Page 1

General Description

The MAX6661 is a remote temperature sensor and fanspeed regulator that provides complete closed-loop fan

control. The remote temperature sensor is typically a

common-collector PNP, such as a substrate PNP of a

microprocessor, or a diode-connected transistor, typically a low-cost, easily mounted 2N3904 NPN type or

2N3906 PNP type.

The device also incorporates a closed-loop fan controller that regulates fan speed with tachometer feedback. The MAX6661 compares temperature data to a

fan threshold temperature and gain setting, both programmed over the SPI™ bus by the user. The result is

automatic fan control that is proportional to the remotejunction temperature. The temperature feedback loop

can be broken at any time for system control over the

speed of the fan.

Fan speed is voltage controlled as opposed to PWM

controlled, greatly reducing acoustic noise and maximizing fan reliability. An on-chip power device drives

fans rated up to 250mA.

Temperature data is updated every 500ms and is readable at any time over the SPI interface. The MAX6661 is

accurate to 1°C (max) when the remote junction is

between +60°C to +100°C. Data is formatted as a 10bit + sign word with 0.125°C resolution.

The MAX6661 is specified between -40°C to +125°C

and is available in a 16-pin QSOP package.

Applications

Telecom Systems

Servers

Workstations

Electronic Instruments

Features

♦ Integrated Thermal Measurement and Fan

Regulation

♦ Programmable Fan Threshold Temperature

♦ Programmable Temperature Range for Full-Scale

Fan Speed

♦ Accurate Closed-Loop Fan-Speed Regulation

♦ On-Chip Power Device Drives Fans Rated

Up to 250mA

♦ Programmable Under/Overtemperature Alarms

♦ SPI-Compatible Serial Interface

♦ ±1°C (+60°C to +100°C) Thermal-Sensing

Accuracy

MAX6661

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

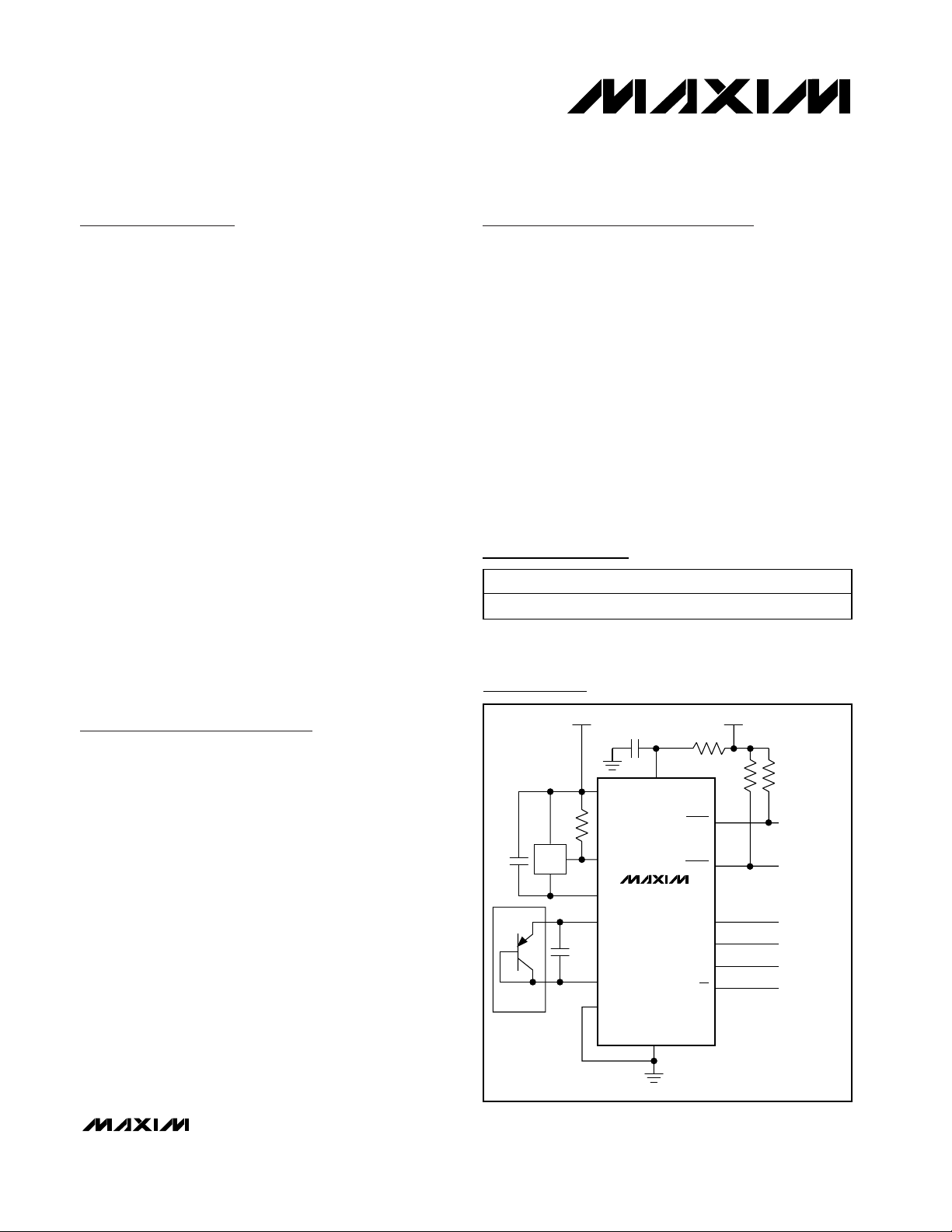

1µF

5kΩ

FAN

12V

2200pF

PENTIUM

SDIN

SC

ALERT

OVERT

SPI CLOCK

SPI DATA IN

DOUT

SPI DATA OUT

CS

SPI CHIP SELECT

INTERRUPT

TO µP

TO SYSTEM

SHUTDOWN

V

FAN

PGND

0.1µF

3V TO 5.5V

50Ω

V

CC

TACH IN

FAN

DXP

DXN

AGND

10kΩ

EACH

MAX6661

Typical Operating Circuit

19-2337; Rev 0; 1/02

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Pin Configuration appears at end of data sheet.

SPI is a trademark of Motorola, Inc.

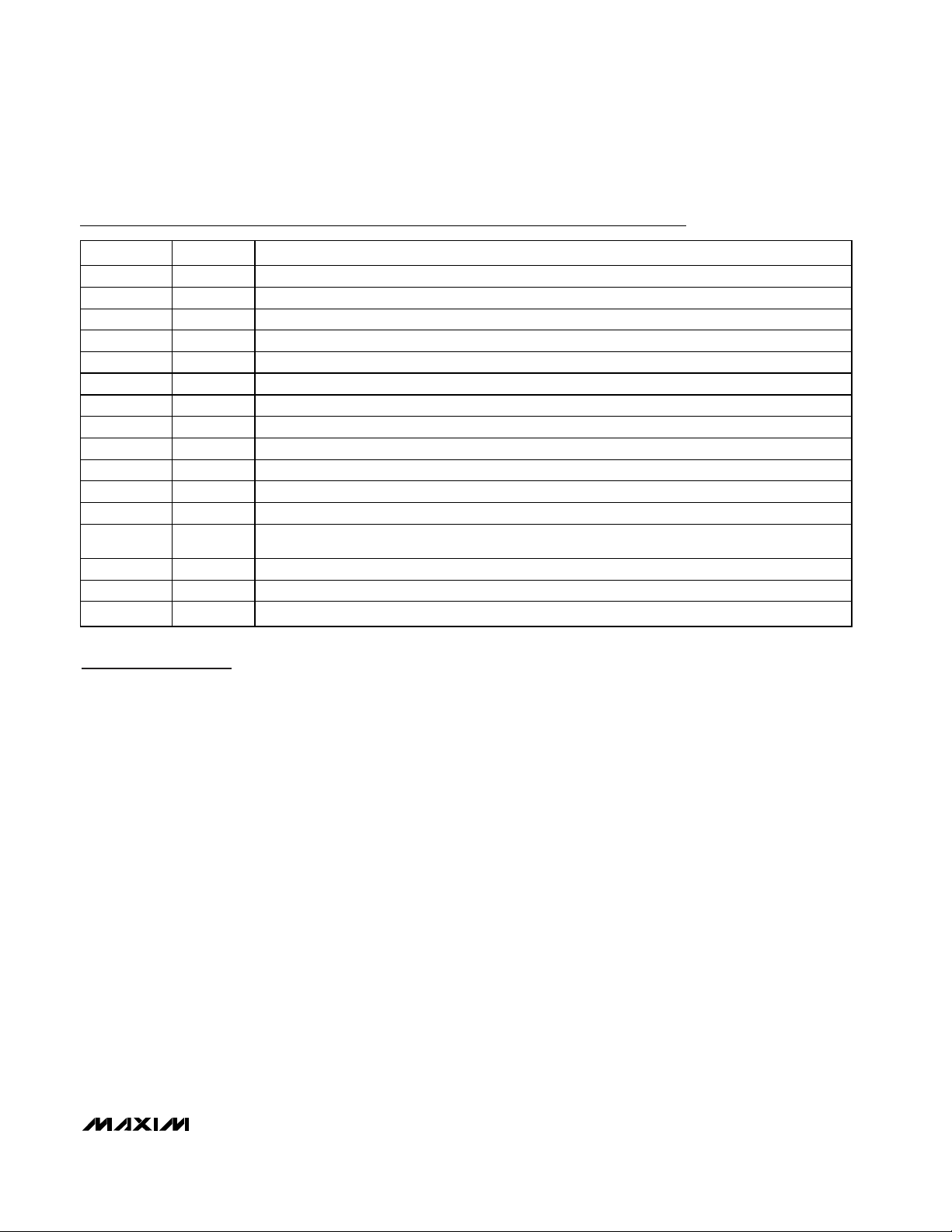

PART TEMP RANGE PIN-PACKAGE

MAX6661AEE -40°C to +125°C 16 QSOP

Page 2

MAX6661

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VCC= 3V to 5.5V, V

FAN

= 12V, TA= -40°C to +125°C, unless otherwise specified. Typical values are at VCC= 3.3V and TA=

