Page 1

General Description

The MAX5051 is a clamped, two-switch power-supply

controller IC. This device can be used both in forward or

flyback configurations with input voltage ranges from 11V

to 76V. It provides comprehensive protection mechanisms against possible faults, resulting in very high reliability power supplies. When used in conjunction with secondary-side synchronous rectification, power-supply

efficiencies can easily reach 92% for a +3.3V output

power supply operated from a 48V bus. The integrated

high- and low-side gate drivers provide more than 2A of

peak gate-drive current to two external N-channel

MOSFETs. Low startup current reduces the power loss

across the bootstrap resistor. A feed-forward voltagemode topology provides excellent line rejection while

avoiding the pitfalls of traditional current-mode control.

The MAX5051 power-supply controller is primary as

well as secondary-side parallelable, allowing the

design of scaleable power systems when necessary.

When paralleling the primary side, dedicated pins allow

for simultaneous wakeup or shutdown of all paralleled

units, thus preventing current-hogging during startup or

fault conditions.

The MAX5051 generates a lookahead signal for driving

secondary-side synchronous MOSFETs. Special

primary-side synchronization inputs/outputs allow two

primaries to be operated 180° out of phase for increased

output power and lower input ripple currents.

The MAX5051 is available in a 28-pin TSSOP-EP

package and operates over a wide -40°C to +125°C

temperature range.

Warning: The MAX5051 is designed to work with

high voltages. Exercise caution.

Applications

High-Efficiency, Isolated Telecom/Datacom

Power Supplies

48V and 12V Server Power Supplies

48V Power-Supply Modules

42V Automotive Power Systems

Industrial Power Supplies

Features

♦ Wide Input Voltage Range, 11V to 76V

♦ Voltage Mode with Input Voltage Feed-Forward

♦ Ripple-Phased Parallel Topology for High

Current/Power Output

♦ 2A Integrated High- and Low-Side MOSFET

Drivers

♦ SYNCIN And SYNCOUT Pins Enable 180° Out-Of-

Phase Operation

♦ Programmable Brownout and Bootstrap UVLOs

♦ High-Side Driver Bootstrap Capacitor Precharge

Driver

♦ Low Current-Limit Threshold for High Efficiency

♦ Programmable Switching Frequency

♦ Reference Voltage Soft-Start for Startup Without

Overshoots

♦ Startup Synchronization with Multiple Paralleled

Primaries

♦ Programmable Integrating Current-Limit Fault

Protection

♦ Look-Ahead PWM Signal for Secondary-Side

Synchronous Rectifier Drivers

♦ Look-Ahead Drivers for Either A High-Speed

Optocoupler or Pulse Transformer

♦ Wide -40°C to +125°C Operating Range

♦ Thermally Enhanced 28-Pin TSSOP Package

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

19-2964; Rev 0; 8/03

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

*EP = Exposed pad.

Pin Configuration appears at end of data sheet.

PART TEMP RANGE PIN-PACKAGE

MAX5051AUI -40°C to +125°C 28-TSSOP-EP*

Page 2

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

2 _______________________________________________________________________________________

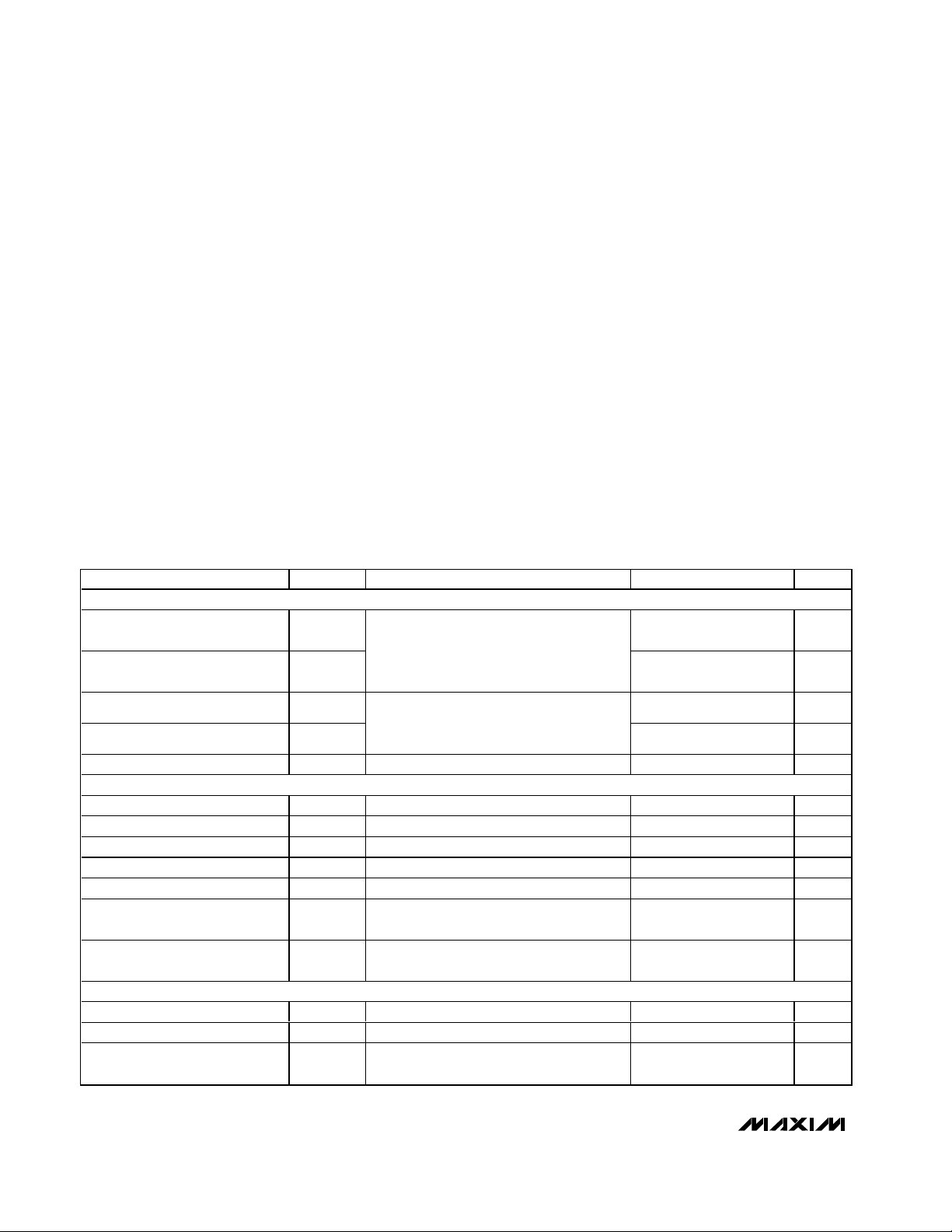

ABSOLUTE MAXIMUM RATINGS

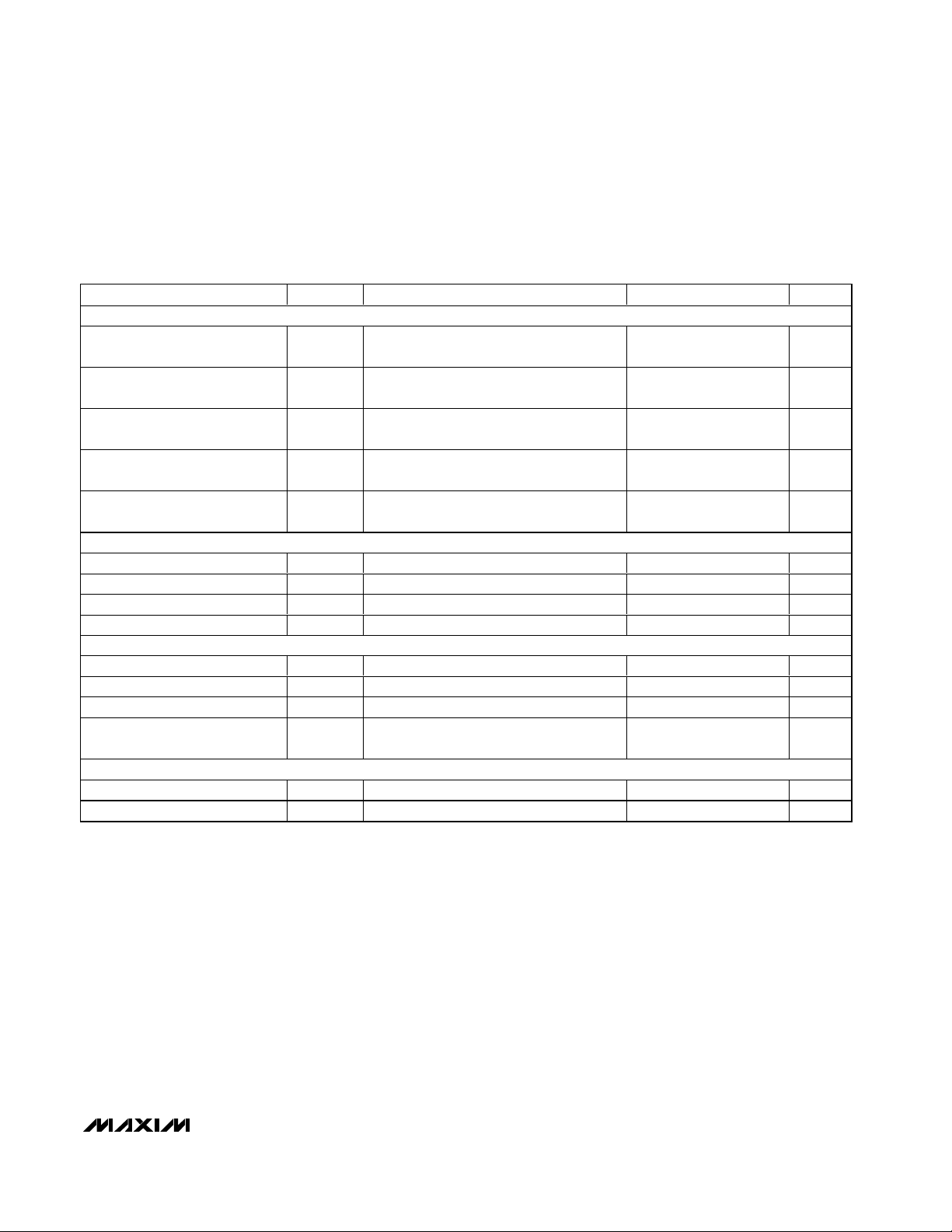

ELECTRICAL CHARACTERISTICS

(AVIN = 12V, PVIN = 12V, V

UVLO

= V

STT

= 3V, V

CON

= 3V, R

RCOSC

= 24kΩ, C

CSS

= 10nF, C

RCOSC

= 100pF, C

REG9

= 4.7µF,

C

REG5

= 4.7µF, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C. All driver, voltage-regulator, and refer-

ence outputs unconnected except for bypass capacitors.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

