Page 1

_______________General Description

The MAX194 is a 14-bit successive-approximation analog-to-digital converter (ADC) that combines high

speed, high accuracy, low power consumption, and a

10µA shutdown mode. Internal calibration circuitry corrects linearity and offset errors to maintain the full rated

performance over the operating temperature range

without external adjustments. The capacitive-DAC

architecture provides an inherent 85ksps track/hold

function.

The MAX194, with an external reference (up to +5V),

offers a unipolar (0V to V

REF

) or bipolar (-V

REF

to V

REF

)

pin-selectable input range. Separate analog and digital

supplies minimize digital-noise coupling.

The chip select (CS) input controls the three-state serial-data output. The output can be read either during

conversion as the bits are determined, or following conversion at up to 5Mbps using the serial clock (SCLK).

The end-of-conversion (EOC) output can be used to

interrupt a processor, or can be connected directly to

the convert input (CONV) for continuous, full-speed

conversions.

The MAX194 is available in 16-pin DIP, wide SO, and

ceramic sidebraze packages. The output data format

provides pin-for-pin and functional compatibility with

the 16-bit MAX195 ADC.

________________________Applications

Portable Instruments Audio

Industrial Controls Robotics

Multiple Transducer Medical Signal

Measurements Acquisition

Vibrations Analysis Digital Signal

Processing

____________________________Features

♦ True 14-Bit Accuracy: 1⁄2LSB INL

82dB SINAD

♦ 9.4µs Conversion Time

♦ 10µA Shutdown Mode

♦ Built-In Track/Hold

♦ AC and DC Specified

♦ Unipolar (0V to V

REF

) and Bipolar (-V

REF

to V

REF

)

Input Range

♦ Three-State Serial-Data Output

♦ Small 16-Pin DIP, SO, and Ceramic SB Packages

♦ Pin-Compatible 16-Bit Upgrade (MAX195)

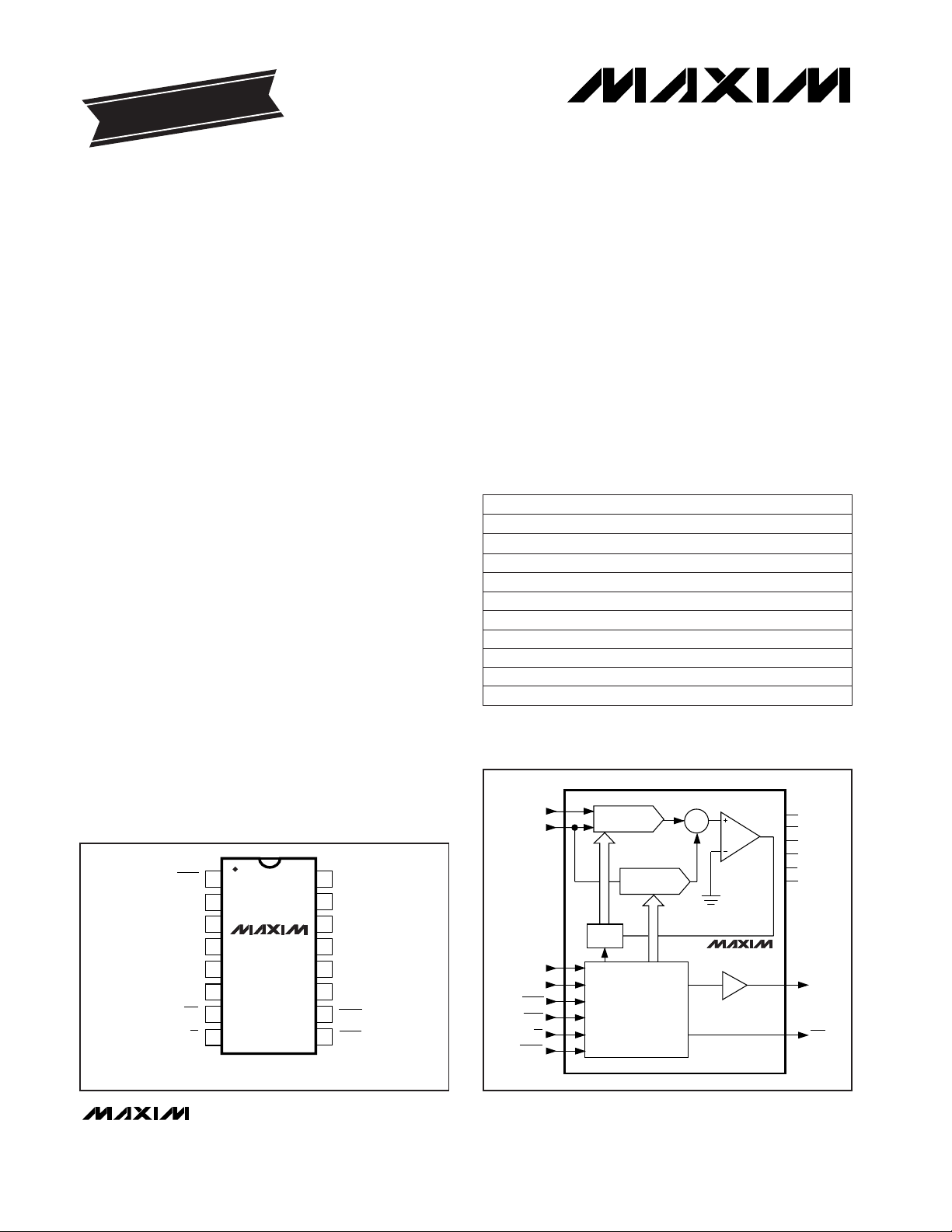

______________Ordering Information

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

________________________________________________________________

Maxim Integrated Products

1

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

VDDA

VSSA

AGND

AIN

VDDD

SCLK

CLK

BP/UP/SHDN

TOP VIEW

MAX194

REF

VSSD

RESET

CONV

CS

EOC

DGND

DOUT

DIP/Wide SO/Ceramic SB

MAX194

AIN

REF

CONV

SCLK

CLK

BP/UP/SHDN

CS

RESET

VSSD

DGND

VDDD

VDDA

AGND

VSSA

DOUT

EOC

SAR

CONTROL LOGIC

COMPARATOR

CALIBRATION

DACs

THREE-STATE BUFFER

4

6

11

16

14

15

5

7

10

8

1

9

3

2

13

12

MAIN DAC

Σ

________________Functional Diagram

__________________Pin Configuration

19-0345; Rev 4; 12/97

PART

MAX194ACPE

MAX194BCPE

MAX194ACWE 0°C to +70°C

0°C to +70°C

0°C to +70°C

TEMP. RANGE PIN-PACKAGE

16 Plastic DIP

16 Plastic DIP

16 Wide SO

MAX194BCWE 0°C to +70°C 16 Wide SO

MAX194AEPE -40°C to +85°C 16 Plastic DIP

MAX194BEPE -40°C to +85°C 16 Plastic DIP

MAX194AEWE -40°C to +85°C 16 Wide SO

MAX194BEWE -40°C to +85°C 16 Wide SO

MAX194AMDE -55°C to +125°C 16 Ceramic SB

MAX194BMDE -55°C to +125°C 16 Ceramic SB

EVALUATION KIT

AVAILABLE

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 408-737-7600 ext. 3468.

Page 2

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

2 _______________________________________________________________________________________

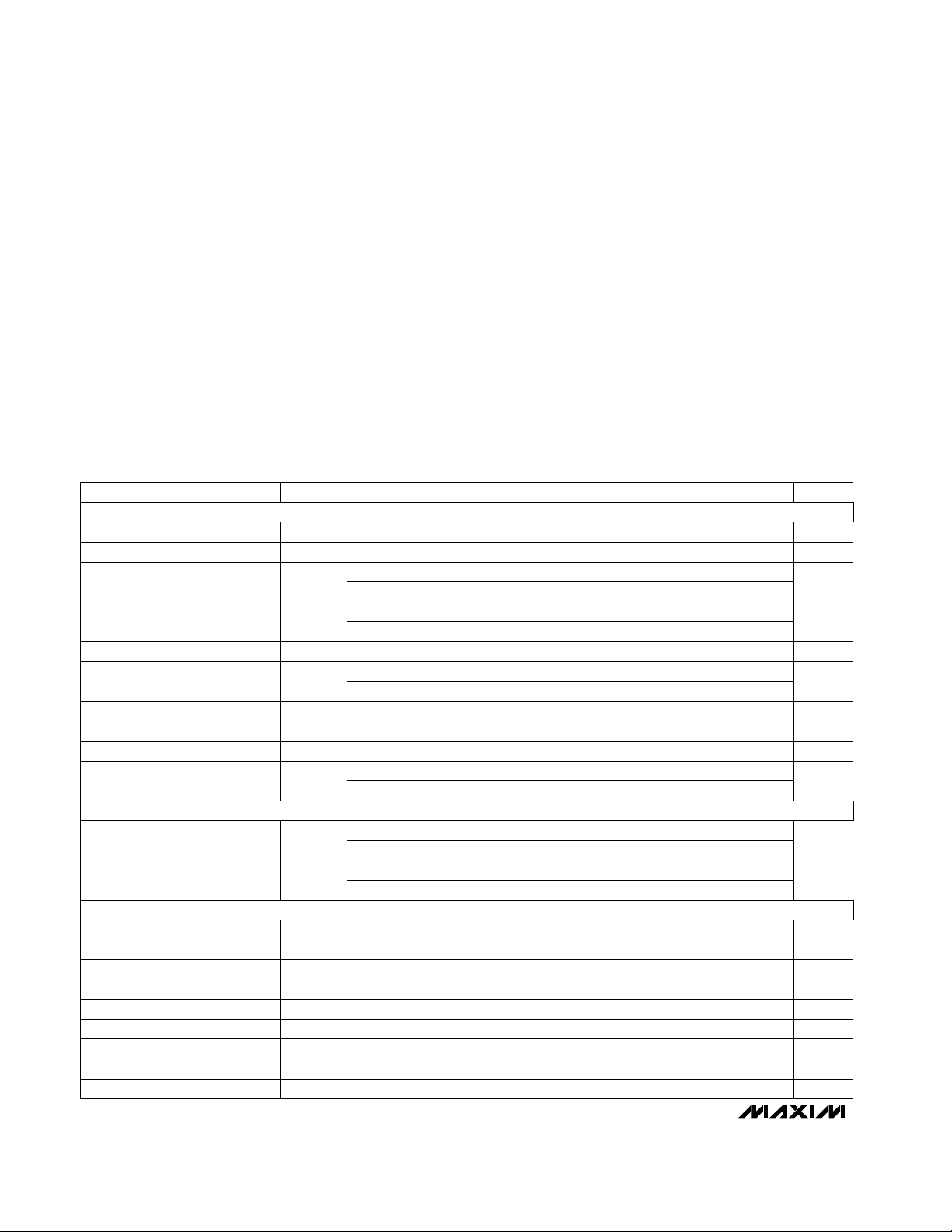

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VDDD = VDDA = +5V, VSSD = VSSA = -5V, f

