Page 1

General Description

The MAX3580 fully integrated, direct-conversion TV tuner

is designed for Digital Video Broadcasting-Terrestrial

(DVB-T) applications. The integrated tuner covers a

170MHz to 230MHz input frequency range for the VHF-III

band and 470MHz to 878MHz for the UHF band.

The MAX3580 direct-conversion tuner integrates an RF

input switch and a multiband tracking filter, allowing

low-power tuner-on-board applications without the cost

and power-dissipation issues of dual-conversion tuner

solutions. The zero-IF architecture eliminates the need

for SAW filters by providing baseband I and Q outputs

directly to the demodulator. In addition, DC-offset cancellation is implemented on-chip using a mixed-signal

architecture to improve the second-order distortion performance and the dynamic range of the downstream

digitizer and demodulator.

The MAX3580 features dynamic gain control of more

than 76dB and a typical midband noise figure of 4.7dB

referred to the LNA input. The VCO architecture optimizes both in-band and wideband phase noise for

OFDM applications where sensitivity to both 1kHz

phase noise and wideband phase noise related to

strong adjacents can be a problem.

The MAX3580 communicates using a 2-wire serial bus.

The device operates from a typical +3.3V power supply

and dissipates 650mW. The MAX3580 is available in a

small 32-pin thin QFN package (5mm x 5mm) with an

exposed paddle. Electrical performance is guaranteed

over the extended -40°C to +85°C temperature range.

Applications

Digital Televisions

Digital Terrestrial Set-Tops

Laptop Televisions

Automotive Televisions

USB Peripherals

Features

o 650mW Power Dissipation (at VCC= +3.3V)

o I and Q Baseband Outputs Eliminate All IF-SAW

Filters

o Integrated RF Tracking Filters

o Tunable Baseband Lowpass Filters

o Full-Band VHF-III and UHF Tuning

o +38dB Digital ACPR, +47dB Analog ACPR

o Low Noise Figure: 4.7dB (typ)

o Frac-N Synthesizer for -90dBc/Hz Close-In

Phase Noise

o Baseband Overload Detector Controls RF AGC if

Desired

o +3.1V to +3.5V Supply Voltage Range

o Ultra-Small, 5mm x 5mm Thin QFN Package

MAX3580

Direct-Conversion TV Tuner

________________________________________________________________

Maxim Integrated Products

1

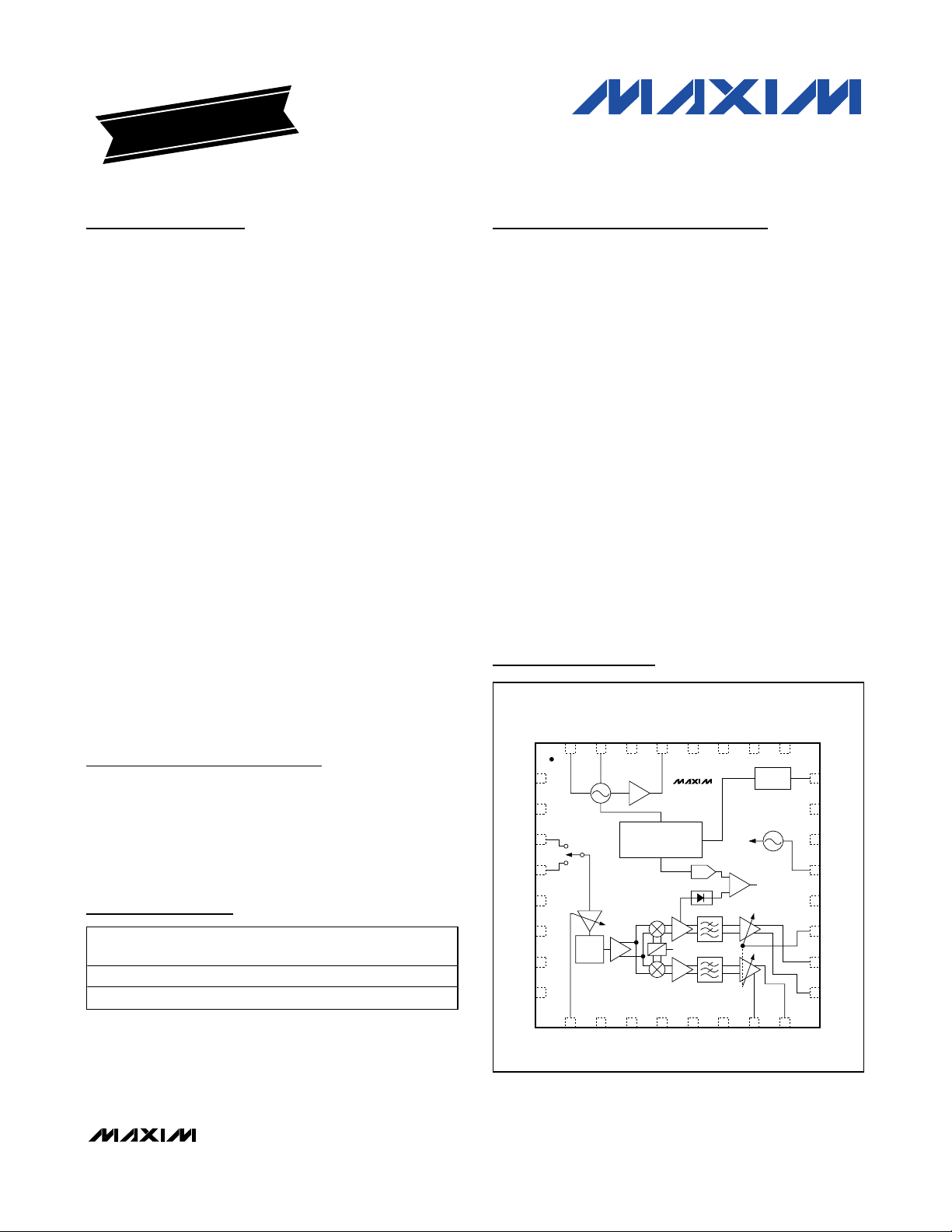

Pin Configuration/

Functional Diagram

Ordering Information

TRACKING

FILTER

GND_TUNE

LDO

XE

XB

VCC_VCO

MUX

RFIN2

ADDR2

LEXT

VCC_SYN

RFIN

RF_AGC

SCL

SDA

BBI-

BBQ-

BBQ+

BB_AGC

BBI+

VCC_BB

REF_BUFF

VCC_RF

OVLD_DET

IND1

IND2

VCC_XTAL

VTUNE

CP

OVLD_DET

GND_LNA

GND_CP

GND_PLL

N.C.

TOP VIEW

32 28

293031

25

26

27

10

13

15

14

1611 12

9

17

18

19

20

21

22

23

24

2

3

4

5

6

7

8

1

MAX3580

0

90

DAC

LO

LO

CHARGE

PUMP

SERIAL INT ERFACE, CON TROL,

AND

SYNTHESIZER

19-0611; Rev 0; 7/06

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

*

EP = Exposed paddle.

+

Denotes lead-free package.

T

= Tape-and-reel package.

EVALUATION KIT

AVAILABLE

PART TEMP RANGE

MAX3580ETJ+ -40°C to +85°C 32 TQFN-EP* T3255-5

MAX3580ETJ+T -40°C to +85°C 32 TQFN-EP* T3255-5

PIN-

PACKAGE

PKG

CODE

Page 2

MAX3580

Direct-Conversion TV Tuner

2 _______________________________________________________________________________________