AVIN, PVIN, XFRMRH to GND................................-0.3V to +80V

BST to GND ............................................................-0.3V to +95V

BST, DRVH to XFRMRH..........................................-0.3V to +12V

REG9, DRVDD, DRVL to GND................................-0.3V to +12V

DRVB, LXVDD, LXL, LXH to GND ..........................-0.3V to +12V

UVLO, STT, COMP, CON to GND ..........................-0.3V to +12V

FLTINT, RCFF to GND ............................................-0.3V to +12V

REG5, CS, CSS, FB to GND .....................................-0.3V to +6V

STARTUP, SYNCIN to GND......................................-0.3V to +6V

SYNCOUT, RCOSC to GND .....................................-0.3V to +6V

PGND to GND .......................................................-0.3V to +0.3V

LXL, LXH Current Continuous...........................................±50mA

DRVL, DRVH Current Continuous...................................±100mA

DRVL, DRVH Peak Current (<500ns) ....................................±5A

PVIN, REG9 Continuous Current ....................................+120mA

REG5 Continuous Current ................................................+80mA

DRVB, RCFF, RCOSC, CSS Continuous Current .............±20mA

COMP, SYNCOUT Continuous Current ............................±20mA

REG9, REG5, and COMP Short to GND ....................Continuous

Continuous Power Dissipation (T

A

= +70°C)

28-Pin TSSOP (derate 23.8mW/°C above +70°C) .....1905mW

28-Pin TSSOP (θ

JA

)......................................................42°C/W

Operating Temperature Range .........................-40°C to +125°C

Maximum Junction Temperature (T

J

) ..............................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SUPPLY CURRENT (AVIN, PVIN)

AVIN Standby Current I

PVIN Standby Current I

AVIN Supply Current I

PVIN Supply Current I

ASTBY

PSTBY

AVIN

PVIN

= V

AVIN

V

STARTUP

V

= V

BST

RCFF floating

V

= V

AVIN

= V

V

BST

STARTUP, RCFF floating

= 11V to 76V;

PVIN

= V

= 0V;

CS

= V

XFRMRH

PVIN

DRVDD

DRVDD

= 11V to 76V; VCS = 0V;

= V

REG9

; V

= V

REG9

XFRMRH

;

= 0V;

300 450 µA

400 650 µA

0.65 1 mA

812mA

V

AVIN Input Voltage Range Inferred from AVIN supply current test 11 76 V

+9V LDO (REG9)

PVIN Input Voltage Range V

REG9 Output-Voltage Set Point V

PVIN

REG9

REG9 Line Regulation V

REG9 Load Regulation I

REG9 Dropout Voltage I

REG9 Undervoltage Lockout

Threshold

REG9 Undervoltage Lockout

Threshold Hysteresis

Inferred from PVIN supply current test 11 76 V

V

= 11V 8.3 9.0 V

PVIN

= 11V to 76V 0.1 mV/V

PVIN

= 0 to 80mA 250 mV

REG9

= 80mA 0.5 V

REG9

V

falling 5.7 6.7 V

REG9

750 mV

+5V LDO (REG5)

REG5 Output-Voltage Set Point V

REG5

REG5 Load Regulation I

REG5 Dropout Voltage

= 0 to 40mA 50 mV

REG5

I

= 40mA, measured with respect

REG5

to V

REG9

4.8 5.1 V

0.5 V

Page 3

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

_______________________________________________________________________________________ 3

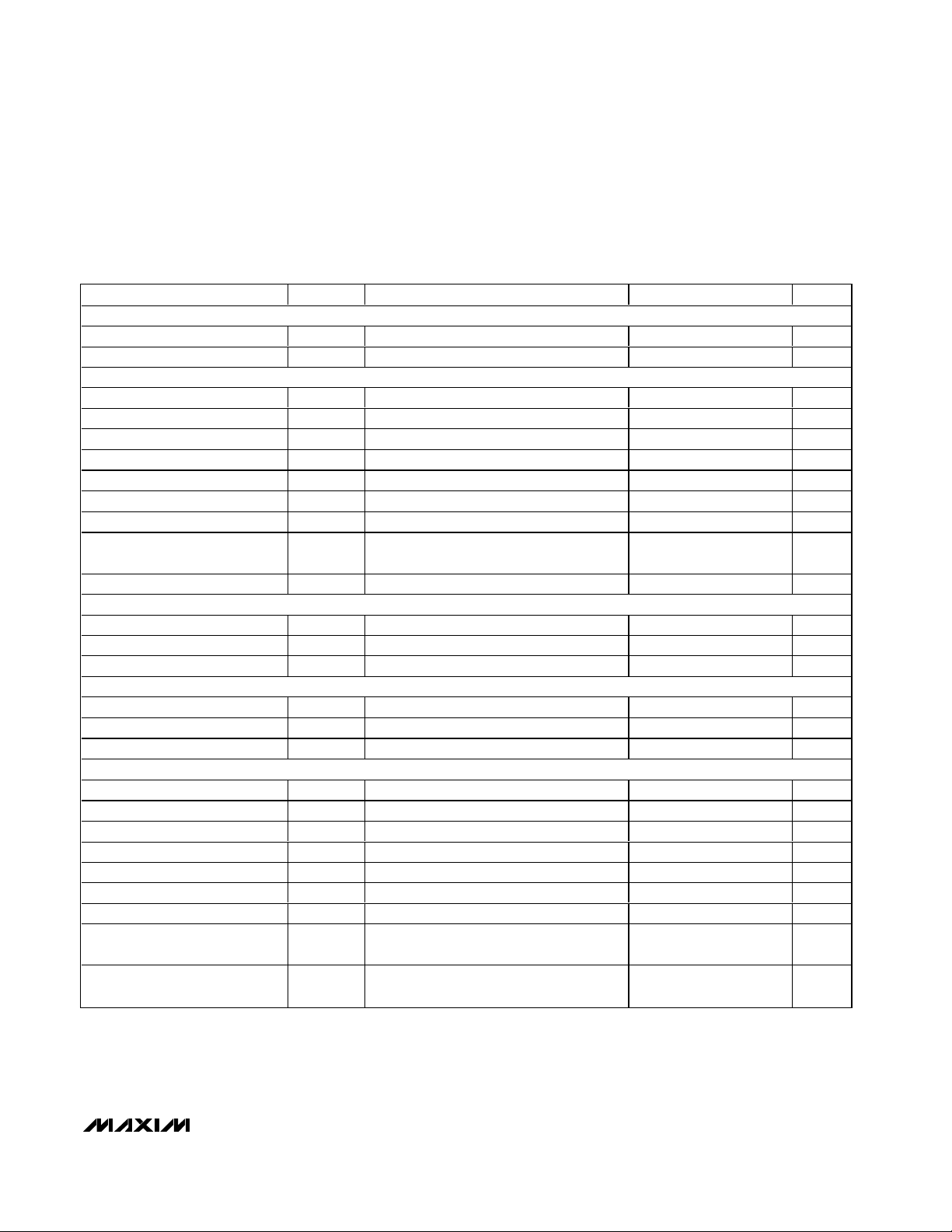

ELECTRICAL CHARACTERISTICS (continued)

(AVIN = 12V, PVIN = 12V, V

UVLO

= V

STT

= 3V, V

CON

= 3V, R

RCOSC

= 24kΩ, C

CSS

= 10nF, C

RCOSC

= 100pF, C

REG9

= 4.7µF,

C

REG5

= 4.7µF, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C. All driver, voltage-regulator, and refer-

ence outputs unconnected except for bypass capacitors.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SOFT-START/REFERENCE (CSS)

Reference Voltage V

Soft-Start Pullup Current I

ERROR AMPLIFIER (CSS, FB, COMP)

FB Input Range V

FB Input Current I

COMP Output Range Inferred from FB offset voltage test 2.1 6.0 V

COMP Output Sink Current VFB = 3V 20 mA

COMP Output Source Current VFB = 0V 30 mA

Open-Loop Gain G

Unity-Gain Bandwidth BW C

FB Offset Voltage V

COMP Output Slew Rate SR C

PVIN UNDERVOLTAGE LOCKOUT (STT)

PVIN Undervoltage Lockout V

STT Threshold V

STT Input Impedance R

INTEGRATING FAULT PROTECTION (FLTINT)

FLTINT Source Current I

FLTINT Shutdown Threshold V

FLTINT Restart Hysteresis V

OSCILLATOR (RCOSC, SYNCIN, SYNCOUT)

PWM Period t

Maximum PWM Duty Cycle D

Maximum RCOSC Frequency f

Maximum SYNCIN Frequency f

SYNCIN High-Level Voltage VH

SYNCIN Low-Level Voltage VL

SYNCIN Pulldown Resistor 100 kΩ

SYNCIN Rising to SYNCOUT

Falling Delay

SYNCIN Falling to SYNCOUT

Rising Delay

CSS

CSS

FB

FB

A

OS

STT

STT

FLTINT

FLTINTSDVFLTINT

FLTINTHY

S

MAX

RCOSCMAX

SYNCIN

SYNCIN

SYNCIN

1.215 1.235 1.255 V

70 µA

Inferred from FB offset voltage test 0 3 V

VFB = V

REF

2.1V < V

COMP

VFB = 0 to 3V; V

I

COMP

COMP

rising 22 23.5 25 V

PVIN

V

rising 1.18 1.24 1.30 V

STT

< 6V 80 dB

COMP

= 50pF, I

= -5mA to +5mA

= ±5mA 3 MHz

COMP

= 2.1V to 6V;

