Page 1

19-5859; Rev 0; 10/11

Ambient and Infrared Proximity Sensor

General Description

The MAX44000 combines a wide-dynamic range ambient

light sensor with an integrated infrared proximity sensor. The

IC is a perfect solution for touch-screen portable devices.

The IC can consume as low as 11µA (time averaged) in

ambient light sensing plus proximity sensing, including

external IR LED current.

The on-chip ambient sensor has the ability to make wide

dynamic range 0.03 lux to 65,535 lux measurements. An

on-chip IR proximity detector is matched with an integrated IR LED driver. All readings are available on an

I2C communication bus. A programmable interrupt pin

minimizes the need to poll the device for data, freeing

up microcontroller resources, reducing system software

overhead, and ultimately, reducing power consumption.

The IC is designed to drive an external IR LED and can

operate from a VDD of 1.7V to 3.6V. It consumes just 5µA

operating current when only the ambient light sensor is

enabled and 7µA when the proximity receiver and driver

are enabled.

Applications

Smartphones

Accessories

Industrial Sensors

Presence Detection

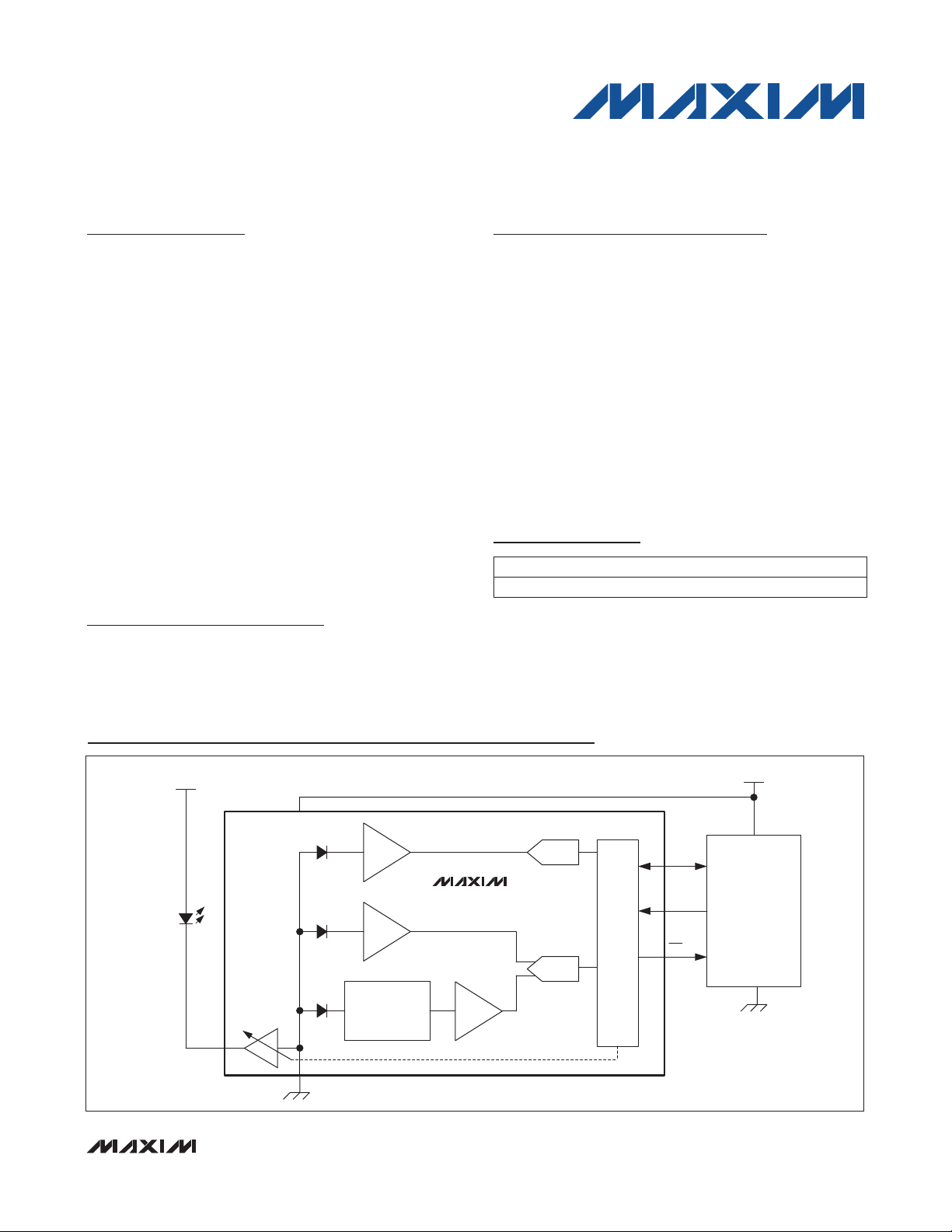

Simplified Block Diagram

Features

S Tiny, 2mm x 2mm x 0.6mm UTDFN-Opto Package

S VDD = 1.7V to 3.6V

S Low-Power Operation

5µA in Ambient Mode

7µA in Ambient Plus Proximity Mode

70µA in Ambient Plus Proximity Mode,

Including 100mA LED Current

S Excellent Light Source Matching

Programmable Green and IR Channel Gains

S Integrated Single-Pulse IR LED Driver

10mA to 110mA Programmable Range

Internal Ambient Cancellation

S -40NC to +105NC Temperature Range

Ordering Information

PART TEMP RANGE PIN-PACKAGE

MAX44000GDT+

+Denotes a lead(Pb)-free/RoHS-compliant package.

*EP = Exposed pad.

Typical Application Circuit appears at end of data sheet.

-40NC to +105NC

6 OTDFN-EP*

MAX44000

V

DD

MICROCONTROLLER

GND

IR LED

V

LED

V

DD

VIS + IR

(ALS)

IR (ALS)

IR (PRX)

DRV

GND

_______________________________________________________________ Maxim Integrated Products 1

ALS

PGA

ALS

PGA

AMBIENT

CANCELLATION

MAX44000

PRX

PGA

14-BIT

14-/8-BIT

I2C

SDA

SCL

INT

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Page 2

Ambient and Infrared Proximity Sensor

ABSOLUTE MAXIMUM RATINGS

All Pins to GND ....................................................-0.3V to +4.0V

Output Short-Circuit Current Duration .......................Continuous

Continuous Input Current into Any Terminal ................... Q20mA

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

Continuous Power Dissipation (TA = +70NC)

6-Pin OTDFN (derate 11.9mW/NC above +70NC) ............ 953mW

Operating Temperature Range ........................ -40NC to +105NC

Soldering Temperature (reflow) ......................................+260NC

MAX44000

ELECTRICAL CHARACTERISTICS

VDD = 1.8V, T

(

AMBIENT LIGHT RECEIVER CHARACTERISTICS

Maximum Ambient Light

Sensitivity

Ambient Light Saturation Level 65,535 Lux

Gain Error

Light Source Matching Fluorescent/incandescent light 10 %

Infrared Transmittance

Ultraviolet Transmittance

Dark Current Level

ADC Conversion Time

ADC Conversion Time Accuracy

INFRARED PROXIMITY RECEIVER CHARACTERISTICS

Maximum Proximity Detection

Sensitivity

Sunlight Rejection Offset No reflector 0 to 100k lux 0 Counts

Sunlight Rejection Gain Error With reflector 0 to 100k lux 0.1

– T

MIN

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

= -40°C to +105°C, TA = +25°C, unless otherwise noted.) (Note 2)

MAX

Fluorescent light (Note 3) 0.03 Lux/LSB

Green LED 538nm response, TA = +25NC

(Note 3)

850nm vs. 538nm, TA = +25NC

363nm vs. 538nm, TA = +25NC

100ms conversion time, 0 lux, TA = +25NC

14-bit resolution, has 50Hz/60Hz rejection 100

12-bit resolution 25

10-bit resolution 6.25

8-bit resolution 1.56

TA = -40NC to +105NC

TA = +25NC

850nm IR LED, 60µW/cm

2

15 %

0.5 %

2 %

0 Count

6

0.7

1.5

mW/cm2/

ms

%

LSB

Counts/

klux

2 ______________________________________________________________________________________

Page 3

Ambient and Infrared Proximity Sensor

ELECTRICAL CHARACTERISTICS (continued)

VDD = 1.8V, T

(

IR LED TRANSMITTER

Minimum IR LED Drive Current

Sink

Maximum IR LED Drive Current

Sink

Current Control Step 10 mA

Current Control Accuracy

DRV Leakage Current I

Voltage Compliance of DRV Pin

Internal Transmit Pulse Width 100

POWER SUPPLY

Power-Supply Voltage V

Quiescent Current

(Ambient Mode)

Software Shutdown Current I

Quiescent Current Proximity During IR LED pulsed operation 375 600

Quiescent Current (ALS +

Proximity, Time Average)

Power-Up Time t

DIGITAL CHARACTERISTICS (SDA, SCL, INT)

Output Low Voltage (SDA, INT)

INT Leakage Current

SDA, SCL Input Current 0.01 1000 nA

I2C Input Low Voltage V

I2C Input High Voltage V

Input Capacitance 3 pF

– T

MIN

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

= -40°C to +105°C, TA = +25°C, unless otherwise noted.) (Note 2)

MAX

I

= 110mA, V

OUT

= 50mA, V

OUT

I

= 10mA, V

OUT

= 0mA, V

OUT

I

= 110mA, DI

DRV

I

= 100mA, DI

DRV

DD

Is 5 10

SHDN

ON

V

IL_I2C

IH_I2C

TA = +25NC

TA = -40NC to +105NC

With proximity and ALS sensing on 6.8

I

OL

= 6mA 0.06 0.4 V

SINK

SDA, SCL 0.4 V

SDA, SCL 1.6 V

= 1.5V 12

DRV

= 1.5V 10

DRV

= 1.5V 12

DRV

= 3.6V 0.1

DRV

= 10%; V

OUT

OUT

= 2%, V

DRV

DRV

= 3.6V

= 3.6V

10 mA

110 mA

0.5

0.6

1.7 3.6 V

0.1 0.3

0.6

100 ms

0.01 1000 nA

MAX44000

%I

FA

V

Fs

FA

FA

FA

FA

_______________________________________________________________________________________ 3

Page 4

Ambient and Infrared Proximity Sensor

ELECTRICAL CHARACTERISTICS (continued)

VDD = 1.8V, T

(

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

I2C TIMING CHARACTERISTICS

Serial-Clock Frequency f

Bus Free Time Between STOP

and START

Hold Time (Repeated) START

MAX44000

Condition

Low Period of the SCL Clock t

High Period of the SCL Clock t

Setup Time for a REPEATED

START

Data Hold Time t

Data Setup Time t

SDA Transmitting Fall Time t

Setup Time for STOP Condition t

Pulse Width of Suppressed Spike t

Note 2: All devices are 100% production tested at TA = +25NC. Temperature limits are guaranteed by design.

