Page 1

General Description

The MAX5945 quad network power controller is designed

for use in IEEE 802.3af-compliant power-sourcing equipment (PSE). The device provides power devices (PD) discovery, classification, current-limit, and both DC and AC

load disconnect detections. The MAX5945 can be used

in either endpoint PSE (LAN switches/routers) or midspan

PSE (power injector) applications. The MAX5945 is pin

and function compatible with LTC4259A.

The MAX5945 can operate autonomously or be controlled by software through an I2C*-compatible interface. Separate input and output data lines (SDAIN and

SDAOUT) allow usage with optocouplers. The

MAX5945 is a slave device. Its four address inputs

allow 16 unique MAX5945 addresses. A separate INT

output and four independent shutdown inputs (SHD_)

allow fast response from a fault to port shutdown. A

RESET input allows hardware reset of the device. A

special watchdog feature allows the hardware to gracefully take over control if the software crashes. A

cadence timing feature allows the MAX5945 to be used

in midspan systems.

The MAX5945 is fully software configurable and programmable. A class-overcurrent detection function enables

system power management to detect if a PD draws more

current than the allowable amount for its class. Other features are input under/overvoltage lockout, overtemperature protection, output-voltage slew-rate limit during

startup, power-good, and fault status. The MAX5945’s

programmability includes gate-charging current, currentlimit threshold, startup timeout, overcurrent timeout,

autorestart duty cycle, PD disconnect AC detection

threshold, and PD disconnect detection timeout.

The MAX5945 is available in a 36-pin SSOP package

and is rated for both extended (-40°C to +85°C) and

commercial (0°C to +70°C) temperature ranges.

Applications

Power-Sourcing Equipment (PSE)

Power-Over-LAN/Power-Over-Ethernet

Switches/Routers

Midspan Power Injectors

Features

♦ IEEE 802.3af Compliant

♦ Pin and Function Compatible with LTC4259A

♦ Controls Four Independent, -48V-Powered

Ethernet Ports in Either Endpoint or Midspan PSE

Applications

♦ Wide Digital Power Input, V

DIG

, Common-Mode

Range: VEEto (AGND + 7.7V)

♦ PD Violation of Class Current Protection

♦ PD Detection and Classification

♦ Provides Both DC and AC Load Removal

Detections

♦ I2C-Compatible, 3-Wire Serial Interface

♦ Fully Programmable and Configurable Operation

Through I

2

C Interface

♦ Current Foldback and Duty-Cycle-

Controlled/Programmable Current Limit

♦ Short-Circuit Protection with Fast Gate Pulldown

♦ Direct Fast Shutdown Control Capability

♦ Programmable Direct Interrupt Output

♦ Watchdog Mode Enable Hardware Graceful

Takeover

MAX5945

Quad Network Power Controller

for Power-Over-LAN

________________________________________________________________ Maxim Integrated Products 1

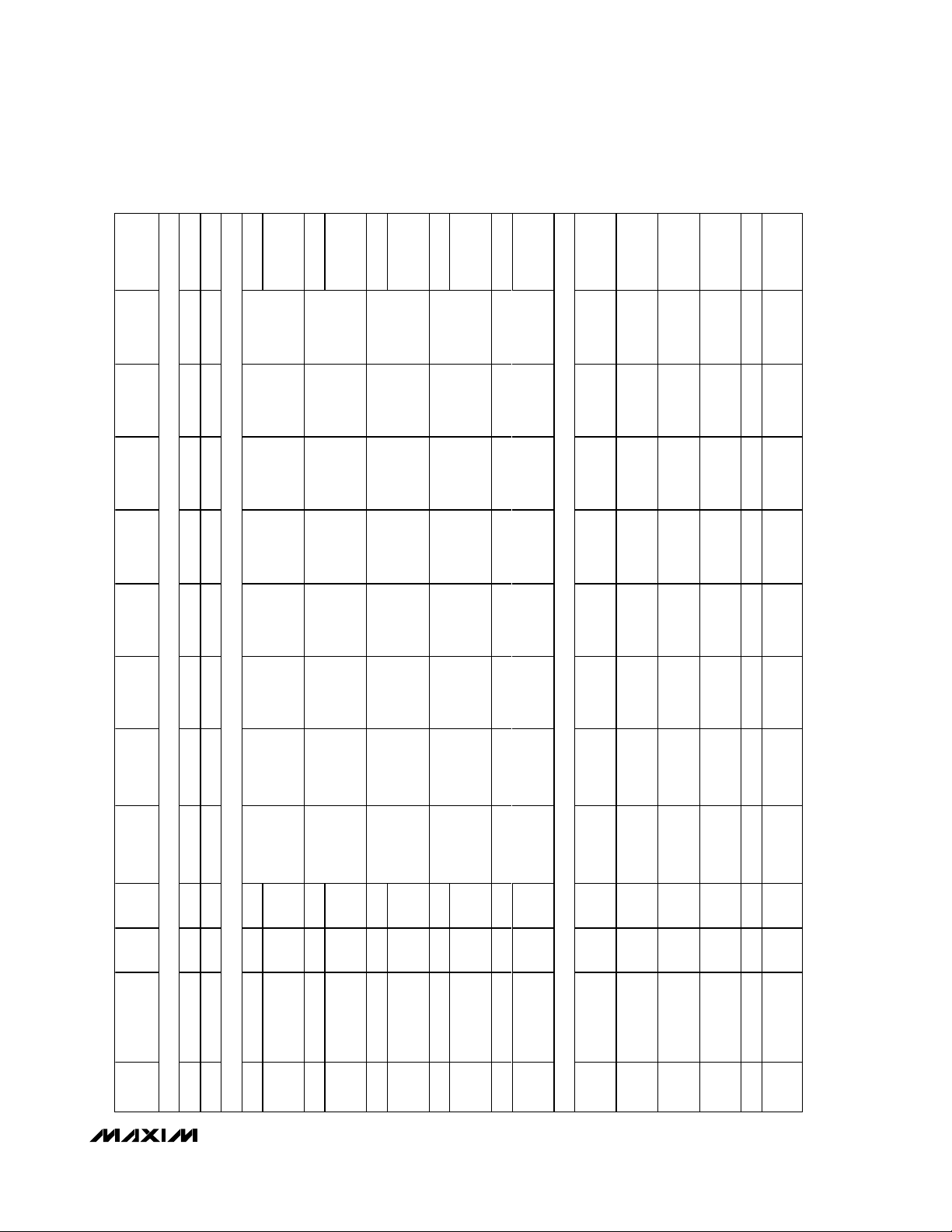

Pin Configuration

19-3428; Rev 1; 9/05

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

Ordering Information

*Purchase of I2C components from Maxim Integrated

Products, Inc. or one of its sublicensed Associated

Companies, conveys a license under the Philips I

2

C Patent

Rights to use these components in an I

2

C system, provided

that the system conforms to the I

2

C Standard Specification as

defined by Philips.

**Future product—contact factory for availability.

Typical Operating Circuits appear at end of data sheet.

PART TEMP RANGE PIN-PACKAGE

MAX5945CAX** 0°C to +70°C 36 SSOP

MAX5945EAX -40°C to +85°C 36 SSOP

TOP VIEW

RESET

MIDSPAN

SDAOUT

SDAIN

DET1

DET2

DET3

DET4

DGND

SHD1

SHD2

1

2

3

INT

4

SCL

5

6

7

A3

8

A2

9

A1

10

A0

11

12

13

14

15

16

DD

17

18

OSC_IN

36

AUTO

35

OUT1

34

33

GATE1

32

MAX5945

SSOP

SENSE1

31

OUT2

GATE2

30

SENSE2

29

V

28

EE

OUT3

27

GATE3

26

SENSE3

25

OUT4

24

GATE4

23

22

SENSE4

21

AGNDV

20

SHD4

19

SHD3

Page 2

MAX5945

Quad Network Power Controller

for Power-Over-LAN

2 _______________________________________________________________________________________

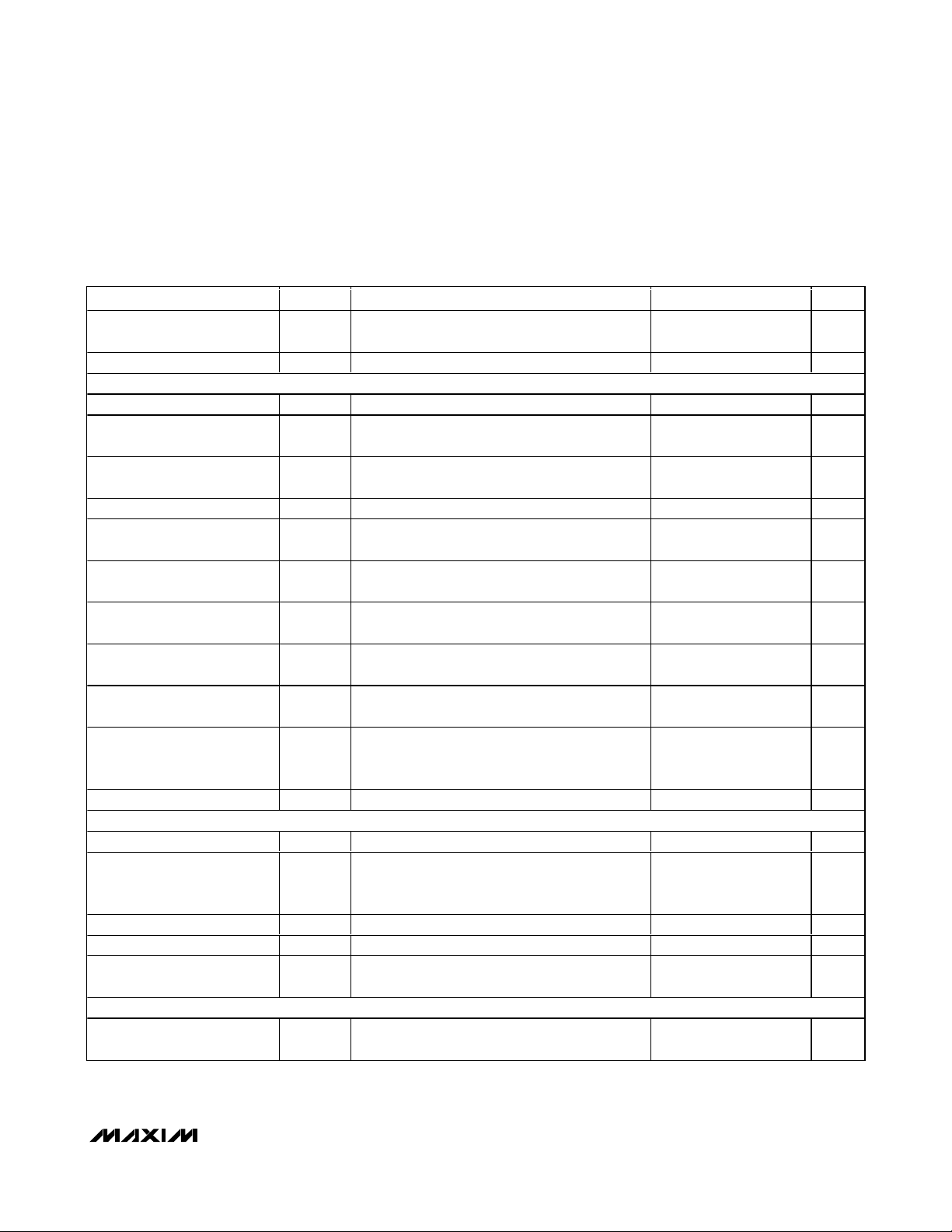

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

(Voltages referenced to VEE, unless otherwise noted.)

AGND, DGND, DET_, V

DD

, RESET, A3, A2, A1, A0, SHD_,

OSC_IN, SCL, SDAIN, OUT_ and AUTO............-0.3V to +80V

GATE_ (internally clamped, Note 1)....................-0.3V to +11.4V

SENSE_ ..................................................................-0.3V to +24V

V

DD

, RESET, A3, A2, A1, A0, SHD_, OSC_IN, SCL, SDAIN and

AUTO to DGND ....................................................-0.3V to +7V

INT and SDAOUT to DGND....................................-0.3V to +12V

Maximum Current into INT, SDAOUT, DET_ .......................80mA

Maximum Power Dissipation

36-Pin SSOP (derate 11.4mW/°C above +70°C) .........941mW

Operating Temperature Ranges:

MAX5945EAX ..................................................-40°C to +85°C

MAX5945CAX .....................................................0°C to +70°C

Storage Temperature Range .............................-65°C to +150°C

Junction Temperature......................................................+150°C

Lead Temperature (soldering, 10s) .................................+300°C

ELECTRICAL CHARACTERISTICS

(AGND = +32V to +60V, VEE= 0V, VDDto DGND = +3.3V, all voltages are referenced to VEE, unless otherwise noted. Typical

values are at AGND = +48V, DGND = +48V, V

DD

= (DGND + 3.3V), TA= +25°C. Currents are positive when entering the pin and

negative otherwise.)

