Page 1

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

General Description

The MAX6900, I2C™-bus-compatible real-time clock

(RTC) in a 6-pin TDFN package contains a real-time

clock/calendar and 31-byte

✕

8-bit wide of static random access memory (SRAM). The real-time clock/calendar provides seconds, minutes, hours, day, date,

month, and year information. The end of the month date

is automatically adjusted for months with fewer than 31

days, including corrections for leap year up to the year

2100. The clock operates in either the 24hr or 12hr format with an AM/PM indicator.

Applications

Portable Instruments

Point-of-Sale Equipment

Intelligent Instruments

Battery-Powered Products

Features

♦ Real-Time Clock Counts Seconds, Minutes,

Hours, Date, Month, Day, and Year

♦ Leap Year Compensation Valid up to Year 2100

♦ Fast (400kHz) I

2

C-Bus-Compatible Interface from

2.0V to 5.5V

♦ 31

✕

8 SRAM for Scratchpad Data Storage

♦ Uses Standard 32.768kHz, 12.5pF Load, Watch

Crystal

♦ Ultra-Low 225nA (typ) Timekeeping Current

♦ Single-Byte or Multiple-Byte (Burst Mode) Data

Transfer for Read or Write of Clock Registers or

SRAM

♦ 6-Pin 3mm x 3mm x 0.8mm TDFN Surface-Mount

Package

♦ No External Crystal Bias Resistors or Capacitors

Required

MAX6900

I2C-Compatible RTC in a TDFN

________________________________________________________________ Maxim Integrated Products 1

19-1942; Rev 3; 6/03

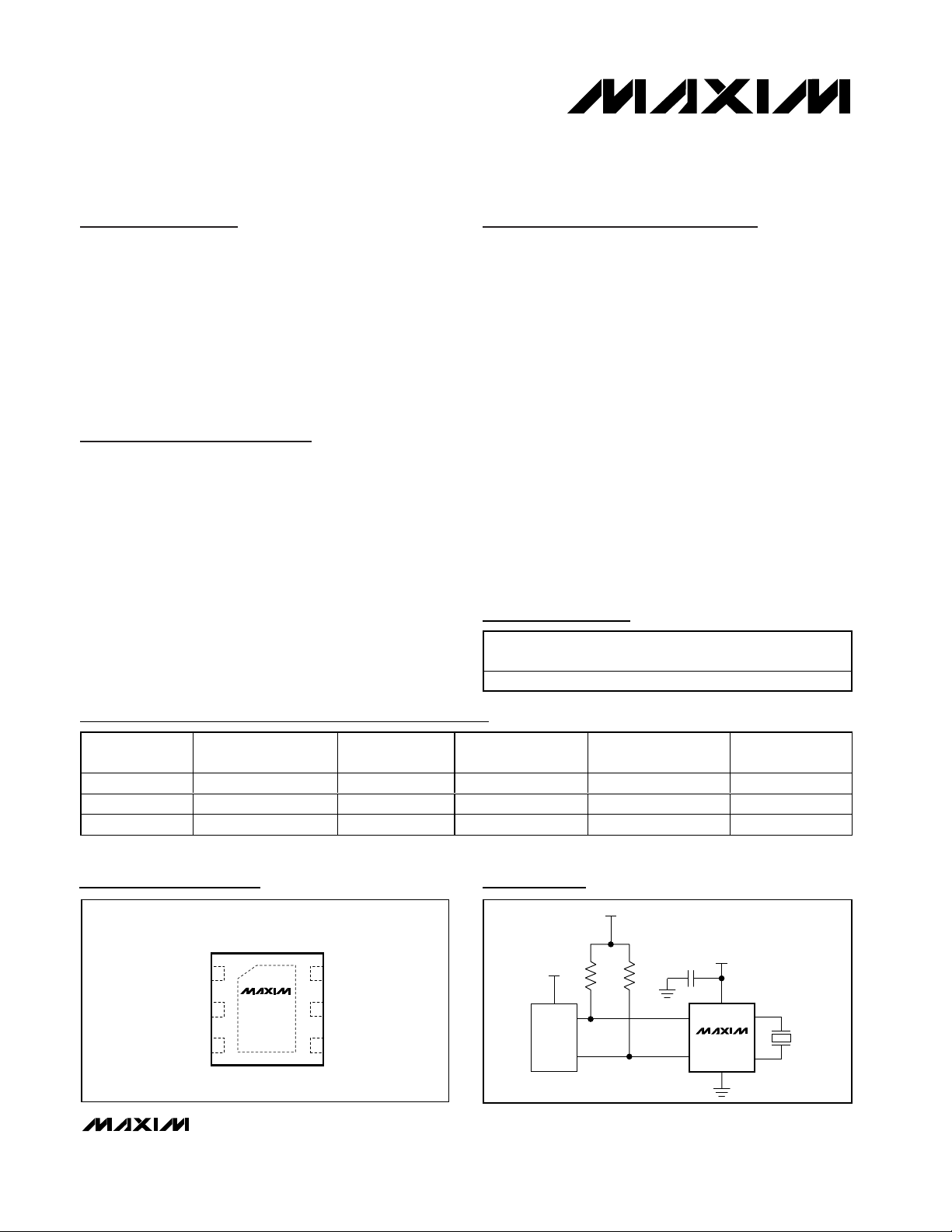

Typical Operating Circuit

X1

GNDX2

1 6 SDA

5 SCL

V

CC

MAX6900

TDFN

TOP VIEW

2

34

Pin Configuration

Ordering Information

Related Real-Time Clock Products

I2C is a trademark of Philips Corp. Purchase of I2C components

of Maxim Integrated Products, Inc., or one of its sublicensed

Associated Companies, conveys a license under the Philips I

2

C

Patent Rights to use these components in an I2C system, provided that the system conforms to the I2C Standard Specification

as defined by Philips.

SPI is a trademark of Motorola, Inc.

PART TEMP RANGE

MAX6900ETT-T -40°C to +85°C 6 TDFN AEU

PINPACKAGE

TOP

MARK

PART SERIAL BUS SRAM

ALARM

FUNCTION

OUTPUT

FREQUENCY

PIN-PACKAGE

MAX6900 I2C compatible 31 ✕ 8 ——6 TDFN

MAX6901 3-wire 31 ✕ 8 Polled 32kHz 8 TDFN

MAX6902 SPI™ compatible 31 ✕ 8 Polled — 8 TDFN

V

CC

V

CC

V

CC

µC

RPU RPU

RPU = t

r/Cbus

0.01µF

5

6

SCL

SDA

1

V

CC

MAX6900

GND

4

X1

X2

2

CRYSTAL

3

Page 2

MAX6900

I2C-Compatible RTC in a TDFN

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VCCto GND..............................................................-0.3V to +6V

All Other Pins to GND ................................-0.3V to (V

CC

+ 0.3V)

Input Current

All Pins ............................................................................20mA

Output Current

All Outputs .......................................................................20mA

Rate of Rise, V

CC

............................................................100V/µs

Continuous Power Dissipation (T

A

= +70°C)

6-Pin TDFN (derate 24.4mW/°C above +70°C) .......1951.0mW

Operating Temperature Range ...............................T

MIN

to T

MAX

MAX6900 ETT-T .......................T

MIN

= -40°C, T

MAX

= +85°C

Junction Temperature .....................................................+150°C

Storage Temperature Range ............................ -65°C to +150°C

ESD Protection (all pins, Human Body model) ..................2000V

Lead Temperature (soldering, 10s) ...…………………….+300°C

DC ELECTRICAL CHARACTERISTICS

(VCC= +2.0V to +5.5V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at VCC= +3.3V, TA= +25°C.) (Note 1)

AC ELECTRICAL CHARACTERISTICS

(VCC= +2.0V to +5.5V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at VCC= +3.3V, TA= +25°C.) (Notes 1, 6)

Operating Voltage Range V

Active Supply Current (Note 2) I

Timekeeping Supply Current

(Note 3)