Note 3: Guaranteed by design. Green 538nm LED chosen for production so that the IC responds to 100 lux flourescent light with

100 lux.

MIN

– T

= -40°C to +105°C, TA = +25°C, unless otherwise noted.) (Note 2)

MAX

SCL

t

BUF

t

HD,STA

LOW

HIGH

t

SU.STA

HD,DAT

SU,DAT

I

P 6mA, tR and tF between 0.3 x VDD

F

SU,STO

SP

SINK

and 0.7 x V

DD

400 kHz

1.3

0.6

1.3

0.6

0.6

0 0.9

100 ns

100 ns

0.6

0 50 ns

Fs

Fs

Fs

Fs

Fs

Fs

Fs

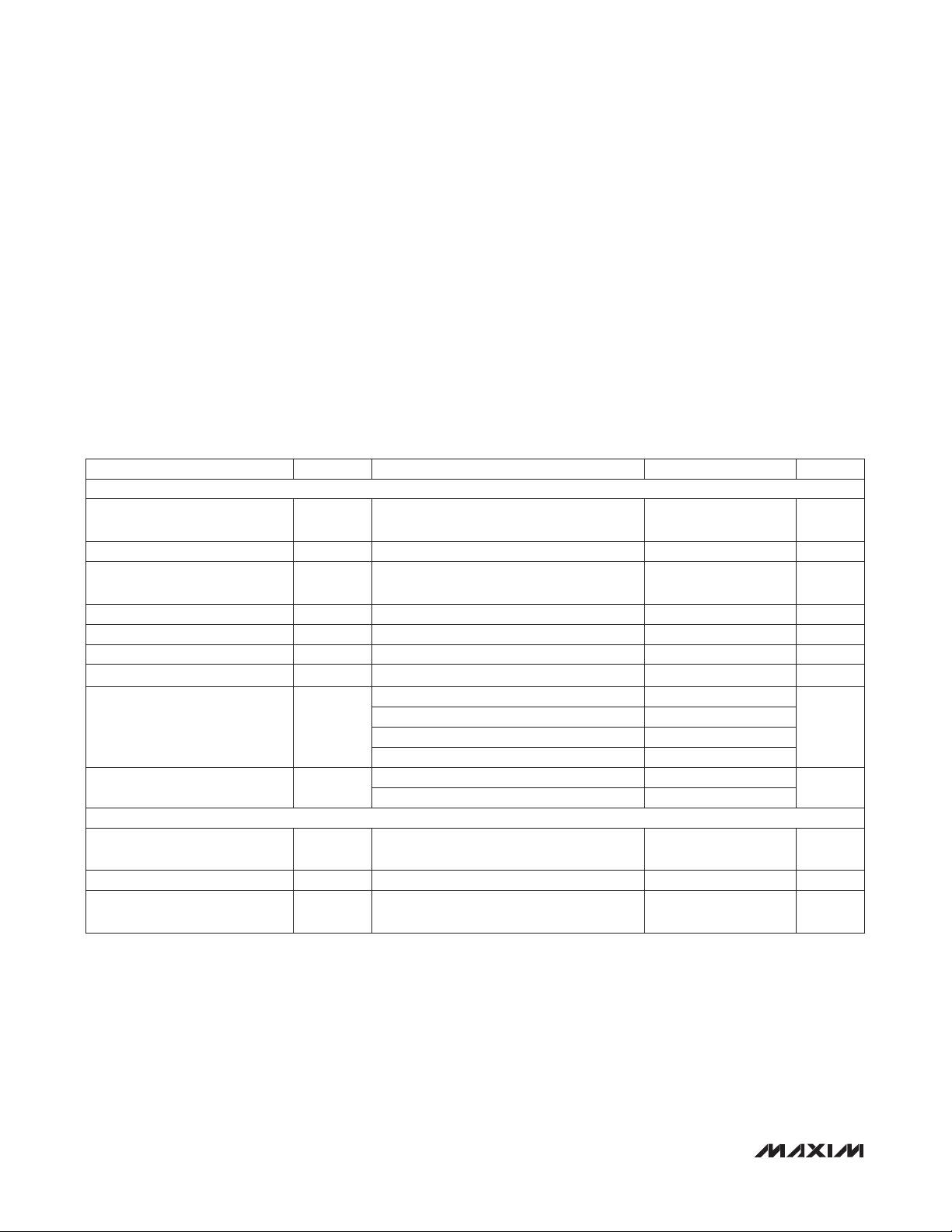

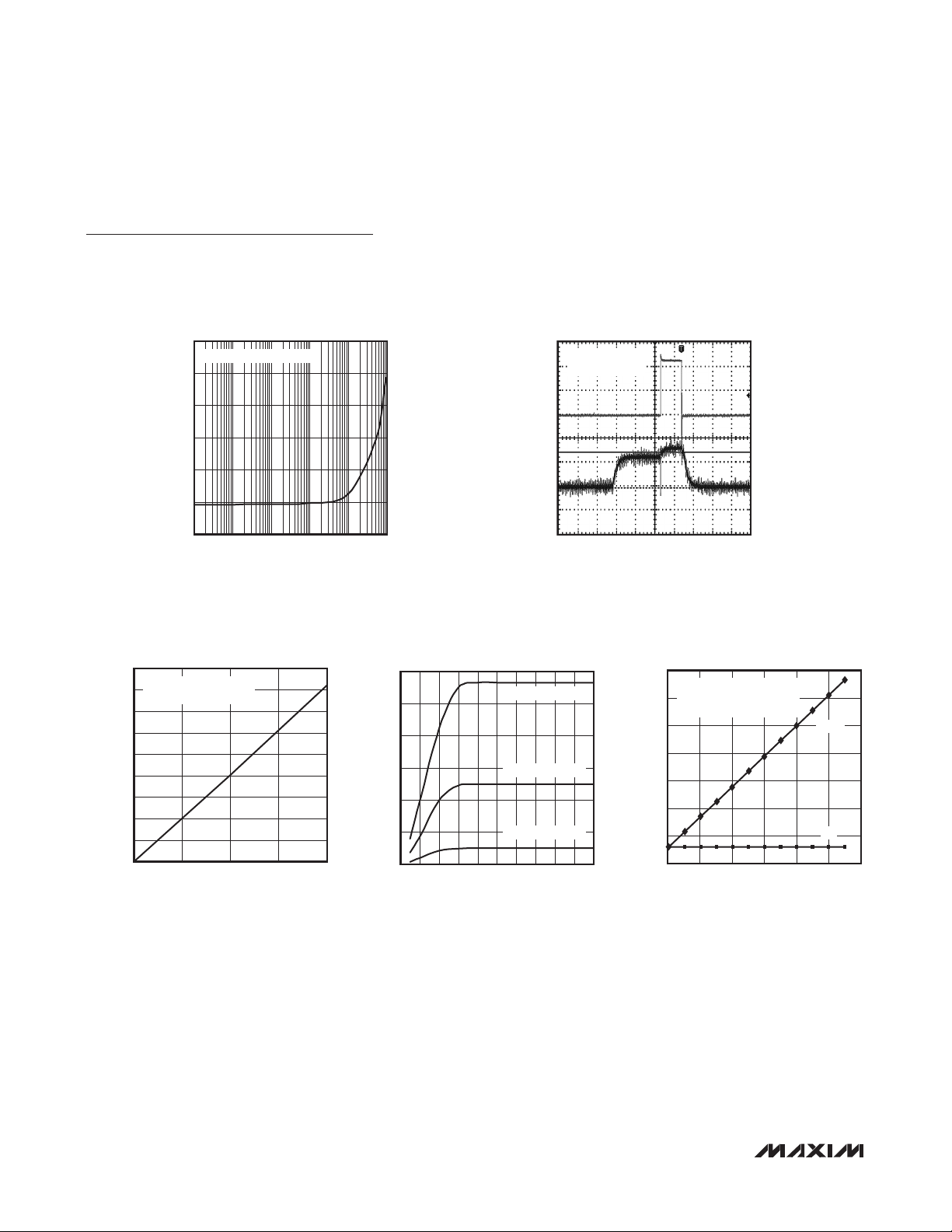

Typical Operating Characteristics

(VDD = 1.8V, T

Temperature limits are guaranteed by design.)

120

100

80

60

40

NORMALIZED OUTPUT

20

0

270 1070

4 ______________________________________________________________________________________

MIN

– T

= -40°C to +85°C, unless otherwise noted. All devices are 100% production tested at T

MAX

SPECTRUM RESPONSE

GREEN CHANNEL

RED CHANNEL

CIE CURVE

WAVE LENGTH (nm)

= +25°C.