+25°C.) (Notes 1 and 2)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VCC, ALERT, OVERT ...............................................-0.3V to +6V

V

FAN

, TACH IN, FAN .............................................-0.3V to +16V

DXP, CS, SDOUT, GAIN, SCL, SDIN..........-0.3V to (V

CC

+ 0.3V)

DXN ..........................................................................-0.3V to +1V

SDOUT Current ...................................................-1mA to +50mA

DXN Current ......................................................................±1mA

FAN Out Current ..............................................................500mA

Continuous Power Dissipation (T

A

= +70°C)

16-Pin QSOP (derate 8.3mW/°C above +70°C)...........667mW

Operating Temperature Range ........................ -40°C to +125°C

Junction Temperature .....................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) ................................+300°C

ADC AND POWER SUPPLY

Temperature Resolution

(Note 3)

Remote-Junction Temperature

Measurement Error (Note 4)

Fan-Speed Measurement

Accuracy

VCC Supply Voltage Range V

V

FAN

Conversion Time 0.25 s

Conversion Rate Timing Error -25 +25 %

Undervoltage Lockout (UVLO)

Threshold

UVLO Threshold Hysteresis V

POR Threshold (VCC)V

POR Threshold Hysteresis 90 mV

Standby Supply Current I

Operating Supply Current I

DXN Source Voltage V

TACH Input Transition Level V

TACH Input Hysteresis V

TACH Input Resistance 250 kΩ

Fan Output Current I

Fan Output Current Limit I

Fan Output On-Resistance R

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Supply Voltage Range V

TRJ = +60°C to +100°C-1 +1°C

TRJ = +25°C to +125°C-3 +3°C

T

= -40°C to +125°C-5 +5°C

RJ

T

E

CC

FAN

V

UVLOVCC

HYST

SHDN

CC

DXN

F

L

ONF

TA = +85°C,

= 3.3V

V

CC

falling 2.50 2.80 2.95 V

rising 1.4 2.0 2.5 V

CC

Shutdown, configuration bit 6 = 1 3 20 µA

Fan off 450 700 µA

= 12V 10.5 V

FAN

= 12V 190 mV

FAN

(Note 5) 320 410 mA

250mA load 4 Ω

0.125 °C

11 Bits

±25 %

3.0 5.5 V

4.5 13.5 V

90 mV

0.7 V

250 mA

Page 3

MAX6661

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VCC= 3V to 5.5V, V

FAN

= 12V, TA= -40°C to +125°C, unless otherwise specified. Typical values are at VCC= 3.3V and TA=

+25°C.) (Notes 1 and 2)

Note 1: T

A

= TJ. This implies zero dissipation in pass transistor (no load, or fan turned off).

Note 2: All parameters are 100% production tested at a single temperature, unless otherwise indicated. Parameter values through

temperature are guaranteed by design.

Note 3: The fan control section of the MAX6661 and temperature comparisons use only 9 bits of the 11-bit temperature measure-

ment with a 0.5°C LSB.

Note 4: Wide-range accuracy is guaranteed by design, not production tested.

Note 5: Guaranteed by design.

INTERFACE PINS (SDIN, SC, CS, DOUT, ALERT, OVERT)

Serial Bus Maximum Clock

Frequency (Note 5)

Logic Input High Voltage

Logic Input Low Voltage VCC = 3V to 5V 0.8 V

Logic Output High-Voltage

DOUT

Logic Output Low-Voltage DOUT VCC = 3V, I

Logic Output Low-Voltage

ALERT, OVERT

ALERT, OVERT Output

High Leakage Current

Logic Input Current Logic inputs forced to VCC or GND -2 2 µA

SPI AC TIMING (Figure 5)

CS High to DOUT Three-State t

CS to SC Setup Time t

SC Fall to DOUT Valid t

DIN to SC Setup Time t

DIN to SC Hold Time t

SC Period t

SC High Time t

SC Low Time t

CS High Pulse Width t

Output Rise Time t

Output Fall Time t

SC Falling Edge to CS Rising

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SC 2.5 MHz

VCC = 3V 2.2

V

= 5.5V 2.4

CC

V

-

CC

0.4V

200 ns

400 ns

200 ns

200 ns

TR

CSS

DO

DS

DH

CP

CH

CL

CSW

R

F

t

SCS

= 3V, I

V

CC

= 3V, I

V

CC

ALERT, OVERT forced to 5.5V 1 µA

= 100pF, R

C

LOAD

(Note 5) 200 ns

C

= 100pF 200 ns

LOAD

(Note 5) 200 ns

(Note 5) 400 ns

C

= 100pF 10 ns

LOAD

= 100pF 10 ns

C

LOAD

(Note 5) 200 ns

= 6mA (Note 5)

SOURCE

= 6mA (Note 5) 0.4 V

SINK

= 6mA (Note 5) 0.4 V

SINK

= 10kΩ (Note 5) 200 ns

GS

V

V

Page 4

MAX6661

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

4 _______________________________________________________________________________________

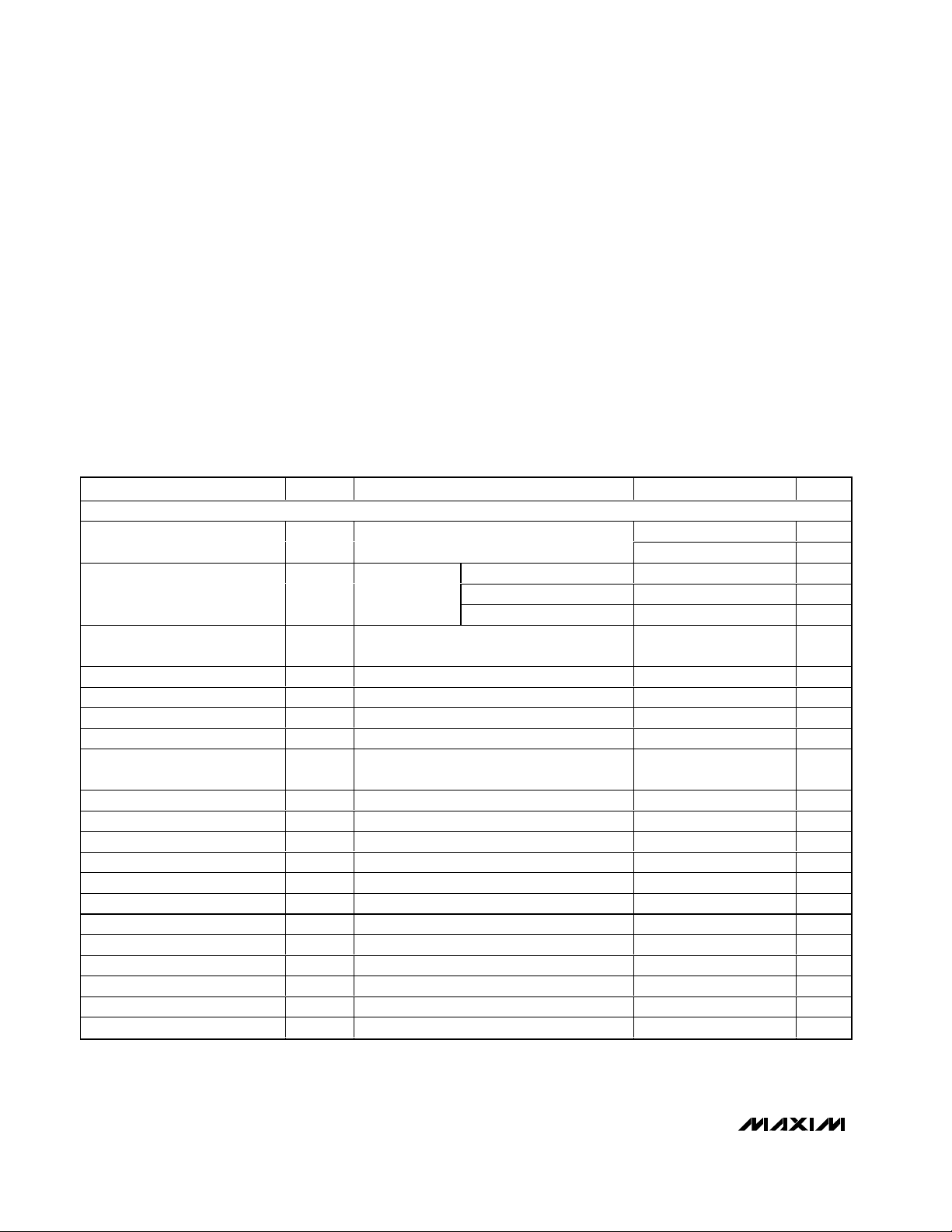

Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

1 10 100

TEMPERATURE ERROR

vs. PC BOARD RESISTANCE

MAX6661 toc01

LEAKAGE RESISTANCE (MΩ)

TEMPERATURE ERROR (°C)

20

-30

-25

-20

-15

-10

-5

0

15

10

5

PATH = DXP TO GND

PATH = DXP TO VCC (5V)

-5

-2

-3

-4

-1

0

1

2

3

4

5

-50 0 50 100 150

MAX6661 toc02

TEMPERATURE (°C)

TEMPERATURE ERROR (°C)

