Page 1

General Description

The MAX5092A/MAX5092B/MAX5093A/MAX5093B lowquiescent-current, low-dropout (LDO) regulators contain

simple boost preregulators operating at a high frequency.

The devices seamlessly provide a preset 3.3V

(MAX5092A/MAX5093A) or 5V (MAX5092B/MAX5093B)

LDO output voltage from an automotive cold-crank

through load-dump (3.5V to 80V) input voltage conditions. The MAX5092_/MAX5093_ deliver up to 250mA

with excellent load and line regulation. During normal

operation, when the battery is healthy, the boost preregulator is completely turned off, reducing quiescent current

to 65µA (typ). This makes the devices suitable for

always-on power supplies.

The buck-boost operation achieved by this combination

of LDO and boost preregulator offers the advantage of

using a single off-the-shelf inductor in place of the multiple-winding custom magnetics needed in typical single-ended primary inductor converter (SEPIC) and

transformer-based flyback topologies. The high operating frequency of the boost regulator significantly

reduces component size. The MAX5092_ integrates a

blocking diode to further reduce the external component count. The boost preregulator output voltage is

preset to 7V. Both LDO and boost output voltages are

programmable using external resistors. The boost preregulator output voltage is adjustable up to 11V

(MAX5092_), or up to 12V (MAX5093_). The LDO output

voltage is adjustable from 1.5V to 9V (MAX5092_) or

from 1.5V to 10V (MAX5093_).

The devices feature a shutdown mode with 5µA (typ)

shutdown current, a HOLD input to implement a self-holding circuit, and a power-on-reset output (RESET) with an

externally programmable timeout period. Additional features include output overload, short-circuit, and thermal

protection.

The MAX5092_/MAX5093_ are available in a thermally

enhanced, 16-pin 5mm x 5mm thin QFN package and can

dissipate up to 2.7W at +70°C on a multilayer PC board.

Applications

Automotive—Body Electronics

Automotive—ECU

Industrial

Features

♦ Wide Operating Input Voltage Range: 3.5V to 72V

with a 4V Startup Voltage

♦ LDO Output Regulates to 5V Seamlessly from an

Input Voltage of 3.5V to 72V

♦ Up to 250mA Output Current

♦ Preset 3.3V, 5V, or Externally Programmable LDO

Output Voltage from 1.5V to 9V (MAX5092_) or

from 1.5V to 10V (MAX5093_)

♦ Preset 7V or Externally Programmable Boost

Output Voltage Up to 11V (MAX5092_) or Up to

12V (MAX5093_)

♦ 65µA Quiescent Current in LDO Mode (VIN≥8V)

♦ 5µA Shutdown Current

♦ Power-On Reset (RESET) with Programmable

Timeout Period

♦ Output Short-Circuit and Thermal Protection

♦ TQFN Package Capable of Dissipating Up to 2.7W

at +70°C

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

________________________________________________________________

Maxim Integrated Products

1

Pin Configuration

Ordering Information

19-0659; Rev 0; 10/06

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

+

Denotes lead-free package.

*

Future product—contact factory for availability.

**

EP = Exposed pad.

Typical Operating Circuit and Selector Guide appear at end

of data sheet.

EVALUATION KIT

AVAILABLE

PART TEMP RANGE

MAX5092AATE+* -40°C to +125°C 16 TQFN-EP** T1655-3

MAX5092BATE+ -40°C to +125°C 16 TQFN-EP** T1655-3

MAX5093AATE+* -40°C to +125°C 16 TQFN-EP** T1655-3

MAX5093BATE+ -40°C to +125°C 16 TQFN-EP** T1655-3

PINPACKAGE

PKG

CODE

TOP VIEW

BSFB

13

LX

PGND_BST

12 11 9

10

BSOUT

OUT

8

RESET

14

VL

CT

15

16

MAX5092_/

MAX5093_

1+2

IN

(5mm x 5mm)

3

EN

SGND LX

THIN QFN

7

6

5

4

HOLD

OUT_SENSE

SET

PGND_LDO

Page 2

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VIN= VEN= 14V, I

OUT

= 1mA, CIN= 47µF, C

BSOUT

= 22µF, C

OUT

= 10µF, CVL= 1µF, TA= TJ= -40°C to +125°C, unless otherwise

noted. See Figures 4–7 as applicable. Typical specifications are at T

A

= +25°C.) (Note 2)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Note 1: As per JEDEC Standard 51 (Multilayer Board).

IN, EN, LX, BSOUT to SGND..................................-0.3V to +80V

PGND_BST, PGND_LDO to SGND .......................-0.3V to +0.3V

VL, RESET, OUT, OUT_SENSE to SGND ...............-0.3V to +12V

BSOUT to LX (MAX5092_)......................................-0.3V to +12V

SET, BSFB, CT to SGND ..........................................-0.3V to +6V

HOLD to SGND….....................................-0.3V to (V

OUT

+ 0.3V)

OUT Current (I

OUT

) Short Circuit to PGND_LDO,

(V

IN

≤ 28V) ..............................................................Continuous

RESET Sinking Current .........................................................5mA

Continuous Power Dissipation (T

A

= +70°C)

16-Pin Thin QFN (derate 33.3mW/°C

above +70°C)...............................................2666mW (Note 1)

Operating Temperature Range .........................-40°C to +125°C

Maximum Junction Temperature .....................................+150°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

INPUT SUPPLY

Input Voltage Range V

Internal Input Undervoltage

Lockout

Supply Current (Boost Converter

Off)

Supply Current (Boost Converter

On)

Shutdown Supply Current I

BOOST CONVERTER

Minimum BSOUT Output Current I

Boost Converter Disable

Threshold

Boost Converter Disable

Threshold Hysteresis

BSOUT Output Voltage V

Maximum BSOUT Output Voltage V

BSFB Regulation Voltage V

BSFB Input Bias Current I

Boost Internal Switch

On-Resistance

Boost Internal Switch Minimum

Off-Time

IN

V

UVLOF

V

UVLOR

I

Q

I

S

SHDN

BSOUT

V

BST_DIS

BSOUT

BSOUT(MAX

BSFB

BSFB

R

DS(ON)

t

OFF

(Note 3) 4 72 V

VIN falling 3.0 3.2 3.4

VIN rising 3.4 3.6 3.8

LDO mode,

= 100µA

I

OUT

LDO mode, I

VIN = 5V 0.4 1.0 mA

VEN ≤ +0.4V

VIN = 4V 250 mA

VIN rising 7.5 8.0 8.5 V

VIN = 4V, BSFB = SGND 6.65 7.00 7.35 V

MAX5092_ 11

MAX5093_ 12

T

= -40°C to +125°C

J

(Note 4)

= 250mA 70 100

OUT

= -40°C to +125°C

T

J

(Note 4)

65 85

610µA

0.5 V

1.18 1.24 1.30 V

100 nA

0.5 1.2 Ω

0.80 1 1.25 µs

V

µA

V

Page 3

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VIN= VEN= 14V, I

OUT

= 1mA, CIN= 47µF, C

BSOUT

= 22µF, C

OUT

= 10µF, CVL= 1µF, TA= TJ= -40°C to +125°C, unless otherwise

noted. See Figures 4–7 as applicable. Typical specifications are at T

A

= +25°C.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Boost Internal Switch Maximum

On-Time

Internal Switch Current Limit I

Boost Turn-On Response Time

Internal Diode Forward Voltage

Drop

LDO

Guaranteed Output Current I

Output Voltage V

Minimum Adjustable Output

Voltage

Maximum Adjustable Output

Voltage

Adjustable Output Voltage V

Dropout Voltage ∆V

LDO Startup Response Time

Line Regulation

SET Reference Voltage V

SET Input Bias Current I

Load Regulation

Power-Supply Rejection Ratio PSRR

Short-Circuit Current I

t

ON-MAX

LIM

V

F

OUT

OUT

V

ADJMIN

V

ADJMAX

ADJ

DOIOUT

∆V

OUT

∆V

IN

SET

SET

∆V

OUT

∆I

OUT

SC

Measured in steady-state condition 1.5 3.0 A

Time from V

BSOUT

to switch on-time

MAX5092_ only, IF = 1A 0.95 V

V

- V

BSOUT

= 2V (Note 5) 250 mA

OUT

SET = SGND,

MAX5092A/

MAX5093A

SET = SGND,

MAX5092B/

MAX5093B

Boost operation, VIN = 4V, V

Boost operation,

V

= 4V

IN

LDO operation, VIN ≥ V

(boost converter off) (Note 6)

