x06

0x40

0x41

0x42

0x43

0x44

0x45

0x46

0x48 Read only 0x00

0x49 Read only 0xFF GPIO input register PORT0–PORT7 input values

0x4A Read only 0x00 Rotary switch count Switch cycles since last read

0x50

0x51

0x52

0x53

0x54

0x55

0x56

0x57

0x58

0x59

0x5A

0x5B

0x5C

0x5D

0x5E

0x5F

READ/

WRITE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

POWER-UP

VALUE (hex)

0x0A Configuration

0xFF Debounce Key debounce time settling and GPO enable

0x00 Interrupt

0xFE GPO

0x00 Key repeat Delay and frequency for key repeat

0x07 Sleep Idle time to autosleep

0x00

0x00 GPIO control PORT0–PORT7 input/output control

0x00 GPIO debounce PORT0–PORT7 debounce time setting

0xC0

0x00 GPIO output mode PORT0–PORT7 output mode control

0x00 Common PWM Common PWM duty-cycle setting

0x00

0x00 PORT0 PWM PORT0 individual duty-cycle setting

0x00 PORT1 PWM PORT1 individual duty-cycle setting

0x00 PORT2 PWM PORT2 individual duty-cycle setting

0x00 PORT3 PWM PORT3 individual duty-cycle setting

0x00 PORT4 PWM PORT4 individual duty-cycle setting

0x00 PORT5 PWM PORT5 individual duty-cycle setting

0x00 PORT6 PWM PORT6 individual duty-cycle setting

0x00 PORT7 PWM PORT7 individual duty-cycle setting

0x00 PORT0 configuration PORT0 interrupt, PWM mode control and blink period setting

0x00 PORT1 configuration PORT1 interrupt, PWM mode control and blink period setting

0x00 PORT2 configuration PORT2 interrupt, PWM mode control and blink period setting

0x00 PORT3 configuration PORT3 interrupt, PWM mode control and blink period setting

0x00 PORT4 configuration PORT4 interrupt, PWM mode control and blink period setting

0x00 PORT5 configuration PORT5 interrupt, PWM mode control and blink period setting

0x00 PORT6 configuration PORT6 interrupt, PWM mode control and blink period setting

0x00 PORT7 configuration PORT7 interrupt, PWM mode control and blink period setting

REGISTER

FUNCTION

Power-down, key-release enable, autowakeup, and I2C timeout enable

Key-switch interrupt INTK frequency setting

COL2–COL7 and INTK GPO control

GPIO global con-

figuration

GPIO constant-

current setting

Rotary switch con-

figuration

I2C timeout flag I2C timeout since last POR

Rotary switch, GPIO standby, GPIO reset, fade

PORT0–PORT7 constant-current output setting

Rotary switch interrupt frequency and debounce time setting

DESCRIPTION

_______________________________________________________________________________________ 9

Page 10

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

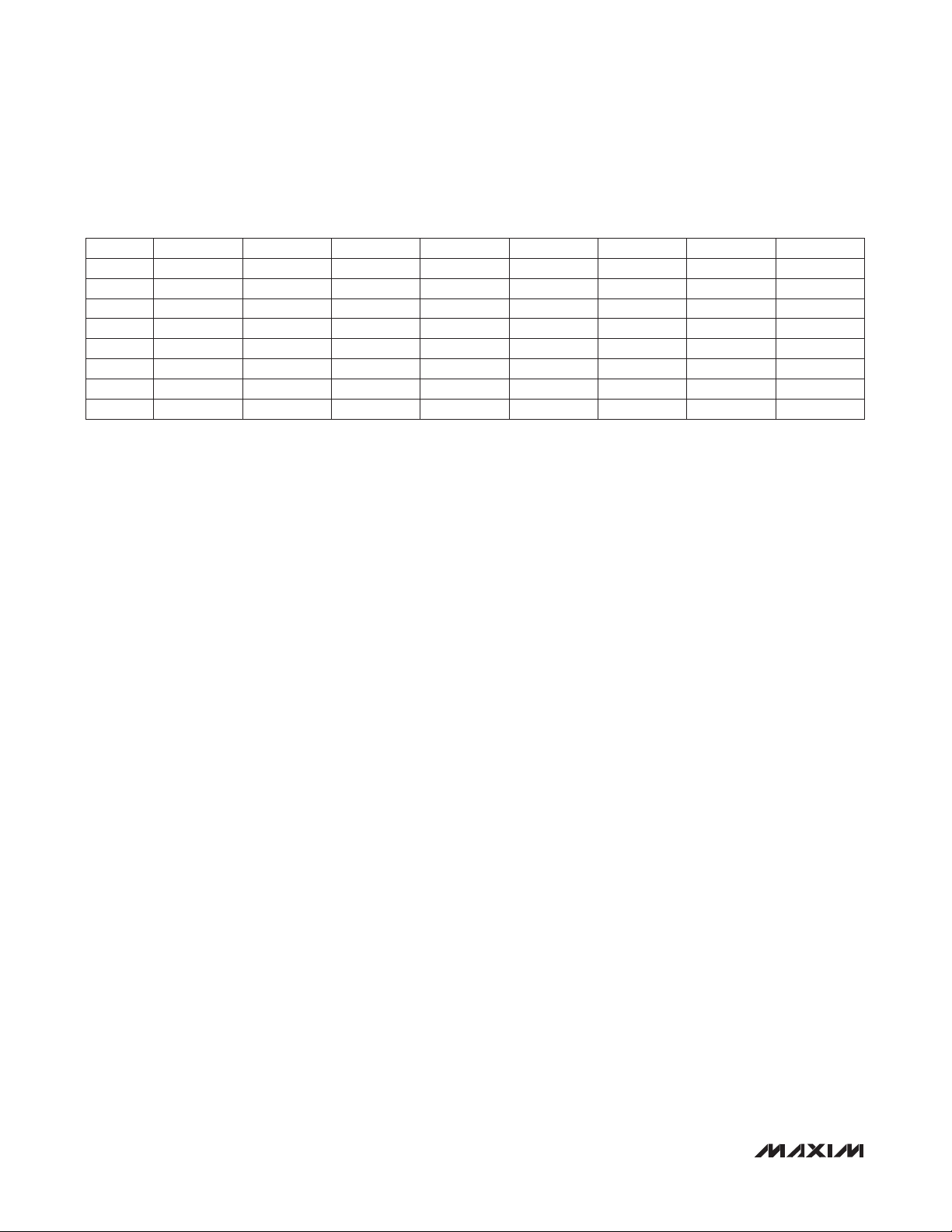

Table 2. Key-Switch Mapping

PIN COL0 COL1 COL2* COL3* COL4* COL5* COL6* COL7*

ROW0

ROW1

ROW2

ROW3

ROW4

MAX7360

ROW5

ROW6

ROW7

*These columns can be configured as GPOs.

