Page 1

General Description

The MAX5481–MAX5484 10-bit (1024-tap) nonvolatile,

linear-taper, programmable voltage-dividers and variable resistors perform the function of a mechanical

potentiometer, but replace the mechanics with a pinconfigurable 3-wire serial SPI™-compatible interface or

up/down digital interface. The MAX5481/MAX5482 are

3-terminal voltage-dividers and the MAX5483/MAX5484

are 2-terminal variable resistors.

The MAX5481–MAX5484 feature an internal, nonvolatile, electrically erasable programmable read-only

memory (EEPROM) that stores the wiper position for initialization during power-up. The 3-wire SPI-compatible

serial interface allows communication at data rates up

to 7MHz. A pin-selectable up/down digital interface is

also available.

The MAX5481–MAX5484 are ideal for applications

requiring digitally controlled potentiometers. Two end-toend resistance values are available (10kΩ and 50kΩ) in a

voltage-divider or a variable-resistor configuration (see

the Selector Guide). The nominal resistor temperature

coefficient is 35ppm/°C end-to-end, and only 5ppm/°C

ratiometric, making these devices ideal for applications

requiring low-temperature-coefficient voltage-dividers,

such as low-drift, programmable gain-amplifiers.

The MAX5481–MAX5484 operate with either a +2.7V to

+5.25V single power supply or ±2.5V dual power supplies. These devices consume 400µA (max) of supply

current when writing data to the nonvolatile memory

and 1.0µA (max) of standby supply current. The

MAX5481–MAX5484 are available in a space-saving

(3mm x 3mm), 16-pin TQFN, or a 14-pin TSSOP package and are specified over the extended (-40°C to

+85°C) temperature range.

Applications

Features

♦ 1024 Tap Positions

♦ Power-On Recall of Wiper Position from

Nonvolatile Memory

♦ 16-Pin (3mm x 3mm x 0.8mm) TQFN or 14-Pin

TSSOP Package

♦ 35ppm/°C End-to-End Resistance Temperature

Coefficient

♦ 5ppm/°C Ratiometric Temperature Coefficient

♦ 10kΩ and 50kΩ End-to-End Resistor Values

♦ Pin-Selectable SPI-Compatible Serial Interface or

Up/Down Digital Interface

♦ 1µA (max) Standby Current

♦ Single +2.7V to +5.25V Supply Operation

♦ Dual ±2.5V Supply Operation

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

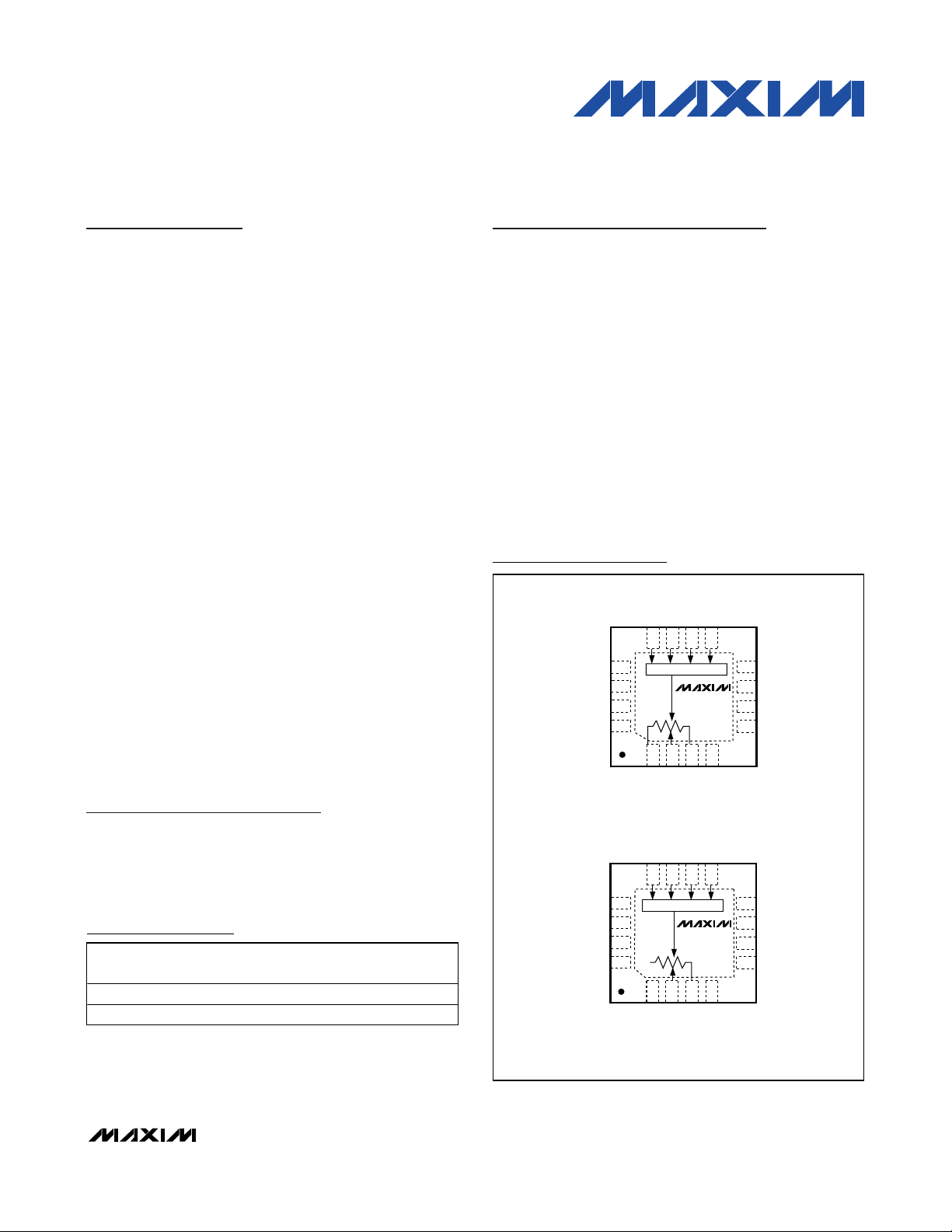

16

15

14

13

V

SS

N.C.

V

DD

GND

9

101112

SPI/UD

DIN(U/D)

SCLK(INC)

CS

4321

N.C.

L

W

H

5

6

7

8

N.C.

N.C.

N.C.

V

SS

INTERFACE

TOP VIEW

TQFN

*SEE FUNCTIONAL DIAGRAM

16

15

14

13

V

SS

N.C.

V

DD

GND

9

101112

SPI/UD

DIN(U/D)

SCLK(INC)

CS

4321

N.C.

L

W

D.N.C.

5

6

7

8

N.C.

N.C.

N.C.

V

SS

MAX5483

MAX5484

INTERFACE

TQFN

MAX5481*

MAX5482*

Pin Configurations

19-3708; Rev 0; 5/05

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Selector Guide appears at end of data sheet.

SPI is a trademark of Motorola, Inc.

†

All devices are specified over the -40°C to +85°C operating

temperature range.

*Future product—contact factory for availability.

**EP = Exposed pad.

Ordering Information continued at end of data sheet.

Pin Configurations continued at end of data sheet.

Gain and Offset

Adjustment

LCD Contrast Adjustment

Pressure Sensors

Low-Drift Programmable

Gain Amplifiers

Mechanical Potentiometer

Replacement

PART

MAX5481ETE 16 TQFN-EP** T1633F-3 ACP

MAX5481EUD* 14 TSSOP — —

†

PIN-PACKAGE PKG CODE

TOP

MARK

Page 2

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDDto GND...........................................................-0.3V to +6.0V

V

SS

to GND............................................................-6.0V to +0.3V

V

DD

to VSS.............................................................-0.3V to +6.0V

H, L, W to V

SS

..................................(VSS- 0.3V) to (VDD+ 0.3V)

CS, SCLK(INC), DIN(U/D), SPI/UD to GND..-0.3V to (V

DD

+ 0.3V)

Maximum Continuous Current into H, L, and W

MAX5481/MAX5483.........................................................±5mA

MAX5482/MAX5484......................................................±1.0mA

Maximum Current into Any Other Pin ...............................±50mA

Continuous Power Dissipation (T

A

= +70°C)

16-Pin TQFN (derate 17.5mW/°C above +70°C) .....1398.6mW

14-Pin TSSOP (derate 9.1mW/°C above +70°C) ..........727mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