= 250mA (Note 7) 0.9 1.6 V

Rising edge of V

V

OUT

7V ≤ VIN ≤ 72V,

/

I

LOAD

7V ≤ VIN ≤ 28V, I

/

I

= 1mA to 250mA 0.2 0.6 mV/mA

OUT

, RL = 500Ω, SET = SGND

= 10mA

BSOUT

LOAD

f = 100Hz

f = 1MHz

1.80 2.25 2.70 µs

falling below regulation

I

= 1mA 3.25 3.3 3.35

OUT

100µA ≤ I

I

= 1mA 4.900 5 5.075

OUT

100µA ≤ I

≤ 250mA 3.2 3.3 3.4

OUT

≤ 250mA 4.85 5 5.10

OUT

= 7V 1.5 V

BSOUT

MAX5092_,

V

BSOUT

= 11V

MAX5093_,

V

BSOUT

BST_DIS

= 12V

1.5 10.0 V

to the rising edge of

25µs

V

9

V

10

200 µs

MAX5092A/MAX5093A 0.4

MAX5092B/MAX5093B 0.5

mV/V

= 250mA 1.6

1.205 1.235 1.265 V

0.5 100 nA

I

= 10mA, V

OUT

= 500mV

I

= 10mA, V

OUT

= 500mV

P-P

P-P

BSOUT(AC)

, V

OUT

BSOUT(AC)

, V

OUT

= 5V

= 5V

80

dB

60

255 490 mA

Page 4

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VIN= VEN= 14V, I

OUT

= 1mA, CIN= 47µF, C

BSOUT

= 22µF, C

OUT

= 10µF, CVL= 1µF, TA= TJ= -40°C to +125°C, unless otherwise

noted. See Figures 4–7 as applicable. Typical specifications are at T

A

= +25°C.) (Note 2)

Note 2: Limits at -40°C are guaranteed by design and characterization; not production tested.

Note 3: Guaranteed minimum operating voltage is 3.5V on V

IN

falling only.

Note 4: Guaranteed by design and not production tested.

Note 5: The continuous maximum output current from the LDO is guaranteed according to the maximum power dissipation imposed

by the package thermal constraints.

Note 6: Maximum output adjustable value is conditioned by the maximum adjustable BSOUT Output Voltage Range minus the maxi-

mum dropout across the pass transistor.

Note 7: Dropout voltage is defined as (V

BSOUT

- V

OUT

) when V

OUT

is 2% below the value of V

OUT

for V

BSOUT

= V

OUT

+ 2V.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

ENABLE, HOLD and RESET

EN High Input Threshold EN

EN Low Input Threshold EN

EN Input Bias Current I

HOLD Low Input Threshold V

HOLD Release Voltage V

HOLD Pullup Current I

RESET Voltage Threshold V

RESET Threshold Hysteresis V

RESET Output Low Voltage V

RESET Output High Leakage

Current

RESET Output Minimum Timeout

Period

EN to RESET Minimum Timeout

Delay

Delay Comparator Threshold

(Rising)

Delay Comparator Threshold

Hysteresis

CT Charge Current I

CT Discharge Current I

EN

IL

IH

HOLD

RESET

RHYST

RL

I

RH

V

CTTH

V

CTTH-HYS

CT-CHG

CT-DIS

H

L

2.4 V

0.25 2 µA

Regulator on, EN transition from high to low 0.4 V

V

-

EN = low

OUT

0.4

Internally connected to OUT 4 µA

% of V

% of V

I

SINK

V

R E SE T

C

CT

C

CT

, V

OUT

OUT

falling 87 90 92 %

OUT

2%

= 1mA 0.4 V

= 5V 1 µA

not connected 25 µs

not connected 260 µs

1.205 1.24 1.265 V

100 mV

1.5 2 2.5 µA

5mA

0.4 V

V

Page 5

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

_______________________________________________________________________________________

5

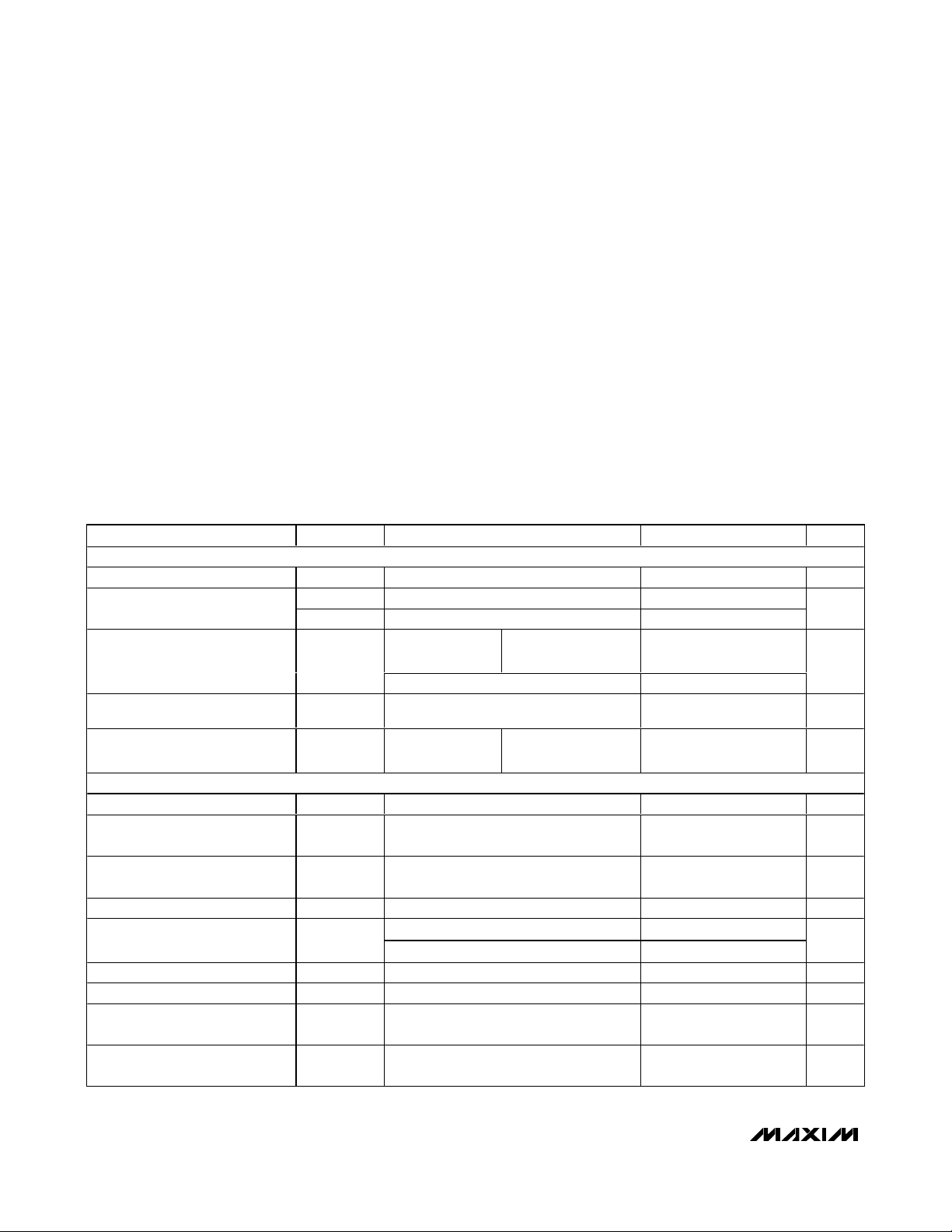

Typical Operating Characteristics

(VIN= VEN= 14V, CIN= 47µF, C

BSOUT

= 22µF, C

OUT

= 10µF, CVL= 1µF, TA= +25°C, unless otherwise noted.) (See Figures 4–7 as

applicable.)

SHUTDOWN SUPPLY CURRENT

vs. TEMPERATURE (MAX5092B)

MAX5092/93 toc07

TEMPERATURE (°C)

SHUTDOWN SUPPLY CURRENT (µA)

11085603510-15

4

6

8

10

2

-40 135

V

EN

= 0V

LINE-TRANSIENT RESPONSE

(V

IN

STEP FROM 4V TO 7V)

MAX5092/93 toc08

200µs/div

V

OUT

50mV/div

V

IN

1V/div

V

BSOUT

1V/div

5V (AC-COUPLED)

7V

4V

7V (AC-COUPLED)

I

OUT

= 250mA

QUIESCENT SUPPLY CURRENT

vs. INPUT VOLTAGE (MAX5092B)

90

85

80

75

70

65

60

QUIESCENT SUPPLY CURRENT (µA)

55

50

872

I

OUT

BOOST CONVERTER NOT SWITCHING,

QUIESCENT SUPPLY CURRENT = I

INPUT VOLTAGE (V)

= 10mA

I

OUT

QUIESCENT SUPPLY CURRENT

vs. TEMPERATURE (MAX5093B)

100

BOOST CONVERTER NOT SWITCHING,

QUIESCENT SUPPLY CURRENT = I

90

80

70

60

QUIESCENT SUPPLY CURRENT (µA)

50

40

-40 135

I

= 10mA

OUT

TEMPERATURE (°C)

I

= 100µA

IN

= 100µA

OUT

IN

- I

OUT

11085603510-15

- I

OUT

645616 24 32 40 48

100

MAX5092/93 toc01

INPUT CURRENT (mA)

0.1

MAX5092/93 toc04

SHUTDOWN SUPPLY CURRENT (µA)

