Page 1

General Description

The MAX7356/MAX7357/MAX7358 8-channel I2C

switches/multiplexers expand the main I

2

C bus to any

combination of 8 extended I

2

C buses. They enable a

master on the main bus to isolate and communicate

with devices or groups of devices that may otherwise

have slave address conflicts. Any extended bus can be

connected or disconnected by control packets from the

main I2C bus writing to the main control register of

these I

2

C switches.

The MAX7357 and MAX7358 feature an enhanced

mode that includes a built-in timer used to monitor all

extended buses for lock-up conditions. If the clock or

data line of any of these buses is low for more than

25ms (typ), a lock condition is detected. An optional

interrupt can be generated through the bidirectional

RST/INT. The master can read the bus lock-up register

to find out which extended bus is locked up. The master can also enable the MAX7357 or the MAX7358 to

send a “flush-out” sequence on the faulty channel.

There is an optional preconnection check that

can be enabled to toggle the extended bus clock and

data line low then high to ensure the downstream bus is

not locked high prior to connecting it to the host bus.

The MAX7356/MAX7357/MAX7358 are transparent

to signals sent and received at each channel, allowing

multiple masters. Any device connected to an I

2

C

bus can transmit and receive signals; however, only the

master connected to the host side of the MAX7356/

MAX7357/MAX7358 should address the device.

The MAX7356/MAX7357/MAX7358 are available in 24-pin

TSSOP and TQFN packages and are specified over the

extended -40°C to +85°C temperature range.

Applications

Features

o Bus Lock-Up Detection and Isolation (MAX7357,

MAX7358)

o Host Notification on Detection of Lock-Up

(MAX7357, MAX7358)

o Maintain Fault Diagnostic Information (MAX7357,

MAX7358)

o Dual-Function RST/INT Provides Lock-Up

Notification and Hardware Reset (MAX7357,

MAX7358)

o RST Input Resets I

2

C Interface (MAX7358)

o 3 Address Control Inputs

o Low RONSwitches

o Logic-Level Translation

o Low 0.1µA (typ) Standby Current

o Support Hot Insertion

o 100kbps Standard-Mode or 400kbps Fast-Mode

I

2

C Interface

o Address Translation Allows Multiple Device with

Same ID

o 5.5V-Tolerant Inputs

o 2.3V to 5.5V Supply

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

________________________________________________________________

Maxim Integrated Products

1

19-4207; Rev 0; 9/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

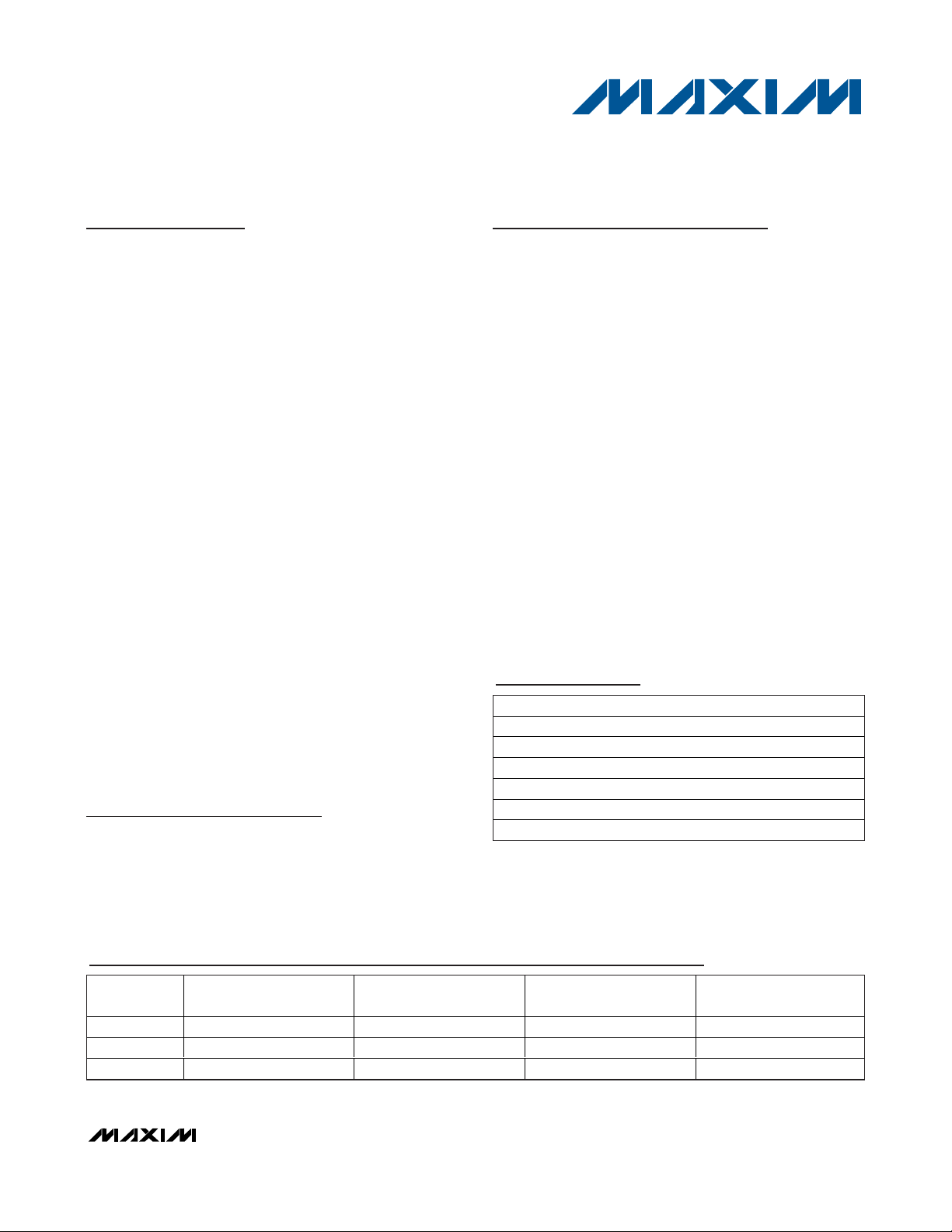

Ordering Information

+

Denotes a lead-free/RoHS-compliant package.

*

EP = Exposed pad.

**

Future product—contact factory for availability.

Typical Operating Circuit and Pin Configurations appear at end of data sheet.

Selector Guide

Servers

RAID

Base Stations

Control and Automation Devices

SFP Control Interface

Networking Equipment

PART TEMP RANGE PIN-PACKAGE

MAX7356ETG+ -40°C to +85°C 24 TQFN-EP*

MAX7356EUG+** -40°C to +85°C 24 TSSOP

MAX7357ETG+ -40°C to +85°C 24 TQFN-EP*

MAX7357EUG+** -40°C to +85°C 24 TSSOP

MAX7358ETG+ -40°C to +85°C 24 TQFN-EP*

MAX7358EUG+** -40°C to +85°C 24 TSSOP

PART

MAX7356 No No Basic mode RST only

MAX7357 Yes Yes, enhanced mode only Enhanced mode Yes

MAX7358 Yes Yes, enhanced mode only Basic mode Yes

ENHANCED

MODE

PRECONNECTION

WIGGLE TEST

POWER-UP

STATE

BIDIRECTIONAL

RST/INT

Page 2

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

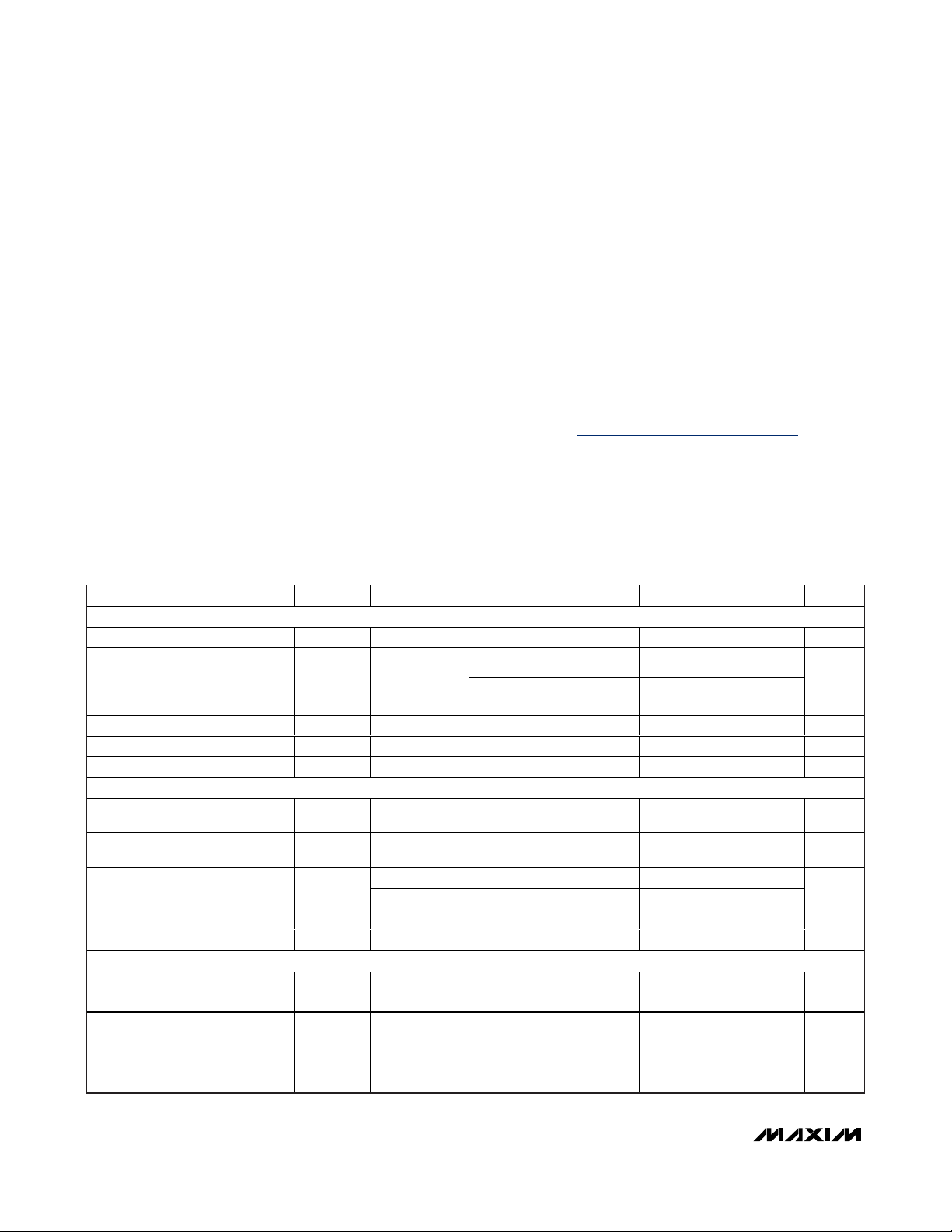

ELECTRICAL CHARACTERISTICS (3.3V SUPPLY)

(VDD= +2.3V to +3.6V, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VDD= +3.3V, TA= +25°C.) (Notes 2–5)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a 4-layer

board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial

.

(Voltages referenced to GND.)