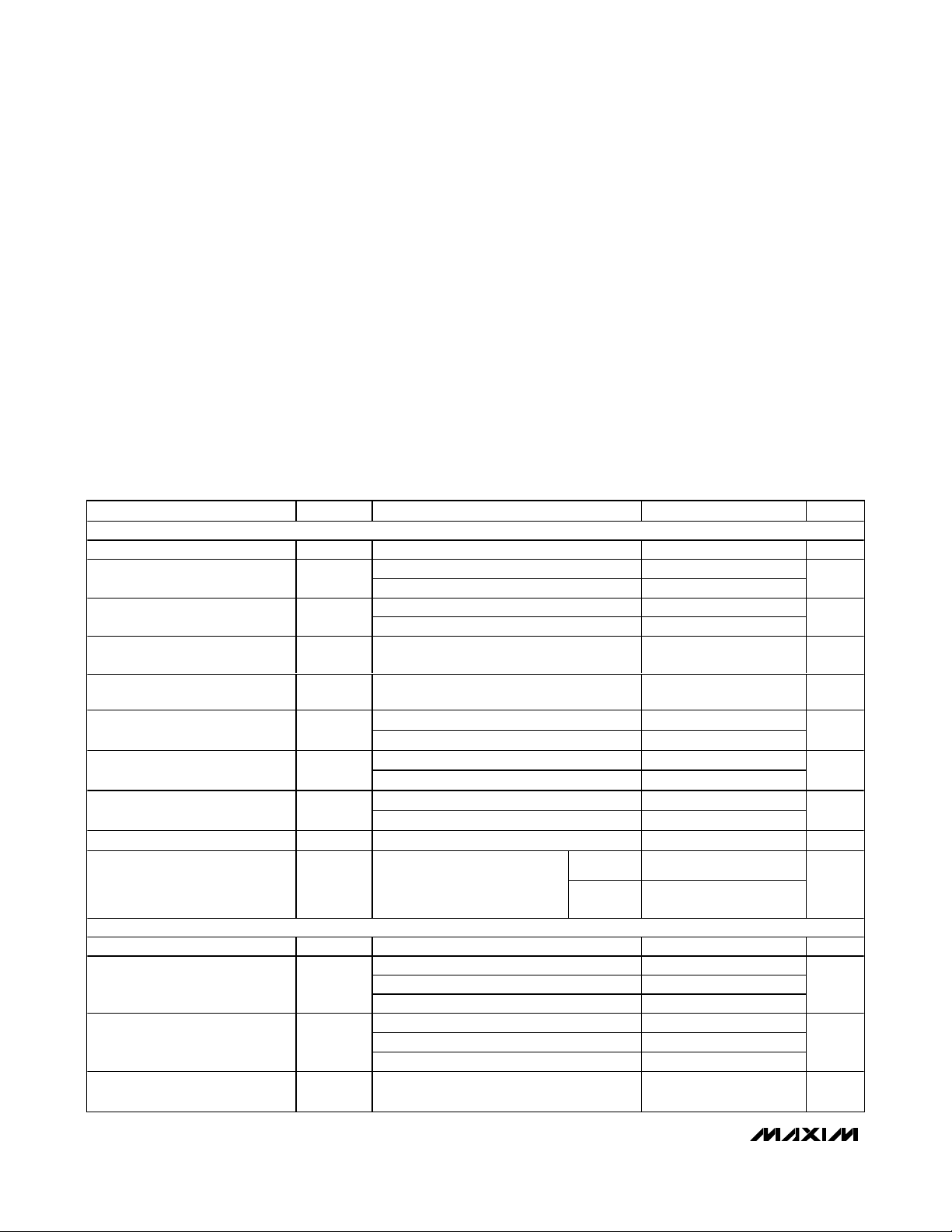

ELECTRICAL CHARACTERISTICS

(VDD= +2.7V to +5.25V, VSS= GND = 0, VH= VDD, VL= 0, TA= -40°C to +85°C, unless otherwise noted. Typical values are at V

DD

= +5.0V, TA= +25°C, unless otherwise noted.) (Note 1)

DC PERFORMANCE (MAX5481/MAX5482 programmable voltage-divider)

Resolution N 10 Bits

Integral Nonlinearity (Note 2) INL

Differential Nonlinearity (Note 2) DNL

End-to-End Resistance

Temperature Coefficient

Ratiometric Resistance

Temperature Coefficient

Full-Scale Error FSE

Zero-Scale Error ZSE

End-to-End Resistance R

Wiper Capacitance C

Resistance from W to L and H

DC PERFORMANCE (MAX5483/MAX5484 variable resistor)

Resolution N 10 Bits

Variable-Resistor Temperature

Coefficient

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

VDD = 2.7V ±2

V

= 5V ±2

DD

VDD = 2.7V ±1

V

= 5V ±1

DD

TC

R

MAX5481 -4 -2.5 0

MAX5482 -4 -0.75 0

MAX5481 0 +3.3 +5

MAX5482 0 +1.45 +5

H-L

TC

MAX5481 7.5 10 12.5

MAX5482 37.5 50 62.5

W

W at code = 15, H and L

shorted to V

resistance from W to H, Figures

1 and 2

VDD = 2.7V -1.6

VDD = 3V -4 -1.4 +4Integral Nonlinearity (Note 3) INL_R

= 5V -4 -1.3 +4

V

DD

VDD = 2.7V +0.45

VDD = 3V -1 +0.4 +1Differential Nonlinearity (Note 3) DNL_R

= 5V -1 +0.35 +1

V

DD

VDD = 3V to 5.25V; code = 128 to 1024 35 ppm/°C

VR

, measure

SS

MAX5481 6.3

MAX5482 25

35 ppm/°C

5 ppm/°C

60 pF

LSB

LSB

LSB

LSB

kΩ

kΩ

LSB

LSB

Page 3

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

_______________________________________________________________________________________ 3

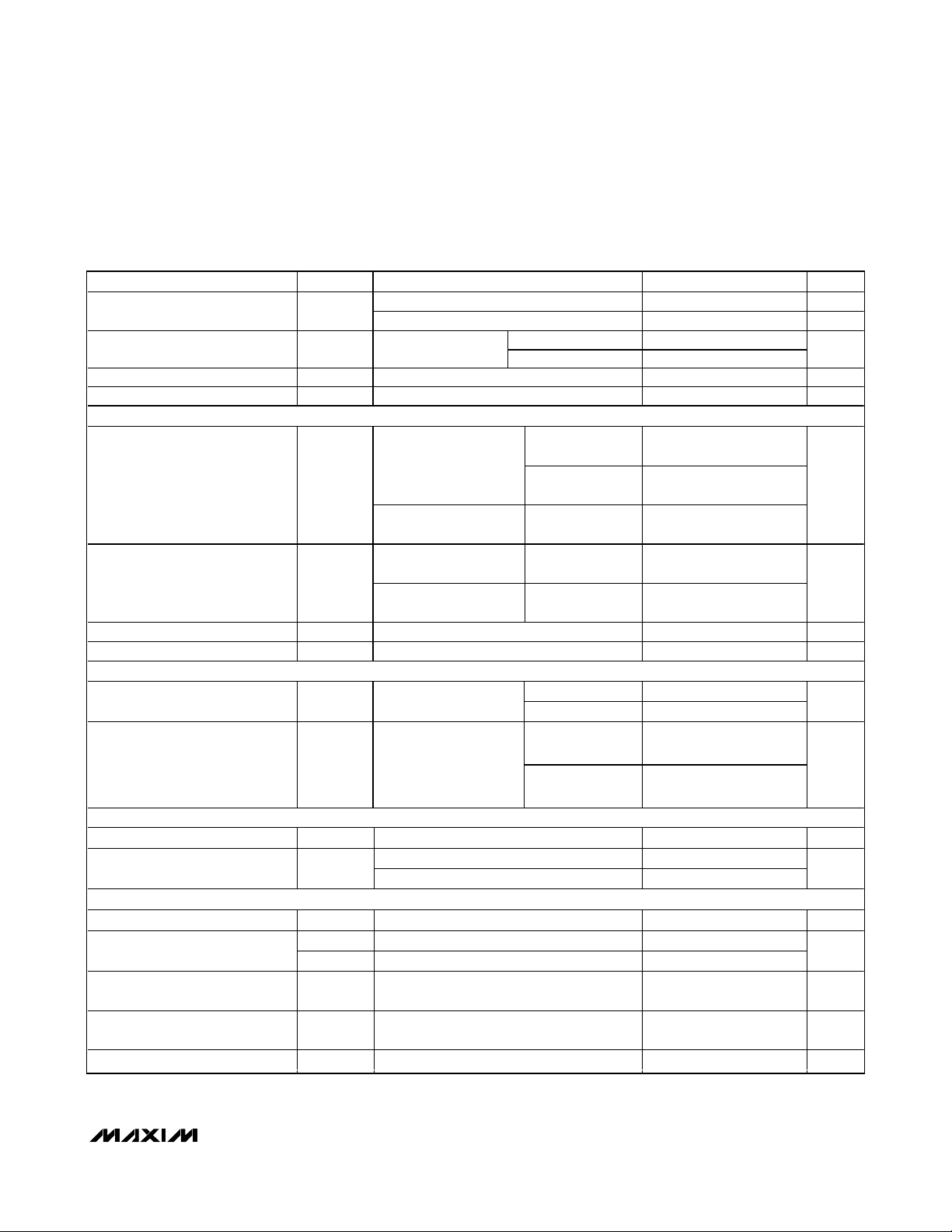

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +2.7V to +5.25V, VSS= GND = 0, VH= VDD, VL= 0, TA= -40°C to +85°C, unless otherwise noted. Typical values are at V

DD

= +5.0V, TA= +25°C, unless otherwise noted.) (Note 1)

Full-Scale Wiper-to-End

Resistance

Zero-Scale Resistor Error R

Wiper Resistance R

Wiper Capacitance C

DIGITAL INPUTS (CS, SCLK(INC), DIN(U/D), SPI/UD) (Note 5)

