Page 1

General Description

The MAX5661 single 16-bit DAC with precision highvoltage amplifiers provides a complete solution for programmable current and voltage-output applications.

The output amplifiers swing to industry-standard levels

of ±10V (voltage output) or source from 0mA (or from

4mA) to 20mA (current output). The voltage output

(OUTV) drives resistive loads greater than 2kΩ and

capacitive loads of up to 1.2µF. Voltage-output forcesense connections compensate for series protection

resistors and field-wiring resistance. Short-circuit protection on the voltage output limits output current to

10mA (typ) sourcing or -11.5mA (typ) sinking. The current output (OUTI) drives resistive loads up to 37.5V

(max) and inductive loads up to 1H.

The MAX5661 provides either a current output or a voltage output. Only one output is active at any given time,

regardless of the configuration. The MAX5661 voltage

output operates with ±13.48V to ±15.75V supplies

(V

DDV

, V

SSV

) and the current output operates with a

single +13.48V to +40V supply (V

DDI

). A +4.75V to

+5.25V digital supply (V

CC

) powers the rest of the internal circuitry. A buffered reference input accepts an

external +4.096V reference voltage.

Update the DAC outputs using software commands or

the asynchronous LDAC input. An asynchronous CLR

input sets the DAC outputs to the value stored in the

clear register or to zero. The FAULT output asserts

when the DAC’s current output is an open circuit, the

DAC’s voltage output is a short circuit, or when the CLR

input is low.

The MAX5661 communicates through a 4-wire 10MHz

SPI™-/QSPI™-/MICROWIRE™-compatible serial interface. The DOUT output allows daisy chaining of multiple devices. The MAX5661 is available in a 10mm x

10mm, 64-pin, LQFP package and operates over the

-40°C to +105°C temperature range.

SPI and QSPI are trademarks of Motorola, Inc.

MICROWIRE is a trademark of National Semiconductor Corp.

Applications

Industrial Analog Output Modules

Industrial Instrumentation

Programmable Logic Controls/Distributed

Control Systems

Process Control

Features

♦ 10-Bit Programmable Full-Scale Output

Adjustment for Up to ±25% Over Range

♦ Programmable Voltage Output

Unipolar Range: 0 to +10.24V ±25%

Bipolar Range: ±10.24V ±25%

♦ Programmable Current Output

Unipolar Low Range: 0 to 20.45mA

Unipolar High Range: 3.97mA to 20.45mA

♦ Flexible Analog Supplies (See Table 16)

±13.48V to ±15.75V for Voltage Output

+13.48V to +40V for Current Output

♦ Force-Sense Connections (Voltage Output)

for Differential Voltage-Output Remote Sensing

♦ Voltage-Output Current Limit

♦ Dropout Detector Senses Out-of-Regulation

Current Output

♦ CLR and LDAC Inputs for Asynchronous DAC

Updates

♦ CLR Input Resets Output to Programmed Value or

Zero Code

♦ FAULT Output Indicates Open-Circuited Current

Output, Short-Circuited Voltage Output, or Clear

State

♦ Temperature Drift

Voltage Output: ±0.4ppm FSR/°C

Current Output: ±7.9ppm FSR/°C

♦ Small 64-Pin LQFP Package (10mm x 10mm)

MAX5661

19-0741; Rev 0; 8/08

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

Pin Configuration and Typical Operating Circuit appear at

end of data sheet.

________________________________________________________________

Maxim Integrated Products

1

For pricing delivery, and ordering information please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Ordering Information

+

Denotes a lead-free/RoHS-compliant package.

PART TEMP RANGE PIN-PACKAGE

MAX5661GCB+

64 LQFP

-40°C to +105°C

Page 2

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

2 ________________________________________________________________________________________

V

DDCORE

to V

SSV

...................................................-0.3V to +42V

V

DDI

to AGND.........................................................-0.3V to +42V

V

DDV

to AGND........................................................-0.3V to +17V

V

SSV

to AGND ........................................................-17V to +0.3V

V

DDI

to V

SSV

...........................................................-0.3V to +59V

V

CC

to DGND ...........................................................-0.3V to +6V

DGND, DUTGND, DUTGNDS, DACGND,

DACGNDS to AGND ............................................-0.3V to +6V

Digital Inputs (CS, DIN, SCLK, CLR, LDAC,

CNF_) to DGND .....................................-0.3V to (V

CC

+ 0.3V)

Digital Outputs (DOUT, FAULT) to DGND....................................

...............................-0.3V to the lesser of (V

CC

+ 0.3V) or +6V

REF to AGND............................................................-0.3V to +6V

OUTV, SVP, SVN, COMPV to V

SSV

...........-0.3V to (V

DDV

+ 0.3V)

OUTI, COMPI, OUTI4/0 to AGND..............-0.3V to (V

DDI

+ 0.3V)

Maximum Current into Any Pin .......................................±100mA

Continuous Power Dissipation (T

A

= +70°C)

64-Pin, 10mm x 10mm TQFP (derate 25mW/°C

above +70°C)............................................................ 2000mW

Junction-to-Ambient Thermal Resistance

in Still Air (θ

JA

) ...………………………………………….40°C/W

Junction-to-Case Thermal Resistance (θ

JC

)...................... 8°C/W

Operating Temperature Range .........................-40°C to +105°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering,10s) ..................................+300°C

ABSOLUTE MAXIMUM RATINGS

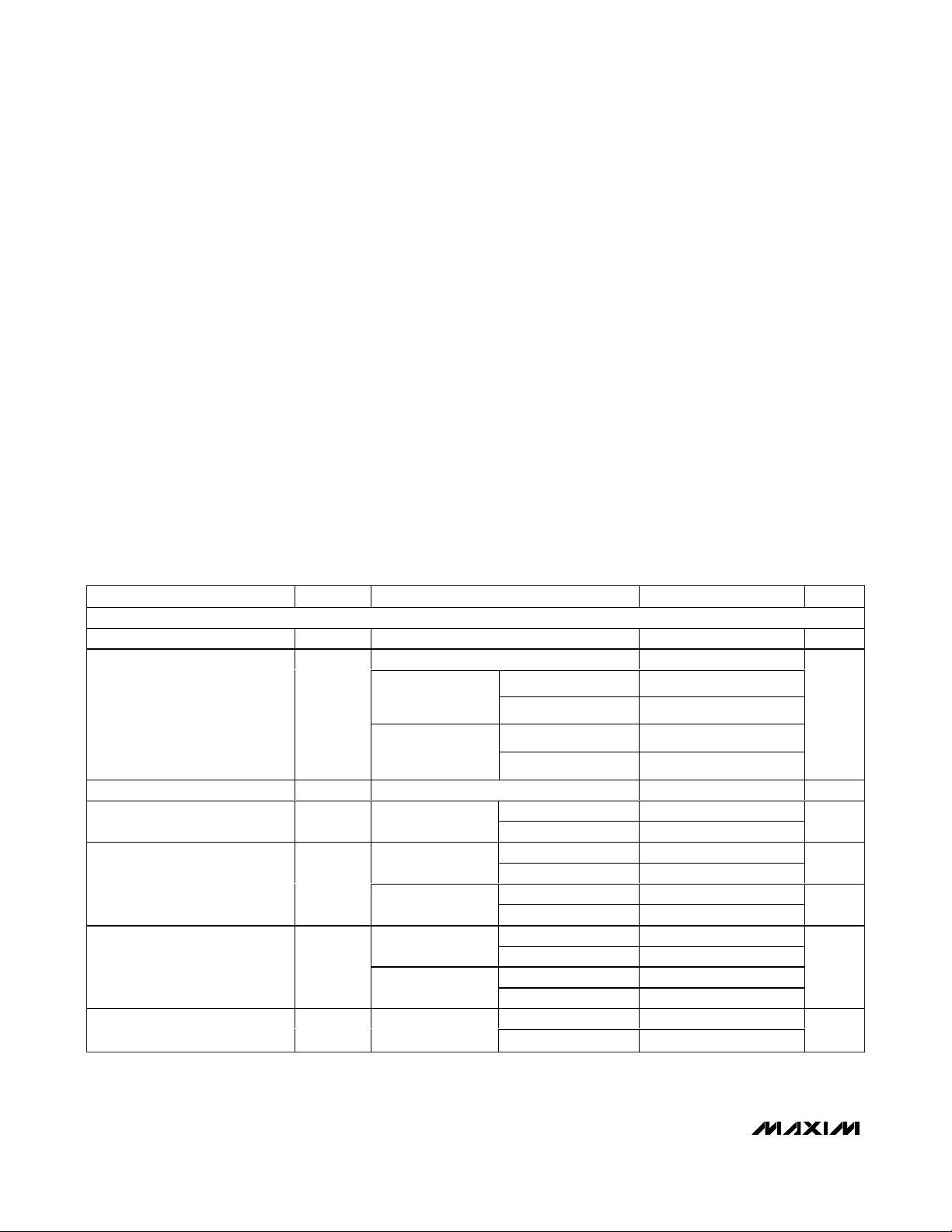

ELECTRICAL CHARACTERISTICS

(VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V, V

AGND

= V

DGND

= V

DUTGND

=

V

DACGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= -40°C to +105°C,

unless otherwise noted. Typical values are at T

A

= +25°C. See the

Typical Operating Circuit

.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

STATIC PERFORMANCE

Resolution 16 Bits

Integral Nonlinearity INL

Differential Nonlinearity DNL Guaranteed monotonic (Note 3) -1.0 +1.0 LSB

Zero-Scale Voltage Error V

Zero-Scale Current

(Note 4)

Zero-Scale Current Error

(Note 4)

Voltage-Offset Error Drift TCV

PARAMETER SYM B O L CONDITIONS MIN TYP MAX UNITS

V

OUT

I

, V

= V

DDI

= 40V,

DDV

OUT

V

SSV

(Note 2)

I

, V

DDI

= V

S S V

OUT

= + 15V , V

(Note 2)

ZSE

OUTV

0 to 20mA mode

4–20mA mode

0 to 20mA mode

I

ZSE

4–20mA mode

OUTV

OS

±0.2 ±4

4–20mA ±6

= 0

0 to 20mA ±10

DDV

4–20mA ±2

= - 15V

0 to 20mA ±6

Unipolar ±0.01 ±3

Bipolar ±2.0 ±10

TA = +25°C -45 -30 -15

= T

MIN

to T

MAX

T

A

-60 -30 0

TA = +25°C 3.955 3.97 3.985

T

= T

MIN

to T

MAX

A

3.94 3.97 4.00

TA = +25°C -15 ±2.0 +15

= T

MIN

to T

MAX

T

A

-30 ±2.0 +30

TA = +25°C -15 ±3.0 +15

T

= T

MIN

to T

MAX

A

-30 ±7.0 +30

Unipolar ±0.5

Bipolar ±0.2

LSB

mV

µA

mA

µA

ppm of

FSR/

o

C

Page 3

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

_______________________________________________________________________________________ 3

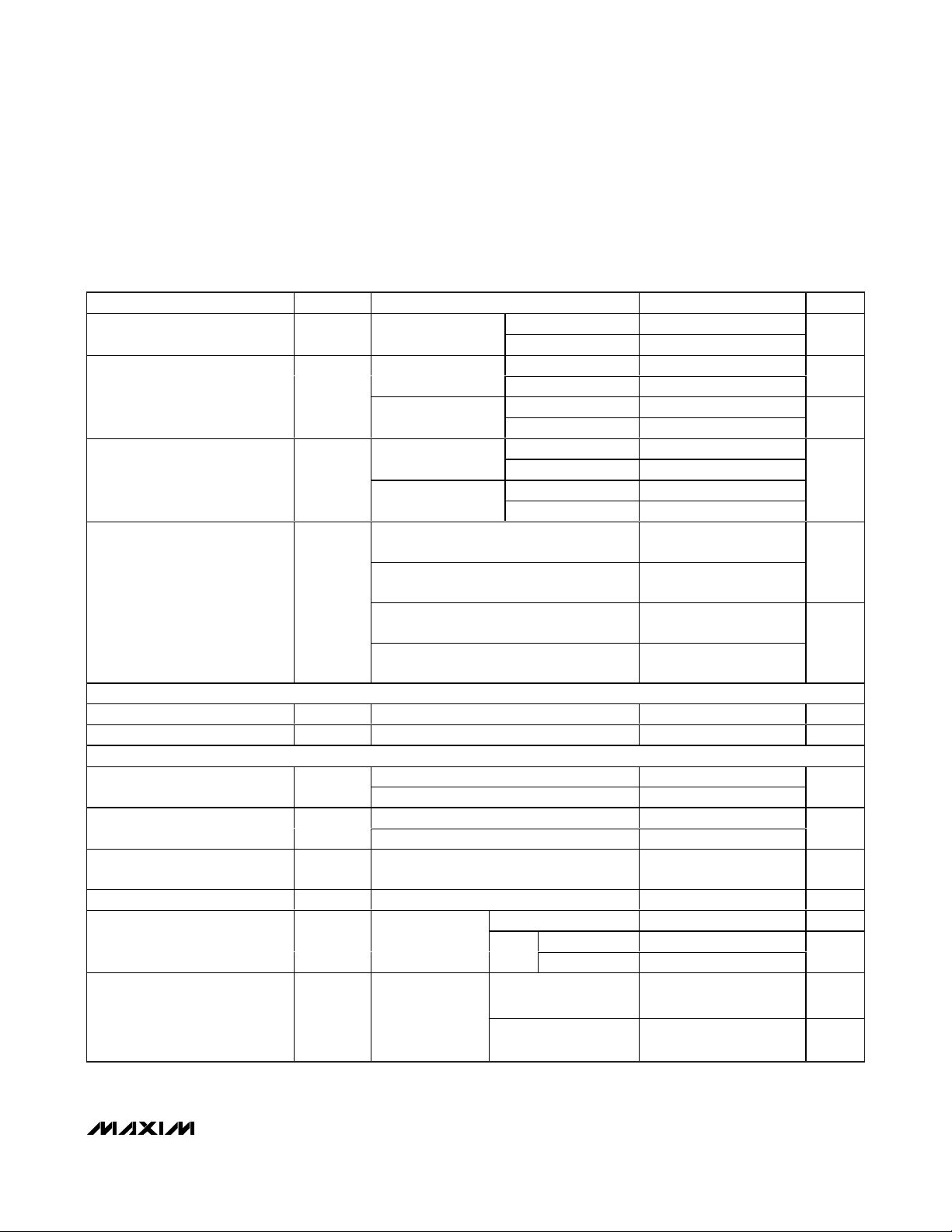

ELECTRICAL CHARACTERISTICS (continued)

(VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V, V

AGND

= V

DGND

= V

DUTGND

=

V

DACGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= -40°C to +105°C,

unless otherwise noted. Typical values are at T

A

= +25°C. See the

Typical Operating Circuit

.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Current-Offset Error Drift TCI

Gain Error GE

Gain-Error Drift TCGE

Power-Supply Rejection Ratio PSRR

REFERENCE INPUT

Reference Input Current I

Reference Input Voltage Range V

DYNAMIC PERFORMANCE

Output-Voltage Noise at 10kHz e

Output-Current Noise at 10kHz i

Voltage-Output Slew Rate

Current-Output Slew Rate L

Major Code Transition Glitch

Digital Feedthrough

OUTI

OS

OUTV

OUTI

OUTV

OUTI

OUTV, unipolar output, full-scale code,

V

from +13.48V to +15.75V

DDV

OUTV, bipolar output, zero-scale code,

V

from -13.48V to -15.75V

SSV

OUTI, full-scale code, V

+40V, V

= -15.75V, V

SSV

OUTI, full-scale code, V

REF

REF

n

+40V, V

Unipolar output, V

n

Bipolar output, V

0 to 20mA range 132

4–20mA range 120

C

OUTV

step = 20V, C

OUTI

= V

DDV

= 100pF, R

EXT

= 0, R

OUTI

SSV

OUTV

= 0nF

= 500Ω, step = 20mA 0.15 mA/µs

From code 7FFFh

to code 8000h

Outputs set to

zero scale, all

digital inputs from

CC

and

0V to V

back to 0V

0 to 20mA ±4

4–20mA ±4

Unipolar ±2.5 ±10

Bipolar ±4.5 ±20

TA = +25°C ±8.0 ±70

T

= T

MIN

to T

MAX

A

±40 ±130

Unipolar ±0.4

Bipolar ±0.4

0 to 20mA -7.9

4–20mA -8.6

20 200

20 200

from +13.48V to

DDI

DDV

DDI

= 0

= +15.75V

from +13.48V to

0.013 5

0.017 5

0.050 1 µA

4.0 4.096 4.2 V

= +10.48V 230

OUTV

= ±10.48V 300

= 2kΩ,

OUTV

0.1 V/µs

OUTV 1 µV•s

OUTI

0 to 20mA 2.0

4–20mA 2.0

OUTV 0.1 nV•s

OUTI, R

= 500Ω 0.2 pA•s

L

ppm of

o

FSR/

mV

µA

ppm of

o

FSR/

µV/V

µA/V

nV/√Hz

pA/√Hz

nA•s

C

C

Page 4

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

4 ________________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V, V

AGND

= V

DGND

= V

DUTGND

=

V

DACGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= -40°C to +105°C,

unless otherwise noted. Typical values are at T

A

= +25°C. See the

Typical Operating Circuit

.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

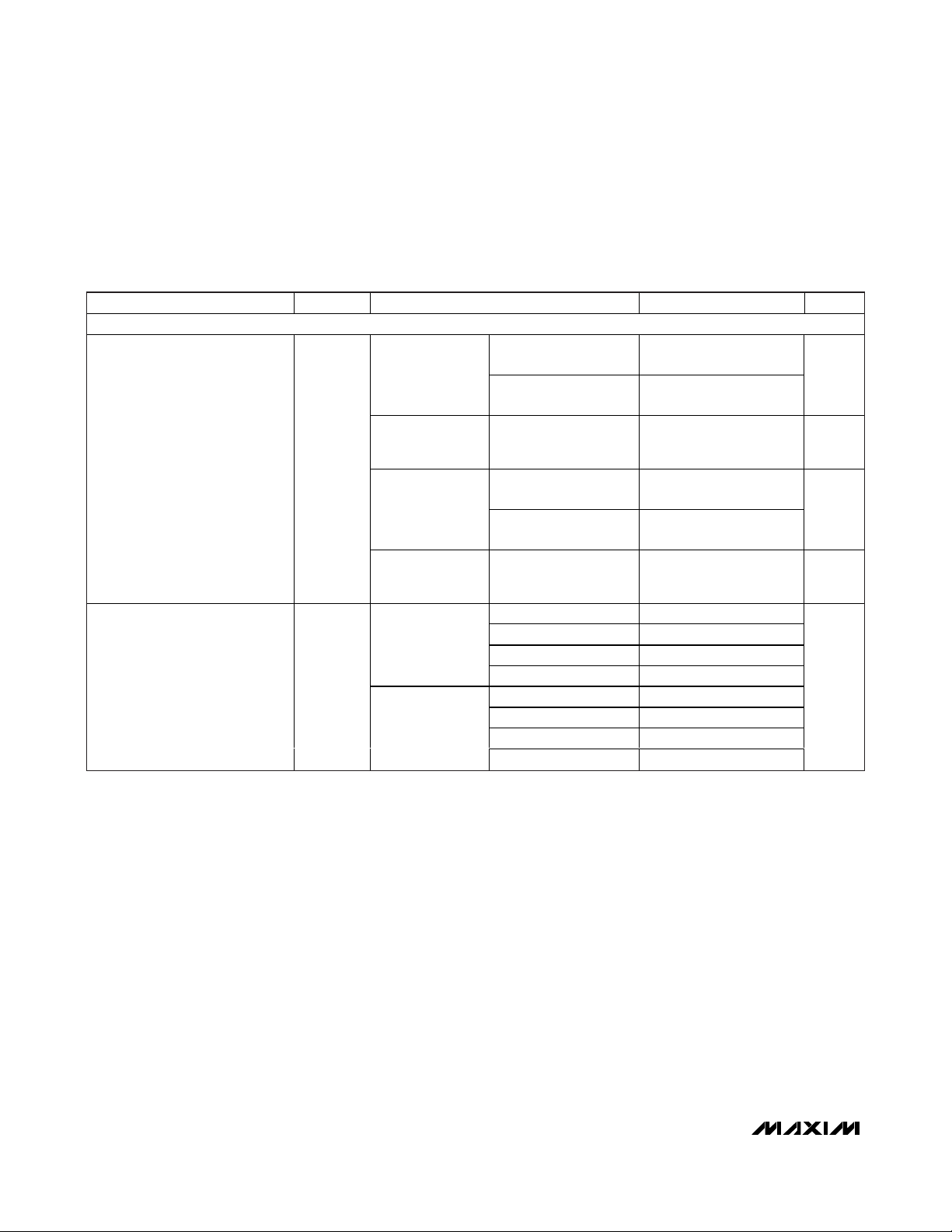

SETTLING TIME

Voltage-Output Settling Time

Current-Output Settling Time

Bipolar output,

C

COMPV

= 3.3nF,

to 0.1%

Bipolar output,

C

COMPV

= 0nF,

to 0.1%

Unipolar output,

C

COMPV

= 3.3nF,

to 0.1%

Unipolar output,

C

COMPV

= 0nF,

to 0.1%

0 to 20.45mA

range to 0.1%

3.97mA to

20.45mA range

to 0.1%

C

= 1nF,

OUTV

R

= 2kΩ

OUTV

= 1.2µF,

C

OUTV

R

= 2kΩ

OUTV

= 100pF,

C

OUTV

R

= 2kΩ

OUTV

C

= 1nF,

OUTV

R

= 2kΩ

OUTV

= 1.2µF,

C

OUTV

R

= 2kΩ

OUTV

= 100pF,

C

OUTV

R

= 2kΩ

OUTV

R

= 500Ω 1.5

OUTI

L

= 1mH 1.66

OUTI

L

= 10mH 1.66

OUTI

L

= 1H 1.97

OUTI

R

= 500Ω 1.43

OUTI

L

= 1mH 1.58

OUTI

L

= 10mH 1.58

OUTI

= 1H 1.73

L

OUTI

3

5.44

244 µs

1.8

3.64

130 µs

ms

ms

ms

Page 5

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V, V

AGND

= V

DGND

= V

DUTGND

=

V

DACGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= -40°C to +105°C,

unless otherwise noted. Typical values are at T

A

= +25°C. See the

Typical Operating Circuit

.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

OUTV OUTPUT

OUTV Linear Output Voltage

Range

Default OUTV Output Voltage

Ranges (0V to Full Scale)

Minimum OUTV Output Voltage

Range (FS to ADJ)

Maximum OUTV Output Voltage

Range (FS to ADJ)

DC Output Impedance 0.1 Ω

OUTV Off-State Leakage Current

OUTV Short-Circuit Output

Current

Minimum OUTV Resistive Load R

Maximum OUTV Capacitive Load C

OUTI OUTPUT

OUTI Voltage Compliance Full-scale output, R

OUTI Output Current Range

DC Output Impedance OUTI = full scale 45 MΩ

OUTI Off-State Leakage Current

Current-Mode Dropout Detection V

FEEDBACK SENSE BUFFER INPUTS

Input Current V

Input Voltage Range SVP, SVN

DIGITAL INPUTS

Input High Voltage V

Input Low Voltage V

Input Capacitance C

Input Leakage Current I

DIGITAL OUTPUTS

Output High Voltage V

Output Low Voltage V

V

OUT

V

OUT

V

OUT

I

SC

OUTV

OUTV

Unipolar, V

Bipolar, V

Unipolar +7.68

Bipolar ±7.68

Unipolar +12.8

Bipolar ±12.8

OUTV off or disabled,

output leakage current from OUTV to AGND

Sourcing 7 10 13

Sinking -18.0 -11.5 -9.0

Full-scale code 2 kΩ

C

C

= 3.3nF 1.2 µF

COMPV

= 0nF 1 nF

COMPV

0 to 20mA mode includes FS calibration

(Note 4)

= +13.48V, V

DDV

= +13.48V, V

DDV

= 1500Ω (Note 5) V

OUTI

V

+

SSV

3.0

= -13.48V 0 +10.48

SSV

= -13.48V -10.48 +10.48

SSV

2.5 10 µA

0 20.45

V

DDV

3.0

- 2.5 V

DDI

-

4–20mA mode includes FS calibration 3.97 20.45

IH

IL

IN

IN

OH

OL

OUTI off or disabled,

0V < V

DDI

SSV

< V

OUTI

- V

+ 1.7V < SVP, SVN < V

DDI

, FAULT does not assert 1.3 V

OUTI

- 1.7V 0.05 1 µA

DDV

V

SSV

+ 1.7

VCC = 4.75V to 5.25V 2.4 V

VCC = 4.75V to 5.25V 0.8 V

VIN = 0V or V

I

= 400µA, except FAULT VCC - 0.5 V

SOURCE

VCC = 4.75V

CC

I

= 1.6mA 0.4

SINK

I

= 10mA 1

SINK

-1 +1 µA

0.1 10 µA

V

DDV

- 1.7

10 pF

V

V

V

V

mA

mA

V

V

Page 6

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

6 ________________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V, V

AGND

= V

DGND

= V

DUTGND

=

V

DACGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= -40°C to +105°C,

unless otherwise noted. Typical values are at T

A

= +25°C. See the

Typical Operating Circuit

.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Output High Leakage Current FAULT only 0.1 2 µA

Thr ee- S tate Outp ut Leakag e C ur r ent DOUT only ±0.1 ±2 µA

POWER SUPPLIES (see Table 16)

VCC Supply Range V

V

Supply Range V

DDV

Supply Range V

SSV

Supply Range V

DDI

V

DDCORE

Supply Range V

Analog and Digital Supply

Currents (OUTV Active)

Analog and Digital Supply

Currents (OUTI Active), 0 to

20mA Mode

Analog and Digital Supply

Currents (OUTI Active), 4–20mA

Mode

Analog and Digital Supply

Currents (Either OUTV or OUTI

Active)