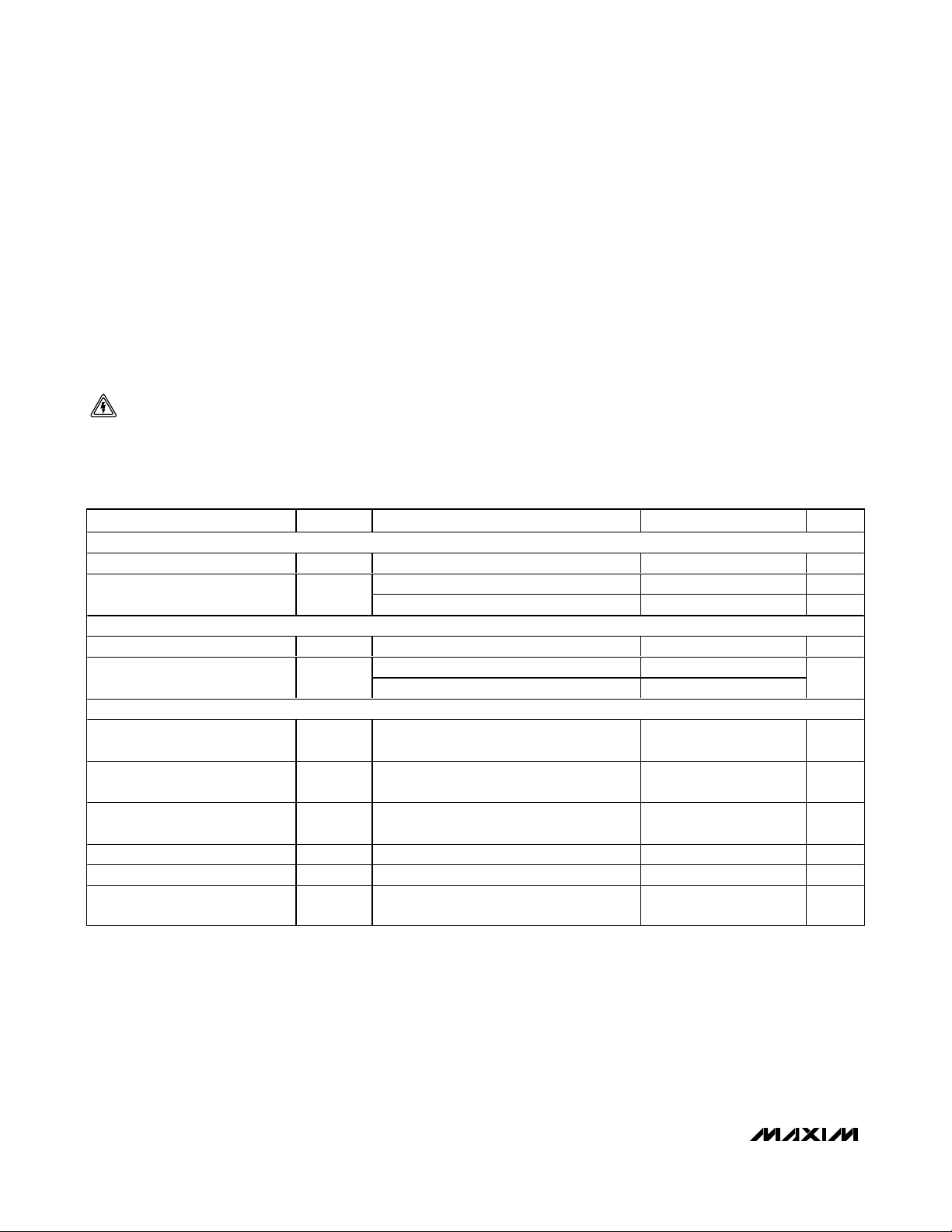

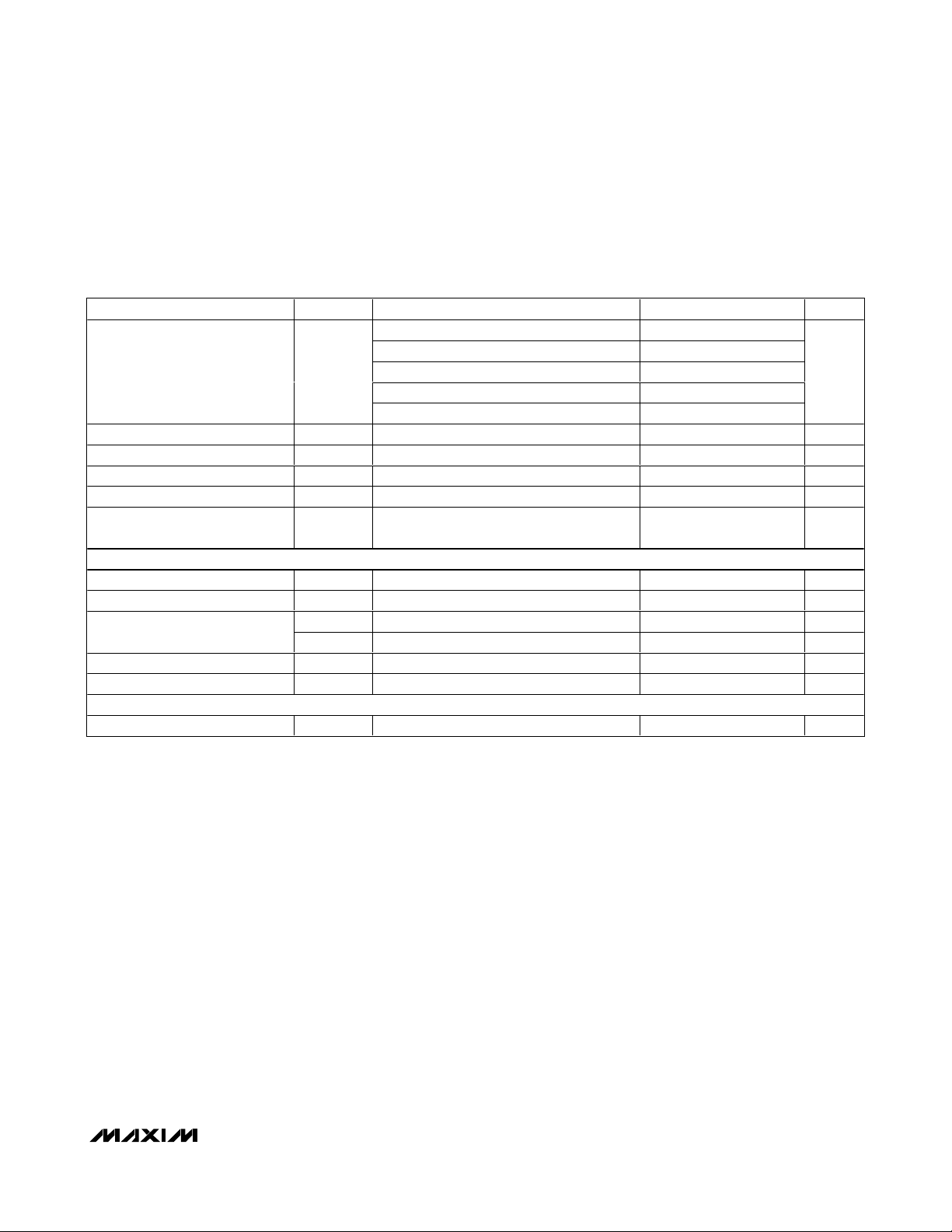

ABSOLUTE MAXIMUM RATINGS

DC ELECTRICAL CHARACTERISTICS

(MAX3580 EV kit, VCC= +3.1V to +3.5V, GND = 0V, BB_AGC = RF_AGC = +2.85V, RF input terminated into a 75Ω load, BBI_ and

BBQ_ are open, no input signal, VCO active, registers set according to the specified default register conditions, T

A

= -40°C to

+85°C, unless otherwise specified. Typical values are at V

CC

= +3.3V, TA=+25°C, unless otherwise specified.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VCCto GND...........................................................-0.3V to +3.6V

SDA, SCL, ADDR2, MUX, REF_BUFF,

BB_AGC, RF_AGC to GND ................................-0.3V to +3.6V

All Other Pins to GND ..............................-0.3V to (+V

CC

+ 0.3V)

RF Input Power ...............................................................+10dBm

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +165°C

Continuous Power Dissipation (T

A

= +70°C)

(derate 21.3mW/°C above +70°C)..............................1702mW

Lead Temperature (soldering, 10s) .................................+300°C

CAUTION! ESD SENSITIVE DEVICE

SUPPLY VOLTAGE AND CURRENT

Supply Voltage V

Supply Current I

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CC

CC

Active 197 225 mA

Shutdown mode 200 µA

RF_AGC AND BB_AGC

Input Bias Current I

RF and Baseband AGC Control

Voltage

V

AGC

AGC

V

at +0.5V and +2.85V -50 +50 µA

AGC

Maximum gain 2.85

Minimum gain 0.5

SERIAL INTERFACE AND MUX OUTPUT (SCL, SDA, MUX)

Input Logic-Level Low V

Input Logic-Level High V

IL

IH

Input Hysteresis

SDA, SCL Input Current -10 +10 µA

Output Logic-Level Low V

Output Logic-Level High V

OL

OH

Sink current = 0.3mA 0.4 V

Source current = 0.3mA

3.1 3.5 V

0.3 x

0.7 x

V

CC

0.05 x

V

V

-

CC

0.5

V

V

CC

V

CC

V

V

V

Page 3

MAX3580

Direct-Conversion TV Tuner

_______________________________________________________________________________________ 3

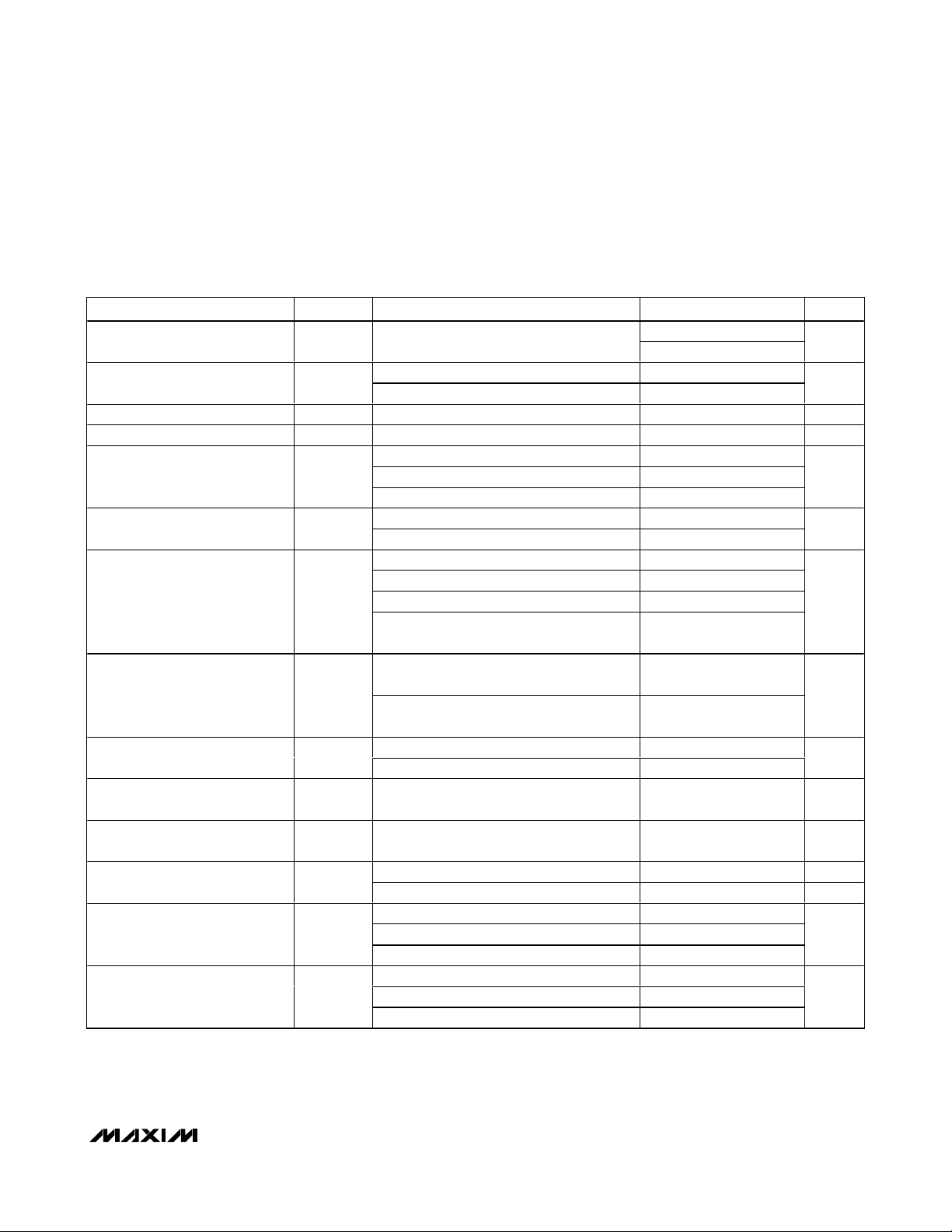

AC ELECTRICAL CHARACTERISTICS

(MAX3580 EV kit, VCC= +3.1V to +3.5V, GND = 0V. RF_AGC = BB_AGC = +2.85V, RF input terminated into a 75Ω load, BBI_ and