Note 1: GATE_ is internally clamped to 11.4V above VEE. Driving GATE_ higher than 11.4V above VEEmay damage the device.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

POWER SUPPLIES

V

AGNDVAGND

V

Operating Voltage Range

Supply Currents

DGND

V

DD

I

EE

I

DIG

GATE DRIVER AND CLAMPING

GATE_ Pullup Current I

Weak GATE_ Pulldown Current I

Maximum Pulldown Current I

External Gate Drive V

PU

PDW

PDS

GS

CURRENT LIMIT

Current-Limit Clamp Voltage V

Overcurrent Threshold After

Startup

Foldback Initial OUT_ Voltage V

Foldback Final OUT_ Voltage V

SU_LIM

V

FLT_LIM

FLBK_ST

FLBK_END

- V

EE

VDD to V

VDD to V

DGND, VDGND

DGND, VDGND

OUT_ = VEE, SENSE_ = VEE, DET_ = AGND,

all logic inputs open, SCL = SDAIN = V

INT and SDAOUT open; measured at AGND

in power mode after GATE_ pullup

All logic inputs high, measured at V

Power mode, gate drive on, V

SHD_ = DGND, V

V

= 1V, V

SENSE

V

- VEE , power mode, gate drive on 9 10 11 V

GATE

Maximum V

V

OUT_

Overcurrent V

SENSE_

= VEE (Note 3)

SENSE_

threshold allowed for

t ≤ t

V

OUT_

V

OUT_

after startup;

FAULT

= V

EE

- VEE, above which the current-limit trip

voltage starts folding back

V

- VEE, above which the current-limit trip

OUT_

voltage reaches V

32 60

060

= V

AGND

= V

EE

DD

= V

GATE

= V

GATE_

= V

GATE_

allowed during current limit,

+ 5V 30 40 50 µA

EE

+ 2V 100 mA

EE

Default, class 0,

class 3, class 4

,

DD

(Note 2) -40 -50 -60 µA

EE

1.71 5.50

3.0 5.5

4.2 6.8

2.7 5.6

202 212 220 mV

178.5 196

Class 1 49 61

Class 2 90 104

30 V

TH_FB

50 V

V

mA

mV

Page 3

MAX5945

Quad Network Power Controller

for Power-Over-LAN

_______________________________________________________________________________________ 3

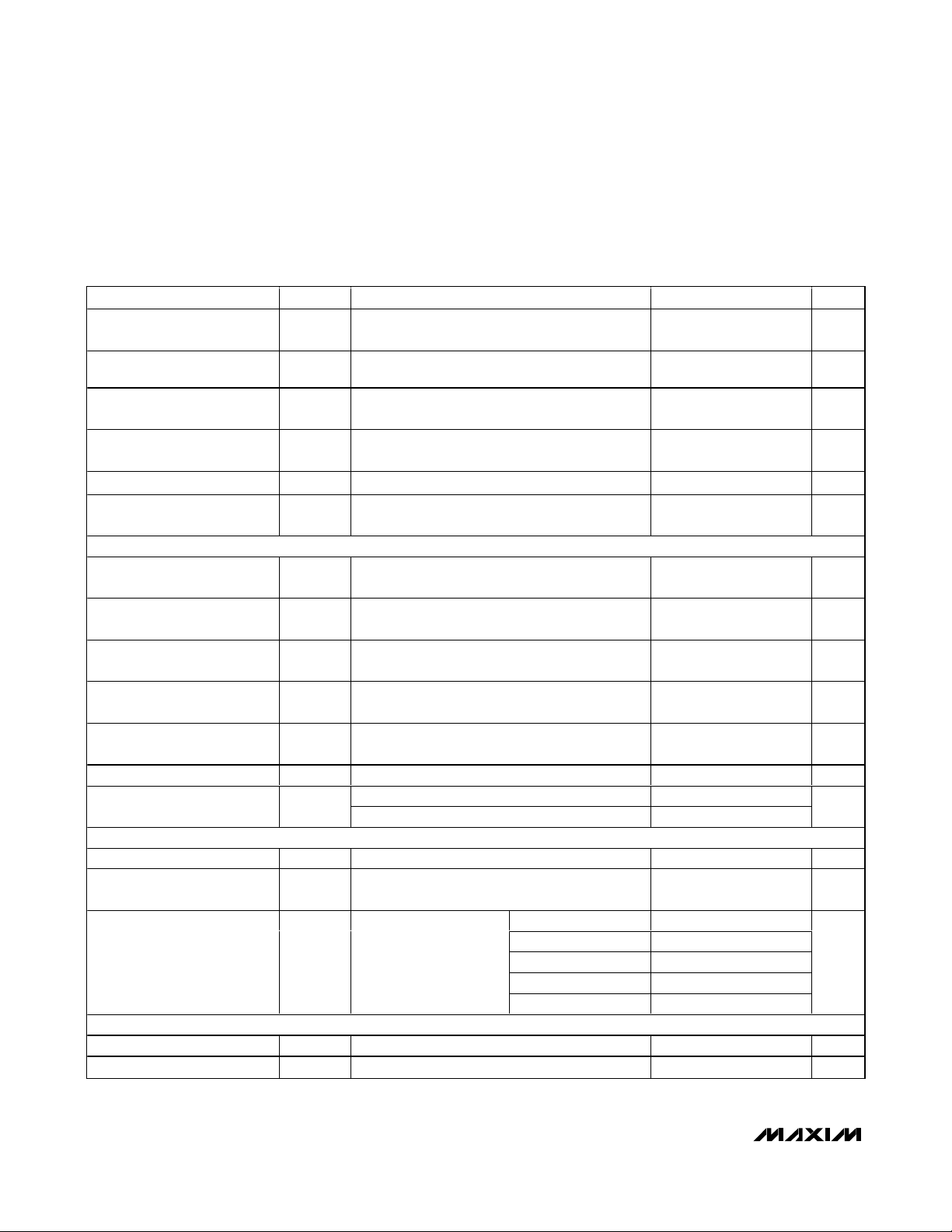

ELECTRICAL CHARACTERISTICS (continued)

(AGND = +32V to +60V, VEE= 0V, VDDto DGND = +3.3V, all voltages are referenced to VEE, unless otherwise noted. Typical

values are at AGND = +48V, DGND = +48V, V

DD

= (DGND + 3.3V), TA= +25°C. Currents are positive when entering the pin and

negative otherwise.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Minimum Foldback CurrentLimit Threshold

V

TH_FBVOUT_

SENSE_ Input Bias Current V

SUPPLY MONITORS

VEE Undervoltage Lockout V

VEE Undervoltage-Lockout

Hysteresis

VEE Overvoltage V

VEE Overvoltage Hysteresis V

VEE Undervoltage V

VDD Overvoltage V

VDD Undervoltage V

VDD Undervoltage Lockout V

VDD Undervoltage-Lockout

Hysteresis

Thermal-Shutdown Threshold T

Thermal-Shutdown Hysteresis T

EEUVLOVAGND

V

EEUVLOH

EE_OV

OVH

EE_UV

DD_OV(VDD

DD_UV(VDD

DDUVLO

V

DDHYS

SHD

SHDH

OUTPUT MONITOR

OUT_ Input Current I

Idle Pullup Current at OUT_ I

PGOOD High Threshold PG

PGOOD Hysteresis PG

PGOOD Low-to-High Glitch

Filter

BOUT

DIS

TH

HYS

t

PGOOD

LOAD DISCONNECT

DC Load Disconnect

Threshold

V

DCTH

= V

SENSE_

AGND

= V

EE

- VEE, (V

- VEE) increasing 27 28.5 30 V

AGND

64 mV

-2 µA

3V

(V

AGND

- VEE) > V

EE_OV

, V

increasing 61 62.5 64 V

AGND

1V

(V

- VEE) < V

AGND

- V

- V

DGND)

DGND

> V

) < V

Device operates when (VDD - V

V

DDUVLO

, VDD increasing

EE_UV

DD_OV

DD_UV

, V

decreasing 39 40 41 V

AGND

, VDD increasing 3.57 3.71 3.90 V

, VDD decreasing 2.55 2.82 2.97 V

) >

DGND

1.7 V

120 mV

Ports shut down and device resets if its junction

temperature exceeds this limit, temperature

+150 °C

increasing

20 °C

V

OUT

= V

, all modes 2 µA

AGND

OUT_ discharge current, detection and

classification off, port shutdown,

V

= V

OUT_

V

- VEE, OUT_ decreasing 1.8 2.0 2.2 V

OUT_

AGND

- 2.8V

200 260 µA

220 mV

Minimum time PGOOD has to be high to set bit in

register 10h

Minimum V

disconnect active), V

allowed before disconnect (DC

SENSE

OUT_

= V

EE

24ms

345mV

Page 4

MAX5945

Quad Network Power Controller

for Power-Over-LAN

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(AGND = +32V to +60V, VEE= 0V, VDDto DGND = +3.3V, all voltages are referenced to VEE, unless otherwise noted. Typical

values are at AGND = +48V, DGND = +48V, V

DD

= (DGND + 3.3V), TA= +25°C. Currents are positive when entering the pin and

negative otherwise.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

AC Load Disconnect

Threshold (Note 4)

Oscillator Buffer Gain A

OSC_IN Fail Threshold

(Note 5)

OSC_IN Input Resistance Z

OSC_IN Input Capacitance C

Load Disconnect Timer t

I

ACTH

OSC

V

OS C _F AI L

OSC

OSC_IN

DISC

DETECTION

Detection Probe Voltage

(First Phase)

Detection Probe Voltage

(Second Phase)

Current-Limit Protection I

Short-Circuit Threshold V

Open-Circuit Threshold I

Resistor Detection Window R

Resistor Rejection Window R

V

DPH1VAGND

V

DPH2

DLIM

DCP

D_OPEN

DOK

DBAD

CLASSIFICATION

Classification Probe Voltage V

Current-Limit Protection I

Classification Current

Thresholds

CL

ClLIM

I

CL

DIGITAL INPUTS/OUTPUTS (REFERRED to DGND)

Digital Input Low V

Digital Input High V

IL

IH

Current into DET_, ACD_EN_ bit = high,

OSC_IN = 2.2V

V

/ V

DET_

= 400nF

C

DET

Port will not power on if V

, ACD_EN_ bit = high,

OSC_IN

OSC_IN

< V

OSC_FAIL

and

ACD_EN_ bit = high

OSC_IN input impedance when all the ACD_EN_

are active

300 325 350 µA

2.92 2.98 3.04 V/V

1.8 1.9 2.1 V

100 kΩ

5pF

Time from V

to gate shutdown (Note 6)

< I

ACTH

- V

V

- V

AGND

phase

V

= V

DET_

current through DET_

If V

A GN D

- V

p hase a shor t ci r cui t to AG N D i s d etected

First point measurement current threshold for

open condition

< V

SENSE

during the first detection phase 3.8 4 4.2 V

DET_

during the second detection

DET_

, during detection, measure

AGND

< V

OU T

or current into DET_

DCTH

after the fi r st d etecti on

D C P

300 400 ms

9.0 9.3 9.6 V

1.5 1.75 2.0 mA

1.62 V

12.5 µA

(Note 7) 18.6 26.5 kΩ

Detection rejects lower values 16

Detection rejects higher values 30

V

- V

AGND

V

= V

DET_

measure current through DET_

during classification 16 20 V

DET_

, during classification,

AGND

50 75 mA

Class 0, class 1 5.5 6.5 7.5

Classification current

thresholds between

classes

Class 1, class 2 13.5 14.5 15.5

Class 2, class 3 21.5 23 24.5

Class 3, class 4 31 33 35

>Class 4 45 48 51

0.9 V

2.4 V

kΩ

mA

Page 5

MAX5945

Quad Network Power Controller

for Power-Over-LAN

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(AGND = +32V to +60V, VEE= 0V, VDDto DGND = +3.3V, all voltages are referenced to VEE, unless otherwise noted. Typical

values are at AGND = +48V, DGND = +48V, V

DD

= (DGND + 3.3V), TA= +25°C. Currents are positive when entering the pin and

negative otherwise.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Internal Input Pullup/Pulldown

Resistor

Open-Drain Output Low

Voltage

Open-Drain Leakage I

TIMING

Startup Time t

Fault Time t

Port Turn-Off Time t

Detection Time t

Midspan Mode Detection

Delay

Classification Time t

V

Restart Timer t

Watchdog Clock Period t

TIMING CHARACTERISTICS for 2-WIRE FAST MODE (Figures 5 and 6)

Serial Clock Frequency f

Bus Free Time Between a

STOP and a START Condition

Hold Time for Start Condition t

Low Period of the SCL Clock t

High Period of the SCL Clock t

Turn-On Delay t

EEUVLO

R

DIN

V

OL

OL

START

FAULT

OFF

DET

t

DMID

CLASS

DLY

RESTART

WD

SCL

t

BUF

HD, STA

LOW

HIGH

Pullup (pulldown) resistor to VDD (DGND) to set

default level

I

= 15mA 0.4 V

SINK

Open-drain high impedance, VO = 3.3V 2 µA

Time during which a current limit set by V

is allowed, starts when the GATE_

is turned on (Note 8)

Maximum allowed time for an overcurrent

condition set by V

Minimum delay between any port turning off,

does not apply in the case of a reset

Maximum time allowed before detection

is completed

Time allowed for classification 40 ms

Time V

thresholds before the device operates

Ti m e a p or t has to w ai t

b efor e tur ni ng on after an

over cur r ent faul t,

RS TR_E N b i t = hi g h

Rate of decrement of the watchdog timer 164 ms

(Note 9) 400 kHz

(Note 9) 1.2 µs

(Note 9) 0.6 µs

(Note 9) 1.2 µs

(Note 9) 0.6 µs

must be above the V

AGND

after startup (Note 8)