CC

+4.75 +5.25 V

Only OUTV powered +13.48 +15.75

DDV

Only OUTI powered AGND

Both OUTV and OUTI powered +13.48 +15.75

Only OUTV powered -15.75 -13.48

SSV

Only OUTI powered AGNDV

Both OUTV and OUTI powered -15.75 -13.48

DDI

DDCORE

I

VDDV

+

I

VDDI

I

VDDCORE

I

VSSV

I

AGND

I

VCC

I

VDDV

+

I

VDDI

I

VDDCORE

I

VSSV

I

AGND

I

VCC

I

VDDV

I

+

VDDI

I

VDDCORE

I

VSSV

I

AGND

I

VCC

I

VDDV

I

VDDCORE

I

VSSV

I

AGND

I

VCC

I

VDDI

I

VDDI

Only OUTV powered V

Only OUTI powered +13.48 +40.00V

Both OUTV and OUTI powered V

DDV

Only OUTV powered V

Only OUTI powered V

Both OUTV and OUTI powered V

+

OUTV powered, V

= +15.75V, V

SSV

OUTV unloaded, all ditgital inputs at V

DGND

= V

DDI

= V

DDCORE

DDV

= -15.75V, VCC = +5.25V,

CC

or

-5 -2.5

-3.0 -1.6

+

OUTI powered, V

= V

V

DDI

DDCORE

+5.25V, zero code

= V

DDV

= AGND,

SSV

= +12V to +40V, VCC =

-1.0 -0.03

-4.0 -2.1

+

OUTI powered, V

V

= V

DDI

DDCORE

+5.25V, zero code

= V

DDV

= AGND,

SSV

= +12V to +40V, VCC =

-1.0 -0.03

-4.0 -2.1

+

Both OU TV and O U TI p ow er ed , V

V

+ 40V , V

cod e, all ditgital inputs at V

D D C ORE

= + 15.75V , V

= + 5.25V , O U TV unl oad ed at zer o

C C

= - 15.75V , V

S S V

CC

=

D D V

or DGND

D D I

=

-4.0 2.6

-4.0 -2.0

0 to 20mA at zero code 1.3 2

4–20mA at zero code 5.3 6.5

DDV

+40

DDV

DDI

DDV

4.5 6.5

0.03 0.2

2.8 5.5

0.03 0.2

6.8 9.5

0.03 0.2

4.2 6

0.03 0.2

V

V

V

V

mA

mA

mA

mA

Page 7

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

_______________________________________________________________________________________ 7

Note 1: Devices are 100% production tested at TA= +25°C and +105°C. Operation to -40°C is guaranteed by design.

Note 2: I

OUT

INL 100% production tested from 0 to 20mA only.

Note 3: I

OUT

DNL guaranteed by V

OUT

DNL.

Note 4: 0 to 20mA zero-scale current extrapolated by interpolation from full scale and code 192. See the

Measuring Zero-Code

Current (0 to 20mA Mode)

section.

Note 5: OUTI voltage compliance measured at V

DDI

= +33.22V.

Note 6: When updating the DAC registers, allow 5µs before sending the next command.

TIMING CHARACTERISTICS

(VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V, AGND = DGND = DUTGND =

DACGND = 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= -40°C to +105°C,

unless otherwise noted. Typical values are at T

A

= +25°C. See Figure 1.) (Notes 1, 6)

PARAMETER SYM B O L CONDITIONS MIN TYP MAX UNITS

SCLK Rise or Fall to CS Fall

Setup Time

CS Fall to SCLK Rise or Fall

Setup Time

SCLK Pulse-Width High t

SCLK Pulse-Width Low t

DIN to SCLK High Setup Time t

DIN to SCLK High Hold Time t

SCLK Period t

CS Pulse-Width High t

CS High to SCLK High or Low

Setup Time

SCLK High to CS Hold Time t

SCLK Fall to DOUT Valid

Propagation Delay

CS Transitions to DOUT

Enable/Disable Delay

SCLK Fall or Rise to CS Rise

Time

LDAC Pulse-Width Low t

CS Rise to LDAC Rise Time t

t

CSO

t

CSS

CH

CL

DS

DH

CP

CSW

t

CS1

CSH

t

DO

t

DV

t

SCS

LDL

CSLD

C

DOUT

C

DOUT

= 100pF 100 ns

= 100pF 100 ns

45 ns

40 ns

45 ns

45 ns

40 ns

0ns

100 ns

100 ns

45 ns

45 ns

15 ns

40 ns

80 ns

Page 8

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

8 ________________________________________________________________________________________

Figure 1. Serial-Interface Timing Diagram

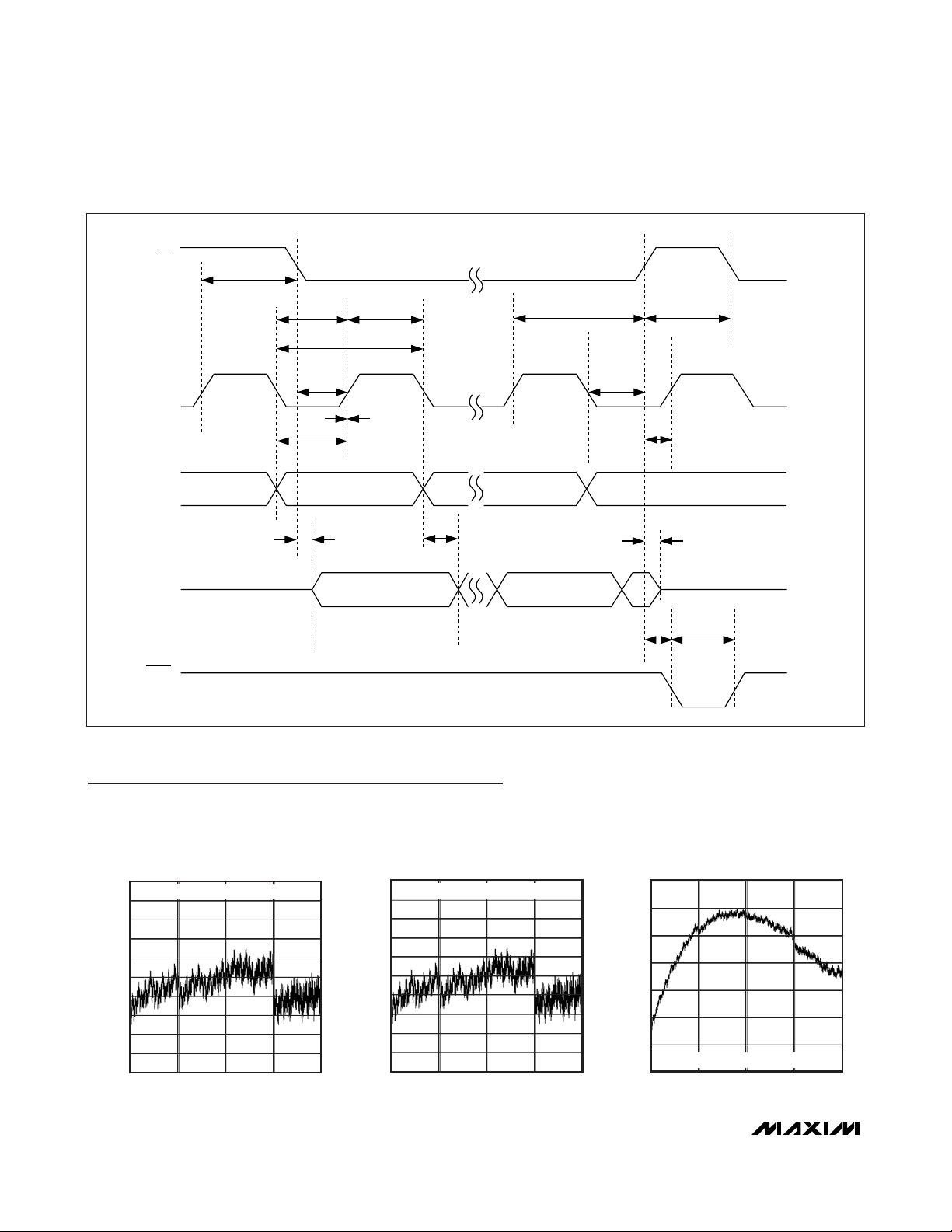

Typical Operating Characteristics

(

Typical Operating Circuit

, VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V,

V

AGND

= V

DGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= +25°C.)

CS

SCLK

DIN

DOUT

LDAC

t

CSO

t

t

CL

t

CSS

t

DS

t

DV

t

CH

t

CP

t

DH

t

DO

CSH

t

SCS

t

CS1

t

DV

t

CSLD

t

CSW

t

LDL

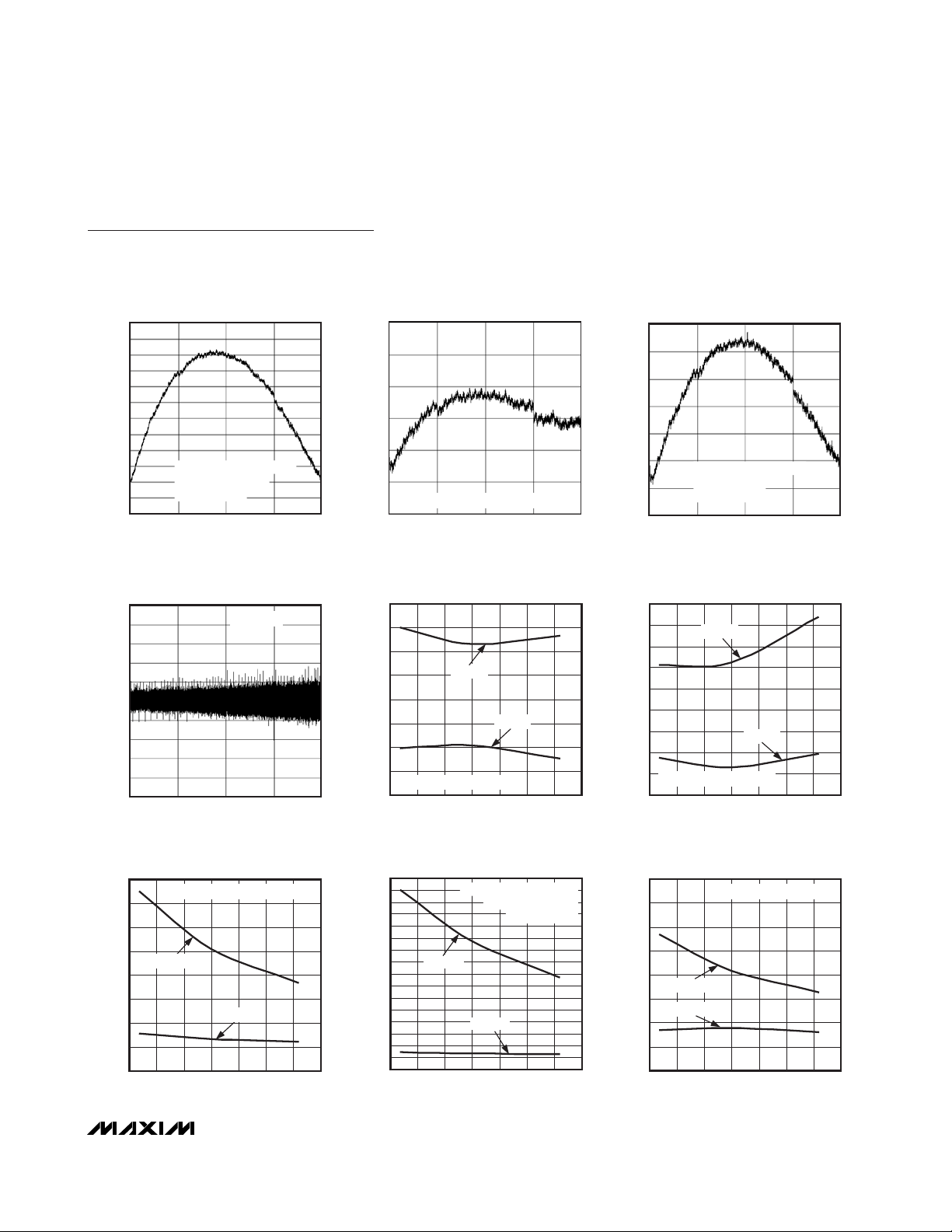

INL vs. DIGITAL INPUT CODE

1.0

0.8

0.6

0.4

0.2

0

INL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

UNIPOLAR VOLTAGE OUTPUT

0 16,384 32,768 49,152 65,536

DIGITAL INPUT CODE

MAX5661 toc01

INL vs. DIGITAL INPUT CODE

1.0

0.8

0.6

0.4

0.2

0

INL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

BIPOLAR VOLTAGE OUTPUT

0 16,384 32,768 49,152 65,536

DIGITAL INPUT CODE

MAX5661 toc02

INL vs. DIGITAL INPUT CODE

5

4

3

2

INL (LSB)

1

0

-1

-2

0 TO 20mA CURRENT OUTPUT

0 16,384 32,768 49,152 65,536

DIGITAL INPUT CODE

MAX5661 toc03

Page 9

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

_______________________________________________________________________________________ 9

Typical Operating Characteristics (continued)

(

Typical Operating Circuit

, VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V,

V

AGND

= V

DGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= +25°C.)

