Page 1

General Description

The MAX5066 is a two-phase, configurable single- or

dual-output buck controller with an input voltage range of

4.75V to 5.5V or from 5V to 28V. Each phase of the

MAX5066 is designed for 180° operation. A mode pin

allows for a dual-output supply or connecting two phases

together for a single-output, high-current supply. Each

output channel of the MAX5066 drives n-channel

MOSFETs and is capable of providing more than 25A of

load current. The MAX5066 uses average current-mode

control with a switching frequency up to 1MHz per phase

where each phase is 180° out of phase with respect to

the other. Out-of-phase operation results in significantly

reduced input capacitor ripple current and output voltage ripple in dual-phase, single-output voltage applications. Each buck regulator output has its own highperformance current and voltage-error amplifier that can

be compensated for optimum output filter L-C values and

transient response.

The device’s switching frequency can be programmed

from 100kHz to 1MHz with an external resistor. The

MAX5066 can be synchronized to an external clock. Each

output voltage is adjustable from 0.61V to 5.5V. Additional

features include thermal shutdown, “hiccup mode” shortcircuit protection. Use the MAX5066 with adaptive voltage

positioning for applications that require a fast transient

response, or accurate output voltage regulation.

The MAX5066 is available in a thermally enhanced 28-pin

TSSOP package capable of dissipating 1.9W. The device

is rated for operation over the -40°C to +85°C extended,

or -40°C to +125°C automotive temperature range.

Applications

High-End Desktop Computers

Graphics Cards

Networking Systems

Point-of-Load High-Current/High-Density

Telecom DC-DC Regulators

RAID Systems

Features

♦ 4.75V to 5.5V or 5V to 28V Input

♦ Dual-Output Synchronous Buck Controller

♦ Configurable for Two Separate Outputs or One

Single Output

♦ Each Output is Capable of Up to 25A Output

Current

♦ Average Current-Mode Control Provides Accurate

Current Limit

♦ 180° Interleaved Operation Reduces Size of Input

Filter Capacitors

♦ Limits Reverse Current Sinking When Operated in

Parallel Mode

♦ Each Output is Adjustable from 0.61V to 5.5V

♦ Independently Programmable Adaptive Voltage

Positioning

♦ 100kHz to 1MHz per Phase Programmable

Switching Frequency

♦ Oscillator Frequency Synchronization from

200kHz to 2MHz

♦ Hiccup Mode Overcurrent Protection

♦ Overtemperature Shutdown

♦ Thermally Enhanced 28-Pin TSSOP Package

Capable of Dissipating 1.9W

♦ Operates Over -40°C to +85°C or -40°C to +125°C

Temperature Range

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

19-3661; Rev 0; 5/05

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

PART TEMP RANGE PIN-PACKAGE

MAX5066EUI -40

ο

C to +85οC 28 TSSOP

MAX5066AUI -40°C to +125°C 28 TSSOP

Page 2

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN to AGND.............................................................-0.3V to +30V

BST_ to AGND........................................................-0.3V to +35V

DH_ to LX_ ....................................-0.3V to (V

BST_

- V

LX_

) + 0.3V

DL_ to PGND..............................................-0.3V to (V

DD

+ 0.3V)

BST_ to LX_ ..............................................................-0.3V to +6V

V

DD

to PGND............................................................-0.3V to +6V

AGND to PGND .....................................................-0.3V to +0.3V

REG, RT/CLKIN, CSP_, CSN_ to AGND ..................-0.3V to +6V

All Other Pins to AGND ............................-0.3V to (V

REG

+ 0.3V)

REG Continuous Output Current

(Limited by Power Dissipation, No Thermal or Short-Circuit

Protection).........................................................................67mA

REF Continuous Output Current ........................................200µA

Continuous Power Dissipation (T

A

= +70°C)

28-Pin TSSOP (derate 23.8mW/°C above +70°C) .....1904mW

Package Thermal Resistance (

θJC) ...................................2°C/W

Operating Temperature Ranges

MAX5066EUI ...................................................-40°C to +85°C

MAX5066AUI .................................................-40°C to +125°C

Maximum Junction Temperature .....................................+150°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

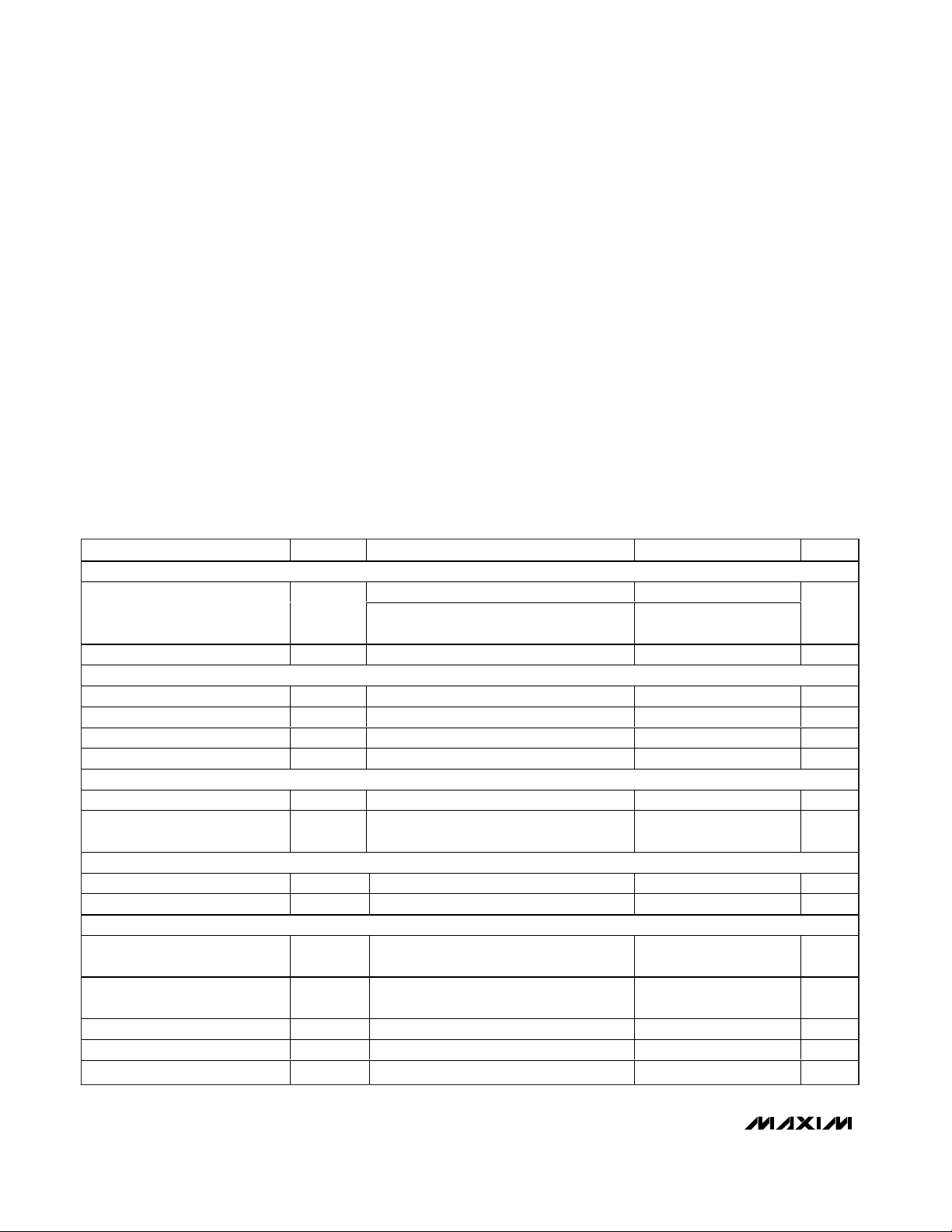

ELECTRICAL CHARACTERISTICS

(VIN= V

REG

= VDD= VEN= +5V, TA= TJ= T

MIN

to T

MAX

, unless otherwise noted, circuit of Figure 6. Typical values are at TA= +25°C.)

(Note 1)

PARAMETER

CONDITIONS

UNITS

SYSTEM SPECIFICATIONS

528

Input Voltage Range V

IN

IN and REG shorted together for +5V

operation

5.5

V

Quiescent Supply Current I

IN

f

OSC

= 500kHz, DH_, DL_ = open 4 20 mA

STARTUP/INTERNAL REGULATOR OUTPUT (REG)

REG Undervoltage Lockout UVLO V

REG

rising 4.0

4.5 V

Hysteresis V

HYST

mV

REG Output Accuracy VIN = 5.8V to 28V, I

SOURCE

= 0 to 65mA

V

REG Dropout VIN < 5.8V, I

SOURCE

= 60mA 0.5 V

INTERNAL REFERENCE

Internal Reference Voltage V

EAN_

EAN_ connected to EAOUT_ (Note 2)

V

Internal Reference Voltage

Accuracy

V

EAN_

VIN = V

REG

= 4.75V to 5.5V or VIN = 5V to

28V, EAN_ connected to EAOUT_ (Note 2)

%

EXTERNAL REFERENCE VOLTAGE OUTPUT (REF)