A

ADC COUNT vs. DISTANCE

300

vs. LED DRIVE CURRENT

250

MAX44000 toc01

200

150

ADC COUNT

100

50

0

970870770670570470370

0 140

I

= 110mA

OUT

I

= 50mA

OUT

I

= 20mA

OUT

DISTANCE (mm)

MAX44000 toc02a

12010080604020

ADC COUNT vs. DISTANCE vs. OBJECT

300

250

200

150

ADC COUNT

100

50

0

GREY CARD

WHITE CARD

DISTANCE (mm)

9080706050403020100 100

MAX44000 toc02b

Page 5

Ambient and Infrared Proximity Sensor

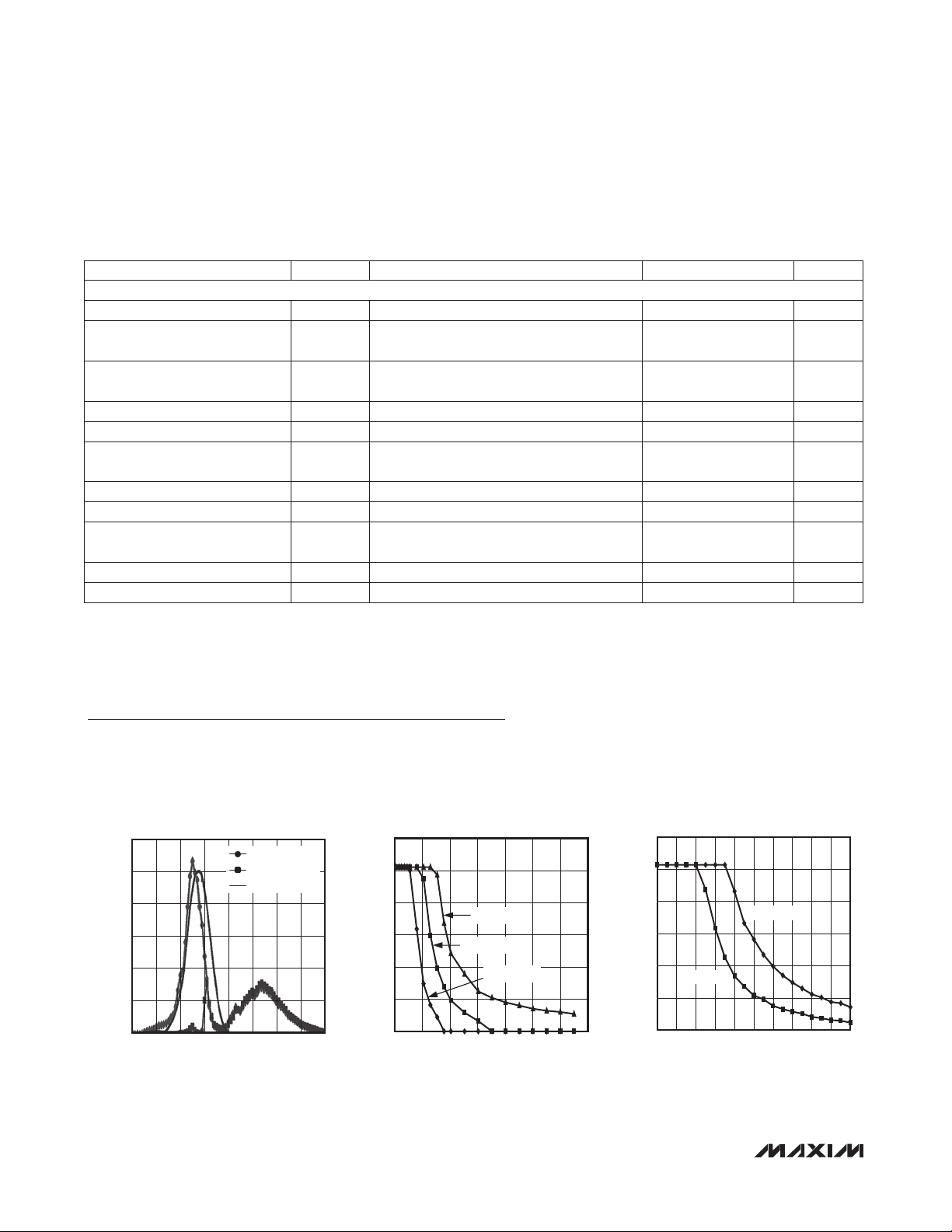

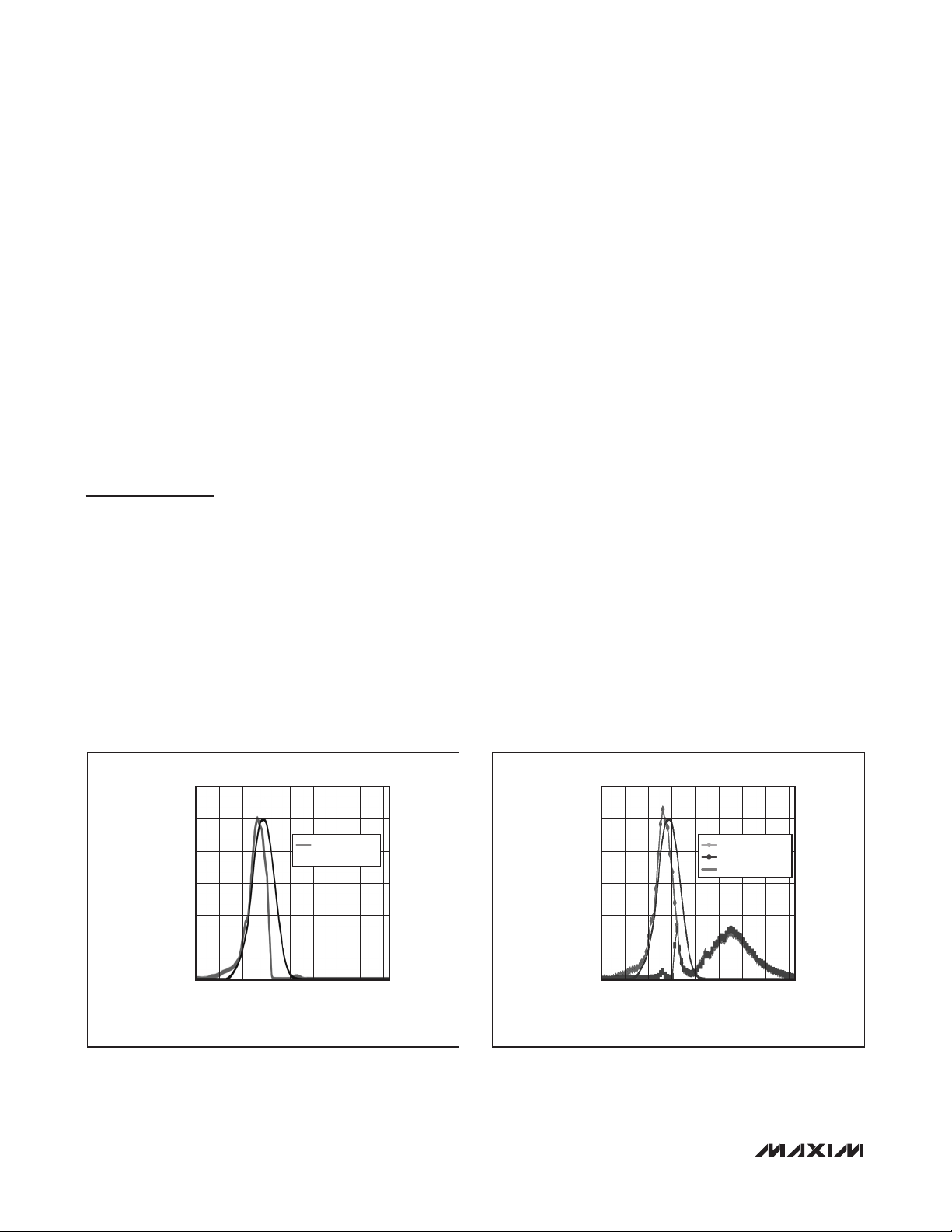

Typical Operating Characteristics (continued)

(VDD = 1.8V, T

Temperature limits are guaranteed by design.)

MIN

– T

= -40°C to +85°C, unless otherwise noted. All devices are 100% production tested at T

MAX

= +25°C.

