Page 1

General Description

The MAX1778/MAX1880–MAX1885 multiple-output

DC-DC converters provide the regulated voltages

required by active matrix thin-film transistor (TFT) liquid

crystal displays (LCD) in a low-profile TSSOP package.

One high-power step-up converter and two low-power

charge pumps convert the 2.7V to 5.5V input voltage

into three independent output voltages. A built-in linear

regulator and VCOM buffer complete the power-supply

requirements.

The main step-up converter accurately generates an

externally set output voltage up to 13V that can supply

the display’s row/column drivers. The converter’s high

switching frequency and current-mode PWM architecture provide fast transient response and allow the use

of small low-profile inductors and ceramic capacitors.

The low-power BiCMOS control circuitry and internal

14V switch (0.35Ω N-channel MOSFET) enable efficiencies up to 91%.

The dual low-power charge pumps (MAX1778/

MAX1880/MAX1881/MAX1882 only) independently regulate one positive output (V

POS

) and one negative out-

put (V

NEG

). These low-power outputs use external

diode and capacitor stages (as many stages as

required) to regulate output voltages up to +40V and

-40V. A unique control scheme minimizes output ripple

as well as capacitor sizes for both charge pumps.

A resistor-programmable, 40mA, low-dropout linear

regulator (MAX1778/MAX1881/MAX1883/MAX1884

only) provides preregulation or postregulation for any of

the supplies. For higher current applications, an external transistor can be added. Additionally, the VCOM

buffer provides a high current output that is ideal for

driving the capacitive backplane of TFT LCD panels.

The VCOM buffer’s output voltage is preset with an

internal 50% resistive-divider or can be externally

adjusted for other voltages.

The MAX1778/MAX1880–MAX1885 are protected

against output undervoltage and thermal overload conditions by a latched fault detection circuit that shuts

down the device. All devices are available in the ultrathin TSSOP package (1.1mm max height).

Applications

TFT LCD Notebook Displays

TFT LCD Desktop Monitor Panels

Features

♦ 500kHz/1MHz Current-Mode PWM Step-Up

Regulator

Up to +13V Main High-Power Output

±1% Accurate

High Efficiency (91%)

♦ Dual Regulated Charge-Pump Outputs

(MAX1778/MAX1880/MAX1881/MAX1882 only)

Up to +40V Positive Charge-Pump Output

Up to -40V Negative Charge-Pump Output

♦ Low-Dropout 40mA Linear Regulator

(MAX1778/MAX1881/MAX1883/MAX1884 only)

Up to +15V LDO Input

♦ Optional Higher Current with External Transistor

♦ 2.7V to 5.5V Input Supply

♦ Internal Supply Sequencing and Soft-Start

♦ Power-Ready Output

♦ Adjustable Fault-Detection Latch

♦ Thermal Protection (+160°C)

♦ 0.1µA Shutdown Current

♦ 0.7mA IN Quiescent Current

♦ Ultra-Small External Components

♦ Thin TSSOP Package (1.1mm max height)

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

________________________________________________________________ Maxim Integrated Products 1

19-1979; Rev 0a; 3/01

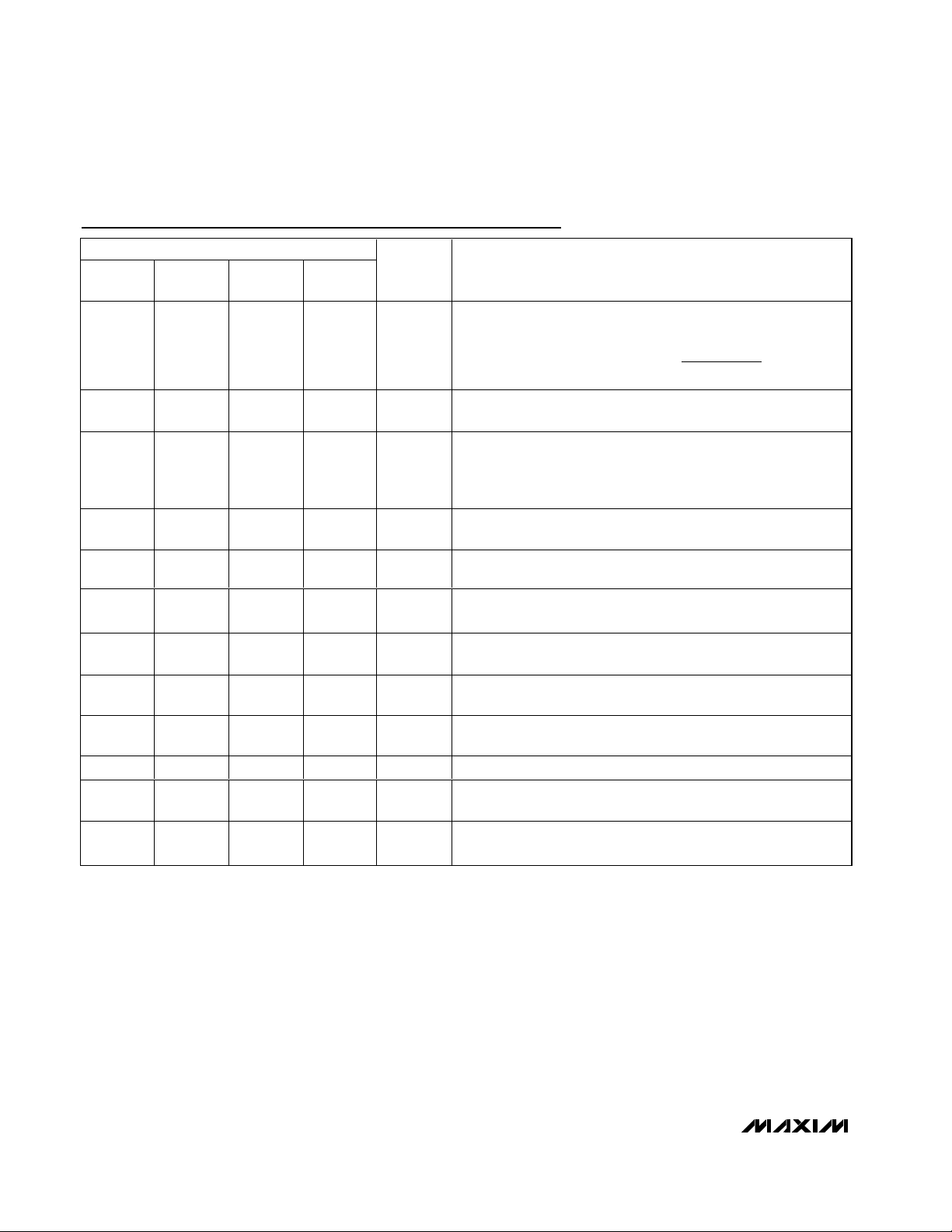

Ordering Information

Typical Operating Circuit appears at end of data sheet.

Pin Configurations and Selector Guide appear at end of

data sheet.

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

PART TEMP. RANGE PIN-PACKAGE

MAX1778EUG -40°C to +85°C 24 TSSOP

MAX1880EUG -40°C to +85°C 24 TSSOP

MAX1881EUG -40°C to +85°C 24 TSSOP

MAX1882EUG -40°C to +85°C 24 TSSOP

MAX1883EUP -40°C to +85°C 20 TSSOP

MAX1884EUP -40°C to +85°C 20 TSSOP

MAX1885EUP -40°C to +85°C 20 TSSOP

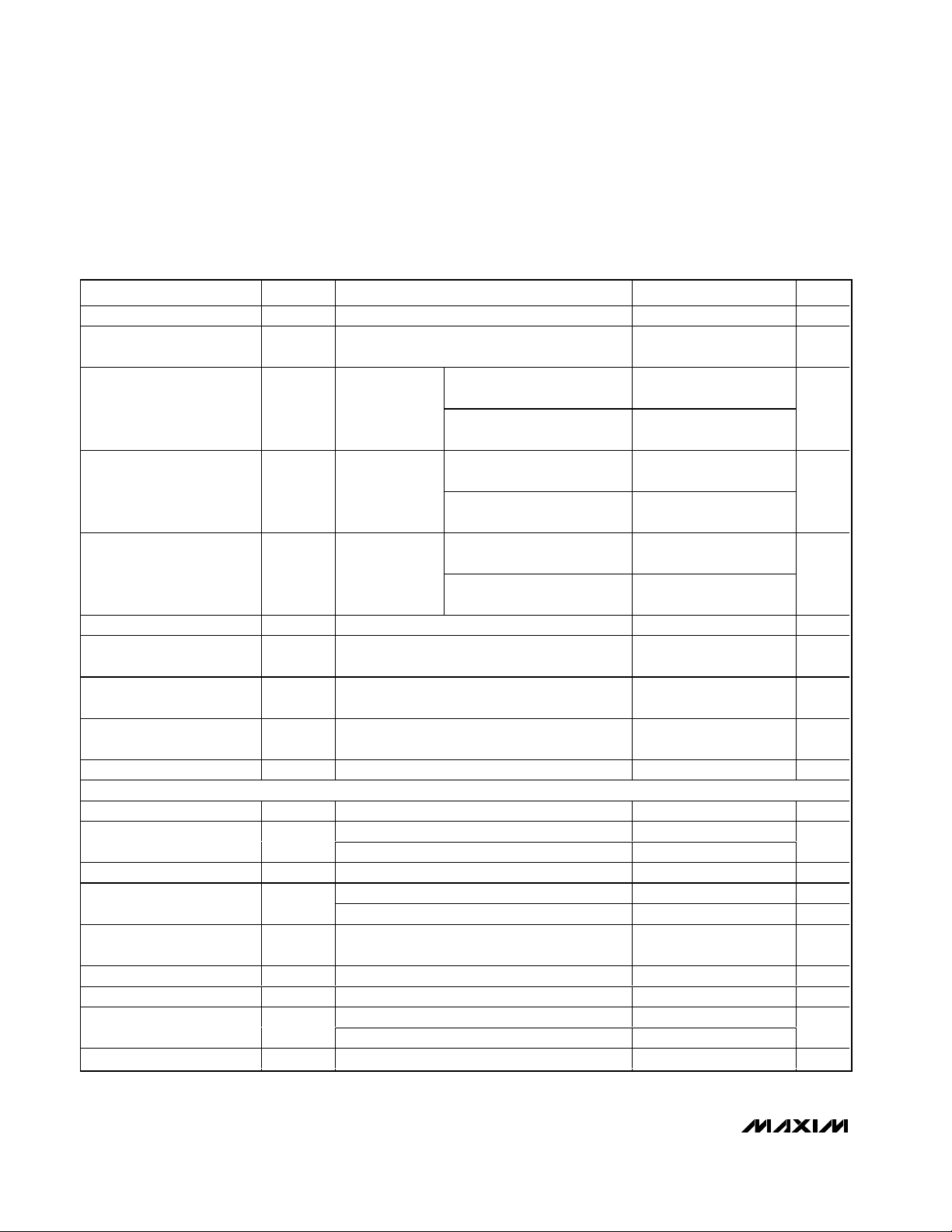

Page 2

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

2 _______________________________________________________________________________________

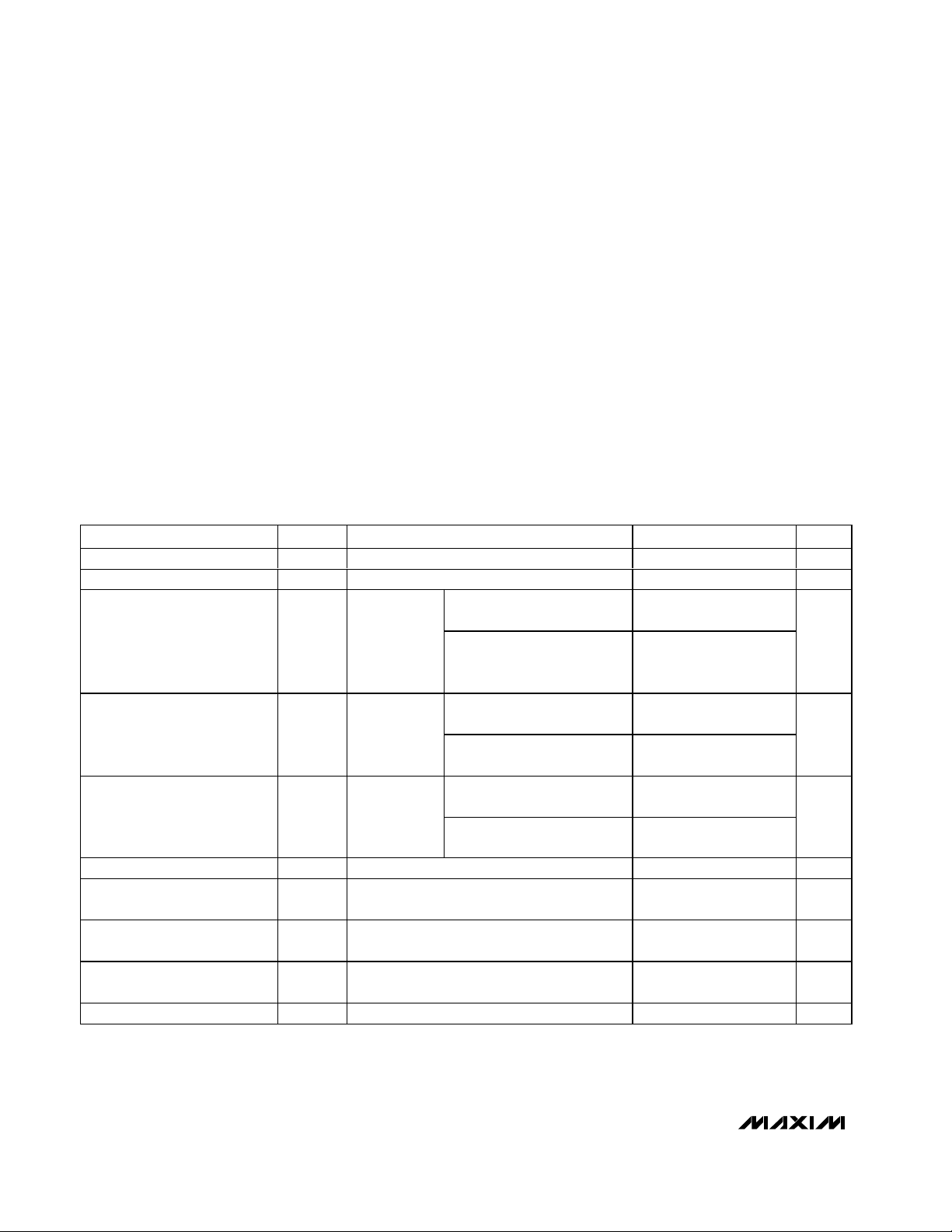

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VIN= +3.0V, SHDN = IN, V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 10V, LDOOUT = FBL, BUF- = BUFOUT, BUF+ = FLTSET = TGND =

PGND = GND, C

REF

= 0.22µF, C

BUF

= 1µF, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN, SHDN, TGND, FLTSET to GND...........................-0.3V to +6V

DRVN to GND .........................................-0.3V to (V

SUPN

+ 0.3V)

DRVP to GND..........................................-0.3V to (V

SUPP

+ 0.3V)

PGND to GND.....................................................................±0.3V

RDY, SUPB to GND ................................................-0.3V to +14V

LX, SUPP, SUPN to PGND .....................................-0.3V to +14V

SUPL to GND..........................................................-0.3V to +18V