2-WIRE DIGITAL INPUTS SCL, SDA

Input High Voltage V

Input Low Voltage V

Input Hysteresis (Note 5) V

Input Leakage Current (Note 4) 0 < VIN < V

Input Capacitance (Note 5) 10 pF

2-WIRE DIGITAL OUTPUT SDA

Output Low Voltage V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CC

CC

I

TK

IH

IL

HYS

OL

VCC = +2.0V 30

VCC = +5.0V 110

VCC = +2.0V 0.225 0.630

VCC = +5.0V 1.2 1.7

CC

I

= 4mA 0.4 V

SINK

2 5.5 V

0.7 x V

CC

0.05 x

V

CC

-10 10 nA

0.3 x

V

CC

µA

µA

V

V

V

OSCILLATOR

X1 to Ground Capacitance 25 pF

X2 to Ground Capacitance 25 pF

FAST I2C-BUS-COMPATIBLE TIMING

SCL Clock Frequency f

Bus Free Time Between STOP

and START Condition (Note 4)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SCL

t

BUF

0 400 kHz

1.3 µs

Page 3

MAX6900

I2C-Compatible RTC in a TDFN

_______________________________________________________________________________________ 3

AC ELECTRICAL CHARACTERISTICS (continued)

(VCC= +2.0V to +5.5V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at VCC= +3.3V, TA= +25°C.) (Notes 1, 6)

Note 1: All parameters are 100% tested at TA= +25°C. Limits over temperature are guaranteed by design and not production tested.

Note 2: I

CC

is specified with SCL = 400kHz and SDA = 400kHz.

Note 3: I

TK

is specified with SCL = Logic High (4.7kΩ pullup resistor) and SDA = Logic High (4.7kΩ pullup resistor);

I

2

C-compatible bus inactive.

Note 4: MAX6900 I/O pins do not obstruct the SDA and SCL lines if V

CC

is switched off.

Note 5: Guaranteed by design. Not subject to production testing.

Note 6: All values referred to V

IH

min

and V

IL

max

levels.

Note 7: The MAX6900 internally provides a hold time of at least 300ns for the SDA signal (referred to the V

IH

min

of the SCL signal)

in order to bridge the undefined region of the falling edge of SCL.

Note 8: C

B

= total capacitance of one bus line in pF.

Note 9: The maximum t

f

for the SDA and SCL bus lines is specified at 300ns. The maximum fall time for the SDA output stage tfis

specified at 250ns. This allows series protection resistors to be connected between the SDA/SCL pins and the SDA/SCL

bus lines without exceeding the maximum specified t

f

.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Hold Time After (Repeated)

START Condition (After this

Period, the First Clock Is

Generated)

Repeated START Condition

Setup Time

STOP Condition Setup Time t

Data Hold Time (Note 7) t

Data Setup Time t

SCL Low Period t

SCL High Period t

Minimum SCL/SDA Rise Time

(Note 8)

Maximum SCL/SDA Rise Time

(Note 8)

Minimum SCL/SDA Fall Time

(Receiving) (Notes 8, 9)

Maximum SCL/SDA Fall Time

(Receiving) (Notes 8, 9)

Minimum SDA Fall Time

(Transmitting) (Notes 8, 9)

Maximum SDA Fall Time

(Transmitting) (Notes 8, 9)