Input-High Voltage V

Input-Low Voltage V

Input Leakage Current I

Input Capacitance C

DYNAMIC CHARACTERISTICS

Wiper -3dB Bandwidth

Total Harmonic Distortion THD

NONVOLATILE MEMORY RELIABILITY

Data Retention TA = +85°C 50 Years

Endurance

POWER SUPPLY

Single-Supply Voltage V

Dual-Supply Voltage

Average Programming Current I

Peak Programming Current

Standby Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

R

W-L

V

V

PG

DD

MAX5483 7.5 10 12.5 kΩ

MAX5484 37.5 50 62.5 kΩ

Code = 0

Z

VDD ≥ 3V (Note 4) 50 Ω

W

W

Single-supply operation

IH

Dual-supply operation

Single-supply operation

IL

Dual-supply operation

IN

IN

Wiper at code = 01111

01111, C

V

DD

code = 01111 01111,

1V

RMS

applied at H, 10pF

load on W

TA = +25°C 200,000

T

= +85°C 50,000

A

DD

DD

VSS = GND = 0 2.70 5.25 V

GND = 0 2.50 5.25

VDD - VSS ≤ 5.25V -2.5 -0.2

SS

During nonvolatile write; digital inputs =

V

DD

During nonvolatile write only; digital inputs

= V

Digital inputs = VDD or GND, TA = +25°C 0.6 1 µA

DD

= 10pF

LW

= 3V, wiper at

at 10kHz is

or GND

or GND

MAX5483 70

MAX5484 110

60 pF

VDD = +3.6V to

+5.25V

= +2.7V to

V

DD

+3.6V

V

= +2.5V, V

DD

= -2.5V

V

= +2.7V to

DD

+5.25V

V

= +2.5V, V

DD

= -2.5V

MAX5481 250

MAX5482 50

MAX5481 0.026

MAX5482 0.03

SS

SS

2.4

0.7 x

V

DD

2.0

5pF

220 400 µA

4mA

Ω

V

0.8

V

0.6

±1 µA

kHz

%

Stores

V

Page 4

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

4 _______________________________________________________________________________________

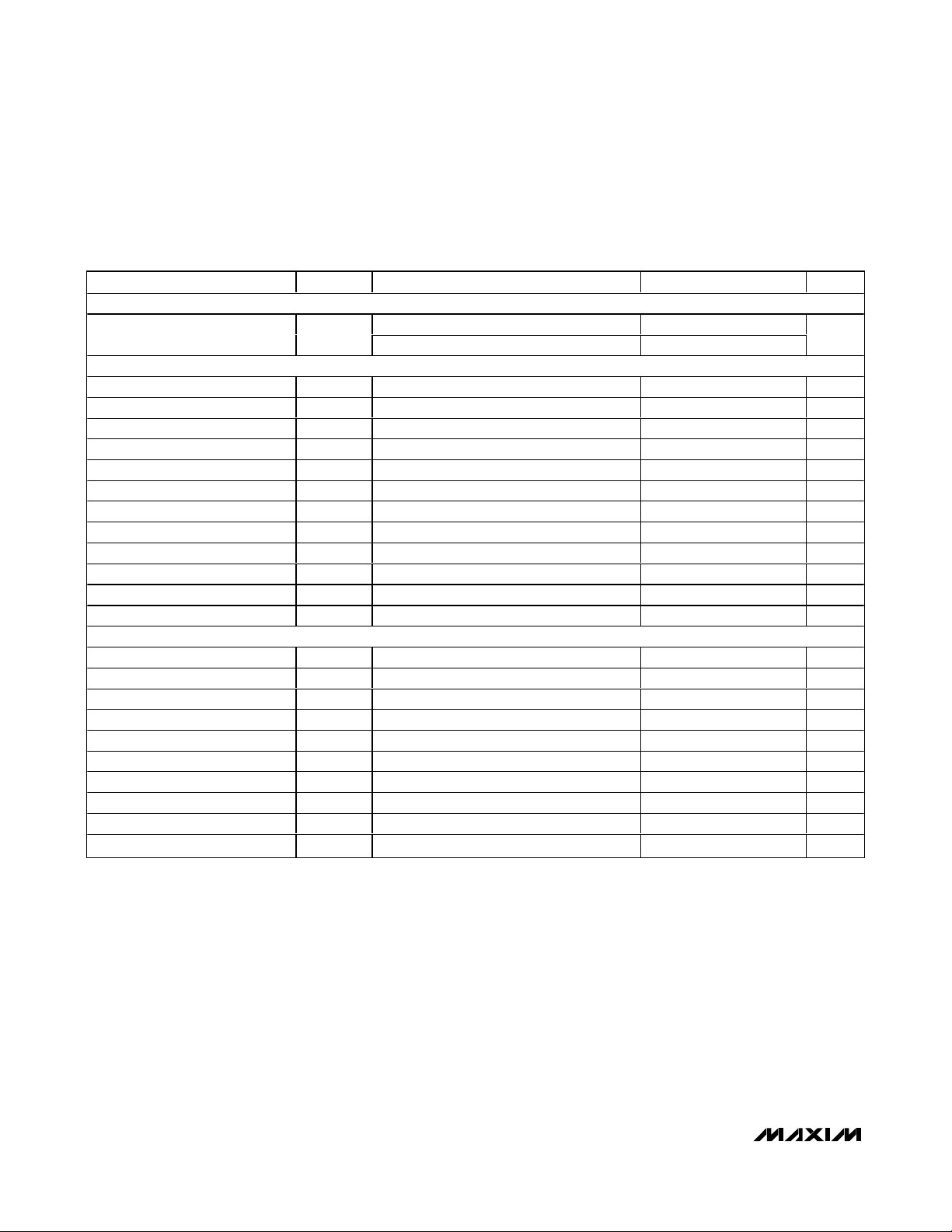

TIMING CHARACTERISTICS

(VDD= +2.7V to +5.25V, VSS= GND = 0, VH= VDD, VL= 0, TA= -40°C to +85°C, unless otherwise noted. Typical values are at V

DD

= +5.0V, TA= +25°C, unless otherwise noted.) (Note 1)

Note 1: 100% production tested at TA= +25°C and TA= +85°C. Guaranteed by design to TA= -40°C.

Note 2: The DNL and INL are measured with the device configured as a voltage-divider with H = V

DD

and L = VSS. The wiper termi-

nal (W) is unloaded and measured with a high-input-impedance voltmeter.

Note 3: The DNL_R and INL_R are measured with D.N.C. unconnected and L = V

SS

= 0. For VDD= 5V, the wiper terminal is driven

with a source current of I

W

= 80µA for the 50kΩ device and 400µA for the 10kΩ device. For VDD= 3V, the wiper terminal is

driven with a source current of 40µA for the 50kΩ device and 200µA for the 10kΩ device.

Note 4: The wiper resistance is measured using the source currents given in Note 3.

Note 5: The device draws higher supply current when the digital inputs are driven with voltages between (V

DD

- 0.5V) and (GND +

0.5V). See Supply Current vs. Digital Input Voltage in the Typical Operating Characteristics.

Note 6: Wiper settling test condition uses the voltage-divider configuration with a 10pF load on W. Transition code from 00000 00000

to 01111 01111 and measure the time from CS going high to the wiper voltage settling to within 0.5% of its final value.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ANALOG SECTION

Wiper Settling Time (Note 6) t

SPI-COMPATIBLE SERIAL INTERFACE (Figure 3)

SCLK Frequency f

SCLK Clock Period t

SCLK Pulse-Width High t

SCLK Pulse-Width Low t

CS Fall to SCLK Rise Setup t

SCLK Rise to CS Rise Hold t

DIN to SCLK Setup t

DIN Hold after SCLK t

SCLK Rise to CS Fall Delay t

CS Rise to SCLK Rise Hold t

CS Pulse-Width High t

Write NV Register Busy Time t

UP/DOWN DIGITAL INTERFACE (Figure 8)