CLK

= 1.7MHz, V

REF

= +5V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical

values are at T

A

= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDDD to DGND .....................................................................+7V

VDDA to AGND......................................................................+7V

VSSD to DGND.........................................................+0.3V to -6V

VSSA to AGND.........................................................+0.3V to -6V

VDDD to VDDA, VSSD to VSSA..........................................±0.3V

AIN, REF ....................................(VSSA - 0.3V) to (VDDA + 0.3V)

AGND to DGND..................................................................±0.3V

Digital Inputs to DGND...............................-0.3V, (VDDA + 0.3V)

Digital Outputs to DGND............................-0.3V, (VDDA + 0.3V)

Continuous Power Dissipation (T

A

= +70°C)

Plastic DIP (derate 10.53mW/°C above +70°C) ............842mW

Wide SO (derate 9.52mW/°C above +70°C)..................762mW

Ceramic SB (derate 10.53mW/°C above +70°C)...........842mW

Operating Temperature Ranges

MAX194_C_E........................................................0°C to +70°C

MAX194_E_E .....................................................-40°C to +85°C

MAX194_MDE..................................................-55°C to +125°C

Storage Temperature Range.............................-65°C to +160°C

Lead Temperature (soldering, 10sec).............................+300°C

16(t

CLK

)

Unipolar

MAX194B, V

REF

= 4.75V

MAX194A, V

REF

= 4.75V

MAX194A

MAX194B

MAX194A, V

REF

= 4.75V

VSSA = -5.25V to -4.75V, V

REF

= 4.75V

MAX194B, V

REF

= 4.75V

VDDA = 4.75V to 5.25V, V

REF

= 4.75V

CONDITIONS

MHz1.7f

CLK

Clock Frequency

(Notes 2, 3)

µs9.4t

CONV

Conversion Time

dB-90Peak Spurious Noise

dB-90THD

Total Harmonic Distortion

(up to the 5th harmonic)

V

0 V

REF

Input Range

dB

65

Power-Supply Rejection

Ratio (VDDA and VSSA only)

65

LSB±1DNLDifferential Nonlinearity

Bits14RESResolution

ppm/°C0.1Full-Scale Tempco

LSB

±2

Unipolar Full-Scale Error

±1

Unipolar/Bipolar Offset Tempco ppm/°C0.4

±1⁄2

LSB

±1

INLIntegral Nonlinearity

±1

LSB

±2

Unipolar/Bipolar Offset Error

UNITSMIN TYP MAXSYMBOLPARAMETER

Unipolar

pF

250

Input Capacitance

dB82SINAD

Signal-to-Noise plus Distortion

Ratio

MHz5f

SCLK

Serial Clock Frequency

Bipolar

Bipolar 125

-V

REF

V

REF

MAX194B, V

REF

= 4.75V

MAX194A, V

REF

= 4.75V

LSB

±4

Bipolar Full-Scale Error

±2

ACCURACY (Note 1)

ANALOG INPUT

DYNAMIC PERFORMANCE (fs= 85kHz, bipolar range AIN = -5V to +5V, 1kHz) (Note 1)

Page 3

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

_______________________________________________________________________________________ 3

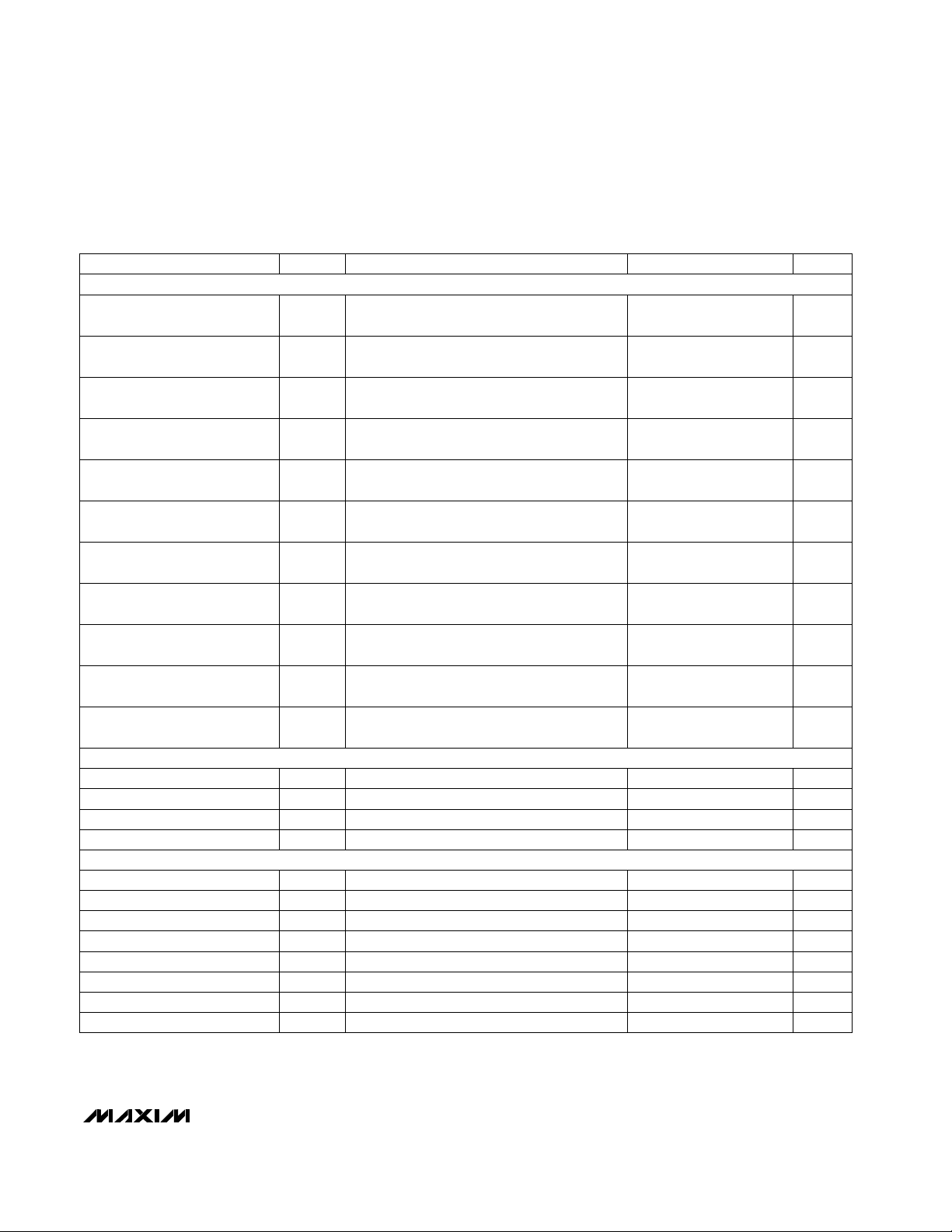

ELECTRICAL CHARACTERISTICS (continued)

(VDDD = VDDA = +5V, VSSD = VSSA = -5V, f

CLK

= 1.7MHz, V

REF

= +5V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical

values are at T

A

= +25°C.)

BP/UP/SHDN = open

VDDD = 5.25V

BP/UP/SHDN = open

BP/UP/SHDN = 0V

BP/UP/SHDN = VDDD

Digital inputs = 0 or 5V

VDDD = 4.75V

CONDITIONS

nA-100 +100

BP/UP/SHDN Max Allowed

Leakage, Mid Input

V2.75V

FLT

BP/UP/SHDN Voltage,

Floating

V1.5 VDDD - 1.5V

IM

BP/UP/SHDN

Mid Input Voltage

µA-4.0I

IL

BP/UP/SHDN

Input Current, Low

µA4.0I

IH

BP/UP/SHDN

Input Current, High

V0.5V

IL

BP/UP/SHDN

Input Low Voltage

V2.4V

IH

CLK, CS, CONV, RESET, SCLK

Input High Voltage

VVDDD - 0.5V

IH

BP/UP/SHDN

Input High Voltage

µA±10

CLK, CS, CONV, RESET, SCLK

Input Current

V0.8V

IL

CLK, CS, CONV, RESET, SCLK

Input Low Voltage

pF10

CLK, CS, CONV, RESET, SCLK

Input Capacitance (Note 2)

UNITSMIN TYP MAXSYMBOLPARAMETER

Output Low Voltage V

OL

VDDD = 4.75V, I

SINK

= 1.6mA 0.4 V

Output High Voltage V

OH

VDDD = 4.75V, I

SOURCE

= 1mA VDDD - 0.5 V

DOUT Leakage Current I

LKG

DOUT = 0 or 5V ±10 µA

Output Capacitance (Note 4) 10 pF

VDDD 4.75 5.25 V

VSSD -5.25 -4.75 V

VDDA By supply-rejection test 4.75 5.25 V

VSSA By supply-rejection test -5.25 -4.75 V

VDDD Supply Current I

DDD

VDDD = VDDA = 5.25V, VSSD = VSSA = -5.25V 2.5 4 mA

VSSD Supply Current I

SSD

VDDD = VDDA = 5.25V, VSSD = VSSA = -5.25V 0.9 2 mA

VDDA Supply Current I

DDA

VDDD = VDDA = 5.25V, VSSD = VSSA = -5.25V 3.8 5 mA

VSSA Supply Current I

SSA

VDDD = VDDA = 5.25V, VSSD = VSSA = -5.25V 3.8 5 mA

DIGITAL INPUTS (CLK, CS, CONV, RESET, SCLK, BP/UP/SHDN)

DIGITAL OUTPUTS (DOUT, EOC)

POWER REQUIREMENTS

Page 4

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

4 _______________________________________________________________________________________

