Page 1

19-0123; Rev. 4; 8/96

EVALUATION KIT

AVAILABLE

_______________General Description

The MAX186/MAX188 are 12-bit data-acquisition systems that combine an 8-channel multiplexer, high-bandwidth track/hold, and serial interface together with high

conversion speed and ultra-low power consumption.

The devices operate with a single +5V supply or dual

±5V supplies. The analog inputs are software configurable for unipolar/bipolar and single-ended/differential

operation.

The 4-wire serial interface directly connects to SPI™,

QSPI™ and Microwire™ devices without external logic. A

serial strobe output allows direct connection to TMS320

family digital signal processors. The MAX186/MAX188

use either the internal clock or an external serial-interface

clock to perform successive-approximation A/D conversions. The serial interface can operate beyond 4MHz

when the internal clock is used.

The MAX186 has an internal 4.096V reference while the

MAX188 requires an external reference. Both parts

have a reference-buffer amplifier that simplifies gain

trim .

The MAX186/MAX188 provide a hard-wired SHDN pin

and two software-selectable power-down modes.

Accessing the serial interface automatically powers up

the devices, and the quick turn-on time allows the

MAX186/MAX188 to be shut down between every

conversion. Using this technique of powering down

between conversions, supply current can be cut to

under 10µA at reduced sampling rates.

The MAX186/MAX188 are available in 20-pin DIP and

SO packages, and in a shrink small-outline package

(SSOP), that occupies 30% less area than an 8-pin DIP.

For applications that call for a parallel interface, see the

MAX180/MAX181 data sheet. For anti-aliasing filters,

consult the MAX274/MAX275 data sheet.

________________________Applications

Portable Data Logging

Data-Acquisition

High-Accuracy Process Control

Automatic Testing

Robotics

Battery-Powered Instruments

Medical Instruments

SPI and QSPI are registered trademarks of Motorola.

Microwire is a registered trademark of National Semiconductor.

Low-Power, 8-Channel,

Serial 12-Bit ADCs

____________________________Features

♦ 8-Channel Single-Ended or 4-Channel

Differential Inputs

♦ Single +5V or ±5V Operation

♦ Low Power: 1.5mA (operating mode)

2µA (power-down mode)

♦ Internal Track/Hold, 133kHz Sampling Rate

♦ Internal 4.096V Reference (MAX186)

♦ SPI-, QSPI-, Microwire-, TMS320-Compatible

4-Wire Serial Interface

♦ Software-Configurable Unipolar or Bipolar Inputs

♦ 20-Pin DIP, SO, SSOP Packages

♦ Evaluation Kit Available

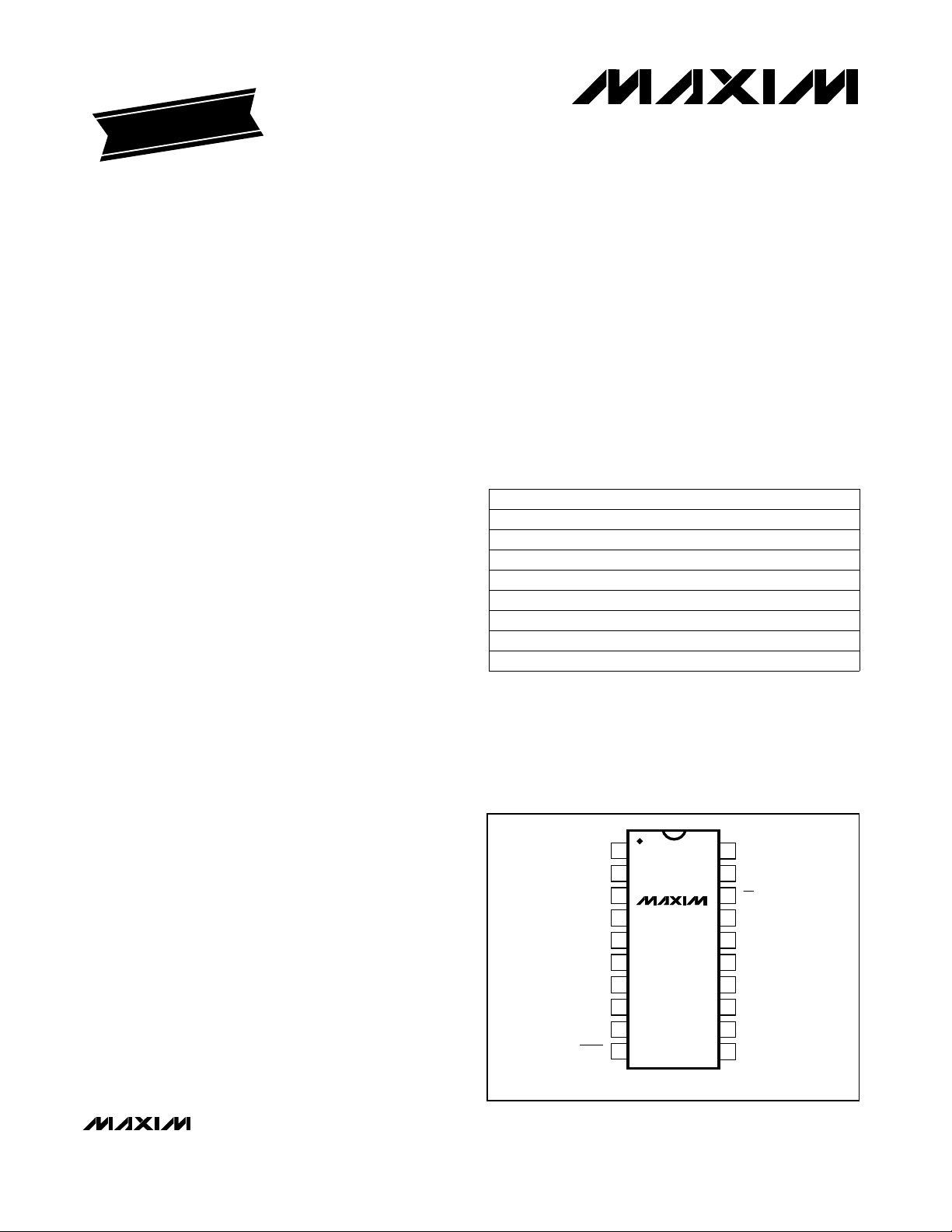

______________Ordering Information

†

PART

MAX186_CPP 20 Plastic DIP

MAX186_CWP 20 SO

MAX186_CAP

MAX186DC/D Dice*

MAX186_EPP 20 Plastic DIP

MAX186_EWP 20 SO

MAX186_EAP -40°C to +85°C 20 SSOP

MAX186_MJP -55°C to +125°C 20 CERDIP**

Ordering Information continued on last page.

†

NOTE: Parts are offered in grades A, B, C and D (grades defined

in Electrical Characteristics). When ordering, please specify grade.

Contact factory for availability of A-grade in SSOP package.

* Dice are specified at +25°C, DC parameters only.

* * Contact factory for availability and processing to MIL-STD-883.

____________________Pin Configuration

TOP VIEW

TEMP. RANGE

0°C to +70°C

0°C to +70°C

0°C to +70°C

0°C to +70°C

-40°C to +85°C

-40°C to +85°C

CH0

1

2

CH1

3

CH2

CH3

4

5

CH4

6

CH5

CH6

7

8

CH7

9

V

SS

10

DIP/SO/SSOP

MAX186

MAX188

PIN-PACKAGE

20 SSOP

V

20

DD

SCLK

19

CS

18

17

DIN

16

SSTRB

DOUT

15

DGND

14

13

AGND

12

REFADJ

11

VREFSHDN

MAX186/MAX188

________________________________________________________________ Maxim Integrated Products

1

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800

Page 2

Low-Power, 8-Channel,

Serial 12-Bit ADCs

ABSOLUTE MAXIMUM RATINGS

VDDto AGND............................................................-0.3V to +6V

VSSto AGND............................................................+0.3V to -6V

VDDto VSS..............................................................-0.3V to +12V

AGND to DGND.....................................................-0.3V to +0.3V

CH0–CH7 to AGND, DGND.............(VSS- 0.3V) to (VDD+ 0.3V)

CH0–CH7 Total Input Current ..........................................±20mA

VREF to AGND ...........................................-0.3V to (VDD+ 0.3V)

REFADJ to AGND.......................................-0.3V to (VDD+ 0.3V)

Digital Inputs to DGND...............................-0.3V to (VDD+ 0.3V)

Digital Outputs to DGND............................-0.3V to (VDD+ 0.3V)

Digital Output Sink Current.................................................25mA

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

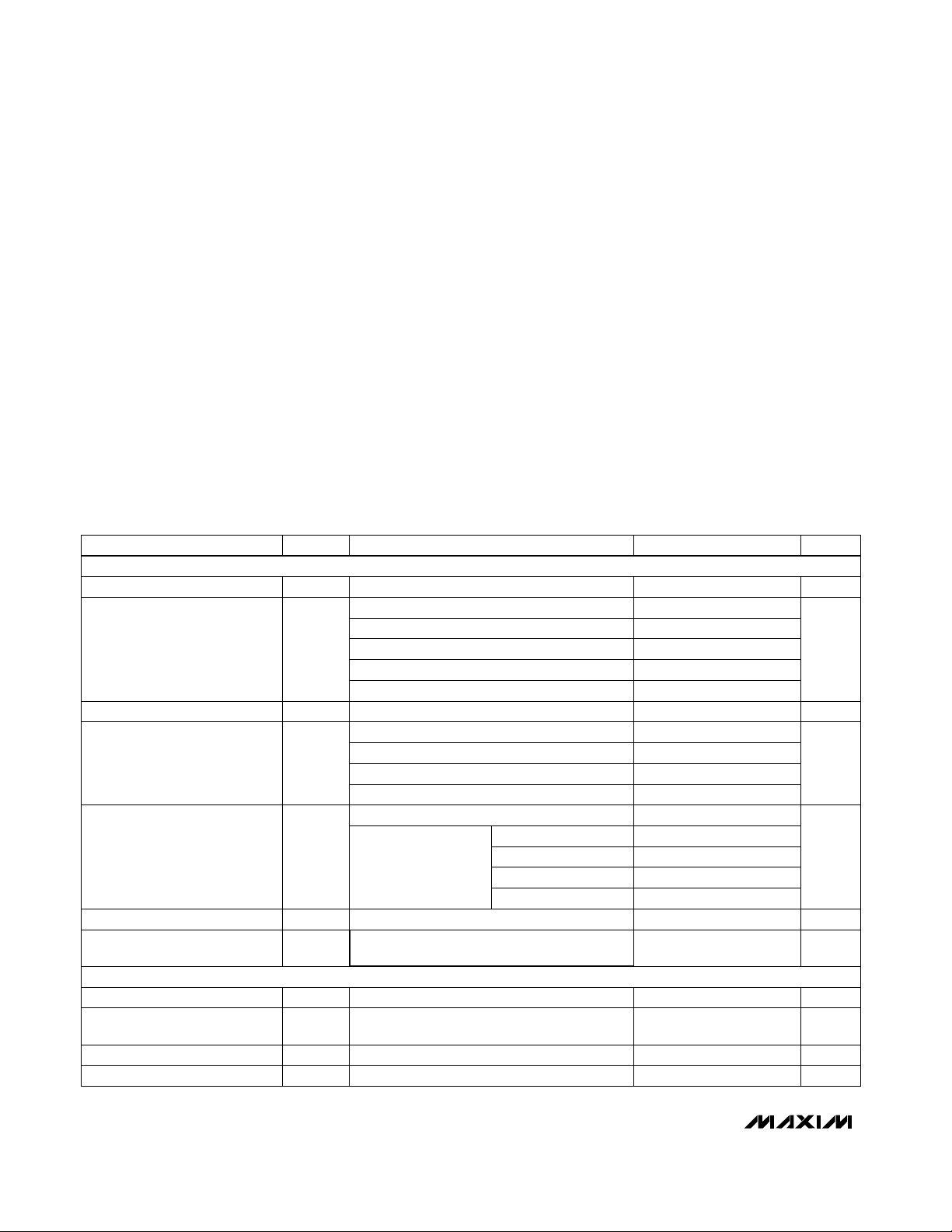

ELECTRICAL CHARACTERISTICS

MAX186/MAX188

(VDD= 5V ±5%; VSS= 0V or -5V; f

4.7µF capacitor at VREF pin; MAX188—external reference, VREF = 4.096V applied to VREF pin; T

noted.)