VDD.................................................................. -0.3V to +6.0V

All Other Pins.....................................................-0.3V to +6.0V

Input Currents

V

DD

...............................................................................100mA

GND ..............................................................................100mA

All Input Pins.....................................................................±20mA

Output Current ....................................................................25mA

Continuous Power Dissipation (T

A

= +70°C)

24-Pin TSSOP (derate 13.9mW/°C above +70°C) .....1111mW

24-Pin TQFN (derate 27.8mW/°C above +70°C) .......2222mW

Junction-to-Case Thermal Resistance (

θ

JC

) (Note 1)

24-Pin TSSOP...............................................................13°C/W

24-Pin TQFN................................................................3.0°C/W

Junction-to-Ambient Thermal Resistance (

θ

JA

) (Note 1)

24-Pin TSSOP............................................................72.0°C/W

24-Pin TQFN..............................................................36.0°C/W

Operating Temperature Range ......................... -40°C to +85°C

Junction Temperature .................................................... +150°C

Storage Temperature Range ........................... -65°C to +150°C

Lead Temperature (soldering, 10s) ................................+300°C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

POWER SUPPLY

Supply Voltage V

Supply Current I

Standby Current I

Power-On Reset Voltage V

Power-On Reset Hysteresis V

INPUT SCL, INPUT/OUTPUT SDA

Low-Level Input Voltage V

High-Level Input Voltage V

Low-Level Output Current I

Input Leakage Current ILH, I

Input Capacitance C

SELECT INPUTS A0 to A2, RST

Low-Level Input Voltage V

High-Level Input Voltage V

Input Leakage Current I

Input Capacitance C

DD

DD

STB

POR

HYST

IL

IH

OL

I

IL

IH

LI

I

VDD = 3.6V;

no load, f

400kHz

No load, VI = V

VDD rising 0.9 1.4 2.1 V

VOL = 0.4V 3

VOL = 0.6V 6

V

LI

and V

SCL

VI = GND 15 pF

A0 to A2, and RST at VDD or GND -1 +1 µA

VI = GND 2 pF

Basic mode 30 50

=

SCL

Enhanced mode

(MAX7357/MAX7358 only)

or GND, VDD = 3.6V 0.1 1 µA

DD

= VDD or GND -1 +1 µA

SDA

2.3 3.6 V

0.7 x

V

DD

0.7 x

V

DD

45 70

0.4 V

0.3 x

V

DD

0.3 x

V

DD

µA

V

V

mA

V

V

Page 3

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

_______________________________________________________________________________________ 3

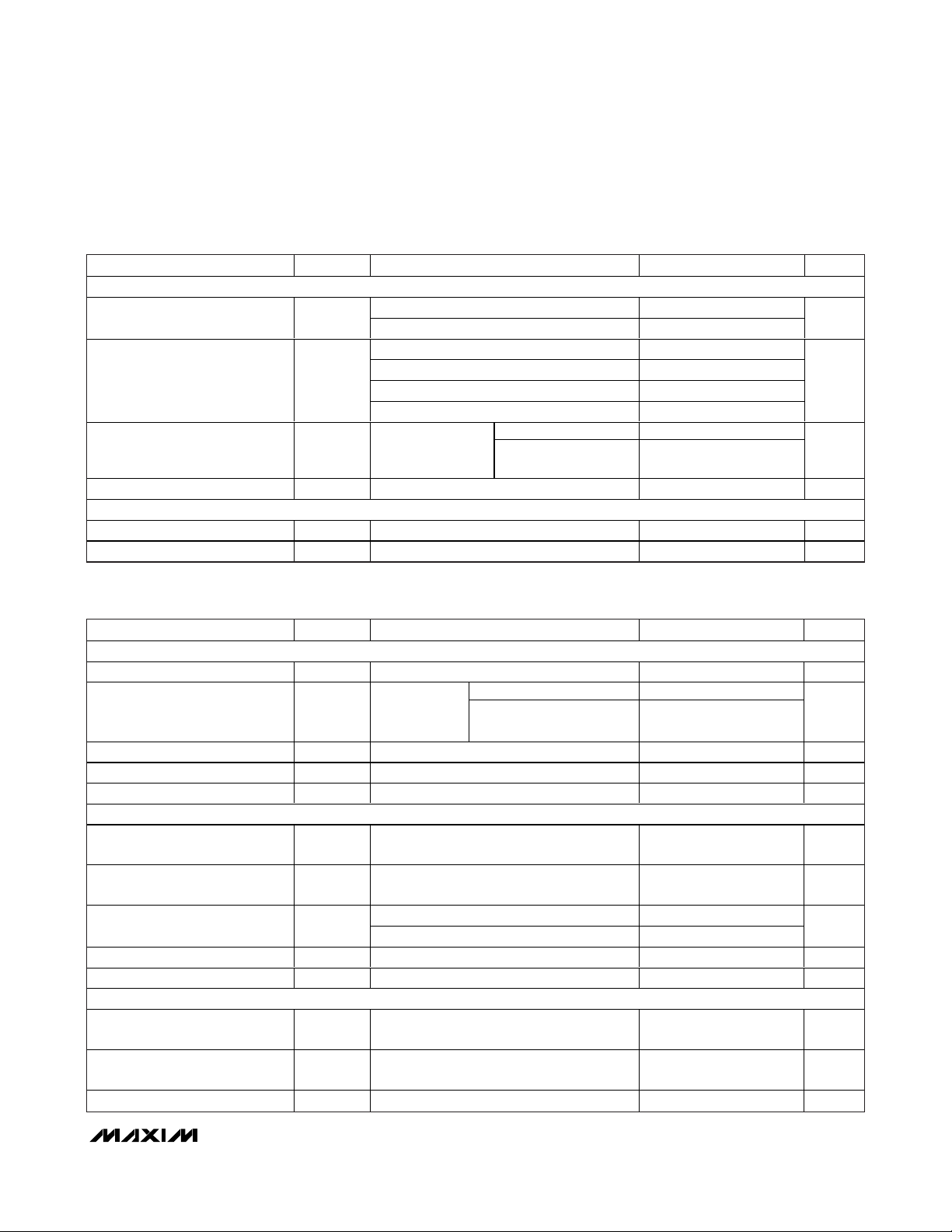

ELECTRICAL CHARACTERISTICS (3.3V SUPPLY) (continued)

(VDD= +2.3V to +3.6V, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VDD= +3.3V, TA= +25°C.) (Notes 2–5)

ELECTRICAL CHARACTERISTICS (5V SUPPLY)

(VDD= +4.5V to +5.5V, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VDD= +5V, TA= +25°C.) (Notes 2–5)

PASS GATE

Switch Resistance R

Switch Output Voltage V

Leakage Current I

Input/Output Capacitance C

OUTPUT RST/INT

Low-Level Output Current I

Leakage Current ILH, I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ON

SW

VDD = 3.0V to 3.6V, VO = 0.4V, IO = 15mA 5 11 30

VDD = 2.3V to 2.7V, VO = 0.4V, IO = 10mA 7 16 55

V

= VDD = 3.3V, I

SWin

V

= V

S Wi n

V

= VDD = 2.5V, I

SWin

V

= V

S Wi n

= 3.0V to 3.6V , I

D D

= 2.3V to 2.7V , I

D D

= -100µA 1.9

SWout

= - 100µA 1.6 2.8

S Wo ut

= -100µA 1.5

SWout

= - 100µA 1.1 2.0

S Wo ut

Basic mode -1 +1

OL

VI = VDD or GND

L

VI = GND 3 pF

IO

Enhanced mode

(MAX7357/MAX7358)

-2 +2

VOL = 0.4V (MAX7357/MAX7358) 3 mA

V

LI

= VDD or GND -1 +1 µA

RST/INT

µA

POWER SUPPLY

Supply Voltage V

Supply Current I

Standby Current I

Power-On Reset Voltage V

Power-On Reset Hysteresis V

INPUT SCL, INPUT/OUTPUT SDA

Low-Level Input Voltage V

High-Level Input Voltage V

Low-Level Output Current I

Input Leakage Current ILH, I

Input Capacitance C

SELECT INPUTS A0 TO A2, RST

Low-Level Input Voltage V

High-Level Input Voltage V

Input Leakage Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DD

DD

STB

POR

HYST

IL

IH

OL

I

IL

IH

LI

VDD = 5V;

no load, f

400kHz

No load, VI = V

Basic mode 65 100

=

Enhanced mode

SCL

(MAX7357/MAX7358 only)

or GND, VDD = 5.5V 0.2 1 µA

DD

VDD rising 0.9 1.4 2.1 V

V

= 0.4V 3

OL

= 0.6V 6

V

OL

V

= V

LI

SCL

= VDD or GND -1 +1 µA

SDA

VI = GND 15 pF

A0 to A2, and RST pins at VDD or GND -1 +1 µA

4.5 5.5 V

90 130

0.4 V

0.3 x

V

DD

0.7 x

V

DD

0.3 x

V

DD

0.7 x

V

DD

µA

mA

Ω

V

V

V

V

V

Page 4

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

4 _______________________________________________________________________________________