BBQ_ loaded by R

L

greater than 2kΩ and CLless than 10pF, VCO active, registers are set according to the recommended default

register conditions, T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at VCC= +3.3V, TA= +25°C, unless otherwise

noted.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Operating Frequency Range f

Overall Voltage Gain (Note 2)

RF Gain Flatness W i thi n each V H F- III and U H F b and ( N ote 10) -3 +3 dB

RF

Gain specification met across this

frequency band

RF_AGC = BB_AGC = +2.85V 74

RF_AGC = BB_AGC = +0.5V 26

170 230

470 878

MHz

dB

Input Return Loss Wor st case acr oss b and sel ected , 75Ω system 7 dB

230MHz 5.4

Noise Figure (DSB) (Notes 3, 4) NF

470MHz 4.7

dB

858MHz 6.5

Input 2nd-Order Intercept Point IIP2

Broadband (Notes 4, 5) 12

Br oad b and , RF_AGC ad j usted for 49d B of g ai n > 26

dBm

Broadband (Notes 4, 6) > -4

Br oad b and , RF_AGC ad j usted for 49d B of g ai n > 12

RF 1dB Desense

LO Harmonic Reception

RF Channel Flatness

Isolation

Quadrature Accuracy

Narrowband (Notes 4, 7) -15 Input 3rd-Order Intercept Point IIP3

Narrowband, RF_AGC adjusted for 49dB of

gain (Note 7)

P

DESIRED

3.75MHz, P

RF_AGC adjusted for 49dB of gain,

P

DESIRED

= -78dBm and converted to

10MHz higher (Note 4)

TONE

= -55dBm

3

-24

-1

RF i np ut r ang e of 170M H z to 960M H z ( N ote 8) -60

RF input range of 960MHz to 1400MHz > -40

8MHz RF channel at baseband, tested at

169MHz and 469MHz

DC to 30MHz, RF input to baseband output,

relative to desired channel

-1 +1 dB

> 60 dBc

I/Q phase error at 1MHz -3 +3 D eg r ees

I/Q amplitude error at 1MHz -1.5 +1.5 dB

dBm

dBm

dBc

50MHz to 470MHz -50 -20

Spurious at the RF Input (Note 3)

470MHz to 878MHz -50 -35

878MHz to 1732MHz < -50 -20

dBmV

At 1kHz to 10kHz (Note 3) -80 -90

Phase Noise (Single-Sideband,

Closed Loop)

ΦN

At 100kHz (Note 3) -94 -107

dBc/Hz

At 1MHz -130

Page 4

MAX3580

Direct-Conversion TV Tuner

4 _______________________________________________________________________________________

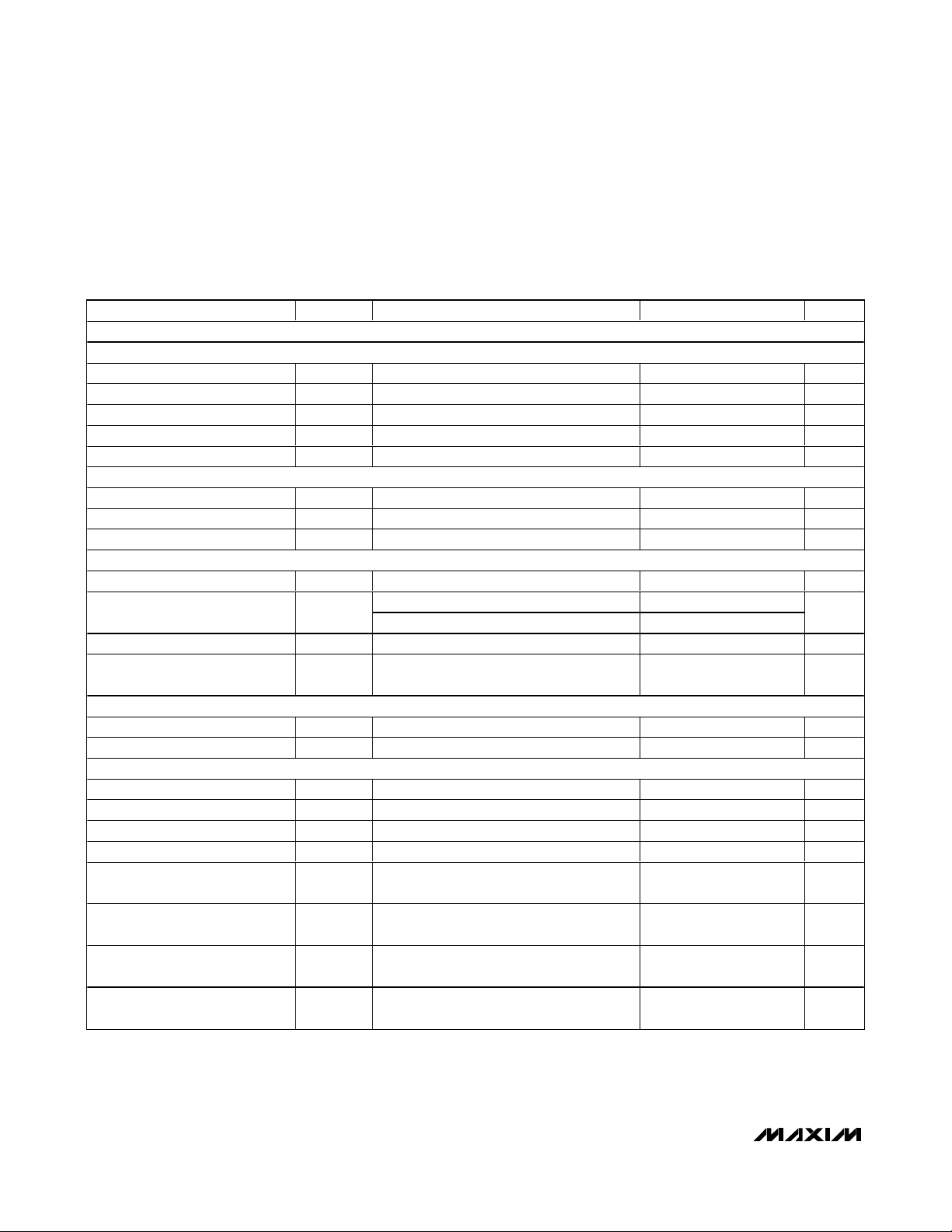

AC ELECTRICAL CHARACTERISTICS (continued)

(MAX3580 EV kit, VCC= +3.1V to +3.5V, GND = 0V. RF_AGC = BB_AGC = +2.85V, RF input terminated into a 75Ω load, BBI_ and

BBQ_ loaded by R

L

greater than 2kΩ and CLless than 10pF, VCO active, registers are set according to the recommended default

register conditions, T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at VCC= +3.3V, TA= +25°C, unless otherwise

noted.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SIGMA-DELTA FRACTIONAL-N SYNTHESIZER

REFERENCE OSCILLATOR

Frequency f

Input Impedance Z

Voltage Gain 30 V/V

Output Impedance Z

Buffered Output 10kΩ || 10pF load 0.7 V

DIVIDERS

RF N Divider Ratio 5 251 —

RF R Divider Ratio 1 2 —

Fractional-N Resolution 20 Bits

LO PHASE DETECTOR AND CHARGE PUMP

Phase-Detector Frequency 4 27 MHz

Charge-Pump Current I

Charge-Pump Tri-State Current -10 +10 µA

Charge-Pump Compliance

Range

LOCAL OSCILLATOR

Tuning Frequency Range f

VCO Dividers 4 16 —

BASEBAND STAGE

Nominal Output Voltage (Note 2) 1 V

1dB Output Compression Point P

Output Impedance Differential 60 Ω

Passband AGC Range BB_AGC = 0.5V to 2.85V 30 50 dB

Passband Cutoff Attenuation

Passband Differential Gain Error

Passband Group Delay

Group Delay Mismatch

REF

IN

OUT

CP

OSC

1dB

Gain = 0 600

Gain = 1 1200

Charge-pump positive to negative current

matching of ≤ ±5%

Tank Frequency 2160 4400 MHz

Differential voltage at 3MHz 1.6 2 V

At 3.8MHz (UHF Mode);

at 3.325MHz (VHF Mode)

2MHz to 3.8MHz, I channel vs. Q channel

(UHF mode)

From DC to 3.8MHz over any 1.1kHz band

(UHF mode)

From 0.1MHz to 3.8MHz, I channel vs. Q

channel (UHF mode) (Note 9)

4 27 MHz

10 kΩ

15 Ω

VCC -

0.4

0.4

2 5 dB

-0.45 +0.45 dB

5 ns

< 2 ns

µA

P-P

V

P-P

P-P

Page 5

MAX3580

Direct-Conversion TV Tuner

_______________________________________________________________________________________ 5

AC ELECTRICAL CHARACTERISTICS (continued)

(MAX3580 EV kit, VCC= +3.1V to +3.5V, GND = 0V. RF_AGC = BB_AGC = +2.85V, RF input terminated into a 75Ω load, BBI_ and

BBQ_ loaded by R

L

greater than 2kΩ and CLless than 10pF, VCO active, registers are set according to the recommended default

register conditions, T

A

= -40°C to +85°C, unless otherwise noted. Typical values are at VCC= +3.3V, TA= +25°C, unless otherwise

noted.) (Note 1)

Note 1: Min and Max limits are guaranteed by test above TA= +25°C and are guaranteed by design and characterization at

T

A

= -40°C. The default register settings are not production tested. Load registers no sooner than 100µs after power-up.