PARAMETER SYMBOL MIN TYP MAX UNITS

DC ACCURACY (Note 1)

Resolution 12 Bits

Relative Accuracy (Note 2)

Differential Nonlinearity DNL ±1 LSB

Offset Error

Gain Error (Note 3)

Gain Temperature Coefficient ±0.8 ppm/°C

Channel-to-Channel

Offset Matching

DYNAMIC SPECIFICATIONS (10kHz sine wave input, 4.096V

Signal-to-Noise + Distortion Ratio

Total Harmonic Distortion

(up to the 5th harmonic)

Spurious-Free Dynamic Range SFDR 80 dB

Channel-to-Channel Crosstalk -85 dB

= 2.0MHz, external clock (50% duty cycle); 15 clocks/conversion cycle (133ksps); MAX186—

CLK

MAX186A/MAX188A

MAX186B/MAX188B

MAX186C

MAX188C

MAX186D/MAX188D

No missing codes over temperature

MAX186A/MAX188A

MAX186B/MAX188B

MAX186C/MAX188C

MAX186D/MAX188D

MAX186 (all grades)

External reference

4.096V (MAX188)

External reference, 4.096V

SINAD 70 dB

THD -80 dB

65kHz, VIN= 4.096V

Continuous Power Dissipation (TA= +70°C)

Plastic DIP (derate 11.11mW/°C above +70°C) ...........889mW

SO (derate 10.00mW/°C above +70°C)........................800mW

SSOP (derate 8.00mW/°C above +70°C) .....................640mW

CERDIP (derate 11.11mW/°C above +70°C)................889mW

Operating Temperature Ranges:

MAX186_C/MAX188_C........................................0°C to +70°C

MAX186_E/MAX188_E......................................-40°C to +85°C

MAX186_M/MAX188_M..................................-55°C to +125°C

Storage Temperature Range.............................-60°C to +150°C

Lead Temperature (soldering, 10sec).............................+300°C

= T

to T

A

MIN

CONDITIONS

MAX188A

MAX188B

MAX188C

MAX188D

±0.1 LSB

, 133ksps, 2.0MHz external clock, bipolar input mode)

P-P

(Note 4)

P-P

, unless otherwise

MAX

±0.5

±0.5

±1.0

±0.75

±1.0

±2.0

±3.0

±3.0

±3.0

±3.0

±1.5

±2.0

±2.0

±3.0

LSB

LSB

LSB

2 _______________________________________________________________________________________

Page 3

Low-Power, 8-Channel,

Serial 12-Bit ADCs

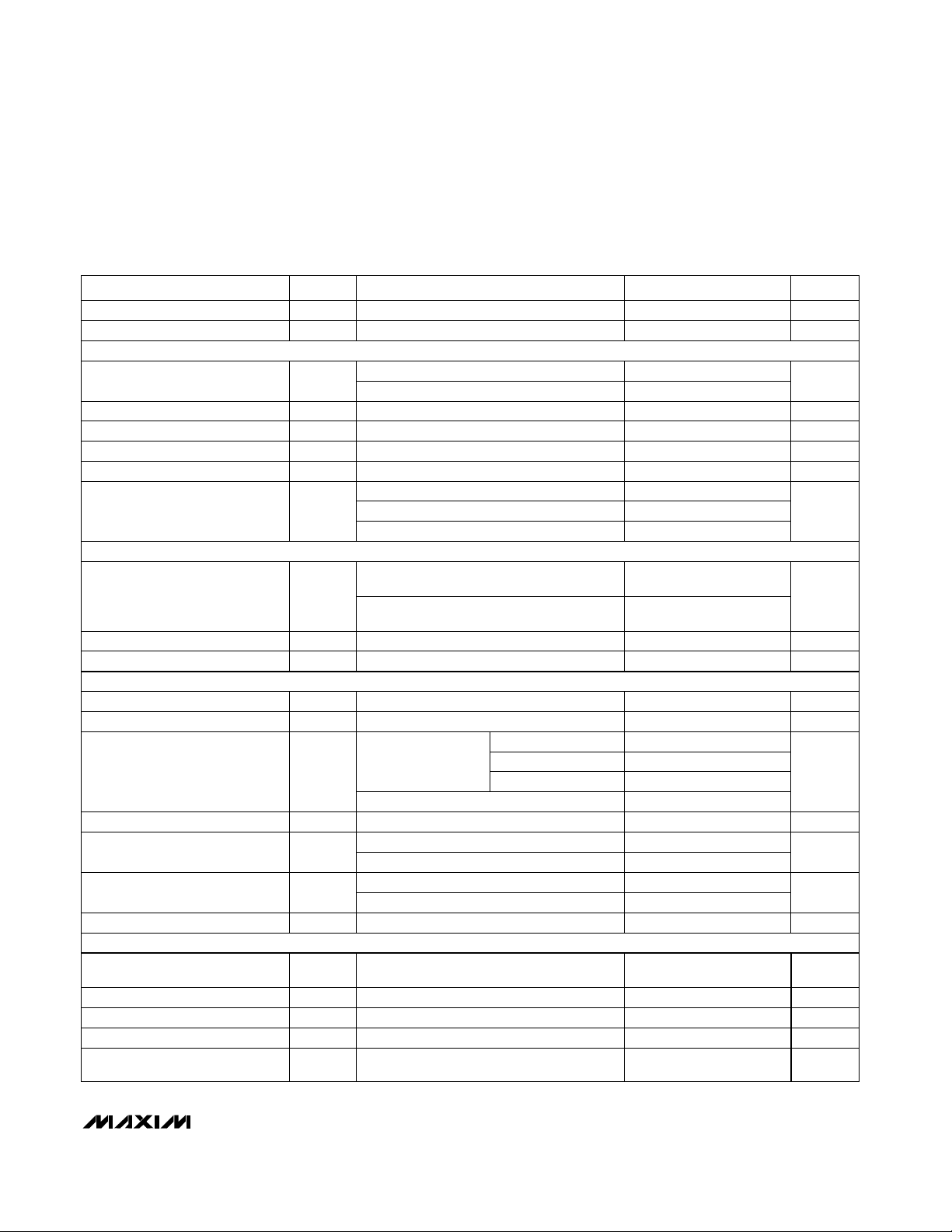

ELECTRICAL CHARACTERISTICS (continued)

(VDD= 5V ±5%; VSS= 0V or -5V; f

4.7µF capacitor at VREF pin; MAX188—external reference, VREF = 4.096V applied to VREF pin; T

noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Small-Signal Bandwidth -3dB rolloff 4.5 MHz

Full-Power Bandwidth 800 kHz

CONVERSION RATE

Conversion Time (Note 5) t

Track/Hold Acquisition Time t

Aperture Delay 10 ns

Aperture Jitter <50 ps

Internal Clock Frequency 1.7 MHz

External Clock Frequency Range

ANALOG INPUT

Input Voltage Range,

Single-Ended and Differential

(Note 9)

Multiplexer Leakage Current

Input Capacitance (Note 6) 16 pF

INTERNAL REFERENCE (MAX186 only, reference buffer enabled)

VREF Output Voltage

VREF Short-Circuit Current 30 mA

VREF Tempco

Load Regulation (Note 7) 0mA to 0.5mA output load 2.5 mV

Capacitive Bypass at VREF

Capacitive Bypass at REFADJ

REFADJ Adjustment Range ±1.5 %

EXTERNAL REFERENCE AT VREF (Buffer disabled, VREF = 4.096V)

Input Voltage Range V

Input Current 200 350 µA

Input Resistance 12 20 kΩ

Shutdown VREF Input Current 1.5 10 µA

Buffer Disable Threshold REFADJ

= 2.0MHz, external clock (50% duty cycle); 15 clocks/conversion cycle (133ksps); MAX186—

CLK

CONV

AZ

Internal clock 5.5 10

External clock, 2MHz, 12 clocks/conversion 6

External compensation, 4.7µF

Internal compensation (Note 6) 0.1 0.4

Used for data transfer only 10

Unipolar, VSS= 0V

Bipolar, VSS= -5V

On/off leakage current, VIN= ±5V

TA= +25°C

MAX186A, MAX186B,

MAX186C

MAX186D ±30

Internal compensation 0

External compensation 4.7

Internal compensation 0.01

External compensation 0.01

MAX186_C

MAX186_E

MAX186_M

= T

to T

A

MIN

0.1 2.0

±0.01 ±1 µA

4.076 4.096 4.116 V

±30 ±50

±30 ±60

±30 ±80

2.50

VDD50mV

, unless otherwise

MAX

1.5 µs

0 to

VREF

±VREF/2

V

DD

+

50mV

ppm/°C

MAX186/MAX188

µs

MHz

V

µF

µF

V

_______________________________________________________________________________________ 3

Page 4

Low-Power, 8-Channel,

SHDN

Serial 12-Bit ADCs

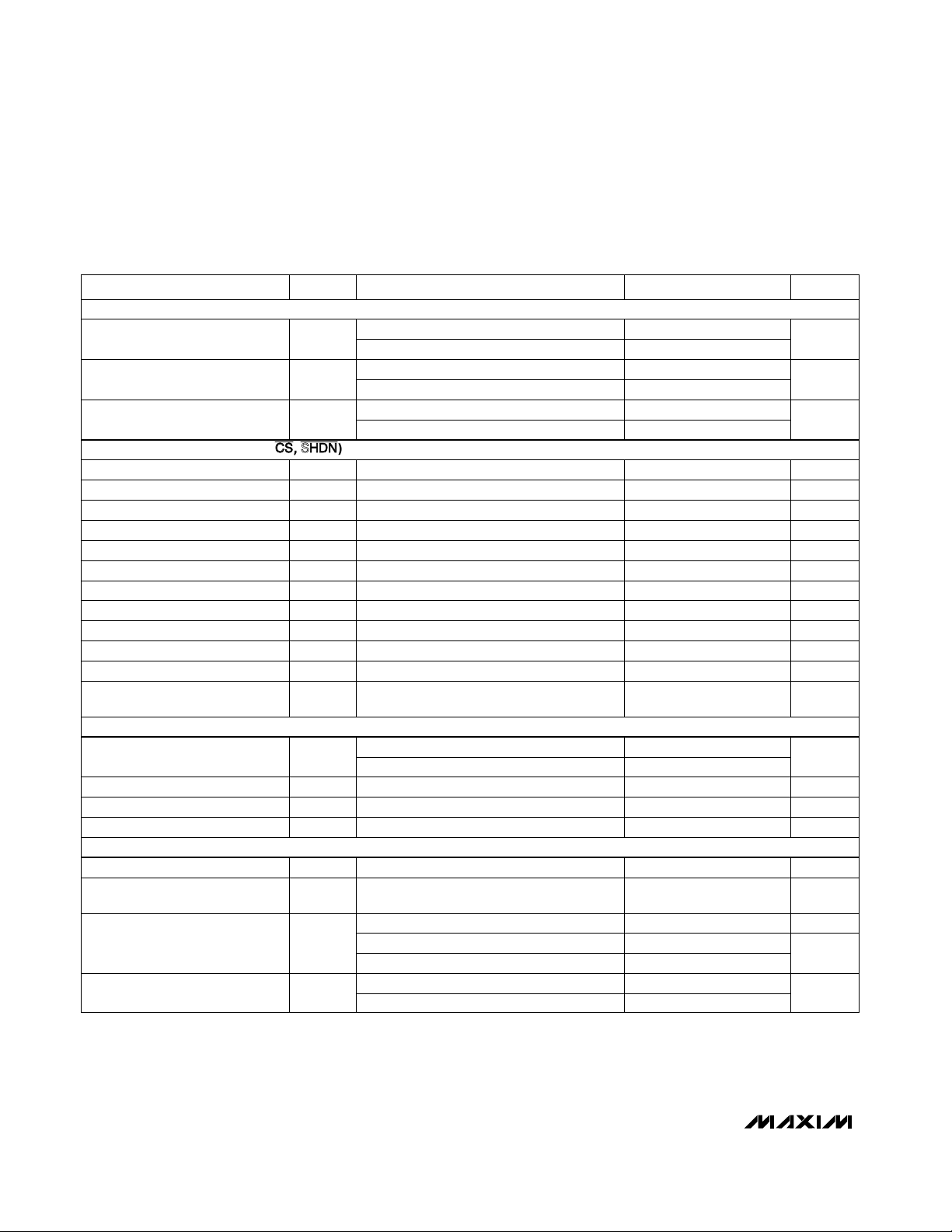

ELECTRICAL CHARACTERISTICS (continued)

(VDD= 5V ±5%; VSS= 0V or -5V; f

4.7µF capacitor at VREF pin; MAX188—external reference, VREF = 4.096V applied to VREF pin; T

noted.)