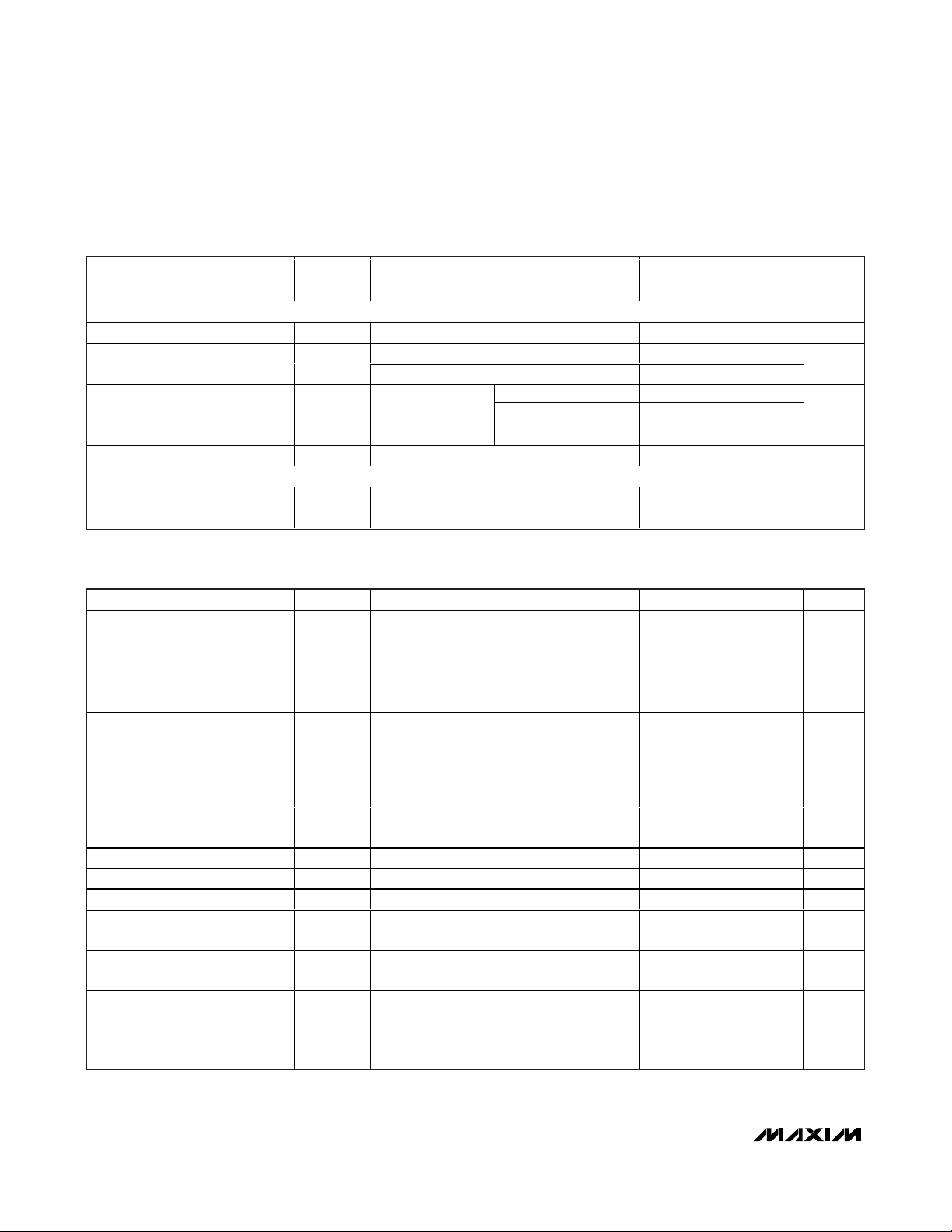

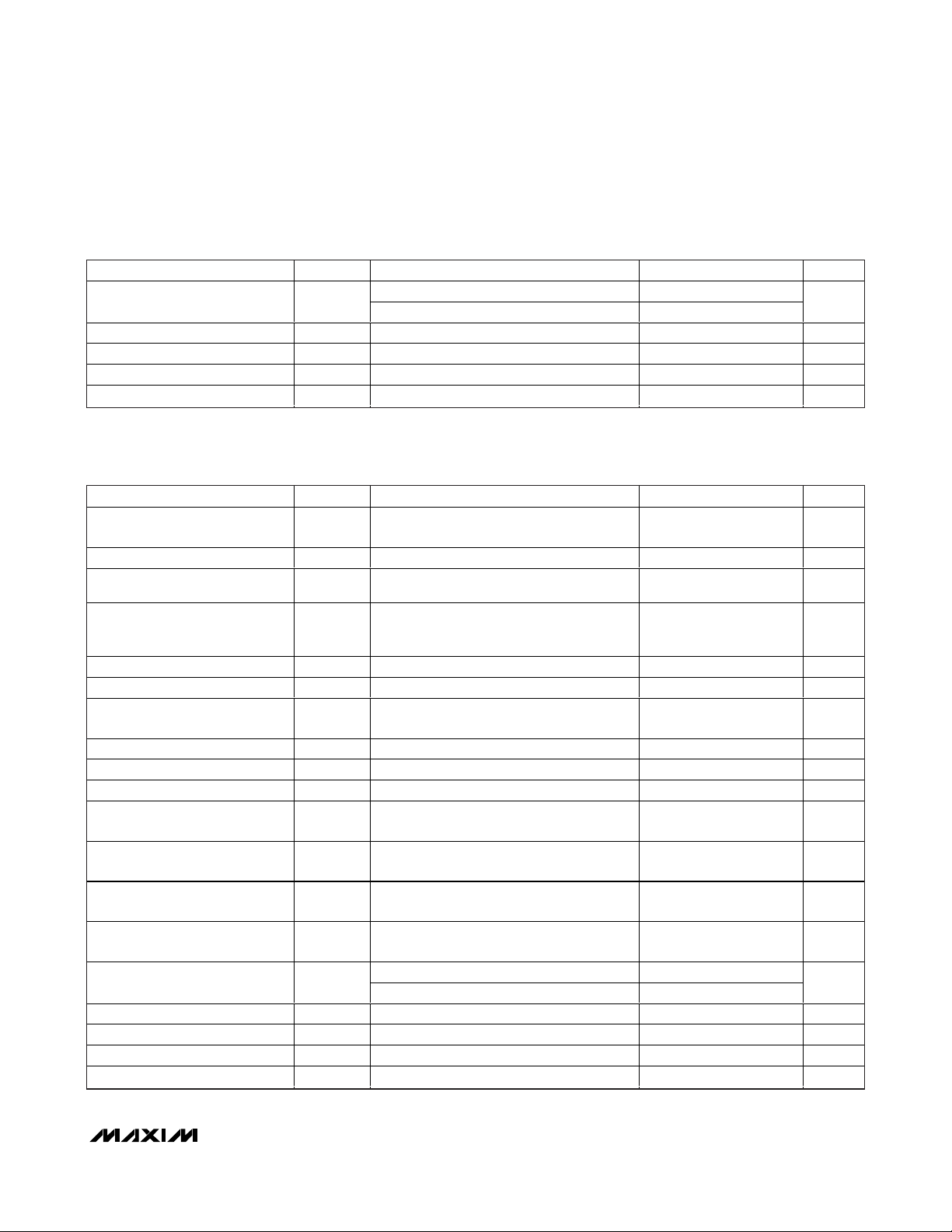

TIMING CHARACTERISTICS (STANDARD-MODE) (Figures 1, 2, 3)

(VDD= 2.3V to 5.5V, TA= -40°C to +85°C, unless otherwise noted.) (Notes 2, 6)

ELECTRICAL CHARACTERISTICS (5V SUPPLY) (continued)

(VDD= +4.5V to +5.5V, TA= -40°C to +85°C, unless otherwise noted. Typical values are at VDD= +5V, TA= +25°C.) (Notes 2–5)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Input Capacitance C

PASS GATE

Switch Resistance R

Switch Output Voltage V

Leakage Current I

Input/Output Capacitance C

OUTPUT RST/INT

Low-Level Output Current I

Leakage Current ILH, I

ON

SW

OL

Propagation Delay from SDA to

SD_ or SCL to SC_

SCL Clock Frequency f

Bus Free Time Between a STOP

and START Condition

Hold Time (Repeated) START

Condition After this Period, the

First Clock Pulse is Generated

LOW Period of the SCL Clock t

HIGH Period of the SCL Clock t

Setup Time for a Repeated

START Condition

Setup Time for a STOP Condition t

Data Hold Time t

Data Setup Time t

Rise Time of Both SDA and SCL

Signals

Fall Time of Both SDA and SCL

Signals

Capacitive Load for Each Bus

Line

Pulse Width of Spikes that Must

be Suppressed by the Input Filter

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

t

PD

SCL

t

BUF

t

HD;STA

LOW

HIGH

t

SU;STA

SU;STO

HD;DAT

SU;DAT

t

t

C

t

SP

VI = GND 2 pF

I

VDD = 4.5V to 5.5V, VO = 0.4V, IO = 15mA 4 9 24 Ω

V

= VDD = 5.0V, I

SWin

V

= V

S Wi n

VI = VDD or GND

L

VI = GND 3 pF

IO

VOL = 0.4V (MAX7357/MAX7358) 3 mA

V

LI

RST/INT

(Note 7) 0.3 ns

(Note 8) 0 3.45 µs

R

F

b

= 4.5V to 5.5V , I

D D

= VDD or GND -1 +1 µA

= -100µA 3.6

SWout

= - 100µA 2.6 4.5

S Wo ut

MAX7356 -1 +1

Enhanced mode

(MAX7357/MAX7358)

-2 +2

0 100 kHz

4.7 µs

4.0 µs

4.7 µs

4.0 µs

4.7 µs

4.0 µs

250 ns

1000 ns

300 ns

400 pF

50 ns

V

µA

Page 5

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

_______________________________________________________________________________________ 5

TIMING CHARACTERISTICS (STANDARD-MODE) (Figures 1, 2, 3) (continued)

(VDD= 2.3V to 5.5V, TA= -40°C to +85°C, unless otherwise noted.) (Notes 2, 6)

TIMING CHARACTERISTICS (FAST-MODE) (Figures 1, 2, 3)

(VDD= 2.3V to 5.5V, TA= -40°C to +85°C, unless otherwise noted.) (Notes 2, 6)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Data Valid Time t

Data Valid Acknowledge t

Low-Level Reset Time t

Reset Time t

Recovery to Start t

VD;DAT

VD:ACK

REC;STA

WL(rst)

rst

(High to low) 1

(Low to high) 0.6

5ns

500 ns

0ns

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Propagation Delay from SDA to

SD_ or SCL to SC_

SCL Clock Frequency f

Bus Free Time Between a STOP

and START Condition

Hold Time (Repeated) START

Condition After this Period,

the Fi r st C l ock P ul se i s Gener ated

LOW Period of the SCL Clock t

HIGH Period of the SCL Clock t

Setup Time for a Repeated

START Condition

Setup Time for a STOP Condition t

Data Hold Time t

Data Setup Time t

Rise Time of Both SDA and SCL

Signals

Fall Time of Both SDA and SCL

Signals

Capacitive Load for Each Bus

Line

Pulse Width of Spikes that Must

be Suppressed by the Input Filter

Data Valid Time t

Data Valid Acknowledge t

Low-Level Reset Time t

Reset Time t

Recovery to START t

t

HD;STA

t

SU;STA

SU;STO

HD;DAT

SU;DAT

VD;DAT

VD;ACK

REC;STA

t

PD

SCL

t

BUF

LOW

HIGH

t

t

C

t

SP

WL(rst)

rst

(Note 7) 0.3 ns

0 400 kHz

1.3 µs

0.6 µs

1.3 µs

0.6 µs

0.6 µs

0.6 µs

(Note 8) 0 0.9 µs

100 ns

R

F

b

(High to low) 1

(Low to high) 0.6

20 +

0.1C

b

20 +

0.1C

b

5ns

500 ns

0ns

µs

1µs

300 ns

300 ns

400 pF

50 ns

µs

1µs

Page 6

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

6 _______________________________________________________________________________________

TIMING CHARACTERISTICS (FAST-MODE) (Figures 1, 2, 3) (continued)

(VDD= 2.3V to 5.5V, TA= -40°C to +85°C, unless otherwise noted.) (Notes 2, 6)

Note 2: All devices are 100% production tested at T

A

= +25°C. Specifications are over -40°C to +85°C and are guaranteed by

design.

Note 3: Subscript SW refers to all SC_ and SD_ pins.

Note 4: V

SWin

= Switch input voltage; I

SWout

= Current between SD_ and SDA or SC_ and SCL. See Figure 4.

Note 5: V

I

= V

SD_

or V

SC_

.

Note 6: All timing is measured using 20% and 80% levels, unless otherwise noted.

Note 7: Pass gate propagation delay is calculated from the 20Ω typical R

ON

and the 15pF load capacitance.

Note 8: A device must internally provide a hold time of at least 300ns for the SDA signal (referred to the V

IH(min)

of the SCL signed)

to bridge the undefined region of the falling edge of SCL.

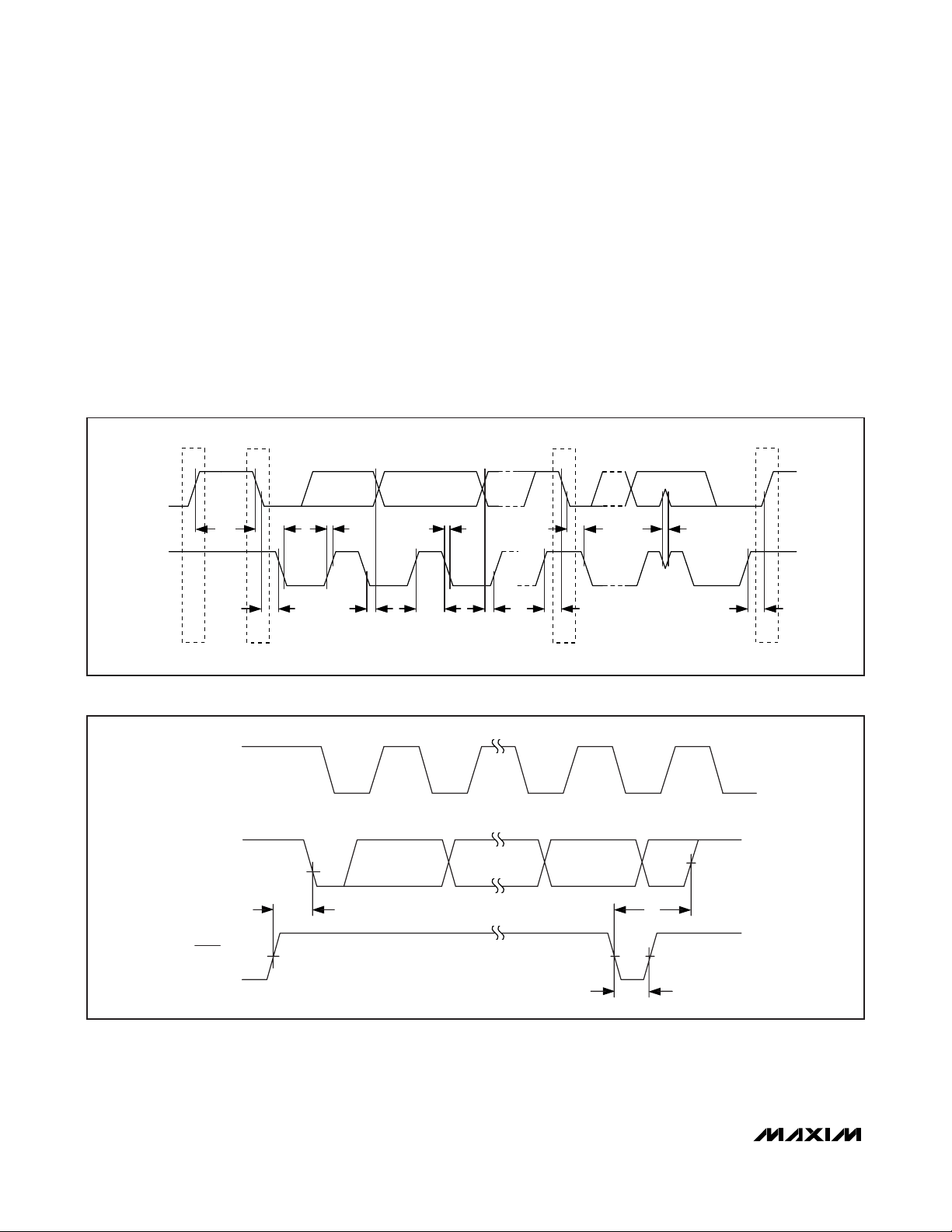

SDA

SCL

t

BUF

t

SU;STO

t

SP

t

HD;STA

t

SU;STA

t

F

t

HIGH

t

HD;DAT

t

R

t

LOW

t

HD;STA

SP

Sr

P

t

SU;DAT

Figure 1. 2-Wire Serial-Interface Timing Diagram

SCL

SDA

RESET

t

REC;STA

t

WL(rst)

t

rst

Figure 2. RST Timing Diagram

Page 7

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

_______________________________________________________________________________________ 7

Figure 3. I2C Bus Timing Diagram

Figure 4. Switch Output Voltage and Current

Typical Operating Characteristics

(VDD= +5V, TA= +25°C, unless otherwise noted.)