Accuracy V

REF

I

REF

= 100µA

3.3

V

Load Regulation I

REF

= 0 to 200µA 3.2 3.4 V

MOSFET DRIVERS

p-Channel Output Driver

Impedance

R

ON_P

4 Ω

n-Channel Output Driver

Impedance

R

ON_N

Ω

Output Driver Source Current

2.5 A

Output Driver Sink Current

8A

Nonoverlap Time (Dead Time) t

NO

C

DH_

or C

DL_

= 5nF 30 ns

SYMBOL

MIN TYP MAX

I

, I

DH_

I

, I

DH_

DL_

DL_

4.75

4.15

200

4.75 5.10 5.30

0.6135

-0.9 +0.9

3.23

1.35

0.45 1.35

3.37

Page 3

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

_______________________________________________________________________________________ 3

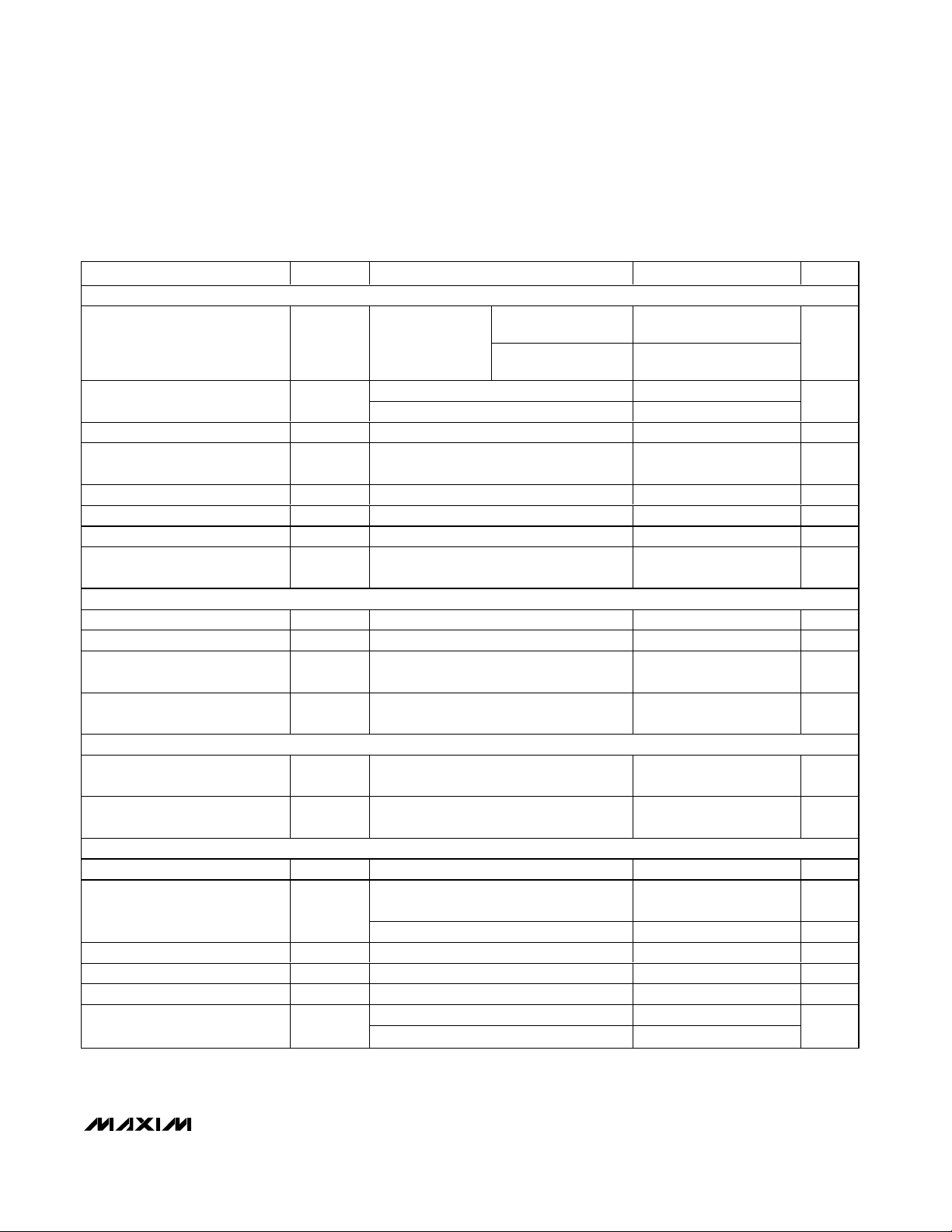

ELECTRICAL CHARACTERISTICS (continued)

(VIN= V

REG

= VDD= VEN= +5V, TA= TJ= T

MIN

to T

MAX

, unless otherwise noted, circuit of Figure 6. Typical values are at TA= +25°C.)

(Note 1)

PARAMETER

CONDITIONS

TYP

UNITS

OSCILLATOR

RRT = 12.4kΩ

Switching Frequency f

SW

1MHz (max)

switching

frequency per

phase

R

RT

= 127kΩ 100

kHz

fSW = 250kHz nominal, RRT = 50kΩ

Switching Frequency Accuracy

f

SW

= 1MHz nominal, RRT = 12.4kΩ

%

RT/CLKIN Output Voltage

V

RT/CLKIN Current Sourcing

Capability

0.5 mA

RT/CLKIN Logic-High Threshold

2.4 V

RT/CLKIN Logic-Low Threshold

0.8 V

RT/CLKIN High Pulse Width

30 ns

RT/CLKIN Synchronization

Frequency Range

kHz

CURRENT LIMIT

Average Current-Limit Threshold

V

CL_

V

CSP_

- V

CSN_

22.5

mV

Reverse Current-Limit Threshold

V

RCL_

V

CSP_

- V

CSN_

mV

Cycle-by-Cycle Current-Limit

Threshold

V

CLpk_VCSP_

- V

CSN_

52.5 mV

Cycle-by-Cycle Current-Limit

Response Time

t

R

260 ns

DIGITAL FAULT INTEGRATION (DF_)

Number of Switching Cycles to

Shutdown in Current-Limit

NS

DF_

Clock

cycles

Number of Switching Cycles to

Recover from Shutdown

NR

DF_

Clock

cycles

CURRENT-SENSE AMPLIFIER

CSP_ to CSN_ Input Resistance R

CS_

kΩ

VIN = V

REG

= 4.75V to 5.5V or

V

IN

= 5V to 10V

V

Common-Mode Range

)

VIN = 7V to 28V

V

Input Offset Voltage

)

100 µV

Amplifier Gain A

V(CS)

36 V/V

-3dB Bandwidth f

-3dB

4

MHz

V

CSP_

= 5.5V, sinking 120

CSP_ Input Bias Current I

CSA(IN)

V

CSP_

= 0V, sourcing 30

µA

SYMBOL

V

V

RT/CLKIN_H

V

RT/CLKIN_L

V

RT/CLKIN

I

RT/CLKIN

t

RT/CLKIN

f

RT/CLKIN

CMR(CS

V

OS(CS

MIN

MAX

1000

-7.5 +7.5

-10 +10

1.225

200 2000

20.4

24.75

-3.13 -1.63 -0.1

32,768

524,288

1.9835

-0.3 +3.6

-0.3 +5.5

Page 4

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

4 _______________________________________________________________________________________

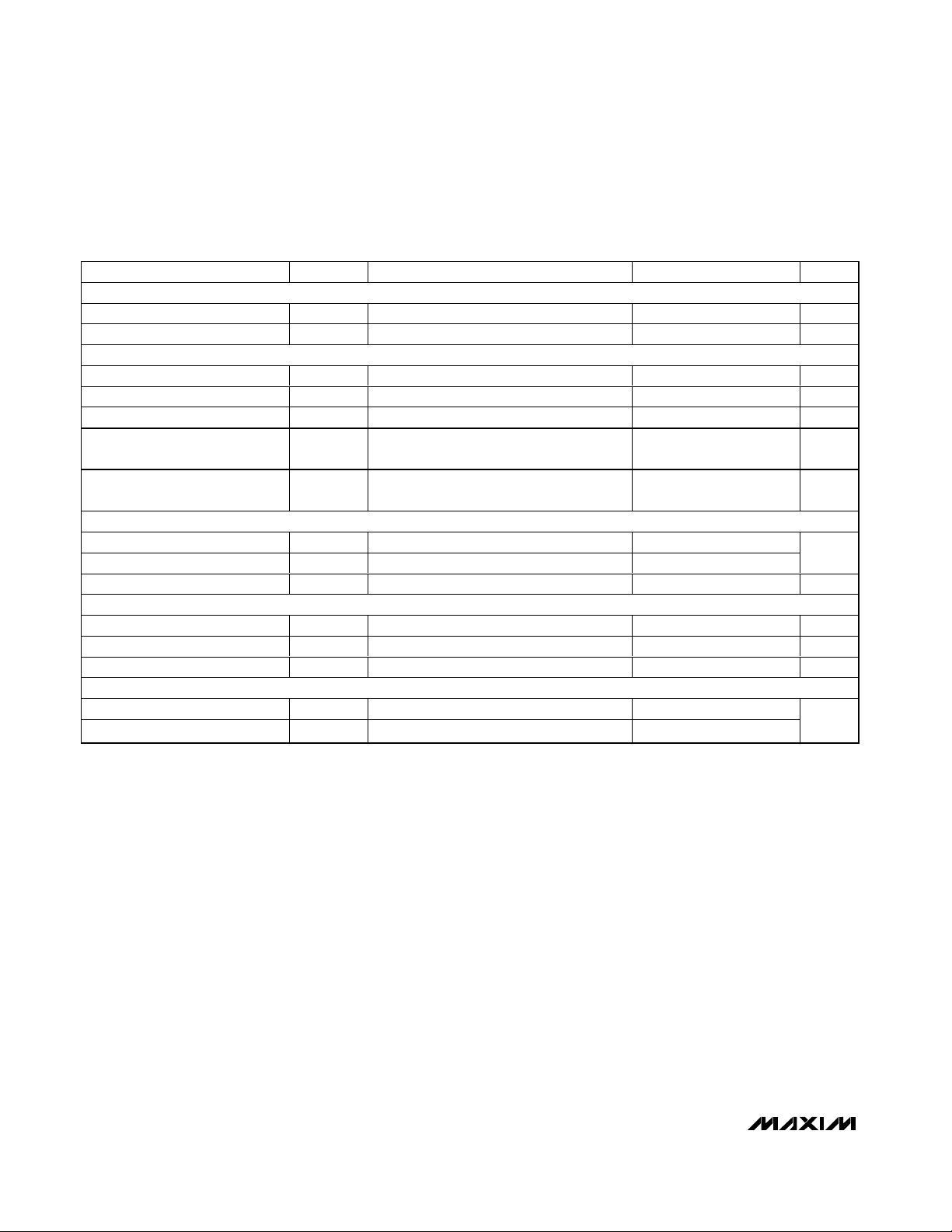

ELECTRICAL CHARACTERISTICS (continued)

(VIN= V

REG

= VDD= VEN= +5V, TA= TJ= T

MIN

to T

MAX

, unless otherwise noted, circuit of Figure 6. Typical values are at TA= +25°C.)