CS to INC Setup t

INC High to U/D Change t

U/D to INC Setup t

INC Low Period t

INC High Period t

INC Inactive to CS Inactive t

CS Deselect Time (Store) t

INC Cycle Time t

INC Active to CS Inactive t

Wiper Store Cycle t

SCLK

CP

CH

CL

CSS

CSH

DS

DH

CS0

CS1

CSW

BUSY

CI

ID

DI

IH

IC

CPH

CYC

IK

WSC

MAX5481 5

S

MAX5482 22

IL

7 MHz

140 ns

60 ns

60 ns

60 ns

0ns

40 ns

0ns

15 ns

60 ns

150 ns

12 ms

25 ns

20 ns

25 ns

25 ns

25 ns

50 ns

50 ns

50 ns

50 ns

12 ms

µs

Page 5

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

_______________________________________________________________________________________ 5

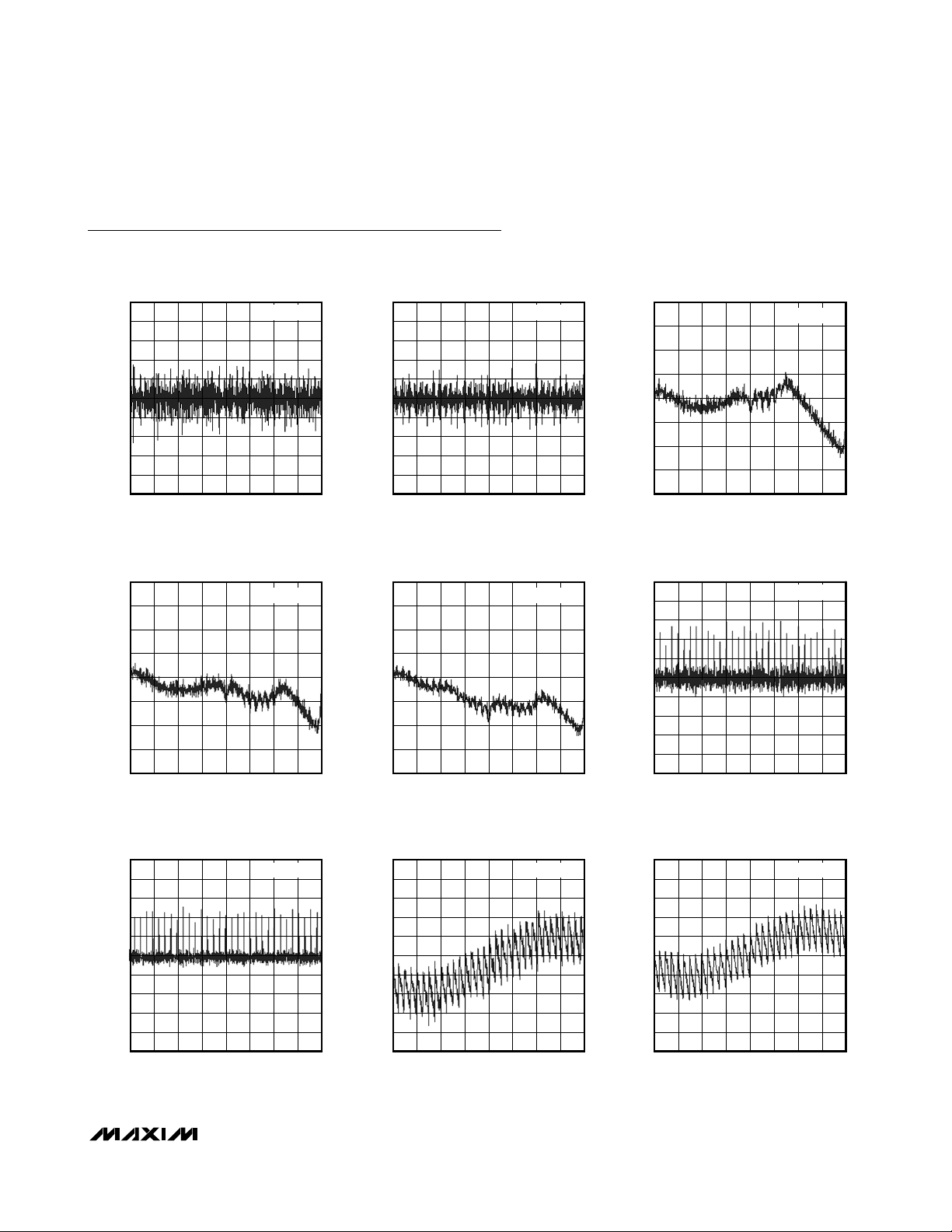

Typical Operating Characteristics

(VDD= 5.0V, VSS= 0, TA= +25°C, unless otherwise noted.)

DNL vs. CODE (MAX5483)

1.0

0.8

0.6

0.4

0.2

0

DNL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

0 256 384128 512 640 768 896 1024

CODE

2.0

1.5

1.0

0.5

0

INL (LSB)

-0.5

-1.0

-1.5

-2.0

INL vs. CODE (MAX5483)

0 256 384128 512 640 768 896 1024

CODE

VDD = 2.7V

VDD = 3V

MAX5481 toc01

MAX5481 toc04

1.0

0.8

0.6

0.4

0.2

0

DNL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

0 256 384128 512 640 768 896 1024

2.0

1.5

1.0

0.5

0

INL (LSB)

-0.5

-1.0

-1.5

-2.0

0 256 384128 512 640 768 896 1024

DNL vs. CODE (MAX5483)

VDD = 5V

CODE

INL vs. CODE (MAX5483)

VDD = 5V

CODE

MAX5481 toc02

MAX5481 toc05

2.0

1.5

1.0

0.5

0

INL (LSB)

-0.5

-1.0

-1.5

-2.0

INL vs. CODE (MAX5483)

0 256 384128 512 640 768 896 1024

CODE

DNL vs. CODE (MAX5481)

1.0

0.8

0.6

0.4

0.2

0

DNL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

0 256 384128 512 640 768 896 1024

CODE

VDD = 2.7V

MAX5481 toc03

VDD = 2.7V

MAX5481 toc06

1.0

0.8

0.6

0.4

0.2

0

DNL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

0 256 384128 512 640 768 896 1024

CODE

DNL vs. CODE (MAX5481)

VDD = 5V

MAX5481 toc07

1.0

INL vs. CODE (MAX5481)

0.8

0.6

0.4

0.2

0

INL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

0 256 384128 512 640 768 896 1024

CODE

VDD = 2.7V

MAX5481 toc08

1.0

INL vs. CODE (MAX5481)

0.8

0.6

0.4

0.2

0

INL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

0 256 384128 512 640 768 896 1024

CODE

VDD = 5V

MAX5481 toc09

Page 6

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

6 _______________________________________________________________________________________

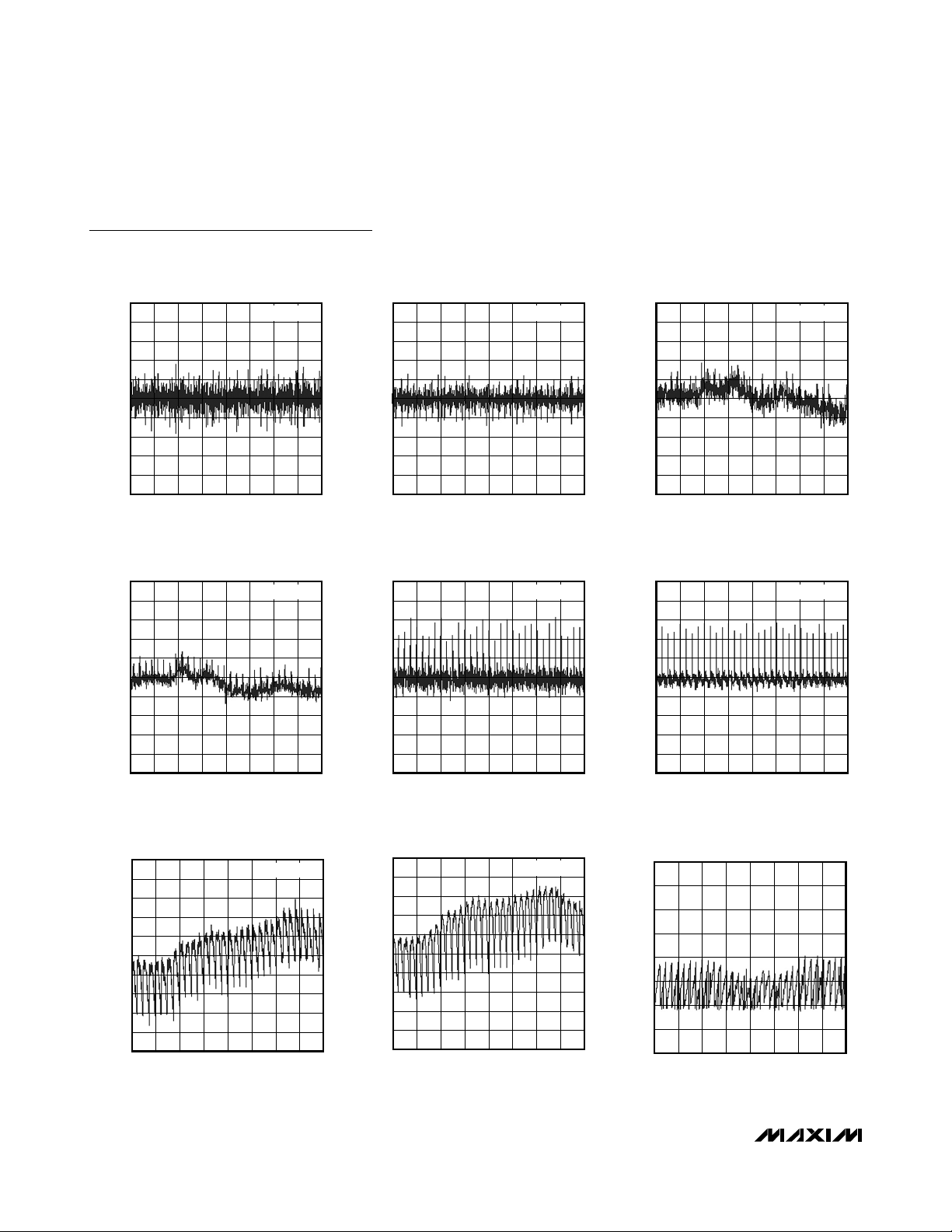

Typical Operating Characteristics (continued)

(VDD= 5.0V, VSS= 0, TA= +25°C, unless otherwise noted.)