INPUT CURRENT (IIN)

vs. INPUT VOLTAGE (MAX5092B)

I

= 10mA

OUT

10

I

= 100µA

1

BOOST CONVERTER SWITCHING

4.0 7.0

OUT

INPUT VOLTAGE (V)

MAX5092/93 toc02

QUIESCENT SUPPLY CURRENT (µA)

6.56.05.55.04.5

SHUTDOWN SUPPLY CURRENT

vs. INPUT VOLTAGE (MAX5092B)

10

8

6

4

2

0

474

INPUT VOLTAGE (V)

V

MAX5092/93 toc05

SHUTDOWN SUPPLY CURRENT (µA)

= 0V

EN

645444342414

QUIESCENT SUPPLY CURRENT

vs. TEMPERATURE (MAX5092B)

100

BOOST CONVERTER NOT SWITCHING,

QUIESCENT SUPPLY CURRENT = I

90

80

70

60

50

40

-40 135

TEMPERATURE (°C)

I

OUT

= 10mA

I

OUT

SHUTDOWN SUPPLY CURRENT

vs. INPUT VOLTAGE (MAX5093B)

10

8

6

4

2

0

474

INPUT VOLTAGE (V)

- I

IN

= 100µA

V

OUT

11085603510-15

EN

MAX5092/93 toc03

MAX5092/93 toc06

= 0V

645444342414

Page 6

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

6 _______________________________________________________________________________________

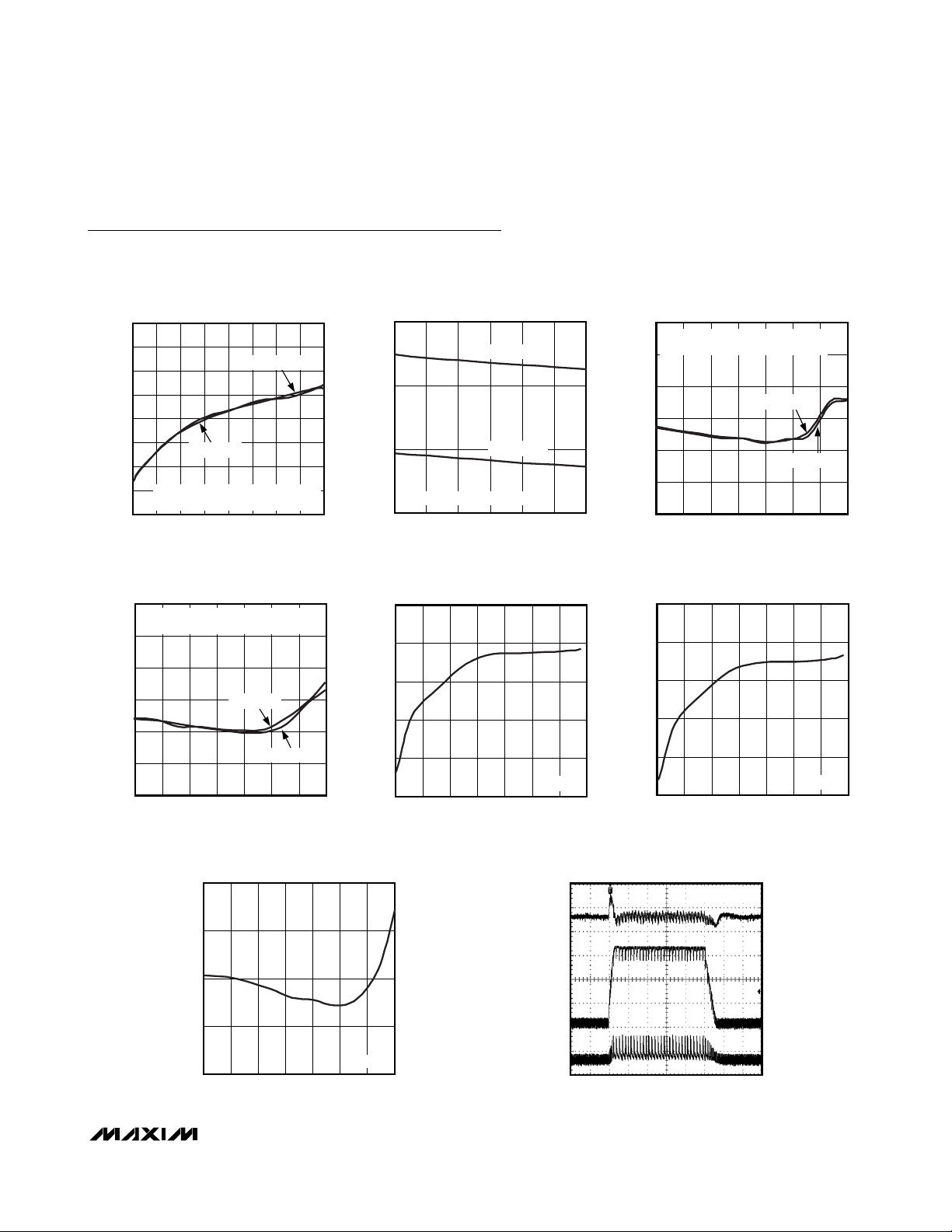

Typical Operating Characteristics (continued)

(VIN= VEN= 14V, CIN= 47µF, C

BSOUT

= 22µF, C

OUT

= 10µF, CVL= 1µF, TA= +25°C, unless otherwise noted.) (See Figures 4–7 as

applicable.)

LINE-TRANSIENT RESPONSE

(V

IN

STEP FROM 3.5V TO 72V)

MAX5092/93 toc09

40ms/div

V

IN

50V/div

V

OUT

50mV/div

V

BSOUT

50V/div

72V

3.5V

5V (AC-COUPLED)

72V

7V

I

OUT

= 5mA

LINE-TRANSIENT RESPONSE

(V

IN

STEP FROM 3.5V TO 14V)

MAX5092/93 toc10

200µs/div

V

OUT

100mV/div

V

BSOUT

5V/div

V

IN

5V/div

14V

14V

7V

5V (AC-COUPLED)

3.5V

POWER-SUPPLY REJECTION RATIO

vs. FREQUENCY

MAX5092/93 toc14

FREQUENCY (Hz)

100k10k1k

-70

0

100 1M

VIN = 8V, I

OUT

= 10mA

PSRR (dB)

10dB/div

STARTUP THROUGH INPUT VOLTAGE

MAX5092/93 toc15

100µs/div

0V

V

IN

10V/div

V

BSOUT

10V/div

I

LX

5A/div

V

OUT

5V/div

0V

0A

0V

I

OUT

= 250mA

DROPOUT VOLTAGE (V

BSOUT

- V

OUT

)

vs. LDO LOAD CURRENT

MAX5092/93 toc11

LDO LOAD CURRENT (mA)

DROPOUT VOLTAGE (mV)

20015010050

200

400

600

800

1000

0

0 250

LDO OUTPUT VOLTAGE

vs. LDO LOAD CURRENT (MAX5092B)

MAX5092/93 toc12

LDO LOAD CURRENT (mA)

LDO OUTPUT VOLTAGE (V)

200100

4.90

4.95

5.00

5.05

5.10

5.15

4.85

0 300

TA = -40°C: CIN = 10µF, C

BSOUT

= 4.7µF, C

OUT

= 10µF

(CERAMIC)

TA = +25°C, +135°C: CIN = 47µF, C

BSOUT

= 22µF

(ELECTROLYTIC), C

OUT

= 10µF (CERAMIC)

TA = +25°C, VIN = 4V

T

A

= +25°C, VIN = 14V

TA = -40°C, VIN = 4V

T

A

= -40°C, VIN = 14V

TA = +135°C, VIN = 4V

T

A

= +135°C, VIN = 14V

POWER-SUPPLY REJECTION RATIO

vs. FREQUENCY

MAX5092/93 toc13

FREQUENCY (Hz)

100k10k1k

-70

0

10dB/div

100 1M

VIN = 14V, I

OUT

= 10mA

PSRR (dB)