LDOOUT to GND ....................................-0.3V to (V

SUPL

+ 0.3V)

INTG, REF, FB, FBN, FBP to GND...............-0.3V to (V

IN

+ 0.3V)

FBL to GND .............-0.3V to the lower of (V

SUP

L

+ 0.3V) or +6V

BUFOUT, BUF+, BUF- to GND ...............-0.3V to (V

SUPB

+ 0.3V)

Continuous Power Dissipation (T

A

= +70°C)

20-Pin TSSOP (derate 10.9mW/°C above +70°C) ......879mW

24-Pin TSSOP (derate 12.2mW/°C above +70°C) ......975mW

Operating Temperature Range

MAX1778EUG, MAX1883EUP ........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Input Supply Range V

Input Undervoltage Threshold V

IN Quiescent Supply Current I

IN

UVLO

IN

VIN rising, 40mV hysteresis (typ) 2.2 2.4 2.6 V

VFB = V

FBP

= 1.5V, V

FBN

= -0.2V

SUPP Quiescent Current I

SUPN Quiescent Current I

SUPP

SUPN

IN Shutdown Current V

SUPP Shutdown Current

SUPN Shutdown Current

SUPL Shutdown Current

SUPB Shutdown Current V

V

= 1.5V

FBP

V

= -0.2V

FBN

= 0, VIN = 5V 0.1 10 µA

SHDN

V

= 0, V

SHDN

SUPP

MAX1778/MAX1880/MAX1881/MAX1882

V

= 0, V

SHDN

SUPN

MAX1778/MAX1880/MAX1881/MAX1882

V

= 0, V

SHDN

SUPL

MAX1778/MAX1881/MAX1883/MAX1884

= 0, V

SHDN

SUPB

2.7 5.5 V

MAX1778/MAX1880/

MAX1883 (f

OSC

= 1MHz)

0.7 1

MAX1881/MAX1882/

MAX1884/MAX1885

(f

= 500kHz)

OSC

MAX1778/MAX1880

(f

= 1MHz)

OSC

MAX1881/MAX1882

(f

= 500kHz)

OSC

MAX1778/MAX1880

(f

= 1MHz)

OSC

MAX1881/MAX1882

(f

= 500kHz)

OSC

= 13V,

= 13V,

= 13V

0.6 1

0.4 0.7

0.3 0.5

0.4 0.7

0.3 0.5

0.1 10 µA

0.1 10 µA

0.1 10 µA

= 13V 6 13 µA

mA

mA

mA

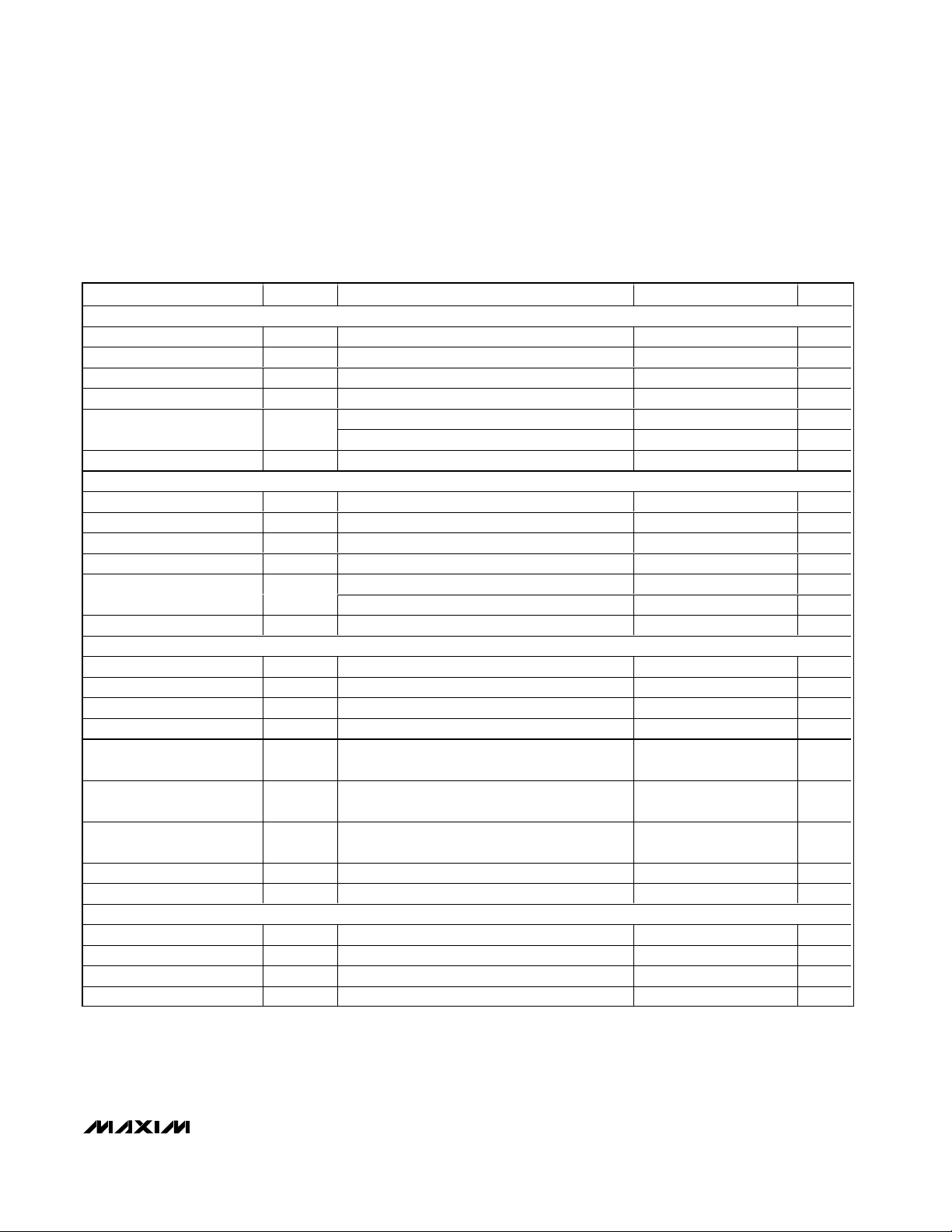

Page 3

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

_______________________________________________________________________________________ 3

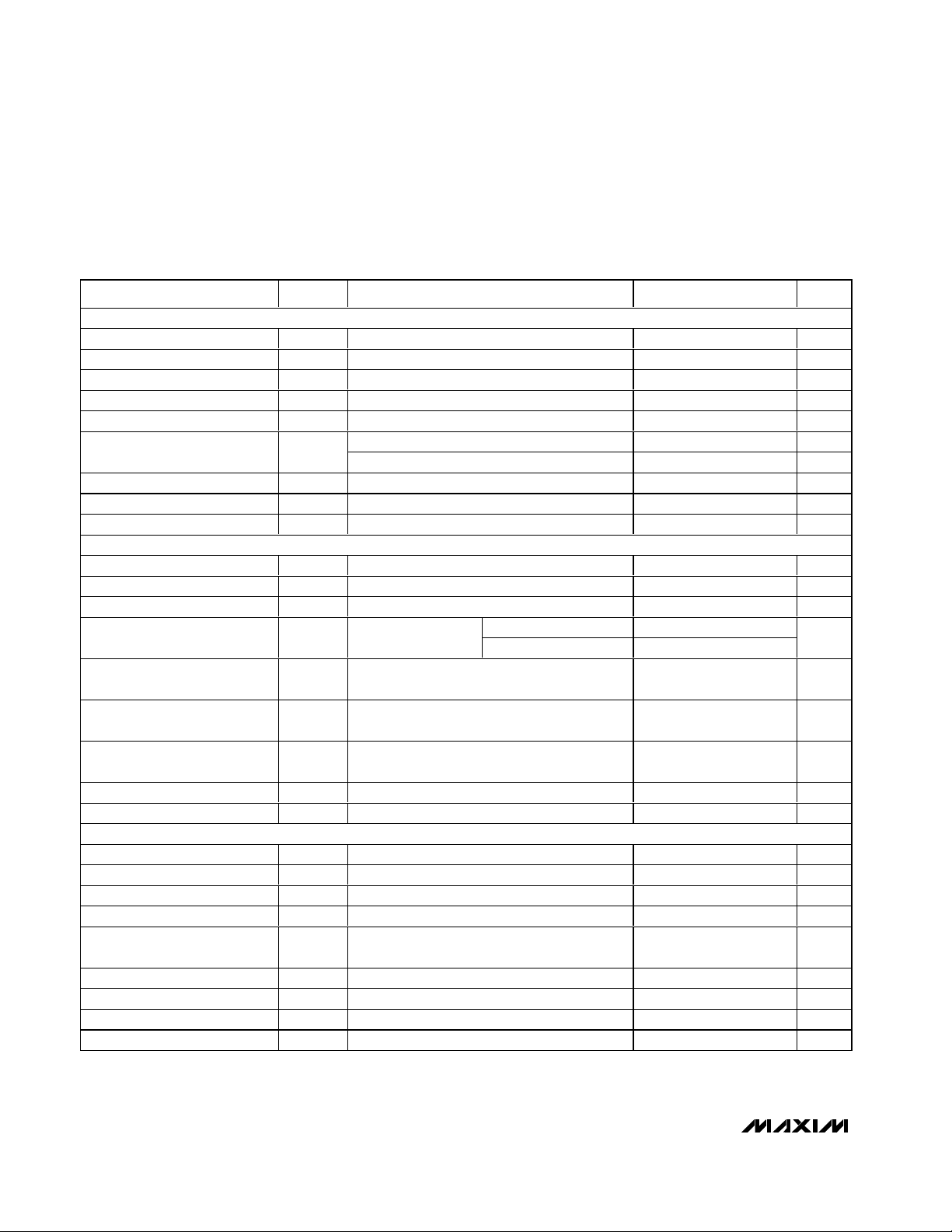

ELECTRICAL CHARACTERISTICS (continued)

(VIN= +3.0V, SHDN = IN, V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 10V, LDOOUT = FBL, BUF- = BUFOUT, BUF+ = FLTSET = TGND =

PGND = GND, C

REF

= 0.22µF, C

BUF

= 1µF, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

)

)

)

PARAMETER SYMBOL

CONDITIONS MIN TYP MAX

UNITS

MAIN STEP-UP CONVERTER

Main Output Voltage Range V

FB Regulation Voltage V

FB Input Bias Current I

Operating Frequency f

Oscillator Maximum Duty

Cycle

Load Regulation

MAIN

FB

FB

OSC

Integrator enabled, C

V

IN

= 1000pF 1.234 1.247 1.260

INTG

13

Integrator disabled (INTG = REF) 1.220 1.280

VFB = 1.25V, INTG = GND -50 +50

MAX1778/MAX1880/MAX1883 0.85 1 1.15

MAX1881/MAX1882/MAX1884/MAX1885 425 500 575

80 85 91 %

I

= 0 to 200mA,

LX

V

= 10V

MAIN

Integrator enabled,

C

= 1000pF

INTG

Integrator disabled

(INTG = REF)

0.01

0.2

V

V

nA

MHz

kHz

%

Line Regulation 0.1 %/V

Integrator Transconductance 317 µs

LX Switch On-Resistance R

LX Leakage Current I

LX Current Limit I

LX(ON

LX

LIM

ILX = 100mA 0.35 0.7 Ω

VLX = 13V 0.01 20 µA

Phase I = soft-start (1024/f

Phase II = soft-start (1024/f

Phase III = soft-start (1024/f

Phase IV = fully-on (after 3072/f

) 0.275 0.38 0.5

OSC

) 0.75

OSC

) 1.12

OSC

) 1.15 1.5 1.85

OSC

A

Maximum RMS LX Current 1A

Soft-Start Period t

FB Fault Trip Level

SS

Power-up to the end of Phase III 3072 / f

OSC

Falling edge, FLTSET = GND 1.07 1.1 1.14

Falling edge, FLTSET = 1V 0.955 0.99 1.025

s

V

POSITIVE CHARGE PUMP (MAX1778/MAX1880/MAX1881/MAX1882 ONLY)

SUPP Input Supply Range

Operating Frequency f

FBP Regulation Voltage V

FBP Input Bias Current I

DRVP PCH On-Resistance R

DRVP NCH On-Resistance R

V

SUPP

CHP

FBP

FBP

PCH(ON

NCH(ON

V

= 1.5V -50 +50

FBP

V

= 1.2V 2 4

FBP

V

= 1.3V 20

FBP

Maximum RMS DRVP Current 0.1

FBP Power-Ready Trip Level Rising edge 1.09 1.125 1.16

FBP Fault Trip Level

Falling edge, FLTSET = GND 1.08 1.11 1.16

Falling edge, FLTSET = 1V 0.955 0.99 1.025

2.7 13 V

0.5 x f

OSC

1.2 1.25 1.3

510

Hz

V

nA

Ω

Ω

kΩ

A

V

V

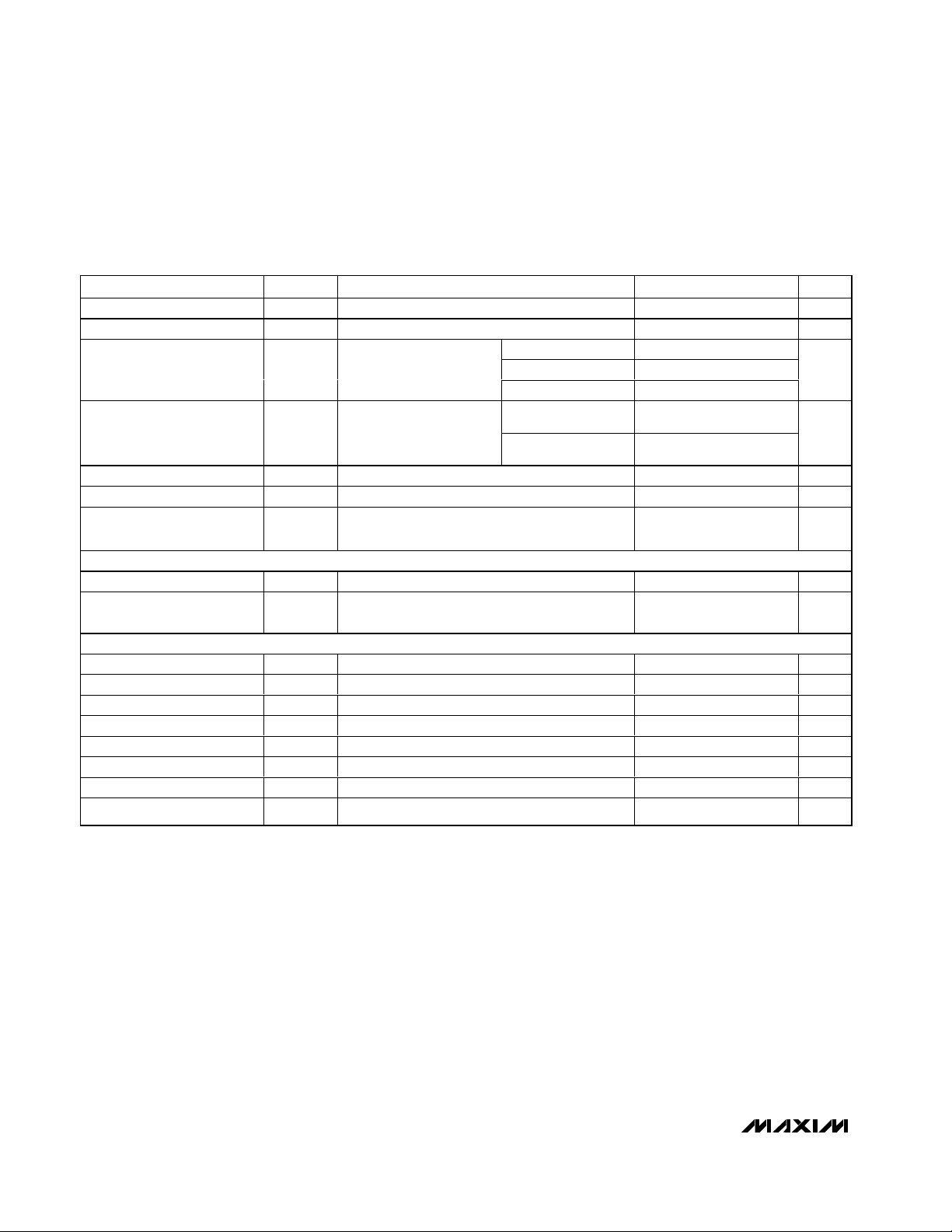

Page 4

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

4 _______________________________________________________________________________________