Pulse Width of Spike Suppressed t

Capacitive Load for Each

Bus Line

t

HD:STA

t

SU:STA

SU:STO

HD:DAT

SU:DAT

LOW

HIGH

t

r

t

r

t

f

t

f

t

f

t

f

SP

C

B

0.6 µs

0.6 µs

0.6 µs

0 0.9 µs

100 ns

1.3 µs

0.6 µs

20 +

0.1C

B

ns

300 ns

20 +

0.1C

B

ns

300 ns

20 +

0.1C

B

ns

250 ns

50 ns

400 pF

Page 4

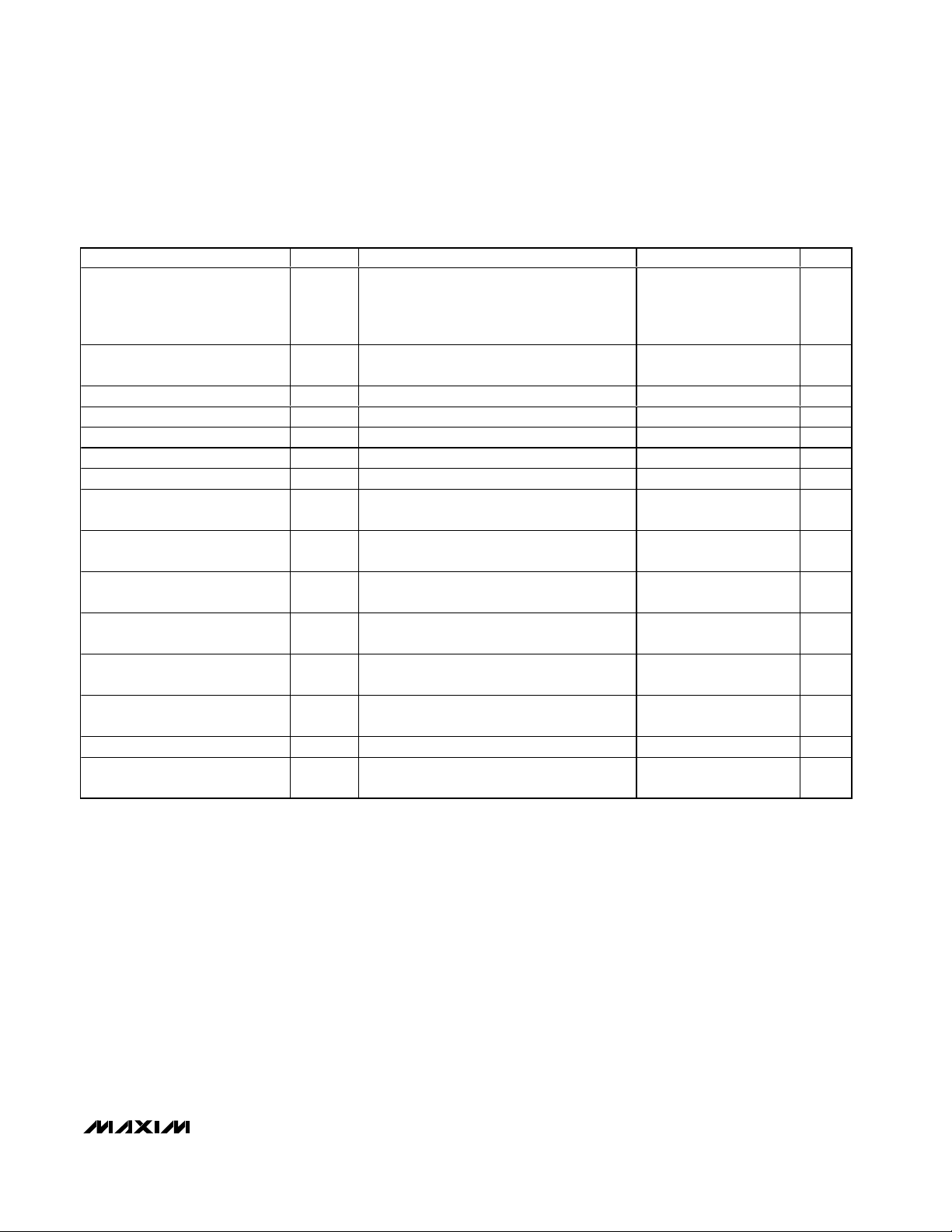

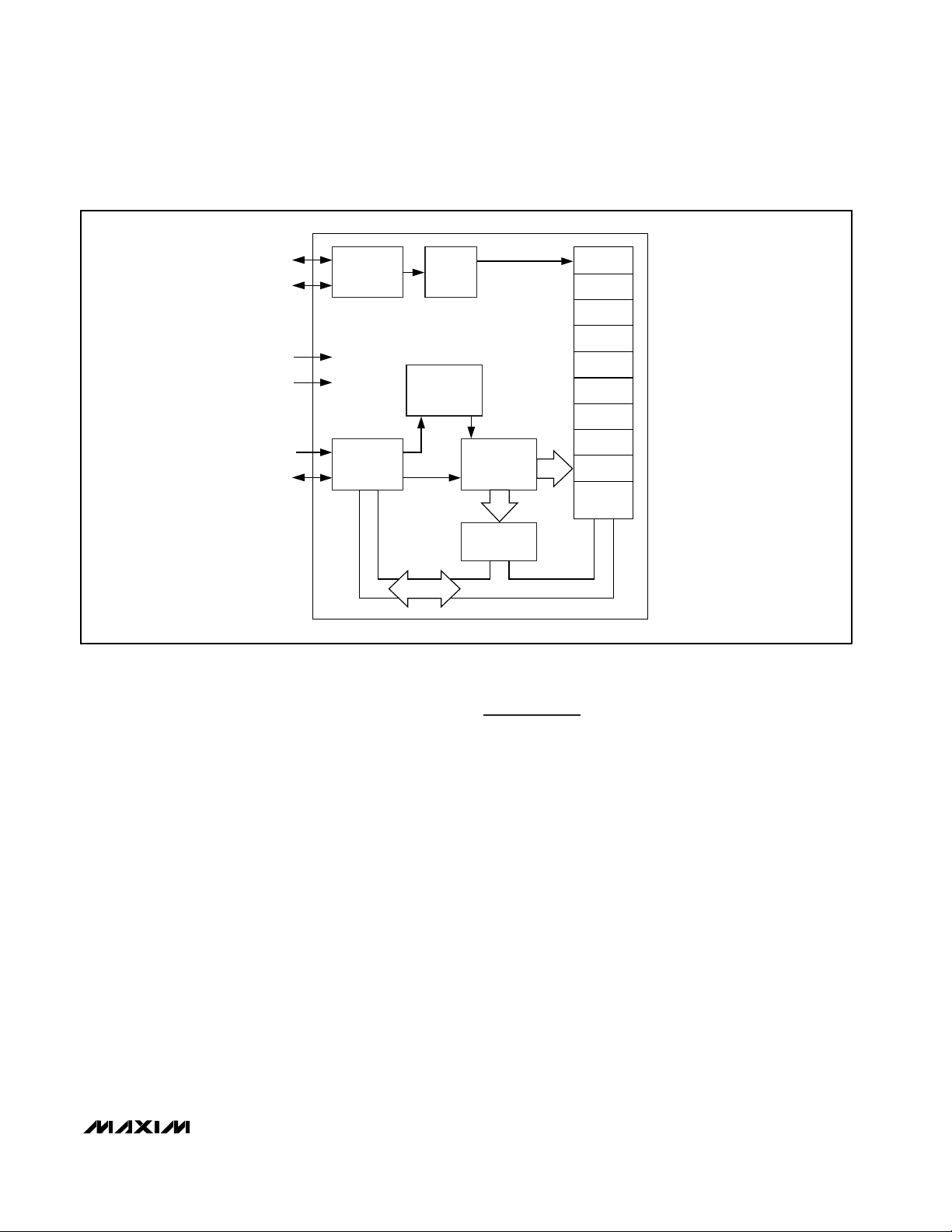

Detailed Description

The MAX6900 contains eight timekeeping registers,

burst address registers, a control register, an on-chip

32.768kHz oscillator circuit, and a serial 2-wire, I2Ccompatible interface. There are also 31 bytes, 8 bits

wide of SRAM on board. Time and calendar data are

stored in the registers in a binary-coded decimal (BCD)

format. Figure 1 shows an I2C-bus-compatible timing

diagram. Figure 2 shows the MAX6900 functional diagram.

Real-Time Clock

The RTC provides seconds, minutes, hours, day, date,

month, and year information. The end of the month is

automatically adjusted for months with fewer than 31

MAX6900

I2C-Compatible RTC in a TDFN

4 _______________________________________________________________________________________

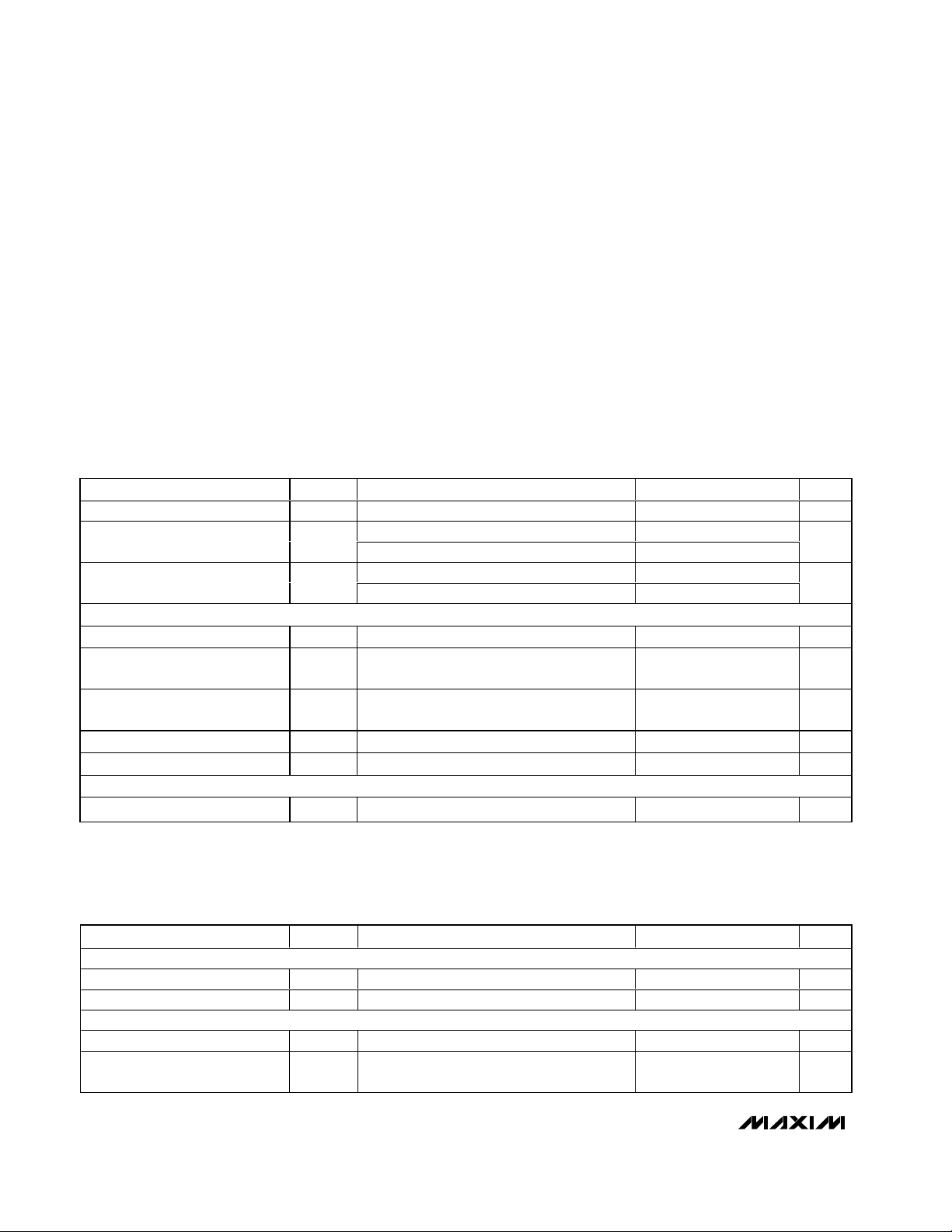

Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

0

0.3

0.4

0.1

0.2

0.6

0.5

1.0

0.7

0.8

0.9

1.1

1.4

1.5

1.2

1.3

1.6

1.0 2.0 2.5 3.01.5 3.5 4.0 4.5 5.55.0 6.0

TIMEKEEPING CURRENT vs. V

CC

MAX6900 toc01

VCC (V)

TIMEKEEPING CURRENT (µA)

Pin Description

Figure 1. Detailed

I

2

C-Bus Timing Diagrams

PIN NAME FUNCTION

1VCCPower Supply

2 X1 32.768kHz External Crystal

3 X2 32.768kHz External Crystal

4 GND Ground

5 SCL I2C-Bus-Compatible Clock Input

6 SDA

— PAD Ground

PROTOCOL

SCL

SDA

2

I

C-Bus-Compatible Data

Input/Output

START

CONDITION

(S)

t

t

LOW

r

t

SU:STA

t

BUF

t

HD:STA

BIT 7

MSB

(A7)

t

HIGH

t

HD:DAT

BIT 6

(A6)

1/f

SCL

t

f

t

HD:DAT

BIT 0

LSB

(R/W)

ACKNOWLEDGE

(A)

t

SU:STO

STOP

CONDITION

(P)

Page 5

days, including corrections for leap year up to the year

2100.