Note 2: The specified overall voltage gain is suitable to amplify -93dBm to -20dBm to 1V

P-P

at the baseband output.

Note 3: Guaranteed by design characterization over the specified operating conditions. Not production tested.

Note 4: BB_AGC adjusted for gain = 72dB with RF_AGC at 2.85V.

Note 5: Two tones at a) 230MHz and 431MHz with IM measured at 201MHz and b) 230MHz and 701MHz with IM measured at

471MHz.

Note 6: Two tones at 499MHz and 689MHz with IM measured at 879MHz.

Note 7: IM3 measured with two tones within the adjacent channel. Production tested at 72dB of gain with two tones at a)

205.75MHz and 210.5MHz with IM measured at 201MHz and b) 475.25MHz and 479.5MHz with IM measured at

471MHz. Production tested at 49dB of gain with two tones at 475.25MHz and 479.5MHz with IM measured at 471MHz.

Note 8: Measured at RF = 171MHz with harmonics at 511MHz (3rd harmonic) and 851MHz (5th harmonic).

Note 9: Delay of 2ns equal 2.74° phase error.

Note 10: UHF rolloff of 4dB in addition to gain flatness specification.

Note 11: Production tested at V

CC

= +3.5V to limits of 1.7V ±0.1V.

Rejection Ratio

DC Output Voltage V

Output DC Offset BB_AGC = 2.85V -70 +70 mV

Baseband Highpass Cutoff Programmable 20 to 200 Hz

AGC Gain Slope BB_AGC = 0.5V to 2.85V 14 35 dB/V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Ratio of Passband to Stopband

Noise

At 5.25MHz (UHF mode) 23

At 4.75MHz (VHF mode) 23

At 13.25MHz (UHF mode) 63

At 11.75MHz (VHF mode) 62

At > 16.2MHz

CM

Common mode (Note 11) 0.485 x V

BB_AGC = 2.85V, 10kHz to 3.8MHz vs.

16.2MHz to 23.8MHz

84

V

CC

15 dB

dB

DC

MIXER OVERLOAD DETECTOR (RSSI)

Attack-Point Accuracy 5.25MHz test tone ±1 dB

Attack-Point Increment 3-bit DAC 1.5 dB

Detector Output Sink

Detector on, V

Detector off, V

= 0.5V 0.3 mA

OUT

= 2.85V 5 µA

OUT

Detector Gain 30 V/V

Detector Response Time < 200 µs

2-WIRE INTERFACE

Clock Rate 400 kHz

Page 6

MAX3580

Direct-Conversion TV Tuner

6 _______________________________________________________________________________________

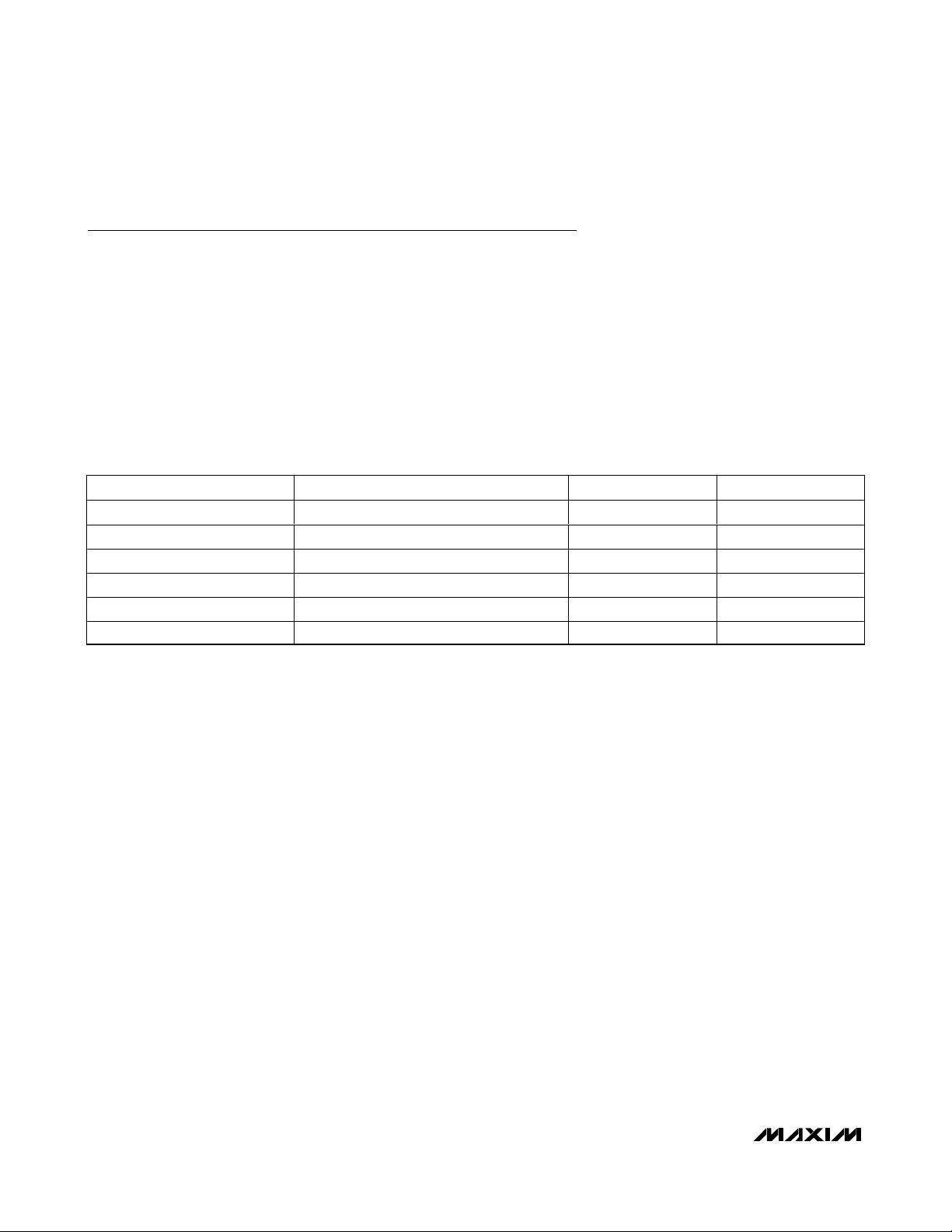

Performance to Standards

The following is selected overall performance data for the

MAX3580 + digital demodulator.

Table 1 shows the typical overall performance as measured using the MAX3580 and one current production

DVB-T demodulator. This reference design is available

in NIM card form factor upon request.

MBRAI refers to standard MBRAI 04-102 IEC 62002-1

available from www.ansi.org.

NorDig refers to standard Unified 1.0.2 available from

www.nordig.org.

Modulation of wanted and interfering channel(s) is 8k

mode, 16 QAM, C/R = 3/4, GI = 1/4, sensitivity or

immunity Reference Bit Error Rate is 2 x 10e-4, unless

stated otherwise.