PARAMETER

EXTERNAL REFERENCE AT REFADJ

Reference-Buffer Gain

DIGITAL INPUTS (DIN, SCLK, CS,

DIN, SCLK, CS Input High Voltage

MAX186/MAX188

DIN, SCLK, CS Input Low Voltage

DIN, SCLK, CS Input Hysteresis

DIN, SCLK, CS Input Leakage

DIN, SCLK, CS Input Capacitance

SHDN Input High Voltage

SHDN Input Low Voltage

SHDN Input Current, High

SHDN Input Current, Low

SHDN Input Mid Voltage

SHDN Voltage, Floating

SHDN Max Allowed Leakage,

Mid Input

DIGITAL OUTPUTS (DOUT, SSTRB)

Output Voltage Low V

Output Voltage High V

Three-State Leakage Current I

Three-State Output Capacitance C

POWER REQUIREMENTS

Positive Supply Voltage V

Negative Supply Voltage V

Positive Supply Current I

Negative Supply Current I

= 2.0MHz, external clock (50% duty cycle); 15 clocks/conversion cycle (133ksps); MAX186—

CLK

SYMBOL CONDITIONS MIN TYP MAX

Internal compensation mode 0

External compensation mode 4.7

MAX186 1.678

MAX188 1.638

MAX186 ±50

MAX188 ±5

)

V

INH

V

INL

V

HYST

C

V

V

I

I

V

V

I

INH

INL

INH

INL

FLT

OH

OUT

DD

DD

SS

VIN= 0V or V

IN

(Note 6) 15 pF

IN

SHDN = V

SHDN = 0V

IM

SHDN = open

SHDN = open

I

OL

SS

SINK

I

SINK

I

SOURCE

CS = 5V

L

CS = 5V (Note 6)

Operating mode 1.5 2.5

Fast power-down 30 70

Full power-down 210

Operating mode and fast power-down 50

Full power-down 10

DD

DD

= 5mA 0.4

= 16mA 0.3

= 1mA 4 V

= T

to T

A

MIN

2.4 V

0.15 V

VDD- 0.5 V

-4.0 µA

1.5 VDD-1.5

2.75 V

-100 100 nA

5 ±5% V

0 or

-5 ±5%

, unless otherwise

MAX

0.8 V

±1 µA

0.5 V

4.0 µA

±10 µA

15 pF

UNITS

V/V

mA

µFCapacitive Bypass at VREF

µAREFADJ Input Current

V

V

V

µA

µA

4 _______________________________________________________________________________________

Page 5

Low-Power, 8-Channel,

Serial 12-Bit ADCs

ELECTRICAL CHARACTERISTICS (continued)

(VDD= 5V ±5%; VSS= 0V or -5V; f

4.7µF capacitor at VREF pin; MAX188—external reference, VREF = 4.096V applied to VREF pin; T

noted.)

PARAMETER SYMBOL CONDITIONS UNITS

Positive Supply Rejection

(Note 8)

Negative Supply Rejection

(Note 8)

Note 1: Tested at VDD= 5.0V; VSS= 0V; unipolar input mode.

Note 2: Relative accuracy is the deviation of the analog value at any code from its theoretical value after the full-scale range has

been calibrated.

Note 3: MAX186 – internal reference, offset nulled; MAX188 – external reference (VREF = +4.096V), offset nulled.

Note 4: Ground on-channel; sine wave applied to all off channels.

Note 5: Conversion time defined as the number of clock cycles times the clock period; clock has 50% duty cycle.

Note 6: Guaranteed by design. Not subject to production testing.

Note 7: External load should not change during conversion for specified accuracy.

Note 8: Measured at V

SUPPLY

+5% and V

Note 9: The common-mode range for the analog inputs is from V

= 2.0MHz, external clock (50% duty cycle); 15 clocks/conversion cycle (133ksps); MAX186—

CLK

= T

to T

A

MIN

, unless otherwise

MAX

MIN TYP MAX

PSR ±0.06 ±0.5 mV

PSR

VDD= 5V ±5%; external reference, 4.096V;

full-scale input

VSS= -5V ±5%; external reference, 4.096V;

full-scale input

-5% only.

SUPPLY

SS

to VDD.

±0.01 ±0.5 mV

TIMING CHARACTERISTICS

(VDD= 5V ±5%; V

=0V or -5V, TA= T

SS

MIN

to T

, unless otherwise noted.)

MAX

MAX186/MAX188

PARAMETER SYMBOL CONDITIONS UNITS

Acquisition Time

DIN to SCLK Setup

DIN to SCLK Hold

SCLK Fall to Output Data Valid

CS Fall to Output Enable

CS Rise to Output Disable

CS to SCLK Rise Setup

CS to SCLK Rise Hold

SCLK Pulse Width High

SCLK Pulse Width Low

SCLK Fall to SSTRB

CS Fall to SSTRB Output Enable

(Note 6)

CS Rise to SSTRB Output Disable

(Note 6)

SSTRB Rise to SCLK Rise

(Note 6)

_______________________________________________________________________________________ 5

t

AZ

t

DS

t

DH

t

DO

t

DV

t

TR

t

CSS

t

CSH

t

CH

t

CL

t

SSTRB

t

SDV

t

STR

t

SCK

MIN TYP MAX

1.5 µs

100 ns

0 ns

C

C

C

LOAD

LOAD

LOAD

= 100pF

= 100pF

= 100pF

MAX18_ _C/E

MAX18_ _M

20 150 ns

20 200 ns

100 ns

100 ns

100 ns

0 ns

200 ns

200 ns

C

= 100pF

LOAD

External clock mode only, C

External clock mode only, C

LOAD

LOAD

= 100pF

= 100pF

200 ns

200 ns

200 ns

Internal clock mode only 0 ns

Page 6

Low-Power, 8-Channel,

Serial 12-Bit ADCs

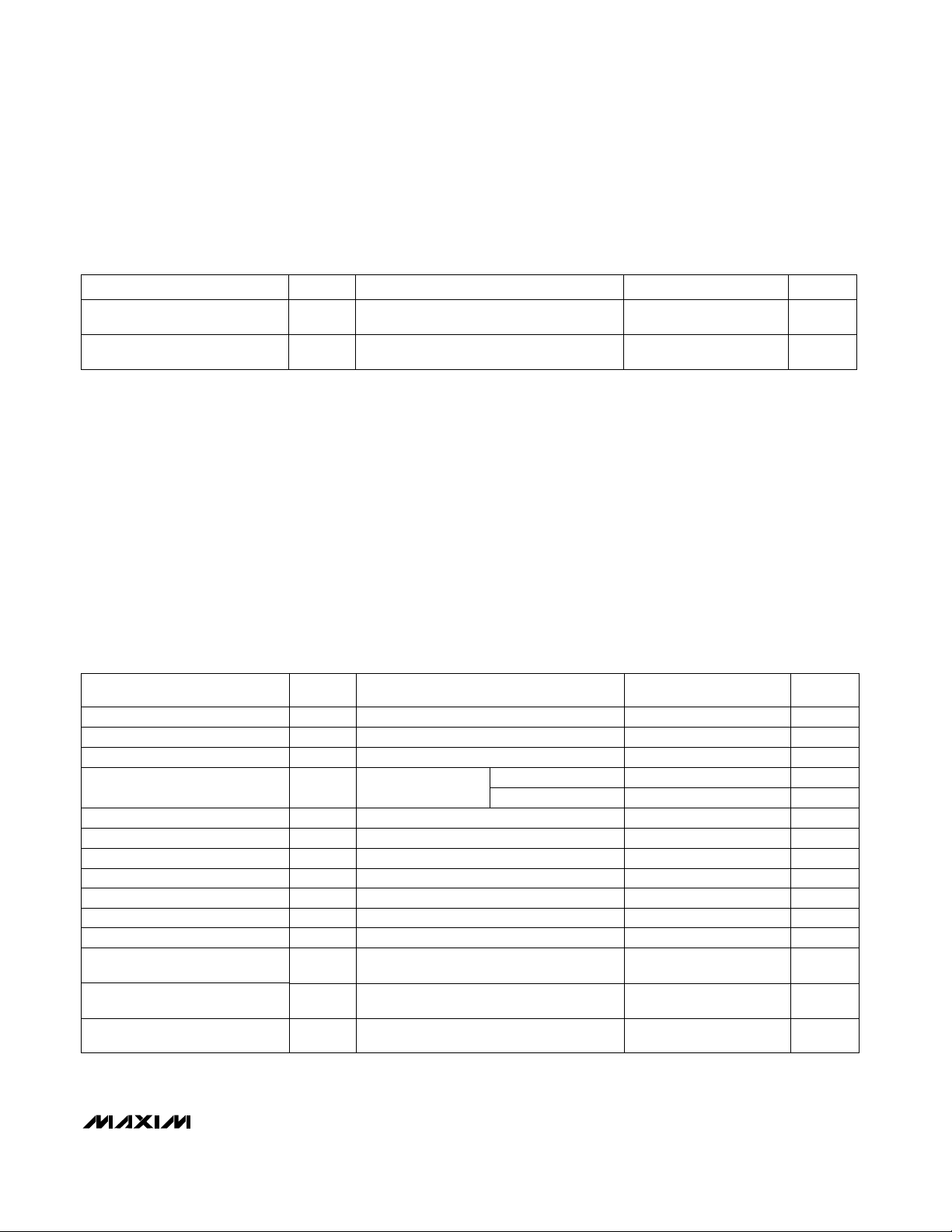

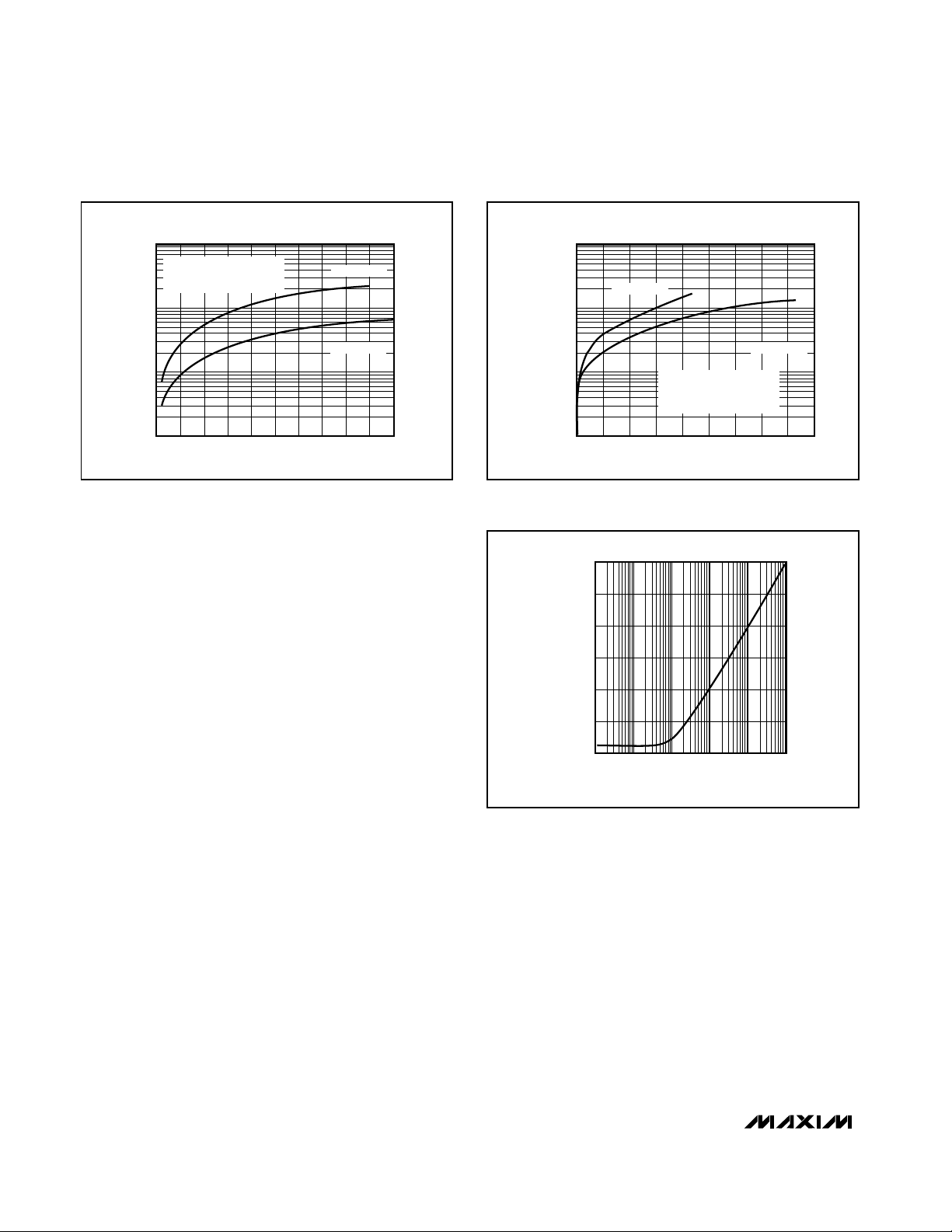

__________________________________________Typical Operating Characteristics

POWER-SUPPLY REJECTION

vs. TEMPERATURE

0.30

0.25

0.20

0.15

0.10

PSR (LSBs)

