Page 1

General Description

The MAX5961 0 to 16V, quad, hot-swap controller provides complete protection for systems with up to four

distinct supply voltages. The device allows the safe

insertion and removal of circuit cards into live backplanes. The MAX5961 is an advanced hot-swap controller that monitors voltage and current with an internal

10-bit ADC. The device provides two levels of overcurrent circuit-breaker protection; a fast-trip threshold for a

fast turn-off, and a lower slow-trip threshold for a

delayed turn-off. The maximum overcurrent circuitbreaker threshold range is set independently for each

channel with a trilevel input (ILIM_) or by programming

though an I2C interface.

The internal 10-bit ADC is multiplexed to monitor the

output voltage and current of each hot-swap channel.

The total time to cycle through all the eight measurements is 100µs (typ). Each 10-bit value is stored in an

internal circular buffer so that 50 past samples of each

signal can be read back through the I2C interface at

any time or after a fault condition.

The MAX5961 can be configured as four independent

hot-swap controllers, hot-swap controllers operating in

pairs, or as a group of four hot-swap controllers.

The device also includes five digital comparators per

hot-swap channel to implement overcurrent warning,

two levels of overvoltage detection, and two levels of

undervoltage detection. The limits for overcurrent, overvoltage, and undervoltage are user-programmable.

When any of the measured values violates the programmable limits, an external ALERT signal is asserted. In

addition to the ALERT signal, depending on the selected operating mode, the MAX5961 can deassert a

power-good signal and/or turn-off the external MOSFET.

The MAX5961 is available in a 48-pin thin QFN package and operates over the -40°C to +85°C extended

temperature range.

Applications

PCI Express®Hot Plug

Servers

Disk Drives

Storage Systems

ASICs

Features

o Four Independent Hot-Swap Controllers Protect

from 0 to 16V (Provided IN ≥ 2.7V)

o 10-Bit ADC Monitors Voltage and Current of Each

Channel

o Circular Buffer Stores 5ms of Current and Voltage

Measurements

o Four Independent Internal Charge Pumps

Generate n-Channel MOSFET Gate Drives

o Internal 500mA Gate Pulldown Current for Fast

Shutdown

o VariableSpeed/BiLevel™ Circuit-Breaker Protection

o Alert Output Indicates Undervoltage Warning,

Undervoltage Critical, Overvoltage Warning,

Overvoltage Critical, and Overcurrent Warning for

Each Channel

o Independent Power-Good Outputs

o Autoretry or Latched Fault Management

o 400kHz I

2

C Interface

o 7mm x 7mm 48-Pin TQFN Package

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

________________________________________________________________

Maxim Integrated Products

1

Pin Configuration

Ordering Information

19-4167; Rev 0; 6/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

PART

PIN-PACKAGE

MAX5961ETM+

48 Thi n QFN–E P *

PCI Express is a registered trademark of PCI-SIG Corp.

VariableSpeed/BiLevel is a trademark of Maxim Integrated

Products, Inc.

+Denotes a lead-free/RoHS-compliant package.

*EP = Exposed pad.

TEMP RANGE

-40°C to +85°C

TOP VIEW

ILIM4

ILIM3

ILIM2

ILIM1

IN

AGND

REG

A1

A0

PROT

MODE

HWEN

MON2

GATE2

SENSE2

35

34 33 32 31 30 29 28 27

36

37

38

39

40

41

42

43

44

45

46

+

47

48

2

345678910

1

MON1

GATE1

SENSE1

GATE4

GND4

GND2

MAX5961

GND3

GND1

GATE3

THIN QFN

7mm x 7mm

MON4

MON3

SENSE4

SENSE3

I.C.

POL

RETRY

26

11

DREG

ON2

ON1

ON4

25

DGND

24

PG4

23

22

PG3

21

PG2

PG1

20

ALERT

19

18

SCL

17

SDA

16

FAULT4

FAULT3

15

FAULT2

14

13

FAULT1

12

ON3

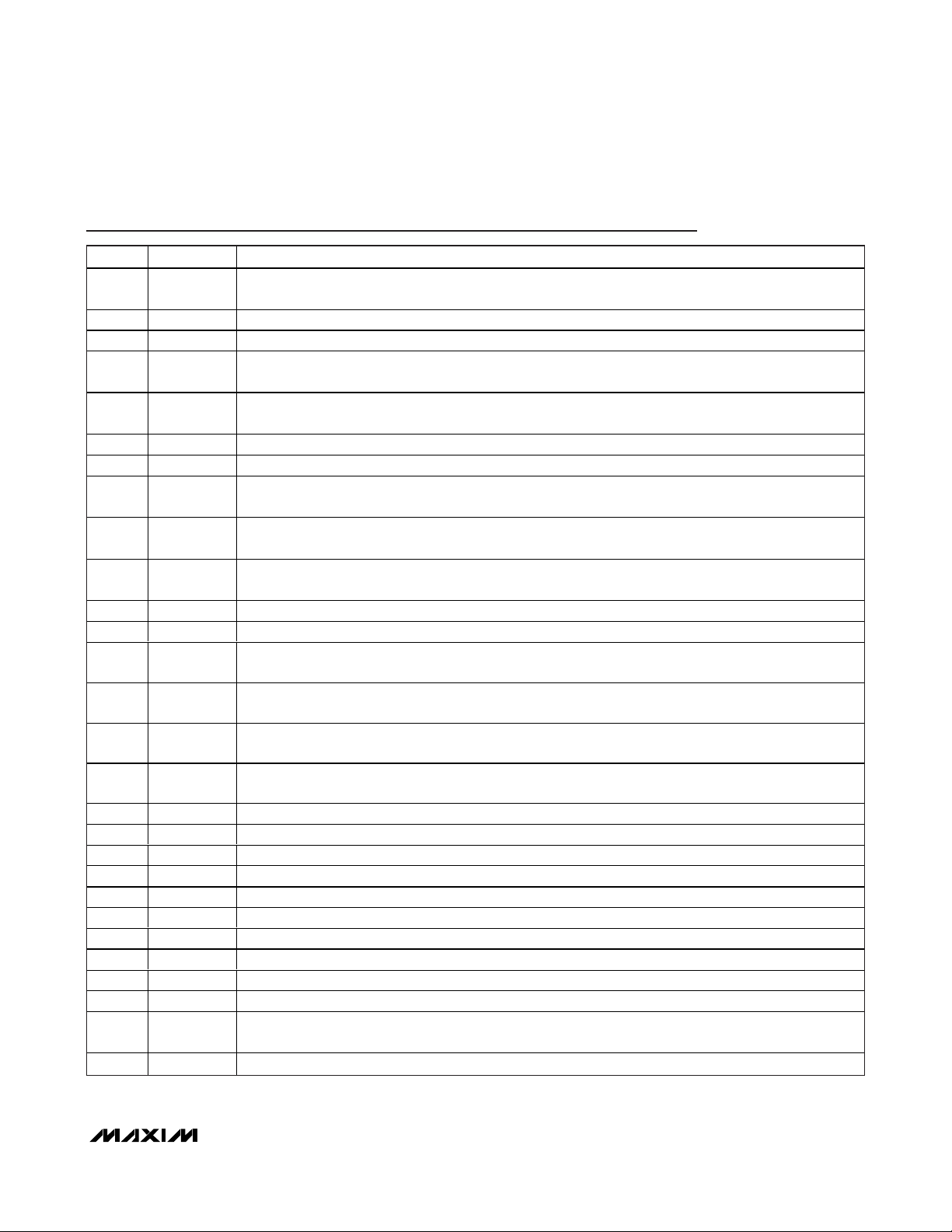

Page 2

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

2 _______________________________________________________________________________________

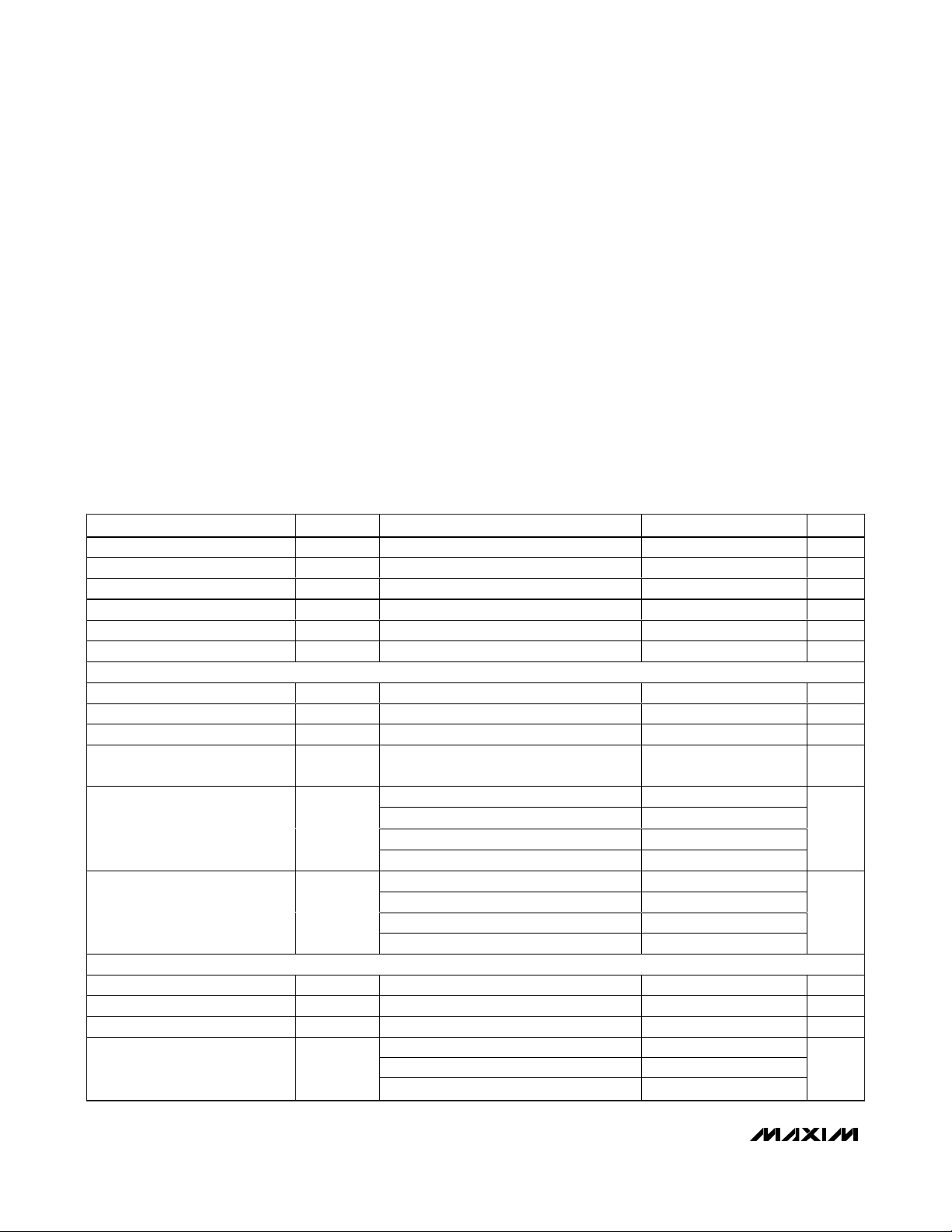

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VIN= 2.7V to 16V, TA = -40°C to +85°C, unless otherwise noted. Typical values are at VIN= 3.3V and TA= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN, SENSE_, MON_, GATE_ to AGND ....................-0.3V to +30V

PG_, ON_, FAULT_, SDA, SCL, ALERT,

REG, DREG, POL, RETRY, HWEN .........................-0.3V to +6V

DREG to REG ........................................................-0.3V to +0.3V

ILIM_, MODE, PROT, A0, A1 ....................-0.3V to (V

REG

+ 0.3V)

GATE_ to MON_ (same channel) .............................-0.3V to +6V

SENSE_ to MON_ (same channel) ...........................-0.3V to +6V

GND1, GND2, GND3, GND4, DGND to AGND.....-0.3V to +0.3V

SDA, ALERT Current ...........................................-20mA to 50mA

GATE_, MON_, GND_ Current ..........................................500mA

Input/Output Current (all other pins) ...................................20mA

Continuous Power Dissipation (T

A

= +70°C)

For Single-Layer Board

48-Pin Thin QFN (derate 27.8mW/°C above +70°C)...2222.2mW

For Multilayer Board

48-Pin Thin QFN (derate 40mW/°C above +70°C) ......3200mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Operating Voltage Range V

Hot-Swap Voltage Range V

Undervoltage Lockout V

Undervoltage Lockout Hysteresis V

Supply Current I

Internal LDO Output Voltage V

ADC PERFORMANCE

Resolution 10 Bits

Maximum Differential Nonlinearity DNL 1 LSB

Maximum Integral Nonlinearity INL 1 LSB

ADC Total Monitoring Cycle Time

MON_ LSB Voltage

MON_ Code 000H to 001H

Transition Voltage

CURRENT MONITORING FUNCTION

MON_, SENSE_ Input Range 0 16 V

SENSE_ Input Current V

MON_ Input Current V

Current Measurement Offset LSB

Voltage

IN

S

UVLO

UVLO,HYSTVIN

CC

REG

VIN rising 2.7 V

f

SCL

2.7V < VIN < 16V 2.49 2.9 V

Four voltage and four current–sense

conversions

16V range 15.25 15.43 15.60

8V range 7.655 7.735 7.805

4V range 3.835 3.870 3.905

2V range 1.915 1.935 1.955

16V range 13 28 41

8V range 7 16 22

4V range 5 9 13

2V range 2 5 9

25mV range

50mV range 48.39

100mV range 96.77

falling 100 mV

= 400kHz, all 4 channels enabled 4 8 mA

, V

SENSE_

, V

SENSE_

= 16V 32 75 µA

MON_

= 16V 180 280 µA

MON_

2.7 16 V

016V

95 100 112 µs

24.34

mV

mV

mV

Page 3

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

_______________________________________________________________________________________ 3

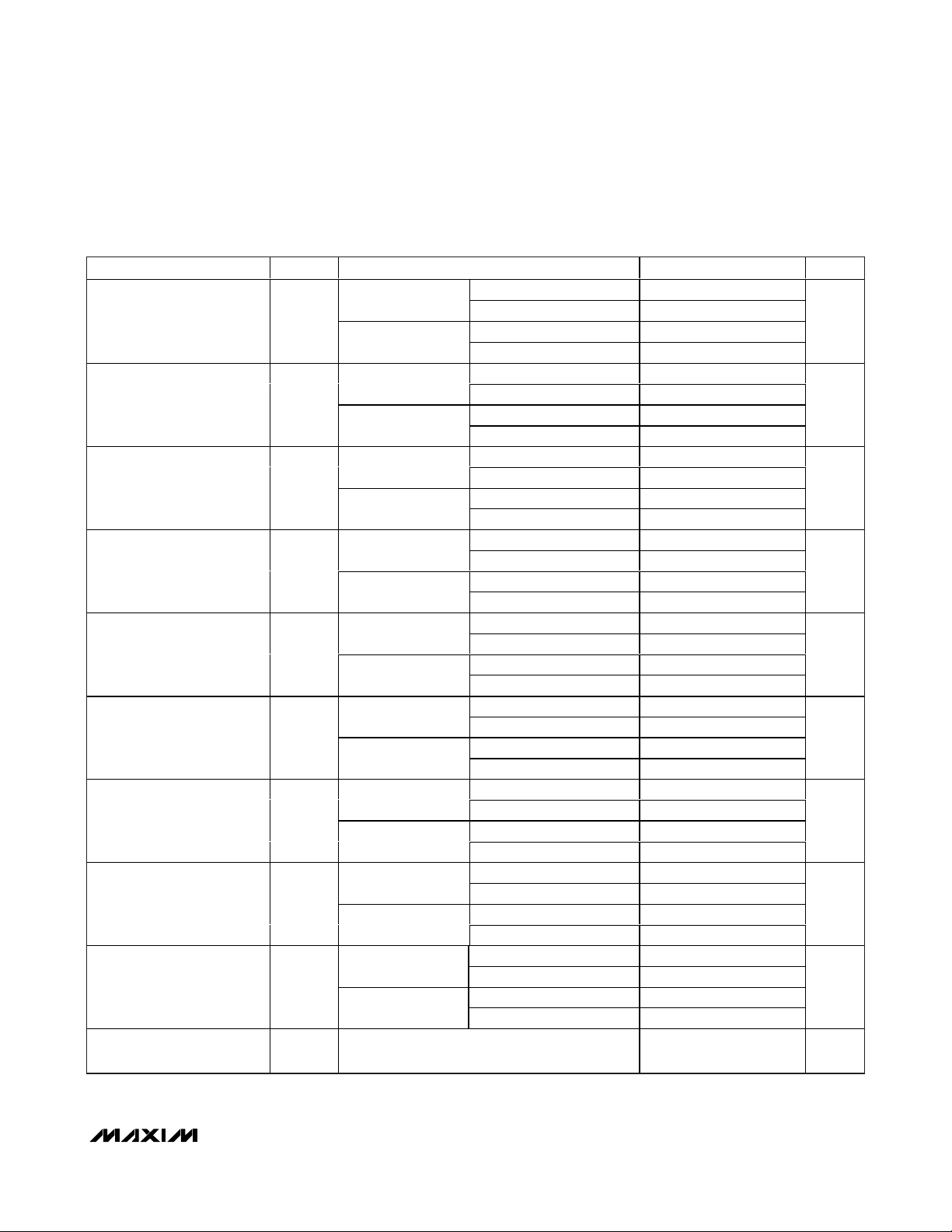

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 2.7V to 16V, TA = -40°C to +85°C, unless otherwise noted. Typical values are at VIN= 3.3V and TA= +25°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Current Measurement Error,