A

MAX44000

LIGHT SENSITIVITY vs. LUX LEVEL

1800

ALSTIM[1:0] = 00

1600

ALSPGA[1:0] = 10

1400

1200

1000

800

ADC COUNT

600

400

200

0

0 1000

REFERENCE METER READING (LUX)

FLUORESCENT

INCANDESCENT

SUPPLY CURRENT vs. SUPPLY VOLTAGE

vs. TEMPERATURE

10

9

8

7

6

5

4

3

SUPPLY CURRENT (µA)

2

1

0

1.7 3.7

TA = +105°C

TA = -40°C

SUPPLY VOLTAGE (V)

MAX44000 toc03

ADC COUNT

900800600 700200 300 400 500100

TA = +85°C

TA = +25°C

STANDARD AMBIENT MODE

DARKROOM CONDITION

3.53.32.9 3.12.1 2.3 2.5 2.71.9

150

SUNLIGHT REJECTION

NO REFLECTOR

100

PRXTIM, PRXPGA : 0x02 = 1111 xxxx

LED CURRENT: 0x03 = xxxx 1110 for 100mA

WITH NO REFLECTOR, PROX COUNT STAYED

AT 0 AT ALL lux LEVEL

WITH A BLACK GLASS AS REFLECTOR AND

lux LEVEL CHANGED FROM 50 TO 75000 lux

50

PROX COUNTS DROPPED BY 7% AT MID-ADC RANGE

PROX COUNT DROPPED BY 35% AT QUARTER

ADC RANGE

0

0 80k

MAX44000 toc05

BLACK GLASS REFLECTOR

SUNLIGHT (LUX)

100

90

80

MAX44000 toc03b

70

60

50

40

30

20

RELATIVE SENSITIVITY (% FROM 0°)

10

70k60k50k40k30k20k10k

0

ROTATED WITH AXIS BETWEEN

PIN 1/2/3 AND 4/5/6

-50

-30

-70

-90 50 70 90

-40

LUMINOSITY ANGLE (°)

OUTPUT ERROR vs. TEMPERATURE

11

STANDARD AMBIENT MODE

10

DARKROOM CONDITION

9

V

= 1.7 V TO 3.6V

DD

8

7

6

5

4

COUNTS (UNITS)

3

2

1

0

-40 110

TEMPERATURE (°C)

RADIATION PATTERN

-20

-10

MAX44000 toc04

3010

40 60 80

20-60

0-80

MAX44000 toc06

85603510-15

_______________________________________________________________________________________ 5

Page 6

Ambient and Infrared Proximity Sensor

51

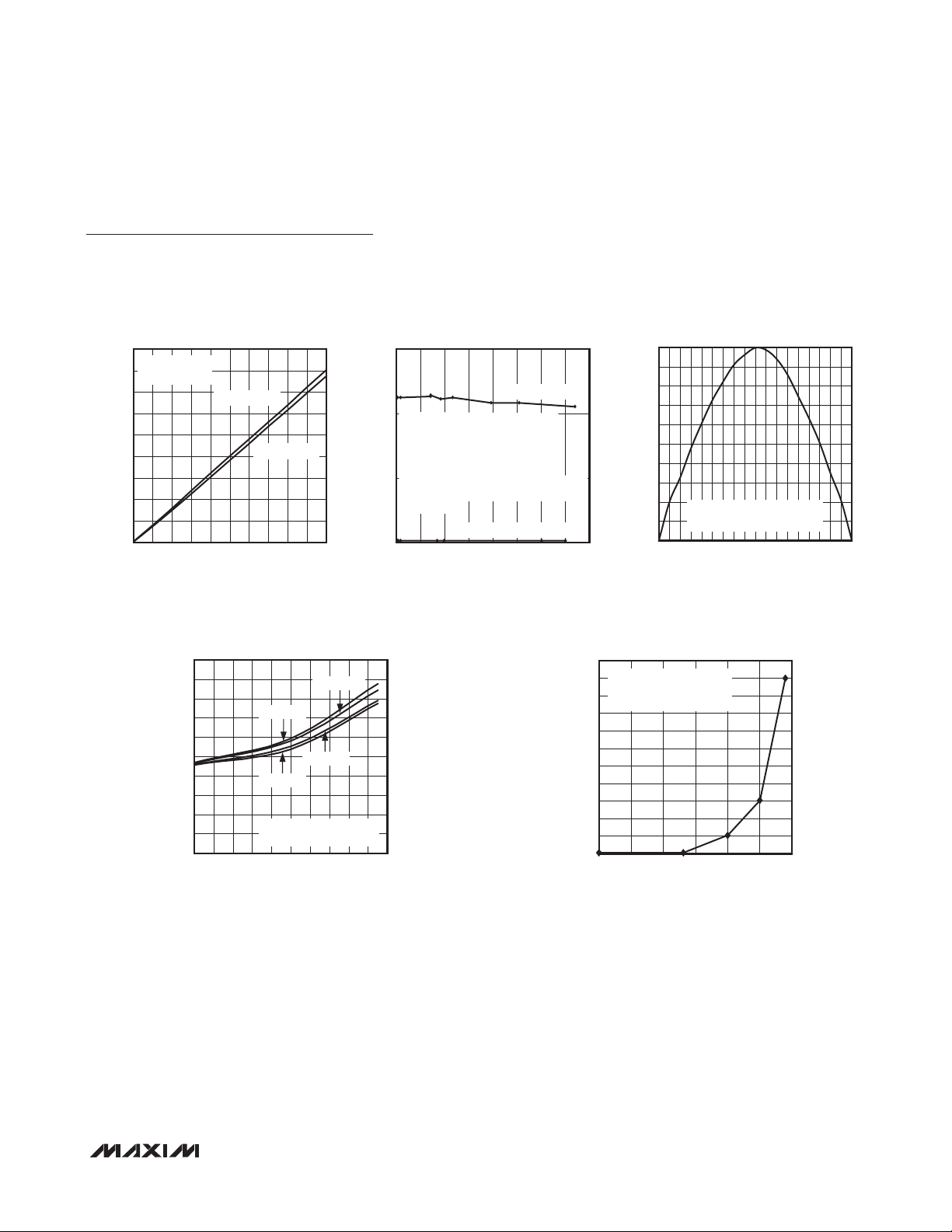

Typical Operating Characteristics (continued)

(VDD = 1.8V, T

Temperature limits are guaranteed by design.)

MIN

– T

= -40°C to +85°C, unless otherwise noted. All devices are 100% production tested at T

MAX

= +25°C.

A

30

STANDARD AMBIENT MODE

MAX44000

25

20

15

10

SUPPLY CURRENT (µA)

5

0

1 100k

OUTPUT LOW VOLTAGE

vs. SINK CURRENT

180

THE DATA WAS TAKEN ON

160

THE INTERRUPT PIN

140

120

100

80

60

OUTPUT LOW VOLTAGE (V)

40

20

0

SINK CURRENT (mA)

SUPPLY CURRENT vs. LUX

10k100010010

LUX

MAX44000 toc09

2010

5

MAX44000 toc07

IR LED CURRENT vs. OUTPUT DRIVE

120

VOLTAGE, I

100

80

(mA)

60

DRV

I

40

20

0 1.0

vs. V

DRV

110mA I

50mA I

10mA I

V

(V)

DRV

DRV

DRV

DRV

DRV

SETTING

SETTING

SETTING

SUPPLY CURRENT vs. TIME

AMBIENT +

PROXIMITY MODE

100µs/div

70

60

MAX44000 toc10

50

40

30

TOTAL CURRENT (uA)

20

10

0.90.80.70.60.50.40.30.20.1

0

MAX44000 toc08

I

DRV

50mA/div

I

DD

200µA/div

TOTAL CURRENT CONSUMPTION

INCLUDING IR LED CURRENT

vs. IR LED CURRENT LEVEL

I

= IDD + I

TOTAL

AMBIENT + PROXIMITY MODE

100ms INTEGRATION TIME

IR_LED

I

IR LED LEVEL (mA)

TOTAL

I

DD

10080604020

MAX44000 toc11

120

6 ______________________________________________________________________________________

Page 7

Ambient and Infrared Proximity Sensor

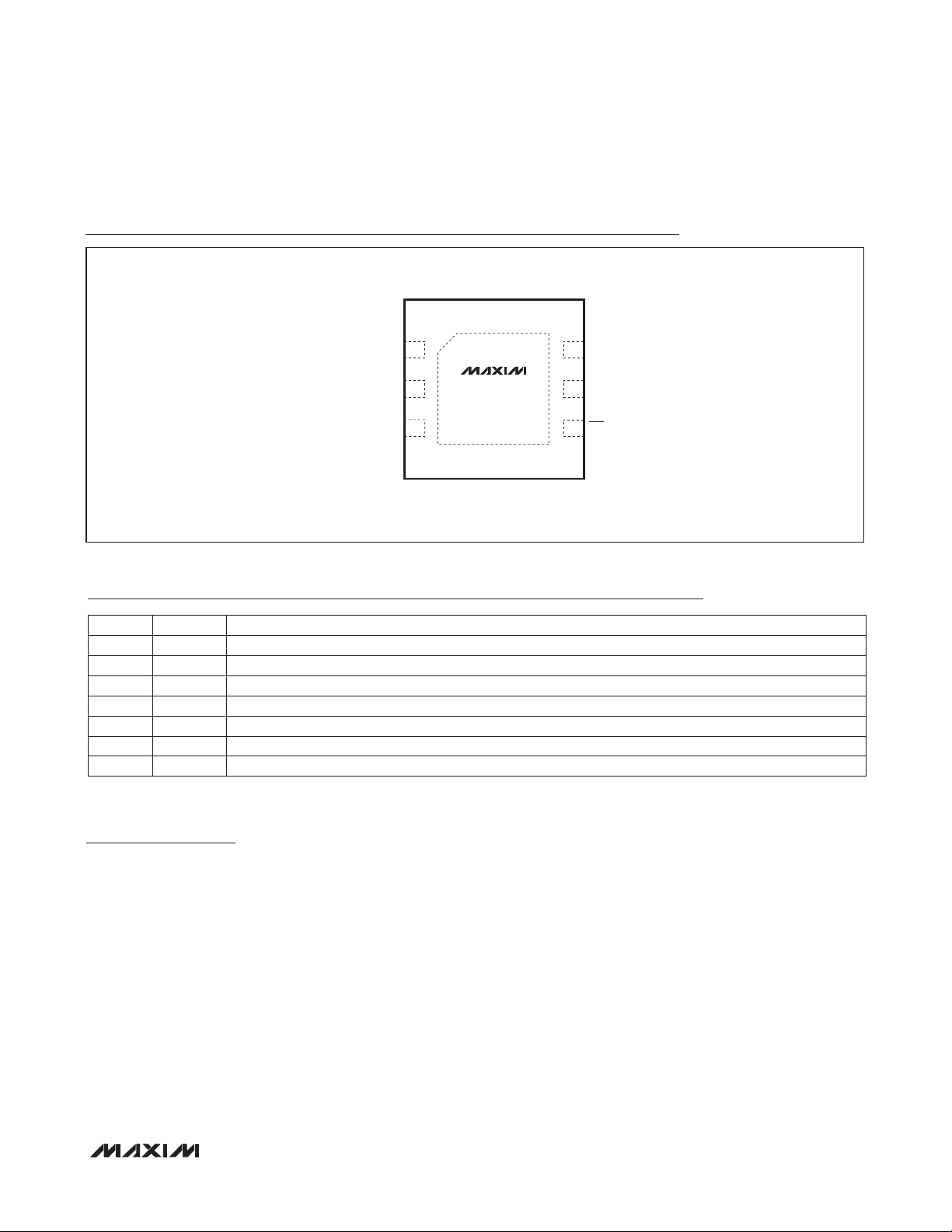

Pin Configuration

TOP VIEW

MAX44000

+

1

V

DD

2

GND SCL

3

DRV

*EP = EXPOSED PAD, CONNECT TO GND.