Crystal Oscillator

The MAX6900 uses an external, standard 12.5pF load

watch crystal. No other external components are

required for this timekeeping oscillator. Power-up oscillator start-time is dependent mainly upon applied V

CC

and ambient temperature. The MAX6900, because of

its low timekeeping current, exhibits a typical startup

time between 5s to 10s.

I2C-Compatible Interface

Interfacing the MAX6900 with a microprocessor or

other I2C master is made easier by using the serial, I2Cbus-compatible or other I2C master interface. Only 2

wires are required to communicate with the clock and

SRAM: SCL (serial clock) and SDA (data line). Data is

transferred to and from the MAX6900 over the I/O data

line, SDA. The MAX6900 uses 7-bit slave ID addressing. The MAX6900 does not respond to general call

address commands.

Applications Information

I2C-Bus-Compatible Interface

The I2C-bus-compatible serial interface allows bidirectional, 2-wire communication between multiple ICs. The

two lines are SDA and SCL. Connect both lines to a

positive supply through individual pullup resistors. A

device on the I2C-compatible bus that generates a

message is called a transmitter and a device that

receives the message is a receiver. The device that

controls the message is the master and the devices

that are controlled by the master are called slaves

(Figure 3). The word message refers to data in the form

of three 8-bit bytes for a Single Read or Write. The first

byte is the Slave ID byte, the second byte is the

Address/Command byte, and the third is the data.

Data transfer can only be initiated when the bus is not

busy (both SDA and SCL are high). A high-to-low transition of SDA while SCL is high is defined as the Start

(S) condition; low-to-high transition of the data line

while SCL is high is defined as the Stop (P) condition

(Figure 4).

MAX6900

I2C-Compatible RTC in a TDFN

_______________________________________________________________________________________ 5

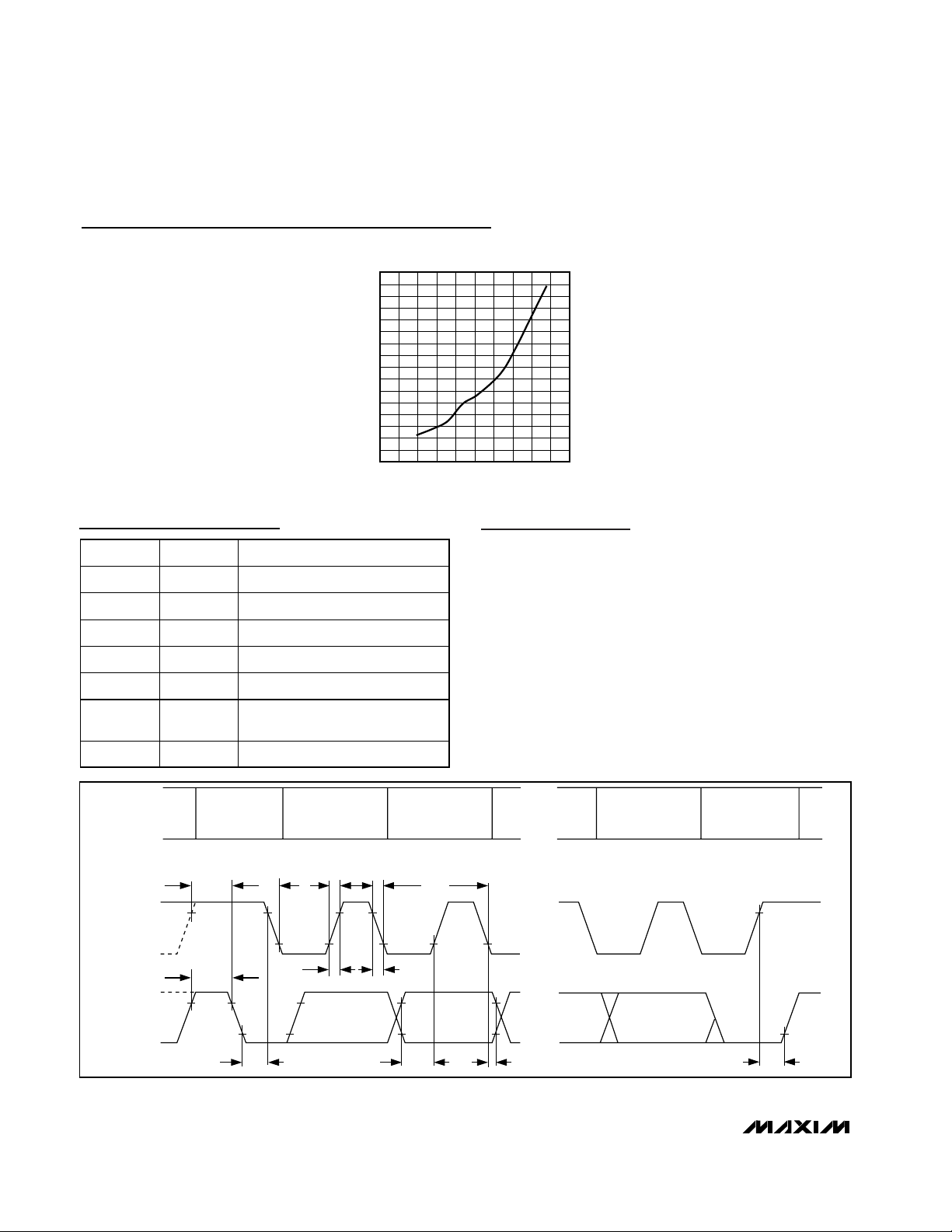

Figure 2. Functional Diagram

VCC

GND

SCL

SDA

ADDRESS

REGISTER

31 X 8

SRAM

1Hz

SECONDS

MINUTES

HOURS

DATE

MONTH

DAY

YEAR

CONTROL

CENTURY

CLOCK

BURST

X1

X2

OSCILLATOR

32.768kHz

2

C BUS

I

INTERFACE

DIVIDER

CONTROL

LOGIC

Page 6

MAX6900

I2C-Compatible RTC in a TDFN

6 _______________________________________________________________________________________

After the Start condition occurs, 1 bit of data is transferred for each clock pulse. The data on SDA must

remain stable during the high portion of the clock pulse

as changes in data during this time are interpreted as a

control signal (Figure 5). Any time a start condition

occurs, the Slave ID must follow immediately, regardless of completion of the previous data transfer.

Before any data is transmitted on the I

2

C-bus-compatible serial interface, the device that is expected to

respond is addressed first. The first byte sent after the

start (S) procedure is the Address byte or 7-bit Slave

ID. The MAX6900 acts as a slave transmitter/receiver.

Therefore, SCL is only an input clock signal and SDA is

a bidirectional data line. The Slave Address for the

MAX6900 is shown in Figure 6.