Table 1. Selected Typical MBRAI and NorDig Performance

TEST SCENARIO COMMENTS SPEC MINIMUM MAX3580 TYPICAL

MBRAI S2 Immunity/ACPR for N ±1 adjacent ch. 29dB 40dB

MBRAI S2 Immunity/ACPR N ±2 alternate ch. 40dB 43dB

MBRAI L3 Li near ity/c r ossm od . w i th N +2 and N +4 ch. 40dB 47dB

NorDig 16 QAM 2/3 S ensi ti vi ty at channel 21 ( 470 M H z) -84.1dBm -85.1dBm

NorDig QPSK 1/2 Sensitivity at channel 42 (642 MHz) -92.1dBm -94.8dBm

NorDig 64 QAM 7/8 Sensitivity at channel 59 (778 MHz) -74.7dBm -76dBm

Page 7

MAX3580

Direct-Conversion TV Tuner

_______________________________________________________________________________________

7

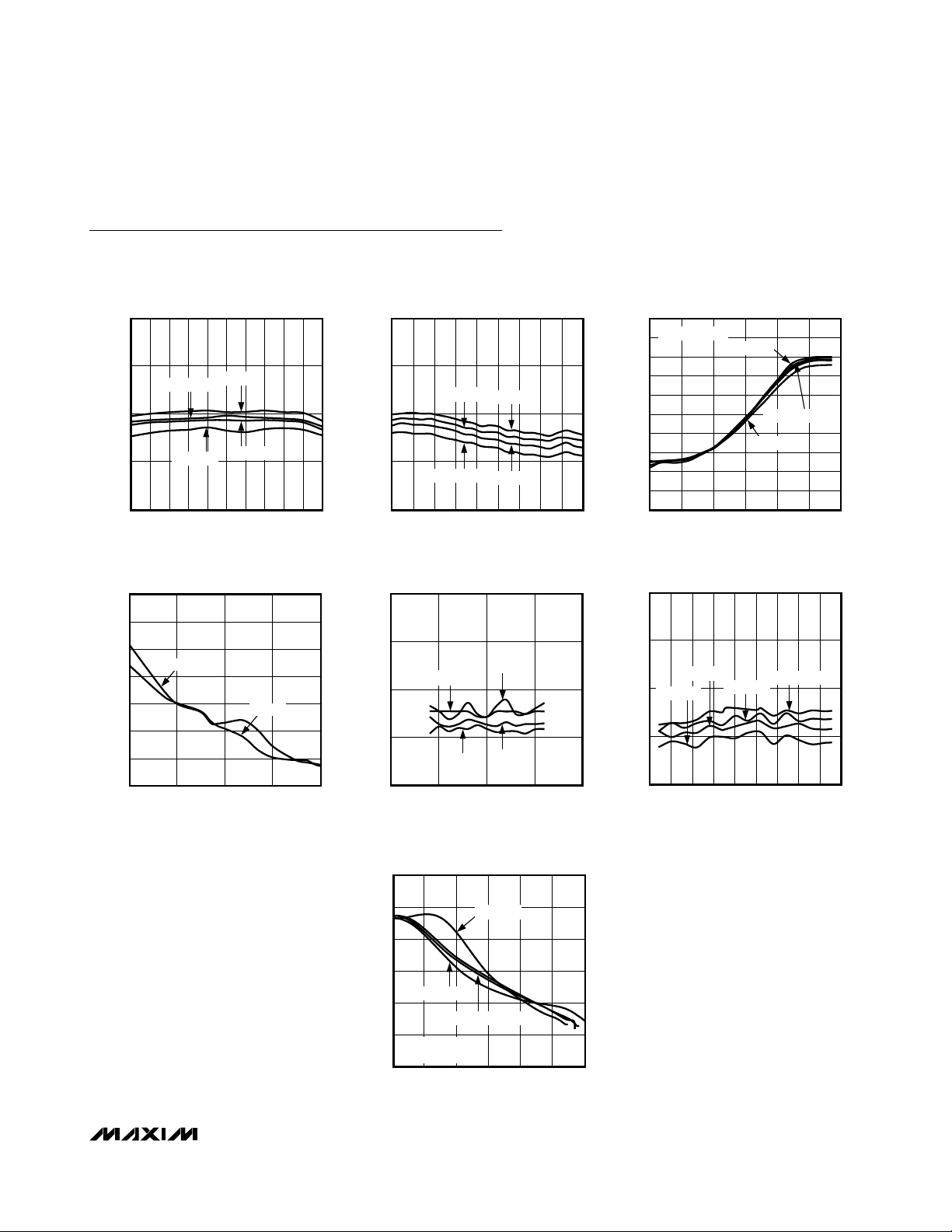

Typical Operating Characteristics

(Typical values are at VCC= +3.3V, TA= +25°C, unless otherwise noted.)

0

10

5

20

15

25

30

VHF MODE NOISE FIGURE

vs. VOLTAGE GAIN

MAX3580 toc07

VOLTAGE GAIN (dB)

NOISE FIGURE (dB)

60 70 7565 80 85 90

TA = +25°C, +55°C

TA = -40°C

TA = +85°C

fRF = 220MHz

BB_AGC = 2.85V

VHF-III BAND VOLTAGE GAIN

vs. FREQUENCY

110

100

TA = +25°C

90

GAIN (dB)

80

70

150 170 180 190 200160 210 220 230 240 250

TA = +85°C

TA = 0°C

TA = +55°C

FREQUENCY (MHz)

PHASE NOISE vs. OFFSET FREQUENCY

-50

-60

-70

-80

-90

PHASE NOISE (dBm/Hz)

-100

-110

-120

620MHz

220MHz

0.1 1 10 100 1000

OFFSET FREQUENCY (kHz)

MAX3580 toc01

MAX3580 toc04

110

100

90

GAIN (dB)

80

70

20

15

10

NOISE FIGURE (dB)

UHF BAND VOLTAGE GAIN

vs. FREQUENCY

TA = +25°C

TA = +85°C

450 550 600 650 700500 750 800 850 900

TA = +55°C

FREQUENCY (MHz)

NOISE FIGURE vs. VHF FREQUENCY

TA = +55°C

5

TA = -40°C

0

150 175 200 225 250

TA = +85°C

TA = +25°C

FREQUENCY (MHz)

TA = 0°C

MAX3580 toc02

MAX3580 toc05

VOLTAGE GAIN

vs. RF_AGC CONTROL VOLTAGE

110

BB_AGC = 2.85V

100

90

80

70

60

GAIN (dB)

50

40

30

20

10

01.00.5 1.5 2.0 2.5 3.0

RF_AGC CONTROL VOLTAGE (V)

TA = -40°C

TA = +25°C, +55°C

TA = +85°C

NOISE FIGURE vs. UHF FREQUENCY

20

15

TA = +25°C

10

TA = -40°C

NOISE FIGURE (dB)

5

0

450 550 600 650 700500 750 800 850 900

TA = +55°C

FREQUENCY (MHz)

TA = +85°C

MAX3580 toc03

MAX3580 toc06

Page 8

MAX3580

Direct-Conversion TV Tuner

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Typical values are at VCC= +3.3V, TA= +25°C, unless otherwise noted.)

UHF MODE NOISE FIGURE

vs. VOLTAGE GAIN

30

25

20

TA = +25°C

15

NOISE FIGURE (dB)

10

5

fRF = 620MHz

BB_AGC = 2.85V

0

60 70 7565 80 85 90

TA = +85°C

TA = -40°C

VOLTAGE GAIN (dB)

NORMALIZED BASEBAND FREQUENCY

RESPONSE

5

0

-5

TA = 0°C

-10

-15

-20

-25

GAIN (dB)

-30

-35

-40

BB_BW<3:0> = "1011"

-45

8MHz CHANNEL MODE

-50

021345

TA = +25°C

FREQUENCY (MHz)

TA = +55°C

TA = +85°C

MAX3580 toc08

MAX3580 toc11

VOLTAGE GAIN

vs. BB_AGC CONTROL VOLTAGE

110

RF_AGC = 2.85V

100

90

80

70

60

GAIN (dB)

50

40

30

20

10

01.00.5 1.5 2.0 2.5 3.0

TA = -40°C

TA = +25°C, +55°C

TA = +85°C

BB_AGC CONTROL VOLTAGE (V)

MAX3580 toc09

NORMALIZED BASEBAND FREQUENCY

RESPONSE

5

0

-5

TA = 0°C

-10

-15

-20

-25

GAIN (dB)

-30

-35

-40

-45

-50

021345

TA = +25°C

BB_BW<3:0> = "1001"

7MHz CHANNEL MODE

FREQUENCY (MHz)

TA = +85°C

MAX3580 toc12

BASEBAND FILTER REJECTION RATIO

0

-10

-20

-30

-40

-50

-60

-70

REJECTION RATIO (dB)

-80

-90

-100

0 5 10 15 20

VHF INPUT

NOISE LIMITED

FREQUENCY (MHz)

UHF INPUT

NORMALIZED BASEBAND FREQUENCY

RESPONSE

5

0

-5

-10

-15

-20

-25

GAIN (dB)

-30

-35

-40

-45

-50

0105152025

BB_BW<3:0> = "1011"

8MHz CHANNEL MODE

TA = +85°C

TA = 0°C

TA = +25°C

FREQUENCY (Hz)

MAX3580 toc10

MAX3580 toc13

NORMALIZED BASEBAND FREQUENCY

RESPONSE

5

0

-5

-10

-15

-20

GAIN (dB)

-25

-30

-35

-40

-45

0 5 10 15 20 25

BB_BW <3:0> = "1001"

7MHz CHANNEL MODE

TA = +85°C

TA = 0°C

FREQUENCY (MHz)

MAX3580 toc14

TA = +25°C

Page 9

MAX3580

Direct-Conversion TV Tuner

_______________________________________________________________________________________

9

Typical Operating Characteristics (continued)

(Typical values are at VCC= +3.3V, TA= +25°C, unless otherwise noted.)

0

-5

-10

-15

-20

150 200175 225 250

RF INPUT RETURN LOSS

vs. VHF FREQUENCY

MAX3580 toc21

VHF FREQUENCY (MHz)

RETURN LOSS (dB)

Zo = 75Ω

200

195

190

185

3.0 3.33.1 3.2 3.4 3.5 3.6

SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX3580 toc22

VCC (V)

I

CC

(mA)

TA = +55°C

TA = +85°C

TA = -40°C

TA = 0°C

TA = +25°C

STOPBAND NOISE vs. FREQUENCY

-45

-55

STOPBAND NOISE (dBm)

-65

-75

02010 30 40 50

BB_BW <3:0> = "1011"

8MHz CHANNEL MODE

BB_BW <3:0> = "1001"

7MHz CHANNEL MODE

FREQUENCY (MHz)

RF PORT-TO-PORT ISOLATION

40

35

30

25

20

GAIN (dB)

15

RFIN TO RFIN2

10

5

0

100 300 400 500 600200 700 800 900 1000

RFIN2 TO RFIN

FREQUENCY (MHz)

30

25

MAX3580 tpc15

20

15

NOISE FIGURE (dB)

10

MAX3580 toc18

POWER-DETECTOR OUTPUT VOLTAGE (V)

VHF MODE NOISE FIGURE

vs. BB_AGC VOLTAGE

TA = +55°C

TA = +85°C

5

TA = -40°C

0

0 1.0 1.50.5 2.0 2.5 3.0

TA = +25°C

BB_AGC VOLTAGE (V)

POWER-DETECTOR OUTPUT VOLTAGE

vs. RF INPUT POWER

4

10kΩ PULLUP TO 3.0V

3

"000"

2

1

0

-60 -30-50 -40 -20 -10 0

RF INPUT POWER (dBm)

220MHz

RF_AGC = 2.85V

"111"

MAX3580 toc16

MAX3580 tpc19

UHF MODE NOISE FIGURE

vs. BB_AGC VOLTAGE

30

25

20

15

NOISE FIGURE (dB)

10

5

TA = -40°C

0

0 1.0 1.50.5 2.0 2.5 3.0

TA = +55°C

BB_AGC VOLTAGE (V)

620MHz

RF_AGC = 2.85V

TA = +85°C

TA = +25°C

RF INPUT RETURN LOSS

vs. UHF FREQUENCY

0

Zo = 75Ω

-5

RETURN LOSS (dB)

-10

-15

450 675525 600 750 825 900

UHF FREQUENCY (MHz)

MAX3580 toc17

MAX3580 toc20

Page 10

MAX3580

Direct-Conversion TV Tuner

10 ______________________________________________________________________________________

Pin Description

PIN NAME FUNCTION

1 SDA Serial-Data Input Line. Requires a pullup resistor to VCC.

2 SCL Serial-Clock Input. Requires a pullup resistor to VCC.

3 RFIN2 Second RF Input

4 RFIN First RF Input

5 ADDR2

6 GND_LNA Not Internally Connected. Connect to ground.

7 VCC_RF DC Supply for RF LNA. Connect as close as possible a 100pF capacitor from this pin to GND.

8 LEXT External Bias Inductor. Connect to VCC with a 270nH inductor.

9 RF_AGC Gain Control Input for RF VGA.

10 IND1 VHF Inductor Pin 1. Keep traces to inductor as short as possible.

11 IND2 VHF Inductor Pin 2. Keep traces to inductor as short as possible.

12 N.C. No Connection

13 OVLD_DET Overload Detector Output. Connect a 10kΩ pullup resistor to VCC and a RC network to RF_AGC.

14 VCC_BB D C S up p l y for Baseb and Fi l ter . C onnect as cl ose as p ossi b l e a 10nF cap aci tor fr om thi s p i n to g r ound .