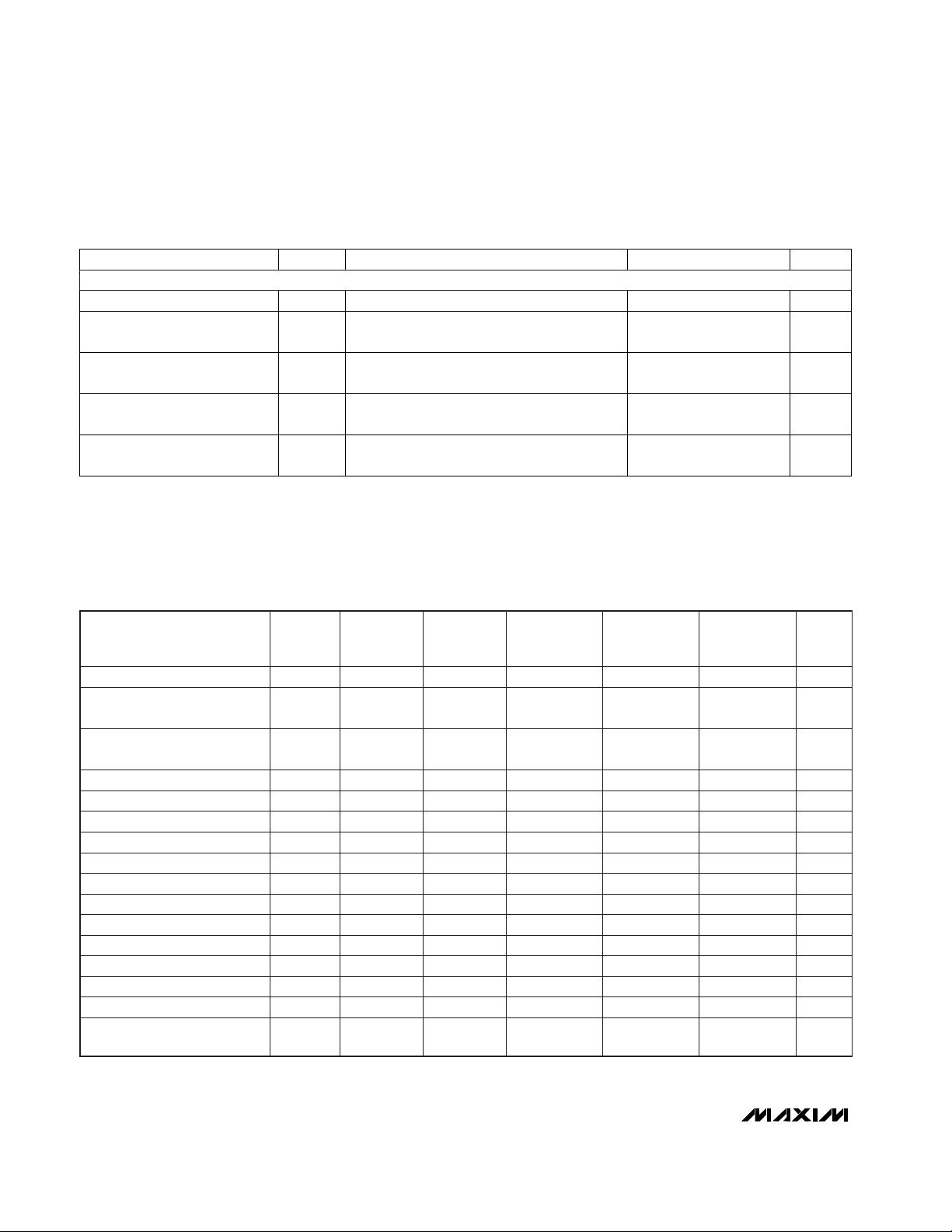

VDDD = VDDA = 5.25V, VSSD = VSSA = -5.25V

VDDD = VDDA = 5.25V, VSSD = VSSA = -5.25V,

BP/UP/SHDN = 0V

VDDD = VDDA = 5.25V, VSSD = VSSA = -5.25V,

BP/UP/SHDN = 0V

VDDD = VDDA = 5.25V, VSSD = VSSA = -5.25V,

BP/UP/SHDN = 0V

VDDD = VDDA = 5.25V, VSSD = VSSA = -5.25V,

BP/UP/SHDN = 0V

CONDITIONS

mW80Power Dissipation

µA0.1 5I

SSA

VSSA Shutdown Supply Current

µA0.1 5I

DDA

VDDA Shutdown Supply Current

µA1.6 5I

DDD

VDDD Shutdown Supply Current

(Note 5)

µA0.1 5I

SSD

VSSD Shutdown Supply Current

UNITSMIN TYP MAXSYMBOLPARAMETER

ELECTRICAL CHARACTERISTICS (continued)

(VDDD = VDDA = +5V, VSSD = VSSA = -5V, f

CLK

= 1.7MHz, V

REF

= +5V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical

values are at T

A

= +25°C.)

TIMING CHARACTERISTICS

(VDDD = VDDA = +5V, VSSD = VSSA = -5V, unless otherwise noted.)

Note 1: Accuracy and dynamic performance tests performed after calibration.

Note 2: Tested with 50% duty cycle. Duty cycles from 25% to 75% at 1.7MHz are acceptable.

Note 3: See

External Clock

section.

Note 4: Guaranteed by design, not tested.

Note 5: Measured in shutdown mode with CLK and SCLK low.

POWER REQUIREMENTS (cont.)

PARAMETER SYMBOL CONDITIONS

TA= +25°C

TYP

TA= 0°C to

+70°C

MIN MAX

TA= -40°C to

+85°C

MIN MAX

TA= -55°C to

+125°C

MIN MAX

UNITS

CONV Pulse Width

t

CW

20 30 35 ns

CONV to CLK Falling

Synchronization (Note 4)

t

CC1

10 10 10 ns

CONV to CLK Rising

Synchronization (Note 4)

t

CC2

40 40 ns

Data Access Time t

DV

CL= 50pF 80 80

40

ns

Bus Relinquish Time t

DH

CL= 10pF 40 40 40 ns

CLK to EOC High

t

CEH

CL= 50pF 300 300 350 ns

CLK to EOC Low

t

CEL

CL= 50pF 300 300 350 ns

CLK to DOUT Valid t

CD

CL= 50pF 100 350 100 375 100 400 ns

SCLK to DOUT Valid t

SD

CL= 50pF 20 140 20 160 20 160 ns

CS to SCLK Setup Time

t

CSS

75 75 75 ns

CS to SCLK Hold Time

t

CSH

-10 -10 -10 ns

Acquisition Time t

AQ

2.4 2.4 2.4 µs

Calibration Time t

CAL

14,000(

CLK

) 8.2 8.2 8.2 ms

RESET to CLK Setup Time

t

RCS

-40 -40 -40 ns

RESET to CLK Hold Time

t

RCH

120 120 120

Start-Up Time (Note 6) t

SU

Exiting

shutdown

3.2

ns

90

µs

Note 6: Settling time required after deasserting shutdown to achieve less than 0.1LSB additional error.

Page 5

_______________Detailed Description

The MAX194 uses a successive-approximation register

(SAR) to convert an analog input to a 14-bit digital

code, which outputs as a serial data stream. The data

bits can be read either during the conversion, at the

CLK clock rate, or between conversions asynchronous

with CLK, at the SCLK rate (up to 5Mbps).

The MAX194 includes a capacitive digital-to-analog

converter (DAC) that provides an inherent track/hold

input. The interface and control logic are designed for

easy connection to most microprocessors (µPs), limiting

the need for external components. In addition to the

SAR and DAC, the MAX194 includes a serial interface, a

sampling comparator used by the SAR, ten calibration

DACs, and control logic for calibration and conversion.

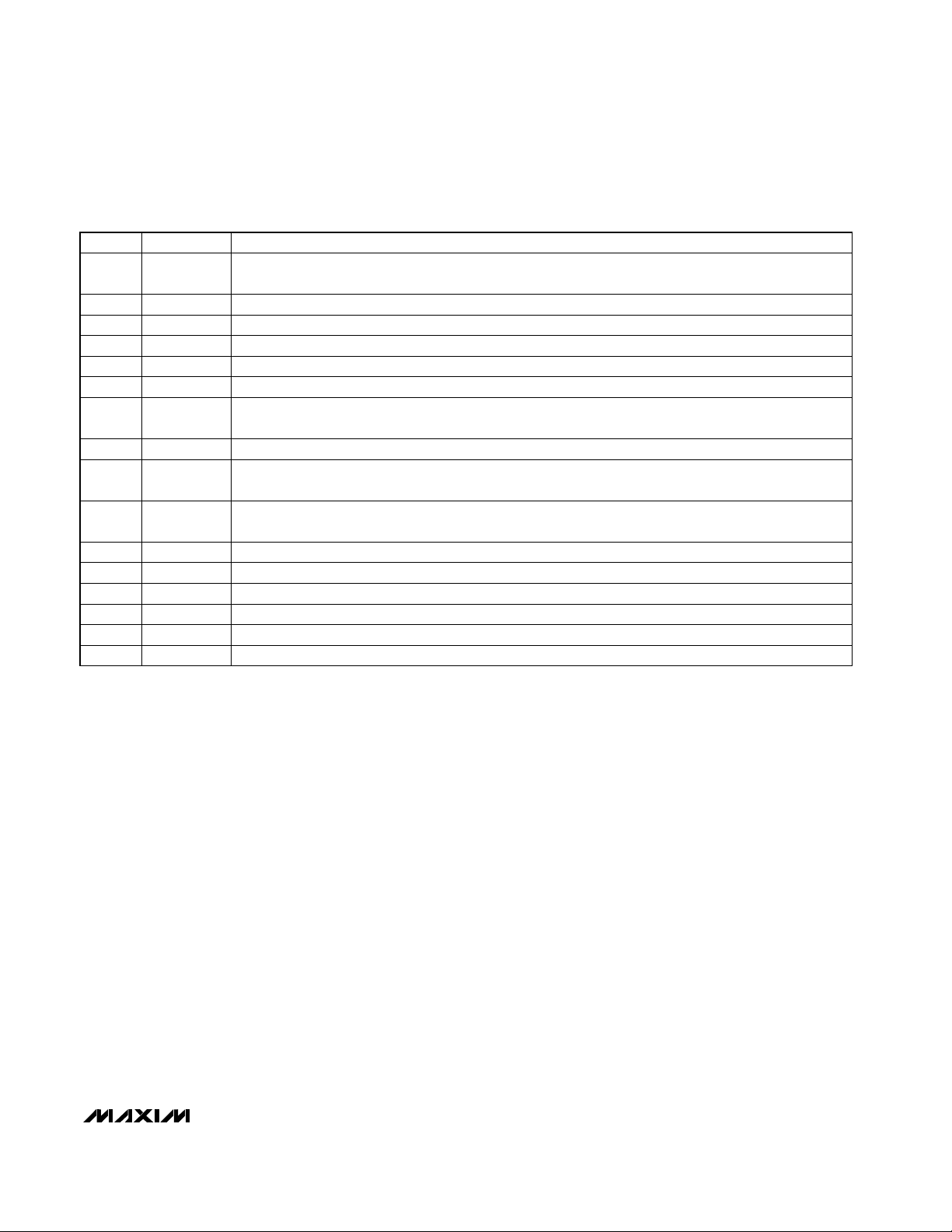

The DAC consists of an array of capacitors with binary

weighted values plus one “dummy sub-LSB” capacitor

(Figure 1). During input acquisition in unipolar mode,

the array’s common terminal is connected to AGND

and all free terminals are connected to the input signal

(AIN). After acquisition, the common terminal is disconnected from AGND and the free terminals are discon-

nected from AIN, trapping a charge proportional to the

input voltage on the capacitor array.