KEY 0 KEY 8 KEY 16 KEY 24 KEY 32 KEY 40 KEY 48 KEY 56

KEY 1 KEY 9 KEY 17 KEY 25 KEY 33 KEY 41 KEY 49 KEY 57

KEY 2 KEY 10 KEY 18 KEY 26 KEY 34 KEY 42 KEY 50 KEY 58

KEY 3 KEY 11 KEY 19 KEY 27 KEY 35 KEY 43 KEY 51 KEY 59

KEY 4 KEY 12 KEY 20 KEY 28 KEY 36 KEY 44 KEY 52 KEY 60

KEY 5 KEY 13 KEY 21 KEY 29 KEY 37 KEY 45 KEY 53 KEY 61

KEY 6 KEY 14 KEY 22 KEY 30 KEY 38 KEY 46 KEY 54 KEY 62

KEY 7 KEY 15 KEY 23 KEY 31 KEY 39 KEY 47 KEY 55 KEY 63

Key-Scan Controller

Key inputs are scanned statically, not dynamically,

to ensure low-EMI operation. As inputs only toggle

in response to switch changes, the key matrix can be

routed closer to sensitive circuit nodes.

The key-scan controller debounces and maintains a FIFO

of keypress and release events (including autorepeated

keypresses, if autorepeat is enabled). Table 2 shows the

key-switch order. The user-programmable key-switch

debounce time, and autosleep timer, is derived from the

64kHz clock, which in turn is derived from the 128kHz

oscillator. Time delay for autorepeat and key-switch

interrupt is based on the key-switch debounce time.

Keys FIFO Register (0x00)

The keys FIFO register contains the information pertaining

to the status of the keys FIFO, as well as the key events

that have been debounced (see Table 7 in the Register

Tables section). Bits D0–D5 denote which of the 64 keys

have been debounced and the keys are numbered as in

Table 1.

D7 indicates if there is more data in the FIFO, except

when D5:D0 indicate key 63 or key 62. When D5:D0

indicate key 63 or key 62, the host should read one more

time to determine whether there is more data in the FIFO.

Use key 62 and key 63 for rarely used keys. D6 indicates

if it is a keypress or release event, except when D5:D0

indicate key 63 or key 62.

Reading the key-scan FIFO clears the interrupt INTK

depending on the setting of bit D5 in the configuration

register (0x01).

Configuration Register (0x01)

The configuration register controls the I2C bus timeout

feature, enables key-release detection, enables autowake,

and determines how INTK is deasserted. Write to bit D7

to put the MAX7360 into sleep mode or operating mode.

Autosleep and autowake, when enabled, also change the

status of D7 (see Table 8 in the Register Tables section).

Debounce Register (0x02)

The debounce register sets the time for each debounce

cycle, as well as setting whether the GPO ports are

enabled or disabled. Bits D0–D4 set the debounce time

in increments of 1ms starting at 9ms and ending at 40ms

(see Table 9 in the Register Tables section). Bits D5, D6,

and D7 set which of the GPO ports is enabled. Note the

GPO ports are enabled only in the combinations shown

in Table 9, from all disabled to all enabled.

Key-Switch Interrupt Register (0x03)

The interrupt register contains information related to the

settings of the interrupt request function, as well as the

status of the INTK output, which can also be configured

as a GPO. If bits D0–D7 are set to 0x00, the INTK output

is configured as a GPO that is controlled by bit D1 in the

port register. There are two types of interrupts, the FIFObased interrupt and time-based interrupt. Set bits D0–D4

to assert interrupts at the end of the selected number of

debounce cycles following a key event (see Table 10 in

the Register Tables section). This number ranges from

1–31 debounce cycles. Setting bits D7, D6, and D5 set

the FIFO-based interrupt when there are 4–16 key events

stored in the FIFO. Both interrupts can be configured

simultaneously and INTK asserts depending on which

condition is met first. INTK deasserts depending on the

status of bit D5 in the configuration register.

Ports Register (0x04)

The ports register sets the values of PORT2–PORT7

and the INTK port, when configured, as open-drain

10 _____________________________________________________________________________________

Page 11

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

GPOs. The settings in this register are ignored for ports

not configured as GPOs, and a read from this register

returns the values stored in the register (see Table 11 in

the Register Tables section).

Autorepeat Register (0x05)

The MAX7360 autorepeat feature notifies the host that at

least one key has been pressed for a continuous period.

The autorepeat register enables or disables this feature,

sets the time delay after the last key event before the key

repeat code (0x7E) is entered into the FIFO, and sets

the frequency at which the key-repeat code is entered

into the FIFO thereafter. Bit D7 specifies whether the

autorepeat function is enabled with 0 denoting autorepeat

disabled, and 1 denoting autorepeat enabled. Bits D0–

D3 specify the autorepeat delay in terms of debounce

cycles ranging from 8–128 debounce cycles (see Table

12 in the Register Tables section). Bits D4, D5, and D6

specify the autorepeat rate or frequency ranging from

4–32 debounce cycles.

When autorepeat is enabled, holding the key pressed

results in a key-repeat event that is denoted by 0x7E. The

key being pressed does not show up again in the FIFO.

Only one autorepeat code is entered into the FIFO,

regardless of the number of keys pressed. The

autorepeat code continues to be entered in the FIFO at

the frequency set by bits D4–D1 until another key event

is recorded. Following the key-release event, if any keys

are still pressed, the MAX7360 restarts the autorepeat

sequence.

Autosleep Register (0x06)

Autosleep puts the MAX7360 in sleep mode to draw

minimal current. When enabled, the MAX7360 enters

sleep mode if no keys are pressed for the autosleep time

(see Table 13 in the Register Tables section).

Key-Switch Sleep Mode

In sleep mode, the MAX7360 draws minimal current.

Switch-matrix current sources are turned off and pulled

up to VCC. When autosleep is enabled, key-switch

inactivity for a period longer than the autosleep time

puts the part into sleep mode (FIFO data is maintained).

Writing a 1 to D7, or a keypress, can take the MAX7360

out of sleep mode. Bit D7 in the configuration register

gives the sleep-mode status and can be read any time.

The FIFO data is maintained while in sleep mode.

Keypresses initiate autowake and the MAX7360 goes into

operating mode. Keypresses that autowake the MAX7360

are not lost. When a key is pressed while the MAX7360

is in sleep mode, all analog circuitry, including switchmatrix current sources, turn on in 2ms. The initial key

needs to be pressed for 2ms plus the debounce time to

be stored in the FIFO. Write a 0 to D1 in the configuration

register (0x01) to disable autowakeup.