TEMPERATURE ERROR

vs. REMOTE-DIODE TEMPERATURE

1 100 10k 1M10 1k 100k 10M 100M

TEMPERATURE ERROR

vs. POWER-SUPPLY NOISE FREQUENCY

MAX6661 toc03

FREQUENCY (Hz)

TEMPERATURE ERROR (°C)

20

-30

-25

-20

-15

-10

-5

0

15

10

5

VIN = 100mV

P-P

VIN = SQUARE WAVE APPLIED TO V

CC

WITH NO 0.1µF VCC CAPACITOR

VIN = 250mV

P-P

4.0

-1.5

-1.0

MAX6661 toc04

FREQUENCY (Hz)

TEMPERATURE ERROR (°C)

-0.5

0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

1 10 100M1M 10M100 1k 10k 100k

TEMPERATURE ERROR

vs. COMMON-MODE NOISE FREQUENCY

VIN = 50mV

P-P

VIN = SQUARE WAVE

AC-COUPLED TO DXN

VIN = 100mV

P-P

VIN = 25mV

P-P

-8

-6

-7

-4

-5

-3

-2

0

-1

1

0102030405060708090100

MAX6661 toc05

DXP-DXN CAPACITANCE (nF)

TEMPERATURE ERROR (°C)

TEMPERATURE ERROR

vs. DXP-DXN CAPACITANCE

0

1

3

2

4

5

MAX6661 toc06

SUPPLY VOLTAGE (V)

STANDBY SUPPLY CURRENT (µA)

3.0 4.0 4.53.5 5.0 5.5

STANDBY SUPPLY CURRENT

vs. SUPPLY VOLTAGE

CONFIG BIT 6 = 1

3.0 3.9 4.23.3 3.6 4.5 4.8 5.1 5.4

MAX6661 toc07

SUPPLY VOLTAGE (V)

AVERAGE SUPPLY CURRENT (µA)

450

AVERAGE SUPPLY CURRENT

vs. SUPPLY VOLTAGE

Page 5

Detailed Description

The MAX6661 is a remote temperature sensor and fan

controller with an SPI interface. The MAX6661 converts

the temperature of a remote PN junction to a 10-bit +

sign digital word. The remote PN junction can be a

diode-connected transistor, such as a 2N3906, or the

type normally found on the substrate of many processors’ ICs. The temperature information is provided to the

fan-speed regulator and is read over the SPI interface.

The temperature data, through the SPI interface, can be

read as a 10-bit + sign two’s complement word with a

0.125°C resolution (LSB) and is updated every 0.5s.

The MAX6661 incorporates a closed-loop fan controller

that regulates the fan speed with tachometer feedback.

The temperature information is compared to a threshold

and range setting, which enables the MAX6661 to automatically set fan speed proportional to temperature.

Full control of the fan is available by being able to open

either the thermal control loop or the fan control loop.

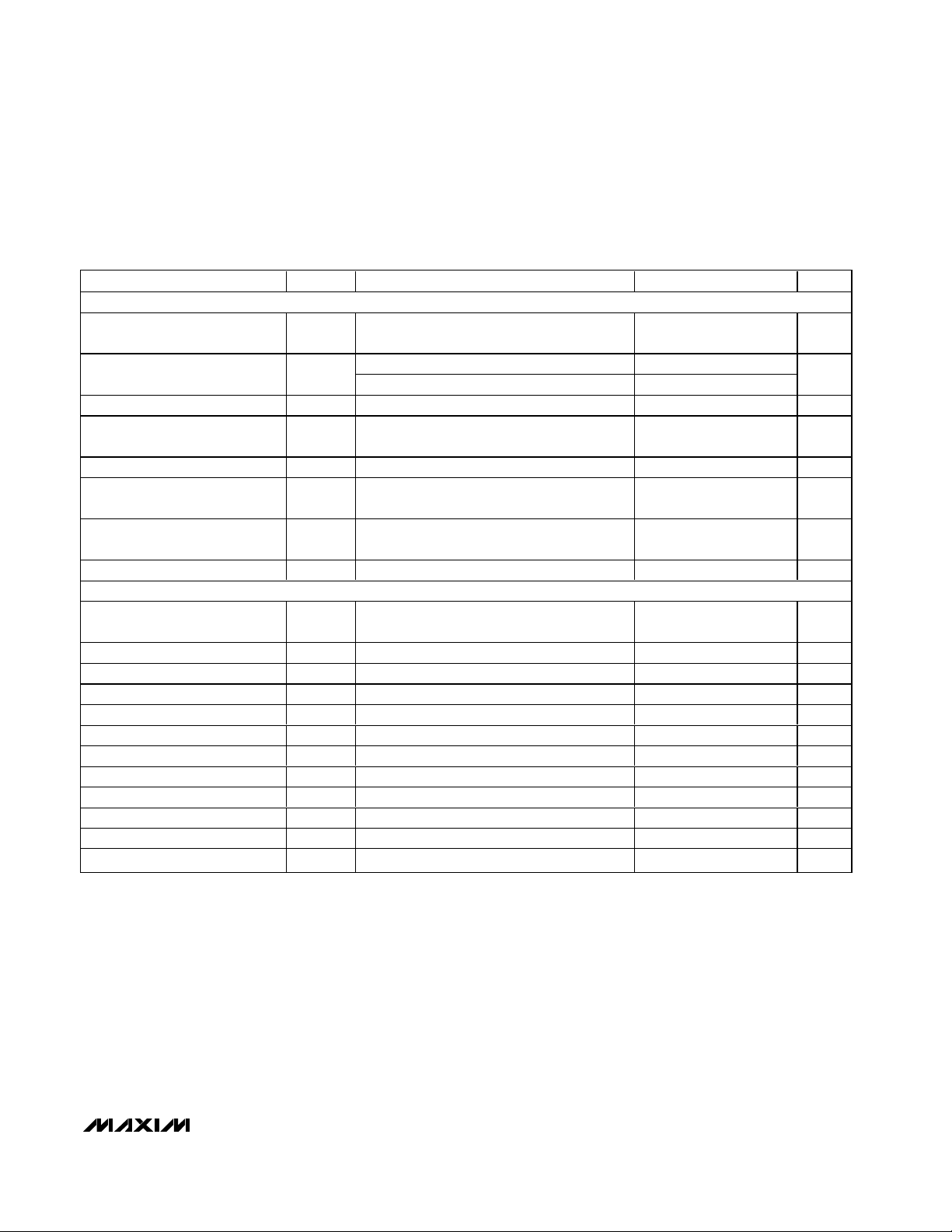

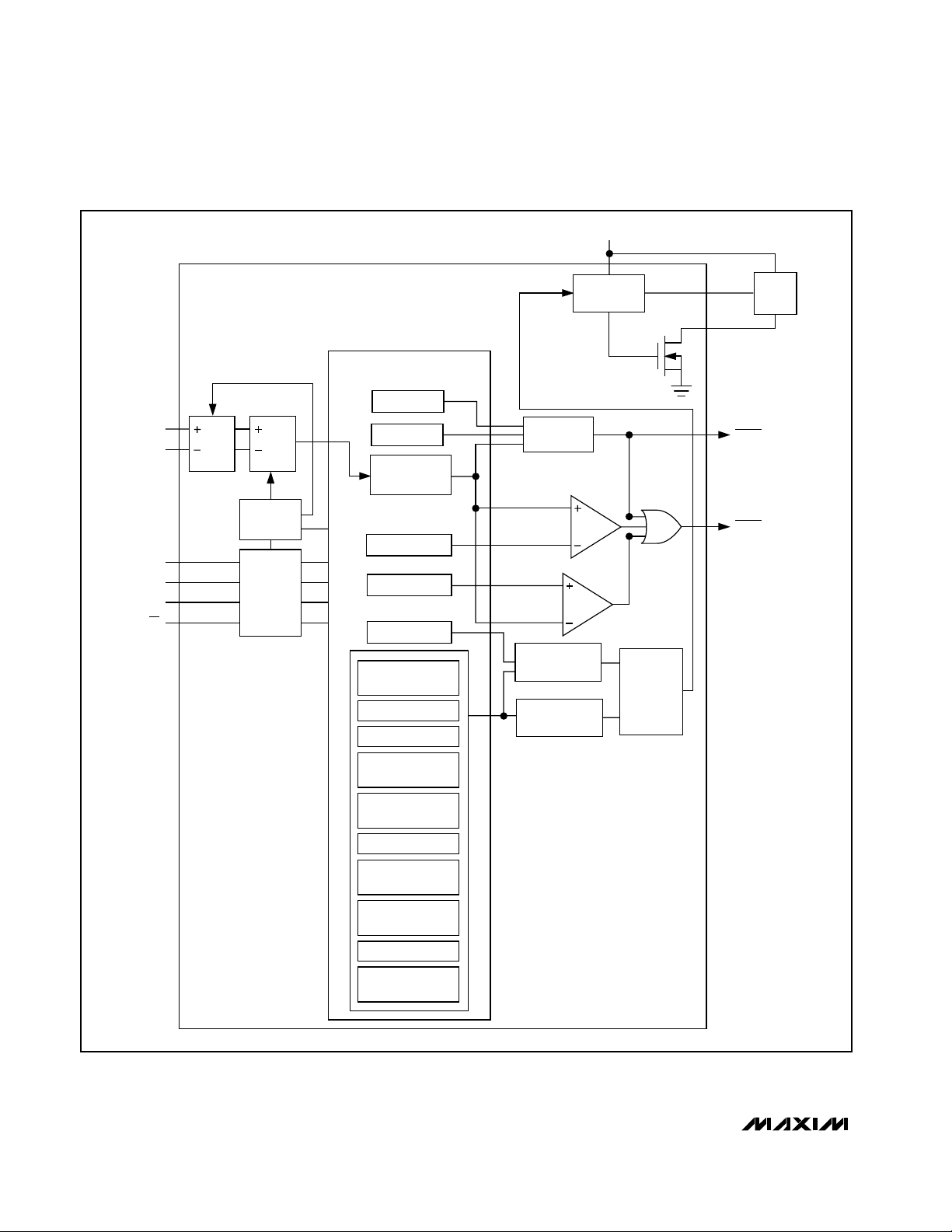

Figure 1 shows a simplified block diagram.