COMP

-3 +3 mV

= 50pF 1 V/µs

±250 nA

100 kΩ

V

= 0V 90 µA

FLTINT

= rising 2.9 V

0.9 V

R

R

RCOSC

RCOSC

= 24kΩ, C

= 24kΩ, C

= 100pF 3.9 µs

RCOSC

= 100pF 48 %

RCOSC

1 MHz

50% duty cycle 500 kHz

Pulse rising 2.1 V

Pulse falling 0.8 V

30 ns

70 ns

Page 4

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

4 _______________________________________________________________________________________

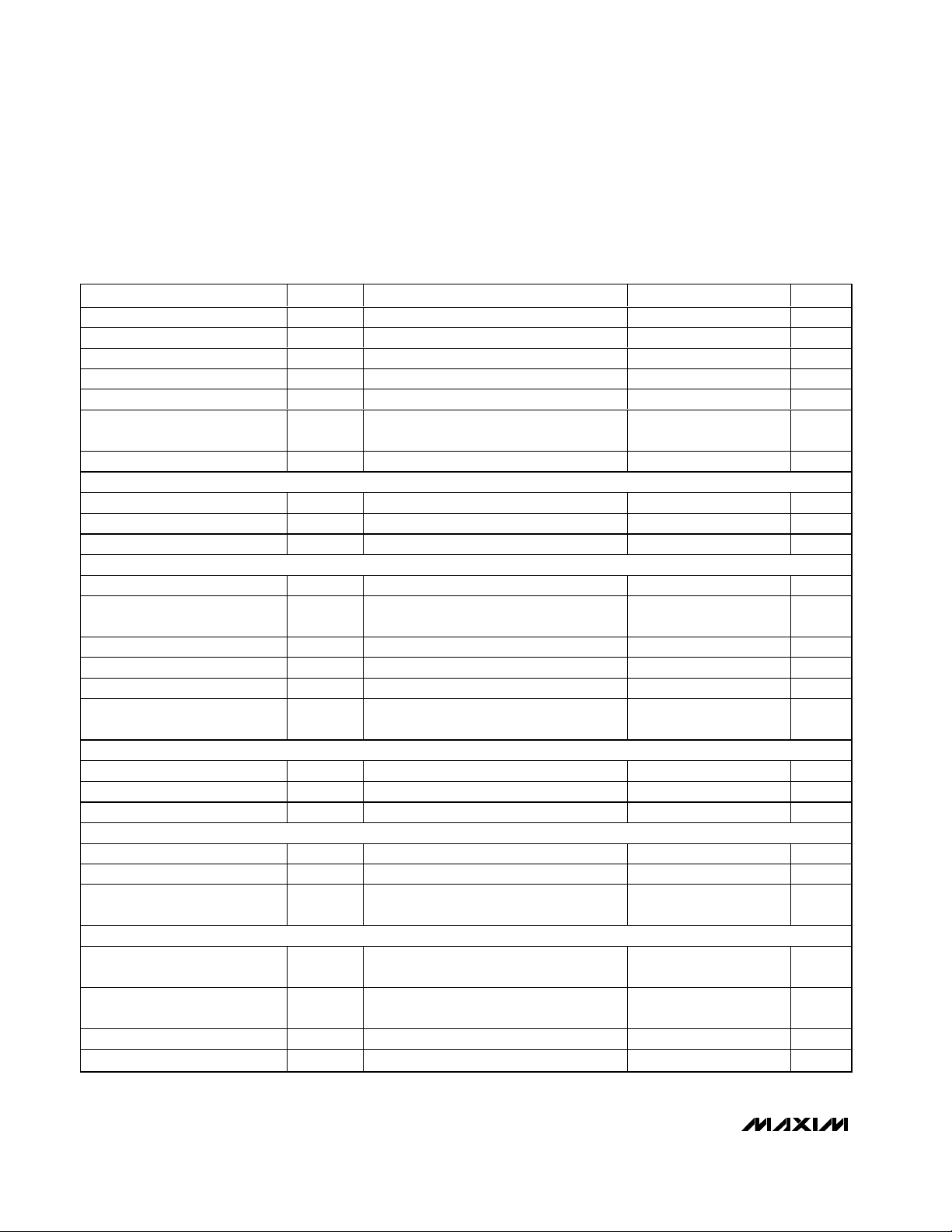

ELECTRICAL CHARACTERISTICS (continued)

(AVIN = 12V, PVIN = 12V, V

UVLO

= V

STT

= 3V, V

CON

= 3V, R

RCOSC

= 24kΩ, C

CSS

= 10nF, C

RCOSC

= 100pF, C

REG9

= 4.7µF,

C

REG5

= 4.7µF, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C. All driver, voltage-regulator, and refer-

ence outputs unconnected except for bypass capacitors.)

)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SYNCOUT Voltage High Sourcing 1.2mA 4.5 5.1 V

SYNCOUT Voltage Low Sinking 2.4mA 0.3 V

RCOSC Peak Trip Level V

RCOSC Valley Trip Level 0.2 V

RCOSC Input Bias Current -0.3 µA

RCOSC Discharge MOSFET

R

DS(ON)

RCOSC Discharge Pulse Width 50 ns

UNDERVOLTAGE LOCKOUT (UVLO)

UVLO Threshold V

UVLO Hysteresis V

UVLO Input Bias Current I

PWM COMPARATOR

RCFF Input Voltage Range 0 3 V

Feed-Forward Discharge

MOSFET R

DS(ON)

CON Input Voltage Range 06V

RCFF Level-Shift Voltage V

CON Input Bias Current I

Propagation Delay to Output t

SYNCHRONOUS RECTIFIER PULSE TRANSFORMER DRIVER (LXVDD, LXH, LXL)

High-Side MOSFET R

Low-Side MOSFET R

DS(ON)

DS(ON)

LXH Rising to DRVL Rising Delay 90 ns

CURRENT-LIMIT COMPARATOR (CS)

Current-Limit Threshold Voltage V

Current-Limit Input Bias Current I

Propagation Delay to Output t

LOW-SIDE MOSFET DRIVER (DRVDD, DRVL, PGND)

Peak Source Current

Peak Sink Current

DRVL Resistance Sourcing I

DRVL Resistance Sinking I

TH

2.5 V

Sinking 10mA 50 100 Ω

V

UVLO

HYS

BUVLOVUVLO

R

DS(RCFF

CPWM

CON

dCPWM

R

DSLXH

R

DSLXL

ILIM

BILIM

dILIM

rising 1.18 1.24 1.30 V

UVLO

130 mV

= 2.5V -100 +100 nA

Sinking 10mA 50 100 Ω

2.2 2.4 V

-2 +2 µA

DRVH, DRVL = unconnected, overdrive =

50mV, measured from CON to DRVL

LXH sourcing 10mA, V

LXL sinking 10mA, V

LXVDD

LXVDD

= V

= V

REG5

REG5

3 6.5 12 Ω

2.0 5 10 Ω

90 ns

144 154 164 mV

0 < VCS < 0.3V -2 +2 µA

DRVH, DRVL = unconnected, overdrive =

10mV, measured from CS to DRVL

V

= 0V, pulse width < 100ns;

DRVL

V

= V

DRVDD

V

DRVL

V

DRVDD

DRVL

DRVL

REG9

= V

REG9

= V

REG9

= 50mA, V

= -50mA, V

, pulse width < 100ns;

= V

DRVDD

DRVDD

= V

REG9

REG9

100 ns

2A

5A

1.7 3.5 Ω

0.6 1.4 Ω

Page 5

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(AVIN = 12V, PVIN = 12V, V

UVLO

= V

STT

= 3V, V

CON

= 3V, R

RCOSC

= 24kΩ, C

CSS

= 10nF, C

RCOSC

= 100pF, C

REG9

= 4.7µF,

C

REG5

= 4.7µF, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at TA= +25°C. All driver, voltage-regulator, and refer-

ence outputs unconnected except for bypass capacitors.)

HIGH-SIDE MOSFET DRIVER (BST, DRVH, XFRMRH)

Peak Source Current

Peak Sink Current

DRVH Resistance Sourcing

DRVH Resistance Sinking

Skew Between Low-Side and

High-Side Drivers

BOOST CAPACITOR CHARGE MOSFET (DRVB)

DRVB Resistance Sourcing I

DRVB Resistance Sinking I

Delay from Clock Fall 200 ns

One-Shot Pulse Width 300 ns

STARTUP (STARTUP)

Startup Threshold V

Startup Threshold Hysteresis 330 mV

Internal Pullup Current I

S TARTU P P ul l d ow n M OS FE T

R

D S ( ON )

OVERTEMPERATURE SHUTDOWN

Shutdown Junction Temperature Temperature rising 150 °C

Hysteresis 10 °C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

STARTUPVSTARTUP

STARTUP

V

= GN D , p ul se w i d th < 100ns,

D RV H

= V

V

B S T

V

D RV H

= V

V

B S T

I

DRVH

V

XFRMRH

I

DRVH

V

XFRMRH

DRVB

DRVB

Sinking 10mA 50 100 Ω

, V

R E G9

= V

, p ul se w i d th < 100ns,

B S T

, V

R E G9

= 50mA, V

= 0V

= -50mA, V

= 0V

= 50mA 8 35 Ω

= 50mA 5 35 Ω

rising 1.4 2.1 V

X FR M R H

X FR M R H

BST

BST

= 0V

= 0V

= V

REG9

= V

REG9

,

,

2A

5A

1.7 3.5 Ω

0.6 1.4 Ω

0ns

50 µA

Page 6

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

6 _______________________________________________________________________________________