INL vs. DIGITAL INPUT CODE

10

9

8

7

6

5

4

INL (LSB)

3

2

1

0

-1

-2

0 16,384 32,768 49,152 65,536

0 TO 20mA CURRENT OUTPUT

= V

V

DDI

DDCORE

V

= V

= 0V

DDV

SSV

DIGITAL INPUT CODE

DNL vs. DIGITAL INPUT CODE

0.5

0.4

0.3

0.2

0.1

0

DNL (LSB)

-0.1

-0.2

-0.3

-0.4

-0.5

0 16,384 32,768 49,152 65,536

DIGITAL INPUT CODE

= +40V

ALL MODES

MAX5661 toc04

MAX5661 toc06

INL vs. DIGITAL INPUT CODE

3

2

1

0

INL (LSB)

-1

-2

-3

4–20mA CURRENT OUTPUT

0 16,384 32,768 49,152 65,536

DIGITAL INPUT CODE

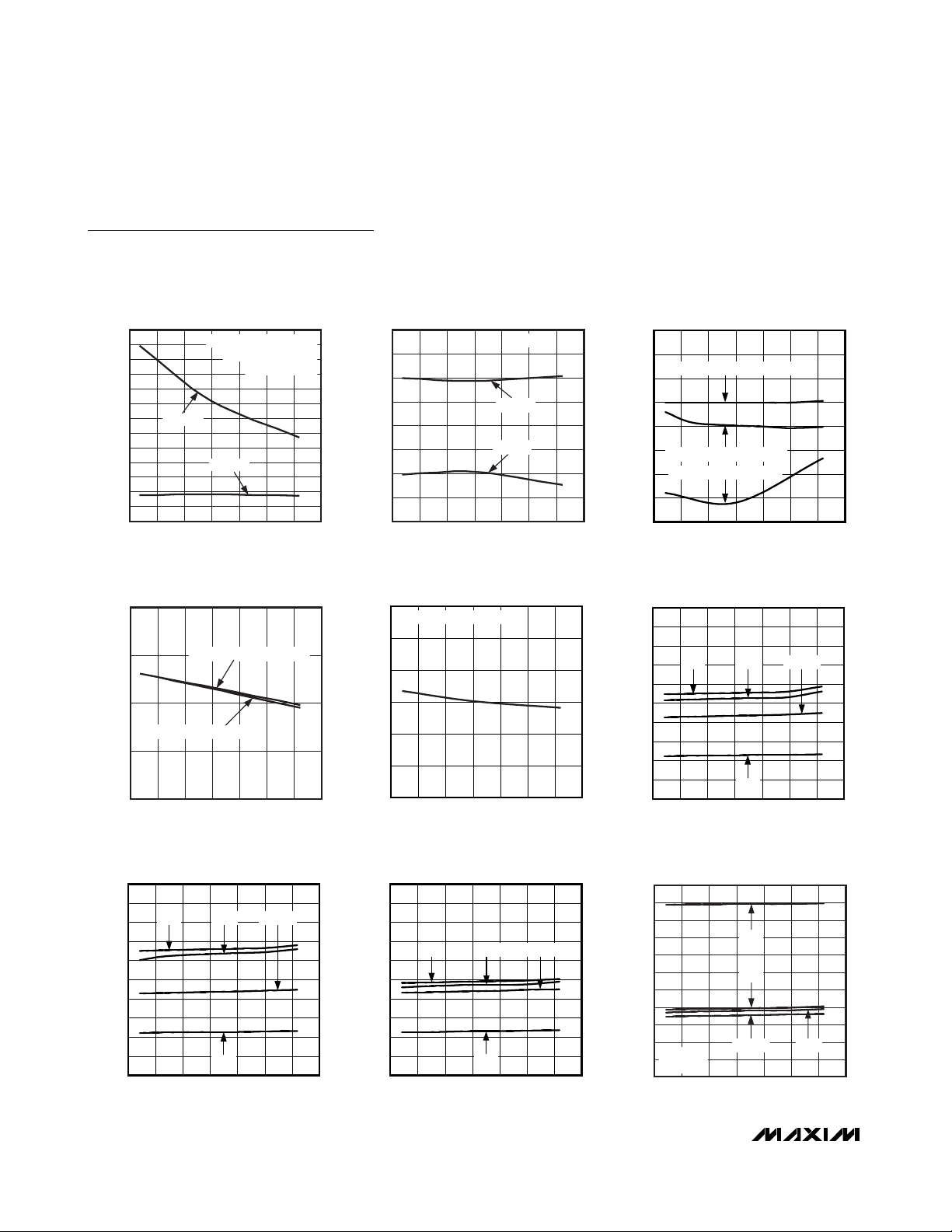

INL vs. TEMPERATURE

0.4

0.3

0.2

0.1

0

INL (LSB)

-0.1

-0.2

-0.3

UNIPOLAR VOLTAGE OUTPUT

-0.4

-50 -25 0 25 50 75 100 125

MAX INL

MIN INL

TEMPERATURE (°C)

MAX5661 toc05a

MAX5661 toc07

INL vs. DIGITAL INPUT CODE

5

4

3

2

INL (LSB)

1

0

-1

-2

0 16,384 32,768 49,152 65,536

4–20mA CURRENT OUTPUT

= V

= V

DDCORE

SSV

= +40V

= 0V

V

DDI

V

DDV

DIGITAL INPUT CODE

INL vs. TEMPERATURE

0.5

0.4

0.3

0.2

0.1

0

INL (LSB)

-0.1

-0.2

-0.3

-0.4

-50 -25 0 25 50 75 100 125

MAX INL

MIN INL

BIPOLAR VOLTAGE OUTPUT

TEMPERATURE (°C)

MAX5661 toc05b

MAX5661 toc08

3.0

2.5

2.0

1.5

1.0

INL (LSB)

0.5

0

-0.5

-1.0

-50 0-25 25 50 75 100 125

0 TO 20mA CURRENT OUTPUT

MAX INL

MIN INL

TEMPERATURE (°C)

INL vs. TEMPERATURE

MAX5661 toc09

INL vs. TEMPERATURE

7.0

6.5

6.0

5.5

5.0

4.5

4.0

3.5

3.0

INL (LSB)

2.5

2.0

1.5

1.0

0.5

0

-0.5

-1.0

-50 -25 0 25 50 75 100 125

0 to 20mA CURRENT OUTPUT

V

DDI

MAX INL

MIN INL

TEMPERATURE (°C)

= V

V

DDCORE

DDV

= V

= +40V

= 0V

SSV

MAX5661 toc10

3.0

2.5

2.0

1.5

1.0

INL (LSB)

0.5

-0.5

-1.0

MAX INL

MIN INL

0

-50 -25 0 25 50 75 100 125

4–20mA CURRENT OUTPUT

TEMPERATURE (°C)

INL vs. TEMPERATURE

MAX5661 toc11a

Page 10

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

10 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(

Typical Operating Circuit

, VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V,

V

AGND

= V

DGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= +25°C.)

INL vs. TEMPERATURE

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

INL (LSB)

1.5

1.0

0.5

0

-0.5

-1.0

MAX INL

-50 -25 0 25 50 75 100 125

TEMPERATURE (°C)

VOLTAGE-OUTPUT FULL-SCALE VOLTAGE

vs. TEMPERATURE

10.4850

10.4825

10.4800

FULL-SCALE VOLTAGE (V)

10.4775

10.4750

-50 25 50-25 0 75 100 125

UNIPOLAR VOLTAGE OUTPUT

BIPOLAR VOLTAGE OUTPUT

TEMPERATURE (°C)

4–20mA CURRENT OUTPUT

V

= V

V

DDCORE

DDV

= V

= +40V

SSV

= 0V

DDI

MIN INL

0.4

0.3

MAX5661 toc11b

0.2

0.1

0

DNL (LSB)

-0.1

-0.2

-0.3

-0.4

-50 -25 0 25 50 75 100 125

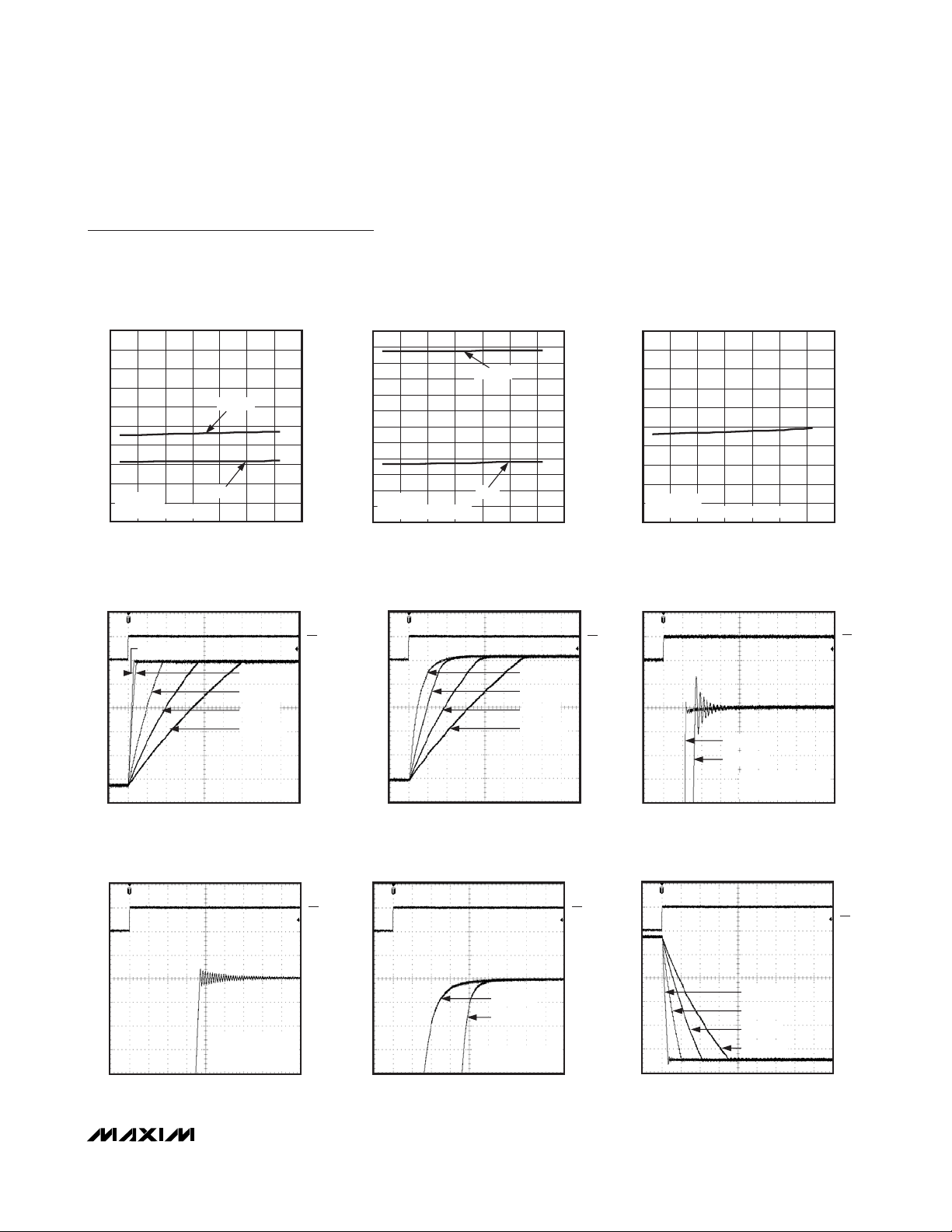

CURRENT-OUTPUT FULL-SCALE CURRENT

20.60

CURRENT OUTPUT = 0 TO 20mA

20.55

MAX5661 toc14

20.50

20.45

20.40

FULL-SCALE CURRENT (mA)

20.35

20.30

-50 25 50-25 0 75 100 125

DNL vs. TEMPERATURE

ALL MODES

MAX DNL

MIN DNL

TEMPERATURE (°C)

vs. TEMPERATURE

TEMPERATURE (°C)

3

MAX5661 toc12

MAX5661 toc15

2

1

0

-1

-2

ZERO-SCALE ERROR (LSB)

-3

-4

-5

4.0

3.6

3.2

2.8

2.4

2.0

1.6

1.2

SUPPLY CURRENT (mA)

0.8

0.4

0

ZERO-SCALE ERROR

vs. TEMPERATURE

CURRENT OUTPUT = 0 TO 20mA

UNIPOLAR VOLTAGE OUTPUT

BIPOLAR VOLTAGE OUTPUT

-50 25 50-25 0 75 100 125

TEMPERATURE (°C)

SUPPLY CURRENT vs. TEMPERATURE

(UNIPOLAR VOLTAGE OUTPUT)

I

VSSV

-50 -25 0 25 50 75 100 125

I

VDDV

I

VDDI

TEMPERATURE (°C)

I

VDDCORE

MAX5661 toc13

MAX5661 toc16

SUPPLY CURRENT vs. TEMPERATURE

(BIPOLAR VOLTAGE OUTPUT)

4.0

3.6

3.2

2.8

2.4

2.0

1.6

1.2

SUPPLY CURRENT (mA)

0.8

0.4

I

VSSV

0

-50 -25 0 25 50 75 100 125

I

VDDV

I

VDDI

TEMPERATURE (°C)

I

VDDCORE

MAX5661 toc17

SUPPLY CURRENT vs. TEMPERATURE

(0 TO 20mA CURRENT OUTPUT)

4.0

3.6

3.2

2.8

2.4

2.0

1.6

1.2

SUPPLY CURRENT (mA)

0.8

0.4

I

VSSV

0

-50 -25 0 25 50 75 100 125

I

VDDV

I

VDDI

TEMPERATURE (°C)

I

VDDCORE

MAX5661 toc18a

SUPPLY CURRENT vs. TEMPERATURE

(4–20mA CURRENT OUTPUT)

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

SUPPLY CURRENT (mA)

1.5

1.0

I

= 4mA

OUTI

0.5

= 500Ω

R

L

0

-50 -25 0 25 50 75 100 125

TEMPERATURE (°C)

I

VDDI

I

VSSV

I

VDDCORE

I

VDDV

MAX5661 toc18b

Page 11

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

______________________________________________________________________________________ 11

µ

µ

Typical Operating Characteristics (continued)

(

Typical Operating Circuit

, VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V,

V

AGND

= V

DGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= +25°C.)

