Page 1

General Description

The MAX3737 is a +3.3V laser driver designed for

multirate transceiver modules with data rates from

155Mbps to 2.7Gbps. Lasers can be DC-coupled to the

MAX3737 for reduced component count and ease of

multirate operation.

Laser extinction ratio control (ERC) combines the features

of automatic power control (APC), modulation compensation, and built-in thermal compensation. The APC loop

maintains constant average optical power. Modulation

compensation increases the modulation current in proportion to the bias current. These control loops combined

with thermal compensation maintain a constant optical

extinction ratio over temperature and lifetime.

The MAX3737 accepts differential data input signals.

The wide 5mA to 60mA (up to 85mA AC-coupled) modulation current range and up to 100mA bias current

range makes the MAX3737 ideal for driving FP/DFB

lasers in fiber-optic modules. External resistors set the

required laser current levels. The MAX3737 provides

transmit disable control (TX_DISABLE), single-point

fault tolerance, bias-current monitoring, modulation-current monitoring, and photocurrent monitoring. The

device also offers a latched failure output (TX_FAULT)

to indicate faults, such as when the APC loop is no

longer able to maintain the average optical power at the

required level. The MAX3737 is compliant with the SFF8472 transmitter diagnostic and SFP MSA timing

requirements.

The MAX3737 is offered in a 5mm x 5mm 32-pin thin QFN

and QFN package and operates over the -40°C to +85°C

extended temperature range.

Applications

Multirate OC-3 to OC-48 FEC Transceivers

Gigabit Ethernet SFF/SFP and GBIC

Transceivers

1Gbps/2Gbps Fibre Channel SFF/SFP and GBIC

Transceivers

Features

♦ Single +3.3V Power Supply

♦ 47mA Power-Supply Current

♦ 85mA Modulation Current

♦ 100mA Bias Current

♦ Automatic Power Control (APC)

♦ Modulation Compensation

♦ On-Chip Temperature Compensation

♦ Self-Biased Inputs for AC-Coupling

♦ Ground-Referenced Current Monitors

♦ Laser Safety, Shutdown, and Alarm Outputs

MAX3737

Multirate Laser Driver with Extinction

Ratio Control

________________________________________________________________ Maxim Integrated Products 1

Pin Configurations

Ordering Information

19-2818; Rev 0; 4/03

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

Functional Diagram and Typical Application Circuit appear

at end of data sheet.

Pin Configurations continued at end of data sheet.

PART TEMP RANGE PIN-PACKAGE

MAX3737ETJ -40°C to +85°C 32 Thin QFN

MAX3737EGJ -40°C to +85°C 32 QFN

TOP VIEW

APCFILT2

APCSET

28

27

13

14

VBS

SHUTDOWN

APCFILT1

25 VMD

26

16GND

15

GND

24 MD

23

22

21

20

19

18

17

TX_DISABLE

V

V

PC_MON

BC_MON

IN+

MODTCOMP

TH_TEMP

MODBCOMP

MODSET

32

31

30

29

1GND

2

3

CC

4

9

10

GND

MC_MON

MAX3737EGJ

11

12

CC

V

TX_FAULT

5mm x 5mm

QFN

5

IN-

6

CC

7

8

V

CC

OUT+

OUT+

OUT-

OUT-

V

CC

BIAS

*THE EXPOSED PADDLE MUST BE SOLDERED TO SUPPLY GROUND

TO ACHIEVE SPECIFIED PERFORMANCE.

Page 2

MAX3737

Multirate Laser Driver with Extinction

Ratio Control

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VCC= +2.97V to +3.63V, TA = -40°C to +85°C. Typical values are at VCC= +3.3V, I

BIAS

= 60mA, I

MOD

= 60mA, TA = +25°C, unless

otherwise noted.) (Notes 1, 2)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Supply Voltage VCC...............................................-0.5V to +6.0V

IN+, IN-, TX_DISABLE, TX_FAULT, SHUTDOWN,

MC_MON, BC_MON, PC_MON, VBS, VMD,

APCFILT1, APCFILT2, MD, TH_TEMP,

MODTCOMP, MODBCOMP, MODSET, and

APCSET Voltage .......................................-0.5V to V

CC

+ 0.5V

OUT+, OUT-, BIAS Current.............................-20mA to +150mA

Continuous Power Dissipation (T

A

= +85°C)

32-Pin QFN (derate 21.2mW/°C above +85°C) ...............1.3W

Operating Junction Temperature Range...........-55°C to +150°C

Storage Temperature Range .............................-55°C to +150°C

POWER SUPPLY

Supply Current I

Power-Supply Noise Rejection PSNR f ≤ 1MHz, 100mV

I/O SPECIFICATIONS

Differential Input Swing V

Common-Mode Input V

LASER BIAS

Bias-Current Setting Range 1 100 mA

Bias Off Current TX_DISABLE = high 0.1 mA

Bias-Current Monitor Ratio I

LASER MODULATION

Modulation-Current Setting

Range

Output Edge Speed

Output Overshoot/Undershoot (Note 7) ±6 %

Random Jitter (Notes 6, 7) 0.65 1.3 ps

Deterministic Jitter (Notes 6, 8)

Modulation-Current Temperature

Stability

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CC

I

MOD

CM

(Note 3) 47 60 mA

DC-coupled, Figure 1 0.2 2.4 V

ID

BIAS/IBC_MON

(Note 5) 5 85 mA

20% to 80%

(Notes 6, 7)

2.7Gbps

1.25Gbps

622Mbps

155Mbps

(Note 6) ±150 ±480 ppm/°C

(Notes 4, 6) 33 dB

P-P

5mA ≤ I

10mA < I

5mA ≤ I

10mA < I

5mA ≤ I

10mA < I

5mA ≤ I

10mA < I

5mA ≤ I

10mA < I

≤ 10mA 71 80

MOD

≤ 85mA 52 80

MOD

≤ 10mA 25.6 40

MOD

≤ 85mA 16 40

MOD

≤ 10mA 32 41

MOD

≤ 85mA 15 41

MOD

≤ 10mA 39 46

MOD

≤ 85mA 21 46

MOD

≤ 10mA 65 100

MOD

≤ 85mA 46 70

MOD

V

-

1.7

68 82 95 mA/mA

CC

/4

V

ID

ps

P-P

V

ps

P-P

Page 3

MAX3737

Multirate Laser Driver with Extinction

Ratio Control

ELECTRICAL CHARACTERISTICS (continued)

(VCC= +2.97V to +3.63V, TA = -40°C to +85°C. Typical values are at VCC= +3.3V, I

BIAS

= 60mA, I

MOD

= 60mA, TA = +25°C, unless

otherwise noted.) (Notes 1, 2)

Note 1: AC characterization is performed using the circuit in Figure 2 using a PRBS 2

23

- 1 or equivalent test pattern.

Note 2: Specifications at -40°C are guaranteed by design and characterization.

Note 3: Excluding I

BIAS

and I

MOD

. Input data is AC-coupled. TX_FAULT open, SHUTDOWN open.

Note 4: Power-supply noise rejection (PSNR) = 20log

10(Vnoise (on VCC)

/∆V

OUT

). V

OUT

is the voltage across the 15Ω load when IN+ is high.

Note 5: The minimum required voltage at the OUT+ and OUT- pins is +0.75V.

Note 6: Guaranteed by design and characterization.

Note 7: Tested with 00001111 pattern at 2.7Gbps.

Note 8: DJ includes pulse-width distortion (PWD).