The MAX7360 has eight GPIO ports with LED control

functions. The ports can be used as logic inputs, logic

outputs, or constant-current PWM LED drivers. In

addition, PORT7 and PORT8 can function as a rotary

switch input pair. When in PWM mode, the ports are set

up to start their PWM cycle in 45N phase increments. This

prevents large current spikes on the LED supply voltage

when driving multiple LEDs.

GPIO Global Configuration Register (0x40)

The GPIO global configuration register controls the main

settings for the eight GPIOs (see Table 14 in the Register

Tables section).

Bit D7 enables PORT[7:6] as inputs for a rotary switch.

Bit D5 enables interrupt generation for I2C timeouts.

D4 is the main enable/shutdown bit for the GPIOs. D3

functions as a software reset for the GPIO registers (0x40

to 0x5F). Bits D[2:0] set the fade in/out time for the GPIOs

configured as constant-current sinks.

GPIO Control Register (0x41)

The GPIO control register configures each port as either

an input or an output (see Table 15 in the Register Tables

section). All GPIOs allow individual configurations,

and power up as inputs. Enabling rotary switch mode

automatically sets D7 and D6 as inputs. The ports

consume additional current if their inputs are left undriven.

GPIO Debounce Configuration Register (0x42)

The GPIO debounce configuration register sets the

amount of time a GPIO must be held for the MAX7360

to register a logic transition (see Table 16 in the

Register Tables section). The GPIO debounce setting

is independent of the key-switch debounce setting. Five

bits (D[4:0]) set 32 possible debounce times from 9ms

up to 40ms.

Autowake

MAX7360

GPIOs

______________________________________________________________________________________ 11

Page 12

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

GPIO Constant-Current Setting Register (0x43)

The GPIO constant-current setting register sets the global

constant-current amount (see Table 17 in the Register

Tables section). Bits D1 and D0 set the global current

values from 5mA up to 20mA.

GPIO Output Mode Register (0x44)

The GPIO output mode register sets an output as either

a constant-current or non-constant-current output for

MAX7360

PORT[7:0] (see Table 18 in the Register Tables section).

Outputs are configured as constant-current outputs by

default to prevent accidental loading of an LED across

an unregulated output. The constant-current circuits

automatically turn off when not in use to reduce current

consumption.

Common PWM Register (0x45)

The common PWM register stores the common constantcurrent output PWM duty cycle (see Table 19 in the

Register Tables section). The values stored in this register

translate over to a PWM duty cycle in the same manner

as the individual PWM registers (0x50 to 0x57). Ports can

use their own individual PWM value, or the common PWM

value. Write to this register to change the duty cycle of

several ports at once.

Rotary Switch Configuration Register (0x46)

The rotary switch configuration register stores rotary

switch settings for PORT7 and PORT6 (see Table 20 in

the Register Tables section). D7 determines whether

switch counts or a time delay will trigger an interrupt

if enabled. D[6:4] set the count or time amount to wait

before sending an interrupt. Bits D[3:0] set the debounce

cycle time for the rotary switch inputs. Debounce time

ranges from 0 to 15ms.

I2C Timeout Flag Register (0x48) (Read Only)

The I2C timeout flag register contains a single bit (D0),

which indicates if an I2C timeout has occurred (see Table

21 in the Register Tables section). Read this register to

clear an I2C timeout initiated interrupt.

GPIO Input Register (0x49) (Read Only)

The GPIO input register contains the input data for all of

the GPIOs (see Table 22 in the Register Tables section).

Ports configured as outputs are read as high. There is

one debounce period delay prior to detecting a transition

on the input port. This prevents a false interrupt from

occurring when changing a port from an output to an

input. The GPIO input register reports the state of all

input ports regardless of any interrupt mask settings.

Ports configured as an input have a 2FA internal pullup

to VCC for PORT[5:0] and a 10FA internal pullup to VCC

for PORT[7:6].

Rotary Switch Count Register (0x4A) (Read Only)

The MAX7360 keeps a count of the rotary switch rotations

in two’s compliment format (see Table 23 in the Register

Tables section). The register values wrap around as the

count value switches from a positive to a negative value

and back again. The count resets to zero after an I2C

read to this register.

PORT0–PORT7 Individual PWM Ratio Registers

(0x50 to 0x57)

Each port has an individual PWM ratio register (0x50 to

0x57, see Table 24 in the Register Tables section). Use

values 0x00 to 0xFE in these registers to configure the

number of cycles out of 256 the output sinks current

(LED is on), from 0 cycles to 254 cycles. Use 0xFF to

have an output continuously sink current (always on).

For applications requiring multiple ports to have the

same intensity, program a particular port’s configuration

register (0x58 to 0x5F) to use the common PWM register

(0x45). New PWM settings take place at the beginning of

a PWM cycle, to allow changes from common intensity to

individual intensity with no interruption in the PWM cycle

PORT0–PORT7 Configuration Registers

(0x58 to 0x5F)

Registers 0x58 to 0x5F set individual configurations for

each port (see Table 25 in the Register Tables section).

Bits D7 and D6 determine the interrupt settings for the

inputs. Interrupts can assert upon detection of a logic

transition, a rising edge, or not at all. D5 sets the port’s

PWM setting to either the common or individual PWM

setting. Bits D[4:2] enable and set the ports’ individual

blink period from 0 to 4096ms. Bits D1 and D0 set a port’s

blink duty cycle.

Fading

Set the fade cycle time in the GPIO global configuration

register (0x40) to a non-zero value to enable fade in/out (see

Table 14 in the Register Tables section). Fade in increases

an LED’s PWM intensity in 16 even steps from zero to its

stored value. Fade out decreases an LED’s PWM intensity in

16 even steps from its current value to zero. Fading occurs

automatically in any of the following scenarios:

1) Change the common PWM register value from any

value to zero to cause all ports using the common

PWM register settings to fade out. No ports using

individual PWM settings are affected.

2) Change the common PWM register value to any value

from zero to cause all ports using the common PWM

register settings to fade in. No ports using individual

PWM settings are affected.

3) Put the part out of shutdown to cause all ports to

fade in. Changing an individual PWM intensity during

12 _____________________________________________________________________________________

Page 13

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

fade in automatically cancels that port’s fade and

immediately output at its newly programmed intensity.

4) Put the part into shutdown to cause all ports to fade

out. Changing an individual PWM intensity during

fade out automatically cancels that port’s fade and

immediately turns off.