(Note 1)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

CURRENT-ERROR AMPLIFIER (CEA_)

Transconductance g

M

550 µS

Open-Loop Gain

)

No load 50 dB

VOLTAGE ERROR AMPLIFIER (EAOUT_)

Open-Loop Gain

)

70 dB

Unity-Gain Bandwidth f

UGEA

3

MHz

EAN_ Input Bias Current

)

V

EAN_

= 2.0V 100 nA

Error Amplifier Output Clamping

High Voltage

V

CLMP_HI

(EA)

With respect to V

CM

1.14 V

Error Amplifier Output Clamping

Low Voltage

V

CLMP_LO

(EA)

With respect to V

CM

V

EN INPUT

EN Input High Voltage V

ENH

EN rising

EN Hysteresis 0.05

V

EN Input Leakage Current I

EN

-1 +1 µA

MODE INPUT

MODE Logic-High Threshold

2.4 V

MODE Logic-Low Threshold

0.8 V

MODE Input Pulldown

5µA

THERMAL SHUTDOWN

Thermal Shutdown T

SHDN

160

Thermal Shutdown Hysteresis T

HYST

10

°C

Note 1: The device is 100% production tested at TA= +85°C (MAX5066EUI). Limits at -40°C and +25°C and TA= TJ= +125°C

(MAX5066AUI) are guaranteed by design.

Note 2: The internal reference voltage accuracy is measured at the negative input of the error amplifiers (EAN_). Output voltage

accuracy must include external resistor-divider tolerances.

A

VOL(CEA

A

VOL(EA

I

BIAS(EA

V

MODE_H

V

MODE_L

I

PULLDWN

-0.234

1.204 1.222 1.240

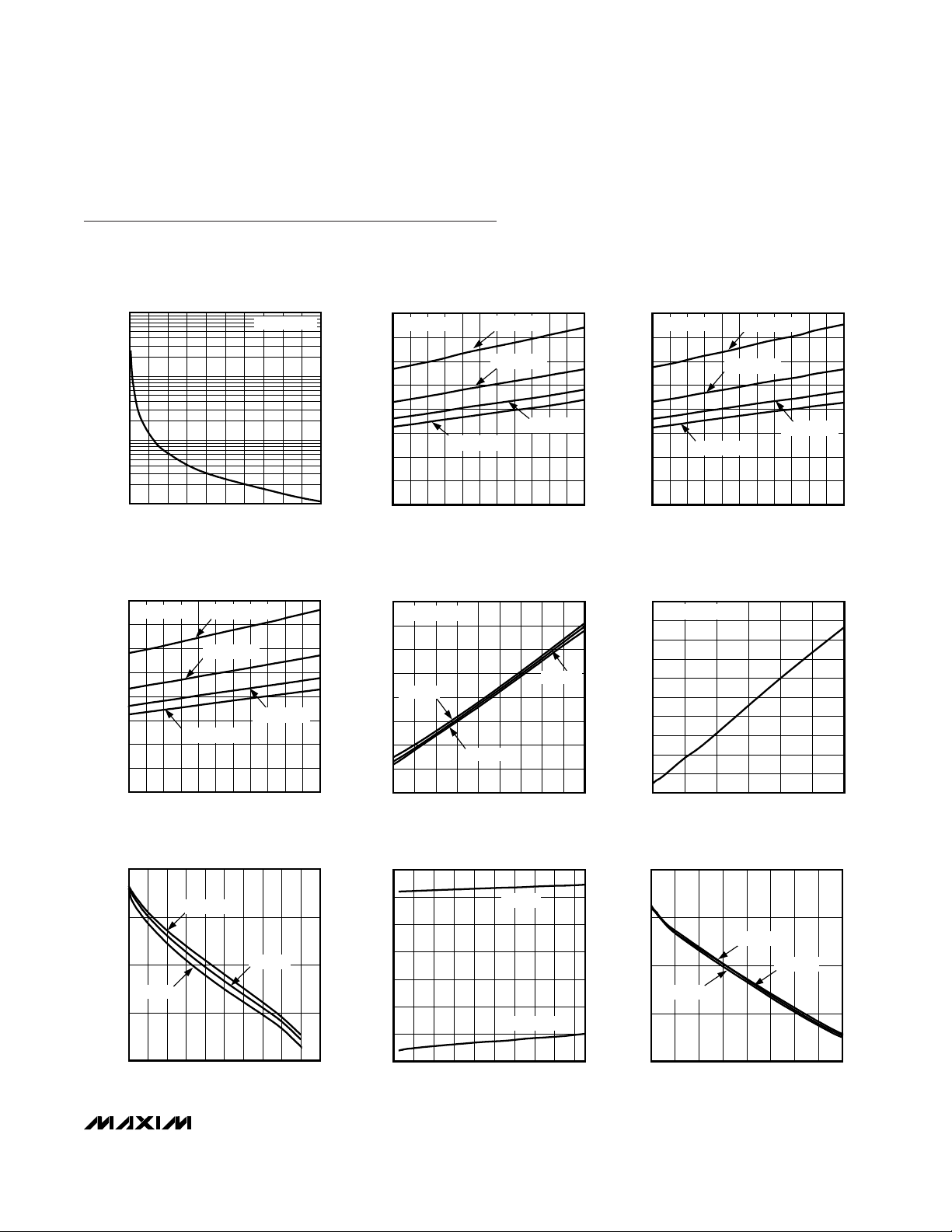

Page 5

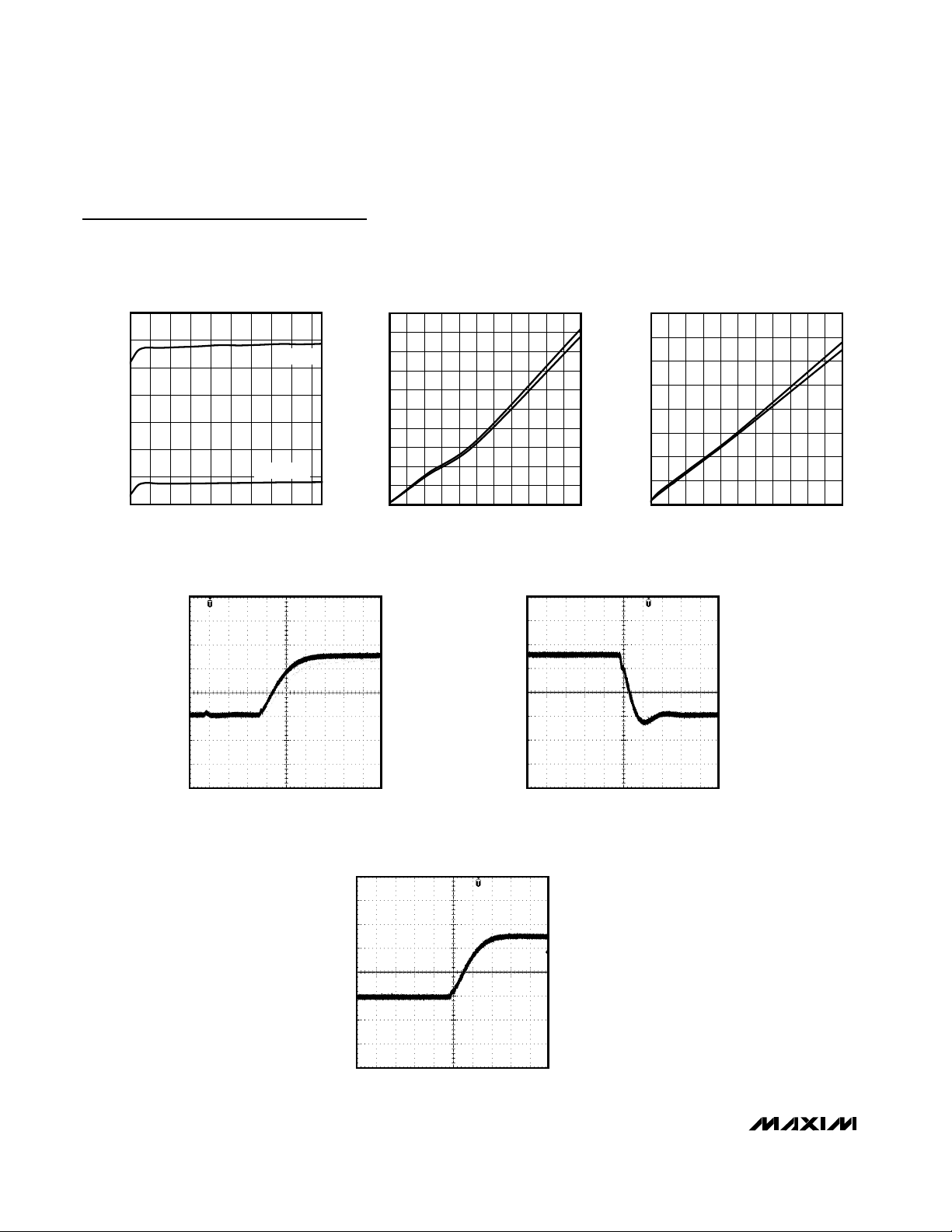

OSCILLATOR FREQUENCY vs. R

T

MAX5066 toc01

RT (kΩ)

OSCILLATOR FREQUENCY (kHz)

900800700600500400300200100

100

1000

10,000

10

01000

CDH = CDL = 0

SUPPLY CURRENT

vs. TEMPERATURE AND FREQUENCY

(V

IN

= 5V)

MAX5066 toc02a

TEMPERATURE (°C)

SUPPLY CURRENT (mA)

11095-25 -10 5 35 50 6520 80

2

4

6

8

10

12

14

16

0

-40 125

CDH = CDL = 0

fSW = 1MHz

fSW = 250kHz

fSW = 500kHz

fSW = 125kHz

SUPPLY CURRENT

vs. TEMPERATURE AND FREQUENCY

(V

IN

= 12V)