MAX44000

EP*

6

SDA

5

4

INT

Pin Description

PIN NAME FUNCTION

1 V

2 GND Ground

3 DRV IR LED Current Driver

4

5 SCL I2C Clock

6 SDA I2C Data

EP — Exposed Pad. EP is internally connected to GND. EP must be connected to GND.

DD

INT

Power Supply

Interrupt. Active-low output.

Detailed Description

The MAX44000 combines a wide-dynamic range ambient light sensor with an integrated infrared proximity

sensor. The die is placed inside an optically transparent

(UTDFN-Opto) package. A photodiode array inside the

IC converts the light to a current, which is then processed by low-power circuitry into a digital value. The

data is then stored in an output register that is read by

an I2C interface.

The IC contains three types of photodiodes: a green photodiode and two types of infrared photodiodes. Ambient

light sensing (ALS) is accomplished by subtracting the

infrared ALS photodiode signal from the green ALS

photodiode signals after applying respective gains. The

_______________________________________________________________________________________ 7

infrared proximity photodiodes are optimized for better

sensitivity for near infrared signals, specifically 850nm,

and can be used for proximity sensor measurements.

In the ALS mode, the ALS photodiodes are connected to

two ADCs. The user can choose to view either just the

green ALS signal, or just the infrared ALS signal, or the

difference of the green and infrared ALS photodiodes.

In the proximity detect mode, the infrared proximity photodiodes are connected to the proximity receiver circuit

and then to an 8-bit ADC.

Three key features of the IC’s analog design are its lowpower design, single-pulse proximity receive operation,

and interrupt pin operation.

Page 8

Ambient and Infrared Proximity Sensor

The IC operates from a VDD of 1.7V to 3.6V and consumes just 5FA current in ALS mode and 7FA time-averaged in proximity mode. The on-chip IR proximity detector DC ambient rejection circuitry is synchronized with

pulsing of an integrated IR LED transmitter to improve

noise immunity from external fluctuating IR sources.

This scheme also reduces IR LED power consumption

compared to alternate methods and eliminates red-glow

problems with the use of 850nm IR LEDs; power con-

MAX44000

sumption is reduced to 11FA (time averaged), including the current consumption of an external IR LED. An

on-chip programmable interrupt function eliminates the

need to continually poll the device for data, resulting in a

significant power saving.

Ambient Light Sensing

The ambient light sensors are designed to detect brightness in the same way as human eyes do. To achieve this,

the light sensor needs to have a spectral sensitivity that

is identical to the photopic curve of the human eye (see

Figure 1). Small deviations from the photopic curve can

affect perceived brightness by ambient light sensors to

be wildly different. However, there are practical difficulties in trying to reproduce the ideal photopic curve in a

small cost-efficient package. The IC instead uses two

different types of photodiodes (a green and an infrared)

that have different spectral sensitivities—each of which

is amplified and subtracted on-chip with suitable gain

coefficients so that the most extreme light sources (fluorescent and incandescent) are well matched to a commercial illuminance lux meter.

The photopic curve represents a typical human eye’s

sensitivity to wavelength. As can be seen in Figure 1

and Figure 2, its peak sensitivity is at 555nm (green).

The human eye is insensitive to infrared (> 700nm) and

ultraviolet (< 400nm) radiation.

Variation between light sources can extend beyond the

visible spectral range. For example, fluorescent and

incandescent light sources with similar visible brightness

(lux) can have substantially different IR radiation content

(since the human eye is blind to it). Since this infrared

radiation can be picked up by silicon photodiodes, differences in light spectra can affect brightness measurement of light sensors. For example, light sources with

high IR content, such as an incandescent bulb or sunlight, would suggest a much brighter environment than

our eyes would perceive them to be. Other light sources

such as fluorescent and LED-based systems have very

little infrared content. The IC incorporates on-chip compensation techniques to minimize these effects and still

output an accurate lux response in a variety of lighting

conditions.

On-chip user-programmable green channel and IR channel gain trim registers allow the light sensor response to

be tailored to the application, such as when the light sensor is placed under dark or colored glass.

120

100

80

60

40

NORMALIZED RESPONSE

20

0

270 1070

WAVELENGTH (nm)

Figure 1. Spectral Response Compared to Ideal Photopic

Curve

8 ______________________________________________________________________________________

STANDARD ALS

(GREEN-RED)

970870770670570470370

Figure 2. Green Channel and IR Channel Response at

Identical Gains on a Typical MAX44000

120

100

80

60

40

NORMALIZED OUTPUT

20

0

270 1070

WAVELENGTH (nm)

GREEN CHANNEL

RED CHANNEL

CIE CURVE

970870770670570470370

Page 9

Ambient and Infrared Proximity Sensor

Proximity Light Sensing

The proximity sensing uses an external, pulsed infrared

LED source to emit controlled amounts of infrared radiation. When an external object reflects back some of this

infrared radiation back to the IC, it is detected by the

integrated light detector. The amount of reflected light

detected is then used to determine the object’s proximity

to the sensor.

It is important to take account for the fact that different

objects at the same distance from the sensor can reflect

different amounts of infrared radiation depending on

their texture and color.

The IC includes on-chip ambient cancellation circuitry

in the receive path of the infrared proximity sensor. This

scheme allows the part to operate in the presence of

large amounts of DC IR radiation. Due to the use of a

single-pulse technique in pulsing the external infrared

LED, the chip is also immune to fixed-frequency external

infrared radiation such as from remote controls, electronic ballasts, etc., leading to more reliable infrared

proximity sensor operation.

LED Driver

The IC features a LED driver that delivers a pulsed current at the output. The pulse amplitude is programmable

through the I2C interface from 0 to 110mA in steps of

10mA. A low-voltage compliance of DRV pin allows IR

LEDs to be powered from lower voltage rails, possibly

even a 1.8V rail. High-current drive accuracy improves

performance by eliminating part-to-part variation.

Register Description

REGISTER B7 B6 B5 B4 B3 B2 B1 B0

STATUS

Interrupt Status PWRON PRXINTS ALSINTS 0x00 0x04 R

CONFIGURATION

Main Configuration TRIM MODE[2:0] PRXINTE ALSINTE 0x01 0x24 R/W

Receive Configuration

Transmit Configuration DRV[3:0] 0x03 0x00 R/W

ADC DATA

ADC High Byte (ALS

ADC Low Byte (ALS

ADC Byte (PROX) PRXDATA[7:0] 0x16 0x00 R

THRESHOLD SET

ALS Upper Threshold

(High Byte

ALS Upper Threshold

(Low Byte)

ALS Lower Threshold

(High Byte)

ALS Lower Threshold

(Low Byte)

)

)

1 1 1 1 ALSTIM[1:0] ALSPGA[1:0] 0x02 0x00 R/W

)

OFL ALSDATA[13:8] 0x04 0x00 R

ALSDATA[7:0] 0x05 0x00 R

UPTHR[13:8] 0x06 0x00 R/W

UPTHR[7:0] 0x07 0x00 R/W

LOTHR[13:8] 0x08 0x00 R/W

LOTHR[7:0] 0x09 0x00 R/W

REGISTER

ADDRESS

POWER-ON

RESET

STATE

R/W

MAX44000

_______________________________________________________________________________________ 9

Page 10

Ambient and Infrared Proximity Sensor

Register Description (continued)

REGISTER B7 B6 B5 B4 B3 B2 B1 B0

Threshold Persist Timer PRXPST[1:0] ALSPST[1:0] 0x0A 0x00 R/W

PROX Threshold

Indicator

MAX44000

PROX Threshold PRXTHR[7:0] 0x0C 0x00 R/W

Digital Gain Trim of

Green Channel

Digital Gain Trim of

Infrared Channel

ABOVE 0x0B 0x00 R/W

TRIM_

TRIM_GAIN_GREEN[6:0]

TRIM_GAIN_IR[8:1] 0x10 0x80 R/W

GREEN_

IR[0]

REGISTER

ADDRESS

0x0F 0x80 R/W

POWER-ON

RESET

STATE

The individual register bits are explained below. Default power-up bit states are highlighted in bold.

Interrupt Status Register (0x00)

REGISTER B7 B6 B5 B4 B3 B2 B1 B0

Interrupt Status PWRON PRXINTS ALSINTS 0x00 0x04 R

REGISTER

ADDRESS

POWER-ON

RESET

STATE

The PWRON bit in the Interrupt Status register 0x00, if set, indicates that a power-on-reset (POR) condition has

occurred, and any user-programmed thresholds cannot be valid anymore. The ALSINTS bit in the Interrupt Status register 0x00 indicates that an ambient light interrupt condition has occurred. The PRXINTS bit in the Interrupt Status register 0x00 indicates that a proximity receive interrupt condition has occurred. If any of these bits is set to 1, the INT pin

is pulled low and asserted. Note: On Rev-1 of the device, the PWRON bit does not pull the INT pin low, even if set to 1.