Page 7

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

_______________________________________________________________________________________

7

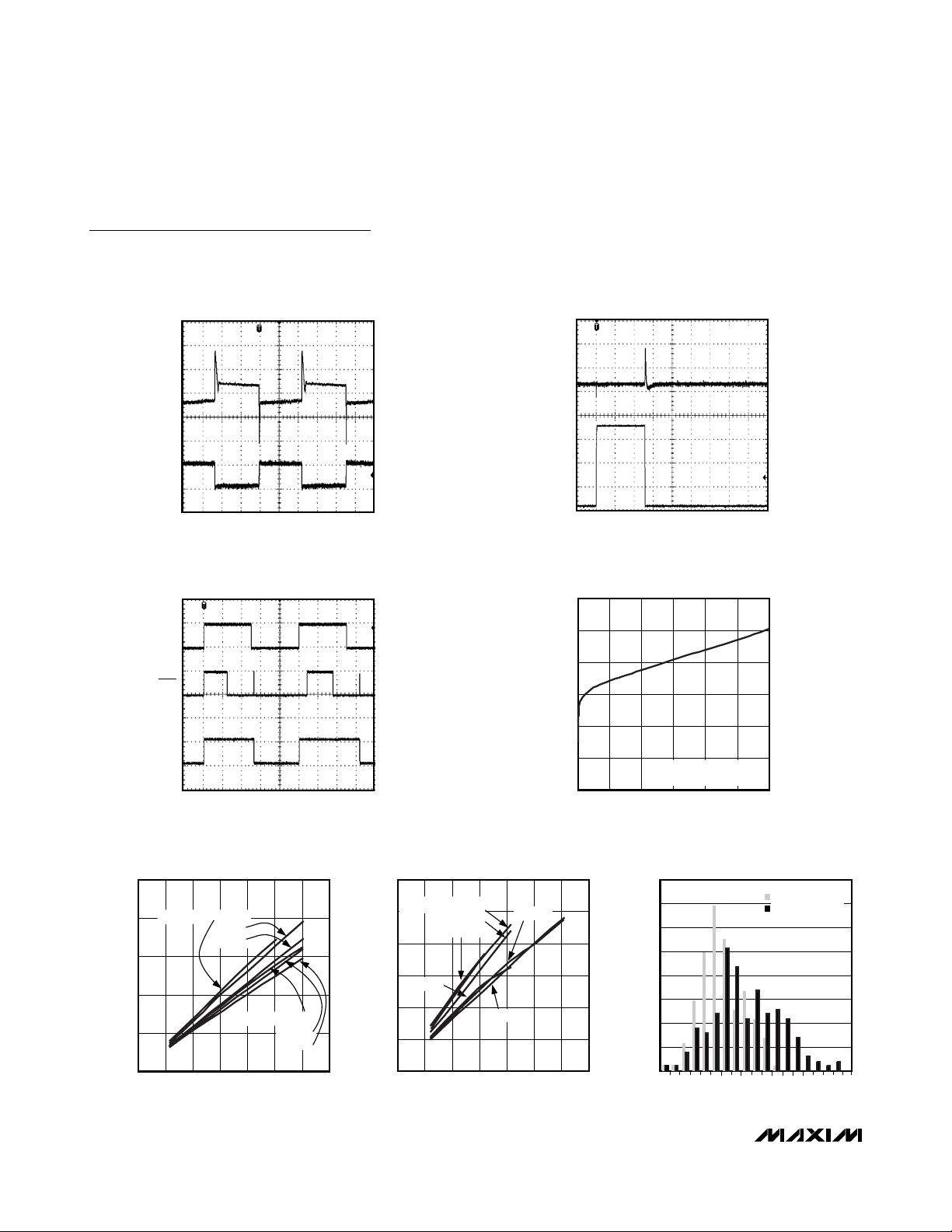

Typical Operating Characteristics (continued)

(VIN= VEN= 14V, CIN= 47µF, C

BSOUT

= 22µF, C

OUT

= 10µF, CVL= 1µF, TA= +25°C, unless otherwise noted.) (See Figures 4–7 as

applicable.)

_______________________________________________________________________________________

7

SHUTDOWN THROUGH V

V

IN

10V/div

V

BSOUT

10V/div

I

LX

1A/div

V

OUT

5V/div

2ms/div

SHUTDOWN THROUGH ENABLE

V

IN

10V/div

V

BSOUT

10V/div

V

OUT

5V/div

V

EN

2V/div

200µs/div

IN

MAX5092/93 toc16

I

= 250mA

OUT

MAX5092/93 toc18

I

= 250mA

OUT

0V

0V

0A

0V

14V

14V

0V

0V

V

10V/div

V

BSOUT

10V/div

V

OUT

5V/div

V

2V/div

V

2V/div

V

RESET

2V/div

2V/div

OUT

V

STARTUP THROUGH ENABLE

IN

EN

200µs/div

RESET TIMING RESPONSE

EN

200µs/div

I

OUT

I

OUT

C

T

MAX5092/93 toc17

= 250mA

MAX5092/93 toc19

= 250mA

= 680pF

14V

14V

0V

0V

0V

0V

0V

V

vs. TEMPERATURE

3.36

3.34

3.32

(V)

3.30

OUT

V

3.28

3.26

3.24

-40 135

OUT

I

= 10mA, R5 = 100kΩ,

OUT

R4 = 165kΩ, FIGURE 6

TEMPERATURE (°C)

V

vs. TEMPERATURE

OUT

(MAX5092B)

5.10

MAX5092/93 toc20

11085603510-15

5.05

(V)

5.00

OUT

V

4.95

I

= 1mA, V

4.90

-40 135

OUT

TEMPERATURE (°C)

MAX5092/93 toc21

= 0V

SET

11085603510-15

Page 8

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VIN= VEN= 14V, CIN= 47µF, C

BSOUT

= 22µF, C

OUT

= 10µF, CVL= 1µF, TA= +25°C, unless otherwise noted.) (See Figures 4–7 as

applicable.)

LDO LOAD-TRANSIENT RESPONSE

(MAX5092B)

V

OUT

50mV/div

I

OUT

100mA/div

2ms/div

MAX5092/93 toc22

(AC-COUPLED)

0mA

V

OUT

20mV/div

20V/div

INPUT-VOLTAGE STEP RESPONSE

V

IN

200ms/div

MAX5092/93 toc23

I

= 5mA

OUT

5V (AC-COUPLED)

72V

3.5V

ENABLE AND HOLD TIMING

V

EN

5V/div

V

HOLD

5V/div

V

OUT

5V/div

BOOST CONVERTER POWER LOSS

= 7V)

(V

1.0

TA = +105°C: VIN = 3.5V

0.8

V

V

0.6

0.4

POWER LOSS (W)

0.2

0

0 350

BSOUT

= 4V

IN

= 5V

IN

TA = +25°C: VIN = 3.5V

V

V

I

(mA)

OUT

200ms/div

IN

IN

= 4V

= 5V

30025020015010050

MAX5092/93 toc24

MAX5092/93 toc26

INTERNAL BOOST DIODE FORWARD DROP

(MAX5092)

1500

1250

0V

0V

0V

BOOST CONVERTER POWER LOSS

= 11V)

(V

IN

IN

BSOUT

= 5V

= 3.5V

I

OUT

VIN = 5V

(mA)

1.2

TA = +105°C: VIN = 4V

1.0

V

V

0.8

0.6

VIN = 3.5V

POWER LOSS (W)

0.4

0.2

0

0350

1000

750

500

DIODE VOLTAGE (mV)

250

VIN = 4V

30025020015010050

VIN = 8V, BOOST CONVERTER

0

03.0

NOT SWITCHING

DIODE CURRENT (A)

GROUND CURRENT DISTRIBUTION

40

35

MAX5092/93 toc27

30

25

20

15

NUMBER OF UNITS

10

5

0

52

54

56 60 62 64 66

MAX5092/93 toc25

2.52.01.51.00.5

(162 UNITS TESTED)

TA = TJ = +125°C

= TJ = -40°C

T

A

58

I

(µA)

GND

MAX5092/93 toc28

68

70

Page 9

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

_______________________________________________________________________________________ 9

Pin Description

PIN NAME FUNCTION

1IN

2EN

3 SGND

4 HOLD

5 PGND_LDO

6 SET

7 OUT_SENSE LDO Regulator Output Sense. Connect OUT_SENSE to OUT at the output capacitor near the load.

8 OUT

9 BSOUT

10, 11 LX

12 PGND_BST

13 BSFB

14 VL

15 CT

16 RESET

—EP

Input Supply Voltage. Bypass IN to the power ground plane with a 47µF (low-ESR) aluminum electrolytic

capacitor in parallel with a 1µF ceramic capacitor placed as close to the IC as possible.

Enable Input. Drive EN high to turn on the IC. Drive EN low to disable the IC. Connect EN directly to IN for

always-on operation.

Signal Ground. Connect SGND to the signal ground plane and the exposed paddle. Connect the power

ground and signal ground plane together at the negative terminal of the input capacitor(s).

Output Hold. When HOLD is forced low, the regulator stores the on-state of the output, allowing the

regulator to remain enabled even if EN is pulled low. To shut down the regulator, release HOLD after EN is

pulled low. If HOLD is unused, either connect HOLD to OUT or leave unconnected. HOLD is internally

connected to OUT through a 4µA pullup current.

LDO Power Ground. Connect PGND_LDO to the power ground plane. Connect the PGND_LDO ground and

signal ground plane together.

Feedback Input for the LDO. Connect SET directly to SGND to set the output voltage of the LDO to the

preset voltage of 3.3V (MAX5092A/MAX5093A) or 5V (MAX5092B/MAX5093B). Connect SET to the center

tap of a resistor-divider connected between the LDO output and SGND to set the output voltage. V

regulates to 1.24V when using an adjustable output.