FLT_LIM

RSTR bits = 00

RSTR bits = 01

RSTR bits = 10

RSTR bits = 11 0

SU_LIM

EEUVLO

25 50 75 kΩ

50 60 70 ms

50 60 70 ms

0.5 0.75 1.0 ms

320 ms

2.0 2.4 s

24ms

16 x

t

FAULT

32 x

t

FAULT

64 x

t

FAULT

ms

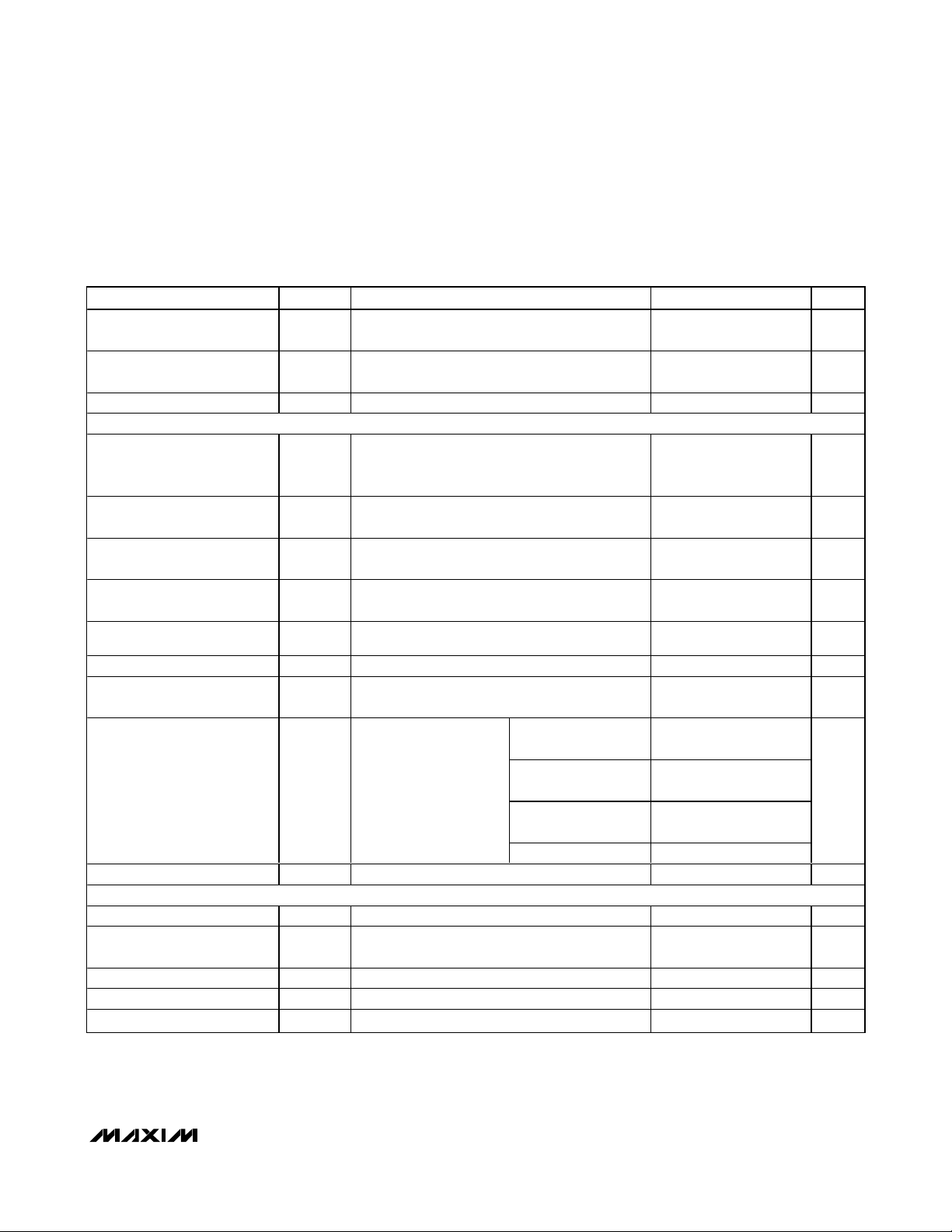

Page 6

MAX5945

Quad Network Power Controller

for Power-Over-LAN

6 _______________________________________________________________________________________

Note 2: Default values. The charge/discharge currents are programmable through the serial interface (see the Register Map and

Description section).

Note 3: Default values. The current-limit thresholds are programmed through the I

2

C-compatible serial interface (see the Register

Map and Description section).

Note 4: This is the default value. Threshold can be programmed through serial interface R23h[2:0].

Note 5: AC disconnect works only if V

DD

- V

DGND

≥ 3V.

Note 6: t

DISC

can also be programmed through the serial interface (R29h) (see the Register Map and Description section).

Note 7: R

D

= (V

OUT_2

- V

OUT_1

) / (I

DET_2

- I

DET_1

). V

OUT_1

, V

OUT_2

, I

DET_2

and I

DET_1

represent the voltage at OUT_ and the current

at DET_ during phase 1 and 2 of the detection.

Note 8: Default values. The startup and fault times can also be programmed through the I

2

C serial interface (see the Register Map

and Description section).

Note 9: Guaranteed by design. Not subject to production testing.

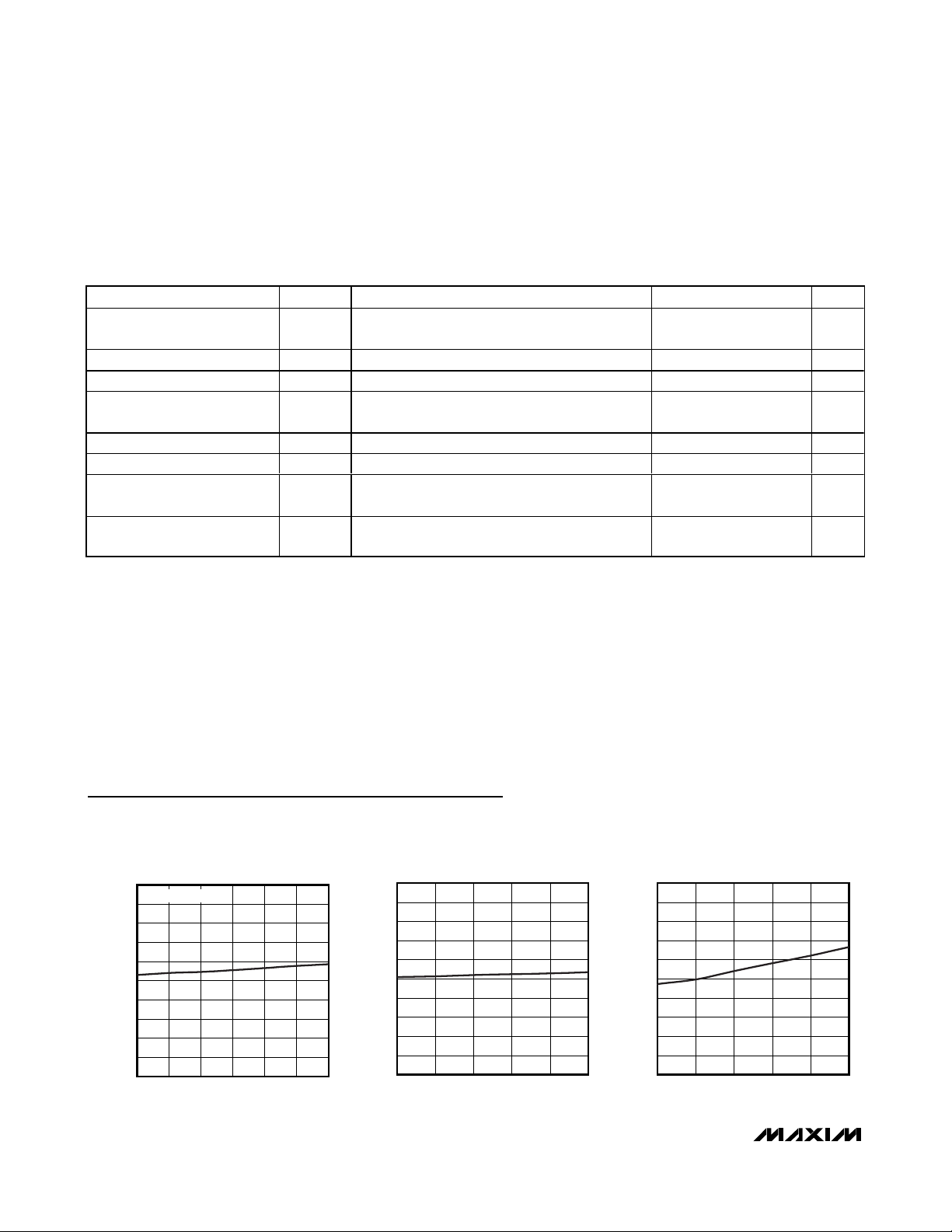

ANALOG SUPPLY CURRENT

vs. INPUT VOLTAGE

MAX5945 toc01

INPUT VOLTAGE (V)

SUPPLY CURRENT (mA)

5752474237

3.6

3.7

3.8

3.9

4.0

4.1

4.2

4.3

4.4

4.5

3.5

32 62

MEASURED AT AGND

ANALOG SUPPLY CURRENT

vs. TEMPERATURE

MAX5945 toc02

TEMPERATURE (°C)

SUPPLY CURRENT (mA)

603510-15

3.2

3.4

3.6

3.8

4.0

4.2

4.4

4.6

4.8

5.0

3.0

-40 85

DIGITAL SUPPLY CURRENT

vs. TEMPERATURE

MAX5945 toc03

TEMPERATURE (°C)

SUPPLY CURRENT (mA)

603510-15

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

0

-40 85

Typical Operating Characteristics

(VEE= -48V, VDD= +3.3V, AUTO = AGND = DGND = 0V, RESET = SHD_ = unconnected, R

SENSE

= 0.5Ω, all registers = default setting,

T

A

= +25°C, unless otherwise noted.)

ELECTRICAL CHARACTERISTICS (continued)

(AGND = +32V to +60V, VEE= 0V, VDDto DGND = +3.3V, all voltages are referenced to VEE, unless otherwise noted. Typical

values are at AGND = +48V, DGND = +48V, V

DD

= (DGND + 3.3V), TA= +25°C. Currents are positive when entering the pin and

negative otherwise.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Setup Time for a Repeated

START Condition (Sr)

Data Hold Time t

Data Setup Time t

Rise Time of Both SDA and

SCL Signals, Receiving

Fall Time of SDA Transmitting t

Setup Time for STOP Condition t

C ap aci ti ve Load for E ach Bus

Li ne

Pulse Width of Spike

Suppressed

t

SU, STA

HD, DAT

SU, DAT

t

R

F

SU, STO

C

B

t

SP

(Note 9) 0.6 µs

(Note 9) 0 150 ns

(Note 9) 100 ns

(Note 9) 20 + 0.1C

(Note 9) 20 + 0.1C

B

B

300 ns

300 ns

(Note 9) 0.6 µs

(Note 9) 400 pF

(Note 9) 50 ns

Page 7

MAX5945

Quad Network Power Controller

for Power-Over-LAN

_______________________________________________________________________________________ 7

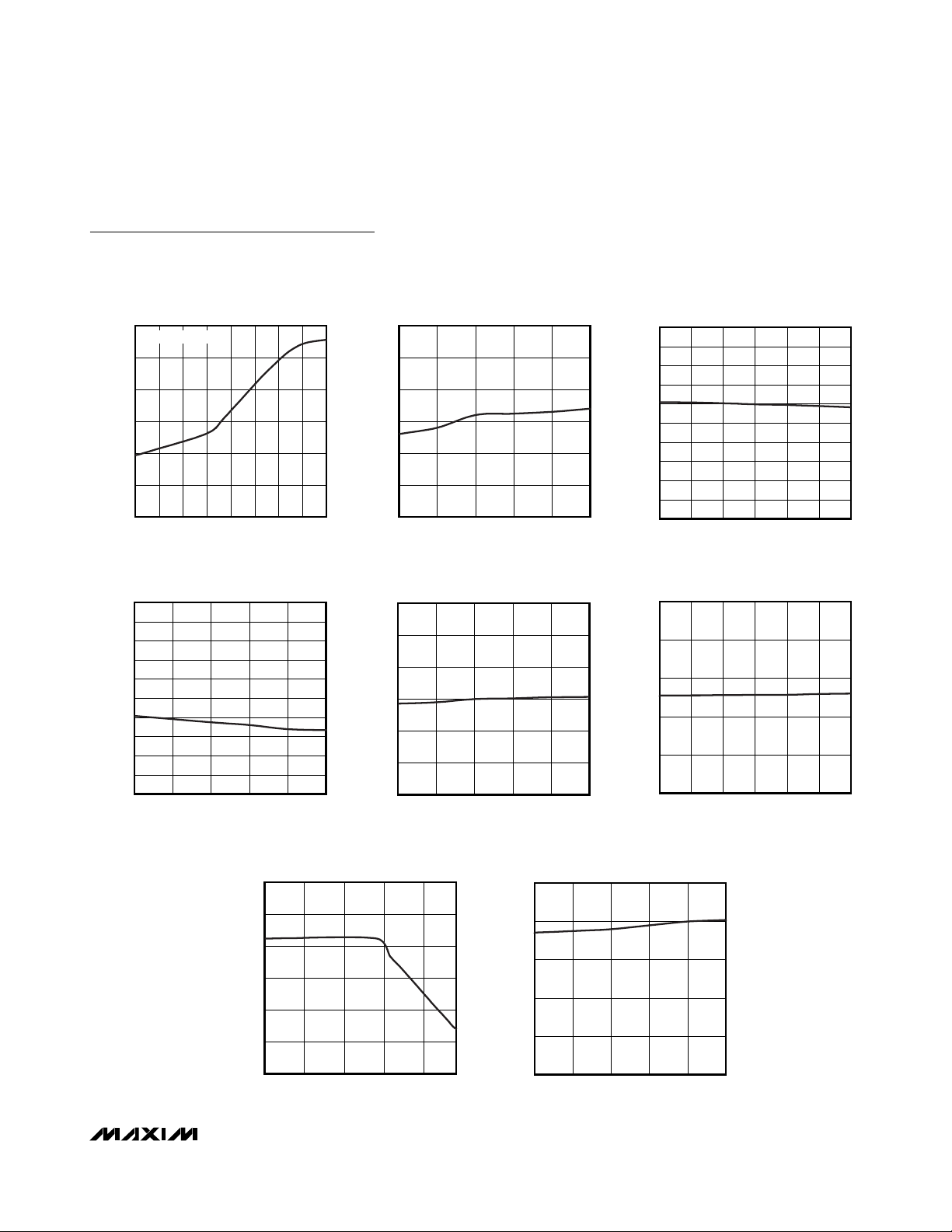

Typical Operating Characteristics (continued)

(VEE= -48V, VDD= +3.3V, AUTO = AGND = DGND = 0V, RESET = SHD_ = unconnected, R

SENSE

= 0.5Ω, all registers = default setting,

T

A

= +25°C, unless otherwise noted.)