The free terminal of the MSB (largest) capacitor is connected to the reference (REF), which pulls the common

terminal (connected to the comparator) positive.

Simultaneously, the free terminals of all other capacitors in the array are connected to AGND, which drives

the comparator input negative. If the analog input is

near V

REF

, connecting the MSB’s free terminal to REF

only pulls the comparator input slightly positive.

However, connecting the remaining capacitor’s free terminals to ground drives the comparator input well

below ground, so that the comparator input is negative,

the comparator output is low, and the MSB is set high.

If the analog input is near ground, the comparator output is high and the MSB is low.

Following this, the next largest capacitor is disconnected from AGND and connected to REF, and the comparator determines the next bit. This continues until all

bits have been determined. For a bipolar input range,

the MSB capacitor is connected to REF rather than AIN

during input acquisition, which results in an input range

of V

REF

to -V

REF

.

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

_______________________________________________________________________________________ 5

______________________________________________________________Pin Description

PIN NAME FUNCTION

1

BP/UP/SHDN

Bipolar/Unipolar/Shutdown Input. Three-state input selects bipolar or unipolar input range, or shutdown.

0V = shutdown, +5V = unipolar, floating = bipolar.

2 CLK Conversion Clock Input

3 SCLK Serial Clock Input is used to shift data out between conversions. May be asynchronous to CLK.

4 VDDD +5V Digital Power Supply

5 DOUT Serial Data Output, MSB first

6 DGND Digital Ground

7

EOC

End-of-Conversion/Calibration Output—normally low. Rises at beginning of conversion or calibration and

falls at the end of either. May be used as an output framing signal.

8

CS

Chip-Select Input—active low. Enables the serial interface and the three-state data output (DOUT).

9

CONV

Convert-Start Input—active low. Conversion begins on the falling edge after CONV goes low if input signal

has been acquired; otherwise, on the falling clock edge after acquisition.

10

RESET

Reset Input. Pulling RESET low places ADC in inactive state. Rising edge resets control logic and begins

calibration.

11 VSSD -5V Digital Power Supply

12 REF Reference Input, 0 to 5V

13 AIN Analog Input, 0 to V

REF

unipolar or ±V

REF

bipolar range

14 AGND Analog Ground

15 VSSA -5V Analog Power Supply

16 VDDA +5V Analog Power Supply

Page 6

MAX194

Calibration

In an ideal DAC, each of the capacitors associated with

the data bits would be exactly twice the value of the

next smaller capacitor. In practice, this results in a

range of values too wide to be realized in an economically feasible size. The capacitor array actually consists

of two arrays, which are capacitively coupled to reduce

the LSB array’s effective value. The capacitors in the

MSB array are production trimmed to reduce errors.

Small variations in the LSB capacitors contribute

insignificant errors to the 14-bit result.

Unfortunately, trimming alone does not yield 14-bit performance or compensate for changes in performance

due to changes in temperature, supply voltage, and

other parameters. For this reason, the MAX194 includes

a calibration DAC for each capacitor in the MSB array.

These DACs are capacitively coupled to the main DAC

output and offset the main DAC’s output according to

the value on their digital inputs. During calibration, the

correct digital code to compensate for the error in each

MSB capacitor is determined and stored. Thereafter,

the stored code is input to the appropriate calibration

DAC whenever the corresponding bit in the main DAC

is high, compensating for errors in the associated

capacitor.

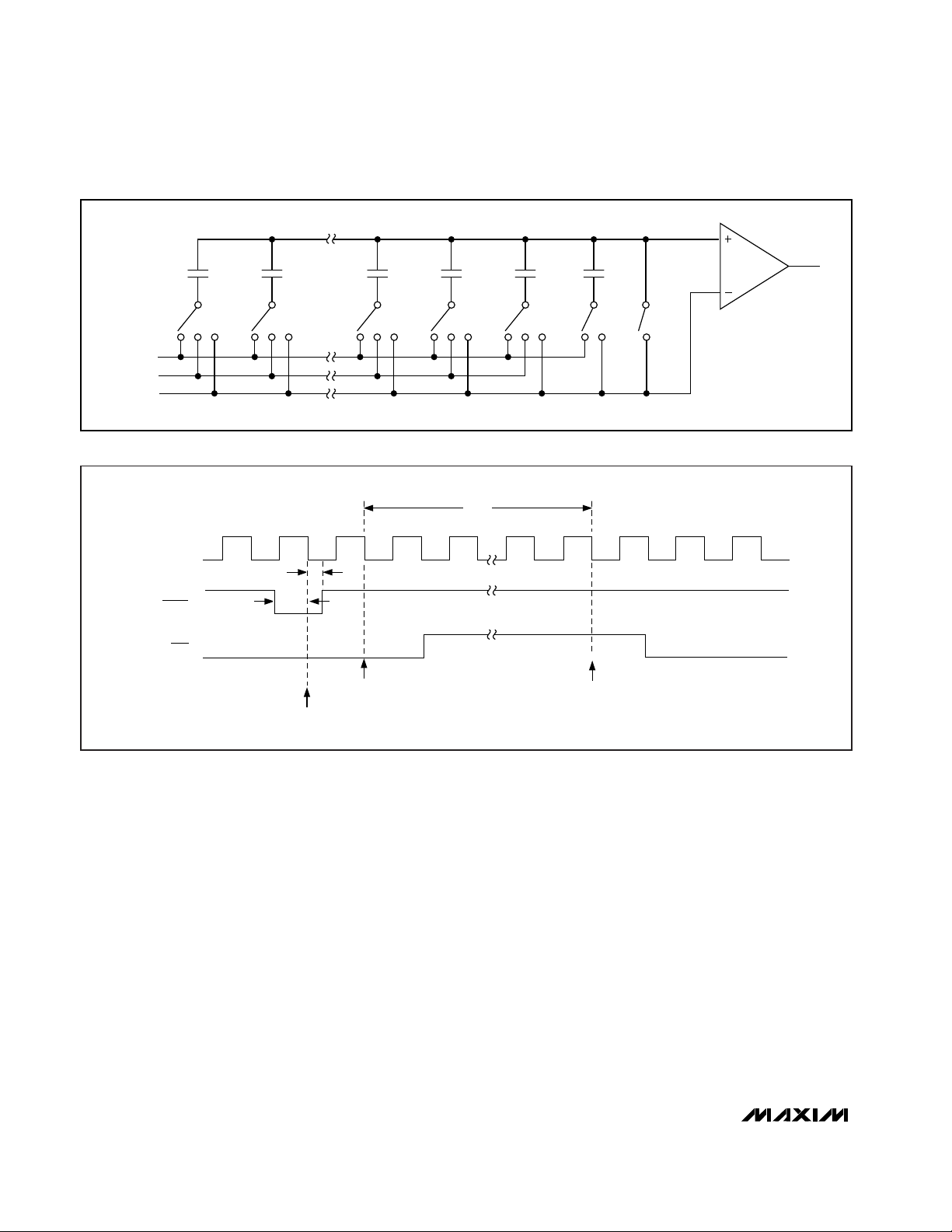

The MAX194 calibrates automatically on power-up. To

reduce the effects of noise, each calibration experiment

is performed many times and the results are averaged.

Calibration requires about 14,000 clock cycles, or

8.2ms at the highest clock (CLK) speed (1.7MHz). In

addition to the power-up calibration, bringing RESET

low halts MAX194 operation, and bringing it high again

initiates a calibration (Figure 2).

14-Bit, 85ksps ADC with 10µA Shutdown

6 _______________________________________________________________________________________

LSBMSB

AIN

REF

AGND

DUMMYSUB-LSBs

32,768C

16,384C 4C 2C C C

EOC

CLK

RESET

CALIBRATION

BEGINS

CALIBRATION

ENDS

MAX194

OPERATION HALTS

t

CAL

t

RCS

t

RCH

Figure 1. Capacitor DAC Functional Diagram

Figure 2. Initiating Calibration

Page 7

If the power supplies do not settle within the MAX194’s

power-on delay (500ns minimum), power-up calibration

may begin with supply voltages that differ from the final

values and the converter may not be properly calibrated. If so, recalibrate the converter (pulse RESET low)

before use. For best DC accuracy, calibrate the

MAX194 any time there is a significant change in supply voltages, temperature, reference voltage, or clock

characteristics (see

External Clock

section) because

these parameters affect the DC offset. If linearity is the

only concern, much larger changes in these parameters can be tolerated.

Because the calibration data is stored digitally, there is

no need either to perform frequent conversions to maintain accuracy or to recalibrate if the MAX194 has been

held in shutdown for long periods. However, recalibration is recommended if it is likely that supply voltages or

ambient temperature has significantly changed since

the previous calibration.

Digital Interface

The digital interface pins consist of BP/UP/SHDN, CLK,

SCLK, EOC, CS, CONV, and RESET.

BP/UP/SHDN is a three-level input. Leave it floating to

configure the MAX194’s analog input in bipolar mode

(AIN = -V

REF

to V

REF

) or connect it high for a unipolar

input (AIN = 0V to V

REF

). Bringing BP/UP/SHDN low

places the MAX194 in its 10µA shutdown mode.

A logic low on RESET halts MAX194 operation. The ris-

ing edge of RESET initiates calibration as described in

the

Calibration

section above.

Begin a conversion by bringing CONV low. The convert

signal must be synchronized with CLK. The falling edge

of CONV must occur during the period shown in

Figures 3 and 4. When CLK is not directly controlled by

your processor, two methods of ensuring synchronization are to drive CONV from EOC (continuous conversions) or to gate the conversion-start signal with the

conversion clock so that CONV can go low only while

CLK is low (Figure 5). Ensure that the maximum propagation delay through the gate is less than 40ns.