SUPPLY CURRENT vs. TEMPERATURE

(0 TO 20mA CURRENT OUTPUT)

4.0

3.6

3.2

2.8

2.4

2.0

1.6

1.2

SUPPLY CURRENT (mA)

0.8

I

= 0mA

OUTI

0.4

V

= V

DDI

0

DDCORE

-50 -25 0 25 50 75 100 125

TEMPERATURE (°C)

= +40V

I

VDDCORE

I

VDDI

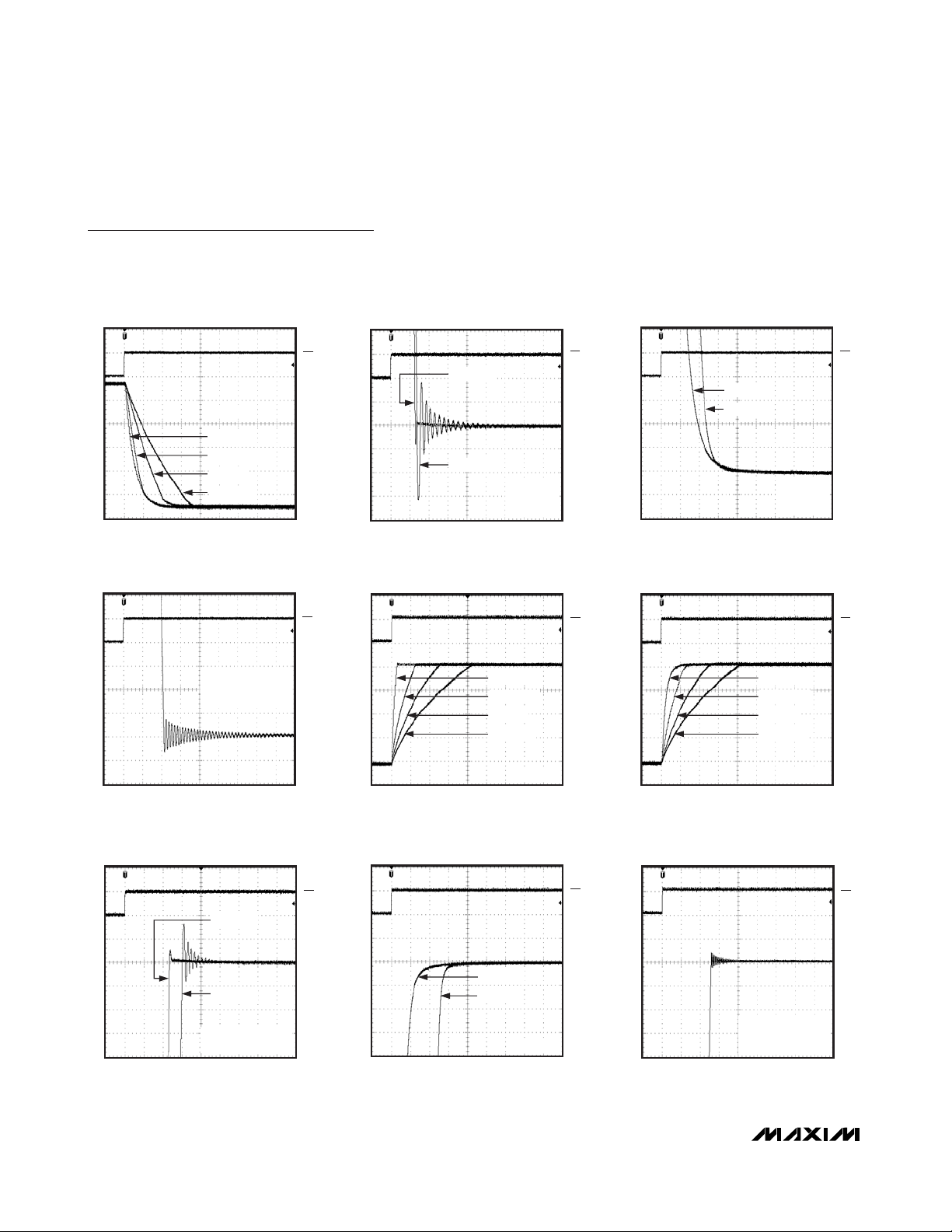

UNIPOLAR VOLTAGE-OUTPUT,

s/div

(C

L

ZS-TO-FS TRANSITION vs. C

CL = 100pF

400

SUPPLY CURRENT vs. TEMPERATURE

(4–20mA CURRENT OUTPUT)

6.0

5.5

5.0

MAX5661 toc18c

4.5

4.0

3.5

3.0

2.5

2.0

SUPPLY CURRENT (mA)

1.5

1.0

I

= 4mA

OUTI

0.5

V

= V

DDI

0

DDCORE

-50 -25 0 25 50 75 100 125

UNIPOLAR VOLTAGE-OUTPUT,

COMP

MAX5661 toc20

CL = 100nF

= 0.47µF

C

L

= 1µF

C

L

CL = 1.8µF

= 2kΩ

R

L

= 0nF)

CS

5V/div

OUTV

2V/div

ZS-TO-FS TRANSITION vs. C

TEMPERATURE (°C)

= +40V

I

VDDCORE

I

VDDI

400

s/div

(C

L

COMP

CL = 100pF

C

C

CL = 1.8µF

MAX5661 toc18d

= 3.3nF)

MAX5661 toc21

= 0.47µF

L

= 1µF

L

R

= 2kΩ

L

CS

5V/div

OUTV

2V/div

DIGITAL SUPPLY CURRENT

vs. TEMPERATURE

38

36

34

32

30

(μA)

28

VCC

I

26

24

22

VCC = +5.25V

20

ALL INPUTS CONNECTED TO VCC

18

-50 0 25-25 50 75 100 125

TEMPERATURE (°C)

UNIPOLAR VOLTAGE-OUTPUT

SETTLING TIME (C

COMP

CL = 100pF

CL = 100nF

RL = 2kΩ

ZS-TO-FS TRANSITION

100μs/div

= 0nF)

MAX5661 toc22

MAX5661 toc19

CS

5V/div

OUTV

100mV/div

UNIPOLAR VOLTAGE-OUTPUT

SETTLING TIME (C

400μs/div

= 0nF)

COMP

MAX5661 toc23

CL = 1μF

R

= 2kΩ

L

ZS-TO-FS TRANSITION

CS

5V/div

OUTV

100mV/div

UNIPOLAR VOLTAGE-OUTPUT

SETTLING TIME (C

400μs/div

= 3.3nF)

COMP

CL = 100pF

CL = 1μF

RL = 2kΩ

ZS-TO-FS TRANSITION

MAX5661 toc24

CS

5V/div

OUTV

100mV/div

UNIPOLAR VOLTAGE-OUTPUT,

FS-TO-ZS TRANSITION (C

CL = 100nF

CL = 0.47μF

CL = 1μF

CL = 1.8μF

400μs/div

COMP

= 0nF)

MAX5661 toc25

RL = 2kΩ

CS

5V/div

OUTV

2V/div

Page 12

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

12 _______________________________________________________________________________________

µ

Typical Operating Characteristics (continued)

(

Typical Operating Circuit

, VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V,

V

AGND

= V

DGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= +25°C.)

UNIPOLAR VOLTAGE-OUTPUT,

FS-TO-ZS TRANSITION (C

= 3.3nF)

COMP

MAX5661 toc26

UNIPOLAR VOLTAGE-OUTPUT

SETTLING TIME (C

= 0nF)

COMP

MAX5661 toc27

UNIPOLAR VOLTAGE-OUTPUT

SETTLING TIME (C

COMP

= 3.3nF)

MAX5661 toc28

400

UNIPOLAR VOLTAGE-OUTPUT

SETTLING TIME (C

400μs/div

RL = 2kΩ

CL = 100pF

CL = 0.47µF

CL = 1µF

CL = 1.8µF

s/div

= 0nF)

COMP

MAX5661 toc29

CL = 1μF

RL = 2kΩ

FS-TO-ZS TRANSITION

CS

5V/div

OUTV

2V/div

CS

5V/div

OUTV

100mV/div

CL = 100pF

CL = 100nF

100μs/div

BIPOLAR VOLTAGE-OUTPUT,

ZS-TO-FS TRANSITION (C

1.0ms/div

RL = 2kΩ

FS-TO-ZS

TRANSITION

= 0nF)

COMP

MAX5661 toc30

CL = 100nF

CL = 0.47µF

CL = 1µF

CL = 1.8µF

RL = 2kΩ

CS

5V/div

OUTV

100mV/div

CS

5V/div

OUTV

5V/div

CL = 100pF

CL = 1μF

400μs/div

BIPOLAR VOLTAGE-OUTPUT,

ZS-TO-FS TRANSITION (C

1.0ms/div

RL = 2kΩ

FS-TO-ZS

TRANSITION

= 3.3nF)

COMP

MAX5661 toc31

CL = 100pF

CL = 0.47µF

CL = 1µF

CL = 1.8µF

RL = 2kΩ

CS

5V/div

OUTV

100mV/div

CS

5V/div

OUTV

5V/div

BIPOLAR VOLTAGE-OUTPUT

SETTLING TIME (C

100μs/div

= 0nF)

COMP

CL = 100pF

CL = 100nF

RL = 2kΩ

ZS-TO-FS TRANSITION

MAX5661 toc32

CS

5V/div

OUTV

100mV/div

BIPOLAR VOLTAGE-OUTPUT

SETTLING TIME (C

COMP

CL = 100pF

CL = 1μF

1.0ms/div

= 3.3nF)

MAX5661 toc33

RL = 2kΩ

CS

5V/div

OUTV

100mV/div

BIPOLAR VOLTAGE-OUTPUT

SETTLING TIME (C

1.0ms/div

= 0nF)

COMP

MAX5661 toc34

CL = 1μF

RL = 2kΩ

ZS-TO-FS TRANSITION

CS

5V/div

OUTV

100mV/div

Page 13

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

______________________________________________________________________________________ 13

µ

µ

Typical Operating Characteristics (continued)

(

Typical Operating Circuit

, VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V,

V

AGND

= V

DGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= +25°C.)

BIPOLAR VOLTAGE-OUTPUT,

FS-TO-ZS TRANSITION (C

CL = 100pF

CL = 0.47μF

CL = 1μF

CL = 1.8μF

1.0ms/div

BIPOLAR VOLTAGE-OUTPUT

SETTLING TIME (C

COMP

CL = 100pF

CL = 1μF

RL = 2kΩ

FS-TO-ZS TRANSITION

1.0ms/div

= 0nF)

COMP

MAX5661 toc35

CS

5V/div

OUTV

5V/div

RL = 2kΩ

= 3.3nF)

MAX5661 toc38

CS

5V/div

OUTV

100mV/div

FS-TO-ZS TRANSITION (C

SETTLING TIME (C

BIPOLAR VOLTAGE-OUTPUT,

= 3.3nF)

COMP

CL = 100pF

CL = 0.47µF

CL = 1µF

CL = 1.8µF

1.0ms/div

BIPOLAR VOLTAGE-OUTPUT

= 0nF)

COMP

CL = 1μF

RL = 2kΩ

FS-TO-ZS TRANSITION

1.0ms/div

MAX5661 toc36

RL = 2kΩ

MAX5661 toc39

CS

5V/div

OUTV

5V/div

CS

5V/div

OUTV

100mV/div

BIPOLAR VOLTAGE-OUTPUT

SETTLING TIME (C

CL = 100pF

COMP

CL = 100nF

RL = 2kΩ

FS-TO-ZS TRANSITION

100μs/div

0 TO 20mA CURRENT-OUTPUT,

ZS-TO-FS TRANSITION vs. INDUCTIVE LOAD

LL = 0mH, LL = 100mH

400

s/div

= 0nF)

LL = 1H

MAX5661 toc37

CS

5V/div

OUTV

100mV/div

MAX5661 toc40

CS

5V/div

OUTI

4mA/div

0 TO 20mA CURRENT-OUTPUT,

ZS-TO-FS SETTLING TIME

LL = 0mH, LL = 100mH

s/div

400

LL = 1H

MAX5661 toc41

CS

5V/div

OUTV

200µA/div

0 TO 20mA CURRENT-OUTPUT,

FS-TO-ZS TRANSITION vs. INDUCTIVE LOAD

LL = 0mH

LL = 100mH

LL = 1H

2ms/div

MAX5661 toc42a

CS

5V/div

OUTI

4mA/div

0 TO 20mA CURRENT-OUTPUT,

FS-TO-ZS SETTLING TIME

LL = 0mH

LL = 100mH

2ms/div

MAX5661 toc42b

LL = 1H

CS

5V/div

OUTI

200µA/div

Page 14

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

14 _______________________________________________________________________________________

µ

µ

Typical Operating Characteristics (continued)

(

Typical Operating Circuit

, VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V,

V

AGND

= V

DGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= +25°C.)