25mV Range

Current Measurement Error,

50mV Range (Note 2)

Current Measurement Error,

100mV Range (Note 2)

Fast Current-Limit Threshold

Error, 25mV Range

Fast Current-Limit Threshold

Error, 50mV Range

Fast Current-Limit Threshold

Error, 100mV Range

Slow Current-Limit Threshold

Error, 25mV Range

Slow Current-Limit Threshold

Error, 50mV Range

Slow Current-Limit Threshold

Error, 100mV Range

Fast Circuit-Breaker

Response Time

t

FCD

V

= 0mV

MON_

V

= 2.5V to

MON_

16V

V

= 0mV

MON_

= 2.5V to

V

MON_

16V

V

= 0mV

MON_

V

= 2.5V to

MON_

16V

V

= 0mV

MON_

V

= 2.5V to

MON_

16V

V

= 0mV

MON_

V

= 2.5V to

MON_

16V

V

= 0mV

MON_

V

= 2.5V to

MON_

16V

V

= 0mV,

MON_

fast/slow 200%

= 2.5V to 16V ,

V

M ON_

fast/slow 200%

V

= 0mV,

MON_

fast/slow 200%

= 2.5V to

V

MON_

16V, fast/slow 200%

V

= 0mV,

MON_

fast/slow 200%

V

= 2.5V to

MON_

16V, fast/slow 200%

V

V

V

V

V

V

V

V

V

V

V

V

Circuit-breaker DAC = 102 -2.3 +1.6

Circuit-breaker DAC = 255 -3 +1.9

Circuit-breaker DAC = 102 -2.5 +1.6

Circuit-breaker DAC = 255 -3 +1.8

Circuit-breaker DAC = 102 -3.4 +2

Circuit-breaker DAC = 255 -5.3 +2.6

Circuit-breaker DAC = 102 -3.2 +1.5

Circuit-breaker DAC = 255 -4.5 +1.6

Circuit-breaker DAC = 102 -6.3 +2.7

Circuit-breaker DAC = 255 -10.7 +4.7

Circuit-breaker DAC = 102 -4.9 +1.6

Circuit-breaker DAC = 255 -7.9 +1.5

Circuit-breaker DAC = 102 -1.2 +2.3

Circuit-breaker DAC = 255 -1.2 +2.7

Circuit-breaker DAC = 102 -1.4 +2.4

Circuit-breaker DAC = 255 -1.2 +2.9

Circuit-breaker DAC = 102 -1.2 +3

Circuit-breaker DAC = 255 -1.4 +3.9

Circuit-breaker DAC = 102 -1.2 +3.1

Circuit-breaker DAC = 255 -1.1 +3.8

Circuit-breaker DAC = 102 -1.5 +4.6

Circuit-breaker DAC = 255 -2.1 +6.6

Circuit-breaker DAC = 102 -0.7 +4.5

Circuit-breaker DAC = 255 -0.9 +6

Overdrive = 10% of current-sense range 2 µs

SENSE_

SENSE_

SENSE_

SENSE_

SENSE_

SENSE_

SENSE_

SENSE_

SENSE_

SENSE_

SENSE_

SENSE_

- V

- V

- V

- V

- V

- V

- V

- V

- V

- V

- V

- V

= 5mV -6.8 +6.8

MON_

= 20mV -7.6 +8

MON_

= 5mV -8 +7.2

MON_

= 20mV -7.6 +7.6

MON

= 10mV -3.8 +4

MON_

= 40mV -5.5 +5.4

MON_

= 10mV -4.2 +3.9

MON_

= 40mV -4 +4.3

MON_

= 20mV -2.9 +2.6

MON_

= 80mV -5.1 +4.7

MON_

= 20mV -2.3 +2

MON_

= 80mV -2.7 +2.4

MON_

% Full

Scale

% Full

Scale

% Full

Scale

mV

mV

mV

mV

mV

mV

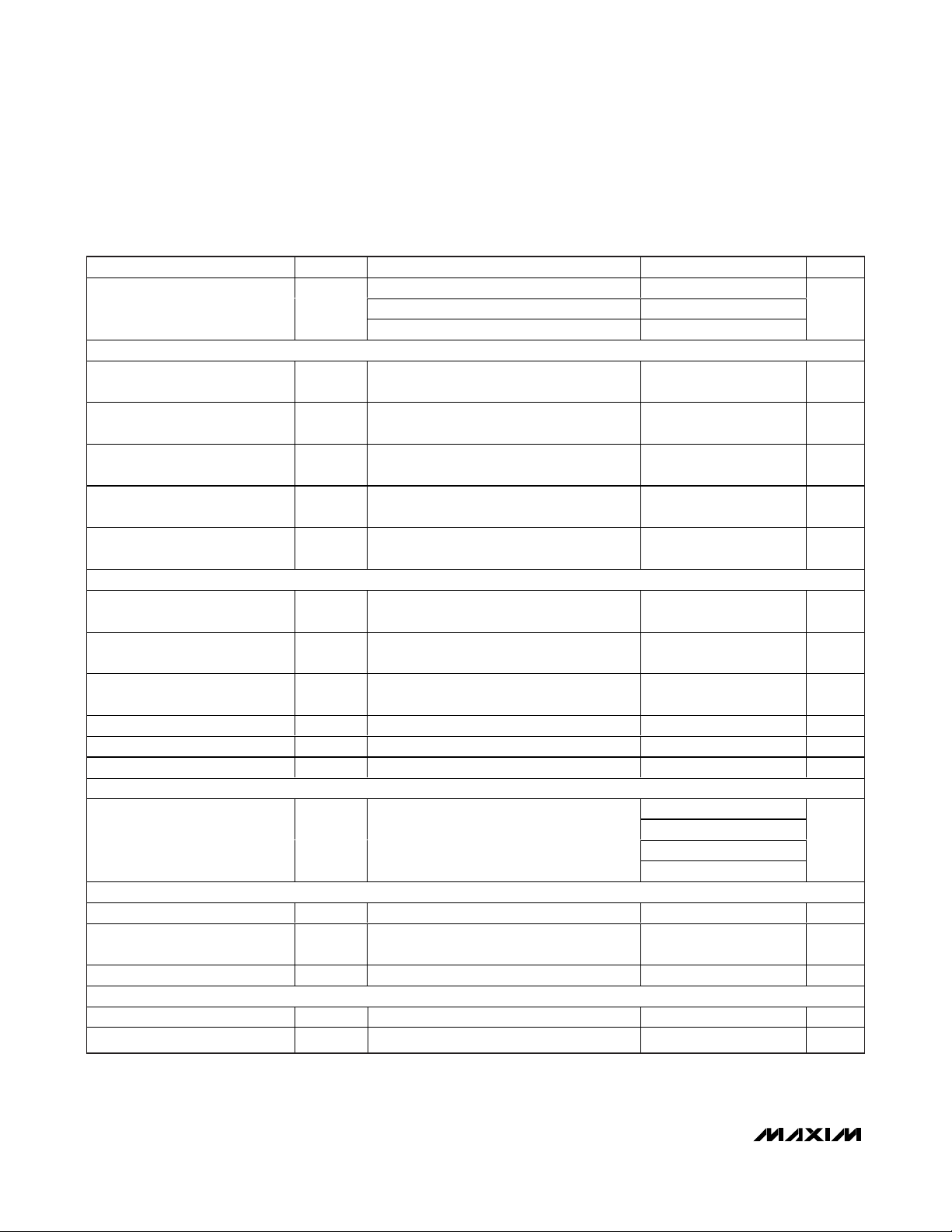

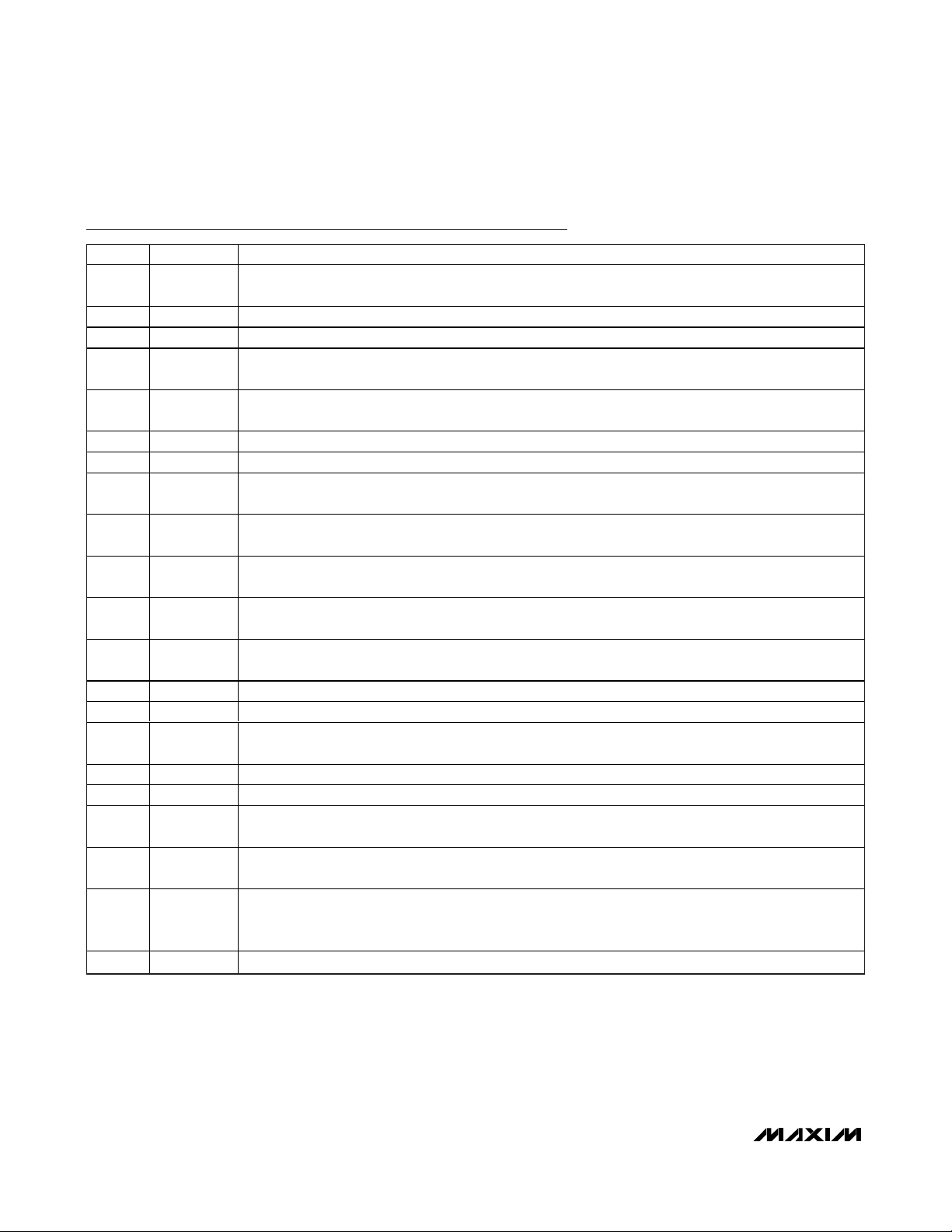

Page 4

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 2.7V to 16V, TA = -40°C to +85°C, unless otherwise noted. Typical values are at VIN= 3.3V and TA= +25°C.) (Note 1)

Slow Current-Limit Response

Time

THREE-STATE INPUTS

A0, A1, ILIM_, MODE, PROT Low

Current

A0, A1, ILIM_, MODE, PROT High

Current

A0, A1, ILIM_, MODE, PROT

Unconnected Current

A0, A1, ILIM_, MODE, PROT Low

Voltage

A0, A1, ILIM_, MODE, PROT High

Voltage

TWO-STATE INPUTS

RETRY, HWEN, POL Input Logic

Low Voltage

RETRY, HWEN, POL Input Logic

High Voltage

RETRY, HWEN, POL Input

Current

ON_ Input Threshold Rising 0.586 0.596 0.606 V

ON_ Input Hysteresis Falling 4 %

ON_ Input Current -100 +100 nA

TIMING

MON_ to PG_ Delay

CHARGE PUMPS (GATE_)

Charge-Pump Output Voltage Relative to V

Charge-Pump Output Source

Current

GATE_ Discharge Current I

OUTPUTS (FAULT_, PG_, ALERT)

Output Voltage Low I

Output Leakage (Open-Drain) 1µA

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Overdrive = 4% of current-sense range 2.4

t

SCD

I

IN,LOW

I

IN,HIGH

I

FLOAT

I

G(UP)

G(DN)VGATE_

Overdrive = 8% of current-sense range 1.2

Overdrive = 16% of current-sense range 0.6

Input voltage = 0.4V -40 µA

Input voltage = V

Maximum source/sink current for

unconnected state

Relative to GND_ 0.4 V

Relative to V

Register configurable (see Tables 31a and

31b)

SINK

REG

MON_

- V

MON_

= 3.2mA 0.2 V

- 0.2V 40 µA

REG

-4 +4 µA

-0.24 V

0.4 V

V

-

REG

0.4

-1 +1 µA

50

100

200

400

4.5 5.3 5.5 V

456µA

= 2V 500 mA

ms

V

ms

Page 5

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 2.7V to 16V, TA = -40°C to +85°C, unless otherwise noted. Typical values are at VIN= 3.3V and TA= +25°C.) (Note 1)

Note 1: All devices 100% production tested at TA= +25°C and TA= +85°C. Limits over the temperature range are guaranteed by

design.