START

t

SU;STA

CONDITION

(S)

PROTOCOL

SCL

t

BUF

SDA

t

HD;STA

DEVICE

+

V

SWin

-

BIT 7

MSB

(A7)

t

LOWtHIGH

t

r

V

SW

I

SWout

t

VD;ACK

STOP

CONDITION

(P)

t

SU;STO

BIT 6

(A6)

1/f

SCL

t

f

t

SU;DAT

t

HD;DAT

BIT 0

(R/W)

ACKNOWLEDGE

t

VD;DAT

(A)

V

vs. SUPPLY VOLTAGE

SW

I

= 100µA

SWout

2.3 5.5

VDD (V)

4.73.93.1

MAX7356 toc01

(V)

V

5.5

5.0

4.5

4.0

3.5

3.0

SW

2.5

2.0

1.5

1.0

0.5

0

SUPPLY CURRENT vs. SUPPLY VOLTAGE

100

f

= 400kHz

SCL

80

ENHANCED MODE

60

(µA)

DD

I

40

20

0

2.3 5.5

BASIC MODE

VDD (V)

SUPPLY CURRENT vs. SCL FREQUENCY

100

MAX7356 toc02

80

60

(µA)

DD

I

4.73.93.1

ENHANCED MODE

40

f

(kHz)

SCL

BASIC MODE

300200100

20

0

0400

MAX7356 toc03

Page 8

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

8 _______________________________________________________________________________________

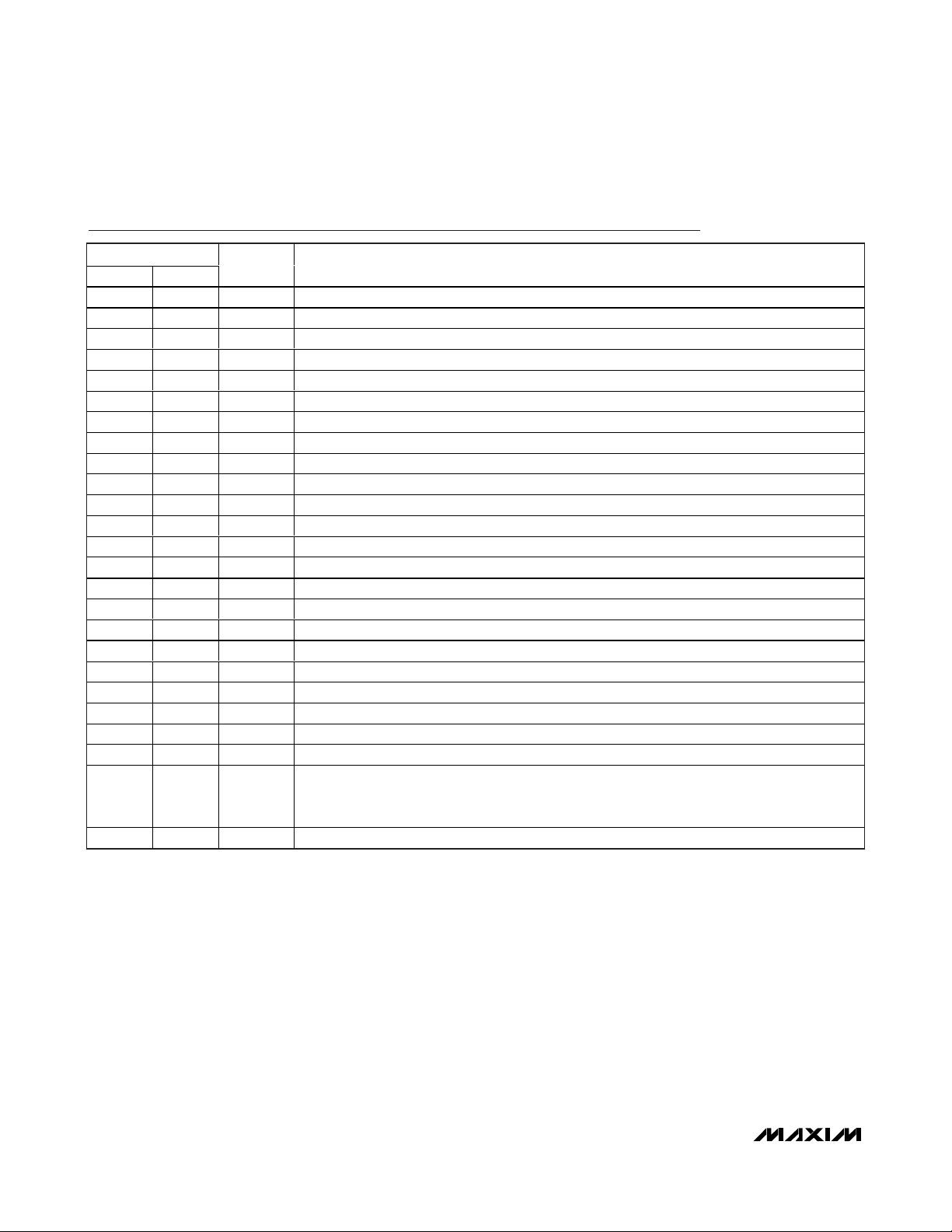

Pin Description

( ) For the MAX7357/MAX7358 only.

PIN

TQFN TSSOP

1 4 SD0 I2C Bus0 Serial Data

2 5 SC0 I2C Bus0 Serial Clock

3 6 SD1 I2C Bus1 Serial Data

4 7 SC1 I2C Bus1 Serial Clock

5 8 SD2 I2C Bus2 Serial Data

6 9 SC2 I2C Bus2 Serial Clock

7 10 SD3 I2C Bus3 Serial Data

8 11 SC3 I2C Bus3 Serial Clock

9 12 GND Supply Ground

10 13 SD4 I2C Bus4 Serial Data

11 14 SC4 I2C Bus4 Serial Clock

12 15 SD5 I2C Bus5 Serial Data

13 16 SC5 I2C Bus5 Serial Clock

14 17 SD6 I2C Bus6 Serial Data

15 18 SC6 I2C Bus6 Serial Clock

16 19 SD7 I2C Bus7 Serial Data

17 20 SC7 I2C Bus7 Serial Clock

18 21 A2 Device Address Bit 2

19 22 SCL Main I2C Bus Clock

20 23 SDA Main I2C Bus Data

21 24 V

22 1 A0 Device Address Bit 0

23 2 A1 Device Address Bit 1

24 3

—— EPE xp osed P ad ( TQ FN O nl y) . C onnect E P to g r ound . D o not use E P as the onl y g r ound connecti on.

NAME FUNCTION

DD

RST

(RST/INT)

Supply Voltage

Active-Low Reset Input and Interrupt Output. RST resets the MAX7356 by a host. RST/INT on

the MAX7357 or MAX7358 is bidirectional. RST/INT is used to reset the device by a host or by

the device to send an interrupt signal to the host.

Page 9

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

_______________________________________________________________________________________ 9

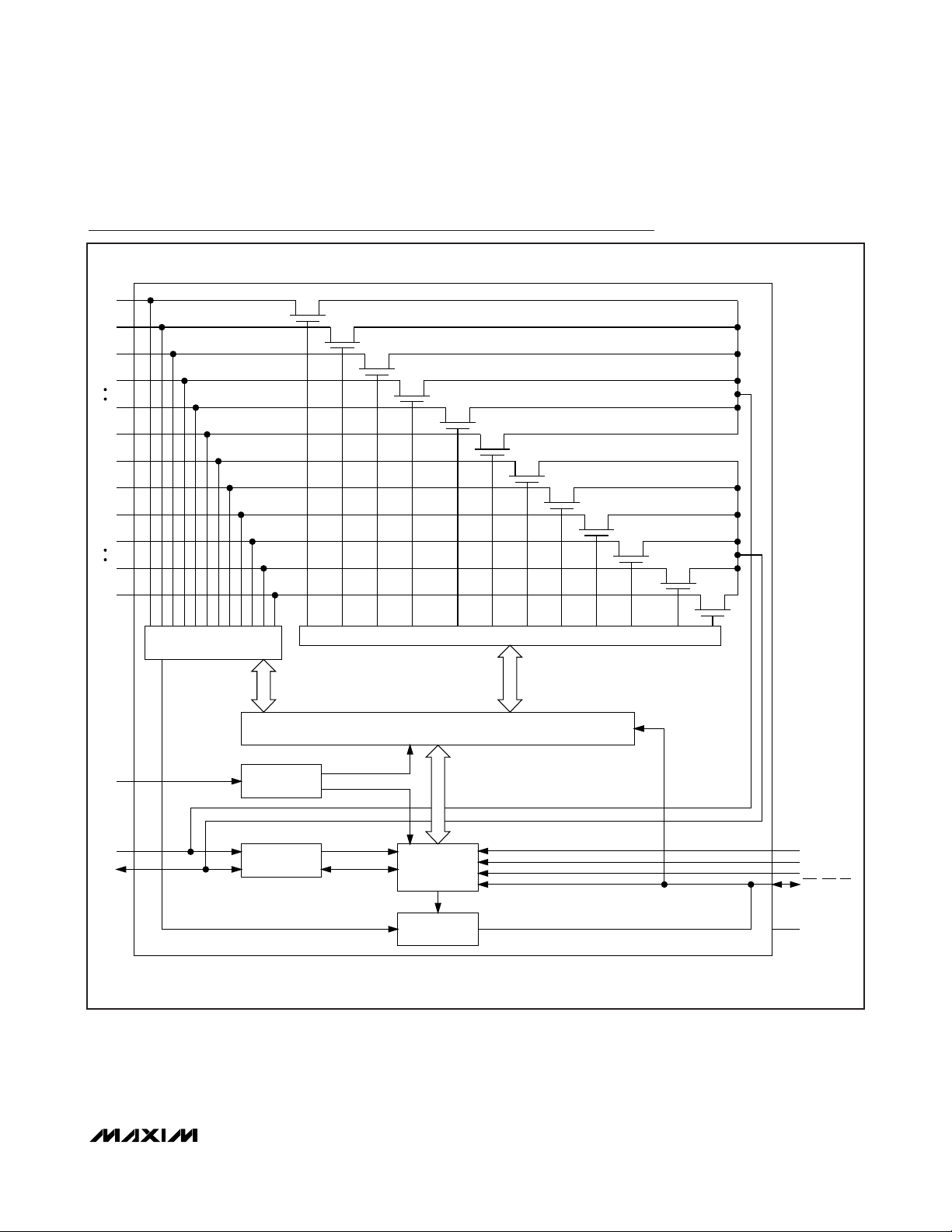

Functional Diagram

SC0

SC1

SC2

SC3

SC6

SC7

SD0

SD1

SD2

SD3

SD6

SD7

LOCK-UP DETECTION

AND WIGGLE TEST

SWITCH ENABLE/DISABLE

V

DD

SCL

SDA

( ) ONLY FOR THE MAX7357 AND MAX7358

POWER-ON

RESET

GLITCH FILTER

REGISTER BANK WITH SWITCH CONTROL LOGIC

I2C BUS

CONTROL

INT LOGIC

A0

A1

A2

RST (RST/INT)

GND

Page 10

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

10 ______________________________________________________________________________________

Detailed Description

The MAX7356/MAX7357/MAX7358 devices are 1-to-8

I

2

C multiplexers/switches for connecting a large num-

ber of I

2

C components to a single master. The circuits

connect a main I

2

C bus to any combination of 8 extended I2C buses. They enable a master on the main bus to

isolate and communicate with devices or groups of

devices that may otherwise have slave address conflicts. Any extended bus can be connected or disconnected by control packets from the main I2C bus writing

to the main control register of these I2C switches.

The MAX7357/MAX7358 feature a built-in timer used to

monitor all extended buses, for lock-up conditions. If the

data line of any of these buses is low for more than

25ms, a lock condition is detected. An optional interrupt

can be generated through the bidirectional RST/INT pin.

The master can read the bus lock-up register to find out

which extended bus is locked up. The master can also

optionally enable the MAX7357 or MAX7358 to send a

flush-out sequence on the faulty channel. There is an

optional preconnection check that can be enabled,

which toggles the extended bus clock and data line low

then high to ensure that the downstream bus is not

locked high prior to connecting it to the host bus.

The bus lock-up detection and isolation features are

enabled by writing a unique series of I2C commands to

the MAX7357/MAX7358.

Power-On Reset

When power is applied to VDD, an internal power-on

reset (POR) holds the MAX7356/MAX7357/MAX7358 in

a reset state until VDDhas reached V

POR

. At this point,

the reset condition is released and the MAX7356/

MAX7357/MAX7358 registers and I2C state machine

are initialized to their default states.

Basic Mode of Operation

The MAX7356/MAX7357/MAX7358 feature a basic

mode of operation. In basic mode, the device operates

solely as a collection of analog switches that enable

any combination of the extended buses (SC_, SD_)

to be connected to the host-side bus (SCL, SDA). Only

the switch control register is accessible in basic mode

of operation.

Enhanced Mode of Operation

(MAX7357/MAX7358)

The MAX7357 and MAX7358 feature an enhanced

mode of operation that enable features and registers

that are unavailable in the basic mode of operation.