15 BBQ- Quadrature Inverted Baseband Output

16 BBQ+ Quadrature Noninverted Baseband Output

17 BBI- In-Phase, Inverted Baseband Output

18 BBI+ In-Phase, Noninverted Baseband Output

19 BB_AGC Gain Control Input for Baseband VGAs

20 VCC_VCO DC Supply for the VCO. Connect as close as possible a 100pF capacitor from this pin to ground.

21 VTUNE VCO Tuning Voltage Input. Connect the PLL loop filter output directly to this pin.

22 GND_TUNE Ground Reference for the Tuning Voltage. Connect to ground of the loop filter.

23 LDO VCO LDO Output. Connect a 0.1µF capacitor to ground.

24 CP Charge-Pump Output. Connect the charge-pump output to the PLL loop filter input.

25 GND_CP Ground for the Charge Pump

26 VCC_SYN

27 GND_PLL Ground for the PLL

28 MUX Multiplex Output Line. Can be used as a PLL lock-detector output.

29 REF_BUFF Buffered Output of Reference Oscillator

30 VCC_XTAL D C S up p l y for Refer ence Osci l l ator . C onnect as cl ose as p ossi b l e a 10nF cap aci tor fr om thi s p i n to g r ound .

31 XB

32 XE Reference Oscillator Feedback. Connect to a capacitive divider when used in self-oscillating mode.

EP EP Exposed Paddle. Solder to the board’s ground plane to achieve the lowest possible impedance path.

Address Line. Sets the 3rd LSB of the device address. Connect to ground to set for “0” or V

for “1.”

DC Supply for Synthesizer and Serial-Interface Control. Connect as close as possible a 10nF

capacitor from this pin to ground.

Reference Input. Connect to a parallel resonant mode XTAL through a load-matching capacitor, or

can also be used as a reference clock input pin.

to set

CC

Page 11

MAX3580

Direct-Conversion TV Tuner

______________________________________________________________________________________ 11

Typical Application Circuit

ADDR2

SDA

SCL

RFIN2

RFIN

V

XE

XB

VCC_XTAL

32 28

1

2

3

4

5

SERIAL I NTERF ACE, CONTROL,

CC

293031

AND

SYNTHESIZER

REF_BUFF

MUX

MAX3580

DAC

V

CC

VCC_SYN

26

OVLD_DET

CHARGE

PUMP

GND_CP

25

CP

24

LDO

23

GND_TUNE

22

VTUNE

21

20

VCC_VCO

V

CC

GND_PLL

27

LO

GND_LNA

6

TRACKING

VCC_RF

LEXT

7

8

V

CC

V

CC

FILTER

10

9

IND1

RF_AGC

IND2

0

LO

90

14

13

N.C.

OVLD_DET

15

BBQ-

VCC_BB

V

CC

19

BBI+

18

BBI-

17

1611 12

BBQ+

I CHANNEL

Q CHANNEL

OVLD_DET

BB_AGC

Page 12

MAX3580

Direct-Conversion TV Tuner

12 ______________________________________________________________________________________

Detailed Description

Programmable Registers

The MAX3580 includes thirteen write/read registers and

three read-only registers. See Table 2 for register configuration and the

Register Description

section. The

register configuration of Table 2 shows each bit name

and the bit usage information for all registers. “U”

labeled under each bit name indicates that the bit

value is user defined to meet specific application

requirements. A “0” or “1” indicates that the bit must be

set to the defined “0” or “1” value for proper operation.

Operation is not tested or guaranteed if these bits are

programmed to other values and is only for

factory/bench evaluation. For field use, always program

to the defined operational state. Note that all registers

must be written after and no earlier than 100µs after

device power-up.

Table 2. Register Configuration

REGISTER

ADDRESS

0x00

0x01

0x02

0x03

0x04

0x05

0x06

0x07

0x08

0x09

0x0A

0x0B

0x0C

0x0D

0x0E

0x0F

0x10 TFR<7> TFR<6> TFR<5> TFR<4> TFR<3> TFR<2> TFR<1> TFR<0>

0x11 POR VASA VASE LD DC_LO DC_HI GKT PD_OVLD N/A N/A

0x12 VCO1A VCO0A BS2A BS1A BS0A ADC2 ADC1 ADC0 N/A N/A

TFS<7>UTFS<6>UTFS<5>UTFS<4>UTFS<3>UTFS<2>UTFS<1>UTFS<0>

VCO_DIV1UVCO_DIV0

RDIV

CP_TST20CP_TST10CP_TST0

VCO1

BB_BW3UBB_BW2UBB_BW1UBB_BW0

BB_BIA0DC_DAC80DC_MO11DC_MO01DC_SP11DC_SP00DC_TH10DC_TH0

DC_DAC70DC_DAC60DC_DAC50DC_DAC40DC_DAC30DC_DAC20DC_DAC10DC_DAC0

TFD<7>0TFD<6>0TFD<5>0TFD<4>0TFD<3>0TFD<2>0TFD<1>0TFD<0>

D7 D6 D5 D4 D3 D2 D1 D0

N7

U

MP

0

F15

U

F7

U

U

X

0

U

X

0

X

0

N6

U

LI1

0

F14

U

F6

U

U

ICP

U

SHDN_BGUSHDN_PDUSHDN_REFUSHDN_SYNUSHDN_MXUSHDN_BBUSHDN_RF

VCO0

U

FUSE_TH

0

X

0

N5

U

LI0

F13

U

F5

U

RFS

U

CPS

U

BS2

U

0

0

X

0

X

0

8-BIT DATA REGISTER SETTINGS

N4

U

INT

U

F12

U

F4

U

TF_BS

U

ADLY10ADLY01LF_DIV2ULF_DIV1ULF_DIV0

X

0

BS1

U

U

WR

0

X

0

N3

U

F19

U

F11

U

F3

U

TFP<3>UTFP<2>UTFP<1>UTFP<0>

TURBO1LD_MUX2ULD_MUX1ULD_MUX0

BS0

U

X

0

TFA<3>UTFA<2>UTFA<1>UTFA<0>

MX_HR<3>0MX_HR<2>0MX_HR<1>0MX_HR<0>

N2

U

F18

U

F10

U

F2

U

VAS

1

PD_TH2UPD_TH1UPD+TH0

N1

U

F17

U

F9

U

F1

U

ADL

0

N0

U

F16

U

F8

U

F0

U

U

U

U

U

U

ADE

0

U

0

0

U

0

0

OPERATION

DEFINED

h38 h40 DC Offset Control

h00 h00 DC Offset DAC

h00 h00

h00 h00

N/A

DEFAULT

SETTINGS

(POR)

— H17 N-Divider Integer

— h18 N-Divider Frac2

— h00 N-Divider Frac1

— h00 N-Divider Frac0

—hDB

— h7C

— h0A PLL Configuration

— h08 Test Functions

— h00 Shutdown Control

— hC0 VCO Control

— h87 Baseband Control

— h00

N/A

REGISTER

Tracking Filter

Series Caps

Tracking Filter

Parallel Cap

ROM Table

Address

ROM Table Fuse

Data

Mixer Harmonic

Rejection

ROM Table Data

Read Back

Chip Status Read

Back

Autotuner Read

Back

NAME

Page 13

MAX3580

Direct-Conversion TV Tuner

______________________________________________________________________________________ 13

Register Descriptions

N-Divider Integer (Register Address 0x00)

N<7:0>: VCO Integer-N Divider Ratio

N-Divider Frac2 (Register Address 0x01)

MP: Minimum CP Pulse Width. Always set to 0

(factory use only).

LI1, LI0; CP Linearity Control. Always set to 00

(factory use only).

INT: Integer Mode ON/OFF. Set to 0 for normal

operation.

F<19:16>: MSB of Main Divider Fractional Divide Ratio

N-Divider Frac1, Frac0

(Register Address 0x02, 0x03)

F<15:0> 16 LSB of Main Divider Fractional Divide

Ratio

Tracking Filter Series Capacitor

(Register Address 0x04)

TFS<7:4>: Tracking Filter Parallel Capacitor.

TFS<3:0>: Tracking Filter Series Capacitor.

See the RF tracking filter description in the

Applications

Information

section.

Tracking Filter Parallel Capacitor and VCO Control

(Register Address 0x05)

VCO_DIV1, VCO_DIV0: VCO Post Divider

00 = Divide by 4 use for RF frequencies of 540 to

868 MHz

01 = Divide by 8 use for RF frequencies of 470 to

550 MHz

10 = Divide by 16 use for RF frequencies of 170 to

230 MHz

11 = Divide by 32 is not used

RFS: RF Input Select

0 = RFIN2 selected

1 = RFIN selected

TF_BS: Tracking Filter Band Select

1 = VHF band

0 = UHF band

TFP<4:0>: Tracking Filter Shunt Capacitor

See the RF tracking filter description in the

Applications

Information

section.