ADC

The ADC is an averaging type that integrates the signal

input over a 125ms period with excellent noise rejection. A bias current is steered through the remote

diode, where the forward voltage is measured, and the

temperature is computed. The DXN pin is the cathode

of the remote diode and is biased at 0.7V above

ground by an internal diode to set up the ADC inputs

for a differential measurement. The worst-case DXPDXN differential input voltage range is 0.25V to 0.95V.

Excess resistance in series with the remote diode causes about 1/2°C error per ohm. Likewise, 200mV of offset voltage forced on DXP-DXN causes approximately

1°C error.

A/D Conversion Sequence

A temperature-conversion sequence is initiated every

500ms in the free-running autoconvert mode (bit 6 = 0

in the configuration register) or immediately by writing a

one-shot command. The result of the new measurement

is available after the end of conversion. The results of

the previous conversion sequence are still available

when the ADC is converting.

Remote-Diode Selection

Temperature accuracy depends on having a goodquality, diode-connected, small-signal transistor.

Accuracy has been experimentally verified for all

devices listed in Table 1. The MAX6661 can also directly measure the die temperature of CPUs and other ICs

that have on-board temperature-sensing diodes.

MAX6661

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

_______________________________________________________________________________________ 5

Pin Description

PIN NAME FUNCTION

1V

2VCCPower Supply: 3V to 5.5V. Bypass with a 0.1µF capacitor to GND.

3 DXP Input: Remote-Junction Anode. Place a 2200pF capacitor between DXP and DXN for noise filtering.

4 DXN Input: Remote-Junction Cathode. DXN is internally biased to a diode voltage above ground.

5 FAN Output to Fan Low Side

6 N.C. No External Connection. Must be left floating.

7 PGND Power Ground

8 AGND Analog Ground

9 OVERT Output to System Shutdown. Active-low output, programmable for active high, if desired. Open drain.

10 CS SPI Chip Select. Active low.

11 ALERT Open-Drain Active-Low Output

12 DOUT SPI Data Output. High-Z when not being read.

13 GAIN

14 SCL SPI Clock

15 SDIN SPI Data In

16 TACH IN Fan Tachometer Input. 13.5V tolerant, pullup from V

FAN

Power Supply for Fan Drive: 4.5V to 13.5V

Leave open if tachometer feedback is being used. Connect an external resistor to V

gain of the current sense.

to 13.5V is allowed on this line.

CC

to reduce the

CC

Page 6

MAX6661

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

6 _______________________________________________________________________________________

Figure 1. MAX6661 Block Diagram

VFAN

DXN

SC

SDIN

DOUT

CS

FAN-SPEED

REGULATOR

REGISTERS

T

MAX

MUXDXP

ADC

CONTROL

LOGIC

SPI

INTERFACE

T

HYST

REMOTE

TEMPERATURE

DATA

T

HIGH

T

LOW

CONFIGURATION

FAN TACHOMETER

DIVISOR (FTD)

T

(FT)

FAN

FAN GAIN (FG)

COMPARAT0R

THERMAL OPEN/

CLOSE LOOP

FAN OPEN/

CLOSE LOOP

FAN

CONTROL

CIRCUIT

TACH IN

FAN

N

FAN

OVERT

ALERT

FULL SCALE

(FS)

FAN TACHOMETER

PERIOD LIMIT (FTPL)

MODE (M)

FAN-CONVERSION

RATE (FCR)

FAN-SPEED CONTROL

(FSC)

STATUS

FAN TACHOMETER

PERIOD (FTP)

Page 7

The transistor must be a small-signal type with a relatively high forward voltage. Otherwise, the A/D input

range could be violated. The forward voltage must be

greater than 0.25V at 10µA. Check to ensure this is true

at the highest expected temperature. The forward voltage must be less than 0.95V at 100µA. Check to ensure

that this is true at the lowest expected temperature.

Large power transistors, power diodes, or small-signal

diodes must not be used. Also, ensure that the base

resistance is less than 100Ω. Tight specifications for

forward-current gain (50 < ß <150, for example) indicate that the manufacturer has good process controls

and that the devices have consistent VBEcharacteristics. Bits 5–2 of the mode register can be used to

adjust the ADC gain to achieve accurate temperature

measurements with diodes not included in the recommended list or to calibrate individually the MAX6661 for

use in specific control systems.

Thermal Mass and Self-Heating

When measuring the temperature of a CPU or other IC

with an on-chip sense junction, the thermal mass of the

sensor has virtually no effect; the measured temperature of the junction tracks the actual temperature within

a conversion cycle. When measuring temperature with

discrete remote sensors, smaller packages (e.g., a

SOT23) yield the best thermal response times. Take

care to account for thermal gradients between the heat

source and the sensor, and ensure that stray air currents across the sensor package do not interfere with

measurement accuracy. Sensor self-heating, caused

by the diode current source, is negligible.

ADC Noise Filtering

The ADC is an integrating type with inherently good

noise rejection, especially of low-frequency noise such

as 60Hz line interference. Micropower operation places

constraints on high-frequency noise rejection; therefore, careful PC board layout and proper external noise

filtering are required for high-accuracy remote measurements in electrically noisy environments. High-frequency EMI is best filtered at DXP and DXN with an

external 2200pF capacitor. This value can be increased

to about 3300pF (max), including cable capacitance.

Capacitance higher than 3300pF introduces errors due

to the rise time of the switched current source. Nearly

all noise sources tested cause the ADC measurements

to be higher than the actual temperature, typically by

1°C to 10°C, depending on the frequency and amplitude (see Typical Operating Characteristics).

PC Board Layout

Follow these guidelines to reduce the measurement

error of the temperature sensors:

1) Place the MAX6661 as close as practical to the

remote diode. In noisy environments, such as a

computer motherboard, this distance can be 4in to

8in (typ). This length can be increased if the worst

noise sources are avoided. Noise sources include

CRTs, clock generators, memory buses, and

ISA/PCI buses.

2) Do not route the DXP-DXN lines next to the deflection coils of a CRT. Also, do not route the traces

across fast digital signals, which can easily introduce a 30°C error, even with good filtering.

3) Route the DXP and DXN traces in parallel and in

close proximity to each other, away from any higher

voltage traces, such as 12VDC. Leakage currents

from PC board contamination must be dealt with

carefully since a 20MΩ leakage path from DXP to

ground causes about a 1°C error. If high-voltage

traces are unavoidable, connect guard traces to GND

on either side of the DXP-DXN traces (Figure 2).

4) Route through as few vias and crossunders as possible to minimize copper/solder thermocouple

effects.

MAX6661

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

_______________________________________________________________________________________ 7

Note: Transistors must be diode connected (base shorted to

collector).

Table 1. Remote-Sensor Transistors

Figure 2. Recommended DXP-DXN PC Trace

MANUFACTURER MODEL NO.

Central Semiconductor (USA) 2N3904, 2N3906

Fairchild Semiconductor (USA) 2N3904, 2N3906

Rohm Semiconductor (Japan) SST3904

Samsung (Korea) KST3904-TF

Siemens (Germany) SMBT3904

Zetex (England) FMMT3904CT-ND

GND

10mils

10mils

10mils

DXP

MINIMUM

DXN

10mils

GND

Page 8

MAX6661

5) When introducing a thermocouple by inserting different metals in the connection path, make sure that

both the DXP and the DXN paths have matching

thermocouples, i.e., the connection paths are symmetrical. A copper-solder thermocouple exhibits

3µV/°C. Adding a few thermocouples causes a negligible error.

6) The 10mil widths and spacings that are recommended in Figure 2 are not absolutely necessary, as they

offer only a minor improvement in leakage and noise

over narrow traces. Use wider traces when practical.

7) Add a 5Ω resistor in series with VCCfor best noise

filtering (see Typical Operating Circuit).

PC Board Layout Checklist

• Place the MAX6661 close to the remote-sense junction.

• Keep traces away from high voltages (12V bus).

• Keep traces away from fast data buses and CRTs.

• Use recommended trace widths and spacings.

• Place a ground plane under the traces.

• Use guard traces connected to GND flanking DXP

and DXN.

• Place the noise filter and the 0.1µF VCCbypass

capacitors close to the MAX6661.

Twisted-Pair and Shielded Cables

Use a twisted-pair cable to connect the remote sensor

for distances longer than 8in or in very noisy environments. Twisted-pair cable lengths can be between 6ft

and 12ft before noise introduces excessive errors. For

longer distances, the best solution is a shielded twisted

pair like that used for audio microphones. For example,

Belden 8451 works well for distances up to 100ft in a

noisy environment. At the device, connect the twisted

pair to DXP and DXN and the shield to GND. Leave the

shield unconnected at the remote sensor. For very long

cable runs, the cable’s parasitic capacitance often provides noise filtering, so the 2200pF capacitor can often

be removed or reduced in value. Cable resistance also

affects remote-sensor accuracy. For every ohm of

series resistance, the error is approximately 1/2°C.

Low-Power Standby Mode

Standby mode reduces the supply current to less than

10µA (typ) by disabling the ADC, the control loop, and

the fan driver. Enter standby mode by setting the

RUN/STOP bit to 1 (bit 6) in the configuration byte register. In standby mode, all data is retained in memory,

and the SPI interface is alive and listening for SPI commands. In standby mode, the one-shot command initiates a conversion. Activity on the SPI bus causes the

device to draw extra supply current.