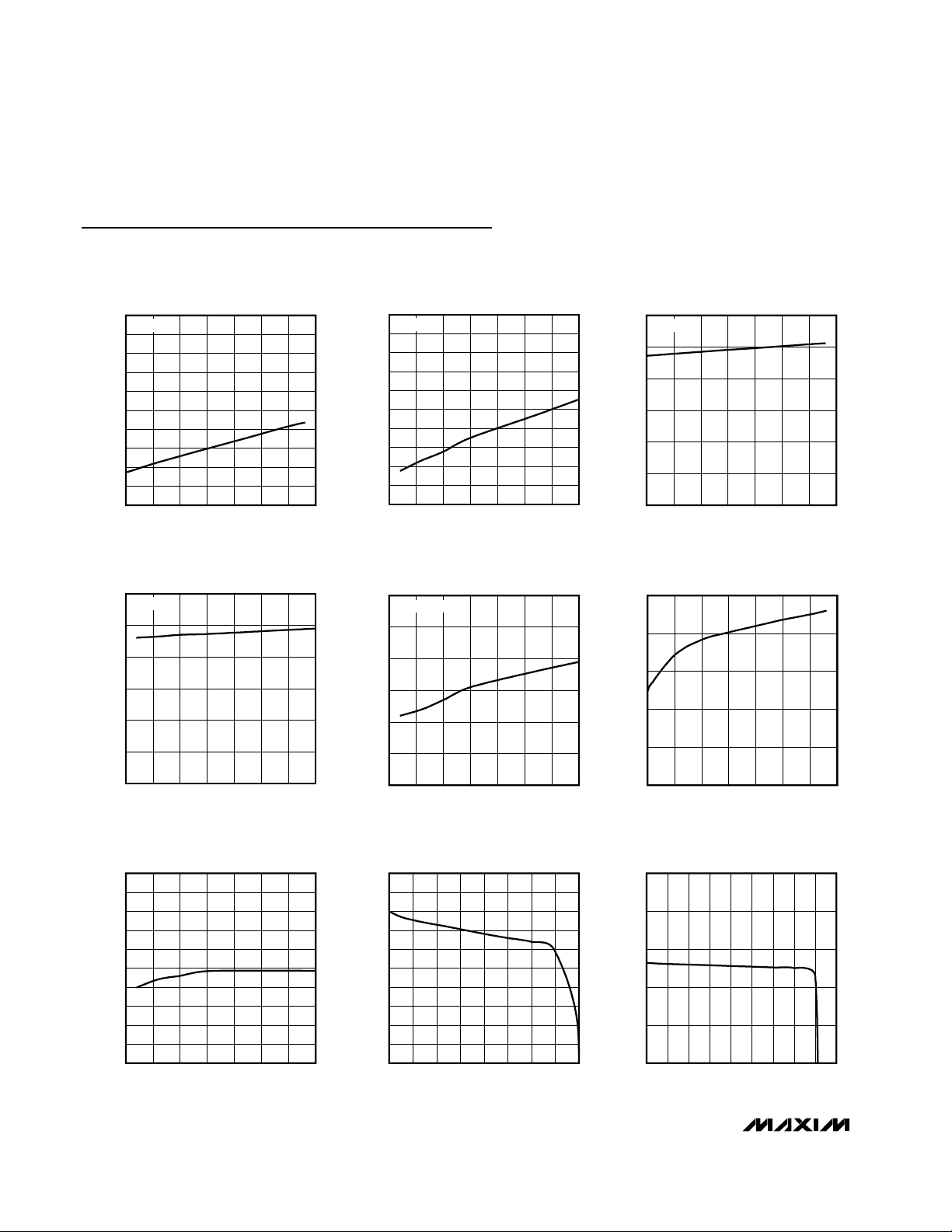

Typical Operating Characteristics

(V

AVIN

= V

PVIN

= 12V, V

UVLO

= V

STT

= 3V, V

CON

= 3V, R

RCOSC

= 24kΩ, C

CSS

= 10nF, C

RCOSC

= 100pF, C

REG9

= 4.7µF, C

REG5

=

4.7µF, T

A

= +25°C, unless otherwise noted.)

AVIN STANDBY CURRENT

vs. AVIN SUPPLY VOLTAGE

MAX5051 toc01

AVIN SUPPLY VOLTAGE (V)

AVIN STANDBY CURRENT (µA)

706040 503020

210

220

230

240

250

260

270

280

290

300

200

10 80

V

UVLO

= 0V

AVIN STANDBY CURRENT

vs. TEMPERATURE

MAX5051 toc02

TEMPERATURE (°C)

AVIN STANDBY CURRENT (µA)

1007525 500-25

210

220

230

240

250

260

270

280

200

190

180

-50 125

V

UVLO

= 0V

PVIN STANDBY CURRENT

vs. SUPPLY VOLTAGE

MAX5051 toc03

PVIN SUPPLY VOLTAGE (V)

PVIN STANDBY CURRENT (µA)

706050403020

100

200

300

400

500

600

0

10 80

V

UVLO

= 0V

PVIN STANDBY CURRENT

vs. TEMPERATURE

MAX5051 toc04

TEMPERATURE (°C)

PVIN STANDBY CURRENT (µA)

1007550250-25

100

200

300

400

500

600

0

-50 125

V

UVLO

= 0V

PVIN STARTUP VOLTAGE

vs. TEMPERATURE

MAX5051 toc05

TEMPERATURE (°C)

PVIN STARTUP VOLTAGE (V)

1007550250-25

23.1

23.2

23.3

23.4

23.5

23.6

23.0

-50 125

STT = FLOATING

REG9 OUTPUT VOLTAGE

vs. PVIN VOLTAGE

MAX5051 toc06

PVIN VOLTAGE (V)

REG9 OUTPUT VOLTAGE (V)

706050403020

8.793

8.796

8.799

8.802

8.805

8.970

10 80

REG9 OUTPUT VOLTAGE

vs. TEMPERATURE

MAX5051 toc07

TEMPERATURE (°C)

REG9 OUTPUT VOLTAGE (V)

1007525 500-25

8.72

8.74

8.76

8.78

8.80

8.82

8.84

8.86

8.88

8.90

8.70

-50 125

REG9 OUTPUT VOLTAGE

vs. REG9 OUTPUT CURRENT

MAX5051 toc08

REG9 OUTPUT CURRENT (mA)

REG9 OUTPUT VOLTAGE (V)

14012080 10040 6020

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

9.0

8.0

0 160

REG5 OUTPUT VOLTAGE

vs. REG5 OUTPUT CURRENT

MAX5051 toc09

REG5 OUTPUT CURRENT (mA)

REG5 OUTPUT VOLTAGE (V)

8070605040302010

4.4

4.8

5.2

5.6

6.0

4.0

090

Page 7

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

_______________________________________________________________________________________ 7

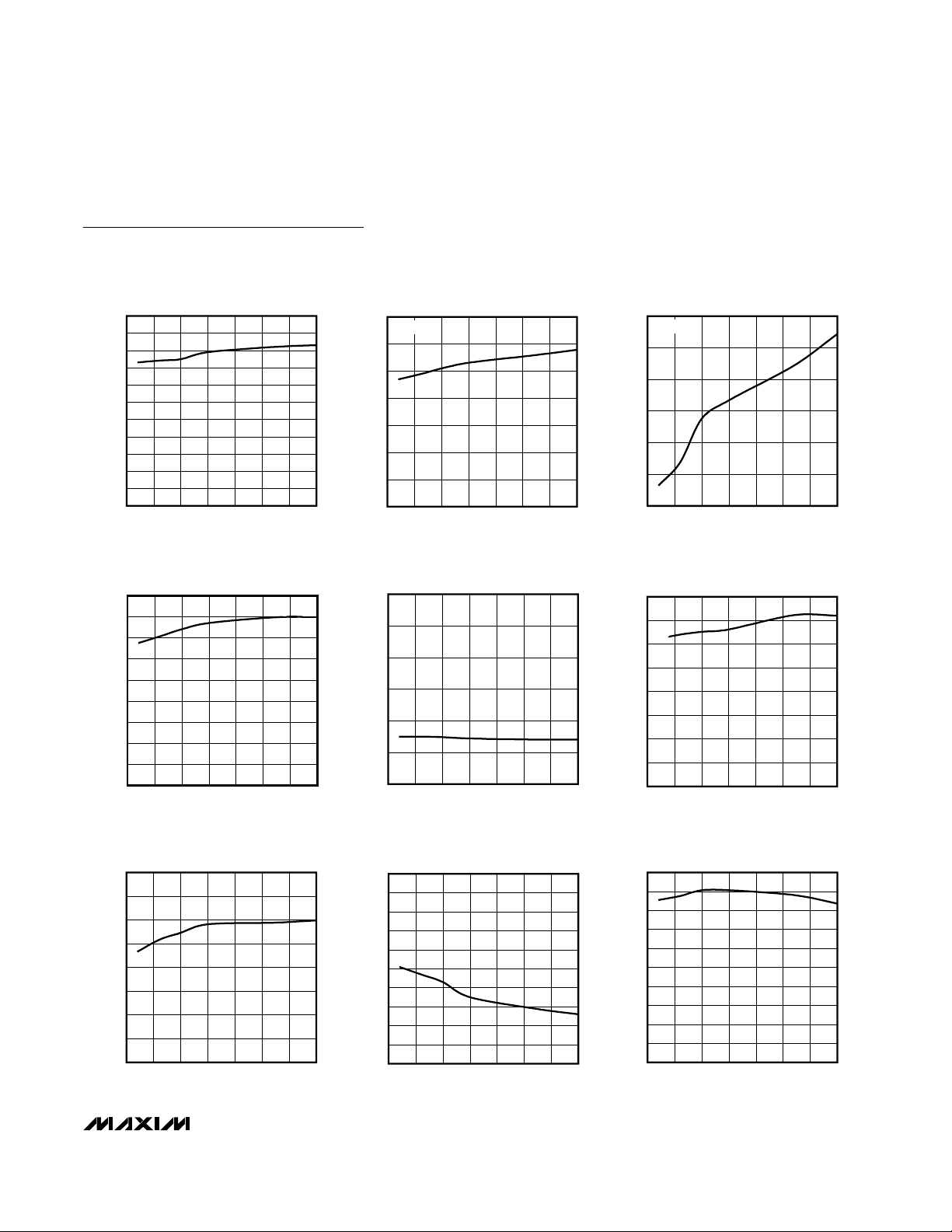

Typical Operating Characteristics (continued)

(V

AVIN

= V

PVIN

= 12V, V

UVLO

= V

STT

= 3V, V

CON

= 3V, R

RCOSC

= 24kΩ, C

CSS

= 10nF, C

RCOSC

= 100pF, C

REG9

= 4.7µF, C

REG5

=

4.7µF, TA= +25°C, unless otherwise noted.)