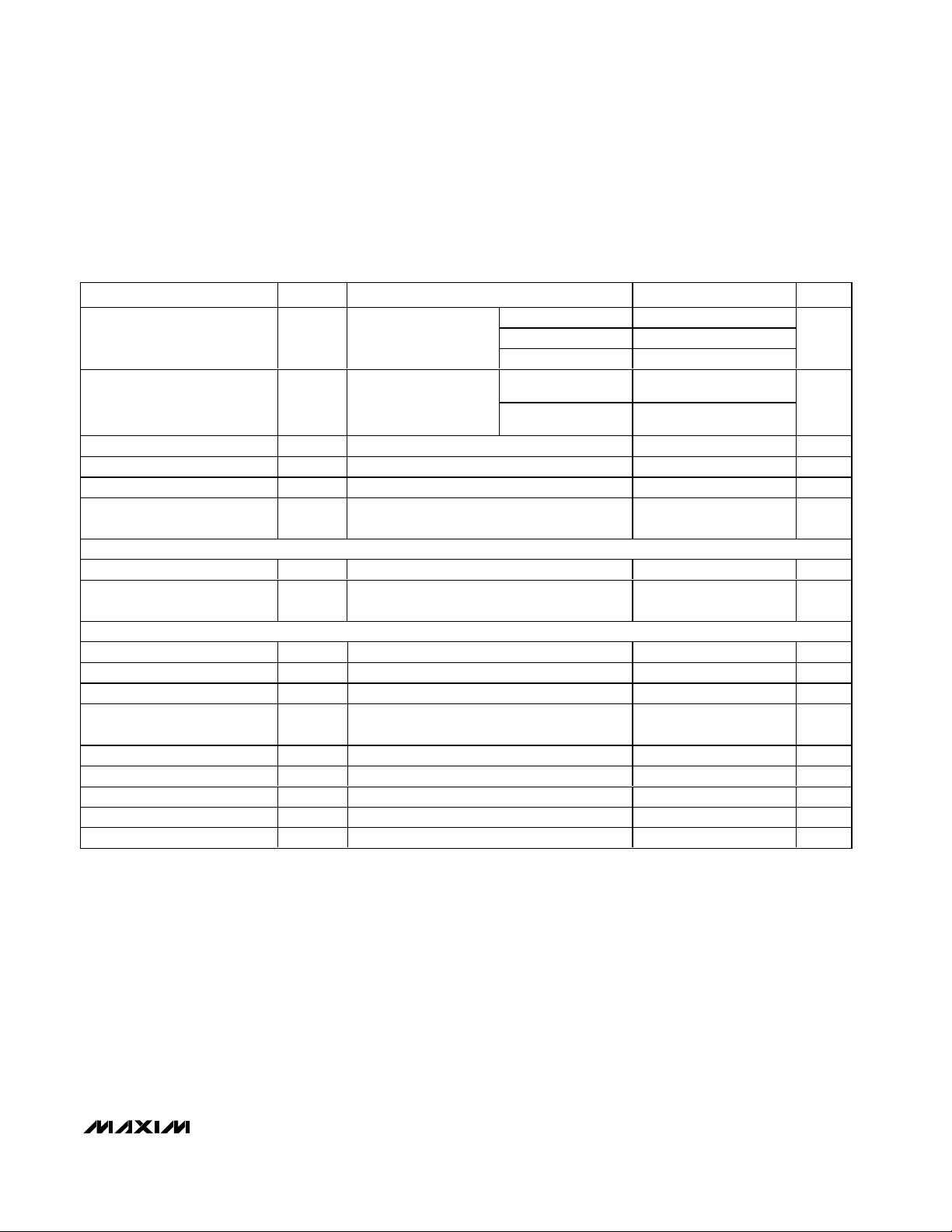

ELECTRICAL CHARACTERISTICS (continued)

(VIN= +3.0V, SHDN = IN, V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 10V, LDOOUT = FBL, BUF- = BUFOUT, BUF+ = FLTSET = TGND =

PGND = GND, C

REF

= 0.22µF, C

BUF

= 1µF, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

)

)

PARAMETER

NEGATIVE CHARGE PUMP (MAX1778/MAX1880/MAX1881/MAX1882 ONLY)

SUPN Input Supply Range

Operating Frequency

FBN Regulation Voltage

FBN Input Bias Current

DRVN PCH On-Resistance

DRVN NCH On-Resistance R

Maximum RMS DRVN Current

FBN Power-Ready Trip Level

FBN Fault Trip Level

LOW-DROPOUT LINEAR REGULATOR (MAX1778/MAX1881/MAX1883/MAX1884 ONLY)

SUPL Input Supply Range V

SUPL Undervoltage Lockout Rising edge, 50mV hysteresis (typ) 3.8 4 4.3 V

SUPL Quiescent Current I

Dropout Voltage (Note 1) V

FBL Regulation Voltage V

LDO Load Regulation

LDO Line Regulation

FBL Input Bias Current I

LDO Current Limit I

VCOM BUFFER

SUPB Input Supply Range V

SUPB Quiescent Current I

BUFOUT Leakage Current -10 +10

Power-Supply Rejection Ratio PSRR V

Input Common-Mode Voltage

Range

Common-Mode Rejection Ratio CMRR VCM = 1.2V to 8.8V 75

Input Bias Current I

Input Offset Current I

Gain Bandwidth Product GBW C

SYMBOL CONDITIONS MIN TYP MAX UNITS

V

SUPN

f

CHP

V

FBN

I

FBN

R

PCH(ON

NCH(ON

V

= 0 -50 +50 nA

FBN

V

= +50mV

FBN

V

= -50mV

FBN

2.7 13 V

0.5 x f

OSC

-50 0 +50 mV

510Ω

24Ω

20 kΩ

0.1 A

Falling edge 80 125 165 mV

Rising edge 80 140 190 mV

SUPL

SUPL

DROP

FBL

FBL

LDOLIMVSUPL

SUPB

SUPB

V

CM

BIAS

OS

I

LDO

LDO is set to

regulate at 9V

V

SUPL

I

LDO

V

SUPL

I

LDO

V

SUPL

I

LDO

V

FBL

V

SUPB

SUPB

|VOS| < 10mV 1.2 8.8

VCM = 5V -100 -10 +100

VCM = 5V -100 +100

BUF

= 100µA 120 220 µA

I

= 40mA 130 300

LDO

I

= 5mA 70

LDO

= 10V, LDO regulating at 9V,

= 15mA

= 10V, LDO regulating at 9V,

= 100µA to 40mA

= 4.5V to 15V, FBL = LDOOUT,

= 15mA

= 1.25V -0.8 +0.8

= 10V, V

LDOOUT

= 9V, V

= 1.2V 40 130 220

FBL

= 13V 420 850

= 4.5V to 13V, VCM = 2.25V 85 98

= 1µF 13

4.5 15 V

1.235 1.25 1.265 V

4.5 13

Hz

mV

1.2 %

0.02 %/V

µA

mA

V

µA

µA

dB

V

dB

nA

nA

kHz

Page 5

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(VIN= +3.0V, SHDN = IN, V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 10V, LDOOUT = FBL, BUF- = BUFOUT, BUF+ = FLTSET = TGND =

PGND = GND, C

REF

= 0.22µF, C

BUF

= 1µF, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

Dual Mode is a registered trademark of Maxim Integrated Products, Inc.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX

Output Voltage V

Input Offset Voltage V

Output Voltage Swing High V

Output Voltage Swing Low V

Peak Buffer Output Current ±150 mA

BUF+ Dual Mode™ Threshold

Voltage

REFERENCE

Reference Voltage V

Reference Undervoltage

Threshold

LOGIC SIGNALS

SHDN Input Low Voltage 0.9 V

SHDN Input High Voltage 2.1 V

SHDN Input Current I

FLTSET Input Voltage Range

FLTSET Threshold Voltage Rising edge, 25mV hysteresis (typ) 80 125 170 mV

FLTSET Input Current V

RDY Output Low Voltage I

RDY Output High Leakage V

Thermal Shutdown Rising temperature 160 °C

BUFOUT

OS

OH

OL

BUF+ = GND

V

= 4.5V to 13V,

SUPB

V

= 1.2V to

CM

–1.2V) I

(V

SUPB

I

I

= -45mA, ∆VOS = 1V 9 9.6 V

BUFOUT

= +45mA, ∆VOS = 1V 0.4 1 V

BUFOUT

I

I

I

I

BUFOUT

BUFOUT

= 0 4.99 5.01

BUFOUT

= ±5mA 4.97 5.03

BUFOUT

= ±45mA 4.93 5.07

BUFOUT

= ±5mA -30 30

= ±45mA -70 70

Falling edge, 20mV hysteresis (typ) 80 125 170 mV

REF

-2µA < I

< 50µA 1.231 1.25 1.269 V

REF

0.9 1.05 1.2 V

SHDN

0.01 1 µA

0.67 x

V

REF

= 1V 0.1 50 nA

FLTSET

= 2mA 0.25 0.5 V

SINK

= 13V 0.01 1 µA

RDY

0.85 x

V

REF

UNITS

V

mV

V

Page 6

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS

(VIN= +3.0V, SHDN = IN, V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 10V, LDOOUT = FBL, BUF- = BUFOUT, BUF+ = FLTSET = TGND =

PGND = GND, C

REF

= 0.22µF, C

BUF

= 1µF, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

)

PARAMETER SYMBOL CONDITIONS MIN MAX UNITS

Input Supply Range V

Input Undervoltage

Threshold

IN Quiescent Supply

Current

SUPP Quiescent Current I

SUPN Quiescent Current I

IN Shutdown Current V

SUPP Shutdown Current

SUPN Shutdown Current

SUPL Shutdown Current

SUPB Shutdown Current V

MAIN STEP-UP CONVERTER

Main Output Voltage Range V

FB Regulation Voltage V

FB Input Bias Current I

Operating Frequency F

Oscillator Maximum Duty

Cycle

LX Switch On-Resistance R

LX Leakage Current I

LX Current Limit I

FB Fault Trip Level Falling edge, FLTSET = GND 1.07 1.14 V

V

IN

UVLO

I

IN

VIN Rising, 40mV hysteresis (typ) 2.2 2.6 V

VFB =

V

FBP

V

FBN

= 1.5V,

= -0.2V

MAX1778/MAX1880/

MAX1883 (f

OSC

= 1MHz)

MAX1881/MAX1882/MAX1884/

MAX1885 (f

= 500kHz)

OSC

MAX1778/MAX1880

(f

= 1MHz)

SUPP

V

= 1.5V

FBP

OSC

MAX1881/MAX1882

(f

= 500kHz)

OSC

MAX1778/MAX1880

(f

= 1MHz)

SUPN

V

= -0.2V

FBN

= 0, VIN = 5V 10 µA

SHDN

V

= 0, V

SHDN

OSC

MAX1881/MAX1882

(f

= 500kHz)

OSC

= 13V,

SUPP

MAX1778/MAX1880/MAX1881/MAX1882

V

SHDN

= 0, V

SUPN

= 13V,

MAX1778/MAX1880/MAX1881/MAX1882

V

SHDN

= 0, V

SUPL

= 13V,

MAX1778/MAX1881/MAX1883/MAX1884

MAIN

FB

FB

OSC

LX(ON

LX

LIM

= 0, V

SHDN

Integrator enabled, C

Integrator disabled (INTG = REF) 1.21 1.29

VFB = 1.25V, INTG = GND -50 +50 nA

MAX1778/MAX1880/MAX1883 0.75 1.25 MHz

MAX1881/MAX1882/MAX1884/MAX1885 375 625 kHz

ILX = 100mA 0.7 Ω

VLX = 13V 20 µA

Phase I = soft-start (1024/f

Phase IV = fully on (after 3072/f

= 13V 13 µA

SUPB

= 1000pF 1.223 1.269

INTG

) 0.275 0.525

OSC

) 1.1 2.05

OSC

2.7 5.5 V

V

IN

79 91 %

1

mA

1

0.7

mA

0.5

0.7

mA

0.5

10 µA

10 µA

10 µA

13 V

V

A

Page 7

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

_______________________________________________________________________________________ 7

ELECTRICAL CHARACTERISTICS (continued)

(VIN= +3.0V, SHDN = IN, V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 10V, LDOOUT = FBL, BUF- = BUFOUT, BUF+ = FLTSET = TGND =

PGND = GND, C

REF

= 0.22µF, C

BUF

= 1µF, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

)

)

)

)

PARAMETER SYMBOL CONDITIONS MIN MAX UNITS

POSITIVE CHARGE PUMP (MAX1778/MAX1880/MAX1881/MAX1882 ONLY)

SUPP Input Supply Range V

FBP Regulation Voltage V

FBP Input Bias Current I

DRVP PCH On-Resistance R

DRVP NCH On-Resistance R

FBP Power-Ready Trip Level Rising edge 1.09 1.16 V

NEGATIVE CHARGE PUMP (MAX1778/MAX1880/MAX1881/MAX1882 ONLY)

SUPN Input Supply Range V

FBN Regulation Voltage V

FBN Input Bias Current I

DRVN PCH On-Resistance R

DRVN NCH On-Resistance R

FBN Power-Ready Trip Level Falling edge 80 165 mV

LOW DROPOUT LINEAR REGULATOR (MAX1778/MAX1881/MAX1883/MAX1884 ONLY)

SUPL Input Supply Range V

SUPL Undervoltage Lockout Rising edge, 50mV hysteresis (typ) 3.8 4.3 V

SUPL Quiescent Current I

Dropout Voltage (Note 1) V

FBL Regulation Voltage V

LDO Load Regulation

LDO Line Regulation

FBL Input Bias Current I

LDO Current Limit I

VCOM BUFFER

SUPB Input Supply Range V

SUPB Quiescent Current I

BUFOUT Leakage Current -10 +10 µA

Input Common-Mode Voltage

PCH(ON

NCH(ON

PCH(ON

NCH(ON

LDOLIM

SUPP

FBP

V

FBP

SUPN

FBN

FBN

SUPL

SUPL

DROP

FBL

FBL

SUPB

SUPB

V

CM

= 1.5V -50 +50 nA

FBP

V

= 1.2V 4 Ω

FBP

V

= 1.3V 20 kΩ

FBP

V

= 0 -50 +50 nA

FBN

V

= +50mV 4 Ω

FBN

V

= -50mV 20 kΩ

FBN

I

= 100µA 240 µA

LDO

LDO regulating to 9V, I

V

= 10V, LDO regulating to 9V,

SUPL

I

= 15mA

LDO

V

= 10V, LDO regulating to 9V,

SUPL

I

= 100µA to 40mA

LDO

= 4.5V to 15V, FBL = LDOOUT,

V

SUPL

I

= 15mA

LDO

V

= 1.25V -1.2 +1.2 µA

FBL

V

= 10V, V

SUPL

V

= 13V 850 µA

SUPB

LDOOUT

= 40mA 330 mV

LDO

= 9V, V

= 1.2V 40 260 mA

FBL

|VOS| < 10mV 1.2 8.8 V

2.7 13 V

1.2 1.3 V

10 Ω

2.7 13 V

-50 +50 mV

10 Ω

4.5 15 V

1.222 1.265 V

1.2 %

0.02 %/V

4.5 13 V

Page 8

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

8 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VIN= +3.0V, SHDN = IN, V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 10V, LDOOUT = FBL, BUF- = BUFOUT, BUF+ = FLTSET = TGND =

PGND = GND, C

REF

= 0.22µF, C

BUF

= 1µF, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

Note 1: Dropout Voltage is defined as the V

SUPL

- V

LDOOUT

, when V

SUPL

is 100mV below the set value of V

LDOOUT

.