The MAX194 automatically ensures four CLK periods

for track/hold acquisition. If, when CONV is asserted, at

least three clock (CLK) cycles have passed since the

end of the previous conversion, a conversion will begin

on CLK’s next falling edge and EOC will go high on the

following falling CLK edge (Figure 3). After conversion

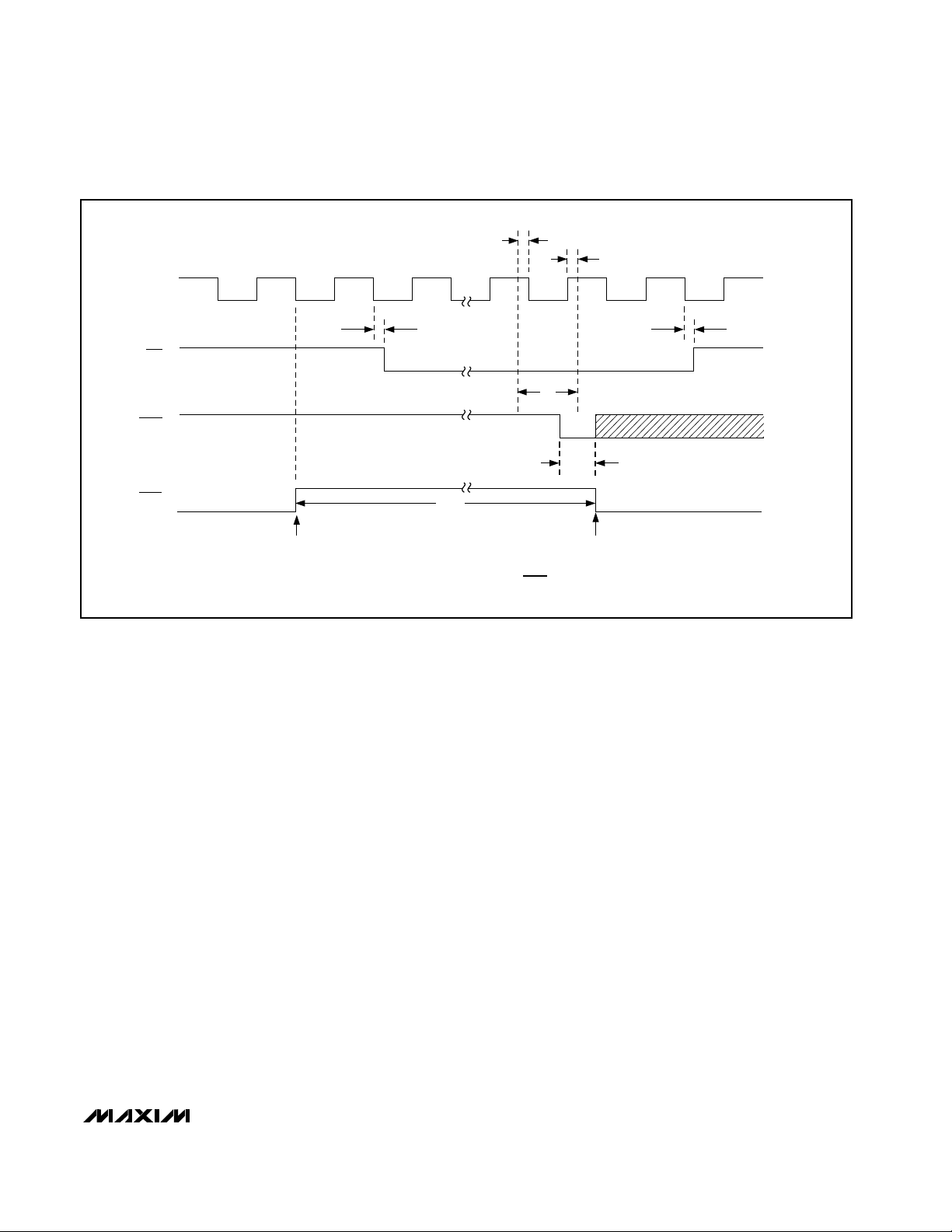

begins, additional convert start pulses are ignored. If,

when convert is asserted, less than three clock cycles

have passed, a conversion will begin on the fourth

falling clock edge after the end of the previous conver-

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

_______________________________________________________________________________________ 7

TRACK/HOLD

CLK

CONVERSION

BEGINS

CONVERSION

ENDS

t

AQ

*

*

THE FALLING EDGE OF CONV MUST OCCUR IN THIS REGION

t

CEL

t

CW

t

CEH

t

CC2

t

CC1

EOC

CONV

Figure 3. Initiating Conversions—At least 3 CLK cycles since end of previous conversion.

Page 8

MAX194

sion and EOC will go high on the following CLK falling

edge (Figure 4). CONV is ignored during conversions.

External Clock

The conversion clock (CLK) should have a duty cycle

between 25% and 75% at 1.7MHz (the maximum clock

frequency). For lower frequency clocks, ensure the

minimum high and low times exceed 150ns. The minimum clock rate for accurate conversion is 125Hz for

temperatures up to +70°C or 1kHz at +125°C due to

leakage of the sampling capacitor array. In addition,

CLK should not remain high longer than 50ms at temperatures up to +70°C or 500µs at +125°C. If CLK is

held high longer than this, RESET must be pulsed low

to initiate a recalibration because it is possible that

state information stored in internal dynamic memory

may be lost. The MAX194’s clock can be stopped

indefinitely if it is held low.

If the frequency, duty cycle, or other aspects of the

clock signal’s shape change, the offset created by coupling between CLK and the analog inputs (AIN and

REF) changes. Recalibration corrects for this offset and

restores DC accuracy.

Output Data

The conversion result is clocked out MSB first, formatted as 14 data bits plus two sub-LSBs. Serial data is

available on DOUT only when CS is held low.

Otherwise, DOUT is in a high-impedance state. There

are two ways to read the data on DOUT. To read the

data bits as they are determined (at the CLK clock

rate), hold CS low during the conversion. To read

results between conversions, hold CS low and clock

SCLK at up to 5MHz.

If you read the serial data bits as they are determined

(at the conversion-clock rate), EOC frames the data bits

(Figure 6). Conversion begins with the first falling CLK

edge, after CONV goes low and the input signal has

been acquired. Data bits are shifted out of DOUT on

subsequent falling CLK edges. Clock data in on CLK’s

rising edge or, if the clock speed is greater than 1MHz,

on the following falling edge of CLK to meet the maximum CLK-to-DOUT timing specification. See the

Operating Modes and SPI™/QSPI™ Interfaces

section

for additional information. Reading the serial data during the conversion results in the maximum conversion

throughput, because a new conversion can begin

immediately after the input acquisition period following

the previous conversion.

14-Bit, 85ksps ADC with 10µA Shutdown

8 _______________________________________________________________________________________

TRACK/HOLD

CLK

CONVERSION

BEGINS

CONVERSION

ENDS

t

AQ

*

*

THE FALLING EDGE OF CONV MUST OCCUR IN THIS REGION

t

CEL

t

CW

t

CEH

t

CC2

t

CC1

EOC

CONV

Figure 4. Initiating Conversions—Less than 3 CLK cycles since end of previous conversion.

SPI/QSPI are trademarks of Motorola Corp.

Page 9

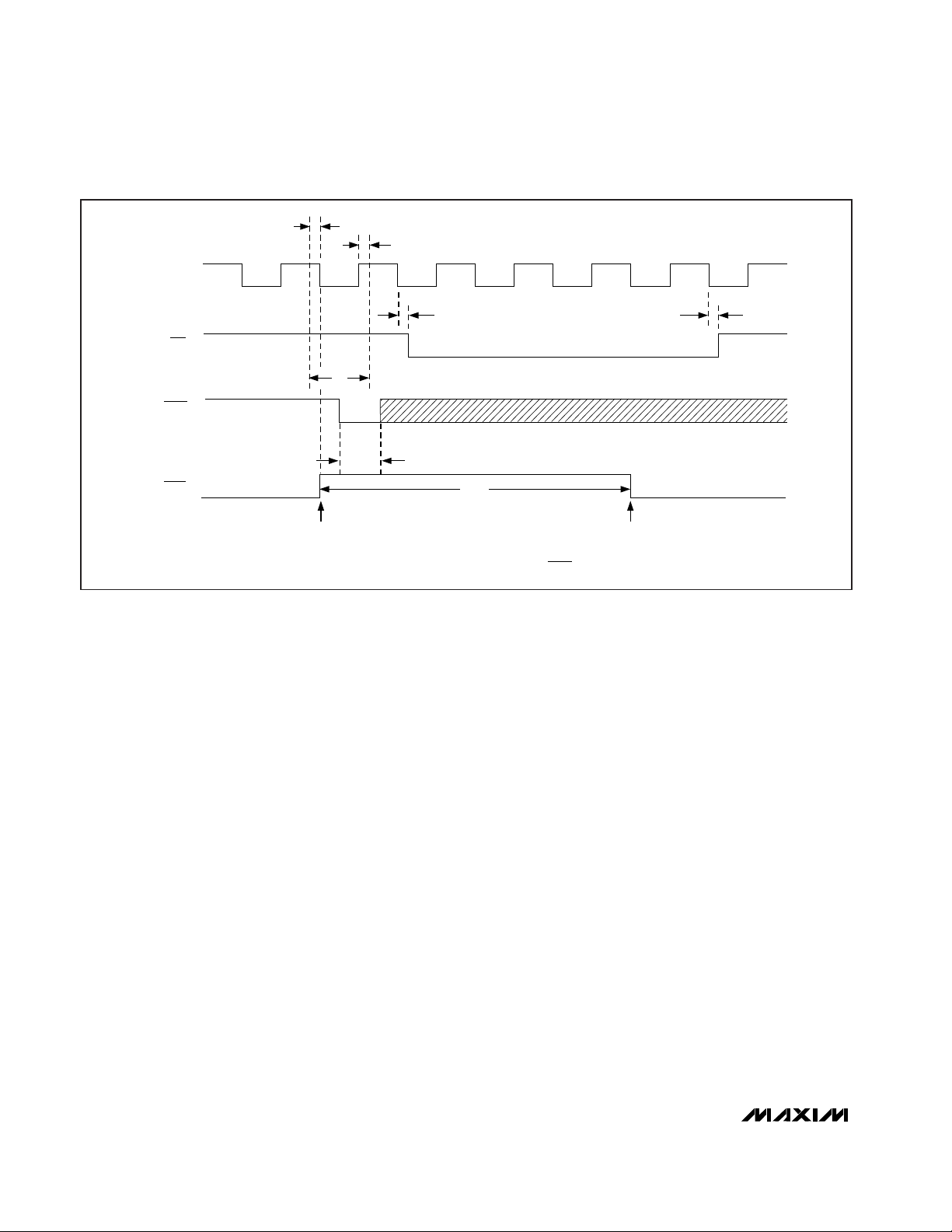

If you read the data bits between conversions, you can

1) count CLK cycles until the end of the conversion, or

2) poll EOC to determine when the conversion is

finished, or

3) generate an interrupt on EOC’s falling edge.