LDO Regulator Output. Bypass OUT to the power ground plane with a 10µF ceramic capacitor. V

regulates to a preset voltage of 3.3V (MAX5092A/MAX5093A) or 5V (MAX5092B/MAX5093B), or is

adjustable from 1.5V to 9V (MAX5902_) or 1.5V to 10V (MAX5093_).

Boost Regulator Output Voltage. Bypass BSOUT to the PGND_BST ground plane with a 22µF (low-ESR)

aluminum electrolytic capacitor in parallel with a 1µF ceramic capacitor placed as close to the IC as

possible. Connect BSFB directly to SGND to regulate the BOOST output to a fixed voltage of 7V for V

BSOUT

follows V

7V. V

by connecting BSFB to the center tap of an external resistor-divider connected between the BOOST output

and PGND_BST.

Inductor Connection to the Drain of the Internal Power MOSFET. Connect LX to the switched side of the

inductor. Connect pins 10 and 11 together as close to the device as possible. For the MAX5093, also

connect LX to the anode of the external Schottky diode.

Boost Regulator Power Ground. Connect PGND_BST to the power ground plane. Connect the PGND_BST

ground plane and the signal ground plane together at the negative terminal of the input capacitor(s).

Feedback Input for the Boost Regulator. Connect BSFB directly to SGND to set the boost regulator output

voltage to 7V. Connect BSFB to the center tap of an external resistor-divider connected between BSOUT

and SGND to set the output voltage. V

Internal Regulator Output for IC Supply. Bypass VL to SGND with a 1µF/6.3V ceramic capacitor placed as

close to the IC as possible. V

RESET Timeout Programming Input. Connect a capacitor from CT to SGND to set the RESET timeout

period. See the CT Capacitor Selection section.

RESET Output. RESET is an open-drain output that goes high impedance when V

output voltage threshold after a programmed time delay. RESET pulls low immediately once V

below 90% of the regulated LDO output voltage.

Exposed Paddle. Connect to the signal ground plane (SGND). Connect to a large-signal ground plane for

increased thermal performance.

for VIN > 7V. V

IN

regulates to 5.5V with V

VL

is programmable up to 11V (MAX5092_) or 12V (MAX5093_)

BSOUT

regulates to 1.24V when using an adjustable output.

BSFB

≥ 5.5V.

BSOUT

exceeds 92% of the

OUT

OUT

SET

OUT

IN

drops

≤

Page 10

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

10 ______________________________________________________________________________________