_______________________________________________________________________________________ 3

Modulation-Current Setting Error

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

5mA ≤ I

10mA < I

MOD

MOD

15Ω load,

T

= +25°C

A

Modulation Off Current TX_DISABLE = high 0.1 mA

Modulation-Current Monitor Ratio I

MOD/IMC_MON

EXTINCTION RATIO CONTROLS

M oni tor - D i od e Inp ut C ur r ent Rang eIMDAverage current into the MD pin 18 1500 µA

MD Pin Voltage 1.4 V

MD-Current Monitor Ratio IMD/I

APC Loop Time Constant C

PC_MON

APC_FILT

= 0.01µF, ∆IMD/∆I

BIAS

APC Setting Stability ±100 ±480 ppm/°C

APC Setting Accuracy TA = +25°C ±15 %

I

Compensation Setting

MOD

Range by Bias

I

Compensation Setting

MOD

Range by Temperature

Threshold Setting Range for

Temperature Compensation

K K = ∆I

TC TC = ∆I

T

TH

(Note 6) 10 60 °C

/∆I

MOD

BIAS

/∆Τ (Note 6) 0 1.0 mA/°C

MOD

LASER SAFETY AND CONTROL

Bias and Modulation Turn-Off

Delay

Bias and Modulation Turn-On

Delay

Threshold Voltage at Monitor Pins V

REF

C

APC_FILT

= 0.01µF, ∆IMD/∆I

BIAS

(Note 6)

C

APC_FILT

= 0.01µF, ∆IMD/∆I

BIAS

(Note 6)

Figure 5 1.14 1.3 1.39 V

INTERFACE SIGNALS

TX_DISABLE Input High V

TX_DISABLE Input Low V

TX_DISABLE Input Current

LO

HI

R

= 7.5kΩ 0.8 V

PULL

V

= V

HI

CC

= GND -450 -800

V

LO

TX_FAULT Output Low Sinking 1mA, open collector 0.4 V

Shutdown Output High Sourcing 100µA

Shutdown Output Low Sinking 100µA 0.4 V

≤ 10mA ±20

≤ 85mA ±15

%

223 262 302 mA/mA

0.85 1.0 1.15 mA/mA

= 1/70 3.3 µs

0 1.5 mA/mA

= 1/80

= 1/80

5µs

600 µs

2.0 V

15

V

-

CC

µA

0.4

V

Page 4

MAX3737

Multirate Laser Driver with Extinction

Ratio Control

4 _______________________________________________________________________________________

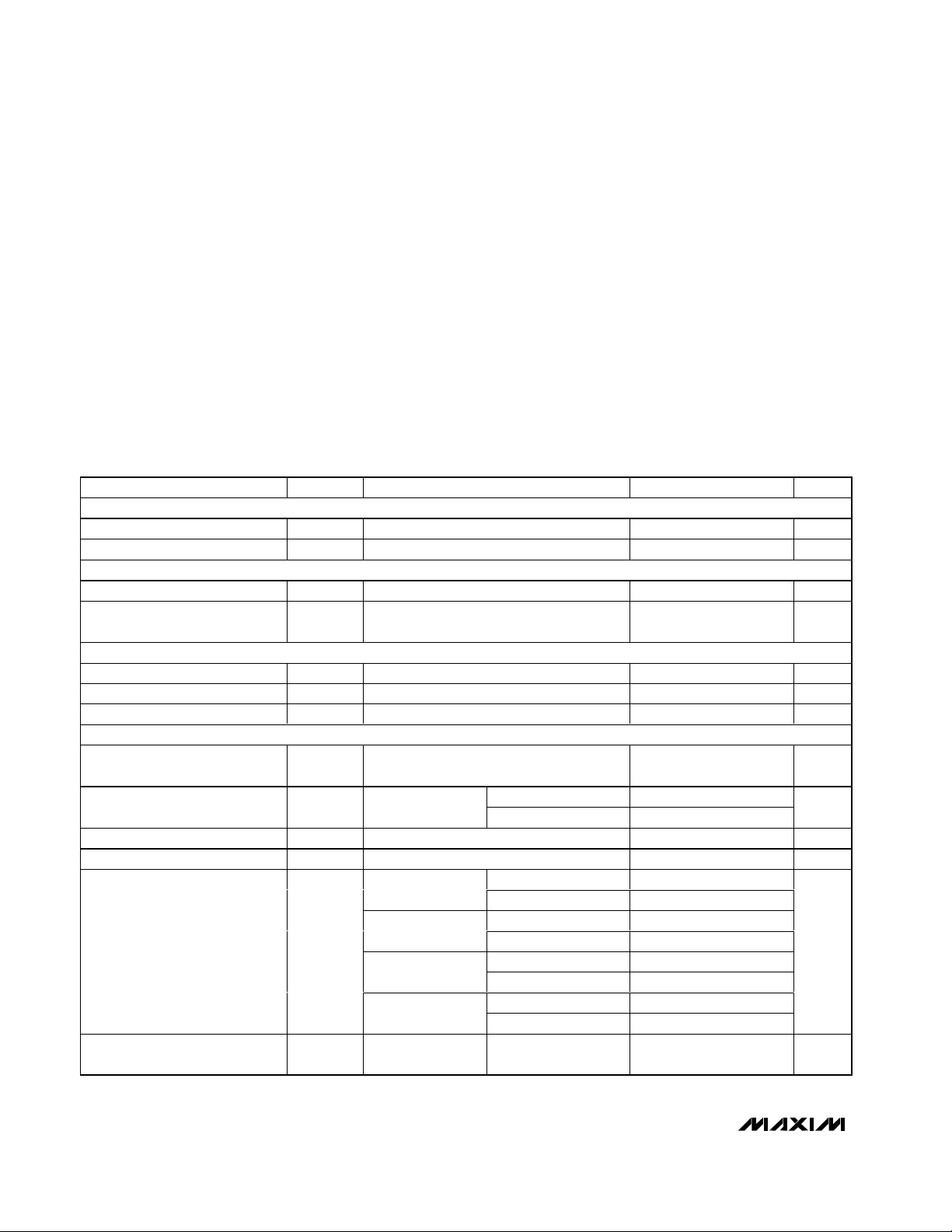

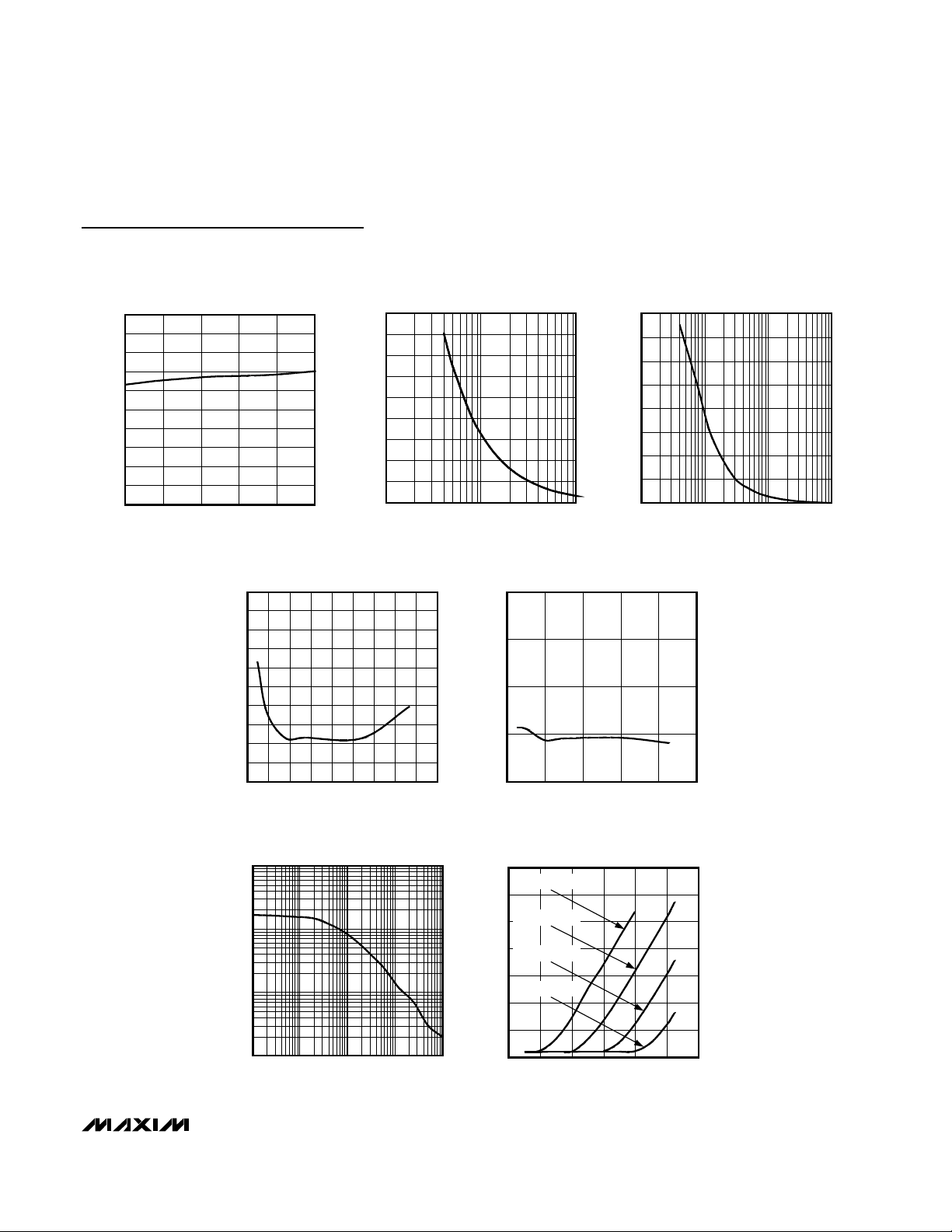

Typical Operating Characteristics

(VCC= +3.3V, C

APC

= 0.01µF, I

BIAS

= 20mA, I

MOD

= 30mA, TA = +25°C, unless otherwise noted.)