Note 2: Guaranteed by design characterization, not production tested.

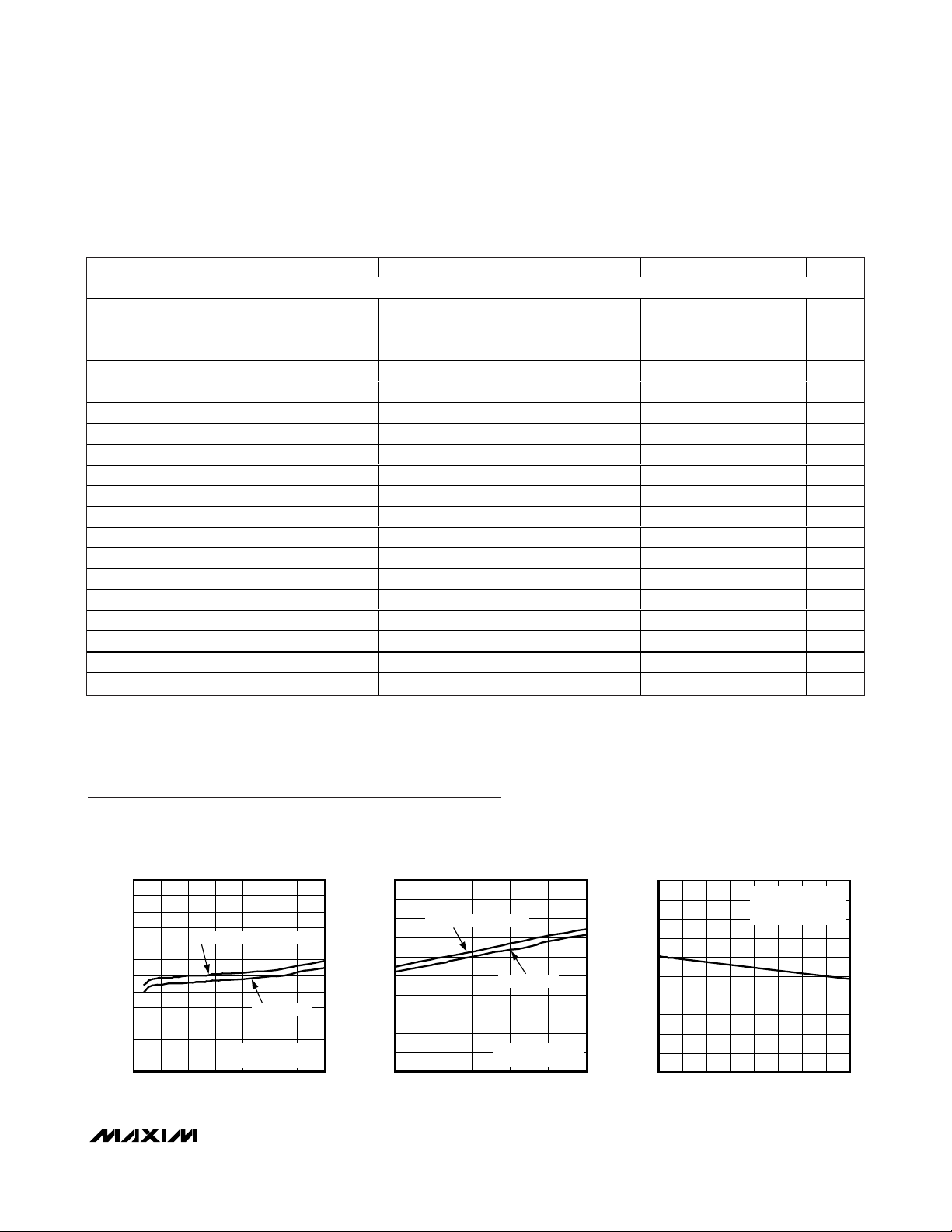

SUPPLY CURRENT

vs. IN VOLTAGE

MAX5961 toc01

VIN (V)

I

IN

(mA)

14128 1064

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

5.0

5.1

5.2

4.0

216

I

IN

(NORMAL OPERATION)

I

IN

(STANDBY)

STANDBY OPERATION

ALL CHANNELS OFF

SUPPLY CURRENT

vs. TEMPERATURE

MAX5961 toc02

TEMPERATURE (°C)

I

IN

(mA)

603510-15

2.4

2.8

3.2

3.6

4.0

4.4

4.8

5.2

5.6

6.0

2.0

-40 85

STANDBY OPERATION

ALL CHANNELS OFF

I

IN

(NORMAL OPERATION)

I

IN

(STANDBY)

GATE_ DRIVE VOLTAGE

vs. MON_ VOLTAGE

MAX5961 toc03

V

MON_

(V)

(V

GATE_

- V

MON_

) (V)

14128 104 62

4.2

4.4

4.6

4.8

5.0

5.2

5.4

5.6

5.8

6.0

4.0

016

GATE_ DRIVE VOLTAGE

REFERRED TO MON_

INPUT VOLTAGE

Typical Operating Characteristics

(VS_= 12V, VIN= 3.3V, TA= +25°C, unless otherwise noted. See the

Typical Application Circuit

.)

I2C INTERFACE

Serial-Clock Frequency f

Bus Free Time Between STOP

and START Condition

START Condition Setup Time t

START Condition Hold Time t

STOP Condition Setup Time t

Clock Low Period t

Clock High Period t

Data Setup Time t

Data Hold Time t

Receive SCL/SDA Rise Time t

Receive SCL/SDA Fall Time t

Pulse Width of Spike Suppressed t

SDA, SCL Input High Voltage V

SDA, SCL Input Low Voltage V

SDA, SCL Input Hysteresis V

SDA, SCL Input Current ±1 µA

SDA, SCL Input Capacitance 15 pF

SDA Output Low Voltage V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SCL

t

BUF

SU:STA

HD:STA

SU:STO

LOW

HIGH

SU:DAT

HD:DAT

R

FP

SP

IH

IL

HYST

OL

1.3 µs

0.6 µs

0.6 µs

0.6 µs

1.3 µs

0.6 µs

100 ns

0.3 0.9 ns

50 ns

1.6 V

0.22 V

0.4 V

400 kHz

1µs

300 ns

0.8 V

Page 6

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

6 _______________________________________________________________________________________

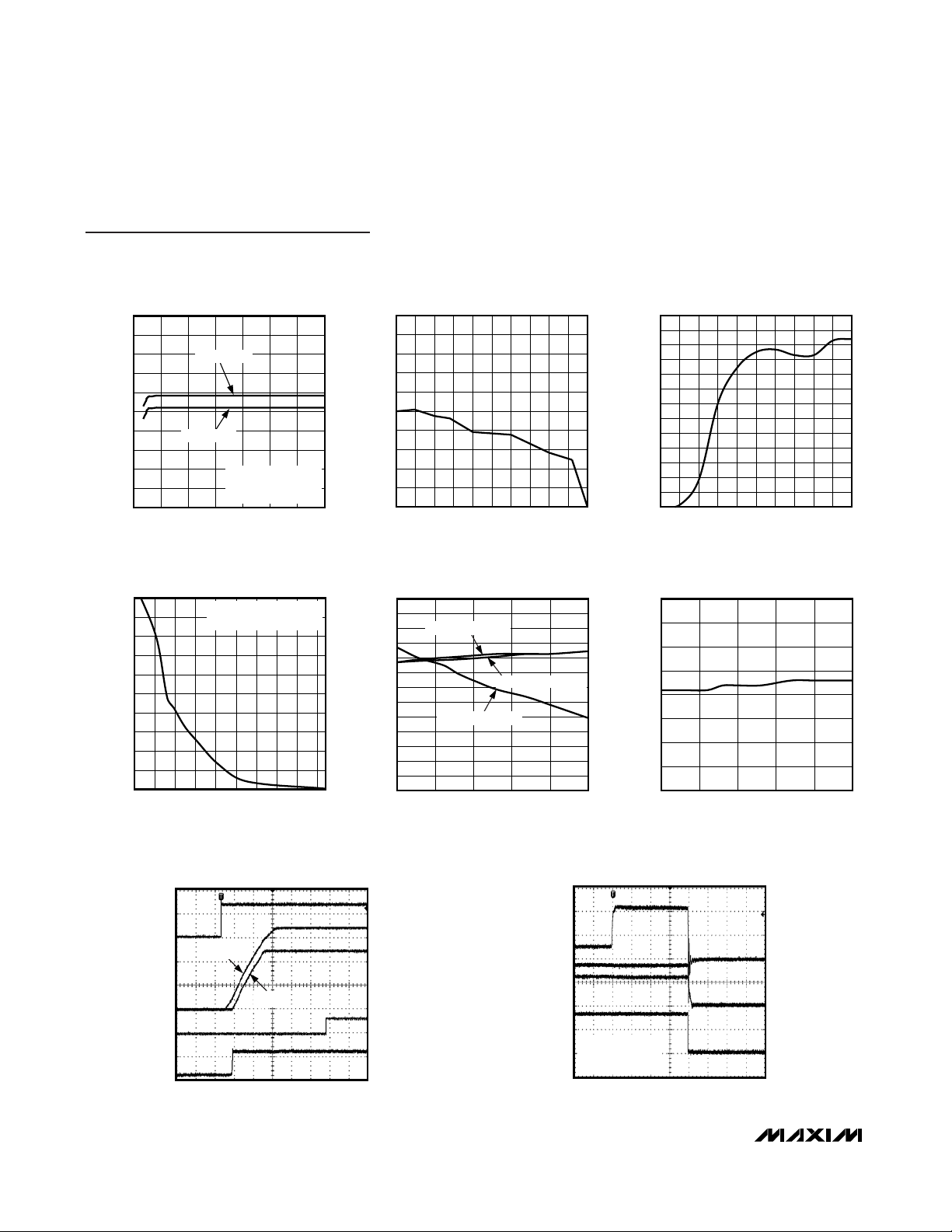

Typical Operating Characteristics (continued)

(VS_= 12V, VIN= 3.3V, TA= +25°C, unless otherwise noted. See the

Typical Application Circuit

.)

START OF WAVEFORM

MAX5961 toc10

10ms/div

V

ON_

V

GATE_

,

V

MON_

V

PG_

I

LOAD_

V

GATE_

V

MON_

TURN-OFF WAVEFORM

(SLOW-COMPARATOR FAULT)

MAX5961 toc11

200μs/div

I

LOAD_

V

GATE_

,

V

MON_

V

FAULT_

DEFAULT RESISTOR

SETTINGS

25mV SENSE RANGE

GATE_ DRIVE VOLTAGE

vs. IN VOLTAGE

6.0

5.8

5.6

) (V)

MON_

- V

GATE_

(V

5.4

5.2

5.0

4.8

4.6

4.4

4.2

4.0

V

V

MON_

SLOW-COMPARATOR TURN-OFF TIME

vs. SENSE VOLTAGE OVERDRIVE

2.0

1.8

1.6

1.4

1.2

1.0

0.8

TURN-OFF TIME (ms)

0.6

0.4

0.2

0

0

[(V

SENSE_

= 3.3V

MON_

= 12V

GATE_ DRIVE VOLTAGE

REFERRED TO MON_

INPUT VOLTAGE

VIN (V)

25mV SENSE RANGE;

DAC = 191, V

- V

) - V

MON_

TH,ST

GATE_ DRIVE CURRENT

10

9

MAX5961 toc04

14128 1064216

8

7

6

(μA)

5

GATE_

I

4

3

2

1

0

05.0

SLOW-COMPARATOR THRESHOLD

VOLTAGE ERROR vs. TEMPERATURE

14

TH,ST

= 9.36mV

986 72 3 4 51

] (V)

12

10

MAX5961 toc07

8

6

4

2

0

-2

-4

-6

-8

-10

-12

SLOW-COMPARATOR THRESHOLD VOLTAGE ERROR (%)

50mV SENSE RANGE

-40 85

vs. (V

25mV SENSE RANGE

- V

GATE_

(V

- V

GATE_

MON_

100mV SENSE RANGE

TEMPERATURE (°C)

MON_

) (V)

GATE_ DISCHARGE CURRENT

- V

MON_

MON_

) (V)

)

MAX5961 toc06

4.54.03.0 3.51.0 1.5 2.0 2.50.5

)

650

600

550

MAX5961 toc05

500

450

400

(mA)

350

300

GATE_

I

250

200

150

100

50

0

4.54.03.0 3.51.0 1.5 2.0 2.50.5

0 5.0

vs. (V

(V

GATE_

GATE_

- V

ON_ INPUT THRESHOLD VOLTAGE

vs. TEMPERATURE

0.615

0.610

MAX5961 toc08

0.605

0.600

0.595

0.590

0.585

ON_ INPUT THRESHOLD VOLTAGE (V)

0.580

0.575

603510-15

-40 85

TEMPERATURE (°C)

6035-15 10

MAX5961 toc09

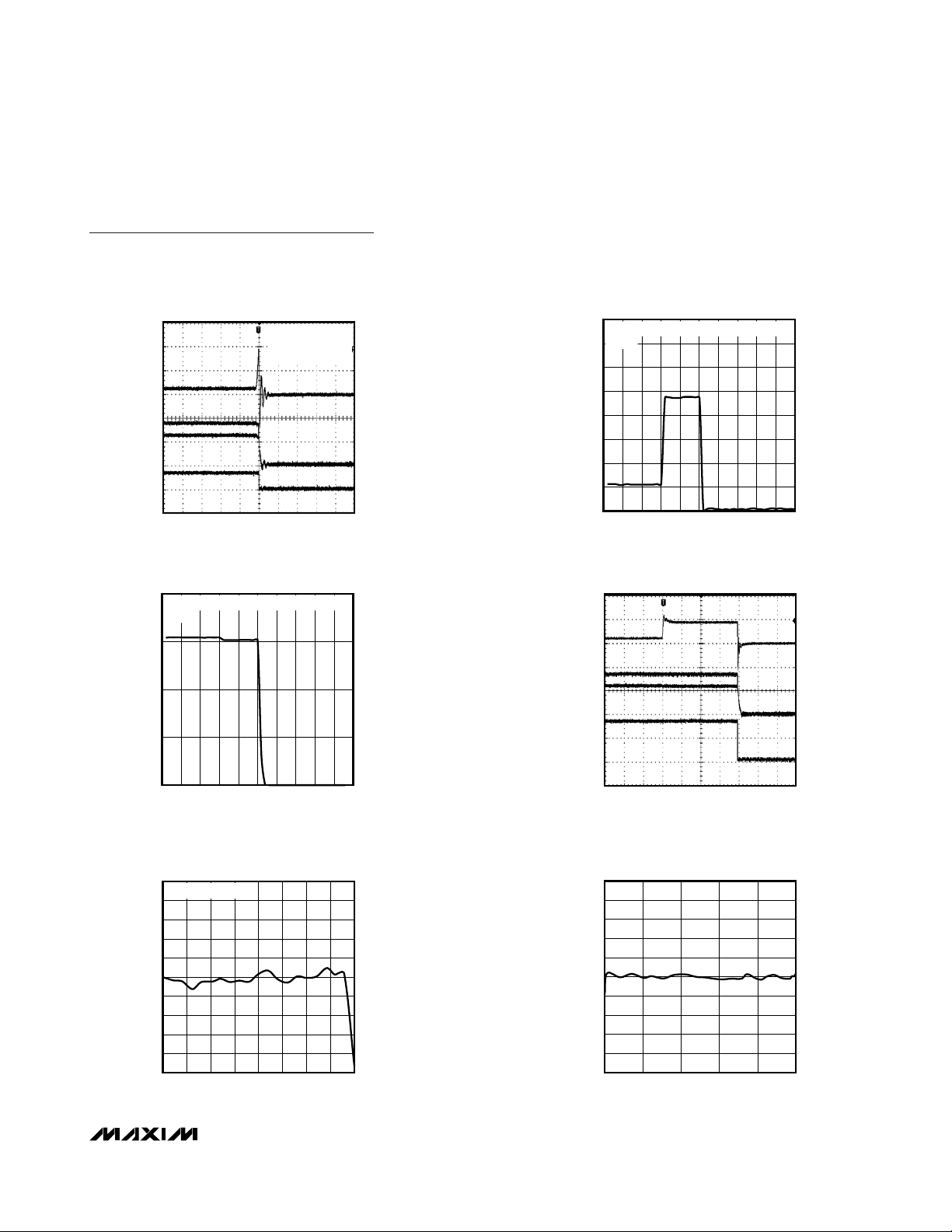

Page 7

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

_______________________________________________________________________________________

7

Typical Operating Characteristics (continued)

(VS_= 12V, VIN= 3.3V, TA= +25°C, unless otherwise noted. See the

Typical Application Circuit

.)