0.05

0.00

MAX186/MAX188

-0.05

-60 140

-20 0 40 80 120

-40 20 100

TEMPERATURE (°C)

VDD = +5V ±5%

VSS = 0V or -5V

60

20

0

-20

-40

-60

INTERNAL REFERENCE VOLTAGE

vs. TEMPERATURE

2.456

2.455

2.454

VREFADJ (V)

2.453

2.452

-40 -20 0 20 40 60 80 100 120

TEMPERATURE (°C)

MAX186/MAX188 FFT PLOT – 133kHz

ft = 10kHz

fs = 133kHz

ft = 10kHz

= 133kHz

f

s

= +25°C

T

A

CHANNEL-TO-CHANNEL OFFSET MATCHING

vs. TEMPERATURE

0.16

0.14

0.12

0.10

0.08

0.06

0.04

OFFSET MATCHING (LSBs)

0.02

0

-60 -20 60 140

-40 0 40 80 120

20 100

TEMPERATURE (°C)

-80

AMPLITUDE (dB)

-100

-120

-140

0

FREQUENCY

33.25kHz

66.5kHz

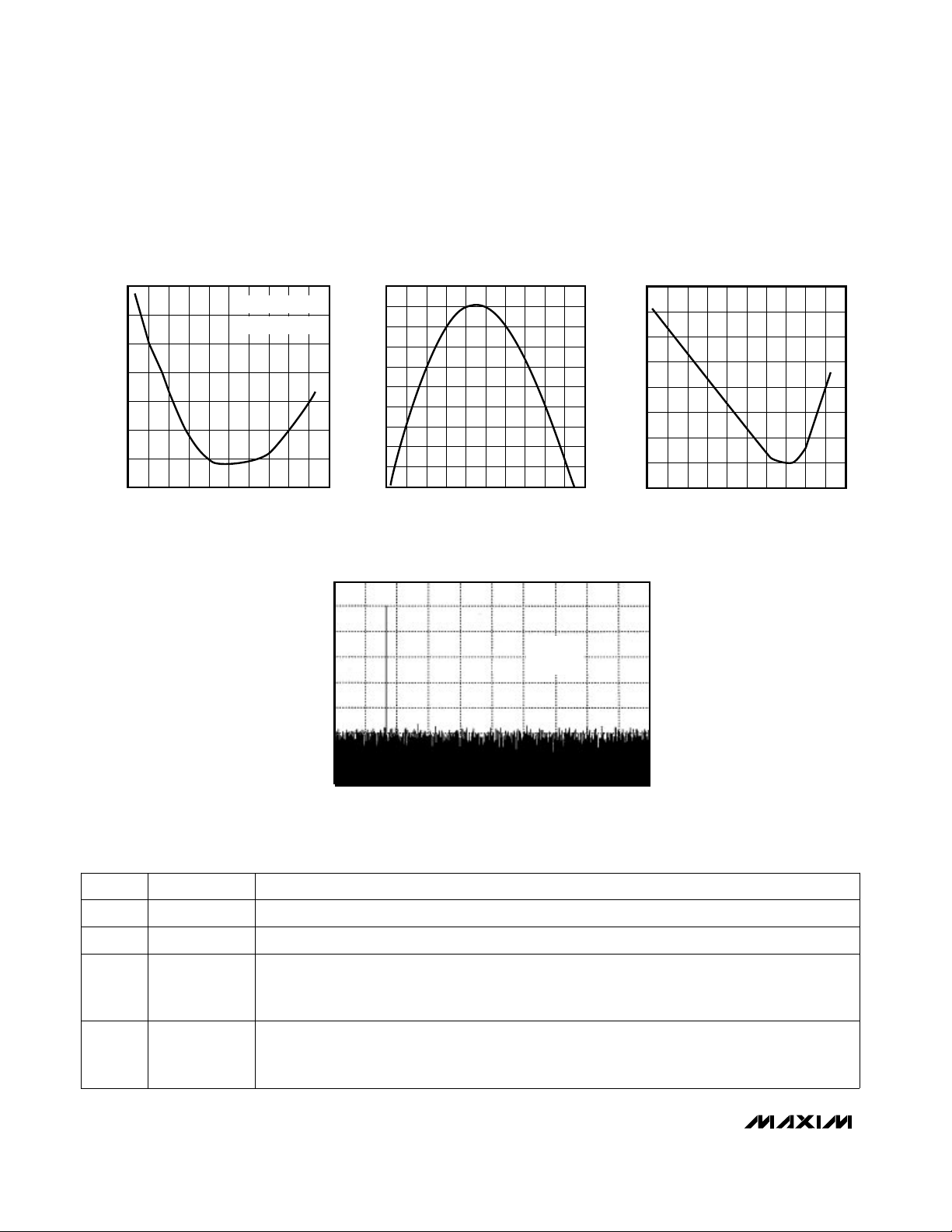

_____________________________________________________________Pin Description

PIN NAME FUNCTION

1-8 CH0-CH7 Sampling Analog Inputs

9

10

11 VREF

6

________________________________________________________________________________________________

V

SS

SHDN

Negative Supply Voltage. Tie to -5V ±5% or AGND

Three-Level Shutdown Input. Pulling SHDN low shuts the MAX186/MAX188 down to 10µA (max)

supply current, otherwise the MAX186/MAX188 are fully operational. Pulling SHDN high puts the reference-buffer amplifier in internal compensation mode. Letting SHDN float puts the reference-buffer

amplifier in external compensation mode.

Reference Voltage for analog-to-digital conversion. Also, Output of the Reference Buffer Amplifier

(4.096V in the MAX186, 1.638 x REFADJ in the MAX188). Add a 4.7µF capacitor to ground when

using external compensation mode. Also functions as an input when used with a precision external

reference.

Page 7

Low-Power, 8-Channel,

Serial 12-Bit ADCs

________________________________________________Pin Description (continued)

PIN NAME FUNCTION

12 REFADJ

13 AGND Analog Ground. Also IN- Input for single-ended conversions.

14 DGND

15 DOUT

16 SSTRB

17 DIN

18

CS

19 SCLK

20

V

DD

Input to the Reference-Buffer Amplifier. To disable the reference-buffer amplifier, tie REFADJ to

V

.

DD

Digital Ground

Serial Data Output. Data is clocked out at the falling edge of SCLK. High impedance when CS is high.

Serial Strobe Output. In internal clock mode, SSTRB goes low when the MAX186/MAX188 begin the

A/D conversion and goes high when the conversion is done. In external clock mode, SSTRB pulses

high for one clock period before the MSB decision. High impedance whenCS is high (external mode).

Serial Data Input. Data is clocked in at the rising edge of SCLK.

Active-Low Chip Select. Data will not be clocked into DIN unless CS is low. When CS is high, DOUT

is high impedance.

Serial Clock Input. Clocks data in and out of serial interface. In external clock mode, SCLK also sets

the conversion speed. (Duty cycle must be 40% to 60% in external clock mode.)

Positive Supply Voltage, +5V ±5%

+5V

MAX186/MAX188

DOUT

3k

a. High-Z to V

DGND

and VOL to V

OH

C

LOAD

OH

DOUT

b. High-Z to VOL and VOH to V

Figure 1. Load Circuits for Enable Time

DOUT

3k

DGND

a VOH to High-Z b VOL to High-Z

C

DOUT

LOAD

Figure 2. Load Circuits for Disabled Time

+5V

3k

C

LOAD

DGND

3k

C

LOAD

DGND

18

CS

19

SCLK

DIN

SHDN

OL

CH0

CH1

CH2

CH3

CH4

CH5

CH6

CH7

AGND

REFADJ

VREF

SHIFT

REGISTER

10

1

2

3

4

ANALOG

INPUT

5

MUX

6

7

8

13

12

11

CONTROL

+2.46V

REFERENCE

(MAX186)

LOGIC

T/H

20k

INPUT

17

CLOCK

IN

A

≈ 1.65

+4.096V

INT

CLOCK

12-BIT

SAR

ADC

REF

OUTPUT

REGISTER

OUT

MAX186

MAX188

SHIFT

15

DOUT

16

SSTRB

20

V

DD

14

DGND

9

V

SS

Figure 3. Block Diagram

_______________________________________________________________________________________ 7

Page 8

Low-Power, 8-Channel,

Serial 12-Bit ADCs

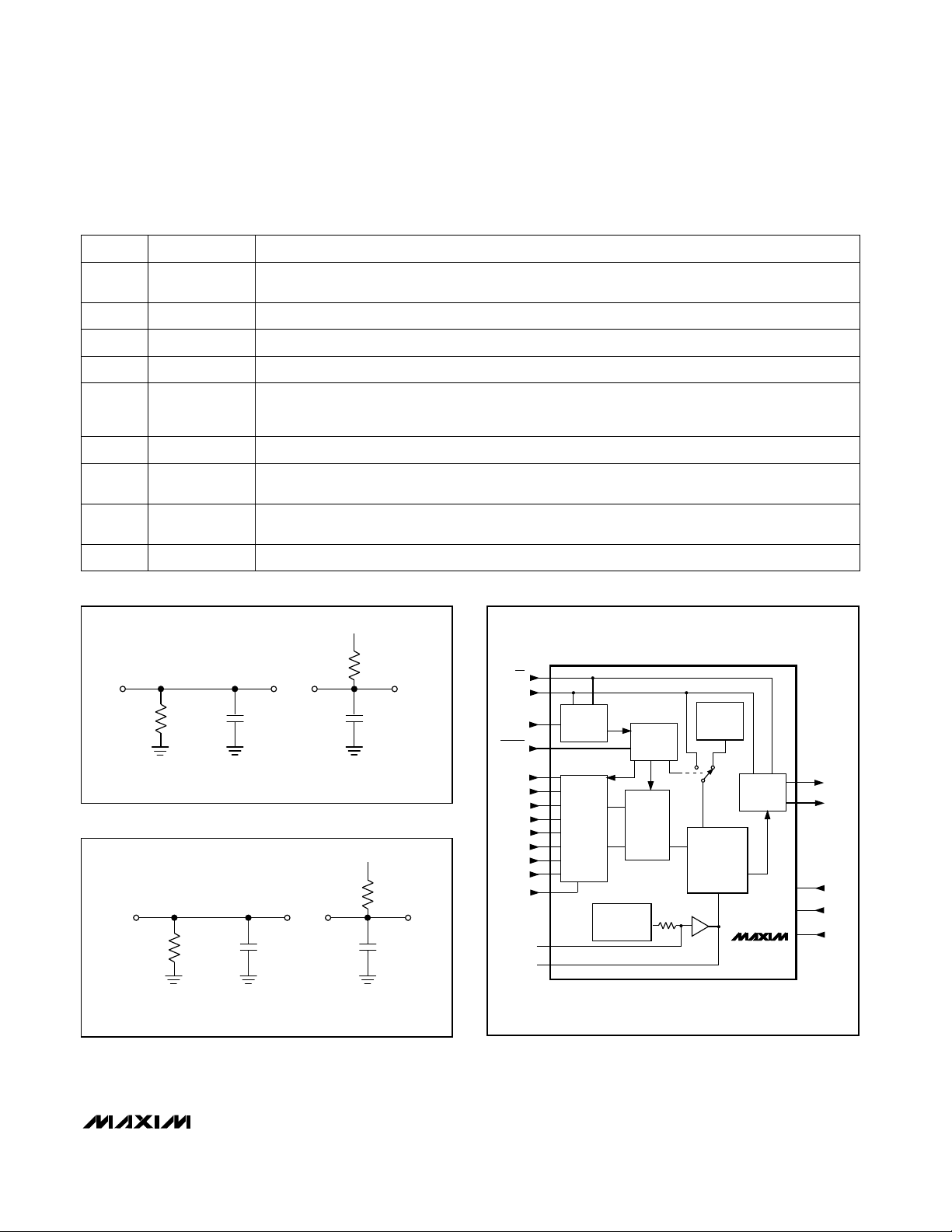

_______________Detailed Description

The MAX186/MAX188 use a successive-approximation

conversion technique and input track/hold (T/H) circuitry to convert an analog signal to a 12-bit digital output.