Figure 5. I2C Bus Bit Transfer

Figure 6. I2C Bus Slave Address or 7-Bit Slave ID

Figure 3. I2C Bus System Configuration

Figure 4. I2C Bus Start and Stop Conditions

SDA

SCL

SDA

SCL

S

START CONDITION STOP CONDITION

SDA

MASTER

TRANSMITTER/

RECEIVER

SLAVE

RECEIVER

SLAVE

TRANSMITTER/

RECEIVER

MASTER

TRANSMITTER

MASTER

TRANSMITTER/

RECEIVER

SDA

SCL

P

SCL

DATA LINE

STABLE;

DATA VALID

CHANGE

OF DATA

ALLOWED

RD/W

0000101

BIT 0BIT 7

Page 7

MAX6900

I2C-Compatible RTC in a TDFN

_______________________________________________________________________________________ 7

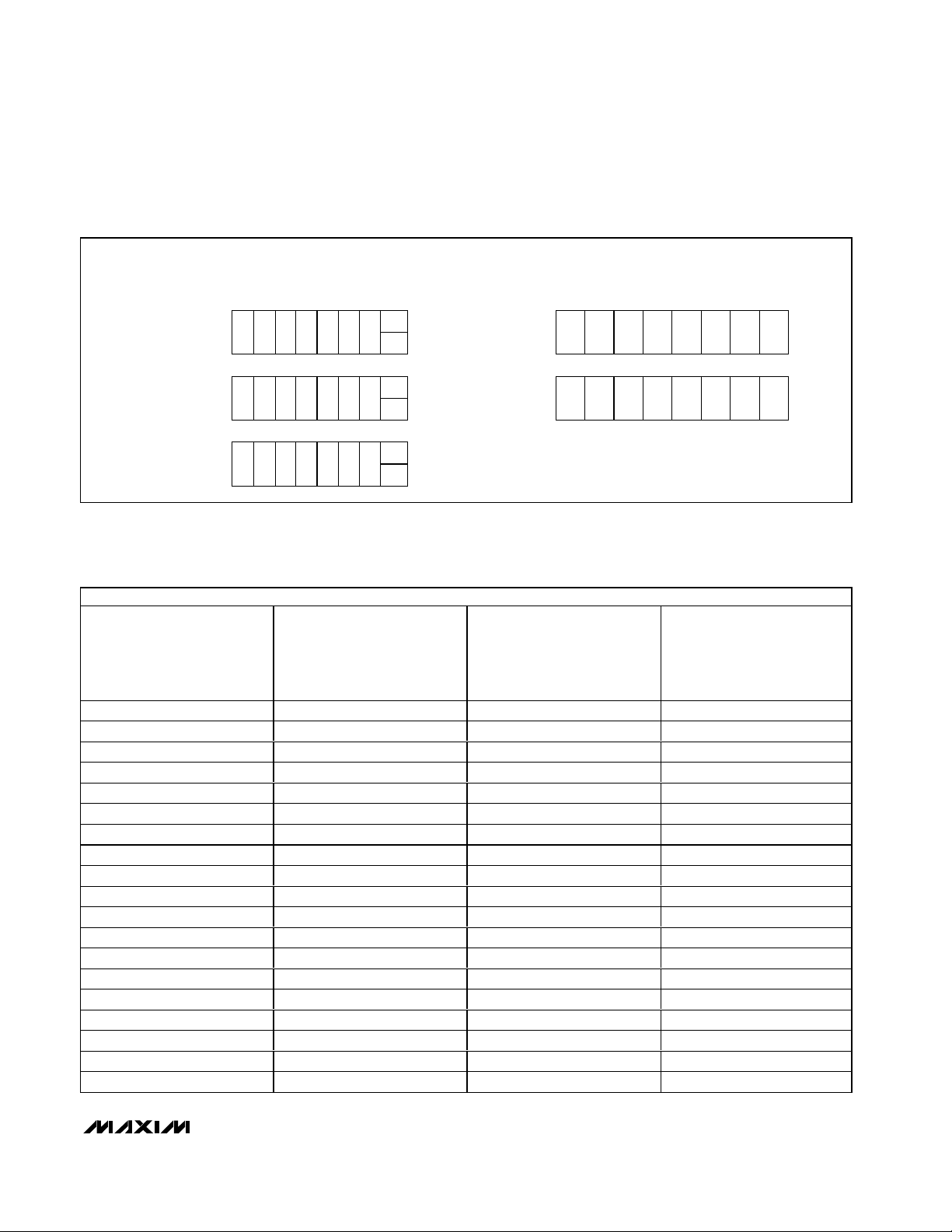

An unlimited number of data bytes between the start

and stop conditions can be sent between the transmitter and receiver. Each 8-bit byte is followed by an

acknowledge bit. Also, a master receiver must generate an acknowledge after each byte it receives that has

been clocked out of the slave transmitter.

The device that acknowledges must pull down the SDA

line during the acknowledge clock pulse (Figure 7), so

that the SDA line is stable low during the high period of

the acknowledge clock pulse (setup and hold times

must also be met). A master receiver must signal an

end of data to the transmitter by not generating an

acknowledge on the last byte that has been clocked

out of the slave. In this case, the transmitter must leave

SDA high to enable the master to generate a stop condition. Any time a stop condition is received before the

current byte of data transfer is complete, the last incomplete byte is ignored.

The second byte of data sent after the start condition is

the Address/Command byte (Figure 8). Each data

transfer is initiated by an Address/Command byte. The

MSB (bit 7) must be a logic 1. When the MSB is zero,

Writes to the MAX6900 are disabled. Bit 6 specifies

clock/calendar data if logic 0 or RAM data if logic 1

(Tables 1 and 2). Bits 1 through 5 specify the designated registers to be input or output. The LSB (bit 0) specifies a Write operation (input) if logic 0 or Read

operation (output) if logic 1. The Command byte is

always input starting with the MSB (bit 7).

Reading from the Timekeeping

Registers

The timekeeping registers (Seconds, Minutes, Hours,

Date, Month, Day, Year, and Century) read either with a

Single Read or a Burst Read. Since the clock runs continuously and a Read takes a finite amount of time, it is

possible that the clock counters could change during a

Read operation, thereby reporting inaccurate timekeeping data. In the MAX6900, the clock counter data is

buffered by a latch. Clock counter data is latched by the

I2C-bus-compatible read command (on the falling edge

of SCL when the Slave Acknowledge bit is sent after the

Address/Command byte has been sent by the master to

read a timekeeping register). Collision-detection circuitry

ensures that this does not happen coincident with a seconds counter update to ensure accurate time data is

being read. This avoids time data changes during a

Read operation. The clock counters continue to count

and keep accurate time during the Read operation.

When using a Single Read to read each of the timekeeping registers individually, perform error checking

Figure 7. I2C Bus Acknowledge

Figure 8. Address/Command Byte

DATA OUTPUT

BY TRANSMITTER

DATA OUTPUT

BY RECEIVER

SCL FROM

MASTER

S

START

CONDITION

CLK1 CLK2

D0D6D7

NOT ACKNOWLEDGE

ACKNOWLEDGE

8921

CLK8

RAM

/CLK

CLK9

CLOCK PULSE FOR

ACKNOWLEDGMENT

A2 A1RDA0A3A4A5A7 A6

A2 A1A3A4A51

/W

Page 8

MAX6900

I2C-Compatible RTC in a TDFN

8 _______________________________________________________________________________________

Table 1. Register Address Definition

FUNCTION A7 A6 A5 A4 A3 A2 A1 A0 VALUE D7 D6 D5 D4 D3 D2 D1 D0

CLOCK

SEC 1 000 000RD 00-59

/W *POR STATE 0 0000000

7 10 SEC 1 SEC

DATE 1 000 011RD

MONTH 1000 100RD 01-12 0 0 0 10M 1 MONTH

DAY 1000 101RD 01-07 0 0 0 0 0 WEEK DAY

YEAR 1 000 110RD 00-99 10 YEAR 1 YEAR

MIN 1 000 001RD 00-59 0 10 MIN 1 MIN

/W *POR STATE 0 0000000

HR 1 000 010RD 00-23 12/24

/W 01-12 1/0

*POR STATE 0 0 0 0 0 0 0 0

01-28/29

01-30

01-31

/W *POR STATE 0 0 000001

/W *POR STATE 0 0 0 00001

/W *POR STATE 0 0 0 0 0 001

/W *POR STATE 0 1 1 1 0000

0 0 10 DATE 1 DATE

10

10

HR

0

A/P

0/1

HR

1 HR

CONTROL 1 000 111RD WP 0 0 0 0 0 0 0

/W *POR STATE 0 0 0 0 0 0 0 0

CENTURY 1001 001RD 00-99 1000 YEAR 100 YEAR

/W *POR STATE 0 0 0 1 1001

RESERVED 1 0 0 1 0 1 1 RD 0 0 0 0 0 0 0 0

/W *POR STATE 0 0 0 0 0 1 1 1

CLOCK

BURST

1011 111RD

/W

Page 9

MAX6900

I2C-Compatible RTC in a TDFN

_______________________________________________________________________________________ 9

Table 1. Register Address Definition (continued)

Table 2. Hex Register Address Definition

Note: POR STATE defines power-on reset state of register contents.