If a standby command is received while a conversion is

in progress, the conversion cycle is interrupted, and

the temperature registers are not updated. The previous data is not changed and remains available.

SPI Interface

The data interface for the MAX6661 is compatible with

SPI, QSPI™, and MICROWIRE™ devices. For SPI/QSPI,

ensure that the CPU serial interface runs in master

mode so that it generates the serial clock signal. Select

a 2.5MHz clock frequency or lower, and set zero values

for clock polarity (CPOL) and phase (CPHA) in the µP

control registers.

Data is clocked into the MAX6661 at SDIN on the rising

edge of SC when CS is low. The first byte is the command byte and the second byte is the data byte. The

command byte can be either a read byte or a write byte

(Table 2). The last bit READ/WRITE (LSB) of the command byte tells the MAX6661 whether it is a read or a

write operation, where a high signifies a read, and a

low signifies a write. When CS is high, the MAX6661

does not respond to any activity on the SPI bus. All

valid communications on the SPI should have 16 bits

except for the SPOR and the OSHT.

During a READ operation, the DOUT line goes low on

the falling clock edge after the READ/WRITE bit (8th

bit). The data in the shift register is moved to the DOUT

line during the 8th to 15th falling-clock edges and the

MSB of the data is available to be read at the rising

edge of the 9th clock pulse. The remaining clock pulses in the READ operation shift the register contents on

the negative clock edge so that they can be latched

into the master on the positive edge. Any READ operation with less than 16 bits results in truncated data.

Figure 3 shows the read cycle.

For a WRITE operation, the command byte is decoded

during the 8th clock pulse. Then data is loaded into the

shift register on the positive edges of the 9th to 16th

clock pulses and transferred to the appropriate register

on the negative edge of the 16th clock period. Any

WRITE operation that does not have the 16th clock

edge does not get shifted out of the shift register and

thus is ignored. Since returning CS high resets the SPI

interface at the end of a transfer, this cannot be done

until after the 16th falling clock edge. If CS is returned

high before this 16th falling clock edge, the appropriate

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

8 _______________________________________________________________________________________

QSPI is a trademark of Motorola, Inc.

MICROWIRE is a trademark of National Semiconductor Corp.

Page 9

register is not loaded. DOUT is high impedance during

a WRITE operation. Figure 4 shows the write cycle.

For single byte commands such as OSHT and SPOR,

the operation need only be 7 bits long where the

READ/WRITE bit is omitted. Here the command is

loaded into the shift register on the rising edge of SC

and the command is decoded during the high period of

the 7th clock pulse. The 7th falling edge of SC shifts the

command from the shift register to the appropriate register. CS can then go high after the SC low to CS high

hold time t

CSH

(see SPI AC Timing, Electrical Char-

acteristics). Figure 5 shows the timing waveforms for

the MAX6661’s SPI interface.

Remote Temperature Data Register

Two registers, at addresses 81h and 83h, store the

measured temperature data from the remote diode. The

data format for the remote-diode temperature is 10 bits

+ sign, with each LSB corresponding to 0.125°C, in

two’s complement format (Table 3). Register 83h contains the sign bit and the first 7 bits. Bits 7, 6, and 5 of

register 81h are the 3LSBs. If the two registers are not

read immediately, one after the other, their contents

may be the result of two different temperature measurements, leading to erroneous temperature data. For this

reason, a parity bit has been added to the 81h register.

Bit 4 of this is zero if the data in 81h and 83h are from

the same temperature conversion and 83h is read first.

Otherwise, bit 4 is one. The remaining bits are don’t

cares. When reading temperature data, register 83h

must be read first.

Alarm Threshold Registers

The MAX6661 provides four alarm threshold registers

that can be programmed with a two’s complement temperature value with each LSB corresponding to 1°C.

The registers are T

HIGH

, T

LOW

, T

MAX

, and T

HYST

. If the

measured temperature equals or exceeds T

HIGH

, or is

less than T

LOW

, an ALERT interrupt is asserted. If the

measured temperature equals or exceeds T

MAX

, the

OVERT output is asserted (see the Overtemperature

Output

OVERT

section). The POR state for T

HIGH

is

MAX6661

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

_______________________________________________________________________________________ 9

Table 2. MAX6661 Command-Byte Bit Assignments

REGISTERS COMMAND POR STATE FUNCTION

RRL 81h 00000000 Read Remote Temperature Low Byte (3MSBs)

RRH 83h 00000000 Read Remote Temperature High Byte (Sign Bit and First 7 Bits)

RSL 85h 00000000 Read Status Byte

RCL/WCL 87h/92h 00000000 Read/Write Configuration Byte

RFCR/WFCR 89h/94h 00000010 Read/Write Fan-Conversion Rate Byte

RTMAX/WTMAX A1h/A4h 01100100 (+100°C) Read/Write Remote T

RTHYST/WTHYST A3h/A6h 01011111 (+95°C) Read/Write Remote T

RTHIGH/WTHIGH 8Fh/9Ah 01111111 (+127°C) Read/Write Remote T

RTLOW/WTLOW 91h/9Ch 11001001 (-55°C) Read/Write Remote T

SPOR F8h N/A Write Software POR

OSHT 9Eh N/A Write One-Shot Temperature Conversion

RTFAN/WTFAN A9h/B2h 00111100 (+60°C) Read/Write Fan-Control Threshold Temperature T

RFSC/WFSC ABh/B4h 00000000 Read/Write Fan-Speed Control

RFG/WFG ADh/B6h 10000000 Read/Write Fan Gain

RFTP AFh 00000000 Read Fan Tachometer Period

RFTCL/WFTPLP B1h/B8h 11111111 Read/Write Fan Tachometer Period Limit (Fan-Failure Limit)

RFTD/WFTD BBh/BCh 00000001 Read/Write Fan Tachometer Divisor

RFS/WFS BFh/C0h 11111111 Read/Write Full-Scale Register

RM/WM F5h/F6h 00000000 Read/Write Mode Register

ID CODE FDh 01001101 Read Manufacturer ID Code

ID CODE FFh 00001001 Read Device ID Code

MAX

HYST

HIGH

LOW

FAN

Page 10

MAX6661

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

10 ______________________________________________________________________________________

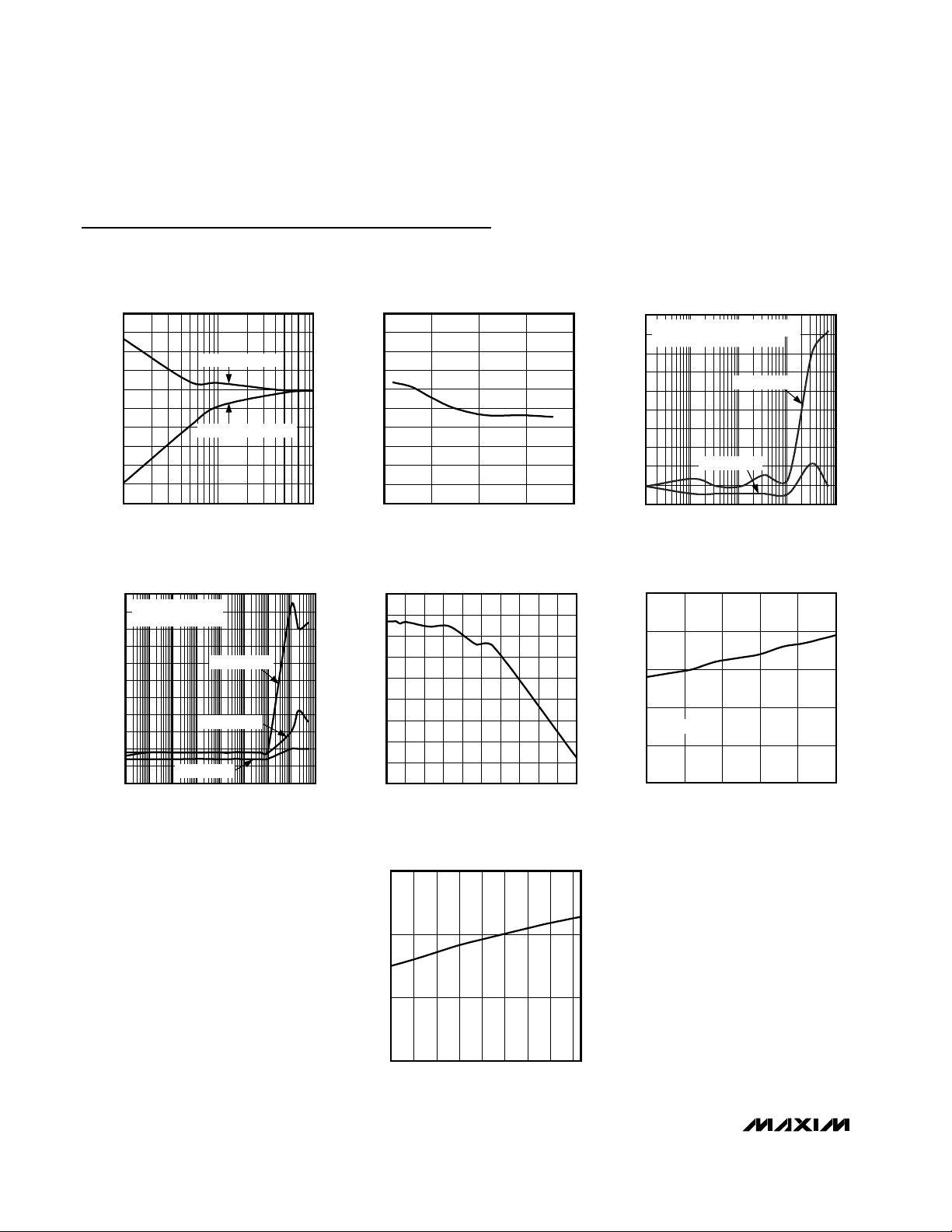

Figure 3. Read Cycle

Figure 4. Write Cycle

Figure 5. Serial Interface Timing

SC

CS

DIN

DOUT

D15 IS START BIT

ALWAYS HIGH

THREE-STATE

SC

CS

DIN

D15 IS START BIT

ALWAYS HIGH

DOUT

THREE-STATE

CS

D15

D15

COMMAND BYTE

D15–D8 COMMAND BYTE

D8

D8 IS READ/WRITE BIT

HIGH FOR READ

D7 D6

D8 D7

D8 IS READ/WRITE BIT

LOW FOR WRITE

D7–D0 DATA BYTE

D7–D0 DATA BYTE

D0

D0

THREE-STATE

THREE-STATE

t

CSW

t

SCS

SDIN

DOUT

t

CSS

SC

t

DS

t

DH

t

CL

t

CH

t

CP

t

DO

t

TR

Page 11

+127°C, for T

LOW

is -55°C, for T

MAX

is +100°C, and for

T

HYST

is +95°C.