When operating in enhanced mode, there are 7 registers available to the host. Features such as bus lock-up

detection, preconnection fault tests, and diagnostic

information are made available to the user. A special

sequence of commands can switch the MAX7357 or

MAX7358 from basic mode to enhanced mode, and a

simple write to the configuration register can switch the

devices from enhanced mode back to basic mode.

Entering Basic Mode from

Enhanced Mode

(MAX7357/MAX7358)

When the 7 registers of Table 2 are enabled, the

MAX7357 and MAX7358 can be put into basic mode by

setting bit B6 of the configuration register. When basic

mode is entered, the value of all registers return to their

POR value. B6 of the configuration register is also maintained to allow operation in basic mode. When in basic

mode, the MAX7357 and MAX7358 can be returned to

full feature mode by receiving a special sequence of

commands from the host as described below.

The sequence of I2C commands for enabling the

MAX7357 or MAX7358 enhanced features (bus lock-up

detection, isolation, and notification) as well as access

to the additional 6 registers consists of a write byte, a

read byte, another write byte, and another read byte

with no data bytes following any of these write or read

bytes, as shown in Figure 5. A write byte consists of

the 7-bit MAX7357 or MAX7358 device address followed by a 0. A read byte consists of the 7-bit

MAX7357 or MAX7358 device address followed by a 1.

The special sequence begins with a START condition

and ends with a STOP condition. Repeated START

conditions are used to interconnect these write and

read bytes.

The complete special sequence of I2C commands

needs to be received by the MAX7357 or MAX7358 to

activate the enhanced mode.

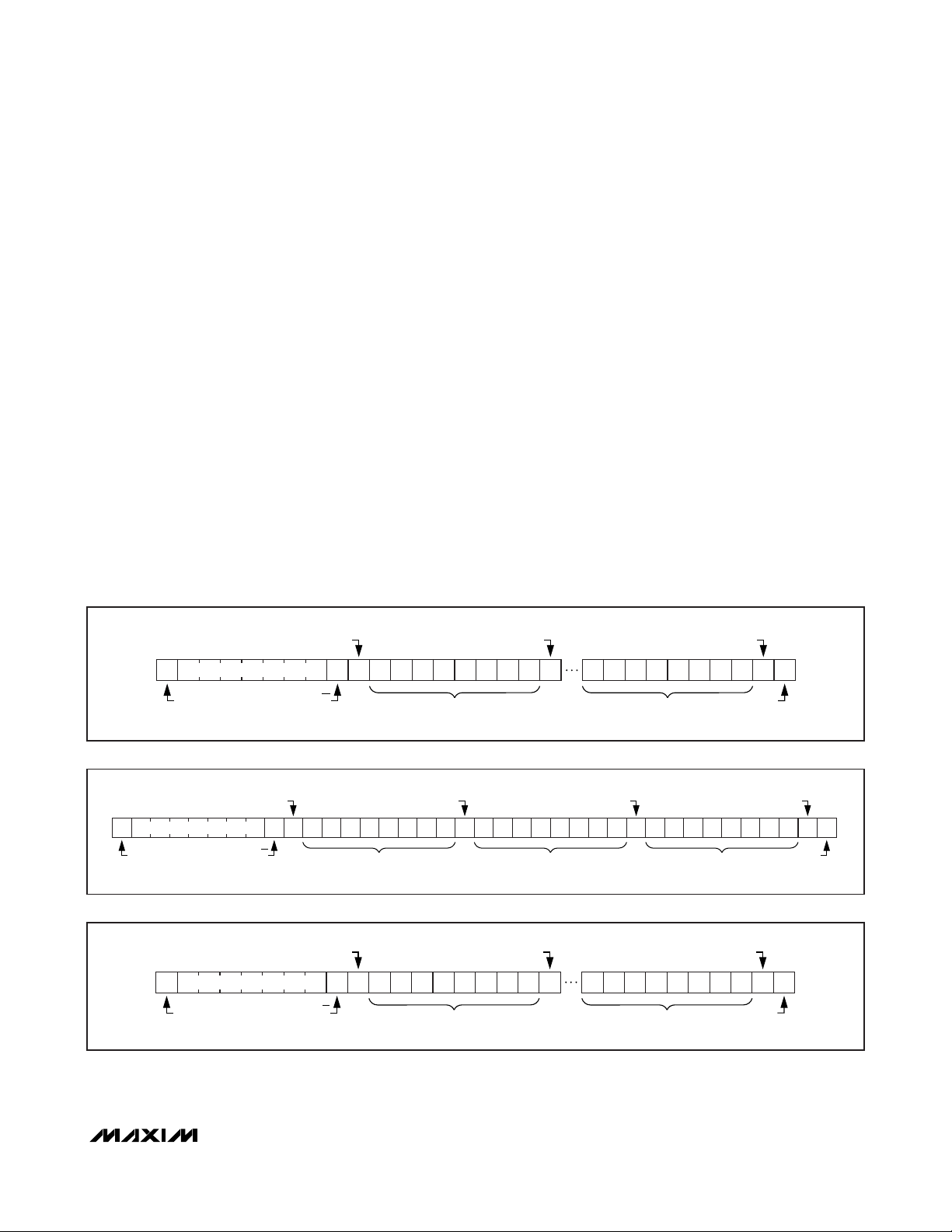

Figure 5. The Special Sequence of I2C Commands for Turning on the Full Feature

ACKNOWLEDGE FROM THE

MAX7357 OR MAX7358

ADDRESS OF MUX/SWT PARTS

START

0 A Sr ADDRESS OF MUX/SWT PART 0 A SrADDRESS OF MUX/SWT PART 1 A Sr ADDRESS OF MUX/SWT PART 1 A P

W

ACKNOWLEDGE FROM THE

MAX7357 OR MAX7358

R

ACKNOWLEDGE FROM THE

MAX7357 OR MAX7358

W

ACKNOWLEDGE FROM THE

MAX7357 OR MAX7358

R

STOP

Page 11

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

______________________________________________________________________________________ 11

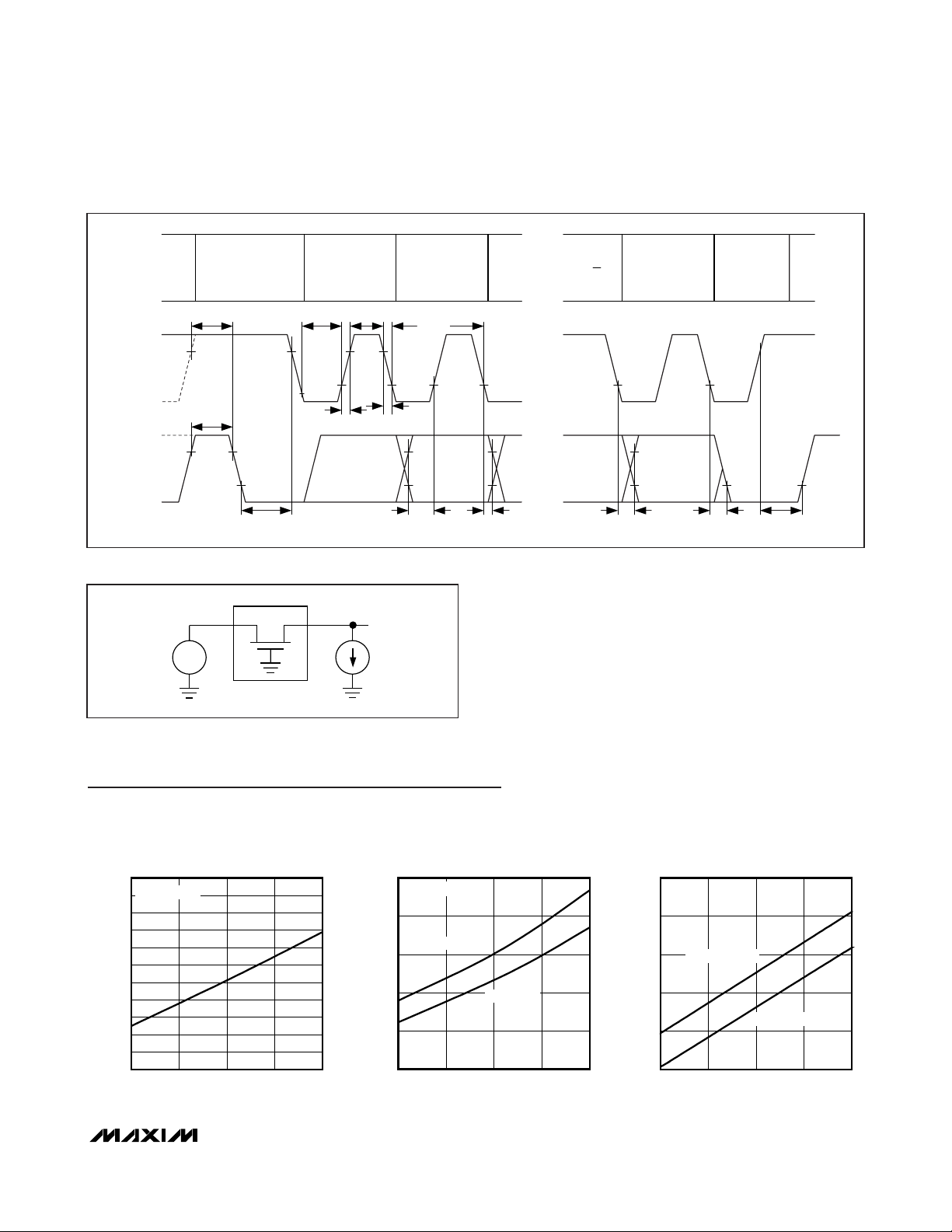

Bus Lock-Up Detection, Isolation,

and Notification Operation

(MAX7357/MAX7358)

SDA Stuck Low

If either line of any downstream bus is low for a period

exceeding 25ms between t1and t2in Figure 6, the

MAX7357/MAX7358 detect a lock-up fault on that bus

and takes the action configured by the user. If the lockup is not on the main bus, SDA and SCL return to the

high state at the same time. The MAX7357 or MAX7358

then identifies which SD_ or SC_ is still pulled low. If the

optional interrupt function is enabled (by setting B0 of

the configuration register), an active-low interrupt is

generated at RST/INT.

If B4 in the configuration register is set to 1, then only

faults on connected buses cause the MAX7357 or

MAX7358 to disconnect all buses from each other.

When this is the case, faults detected on disconnected

buses set the flag in the lock-up status register, and, if

enabled, notify the host of the fault, but do not disconnect the buses from one another.

B1 of the configuration register enables the flush-out

sequence. If this bit is set to 1, the MAX7357 or

MAX7358 attempts to send a flush-out sequence over

the locked SD_ and SC_ pair (the sequence begins at

t

5

in Figure 6). If the flush-out sequence is successful,

the locked bus (SD_ and SC_) is released at t

6

(Figure

6). The I2C master (at SDA and SCL) reads the

MAX7357 or MAX7358 lock-up status register to identify the locked-up bus. If RST/INT is enabled as an

interrupt, it is released once a read command to the

lock-up indication register is received by the MAX7357

or MAX7358 (shown at t7in Figure 6). The RST/INT

can also be automatically released after a 1.6s delay

by setting bit 2 of the configuration register.

Preconnection Wiggle Test

(Stuck High Fault)

(MAX7357/MAX7358)

By setting bit B7 in the configuration register to 1, a preconnection wiggle test is enabled for all downstream

buses. This test only runs on the downstream bus when

the bus is selected through the switch control register.

Enabling this test does not affect any bus that is already

connected to the host bus; however, deselecting and

subsequently reselecting the bus will cause the test to

occur. The test is performed when the switch control register bit (or bits if multiple buses are selected in the same

I2C transaction) toggles from 0 to 1 and a stop condition

is received. It consists of the MAX7357 or MAX7358

pulling the downstream clock line low, then the downstream data line low. Both lines are checked for a nominal low value, and then the clock line is released followed

by the data line (Note: This is an I

2

C stop condition and

is seen by any I2C devices connected to the extended

bus). If either the clock or data line (or both) fail to pull

low during the test, the MAX7357 or MAX7358 do not

allow that downstream bus to connect to the host. If the

optional interrupt notification bit is set (B0), the device

notifies the host that a fault has occurred. The I2C master

can then read the MAX7357 or MAX7358 registers to find

out which bus or buses caused the fault. Faults detected

by this test are stored in the preconnection fault register

(0x06). The stuck high Fault register is cleared once this

register is read, resetting the device, or disabling the

preconnection test.