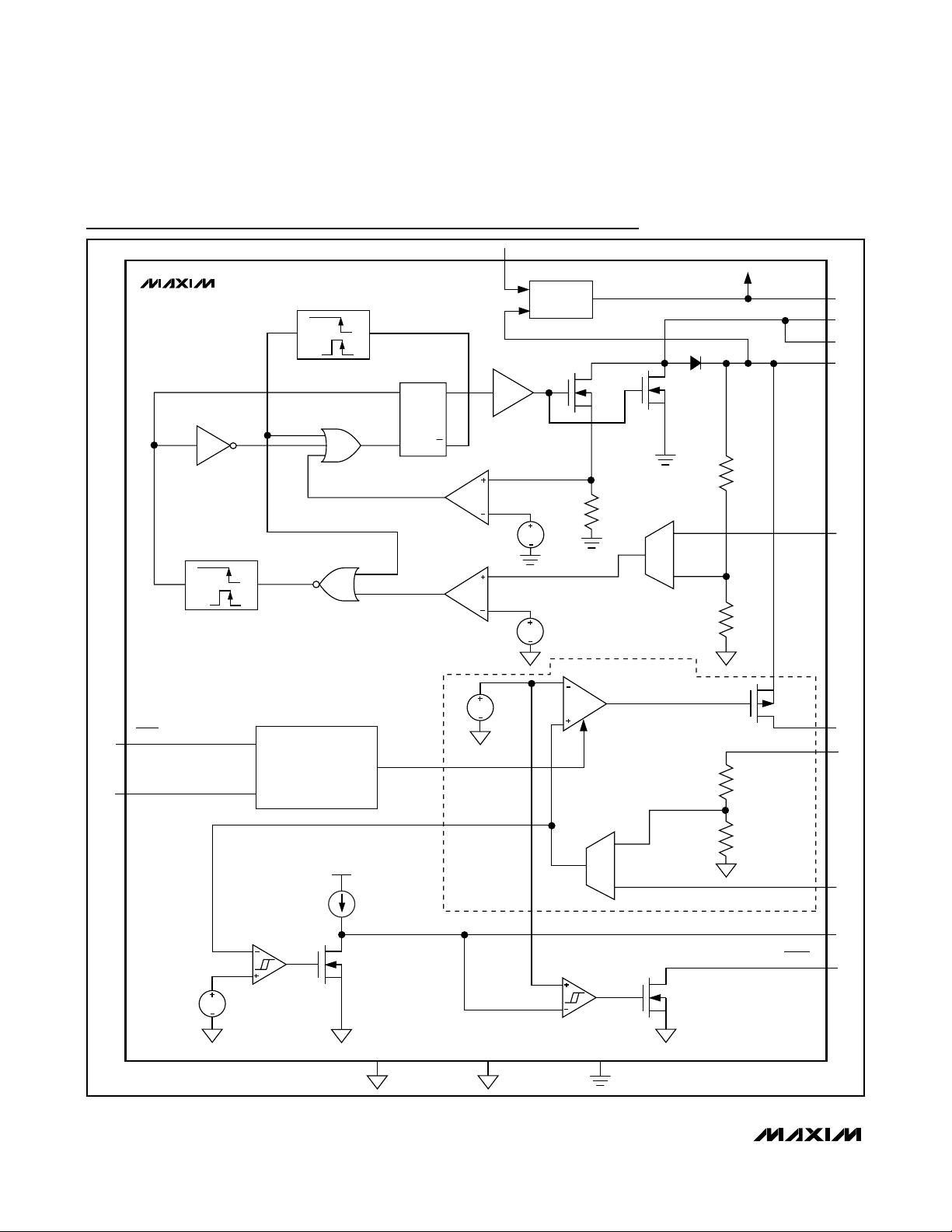

Figure 1. MAX5092_ Functional Diagram

Functional Diagrams

MAX5092_

HOLD

EN

2.25µs

ONE-SHOT

INOUT

THERMAL SHUTDOWN,

AND OVERCURRENT

1µs

ONE-SHOT

INOUT

CONTROL LOGIC,

PROTECTION

IN

INTERNAL

LDO

Q

S

Q

R

DRIVER

CURRENT-LIMITING

COMPARATOR

V

PK

V

REF

V

REF

R

S

MUX

ERROR AMPLIFIER

LDO

VL

VL

LX

LX

BSOUT

R1

BSFB

R2

OUT

OUT_SENSE

R3

MUX

DELAY

COMPARATOR

PGND_BST

0.92 x V

REF

CT

COMPARATOR

VL

2µA

SGND

PGND_LDO

P

R4

SET

CT

RESET

Page 11

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

______________________________________________________________________________________ 11

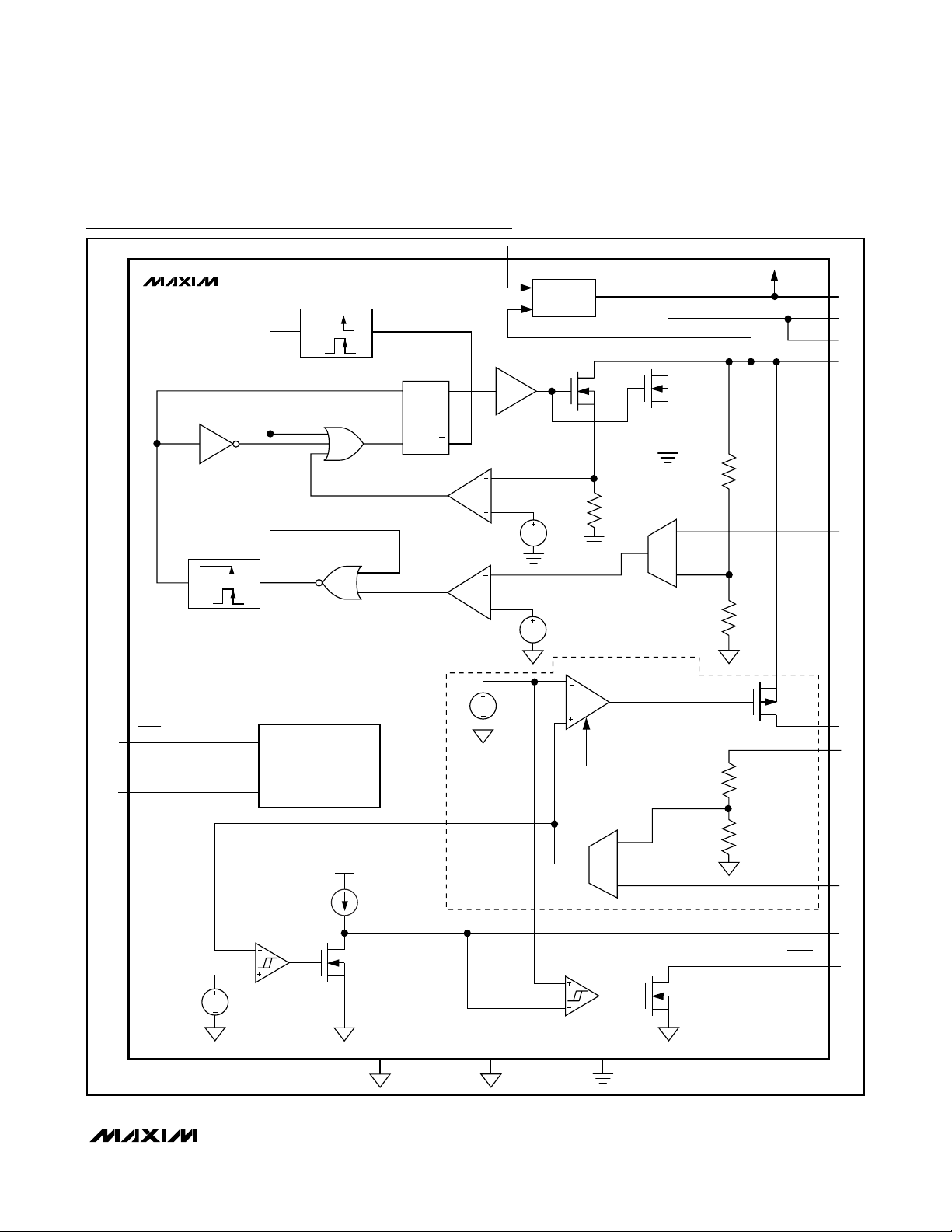

Figure 2. MAX5093_ Functional Diagram

Functional Diagrams (continued)

MAX5093_

2.25µs

ONE-SHOT

IN

1µs

ONE-SHOT

INOUT

Q

S

Q

R

INOUT

CURRENT-LIMITING

DRIVER

COMPARATOR

V

PK

V

REF

INTERNAL

LDO

R

S

MUX

LDO

VL

VL

LX

LX

BSOUT

R1

BSFB

R2

HOLD

EN

0.92 x V

REF

CONTROL LOGIC,

THERMAL SHUTDOWN,

AND OVERCURRENT

PROTECTION

CT

COMPARATOR

V

REF

VL

2µA

SGND

PGND_LDO

P

ERROR AMPLIFIER

R3

R4

MUX

DELAY

COMPARATOR

PGND_BST

OUT

OUT_SENSE

SET

CT

RESET

Page 12

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

12 ______________________________________________________________________________________

Detailed Description

The MAX5092A/MAX5092B/MAX5093A/MAX5093B

include a step-up, switch-mode DC-DC converter and a

linear regulator to provide step-up/-down voltage conversion over a wide range of input voltages. This combination of an LDO and a boost converter offers the

advantage of using a single off-the-shelf inductor in

place of the multiple-winding custom magnetics needed

in typical SEPIC or transformer-based flyback topologies. The boost preregulator is completely turned off

during normal automotive operation (VIN= 14V),

reduces quiescent current to 65µA (typ), and makes the

devices suitable for always-on power supplies.

The devices have an internal UVLO threshold of 3.8V

(max, VINrising) that must be exceeded before the

device is enabled. When VINis above V

UVLO

, the internal boost converter starts switching and regulates

V

BSOUT

to the programmed boost output voltage. The

low quiescent-current LDO steps down V

BSOUT

to the

programmed LDO output voltage. The boost output is

preset to 7V, and the LDO output is preset to 3.3V

(MAX5092A/MAX5093A) or 5V (MAX5092B/MAX5093B).

Both output voltages can be adjusted by using external

resistor-dividers.

If VINrises above 8V (typ), the boost converter is disabled, forcing V

BSOUT

to follow VIN. If VINfalls below

7.5V (typ), the boost converter starts switching and

regulates V

BSOUT

to 7V if BSFB is directly connected to

SGND. The boost converter regulates V

BSOUT

for V

IN

down to 3.5V, providing uninterrupted operation during

low cold-crank voltages even if the programmed LDO

output voltage is greater than VIN(but less than 9V).

The boost converter turn-on response time is less than

10µs, making cold-crank input glitches transparent to

the system even at full load.

The boost-converter output is followed by a high PSRR,

low-quiescent-current LDO. The LDO rejects the

switching noise present at BSOUT and provides a

clean, regulated output voltage. The linear regulator

uses an internal p-channel MOSFET pass element.

Additional features include a power-on-reset function

with an externally adjustable timeout, an enable (EN)

input, and a hold (HOLD) regulator control input.

Boost Converter

The switch-mode converter uses a minimum off-time,

maximum on-time pulse frequency modulation (PFM)

control scheme. The internal MOSFET turns on whenever V

BSOUT

falls below the regulation point determined

by V

BSFB

(see the

Setting the Boost Output Voltage

(V

BSOUT

)

section). The MOSFET turns off when the

inductor current reaches the peak current limit (2.5A

typ) or after 2.25µs maximum on-time, whichever

occurs first. The MOSFET is held off for at least 1µs

after the turn-on phase. A new switching cycle initiates

once V

BSOUT

falls below the threshold. In this control

scheme, switching frequency and output ripple are

functions of load current and input voltage. No frequency compensation is needed in the PFM control scheme.

The output of the boost converter is preset to 7V and is

adjustable by using external resistors. See the

Setting

the Boost Output Voltage V

BSOUT

section. Due to the

integrated blocking diode in the MAX5092_, V

BSOUT

is

limited to 11V. Use the MAX5093_ for higher boost output voltages (or to reduce the power dissipation in to

the package). The MAX5093_ requires an external

diode for the boost converter. Select the external diode

according to the

Schottky Diode Selection (MAX5093_)

section.

Linear Regulator

The MAX5092_/MAX5093_ contain an internal p-channel MOSFET used as the pass transistor for the LDO.

The output of the boost regulator is connected to the

source of the p-MOSFET. The LDO starts up 200µs

after the boost regulator starts up. The LDO supplies

up to 250mA with a typical dropout voltage of 0.9V. The

maximum LDO output current is determined by the

package power-dissipation limit as well as the internal

current limit. The LDO is designed to be a low-quiescent-current type. During normal operation when the

battery voltage is > 9V, the MAX5092_/MAX5093_ consume only 75µA (max) at +85°C and 100µA load.

The output voltage of the LDO is set using the SET

input. Connect SET to SGND to use the factory-preset

output voltage. Connect SET to the center of an external resistor-divider connected from OUT to SGND to

program a different output voltage. See the

Setting the

LDO Output Voltage (V

OUT

)

section.

Page 13

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

______________________________________________________________________________________ 13

Internal Regulator (VL)

An internal regulator (VL) is used to supply all internal

low-voltage blocks. Bypass VL to SGND with a 1µF

ceramic capacitor placed as close to the IC as possible. V

VL

regulates to 5.5V when V

BSOUT

is above 5.5V.

VVLtracks the voltage at BSOUT when V

BSOUT

is

below 5.5V.

Power-On-Reset Output (

RESET

)

The MAX5092_/MAX5093_ contain an open-drain output

(RESET) that indicates when the LDO output (V

OUT

) is

out of regulation. If the output of the LDO falls below 90%

of the nominal output voltage, RESET pulls low after a

short delay. Once the output rises above 92% of the

nominal output voltage, RESET goes high impedance

after the programmed reset timeout period. Connect a

100kΩ pullup resistor from OUT to RESET. See the

CT

Capacitor Selection

section for details on setting the

RESET timeout period.

Enable and Hold Inputs

The MAX5092_/MAX5093_ utilize two logic inputs, EN

(active-high) and HOLD (active low), to implement a

self-holding circuit with no additional components. For

example, an automotive ignition switch drives EN high

and the regulator turns on. If HOLD is then driven low,

the regulator remains on even if EN goes low. As long

as HOLD is forced low and remains low after initial regulator power-up, the regulator remains on. From this

state, release HOLD (an internal current source connects HOLD to OUT), or connect HOLD to OUT to turn

the regulator off. Drive EN low and HOLD high to place

the IC into shutdown mode. Shutdown mode reduces

supply current to 5µA. Figure 3 shows the timing diagram for the enable and hold functions. Table 1 shows

the state of the regulator output with respect to the voltage level at EN and HOLD with reference to Figure 3.

Connect HOLD to OUT or leave unconnected to disable the hold feature and use EN as a standard on/off

control input.

3

1

HOLD

EN

OUT

ORDER

2

4 56

Figure 3. Enable and Hold Timing Diagram

EN

COMMENTS

1

X

Initial State. EN has a 500nA pulldown to GND. HOLD has an internal current source to OUT.

HOLD follows OUT.

2

Regulator output is active when EN is pulled high. HOLD is in release state, and it follows

OUT.

3

HOLD is in release state. OUT follows EN.

4

Low

HOLD is pulled low externally after OUT turns on. The regulator output is forced on

regardless of the state of EN. A self-holding state.