OPTICAL EYE DIAGRAM

(2.7Gbps, 2

7

- 1PRBS, 2.3GHz FILTER)

MAX3737 toc01

54ps/div

1310nm FP LASER

E

r

= 8.2dB

OPTICAL EYE DIAGRAM

(1.25Gbps, 2

7

- 1PRBS, 940MHz FILTER)

MAX3737 toc02

116ps/div

1310nm FP LASER

E

r

= 8.2dB

OPTICAL EYE DIAGRAM

(155Mbps, 2

7

- 1PRBS, 117MHz FILTER, C

APC

= 0.1µF)

MAX3737 toc03

920ps/div

ELECTRICAL EYE DIAGRAM

(I

MOD

= 30mA, 2.7Gbps, 27 - 1PRBS)

MAX3737 toc04

52ps/div

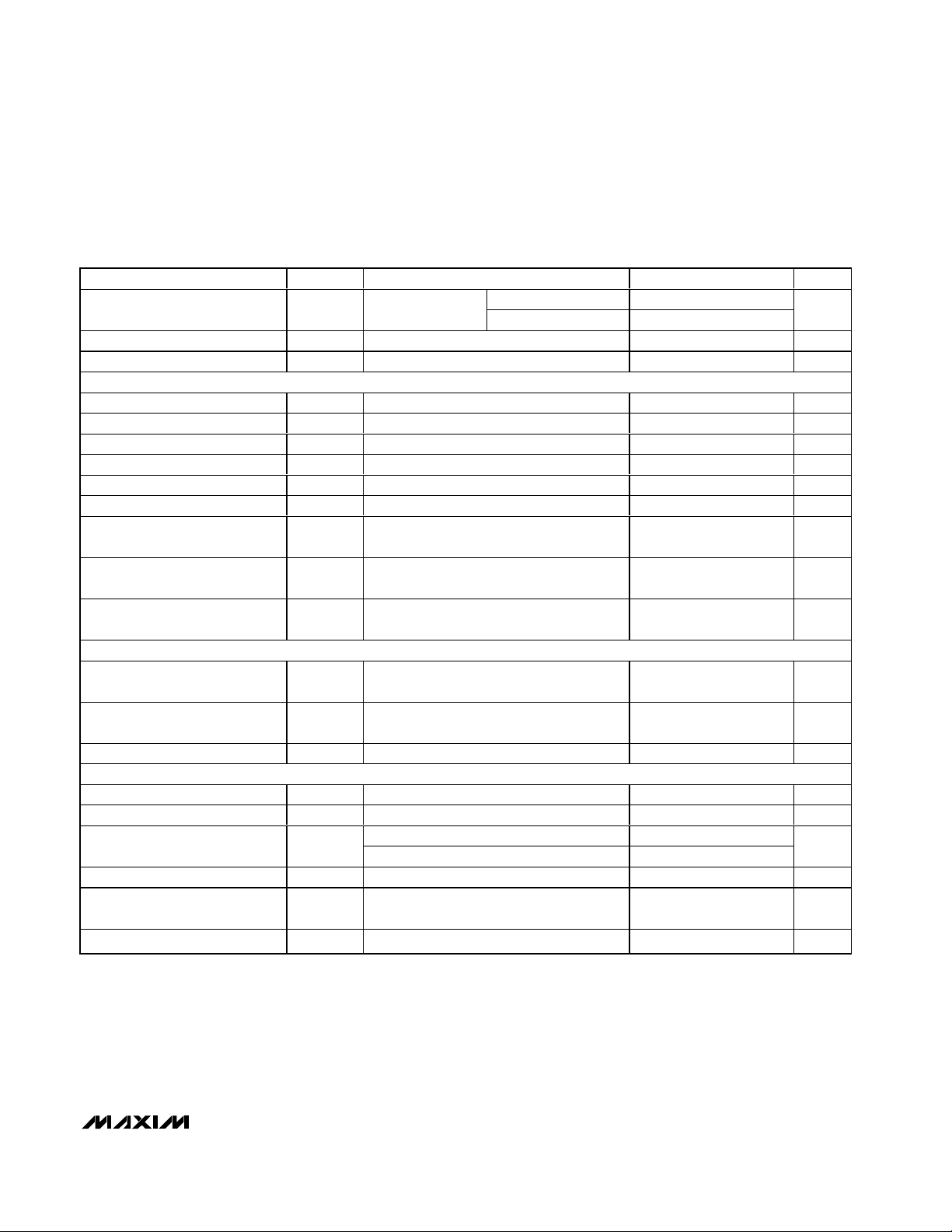

75mV/div

SUPPLY CURRENT (ICC) vs. TEMPERATURE

(EXCLUDES BIAS AND MODULATION CURRENTS)

MAX3737 toc05

TEMPERATURE (°C)

SUPPLY CURRENT (mA)

60

40

20

0-20

40

45

50

55

60

65

35

-40 80

VCC = 3.63V

VCC = 2.97V

VCC = 3.3V

I

MOD

= 60mA

I

BIAS

= 60mA

BIAS-CURRENT MONITOR GAIN

vs. TEMPERATURE

MAX3737 toc06

TEMPERATURE (°C)

I

BIAS

/I

BC_MON

(mA/mA)

603510-15

72

74

76

78

80

82

84

86

88

90

70

-40 85

PHOTO-CURRENT MONITOR GAIN

vs. TEMPERATURE

MAX3737 toc07

TEMPERATURE (°C)

I

MD

/I

PC_MON

(mA/mA)