MAX5066 toc02b

TEMPERATURE (°C)

SUPPLY CURRENT (mA)

11095-25 -10 5 35 50 6520 80

2

4

6

8

10

12

14

16

0

-40 125

CDH = CDL = 0

fSW = 1MHz

fSW = 250kHz

fSW = 500kHz

fSW = 125kHz

SUPPLY CURRENT

vs. TEMPERATURE AND FREQUENCY

(V

IN

= 24V)

MAX5066 toc02c

TEMPERATURE (°C)

SUPPLY CURRENT (mA)

11095-25 -10 5 35 50 6520 80

2

4

6

8

10

12

14

16

0

-40 125

CDH = CDL = 0

fSW = 1MHz

fSW = 250kHz

fSW = 500kHz

fSW = 125kHz

SUPPLY CURRENT

vs. OSCILLATOR FREQUENCY

MAX5066 toc03

FREQUENCY (kHz)

SUPPLY CURRENT (mA)

18001600400 600 800 12001000 1400

7

8

9

10

11

12

13

14

6

200 2000

C

DH_

= C

DL_

= 0

VIN = 24V

VIN = 5V

VIN = 12V

SUPPLY CURRENT

vs. DRIVER LOAD CAPACITANCE

MAX5066 toc04

C

LOAD

(nF)

SUPPLY CURRENT (mA)

252015105

10

20

30

40

50

60

70

80

90

100

0

030

C

LOAD

= CDH = C

DL

REG LOAD REGULATION

MAX5066 toc05

I

REG

(mA)

V

REG

(V)

908070605040302010

4.95

5.00

5.05

5.10

4.90

0100

VIN = 12V

VIN = 24V

VIN = 5.5V

REG LINE REGULATION

MAX5066 toc06

VIN (V)

V

REG

(V)

2321191715131197

4.98

5.00

5.02

5.04

5.06

5.08

5.10

4.96

5

I

REG

= 0

I

REG

= 60mA

REF LOAD REGULATION

MAX5066 toc07

I

REF

(µA)

V

REF

(V)

700600500400300200100

3.290

3.295

3.300

3.305

3.285

0800

VIN = 24V

VIN = 5V

VIN = 12V

Typical Operating Characteristics

(Circuit of Figure 6, TA= +25°C, unless otherwise noted. VIN= 12V, V

OUT1

= 0.8V, V

OUT2

= 1.3V, fSW= 500kHz per phase.)

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

_______________________________________________________________________________________ 5

Page 6

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

6 _______________________________________________________________________________________

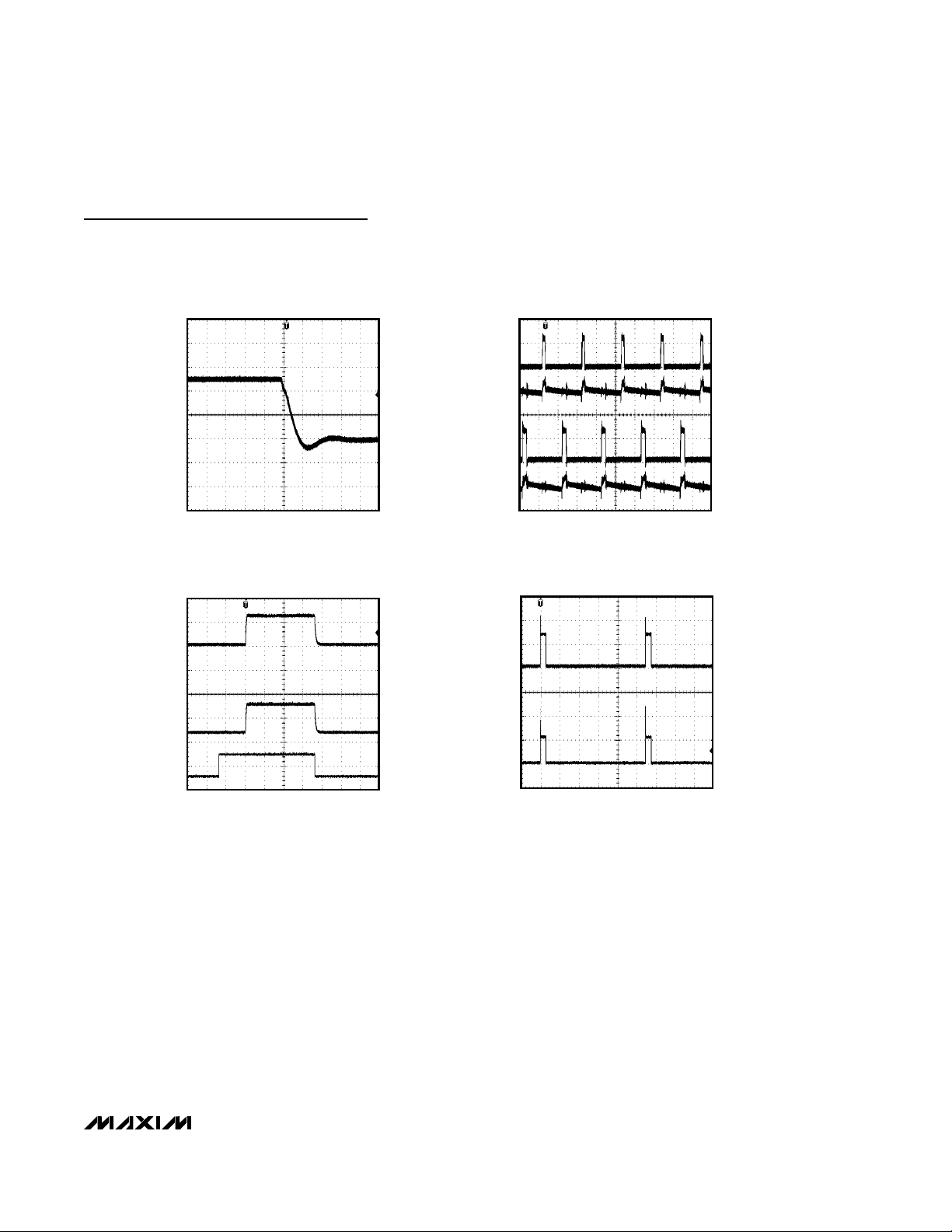

REF LINE REGULATION

MAX5066 toc08

VIN (V)

V

REF

(V)

232119171513119

7

3.297

3.298

3.299

3.300

3.301

3.302

3.303

3.296

5

I

REF

= 200µA

I

REF

= 0

DRIVER RISE TIME

vs. LOAD CAPACITANCE

MAX5066 toc09

C

LOAD

(nF)

t

RISE

(ns)

201814 164 6 8 10 122

10

20

30

40

50

60

70

80

90

100

0

022

DH

DL

DRIVER FALL TIME

vs. LOAD CAPACITANCE

MAX5066 toc10

C

LOAD

(nF)

t

FALL

(ns)

201814 164 6 8 10 122

5

10

15

20

25

30

35

40

0

022

DH

DL

HIGH-SIDE DRIVER RISE TIME

(V

IN

= 12V, C

LOAD

= 10nF)

MAX5066 toc11

DH_

2V/div

20ns/div

HIGH-SIDE DRIVER FALL TIME

(V

IN

= 12V, C

LOAD

= 10nF)

MAX5066 toc12

DH_

2V/div

20ns/div

LOW-SIDE DRIVER RISE TIME

(V

IN

= 12V, C

LOAD

= 10nF)

MAX5066 toc13

DL_

2V/div

20ns/div

Typical Operating Characteristics (continued)

(Circuit of Figure 6, TA= +25°C, unless otherwise noted. VIN= 12V, V

OUT1

= 0.8V, V

OUT2

= 1.3V, fSW= 500kHz per phase.)

Page 7

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

_______________________________________________________________________________________ 7

LOW-SIDE DRIVER FALL TIME

(V

IN

= 12V, C

LOAD

= 10nF)

MAX5066 toc14

DL_

2V/div

20ns/div

OUT1/OUT2 OUT-OF-PHASE WAVEFORMS

(V

OUT1

= 0.8V, V

OUT2

= 1.3V)

MAX5066 toc15

OUT1

100mV/div

10µs/div

OUT2

100mV/div

LX2

10V/div

LX1

10V/div

TURN-ON/-OFF WAVEFORMS

(I

OUT1

= I

OUT2

= 10A)

MAX5066 toc16

2ms/div

EN

5V/div

V

OUT2

1V/div

V

OUT1

1V/div

SHORT-CIRCUIT CURRENT WAVEFORMS

(V

IN

= 5V)

MAX5066 toc17

200ms/div

I

OUT2

10A/div

I

OUT1

10A/div

Typical Operating Characteristics (continued)

(Circuit of Figure 6, TA= +25°C, unless otherwise noted. VIN= 12V, V

OUT1

= 0.8V, V

OUT2

= 1.3V, fSW= 500kHz per phase.)

Page 8

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

8 _______________________________________________________________________________________

Pin Description

PIN NAME FUNCTION

1 CSN2

Current-Sense Differential Amplifier Negative Input for Output2. Connect CSN2 to the negative

terminal of the sense resistor. The differential voltage between CSP2 and CSN2 is internally amplified

by the current-sense amplifier (A

V(CS)

= 36V/V).

2 CSP2

Current-Sense Differential Amplifier Positive Input for Output2. Connect CSP2 to the positive terminal

of the sense resistor. The differential voltage between CSP2 and CSN2 is internally amplified by the

current-sense amplifier (A

V(CS)

= 36V/V).

3 EAOUT2

Voltage Error-Amplifier Output2. Connect to an external gain-setting feedback resistor. The erroramplifier gain determines the output voltage load regulation for adaptive voltage positioning. This

output also serves as the compensation network connection from EAOUT2 to EAN2. A resistive

network results in a drooped output voltage regulation characteristic. An integrator configuration

results in very tight output voltage regulation (see the Adaptive Voltage Positioning section).