Note 2: Specifications to -40°C are guaranteed by design, not production tested.

PARAMETER SYMBOL CONDITIONS MIN MAX UNITS

Input Bias Current I

Input Offset Current I

Input Offset Voltage V

Output Voltage Swing High V

Output Voltage Swing Low V

BUF+ Dual Mode

Threshold Voltage

REFERENCE

Reference Voltage V

Reference Undervoltage

Threshold

LOGIC SIGNALS

SHDN Input Low Voltage 0.9 V

SHDN Input High Voltage 2.1 V

SHDN Input Current I

FLTSET Input Voltage Range 0.74 x V

FLTSET Threshold Voltage Rising edge, 25mV hysteresis (typ) 80 170 mV

FLTSET Input Current V

RDY Output Low Voltage I

RDY Output High Leakage V

BUFOUT

BIAS

OS

OS

OH

OL

VCM = 5V -500 +500 nA

VCM = 5V -500 +500 nA

BUF+ = GND

V

= 4.5V to 13V

SUPB

= 1.2V to

V

CM

(V

- 1.2V)

SUPB

I

I

= -45mA, ∆VOS = 1V 9 V

BUFOUT

= +45mA, ∆VOS = 1V 1 V

BUFOUT

I

I

I

I

I

= 0 4.988 5.012

BUFOUT

= ±5mA 4.97 5.03Output Voltage V

BUFOUT

= ±45mA 4.93 5.07

BUFOUT

= ±5mA -30 30

BUFOUT

= ±45mA -70 70

BUFOUT

Falling edge, 20mV hysteresis (typ) 80 170 mV

REF

SHDN

-2µA < I

FLTSET

SINK

RDY

< 50µA 1.223 1.269 V

REF

= 1V 50 nA

= 2mA 0.5 V

= 13V 1 µA

0.9 1.2 V

0.85 x V

REF

V

mV

1µA

REF

V

Page 9

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

_______________________________________________________________________________________ 9

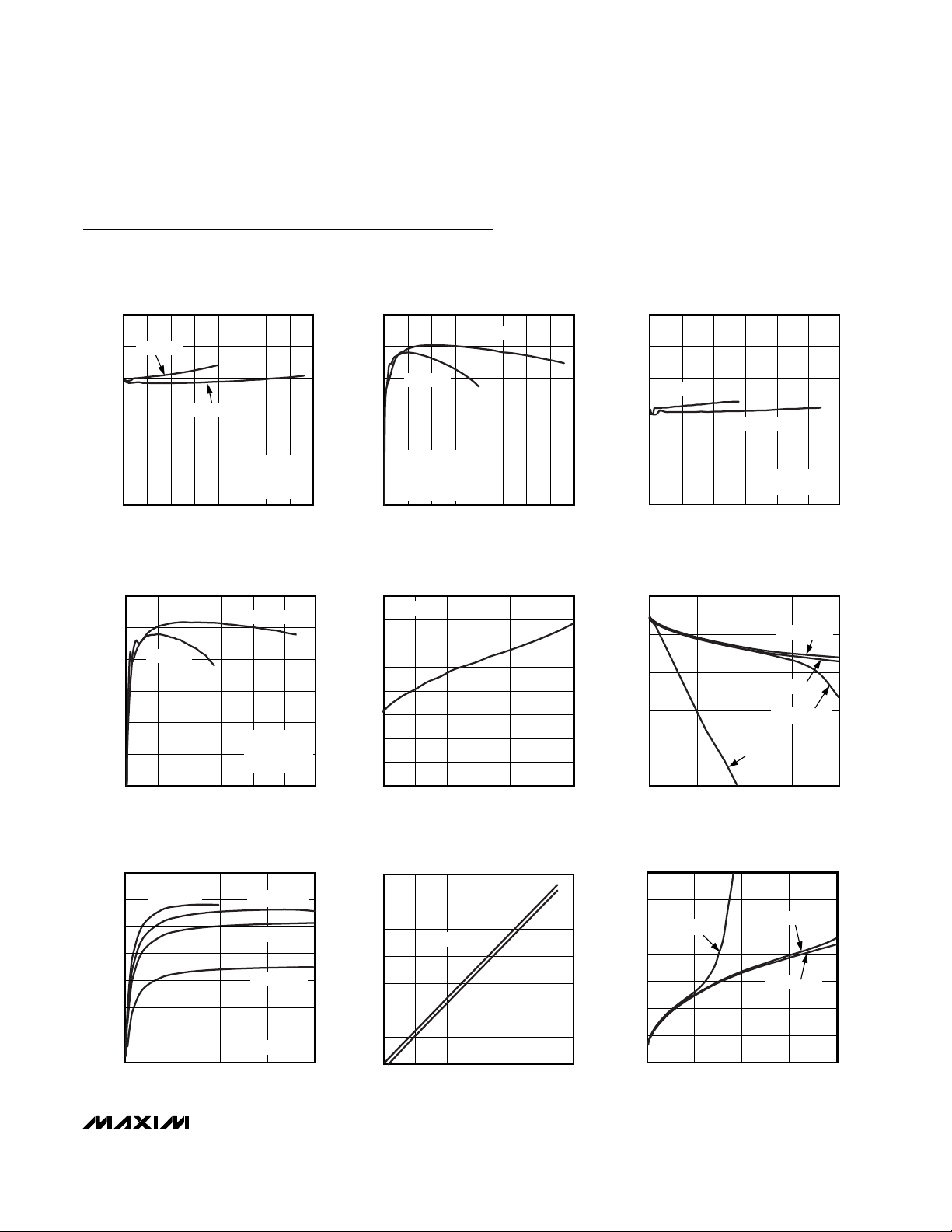

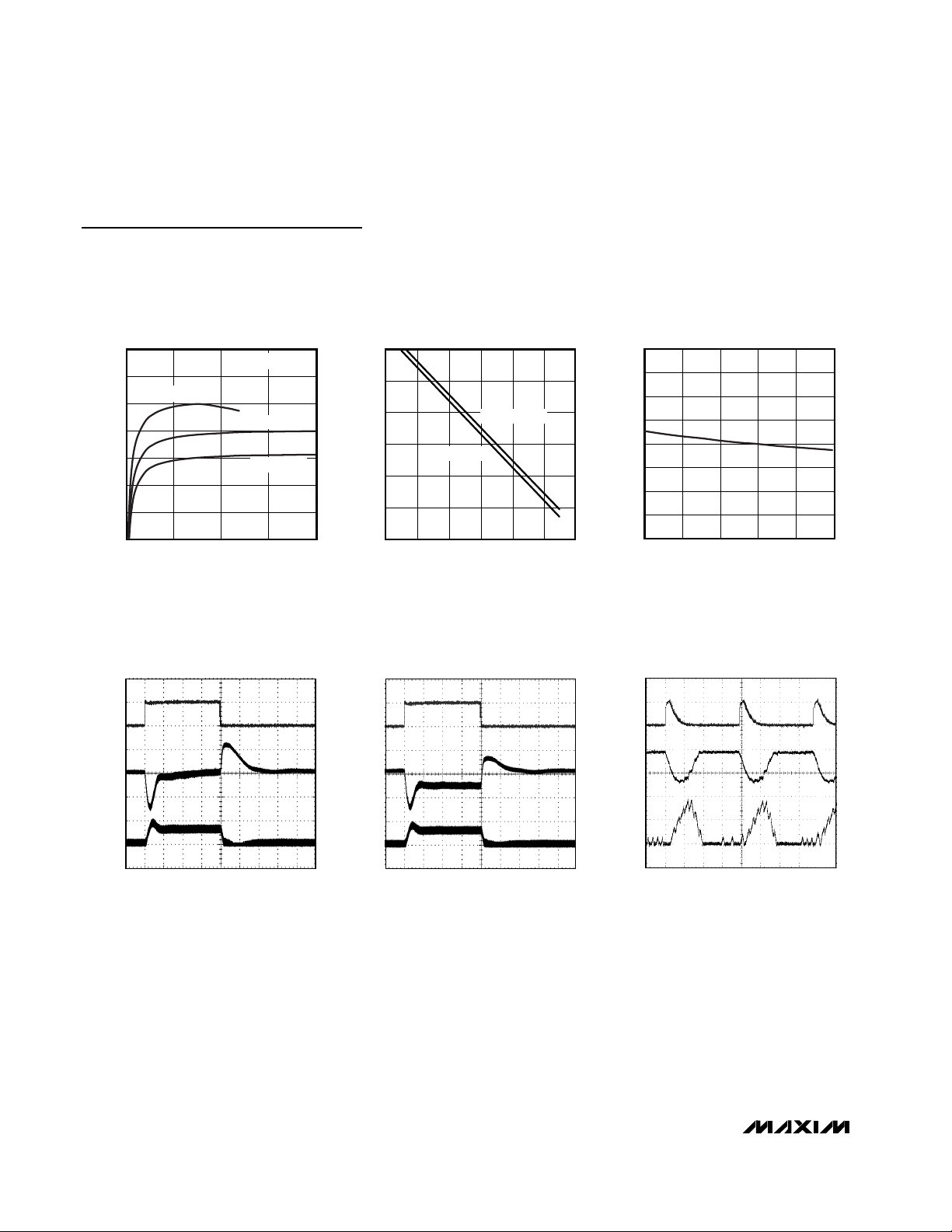

Typical Operating Characteristics

(Circuit of Figure 1, VIN= +3.3V, SHDN = IN, V

MAIN

= V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 8V, BUF- = BUFOUT,

BUF+ = FLTSET = TGND = PGND = GND, T

A

= +25°C.)

MAIN 8V OUTPUT VOLTAGE

vs. LOAD CURRENT

8.12

8.08

VIN = 3.3V

MAX1778 toc01

100

90

MAIN 8V OUTPUT EFFICIENCY

vs. LOAD CURRENT

VIN = 5V

MAX1778 toc02

12.24

12.16

MAIN 12V OUTPUT VOLTAGE

vs. LOAD CURRENT

MAX1778 toc03

8.04

(V)

8.00

OUT

V

7.96

7.92

7.88

0 200 400 600 800

VIN = 5V

I

OUT

(mA)

R

C

C

COMP

COMP

INTG

= 470pF

= 24kΩ

= 470pF

MAIN 12V OUTPUT EFFICIENCY

vs. LOAD CURRENT

100

V

5V

=

(mA)

IN

FIGURE 8

V

OUT

C

INTG

= 12V

= 470pF

MAX1778 toc04

90

V

3.3V

=

IN

80

70

EFFICIENCY (%)

60

50

40

0 200 300100 400 500 600

I

OUT

POSITIVE CHARGE-PUMP EFFICIENCY

vs. LOAD CURRENT

100

V

= 7V

90

80

70

60

EFFICIENCY (%)

50

40

30

SUPP

01051520

I

NEG

(mA)

V

= 7.5V

SUPP

V

V

V

SUPP

SUPP

POS

MAX1778 toc07

= 8V

= 10V

= 20V

80

VIN = 3.3V

70

EFFICIENCY (%)

60

V

= 8V

OUT

= 24kΩ

R

COMP

50

40

= 470pF

C

COMP

= 470pF

C

INTG

0 200 400 600 800

I

(mA)

OUT

STEP UP CONVERTERS

SWITCHING FREQUENCY vs. INPUT VOLTAGE

1.20

MAX1778

1.15

1.10

1.05

1.00

0.95

0.90

SWITCHING FREQUENCY (MHz)

0.85

0.80

2.5 3.53.0 4.0 4.5 5.0 5.5

VIN (V)

MAXIMUM POSITIVE CHARGE-PUMP

OUTPUT VOLTAGE vs. SUPPLY VOLTAGE

40

35

30

25

(V)

POS

V

20

15

10

5

2684 101214

I

= 1mA

POS

I

= 10mA

POS

V

(V)

SUPP

MAX1778 toc05

MAX1778 toc08

12.08

V

3.3V

=

(V)

12.00

OUT

V

11.92

11.84

11.76

IN

V

5V

=

IN

FIGURE 8

= 470pF

C

INTG

0 200 300100 400 500 600

I

(mA)

OUT

POSITIVE CHARGE-PUMP OUTPUT VOLTAGE

vs. LOAD CURRENT

20.2

= 10V

= 7.5V

MAX1778 toc06

V

V

SUPP

(mA)

V

= 7V

SUPP

V

SUPP

= 8V

SUPP

20.0

19.8

(V)

POS

V

19.6

19.4

19.2

01051520

I

POS

NEGATIVE CHARGE-PUMP OUTPUT VOLTAGE

vs. LOAD CURRENT

-4.90

-4.92

V

= 7V

V

-4.94

-4.96

(V)

NEG

V

-4.98

-5.00

-5.02

-5.04

0 10203040

SUPN

= 6V

SUPN

V

= 8V

SUPN

I

(mA)

NEG

MAX1778 toc09

Page 10

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

10 ______________________________________________________________________________________