TURN-OFF WAVEFORM (FAST COMPARATOR

FAULT/SHORT-CIRCUIT RESPONSE)

DEFAULT RESISTOR

SETTINGS

25mV SENSE RANGE

100μs/div

VOLTAGE BUFFER vs. TIME

16

CIRCULAR BUFFER CONTENT AT SLOW-TRIP

FAULT

12

8

VOLTAGE BUFFER (V)

4

MAX5961 toc12

I

LOAD_

V

GATE_

V

MON_

V

FAULT_

MAX5961 toc13b

4.0

CURRENT BUFFER vs. TIME

CIRCULAR BUFFER CONTENT AT SLOW-TRIP

FAULT

3.5

3.0

2.5

,

2.0

1.5

CURRENT BUFFER (A)

1.0

0.5

0

-2.5 2.5

TIME (ms)

SLOW-COMPARATOR FAULT EVENT

2.01.5-2.0 -1.5 -1.0 0 0.5-0.5 1.0

MAX5961 toc14

MAX5961 toc13a

I

LOAD_

V

GATE_

V

MON_

V

FAULT_

,

0

-2.5 2.5

TIME (ms)

2.01.51.00.50-0.5-1.0-1.5-2.0

VOLTAGE ADC ACCURACY

vs. MON_ VOLTAGE

1.0

4V MON_ RANGE

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

VOLTAGE ADC ACCURACY (% FS)

-0.8

-1.0

04.0

V

(V)

MON_

MAX5961 toc15

3.53.02.0 2.51.0 1.50.5

200μs/div

CURRENT ADC ACCURACY

- V

vs. (V

(V

SENSE_

SENSE_

- V

MON_

5

4

3

2

1

0

-1

-2

-3

CURRENT ADC ACCURACY (% FS)

-4

-5

025

MON_

) (mV)

)

MAX5961 toc16

2015105

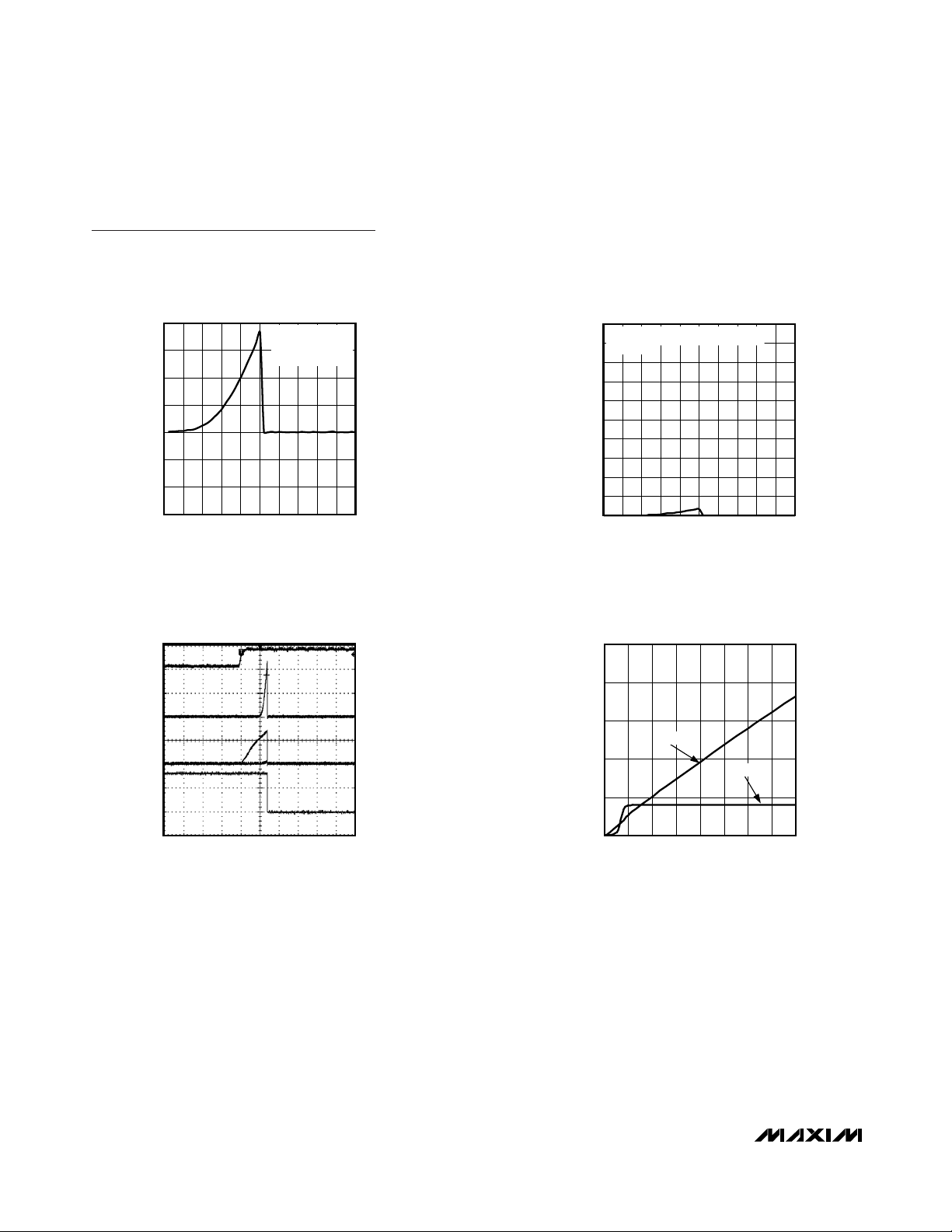

Page 8

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VS_= 12V, VIN= 3.3V, TA= +25°C, unless otherwise noted. See the

Typical Application Circuit

.)

CURRENT BUFFER vs. TIME

MAX5961 toc17a

TIME (ms)

CURRENT BUFFER (A)

2.01.51.00.50-0.5-1.0-1.5-2.0

-2

-1

0

1

2

3

4

-3

-2.5 2.5

CURRENT DATA

AT SHORT CIRCUIT

ON POWER-UP

VOLTAGE BUFFER vs. TIME

MAX5961 toc17b

TIME (ms)

VOLTAGE BUFFER (V)

2.01.50.5 1.0-1.5 -1.0 -0.5 0-2.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

0

-2.5 2.5

VOLTAGE DATA AT SHORT CIRCUIT ON

POWER-UP

STARTUP INTO SHORT LOAD

MAX5961 toc18

4ms/div

V

ON_

V

GATE_

,

V

MON_

V

FAULT_

I

LOAD_

INPUT LEAKAGE CURRENT

vs. MON_ VOLTAGE

MAX5961 toc19

V

MON_

(V)

INPUT LEAKAGE CURRENT (μA)

1412108642

50

100

150

200

250

0

016

I

MON_

I

SEN

Page 9

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

_______________________________________________________________________________________ 9

Pin Description

PIN NAME FUNCTION

1 SENSE1

2 MON1 Channel 1 Voltage Monitoring Input

3 GATE1 Channel 1 Gate-Drive Output. Connect to gate of an external n-channel MOSFET.

4 GND1

5 GND3

6 GATE3 Channel 3 Gate-Drive Output. Connect to the gate of an external n-channel MOSFET.

7 MON3 Channel 3 Voltage Monitoring Input

8 SENSE3

9 POL

10 DREG

11 ON1 Channel 1 Precision Turn-On Input

12 ON3 Channel 3 Precision Turn-On Input

13 FAULT1

14 FAULT2

15 FAULT3

16 FAULT4

17 SDA I2C Serial-Data Input/Output

18 SCL I2C Serial-Clock Input

19 ALERT Open-Drain Alert Output. ALERT goes low during a fault to notify the system of an impending failure.

20 PG1 Channel 1 Open-Drain Power-Good Output

21 PG2 Channel 2 Open-Drain Power-Good Output

22 PG3 Channel 3 Open-Drain Power-Good Output

23 PG4 Channel 4 Open-Drain Power-Good Output

24 DGND Digital Ground. Connect all GND_ and DGND to AGND externally using a star connection.

25 ON4 Channel 4 Precision Turn-On Input

26 ON2 Channel 2 Precision Turn-On Input

27 RETRY

28 I.C. Internally Connected. Connect to AGND only.

Channel 1 Current-Sense Input. Connect SENSE1 to the source of an external MOSFET and to one end of

R

Channel 1 Gate Discharge Current Ground Return. Connect all GND_ and DGND to AGND externally

using a star connection.

Channel 3 Gate Discharge Current Ground Return. Connect all GND_ and DGND to AGND externally

using a star connection.

Channel 3 Current-Sense Input. Connect SENSE3 to the source of an external MOSFET and to one end of

R

Polarity Select Input. Connect to DREG for active-high power-good outputs (PG_). Connect to GND_ for

active-low power-good outputs.

Logic Power-Supply Input. Connect to REG externally through a 10Ω resistor and to DGND with a 1µF

ceramic capacitor.

Channel 1 Active-Low Open-Drain Fault Output. FAULT1 goes low if an overcurrent shutdown occurs on

channel 1.

Channel 2 Active-Low Open-Drain Fault Output. FAULT2 goes low if an overcurrent shutdown occurs on

channel 2.

Channel 3 Active-Low Open-Drain Fault Output. FAULT3 goes low if an overcurrent shutdown occurs on

channel 3.

Channel 4 Active-Low Open-Drain Fault Output. FAULT4 goes low if an overcurrent shutdown occurs on

channel 4.

Autoretry Fault Management Input. Connect to DREG to enable autoretry operation. Connect to DGND to

enable latched-off operation.

(see the Typical Application Circuit).

SENSE1

(see the Typical Application Circuit).

SENSE3

Page 10

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

10 ______________________________________________________________________________________

Pin Description (continued)

PIN NAME FUNCTION

29 SENSE4

30 MON4 Channel 4 Voltage Monitoring Input

31 GATE4 Channel 4 Gate-Drive Output. Connect to gate of an external n-channel MOSFET.

32 GND4

33 GND2

34 GATE2 Channel 2 Gate-Drive Output. Connect to gate of an external n-channel MOSFET.

35 MON2 Channel 2 Voltage Monitoring Input

36 SENSE2

37 ILIM4

38 ILIM3

39 ILIM2

40 ILIM1

41 IN Power-Supply Input. Connect to a voltage from 2.7V to 16V. Bypass to AGND with a 1µF capacitor.

42 AGND Analog Ground. Connect all GND_ and DGND to AGND externally using a star connection.

43 REG

44 A1 Three-State I2C Address Input 1

45 A0 Three-State I2C Address Input 0

46 PROT

47 MODE

48 HWEN

— EP Exposed Pad. EP is internally grounded. Connect externally to AGND.

Channel 4 Current-Sense Input. Connect SENSE4 to the source of an external MOSFET and to one end of

R

Channel 4 Gate Discharge Current Ground Return. Connect all GND_ and DGND to AGND externally

using a star connection.

Channel 2 Gate Discharge Current Ground Return. Connect all GND_ and DGND to AGND externally

using a star connection.

Channel 2 Current-Sense Input. Connect SENSE2 to the source of an external MOSFET and to one end of

R

Channel 4 Three-State Current-Sense Range Selection Input. Set the circuit-breaker threshold range by

connecting to DGND, DREG, or leave unconnected (see Table 7b).

Channel 3 Three-State Current-Sense Range Selection Input. Set the circuit-breaker threshold range by

connecting to DGND, DREG, or leave unconnected (see Table 7b).

Channel 2 Three-State Current-Sense Range Selection Input. Set the circuit-breaker threshold range by

connecting to DGND, DREG, or leave unconnected (see Table 7b).

Channel 1 Three-State Current-Sense Range Selection Input. Set the circuit-breaker threshold range by

connecting to DGND, DREG, or leave unconnected (see Table 7b).

Internal Regulator Output. Bypass to ground with a 1µF capacitor. Connect only to DREG and logic-input

pullup resistors. Do not use to power external circuitry.

Protection Behavior Input. Three-state input sets one of three different response options for undervoltage

and overvoltage events (see Table 29).

Hot-Swap Three-State Mode Select Input. Connect MODE to DGND, DREG, or leave it unconnected to

operate the hot-swap channels independently, in pairs, or as a group of four, respectively (see Table 2).

Hardware Enable Input. Connect to DREG or DGND. State is read upon power-up as V

UVLO threshold and sets Chx_EN2 bits with this value. After UVLO, this input becomes inactive until

power is cycled.

(see the Typical Application Circuit).

SENSE4

(see the Typical Application Circuit).