DIGITAL SUPPLY CURRENT

vs. INPUT VOLTAGE

6

MEASURED AT V

5

4

3

2

SUPPLY CURRENT (mA)

1

0

1.8 5.0

DD

INPUT VOLTAGE (V)

GATE OVERDRIVE

vs. TEMPERATURE

10.5

10.4

10.3

10.2

10.1

10.0

9.9

GATE OVERDRIVE (V)

9.8

9.7

9.6

9.5

-40 85

TEMPERATURE (°C)

30.0

29.5

MAX5945 toc04

29.0

28.5

28.0

UNDERVOLTAGE LOCKOUT (V)

27.5

4.64.23.83.43.02.62.2

603510-15

27.0

MAX5945 toc07

SENSE TRIP VOLTAGE (mV)

VEE UNDERVOLTAGE LOCKOUT

vs. TEMPERATURE

-40 85

TEMPERATURE (°C)

SENSE TRIP VOLTAGE

vs. TEMPERATURE

200

195

190

185

180

175

170

-40 85

TEMPERATURE (°C)

MAX5945 toc05

603510-15

MAX5945 toc08

603510-15

GATE OVERDRIVE

vs. INPUT VOLTAGE

9.98

9.96

9.94

9.92

9.90

9.88

9.86

GATE OVERDRIVE (V)

9.84

9.82

9.80

9.78

32 62

INPUT VOLTAGE (V)

SENSE TRIP VOLTAGE

vs. INPUT VOLTAGE

190

188

186

184

SENSE TRIP VOLTAGE (mV)

182

180

32 62

INPUT VOLTAGE (V)

MAX5945 toc06

5752474237

MAX5945 toc09

5752474237

FOLDBACK CURRENT-LIMIT

THRESHOLD vs. OUTPUT VOLTAGE

300

250

200

(mV)

EE

150

- V

SENSE

V

100

50

0

050

V

- VEE (V)

OUT

MAX5945 toc10

DETECTION THRESHOLD (mV)

40302010

ZERO-CURRENT DETECTION

THRESHOLD vs. TEMPERATURE

5

4

3

2

1

0

-40 85

TEMPERATURE (°C)

603510-15

MAX5945 toc11

Page 8

MAX5945

Quad Network Power Controller

for Power-Over-LAN

8 _______________________________________________________________________________________

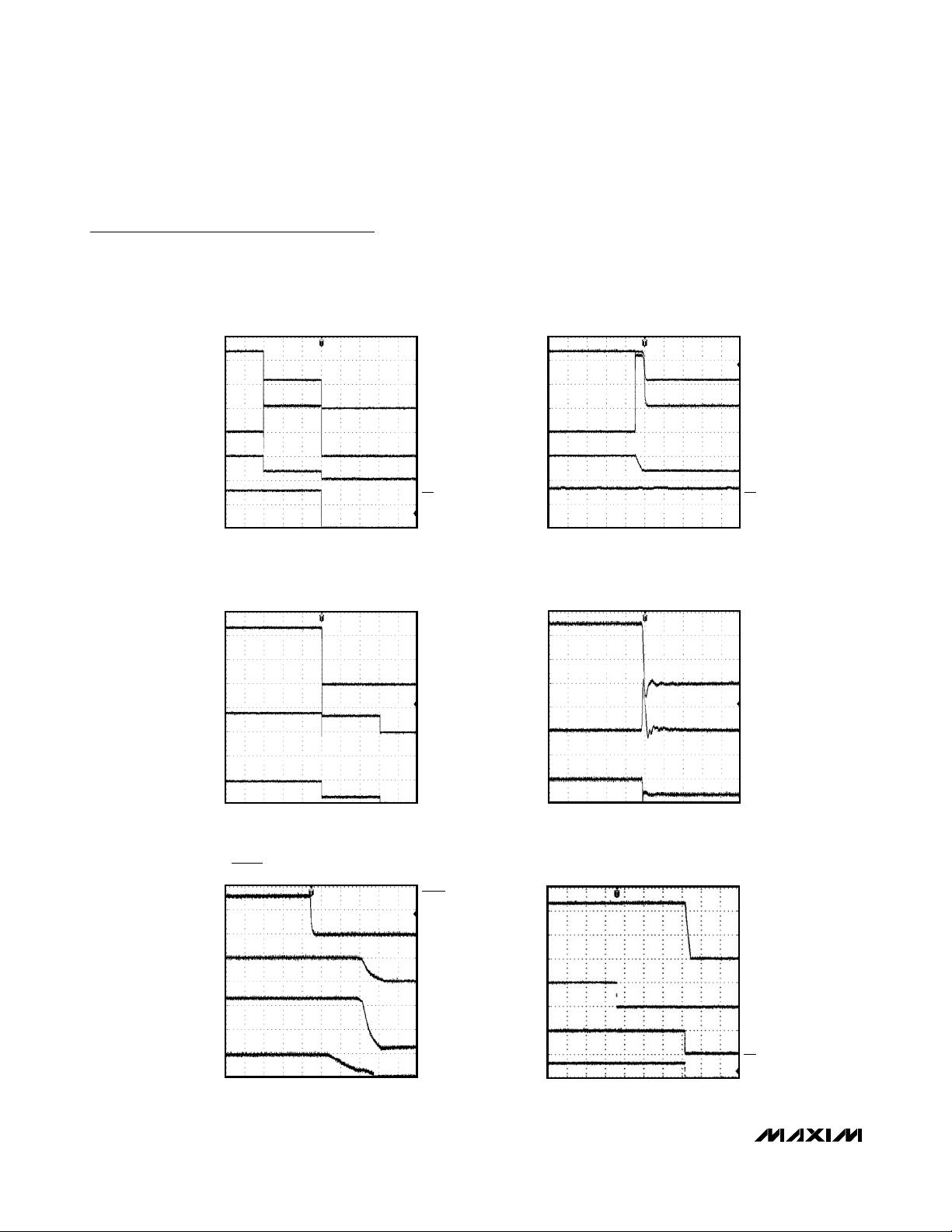

Typical Operating Characteristics (continued)

(VEE= -48V, VDD= +3.3V, AUTO = AGND = DGND = 0V, RESET = SHD_ = unconnected, R

SENSE

= 0.5Ω, all registers = default setting,

T

A

= +25°C, unless otherwise noted.)

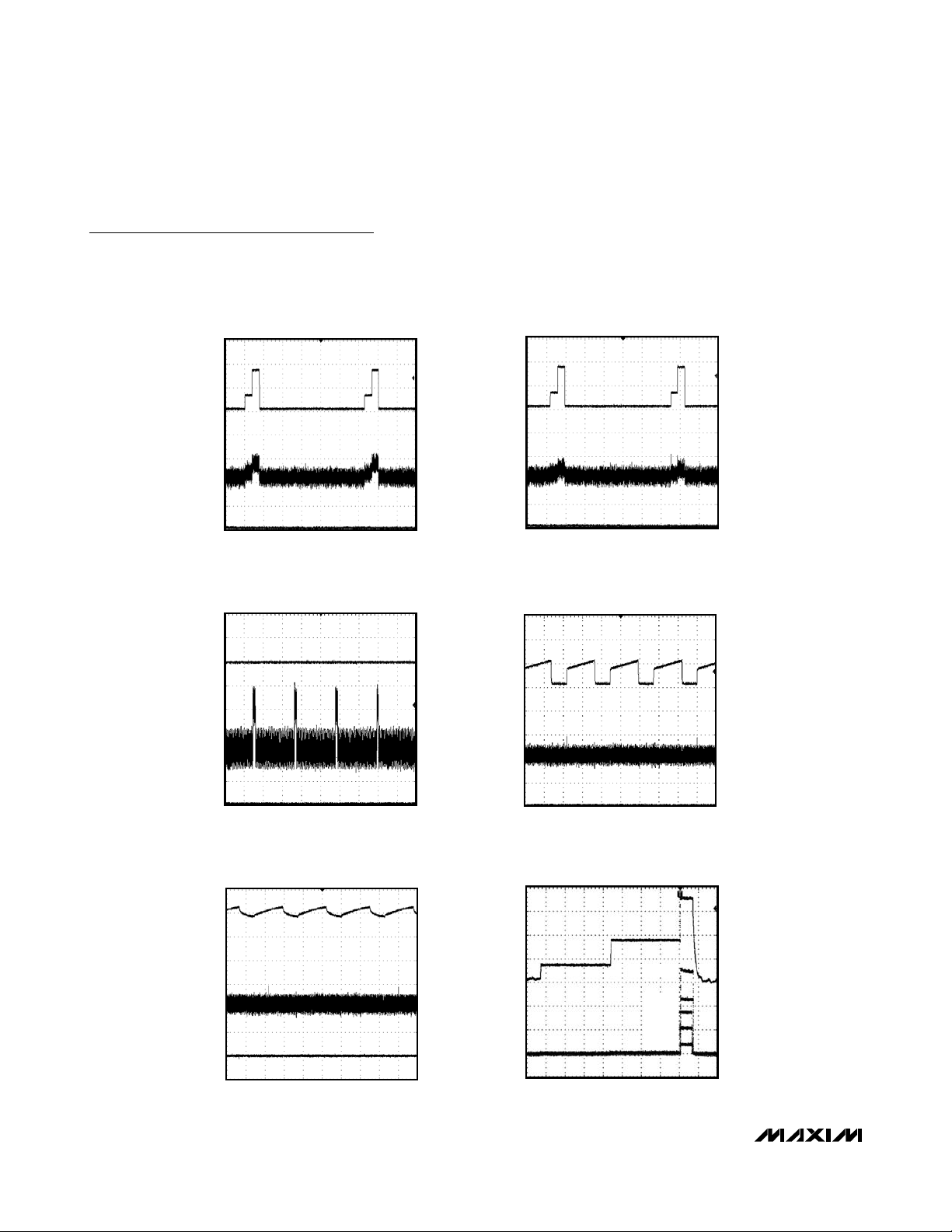

OVERCURRENT TIMEOUT

= 240Ω TO 57Ω)

(R

LOAD

20ms/div

SHORT-CIRCUIT RESPONSE TIME

MAX5945 toc12

MAX5945 toc14

(AGND - OUT)

20V/div

0V

I

OUT

200mA/div

0A

GATE 10V/div

V

EE

INT

2V/div

0V

(AGND - OUT)

20V/div

0V

I

OUT

250mA/div

0A

OVERCURRENT RESPONSE WAVEFORM

= 240Ω TO 57Ω)

(R

LOAD

I

OUT

200mA/div

0A

400µs/div

SHORT-CIRCUIT RESPONSE TIME

MAX5945 toc13

MAX5945 toc15

(AGND - OUT)

20V/div

0V

GATE

10V/div

V

EE

INT

2V/div

0V

(AGND - OUT)

20V/div

0V

I

OUT

5A/div

0A

GATE

10V/div

V

20ms/div

RESET TO OUTPUT TURN-OFF DELAY

100µs/div

MAX5945 toc16

EE

RESET

0V

I

OUT

200mA/div

0A

(AGND - OUT)

20V/div

GATE

10V/div

V

EE

ZERO-CURRENT DETECTION WAVEFORM

4µs/div

MAX5945 toc17

100ms/div

GATE

10V/div

V

EE

(AGND - OUT)

20V/div

0V

I

OUT

200mA/div

GATE

10V/div

INT

5V/div

Page 9

MAX5945

Quad Network Power Controller

for Power-Over-LAN

_______________________________________________________________________________________ 9

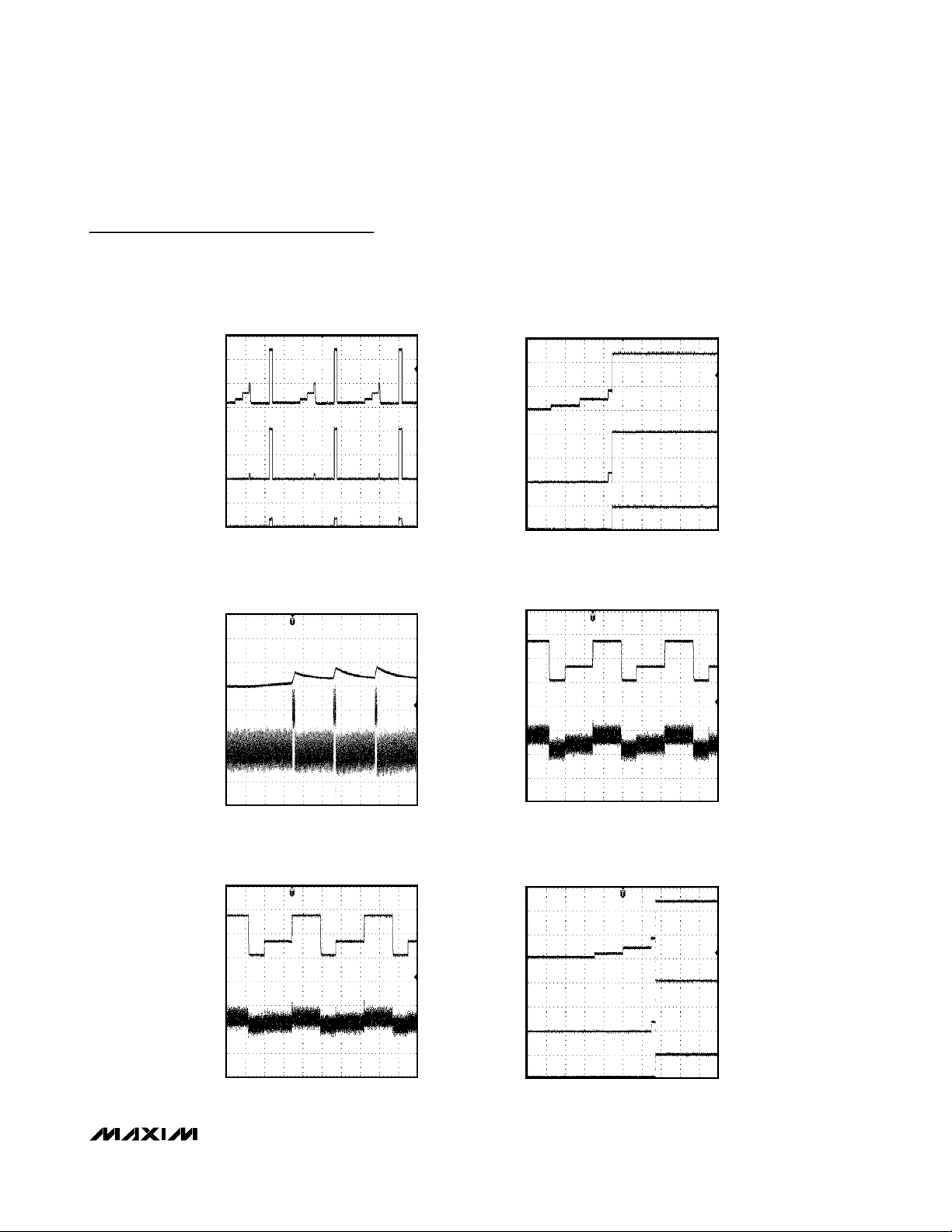

Typical Operating Characteristics (continued)

(VEE= -48V, VDD= +3.3V, AUTO = AGND = DGND = 0V, RESET = SHD_ = unconnected, R

SENSE

= 0.5Ω, all registers = default setting,

T

A

= +25°C, unless otherwise noted.)