Blink

Each port has its own blink control settings through

registers 0x58 to 0x5F (see Table 25 in the Register Tables

section). The blink period ranges from 0 (blink disabled)

to 4.096s. Settable blink duty cycles range from 6.25%

to 50%. All blink periods start at the same PWM cycle for

synchronized blinking between multiple ports.

GPIO Port Interrupts (INTI)

Three possible sources generate INTI: I2C timeout,

GPIOs configured as inputs, and the rotary switch

(registers 0x48, 0x49, and 0x4A). Read the respective

data/status registers for each type of interrupt to clear

INTI. Set register 0x46 for rotary switch-based interrupts.

PORT7

PORT6

PORT7

PORT6

ROTARY SWITCH

DEBOUNCE

Figure 1. Rotary Switch Input Signal Timing

INCREMENT

DECREMENT

Set registers 0x58 to 0x5F for individual GPI-based

interrupts. If multiple sources generate the interrupt, all

the related status registers must be read to clear INTI.

Rotary Switch

The MAX7360 can accept a 2-bit rotary switch inputs on

PORT6 and PORT7. Rotation of the switch in a clockwise

direction increments the count. Enable rotary switch

mode from the GPIO global configuration register (0x40).

Several settings for PORT6 and PORT7 occur during

rotary switch mode:

1) Each port has a 10FA pullup to VCC.

2) Register 0x46 sets the debounce time.

3) A debounced rising edge on PORT6 while PORT7 is

high decreases the count.

4) A debounced rising edge on PORT6 while PORT7 is

low increases the count.

For more details, see Figure 1.

Serial Interface

Figure 2 shows the 2-wire serial interface timing details.

Serial Addressing

The MAX7360 operates as a slave that sends and

receives data through an I2C-compatible 2-wire interface.

The interface uses a serial-data line (SDA) and a serialclock line (SCL) to achieve bidirectional communication

between master(s) and slave(s). A master (typically a

microcontroller) initiates all data transfers to and from the

MAX7360 and generates the SCL clock that synchronizes

the data transfer.

The MAX7360’s SDA line operates as both an input and

an open-drain output. A pullup resistor, typically 4.7kI,

MAX7360

SDA

t

SU, DAT

t

LOW

t

SCL

t

HD, STA

START

CONDITION

HIGH

t

t

R

F

Figure 2. 2-Wire Serial Interface Timing Details

______________________________________________________________________________________ 13

t

HD, DAT

t

SU, STA

START CONDITION

REPEATED

t

R

t

HD, STA

t

SU, STO

t

F

t

F,TX

STOP

CONDITION

t

BUF

START

CONDITION

Page 14

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

is required on SDA. The MAX7360’s SCL line operates

only as an input. A pullup resistor is required on SCL if

there are multiple masters on the 2-wire interface, or if

the master in a single-master system has an open-drain

SCL output.

Each transmission consists of a START condition (Figure

3) sent by a master, followed by the MAX7360 7-bit slave

address plus R/W bit, a register address byte, one or

MAX7360

more data bytes, and finally, a STOP condition.

START and STOP Conditions

Both SCL and SDA remain high when the interface is not

busy. A master signals the beginning of a transmission

with a START (S) condition by transitioning SDA from

high to low while SCL is high. When the master has

finished communicating with the slave, it issues a STOP

(P) condition by transitioning SDA from low to high while

SCL is high. The bus is then free for another transmission.

Bit Transfer

One data bit is transferred during each clock pulse

(Figure 4). The data on SDA must remain stable while

SCL is high.

Acknowledge

The acknowledge bit is a clocked 9th bit (Figure 4), which

the recipient uses to handshake receipt of each byte of

data. Thus, each byte transferred effectively requires

9 bits. The master generates the 9th clock pulse, and

the recipient pulls down SDA during the acknowledge

clock pulse; therefore, the SDA line is stable low during

the high period of the clock pulse. When the master is

transmitting to the MAX7360, the MAX7360 generates the

acknowledge bit because the MAX7360 is the recipient.

When the MAX7360 is transmitting to the master, the

master generates the acknowledge bit because the

master is the recipient.

Table 3. 2-Wire Interface Address Map

PIN AD0

GND 0 1 1 1 0 0 0

V

CC

SDA 0 1 1 1 1 0 0

SCL 0 1 1 1 1 1 0

A7 A6 A5 A4 A3 A2 A1 A0

0 1 1 1 0 1 0

DEVICE ADDRESS

R/W

R/W

R/W

R/W

SDA

SCL

Figure 3. START and STOP Conditions

Figure 4. Bit Transfer

14 _____________________________________________________________________________________

SDA

SCL

S

START

CONDITION

DATA LINE STABLE;

DATA VALID

CHANGE OF DATA

ALLOWED

P

STOP

CONDITION

Page 15

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

Figure 5. Acknowledge

SCL

SDA

TRANSMITTER

SDA

RECEIVER

BY

BY

START

CONDITION

S

1 2 8 9

CLOCK PULSE FOR

ACKNOWLEDGE

MAX7360

SDA

SCL

0 1 1 A3 A2 A11

MSB

LSB

Figure 6. Slave Address

COMMAND BYTE IS STORED ON RECEIPT OF

S A A P0SLAVE ADDRESS COMMAND BYTE

ACKNOWLEDGE CONDITION

ACKNOWLEDGE FROM MAX7360

R/W

D7 D6 D5 D4 D3 D2 D1 D0

ACKNOWLEDGE FROM MAX7360

Figure 7. Command Byte Received

ACKNOWLEDGE FROM MAX7360

D7 D6 D5 D4 D3 D2 D1 D0 D1 D0D3 D2D5 D4D7 D6

ACKNOWLEDGE FROM MAX7360

S A A A P0SLAVE ADDRESS COMMAND BYTE DATA BYTE

R/W

Figure 8. Command and Single Data Byte Received

Slave Addresses

The MAX7360 has a 7-bit long slave address (Figure

6). The bit following a 7-bit slave address is the R/W bit,

which is low for a write command and high for a read

command.

The first 4 bits (MSBs) of the MAX7360 slave address

dynamic signals, care must be taken to ensure that AD0

transitions no sooner than the signals on SDA and SCL.