REG5 OUTPUT VOLTAGE

vs. TEMPERATURE

5.001

5.000

4.999

4.998

4.997

4.996

4.995

4.994

OUTPUT VOLTAGE (V)

4.993

4.992

4.991

4.990

-50 125

TEMPERATURE (°C)

MAX5051 toc10

1007525 500-25

SOFT-START/REFERENCE VOLTAGE

vs. TEMPERATURE

1.245

1.240

1.235

1.230

1.225

1.220

1.215

1.210

SOFT-START/REFERENCE VOLTAGE (V)

1.205

1.200

-50 125

TEMPERATURE (°C)

MAX5051 toc13

1007525 500-25

700

V

UVLO

600

500

400

300

200

AVIN SUPPLY CURRENT (µA)

100

0

-50 125

90

85

80

75

70

CSS SOFT-START CURRENT (µA)

65

60

-50 125

AVIN SUPPLY CURRENT

vs. TEMPERATURE

= 0V

TEMPERATURE (°C)

CSS SOFT-START CURRENT

vs. TEMPERATURE

TEMPERATURE (°C)

MAX5051 toc11

1007550250-25

MAX5051 toc14

1007550250-25

PVIN SUPPLY CURRENT

vs. TEMPERATURE

7.2

V

= 12V

PVIN

7.1

7.0

6.9

6.8

PVIN SUPPLY CURRENT (mA)

6.7

6.6

-50 125

TEMPERATURE (°C)

UVLO THRESHOLD vs. TEMPERATURE

1.240

1.235

1.230

1.225

1.220

UVLO (V)

1.215

1.210

1.205

1.200

-50 125

TEMPERATURE (°C)

1007550250-25

10075-25 0 25 50

MAX5051 toc12

MAX5051 toc15

STT STARTUP THRESHOLD

vs. TEMPERATURE

1.240

1.235

1.230

1.225

1.220

STT (V)

1.215

1.210

1.205

1.200

-50 125

TEMPERATURE (°C)

RCFF LEVEL-SHIFT VOLTAGE

FLTINT CURRENT vs. TEMPERATURE

95

MAX5051 toc16

10075-25 0 25 50

94

93

92

91

90

89

FLTINT CURRENT (µA)

88

87

86

85

-50 125

TEMPERATURE (°C)

1007525 500-25

2.30

2.29

MAX5051 toc17

2.28

2.27

2.26

2.25

2.24

2.23

RCFF LEVEL-SHIFT VOLTAGE (V)

2.22

2.21

2.20

-50 125

vs. TEMPERATURE

MAX5051 toc18

1007525 500-25

TEMPERATURE (°C)

Page 8

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(V

AVIN

= V

PVIN

= 12V, V

UVLO

= V

STT

= 3V, V

CON

= 3V, R

RCOSC

= 24kΩ, C

CSS

= 10nF, C

RCOSC

= 100pF, C

REG9

= 4.7µF, C

REG5

=

4.7µF, T

A

= +25°C, unless otherwise noted.)

170

165

160

155

150

CS THRESHOLD VOLTAGE (mV)

145

140

-50 125

CURRENT-LIMIT THRESHOLD

vs. TEMPERATURE

1007550250-25

TEMPERATURE (°C)

OPEN-LOOP GAIN/PHASE

vs. FREQUENCY

100 270

80

MAX5051 toc19

60

40

GAIN (dB)

20

PHASE

0

-20

0.01 10 100 10000.1 1 10,000

GAIN

FREQUENCY (kHz)

MAX5051 toc20

240

210

180

150

120

90

60

30

0

8

7

6

5

4

3

PHASE (DEGREES)

2

COMP OUTPUT VOLTAGE (V)

1

0

-50 125

COMP OUTPUT VOLTAGE

vs. TEMPERATURE

I

= 5mA

SOURCE

I

= 5mA

SINK

TEMPERATURE (°C)

10075-25 0 25 50

MAX5051 toc21

DRVH AND DRVL R

vs. TEMPERATURE

4.0

3.5

3.0

DRVH AND DRVL SOURCING 50mA

2.5

(Ω)

2.0

DSON

R

1.5

1.0

0.5

DRVH AND DRVL SINKING 50mA

0

-50 125

TEMPERATURE (°C)

NORMALIZED SWITCHING FREQUENCY

vs. TEMPERATURE

1.020

1.010

1.000

0.990

0.980

0.970

0.960

NORMALIZED SWITCHING FREQUENCY

SWITCHING

0.950

-50 125

TEMPERATURE (°C)

DSON

LXL AND LXH R

vs. TEMPERATURE

12

11

MAX5051 toc22

10

9

(Ω)

8

DSON

R

7

6

5

4

10075-25 0 25 50

-40 110

LXH SOURCING 10mA

TEMPERATURE (°C)

SYNCIN TO SYNCOUT PROPAGATION

DELAY vs. TEMPERATURE

130

SYNCIN FALL TO SYNCOUT RISE

120

MAX5051 toc25

110

100

90

80

70

60

PROPAGATION DELAY (ns)

50

SYNCIN RISE TO SYNCOUT FALL

40

30

1007550250-25

-50 125

TEMPERATURE (°C)

DSON

LXH SINKING 10mA

8560-15 10 35

1007525 500-25

MAX5051 toc23

MAX5051 toc26

SWITCHING PERIOD vs. R

50

45

40

35

30

25

20

15

SWITCHING PERIOD (µs)

10

5

0

0200

R

RCOSC

RCOSC

MAX5051 toc24

1601208040

(kΩ)

DRVH MAXIMUM DUTY CYCLE

vs. TEMPERATURE

50.0

49.6

49.2

48.8

48.4

48.0

47.6

47.2

DRVH DUTY CYCLE (%)

46.8

46.4

46.0

-50 125

TEMPERATURE (°C)

MAX5051 toc27

1007525 500-25

Page 9

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

_______________________________________________________________________________________ 9

Pin Description

CON TO DRVL PROPAGATION DELAY

vs. TEMPERATURE

MAX5051 toc28

TEMPERATURE (°C)

PROPAGATION DELAY (ns)

1007525 500-25

65

70

75

80

85

90

95

100

105

110

60

-50 125

50mV OVERDRIVE

CS CURRENT LIMIT TO DRVH

PROPAGATION DELAY vs. TEMPERATURE

MAX5051 toc29

TEMPERATURE (°C)

PROPAGATION DELAY (ns)

1007550250-25

90

100

110

120

130

140

150

80

-50 125

50mV OVERDRIVE

Typical Operating Characteristics (continued)

(V

AVIN

= V

PVIN

= 12V, V

UVLO

= V

STT

= 3V, V

CON

= 3V, R

RCOSC

= 24kΩ, C

CSS

= 10nF, C

RCOSC

= 100pF, C

REG9

= 4.7µF, C

REG5

=

4.7µF, T

A

= +25°C, unless otherwise noted.)

PIN NAME FUNCTION

1 RCOSC

2 SYNCOUT Synchronization Output. Synchronization signal to drive SYNCIN of a second MAX5051, if used.

3 RCFF

4 CON

5 CSS

6 COMP Internal Error Amplifier Output

7FB

8 REG5 5V Linear Regulator Output. Bypass REG5 to GND with a 4.7µF ceramic capacitor.

9 REG9 9V Linear Regulator Output. Bypass REG9 to GND with a 4.7µF ceramic capacitor.

10 PVIN

11 STT

12 LXVDD

Osci l l ator Fr eq uency S et Inp ut. C onnect a r esi stor fr om RC OS C to RE G5 and a cap aci tor fr om RC OS C to GN D

to set the osci l l ator fr eq uency. S w i tchi ng fr eq uency i s 1/2 the fr eq uency of the saw tooth si g nal at RC OS C .

Feed-Forward Input. Connect a resistor from RCFF to AVIN and a capacitor from RCFF to GND. This is

the PWM ramp.

PWM Comparator Noninverting Input. Connect CON to the optocoupler output for isolated applications,

or to COMP for nonisolated applications.

Soft-Start and Reference. Connect a 0.01µF or greater capacitor from CSS to GND. The 1.24V reference

voltage appears across this capacitor.

Feedback Input. Inverting input of the internal error amplifier. The soft-started reference is connected to

the noninverting input of this amplifier.

Regulator Voltage Input. Voltage input to the internal 5V and 9V linear regulators. A high-value resistor

connected from the input supply to PVIN provides the necessary current to charge up the startup

capacitor, and the 400µA standby current required by the MAX5051. After startup, the output of a tertiary

winding is used to provide continued bias to the controller.

Startup Threshold Input. Leave STT floating for a default startup voltage of 24V at PVIN. STT can be

modified by connecting external resistors. For high accuracy, choose external resistors with 50kΩ or less

impedance looking back into the divider.

Supply Input for the Secondary-Side Synchronous Pulse Transformer or Optocoupler Driver. LXVDD is

normally connected to REG5.

Page 10

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

10 ______________________________________________________________________________________

Pin Description (continued)

PIN NAME FUNCTION

13 LXH

14 LXL

15 CS

16 DRVL

17 PGND Power Ground

18 DRVDD

19 DRVB

20 XFRMRH Transformer Input. Transformer primary high-side connection.

21 DRVH Gate-Drive Output for High-Side MOSFET

22 BST

23 AVIN Supply Voltage Input. Connect AVIN directly to the input supply line.

24 GND Analog Signal Ground

25 UVLO

26 STARTUP

27 FLTINT

28 SYNCIN

Synchronous-Pulse Transformer Driver, PMOS Open Drain. LXH is the high-side driver for the secondaryside synchronous-pulse transformer. LXH can also drive a high-speed switching optocoupler. If not

used, connect LXH to LXVDD.

Synchronous-Pulse Transformer Driver, NMOS Open Drain. LXL is the low-side driver for the secondaryside synchronous-pulse transformer. LXL can also drive a high-speed switching optocoupler. If not used,

connect LXL to PGND.