Note that the MSB conversion result appears at DOUT

after CS goes low but before the first SCLK pulse. Each

subsequent SCLK pulse shifts out the next conversion

bit. The 15th SCLK pulse shifts out the sub-LSB (S0).

Additional clock pulses shift out zeros.

Data is clocked out on SCLK’s falling edge. Clock data

in on SCLK’s rising edge or, for clock speeds above

2.5MHz, on the following falling edge to meet the maximum SCLK-to-DOUT timing specification (Figure 7).

The maximum SCLK speed is 5MHz. See the

Operating

Modes and SPI/QSPI Interfaces

section for additional

information. When the conversion clock is near its maxi-

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

_______________________________________________________________________________________ 9

CLK

START

CONV

MAX194

CONV

START

CLK

SEE

DIGITAL INTERFACE

SECTION

Figure 5. Gating CONV to Synchronize with CLK

Figure 6. Output Data Format, Reading Data During Conversion (Mode 1)

CS

CONV

t

CW

CLK

(CASE 1)

CLK

(CASE 2)

EOC

DOUT

CASE 1: CLK IDLES LOW, DATA LATCHED ON RISING EDGE (CPOL = 0, CPHA = 0)

CASE 2: CLK IDLES LOW, DATA LATCHED ON FALLING EDGE (CPOL = 0, CPHA = 1)

NOTE: ARROWS ON CLK TRANSITIONS INDICATE LATCHING EDGE

t

DV

B13 FROM PREVIOUS

CONVERSION

CONVERSION

BEGINS

t

CEH

t

CD

B13

B12 B11 B10 B0 S1 S0 B13

MSB LSB SUB-LSBs

CONVERSION

ENDS

t

CEL

t

DH

Page 10

MAX194

mum (1.7MHz), reading the data after each conversion

(during the acquisition time) results in lower throughput

(about 70ksps max) than reading the data during conversions, because it takes longer than the minimum

input acquisition time (four cycles at 1.7MHz) to clock

16 data bits at 5Mbps. After the data has been clocked

in, leave some time (about 1µs) for any coupled noise

on AIN to settle before beginning the next conversion.

Whichever method is chosen for reading the data, conversions can be individually initiated by bringing CONV

low, or they can occur continuously by connecting EOC

to CONV. Figure 8 shows the MAX194 in its simplest

operational configuration.

14-Bit, 85ksps ADC with 10µA Shutdown

10 ______________________________________________________________________________________

EOC

CS

SCLK

(CASE 1)

SCLK

(CASE 2)

CASE 1: SCLK IDLES LOW, DATA LATCHED ON RISING EDGE (CPOL = 0, CPHA = 0)

CASE 2: SCLK IDLES LOW, DATA LATCHED ON FALLING EDGE (CPOL = 0, CPHA = 1)

CASE 3: SCLK IDLES HIGH, DATA LATCHED ON FALLING EDGE (CPOL = 1, CPHA = 0)

NOTE: ARROWS ON SCLK TRANSITIONS INDICATE LATCHING EDGE

DOUT

SCLK

(CASE 3)

t

CONV

t

DH

t

SD

t

DV

MSB LSB

SUB-LSBs

B13

B12 B11 B10 B1 B0 S1

S0

B9

t

CSS

t

CSH

Figure 7. Output Data Format, Reading Data Between Conversions (Mode 2)

Figure 8. MAX194 in the Simplest Operating Configuration

+5V

10µF

CONVERSION CLOCK

0.1µF

1

2

3

4

5

6

7

8

BP/UP/SHDN

CLK

SCLK

VDDD

DOUT

DGND

EOC

CS

MAX194

VDDA

VSSA

AGND

AIN

REF

VSSD

RESET

CONV

16

15

14

13

12

11

10

9

-5V

10µF0.1µF

ANALOG INPUT

REFERENCE (0V TO VDDA)

Page 11

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

______________________________________________________________________________________ 11

BRIDGE

INSTRUMENTATION

AMPLIFIER

+5V

AIN

MAX194

VDDA

47µF

LOW

ESR

0.1µF

CERAMIC

REF

COMPANY CAPACITOR FACTORY FAX [COUNTRY CODE] USA TELEPHONE

Sprague

595D series,

592D series

[1]-603-224-1430 603-224-1961

AVX TPS series [1]-207-283-1941 800-282-4975

Sanyo

OS-CON series,

MV-GX series

[81]-7-2070-1174 619-661-6835

Nichicon PL series [1]-708-843-2798 708-843-7500

Figure 9. Ratiometric Measurement Without an Accurate Reference

Table 1. Low-ESR Capacitor Suppliers

__________Applications Information

Reference

The MAX194 reference voltage range is 0V to VDDA.

When choosing the reference voltage, the MAX194’s

equivalent input noise (40µV

RMS

in unipolar mode,

80µV

RMS

in bipolar mode) should be considered. Also, if

V

REF

exceeds VDDA, errors will occur due to the internal

protection diodes that will begin to conduct, so use caution when using a reference near VDDA (unless V

REF

and VDDA are virtually identical). V

REF

must never

exceed its absolute maximum rating (VDDA + 0.3V).

The MAX194 needs a good reference to achieve its

rated performance. The most important requirement is

that the reference must present a low impedance to the

REF input. This is often achieved by buffering the reference through an op amp and bypassing the REF input

with a large (1µF to 47µF), low-ESR capacitor in parallel

with a 0.1µF ceramic capacitor. Low-ESR capacitors

are available from the manufacturers listed in Table 1.

The reference must drive the main conversion DAC

capacitors as well as the capacitors in the calibration

DACs, all of which may be switching between GND and

REF at the conversion clock frequency. The total

capacitive load presented can exceed 1000pF and,

unlike the analog input (AIN), REF is sampled continuously throughout the conversion.

The first step in choosing a reference circuit is to

decide what kind of performance is required. This often

suggests compromises made in the interests of cost

and size. It is possible that a system may not require an

accurate reference at all. If a system makes a ratiometric measurement such as Figure 9’s bridge circuit, any

relatively noise-free voltage that presents a low impedance at the REF input will serve as a reference. The

+5V analog supply suffices if you use a large, lowimpedance bypass capacitor to keep REF stable during switching of the capacitor arrays. Do not place a

resistance between the +5V supply and the bypass

capacitor, because it will cause linearity errors due to

the dynamic REF input current, which typically ranges

from 300µA to 400µA.

Figure 10 shows a more typical scheme that provides

good AC accuracy. The MAX874’s initial accuracy can

Page 12

MAX194

be improved by trimming, but the drift is too great to

provide good stability over temperature. The MAX427

buffer provides the necessary drive current to stabilize

the REF input quickly after capacitance changes.

The reference inaccuracies contribute additional fullscale error. A reference with less than 1⁄

2

14

total error

(61 parts per million) over the operating temperature

range is required to maintain full 14-bit accuracy. The

MAX6241 achieves a drift specification of 1ppm/°C

(typ) and easily drives the REF input directly. This

allows large temperature changes with less than 1LSB

error. While the MAX6241’s initial-accuracy specification (0.02%) results in a maximum error of about

±4LSB, the reference voltage can be trimmed or the

offset can be corrected in software if absolute DC

accuracy is essential. Figure 11’s circuit provides outstanding temperature stability and also provides excellent DC accuracy if the initial error is corrected.

14-Bit, 85ksps ADC with 10µA Shutdown

12 ______________________________________________________________________________________

14

16

15

12

MAX194

MAX427

AGNDVSSA

VDDA

4

4

7

6

8

6

2

2

3

MAX874

GND

V

IN

COMP

V

OUT

4.096V

+15V

-15V

47µF

LOW

ESR

0.1µF

0.1µF

0.1µF

0.1µF

1000pF

0.1µF

0.1µF

1k

10Ω

2k

REF

1N914

1N914

10Ω

-5V

+5V

Figure 10. Typical Reference Circuit for AC Accuracy

Figure 11. High-Accuracy Reference

≥ 8V

V

IN

2

IN

2.2µF

1µF

MAX6241

3

NR

GND

4 14

OUT

TRIM

6

5

10k

2.2µF

0.1µF

12

REF

MAX194

AGND

Page 13

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

______________________________________________________________________________________ 13

INPUT

SIGNAL

1N914

DIODE

CLAMPS

+5V

AIN

MAX194

-5V

VSSA

VDDA

+15V

-15V

10Ω

Figure 12. Analog Input Protection for Overvoltage or Improper Supply Sequence

Figure 13. Change multiplexer input near beginning of conversion to allow time for slewing and settling.

A0 A1

IN1

IN2

4-TO-1

MAX194

MUX

CLK

EOC

IN3

IN4

A0

A1

OUT

CONVERSION

CHANGE MUX INPUT HERE

AQUISITION

AIN

EOC

Page 14

MAX194

REF and AIN Input Protection

The REF and AIN signals should not exceed the

MAX194 supply rails. If this can occur, diode clamp the

signal to the supply rails. Use silicon diodes and a 10Ω

current-limiting resistor (Figures 10 and 12) or Schottky

diodes without the resistor.

When using the current-limiting resistor, place the resistor between the appropriate input (AIN or REF) and any

bypass capacitor. While this results in AC transients at

the input due to dynamic input currents, the transients

settle quickly and do not affect conversion results.

Improperly placing the bypass capacitor directly at the

input forms an RC lowpass filter with the current-limiting

resistor, which averages the dynamic input current and

causes linearity errors.

Analog Input

The MAX194 uses a capacitive DAC that provides an

inherent track/hold function. The input impedance is

typically 30Ω in series with 250pF in unipolar mode and

50Ω in series with 125pF in bipolar mode.

Input Range

The analog input range can be either unipolar (0V to

V

REF

) or bipolar (-V

REF

to V

REF

), depending on the

state of the BP/UP/SHDN pin (see

Digital Interface

section). The reference range is 0V to VDDA. When choosing the reference voltage, the equivalent MAX194 input

noise (40µV

RMS

in unipolar mode, 80µV

RMS

in bipolar

mode) should be considered.