Overtemperature Output (

OVERT

)

The MAX6661 has an overtemperature output (OVERT)

that is set when the remote-diode temperature crosses

the limits set in the T

MAX

register. It is always active if

the remote-diode temperature exceeds T

MAX

. The

OVERT line clears when the temperature drops below

T

HYST

. Bit 1 of the configuration register can be used to

mask the OVERT output. Typically, the OVERT output is

connected to a power-supply shutdown line to turn system power off. At power-up, OVERT defaults to low

when activated but the logic can be reversed by setting

bit 5 of the configuration register. If reversed, OVERT is

a logic one when the t

MAX

register temperature value is

exceeded. The OVERT line can be taken active, either

by the MAX6661 or driven by an external source.

OVERT also acts as an input when set to go low when

activated (default). If OVERT is driven or forced low

externally, the fan loop forces the fan to full speed and

bit 1 of the status register is set. The OVERT input can

be masked out by bit 2 of the configuration register.

Diode Fault Alarm

A continuity fault detector at DXP detects an open circuit between DXP and DXN. If an open or short circuit

exists, register 83h is loaded with 1000 0000.

Additionally, if the fault is an open circuit, bit 2 of the

status byte is set to 1 and the ALERT condition is activated at the end of the conversion. Immediately after

POR, the status register indicates that no fault is present until the end of the first conversion.

ALERT

Interrupts

The ALERT interrupt output signal is activated (unless it

is masked by bit 7 in the configuration register) whenever the remote-diode’s temperature is below T

LOW

or

exceeds T

HIGH

. A disconnected remote diode (for con-

tinuity detection), a shorted diode, or an active OVERT

also activates the ALERT signal. The activation of the

ALERT signal sets the corresponding bits in the status

register. Once activated, ALERT is latched until

cleared. To clear the ALERT, read the status register.

The interrupt does not halt automatic conversions. New

temperature data continues to be available over the SPI

interface after ALERT is asserted. ALERT is an activelow open-drain output so that devices can share a

common interrupt line. The interrupt is updated at the

end of each temperature conversion so, after being

cleared, it reappears after the next temperature conversion if the cause of the fault has not been removed.

By setting bit 0 in the configuration register to 1, the

ALERT line always remains high. Prior to taking corrective action, always check to ensure that an interrupt is

valid by reading the current temperature and the status

register.

Example: The remote temperature reading crosses

T

HIGH

, activating ALERT. The host responds to the

interrupt by reading the status register, clearing the

interrupt. If the condition persists, the interrupt reappears.

One Shot

The one-shot command immediately forces a new conversion cycle to begin. In software standby mode

(RUN/STOP bit = high), a new conversion is begun by

writing an OSHT (9Eh) command. After the conversion,

the device returns to standby mode. If a conversion is

in progress when a one-shot command is received, the

command is ignored. If a one-shot command is

between conversions in autoconvert mode (RUN/STOP

bit = low), a new conversion begins immediately.

Configuration Register Functions

The configuration register table (Table 4) describes this

register’s bit assignments.

Status Register Functions

The status byte (Table 5) reports several fault conditions. It indicates when the fan driver transistor of the

MAX6661 has overheated and/or in thermal shutdown,

when the temperature thresholds, T

LOW

and T

HIGH

,

have been exceeded, and whether there is an open circuit in the DXP-DXN path. The register also reports the

state of the ALERT and OVERT lines and indicates

when the fan driver is fully on. The final bit in the status

register indicates when a fan failure has occurred.

After POR, the normal state of the flag bits is zero,

assuming no alert or overtemperature conditions are

MAX6661

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

______________________________________________________________________________________ 11

Table 3. Temperature Data Format

(Two’s Complement)

TEMP (°C) DIGITAL OUTPUT

+127 0111 1111 111

+125.00 0111 1101 000

+25 0001 1001 000

+0.125 0000 0000 001

0 0000 0000 000

-0.125 1111 1111 111

-25 1110 0111 111

-40 1101 1000111

Page 12

MAX6661

present. Bits 2 through 6 of the status register are

cleared by any successful read of the status register,

unless the fault persists. The ALERT output follows the

status flag bit. Both are cleared when successfully

read, but if the condition still exists, the ALERT and the

corresponding status bit are reasserted at the end of

the next conversion.

When autoconverting, if the T

HIGH

and T

LOW

limits are

close together, it is possible for both high-temperature

and low-temperature status bits to be set, depending

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

12 ______________________________________________________________________________________

Table 4. Configuration Register Bit Assignments

Table 5. Status Register Bit Assignments

BIT NAME POR STATE DESCRIPTION

7(MSB) ALERT Mask 0 When set to 1, ALERT is masked from internally generated errors.

6 Run/Stop 0 When set to 1, the MAX6661 enters low-power standby.

5 OVERT Polarity 0 0 provides active low, 1 provides active high.

When set to 1, Write Protect is in effect for the following applicable registers:

1. Configuration register bits 6, 5, 4, 3

4 Write Protect 0

3

2 OVERT Input Inhibit 0

1

0 N/A 0 Not used.

Thermal Closed/

Open Loop

Mask OVERT

Output

0

0 Mask the OVERT output from an internally generated overtemperature error.

2. T

register

MAX

3. T

4. Fan conversion rate register

When set to 1, the thermal loop is open. The fan speed control retains the

last closed-loop value unless overwritten by a bus command (in closed

loop, the fan speed control is read only). If fan mode is set to open loop by

writing a 1 to bit 0 of the fan gain register, then this bit is automatically set.

When set to 1, an external signal on OVERT is masked from bit 1 of the

status register.

HYST

register

BIT NAME POR STATE DESCRIPTION

7(MSB)

6 ALERT 0

5

4 Remote High 0

3 Remote Low 0

2 Diode Open 0 When high, the remote-junction diode is open.

1 OVERT 0

0 Fan Failure 0

MAX6661

Overheat

Fan Driver Full

Scale

0

0

When high, indicates that the fan driver transistor of the MAX6661 has

overheated (temperature > +150°C) and is in thermal shutdown. The fan driver

remains disabled until temperature falls below +140°C.

When high, indicates ALERT has been activated (pulled low), regardless of

cause (internal or external).

When high, indicates the fan driver is at full scale. Only valid in fan

closed-loop mode.

When high, the remote-junction temperature exceeds the temperature in the

remote high register.

When low, the remote-junction temperature is lower than the temperature in the

remote low register.

When active, indicates that OVERT has been activated, regardless of cause

(internal or external).

When high, indicates the count in the fan tachometer period register is higher

than the limit set in the fan tachometer period limit register.

Page 13

on the amount of time between status read operations.

In these circumstances, it is best not to rely on the status bits to indicate reversals in long-term temperature

changes. Instead, use a current temperature reading to

establish the trend direction.

Manufacturer and Device ID Codes

Two ROM registers provide manufacturer and device

ID codes. Reading the manufacturer ID returns 4D,

which is the ASCII code M (for Maxim). Reading the

device ID returns 09h, indicating the MAX6661 device.

POR and UVLO

The MAX6661 has a volatile memory. To prevent unreliable power-supply conditions from corrupting the data

in memory and causing erratic behavior, a POR voltage

detector monitors V

CC

and clears the memory if V

CC

falls below 1.91V (see Electrical Characteristics). When

power is first applied and VCCrises above 2.0V (typ),

the logic blocks begin operating, although reads and

writes at V

CC

levels below 3.0V are not recommended.

A second V

CC

comparator, the ADC UVLO comparator

prevents the ADC from converting until there is sufficient headroom (V

CC

= 2.89V typ).

The software POR (SPOR) command can force a

power-on reset of the MAX6661 registers through the

serial interface. This can be done by writing F8h to the

MAX6661.

Power-up defaults include:

• Interrupt latch is cleared.

• ADC begins autoconverting.

• Command register is set to 00h to facilitate quick-

internal Receive Byte queries.

• T

HIGH

and T

LOW

registers are set to +127°C and

-55°C, respectively.

• T

HYST

and T

MAX

are set to +95°C and +100°C,

respectively.

Fan Control

The fan-control function can be divided into the thermal

loop, the fan-speed-regulation loop (fan loop), and the

fan-failure sensor. The thermal loop sets the desired fan

speed based on temperature while the fan-speed-regulation loop uses an internally divided down reference

oscillator to regulate the fan speed. The fan-speed-regulation loop includes the fan driver and the tachometer

sensor. The fan-failure sensor provides a FAN FAIL

alarm that signals when the value in the fan tachometer

period register is greater than the fan tachometer period limit register value, which corresponds to a fan

going slower than the limit. The fan driver is an N-channel, 4Ω MOSFET with a 13.5V maximum V

DS

whose

drain terminal connects to the low side of the fan. The

tachometer sensor (TACH IN) of the MAX6661 is driven

from the tachometer output of the fan and provides the

feedback signal to the fan-speed regulation loop for

controlling the fan speed. For fans without tachometer

outputs, the MAX6661 can generate its own tachometer

pulses by monitoring the commutating current pulses

(see the Commutating Current Pulses section).