OVERCURRENT RESTART DELAY

400ms/div

MAX5945 toc18

DETECTION WITH INVALID PD

(25kΩ AND 10µF)

MAX5945 toc20

(AGND - OUT)

20V/div

0V

I

OUT

200mA/div

0A

GATE

10V/div

V

EE

(AGND - OUT)

2V/div

0V

I

OUT

1mA/div

STARTUP WITH VALID PD

(25kΩ AND 0.1µF)

100ms/div

DETECTION WITH INVALID PD (15kΩ)

MAX5945 toc19

MAX5945 toc21

(AGND - OUT)

20V/div

0V

I

OUT

100mA/div

GATE_

V

EE

(AGND - OUT)

5V/div

0V

I

OUT

1mA/div

0A

40ms/div

100ms/div

STARTUP IN MIDSPAN MODE

DETECTION WITH INVALID PD (33kΩ)

100ms/div

MAX5945 toc22

(AGND - OUT)

5V/div

0V

I

OUT

1mA/div

0A

WITH VALID PD (25kΩ AND 0.1µF)

100ms/div

MAX5945 toc23

(AGND - OUT)

20V/div

0V

I

OUT

100mA/div

0A

GATE_

10V/div

V

EE

Page 10

MAX5945

Quad Network Power Controller

for Power-Over-LAN

10 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VEE= -48V, VDD= +3.3V, AUTO = AGND = DGND = 0V, RESET = SHD_ = unconnected, R

SENSE

= 0.5Ω, all registers = default setting,

T

A

= +25°C, unless otherwise noted.)

DETECTION WITH MIDSPAN MODE

WITH INVALID PD (15kΩ)

400ms/div

DETECTION WITH OUTPUT SHORTED

40ms/div

MAX5945 toc24

MAX5945 toc26

(AGND - OUT)

5V/div

0V

I

OUT

1mA/div

0A

GATE_

10V/div

V

EE

(AGND - OUT)

5V/div

0V

I

OUT

1mA/div

0A

GATE_

10V/div

V

EE

DETECTION WITH MIDSPAN MODE

WITH INVALID PD (33kΩ)

400ms/div

MAX5945 toc25

DETECTION WITH INVALID PD (OPEN CIRCUIT,

USING TYPICAL OPERATING CIRCUIT 1)

100ms/div

MAX5945 toc27

(AGND - OUT)

5V/div

0V

I

1mA/div

0A

GATE_

10V/div

V

(AGND - OUT)

5V/div

0V

I

OUT

1mA/div

0A

GATE_

10V/div

V

EE

OUT

EE

DETECTION WITH INVALID PD (OPEN CIRCUIT,

USING TYPICAL OPERATING CIRCUIT 2)

100ms/div

MAX5945 toc28

(AGND - OUT)

5V/div

I

OUT

2mA/div

GATE_

10V/div

0V

STARTUP WITH DIFFERENT PD CLASSES

40ms/div

MAX5945 toc29

CLASS4

CLASS3

CLASS2

CLASS1

CLASS0

(AGND - OUT)

5V/div

I

OUT

10mA/div

Page 11

MAX5945

Quad Network Power Controller

for Power-Over-LAN

______________________________________________________________________________________ 11

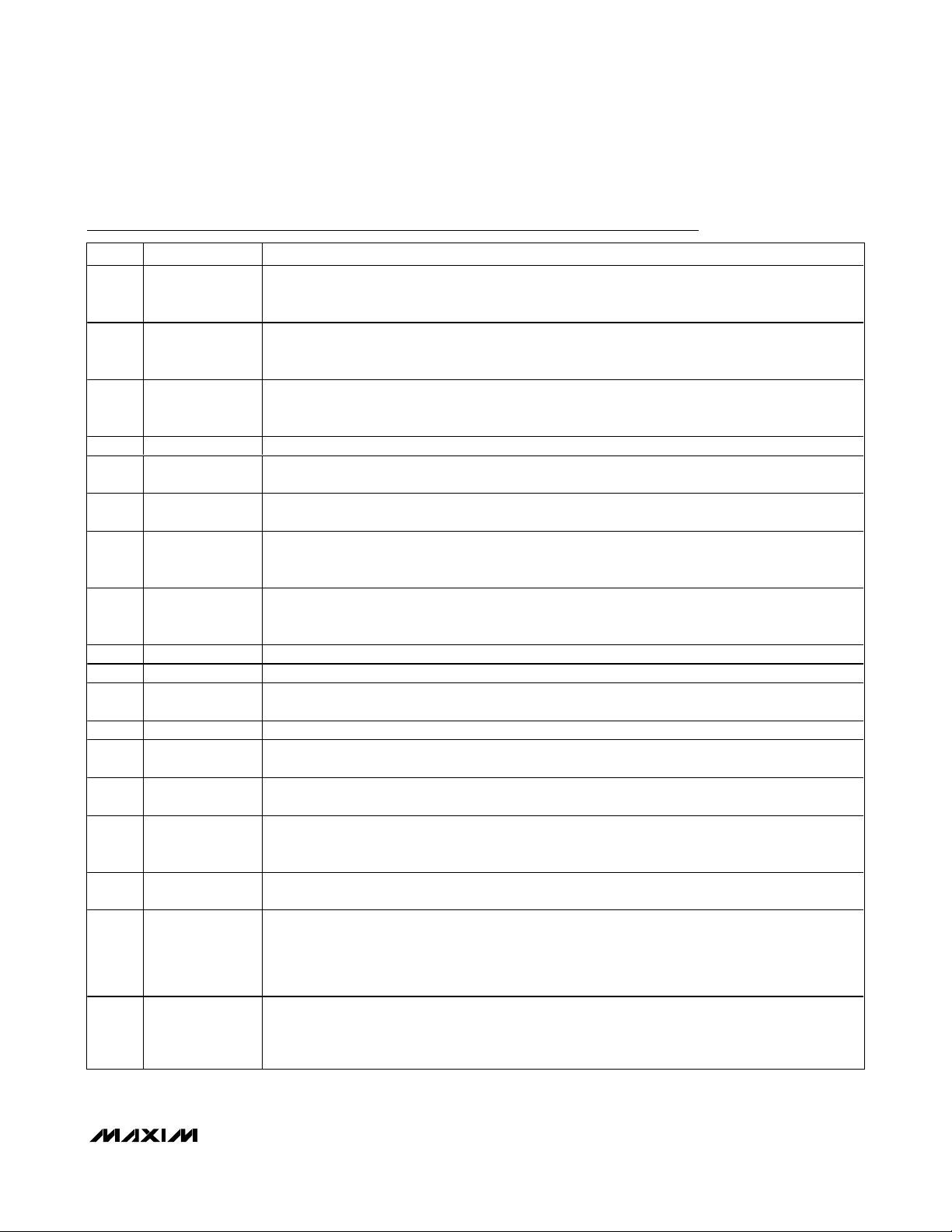

Pin Description

PIN NAME FUNCTION

Hardware Reset. Pull RESET low for at least 300µs to reset the device. All internal registers reset to

1 RESET

2 MIDSPAN

3 INT

4 SCL Serial Interface Clock Line

5 SDAOUT

6 SDAIN

7–10 A3, A2, A1, A0

11–14

15 DGND Connect to Digital Ground

16 V

17–20

21 AGND Analog Ground. Connect to the high-side analog supply.

22, 25,

29, 32

23, 26,

30, 33

24, 27,

31, 34

28 V

35 AUTO

36 OSC_IN

DET1, DET2,

DET3, DET4

DD

SHD1, SHD2,

SHD3, SHD4

SENSE4, SENSE3,

SENSE2, SENSE1

GATE4, GATE3,

GATE2, GATE1

OUT4, OUT3,

OUT2, OUT1

EE

their default value. The address (A0–A3), and AUTO and MIDSPAN input logic levels latch on during

low-to-high transition of RESET. Internally pulled up to V

MIDSPAN Mode Input. An internal 50kΩ pulldown resistor to DGND sets the default mode to endpoint

PSE operation (power-over-signal pairs). Pull MIDSPAN TO V

MIDSPAN value latches after the IC is powered up or reset (see the PD Detection section).

Open-Drain Interrupt Output. INT goes low whenever a fault condition exists. Reset the fault condition

using software or by pulling RESET low (see the Interrupt section of the Detailed Description for more

information about interrupt management).

Serial Output Data Line. Connect the data line optocoupler input to SDAOUT (see the Typical

Application Circuit). Connect SDAOUT to SDAIN if using a 2-wire I

Serial Interface Input Data Line. Connect the data line optocoupler output SDAIN (see the Typical

Application Circuit). Connect SDAIN to SDAOUT if using a 2-wire wire I

Address Bits. A3, A2, A1, and A0 form the lower part of the device’s address. Address inputs default

high with an internal 50kΩ pullup resistor to V

up and exceeds its UVLO threshold or after a reset. The 3 MSB bits of the address are set to 010.

Detection and Classification Voltage Outputs. Use DET1 to set the detection and classification probe

voltages on port 1. Use DET1 for the AC voltage sensing of port 1 when using the AC disconnect

scheme (see the Typical Application Circuit).

Positive Digital Supply. Connect to digital supply (referenced to DGND).

Port Shutdown Inputs. Pull SHD_ low to turn off the external FET on port_. Internally pulled up to V

with a 50kΩ resistor.

MOSFET Source Current-Sense Negative Inputs. Connect to the source of the power MOSFET and

connect a current-sense resistor between SENSE_ and V

Port_ MOSFET Gate Drivers. Connect GATE_ to the gate of the external FET (see the Typical

Application Circuit).

MOSFET Drain-Output Voltage Senses. Connect OUT_ to the power MOSFET drain through a resistor

(100Ω to 100kΩ). The low leakage at OUT_ limits the drop across the resistor to less than 100mV

(see the Typical Application Circuit).

Low-Side Analog Supply Input. Connect the low-side analog supply to VEE (-48V). Bypass with a 1µF

capacitor between AGND and V

AUTO or SHUTDOWN Mode Input. Force high to enter AUTO mode after a reset or power-up. Drive

low to put the MAX5945 into SHUTDOWN mode. In SHUTDOWN mode, software controls the

operational modes of the MAX5945. A 50kΩ internal pulldown resistor defaults AUTO low. AUTO

latches when V

Software commands can take the MAX5945 out of AUTO while AUTO is high.

Oscillator Input. AC-disconnect detection function uses OSC_IN. Connect a 100Hz ±10%, 2V

±5%, +1.2V offset sine wave to OSC_IN. If the oscillator positive peak falls below the OSC_FAIL

threshold of 2V, the ports that have the AC function enabled shut down and are not allowed to power

up. When not using the AC-disconnect detection function, leave OSC_IN unconnected.

or VEE ramps up and exceeds its UVLO threshold or when the device resets.

DD

EE

.

. The address values latch when VDD or VEE ramps

DD

with 50kΩ resistor.

DD

to set MIDSPAN operation. The

DIG

2

C-compatible system.

2

C-compatible system.

(see the Typical Application Circuit).

EE

DD

P-P

Page 12

MAX5945

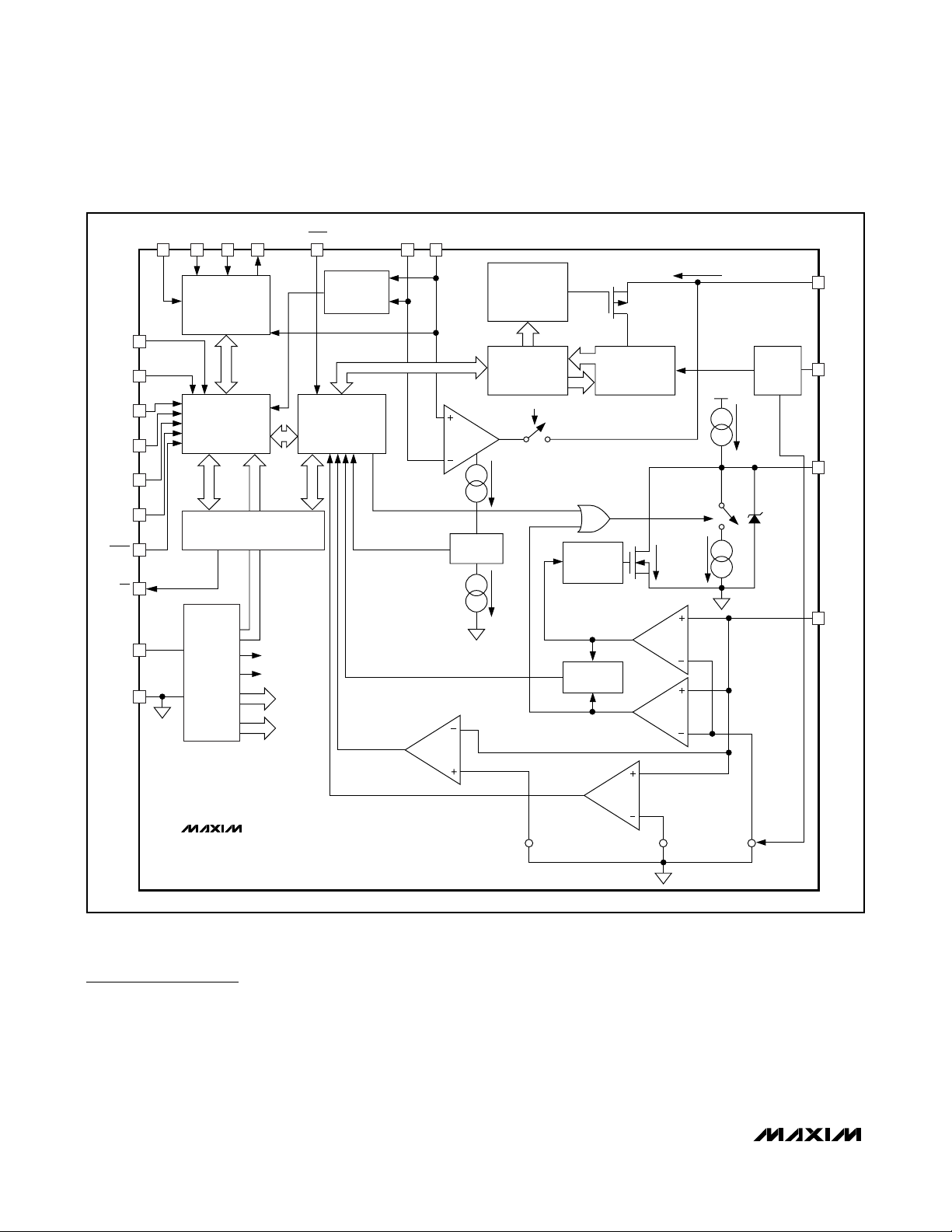

Detailed Description

The MAX5945 four-port network power controller controls -32V to -60V negative supply rail systems. Use the

MAX5945, which is compliant with the IEEE 802.3af

standard for PSE in power-over-LAN applications. The

MAX5945 provides PD discovery, classification, current

limit, both DC and AC load disconnect detections, and

other necessary functions for an IEEE 802.3af-compli-

ant PSE. The MAX5945 can be used in either endpoint

PSE (LAN switch/router) or midspan PSE (power injector) applications.