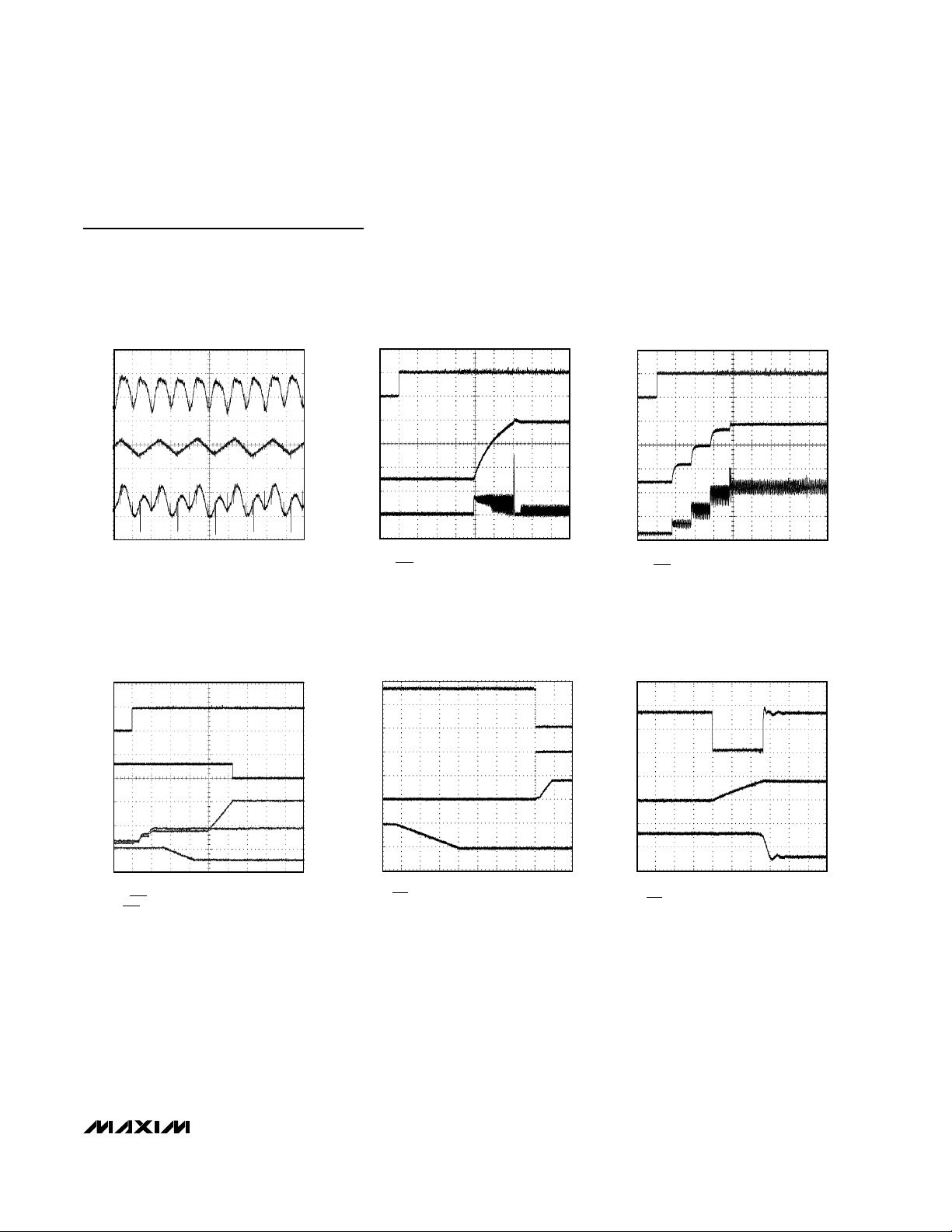

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= +3.3V, SHDN = IN, V

MAIN

= V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 8V, BUF- = BUFOUT,

BUF+ = FLTSET = TGND = PGND = GND, T

A

= +25°C.)

30

50

40

70

60

90

80

100

NEGATIVE CHARGE-PUMP EFFICIENCY

vs. LOAD CURRENT

MAX1778 toc10

I

NEG

(mA)

EFFICIENCY (%)

0 10203040

V

SUPN

= 7V

V

SUPN

= 8V

V

SUPN

= 6V

V

NEG

= -5V

-14

-10

-12

-6

-8

-4

-2

2684 101214

MAXIMUM NEGATIVE CHARGE-PUMP

OUTPUT VOLTAGE vs. SUPPLY VOLTAGE

MAX1778 toc11

V

SUPN

(V)

V

NEG

(V)

I

NEG

= 10mA

I

NEG

= 1mA

1.23

1.24

1.25

1.26

1.27

0 20406080100

REFERENCE VOLTAGE

vs. REFERENCE LOAD CURRENT

MAX1778 toc12

I

REF

(µA)

V

REF

(V)

STEP-UP CONVERTER LOAD-TRANSIENT

RESPONSE

MAX1778 toc13

200mA

0

8.1V

8.0V

7.9V

1A

0

40µs/div

A. I

MAIN

= 20mA to 200mA, 200mA/div

B. V

MAIN

= 8V, 100mV/div

C. INDUCTOR CURRENT, 1A/div

C

INTG

= 1000pF

C

B

A

STEP-UP CONVERTER LOAD-TRANSIENT

RESPONSE WITHOUT INTEGRATOR

MAX1778 toc14

200mA

0

8.1V

8.0V

7.9V

1A

0

40µs/div

A. I

MAIN

= 20mA to 200mA, 200mA/div

B. V

MAIN

= 8V, 100mV/div

C. INDUCTOR CURRENT, 1A/div

INTG = REF

C

B

A

STEP-UP CONVERTER LOAD-TRANSIENT

RESPONSE (1µs PULSES)

MAX1778 toc15

0.5A

0

8.0V

7.9V

1A

0.5A

0

4µs/div

A. I

MAIN

= 0 to 500mA, 500mA/div

B. V

MAIN

= 8V, 100mV/div

C. INDUCTOR CURRENT, 500mA/div

C

B

A

Page 11

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

______________________________________________________________________________________ 11

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= +3.3V, SHDN = IN, V

MAIN

= V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 8V, BUF- = BUFOUT,

BUF+ = FLTSET = TGND = PGND = GND, T

A

= +25°C.)

RIPPLE VOLTAGE WAVEFORMS

8V

-5V

20V

= 8V, I

A. V

MAIN

MAIN

= -5V, I

= 20V, I

= 10mA, 20mV/div

NEG

POS

B. V

C. V

NEG

POS

POWER-UP SEQUENCE

2V

0

5V

0

20V

10V

0

-10V

= O TO 2V, 2V/div

A. V

SHDN

B. RDY, 5V/div

C. POSITIVE CHARGE PUMP = V

D. STEP-UP CONVERTER: V

E. NEGATIVE CHARGE PUMP: V

1µs/div

= 200mA, 10mV/div

= 5mA, 20mV/div

2ms/div

MAIN

POS

= 8V, R

NEG

MAX1778 toc16

MAX1778 toc19

= 20V, R

LOAD

= -5V, R

= 4kΩ, 10V/div

LOAD

= 40Ω, 10V/div

= 500Ω, 10V/div

LOAD

A

B

C

A

B

C

D

E

2V

0

8V

6V

4V

0.5A

0

A. V

SHDN

B. V

MAIN

C. INDUCTOR CURRENT, 500mA/div

R

LOAD

4V

2V

0

20V

10V

0

0

-5V

A. RDY, 2V/div

B. POSITIVE CHARGE PUMP, V

C. STEP-UP CONVERTER: V

D. NEGATIVE CHARGE PUMP, V

STEP-UP CONVERTER

SOFT-START (LIGHT LOAD)

1ms/div

= O TO 2V, 2V/div

= 8V, 2V/div

= 400

Ω

POWER-UP SEQUENCE

(CIRCUIT OF FIG.10)

1ms/div

POS(SYS)

MAIN(SYS)

NEG

MAX1778 toc17

MAX1778 toc20

= 20V, 10V/div

= 8V, 10V/div

= -5V, -5V/div

A

B

C

A

B

C

D

SOFT-START (HEAVY LOAD)

2V

0

8V

6V

4V

1.0A

0.5A

0

= O TO 2V, 2V/div

A. V

SHDN

= 8V, 2V/div

B. V

MAIN

C. INDUCTOR CURRENT, 500mA/div

= 20

R

LOAD

POWER-UP INTO SHORT-CIRCUIT

4V

2V

0

5V

0

10V

5V

0

A. RDY, 2V/div

B. GATE OF N-CH MOSFET, 5V/div

C. STEP-UP CONVERTER, V

V

MAIN(SYS)

STEP-UP CONVERTER

MAX1778 toc18

1ms/div

Ω

(CIRCUIT OF FIG. 10)

100µs/div

= GND

MAIN(START)

MAX1778 toc21

= 8V, 5V/div

A

B

C

A

B

C

Page 12

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

12 ______________________________________________________________________________________

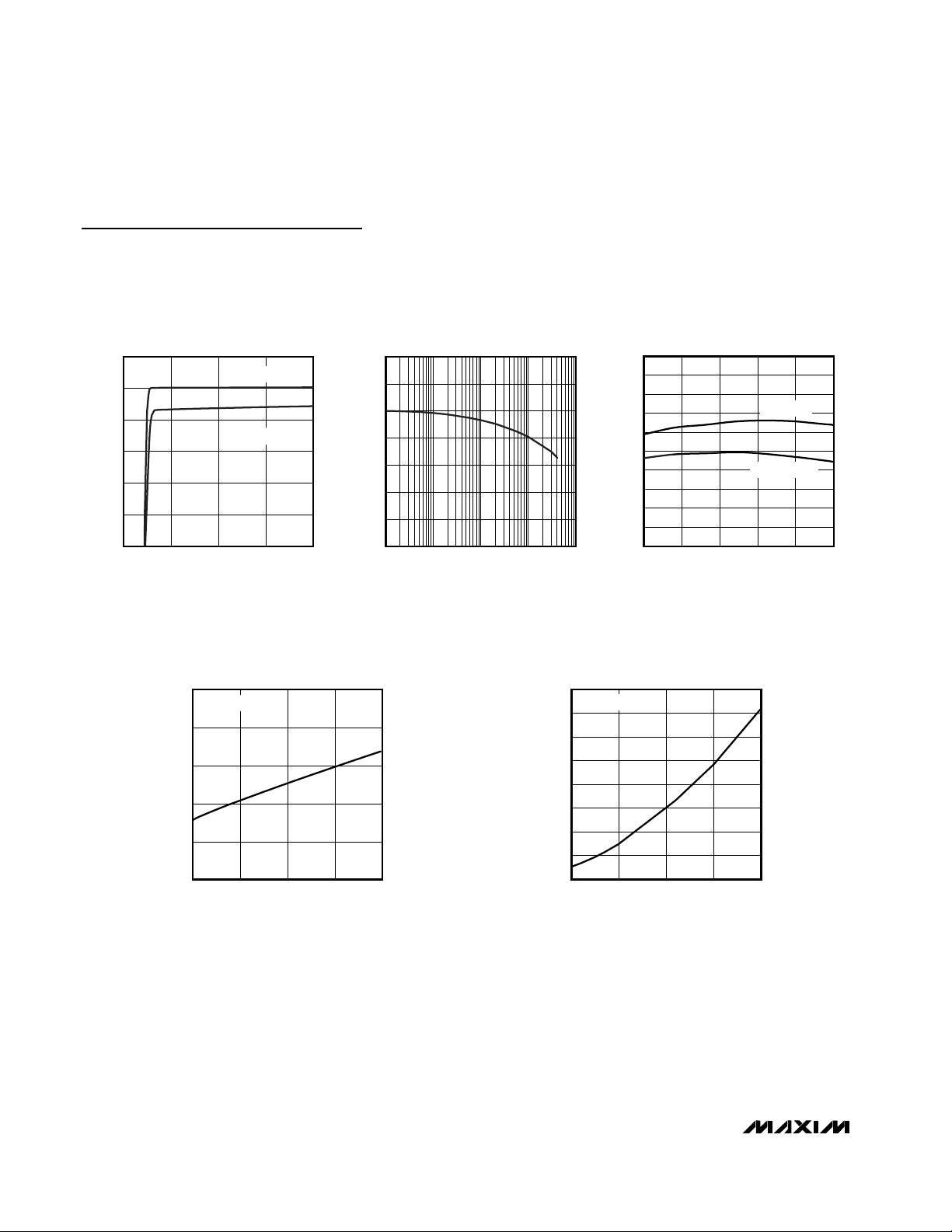

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= +3.3V, SHDN = IN, V

MAIN

= V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 8V, BUF- = BUFOUT,

BUF+ = FLTSET = TGND = PGND = GND, T

A

= +25°C.)

LDO OUTPUT VOLTAGE

vs. LDO INPUT VOLTAGE

(INTERNAL LINEAR REGULATOR)

5.05

I

= 0

(V)

LDOOUT

I

LDOOUT

MAX1778 toc22

= 40mA

5.00

4.95

(V)

4.90

LDOOUT

V

4.85

4.80

4.75

4861012

V

SUPL

5.04

5.02

5.00

(V)

4.98

LDOOUT

4.96

V

4.94

4.92

4.90

0.01 0.1 10 100

LDO OUTPUT VOLTAGE

vs. LDO OUTPUT CURRENT

(INTERNAL LINEAR REGULATOR)

1

I

(mA)

LDOOUT

DROPOUT VOLTAGE

vs. LDO LOAD CURRENT

(INTERNAL LINEAR REGULATOR)

200

V

= 5V

LDOOUT

160

(mV)

120

LDOOUT

- V

80

SUPL

V

40

0

02010 30 40

I

(mA)

LDOOUT

MAX1778 toc25

LDO OUTPUT VOLTAGE vs. TEMPERATURE

(INTERNAL LINEAR REGULATOR)

5.10

5.08

MAX1778 toc23

5.06

5.04

5.02

(V)

5.00

LDO

V

4.98

4.96

4.94

4.92

4.90

-40 10-15 35 60 85

TEMPERATURE (°C)

LDO SUPPLY CURRENT

vs. LDO OUTPUT CURRENT

(INTERNAL LINEAR REGULATOR)

4.0

V

= 5V

LDOOUT

3.5

3.0

(mA)

2.5

2.0

LDOOUT

- I

1.5

SUPL

I

1.0

0.5

0

0 10203040

I

(mA)

LDOOUT

I

LDOOUT

I

LDOOUT

MAX1778 toc24

= 0

= 40mA

MAX1778 toc26

Page 13

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

______________________________________________________________________________________ 13

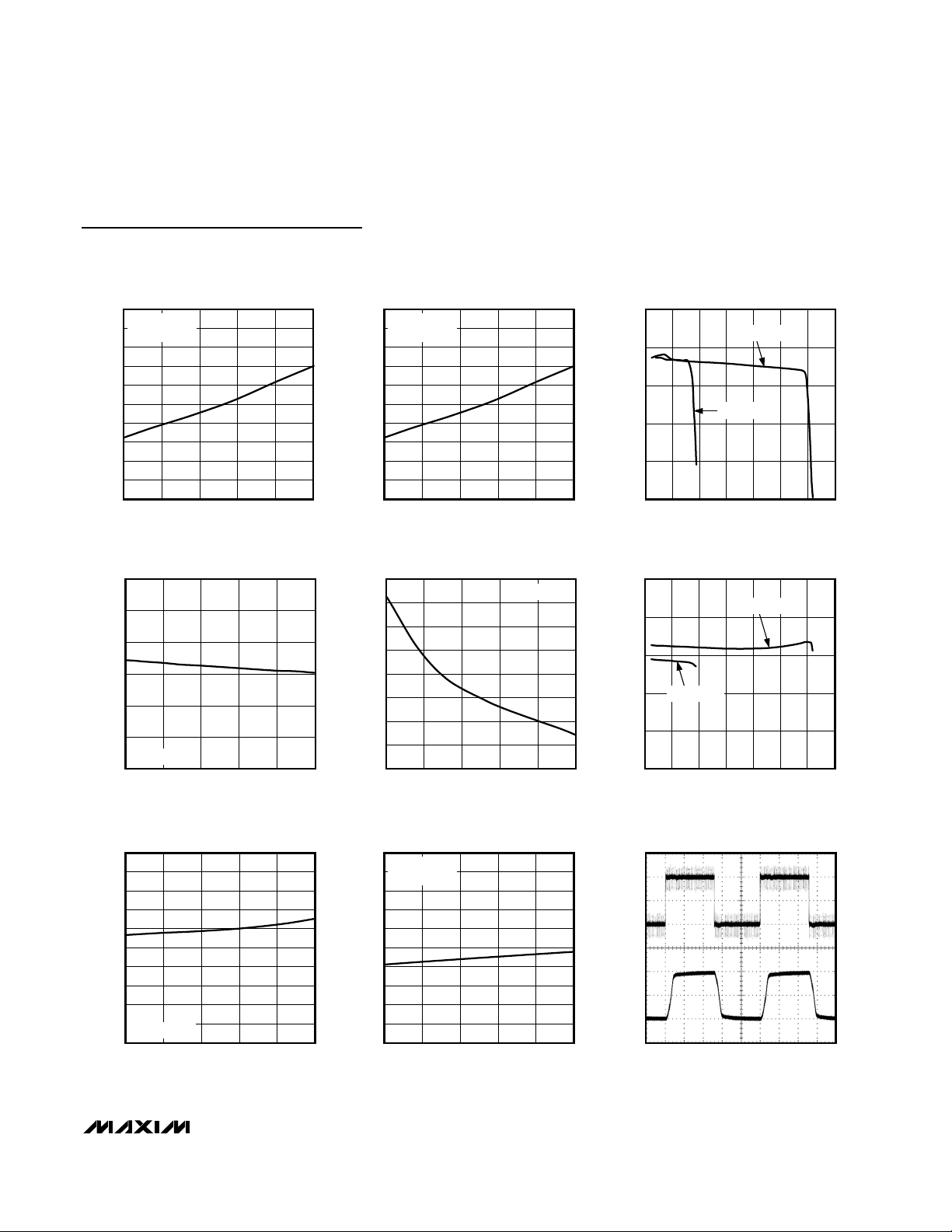

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= +3.3V, SHDN = IN, V

MAIN

= V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 8V, BUF- = BUFOUT,

BUF+ = FLTSET = TGND = PGND = GND, T

A

= +25°C.)