A flexible serial interface provides easy interface to

microprocessors. No external hold capacitors are

required. Figure 3 shows the block diagram for the

MAX186/MAX188.

Pseudo-Differential Input

The sampling architecture of the ADC’s analog comparator is illustrated in the Equivalent Input Circuit

(Figure 4). In single-ended mode, IN+ is internally

switched to CH0-CH7 and IN- is switched to AGND. In

differential mode, IN+ and IN- are selected from pairs

of CH0/CH1, CH2/CH3, CH4/CH5 and CH6/CH7.

MAX186/MAX188

Configure the channels with Table 3 and Table 4.

In differential mode, IN- and IN+ are internally switched

to either one of the analog inputs. This configuration is

pseudo-differential to the effect that only the signal at

IN+ is sampled. The return side (IN-) must remain stable within ±0.5LSB (±0.1LSB for best results) with

respect to AGND during a conversion. Accomplish this

by connecting a 0.1µF capacitor from AIN- (the selected analog input, respectively) to AGND.

During the acquisition interval, the channel selected as

the positive input (IN+) charges capacitor C

acquisition interval spans three SCLK cycles and ends

on the falling SCLK edge after the last bit of the input

control word has been entered. At the end of the acquisition interval, the T/H switch opens, retaining charge

on C

as a sample of the signal at IN+.

HOLD

The conversion interval begins with the input multiplexer switching C

from the positive input (IN+) to the

HOLD

negative input (IN-). In single-ended mode, IN- is simply AGND. This unbalances node ZERO at the input of

the comparator. The capacitive DAC adjusts during the

remainder of the conversion cycle to restore node

ZERO to 0V within the limits of 12-bit resolution. This

action is equivalent to transferring a charge of 16pF x

+) - (VIN-)] from C

[(V

IN

to the binary-weighted

HOLD

capacitive DAC, which in turn forms a digital representation of the analog input signal.

The T/H enters its tracking mode on the falling clock

edge after the fifth bit of the 8-bit control word has been

shifted in. The T/H enters its hold mode on the falling

clock edge after the eighth bit of the control word has

been shifted in. If the converter is set up for

HOLD

Track/Hold

. The

12-BIT CAPACITIVE DAC

VREF

C

INPUT

CH0

CH1

CH2

CH3

CH4

CH5

CH6

CH7

AGND

SINGLE-ENDED MODE: IN+ = CHO-CH7, IN– = AGND.

DIFFERENTIAL MODE: IN+ AND IN– SELECTED FROM PAIRS OF

CH0/CH1, CH2/CH3, CH4/CH5, CH6/CH7.

Figure 4. Equivalent Input Circuit

MUX

–

C

SWITCH

HOLD

16pF

TRACK

+

T/H

SWITCH

10k

R

S

COMPARATOR

ZERO

HOLD

AT THE SAMPLING INSTANT,

THE MUX INPUT SWITCHES

FROM THE SELECTED IN+

CHANNEL TO THE SELECTED

IN– CHANNEL.

single-ended inputs, IN- is connected to AGND, and

the converter samples the “+” input. If the converter is

set up for differential inputs, IN- connects to the “-”

input, and the difference of

|IN+ - IN-| is sampled. At

the end of the conversion, the positive input connects

back to IN+, and C

charges to the input signal.

HOLD

The time required for the T/H to acquire an input signal

is a function of how quickly its input capacitance is

charged. If the input signal’s source impedance is high,

the acquisition time lengthens and more time must be

allowed between conversions. Acquisition time is calculated by:

= 9 x (RS+ RIN) x 16pF,

t

AZ

where R

input signal, and t

= 5kΩ, RS= the source impedance of the

IN

is never less than 1.5µs. Note that

AZ

source impedances below 5kΩ do not significantly

affect the AC performance of the ADC. Higher source

impedances can be used if an input capacitor is connected to the analog inputs, as shown in Figure 5. Note

that the input capacitor forms an RC filter with the input

source impedance, limiting the ADC’s signal bandwidth.

Input Bandwidth

The ADC’s input tracking circuitry has a 4.5MHz

small-signal bandwidth, so it is possible to digitize

high-speed transient events and measure periodic signals with bandwidths exceeding the ADC’s sampling

rate by using undersampling techniques. To avoid

high-frequency signals being aliased into the frequency

band of interest, anti-alias filtering is recommended.

8 _______________________________________________________________________________________

Page 9

Low-Power, 8-Channel,

Serial 12-Bit ADCs

MAX186/MAX188

V

DD

DGND

AGND

V

SCLK

DOUT

SSTRB

SHDN

**

CS

DIN

SS

+5V

N.C.

0V TO

4.096V

ANALOG

0.01µF

INPUT

+5V

D1

1N4148

C2

0.01µF

* FULL-SCALE ANALOG INPUT, CONVERSION RESULT = $FFF (HEX)

**REQUIRED FOR MAX188 ONLY. A POTENTIOMETER MAY BE USED IN PLACE OF THE REFERENCE FOR TEST PURPOSES.

C1

4.7µF

CH7

REFADJ

VREF

+2.5V

MAX186

MAX188

+2.5V

REFERENCE

+5V

0.1µF

2MHz

OSCILLATOR

CH1 CH2

OSCILLOSCOPE

CH3

SCLK

SSTRB

DOUT*

CH4

Figure 5. Quick-Look Circuit

Analog Input Range and Input Protection

Internal protection diodes, which clamp the analog

input to V

swing from V

and VSS, allow the channel input pins to

DD

- 0.3V to VDD+ 0.3V without damage.

SS

However, for accurate conversions near full scale, the

inputs must not exceed V

lower than V

by 50mV.

SS

by more than 50mV, or be

DD

If the analog input exceeds 50mV beyond the supplies, do not forward bias the protection diodes of

off-channels over two milliamperes, as excessive

current will degrade the conversion accuracy of the

on-channel.

The full-scale input voltage depends on the voltage at

VREF. See Tables 1a and 1b.

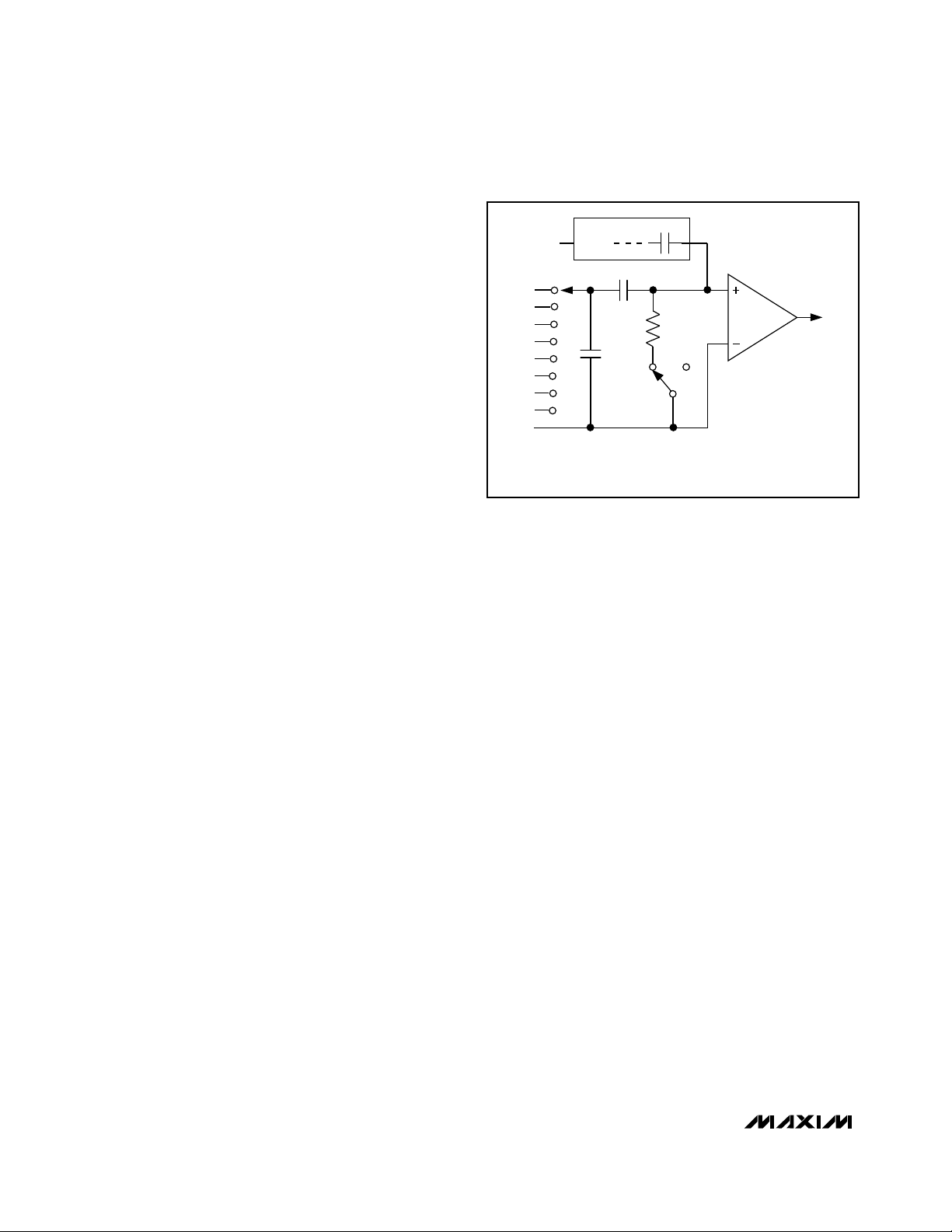

Quick Look

To evaluate the analog performance of the

MAX186/MAX188 quickly, use the circuit of Figure 5.

The MAX186/MAX188 require a control byte to be written to DIN before each conversion. Tying DIN to +5V

feeds in control bytes of $FF (HEX), which trigger

_______________________________________________________________________________________ 9

Table 1a. Unipolar Full Scale and Zero Scale

Reference

Internal Reference

(MAX186 only)

External Reference

at REFADJ

at VREF 0V VREF

Zero

Scale

0V +4.096V

0V

* A = 1.678 for the MAX186, 1.638 for the MAX188

Full Scale

V

REFADJ

Table 1b. Bipolar Full Scale, Zero Scale, and

Negative Full Scale

Reference

Internal Reference

(MAX186 only)

External Reference

at REFADJ

at VREF -1/2 VREF 0V

Negative

Full Scale

-4.096V/2

-1/2V

REFADJ

x A*

* A = 1.678 for the MAX186, 1.638 for the MAX188

Zero

Scale

0V

0V

Full Scale

+4.096V/2

+1/2V

+1/2 VREF

REFADJ

x A*

x A*

Page 10

Low-Power, 8-Channel,

Serial 12-Bit ADCs

single-ended unipolar conversions on CH7 in external

clock mode without powering down between conversions. In external clock mode, the SSTRB output pulses

high for one clock period before the most significant bit

of the 12-bit conversion result comes out of DOUT.

Varying the analog input to CH7 should alter the

sequence of bits from DOUT. A total of 15 clock cycles

is required per conversion. All transitions of the SSTRB

and DOUT outputs occur on the falling edge of SCLK.

How to Start a Conversion

A conversion is started on the MAX186/MAX188 by

clocking a control byte into DIN. Each rising edge on

SCLK, with CS low, clocks a bit from DIN into the

MAX186/MAX188’s internal shift register. After CS falls,

the first arriving logic “1” bit defines the MSB of the

MAX186/MAX188

control byte. Until this first “start” bit arrives, any number of logic “0” bits can be clocked into DIN with no

effect. Table 2 shows the control-byte format.

Table 2. Control-Byte Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

(MSB) (LSB)

START SEL2 SEL1 SEL0 UNI/BIP SGL/DIF PD1 PD0

The MAX186/MAX188 are fully compatible with

Microwire and SPI devices. For SPI, select the correct

clock polarity and sampling edge in the SPI control registers: set CPOL = 0 and CPHA = 0. Microwire and SPI

both transmit a byte and receive a byte at the same

time. Using the

software interface requires only three 8-bit transfers to

perform a conversion (one 8-bit transfer to configure

the ADC, and two more 8-bit transfers to clock out the

12-bit conversion result).