The MAX7360 monitors the bus continuously, waiting for a

START condition, followed by its slave address. When the

MAX7360 recognizes its slave address, it acknowledges

and is then ready for continued communication.

are always 0111. Slave address bits A3, A2, and A1

correspond, by the matrix in Table 3, to the states of the

device address input AD0, and A0 corresponds to the

R/W bit. The AD0 input can be connected to any of four

signals (GND, VCC, SDA, or SCL), giving four possible

slave address pairs and allowing up to four MAX7360

devices to share the bus. Because SDA and SCL are

The MAX7360 features a 20ms minimum bus timeout

on the 2-wire serial interface, largely to prevent the

MAX7360 from holding the SDA I/O low during a read

transaction should the SCL lock up for any reason before

a serial transaction is completed. Bus timeout operates

by causing the MAX7360 to internally terminate a serial

ACKR/W

ACKNOWLEDGE FROM MAX7360

1 BYTE

AUTOINCREMENT

COMMAND BYTE ADDRESS

Bus Timeout

______________________________________________________________________________________ 15

Page 16

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

D7 D6 D5 D4 D3 D2 D1 D0 D1 D0D3 D2D5 D4D7 D6

ACKNOWLEDGE FROM MAX7360

S A A A P0SLAVE ADDRESS COMMAND BYTE DATA BYTE

R/W

MAX7360

Figure 9. N Data Bytes Received

Table 4. Autoincrement Rules

REGISTER

FUNCTION

Keys FIFO 0x00 0x00

Autoshutdown 0x06 0x00

All other key switch 0x01 to 0x05 Addr + 0x01

All other GPIO 0x40 to 0x5F Addr + 0x01

transaction, either read or write, if SCL low exceeds

20ms. After a bus timeout, the MAX7360 waits for a valid

START condition before responding to a consecutive

transmission. This feature can be enabled or disabled

under user control by writing to the configuration register

(Table 8 in the Register Tables section).

A write to the MAX7360 comprises the transmission of the

slave address with the R/W bit set to zero, followed by at

least 1 byte of information. The first byte of information

is the command byte. The command byte determines

which register of the MAX7360 is to be written by the next

byte, if received. If a STOP condition is detected after the

command byte is received, the MAX7360 takes no further

action (Figure 7) beyond storing the command byte.

Any bytes received after the command byte are data bytes.

The first data byte goes into the internal register of the

MAX7360 selected by the command byte (Figure 8).

If multiple data bytes are transmitted before a STOP condition

is detected, these bytes are generally stored in subsequent

MAX7360 internal registers, because the command byte

address generally autoincrements (Table 4).

The MAX7360 is read using the internally stored

command byte as an address pointer, the same way the

stored command byte is used as an address pointer for

a write. The pointer generally autoincrements after each

data byte is read using the same rules as for a write

ADDRESS

CODE (hex)

AUTOINCREMENT

ADDRESS (hex)

Message Format for Writing

the Key-Scan Controller

Message Format for Reading

the Key-Scan Controller

ACKNOWLEDGE FROM MAX7360

(Table 4). Thus, a read is initiated by first configuring the

MAX7360’s command byte by performing a write (Figure

6). The master can now read n consecutive bytes from

the MAX7360, with the first data byte being read from

the register addressed by the initialized command byte.

When performing read-after-write verification, remember

to reset the command byte’s address, because the stored

command byte address is generally autoincremented

after the write (Figure 9, Table 4).

When the MAX7360 is operated on a 2-wire interface with

multiple masters, a master reading the MAX7360 uses a

repeated start between the write that sets the MAX7360’s

address pointer, and the read(s) that takes the data

from the location(s). This is because it is possible for

master 2 to take over the bus after master 1 has set up

the MAX7360’s address pointer, but before master 1

has read the data. If master 2 subsequently resets the

MAX7360’s address pointer, master 1’s read can be from

an unexpected location.

Address autoincrementing allows the MAX7360 to be

configured with fewer transmissions by minimizing the

number of times the command address needs to be sent.

The command address stored in the MAX7360 generally

increments after each data byte is written or read (Table

4). Autoincrement only works when doing a multiburst

read or write.

Applications Information

After a catastrophic event such as ESD discharge or

microcontroller reset, use bit D7 of the configuration

register (0x01) as a software reset for the key-switch

state (the key-switch register values and FIFO remain

unaffected). Use bit D4 of the GPIO global configuration

register (0x40) as a software reset for the GPIOs.

ACKNOWLEDGE FROM MAX7360

N BYTES

AUTOINCREMENT

COMMAND BYTE ADDRESS

Operation with Multiple Masters

Command Address Autoincrementing

Reset from I2C

16 _____________________________________________________________________________________

Page 17

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

REGULAR KEYPRESS

EVENT

GHOST-KEY

EVENT

EXAMPLES OF VALID THREE-KEY COMBINATIONS

MAX7360

KEY-SWITCH MATRIX

Figure 10. Ghost-Key Phenomenon

Ghost-Key Elimination

Ghost keys are a phenomenon inherent with key-switch

matrices. When three switches located at the corners

of a matrix rectangle are pressed simultaneously, the

switch that is located at the last corner of the rectangle

(the ghost key) also appears to be pressed. This occurs

because the potentials at the two sides of the ghost-key

switch are identical due to the other three connections—

the switch is electrically shorted by the combination of

the other three switches (Figure 10). Because the key

appears to be pressed electrically, it is impossible to

detect which of the four keys is the ghost key.

The MAX7360 employs a proprietary scheme that detects

any three-key combination that generates a fourth ghost

key, and does not report the third key that causes a

ghost-key event. This means that although ghost keys

are never reported, many combinations of three keys

are effectively ignored when pressed at the same time.

Applications requiring three-key combinations (such

as <Ctrl><Alt><Del>) must ensure that the three keys

are not wired in positions that define the vertices of a

rectangle (Figure 11). There is no limit on the number of

keys that can be pressed simultaneously as long as the

keys do not generate ghost-key events and FIFO is not full.

Low-EMI Operation

The MAX7360 uses two techniques to minimize EMI

radiating from the key-switch wiring. First, the voltage

across the switch matrix never exceeds +0.55V if not in

sleep mode, independent of supply voltage VCC. This

reduces the voltage swing at any node when a switch

is pressed to +0.55V maximum. Second, the keys are

not dynamically scanned, which would cause the keyswitch wiring to continuously radiate interference.

Instead, the keys are monitored for current draw (only

occurs when pressed), and debounce circuitry only

operates when one or more keys are actually pressed.

KEY-SWITCH MATRIX KEY-SWITCH MATRIX

Figure 11. Valid Three-Key Combinations

Switch On-Resistance

The MAX7360 is designed to be insensitive to resistance,

either in the key switches, or the switch routing to and

from the appropriate COL_ and ROW_ up to 4kI (max).

These controllers are therefore compatible with low-cost

membrane and conductive carbon switches.

Hot Insertion

The INTI, INTK, SCL, and AD0 inputs and SDA remain

high impedance with up to +3.6V asserted on them when

the MAX7360 powers down (VCC = 0). I/O ports (PORT0–

PORT7) remain high impedance with up to +14V asserted

on them when not powered. Use the MAX7360 in hot-

swap applications.