POWER-SUPPLY REJECTION RATIO

vs. FREQUENCY

100

80

60

PSRR (dB)

40

20

C

= 4.7µF

LDOOUT

= 40mA

I

LDOOUT

0

1100010010

FREQUENCY (kHz)

LOAD-TRANSIENT RESPONSE NEAR

DROPOUT (INTERNAL LINEAR REGULATOR)

MAX1778 toc30

MAX1778 toc27

100

10

ESR (Ω)

1

LDOOUT

C

0.1

0.01

040

REGION OF STABLE C

LDOOUT

vs. LOAD CURRENT

C

LDOOUT

STABLE REGION

10 20 30

I

(mA)

LDOOUT

INTERNAL LINEAR-REGULATOR

RIPPLE REJECTION

ESR

= 1µF

MAX1778 toc31

MAX1778 toc28

4OmA

5.00V

4.96V

LOAD-TRANSIENT RESPONSE

(INTERNAL LINEAR REGULATOR)

0

100µs/div

A. I

= 100µA TO 40mA, 40mA/div

LDO

= 5V, 20mV/div

B. V

LDO

= V

LDO

+ 500mV

V

SUPL

INTERNAL LINEAR-REGULATOR

STARTUP

MAX1778 toc29

A

B

MAX1778 toc32

4OmA

5.00V

4.94V

0

A. I

= 100µA TO 40mA, 40mA/div

LDO

= 5V, 20mV/div

B. V

LDO

= V

+ 100mV

V

IN

LDO

2V

A

B

C

0

4V

2V

0

4V

2V

A. V

S

HDN

B. V

LDOOUT

C. V

MAIN

400µs/div

= 0 TO 2V, 2V/div

= 5V, R

LDOOUT

= 8V, R

= 40Ω, 2V/div

MAIN

= 125Ω, 2V/div

100µs/div

5.0V

A

8.0V

B

1.0A

0.5A

0

10µs/div

A. V

= 5V, I

LDOOUT

= V

B. V

MAIN

SUPL

= 0 TO 750mA, 500mA/div

C. I

MAIN

= 40mA, 10mV/div

LDOOUT

= 8V, 200mV/div

A

B

C

Page 14

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

14 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= +3.3V, SHDN = IN, V

MAIN

= V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 8V, BUF- = BUFOUT,

BUF+ = FLTSET = TGND = PGND = GND, T

A

= +25°C.)

LINEAR-REGULATOR OUTPUT VOLTAGE

vs. INPUT VOLTAGE

(EXTERNAL LINEAR REGULATOR)

2.55

2.53

I

I

LDO

LDO

= 750mA

VIN (V)

= 0

2.51

(V)

LDO

V

2.49

2.47

FIGURE 7

2.45

2.5 3.53.0 4.0 4.5 5.0 5.5

MAX1778 toc33

EXTERNAL LINEAR-REGULATOR

RIPPLE REJECTION

2.5V

8.0V

7.8V

1A

0.5A

0

10µs/div

A. V

= 2.5V, I

= V

SUPL

= 200mA, 10mV/div

LDO

= 8V, 200mV/div

LDO

B. V

MAIN

= 0 TO 750mA, 500mA/div

C. I

MAIN

FIGURE 7

MAX1778 toc36

A

B

C

LINEAR-REGULATOR OUTPUT VOLTAGE

vs. LOAD CURRENT

(EXTERNAL LINEAR REGULATOR)

2.55

2.53

2.51

(V)

LDO

V

2.49

2.47

2.45

0.1 1 10 100 1000

I

(mA)

LDO

INPUT OFFSET VOLTAGE DEVIATION

vs. COMMON-MODE VOLTAGE

2.5

1.5

V

= 4.5V

SUPB

0.5

(mV)

OS

∆V

-0.5

-1.5

-2.5

02468101214

VCM (V)

V

= 13V

SUPB

FIGURE 7

MAX1778 toc34

MAX1778 toc37

EXTERNAL LINEAR-REGULATOR

250mA

50mA

2.55V

2.50V

2.45V

LOAD-TRANSIENT RESPONSE

100µs/div

A. I

= 50mA TO 250mA, 200mA/div

LDO

= 2.5V, 50mV/div

B. V

LDO

FIGURE 7

MAX1778 toc35

INPUT OFFSET VOLTAGE DEVIATION

vs. BUFFER SUPPLY VOLTAGE

1.0

0.6

0.2

(mV)

OS

∆V

-0.2

-0.6

-1.0

486101214

V

SUPB

(V)

VCM = V

SUPB

/ 2

A

B

MAX1778 toc38

Page 15

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

______________________________________________________________________________________ 15

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= +3.3V, SHDN = IN, V

MAIN

= V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 8V, BUF- = BUFOUT,

BUF+ = FLTSET = TGND = PGND = GND, T

A

= +25°C.)

INPUT OFFSET VOLTAGE DEVIATION

vs. TEMPERATURE

1.0

V

= 13V

SUPB

= V

CM

/ 2

SUPB

TEMPERATURE (°C)

V

0.6

0.2

(mV)

OS

∆V

-0.2

-0.6

0

-40 10-15 35 60 85

BUFFER INPUT BIAS CURRENT

vs. BUFFER SUPPLY VOLTAGE

10

8

(nA)

BIAS

I

6

VCM = V

4

486 101214

SUPB

/ 2

V

(V)

SUPB

BUFFER SUPPLY CURRENT

vs. BUFFER SUPPLY VOLTAGE

0.50

0.46

0.42

(mA)

SUPB

I

0.38

0.34

VCM = V

0.30

486101214

SUPB

/ 2

V

(V)

SUPB

MAX1778 toc39

MAX1778 toc42

MAX1778 toc45

INPUT OFFSET VOLTAGE DEVIATION

1.0

V

V

0.6

0.2

(mV)

OS

∆V

-0.2

-0.6

0

-40 10-15 35 60 85

12

11

10

9

(nA)

8

BIAS

I

7

6

5

4

-40 -15 10 35 60 85

NO-LOAD BUFFER SUPPLY CURRENT

1.0

V

0.9

V

0.8

0.7

0.6

(mA)

0.5

SUPB

I

0.4

0.3

0.2

0.1

0

-40 10-15 35 60 85

vs. TEMPERATURE

= 13V

SUPB

= V

/ 2

CM

SUPB

TEMPERATURE (°C)

BUFFER INPUT BIAS CURRENT

vs. TEMPERATURE

VCM = V

TEMPERATURE (°C)

vs. TEMPERATURE

= 13V

SUPB

= V

/ 2

CM

SUPB

TEMPERATURE (°C)

SUPB

MAX1778 toc39

/ 2

MAX1778 toc43

MAX1778 toc46

(mA)

SUPB

I

BUFFER INPUT BIAS CURRENT

vs. COMMON-MODE VOLTAGE

10

V

= 13V

V

SUPB

VCM (V)

SUPB

= 4.5V

8

6

(nA)

BIAS

I

4

2

0

042 6 8 101214

BUFFER SUPPLY CURRENT

vs. COMMON-MODE VOLTAGE

0.50

V

= 13V

0.46

0.42

V

0.38

0.34

0.30

042 6 8 101214

SUPB

= 4.5V

SUPB

VCM (V)

VCOM BUFFER

SMALL-SIGNAL RESPONSE

4.05V

4.00V

3.95V

4.05V

4.00V

3.95V

4µs/div

A. V

= 3.95V TO 4.05V, 50mV/div

BUF+

B. BUFOUT = BUF-, 50mV/div

C

BUF

= 1µF, V

SUPB

= 8V

MAX1778 toc41

MAX1778 toc44

MAX1778 toc47

A

B

Page 16

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

16 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= +3.3V, SHDN = IN, V

MAIN

= V

SUPP

= V

SUPN

= V

SUPB

= V

SUPL

= 8V, BUF- = BUFOUT,

BUF+ = FLTSET = TGND = PGND = GND, T

A

= +25°C.)

MAX1778 toc51

C

B

A

8.1V

7.8V

2V

4V

2V

0

4V

0

100µs/div

VCOM BUFFER STARTUP

A. RDY, 2V/div

B. BUFOUT = BUF-, C

BUF

= 1µF, 2V/div

C. V

SUPB

= V

MAIN

= 8V, I

MAIN

= 20mA, 200mV/div

BUF+ = GND

MAX1778 toc51

C

B

A

8.1V

7.8V

2V

4V

2V

0

4V

0

100µs/div

VCOM BUFFER STARTUP

A. RDY, 2V/div

B. BUFOUT = BUF-, C

BUF

= 1µF, 2V/div

C. V

SUPB

= V

MAIN

= 8V, I

MAIN

= 20mA, 200mV/div

BUF+ = GND

LARGE-SIGNAL RESPONSE

4.50V

4.00V

3.50V

4.50V

4.00V

3.50V

A. V

= 3.50V TO 4.50V, 0.5V/div

BUF+

B. BUFOUT = BUF-, 0.5V/div

= 1µF, V

C

BUF

VCOM BUFFER

10µs/div

= 8V

SUPB

MAX1778 toc48

200mA

A

B

0

-200mA

4.2V

4.0V

3.8V

8.0V

A. I

BUFOUT

B. BUFOUT = BUF-, 200mV/div

C. V

V

SUPB

VCOM BUFFER

LOAD-TRANSIENT RESPONSE

4µs/div

= 200mA PULSES, 200mA/div

= 8V, 50mV/div

MAIN

= V

, BUF+ = GND, C

MAIN

BUF

= 1µF

MAX1778 toc49

VCOM BUFFER

LOAD-TRANSIENT RESPONSE

500mA

A

B

C

0

-500mA

4.5V

4.0V

3.5V

8.0V

A. I

BUFOUT

B. BUFOUT = BUF-, 0.5V/div

C. V

MAIN

= V

V

SUPB

4µs/div

= 400mA PULSES, 500mA/div

= 8V, 100mV/div

, BUF+ = GND, C

MAIN

BUF

MAX1778 toc50

A

B

C

= 1µF

Page 17

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

______________________________________________________________________________________ 17

Pin Description

PIN

MAX1778

MAX1881

1111FB

2222INTG

3333IN

4444BUF+

5555BUF-

6666SUPB

7777BUFOUT VCOM Buffer (Operational Transconductance Amplifier) Output

8888GND

MAX1880

MAX1882

MAX1883

MAX1884

MAX1885 NAME FUNCTION

Main Step-Up Regulator Feedback Input. Regulates to 1.25V

nominal. Connect a resistive divider from the output (V

to analog ground (GND).

Main Step-Up Integrator Output. When using the integrator,

connect 1000pF to analog ground (GND). To disable the

integrator, connect INTG to REF.

Main Supply Voltage. The supply voltage powers the control

circuitry for all of the regulators and may range from 2.7V to 5.5V.

Bypass with a 0.1µF capacitor between IN and GND, as close to

the pins as possible.

VCOM Buffer (Operational Transconductance Amplifier) Positive

Feedback Input. Connect to GND to select the internal resistive

divider that sets the positive input to half the amplifier’s supply

voltage (V

VCOM Buffer (Operational Transconductance Amplifier) Negative

Feedback Input

VCOM Buffer (Operational Transconductance Amplifier) Supply

Voltage

Analog Ground. Connect to power ground (PGND) underneath the

IC.

BUF+

= V

SUPB

/2).

MAIN

) to FB

Internal Reference Bypass Terminal. Connect a 0.22µF ceramic

9999REF

10 10 −−FBP

11 11 −−FBN

12 12 10 10 SHDN

13 − 11 − SUPL

capacitor from REF to analog ground (GND). External load

capability up to 50µA.

Positive Charge-Pump Regulator Feedback Input. Regulates to

1.25V nominal. Connect a resistive divider from the positive

charge-pump output (V

Negative Charge-Pump Regulator Feedback Input. Regulates to

0V nominal. Connect a resistive divider from the negative chargepump output (V

Active-Low Shutdown Control Input. Pull SHDN low to force the

controller into shutdown. If unused, connect SHDN to IN for normal

operation. A rising edge on SHDN clears the fault latch.

Low-Dropout Linear Regulator Input Voltage. Can range from 4.5V

to 15V. Bypass with a 1µF capacitor to GND (see Capacitor

Selection and Regulator Stability). Connect both input pins

together externally.

) to FBP to analog ground (GND).

POS

) to FBN to the reference (REF).

NEG

Page 18

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

18 ______________________________________________________________________________________

Pin Description (continued)

PIN

MAX1778

MAX1881

14 − 12 − LDOOUT

15 − 13 − FBL

16 16 14 14 FLTSET

17 17 −−SUPN

18 18 −−DRVN

19 19 −−SUPP

20 20 −−DRVP

21 21 17 17 PGND

MAX1880

MAX1882

MAX1883

MAX1884

MAX1885

22 22 18 18 LX

23 23 19 19 TGND Must be connected to ground.