Make sure the CPU’s serial interface runs in master

mode so the CPU generates the serial clock. Choose a

clock frequency from 100kHz to 2MHz.

1) Set up the control byte for external clock mode, call

it TB1. TB1 should be of the format: 1XXXXX11

Binary, where the Xs denote the particular channel

and conversion-mode selected.

Typical Operating Circuit

Example: Simple Software Interface

, the simplest

Bit Name Description

7(MSB) START The first logic “1” bit after CS goes low defines the beginning of the control byte.

6 SEL2 These three bits select which of the eight channels are used for the conversion.

5 SEL1 See Tables 3 and 4.

4 SEL0

3 UNI/BIP 1 = unipolar, 0 = bipolar. Selects unipolar or bipolar conversion mode. In unipolar

mode, an analog input signal from 0V to VREF can be converted; in bipolar mode, the

signal can range from -VREF/2 to +VREF/2.

2 SGL/DIF 1 = single ended, 0 = differential. Selects single-ended or differential conversions. In

single-ended mode, input signal voltages are referred to AGND. In differential mode,

the voltage difference between two channels is measured. See Tables 3 and 4.

1 PD1 Selects clock and power-down modes.

0(LSB) PD0 PD1 PD0 Mode

00Full power-down (IQ= 2µA)

01Fast power-down (IQ= 30µA)

10Internal clock mode

1 1 External clock mode

10 ______________________________________________________________________________________

Page 11

Low-Power, 8-Channel,

DIFF

DIFF

Serial 12-Bit ADCs

Table 3. Channel Selection in Single-Ended Mode (SGL/

SEL2 SEL1 SEL0 CH0 CH1 CH2 CH3 CH4 CH5 CH6 CH7 AGND

000 + –

100 + –

001 + –

101 + –

010 + –

110 + –

011 + –

111 + –

Table 4. Channel Selection in Differential Mode (SGL/

SEL2 SEL1 SEL0 CH0 CH1 CH2 CH3 CH4 CH5 CH6 CH7

000 + –

001 + –

010 + –

= 1)

= 0)

MAX186/MAX188

011 +–

100 – +

101 – +

110 – +

111 –+

2) Use a general-purpose I/O line on the CPU to pull

CS on the MAX186/MAX188 low.

3) Transmit TB1 and simultaneously receive a byte

and call it RB1. Ignore RB1.

4) Transmit a byte of all zeros ($00 HEX) and simultaneously receive byte RB2.

5) Transmit a byte of all zeros ($00 HEX) and simultaneously receive byte RB3.

6) Pull CS on the MAX186/MAX188 high.

______________________________________________________________________________________ 11

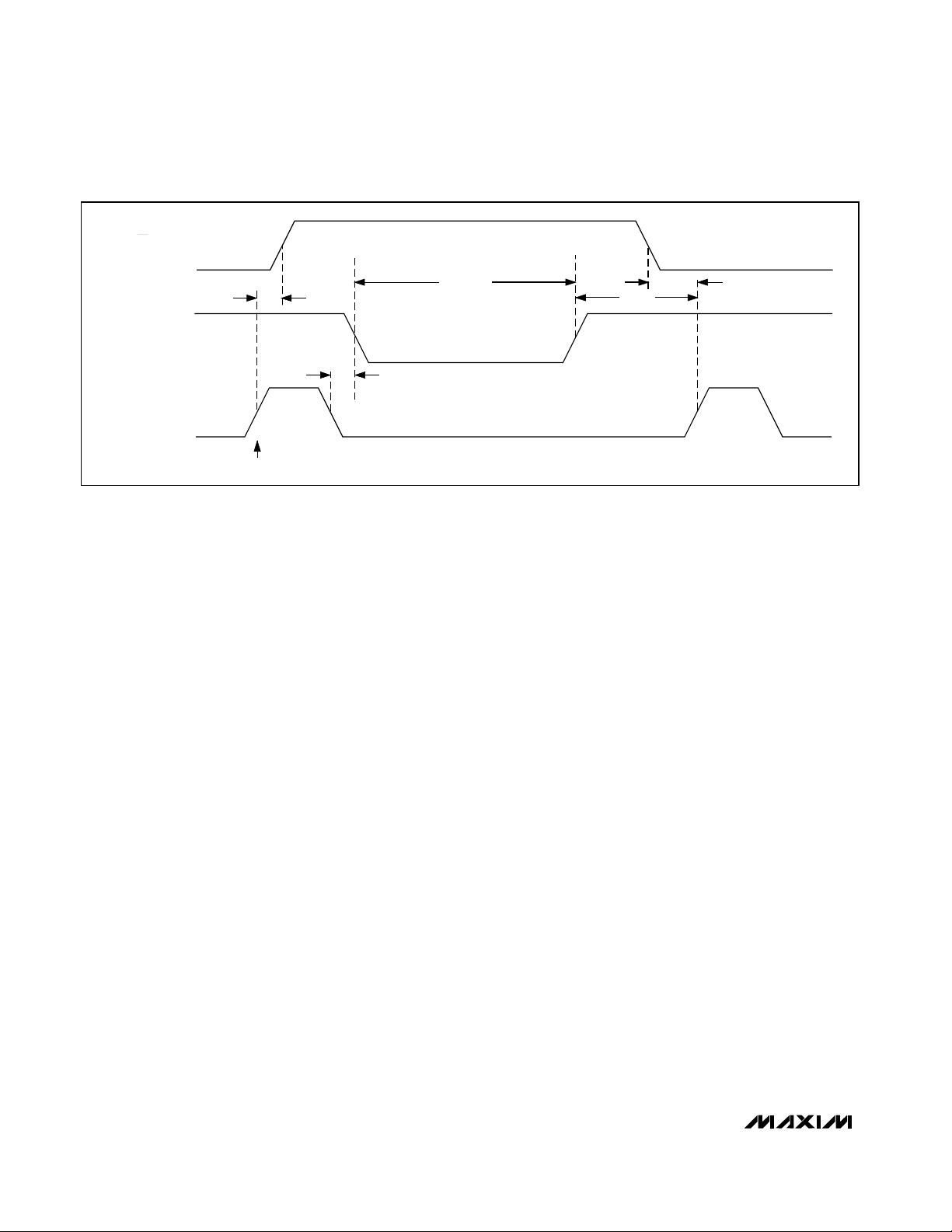

Figure 6 shows the timing for this sequence. Bytes RB2

and RB3 will contain the result of the conversion

padded with one leading zero and three trailing zeros.

The total conversion time is a function of the serial

clock frequency and the amount of dead time between

8-bit transfers. Make sure that the total conversion time

does not exceed 120µs, to avoid excessive T/H droop.

Digital Output

In unipolar input mode, the output is straight binary

(see Figure 15). For bipolar inputs, the output is

twos-complement (see Figure 16). Data is clocked out

at the falling edge of SCLK in MSB-first format.

Page 12

Low-Power, 8-Channel,

Serial 12-Bit ADCs

CS

t

ACQ

SCLK

DIN

14 8 12 16 20 24

UNI/

START

SEL2 SEL1 SEL0

BIP

SCL/

DIFF

PD1 PD0

SSTRB

RB1

DOUT

ACQUISITION

1.5µs (CLK = 2MHz)

t

CSS

t

DS

t

DH

DV

t

CL

t

IDLE

CSH

t

A/D STATE

Figure 6. 24-Bit External Clock Mode Conversion Timing (SPI, QSPI and Microwire Compatible)

MAX186/MAX188

CS

SCLK

DIN

DOUT

MSB

t

B11

CH

RB2

B10 B9 B8 B7 B6 B5 B4 B3 B2 B1

CONVERSION

• • •

• • •

• • •

• • •

RB3

FILLED WITH

B0

ZEROS

LSB

IDLE

t

CSH

t

DO

t

TR

Figure 7. Detailed Serial-Interface Timing

Internal and External Clock Modes

The MAX186/MAX188 may use either an external serial

clock or the internal clock to perform the

successive-approximation conversion. In both clock

modes, the external clock shifts data in and out of the

MAX186/MAX188. The T/H acquires the input signal as

the last three bits of the control byte are clocked into

DIN. Bits PD1 and PD0 of the control byte program the

clock mode. Figures 7 through 10 show the timing

characteristics common to both modes.

External Clock

In external clock mode, the external clock not only shifts

data in and out, it also drives the analog-to-digital con-

version steps. SSTRB pulses high for one clock period

after the last bit of the control byte. Successive-approximation bit decisions are made and appear at DOUT on

each of the next 12 SCLK falling edges (see Figure 6).

SSTRB and DOUT go into a high-impedance state when

CS goes high; after the next CS falling edge, SSTRB will

output a logic low. Figure 8 shows the SSTRB timing in

external clock mode.

The conversion must complete in some minimum time, or

else droop on the sample-and-hold capacitors may

degrade conversion results. Use internal clock mode if the

clock period exceeds 10µs, or if serial-clock interruptions

could cause the conversion interval to exceed 120µs.

12 ______________________________________________________________________________________

Page 13

Low-Power, 8-Channel,

Serial 12-Bit ADCs

MAX186/MAX188

CS

SSTRB

SCLK

• • •

t

SDV

• • •

• • •

Figure 8. External Clock Mode SSTRB Detailed Timing

CS

SCLK

DIN

SSTRB

DOUT

A/D STATE

14 8

2 3 5 6 7 9 10 11 19 21 22 23

UNI/

START

SEL2 SEL1 SEL0

IDLE

SCL/

DIP

PD1 PD0

DIFF

ACQUISITION

1.5µs (CLK = 2MHz)

PD0 CLOCKED IN

t

CONV

CONVERSION

10µs MAX

t

SSTRB

12

B11

B10 B9 B2 B1

MSB

IDLE

• • •

t

STR

• • •

t

SSTRB

• • • • •

18

20

FILLED WITH

B0

ZEROS

LSB

24

Figure 9. Internal Clock Mode Timing

Internal Clock

In internal clock mode, the MAX186/MAX188 generate

their own conversion clock internally. This frees the

microprocessor from the burden of running the SAR conversion clock, and allows the conversion results to be

read back at the processor’s convenience, at any clock

rate from zero to typically 10MHz. SSTRB goes low at the

start of the conversion and then goes high when the conversion is complete. SSTRB will be low for a maximum of

10µs, during which time SCLK should remain low for best

noise performance. An internal register stores data when

the conversion is in progress. SCLK clocks the data out

at this register at any time after the conversion is complete. After SSTRB goes high, the next falling clock edge

______________________________________________________________________________________ 13

will produce the MSB of the conversion at DOUT, followed by the remaining bits in MSB-first format (see

Figure 9). CS does not need to be held low once a conversion is started. Pulling CS high prevents data from

being clocked into the MAX186/MAX188 and threestates DOUT, but it does not adversely effect an internal

clock-mode conversion already in progress. When internal clock mode is selected, SSTRB does not go into a

high-impedance state when CS goes high.

Figure 10 shows the SSTRB timing in internal clock

mode. In internal clock mode, data can be shifted in and

out of the MAX186/MAX188 at clock rates exceeding

4.0MHz, provided that the minimum acquisition time, t

AZ

is kept above 1.5µs.

,

Page 14

Low-Power, 8-Channel,

Serial 12-Bit ADCs

CS • • •

t

CSH

SSTRB • • •

t

SSTRB

SCLK • • •

PD0 CLOCK IN

MAX186/MAX188

Figure 10. Internal Clock Mode SSTRB Detailed Timing

Data Framing

The falling edge of CS does not start a conversion on the

MAX186/MAX188. The first logic high clocked into DIN is

interpreted as a start bit and defines the first bit of the

control byte. A conversion starts on the falling edge of

SCLK, after the eighth bit of the control byte (the PD0 bit)

is clocked into DIN. The start bit is defined as:

The first high bit clocked into DIN with CS low anytime the converter is idle, e.g. after V

OR

The first high bit clocked into DIN after bit 5 of a

conversion in progress is clocked onto the DOUT pin.

If a falling edge on CS forces a start bit before bit 5

(B5) becomes available, then the current conversion

will be terminated and a new one started. Thus, the

fastest the MAX186/MAX188 can run is 15 clocks per

conversion. Figure 11a shows the serial-interface timing

necessary to perform a conversion every 15 SCLK

cycles in external clock mode. If CS is low and SCLK is

continuous, guarantee a start bit by first clocking in 16

zeros.

Most microcontrollers require that conversions occur in

multiples of 8 SCLK clocks; 16 clocks per conversion

will typically be the fastest that a microcontroller can

drive the MAX186/MAX188. Figure 11b shows the

serial-interface timing necessary to perform a conversion every 16 SCLK cycles in external clock mode.

is applied.