1.0

0.8

0.6

0.4

0.2

0

DNL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

0 256 384128 512 640 768 896 1024

CODE

VDD = 2.7V

MAX5481 toc10

DNL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

DNL vs. CODE (MAX5484)

1.0

0.8

0.6

0.4

0.2

0

INL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

INL vs. CODE (MAX5484)

VDD = 5V

0 256 384128 512 640 768 896 1024

CODE

MAX5481 toc13

DNL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

1.0

0.8

0.6

0.4

0.2

0

0 256 384128 512 640 768 896 1024

CODE

VDD = 5V

DNL vs. CODE (MAX5482)

DNL vs. CODE (MAX5484)

1.0

0.8

0.6

0.4

0.2

0

0 256 384128 512 640 768 896 1024

CODE

VDD = 2.7V

MAX5481 toc11

MAX5481 toc14

1.0

0.8

0.6

0.4

0.2

0

INL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

0 256 384128 512 640 768 896 1024

CODE

DNL vs. CODE (MAX5482)

1.0

0.8

0.6

0.4

0.2

0

DNL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

0 256 384128 512 640 768 896 1024

CODE

INL vs. CODE (MAX5484)

VDD = 2.7V

MAX5481 toc12

VDD = 5V

MAX5481 toc15

1.0

INL vs. CODE (MAX5482)

0.8

0.6

0.4

0.2

0

INL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

0 256 384128 512 640 768 896 1024

CODE

VDD = 2.7V

MAX5481 toc16

1.0

INL vs. CODE (MAX5482)

0.8

0.6

0.4

0.2

0

INL (LSB)

-0.2

-0.4

-0.6

-0.8

-1.0

0 256 384128 512 640 768 896 1024

CODE

VDD = 5V

MAX5481 toc17

(Ω)

W

R

WIPER RESISTANCE vs. CODE

(VARIABLE RESISTOR, T

80

70

60

50

40

30

20

10

0

0 256 384128 512 640 768 896 1024

CODE

= -40°C)

A

MAX5481 toc18

Page 7

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

_______________________________________________________________________________________ 7

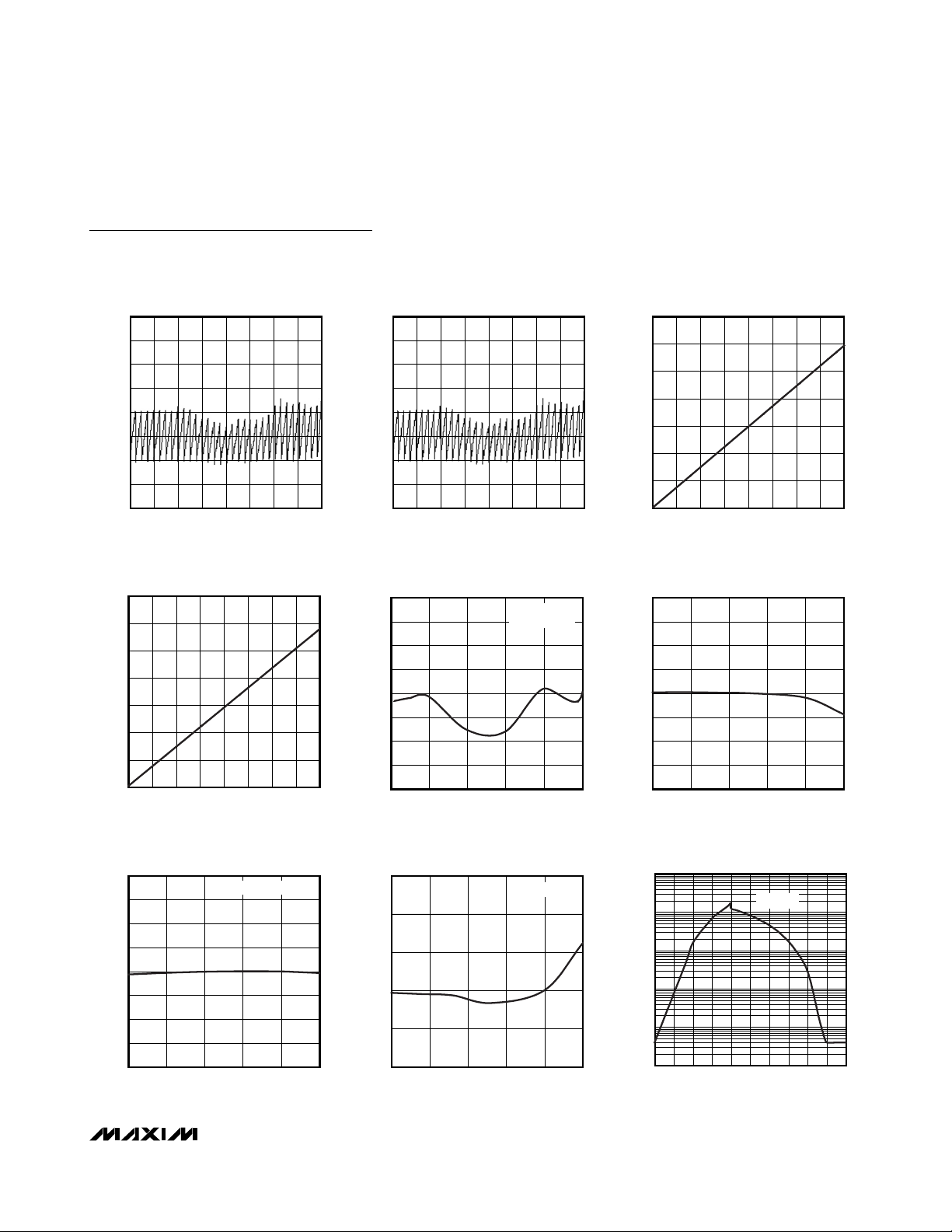

Typical Operating Characteristics (continued)

(VDD= 5.0V, VSS= 0, TA= +25°C, unless otherwise noted.)

WIPER RESISTANCE vs. CODE

(VARIABLE RESISTOR, T

80

70

60

50

(Ω)

40

W

R

30

20

10

0

0 256 384128 512 640 768 896 1024

CODE

= +25°C)

A

W-TO-L RESISTANCE vs. CODE

(MAX5483)

14

12

10

8

(kΩ)

WL

R

6

4

2

0

0 256 384128 512 640 768 896 1024

CODE

WIPER-TO-END RESISTANCE (RWL) % CHANGE

vs. TEMPERATURE (VARIABLE RESISTOR)

2.0

1.5

1.0

0.5

0

-0.5

-1.0

-1.5

WIPER-TO-END RESISTANCE CHANGE (%)

-2.0

-40 -15 10 35 60 85

CODE = 11 1111 1111

TEMPERATURE (°C)

MAX5481 toc19

MAX5481 toc22

MAX5481 toc25

(Ω)

W

R

22.0

21.5

21.0

20.5

(Ω)

20.0

W

R

19.5

19.0

18.5

18.0

(µA)

DD

I

WIPER RESISTANCE vs. CODE

(VARIABLE RESISTOR, T

80

70

60

50

40

30

20

10

0

0 256 384128 512 640 768 896 1024

WIPER RESISTANCE vs. WIPER VOLTAGE

012345

STANDBY SUPPLY CURRENT

1.5

1.2

0.9

0.6

0.3

0

-40 10-15 35 60 85

= +85°C)

A

CODE

(VARIABLE RESISTOR)

CODE = 00 0000

WIPER VOLTAGE (V)

vs. TEMPERATURE

VDD = 5.25V

TEMPERATURE (°C)

VDD = 5V

W-TO-L RESISTANCE vs. CODE

70

60

MAX5481 toc20

50

40

(kΩ)

WL

R

30

20

10

0

0 256 384128 512 640 768 896 1024

END-TO-END (RHL) % CHANGE

vs. TEMPERATURE (VOLTAGE-DIVIDER)

2.0

1.5

MAX5481 toc23

1.0

0.5

0

-0.5

-1.0

END-TO-END RESISTANCE CHANGE (%)

-1.5

-2.0

-40 -15 10 35 60 85

DIGITAL SUPPLY CURRENT

vs. DIGITAL INPUT VOLTAGE

10,000

MAX5481 toc26

1000

100

(µA)

DD

I

10

1

0.1

0 5.0

DIGITAL INPUT VOLTAGE (V)

(MAX5484)

CODE

TEMPERATURE (°C)

VDD = 5V

MAX5481 toc21

MAX5481 toc24

MAX5481 toc27

4.54.03.53.02.52.01.51.00.5

Page 8

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Circuit of Figure 1, TA= +25°C, unless otherwise noted.)