SENSE2

crosses the

IN

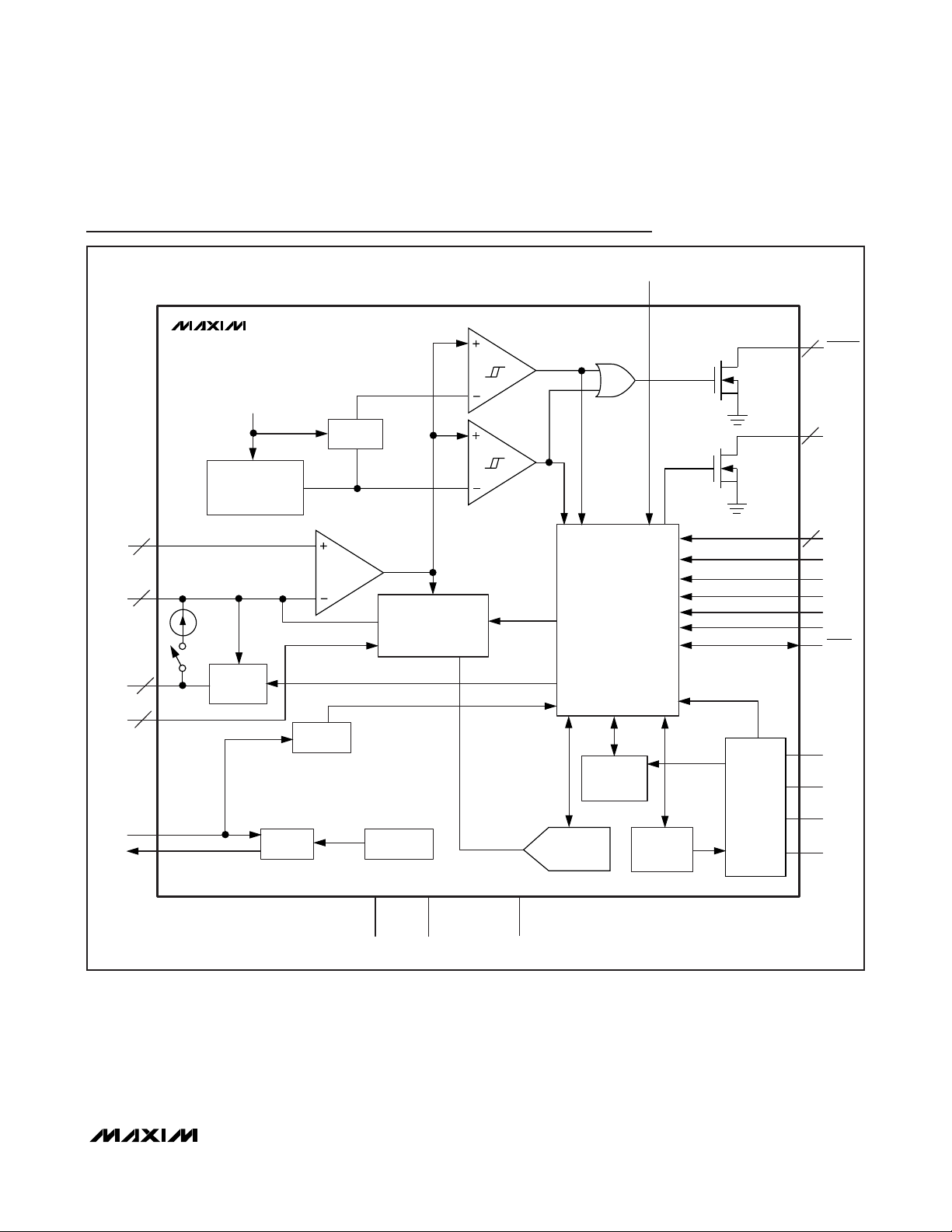

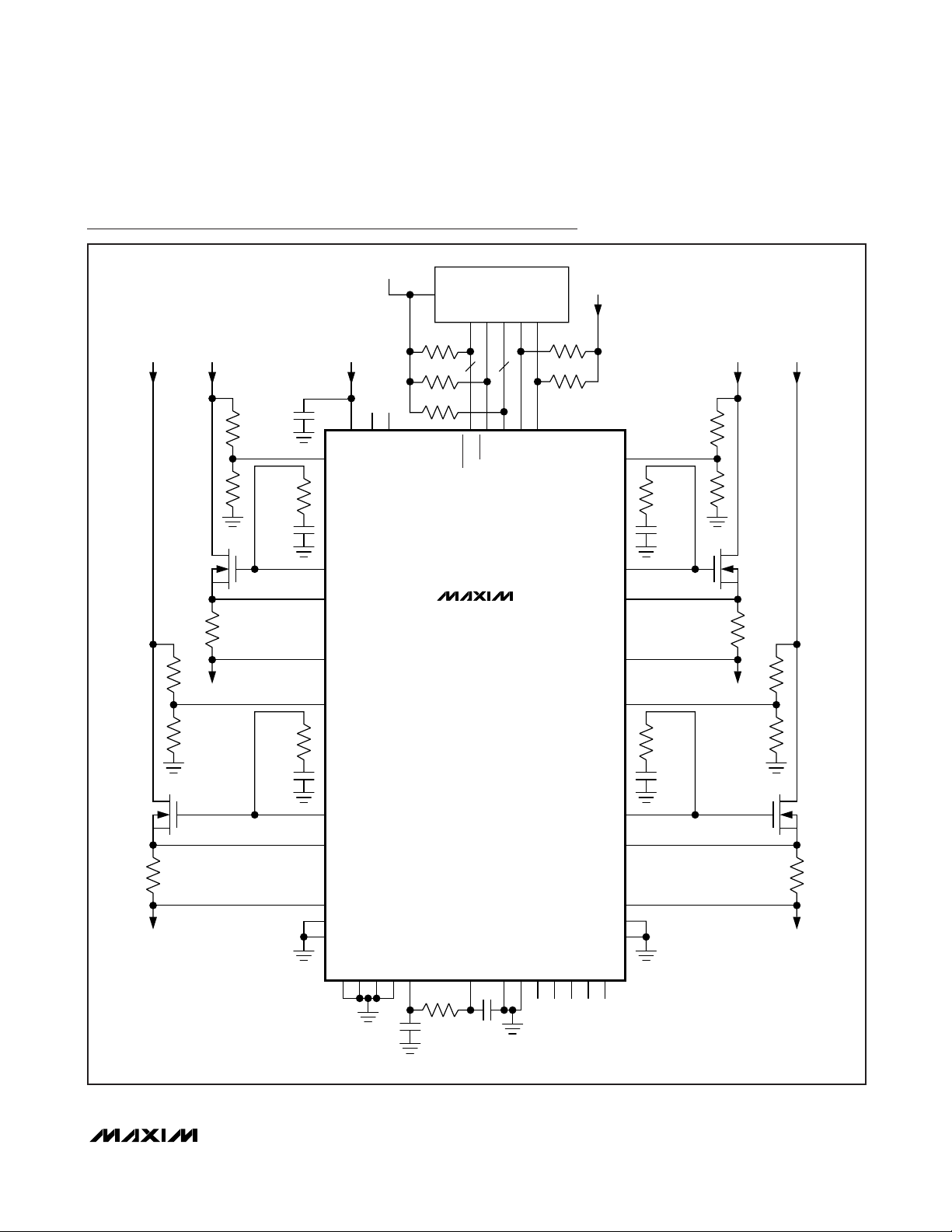

Page 11

MAX5961

Functional Diagram

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

______________________________________________________________________________________ 11

SENSE_

MON_

GATE_

ILIM_

REG

DREG

MAX5961

FROM

CONFIGURATION

REGISTERS

RATIO

CIRCUITBREAKER

DAC

4

4

500mA

4

4

IN

CHARGE

PUMP

UVLO

LDO

VOLTAGE SCALER AND

MULTIPLEXER

REF/BIAS

SLOW

FAST

10-BIT ADC

DEVICE

CONTROL

LOGIC

REGISTER

BANK

I2C

CIRCULAR

BUFFER

4

FAULT_

4

PG_

4

ON_

HWEN

RETRY

MODE

POL

PROT

ALERT

SDA

SCL

A0

A1

AGND DGND GND1, GND2, GND3, GND4

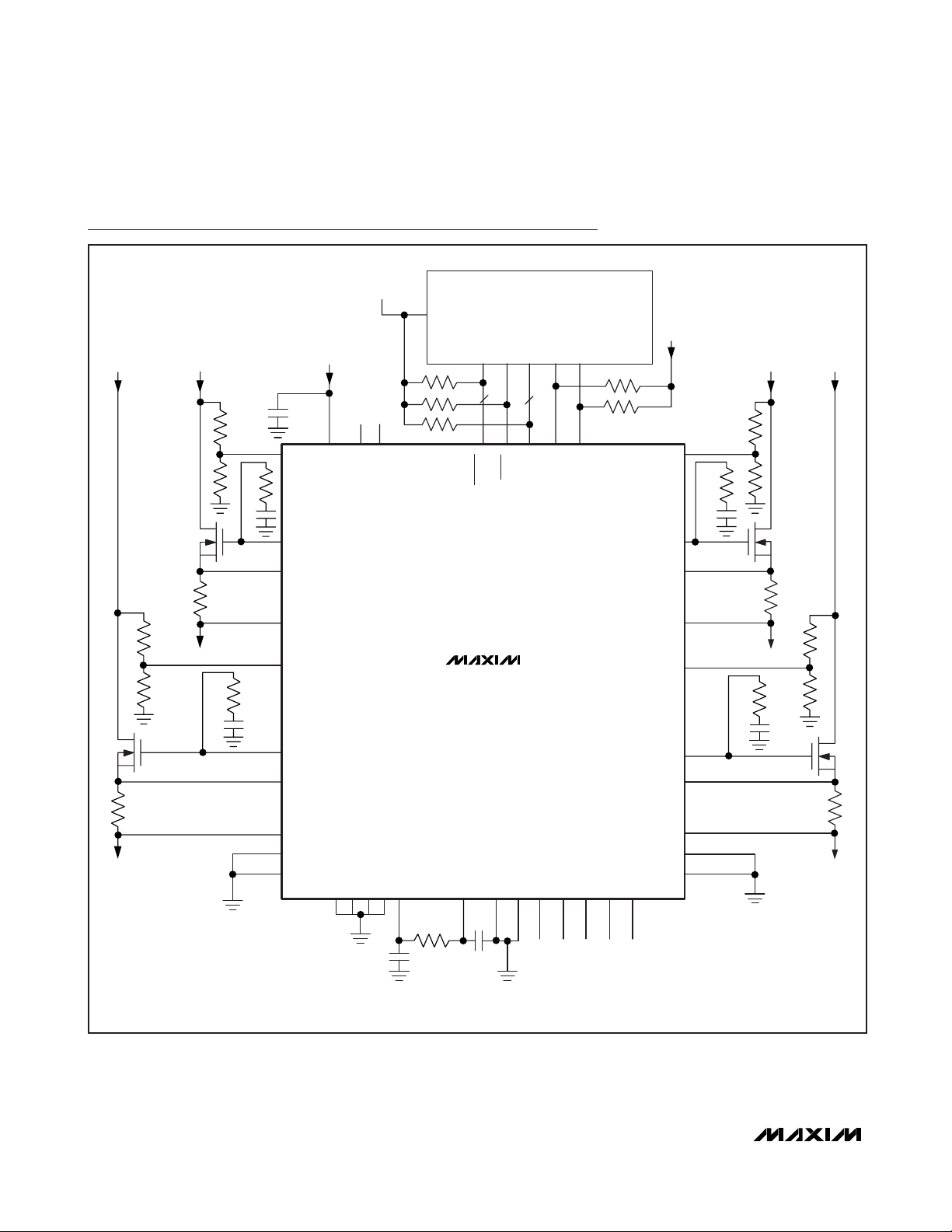

Page 12

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

12 ______________________________________________________________________________________

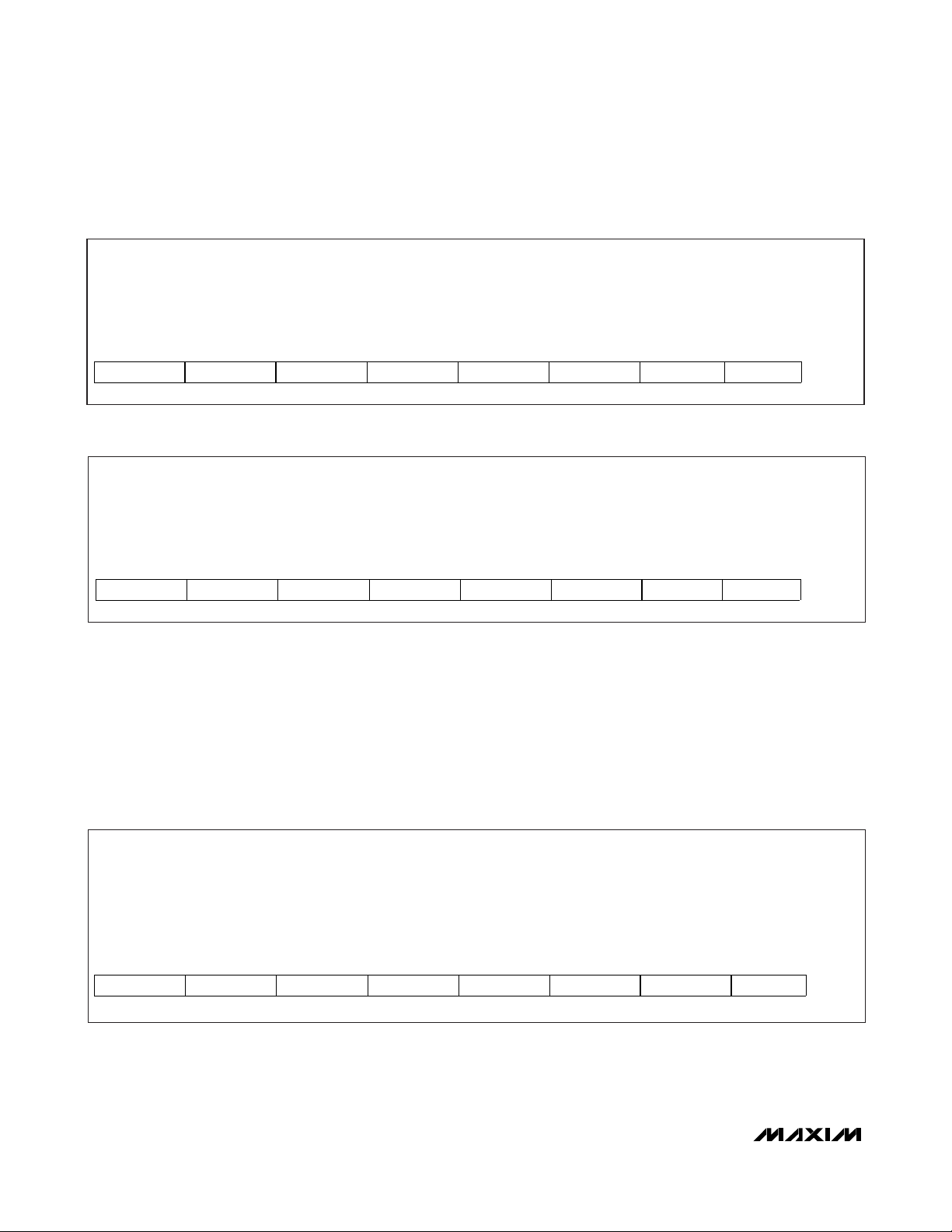

Typical Operating Circuit

V

VS3*

VS1*

2.7V to 16V

DD

V

DD

I/O

INT

μC

V

DD

I/O

SDA

SCL

44

SCL

SDA

PG_

ALERT

ON2

ON1

ID

SETTING

IN

A0

A1

FAULT_

VS2*

VS4*

TO LOAD

R

SENSE3

TO LOAD

R

SENSE1

ON4

**

R

SENSE2

TO LOAD

**

GATE1

SENSE1

MON1

ON3

GATE2

SENSE2

MON2

MAX5961

**

**

GATE3

SENSE3

MON3

GND1

GND3

ILIM1

ILIM2

ILIM3

ILIM4

REG

1μF

DREG

1μF

DGND

AGND

HWEN

MODE

POL

CONFIGURATION

SETTING

PROT

RETRY

GATE4

SENSE4

MON4

GND2

GND4

R

SENSE4

TO LOAD

*HOT-SWAPPABLE SUPPLY RANGE, VS_ = 0 TO 16V.