FUNCTION A7 A6 A5 A4 A3 A2 A1 A0 VALUE D7 D6 D5 D4 D3 D2 D1 D0

CLOCK

RAM

RAM 0 1100 000RD RAM DATA 0 xx xx x xx x

/W

RAM 30 1 111 110RD RAM DATA 30 xx xx x xx x

/W

RAM BURST 1 111 111RD

/W

WRITE

ADDRESS/

COMMAND

BYTE

(HEX)

80 81 Seconds 00

82 83 Minutes 00

84 85 Hours 00

86 87 Date 01

88 89 Month 01

8A 8B Day 01

8C 8D Year 70

8E 8F Control 00

92 93 Century 19

96 97 Reserved 07

BE BF Clock Burst N/A

C0 C1 RAM 0 Indeterminate

C2 C3 RAM 1 Indeterminate

C4 C5 RAM 2 Indeterminate

C6 C7 RAM 3 Indeterminate

C8 C9 RAM 4 Indeterminate

CA CB RAM 5 Indeterminate

CC CD RAM 6 Indeterminate

CE CF RAM 7 Indeterminate

HEX REGISTER ADDRESS/DESCRIPTION

READ

ADDRESS/

COMMAND

BYTE

(HEX)

DESCRIPTION

POR

CONTENTS

Page 10

MAX6900

I2C-Compatible RTC in a TDFN

10 ______________________________________________________________________________________

Table 2. Hex Register Address Definition (continued)

on the receiving end. The potential for errors occurs

when the seconds counter increments before all the

other registers are read out. For example, suppose a

carry of 13:59:59 to 14:00:00 occurs during Single

Read operations of the timekeeping registers. The net

data could become 14:59:59, which is erroneous realtime data. To prevent this with Single Read operations,

read the Seconds register first (initial seconds) and

store this value for future comparison. When the

remaining timekeeping registers have been read out,

read the Seconds register again (final seconds). If the

initial seconds value is 59, check that the final seconds

value is still 59; if not, repeat the entire Single Read

process for the timekeeping registers. A comparison of

the initial seconds value with the final seconds value

can indicate if there was a bus delay problem in reading the timekeeping data (difference should always be

1s or less). Using a 100kHz bus speed, sequential

Single Reads take under 2.5ms to read all seven of the

timekeeping registers plus a second read of the

Seconds register.

The most accurate way to read the timekeeping registers is a Burst Read. In the Burst Read mode, the main

timekeeping registers (Seconds, Minutes, Hours, Date,

Month, Day, Year) and the Control register are read

sequentially. All of the main timekeeping registers and

the Control register must be read out as a group of

eight registers, with 8 bytes each, for proper execution

WRITE

ADDRESS/

COMMAND

BYTE

(HEX)

D0 D1 RAM 8 Indeterminate

D2 D3 RAM 9 Indeterminate

D4 D5 RAM 10 Indeterminate

D6 D7 RAM 11 Indeterminate

D8 D9 RAM 12 Indeterminate

DA DB RAM 13 Indeterminate

DC DD RAM 14 Indeterminate

DE DF RAM 15 Indeterminate

E0 E1 RAM 16 Indeterminate

E2 E3 RAM 17 Indeterminate

E4 E5 RAM 18 Indeterminate

E6 E7 RAM 19 Indeterminate

E8 E9 RAM 20 Indeterminate

EA EB RAM 21 Indeterminate

EC ED RAM 22 Indeterminate

EE EF RAM 23 Indeterminate

F0 F1 RAM 24 Indeterminate

F2 F3 RAM 25 Indeterminate

F4 F5 RAM 26 Indeterminate

F6 F7 RAM 27 Indeterminate

F8 F9 RAM 28 Indeterminate

FA FB RAM 29 Indeterminate

FC FD RAM 30 Indeterminate

FE FF RAM Burst N/A

HEX REGISTER ADDRESS/DESCRIPTION

READ

ADDRESS/

COMMAND

BYTE

(HEX)

DESCRIPTION

POR

CONTENTS

Page 11

MAX6900

I2C-Compatible RTC in a TDFN

______________________________________________________________________________________ 11

Table 3. Data Transfer Summary

8_BIT DATA AS

BIT 7…….…….…………BIT 0 ACK BIT

0ASR

ADDR.

/AM

8_BIT DATA

BIT 7…….…………BIT 0 ACK BIT

BIT 7…………….…………BIT 0 ACK BIT

1AS

AS7-BIT SLAVE ID 0 AS 0111111 AS LAST 8_BIT DATA AS PS

7-BIT SLAVE ID

BIT 7………….…………BIT 0 ACK BITBIT 7…………….……………BIT 0 ACK BIT

FIRST 8_BIT DATA

P

BIT 7……….…………………BIT 0 ACK BIT

S

LAST 8_BIT DATA /AM

BIT 7……….……………BIT 0 ACK BIT

ADDRESS/COMMAND BYTE

7-BIT SLAVE ID 0 AS 1

BIT 7…………….……………… BIT 0 ACK BIT BIT 7…………….…………………BIT ACK BIT

S P

SINGLE WRITE

SINGLE READ

AS S

ADDR.

R

ADDRESS/COMMAND BYTE

ADDRESS/COMMAND BYTE

BIT 7…………….………BIT 0 ACK BIT BIT 7…………….……………BIT 0 ACK BIT

0AS 1 1

7-BIT SLAVE ID

BIT 7…………….……….BIT 0 ACK BIT

BURST WRITE

S P

BIT 7…………….…………BIT 0 ACK BIT

ADDRESS/COMMAND BYTE

BIT 7…………….…………… BIT 0 ACK BIT

0 AS 1 11111 1 AS 7-BIT SLAVE ID 1 AS FIRST 8_BIT DATA AM

7-BIT SLAVE ID

BIT 7…………….………… BIT 0 ACK BIT

BURST READ

S

SLAVE ID: 1010000

ADDR: 5-BIT RAM OR REGISTER ADDRESS

R: RAM/REGISTER SELECTION BIT. R = 0 WHEN REGISTER IS SELECTED, R = 1 WHEN RAM IS SELECTED

S: 2-WIRE BUS START CONDITION BY MASTER

P: 2-WIRE BUS STOP CONDITION BY MASTER

AS: ACKNOWLEDGE BY SLAVE

AM: ACKNOWLEDGE BY MASTER

/AM: NO ACKNOWLEDGE BY MASTER

Page 12

MAX6900

I2C-Compatible RTC in a TDFN

12 ______________________________________________________________________________________

of the Burst Read function. The seven timekeeping registers are latched upon the receipt of the Burst Read

command. The worst-case error that can occur

between the actual time and the read time is 1s,

assuming the entire Burst Read is done in less than 1s.