4 EAN2

Voltage Error-Amplifier Inverting Input for Output2. Connect a resistive divider from V

OUT2

to EAN2 to

AGND to set the output voltage. A compensation network connects from EAOUT2 to EAN2. A

resistive network results in a drooped output-voltage-regulation characteristic. An integrator

configuration results in very tight output-voltage regulation (see the Adaptive Voltage Positioning

section).

5 CLP2

Current-Error Amplifier Output2. Compensate the current loop by connecting an R-C network from

CLP2 to AGND.

6 REF

3.3V Reference Output. Bypass REF to AGND with a minimum 0.1µF ceramic capacitor. REF can

source up to 200µA for external loads.

7 RT/CLKIN

External Clock Input or Internal Frequency-Setting Connection. Connect a resistor from RT/CLKIN to

AGND to set the switching frequency. Connect an external clock at RT/CLKIN for external frequency

synchronization.

8 AGND Analog Ground

9 MODE

Mode Function Input. MODE selects between a single-output dual phase or a dual-output buck

regulator. When MODE is grounded, VEA1 and VEA2 connect to CEA1 and CEA2, respectively (see

Figure 1) and the device operates as a two-output, out-of-phase buck regulator. When MODE is

connected to REG (logic high), VEA2 is disconnected and VEA1 is routed to both CEA1 and CEA2.

10 CLP1

Current-Error Amplifier Output1. Compensate the current loop by connecting an R-C network from

CLP1 to AGND.

11 EAN1

Voltage Error Amplifier Inverting Input for Output1. Connect a resistive divider from V

OUT1

to EAN1 to

regulate the output voltage. A compensation network connects from EAOUT1 to EAN1. A resistive

network results in a drooped output-voltage-regulation characteristic. An integrator configuration

results in very tight output voltage regulation (see the Adaptive Voltage Positioning section).

12 EAOUT1

Voltage Error Amplifier Output1. Connect to an external gain-setting feedback resistor. The error

amplifier gain determines the output-voltage-load regulation for adaptive voltage positioning. This

output also serves as the compensation network connection from EAOUT1 to EAN1. A resistive

network results in a drooped output-voltage-regulation characteristic. An integrator configuration

results in very tight output-voltage regulation (see the Adaptive Voltage Positioning section).

13 CSP1

Current-Sense Differential Amplifier Positive Input for Output1. Connect CSP1 to the positive terminal

of the sense resistor. The differential voltage between CSP1 and CSN1 is internally amplified by the

current-sense amplifier (A

V(CS)

= 36V/V).

Page 9

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

_______________________________________________________________________________________ 9

Detailed Description

The MAX5066 switching power-supply controller can

be configured in two ways. With the MODE input high, it

operates as a single-output, dual-phase, step-down

switching regulator where each output is 180° out of

phase. With the MODE pin connected low, the

MAX5066 operates as a dual-output, step-down switching regulator. The average current-mode control topology of the MAX5066 offers high-noise immunity while

having benefits similar to those of peak current-mode

control. Average current-mode control has the intrinsic

ability to accurately limit the average current sourced

by the converter during a fault condition. When a fault

condition occurs, the error amplifier output voltage

(EAOUT1 or EAOUT2) that connects to the positive

input of the transconductance amplifier (CA1 or CA2) is

clamped thus limiting the output current.

The MAX5066 contains all blocks necessary for two

independently regulated average current-mode PWM

regulators. It has two voltage error amplifiers (VEA1

and VEA2), two current-error amplifiers (CEA1 and

CEA2), two current-sensing amplifiers (CA1 and CA2),

two PWM comparators (CPWM1 and CPWM2), and drivers for both low- and high-side power MOSFETs (see

Figure 1). Each PWM section is also equipped with a

pulse-by-pulse, current-limit protection and a fault integration block for hiccup protection.

Pin Description (continued)

PIN NAME FUNCTION

14 CSN1

Current-Sense Differential Amplifier Negative Input for Output1. Connect CSN1 to the negative

terminal of the sense resistor. The differential voltage between CSP1 and CSN1 is internally amplified

by the current-sense amplifier (A

V(CS)

= 36V/V).

15, 28 EN

Output Enable. A logic low shuts down both channel MOSFET drivers. Pins 15 and 28 must be tied

together externally.

16 BST1

Boost Flying Capacitor Connection. Reservoir capacitor connection for the high-side MOSFET driver

supply. Connect a 0.47µF ceramic capacitor between BST1 and LX1.

17 DH1 High-Side Gate Driver Output1. DH1 drives the gate of the high-side MOSFET.

18 LX1

External inductor connection and source connection for the high-side MOSFET for Output1. LX1 also

serves as the return terminal for the high-side MOSFET driver.

19 DL1 Low-Side Gate Driver Output1. Gate driver output for the synchronous MOSFET.

20 V

DD

Supply Voltage for Low-Side Drivers. REG powers VDD. Connect a parallel combination of 0.1µF and

1µF ceramic capacitors from V

DD

to PGND and a 1Ω resistor from VDD to REG to filter out the high-

peak currents of the driver from the internal circuitry.

21 REG

Internal 5V Regulator Output. REG is derived internally from IN and is used to power the internal bias

circuitry. Bypass REG to AGND with a 4.7µF ceramic capacitor.

22 IN Supply Voltage Connection. Connect IN to a 5V to 28V input supply.

23 PGND

Power Ground. Source connection for the low-side MOSFET. Connect V

DD

’s bypass capacitor returns

to PGND.

24 DL2 Low-Side Gate Driver Output2. Gate driver for the synchronous MOSFET.

25 LX2

External inductor connection and source connection for the high-side MOSFET for Output2. Also

serves as the return terminal for the high-side MOSFET driver.

26 DH2 High-Side Gate Driver Output2. DH2 drives the gate of the high-side MOSFET.

27 BST2

Boost Flying Capacitor Connection. Reservoir capacitor connection for the high-side MOSFET driver

supply. Connect a 0.47µF ceramic capacitor between BST2 and LX2.

EP EP Exposed Pad. Connect exposed pad to ground plane.

Page 10

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

10 ______________________________________________________________________________________

An oscillator, with an externally programmable frequency generates two clock pulse trains and two ramps for

both PWM sections. The two clocks and the two ramps

are 180° out of phase with each other.

A linear regulator (REG) generates the 5V to supply the

device. This regulator has the output-current capability

necessary to provide for the MAX5066’s internal circuitry and the power for the external MOSFET’s gate drivers. A low-current linear regulator (REF) provides a

precise 3.3V reference output and is capable of driving

loads of up to 200µA. Internal UVLO circuitry ensures

that the MAX5066 starts up only when V

REG

and V

REF

are at the correct voltage levels to guarantee safe operation of the IC and of the power MOSFETs.

Finally, a thermal-shutdown feature protects the device

during thermal faults and shuts down the MAX5066

when the die temperature exceeds +160°C.

16

17

18

19

BST1

DH1

LX1

DL1

20

27

26

25

24

23

BST2

DH2

LX2

DL2

PGND

V

DD

2

CSP2

1

CSN2

13

CSP1

14

CSN1

CA1

11

EAN1

6

REF

AGND

8

EN

15

EN

28

CA2

CPWM1

CPWM2

7

RT/CLKIN

CEA1

CEA2

12EAOUT1

9

MODE

3

EAOUT2

5

CLP2

10

CLP1

22

IN

21

REG

1.225V

1.225V

THERMAL

SHUTDOWN

V

DD

MUX

4

EAN2

CEN

VEA1

DF1 AND

HICCUP

LOGIC

EXTERNAL FREQUENCY SYNC

0°

CONTROL

AND DRIVER

LOGIC 1

CONTROL

AND DRIVER

LOGIC 2

DF2 AND

HICCUP

LOGIC

OSCILLATOR

AND PHASE

SPLITTER

180°

2V

P-P

RAMP

V

REG

= 5V

FOR INTERNAL

BIASING

UVLO

V

REF

= 3.3V

UV33

V

INTREF

= 0.61V

VEA2

CEN

2V

P-P

RAMP

Figure 1. Block Diagram

Page 11

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

______________________________________________________________________________________ 11

Dual-Output/Dual-Phase Select (MODE)

The MAX5066 can operate as a dual-output independently regulated buck converter, or as a dual-phase,

single-output buck converter. The MODE input selects

between the two operating modes. When MODE is

grounded (logic low), VEA1 and VEA2 connect to CEA1

and CEA2, respectively (see Figure 1) and the device

operates as a two-output DC-DC converter. When

MODE is connected to REG (logic high), VEA2 is disconnected and VEA1 is routed to both CEA1 and CEA2

and the device works as a dual-phase, single-output

buck regulator with each output 180° out of phase with

respect to each other.

Supply Voltage Connections (VIN/V

REG

)

The MAX5066 accepts a wide input voltage range at IN

of 5V to 28V. An internal linear regulator steps down V

IN

to 5.1V (typ) and provides power to the MAX5066. The

output of this regulator is available at REG. For VIN=

4.75V to 5.5V, connect IN and REG together externally.

REG can supply up to 65mA for external loads. Bypass

REG to AGND with a 4.7µF ceramic capacitor for highfrequency noise rejection and stable operation.

REG supplies the current for both the MAX5066’s internal circuitry and for the MOSFET gate drivers (when

connected externally to VDD), and can source up to

65mA. Calculate the maximum bias current (I

BIAS

) for

the MAX5066:

where IINis the quiescent supply current into IN (4mA,

typ), Q

GQ1

, Q

GQ2

, Q

GQ3

, Q

GQ4

are the total gate

charges of MOSFETs Q1 through Q4 at VGS= 5V (see

Figure 6), and fSWis the switching frequency of each

individual phase.

Low-Side MOSFET Driver Supply (VDD)

VDDis the power input for the low-side MOSFET drivers. Connect the regulator output REG externally to

VDDthrough an R-C lowpass filter. Use a 1Ω resistor

and a parallel combination of 1µF and 0.1µF ceramic

capacitors to filter out the high peak currents of the

MOSFET drivers from the sensitive internal circuitry.