6035-15 10

0.85

0.90

0.95

1.00

1.05

1.10

1.15

1.20

0.80

-40 85

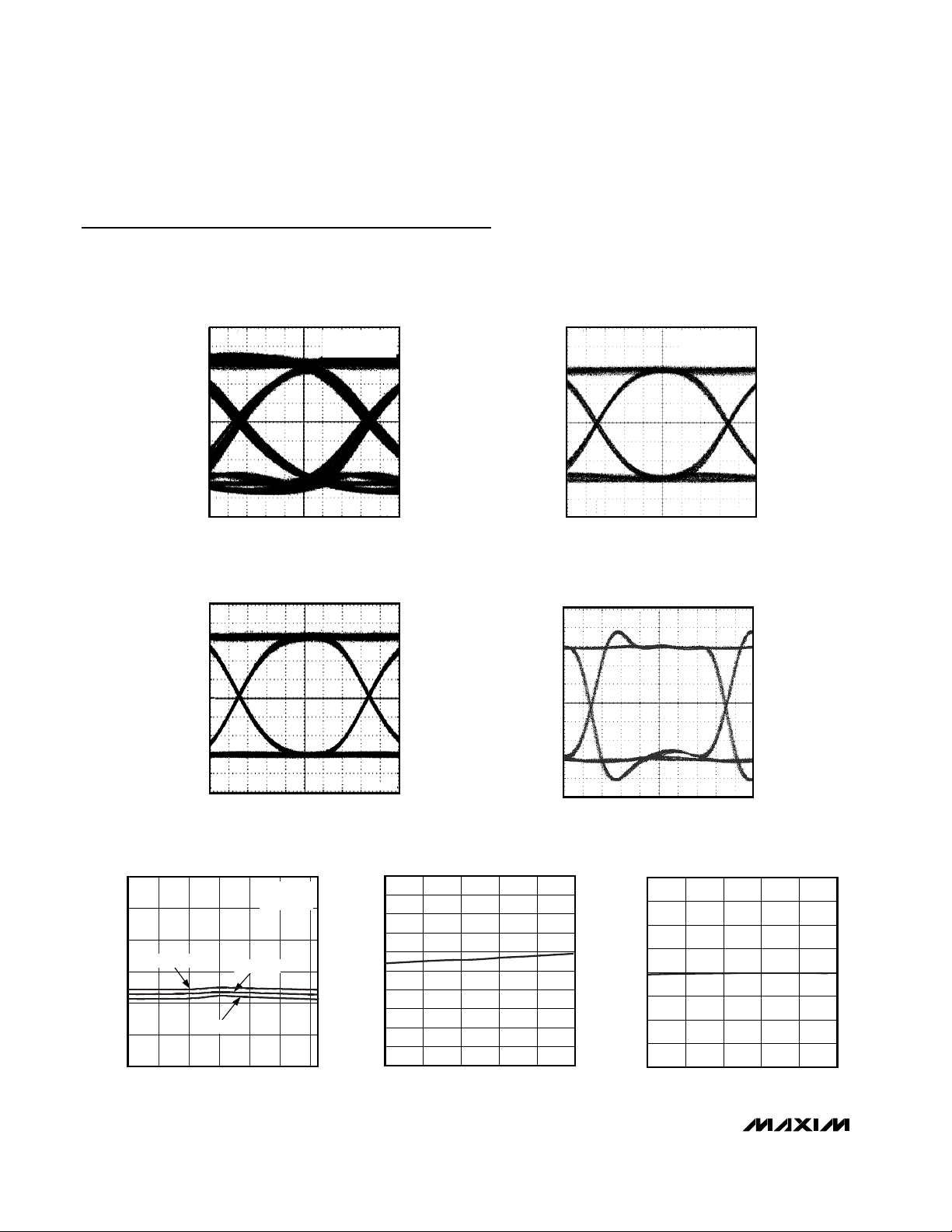

Page 5

MAX3737

Multirate Laser Driver with Extinction

Ratio Control

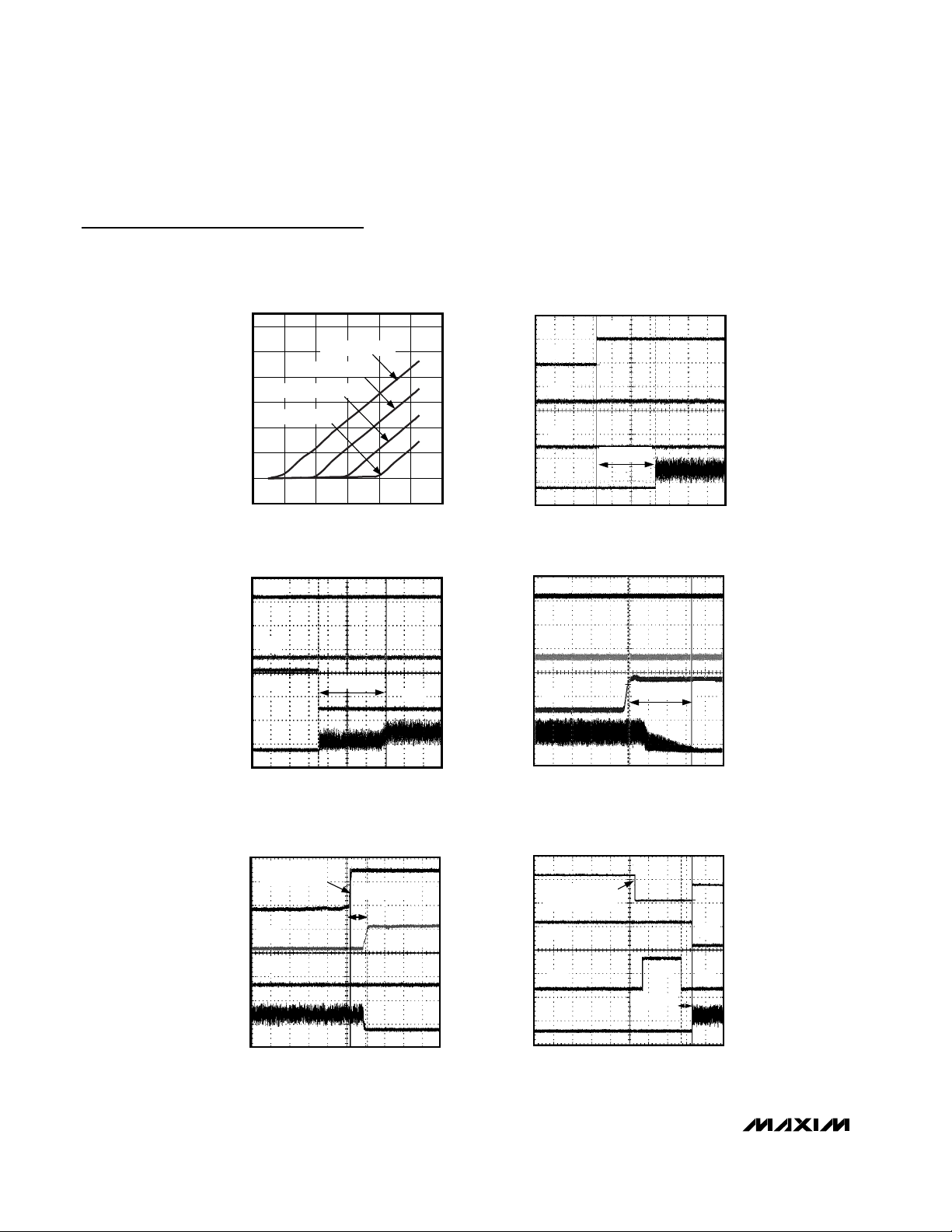

200

230

220

210

240

250

260

270

280

290

300

-40 10-15 35 60 85

MODULATION-CURRENT MONITOR GAIN

vs. TEMPERATURE

MAX3737 toc08

TEMPERATURE (°C)

I

MOD

/I

MC_MON

(mA/mA)

90

0

1 10 100

MODULATION CURRENT

vs. R

MODSET

20

10

MAX3737 toc09

R

MODSET

(kΩ)

I

MOD

(mA)

40

30

60

70

50

80

0

15

10

5

20

25

30

35

40

45

50

02010 30 5040 70 8060 90

DETERMINISTIC JITTER

vs. MODULATION CURRENT

MAX3737 toc11

I

MOD

(mA)

DJ

(ps

P-P

)

0

0.5

1.0

1.5

2.0

0 20 40 60 80 100

RANDOM JITTER

vs. MODULATION CURRENT

MAX3737 toc12

I

MOD

(mA)

RJ

(ps

RMS

)

10

0.01

0 0.1 100

COMPENSATION (K)

vs. R

MODBCOMP

0.1

1

MAX3737 toc13

R

MODBCOMP

(kΩ)

K

(mA/mA)

110

30

50

40

60

70

80

90

100

-20 200 40 60 80 100

TEMPERATURE COMPENSATION

vs. R

TH_TEMP

(R

MODCOMP

= 500Ω)

MAX3737 toc14

TEMPERATURE (°C)

I

MOD

(mA)

R

TH_TEMP

= 12kΩ

R

TH_TEMP

= 7kΩ

R

TH_TEMP

= 4kΩ

R

TH_TEMP

= 2kΩ

Typical Operating Characteristics (continued)

(VCC= +3.3V, C

APC

= 0.01µF, I

BIAS

= 20mA, I

MOD

= 30mA, TA = +25°C, unless otherwise noted.)

1.6

0

0.1 10 100

PHOTODIODE CURRENT

vs. R

APCSET

0.4

0.2

0.6

0.8

1.0

1.2

1.4

MAX3737 toc10

R

APCSET

(kΩ)

I

MD

(mA)

1

_______________________________________________________________________________________ 5

Page 6

MAX3737

Multirate Laser Driver with Extinction

Ratio Control

6 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VCC= +3.3V, C

APC

= 0.01µF, I

BIAS

= 20mA, I

MOD

= 30mA, TA = +25°C, unless otherwise noted.)