Writing to the Timekeeping

Registers

The time and date may be set by writing to the timekeeping registers (Seconds, Minutes, Hours, Date, Month,

Day, Year, and Century). To avoid changing the current

time by an incomplete Write operation, the current time

value is buffered from being written directly to the clock

counters. Current time data is loaded into this buffer at

the falling edge of SCL, on the Slave Acknowledge bit,

before the data input byte or bytes are sent to the

MAX6900. The clock counters continue to count. The

new data replaces the current contents of this input

buffer. The time update data is loaded into the clock

counters by the Stop bit at the end of the I2C- bus-compatible Write operation. Collision-detection circuitry

ensures that this does not happen coincident with a seconds counter update to ensure accurate time data is

being written. This avoids time data changes during a

Write operation. An incomplete Write operation aborts

the time update procedure and the contents of the input

buffer are discarded. The clock counters reflect the new

time data beginning with the first 1s clock cycle after the

Stop bit.

When using single Write operations to write to each of

the timekeeping registers, error checking is needed. If

the Seconds register is the one to be updated, update it

first and then read it back and store its value as the initial seconds. Update the remaining timekeeping registers and then read the Seconds register again (final

seconds). If initial seconds was 59, ensure that it is still

59. If initial seconds was not 59, ensure that final seconds is within 1s of initial seconds. If the Seconds register is not to be written to, then read the Seconds register

first and save it as initial seconds. Write to the required

timekeeping registers and then read the Seconds register again (final seconds). If initial seconds was 59,

ensure it is still 59. If initial seconds was not 59, ensure

that final seconds is within 1s of initial seconds.

The burst write mode is the most accurate way to write to

the timekeeping registers, although both single Writes

and Burst Writes are possible. In Burst Write, the main

timekeeping registers (Seconds, Minutes, Hours, Date,

Month, Day, Year) and the control register are written to

sequentially. All the main timekeeping registers and the

Control register must be written to as a group of eight

registers, with 8 bytes each, for proper execution of the

burst write function. All seven timekeeping registers are

simultaneously loaded into the clock counters by the

Stop bit at the end of the I2C-bus-compatible Write operation. The worst-case error that can occur between the

actual time and the write time update is 1s, assuming the

entire Burst Write is done in less than 1s. Note: After

writing to any time or date register, no read or write

operations are allowed for 2.5ms.

Write Protect Bit

Bit 7 of the Control register is the Write Protect bit. The

lower 7 bits (bits 0 to 6) are forced to zero and always

read a zero when read. Before any Write operation to

the clock or RAM, bit 7 must be zero. When high, the

Write Protect bit prevents a Write operation to any other

register.

AM-PM/12Hr-24Hr Mode

Bit 7 of the Hours register is defined as the 12hr or 24hr

Mode Select bit. When high, the 12hr mode is selected.

In the 12hr mode, bit 5 is the AM/PM bit with logic high

being PM. In the 24hr mode, bit 5 is the second 10hr

bit (20hr to 23hr).

Clock Burst Mode

Addressing the Clock Burst register (BEh for write, or

BFh for read) specifies burst mode operation. In this

mode, the first eight clock/calendar registers can be

consecutively read or written starting with bit 7 of

Address/Command 81h (Read) or 80h (Write). If the

Write Protect bit is set high when a write clock/calendar

burst mode is specified, no data transfer occurs to any

of the eight clock/calendar registers or the Control register. When writing to the clock registers in the burst

mode, the first eight registers must be written in order

for the data to be transferred.

RAM

The static RAM is 31 bytes addressed consecutively in

the RAM address space. Even Address/Commands

(C0h–FCh) are used for Writes, and odd Address/

Commands (C1h–FDh) are used for Reads. The contents of the RAM are static and remain valid for V

CC

down to 2V.

RAM Burst Mode

Addressing the RAM Burst register (FEh for Write, or

FFh for Read) specifies burst mode operation. In this

mode, the 31 RAM locations can be consecutively read

or written starting with bit 7 of Address/Command C1h

(Read) or C0h (Write). When writing to RAM in burst

mode, it is not necessary to write all 31 bytes for the

data to transfer. Each byte that is written to is transferred to RAM. If the Write Protect bit is set high when a

Page 13

MAX6900

I2C-Compatible RTC in a TDFN

______________________________________________________________________________________ 13

Table 4. Quartz Crystal Parameters

Table 5. Crystal Manufacturers

RAM burst mode is specified, no data transfer occurs

to any of the RAM locations. Burst writes of data greater

than 31 bytes could cause erroneous data in the

MAX6900.

Power-On Reset (POR)

The MAX6900 contains an integral POR circuit that

ensures all registers are reset to a known state on

power-up. Once VCCrises above 1.6V (typ), the POR

circuit releases the registers for normal operation.

When VCCdrops to less than 1.6V (typ), the MAX6900

resets all register contents to the POR defaults.

Oscillator Startup

The MAX6900 oscillator typically takes 5s to 10s to

begin oscillating. To ensure the oscillator is operating

correctly, the software should validate proper timekeeping. This is accomplished by reading the Seconds

register. Any reading of 1s or more from the POR is a

validation of proper startup.

Reserved Register

This is reserved for factory testing ONLY. Do not write

to this register. If inadvertent Writes are done to this

register, cycle power on the MAX6900.

Crystal Selection

Connect a 32.768kHz watch crystal directly to the

MAX6900 through pin 2 and pin 3 (X1, X2). Use a crys-

tal with a specified load capacitance (CL) of 12.5pF.

See Table 4 for a list of crystal parameters.

Table 5 lists some crystal manufacturers and part numbers for their surface-mount 32.768kHz watch crystals

that require 12.5pF. In addition, these manufacturers

offer other package options depending upon the specific application considerations.

Frequency Stability Overtemperature

Timekeeping accuracy of the MAX6900 is dependent

on the frequency stability of the external crystal. To

Figure 9. Oscillator Functional Schematic

Rf

MAX6900

Rd

Cg

25pF

X1 X2

EXTERNAL

CRYSTAL

Cd

25pF

Frequency f 32.768 kHz

Equivalent Series Resistance (ESR) R

Parallel Load Capacitance C

Q Factor Q 40,000 60,000

MANUFACTURER

Abracon Corporation

Caliber Electronics

ECS INC International ECS-.327-12.5-17 -10°C to +60°C 12.5 ±20

Fox Electronics FSM327 -40°C to +85°C 12.5 ±20

M-tron SX2010/SX2020 -20°C to +75°C 12.5 ±20

Raltron RSE-32.768-12.5-C-T -10°C to +60°C 12.5 ±20

SaRonix 32S12A -40°C to +85°C 12.5 ±20

PARAMETER SYMBOL MIN TYP MAX UNITS

s

L

MANUFACTURER

PART NO.

ABS25-32.768-12.5-B-

AWS2A-32.768KHz

TEMP.

RANGE

-40°C to +85°C 12.5 ±20

-20°C to +70°C 12.5 ±20

40 60 kΩ

11.2 12.5 13.7 pF

C

(pF)

L

+25°C FREQUENCY

TOLERANCE (ppm)

Page 14

MAX6900

14 ______________________________________________________________________________________

determine frequency stability, use the parabolic curve

in Figure 10 and the following equations:

∆f = f

✕k ✕

(T0- T )

2

where:

∆f= change in frequency from +20°C.

f = nominal crystal frequency.

k = parabolic curvature constant (-0.035

±0.005ppm/°C

2

for 32.768kHz watch crystals).

T0= turnover temperature

(+25°C ±5°C for 32.768kHz watch crystals).

T = temperature of interest (°C).

For example: What is the worst-case change in oscillator frequency from +25°C to +45°C ambient?

∆f(worst case) = 32,768 ✕(-0.04 / 1 ✕10e6)

✕

(20 -45)2= -0.8192Hz

After 1 month, that translates to:

Assuming ±20ppm initial crystal tolerance (±53s initial

accuracy); total worst-case timekeeping error at the

end of 1 month = 66.96s - 53s = -119.96s or about 2

minutes (assumes negligible parasitic layout capacitance).

Power-Supply Considerations

For most applications, a 0.1µF capacitor from VCCto

GND provides adequate bypassing for the MAX6900.