CC

t

CONV

NOTE: FOR BEST NOISE PERFORMANCE, KEEP SCLK LOW DURING CONVERSION.

t

SCK

t

CSS

__________ Applications Information

Power-On Reset

When power is first applied and if SHDN is not pulled

low, internal power-on reset circuitry will activate the

MAX186/MAX188 in internal clock mode, ready to convert with SSTRB = high. After the power supplies have

been stabilized, the internal reset time is 100µs and no

conversions should be performed during this phase.

SSTRB is high on power-up and, if CS is low, the first

logical 1 on DIN will be interpreted as a start bit. Until a

conversion takes place, DOUT will shift out zeros.

Reference-Buffer Compensation

In addition to its shutdown function, the SHDN pin also

selects internal or external compensation. The compensation affects both power-up time and maximum conversion speed. Compensated or not, the minimum clock

rate is 100kHz due to droop on the sample-and-hold.

To select external compensation, float SHDN. See the

Typical Operating Circuit

VREF. A value of 4.7µF or greater ensures stability and

allows operation of the converter at the full clock speed of

2MHz. External compensation increases power-up time (see

the

Choosing Power-Down Mode

Internal compensation requires no external capacitor at

VREF, and is selected by pulling SHDN high. Internal compensation allows for shortest power-up times, but is only

available using an external clock and reduces the maximum clock rate to 400kHz.

, which uses a 4.7µF capacitor at

section, and Table 5).

14 ______________________________________________________________________________________

Page 15

CS

SCLK

Low-Power, 8-Channel,

Serial 12-Bit ADCs

MAX186/MAX188

1

8181

DIN

DOUT

SSTRB

Figure 11a. External Clock Mode, 15 Clocks/Conversion Timing

CS

SCLK

DIN

DOUT

Figure 11b. External Clock Mode, 16 Clocks/Conversion Timing

S CONTROL BYTE 0

B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 B0

CONVERSION RESULT 0

S CONTROL BYTE 0

B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 B0 B11 B10 B9 B8

CONVERSION RESULT 0

Power-Down

Choosing Power-Down Mode

You can save power by placing the converter in a

low-current shutdown state between conversions.

Select full power-down or fast power-down mode via

bits 7 and 8 of the DIN control byte with SHDN high or

floating (see Tables 2 and 6). Pull SHDN low at any time

to shut down the converter completely. SHDN overrides

bits 7 and 8 of DIN word (see Table 7).

Full power-down mode turns off all chip functions that draw

quiescent current, reducing IDDand ISStypically to 2µA.

Fast power-down mode turns off all circuitry except the

bandgap reference. With the fast power-down mode, the

supply current is 30µA. Power-up time can be shortened

to 5µs in internal compensation mode.

In both software shutdown modes, the serial interface

remains operational, however, the ADC will not convert.

Table 5 illustrates how the choice of reference-buffer

compensation and power-down mode affects both

power-up delay and maximum sample rate.

In external compensation mode, the power-up time is

20ms with a 4.7µF compensation capacitor (200ms with

a 33µF capacitor) when the capacitor is fully discharged.

In fast power-down, you can eliminate start-up time by

CONTROL BYTE 1S

B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 B0

CONVERSION RESULT 1

CONTROL BYTE 1S

CONTROL BYTE 2S

• • •

• • •

• • •

• • •

CONVERSION RESULT 1

using low-leakage capacitors that will not discharge

more than 1/2LSB while shut down. In shutdown, the

capacitor has to supply the current into the reference

(1.5µA typ) and the transient currents at power-up.

Figures 12a and 12b illustrate the various power-down

sequences in both external and internal clock modes.

Software Power-Down

Software power-down is activated using bits PD1 and

PD0 of the control byte. As shown in Table 6, PD1 and

PD0 also specify the clock mode. When software shutdown is asserted, the ADC will continue to operate in

the last specified clock mode until the conversion is

complete. Then the ADC powers down into a low quiescent-current state. In internal clock mode, the interface

remains active and conversion results may be clocked

out while the MAX186/MAX188 have already entered a

software power-down.

The first logical 1 on DIN will be interpreted as a start

bit, and powers up the MAX186/MAX188. Following the

start bit, the data input word or control byte also determines clock and power-down modes. For example, if

the DIN word contains PD1 = 1, then the chip will

remain powered up. If PD1 = 0, a power-down will

resume after one conversion.

______________________________________________________________________________________ 15

Page 16

Low-Power, 8-Channel,

SHDN

Serial 12-Bit ADCs

CLOCK

MODE

SHDN

DOUT

MODE

MAX186/MAX188

Figure 12a. Timing Diagram Power-Down Modes, External Clock

DIN

INTERNAL

XXXX

SX

EXTERNAL

SETS EXTERNAL

CLOCK MODE

11 S 01

DATA VALID

(12 DATA BITS)

POWERED UP

XXXXX XXXXX

SETS FAST

POWER-DOWN

MODE

DATA VALID

(12 DATA BITS)

SETS EXTERNAL

CLOCK MODE

S11

FAST

POWER-DOWN

POWERED UP

VALID

EXTERNAL

DATA INVALID

FULL

POWER

DOWN

Table 5. Typical Power-Up Delay Times

Reference Reference- VREF Power- Power-Up Maximum

Buffer Buffer Capacitor Down Delay Sampling

Compensation (µF) Mode (sec) Rate (ksps)

Mode

Enabled Internal Fast 5µ 26

Enabled Internal Full 300µ 26

Enabled External 4.7 Fast See Figure 14c 133

Enabled External 4.7 Full See Figure 14c 133

Disabled Fast 2µ 133

Disabled Full 2µ 133

POWERED

UP

Table 6. Software Shutdown and Clock Mode

Table 7. Hard-Wired Shutdown and

Compensation Mode

PD1 PD0 Device Mode

1 1 External Clock Mode

1 0 Internal Clock Mode

0 1 Fast Power-Down Mode

0 0 Full Power-Down Mode

16 ______________________________________________________________________________________

State Mode Compensation

1 Enabled Internal Compensation

Floating Enabled External Compensation

0 Full Power-Down N/A

Device Reference-Buffer

Page 17

Low-Power, 8-Channel,

Serial 12-Bit ADCs

MAX186/MAX188

CLOCK

MODE

DIN

DOUT

SSTRB

MODE

SX

SETS INTERNAL

CLOCK MODE

XXXX

10 S 00

CONVERSION

POWERED UP

INTERNAL CLOCK MODE

DATA VALID

Figure 12b. Timing Diagram Power-Down Modes, Internal Clock

Hardware Power-Down

The SHDN pin places the converter into the full

power-down mode. Unlike with the software shut-down

modes, conversion is not completed. It stops coincidentally with SHDN being brought low. There is no

power-up delay if an external reference is used and is

not shut down. The SHDN pin also selects internal or

external reference compensation (see Table 7).

Power-Down Sequencing

The MAX186/MAX188 auto power-down modes can

save considerable power when operating at less than

maximum sample rates. The following discussion illustrates the various power-down sequences.

SETS FULL

POWER-DOWN

XXXXX

DATA VALID

CONVERSION

FULL

POWER-DOWN

S

POWERED

UP

Lowest Power at up to 500

Conversions/Channel/Second

The following examples illustrate two different power-down

sequences. Other combinations of clock rates, compensation modes, and power-down modes may give lowest

power consumption in other applications.

Figure 14a depicts the MAX186 power consumption for

one or eight channel conversions utilizing full

power-down mode and internal reference compensation.

A 0.01µF bypass capacitor at REFADJ forms an RC filter

with the internal 20kΩ reference resistor with a 0.2ms

time constant. To achieve full 12-bit accuracy, 10 time

constants or 2ms are required after power-up. Waiting

2ms in FASTPD mode instead of full power-up will reduce

the power consumption by a factor of 10 or more. This is

achieved by using the sequence shown in Figure 13.

COMPLETE CONVERSION SEQUENCE

DIN

100

FULLPD FASTPD NOPD FULLPD FASTPD

REFADJ

VREF

2.5V

0V

4V

0V

(ZEROS)

101 1 11100 101

τ = RC = 20kΩ x C

Figure 13. MAX186 FULLPD/FASTPD Power-Up Sequence

______________________________________________________________________________________ 17

2ms WAIT

REFADJ

CH1 CH7

t

≈ 15µs

BUFFEN

(ZEROS)

Page 18

Low-Power, 8-Channel,

Serial 12-Bit ADCs

MAX186

1000

2ms FASTPD WAIT

400kHz EXTERNAL CLOCK

INTERNAL COMPENSATION

100

10

AVG. SUPPLY CURRENT (µA)

1

0 100 300 500

50 150 250 350 450

MAX186/MAX188

Figure 14a. MAX186 Supply Current vs. Sample Rate/Second,

FULLPD, 400kHz Clock

FULL POWER-DOWN

8 CHANNELS

1 CHANNEL

200 400

CONVERSIONS PER CHANNEL PER SECOND

Lowest Power at Higher Throughputs

Figure 14b shows the power consumption with

external-reference compensation in fast power-down,

with one and eight channels converted. The external

4.7µF compensation requires a 50µs wait after power-up,

accomplished by 75 idle clocks after a dummy conversion. This circuit combines fast multi-channel conversion

with lowest power consumption possible. Full

power-down mode may provide increased power savings in applications where the MAX186/MAX188 are

inactive for long periods of time, but where intermittent

bursts of high-speed conversions are required.

External and Internal References

The MAX186 can be used with an internal or external

reference, whereas an external reference is required for

the MAX188. Diode D1 shown in the

Circuit

ensures correct start-up. Any standard signal

Typical Operating

diode can be used. For both parts, an external reference can either be connected directly at the VREF terminal or at the REFADJ pin.

An internal buffer is designed to provide 4.096V at

VREF for both the MAX186 and MAX188. The

MAX186’s internally trimmed 2.46V reference is

buffered with a gain of 1.678. The MAX188's buffer is

trimmed with a buffer gain of 1.638 to scale an external

2.5V reference at REFADJ to 4.096V at VREF.

MAX186 Internal Reference

The full-scale range of the MAX186 with internal reference

is 4.096V with unipolar inputs, and ±2.048V with bipolar

inputs. The internal reference voltage is adjustable to

±1.5% with the Reference-Adjust Circuit of Figure 17.

MAX186-14A

MAX186/MAX188

10,000

1000

100

AVG. SUPPLY CURRENT (µA)

10

0

2k

Figure 14b. MAX186/MAX188 Supply Current vs. Sample

Rate/Second, FASTPD, 2MHz Clock

3.0

2.5

2.0

1.5

1.0

POWER-UP DELAY (ms)

0.5

0

0.0001 0.001 0.01 0.1 1 10

Figure 14c. Typical Power-Up Delay vs. Time in Shutdown

FAST POWER-DOWN

8 CHANNELS

1 CHANNEL

2MHz EXTERNAL CLOCK

EXTERNAL COMPENSATION

50µs WAIT

4k 6k 8k 10k 12k 14k 16k 18k

CONVERSIONS PER CHANNEL PER SECOND

TIME IN SHUTDOWN (sec)

External Reference

With both the MAX186 and MAX188, an external reference can be placed at either the input (REFADJ) or the

output (VREF) of the internal buffer amplifier. The

REFADJ input impedance is typically 20kΩ for the

MAX186 and higher than 100kΩ for the MAX188, where

the internal reference is omitted. At VREF, the input

impedance is a minimum of 12kΩ for DC currents.

During conversion, an external reference at VREF must

be able to deliver up to 350µA DC load current and have

an output impedance of 10Ω or less. If the reference has

higher output impedance or is noisy, bypass it close to

the VREF pin with a 4.7µF capacitor.

18 ______________________________________________________________________________________

Page 19

OUTPUT CODE

11 . . . 111

11 . . . 110

11 . . . 101

00 . . . 011

00 . . . 010

00 . . . 001

00 . . . 000

0

123

INPUT VOLTAGE (LSBs)

FULL-SCALE

TRANSITION

FS = +4.096V

1LSB = FS

4096

FS - 3/2LSB

Low-Power, 8-Channel,

Serial 12-Bit ADCs

MAX186/MAX188

011 . . . 111

011 . . . 110

000 . . . 010

000 . . . 001

000 . . . 000

111 . . . 111

111 . . . 110

111 . . . 101

100 . . . 001

100 . . . 000

FS

FS = +4.096

2

1LSB = +4.096

4096

-FS

0V

INPUT VOLTAGE (LSBs)

+FS - 1LSB

Figure 15. MAX186/MAX188 Unipolar Transfer Function,

4.096V = Full Scale

Using the buffered REFADJ input avoids external

buffering of the reference. To use the direct VREF input,

disable the internal buffer by tying REFADJ to VDD.