30

32

34

36

38

40

42

44

-20 200 406080100

TEMPERATURE COMPENSATION

vs. R

TH_TEMP

(R

MODTCOMP

= 10kΩ)

MAX3737 toc15

TEMPERATURE (°C)

I

MOD

(mA)

R

TH_TEMP

= 12kΩ

R

TH_TEMP

= 7kΩ

R

TH_TEMP

= 4kΩ

R

TH_TEMP

= 2kΩ

20ms/div

HOT PLUG WITH TX_DISABLE LOW

V

CC

FAULT

MAX3737 toc16

TX_DISABLE

LASER

OUTPUT

t_init = 60ms

3.3V

0V

LOW

LOW

20

µs/div

TRANSMITTER ENABLE

V

CC

FAULT

MAX3737 toc17

TX_DISABLE

LASER

OUTPUT

t_on = 75µs

3.3V

LOW

HIGH

LOW

40ns/div

TRANSMITTER DISABLE

V

CC

FAULT

MAX3737 toc18

TX_DISABLE

LASER

OUTPUT

3.3V

LOW

LOW

t_off = 134ns

HIGH

1µs/div

RESPONSE TO FAULT

V

PC_MON

FAULT

MAX3737 toc19

TX_DISABLE

LASER

OUTPUT

t_fault = 0.9µs

HIGH

EXTERNALLY

FORCED FAULT

LOW

LOW

100ms/div

FAULT RECOVERY TIME

V

PC_MON

FAULT

MAX3737 toc20

TX_DISABLE

LASER

OUTPUT

t_init = 68ms

LOW

EXTERNAL FAULT

REMOVED

LOW

HIGH

HIGH

LOW

Page 7

MAX3737

Multirate Laser Driver with Extinction

Ratio Control

Pin Description

_______________________________________________________________________________________ 7

PIN NAME FUNCTION

1, 10, 15, 16 GND Ground

2 TX_DISABLE

3, 6, 11, 18, 23 V

4 IN+ Noninverted Data Input

5 IN- Inverted Data Input

7 PC_MON

8 BC_MON

9 MC_MON

12 TX_FAULT Open-Collector Transmit Fault Indicator (Table 1)

13 SHUTDOWN

14 VBS

17 BIAS Laser Bias-Current Output

19, 20 OUT-

21, 22 OUT+

24 MD

25 VMD

26 APCFILT1

27 APCFILT2 (See Pin 26.)

28 APCSET A resistor connected from this pin to ground sets the desired average optical power.

29 MODSET

30 MODBCOMP

31 TH_TEMP

32 MODTCOMP

CC

Transmitter Disable, TTL. Laser output is disabled when TX_DISABLE is asserted high or left

unconnected. The laser ouput is enabled when this pin is asserted low.

+3.3V Supply Voltage

Photodiode-Current Monitor Output. Current out of this pin develops a ground-referenced voltage

across an external resistor that is proportional to the monitor-diode current.

Bias-Current Monitor Output. Current out of this pin develops a ground-referenced voltage across

an external resistor that is proportional to the bias current.

Modulation-Current Monitor Output. Current out of this pin develops a ground-referenced voltage

across an external resistor that is proportional to the modulation current amplitude.

Shutdown Driver Output. Voltage output to control an external transistor for optional shutdown

circuitry.

Bias Voltage Sense. Isolated tap (3kΩ ±15%) on the bias output reduces component count when a

precision bias sense resistor is used.

Inverted Modulation-Current Output (Connect Pins 19 and 20 Together). I

when input data is low.

Noninverted Modulation-Current Output (Connect Pins 21 and 22 Together). I

when input data is high.

Monitor Photodiode Input. Connect this pin to the anode of a monitor photodiode. A capacitor to

ground is required to filter the high-speed AC monitor photocurrent.

Monitor Photodiode Voltage Sense. Isolated tap (3kΩ ±15%) on the MD input reduces component

count when a precision photodiode current-sense resistor is used.

Connect a capcitor (C

pole of the APC feedback loop.

A resistor connected from this pin to ground sets the desired constant portion of the modulation

current.

Modulation-Current Compensation from Bias. Couples the bias current to the modulation current.

Mirrors I

Threshold for Temperature Compensation. A resistor at this pin programs the temperature, above

which compensation is added to the modulation current.

Modulation-Current Compensation from Temperature. A resistor at this pin sets the temperature

coefficient of the modulation current when above the threshold temperature. Leave open for zero

temperature compensation.

through an external resistor. Leave open for zero coupling.

BIAS

) between pin 26 (APCFILT1) and pin 27 (APCFILT2) to set the dominant

APC

flows into this pin

MOD

flows into this pin

MOD

EP Exposed Pad

Ground. Solder the exposed pad to the circuit board ground for specified thermal and electrical

performance.

Page 8

MAX3737

Detailed Description

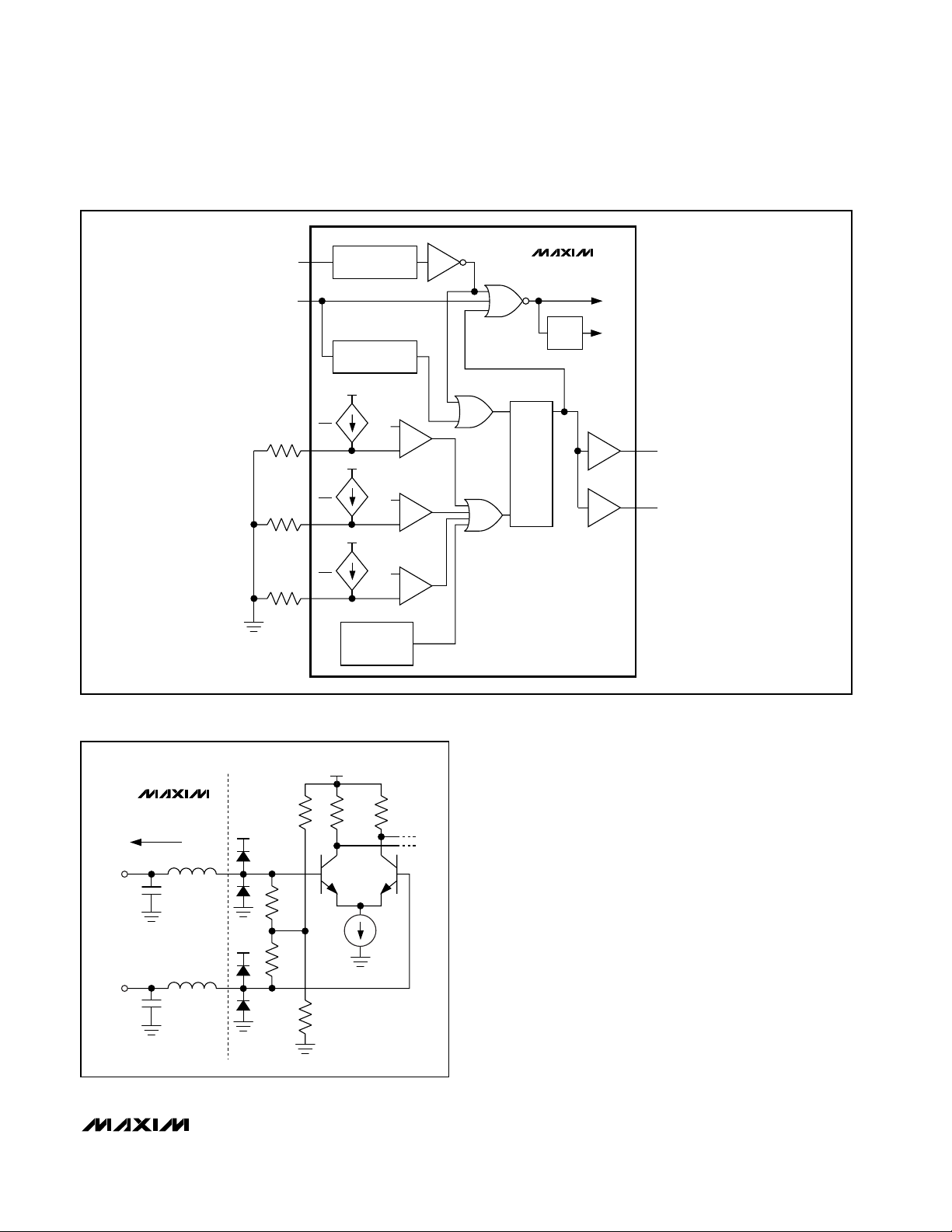

The MAX3737 laser driver consists of three main parts: a

high-speed modulation driver, biasing block with ERC,

and safety circuitry. The circuit design is optimized for

high-speed, low-voltage (+3.3V) operation (Figure 4).

High-Speed Modulation Driver

The output stage is composed of a high-speed differential pair and a programmable modulation current

source. The MAX3737 is optimized for driving a 15Ω

load. The minimum instantaneous voltage required at

OUT+ is 0.7V for modulation current up to 60mA and

0.75V for currents from 60mA to 85mA. Operation

above 60mA can be accomplished by AC-coupling or

with sufficient voltage at the laser to meet the driver

output voltage requirement.

To interface with the laser diode, a damping resistor (RD)

is required. The combined resistance due to the series

damping resistor and the equivalent series resistance

(ESR) of the laser diode should equal 15Ω. To further

damp aberrations caused by laser diode parasitic inductance, an RC shunt network may be necessary. Refer to

Maxim Application Note HFAN 02.0: Interfacing Maxim’s

Laser Drivers to Laser Diodes for more information.