0 TO 20mA CURRENT-OUTPUT,

ZS-TO-FS TRANSITION vs. INDUCTIVE LOAD

MAX5661 toc43a

0 TO 20mA CURRENT-OUTPUT,

ZS-TO-FS SETTLING TIME

MAX5661 toc43b

0 TO 20mA CURRENT-OUTPUT,

FS-TO-ZS TRANSITION vs. INDUCTIVE LOAD

MAX5661 toc43c

LL = 0mH, 100mH

LL = 1H

V

V

400

s/div

0 TO 20mA CURRENT-OUTPUT,

FS-TO-ZS SETTLING TIME

LL = 0mH

V

DDI

V

DDV

2ms/div

OUTI OUTPUT CURRENT

vs. OUTPUT VOLTAGE

25

20

= V

DDI

DDCORE

= V

DDV

SSV

LL = 100mH

LL = 1H

= V

DDCORE

= V

SSV

= +40V

= 0V

MAX5661 toc43d

= +40V

= 0V

CS

5V/div

OUTI

4mA/div

CS

5V/div

OUTI

200µA/div

MAX5661 toc46

CS

5V/div

LL = 1H

OUTI

LL = 0mH, LL = 100mH

V

= V

DDI

= V

V

DDV

400

s/div

DDCORE

SSV

= 0V

200µA/div

= +40V

OUTV OUTPUT VOLTAGE

vs. LOAD CURRENT (SOURCING)

10.484

10.482

10.480

(V)

10.478

OUTV

V

10.476

10.474

10.472

12345678910

011

UNIPOLAR OUTV MODE

MAX5661 toc44

BIPOLAR OUTV MODE

SOURCE CURRENT (mA)

OUTI OUTPUT CURRENT

vs. OUTPUT VOLTAGE

25

20

MAX5661 toc47

100

80

60

(V)

40

OUTV

V

20

0

UNIPOLAR OUTV MODE

-20

-12 0-11 -10 -9 -8 -7 -6 -5 -4 -3 -2 -1

UNIPOLAR VOLTAGE-OUTPUT, POSITIVE MAJOR

CARRY TRANSITION GLITCH (C

V

= V

DDI

DDCORE

= V

DDV

SSV

= 0V

V

LL = 1H

LL = 100mH

LL = 0mH

2ms/div

OUTV OUTPUT VOLTAGE

vs. LOAD CURRENT (SINKING)

SINK CURRENT (mA)

COMP

MAX5661 toc48

= +40V

= 3.3nF)

CS

5V/div

OUTI

4mA/div

MAX5661 toc45

CS

5V/div

15

(mA)

OUTI

I

10

5

V

= V

DDCORE

0

0105152025

= +24V

DDI

OUTPUT VOLTAGE (V)

15

(mA)

OUTI

I

10

5

V

= V

DDCORE

0

0101520530354025 45

= +40V

DDI

OUTPUT VOLTAGE (V)

100µs/div

OUTV

1mV/div

Page 15

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

______________________________________________________________________________________ 15

Typical Operating Characteristics (continued)

(

Typical Operating Circuit

, VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V,

V

AGND

= V

DGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= +25°C.)

UNIPOLAR VOLTAGE-OUTPUT, NEGATIVE MAJOR

CARRY TRANSITION GLITCH (C

100µs/div

COMP

= 3.3nF)

MAX5661 toc49

CS

5V/div

OUTV

1mV/div

UNIPOLAR VOLTAGE-OUTPUT, POSITIVE MAJOR

CARRY TRANSITION GLITCH (C

COMP

MAX5661 toc52

= 0nF)

CS

5V/div

BIPOLAR VOLTAGE-OUTPUT, POSITIVE MAJOR

CARRY TRANSITION GLITCH (C

UNIPOLAR VOLTAGE-OUTPUT, NEGATIVE MAJOR

CARRY TRANSITION GLITCH (C

100µs/div

COMP

COMP

= 3.3nF)

MAX5661 toc50

= 0nF)

MAX5661 toc53

CS

5V/div

OUTV

1mV/div

CS

5V/div

BIPOLAR VOLTAGE-OUTPUT, NEGATIVE MAJOR

CARRY TRANSITION GLITCH (C

100µs/div

BIPOLAR VOLTAGE-OUTPUT, POSITIVE MAJOR

CARRY TRANSITION GLITCH (C

= 3.3nF)

COMP

MAX5661 toc51

= 0nF)

COMP

MAX5661 toc54

CS

5V/div

OUTV

1mV/div

CS

5V/div

OUTV

50mV/div

4µs/div

BIPOLAR VOLTAGE-OUTPUT, NEGATIVE MAJOR

CARRY TRANSITION GLITCH (C

4µs/div

COMP

MAX5661 toc55

= 0nF)

CS

5V/div

OUTV

50mV/div

4µs/div

0 TO 20mA CURRENT-OUTPUT, POSITIVE

MAJOR CARRY TRANSITION GLITCH

100µs/div

MAX5661 toc56

OUTV

50mV/div

CS

5V/div

OUTI

2µA/div

4µs/div

0 TO 20mA CURRENT-OUTPUT, NEGATIVE

MAJOR CARRY TRANSITION GLITCH

100µs/div

MAX5661 toc57

OUTV

50mV/div

CS

5V/div

OUTI

2µA/div

Page 16

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

16 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(

Typical Operating Circuit

, VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V,

V

AGND

= V

DGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= +25°C.)

4–20mA CURRENT-OUTPUT, POSITIVE

MAJOR CARRY TRANSITION GLITCH

100µs/div

MAX5661 toc58

CS

5V/div

OUTI

2µA/div

UNIPOLAR VOLTAGE-OUTPUT

DIGITAL FEEDTHROUGH

MAX5661 toc61

CS = V

DIN = SCLK

f = 1MHz

4–20mA CURRENT-OUTPUT, NEGATIVE

MAJOR CARRY TRANSITION GLITCH

100µs/div

CC

DIN, SCLK

5V/div

OUTV

1mV/div

MAX5661 toc59

10,000

CS

5V/div

1000

(µA)

OUTI

2µA/div

VCC

I

100

10

06

BIPOLAR VOLTAGE-OUTPUT

DIGITAL FEEDTHROUGH

CS = V

DIN = SCLK

f = 1MHz

VCC SUPPLY CURRENT

vs. DIGITAL INPUT VOLTAGE

VCC = 5.25V

DIGITAL INPUT VOLTAGE (V)

MAX5661 toc62

CC

DIN, SCLK

5V/div

OUTV

2mV/div

MAX5661 toc60

54321

200ns/div

CURRENT-OUTPUT

DIGITAL FEEDTHROUGH

200ns/div

MAX5661 toc63

CS = V

CC

DIN = SCLK

f = 1MHz

DIN, SCLK

5V/div

OUTI

2µA/div

FULL-SCALE CURRENT vs. FULL-SCALE

OUTPUT CURRENT TRIM CODE

27

26

25

24

23

22

21

20

19

18

FULL-SCALE CURRENT (mA)

17

16

15

14

0 1024

200ns/div

768512256

CODE

MAX5661 toc64

Page 17

MAX5661

Pin Description

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

______________________________________________________________________________________ 17

Typical Operating Characteristics (continued)

(

Typical Operating Circuit

, VCC= +5V, C

COMPI

= 22nF, V

DDV

= V

DDCORE

= +15V, V

SSV

= -15V, V

DDI

= +24V, V

REF

= +4.096V,

V

AGND

= V

DGND

= 0V, R

SERIES

= 47Ω, OUTV loaded with 2kΩ || 100pF to AGND, OUTI loaded with 500Ω to AGND, TA= +25°C.)

14

13

12

11

10

9

FULL-SCALE VOLTAGE (V)

8

7

6

0 1024

PIN NAME FUNCTION

1, 3, 5, 7, 8,

10, 15–20,

29–34, 36, 38,

42, 44, 46–52,

58, 61–64

2 OUTI DAC Current-Source Output. OUTI sources either from 0 to 20mA or from 4–20mA.

4V

6 COMPI

9 OUTI4/0

11 REF

12 DACGND

13 DACGNDS

14 CNF1

21 CNF0

POSITIVE FULL-SCALE VOLTAGE

vs. FULL-SCALE OUTPUT TRIM CODE

UNIPOLAR OR BIPOLAR MODE

CODE

768512256

MAX5661 toc65

N.C. No Connection. Not internally connected.

DAC Current-Output Positive Supply. Connect V

DDI

+40V to power the DAC current-output (OUTI) buffer. Bypass V

AGND, as close as possible to the device.

OUTI Noise-Limiting Capacitor Connection. Connect a 22nF capacitor from COMPI to V

reduce transient noise at OUTI.

Current-Output Range Selection Input. Connect OUTI4/0 to AGND to select the 0 to 20mA OUTI

current-output range. Connect OUTI4/0 to V

The OUTI current range can also be set by software. When using software to set the OUTI current

range, connect OUTI4/0 to AGND.

Buffered Voltage Reference Input. Connect an external +4.096V voltage reference to REF. Bypass

REF with a 0.1µF capacitor to DACGND, as close as possible to the device. Use a 1kΩ resistor in

series to the reference input for optimum performance.

DAC Analog Ground. Connect DACGND, DACGNDS, DUTGND, and DUTGNDS together on a

low-noise ground plane with a star connection.

DAC Analog Sense Ground. Connect DACGND, DACGNDS, DUTGND, and DUTGNDS together

on a low-noise ground plane with a star connection.

Voltage/Current Configuration Input. CNF1 and CNF0 control the OUTV and OUTI outputs. See

Tables 13 and 14.

Voltage/Current Configuration Input. CNF0 and CNF1 control the OUTV and OUTI outputs. See

Tables 13 and 14.

NEGATIVE FULL-SCALE VOLTAGE

vs. FULL-SCALE OUTPUT TRIM CODE

-6

-7

-8

-9

-10

-11

FULL-SCALE VOLTAGE (V)

-12

-13

-14

0 1024

CODE

768512256

MAX5661 toc66

to a power supply between +13.48V and

DDI

to select the 4–20mA OUTI current-output range.

DDI

with a 0.1µF capacitor to

DDI

DDI

to

Page 18

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

18 _______________________________________________________________________________________

Pin Description (continued)

PIN NAME FUNCTION

22 DIN Serial-Data Input. Data is clocked into the serial interface on the rising edge of SCLK.

23 SCLK Serial-Clock Input

24 CS

25 DGND Digital Ground

26 V

27 LDAC

28 FAULT

35 DOUT

37 CLR

39 V

40 DUTGNDS

41 DUTGND

43 COMPV

45 AGND Analog Ground

53 SVP

54, 59 I.C. Internal Connection. Leave unconnected.

55 V

56 OUTV

57 V

60 SVN Rem ote V ol tag e S ense Inp ut. C onnect to the top ter m i nal of R

CC

DDCORE

SSV

DDV

Active-Low Chip-Select Input. Drive CS low to enable the serial interface. Drive CS high to disable

the serial interface. DOUT is high impedance when CS is high.

Digital Power Supply. Connect V

with a 0.1µF capacitor to DGND, as close as possible to the device.

Active-Low Asynchronous Load DAC Input. Drive LDAC low to transfer the contents of the input

register to the DAC register to immediately update the output. Connect LDAC to V

Active-Low Open-Drain Fault Output. FAULT asserts low for an OUTI open-circuit condition, an

OUTV short-circuit condition, or when the CLR input is low (see Table 12 and Figure 9).

Serial Data Output. Data transitions at DOUT on SCLK’s falling edge. DOUT is high impedance

when CS is high. Use DOUT to read the shift register contents or for daisy chaining multiple

MAX5661 devices.

Active-Low Clear Input. Drive CLR low to set the DAC code to the value stored in the clear

register, to 0V in voltage mode, or 0mA/4mA depending on the output current mode. Program the

contents of the clear register through the serial interface. Enable and disable the CLR input

through the control register’s CLREN bit (see Table 4).

DAC Core Positive Supply. Connect V

with a 0.1µF capacitor to AGND, as close as possible to the device.

DUT Analog Sense Ground. Connect DACGND, DACGNDS, DUTGND, and DUTGNDS together

on a low-noise ground plane with a star connection.

DUT Analog Ground. Connect DACGND, DACGNDS, DUTGND, and DUTGNDS together on a

low-noise ground plane with a star connection.

OUTV Amplifier Compensation Feedback Node. Connect a 3.3nF capacitor from OUTV to COMPV

when OUTV drives capacitive loads of up to 1.2µF. Leave COMPV open for faster response time.

Remote Ground Sense Input. Connect SVP to the bottom terminal of R

Operating Circuit.

D AC V ol tag e- Outp ut N eg ati ve P ow er S up p l y. Al w ays connect V

and -15.75V. Bypass V

DAC Unipolar/Bipolar Voltage Output. OUTV provides 0 to +10.48V in unipolar mode and -10.48V

to +10.48V in bipolar mode.

DAC Voltage-Output Positive Power Supply. Connect V

and +15.75V. Bypass V

with a 0.1µF capacitor to AGND, as close as possible to the device.

SSV

DDV

to a power supply between +4.75V and +5.25V. Bypass V

CC

CC

or V

DDCORE

with a 0.1µF capacitor to AGND, as close as possible to the device.

to V

DDI

(see Table 16). Bypass V

DDV

. See the Typical

OUTV

to a p ow er sup p l y b etw een - 13.48V

S S V

to a power supply between +13.48V

DDV

. S ee the Typ i cal Op er ati ng C i r cui t.

OU T V

CC

if unused.