High-Side MOSFET Drive Supply (BST_)

BST1 and BST2 supply the power for the high-side

MOSFET drivers for output 1 and output 2, respectively.

Connect BST1 and BST2 to VDDthrough rectifier

diodes D1 and D2 (see Figure 6). Connect a 0.1µF

ceramic capacitor between BST_ and LX_.

Minimize the trace inductance from BST_ and VDDto

rectifier diodes, D1 and D2, and from BST_ and LX_ to

the boost capacitors, C8 and C9 (see Figure 6). This is

accomplished by using short, wide trace lengths.

Undervoltage Lockout (UVLO)/

Power-On Reset (POR)/Soft-Start

The MAX5066 includes an undervoltage lockout

(UVLO) with hysteresis, and a power-on reset circuit for

converter turn-on and monotonic rise of the output voltage. The UVLO threshold monitors V

REG

and is internally set between 4.0V and 4.5V with 200mV of

hysteresis. Hysteresis eliminates “chattering” during

startup. Most of the internal circuitry, including the

oscillator, turns on when V

REG

reaches 4.5V. The

MAX5066 draws up to 4mA (typ) of current before

V

REG

reaches the UVLO threshold.

The compensation network at the current-error amplifiers (CLP1 and CLP2) provides an inherent soft-start of

the output voltage. It includes (R14 and C10) in parallel

with C11 at CLP1 and (R15 and C12) in parallel with

C13 at CLP2 (see Figure 6). The voltage at the currenterror amplifier output limits the maximum current available to charge the output capacitors. The capacitor at

CLP_ in conjunction with the finite output-drive current

of the current-error amplifier yields a finite rise time for

the output current and thus the output voltage.

Setting the Switching Frequency (fSW)

An internal oscillator generates the 180oout-of-phase

clock signals required for both PWM modulators. The

oscillator also generates the 2V

P-P

voltage ramps necessary for the PWM comparators. The oscillator frequency can be set from 200kHz to 2MHz by an external

resistor (RT) connected from RT/CLKIN to AGND (see

Figure 6). The equation below shows the relationship

between RTand the switching frequency:

where R

RT

is in ohms and f

SW(PER PHASE)

= f

OSC

/2.

Use RT/CLKIN as a clock input to synchronize the

MAX5066 to an external frequency (f

RT/CLKIN

). Applying

an external clock to RT/CLKIN allows each PWM section

to work at a frequency equal to f

RT/CLKIN

/2. An internal

comparator with a 1.6V threshold detects f

RT/CLKIN

. If

f

RT/CLKIN

is present, internal logic switches from the

internal oscillator clock, to the clock present at

RT/CLKIN.

Hiccup Fault Protection

The MAX5066 includes overload fault protection circuitry that prevents damage to the power MOSFETs. The

fault protection consists of two digital fault integration

f

R

Hz

OSC

RT

=

×25 10

10

.

IIfQQQQ

BIAS IN SW GQ GQ GQ GQ

=+× +++ ()

1 234

Page 12

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

12 ______________________________________________________________________________________

blocks that enable “hiccuping” under overcurrent conditions. This circuit works as follows: for every clock

cycle the current-limit threshold is exceeded, the fault

integration counter increments by one count. Thus, if

the current-limit condition persists, then the counter

reaches its shutdown threshold in 32,768 counts and

shuts down the external MOSFETs. When the MAX5066

shuts down due to a fault, the counter begins to count

down, (since the current-limit condition has ended),

once every 16 clock cycles. Thus, the device counts

down for 524,288 clock cycles. At this point, switching

resumes. This produces an effective duty cycle of

6.25% power-up and 93.75% power-down under fault

conditions. With a switching frequency set to 250kHz,

power-up and power-down times are approximately

131ms and 2.09s, respectively.

Control Loop

The MAX5066 uses an average current-mode control

topology to regulate the output voltage. The control

loop consists of an inner current loop and an outer voltage loop. The inner current loop controls the output

current, while the outer voltage loop controls the output

voltage. The inner current loop absorbs the inductor

pole, reducing the order of the outer voltage loop to

that of a single-pole system. Figure 2 is the block diagram of OUT1’s control loop.

The current loop consists of a current-sense resistor,

R

SENSE

, a current-sense amplifier (CA1), a currenterror amplifier (CEA1), an oscillator providing the carrier ramp, and a PWM comparator (CPWM1). The

precision current-sense amplifier (CA1) amplifies the

sense voltage across R

SENSE

by a factor of 36. The

inverting input to CEA1 senses the output of CA1. The

output of CEA1 is the difference between the voltageerror amplifier output (EAOUT1) and the gained-up voltage from CA1. The RC compensation network

connected to CLP1 provides external frequency compensation for the respective CEA1 (see the

Compensation section). The start of every clock cycle

enables the high-side driver and initiates a PWM oncycle. Comparator CPWM1 compares the output voltage from CEA1 against a 0 to 2V ramp from the

oscillator. The PWM on-cycle terminates when the ramp

voltage exceeds the error voltage from the current-error

amplifier (CEA1).

DRIVE

V

IN

V

OUT1

C

OUT

V

REF

= 0.61V

R

F

C

CFF

C

CF

I

L

R

CF

CSN1

CSP1

CLP1

2V

P-P

R

SENSE

LOAD

R1

R2

CA 1

CEA1

CPWM1

VEA1

Figure 2. Current and Voltage Loops

Page 13

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

______________________________________________________________________________________ 13

The outer voltage control loop consists of the voltageerror amplifier (VEA1). The noninverting input (EAN1) is

externally connected to the midpoint of a resistive voltage-divider from OUT1 to EAN1 to AGND. The voltage

loop gain is set by using an external resistor from the

output of this amplifier (EAOUT1) to its inverting input

(EAN1). The noninverting input of (VEA1) is connected

to the 0.61V internal reference.

Peak-Current Comparator

The peak-current comparator (see Figure 3) monitors

the voltage across the current-sense resistor (R

SENSE

)

and provides a fast cycle-by-cycle current limit with a

threshold of 52.5mV. Note that the average current-limit

threshold of 22.5mV still limits the output current during

short-circuit conditions. To prevent inductor saturation,

select an output inductor with a saturation current

specification greater than the average current limit of

22.5mV/R

SENSE

. Proper inductor selection ensures that

only extreme conditions trip the peak-current comparator, such as a damaged output inductor. The typical

propagation delay of the peak current-limit comparator

is 260ns.

Current-Error Amplifier

The MAX5066 has two dedicated transconductance

current-error amplifiers CEA1 and CEA2 with a typical

gMof 550µS and 320µA output sink and source capability. The current-error amplifier outputs (CLP1 and CLP2)

serve as the inverting input to the PWM comparators.

CLP1 and CLP2 are externally accessible to provide frequency compensation for the inner current loops (see

C

CFF

, CCF, and RCFin Figure 2). Compensate the current-error amplifier such that the inductor current down

slope, which becomes the up slope at the inverting

input of the PWM comparator, is less than the slope of

the internally generated voltage ramp (see the

Compensation section).

PWM Comparator and R-S Flip-Flop

The PWM comparator (CPWM1 or CPWM2) sets the

duty cycle for each cycle by comparing the currenterror amplifier output to a 2V

P-P

ramp. At the start of

each clock cycle an R-S flip-flop resets and the highside drivers (DH1 and DH2) turn on. The comparator

sets the flip-flop as soon as the ramp voltage exceeds

the current-error amplifier output voltage, thus terminating the on cycle.

Voltage Error Amplifier

The voltage-error amplifier (VEA_) sets the gain of the

voltage control loop. Its output clamps to 1.14V and

-0.234V relative to VCM= 0.61V. Set the MAX5066 output voltage by connecting a voltage-divider from the

output to EAN_ to GND (see Figure 4). At no load the

output of the voltage error amplifier is zero.

Use the equation below to calculate the no load voltage:

The voltage at full load is given by:

where ∆V

OUT

is the voltage-positioning window

described in the Adaptive Voltage Positioning section.

Adaptive Voltage Positioning

Powering new-generation ICs requires new techniques

to reduce cost, size, and power dissipation. Voltage

positioning (Figure 5) reduces the total number of output capacitors to meet a given transient response

requirement. Setting the no-load output voltage slightly

higher than the output voltage during nominally loaded

conditions allows a larger downward voltage excursion

when the output current suddenly increases.

Regulating at a lower output voltage under a heavy

load allows a larger upward-voltage excursion when

the output current suddenly decreases. A larger

allowed voltage-step excursion reduces the required

number of output capacitors and/or allows the use of

higher ESR capacitors.

The internal 0.61V reference in the MAX5066 has a tolerance of ±0.9%. If we use 0.1% resistors for R1and R2,

we still have another 4% available for the variation in the

output voltage from nominal. This available voltage

range allows us to reduce the total number of output

capacitors to meet a given transient response requirement. This results in a voltage-positioning window as

shown in Figure 5.

From the allowable voltage-positioning window we can

calculate the value of R

F

from the equation below.

where ∆V

OUT

is the allowable voltage-positioning win-

dow, R

SENSE

is the sense resistor, 36 is the current-

sense amplifier gain, and R1is as shown in Figure 4.

MOSFET Gate Drivers (DH_, DL_)

The high-side drivers (DH1 and DH2) and low-side drivers (DL1 and DL2) drive the gates of external n-channel

MOSFETs. The high-peak sink and source current capa-

R

IR R

V

F

OUT SENSE

OUT

=

×××36

1

∆

V

R

R

V

OUT FL OUT()

. =×+

−0 6135 1

1

2

∆

V

R

R

OUT NL()

. =×+

0 6135 1

1

2

Page 14

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

14 ______________________________________________________________________________________

bility of these drivers provides ample drive for the fast

rise and fall times of the switching MOSFETs. Faster rise

and fall times result in reduced switching losses. For lowoutput, voltage-regulating applications where the duty

cycle is less than 50%, choose high-side MOSFETs (Q2

and Q4, Figure 6) with a moderate R

DS(ON)

and a very

low gate charge. Choose low-side MOSFETs (Q1 and

Q3, Figure 6) with very low R

DS(ON)

and moderate gate

charge. The driver block also includes a logic circuit that

provides an adaptive nonoverlap time (30ns typical) to

prevent shoot-through currents during transition. Figure 7

shows the dual-phase, single-output buck regulator.