At data rates of 2.7Gbps, any capacitive load at the

cathode of a laser diode degrades optical output performance. Because the BIAS output is directly connected

to the laser cathode, minimize the parasitic capacitance

associated with the pin by using an inductor to isolate

the BIAS pin parasitics from the laser cathode.

Extinction Ratio Control

The extinction ratio (re) is the laser on-state power

divided by the off-state power. Extinction ratio remains

constant if peak-to-peak and average power are held

constant:

P

AVG

+ P

P-P

/ 2P

AVG

- P

P-P

Average power is regulated using APC, which keeps

constant current from a photodiode coupled to the

laser. Peak-to-peak power is maintained by compensating the modulation current for reduced slope efficiency (η) of the laser over time and temperature:

P

P-P

= η x I

MOD

Multirate Laser Driver with Extinction

Ratio Control

8 _______________________________________________________________________________________

,

Figure 1. Required Input Signal and Output Polarity

Figure 2. Test Circuit for Characterization

Figure 3. Supply Filter

V

V

CC

OUT-

OUT-

OUT+

OUT+

CC

30Ω

30Ω

0.5pF

+

I

OUT

VOLTAGE

V

+

IN

-

V

IN

+) - (VIN-)

(V

IN

CURRENT

I

OUT

+

SINGLE ENDED

DIFFERENTIAL

100mV (MIN)

1200mV (MAX)

(MIN)

200mV

P-P

2400mV (MAX)

I

MOD

MAX3737

Z0 = 30Ω

Z0 = 30Ω

30Ω

75Ω

Z0 = 50Ω

50Ω

TIME

HOST BOARD

SOURCE

NOISE

VOLTAGE

SUPPLY

FILTER DEFINED BY SFP MSA

C1

0.1µF

C2

10µF

MODULE

TO LASER

DRIVER V

L1

1µH

C3

0.1µF

OPTIONAL

OPTIONAL

CC

P

AVG

=

ρ

I

MD

MON

OSCILLOSCOPE

Page 9

Modulation compensation from bias increases the modulation current by a user-selected proportion (K) needed to maintain peak-to-peak laser power as bias

current increases with temperature. Refer to Maxim

Application Note HFAN-02.2.1 for details:

This provides a first-order approximation of the current

increase needed to maintain peak-to-peak power. Slope

efficiency decreases more rapidly as temperature

increases. The MAX3737 provides additional temperature compensation as temperature increases past a

user-defined threshold (T

TH

).

Safety Circuitry

The safety circuitry contains a disable, input (TX_DISABLE), a latched fault output (TX_FAULT), and fault

detectors (Figure 5). This circuitry monitors the operation of the laser driver and forces a shutdown if a fault

is detected (Table 1). The TX_FAULT pin should be

pulled high with a 4.7kΩ to 10kΩ resistor to VCCas

required by the SFP MSA. A single-point fault can be a

short to VCCor GND. See Table 2 to view the circuit

response to various single-point failures. The transmit

fault condition is latched until reset by a toggle of

TX_DISABLE or VCC. The laser driver offers redundant

laser diode shutdown through the optional shutdown

circuitry as shown in the Typical Operating Circuit. This

shutdown transistor prevents a single-point fault at the

laser from creating an unsafe condition.

MAX3737

Multirate Laser Driver with Extinction

Ratio Control

Figure 4. Functional Diagram

_______________________________________________________________________________________ 9

R

MDMON

R

BC_MON

R

MC_MON

SHUTDOWN

TX_FAULT

TX_DISABLE

PC_MON

BC_MON

MC_MON

SHUTDOWN

V

CC

MAX3737

R

PULL

INPUT BUFFER

DATA

PATH

I

ENABLE

H

T

R

MOD

I

BIAS

MODTCOMP

ENABLE

xTC

x268 xK

V

BG

R

MODSET

R

SAFETY LOGIC

AND POWER

DETECTOR

= 7.5Ω

I

MD

1

I

BIAS

82

I

MOD

268

V

CC

T > T

TH_TEMP MODTCOMP MODBCOMP APCFILT2MODSET APCFILT1

R

TH_TEMP

MODBCOMP

I

MOD

V

CC

I

BIAS

V

X1/2

C

APC

IN+

IN-

BG

I

APCSET

X1

OUT-

OUT+

BIAS

APCSET

MD

R

APCSET

R

D

I

BIAS

I

MD

C

MD

I

∆

MOD

K

=

I

∆

BIAS

Page 10

MAX3737

Safety Circuitry Current Monitors

The MAX3737 features monitors (MC_MON, BC_MON,

PC_MON) for modulation current (I

MOD

), bias current

(I

BIAS

), and photocurrent (IMD). The monitors are realized

by mirroring a fraction of the currents and developing voltages across external resistors connected to ground.

Voltages greater than V

REF

at MC_MON, PC_MON, or

BC_MON result in a fault state. For example, connecting a

Multirate Laser Driver with Extinction

Ratio Control

10 ______________________________________________________________________________________

Table 1. Typical Fault Conditions

Table 2. Circuit Responses to Various Single-Point Faults

*A fault state asserts the TX_FAULT pin, disables the modulation and bias currents, and asserts the SHUTDOWN pin.

If any of the I/O pins is shorted to GND or V

1

exceed the programmed threshold.

2 End-of-life (EOL) condition of the laser diode. The bias current and/or the photocurrent exceed the programmed threshold.

3 Laser cathode is grounded and photocurrent exceeds the programming threshold.

No feedback for the APC loop (broken interconnection, defective monitor photodiode), and the bias current exceeds the

4

programmed threshold.

(single-point failure; see Table 2), and the bias current or the photocurrent

CC

PIN

TX_FAULT Does not affect laser power. Does not effect laser power.

TX_DISABLE Modulation and bias currents are disabled. Normal condition for circuit operation.

IN+

IN-

MD This disables bias current. A fault state occurs.

SHUTDOWN

BIAS

OUT+

OUT- Does not affect laser power. Does not affect laser power.

PC_MON Fault state* occurs. Does not affect laser power.

BC_MON Fault state* occurs. Does not affect laser power.

MC_MON Fault state* occurs. Does not affect laser power.

APCFILT1

APCFILT2

MODSET Does not affect laser power. Fault state* occurs.

APCSET Does not affect laser power. Fault state* occurs.

CIRCUIT RESPONSE TO OVERVOLTAGE

OR SHORT TO V

The optical average power increases and a fault occurs

if V

PC_MON

responds by decreasing the bias current.

The optical average power decreases and the APC loop

responds by increasing the bias current. A fault state

occurs if V

Does not affect laser power. If the shutdown circuitry is

used, laser current is disabled.

In this condition, laser forward voltage is 0V and no light

is emitted.

The APC circuit responds by increasing the bias current

until a fault is detected, then a fault state* occurs.

I

BIAS

voltage.

I

BIAS

voltage.

exceeds the threshold. The APC loop

exceeds the threshold voltage.

BC_MON

increases until V

increases until V

BC_MON

BC_MON

CC

exceeds the threshold

exceeds the threshold

CIRCUIT RESPONSE TO UNDERVOLTAGE

OR SHORT TO GROUND

The optical average power decreases and the APC loop

responds by increasing the bias current. A fault state

occurs if V

The optical average power increases and a fault occurs

if V

responds by decreasing the bias current.

The APC circuit responds by increasing bias current

until a fault is detected, then a fault* state occurs.

Does not affect laser power.

Fault state* occurs. If the shutdown circuitry is used,

laser current is disabled.

Fault state* occurs. If the shutdown circuitry is used,

laser current is disabled.

I

BIAS

voltage.

I

BIAS

voltage.

BC_MON

PC_MON

increases until V

increases until V

exceeds the threshold voltage.

exceeds the threshold. The APC loop

BC_MON

BC_MON

exceeds the threshold

exceeds the threshold

Page 11

100Ω resistor to ground at each monitor output gives the

following relationships:

V

MC_MON

= (I

MOD

/ 268) ✕ 100Ω

V

BC_MON

= (I

BIAS

/ 82) ✕ 100Ω

V

PC_MON

= I

MD

✕ 100Ω

External sense resistors can be used for high-accuracy

measurement of bias and photodiode currents. On-chip

isolation resistors are included to reduce the number of

components needed to implement this function.

Design Procedure

When designing a laser transmitter, the optical output is

usually expressed in terms of average power and

extinction ratio. Table 3 gives relationships that are

helpful in converting between the optical average

power and the modulation current. These relationships

are valid if the mark density and duty cycle of the optical waveform are 50%.