Staggered PWM

The LED’s on-time in each PWM cycle are phase

delayed 45N into eight evenly spaced start positions.

Optimize phasing when using fewer than eight ports as

constant-current outputs by allocating the ports with the

most appropriate start positions. For example, if using

four constant-current outputs, choose PORT0, PORT2,

PORT4, and PORT6 because their PWM start positions

are evenly spaced. In general, choose the ports that

spread the PWM start positions as evenly as possible.

This optimally spreads out the current demand from the

ports’ load supply.

INTK/INTI

There are two interrupt outputs, INTK and INTI. Each

interrupt operates independently from the other. See

the Key-Switch Interrupt Register (0x03) and the GPIO

Port Interrupts (INTI) sections for additional information

regarding these two interrupts.

Power-Supply Considerations

The MAX7360 operates with a +1.62V to +3.6V power-

supply voltage. Bypass the power supply to GND with a

0.1FF or higher ceramic capacitor as close as possible

to the device.

______________________________________________________________________________________ 17

Page 18

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

ESD Protection

All of the MAX7360 pins meet the 2kV Human Body Model

ESD tolerances. Key-switch inputs and GPIOs meet IEC

61000-4-2 ESD protection. The IEC test stresses consist

of 10 consecutive ESD discharges per polarity, at the

maximum specified level and below (per IEC 61000-4-2).

Test criteria include:

1) The powered device does not latch up during the

MAX7360

ESD discharge event.

2) The device subsequently passes the final test used

for prescreening.

Tables 5 and 6 are from the IEC 61000-4-2: Edition 1.1

1999-05: Electromagnetic compatibility (EMC) Testing

and measurement techniques—Electrostatic discharge

immunity test

Table 6. ESD Waveform Parameters

INDICATED

LEVEL

1 2 7.5 0.7 to 1 4 2

2 4 15 0.7 to 1 8 4

3 6 22.5 0.7 to 1 12 6

4 8 30 0.7 to 1 16 8

VOLTGE

(kV)

FIRST PEAK OF

CURRENT

DISCHARGE ±10%

(A)

Table 5. ESD Test Levels

1A—CONTACT

DISCHARGE

LEVEL

1 2 1 2

2 4 2 4

3 6 3 8

4 8 4 10

X Special X Special

X = Open level. The level has to be specified in the

dedicated equipment specification. If higher voltages

than those shown are specified, special test equipment

could be needed.

RISE TIME (tr) WITH

DISCHARGE SWITCH

(ns)

TEST

VOLTAGE (kV)

CURRENT (±30%)

AT 30ns

(A)

1B—AIR-GAP DISCHARGE

LEVEL

TEST

VOLTAGE (kV)

CURRENT

(±30%) AT 60ns

(A)

18 _____________________________________________________________________________________

Page 19

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

Register Tables

Table 7. Keys FIFO Register Format (0x00)

MAX7360

SPECIAL FUNCTION

The key number indicated by D5:D0 is a key

event. D7 is always for a key press of key 62

and key 63. When D7 is 0, the key read is the

last data in the FIFO. When D7 is 1, there is

more data in the FIFO. When D6 is 1, key data

read from FIFO is a key release. When D6 is 0,

key data read from FIFO is a key press.

FIFO is empty. 0 0 1 1 1 1 1 1

FIFO is overflow. Continue to read data in FIFO. 0 1 1 1 1 1 1 1

Key 63 is pressed. Read one more time to

determine whether there is more data in FIFO.

Key 63 is released. Read one more time to

determine whether there is more data in FIFO.

Key repeat. Indicates the last data in FIFO. 0 0 1 1 1 1 1 0

Key repeat. Indicates more data in FIFO. 0 1 1 1 1 1 1 0

Key 62 is pressed. Read one more time to

determine whether there is more data in FIFO.

Key 62 is released. Read one more time to

determine whether there is more data in FIFO.

D7 D6 D5 D4 D3 D2 D1 D0

FIFO

empty

flag

1 0 1 1 1 1 1 1

1 1 1 1 1 1 1 1

1 0 1 1 1 1 1 0

1 1 1 1 1 1 1 0

Key

release

flag

KEYS FIFO REGISTER DATA

X X X X X X

______________________________________________________________________________________ 19

Page 20

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

Table 8. Configuration Register Format (0x01)

REGISTER

BIT

MAX7360

D7 Sleep

D6 Reserved 0 — 0

D5 Interrupt

D4 Reserved 0 — 0

D3

D2 Reserved 0 — 0

D1

D0

DESCRIPTION VALUE FUNCTION

Key-release

enable

Autowakeup

enable

Timeout

disable

X

(when 0x40

D4 = 1)

0

(when 0x40

D4 = 0)

1

(when 0x40

D4 = 0)

0

1

0 Disable key releases

1 Enable key releases

0 Disable keypress wakeup

1 Enable keypress wakeup

0

1

Key-switch operating mode. Key switches always remain active

when constant-current PWM is enabled (bit 4 of register 0x40 is

high) regardless of autosleep, autowakeup, or an I2C write to this bit.

Key-switch sleep

mode. The entire

chip is shut down.

Key-switch operating

mode

INTK cleared when FIFO is empty

INTK cleared after host read. In this mode, I2C should read the

FIFO until interrupt condition is removed or further INT may be lost.

I2C timeout enabled

I2C timeout disabled

When constant-current PWM is disabled

(bit 4 of register 0x40 is low), I2C write,

autosleep, and autowakeup all can change

this bit. This bit can be read back by I2C

any time for current status.

DEFAULT

VALUE

0

0

1

1

0

Table 9. Debounce Register Format (0x02)

REGISTER DATA

REGISTER DESCRIPTION

Debounce time is 9ms X X X 0 0 0 0 0

Debounce time is 10ms X X X 0 0 0 0 1

Debounce time is 11ms X X X 0 0 0 1 0

Debounce time is 12ms X X X 0 0 0 1 1

Debounce time is 37ms X X X 1 1 1 0 0

Debounce time is 38ms X X X 1 1 1 0 1

Debounce time is 39ms X X X 1 1 1 1 0

Debounce time is 40ms X X X 1 1 1 1 1

GPO ports disabled (full key-scan functionality) 0 0 0 X X X X X

GPO port 7 enabled 0 0 1 X X X X X

GPO ports 7 and 6 enabled 0 1 0 X X X X X

20 _____________________________________________________________________________________

D7 D6 D5 D4 D3 D2 D1 D0

PORTS ENABLE DEBOUNCE TIME

.

.

.