2 x fSW (V/S)

RAMP

CLK

CSP_

CSN_

GM

IN

EN_

1.225V

CLP_

V

DD

BST_

DH_

LX_

DL_

PGND

A

V

= 36

PWM

COMPARATOR

PEAK-CURRENT

COMPARATOR

52.5mV

S

R

Q

Q

gM = 500µS

Figure 3. Current Comparator and MOSFET Driver Logic

LOAD

C

OUT

V

OUT

V

REF

= 0.61V

R

F

R

1

R

2

EAN_

EAOUT_

Figure 4. Voltage Error Amplifier

LOAD (A)

V

CNTR

NO LOAD

1/2 LOAD

FULL LOAD

VOLTAGE-POSITIONING WINDOW

V

CNTR

+ ∆V

OUT

/2

V

CNTR

- ∆V

OUT

/2

Figure 5. Defining the Voltage-Positioning Window

Page 15

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

______________________________________________________________________________________ 15

R

T

24.9kΩ

C1

0.22µF

R8

29.4kΩ

V

REG

OR V

REF

R5

4.64kΩ

R4

1.74kΩ

C6

680µF

0.8V/10A

R1

2mΩ

L1

0.5µH

D3

(1A, 30V)

Q1

IRF7832

Q2

IRF7821

C8

0.1µF

D1

(100mA, 30V)

C2

1µF

Q4

IRF7821

D2

(100mA, 30V)

C3

0.1µF

C4

4.7µF

R3

1Ω

C5

10µF

V

IN

1.3V/10A

C9

0.1µF

Q3

IRF7832

D4

(1A, 30V)

L2

0.8µH

R2

2mΩ

R14

1kΩ

C10

15nF

C11

120pF

R15

1kΩ

C12

15nF

C13

120pF

AGND

REF

RT/CLKIN

EN

EN

EAOUT1

EAN1

CSP1

CSN1

DL1

LX1

DH1

BST1

V

DD

IN

REG

BST2

DH2

LX2

DL2

PGND

CSP2

CSN2

EAN2

EAOUT2

MODE

CLP1

CLP2

MAX5066

C7

680µF

R9

60.4kΩ

R7

4.75kΩ

R6

5.11kΩ

EXTERNAL FREQUENCY SYNC

22Ω

22Ω

Figure 6. Dual-Output Buck Regulator

Page 16

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

16 ______________________________________________________________________________________

R

T

24.9kΩ

C1

0.22µF

R8

60.4kΩ

V

REG

OR V

REF

R5

4.75kΩ

R4

5.11kΩ

C6

680µF

1.3V/20A

R1

2mΩ

L1

0.8µH

D3

(1A, 30V)

Q1

IRF7832

Q2

IRF7821

C8

0.1µF

D1

(100mA, 30V)

C2

1µF

Q4

IRF7821

D2

(100mA, 30V)

C3

0.1µF

C4

4.7µF

R3

1Ω

C5

10µF

V

IN

C9

0.1µF

Q3

IRF7832

D4

(1A, 30V)

L2

0.8µH

R2

2mΩ

R14

1kΩ

C10

15nF

C11

120pF

R15

1kΩ

C12

15nF

C13

120pF

AGND

REF

RT/CLKIN

EN

EN

EAOUT1

EAN1

CSP1

CSN1

DL1

LX1

DH1

BST1

V

DD

IN

REG

BST2

DH2

LX2

DL2

PGND

CSP2

CSN2

EAN2

EAOUT2

MODE

CLP1

CLP2

MAX5066

EXTERNAL FREQUENCY SYNC

22Ω

22Ω

TO REG

Figure 7. Dual-Phase, Single-Output Buck Regulator

Page 17

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

______________________________________________________________________________________ 17

Design Procedures

Inductor Selection

The switching frequency per phase, peak-to-peak ripple

current in each phase, and allowable voltage ripple at

the output, determine the inductance value. Selecting

higher switching frequencies reduces the inductance

requirement, but at the cost of lower efficiency due to

the charge/discharge cycle of the gate and drain

capacitances in the switching MOSFETs. The situation

worsens at higher input voltages, since capacitive

switching losses are proportional to the square of the

input voltage. Lower switching frequencies on the other

hand will increase the peak-to-peak inductor ripple current (∆I

L

) and therefore increase the MOSFET conduction losses (see the Power MOSFET Selection section for

a detailed description of MOSFET power loss).

When using higher inductor ripple current, the ripple

cancellation in the multiphase topology, reduces the

input and output capacitor RMS ripple current. Use the

following equation to determine the minimum inductance value:

Choose ∆ILto be equal to about 30% of the output current per channel. Since ∆ILaffects the output-ripple voltage, the inductance value may need minor adjustment

after choosing the output capacitors for full-rated efficiency. Choose inductors from the standard high-current, surface-mount inductor series available from various

manufacturers. Particular applications may require custom-made inductors. Use high-frequency core material

for custom inductors. High ∆ILcauses large peak-to-peak

flux excursion increasing the core losses at higher

frequencies. The high-frequency operation coupled with

high ∆IL, reduces the required minimum inductance and

even makes the use of planar inductors possible. The

advantages of using planar magnetics include low-profile

design, excellent current sharing between phases due to

the tight control of parasitics, and low cost. For example,

the minimum inductance at VIN= 12V, V

OUT

= 0.8V, ∆I

L

= 3A, and fSW= 500kHz is 0.5µH.

The average current-mode control feature of the

MAX5066 limits the maximum inductor current, which

prevents the inductor from saturating. Choose an

inductor with a saturating current greater than the

worst-case peak inductor current:

where 24.75mV is the maximum average current-limit

threshold for the current-sense amplifier and R

SENSE

is

the sense resistor.

Power MOSFET Selection

When choosing the MOSFETs, consider the total gate

charge, R

DS(ON)

, power dissipation, the maximum

drain-to-source voltage, and package thermal impedance. The product of the MOSFET gate charge and onresistance is a figure of merit, with a lower number

signifying better performance. Choose MOSFETs optimized for high-frequency switching applications. The

average gate-drive current from the MAX5066’s output

is proportional to the total capacitance it drives at DH1,

DH2, DL1, and DL2. The power dissipated in the

MAX5066 is proportional to the input voltage and the

average drive current. See the Supply Voltage

Connection (VIN/V

REG

) and the Low-Side MOSFET

Drives Supply (VDD) sections to determine the maxi-

mum total gate charge allowed from all driver outputs

together.

The losses may be broken into four categories: conduction loss, gate drive loss, switching loss and output loss.

The following simplified power loss equation is true for

both MOSFETs in the synchronous buck-converter:

For the low-side MOSFET, the P

SWITCH

term becomes

virtually zero because the body diode of the MOSFET is

conducting before the MOSFET is turned on.

Tables 1 and 2 describe the different losses and shows

an approximation of the losses during that period.

Input Capacitance

The discontinuous input-current waveform of the buck

converter causes large ripple currents in the input

capacitor. The switching frequency, peak inductor current, and the allowable peak-to-peak voltage ripple

reflected back to the source, dictate the capacitance

requirement. Increasing the number of phases increases the effective switching frequency and lowers the

peak-to-average current ratio, yielding lower input

capacitance requirement. It can be shown that the

worst-case RMS current occurs when only one controller section is operating. The controller section with

PP P P P

LOSS CONDUCTION GATEDRIVE SWITCH OUTPUT

=+++

I

R

I

L PEAK

SENSE

L

_

. =×

+

−

24 75 10

2

3

∆

L

VV V

Vf I

OUT IN MAX OUT

IN SW L

=

−

××

()

()

∆

Page 18

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

18 ______________________________________________________________________________________

the highest output power needs to be used in determining the maximum input RMS ripple current requirement.

Increasing the output current drawn from the other outof-phase controller section results in reducing the input

ripple current. A low-ESR input capacitor that can handle the maximum input RMS ripple current of one channel must be used. The maximum RMS capacitor ripple

current is given by:

where I

MAX

is the full load current of the regulator.

V

OUT

is the output voltage of the same regulator and

CINis C5 in Figure 6. The ESR of the input capacitors

wastes power from the input and heats up the capacitor. Reducing the ESR is important to maintain a high

overall efficiency and in reducing the heating of the

capacitors.

Output Capacitors

The worst-case peak-to-peak inductor ripple current,

the allowable peak-to-peak output ripple voltage, and

the maximum deviation of the output voltage during

step loads determine the capacitance and the ESR

requirements for the output capacitors. The output ripple can be approximated as the inductor current ripple

multiplied by the output capacitor’s ESR (R

ESR_OUT

).

The peak-to-peak inductor current ripple is given by:

During a load step, the allowable deviation of the output voltage during the fast transient load dictates the

output capacitance and ESR. The output capacitors

supply the load step until the controller responds with a

greater duty cycle. The response time (t

RESPONSE

)

depends on the closed-loop bandwidth of the regulator. The resistive drop across the capacitor’s ESR and

capacitor discharge causes a voltage drop during a

∆I

VD

Lf

L

OUT

SW

=

−×()1

II

VVV

V

CIN RMS MAX

OUT IN OUT

IN

()

()

≈

−

LOSS DESCRIPTION SEGMENT LOSS

Conduction Loss

Losses associated with MOSFET on-time and

on-resistance. I

RMS

is a function of load current

and duty cycle.

Gate Drive Loss

Losses associated with charging and

discharging the gate capacitance of the

MOSFET every cycle. Use the MOSFET’s (Q

G

)

specification.

Switching Loss

Losses during the drain voltage and drain

current transitions for every switching cycle.

Losses occur only during the Q

GS2

and Q

GD

time period and not during the initial Q

GS1

period. The initial Q

GS1

period is the rise in the

gate voltage from zero to V

TH.