For a desired laser average optical power (P

AVG

) and

optical extinction ratio (re), the required bias and modulation currents can be calculated using the equations in

Table 3. Proper setting of these currents requires knowl-

edge of the laser to monitor transfer (ρ

MON

) and slope

efficiency (η).

Programming the Monitor Diode Current

Set Point

The MAX3737 operates in APC mode at all times. The

bias current is automatically set so average laser power

is determined by the APCSET resistor:

The APCSET pin controls the set point for the monitordiode current. An internal current regulator establishes

the APCSET current in the same manner as the MODSET

pin. See the I

MD

vs. R

APCSET

graph in the Typical

Operating Characteristics and select the value of R

APC-

SET

that corresponds to the required current at +25°C:

The laser driver automatically adjusts the bias to maintain

the constant average power. For DC-coupled laser diodes:

Programming the Modulation Current with

Compensation

Determine the modulation current from the laser slope

efficiency:

The modulation current of the MAX3737 consists of a

static modulation current (I

MODS

), a current proportional

to I

BIAS,

and a current proportional to temperature. The

portion of I

MOD

set by MODSET is established by an

internal current regulator, which maintains the reference

voltage of V

REF

across the external programming resis-

tor. See to the I

MOD

vs. R

MODSET

graph in the Typical

Operating Characteristics and select the value of R

MOD-

SET

that corresponds to the required current at +25°C:

MAX3737

Multirate Laser Driver with Extinction

Ratio Control

______________________________________________________________________________________ 11

Table 3. Optical Power Relations

Note: Assuming a 50% average input duty cycle and mark density.

P

AVG

I

MD

=

ρ

MON

I

MD

1

=×

2

V

REF

R

APCSET

II

=+

AVG BIAS

I

MOD

2

I

=× ×

2

MOD

Pr

AVG e

η

1

-

+

r

1

e

Average power P

Extinction ratio r

Optical power of a 1 P

Optical power of a zero P

Optical amplitude P

Laser slope efficiency ηη = P

Modulation current I

Threshold current I

Bias current (AC-coupled) I

Laser to monitor transfer ρ

PARAMETER SYMBOL RELATION

AVG

e

1

0

P-P

MOD

TH

BIAS

MON

P

AVG

P1 = 2P

P0 = 2P

P

I

MOD

I

BIAS

= (P0 + P1) / 2

re = P1 / P

AVG re

P-P

P0 at I ≥ I

≥ ITH + I

I

MD

/ (re + 1)

/ (re + 1)

AVG

= P1 - P

/ I

P-P

MOD

= P

P-P

MOD

/ P

AVG

0

0

/ η

TH

/ 2

Page 12

MAX3737

An external resistor at the MODBCOMP pin sets current

proportional to I

BIAS

. Open circuiting the MODBCOMP

pin can turn off the interaction between I

BIAS

and I

MOD

:

If I

MOD

must be increased from I

MOD1

to I

MOD2

to

maintain the extinction ratio at elevated temperature,

the required compensation factor is:

A threshold for additional temperature compensation

can be set with a programming resistor at the

TH_TEMP pin:

The temperature coefficient of thermal compensation

above TTHis set by R

MODTCOMP

. Leaving the MODT-

COMP pin open disables additional thermal compensation:

Current Compliance (I

MOD

≤ 60mA),

DC-Coupled

The minimum voltage at the OUT+ and OUT- pins is

0.7V.

For:

V

DIODE

—Diode bias point voltage (1.2V typ)

R

L

—Diode bias point resistance (5Ω typ)

RD—Series matching resistor (20Ω typ)

For compliance:

Current Compliance (I

MOD

> 60mA),

AC-Coupled

For applications requiring modulation current greater

than 60mA, headroom is insufficient for proper operation of the laser driver if the laser is DC-coupled. To

avoid this problem, the MAX3737’s modulation output

can be AC-coupled to the cathode of a laser diode. An

external pullup inductor is necessary to DC-bias the

modulation output at VCC. Such a configuration isolates

laser forward voltage from the output circuitry and

allows the output at OUT+ to swing above and below

the supply voltage (VCC). When AC-coupled, the

MAX3737 modulation current can be programmed up

to 85mA. Refer to Maxim Application Note HFAN 02.0:

Interfacing Maxim’s Laser Drivers to Laser Diodes for

more information on AC-coupling laser drivers to laser

diodes.

For compliance:

Determine C

APC

The APC loop filter capacitor C

APC

must be selected to

balance the requirements for fast turn-on and minimal

interaction with low frequencies in the data pattern. The

low-frequency cutoff is:

High-frequency noise can be filtered with an additional

cap CMDfrom the MD pin to ground:

The MAX3737 is designed so that turn-on time is faster

than 1ms for most laser gain values (η ✕ ρ

MON

).

Choosing a smaller value of C

APC

reduces turn-on

time. Careful balance between turn-on time and low-frequency cutoff may be needed at low data rates for

some values of laser gain.

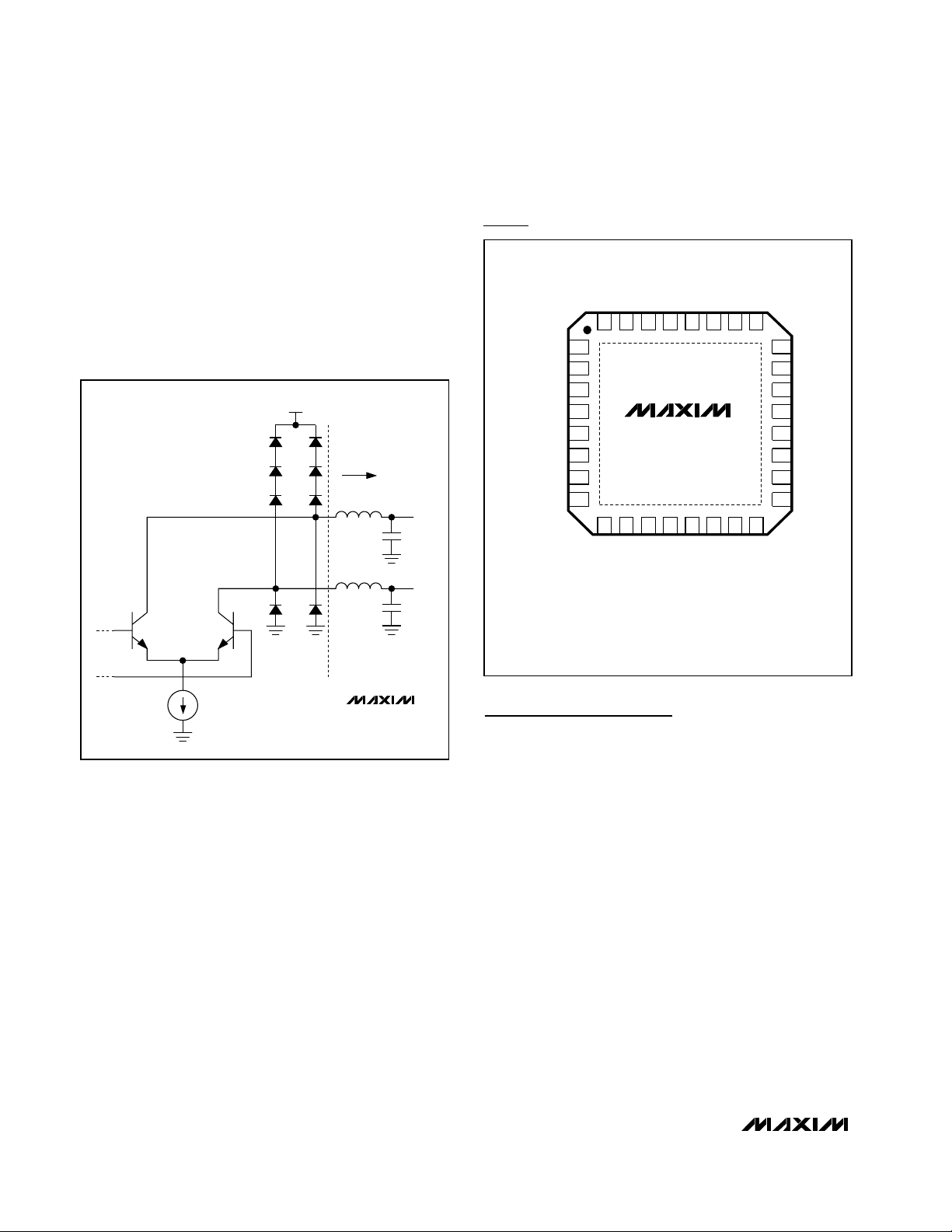

Interface Models

Figures 6 and 7 show simplified input and output circuits for the MAX3737 laser driver. If dice are used,

replace package parasitic elements with bondwire parasitic elements.