Current-Sense Input. The current-limit threshold is internally set to 156mV relative to PGND. The device

has an internal noise filter. If necessary, connect an additional external RC filter.

Gate-Drive Output for Low-Side MOSFET. DRVL is capable of sourcing and sinking approximately 2A

peak current.

Supply Input for Low-Side MOSFET Driver. Bypass DRVDD locally with good quality 1µF || 0.1µF ceramic

capacitors. DRVDD is normally connected to REG9.

Gate-Drive Output for Boost MOSFET. Connect the gate of a small high-voltage external FET to this pin to

enable charging of the high-side boost capacitor connected between pins 20 and 22. This FET may be

necessary to keep the boost capacitor charged at light loads.

Boost Input. Boost supply connection point for the high-side MOSFET driver. Connect at least a 1µF ||

0.1µF ceramic capacitor from BST to XFRMRH with short and wide PC board traces. If the voltage across

the boost capacitor falls below the high-side undervoltage lockout threshold, the DRVH output stops

switching.

Undervoltage Lockout Input. An external voltage-divider from the input supply sets the startup voltage;

the threshold is 1.24V with 130mV hysteresis. UVLO can also be used as a shutdown input. If unused,

connect UVLO to REG5

Startup Input. STARTUP coordinates simultaneous startup of multiple units from faults, during initial turnon, and UVLO recovery. When paralleling the secondaries of two MAX5051’s, the STARTUP inputs of

each device must be connected together.

Faul t Integ r ati on Inp ut. D ur i ng p er si st ent cur r ent- l i m i t faul ts, a cap aci tor connected to FLTIN T i s char g ed

w i th an i nter nal 90µA cur r ent sour ce. S w i tchi ng i s ter m i nated w hen the vol tag e r eaches 2.9V . An exter nal

r esi stor connected i n p ar al l el d i schar g es the cap aci tor . S w i tchi ng r esum es w hen the vol tag e d r op s to 2V .

Synchronization Input. SYNCIN accepts the synchronization signal from SYNCOUT of another MAX5051

and shifts the switching of the synchronized unit by 180° allowing the reduction of input bypass

capacitors. The MAX5051 switches at the same frequency at SYNCIN. SYNCIN must be 50% duty cycle.

Leave SYNCIN floating if unused.

Page 11

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

______________________________________________________________________________________ 11

Functional Diagram

PVIN

STT

UVLO

AVIN

RCOSC

18R

R

9V

LDO

1.25V

1.125V

1.25V

1.125V

INTERNAL

REGULATOR

OSC

REG9 OK

INTERNAL

SUPPLY

1.25V

REFERENCE

OVER

TEMP

5V

LDO

REG5 OK

THERMAL

SHUTDOWN

25µs

RISING-

EDGE

DELAY

SHDN

REG9

REG5

MAX5051

BST

60ns

RISING-

EDGE

DELAY

LEVEL

SHIFT

LEVEL

SHIFT

80µA

DRVH

XFRMRH

DRVDD

DRVL

PGND

LXVDD

LXH

LXL

SYNCIN

SYNCOUT

RCFF

CON

COMP

CSS

GND

FLTINT

2.7V/1.8V

CS

156mV

50µA

LEVEL

SHIFT

2.7V/1.8V

300ns

ONE

SHOT

CILIM

2.34V

CPWM

FB

E/A

SHDN

64µA

SSA

1.25V

SHDN

1

S

D

Q

Q

R

200ns

RISING-

EDGE

DELAY

10MHz

STARTUP

DRVDD

DRVB

Page 12

MAX5051

Detailed Description

The MAX5051 controller IC is designed for two-switch

forward converter power-supply topologies. It incorporates an advanced set of protection features that

makes it uniquely suitable when high reliability and

comprehensive fault protection are required, as in

power supplies intended for telecommunication

equipment. The device operates over a wide 11V to

76V supply range. By using the MAX5051 with a

secondary-side synchronous rectifier circuit, a very

efficient low output voltage and high output-current

power supply can be designed.

In a typical application, the AVIN pin is connected

directly to the input supply. The PVIN pin is connected

to the input supply through a bleed resistor. This is

used to charge up a reservoir capacitor. When the

voltage across this capacitor reaches approximately

24V, then primary switching commences. If the tertiary

winding is able to supply bias to the IC, then self

boot-strapping takes place and operation continues

normally. If the voltage across the reservoir capacitor

connected to PVIN falls below 6.2V, then switching

stops and the capacitor starts charging up again until

the voltage across it reaches 24V.

This device incorporates synchronization circuitry,

enabling the direct paralleling of two devices for higher

output power and lower input ripple current. Using a

single pin, the circuitry synchronizes and shifts the

phase of the second device by 180°. To enable simultaneous wakeup and shutdown, a STARTUP pin is provided. Connect all the STARTUP pins of all MAX5051

devices together to facilitate parallel operation in the

primary side. When each power supply generates different output voltages, connecting the STARTUP pins is

not necessary.

Power Topology

The two-switch forward-converter topology offers

outstanding robustness against faults and transformer

saturation while allowing the use of SO-8 power

MOSFETs with a voltage rating equal to only that of the

input supply voltage.

Voltage-mode control with feed-forward compensation

allows the rejection of input supply disturbances within

a single cycle, similar to that of current-mode controlled

topologies. This control method offers some significant

benefits not possible with current-mode control. These

benefits are:

• No minimum duty-cycle requirement because of current-signal blanking;

• Clean modulator ramp and higher amplitude for

increased stability;

• Stable operating current of the optocoupler LED and

phototransistor for maximized control-loop bandwidth (in current-mode applications, the optocoupler

bias point is output-load dependent);

• Predictable loop dynamics simplifying the design of

the control loop.

The two-switch power topology has the added benefit

of recovering practically all magnetizing as well as the

leakage energy stored in the parasitics of the isolation

transformer. The lower clamped voltages on the primary power FETs allow for the use of low R

DS(ON)

devices.

Figure 2 shows the schematic diagram of a 48V input

3.3V/10A output power supply built around the

MAX5051.

MOSFET Drivers

The MAX5051’s integrated high- and low-side MOSFET

drivers source and sink up to 2A of peak currents,

resulting in very low losses even when switching high

gate charge MOSFETs. The high-side gate driver

requires its own bypass capacitor connected between

BST and XFRMRH. Use high-quality ceramic capacitors

close to these two pins for bypass. Under normal operating conditions, the energy stored in the transformer

parasitics swings the XFRMRH pin to ground while the

transformer is resetting. During this time, the charge on

the boost capacitor connected to the BST pin is replenished. However, under certain conditions, such as

when the magnetizing inductance of the transformer is

very high or when using conventional rectification at the

output, the duty cycle with light loads may become very

small. Thus, the energy stored could be insufficient to

swing XFRMRH to ground and replenish the boost

capacitor. Figure 3 shows the equivalent circuit during

the magnetizing inductance reset interval, assuming

synchronous rectification where the output inductor is

not allowed to run discontinuous.

If the magnetizing inductance is kept below the following minimum, then the boost capacitor charge will

not deplete:

where d is the duty cycle, VINis the input voltage, fSis

the switching frequency, and Q

gtotal

is the total gate

charge for the high-side MOSFET. The above formula is

only an approximation; the actual value will depend on

other parasitics as well.

Ld

V

fQg Af

M

IN

s total s

≤+0 294

0 005

2

2

.

(. )

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

12 ______________________________________________________________________________________

Page 13

If the charge stored on the boost capacitor is not adequately replenished then the gate-driver lockout for the

high-side MOSFET is triggered, stopping the high side

from switching. The low side continues switching, eventually recharging the capacitor, at which point the high

side starts switching again. To prevent this behavior,

use the boost capacitor’s cycle-by-cycle charging circuit to prevent unwanted shutdowns of the high side

(Figure 2). Connect the gate of a small high-voltage

FET (with the same voltage rating or higher as the main

FETs) to the DRVB output of the MAX5051. Connect the

drain of this FET to XFRMRH, and connect the source

to the primary ground. DRVB will briefly (300ns) turn

this FET ON every cycle after the main PWM clock terminates. This allows the boost capacitor to be replenished under all conditions, even when switching stops

completely. A suitable FET for this is BSS123 or equivalent (100V, 170mA rated). The boost-capacitor charge

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

______________________________________________________________________________________ 13

Figure 2. Typical Application Circuit

Figure 3. Boost Capacitor Charging Path During Transformer

Reset

V

IN+

R9

15kΩ

C11

R12

1MΩ

C12

220nF

C13

100pF

C14

390pF

R13

100kΩ

R14

24.9kΩ

R15

1MΩ

V

IN-

0.1µF

FLTINT

GND

RCOSC

STARTUP

RCFF

CON

COMP

STT

FB

R11

39.2kΩ

CSS

UVLO

AVIN

PVIN

MAX5051

SYNCOUT

REG5

R10

10Ω

C10

4.7µFC91µF

SYNCIN

LXVDD

D4

MA111CT

C8

4.7µF

REG9

XFRMRH

LXH

BST

DRVDD

DRVH

DRVB

DRVL

PGND

LXL

R8

2.2kΩ

R6

47Ω

BAT46W

USED FOR

BOOST

CAPACITOR

PRECHARGE

D3

C5

N1

SI4486

N2

SI4486

28mΩ

1µF

D1

R4

D2

B2100

B2100

L

: 150µH

M

P: 14T

S: 4T

T: 6 T

T1

T1

fs = 250kHz

L1

220nF

475Ω

U2

PS2913

C2

2µH

R3

3 x 270µF

MAX8515

3.3V

R1

11.5kΩ

R2

2.55kΩ

10A

R

LOAD

C4

C3

150nF

C1

47nF

D5

R5

10Ω

C7

4.7µF

N3

BSS123

CS

R7

360Ω

C6

270nF

I

BST

BST

I

BST

I

GD

V

IN

REG9

DRVH

DRVL

XFMRH

I

LM

L

M

Page 14

MAX5051

diode is a high-voltage, small-signal Schottky type. It

may be helpful to connect a resistor in series with this

diode to minimize noise as well as reduce the peak

charging currents. As in any other switching powersupply circuit, the gate-drive loops must be kept to a

minimum. Plan PC board layout with the critical current

carrying loops of the circuit as a starting point.