14-Bit, 85ksps ADC with 10µA Shutdown

14 ______________________________________________________________________________________

MAX427

4

7

6

2

2

3

IN

+15V

-15V

0.0033µF

0.1µF

0.1µF

ELANTEC

EL2003

4

1

7

+15V

-15V

0.1µF

0.1µF

100pF

1k

1k

1N914

1N914

+5V

-5V

AIN

10Ω

Figure 14. MAX400 Drives AIN for Low-Frequency Use

Figure 15. AIN Buffer for AC/DC Use

1k

+15V

+5V

2

IN

3

7

MAX400

4

-15V

0.1µF

6

0.1µF

1000pF

100Ω

1N914

10Ω

AIN

1N914

1.0µF

-5V

Page 15

Input Acquisition and Settling

Four conversion-clock periods are allocated for acquiring the input signal. At the highest conversion rate, four

clock periods is 2.4µs. If more than three clock cycles

have occurred since the end of the previous conversion, conversion begins on the next falling clock edge

after CONV goes low. Otherwise, bringing CONV low

begins a conversion on the fourth falling clock edge

after the previous conversion. This scheme ensures the

minimum input acquisition time is four clock periods.

Most applications require an input buffer amplifier. If

the input signal is multiplexed, the input channel should

be switched near the beginning of a conversion, rather

than near the end of or after a conversion (Figure 13).

This allows time for the input buffer amplifier to respond

to a large step change in input signal. The input amplifier must have a high enough slew rate to complete the

required output voltage change

before

the beginning of

the acquisition time.

At the beginning of acquisition, the capacitive DAC is

connected to the amplifier output, causing some output

disturbance. Ensure that the sampled voltage has settled to within the required limits before the end of the

acquisition time. If the frequency of interest is low, AIN

can be bypassed with a large enough capacitor to

charge the capacitive DAC with very little change in

voltage (Figure 14). However, for AC use, AIN must be

driven by a wideband buffer (at least 10MHz), which

must be stable with the DAC’s capacitive load (in parallel with any AIN bypass capacitor used) and also must

settle quickly (Figure 15 or 16).

Digital Noise

Digital noise can easily be coupled to AIN and REF.

The conversion clock (CLK) and other digital signals

that are active during input acquisition contribute noise

to the conversion result. If the noise signal is synchronous to the sampling interval, an effective input offset is

produced. Asynchronous signals produce random

noise on the input, whose high-frequency components

may be aliased into the frequency band of interest.

Minimize noise by presenting a low impedance (at the

frequencies contained in the noise signal) at the inputs.

This requires bypassing AIN to AGND, or buffering the

input with an amplifier that has a small-signal bandwidth of several megahertz, or preferably both. AIN has

a bandwidth of about 16MHz.

Offsets resulting from synchronous noise (such as the

conversion clock) are canceled by the MAX194’s calibration scheme. However, because the magnitude of

the offset produced by a synchronous signal depends

on the signal’s shape, recalibration may be appropriate

if the shape or relative timing of the clock or other digital signals change, as might occur if more than one

clock signal or frequency is used.

Distortion

Avoid degrading dynamic performance by choosing an

amplifier with distortion much less than the MAX194’s

THD (-90dB, or 0.0032%) at frequencies of interest. If

the chosen amplifier has insufficient common-mode

rejection, which results in degraded THD performance,

use the inverting configuration (positive input grounded) to eliminate errors from this source. Low temperature-coefficient, gain-setting resistors reduce linearity

errors caused by resistance changes due to self-heating. Also, to reduce linearity errors due to finite amplifier

gain, use an amplifier circuit with sufficient loop gain at

the frequencies of interest (Figures 14, 15, 16).

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

______________________________________________________________________________________ 15

MAX410

4

7

6

2

3

IN

+5V

-5V

0.1µF 0.01µF

22Ω

510Ω

0.1µF

AIN

Figure 16. ±5V Buffer for AC/DC Use Has ±3.5V Swing

Page 16

MAX194

DC Accuracy

If DC accuracy is important, choose a buffer with an

offset much less than the MAX194’s maximum offset

(±1 LSB = ±488µV for a ±4V input range), or whose offset can be trimmed while maintaining good stability

over the required temperature range.

Recommended Circuits

Figure 14 shows a good circuit for DC and low-frequency use. The MAX400 has very low offset (10µV) and

drift (0.2µV/°C), and low voltage noise (10nV/√Hz) as

well. However, its gain-bandwidth product (GBW) is

much too low to drive AIN directly, so the analog input

is bypassed to present a low impedance at high frequencies. The large bypass capacitor is isolated from

the amplifier output by a 100Ω resistor, which provides

additional noise filtering. Since the ±15V supplies

exceed the AIN range, add protection diodes at AIN.

Figure 15 shows a wide-bandwidth amplifier (MAX427)

driving a wideband video buffer, which is capable of driving AIN and a small bypass capacitor (for noise reduction) directly. The video buffer is inside the MAX427’s

feedback loop, providing good DC accuracy, while the

buffer’s low output impedance and high current capabil-

ity provide good AC performance. AIN is diodeclamped to the ±5V rails to prevent overvoltage. The

MAX427’s 15µV maximum offset voltage, 0.8µV/°C maximum drift, and less than 5nV/

√

Hz noise specifications

make this an excellent choice for AC/DC use.

If ±15V supplies are unavailable, Figure 16’s circuit works

very well with the ±5V analog supplies used by the

MAX194. The MAX410 has a minimum ±3.5V commonmode input range, with a similar output voltage swing,

which allows use of a reference voltage to 3.5V. The offset

voltage (250µV), drift (1µV/°C), unity-gain bandwidth

(28MHz), and low voltage noise (2.4nV/√Hz) are appropriate for 14-bit performance. The 0.01µF bypass capacitor

improves the noise performance.

Operating Modes and SPI/QSPI Interfaces

The two basic interface modes are defined according

to whether serial data is received during the conversion

(clocked with CLK, SCLK unused) or in bursts between

conversions (clocked with SCLK). Each mode is presented interfaced to a QSPI processor, but is also compatible with SPI.

Mode 1 (Simultaneous

Conversion and Data Transfer)

In this mode, each data bit is read from the MAX194 during the conversion as it is determined. SCLK is grounded

and CLK is used as both the conversion clock and the

serial data clock. Figure 17 shows a QSPI processor

connected to the MAX194 for use in this mode and

Figure 18 is the associated timing diagram.

In addition to the standard QSPI interface signals, general I/O lines are used to monitor EOC and to drive

BP/UP/SHDN and RESET. The two general output pins

may not be necessary for a given application and, if I/O

lines are unavailable, the EOC connection can be omitted as well.

The EOC signal is monitored during calibration to determine when calibration is finished and before beginning

a conversion to ensure the MAX194 is not in mid-conversion, but it is possible for a system to ignore EOC

completely. On power-up or after pulsing RESET low,

the µP must provide 14,000 CLK cycles to complete the

calibration sequence (Figure 2). One way to do this is

to toggle CLK and monitor EOC until it goes low, but it

is possible to simply count 14,000 CLK cycles to complete the calibration. Similarly, it is unnecessary to

check the status of EOC before beginning a conversion

if you are sure the last conversion is complete. This can

be done by ensuring that every conversion consists of

at least 20 CLK cycles.

14-Bit, 85ksps ADC with 10µA Shutdown

16 ______________________________________________________________________________________

MAX194

QSPI

GPT

BP/UP/SHDN

CLK

SCLK

EOC

DOUT

RESET

CONV

CS

*OC3

SCK

*IC1

MISO

*OC2

* THE USE OF THESE SIGNALS ADDS FLEXIBILITY AND FUNCTIONALITY

BUT IS NOT REQUIRED TO IMPLEMENT THE INTERFACE.

PCS0

Figure 17. MAX194 Connection to QSPI Processor Clocking

Data Out During Conversions

Page 17

Data is clocked out of the MAX194 on CLK’s falling

edge and can be clocked into the µP on the rising

edge or the following falling edge. If you clock data in

on the rising edge (SPI/QSPI with CPOL = 0 and CPHA

= 0; standard MicroWire™: Hitachi H8), the maximum

CLK rate is given by:

where tCDis the MAX194’s CLK-to-DOUT valid delay

and tSDis the data setup time for your µP.

If clocking data in on the falling edge (CPOL = 0,

CPHA = 1), the maximum CLK rate is given by:

Do not exceed the maximum CLK frequency given in

the

Electrical Characteristics

table. To clock data in on

the falling edge, your processor hold time must not

exceed tCDminimum (100ns).

While QSPI can provide the required 20 CLK cycles as

two continuous 10-bit transfers, SPI is limited to 8-bit

transfers. This means that with SPI, a conversion must

consist of three 8-bit transfers. Ensure that the pauses

between 8-bit operations at your selected clock rate

are short enough to maintain a 20ms or shorter conversion time, or the leakage of the capacitive DAC may

cause errors.

f =

1

t + t

CLK(max)

CD SD

f = /

1

t + t

CLK(max)

1

2

CD SD

•

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

______________________________________________________________________________________ 17

EOC

CLK

t

CD

t

DV

DATA LATCHED:

t

DH

CS, CONV

DOUT

B13 FROM PREVIOUS

CONVERSION

B13 B13B0B12 S1 S0

Figure 19. MAX194 Connection to QSPI Processor Clocking

Data Out with SCLK Between Conversions

Figure 18. Timing Diagram for Circuit of Figure 17

MicroWire is a trademark of National Semiconductor Corp.

QSPI

PCS0

SCK

MAX194

CS

SCLK

START

GPT

MISO

OC3

DOUT

BP/UP/SHDN

IC1

OC2

1.3µs

EOC

RESET

CONV

CLKIC3

74HC32

1.7MHz

Page 18

MAX194

Complete source code for the Motorola 68HC16 and

the MAX194 evaluation kit (EV kit) using this mode is

available in the MAX194 EV kit manual.

Mode 2 (Asynchronous Data Transfer)

This mode uses a conversion clock (CLK) and a serial

clock (SCLK). The serial data is clocked out between

conversions, which reduces the maximum throughput

for high CLK rates, but may be more convenient for

some applications. Figure 19 is a block diagram with a

QSPI processor (Motorola 68HC16) connected to the

MAX194. Figure 20 shows the associated timing diagram. Figure 21 gives an assembly language listing for

this arrangement.

An OR gate is used to synchronize the “start” signal to

the asynchronous CLK, as described in the

External

Clock

section. As with Mode 1, the QSPI processor must

run CLK during calibration and either count CLK cycles

or, as is done here, monitor EOC to determine when calibration is complete. Also, EOC is polled by the µP to

determine when a conversion result is available. When

EOC goes low, data is clocked out at the highest QSPI

data rate (4.19Mbps). After the data is transferred, a

new conversion can be initiated whenever desired.