Thermal Loop

Thermal Closed Loop

The MAX6661 can be operated in a complete closedloop mode, with both the thermal and fan loops closed,

where the remote-diode sensor temperature directly

controls fan speed. Setting bit 3 of the configuration

register to zero places the MAX6661 in thermal closed

loop (Figure 6). The remote-diode temperature sensor

is updated every 500ms. The value is stored in a temporary register (TEMPDATA) and compared to the programmed temperature values in the T

HIGH

, T

LOW

,

T

HYST

, T

MAX

, and T

FAN

registers to produce the error

outputs OVERT and ALERT.

The fan conversion rate (FCR) register (Table 6) can be

programmed to update the TEMPDATA register every

0.5s to 32s. This enables control over timing of the thermal feedback loop to optimize stability.

The fan threshold (TFAN) register value is subtracted

from the UPDATE register value. If UPDATE exceeds

T

FAN

temperature, then the fan-speed control (FSC)

register (Table 7), stores the excess temperature in the

form of a 7-bit word with an LSB of 0.5°C. If the difference between the T

FAN

and UPDATE registers is higher than 32°C, then bits 6-0 are set to 1. In thermal

closed loop, the FSC register is READ ONLY.

The fan gain (FG) register (Table 8) determines the

number of bits used in the fan-speed control register.

This gain can be set to 4, 5, or 6. If bits 6 and 5 are set

to 10, all 6 bits of TEMPDATA are used directly to program the speed of the fan so that the thermal loop has

a control range of 32°C with 64 temperature steps from

fan off to full fan speed. If bits 6 and 5 are set to 01, the

thermal control loop has a control range of 16°C with 32

temperature steps from fan off to full fan speed. If bits 6

and 5 are set to 00, the thermal control loop has a control range of 8°C with 16 temperature steps from fan off

to full fan speed.

Thermal Open Loop

Setting bit 3 of the configuration register (Table 4) to 1

places the MAX6661 in thermal open loop. In thermal

open-loop mode, the FSC register is read/write.

MAX6661

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

______________________________________________________________________________________ 13

Page 14

MAX6661

In thermal open-loop mode, the fan loop can operate in

open or closed mode. In fan open loop, the FSC register programs fan voltage directly, accepting values

from 0 to 64 (40h). For example, in fan open-loop

mode, zero corresponds to no voltage across the fan

and 40h corresponds to full fan voltage. Proportional

control is available over the 0 to 63 (3Fh) range with 64

(40h) forcing unconditional full speed.

In fan closed-loop mode, zero corresponds to zero fan

speed. When the FG register is set to 4 bits, 10h corresponds to 100% fan speed; 100% fan speed is 20h at 5

bits, and 3Fh at 6 bits.

Fan Loop

The fan loop (Figure 7) is based on an up/down counter

where a reference clock representing the desired fan

speed drives the count up, while tachometer pulses

drive it down. The reference clock frequency is divided

down from the MAX6661 internal clock to a frequency

of 8415Hz. This clock frequency is further divided by

the fan full-scale (FS) register (Table 9), which is limited

to values between 127 to 255, for a range of reference

clock full-scale frequencies from 33Hz to 66Hz. A further division is performed to set the actual desired fan

speed. This value appears in the fan-speed control register in thermal closed-loop mode. If the thermal loop is

open, but the fan-speed control loop is closed, this

value is programmable in the FSC. When in fan openloop mode (which forces the thermal loop to open), the

FSC register becomes a true DAC, programming the

voltage across the fan from zero to nearly V

FAN

. The

tachometer input (TACH IN) includes a programmable

(1/2/4/8) prescaler. The divider ratio for the (1/2/4/8)

prescaler is stored in the fan tachometer divisor (FTD)

register (Table 10). In general, the values in FTD should

be set such that the full-speed fan frequency divided

by the prescaler fall in the 33Hz to 66Hz range.

The UP/DN counter has six stages that form the input of

a 6-bit resistive ladder DAC whose voltage is divided

down from V

FAN

. This DAC determines the voltage

applied to the fan. Internal coding is structured such

that when in fan closed-loop mode (which includes

thermal closed loop), higher values in the 0 to 32 range

correspond to higher fan speeds and greater voltage

across the fan. In fan open-loop mode (which forces

thermal open loop), acceptable values range from 0 to

63 (3Fh) for proportional control; a value of 64 (40h)

commands unconditional full speed.

Fan closed-loop mode is selected by setting bit 0 of the

FG to zero; open-loop mode is selected by setting bit 0

to 1. In open-loop mode, the gain block is bypassed

and the FSC register is used to program the fan voltage

rather than the fan speed. When in fan open-loop

mode, both the temperature feedback loop and fanspeed control loop are broken, which result in the

TACH IN input becoming disabled. A direct voltage

can be applied to the fan after reading the temperature,

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

14 ______________________________________________________________________________________

Table 6. Fan Conversion Update Rate

Figure 6. MAX6661 Thermal Loop

REMOTE

SENSOR

TEMPERATURE

CONVERTER

FAN

CONVERSION

RATE

FAN

THRESHOLD

TEMPERATURE

)

(T

FAN

TACH IN

TEMP DATA

UPDATE

FCR

0.25s TO 16s

UPDATE

FAN-SPEED

CONTROL

(FSC)

DATA BINARY

00h 00000000 0.0625 16

01h 00000001 0.125 8

02h 00000010 0.25 4 (POR)

03h 00000011 0.5 2

04h 00000100 1 1

05h 00000101 2 0.5

06h 00000110 4 0.25

FAN UPDATE

RATE (Hz)

SECONDS

BETWEEN

UPDATES

Page 15

MAX6661

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

______________________________________________________________________________________ 15

Table 9. Fan Full-Scale Register (RFS/WFS)

Note: This register determines the maximum reference frequency at the input of the up/down counter. It controls a programmable

divider that can be set anywhere between 127 and 255. The value in this register must be set in accordance with the procedure

described in the TACH IN section (equivalent 8415/(Max Tachometer Frequency

✕ Fan Tachometer Divisor)). Programmed value

below 127 defaults to 127. POR value is 255.

Table 10. Fan Tachometer Divisor Register (RFTD/WFTD)

Note: This byte sets the prescalar division ratio for tachometer or current-sense feedback. (This register does not apply to the tach

signal used in the fan-speed register.) Select this value such that the fan frequency (rpm / 60s x number of poles) divided by the

FCD falls in the 33Hz to 66Hz range. See TACH IN section:

Bits 1, 0: 00 = divide by 1, 01 = divide by 2, 10 = divide by 4, 11 = divide by 8.

Table 7. Fan Speed Control Register (RFSC/WFSC)

Table 8. Fan Gain Register (RFG/WFG)

Notes: Bit 0: Fan driver mode. When bit 0 is set to 1, the fan driver is in fan open-loop mode. In this mode, the fan DAC programs the

fan voltage rather than the fan speed. Tachometer feedback is ignored, and the user must consider minimum fan drive and startup

issues. Thermal open loop is automatically set to 1 (see configuration register). Fan Fail (bit 0 of the status register) is set to 1 in this

mode and should be ignored.

Bit 1: Fan feedback mode. When bit 1 is set to 1, the fan loop uses driver current sense rather than tachometer feedback.

Bits 6, 5: Fan gain of the fan loop, where 00 = 8°C with resolution = 4 bits. This means that the fan reaches its full-scale (maximum)

speed when there is an 8°C difference between the remote-diode temperature and the value stored in T

FAN

, 01 = +16°C, with a 5-bit

resolution and 10 = +32°C with a 6-bit resolution.

Bit 7: Writing a zero to bit 7 forces bits 6 and 5 to their POR values.

REGISTER/ADDRESS FSC (ABH = READ, B4H = WRITE)

COMMAND READ/WRITE FAN DAC REGISTER

Label

POR State 0 0 0 0 0 0 0 0

REGISTER/ADDRESS FG (ADH = READ, B6H = WRITE)

COMMAND READ/WRITE FAN GAIN REGISTER

Label

POR State 1 0 0 0 0 0 0 0

REGISTER/ADDRESS FS (BFH = READ, C0H = WRITE)

COMMAND READ/WRITE MAXIMUM TEMPERATURE LIMIT BYTE

Label

POR State 11111111

7

Not Used

7

Always

Write

a 1

7

MSB

6

Overflow Bit5(MSB)

6

Fan

Gain

5

Fan Gain

6

Data Bit5Data Bit4Data Bit

4

Always

Write

a 0

4

Data

3

Always

Write

a 0

3

Data

3

Data Bit

2

Data

2

Always

Write

a 0

1

Fan

Driver

Mode Bit

2

Data Bit1Data Bit0Data Bit

1

Data

0

Data

0

Fan

Feedback

Mode

REGISTER/ADDRESS FTD (BBH = READ, BCH = WRITE)

COMMAND READ LIMIT/FAILURE REGISTER

Label

POR State 0 0 0000 01

7

Not Used6Not Used5Not Used4Not Used3Not Used2Not Used

1

Divisor

Bit 1

0

Divisor

Bit 0

Page 16

MAX6661

using the FSC register. By selecting fan open-loop

mode, the MAX6661 automatically invokes thermal

open-loop mode.