1µs/div

TAP-TO-TAP SWITCHING TRANSIENT

RESPONSE (MAX5481)

V

W

(AC-COUPLED)

20mV/div

CS

2V/div

MAX5481 toc28

H = VDD, L = GND

C

W

= 10pF

FROM CODE 01 1111 1111

TO CODE 10 0000 0000

4

µs/div

TAP-TO-TAP SWITCHING TRANSIENT

RESPONSE (MAX5482)

VW

(AC-COUPLED)

20mV/div

CS

2V/div

MAX5481 toc29

H = VDD, L = GND

C

W

= 10pF

FROM CODE 01 1111 1111

TO CODE 10 0000 0000

WIPER RESPONSE vs. FREQUENCY

(MAX5481)

MAX5481 toc30

FREQUENCY (kHz)

GAIN (dB)

100101

-20

-15

-10

-5

0

-25

0.1 1000

CW = 10pF

CW = 30pF

CODE = 01111 01111

WIPER RESPONSE vs. FREQUENCY

(MAX5482)

MAX5481 toc31

FREQUENCY (kHz)

GAIN (dB)

100101

-20

-15

-10

-5

0

-25

0.1 1000

CW = 10pF

CW = 30pF

CODE = 01111 01111

THD+N vs. FREQUENCY

(MAX5481)

MAX5481 toc32

FREQUENCY (kHz)

THD+N (%)

1010.1

0.001

0.01

0.1

1

10

0.0001

0.01 100

CODE 01111 01111

C

W

= 10pF

THD+N vs. FREQUENCY

(MAX5482)

MAX5481 toc33

FREQUENCY (kHz)

THD+N (%)

1010.1

0.001

0.01

0.1

1

10

0.0001

0.01 100

CODE 01111 01111

C

W

= 10pF

0

40

20

80

60

120

100

140

180

160

200

0 256 384128 512 640 768 896 1024

RATIOMETRIC TEMPERATURE

COEFFICIENT vs. CODE

MAX5481 toc34

CODE

RATIOMETRIC TEMPCO (ppm)

50kΩ

VOLTAGE-DIVIDER

V

DD

= +3V

T

A

= -40°C TO +85°C

10kΩ

0

100

300

200

500

600

400

700

VARIABLE-RESISTOR TEMPERATURE

COEFFICIENT vs. CODE

MAX5481 toc35

TC

VR

(ppm)

0 256 384128 512 640 768 896 1024

CODE

50kΩ

VDD = +3V

T

A

= -40°C TO +85°C

10kΩ

Page 9

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

_______________________________________________________________________________________ 9

Pin Description

(MAX5481/MAX5482 Voltage-Dividers)

PIN

TQFN TSSOP

1 12 H High Terminal

2 11 W Wiper Terminal

3 10 L Low Terminal

4–7, 15 7, 8, 9, 13 N.C. No Connection. Not internally connected.

8, 16 14 V

9 6 SPI/UD

10 5 DIN(U/D)

11 4 SCLK(INC)

12 3 CS Active-Low Digital Input Chip Select

13 2 GND Ground

14 1 V

EP — EP Exposed Pad. Externally connect EP to VSS or leave unconnected.

NAME FUNCTION

Negative Power-Supply Input. For single-supply operation, connect VSS to GND. For dual-

SS

DD

supply operation, -2.5V ≤ V

with a 0.1µF ceramic capacitor as close to the device as possible.

Interface-Mode Select. Select serial SPI interface when SPI/UD = 1. Select serial up/down

interface when SPI/UD = 0.

Serial SPI Interface Data Input (SPI/UD = 1)

Up/Down Control Input (SPI/UD = 0). With DIN(U/D) low, a high-to-low SCLK(INC) transition

decrements the wiper position. With DIN(U/D) high, a high-to-low SCLK(INC) transition

increments the wiper position.

Serial SPI Interface Clock Input (SPI/UD = 1)

Wiper-Increment Control Input (SPI/UD = 0). With CS low, the wiper position moves in the

direction determined by the state of DIN(U/D) on a high-to-low transition.

Positive Power-Supply Input (+2.7V ≤ VDD ≤ +5.25V). Bypass VDD to GND with a 0.1µF

ceramic capacitor as close to the device as possible.

≤ -0.2V as long as (V

SS

DD

- VSS) ≤ +5.25V. Bypass V

SS

to GND

Page 10

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

10 ______________________________________________________________________________________

Pin Description (continued)

(MAX5483/MAX5484 Variable Resistors)

PIN

TQFN TSSOP

4–7, 15 7, 8, 9, 13 N.C. No Connection. Not internally connected.

1 12 D.N.C. Do Not Connect. Leave unconnected for proper operation.

2 11 W Wiper Terminal

3 10 L Low Terminal

8, 16 14 V

NAME FUNCTION

Negative Power-Supply Input. For single-supply operation, connect VSS to GND. For dual-

SS

supply operation, -2.5V ≤ V

with a 0.1µF ceramic capacitor as close to the device as possible.

≤ -0.2V as long as (V

SS

- VSS) ≤ 5.25V. Bypass V

DD

SS

to GND

9 6 SPI/UD

10 5 DIN(U/D)

11 4 SCLK(INC)

12 3 CS Active-Low Digital Input Chip Select

13 2 GND Ground

14 1 V

EP — EP Exposed Pad. Externally connect EP to VSS or leave unconnected.

DD

Interface-Mode Select. Select serial SPI interface when SPI/UD = 1. Select serial up/down

interface when SPI/UD = 0.

Serial SPI Interface Data Input (SPI/UD = 1)

Up/Down Control Input (SPI/UD = 0). With DIN(U/D) low, a high-to-low SCLK(INC) transition

decrements the wiper position. With DIN(U/D) high, a high-to-low SCLK(INC) transition

increments the wiper position.

Serial SPI Interface Clock Input (SPI/UD = 1)

Wiper Increment Control Input (SPI/UD = 0). With CS low, the wiper position moves in the

direction determined by the state of DIN(U/D) on a high-to-low transition.

Positive Power-Supply Input (+2.7V ≤ VDD ≤ +5.25V). Bypass VDD to GND with a 0.1µF

ceramic capacitor as close to the device as possible.

Page 11

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

______________________________________________________________________________________ 11

Functional Diagrams

GND

SCLK(INC)

DIN(U/D)

V

DD

10-BIT

NV

V

SS

CS

MEMORY

SPI

INTERFACE

10-BIT

LATCH

POR

MUX

10

DECODER

10

H

W

L

UP/DOWN

INTERFACE

MAX5481

MAX5482

NOTE: THE MAX5481/MAX5482 ARE NOT INTENDED FOR CURRENT TO FLOW THROUGH THE WIPER

MAX5481/MAX5482 PROGRAMMABLE VOLTAGE-DIVIDER

(SEE THE

SECTION).

SPI/UD

Page 12

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

12 ______________________________________________________________________________________

Detailed Description

The MAX5481/MAX5482 linear programmable voltagedividers and the MAX5483/MAX5484 variable resistors

feature 1024 tap points (10-bit resolution) (see the

Functional Diagrams). These devices consist of multiple strings of equal resistor segments with a wiper contact that moves among the 1024 points through a

pin-selectable 3-wire SPI-compatible serial interface or

up/down interface. The MAX5481/MAX5483 provide a

total end-to-end resistance of 10kΩ, and the

MAX5482/MAX5484 have an end-to-end resistance of

50kΩ. The MAX5481/MAX5482 allow access to the

high, low, and wiper terminals for a standard voltagedivider configuration.

MAX5481/MAX5482 Programmable

Voltage-Dividers

The MAX5481/MAX5482 programmable voltagedividers provide a weighted average of the voltage

between the H and L inputs at the W output. Both

devices feature 10-bit resolution and provide up to

1024 tap points between the H and L voltages. Ideally,

the V

L

voltage occurs at the wiper terminal (W) when all

data bits are zero and the VHvoltage occurs at the

wiper terminal when all data bits are one. The step size

(1 LSB) voltage is equal to the voltage applied across

terminals H and L divided by 210. Calculate the wiper

voltage VWas follows:

Functional Diagrams (continued)

V

DD

10-BIT

NV

MEMORY

SPI

INTERFACE

SCLK(INC)

DIN(U/D)

GND

V

CS

SS

UP/DOWN

INTERFACE

POR

10-BIT

LATCH

MUX

10

DECODER

10

MAX5483

MAX5484

H

L

SPI/UD

⎡

()=

⎢

⎢

⎢

⎣

VD D

W

VV V

HL FSE ZSE

−

+

⏐⏐⏐⏐

()

1023

⎤

⎥

++

VV

L ZSE

⎥

⎥

⎦

⏐⏐

Page 13

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

______________________________________________________________________________________ 13

where D is the decimal equivalent of the 10 data bits written (0 to 1023), VHLis the voltage difference between the

H and L terminals:

The MAX5481 includes a total end-to-end resistance

value of 10kΩ while the MAX5482 features an end-toend resistance value of 50kΩ. These devices are not

intended to be used as a variable resistor. Wiper current creates a nonlinear voltage drop in series with the

wiper. To ensure temperature drift remains within specifications, do not pull current through the voltage-divider

wiper. Connect the wiper to a high-impedance node.

Figures 1 and 2 show the behavior of the MAX5481’s

resistance from W to H and from W to L. This does not

apply to the variable-resistor devices

MAX5483/MAX5484 Variable Resistors

The MAX5483/MAX5484 provide a programmable

resistance between W and L. The MAX5483 features a

total end-to-end resistance value of 10kΩ, while the

MAX5484 provides an end-to-end resistance value of

50kΩ. The programmable resolution of this resistance is

equal to the nominal end-to-end resistance divided by

1024 (10-bit resolution). For example, each nominal

segment resistance is 9.8Ω and 48.8Ω for the MAX5483

and the MAX5484, respectively.

The 10-bit data in the 10-bit latch register selects a

wiper position from the 1024 possible positions, resulting in 1024 values for the resistance from W to L.

Calculate the resistance from W to L (RWL) by using the

following formula:

where D is decimal equivalent of the 10 data bits written, R

W-L

is the nominal end-to-end resistance, and R

Z

is the zero-scale error. Table 1 shows the values of R

WL

at selected codes for the MAX5483/MAX5484.

Digital Interface

Configure the MAX5481–MAX5484 by a pin-selectable,

3-wire, SPI-compatible serial data interface or an

up/down interface. Drive SPI/UD high to select the 3wire SPI-compatible interface. Pull SPI/UD low to select

the up/down interface.