The timing specification for SCLK-to-DOUT valid (t

SD

)

imposes some constraints on the serial interface. At

SCLK rates up to 2.5Mbps, data is clocked out of the

MAX194 by a falling edge of SCLK and may be

clocked into the µP by the next rising edge (CPOL = 0,

CPHA = 0). For data rates greater than 2.5Mbps (or for

lower rates, if desired) it is necessary to clock data out

of the MAX194 on SCLK’s falling edge and to clock it

into the µP on SCLK’s next falling edge (CPOL = 0,

CPHA = 1). Also, your processor hold time must not

exceed tSDminimum (20ns). As with CLK in mode 1,

maximum SCLK rates may not be possible with some

interface specifications that are subsets of SPI.

Supplies, Layout, Grounding

and Bypassing

For best system performance, use printed circuit boards

with separate analog and digital ground planes. Wirewrap boards are not recommended. The two ground

planes should be tied together at the low-impedance

power-supply source and at the MAX194, as shown in

Figure 22. If the analog and digital supplies come from

the same source, isolate the digital supply from the analog supply with a low-value resistor (10Ω).

14-Bit, 85ksps ADC with 10µA Shutdown

18 ______________________________________________________________________________________

CS

CLK

START

588ns

239ns

CONVERSION TIME

4.19MHz

1.3µs 9.4µs 17µs 5.1µs

4µs

EOC

SCLK

DOUT

B13 B1 B0B11B12 S1 S0

Figure 20. Timing Diagram for Circuit of Figure 19

Page 19

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

______________________________________________________________________________________ 19

Figure 21. MAX194 Code Listing for 68HC16 Module and Circuit of Figure 19

Page 20

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

20 ______________________________________________________________________________________

Figure 21. MAX194 Code Listing for 68HC16 Module and Circuit of Figure 19 (continued)

Page 21

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

______________________________________________________________________________________ 21

Constraints on sequencing the four power supplies are

as follows.

• Apply VDDA before VDDD.

• Apply VSSA before VSSD.

• Apply AIN and REF after VDDA and VSSA are present.

• The power supplies should settle within the

MAX194’s power-on delay (minimum 500ns) or you

should recalibrate the converter (pulse RESET low)

before use.

Be sure that digital return currents do not pass through

the analog ground and that return-current paths are low

impedance. A 5mA current flowing through a PC board

ground trace impedance of only 0.1Ω creates an error

voltage of about 500µV, or about 1LSB error with a ±4V

full-scale system.

The board layout should ensure as much as possible

that digital and analog signal lines are kept separate.

Do not run analog and digital (especially clock) lines

parallel to one another. If you must cross one with the

other, do so at right angles.

The ADC’s high-speed comparator is sensitive to highfrequency noise on the VDDA and VSSA power supplies. Bypass these supplies to the analog ground

plane with 0.1µF in parallel with 1µF or 10µF low-ESR

capacitors. Keep capacitor leads short for best supplynoise rejection.

Shutdown

The MAX194 may be shut down by pulling BP/UP/

SHDN low. In addition to lowering power dissipation to

10µW (100µW max) when the device is not in use, considerable power savings is possible by shutting the

converter down for short periods between conversions.

There is no need to perform a reset (calibration) after

the converter has been shut down unless the time in

shutdown is long enough that the supply voltages or

ambient temperature may have changed.

The time required for the converter to “wake up” and

settle depends heavily on the amount of additional error

acceptable. For 0.1LSB additional error, 3.2µs is sufficient settling time and also allows enough time for reacquisition of the analog input signal. 20µs settling is

required for less than 0.05LSB error. Figure 23 is a

Figure 21. MAX194 Code Listing for 68HC16 Module and Circuit of Figure 19 (continued)

Page 22

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

22 ______________________________________________________________________________________

MAX194

10µF

VDDD

VDDA

VSSA

VSSD

AGND

DGND

5V

5V

0.1µF

0.1µF

10µF

10Ω

10Ω

10µF

0.1µF

0.1µF

10µF

100

0.01

1 10 100 1000 10,000 100,000

0.1

MAX194-FIG23

CONVERSIONS PER SECOND

POWER DISSIPATION (mW)

1

10

20µs WAKE-UP DELAY

0.05LSB ERROR

3.2µs WAKE-UP DELAY

0.1LSB ERROR

graph of theoretical power consumption vs. conversions per second for the MAX194 that assumes the

conversion clock is 1.7MHz and the converter is shut

down as much as possible between conversions.

Stop CLK before shutting down the MAX194. CLK must

be stopped without generating short clock pulses. Short

CLK pulses (less than 150ns), or shutting down the

MAX194 without stopping CLK, may adversely affect the

MAX194’s internal calibration data. In applications

where CLK is free-running and asynchronous, use the

circuit of Figure 24 to stop CLK cleanly.

To minimize the time required to settle and perform a

conversion, shut the converter down only after a conversion is finished and the desired mode (unipolar or

bipolar) has been set. This ensures that the sampling

capacitor array is properly connected to the input signal. If shut down in mid-conversion, when awakened,

the MAX194 finishes the old conversion, allows four

clock (CLK) cycles for input acquisition, then begins

the new conversion.

_____________Dynamic Performance

High-speed sampling capability, 85ksps throughput,

and wide dynamic range make the MAX194 ideal for

AC applications and signal processing. To support

these and other related applications, Fast Fourier

Transform (FFT) test techniques are used to guarantee

the ADC’s dynamic frequency response, distortion, and

noise at the rated throughput. Specifically, this involves

applying a low-distortion sine wave to the ADC input

and recording the digital conversion results for a

specified time. The data is then analyzed using an FFT

algorithm, which determines its spectral content.

Conversion errors are then seen as spectral elements

other than the fundamental input frequency.

Signal-to-Noise Ratio and

Effective Number of Bits

Signal-to-Noise Ratio (SNR) is the ratio between the

RMS amplitude of the fundamental input frequency to

the RMS amplitude of all other ADC output signals. The

output band is limited to frequencies above DC and

below one-half the ADC sample rate. This usually (but

not always) includes distortion as well as noise components. For this reason, the ratio is sometimes referred to

as Signal-to-Noise + Distortion (SINAD).

The theoretical minimum ADC noise is caused by quantization error and is a direct result of the ADC’s resolution: SNR = (6.02N + 1.76)dB, where N is the number

of bits of resolution. A perfect 14-bit ADC can, therefore, do no better than 86dB. An FFT plot of the output

shows the output level in various spectral bands. Figure

25 shows the result of sampling a pure 1kHz sinusoid at

85ksps with the MAX194.

By transposing the equation that converts resolution to

SNR, we can, from the measured SNR, determine the

effective resolution or the “effective number of bits” the

ADC provides: N = (SNR - 1.76) / 6.02. Substituting

SINAD for SNR in this formula results in a better

Figure 22. Supply Bypassing and Grounding

Figure 23. Power Dissipation vs. Conversions/sec When

Shutting the MAX194 Down Between Conversions

Page 23

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

______________________________________________________________________________________ 23

measure of the ADC’s usefulness. Figure 26 shows the

effective number of bits as a function of the MAX194’s

input frequency calculated from the SINAD.

Total Harmonic Distortion

If a pure sine wave is input to an ADC, AC integral nonlinearity (INL) of an ADC’s transfer function results in

harmonics of the input frequency being present in the

sampled output data.

Total Harmonic Distortion (THD) is the ratio of the RMS

sum of all the harmonics (in the frequency band above

DC and below one-half the sample rate, but not including the DC component) to the RMS amplitude of the

fundamental frequency. This is expressed as follows:

√

(V

2

2

+ V

3

2

+ V

4

2

+ ... + V

N

2

)

THD = 20log——————————————

V1

where V1is the fundamental RMS amplitude, and V

2

through VNare the amplitudes of the 2nd through Nth

harmonics. The THD specification in the

Electrical

Characteristics

includes the 2nd through 5th harmonics. In the MAX194, this distortion is caused primarily

by the changes in on-resistance of the AIN sampling

switches with changing input voltage. These resistance

changes, together with the DAC’s capacitance (which

can also vary with input voltage), cause a varying time

delay for AC signals, which causes significant distortion

at moderately high frequencies (Figure 27).

CK

(2 x CLK)

J

Q

+5V

K

CLK

BP/UP/SHDN

CK

2 x CLK

1

/

2

74HC73

CLOCK SHUTDOWN

Q

(CLK)

J

(CLOCK SHUTDOWN)

MAX194

Figure 24. Circuit to Stop Free-Running Asynchronous CLK

-150

-130

-110

-90

0 5 10 20 25

40

-30

-50

-70

-10

FREQUENCY (kHz)

SIGNAL AMPLITUDE (dB)

15 30 35

fIN = 1kHz

f

S

= 85kHz

T

A

= +25°C

Figure 25. MAX194 FFT Plot

Page 24

MAX194

14-Bit, 85ksps ADC with 10µA Shutdown

Spurious-Free Dynamic Range

Spurious-free dynamic range is the ratio of the fundamental RMS amplitude to the amplitude of the next

largest spectral component (in the frequency band

above DC and below one-half the sample rate). Usually,

this peak occurs at some harmonic of the input frequency. However, if the ADC is exceptionally linear, it may

occur only at a random peak in the ADC’s noise floor.

Transfer Function

Figures 28 and 29 show the MAX194’s transfer functions. In unipolar mode, the output data is in binary format and in bipolar mode it is offset binary.

TRANSISTOR COUNT: 7966

11 . . . 111

11 . . . 110

11 . . . 101

11 . . . 100

11 . . . 011

11 . . . 010

00 . . . 110

00 . . . 101

00 . . . 100

00 . . . 011

00 . . . 010

00 . . . 001

00 . . . 000

0V V

REF

- (1LSB)

Figure 28. MAX194 Unipolar Transfer Function Figure 29. MAX194 Bipolar Transfer Function

90

60

0.1 10 100

65

70

75

80

85

MAX194-27

FREQUENCY (kHz)

SINAD (dB)

1

fS = 85kHz

T

A

= +25°C

Figure 27. Signal-to-Noise + Distortion vs. FrequencyFigure 26. Effective Bits vs. Input Frequency

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

24

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 1997 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

14.0

13.5

13.0

12.5

12.0

11.5

EFFECTIVE BITS

11.0

10.5

10.0

fS = 85kHz

= +25°C

T

A

0.1 1 10 100

INPUT FREQUENCY (kHz)

MAX194-26

11 . . . 111

11 . . . 110

11 . . . 101

10 . . . 010

10 . . . 001

10 . . . 000

01 . . . 111

01 . . . 110

00 . . . 010

00 . . . 001

00 . . . 000

-V

REF

V

- (1LSB)0V

REF

Loading...

Loading...