5

HOLD is released after EN is pulled low. Output turns off.

5

X

Regulator enabled. Normal turn-on behavior. Regulator follows EN and HOLD follows OUT.

Table 1. Truth Table for Enable and Hold Timing Diagram

ORDER

Low

High Released On

Low Released Off

High

Low Released Off

High

HOLD OUT

Off

On

On

Page 14

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

14 ______________________________________________________________________________________

Applications Information

Figure 4. MAX5092A Typical Application Circuit with Factory Preprogrammed LDO and Boost Output Voltages

L1

4.7µH

INPUT

4V TO 72V

C1*

47µF

VOUT

RESET

***

ON

OFF

1µF

R1

100kΩ

0.22µF

C2*

10 11

LX

1

IN

MAX5092A

16

RESET

2

EN

3

SGND

15

CT

C5

U1

LX

BSOUT

PGND_BST

BSFB

HOLD

OUT_SENSE

OUT

PGND_LDO

SET

14

VL

C6

1µF

9

C3*

12

13

4

7

8

5

6

1µF

C7

10µF

P

7V

C4*

22µF

µP

SIGNAL

OUTPUT

3.3V AT 250mA**

VOUT

P

*THESE CAPACITORS MUST BE RATED AT THE HIGHEST VIN VOLTAGE.

**OUTPUT CURRENT IS LIMITED BY THE TOTAL POWER-DISSIPATION CAPABILITY OF THE PACKAGE.

***SEE PC BOARD LAYOUT GUIDELINES SECTION.

Page 15

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

______________________________________________________________________________________ 15

Applications Information (continued)

Figure 5. MAX5093A Typical Application Circuit with Factory Preprogrammed Boost and LDO Output Voltages

***

INPUT

4V TO 72V

VOUT

RESET

OFF

C1*

47µF

ON

L1

4.7µH

R1

100kΩ

0.22µF

C2*

1µF

C5

10 11

LX

1

IN

MAX5093A

16

RESET

2

EN

3

SGND

15

CT

U1

LX

BSOUT

PGND_BST

BSFB

HOLD

OUT_SENSE

OUT

PGND_LDO

SET

14

VL

C6

1µF

9

C3*

12

13

4

7

8

5

6

1µF

C7

10µF

P

7V

C4*

22µF

µP

SIGNAL

OUTPUT

3.3V AT 250mA**

VOUT

P

*THESE CAPACITORS MUST BE RATED AT THE HIGHEST VIN VOLTAGE.

**OUTPUT CURRENT IS LIMITED BY THE TOTAL POWER-DISSIPATION CAPABILITY OF THE PACKAGE.

***SEE PC BOARD LAYOUT GUIDELINES SECTION.

Page 16

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

16 ______________________________________________________________________________________

Applications Information (continued)

Figure 6. MAX5092A Typical Application Circuit with User-Programmed LDO and Boost Output Voltages

L1

4.7µH

INPUT

4V TO 72V

C1*

47µF

VOUT

RESET

***

ON

OFF

C2*

1µF

R3

100kΩ

C5

0.22µF

10 11

LX

1

IN

MAX5092A

16

RESET

2

EN

3

SGND

15

CT

U1

LX

BSOUT

PGND_BST

BSFB

HOLD

OUT_SENSE

OUT

PGND_LDO

SET

14

VL

9

12

13

4

7

8

5

6

C6

1µF

C3*

1µF

C7

10µF

P

5.5V

µP

SIGNAL

C4*

22µF

OUTPUT

8V (11V MAX)

R1

2.74MΩ (3.92MΩ)

R2

499kΩ

VOUT

OUTPUT

5V** (9V MAX)

R4

301kΩ (619kΩ)

R5

100kΩ

P

*THESE CAPACITORS MUST BE RATED AT THE HIGHEST V

**OUTPUT CURRENT IS LIMITED BY THE TOTAL OUTPUT POWER AND THE DISSIPATION CAPABILITY OF THE PACKAGE.

***SEE PC BOARD LAYOUT GUIDELINES SECTION.

VOLTAGE.

IN

Page 17

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

______________________________________________________________________________________ 17

Applications Information (continued)

Figure 7. MAX5093A Typical Application Circuit with User-Programmable Boost Output Voltage and LDO Output Voltage

***

INPUT

4V TO 72V

VOUT

RESET

OFF

C1*

47µF

ON

L1

4.7µH

R3

100kΩ

0.22µF

C2*

1µF

C5

10 11

LX

1

IN

MAX5093A

16

RESET

2

EN

3

SGND

15

CT

U1

LX

BSOUT

PGND_BST

BSFB

HOLD

OUT_SENSE

OUT

PGND_LDO

SET

14

VL

C6

1µF

OUTPUT

9

C3*

12

13

4

7

8

5

6

1µF

C7

10µF

C4*

22µF

µP

SIGNAL

9V (12V MAX)

R1

3.16MΩ (4.32MΩ)

R2

499kΩ

VOUT

OUTPUT

5V** (10V MAX)

R4

301kΩ (698kΩ)

R5

P

*THESE CAPACITORS MUST BE RATED AT THE HIGHEST V

**OUTPUT CURRENT IS LIMITED BY THE TOTAL OUTPUT POWER AND THE DISSIPATION CAPABILITY OF THE PACKAGE.

***SEE PC BOARD LAYOUT GUIDELINES SECTION.

VOLTAGE.

IN

100kΩ

Page 18

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

18 ______________________________________________________________________________________

Design Guidelines

Input Capacitor (CIN) and

Boost Capacitor (C

BSOUT

) Selection

The input current waveform of the boost converter is

continuous, and usually does not demand high capacitance at its input. However, the MAX5092_/MAX5093_

boost converter is designed to fully turn on as soon as

the input drops below a certain voltage in order to ride

out cold-crank droops. This operation demands low

input source impedance for proper operation. If the

source (battery) is located far from the IC, high-capacity, low-ESR capacitors are recommended for C

IN

. The

worst-case peak capacitor current could be as high as

3A. Use a 47µF, 100mΩ low-ESR capacitor placed as

close as possible to the input of the device. Note that

the aluminum electrolytic capacitor ESR increases significantly at cold temperatures. In the cold temperature

case, choose an electrolyte capacitor with ESR lower

than 40mΩ or connect a low-ESR ceramic capacitor

(10µF) in parallel with the electrolytic capacitor.

The boost converter output (BSOUT) is fed to the input

of the internal 250mA LDO. The boost-converter output

current waveform is discontinuous and requires highcapacity, low-ESR capacitors at BSOUT to ensure low

V

BSOUT

ripple. During the on-time of the internal MOSFET,

the BSOUT capacitor supplies 250mA current to the

LDO input. During the off-time, the inductor dumps current into the output capacitor while supplying the output

load current. The internal 250mA LDO is designed with

high PSRR; however, high-frequency spikes may not be

rejected by the LDO. Thus, high-value, low-ESR electrolytic capacitors are recommended for C

BSOUT

.

Peak-to-peak V

BSOUT

ripple depends on the ESR of the

electrolyte capacitor. Use the following equation to calculate the required ESR (ESR

BSOUT

) of the BSOUT

capacitor:

where ∆V

ESRBS

is 75% of total peak-to-peak ripple at

BSOUT, I

LIM

is the internal switch current limit (3A max),

and I

OUT

is the LDO output current. Use a 100mΩ or

lower ESR electrolytic capacitor. Make sure the ESR at

cold temperatures does not cause excessive ripple

voltage. Alternately, use a 10µF ceramic capacitor in

parallel with the electrolyte capacitor.

During the switch on-time, the BSOUT capacitor discharges while supplying I

OUT

. The ripple caused by

the capacitor discharge (∆V

CBS

) is estimated by using

the following equation:

where I

OUT

is the LDO output current and C

BSOUT

is

the BSOUT capacitance.

Inductor Selection

The control scheme of the MAX5092/MAX5093 permits

flexibility in choosing an inductor value. Smaller inductance values typically offer smaller physical size for a

given series resistance, allowing the smallest overall

circuit dimensions. Circuits using larger inductance

may provide higher efficiency and exhibit less ripple,

but also may reduce the maximum output current. This

occurs when the inductance is sufficiently large to prevent the LX current limit (I

LIM

) from being reached

before the maximum on-time (t

ON-MAX

) expires.

For maximum output current, choose the inductor value

so that the controller reaches the current limit before

the maximum on-time is reached:

where t

ON-MAX

is typically 2.25µs, and the current limit

(I

LIM

) is a maximum of 3A (see the

Electrical

Characteristics

). Choose an inductor with the maximum

saturation current (I

SAT

) greater than 3A.

∆

V

ESR

BSOUT

ESRBS

=

−

II

LIM OUT

−

6

27 10

I

∆V

CBS

OUT

=

.

××

C

BSOUT

Vt

IN ON MAX

L

≤

×

I

LIM

−

Page 19

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

______________________________________________________________________________________ 19

Setting the Boost

Output Voltage (V

BSOUT

)

The MAX5092_/MAX5093_ feature Dual Mode™ operation for the internal boost converter output voltage.