The MAX5945 is fully software-configurable and programmable with more than 25 internal registers. The

device features an I

2

C-compatible, 3-wire serial interface and a class-overcurrent detection. The class-overcurrent detection function enables system power man-

Quad Network Power Controller

for Power-Over-LAN

12 ______________________________________________________________________________________

Figure 1. MAX5945 Functional Diagram

V

DD

SHD_

DGNDOSC_INSCL SDAIN SDAOUT

A0

AUTO

MIDSPAN

RESET

AGND

A1

A2

A3

INT

ANALOG

SUPPLY

V

EE

MONITOR

SERIAL

PORT

INTERFACE

(SPI)

REGISTER FILE

CENTRAL LOGIC UNIT

BIAS/

(CLU)

+10V ANALOG

+5V DIG

VOLTAGE

REFERENCES

CURRENT

REFERENCES

OSCILLATOR

MONITOR

PORT

STATE

MACHINE

(SM)

AC DISCONNECT

SIGNAL

(ACD)

OPEN CIRCUIT

(OC)

ACD

REFERENCE

CURRENT

A = 3

AC

DETECTION

VOLTAGE PROBING

AND

CURRENT-LIMIT

CONTROL

DETECTION/

CLASSIFICATION

SM

ACD_ENABLE

PWR_EN

CURRENT

LIMIT (ILIM)

FAST

DISCHARGE

CONTROL

CURRENT-LIMIT

DETECTOR

9-BIT ADC

CONVERTER

CURRENT SENSING

100mA

90µA

MAX

DET_

VOLTAGE

SENSING

10V

50µA

13V CLAMP

OUT_

GATE_

SENSE_

OVERCURRENT

(OVC)

MAX5945

4mV

FOLDBACK

CONTROL

212mV182mV

Page 13

agement where it detects a PD that draws more current

than the allowable amount for its class. The MAX5945’s

extensive programmability enhances system flexibility

and allows for uses in other applications.

The MAX5945 has four different operating modes: auto

mode, semi-auto mode, manual mode, and shutdown

mode (see the Operation Modes section). A special

watchdog feature allows the hardware to gracefully

take over control if the software/firmware crashes. A

cadence timing feature allows the MAX5945 to be used

in midspan systems.

The MAX5945 provides input undervoltage lockout,

input undervoltage detection, input overvoltage lockout,

overtemperature protection, output-voltage slew-rate

limit during startup, power-good status, and fault

status. The MAX5945’s programmability includes

gate-charging current, current-limit threshold, startup

timeout, overcurrent timeout, autorestart duty cycle, PD

disconnect AC detection threshold and PD disconnect

detection timeout.

The MAX5945 communicates with the system

microcontroller through an I2C-compatible interface.

The MAX5945 features separate input and output data

lines (SDAIN and SDAOUT) for use with optocoupler

isolation. The MAX5945 is a slave device. Its four

address inputs allow 16 unique MAX5945 addresses. A

separate INT output and four independent shutdown

inputs (SHD_) allow fast interrupt signals between the

MAX5945 and the microcontroller. A RESET input

allows hardware reset of the device.

Reset

Reset is a condition the MAX5945 enters after any of

the following conditions:

• After power-up (VEEand VDDrise above their UVLO

thresholds).

• Hardware reset. The RESET input is driven low and

up high again any time after power-up.

• Software reset. Writing a 1 into R1Ah[4] any time

after power-up.

• Thermal shutdown.

During a reset, the MAX5945 resets its register map to

the reset state as shown in Table 30 and latches in the

state of AUTO (pin 35) and MIDSPAN (pin 2). During

normal operation, changes at the AUTO and MIDSPAN

inputs are ignored. While the condition that caused the

reset persists (i.e., high temperature, RESET input low,

or UVLO conditions) the MAX5945 will not acknowledge any addressing from the serial interface.

Port Reset (R1Ah[3:0])

Set high anytime during normal operation to turn off

power and clear the events and status registers of the

corresponding port. Port reset only resets the events

and status registers.

Operation Modes

The MAX5945 contains four independent but identical

state machines to provide reliable and real-time control

of the four network ports. Each state machine has four

different operating modes: auto, semi-auto, manual,

and shutdown. Auto mode allows the device to operate

automatically without any software supervision. Semiauto mode, upon request, continuously detects and

classifies a device connected to a port but does not

power up that port until instructed by software. Manual

mode allows total software control of the device and is

useful in system diagnostic. Shutdown mode terminates

all activities and securely turns off power to the ports.

Switching between AUTO, SEMI, or MANUAL mode

does not take effect until the part finishes its current

task. When the port is set into SHUTDOWN mode, all

the port operations are immediately stopped and the

port remains idle until SHUTDOWN is exited.

Automatic (AUTO) Mode

Enter automatic (AUTO) mode by forcing the

AUTO input high prior to a reset, or by setting

R12h[P_ M1,P_M0] to [1,1] during normal operation

(see Tables 15 and 15a). In AUTO mode, the MAX5945

performs detection, classification, and powers up the

port automatically once a valid PD is detected at the

port. If a valid PD is not detected at the port, the

MAX5945 repeats the detection routine continuously

until a valid PD is detected.

Going into AUTO mode, the DET_EN and CLASS_EN

bits are set to high and stay high unless changed by

software. Using software to set DET_EN and/or

CLASS_EN low causes the MAX5945 to skip detection

and/or classification. As a protection, disabling the

detection routine in AUTO mode will not allow the corresponding port to power up, unless the DET_BYP

(R23H[4]) is set to 1.

The AUTO status is latched into the register only during

a reset. Any changes to the AUTO input after reset is

ignored.

Semi-Automatic (SEMI) Mode

Enter semi-automatic (SEMI) mode by setting

R12h[P_M1,P_M0] to [1,0] during normal operation

(see Tables 15 and 15a). In SEMI mode, the MAX5945,

upon request, performs detection and/or classification

repeatedly but does not power up the port(s), regardless of the status of the port connection.

MAX5945

Quad Network Power Controller

for Power-Over-LAN

______________________________________________________________________________________ 13

Page 14

MAX5945

Setting R19h[PWR_ON_] (Table 21) high immediately

terminates detection/classification routines and turns on

power to the port(s).

R14h[DET_EN_, CLASS_EN_] default to low in SEMI

mode. Use software to set R14h[DET_EN_,

CLASS_EN_] to high to start the detection and/or classification routines. R14h[DET_EN_, CLASS_EN_] are

reset every time the software commands a power-off of

the port (either through reset or PWR_OFF). In any other

case, the status of the bits is left unchanged (including

when the state machine turns off the power because a

load disconnect or a fault condition is encountered).

MANUAL Mode

Enter MANUAL mode by setting R12h[P_M1,P_M0] to

[0,1] during normal operation (see Tables 15 and 15a).

MANUAL mode allows the software to dictate any

sequence of operation. Write a 1 to both R14h[DET_ EN_]

and R14h[CLASS_EN_] start detection and classification operations, respectively, and in that priority order.

After execution, the command is cleared from the register(s). PWR_ON_ has highest priority. Setting PWR_ON_

high at any time causes the device to immediately enter

the powered mode. Setting DET_EN and CLASS_EN

high at the same time causes detection to be performed first. Once in the powered state, the device

ignores DET_EN_ or CLASS_EN_ commands.

When switching to MANUAL mode from another mode,

DET_EN_, CLASS_EN_ default to low. These bits

become pushbutton rather than configuration bits (i.e.,

writing ones to these bits while in MANUAL mode commands the device to execute one cycle of detection

and/or classification. The bits are reset back to zeros at

the end of the execution). Putting the MAX5945 into

shutdown mode immediately turns off power and halts

all operations to the corresponding port. The event and

status bits of the affected port(s) are also cleared. In

SHUTDOWN mode, the DET_EN_, CLASS_EN_, and

PWR_ON_ commands are ignored.

In SHUTDOWN mode, the serial interface operates

normally.

Watchdog

R1Dh, R1Eh, and R1Fh registers control watchdog operation. The watchdog function, when enabled, allows the

MAX5945 to gracefully take over control or securely shut

down the power to the ports in case of software/firmware

crashes. Contact the factory for more details.

PD Detection

When PD detection is activated, the MAX5945 probes

the output for a valid PD. After each detection cycle,

the device sets the DET_END_ bit R04h/05h[3:0] high

and reports the detection results in the status registers

R0Ch[2:0], R0Dh[2:0], R0Eh[2:0], and R0Fh[2:0]. The

DET_END_ bit is reset to low when read through R05h

or after a port reset. Both DET_END_ bit status registers

are cleared after the port powers down.

A valid PD has a 25kΩ discovery signature characteristic as specified in the IEEE 802.3af standard. Table 1

shows the IEEE 802.3af specification for a PSE detecting a valid PD signature (see the Typical Application

Circuit and Figure 2). The MAX5945 can probe and categorize different types of devices connected to the port

such as a valid PD, an open circuit, a low resistive load,

a high resistive load, a high capacitive load, a positive

DC supply, or a negative DC supply.

During detection, the MAX5945 turns off the external

MOSFET and forces two probe voltages through the

DET_ input. The current through the DET_ input is measured as well as the voltage at OUT_. A two-point slope

measurement is used as specified by the IEEE 802.3af

standard to verify the device connected to the port. The

MAX5945 implements appropriate settling times and a

100ms digital integration to reject 50Hz/60Hz powerline noise coupling.

An external diode, in series with the DET_ input,

restricts PD detection to the 1st quadrant as specified

by the IEEE 802.3af standard. To prevent damage to

non-PD devices and to protect itself from an output

short circuit, the MAX5945 limits the current into DET_

to less than 2mA maximum during PD detection.

In midspan mode, the MAX5945 waits 2.2s before

attempting another detection cycle after every failed

detection. The first detection, however, happens immediately after issuing the detection command.

Power Device Classification

(PD Classification)

During the PD classification mode, the MAX5945 forces

a probe voltage (-18V) at DET_ and measures the current into DET_. The measured current determines the

class of the PD.

After each classification cycle, the device sets the

CL_END_ bit (R04h/05h[7:4]) high and reports the classification results in the status registers R0Ch[6:4],

R0Dh[6:4], R0Eh[6:4], and R0Fh[6:4]. The CL_END_ bit

is reset to low when read through register R05h or after

a port reset. Both Class_END_ bit status registers are

cleared after the port powers down.

Quad Network Power Controller

for Power-Over-LAN

14 ______________________________________________________________________________________

Page 15

Table 2 shows the IEEE 802.3af requirement for a PSE

classifying a PD at the power interface (PI).

Powered State

When the part enters PWR MODE, the t

START

and t

DISC

timers are reset. Before turning on the power, the part

checks if any other port is not turning on and if the

t

FAULT

timer is zero. Another check is performed if the

ACD_EN bit is set, in this case OSC_FAIL bit must be

low (oscillator is okay) for the port to be powered.

If these conditions are met then the part enters startup

where it turns on power to the port. An internal signal,

POK_, is asserted high when V

OUT

is within 2V from

VEE. PGOOD_ status bits are set high if POK_ stays

high longer than t

PGOOD

. PGOOD immediately resets

when POK goes low.

The PWR_CHG bit sets when a port powers up or down.

PWR_EN sets when a port powers up and resets when a

port shuts down. The port shutdown timer lasts 0.5ms

and prevents other ports from turning off during that period, except in the case of emergency shutdowns (RESET

= L, RESET_IC = H, V

EEUVLO

, V

DDUVLO

, and TSHD).

The MAX5945 always checks the status of all ports before

turning off. A priority logic system determines the order to

prevent the simultaneous turn-on or turn-off of the ports.

The port with the lesser ordinal number gets priority over

the others (i.e., port 1 turns on first, port 2 second, port 3

third and port 4 fourth). Setting PWR_OFF_ high turns off

power to the corresponding port.