Reading the Interrupt Status register clears the PWRON, ALSINTS, and PRXINTS bits, if set, and deasserts the INT

pin. INT is pulled high by the off-chip pullup resistor. The ALSINTS and PRXINTS bits are disabled and set to 0 if the

respective interrupt enable bits in Main Configuration register 0x01 are set to 0.

R/W

R/W

Ambient Interrupt Status (ALSINTS)

BIT 0 OPERATION

0 No interrupt trigger event has occurred.

The ambient light intensity has traversed outside the designated window limits defined by

1

10 _____________________________________________________________________________________

Threshold registers for greater than persist timer count ALSPST[1:0], or an overflow condition in the ambient light

readings has occurred. This bit also causes the INT pin to be pulled low. Once set, the only way to clear this bit is

to read this register or to set the ALSINTE bit in register 0x01 to 0.

Page 11

Ambient and Infrared Proximity Sensor

Proximity Interrupt Status (PRXINTS)

BIT 1 OPERATION

0 No interrupt trigger event has occurred.

The IR proximity receive intensity has exceeded the threshold limit for greater than persist

1

timer count PRXPST[1:0]. This bit also causes the INT pin to be pulled low. Once set, the only way to clear this bit is

to read this register or to set PRXINTE bit to 0.

Power-On Reset Status (PWRON)

BIT 2 OPERATION

0 No interrupt trigger event has occurred.

The part went through a power-up event, either because the part was turned on or because there was a power-

1

supply voltage glitch. All interrupt threshold settings in the registers have been reset to a default state and should

be examined. A 1 on this bit also causes the INT pin to be pulled low. Note: INT is not pulled low on Rev-1 of the

IC. Once this bit is set, the only way to clear this bit is to read this register.

Main Configuration Register (0x01)

REGISTER B7 B6 B5 B4 B3 B2 B1 B0

Main Configuration TRIM MODE[2:0] PRXINTE ALSINTE 0x01 0x24 R/W

REGISTER

ADDRESS

POWER-ON

RESET

STATE

R/W

This register is used to set the operating mode of the IC (ALS and/or proximity) and enable interrupt operation of the

device.

MAX44000

BIT 5 OPERATION

0

1

Use bytes written to TRIM_GAIN_GREEN[7:0] and TRIM_GAIN_IR[7:0] registers to set the fine-trim gain of the

green and IR gain channels.

Use factory-programmed gains for green and IR channels. Ignore bytes written to TRIM_GAIN_GREEN[7:0] and

TRIM_GAIN_IR[7:0] registers.

The 3-bit MODE[2:0] defines eight operating modes for the IC, as shown below.

MODE[2:0]

000 Shutdown Analog circuits are shut down, but the digital register retains values.

001 ALS G-IR

010 ALS G ALS green channel only. Proximity channel operation and updates are disabled.

011 ALS IR Infrared channel only. Proximity channel operation and updates are disabled.

100 ALS/PROX ALS and PROX are interleaved continuously.

101 PROX Only PROX only continuously. ALS channel operation and updates are disabled.

110 Reserved Do not use.

111 Reserved Do not use.

OPERATING

MODE

Standard ALS mode stores the difference between green and infrared channel readings.

Proximity channel operation and updates are disabled.

______________________________________________________________________________________ 11

OPERATION

TRIM

MODE[2:0]

Page 12

Ambient and Infrared Proximity Sensor

Proximity Interrupt Enable (PRXINTE)

BIT 1 OPERATION

0 The PRXINTS bit remains unasserted, and proximity channel readings are not compared with interrupt thresholds.

Detection of a proximity interrupt event triggers a hardware interrupt (INT pin is pulled low) and sets the PRXINTS

1

bit (register 0x00, B1). Proximity channel readings are compared with proximity interrupt threshold settings and

proximity persist timer.

MAX44000

BIT 0 OPERATION

0 The ALSINTS bit remains unasserted, and ALS channel readings are not compared with interrupt thresholds.

Detection of an ambient light interrupt event triggers a hardware interrupt (INT pin is pulled low) and sets the

1

ALSINTS bit (register 0x00, B0). ALS channel readings are compared with ALS interrupt threshold settings and

ALS persist timer.

Ambient Interrupt Enable (ALSINTE)

Receive Configuration Register (0x02)

REGISTER B7 B6 B5 B4 B3 B2 B1 B0

Receive Configuration 1 1 1 1 ALSTIM[1:0] ALSPGA[1:0] 0x02 0x00 R/W

REGISTER

ADDRESS

POWER-ON

RESET

STATE

This register sets the ADC integration time and front-end photodiode circuitry sensitivity (gain) for the ALS channel.

The ADC integration time also controls the bit resolution of measurements. ADC conversions are made of MSB first

(the IC needs longer conversion times for higher resolution measurements). Use of lower PGA gains helps expand the

full-scale range of the ADC at the expense of per-LSB sensitivity.

R/W

12 _____________________________________________________________________________________

Page 13

Ambient and Infrared Proximity Sensor

Ambient ADC Conversion Time (ALSTIM)

The 2-bit ALSTIM[1:0] sets the integration time for ALS ADC conversion, as shown in Table 1.

Table 1. Ambient ADC Conversion Time

ALSTIM[1:0] INTEGRATION TIME (ms)

00 100 16,384 14 1x

01 25 4096 12 4x

10 6.25 1024 10 16x

11 1.5625 256 8 64x

The 2-bit ALSPGA[1:0] sets the gain of the ambient light sensing measurement according to Table 2.

FULL-SCALE ADC

COUNTS

BIT RESOLUTION RELATIVE LSB SIZE

Ambient Light Measurement Gain (ALSPGA)

Table 2. Ambient Light Measurement Gain

ALSPGA[1:0] LUX/LSB RELATIVE LSB SIZE

00 0.03125 1x

01 0.125 4x

10 0.5 16x

11 4 128x

MAX44000

Transmit Configuration Register (0x03)

This register controls the driver current setting and is used when the Proximity channel is enabled.

REGISTER B7 B6 B5 B4 B3 B2 B1 B0

Transmit Configuration DRV[3:0] 0x03 0x00 R/W

REGISTER

ADDRESS

POWER-ON

RESET

STATE

R/W

LED Drive Current Setting (DRV)

The 4 bits of DRV set the LED drive current according to Table 3.

Table 3. LED Drive Current Settings

DRV[3:0] LED CURRENT (mA) DRV[3:0] LED CURRENT (mA)

0000 LED driver disabled 1000 40

0001 10 1001 50

0010 20 1010 60

0011 30 1011 70

0100 40 1100 80

0101 50 1101 90

0110 60 1110 100

0111 70 1111 110

______________________________________________________________________________________ 13

Page 14

Ambient and Infrared Proximity Sensor

ALS Data Register (0x04, 0x05)

REGISTER B7 B6 B5 B4 B3 B2 B1 B0

ADC High Byte (ALS) OFL ALSDATA[13:8] 0x04 0x00 R

ADC Low Byte (ALS) ALSDATA[7:0] 0x05 0x00 R

The 2 bytes here (ALSDATA[13:0]) hold the results of the ALS signal conversion. The resolution and bit length of the

MAX44000

result is controlled by the value of ALSTIM[1:0] and ALSPGA[1:0] bits. The result is always right justified in the two

registers, and the unused high bits are zero.

OFL indicates an overflow condition on the ALS channel. If this occurs, set the ALS range (ALSPGA[1:0]) to a higher

range. If the OFL bit is set to 1 (there is an overflow condition), and the ALSINTE bit is set to 1 (enabled), then the

ALSINTS bit is set to 1 and the INT pin is pulled low.

The data in this register could be the green channel, infrared channel, or ALS readings (green channel, infrared channel readings), depending on the mode selected by the user.

Internal update of these two registers is disabled during I2C read operations to ensure proper data handoff between

the ADC and the I2C registers. Update of the I2C registers is resumed once the master sends a STOP (P) command.

Therefore, when reading the 2 bytes of this register, the master should not send a STOP command between the 2-byte

reads. Instead, a Repeated START (Sr) command should be used. The exact read sequence using the Repeated

START command is shown in the I2C Serial Interface section.

REGISTER

ADDRESS

POWER-ON

RESET

STATE

PROX Data Registers (0x15, 0x16)

REGISTER B7 B6 B5 B4 B3 B2 B1 B0

ADC Byte (PROX) PRXDATA[7:0] 0x16 0x00 R

The byte here (PRXDATA[7:0]) hold the results of the proximity receive signal conversion. Internal update of the register

is disabled during I2C read operations to ensure proper data handoff between the ADC and the I2C registers. Update

of the I2C registers is resumed once the master sends a STOP command.

REGISTER

ADDRESS

POWER-ON

RESET

STATE

R/W

R/W

14 _____________________________________________________________________________________

Page 15

Ambient and Infrared Proximity Sensor

ALS Interrupt Threshold Registers (0x06–0x09)

POWER-ON

RESET

STATE

R/W

REGISTER B7 B6 B5 B4 B3 B2 B1 B0

ALS Upper Threshold

(High Byte)

ALS Upper Threshold

(Low Byte)

ALS Lower Threshold

(High Byte)

ALS Lower Threshold

(Low Byte)

UPTHR[7:0] 0x07 0x00 R/W

LOTHR[7:0] 0x09 0x00 R/W

UPTHR[13:8] 0x06 0x00 R/W

LOTHR[13:8] 0x08 0x00 R/W

REGISTER

ADDRESS

The ALS upper threshold and ALS lower threshold (UPTHR[13:0] and LOTHR[13:0]) set the window limits that are used

to trigger an ALS interrupt. It is important to set these values according to the selected bit resolution/integration time

chosen for the ALS measurement based on the ALSTIM[1:0] and ALSPGA[1:0] settings. The upper 2 bits are always

ignored. If the INTE bit is set, and the lux level is greater or lower than the respective thresholds for a period greater

than that defined by the ALSPST persist time, the INTS bit in the Status register is set and the INT pin is pulled low.