Multirate Laser Driver with Extinction

Ratio Control

12 ______________________________________________________________________________________

II KII

=+×+

MOD MODS BIAS MODT

V

-

R

MODSET

REF

>

I

=×268

MODS

ITCTTTT

=×

|

MODT TH TH

ITT

=≤

MODT TH

()

|

0

K

±

10%

=

1700

R

+

1000

MODBCOMP

II

MOD MOD

K

=

II

BIAS BIAS

-

21

-

21

I

VV

-

=

OUT C

C

MOD

×+

RR V

()

2

DL+

≥

075 .

TC

=°+

TH

-70

kR

.

92

Ω

.

145

+

M

Ω

TH TEMP

_

°±

C

%

10

TC

=

0510. ()

1

Rk

+°

MODTCOMP

mA

±

%

C

Ω

VVV I RRI R V

- - - .07

=

OUT CC DIODE MOD D L BIAS L+

×+

()

×≥

CF

()

µηρ≈××

APC

68

f kHz

()

3

DB

( )

11

MON

x

C

MD

C

APC

≈

4

Page 13

Layout Considerations

To minimize loss and crosstalk, keep the connections

between the MAX3737 output and the laser diode as

short as possible. Use good high-frequency layout

techniques and multilayer boards with uninterrupted

ground plane to minimize EMI and crosstalk. Circuit

boards should be made using low-loss dielectrics. Use

controlled-impedance lines for data inputs, as well as

the module output.

Laser Safety and IEC 825

Using the MAX3737 laser driver alone does not ensure

that a transmitter design is IEC 825 compliant. The entire

transmitter circuit and component selections must be

considered. Each customer must determine the level of

fault tolerance required by their application, recognizing

that Maxim products are not designed or authorized for

use as components in systems intended for surgical

implant into the body, for applications intended to support

or sustain life, or for any other application where the failure of a Maxim product could create a situation where

personal injury or death may occur.

MAX3737

Multirate Laser Driver with Extinction

Ratio Control

______________________________________________________________________________________ 13

Figure 5. Simplified Safety Circuit

Figure 6. Simplified Input Structure

V

TX_DISABLE

PC_MON

R

PC_MON

BC_MON

R

BC_MON

MC_MON

R

MC_MON

CC

POR AND COUNTER

60ms DELAY

COUNTER

60ms DELAY

V

CC

I

MD

1

V

CC

I

BIAS

82

V

CC

I

MOD

268

EXCESSIVE

MODULATION

CURRENT

MAX3737

I

MOD

ENABLE

100ns

DELAY

V

REF

COMP

V

REF

COMP

V

REF

COMP

RQ

RS

LATCH

S

I

BIAS

ENABLE

CMOS

TTL

OPEN

COLLECTOR

SHUTDOWN

TX_FAULT

MAX3737

PACKAGE

0.83nH

0.11pF

0.83nH

0.11pF

V

CC

V

CC

16kΩ

5kΩ

5kΩ

24kΩ

V

CC

Page 14

MAX3737

Exposed-Pad (EP) Package

The exposed-pad on the 32-pin QFN provides a very low

thermal resistance path for heat removal from the IC. The

pad is also electrical ground on the MAX3737 and should

be soldered to the circuit board ground for proper thermal and electrical performance. Refer to Maxim

Application Note HFAN-08.1: Thermal Considerations for

QFN and Other Exposed Pad Packages at www.maximic.com for additional information.

Multirate Laser Driver with Extinction

Ratio Control

14 ______________________________________________________________________________________

Figure 7. Simplified Output Structure

Pin Configurations (continued)

Chip Information

TRANSISTOR COUNT: 2727

PROCESS: SiGe/Bipolar

V

CC

PACKAGE

0.82nH

0.82nH

0.11pF

0.11pF

OUT-

OUT+

TOP VIEW

APCFILT2

MODTCOMP

TH_TEMP

MODBCOMP

MODSET

32

31

30

29

1GND

TX_DISABLE

PC_MON

BC_MON

2

V

3

CC

IN+

4

9

10

GND

MC_MON

MAX3737ETJ

11

12

CC

V

TX_FAULT

IN-

5

6

V

CC

7

8

5mm x 5mm

THIN QFN

*THE EXPOSED PADDLE MUST BE SOLDERED TO SUPPLY GROUND

TO ACHIEVE SPECIFIED PERFORMANCE.

APCSET

28

27

13

14

VBS

SHUTDOWN

APCFILT1

25 VMD

26

16GND

15

GND

24 MD

23

V

22

OUT+

21

OUT+

20

OUT-

19

OUT-

18

V

BIAS

17

CC

CC

MAX3737

Page 15

MAX3737

Multirate Laser Driver with Extinction

Ratio Control

______________________________________________________________________________________ 15

Typical Operating Circuit

CDR

0.1µF

0.1µF

R

MODBCOMP

R

MODTCOMP

R

TH_TEMP

IN+

IN-

MODBCOMP

MODTCOMP

TH_TEMP

GND

R

MODSET

MODSET

R

APCSET

APCFILT1

APCSET

TX_DISABLE

C

APC

TX_FAULT

MAX3737

APCFILT2

R

MC_MON

+3.3V

CC

V

MC_MON

R

BC_MON

+3.3V

OPTIONAL SHUTDOWN

CIRCUITRY

+3.3V

15Ω

OUT-

SHUTDOWN

BC_MON

R

PC_MON

OUT+

BIAS

MD

PC_MON

10Ω

FERRITE BEAD

C

MD

0.01µF

REPRESENTS A CONTROLLED-IMPEDANCE TRANSMISSION LINE

Page 16

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

MAX3737

Multirate Laser Driver with Extinction

Ratio Control

16 ______________________________________________________________________________________

32L QFN.EPS

PACKAGE OUTLINE, 16,20,28,32L QFN,

5x5x0.90 MM

21-0091

PACKAGE OUTLINE, 16,20,28,32L QFN,

5x5x0.90 MM

21-0091

I

I

1

2

2

2

Page 17

MAX3737

Multirate Laser Driver with Extinction

Ratio Control

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 17

© 2003 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

PIN # 1

I.D.

D

C

0.15 C A

D/2

0.15

C B

E/2

E

0.10

C

A

0.08 C

A3

A1

(NE-1) X e

DETAIL A

L

D2

k

e

(ND-1) X e

L

e e

PROPRIETARY INFORMATION

TITLE:

PACKAGE OUTLINE

16, 20, 28, 32L, QFN THIN, 5x5x0.8 mm

APPROVAL

C

L

D2/2

b

0.10 M

E2/2

L

DOCUMENT CONTROL NO.

21-0140

C A B

PIN # 1 I.D.

0.35x45

C

E2

L

k

CC

L

REV.

C

L

1

2

QFN THIN.EPS

COMMON DIMENSIONS

NOTES:

1. DIMENSIONING & TOLERANCING CONFORM TO ASME Y14.5M-1994.

2. ALL DIMENSIONS ARE IN MILLIMETERS. ANGLES ARE IN DEGREES.

3. N IS THE TOTAL NUMBER OF TERMINALS.

4. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL CONFORM TO JESD 95-1

SPP-012. DETAILS OF TERMINAL #1 IDENTIFIER ARE OPTIONAL, BUT MUST BE LOCATED WITHIN THE

ZONE INDICATED. THE TERMINAL #1 IDENTIFIER MAY BE EITHER A MOLD OR MARKED FEATURE.

5. DIMENSION b APPLIES TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.25 mm AND 0.30 mm

FROM TERMINAL TIP.

6. ND AND NE REFER TO THE NUMBER OF TERMINALS ON EACH D AND E SIDE RESPECTIVELY.

7. DEPOPULATION IS POSSIBLE IN A SYMMETRICAL FASHION.

8. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS.

9. DRAWING CONFORMS TO JEDEC MO220.

10. WARPAGE SHALL NOT EXCEED 0.10 mm.

EXPOSED PAD VARIATIONS

PROPRIETARY INFORMATION

TITLE:

PACKAGE OUTLINE

16, 20, 28, 32L, QFN THIN, 5x5x0.8 mm

21-0140

REV.DOCUMENT CONTROL NO.APPROVAL

2

C

2

Loading...

Loading...