Device Address

The MAX7356/MAX7357/MAX7358 family of devices

has selectable device addresses through three external

inputs. The slave address consists of 4 fixed bits

(A6–A3 set to 1110); followed by 3 pin-programmable

bits (A2, A1, A0), as shown in Figure 7. The addresses

A2, A1, and A0 can also be driven dynamically if

required, but the values must be stable when they are

expected in the address sequence.

Figure 6. Bus Lock-Up Detection, Isolation, and Notification Timing Diagram

t

3

t

t

5

t

4

2

NOTE: THE FLUSH-OUT SEQUENCE RUNS AT AN SC_ FREQUENCY OF 40kHz.

THE HOST MAY COMMUNICATE AT UP TO 400kHz. THE TIMING SHOWN IS NOT TO SCALE.

t

SDA

SCL

SD_

SC_

RST/INT

t

1

6

BYTE1

FLUSH-OUT DATA

BYTE4

t

7

Page 12

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

12 ______________________________________________________________________________________

Available addresses depend on the hardware connections of pins A2, A1, and A0 as shown in Table 1.

The last bit following the slave address bit A0 on an I

2

C

command defines the operation to be performed. When

the last bit sets to logic 1, a read is selected while logic

0 selects a write operation.

Register Map (MAX7357/MAX7358)

The MAX7357 and MAX7358 have 7 registers (shown in

Table 2) that can be accessed through the I2C bus. The

MAX7357 powers up with all of these registers accessible. The initial register address counter is at 0x00. The

MAX7358 powers up in basic mode with only the switch

control register available. Writing to a MAX7358

changes only the contents of the switch control register.

By sending a unique I2C sequence to the MAX7358, all

7 registers become available.

Register Access Protocol (MAX7356)

Only the MAX7356 device address is required to gain

access to its registers. A typical I2C command to communicate with the MAX7356 starts with its device

address followed directly by data bytes.

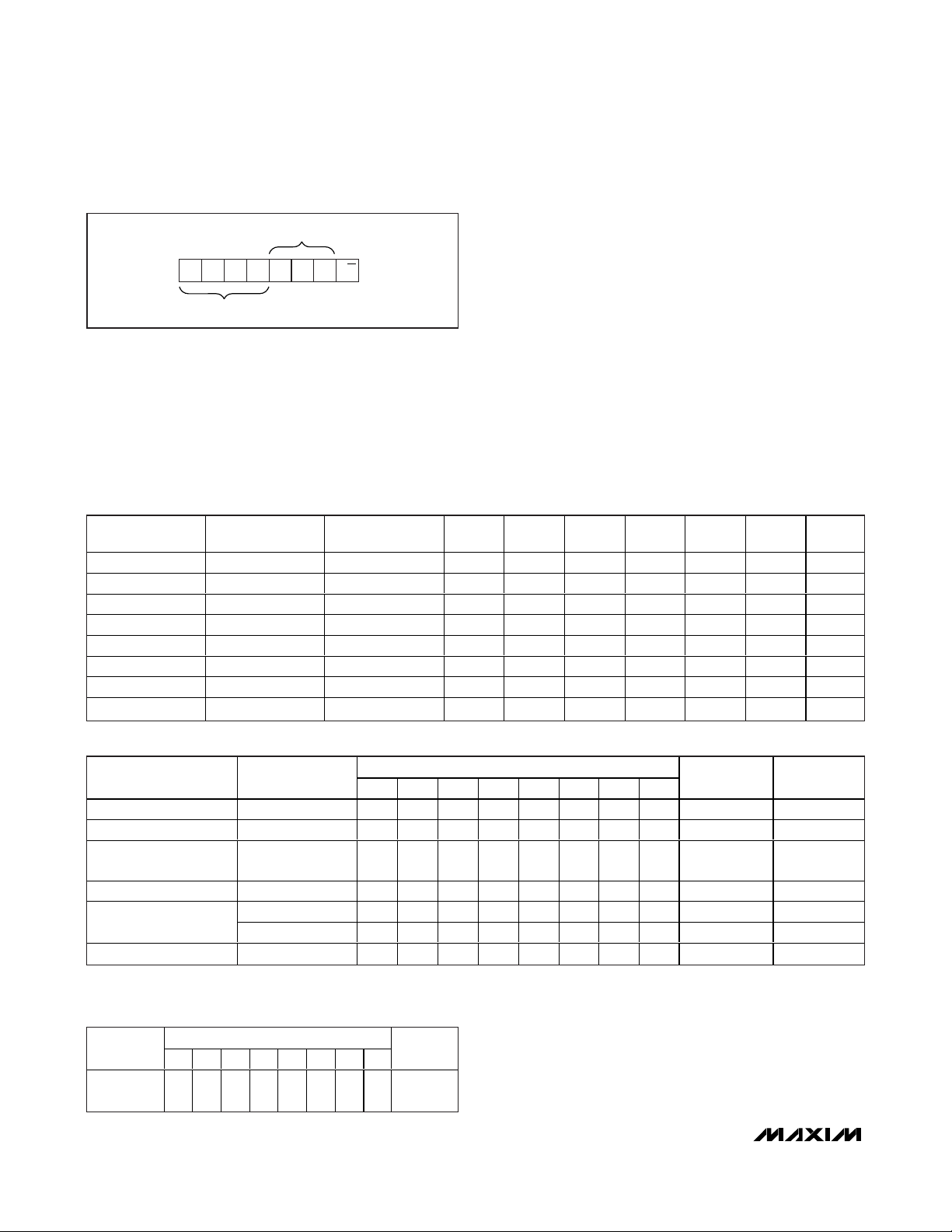

Figure 7. MAX7356/MAX7357/MAX7358 Slave Address

Table 1. MAX7356/MAX7357/MAX7358 Switch Multiplexer Device Address

Table 3. MAX7357 and MAX7358 BasicMode Register Map

Table 2. MAX7357/MAX7358 Enhanced-Mode Register Map

PIN-SELECTABLE BITS

A5 R/WA6 A4 A3 A2 A1 A0

FIXED

A2

CONNECTION

GND GND GND 1110000

GND GND V

GND V

GND V

V

DD

V

DD

V

DD

V

DD

A1

CONNECTION

DD

DD

GND GND 1110100

GND V

V

DD

V

DD

A0

CONNECTION

DD

GND 1110010

V

DD

DD

GND 1110110

V

DD

A6 A5 A4 A3 A2 A1 A0

1110001

1110011

1110101

1110111

REGISTER NAME

Switch Control 0x00 0 0 0 0 0 0 0 0 0x01 R/W

Configuration 0x01 0 0 0 0 0 0 0 1 0x02 R/W

Flush-Out Sequence 0x02 1 1 1 1 1 1 1 1

Lock-Up Indication 0x03 0 0 0 0 0 0 0 0 0x04 R

Traffic Prior to Lock-Up

Stuck High Fault 0x06 0 0 0 0 0 0 0 0 0x00 R

INTERNAL

ADDRESS

0x04 0 0 0 0 0 0 0 0 0x05 R

0x05 0 0 0 0 0 0 0 0 0x06 R

B7 B6 B5 B4 B3 B2 B1 B0

POR DEFAULT SETTING

NEXT

ADDRESS

0x00 (W)

0x03 (R)

REGISTER

NAME

Switch

Control

POR DEFAULT SETTING

B7 B6 B5 B4 B3 B2 B1 B0

00000000 R/W

ACCESS

ACCESS

R/W

Page 13

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

______________________________________________________________________________________ 13

Only the switch control register can be accessed through

an I2C write or read command. All data bytes are for

the switch control register. The last data byte in an I2C

write command is retained by the switch control register.

Register Access Protocol

(MAX7357/MAX7358)

Only the MAX7357 or MAX7358 I2C device address is

required to gain access to its registers. A typical I2C

command to communicate with the MAX7357 or

MAX7358 starts with its device address and is followed

directly by data bytes. Internal register addresses are

not used in an I2C write or read command.

For enhanced mode, all registers are accessed in

sequence starting with the switch control register and

follows the order defined by internal register addresses

as shown in Table 2. Internal register addresses are

0x00, 0x01, 0x02, 0x03, 0x04, 0x05, and 0x06 for

switch control, configuration, flush-out sequence, lockup indication, first and second bytes of the traffic prior

to lock-up, and preconnection fault registers, respectively. When writing data to the register(s), addressing

starts with address 0x00 and goes one higher in each

subsequent byte and comes back to 0x00 again after

0x02 since the next four higher addressed registers are

read only. Read access also starts with the internal register address 0x00 and goes one higher in each subsequent byte and comes back to 0x00 again after 0x06.

For basic mode, only the switch control register can be

accessed through an I2C write or read command. All

data bytes are for the switch control register. The last

data byte in an I2C write command is retained by the

switch control register. Incomplete bytes are ignored.

Switch Control Register

The switch control register (Figure 8) selects which

channels will be connected to the main I2C bus. This

register can be written and read through the main I2C

bus. The POR value for the switch control register is

0x00—all switches disconnected.

A SC_/SD_ downstream pair, or channel, is selected by

the contents of the switch control register. All bits of the

control byte are used to determine which channel is to

Figure 8. Switch Control Register

Table 4. Switch Control Register Channel Selection

X = Don’t care.

B7 B6 B5 B4 B3 B2 B1 B0 COMMAND

XXXXXXX 0Channel 0 disabled

XXXXXXX 1Channel 0 enabled

X X X X X X 0 X Channel 1 disabled

X X X X X X 1 X Channel 1 enabled

X X X X X 0 X X Channel 2 disabled

X X X X X 1 X X Channel 2 enabled

X X X X 0 X X X Channel 3 disabled

X X X X 1 X X X Channel 3 enabled

X X X 0 X X X X Channel 4 disabled

X X X 1 X X X X Channel 4 enabled

XX0XXXX XChannel 5 disabled

XX1XXXX XChannel 5 enabled

X0XXXXX XChannel 6 disabled

X1XXXXX XChannel 6 enabled

0XXXXXXXChannel 7 disabled

1XXXXXXXChannel 7 enabled

CHANNEL SELECTION BITS (READ/WRITE)

B6 B0B7 B5 B4 B3 B2 B1

CHANNEL 0

CHANNEL 1

CHANNEL 2

CHANNEL 3

CHANNEL 4

CHANNEL 5

CHANNEL 6

CHANNEL 7

Page 14

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

14 ______________________________________________________________________________________

Table 5. Configuration Register Definition

X = Don’t care.

be selected. More than one channel can be selected

simultaneously. When a channel is selected, the channel

becomes active immediately after a stop condition has

been placed on the I2C bus. This ensures that all

SC_/SD_ lines are in a HIGH state when the channel is

made active, so that no false conditions are generated at

the time of connection.

Configuration Register

(MAX7357/MAX7358)

B0 = RST/INT serves as an interrupt when a bus lockup condition is detected.

B1 = Flush-out sequence is sent automatically on lockedup channels when a lock-up condition is detected.

B2 = When B0 = 1, release the RST/INT output after

asserting for 1.6 seconds.

B3 = Data in the lock-up indication register cleared only

after reading the register.

B4 = Connected channels remain connected on detection of lock-up if the lock-up condition is present only on

a channel that is not connected.

B5 = Disable bus lock-up detection.

B6 = Basic mode.

B7 = Enables the preconnection wiggle test for SC_

and SD_.

Flush-Out Sequence Register

(MAX7357/MAX7358)

A flush-out sequence can be sent to a particular auxiliary bus automatically after the identification of the lockup condition. The flush-out sequence consists of 18

SC_ clock cycles. An 8-bit sequence for the SD_ to follow during the flush-out cycle can also be defined by

writing to the flush-out sequence register. By default,

the flush-out sequence register is all ones. The

MAX7357 or MAX7358 attempt to send the one-byte

sequence followed by an additional clock cycle (NACK)

two times sequentially, followed by a stop condition.

The effectiveness of sending the flush-out sequence

depends on the behavior of the locked-up device. For

an auxiliary bus with only slave devices, it is more likely

that the SCL line can still be driven by the MAX7357 or

MAX7358. In this case, a slave device may respond to

a particular flush-out sequence. After the release of the

SD_ line by a “stuck” device, the remaining sequence

on the SD_ line can be used to reset itself.