PLL Configuration (Register Address 0x06)

LF_DIV2, LF_DIV1, LF_DIV0: Prescaler for Internal

Low Frequency Clocks

000 - 110 = Divided by 8 to 14 for REF crystal frequencies of 15MHz to 28MHz

111 = Divide by 2 for REF crystal frequencies of

4MHz

ADLY1, ADLY0: VCO Autotuner Delay Selection

CPS: Charge-Pump Current Mode

0 = Controlled by ICP bit

1 = Controlled by VCO autotuner

ICP: Charge-Pump Current

0 = 600µA

1 = 1200µA

RDIV: PLL Reference Divider Ratio

0 = Divide by 1

1 = Divide by 2

Test Functions (Register Address 0x07)

CP_TST<2:0>: Charge-Pump Test Modes

000 = Normal operation

100 = Low impedance*

101 = Source

110 = Sink

111 = High impedance

LD_MUX: Lock-Detector Mode

000 = Normal operation: high = PLL locked,

low = unlocked

001 = Monitor N-divider output, post-divided by 2

010 = Monitor R-divider output*

011 = Modulator test vector output

(factory use only)

1XX = Bias current trim (factory use only)

*

Not production tested.

Page 14

MAX3580

Direct-Conversion TV Tuner

14 ______________________________________________________________________________________

Shutdown Control (Register Address 0x08)

SHDN_BG: Main Bandgap

0 = Enabled

1 = Disabled

The main bandgap can and will be shut down

once all other blocks are shut down (i.e., all bits in this

shutdown register and bits VCO_ in the VCO

Control Register and bits DC_MO_ in the DC

Offset Control Register are shut down).

SHDN_PD: Baseband Power Detector

0 = Enabled

1 = Disabled

SHDN_RF: RF LNA/VGA:

0 = Enabled

1 = Disabled

SHDN_MIX: I/Q Mixer and LO Drivers

0 = Enabled

1 = Disabled

SHDN_BB: Baseband Filters and VGA

0 = Enabled

1 = Disabled

SHDN_SYN: Fractional PLL

0 = Enabled

1 = Disabled

SHDN_REF: Controls the Crystal Oscillator Buffered

Output

0 = Enabled

1 = Disabled

The XTAL oscillator activation results from the

SHDN_SYN, SHDN_REF bits: If either one is on,

the XTAL oscillator runs. The XTAL oscillator is

shut down only if both bits are off.

VCO Control (Register Address 0x09)

VCO<1:0>: Selects 1 of 3 VCO Bands. 00 turns off

VCO block completely.

BS<2:0>: Selects 1 of 8 VCO Sub-Bands

VAS: VCO Band Autoselect

0 = VCO band select controlled by bits VCO<1:0>

1 = Controlled by autotuner

ADL: VCO ADC Latch Enable Bit

1 = Latches ADC value

0 = Default

ADE: Enable VCO Tune Voltage DAC Read

1 = Enables ADC read

0 = Default

Baseband Control (Register Address 0x0A)

PD_TH<2:0>: Detection Threshold for Baseband

Power Detector

BB_BW<3:0>: Baseband Filter Bandwidth. Optimum

values for 7MHz and 8MHz wide RF channels can

be taken from the ROM table.

DC Offset Control (Register Address 0x0B)

DC_TH<1:0>: DC Offset Correction Thresholds.

Keeps output within:

00 = Output within ±0.55V of balanced state

11 = Output within ±0.75V of balanced state

DC_SP<1:0>: DC Offset Correction Speed (or Highpass

Corner Frequency).

11 = Fast (~500Hz)

01 = Slow (~20Hz)

00 = Off/hold DAC values

DC_MO<1:0>: Mode of Operation

00 = Off

10/01 = Sets I/Q channel DACs direct from register

11 = Normal operation

DC_DAC<8>: MSB for DC Offset DAC

BB_BIA: Baseband Filter Op-Amp Bias Settings

0 = Low

1 = High

*

Not production tested.

Page 15

MAX3580

Direct-Conversion TV Tuner

______________________________________________________________________________________ 15

DC Offset DAC (Register Address 0x0C)

DC_DAC<7:0>: Value to Program to I/Q DC Offset

DAC. Note that the MSB is located in the previous register.

Tracking Filter ROM Address

(Register Address 0x0D)

TFA<3:0>: Tracking Filter ROM Address. See Table 3.

Tracking Filter Write Data (Register Address 0x0E)

TFD<7:0>: Tracking Filter Data for ROM

Tracking Filter ROM Read Back (Read Only)

(Register Address 0x10)

TFR<7:0>: Tracking Filter ROM Data Read Back

Status (Read Only, for Factory Use Only)

(Register Address 0x11)

POR: Power-On Reset

0 = Power has not been reset since the last read.

1 = Power has been reset since the last read. Gets

reset after reading back address 8’h0C.

VASA, VASE: VCO Autotuner Status*

LD: PLL Lock Detector

0 = PLL unlocked

1 = PLL locked

DC_HI: DC Offset Correction Detected Positive Signal

Excursion in Either I or Q Channel*

DC_LO: DC Offset Correction Detected Negative Signal

Excursions in Either I or Q Channel*

PD_OVLD: Baseband Power Detector

0 = Baseband signal below threshold

1 = Baseband signal above threshold

Autotuner Read Back (Read Only, for Factory Use

Only) (Register Address 0x12)

VCOA<1:0> VCO Tank Selected by Autotuner*

BSA<1:0> Sub-Band VCO Selected by Autotuner*

ADC<2:0> VCO Tank Voltage ADC*

Table 3. MAX3580 Fuse Table

*

Not production tested.

BYTE 7 6543 21 0 DESCRIPTION

00 Unused Bias Bias trim

01 VHF (200MHz) parallel cap VHF (200MHz) series cap VHF high series cap

02 Unused VHF (200MHz) shunt cap VHF shunt cap

03 UHF low (470MHz) parallel cap UHF low (470MHz) series cap UHF low series cap low

04 UHF high (860MHz) shunt cap UHF low (470MHz) shunt cap UHFhigh/low parallel cap

05 UHF high (860MHz) parallel cap UHF high (860MHz) series cap UHF high series cap

06 Baseband filter UHF (8MHz) coefficient. Baseband filter VHF (7MHz) coefficient. BB filter bandwidth

07 X X X X X X X RO Read only

Page 16

MAX3580

Direct-Conversion TV Tuner

16 ______________________________________________________________________________________

To Read Back Fuses

IMPORTANT NOTICE: When reading other addresses

than 8’h00 (the system trim bits), it is possible that the

data going to the bias cells will be disturbed due to the

architecture of the fuse bank. This means the bias current could change while reading back fuse data.

1) Write 8’hXX to TFA. XX is the address of the fuse column you want to read.

2) Read 8’hXX from TFR. TFR is the Tracking Filter

Read Register.

3) Repeat steps 1 and 2 for other addresses.

2-Wire Serial Interface

The MAX3580 uses a 2-wire I2C*-compatible serial

interface consisting of a serial-data line (SDA) and a

serial-clock line (SCL). The serial interface allows communication between the MAX3580 and the master at

clock frequencies up to 400kHz. The master initiates a

data transfer on the bus and generates the SCL signal

to permit data transfer. The MAX3580 behaves as slave

devices that transfer and receive data to and from the

master. Pull SDA and SCL high with external pullup

resistors (1kΩ or greater) for proper bus operation.

One bit is transferred during each SCL clock cycle. A

minimum of nine clock cycles are required to transfer a

byte in or out of the MAX3580 (8 bits and an ACK/NACK).

The data on SDA must remain stable during the high period of the SCL clock pulse. Changes in SDA while SCL is

high and stable are considered control signals (see the

START and STOP Conditions

section). Both SDA and

SCL remain high when the bus is not busy.

START and STOP Conditions

The master initiates a transmission with a START condition (S), which is a high-to-low transition on SDA while

SCL is high. The master terminates a transmission with

a STOP condition (P), which is a low-to-high transition

on SDA while SCL is high.

Acknowledge and Not-Acknowledge Conditions

Data transfers are framed with an acknowledge bit

(ACK) or a not-acknowledge bit (NACK). Both the master and the MAX3580 (slave) generate acknowledge

bits. To generate an acknowledge, the receiving device

must pull SDA low before the rising edge of the

acknowledge-related clock pulse (ninth pulse) and

keep it low during the high period of the clock pulse.

To generate a not-acknowledge condition, the receiver

allows SDA to be pulled high before the rising edge of

the acknowledge-related clock pulse, and leaves SDA

high during the high period of the clock pulse.

Monitoring the acknowledge bits allows for detection of

unsuccessful data transfers. An unsuccessful data

transfer happens if a receiving device is busy or if a

system fault has occurred. In the event of an unsuccessful data transfer, the bus master must reattempt

communication at a later time.

Slave Address

The MAX3580 has a 7-bit slave address that must be

sent to the device following a START condition to initiate communication. The slave address is determined

by the state of the ADDR2 pin and is equal to

11000[ADDR2]0 (see Table 4). The eighth bit (R/W) following the 7-bit address determines whether a read or

write operation will occur.

The MAX3580 continuously awaits a START condition

followed by its slave address. When the device recognizes its slave address, it acknowledges by pulling the

SDA line low for one clock period; it is ready to accept

or send data depending on the R/W bit (Figure 1).

*Purchase of I2C components of Maxim Integrated Products, Inc., or one of its sublicensed Associated Companies, conveys a

license under the Philips I

2

C Patent rights to use these components in an I2C system, provided that the system conforms to the I2C

Standard Specification as defined by Philips.