Page 21

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

Table 9. Debounce Register Format (0x02) (continued)

REGISTER DATA

REGISTER DESCRIPTION

GPO ports 7, 6, and 5 enabled 0 1 1 X X X X X

GPO ports 7, 6, 5, and 4 enabled 1 0 0 X X X X X

GPO ports 7, 6, 5, 4, and 3 enabled 1 0 1 X X X X X

GPO ports 7, 6, 5, 4, 3, and 2 enabled 1 1 X X X X X X

Power-up default setting 1 1 1 1 1 1 1 1

Table 10. Key-Switch Interrupt Register Format (0x03)

REGISTER DESCRIPTION

INTK used as GPO

FIFO-based INTK disabled

INTK asserts every debounce cycle

INTK asserts every 2 debounce cycles

D7 D6 D5 D4 D3 D2 D1 D0

PORTS ENABLE DEBOUNCE TIME

REGISTER DATA

D7 D6 D5 D4 D3 D2 D1 D0

FIFO-BASED INTK TIME-BASED INTK

0 0 0 0 0 0 0 0

0 0 0 Not all zero

0 0 0 0 0 0 0 1

0 0 0 0 0 0 1 0

MAX7360

.

.

.

INTK asserts every 29 debounce cycles

INTK asserts every 30 debounce cycles

INTK asserts every 31 debounce cycles

Time-based INTK disabled

INTK asserts when FIFO has 2 key events

INTK asserts when FIFO has 4 key events

INTK asserts when FIFO has 6 key events

INTK asserts when FIFO has 16 key events

Both time-based and FIFO-based interrupts

active

Power-up default setting 0 0 0 0 0 0 0 0

0 0 0 1 1 1 0 1

0 0 0 1 1 1 1 0

0 0 0 1 1 1 1 1

Not all zero 0 0 0 0 0

0 0 1 0 0 0 0 0

0 1 0 0 0 0 0 0

0 1 1 0 0 0 0 0

.

.

.

1 1 1 0 0 0 0 0

Not all zero Not all zero

______________________________________________________________________________________ 21

Page 22

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

Table 11. Ports Register Format (0x04)

REGISTER

BIT

D7 PORT 7 Control

D6 PORT 6 Control

MAX7360

D5 PORT 5 Control

D4 PORT 4 Control

D3 PORT 3 Control

D2 PORT 2 Control

D1

D0 Reserved 0 — 0

DESCRIPTION VALUE FUNCTION

0 Clear port 7 low

1 Set port 7 high (high impedance)

0 Clear port 6 low

1 Set port 6 high (high impedance)

0 Clear port 5 low

1 Set port 5 high (high impedance)

0 Clear port 4 low

1 Set port 4 high (high impedance)

0 Clear port 3 low

1 Set port 3 high (high impedance)

0 Clear port 2 low

1 Set port 2 high (high impedance)

INTK Port

Control

0

1

Clear port INTK low

Set port INTK high (high impedance)

DEFAULT

VALUE

1

1

1

1

1

1

1

22 _____________________________________________________________________________________

Page 23

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

Table 12. Autorepeat Register Format (0x05)

REGISTER DATA

REGISTER DESCRIPTION

Autorepeat is disabled 0 X X X X X X X

Autorepeat is enabled 1

D7 D6 D5 D4 D3 D2 D1 D0

ENABLE AUTOREPEAT RATE AUTOREPEAT DELAY

AUTOREPEAT RATE AUTOREPEAT DELAY

MAX7360

Key-switch autorepeat delay is 8 debounce

cycles

Key-switch autorepeat delay is 16 debounce

cycles

Key-switch autorepeat delay is 24 debounce

cycles

Key-switch autorepeat delay is 112 debounce

cycles

Key-switch autorepeat delay is 120 debounce

cycles

Key-switch autorepeat delay is 128 debounce

cycles

Key-switch autorepeat frequency is 4

debounce cycles

Key-switch autorepeat frequency is 8

debounce cycles

Key-switch autorepeat frequency is 12

debounce cycles

1 X X X 0 0 0 0

1 X X X 0 0 0 1

1 X X X 0 0 1 0

.

.

.

1 X X X 1 1 0 1

1 X X X 1 1 1 0

1 X X X 1 1 1 1

1 0 0 0 X X X X

1 0 0 1 X X X X

1 0 1 0 X X X X

.

.

.

Key-switch autorepeat frequency is 32

debounce cycles

Power-up default setting 0 0 0 0 0 0 0 0

______________________________________________________________________________________ 23

1 1 1 1 X X X X

Page 24

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

Table 13. Autosleep Register Format (0x06)

REGISTER REGISTER DATA

AUTOSLEEP REGISTER

No Autosleep 0 0 0 0 0 0 0 0

Autosleep for (ms)

8192 0 0 0 0 0 0 0 1

MAX7360

4096 0 0 0 0 0 0 1 0

2048 0 0 0 0 0 0 1 1

1024 0 0 0 0 0 1 0 0

512 0 0 0 0 0 1 0 1

256 0 0 0 0 0 1 1 0

256 0 0 0 0 0 1 1 1

Power-up default settings 0 0 0 0 0 1 1 1

D7 D6 D5 D4 D3 D2 D1 D0

Table 14. GPIO Global Configuration Register (0x40)

REGISTER

BIT

D7

D6 Reserved 0 — 0

D5

D4 GPIO enable

D3 GPIO reset

D[2:0]

DESCRIPTION VALUE FUNCTION

PORT6/PORT7

rotary switch

I2C timeout

interrupt

enable

Fade in/out

time

0 PORT6/PORT7 operate as GPIOs

1 PORT6/PORT7 operate as a rotary switch input

0 Disabled

1

0

1

0 Normal operation

1

000 No fading

XXX

INTI is asserted when I2C bus times out. INTI is deasserted when a

read is performed on the I2C timeout flag register (0x48).

PWM, constant-current circuits, and GPIs are shut down. GPO

values depend on their setting. Register 0x41 to 0x5F values are

stored and cannot be changed. The entire part is shut down if the

key switches are in sleep mode (D7 of register 0x01).

Normal GPIO operation. PWM, constant-current circuits, and GPIOs are

enabled regardless of key-switch sleep mode state (see Table 8).

Return all GPIO registers (registers 0x40 to 0x5F) to their POR value.

This bit is momentary and resets itself to 0 after the write cycle.