Secondary-Side Synchronization

The MAX5051 has additional (LXH and LXL) outputs to

make the driving of secondary-side synchronous rectifiers possible with a signal from the primary. These signals lead in time, the actual gate drive applied to the

main power FETs, and allow the secondary-side synchronous FETs to be commutated in advance of the

power pulse. The synchronizing pulse is generated

approximately 90ns ahead of the main pulse that drives

the two power FETs.

Synchronization is accomplished by connecting a small

pulse transformer between LXH and LXL, along with

some clamp diodes (D1 and D2 in Figure 4). This is a

small integrated two-switch driver configuration that

allows for full recovery of the stored energy in the magnetizing inductance of the pulse transformer, thereby

significantly reducing the running bias current of the

controller. It also allows for correct transfer of DC levels

without requiring series capacitors with large time constants, assuring correct drive levels for the secondary

circuit.

Select a pulse transformer, T1, so the current buildup in

its magnetizing inductance is low enough not to create

a significant voltage droop across the internal driver

FETs. Use the following formula to calculate the

approximate value of the primary magnetizing inductance of T1:

where R

dsLXH

and R

dsLXL

are the internal high- and lowside pulse transformer driver on-resistances, fsis the

switching frequency, LMis the pulse transformer primary

magnetizing inductance, tsis the transition time at the

drains of these FETs (typically < 40ns), and Cdsis the

total drain-source capacitance (approximately 10pF).

Alternatively, a high-speed optocoupler (Figure 5) can

be used instead of the pulse transformer. The lookahead pulse accommodates the propagation delays of

the high-speed optocoupler as well as the delays

through the gate drivers of the secondary-side FETs.

Choose optocouplers with propagation delays of less

than 50ns.

Error Amplifier And Reference Soft-Start

The error amplifier in the MAX5051 has an uncommitted

inverting input (FB) and output (COMP). Use this amplifier when secondary isolation is not required. COMP

can then be directly connected to CON (the input of the

PWM comparator). The noninverting input of the error

amplifier is connected to the soft-start generator and is

also available externally at CSS. A capacitor connected

to CSS is slewed linearly during initial startup with the

70µA internal current source (see Figure 2). This provides a linearly increasing reference to the noninverting

input of the error amplifier forcing the output voltage

also to slew proportionally. This method of soft-start is

superior to other methods because the loop is always

2516.

RR

f

L

t

Cf

dsLXH dsLXL

s

M

s

ds s

+

≤≤

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

14 ______________________________________________________________________________________

Figure 4. Secondary-Side Synchronous Rectifier Driver Using

Pulse Transformer

Figure 5. Secondary-Side Synchronous Rectifier Driver Using

High-Speed Optocoupler

MAX5051

REG5

LXVDD

LXH

LXL

PGND

R1

4.7Ω

D3

1N4148

T1

C1

1µF

D1

D2

T1: PULSE ENGINEERING, PE-68386.

D1, D2: CENTRAL SEMICONDUCTOR, CMOSH-3.

MAX5051

LXVDD

R2

2kΩ

PGND

REG5

LXH

LXL

R1

4.7Ω

R2

2kΩ

C1

1µF

R3

560Ω

U2

PS9715

HIGH-SPEED

OPTO

5V

C2

Page 15

in control. Thus, the output-voltage slew rate is constant

at light or heavy loads. Once the soft-start ends, the

voltage on CSS regulates to 1.24V. Do not load CSS

with external circuitry. A suitable range of capacitors

connected to CSS is from 10nF to 0.1µF. Calculate the

required soft-start capacitor based on the total outputvoltage startup time as follows:

where C

CSS

is the capacitor connected to CSS, tSSis

the soft-start time required for the output voltage to rise

from 0V to the rated output voltage. This only applies

when this amplifier is used for output voltage regulation.

PWM Ramp

The PWM ramp is generated at RCFF. Connect a

capacitor C

RCFF

from RCFF to ground and a resistor

R

RCFF

from RCFF to AVIN. The ramp generated on

RCFF is internally offset by 2.3V and applied to the noninverting input of the PWM comparator. The slope of the

ramp is part of the overall loop gain. The dynamic

range of RCFF is 0 to 3V, and so the ramp peak must

be kept below that. Assuming the maximum duty cycle

approaches 50% at minimum input voltage, use the following formula to calculate the minimum value of either

the ramp capacitor or resistor:

where V

INUVLO

is the minimum input supply voltage

(typically the PWM UVLO turn-on voltage), fS is the

switching frequency, and V

RPP

is the peak-to-peak

ramp voltage, typically 2V.

Allow the ramp peak to be as high as possible to maximize the signal-to-noise ratio. The low-frequency smallsignal gain of the power stage, Gps (the gain from the

inverting input of the PWM comparator to the output)

can be calculated by using the following formula:

where Nspis the secondary-to-primary power transformer turns ratio.

Internal Regulators

The MAX5051 has two internal linear regulators that are

used to power internal and external control circuits. The

9V regulator, REG9, is primarily used to power the high-

and low-side gate drivers. Bypass REG9 with a 4.7µF

ceramic capacitor or any other high-quality capacitor;

use low-value ceramics in parallel as necessary. A 5V

regulator also is provided, REG5, primarily used to bias

the internal circuitry of the MAX5051. Bypass REG5 with

a 4.7µF ceramic capacitor similar to the one used for

REG9. Both of these regulators are always powered.

When using bootstrapped startup through a bleed resistor, do not load these outputs while the MAX5051 is in

standby as it may fail to start. Any external loading to

this output should be such that the sum of their load and

the standby current through PVIN of the MAX5051 is

less than the current that the bleed resistor can supply.

Startup Modes

The MAX5051 can be configured for two different

startup modes, allowing operation in either bootstrapped or direct power mode.

Direct Power Mode

In direct power mode, AVIN and PVIN are connected

directly to the input supply. This is typical in 12V to 24V

systems. The undervoltage lockout set at STT needs to

be adjusted down with an external resistor-divider to an

appropriate level.

Bootstrapped Startup

In bootstrap mode, a resistor is connected from the

input supply to PVIN, where a capacitor to GND is

charged towards the input supply. When this voltage

reaches the startup threshold, the device wakes up and

begins switching. A tertiary winding from the transformer is then used to sustain operation. The MAX5051

draws little current from PVIN before reaching the

threshold, which allows a large-value bootstrap resistor

and reduces its power dissipation after startup. A large

startup hysteresis helps the design of the bootstrap

circuit by providing longer running times during startup.

After coming out of standby and before initiating the

soft-start, the MAX5051 turns on the low-side FET to

charge up the boost capacitor. A voltage detector has

been incorporated in the high-side driver that prevents

the high-side switch from turning on with insufficient

voltage. It is also used to indicate when the boost

capacitor has been charged. Once the capacitor is

charged, soft-start commences. If the duty cycle is low,

the magnetizing energy in the transformer may be

insufficient to keep the bootstrap capacitor charged.

DRVB (see Figure 2 dotted lines) has been provided to

drive a small external FET connected between

XFRMRH and PGND, and is pulsed every cycle to keep

the capacitor charged.

GNR C f

ps sp RCFF RCFF s

=

RC

V

fV

RCFF RCFF

INUVLO

s RPP

≥

2

CFst

CSS SS

=µ ×56 /

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

______________________________________________________________________________________ 15

Page 16

MAX5051

Normally PVIN is derived from a tertiary winding of the

transformer. However, at startup there is no energy

delivered through the transformer, hence, a special

bootstrap sequence is required. Figure 6 shows the

voltages on PVIN, REG9, and REG5 during startup.

Initially, PVIN, REG9, and REG5 are 0V. After the input

voltage is applied, C21 (Figure 8) charges PVIN

through the startup resistor, R22, to an intermediate

voltage. At this point, the internal regulators begin

charging C3 and C4. The MAX5051 uses only 400µA

(typ) of the current supplied by R22, and the remaining

current charges C21, C3, and C4. The charging of C4

and C3 stops when their voltages reach approximately

5V and 9V, respectively, while PVIN continues rising

until it reaches the wakeup level of 24V. Once PVIN

exceeds this wakeup level, switching of the external

MOSFETs begins and energy is transferred to the secondary and tertiary outputs. When the voltage on the

tertiary output builds to higher than 9V, startup has

been accomplished and operation is sustained.

However, if REG9 drops below 6.2V (typ) before startup

is complete, the device goes back into standby. In this

case, increase the value of C21 to store enough energy

allowing for voltage buildup at the tertiary winding.

Startup Time Considerations

The PVIN bypass capacitor, C21, supplies current

immediately after wakeup (see Figure 8). The size of

C21 and the connection of the tertiary winding determine the number of cycles available for startup. Large

values of C21 increase the startup time and supply

gate charge for more cycles during initial startup. If the

value of C21 is too small, REG9 drops below 6.2V

because the MOSFETs did not have enough time to

switch and build up sufficient voltage across the tertiary

output to power the device. The device goes back into

standby and will not attempt to restart until PVIN rises

above 24V. Use a low-leakage capacitor for C21, C3,

and C4 (see Figure 8). Generally, power supplies keep

typical startup times to less than 500ms even in low-line

conditions (36VDC for telecom applications). Size the

startup resistor, R22 (Figure 8) to supply both the maximum startup bias of the device and the charging current for C21, C3, and C4.

Oscillator and Synchronization

The MAX5051 oscillator is externally programmable

through a resistor and capacitor connected to RCOSC.

The PWM frequency will be 1/2 the frequency at RCOSC

with a 50% duty cycle, and is available at SYNCOUT.

The maximum duty cycle is limited to < 50% by a 60ns

internal blanking circuit in the power drivers in addition

to the gate and driver delays.

Use the following formula to calculate the oscillator

components:

where C

PCB

is the stray capacitance on the PC board

(about 14pF), REG5 = 5V, VTHis the RCOSC peak trip

level, and fsis the switching frequency.

The MAX5051 contains circuitry that allows it to be synchronized to an external clock whose duty cycle is 50%.