Because the MAX6900’s supply current is well under

1µA, a series resistor can be added to the supply to

reject extremely harsh noise.

PC Board Layout Considerations

When designing the PC board, keep the crystal as

close to the X1 and X2 pins of the MAX6900 as possible (Figure 11). Keep the trace lengths short and small

to avoid introducing excessive capacitive loading and

preventing unwanted noise pickup. Place a guard ring

around the crystal and tie the ring to ground to help isolate the crystal from unwanted noise pickup. Keep all

signals away from the crystal and the X1 and X2 pins to

prevent noise coupling. Finally, an additional local

ground plane on an adjacent PC board layer can be

added under the crystal to shield it from unwanted

pickup from traces on other layers of the board. This

plane should be isolated from the regular PC board

ground plane and tied to the GND pin of the MAX6900.

This plane needs to be no larger than the perimeter of

the guard ring. Ensure that this ground plane does not

contribute to significant capacitance between ground

and the traces that run from X1 and X2 to the crystal.

Chip Information

TRANSISTOR COUNT: 19,307

PROCESS: CMOS

Figure 10. Typical Temperature Curve for 32.768kHz Watch Crystal

I2C-Compatible RTC in a TDFN

-50-40-30-20-100 10202530405060708090

0

-50

-100

∆f (ppm)

-150

-200

-250

TEMPERATURE (°C)

TYPICAL TEMPERATURE CHARACTERISITICS

(k = -0.035ppm/°C

2

, TO = +25°C)

×

×

-0.8192Hz

32768Hz

∆t31days 24

=

()

s

60

×

min

hr

day

×

60

66.96s

=

min

hr

Page 15

MAX6900

I2C-Compatible RTC in a TDFN

______________________________________________________________________________________ 15

Figure 11. Recommended Board Layout

GUARD RING

*

**

GROUND PLANE

VIA CONNECTION

GROUND PLANE

VIA CONNECTION

PLANE

V

CC

VIA CONNECTION

****

SM WATCH CRYSTAL

*

0.1µF

SM CAP

*

*

LAYER 1 TRACE

*

*

*

*

**

*

MAX6900

*

GROUND PLANE

VIA CONNECTION

**

LAYER 2 LOCAL GROUND PLANE

CONNECT ONLY TO PIN 4

GROUND PLANE VIA

Page 16

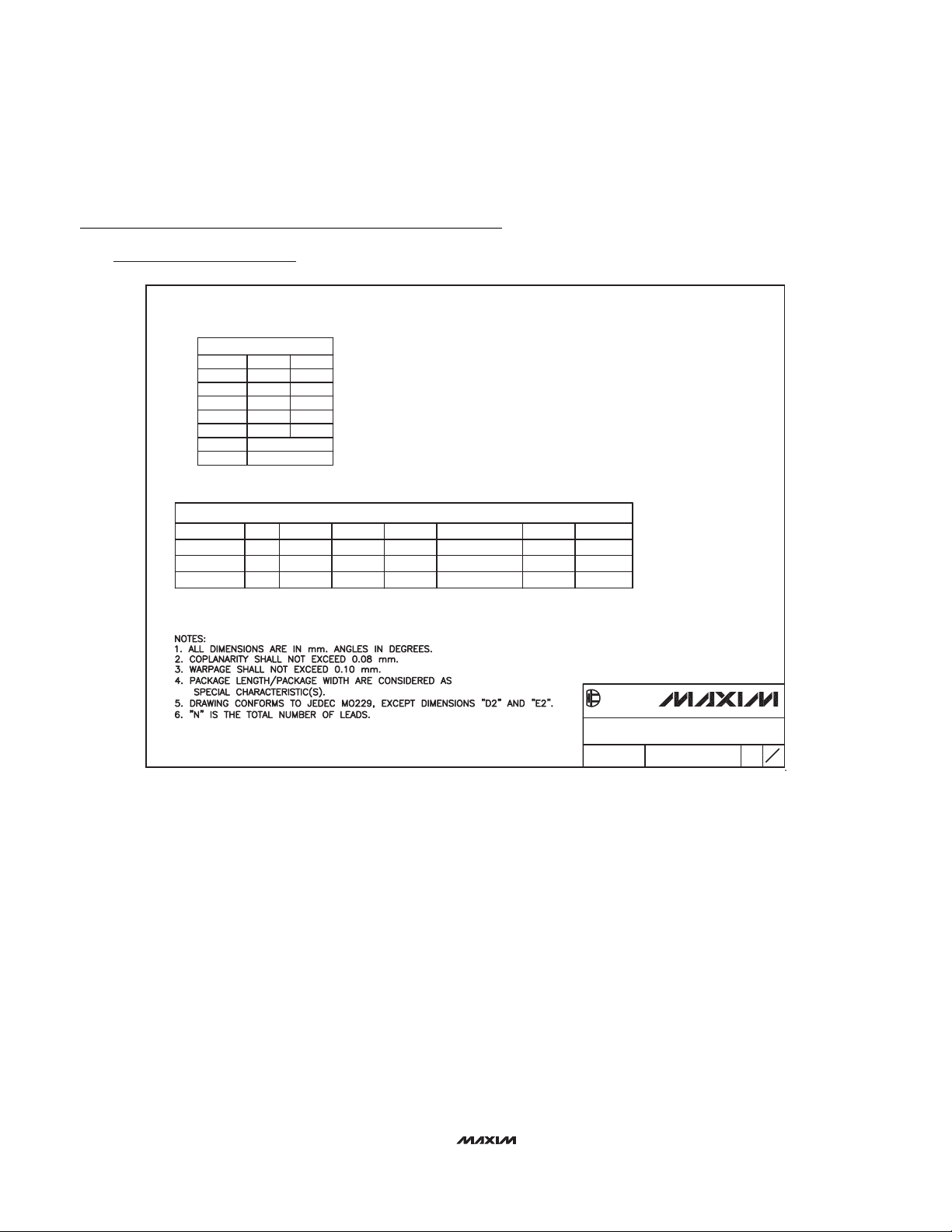

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

MAX6900

I2C-Compatible RTC in a TDFN

16 ______________________________________________________________________________________

PIN 1

INDEX

AREA

D

E

A

NUMBER OF LEADS SHOWN ARE FOR REFERENCE ONLY

A

A1

A2

L

DETAIL A

D2

b

E2

e

C

L

e

C0.35

C

L

e

DALLAS

SEMICONDUCTOR

PROPRIETARY INFORMATION

TITLE:

PACKAGE OUTLINE, 6, 8 & 10L,

TDFN, EXPOSED PAD, 3x3x0.80 mm

APPROVAL

DOCUMENT CONTROL NO. REV.

L

PIN 1 ID

1N1

[(N/2)-1] x e

REF.

k

L

21-0137 D

6, 8, &10L, QFN THIN.EPS

1

2

Page 17

I2C-Compatible RTC in a TDFN

MAX6900

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 17

© 2003 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

COMMON DIMENSIONS

SYMBOL

A

D

E

A1

L

k

A2 0.20 REF.

PACKAGE VARIATIONS

PKG. CODE

T633-1 1.50–0.10D22.30–0.10

MIN. MAX.

0.70 0.80

2.90 3.10

2.90 3.10

0.00 0.05

0.20 0.40

0.25 MIN.

N

6

1.50–0.10

E2

0.95 BSCeMO229 / WEEA

2.30–0.10T833-1 8

0.65 BSC

JEDEC SPEC

MO229 / WEEC

[(N/2)-1] x e

0.40–0.05b1.90 REF

1.95 REF0.30–0.05

0.25–0.05 2.00 REFMO229 / WEED-30.50 BSC1.50–0.10 2.30–0.1010T1033-1

DALLAS

SEMICONDUCTOR

PROPRIETARY INFORMATION

TITLE:

PACKAGE OUTLINE, 6, 8 & 10L,

TDFN, EXPOSED PAD, 3x3x0.80 mm

DOCUMENT CONTROL NO.APPROVAL

21-0137

REV.

2

2

D

Loading...

Loading...