**OPTIONAL COMPONENTS.

Page 13

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

______________________________________________________________________________________ 13

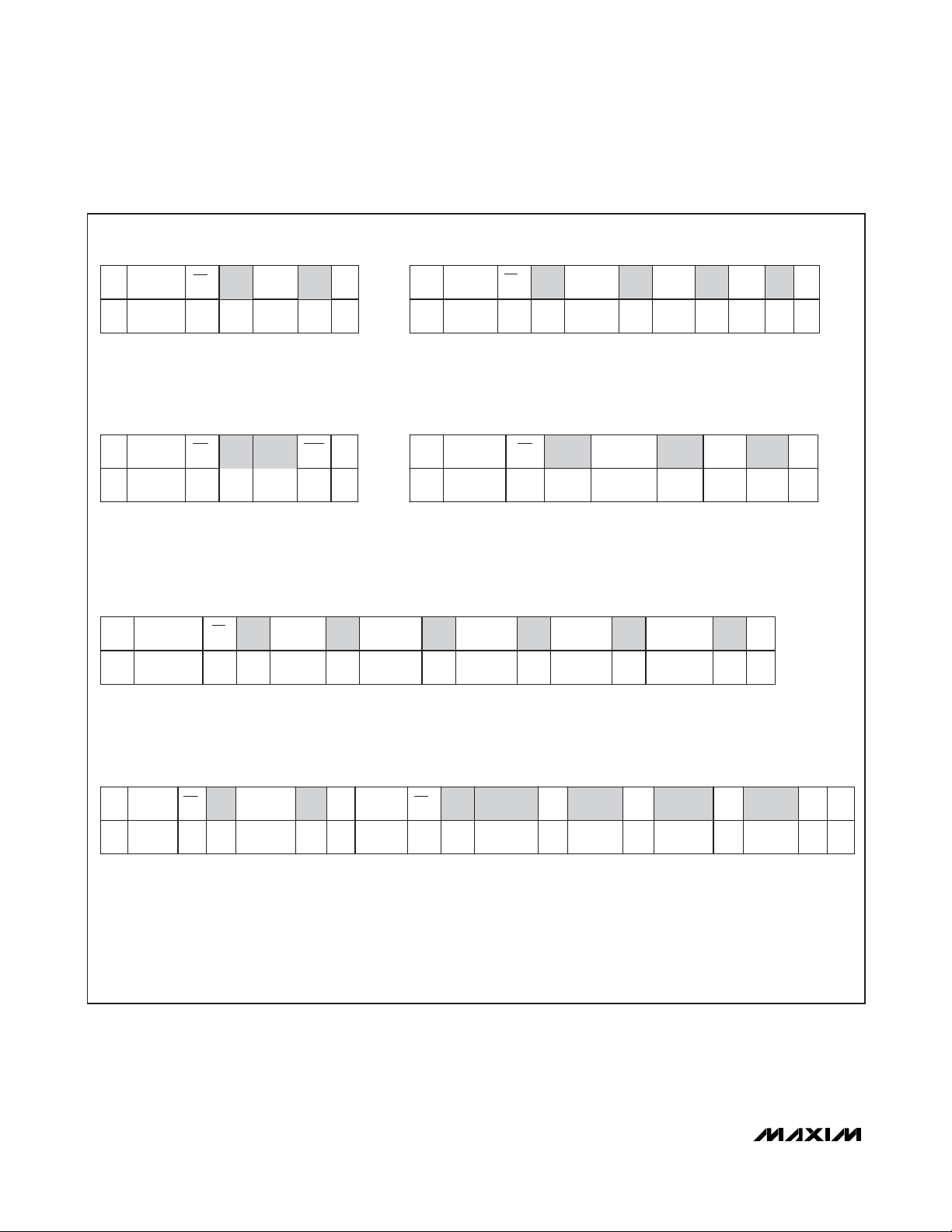

Typical Application Circuit

VS3*

R

SENSE1

5MΩ

VS1*

1μF

1kΩ

4700pF

2.7V TO 16V

SETTING

IN

ON1

GATE1

SENSE1

MON1

V

DD

V

DD

100kΩ

100kΩ

ID

A0

100kΩ

A1

MAX5961

I/O

INT

4

ALERT

FAULT_

μC

I/O

4

PG_

SDA

SDA

SCL

SCL

3.9kΩ

3.9kΩ

V

DD

ON2

GATE2

SENSE2

MON2

1kΩ

4700pF

VS2* VS4*

R

SENSE2

5MΩ

TO LOAD

1kΩ

4700pF

R

SENSE3

5MΩ

TO LOAD

*HOT-SWAPPABLE SUPPLY RANGE, VS_ = 0 TO 16V

ON3

GATE3

SENSE3

MON3

GND1

GND3

ILIM1

ILIM2

ILIM3

1μF

ILIM4

REG

10Ω

DREG

1μF

AGND

DGND

CONFIGURATION

HWEN

SETTING

POL

MODE

ON4

GATE4

SENSE4

MON4

GND2

GND4

PROT

RETRY

1kΩ

4700pF

TO LOAD

TO LOAD

R

SENSE4

5MΩ

Page 14

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

14 ______________________________________________________________________________________

Detailed Description

The MAX5961 0 to 16V, quad, hot-swap controller provides complete protection for multisupply systems. The

device allows the safe insertion and removal of circuit

cards into live backplanes. The MAX5961 is an

advanced hot-swap controller that monitors voltage and

current with an internal 10-bit ADC. The device provides

two levels of overcurrent circuit-breaker protection; a

fast-trip threshold for a fast turn-off and a lower slow-trip

threshold for a delayed turn-off. The maximum overcurrent circuit-breaker threshold range is set independently

for each channel with a three-state input (ILIM_) or by

programming though an I2C interface.

The internal 10-bit ADC is multiplexed to monitor the

output voltage and current of each hot-swap channel.

The total time to cycle through all the eight measure-

ments is 100µs (typ). Each 10-bit value is stored in an

internal circular buffer so that 50 past samples of each

signal can be read back through the I2C interface at

any time or after a fault condition.

The MAX5961 can be configured as four independent

hot-swap controllers, hot-swap controllers operating in

pairs, or as a group of four hot-swap controllers.

The device also includes five digital comparators per

hot-swap channel to implement overcurrent warning,

two levels of overvoltage detection, and two levels of

undervoltage detection. The limits for overcurrent, overvoltage, and undervoltage are user-programmable.

When any of the measured values violates the programmable limits, an external ALERT signal is asserted. In

addition to the ALERT signal, depending on the selected operating mode, the MAX5961 can deassert a

power-good signal and/or turn-off the external MOSFET.

Table 1a. Register Address Map (Channel Specific)

REGISTER DESCRIPTION

adc_chx_cs_h

adc_chx_cs_l

adc_chx_mon_h

adc_chx_mon_l

min_chx_cs_h

min_chx_cs_l

max_chx_cs_h

max_chx_cs_l

min_chx_mon_h

min_chx_mon_l

max_chx_mon_h

max_chx_mon_l

High 8 bits ([9:2]) of latest

current-signal ADC result

Low 2 bits ([1:0]) of latest

current-signal ADC result

High 8 bits ([9:2]) of latest

voltage-signal ADC result

Low 2 bits ([1:0]) of latest

voltage-signal ADC result

High 8 bits ([9:2]) of currentsignal minimum value

Low 2 bits ([1:0]) of currentsignal minimum value

High 8 bits ([9:2]) of currentsignal maximum value

Low 2 bits ([1:0]) of currentsignal maximum value

High 8 bits ([9:2]) of voltagesignal minimum value

Low 2 bits ([1:0]) of voltagesignal minimum value

High 8 bits ([9:2]) of voltagesignal maximum value

Low 2 bits ([1:0]) of voltagesignal maximum value

CHANNEL 1 CHANNEL 2 CHANNEL 3 CHANNEL 4

0x00 0x04 0x08 0x0C 0x00 9

0x01 0x05 0x09 0x0D 0x00 10

0x02 0x06 0x0A 0x0E 0x00 19

0x03 0x07 0x0B 0x0F 0x00 20

0x10 0x18 0x20 0x28 0xFF 13

0x11 0x19 0x21 0x29 0x03 14

0x12 0x1A 0x22 0x2A 0x00 15

0x13 0x1B 0x23 0x2B 0x00 16

0x14 0x1C 0x24 0x2C 0xFF 32

0x15 0x1D 0x25 0x2D 0x03 33

0x16 0x1E 0x26 0x2E 0x00 34

0x17 0x1F 0x27 0x2F 0x00 35

ADDRESS (HEX CODE)

RESET

VALUE

TABLE

Page 15

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

______________________________________________________________________________________ 15

Table 1a. Register Address Map (Channel Specific) (continued)

REGISTER DESCRIPTION

High 8 bits ([9:2]) of

uv1_chx_h

uv1_chx_l

uv2_chx_h

uv2_chx_l

ov1_chx_h

undervoltage warning (UV1)

threshold

Low 2 bits ([1:0]) of

undervoltage warning (UV1)

threshold

High 8 bits ([9:2]) of

undervoltage critical (UV2)

threshold

Low 2 bits ([1:0]) of

undervoltage critical (UV2)

threshold

High 8 bits ([9:2]) of

overvoltage warning (OV1)

threshold

CHANNEL 1 CHANNEL 2 CHANNEL 3 CHANNEL 4

0x32 0x3C 0x46 0x50 0x00 21

0x33 0x3D 0x47 0x51 0x00 22

0x34 0x3E 0x48 0x52 0x00 23

0x35 0x3F 0x49 0x53 0x00 24

0x36 0x40 0x4A 0x54 0xFF 25

ADDRESS (HEX CODE)

RESET

VALUE

TABLE

ov1_chx_l

ov2_chx_h

ov2_chx_l

oc_chx_h

oc_chx_l

dac_chx

cbuf_ba_chx_v

cbuf_ba_chx_i

Low 2 bits ([1:0]) of

overvoltage warning (OV1)

threshold

High 8 bits ([9:2]) of

overvoltage critical (OV2)

threshold

Low 2 bits ([1:0]) of

overvoltage critical (OV2)

threshold

High 8 bits ([9:2]) of

overcurrent warning threshold

Low 2 bits ([1:0]) of

overcurrent warning threshold

Fast-comparator threshold

setting (8-bit DAC)

Base address for block read

of 50-sample voltage-signal

data buffer

Base address for block read

of 50-sample current-signal

data buffer

0x37 0x41 0x4B 0x55 0x03 26

0x38 0x42 0x4C 0x56 0xFF 27

0x39 0x43 0x4D 0x57 0x03 28

0x3A 0x44 0x4E 0x58 0xFF 11

0x3B 0x45 0x4F 0x59 0x03 12

0x5A 0x5B 0x5C 0x5D 0xBF 8

0x80 0x82 0x84 0x86 — 41

0x81 0x83 0x85 0x87 — 41

Page 16

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

16 ______________________________________________________________________________________

Table 1b. Register Address Map (General)

Table 2. Grouping Hot-Swap Channels

Grouping Hot-Swap Channels

Depending on the state of the MODE input, the fourchannel MAX5961 can operate as four independent

hot-swap controllers, two pairs of controllers, or with all

four controllers grouped together (see Tables 2 and 4a).

REGISTER DESCRIPTION

mon_range MON_ input range selection 0x30 0x00 17, 18

cbuf_chx_store Selective enabling of individual blocks in the circular buffer 0x31 0xFF 42

ifast2slow

status0 Slow-trip and fast-trip comparators status register 0x5F Cx00 50

status1 PROT, MODE, and ON_ inputs status register 0x60 — 2, 4a, 4b, 29

sense_range ILIM_ inputs status register 0x61 — 6, 7a, 7b

status3 RETRY, POL, ALERT, and PG_ status register 0x62 — 30

fault0 Status register for undervoltage detection (warning or critical) 0x63 0x00 47

fault1 Status register for overvoltage detection (warning or critical) 0x64 0x00 48

fault2 Status register for overcurrent detection (warning) 0x65 0x00 49

pgdly Delay setting between MON_ measurement and PG_ assertion 0x66 0x00 31a, 31b

fokey Load register with 0xA5 to enable force-on function 0x67 0x00 46

foset Register that enables force-on function for a channel 0x68 0x00 45

chxen Channel enable bits 0x69 — 3

dgl_i OC deglitch enable bits 0x6A 0x00 38

dgl_uv UV deglitch enable bits 0x6B 0x00 39

dgl_ov OV deglitch enable bits 0x6C 0x00 40

cbufrd_hibyonly Circular buffers readout mode: 8 bit or 10 bit 0x6D 0x00 43

cbuf_dly_stop

peak_log_rst Reset control bits for peak-detection registers 0x73 0x00 36

peak_log_hold Hold control bits for peak-detection registers 0x74 0x00 37

Current threshold ratio setting for the fast comparator vs. slow

comparator

Circular buffer stop-delay. Number of samples recorded to the

circular buffer after channel shutdown.

ADDRESS

(HEX CODE)

0x5E 0xFF 5a, 5b

0x72 0x19 44

RESET

VALUE

TABLE

MODE INPUT

STATUS

Low 1 0 Independent

High 0 1 Paired

Unconnected 0 0 Grouped

MODE [1] MODE [0] FUNCTION DESCRIPTION

Each channel operates as an independent hot-swap controller. A fault

shutdown in one channel does not affect operation of other channels.

Channels 1 and 3 operate together as one pair while channels 2 and 4

operate as another pair. A fault shutdown in one channel of a pair shuts

down both channels in the pair.

All channels operate as a group. A fault shutdown in one channel shuts

down all four channels.

Page 17

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

______________________________________________________________________________________ 17

Hot-Swap Channels On-Off Control

Depending on the configuration of the Chx_EN1 and

Chx_EN2 bits, when VINis above the V

UVLO

threshold

and the ON_ input reaches its internal threshold, the

MAX5961 turns on the external n-channel MOSFET for

the corresponding channel, allowing power to flow to

the load. The channel is enabled depending on the output of a majority function. Chx_EN1, Chx_EN2, and ON_

are the inputs to the majority function and the channel is

enabled when two or more of these inputs are 1.

Channel enabled = (Chx_EN1 x Chx_EN2) +

(Chx_EN1 x ON_) + (Chx_EN2 x ON_)

The inputs ON_ and Chx_EN2 can be set externally; the

initial state of the Chx_EN2 bits in register chxen is set

by the state of the HWEN input when IN rises above

V

UVLO

. The ON_ inputs connect to internal precision

analog comparators with a 0.6V threshold. Whenever

V

ON_

is above 0.6V, the corresponding ON_ bit in register status1[3:0] is set to 1. The inputs Chx_EN1 and

Chx_EN2 can be set using the I

2

C interface; the

Chx_EN1 bits have a default value of 0. This makes it

possible to enable or disable each of the MAX5961

channels independently with or without using the I

2

C

interface (see Tables 3, 4a, and 4b).

Table 4a. status1 Register Function

Table 3. chxen Register Format

Description: Channel enable bits

Register Title: chxen

Register Address: 0x69

R/W R/W R/W R/W R/W R/W R/W R/W

Ch4_EN2 Ch4_EN1 Ch3_EN2 Ch3_EN1 Ch2_EN2 Ch2_EN1 Ch1_EN2 Ch1_EN1

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

RESET

VALUE

AA (HWEN

= high)

00 (HWEN

= low)

REGISTER

ADDRESS

0x60

BIT RANGE DESCRIPTION

ON_ Inputs State

1 = ON_ above 600mV channel enable threshold

0 = ON_ below 600mV channel enable threshold

[3:0]

[5:4]

[7:6]

Bit 0: ON1

Bit 1: ON2

Bit 2: ON3

Bit 3: ON4

Channel Grouping Mode (MODE Input)

00 = Grouped (MODE unconnected)

01 = Paired (MODE high)

10 = Independent (MODE low)

11 = (Not possible)

Voltage Critical Behavior (PROT Input)

00 = Assert ALERT upon UV/OV critical (same as UV/OV warning behavior)

01 = Assert ALERT and deassert PG_ upon UV/OV critical

10 = Assert ALERT, deassert PG_, and shutdown channel(s) upon UV/OV critical

11 = (Not possible)

Page 18

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

18 ______________________________________________________________________________________

Figure 1 shows the detailed logic operation of the hotswap enable signals Chx_EN1, Chx_EN2, and ON_, as

well as the effect of various fault conditions.