Table 1. R

WL

at Selected Codes

Figure 1. Resistance from W to H vs. Code (10kΩ Voltage-Divider)

Figure 2. Resistance from W to L vs. Code (10kΩ Voltage-Divider)

18

16

14

12

10

(kΩ)

W-H

8

R

6

4

2

0

0 1024

CODE (DECIMAL)

50kΩ DEVICE SCALES BY A FACTOR OF FIVE

896768512 640256 384128

V

⎡

⎤

V FSE

=

FSE

V ZSE

=

ZSE

⎢

1024

⎣

V

⎡

⎢

1024

⎣

HL

HL

⎥

⎦

⎤

⎥

⎦

and

,

18

16

14

12

10

(kΩ)

W-L

8

R

6

4

2

0

0 1024

50kΩ DEVICE SCALES BY A FACTOR OF FIVE

CODE

(DECIMAL)

0 70 110

1 80 160

512 5070 25,110

1023 10,070 50,110

(10kΩ DEVICE)

CODE (DECIMAL)

MAX5483

(Ω)R

R

WL

896768512 640256 384128

MAX5484

(50kΩ DEVICE)

(Ω)

WL

RD

WL W L Z

D

1023

RR

−

()=×+

Page 14

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

14 ______________________________________________________________________________________

SPI-Compatible Serial Interface

Drive SPI/UD high to enable the 3-wire SPI-compatible

serial interface (see Figure 3). This write-only interface

contains three inputs: chip select (CS), data in

(DIN(U/D)), and data clock (SCLK(INC)). Drive CS low

to load the data at DIN(U/D) synchronously into the shift

register on each SCLK(INC) rising edge.

The WRITE command (C1, C0 = 00) requires 24 clock

cycles to transfer the command and data (Figure 4a).

The COPY commands (C1, C0 = 10 or 11) use either

eight clock cycles to transfer the command bits (Figure

4b) or 24 clock cycles with the last 16 data bits disregarded by the device.

After loading the data into the shift register, drive CS

high to latch the data into the appropriate control register. Keep CS low during the entire serial data stream to

avoid corruption of the data. Table 2 shows the command decoding.

Write Wiper Register

Data written to this register (C1, C0 = 00) controls the

wiper position. The 10 data bits (D9–D0) indicate the

position of the wiper. For example, if DIN(U/D) = 00 0000

0000, the wiper moves to the position closest to L. If

DIN(U/D) = 11 1111 1111, the wiper moves closest to H.

This command writes data to the volatile random

access memory (RAM), leaving the NV register

unchanged. When the device powers up, the data

stored in the NV register transfers to the wiper register,

moving the wiper to the stored position. Figure 5 shows

how to write data to the wiper register.

Table 2. Command Decoding*

*D9 is the MSB and D0 is the LSB.

X = Don’t care.

Figure 3. SPI-Compatible Serial-Interface Timing Diagram (SPI/UD= 1)

CLOCK EDGE 1 2 345678910111213141516171819…24

Bit Name — — C1 C0 — — — — D9 D8 D7 D6 D5 D4 D3 D2 D1 D0 — … —

Write Wiper Register 0 0 000000D9D8D7D6D5D4D3D2D1D0X…X

Copy Wiper Register

to NV Register

Copy NV Register to

Wiper Register

00100000———————————…—

00110000———————————…—

CS

t

t

CSO

SCLK(INC)

DIN(U/D)

CSS

t

CL

t

DS

t

DH

t

CSW

t

t

CH

t

CP

t

CSH

CS1

Page 15

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

______________________________________________________________________________________ 15

Figure 4. Serial SPI-Compatible Interface Format

Figure 5. Write Wiper Register Operation

a) 24-BIT COMMAND/DATA WORD

CS

SCLK(INC)

1 2 3 4 5 6 7 8 9

DIN(U/D)

b) 8-BIT COMMAND WORD

CS

SCLK(INC)

DIN(U/D)

C1 C0

1 2 3 4 5 6 7 8

C1 C0

CS

12345678 910111213141516 1718192021222324

SCLK(INC)

C1 C0

DIN(U/D)

0 0 0 0 0 0 0 0 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

11 12

10

D9 D8 D7 D6 D5 D4 D3 D2

13 14 15 16

18 19 20 21 22

17

D1 D0

23 24

XXXXXX

ACTION

WIPER

REGISTER

UPDATED

Page 16

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

16 ______________________________________________________________________________________

Copy Wiper Register to NV Register

The copy wiper register to NV register command (C1,

C0 = 10) stores the current position of the wiper to the

NV register for use at power-up. Figure 6 shows how to

copy data from wiper register to NV register. The operation takes up to 12ms (max) after CS goes high to

complete and no other operation should be performed

until completion.

Copy NV Register to Wiper Register

The copy NV register to wiper register (C1, C0 = 11)

restores the wiper position to the current value stored in

the NV register. Figure 7 shows how to copy data from

the NV register to the wiper register.

Digital Up/Down Interface

Figure 8 illustrates an up/down serial-interface timing

diagram. In digital up/down interface mode (SPI/UD =

0), the logic inputs CS, DIN(U/D), and SCLK(INC) control the wiper position and store it in nonvolatile memory

(see Table 3). The chip-select (CS) input enables the

serial interface when low and disables the interface

when high. The position of the wiper is stored in the

nonvolatile register when CS transitions from low to

high while SCLK(INC) is high.

When the serial interface is active (CS low), a high-tolow (falling edge) transition on SCLK(INC) increments

or decrements the internal 10-bit counter depending on

the state of DIN(U/D). If DIN(U/D) is high, the wiper

increments. If DIN(U/D) is low, the wiper decrements.

The device stores the value of the wiper position in the

nonvolatile memory when CS transitions from low to high

while SCLK(INC) is high. The host system can disable

the serial interface and deselect the device without storing the latest wiper position in the nonvolatile memory by

keeping SCLK(INC) low while taking CS high.

Upon power-up, the MAX5481–MAX5484 load the

value of nonvolatile memory into the wiper register, and

set the wiper position to the value last stored.

Figure 6. Copy Wiper Register to NV Register Operation

Table 3. Truth Table

↑ = High-to-low transition.

↓ = Low-to-high transition.

X = Don’t care.

Figure 7. Copy NV Register to Wiper Register Operation

SCLK(INC)

DIN(U/D)

ACTION

CS

CS

12345678

C1 C0

00100000

CS DIN(U/D) SCLK(INC)W

LL ↓ Decrement

LH ↓ Increment

LX ↑ No Change

H X X No Change

↓ X X No Change

↑ X L Position Not Stored

↑ X H Position Stored

t

BUSY

WRITE NV

REGISTER

(DEVICE IS

BUSY)

SCLK(INC)

DIN(U/D)

ACTION

12345678

C1 C0

00110000

WIPER

REGISTER

UPDATED

Page 17

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

______________________________________________________________________________________ 17

Standby Mode

The MAX5481–MAX5484 feature a low-power standby

mode. When the device is not being programmed, it

enters into standby mode and supply current drops to

0.5µA (typ).

Nonvolatile Memory

The internal EEPROM consists of a nonvolatile register

that retains the last value stored prior to power-down.

The nonvolatile register is programmed to midscale at

the factory. The nonvolatile memory is guaranteed for

50 years of wiper data retention and up to 200,000

wiper write cycles.

Power-Up

Upon power-up, the MAX5481–MAX5484 load the data

stored in the nonvolatile wiper register into the volatile

wiper register, updating the wiper position with the data

stored in the nonvolatile wiper register.

Applications Information

The MAX5481–MAX5484 are ideal for circuits requiring

digitally controlled adjustable resistance, such as LCD

contrast control (where voltage biasing adjusts the display contrast), or programmable filters with adjustable

gain and/or cutoff frequency.

Positive LCD Bias Control

Figures 9 and 10 show an application where a voltagedivider or a variable resistor is used to make an

adjustable, positive LCD-bias voltage. The op amp provides buffering and gain to the voltage-divider network

made by the programmable voltage-divider (Figure 9) or

to a fixed resistor and a variable resistor (see Figure 10).

Programmable Gain and Offset Adjustment

Figure 11 shows an application where a voltage-divider

and a variable resistor are used to make a programmable gain and offset adjustment.

Figure 8. Up/Down Serial-Interface Timing Diagram (SPI/UD= 0)

CS

WIPER POSITION

STORED

WIPER POSITION

NOT STORED

t

t

CI

SCLK(INC)

DIN(U/D)

t

S

V

W

NOTES:

IS NOT A DIGITAL SIGNAL. IT REPRESENTS A WIPER TRANSITION.

V

W

SCLK(INC) MUST BE AT LOGIC HIGH WHEN DIN(U/D) CHANGES STATE.

CYC

t

IL

t

IH

t

t

DI

ID

t

IC

t

CPH

t

WSC

t

IK

Page 18

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

18 ______________________________________________________________________________________

Programmable Filter

Figure 12 shows the configuration for a 1st-order programmable filter using two variable resistors. Adjust R2

for the gain and adjust R3 for the cutoff frequency. Use

the following equations to estimate the gain (G) and the

3dB cutoff frequency (fC):

Figure 10. Positive LCD Bias Control Using a Variable Resistor

Figure 12. Programmable Filter

Figure 11. Programmable Gain/Offset Adjustment

Figure 9. Positive LCD Bias Control Using a Voltage-Divider

V

REF

H

W

L

W

MAX5481

MAX5482

5V

H

W

L

30V

MAX480

MAX5481

MAX5482

V

OUT

MAX5483

MAX5484

V

OUT

5V

30V

MAX480

MAX5483

MAX5484

W

L

V

IN

L

C

V

IN

V

OUT

MAX5483

V

OUT

MAX5484

MAX5483

MAX5484

R3

W

L

R2

W

L

R1

G

f

C

=+

1

=

23π

R

1

⎛

⎞

⎜

⎟

⎝

⎠

R

2

1

RC

××

Page 19

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

______________________________________________________________________________________ 19

Chip Information

TRANSISTOR COUNT: 20,029

PROCESS: BiCMOS

Selector Guide

*SEE FUNCTIONAL DIAGRAM

14

13

12

11

10

9

8

1

2

3

4

5

6

7

V

SS

N.C.