24 24 20 20 RDY

− 13, 14, 15 15, 16

11, 12, 13,

15, 16

NAME FUNCTION

Linear Regulator Output. Sources up to 40mA. Bypass to GND with

a ceramic capacitor determined by:

Voltage Setting Input. Connect a resistive divider from the linear

regulator output (V

Fault Trip-Level Set Input. Connect to a resistive divider between

REF and GND to set the main step-up converter’s and positive

charge pump’s fault thresholds between 0.67 x V

. Connect to GND for the preset fault threshold (0.9 x V

V

REF

Negative Charge-Pump Driver Supply Voltage. Bypass to power

ground (PGND) with a 0.1µF capacitor.

Negative Charge-Pump Driver Output. Output high level is V

and low level is PGND.

Positive Charge-Pump Driver Supply Voltage. Bypass to power

ground (PGND) with a 0.1µF capacitor.

Positive Charge-Pump Driver Output. Output high level is V

and low level is PGND

Power Ground. Connect to analog ground (GND) underneath the

IC.

Main Step-Up Regulator Power MOSFET N-Channel Drain. Place

output diode and output capacitor as close to PGND as possible.

Active-Low, Open-Drain Output. Indicates all outputs are ready.

On-resistance is 125Ω (typ).

N.C. No Connection. Not internally connected.

I

CmsX

LDOOUT

.

≥

05

) to FBL to analog ground (GND).

LDOOUT

LDOOUT MAX

V

LDOOUT

()

and 0.85 x

REF

REF

SUPN

SUPP

).

Page 19

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

______________________________________________________________________________________ 19

Detailed Description

The MAX1778/MAX1880–MAX1885 are highly efficient

multiple-output power supplies for thin-film transistor

(TFT) liquid crystal display (LCD) applications. The

devices contain one high-power step-up converter, two

low-power charge pumps, an operational transconductance amplifier (V

COM

buffer), and a low-dropout linear

regulator. The primary step-up converter uses an internal N-channel MOSFET to provide maximum efficiency

and to minimize the number of external components.

The output voltage of the main step-up converter

(V

MAIN

) can be set from VINto 13V with external resis-

tors.

The dual charge pumps (MAX1778/MAX1880/

MAX1881/MAX1882 only) independently regulate a

positive output (V

POS

) and a negative output (V

NEG

).

These low-power outputs use external diode and

capacitor stages (as many stages as required) to regulate output voltages from -40V to +40V. A unique

control scheme minimizes output ripple as well as

capacitor sizes for both charge pumps.

A resistor-programmable 40mA linear regulator

(MAX1778/MAX1881/MAX1883/MAX1884 only) can

provide preregulation or postregulation for any of the

supplies. For higher current applications, an external

transistor can be added.

Additionally, the V

COM

buffer provides a high current

output that is ideal for driving capacitive loads, such as

the backplane of a TFT LCD panel. The positive feedback input features dual mode operation, allowing this

input to be connected to an internal 50% resistivedivider between the buffer’s supply voltage and

ground, or externally adjusted for other voltages.

Also included in the MAX1778/MAX1880–MAX1885 is a

precision 1.25V reference that sources up to 50µA,

logic shutdown, soft-start, power-up sequencing,

adjustable fault detection, thermal shutdown, and an

active-low, open-drain ready output.

Figure 1. Typical Application Circuit

V

= 3.3V

IN

INPUT

V

4.7µF

LDOOUT

NEGATIVE

V

NEG

C

IN

TO LOGIC

LDO

= 5V

= -5V

C

4.7µF

1.0µF

LDO

C3

R

RDY

100kΩ

0.22µF

49.9kΩ

C

0.22µF

MAIN

(8V)

R8

200kΩ

49.9kΩ

REF

L1

6.8µH

274kΩ

49.9kΩ

C4

0.1µF

C4

0.1µF

R2

R2

750kΩ

R4

49.9kΩ

R3

BUFFER OUTPUT

V

C

BUF

1.0µF

BUFOUT

LX

FB

SUPB

SUPN

SUPP

DRVP

FBP

BUFOUT

BUF-

BUF+

GND

TGND

R7

150kΩ

C2

0.1µF

IN

SHDN

RDY

SUPL

LDOOUT

MAX1778

FBL

DRVN

FBN

REF

INTG

FLTSET

PGND

C1

R5

R6

C

OUT

(2) 4.7µF

C5

1.0µF

= V

MAIN

V

SUPB

MAIN

C7

1.0µF

/2

= 8V

POSITIVE

V

POS

= 20V

Page 20

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

20 ______________________________________________________________________________________

Main Step-up Controller

During normal pulse-width modulation (PWM) operation, the MAX1778/MAX1880–MAX1885 main step-up

controllers switch at a constant frequency of 500kHz or

1MHz (see Selector Guide), allowing the use of lowprofile inductors and output capacitors. Depending on

the input-to-output voltage ratio, the controller regulates

the output voltage and controls the power transfer by

modulating the duty cycle (D) of each switching cycle:

On the rising edge of the internal clock, the controller

sets a flip-flop when the output voltage is too low, which

turns on the N-channel MOSFET (Figure 2). The inductor current ramps up linearly, storing energy in a magnetic field. Once the sum of the feedback voltage error

amplifier, slope-compensation, and current-feedback

signals trip the multi-input comparator, the MOSFET

turns off, the flip-flop resets, and the diode (D1) turns

on. This forces the current through the inductor to ramp

back down, transferring the energy stored in the magnetic field to the output capacitor and load. The MOSFET remains off for the rest of the clock cycle. Changes

in the feedback voltage-error signal shift the switch-current trip level, consequently modulating the MOSFET

duty cycle.

Under very light loads, an inherent switchover to pulseskipping takes place (Figure 3). When this occurs, the

controller skips most of the oscillator pulses in order to

reduce the switching frequency and gate charge losses. When pulse-skipping, the step-up controller initiates

a new switching cycle only when the output voltage

drops too low. The N-channel MOSFET turns on, allowing the inductor current to ramp up until the multi-input

comparator trips. Then, the MOSFET turns off and the

diode turns on, forcing the inductor current to ramp

down. When the inductor current reaches zero, the

diode turns off, so the inductor stops conducting current. This forces the threshold between pulse-skipping

and PWM operation to coincide with the boundary

between continuous and discontinuous inductor-current operation:

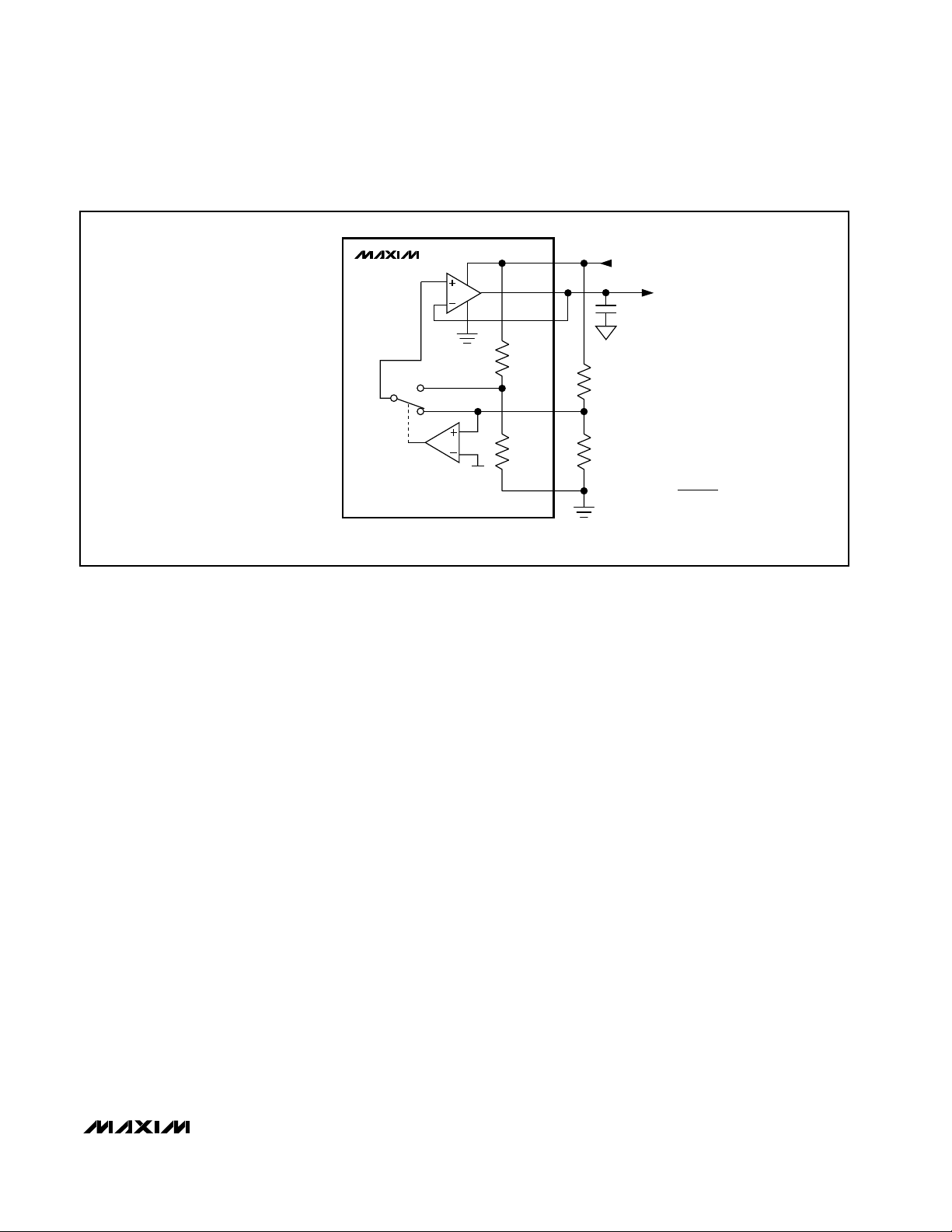

Figure 2. Main Step-Up Converter block Diagram

VV

MAIN IN

D

≈

V

MAIN

-

I

LOAD CROSSOVER

ILIM

OSC

(80% DUTY)

S

R

Q

LX

I

LIM

PGND

FB

MAX1778

MAX1880

MAX1881

MAX1882

MAX1883

MAX1884

MAX1885

PWM

COMPARATOR

COMPARATOR

1

2

(2.7V TO 5.5V)

V

(UP TO 13V)

V

V

MAIN

V

IN

MAIN

R1

R

COMP

(OPTIONAL)

≈

C

IN

C

OUT

()

L1

D1

IN

2

VV

MAIN IN

fL

OSC

-

C

R1

R2

COMP

(OPTIONAL)

REF

ERROR

AMPLIFIER

INTG

g

m

C

INTG

V

REF

1.25V

REF

GND

R2

C

REF

V

= 1 + V

MAIN

( )

V

= 1.25V

REF

Page 21

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

______________________________________________________________________________________ 21

The switching waveforms will appear noisy and asynchronous when light loading causes pulse-skipping

operation; this is a normal operating condition that

improves light-load efficiency.

Dual Charge-Pump Regulator (MAX1778/

MAX1880/MAX1881/MAX1882 Only)

The MAX1778/MAX1880/MAX1881/MAX1882 controllers contain two independent low-power charge

pumps (Figure 4). One charge pump inverts the input

voltage and provides a regulated negative output voltage. The second charge pump doubles the input voltage and provides a regulated positive output voltage.

The controllers contain internal P-channel and N-channel MOSFETs to control the power transfer. The

internal MOSFETs switch at a constant frequency

(fCHP = fOSC/2).

Positive Charge Pump

During the first half-cycle, the N-channel MOSFET turns

on and charges flying capacitor C

X(POS)

(Figure 4).

This initial charge is controlled by the variable N-channel on-resistance. During the second half-cycle, the Nchannel MOSFET turns off and the P-channel MOSFET

turns on, level shifting C

X(POS)

by V

SUPP

volts. This

connects C

X(POS)

in parallel with the reservoir capaci-

tor C

OUT(POS)

. If the voltage across C

OUT(POS)

plus a

diode drop (V

POS

+ V

DIODE

) is smaller than the level-

shifted flying capacitor voltage (V

CX(POS)

+ V

SUPP

),

charge flows from C

X(POS)

to C

OUT(POS)

until the diode

(D3) turns off.

Figure 3. Discontinuous-to-Continuous Conduction Crossover

Point

Figure 4. Low-Power Charge Pump Block Diagram

I

PEAK

I

INDUCTOR CURRENT

t

ON

t

OFF

TIME

LOAD

V

SUPP

2.7V TO 13V

V

SUPD

V

POS

V

= 1 + V

POS

V

= 1.25V

REF

C

OUT(POS)

R3

( )

R4

D2

C

X(POS)

D3

R3

R4

REF

SUPP

DRVP

FBP

1.25V

V

REF

MAX1778

MAX1880

MAX1881

MAX1882

OSC

SUPN

D4

C

X(NEG)

DRVN

D5

R6

C

REF

0.22µF

R5

FBN

REF

PGNDGND

V

NEG

V

REF

C

OUT(NEG)

R5

= - V

( )

R6

= 1.25V

V

SUPN

2.7V TO 13V

V

NEG

REF

Page 22

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

22 ______________________________________________________________________________________

Negative Charge Pump

During the first half-cycle, the P-channel MOSFET turns

on, and flying capacitor C

X(NEG)

charges to V

SUPN

minus a diode drop (Figure 4). During the second halfcycle, the P-channel MOSFET turns off, and the Nchannel MOSFET turns on, level shifting C

X(NEG)

. This

connects C

X(NEG)

in parallel with reservoir capacitor

C

OUT(NEG)

. If the voltage across C

OUT(NEG)

minus a

diode drop is greater than the voltage across C

X(NEG)

,

charge flows from C

OUT(NEG)

to C

X(NEG)

until the diode

(D5) turns off. The amount of charge transferred to the

output is controlled by the variable N-channel on-resistance.

Low-Dropout Linear Regulator (MAX1778/

MAX1881/MAX1883/MAX1884 Only)

The MAX1778/MAX1881/MAX1883/MAX1884 contain a

low-dropout linear regulator (Figure 5) that uses an

internal PNP pass transistor (QP) to supply loads up to

40mA. As illustrated in Figure 5, the 1.25V reference is

connected to the error amplifier, which compares this

reference with the feedback voltage and amplifies the

difference. If the feedback voltage is higher than the

reference voltage, the controller lowers the base current of QP, which reduces the amount of current to the

output. If the feedback voltage is too low, the device

increases the pass transistor base current, which

allows more current to pass to the output and increases

the output voltage. However, the linear regulator also

includes an output current limit to protect the internal

pass transistor against short circuits.

The low-dropout linear regulator monitors and controls

the pass transistor’s base current, limiting the output

current to 130mA (typ). In conjunction with the thermal

overload protection, this current limit protects the output, allowing it to be shorted to ground for an indefinite

period of time without damaging the part.