An input undervoltage threshold control for enabling the

hot-swap channel can be implemented by placing a

resistive divider between the drain of the hot-swap FET

and ground, with the midpoint connected to ON_. The

turn-on threshold voltage for the channel is then:

VEN= 0.6V x (R1 + R2)/R2

The maximum rating for the ON_ pin is 6V; do not

exceed this value.

Table 4b. status1 Register Format

Figure 1. Channel On-Off Control Logic Functional Schematic

Description:

Register Title: status1

Register Address: 0x60

RRRRRRRR

Channel grouping (three-state MODE input), fault-detection behavior (three-state PROT input), and

ON_ inputs status register

prot[1] prot[0] mode[1] mode[0] ON4 ON3 ON2 ON1 —

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

ON_

RESET

VALUE

FORCE-ON

BIT

EN1_BIT

EN2_BIT

ANALOG SLOW_TRIP

ANALOG FAST_TRIP

UV/OV CRITICAL

PROT

SRQ

Q

SRQ

Q

RETRY PIN

200ms DELAY,

THEN PULSE

CHANNEL

ENABLED

Page 19

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

______________________________________________________________________________________ 19

Startup

When all conditions for channel turn-on are met, the

external n-channel MOSFET switch is fully enhanced

with a typical gate-to-source voltage of 5.5V to ensure a

low drain-to-source resistance. The charge pump at

each GATE_ driver sources 5µA to control the outputvoltage turn-on slew rate. An external capacitor can be

added from GATE_ to GND_ to further reduce the voltage slew rate. Placing a 1kΩ resistor in series with this

capacitance will prevent the added capacitance from

increasing the gate turn-off time; see the

Typical

Application Circuit

. Total inrush current is the load current summed with the product of the gate voltage slew

rate dv/dt and the load capacitance.

To determine the output dv/dt during startup, divide the

GATE_ pullup current I

G(UP)

by the gate-to-ground

capacitance. The voltage at the source of the external FET

follows the gate voltage, so the load dv/dt is the same as

the gate dv/dt. Inrush current is the product of the dv/dt

and the load capacitance. The time to start up tSUis the

hot-swap voltage VS_ divided by the output dv/dt.

Be sure to choose an external MOSFET that can handle

the power dissipated during startup. The inrush current

is roughly constant during startup, and the voltage drop

across the FET (drain to source) decreases linearly as

the load capacitance charges. The resulting power dissi-

pation is therefore roughly equivalent to a single pulse of

magnitude (VS_ x I_

INRUSH

)/2 and duration tSU. Refer to

the thermal resistance charts in the MOSFET data sheet

to determine the junction temperature rise during startup,

and ensure that this does not exceed the maximum junction temperature for worst-case ambient conditions.

Circuit-Breaker Protection

As the channel is turned on and during normal operation, two analog comparators are used to detect an

overcurrent condition by sensing the voltage across an

external resistor connected between SENSE_ and

MON_. If the voltage across the sense resistor is less

than the slow-trip and fast-trip circuit-breaker thresholds, the GATE_ output remains high. If either of the

thresholds are exceeded due to an overcurrent condition, the gate of the MOSFET is pulled down to MON_

by an internal 500mA current source.

The higher of the two comparator thresholds, the fasttrip, is set by an internal 8-bit DAC (see Table 8), within

one of three configurable full-scale current-sense

ranges: 25mV, 50mV, or 100mV (see Tables 7a and

7b). The 8-bit fast-trip threshold DAC can be programmed from 40% to 100% of the selected full-scale

current-sense range. The slow-trip threshold follows the

fast-trip threshold as one of four programmable ratios,

set by the ifast2slow register (see Tables 5a and 5b).

Table 5a. ifast2slow Register Format

Table 5b. Setting Fast-Trip to Slow-Trip Threshold Ratio

Description: Fast-trip to slow-trip threshold ratio setting bits

Register Title: ifast2slow

Register Address: 0x5E

R/W R/W R/W R/W R/W R/W R/W R/W

Ch4_FS1 Ch4_FS0 Ch3_FS1 Ch3_FS0 Ch2_FS1 Ch2_FS0 Ch1_FS1 Ch1_FS0 0xFF

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Chx_FS1 Chx_FS0 FAST-TRIP TO SLOW-TRIP RATIO (%)

0 0 125

0 1 150

1 0 175

1 1 200

RESET

VALUE

Page 20

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

20 ______________________________________________________________________________________

The fast-trip threshold is always higher than the slow-trip

threshold, and the fast-trip comparator responds very

quickly to protect the system against sudden, severe

overcurrent events. The slower response of the slow-trip

comparator varies depending upon the amount of overdrive beyond the slow-trip threshold. If the overdrive is

small and short-lived, the comparator will not shut down

the affected channel. As the overcurrent event increases in magnitude, the response time of the slow-trip comparator decreases. This scheme provides good

rejection of noise and spurious overcurrent transients

near the slow-trip threshold while aggressively protecting the system against larger overcurrent events that

occur as a result of a load fault (see Figure 2).

Setting Circuit-Breaker Thresholds

To select and set the MAX5961 slow-trip and fast-trip

comparator thresholds, use the following procedure.

1) Select one of four ratios between the fast-trip threshold and the slow-trip threshold: 200%, 175%, 150%,

or 125%. A system that experiences brief but large

transient load currents should use a higher ratio,

whereas a system that operates continuously at

higher average load currents might benefit from a

smaller ratio to ensure adequate protection. The

ratio is set by writing to the ifast2slow register. (The

default setting on power-up is 200%.)

2) Determine the slow-trip threshold V

TH,ST

based on

the anticipated maximum continuous load current

during normal operation, and the value of the current-sense resistor. The slow-trip threshold should

include some margin (possibly 20%) above the maximum load current to prevent spurious circuit-breaker shutdown and to accommodate passive

component tolerances:

V

TH,ST

= R

SENSE_

x I

LOAD,MAX

x 120%

3) Calculate the necessary fast-trip threshold V

TH,FT

based on the ratio set in step 1:

V

TH,FT

= V

TH,ST

x (ifast2slow ratio)

4) Select one of the three maximum current-sense

ranges: 25mV, 50mV, or 100mV. The current-sense

range is initially set upon power-up by the state of

the associated ILIM_ input, but can be altered at any

time by writing to the status2 register. For maximum

accuracy and best measurement resolution, select

the lowest current-sense range that is larger than the

V

TH,FT

value calculated in step 3.

5) Program the fast-trip and slow-trip thresholds by

writing an 8-bit value to the

dac_chx

register. This 8-

bit value is determined from the desired V

TH,ST

value that was calculated in step 2, the threshold

ratio from step 1, and the current-sense range from

step 4:

DAC = V

TH,ST

x 255 x (ifast2slow ratio)/(ILIM_ current

sense range)

The MAX5961 provides a great deal of system flexibility

because the current-sense range, DAC setting, and

threshold ratio can be changed “on the fly” for systems

that must protect a wide range of interchangeable load

devices, or for systems that control the allocation of

power to smart loads. Table 6 shows the specified

ranges for the fast-trip and slow-trip thresholds for all

combinations of current-sense range and threshold

ratio. The fast-trip DAC can be programmed to values

below 0x66 (40% of the current-sense range), but

accuracy is not specified for operation below 40%.

MAX5961 fig02

[(V

SENSE_

- V

MON_

) - V

TH,ST

] (V)

TURN-OFF TIME (ms)

986 72 3 4 51

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

0

0

25mV SENSE RANGE;

DAC = 191, V

TH,ST

= 9.36mV

Figure 2. Slow-Comparator Turn-Off Time vs. Overdrive

Page 21

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

______________________________________________________________________________________ 21

When an overcurrent event causes the MAX5961 to

shut down a channel, a corresponding open-drain

FAULT_ output alerts the system. Figure 3 shows the

operation and fault-management flowchart for one

channel of the MAX5961.

Table 6. Specified Current-Sense and Circuit-Breaker Threshold Ranges

Table 7a. sense_range Register Format

Table 7b. Setting Current-Sense Range

ILIM_

INPUT

Low 0 to 25

High 0 to 50

Unconnected 0 to 100

CURRENT-

SENSE

RANGE (mV)

SPECIFIED FAST-TRIP

THRESHOLD RANGE (mV)

10 to 25

(40% to 100%)

(DAC = 0x66 to 0xFF)

20 to 50

(40% to 100%)

(DAC = 0x66 to 0xFF)

40 to 100

(40% to 100%)

(DAC = 0x66 to 0xFF)

FAST-TRIP/

SLOW-TRIP

RATIO (%)

200 5.0 to 12.5

175 5.7 to 14.3

150 6.7 to 16.7

125 8 to 20

200 10 to 25

175 11.5 to 28.6

150 13.3 to 33.3

125 16 to 40

200 20 to 50

175 22.9 to 57.1

150 26.7 to 66.7

125 32 to 80

THRESHOLD RANGE (mV)

SPECIFIED

SLOW-TRIP

Description: Fast-trip threshold maximum range setting bits, from ILIM_ three-state inputs

Register Title: sense_range

Register Address: 0x61

R/W R/W R/W R/W R/W R/W R/W R/W

Ch4_IGS1 Ch4_IGS0 Ch3_IGS1 Ch3_IGS0 Ch2_IGS1 Ch2_IGS0 Ch1_IGS1 Ch1_IGS0

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

ILIM_ INPUT STATE Chx_IGS1 Chx_IGS0 MAXIMUM CURRENT-SENSE SIGNAL (mV)

Low 1 0 25

High 0 1 50

Unconnected 0 0 100

—1 1 —

Page 22

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

22 ______________________________________________________________________________________

Figure 3. Operation and Fault-Management Flowchart for One Channel

VIN > 2.7V

SET FAULT_, CLEAR PG_, AND SHUTDOWN

AFFECTED CHANNEL(S) PER MODE

NO

CONTINUOUSLY SAMPLE VOLTAGE AND

CURRENT, UPDATE MIN-MAX VALUES,

2

HANDLE I

STORE SAMPLES TO CIRCULAR BUFFERS...

CIRCUIT-BREAKER

C COMMUNICATIONS,

TRIP?

NO

READ MODE, PROT, A0,

A1, RETRY, HWEN, ILIM_

INPUTS, CLEAR FLAGS

NORMAL OPERATION

ARE 2 OR MORE OF

3 ENABLE SET?

NO

CHANNEL(S) PER MODE INPUT

ASSERT PG_ AFTER ADJUSTABLE DELAY

CLEAR PG_ AND

SHUTDOWN AFFECTED

ARE 2 OR MORE OF 3

ENABLE SET?

NO

UV, OV, OR OC

WARNING OR

CRITICAL

NO

YES

CHANNEL ENABLED

START CIRCULAR BUFFER

ENABLE GATE_ PULLUP

YES

YES

SET ALERT, PG_

PER PROT INPUT

PROT INPUT = GND

MON_ > UV1

AND UV2?

NO

BUFFER

STOP-DELAY

EXPIRED

NO

CHANNEL

ENABLED

YES

STOP CIRCULAR BUFFER

AUTORETRY DELAY

CLEAR FLAGS, CLEAR ALERT,

ARE 2 OR MORE OF

3 ENABLE SET?

WAIT FOR

READ ILIM_ INPUTS,

CLEAR FAULT_

NO

YES

RETRY = V

YES

?

DREG

ARE 2 OR MORE OF

NO

3 ENABLE SET?

NO

NO

NORMAL

OPERATION

Page 23

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

______________________________________________________________________________________ 23

Digital Current Monitoring

The four current-sense signals are sampled by the

internal 10-bit ADC, and the most recent results are

stored in registers for retrieval through the I

2

C interface.

The current conversion values are 10 bits wide, with the

8 high-order bits written to one 8-bit register and the 2

low-order bits written to the next higher 8-bit register

address (Tables 9 and 10). This allows use of just the

high-order byte in applications where 10-bit precision is

not required. This split 8-bit/2-bit storage scheme is

used throughout the MAX5961 for all 10-bit ADC conversion results and 10-bit digital comparator thresholds.

Once the PG_ output is asserted (see the

Digital Voltage

Monitoring and Power-Good Outputs

section), the most

recent current samples are continuously compared to

the programmable overcurrent warning register values.

If the measured current value exceeds the warning level,

the ALERT output is asserted. The MAX5961 response

to the overcurrent digital comparator is not altered by

the setting of the PROT input (Tables 11 and 12).

Table 8. dac_chx Register Format

Table 9. ADC Current Conversion Results Register Format (High-Order Bits)

Table 10. ADC Current Conversion Results Register Format (Low-Order Bits)

Description: Fast-comparator threshold DAC setting

Register Titles: dac_ch1 dac_ch2 dac_ch3 dac_ch4

Register Addresses: 0x5A 0x5B 0x5C 0x5D

R/W R/W R/W R/W R/W R/W R/W R/W

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Description: Most recent current conversion result, high-order bits [9:2]

Register Titles: adc_ch1_cs_h adc_ch2_cs_h adc_ch3_cs_h adc_ch4_cs_h

Register Addresses: 0x00 0x04 0x08 0x0C

RRRRRRRR

inew_9 inew_8 inew_7 inew_6 inew_5 inew_4 inew_3 inew_2 0x00

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

RESET

VALUE

0xBF

RESET

VALUE

Description: Most recent current conversion result, low-order bits [1:0]

Register Titles: adc_ch1_cs_l adc_ch2_cs_l adc_ch3_cs_l adc_ch4_cs_l

Register Addresses: 0x01 0x05 0x09 0x0D

RRRRRRRR

inew_1 inew_0 0x00

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

RESET

VALUE

Page 24

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

24 ______________________________________________________________________________________

Minimum and Maximum Value Detection

for Current Measurement Values

All current measurement values from the ADC are continuously compared with the contents of minimum- and

maximum-value registers, and if the most recent measurement exceeds the stored maximum or is less than

the stored minimum, the corresponding register is

updated with the new value. These “peak detection”

registers are read/write accessible through the I

2

C

interface (Tables 13–16). The minimum-value registers

are reset to 0x3FF, and the maximum-value registers

are reset to 0x000. These reset values are loaded upon

startup of a channel or at any time as commanded by

register peak_log_rst (Table 36).