For proper synchronization, the frequency of this clock

should be 15% to 20% higher than half the RCOSC frequency of the MAX5051’s internal oscillator. This is

because the external source SYNCIN directly drives the

power stage, whereas the internal clock is divided by

two. The synchronization feature in the MAX5051 has

been designed primarily for two devices connected to

the same power source with a short physical distance

between the two circuits. Under these circumstances,

the SYNCOUT from one of the circuits can be connected to the SYNCIN of the other one; this forces the power

cycle of the second unit to be 180° out-of-phase. To

synchronize a second MAX5051, feed the SYNCOUT of

the first device to the SYNCIN of the second device. If

necessary, many devices can be daisy-chained in this

manner. Each device will then have 180° phase difference from the device that drives it.

R

RCOSC

s RCOSC PCB

TH

fC C In

REG

REG V

()

≈

+

−

1

2

5

5

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

16 ______________________________________________________________________________________

Figure 6. PVIN, REG5, and REG9 During Startup in

Bootstrapped Mode

PVIN

10V/div

REG9

5V/div

REG5

5V/div

40ms/div

Page 17

Integrating Fault Protection

The integrating fault protection feature allows transient

overcurrent conditions to be ignored for a programmable

amount of time, giving the power supply time to behave

like a current source to the load. This can

happen, for example, under load-current transients when

the control loop requests maximum current to keep the

output voltage from going out of regulation. The fault

integration time can be programmed externally by connecting a suitably sized capacitor to the FLTINT pin.

Under sustained overcurrent faults, the voltage across

this capacitor is allowed to ramp up towards the FLTINT

shutdown threshold (2.9V, typ). Once the threshold is

reached, the power supply shuts down. A high-value

bleed resistor connected in parallel with the FLTINT

capacitor allows it to discharge towards the restart

threshold (1.8V, typ). Once this threshold is reached, the

supply restarts with a new soft-started cycle.

Note that cycle-by-cycle current limiting is provided at

all times by CS with a threshold of 154mV (typ). The

fault integration circuit works by forcing a 90µA current

out of FLTINT every time that the current-limit comparator (Figure 1, CILIM) is tripped. Use the following formula to calculate the value of the capacitor necessary for

the desired shutdown time of this circuit.

where I

FLTINT

= 90µA, tSHis the desired fault integration time after the first shutdown cycle during which

current-limit events from the current-limit comparator

are ignored. For example, a 0.1µF capacitor gives a

fault integration time of 2.25ms.

Some testing may be required to fine-tune the actual

value of the capacitor. To calculate the required bleed

resistance R

FLTINT

, use the following formula:

where tRTis the desired recovery time.

Typically choose tRT= 10 x tSH. Typical values for t

SH

range from a few hundred microseconds to a few milliseconds.

Synchronizing Primary-Side STARTUP For

Parallel Operation

Figure 7 shows the connection diagram of two or more

MAX5051s for synchronized primary-side operation.

The common connection of STARTUP ensures all paralleled modules wakeup and shutdown in tandem. This

helps prevent startup conflicts when the secondaries of

the power supplies are paralleled. Connecting

SYNCOUT to SYNCIN is not necessary; however, when

used, this minimizes the ripple current though the input

bypass capacitors.

Applications Information

Isolated Telecom Power Supply

Figure 8 shows a complete design of an isolated synchronously rectified power supply with a 36V to 72V

telecom voltage range. This power supply is fully protected and can sustain a continuous short circuit at its

output terminals. Figures 9 though 14 show some of the

performance aspects of this power-supply design. This

circuit is available as a completely built and tested

evaluation kit.

R

t

C

FLTINT

RT

FLTINT

=

×0 372.

C

It

V

FLTINT

FLTINT SH

=

.09

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

______________________________________________________________________________________ 17

Figure 7. Connection for Synchronized STARTUP of Two or

More MAX5051s

#1

RCOSC

SYNCOUT

RCFF

CON

#2

RCOSC

SYNCOUT

RCFF

CON

MAX5051

MAX5051

SYNCIN

FLTINT

STARTUP

UVLO

SYNCIN

FLTINT

STARTUP

UVLO

Page 18

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

18 ______________________________________________________________________________________

Figure 8. Schematic of a 48V Input 3.3V at 15A Output Synchronously Rectified, Isolated Power Supply

DRVB

R28

R26

560Ω

1

AN

U6

VCC

OUT

5

4

0.1µF

5V

6

5

IN-

IN+

U7

V+

P_OUT

1

2

5V

C30

0.1µF

IN

R22

15kΩ

PVIN +V

C21

OUT

V

C27

0.15µF

0Ω

R20

LXL

14

TP3

REG5

LXH

IN

+V

XFRMRH

R4

1MΩ

28

SYNCIN

U1

RCOSC

1

C1

1%

R21

24.9kΩ

REG5

8

N1

2

3

D2

IN

+V

1%

100pF

IN

-V

IN

+V

C25

0.07µF

100V

C12

1µF

100V

C11

0.47µF

100V

C10

0.47µF

100V

6

7

5

4

1

21

R5

R6

1MΩ

C7

0.22µF

27

FLTINT

MAX5051

2

TP1

R25

IN

+V

R29

XFRMRH

3

5V

C35

1%

38.3kΩ

1%

26

STARTUP ON/OFF

RCFF

SYNCOUT

3

100kΩ

1µF

25

C2

1Ω

N5

UVLO

390pF

1

8

IN OUT

1

IN

+V

24

2

C16

3.3µF

7

WDI

U5

EN

2

C32

D6

21

REG9

R7

0Ω

2

D1

23

GND

AVIN

5

VOUT

C33

1µF

OUT

V

C15

270µF

C14

270µF

C13

L1

R13

DRVH

31.6kΩ

10.5kΩ

2.4µH

XFRMRH

47Ω

R8

XFRMRH

20

XFRMRH

1%

1%

270µF

N4

6

5

7

8

1

D4

T1

2

C34

8.2Ω

DRVB

REG9

19

18

DRVB

REG5

C4

4.7µF

6

5

N.C.

HOLD

GND

RESET

3

4

1µF

C8

4.7µF

22

21

BST

CSS4COM6COMP7FB8REG5

R15

C5

4700pF

R16

D8

21

10V

4V

4V

4V

3

2

R10

8

8T

330pF

+VIN

DRVDD

REG9

C3

C9

2

20Ω

D3

SGND

4

1

5

9

4.7µF

4

3

C23

1

8

5

6

12

1µF

17

PGND

REG9

PVIN

C6

GND

U4

N_OUT

1000pF

2T

7

R9

10

0.1µF

N2

8.2Ω

5

IN-

P_OUT

2

5V

4

16CS15

PVIN

6

10

4T

2

DRVL

5

3

1

11

LXH

5V

C31

6

IN+

V+

1

C29

0.1µF

4

N3

1

7

2

3

8

1

2

D7

6

R18

D5

2

STT12LXVDD13LXH

4.7Ω

1

1%

R17

0.027Ω

R14

150Ω

C20

220pF

IC_PADDLE

C19

1µF

C18

100pF

R27

10Ω

REG5

2kΩ

2

CA

GND

3

U1: MAX5051

U2: PS2913-1-M

U3: MAX8515

U4, U7: MAX5048A

U5: MAX5023M

U6: PS9715

N1, N2: SI4486

N3, N4: SI4864

N5: BSS123

4

GND

M_OUT

3

80V

4.7µF

R19

R12

475Ω

100kΩ

1

U2

4

R3

2.2kΩ

C24

C26

0.1µF

REG9

2kV

C22

2200pF

R24

OUT

V

1

4

IN

GND

PGND

U3

OUT

FB

3

52

R2

2.55kΩ

1%

TRIM

R1

1%

1%

R11

2

3

360Ω

1000pF

11.5kΩ

C28

0.047µF

OUT

V

C36

0.22µF

C17

0.33µF

10Ω

SENSE (+) SENSE (-)

R23

10Ω

Page 19

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

______________________________________________________________________________________ 19

Figure 9. Efficiency at Nominal Output Voltage vs. Load

Current 48V Nominal Input Voltage

Figure 10. Power Dissipation at Nominal Output Voltage vs.

Load Current for 48V Input Voltage.

Figure 11. Turn-On Transient at Full Load (Resistive Load)

Figure 12. Output Voltage Response to Step-Change in Load

Current

95

90

85

80

75

EFFICIENCY (%)

70

65

60

0462 8 10 12 14

LOAD CURRENT (A)

RL = 0.22Ω

V

OUT

1V/div

8

7

6

5

4

3

POWER DISSIPATION (W)

2

1

0

0462 8 10 12 14

LOAD CURRENT (A)

V

OUT

100mV/div

I

OUT

5A/div

4ms/div

I

OUT

5A/div

1ms/div

50% > 75% > 50% OF I

OUT(MAX)

, dl/dt = 5A/µs

Page 20

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

20 ______________________________________________________________________________________

Figure 13. Output Voltage Ripple At Nominal Input Voltage and

Full Load Current (Scope Bandwidth = 20MHz)

Figure 14. Load Current (10A/div) as a Function of Time When

the Converter Attempts to Turn On into a 50mΩ Short Circuit

Chip Information

TRANSISTOR COUNT: 2049

PROCESS: BiCMOS/DMOS

Exposed Paddle Connected to GND

28

27

26

25

24

23

22

21

20

19

18

17

16

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SYNCIN

FLTINT

STARTUP

UVLO

GND

AVIN

CS

BST

DRVH

XFRMRH

DRVB

DRVDD

PGND

DRVL

LXL

LXH

LXVDD

STT

PVIN

REG9

REG5

FB

COMP

CSS

CON

RCFF

SYNCOUT

RCOSC

TSSOP

TOP VIEW

EXPOSED PADDLE IS INTERNALLY CONNECTED TO GND.

MAX5051

Pin Configuration

A

V

OUT

50mV/div

B

I

OUT

10A/div

I

OUT

10A/div

2µs/div

A: 1ms/div

B: 20ms/div

Page 21

MAX5051

Parallelable, Clamped Two-Switch

Power-Supply Controller IC

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 21

© 2003 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

TSSOP 4.4mm BODY.EPS

Loading...

Loading...