MAX5945

Quad Network Power Controller

for Power-Over-LAN

______________________________________________________________________________________ 15

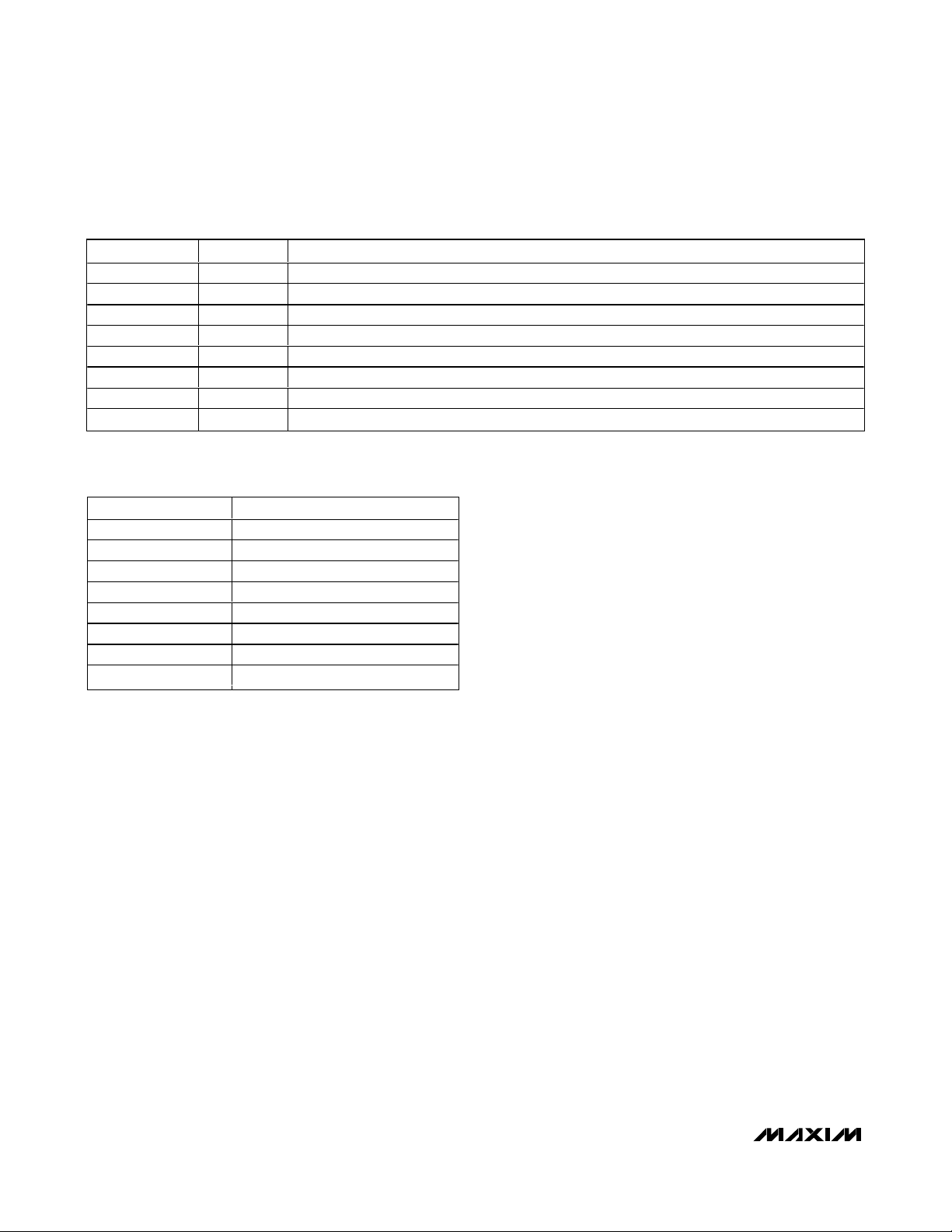

Table 1. PSE PI Detection Modes Electrical Requirement

(Table 33-2 of the IEEE 802.3af Standard)

Table 2. PSE Classification of a PD

(Table 33-4 of the IEEE 802.3af Standard)

PARAMETER SYMBOL MIN MAX UNITS ADDITIONAL INFORMATION

Open-Circuit Voltage V

Short-Circuit Current I

Valid Test Voltage V

Voltage Difference Between

Test Points

Time Between Any Two Test

Points

Slew Rate V

Accept Signature Resistance R

Reject Signature Resistance R

Open-Circuit Resistance R

Accept Signature

Capacitance

Reject Signature

Capacitance

Signature Offset Voltage

Tolerance

Signature Offset Current

Tolerance

∆V

C

OC

SC

VALID

TEST

t

BP

SLEW

GOOD

BAD

OPEN

GOOD

C

BAD

V

OS

I

OS

— 30 V In detection mode only

— 5 mA In detection mode only

2.8 10 V

1—V

2 — ms This timing implies a 500Hz maximum probing frequency

— 0.1 V/µs

19 26.5 kΩ

< 15 > 33 kΩ

500 — kΩ

— 150 nF

10 — µF

0 2.0 V

012µA

MEASURED I

0 to 5 Class 0

> 5 and < 8 May be Class 0 and 1

8 to 13 Class 1

> 13 and < 16 May be Class 0, 1, or 2

16 to 21 Class 2

> 21 and < 25 May be Class 0, 2, or 3

25 to 31 Class 3

> 31 and <35 May be Class 0, 3, or 4

35 to 45 Class 4

> 45 and < 51 May be Class 0 or 4

(mA) CLASSIFICATION

CLASS

Page 16

MAX5945

Overcurrent Protection

A sense resistor (RS), connected between SENSE_ and

VEE, monitors the load current. Under all circumstances, the voltage across RSnever exceeds the

threshold V

SU_LIM

. If SENSE_ exceeds V

SU_LIM

, an

internal current-limiting circuit regulates the GATE voltage, limiting the current to I

LIM

= V

SU_LIM

/ RS. During

transient conditions, if the SENSE_ voltage exceeds

V

SU_LIM

, a fast pulldown circuit activates to quickly

recover from the current overshoot. During startup, if

the current-limit condition persists, when the startup

timer, t

START

, times out, the port shuts off and the

STRT_FLT_ bit is set. In normal powered state, the

MAX5945 checks for overcurrent conditions as determined by V

FLT_LIM

= ~88% of V

SU_LIM

. The t

FAULT

counter sets the maximum allowed continuous

overcurrent period. The t

FAULT

counter increases when

V

SENSE

exceeds V

FLT_LIM

and decreases at a slower

pace when V

SENSE

drops below V

FLT_LIM

. A slower

decrement for the t

FAULT

counter allows for detecting

repeated short-duration overcurrents. When the counter

reaches the t

FAULT

limit, the MAX5945 powers off the

port and asserts the IMAX_FLT_ bit. For a continuous

overstress, a fault latches exactly after a period of

t

FAULT

. V

SU_LIM

, is programmable using R27h[4-7].

t

FAULT

is programmable using R16h[2-3] and R28[4-7].

After power-off due to an overcurrent fault, and if the

RSTR_EN bit is set, the t

FAULT

timer is not immediately

reset but starts decrementing at the same slower pace.

The MAX5945 allows the port to be powered on only

when the t

FAULT

counter is at zero. This feature sets an

automatic duty-cycle protection to the external MOSFET

to avoid overheating. The duty cycle is programmable

using R16h[6-7].

The MAX5945 continuously flags when the current

exceeds the maximum current allowed for the class as

indicated in the CLASS status register. When class

overcurrent occurs, the MAX5945 sets the IVC bit in

register R09h.

Foldback Current

During startup and normal operation, an internal circuit

senses the voltage at OUT_ and reduces the currentlimit value when (V

OUT

_ - VEE) > 30V. The foldback

function helps to reduce the power dissipation on the

FET. The current limit eventually reduces to 1/3 of I

LIM

when (V

OUT

_ - VEE) > 50V (see Figure 4).

Quad Network Power Controller

for Power-Over-LAN

16 ______________________________________________________________________________________

Figure 2. Detection, Classification, and Power-Up Port

Sequence

Figure 3. PGOOD Timing

150ms 150ms

t

DETI

t

DETII

-4V

80ms

0V

0V

-9V

OUT_

-18V

-48V

t

POK

PGOOD

21.3ms

t

CLASS

t

PGOOD

Page 17

MOSFET Gate Driver

Connect the gate of the external n-channel MOSFET to

GATE_. An internal 50µA current source pulls GATE_ to

(VEE+ 10V) to turn on the MOSFET. An internal 40µA

current source pulls down GATE_ to VEEto turn off the

MOSFET.

The pullup and pulldown current controls the maximum

slew rate at the output during turn-on or turn-off. The

pullup current (gate-charging current) is programmable

using R23h[5-7]. Use the following equation to set the

maximum slew rate:

where C

GD

is the total capacitance between GATE and

DRAIN of the external FET. Current limit and the capacitive load at the drain control the slew rate during startup. During current-limit regulation, the MAX5945

manipulates the GATE_ voltage to control the voltage at

SENSE_. A fast pulldown activates if SENSE_ overshoots the limit threshold. The fast pulldown current

increases with the amount of overshoot. The maximum

fast pulldown current is 100mA.

During turn-off, when the GATE voltage reaches a value

lower than 1.2V, a strong pulldown switch is activated

to keep the FET securely off.

Digital Logic

VDDsupplies power for the internal logic circuitry. V

DD

ranges from +1.71V to +3.7V and determines the logic

thresholds for the CMOS connections (SDAIN,

SDAOUT, SCL, AUTO, SHD_, A_). This voltage range

enables the MAX5945 to interface with a nonisolated

low-voltage microcontroller. The MAX5945 checks the

digital supply for compatibility with the internal logic.

The MAX5945 also features a VDDundervoltage lockout

(V

DDUVLO

) of +1.35V. A V

DDUVLO

condition keeps the

MAX5945 in reset and the ports shut off. Bit 0 in the

supply event register shows the status of V

DDUVLO

(Table 11) after VDDhas recovered. All logic inputs and

outputs reference to DGND. DGND and AGND are

completely isolated internally to the MAX5945. In a

completely isolated system, the digital signal can be

referenced indifferently to V

AGND

or VEEor at voltages

even higher than AGND (up to 60V). V

DD

- V

DGND

must

be greater than 3.0V when V

DGND

≤ (VEE+ 3.0V)

When using the AC disconnect detection feature,

AGND must be connected directly to DGND and V

DD

must be greater than +3V. In this configuration, connect DGND to AGND at a single point in the system as

close to MAX5945 as possible.

Hardware Shutdown

SHD_ shuts down the respective ports without using

the serial interface. Hardware shutdown offers an emergency turn-off feature that allows a fast disconnect of

the power supply from the port. Pull SHD_ low to

remove power.

Interrupt

The MAX5945 contains an open-drain logic output (INT)

that goes low when an interrupt condition exists. R00h

and R01h (Tables 5 and 6) contain the definitions of the

interrupt registers. The mask register R01h determines

events that trigger an interrupt. As a response to an

interrupt, the controller reads the status of the event register to determine the cause of the interrupt and takes

subsequent actions. Each interrupt event register also

contains a clear-on-read (CoR) register. Reading

through the CoR register address clears the interrupt.

INT remains low when reading the interrupt through the

read-only addresses. For example, to clear a startup

fault on port 4 read address 09h (see Table 10). Use the

global pushbutton bit on register 1Ah (bit 7, Table 22) to

clear interrupts, or use a software or hardware reset.

Undervoltage and Overvoltage Protection

The MAX5945 contains several undervoltage and overvoltage protection features. Table 11 in the Register Map

and Description section shows a detailed list of the

undervoltage and overvoltage protection features. An

internal VEEundervoltage lockout (V

EEUVLO

) circuit

keeps the MOSFET off and the MAX5945 in reset until

V

AGND

- VEEexceeds 29V for more than 3ms. An internal

VEEovervoltage (V

EE_OV

) circuit shuts down the ports

when (V

AGND

- VEE) exceeds 60V. The digital supply also

contains an undervoltage lockout (V

DDUVLO

).

MAX5945

Quad Network Power Controller

for Power-Over-LAN

______________________________________________________________________________________ 17

Figure 4. Foldback Current Characteristics

- VEE)

(V

SENSE_

V

SU_LIM

V

/ 3

SU_LIM

50V30V

- VEE)

(V

OUT_

∆∆V

OUT GATE

I

=

t

C

GD

Page 18

MAX5945

The MAX5945 also features three other undervoltage

and overvoltage interrupts: VEEundervoltage interrupt

(V

EEUV

), VDDundervoltage interrupt (V

DDUV

), and V

DD

overvoltage interrupt (V

DDOV

). A fault latches into the

supply events register (Table 11) but the MAX5945 does

not shut down the ports with a V

EEUV

, V

DDUV

, or V

DDOV

.

DC Disconnect Monitoring

Setting R13h[DCD_EN_] bits high enable DC load monitoring during a normal powered state. If SENSE_ falls

below the DC load disconnect threshold, V

DCTH

, for

more than t

DISC

, the device turns off power and asserts

the LD_DISC_ bit of the corresponding port. t

DISC

is

programmable using R16h[0-1] and R27h[0-3].

AC Disconnect Monitoring

The MAX5945 features AC load disconnect monitoring.

Connect an external sine wave to OSC_IN. The oscillator requirements are:

• Frequency x V

P-P

= 200V

P-P

x Hz ±15%

• Positive peak voltage > +2V

• Frequency > 60Hz

• A 100Hz ±10%, 2V

P-P

±5%, with +1.2V offset

(V

PEAK

= +2.2V, typ) is recommended.

The MAX5945 buffers and amplifies 3x the external

oscillator signal and sends the signal to DET_, where

the sine wave is AC coupled to the output. The

MAX5945 senses the presence of the load by monitoring the amplitude of the AC current returned to DET_

(see the Functional Diagram).

Setting R13h[ACD_EN_] bits high enable AC load disconnect monitoring during the normal powered state. If

the AC current peak at the DET_ pin falls below I

ACTH

for more than t

DISC

, the device turns off power and

asserts the LD_DISC_ bit of the corresponding port.

I

ACTH

is programmable using R23h[0-3].

An internal comparator checks for a proper amplitude

of the oscillator input. If the positive peak of the input

sinusoid falls below a safety value of 2V, OSC_FAIL

sets and the port shuts down. Power cannot be applied

to the ports when ACD_EN is set high and OSC_FAIL is

set high. Leave OSC_IN unconnected or connect it to

DGND when not using AC disconnect detection.

When using the AC disconnect detection feature, connect AGND directly to DNGD as close as possible to

the IC. The MAX5945 also requires a VDDof greater

than +3V for this function. See the Typical Application

Circuit with AC disconnect for other external component requirements.

Thermal Shutdown

If the MAX5945 die temperature reaches +150°C, an

overtemperature fault generates and the MAX5945

shuts down and the MOSFETs turn off. The die temperature of the MAX5945 must cool down below +130°C to

remove the overtemperature fault condition. After a

thermal shutdown, the part is reset.

Address Inputs

A3, A2, A1, and A0 represent the four LSBs of the chip

address, the complete 7-bit chip address (see Table 3).

The four LSBs latch on the low-to-high transition of

RESET or after a power-supply start (either on VDDor

V

EE

). Address inputs default high through an internal

50kΩ pullup resistor to V

DD

. The MAX5945 also

responds to the call through a global address 60h (see

the Global Addressing and Alert Response Protocol

section).

I2C-Compatible Serial Interface

The MAX5945 operates as a slave that sends and

receives data through an I2C-compatible, 2-wire or 3wire interface. The interface uses a serial data input line

(SDAIN), a serial data output line (SDAOUT), and a serial clock line (SCL) to achieve bidirectional communication between master(s) and slave(s). A master (typically

a microcontroller) initiates all data transfers to and from

the MAX5945, and generates the SCL clock that synchronizes the data transfer. In most applications, connect the SDAIN and the SDAOUT lines together to form

the serial data line (SDA).