Bus Lock-Up Indication Register

(MAX7357/MAX7358)

The bus master can read the lock-up indication byte to

identify the stuck channels. A bit set to ”1” indicates

that the associated channel is stuck. The indication for

a given channel remains as long as the lock-up condi-

B7 B6 B5 B4 B3 B2 B1 B0 COMMAND

XXXXXXX0Interrupt with RST/INT disabled

XXXXXXX1Interrupt with RST/INT enabled

XXXXXX0XFlush-out disabled

XXXXXX1XFlush-out enabled

XXXXX0XXRST/INT released after a register read

XXXXX1XXRST/INT released after 1.6 seconds

XXXX0XXX

XXXX1XXX

X X X 0 X X X X Disconnect all channels on bus lock-up

X X X 1 X X X X Disconnect only the locked up bus

X X 0 X X X X X Bus lock-up detection enabled

X X 1 X X X X X Bus lock-up detection disabled

X0XXXXXXEnhanced mode

X1XXXXXXBasic mode enabled

0XXXXXXXPreconnect test is disabled

1XXXXXXXPreconnect test is enabled

The lock-up register shows the current

condition

The lock-up register data is not cleared

until a read

Page 15

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

______________________________________________________________________________________ 15

tion exists on that channel. If the interrupt feature is

selected (B0 of the configuration register is 1), however, the interrupt signal, RST/INT, deasserts (goes to

high) once this bus lock-up indication register is read.

If desired, setting bit B3 of the configuration register to

1 can latch the lock-up data. When B3 is set, the lockup bits remain set (even if a channel becomes

“unstuck”) until the lock-up indication register is read

by the master. Lock-up conditions on unconnected auxiliary buses are also detected. When this happens, operation is the same as when lock-ups are detected on

connected buses, except that, if desired, bus connections may be maintained as long as any detected lockups are present only on unconnected channels. This

option is selected using bit B4 of the configuration register. (Figure 9)

Traffic Prior to Lock-Up Register

(MAX7357/MAX7358)

The I2C bus traffic information per SCL clock is monitored and stored into the two-byte traffic prior to lock-up

register. The first two bytes of information after a START

are stored in this register. This I

2

C bus traffic information is frozen upon a bus lock-up detection. A host can

read these two bytes of traffic information upon the

reception of an interrupt signal. The contents of the traffic prior to lock-up register is released and refreshed

once it is read.

The traffic prior to lock-up register can be used to identify the device address as well as the following byte

involved in a bus lock-up.

When troubleshooting an I2C bus, a scope is usually

used to capture traffic leading to the problem. The contents of the traffic prior to the bus fault can usually be

determined by identifying a device address, a register

address, or a part of this data.

Table 7 shows contents of the traffic prior to the lock-up

register corresponding to a lock-up situation as demonstrated by Figure 10.

Figure 9. Lock-Up Indication Bits

Table 6. Lock-Up Register Channel Indication

X = Don’t care.

B7 B6 B5 B4 B3 B2 B1 B0 COMMAND

XXXXXXX0Channel 0 no lock-up

XXXXXXX1Channel 0 lock-up

XXXXXX0XChannel 1 no lock-up

XXXXXX1XChannel 1 lock-up

X X X X X 0 X X Channel 2 no lock-up

X X X X X 1 X X Channel 2 lock-up

X X X X 0 X X X Channel 3 no lock-up

X X X X 1 X X X Channel 3 lock-up

X X X 0 X X X X Channel 4 no lock-up

X X X 1 X X X X Channel 4 lock-up

X X 0 X X X X X Channel 5 no lock-up

X X 1 X X X X X Channel 5 lock-up

X0XXXXXXChannel 6 no lock-up

X1XXXXXXChannel 6 lock-up

0XXXXXXXChannel 7 no lock-up

1XXXXXXXChannel 7 lock-up

CHANNEL LOCK-UP INDICATION BITS (READ)

B6 B0B7 B5 B4 B3 B2 B1

CHANNEL 0

CHANNEL 1

CHANNEL 2

CHANNEL 3

CHANNEL 4

CHANNEL 5

CHANNEL 6

CHANNEL 7

Page 16

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

16 ______________________________________________________________________________________

Table 8. Stuck HIGH Fault Register Channel Indication

X = Don’t care.

Table 7. A Traffic Prior to Lock-Up Register Contents Example

Stuck HIGH Fault Register

(MAX7357/MAX7358)

Following an interrupt when bit B0 and B7 are enabled,

the bus master can read the stuck high fault byte to

identify stuck channels. A bit set to ”1” indicates that

the associated channel is stuck, and will not be allowed

to be connected to the host bus. The stuck high fault

register is cleared, and, if the interrupt feature is

enabled, RST/INT deasserts (goes to high) once this

register is read. However, while B7 is set to one, any

time a disconnected bus is selected for connection, the

preconnect test runs. If the fault still exists, the fault

handling sequence repeats and the faulty bus will not

be allowed to connect to the host bus.

RST

(MAX7356)

The RST on the MAX7356 can be used to reset the

MAX7356 by a host. The RST input is an active-low signal. By asserting this signal low for a minimum of t

WL(rst)

externally, the MAX7356 resets its I2C state machine

and deselects all channels. RST is overvoltage-tolerant

to +6V. The RST input must be connected to V

DD

through a pullup resistor.

RST/INT

(MAX7357/MAX7358)

The RST/INT on the MAX7357 or MAX7358 is bidirectional. It can be used to reset the device by a host or by

the device to send an interrupt signal to the host. The

RST/INT input is an active-low signal. By asserting

RST/INT low for a minimum of t

WL(rst)

externally, the

device resets its registers and I2C state machine and

deselects all channels. When RST/INT is configured to

notify the host of fault conditions, and while RST/INT

is being used as an output by the MAX7357 or

MAX7358 (sending an interrupt to the host), it does not

function as a reset input. RST/INT is overvoltage-tolerant

to +6V. RST/INT must be connected to VDDthrough a

pullup resistor.

Interrupt Signal (MAX7357/MAX7358)

A bus lock-up-caused interrupt signal can be sent to a

host through the bidirectional RST/INT pin depending

on whether or not bit B0 of the configuration register is

set. Configuration register bit B2 controls how the interrupt signal is reset. When B2 = 0, the interrupt signal

asserts (stays low) until the lock-up indication register is

read. When B2 = 1, the interrupt signal deasserts after

ADDRESS B7 B6 B5 B4 B3 B2 B1 B0 NOTE

0x04 0 1 1 01000Write to the troubled device address

0x05 0 1 1 00000The first data byte with trailing 0’s due to lock-up

B7 B6 B5 B4 B3 B2 B1 B0 COMMAND

XXXXXXX0Channel 0 not stuck high

XXXXXXX1Channel 0 stuck high

XXXXXX0XChannel 1 not stuck high

XXXXXX1XChannel 1 stuck high

X X X X X 0 X X Channel 2 not stuck high

X X X X X 1 X X Channel 2 stuck high

X X X X 0 X X X Channel 3 not stuck high

X X X X 1 X X X Channel 3 stuck high

X X X 0 X X X X Channel 4 not stuck high

X X X 1 X X X X Channel 4 stuck high

X X 0 X X X X X Channel 5 not stuck high

X X 1 X X X X X Channel 5 stuck high

X0XXXXXXChannel 6 not stuck high

X1XXXXXXChannel 6 stuck high

0XXXXXXXChannel 7 not stuck high

1XXXXXXXChannel 7 stuck high

Page 17

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

______________________________________________________________________________________ 17

2 seconds. The interrupt signal asserts again once a

new lock-up is detected. The interrupt signal does not

activate the reset function.

Serial Interface

Serial Addressing

The MAX7356/MAX7357/MAX7358 operate as a slave

that sends and receives data through an I

2

C interface.

The interface uses a serial-data line (SDA) and a serialclock line (SCL) to achieve bidirectional communication

between master(s) and slave(s). The master initiates all

data transfers to and from the MAX7357 or MAX7358

and generates the SCL clock that synchronizes the

data transfer.

SDA operates as both an input and an open-drain output. A pullup resistor (4.7kΩ, typ) is required on SDA.

SCL operates only as an input. A pullup resistor (4.7kΩ,

typ) is required on SCL if there are multiple masters on

the 2-wire interface, or if the master in a single-master

system has an open-drain SCL output.

Each transmission consists of a START condition sent

by a master, followed by the MAX7356/MAX7357/

MAX7358’s 7-bit slave address plus R/W bit, and then

optionally 1 or more data bytes, and finally a STOP condition (Figure 10).

START and STOP Conditions

Both SCL and SDA remain high when the interface is

not busy. The master signals the beginning of a transmission with a START (S) condition by transitioning SDA

from high to low while SCL is high. When the master

has finished communicating with the slave, the master

issues a STOP (P) condition by transitioning SDA from

low to high while SCL is high. The bus is then free for

another transmission (Figure 11).

Bit Transfer

One data bit is transferred during each clock pulse.

The data on SDA must remain stable while SCL is high

(Figure 12).

Acknowledge

The acknowledge bit is a clocked 9th bit the recipient

uses to handshake receipt of each byte of data (Figure

13). Each byte transferred effectively requires 9 bits.

The master generates the 9th clock pulse, and the

recipient pulls down SDA during the acknowledge

clock pulse, so the SDA line is stable low during the

high period of the clock pulse. When the master is

transmitting to the MAX7356/MAX7357/MAX7358, the

MAX7356/MAX7357/MAX7358 generate the acknowl-

Figure 10. Bus Lock-Up During a 3-Byte Write Command

Figure 11. Start and Stop Conditions

Figure 12. Bit Transfer

Figure 13. Acknowledge

ACKNOWLEDGE FROM

THE TROUBLED DEVICE

0 A 01 0 01 1 0S 0 0 L L L L L L L L L L L L L L L1 1

LOCK-UP

OCCURS

START

SDA

SCL

S

START

CONDITION

SDA

SCL

DATA STABLE

DATA VALID

START

CONDITION

SCL

SDA

12 8 9

CHANGE OF

DATA ALLOWED

W

CONDITION

CLOCK PULSE FOR

ACKNOWLEDGMENT

NOT ACKNOWLEDGE

ACKNOWLEDGE

FIRST DATA BYTE SECOND DATA BYTE

P

STOP

Page 18

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

18 ______________________________________________________________________________________

edge bit because the device is the recipient. When the

MAX7356/MAX7357/MAX7358 are transmitting to the

master, the master generates the acknowledge bit

because the master is the recipient.

Slave Address

The MAX7356/MAX7357/MAX7358 have 7-bit-long

slave addresses (Figure 6). The eighth bit following the

7-bit slave address is the R/W bit. It is low for a write

command, and high for a read command.

Accessing the MAX7356

A single-byte write to the MAX7356 sets the switch

control register.

A multibyte write to the MAX7356 writes repeatedly to

the switch control register. The last byte written determines the contents of the register.

A single-byte read from the MAX7356 returns the con-

tents of the switch control register.

A multibyte read (2 or more bytes before the I2C STOP

bit) from the MAX7356 returns the contents of the

switch control register repeatedly.

Accessing the MAX7357/MAX7358 in

Enhanced Mode

In enhanced mode, all 7 registers are enabled. These

registers are autoincremented starting with the switch

control register during each I2C transaction. When a

new transaction begins, the switch control register is

the first register accessed.

A single-byte write to the MAX7357 or MAX7358 sets

the switch control register.

A 2-byte write to the MAX7357 or MAX7358 sets the

switch control and configuration registers.

A 3-byte write to the MAX7357 or MAX7358 sets the

switch control, configuration, and flush-out sequence

registers.

A multibyte write to the MAX7357 or MAX7358 with

more than three bytes sets the first three registers, then

resets the pointer back to the switch control register

(0x00) since the remaining registers are read only.

Subsequent bytes of data, after 3 bytes, begin overwriting the first set of data starting with 0x00, 0x01, 0x02,

then looping back to 0x00 again, and continuing until a

STOP condition is received.

A single-byte read from the MAX7357 or MAX7358

returns the contents of the switch control register.

A multibyte read from the MAX7357 or MAX7358 returns

contents of all 7 registers in sequence and repeats.

The internal register address count always begins with

the switch control register, 0x00.

Accessing the MAX7357/MAX7358

in Basic Mode

In basic mode, only the switch control register is

enabled.

A single-byte write to the MAX7357 or MAX7358 sets

the switch control register.

A multibyte write to the MAX7357 or MAX7358 in basic

mode writes repeatedly to the switch control register.

The last byte written determines the contents of the register.

A single-byte read from the MAX7357 or MAX7358

returns the contents of the switch control register.

A multibyte read (2 or more bytes before the I

2

C STOP

bit) from the MAX7357 or MAX7358 returns the contents

of the switch control register repeatedly.

Writing to the MAX7356

The MAX7356’s switch control register can be written by

an I2C write command starting with the device address

for the MAX7356 and followed by data bytes. The last

data byte is stored into the switch control register.

A write to the MAX7356 starts with the master transmitting

the slave address with the R/W bit set low. The MAX7356

acknowledges the slave address. The master can then

issue a STOP condition after the acknowledge (Figure 14),

but typically the master proceeds to transmit one or more

bytes of data. The MAX7356 acknowledges these subsequent bytes of data and updates the switch control register when the master issues a STOP condition (Figure 14).