Table 11. Overcurrent Warning Threshold Register Format (High-Order Bits)

Table 12. Overcurrent Warning Threshold Register Format (Low-Order Bits)

Table 13. ADC Minimum Current Conversion Register Format (High-Order Bits)

Description: Overcurrent warning threshold, high-order bits [9:2]

Register Titles: oc_ch1_h oc_ch2_h oc_ch3_h oc_ch4_h

Register Addresses: 0x3A 0x44 0x4E 0x58

R/W R/W R/W R/W R/W R/W R/W R/W

oc_9 oc_8 oc_7 oc_6 oc_5 oc_4 oc_3 oc_2 0xFF

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Description: Overcurrent warning threshold, low-order bits [1:0]

Register Titles: oc_ch1_l oc_ch2_l oc_ch3_l oc_ch4_l

Register Addresses: 0x3B 0x45 0x4F 0x59

R/W R/W R/W R/W R/W R/W R/W R/W

oc_1 oc_0 0x03

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

RESET

VALUE

RESET

VALUE

Description: Minimum current conversion result, high-order bits [9:2]

Register Titles: min_ch1_cs_h min_ch2_cs_h min_ch3_cs_h min_ch4_cs_h

Register Addresses: 0x10 0x18 0x20 0x28

R/W R/W R/W R/W R/W R/W R/W R/W

imin_9 imin_8 imin_7 imin_6 imin_5 imin_4 imin_3 imin_2 0xFF

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

RESET

VALUE

Page 25

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

______________________________________________________________________________________ 25

Table 14. ADC Minimum Current Conversion Register Format (Low-Order Bits)

Table 15. ADC Maximum Current Conversion Register Format (High-Order Bits)

Table 16. ADC Maximum Current Conversion Register Format (Low-Order Bits)

Description: Minimum current conversion result, low-order bits [1:0]

Register Titles: min_ch1_cs_l min_ch2_cs_l min_ch3_cs_l min_ch4_cs_l

Register Addresses: 0x11 0x19 0x21 0x29

R/W R/W R/W R/W R/W R/W R/W R/W

imin_1 imin_0 0x03

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Description: Maximum current conversion result, high-order bits [9:2]

Register Titles: max_ch1_cs_h max_ch2_cs_h max_ch3_cs_h max_ch4_cs_h

Register Addresses: 0x12 0x1A 0x22 0x2A

R/W R/W R/W R/W R/W R/W R/W R/W

imax_9 imax_8 imax_7 imax_6 imax_5 imax_4 imax_3 imax_2 0x00

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

RESET

VALUE

RESET

VALUE

Description: Maximum current conversion result, low-order bits [1:0]

Register Titles: max_ch1_cs_l max_ch2_cs_l max_ch3_cs_l max_ch4_cs_l

Register Addresses: 0x13 0x1B 0x23 0x2B

R/W R/W R/W R/W R/W R/W R/W R/W

imax_1 imax_0 0x00

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

RESET

VALUE

Page 26

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

26 ______________________________________________________________________________________

Digital Voltage Monitoring and

Power-Good Outputs

The voltage at the load (MON_ inputs) is sampled by

the internal ADC. The MON_ full-scale voltage for each

channel can be set to 16V, 8V, 4V, or 2V by writing to

register mon_range. The default range is 16V (Tables

17 and 18).

The most recent voltage conversion results can be read

from the adc_chx_mon_h and adc_chx_mon_l registers

(see Tables 19 and 20).

Table 17. ADC Voltage Monitor Settings Register Format

Table 19. ADC Voltage Conversion Result Register Format (High-Order Bits)

Table 20. ADC Voltage Conversion Result Register Format (Low-Order Bits)

Table 18. ADC Full-Scale Voltage Setting

Description: ADC voltage monitor full-scale range settings (for MON_ inputs)

Register Titles: mon_range

Register Addresses: 0x30

R/W R/W R/W R/W R/Wxxx R/W R/W R/W

MON4_rng1 MON4_rng0 MON3_rng1 MON3_rng0 MON2_rng1 MON2_rng0 MON1_rng1 MON1_rng0 0x00

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

MONx_rng1 MONx_rng0 ADC FULL-SCALE VOLTAGE (V)

00 16

01 8

10 4

11 2

RESET

VALUE

Description: Most recent voltage conversion result, high-order bits [9:2]

Register Titles: adc_ch1_mon_h adc_ch2_mon_h adc_ch3_mon_h adc_ch4_mon_h

Register Addresses: 0x02 0x06 0x0A 0x0E

R RRRRRRR

vnew_9 vnew_8 vnew_7 vnew_6 vnew_5 vnew_4 vnew_3 vnew_2 0x00

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Description: Most recent voltage conversion result, low-order bits [1:0]

Register Titles: adc_ch1_mon_l adc_ch2_mon_l adc_ch3_mon_l adc_ch4_mon_l

Register Addresses: 0x03 0x07 0x0B 0x0F

R R RRR R R R

vnew_1 vnew_0 0x00

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

RESET

VALUE

RESET

VALUE

Page 27

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

______________________________________________________________________________________ 27

Digital Undervoltage and

Overvoltage Detection Thresholds

The most recent voltage values are continuously compared to four programmable limits, comprising two

undervoltage (UV) levels (see Tables 21–24) and two

overvoltage (OV) levels (see Tables 25–28).

Table 21. Undervoltage Warning Threshold Register Format (High-Order Bits)

Table 22. Undervoltage Warning Threshold Register Format (Low-Order Bits)

Table 23. Undervoltage Critical Threshold Register Format (High-Order Bits)

Table 24. Undervoltage Critical Threshold Register Format (Low-Order Bits)

Description: Undervoltage warning threshold high-order bits [9:2]

Register Titles: uv1_ch1_h uv1_ch2_h uv1_ch3_h uv1_ch4_h

Register Addresses: 0x32 0x3C 0x46 0x50

R/W R/W R/W R/W R/W R/W R/W R/W

uv1_9 uv1_8 uv1_7 uv1_6 uv1_5 uv1_4 uv1_3 uv1_2 0x00

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Description: Undervoltage warning threshold low-order bits [1:0]

Register Titles: uv1_ch1_l uv1_ch2_l uv1_ch3_l uv1_ch4_l

Register Addresses: 0x33 0x3D 0x47 0x51

R/W R/W R/W R/W R/W R/W R/W R/W

uv1_1 uv1_0 0x00

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

RESET

VALUE

RESET

VALUE

Description: Undervoltage critical threshold high-order bits [9:2]

Register Titles: uv2_ch1_h uv2_ch2_h uv2_ch3_h uv2_ch4_h

Register Addresses: 0x34 0x3E 0x48 0x52

R/W R/W R/W R/W R/W R/W R/W R/W

uv2_9 uv2_8 uv2_7 uv2_6 uv2_5 uv2_4 uv2_3 uv2_2 0x00

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Description: Undervoltage critical threshold low-order bits [1:0]

Register Titles: uv2_ch1_l uv2_ch2_l uv2_ch3_l uv2_ch4_l

Register Addresses: 0x35 0x3F 0x49 0x53

R/W R/W R/W R/W R/W R/W R/W R/W

uv2_1 uv2_0 0x00

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

RESET

VALUE

RESET

VALUE

Page 28

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

28 ______________________________________________________________________________________

Table 25. Overvoltage Warning Threshold Register Format (High-Order Bits)

Table 26. Overvoltage Warning Threshold Register Format (Low-Order Bits)

Table 27. Overvoltage Critical Threshold Register Format (High-Order Bits)

Table 28. Overvoltage Critical Threshold Register Format (Low-Order Bits)

Description: Overvoltage warning threshold high-order bits [9:2]

Register Titles: ov1_ch1_h ov1_ch2_h ov1_ch3_h ov1_ch4_h

Register Addresses: 0x36 0x40 0x4A 0x54

R/W R/W R/W R/W R/W R/W R/W R/W

ov1_9 ov1_8 ov1_7 ov1_6 ov1_5 ov1_4 ov1_3 ov1_2 0xFF

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Description: Overvoltage warning threshold low-order bits [1:0]

Register Titles: ov1_ch1_l ov1_ch2_l ov1_ch3_l ov1_ch4_l

Register Addresses: 0x37 0x41 0x4B 0x55

R/W R/W R/W R/W R/W R/W R/W R/W

ov1_1 ov1_0 0x03

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Description: Overvoltage critical threshold high-order bits [9:2]

Register Titles: ov2_ch1_h ov2_ch2_h ov2_ch3_h ov2_ch4_h

Register Addresses: 0x38 0x42 0x4C 0x56

R/W R/W R/W R/W R/W R/W R/W R/W

ov2_9 ov2_8 ov2_7 ov2_6 ov2_5 ov2_4 ov2_3 ov2_2 0xFF

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

RESET

VALUE

RESET

VALUE

RESET

VALUE

Description: Overvoltage critical threshold low-order bits [1:0]

Register Titles: ov2_ch1_l ov2_ch2_l ov2_ch3_l ov2_ch4_l

Register Addresses: 0x39 0x43 0x4D 0x57

R/W R/W R/W R/W R/W R/W R/W R/W

ov2_1 ov2_0 0x03

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

RESET

VALUE

Page 29

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

______________________________________________________________________________________ 29

If PG_ is asserted and the voltage is outside the warning limits, the ALERT output is asserted low. Depending

on the status of the prot[] bits in register status1[7:6],

the MAX5961 can also deassert the PG_ output or turn

off the external MOSFET when the voltage is outside the

critical limits (see Figure 4). Table 29 shows the behavior for the three possible states of the PROT input. Note

that the PROT input does not affect the MAX5961

response to the UV or OV warning digital comparators;

it only determines the system response to the critical

digital comparators (see Tables 4a, 4b, and 29).

In a typical application, the UV1 and OV1 thresholds

would be set closer to the nominal output voltage, and

the UV2 and OV2 thresholds would be set further from

nominal (see Figure 4). This provides a “progressive”

response to a voltage excursion. However, the thresholds can be configured in any arrangement or combination as desired to suit a given application.

Table 29. PROT Input and prot[] Bits

Figure 4. Graphical Representation of Typical UV and OV Thresholds Configuration

PROT INPUT

STATE

Unconnected 0 0 Assert ALERT Assert ALERT

High 0 1 Assert ALERT Assert ALERT, clear PG_

Low 1 0 Assert ALERT Assert ALERT, clear PG_, and shutdown channel(s)

prot[1] prot[0]

UV/OV WARNING

ACTION

UV/OV CRITICAL ACTION

OV2 "CRITICAL" THRESHOLD

OV1 "WARNING" THRESHOLD

UV1 "WARNING" THRESHOLD

UV2 "CRITICAL" THRESHOLD

Page 30

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

30 ______________________________________________________________________________________

Power-Good Detection and PG_ Outputs

The PG_ output for a given channel is asserted when

the voltage at MON_ is between the undervoltage and

overvoltage critical limits. The status of the power-good

signals is maintained in register status3[3:0]. A value of

1 in any of the pg[] bits indicates a power-good condition, regardless of the POL setting, which only affects

the PG_ output polarity. The open-drain PG_ output can

be configured for active-high or active-low status indication by the state of the POL input (see Table 30).

The POL input sets the value of bit 5 of the status3 register, which is a read-only bit; the state of the POL input

can be changed at any time during operation and the

polarity of the PG_ outputs will change accordingly.

The assertion of the PG_ output is delayed by a userselectable time delay of 50ms, 100ms, 200ms, or

400ms (see Tables 31a and 31b).

Table 30. status3 Register Format

Table 31a. Power-Good Assertion Delay-Time Register Format

Table 31b. Power-Good Assertion Delay

Description: Power-good status register; RETRY, POL, and alert bits

Register Title: status3

Register Address: 0x62

R R R R/W R R R R

RETRY POL alert pg[4] pg[3] pg[2] pg[1] —

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Description: Power-good assertion delay-time register

Register Title: pgdly

Register Address: 0x66

RESET

VALUE

R/W R/W R/W R/W R/W R/W R/W R/W

Ch4_dly1 Ch4_dly0 Ch3_dly1 Ch3_dly0 Ch2_dly1 Ch2_dly0 Ch1_dly1 Ch1_dly0 0x00

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Chx_dly1 Chx_dly0 PG_ ASSERTION DELAY (ms)

00 50

0 1 100

1 0 200

1 1 400

RESET

VALUE

Page 31

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

______________________________________________________________________________________ 31

Minimum and Maximum Value Detection

for Voltage Measurement Values

All voltage measurement values are compared with the

contents of minimum- and maximum-value registers,

and if the most recent measurement exceeds the

stored maximum or is less than the stored minimum, the

corresponding register is updated with the new value.

These peak detection registers are read/write accessible through the I

2

C interface (see Tables 32–35). The

minimum-value registers are reset to 0x3FF, and the

maximum-value registers are reset to 0x000. These

reset values are loaded upon startup of a channel or at

any time as commanded by register peak_log_rst (see

Table 36).

Table 32. ADC Minimum Voltage Conversion Register Format (High-Order Bits)

Table 33. ADC Minimum Voltage Conversion Register Format (Low-Order Bits)

Table 34. ADC Maximum Voltage Conversion Register Format (High-Order Bits)

Description: Minimum voltage conversion result, high-order bits [9:2]

Register Titles: min_ch1_mon_h min_ch2_mon_h min_ch3_mon_h min_ch4_mon_h

Register Addresses: 0x14 0x1C 0x24 0x2C

R/W R/W R/W R/W R/W R/W R/W R/W

vmin_9 vmin_8 vmin_7 vmin_6 vmin_5 vmin_4 vmin_3 vmin_2 0xFF

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Description: Minimum voltage conversion result, low-order bits [1:0]

Register Titles: min_ch1_mon_l min_ch2_mon_l min_ch3_mon_l min_ch4_mon_l

Register Addresses: 0x15 0x1D 0x25 0x2D

RESET

VALUE

R/W R/W R/W R/W R/W R/W R/W R/W

vmin_1 vmin_0 0x03

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Description: Maximum voltage conversion result, high-order bits [9:2]

Register Titles: max_ch1_mon_h max_ch2_mon_h max_ch3_mon_h max_ch4_mon_h

Register Addresses: 0x16 0x1E 0x26 0x2E

R/W R/W R/W R/W R/W R/W R/W R/W

vmax_9 vmax_8 vmax_7 vmax_6 vmax_5 vmax_4 vmax_3 vmax_2 0x00

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

RESET

VALUE

RESET

VALUE

Page 32

MAX5961

0 to 16V, Quad, Hot-Swap Controller

with 10-Bit Current and Voltage Monitor

32 ______________________________________________________________________________________

Using the Voltage and

Current Peak-Detection Registers

The voltage and current minimum- and maximum-value

records in register locations 0x10 through 0x2F can be

reset by writing a 1 to the appropriate location in register peak_log_rst (see Table 36). The minimum-value

registers are reset to 0x3FF, and the maximum-value

registers are reset to 0x000.

As long as a bit in register peak_log_rst is 1, the corresponding peak-detection registers are disabled and

are “cleared” to their power-up reset values. The voltage and current minimum- and maximum-detection

register contents for each signal can be “held” by setting bits in register peak_log_hold (see Table 37).

Writing a 1 to a location in register peak_log_hold locks

the register contents for the corresponding signal and

stops the min/max detection and logging; writing a 0

enables the detection and logging. Note that the peakdetection registers cannot be cleared while they are

held by register peak_log_hold.

The combination of these two control registers allows

the user to monitor voltage and current peak-to-peak

values during a particular time period.

Table 35. ADC Maximum Voltage Conversion Register Format (Low-Order Bits)

Table 36. Peak-Detection Reset-Control Register Format

Table 37. Peak-Detection Hold-Control Register Format

Description: Maximum voltage conversion result, low-order bits [1:0]

Register Titles: max_ch1_mon_l max_ch2_mon_l max_ch3_mon_l max_ch4_mon_l

Register Addresses: 0x17 0x1F 0x27 0x2F

R/W R/W R/W R/W R/W R/W R/W R/W

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Description: Reset control bits for peak-detection registers

Register Title: peak_log_rst

Register Address: 0x73

R/W R/W R/W R/W R/W R/W R/W R/W

ch4_v_rst ch4_i_rst ch3_v_rst ch3_i_rst ch2_v_rst ch2_i_rst ch1_v_rst ch1_i_rst 0x00

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

RESET

VALUE

vmax_1 vmax_0 0x00

RESET

VALUE