Fan Conversion Rate Register

The FCR register (Table 6) programs the fan’s update

time interval in free-running autonomous mode

(RUN/STOP = 0). The conversion rate byte’s POR state

is 02h (0.25Hz). The MAX6661 uses only the 3LSBs of

this register. The 5MSBs are don’t cares. The update

rate tolerance is ±25% (max) at any rate setting.

Fan Driver

The fan driver consists of an amplifier and low-side

NMOS power device whose drain is connected to FAN

and is the connection for the low side of the fan. There

is an internal connection from the fan to the input of the

amplifier. The FET has 4Ω on-resistance with 320mA

(typ) current limit. The driver has a thermal shutdown

sensor that senses the driver’s temperature. It shuts

down the driver if the temperature exceeds +150°C.

The driver is reactivated once the temperature has

dropped below +140°C.

TACH IN

The TACH IN input connects directly to the tachometer

output of a fan. Most commercially available fans have

two tachometer pulses per revolution. The tachometer

input is fully compatible with tachometer signals, which

are pulled up to V

FAN

.

Commutating Current Pulses

When a fan does not come equipped with a tachometer

output, the MAX6661 uses commutating generated current pulses for speed detection. This mode is entered

by setting the FG register’s bit 1 to 1. An internal pulse

is generated whenever a step increase occurs in the

fan current. Connecting an external resistor between

the GAIN pin and V

CC

can reduce the sensitivity of

pulses to changes in fan current. In general, the lower

the resistor value, the lower the sensitivity, and the fan

is easier to turn ON and can use a smaller external

capacitor across its terminals. A suitable resistor range

is 1kΩ to 5kΩ.

Fan-Failure Detection

The MAX6661 detects fan failure by comparing the

value in the fan tachometer period (FTP) register, a

READ ONLY register, with a limit stored in the fan

tachometer period limit (FTPL) register (Table 11). A

counter counts the number of on-chip oscillator pulses

between successive tachometer pulses and loads its

value into the FTP register every time a tachometer

pulse arrives. If the value in FTP is greater than the

value in FTPL, a failure is indicated. In fan closed loop,

a flag is activated when the fan is at full speed.

Set the fan tachometer period limit byte to:

f

TACH

= 8415 / [N ✕ f]

where N = fan-fail ratio and f

TACH

= maximum frequency of the fan tachometer. The factor N is less than 1

and produces a fan-failure indication when the fan

should be running at full speed, but is only reaching a

factor of N of its expected frequency. The factor N is

typically set to 0.75 for all fan speeds except at very

low speeds where a fan failure is indicated by an overflow of the fan-speed counter. The overflow flag cannot

be viewed separately in the status byte but is ORed

with bit 0, the fan-fail bit.

Applications Information

Mode Register

Resistance in series with the remote-sensing junction

causes conversion errors on the order of 0.5°C per

ohm.

The MAX6661 mode register gives the ability to eliminate the effects of external series resistance of up to

several hundred ohms on the remote temperature measurement and to adjust the temperature-measuring

ADC to suit different types of remote-diode sensor. For

systems using external switches or long cables to connect to the remote sensor, a parasitic resistance cancellation mode can be entered by setting mode register

bit 7 = 1. This mode requires a longer conversion time

and so can only be used for fan conversion rates of

1Hz or slower. Bits 6, 1, and 0 of the mode register are

not used. Use bits 5–2 to adjust the ADC gain to

achieve accurate temperature measurements with

diodes not included in the recommended list or to individually calibrate the MAX6661 for use in specific control systems. These bits adjust gain to set the

temperature reading at +25°C, using two’s complement

format reading. Bit 5 is the sign (1 = increase, 0 =

decrease), bit 4 = 2°C shift, bit 3 = 1°C shift, bit 2 =

1/2°C shift. Origin of gain curve is referred to 0°K. To

use this feature, the sensor must be calibrated by the

user.

General Programming Techniques

The full-scale range of the fan-regulation loop is

designed to accommodate fans operating between the

1000rpm to 8000rpm range of different fans. An onchip 8415Hz oscillator is used to generate the 33Hz to

66Hz reference frequency. Choose the FTD value such

that the fan full-speed frequency divided by this value

falls in the 33Hz to 66Hz range. The full-scale reference

frequency is further divided by the value in the FSC

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

16 ______________________________________________________________________________________

Page 17

register to the desired fan frequency [read: speed]. The

8415Hz is divided down from the MAX6661 internal

clock, and has a ±25°C tolerance.

1) Determine the fan’s maximum tachometer frequency:

f

(TACH)

Hz = (rpm/60s / min) ✕ number of poles

Where poles = number of pulses per revolution.

Most fans are two poles; therefore, they have two

pulses per revolution.

2) Set the programmable FTD so that the frequency of

the fan tachometer divided by the prescaler value in

the FCD register falls in the 33Hz to 66Hz range.

3) Determine the value required for the fan FS register:

FS = 8415 / (f

TACH

✕ P)

Where P is the prescaler division ratio of the FCD

register.

Example: Fan A has a 2500rpm rating and 2 poles:

f

TACH

= 2500 / 60 ✕ 2 = 83.4Hz

MAX6661

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

______________________________________________________________________________________ 17

Figure 7. MAX6661 Fan Loop Functional Diagram

Table 11. Fan Tachometer Period Limit (RFTCL/WWFTCL)

Note: The fan tachometer period limit register is programmed with the maximum speed that is compared against the value in the FS

register to produce an error output to the status register.

REF FREQ

8415Hz

TACH IN

FAN FULL

SCALE (FS)

127 TO 255

FAN TACHOMETER

DIVISOR (FTD)

1, 2, 4, 8

TEMP DATA

FAN GAIN (FG)

8°C, 16°C, 32°C

RANGE

FAN-SPEED

CONTROL

1 TO 63

UP/DOWN

DAC

FAN

TACHOMETER

PERIOD (FTP)

COUNTER

FAN OPEN/CLOSED

LOOP

DRIVER

TACHOMETER

PERIOD LIMIT (FTPL)

COMPARATOR

TACH

N

FAN

FAN FAIL

V

FAN

FAN

REGISTER/ADDRESS FL (B1H = READ, B8H = WRITE)

COMMAND READ LIMIT/FAILURE REGISTER

Label

POR State 1 1 1 1 1 1 1 1

7

(MSB)

6

Data Bit

5

Data Bit

4

Data Bit3Data Bit

2

Data Bit1Data Bit0Data Bit

Page 18

MAX6661

The 83.4Hz value is out of the 33Hz to 66Hz decrement/increment range.

Set bits in the FTD register to divide the signal down

within the 33Hz to 66Hz range. Bits 1, 0 = 10 (divide

by 2: P = 2). The result is 83.4Hz/2 = 41.7Hz.

4) Set the FS register to yield approximately 42Hz:

42Hz = 8415Hz / FS (value)

FS (value) ≈ 200

FS register = 11001000

5) In current-sense feedback, a pulse is generated

whenever there is a step increase in fan current. The

frequency of pulses is then not only determined by

the fan rpms and the number of poles, but also by

the update rate at which the fan driver forces an

increase in voltage across the fan.

The maximum pulse frequency is then given by:

fCHz = f

TACH

✕ P / (P-1)

Where f = (rpm/60) ✕ poles and P is the value in

FTD.

The value required for the fan FS register is:

FS = 8415Hz / (f

TACH

/ (P-1))

The fan speed limit in FTPL should be set to:

fL= 8415Hz / (N ✕ f

TACH

)

A value of P = 1 cannot be used in current-sense

mode.

Fan Selection

For closed-loop operation and fan monitoring, the

MAX6661 requires fans with tachometer outputs. A

tachometer output is typically specified as an option on

many fan models from a variety of manufacturers. Verify

the nature of the tachometer output (open collector,

totem pole) and the resultant levels and configure the

connection to the MAX6661. For a fan with an opendrain/collector output, a pullup resistor of typically 5kΩ

must be connected between TACH IN and V

FAN

. Note

how many pulses per revolution are generated by the

tachometer output (this varies from model to model and

among manufacturers, though two pulses per revolution are the most common). Table 12 lists the representative fan manufacturers and the model they make

available with tachometer outputs.

Low-Speed Operation

Brushless DC fans increase reliability by replacing

mechanical commutation with electronic commutation.

By lowering the voltage across the fan to reduce its

speed, the MAX6661 is also lowering the supply voltage for the electronic commutation and tachometer

electronics. If the voltage supplied to the fan is lowered

too far, the internal electronics may no longer function

properly. Some of the following symptoms are possible:

• The fan may stop spinning.

• The tachometer output may stop generating a signal.

• The tachometer output may generate more than two

pulses per revolution.

The problems that occur and the supply voltages at

which they occur depend on which fan is used. As a

rule of thumb, 12V fans can be expected to experience

problems somewhere around 1/4 and 1/2 their rated

speed.

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

18 ______________________________________________________________________________________

Table 12. Fan Manufacturers

Chip Information

TRANSISTOR COUNT: 6479

PROCESS: BiCMOS

MANUFACTURER FAN MODEL OPTION

All DC brushless models can be

Comair Roton

EBM-Papst

JMC Tachometer output optional.

NMB

Panasonic

Sunon

ordered with optional tachometer

output.

Tachometer output optional on

some models.

All DC brushless models can be

ordered with optional tachometer

output.

Panaflo and flat unidirectional

miniature fans can be ordered

with tachometer output.

Tachometer output optional on

some models.

Page 19

MAX6661

Remote Temperature-Controlled Fan-Speed

Regulator with SPI-Compatible Interface

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 19

© 2002 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

Pin Configuration

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

V

FAN

TACH IN

SDIN

SCL

GAIN

DOUT

ALERT

CS

OVERT

TOP VIEW

MAX6661

V

CC

DXP

N.C.

DXN

FAN

PGND

AGND

QSOP

QSOP.EPS

Loading...

Loading...