PWM intensity ramps up (down) between the common PWM value

and 0% duty cycle in 16 steps over the following time period:

D[2:0] = 001 = 256ms

D[2:0] = 010 = 512ms

D[2:0] = 011 = 1024ms

D[2:0] = 100 = 2048ms

D[2:0] = 101 = 4096ms

D[2:0] = 110/111 = Undefined

RESERVED AUTOSHUTDOWN TIME

DEFAULT

VALUE

0

0

0

0

000

24 _____________________________________________________________________________________

Page 25

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

Table 15. GPIO Control Register (0x41)

REGISTER

BIT

D7 PORT7

D6 PORT6

D5 PORT5

D4 PORT4

D3 PORT3

D2 PORT2

D1 PORT1

D0 PORT0

DESCRIPTION VALUE FUNCTION

0 Port is an input

1 Port is an output

0 Port is an input

1 Port is an output

0 Port is an input

1 Port is an output

0 Port is an input

1 Port is an output

0 Port is an input

1 Port is an output

0 Port is an input

1 Port is an output

0 Port is an input

1 Port is an output

0 Port is an input

1 Port is an output

DEFAULT

MAX7360

VALUE

0

0

0

0

0

0

0

0

Table 16. GPIO Debounce Configuration Register (0x42)

REGISTER DATA

REGISTER DESCRIPTION

Power-up default setting

debounce time is 9ms

Debounce time is 10ms 0 0 0 0 0 0 0 1

Debounce time is 11ms 0 0 0 0 0 0 1 0

Debounce time is 12ms 0 0 0 0 0 0 1 1

Debounce time is 37ms 0 0 0 1 1 1 0 0

Debounce time is 38ms 0 0 0 1 1 1 0 1

Debounce time is 39ms 0 0 0 1 1 1 1 0

Debounce time is 40ms 0 0 0 1 1 1 1 1

D7 D6 D5 D4 D3 D2 D1 D0

RESERVED DEBOUNCE TIME

0 0 0 0 0 0 0 0

.

.

.

______________________________________________________________________________________ 25

Page 26

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

Table 17. GPIO Constant-Current Setting Register (0x43)

REGISTER

BIT

D[7:6] Reserved 11 Set always as 11 11

D[5:2] Reserved 0000 — 0000

MAX7360

D[1:0]

DESCRIPTION VALUE FUNCTION

00 Constant current is 5mA

Constant-

current setting

01 Constant current is 6.67mA

10 Constant current is 10mA

11 Constant current is 20mA

Table 18. GPIO Output Mode Register (0x44)

REGISTER

BIT

D7 PORT7

D6 PORT6

D5 PORT5

D4 PORT4

D3 PORT3

D2 PORT2

D1 PORT1

D0 PORT0

DESCRIPTION VALUE FUNCTION

0 Port is a constant-current open-drain output

1 Port is a non-constant-current open-drain output

0 Port is a constant-current open-drain output

1 Port is a non-constant-current open-drain output

0 Port is a constant-current open-drain output

1 Port is a non-constant-current open-drain output

0 Port is a constant-current open-drain output

1 Port is a non-constant-current open-drain output

0 Port is a constant-current open-drain output

1 Port is a non-constant-current open-drain output

0 Port is a constant-current open-drain output

1 Port is a non-constant-current open-drain output

0 Port is a constant-current open-drain output

1 Port is a non-constant-current open-drain output

0 Port is a constant-current open-drain output

1 Port is a non-constant-current open-drain output

DEFAULT

VALUE

00

DEFAULT

VALUE

0

0

0

0

0

0

0

0

Table 19. Common PWM Register (0x45)

REGISTER DATA

REGISTER DESCRIPTION

Power-up default setting (common

PWM ratio is 0/256)

Common PWM ratio is 1/256 0 0 0 0 0 0 0 1

Common PWM ratio is 2/256 0 0 0 0 0 0 1 0

Common PWM ratio is 3/256 0 0 0 0 0 0 1 1

26 _____________________________________________________________________________________

D7 D6 D5 D4 D3 D2 D1 D0

COMMON PWM

0 0 0 0 0 0 0 0

.

.

.

Page 27

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

Table 19. Common PWM Register (0x45) (continued)

REGISTER DATA

REGISTER DESCRIPTION

Common PWM ratio is 252/256 1 1 1 1 1 1 0 0

Common PWM ratio is 253/256 1 1 1 1 1 1 0 1

Common PWM ratio is 254/256 1 1 1 1 1 1 1 0

Common PWM ratio is 256/256

(100% duty cycle)

Table 20. Rotary Switch Configuration Register (0x46)

REGISTER DESCRIPTION

No debounce time X X X X 0 0 0 0

Debounce time is 1ms X X X X 0 0 0 1

Debounce time is 2ms X X X X 0 0 1 0

Debounce time is 3ms X X X X 0 0 1 1

Debounce time is 15ms X X X X 1 1 1 1

No interrupt generated by rotary switch X 0 0 0 X X X X

INTI asserted when rotary switch count = ±1

INTI asserted when rotary switch count = ±2

INTI asserted when rotary switch count = ±3

INTI asserted when rotary switch count = ±7

INTI asserted 25ms after first debounced event

INTI asserted 50ms after first debounced event

INTI asserted 75ms after first debounced event

INTI asserted 175ms after first debounced event

Power-up default setting

D7 D6 D5 D4 D3 D2 D1 D0

COMMON PWM

1 1 1 1 1 1 1 1

REGISTER DATA

D7 D6 D5 D4 D3 D2 D1 D0

INT

TYPE

0 0 0 1 X X X X

0 0 1 0 X X X X

0 0 1 1 X X X X

0 1 1 1 X X X X

1 0 0 1 X X X X

1 0 1 0 X X X X

1 0 1 1 X X X X

1 1 1 1 X X X X

0 0 0 0 0 0 0 0

COUNTS/CYCLES DEBOUNCE CYCLE TIME

.

.

.

.

.

.

.

.

.

MAX7360

______________________________________________________________________________________ 27

Page 28

I2C-Interfaced Key-Switch Controller and LED

Driver/GPIOs with Integrated ESD Protection

Table 21. I2C Timeout Flag Register (0x48) (Read Only)

REGISTER

BIT

D[7:1] Reserved 0000000 — 0000000

D0

MAX7360

DESCRIPTION VALUE FUNCTION

I2C timeout flag

0

1

No I2C timeout has occurred since last read or POR

I2C timeout has occurred since last read or POR. This bit is reset to

zero when a read is performed on this register. I2C timeouts must

be enabled for this function to work (see Table 8).

Table 22. GPIO Input Register (0x49) (Read Only)

REGISTER

BIT

D7 PORT7

D6 PORT6

D5 PORT5

D4 PORT4

D3 PORT3

D2 PORT2

D1 PORT1

D0 PORT0

DESCRIPTION VALUE FUNCTION

0 Port is input low

1 Port is input high

0 Port is input low

1 Port is input high

0 Port is input low

1 Port is input high

0 Port is input low

1 Port is input high

0 Port is input low

1 Port is input high