DDCORE

Page 19

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

______________________________________________________________________________________ 19

Detailed Description

The MAX5661 single 16-bit DAC with precision high-voltage amplifiers provides a complete solution for programmable current and voltage-output applications. The

programmable output amplifiers swing to industry-standard voltage levels of ±10V or current levels from 0mA

(or from 4mA) to 20mA. The OUTV voltage output drives

resistive loads greater than 2kΩ and capacitive loads up

to 1.2µF. Force and sense connections on the voltage

output compensate for series protection resistors and

field wiring resistance. Short-circuit protection on the

voltage output limits output current. The OUTI current

output drives resistive loads from 0Ω and higher, up to a

compliance voltage of (V

DDI

- 2.5V). The OUTI current

output also drives inductive loads up to 1H.

The MAX5661 provides a current output or a voltage

output, with only one output active at any given time.

The MAX5661 operates with ±13.48V to ±15.75V dual

supplies (V

DDV

, V

SSV

) for the voltage output and a

+13.48V to +40V single supply (V

DDI

) for the current

output (see Table 16). The +4.75V to +5.25V digital supply (VCC) powers the digital circuitry and V

DDCORE

powers the rest of the internal analog circuitry. A buffered

reference input accepts a +4.096V reference voltage.

The LDAC and CLR inputs asynchronously update the

DAC outputs. CLR sets the DAC code to the value

stored in the clear register (software clear), or to zero

scale (hardware clear). The FAULT output asserts for

an open-circuit current output, a short-circuit voltage

output, or a clear state condition when CLR is low. The

power-on reset circuitry guarantees the outputs remain

off at power-up and all register bits are set to zero to

ensure a glitchless power-up sequence.

A 10MHz SPI-/QSPI-/MICROWIRE-compatible serial

interface programs the DAC outputs and configures the

device. The DOUT output allows shift-register reads or

daisy chaining of several devices. The double-buffered

interface includes an input register and a DAC register.

Use software commands or the asynchronous LDAC

input to transfer the input register contents to the DAC

register and update the DAC outputs.

4-Wire SPI-Compatible Serial Interface

The MAX5661 communicates through a serial interface

compatible with SPI, QSPI, and MICROWIRE devices.

For SPI, ensure that the SPI bus master (typically a

microcontroller (µC)) runs in master mode to generate

the serial-clock signal. Set the SCLK frequency to

10MHz or less, and set the clock polarity (CPOL) and

phase (CPHA) in the µC control registers to the same

value. The MAX5661 operates with SCLK idling high or

low, and thus operates with CPOL = CPHA = 0 (see

Figure 2) or CPOL = CPHA = 1 (see Figure 3). Force

CS low to input data at DIN on the rising edge of SCLK.

Output data at DOUT updates on the falling edge of

SCLK (see Figure 1).

A high-to-low transition on CS initiates the 24-bit data

input cycle. Once CS is low, write an 8-bit command

byte (MSB first) at DIN to send data to the appropriate

internal register (see Tables 1, 2, and 3). C7 is the MSB

of the command byte and C0 is the LSB. Following the

command byte, write 2 data bytes containing bits

D15–D0. D15 is the MSB of the 2 data bytes and D0 is

the LSB (see Figure 4 and the

Register Descriptions

sec-

tion). Data loads into the shift register 1 bit at a time.

Write the data as one continuous 24-bit stream, always

keeping CS low throughout the entire 24-bit word. The

MAX5661 stores the 24 most recent bits received,

including bits from previous transmission(s). Ensure

SCLK has 24 rising and falling edges between CS

falling low to CS returning high. Data loads into the shift

register on the rising edge of SCLK. Once CS returns

high, data transfers from the shift register into the

appropriate internal register.

When reading data, write an 8-bit command byte and

16 data bits at DIN. On the following 24-bit sequence,

read out the shift register’s contents (command byte

and the 16 data bits) at DOUT (see Figure 5). Data transitions at DOUT on the falling edge of SCLK. While

reading data at DOUT on the second 24-bit sequence,

load another command byte and 2 data bytes at DIN or

write a no-operation command. DOUT three-states

when CS is high. The DAC outputs update on the rising

edge of CS after writing to the DAC register or by

pulling LDAC low.

Daisy chain multiple devices by connecting the first

DOUT to the second DIN, and so forth. Daisy chaining

allows communication with multiple MAX5661 devices

using single CS and SCLK signals. See the

Daisy

Chaining Multiple MAX5661 Devices

section.

Page 20

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

20 _______________________________________________________________________________________

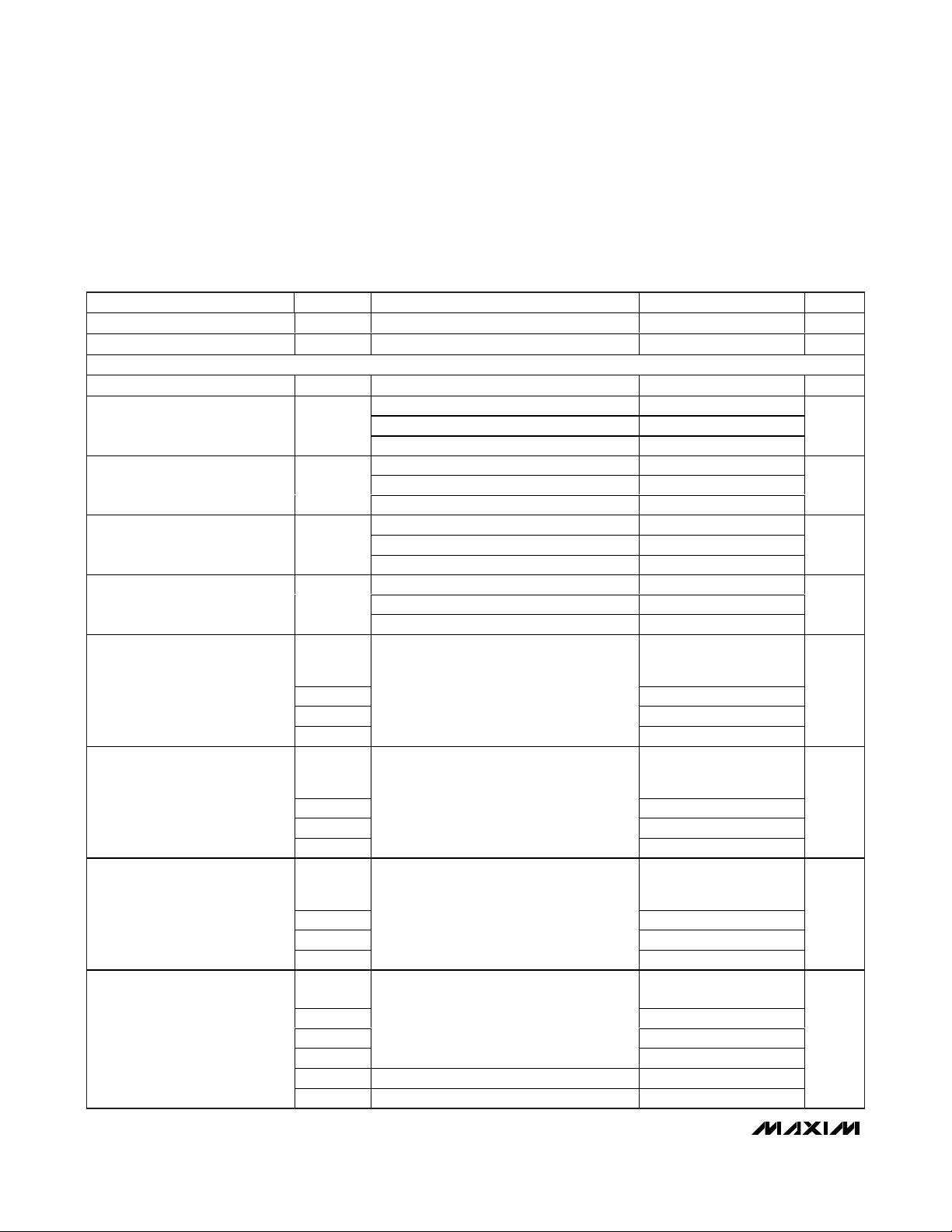

Figure 3. SPI-Interface Timing Diagram (CPOL = CPHA = 1)

Figure 2. MICROWIRE- or SPI-Interface Timing Diagram (CPOL = CPHA = 0)

CS

SCLK

DIN

DOUT

BITS WITH CAPITAL LETTERS REPRESENT DATA BEING WRITTEN TO THE SHIFT REGISTER.

BITS WITH LOWERCASE LETTERS REPRESENT DATA IN THE SHIFT REGISTER FROM THE PREVIOUS 24-BIT CYCLE.

CS

SCLK

DIN

DOUT

p IS DATA LEFT FROM THE PREVIOUS INSTRUCTION CYCLE.

BITS WITH CAPITAL LETTERS REPRESENT DATA BEING WRITTEN TO THE SHIFT REGISTER.

BITS WITH LOWERCASE LETTERS REPRESENT DATA IN THE SHIFT REGISTER FROM THE PREVIOUS 24-BIT CYCLE.

C7 C6 C5 C4 D3 D2 D1 D0

c7 c6 c5 c4 d3 d2 d1 d0 C7

C7 C6 C5 C4 D3 D2 D1 D0

c7 c6 c5 c4 d3 d2 d1 d0

p

Page 21

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

______________________________________________________________________________________ 21

Table 1. Input Command Bits

Table 2. Register Description

Register Descriptions

The MAX5661 communicates between its internal registers and the external bus lines through the 4-wire

SPI-/QSPI-/MICROWIRE-compatible serial interface.

Table 1 details the command bits (C7–C0) and the data

bits (D15–D0) of the serial input word. Tables 2 and 3

detail the command byte and the subsequent register

accessed. Tables 4–8 detail the various read/write

internal registers and their power-on reset states. When

updating the DAC register, allow 5µs before sending

the next command.

Control Register (Read/Write)

Write to the control register to enable the current or voltage output, set the voltage output for unipolar or bipolar

mode, and set the current-output range. The control

register also initializes the clear and fault modes. Set

the command byte to 0x01 to write to the control register. Set the command byte to 0x02 to read from the

control register. Write or read data bits D15–D5. D4–D0

are don’t-care bits for a write operation. D4, D3, and D2

are read-only bits. D1 and D0 are don’t-care bits for a

read operation (see Table 4).

Set the OUTVON bit (D15) to 1 to enable the OUTV

DAC voltage output. Set the OUTION bit (D14) to 1 to

enable the OUTI DAC current output. Always set bit

D13 to 0. Set the B/U bit (D12) to determine whether the

OUTV output operates in bipolar mode (B/U = 0) or

unipolar mode (B/U = 1).

X = Don’t care. All other commands are reserved for factory use. Do not use.

24-BIT SERIAL INPUT WORD

COMMAND BYTE DATA BITS

MSB LSB

C7 C6 C5 C4 C3 C2 C1 C0 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

COMMAND BITS

C7 C6 C5 C4 C3 C2 C1 C0

X X X X 0 0 0 0 No operation. Transfer shift register’s data to DOUT.

X X X X 0 0 0 1 Write control register.

X X X X 0 0 1 0 Read control register.

X X X X 0 0 1 1 Load input register. DAC register unchanged.

X X X X 0 1 0 0 Load DAC and input register.

XXXX0101

X X X X 0 1 1 0 Write clear register.

X X X X 0 1 1 1 Read input register.

X X X X 1 0 0 0 Read DAC register.

X X X X 1 0 0 1 Read clear register.

X X X X 1 1 1 1 No operation. Transfer shift register’s data to DOUT.

Load DAC register. Transfer input register data to DAC

register. DAC outputs update on CS’s rising edge.

OPERATION

Page 22

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

22 _______________________________________________________________________________________

Table 3. Register Bit Descriptions

OPERATION

No operation.

Transfer shift-

register data

to DOUT.

No operation.

Transfer shift-

register data

to DOUT.

Write control

register

Read control

register

Load input

register from shift

register. DAC

register unchanged.

Load input

register and DAC

register from shift

register.

Load DAC register

from input

register

Write clear

register

Read input register

Read DAC

register

Read clear

register

Write full-scale

output trim

register

DESCRIPTION

Data in shift register

before CS driven high and

command executed

Data in shift register

after CS driven high and

command executed

Data in shift register

before CS driven high and

command executed

Data in shift register

after CS driven high and

command executed

Data in shift register

before CS driven high and

command executed

Data in shift register

after CS driven high and

command executed

Data in shift register

before CS driven high and

command executed

Data in shift register

after CS driven high and

command executed

Data in shift register

before CS driven high and

command executed

Data in shift register

after CS driven high and

command executed

Data in shift register

before CS driven high and

command executed

Data in shift register

after CS driven high and

command executed

Data in shift register

before CS driven high and

command executed

Data in shift register

after CS driven high and

command executed

Data in shift register

before CS driven high and

command executed

Data in shift register

after CS driven high and

command executed

Data in shift register

before CS driven high and

command executed

Data in shift register

after CS driven high and

command executed

Data in shift register

before CS driven high and

command executed

Data in shift register

after CS driven high and

command executed

Data in shift register

before CS driven high and

command executed

Data in shift register

after CS driven high and

command executed

Data in shift register

before CS driven high and

command executed

Data in shift register

after CS driven high and

command executed

C7 C6 C5 C4 C3 C2 C1 C0 D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

X

COMMAND BYTE 1ST DATA BYTE 2ND DATA BYTE

0000

X

1111

XXXXX

X

0001

XXXX

XXXX0010 XXXXX

XXXX0011

XXXX0100

XXXX0101XX XXXXXX XXXXX XXX

XXXX0110 MSB <-- 16-Bit Clear-Register Data --> LSB

0111XX XXXXXX XXXXX XXX

XXXX

Same as line above.