Writing to the MAX7357/MAX7358 in

Enhanced Mode

The MAX7357 and MAX7358 registers can be written

by an I2C write command starting with the device

address for the MAX7357 or MAX7358 and followed by

data bytes. The first data byte is stored into the switch

control register and subsequent data bytes are stored

into the subsequent registers.

A write to the MAX7357 or MAX7358 starts with the

master transmitting the slave address with the R/W bit

set low. The MAX7357 or MAX7358 acknowledge the

slave address. The master can then issue a STOP condition after the acknowledge (Figure 15), but typically

Page 19

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

______________________________________________________________________________________ 19

the master proceeds to transmit one or more bytes of

data. The MAX7357 or MAX7358 acknowledge these

subsequent bytes of data and update corresponding

registers with each new byte until the master issues a

STOP condition (Figure 15).

Writing to the MAX7357/MAX7358

in Basic Mode

The MAX7357 and MAX7358 switch control register can

be written by an I2C write command starting with the

device address for the MAX7357 or MAX7358 and followed by data bytes. The last data byte is stored in the

switch control register.

A write to the MAX7357 or MAX7358 starts with the

master transmitting the slave address with the R/W bit

set low. The device acknowledges the slave address.

The master can then issue a STOP condition after the

acknowledge (Figure 16), but typically the master proceeds to transmit one or more bytes of data. The

MAX7357 or MAX7358 acknowledge these subsequent

bytes of data and update the switch control register

when the master issues a STOP condition (Figure 16).

Reading from the MAX7356

A read from the MAX7356 starts with the master transmitting the slave address with the R/W bit set high. The

MAX7356 acknowledges the slave address. The master

can read 1 byte from the switch control register and

then issue a STOP condition (Figure 17). If the master

reads more than one byte, the master upon reception

acknowledges each byte. All bytes return the contents

of the switch control register.

Reading from the MAX7357/MAX7358

in Enhanced Mode

A read from the MAX7357 or MAX7358 starts with the

master transmitting the slave address with the R/W bit

set high. The device acknowledges the slave address.

The master can read 1 byte from the device and then

issue a STOP condition (Figure 18). In this case, the

device transmits the data byte from the switch control

register. Typically, the master reads 1 or 2 bytes with

each byte being acknowledged by the master upon

reception. The first data byte comes from the switch

control register and subsequent data bytes come from

the subsequent registers in order.

Figure 14. Writing to the MAX7356

Figure 15. Writing to the MAX7357 or MAX7358 in Enhanced Mode

ADDRESS OF MUX/SWT PARTS

START

0 A D7 D6 D5 D4 D3 D2 D1 D0 A P

R/W

ACKNOWLEDGE FROM THE

MAX7357 OR MAX7358

ACKNOWLEDGE FROM THE

MAX7357 OR MAX7358

STOP

DATA BYTE TO THE SWITCH

CONTROL REGISTER

D7 D6 D5 D4 D3 D2 D1 D0 A

ACKNOWLEDGE FROM THE

MAX7357 OR MAX7358

DATA BYTE TO THE SWITCH

CONTROL REGISTER

Figure 16. Writing to the MAX7357 or MAX7358 in Basic Mode

ACKNOWLEDGE FROM THE

ADDRESS OF MUX/SWT PARTS

MAX7356

0 A D7 D6 D5 D4 D3 D2 D1 D0 A P

ACKNOWLEDGE FROM THE

MAX7356

D7 D6 D5 D4 D3 D2 D1 D0 A

ACKNOWLEDGE FROM THE

MAX7356

START

R/W

DATA BYTE TO THE SWITCH

CONTROL REGISTER

START

ACKNOWLEDGE FROM THE

ADDRESS OF MUX/SWT PARTS

MAX7357 OR MAX7358

0 A D7 D6 D5 D4 D3 D2 D1 D0 A

R/W

ACKNOWLEDGE FROM THE

MAX7357 OR MAX7358

DATA BYTE TO THE SWITCH

CONTROL REGISTER

DATA BYTE TO THE SWITCH

ACKNOWLEDGE FROM THE

D7 D6 D5 D4 D3 D2 D1 D0 A

DATA BYTE TO THE CONFIGURATION

REGISTERS

MAX7358

CONTROL REGISTER

ACKNOWLEDGE FROM THE

D7 D6 D5 D4 D3 D2 D1 D0 A

DATA BYTE TO THE FLUSH-OUT

SEQUENCE

STOP

MAX7358

P

STOP

Page 20

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

20 ______________________________________________________________________________________

Figure 17. Reading the MAX7356

ADDRESS OF MUX/SWT PARTS

START

1 A D7 D6 D1 D0 A P

R/W

ACKNOWLEDGE FROM THE

MAX7357 OR MAX7358

ACKNOWLEDGE

FROM A HOST

STOP

DATA BYTE FROM THE SWITCH

CONTROL REGISTER

DATA BYTE FROM

REGISTERS

0X01 TO 0X06

D7 D6 D5 D4 D3 D2 D1 D0 A

ACKNOWLEDGE FROM A

HOST

DATA BYTE FROM THE

STUCK HIGH FAULT REGISTER

Figure 18. Reading the MAX7357 or MAX7358 in Enhanced Mode

ADDRESS OF MUX/SWT PARTS

START

1 A D7 D6 D5 D4 D3 D2 D1 D0 A P

R/W

ACKNOWLEDGE FROM THE

MAX7357 OR MAX7358

ACKNOWLEDGE FROM A

HOST

STOP

DATA BYTE FROM THE SWITCH

CONTROL REGISTER

D7 D6 D5 D4 D3 D2 D1 D0 A

ACKNOWLEDGE FROM A

HOST

DATA BYTE FROM THE SWITCH

CONTROL REGISTER

Figure 19. Reading the MAX7357 or MAX7358 in Basic Mode

Reading from the MAX7357/MAX7358

in Basic Mode

A read from the MAX7357 or MAX7358 in basic mode

starts with the master transmitting the slave address

with the R/W bit set high. The device acknowledges the

slave address. The master can read 1 byte from the

switch control register and then issue a STOP condition

(Figure 19). If the master reads more than one byte, the

master upon reception acknowledges each byte. All

bytes return the contents of the switch control register.

Applications Information

Voltage Level Translation

The pass gates of the MAX7356/MAX7357/MAX7358

are designed so VDDcan be used to limit the voltage

levels transferred from one bus to another. The powersupply voltage of the part should be selected to be no

larger than one VGSON(0.7V, typ) above the lowest

bus voltage in the system. This ensures that the analog

switches do not allow current to flow from higher voltage buses to lower voltage buses.

Chip Information

PROCESS: CMOS

START

ACKNOWLEDGE FROM THE

MAX7357 OR MAX7358

ADDRESS OF MUX/SWT PARTS

0 A D7 D6 D5 D4 D3 D2 D1 D0 A P

R/W

ACKNOWLEDGE FROM THE

MAX7357 OR MAX7358

DATA BYTE TO THE SWITCH

CONTROL REGISTER

ACKNOWLEDGE FROM THE

MAX7357 OR MAX7358

D7 D6 D5 D4 D3 D2 D1 D0 A

DATA BYTE TO THE SWITCH

CONTROL REGISTER

STOP

Page 21

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

______________________________________________________________________________________ 21

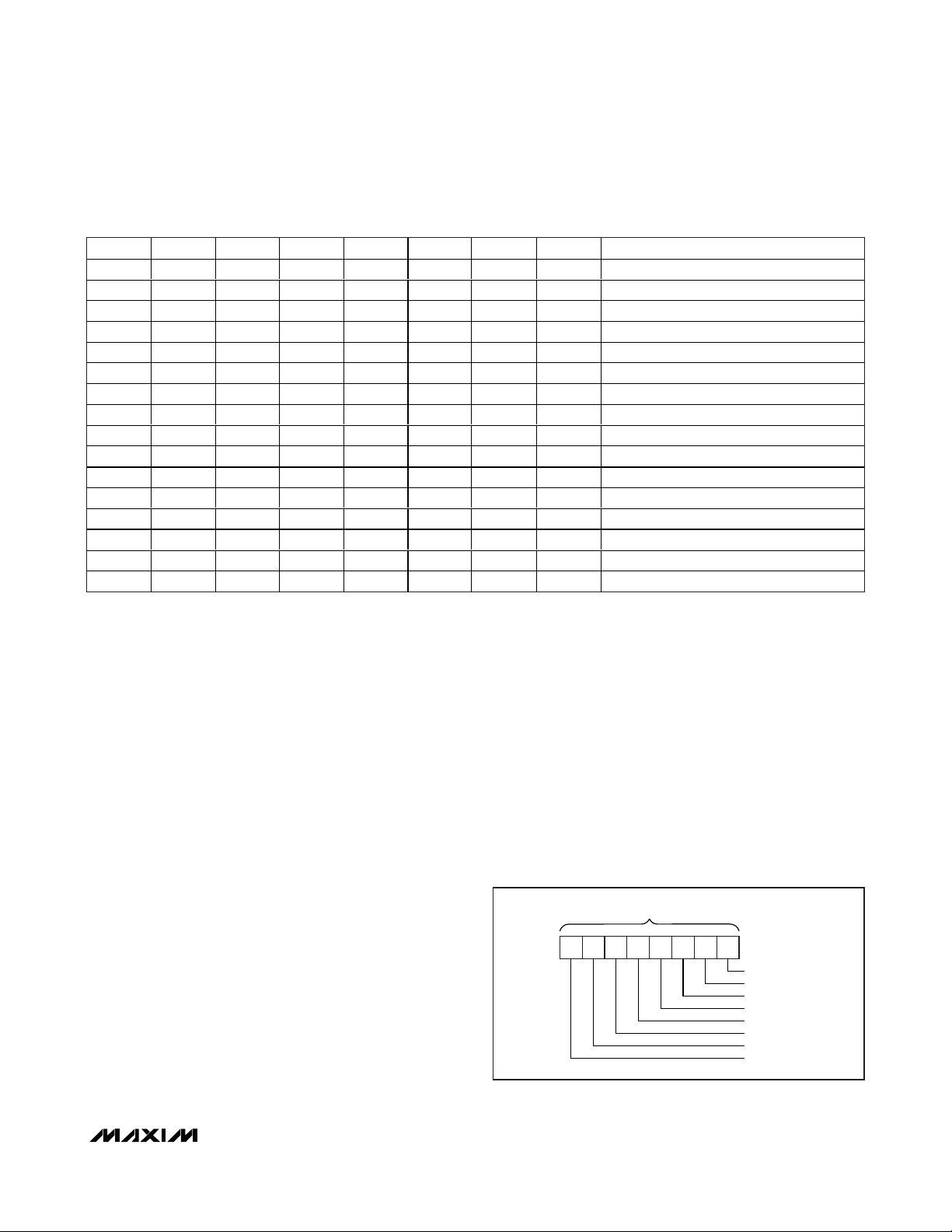

Typical Operating Circuit

Pin Configurations

V

CC

MASTER

SDA

SCL

RST

INT

SDA

SCL

RST(RST/INT)

GND

V

DD

V

DD

MAX7356

MAX7357

MAX7358

A0

A1

A2

SD0

SC0

SD1

SC1

SD7

SC7

V

DD

V

DD

V

DD

( ) ONLY FOR THE MAX7357 AND MAX7358

+

A0

MAX7356

MAX7357

MAX7358

TSSOP

( ) ONLY FOR THE MAX7357 AND MAX7358

241 V

232 SDAA1

223 SCLRST (RST/INT)

214A2SD0

205 SC7SC0

196 SD7SD1

187 SC6SC1

178 SD6SD2

169 SC5SC2

1510 SD5SD3

1411 SC4SC3

1312 SD4GND

DD

TOP VIEW

SD0

SC0

SD1

SC1

SD2

SC2

*CONNECT EXPOSED PAD TO GND.

( ) ONLY FOR THE MAX7357 AND MAX7358

RST

(RST/INT)

A1

2324 22 21

+

1

2

3

4

5

6

879

SC3

SD3

A0

MAX7356

MAX7357

MAX7358

10

GND

TQFN-EP

DD

V

SD4

SDA

SCL

19

20

18

A2

SC7

17

SD7

16

15

SC6

SD6

14

*EP

12

11

SC4

SD5

SC5

13

Page 22

MAX7356/MAX7357/MAX7358

1-to-8 I2C Bus Switches/Multiplexers with Bus

Lock-Up Detection, Isolation, and Notification

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

22

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2008 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Package Information

For the latest package outline information and land patterns, go to www.maxim-ic.com/packages.

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

24 TSSOP U24+1

21-0066

24 TQFN-EP T2444+4

21-0139

Loading...

Loading...