H

WSCLK(INC)

CS

GND

V

DD

TOP VIEW

MAX5481*

MAX5482*

L

N.C.

N.C.N.C.

SPI/UD

DIN(U/D)

TSSOP

14

13

12

11

10

9

8

1

2

3

4

5

6

7

V

SS

N.C.

D.N.C.

WSCLK(INC)

CS

GND

V

DD

MAX5483

MAX5484

L

N.C.

N.C.N.C.

SPI/UD

DIN(U/D)

TSSOP

Pin Configurations (continued)

Ordering Information (continued)

†

All devices are specified over the -40°C to +85°C operating

temperature range.

*Future product—contact factory for availability.

**EP = Exposed pad.

PART CONFIGURATION

MAX5481ETE Voltage-divider 10

MAX5481EUD Voltage-divider 10

MAX5482ETE Voltage-divider 50

MAX5482EUD Voltage-divider 50

MAX5483ETE Variable resistor 10

MAX5483EUD Variable resistor 10

MAX5484ETE Variable resistor 50

MAX5484EUD Variable resistor 50

END-TO-END

RESISTANCE (kΩ)

†

PART

PIN-PACKAGE PKG CODE

MAX5482ETE* 16 TQFN-EP** T1633F-3 ACQ

MAX5482EUD* 14 TSSOP — —

MAX5483ETE 16 TQFN-EP** T1633F-3 ACR

MAX5483EUD* 14 TSSOP — —

MAX5484ETE* 16 TQFN-EP** T1633F-3 ACS

MAX5484EUD* 14 TSSOP — —

TOP

MARK

Page 20

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

20 ______________________________________________________________________________________

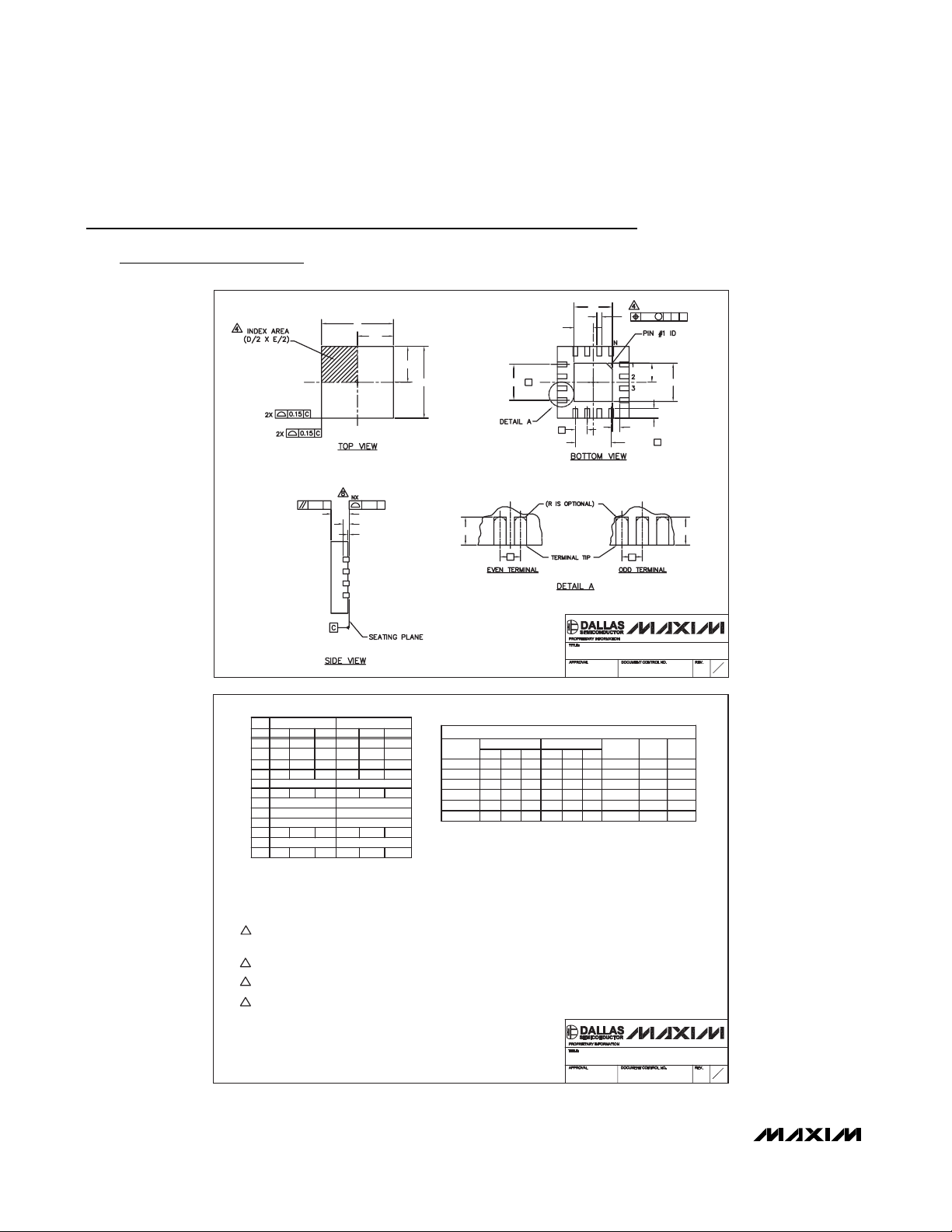

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

D2

b

0.10 M

D

D/2

D2/2

C A B

C

L

C

L

0.10 C 0.08 C

PKG

12L 3x3

REF. MIN.

NOM. MAX. NOM.

0.70

0.75

A

b

0.20

0.25

D

2.90

3.00

3.00

2.90

E

e

0.50 BSC.

0.55

0.45

L

N

12

ND

NE

3

0.0230.05

A1

0

A2

0.20 REF

-

k

0.25

MIN. MAX.

0.80

0.70

0.30

0.20

3.10

2.90

2.90

3.10

0.30

0.65

-

0.25

A

A2

A1

16L 3x3

0.75

0.25

3.00

3.00

0.50 BSC.

0.40

16

0.02

0

0.20 REF

E/2

E

0.80

0.30

3.10

3.10

0.50

4

4

0.05

-

-

PKG.

CODES

T1233-1

T1233-3

T1633-1 0.95

T1633-2

T1633F-3 0.65

T1633-4

(NE - 1) X e

C

L

L

e

EXPOSED PAD VARIATIONS

D2

MIN.

NOM.

1.10

0.95

1.10

0.95

1.10

0.95

1.10

0.80

0.95

1.10

MAX.

1.25

1.25

1.25

1.25

0.95

1.25

e

PACKAGE OUTLINE

12, 16L, THIN QFN, 3x3x0.8mm

E2

NOM.

MIN.

MAX.

1.10

0.95

0.95 1.10

1.10

0.95

1.10

0.95

0.80

0.65

1.10

0.95

1.25

1.25

1.25

0.95

1.25

E2/2

k

(ND - 1) X e

C

L

e

21-0136

PIN ID

JEDEC

0.35 x 45∞

WEED-1

0.35 x 45∞1.25 WEED-1

0.35 x 45∞ WEED-2

0.35 x 45∞

WEED-2

0.225 x 45∞

WEED-2

0.35 x 45∞

WEED-2

E2

L

L

DOWN

BONDS

ALLOWED

NO

YES

NO

YES

N/A

NO

12x16L QFN THIN.EPS

1

E

2

NOTES:

1. DIMENSIONING & TOLERANCING CONFORM TO ASME Y14.5M-1994.

2. ALL DIMENSIONS ARE IN MILLIMETERS. ANGLES ARE IN DEGREES.

3. N IS THE TOTAL NUMBER OF TERMINALS.

4. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL CONFORM TO

JESD 95-1 SPP-012. DETAILS OF TERMINAL #1 IDENTIFIER ARE OPTIONAL, BUT MUST BE LOCATED

WITHIN THE ZONE INDICATED. THE TERMINAL #1 IDENTIFIER MAY BE EITHER A MOLD OR

MARKED FEATURE.

5. DIMENSION b APPLIES TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.20 mm AND 0.25 mm

FROM TERMINAL TIP.

6. ND AND NE REFER TO THE NUMBER OF TERMINALS ON EACH D AND E SIDE RESPECTIVELY.

7. DEPOPULATION IS POSSIBLE IN A SYMMETRICAL FASHION.

8. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS.

9. DRAWING CONFORMS TO JEDEC MO220 REVISION C.

PACKAGE OUTLINE

12, 16L, THIN QFN, 3x3x0.8mm

21-0136

2

E

2

Page 21

MAX5481–MAX5484

10-Bit, Nonvolatile, Linear-Taper Digital

Potentiometers

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 21

© 2005 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products, Inc.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

TSSOP4.40mm.EPS

Loading...

Loading...