1000XX XXXXXX XXXXX XXX

XXXX

Same as line above.

XXXX

1001XX XXXXXX XXXXX XXX

Same as line above.

XXXX

10101XX XX X

Same as line above.

XXXXXXXXX

Same as line above. Shift-register data not changed by this operation.

XXXXXXXXXX

Same as line above. Shift-register data not changed by this operation.

0

OUTIONOUTION

OUTVONOUTVON

Same as line above. Shift-register data not changed by this operation.

XXXX XXXXXXX

0

Same as line above. Shift-register data not changed by this operation.

Same as line above. Shift-register data not changed by this operation.

Same as line above. Shift-register data not changed by this operation.

Same as line above. Shift-register data not changed by this operation.

XXXXX

FS_ EN

EN

B/UB/U

OUTI4/0

OUTI4/0

MSB <-- 16-Bit DAC Clear Register Data --> LSB

CLRENCLREN

CLRMODECLRMODE

14 to 20 BIT

EN

14 to

20 BIT

MSB <-- 16-Bit DAC Data --> LSB

MSB <-- 16-Bit DAC Data --> LSB

MSB <-- 16-Bit Input-Register Data --> LSB

MSB <-- 16-Bit DAC-Register Data --> LSB

XXXX XXX XXX

FS_ BIT 8

FS_ BIT 9 (MSB)

XXXX XXX

XXXXXX

FAULTENFAULTEN

FS_ BIT 6

X

CLRFLAGENCLRFLAGEN

FS_ BIT 5

FAULTV

FS_ BIT 4

FAULTI

FS_ BIT 3

CLEARST

FS_ BIT 2

RCLRRCLR

FS_ BIT 7

FS_ BIT 1

XXXX

XXSame as line above.

FS_ BIT 0 (LSB)

Page 23

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

______________________________________________________________________________________ 23

Set the OUTI4/0EN bit (D11) low to enable the OUTI4/0

hardware input. Set the I4TO20BIT bit (D10) high to

select the current-output range through the software.

Set the CLREN bit (D9) low to enable the CLR hardware

input. Set the CLRMODE bit (D8) high to force the output to the value in the clear register or the zero state

when the CLR hardware input is pulled low. Set the

RCLR bit (D7) high to remain in the clear state. Set the

FAULTEN bit (D6) high to enable the FAULT output

functionality. Set the CLRFLAGEN bit (D5) high to activate the FAULT output when the MAX5661 is in the

clear state.

Bits D4, D3, and D2 are read-only bits. The FAULTV bit

(D4) is set to 1 when OUTV is short circuited. The

FAULTI bit (D3) is set to 1 when OUTI is open circuited.

The CLEARST bit (D2) is set to 1 when the MAX5661 is

in the clear state.

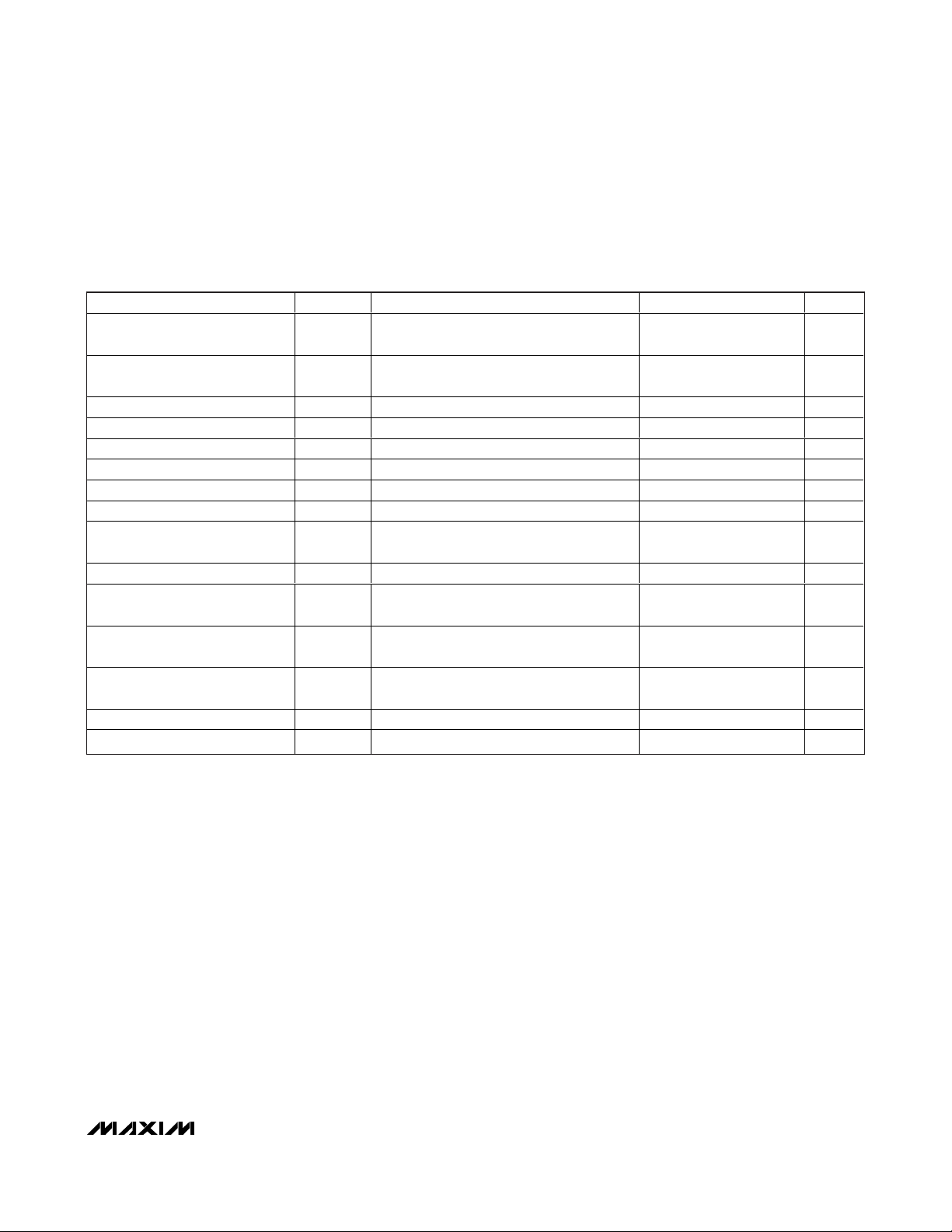

Figure 4. Write Timing

Figure 5. Read Timing

DIN CLOCKED IN ON THE

SCLK RISING EDGE

CS

SCLK

DIN

CS

SCLK

DIN

DOUT

CS

WRITE COMMAND EXECUTED

C7 C6 C5 C4 C0 D15 D14 D13 D0

READ COMMAND EXECUTED

C7 C6 C5 C4 C0 D15 D14 D13 D0

DOUT READY

SCLK

DIN

DOUT

X = DON'T CARE.

XXXX XXXX X

C7 C6 C5 C4 C0 D15 D14 D13 D0

DOUT TRANSITIONS ON THE FALLING SCLK EDGE

Page 24

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

24 _______________________________________________________________________________________

Table 4. Control Register (Read/Write)

BIT NAME

OUTVON D15 0 DAC OUTV output enable bit. Set to 1 to enable the OUTV output.

OUTION D14 0 DAC OUTI output enable bit. Set to 1 to enable the OUTI output.

— D13 0 Reserved. Always set to 0.

B/U D12 0

OUTI4/0EN D11 0

I4TO20BIT D10 0

CLREN D9 0

CLRMODE D8 0

RCLR D7 0

FAULTEN D6 0

CLRFLAGEN D5 0 C l ear fl ag enab l e. S et to 1 to enab l e the FAU LT outp ut to r ep or t w hen the d evi ce i s i n the cl ear state.

FAULTV D4 0

FAULTI D3 0

CLEARST D2 0

X D1, D0 0 Not used.

DATA

BIT

RESET

STATE

FUNCTION

Voltage-output unipolar/bipolar mode select bit. Set to 0 (default power-up state) to select the

bipolar output range (±10.48V). Set to 1 to select the unipolar output range (0 to +10.48V).

OUTI4/0 enable bit. Set to 0 (default power-up state) to enable the OUTI4/0 hardware input. Set

to 1 to disable the OUTI4/0 hardware input, thereby controlling the current-output range

through software commands.

OUTI current range bit. Set to 0 to set the OUTI current range from 0 to 20mA. Set to 1 to set

the OUTI current range from 4–20mA.

Clear enable bit. Set to 0 to enable the external CLR input. Set to 1 to disable the external CLR

input.

Clear mode bit. Set to 1 and drive the external CLR input low to force the DAC output to the

value stored in the clear register. Set to 0 and drive the external CLR input low to force the DAC

output to 0V in voltage mode or 0mA/4mA depending on output-current mode.

Remain in clear bit. Set to 1 to remain in the clear state. The RCLR bit determines the steps

CLR

required to exit the clear state. See the

Fault output enable. Set to 1 to enable the FAULT output functionality. Set to 0 to disable the

FAULT output functionality.

Output voltage fault bit (read only). The FAULTV bit is set to 1 when FAULT triggers due to an

OUTV short-circuit condition. The FAULTV bit is a don’t-care bit for control-register write

commands.

Output-current fault bit (read only). The FAULTI bit is set to 1 when FAULT triggers due to an

OUTI open-circuit condition. The FAULTI bit is a don’t-care bit for the control register write

commands.

C l ear state b i t ( r ead onl y) . The C LE ARS T b i t i s set to 1 w hen CLR i s l ow and C LRE N = 0. The C LRS T

b i t i s a d on’ t- car e b i t for contr ol r eg i ster w r i te com m and s.

Input section.

Page 25

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

______________________________________________________________________________________ 25

Input Register (Read/Write)

Write to the input register to store the DAC code.

Transfer the value written to the input register to the

DAC register by pulling the LDAC input low or by writing to the load DAC register (0x05). Set the command

byte to 0x03 to write to the input register. Set the command byte to 0x07 to read from the input register. Bits

D15–D0 contain the straight binary data (see Table 5).

DAC Register (Read/Write)

Write to the DAC register to update the OUTV and OUTI

outputs after CS returns high. Set the command byte to

0x04 to write to the DAC register. Set the command

byte to 0x08 to read from the DAC register. Bits

D15–D0 contain the straight binary data (see Table 6).

Load DAC Register (Write)

Write to the load DAC register to transfer the input register data to the DAC register and update the DAC out-

put. Set the command byte to 0x05 to write to the load

DAC register. Bits D15–D0 are don’t-care bits.

Clear Register (Read/Write)

Write to the clear register to set the DAC output value

when the CLR hardware input is pulled low (forcing the

MAX5661 into the clear state). Set the command byte to

0x06 to write to the clear register. Set the command

byte to 0x09 to read the clear register. Bits D15–D0

contain the straight binary data (see Table 7).

No Operation

Set the command byte to 0x0F or 0x00 to perform a nooperation command. After writing the command byte

and 2 data bytes (16 don’t-care bits), read out the shift

register’s contents on the following 24-bit cycle.

Table 5. Input Register (Read/Write)

Table 6. DAC Register (Read/Write)

Table 7. Clear Register (Read/Write)

Table 8. Full-Scale Output Trim Register (Write)

BIT NAME DATA BIT RESET STATE FUNCTION

0000 0000 0000 0000

IN15–IN0 D15–D0

(unipolar/current)

1000 0000 0000 0000

(bipolar)

IN15 is the MSB and IN0 is the LSB. Data format is straight binary.

BIT NAME DATA BIT RESET STATE FUNCTION

0000 0000 0000 0000

DAC15–DAC0 D15–D0

(unipolar/current)

0000 0000 0000 0000

(bipolar)

DAC15 is the MSB and DAC0 is the LSB. Data format is straight

binary.

BIT NAME DATA BIT RESET STATE FUNCTION

0000 0000 0000 0000

CLR15–CLR0 D15–D0

(unipolar/current)

1000 0000 0000 0000

(bipolar)

CLR15 is the MSB and CLR0 is the LSB. Data format is straight

binary.

BIT NAME DATA BIT RESET STATE FUNCTION

FS_EN +

FS_BIT9–

FS_BIT0

D9–D0 0000 0000 0000 0000

FS_EN (D15) enables the full-scale output adjustment feature. D9

is the MSB and D0 is the LSB. D9 is straight binary, D8–D0 are

inverted binary.

Page 26

MAX5661

Single 16-Bit DAC with Current and Voltage

Outputs for Industrial Analog Output Modules

26 _______________________________________________________________________________________

Table 9. N to D: Full-Scale Output Trim Register Bits Map

Table 10. Full-Scale Output Variation vs.

N and B

Figure 6. Transfer Function of Bits (B) to Numerical (N)

Representation

Full-Scale Output

Current Trim Register (Write)

Write to the full-scale output trim register to adjust the

output voltage or current ±25%. Set command bits to

0x06 to write to the output trim register. Bit 15 enables