Using the separate input and output data lines allows

optocoupling with the controller bus when an isolated

supply powers the microcontroller.

The MAX5945 SDAIN line operates as an input. The

MAX5945 SDAOUT operates as an open-drain output.

A pullup resistor, typically 4.7kΩ, is required on

SDAOUT. The MAX5945 SCL line operates only as an

input. A pullup resistor, typically 4.7kΩ, is required on

SCL if there are multiple masters, or if the master in a

single-master system has an open-drain SCL output.

Serial Addressing

Each transmission consists of a START condition (Figure

7) sent by a master, followed by the MAX5945 7-bit slave

address plus R/W bit, a register address byte, one or

more data bytes, and finally a STOP condition.

Quad Network Power Controller

for Power-Over-LAN

18 ______________________________________________________________________________________

Table 3. MAX5945 Address

0 1 0 A3 A2 A1 A0 R/W

Page 19

Start and Stop Conditions

Both SCL and SDA remain high when the interface is

not busy. A master signals the beginning of a transmission with a START (S) condition by transitioning SDA

from high to low while SCL is high. When the master fin-

ishes communicating with the slave, the master issues

a STOP (P) condition by transitioning SDA from low to

high while SCL is high. The stop condition frees the bus

for another transmission.

MAX5945

Quad Network Power Controller

for Power-Over-LAN

______________________________________________________________________________________ 19

Figure 5. 2-Wire Serial Interface Timing Details

Figure 6. 3-Wire Serial Interface Timing Details

Figure 8. Bit Transfer

Figure 7. Start and Stop Conditions

SDAIN

t

SU, DAT

t

LOW

SCL

t

HD, STA

START CONDITION

t

HIGH

t

R

t

F

SDAIN/SDA

t

SU, DAT

t

LOW

SCL

t

HD, STA

START CONDITION

t

HIGH

t

R

t

F

t

HD, DAT

t

HD, DAT

t

SU, STA

REPEATED START CONDITION

t

SU, STA

REPEATED START CONDITION

t

HD, STA

t

HD, STA

t

SU, STO

t

SU, STO

STOP

CONDITION

STOP

CONDITION

t

BUF

t

BUF

START

CONDITION

START

CONDITION

SDA/

SDAIN

SCL

SP

START STOP

SDA

SCL

DATA LINE STABLE;

DATA VALID

CHANGE OF

DATA ALLOWED

.

Page 20

MAX5945

Bit Transfer

Each clock pulse transfers one data bit (Figure 8). The

data on SDA must remain stable while SCL is high.

Acknowledge

The acknowledge bit is a clocked 9th bit (Figure 9),

which the recipient uses as a handshake receipt of each

byte of data. Thus each byte effectively transferred

requires 9 bits. The master generates the 9th clock

pulse, and the recipient pulls down SDA (or the SDAOUT

in the 3-wire interface) during the acknowledge clock

pulse, so the SDA line is stable low during the high period of the clock pulse. When the master transmits to the

MAX5945, the MAX5945 generates the acknowledge bit.

When the MAX5945 transmits to the master, the master

generates the acknowledge bit.

Slave Address

The MAX5945 has a 7-bit long slave address (Figure

10). The bit following the 7-bit slave address (bit eight)

is the R/W bit, which is low for a write command and

high for a read command.

010 always represent the first three bits (MSBs) of the

MAX5945 slave address. Slave address bits A3, A2,

A1, and A0 represent the states of the MAX5945’s A3,

A2, A1, and A0 inputs, allowing up to sixteen MAX5945

devices to share the bus. The states of the A3, A2, A1,

and A0 latch in upon the reset of the MAX5945 into register R11h. The MAX5945 monitors the bus continuously, waiting for a START condition followed by the

MAX5945’s slave address. When the MAX5945 recognizes its slave address, it acknowledges and is then

ready for continued communication.

Global Addressing and Alert Response Protocol

The global address call is used in writing mode to write

the same register to multiple devices (address 0x60). In

read mode (address 0x61), the global address call is

used as the alert response address. When responding to

a global call, the MAX5945 puts out on the data line its

own address whenever its interrupt is active and so does

every other device connected to the SDAOUT line that

has an active interrupt. After every bit is transmitted, the

MAX5945 checks that the data line effectively corresponds to the data it is delivering. If it is not, it then backs

off and frees the data line. This litigation protocol always

allows the part with the lowest address to complete the

transmission. The microcontroller can then respond to

the interrupt and take proper actions. The MAX5945

does not reset its own interrupt at the end of the alert

response protocol. The microcontroller has to do it by

clearing the event register through their CoR addresses

or activating the CLR_INT pushbutton.

Quad Network Power Controller

for Power-Over-LAN

20 ______________________________________________________________________________________

Figure 9. Acknowledge

Figure 10. Slave Address

START CONDITION

12 89

BY TRANSMITTER

BY RECEIVER

MSB

0

SDA

SCL

SCL

SDA

S

SDA

1

CLOCK PULSE FOR ACKNOWLEDGEMENT

LSB

A3 A2 A1 A00

ACKR/W

Page 21

Message Format for Writing the MAX5945

A write to the MAX5945 comprises of the MAX5945’s

slave address transmission with the R/W bit set to 0, followed by at least one byte of information. The first byte

of information is the command byte (Figure 11). The

command byte determines which register of the

MAX5945 is written to by the next byte, if received. If

the MAX5945 detects a STOP condition after receiving

the command byte, then the MAX5945 takes no further

action beyond storing the command byte. Any bytes

received after the command byte are data bytes. The

first data byte goes into the internal register of the

MAX5945 selected by the command byte. If the

MAX5945 transmits multiple data bytes before the

MAX5945 detects a STOP condition, these bytes store

in subsequent MAX5945 internal registers because the

control byte address auto-increments.

Any bytes received after the control byte are data

bytes. The first data byte goes into the internal register

of the MAX5945 selected by the control byte (Figure 8).

If multiple data bytes are transmitted before a STOP

condition is detected, these bytes are stored in subsequent MAX5945 internal registers because the control

byte address auto-increments.

MAX5945

Quad Network Power Controller

for Power-Over-LAN

______________________________________________________________________________________ 21

Figure 11. Control Byte Received

Figure 12. Control and Single Data Byte Received

Figure 13. ‘n’ Data Bytes Received

CONTROL BYTE IS STORED ON RECEIPT OF STOP CONDITION

ACKNOWLEDGE FROM MAX5945

SAAP0SLAVE ADDRESS CONTROL BYTE

D15 D14 D13 D12 D11 D10 D9 D8

R/W

HOW CONTROL BYTE AND DATA BYTE MAP

ACKNOWLEDGE FROM MAX5945

SAAAP0SLAVE ADDRESS CONTROL BYTE DATA BYTE

HOW CONTROL BYTE AND DATA BYTE MAP

ACKNOWLEDGE FROM MAX5945

SAAAP0SLAVE ADDRESS CONTROL BYTE DATA BYTE

INTO THE REGISTER

R/W

INTO THE REGISTER

R/W

D15 D14 D13 D12 D11 D10 D9 D8 D1 D0D3 D2D5 D4D7 D6

D15 D14 D13 D12 D11 D10 D9 D8 D1 D0D3 D2D5 D4D7 D6

ACKNOWLEDGE FROM MAX5945

ACKNOWLEDGE FROM MAX5945

ACKNOWLEDGE FROM MAX5945

ACKNOWLEDGE FROM MAX5945

1 BYTE

AUTO-INCREMENT

MEMORY WORD ADDRESS

ACKNOWLEDGE FROM MAX5945

n BYTES

AUTO-INCREMENT

MEMORY WORD ADDRESS

Page 22

MAX5945

Message Format for Reading

The MAX5945 reads using the MAX5945’s internally

stored command byte as an address pointer, the same

way the stored command byte is used as an address

pointer for a write. The pointer auto-increments after

reading each data byte using the same rules as for a

write. Thus, a read is initiated by first configuring the

MAX5945’s command byte by performing a write

(Figure 12). The master now reads ‘n’ consecutive

bytes from the MAX5945, with the first data byte read

from the register addressed by the initialized command

byte (Figure 13). When performing read-after-write verification, remember to reset the command byte’s

address because the stored control byte address autoincrements after the write.

Operation with Multiple Masters

When the MAX5945 operates on a 2-wire interface with

multiple masters, a master reading the MAX5945

should use repeated starts between the write that sets

the MAX5945’s address pointer, and the read(s) that

takes the data from the location(s). It is possible for

master 2 to take over the bus after master 1 has set up

the MAX5945’s address pointer but before master 1

has read the data. If master 2 subsequently resets the

MAX5945’s address pointer then master 1’s read may

be from an unexpected location.

Command Address Auto-Incrementing

Address auto-incrementing allows the MAX5945 to be

configured with fewer transmissions by minimizing the

number of times the command address needs to be

sent. The command address stored in the MAX5945

generally increments after each data byte is written or

read (Table 4). The MAX5945 is designed to prevent

overwrites on unavailable register addresses and unintentional wrap-around of addresses.

Register Map And Description

The interrupt register (Table 5) summarizes the event

register status and is used to send an interrupt signal

(INT goes low) to the controller. Writing a 1 to R1Ah[7]

clears all interrupt and events registers. A reset sets

R00h to 00h.

INT_EN (R17h[7]) is a global interrupt mask (Table 6).

The MASK_ bits activate the corresponding interrupt

bits in register R00h. Writing a 0 to INT_EN (R17h[7])

disables the INT output.

A reset sets R01h to AAA00A00b, where A is the state

of the AUTO input prior to the reset.

The power event register (Table 7) records changes in

the power status of the four ports. Any change in

PGOOD_ (R10h[7:4]) sets PG_CHG_ to 1. Any change

in the PWR_EN_ (R10h[3:0]) sets PWEN_CHG_ to 1.

PG_CHG_ and PWEN_CHG_ trigger on the edges of

PGOOD_ and PWR_EN_ and do not depend on the

actual level of the bits. The power event register has

two addresses. When read through the R02h address,

the content of the register is left unchanged. When read

through the CoR R03h address, the register content will

be cleared. A reset sets R02h/R03h = 00h.

DET_END_/CL_END_ is set high whenever detection/

classification is completed on the corresponding port.

A 1 in any of the CL_END_ bits forces R00h[4] to 1. A 1

in any of the DET_END_ bits forces R00h[3] to 1. As

with any other events register, the detect event register

(Table 8) has two addresses. When read through the

R04h address, the content of the register is left

unchanged. When read through the CoR R05h

address, the register content will be cleared. A reset

sets R04h/R05h = 00h.

LD_DISC_ is set high whenever the corresponding port

shuts down due to detection of load removal.

IMAX_FLT_ is set high when the port shuts down due to

an extended overcurrent event after a successful startup. A 1 in any of the LD_DISC_ bits forces R00h[2] to 1.

A 1 in any of the IMAX_FLT_ bits forces R00h[5] to 1.

As with any of the other events register, the fault event

register (Table 9) has two addresses. When read

through the R06h address, the content of the register is

left unchanged. When read through the CoR R07h

address, the register content will be cleared. A reset

sets R06h/R07h = 00h.

Quad Network Power Controller

for Power-Over-LAN

22 ______________________________________________________________________________________

Table 4. Auto-Increment Rules

COMMAND BYTE

ADDRESS RANGE

0x00 to 0x26

0x26

AUTO-INCREMENT BEHAVIOR

Command address will autoincrement after byte read or written

Command address remains at 0x26

after byte written or read

Page 23

MAX5945

Quad Network Power Controller

for Power-Over-LAN

______________________________________________________________________________________ 23

Table 5. Interrupt Register

Table 6. Interrupt Mask Register

ADDRESS = 00h

SYMBOL BIT R/W

SUP_FLT 7 R

TSTR_FLT 6 R

IMAX_FLT 5 R

CL_END 4 R

DET_END 3 R

LD_DISC 2 R

PG_INT 1 R

PE_INT 0 R

Interrupt signal for supply faults. SUP_FLT is the logic OR of all the bits [7:0] in register R0Ah/R0Bh

(Table 8).

Interrupt signal for startup failures. TSRT_FLT is the logic OR of bits [7:0] in register R08h/R09h

(Table 7).

Interrupt signal for current-limit violations. IMAX_FLT is the logic OR of bits [3:0] in register

R06h/R07h (Table 6).

Interrupt signal for completion of classification. CL_END is the logic OR of bits [7:4] in register

R04h/R05h (Table 5)

Interrupt signal for completion of detection. DET_END is the logic OR of bits [3:0] in register

R04h/R05h (Table 5).

Interrupt signal for load disconnection. LD_DISC is the logic OR of bits [7:4] in register R06h/R07h

(Table 6).

Interrupt signal for PGOOD status change. PG_INT is the logic OR of bits [7:4] in register R02h/R03h

(Table 4).

Interrupt signal for power-enable status change. PEN_INT is the logic OR of bits [3:0] in register

R02h/R03h (Table 4).

ADDRESS = 01h

SYMBOL BIT R/W

MASK7 7 R/W

MASK6 6 R/W

MASK5 5 R/W

MASK4 4 R/W

MASK3 3 R/W

MASK2 2 R/W

MASK1 1 R/W

MASK0 0 R/W

Interrupt mask bit 7. A logic high enables the SUP_FLT interrupts. A logic low disables the SUP_FLT

interrupts.

Interrupt mask bit 6. A logic high enables the TSTR_FLT interrupts. A low disables the TSTR_FLT

interrupts.

Interrupt mask bit 5. A logic high enables the IMAX_FLT interrupts. A logic low disables the

IMAX_FLT interrupts.

Interrupt mask bit 4. A logic high enables the CL_END interrupts. A logic low disables the CL_END

interrupts.

Interrupt mask bit 3. A logic high enables the DET_END interrupts. A logic low disables the

DET_END interrupts.

Interrupt mask bit 2. A logic high enables the LD_DISC interrupts. A logic low disables the LD_DISC

interrupts.

Interrupt mask bit 1. A logic high enables the PG_INT interrupts. A logic low disables the PG_INT

interrupts.

Interrupt mask bit 0. A logic high enables the PEN_INT interrupts. A logic low disables the PEN_INT

interrupts.

DESCRIPTION

DESCRIPTION