These devices operate in a preset output-voltage mode

or an adjustable output-voltage mode. In preset mode,

internal trimmed feedback resistors set V

BSOUT

to a

fixed 7V. Select the preset mode by directly connecting

BSFB to SGND (Figures 4 and 5). Ensure a low-impedance path between BSFB and SGND to limit the transient at BSFB to below 100mV. In adjustable mode,

connect BSFB to the center tap of an external resistordivider connected between BSOUT and SGND to program V

BSOUT

(Figures 6 and 7). Note that the current

drawn by the resistor-divider at BSOUT adds to the quiescent current and the shutdown current of the IC. Use

the resistor-divider only if V

BSOUT

is required to be sig-

nificantly different than 7V. Select 499kΩ or lower resistance value for the bottom resistor (R2) of the divider

connected to SGND. The top resistor (R1) value is calculated as:

where V

BSFB

is the regulation voltage at BSFB (1.24V

typ) and V

BSOUT

is the desired output voltage for

BSOUT.

Setting the LDO Output Voltage (V

OUT

)

The LDO output voltage is also Dual Mode (preset and

adjustable). Preset mode is selected by connecting

SET to SGND (Figures 4 and 5). In preset mode, V

OUT

regulates to 3.3V (MAX5092A/MAX5093A) or 5V

(MAX5092B/MAX5093B) by internal trimmed feedback

resistors. Adjustable mode is selected by connecting

SET to the center tap of an external resistor-divider

connected between OUT and SGND (Figures 6 and 7).

Note that the current drawn by the resistor-divider at

OUT adds to the quiescent current of the LDO. Use the

resistor-divider only if V

OUT

is required to be signifi-

cantly different than the preset voltage. Select 100kΩ or

lower value for the bottom resistor (R5) of the divider

connected to SGND. The top resistor (R4) value is calculated as:

where V

SET

is the regulation voltage at SET (1.24V typ)

and V

OUT

is the desired output voltage for the LDO

output.

Schottky Diode Selection (MAX5093_)

The MAX5093_ requires an external diode connected

between LX and BSOUT (Figures 5 and 7). Proper

selection of an external diode can offer a lower forwardvoltage drop and a higher reverse-voltage handling

capability. Since the high switching frequency of the IC

demands a high-speed rectifier, Schottky diodes are

recommended for most applications because of their

fast recovery time and low forward-voltage drop.

Ensure that the diode’s peak current rating is greater

than or equal to the peak current limit of internal boost

converter MOSFET. A diode average forward current

rating of at least 1A is recommended. Additionally, the

diode reverse breakdown voltage must be greater than

the worst-case load-dump-condition voltage.

CT Capacitor Selection

The MAX5092_/MAX5093_ contain an open-drain

power-on-reset output (RESET) that indicates when the

LDO output voltage (V

OUT

) is out of regulation. When

V

OUT

rises above 92% of the nominal output voltage,

RESET goes high impedance after a user-programmable time delay. This time duration is programmable by a

capacitor (CCT) from CT to SGND (Figures 4–7). For a

chosen RESET active timeout period (t

DELAY

), calculate

the required capacitor value as:

When V

OUT

drops below 90% of the LDO output regulation voltage, a 5mA pulldown current from CT to SGND

discharges C

CT

. The time required to discharge CT

determines the delay necessary to pull RESET low. This

delay provides glitch immunity to the RESET function.

The glitch immunity delay is directly proportional to the

CT capacitor and is approximately 70µs for a 0.1µF

capacitor at CT.

Dual Mode is a trademark of Maxim Integrated Products, Inc.

RR

12 1=×

⎛

⎜

⎝

V

BSOUT

V

BSFB

⎞

−

⎟

⎠

C

CT

−

6

210

××

=

.

124

t

DELAY

⎛

V

RR

45 1=×

OUT

⎜

V

⎝

SET

⎞

−

⎟

⎠

Page 20

MAX5092/MAX5093

Maximum Output Current (I

OUT_MAX

)

The MAX5092_/MAX5093_ high input voltage (+72V

max) provides up to 250mA of current from OUT.

Package power-dissipation limits the amount of output

current available for a given input/output voltage and

ambient temperature. Figure 8 depicts the maximum

power-dissipation curve for the devices. The graph

assumes that the exposed metal pad of the IC package

is soldered to the PC board copper according to the

JEDEC 51 standard (multilayer board). Use Figure 8 to

determine the allowable package dissipation for a

given ambient temperature. Alternately, use the following formula to calculate the allowable package dissipation (P

DISS

) in watts:

For TA≤ +70°C:

P

DISS

= 2.67

For +70°C < TA≤ +125°C:

P

DISS

= 2.67 - (0.0333 x (TA- 70))

where +70°C < TA≤ +125°C and 0.0333W/°C is the

package thermal derating. After determining the allowable package dissipation, calculate the maximum output current (I

OUT_MAX

) using the following formula:

where P

DISS

is the allowable package power dissipa-

tion and P

LOSS(BST)

is the boost converter power loss.

P

DISS

includes the losses in the boost converter operation and the LDO itself. The boost converter loss

P

LOSS(BST)

, depends on VIN, V

BSOUT

, and I

OUT

. See

the Boost Converter Power Loss graphs in the

Typical

Operating Characteristics

to estimate the losses at a

given VINand V

BSOUT

at room temperature. At a higher

ambient temperature of +105°C, P

LOSS(BST)

increases

by up to 20% due to higher R

DS-ON

and switching losses of the internal boost converter MOSFET. (Note:

I

OUT_MAX

must be less than 250mA).

PC Board Layout Guidelines

Good PC board (PCB) layout and routing are required

in high-frequency switching power supplies to achieve

proper regulation and stability. It is strongly recommended that the evaluation kit PCB layouts be followed

as closely as possible. Refer to the MAX5092 EV kit for

an example layout. Follow these guidelines for good

PCB layout:

1) For SGND, use a large copper plane under the IC

and solder it to the exposed paddle. To effectively

use this copper area as a heat exchanger between

the PCB and ambient, expose this copper area on

the top and bottom side of the PCB. Do not make a

direct connection from the EP copper plane to pin 3

(SGND) underneath the IC so as to minimize

ground bounce.

2) Isolate the power components and high-current

path from the sensitive analog circuit.

3) Keep the high-current paths short, especially at the

ground terminals. This practice is essential for stable, jitter-free operation.

4) Connect the return terminals of input capacitors

and boost output capacitors to the PGND_BST

power ground plane. Connect the power ground

(PGND_BST) and signal ground (SGND) planes

together at the negative terminal of the input capacitors. Do not connect them anywhere else. Connect

PGND_LDO ground plane to SGND ground plane

at a single point.

5) Ensure that the feedback connections are short and

direct. Ensure a low-impedance path between

BSFB and SGND to limit the transient at BSFB to

100mV.

6) Route high-speed switching nodes away from the

sensitive analog areas. Use the internal PCB layer

for SGND as an EMI shield to keep radiated noise

away from the IC, feedback dividers, and bypass

capacitors.

4V to 72V Input LDOs with Boost Preregulator

20 ______________________________________________________________________________________

Figure 8. MAX5092/MAX5093 Package Power Dissipation

MAXIMUM POWER DISSIPATION

3.0

2.5

2.0

1.5

1.0

0.5

MAXIMUM POWER DISSIPATION (W)

vs. AMBIENT TEMPERATURE

0

-40 125

AMBIENT TEMPERATURE (°C)

1109580655035205-10-25

I

OUT MAX

PP

−

_

VV

IN OUT

DISS LOSS BST

=

()

−

MAX5092/93 fig08

Page 21

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

______________________________________________________________________________________ 21

Chip Information

PROCESS: BiCMOS

Selector Guide

Typical Operating Circuit

INPUT

4V TO 72V

VOUT

RESET

OUTPUT

ENABLE

*

P

IN

RESET

EN

SGND

CT

LX

MAX5092B

LX

BSOUT

PGND_BST

BSFB

HOLD

OUT_SENSE

OUT

PGND_LDO

SET

VL

+7V OUTPUT

+5V OUTPUT

VOUT

P

*SEE PC BOARD LAYOUT GUIDELINES SECTION.

PART

MAX5092AATE+ 3.3 Yes 7 Yes Internal

MAX5092BATE+ 5 Yes 7 Yes Internal

MAX5093AATE+ 3.3 Yes 7 Yes External

MAX5093BATE+ 5 Yes 7 Yes External

PRESET LDO

OUTPUT (V)

ADJUSTABLE

LDO OUTPUT

PRESET BSOUT

OUTPUT (V)

ADJUSTABLE BSOUT

OUTPUT

BOOST DIODE

Page 22

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

22 ______________________________________________________________________________________

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

QFN THIN.EPS

Page 23

MAX5092/MAX5093

4V to 72V Input LDOs with Boost Preregulator

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________

23

© 2006 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

Loading...

Loading...