ALS/PROX Threshold Persist Timer Register (0x0A)

REGISTER B7 B6 B5 B4 B3 B2 B1 B0

Threshold Persist Timer PRXPST[1:0] ALSPST[1:0] 0x0A 0x00 R/W

REGISTER

ADDRESS

POWER-ON

RESET

STATE

R/W

MAX44000

The MAX44000 incorporates a persist function that allows the users to set the number of consecutive triggers before

interrupt. PRXPST[1:0] and ALSPST[1:0] set one of four persist values that control how readily the interrupt logic reacts

to a detected event. This feature is added to reduce false or nuisance interrupts.

PRXPST[1:0] OR ALSPST[1:0] NO. OF CONSECUTIVE TRIGGERS BEFORE INTERRUPT

00 1

01 2

10 4

11 16

When ALSPST[1:0] is set to 00, and the ALSINTE bit is set to 1, the first time an ALS interrupt event is detected, the

ALSINTE interrupt bit is set and the INT pin goes low. If ALSPST[1:0] is set to 01, then four consecutive interrupt events

must be detected on four consecutive measurement cycles. Similarly, if ALSPST[1:0] is set to 10, or 11, then 8 or 16

consecutive interrupts must be detected. If there is an intervening measurement cycle where no interrupt is detected,

then the count is reset to zero. The proximity interrupt function is managed in the same way with PRXPST[1:0].

______________________________________________________________________________________ 15

Page 16

Ambient and Infrared Proximity Sensor

Proximity Threshold Registers (0x0B, 0x0C)

REGISTER B7 B6 B5 B4 B3 B2 B1 B0

PROX Threshold Indicator ABOVE 0x0B 0x00 R/W

PROX Threshold PRXTHR[7:0] 0x0C 0x00 R/W

REGISTER

ADDRESS

POWER-ON

RESET

STATE

The value set by PRXTHR[7:0] in combination with the ABOVE bit controls the operation of the proximity interrupt function. If the ABOVE bit is set to 1, the proximity interrupt has been enabled (PRXINTE = 1), and the result of a proximity

MAX44000

measurement is greater than the value stored in PRXTHR[7:0], then a proximity interrupt event is recorded. The interrupt bit is set subject to count conditions set by PRXPST[1:0]. Similarly, if the ABOVE bit is set to 0, then an interrupt

event is recorded if the result of a proximity measurement is less than value stored in PRXTHR[7:0].

Digital Gain Trim Registers (0x0F, 0x10)

REGISTER B7 B6 B5 B4 B3 B2 B1 B0

Digital Gain Trim of

Green Channel

Digital Gain Trim of

Infrared Channel

Note: Values read from TRIM_GAIN_ registers are the complements of the written value. This is true for reading both the factoryprogrammed values and the customer-programmed values.

TRIM_GAIN_GREEN[6:0]

TRIM_GAIN_IR[8:1] 0x10 0x80 R/TW

TRIM_

GAIN_

REGISTER

ADDRESS

0x0F 0x80 R/TW

IR[0]

POWER-ON

RESET

STATE

R/W

R/W

TRIM_GAIN_GREEN[6:0] is used to modify the gain of the green channel.

TRIM_GAIN_IR[8:0] is used to modify the gain of the IR channel.

To tell the part to use the values written to this register, set the TRIM bit to 0 in the Main Configuration register after

writing new values to these registers.

16 _____________________________________________________________________________________

Page 17

Ambient and Infrared Proximity Sensor

Applications Information

Ambient Sensing Applications

Typical applications involve placing the IC behind a

glass with a small semitransparent window placed above

it. Use the photodiode sensitive area as shown in Figure

3 to properly position the window above the part.

The part comes equipped with internal gain trim registers for the green and IR ALS photodiodes. By suitably

choosing the gains for these channels, accurate ambient

light readings can be generated in all lighting conditions

irrespective of the type of glass the part is used under.

This is especially useful for black-glass applications,

where for cosmetic reasons, the part is placed behind

a black film to hide its presence, and this film has the

peculiar property of attenuating most ambient light, but

passing through infrared radiation.

In standard ALS mode, the green channel and infrared

channel readings are internally subtracted. Since one is

observing only the difference in two separate ADC measurements, wrong readings can be obtained if one of the

channels becomes saturated, while the other channel

continues to rise. Since both the green photodiode also

picks up a lot of the infrared signal, this saturation can

occur much before the maximum expected full-scale

range in certain lighting conditions. For example, under

incandescent light, there is a lot more infrared optical

power than in the visible spectral range. In these situations, the green channel can saturate much earlier than

511 lux in the most sensitive range. To assist the user in

detecting these conditions, an OFL bit is provided that

alerts the user of an overrange condition. This bit also

triggers an ALS interrupt if it has been enabled.

Proximity Sensing Applications

The IC integrates a novel proximity sensor interface

circuit with a robust built-in ambient IR cancellation

scheme. The internal DC IR rejection circuit eliminates

problems of ADC saturation in the presence of strong

ambient infrared radiation, such as bright sunlight.

Further, the proximity sensor uses a single-pulse scheme

for the IR transmitter that eliminates red-glow problems

seen in competing solutions to drive 850nm IR LEDs,

while also reducing average IR LED power consumption

to less than 0.1% of the IR LED peak current.

2mm

V

CC

1

1.226mm

GND

0.39mm

DRV

Figure 3. Photodiode Location

0.753mm

2

3

MAX44000

TOP VIEW

PHOTO-

DIODE

0.492mm

6 SDA

5SCL

4

INT

2mm

Interrupt Operation

Ambient interrupt is enabled by setting bit 0 of register

0x01 to 1 and proximity interrupt is enabled by setting

bit 1 of register 0x01 to 1 (see Table 1 and Table 2). The

interrupt pin, INT, is an open-drain output and pulls low

when an interrupt condition occurs (e.g., when ambient

lux readings exceed threshold limits for a period greater

than that set by the Time register). The interrupt status bit

is cleared automatically if register 0x00 is read or if the

interrupts are disabled.

A PWRON interrupt bit is set to alert the master of a chip

reset operation in case of a power-supply glitch that can

happen on smartphones that place the light sensor on a

flex with a small connector.

It is best to utilize the interrupt pin on the IC to alert the

master to come and read measurements from the IC. This

eliminates the need for the microcontroller (I2C master)

to continually poll the device for information. Due to the

use of pullup resistors on the I2C bus, minimizing I2C bus

activity can reduce power consumption substantially. In

addition, this frees up the microcontroller resources to

service other background processes to improve device

performance. The wide variety of smarts available on the

chip, such as the ability to set the threshold levels and to

count persist timer limits, allow the part to operate in an

autonomous mode most of the time.

MAX44000

______________________________________________________________________________________ 17

Page 18

Ambient and Infrared Proximity Sensor

Interrupt Pin Voltage Compliance

The interrupt pin can withstand external voltages up

to 4V when in high-impedance mode per the absolute

maximum ratings of the IC. However, when the voltage

on the INT pin is higher than the VDD of the part (such as

when external pullup voltage is greater than VDD of part),

there is a small leakage current of 25µA sink into INT. This

additional current drawn through the INT pin should also

be accounted for in power-sensitive applications.

MAX44000

The typical operating sequence for the master to communicate to the IC is shown below:

1) Read the Interrupt Status register (0x00) to confirm

only the PWRON bit is set. This also clears a hardware interrupt. Note: For Rev-1 devices, a PWRON

interrupt does not trigger a hardware interrupt.

2) Set the Threshold and Threshold Persist Timer

registers for ambient and proximity sensor measurements (Registers 0x06–0x0C). Note: For Rev-1

devices, leave the Threshold Persist Timer register

(Register 0x0A) set to 0.

3) Write F0 to the Receive Configuration register

(Register 0x02) to set the ALS sensor in the highest gain setting and ALS ADCs in 14-bit modes of

operation.

4) Set the IR LED current to a suitable level by writing

to the Transmit Configuration register (0x03).

5) Write 0x13 to Main Configuration register (register

0x01) to set the part in ALS + proximity mode, and

to enable ALS and proximity interrupts.

6) Set the new green channel gains and infrared

channel gains, if necessary, to customize ALS

operation for application conditions. Ensure the

TRIM bit is set to 0 when not using default factorytrim settings.

7) Wait for interrupt.

8) Read the Interrupt Status register (0x00) to confirm

the IC to be the source of interrupt, and to check

for the type of interrupt. If set, this should clear the

hardware interrupt on the part.

Typical Operating Sequence

9) If an ALS interrupt has occurred, read the ADC

High Byte (ALS) and ADC Low Byte (ALS) registers

(registers 0x04, 0x05) to confirm if data is valid (i.e.,

OFL = 0), and take appropriate action (e.g., sets

new backlight strength). Set new ALS thresholds, if

necessary.

10) If a PROX interrupt has occurred, read the PROX

ADC registers (register 0x15) and take appropriate

action (typically, turn off or turn on touch screen

and backlight). Set new proximity thresholds, if

necessary.

11) Return to step 7.