VCOM Buffer

The MAX1778/MAX1880–MAX1885 include a VCOM

buffer, which uses an operational transconductance

amplifier (OTA) to provide a current output that is ideal

for driving capacitive loads, such as the backplane of a

TFT LCD panel. The unity-gain bandwidth of this current-output buffer is:

GBW = gm/C

OUT

where gm is the amplifier’s transconductance. The

bandwidth is inversely proportional to the output

capacitor, so large capacitive loads improve stability;

however, lower bandwidth decreases the buffer’s transient response time. To improve the transient response

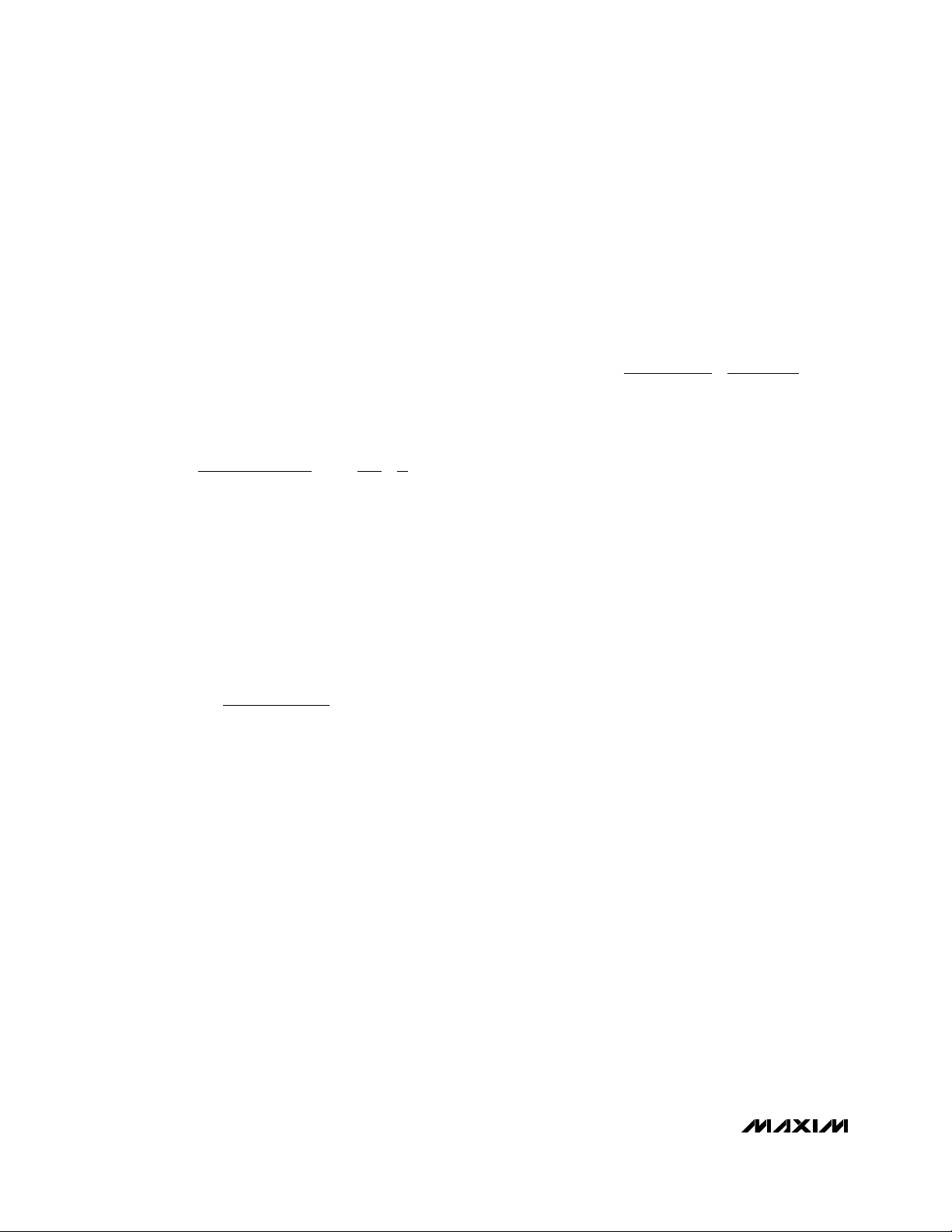

Figure 5. Low-Dropout Linear Regulator Block Diagram

MAX1778

MAX1881

MAX1883

MAX1884

ERROR

AMPLIFIER

THERMAL

SENSOR

CURRENT

LIMIT

V

REF

1.25V

SUPL

LDOOUT

FBL

GND

C

SUPL

Q

P

C

R7

R8

LDOOUT

V

LDOOUT

V

REF

= 1.25V

V

SUPL

4.5V TO 15V

V

LDOOUT

1.25V TO (V

R7

= (1 + )V

R8

SUPL

- 0.3V)

REF

Page 23

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

______________________________________________________________________________________ 23

times, the amplifier’s transconductance increases as

the output current increases (see Typical Operating

Characteristics).

The VCOM buffer’s positive feedback input features

dual mode operation. The buffer’s output voltage can

be internally set by a 50% resistive divider connected

to the buffer’s supply voltage (SUPB), or the output voltage can be externally adjusted for other voltages.

Shutdown (SHDN)

A logic-low level on SHDN shuts down all of the converters and the reference. When shut down, the supply

current drops to 0.1µA to maximize battery life, and the

reference is pulled to ground. The output capacitance,

feedback resistors, and load current determine the rate

at which each output voltage will decay. A logic-level

high on SHDN power activates the MAX1778/

MAX1880–MAX1885 (see Power-Up Sequencing). Do

not leave SHDN floating. If unused, connect SHDN to

IN. A logic-level transition on SHDN clears the fault

latch.

Power-Up Sequencing

Upon power-up or exiting shutdown, the MAX1778/

MAX1880–MAX1885 start a power-up sequence. First,

the reference powers up. Then, the main DC-DC stepup converter powers up with soft-start enabled. The linear regulator powers up at the same time as the main

step-up converter; however, the power sequence and

ready output signal are not affected by the regulation of

the linear regulator. While the main step-up converter

powers up, the output of the PWM comparator remains

low (Figure 2), and the step-up converter charges the

output capacitors, limited only by the maximum duty

cycle and current-limit comparator. When the step-up

converter approaches its nominal regulation value and

the PWM comparator’s output changes states for the

first time, the negative charge pump turns on. When the

negative output voltage reaches approximately 90% of

its nominal value (V

FBN

< 110mV), the positive charge

pump starts up. Finally, when the positive output voltage reaches 90% of its nominal value (V

FBP

> 1.125V),

the active-low ready signal (RDY) goes low (see Power

Ready), and the VCOM buffer powers up. The

MAX1883/MAX1884/MAX1885 do not contain the

charge pumps, but the power-up sequence still contains the charge pumps’ startup logic, which appears

as a delay (2 ✕4096/fOSC) between the step-up converter reaching regulation and when the ready signal

and VCOM buffer are activated.

Soft-Start

For the main step-up regulator, soft-start allows a gradual increase of the current-limit level during startup to

reduce input surge currents. The MAX1778/MAX1880–

MAX1885 divide the soft-start period into four phases.

During the first phase, the controller limits the current

limit to only 0.38A (see Electrical Characteristics),

approximately a quarter of the maximum current limit

Figure 6. VCOM Buffer Block Diagram

MAX1778

MAX1880

MAX1881

MAX1882

MAX1883

MAX1884

MAX1885

gm

125mV

SUPB

BUFOUT

BUF-

R

BUF+

R

GND

R11

R12

V

SUPB

4.5V TO 13V

C

BUF

V

BUFOUT

V

BUFOUT

1.2V TO (V

=

(

R11 + R12

SUPB

R12

)V

- 1.2V)

SUPB

Page 24

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

24 ______________________________________________________________________________________

(I

LX(MAX)

). If the output does not reach regulation within

1ms, soft-start enters phase II, and the current limit is

increased by another 25%. This process is repeated for

phase III. The maximum 1.5A (typ) current limit is

reached within 3072 clock cycles or when the output

reaches regulation, whichever occurs first (see the

startup waveforms in the Typical Operating

Characteristics).

For the charge pumps (MAX1778/MAX1880/

MAX1881/MAX1882 only), soft-start is achieved by controlling the rate of rise of the output voltage. Both

charge-pump output voltages are controlled to be in

regulation within 4096 clock cycles, irregardless of output capacitance and load, limited only by the charge

pump’s output impedance. Although the MAX1883/

MAX1884/MAX1885 controllers do not include the

charge pumps, the soft-start logic still contains the

4096 clock cycle startup periods for both charge

pumps.

Fault Trip Level (FLTSET)

The MAX1778/MAX1880–MAX1885 feature dual mode

operation to allow operation with either a preset fault

trip level or an adjustable trip level for the step-up converter and positive charge-pump outputs. Connect FLTSET to GND to select the preset 0.9 ✕V

REF

fault

threshold. The fault trip level may also be adjusted by

connecting a voltage divider from REF to FLTSET

(Figure 8). For greatest accuracy, the total load on the

reference (including current through the negative

charge-pump feedback resistors) should not exceed

50µA so that VREF is guaranteed to be in regulation

(see Electrical Characteristics Table). Therefore, select

R10 in the 100kΩ to 1MΩ range, and calculate R9 with

the following equation:

R9 = R10 [(V

REF

/ V

FLTSET

) - 1]

where V

REF

= 1.25V, and V

FLTSET

may range from 0.67

x V

REF

to 0.85 x V

REF

. FLTSET’s input bias current has

a maximum value of 50nA. For 1% error, the current

through R10 should be at least 100 times the FLTSET

input bias current (I

FLTSET

).

Fault Condition

Once RDY is low, if the output of the main regulator or

either low-power charge pump falls below its fault

detection threshold, or if the input drops below its

undervoltage threshold, then RDY goes high impedance and all outputs shut down; however, the reference

remains active. After removing the fault condition, toggle shutdown (below 0.8V) or cycle the input voltage

(below 0.2V) to clear the fault latch and reactivate the

device.

The reference fault threshold is 1.05V. For the step-up

converter and positive charge-pump, the fault trip level is

set by FLTSET (see Fault Trip Level). For the negative

charge pump, the fault threshold measured at the

charge-pump’s feedback input (FBN) is 140mV (typ).

Power Ready (RDY)

Power ready is an open-drain output. When the powerup sequence for the main step-up converter and lowpower charge pumps has properly completed, the 14V

MOSFET turns on and pulls RDY low with a 125Ω (typ)

on-resistance. If a fault is detected on any of these

three outputs, the internal open-drain MOSFET appears

as a high impedance. Connect a 100kΩ pullup resistor

between RDY and IN for a logic-level output.

Voltage Reference (REF)

The voltage at REF is nominally 1.25V. The reference

can source up to 50µA with good load regulation (see

Typical Operating Characteristics). Connect a 0.22µF

ceramic bypass capacitor between REF and GND.

Thermal-Overload Protection

Thermal-overload protection limits total power dissipation in the MAX1778/MAX1880–MAX1885. When the

junction temperature exceeds T

J

= +160°C, a thermal

sensor activates the fault protection, which shuts down

the controller, allowing the IC to cool. Once the device

cools down by 15°C, toggle shutdown (below 0.8V) or

cycle the input voltage (below 0.2V) to clear the fault

latch and reactivate the controller. Thermal-overload

protection protects the controller in the event of fault

conditions. For continuous operation, do not exceed

the absolute maximum junction-temperature rating of

T

J

= +150°C.

Operating Region and Power Dissipation

The MAX1778/MAX1880–MAX1885s’ maximum power

dissipation depends on the thermal resistance of the IC

package and circuit board, the temperature difference

between the die junction and ambient air, and the rate

of any airflow. The power dissipated in the device

depends on the operating conditions of each regulator

and the buffer.

The step-up controller dissipates power across the

internal N-channel MOSFET as the controller ramps up

the inductor current. In continuous conduction, the

power dissipated internally can be approximated by:

P

STEP UP

IV

MAIN MAIN

≈

−

V

×

IN

RD

()

DS ON

22

+

12

1

VD

fL

OSC

IN

Page 25

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC

Converters with Buffer

______________________________________________________________________________________ 25

where I

MAIN

includes the primary load current and the

input supply currents for the charge pumps (see

Charge-Pump Input Power and Efficiency

Considerations), linear regulator, and VCOM buffer.

The linear regulator generates an output voltage by dissipating power across an internal pass transistor, so

the power dissipation is simply the load current times

the input-to-output voltage differential:

When driving an external transistor, the internal linear

regulator provides the base drive current. Depending

on the external transistor’s current gain (β) and the

maximum load current, the power dissipated by the

internal linear regulator may still be significant:

The charge pumps provide regulated output voltages

by dissipating power in the low-side N-channel MOSFET, so they could be modeled as linear regulators followed by unregulated charge pumps. Therefore, their

power dissipation is similar to a linear regulator:

where N is the number of charge-pump stages, V

DIODE

is the diodes’ forward voltage, and V

SUPD

is the posi-

tive charge-pump diode supply (Figure 4).

The VCOM buffer’s power dissipation depends on the

capacitive load (C

LOAD

) being driven, the peak-to-

peak voltage change (V

P-P

) across the load, and the

load’s switching rate:

To find the total power dissipated in the device, the

power dissipated by each regulator and the buffer must

be added together:

The maximum allowed power dissipation is 975mW (24pin TSSOP) / 879mW (20-pin TSSOP) or:

P

MAX

= (T

J(MAX

) - TA) / ( θJB+ θBA)

where T

J

- TAis the temperature difference between

the controller’s junction and the surrounding air, θJB(or

θJC) is the thermal resistance of the package to the

board, and θBAis the thermal resistance from the printed circuit board to the surrounding air.

Design Procedure

Main Step-Up Converter

Output Voltage Selection

Adjust the output voltage by connecting a voltagedivider from the output (VMAIN) to FB to GND (see

Typical Operating Circuit). Select R2 in the 10kΩ to

50kΩ range. Calculate R1 with the following equations:

R1 = R2 [(V

MAIN

/ V

REF

) - 1]

where V

REF

= 1.25V. V

MAIN

may range from VINto 13V.

Inductor Selection

Inductor selection depends upon the minimum required

inductance value, saturation rating, series resistance, and

size. These factors influence the converter’s efficiency,

maximum output load capability, transient response time,

and output voltage ripple. For most applications, values

between 4.7µH and 22µH work best with the controller’s

switching frequency (Tables 1 and 2).

The inductor value depends on the maximum output

load the application must support, input voltage, output

voltage, and switching frequency. With high inductor

values, the MAX1778/MAX1880–MAX1885 source higher output currents, have less output ripple, and enter

continuous conduction operation with lighter loads;

however, the circuit’s transient response time is slower.

On the other hand, low-value inductors respond faster

to transients, remain in discontinuous conduction operation, and typically offer smaller physical size for a

given series resistance and current rating. The equations provided here include a constant LIR, which is the

ratio of the peak-to-peak AC inductor current to the

average DC inductor current. For a good compromise

between the size of the inductor, power loss, and output voltage ripple, select an LIR of 0.3 to 0.5. The

inductance value is then given by:

P

PIV VNV

NEG NEG SUPN DIODE NEG

PIV VNV V

POS POS SUPP DIODE SUPD POS

PIVV

LDO INT LDO SUPL LDO()

LDO INT

()

=

=

PVCfV

BUF P P LOAD LOAD SUPB

PP P

TOTAL STEP UP LDO INT

( )= -

I

LDO

.

=+

=

()

[]

()

[]

=

VV V

[]

β

IVV

( )

LDOOUT SUPL LDOOUT

--

--

-

=+

PPP

+++

NEG POS BUF

-

SUPL LDO

2

2

()

-

-

+

07

()

L

MIN

=

2

V

IN MIN

() ()

V

MAIN

VV

MAIN IN MIN

I f LIR

MAIN MAX OSC

-

()

1

η

Page 26

MAX1778/MAX1880–MAX1885

Quad-Output TFT LCD DC-DC