RDH is the high-side MOSFET driver’s onresistance and R

GATE

is the internal gate

resistance of the high-side MOSFET (Q

GD

and

Q

GS2

are found in the MOSFET data sheet).

Output Loss

Losses associated with Q

OSS

of the MOSFET

occur every cycle when the high-side MOSFET

turns on. The losses are caused by both

MOSFETs but are dissipated in the high-side

MOSFET.

Table 1. High-Side MOSFET Losses

PIR

where I

V

V

I

CONDUCTION RMS DS ON

RMS

OUT

IN

LOAD

=×

≈×

2

()

PVQf

GATEDRIVE DD G SW

=××

PVIf

QQ

I

SWITCH IN LOAD SW

GS GD

GATE

=× × ×

+

2

()

where I

V

RR

GATE

DD

DH GATE

=

×+2 ()

P

QQ

Vf

OUTPUT

OSS HS OSS LS

IN SW

=

+

××

2

() ()

Page 19

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

______________________________________________________________________________________ 19

load step. Use a combination of SP polymer and

ceramic capacitors for better transient load and ripple/noise performance.

Keep the maximum output-voltage deviation less than

or equal to the adaptive voltage-positioning window

(∆V

OUT

). During a load step, assume a 50% contribu-

tion each from the output capacitance discharge and

the voltage drop across the ESR (∆V

OUT

= ∆V

ESR_

OUT

+ ∆V

Q_OUT

). Use the following equations to calculate

the required ESR and capacitance value:

where I

LOAD_STEP

is the step in load current and

t

RESPONSE

is the response time of the controller.

Controller response time depends on the control-loop

bandwidth. C

OUT

is C6 and C7 in Figure 6.

Current Limit

The average current-mode control technique of the

MAX5066 accurately limits the maximum average output current per phase. The MAX5066 senses the voltage across the sense resistor and limits the maximum

inductor current accordingly. Use the equations below

to calculate the current-sense resistor values:

Due to tolerances involved, the minimum average voltage at which the voltage across the current-sense

resistor is clamped is 20.4mV. Therefore, the minimum

average current limit is set at:

For example, the current-sense resistor:

for a maximum output current of 10A. The standard

value is 2mΩ. Also, adjust the value of the currentsense resistor to compensate for parasitics associated

with the PC board. Select a noninductive resistor with

appropriate wattage rating.

The second type of current limit is the peak current limit

as explained in the Peak-Current Comparator section.

The third current-protection circuit is the hiccup fault

protection as explained in the Hiccup Fault Protection

section. The average current during a short at the output is given by:

Reverse Current Limit

The MAX5066 limits the reverse current when the output

capacitor voltage is higher than the preset output voltage. Calculate the maximum reverse current limit based

on V

CLAMP_LO

and the current-sense resistor R

SENSE

.

I

R

AVG SHORT

SENSE

()

.

=

×

−

141 10

3

R

mV

A

m

SENSE

==

20 4

10

204.. Ω

I

R

LIMIT MIN

SENSE

()

. =×

−

20 4 10

3

I

R

LOAD MAX

SENSE

()

.

=

×

−

24 75 10

3

R

V

I

C

It

V

ESR OUT

ESR OUT

LOAD STEP

OUT

LOAD STEP RESPONSE

Q OUT

_

_

_

_

_

=

=

×

∆

∆

LOSS DESCRIPTION SEGMENT LOSSES

Conduction Loss

Losses associated with MOSFET on-time, I

RMS

is a function of load current and duty cycle.

Gate Drive Loss

Losses associated with charging and

discharging the gate of the MOSFET every

cycle. There is no QGD charging involved in this

MOSFET due to the zero-voltage turn-on. The

charge involved is (Q

G

- QGD).

Table 2. Low-Side MOSFET Losses

PIR

where I

VV

V

I

CONDUCTION RMS DS ON

RMS

IN OUT

IN

LOAD

=×

≈

−

×

2

()

PVQQf

GATEDRIVE DD G GD SW

=×− ×()

Note: The gate drive losses are distributed between the drivers and the MOSFETs in the ratio of the gate driver’s resistance and the

MOSFET’s internal gate resistance.

Page 20

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

20 ______________________________________________________________________________________

Output-Voltage Setting

The output voltage is set by the combination of resistors

R1, R2, and RFas described in the Voltage Error Amplifier

section. First select a value for resistor R2. Then calculate

the value of R1 from the following equation:

where V

OUT(NL)

is the voltage at no load. Then find the

value of RFfrom the following equation:

where ∆V

OUT

is the allowable drop in voltage from no

load to full load. R

F

is R8 and R9, R1 is R4 and R6, R2

is R5 and R7 in Figure 6.

Compensation

The MAX5066 uses an average current-mode control

scheme to regulate the output voltage (see Figure 2).

The main control loop consists of an inner current loop

and an outer voltage loop. The voltage error amplifier

(VEA1 and VEA2) provides the controlling voltage for

the current loop in each phase. The output inductor is

“hidden” inside the inner current loop. This simplifies

the design of the outer voltage control loop and also

improves the power-supply dynamics. The objective of

the inner current loop is to control the average inductor

current. The gain-bandwidth characteristic of the current loop can be tailored for optimum performance by

the compensation network at the output of the currenterror amplifier (CEA1 or CEA2). Compared with peak

current-mode control, the current-loop gain crossover

frequency, fC, can be made approximately the same,

but the gain at low frequencies is much higher. This

results in the following advantages over peak currentmode control.

1) The average current tracks the programmed current with a high degree of accuracy.

2) Slope compensation is not required, but there is a

limit to the loop gain at the switching frequency in

order to achieve stability.

3) Noise immunity is excellent.

4) The average current-mode method can be used to

sense and control the current in any circuit branch.

For stability of the current loop, the amplified inductorcurrent downslope at the negative input of the PWM

comparator (CPWM1 and CPWM2) must not exceed

the ramp slope at the comparator’s positive input. This

puts an upper limit on the current-error amplifier gain at

the switching frequency. The inductor current downslope is given by V

OUT

/L where L is the value of the

inductor (L1 and L2 in Figure 6) and V

OUT

is the output

voltage. The amplified inductor current downslope at

the negative input of the PWM comparator is given by:

where R

SENSE

is the current-sense resistor (R1 and R2

in Figure 6) and gMx RCFis the gain of the current-error

amplifier (CEA_) at the switching frequency. The slope

of the ramp at the positive input of the PWM comparator

is 2V x fSW. Use the following equation to calculate the

maximum value of RCF(R14 or R15 in Figure 6).

The highest crossover frequency f

CMAX

is given by:

or alternatively:

Equation (1) can now be rewritten as:

In practical applications, pick the crossover frequency

(fC) in the range of:

First calculate R

CF

in equation 2 above. Calculate C

CF

such that:

where C

CF

is C10 and C12 in Figure 6.

C

fR

CF

CCF

=

×× ×

10

2 π

f

f

f

SW

C

SW

10 2

<< .

R

fL

VR g

CF

C

IN S M

=

××

×××

π

9

2()

f

fV

V

SW

CMAX OUT

IN

=

××2π

f

fV

V

CMAX

SW IN

OUT

=

×

×2π

R

fL

VR g

CF

SW

OUT SENSE M

≤

××

×××

2

36

1()

∆∆VtV

L

RgR

L OUT

SENSE M CF

=× ×××36

R

IR R

V

F

OUT SENSE

OUT

=

×××36

1

∆

R

V

R

OUT NL

1

0 6135

0 6135

2

(.)

.

()

=

−

×

I

R

REVERSE

SENSE

=

×

−

163 10

3

.

Page 21

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

______________________________________________________________________________________ 21

Calculate C

CFF

such that:

where C

CFF

is C11 and C13 in Figure 6.

Applications Information

PC Board Layout Guidelines

Careful PC board layout is critical to achieve low losses, low output noise, and clean and stable operation.

This is especially true for dual-phase converters where

one channel can affect the other. Use the following

guidelines for PC board layout:

1) Place the VDD, REG, and the BST1 and BST2

bypass capacitors close to the MAX5066.

2) Minimize all high-current switching loops.

3) Keep the power traces and load connections short.

This practice is essential for high efficiency. Use

thick copper PC boards (2oz or higher) to enhance

efficiency and minimize trace inductance and

resistance.

4) Run the current-sense lines CSP_ and CSN_ very

close to each other to minimize loop areas. Do not

cross these critical signal lines through power circuitry. Sense the current right at the pads of the

current-sense resistors.

5) Place the bank of output capacitors close to the

load.

6) Isolate the power components on the top side from

the analog components on the bottom side with a

ground plane in between.

7) Provide enough copper area around the switching

MOSFETs, inductors, and sense resistors to aid in

thermal dissipation and reducing resistance.

8) Distribute the power components evenly across the

top side for proper heat dissipation.

9) Keep AGND and PGND isolated and connect them

at one single point close to the IC. Do not connect

them together anywhere else.

10) Place all input bypass capacitors for each input as

close to each other as is practical.

C

fR

CFF

CCF

=

×× × ×

1

210π

28

27

26

25

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

EN

BST2

DH2

LX2

DL2

PGND

EN

IN

REG

V

DD

DL1

LX1

DH1

BST1

CSN1

CSP1

EAOUT1

EAN1

CLP1

MODE

AGND

RT/CLKIN

REF

CLP2

EAN2

EAOUT2

CSP2

CSN2

TSSOP

TOP VIEW

MAX5066

*EXPOSED PADDLE

*CONNECT EXPOSED PAD TO GROUND PLANE.

Pin Configuration

Chip Information

TRANSISTOR COUNT: 6252

PROCESS: BiCMOS

Page 22

MAX5066

Configurable, Single-/Dual-Output, Synchronous

Buck Controller for High-Current Applications

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

22 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2005 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products, Inc.

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

22 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2005 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products, Inc.

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

TSSOP4.40mm.EPS

PACKAGE OUTLINE, TSSOP 4.40mm BODY

21-0066

1

1

G

Loading...

Loading...