I2C Serial Interface

The IC features an I2C/SMBus-compatible, 2-wire serial

interface consisting of a serial-data line (SDA) and a

serial-clock line (SCL). SDA and SCL facilitate communication between the IC and the master at clock rates

up to 400kHz. Figure 4 shows the 2-wire interface timing diagram. The master generates SCL and initiates

data transfer on the bus. A master device writes data

to the IC by transmitting the proper slave address followed by the register address and then the data word.

Each transmit sequence is framed by a START (S) or

Repeated START condition and a STOP condition. Each

word transmitted to the IC is 8 bits long and is followed

by an acknowledge clock pulse. A master reading data

from the IC transmits the proper slave address followed

by a series of nine SCL pulses. The IC transmits data

on SDA in sync with the master-generated SCL pulses.

The master acknowledges receipt of each byte of data.

Each read sequence is framed by a START or Repeated

START condition, a not acknowledge, and a STOP condition. SDA operates as both an input and an open-drain

output. A pullup resistor, typically greater than 500I, is

required on the SDA bus. SCL operates as only an input.

A pullup resistor, typically greater than 500I, is required

on SCL if there are multiple masters on the bus, or if the

master in a single-master system has an open-drain SCL

output. Series resistors in line with SDA and SCL are

optional. Series resistors protect the digital inputs of the

IC from high-voltage spikes on the bus lines, and minimize crosstalk and undershoot of the bus signal.

Table 4. Slave Address

SLAVE ADDRESS FOR WRITING SLAVE ADDRESS FOR READING

1001 0100 1001 0101

18 _____________________________________________________________________________________

Page 19

Ambient and Infrared Proximity Sensor

rP

SDA

t

SU,DAT

t

LOW

SCL

t

t

HD,STA

START

CONDITION

Figure 4. 2-Wire Interface Timing Diagram

HIGH

t

R

MAX44000

t

STOP

BUF

START

CONDITION

t

SU,STA

t

HD,DAT

t

F

REPEATED

START CONDITION

t

HD,STA

t

SP

t

SU,STO

CONDITION

Bit Transfer

One data bit is transferred during each SCL cycle. The

data on SDA must remain stable during the high period

of the SCL pulse. Changes in SDA while SCL is high are

control signals. See the START and STOP Conditions section. SDA and SCL idle high when the I2C bus is not busy.

START and STOP Conditions

SDA and SCL idle high when the bus is not in use. A

master initiates communication by issuing a START condition. A START condition is a high-to-low transition on

SDA with SCL high. A STOP condition is a low-to-high

transition on SDA while SCL is high (Figure 5). A START

condition from the master signals the beginning of a

transmission to the IC. The master terminates transmission, and frees the bus by issuing a STOP condition. The

bus remains active if a Repeated START condition is

generated instead of a STOP condition.

Early STOP Conditions

The IC recognizes a STOP condition at any point during

data transmission except if the STOP condition occurs in

SS

SCL

the same high pulse as a START condition. For proper

operation, do not send a STOP condition during the

same SCL high pulse as the START condition.

Acknowledge

The acknowledge bit (ACK) is a clocked 9th bit that the

IC uses to handshake receipt of each byte of data when

in write mode (Figure 6). The IC pulls down SDA during the entire master-generated ninth clock pulse if the

previous byte is successfully received. Monitoring ACK

allows for detection of unsuccessful data transfers. An

unsuccessful data transfer occurs if a receiving device

is busy or if a system fault has occurred. In the event of

an unsuccessful data transfer, the bus master can retry

communication. The master pulls down SDA during the

ninth clock cycle to acknowledge receipt of data when

the IC is in read mode. An acknowledge is sent by the

master after each read byte to allow data transfer to

continue. A not acknowledge is sent when the master

reads the final byte of data from the IC, followed by a

STOP condition.

CLOCK PULSE FOR

ACKNOWLEDGMENT

CONDITION

SCL

START

1

289

SDA

SDA

Figure 5. START, STOP, and Repeated START Conditions Figure 6. Acknowledge

______________________________________________________________________________________ 19

NOT ACKNOWLEDGE

ACKNOWLEDGE

Page 20

Ambient and Infrared Proximity Sensor

Write Data Format

A write to the IC includes transmission of a START condition, the slave address with the R/W bit set to 0, 1 byte

of data to configure the internal register address pointer,

one or more bytes of data, and a STOP condition. Figure

7 illustrates the proper frame format for writing 1 byte of

data to the IC.

The slave address with the R/W bit set to 0 indicates

that the master intends to write data to the IC. The IC

MAX44000

acknowledges receipt of the address byte during the

master-generated ninth SCL pulse.

The second byte transmitted from the master configures

the IC’s internal register address pointer. The pointer

tells the IC where to write the next byte of data. An

acknowledge pulse is sent by the IC upon receipt of the

address pointer data.

The third byte sent to the IC contains the data that is

written to the chosen register. An acknowledge pulse

from the IC signals receipt of the data byte. Figure 8 illustrates how to write to multiple registers with one frame.

The master signals the end of transmission by issuing a

STOP condition.

Read Data Format

Send the slave address with the R/W bit set to 1 to initiate a read operation. The IC acknowledges receipt of

its slave address by pulling SDA low during the ninth

SCL clock pulse. A START command followed by a read

command resets the address pointer to register 0x00.

The first byte transmitted from the IC is the contents of

register 0x00. Transmitted data is valid on the rising edge

of the master-generated serial clock (SCL). The address

pointer autoincrements after each read data byte. This

autoincrement feature allows all registers to be read

sequentially within one continuous frame. A STOP condition can be issued after any number of read data bytes.

If a STOP condition is issued followed by another read

operation, the first data byte to be read is from register

0x00 and subsequent reads autoincrement the address

pointer until the next STOP condition. The address

pointer can be preset to a specific register before a read

command is issued. The master presets the address

pointer by first sending the IC’s slave address with the

R/W bit set to 0 followed by the register address. A

Repeated START condition is then sent, followed by the

slave address with the R/W bit set to 1. The IC transmits the contents of the specified register. The address

pointer autoincrements after transmitting the first byte.

Attempting to read from register addresses higher than

0xFF results in repeated reads of 0xFF. Note that 0xF6

to 0xFF are reserved registers. The master acknowledges receipt of each read byte during the acknowledge

clock pulse. The master must acknowledge all correctly

received bytes except the last byte. The final byte must

be followed by a not acknowledge from the master and

then a STOP condition. Figure 8 illustrates the frame

format for reading 1 byte from the IC. Figure 9 illustrates

the frame format for reading two registers consecutively

without a STOP condition in between reads.

ACKNOWLEDGE FROM MAX44000

ACKNOWLEDGE FROM MAX44000

S AA

Figure 7. Writing 1 Byte of Data to the IC

20 _____________________________________________________________________________________

0SLAVE ADDRESS REGISTER ADDRESS DATA BYTE

R/W

ACKNOWLEDGE FROM MAX44000

1 BYTE

B1 B0B3 B2B5 B4B7 B6

A

P

Page 21

Ambient and Infrared Proximity Sensor

MAX44000

ACKNOWLEDGE FROM MAX44000

SA

R/W

ACKNOWLEDGE FROM MAX44000

0

Figure 8. Reading 1 Indexed Byte of Data from the IC

ACKNOWLEDGE FROM MAX44000

SA

R/W

ACKNOWLEDGE FROM MAX44000

ACKNOWLEDGE FROM MAX44000

0

ACKNOWLEDGE FROM MAX44000

0

AS

R/W

ACKNOWLEDGE FROM MAX44000

Sr 1SLAVE ADDRESS REGISTER ADDRESS SLAVE ADDRESS DATA BYTE

ACKNOWLEDGE FROM MAX44000

Sr 1SLAVE ADDRESS REGISTER ADDRESS 1 SLAVE ADDRESS DATA BYTE 1

ACKNOWLEDGE FROM MAX44000

Sr 1SLAVE ADDRESS REGISTER ADDRESS 2 SLAVE ADDRESS

NOT ACKNOWLEDGE FROM MASTER

AA

R/WREPEATED START

NOT ACKNOWLEDGE FROM MASTER

AA

R/WREPEATED START

NOT ACKNOWLEDGE FROM MASTER

AA

R/WREPEATED START

1 BYTE

1 BYTE

DATA BYTE 2

1 BYTE

A

P

A

Sr

AP

Figure 9. Reading Two Registers Consecutively Without a STOP Condition Between Reads

______________________________________________________________________________________ 21

Page 22

Ambient and Infrared Proximity Sensor

Typical Applications Circuit

V

=

LED

1.7V TO 3.6V

1.7V TO 3.6V

1.7V TO 3.6V

MAX44000

IR LED

1µF

V

DD

GND

MAX44000

DRV

SDA

SCL

INT

10kI 10kI 10kI

SDA

SCL

2

I

C SLAVE_1

2

I

C SLAVE_1

SDA

SCL

SDA

SCL

INT

(I

µC

2

C MASTER)

22 _____________________________________________________________________________________

Page 23

Ambient and Infrared Proximity Sensor

Package Information

For the latest package outline information and land patterns (footprints), go to www.maxim-ic.com/packages. Note that a “+”, “#”,

or “-” in the package code indicates RoHS status only. Package drawings may show a different suffix character, but the drawing

pertains to the package regardless of RoHS status.

PACKAGE TYPE PACKAGE CODE OUTLINE NO. LAND PATTERN NO.

6 OTDFN-EP D622N+2

21-0490 90-0344

MAX44000

______________________________________________________________________________________ 23

Page 24

Ambient and Infrared Proximity Sensor

Revision History

REVISION

NUMBER

0 10/11 Initial release —

REVISION

DATE

MAX44000

DESCRIPTION

PAGES

CHANGED

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied.

Maxim reserves the right to change the circuitry and specifications without notice at any time.

24 Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

©

2011 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Loading...

Loading...