Table 4. Address Configuration

Figure 1. MAX3580 Slave Address Byte

SLAVE ADDRESS

ADDRESS (WRITE/READ) ADDR2

C0/C1

C4/C5

HEX

HEX

0

1

S11000 0R/ WACK

SDA

SCL

123456789

ADDR2

Page 17

MAX3580

Direct-Conversion TV Tuner

______________________________________________________________________________________ 17

Write Cycle

When addressed with a write command, the MAX3580

allows the master to write to a single register or to multiple successive registers.

A write cycle begins with the bus master issuing a

START condition followed by the seven slave address

bits and a write bit (R/W = 0). The MAX3580 issues an

ACK if the slave address byte is successfully received.

The bus master must then send to the slave the

address of the first register it wishes to write to. If the

slave acknowledges the address, the master can then

write one byte to the register at the specified address.

Data is written beginning with the most significant bit.

The MAX3580 again issues an ACK if the data is successfully written to the register. The master can continue to write data to the successive internal registers with

the MAX3580 acknowledging each successful transfer,

or it can terminate transmission by issuing a STOP condition. The write cycle does not terminate until the master issues a STOP condition.

Figure 2 illustrates an example in which Registers 0

through 2 are written with 0x0E, 0xD8, and 0xE1,

respectively.

Read Cycle

When addressed with a read command, the MAX3580

allows the master to read back a single register or multiple successive registers.

A read cycle begins with the bus master issuing a

START condition followed by the 7 slave address bits

and a write bit (R/W = 0). The MAX3580 issues an ACK if

the slave address byte is successfully received. The bus

master must then send the address of the first register it

wishes to read. The slave acknowledges the address.

Then a START condition is issued by the master, followed by the 7 slave address bits and a read bit (R/W =

1). The MAX3580 issues an ACK if the slave address

byte is successfully received. The MAX3580 starts sending data MSB first with each SCL clock cycle. At the 9th

clock cycle, the master can issue an ACK, and continue

to read successive registers, or the master terminate the

transmission by issuing a NACK. The read cycle does

not terminate until the master issues a STOP condition.

Figure 3 illustrates an example in which Registers 0

through 2 are read back.

Figure 2. Example: Write Registers 0 through 2 with 0x0E, 0xD8 and 0xE1, respectively.

Figure 3. Example: Receive data from read registers.

START

WRITE DEVICE

ADDRESS

1100000

R/ W

ACK

WRITE REGISTER

ADDRESS

0x000

ACK

WRITE DATA TO

REGISTER 0x00

0x0E

ACK

WRITE DATA TO

REGISTER 0x01

0xD8

ACK

WRITE DATA TO

REGISTER 0x02

0xE1

ACK

STOP

S

DEVICE

T

ADDRESS

A

R

11000000 00000000 11000000 xxxxxxxx xxxxxxxx xxxxxxxx01

T

R/ W

REGISTER

A

ADDRESS

C

K

S

A

C

K

ADDRESS

A

R

T

DEVICE

T

R/ W

REG 00

A

DATA

C

K

REG 01

A

DATA

C

K

REG 02

A

DATA

C

K

N

S

A

T

C

O

K

P

Page 18

MAX3580

Direct-Conversion TV Tuner

18 ______________________________________________________________________________________

Applications Information

Band Selection

The MAX3580 is designed to be suitable for operation

in the 170MHz to 230MHz VHF-III band and in the

470MHz to 878MHz UHF band.

RF Inputs

A switch selects either RFIN or RFIN2 as the input to the

single-ended broadband matched LNA. This switch is

programmed through the RFS bit (bit 5) of register 0x05.

The LNA provides a continuous gain control range of

typically 50dB before the signal is downconverted.

For optimal matching above 600MHz, add a 5nH to

6nH inductor in series with a capacitor at either of the

RF input. Application Note:

Front End Diplexer Filter for

MAX3580

is available, detailing the implementation of a

UHF and VHF simple diplexer. This simple diplexerl

improves strong-signal-handling capabilities of the

MAX3580.

DC-Offset Cancellation

The MAX3580 features an on-chip fast-settling, DC-offset cancellation circuitry that requires no off-chip components. Note that the offset correction circuit is not

enabled when the device is powered up. To enable the

offset correction circuit, program the DC-Offset Control

Register to the recommended default setting.

When active, the offset correction circuit creates a

highpass characteristic in the signal path with a typical

corner frequency of 200Hz, and the residual DC offset

can be as high as ±70mV.

Gain Control

The MAX3580 features two VGA circuits that can be

used to achieve the optimum SNR. The two circuits can

be driven independently by the baseband controller,

which allows balancing the gain based on SNR measurements in the digital demodulator. If only one gain control

voltage can be provided by the digital demodulator, the

RF VGA is controlled by the baseband power detector of

the MAX3580. See the

Baseband Power Detector

section. In this operation mode, the baseband gain is set by

an amplitude detector in the digital demodulator.

Baseband Power Detector

The MAX3580 baseband power detector compares the

total weighted receive input signal within approximately

2 channels of the wanted channel to a programmable

threshold. This threshold can be programmed to different values with the PD_TH<2:0> bits in the Baseband

Control Register.

To close the RF gain control loop, connect the 300µA

control current sink of the power detector (pin

OVLD_DET) to VCCwith a 10kΩ pullup resistor. The

resulting voltage is fed with an RC lowpass to the

RF_AGC input.

Synthesizer Loop Filters

A second-order lowpass loop filter is used to connect

the PLL to the RF local oscillator. A loop filter bandwidth

of 30kHz is optimal for fractional PLL spurs and integrated LO phase noise. Refer to the EV kit data sheet for the

recommended loop-filter component values.

Crystal-Oscillator Interface

The MAX3580 reference oscillator circuitry can be used

either as a high-impedance reference input driven by

an external source, or be configured as a crystal oscillator. In the latter case, the resulting frequency can be

used to drive the digital demodulator chip through the

buffered reference output of the MAX3580. When using

an external reference oscillator, drive the XB input

through an AC-coupling capacitor with amplitude of

approximately 1.5V

P-P

, and leave XE unconnected.

Note that the phase noise of the external reference

needs to exceed -140dBc/Hz at offsets of 1kHz to

100kHz. When connecting directly to a crystal, see the

Typical Application Circuit

for the required topology.

For particular capacitor values, possible changes to

accommodate for different crystal frequencies, crystal

load-capacitance requirements, and crystal power-dissipation requirements, refer to the EV kit data sheet.

Page 19

MAX3580

Direct-Conversion TV Tuner

______________________________________________________________________________________ 19

RF Tracking Filter

The MAX3580 utilizes two narrowband RF tracking filters,

one for VHF and one for UHF. Each filter is comprised of

a fixed inductor and three digitally controlled variable

capacitors named series, shunt, and parallel capacitors.

The integrated RF tracking filters uses an external inductor between IND1 and IND2 pins to set the filter’s center

frequency. The inductor value must be 68nH ±2% in

order to achieve the corner frequency response. The variable capacitors are factory calibrated to this particular

inductor value. The value of each capacitor is also set to

compensate for process variation of each individual part

and to receive the desired RF channel.

The process variation is factory calibrated by determining the best capacitor values for three discrete frequencies, which are stored in the on-chip ROM table. Upon

power-up these values (6 bytes total) have to be read

out of the MAX3580 ROM table and stored in the microprocessor local memory.

When tuning the MAX3580 to a given Rx frequency, the

correct capacitor value has to be calculated using the

following linear formulas and written to the appropriate

registers. This is in addition to programming the PLL

with the desired frequency.

The formulas differ for VHF and UHF bands but are the

same for all three capacitor values. Since the factory

calibration coefficients stored on the MAX3580 can differ for each capacitor, the calculations have to be executed for all three capacitor values separately.

VHF: Capacitor = ROM_value_VHF (RX_frequency_in_MHz - 200MHz ) / 10MHz

In other words, the capacitor values to be written to the

MAX3550 decrease 1 count per 10MHz above 200MHz

and increase accordingly below 200MHz.

UHF: Capacitor = ROM_value_UHF_lo (ROM_value_UHF_lo - ROM_value_UHF_hi)

x (RX_frequency_in_MHz - 470MHz ) / 390MHz

This means the capacitor values stored in the UHF_lo

entries of the MAX3580 ROM table are the correct values

for 470MHz reception and the UHF_hi values for 860MHz

reception. For any frequency in between, the capacitor

values are obtained by a simple linear interpolation.

Note: When tuning to frequencies above 860MHz

channel center frequency, do not use the formula

above, but rather keep programming the tracking filter

with the coefficients obtained for 860MHz.

Examples: Assuming the MAX3580 ROM table entries

are C

SERIES

VHF = 8, C

SERIES

UHF_lo = 15, C

SERIES

UHF_hi = 3

208MHz: C

SERIES

= 8 - round ( ( 208-200 ) / 10 ) = 7

(floating point division, round to nearest

integer after division)

8 - floor ( ( 208 - 200 + 5) / 10 ) = 7

(all calculations using signed integer values,

truncate result of division)

677MHz: C

SERIES

= 15 - round ( (15-3) x (677 - 470) /

390 ) = 9 (floating point division, round to

nearest integer after division) 15 - floor

( ( ( 15-3) x (677-470) + 195 ) / 390 ) = 9

(all calculations using signed integer values,

truncate result of division)

Power-Supply Layout

To minimize coupling between different sections of the

IC, the ideal power-supply layout is a star configuration,

which has a large decoupling capacitor at the central

VCCnode. The VCCtraces branch out from this node,

with each trace going to separate VCCpins of the

MAX3580. Next to each VCCpin is a bypass capacitor

with a low impedance to ground at the frequency of

interest. Use at least one via per bypass capacitor for a

low-inductance ground connection.

The three ground pins (GND_PLL, GND_CP,

GND_TUNE) must be connected to the ground plane

by separate via holes and must not be directly connected to the exposed paddle.

Chip Information

PROCESS: BiCMOS

Page 20

MAX3580

Direct-Conversion TV Tuner

20 ______________________________________________________________________________________

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

QFN THIN.EPS

Page 21

MAX3580

Direct-Conversion TV Tuner

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________

21

© 2006 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

Loading...

Loading...