Transfer Function and Gain Adjust

Figure 15 depicts the nominal, unipolar input/output

(I/O) transfer function, and Figure 16 shows the bipolar

input/output transfer function. Code transitions occur

halfway between successive integer LSB values. Output

coding is binary with 1 LSB = 1.00mV (4.096V/4096) for

unipolar operation and 1 LSB = 1.00mV ((4.096V/2 -

-4.096V/2)/4096) for bipolar operation.

Figure 17, the MAX186 Reference-Adjust Circuit, shows

how to adjust the ADC gain in applications that use the

internal reference. The circuit provides ±1.5%

(±65LSBs) of gain adjustment range.

Layout, Grounding, Bypassing

For best performance, use printed circuit boards.

Wire-wrap boards are not recommended. Board layout

should ensure that digital and analog signal lines are

separated from each other. Do not run analog and digital (especially clock) lines parallel to one another, or

digital lines underneath the ADC package.

Figure 18 shows the recommended system ground

connections. A single-point analog ground (“star”

ground point) should be established at AGND, separate from the logic ground. All other analog grounds

Figure 16. MAX186/MAX188 Bipolar Transfer Function,

±4.096V/2 = Full Scale

+5V

510k

100k

24k

Figure 17. MAX186 Reference-Adjust Circuit

0.01µF

MAX186

REFADJ

12

and DGND should be connected to this ground. No

other digital system ground should be connected to

this single-point analog ground. The ground return to

the power supply for this ground should be low impedance and as short as possible for noise-free operation.

High-frequency noise in the V

power supply may

DD

affect the high-speed comparator in the ADC. Bypass

these supplies to the single-point analog ground with

0.1µF and 4.7µF bypass capacitors close to the

MAX186/MAX188. Minimize capacitor lead lengths for

best supply-noise rejection. If the +5V power supply is

very noisy, a 10Ω resistor can be connected as a lowpass filter, as shown in Figure 18.

______________________________________________________________________________________ 19

Page 20

Low-Power, 8-Channel,

Serial 12-Bit ADCs

SUPPLIES

+5V

R* = 10Ω

DD

MAX186/MAX188

* OPTIONAL

AGNDV

MAX186/MAX188

Figure 18. Power-Supply Grounding Connection

-5V

GND

SS

DGND+5VDGNDV

DIGITAL

CIRCUITRY

High-Speed Digital Interfacing with QSPI

The MAX186/MAX188 can interface with QSPI at high

throughput rates using the circuit in Figure 19. This

QSPI circuit can be programmed to do a conversion on

each of the eight channels. The result is stored in memory without taxing the CPU since QSPI incorporates its

own micro-sequencer. Figure 19 depicts the MAX186,

but the same circuit could be used with the MAX188 by

adding an external reference to VREF and connecting

REFADJ to V

Figure 20 details the code that sets up QSPI for

autonomous operation. In external clock mode, the

MAX186/MAX188 perform a single-ended, unipolar conversion on each of their eight analog input channels.

Figure 21, QSPI Assembly-Code Timing, shows the timing associated with the assembly code of Figure 20. The

first byte clocked into the MAX186/MAX188 is the control

byte, which triggers the first conversion on CH0. The last

two bytes clocked into the MAX186/MAX188 are all zero

and clock out the results of the CH7 conversion.

DD

.

1

CH0

2

CH1

CH2

3

4

10

5

6

7

8

9

CH3

CH4

CH5

CH6

CH7

V

SS

SHDN

MAX186

ANALOG

INPUTS

Figure 19. MAX186 QSPI Connection

V

SCLK

CS

DIN

SSTRB

DOUT

DGND

AGND

REFADJ

VREF

DD

20

19

18

17

16

15

14

13

12

11

+5V

V

, V

0.1µF 4.7µF

0.1µF

+

4.7µF

0.01µF

* CLOCK CONNECTIONS NOT SHOWN

DDI

SCK

PCS0

MOSI

MISO

, V

DDE

MC68HC16

VSSE

V

SSI

DDSYN

, V

STBY

20 ______________________________________________________________________________________

Page 21

Low-Power, 8-Channel,

Serial 12-Bit ADCs

*Title : MAX186.ASM

* Description :

* This is a shell program for using a stand-alone 68HC16 without any external memory. The internal 1K RAM

* is put into bank $0F to maintain 68HC11 code compatibility. This program was written with software

* provided in the Motorola 68HC16 Evaluation Kit.

*

* Roger J.A. Chen, Applications Engineer

* MAXIM Integrated Products

* November 20, 1992

*

******************************************************************************************************************************************************

INCLUDE ‘EQUATES.ASM’ ;Equates for common reg addrs

INCLUDE ‘ORG00000.ASM’ ;initialize reset vector

INCLUDE ‘ORG00008.ASM’ ;initialize interrupt vectors

ORG $0200 ;start program after interrupt vectors

INCLUDE ‘INITSYS.ASM’ ;set EK=F,XK=0,YK=0,ZK=0

;set sys clock at 16.78 MHz, COP off

INCLUDE ‘INITRAM.ASM’ ;turn on internal SRAM at $10000

;set stack (SK=1, SP=03FE)

MAIN:

JSR INITQSPI

MAINLOOP:

JSR READ186

WAIT:

LDAA SPSR

ANDA #$80

BEQ WAIT ;wait for QSPI to finish

BRA MAINLOOP

ENDPROGRAM:

MAX186/MAX188

INITQSPI:

;This routine sets up the QSPI microsequencer to operate on its own.

;The sequencer will read all eight channels of a MAX186/MAX188 each time

;it is triggered. The A/D converter results will be left in the

;receive data RAM. Each 16 bit receive data RAM location will

;have a leading zero, 12 bits of conversion result and three zeros.

;

;Receive RAM Bits 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

;A/D Result 0 MSB LSB 0 0 0

***** Initialize the QSPI Registers ******

PSHA

PSHB

LDAA #%01111000

STAA QPDR ;idle state for PCS0-3 = high

LDAA #%01111011

STAA QPAR ;assign port D to be QSPI

LDAA #%01111110

STAA QDDR ;only MISO is an input

LDD #$8008

STD SPCR0 ;master mode,16 bits/transfer,

;CPOL=CPHA=0,1MHz Ser Clock

LDD #$0000

STD SPCR1 ;set delay between PCS0 and SCK,

Figure 20. MAX186/MAX188 Assembly-Code Listing

______________________________________________________________________________________ 21

Page 22

Low-Power, 8-Channel,

Serial 12-Bit ADCs

;set delay between transfers

LDD #$0800

STD SPCR2 ;set ENDQP to $8 for 9 transfers

***** Initialize QSPI Command RAM *****

LDAA #$80 ;CONT=1,BITSE=0,DT=0,DSCK=0,PCS0=ACTIVE

STAA $FD40 ;store first byte in COMMAND RAM

LDAA #$C0 ;CONT=1,BITSE=1,DT=0,DSCK=0,PCS0=ACTIVE

STAA $FD41

STAA $FD42

STAA $FD43

STAA $FD44

STAA $FD45

STAA $FD46

STAA $FD47

LDAA #$40 ;CONT=0,BITSE=1,DT=0,DSCK=0,PCS0=ACTIVE

MAX186/MAX188

STAA $FD48

***** Initialize QSPI Transmit RAM *****

LDD #$008F

STD $FD20

LDD #$00CF

STD $FD22

LDD #$009F

STD $FD24

LDD #$00DF

STD $FD26

LDD #$00AF

STD $FD28

LDD #$00EF

STD $FD2A

LDD #$00BF

STD $FD2C

LDD #$00FF

STD $FD2E

LDD #$0000

STD $FD30

PULB

PULA

RTS

READ186:

;This routine triggers the QSPI microsequencer to autonomously

;trigger conversions on all 8 channels of the MAX186. Each

;conversion result is stored in the receive data RAM.

PSHA

LDAA #$80

ORAA SPCR1

STAA SPCR1 ;just set SPE

PULA

RTS

***** Interrupts/Exceptions *****

BDM: BGND ;exception vectors point here

Figure 20. MAX186/MAX188 Assembly-Code Listing (continued)

22 ______________________________________________________________________________________

Page 23

• • • •

Low-Power, 8-Channel,

Serial 12-Bit ADCs

MAX186/MAX188

CS

Figure 21. QSPI Assembly-Code Timing

TMS320C3x to MAX186 Interface

Figure 22 shows an application circuit to interface the

MAX186/MAX188 to the TMS320 in external clock

mode. The timing diagram for this interface circuit is

shown in Figure 23.

Use the following steps to initiate a conversion in the

MAX186/MAX188 and to read the results:

1) The TMS320 should be configured with CLKX (transmit clock) as an active-high output clock and CLKR

(TMS320 receive clock) as an active-high input clock.

CLKX and CLKR of the TMS320 are tied together with

the SCLK input of the MAX186/MAX188.

2) The MAX186/MAX188 CS is driven low by the XF_

I/O port of the TMS320 to enable data to be clocked

into DIN of the MAX186/MAX188.

3) An 8-bit word (1XXXXX11) should be written to the

MAX186/MAX188 to initiate a conversion and place

the device into external clock mode. Refer to Table

2 to select the proper XXXXX bit values for your specific application.

4) The SSTRB output of the MAX186/MAX188 is monitored via the FSR input of the TMS320. A falling

edge on the SSTRB output indicates that the conversion is in progress and data is ready to be received

from the MAX186/MAX188.

• • • •

• • • •

• • • •

SCLK

SSTRB

DIN

XF

CLKX

TMS320C3x

CLKR

DX

DR

FSR

Figure 22. MAX186/MAX188 to TMS320 Serial Interface

CS

SCLK

DIN

DOUT

SSTRB

MAX186

MAX188

5) The TMS320 reads in one data bit on each of the

next 16 rising edges of SCLK. These data bits represent the 12-bit conversion result followed by four

trailing bits, which should be ignored.

6) Pull CS high to disable the MAX186/MAX188 until

the next conversion is initiated.

______________________________________________________________________________________ 23

Page 24

Low-Power, 8-Channel,

Serial 12-Bit ADCs

CS

SCLK

DIN

SSTRB

DOUT

START SEL2 SEL1 SEL0 UNI/BIP SGL/DIF PD1 PD0

Figure 23. TMS320 Serial Interface Timing Diagram

MAX186/MAX188

__________Typical Operating Circuit

+5V

C4

0.1µF

V

DD

I/O

SCK (SK)*

MOSI (SO)

MISO (SI)

C1

4.7µF

0V to

4.096V

ANALOG

INPUTS

C2

0.01µF

CH0

CH7

VREF

REFADJ

MAX186

V

DGND

AGND

V

CS

SCLK

DIN

DOUT

SSTRB

SHDN

DD

C3

0.1µF

SS

CPU

V

SS

HIGH

IMPEDANCE

MSB B10 B1 LSB

HIGH

IMPEDANCE

___________________Chip Topography

SCLK

CS

DIN

SSTRB

DOUT

DGND

AGND

0.151"

(3.84 mm)

CH2

CH3

CH4

CH5

CH6

CH7

V

CH0CH1

DD

_Ordering Information (continued)

†

PART

MAX188_CPP 20 Plastic DIP

MAX188_CWP 20 SO

MAX188_CAP 20 SSOP

MAX188DC/D Dice*

MAX188_EPP Plastic DIP

MAX188_EWP 20 SO

TEMP. RANGE

0°C to +70°C

0°C to +70°C

0°C to +70°C

0°C to +70°C

-40°C to +85°C

-40°C to +85°C

PIN-PACKAGE

SHDN VREF REFADJ

SS

0.117"

(2.97 mm)

MAX186/MAX188

TRANSISTOR COUNT: 2278;

SUBSTRATE CONNECTED TO V

AGNDV

DD

MAX188_EAP -40°C to +85°C 20 SSOP

MAX188_MJP

-55°C to +125°C

PART BOARD TYPETEMP. RANGE

MAX186EVKIT-DIP Through-Hole

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

24

____________________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

0°C to +70°C

20 CERDIP**

†

NOTE: Parts are offered in grades A, B, C and D (grades defined

in Electrical Characteristics). When ordering, please specify grade.

* Dice are specified at +25°C, DC parameters only.

* * Contact factory for availability and processing to MIL-STD-883.

© 1996 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Loading...

Loading...